Wire harness test production line

A technology for production lines and wire harnesses, which is applied in the manufacture of wire harnesses, measuring electricity, measuring devices, etc., can solve the problems of slow test speed, damage, affecting production speed and efficiency, etc., to achieve less accidents and errors, accurate test results, and labor reduction. the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

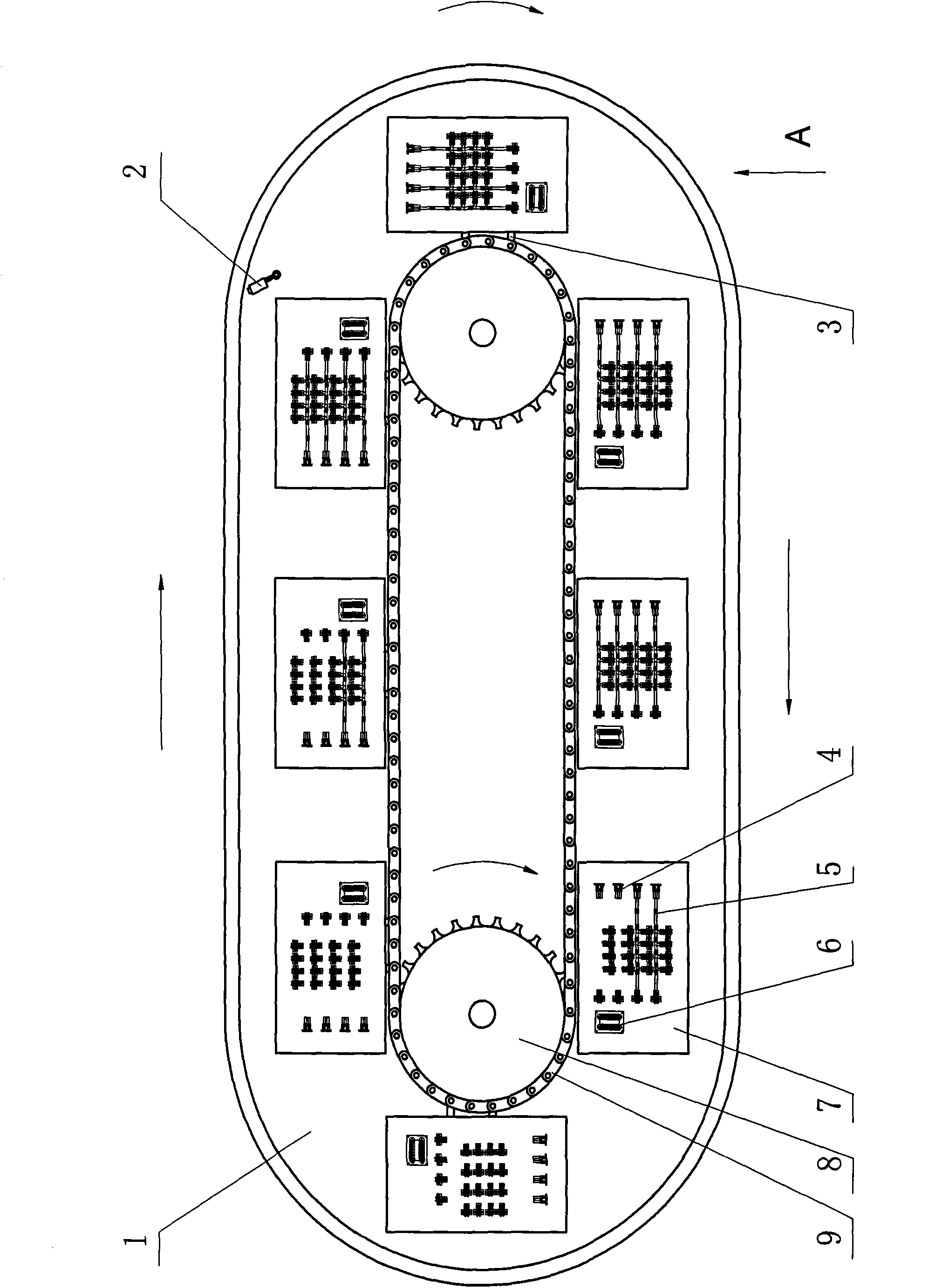

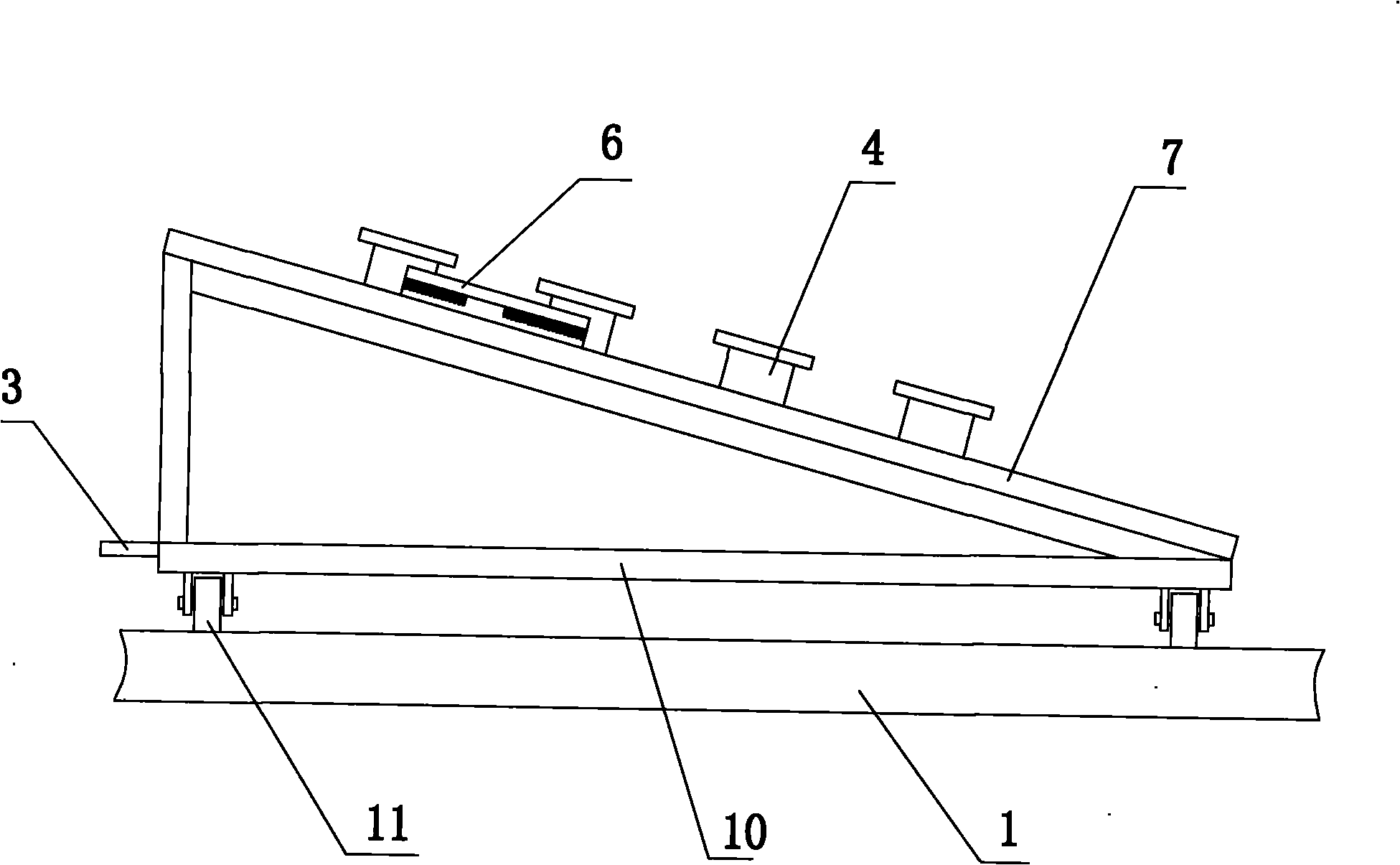

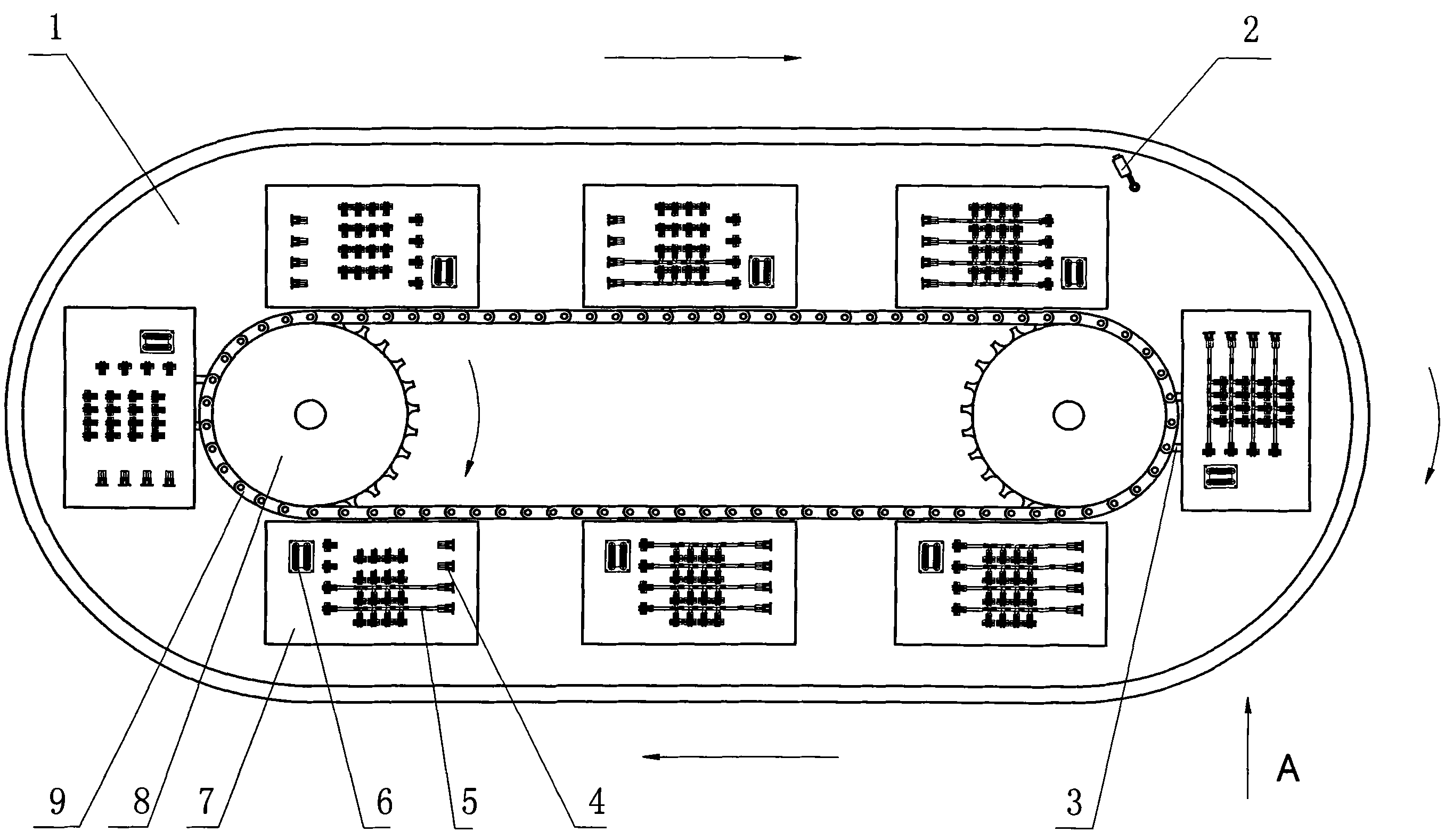

[0034] Embodiment 1, six test boards 7 are connected to the chain 9 via hooks 3 , and four groups of wiring harness sockets 4 are installed on each test board 7 . On a production line, two people are arranged on both sides, each person plugs in a wire harness, four people arrange four groups, the insertion is orderly, and one station at the end is tested and unplugged.

Embodiment 2

[0035] Embodiment 2, eight test boards 7 are connected to the chain 9 via hooks 3, and six groups of wire harness sockets 4 are installed on each test board 7. On a production line, three people are arranged on both sides, each person plugs in a wire harness, six people arrange six groups, the insertion is orderly, and one station at the end is tested and unplugged.

[0036] In short, according to the number of wire harnesses that can be detected by the electronic wire harness tester at the same time, the corresponding wire harness socket 4 is configured on the test board 7, and the plug-in operators at the corresponding stations are arranged on a circle of the production line to work evenly and obtain fast and accurate detection. Effect.

[0037] On the test platform 1, an elastic travel switch 2 is set at the passing position of the corner of the test board 7. In order to realize that the test board 7 stays accurately at each station, when the test board 7 is running, the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com