Patents

Literature

66results about How to "Avoid reverse motion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

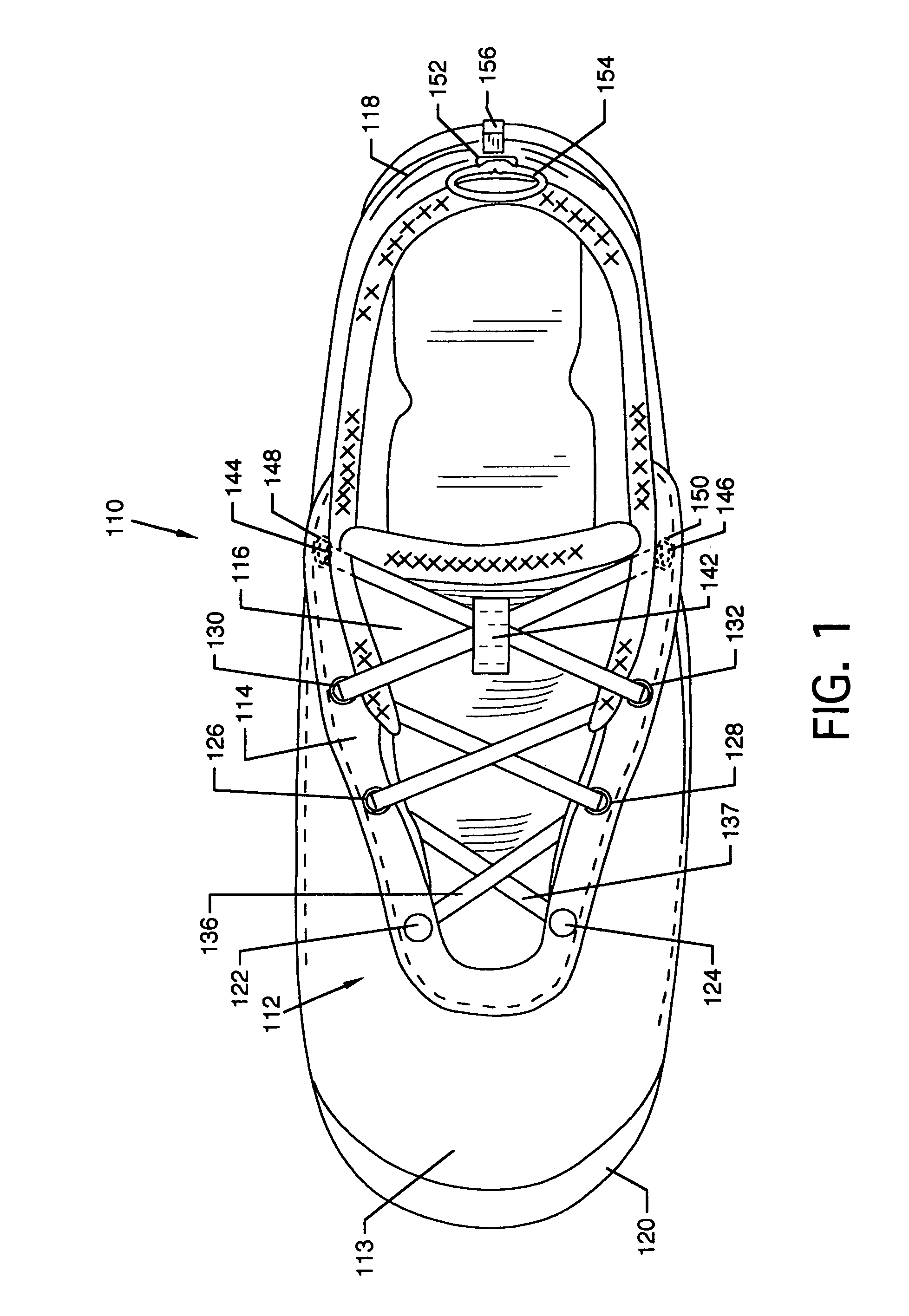

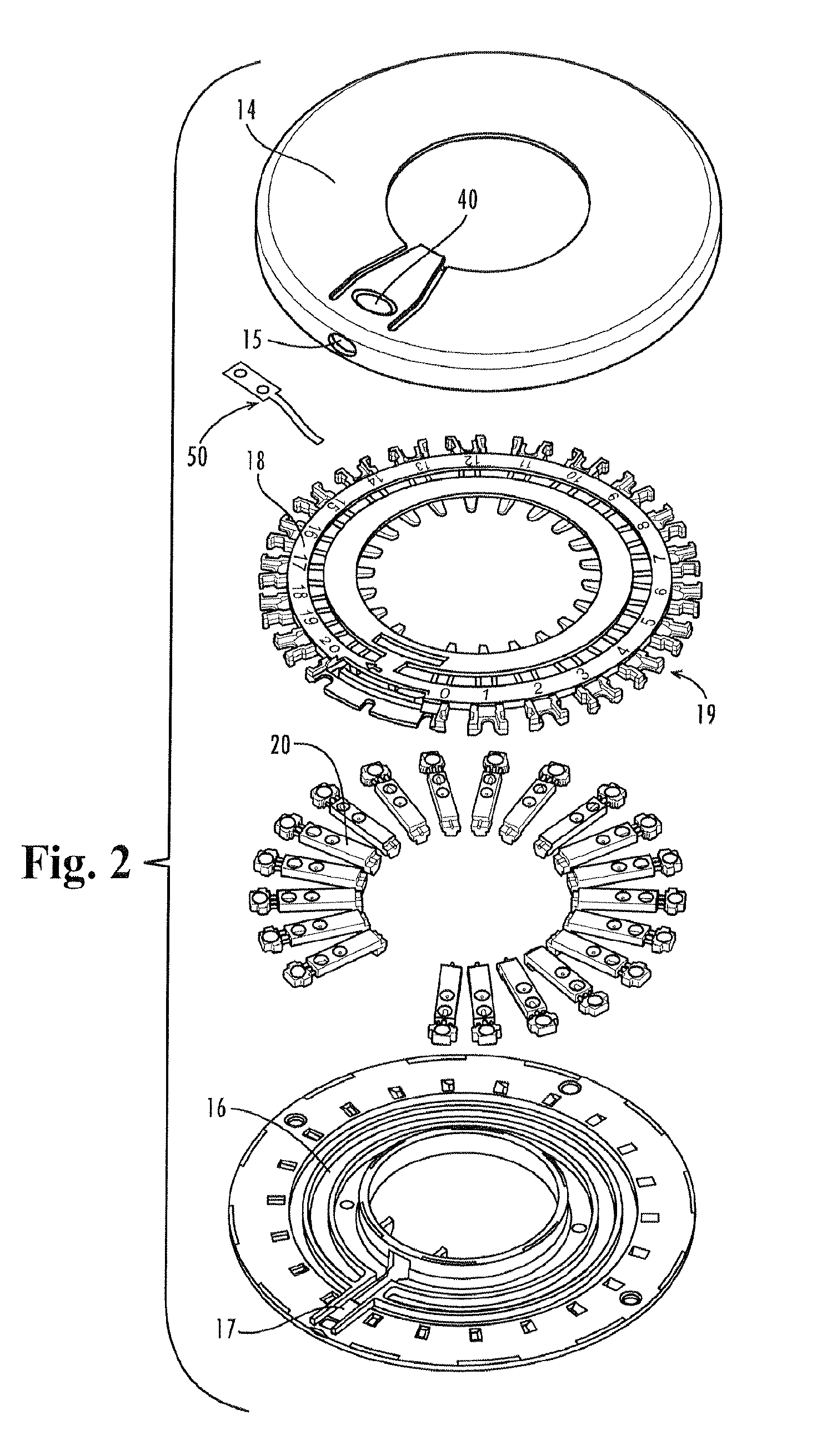

Automated tightening shoe

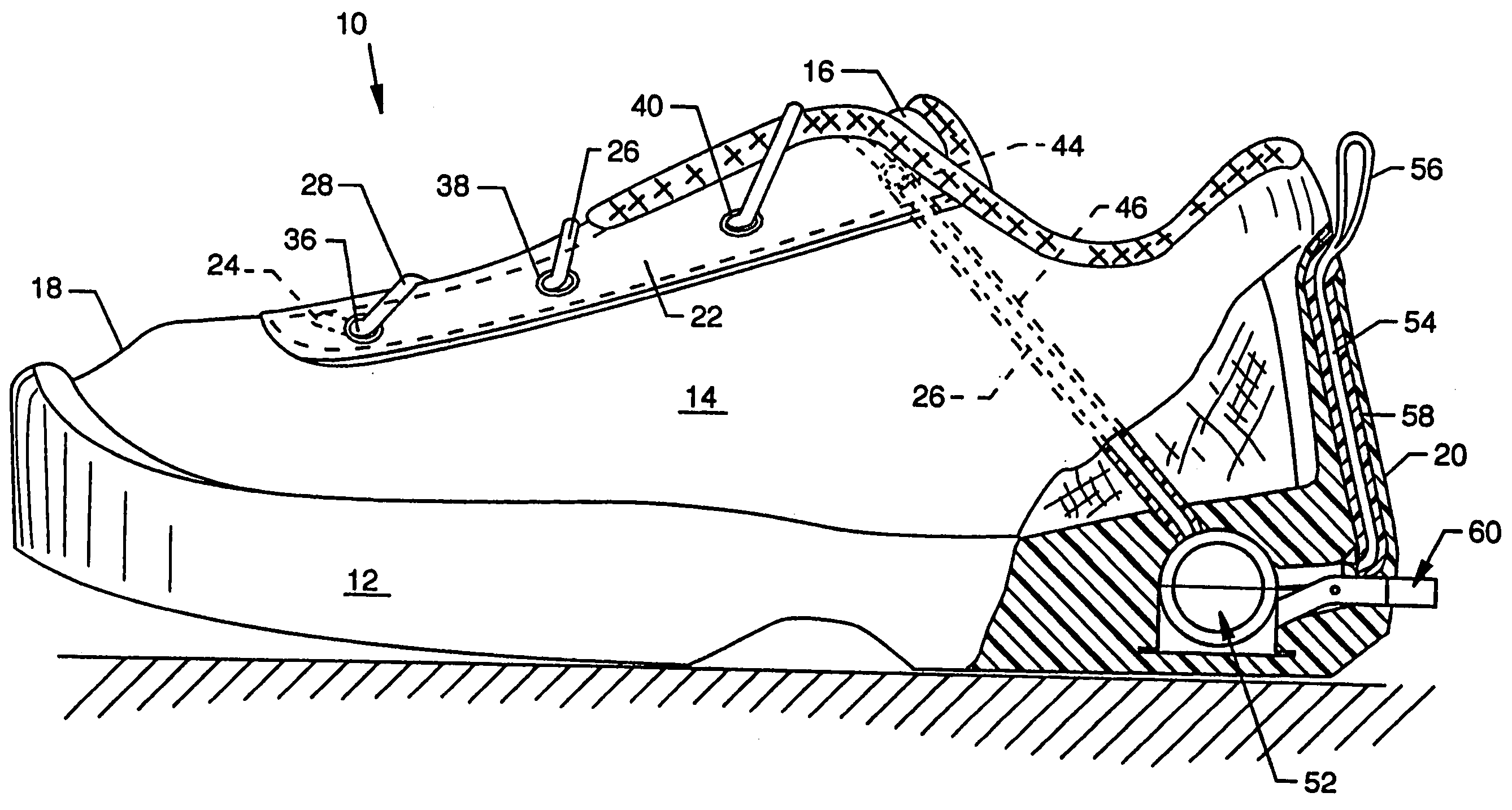

InactiveUS20070240334A1Easy to operate and performSuperior qualityShoe lace fasteningsBiomedical engineeringShoe laces

Owner:HANDS FREE ENTERPRISES LLC

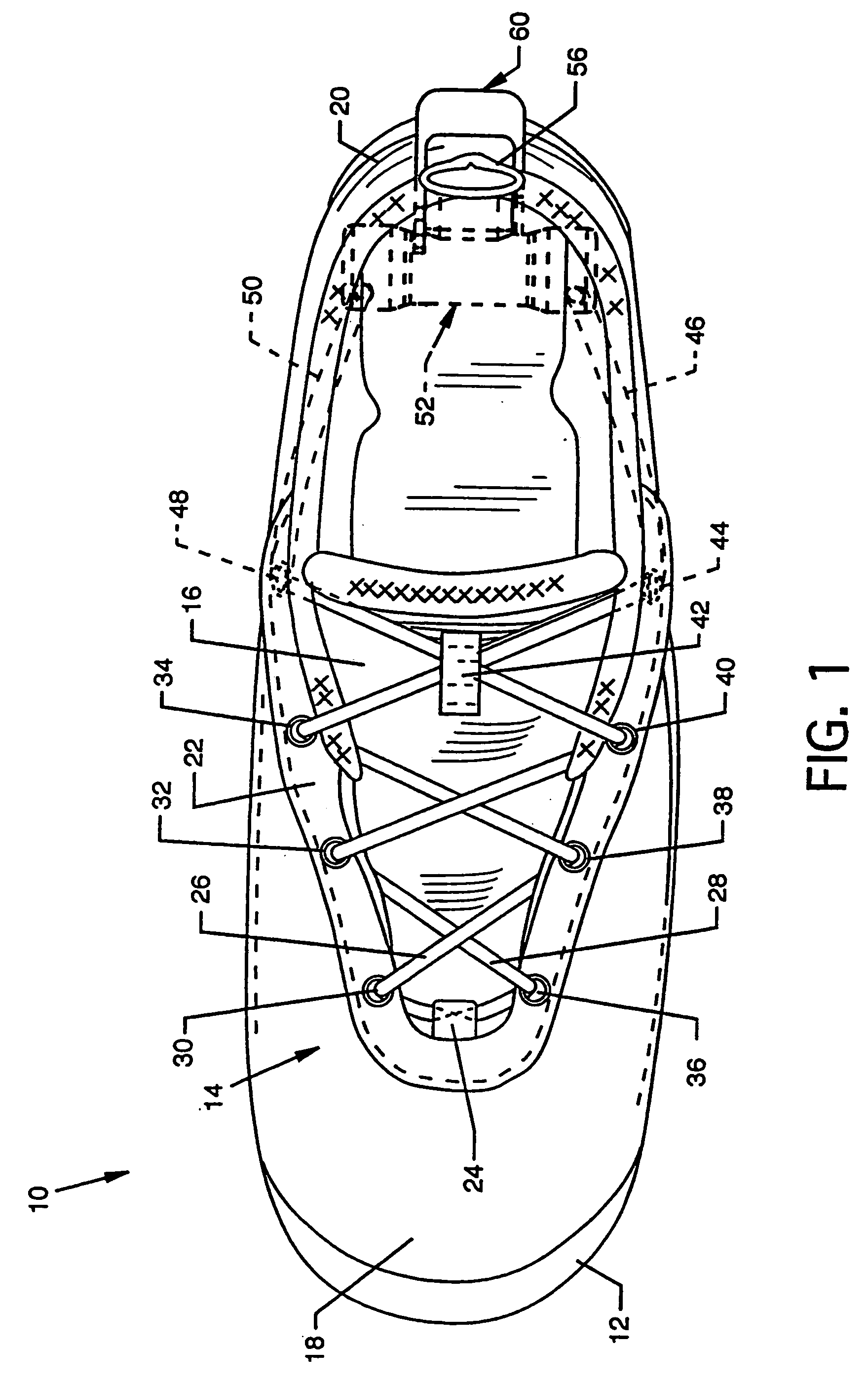

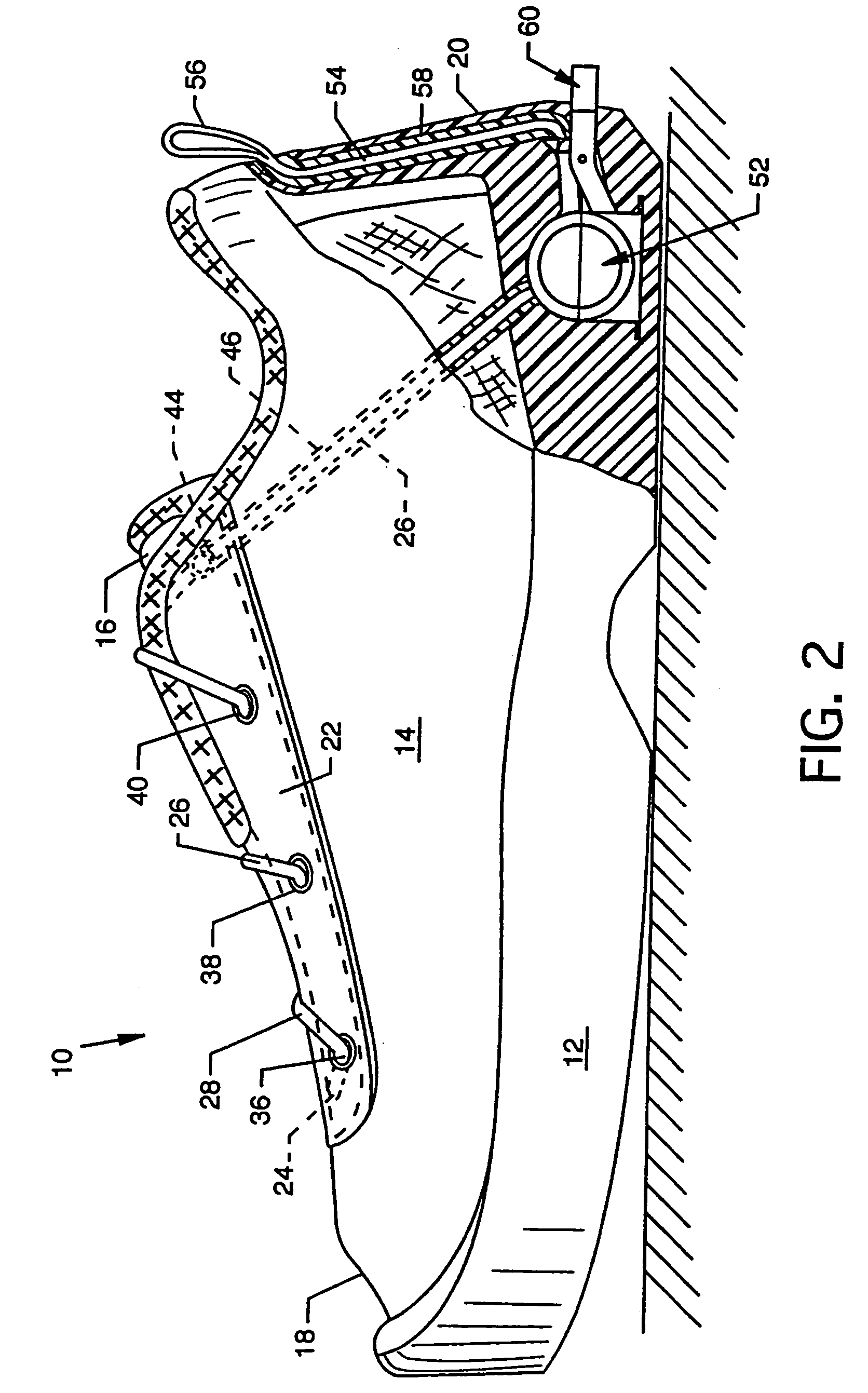

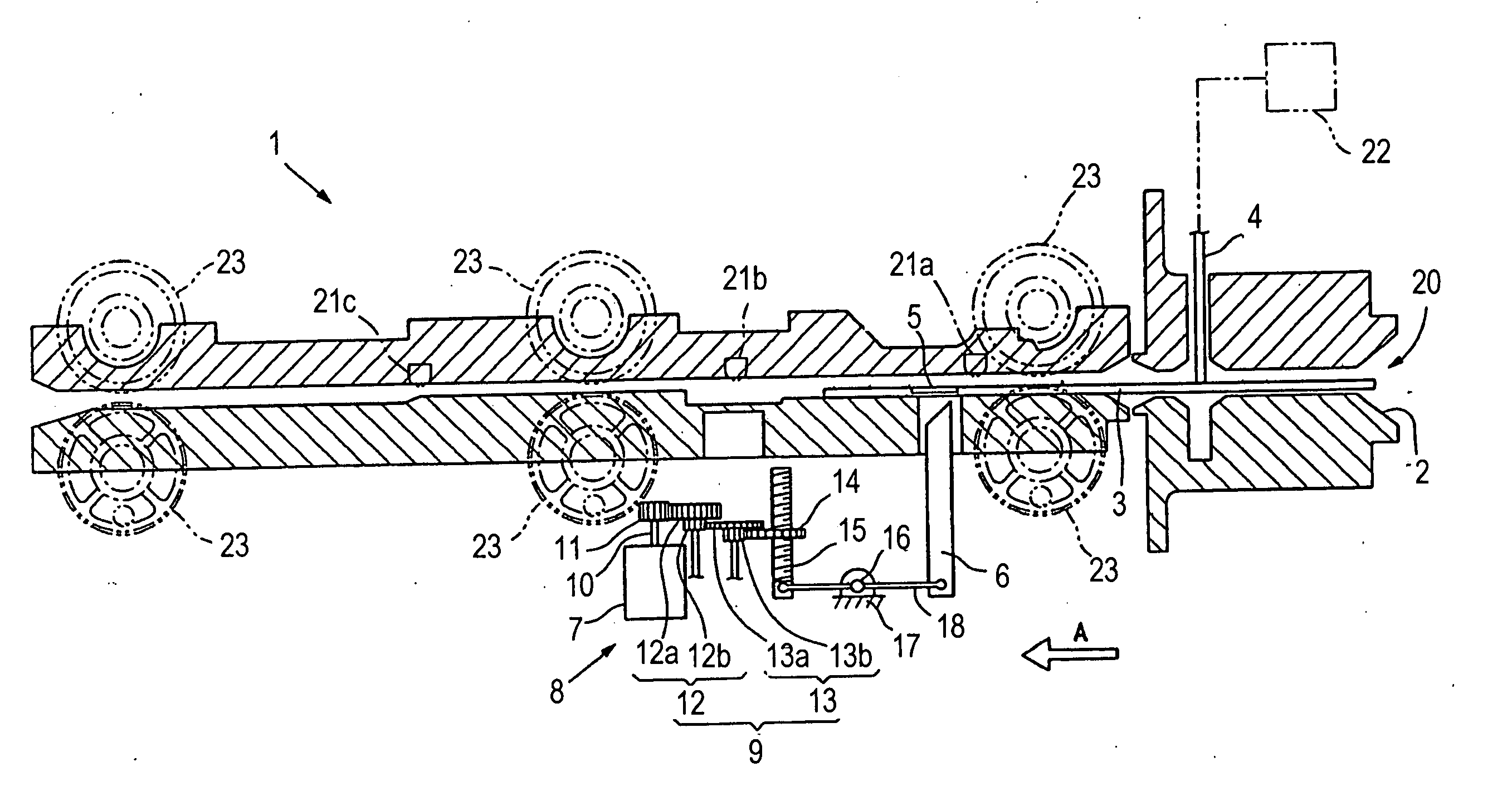

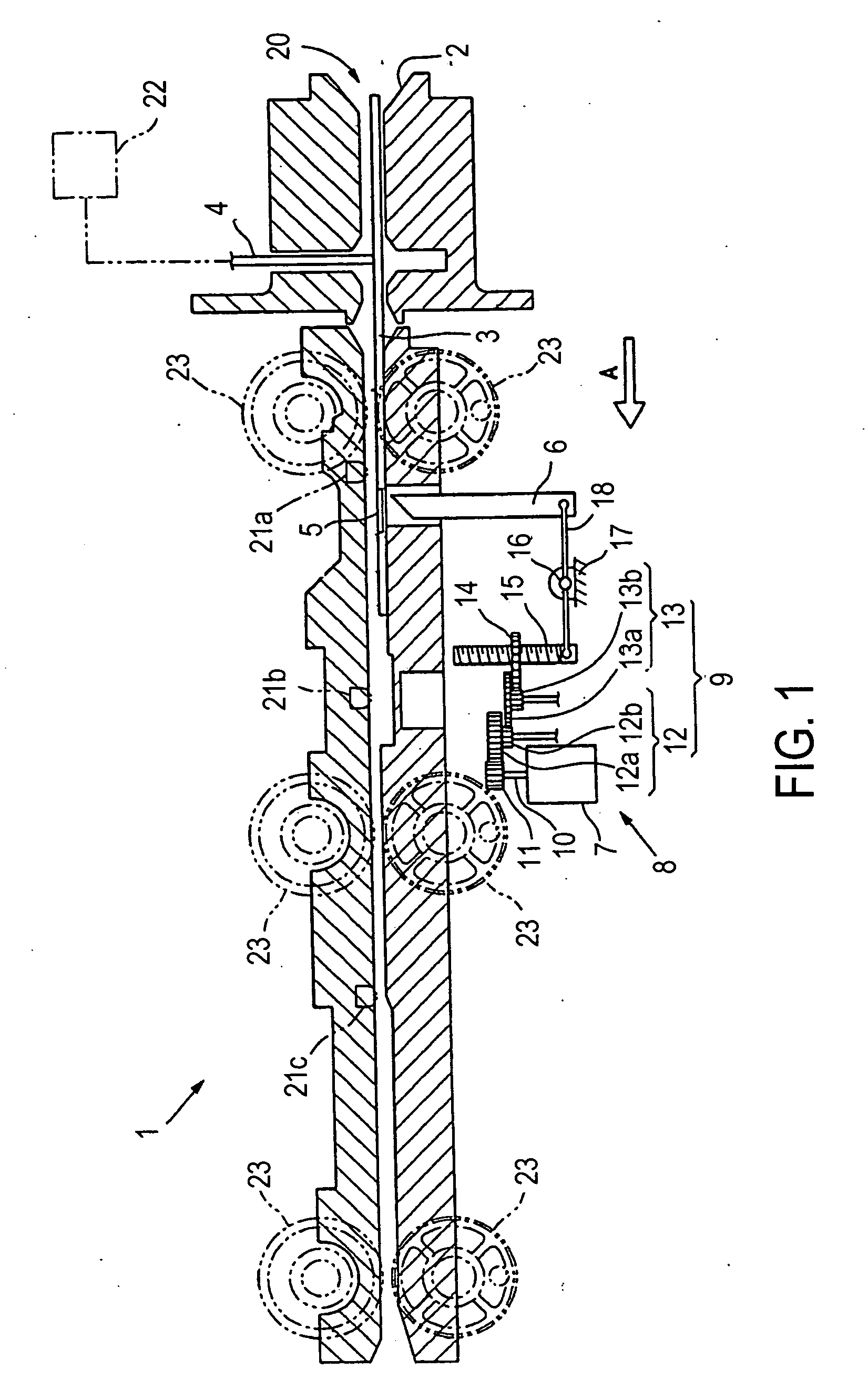

Automated tightening shoe

InactiveUS6896128B1Quality improvementEasy to operateShoe lace fasteningsShoe lacesBiomedical engineering

Owner:HANDS FREE ENTERPRISES LLC

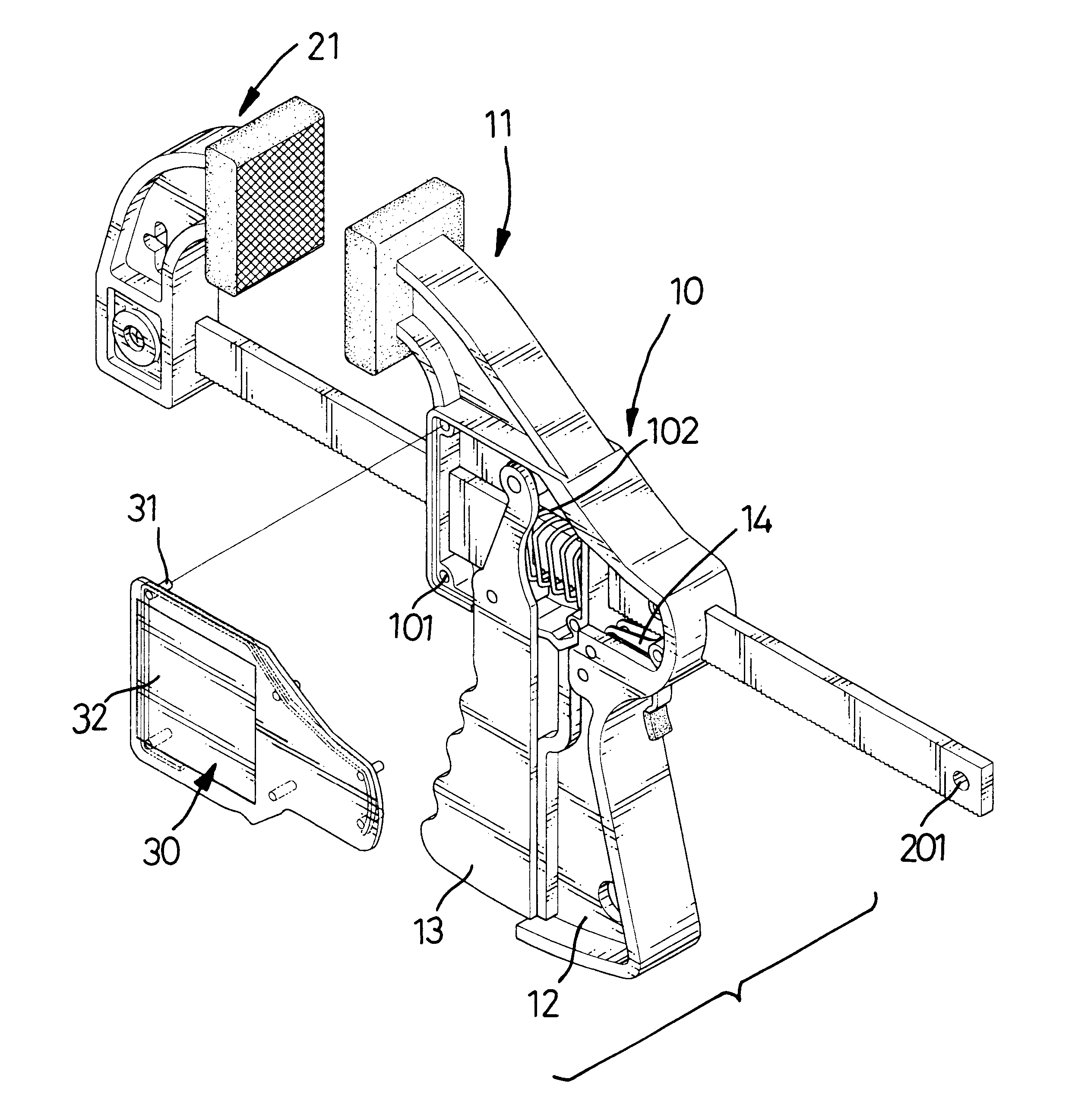

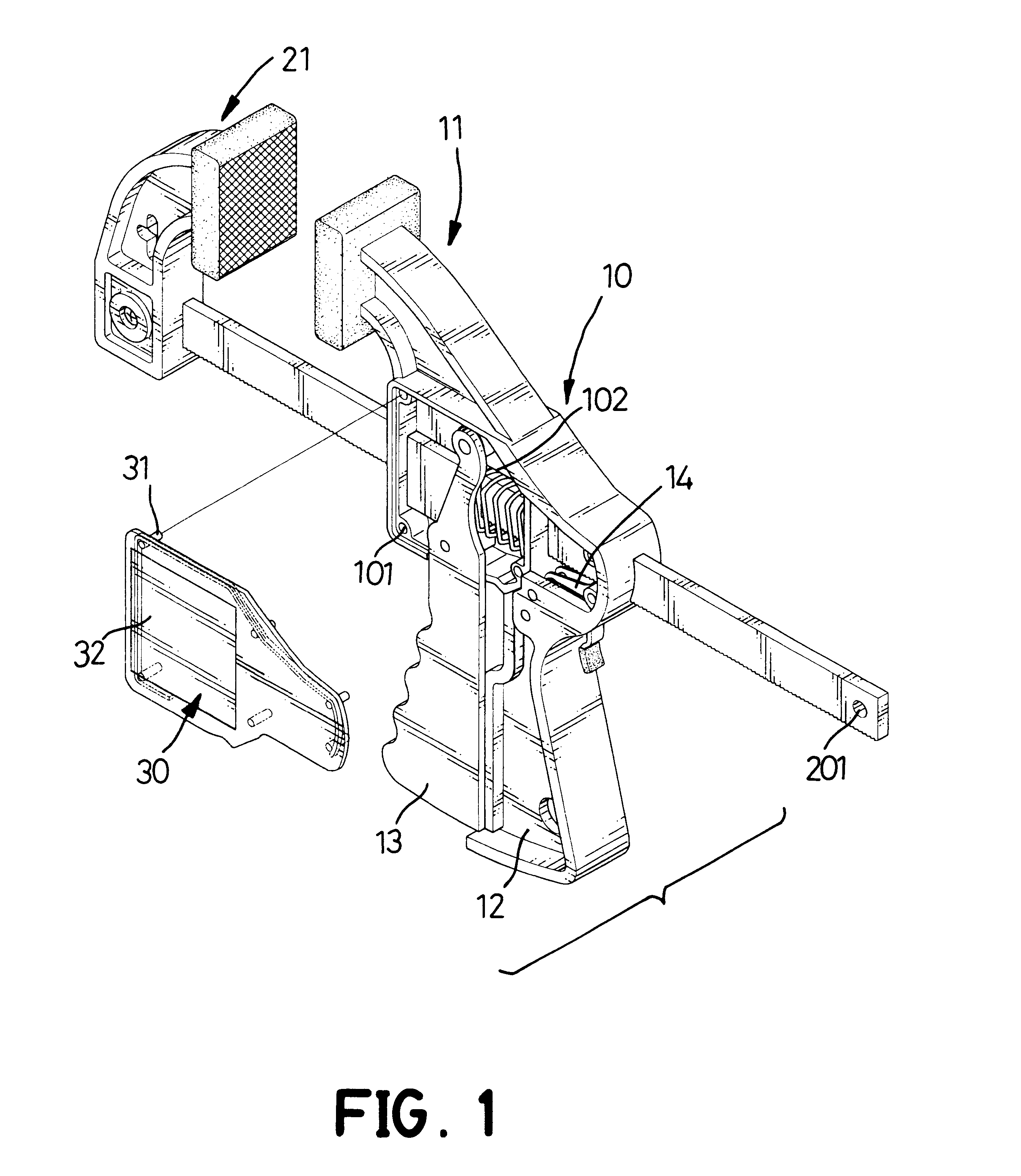

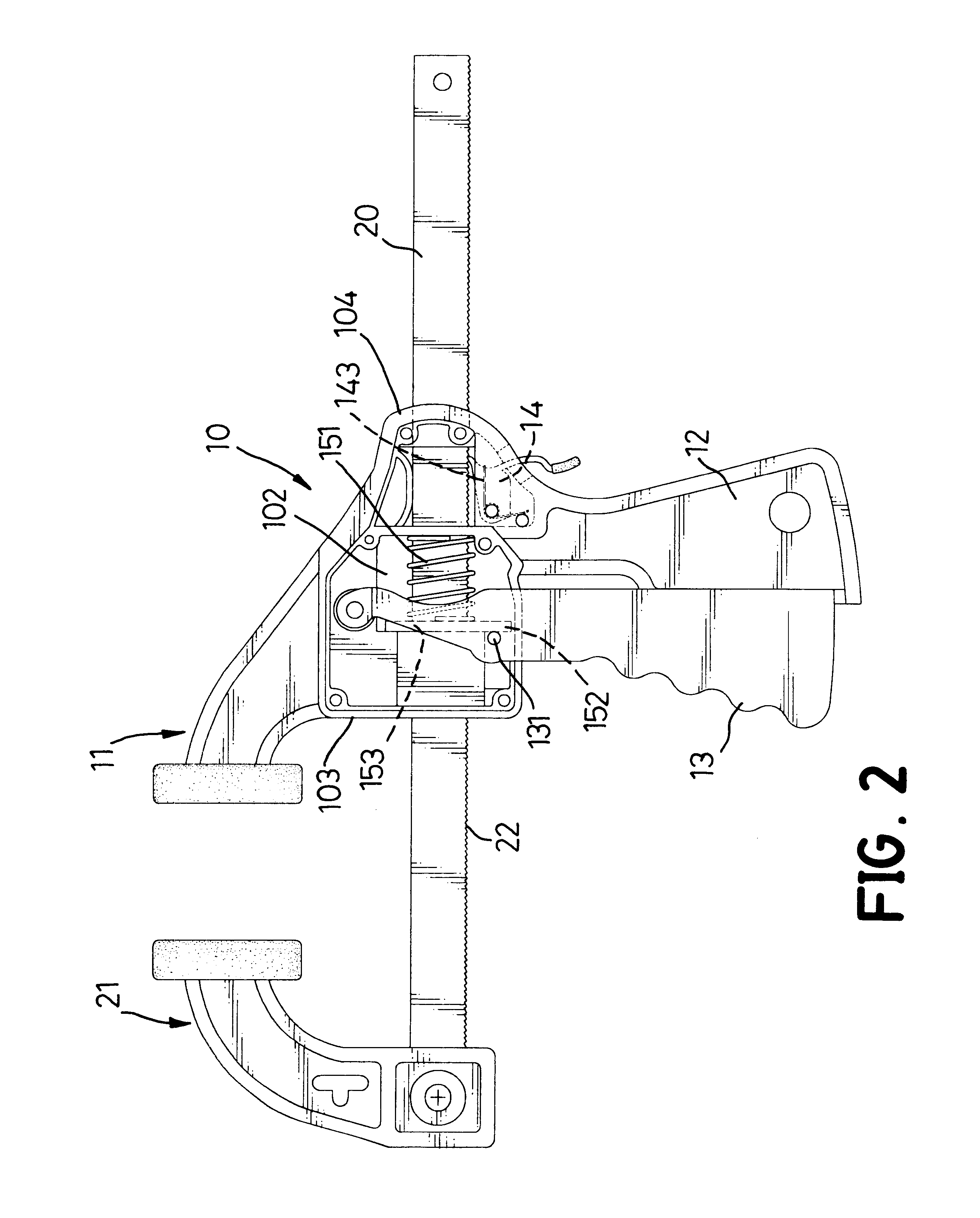

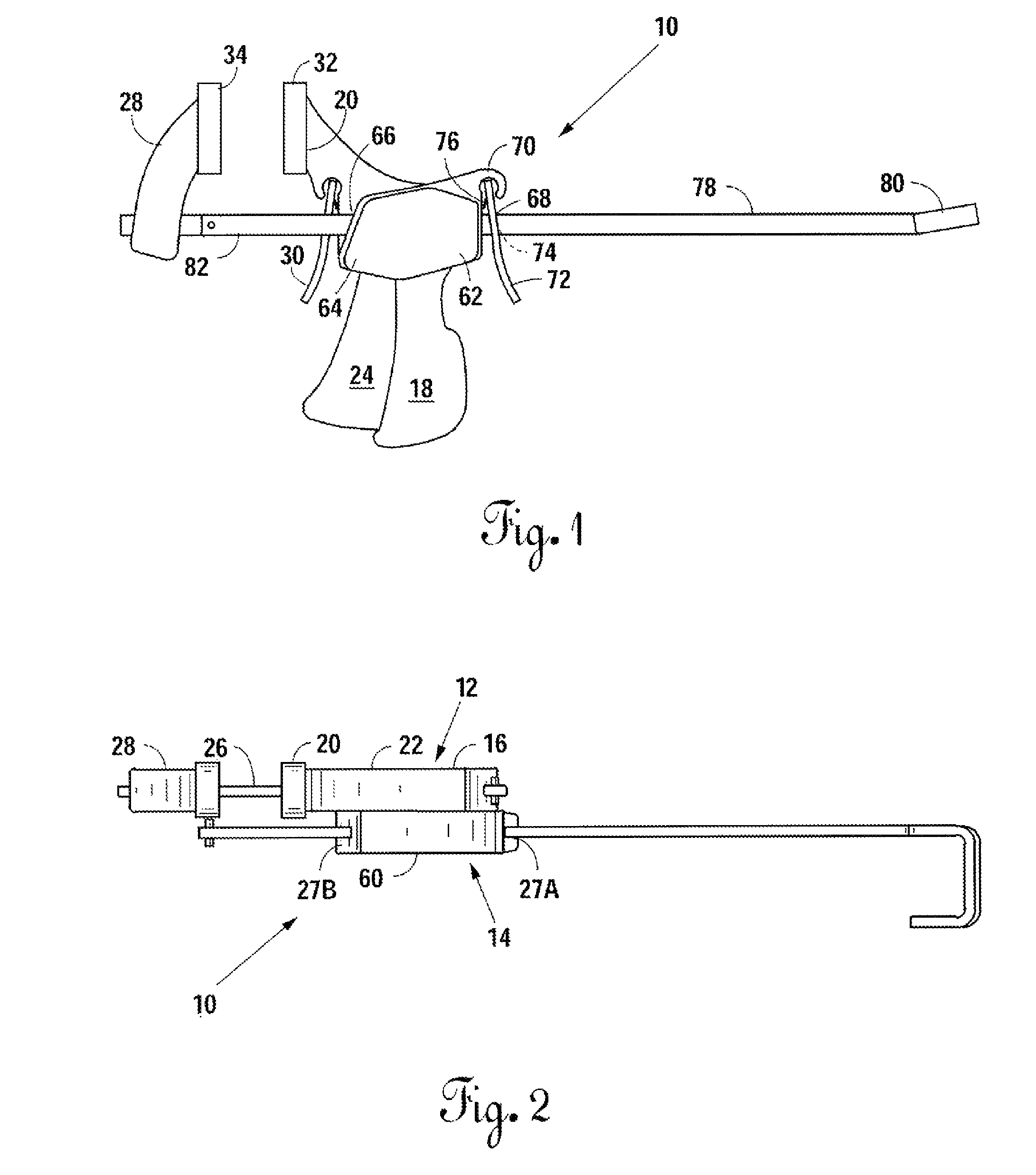

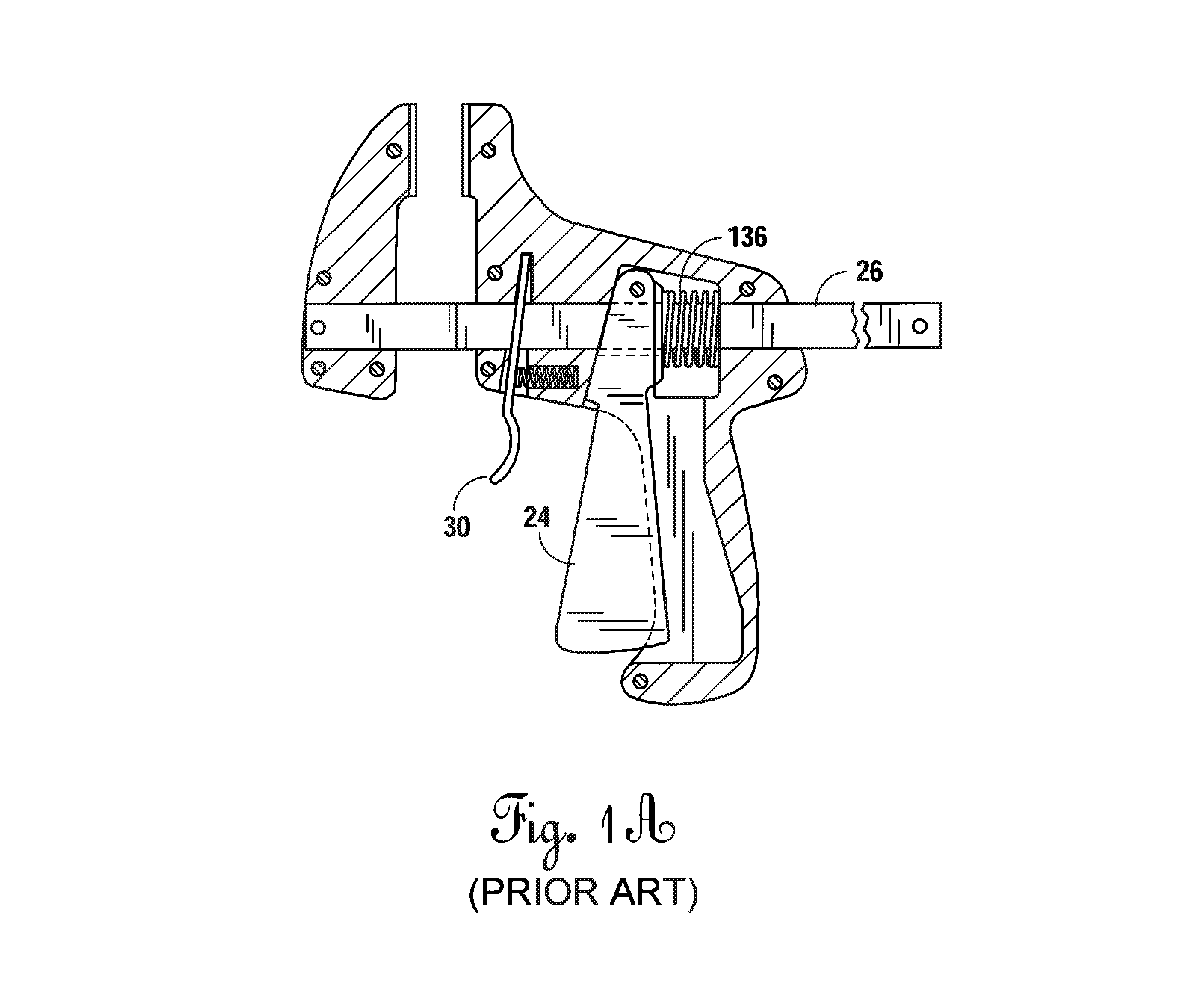

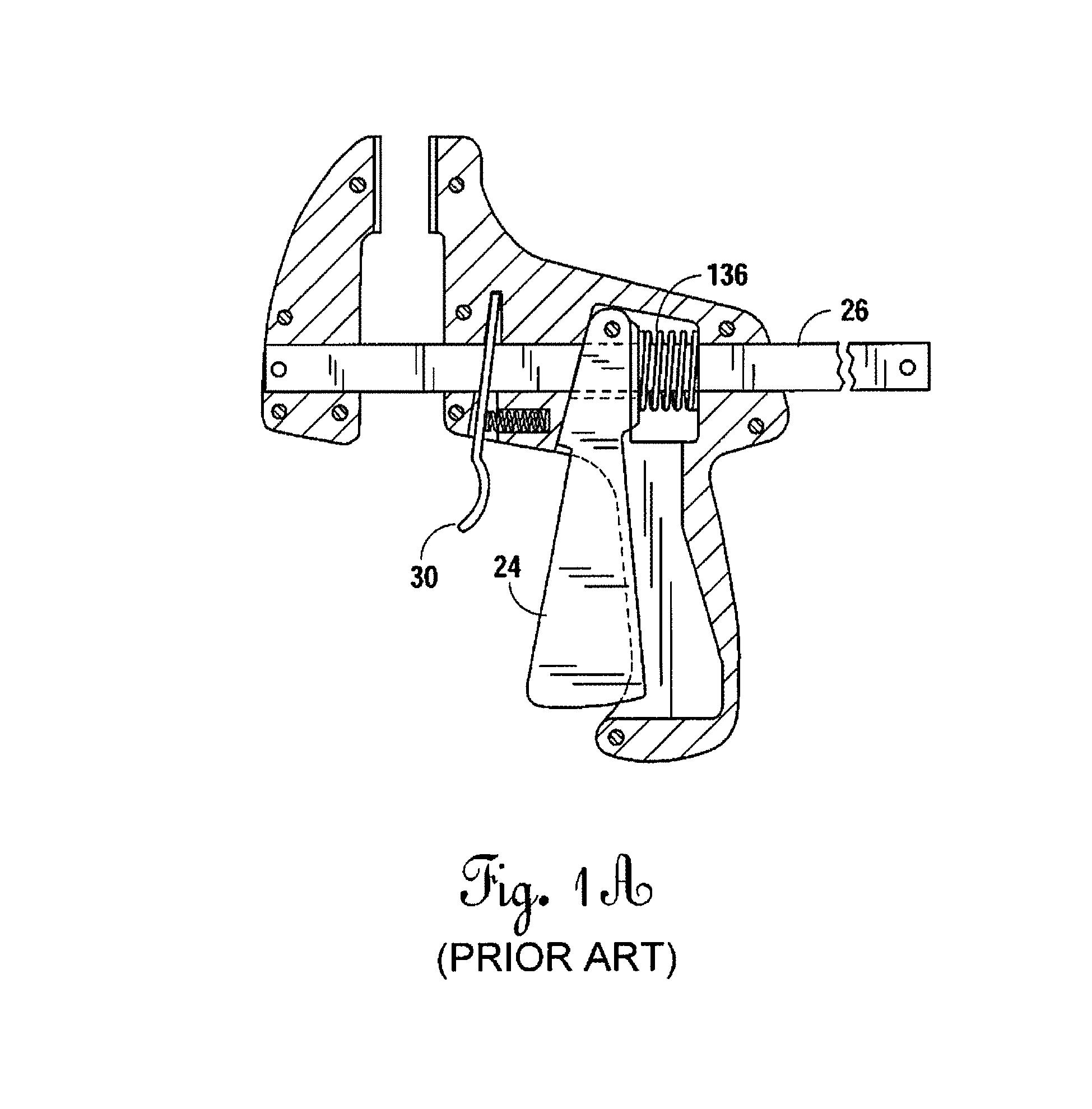

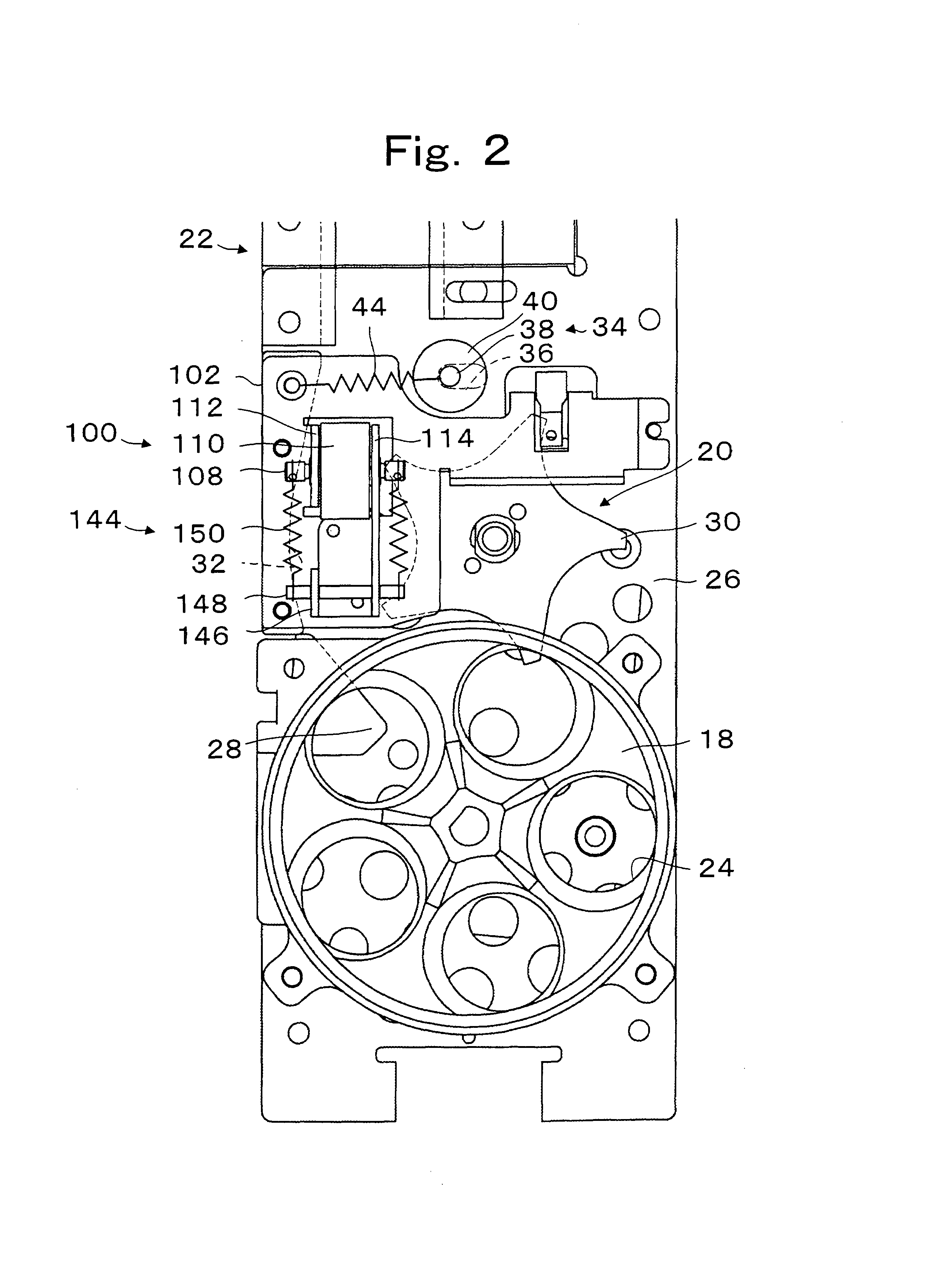

Quick-action bar clamp

A quick-action bar clamp comprises a body, a slide bar, clamp mechanism, a drive assembly and a pawl assembly. The slide bar has a series of teeth along one edge and is movably mounted in the body. The clamp mechanism includes a stationary jaw mounted on the body and a movable jaw opposing the stationary jaw connected to one end of the slide bar. The drive assembly includes a trigger, a drive lever and a spring. A push pin mounted in the trigger presses the drive lever and moves the slide bar when the trigger is squeezed. The pawl assembly includes a pawl, a release tab, a biasing element and a plastic tag. The pawl engages the teeth on the slide bar to positively hold the slide bar in position when the trigger is released.

Owner:LI TSUNG HSIANG

Automated tightening shoe

Owner:HANDS FREE ENTERPRISES LLC

Automated tightening shoe

InactiveUS20050210706A1Easy to operateEasy to looseShoe lace fasteningsShoe lacesBiomedical engineering

Owner:HANDS FREE ENTERPRISES LLC

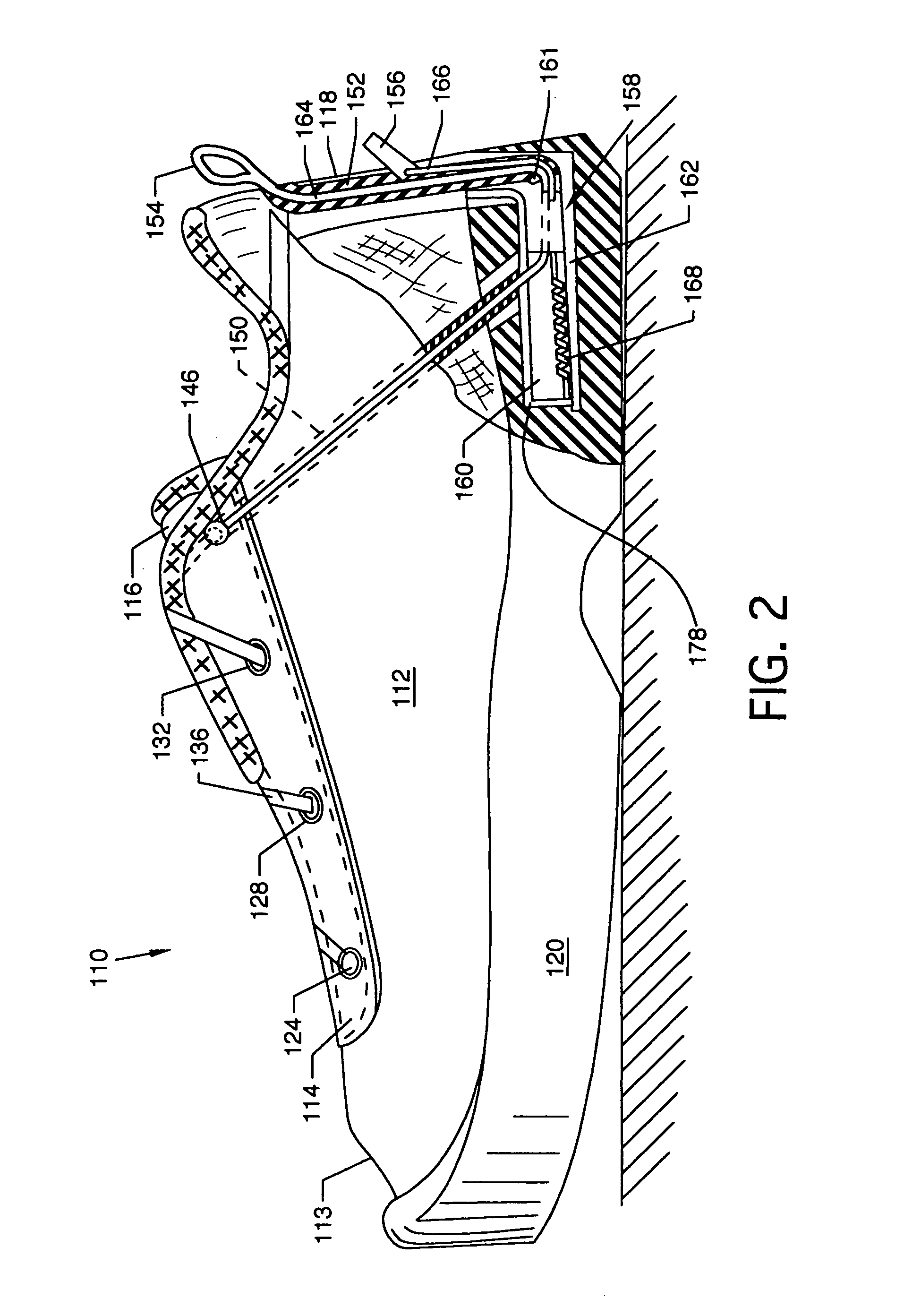

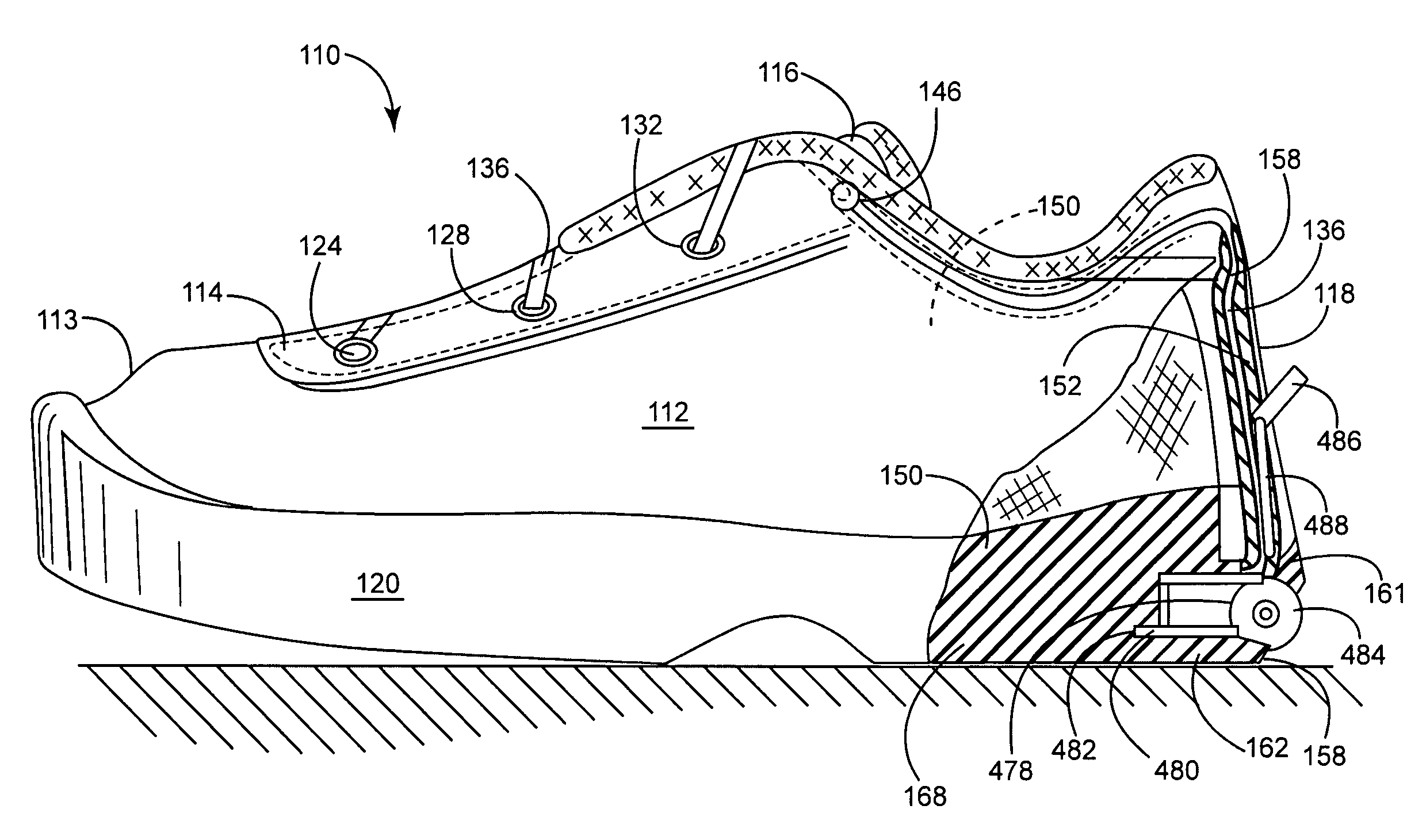

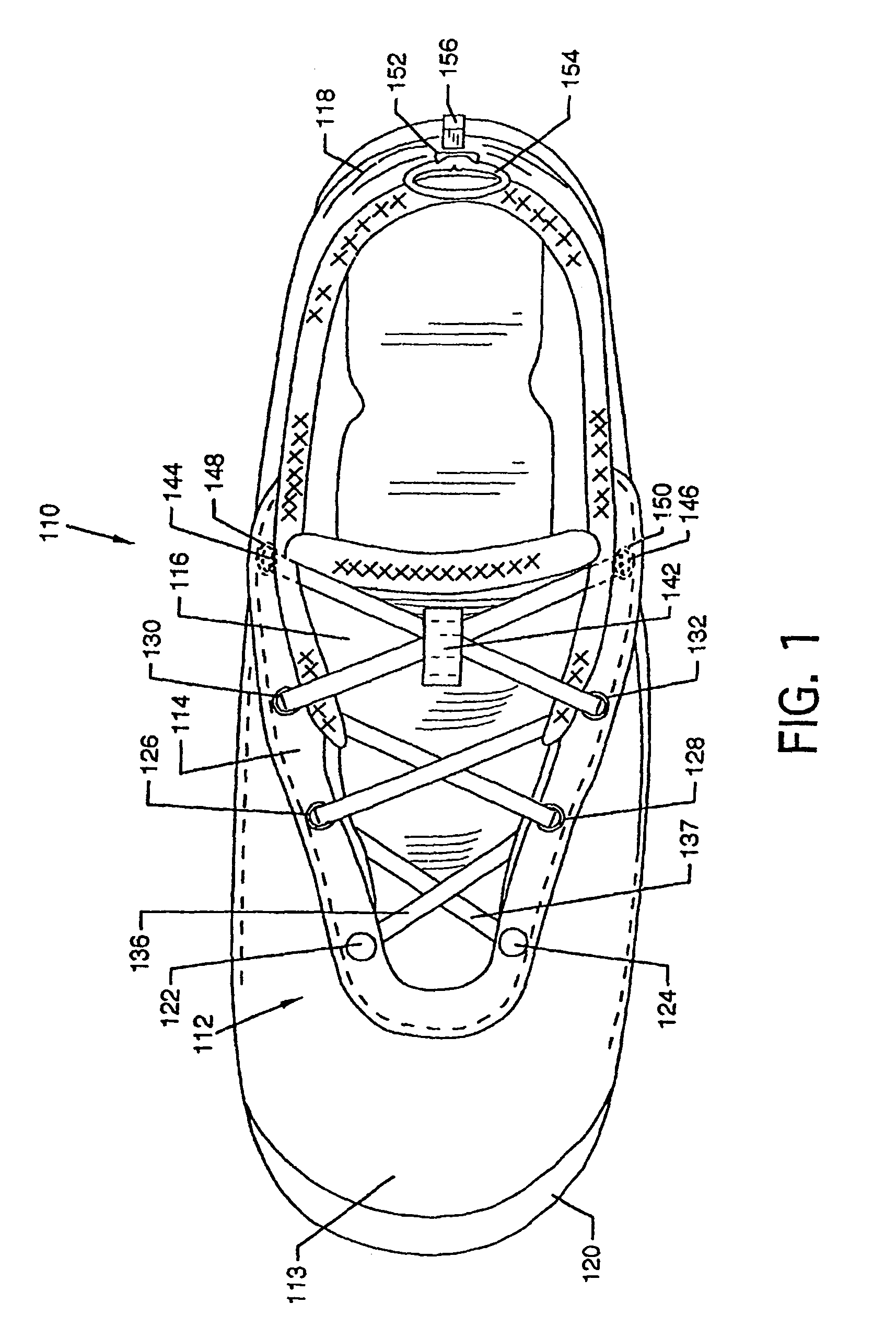

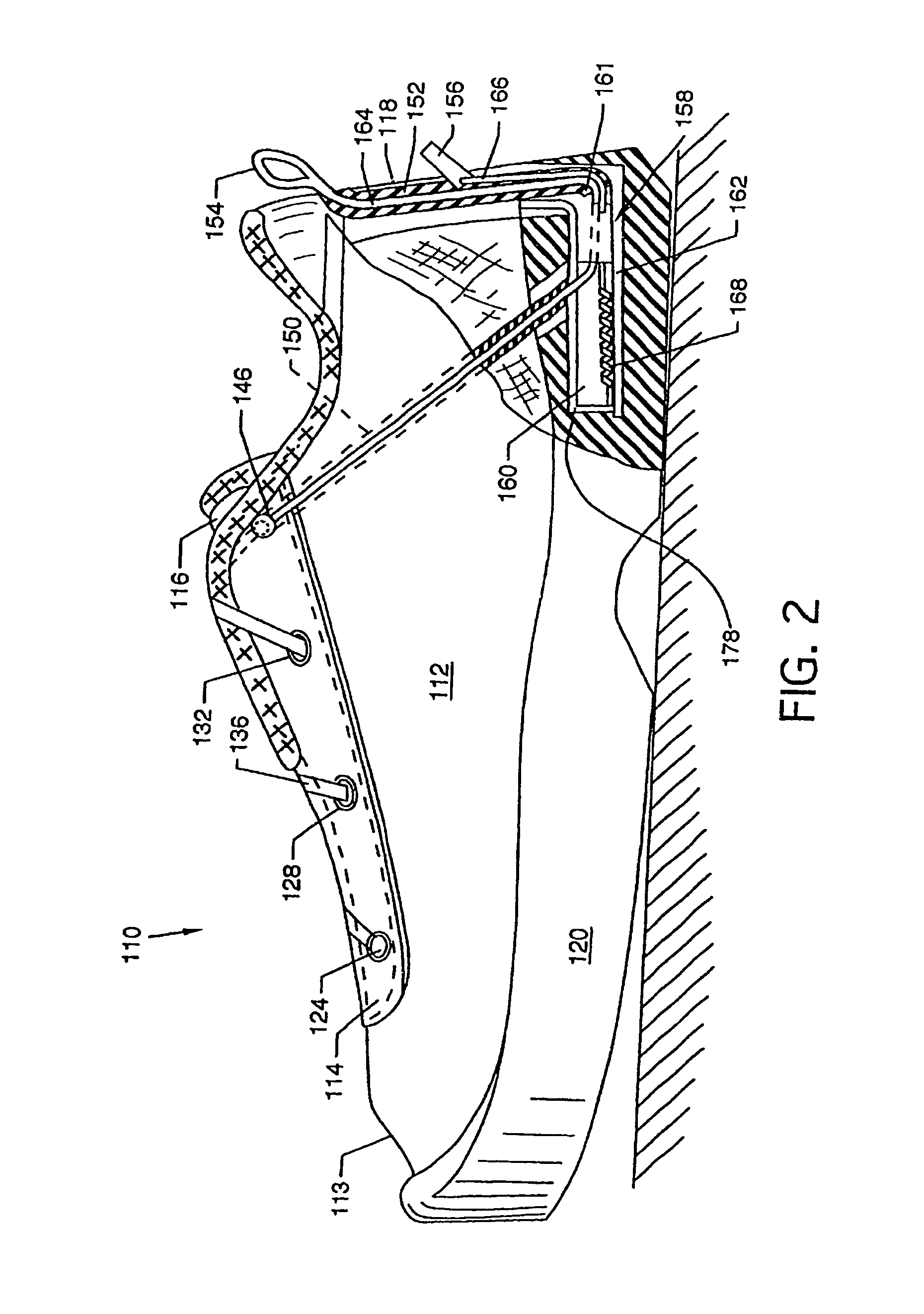

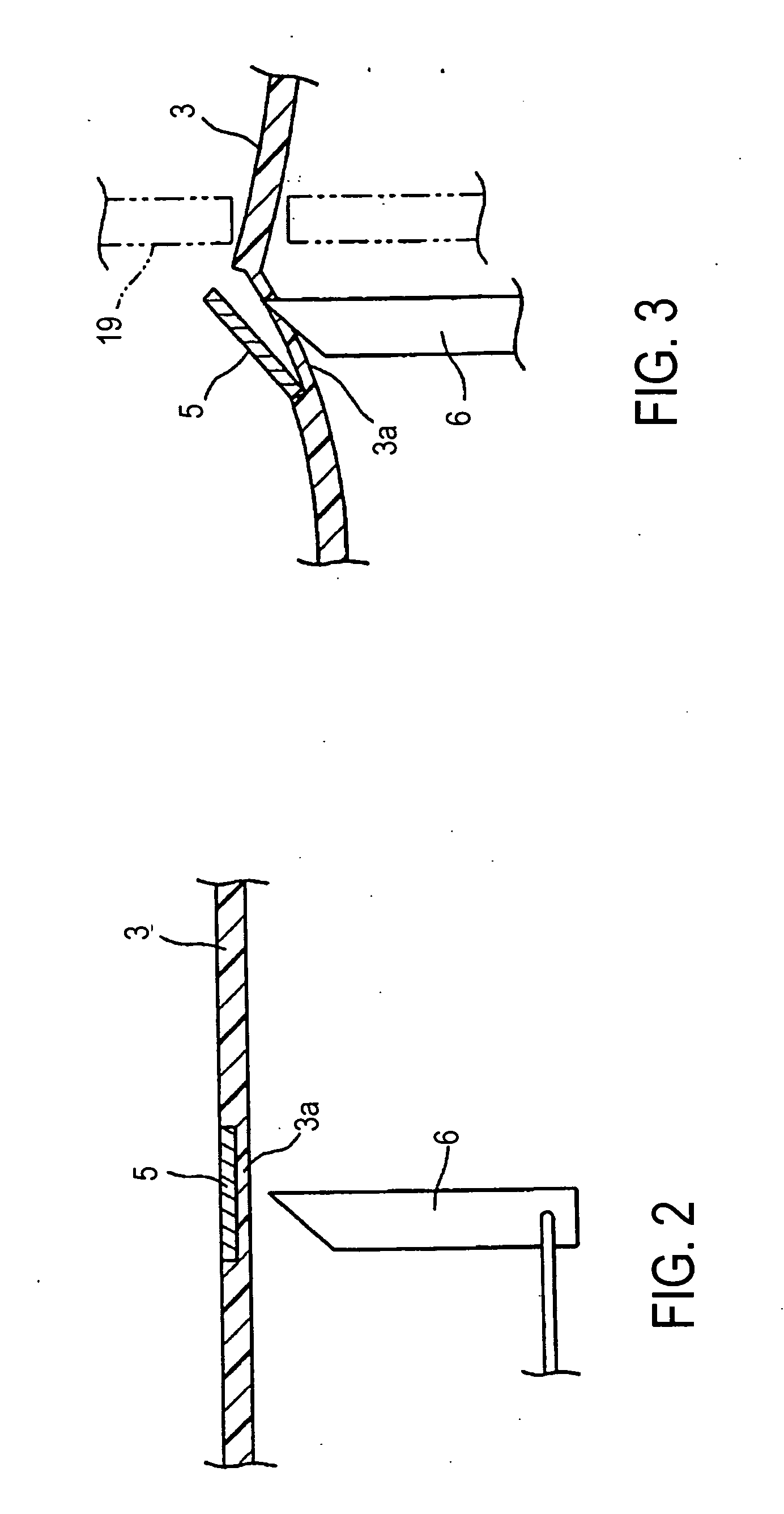

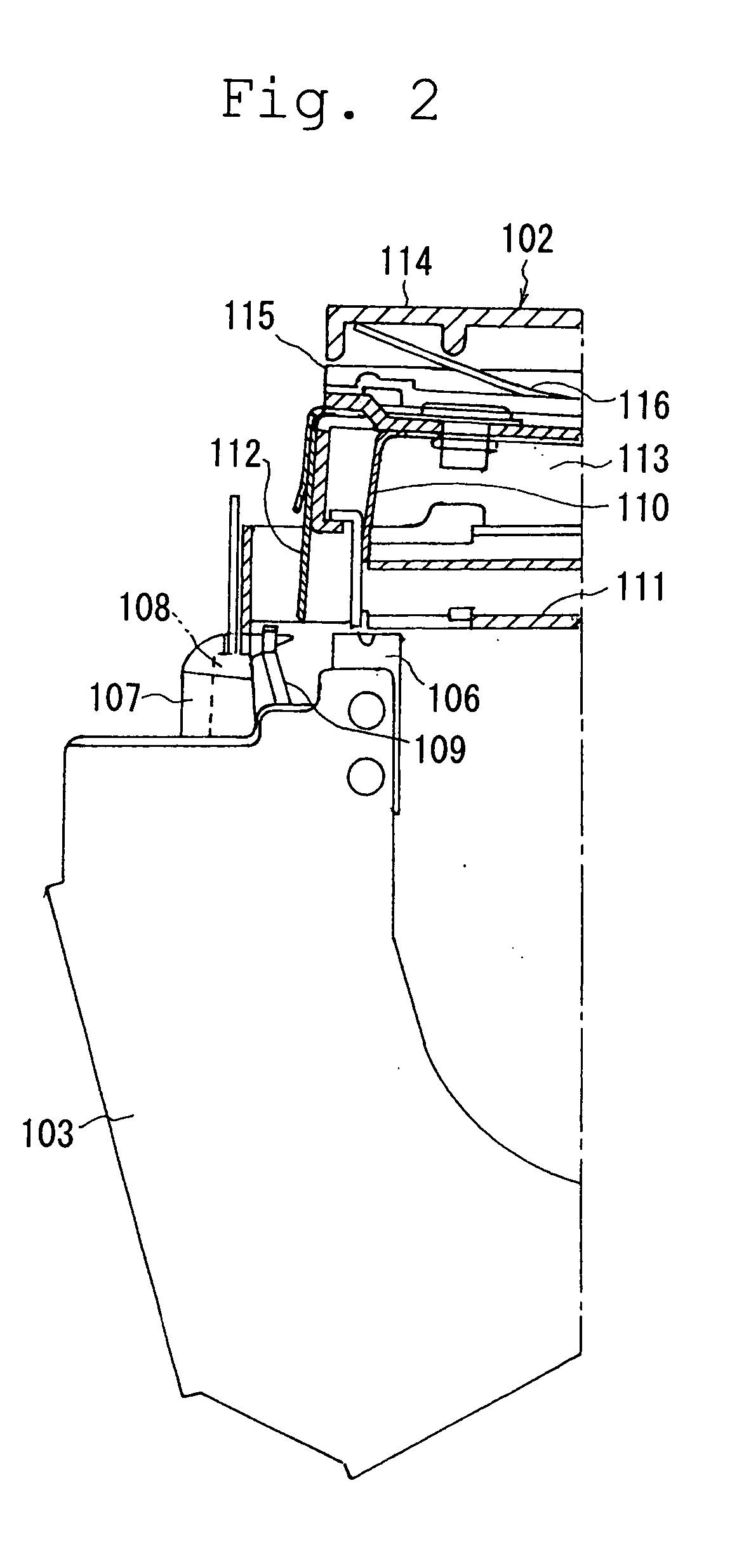

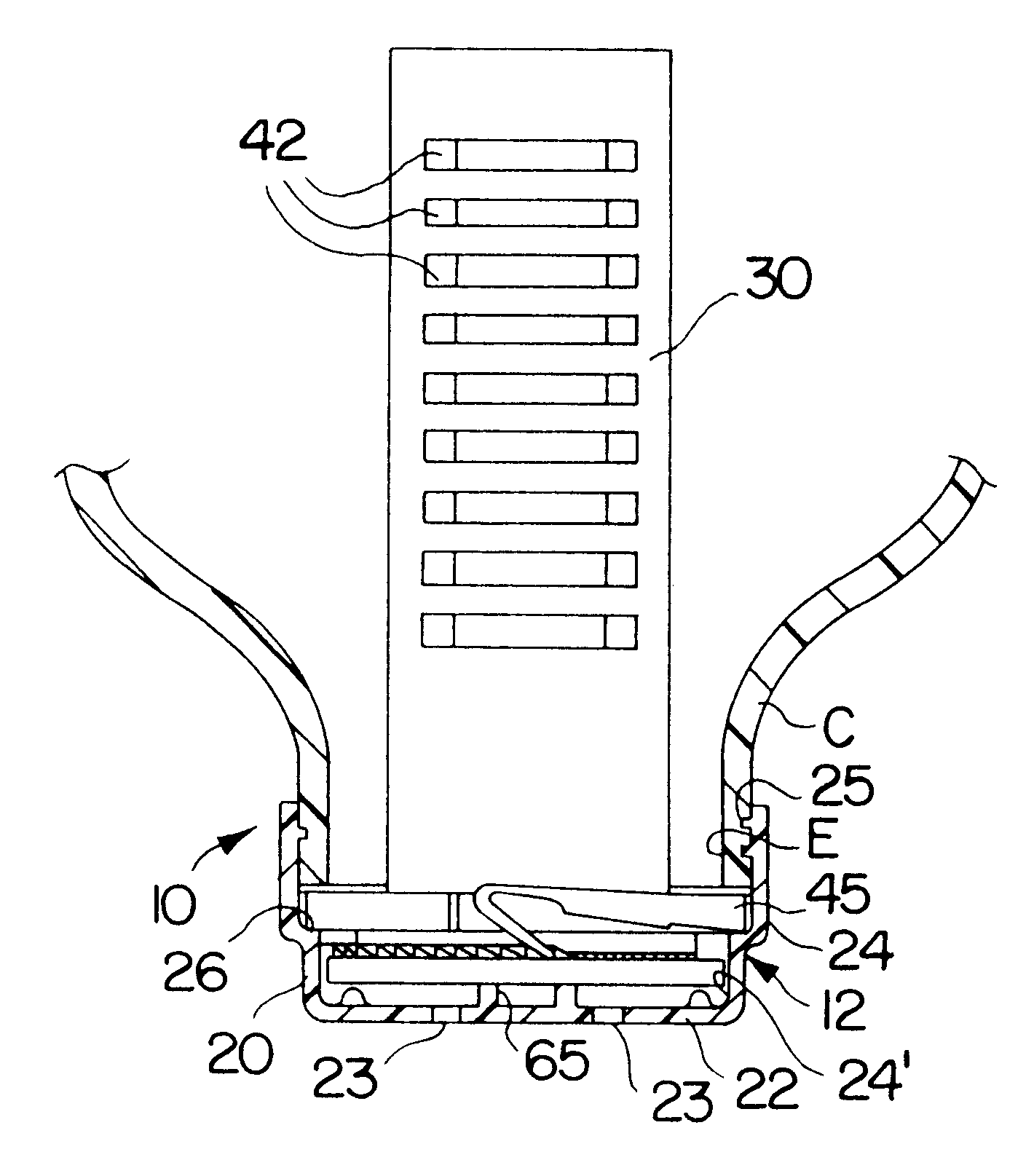

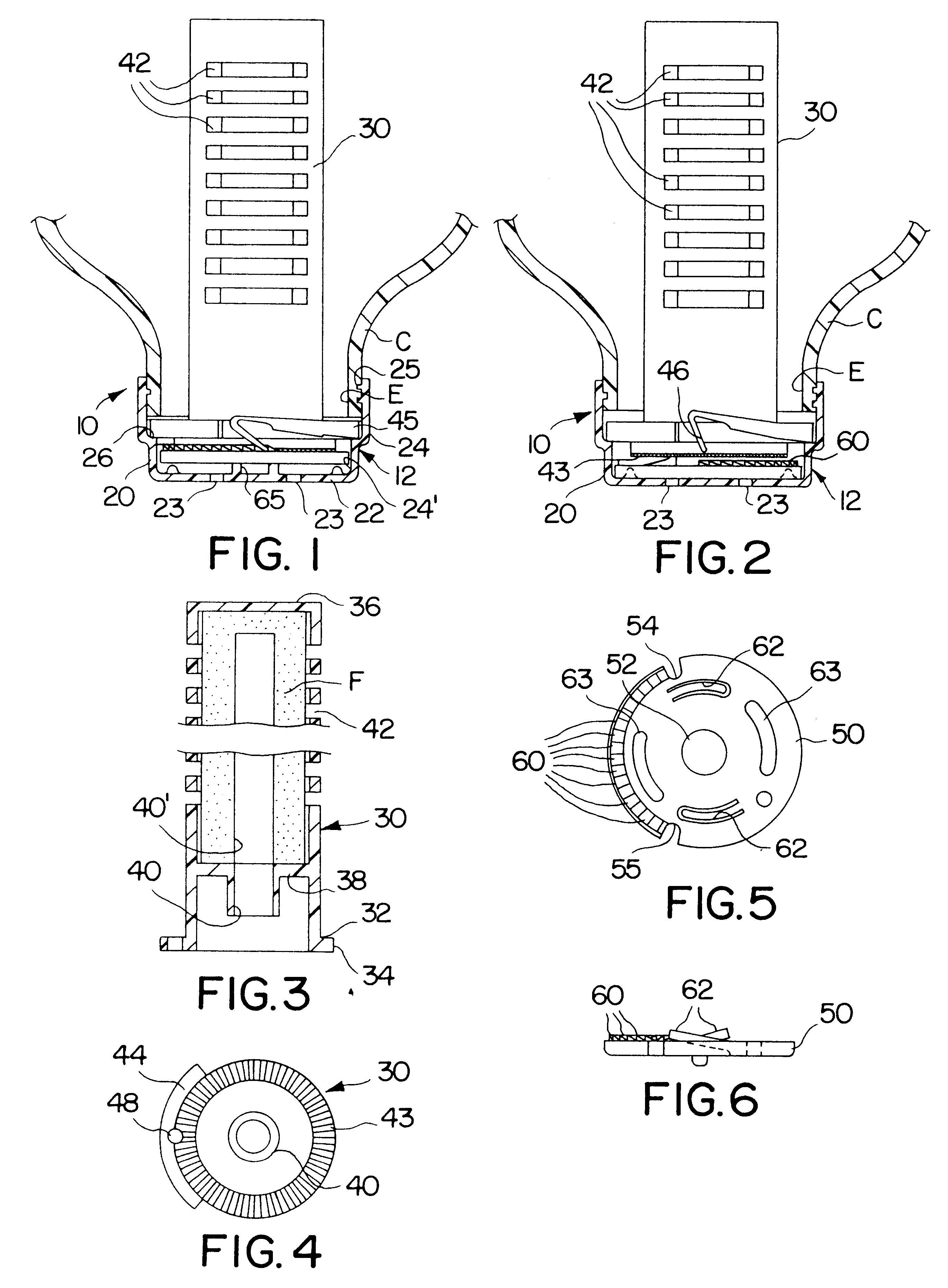

Automated tightening shoe

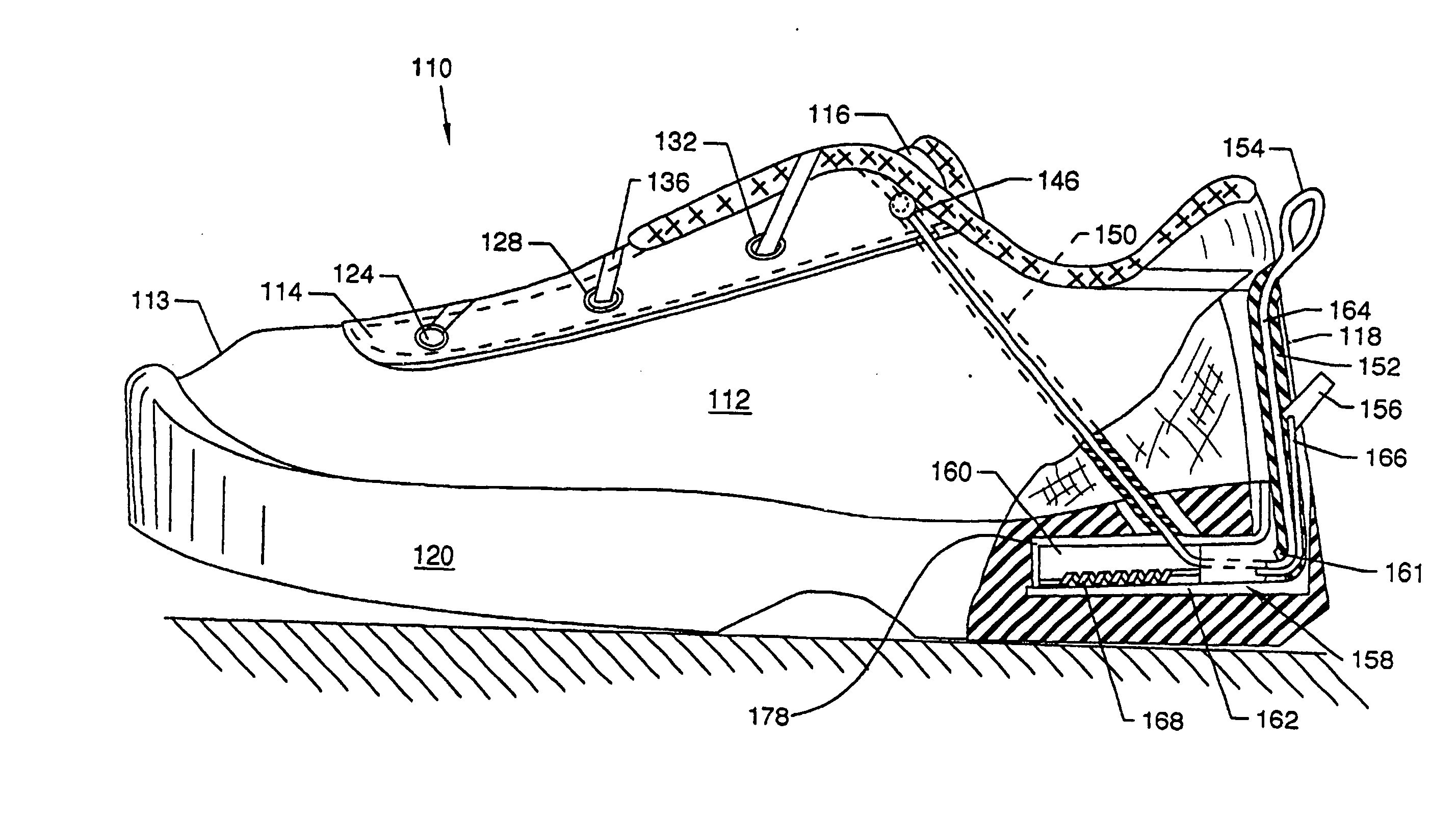

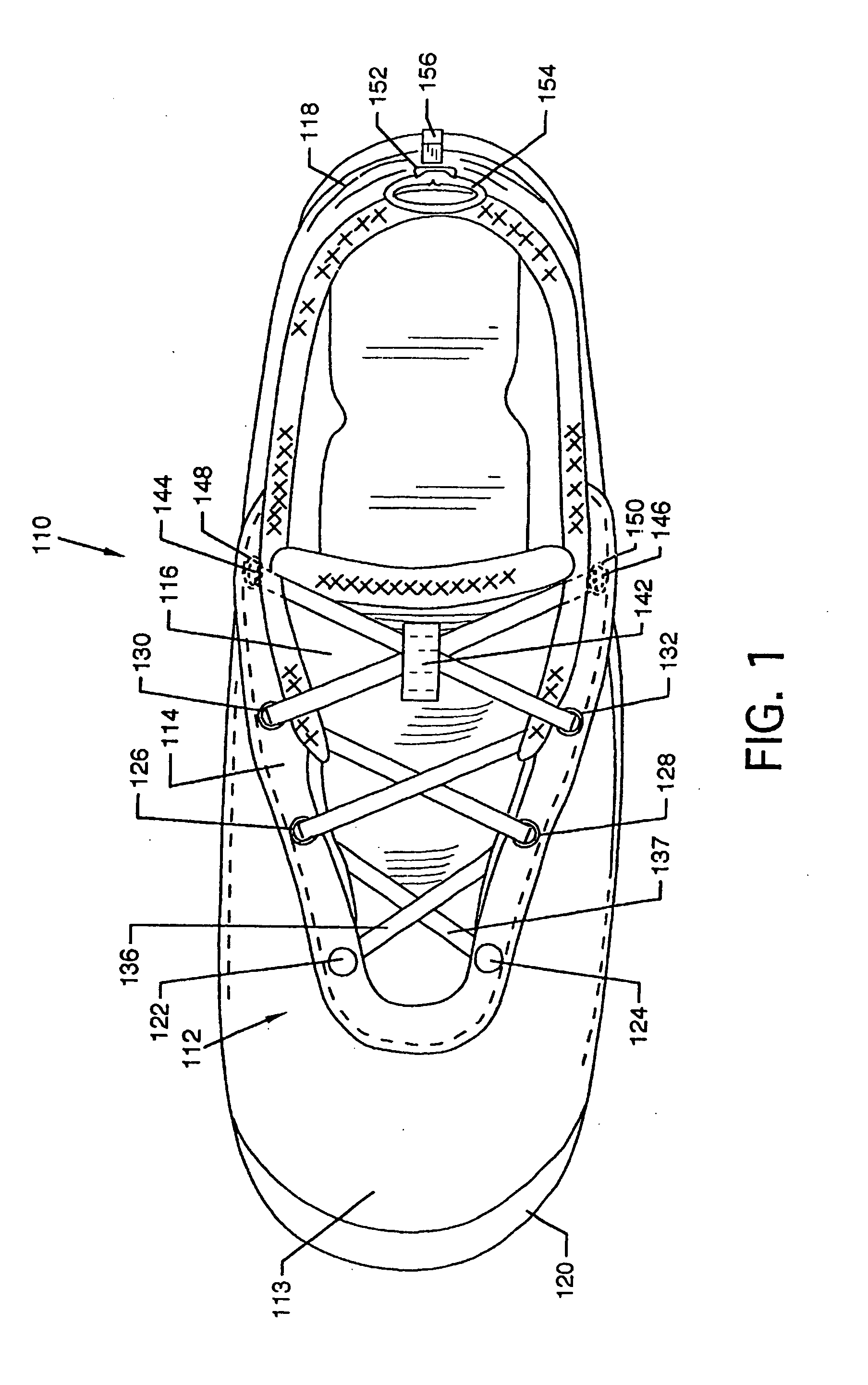

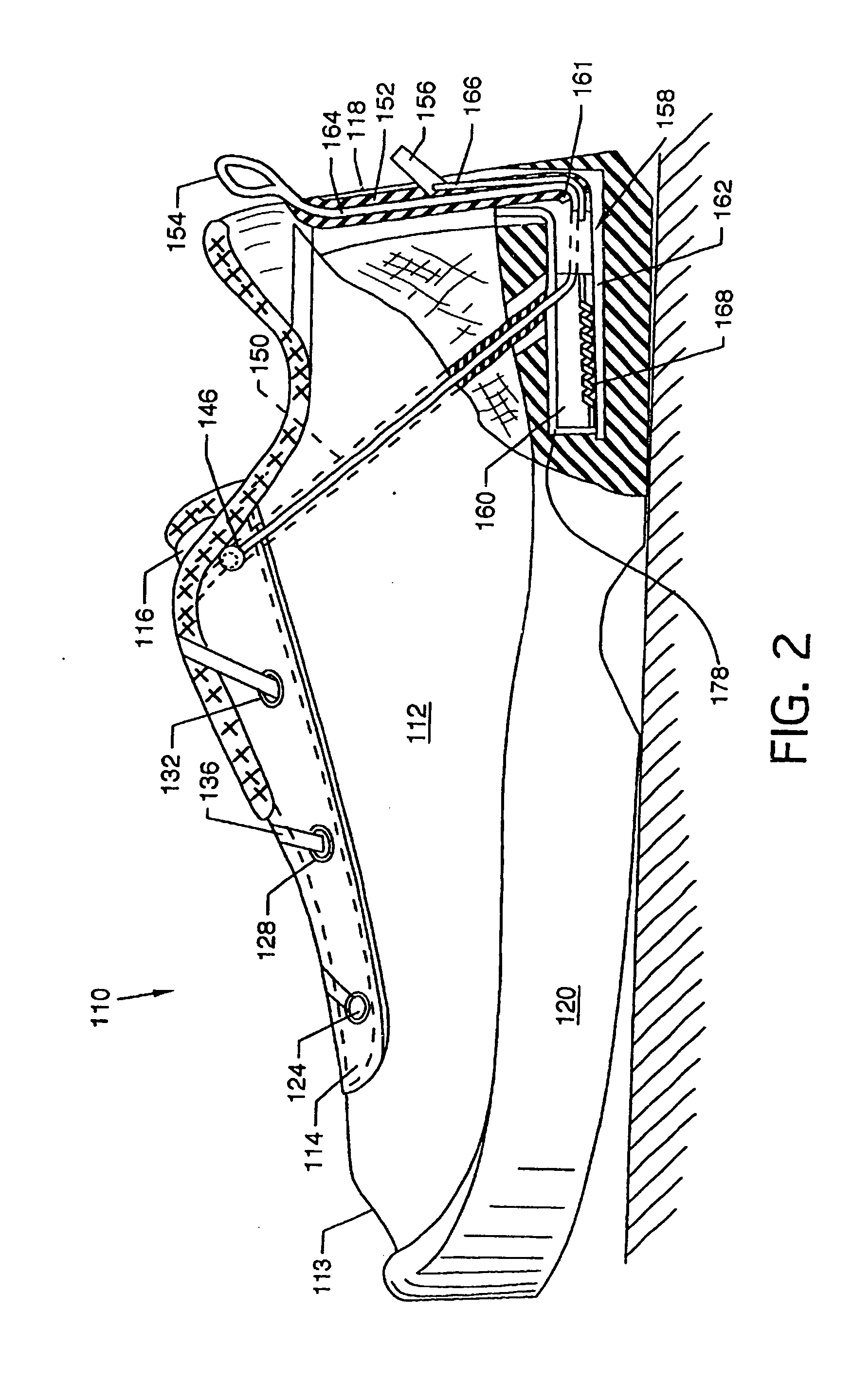

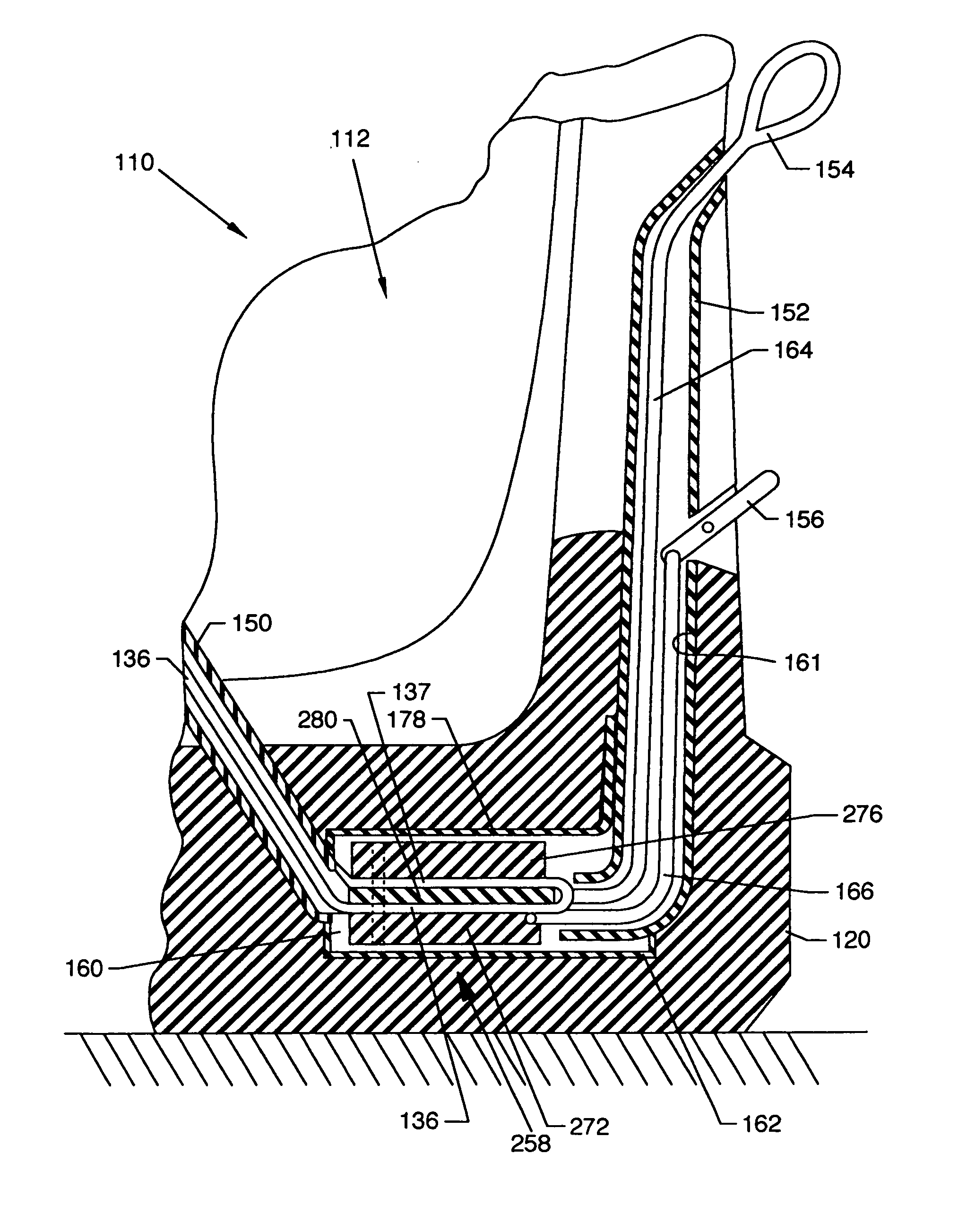

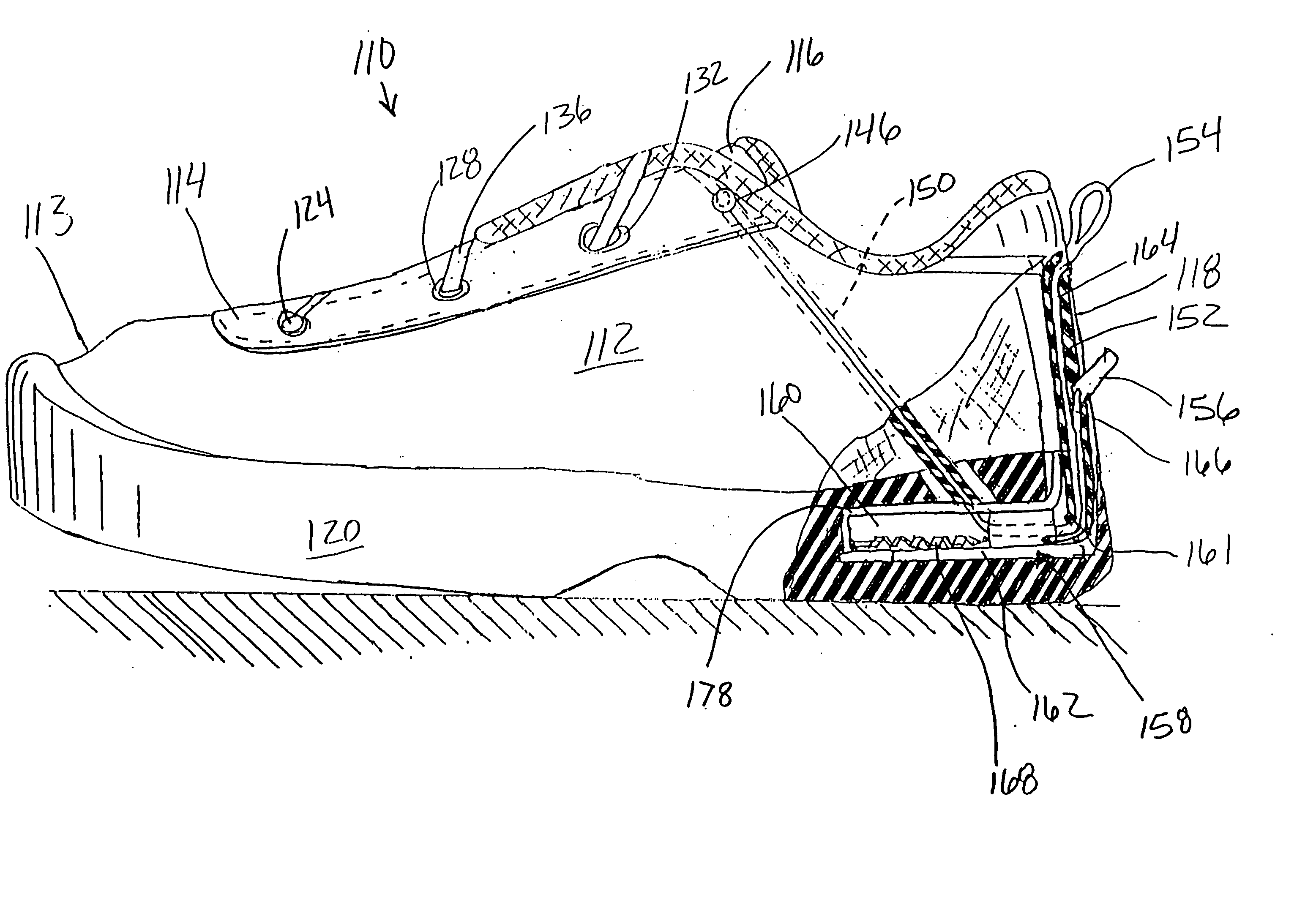

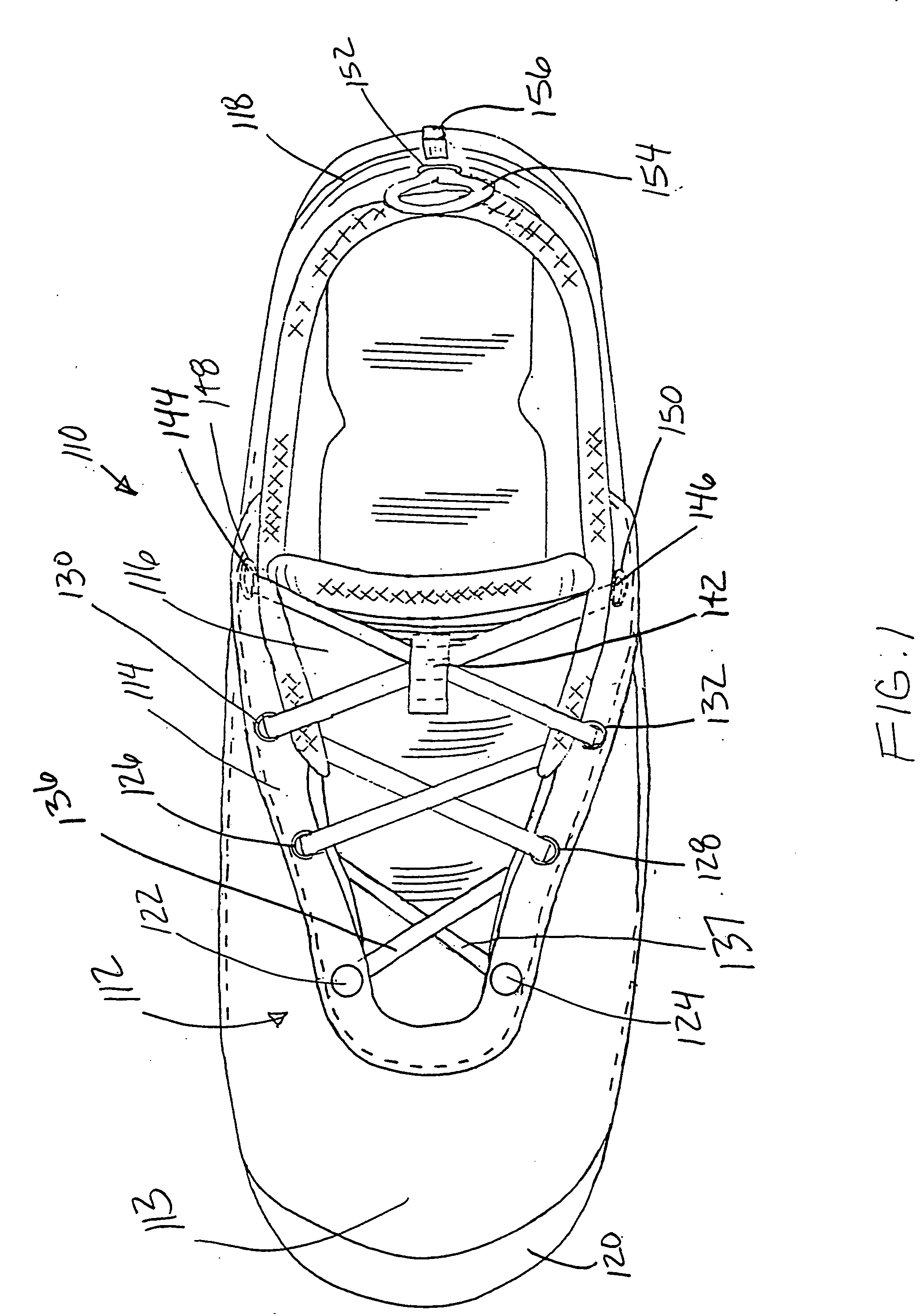

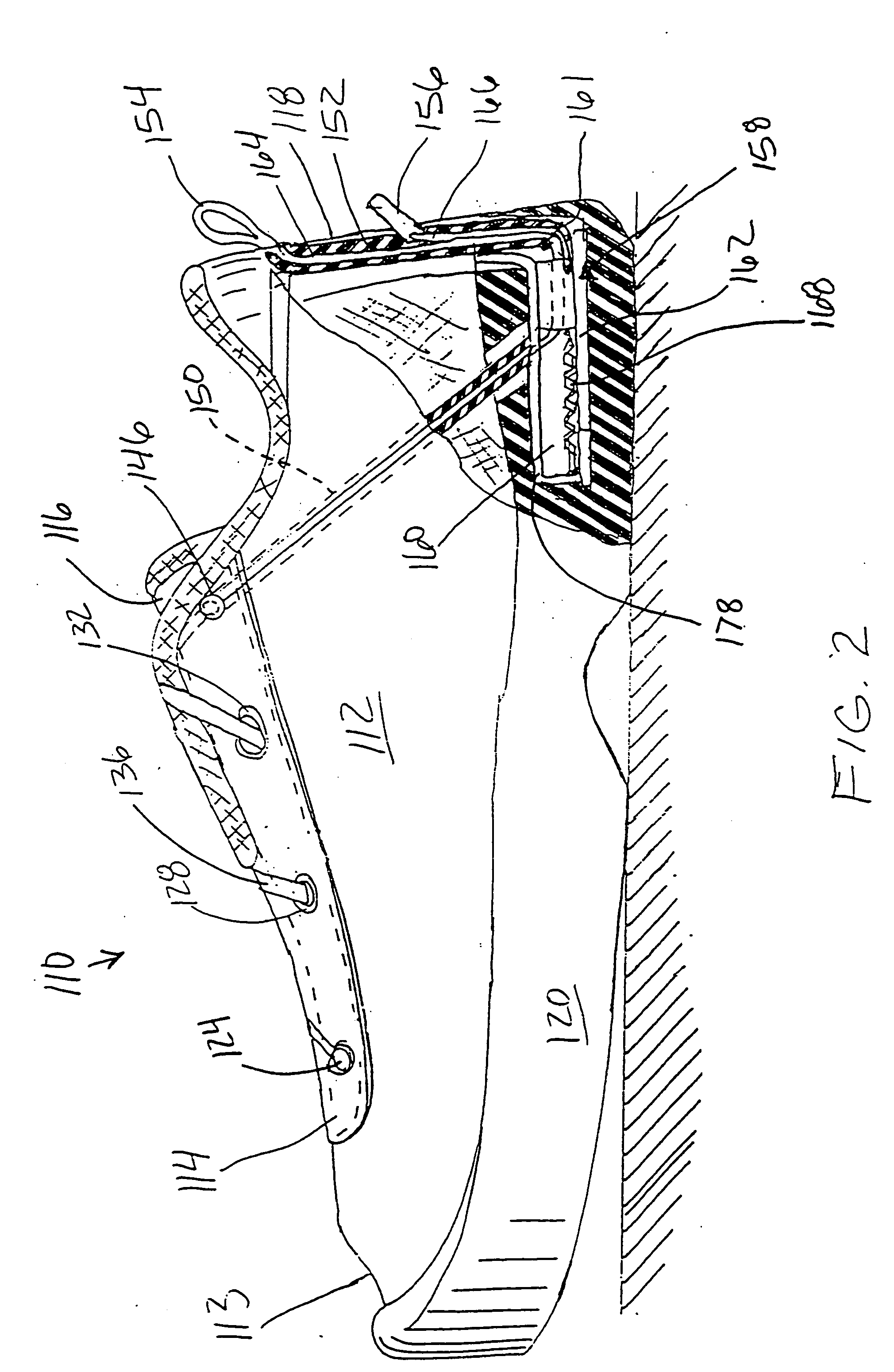

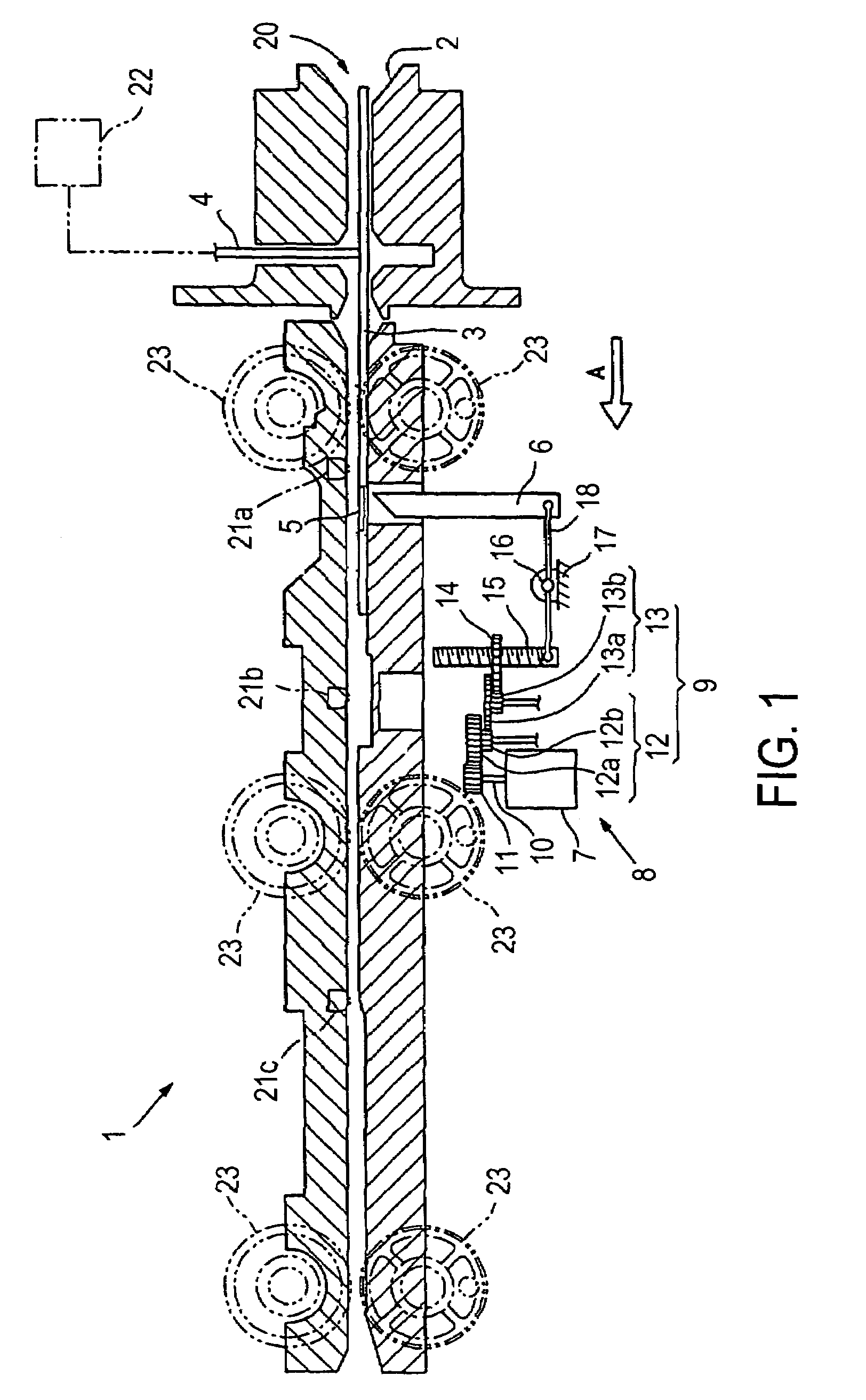

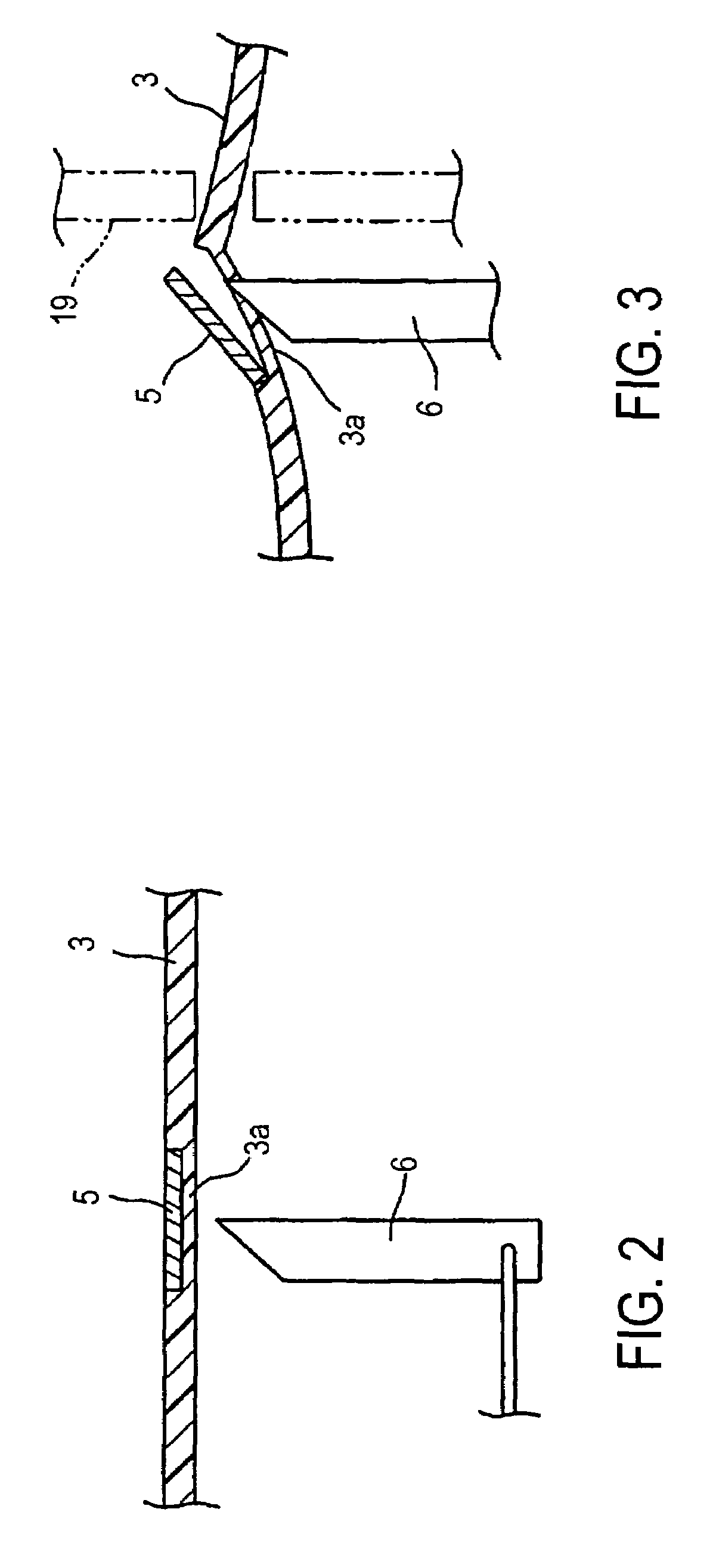

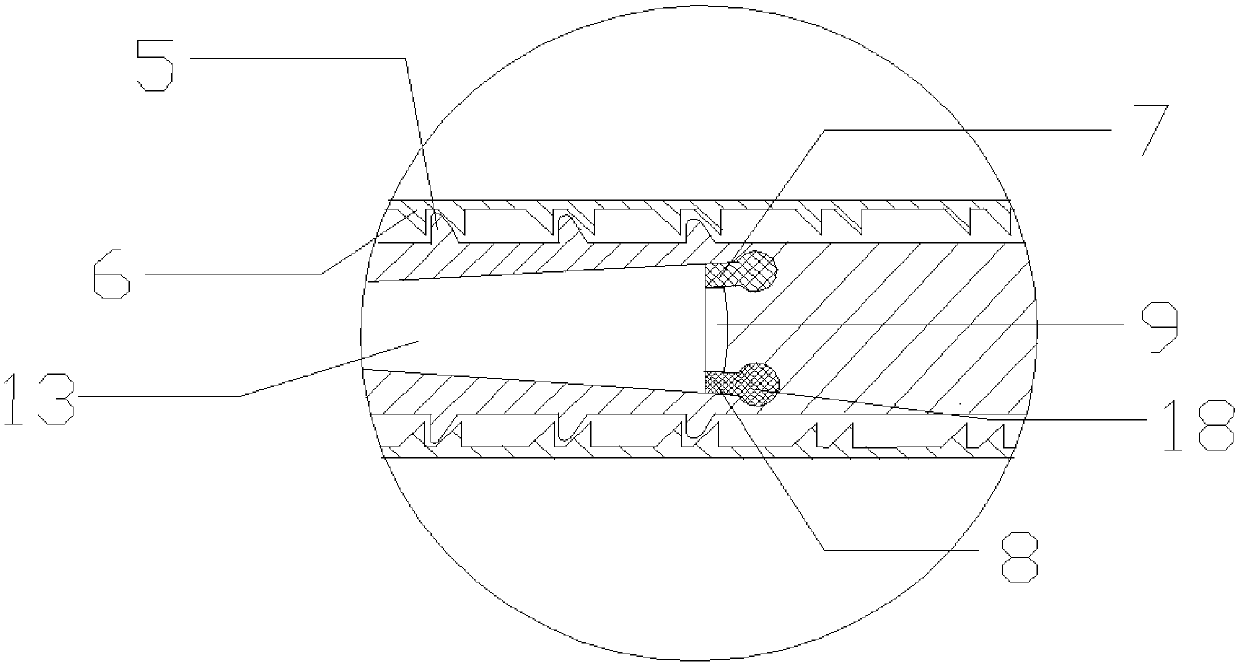

InactiveUS20060053659A1Avoid reverse motionEasy to operateSolesShoe lace fasteningsLocking mechanismShoe laces

An automated tightening shoe is provided where a tightening mechanism operates to cause automatic tightening of the shoe laces about a wearer's foot and which releases the laces to allow loosening of the shoe. The shoe laces travel to the interior of the tightening mechanism located at the heel whereat the laces are operatively associated in a tightening or a loosening direction with the tightening mechanism. The tightening shoe further has a locking mechanism for locking said at least one lace in a tightened condition and a release mechanism for unlocking the locking mechanism and releasing the shoe laces. The release mechanism includes a lever arm which projects rearwardly from the rear of said shoe. Depression upon the lever arm causes the locking mechanism to unlock and release the shoe laces from being in a tightened condition.

Owner:HANDS FREE ENTERPRISES LLC

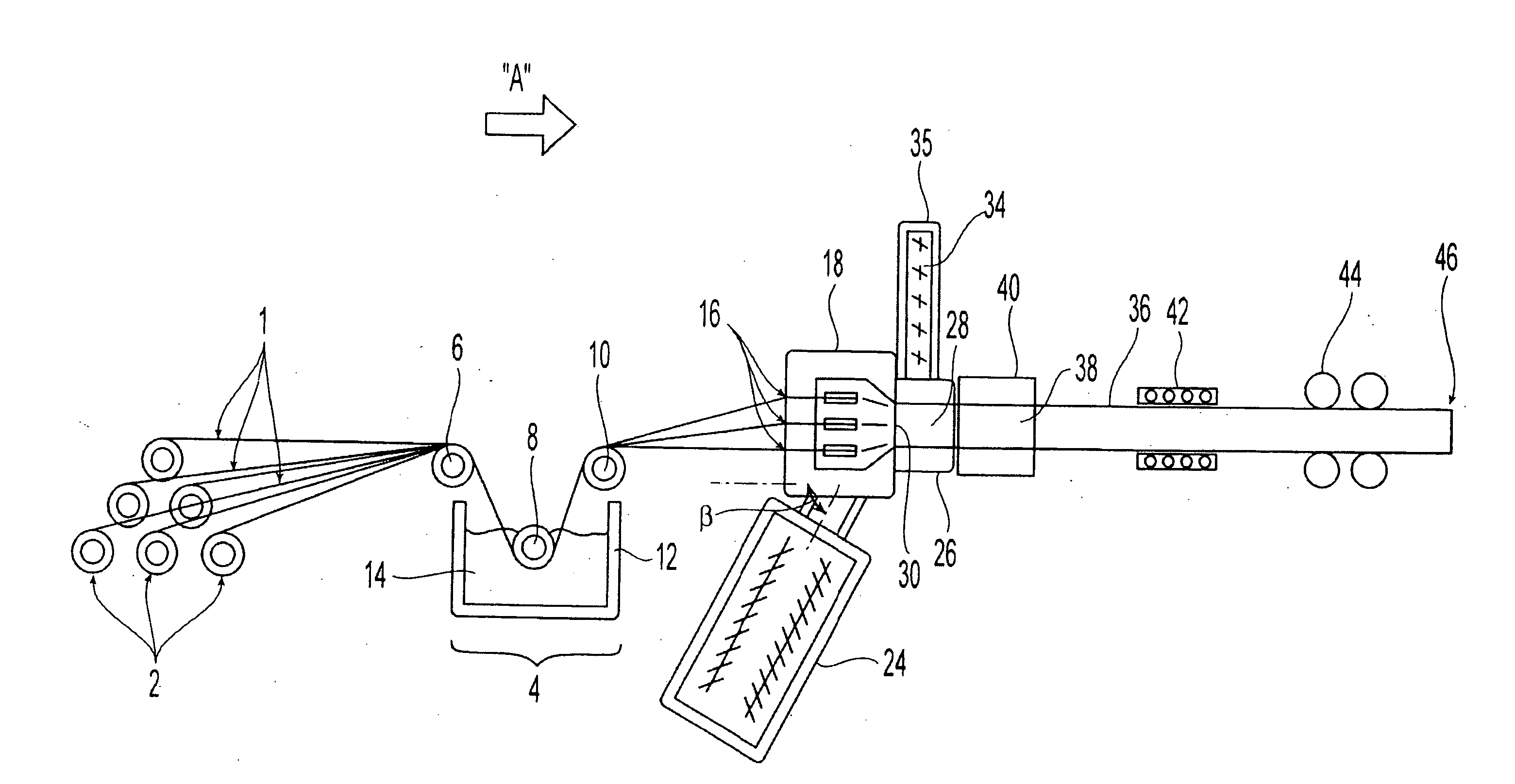

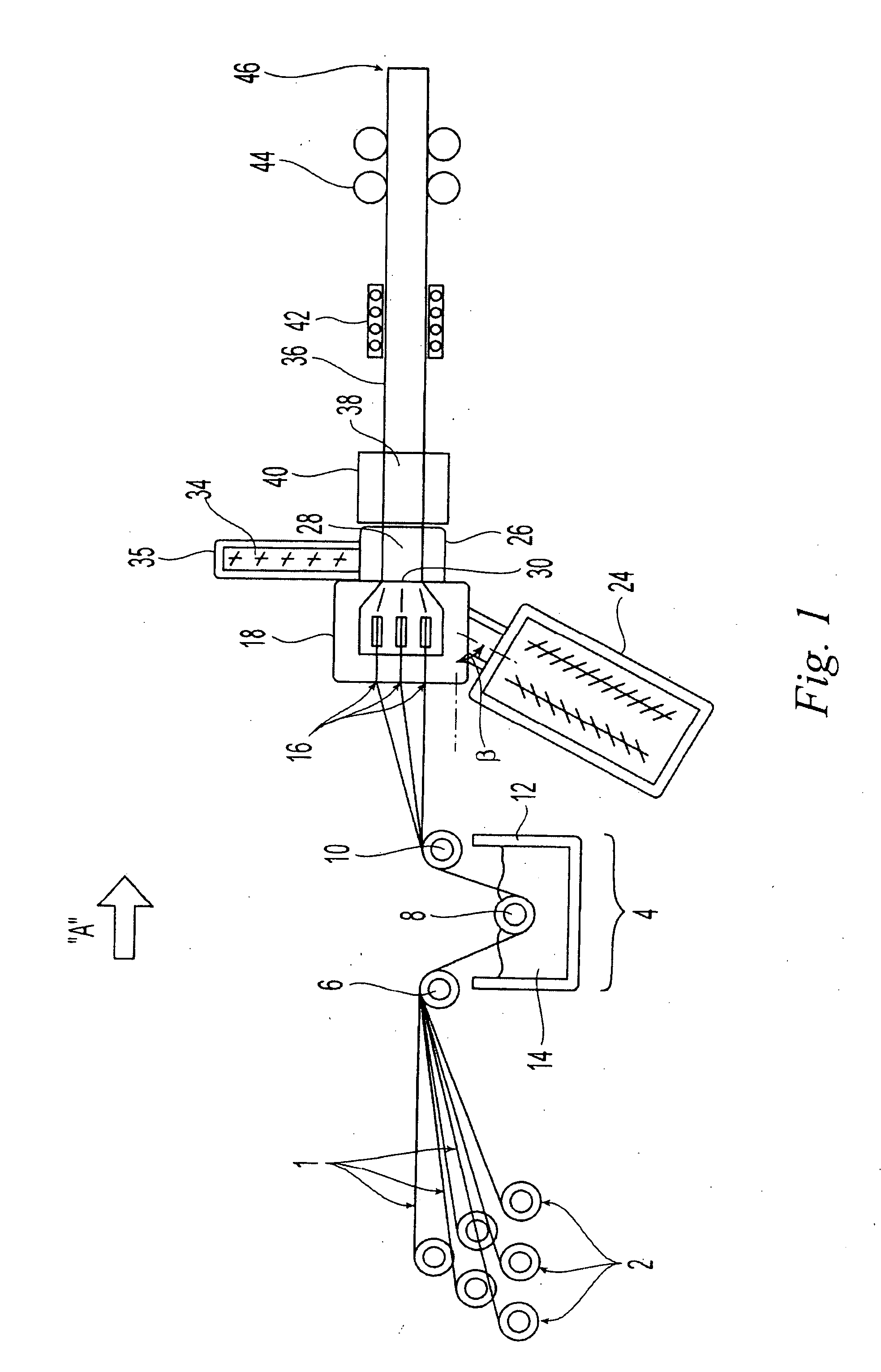

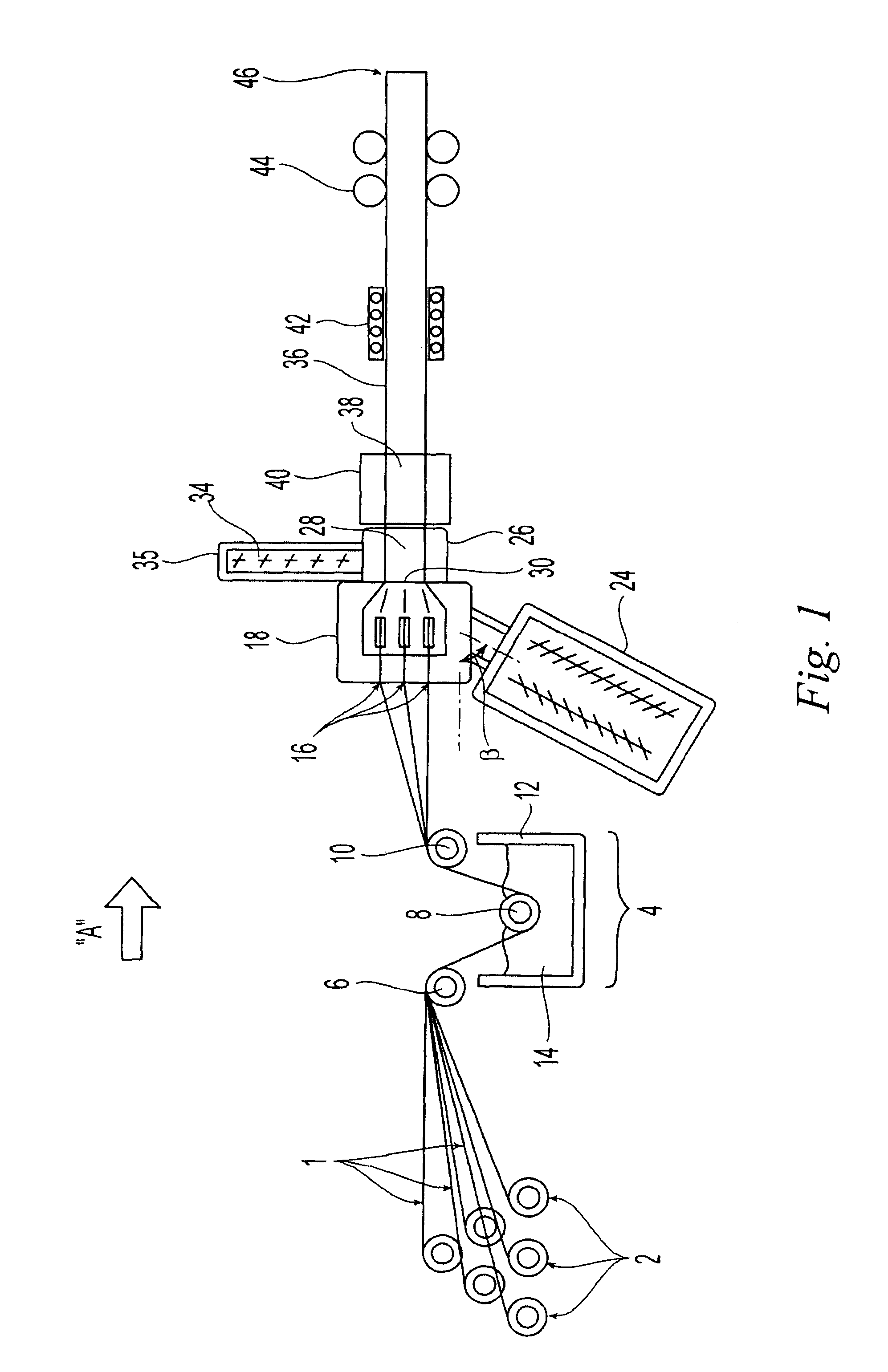

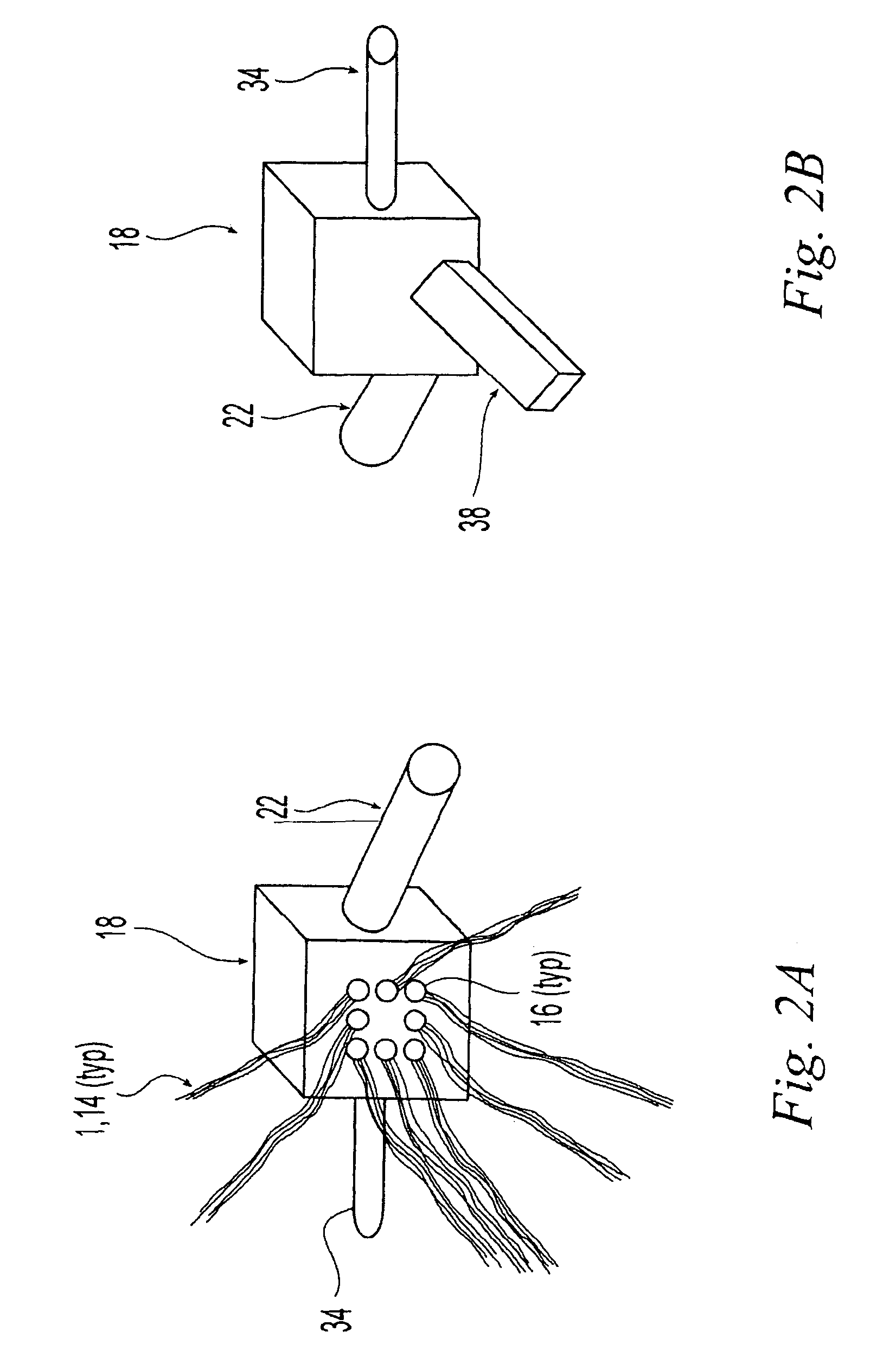

System and die for forming a continuous filament reinforced structural plastic profile by pultrusion/coextrusion

InactiveUS20070125301A1Reinforced thermoplasticAvoid reverse motionLiquid surface applicatorsConfectioneryThermoplasticPolymer science

A system and method are disclosed for producing a continuous filament reinforced thermoplastic profile having consistent cross section. A continuous reinforcing filament is pre-wetted with a first thermoplastic resin and introduced into a die, where it is contacted with a second thermoplastic resin extruded from an extruder at melt state. The temperature of the die is carefully controlled so that the pre-wetted filament and first resin do not cure or solidify until after they have contacted and mixed with the second thermoplastic resin. The mixture temperature is then controlled to make a substantially solidified profile pre-shape. A capping layer comprising a third thermoplastic resin is then coextruded onto the outer surface of the pre-shape. A multistage die for bringing together the filament and thermoplastic resins and for maintaining appropriate temperatures at each stage of the profile-forming process is also disclosed.

Owner:SAINT GOBAIN PERFORMANCE PLASTICS CORP

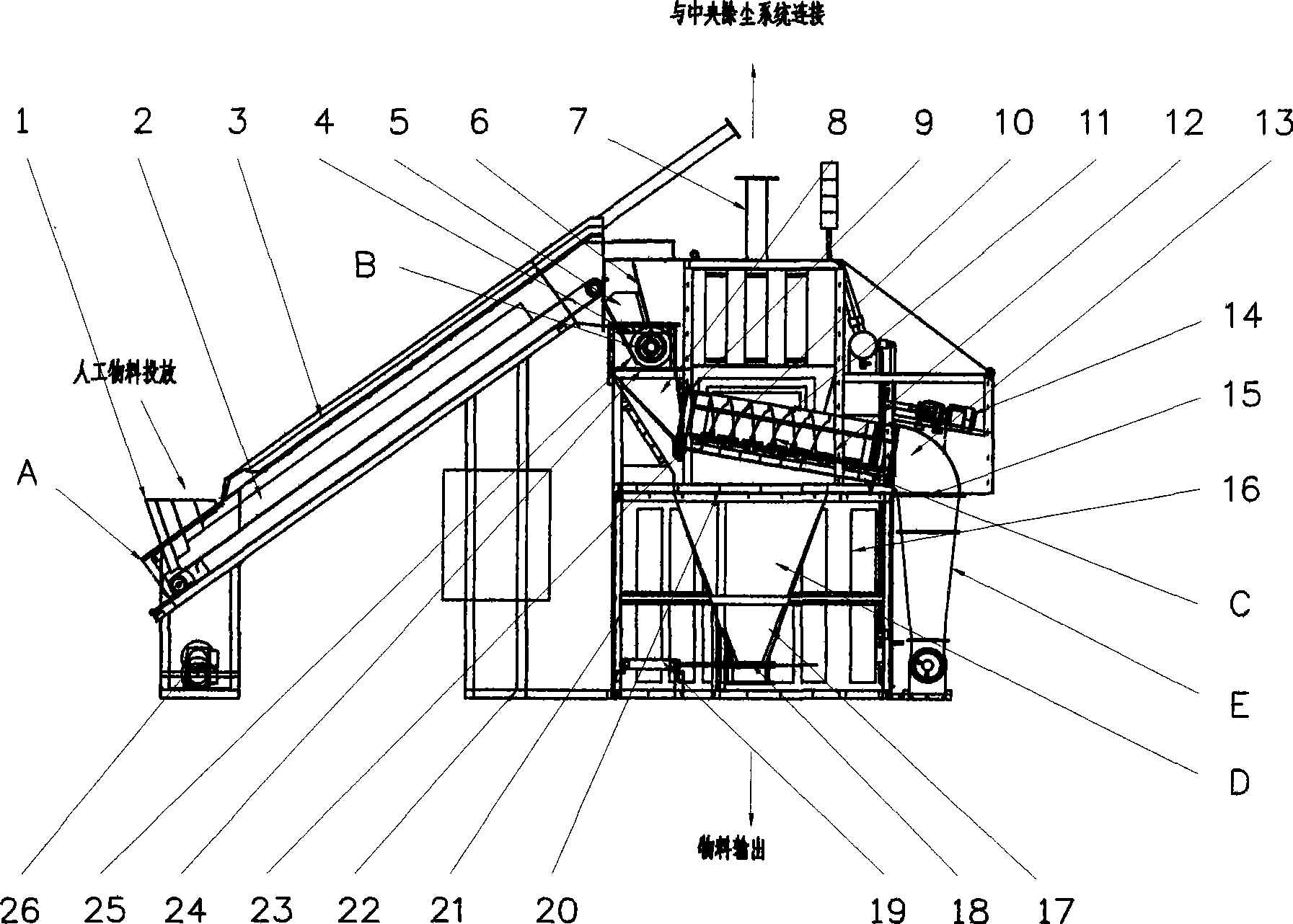

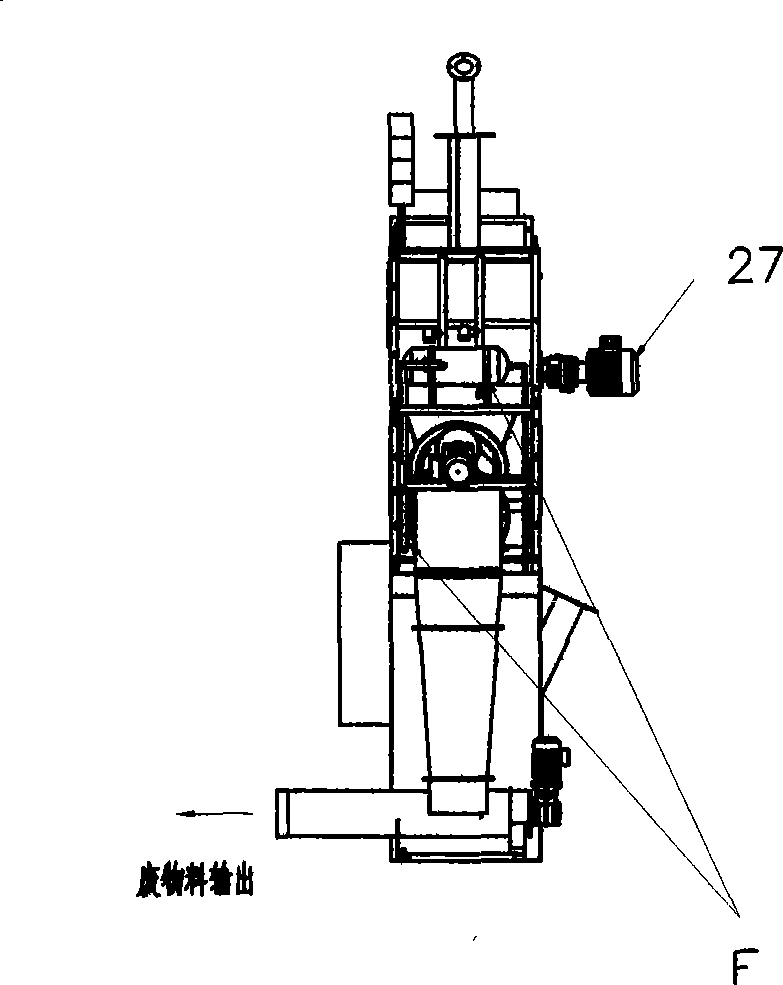

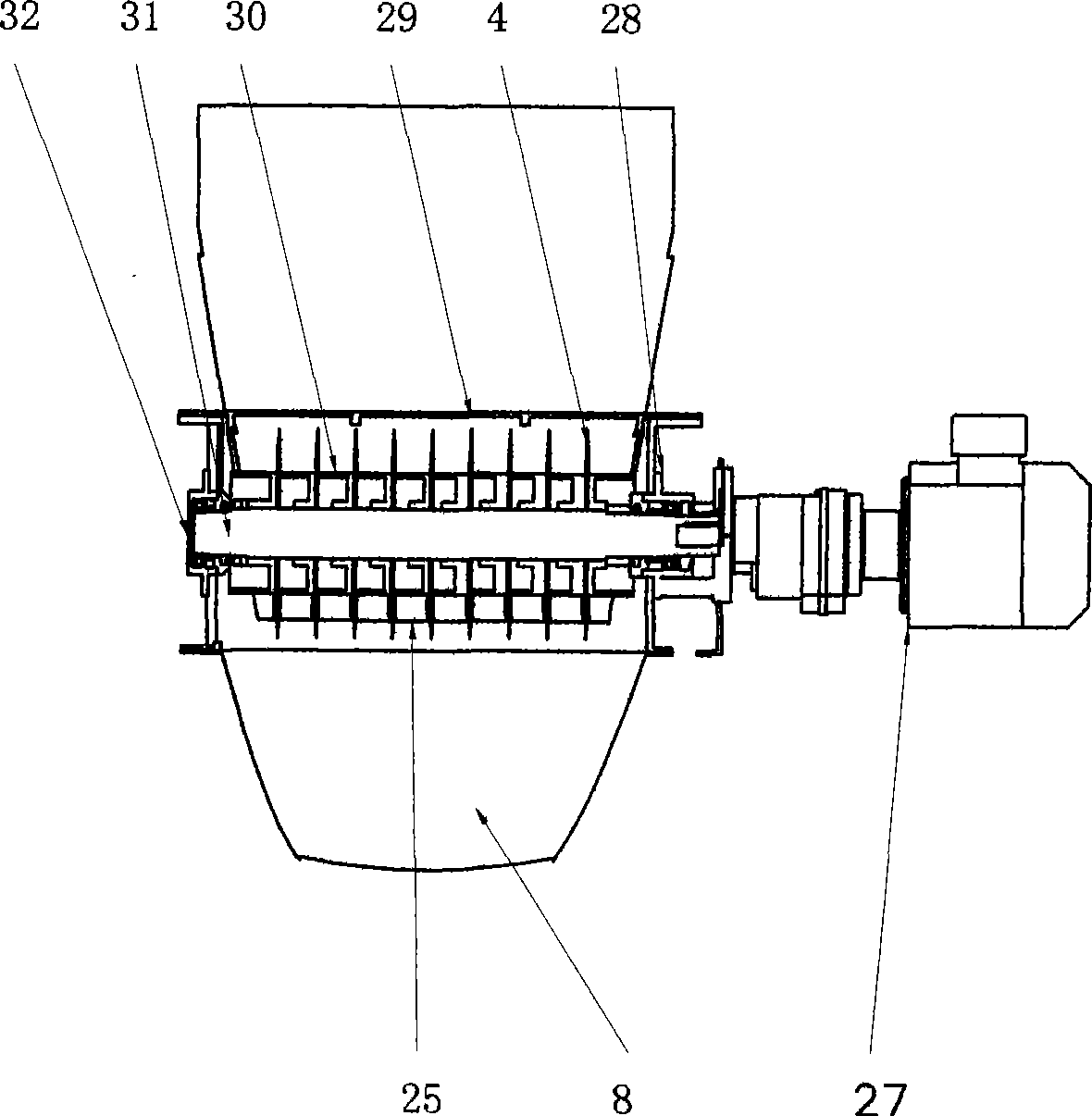

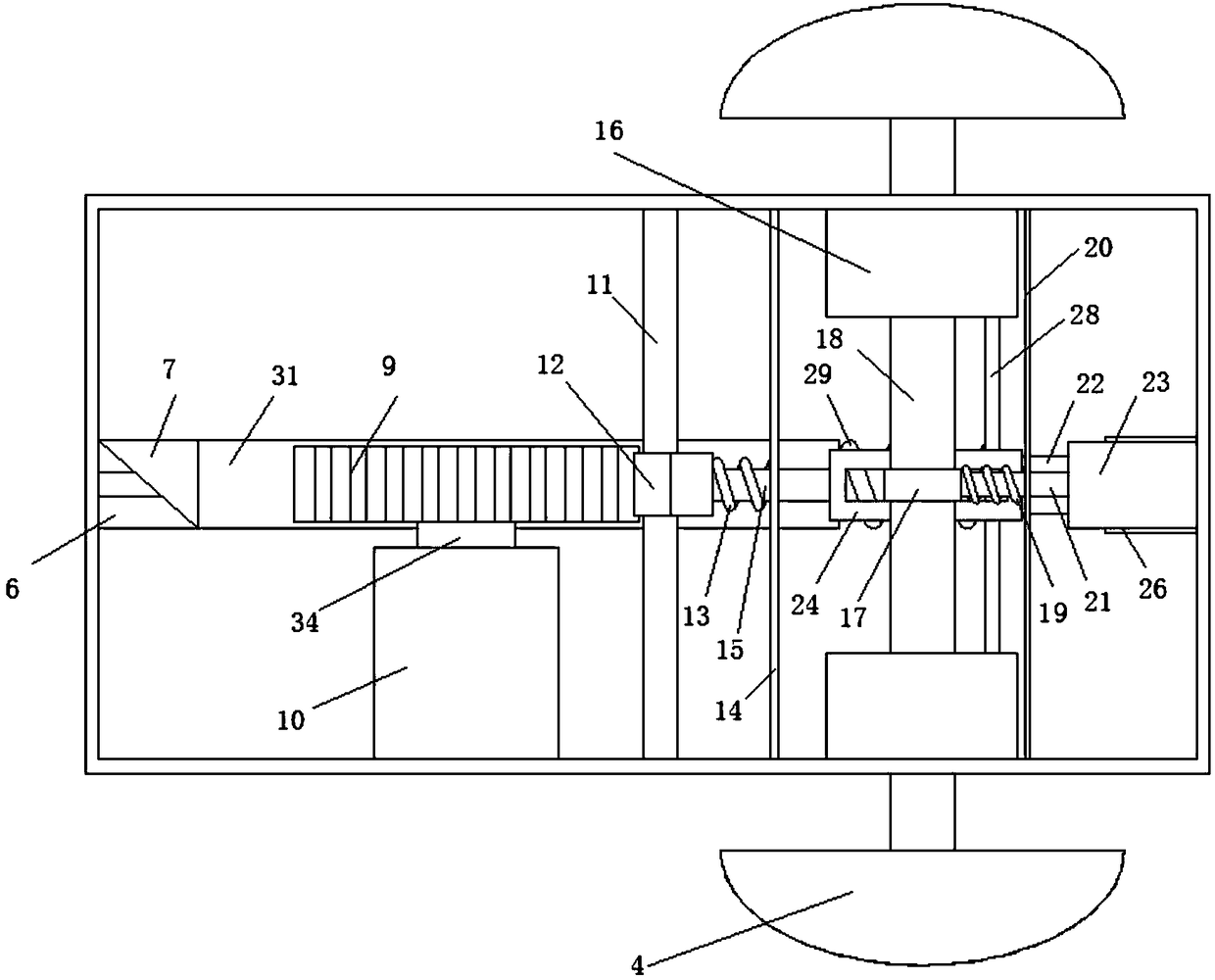

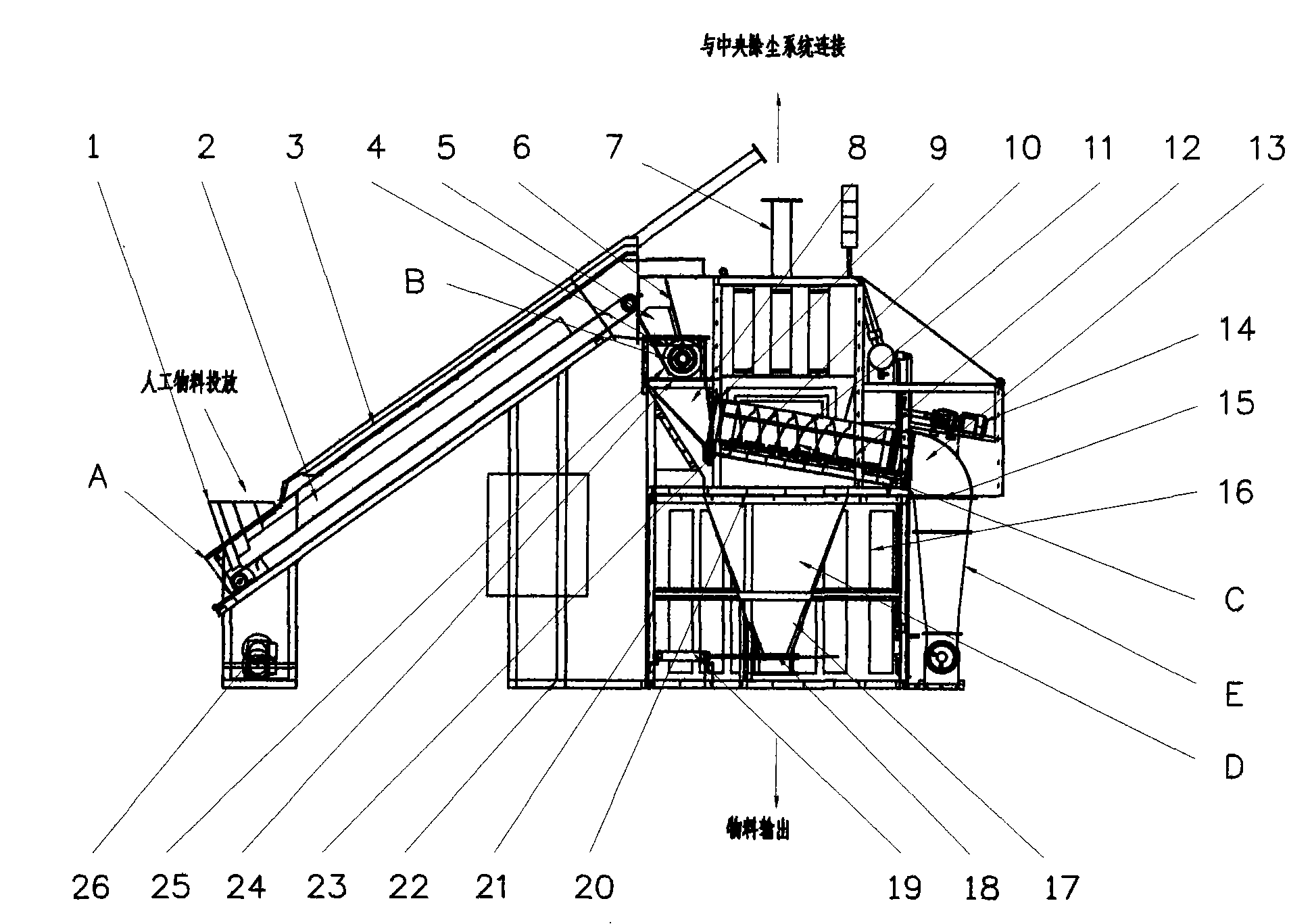

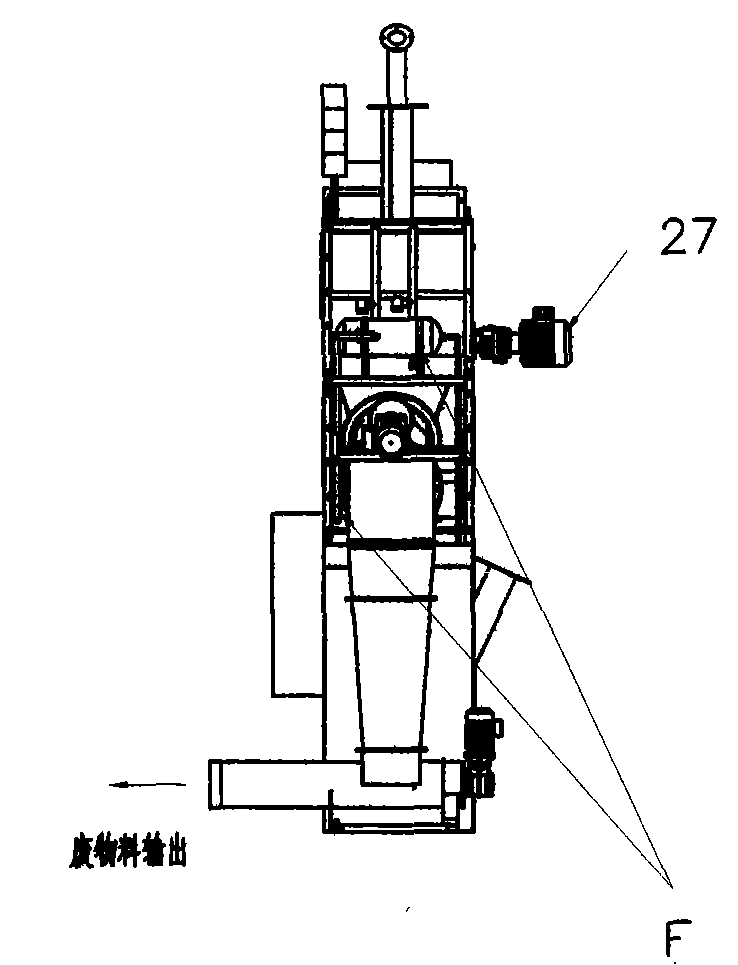

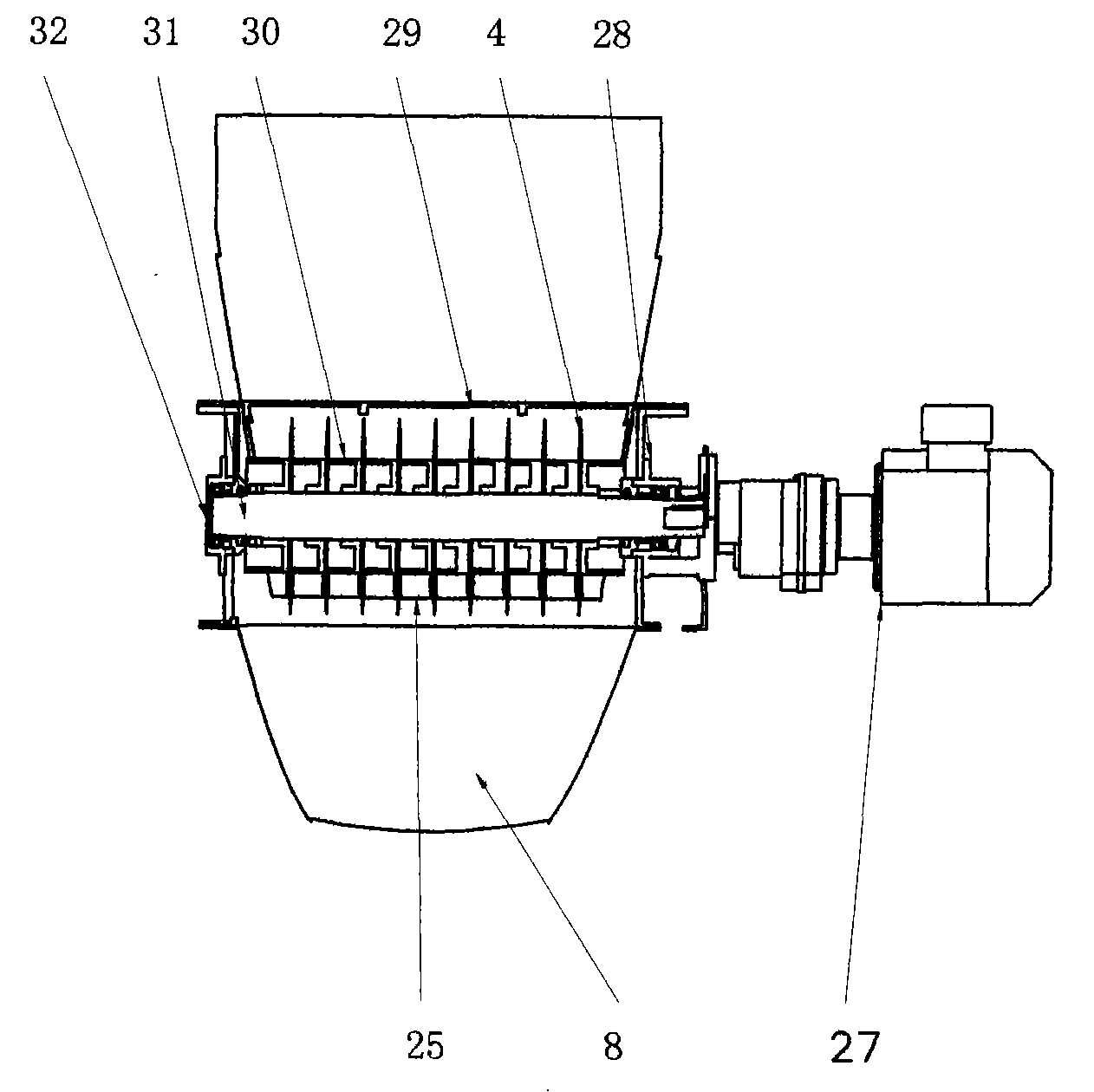

Full automatic unpacking unloader

The invention relates to a solid material unpacking machine, in particular to a full automatic unpacking and unloading machine, which is characterized in that: all stages of mechanisms are connected through flanges; a bag breaking mechanism, a screening mechanism and a material output mechanism are arranged on a main body frame; the outer surface of the main body frame is connected with a surface panel in a splicing mode; the surface panel on the top of the main body frame is provided with a main dust removal outlet; and a channel formed from the feeding inlet end of a feeding mechanism to the outlet end of the material output mechanism and the outlet end of a waste bag output mechanism is a one-way communication channel. The full automatic unpacking and unloading machine has the advantages that the machine has high work efficiency, energy conservation, environmental protection, small volume, light weight and the like, can safely and stably separate solid materials from packages in automatic high-speed running, and convey the materials to downstream equipment, while the waste packages enter a waste bag recovery device for recovery, and the machine can particularly meet the requirements of unloading, separating and collecting toxic and corrosive powder, and particle materials.

Owner:HANRUI PUZER BULK HANDLING TECH SHANGHAI

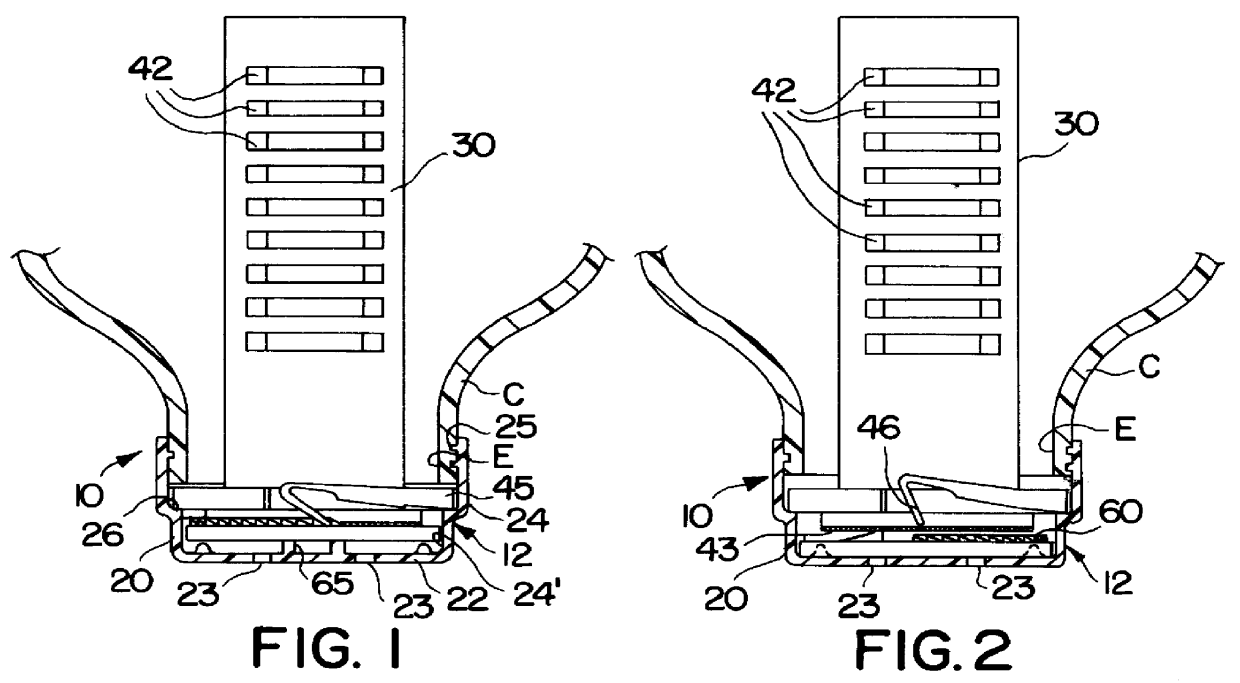

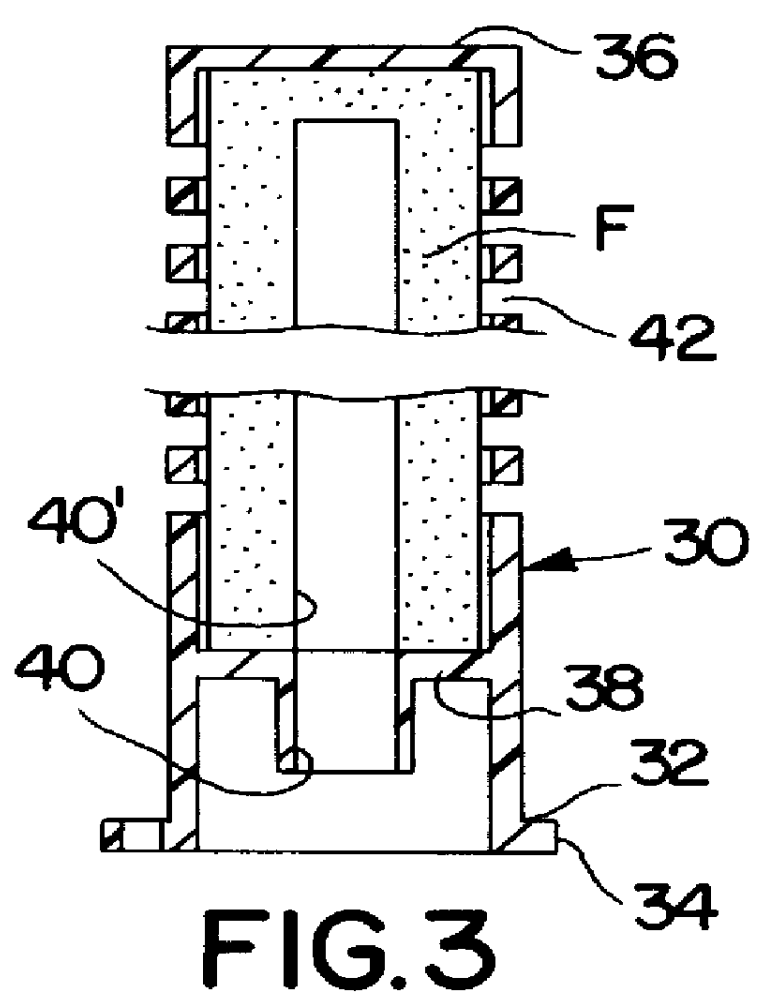

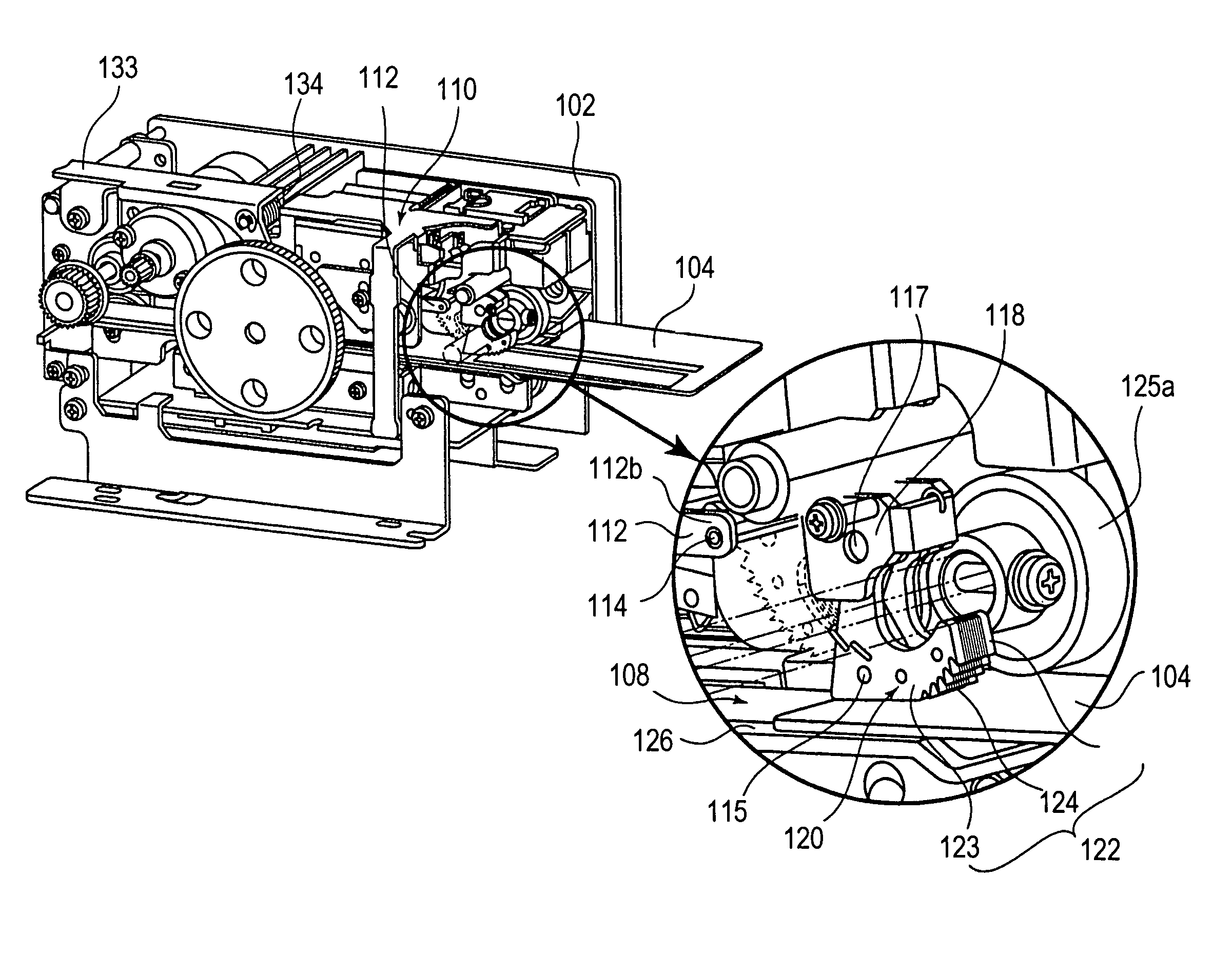

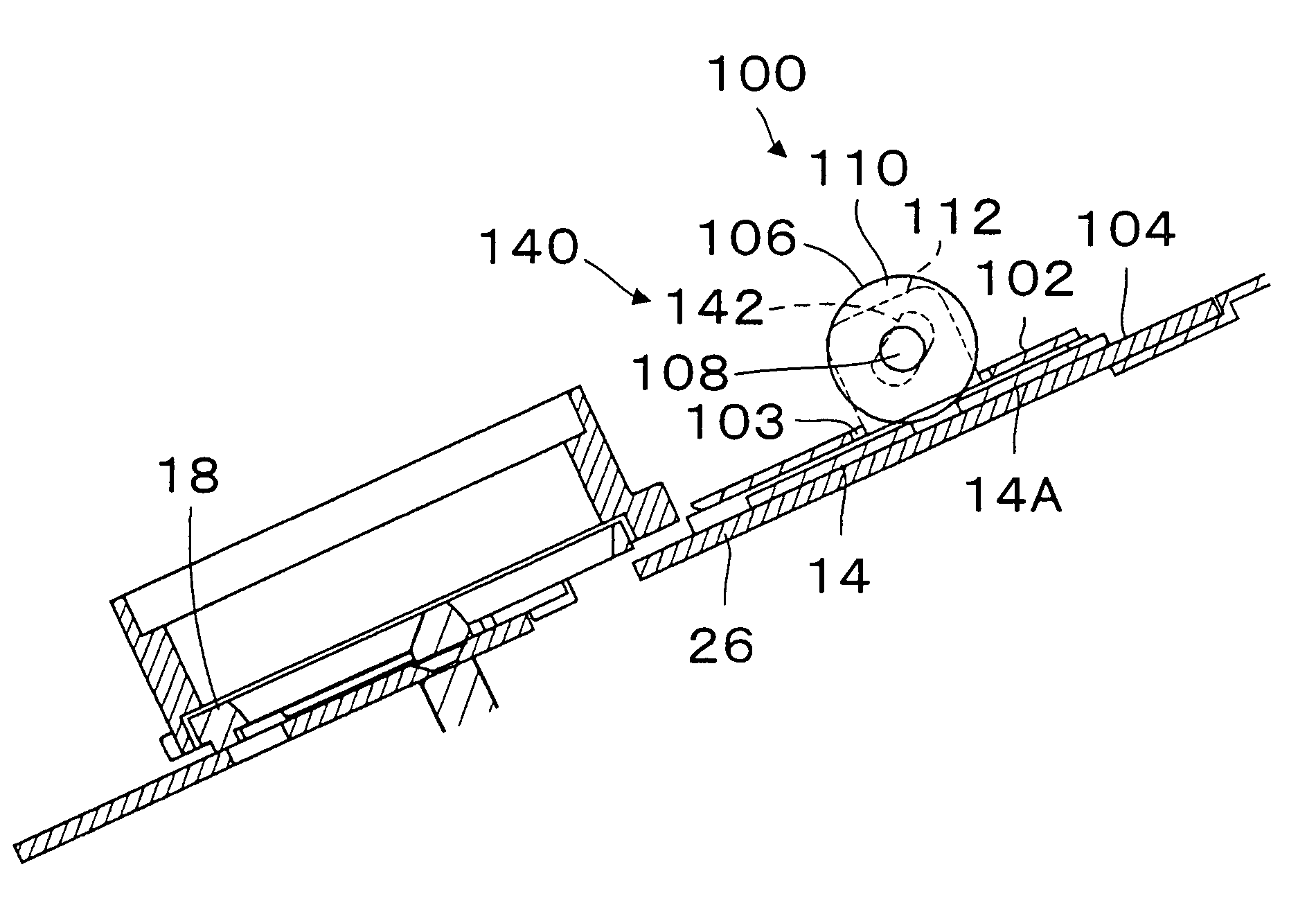

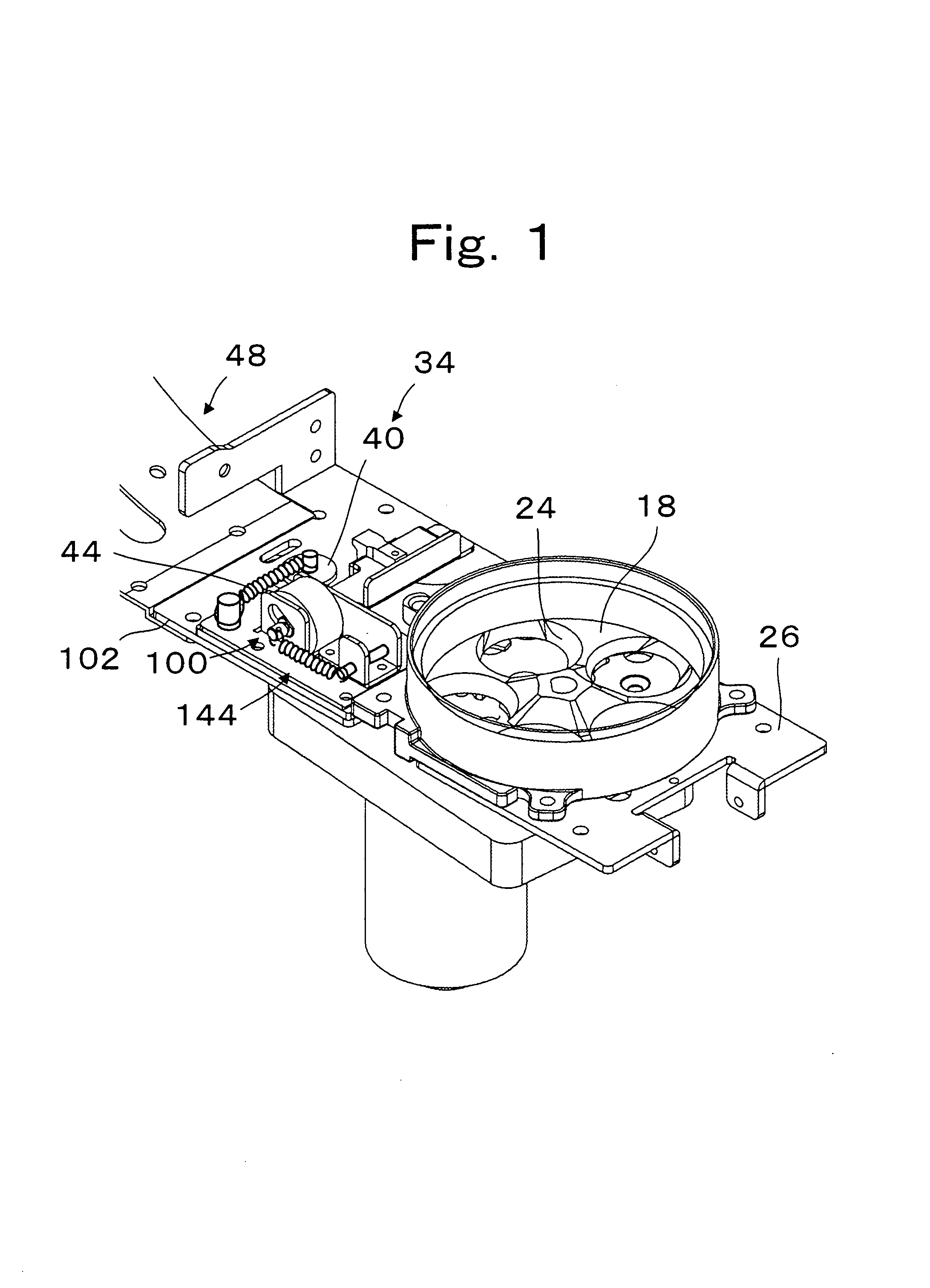

Card reader

ActiveUS20060086793A1Prevent movementIncrease freedomConveying record carriersSensing record carriersEngineeringCard reader

A card reader is provided with a card locking device preventing a card shaped medium from pulling out for illegal taking-out The card locking device includes a lock member which is turnably supported and provided with an engaging part so as to abut with the surface of the card shaped medium and a movable member which is connected to the lock member and is reciprocally movable in a direction to the card insertion port. The movable member turns the lock member around the support shaft pin such that the engaging part abuts with the card shaped medium to lock the card shaped medium. The engaging part may be constructed by a plurality of plate members whose thicknesses are different is laminated in a width direction of the card shaped medium.

Owner:SANKYO SEIKI MFG CO LTD

System and die for forming a continuous filament reinforced structural plastic profile by pultrusion/coextrusion

InactiveUS7987885B2Reinforced thermoplasticAvoid reverse motionTailstocks/centresConfectioneryThermoplasticEngineering

A system and method are disclosed for producing a continuous filament reinforced thermoplastic profile having consistent cross section. A continuous reinforcing filament is pre-wetted with a first thermoplastic resin and introduced into a die, where it is contacted with a second thermoplastic resin extruded from an extruder at melt state. The temperature of the die is carefully controlled so that the pre-wetted filament and first resin do not cure or solidify until after they have contacted and mixed with the second thermoplastic resin. The mixture temperature is then controlled to make a substantially solidified profile pre-shape. A capping layer comprising a third thermoplastic resin is then coextruded onto the outer surface of the pre-shape. A multistage die for bringing together the filament and thermoplastic resins and for maintaining appropriate temperatures at each stage of the profile-forming process is also disclosed.

Owner:SAINT GOBAIN PERFORMANCE PLASTICS CORP

Tape guide device for gardening buncher

InactiveUS20050028497A1Avoid reverse motionStapling toolsWrapper twisting/gatheringMagnetic tapeConduction band

A rib (206c) is formed on a ceiling surface of a tape guide mounted on a driver handle of a binding machine for gardening, and two plate springs (224a, 224b) are mounted on the bottom plate portion of the tape guide. The plate spring (224a), which is situated on the downstream side, is elastically contacted with the rib (206c) to thereby allow the plate spring (224a) and rib (206c) to hold tape (T) between them, while the upstream-side plate spring (224b) is contacted with the tape. When a tape roll is rotated reversely and the tape is thereby pulled back, tension is applied to the tape existing between the rib (206c) and tape roll, and the upstream-side plate spring (224b) is raised up due to the friction of the tape to curve a passage of the tape, which increases the frictional resistance of the tape to thereby be able to prevent the tape (T) against reverse movement.

Owner:MAX CO LTD

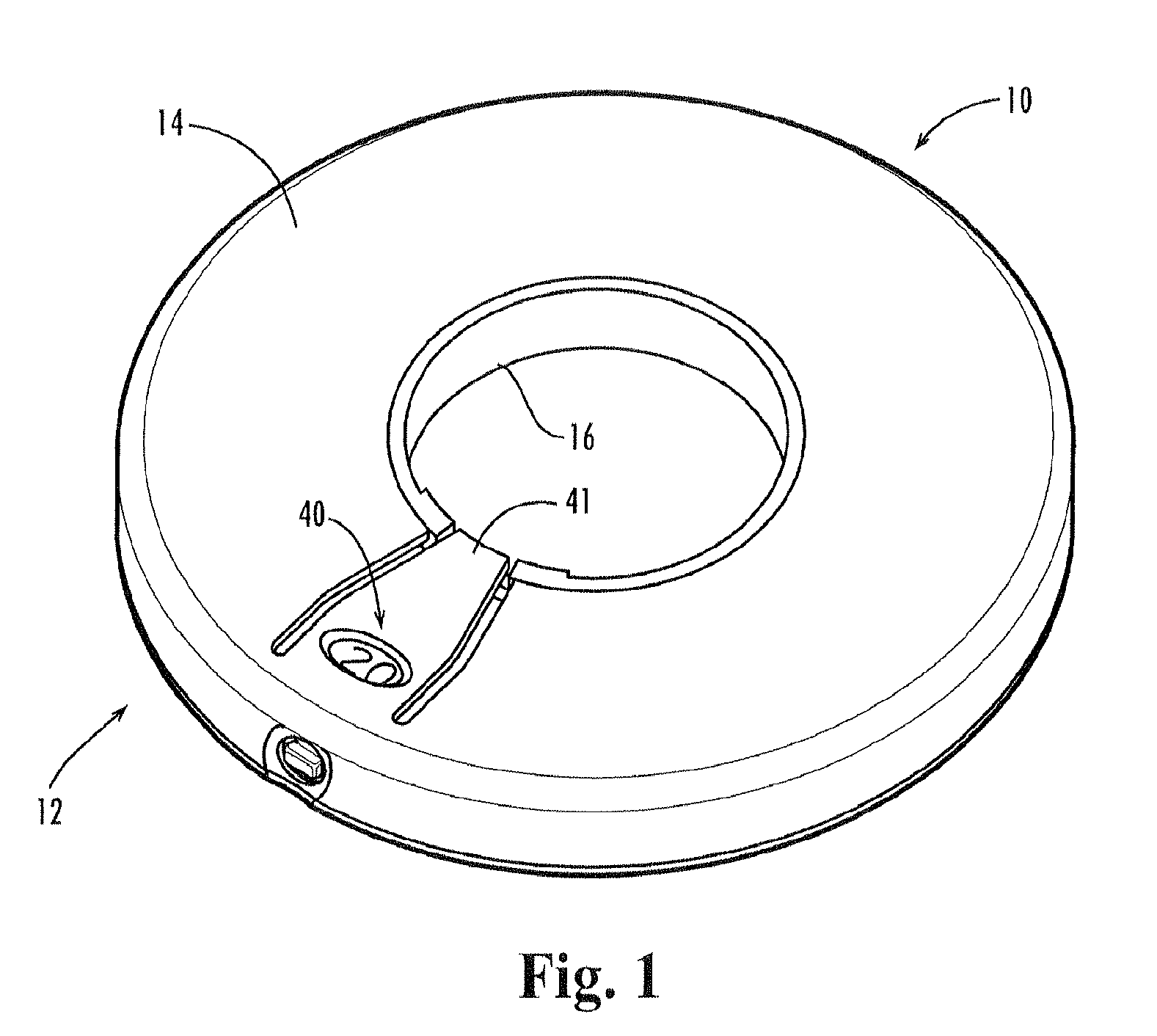

Filter use limitation device for liquid containers

InactiveUS6033557AAccurate monitoringDifferent typeLiquid separation auxillary apparatusIndication apparatusEngineeringWrench

A filter use device is adapted for use with various types of containers, such as, liquid containers for water coolers in which the device includes a cap to be threaded onto an open end of the container, a filter cartridge in the cap which retains a conventional filter and a resilient pawl which is engageable with a disk having an indicator aligned with a slot in the cap and engageable with ratchet teeth to incrementally advance the indicator each time that the cap is threaded onto the end of the container; and when the indicator reaches the end of the slot is shifted to prevent any further advancement of the disk or passage of water through the filter or device and thereby signify the end of the life of the filter and the need for replacement of the filter. The number of rachet teeth may be varied in accordance with the number of containers with which the filter is to be used. In an alternate form, a resetting wrench is provided to return the pawl to its starting point for reuse with a replacement filter without discarding the entire cap.

Owner:GEBRHARD ALBERT W +1

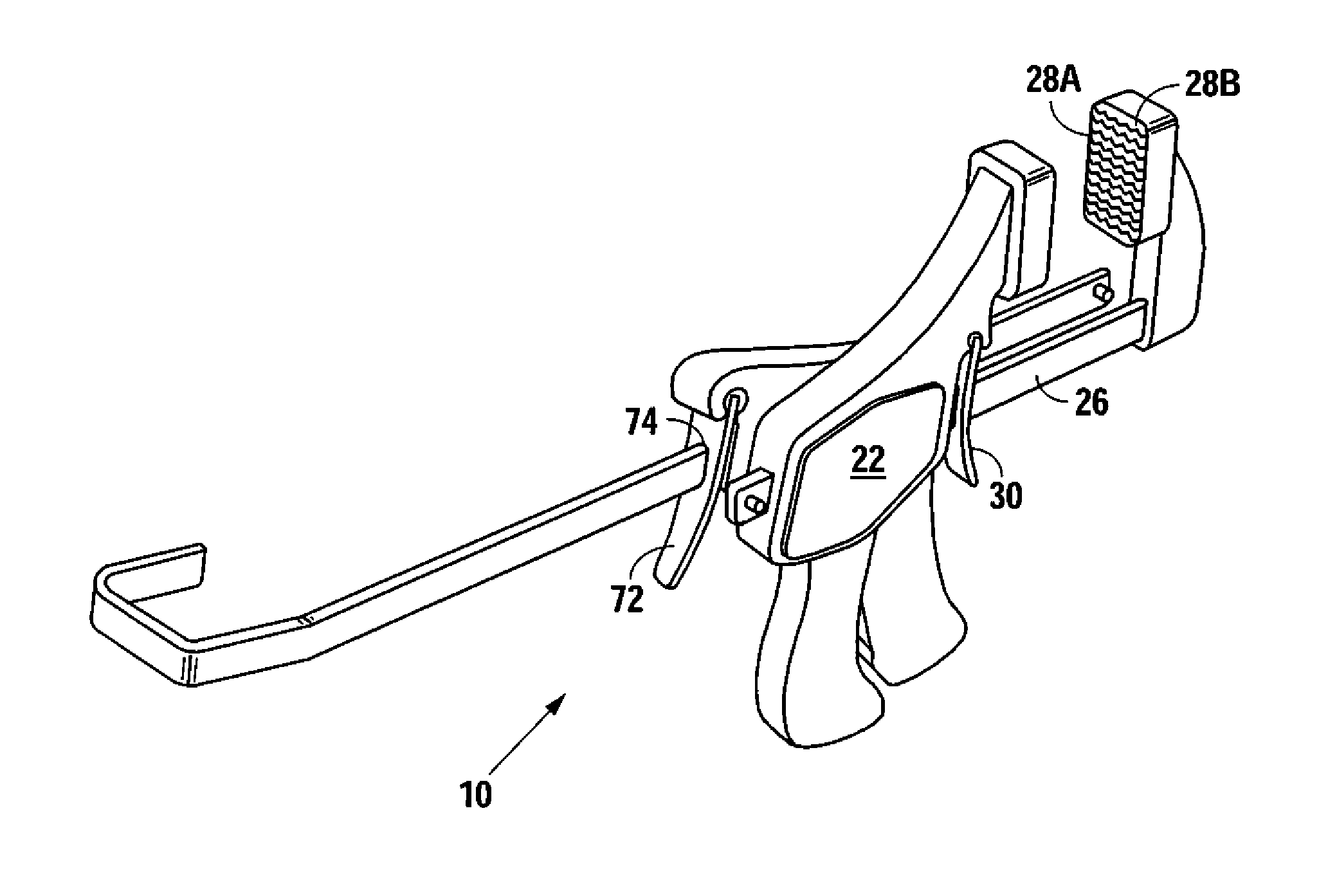

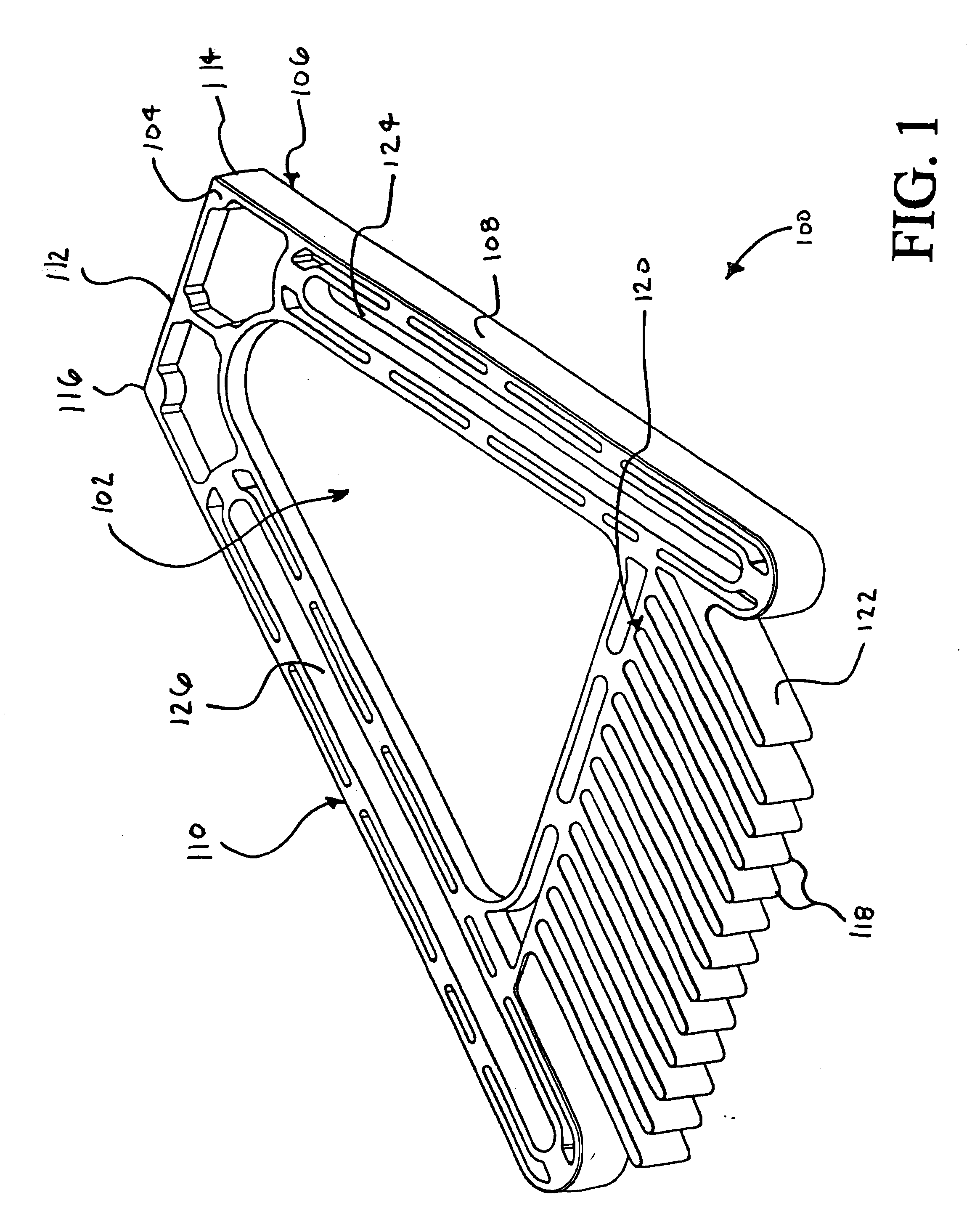

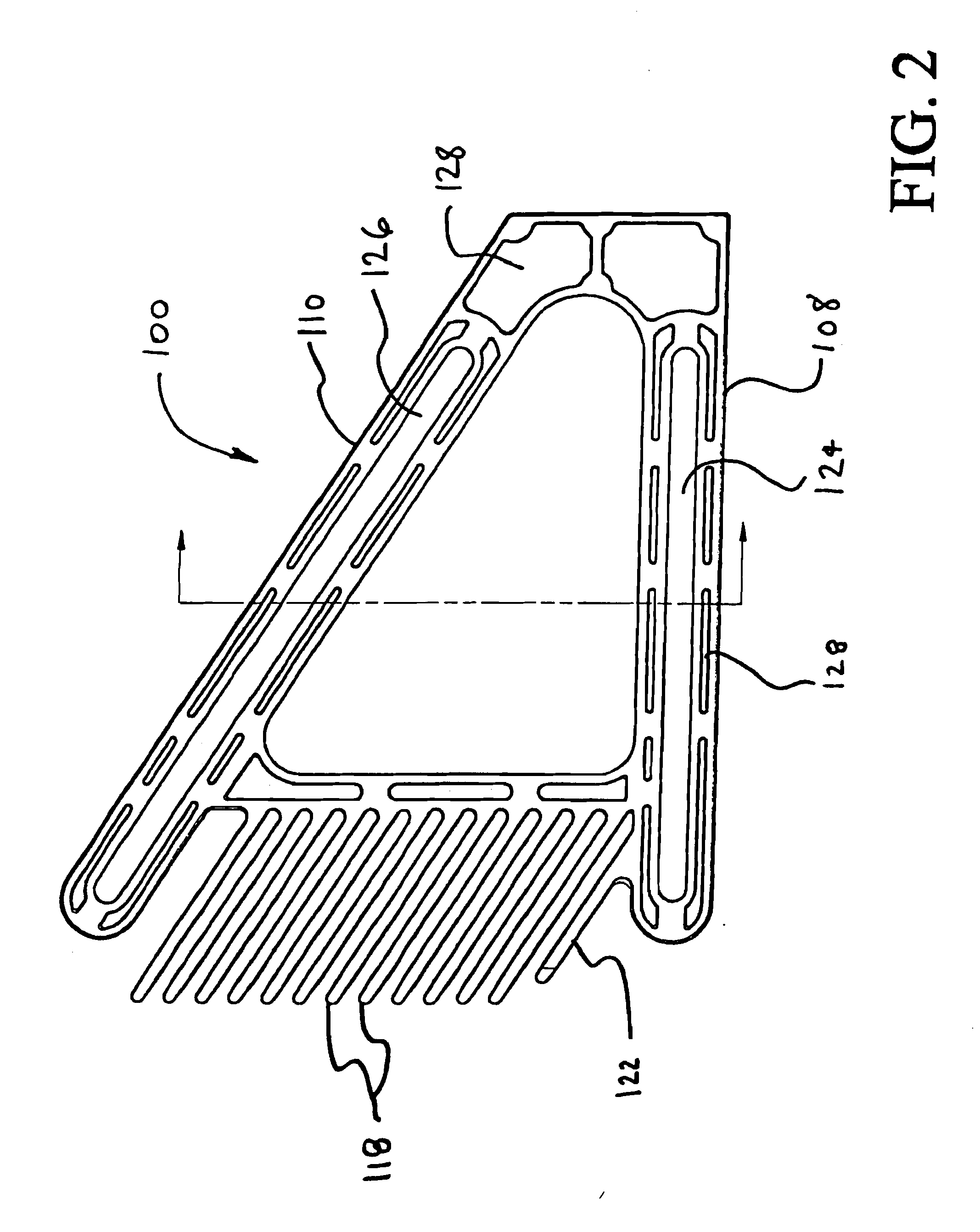

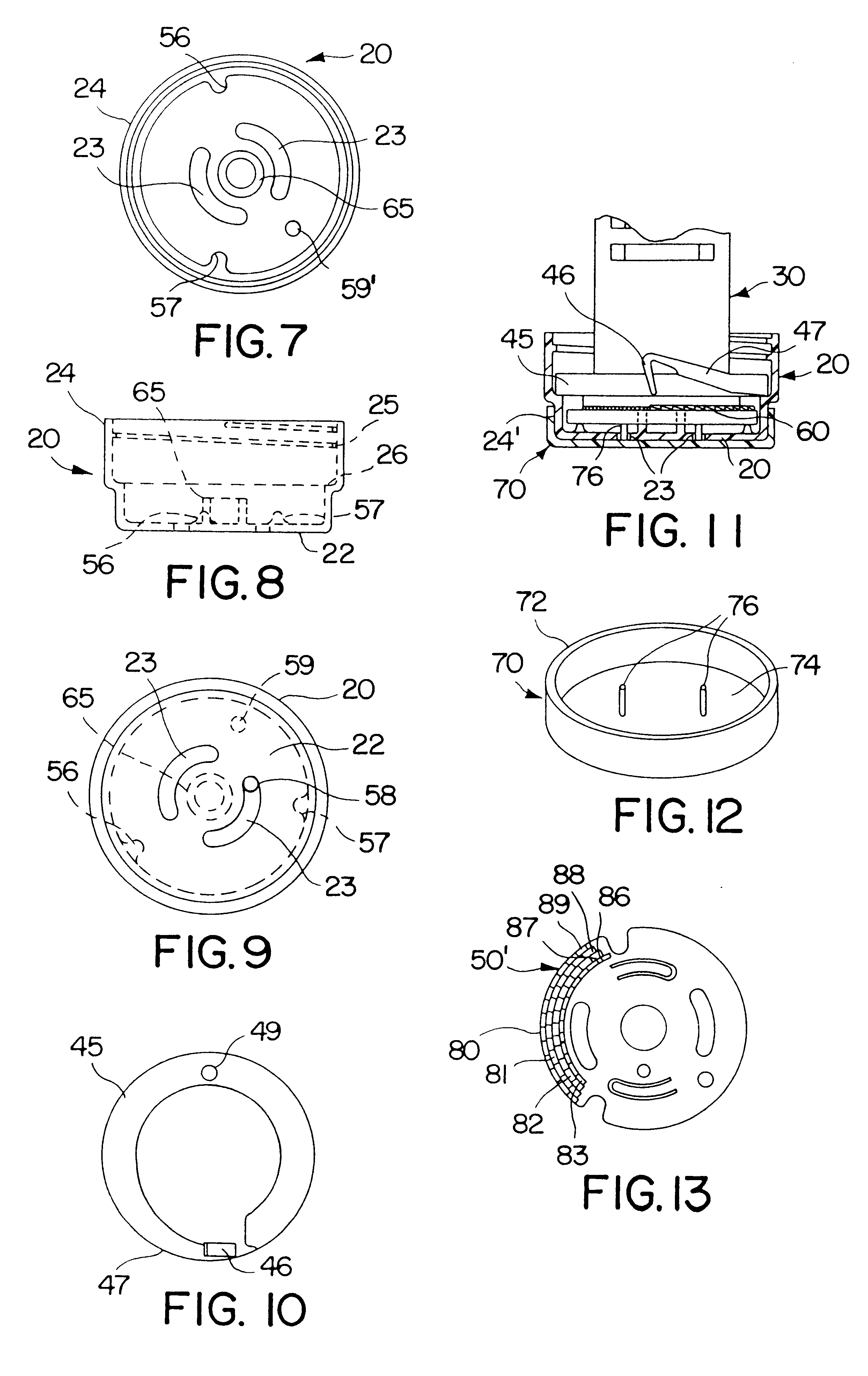

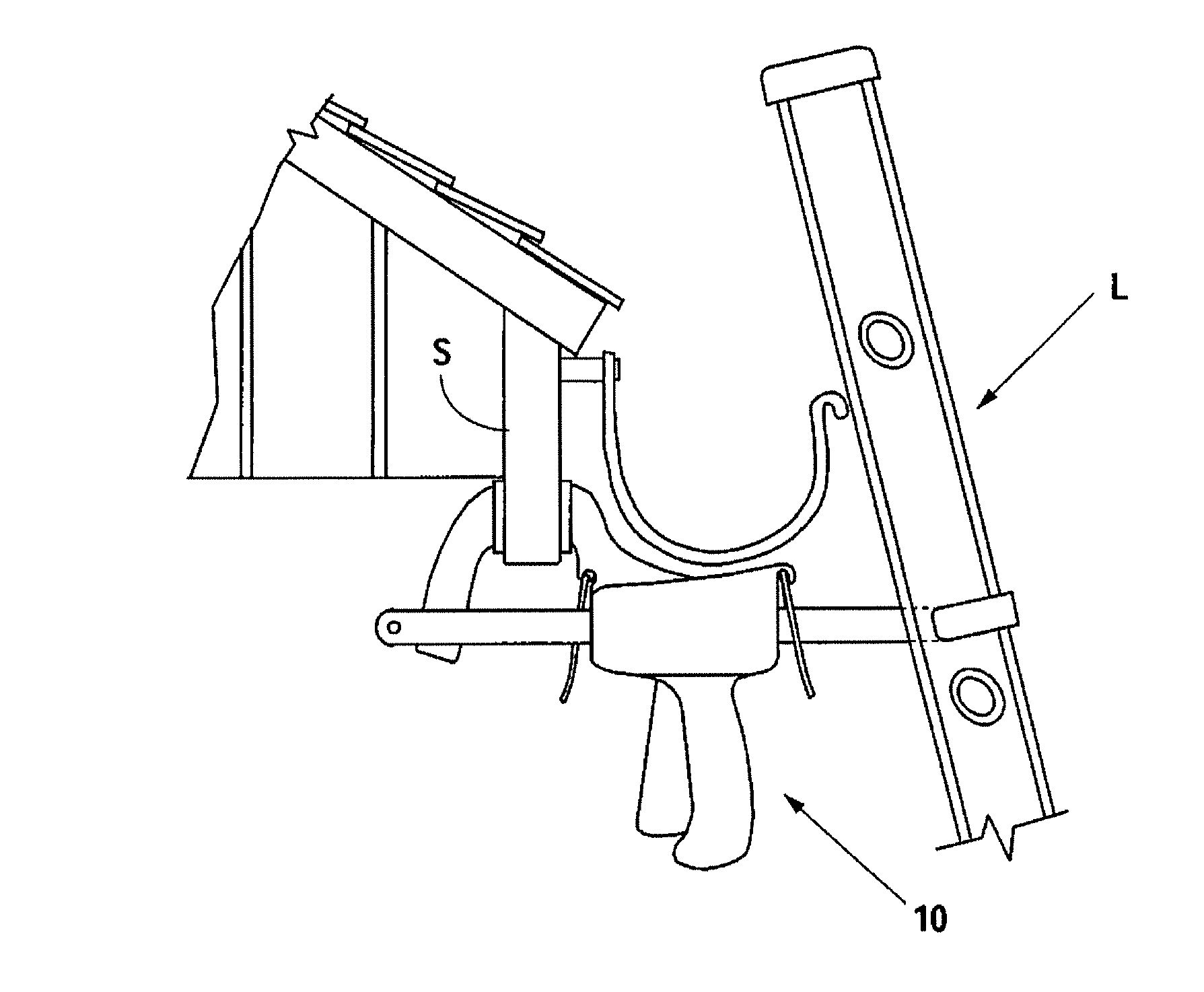

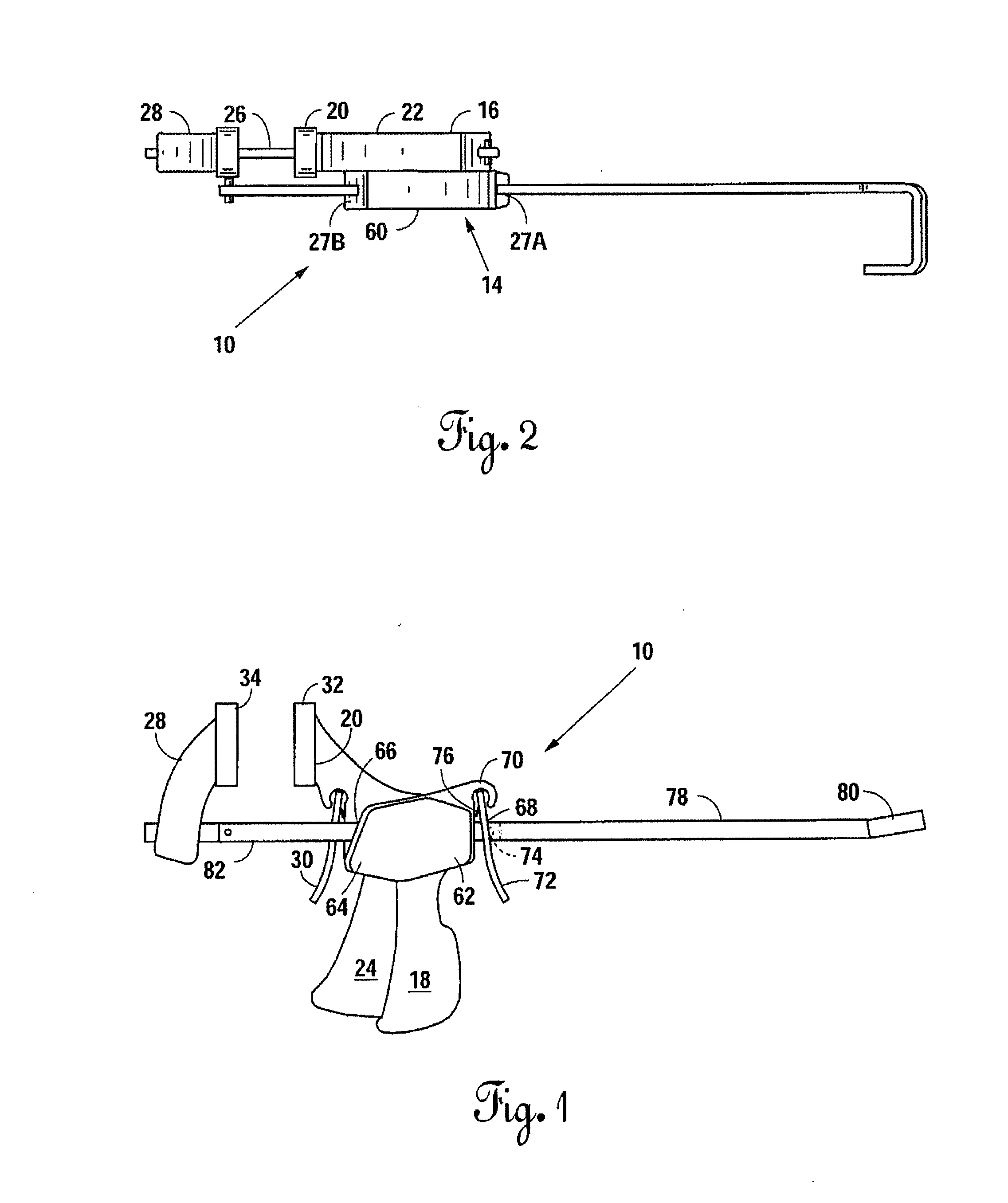

Ladder safety device and method of using the same

InactiveUS8316993B1Move quicklyQuick installationScaffold accessoriesLaddersEngineeringMechanical engineering

A house clamp assembly having a fixed jaw and a slide bar mounted movable jaw, the fixed jaw opposing the movable jaw. A one-way drive means, by operation of a trigger handle grip, releasably engages the slide bar and advances the movable jaw towards the fixed jaw. The one-way drive means is incapable of moving the slide bar and movable jaw away from the fixed jaw. A return motion of the movable jaw (separating) is accomplished manually when the one-way drive means is disengaged. A braking lever, which is biased to bind the slide bar, prevents reverse motion of the slideable jaw away from the fixed jaw, except when the first lever is disengaged from the slide bar. A device for securing a ladder to a building, wherein the removed end of the slide member has a hook shape; wherein the jaws include jaw faces having multiple raised portions, wherein the releasable braking means of the building clamp assembly means includes a pivoting lever; wherein the locking member of the ladder hook assembly includes a pivoting lever, attached at one end to the body, and having a slot dimensioned to slideably receive the hook slide member therethrough; wherein the body of the ladder hook assembly includes a pair of slots dimensioned for and adapted to slideably receive the slide member therethrough; and wherein the slots are arranged to maintain the hook slide member substantially parallel to the slide bar of the building clamp assembly.

Owner:RUDD DAVID MICHAEL

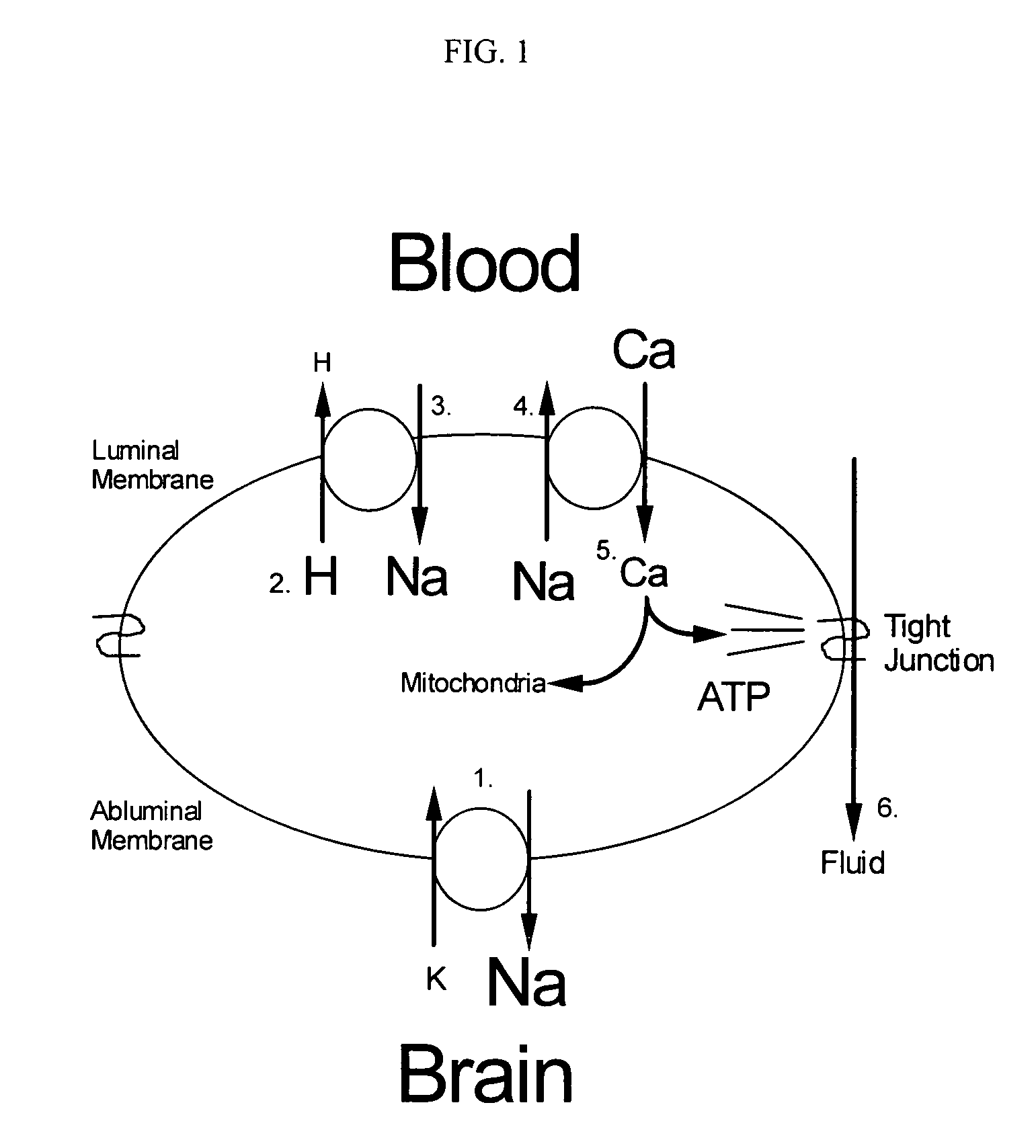

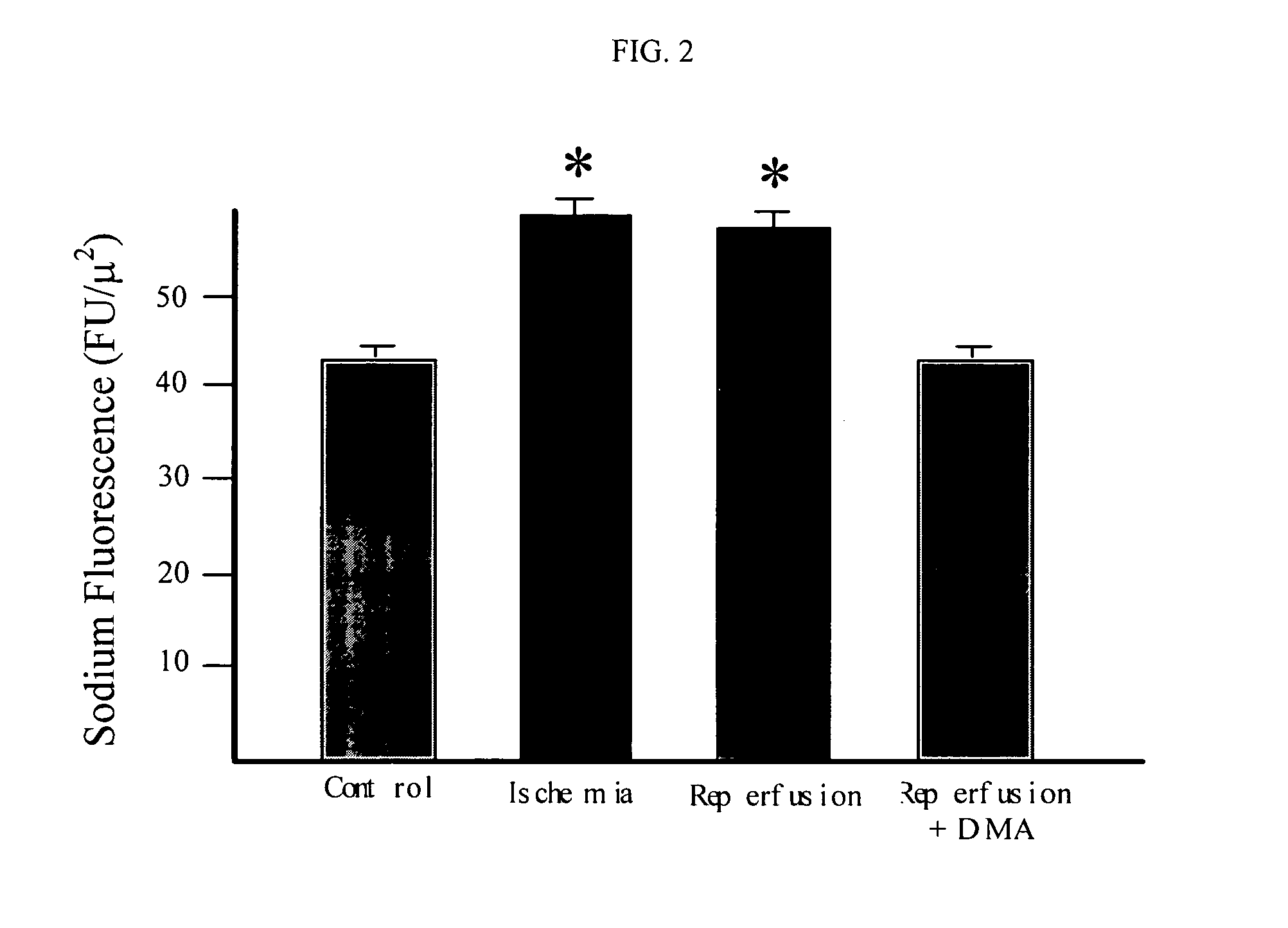

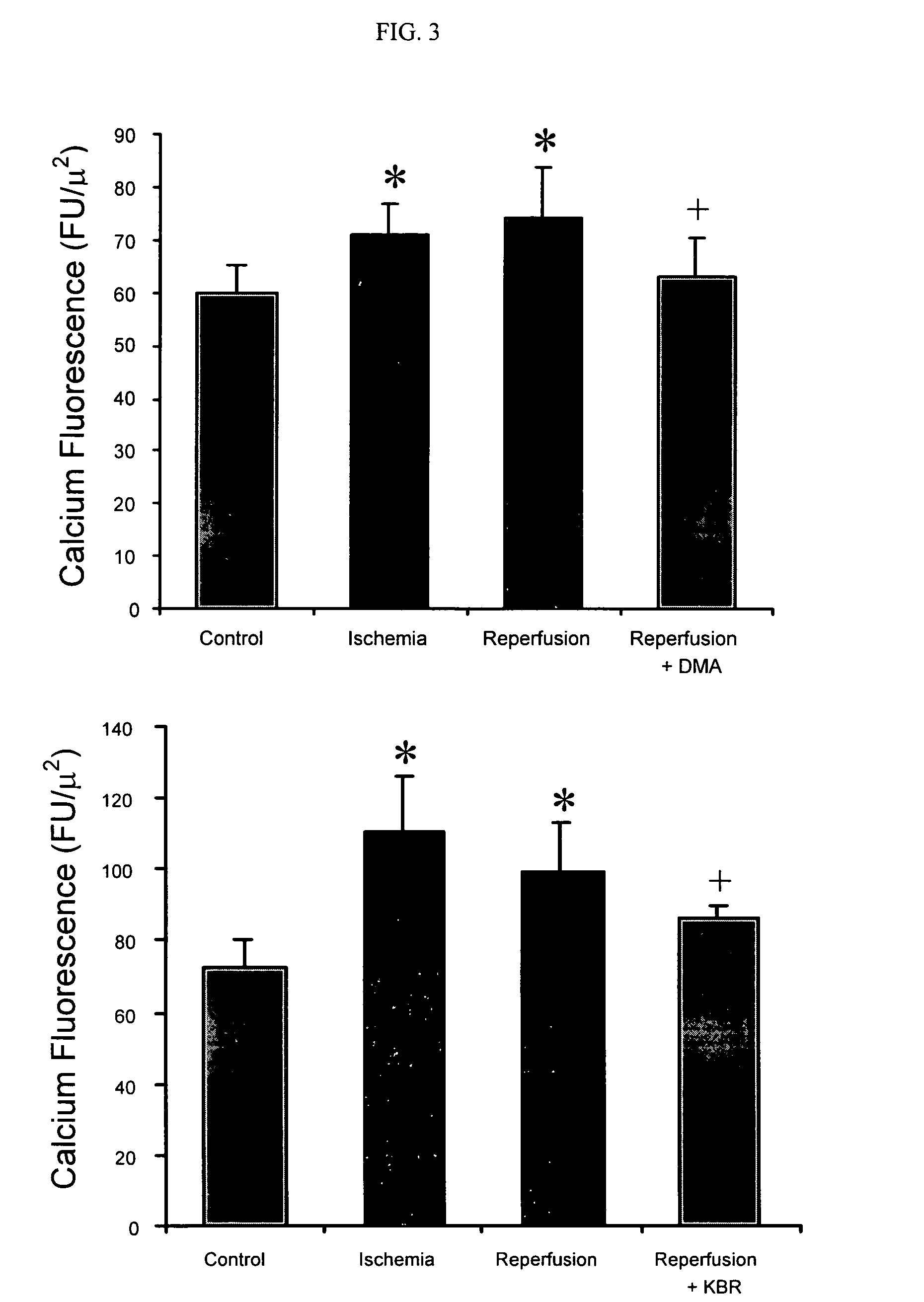

Cytoprotective thereapeutic agents for the prevention of reperfusion injury following ischemic stroke

ActiveUS20070293436A1Reduce decreaseAvoid reverse motionBiocideNervous disorderReperfusion injuryCysteine thiolate

The present invention relates generally to the use of γ-glutamyl antioxidants, particularly γ-glutamyl-cysteine, as cytoprotective agents to prevent reperfusion injury (i.e., hemorrhagic transformation) of the blood-brain barrier during reperfusion following an ischemic stroke. The γ-glutamyl antioxidants can be used alone or used in combination with an agent which inhibits the reverse movement of Na / Ca exchange in the blood-brain barrier such as 2-[2-[4-(4-nitrobenzyloxy)phenyl]ethyl]isothiourea methanesulphonate (KB-R7943).

Owner:ROSALIND FRANKLIN UNIVERSITY OF MEDICINE AND SCIENCE

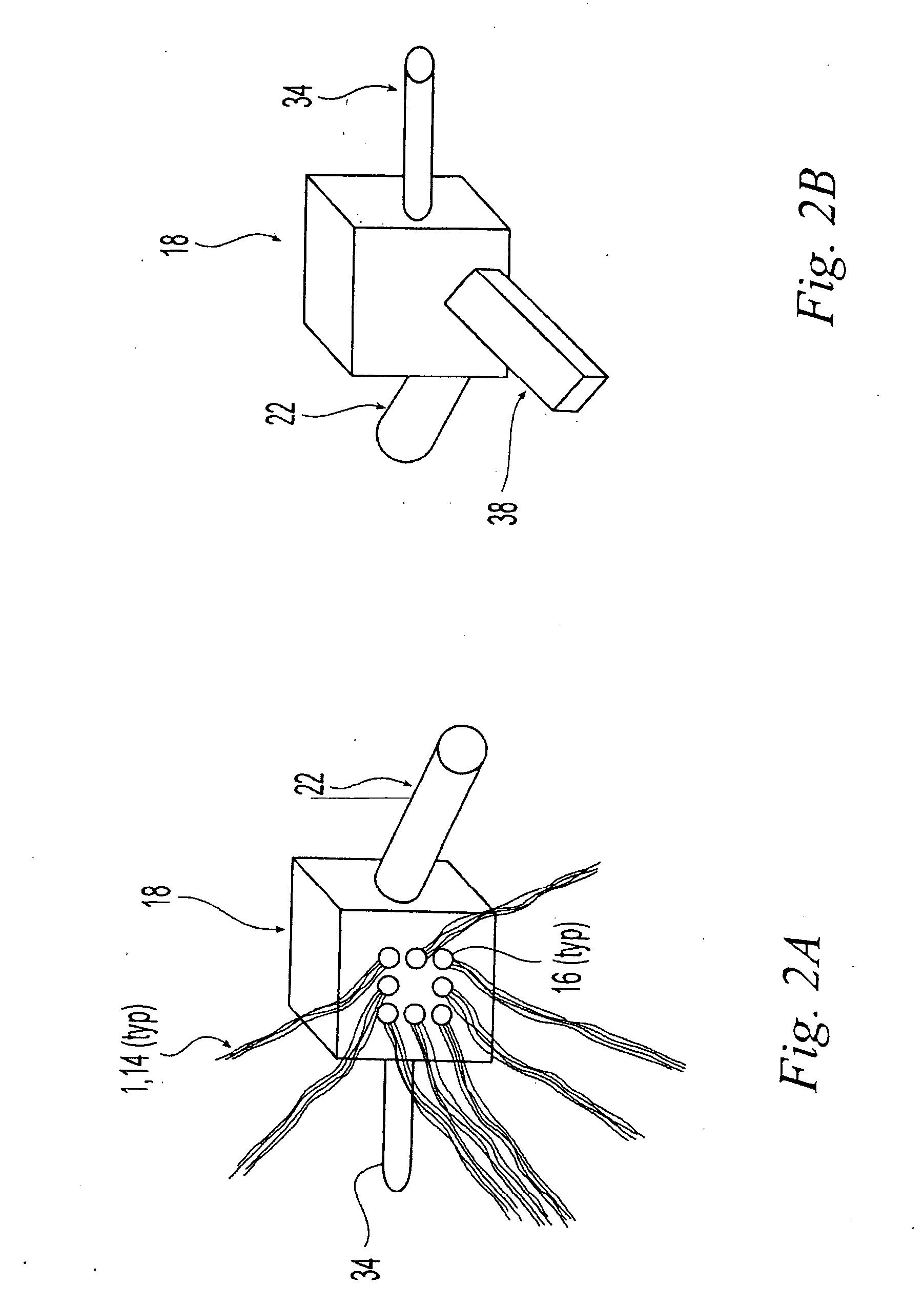

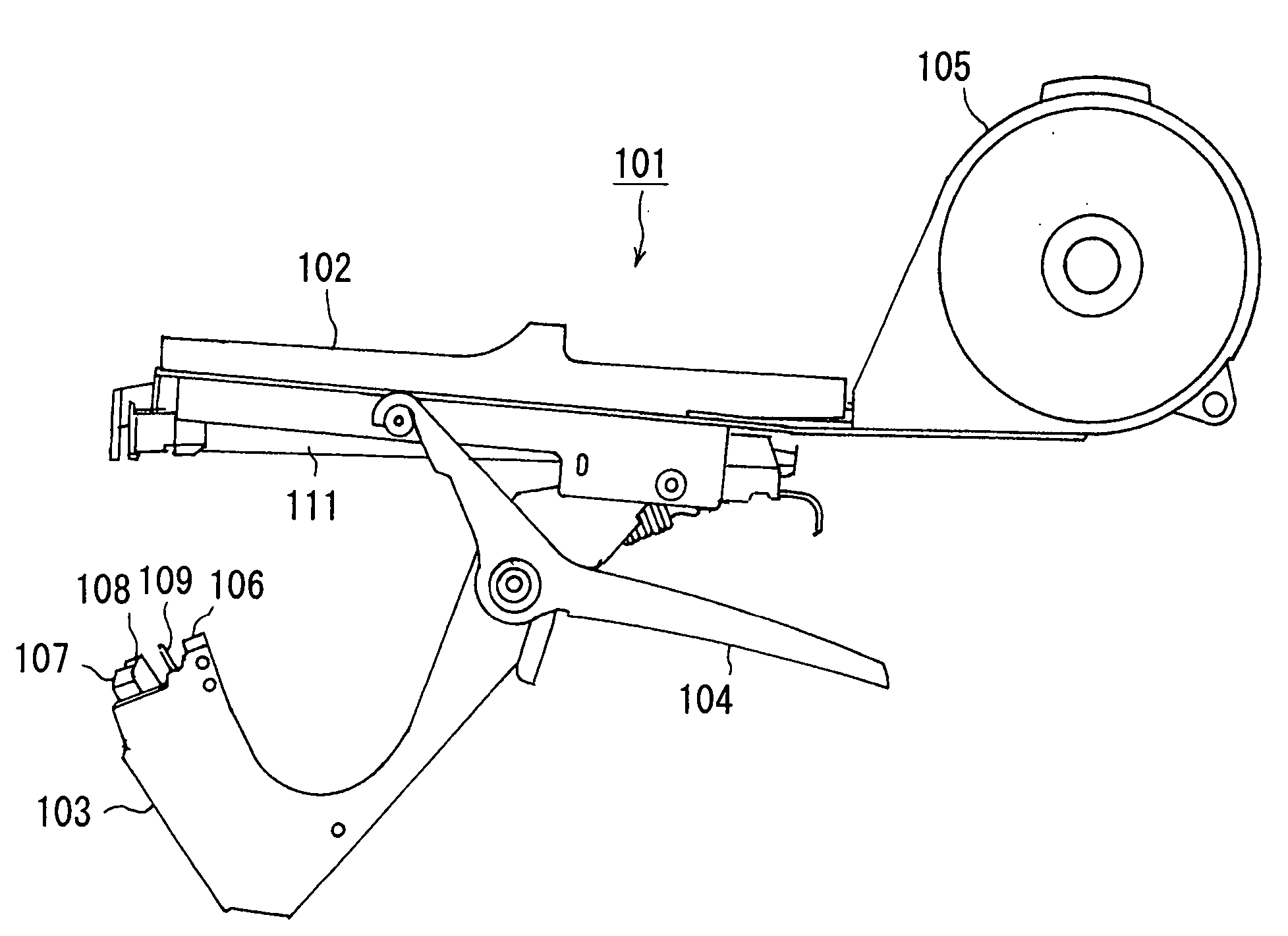

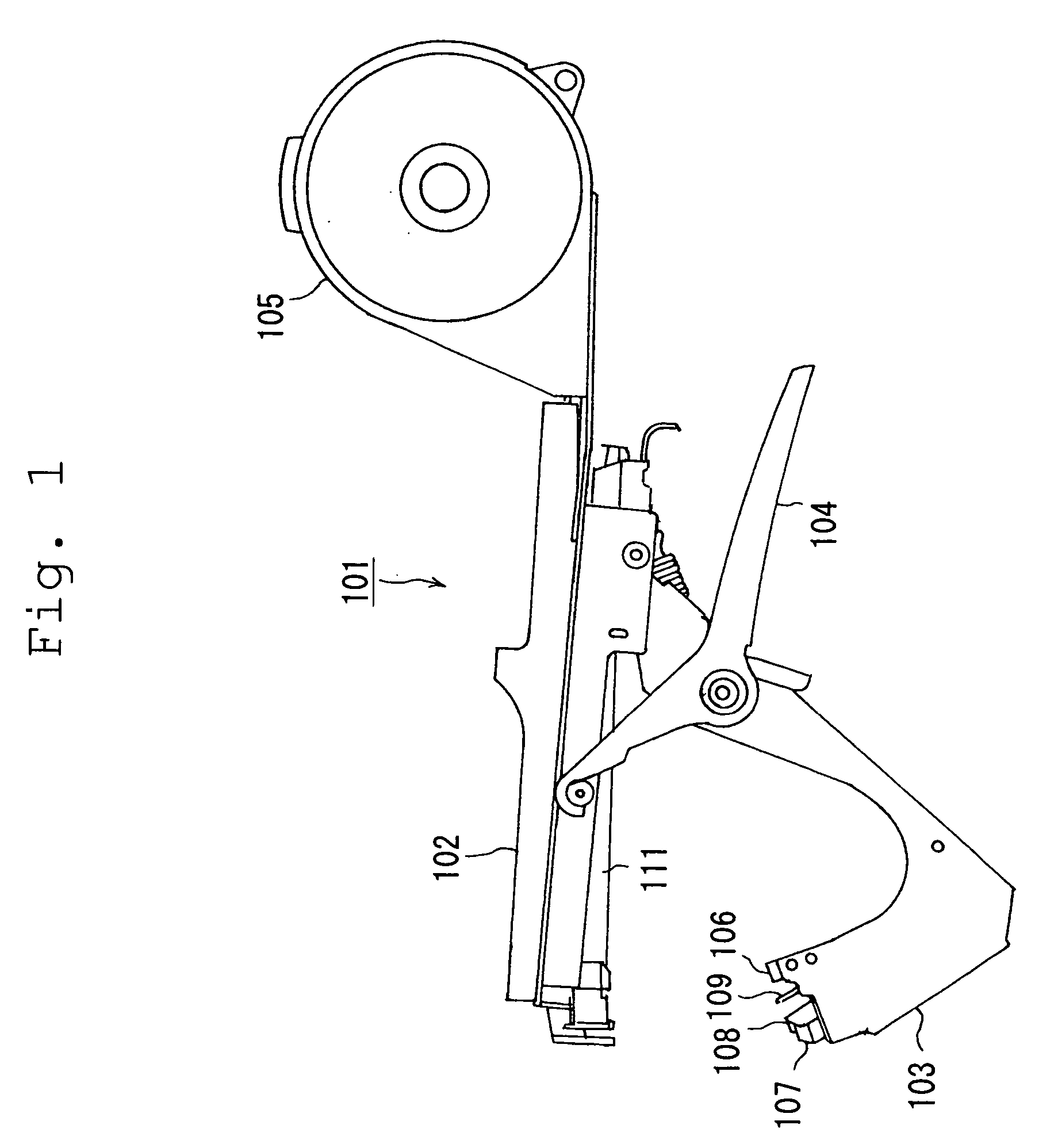

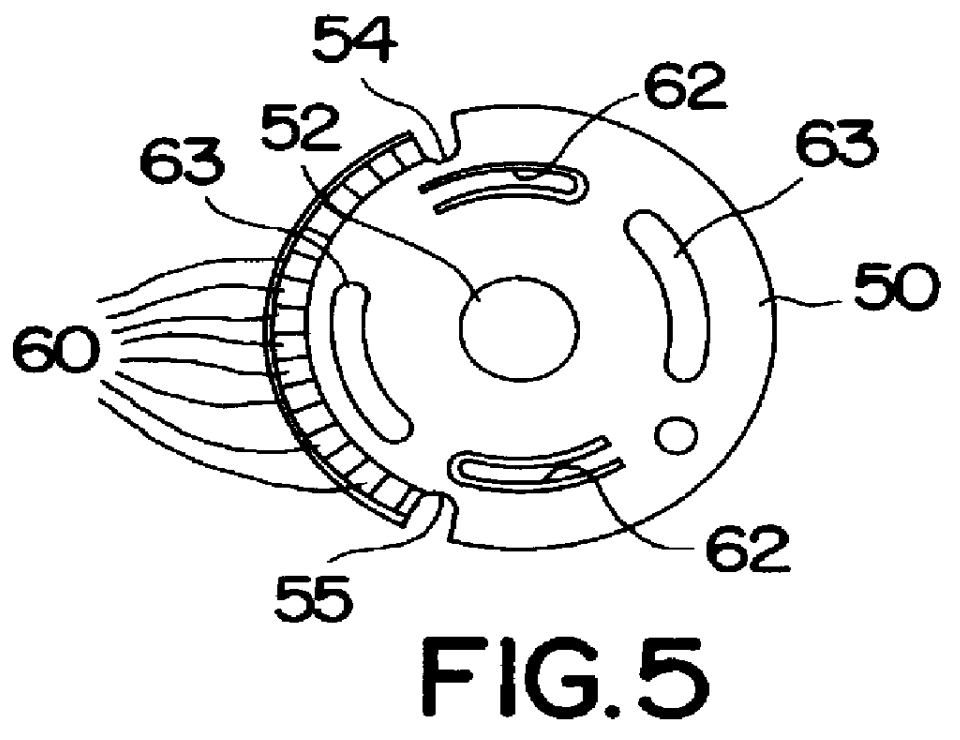

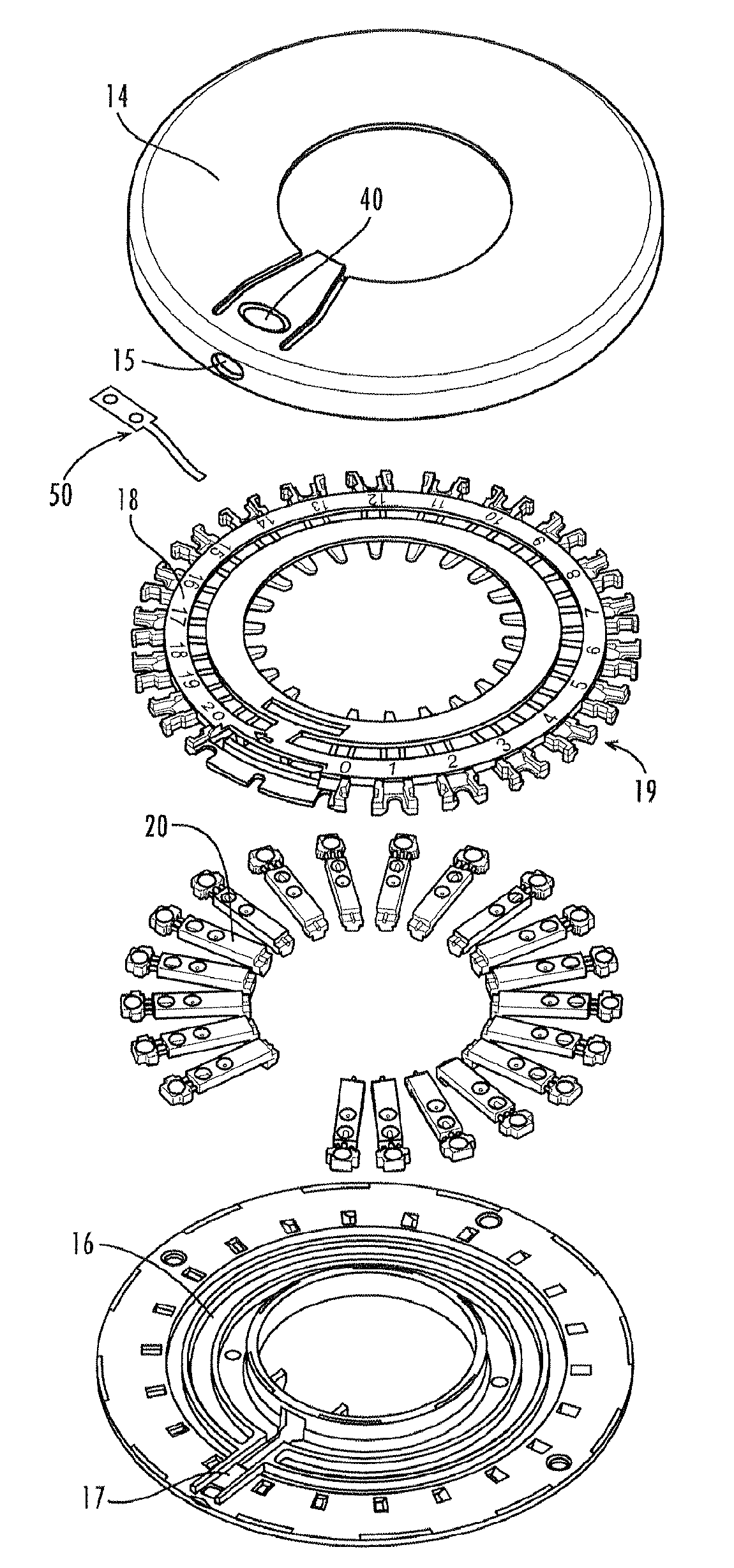

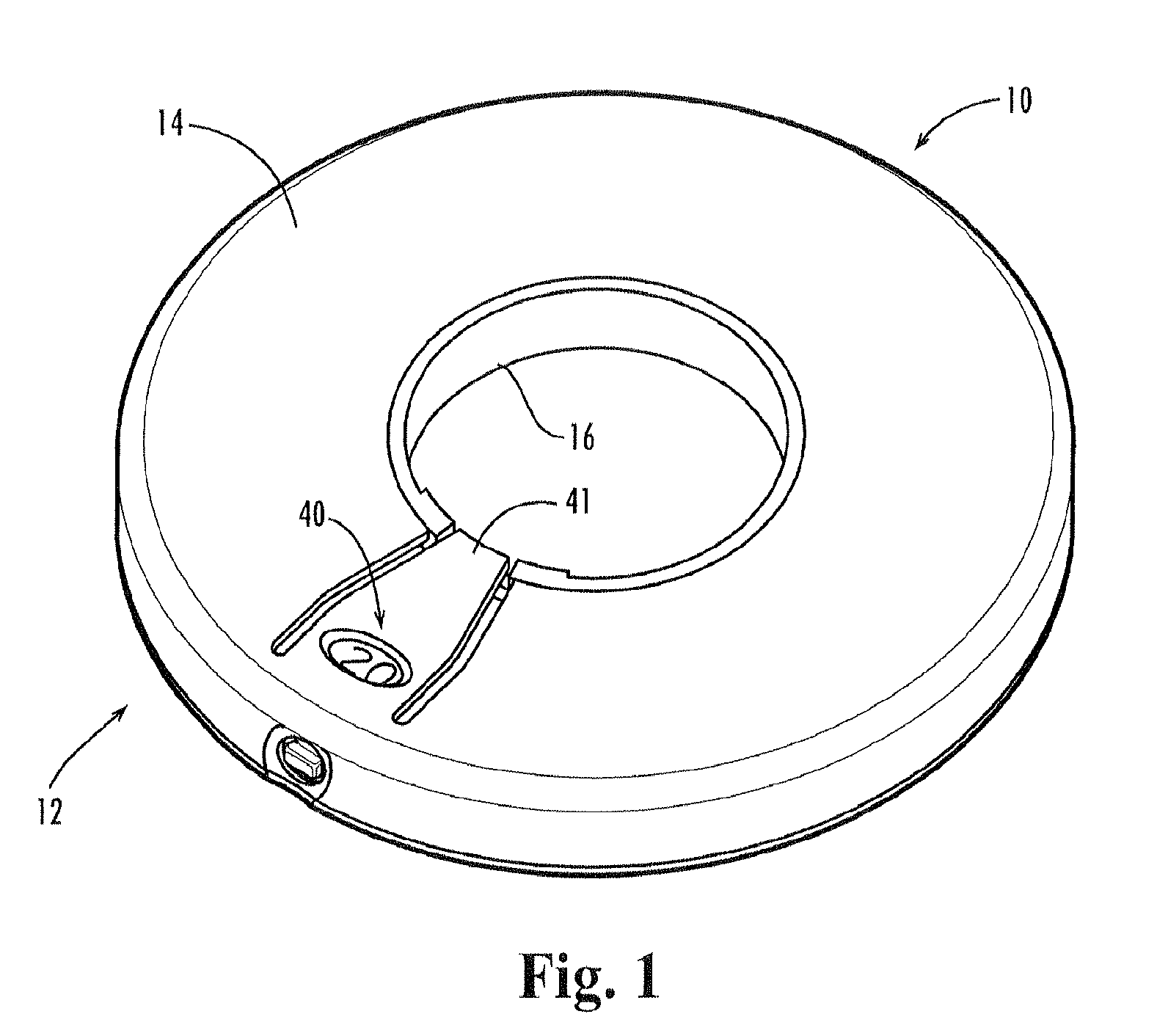

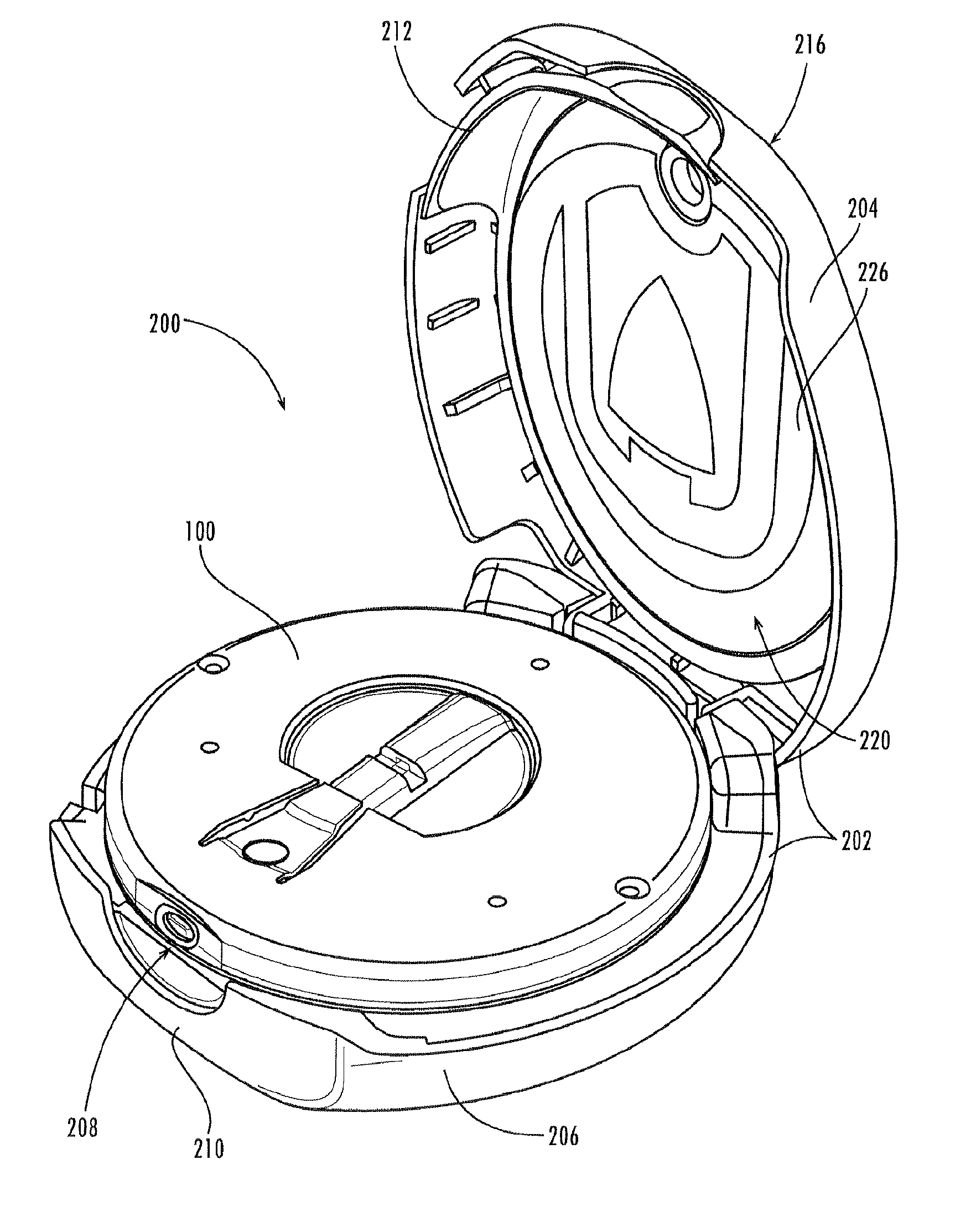

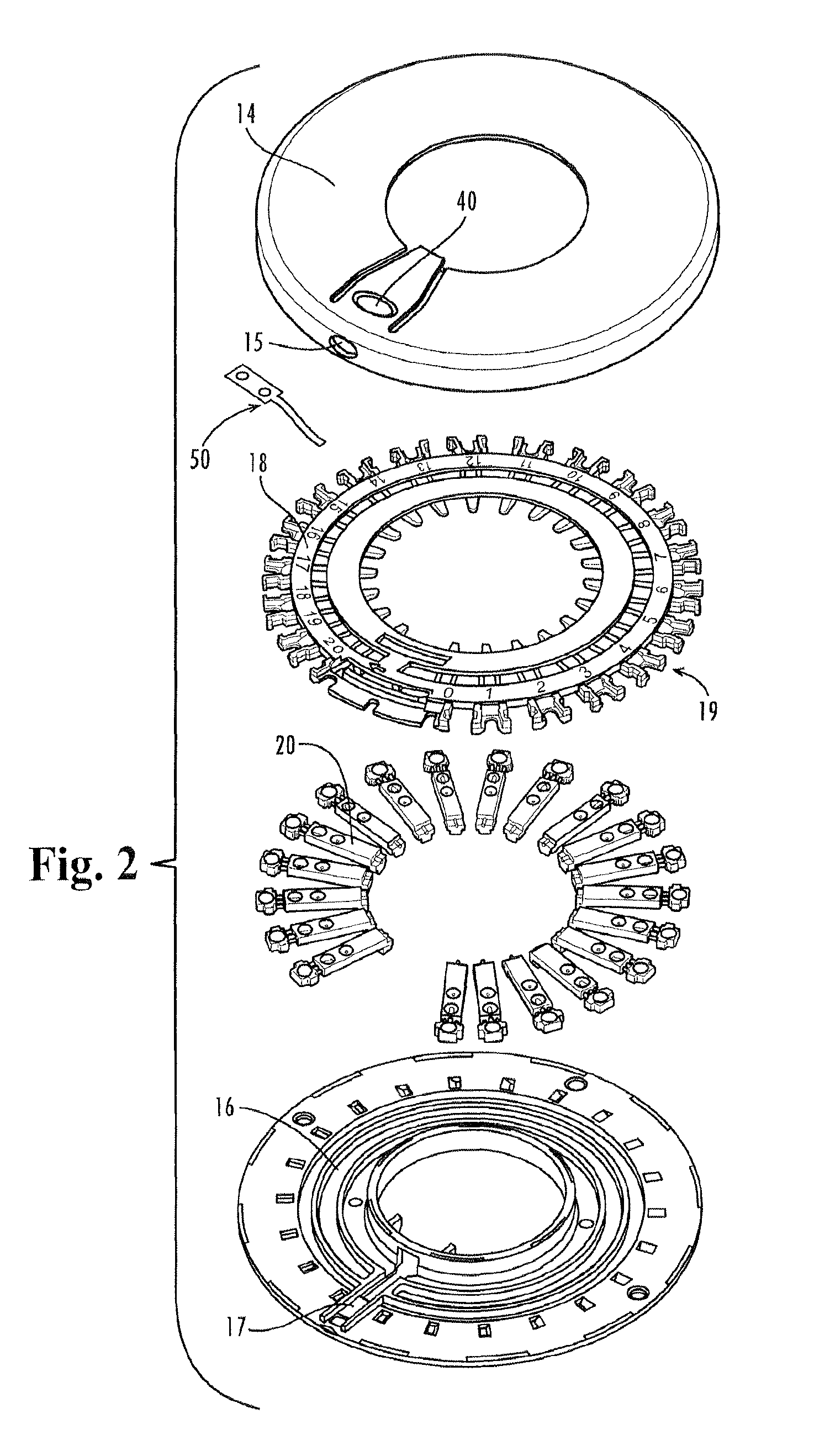

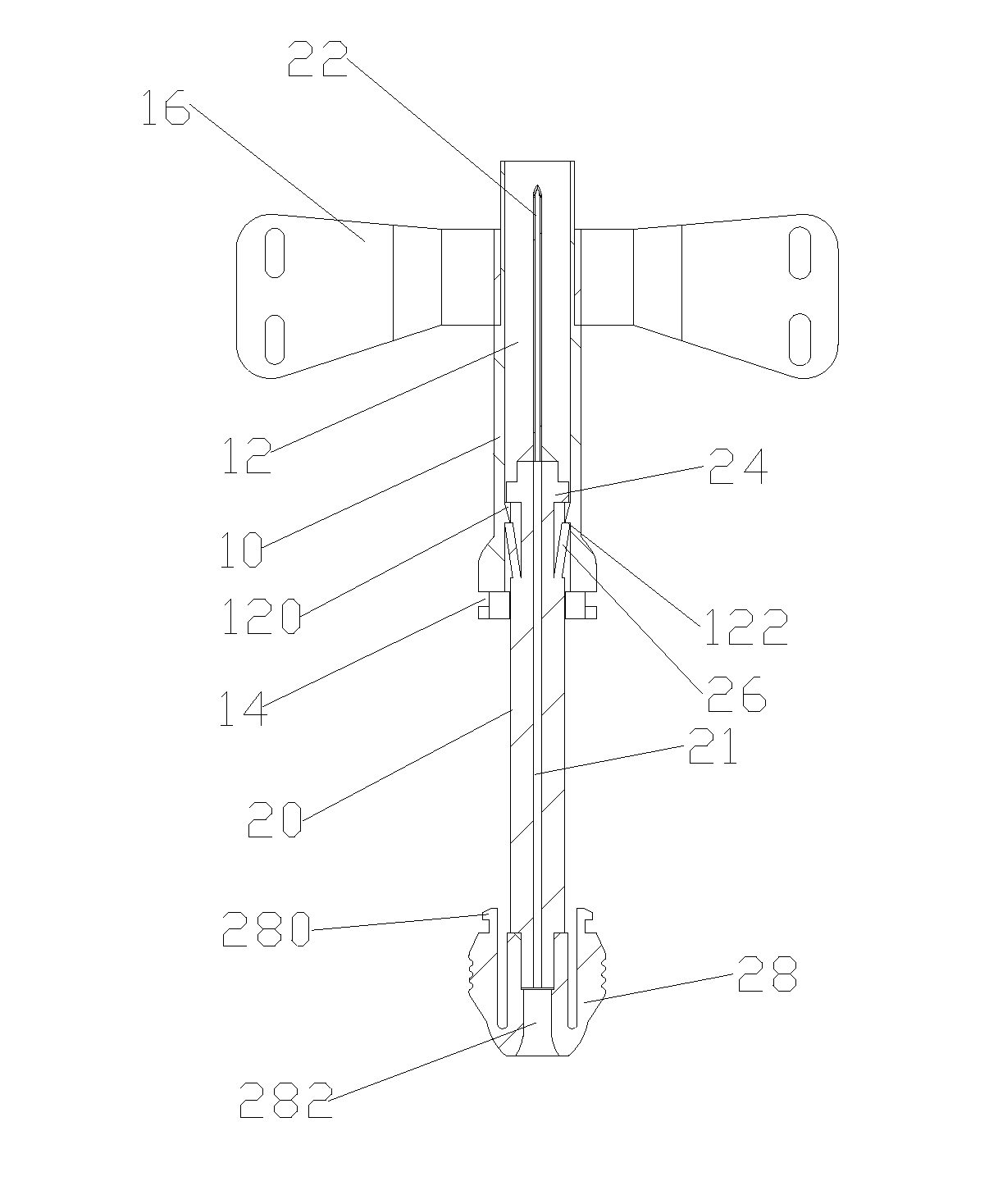

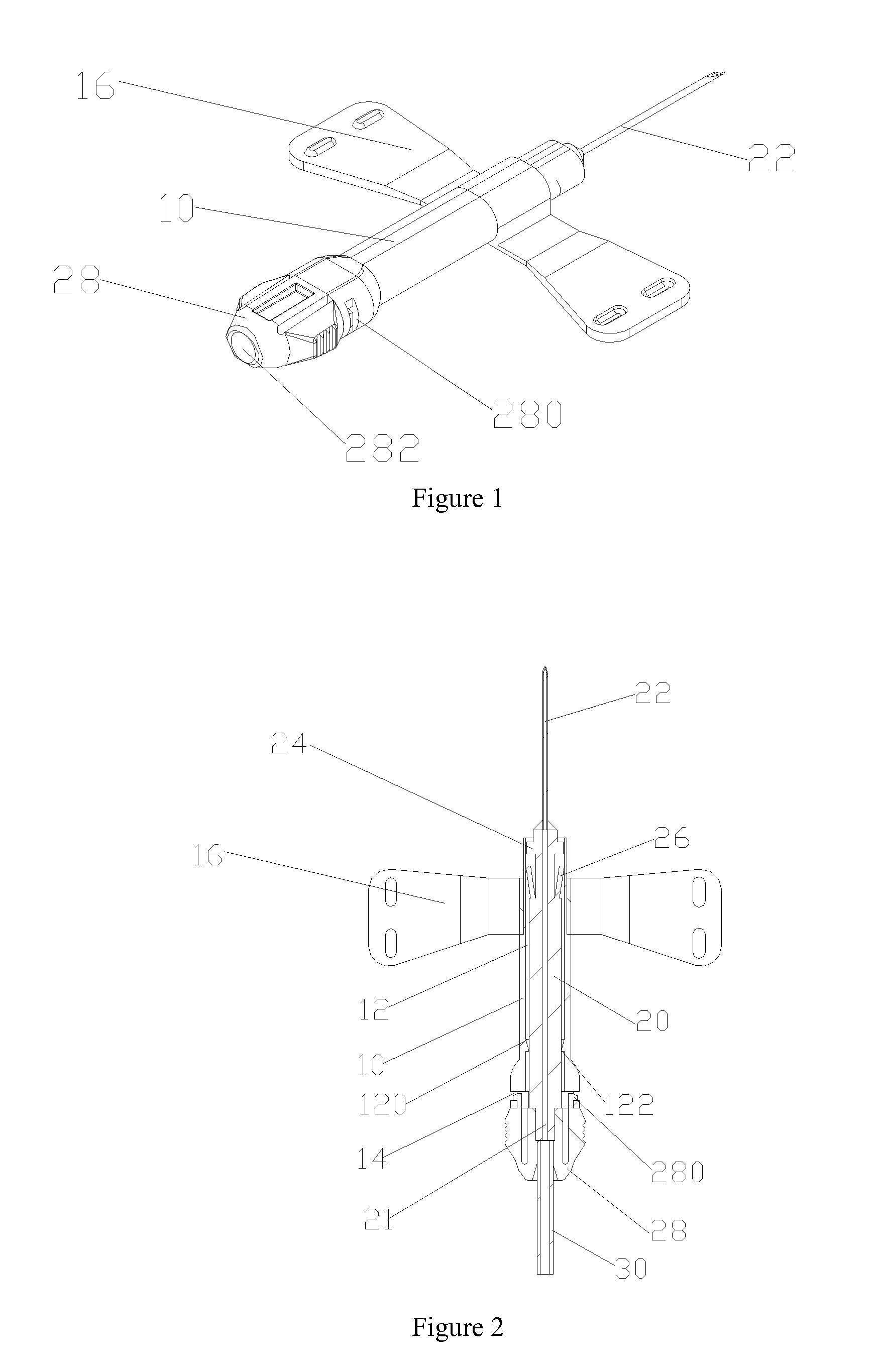

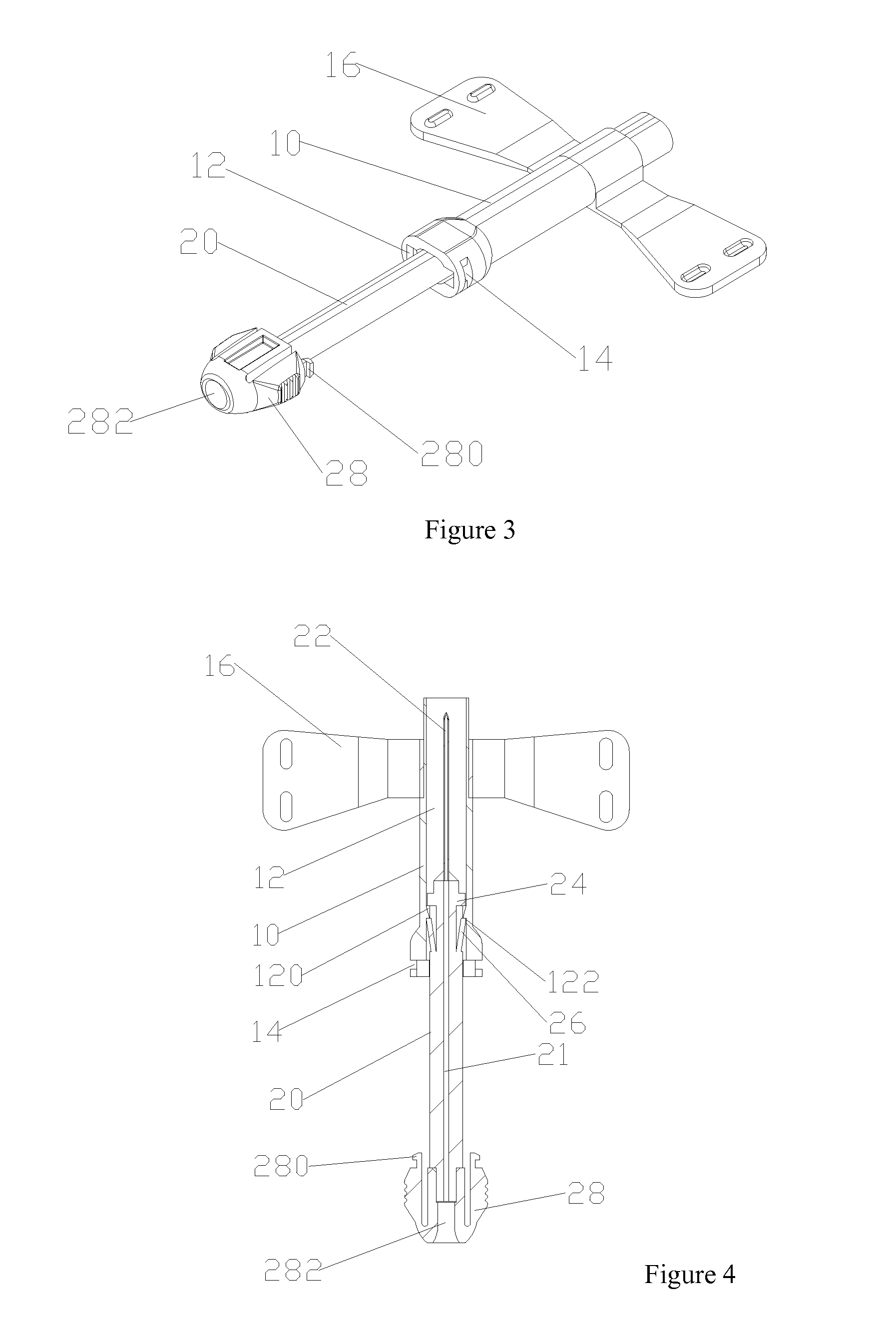

Multi-lancet cartridge and lancing device

ActiveUS20100057119A1Prevent rattlingLower potentialIncision instrumentsDiagnostic recording/measuringEngineeringBiological activation

A lancing device including a replaceable multi-lancet cartridge The lancing device includes a drive mechanism an activation mechanism, and an advancing mechanism The advancing mechanism includes a linear-pull slide controls an indexing mechanism, a charger mechanism, and a cap-displacement mechanism. The indexing mechanism sequentially advances the lancets to an active position The charger mechanism charges the drive mechanism and removes the lancet caps And the cap-displacement mechanism moves the separated caps from the lancing stroke path The activation mechanism then releases the charged lancet to traverse the lancing stroke path to pierce the subject's skin Some embodiments include an anti-reverse mechanism to prevent reuse of the lancets, and some include an emergency lancet reuse mechanism that permits emergency reuse of the last lancet And some embodiments include a movable depth-control wall for providing control and adjustment of the lancing penetration depth.

Owner:FACET TECH LLC

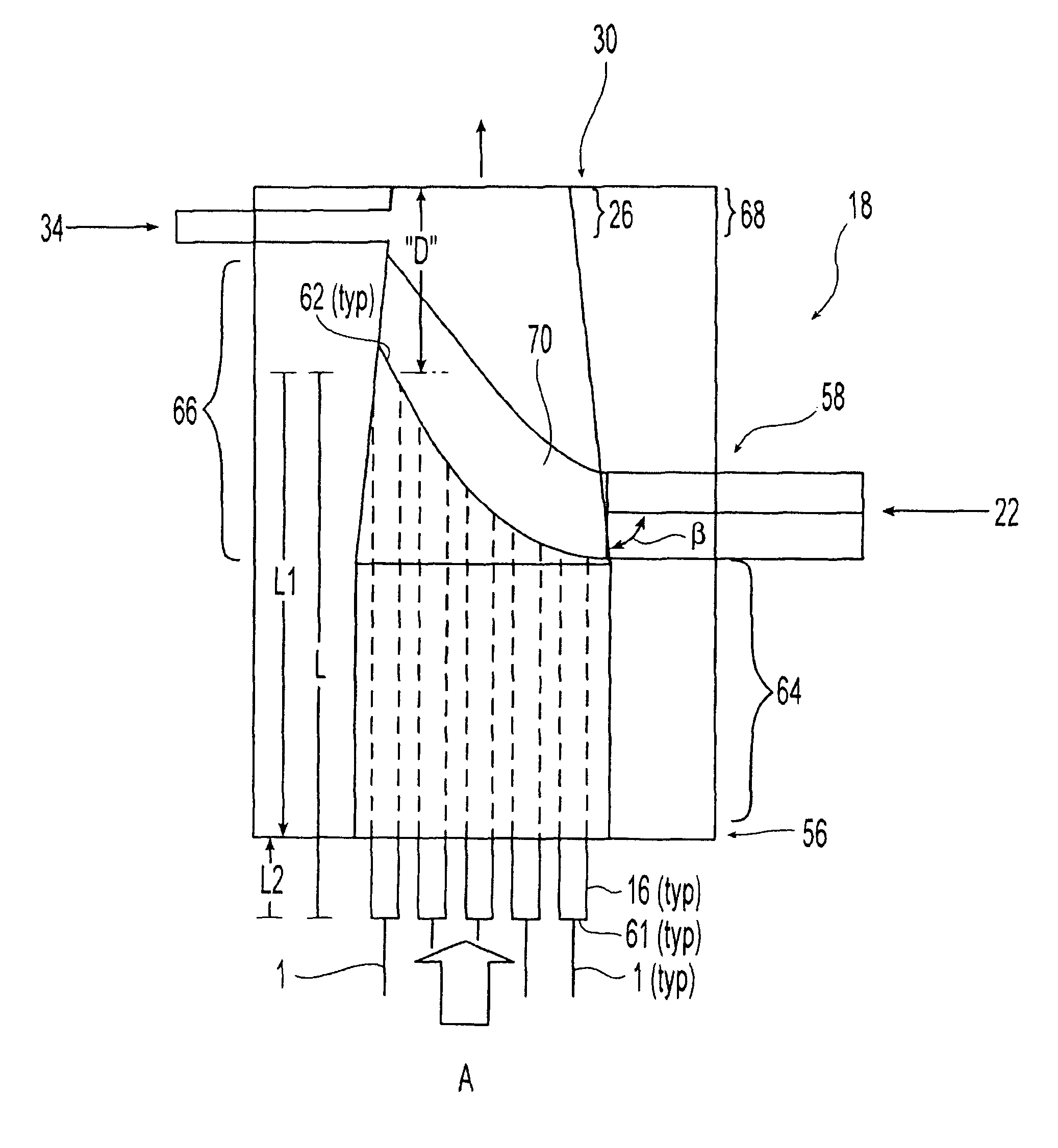

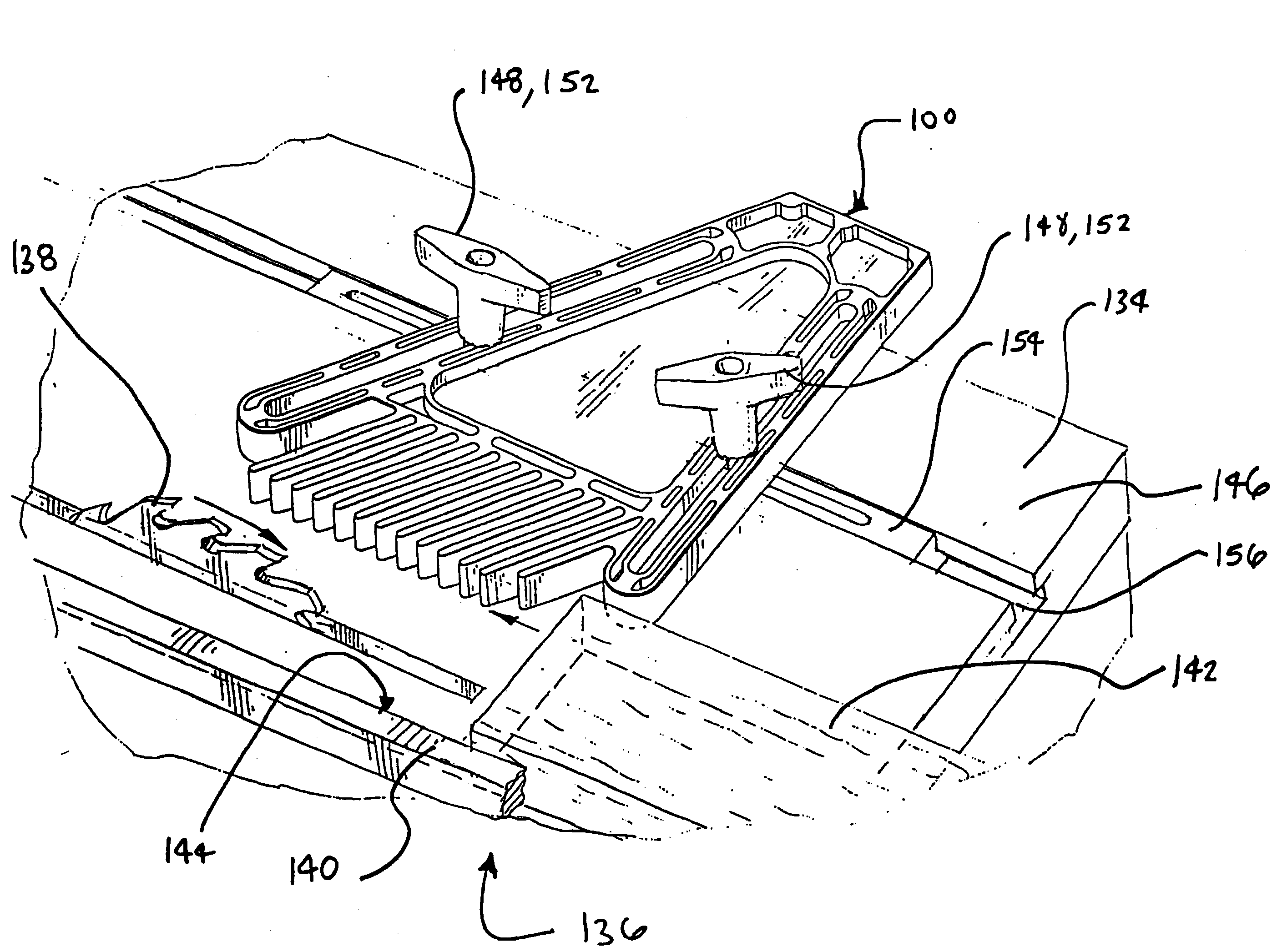

Workpiece motion guide and method

InactiveUS20060191596A1Prevent kickbackAvoid reverse motionGuide fencesMulti-purpose machinesEngineeringMechanical engineering

A motion guide for use with a machine having a table is disclosed. A motion guide in accordance with the present invention includes a body portion defining a top surface and a bottom surface, a first guiding surface extending between the top surface and the bottom surface, a second guiding surface extending between the top surface and the bottom surface, the second guiding surface being disposed at an angle relative to the first guiding surface, a plurality of keeper fingers protruding from a keeper surface extending between the top surface and the bottom surface, and disposed between the first guiding surface and the second guiding surface, the keeper fingers being generally parallel to each other, and an alignment member protruding from the keeper surface.

Owner:BENCH DOG

Filter use limitation device for liquid containers

InactiveUS6303023B1Accurate monitoringDifferent typeIndication apparatusTreatment involving filtrationEngineeringMechanical engineering

A filter use device is adapted for use with various types of containers, such as, liquid containers for water coolers in which the device includes a cap to be threaded onto an open end of the container, a filter cartridge in the cap which retains a conventional filter and a resilient pawl which is engageable with a disk having an indicator aligned with a slot in the cap and engageable with ratchet teeth to incrementally advance the indicator each time that the cap is threaded onto the end of the container; and when the indicator reaches the end of the slot is shifted to prevent any further advancement of the disk or passage of water through the filter or device and thereby signify the end of the life of the filter and the need for replacement of the filter.

Owner:GEBRHARD ALBERT W +1

Ladder safety device having a building clamp assembly and a ladder hook assembly

InactiveUS20160281428A1Move quicklyQuick installationFriction grip releasable fasteningsLaddersMechanical engineeringEngineering

A house clamp assembly having a fixed jaw and a slide bar mounted movable jaw, the fixed jaw opposing the movable jaw. A one-way drive means, by operation of a trigger handle grip, releasably engages the slide bar and advances the movable jaw towards the fixed jaw. The one-way drive means is incapable of moving the slide bar and movable jaw away from the fixed jaw. A return motion of the movable jaw (separating) is accomplished manually when the one-way drive means is disengaged. A braking lever, which is biased to bind the slide bar, prevents reverse motion of the slideable jaw away from the fixed jaw, except when the first lever is disengaged from the slide bar. A device for securing a ladder to a building, wherein the removed end of the slide member has a hook shape; wherein the jaws include jaw faces having multiple raised portions, wherein the releasable braking means of the building clamp assembly means includes a pivoting lever; wherein the locking member of the ladder hook assembly includes a pivoting lever, attached at one end to the body, and having a slot dimensioned to slideably receive the hook slide member therethrough; wherein the body of the ladder hook assembly includes a pair of slots dimensioned for and adapted to slideably receive the slide member therethrough; and wherein the slots are arranged to maintain the hook slide member substantially parallel to the slide bar of the building clamp assembly

Owner:RUDD DAVID MICHAEL

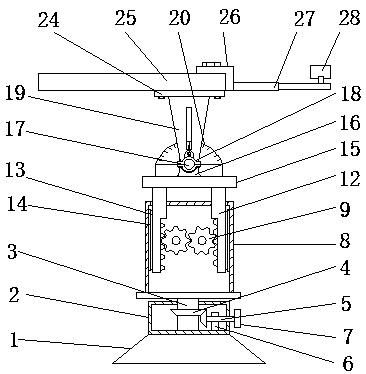

Intelligent lock control method

ActiveCN109458061ARealize automatic openingPrevent reversalWing handlesNon-mechanical controlsGear drivePassword

The invention relates to the technical field of lockset, and in particular relates to an intelligent lock control method. The intelligent lock control method comprises the following steps of S1, identifying the person who opens a door; S2, after the person who opens the door is identified successfully, energizing a motor, driving a locking bar to move to a spring III by the motor, withdrawing a lock tongue into a lock body, and thus realizing the automatic unlocking of an intelligent lock; S3, after the intelligent lock is unlocked, clamping a gear by a pawl to prevent inversion, and thus keeping the lock tongue in the lock body; and S4, after the person who opens the door completes the door-opening operation and closes the door, turning a handle to eject the lock tongue from the lock body, and thus realizing door-locking operation. According to the intelligent lock control method, the opening of the lock tongue is driven by the gear; after password or fingerprint verification is successful, the motor is energized to drive the gear to rotate, the gear drives the locking bar to slide to the inner part of the lock body, and therefore the lock tongue is pulled into the lock body; andat the moment, the door can be opened by pulling the handle.

Owner:FANGZHEN DIGIT BEIJING

Multi-lancet cartridge and lancing device

ActiveUS8221332B2Prevent rattlingLower potentialIncision instrumentsDiagnostic recording/measuringEngineeringBiological activation

A lancing device including a replaceable multi-lancet cartridge The lancing device includes a drive mechanism an activation mechanism, and an advancing mechanism The advancing mechanism includes a linear-pull slide controls an indexing mechanism, a charger mechanism, and a cap-displacement mechanism. The indexing mechanism sequentially advances the lancets to an active position The charger mechanism charges the drive mechanism and removes the lancet caps And the cap-displacement mechanism moves the separated caps from the lancing stroke path The activation mechanism then releases the charged lancet to traverse the lancing stroke path to pierce the subject's skin Some embodiments include an anti-reverse mechanism to prevent reuse of the lancets, and some include an emergency lancet reuse mechanism that permits emergency reuse of the last lancet And some embodiments include a movable depth-control wall for providing control and adjustment of the lancing penetration depth.

Owner:FACET TECH LLC

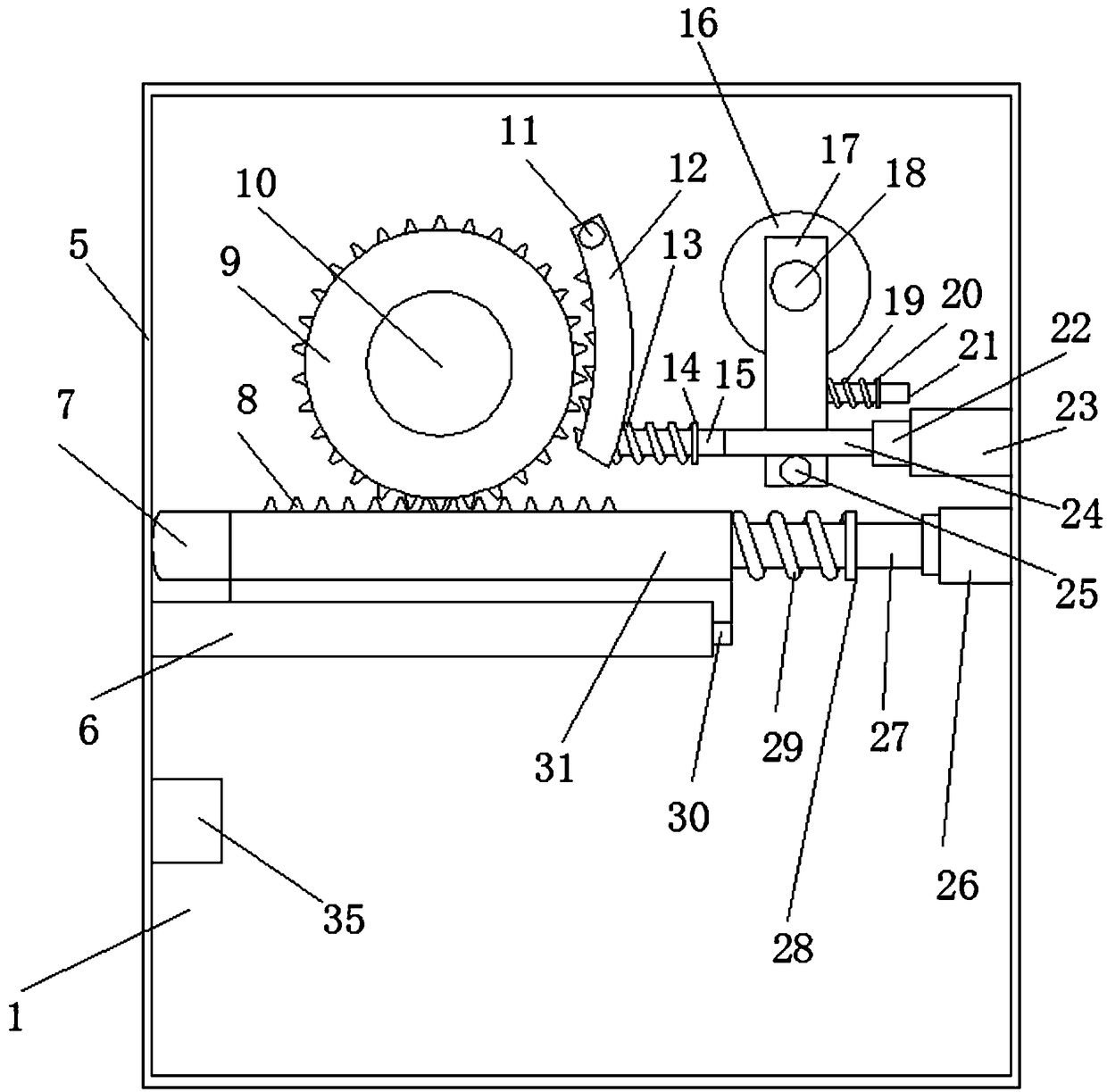

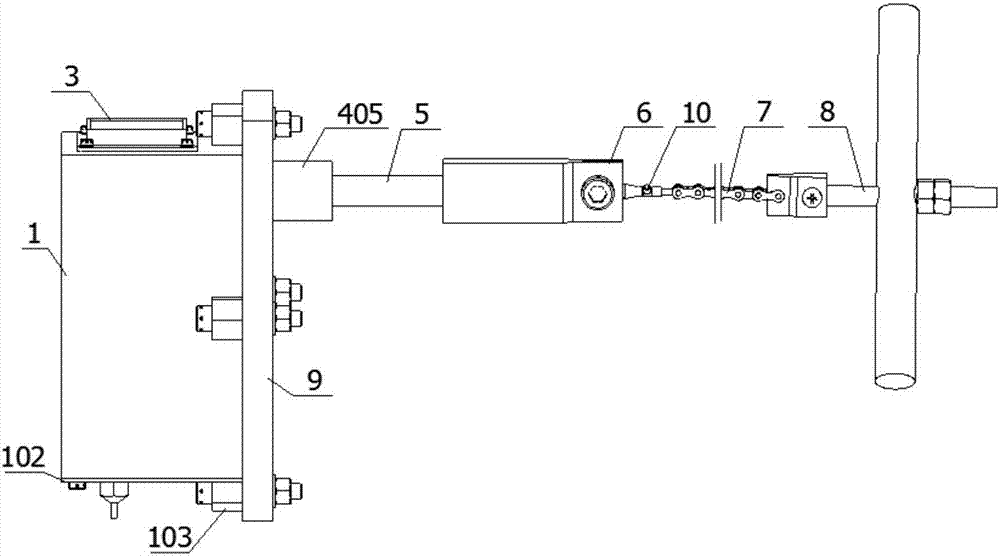

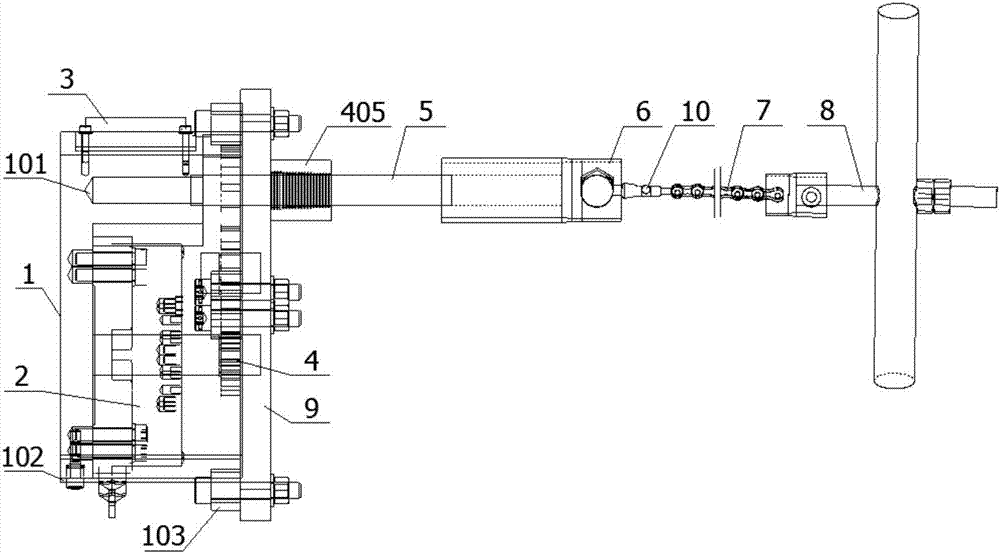

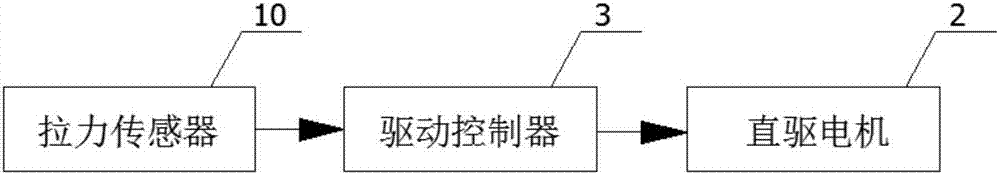

Chain tensioning adjusting mechanism

ActiveCN106931110AImprove driving precisionAvoid chain dropGearingElectric machineryWorking environment

The invention relates to a chain tensioning adjusting mechanism which comprises a shell, a direct drive motor, a drive controller, a transmission device, a transmission lead screw, a first connector device, a chain and a second connector device. The direct drive motor is arranged in the shell, and the drive controller is arranged at the upper end of the shell and is connected with the direct drive motor through a line; a supporting plate is arranged on the outer side of the shell, the transmission device is arranged on the side, close to the shell, of the supporting plate, and the direct drive motor is connected with the transmission device; one end of the transmission lead screw penetrates the supporting plate to be connected with the output end of the transmission device, and the other end of the transmission lead screw is connected with one end of the first connector device; the other end of the first connector device is connected with the second connector device through a chain; and a tension sensor is arranged at the connecting position of the first connector device and the chain and is connected with the drive controller through a line. By means of the chain tensioning adjusting mechanism, automatic chain tensioning is achieved, the chain driving accuracy is improved, chain falling is prevented, the chain tensioning adjusting mechanism can adapt to the wicked work environment, and the reliability coefficient is high.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Card reader

ActiveUS7364076B2Prevent movementIncrease freedomConveying record carriersSensing record carriersEngineeringCard reader

Owner:SANKYO SEIKI MFG CO LTD

Coin dispensing device

ActiveUS7201649B2Prevent resultPrevent returnCoin countersCoin dispensersEngineeringMechanical engineering

A coin dispensing device is provided that prevents a returning of a first coin to prevent a clink noise. The coin dispensing device has a rotating disk that dispenses coins to a guiding unit one by one. The dispensed coins are guided upwards by the guiding unit in a line. A coin return preventing unit prevents the first coin going backward which is located adjacent to the rotating disk. The first coin dispensed by the rotating disk is prevented from moving backwards.

Owner:ASAHI SEIKO CO LTD

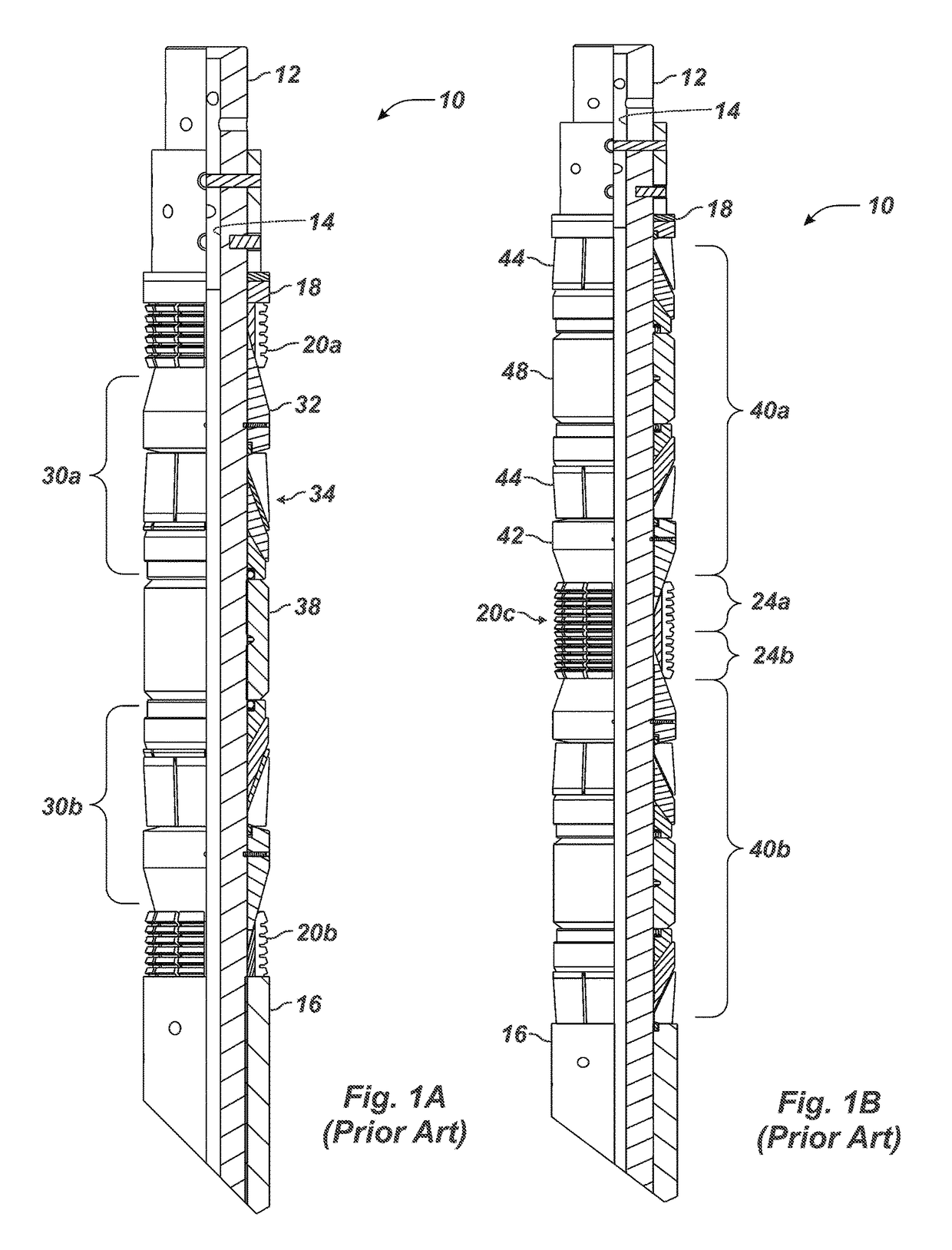

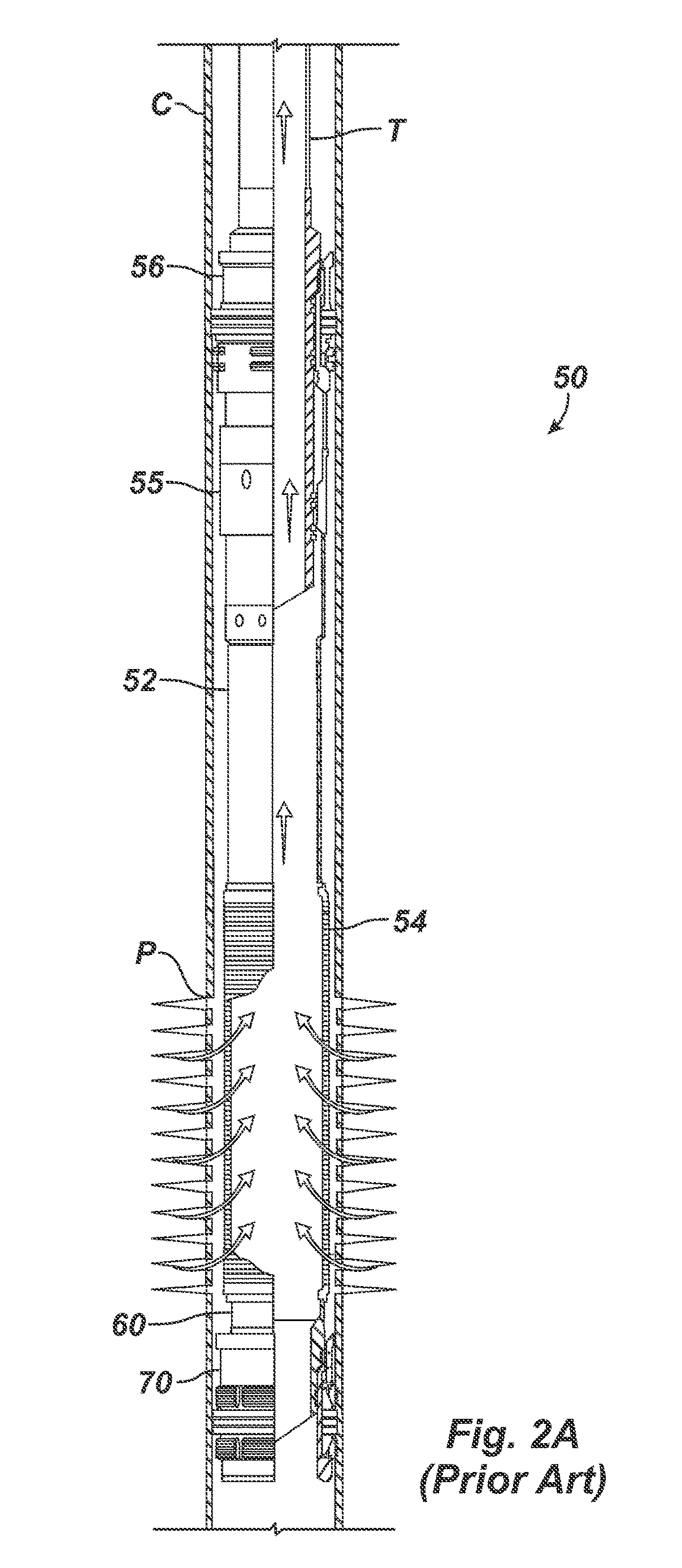

Downhole Tool having Slips Set by Stacked Rings

An apparatus installs downhole in a surrounding tubular. A first shoulder on a mandrel of the apparatus is movable toward a second shoulder. A plurality of stacked rings are disposed about the mandrel and are spaced between the first and second shoulders. A first of the stacked rings decreases in spacing in response to the movement of the first shoulder toward the second shoulder, and a second of the stacked rings expands outward from the mandrel in response to the decrease in spacing. A slip disposed on the stacked rings is movable away from the mandrel toward the surrounding tubular in response to the outward expansion. The apparatus can be a plug, a bridge plug, a fracture plug, a packer, a permanent packer, a retrievable packer, a sump packer, and a sealbore packer. Additionally, the apparatus can include a completion assembly with packer and screen supported on the mandrel.

Owner:WEATHERFORD TECH HLDG LLC

Full automatic unpacking unloader

InactiveCN101508358BAchieve isolationAvoid reverse motionSievingConveyorsEngineeringEnergy conservation

The invention relates to a solid material unpacking machine, in particular to a full automatic unpacking and unloading machine, which is characterized in that: all stages of mechanisms are connected through flanges; a bag breaking mechanism, a screening mechanism and a material output mechanism are arranged on a main body frame; the outer surface of the main body frame is connected with a surfacepanel in a splicing mode; the surface panel on the top of the main body frame is provided with a main dust removal outlet; and a channel formed from the feeding inlet end of a feeding mechanism to the outlet end of the material output mechanism and the outlet end of a waste bag output mechanism is a one-way communication channel. The full automatic unpacking and unloading machine has the advantages that the machine has high work efficiency, energy conservation, environmental protection, small volume, light weight and the like, can safely and stably separate solid materials from packages in automatic high-speed running, and convey the materials to downstream equipment, while the waste packages enter a waste bag recovery device for recovery, and the machine can particularly meet the requirements of unloading, separating and collecting toxic and corrosive powder, and particle materials.

Owner:HANRUI PUZER BULK HANDLING TECH SHANGHAI

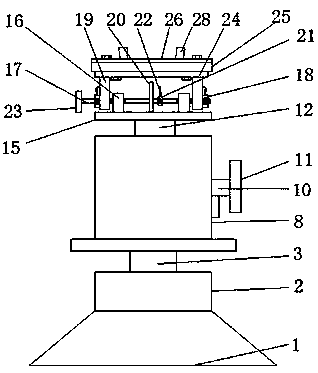

Adjusting support used for atmosphere infrared detector

ActiveCN107703060AAvoid reverse motionHigh precisionMaterial analysis by optical meansCircular discManufacturing technology

The invention discloses an adjusting support used for an atmosphere infrared detector, which belongs to the technical field of design and manufacture of an atmosphere infrared detector. The adjustingsupport includes a pedestal; the top end of the pedestal is equipped with a gear case; the inner chamber of the gear case is provided with a bevel gear rotating shaft; the right end of a bevel gear shaft is provided with a turning handle I; the top of the bevel gear rotating shaft is provided with a rotary case; the inner chamber of the rotary case is equipped with a pair of engaged gears; a frontend of a rotating shaft adjacent to the left end is equipped with a turning handle II; the left and right sides of the pair of engaged gears are engaged to a group of racks; one sides, adjacent to the inner walls of the rotary case, of the racks are provided with slide strips; the top ends of the racks are equipped with a disc; the top of a fixed plate is provided with a supporting board; the topof the right side of the supporting board is equipped with an L-shaped board; the right end of the L-shaped board is equipped with a telescopic rod; and the right end of the telescopic rod is equipped with an arc-shaped bracket. The adjusting support can meet different adjusting manners, and is simple and convenient in manual adjusting and simple in motion principle.

Owner:SUZHOU GUANGSHENG ENVIRONMENTAL TECH CO LTD

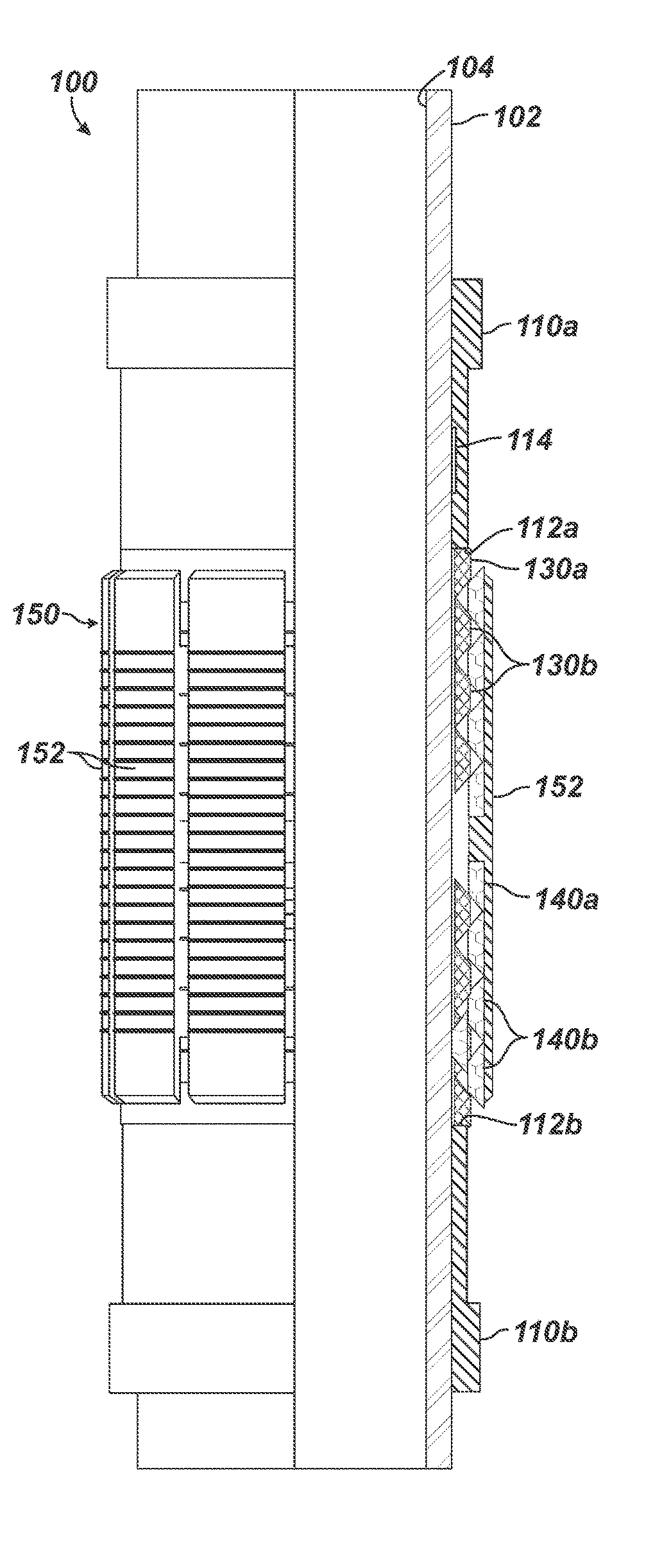

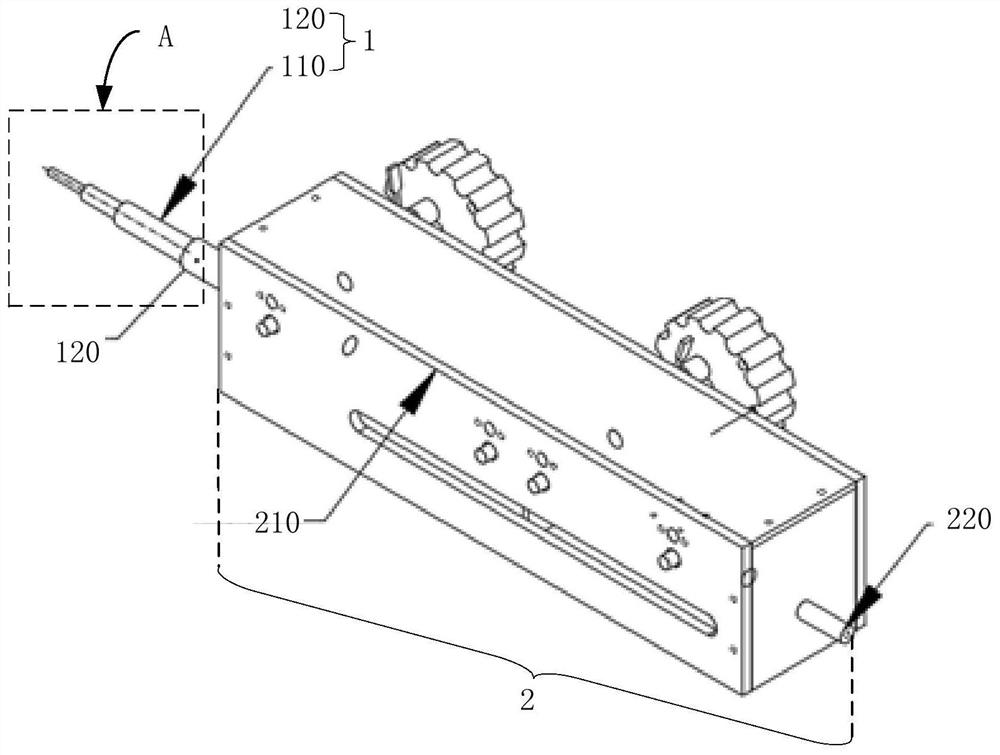

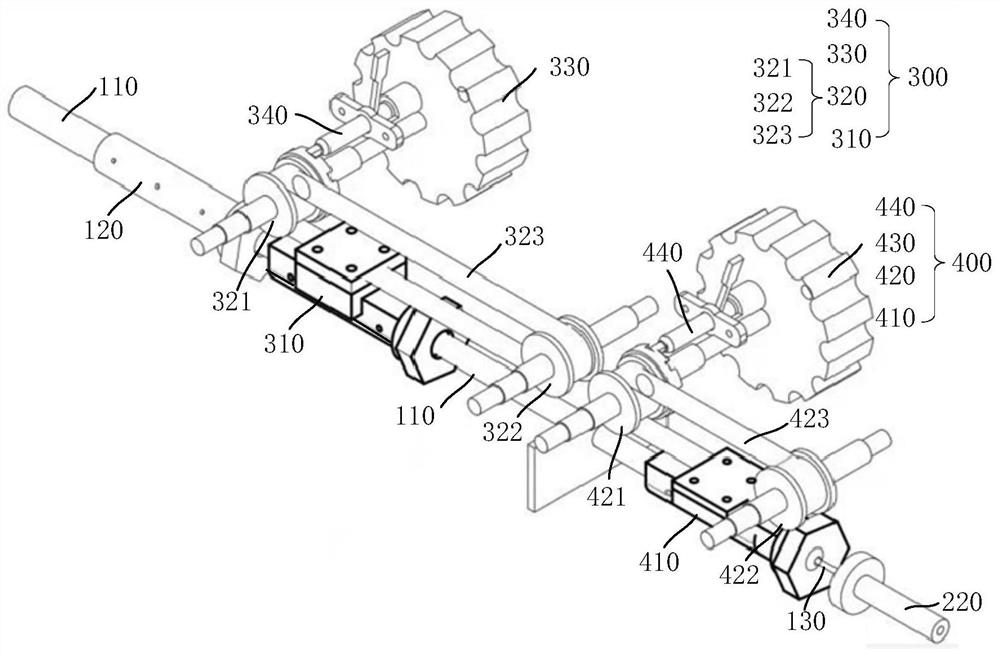

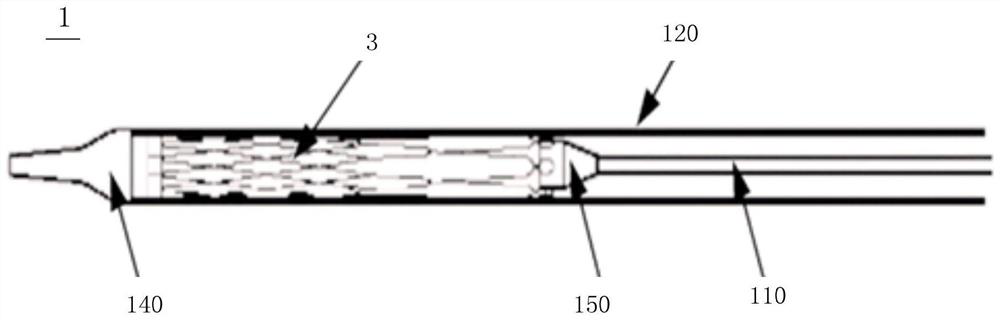

Implant conveying handle, implant system, conveying system and working method of conveying system

The invention provides an implant conveying handle, an implant system, a conveying system and a working method of the conveying system. The implant conveying handle comprises two conveying subsystems arranged in the axial direction of a catheter assembly, and the conveying subsystem located at the far end is connected with the near end of an outer tube of the catheter assembly; the delivery subsystem located at the near end is connected with the near end of an inner tube of the catheter assembly; each conveying subsystem comprises synchronous conveying devices and ratchet wheel devices, wherein each ratchet wheel device is fixed on the corresponding synchronous conveying device and is used for carrying out safe self-locking and transmission guiding on the outer tube or the inner tube through the corresponding synchronous conveying device so as to realize locking of the inner tube and the outer tube in a single direction; and reverse movement of the inner tube or the outer tube caused by misoperation of an operator is avoided, safe self-locking of the implant conveying handle is achieved, and the inner tube or the outer tube is prevented from being out of control at an uncontrolled position.

Owner:SHANGHAI TRULIVE MEDTECH CO LTD +1

Self-destructive type safe medical needle

InactiveUS20160106933A1Improve securityReduce usageCatheterSensorsReciprocating motionSyringe needle

A self-destructive type safe medical needle comprises: a sleeve with an inner cavity, a needle base which can do reciprocating motion in the inner cavity and a needle head, a lock catch head buckled with the needle base, a lock catch head buckled with the needle base, and a conduit connected with the inside of the lock catch head, wherein the sleeve is provided with a barrier block and a lock catch block in the inner cavity, and the needle base is provided with a limiting part which is propped against and matched with the barrier block and a deformable locking part which is locked and matched with the lock catch block. The needle avoids cross infection between patients, secondary use of needle and puncture of staff after use or in the process of destroying. Further, this needle also can realize self-destruction and prevent man-made rotation of the medical needle.

Owner:JIANGSU CAINA MEDICAL TECH

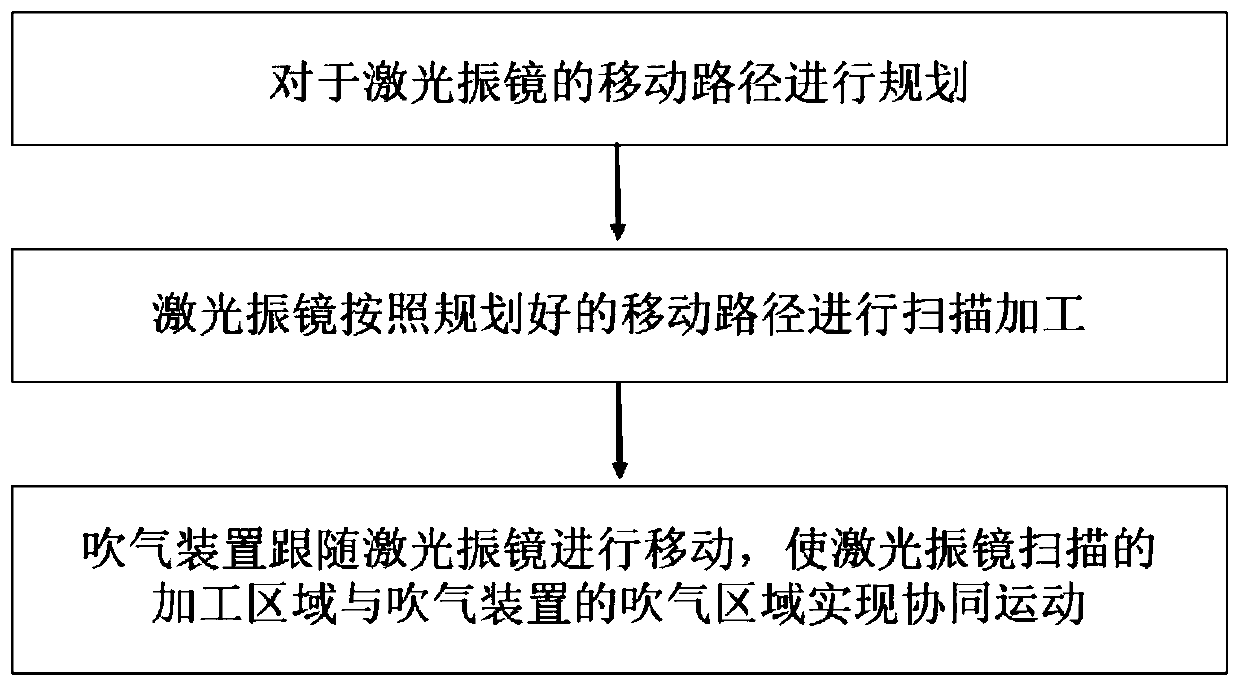

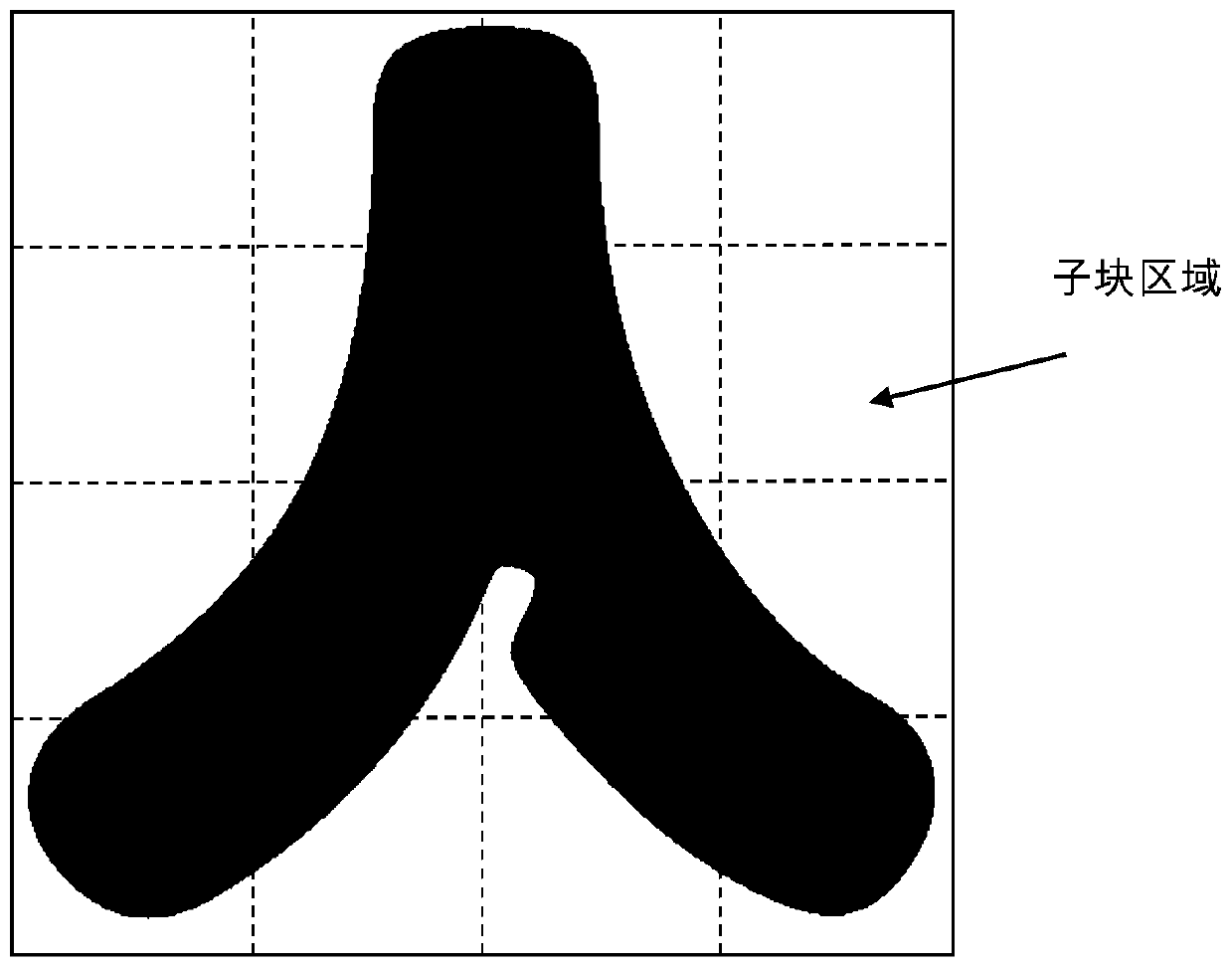

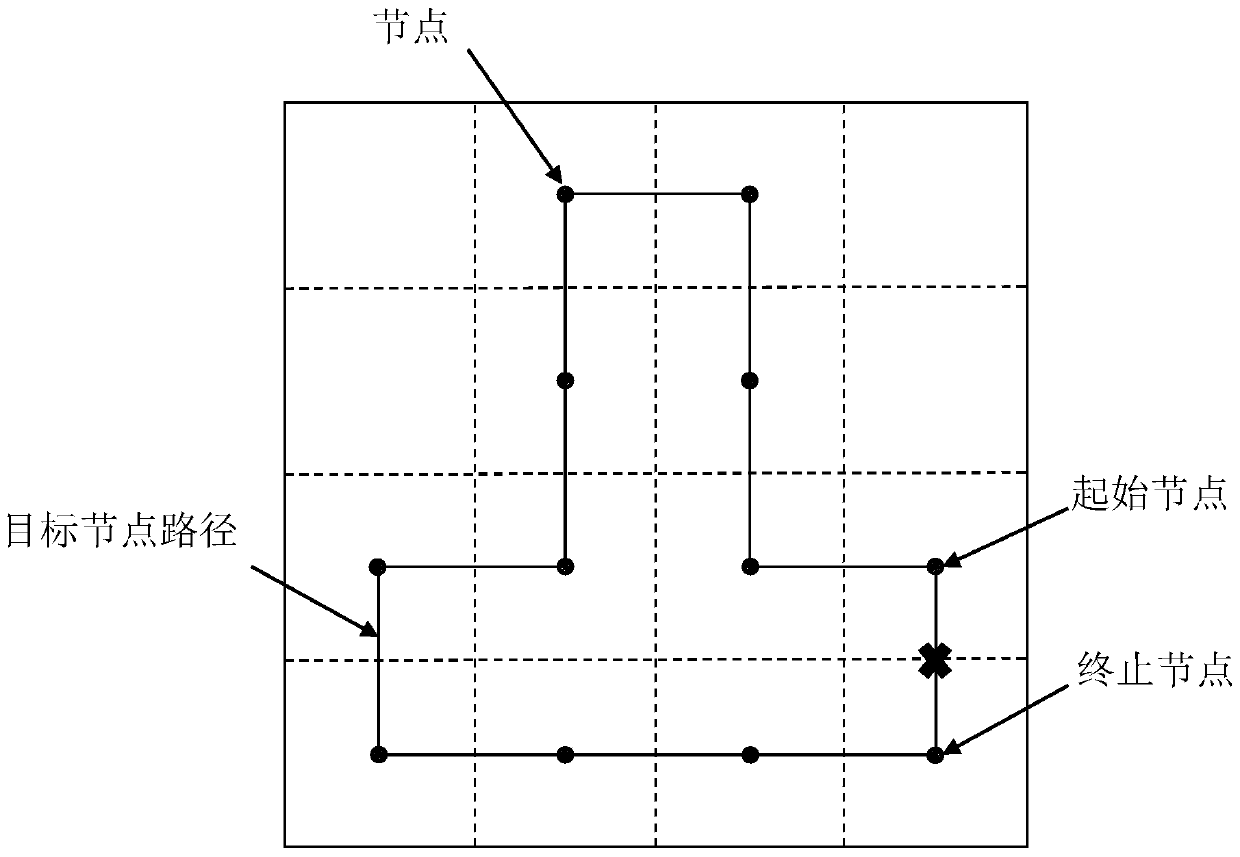

Laser machining method and device for cooperative motion of laser galvanometer and air blowing device

ActiveCN110560886ASolve matching problemsImprove qualityLaser beam welding apparatusGalvanometerLight beam

The invention discloses a laser machining method and device for cooperative motion of a laser galvanometer and an air blowing device. The method comprises the steps that a moving path of the laser galvanometer is planned; scanning machining is carried out by the laser galvanometer according to a planned moving path; the air blowing device moves cooperatively along with the laser galvanometer; andthe device comprises the laser galvanometer, the air blowing device and a driving device, wherein the laser galvanometer is arranged opposite to a laser source, the air blowing device is arranged below the laser galvanometer, and the driving device is used for moving the air blowing device. According to the method, through the optimized path and the mode of block machining on the path, the problemof matching between the high-speed mobility of the galvanometer and the motion of a motor platform is solved; and meanwhile, idle stroke waiting of the galvanometer redundancy is avoided, and the waiting time of the galvanometer idle stroke is reduced to the minimum, so under the condition that the machining efficiency is guaranteed, the influence of the heat effect on the machining effect in thelaser machining process can be reduced, the problem of shielding of a galvanometer light beam in the moving process of the air blowing device is avoided, and the quality of a laser machining workpiece is improved.

Owner:HUAZHONG UNIV OF SCI & TECH

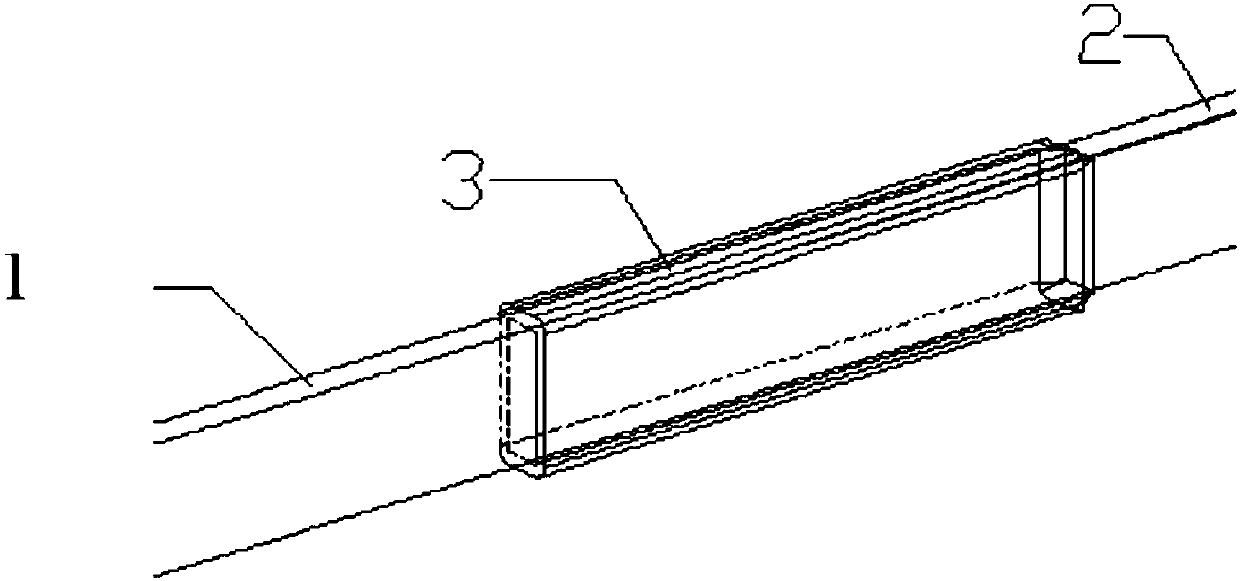

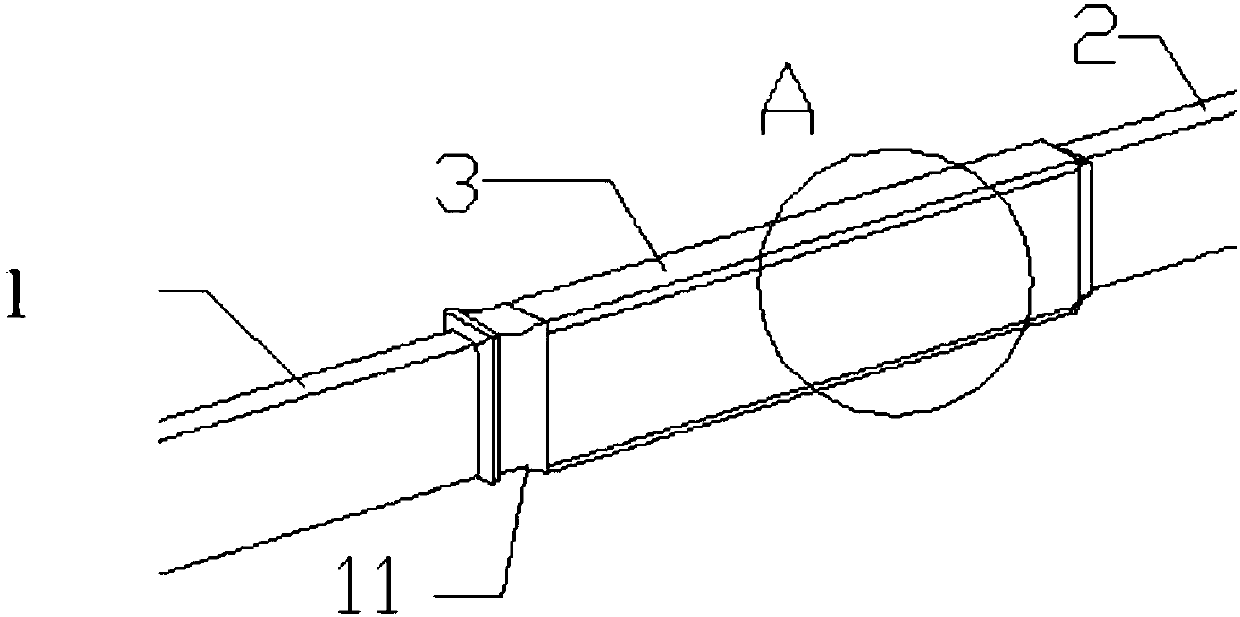

Stretchable artificial rib

Owner:大连派思益科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com