Suction matching device capable of improving uplift bearing capacity of tubular pile

A technology for pipe piles and performance, applied in sheet pile walls, buildings, infrastructure engineering, etc., can solve the problems of difficult recycling and reuse of pipe piles, and achieve the effect of reasonable and reliable structure, stable pull-out resistance, and improved adsorption capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

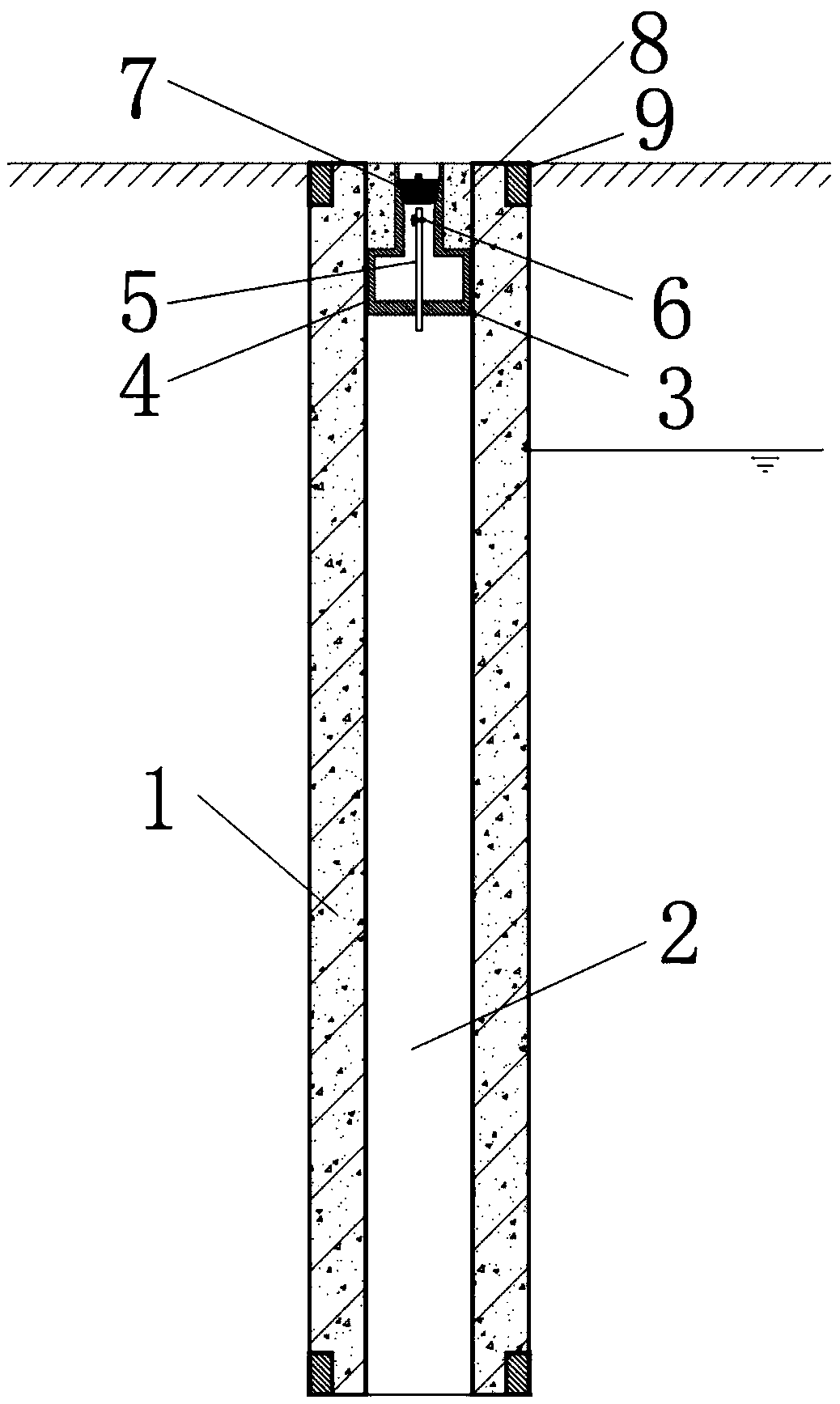

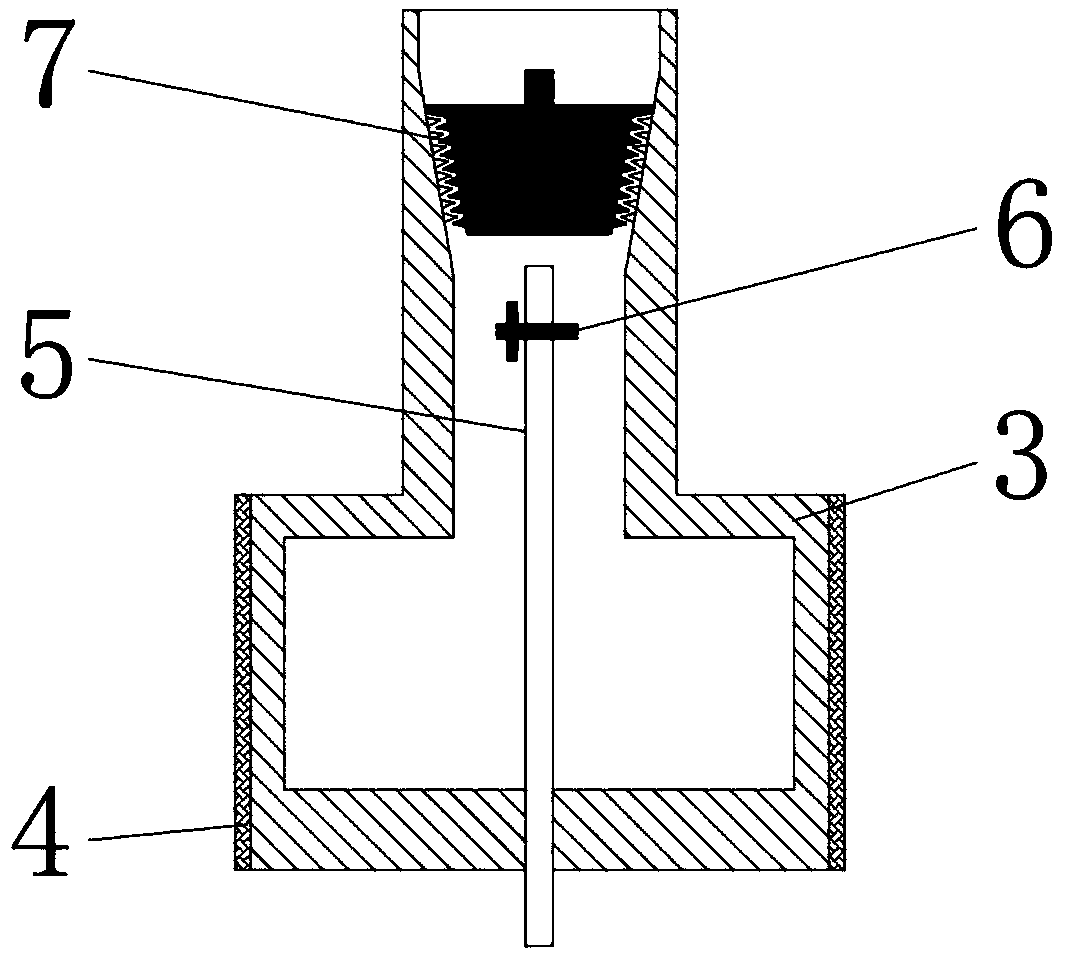

[0020] Such as figure 1 , figure 2 As shown, a suction matching device for improving the uplift bearing performance of pipe piles includes a pipe pile body 1, a suction box, and a pile collar 9. The pile hoop 9 is ring-shaped and welded to the upper and lower ends of the pipe pile body 1 to ensure the stability and strength of the overall structure of the pipe pile body 1 during the installation and construction of the pipe pile body 1 . There is a coaxial hollow cavity 2 on the pile body 1 of the pipe pile, and the suction box is arranged on the top of the hollow cavity 2 .

[0021] The suction box includes a box body 3 , a suction pipe 5 , an air valve 6 and a piston 7 . The box body 3 is made of steel, with a height of 1-1.3m, and the outer diameter can be customized according to the inner diameter of the pipe pile. There are through holes on the upper and lower sides of the box body 3 , the through holes on the lower side of the box body 3 are used to communicate with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com