Patents

Literature

154results about How to "Less prone to accidents" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nano metal fluid with high heat-transfer performance

ActiveCN1955252AImprove thermal conductivityFast absorption and deliveryDigital data processing detailsSemiconductor/solid-state device detailsLiquid metalSolvent

This invention provides a high heat transfer performance liquid nano-metal. It relates to cooling fluid working medium, and especially it can be used under high rush density condition which need high intensity cooling fluid working medium for heat exchanging and cooling, such as computer array and reactor. The solvent of this invention is liquid metal, and the soluble of this invention is nanometer particle. This invention solve the problem of high price of present metal liquid cooling working medium and the limited performance of common metal liquid, leaking out easily taken place using common liquid and easy forming sediment of present nanometer cooling agent.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

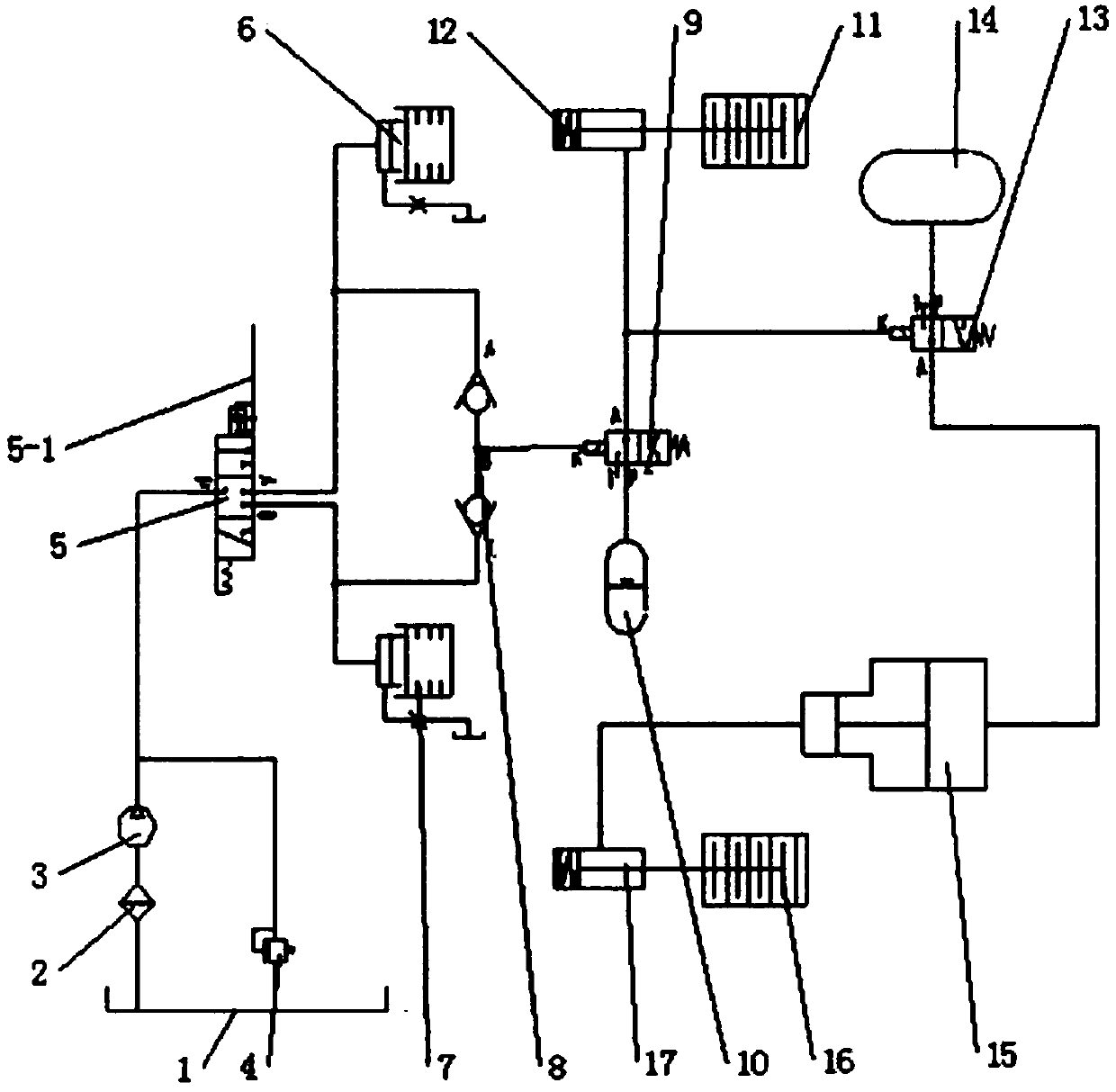

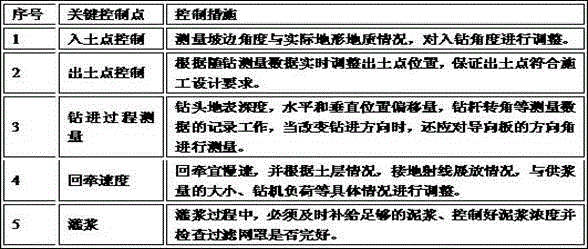

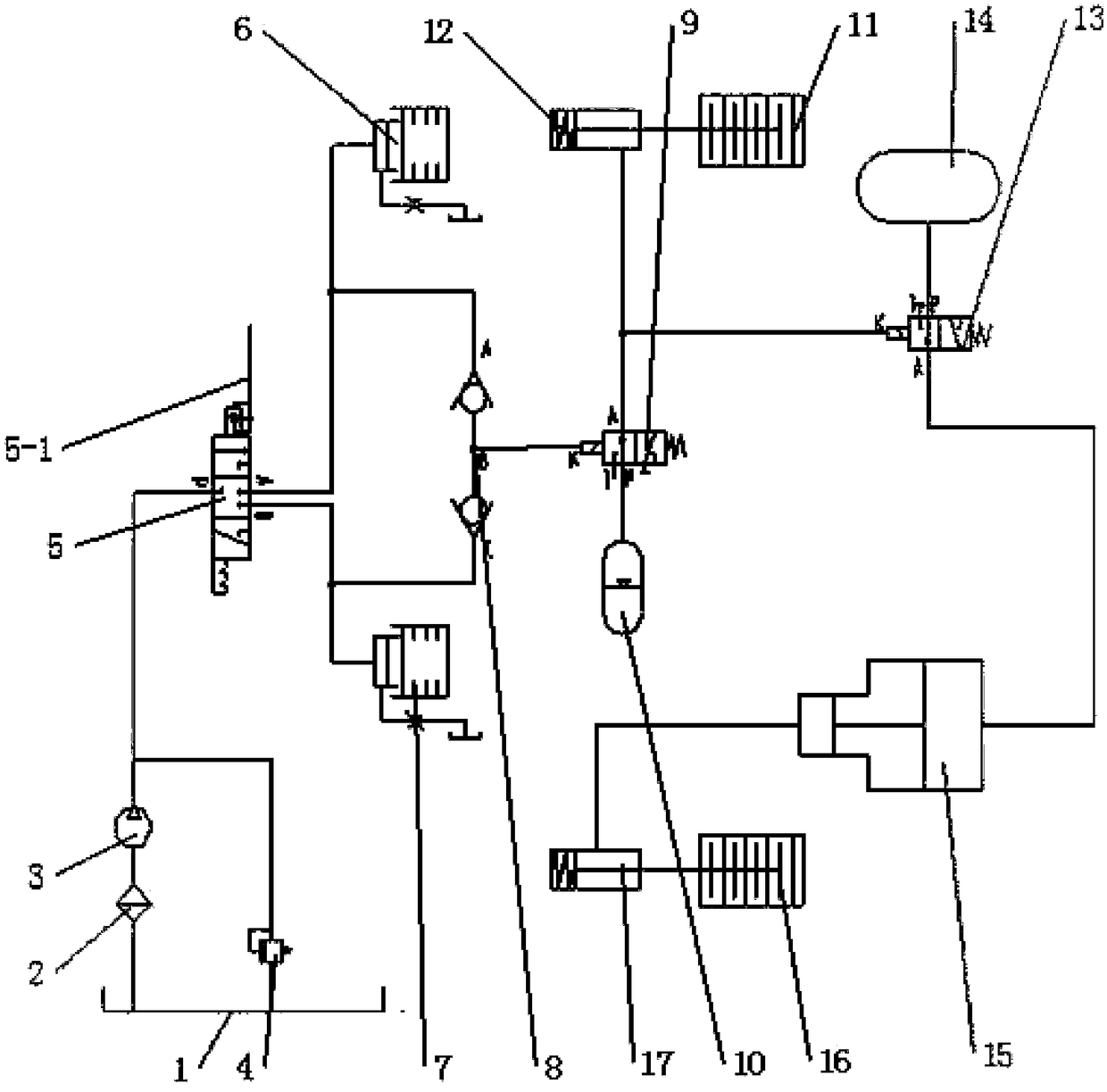

Vehicle gear selection and parking brake joint control system

ActiveCN105501200ASimple systemLess prone to accidentsFluid braking transmissionHydraulic cylinderRelay valve

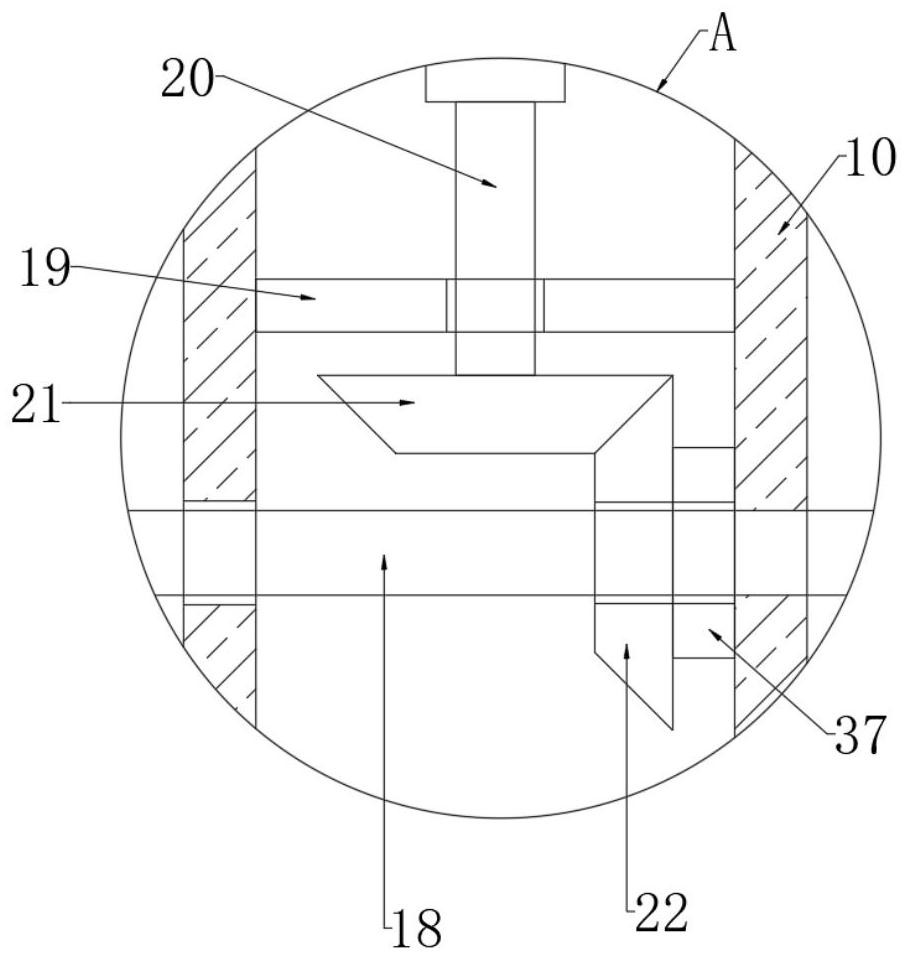

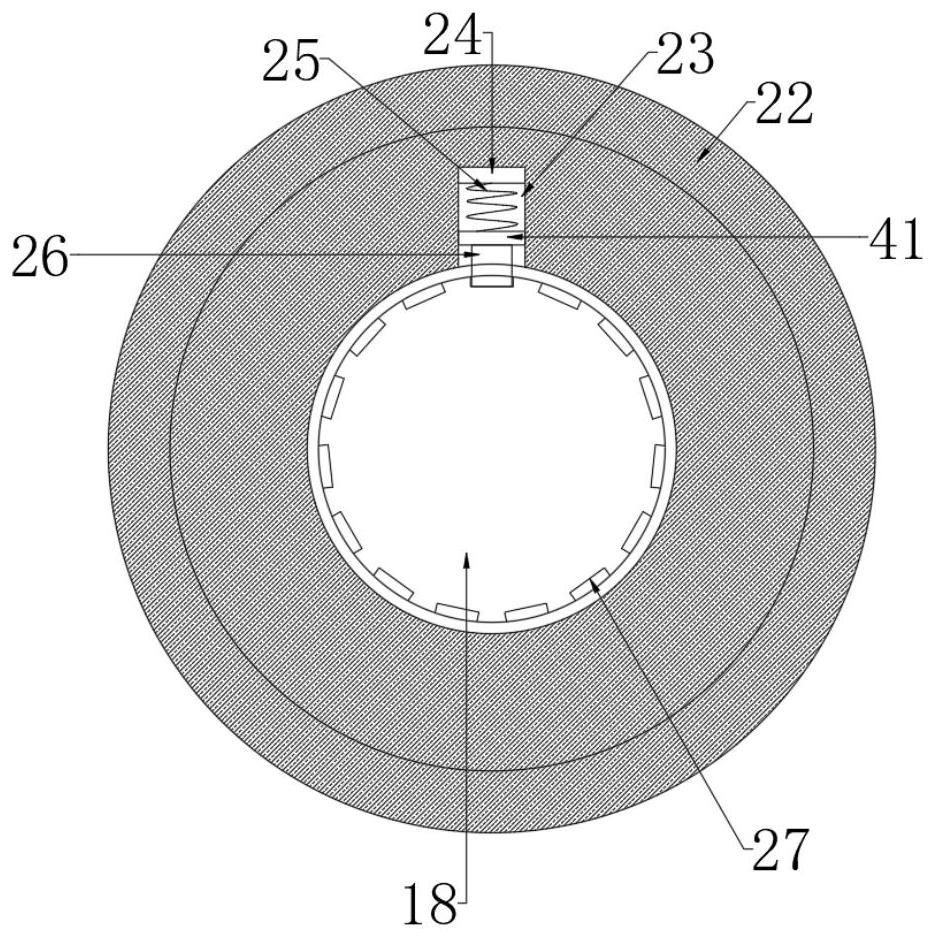

The invention provides a vehicle gear selection and parking brake joint control system which comprises an oil tank, a filter, a hydraulic pump, a safety valve, a gear selection operating valve, a forward gear clutch, a backward gear clutch, a reverse gear clutch, a shuttle valve, a liquid control valve, an energy accumulator, a towing vehicle parking brake, a towing vehicle parking hydraulic cylinder, a liquid control air valve, an air bag, an assistor, a trailer parking brake and a trailer parking hydraulic cylinder. The gear selection operating valve comprises an operating level. According to the vehicle gear selection and parking brake joint control system, when the vehicle is at a neutral gear, a towing vehicle and a trailer have a parking brake function, so that accidents do not occur easily when the vehicles are parked on a ramp for operation. According to the vehicle gear selection and parking brake joint control system, the trailer also has a parking brake function during the parking brake of the towing vehicle without needing the arrangement of a towing vehicle parking brake valve, a pneumatic control valve, a relay valve, a check valve and a second air bag, and a vehicle system is simplified.

Owner:青岛齐力铸钢有限公司

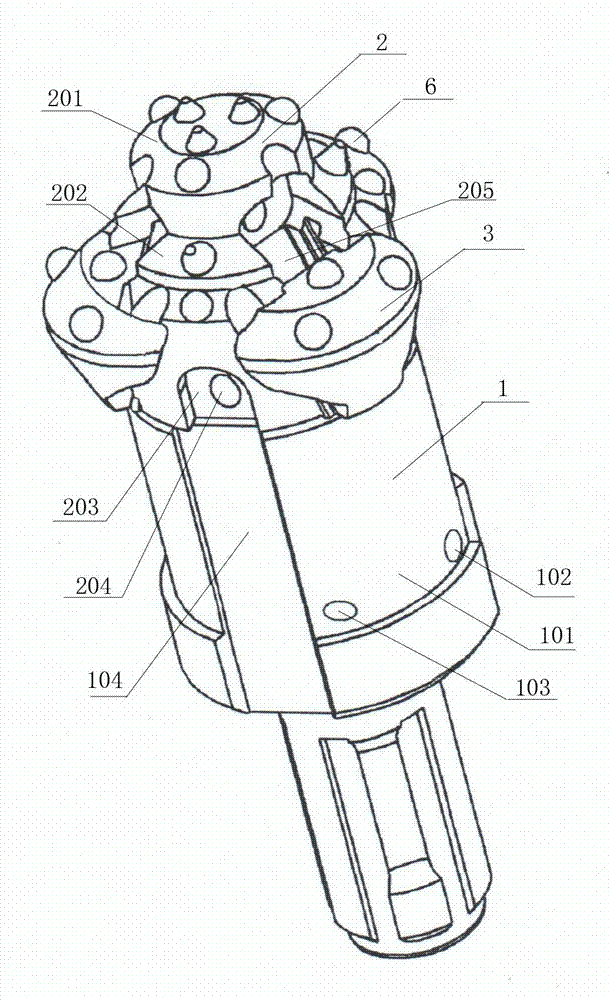

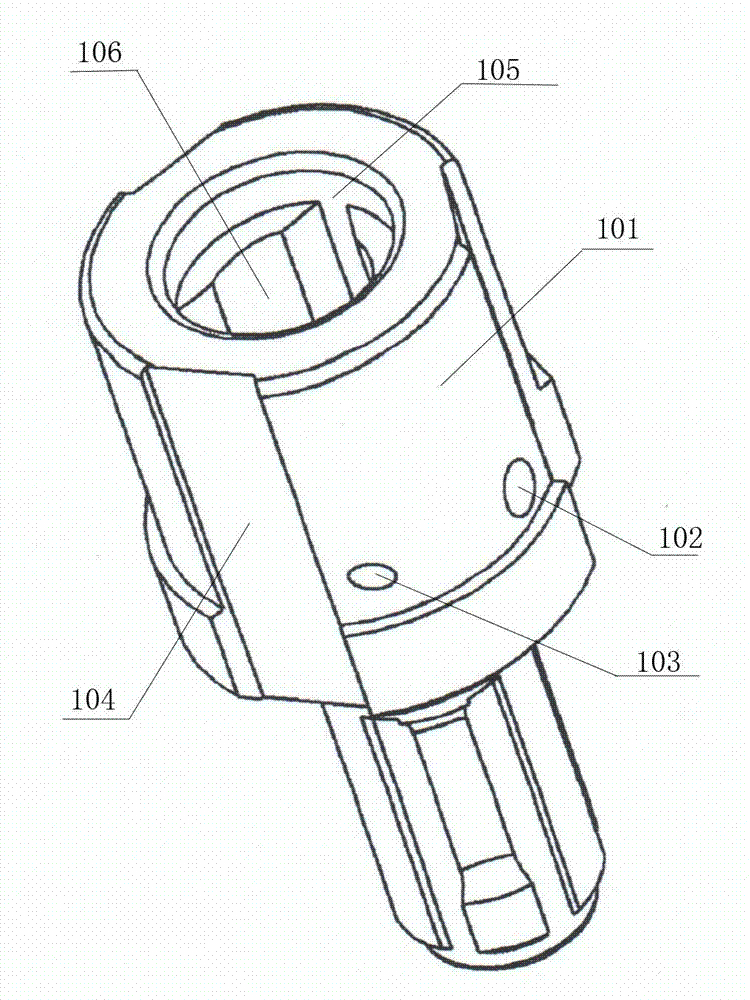

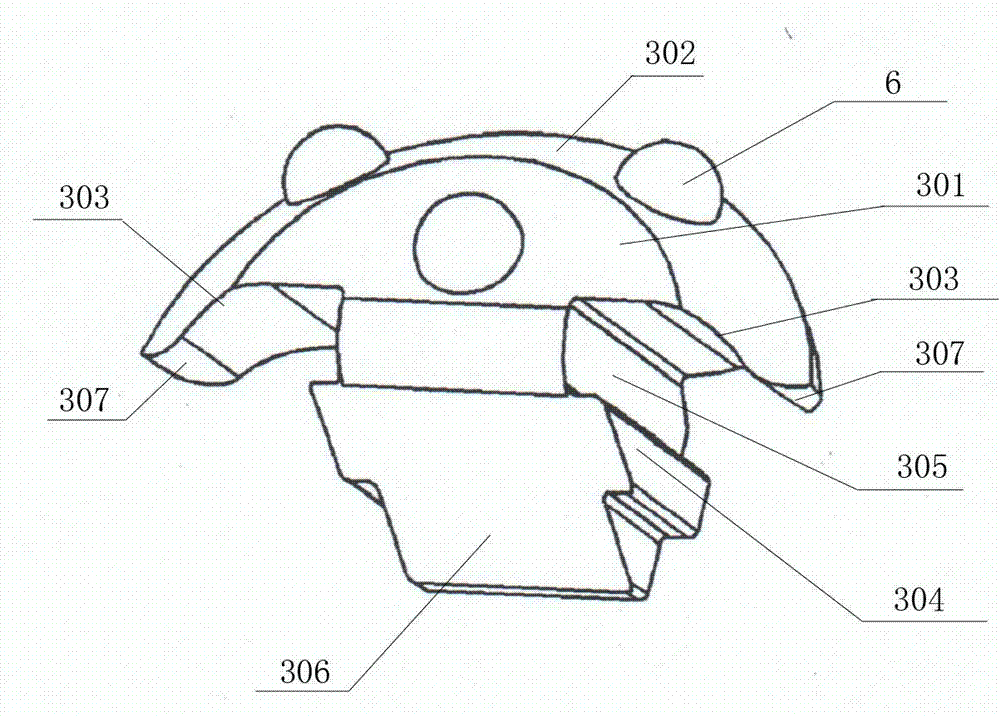

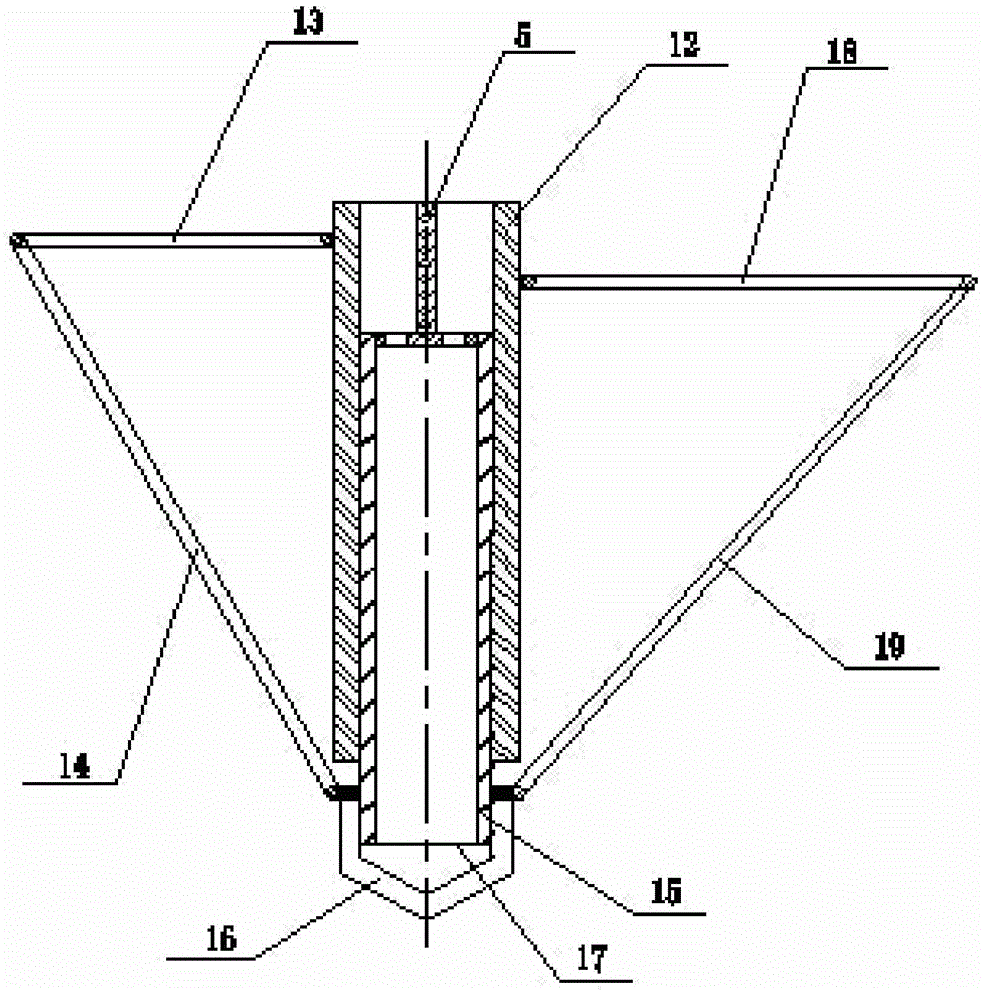

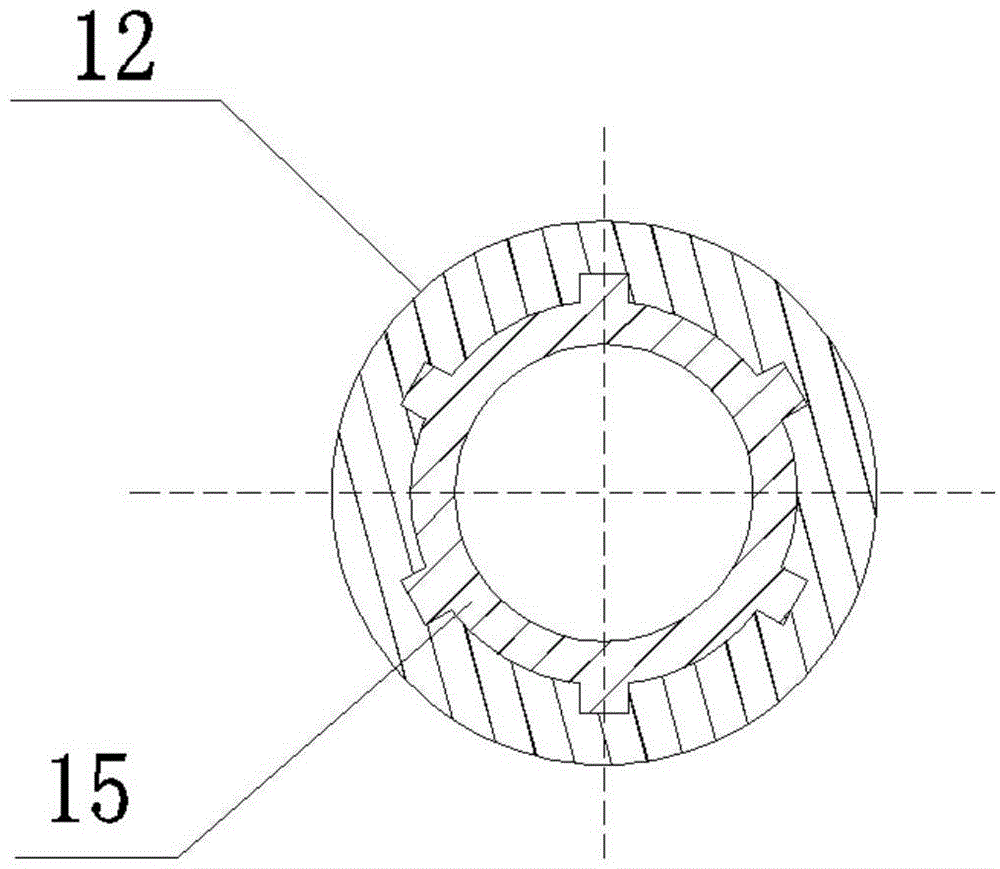

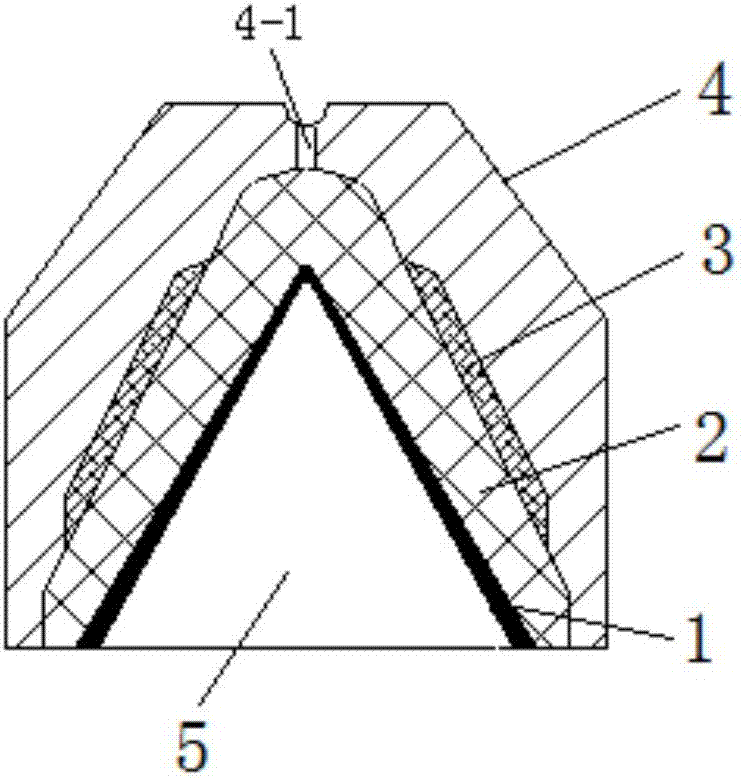

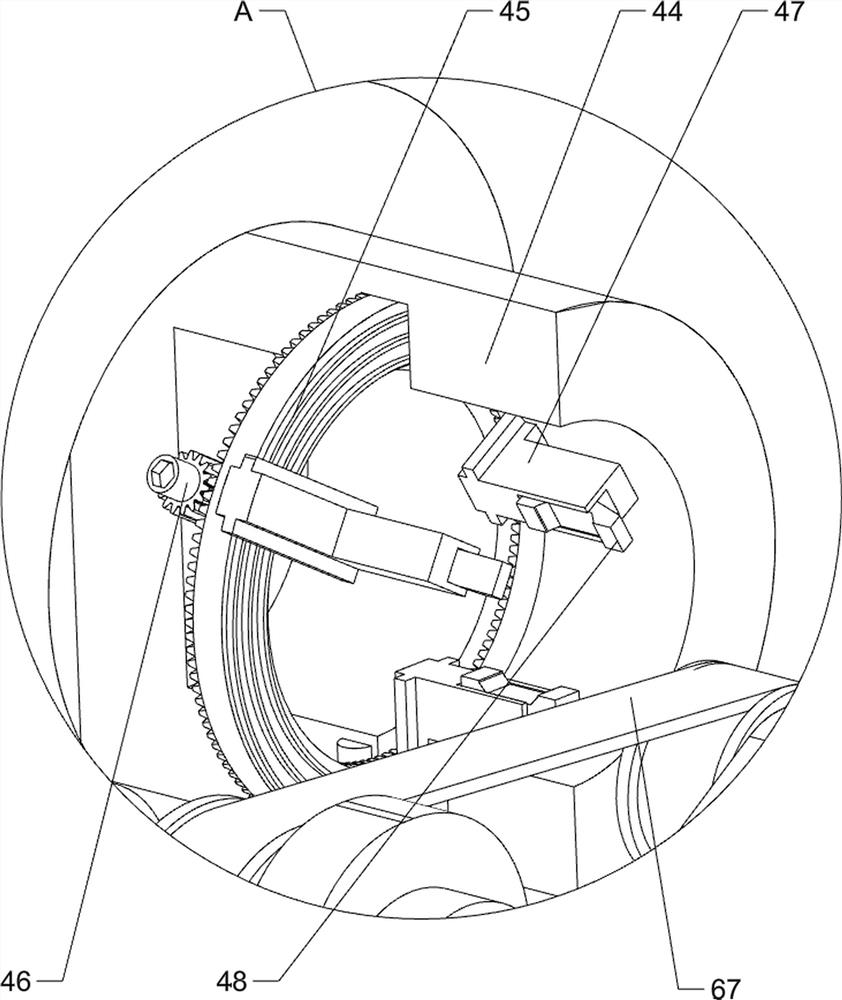

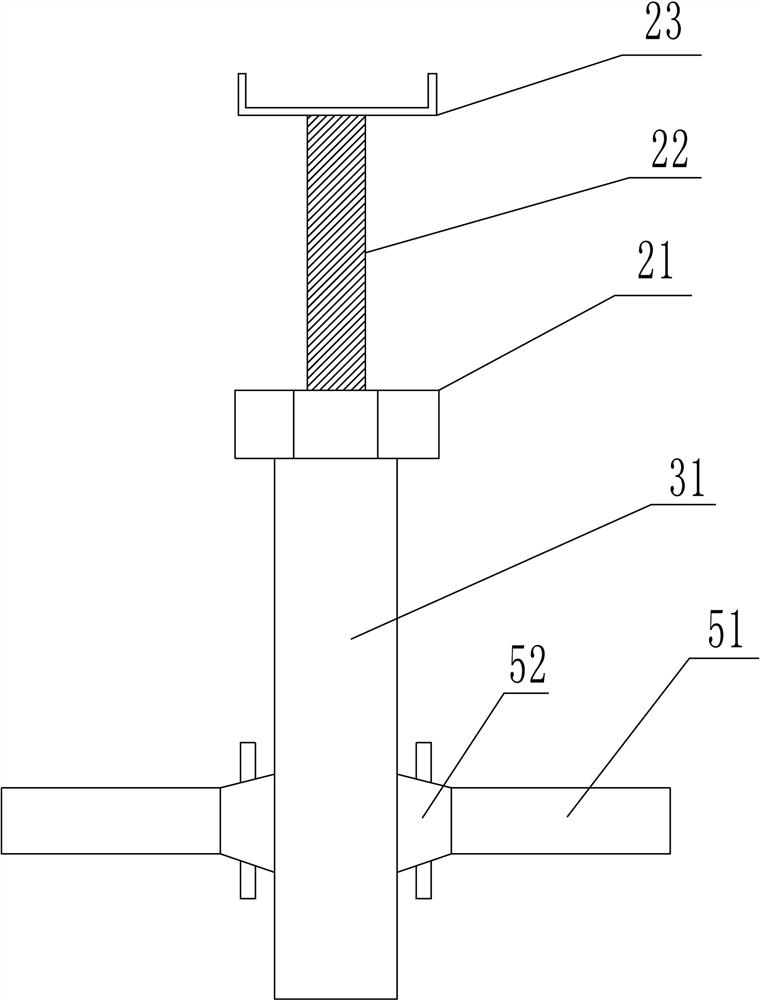

Concentric sliding block simultaneous casing drilling tool, center drilling bit and centralizer

ActiveCN102926663AReduce areaNo swingDrill bitsBorehole drivesClassical mechanicsTorque transmission

The invention discloses a concentric sliding block simultaneous casing drilling tool, a center drilling bit and centralizer. The concentric sliding block simultaneous casing drilling tool is formed by the centralizer, a ladder-shaped tapping center drilling bit and semicircle-shaped expanding drilling pieces, wherein the ladder-shaped tapping center drilling bit is connected and matched with a hole to which the centralizer is aligned for torque transmission, the ladder-shaped tapping center drilling bit is connected and located through a locating groove, a locating hole, a solid cylindrical pin and a hollow expansion pin, three semicircle-shaped expanding drilling pieces are in torque transmission through a T-shaped oblique groove and an R arc-shaped oblique groove, mutual included angles of the T-shaped oblique groove and the R arc-shaped oblique groove are 120 degrees by using an axis of the ladder-shaped tapping center drilling bit as the center, the semicircle-shaped expanding drilling pieces slide backwards to the end surface of the centralizer along the T-shaped oblique groove and the R arc-shaped oblique groove when being subjected to rock resistance and can be located, an expanding simultaneous casing can be formed, and the semicircle-shaped expanding drilling pieces slide downwards, can be narrowed and withdrawn due to the resistance of a pipe boot during upward drawing. According to the concentric sliding block simultaneous casing drilling tool disclosed by the invention, the front area of the tapping drilling bit is small, the force is concentrated, and the tapping drilling bit can crush harder or large rocks firstly at stages at crushing speed.

Owner:广汉珂普瑞科技有限公司

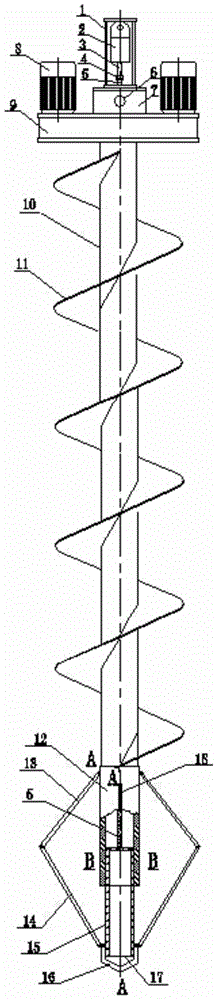

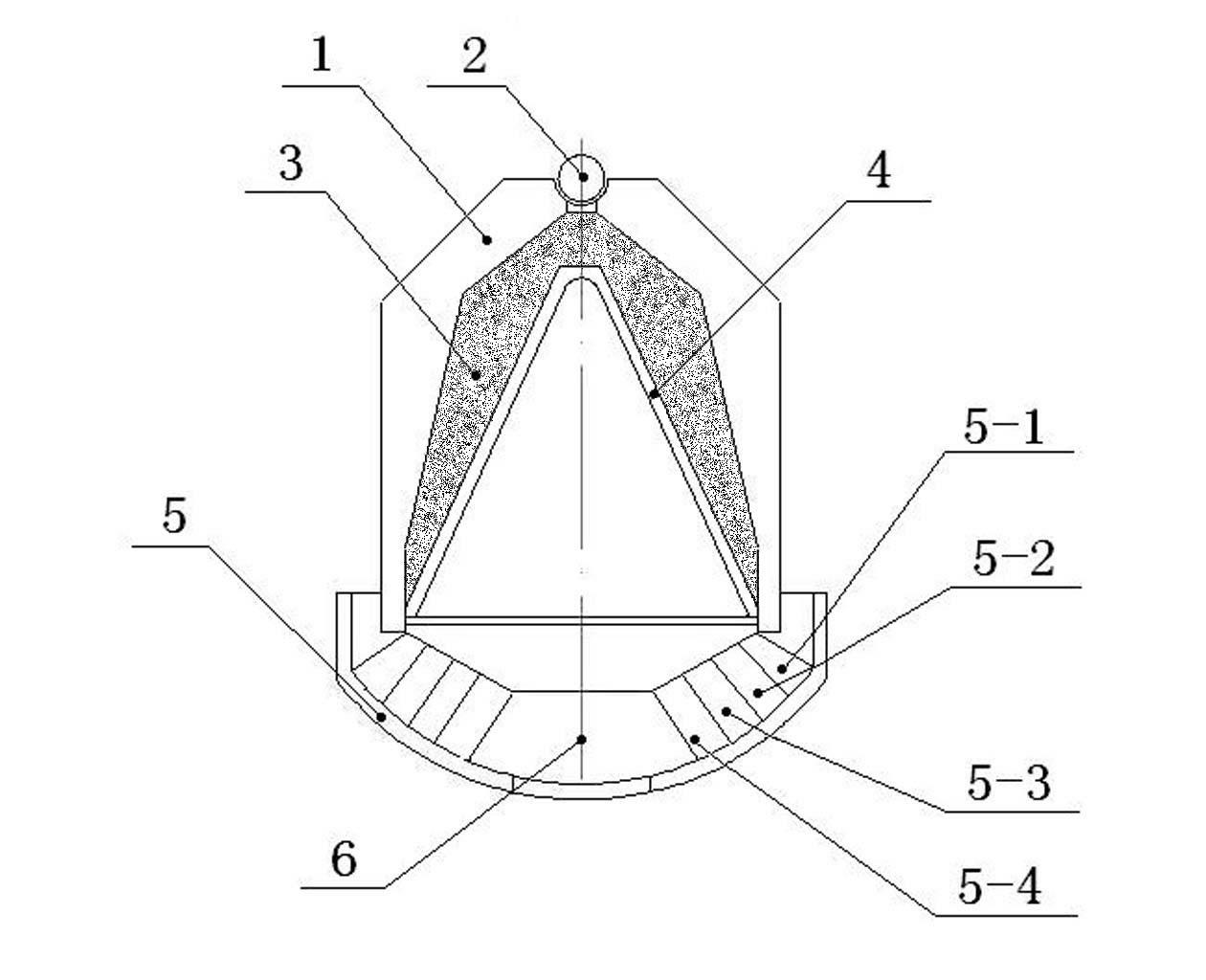

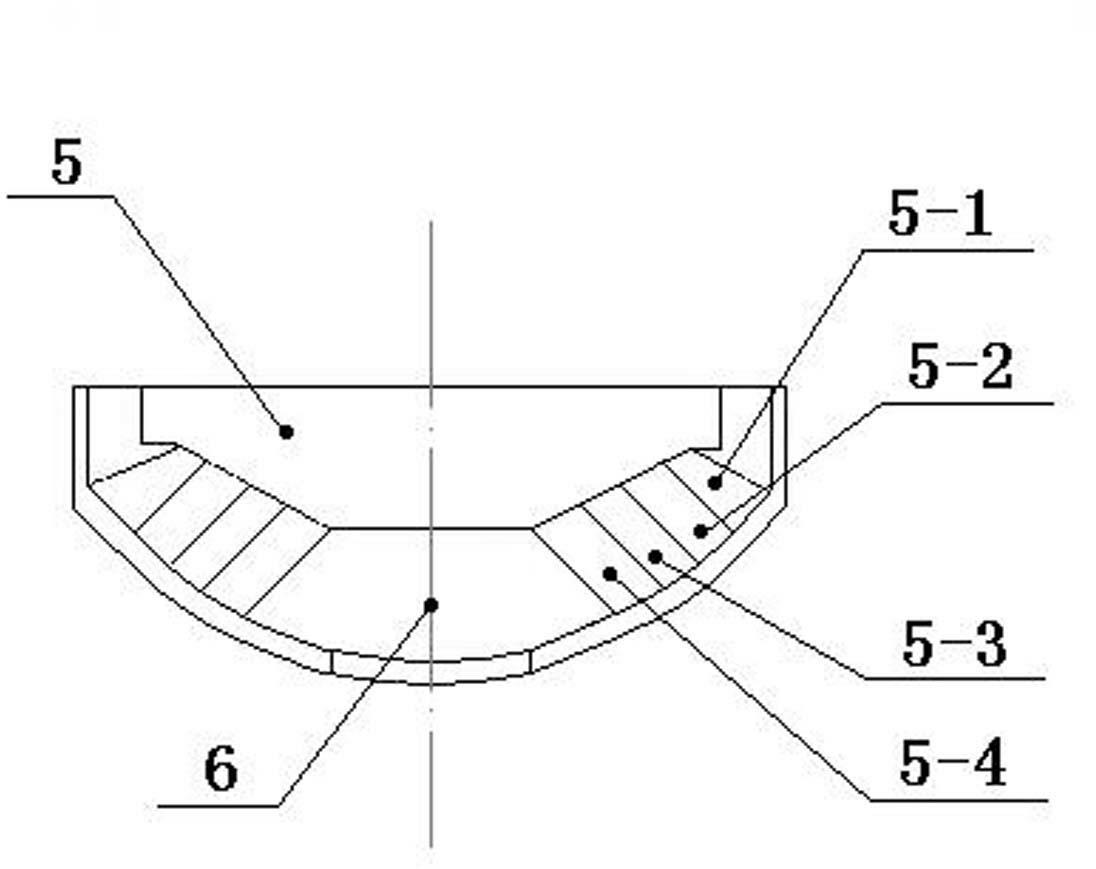

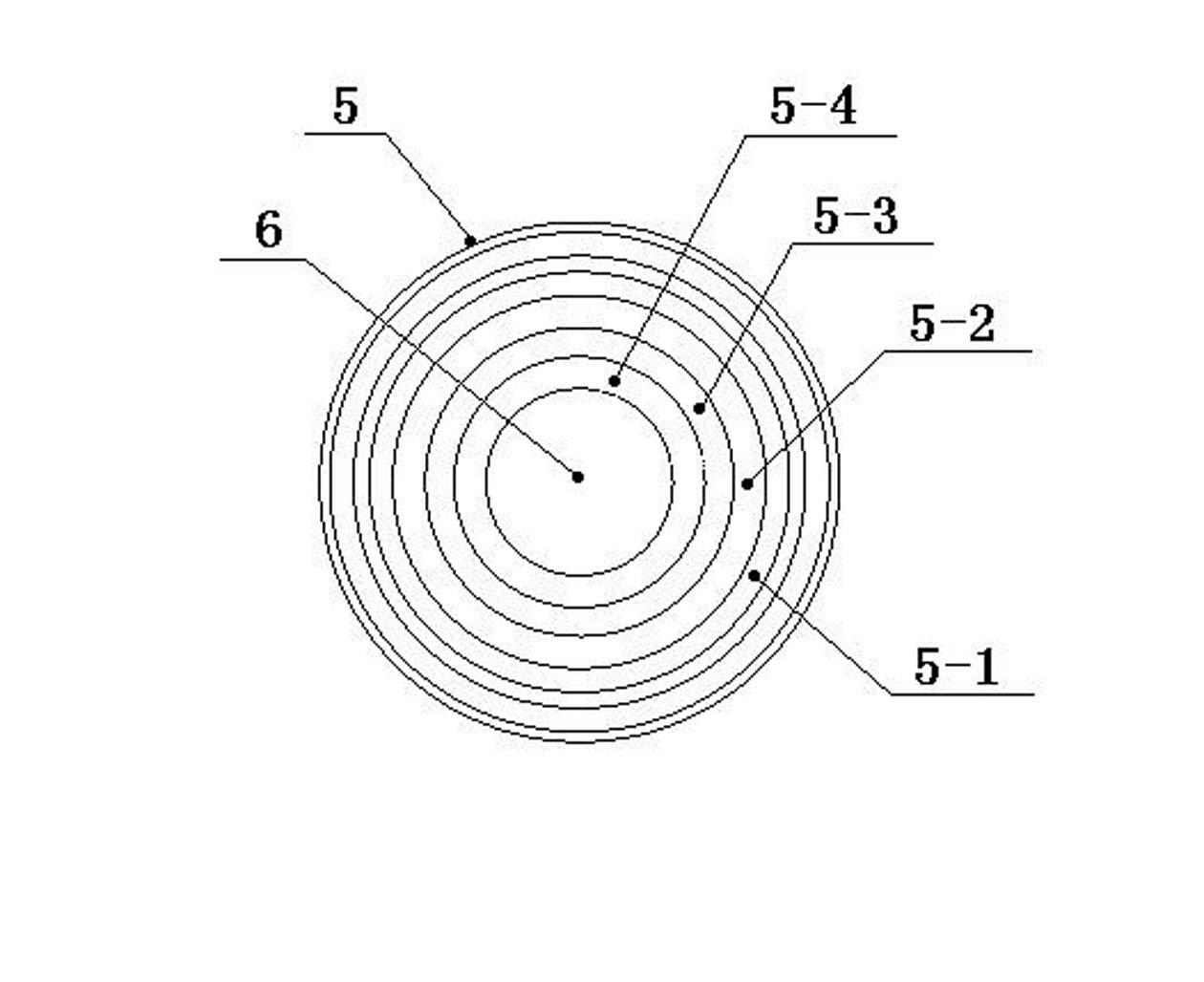

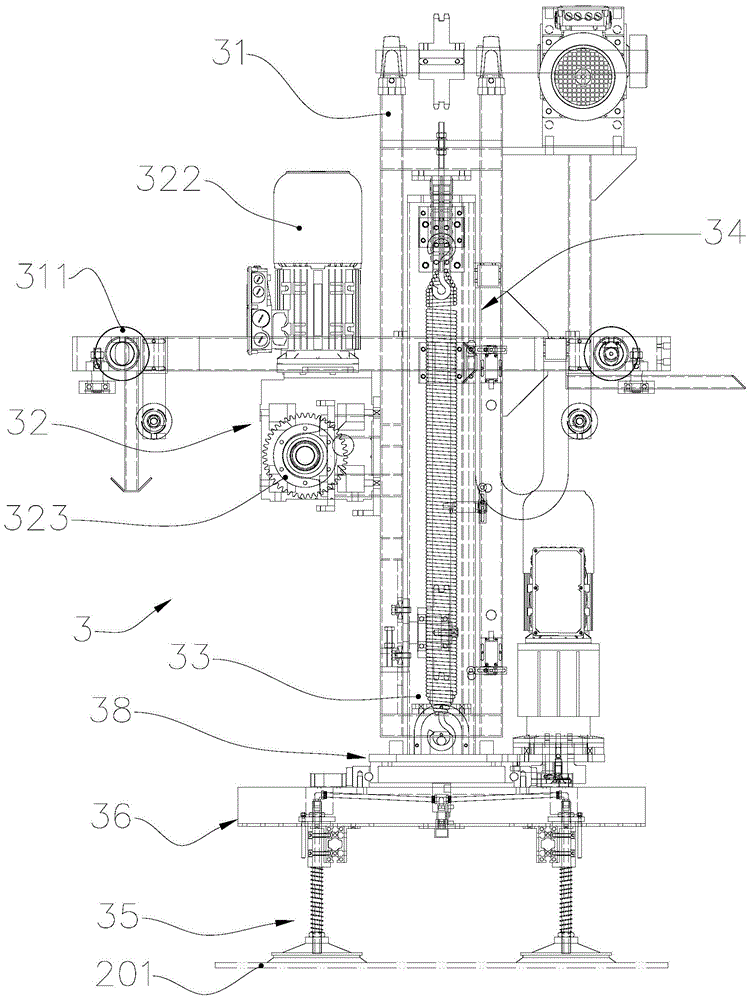

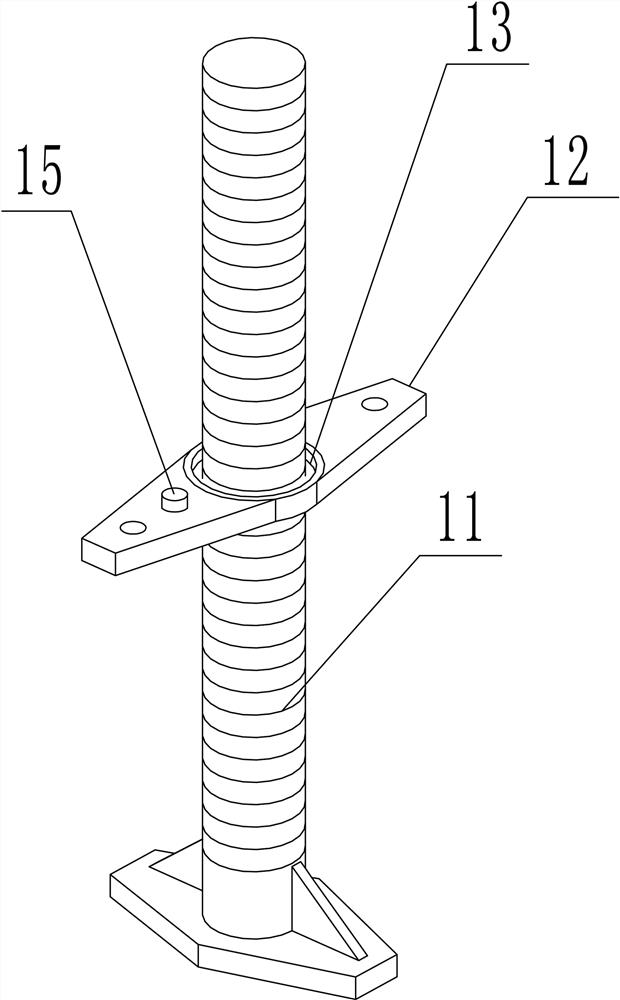

Long auger drilling and bottom expanding device and expanded anchor rod construction method

ActiveCN104453717AImprove the pull-out capacityImprove bearing capacityDrill bitsBulkheads/pilesSlurryUltimate tensile strength

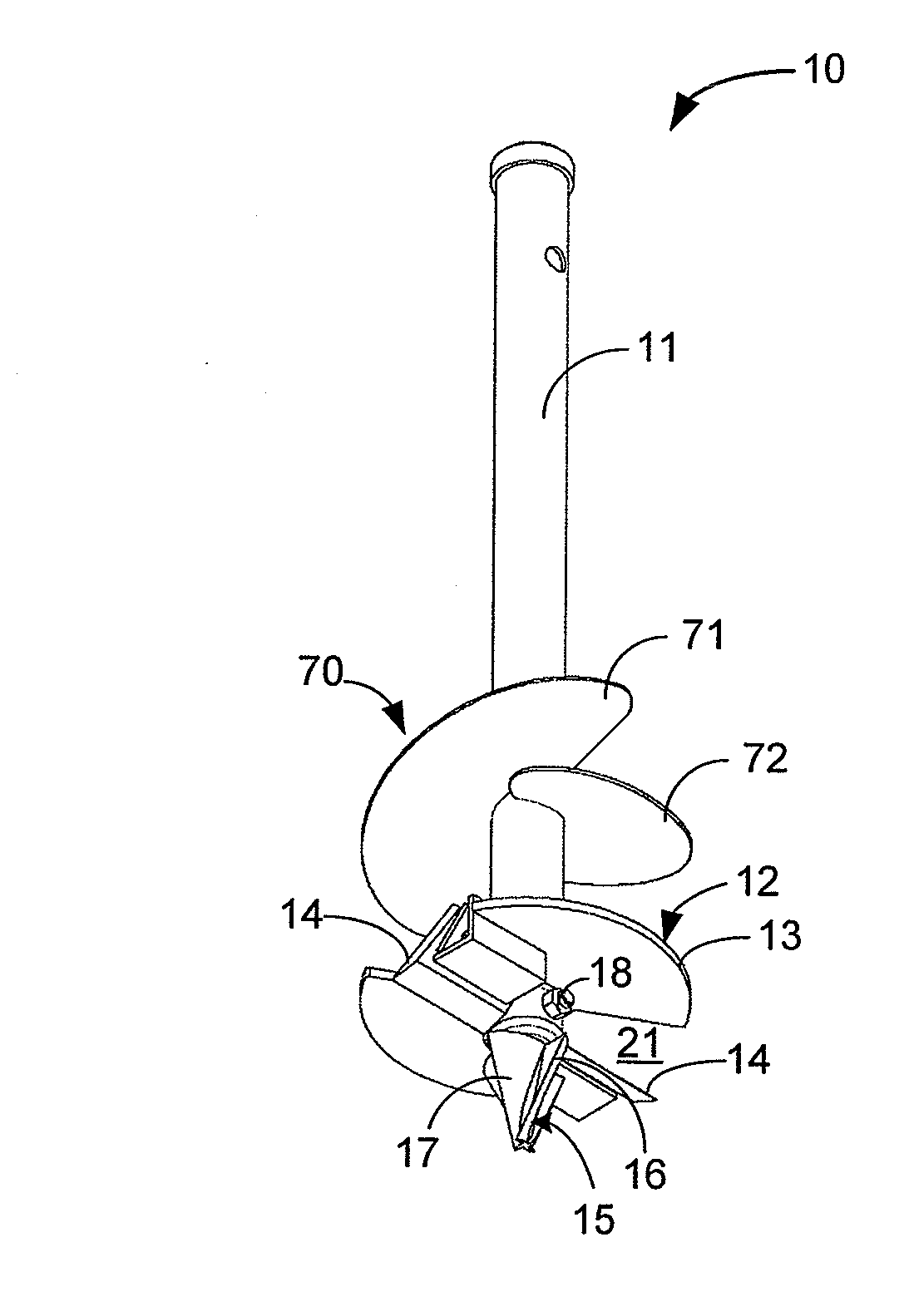

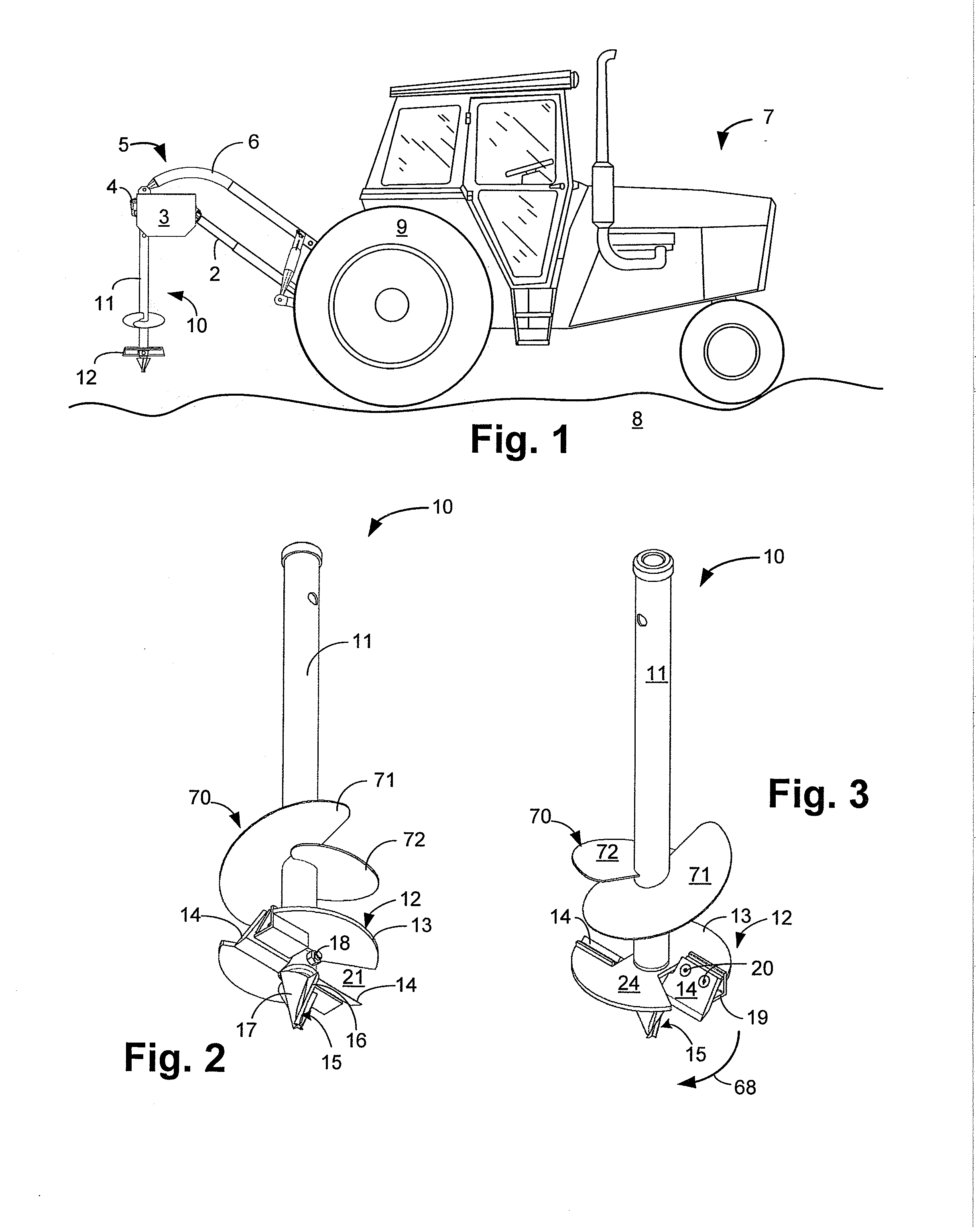

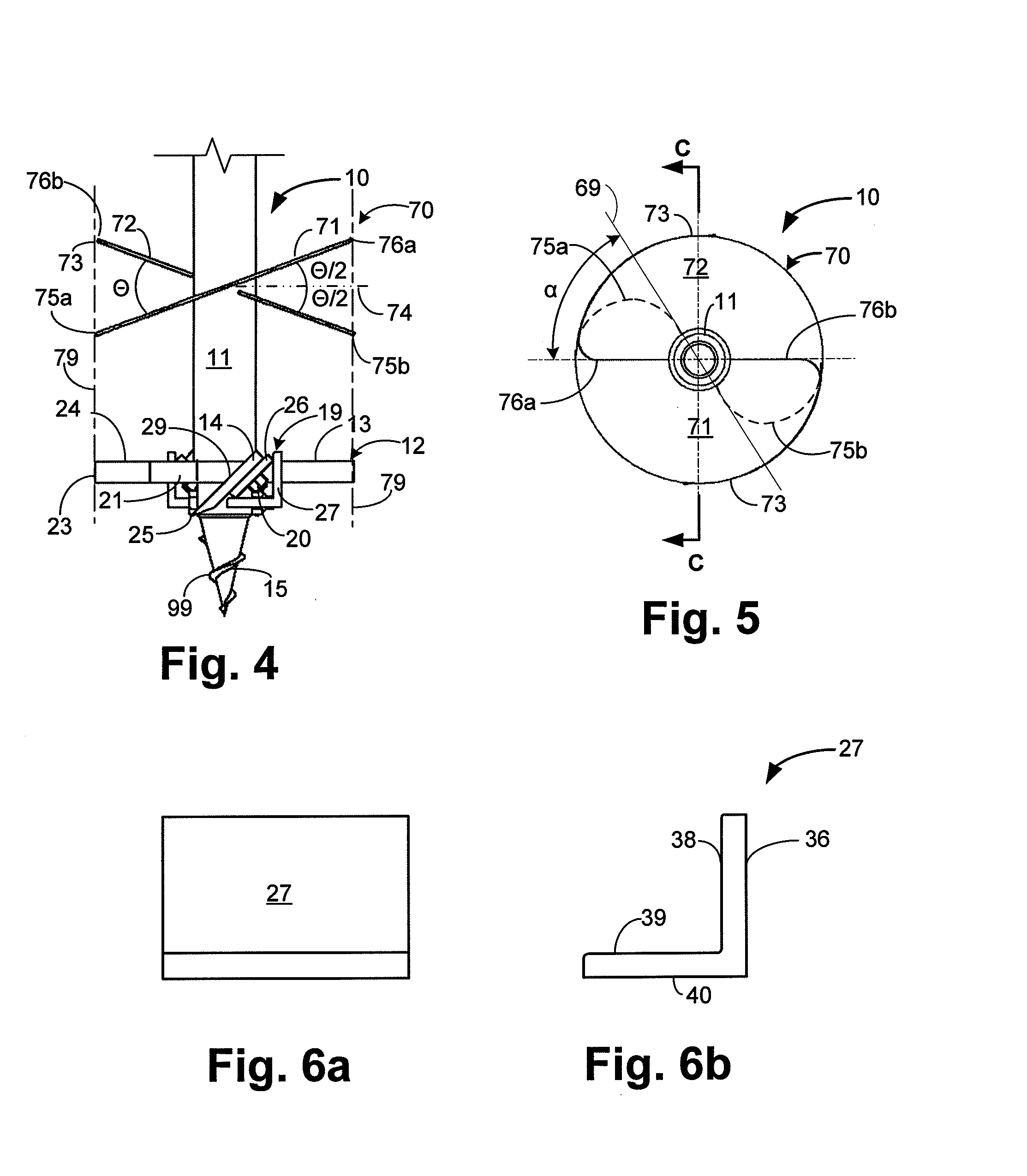

The invention relates to a long auger drilling and bottom expanding device and an expanded anchor rod construction method. The long auger drilling and bottom expanding device comprises an auger drilling rod with an auger blade and a front guide drill bit. The upper portion of the auger drilling rod is connected with a power box of a pile machine through a rotary connector, a slurry inlet is formed in the rotary connector, motors are arranged on the two sides of the upper portion of the power box, a broaching oil cylinder support and a broaching oil cylinder are arranged in the middle of the upper portion of the power box, a connecting lug is arranged in the middle of the upper portion of the oil cylinder support, the broaching oil cylinder is hinged to the broaching oil cylinder support through the connecting lug, the lower end of a piston rod of the broaching oil cylinder is connected with the top of a broaching connecting rod through a transfer connector, the lower portion of the broaching connecting rod is arranged in an axial central through hole of the auger drilling rod, a rotary broaching device is arranged between the front guide drill bit and the auger drilling rod, the lower end of the broaching connecting rod is connected with the rotary broaching device, and the lower portion of the rotary broaching device is connected with the front guide drill bit. According to the long auger drilling and bottom expanding device and the expanded anchor rod construction method, noise, vibration and slurry are avoided in the construction process, an anchoring body is high in strength, good in quality, low in cost, high in working efficiency and good in environmental friendliness, and the uplift bearing capability of an anchor rod is high.

Owner:SHANDONG ZHENGYUAN CONSTR ENG

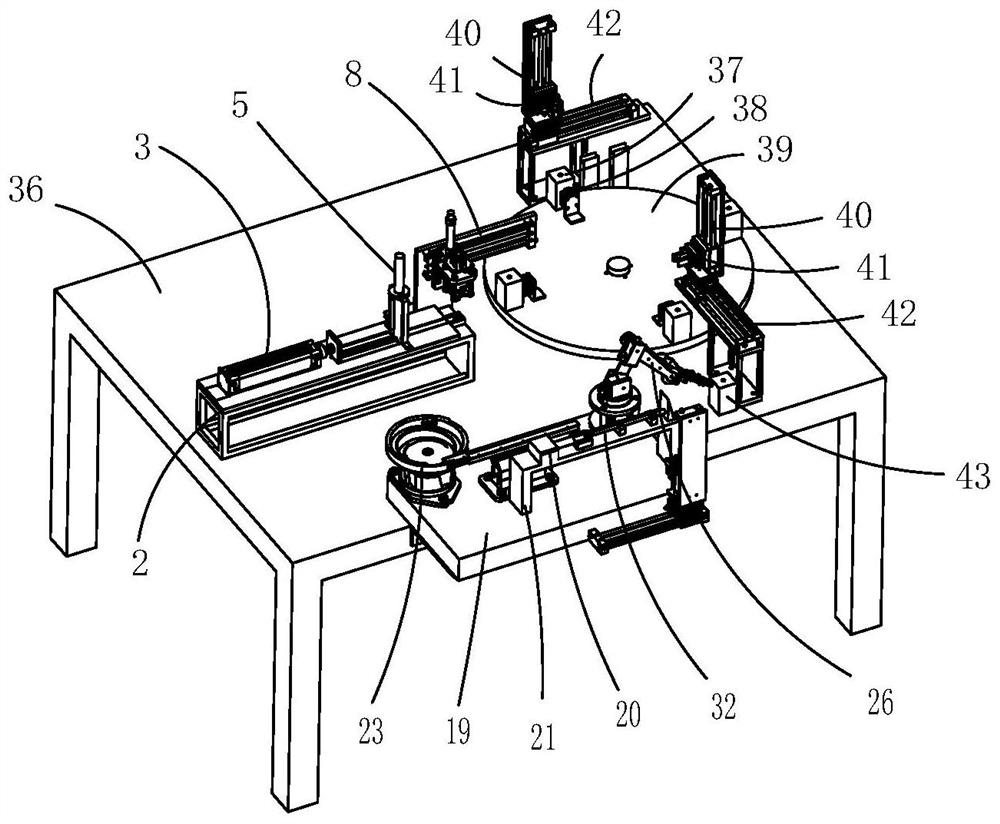

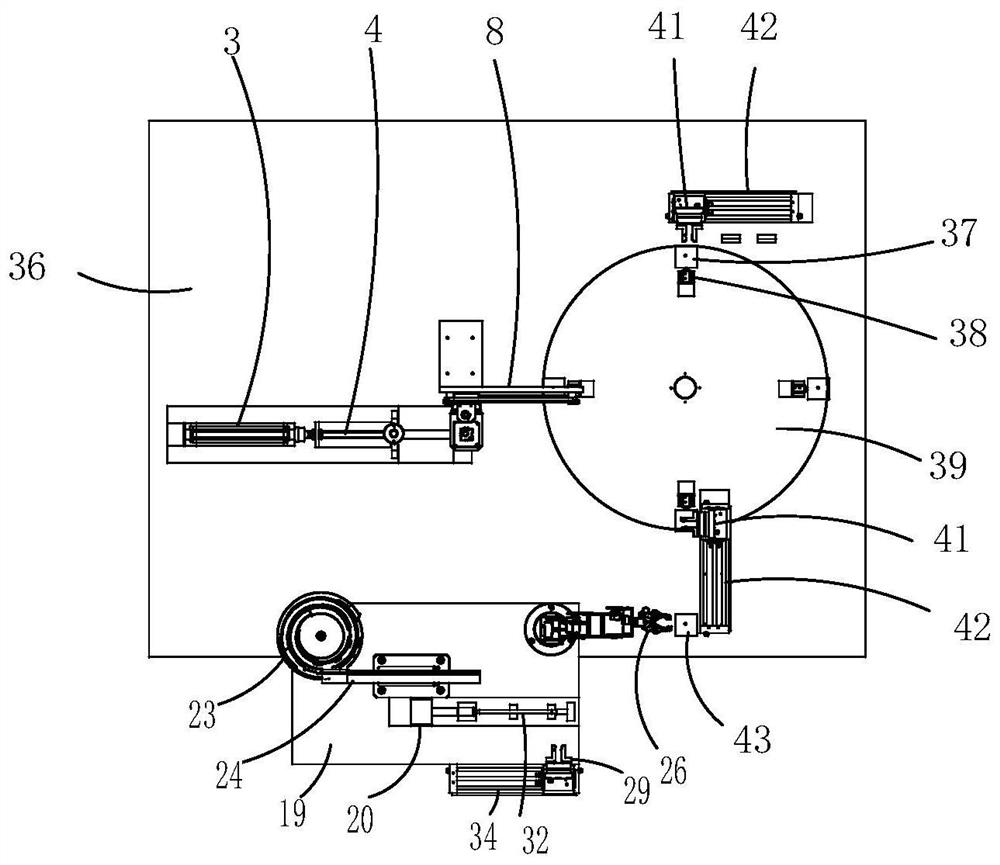

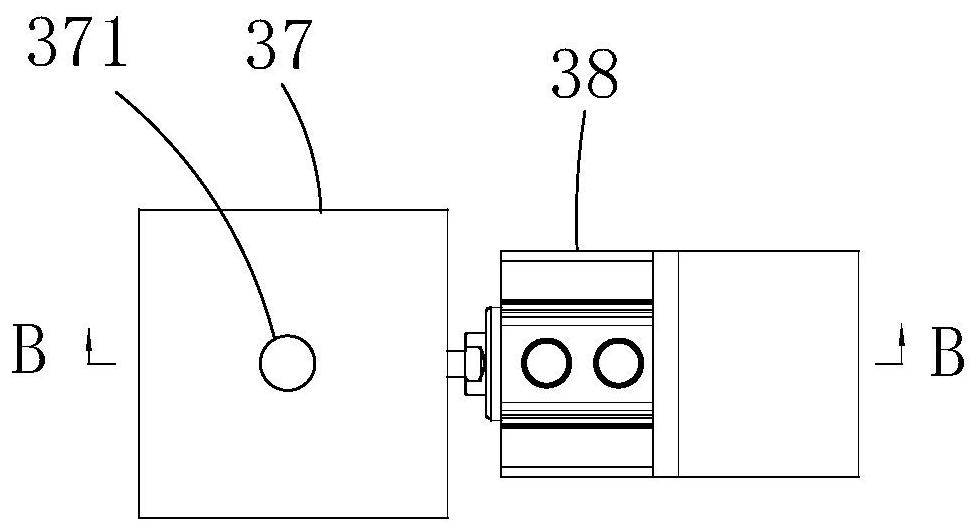

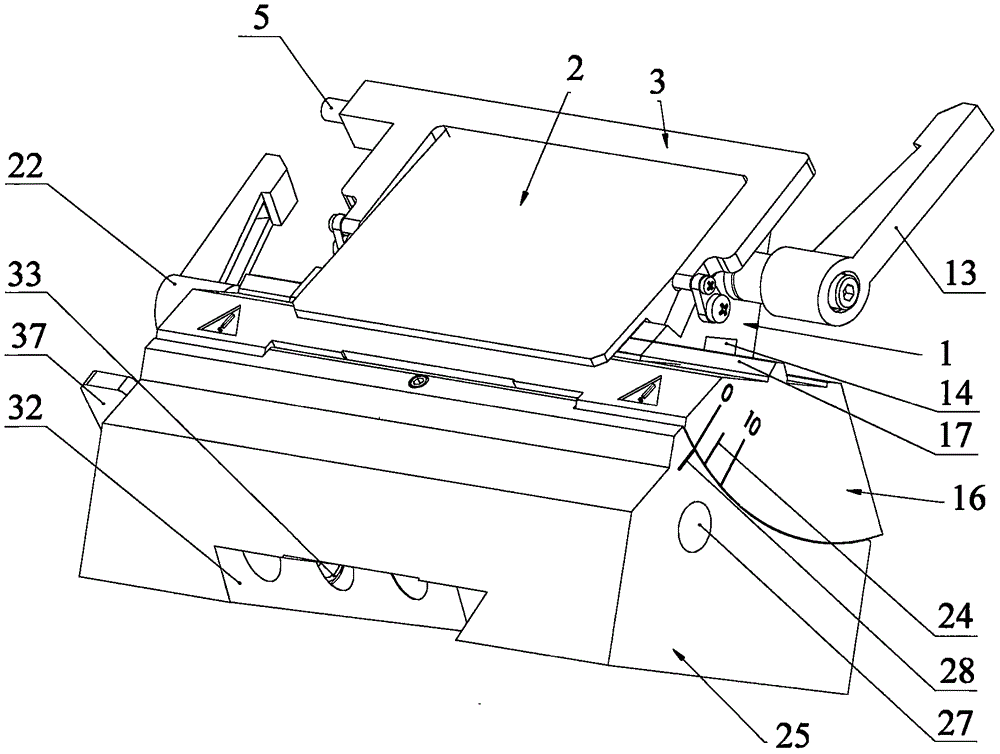

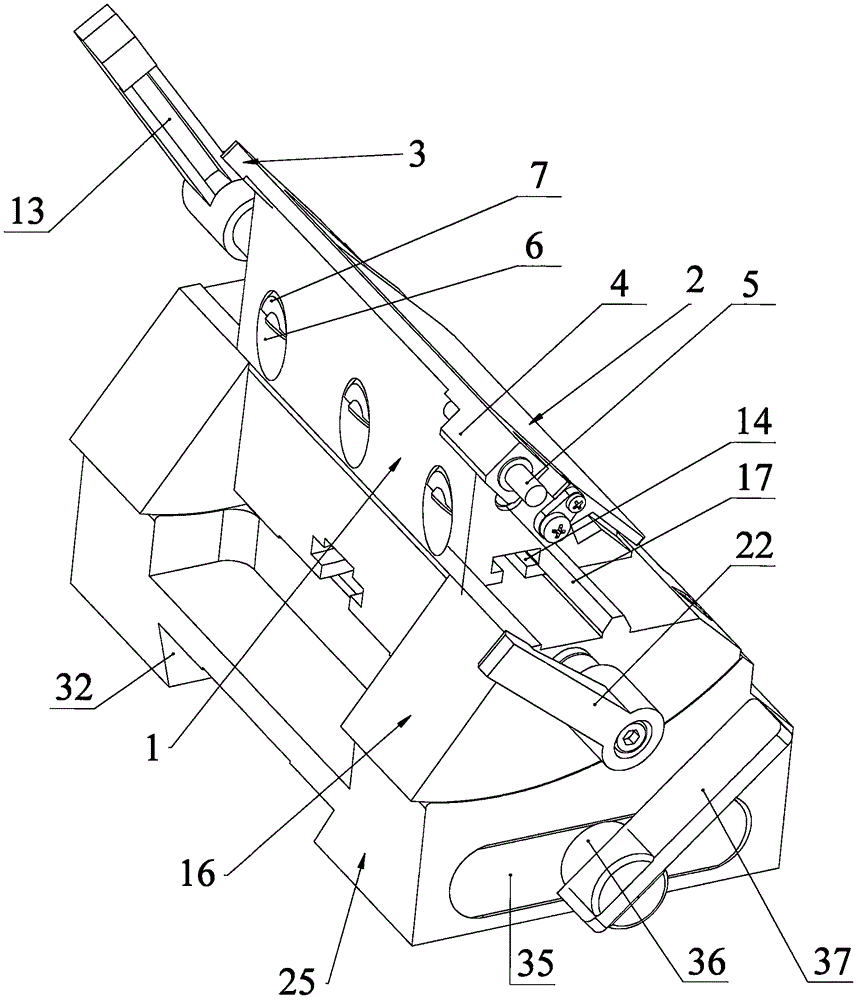

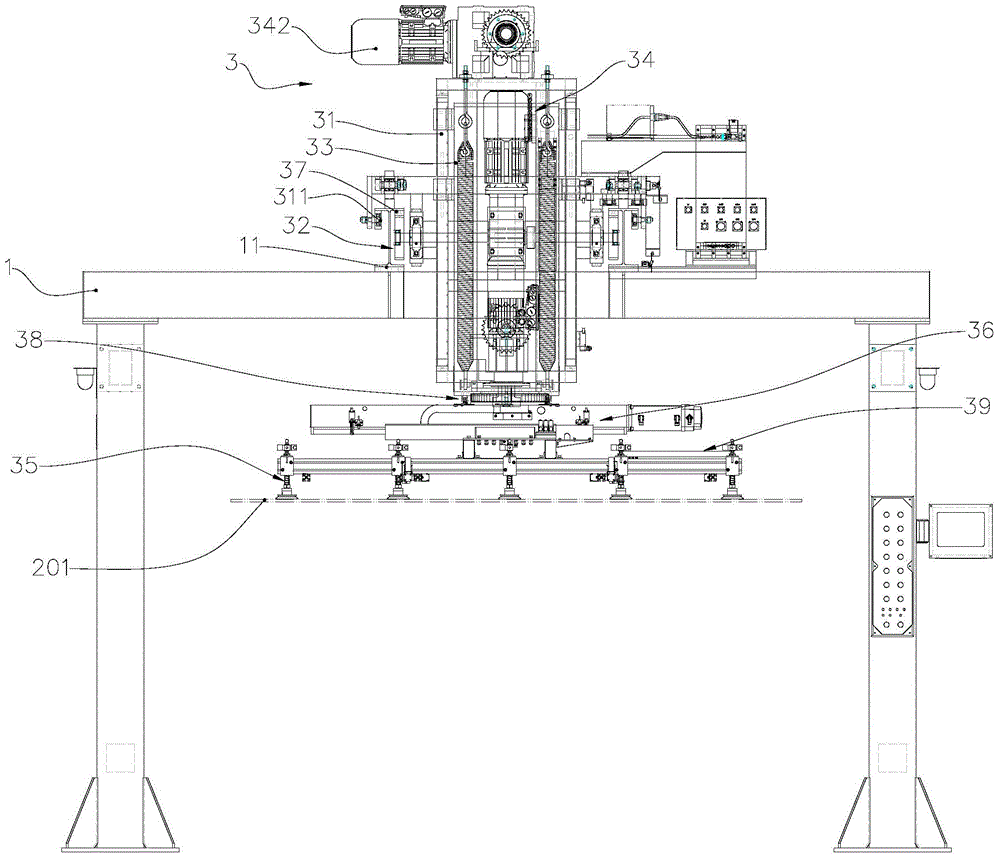

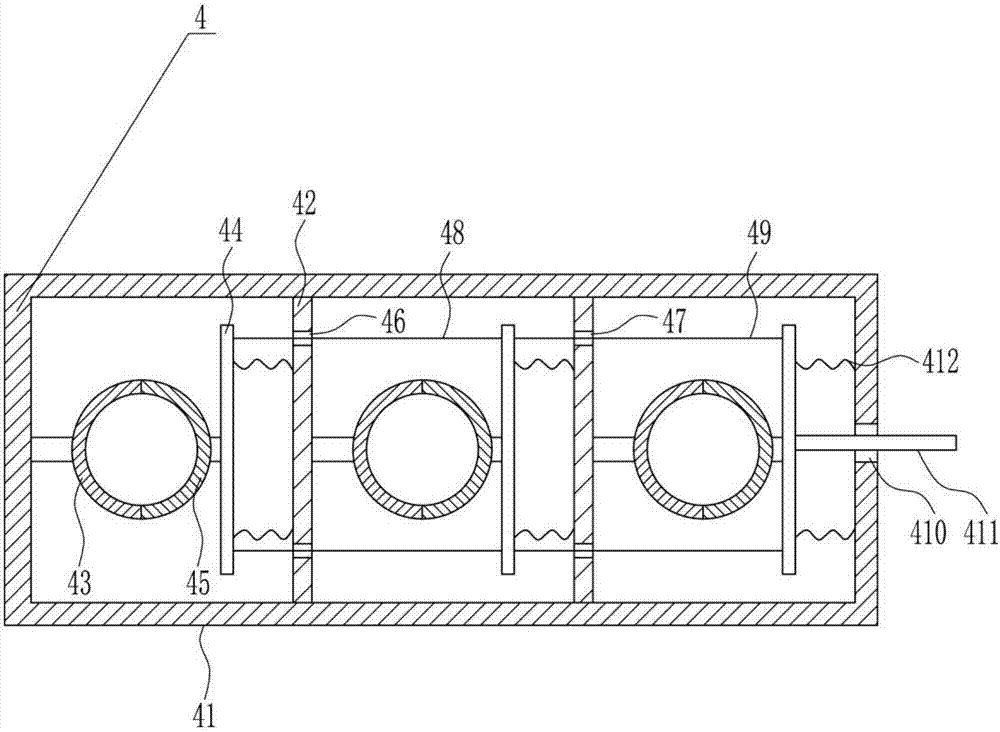

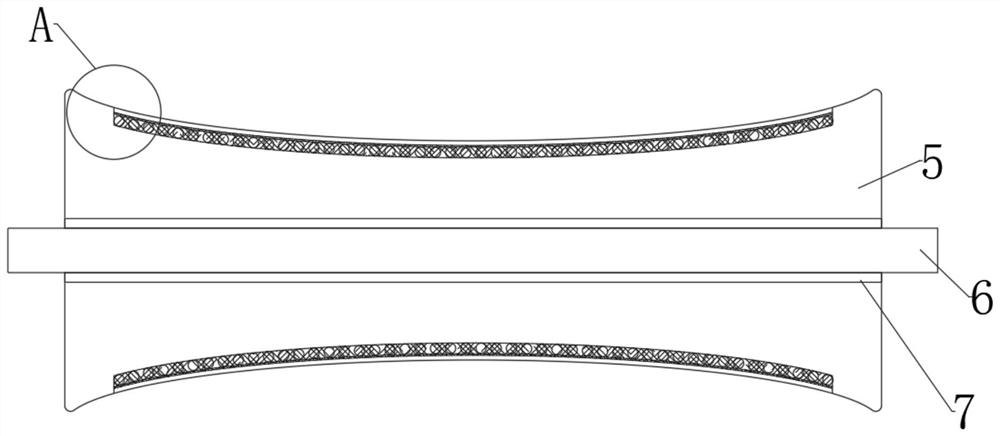

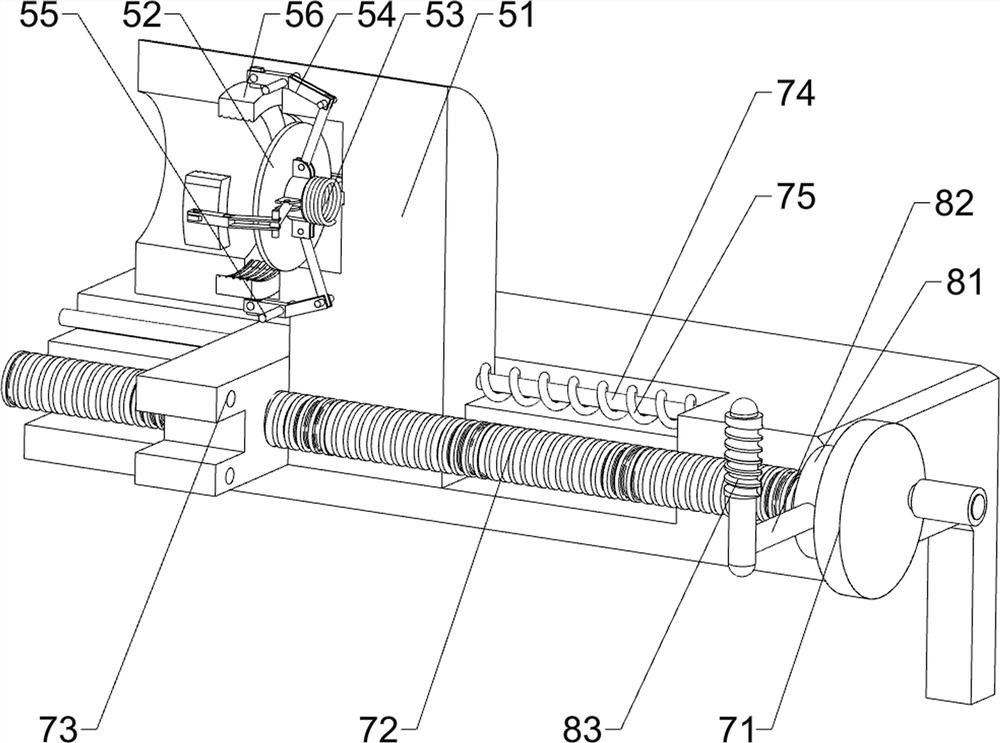

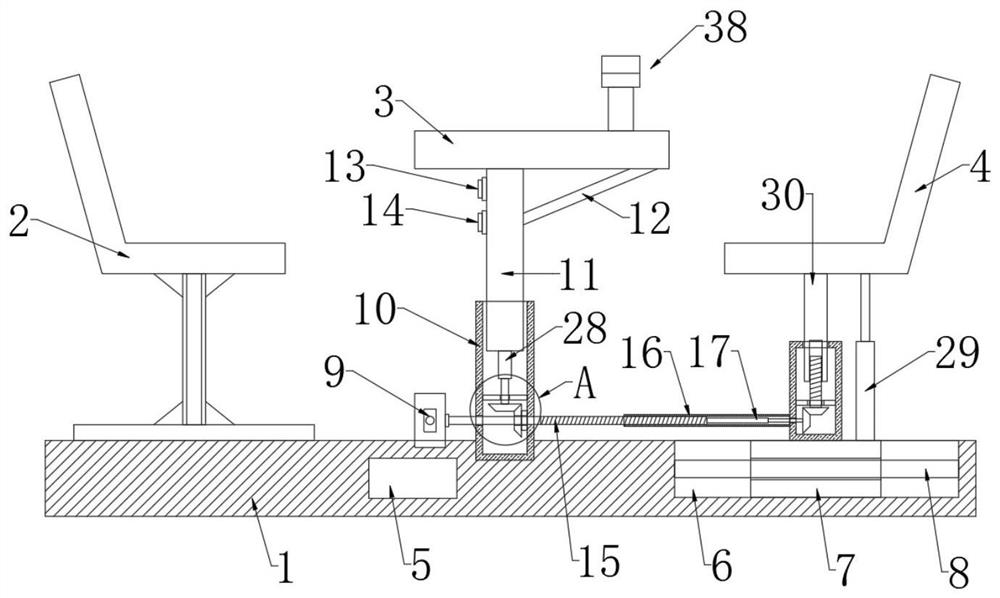

Automatic assembling machine for gas spring

ActiveCN111872674ANo manual operationImprove assembly efficiencyAssembly machinesMetal working apparatusGas springEngineering

The invention provides an automatic assembling machine for a gas spring, and belongs to the technical field of gas spring automatic assembly. The automatic assembling machine comprises a support platform, a rotating disc, a piston rod press fitting mechanism, a piston rod feeding mechanism and a sealing ring feeding mechanism; the piston rod press fitting mechanism comprises an assembly rack, a multi-degree-of-freedom manipulator, a piston rod grabbing manipulator assembly and a guide sleeve vibration feeding assembly; the piston rod grabbing manipulator assembly grabs a piston rod to the assembly rack, the guide sleeve vibration feeding assembly feeds a guide sleeve to a feeding position, the multi-degree-of-freedom manipulator places the guide sleeve to the assembly rack, and a press-fitting air cylinder presses the guide sleeve into the piston rod; the piston rod feeding mechanism is used for vertically placing the piston rod obtained after the guide sleeve is assembled onto the rotating disc; and the sealing ring feeding mechanism grabs a sealing ring and presses the sealing ring on the piston rod obtained after the guide sleeve is assembled. According to the automatic assembling machine for the gas spring, manual operation is not needed in the installation process, the assembly efficiency can be improved, and the stability of the assembly quality is improved.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

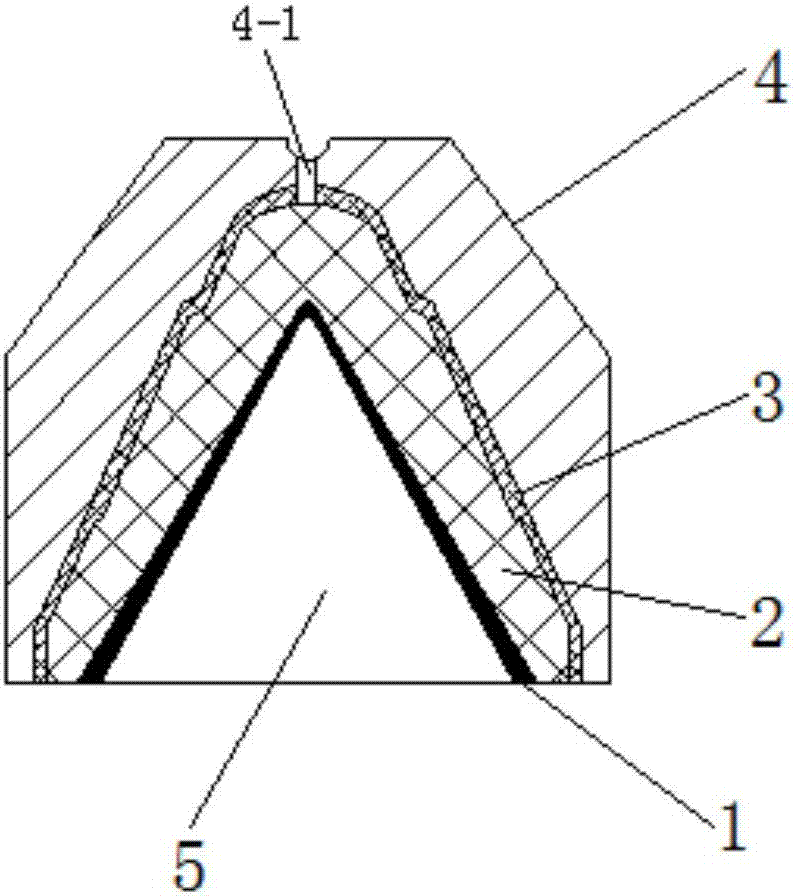

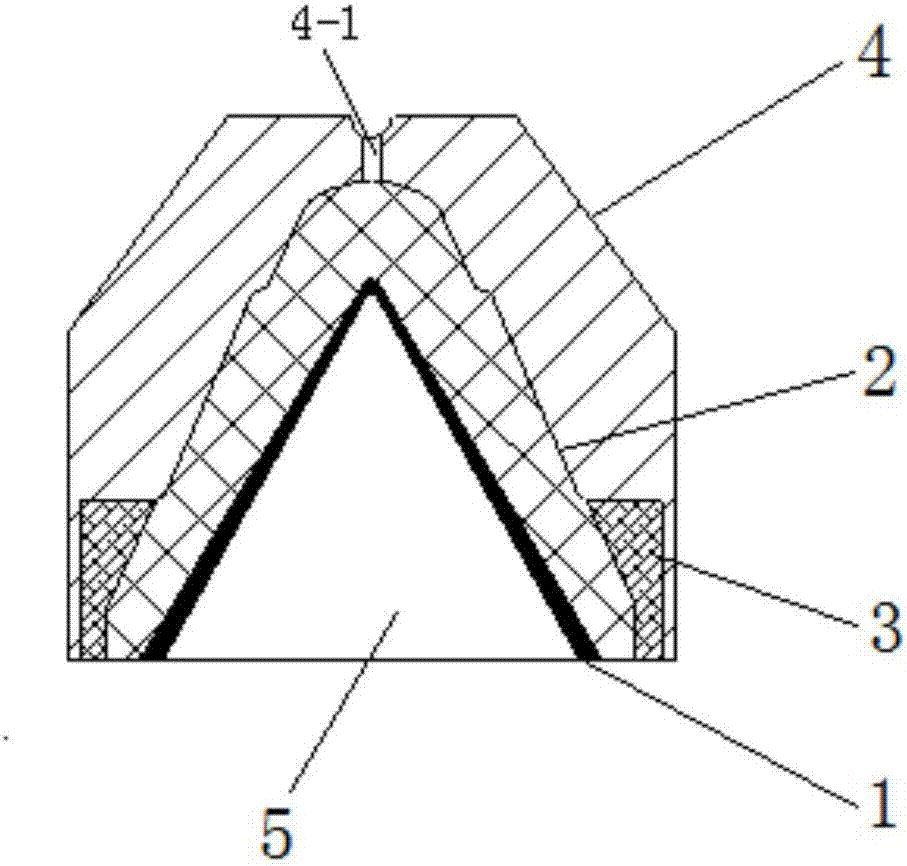

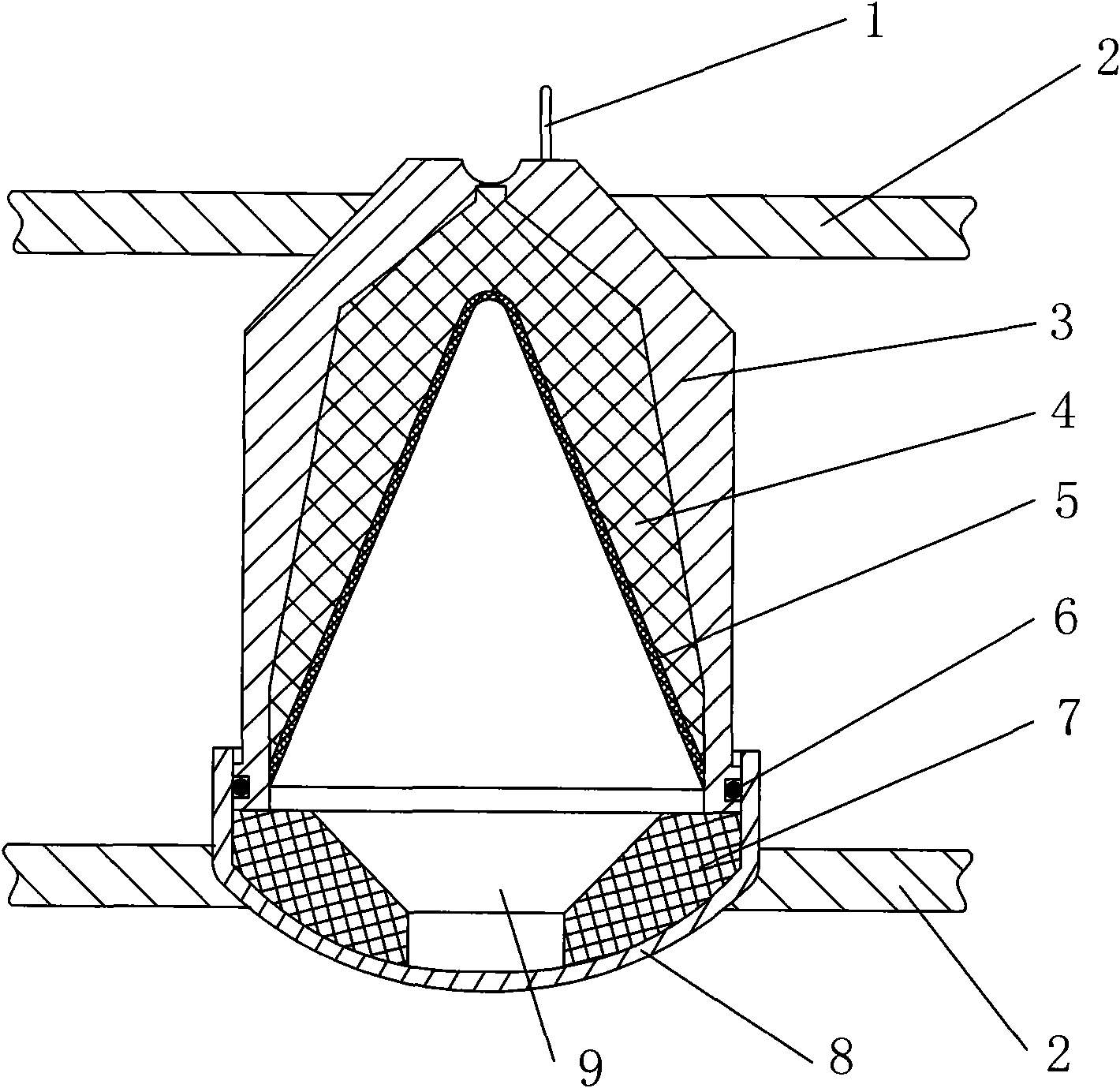

Double-effect perforating bullet containing active material layer, and active material

PendingCN107130946ASimple structureCompact structureFluid removalExplosivesAl powderManufacturing technology

The invention discloses a double-effect perforating bullet containing an active material layer, and an active material. The double-effect perforating bullet comprises a common perforating bullet and the active material layer, wherein the common perforating bullet comprises a cartridge shape cover, a cartridge case and a high explosive layer; the active material layer is arranged between the cartridge case and the high explosive layer; the active material is prepared from the following materials: aluminum powder, nickel powder, magnesium powder, potassium perchlorate, ammonium perchlorate, potassium nitrate, ferric oxide, copper oxide, polytetrafluoroethylene, fluorine rubber, and the like. The double-effect perforating bullet is reasonable in structural design and safe and reliable in manufacturing technology, and has double effects of perforating and removing a perforation compaction band and fracture forming in a pore path.

Owner:NORTH SCHLUMBERGER OILFIELD TECH XIAN

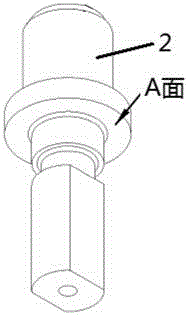

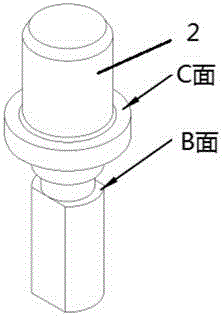

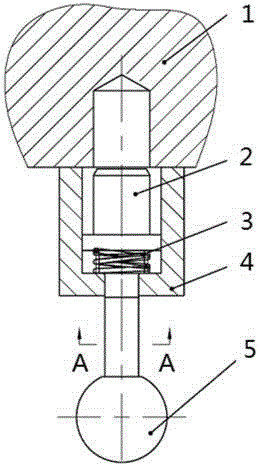

Automatic locking safety pin

The invention discloses an automatic locking safety pin, and the safety pin comprises a safety pin main body. The upper end of a cylinder of the safety pin main body is used for cooperating with a pin hole of mobile equipment. The lower end face of a convex cylinder of the safety pin main body and an inner end of a circular hole of fixed equipment abut against springs. An end, passing out from the circular hole of the fixed equipment, of a cut-surface cylinder of the safety pin main body is fixedly provided with a handle. The main body of the safety pin main body is a multi-layer step pin, and is sequentially provided with the cylinder, the convex cylinder, a fine cylinder, a thin neck and the cut-surface cylinder from the top to the bottom. The safety pin does not need assembly welding, is simple in process, and is convenient and quick in replacement. Moreover, the safety pin does not need to be inserted into a pin seat when the safety pin is not in use, thereby effectively reducing production accidents, and improving the production.

Owner:MCC SFRE HEAVY IND EQUIP

Body-free coaxial following synergistic perforator

The invention discloses a body-free coaxial following synergistic perforator, which comprises a body-free perforator firing mount and a body-free perforating bullet arranged on the firing mount, wherein the body-free perforating bullet comprises a cartridge case, a powder-type cover and a high explosive, the front end outer wall of the cartridge case is provided with an initiation half slot and a pressure wire, the front end inner wall of the cartridge case is provided with a booster hole, the back end of the cartridge case is provided with a fracturing powder box airtightly, and special fracturing powder is poured in the fracturing powder box and is distributed annularly along the inner wall of the fracturing powder box, wherein the special fracturing powder is prepared by evenly mixing ammonium permanganate of which the weight percentage is between 50 and 80 percent and aluminum powder of which the weight percentage is between 20 and 50 percent. The body-free coaxial following synergistic perforator has a simple structure and reliable mounting, the special fracturing powder is initiated and performs pulse fracturing on stratums directly while the powder-type cover forms high-speed jet flow to perform perforation, and the fracturing effect of the perforation is good, thus the body-free coaxial following synergistic perforator is particularly suitable for operations of high-density and low-permeability stratums.

Owner:XIAN RUITONG ENERGY TECH

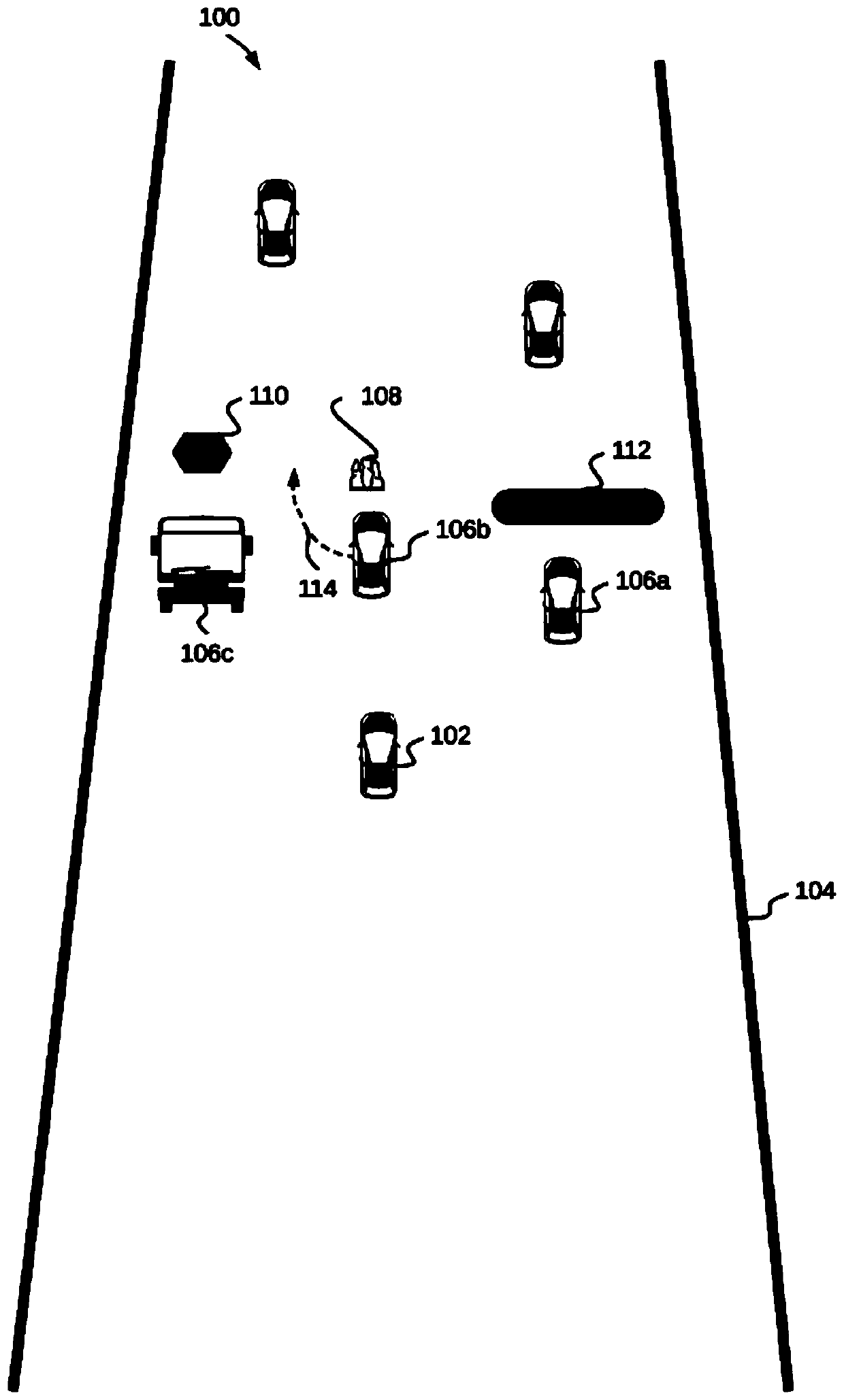

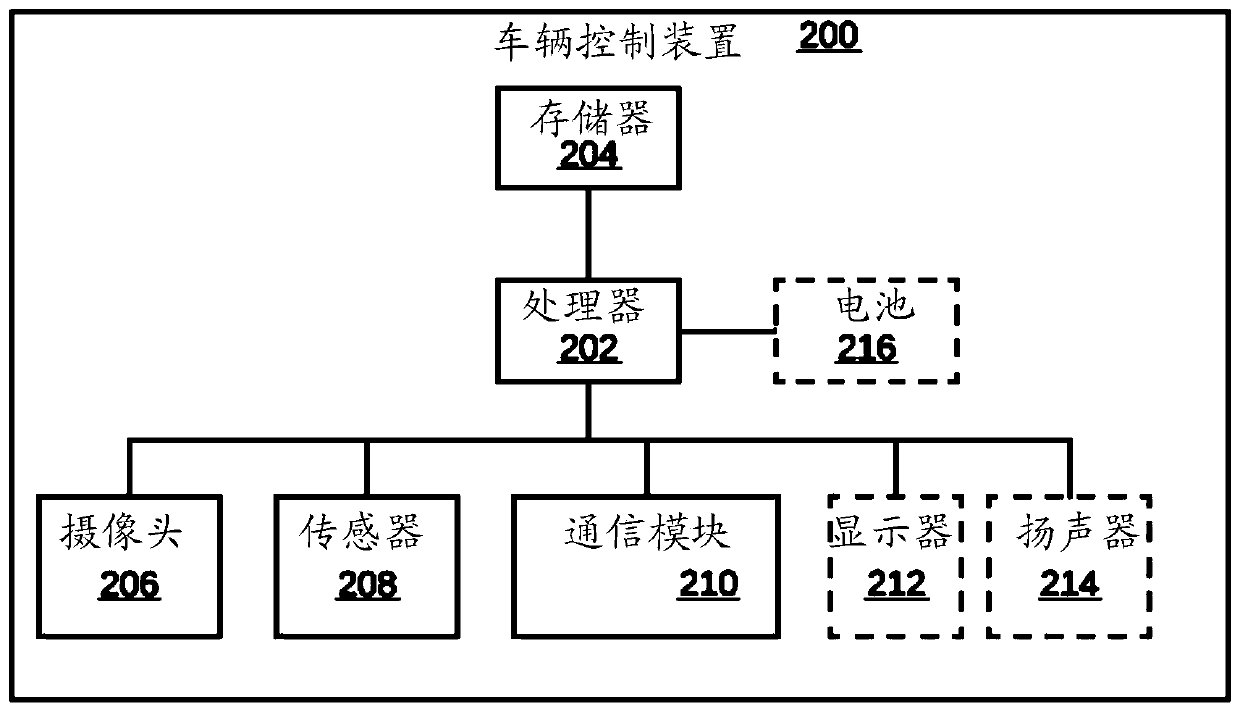

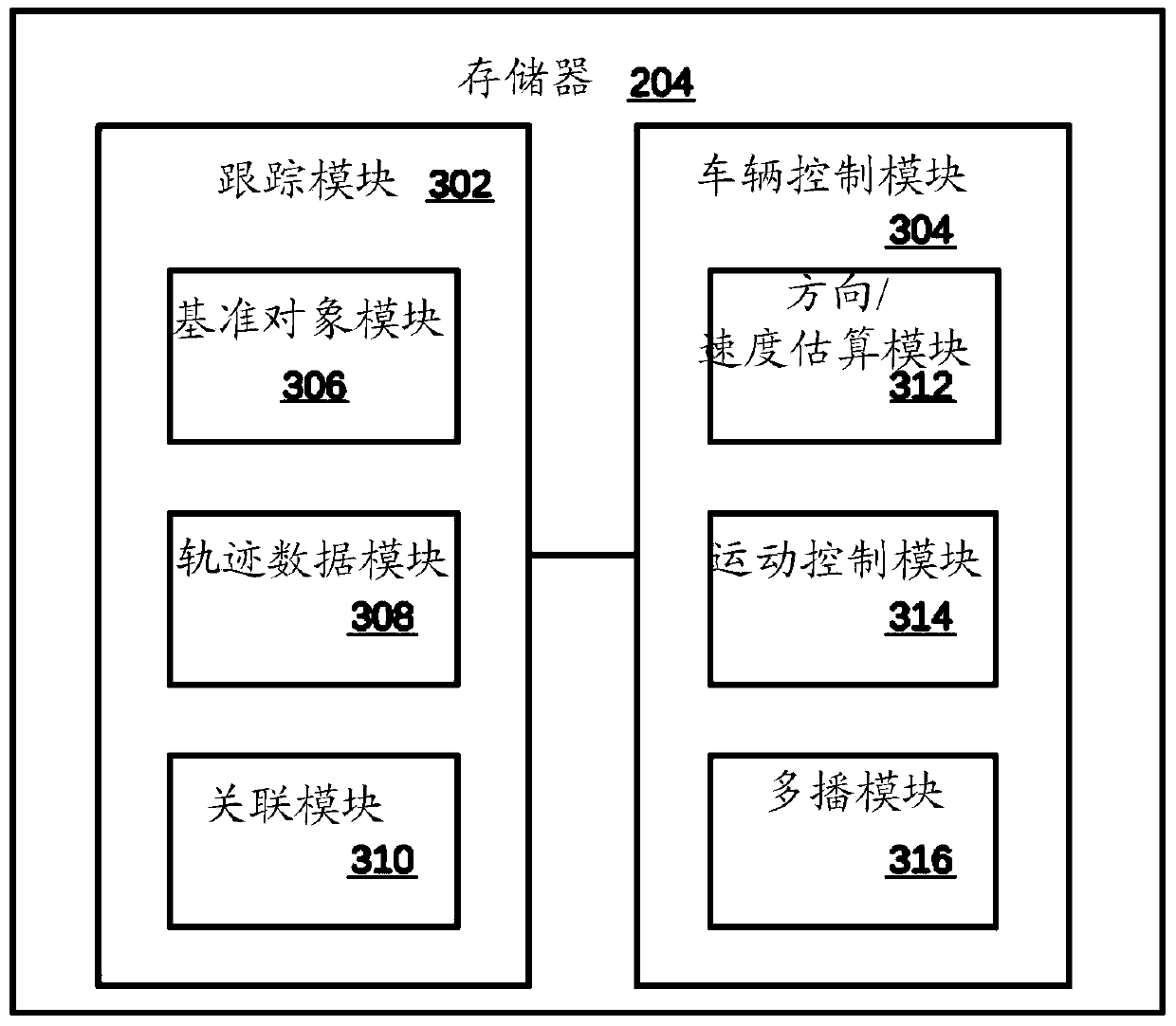

Method and device for controlling vehicle based on neighboring vehicles

ActiveCN110920611ALess prone to accidentsEfficient clusteringImage enhancementImage analysisImage captureVehicle control

Owner:WIPRO LTD

Blade rest of slicing machine

ActiveCN106239608AAvoid scratchesEasy to useMetal working apparatusEngineeringMechanical engineering

The invention discloses a blade rest of a slicing machine. The blade rest comprises a mounting seat, and a clamping piece which is matched with the mounting seat and used for clamping a blade. The blade rest further comprises a rotary rack, a blade dismounting piece and an elastic piece; the rotary rack is rotationally mounted on the mounting seat, and is provided with a first working position and a second working position; the rotary rack is turned upwards to be in the first working position to cover the blade, and is turned downwards to be in the second working position; the blade dismounting piece is slidingly arranged at the free end of the rotary rack, is used be matched with the blade and pushes the blade out of the mounting seat when the rotary rack is located in the first working position; and the elastic piece is used to allow the blade dismounting piece to be reset. With the adoption of the rotary rack, after slicing operation is finished, the rotary rack can be turned upwards to be in the first working position, by this time, the rotary rack can cover the blade, the blade can be prevented from scratching people and the blade can also be protected; with the design of the blade dismounting piece and the elastic piece, by pressing the blade dismounting piece, the blade dismounting piece moves to push the blade out of the mounting seat, so that manual taking-out is facilitated, and the possibility of accidents is low.

Owner:浙江省金华市科迪仪器设备有限公司

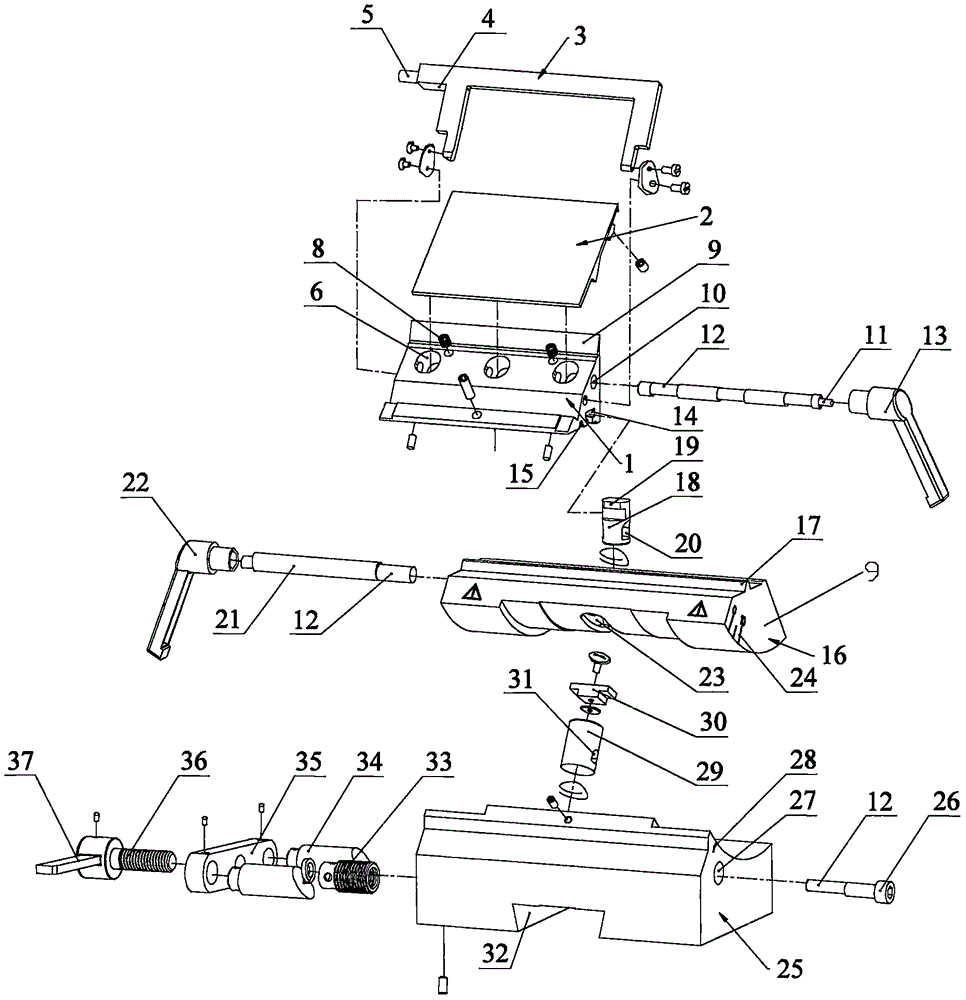

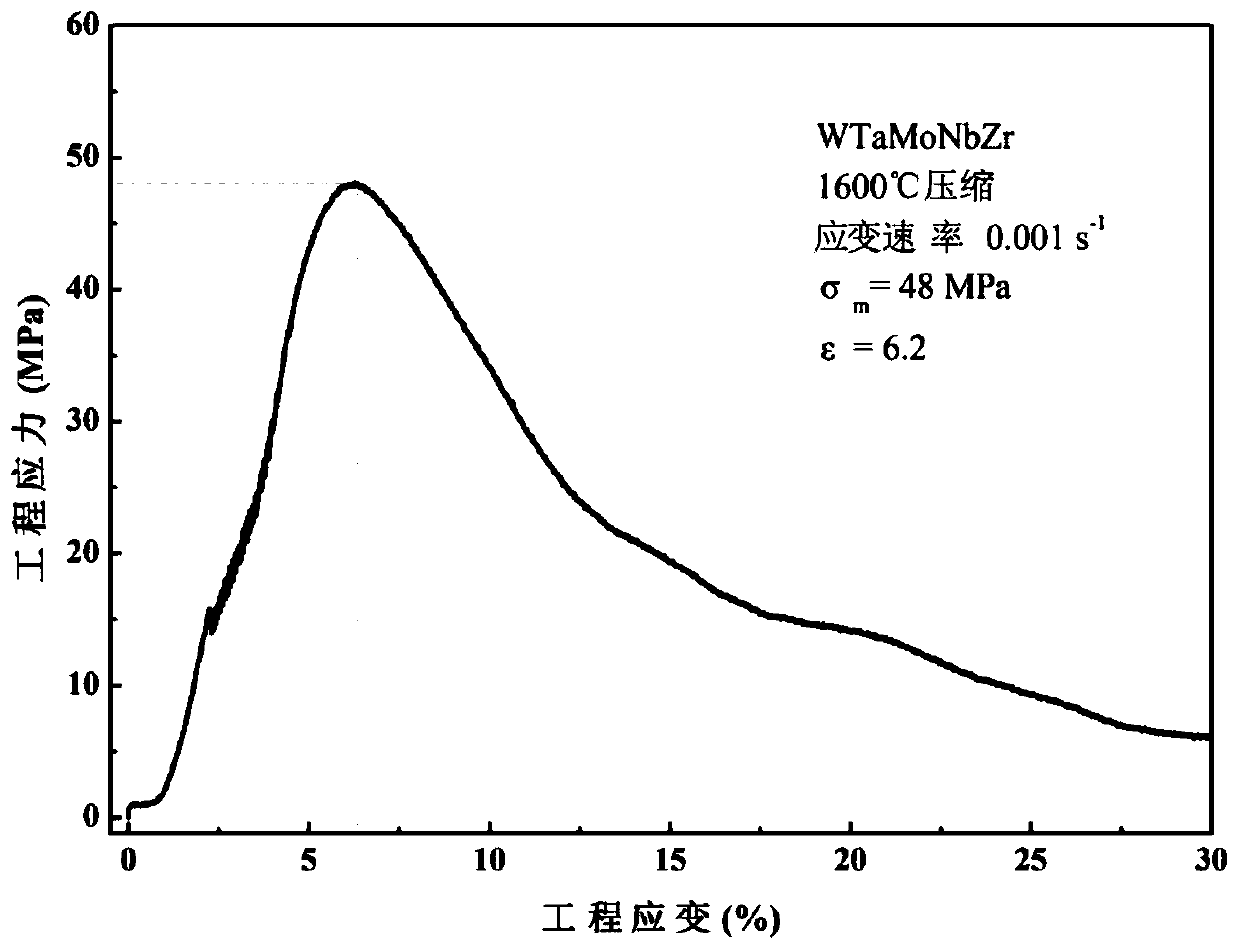

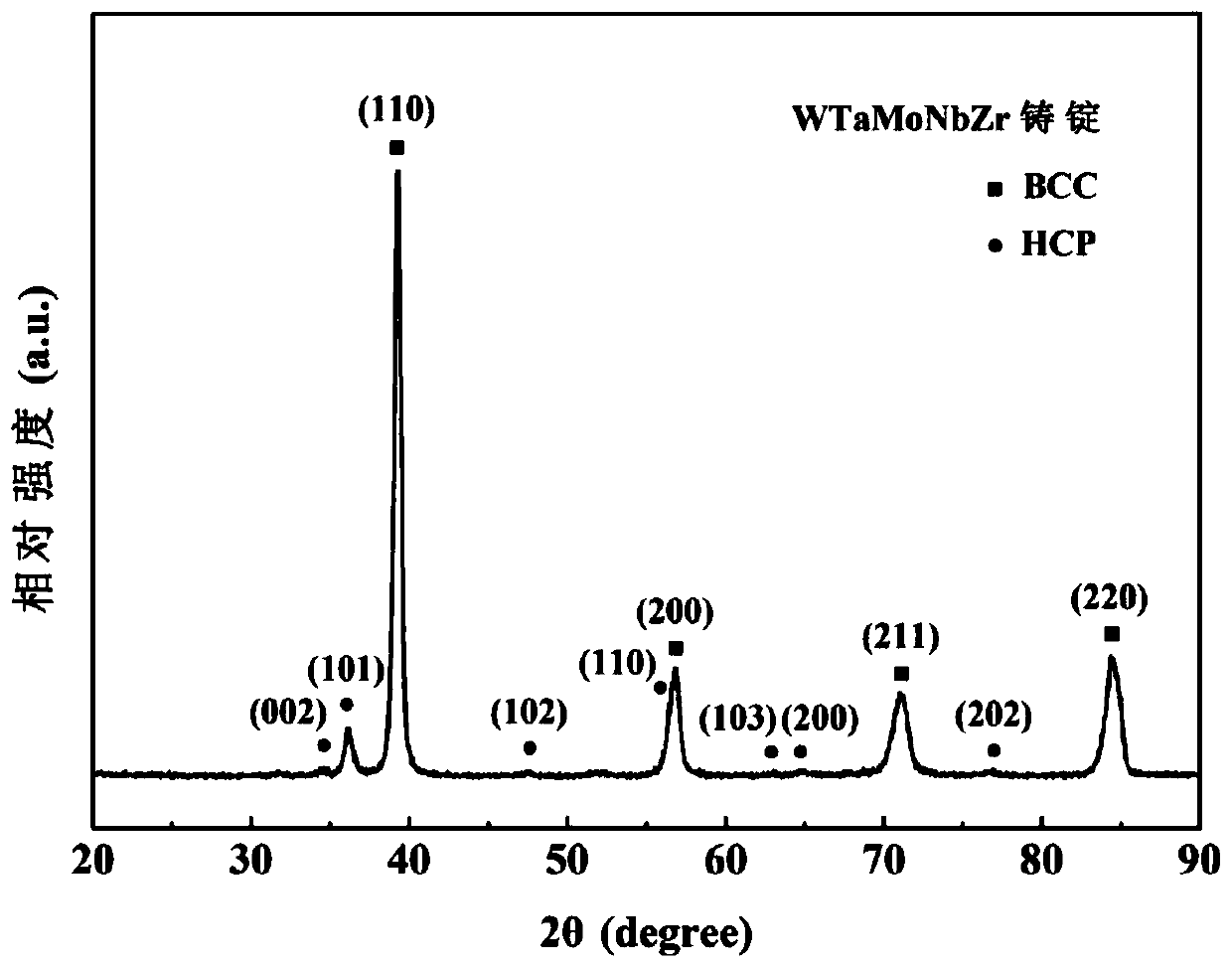

W-Ta-Mo-Nb-Zr high-temperature high-entropy alloy and preparation method thereof

ActiveCN111235455AOvercoming pollutionSimple preparation stepsHigh entropy alloysUltimate tensile strength

The invention provides a W-Ta-Mo-Nb-Zr high-temperature high-entropy alloy and a preparation method thereof. The high-temperature high-entropy alloy is composed of W, Ta, Mo, Nb and Zr according to anequal or an unequal atomic ratio. The preparation method of the high-temperature high-entropy alloy is further provided and comprises the steps that 1) W, Ta, Mo, Nb and Zr raw materials with the needed weight are weighed; and 2) vacuum electric arc melting is carried out. The W-Ta-Mo-Nb-Zr high-temperature high-entropy alloy prepared through the method can be used for overcoming the strength defect of a nickel-based high-temperature alloy at the temperature of 120 DEG C or above, and replaces the nickel-based high-temperature alloy to be used for the field of high-temperature structures.

Owner:NAT INNOVATION INST OF DEFENSE TECH PLA ACAD OF MILITARY SCI +1

Vehicle gear selecting and parking brake combined control method

ActiveCN107914688ASimple systemLess prone to accidentsFluid braking transmissionHydraulic pumpFuel tank

Owner:靖江市恒大汽车部件制造有限公司

Variable burning rate synergistic perforating charge

The invention discloses a variable-burning rate synergistic perforating propellant which can be used for solving the problems of insufficient ignition, incomplete burning, short acting time and small amount of gas production resulting from the single propellant and unreasonable propellant structure of the conventional composite perforation technology. The variable-burning rate synergistic perforating propellant disclosed by the invention comprises a perforating bullet and a propellant front bin which is mounted at the port of the inner cavity of the perforating bullet, wherein a jet flow channel is arranged in the center of the bottom plate of the propellant front bin; an ignition powder coil, a delay powder coil, a speed-up powder coil and a deflagration powder coil are sequentially arranged from high to low between the circumference and the jet flow channel in the propellant front bin; the four powder coils have the same height at a width ratio of (1-2):(2-4):(2-4):(10-15); and the four powder coils consist of powder of four different formulas and can realize gradual variable-burning rate synergy from the ignition powder coil to the deflagration powder coil. The variable-burning rate synergistic perforating propellant disclosed by the invention has the advantages of simple structure, low ignition power, strong burning resistance and long blast acting time, is convenient to operate, has the reaming pressure increased by 60%, can at least double the synergistic time, and be used for remarkably improving the producing efficiency of an oil gas well.

Owner:ZHONGBEI UNIV

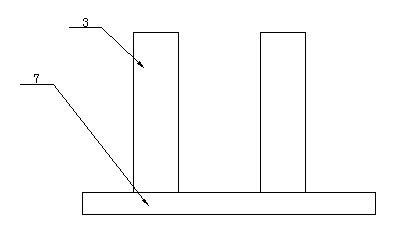

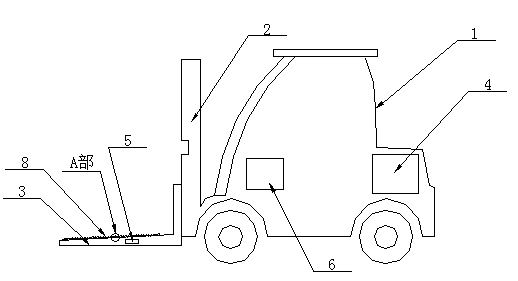

Novel forklift

The invention relates to the technical field of mechanical equipment and provides a novel forklift. The front portion of a forklift body (1) is provided with a telescopic rod (2), two fork levers (3) are connected with a slide rail (7) in a sliding mode, and the slide rail (7) is connected with a stretching and lifting rod (2) in a sliding mode. A storage battery (4) is arranged on the back side of the forklift body. A controller (6) is arranged in a control room of the forklift body (1). Two weighting sensors (5) are arranged in the two fork levers (3) respectively. The controller (6) is connected with the storage battery (4) and the weighting sensors (5) respectively. The two fork levers (3) are respectively provided with an anti-slip layer (8). The novel forklift is convenient to use, easy to operate and simple in structure; time is saved, overload operation is avoided, and accidents will not happen easily.

Owner:KUNSHAN SHANGDAZHI MACHINERY

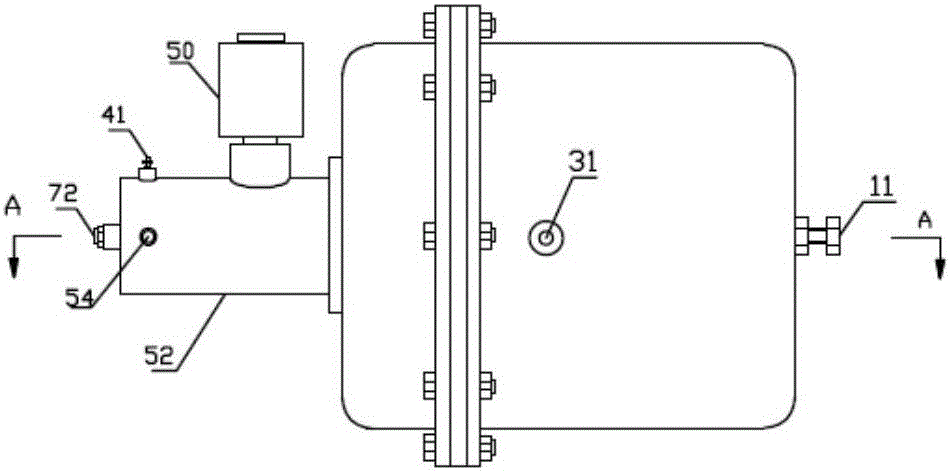

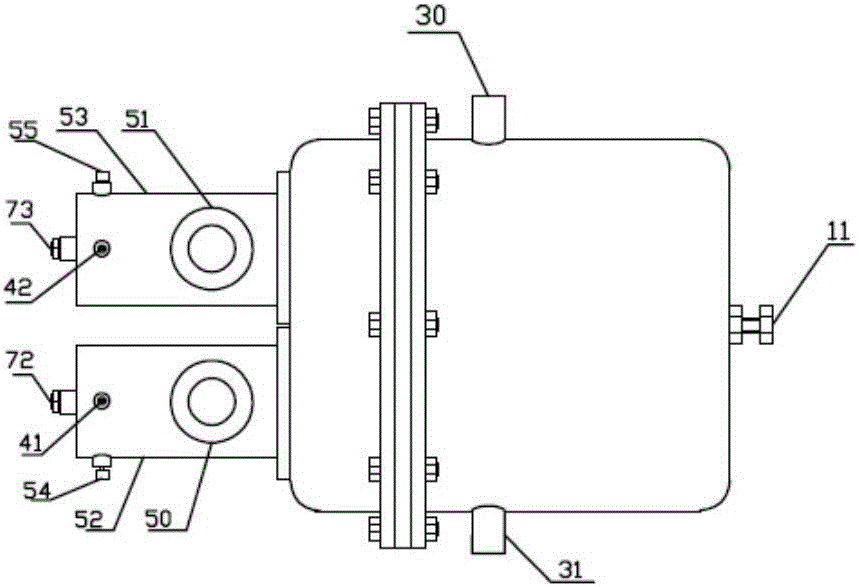

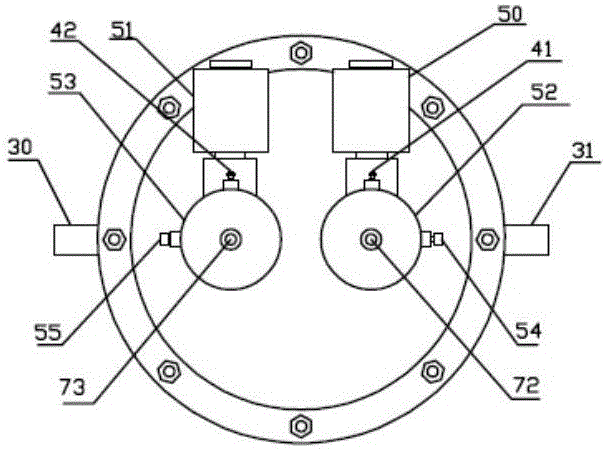

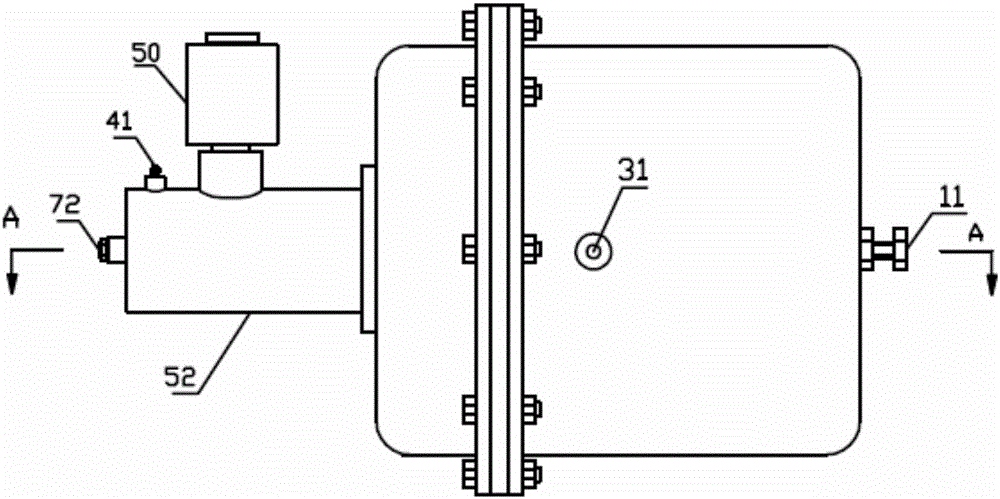

Brake pump of loader

ActiveCN105673741AImprove braking effectEasy to useBrake actuating mechanismsActuatorsLiquid storage tankControl engineering

The invention discloses a brake pump of a loader. Two brake cavities, a traveling brake cavity and a stop brake cavity are formed in a brake pump shell; a first piston is arranged in the stop brake cavity; a first push rod is arranged on the left side of the first piston; a main spring is arranged on the right side of the first piston; a rubber bowl is arranged in the traveling brake cavity; the two braking cavities comprise a left brake cavity and a right brake cavity; a second piston is arranged in the left brake cavity; a first resetting spring is arranged on the left side of the second piston; a third piston is arranged in the right brake cavity; a second resetting spring is arranged on the left side of the third piston; a spring base is arranged on the left side of the rubber bowl; a second push rod and a third push rod are fixed on the left end face of the spring base; a first spring sleeves the second push rod; a second spring sleeves the third push rod; the second push rod corresponds to the second piston; the third push rod corresponds to the third piston; a first liquid storage tank is arranged above the left brake cavity; and a second liquid storage tank is arranged above the right brake cavity. The brake pump is good in brake effect and can be used safely and reliably.

Owner:莱州虎威机械科技有限公司

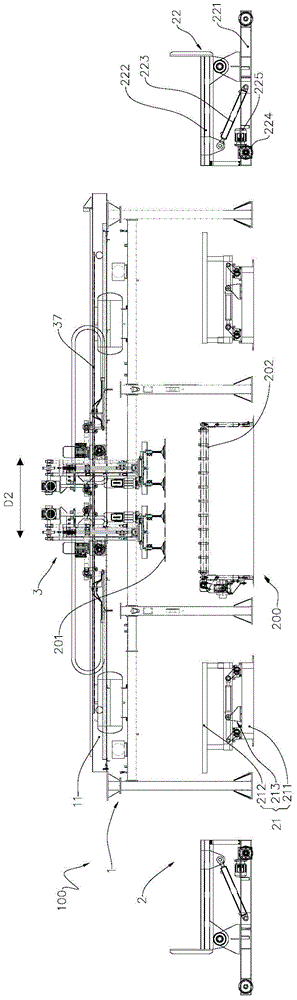

Full-automatic horizontal glass stacking machine and glass stacking method

ActiveCN105984729AImprove gripReduce stacking timeStacking articlesDe-stacking articlesState of artFixed frame

The invention relates to the technical field of float glass, and provides a full-automatic horizontal glass stacking machine and a glass stacking method. The full-automatic horizontal glass stacking machine comprises a transverse rail, stacking platform assemblies and suction main engines used for sucking glass on a glass production line and then transferring the glass to the stacking platform assemblies to be stacked. Each suction main engine comprises a fixed framework, a traveling device, a movable framework, a lifting device, a suction cup frame and a mobile device. Compared with the prior art, the full-automatic horizontal glass stacking machine provided by the invention improves the grabbing efficiency, accidents are not likely to happen in the glass grabbing process, the stacking time of each piece of glass board is shortened, and the production efficiency is improved. According to the glass stacking method, the suction cup frames are driven to move towards the glass moving direction at the speed the same as the glass moving speed while suction assemblies compress the surface of glass, so that glass is grabbed more conveniently, rapidly and firmly, and the grabbing and production efficiency is improved.

Owner:深圳市天圣实业有限公司

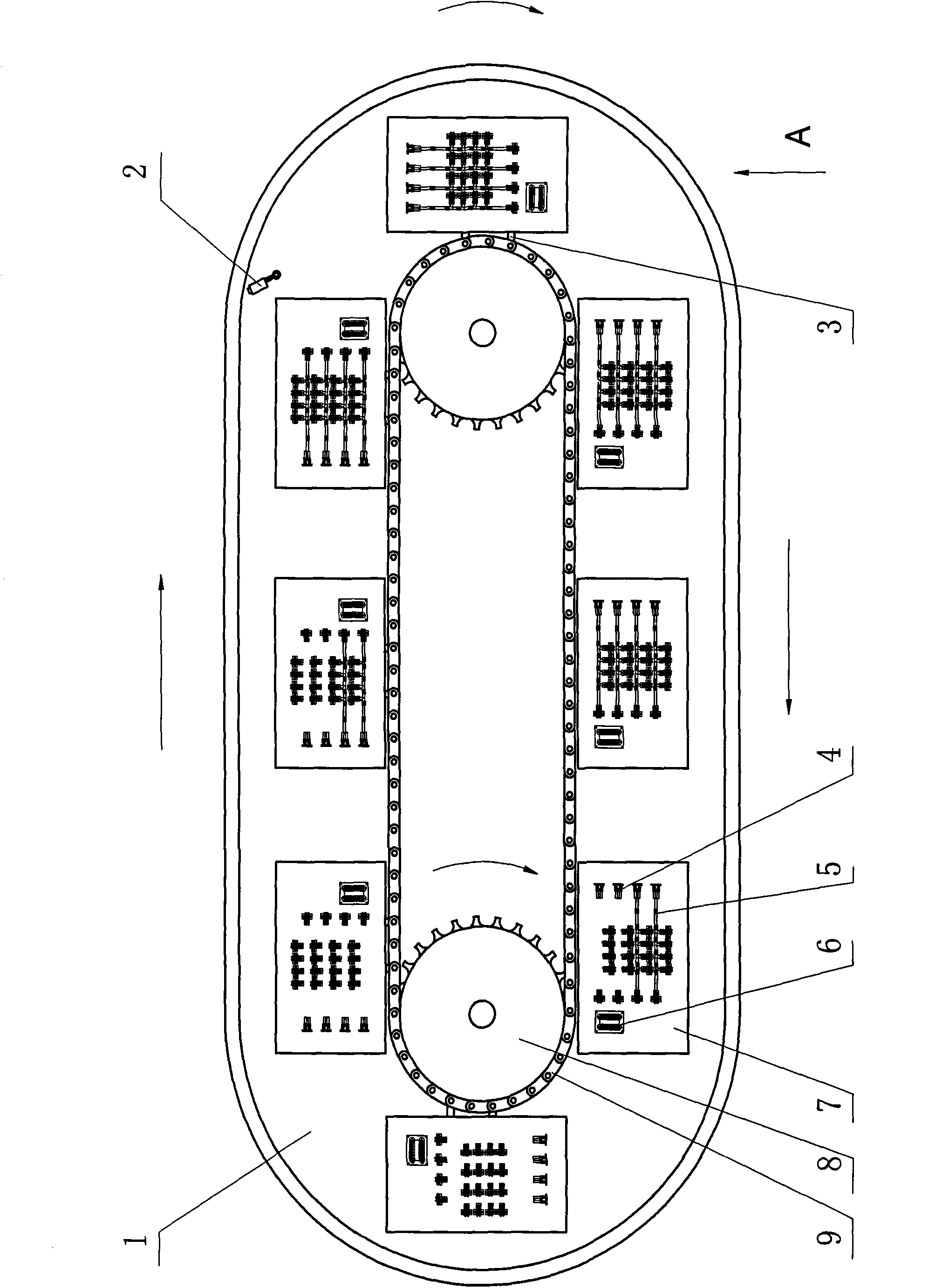

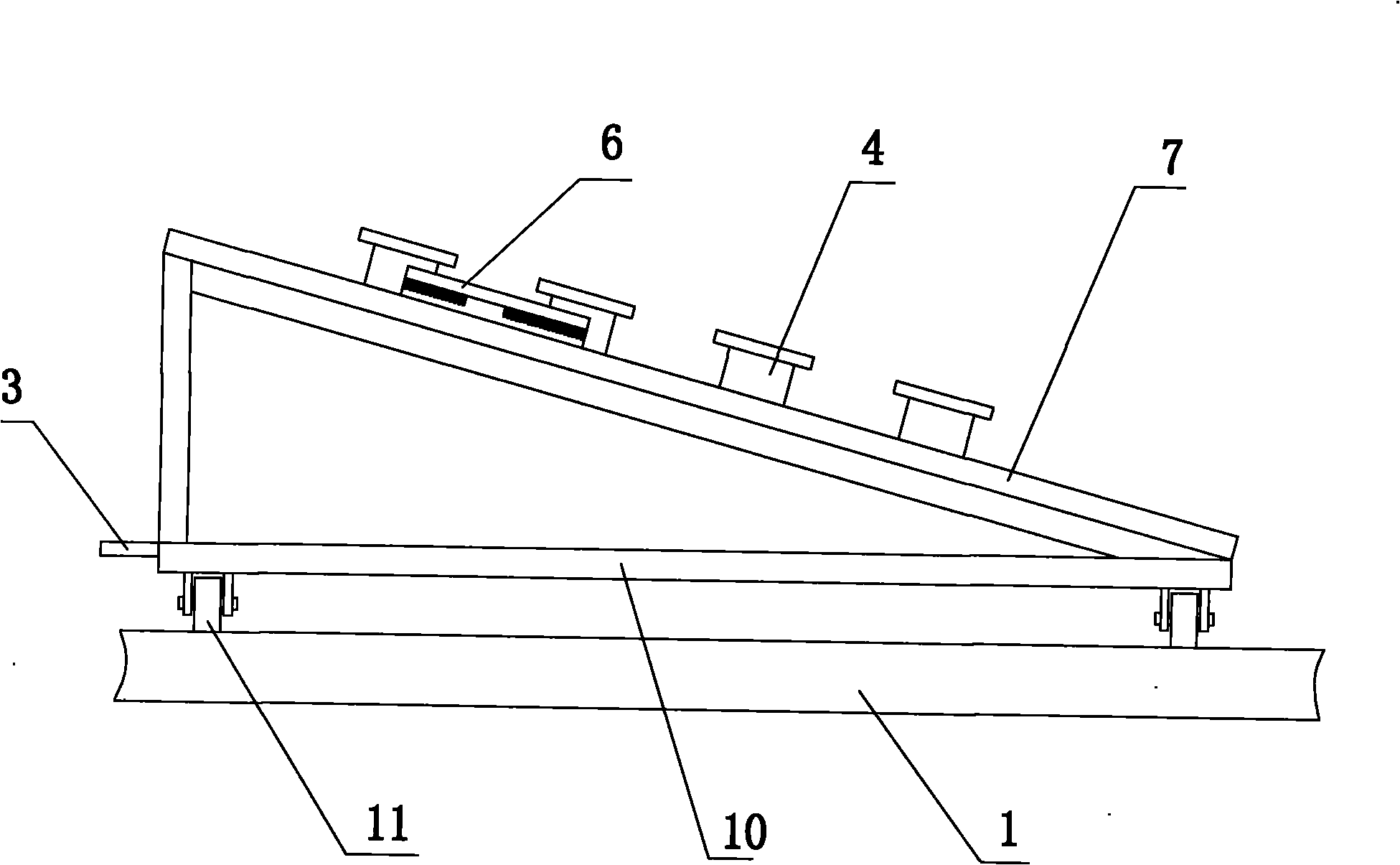

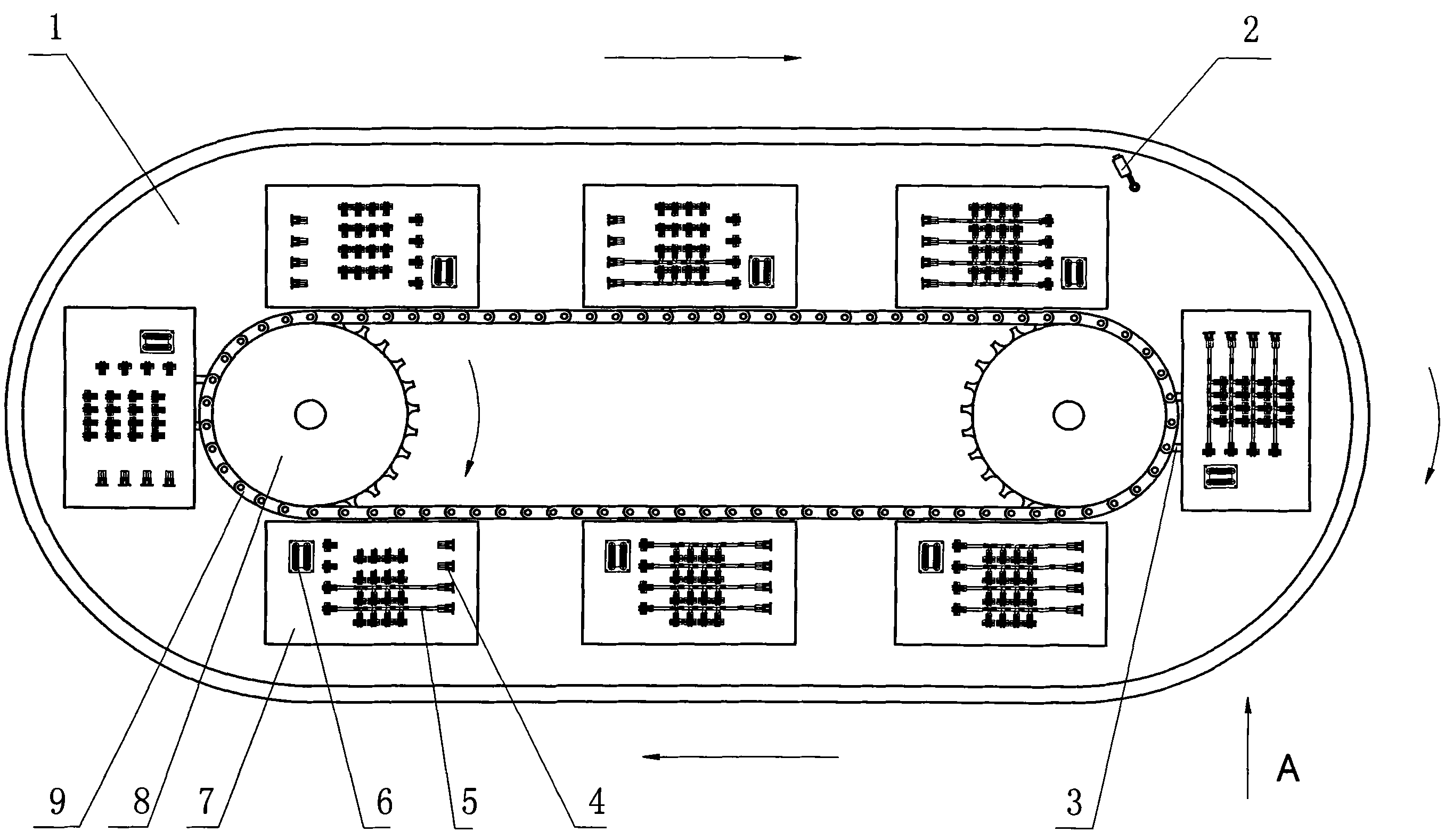

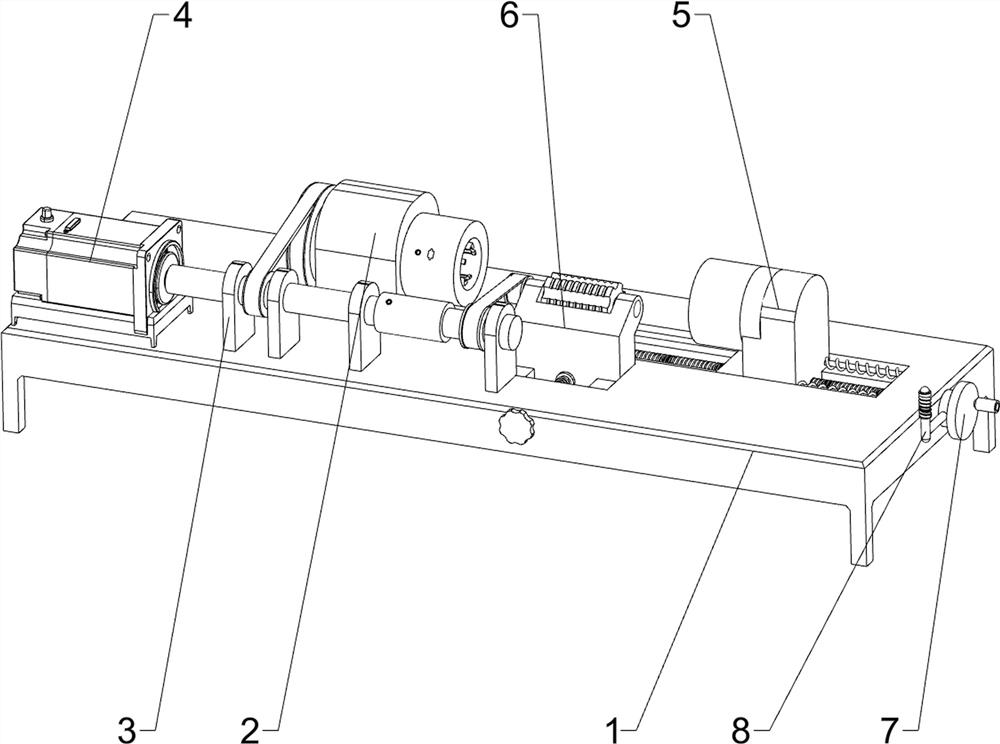

Wire harness test production line

InactiveCN101916628AConvenient CNC testingAccurately Test EfficiencyElectrical testingManufacturing wire harnessesElectricityProduction line

The invention relates to a device for processing an electric appliance wire harness, in particular to a wire harness test production device. According to a wire harness test production line, in a horizontal test platform (1), two horizontally rotating chain wheels (8) are arranged in the length direction, wherein one chain wheel is a driving chain wheel, and the other chain wheel is a driven chain wheel; a chain (9) encircles the two chain wheels (8) to form a circle of conveying chain; a plurality of hooks (3) are outwards extended on the chain (9), every two hooks (3) are connected with a test plate (7), a plurality of groups of wire harness sockets (4) are arranged on the test plate (7), and each group of wire harness sockets (4) is electrically connected with a wire harness tester (6) respectively; and the test plate (7) is arranged on an oblique bracket (10), and the lower part of the oblique bracket (10) is provided with a roller (11). The wire harness test production line relieves the labor intensity, has simple and labor-saving action, is not easy to cause accidents and errors, greatly improves the test speed, has accurate and reliable test result, and improves the turnover efficiency and the speed of the whole work.

Owner:SHANGHAI FEILE ELECTRONICS SYST

Auger with Butterfly Flighting

An auger for digging holes in soil is coupled to a gearbox and powered by the power take-off of a tractor. The auger comprises a shaft with a cutting head disposed near its bottom end. The cutting head comprises a plurality of cutting (i.e. digging) blades that cut into soil. Flighting disposed above the cutting head moves and lightens soil, but the flighting does not extend far above the cutting head. The majority of the shaft is free from protrusions that may ensnare a user of the auger during use.

Owner:KING KUTTER

Breaker pump and applications thereof on loaders

ActiveCN106043258AGuarantee the safety of useEasy to useBraking action transmissionBrake actuating mechanismsPistonAir receiver

The invention discloses a breaker pump and applications thereof on loaders. The breaker pump comprises a brake chamber, a driving vehicle brake chamber and a stopped vehicle brake chamber; the driving vehicle brake chamber is provided with a first rubber skin cup; the driving vehicle brake chamber is divided into a driving vehicle brake left chamber and a driving vehicle brake chamber air receiver by the first rubber skin cup; the stopped vehicle brake chamber is provided with a first piston; the stopped vehicle brake chamber is divided into a stopped vehicle brake air receiver and a stopped vehicle brake right chamber by the first piston; a first push rod is installed at the left side of the first piston; a main spring is installed at the right side of the first piston; the brake chamber is provided with a liquid outlet channel; the brake chamber is provided with a second piston; a first reset spring is installed at the left side of the second piston; a second push rod is installed at the left side of the first rubber skin cup; the second push rod is sleeved by an auxiliary spring; the brake chamber is provided with a liquid outlet chamber; the liquid outlet chamber is communicated with the brake chamber; a liquid storage tank is installed above the liquid outlet chamber; the liquid outlet chamber is provided with a first control valve; the connection or disconnection of the inner chamber and the liquid outlet chamber of the liquid storage tank are controlled by the first control valve. The breaker pump has the advantages of good braking effect, safe use and high reliability.

Owner:莱州虎威机械科技有限公司

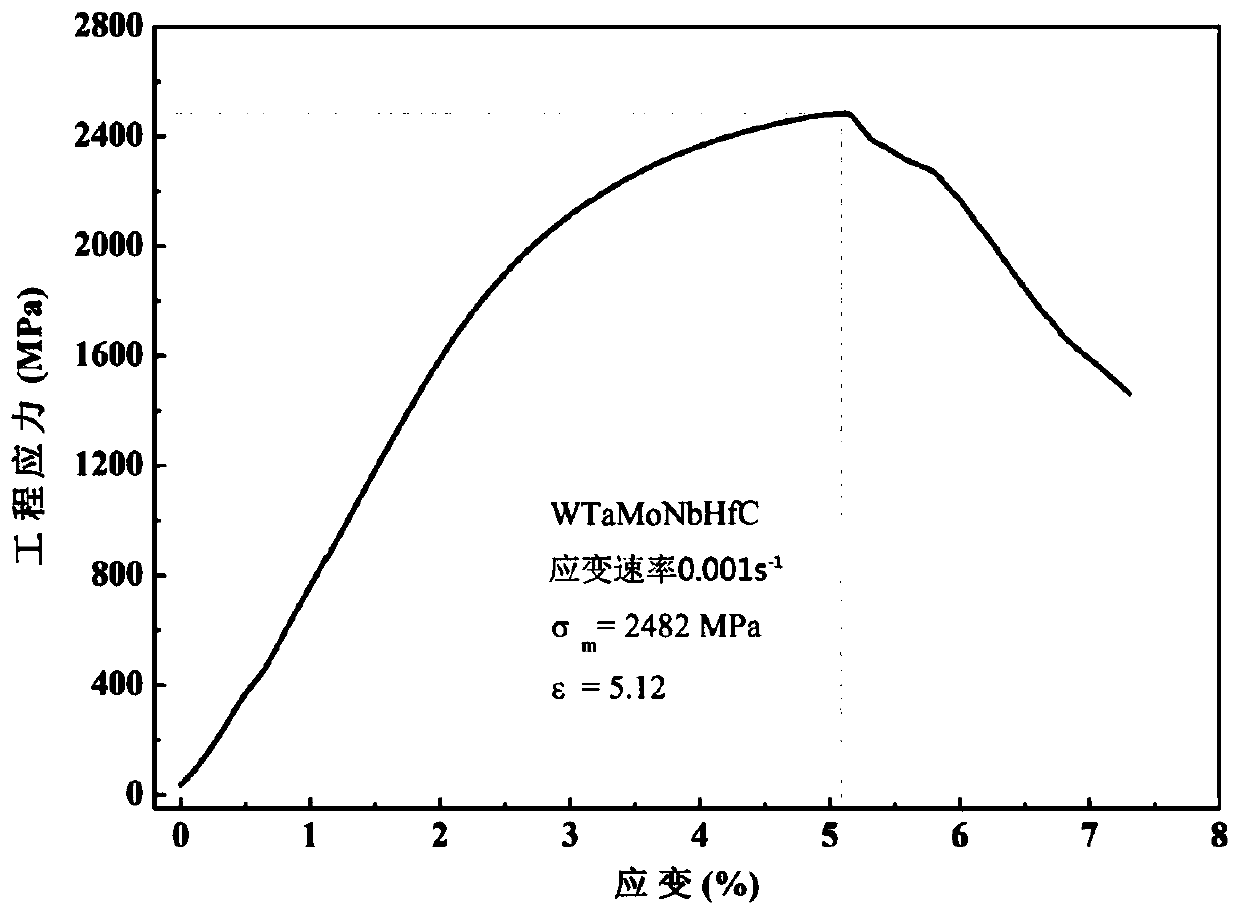

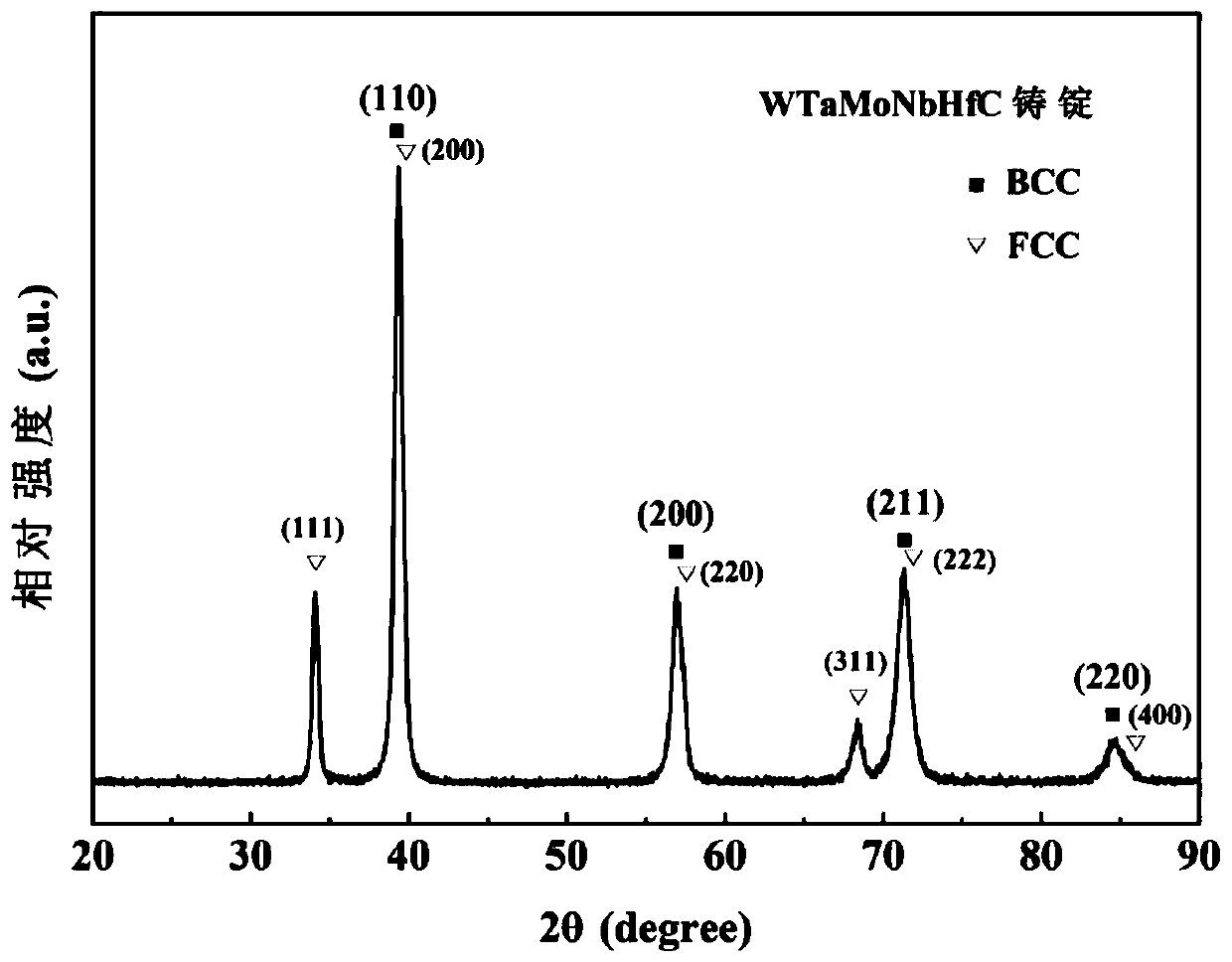

W-Ta-Mo-Nb-Hf-C high-temperature high-entropy alloy and preparation method thereof

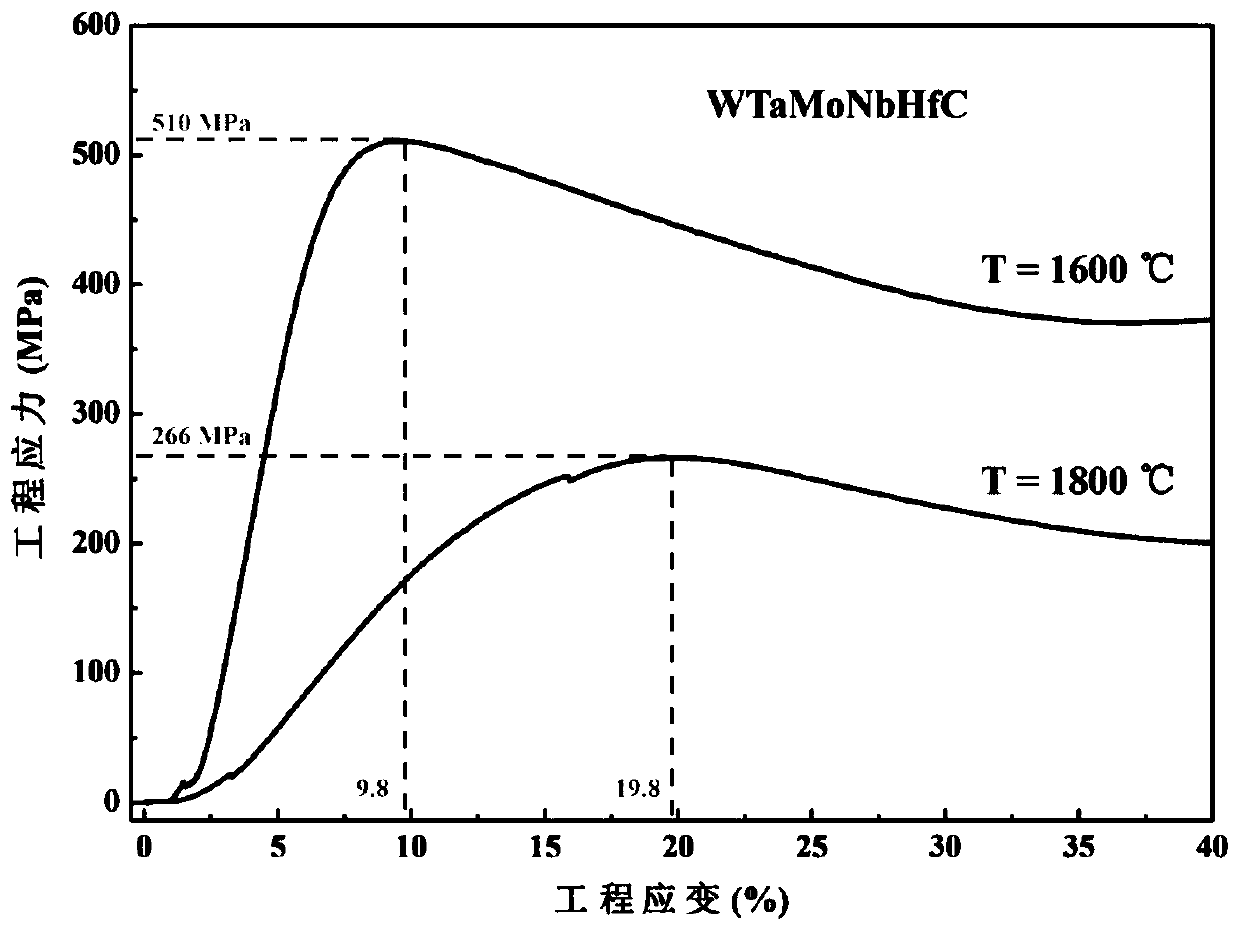

ActiveCN111363964AOvercoming pollutionSimple preparation stepsHigh entropy alloysUltimate tensile strength

The invention provides a W-Ta-Mo-Nb-Hf-C high-temperature high-entropy alloy and a preparation method thereof. The high-temperature high-entropy alloy is composed of an atomic ratio or a non-atomic ratio such as W, Ta, Mo, Nb, Hf, and C. The preparation method of the high-temperature high-entropy alloy comprises the following steps that 1) raw materials with the required weight of W, Ta, Mo, Nb, Hf, and C are weighed; and 2) vacuum arc melting is carried out. The W-Ta-Mo-Nb-Hf-C high-temperature high-entropy alloy prepared through the preparation method still has the strength of 266 MPa at 1800 DEG C, can be used for compensating the insufficient strength of nickel-base high-temperature alloy at the temperature of 1200 DEG C or above, and can replace the nickel-base high-temperature alloyto be used in the field of high-temperature structures.

Owner:NAT INNOVATION INST OF DEFENSE TECH PLA ACAD OF MILITARY SCI +1

Transfer device for test tubes for biological experiments

InactiveCN107472336ANot easy to bumpAvoid damageHand carts with multiple axesRadiationTesting tubesEngineering

Owner:黄轩

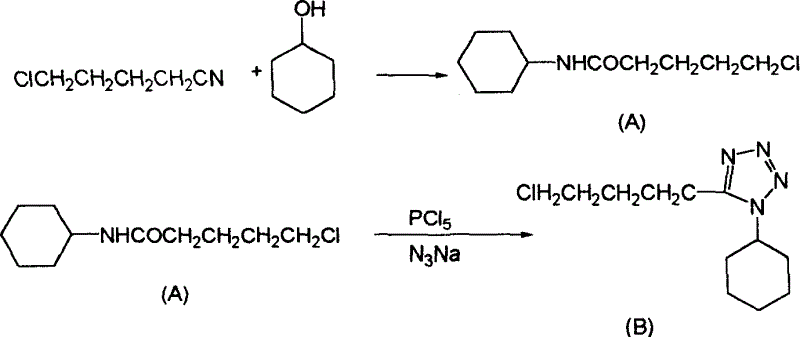

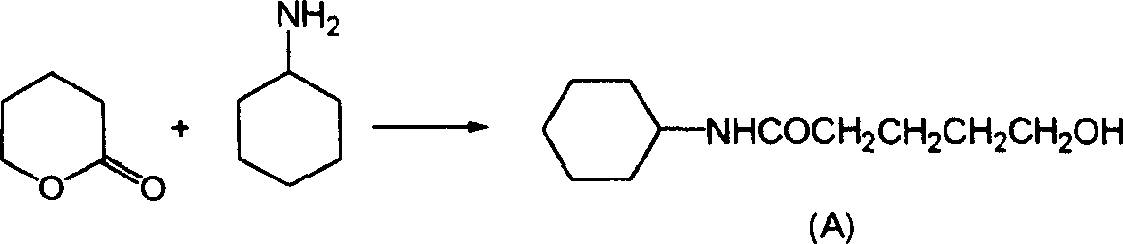

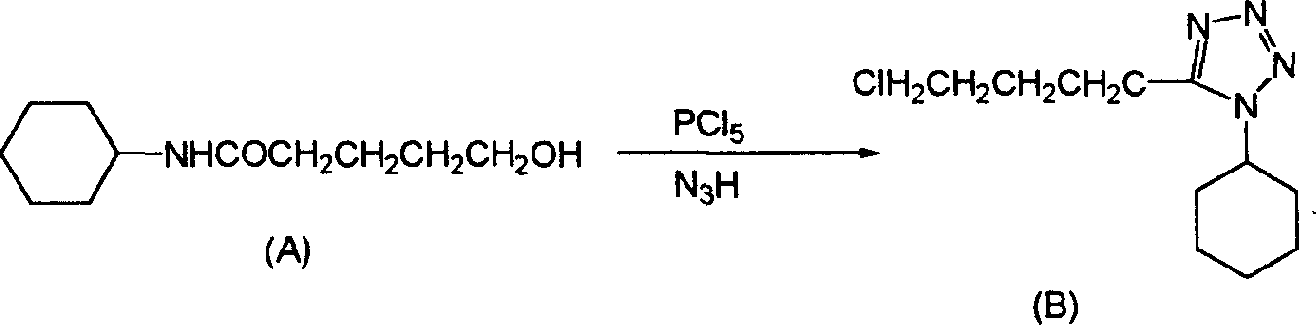

Tech. for synthetic (4-chlorobutyl) 1-cyclohexyl-1,2,3,4-tetrazole

The invention relates to compounding technology for 5-(4-chlorin butyl)-1-cyclohexyl-1, 2, 3, 4-tetrazole. It adopts 5-chlorin butyl cyanide and cyclohexanol to take reaction to form 5-Cl-N-cyclohexyl pentanamide, adds a little phosphoric chloride, sodium azide into benzene solvent to react to form sample. 5-chlorin butyl cyanide and cyclohexanol are reacting in concentrated sulphuric acid, heating to 60 degree centigrade, keeping for 15 hours, cooling to room temperature, sucking the 5-Cl-N-cyclohexyl pentanamide reaction solution into 0 degree centigrade second reacting kettle, keeping 10 degree centigrade for 4 hours, adding petroleum ether to extract, cooling the organic phase at the third cooling kettle to gain 5-Cl-N-cyclohexyl pentanamide crystal that would be sucked into the fourth reacting kettle, adding toluene solvent adding phosphoric chloride at 0 degree centigrade and heating to 60 degree centigrade for reacting for 2 hours, heating to 112 degree centigrade and keeping for 4 hours, cooling to 25 degree centigrade, being sucked into the fifth reacting kattle, adjusting the pH value to 7 by sodium bicarbonate solution, steaming up toluene at the sixth distiller, adding ethane and cooling to 5 degree centigrade, taking centrifugal separation to the white crystal, drying, the product 5-(4-chlorin butyl)-1-cyclohexyl-1, 2, 3, 4-tetrazole would be gained. The advantage of the invention is that its raw material is low cost, and accidents would be declined.

Owner:许建强

Elevator compensation chain guiding control device

The invention discloses an elevator compensation chain guiding control device, and belongs to the field of compensation chain guiding devices. According to the elevator compensation chain guiding control device, in the scheme, a pair of guiding rollers can restrain a compensation chain, overall shaking of the compensation chain is reduced, the surface of a roller body is treated, the the elasticity of the surface of the roller body is increased through laid filling balls, so that abrasion between the compensation chain and the roller body is reduced. For the filling balls located in a filling groove, the multiple filling balls can be kept in a tiled state in the filling groove through matching of filling fibers between the adjacent filling balls and connection between the filling fibers and a reinforcing net, a relatively stable structure of the multiple filling balls can be easily kept, the loss of the elevator compensation chain in the using process can be greatly reduced, the instability phenomenon in the using process of an elevator is not likely to occur, the working loss of the elevator is reduced, the service life of the elevator is not likely to be affected, and casualties of passengers are not likely to be caused.

Owner:NANTONG PUSIMAN MACHINERY

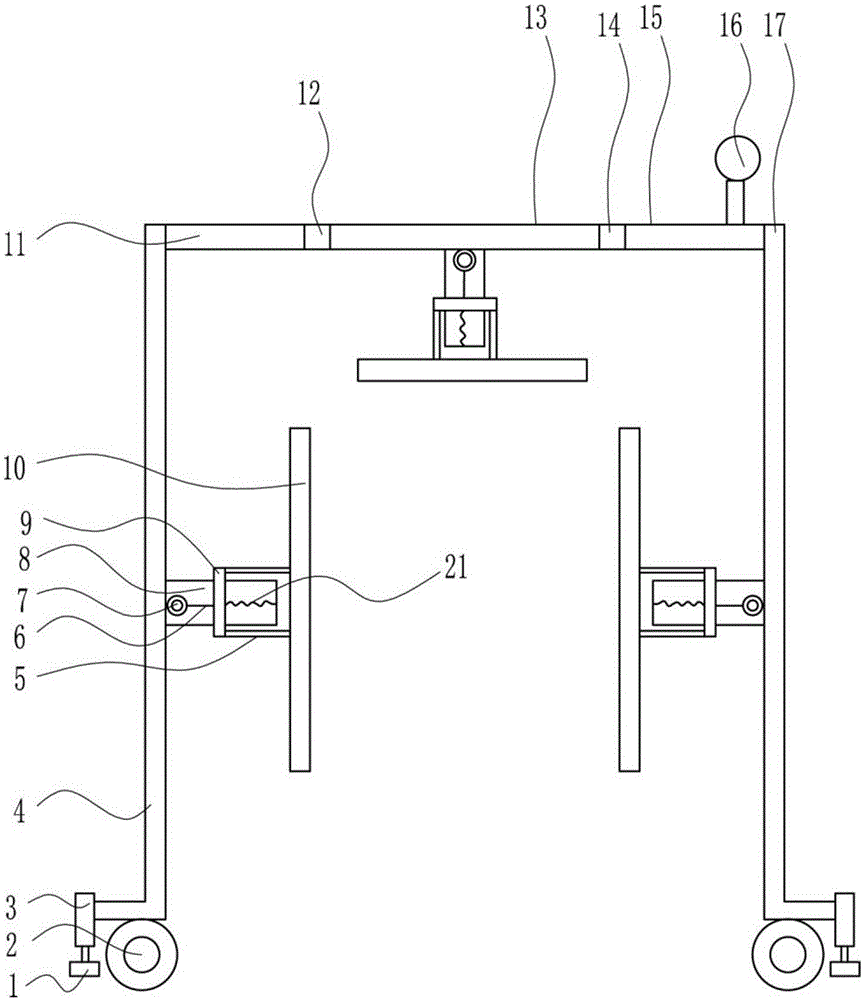

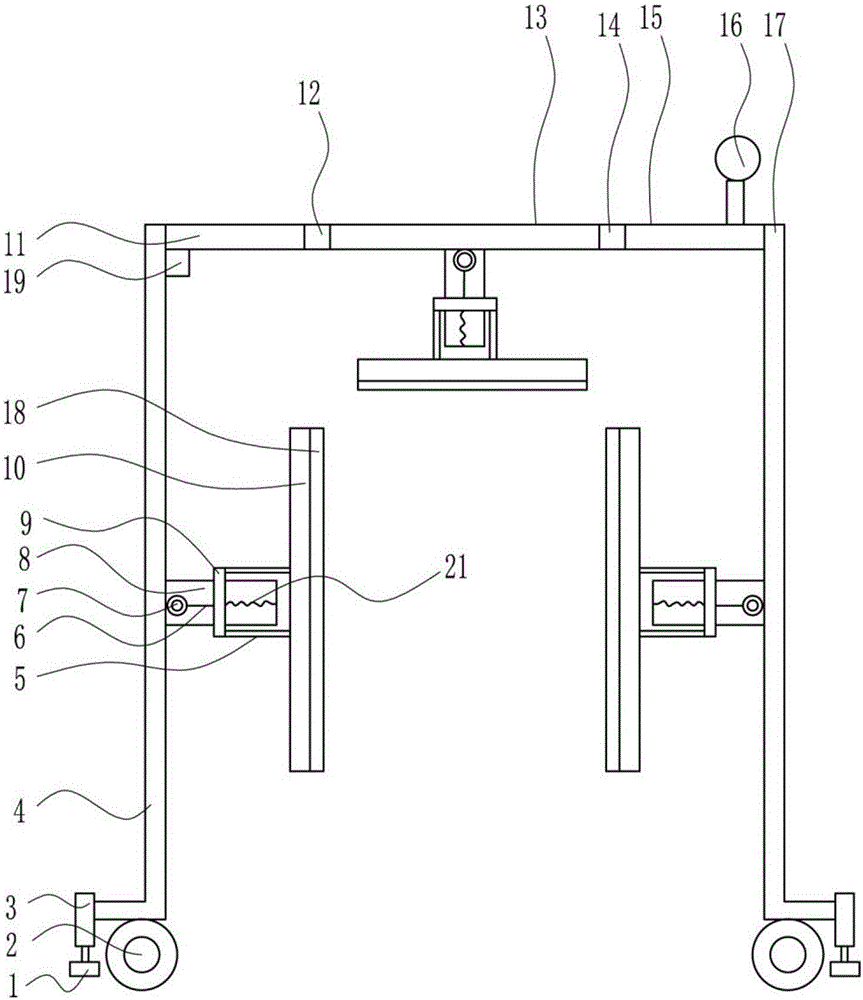

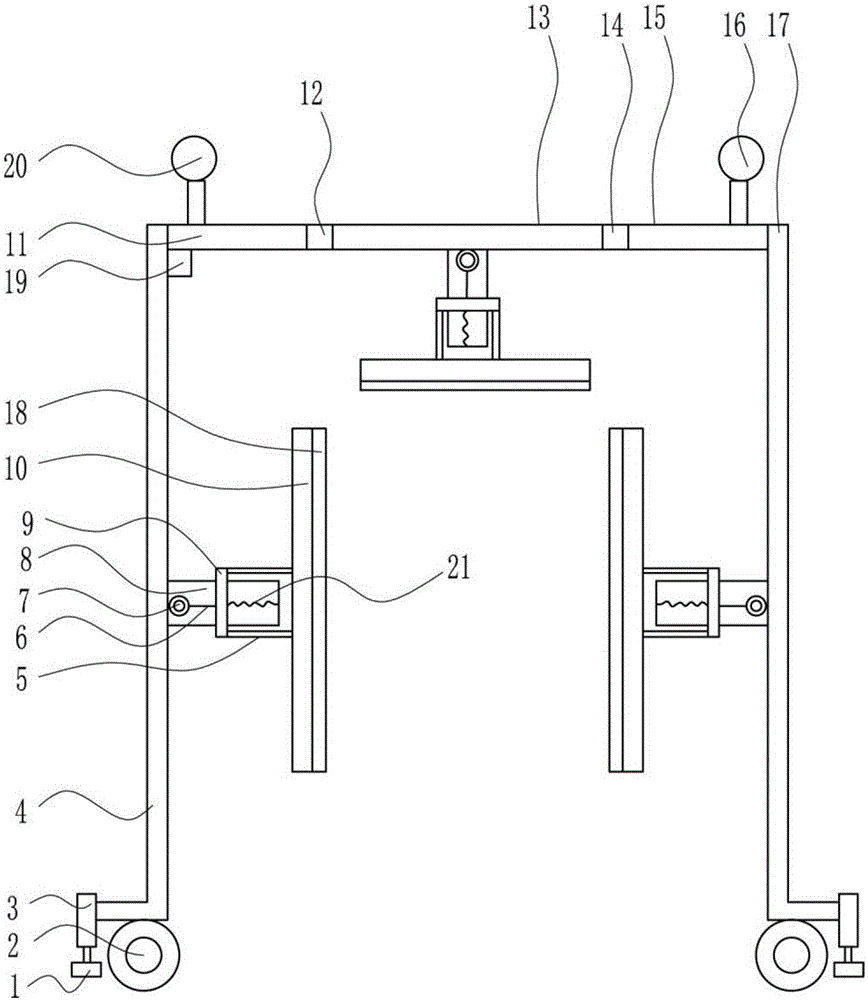

Rotary welding and polishing device for intelligent manufacturing

ActiveCN113732857ALess prone to accidentsDoes not affect physical and mental healthEdge grinding machinesGrinding carriagesEngineeringPsychological health

The invention relates to a welding and polishing device, in particular to a rotary welding and polishing device for intelligent manufacturing. The rotary welding and polishing device for intelligent manufacturing is not prone to causing accidents, does not affect physical and psychological health of people and can polish welding positions. A rotary welding and polishing device for intelligent manufacturing comprises a base, supporting plates and a rotating mechanism. A supporting seat is installed on one side of the base; the supporting plates are mounted on the base at intervals; and the rotating mechanism is mounted among the base, the supporting seat and the supporting plates and used for driving a steel pipe to rotate. One steel pipe is placed in a driven rotating shaft, a locking screw is twisted to enable a clamping claw to limit the steel pipe, then the other steel pipe is inserted into a movable seat to enable a fixed locking block to limit the steel pipe, a servo motor is started, the driven rotating shaft rotates to drive the steel pipe to rotate through the clamping claw, the steel pipe rotates to make contact with the other steel pipe, and then welding is conducted. Therefore, accidents are not prone to occurring, and physical and psychological health of people is not affected.

Owner:东莞市正信激光科技有限公司

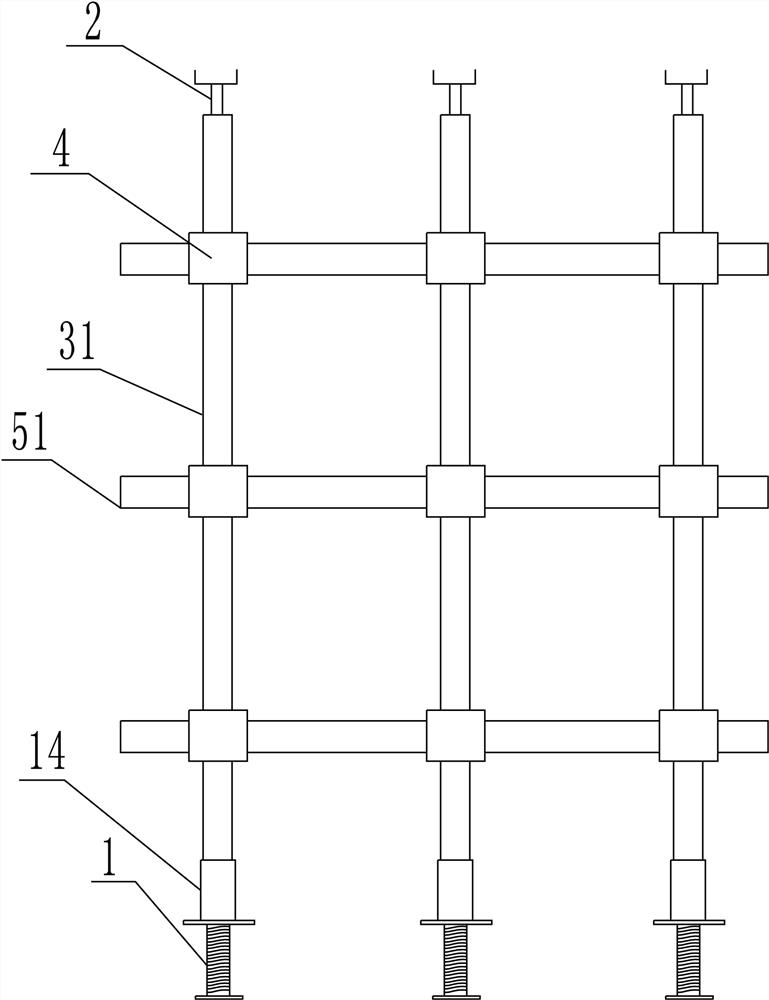

Formwork support system and construction method

ActiveCN113931436AEasy to transportEasy to manageHydro energy generationForms/shuttering/falseworksSupporting systemArchitectural engineering

The invention discloses a formwork support system and a construction method. The formwork support system comprises a support system and a formwork system. The support system comprises an adjustable base, wherein the bottom end of the adjustable base is connected with a positioning point, and the top end of the adjustable base is sleeved with vertical rod systems. A transverse rod system is connected between the vertical rod systems through disc buckle joints; a cross bridging or an inclined rod is connected between the vertical rod system and the transverse rod system. The formwork system comprises a top formwork and a wall formwork, wherein the top formwork is matched with an adjustable bracket at the top of the support system, and the wall formwork is connected with the support system through bolts. Compared with a traditional method, the construction method is stable in structure, high in construction efficiency and capable of effectively avoiding the problems that materials are difficult to transfer and pouring is difficult, the whole formwork support system is stable and safe, and accidents are not prone to happening.

Owner:CHINA GEZHOUBA GRP MECHANICAL & ELECTRICAL CONSTR +1

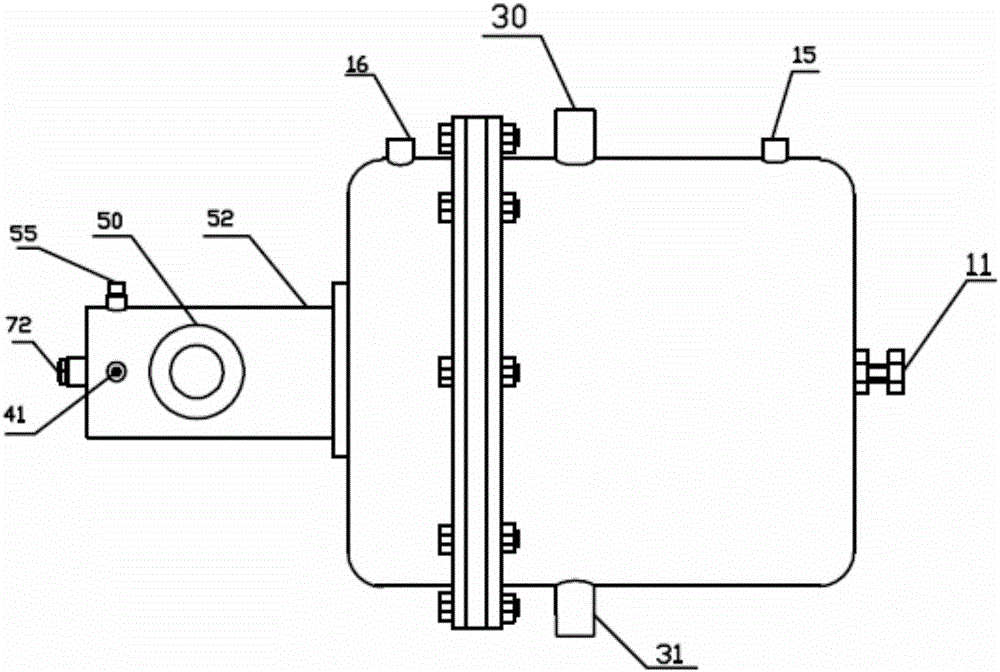

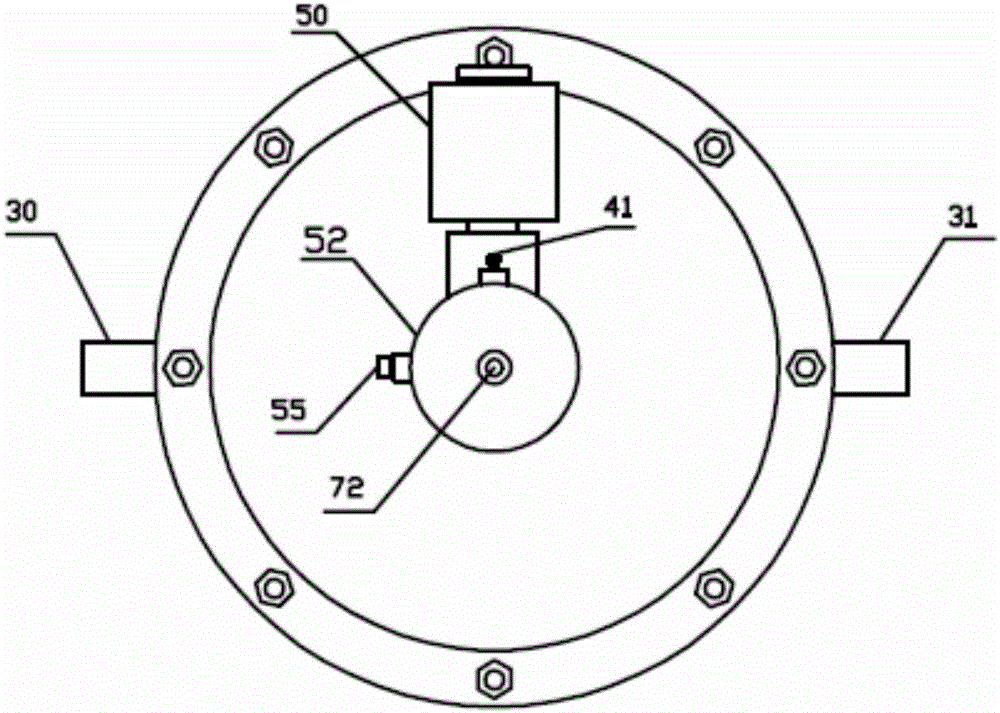

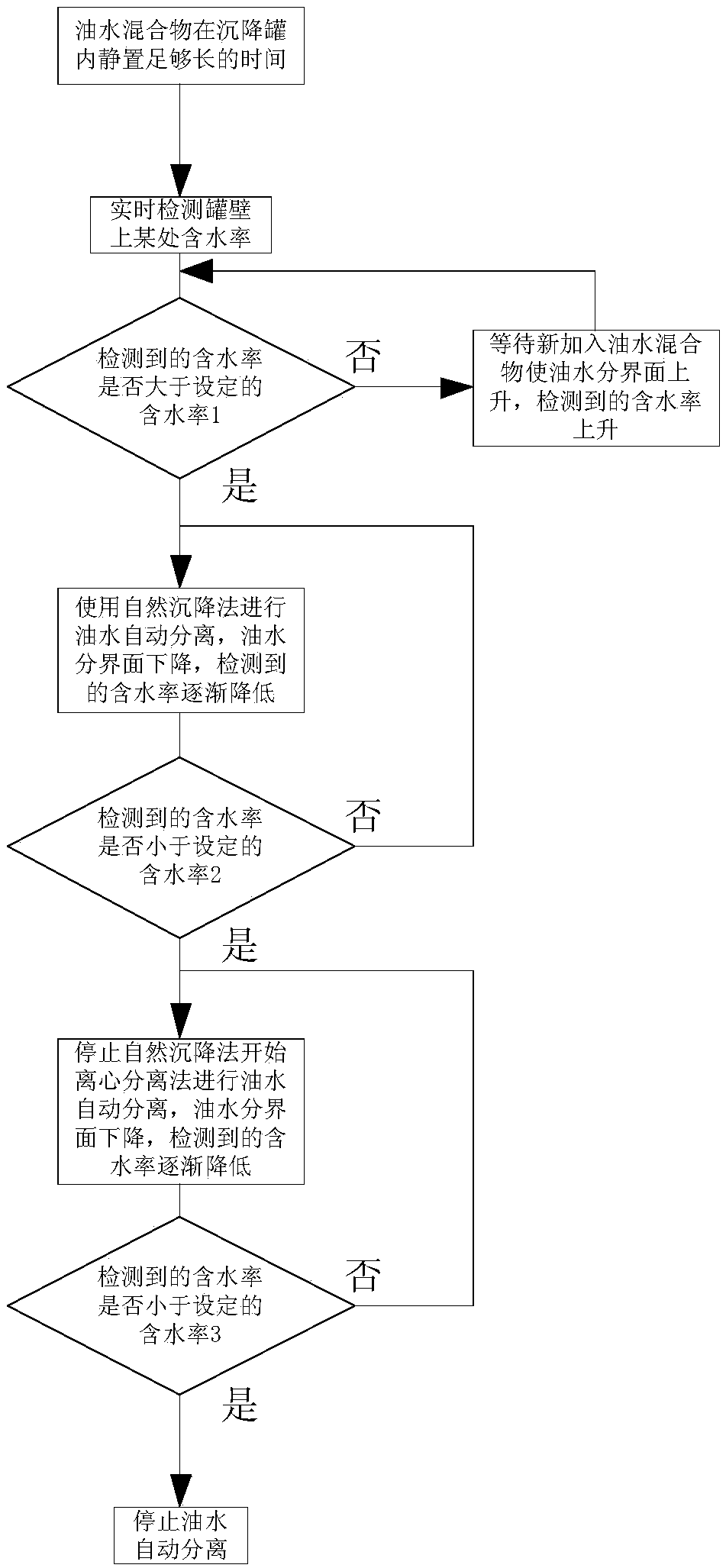

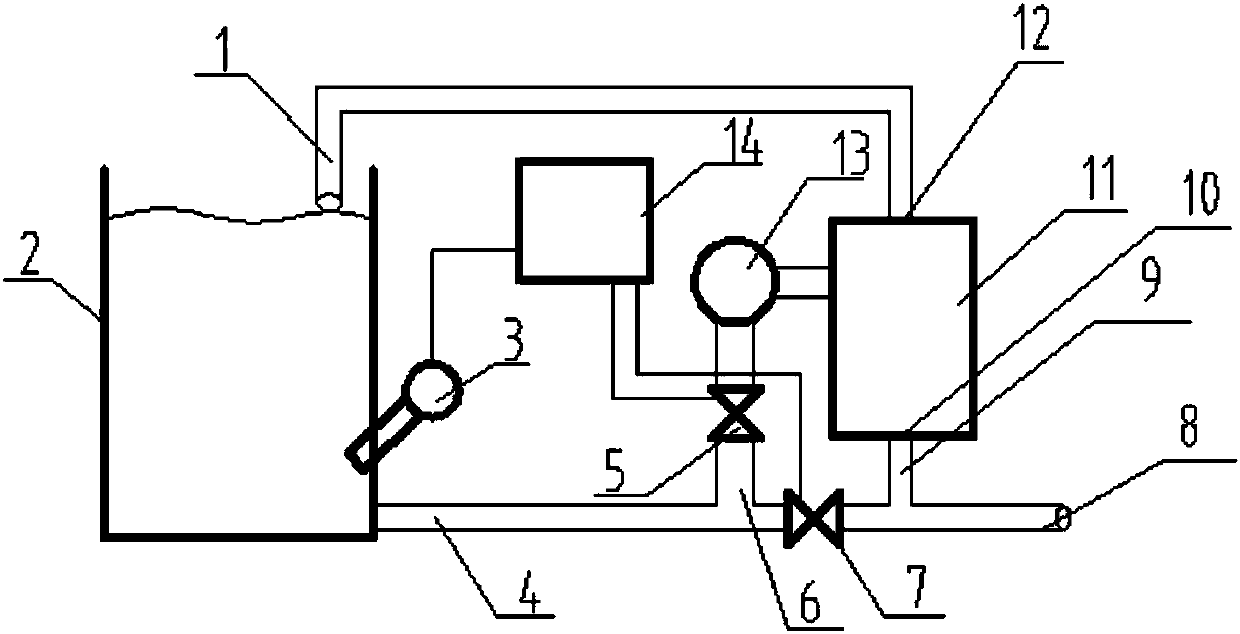

Oil-water automatic separation method and apparatus

PendingCN107935212AEasy to operateSave human effortWater/sewage treatment by centrifugal separationWater treatment parameter controlWater dischargeSolenoid valve

The invention relates to an oil-water automatic separation method and apparatus. The separation method comprises: adding an oil-water mixture, performing natural sedimentation and layering, detectingthe water content in real time, sending the water content to a controller, discharging the lower water layer of the oil-water mixture after natural layering, stopping discharging, controlling the oil-water mixture to undergo separation via a centrifugal process, stopping the centrifugal process, and separating oil from water. The apparatus includes a sedimentation tank and a cyclone. The sedimentation tank is internally provided with a water content detector; the lower part of the sedimentation tank is connected to a liquid discharging pipe, which is connected to a water discharging pipe via afirst solenoid valve, and which is connected to the cyclone via a liquid pumping pipe; the liquid pumping pipe is internally provided with a water pump and a second solenoid valve; and an overflow port formed at the top of the cyclone is connected to the sedimentation tank via an oil discharging pipe, and a bottom flowing port formed at the bottom of cyclone is connected to the water dischargingpipe via a water outlet pipe. The method and apparatus are relatively high in oil-water mixture separation degree, can be automatically controlled, are simple to operate and saved in labor, and have good economy.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

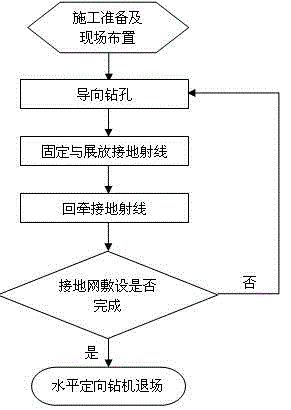

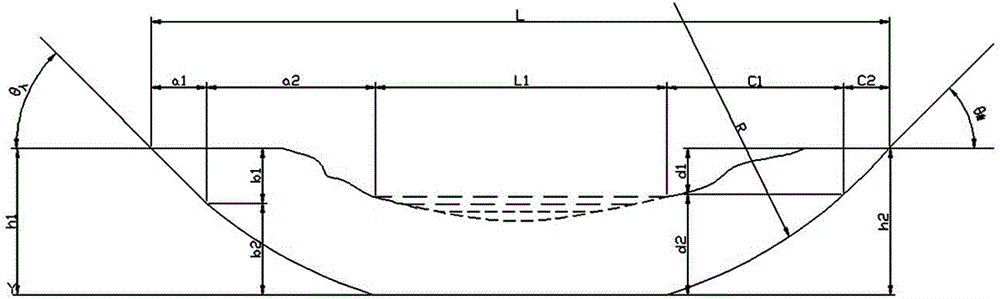

Overhead transmission line grounding grid non-excavation construction method

ActiveCN104533289AImprove work efficiencyImprove securityLine/current collector detailsDirectional drillingGrounding gridEconomic benefits

The invention relates to an overhead transmission line grounding grid non-excavation construction method. Through a horizontal directional drill, from retesting on a construction zone and a surrounding environment before drilling to procedures such as drilling guiding, grounding radial laying out, fixing and grounding radial back leading, laying of a grounding device is completed, safety is high, and laying working efficiency can be greatly improved. When geological conditions are met, the project time limit needed for grounding device laying can be greatly shortened, a construction process is safe, and accidents can be avoided. From economic benefit, currently, the lease expense of equipment is high and is much higher than the expense of hand excavation, accordingly economic benefit is not very good, however, non excavation is achieved during a construction process, crop compensation expense is saved, and therefore directional driller laying construction has optimistic using prospect under the current environment that labor cost and crop compensation expense rise gradually, and environment protection requirements are improved ceaselessly.

Owner:STATE GRID CORP OF CHINA +2

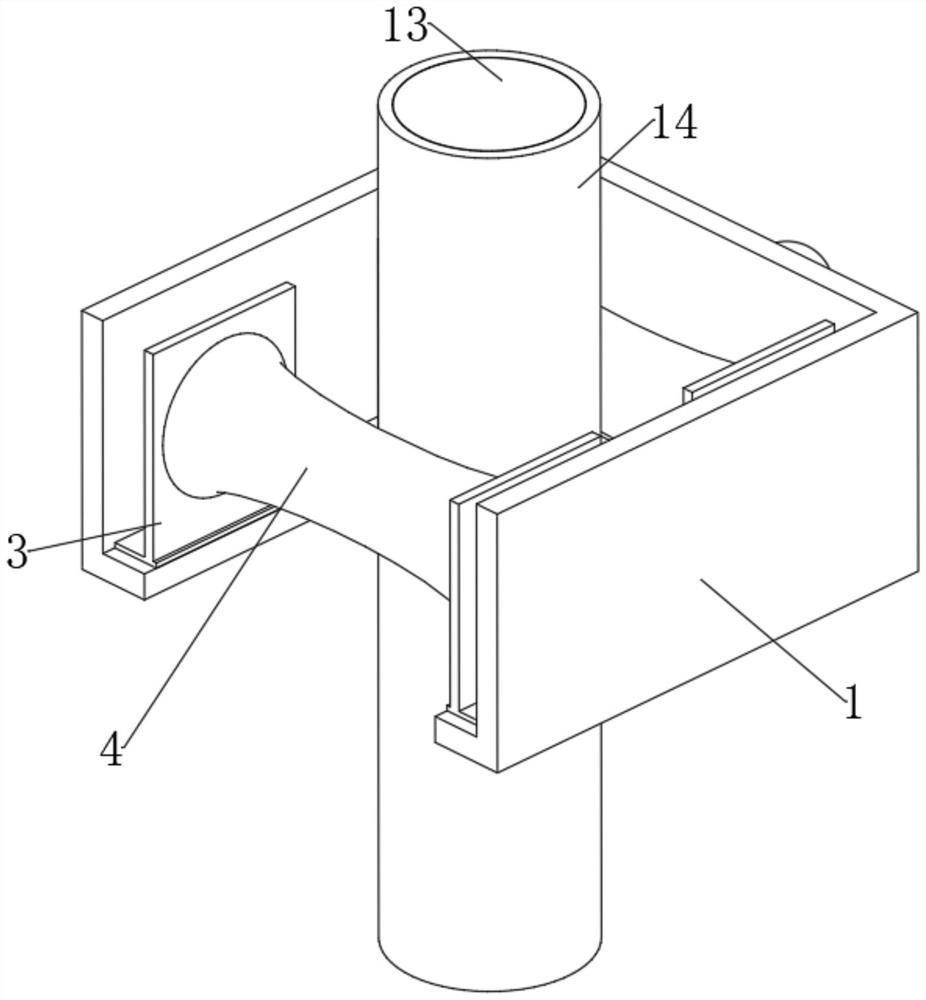

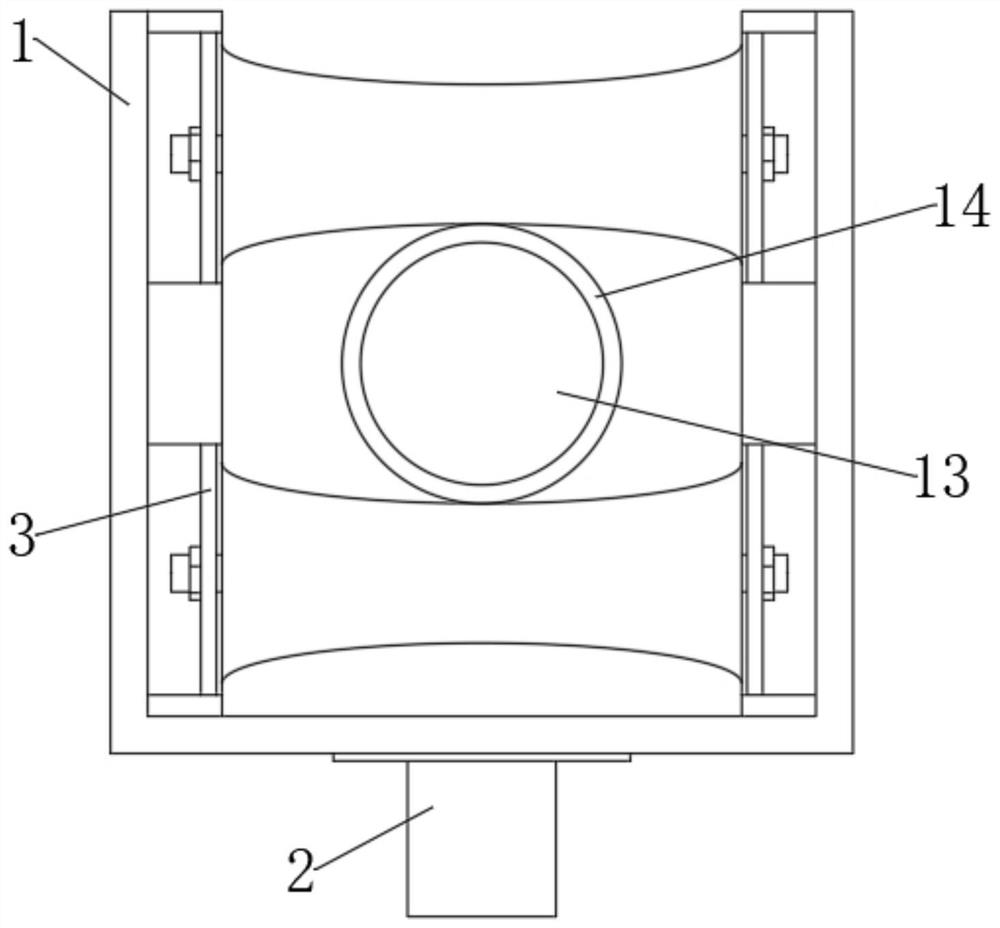

Vehicle gear selecting, parking and braking joint control system and work method

ActiveCN108068783ASimple systemLess prone to accidentsFluid braking transmissionFuel tankHydraulic pump

The invention provides a vehicle gear selecting, parking and braking joint control system and a work method. The vehicle gear selecting, parking and braking joint control system comprises an oil box,a filter, a hydraulic pump, a safety valve, a gear selecting operation valve, a forwarding gear clutch, a retreating gear clutch, a shuttle valve, a hydraulic control valve, an energy accumulator, a tractor parking brake, a tractor parking hydraulic cylinder, a hydraulic control air valve, an airbag, an assistor, a trailer parking brake and a trailer parking hydraulic cylinder. The gear selectingoperation valve comprises an operation rod. When a vehicle is shifted to be neutral, a tractor and a trailer are under parking braking, so that when the vehicle is stopped on a slope for work, an accident does not easily occur; when the tractor is under parking braking, the trailer is also under parking braking without the arrangement of a tractor parking braking valve, an air control valve, a relay valve, a one-way valve and a second airbag, and the system of the vehicle is simplified.

Owner:YANGZHOU HUIJIAN INFORMATION IND CO LTD

Convenient-to-adjust examination table for ophthalmology

PendingCN112656360AEasy to sitHumanized goodOperating chairsOperating tablesOphthalmology departmentMechanical engineering

The invention relates to a convenient-to-adjust examination table for ophthalmology, which comprises a base, a first seat is fixedly connected to the base, a first hollow rod is placed on the base, a first rectangular rod is slidably connected into the first hollow rod, an examination table body is fixedly connected to the upper end of the first rectangular rod, a sliding block slidably connected with the base is embedded in the upper end of the base, a second hollow rod is fixedly connected to the upper end of the sliding block, and a second rectangular rod slidably connected with the second hollow rod is arranged at the upper end of the second hollow rod in a penetrating mode. The examination table is reasonable in structure, the position of a second seat can be adjusted through one servo motor, the height of the second seat can also be adjusted, the height of the examination table can also be adjusted, and therefore the use requirements of different patients can be met, manual adjustment of medical staff is not needed, the workload of the medical staff is reduced, meanwhile, the second seat is supported more stably, and accidents are not likely to happen.

Owner:张建华

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com