Long auger drilling and bottom expanding device and expanded anchor rod construction method

A technology of long helical drilling and auger rod, applied in drilling equipment and methods, drill bits, drilling equipment, etc., can solve the problems of waste slurry pollution, high construction cost, slow construction speed, etc., and achieve flexible movement and construction. The effect of low cost and fast construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

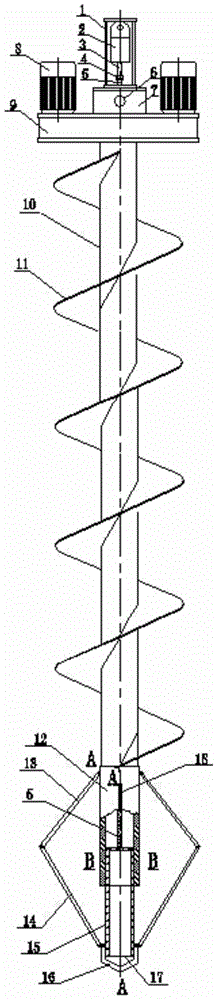

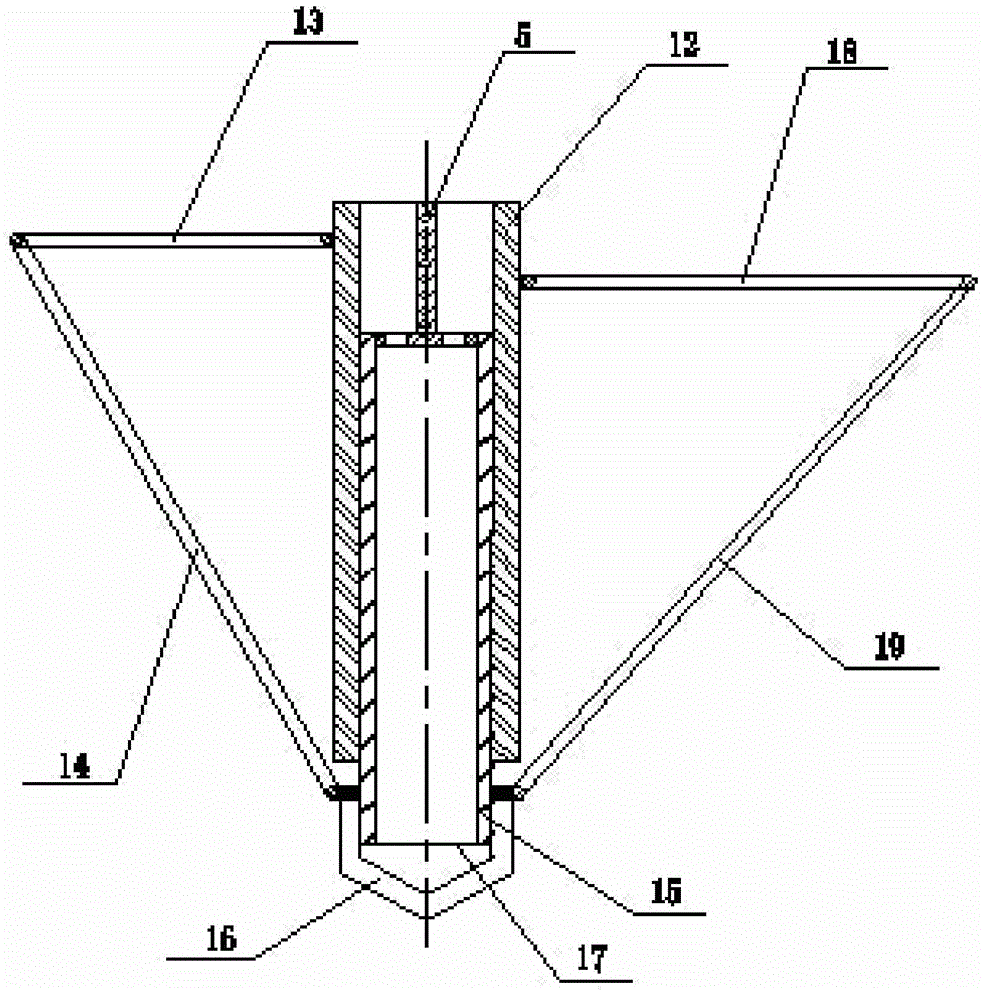

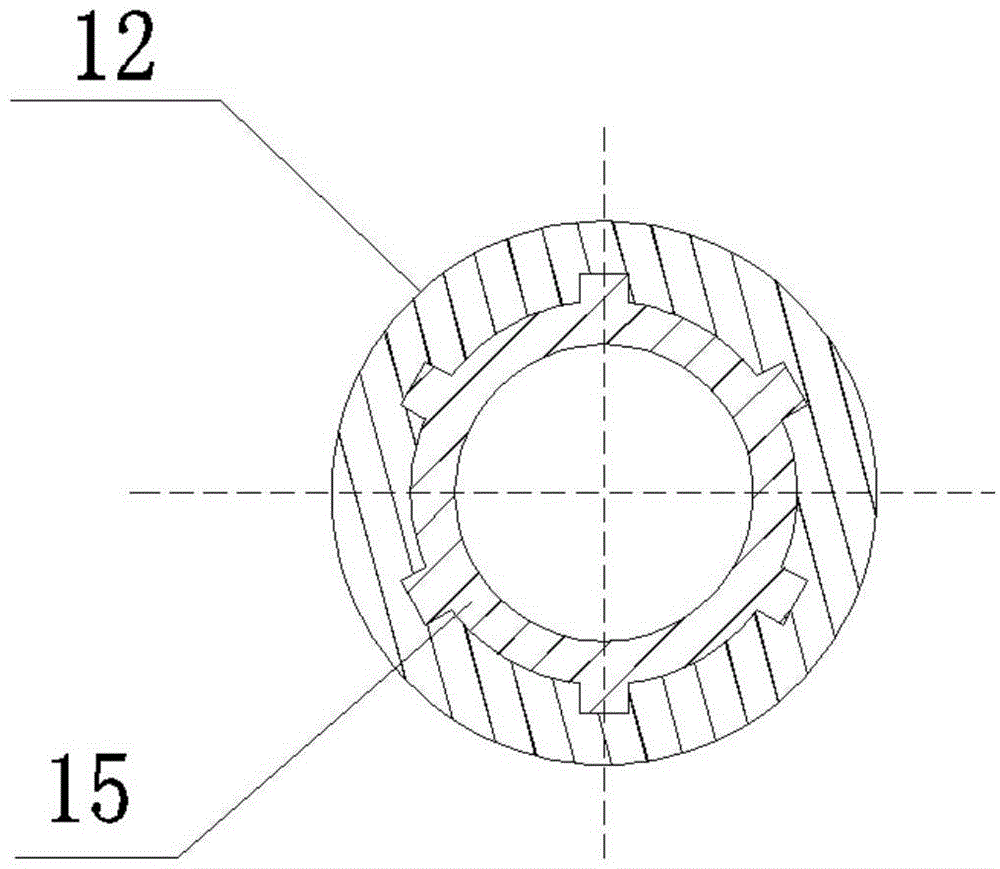

[0031] Embodiment one: the following combination Figure 1 to Figure 7 , Figure 9 , to specifically illustrate the present embodiment, a long auger drilling and reaming device, including an auger rod 10 provided with helical blades 11 and a leading drill bit 16, the upper part of the auger rod 10 is connected with the power of the pile driver through the rotary joint 7 The box 9 is connected, the rotary joint 7 is provided with a slurry inlet 6, the two sides of the power box 9 top are provided with motors 8, and the middle of the power box 9 top is provided with a reaming oil cylinder support 1 and a reaming oil cylinder 2. Connecting ears 20 are arranged in the middle of the upper part, and the reaming cylinder 2 is hinged with the reaming cylinder support 1 through the connecting ears 20. The lower end of the piston rod 3 of the reaming cylinder is connected with the top of the reaming connecting rod 5 through a transfer connector 4. The lower part of the hole connecting ...

Embodiment 2

[0043] Embodiment two: combine below Figure 8 , Figure 10 , to specifically illustrate the present embodiment, at first the reaming cylinder piston rod 3 is in the extended state, and the reaming connecting rod 5 and the reaming bit body lower tube 15 are pushed, so that the upper wing 13 of the primary reaming wing and the secondary reaming wing The upper wing 18, the lower wing 14 of the primary reaming wing, and the lower wing 19 of the secondary reaming wing are all in a retracted state, and are drilled to a specified depth with a long screw drill to form a image 3 A borehole with a diameter of d2 is shown, and the bottom of the borehole is a borehole with a diameter of d1 formed by the leading drill bit.

[0044] After the diameter d2 drilling is completed, the pile driver continues to rotate clockwise on the spot, and at the same time, start the oil pump to gradually retract the reaming cylinder piston rod 3, pull up the reaming connecting rod 5, and make the lower p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com