Oil-water automatic separation method and apparatus

A technology for automatic separation and oil-water separation, which is used in oil/oil/float removal devices, chemical instruments and methods, centrifugal separation of water/sewage treatment, etc. Large demand and other problems, to achieve the effect of reducing manpower, less accident, and high safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] specific implementation plan

[0023] The principles and features of the present invention are described below, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

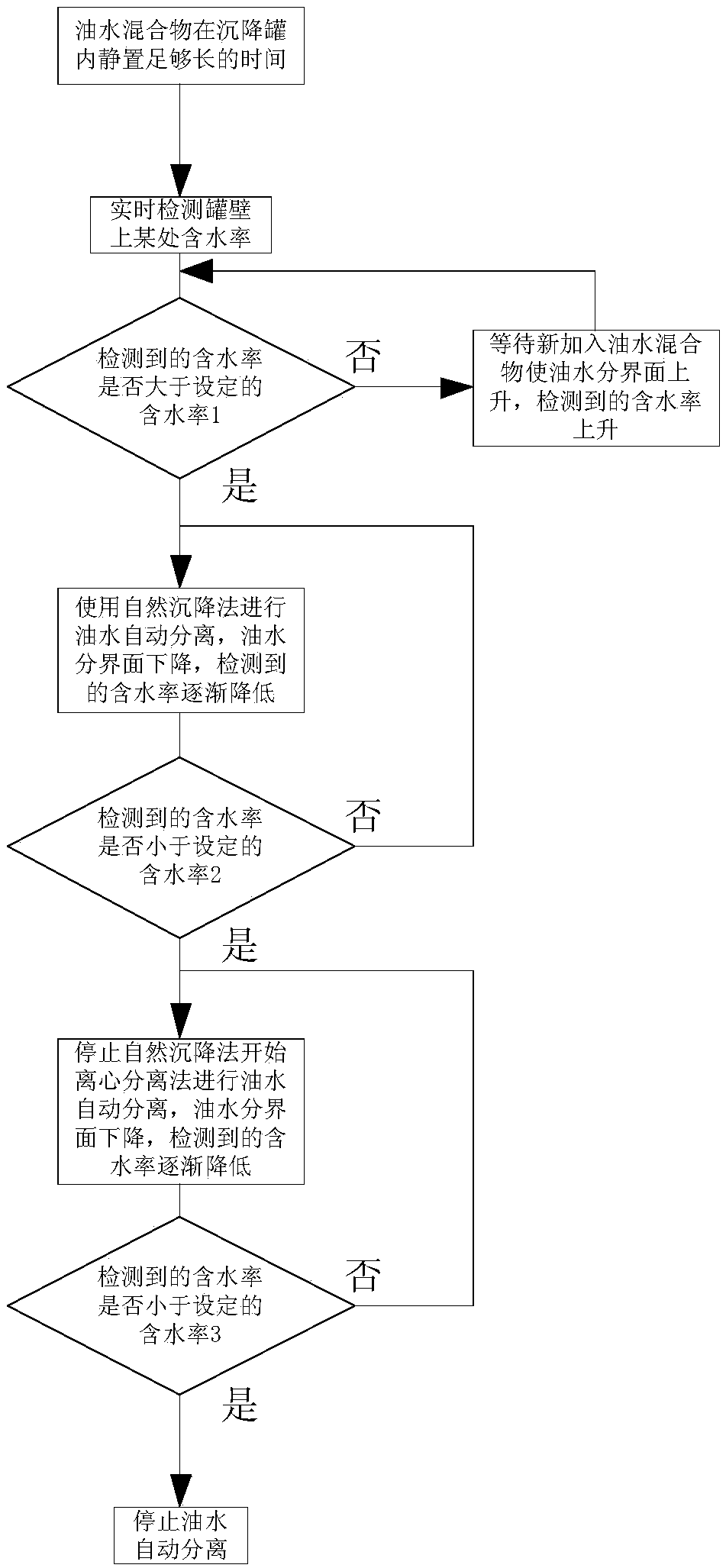

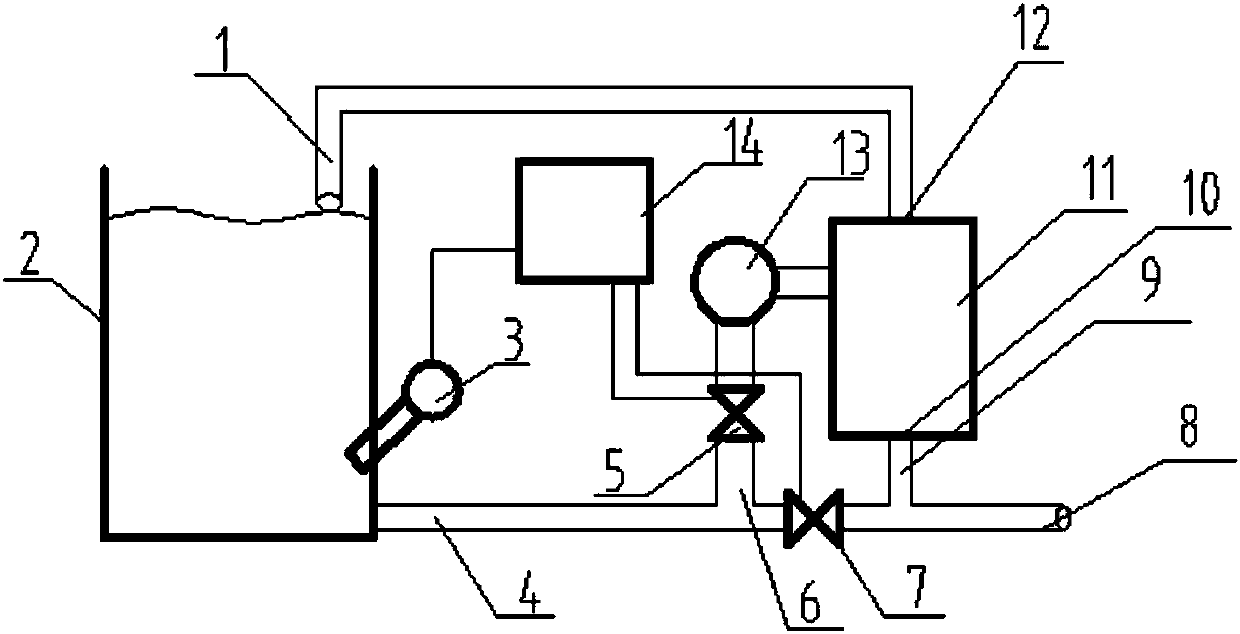

[0024] Such as figure 1 Shown, the invention provides a kind of oil-water separation method, comprises the following steps:

[0025] (1) Preset water content 1, water content 2 and water content 3 on the controller, put the oil-water mixture to be treated into the sedimentation tank and let it stand still, and detect the water content of the oil-water mixture in real time and send it back to the controller, After the stratification of the oil-water mixture is completed, if the detected water content is less than the water content 1, wait for the new oil-water mixture to rise the oil-water interface; When the water content is 2, stop releasing the lower part of the water. The water content 1 is greater than the water conte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com