Sealing round disc feeding machine

A disc feeder and feeder technology, used in conveyors, rotary conveyors, transportation and packaging, etc., can solve the problems of gear wear, pollution of lubricating oil, easy entry into the gear box of the reducer, etc. Simple design and labor-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

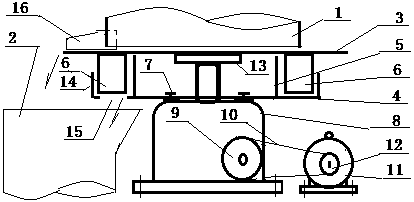

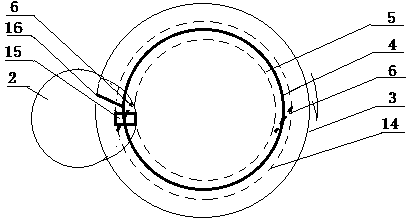

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0031] A sealed disc feeder includes: silo outlet 1, feeding interface 2, feeder disc 3, sealing assembly chassis 4, sealing inner ring 5, dust cleaning inclined scraper 6, chassis locking screw 7, Reducer 8, reducer pulley 9, V-belt 10, speed-regulating motor 11, motor pulley 12, output flange 13, sealing outer ring 14, dust cleaning discharge port 15, material retaining plate 16.

[0032] It is characterized in that: the disc feeder is installed under the outlet 1 of the silo, and the distance between the outlet 1 of the silo and the disc 3 of the feeder is determined according to the feeding speed of the silo.

[0033] The feeder disc 3 is installed above the output flange 13 of the reducer 8, and the diameter of the feeder disc 3 is required to be 2-2.4 times larger than the diameter of the outlet 1 of the feeder.

[0034] A baffle plate 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com