Auger with Butterfly Flighting

a technology of augers and butterflies, applied in the field of augers for drilling holes, can solve the problems of serious accidents and even deaths of augers with continuous flying, and achieve the effect of less susceptible to accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

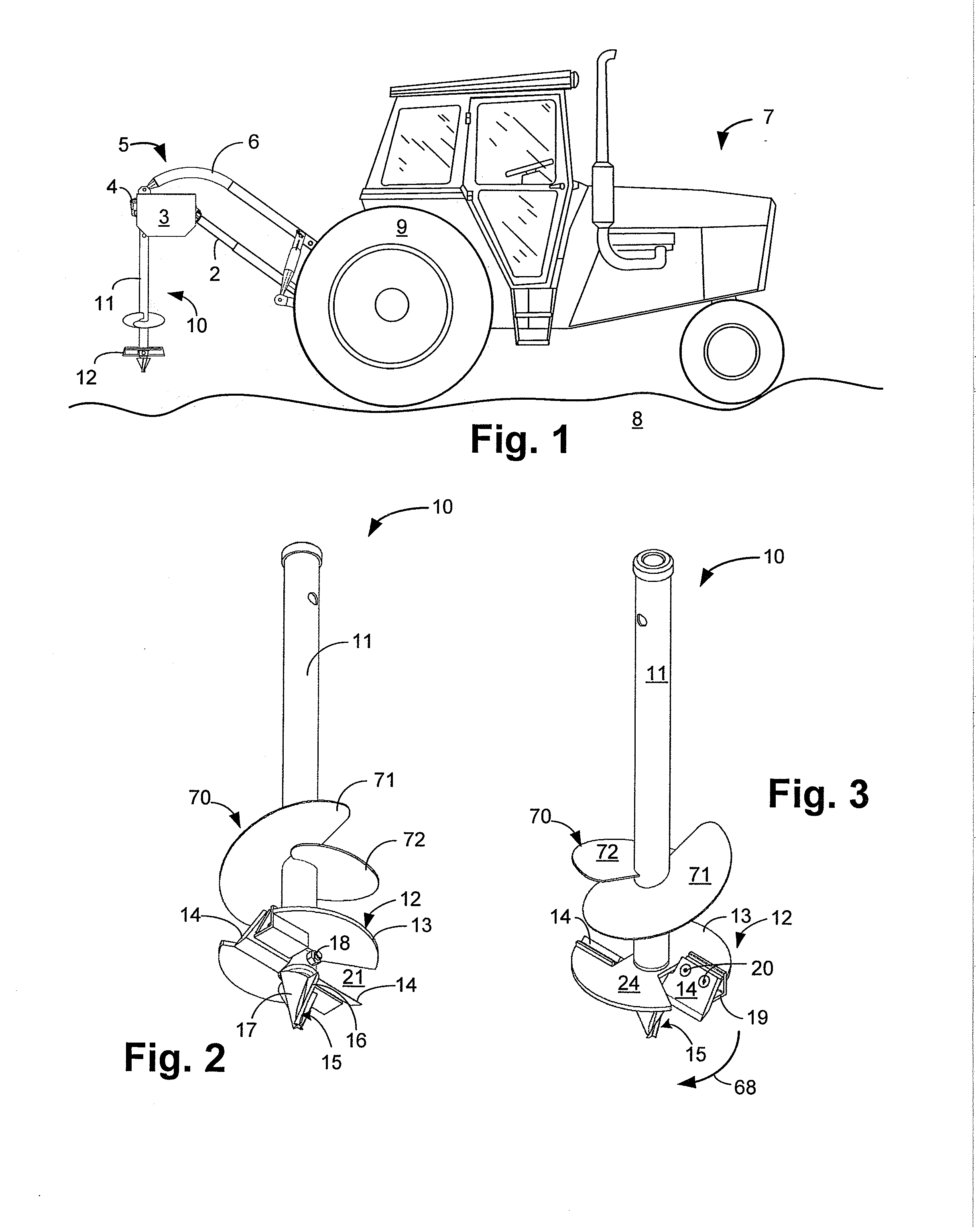

[0030]FIG. 1 is a side plan view of a post hole digger 5 according to an exemplary embodiment of the present disclosure. The digger 5 is shown installed on a tractor 7 and is used to dig generally-cylindrical holes (not shown) in the ground 8, for example, holes for fence posts. The digger 5 is disposed at the rear of the tractor 7 between the rear wheels 9 (only one of which is illustrated).

[0031]The digger 5 comprises an auger 10 for drilling into the ground 8. The auger 10 is supported by a top support arm 6 that extends from the tractor 7 as further discussed herein. A rotating shaft 2 extends from a PTO shaft (not shown) of the tractor 7 and translates rotation from the PTO shaft to a gearbox 4, and ultimately to the auger 10. A shield 3 covers moving parts (not shown) that can pose a safety hazard to users (not shown) of the digger 5.

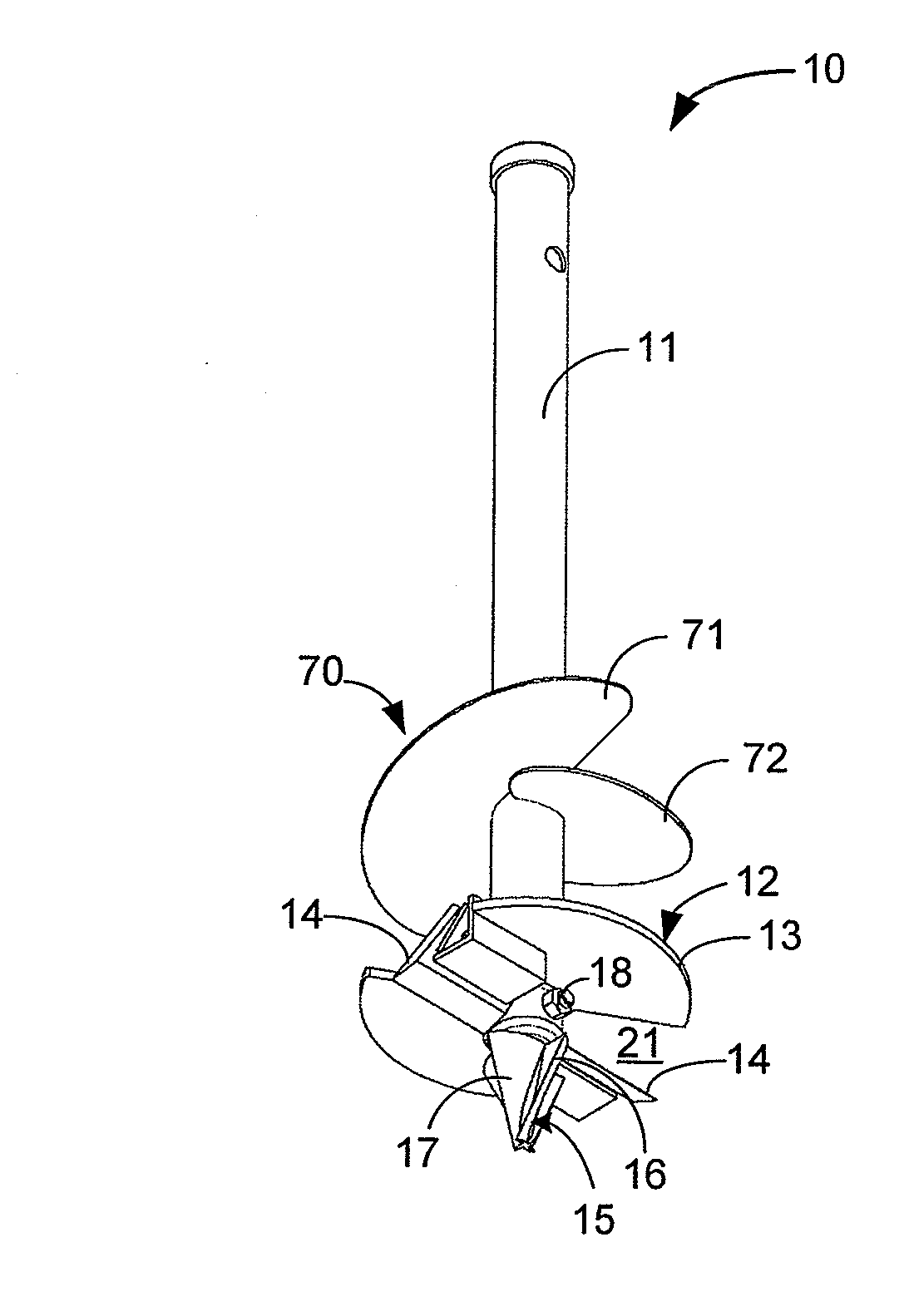

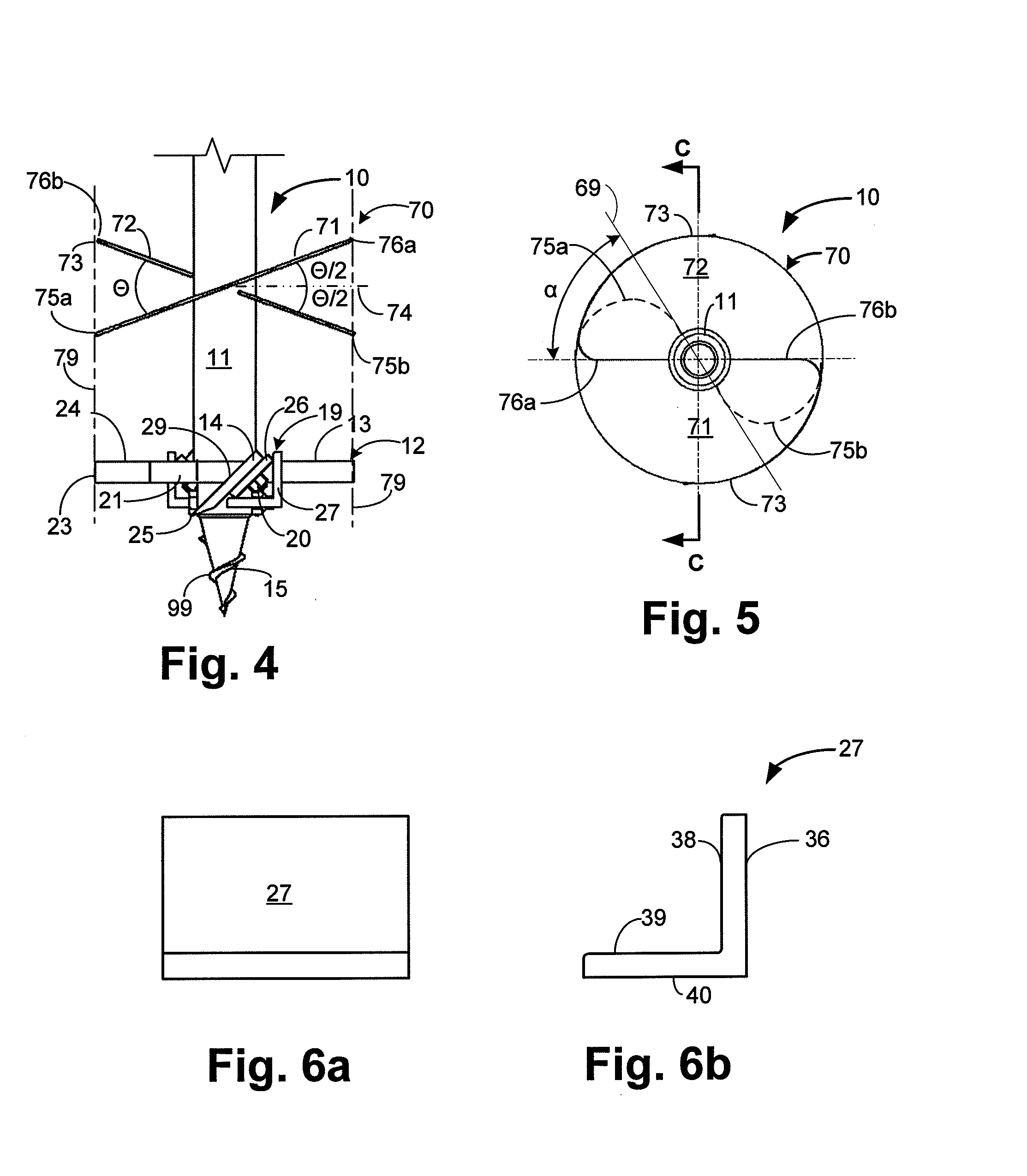

[0032]The auger 10 comprises a cutting head 12 rigidly mounted to a rotatable shaft 11. The shaft 11 extends downwardly from the gearbox 4, which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com