Patents

Literature

147results about How to "Will not deposit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nano metal fluid with high heat-transfer performance

ActiveCN1955252AImprove thermal conductivityFast absorption and deliveryDigital data processing detailsSemiconductor/solid-state device detailsLiquid metalSolvent

This invention provides a high heat transfer performance liquid nano-metal. It relates to cooling fluid working medium, and especially it can be used under high rush density condition which need high intensity cooling fluid working medium for heat exchanging and cooling, such as computer array and reactor. The solvent of this invention is liquid metal, and the soluble of this invention is nanometer particle. This invention solve the problem of high price of present metal liquid cooling working medium and the limited performance of common metal liquid, leaking out easily taken place using common liquid and easy forming sediment of present nanometer cooling agent.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

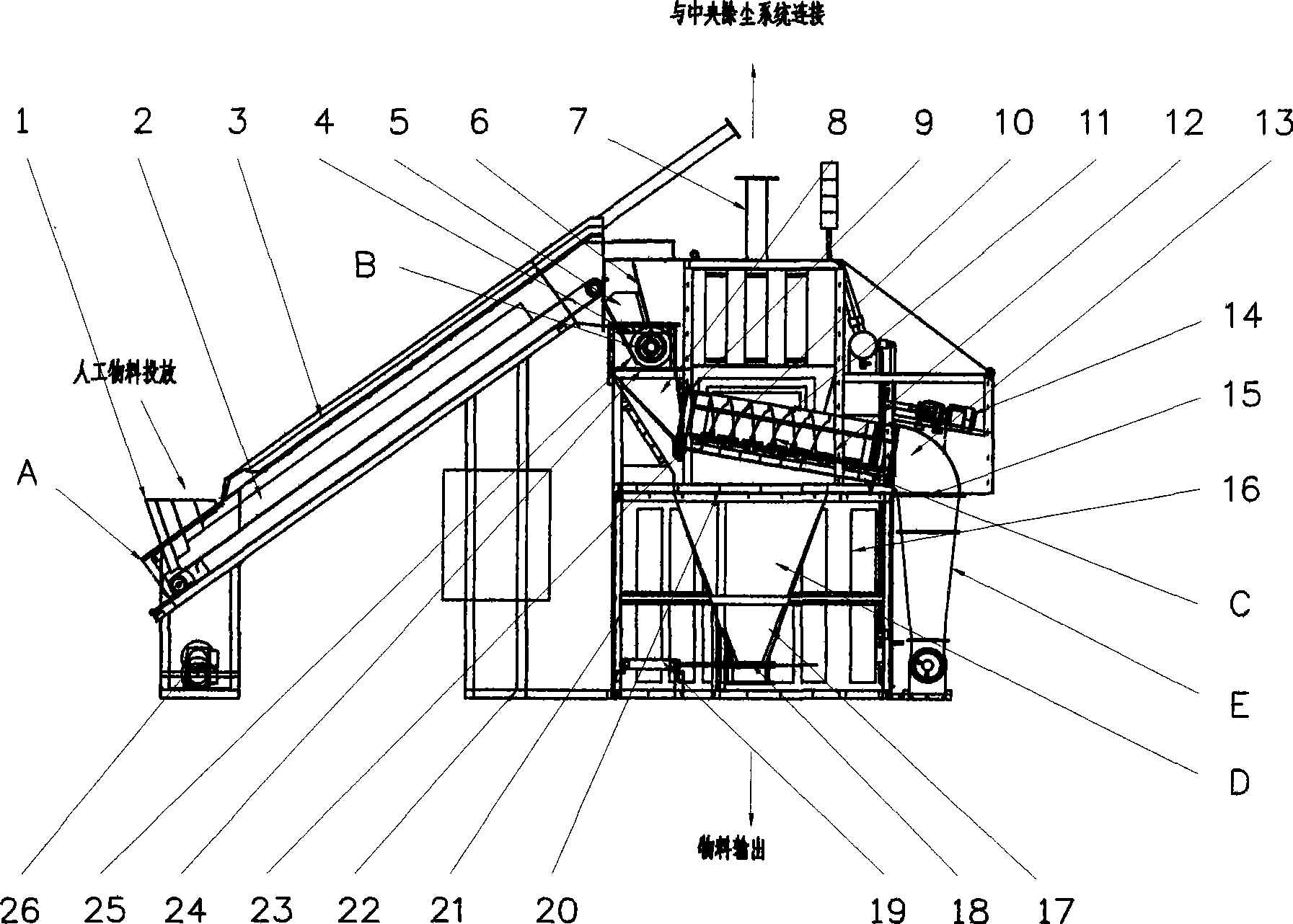

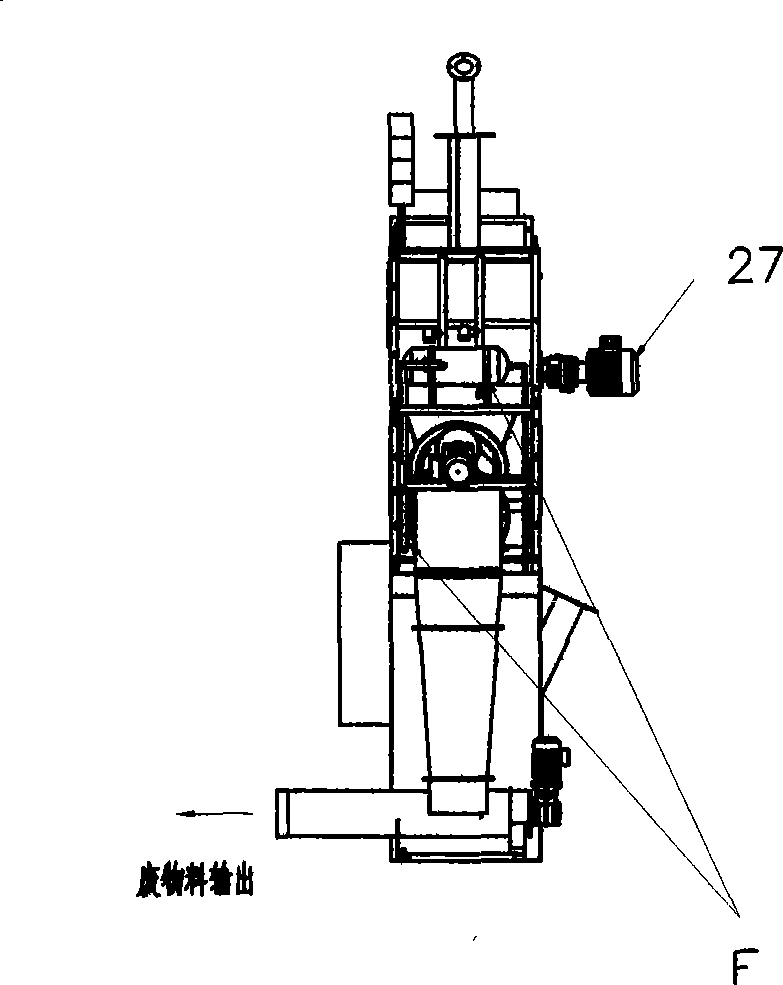

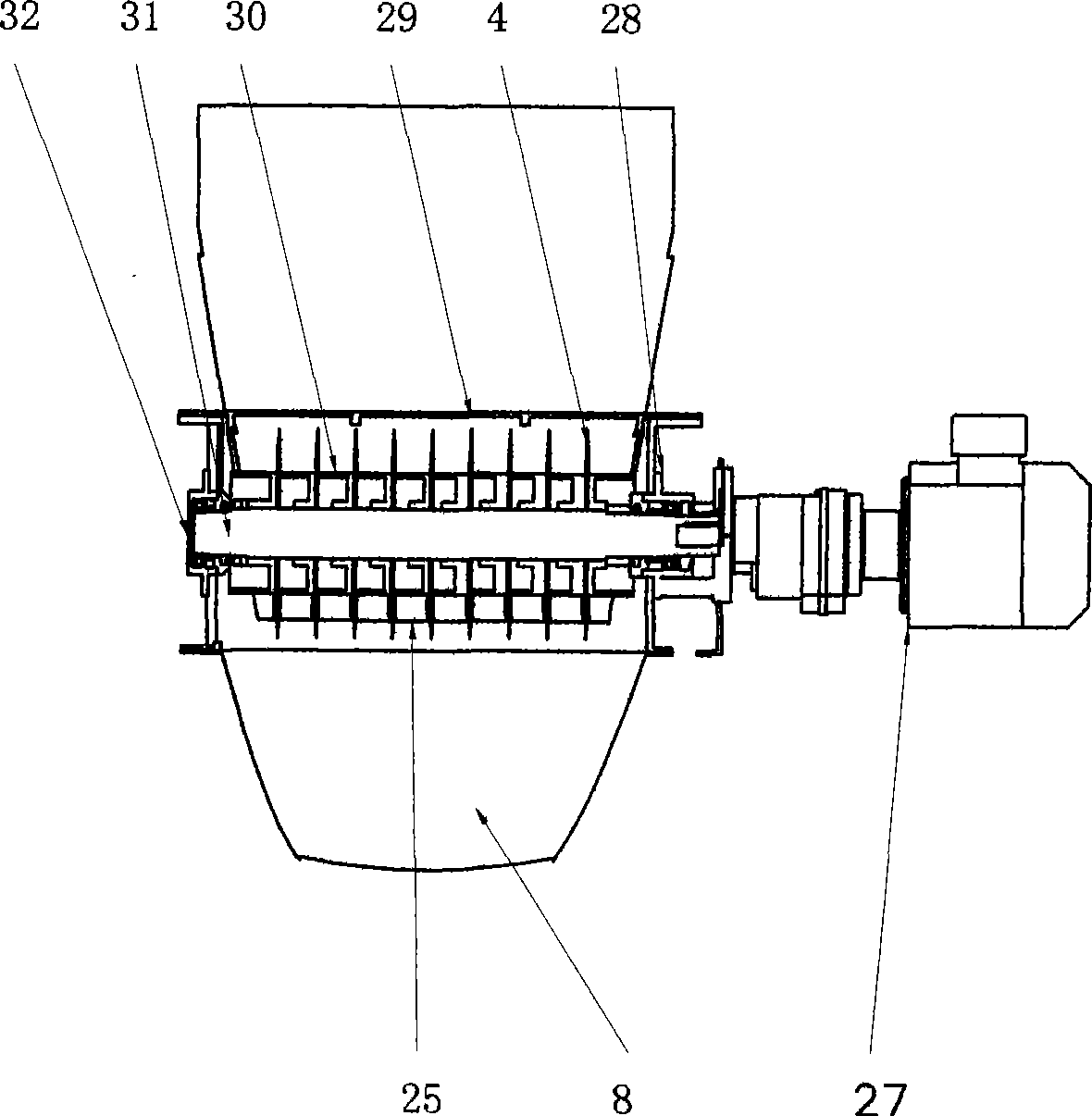

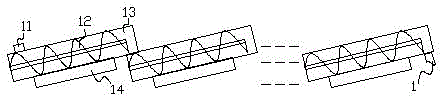

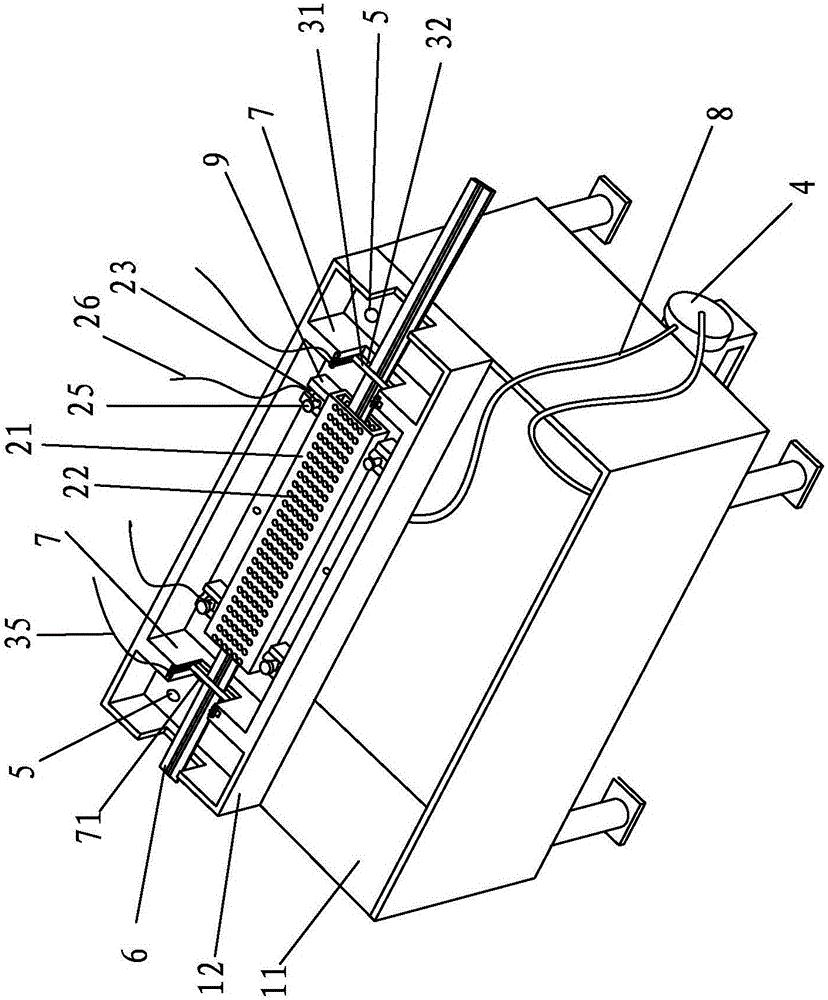

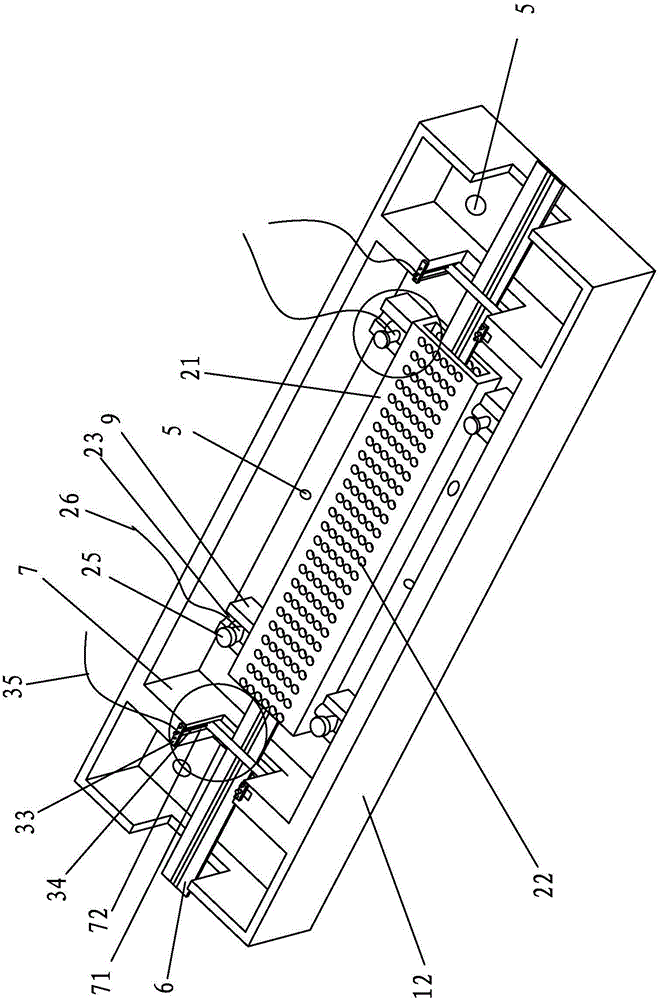

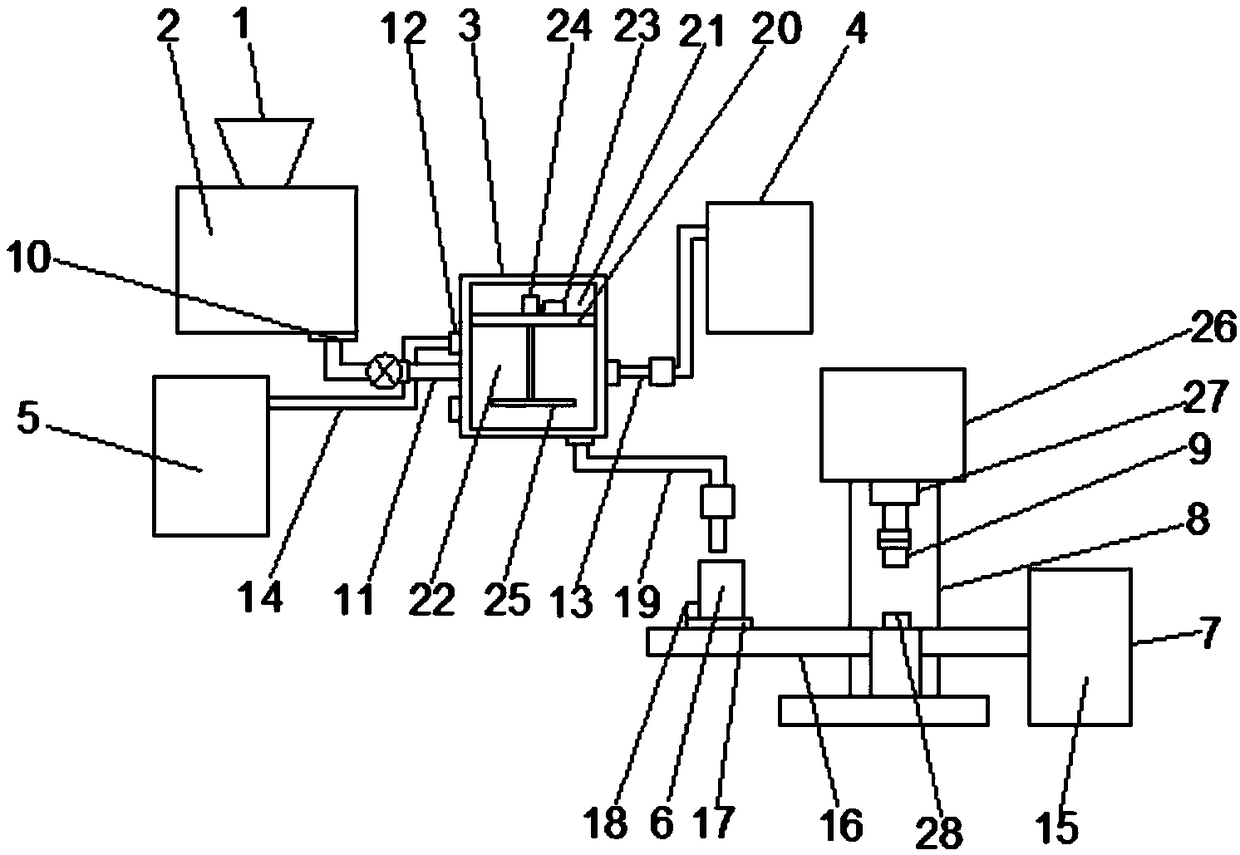

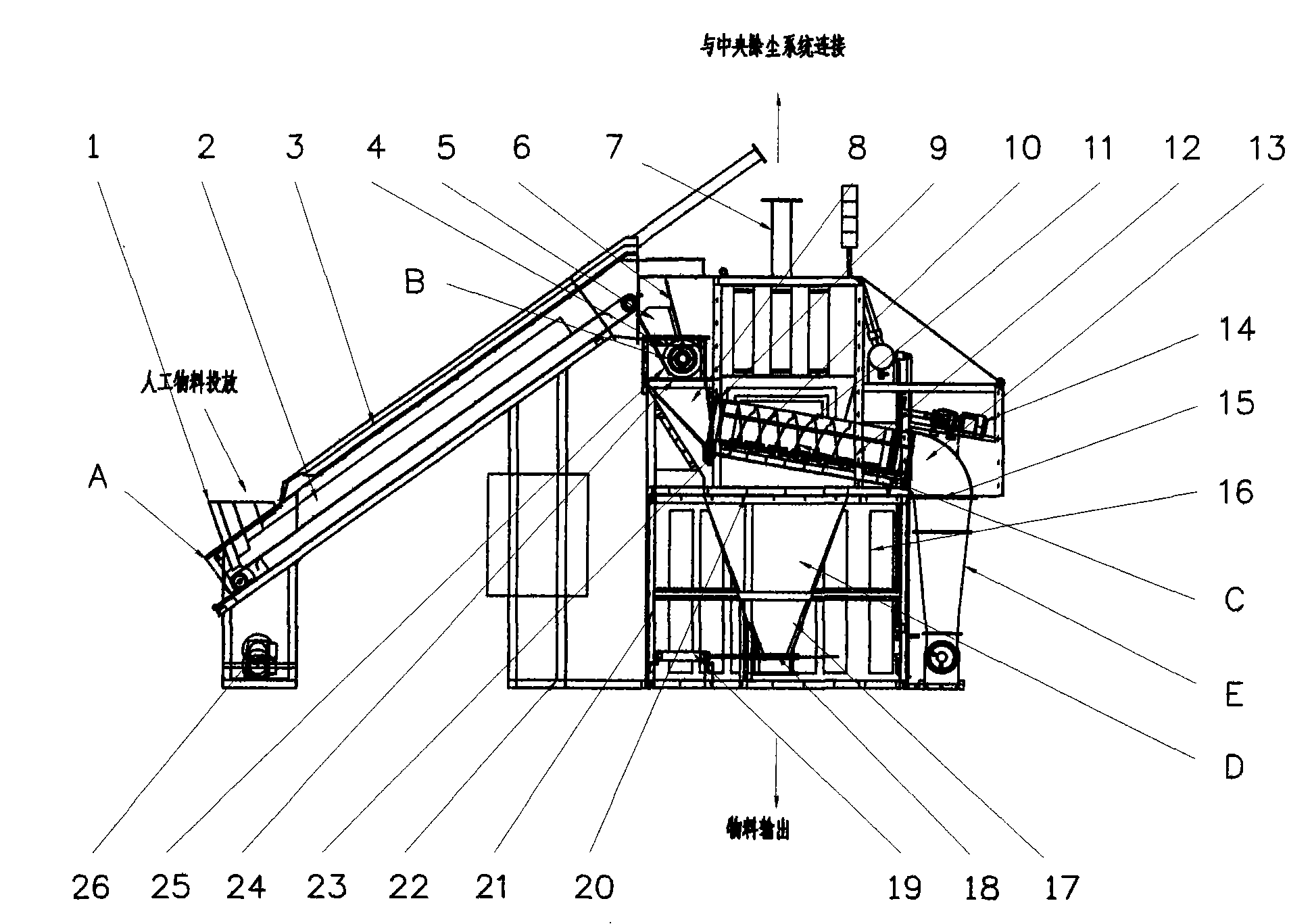

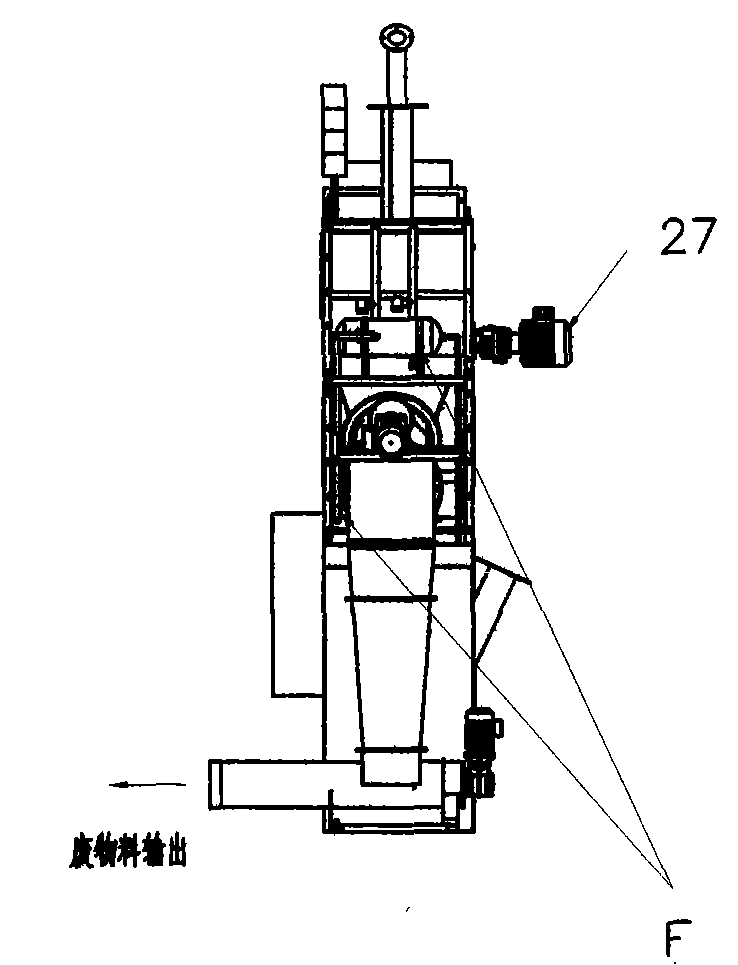

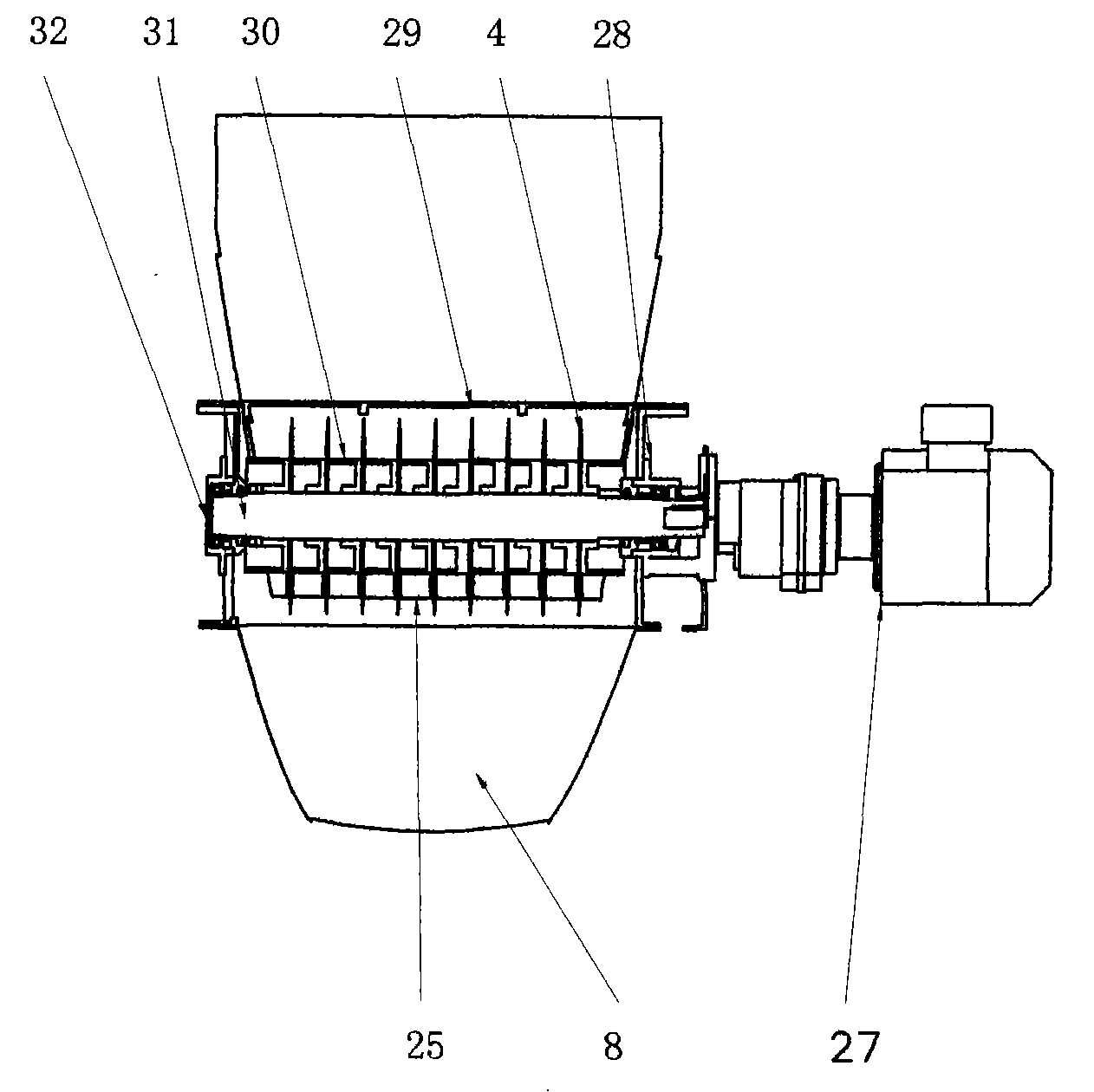

Full automatic unpacking unloader

The invention relates to a solid material unpacking machine, in particular to a full automatic unpacking and unloading machine, which is characterized in that: all stages of mechanisms are connected through flanges; a bag breaking mechanism, a screening mechanism and a material output mechanism are arranged on a main body frame; the outer surface of the main body frame is connected with a surface panel in a splicing mode; the surface panel on the top of the main body frame is provided with a main dust removal outlet; and a channel formed from the feeding inlet end of a feeding mechanism to the outlet end of the material output mechanism and the outlet end of a waste bag output mechanism is a one-way communication channel. The full automatic unpacking and unloading machine has the advantages that the machine has high work efficiency, energy conservation, environmental protection, small volume, light weight and the like, can safely and stably separate solid materials from packages in automatic high-speed running, and convey the materials to downstream equipment, while the waste packages enter a waste bag recovery device for recovery, and the machine can particularly meet the requirements of unloading, separating and collecting toxic and corrosive powder, and particle materials.

Owner:HANRUI PUZER BULK HANDLING TECH SHANGHAI

Chinese medicinal herb additive for meat chickens and application

InactiveCN101543261AImprove immunityFormulation ScienceFood processingAnimal feeding stuffCoccidiosisEscherichia coli

The invention discloses a Chinese medicinal herb additive for meat chickens and application. The Chinese medicinal herb additive comprises heterophylly falsestarwort root, nutgrass galingale rhizome, amur corktree bark, coptis root, medicated leaven, sanguisorba, hawthorn, Indian Buead, officinal magnolia bark, largehead atractylodes rhizome, tangerine peel, malt, indigowoad root, swordlike atractylodes rhizome, indigowoad leaf, cyrtomium fortune, chatoyancy and calamus; and mixture of the compositions is added with calcium bicarbonate, phytase, mulitivitamin for birds and lysine. The Chinese medicinal herb additive effectively promotes absorption of nutrient, can resist bacteria and virus, strengthen immunity of the meat chickens, effectively prevents bird flu, has obvious curative effect on diseases having respiratory tract symptoms as the major symptom, and has inhibiting function on familiar newcastle disease, colon bacillus, Pasteurella, enteritis, diarrhea, feather pecking, hair shedding, anus pecking, coccidiosis and the like. The additive cannot restrict the growth and disease resistance of the meat chickens, the meat quality of the meat chickens fed by the additive is obviously better than that of the meat chickens fed by the prior feed additive, the average daily gain of the meat chickens is improved by 23 to 28 percent than that of the meat chickens fed by the prior feed additive, the cultivation cycle is obviously shortened, and no harmful substance is deposited.

Owner:CHONGQING KAIZHOU JIUDING ANIMAL HUSBANDRY SCI & TECH DEV

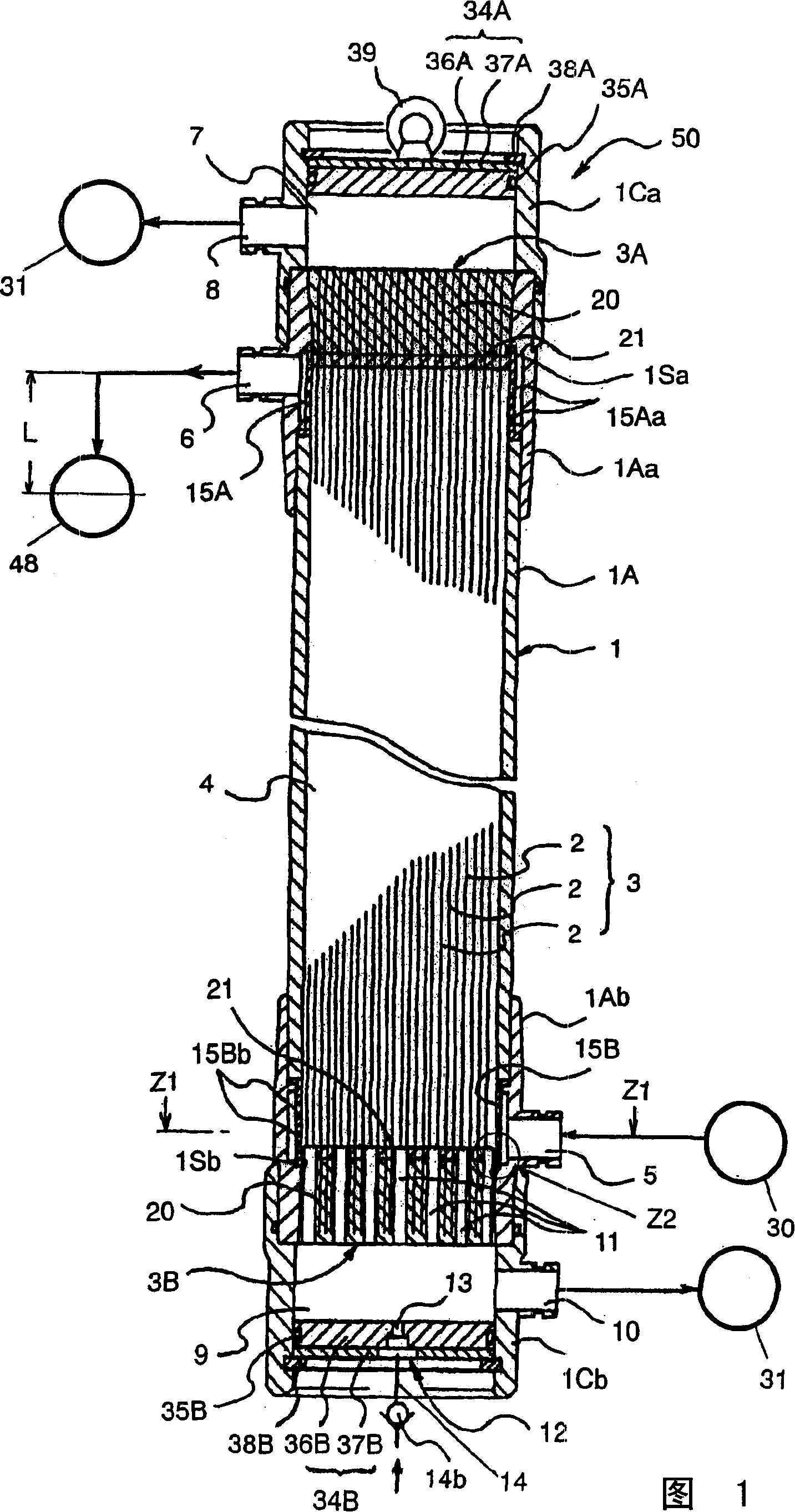

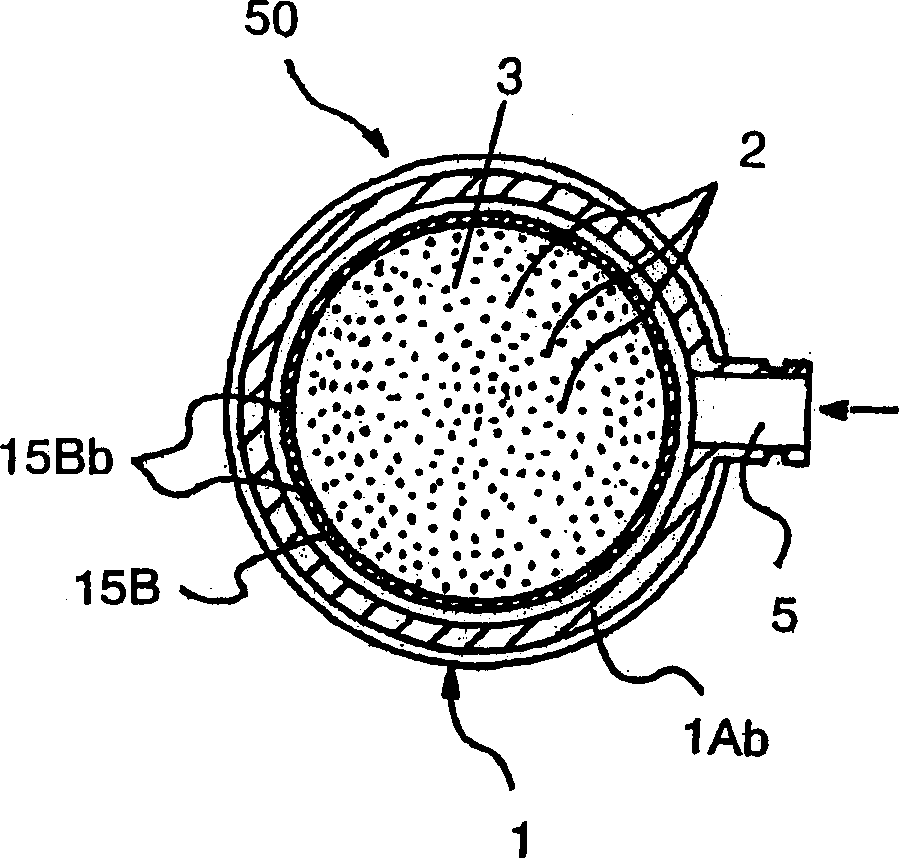

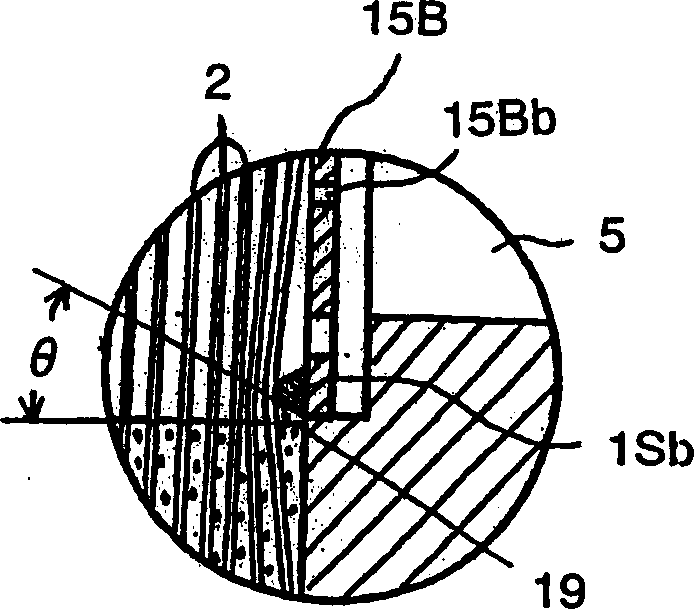

Hollow yarn membrane module, hollow yarn membrane module unit, and method for producing hollow yarn membrane modules

A hollow yarn membrane module, wherein into a filter chamber surrounded by a first sealing body having a opening end for a number of hollow yarn membranes forming a hollow yarn membrane bundle, a cylindrical case, and a second sealing body and having a hollow yarn membrane bundle received therein is fed raw water from a raw water feed port formed in the cylindrical case in the vicinity of the second sealing body, and the drain produced during back washing is discharged through a drain hole formed in the second sealing body.

Owner:TORAY IND INC

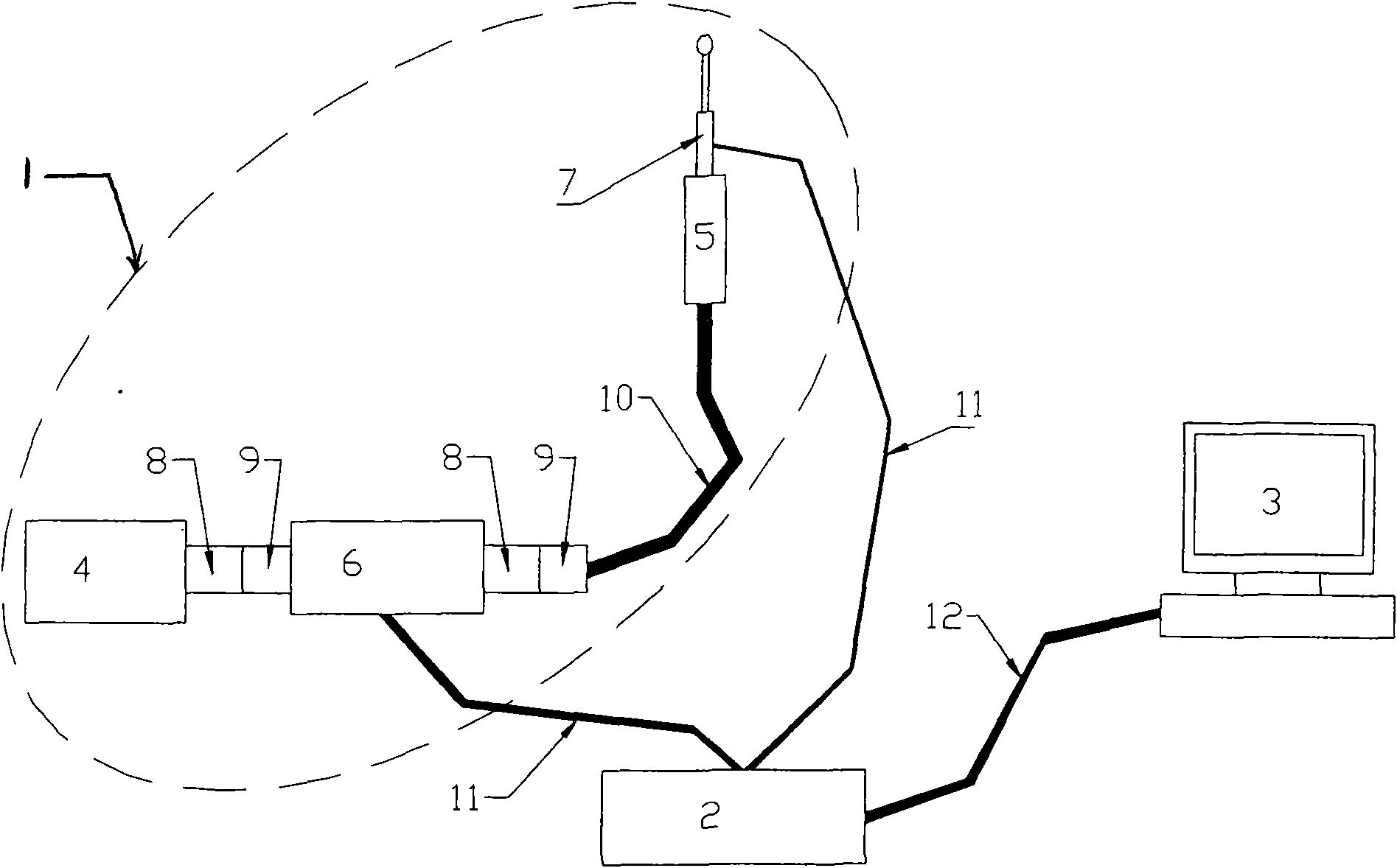

Intelligent control device of surgical electric drill

InactiveCN101579250AImprove the level of surgical operationAvoid mistakesSurgeryProgramme control in sequence/logic controllersMultiple sensorMulti dimensional

An intelligent control device of a surgical electric drill belongs to the technical field of medical appliances, which is characterized by being capable of assisting doctors in reducing surgical accidents and being used under complicated back-and-forth grinding surgical environments including changing power and changing grinding direction. The intelligent control device comprises three systems: a converted surgical electric drill, a high-speed embedded system and a host computer; wherein, the converted surgical electric drill comprises a multi-dimensional pressure sensor, a bit speed sensor, a current sensor, a voltage sensor and a voltage reverse brake. The working processes of the intelligent control device are as follows: acquiring the operation information of the surgical electric drill by a multisensor system; identifying the operation state of the surgical electric drill in real time by the high-speed embedded system and displaying and recording the information of the sensors in real time by the host computer.

Owner:UNIV OF SCI & TECH BEIJING +1

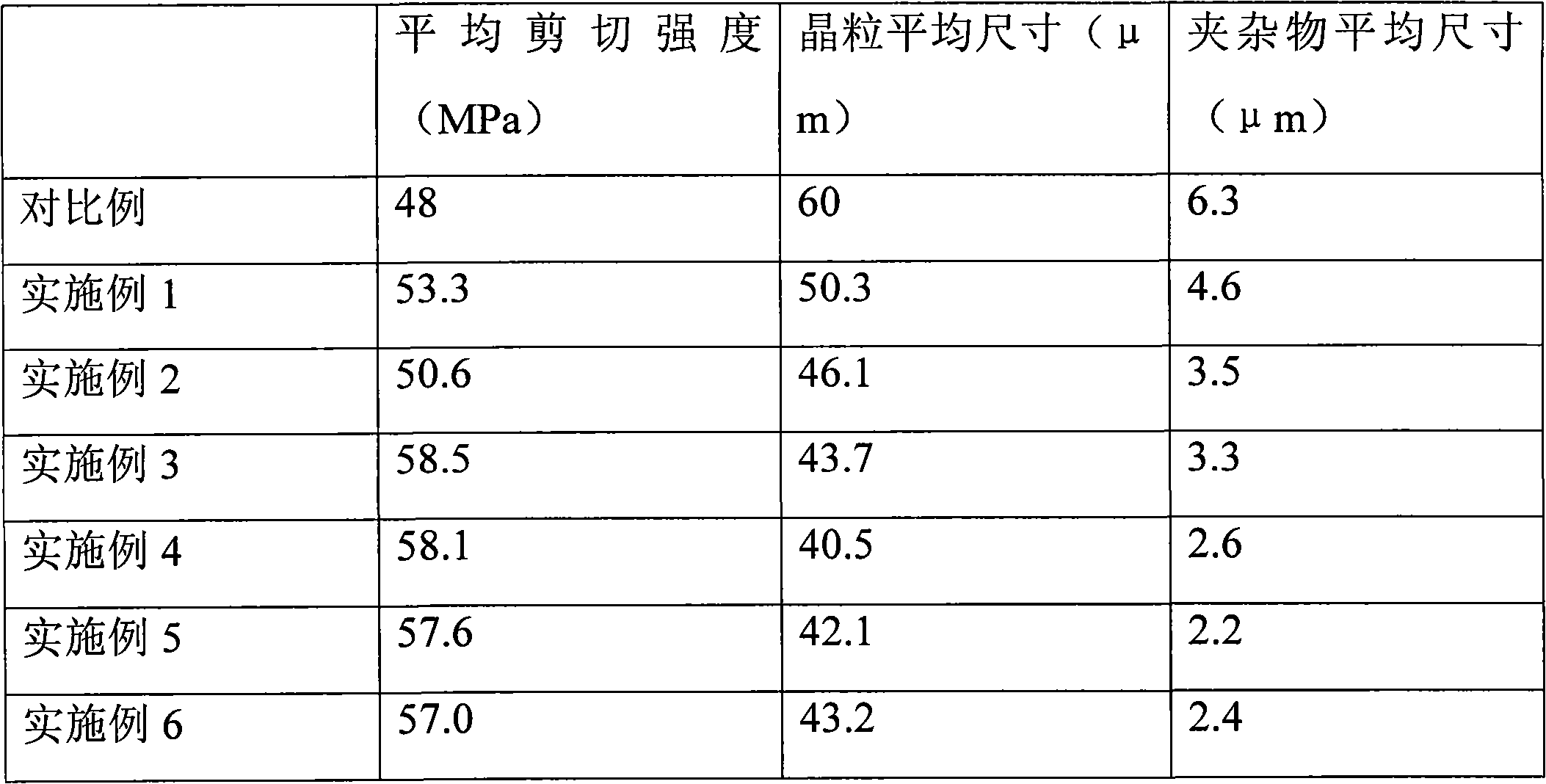

A kind of magnesium alloy solder containing rare earth element Er and preparation method thereof

InactiveCN102294553ASolve severe segregationSolve the coarse grainWelding/cutting media/materialsSoldering mediaRare-earth elementSlag

The invention relates to a magnesium alloy brazing filler metal containing a rare-earth element Er and a preparation method thereof, and belongs to the technical field of magnesium alloy connection. The magnesium alloy brazing filler metal comprises the following components in percentage by weight: 40-55% of Mg, 39-55% of Zn, 1-5% of Al and 0.1-1.5% of Er, wherein the Er is uniformly distributed.The preparation method comprises the steps of arranging alloy ingots in a preheat crucible, heating under protective atmosphere and mechanical stirring, fishing slag after the alloy ingots are completely fused, stopping heating brazing filler metal, stirring the brazing filler metal, applying ultrasonic waves on the fused brazing filler metal after the brazing filler metal is cooled to 380-600 DEG C, inserting an ultrasonic rod preheated to 300-700 DEG C into a brazing filler metal liquid level with the ultrasonic frequency of 18-22kHz, ultrasonic intensity of 0.5-5W / cm2 and the time of 10-150s, standing still after moving out the ultrasonic rod after ending, pouring the brazing filler metal liquid into a mould and air cooling to room temperature. The number of dendritic crystals of the obtained product is obviously reduced, crystal grains are refined, and the strength and the toughness are improved.

Owner:BEIJING UNIV OF TECH

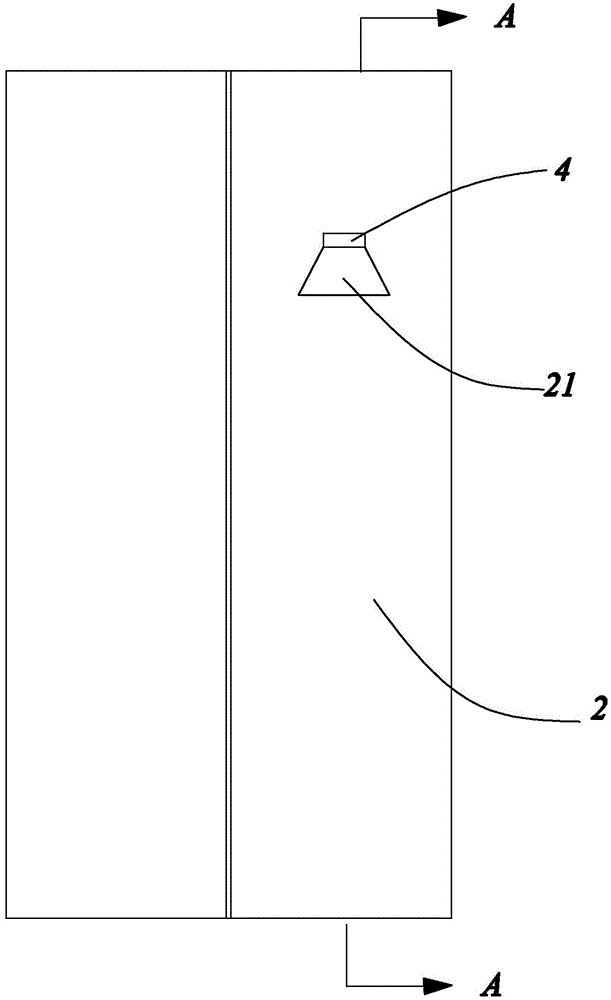

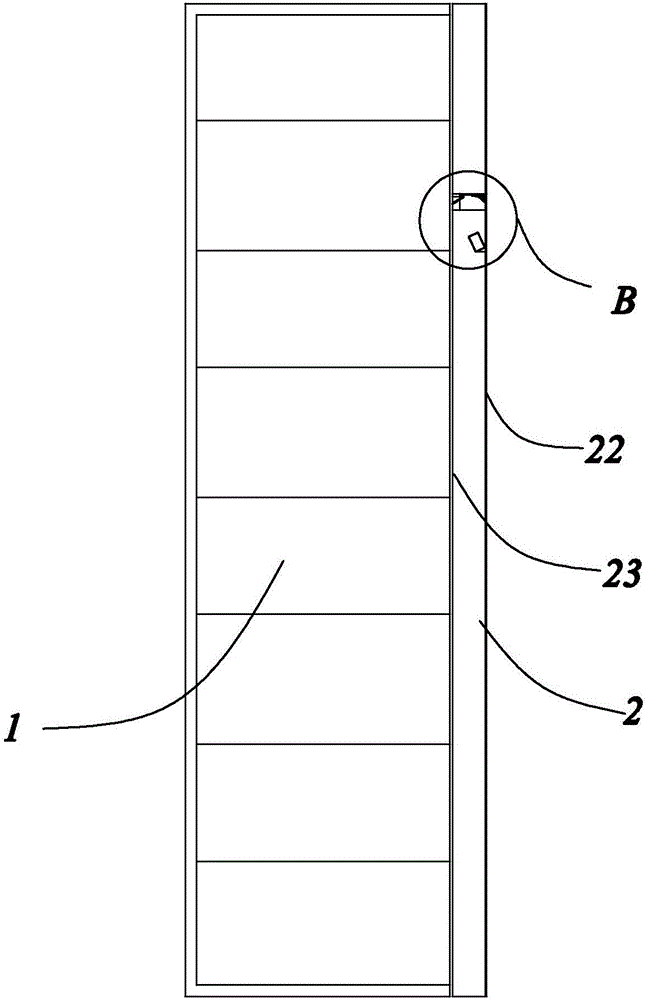

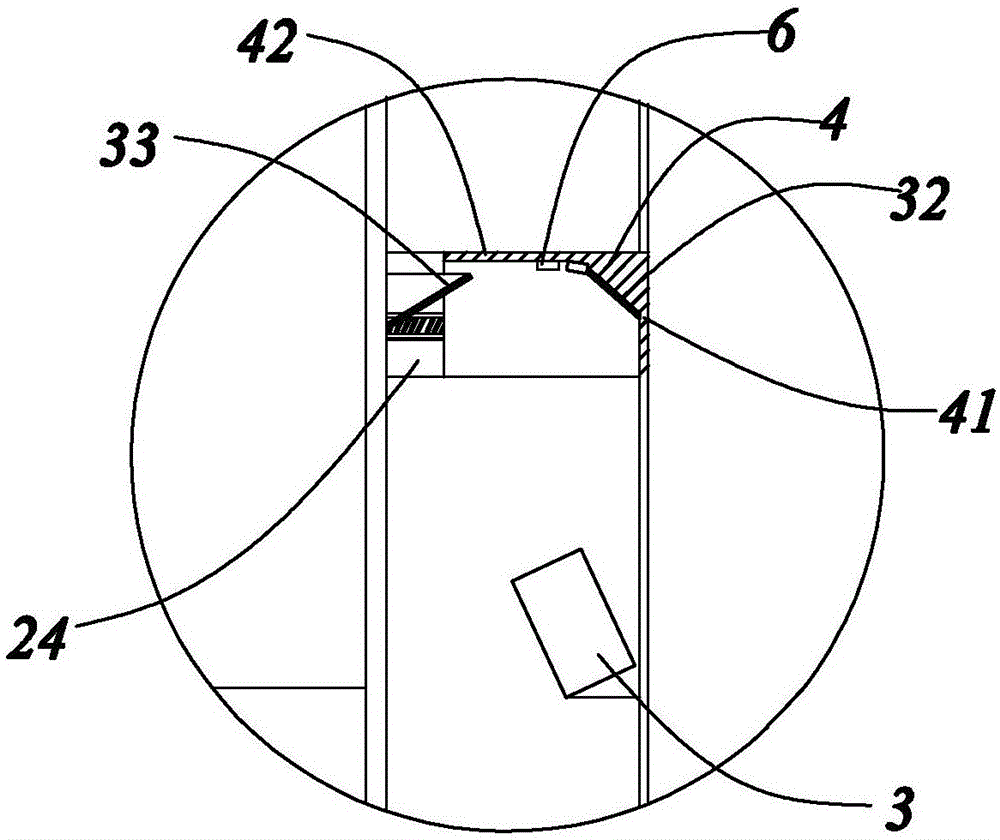

Refrigerator with projection device

ActiveCN106595173ADoes not affect appearanceWill not depositLighting and heating apparatusDomestic refrigeratorsEngineeringRefrigerated temperature

Owner:QINGDAO HAIGAO DESIGN MFG CO LTD

Laundry detergent composition for inhibiting ash deposition

ActiveCN103756803AInhibits the formation of precipitatesDeposition will notNon-ionic surface-active compoundsOrganic/inorganic per-compounds compounding agentsActive agentPhysical chemistry

The invention provides a laundry detergent composition for inhibiting ash deposition. The composition comprises an anionic surfactant, a nonionic surfactant, carbonate, hydrocarbonate and sodium peroxycarbonate, and does not contain sodium tripolyphosphate and a 4A zeolite additive system. According to the composition, hardness ion deposition can be inhibited and cannot be deposited on fabrics, so that the ash deposition is reduced and the washed fabrics are still kept soft, smooth and unhardened.

Owner:HUNAN JIEYU DAILY CHEM NEW TECH

Method for producing biogas and organic fertilizer by dry fermentation of livestock and poultry feces

InactiveCN102344232ANo need to diluteReduce lossesBio-organic fraction processingClimate change adaptationBiotechnologyFeces

The invention discloses a method for producing biogas and organic fertilizer by dry fermentation of livestock and poultry feces. The method comprises the following steps of feeding directly solid livestock and poultry feces of which dry matter concentration is above 15% into a biogas fermentation device, or mixing the solid livestock and poultry feces and livestock and poultry feces fermentation residues and then feeding the mixture into the biogas fermentation device to carry out biogas production, wherein the fermentation residues obtained by the previous step can be utilized as organic fertilizer or the fermentation residues are subjected to composting and then are utilized for organic fertilizer production. Through the method provided by the invention, livestock and poultry feces is subjected directly to dry fermentation without dilution and desanding pretreatment; scum is not formed in the biogas fermentation device; temperature rise and heat preservation are easy; nutrient loss is less; and produced organic fertilizer has high fertilizer efficiency.

Owner:BIOGAS SCI RES INST MIN OF AGRI

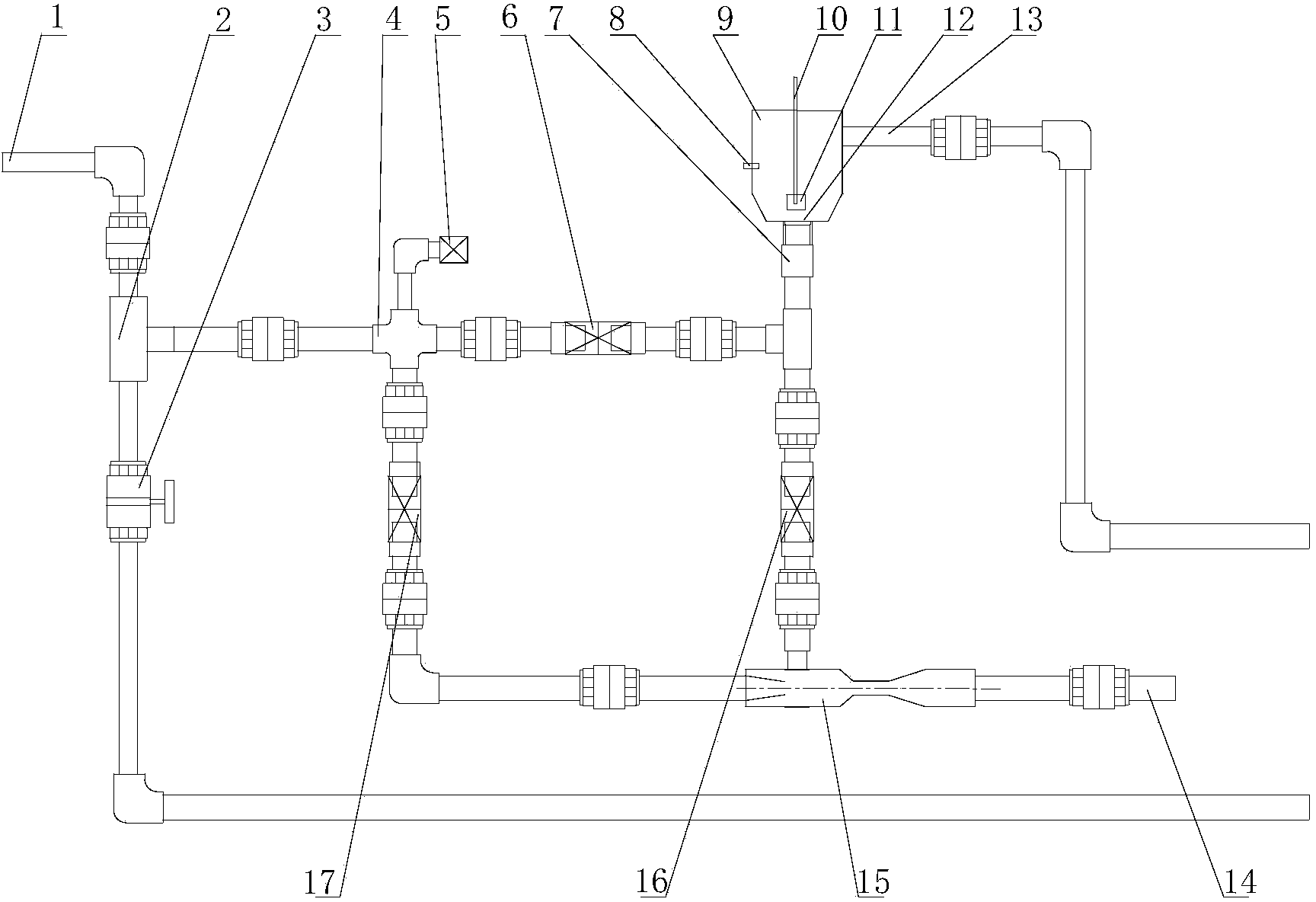

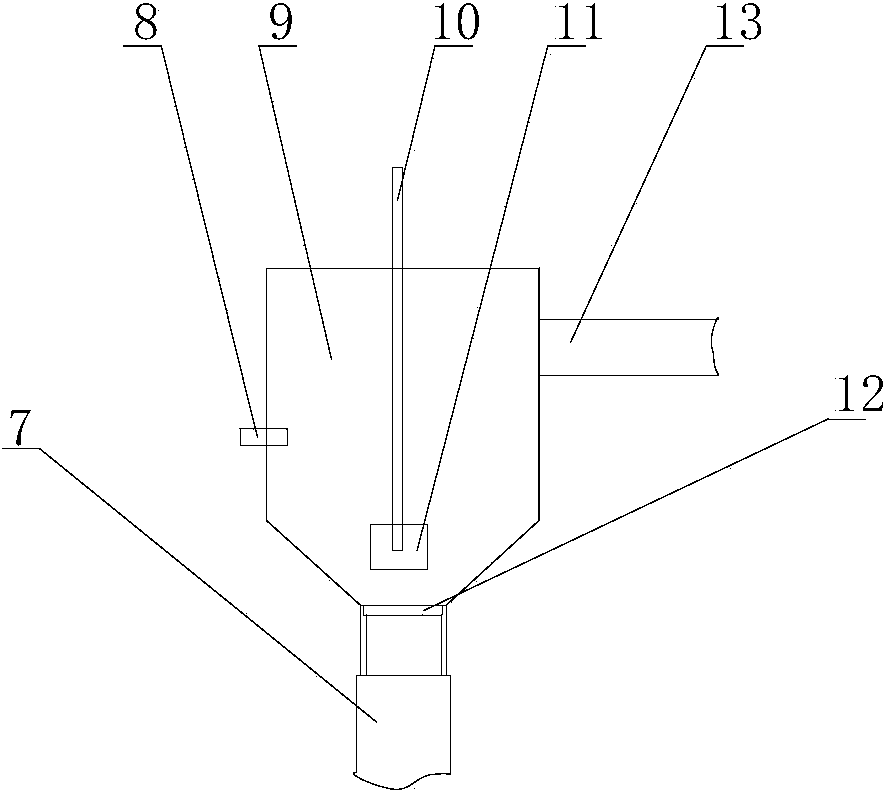

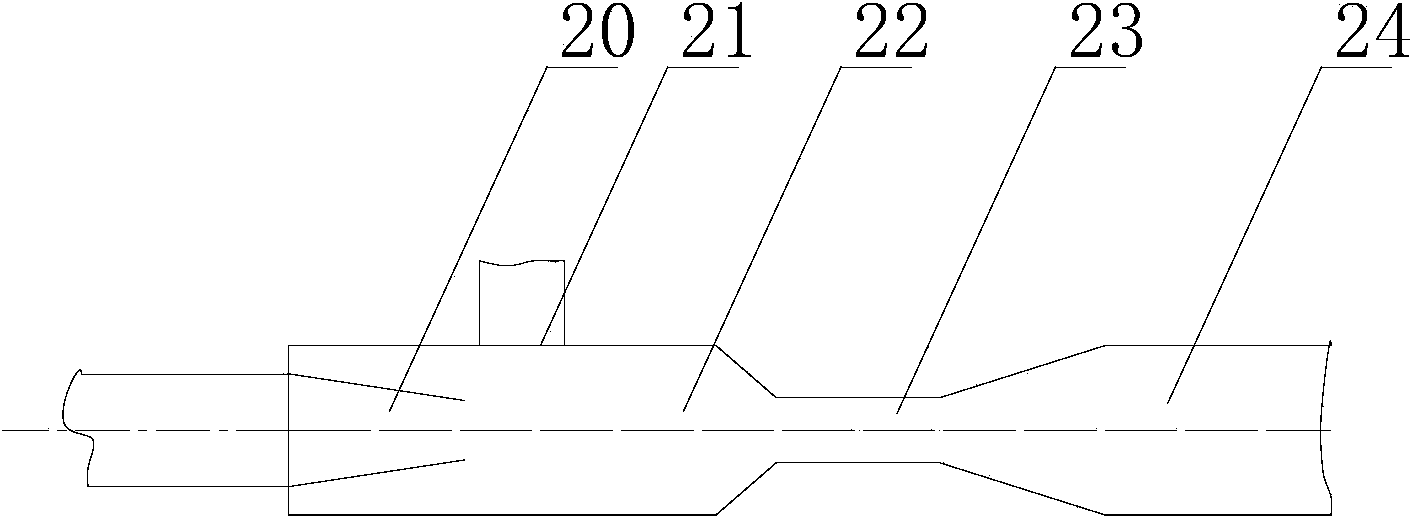

Pretreating device of online water quality analyzer

InactiveCN104132837ASimple structureEasy for mass productionWithdrawing sample devicesPreparing sample for investigationPipingPre treatment

The invention relates to a pretreating device of an online water quality analyzer. By adoption of the pretreating device, the problems in the prior art that a sampling control valve is easily damaged, a filter is more easily blocked, and the use place is limited by tap water are solved. The pretreating device comprises a water feeding pipe, a water discharging pipe, a primary filter, a precise filter, an ejector, a pipeline branch part, a normally closed electromagnetic valve, a first normally open electromagnetic valve and a second normally open electromagnetic valve; the water feeding pipe is connected with a first opening of the pipeline branch part by the primary filter; a second opening of the pipeline branch part is connected with a spraying nozzle of the ejector by the normally closed electromagnetic valve; a diffusion chamber of the ejector is connected with the water discharging pipe; a third opening of the pipeline branch part is connected with an inlet / outlet under a precise filter by the first normally opened electromagnetic valve; the inlet / outlet under the precise filter is also connected with a suction chamber of the ejector by the second normally open electromagnetic valve. The pretreating device has the beneficial effects that a water sample filtered by two stages can be supplied to the online water quality analyzer in real time, and separated automatic cleaning of two stages of filtering nets can be realized.

Owner:YANTAI DONGRUN INSTR

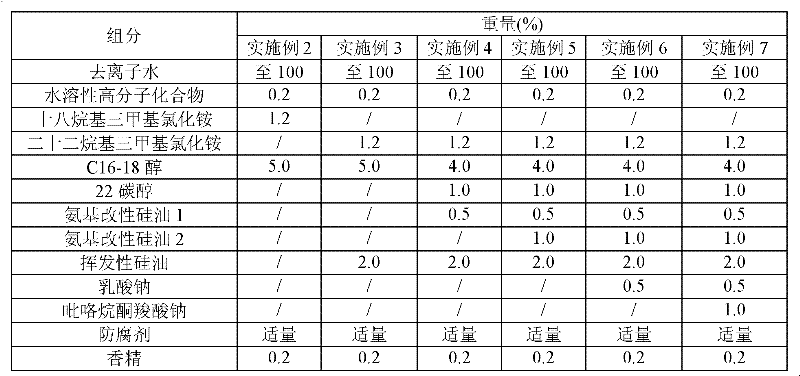

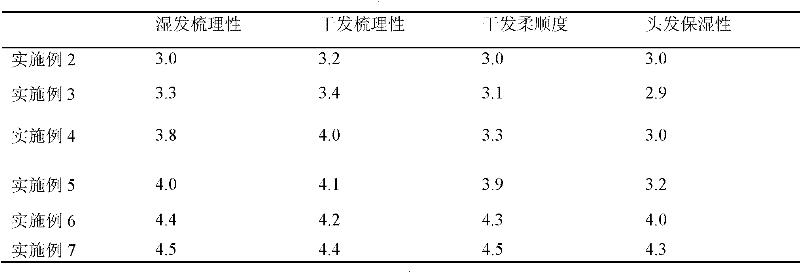

Hair care composition and preparation method thereof

ActiveCN102525846AGood moisturizing effectGood conditioning effectCosmetic preparationsHair cosmeticsActive agentMedicine

The invention relates to the field of daily chemicals and in particular relates to a hair care composition and a preparation method thereof. The hair care composition comprises lactate, pyrrolidone carboxylate, amino-modified siloxane, volatile siloxane and a water-containing carrier; and the water-containing carrier comprises a cationic surfactant, an aliphatic compound, deionized water and other components. The composition disclosed by the invention can provide good moisture retention and excellent conditioning property for hair, such as combability of wet and dry hair and the like.

Owner:纳爱斯丽水日化有限公司

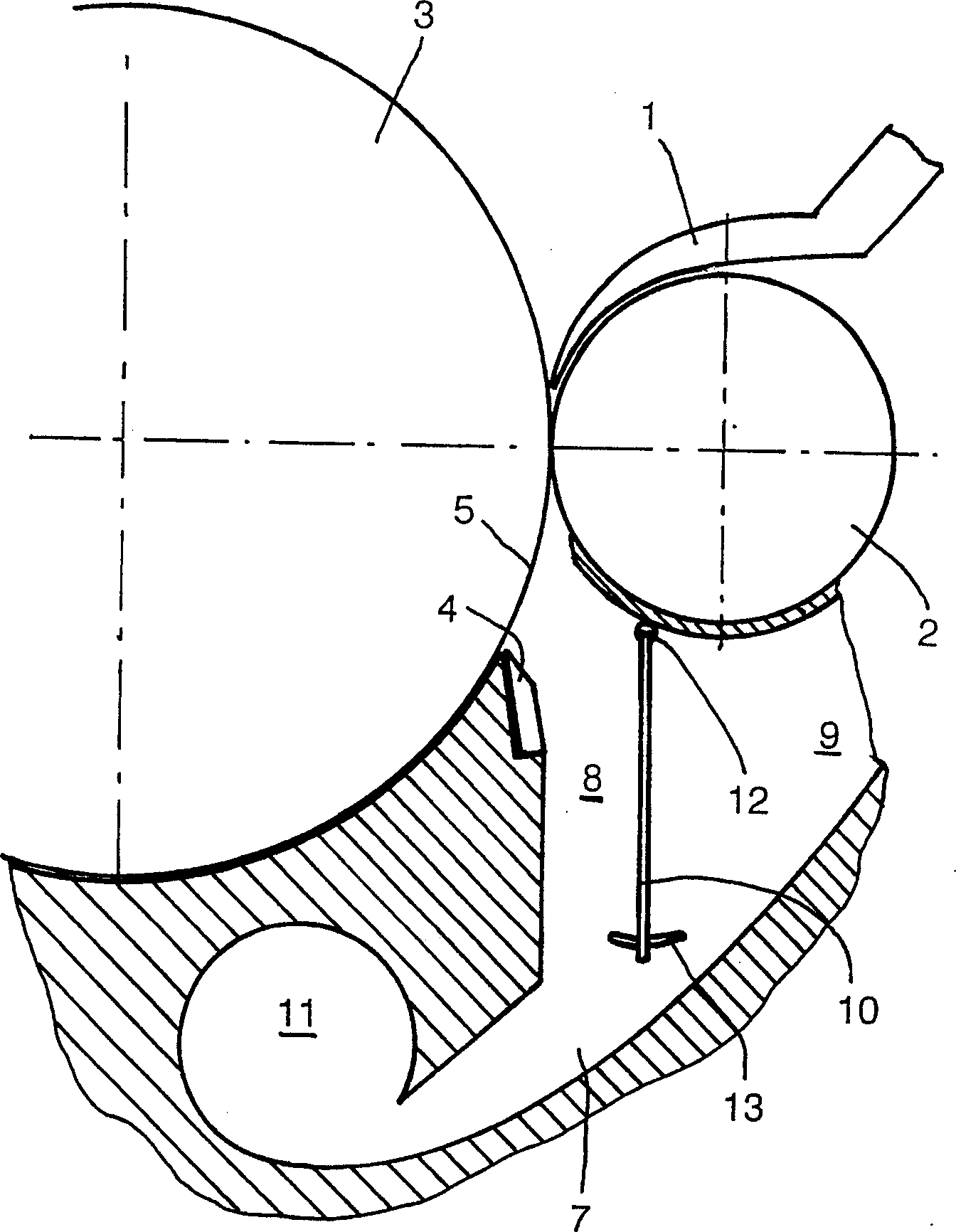

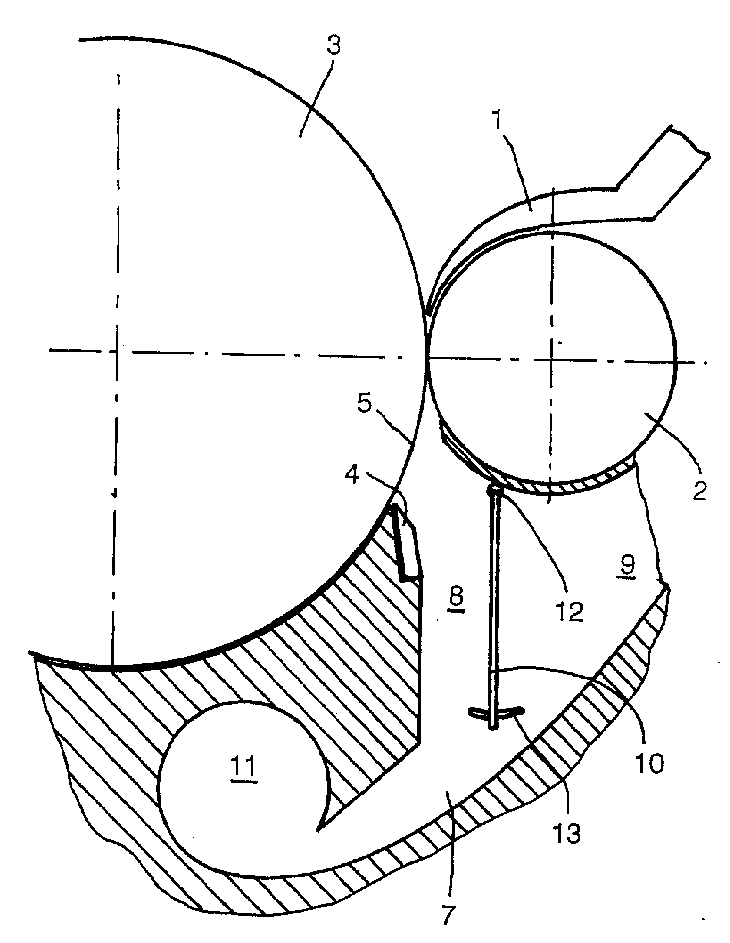

Carding machine

InactiveCN1358889AEnsure complete removalGuaranteed not to flowCarding machinesForeign bodyWaste management

A textile carding machine has a feed roller advancing a non-woven fibres to a separation roller. The foreign body separation hole is disposed in the discharge roller zone to separate the fiber and the foreign body. The outlet has a discharge passage with a discharge zone and an air flow zone. The foreign body outlet zone is disposed in the zone of foreign body separation hole and separated from the air flow zone. A curtain is arranged in the foreign body separation zone and air flow zone for the purpose of preventing against interference of the discharge of the foreign body inside the air flow.

Owner:MASCHINENFABRIK RIETER AG

Method for preparing magnesium alloy solder

InactiveCN102071337AEvenly distributedReduce in quantityWelding/cutting media/materialsSoldering mediaSlagLiquid surfaces

The invention discloses a method for preparing a magnesium alloy solder, which comprises the following steps of: preheating a crucible or a smelting furnace, spreading a covering agent, and heating an alloy ingot in protective atmosphere to the temperature which is 50 to 150 DEG C higher than the prepared solder liquid phase line; melting the alloy ingot, collecting slag, and stirring; applying ultrasonic waves to the melted magnesium alloy solder by adopting an ultrasonic generator, namely inserting a preheated ultrasonic rod to a position 5 to 50mm lower than the liquid surface of the melted magnesium alloy solder, wherein the difference between the preheating temperature of the ultrasonic rod and the melting temperature of the solder does not exceed 20 DEG C, the frequency of the ultrasonic waves is 18 to 22kHz, the intensity of the ultrasonic waves is 0.5 to 5W / cm<2> and the time is 0 to 150 seconds; moving the ultrasonic rod out, and standing alloy melt; and injecting the melted solder into a stainless steel mold, and cooling to room temperature to obtain the solder. Alloy elements, particularly microalloy elements are uniformly distributed, the crystals are fine, the toughness is improved, and the shearing strength of brazing lap joints is improved by 5 to 20 percent.

Owner:BEIJING UNIV OF TECH

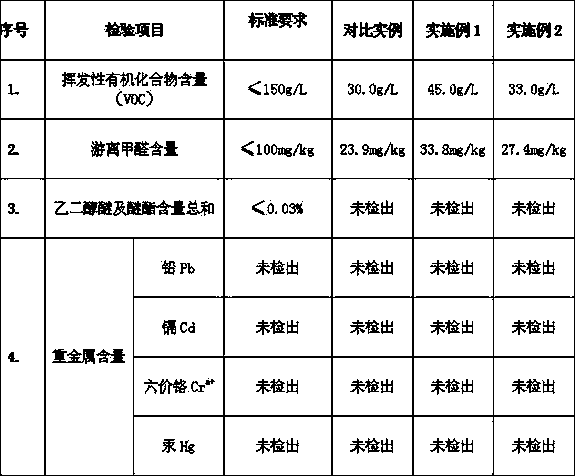

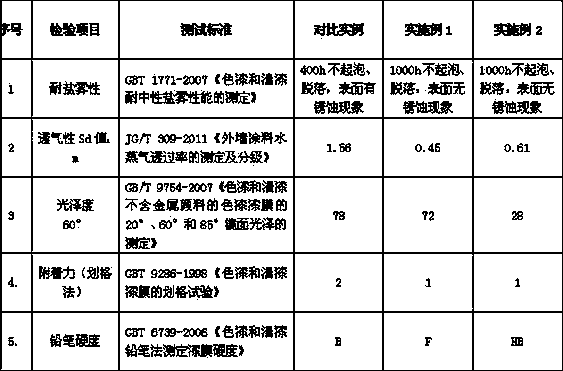

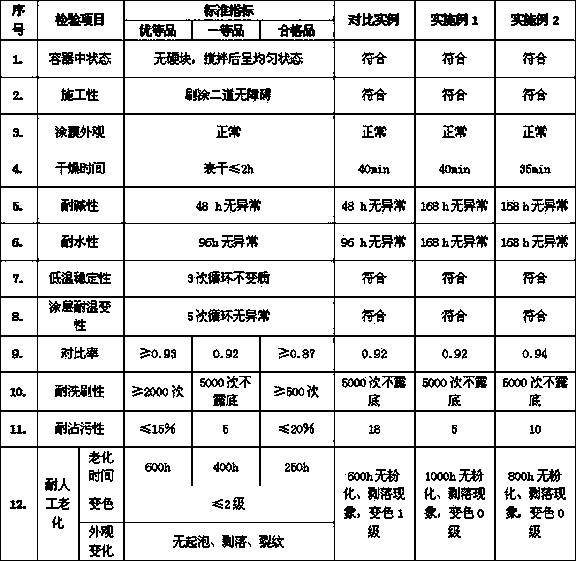

Water-based metallic paint with rustproof function for outer walls and preparation method thereof

ActiveCN103965726AWith anti-rust functionImprove waterproof performanceAnti-corrosive paintsWater basedEmulsion

The invention provides water-based metallic paint with a rustproof function for outer wall painting. The water-based metallic paint comprises the following components in parts by weight: 40-60% of silicone resin emulsion, 1-2% of film-forming agent, 10-20% of pearl pigment, 0.5-1% of flash-rust inhibitor, 0.3-0.6% of dispersant, 0.2-0.4% of wetting agent, 0.2-0.5% of defoaming agent, 0.3-1.0% of thickener, 0-5% of extinction powder and 25-35% of deionized water, wherein the silicone resin emulsion is water dilution type pure silicone resin emulsion, and the flash-rust inhibitor is modified zinc chelate. The water-based metallic paint provided by the invention has the advantages that the pure silicone resin emulsion is used as a film-forming agent, and meanwhile, the modified zinc chelate is added to the metallic paint and serves as the flash-rust inhibitor, so that a paint film has a good rustproof property, good stain resistance weather resistance and a very good decoration effect on outer walls and prolongs the service life of the walls relatively well. The invention aslo provides a preparation method with the rustproof function for the outer walls.

Owner:广东龙湖科技股份有限公司

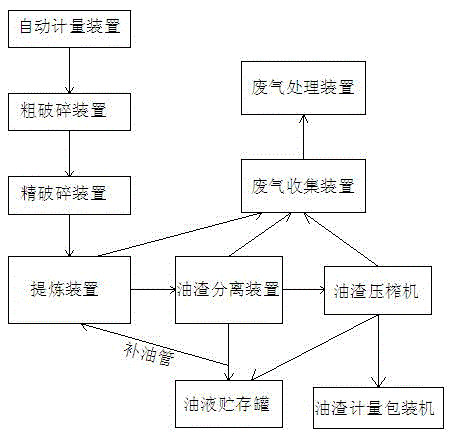

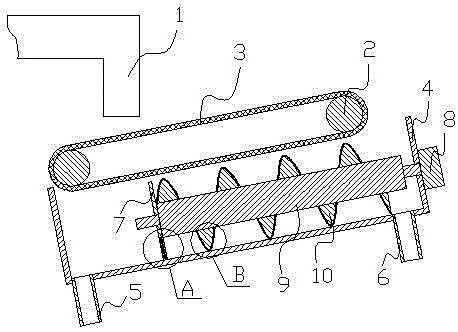

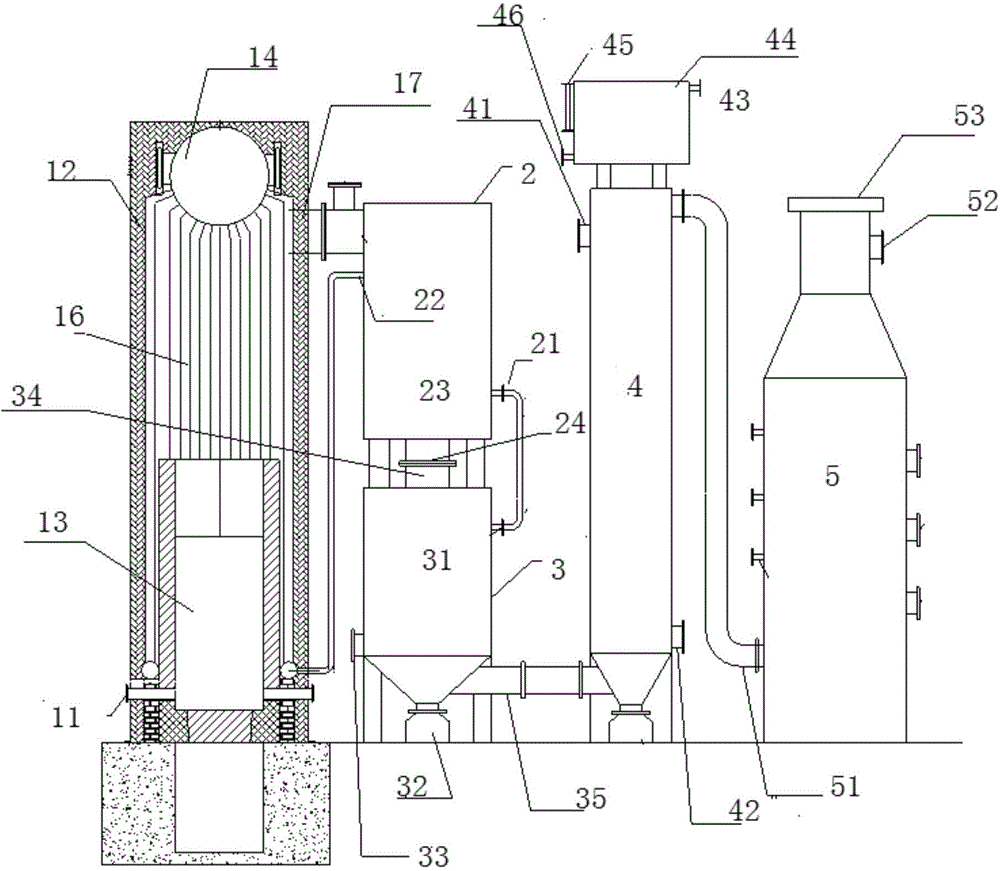

Non-intermittent industrial oil refining treatment technology and automatic refining system

ActiveCN105219514APrevent scorching etc.Batchless RefiningFatty-oils/fats productionOil and greaseAutomatic control

The invention relates to a non-intermittent industrial oil refining treatment technology. The technology comprises the steps of metering, crushing, refining, oil residue separation, squeezing, waste gas collection, waste gas treatment and the like. The invention further relates to an automatic refining system for non-intermittent industrial oil refining. The system is characterized by comprising an automatic metering device, a coarse crushing device, a fine crushing device, a refining device, an oil residue separating device, an oil residue squeezing machine, a waste gas collecting device, a waste gas treating device, an oil residue metering packaging machine, an oil liquid storage pot and an automatic control system. By the adoption of the non-intermittent industrial oil refining treatment technology and the automatic refining system, non-intermittent oil refining can be achieved, the temperature in different stages of the refining process is better controlled, the oil refining quality is improved, oil residues and waste gas are treated, environmental protection is achieved, and meanwhile oil residue utilization rate is improved.

Owner:HUNAN XIANGBO COMML GREASE CO LTD

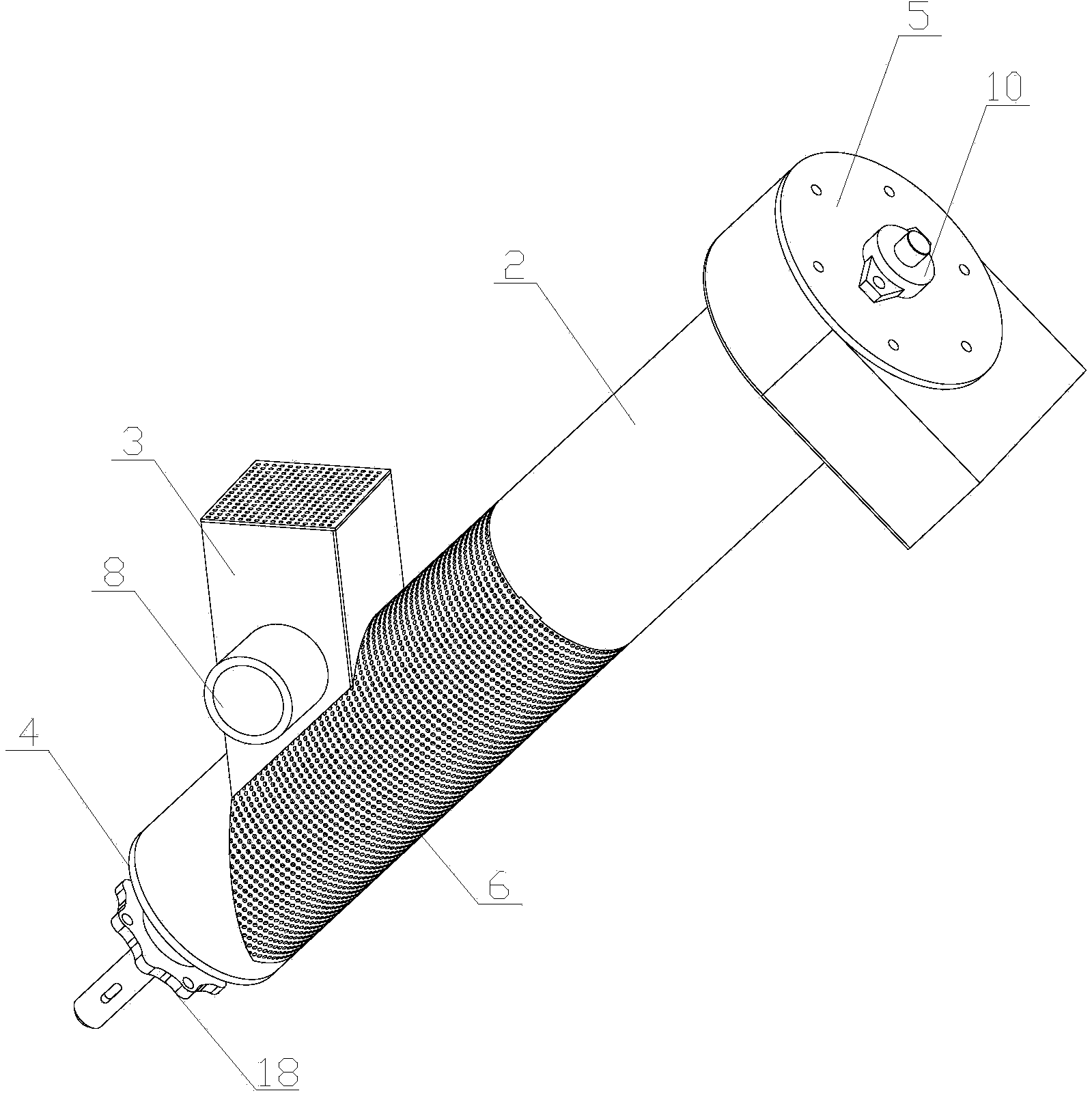

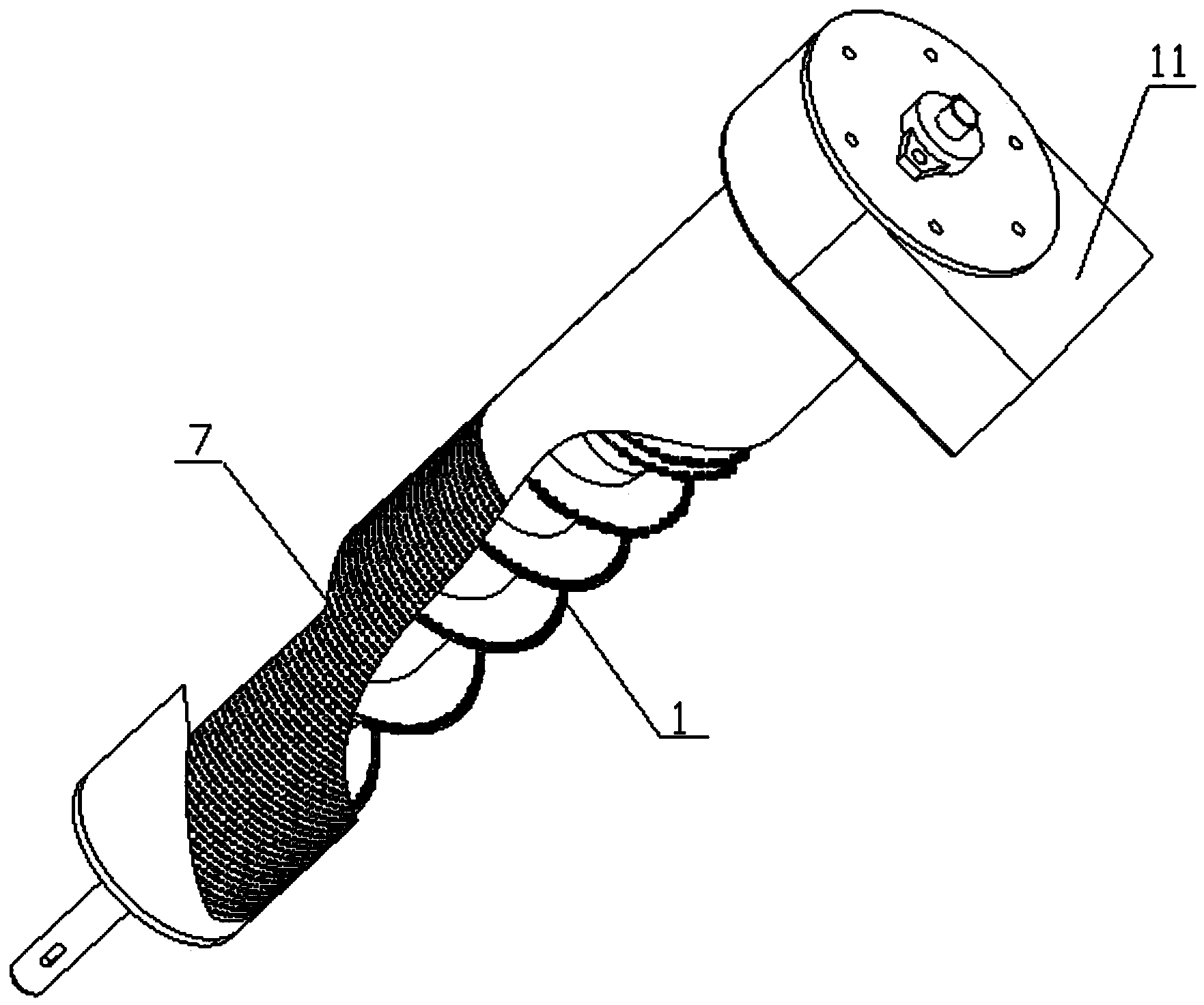

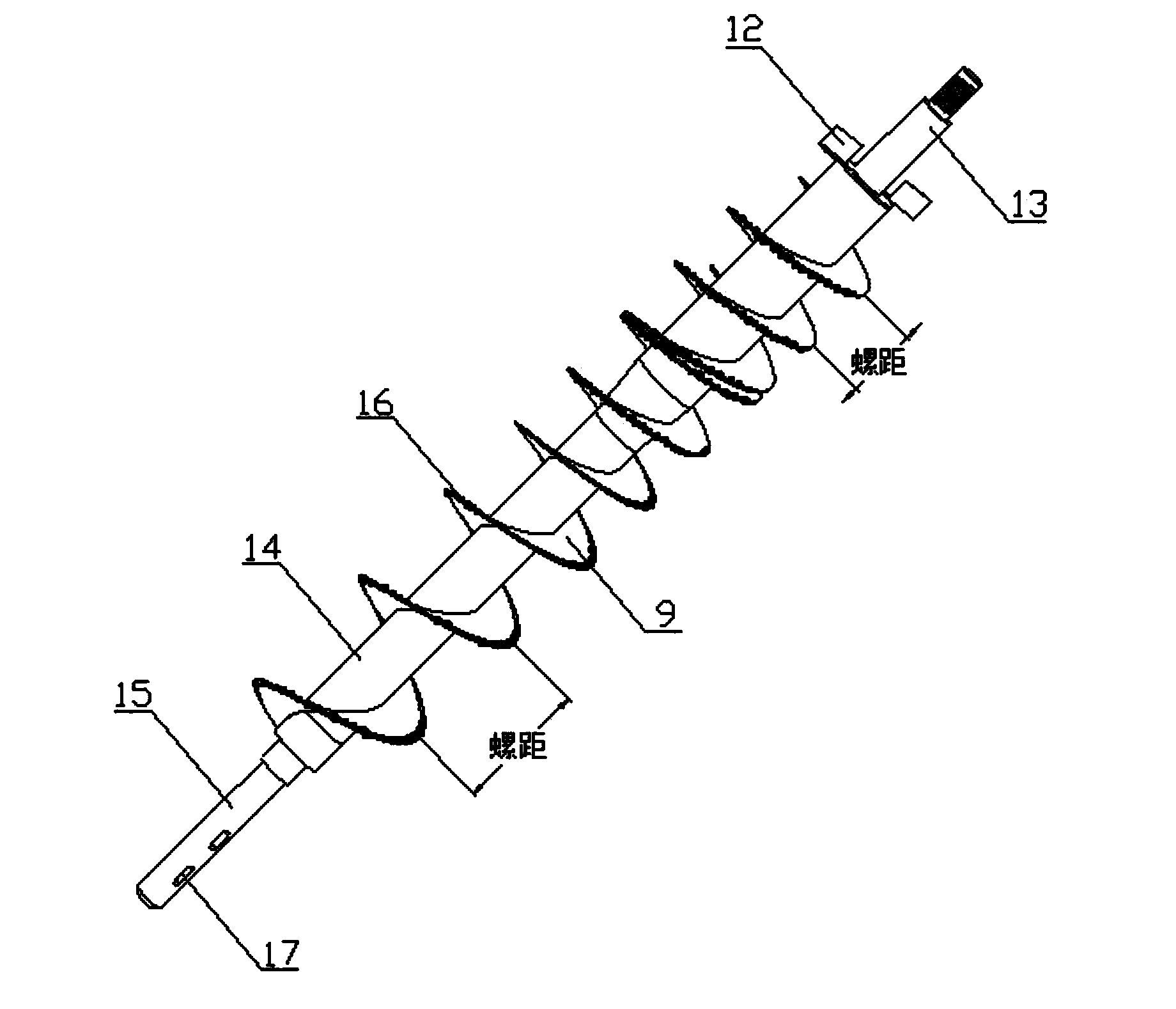

Auger assembly

InactiveCN104107577AFlexible structureEasy to disassemble and cleanStationary filtering element filtersAugerSpiral blade

An auger assembly comprises a spiral auger, a filter cartridge and a connection net cover. the filter cartridge is a column-shaped hollow container; the bottom part of the filter cartridge is provided with a sealed bearing end cover; the upper end of the filter cartridge is provided with a movable end cover; the filter cartridge at the lower side of the movable end cover is provided with a drain outlet; the spiral auger is coaxially matched in the filter cartridge; the lower end of a central rotary shaft passes through the bearing end cover to extend outside the filter cartridge; the upper end of the central rotary shaft passes through the movable end cover and fastened with the movable end cover via a fastener; net holes are uniformly arranged on the outer surface of the lower part of the filter cartridge; the outer surface with the net holes arranged is provided with a feeding port connected with the connection net cover; the connection net cover is located right above the feeding port; and the connection net cover realizes outer feeding via a pipeline. In the mode, an auger assembly is provided. The structure is flexible and easy to be disassembled and cleaned; matching among components is delicate, discard deposition does not happen, solid-liquid separation ability is strong, and the working quality can be improved due to mutual matching among components.

Owner:SUZHOU MEISHENG ENVIRONMENTAL PROTECTION TECH

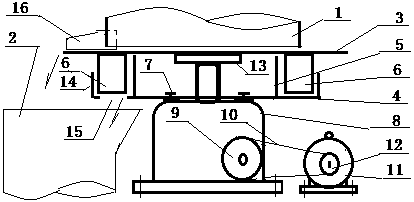

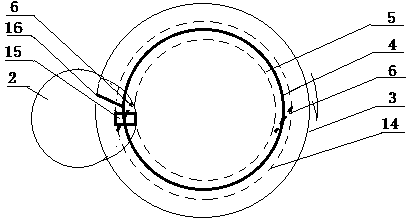

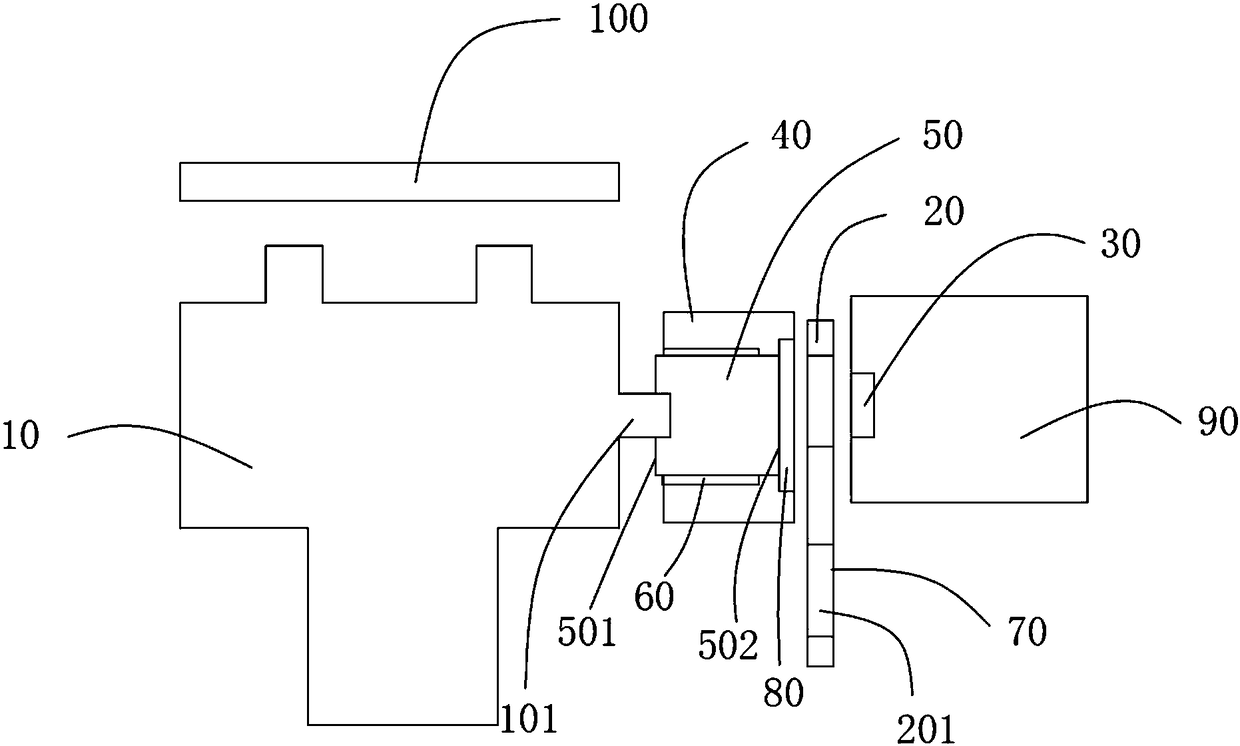

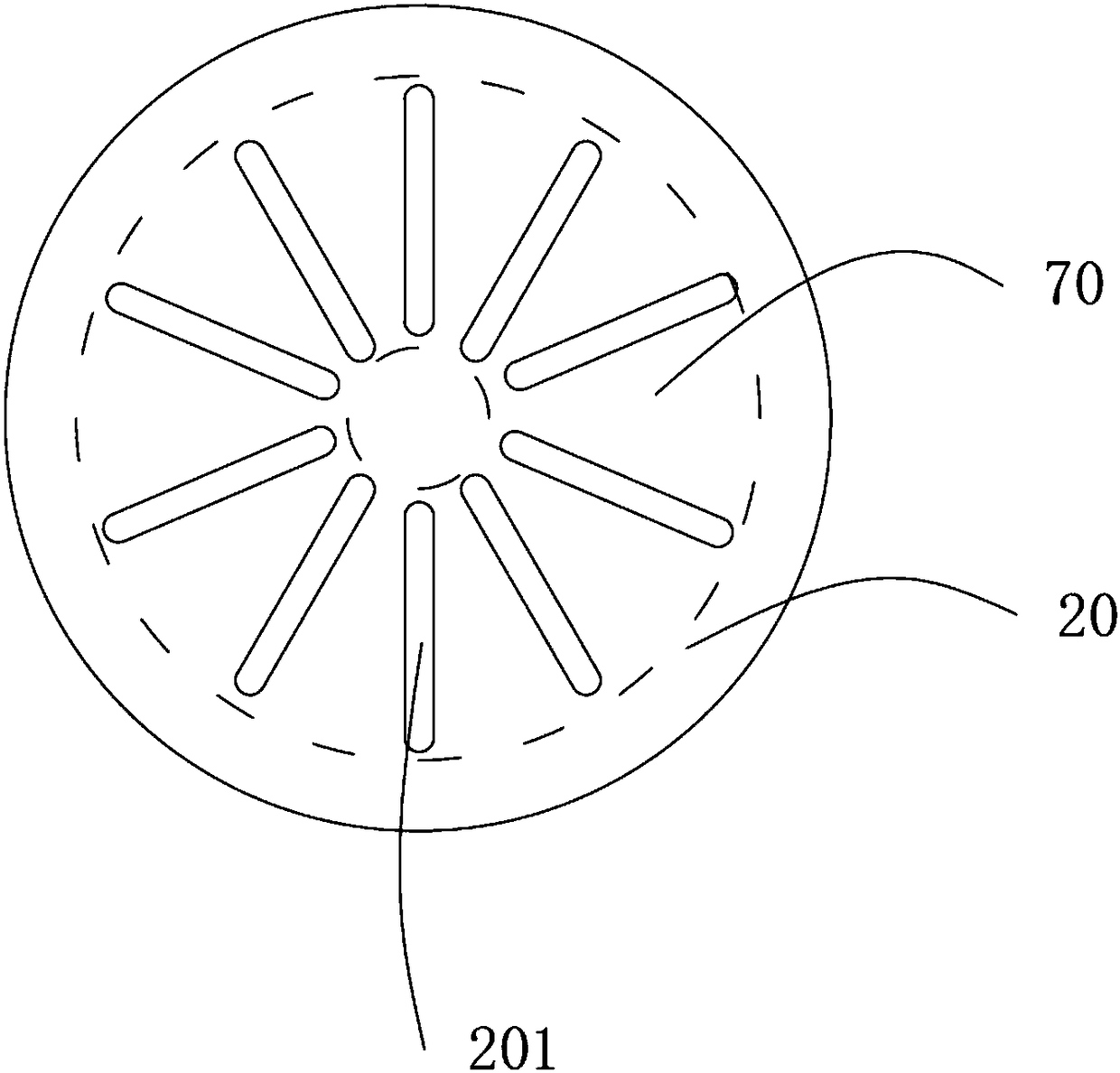

Improved zinc alloy zipper electroplating device

InactiveCN105755515AWon't wear outWill not depositSlide fastenersElectrodesZinc alloysElectroplating

The invention relates to an improved zinc alloy zipper electroplating device and belongs to the field of zipper electroplating devices.The improved zinc alloy zipper electroplating device comprises a plating tank, an anode device, a cathode device electrically in contact with a zipper and a zipper driving device for driving a zipper to move in the length direction of the plating tank, wherein the anode device comprises an anode plate, the anode plate is provided with a channel formed in the length direction of the anode plate, and the zipper penetrates through along the central axis of the channel.After the technical scheme is adopted, the zipper penetrates through the channel formed in the anode plate, zipper teeth on the zipper are electroplated when the zipper passes through the channel formed in the anode plate, the zipper teeth of the zipper in the channel do not produce friction with other devices in the electroplating process, and zipper tooth abrasion is not caused.The zipper located outside the channel cannot reach the deposition potential due to the fact that the current density is very small, so that a plating layer does not deposit basically.In addition, the zipper penetrates through along the central axis of the channel, the zipper teeth located in the channel are basically consistent in current density during electroplating, and it can be ensured that the plating layer is uniform during electroplating.

Owner:陈远婷

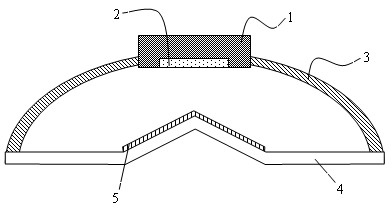

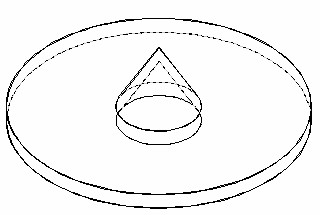

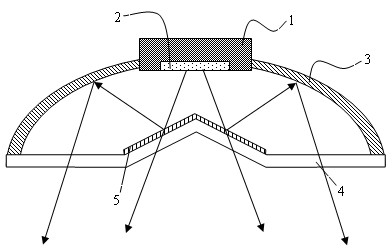

Even high-power light-emitting diode (LED) light source based on reflection and transmission type

InactiveCN102588787ASolution volumeSolve Thickness ProblemsPoint-like light sourceElectric lightingLed arrayHeat spreader

The invention discloses an even high-power light-emitting diode (LED) light source based on a reflection and transmission type, which comprises a radiator, an LED array light source, an arc reflection board, a full transparent glass plate with a cone-shaped structure and a semi-transparent semi-reflection film. The LED array light source is arranged in the right center of the bottom face of the reflection board, the arc reflection board is tightly adhered to and fixed on the periphery of the radiator, the edge of the full transparent glass plate with the cone-shaped structure is fixedly connected with a lower edge of the arc reflection board, a closed semicircular cavity is formed by the full transparent glass plate with the cone-shaped structure, the radiator and the LED array light source, the semi-transparent semi-reflection film is tightly adhered to the upper surface of the full transparent glass plate with the cone-shaped structure and evenly distributed. The light source uses reflection characteristics of a cone-shaped structure of the semi-transparent semi-reflection film to distribute light, has the advantages of being small and exquisite in structure, small in loss, small in dispersion, even and flexible in light distribution and the like, improves LED light efficiency and improves reliability and practical applicability.

Owner:浙江光锥科技有限公司

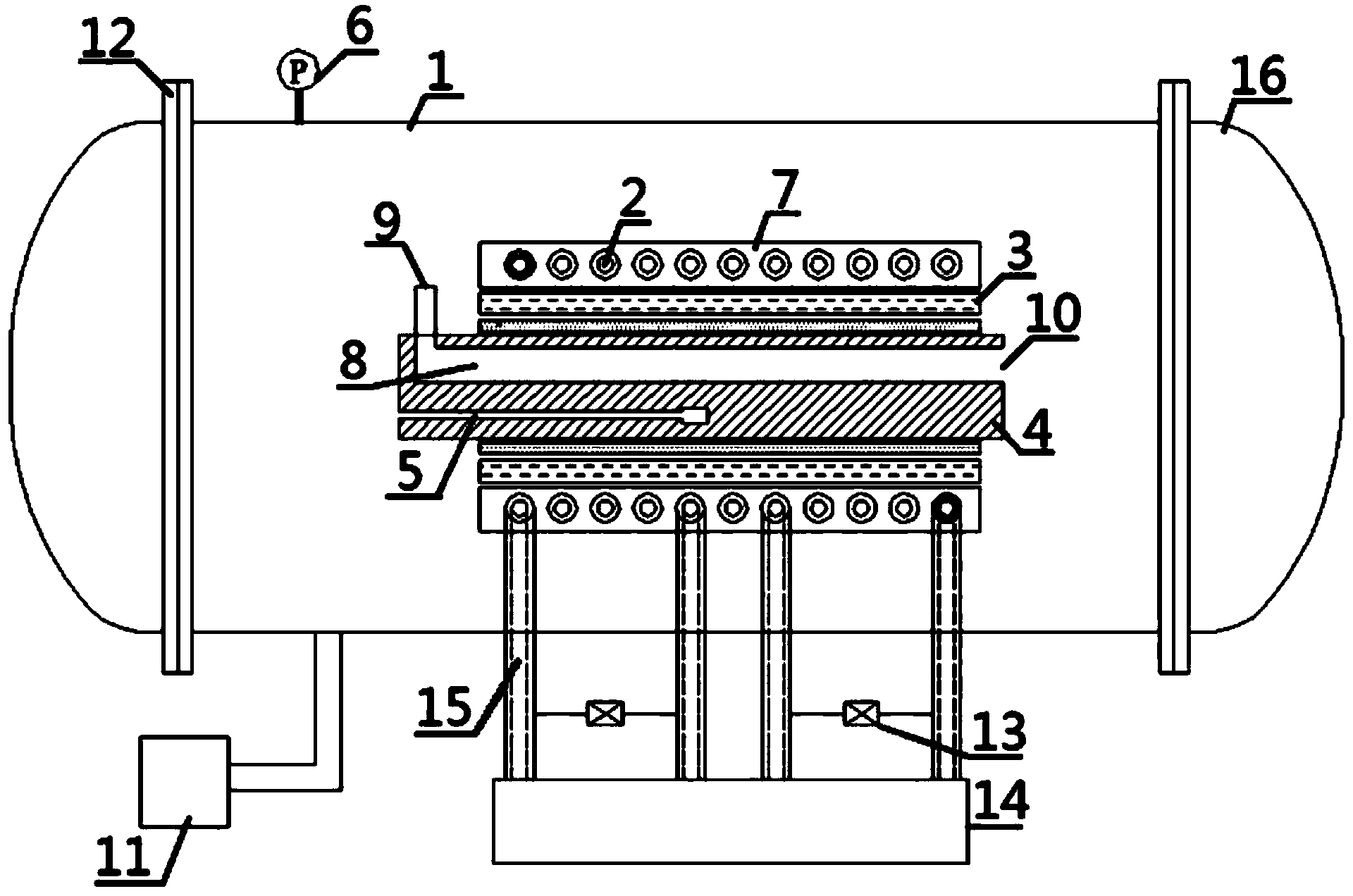

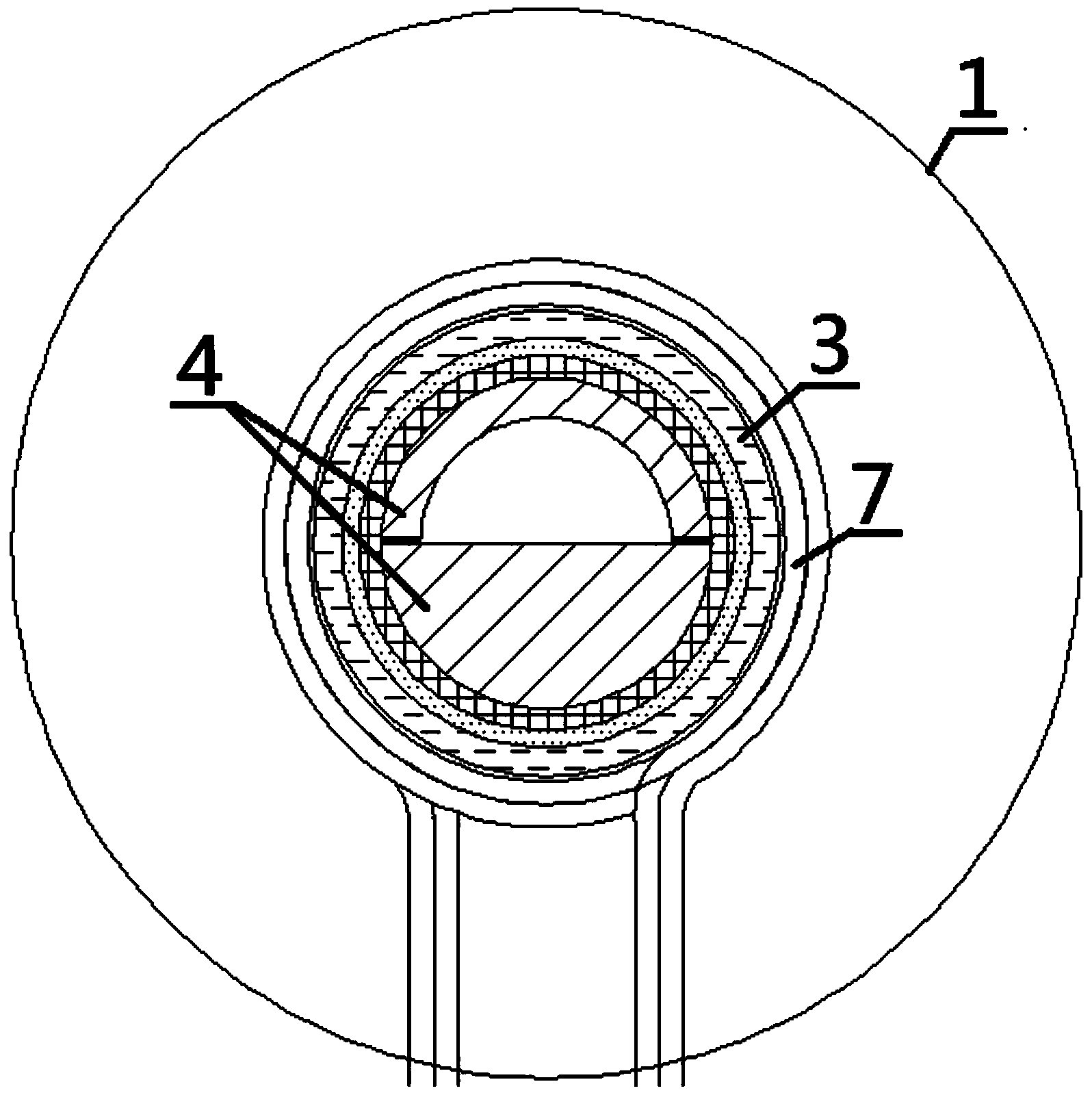

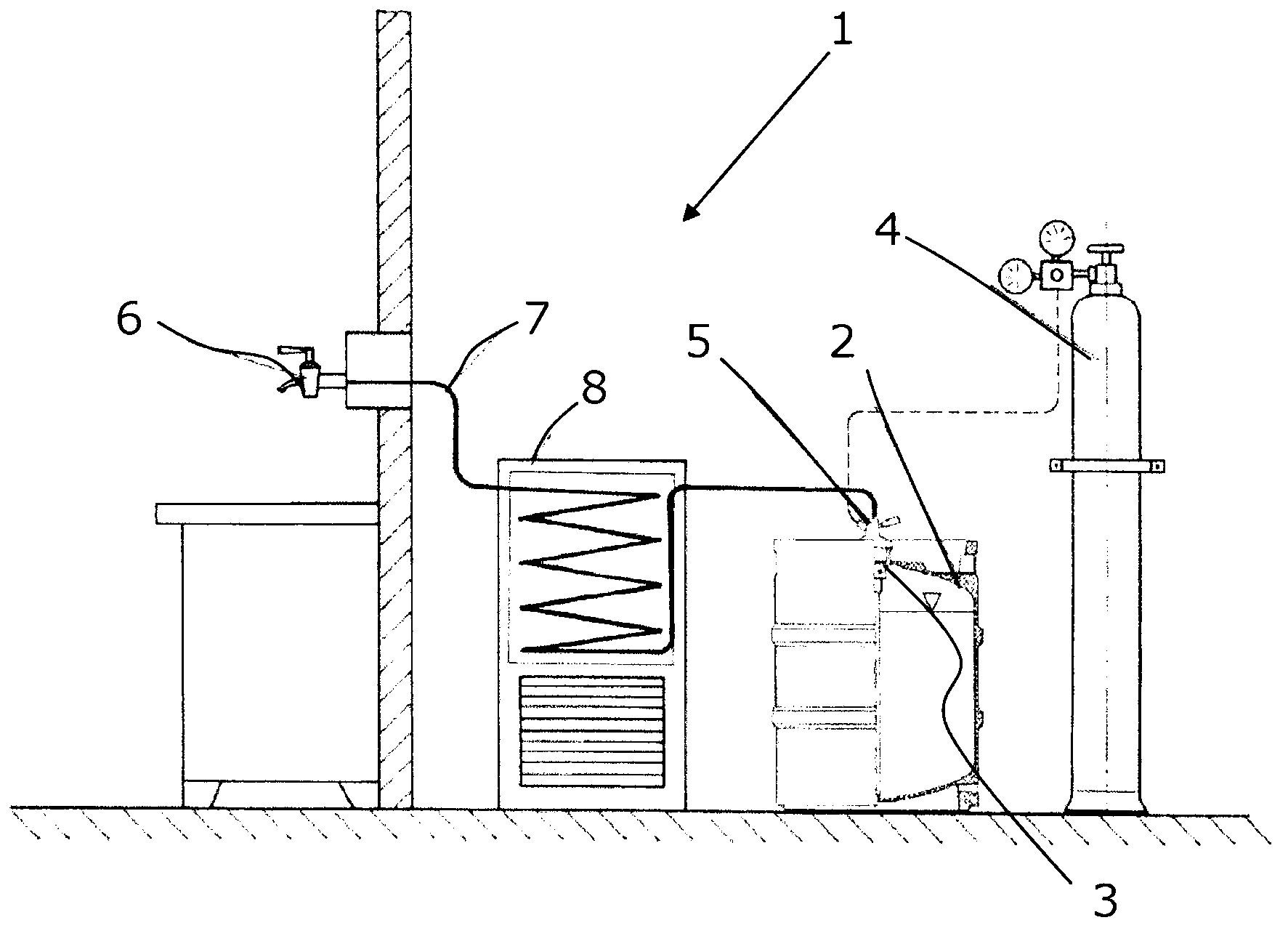

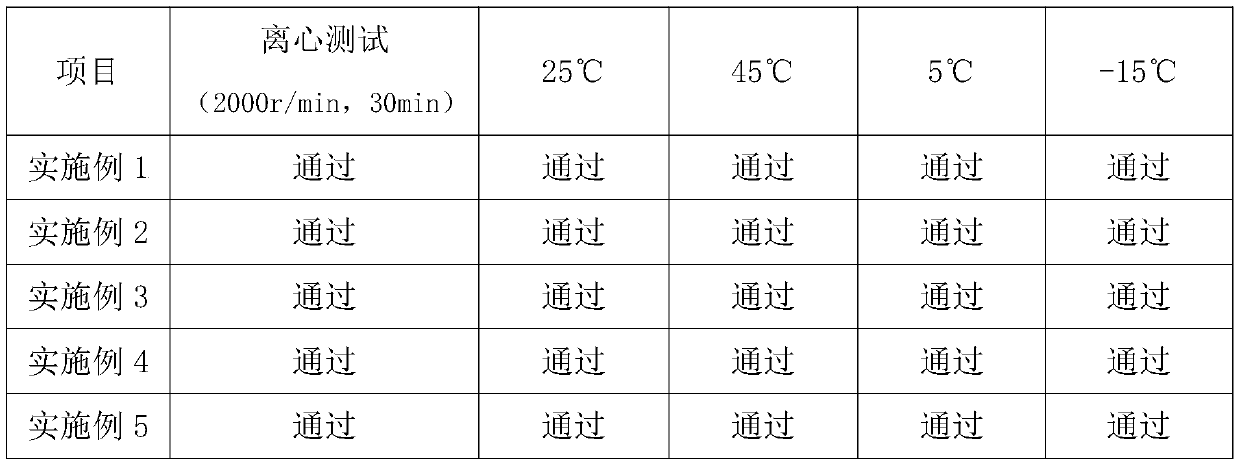

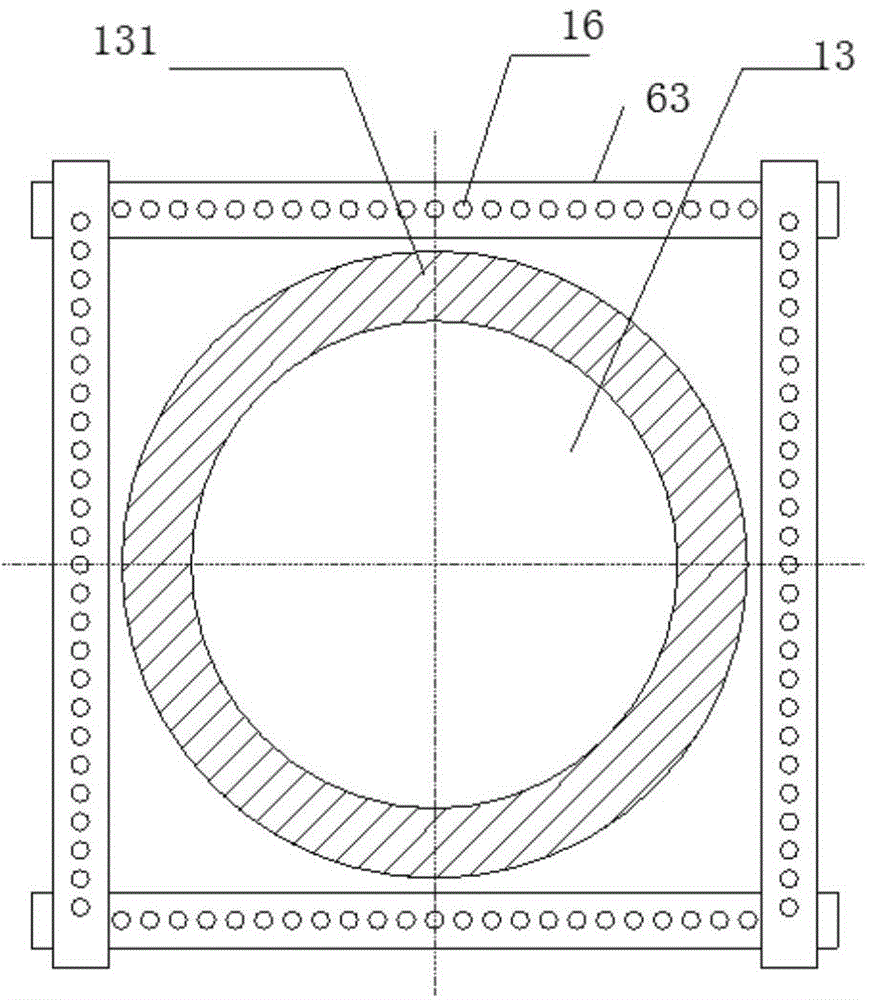

Electromagnetic type fused salt evaporating method

ActiveCN104138668AImprove cooling effectWill not depositVacuum distillation separationEvaporationMolten salt

The invention provides an electromagnetic type fused salt evaporating method applied to an electromagnetic type fused salt evaporator. The electromagnetic type fused salt evaporator comprises an evaporation cavity, a fused salt evaporation body and an electromagnetic induction coil. The electromagnetic induction coil surrounds the fused salt evaporation body. A fused salt evaporation pipe is arranged in the fused salt evaporation body. The electromagnetic type fused salt evaporating method comprises the following steps that S1, a gas compression refrigerator is started so that refrigerating gas can circulate in a gas flow channel; S2, the electromagnetic induction coil is used for preheating the fused salt evaporation pipe until the temperature higher than 1000 DEG C; S3, fused salt is poured into a fused salt liquid inlet of the fused salt evaporation pipe, and fused salt liquid is recovered from a fused salt liquid outlet. In the refrigerating step S1, by means of the electromagnetic induction coil with the gas flow channel and the gas compression refrigerator, the electromagnetic type fused salt evaporating method has the advantages that the refrigerating effect is stable, and dirt deposition is avoided.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

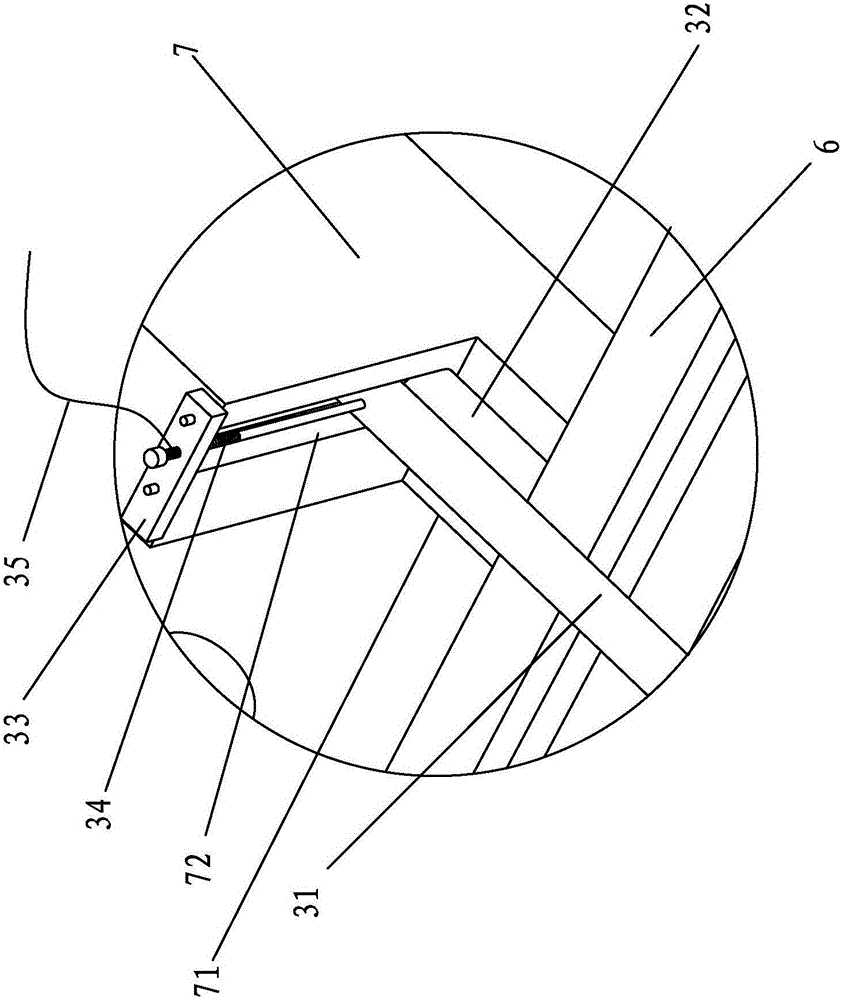

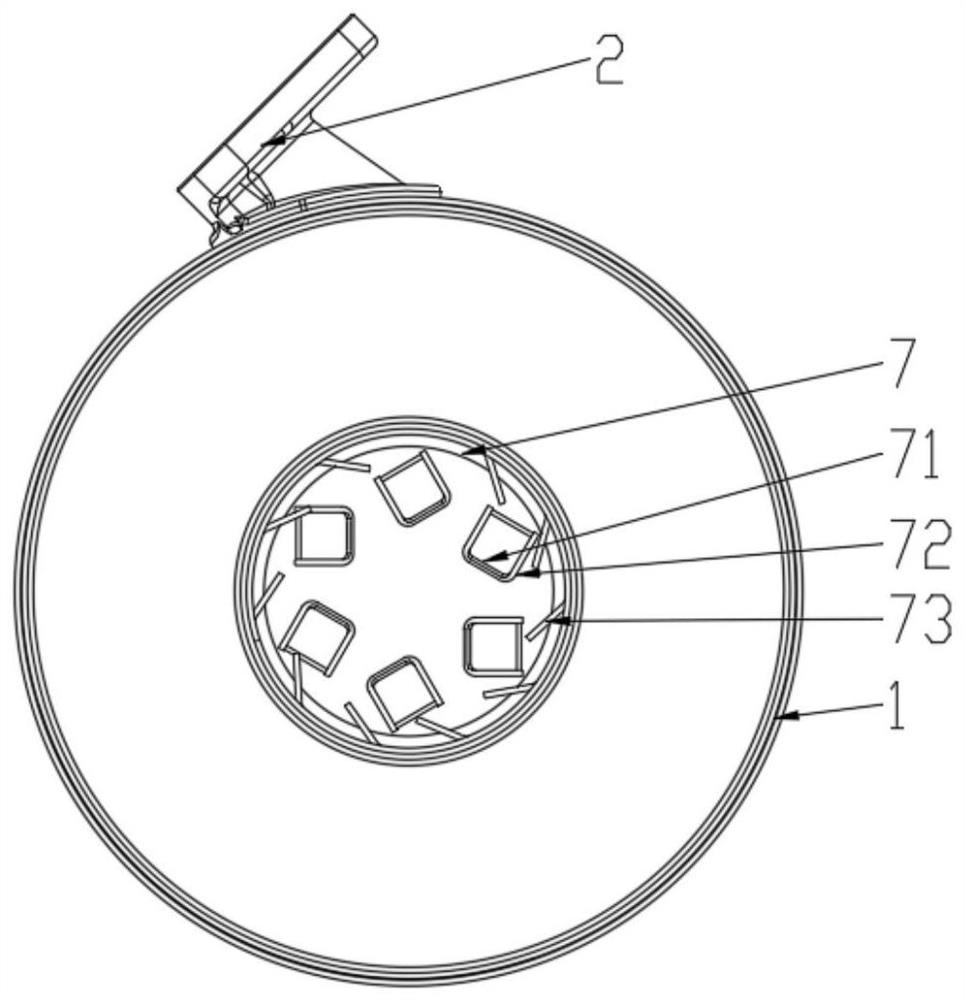

Sealing round disc feeding machine

The invention provides a sealing round disc feeding machine. The sealing round disc feeding machine comprises a feed bin outlet, a discharging receiving opening, a feeding machine round disc, a sealing component chassis, a sealing inner ring, a dust removing slant scraping plate, a reducer, belt pulleys, a triangular belt, a speed adjusting motor, an output flange, a sealing outer ring, a dust removing unloading opening and a feed stopping plate. The sealing round disc feeding machine is characterized in that a round disc feeding machine body is installed below the feed bin outlet, the feedingmachine round disc is installed above the reducer output flange, the feed stopping plate is installed at one side of the feed bin outlet, and feed is scraped into the discharging receiving opening; the sealing component chassis is installed above a reducer case of the reducer and is welded to the sealing inner ring, the external circle is welded to the sealing outer ring, the bottom face of the round disc is downwards welded to the dust removing slant scraping plate, and the width of the dust removing slant scraping plate should not exceed the width of the spacing reserved between the sealinginner ring and the sealing outer ring; the dust removing unloading opening is formed in the sealing component chassis and right faces the discharging receiving opening; the motor belt pulley is connected with the reducer belt pulley through the triangular belt, and the speed adjusting motor can control the round disc feeding machine body to run at any rotation speed.

Owner:杨朴

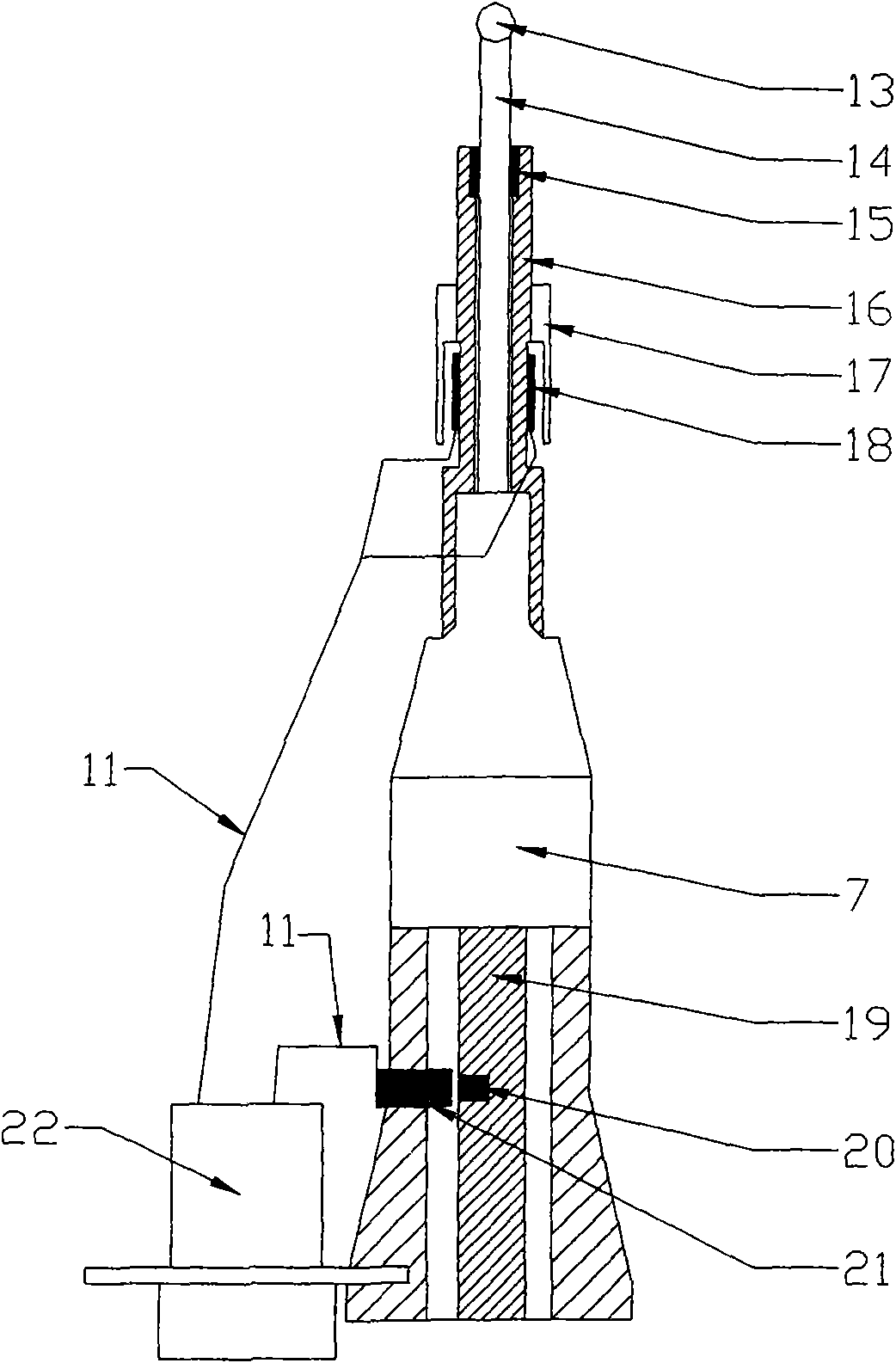

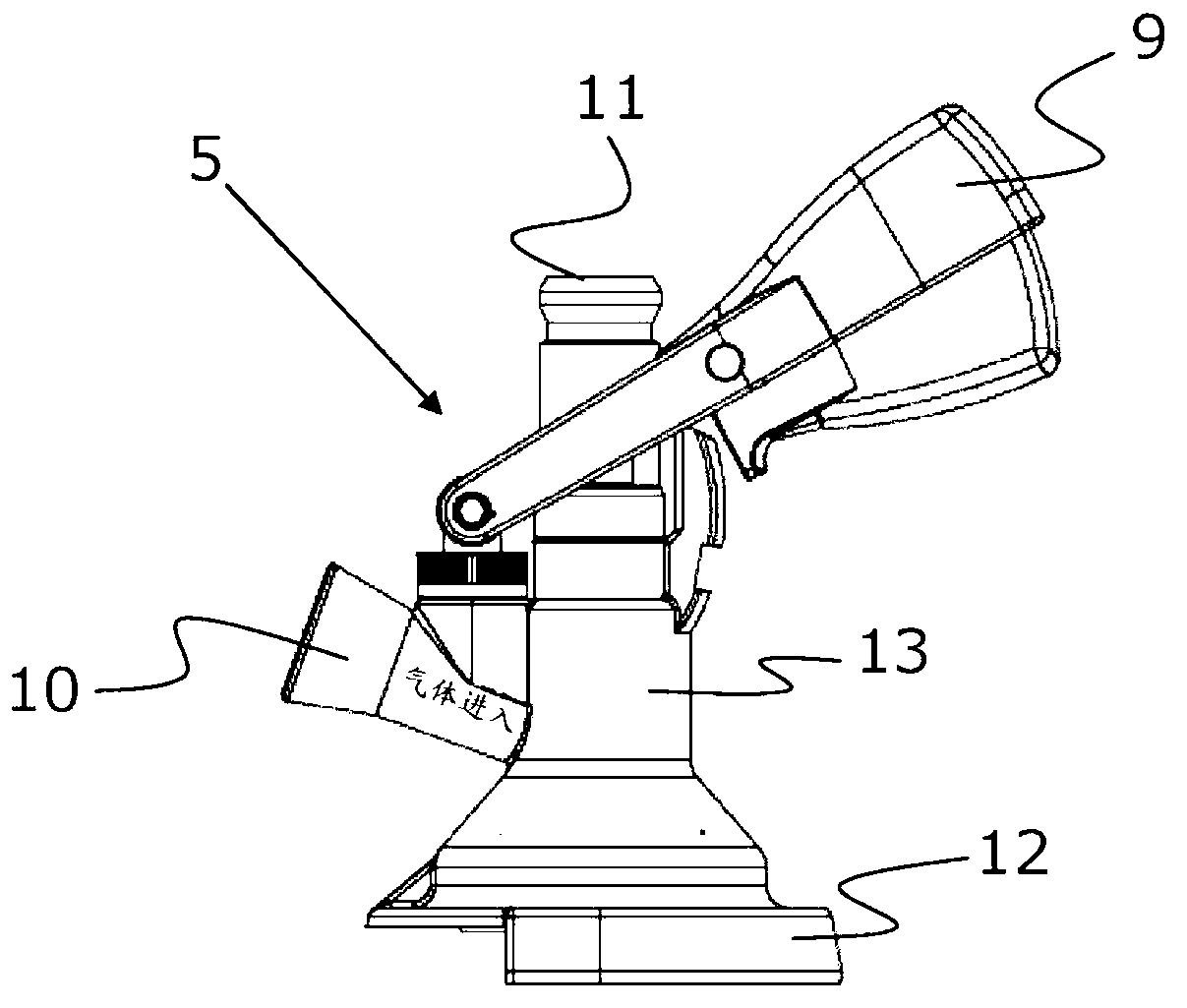

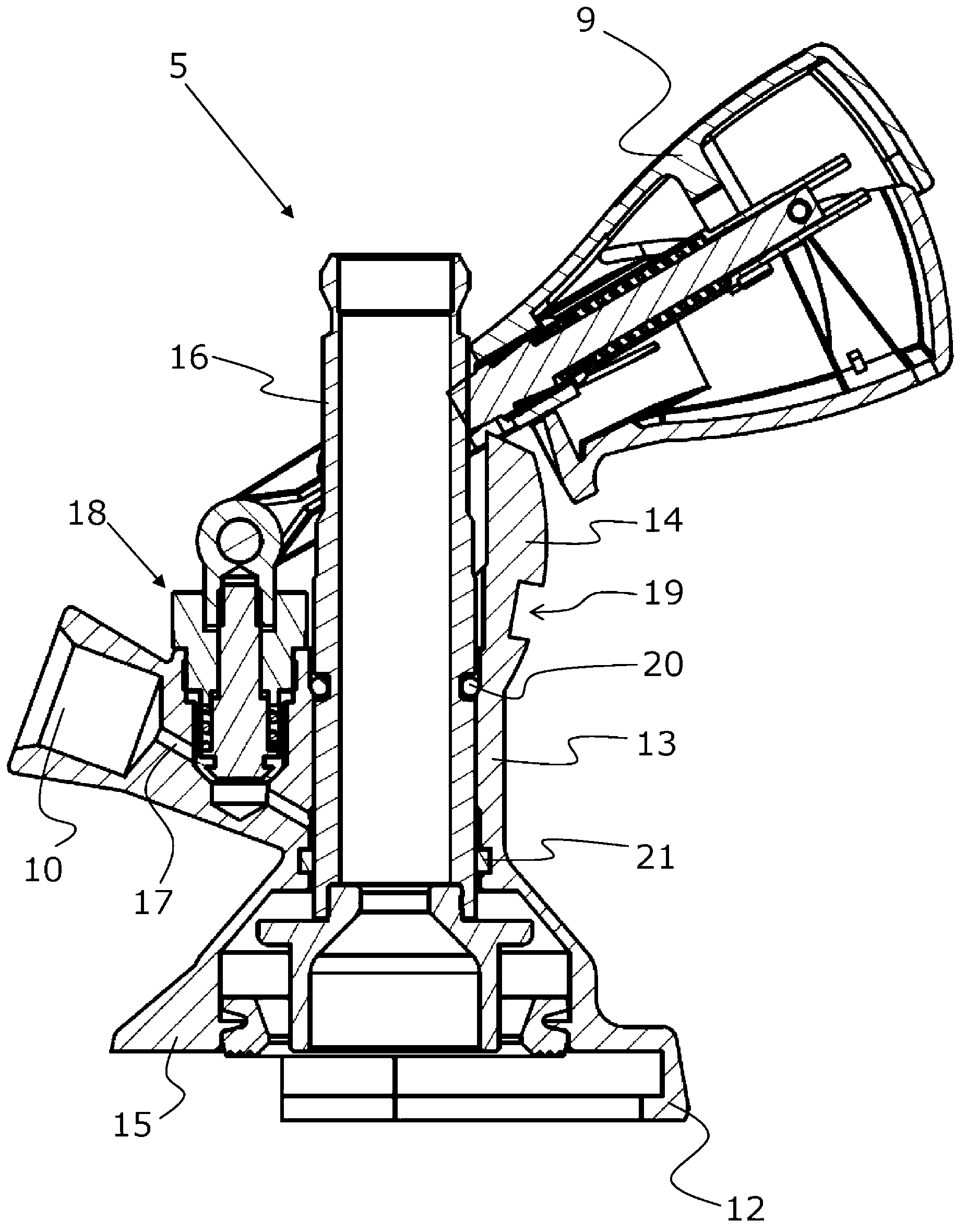

Dispense head for a dispensing system

ActiveCN103153838AAchieving a simple designEasy to cleanLiquid dispensingEngineeringBiological activation

The present invention relates to a dispense head (5) adapted to be coupled to a beverage container above an extractor tube arranged in the beverage container in a dispensing system. The dispense head comprises a housing (13) having a first end (14) and a second end (15), a hollow piston (16) arranged axially displaceably within the housing (13), the piston (16) being connected to a handle (9) so that upon activation of the handle (9), the piston (16) will be displaced axially towards and beyond a second end (15) of the housing (13), and a gas inlet (10) arranged in the housing (13), which via a fluid channel is in connection with a space extending along the piston (16) and between the housing (13) and the piston (16). Furthermore, a gas shut-off element (18) is arranged in the fluid channel (17).

Owner:微马蒂奇股份公司

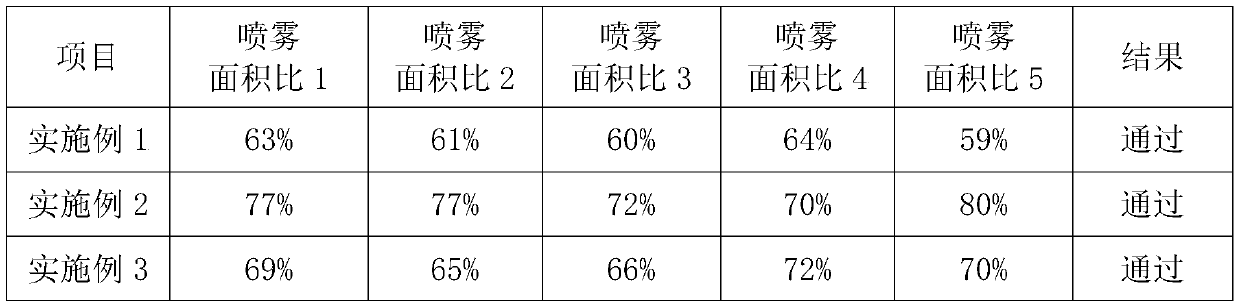

Water-in-oil phase inversion emulsion spray and preparation method thereof

PendingCN110859761AFast absorptionImprove water and sweat resistanceCosmetic preparationsToilet preparationsActive agentSodium silicate

The invention discloses a water-in-oil phase inversion emulsion spray and a preparation method thereof, and aims to provide a water-in-oil phase inversion emulsion spray which has the characteristicsof light skin feeling, water resistance, sweat resistance, skin nourishing, uniform atomization coverage and high stability. The technical scheme of the invention is as follows: the emulsion spray iscomposed of the following components in percentage by mass. 3.0-6.0% of surface active agents; 4.0-8.0 % of isopropyl myristate; 0.5-1.5% of petrolatum; 1.0-5.0% of polydimethylsiloxane; 0.1-0.3% of tocopherol; 0.2-0.6% of preservatives, 4.5-11.0% of humectants, 0.03-0.15% of carbomer, 0.2-1.0% of sodium magnesium lithium silicate, 0.5-1.5% of stabilizers, 0.02-0.1% of a chelating agent, 0.1-0.7%of a pH regulator, 0.01-0.5% of an odorant and the balance of deionized water, totaling 100%. The emulsion spray belongs to the technical field of cosmetics.

Owner:广州欧正化妆品技术研究院有限公司

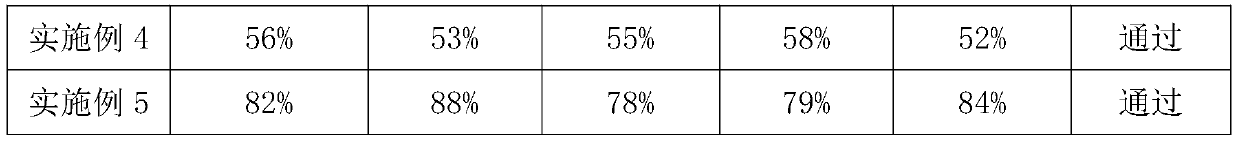

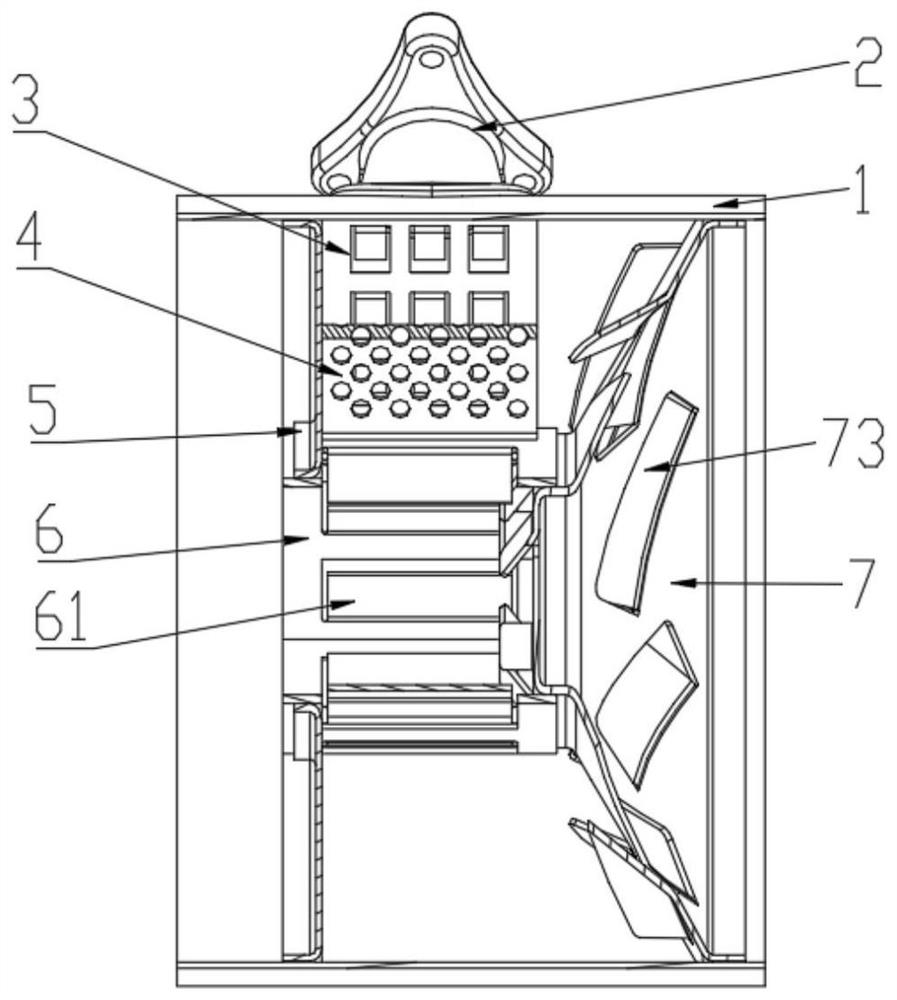

Mixing device with multi-rotational-flow structure

ActiveCN113586212AReduced risk of crystallizationWill not depositInternal combustion piston enginesExhaust apparatusDieselingEngineering

The invention belongs to the technical field of diesel engine tail gas after-treatment, and particularly relates to a mixing device with a multi-rotational-flow structure. The mixing device comprises a barrel body with two open ends and a nozzle base arranged on the side wall of the barrel body, the rotational-flow structure is arranged in the barrel body, the rotational-flow structure comprises an upper crushing plate, a lower crushing pore plate, a baffle, a rotational-flow pipe and a rotational-flow plate, one end of the rotational-flow pipe is connected to the baffle, the other end of the rotational-flow pipe is connected to the rotational-flow plate, the baffle is arranged at one end of the barrel body, the rotational-flow plate is arranged at the other end of the barrel body, the upper crushing plate and the lower crushing pore plate are arranged in the position, where the nozzle base is located, of the barrel body, the lower ends of the upper crushing plate and the lower crushing pore plate are both connected to the rotational-flow pipe, and the left sides are both fixed to the baffle. The mixing device is good in urea distribution uniformity, urea is not prone to crystallization, it can be ensured that the urea can be evenly distributed on the end surface of an SCR carrier, exhausted gas and ammonia gas are evenly mixed, and it is ensured that the SCR can work efficiently and stably.

Owner:WUXI WEIFU LIDA CATALYTIC CONVERTER

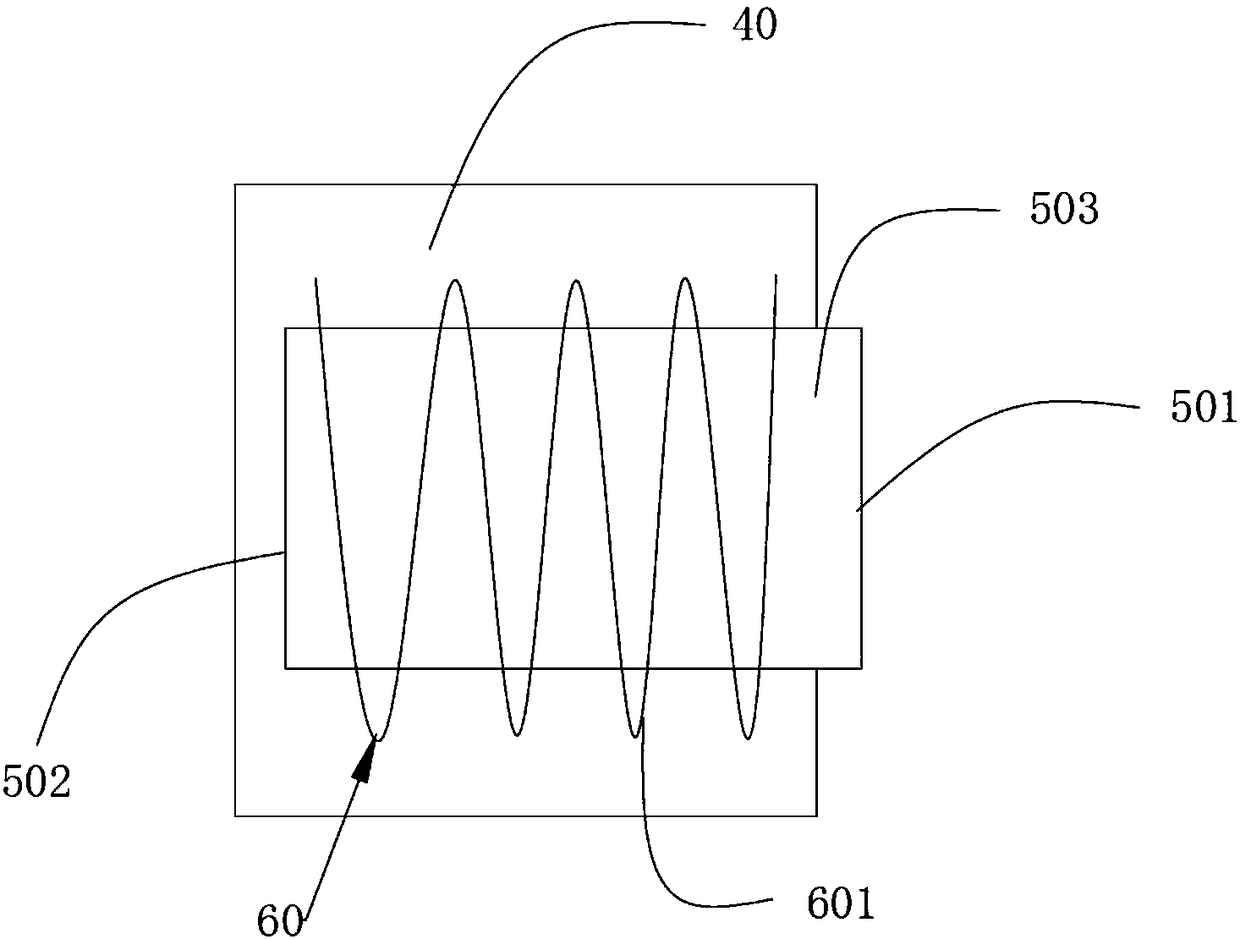

Film thickness detection device and vacuum evaporating machine

ActiveCN108277459AWill not depositAvoid coolingVacuum evaporation coatingSputtering coatingSpray nozzleEngineering

The invention provides a film thickness detection device. The film thickness detection device is used for detecting an evaporation rate of a substrate plate when the substrate plate is evaporated. Thefilm thickness detection device comprises an evaporation source, the film thickness detector, an adjusting part, a gas pipeline and a heating part, wherein the evaporation source is provided with a nozzle; the nozzle, the gas pipeline, the adjusting part and the film thickness detector are arranged at a first direction in sequence; the nozzle communicates with a material feeding port of the gas pipeline, the adjusting part can rotate around a fixed shaft, and a plurality of through holes which are arranged at intervals are formed in the adjusting part; and the heating part is arranged aroundthe periphery of the gas pipeline, and then a vacuum evaporated material evaporated from the nozzle is kept in a gas state when passes through the gas pipeline in the first direction, and is vacuum evaporated on the film thickness detector through the through holes. According to the film thickness detection device and the vacuum evaporating machine, the technical problem that the production efficiency is low due to the fact that blockage of the through holes caused by the vacuum evaporated material is solved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

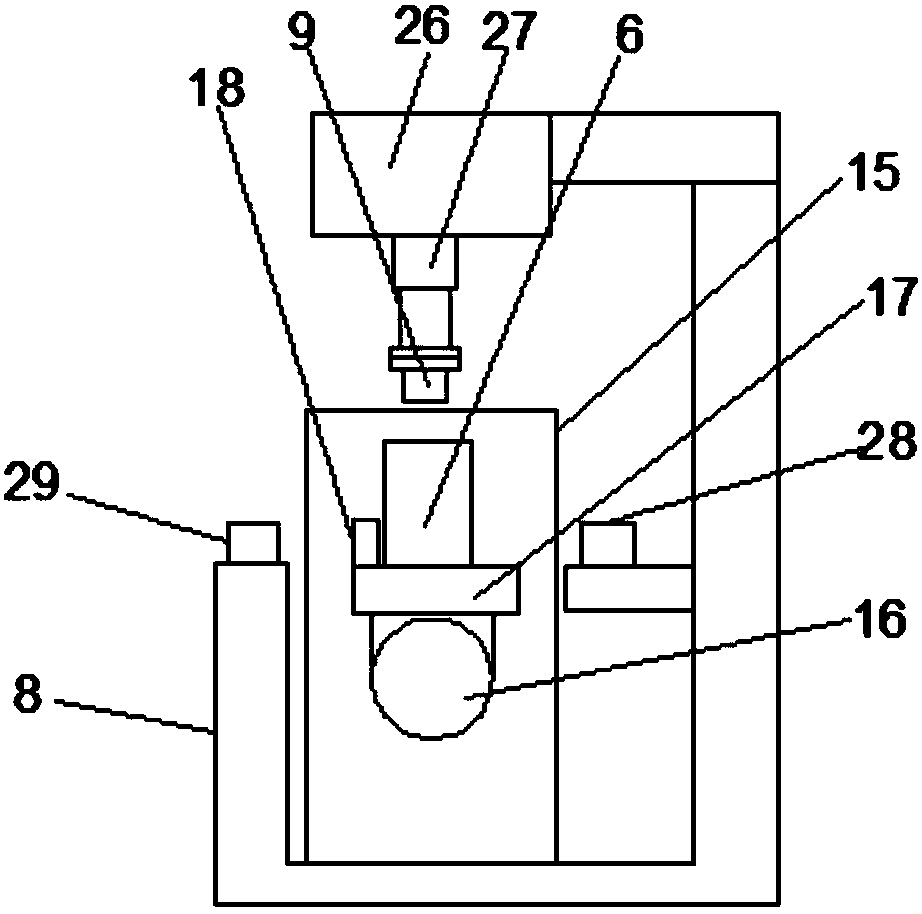

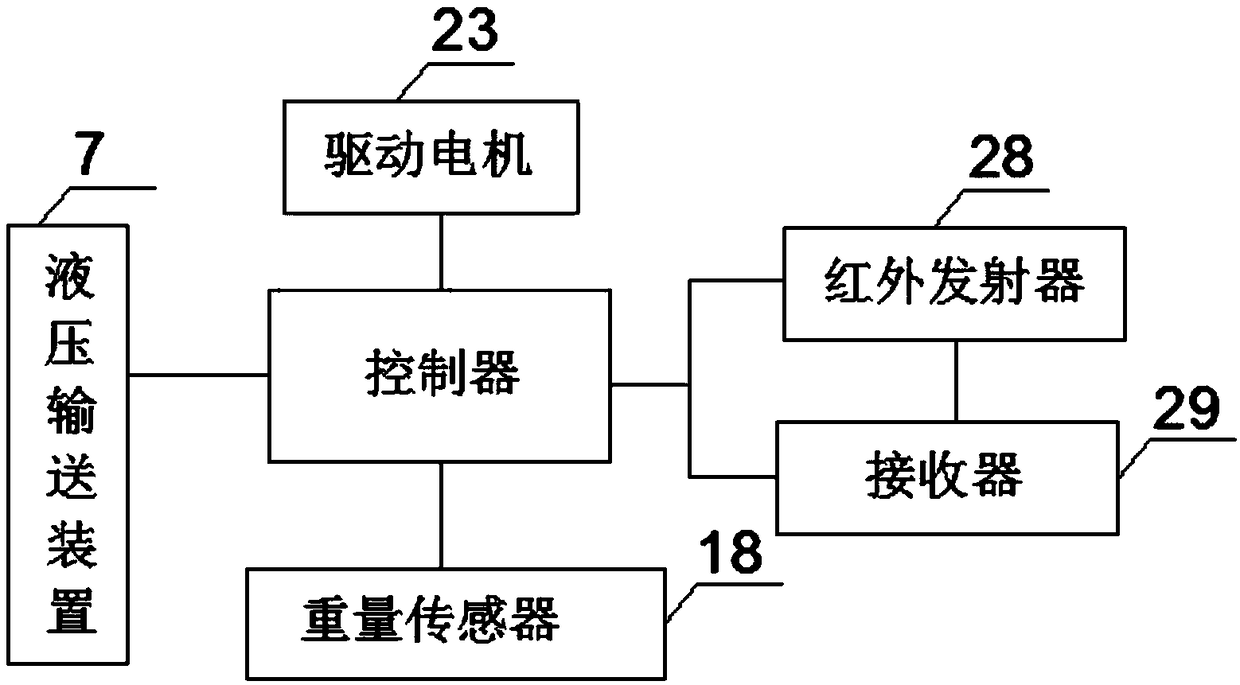

Food detection system

InactiveCN109030759AWill not depositReduce workloadPreparing sample for investigationTesting foodHydraulic cylinderEngineering

The invention discloses a food detection system. The system comprises a feed port, a grinder, a storage tank, a solvent barrel, a bearing barrel, a hydraulic conveying device, a detection platform, and a detection sensor; the feed port is fixedly arranged at the top of the grinder, a power outlet of the grinder is connected with a powder inlet of the storage tank through a conveying pipeline; thesolvent barrel is connected with the storage tank through a solvent tube, a cleaning barrel is connected with the storage tank through a water duct; the hydraulic conveying device comprises a first hydraulic cylinder and a first hydraulic telescopic rod arranged at one side of the first hydraulic cylinder; a bearer is arranged at the bottom of the bearing barrel, a weight sensor is arranged at oneside of the bearing barrel and the top of the bearer; the bearer is fixedly arranged at one end, far away from the first hydraulic cylinder, of the first hydraulic telescopic rod. The system has theadvantages that the solvent component cannot deposit, a controller is used for controlling the detection stroke, and the workload is small and the structure is stable.

Owner:邓林意

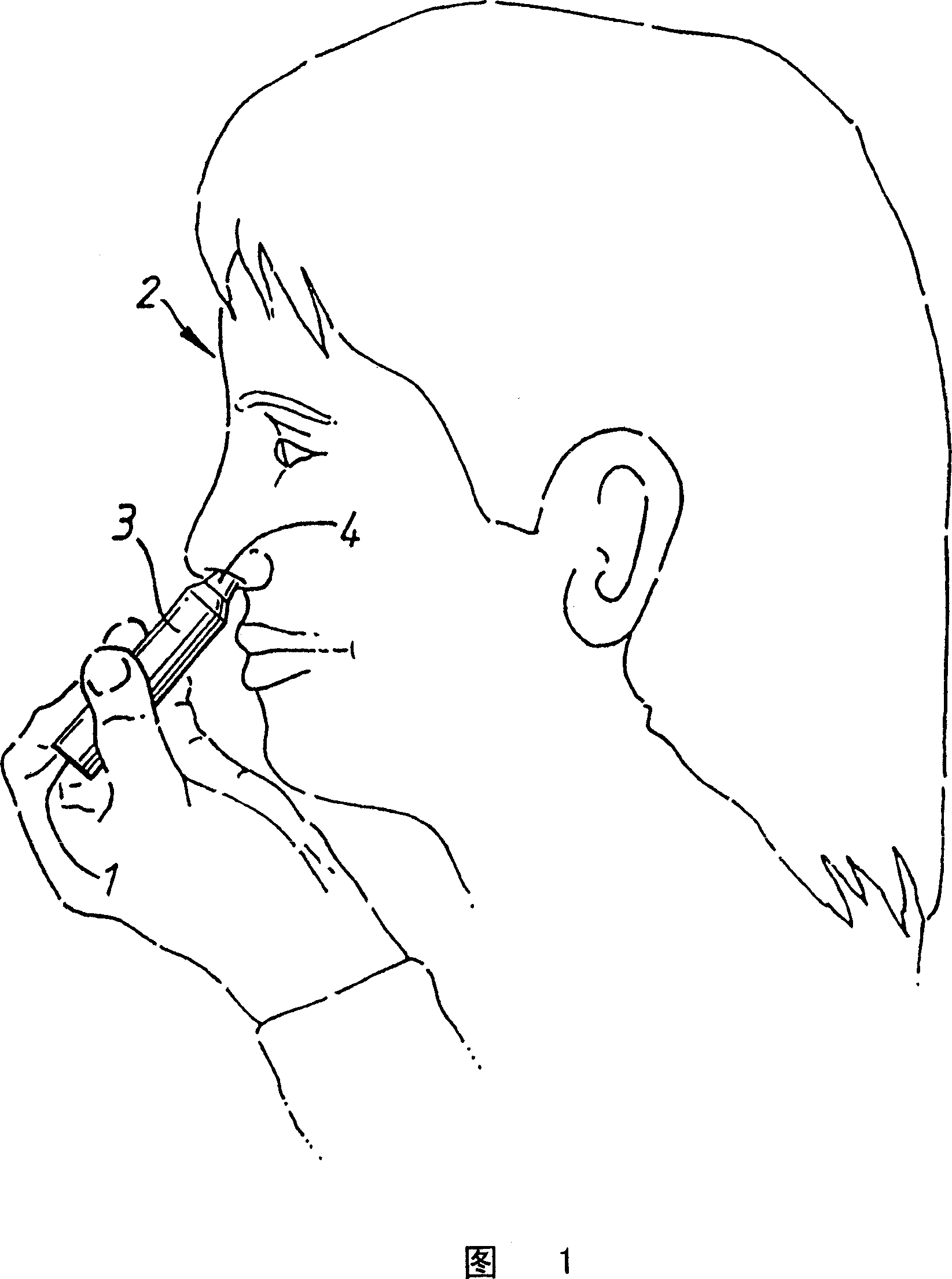

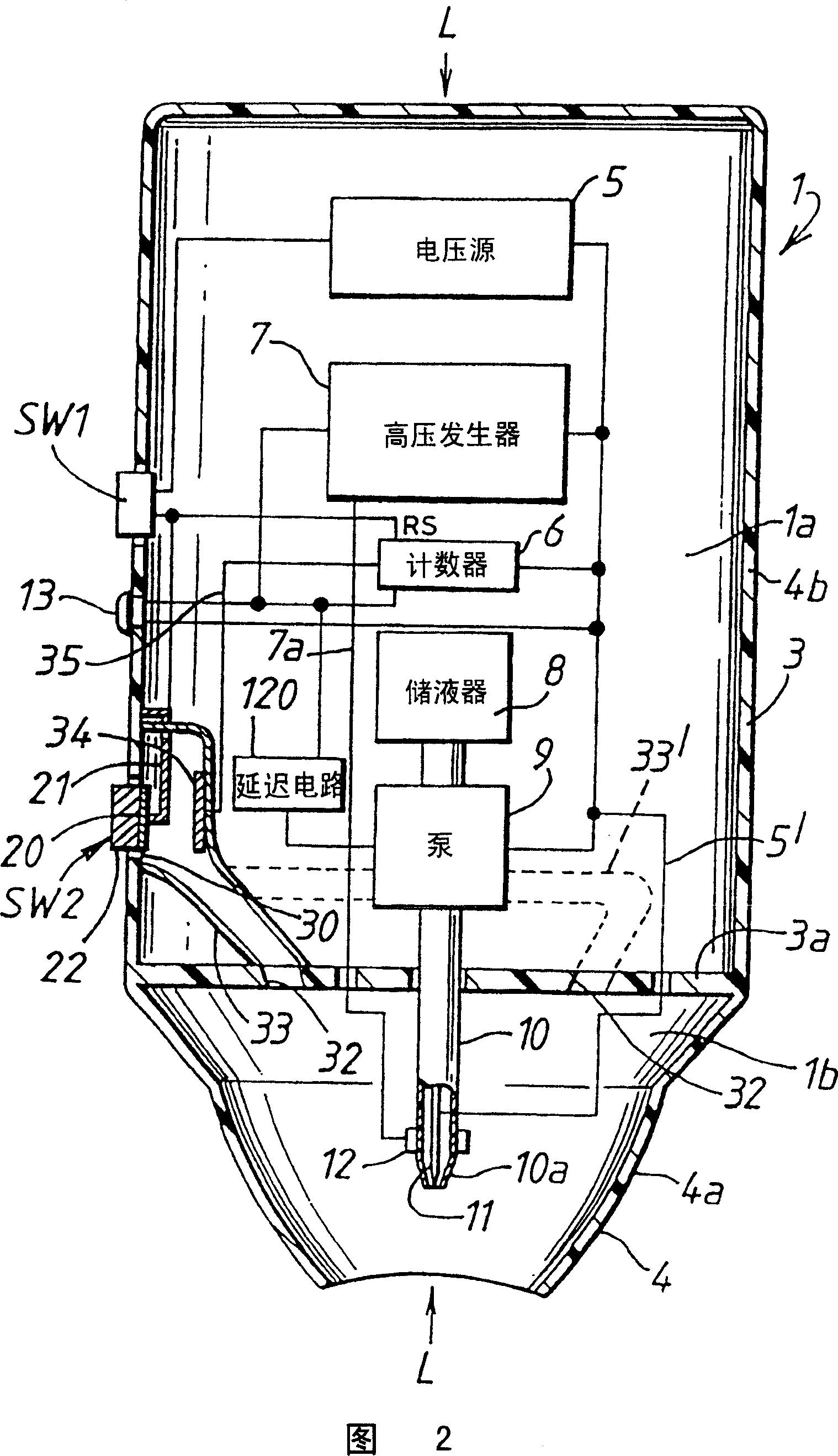

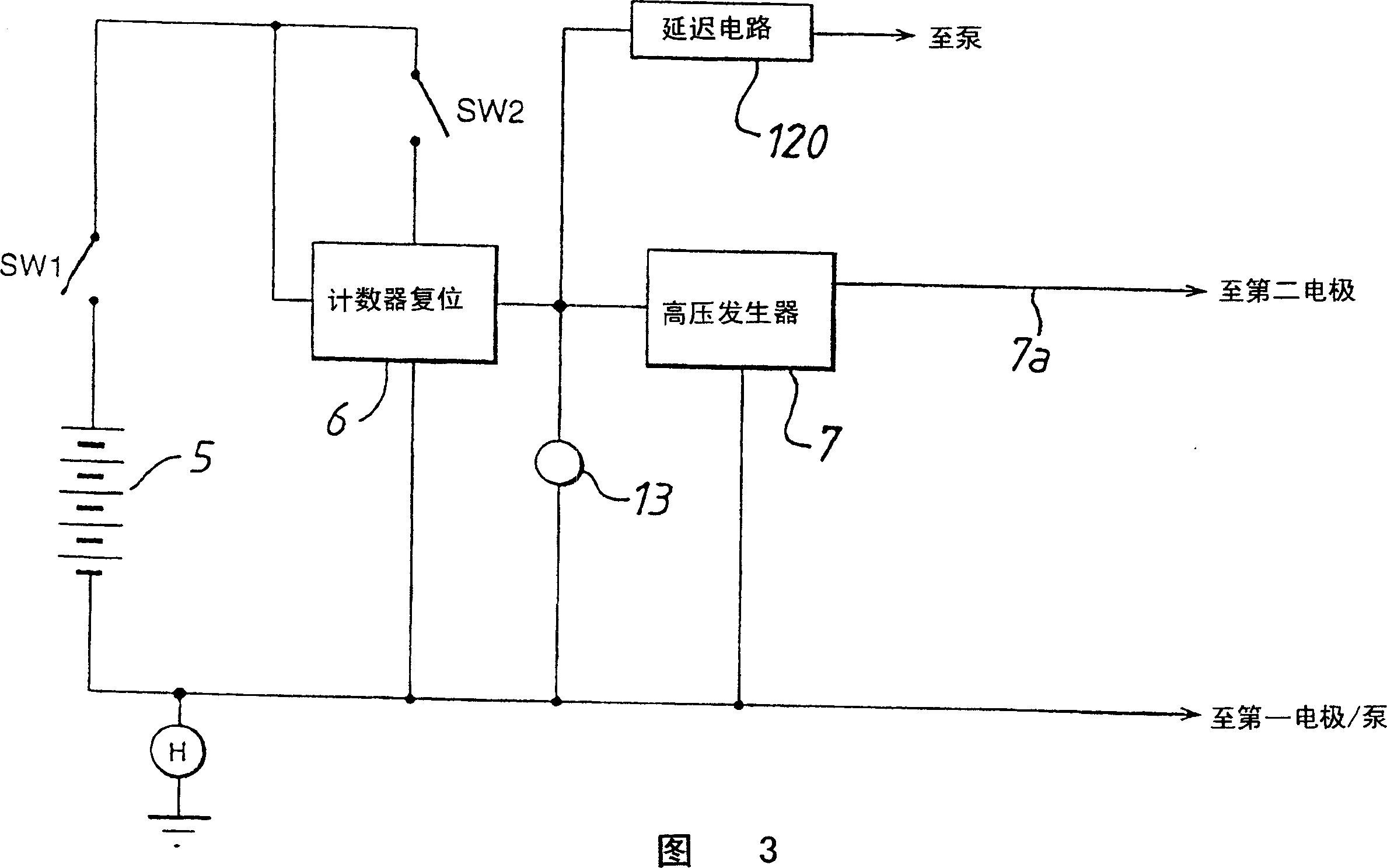

Inhaler

InactiveCN100376297CSatisfactory and efficient inputWill not depositOxygen/ozone/oxide/hydroxideLiquid supply arrangementsPotential differenceActive ingredient

An inhaler has a housing containing a chamber (1a) providing a reservoir (8) for liquid providing an active ingredient to be supplied to a liquid outlet (10a). First and second electrodes are spaced apart (11 and 12) with the first electrode being spaced apart (11 and 12) with the first electrode being provided at or adjacent the liquid outlet (10a). A voltage supply (5, 7) is activated in response to air flowing through an air inlet (30) of the housing to provide a potential difference between the first and second electrodes (11 and 12) to create an electric field for causing comminution of liquid issuing from the liquid supply outlet (10a) to produce a stream of electrically charged comminuted matter for supply to the nasal passages of a user via an outlet (4) of the housing.

Owner:BATTELLE MEMORIAL INST

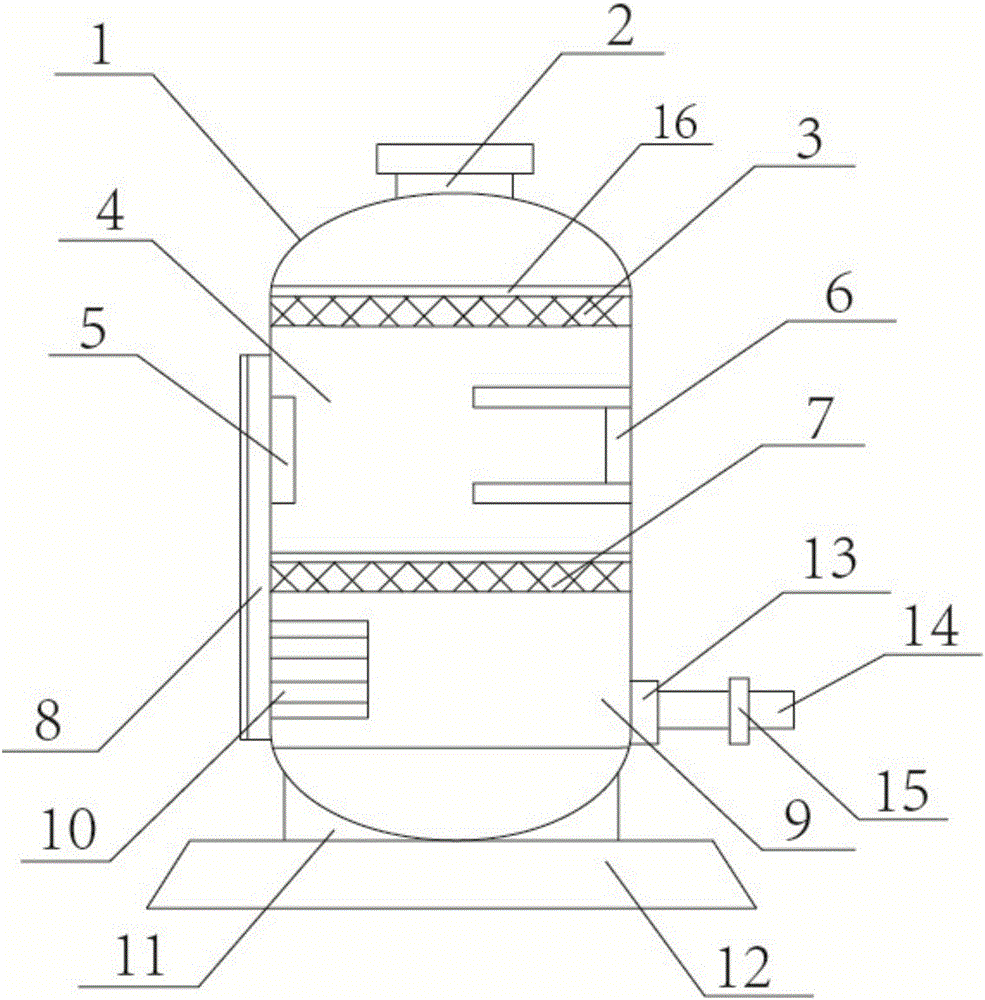

Electric flocculation sewage treatment tank

InactiveCN106186212APrevent splashPlay the role of stirringWater contaminantsTreatment involving filtrationFlocculationBio filtration

The invention provides an electric flocculation sewage treatment tank which comprises a sewage treatment tank body, a sewage inlet, a first filter net, an electric flocculation reaction cavity, an electric flocculation reactor, a second filter net, a biological filter cavity, a biological filter device, a fixing bracket, a supporting base, a sewage outlet and a sewage discharging pipe. The electric flocculation sewage treatment tank is characterized in that the sewage treatment tank is arranged on the fixing bracket, the fixing bracket and the sewage treatment tank body are fixedly connected, the fixing bracket is arranged on the supporting base, the fixing bracket and the supporting base are fixedly connected, and the sewage inlet is formed in the upper end of the sewage treatment tank body. The biological filter cavity is formed in the sewage treatment tank body, the biological filter device is arranged in the biological filter cavity, a biological filter material is arranged in the biological filter device, macromolecule organic pollutants are decomposed into micromolecule organic pollutants through microorganisms in the biological filter material, and later-stage treatment is promoted.

Owner:霍普科技(天津)股份有限公司

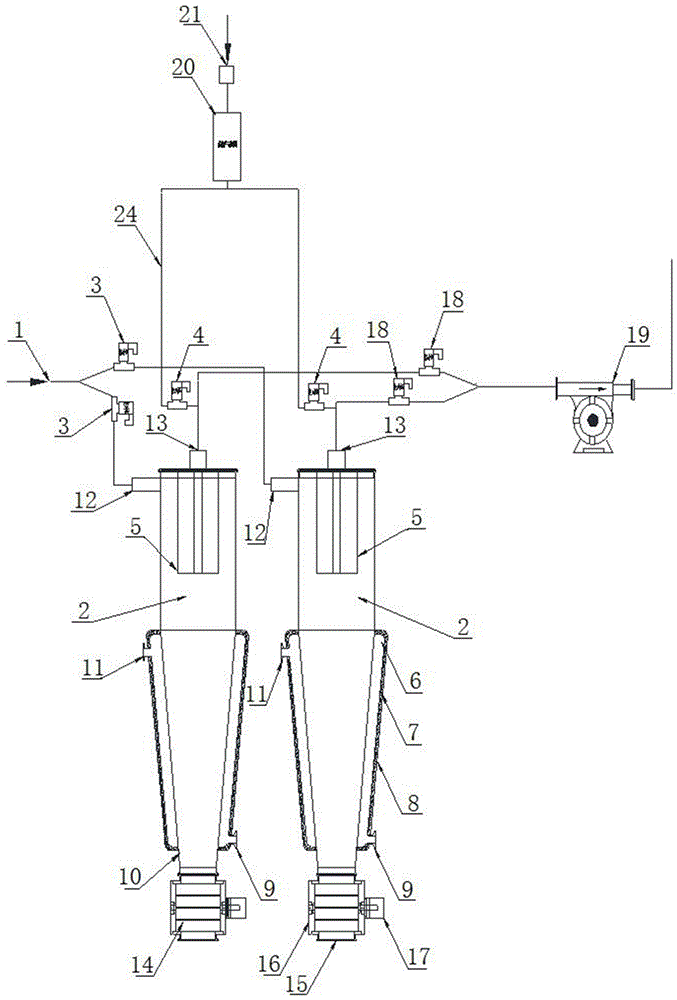

Parallel separating and cooling recovery device for processing drug and food powder

ActiveCN106110356ASlow downAvoid emissionsCombination devicesLavatory sanitoryExhaust valveThermal insulation

The invention relates to a parallel separating and cooling recovery device for processing drug and food powder. The device comprises a vertical powder separation recovery tower comprising two identical tower bodies, wherein the tower is of an interlayer structure from the middle to the lower part of the tower body; a refrigerant channel is formed in the interlayer; a thermal insulation layer is arranged outside the interlayer; a feeding hole is formed in the top of the tower body; an exhaust port is formed in the center of the top; a precise powder filter is arranged in the exhaust port; a powder discharge opening is positioned at the bottom of the tower body and is equipped with a discharge valve; two feeding valves are respectively butted with feeding holes of the two tower bodies so as to form parallel feeding branches; two recoil valves and two exhaust valves are respectively butted with the exhaust ports of the two tower bodies so as to form parallel recoil branches and parallel exhaust branches; feeding valves of the two feeding branches are butted with outlets of residual powder which is not separated at the preceding stage by virtue of pipelines; recoil valves of the two recoil branches are butted with an air storage tank by virtue of pipelines; and the exhaust valves of the two exhaust branches are butted with a negative pressure exhaust fan by virtue of pipelines.

Owner:JIANGSU WANCHUANG STERILIZATION EQUIPEMNT TECHNOLOYG CO LTD

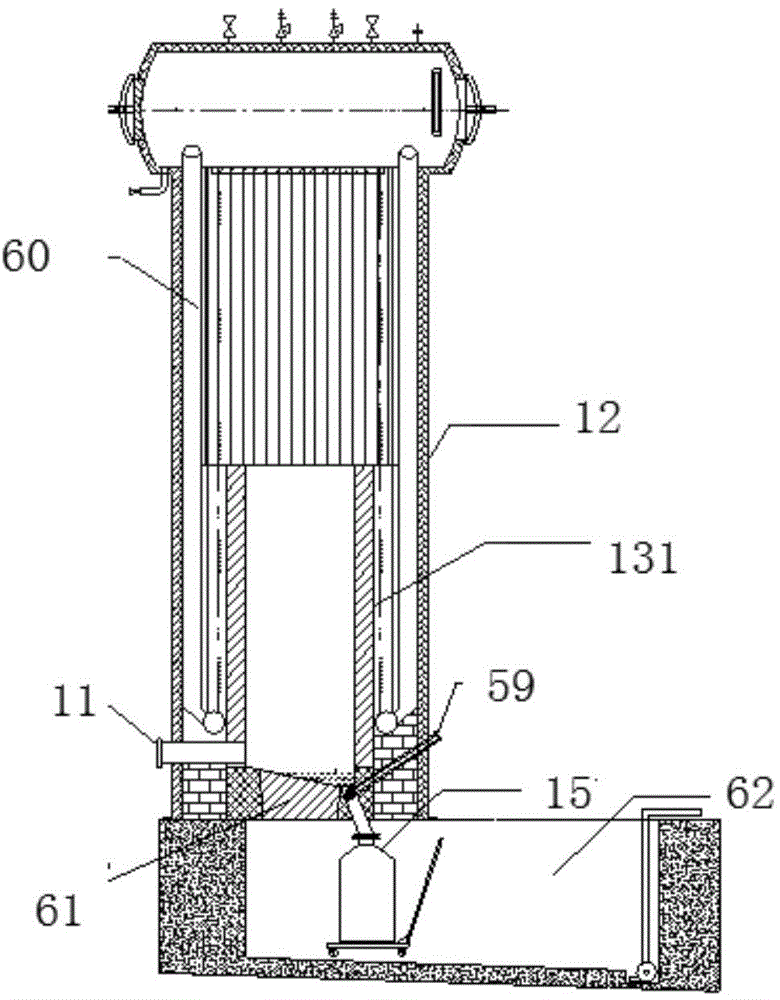

Clean and efficient biomass micron fuel high-temperature industrial boiler

ActiveCN105674232ARaise the combustion temperatureWill not depositLiquid fuel pretreatmentPulverulent fuel combustion burnersAir preheaterCombustion chamber

The invention discloses a clean and efficient biomass micron fuel high-temperature industrial boiler. The boiler comprises a radiation heat exchange furnace, a convective heat exchange unit, an economizer, an air preheater and the like, wherein a heat insulation combustion chamber is arranged in the radiation heat exchange furnace, so that a relatively closed heat storage and combustion space is formed; the top of the combustion chamber is provided with a radiation heat exchange water cooling wall which is used for conducting efficient radiation heat exchange on the combustion chamber; the convective heat exchange unit and the radiation heat exchange furnace are arranged in a split mode; the convective heat exchange unit communicates with the radiation heat exchange furnace through a smoke outlet, and accordingly smoke produced after combustion is used for performing convective heat exchange; the economizer and the air preheater are sequentially arranged on the downstream side of the convective heat exchange unit, the smoke is used for preheating air, and then the heated air is conveyed to the radiation heat exchange furnace. Through the clean and efficient biomass micron fuel high-temperature industrial boiler, the combustion temperature up to 1500 DEG C or more can be obtained; the boiler thermal efficiency can reach 90% or more; the more requirements for heating of industrial steam and thermal oil furnaces are met; and meanwhile, compared with the prior art, a product does not contain tar basically and has no residual carbon and ash content.

Owner:WUHAN JIANGHECHANG ENERGY TECH CO LTD

Full automatic unpacking unloader

InactiveCN101508358BAchieve isolationAvoid reverse motionSievingConveyorsEngineeringEnergy conservation

The invention relates to a solid material unpacking machine, in particular to a full automatic unpacking and unloading machine, which is characterized in that: all stages of mechanisms are connected through flanges; a bag breaking mechanism, a screening mechanism and a material output mechanism are arranged on a main body frame; the outer surface of the main body frame is connected with a surfacepanel in a splicing mode; the surface panel on the top of the main body frame is provided with a main dust removal outlet; and a channel formed from the feeding inlet end of a feeding mechanism to the outlet end of the material output mechanism and the outlet end of a waste bag output mechanism is a one-way communication channel. The full automatic unpacking and unloading machine has the advantages that the machine has high work efficiency, energy conservation, environmental protection, small volume, light weight and the like, can safely and stably separate solid materials from packages in automatic high-speed running, and convey the materials to downstream equipment, while the waste packages enter a waste bag recovery device for recovery, and the machine can particularly meet the requirements of unloading, separating and collecting toxic and corrosive powder, and particle materials.

Owner:HANRUI PUZER BULK HANDLING TECH SHANGHAI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com