Formwork support system and construction method

A support system and formwork technology, applied in the direction of formwork/formwork/work frame, connection parts of formwork/formwork/work frame, formwork/formwork member, etc., can solve the problems of difficult pouring and difficult material turnover, etc. Achieve high construction efficiency, avoid material turnover difficulties, and stabilize the system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

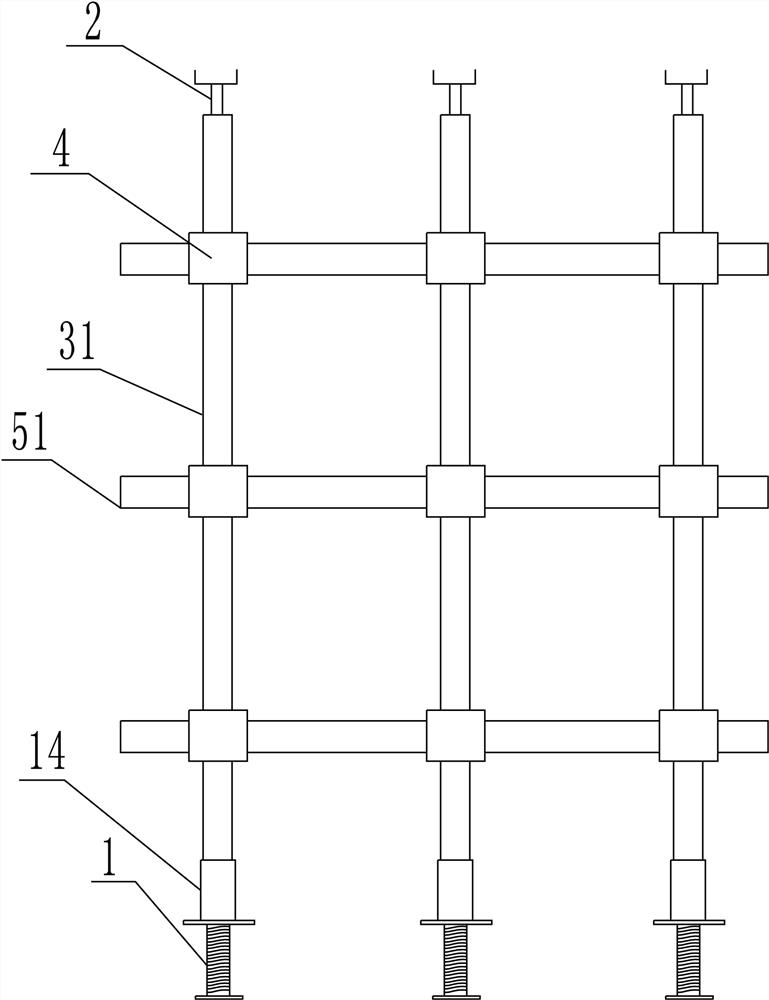

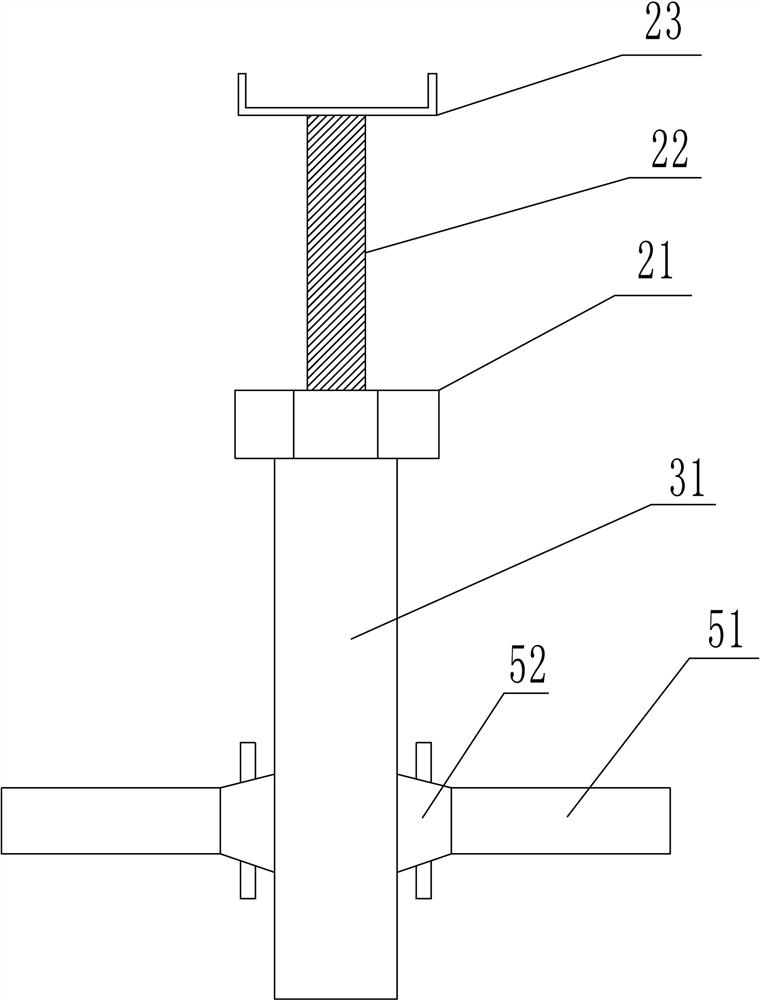

[0037] Such as Figure 1~Figure 7 Among them, a formwork support system, including a support system and a formwork system; the support system includes an adjustable base 1, the bottom end of the adjustable base 1 is connected to the positioning point, and the top end of the adjustable base 1 is socketed with the vertical rod 31 system; the vertical rod 31 The system is connected with a cross bar 51 system through the buckle node 4; the scissor brace or inclined bar is connected between the vertical bar 31 system and the cross bar 51 system; Adjust the bracket 232 to cooperate, and the wall template is bolted to the support system.

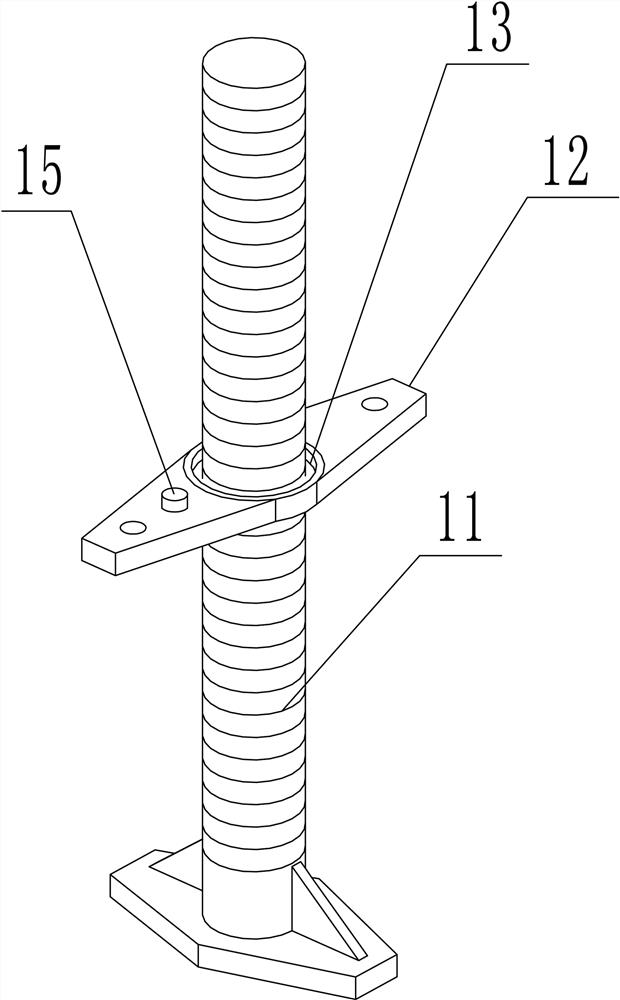

[0038] Preferably, the adjustable base 1 includes a threaded rod 11, the surface of the threaded rod 11 is threadedly connected with a support plate 12, the upper surface of the support plate 12 is provided with an annular positioning groove 13; the bottom surface of the positioning groove 13 is provided with a sheet pressure sensor, the pressure s...

Embodiment 2

[0058] (1) Roof formwork structure:

[0059] The roof template is made of 15mm film-coated wood plywood, the main keel is made of 6.3# channel steel, the secondary keel is made of 40×80mm wooden beams, and the distance between the back corrugated is 150mm. When the formwork is installed, ensure that there is a keel under the joint, and the joint is tight, and there is no wrong platform on the surface.

[0060] (2) Support system:

[0061] See the floor formwork parameter table for the distance between vertical and horizontal poles 31 of buckle-type steel pipe frame on the slab chassis. The upper part of the pole 31 is provided with a jacking bracket. The gap with the inner diameter of the column steel pipe shall not be greater than 3mm, and the upper and lower concentricity shall be ensured during installation.

[0062] The erection height of each floor of the main factory building shall not exceed 8m, and shall be arranged in the following way: vertical slanting rods shall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com