Patents

Literature

267results about How to "Easy to loose" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

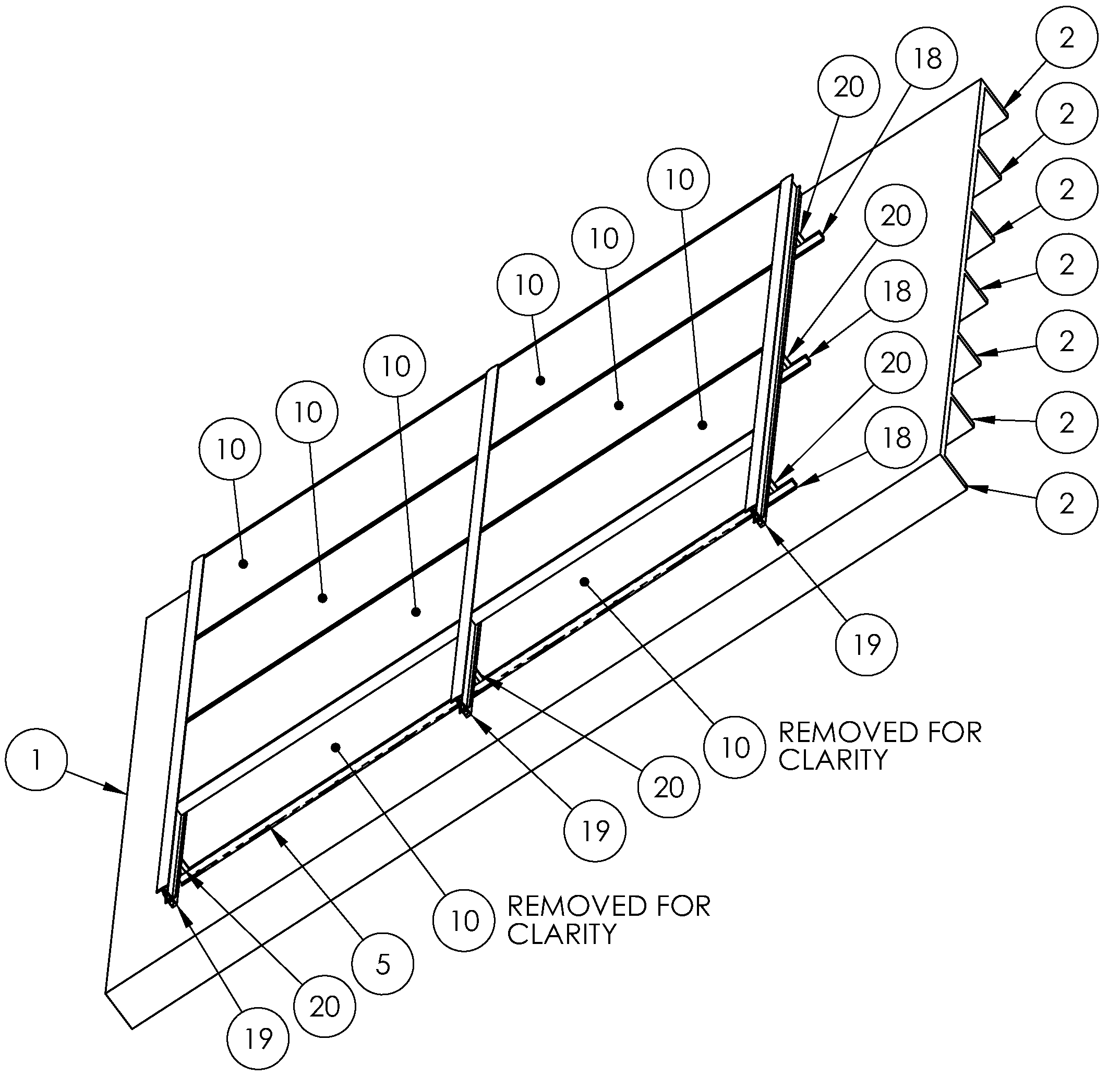

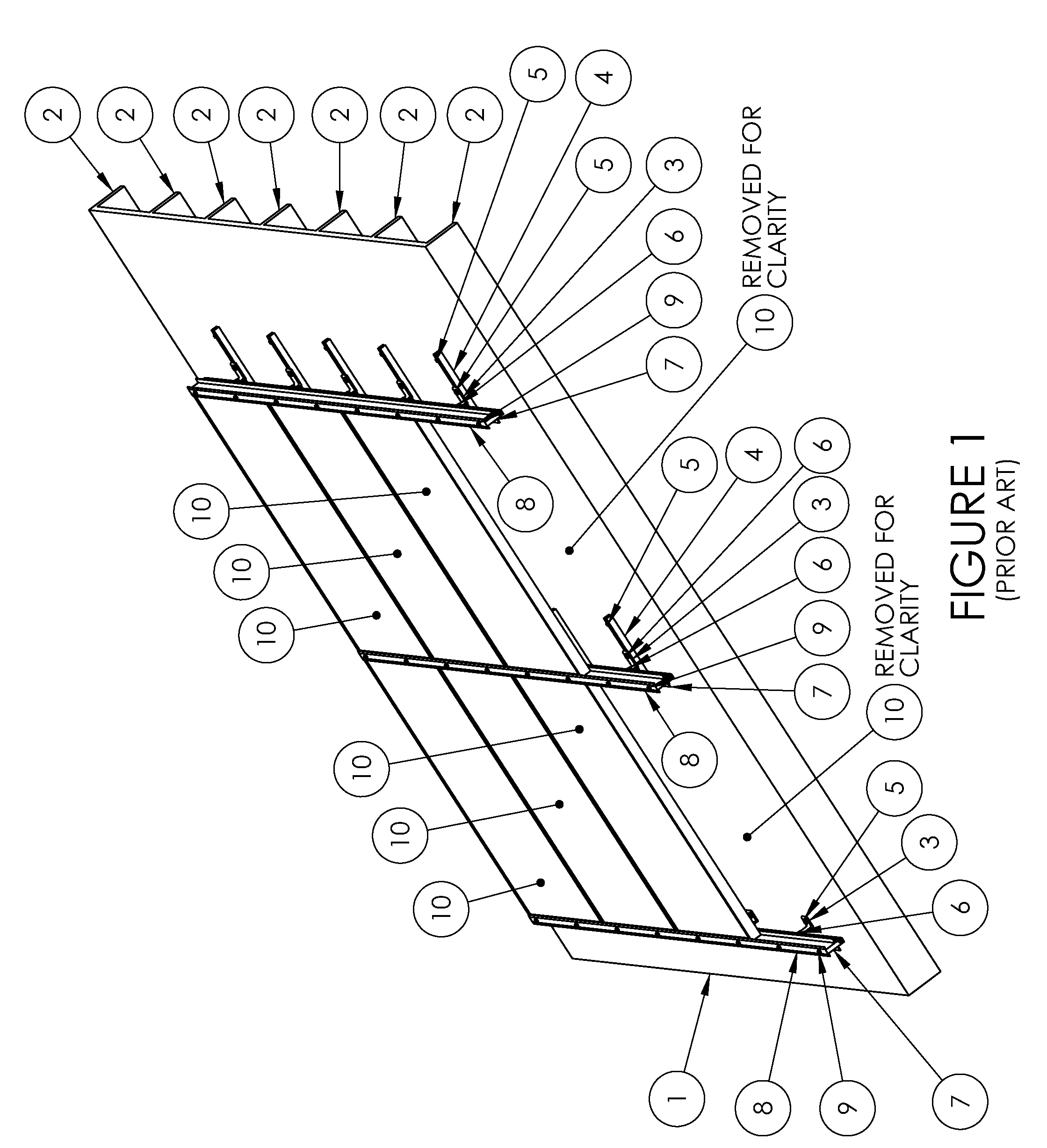

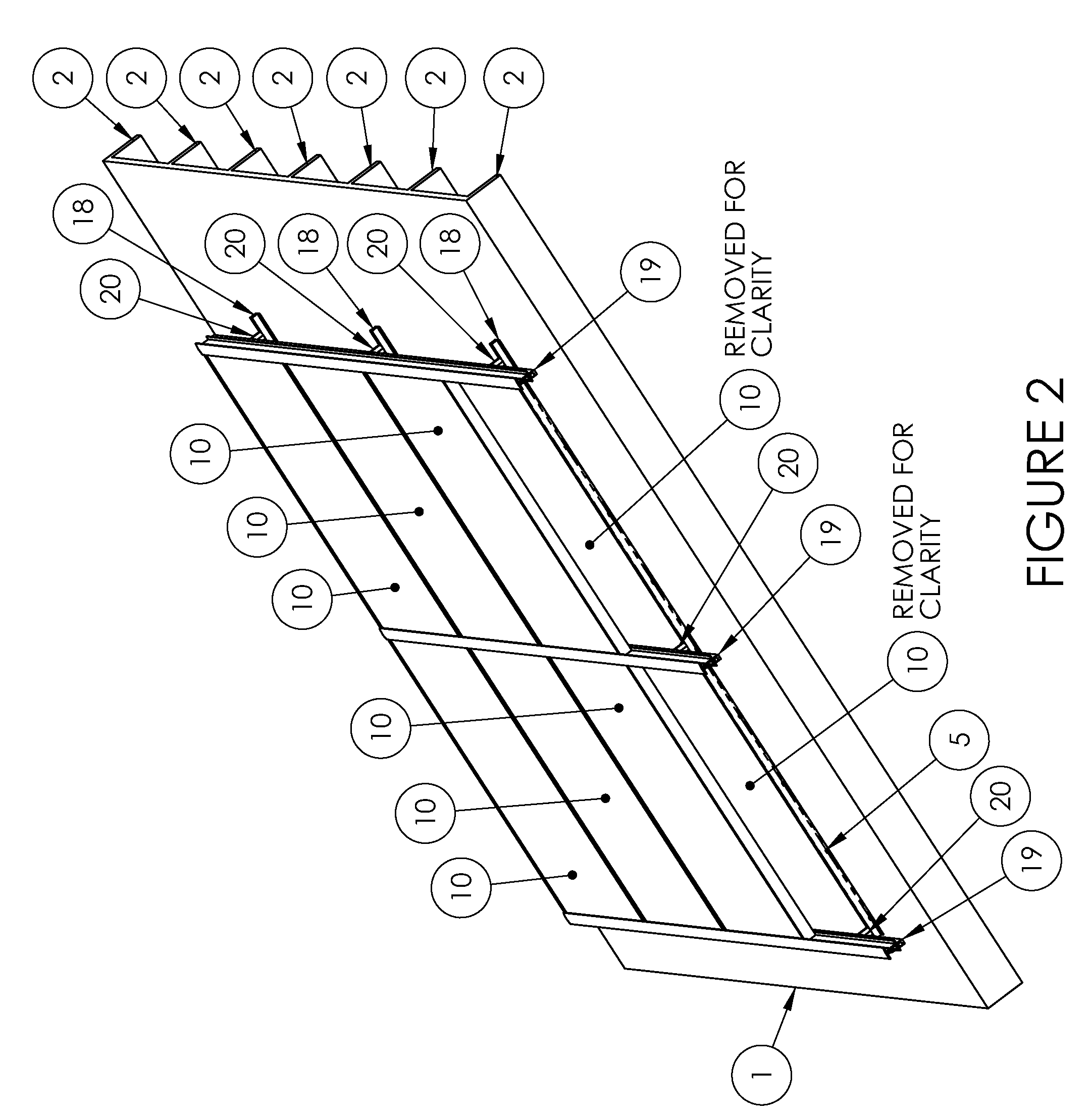

Photovoltaic mounting system with locking connectors, adjustable rail height and hinge lock

InactiveUS20090282755A1Cost-effectiveTurn easilyPhotovoltaic supportsSolar heating energyElectricityPhotovoltaic mounting system

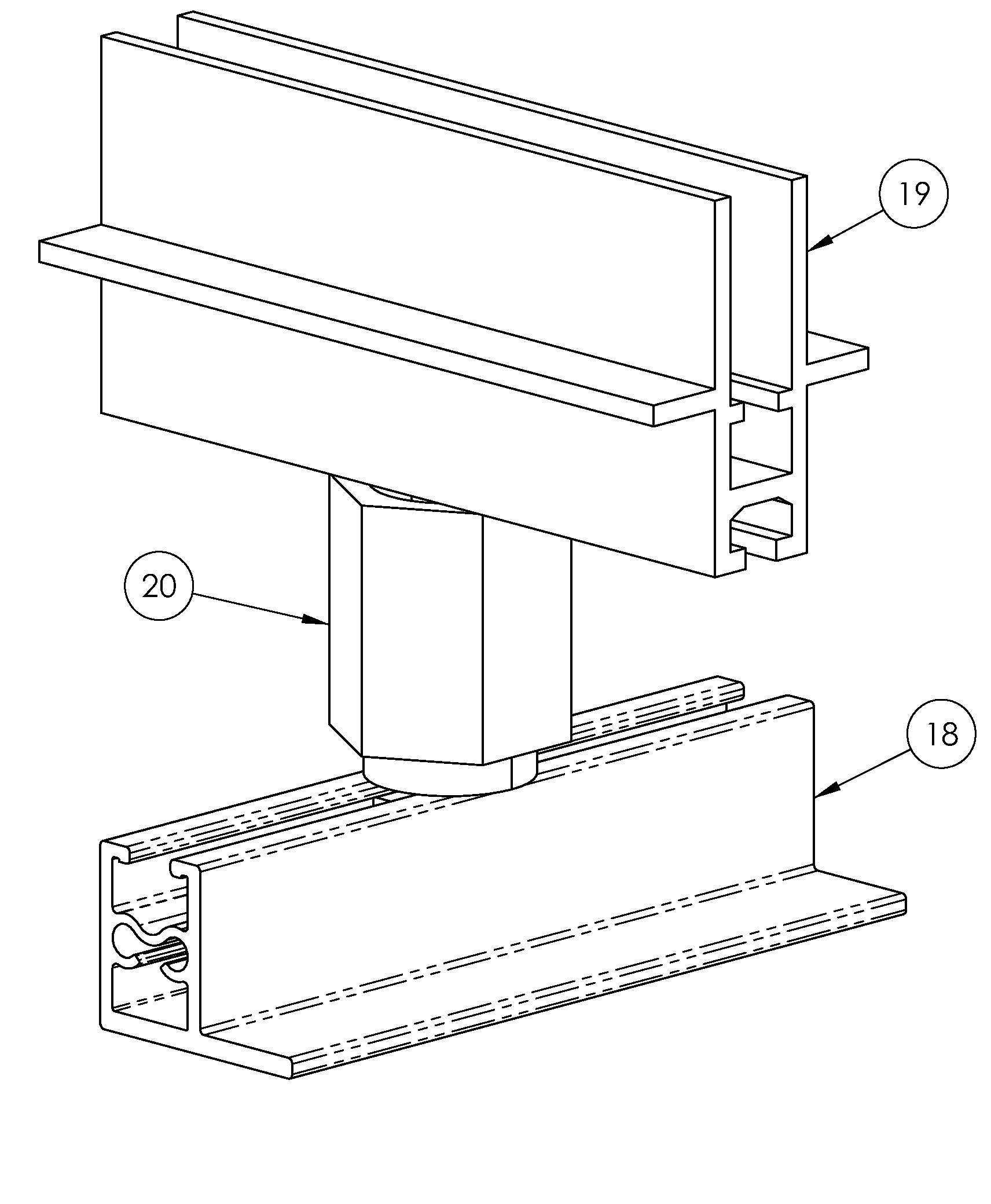

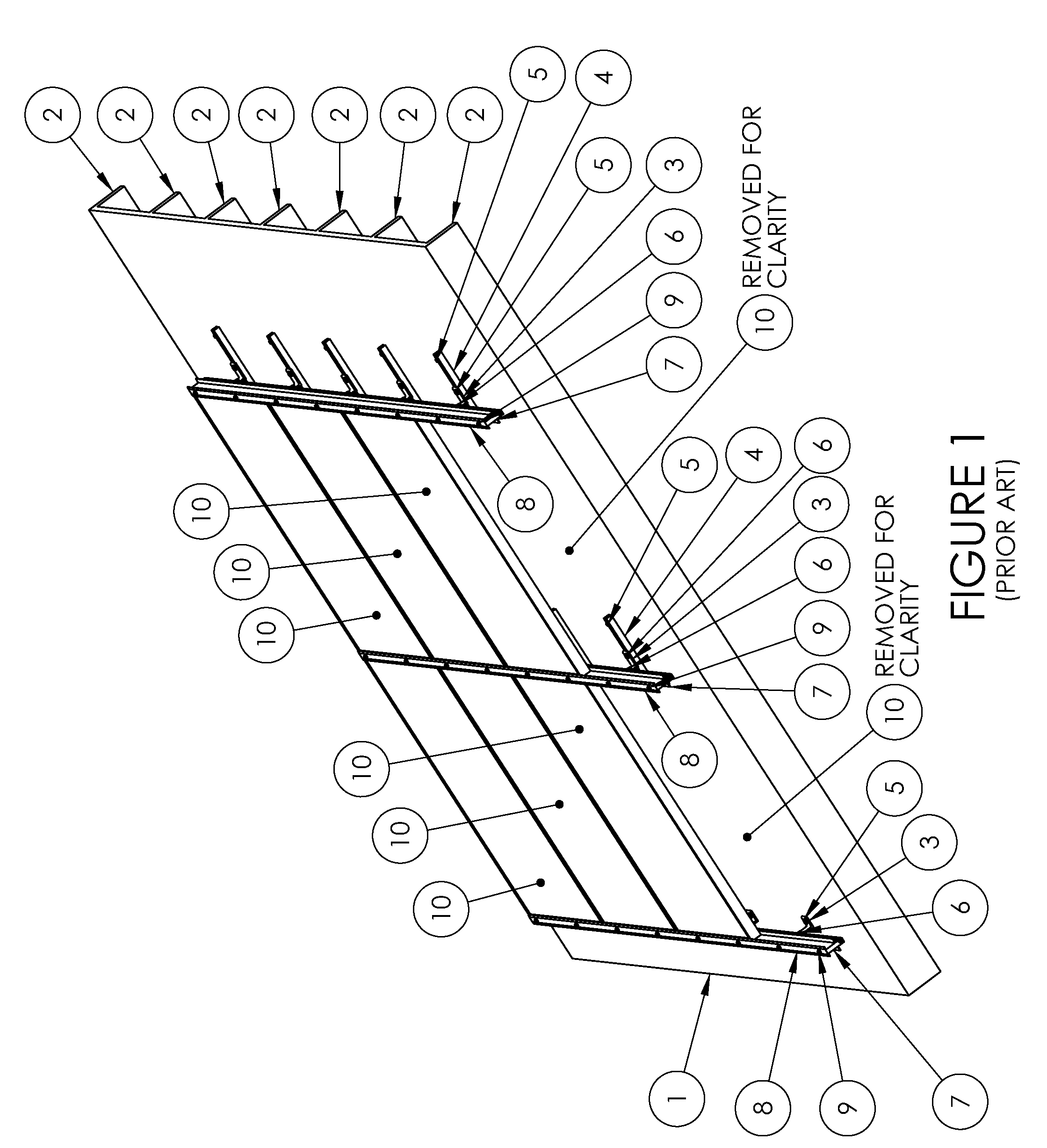

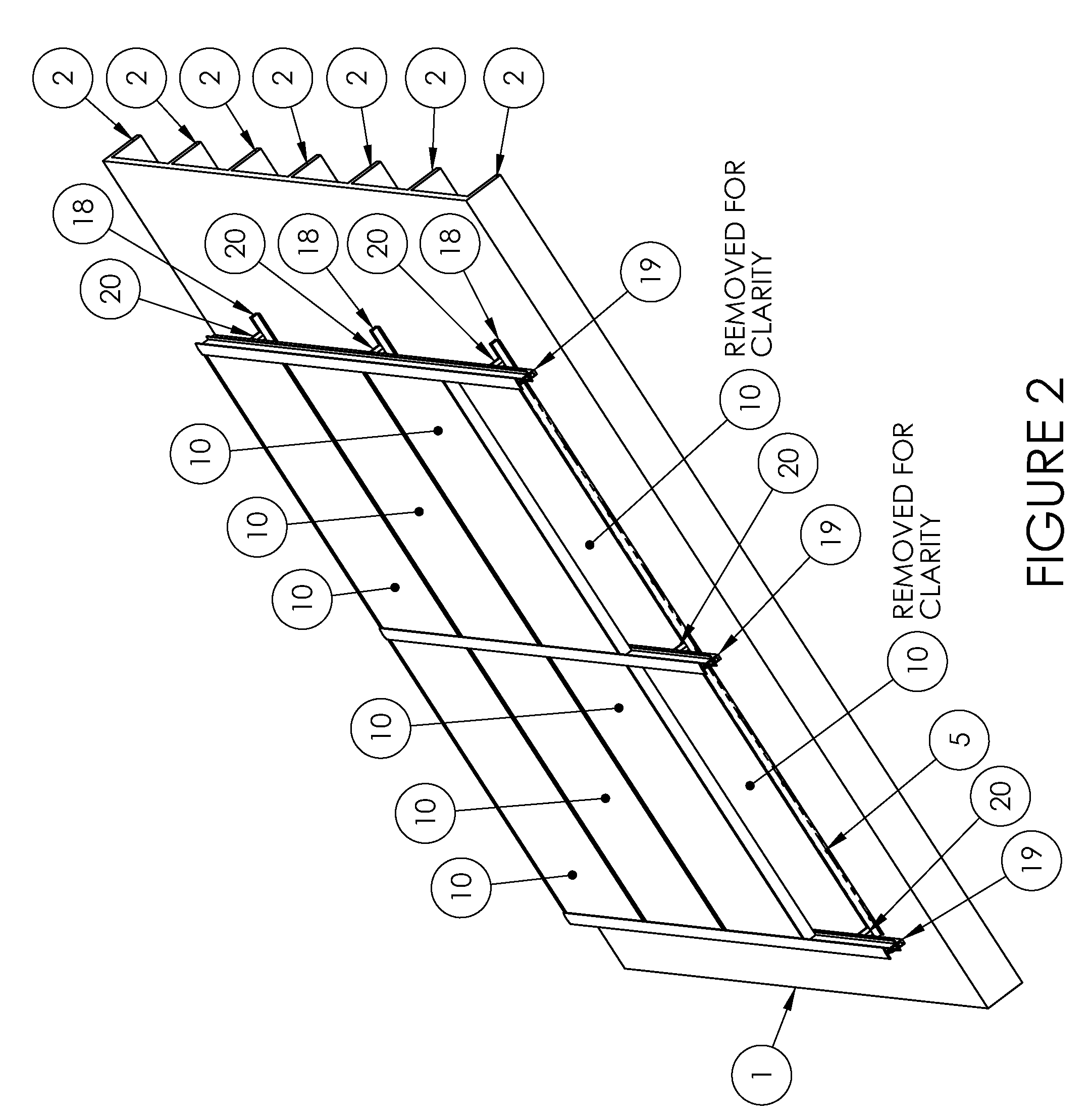

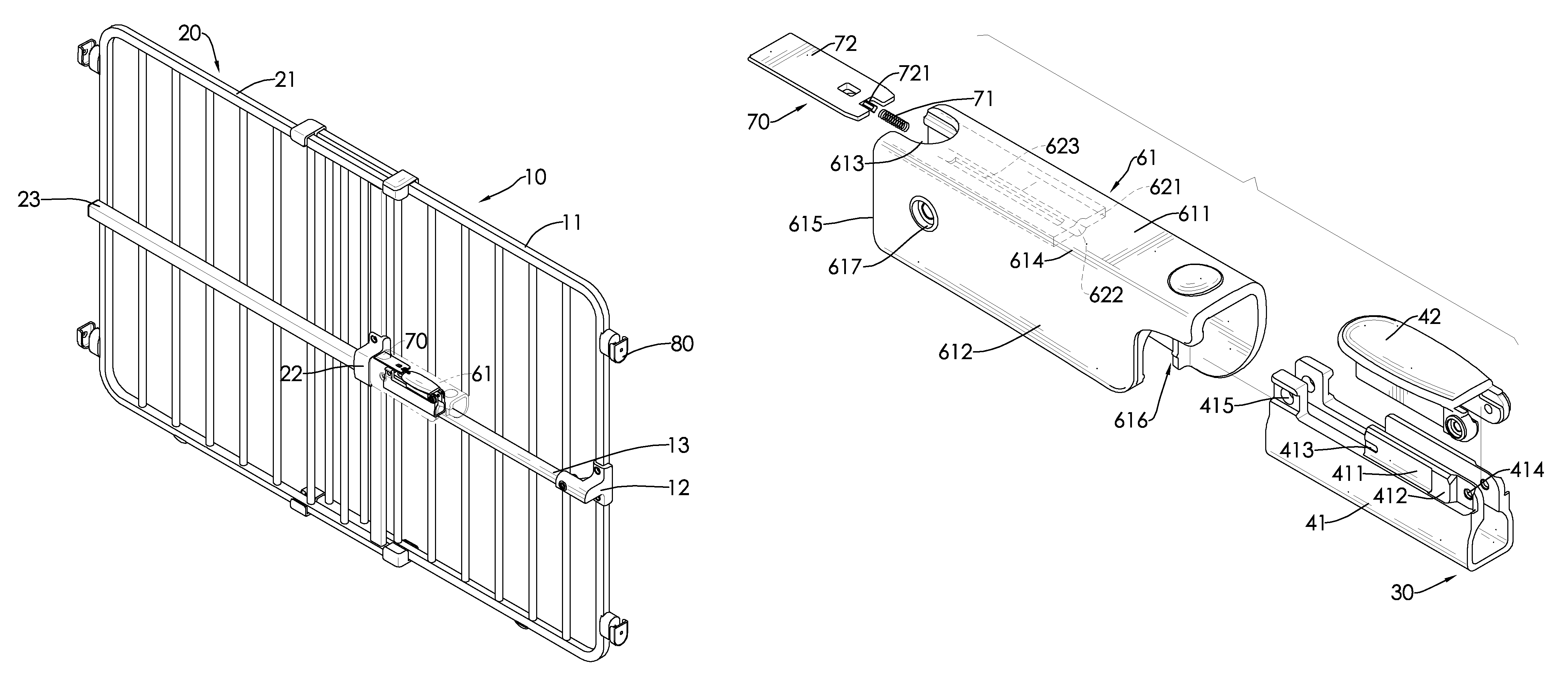

A cam-actuated connection device joins rail mounting members of a photovoltaic panel array. The connection device slides within channels of mounting members until the members are in a properly positioned grid. When in position, the connection device is rotated to lock the mounting members in a rigid grid network. The connecting device can be subsequently loosened, repositioned and locked into position. The rail-mounting members create a grid for installation of multiple PV panels. The mounting rail allows the unit to remain relatively compact in nature but still covers a wide range of PV panel thicknesses. The rail system has a hinged connection with the mounting rail that allows an installer to assemble the module in a near perpendicular fashion to the mounting rail, make the required electrical connections and then lower the PV module into its working position. The unit is then locked into its working position.

Owner:POWERMOUNT SYST +1

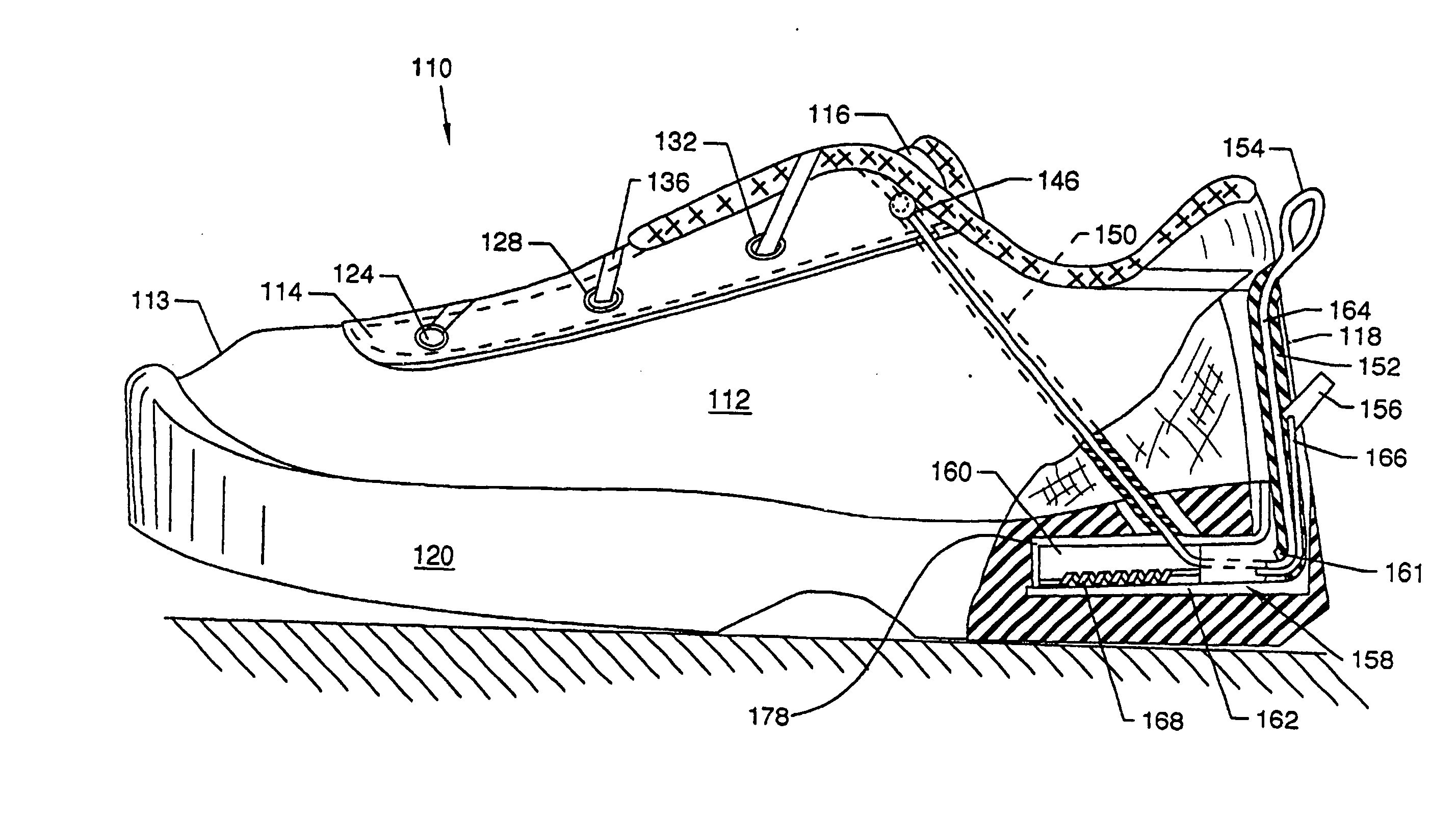

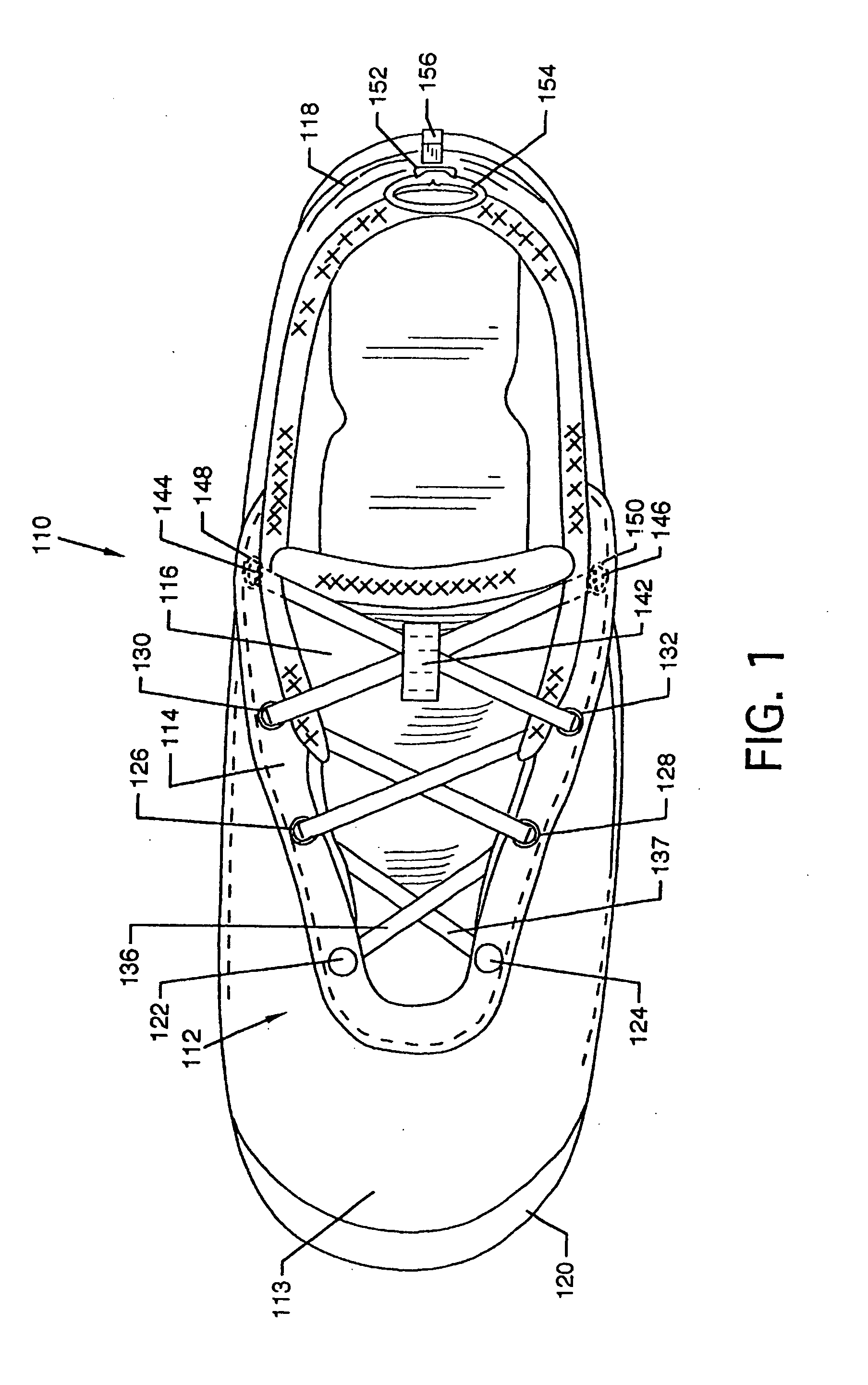

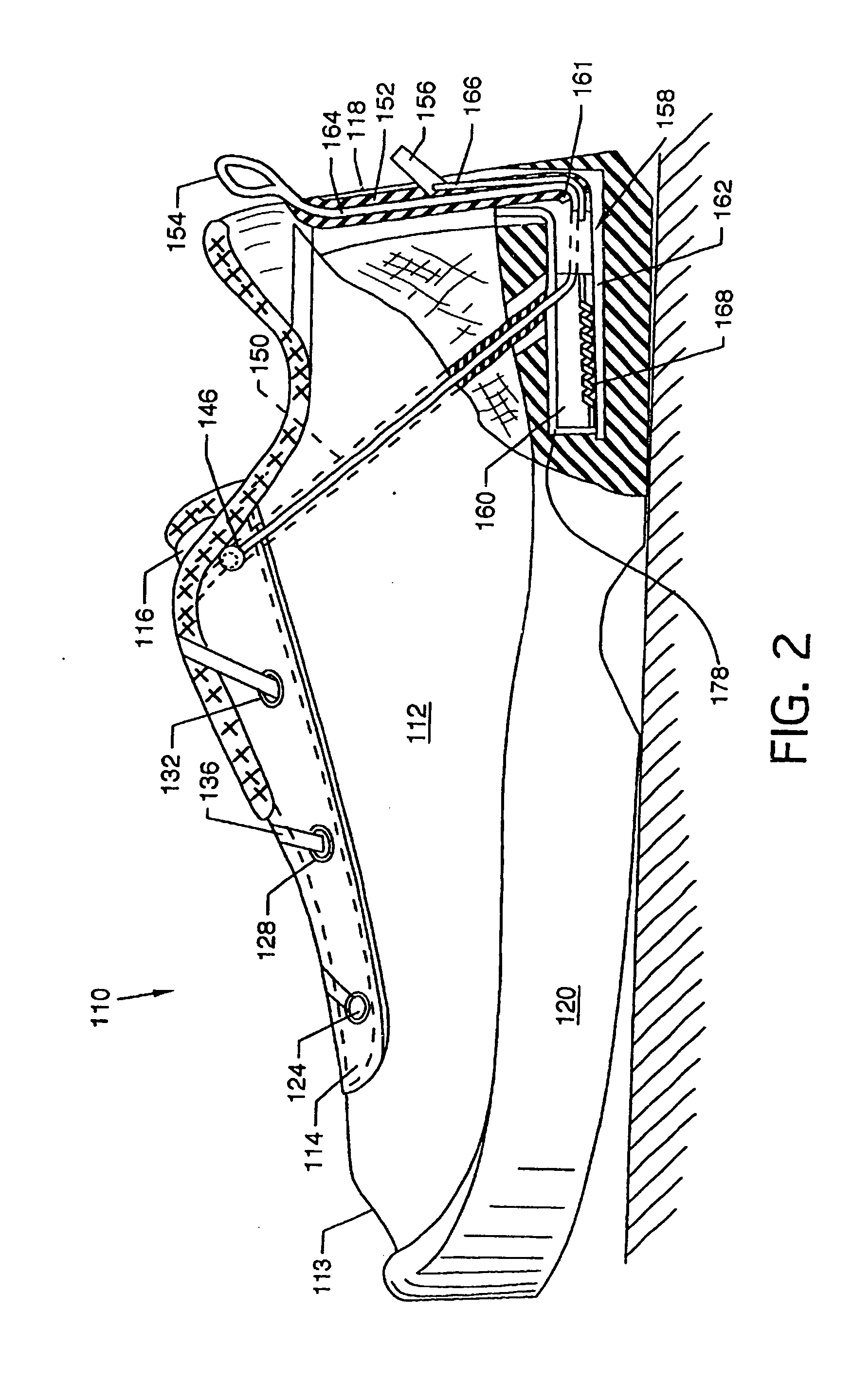

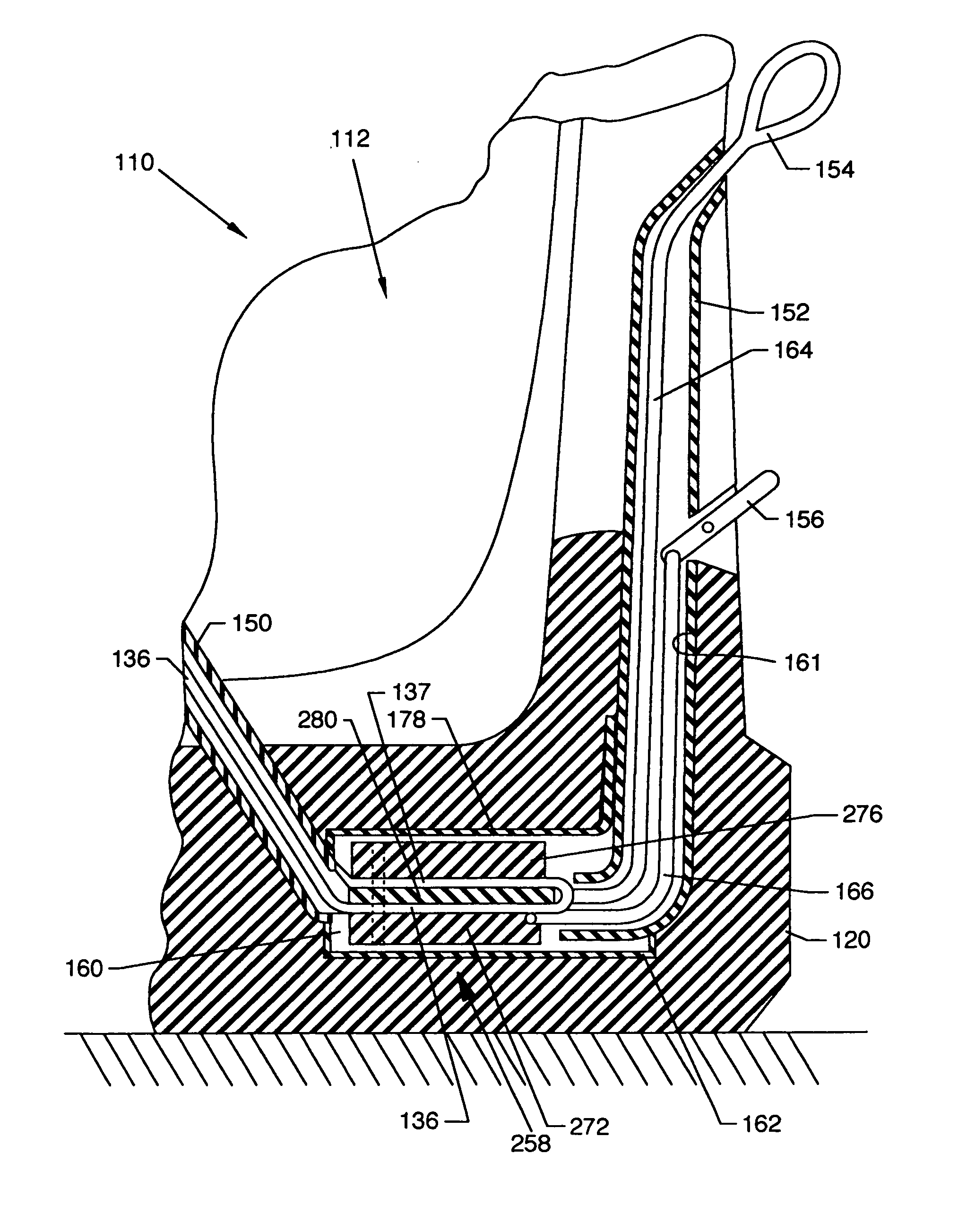

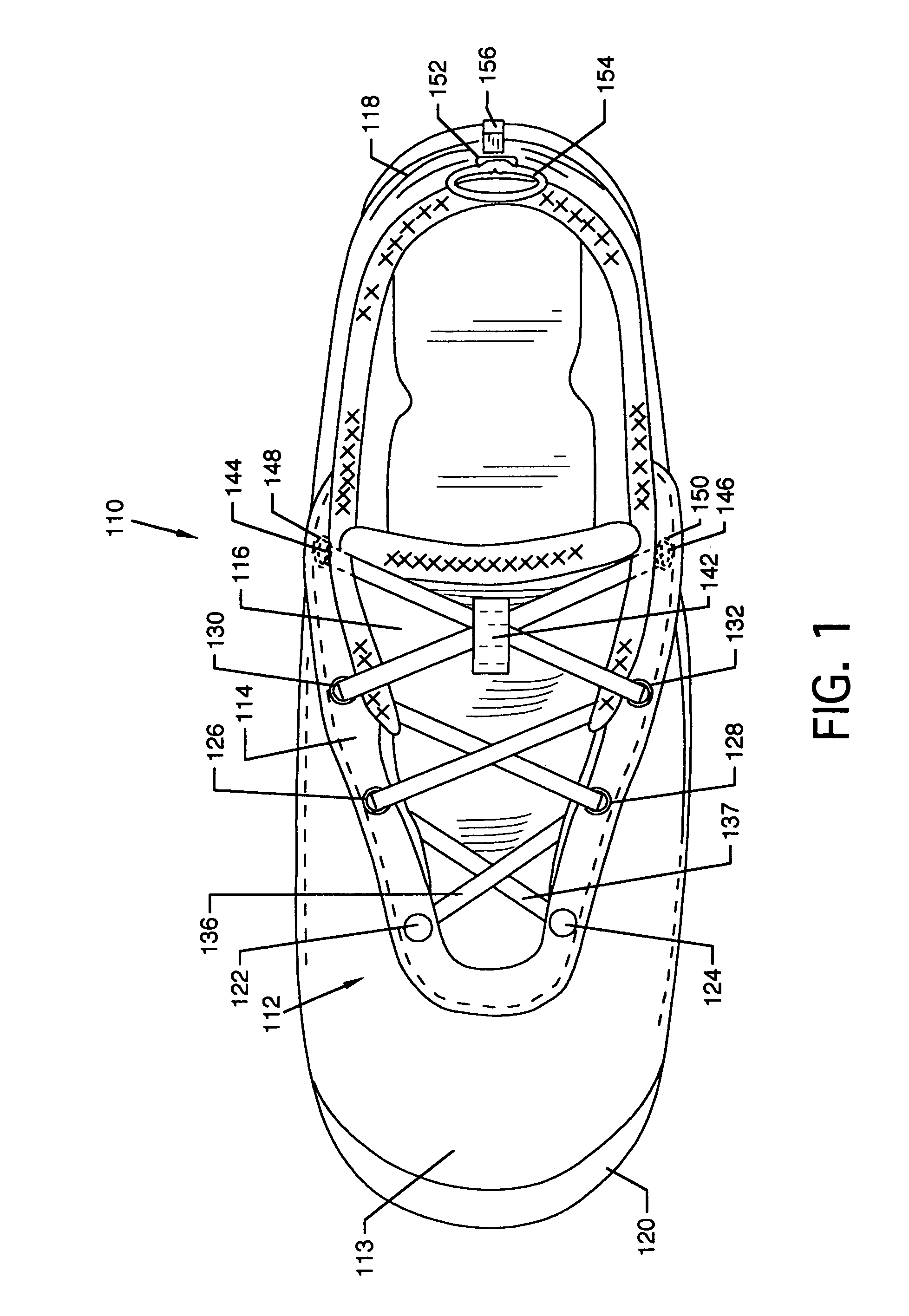

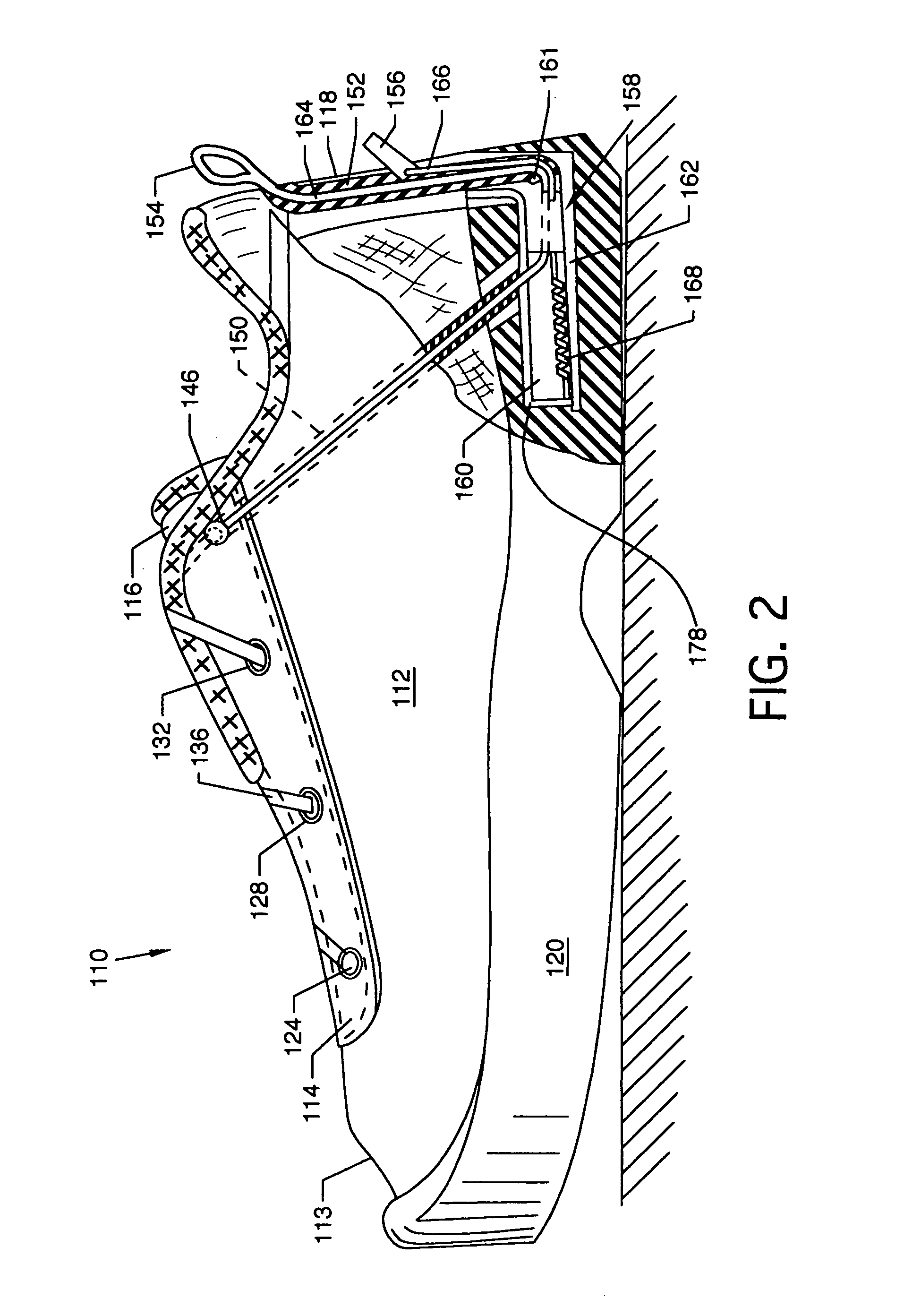

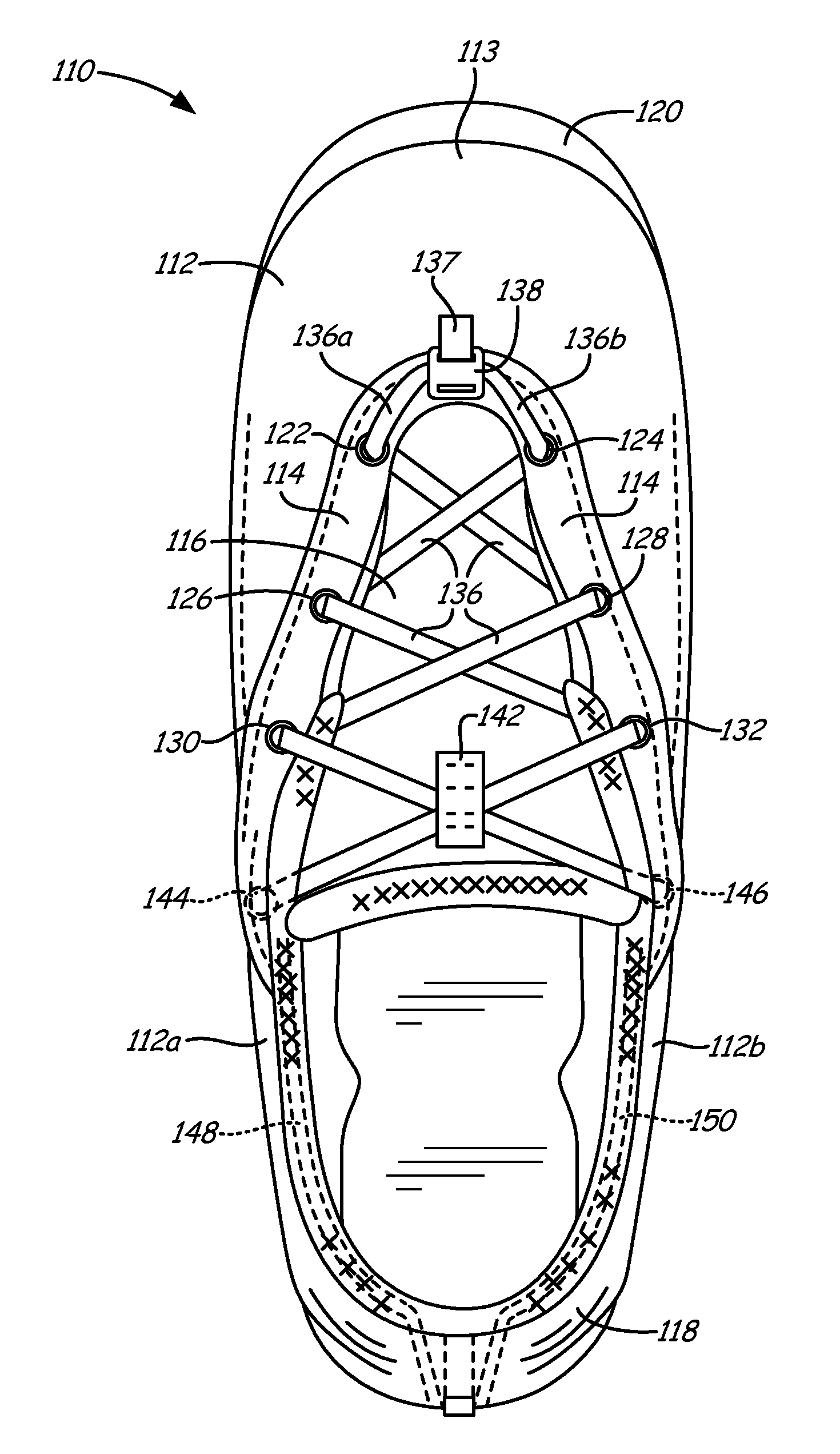

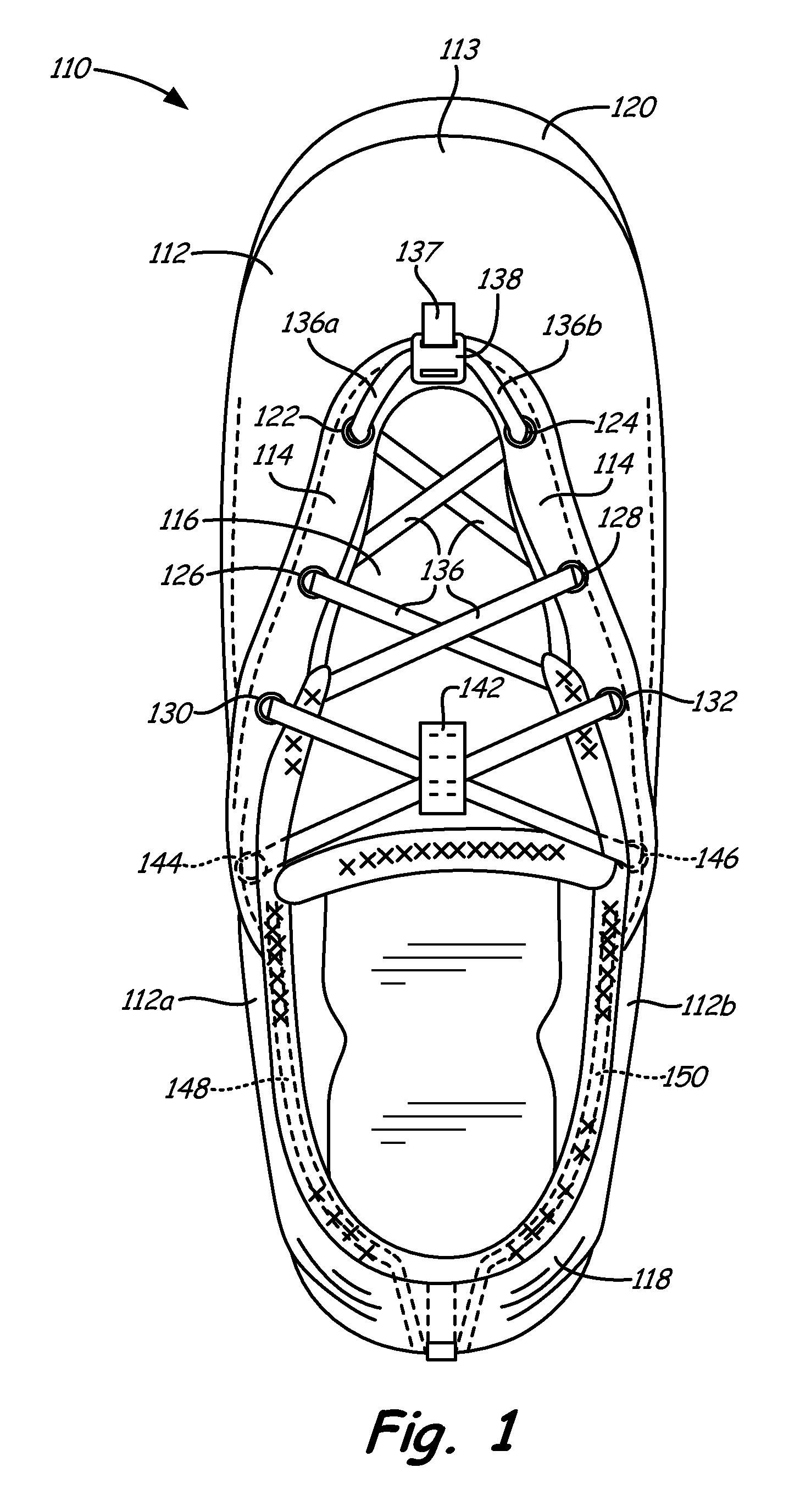

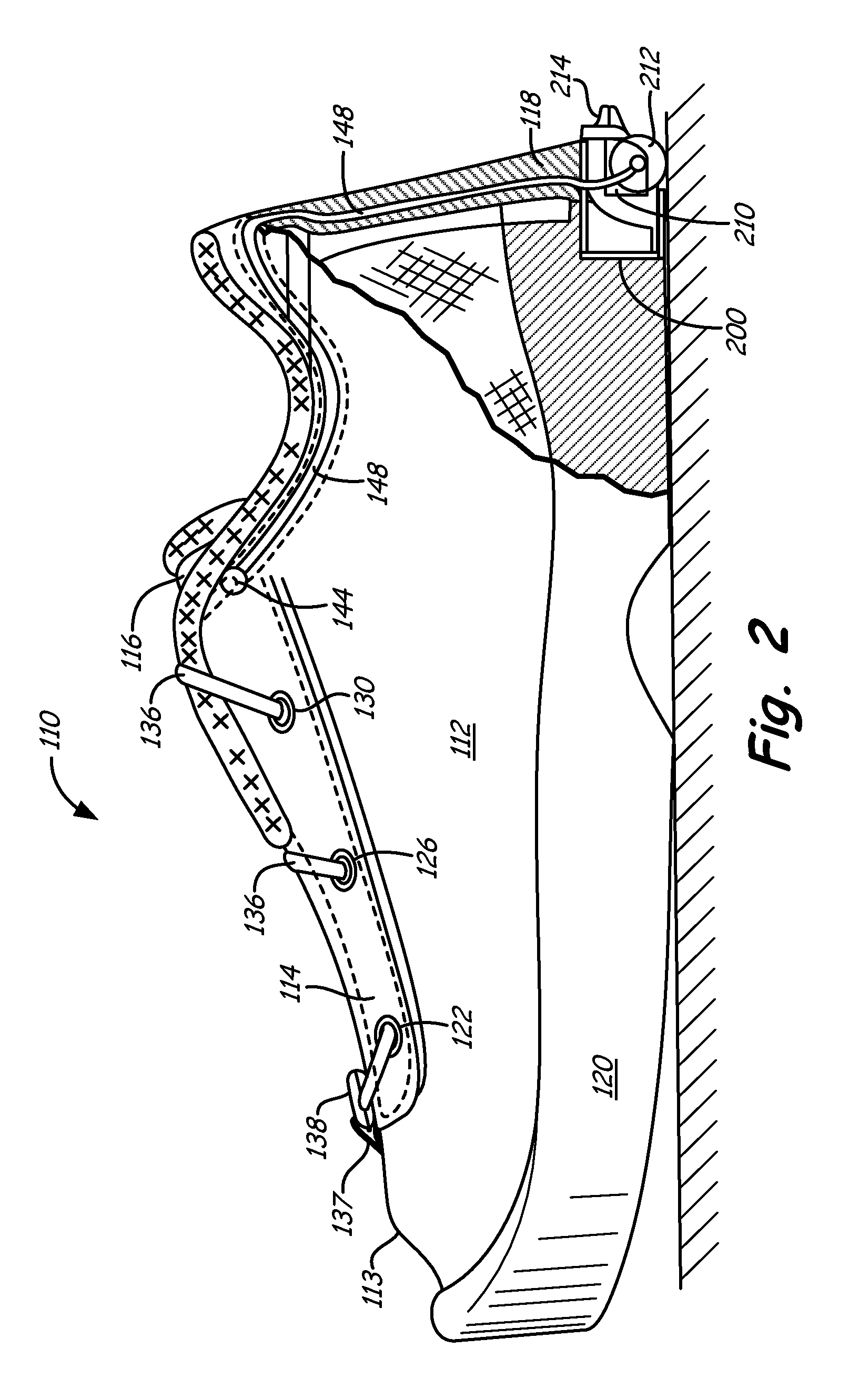

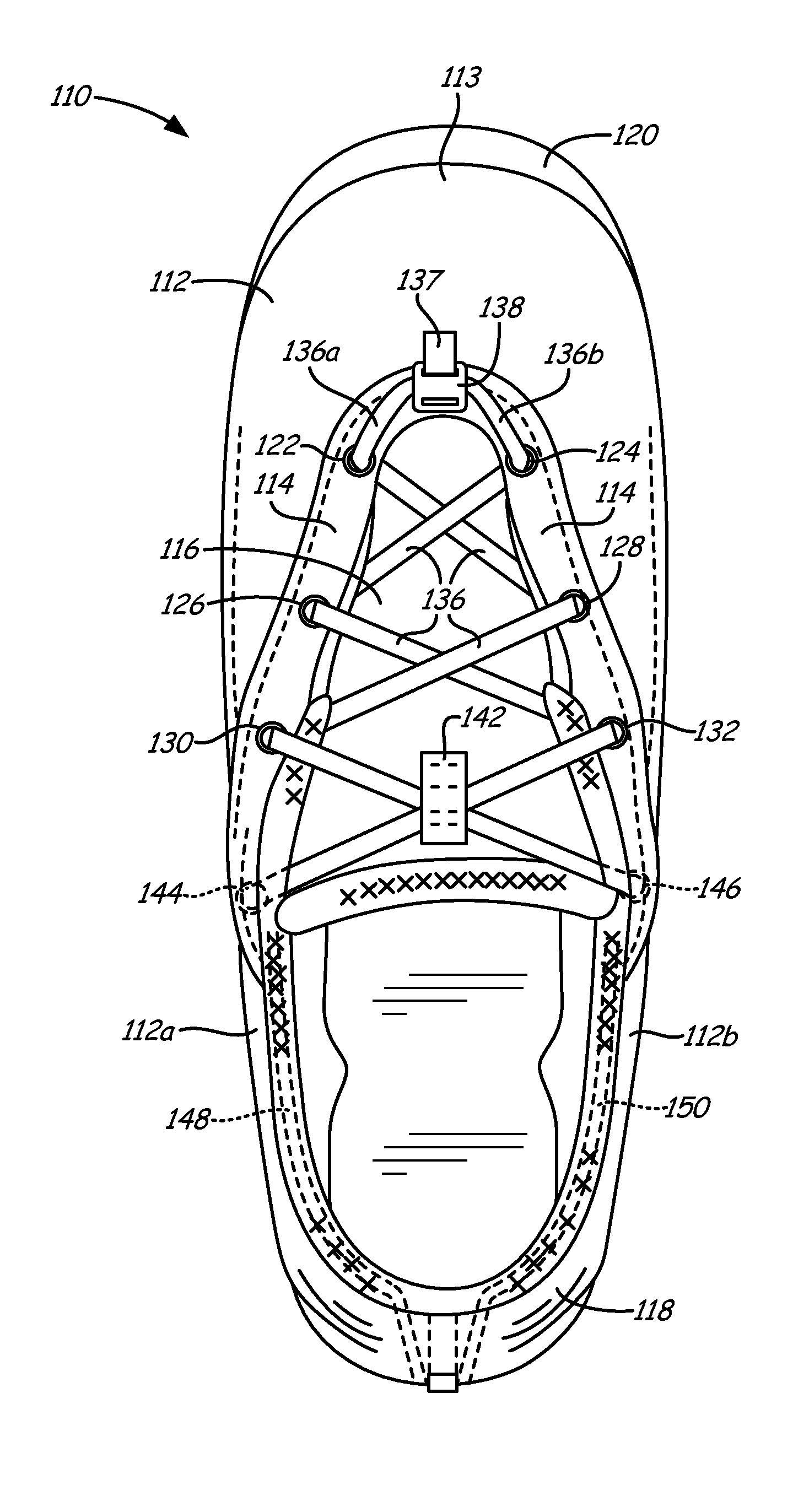

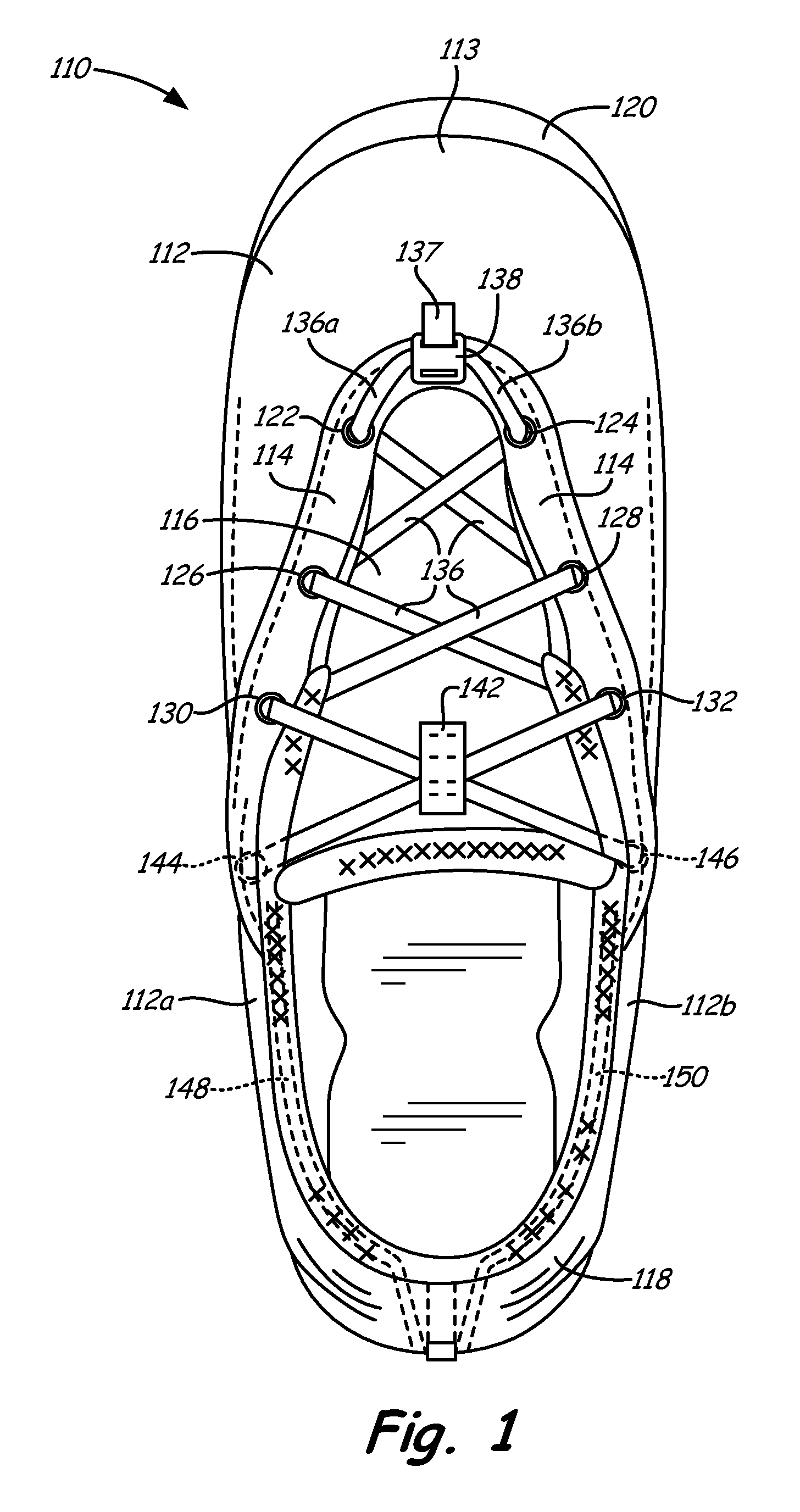

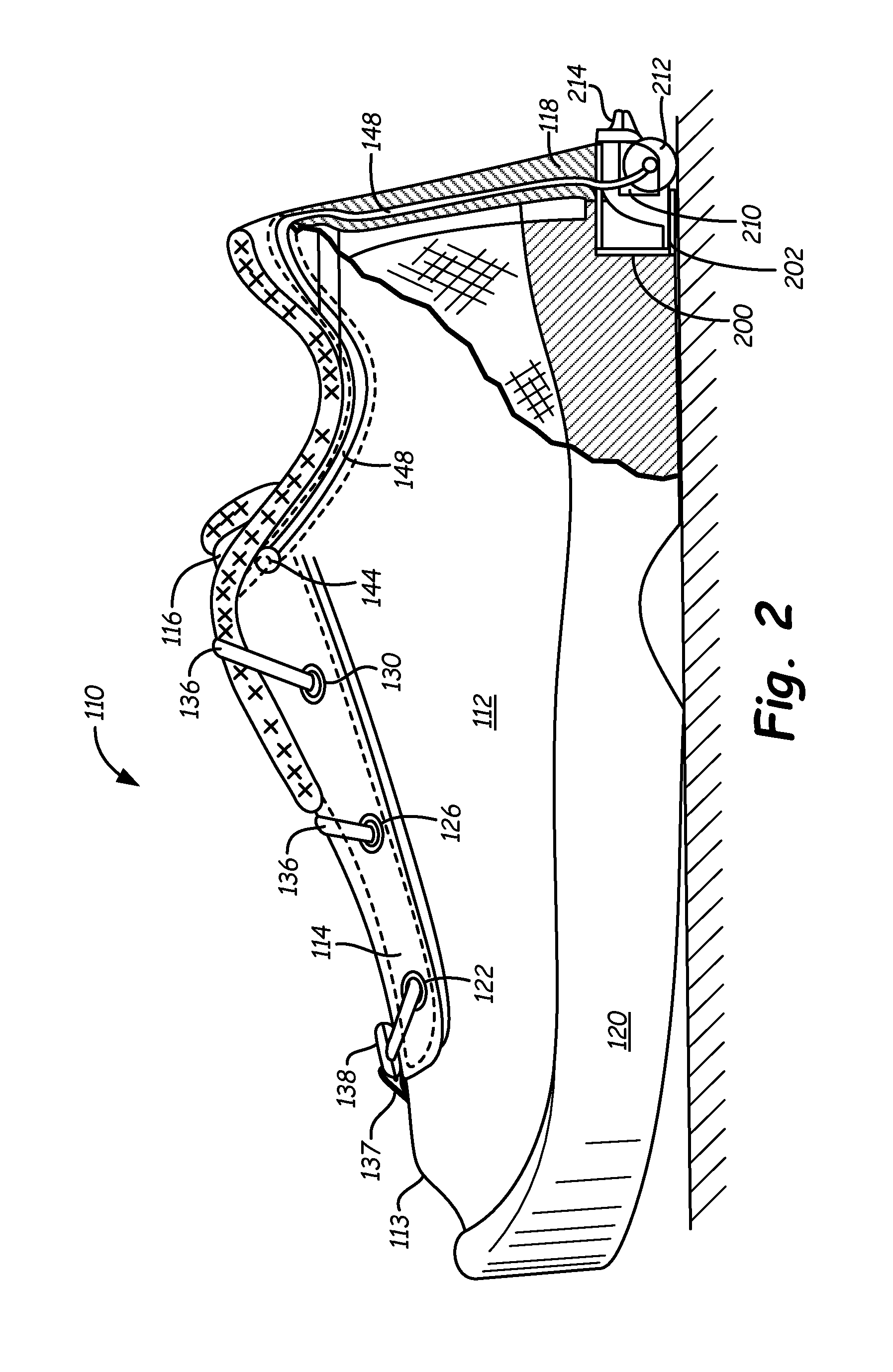

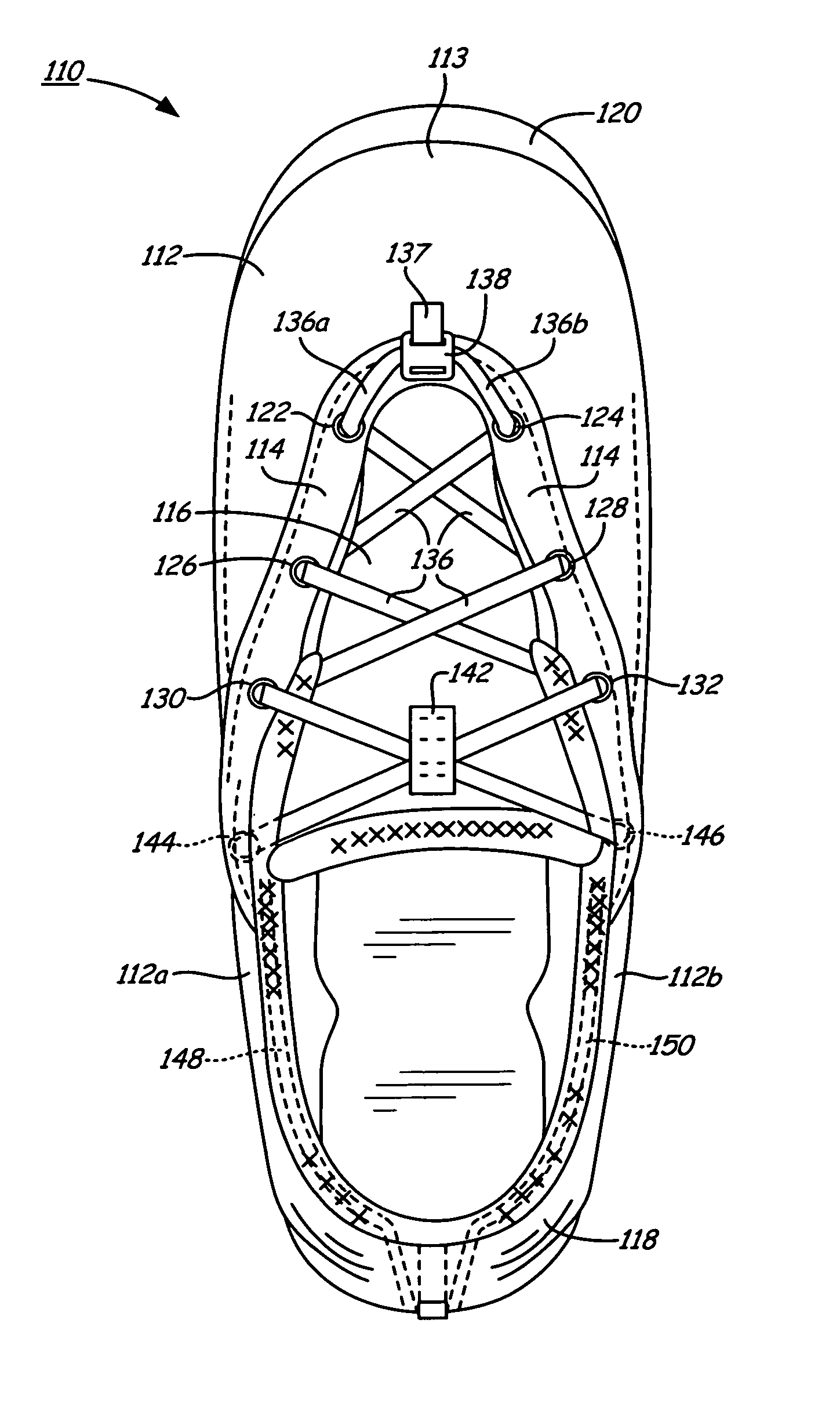

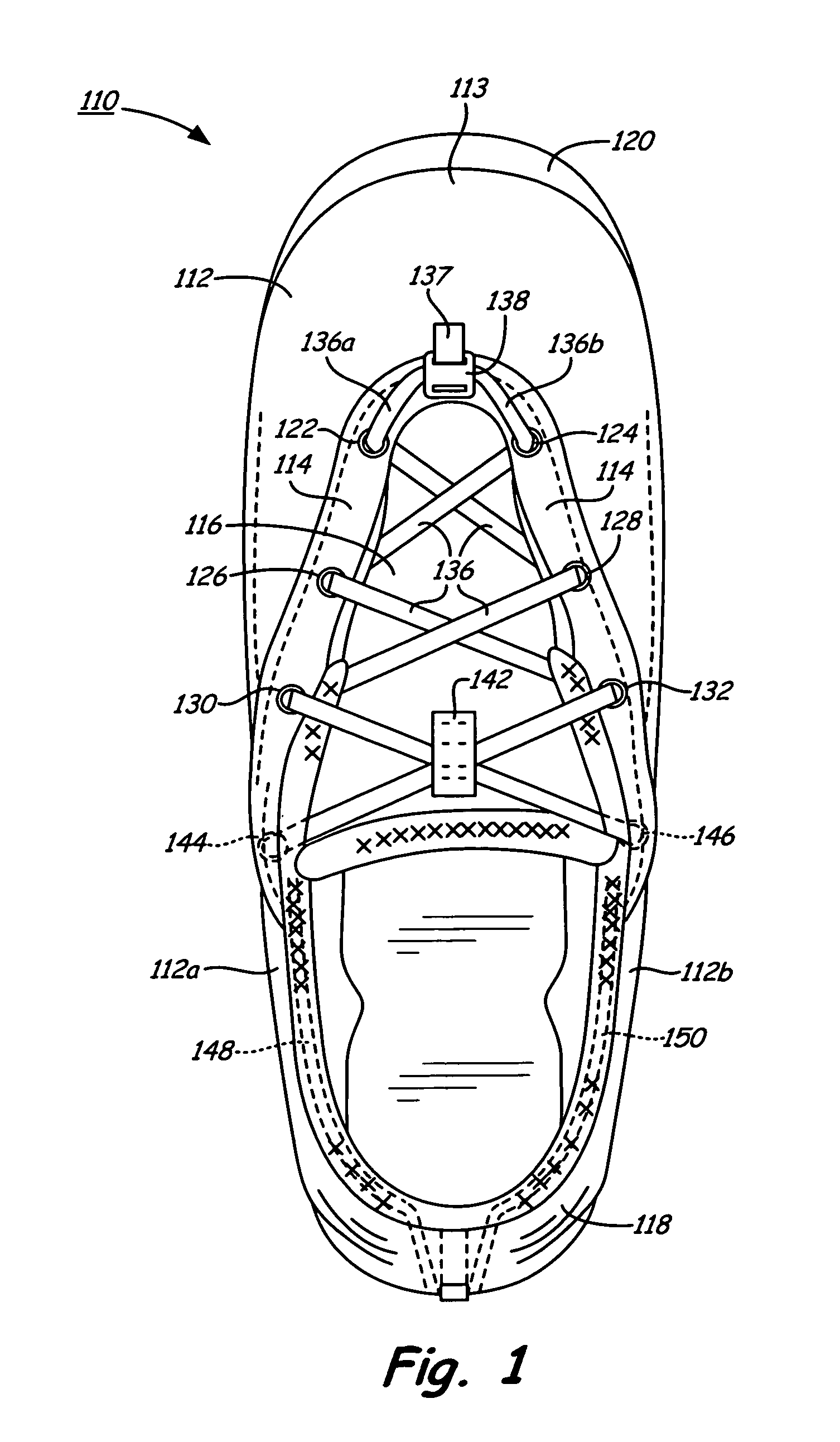

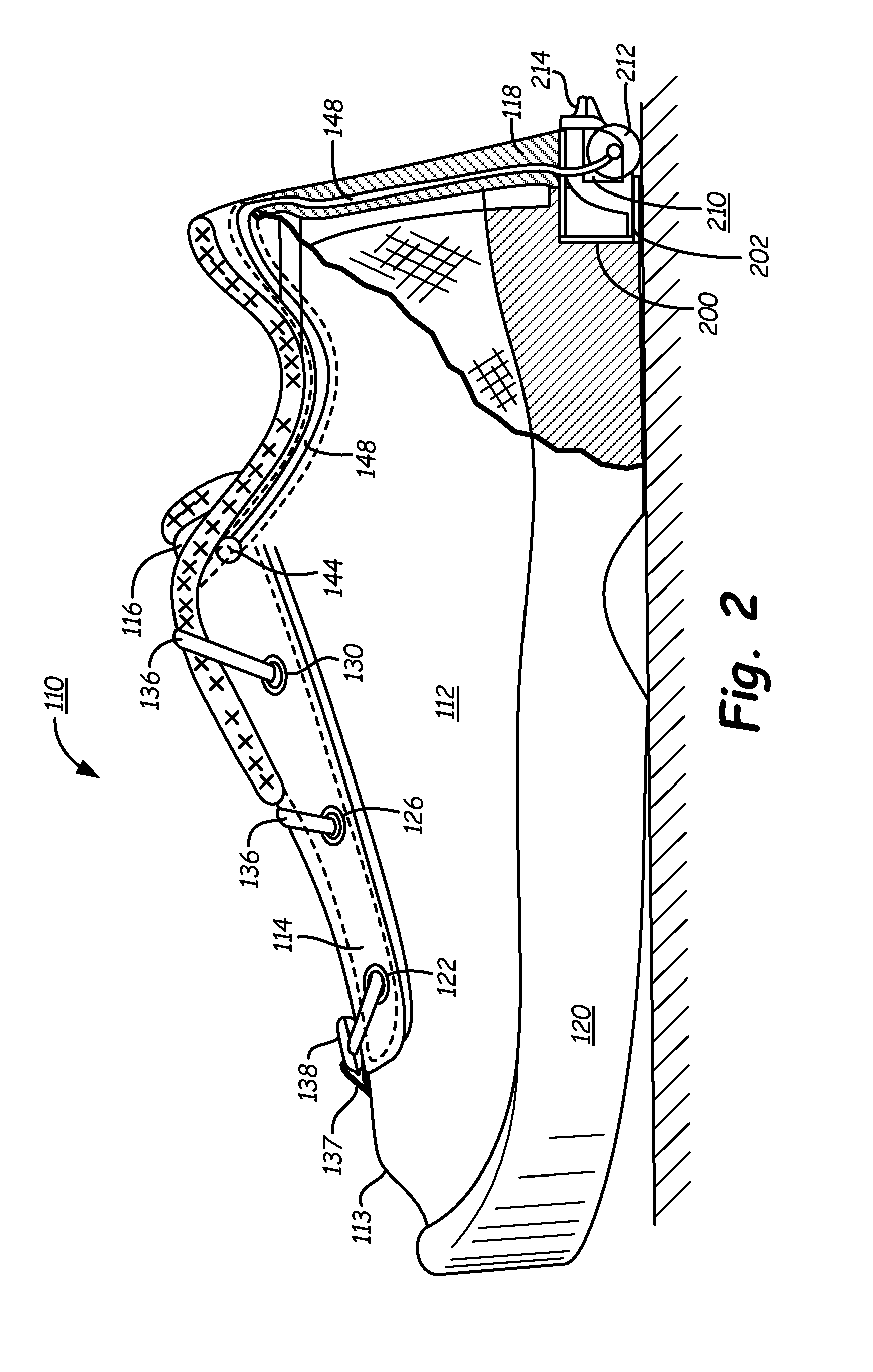

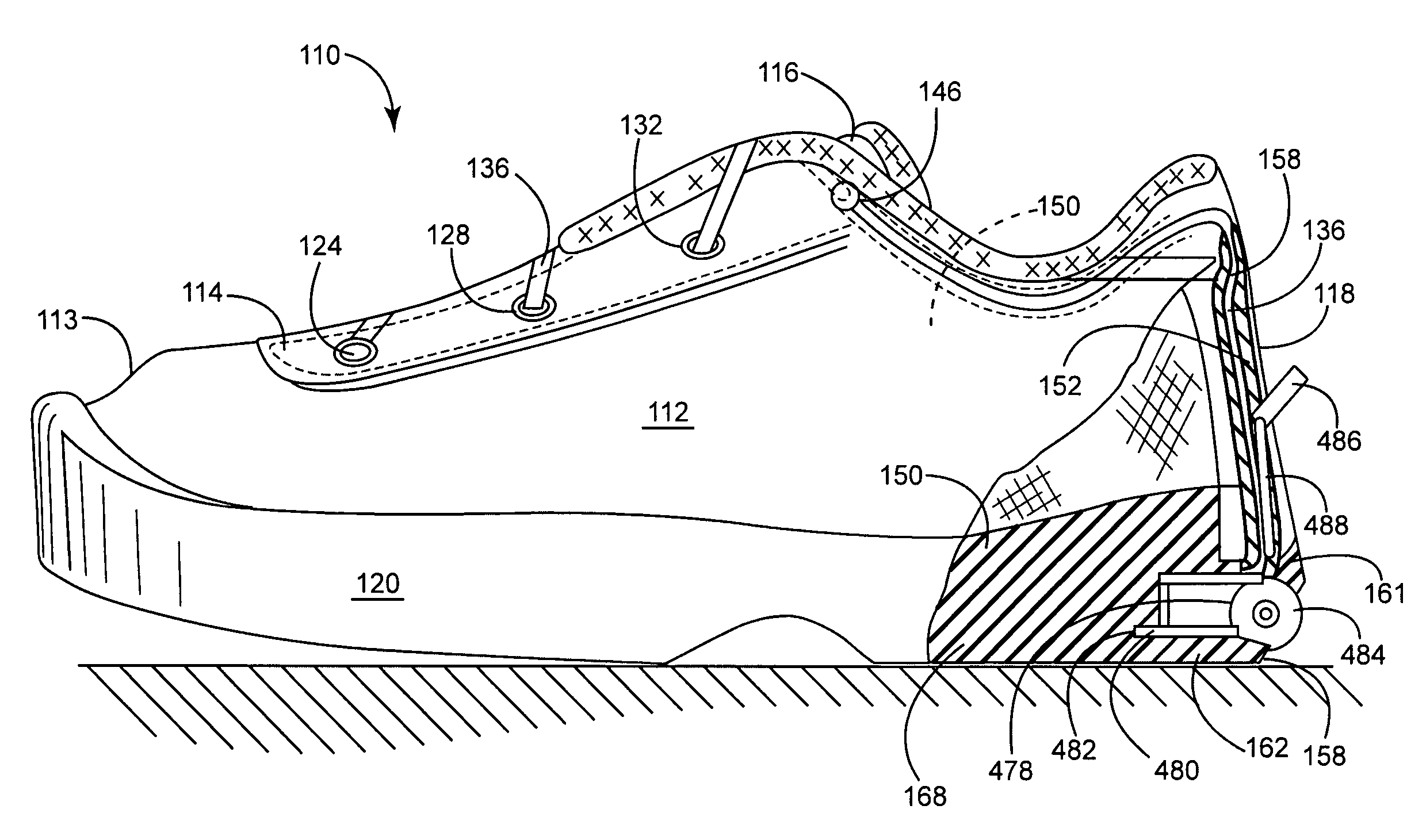

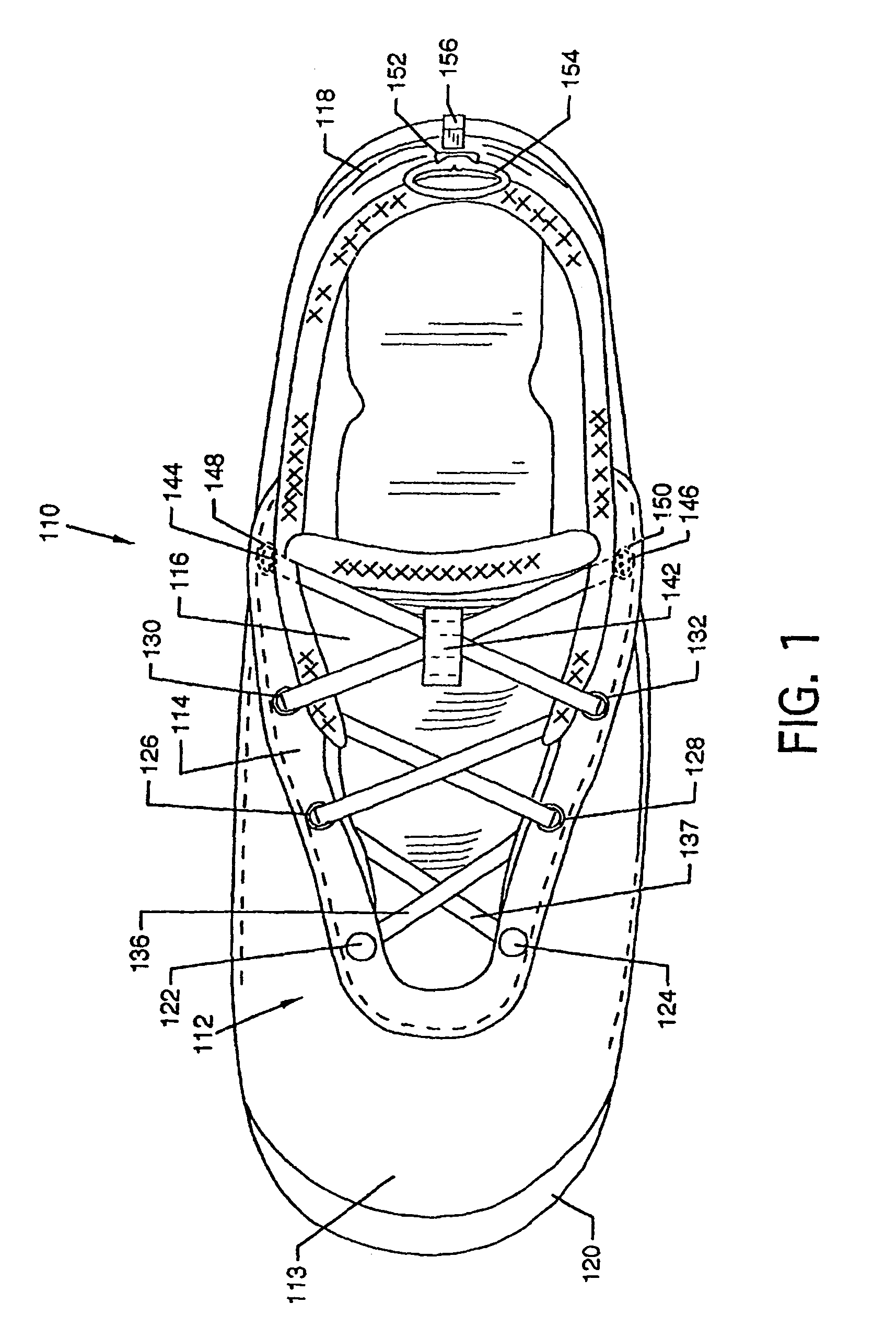

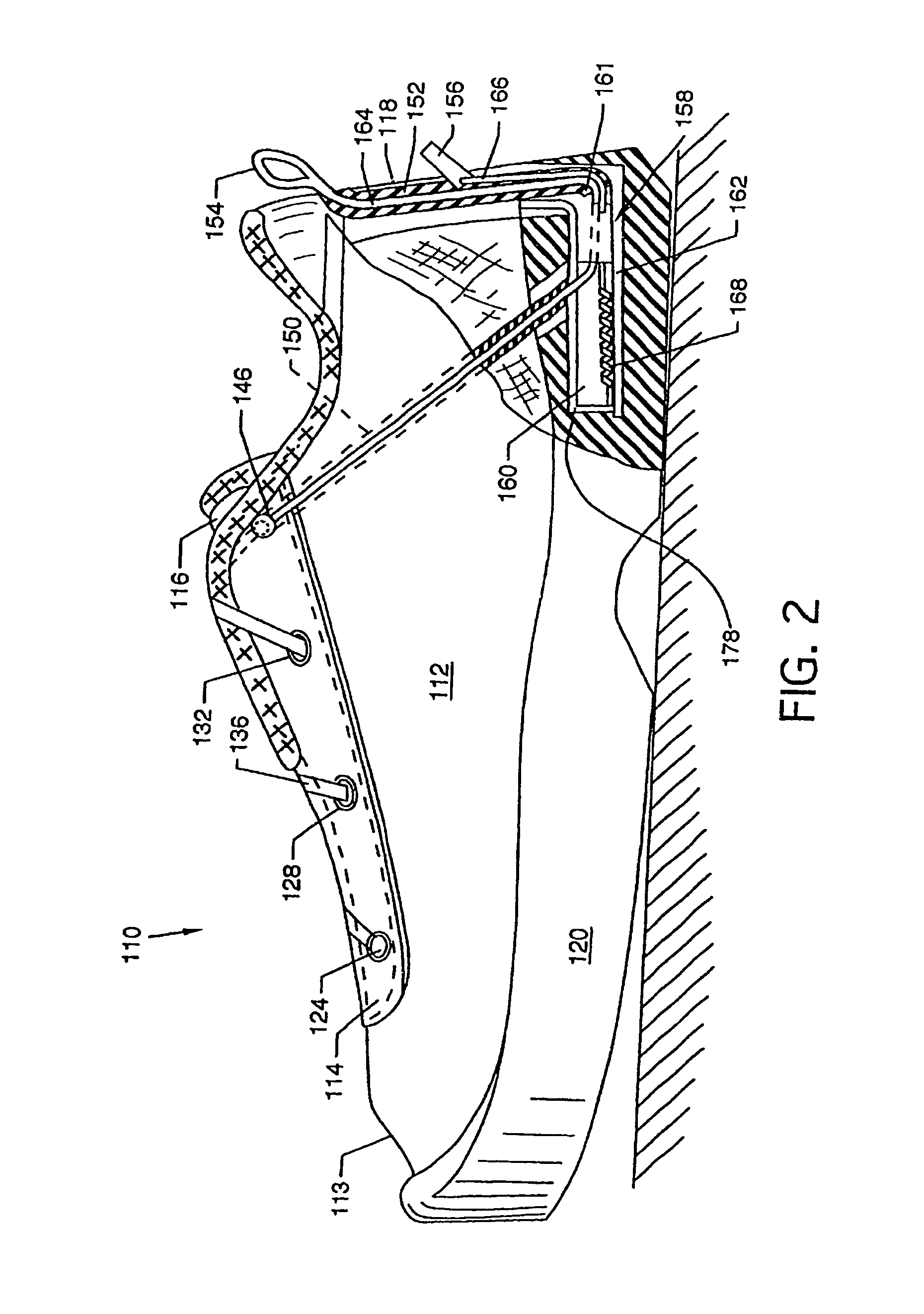

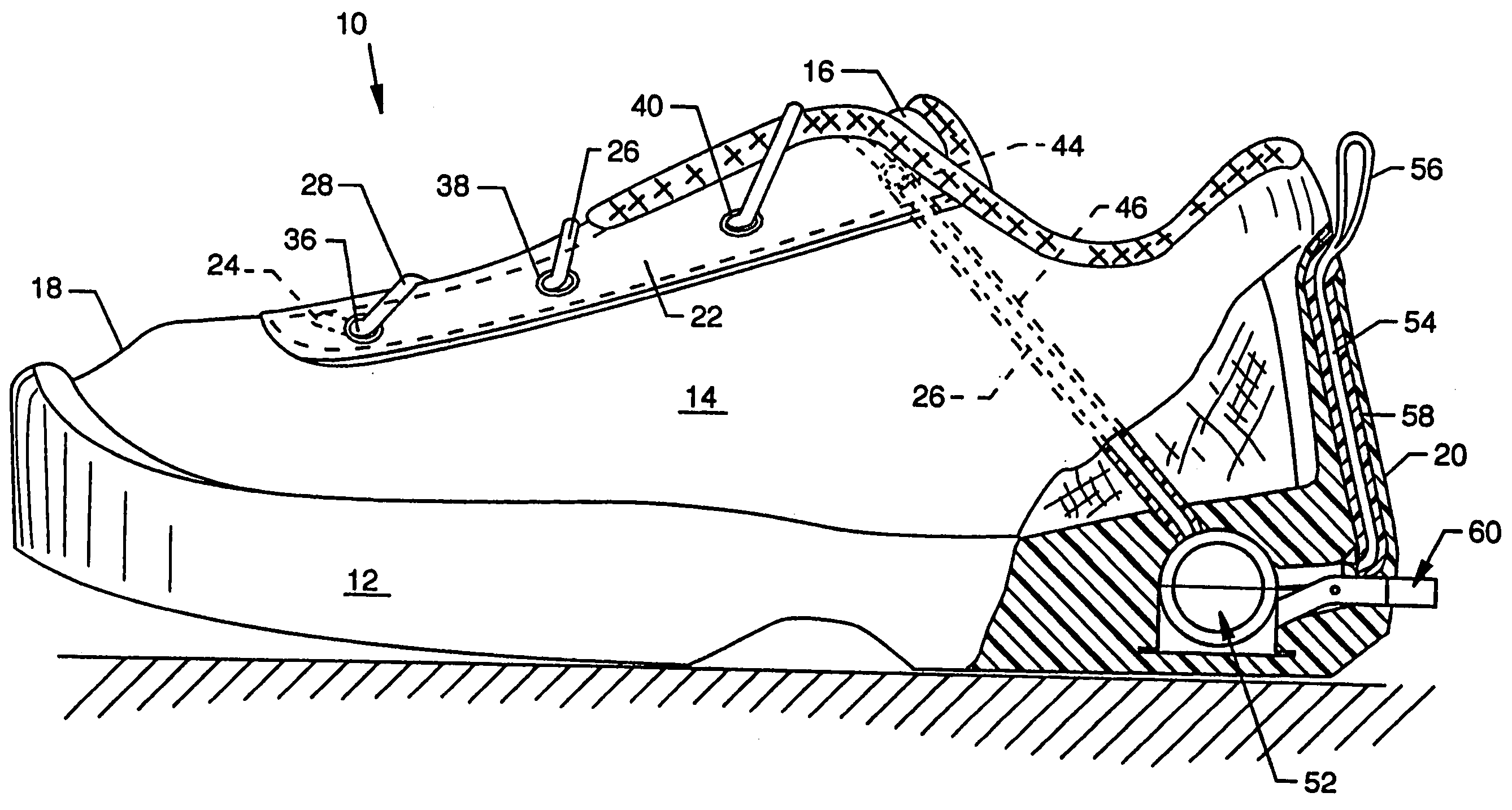

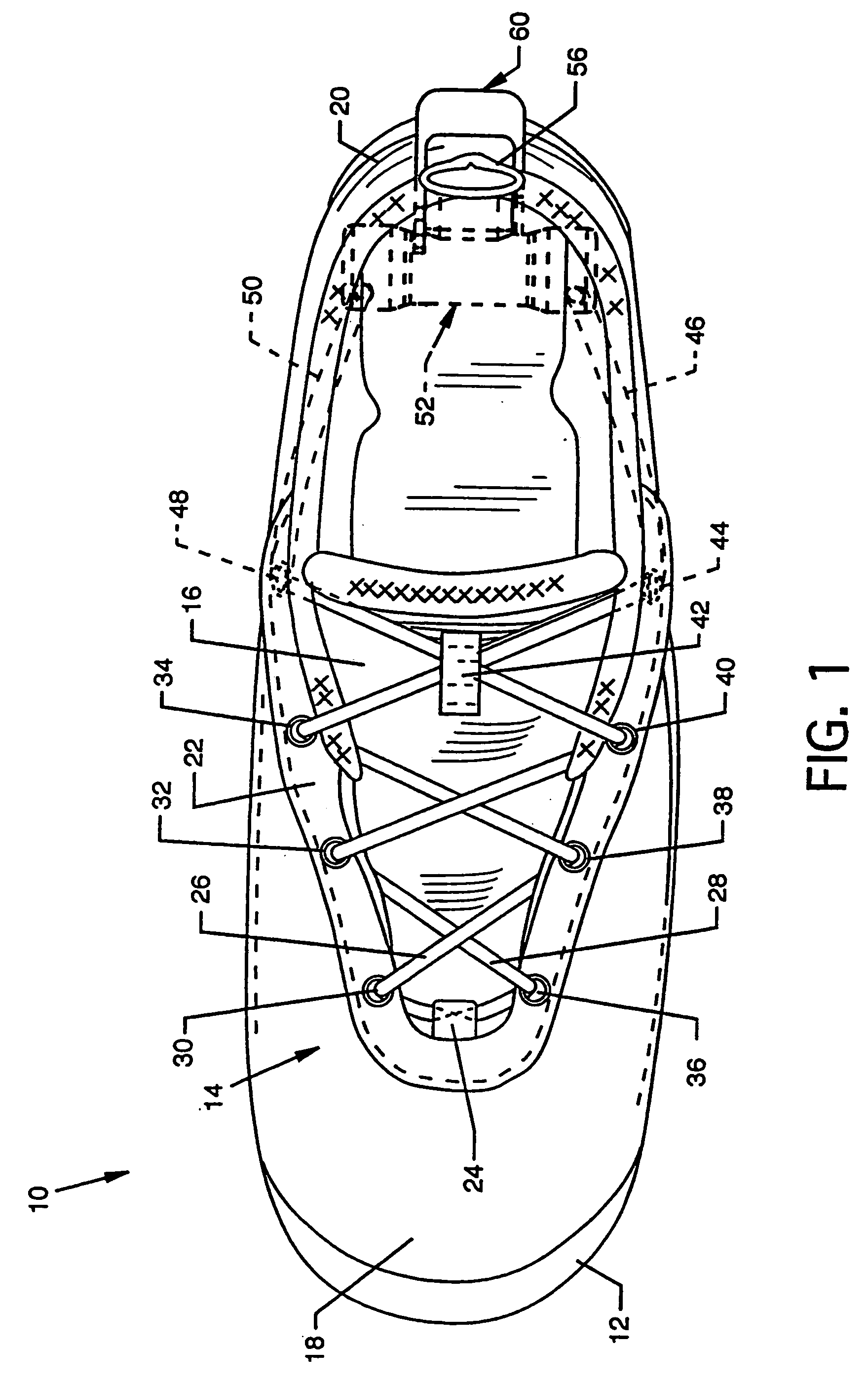

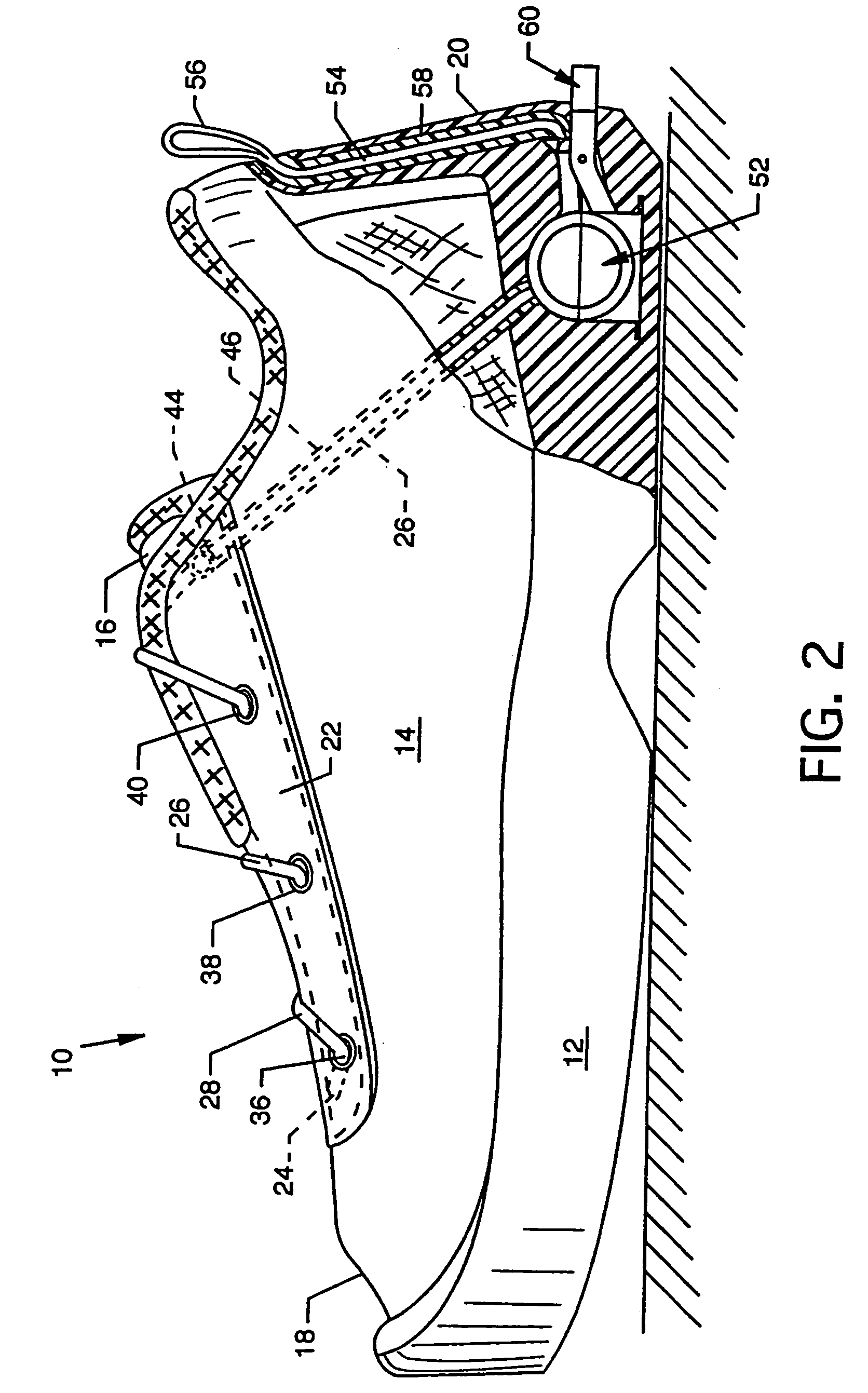

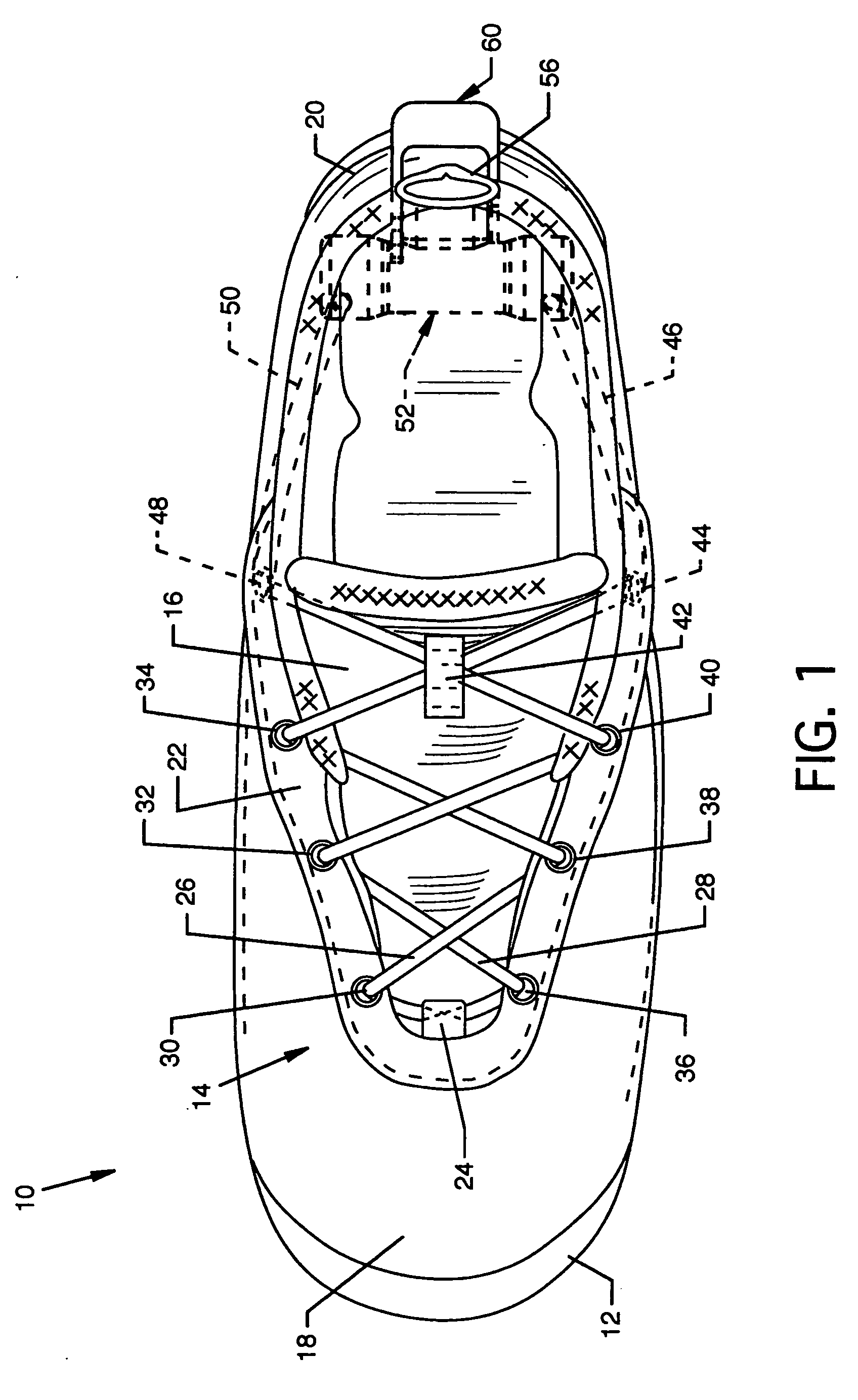

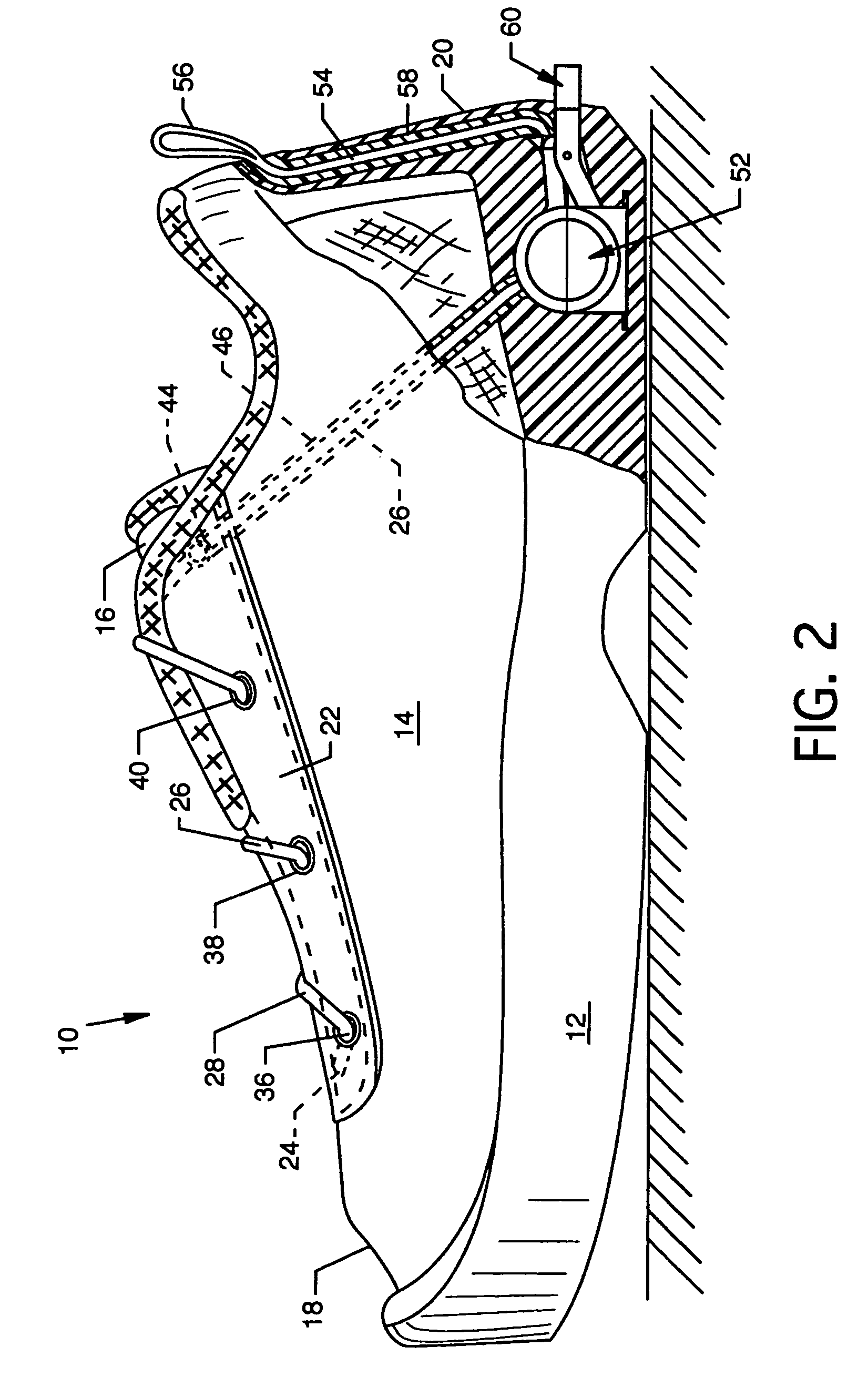

Automated tightening shoe

InactiveUS20070240334A1Easy to operate and performSuperior qualityShoe lace fasteningsBiomedical engineeringShoe laces

Owner:HANDS FREE ENTERPRISES LLC

Automated tightening shoe

InactiveUS6896128B1Quality improvementEasy to operateShoe lace fasteningsShoe lacesBiomedical engineering

Owner:HANDS FREE ENTERPRISES LLC

Automated tightening shoe

Owner:HANDS FREE ENTERPRISES LLC

Photovoltaic mounting system with locking connectors, adjustable rail height and hinge lock

InactiveUS8176693B2Turn easilyQuick and securePhotovoltaic supportsSolar heating energyElectricityPhotovoltaic mounting system

Owner:POWERMOUNT SYST +1

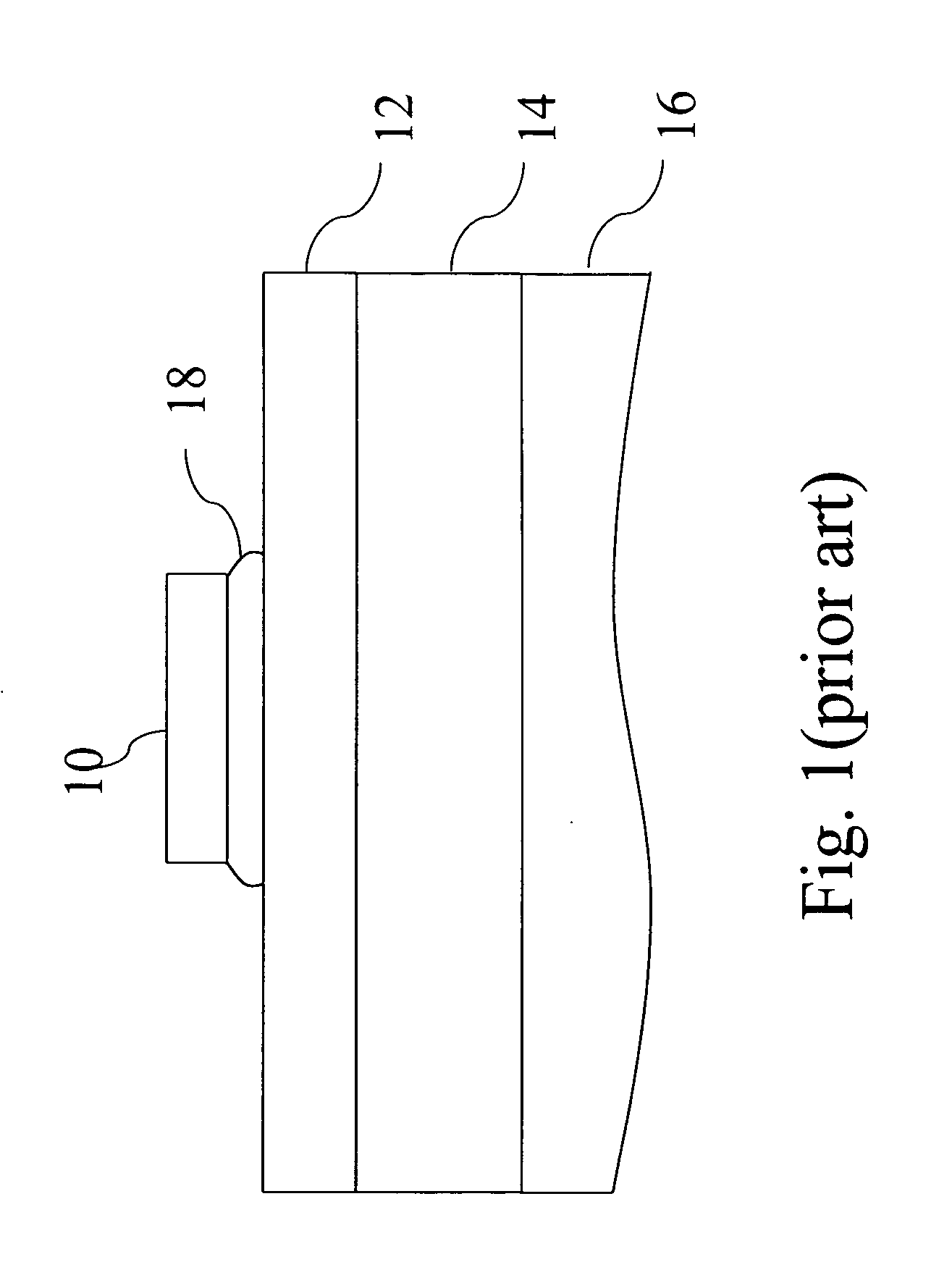

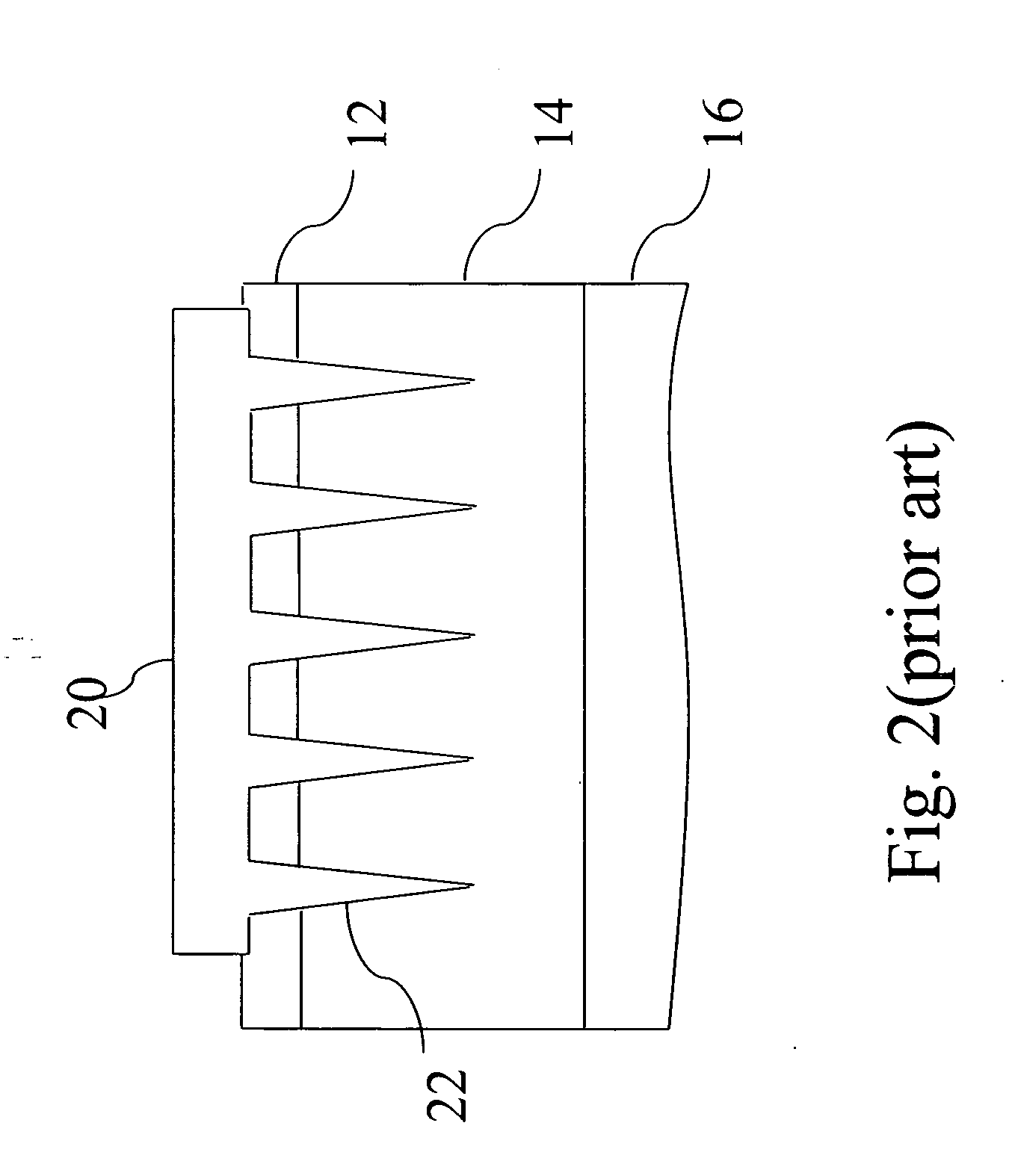

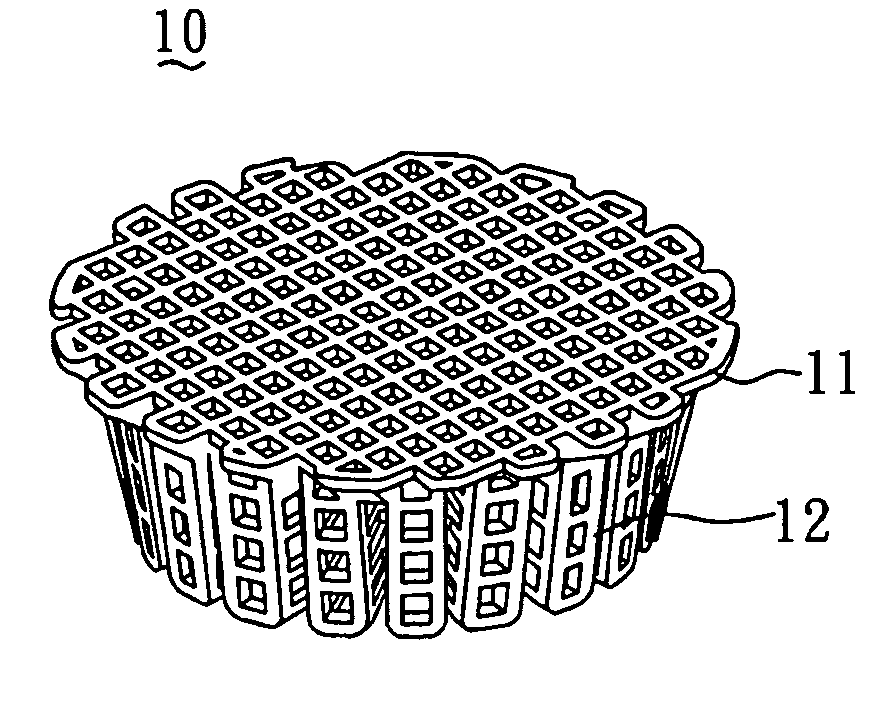

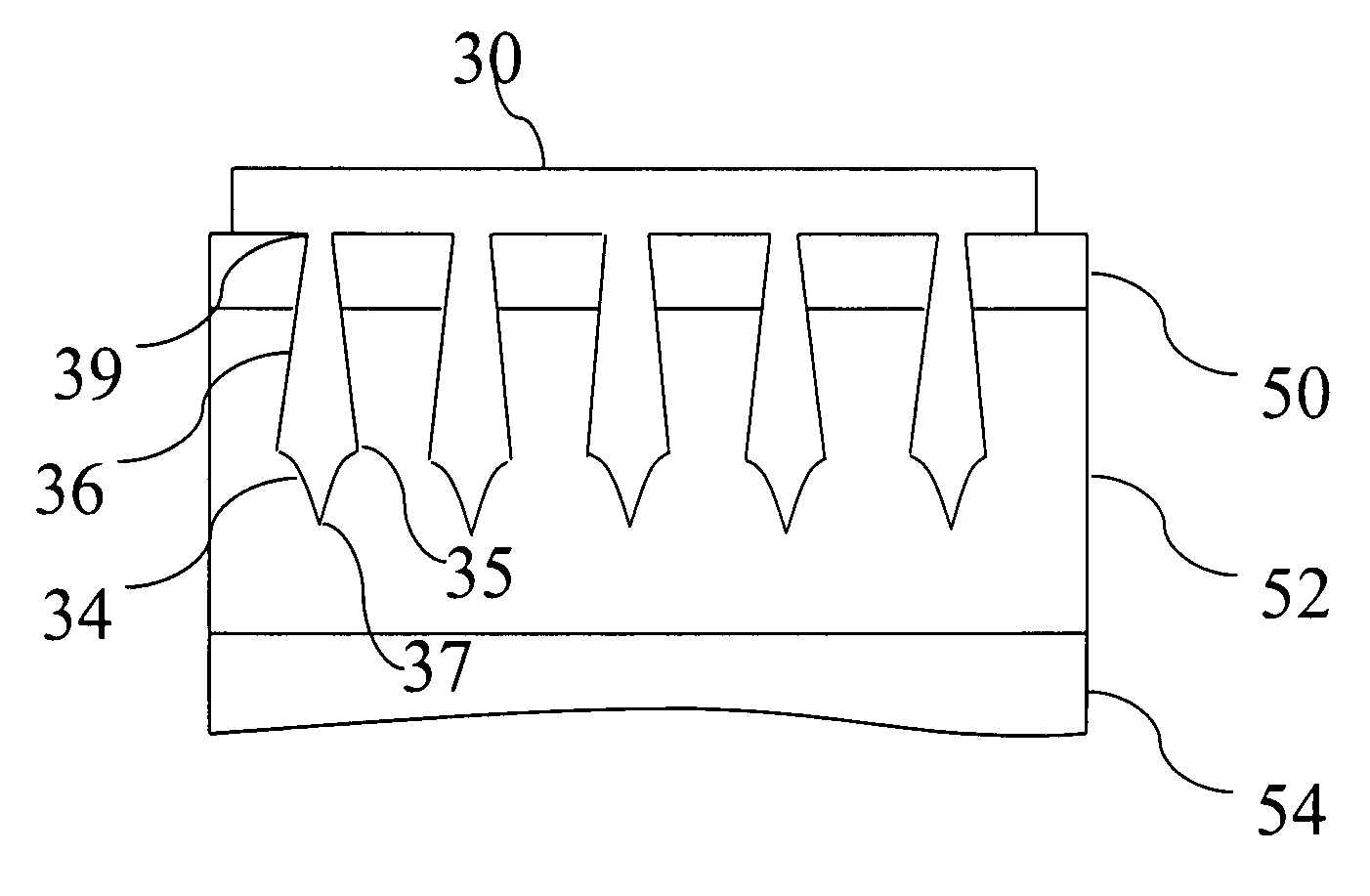

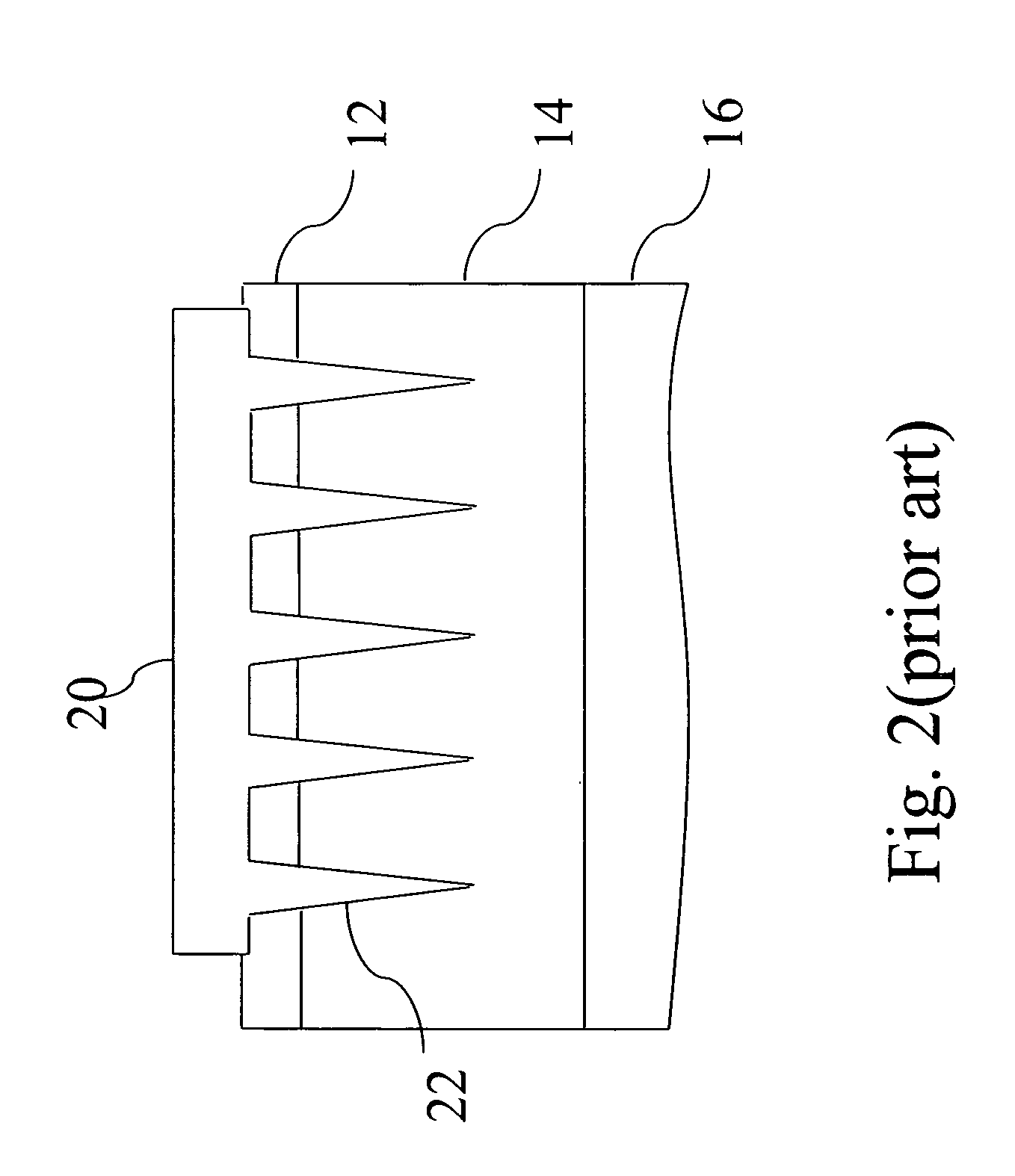

Microprobe array structure and method for manufacturing the same

InactiveUS20080009763A1Overcomes drawbackGood made and maintainedElectroencephalographyElectrocardiographyEngineeringSelf-stabilization

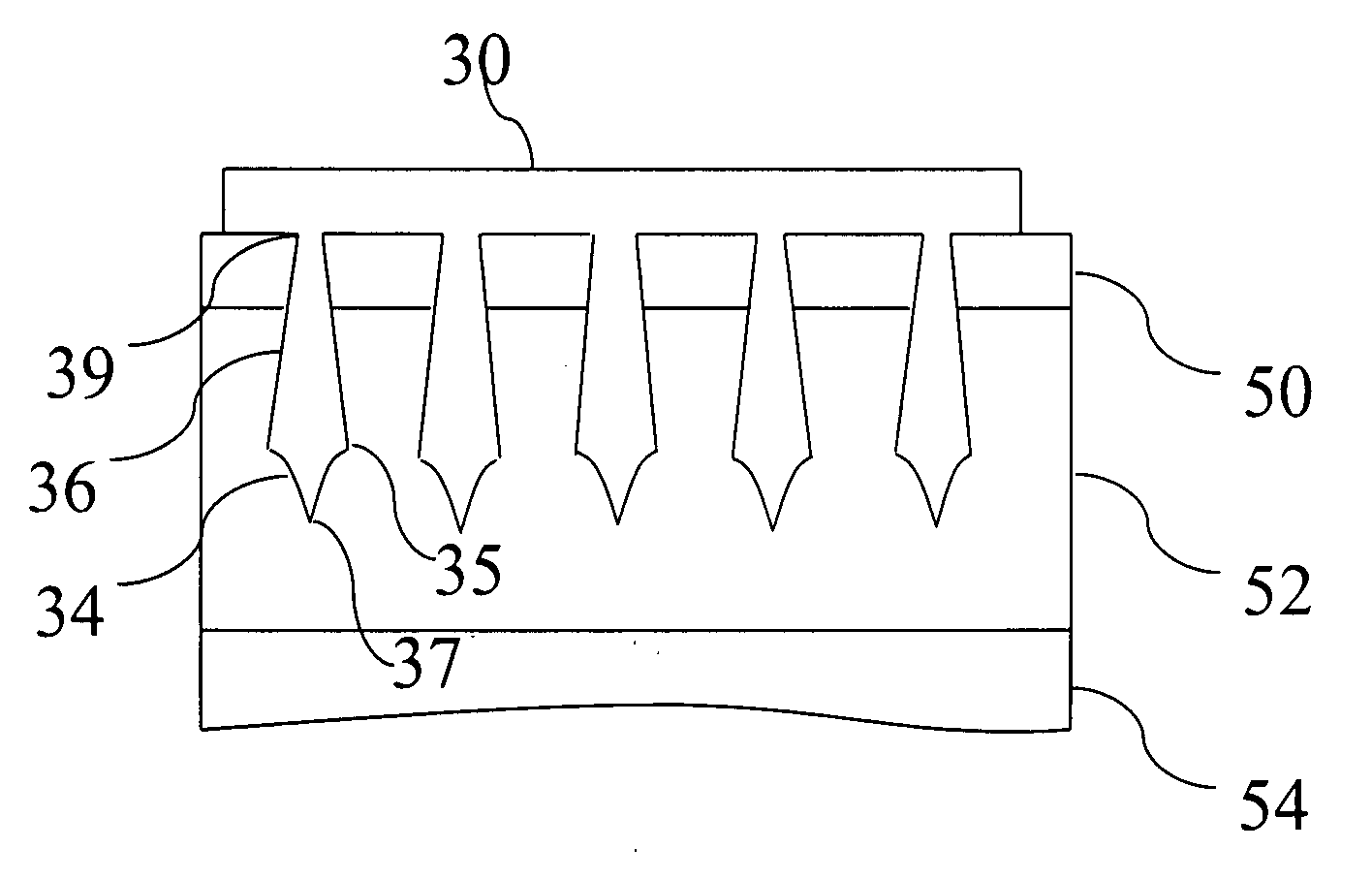

A microprobe array structure with self-stabilization capability and a method for manufacturing the same are proposed. The microprobe array structure is used to sense various biopotential signals, and is characterized in that the etching parameters are controlled during etching to manufacture a microprobe structure with a reduced bottom cross section so that the microprobe can be firmly stabilized in the skin tissue. Moreover, a conducting layer is formed on the microprobe to sense signals. A design of electric isolation between microprobes is also proposed. The microprobe array can therefore be used for the measurement of various biopotential signals, and can also be used as a stimulus.

Owner:NAT CHIAO TUNG UNIV

Automated tightening shoe

Owner:HANDS FREE ENTERPRISES LLC

Automated tightening shoe

Owner:HANDS FREE ENTERPRISES LLC

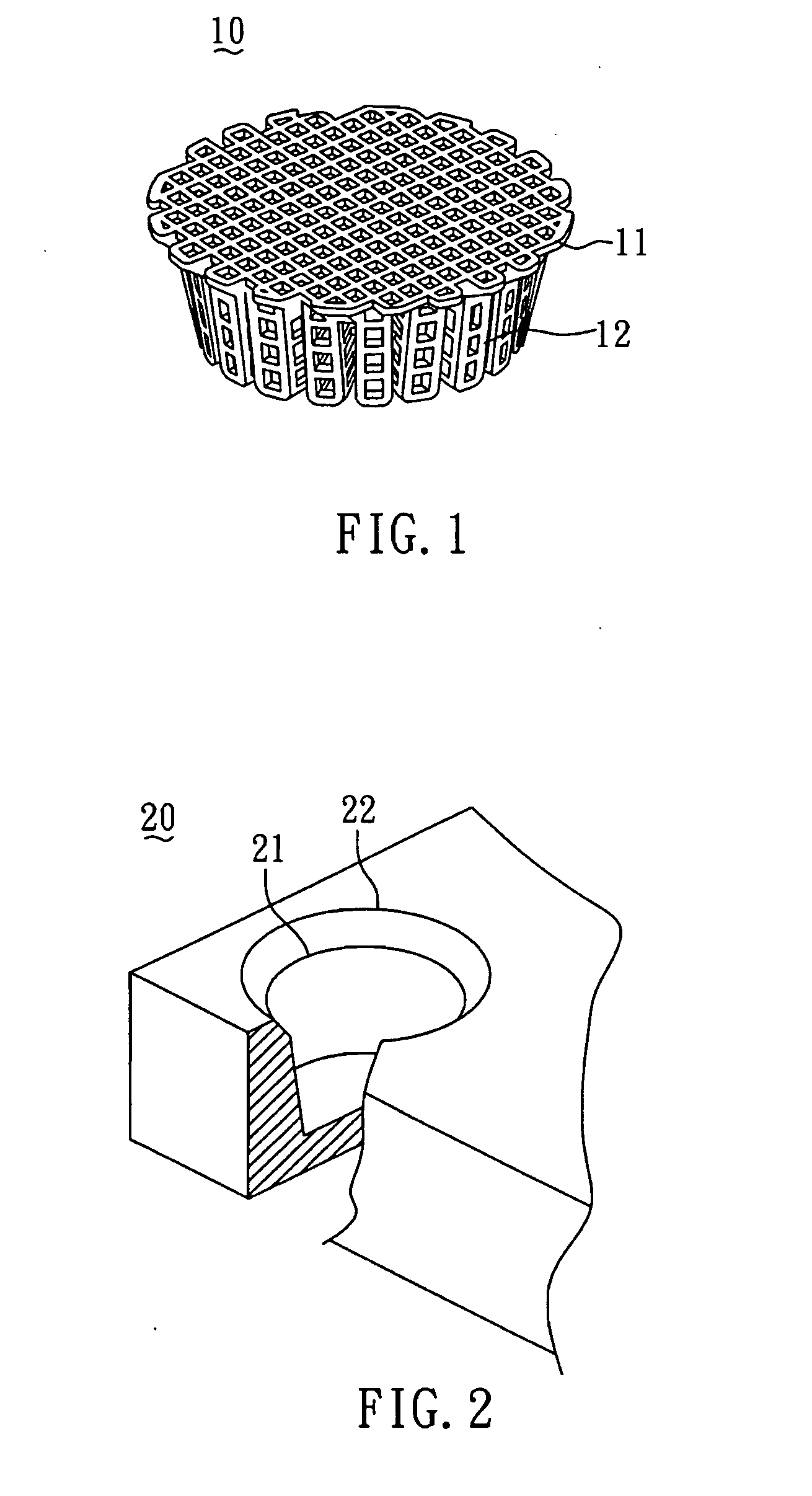

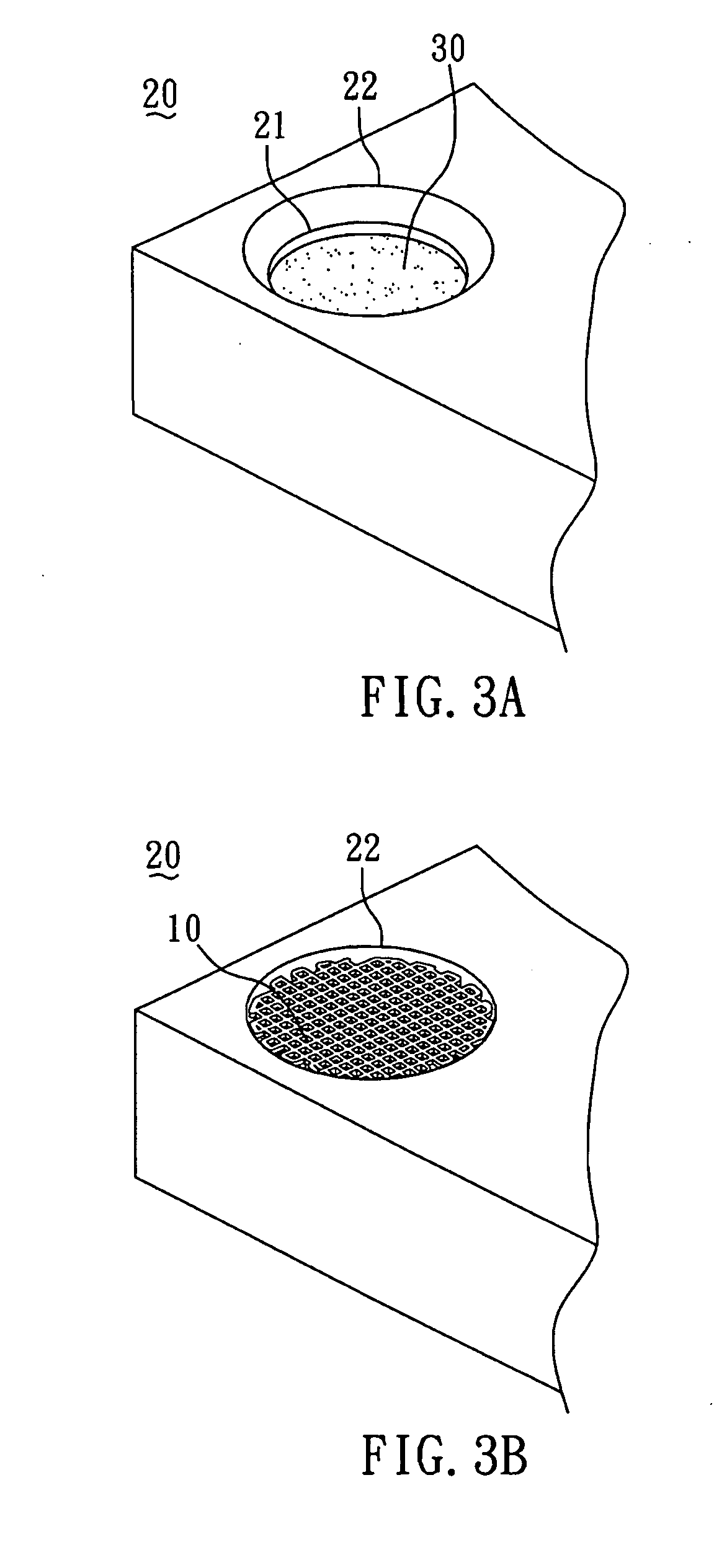

Biodegradable bone graft for orthopedic use

InactiveUS20090317447A1Sufficient hydrophilicitySufficient plasticitySkullMicro porosityTissue fluid

In the present invention, a biodegradable bone graft is disclosed, which includes: a scaffold made of a biodegradable material; and a collagen-embedding matrix portion which completely encompasses the scaffold. The above-mentioned bone graft can increase the micro-porosity of the scaffold to enable cells to grow adhesively thereon. Compared with the scaffold only, the above-mentioned bone graft has high hydrophilicity. Hence, the bone graft of the present invention can efficiently retain tissue fluid, cell growth factors, blood and / or bone marrow which are mixed with the bone graft beforehand to achieve osteoinduction. Furthermore, the collagen-embedding matrix portion can also serve as a carrier to encompass other bone graft materials and drug molecules. The present invention also relates to a method for manufacturing the above-mentioned bone graft.

Owner:SUNMAX BIOTECH

Automated tightening shoe

Owner:HANDS FREE ENTERPRISES LLC

Microprobe array structure and method for manufacturing the same

InactiveUS7941201B2Overcomes drawbackGood made and maintainedElectroencephalographyElectrocardiographyEngineeringSelf-stabilization

A microprobe array structure with self-stabilization capability and a method for manufacturing the same are proposed. The microprobe array structure is used to sense various biopotential signals, and is characterized in that the etching parameters are controlled during etching to manufacture a microprobe structure with a reduced bottom cross section so that the microprobe can be firmly stabilized in the skin tissue. Moreover, a conducting layer is formed on the microprobe to sense signals. A design of electric isolation between microprobes is also proposed. The microprobe array can therefore be used for the measurement of various biopotential signals, and can also be used as a stimulus.

Owner:NAT CHIAO TUNG UNIV

Automated tightening shoe

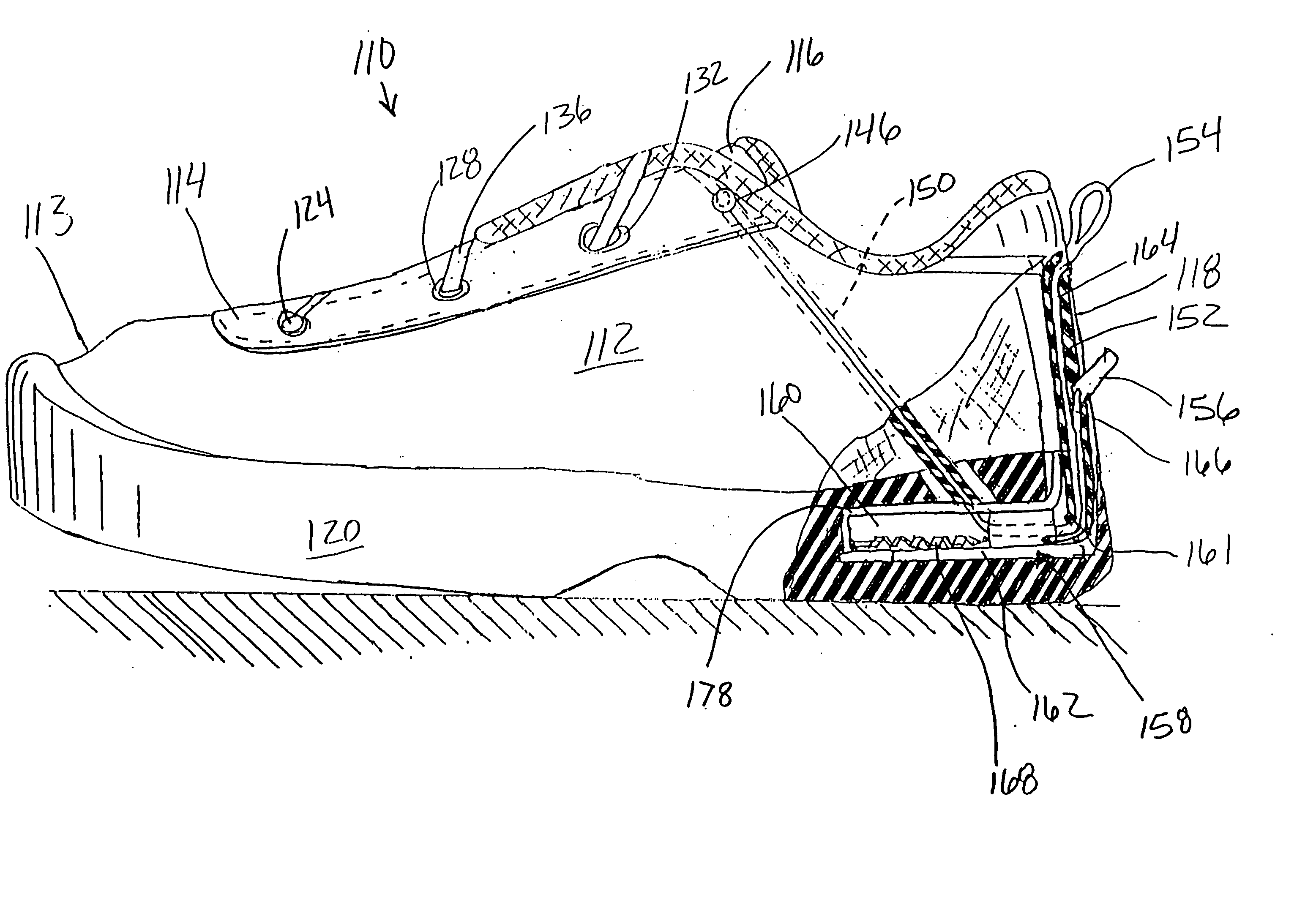

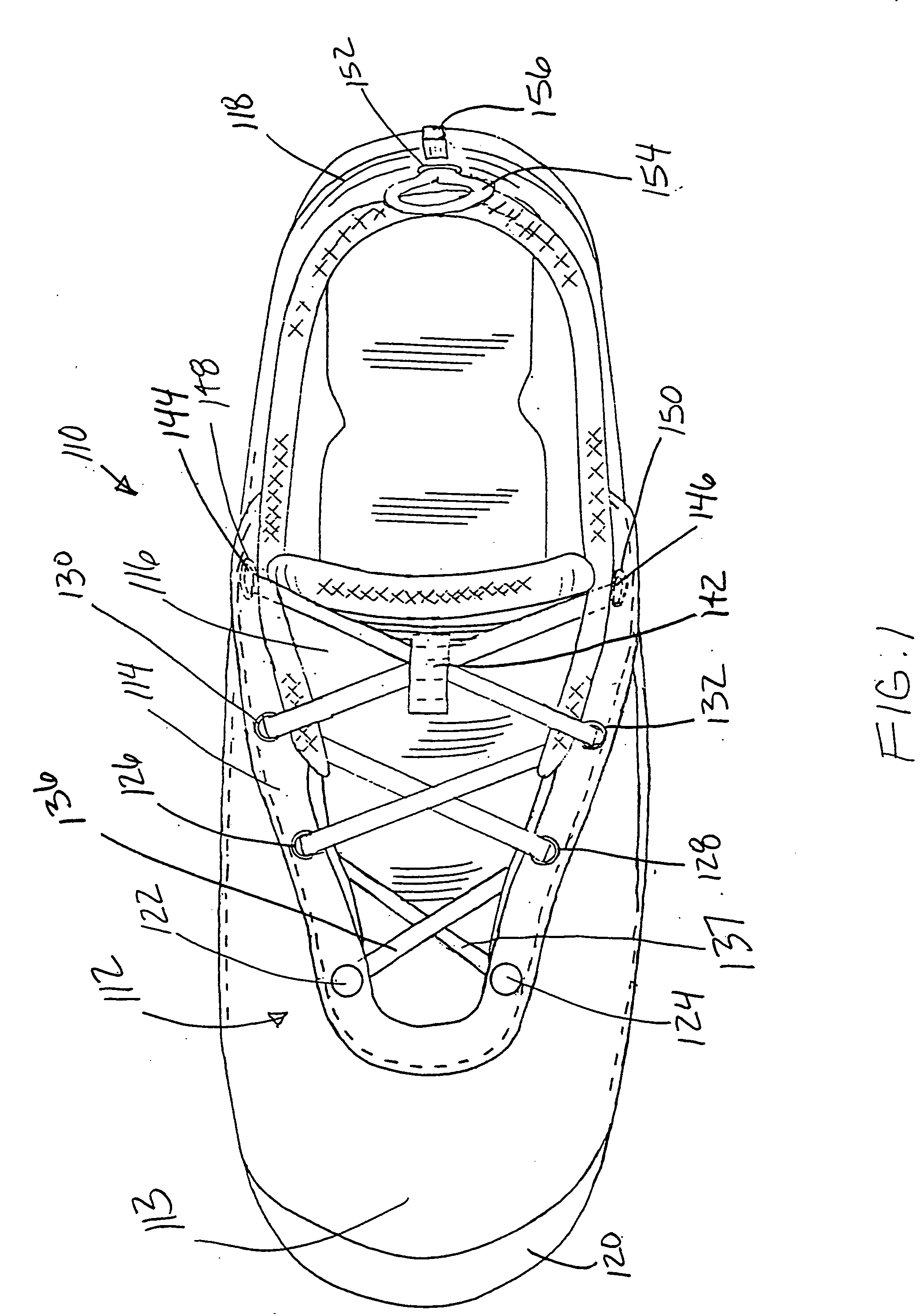

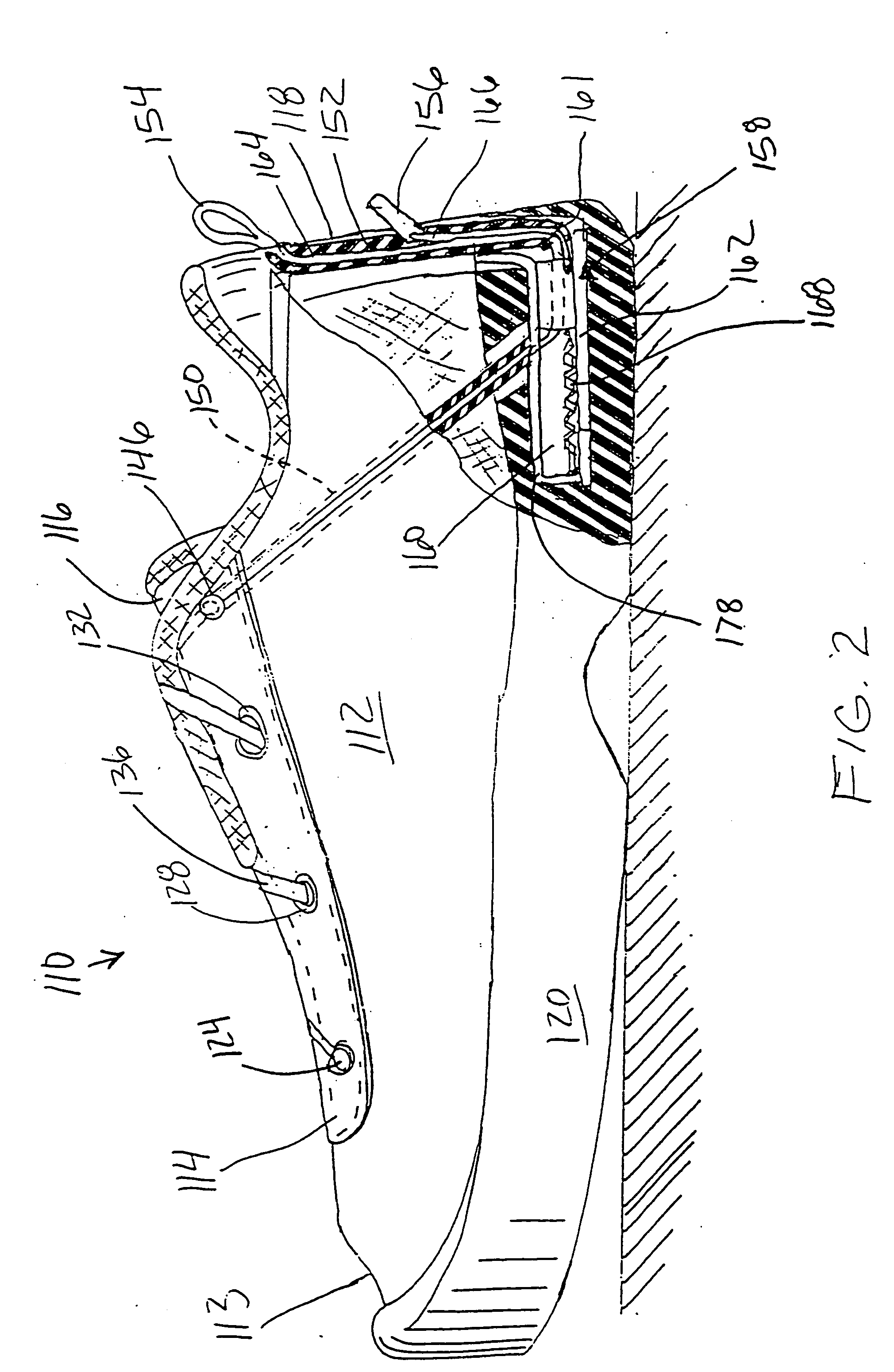

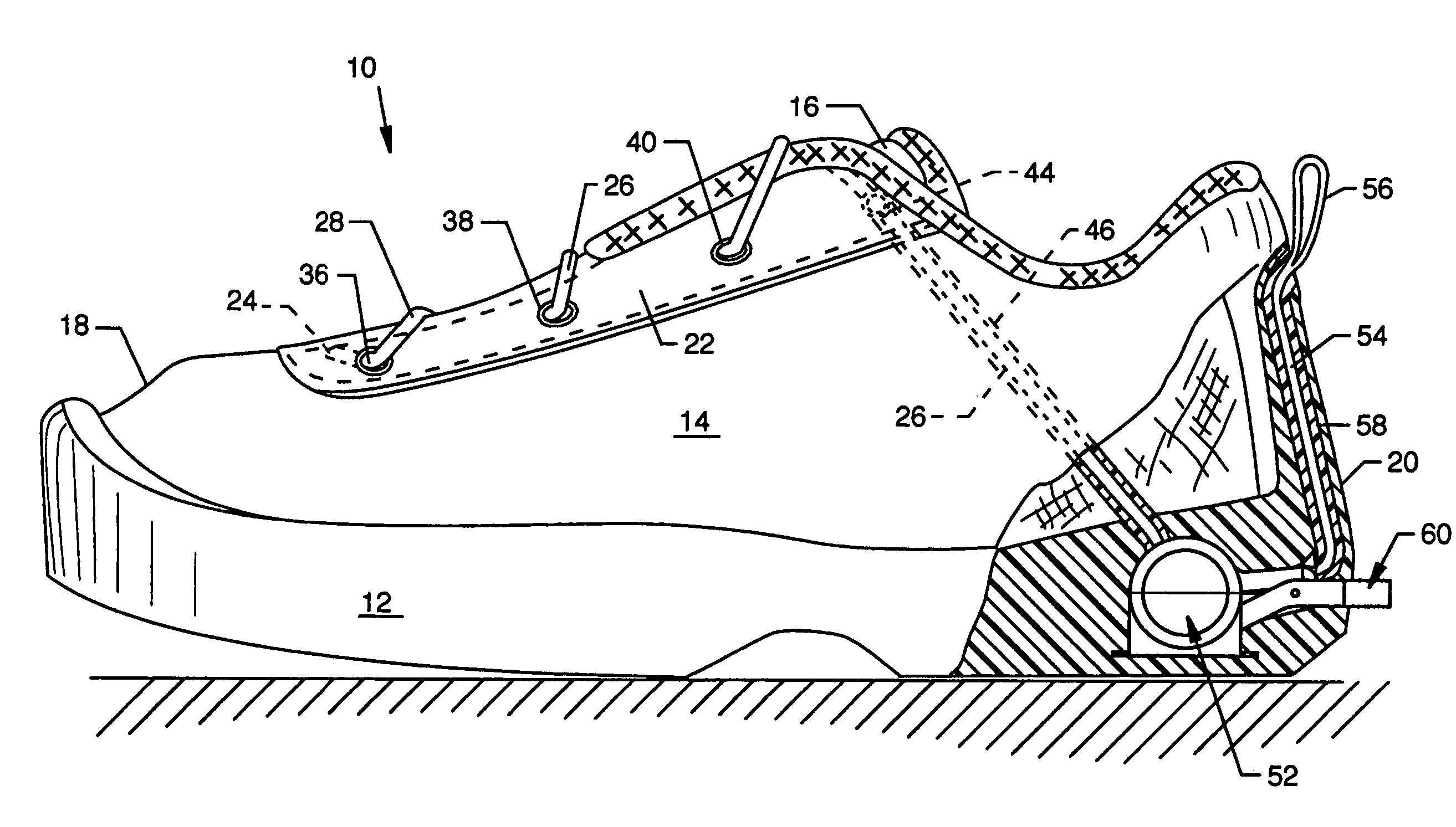

InactiveUS20060053659A1Avoid reverse motionEasy to operateSolesShoe lace fasteningsLocking mechanismShoe laces

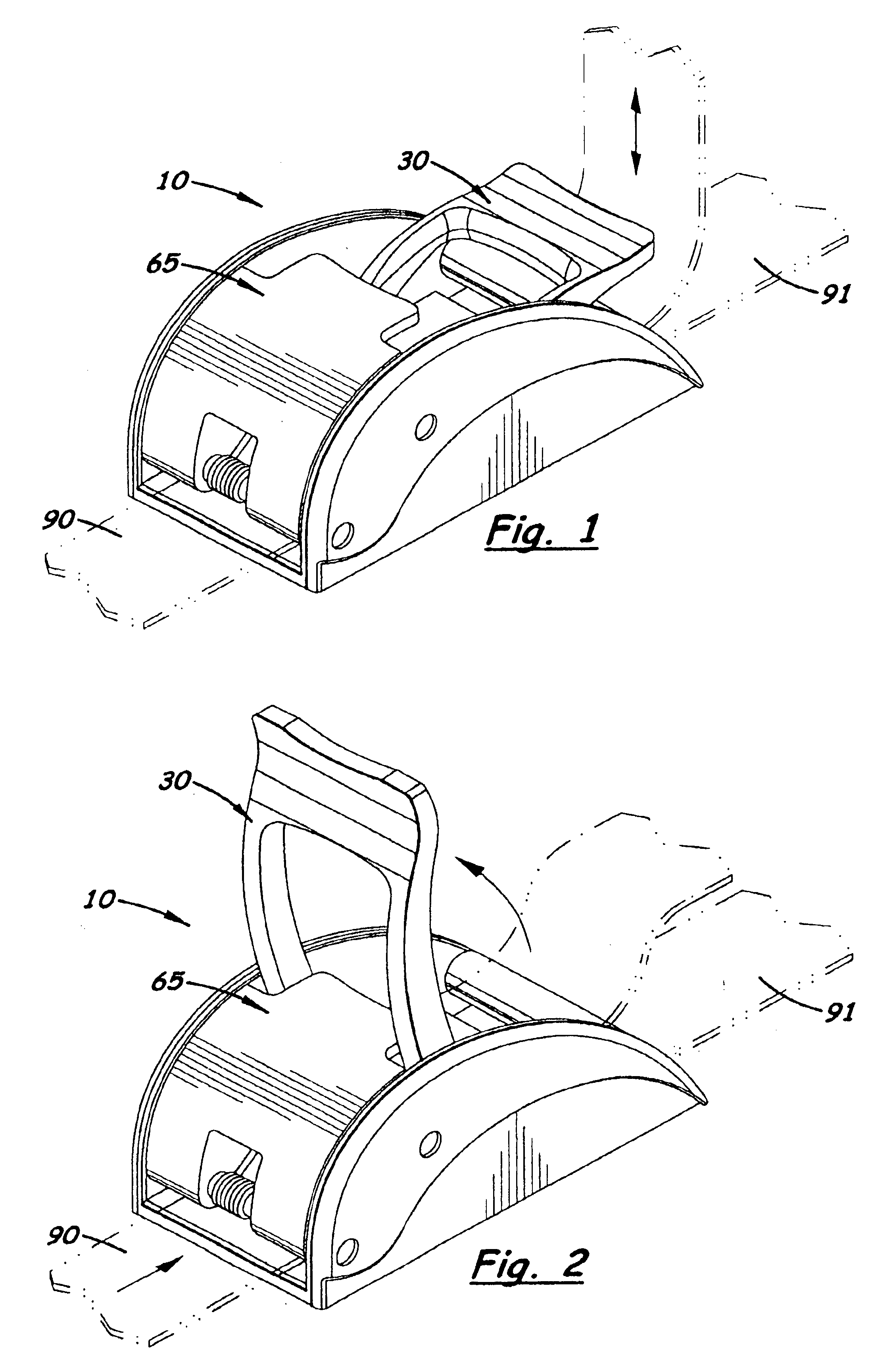

An automated tightening shoe is provided where a tightening mechanism operates to cause automatic tightening of the shoe laces about a wearer's foot and which releases the laces to allow loosening of the shoe. The shoe laces travel to the interior of the tightening mechanism located at the heel whereat the laces are operatively associated in a tightening or a loosening direction with the tightening mechanism. The tightening shoe further has a locking mechanism for locking said at least one lace in a tightened condition and a release mechanism for unlocking the locking mechanism and releasing the shoe laces. The release mechanism includes a lever arm which projects rearwardly from the rear of said shoe. Depression upon the lever arm causes the locking mechanism to unlock and release the shoe laces from being in a tightened condition.

Owner:HANDS FREE ENTERPRISES LLC

Automated tightening shoe

InactiveUS20050210706A1Easy to operateEasy to looseShoe lace fasteningsShoe lacesBiomedical engineering

Owner:HANDS FREE ENTERPRISES LLC

Automated tightening shoe

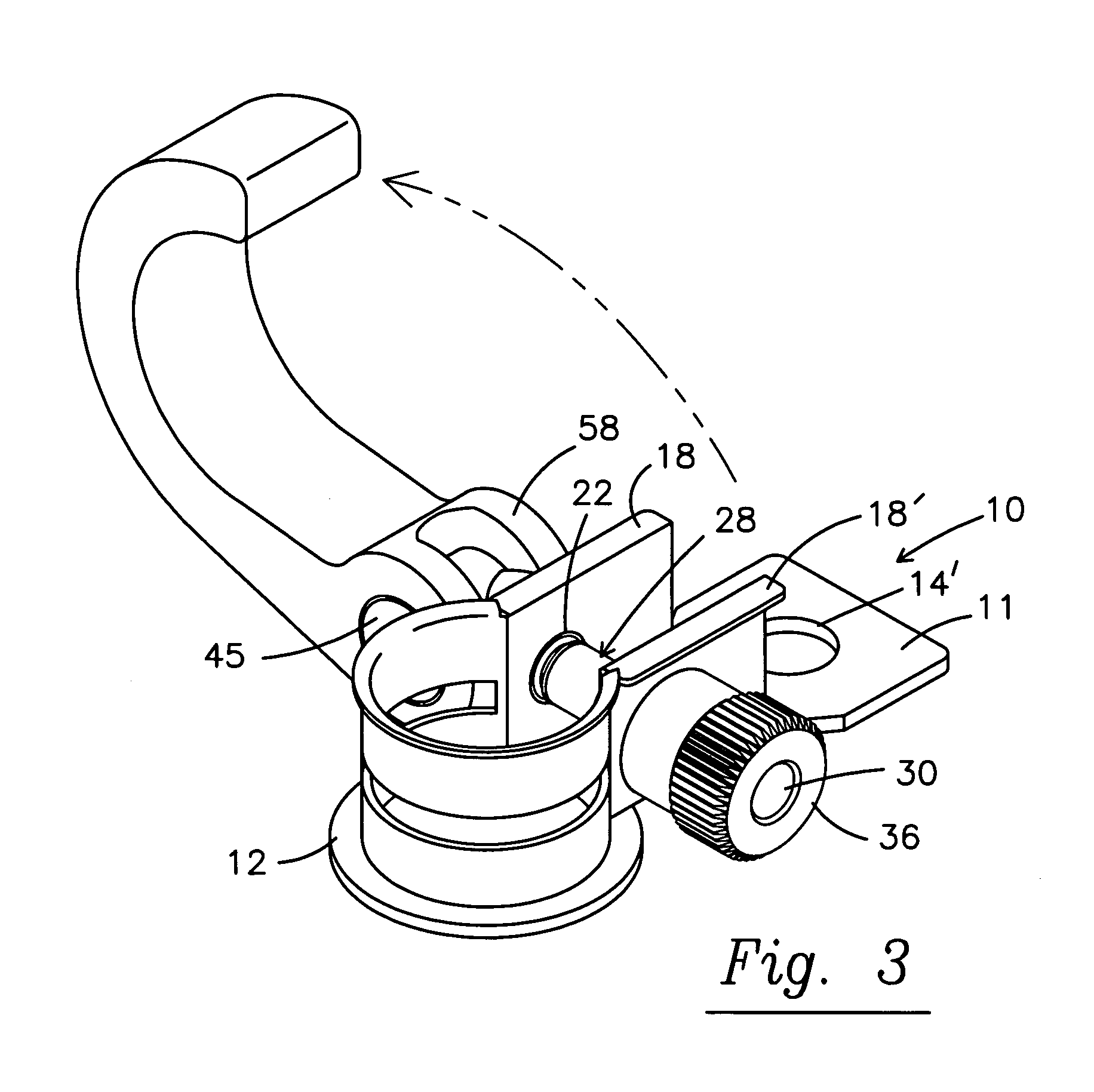

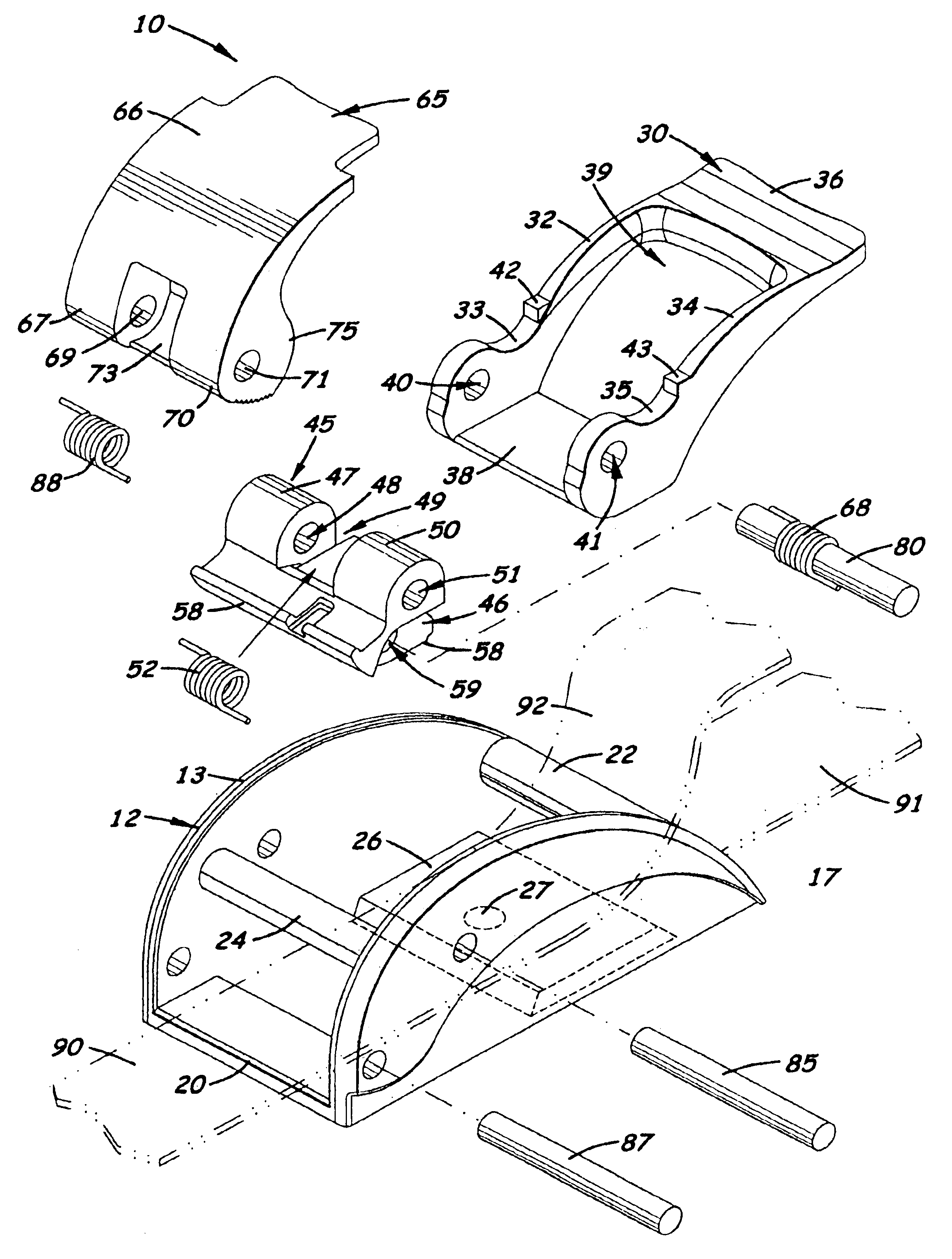

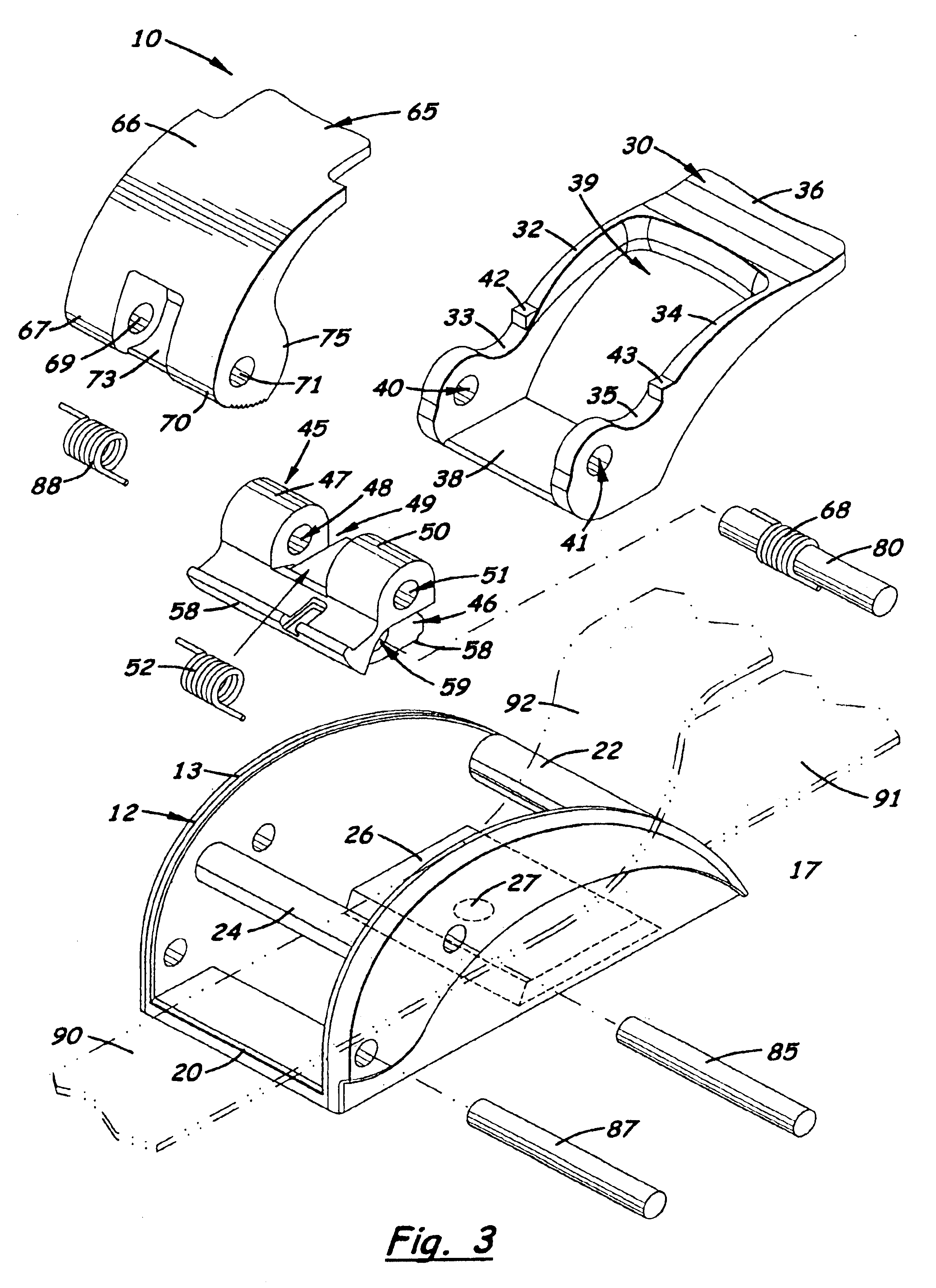

An automated tightening shoe where a tightening mechanism is actuated which operates in one direction to cause automatic tightening of the shoe about a wearer's foot and which releases to allow loosening of the shoe. Shoe laces are led to the interior of the tightening mechanism in the heel whereat the laces are operatively associated in a tightening or in a loosening direction with the tightening mechanism. The tightening mechanism includes a rotatable central shaft which may have drums mounted thereto, a ratcheted coupling collar or ratcheted cam disk, a ratcheted actuator spool, a compression spring, a return spring, a ratchet wheel, and a release lever including a pawl and a cam actuator bar, all of which extend along the central shaft and operate to tighten as well as to allow loosening of the shoe laces.

Owner:HANDS FREE ENTERPRISES LLC

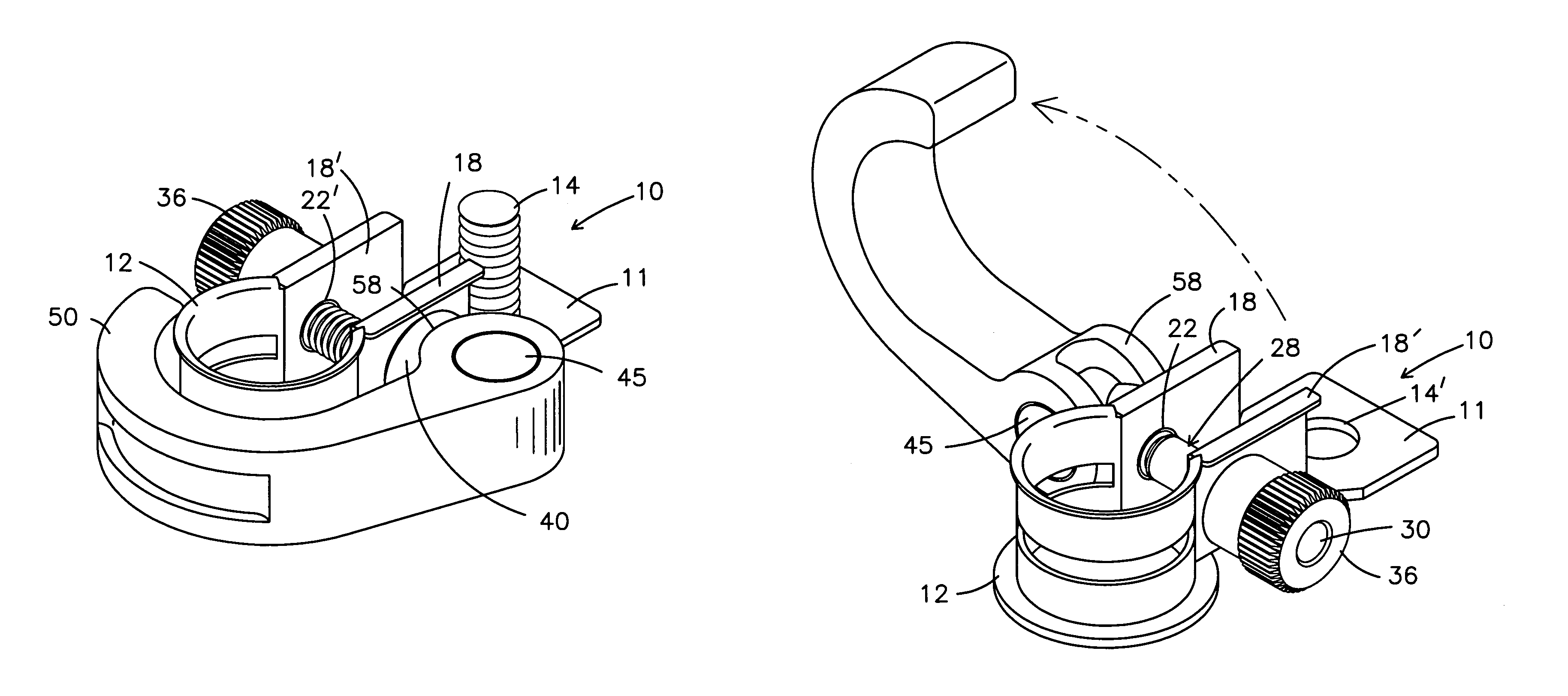

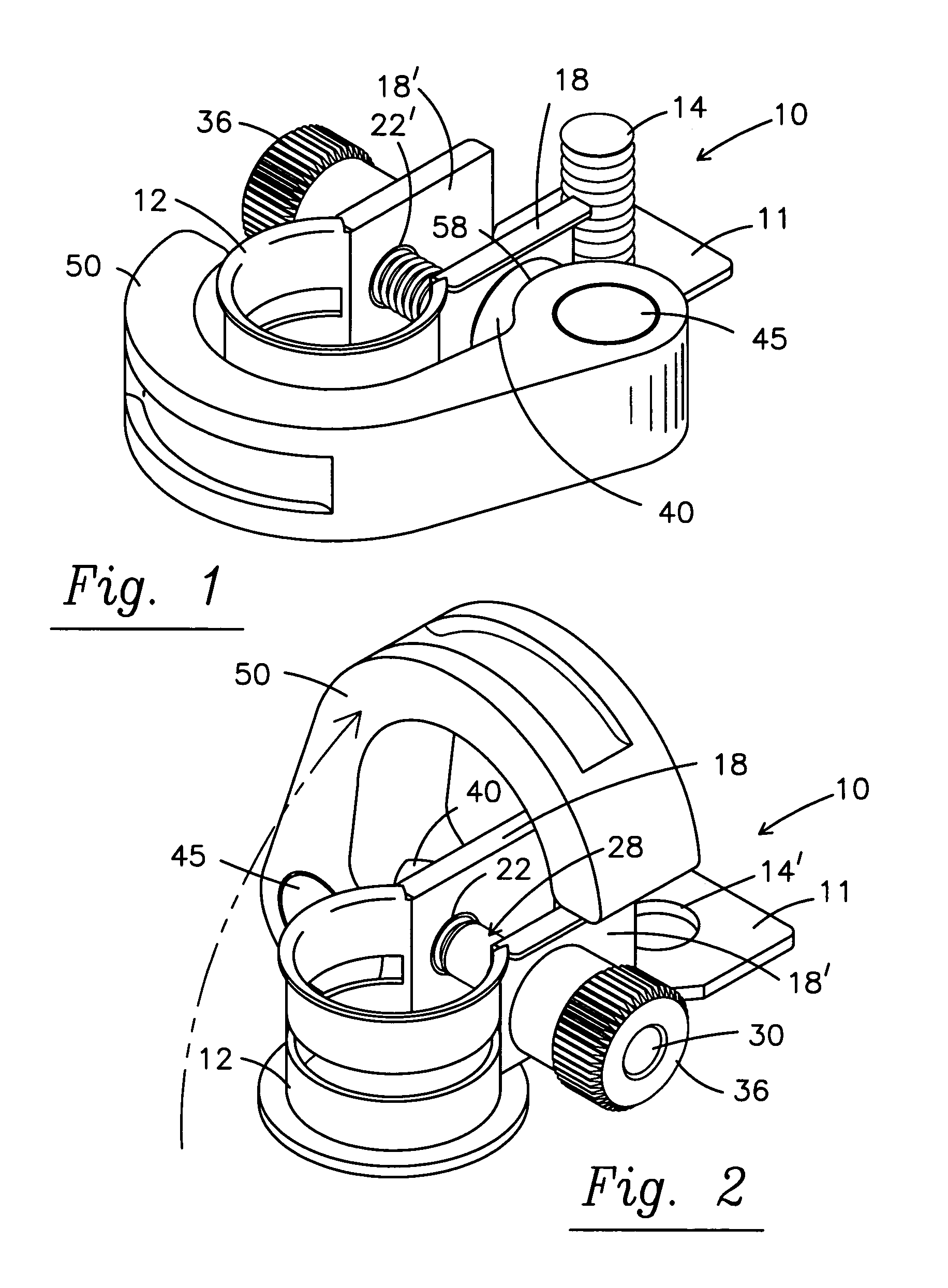

Rotatable connector for a battery cable clamp

InactiveUS6971925B1Increase pressureIncrease clamping pressureElectric connection basesClamped/spring connectionsEngineeringElectrical and Electronics engineering

An improved rotatable battery cable clamp connector is designed for use with applying pressure to legs of the clamp intermediate the cable section and post section of the clamp. Self-lubricating and non-corrosive materials are also used to advantage in the manufacture of the connector.

Owner:FENELON MARGARET FENE +1

Strap tensioner

InactiveUS6868587B2Easy to tightenDesired amount of tensionSnap fastenersFastening devicesEngineeringCam

An improved strap tensioner that allows a user to manually shorten the strap by applying greater tension on the strap and easily lengthening the strap after being tightened. The tensioner includes a tension lever, an intermediate member, and a brake lever all pivotally mounted on a rigid base. The tension lever and brake member are longitudinally aligned on opposite sides of the rigid base. Formed on the tension lever is a transversely aligned clamping flange that extends under the strap when longitudinally extended through the rigid base. Formed on the intermediate member and disposed above the clamping flange is a first cam surface that forms a slot for the strap to extend through. The brake lever includes a second cam surface that is spaced above the front flange member to form a second slot. During operation, the brake lever is rotated to press the second cam surface against the front flange member to temporarily hold the strap inside the rigid base. During use, the tension lever, the intermediate member and the brake lever are sequentially coupled together to selectively engage, pull and release the strap allowing the strap to be tightened or loosened.

Owner:RARD ROY

Buckle with strap securing bar

InactiveUS20060218761A1Prevents inadvertent slippageEasy to looseSnap fastenersClothes buttonsEngineeringMechanical engineering

Owner:ANSCHER JOSEPH

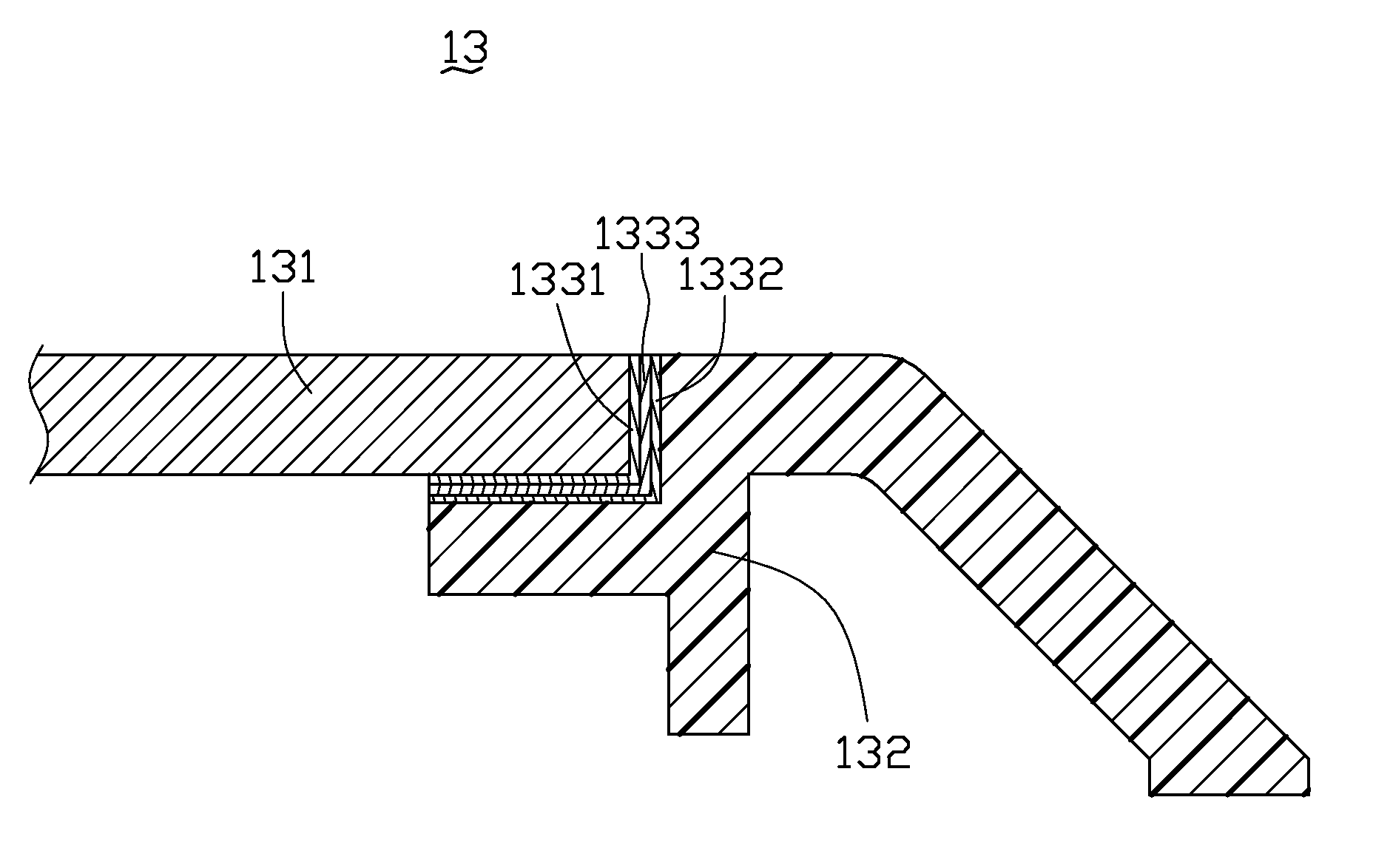

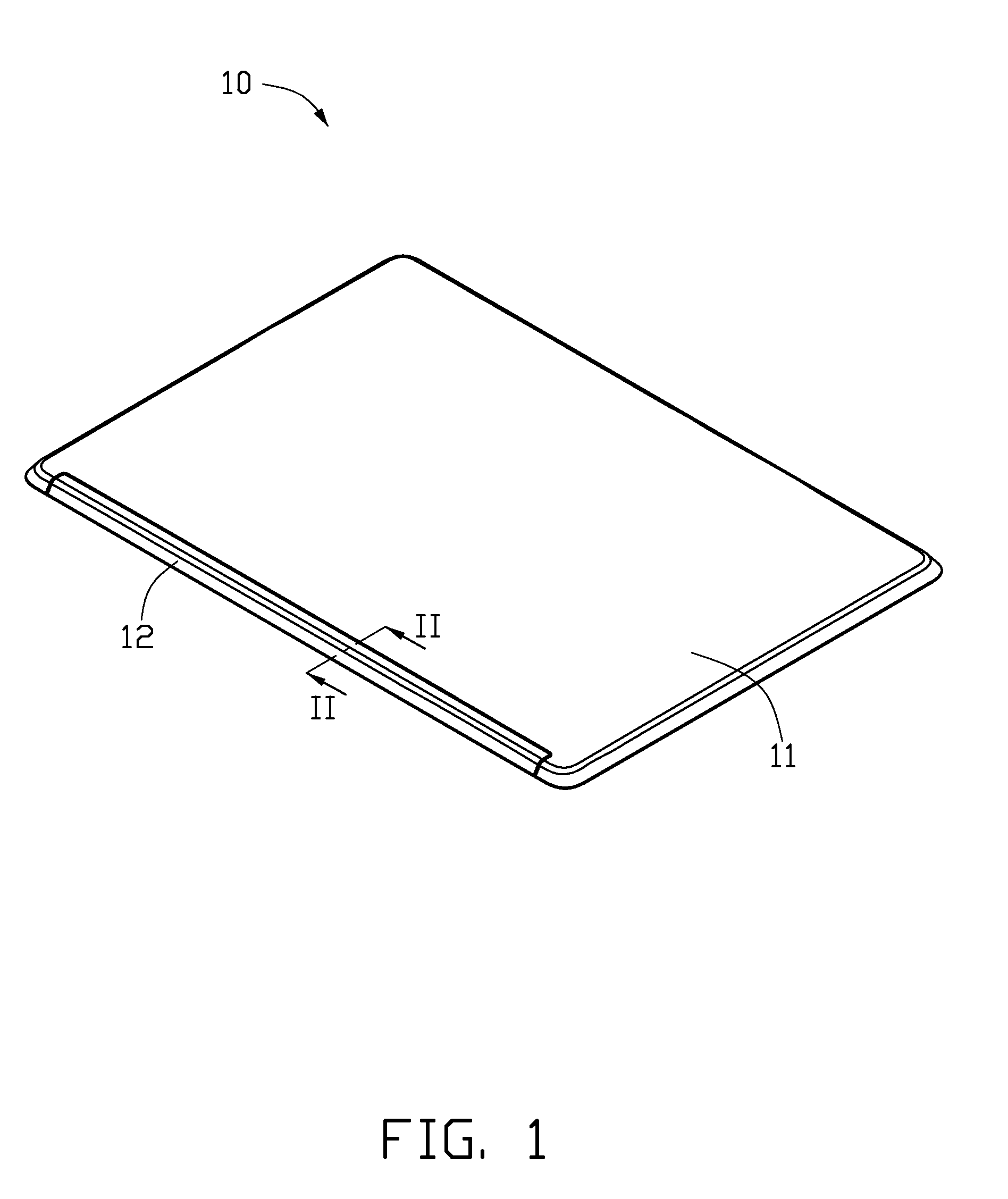

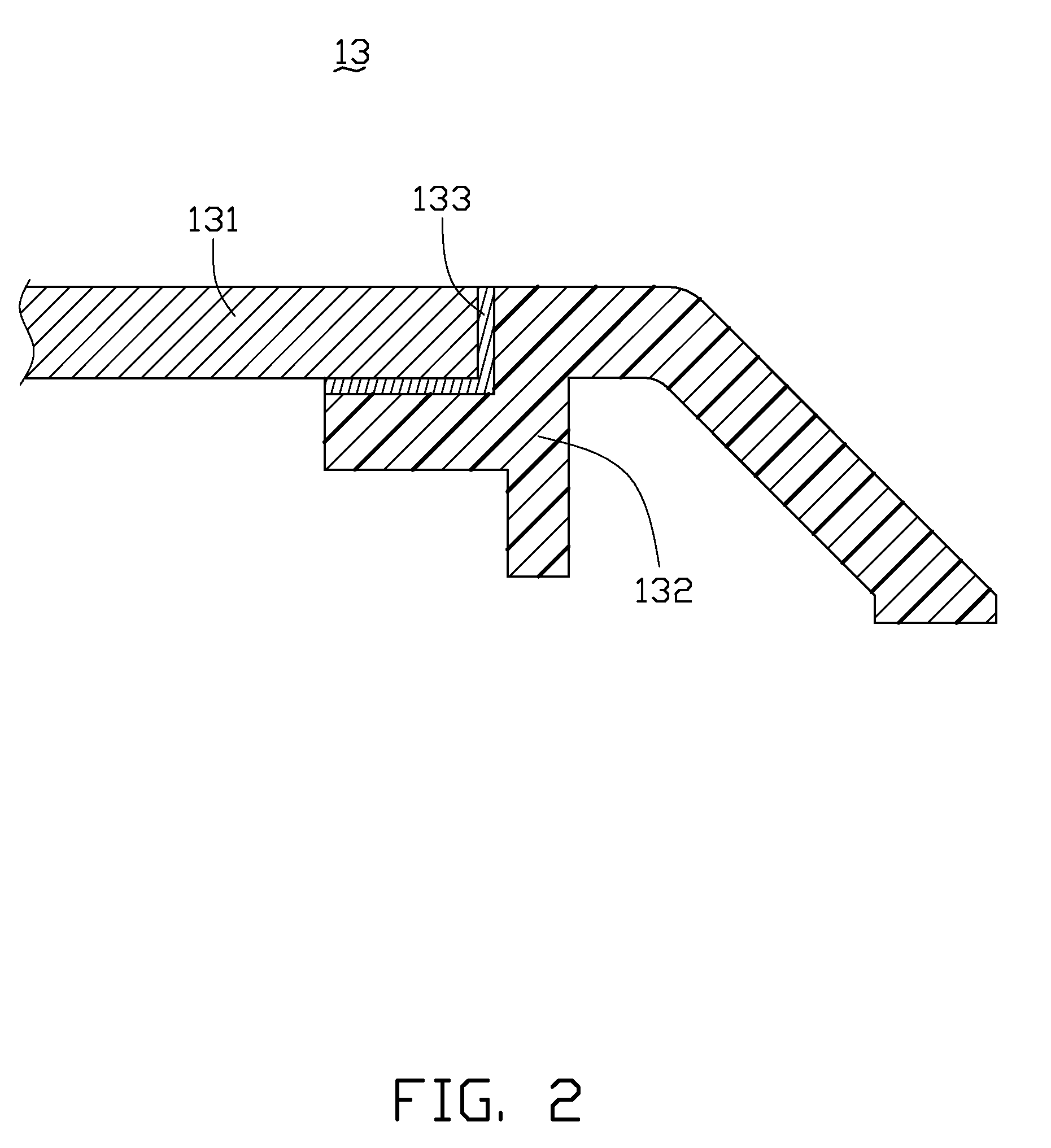

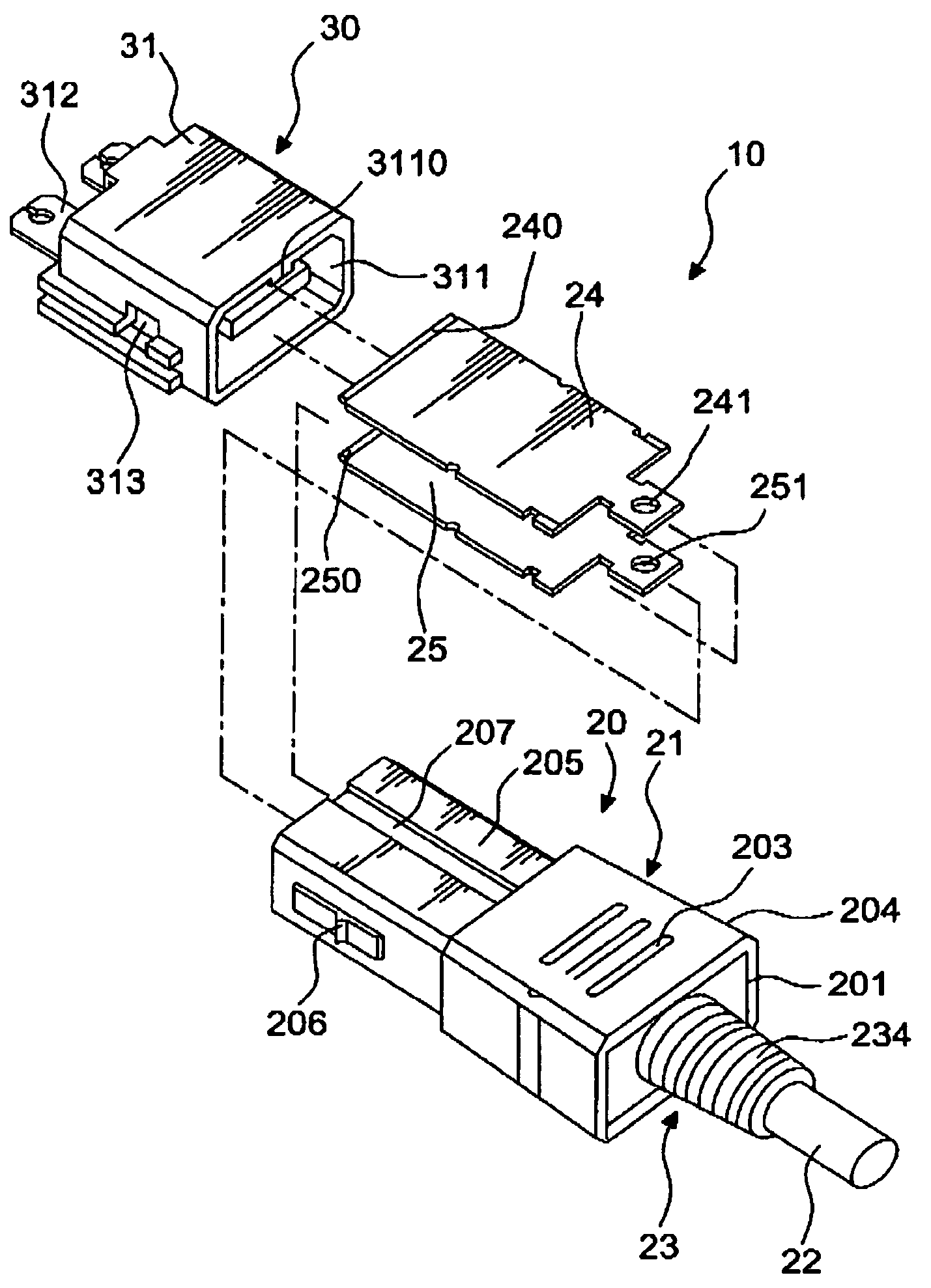

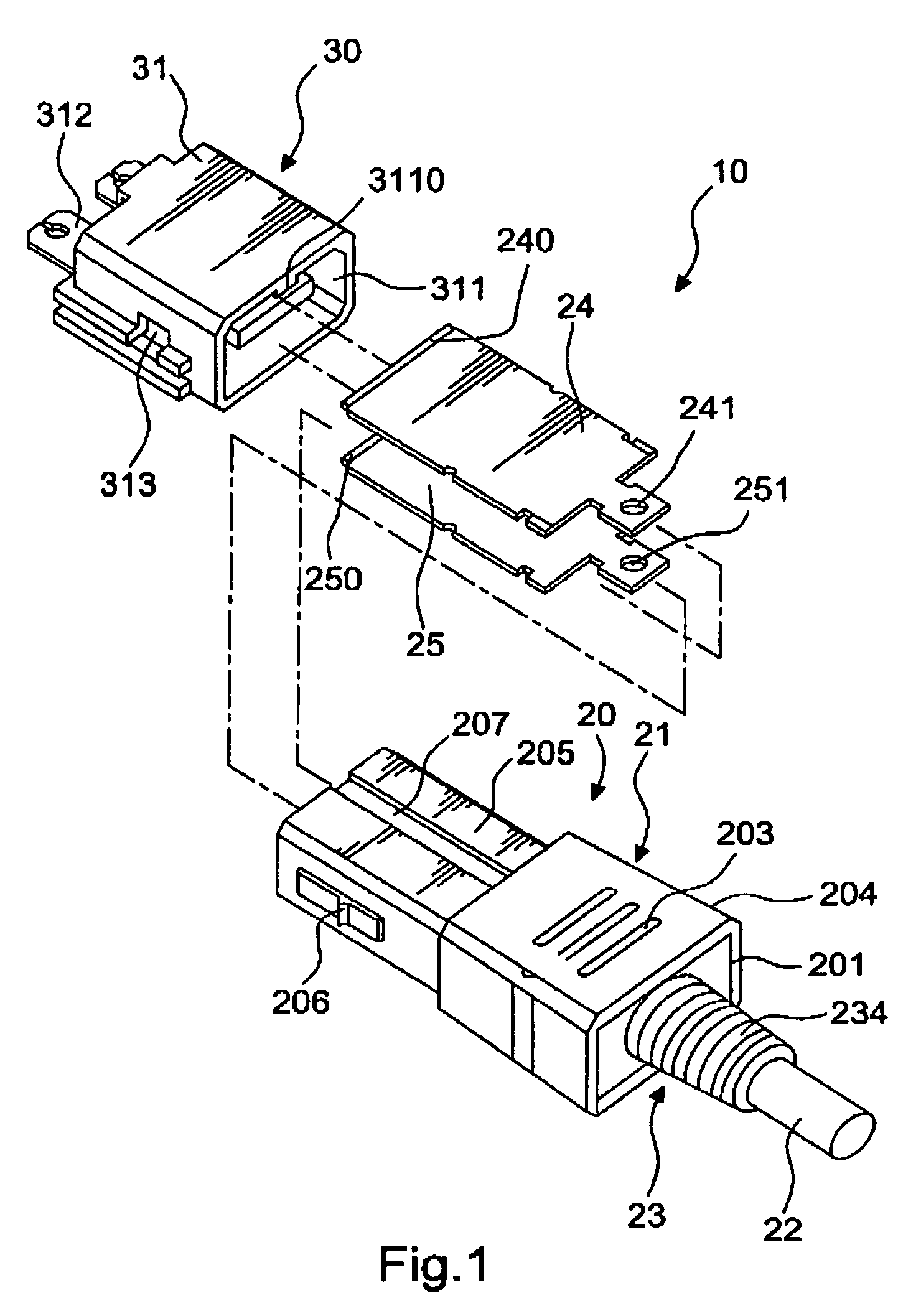

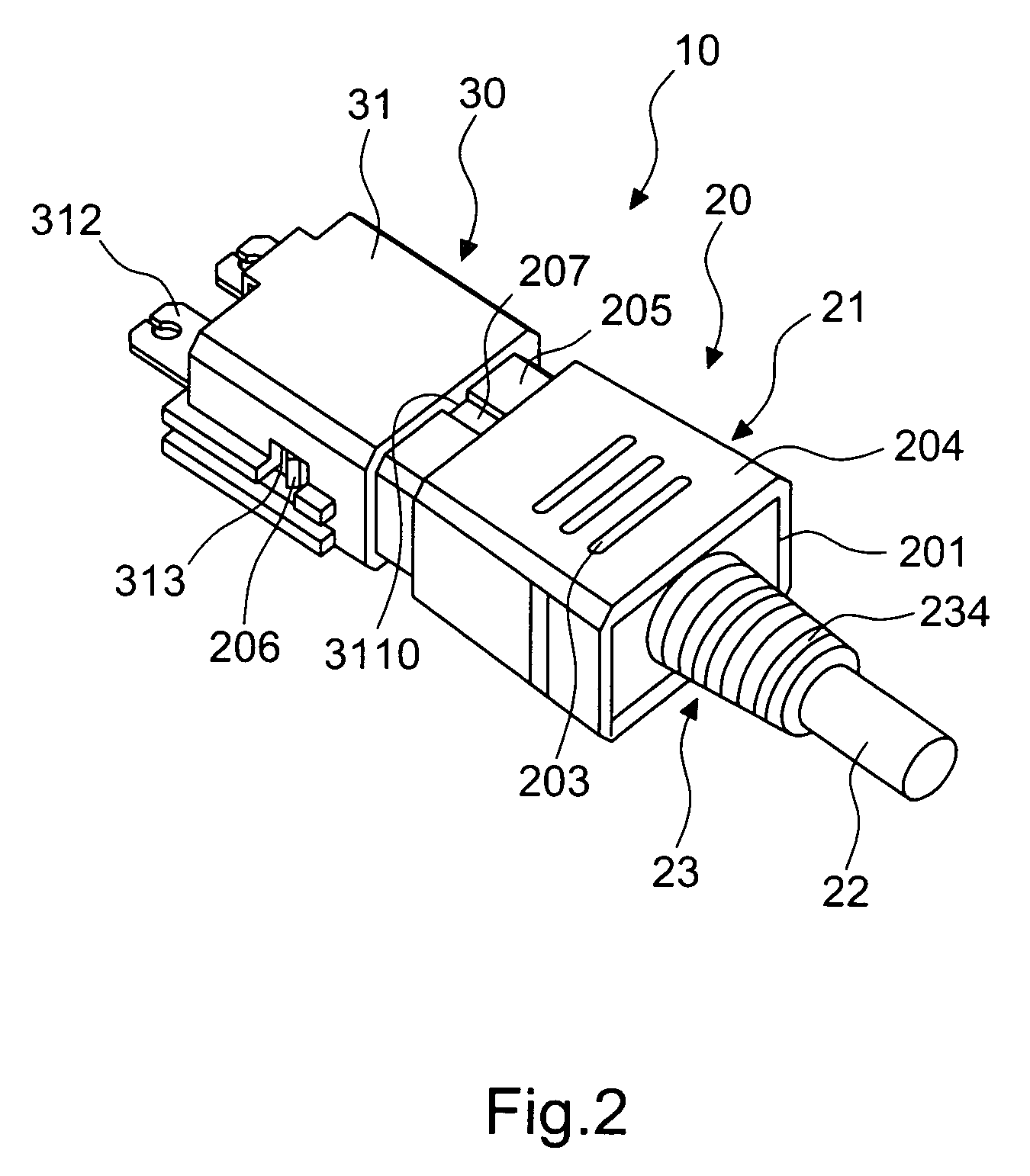

Joining structure and insert-molded cover using same

InactiveUS20090280316A1Improve electromagnetic shielding performanceDurability be compromisedRecord information storageDetails for portable computersEngineeringMechanical engineering

An exemplary joining structure, used for insert-molded covers, includes a metallic portion (131), a plastic portion (132) integrally formed with the metallic portion, and an adhesive film (133) formed between the metallic portion and the plastic portion. The metallic portion and the plastic portion are bonded together by the adhesive film. The present invention also relates an insert-molded cover (10) for electronic devices using the joining structure and a method for manufacturing the insert-molded cover for electronic devices.

Owner:HON HAI PRECISION IND CO LTD

Ostomy appliance

InactiveUS20140128826A1Good peeling effectEasy to peelNon-surgical orthopedic devicesBodily discharge devicesEngineeringOstomy appliances

Owner:COLOPLAST AS

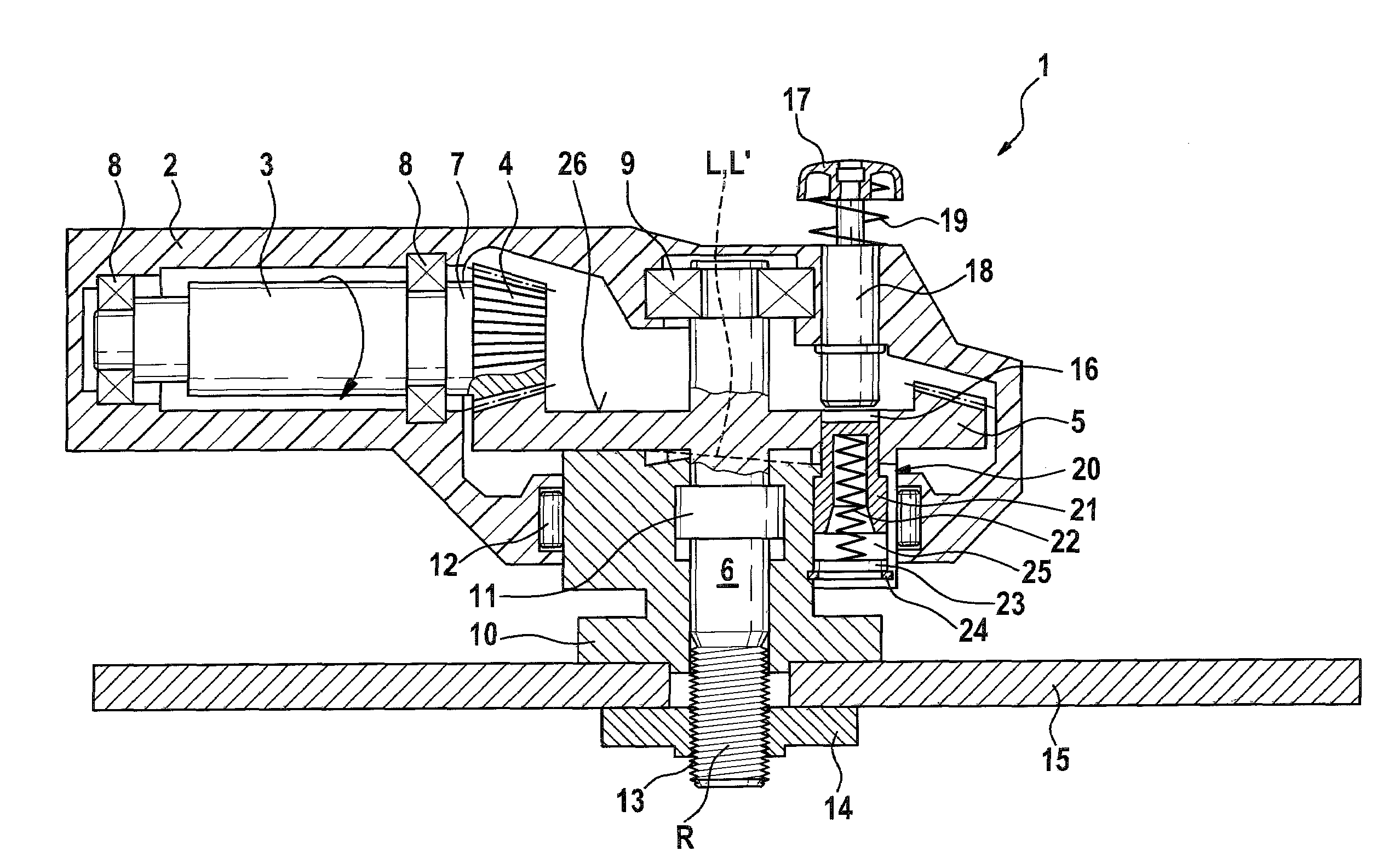

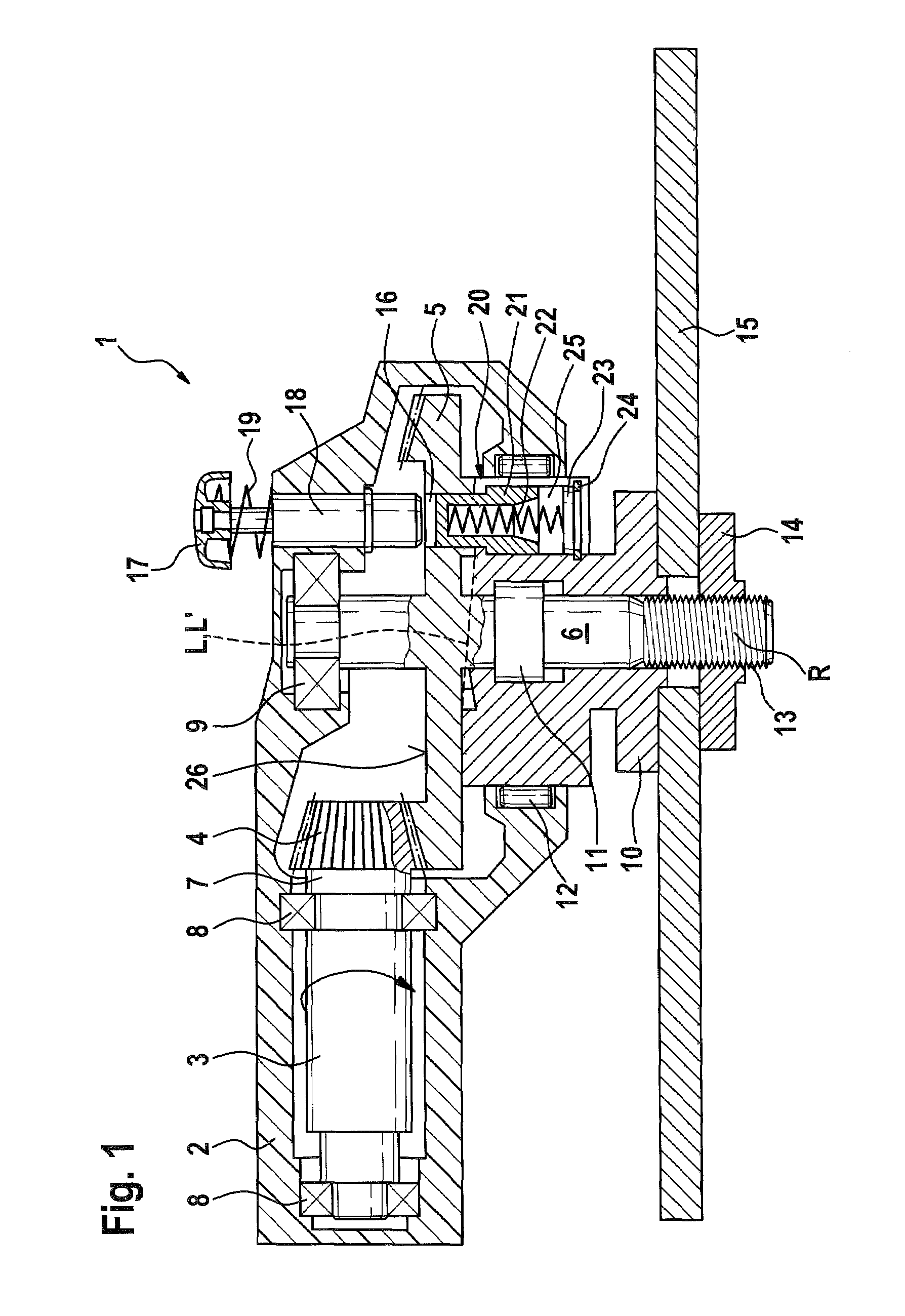

Clamping fixture for detachably fastening a disk-shaped tool

InactiveUS7438634B2Easy to looseWithout usingGrinding wheel securing apparatusPortable grinding machinesFlange

A clamping fixture for detachably fastening a disk-shaped tool on a rotatably driven working spindle with a driven gear includes a fastening element a supporting flange arranged so that the tool is accommodated between the fastening element and the supporting flange and rotatably displaceable relative to the working spindle in the tightening direction and axially in a direction toward the tool. The supporting flange is displaceable relative to the working spindle in a release direction and axially away from the tool when the fastening element is released, and is lockable with the working spindle or a component which is non-rotatably connected with the working spindle in a position which is displaced axially in a direction of the tool, and the supporting flange cannot be displaced axially away from the tool until a lock is released.

Owner:ROBERT BOSCH GMBH

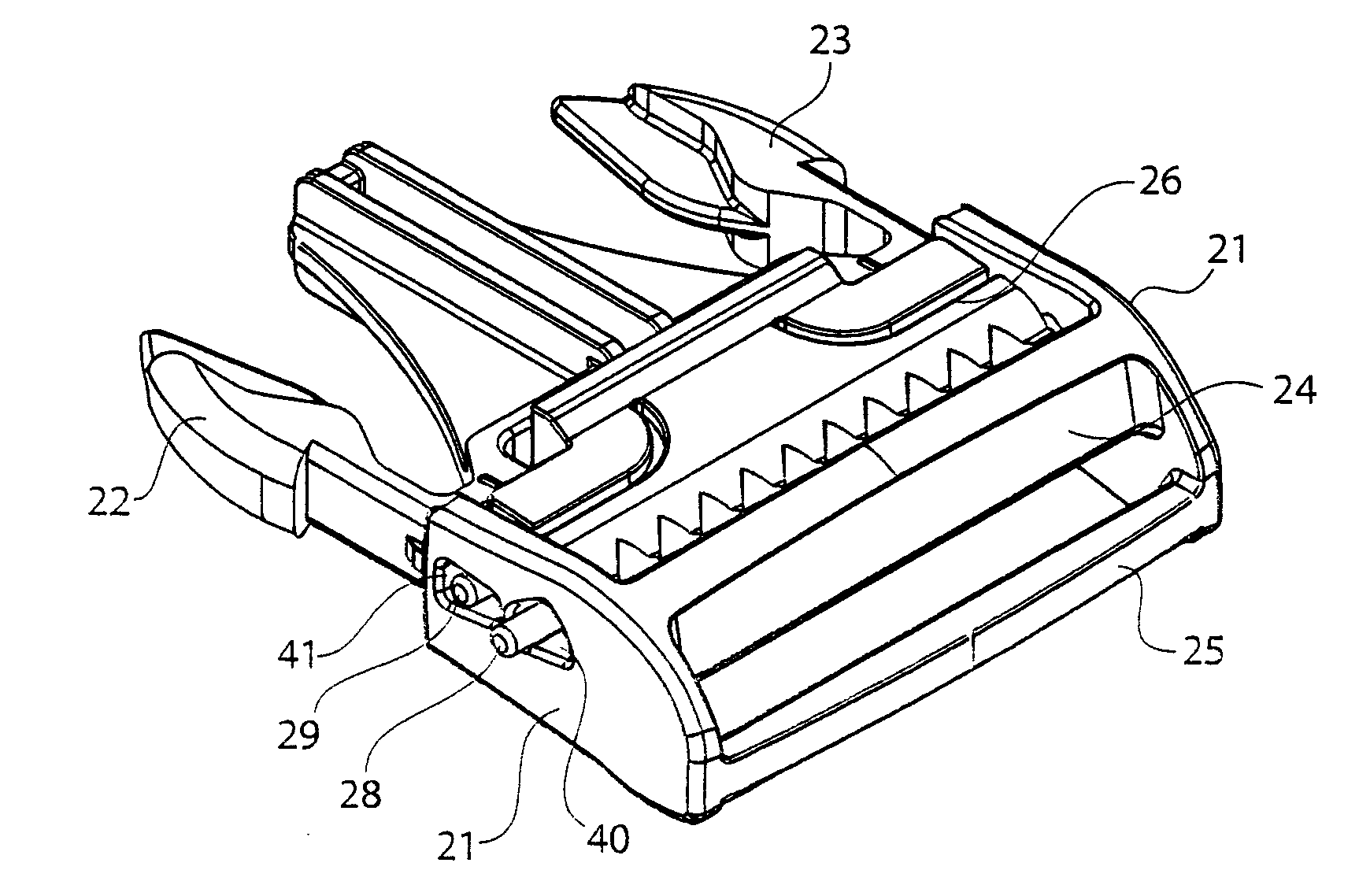

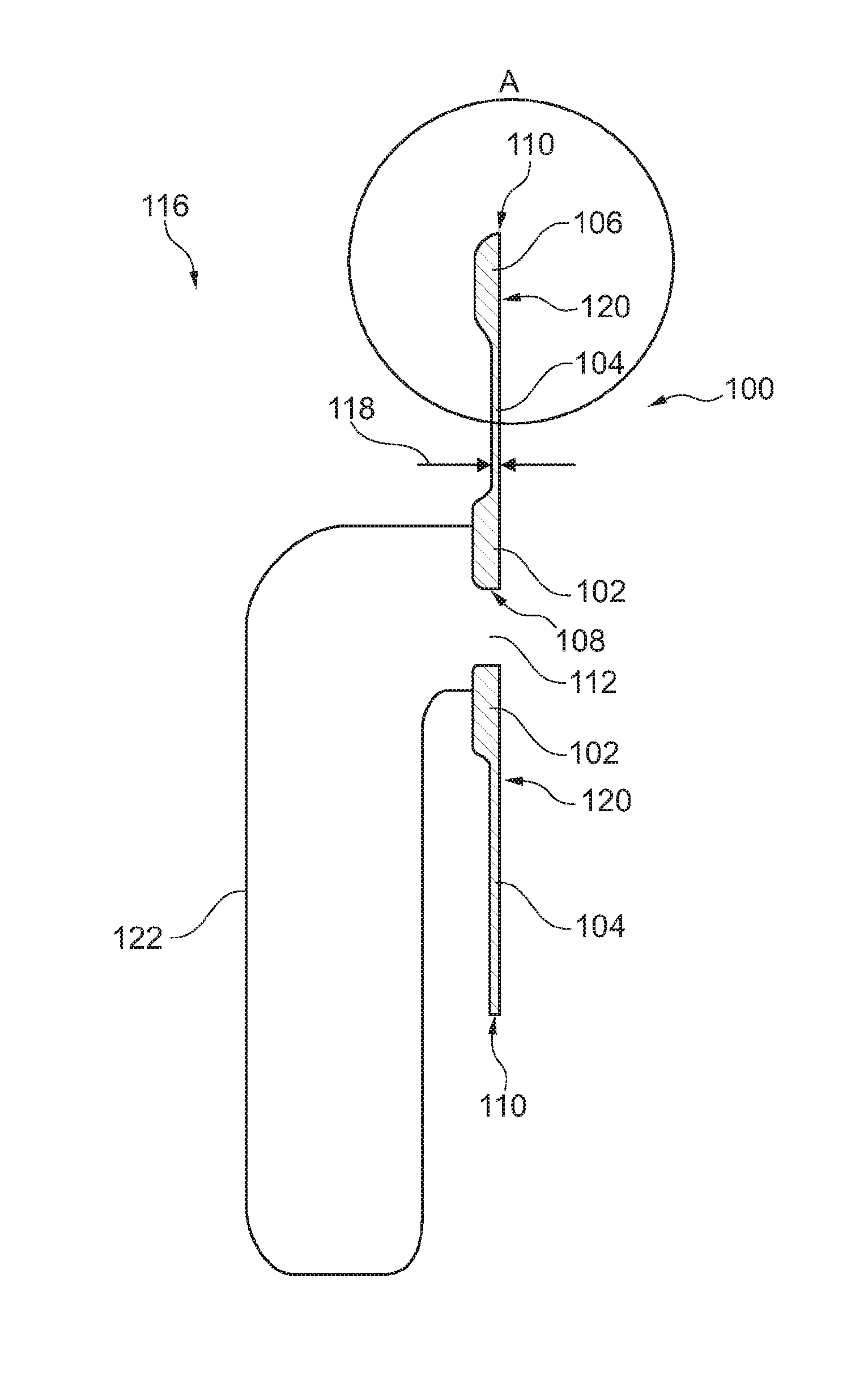

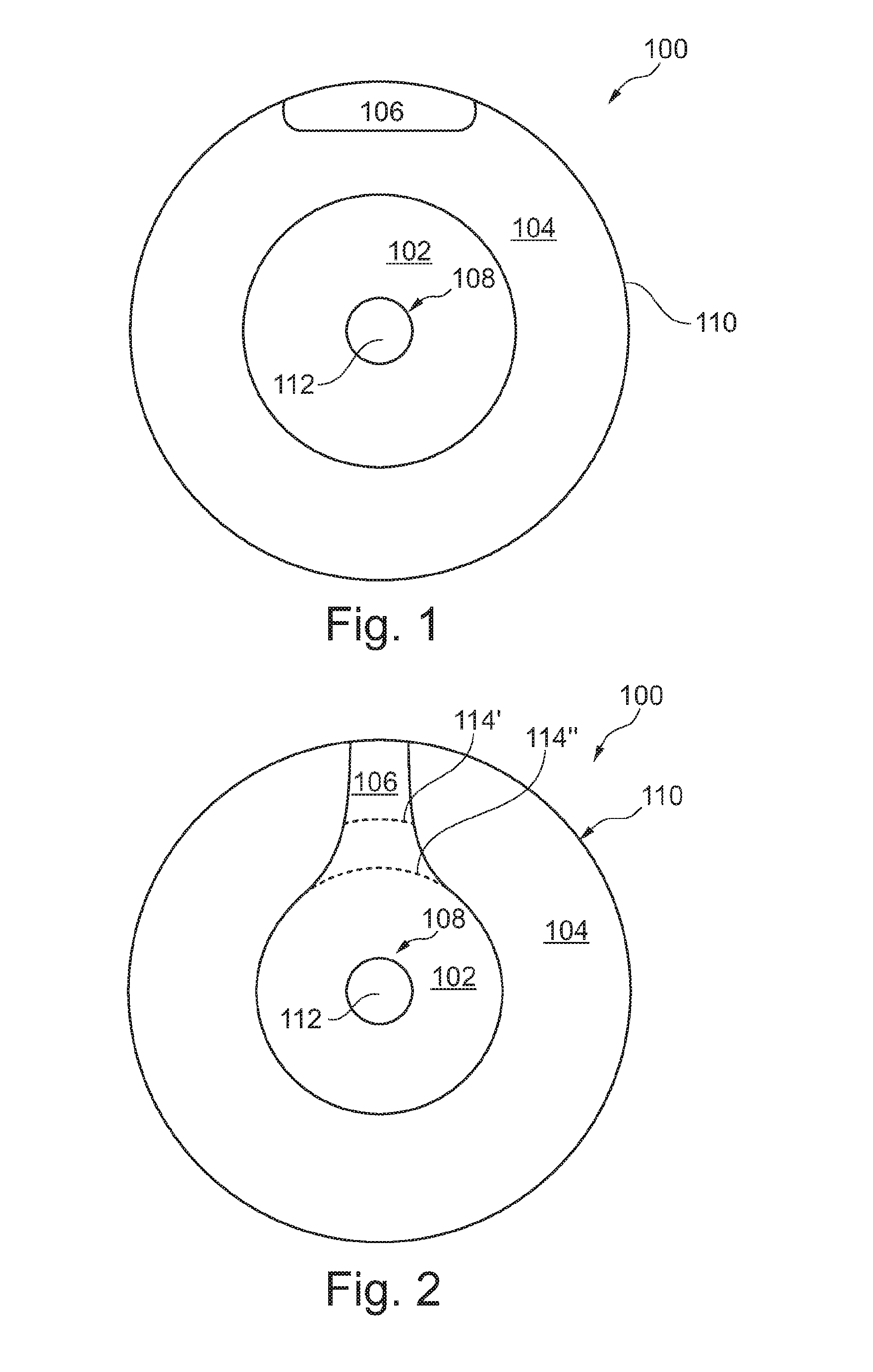

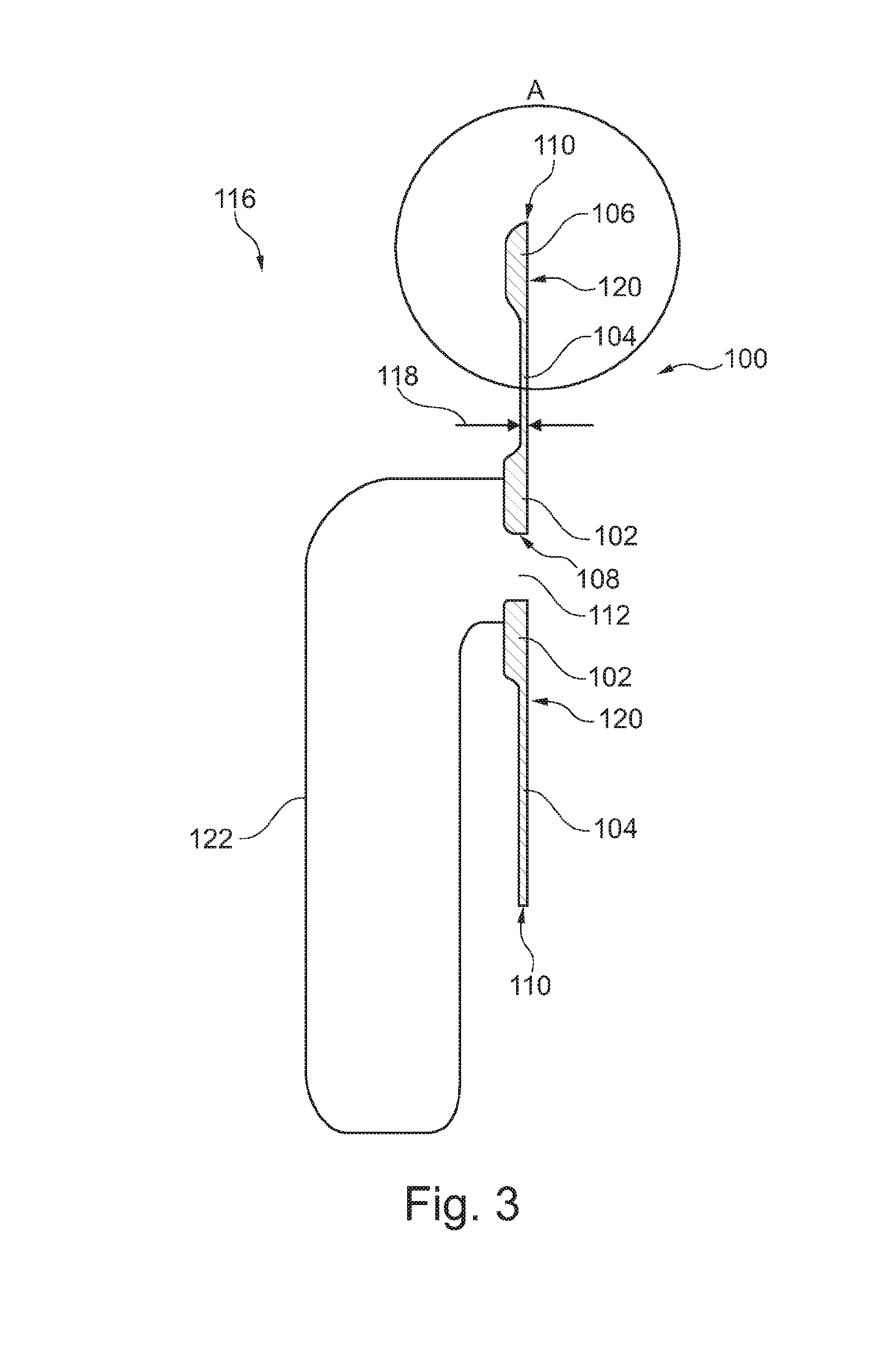

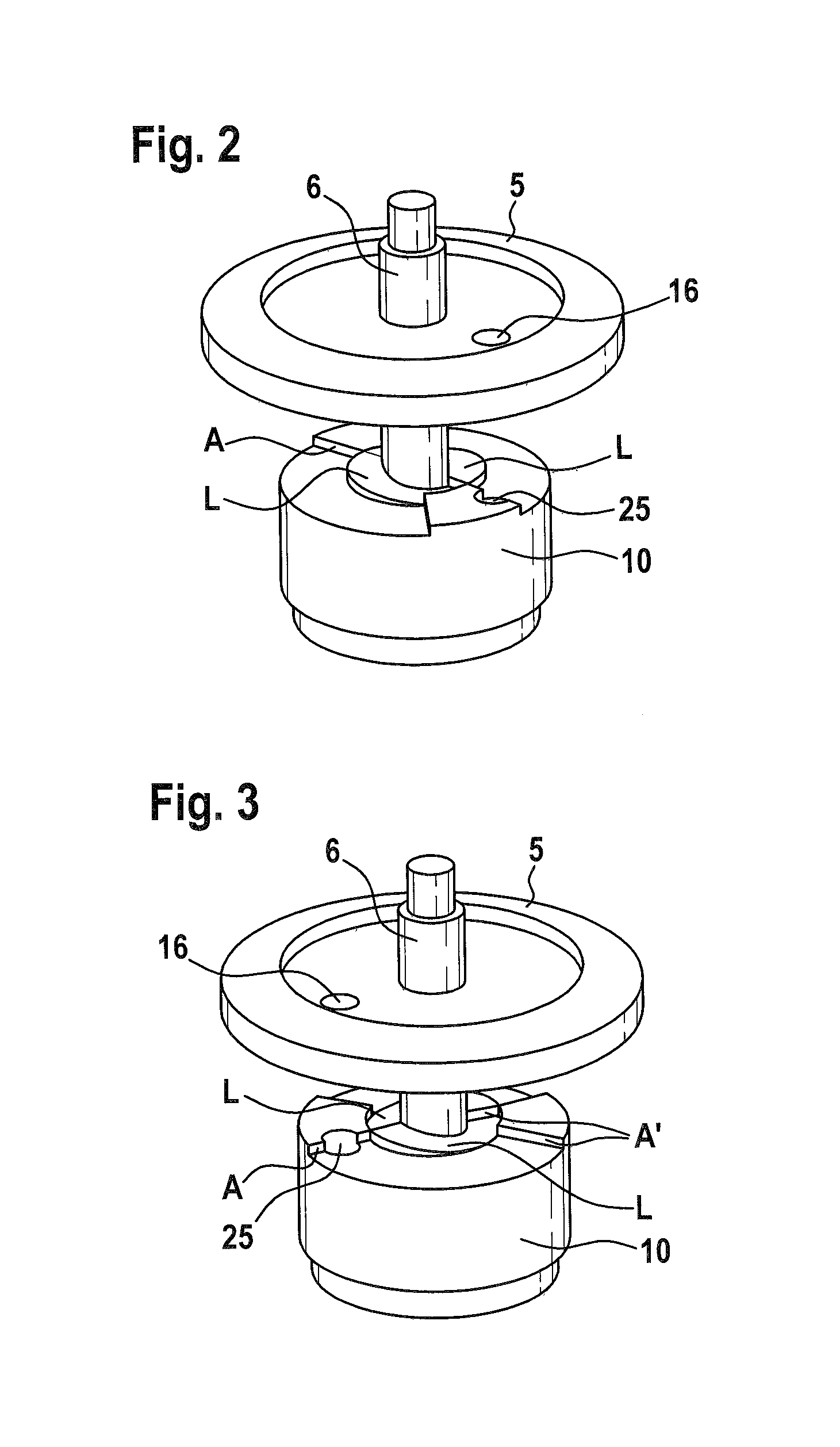

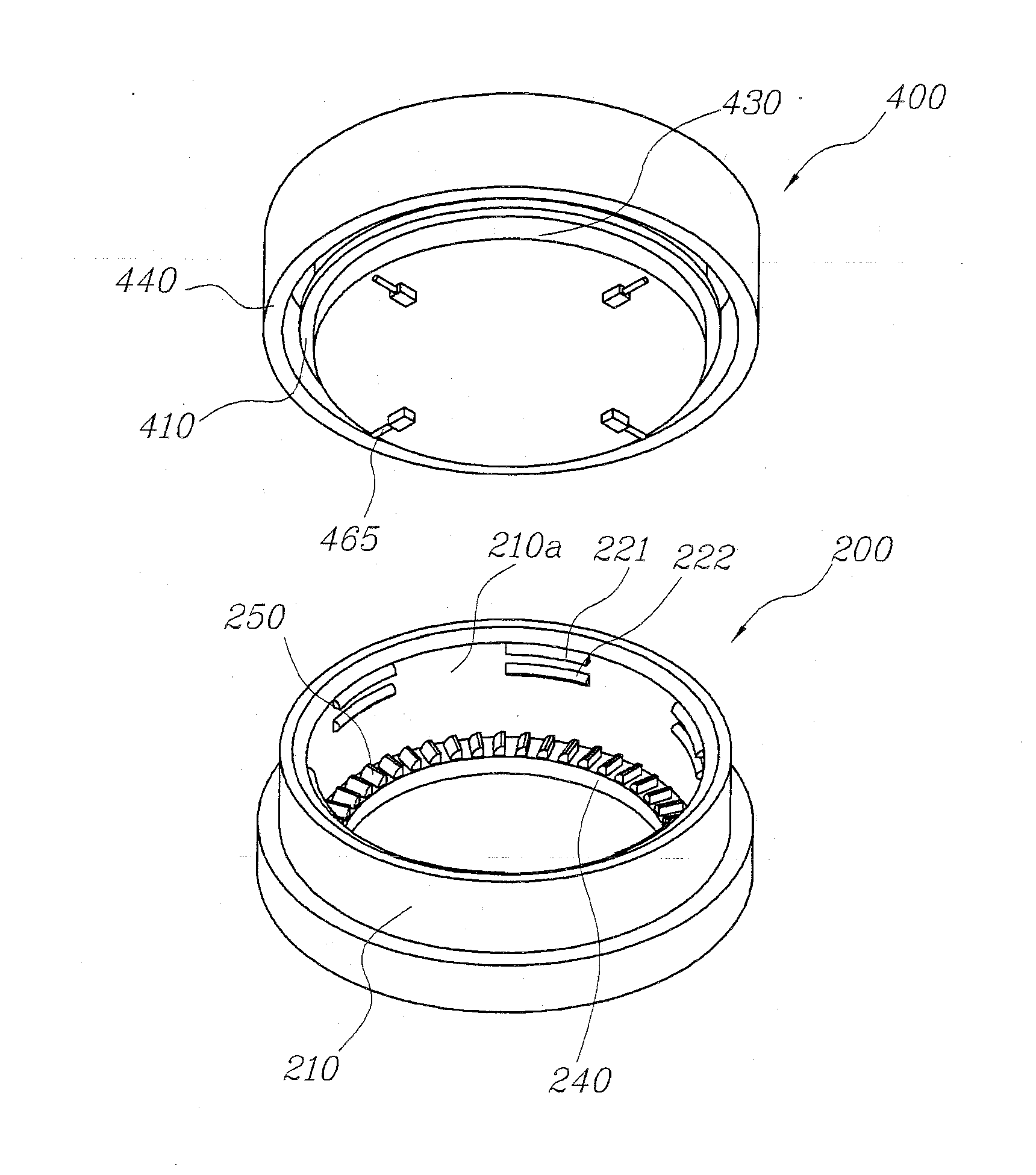

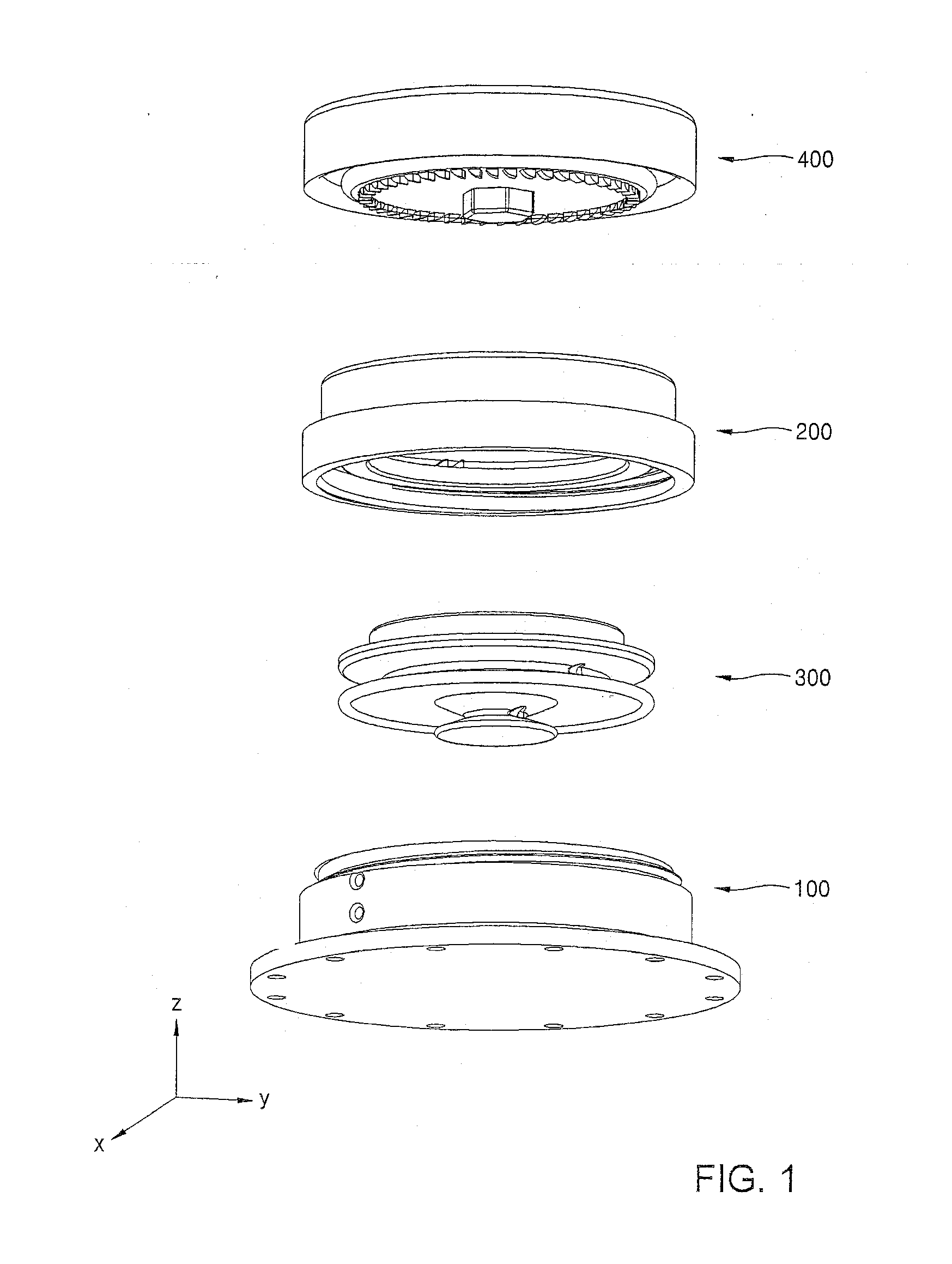

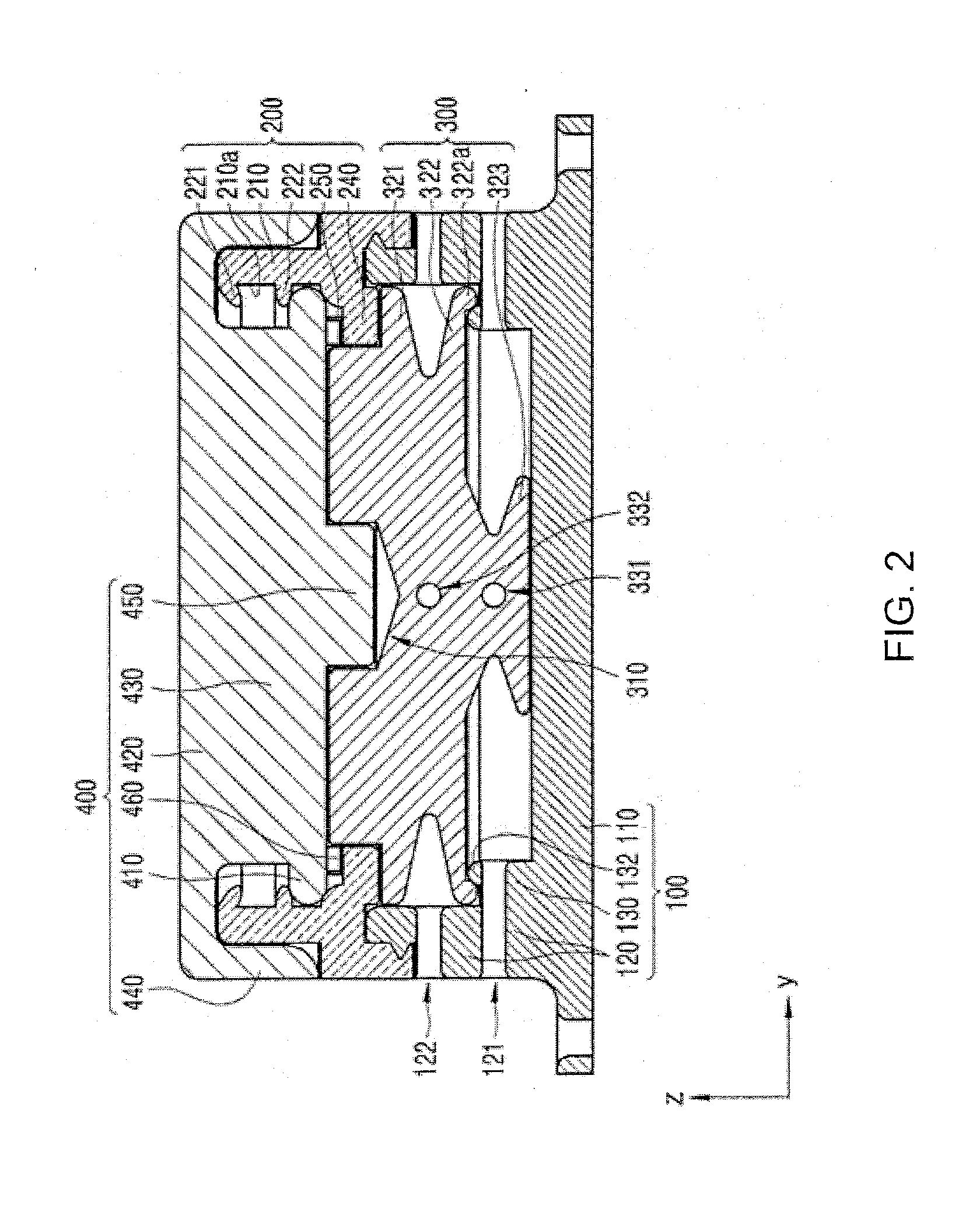

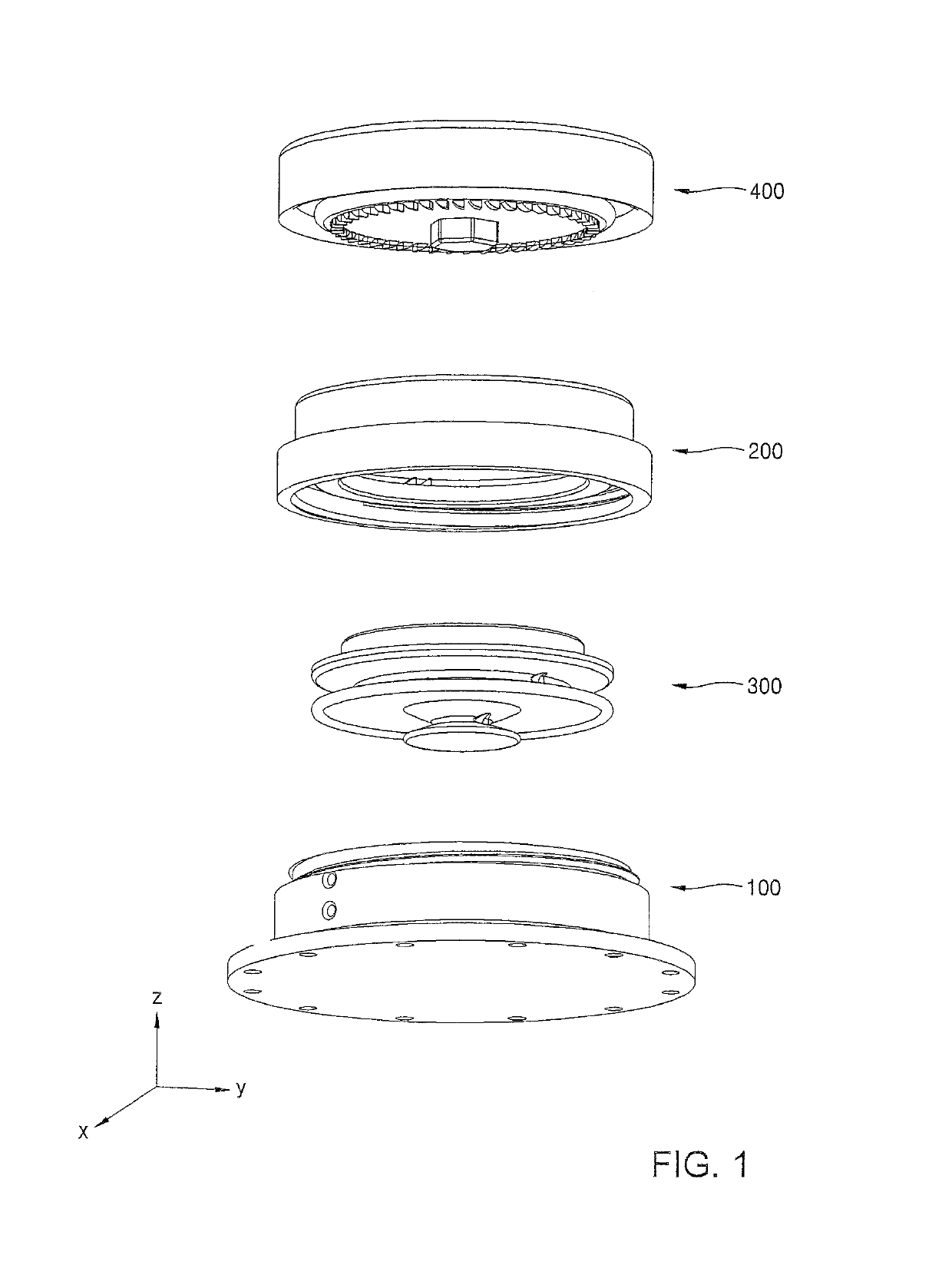

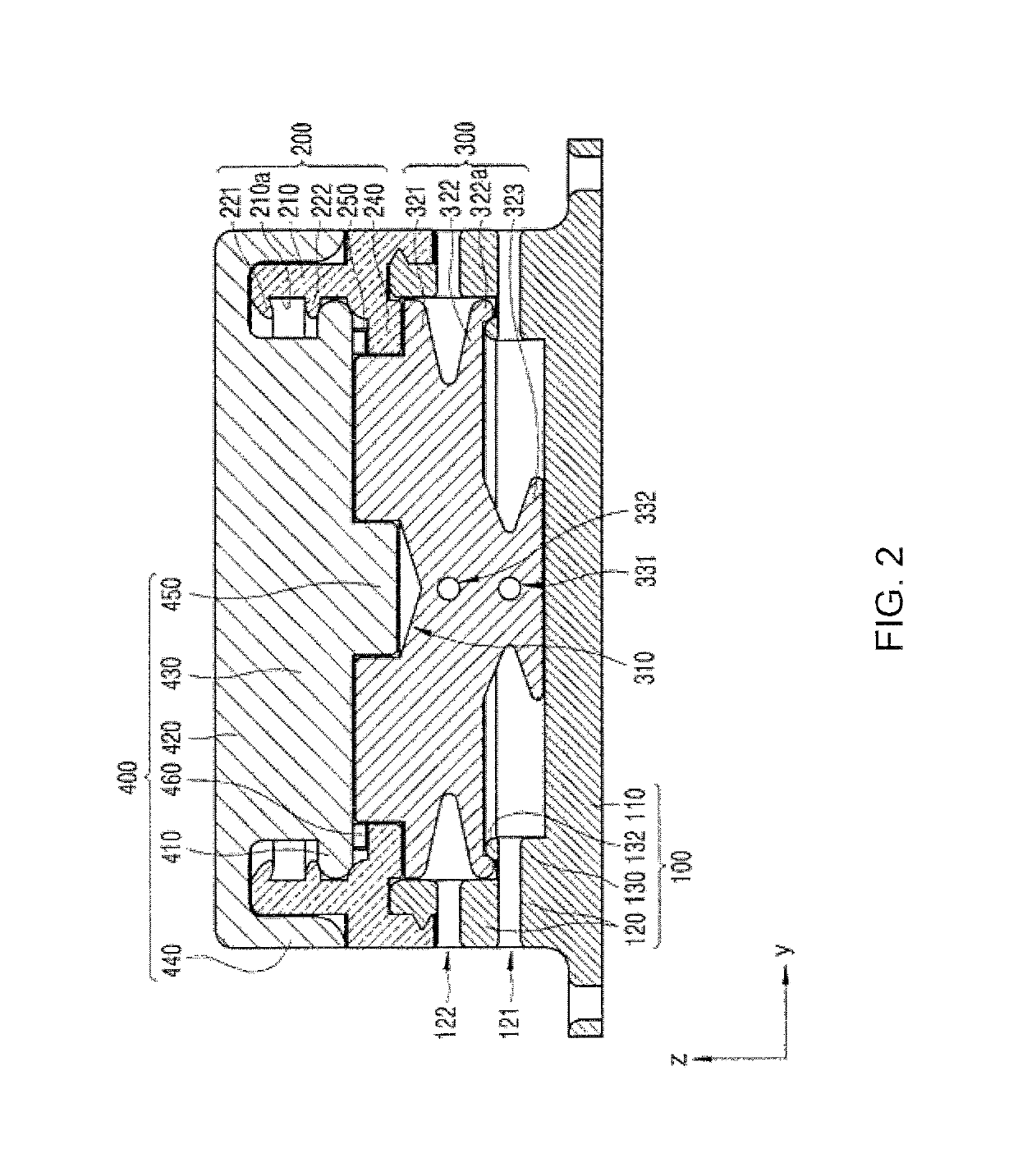

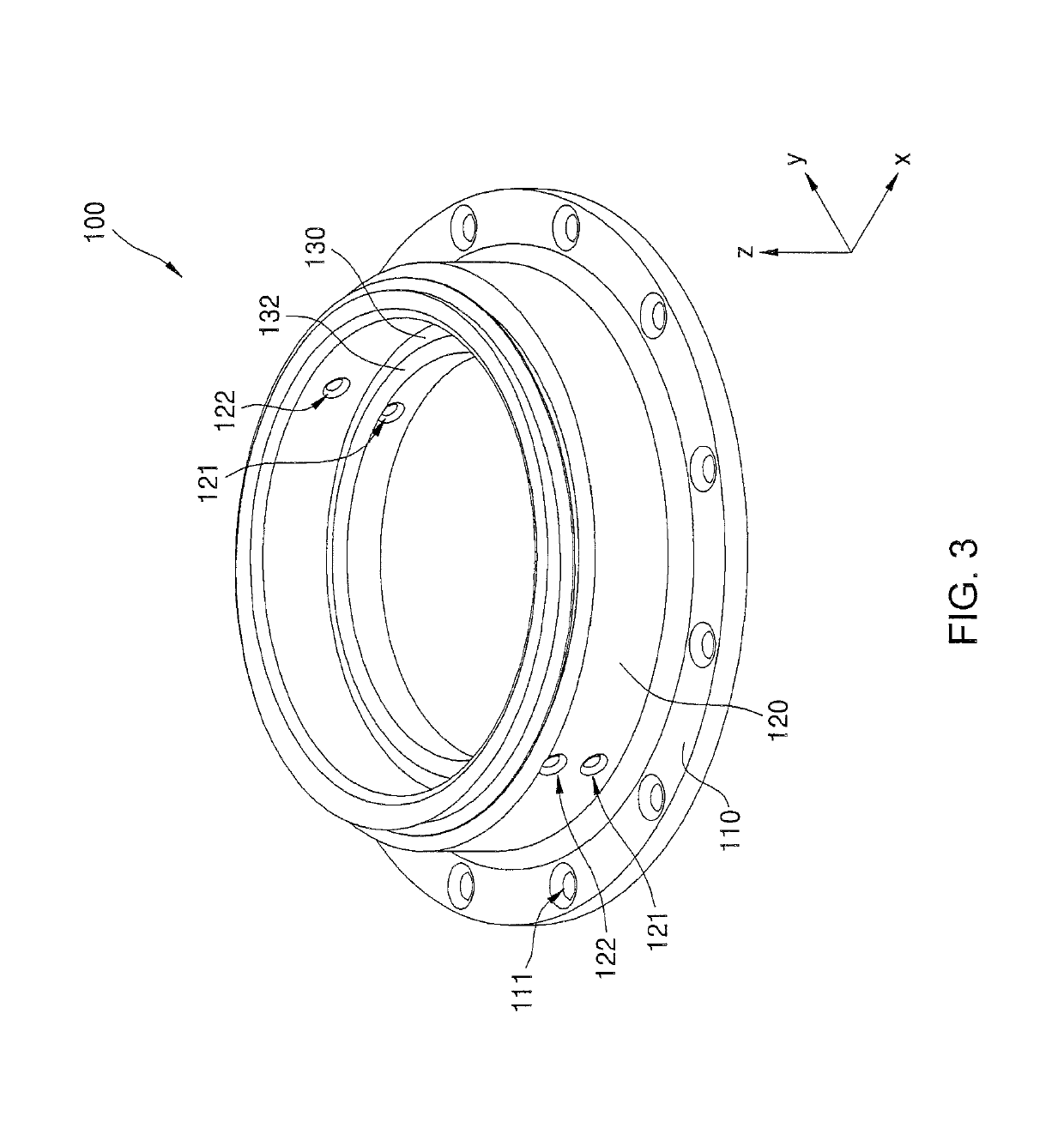

String winding and unwinding apparatus

ActiveUS20160198801A1Convenient tightening and looseningEasy to looseSnap fastenersShoe lace fasteningsMechanical engineeringEngineering

Embodiments of the present invention provide an apparatus for convenient tightening and loosening of strings such as those found in shoelaces of footwear. The apparatus includes a rotating portion within a base portion. A cover portion, when operated in a first position, provides a ratchet movement that allows rotation in a tightening direction while preventing movement in a loosening direction. When the cover is moved to a second position, the ratchet mechanism disengages, and the strings can then be easily loosened.

Owner:KIM SUG WHAN +1

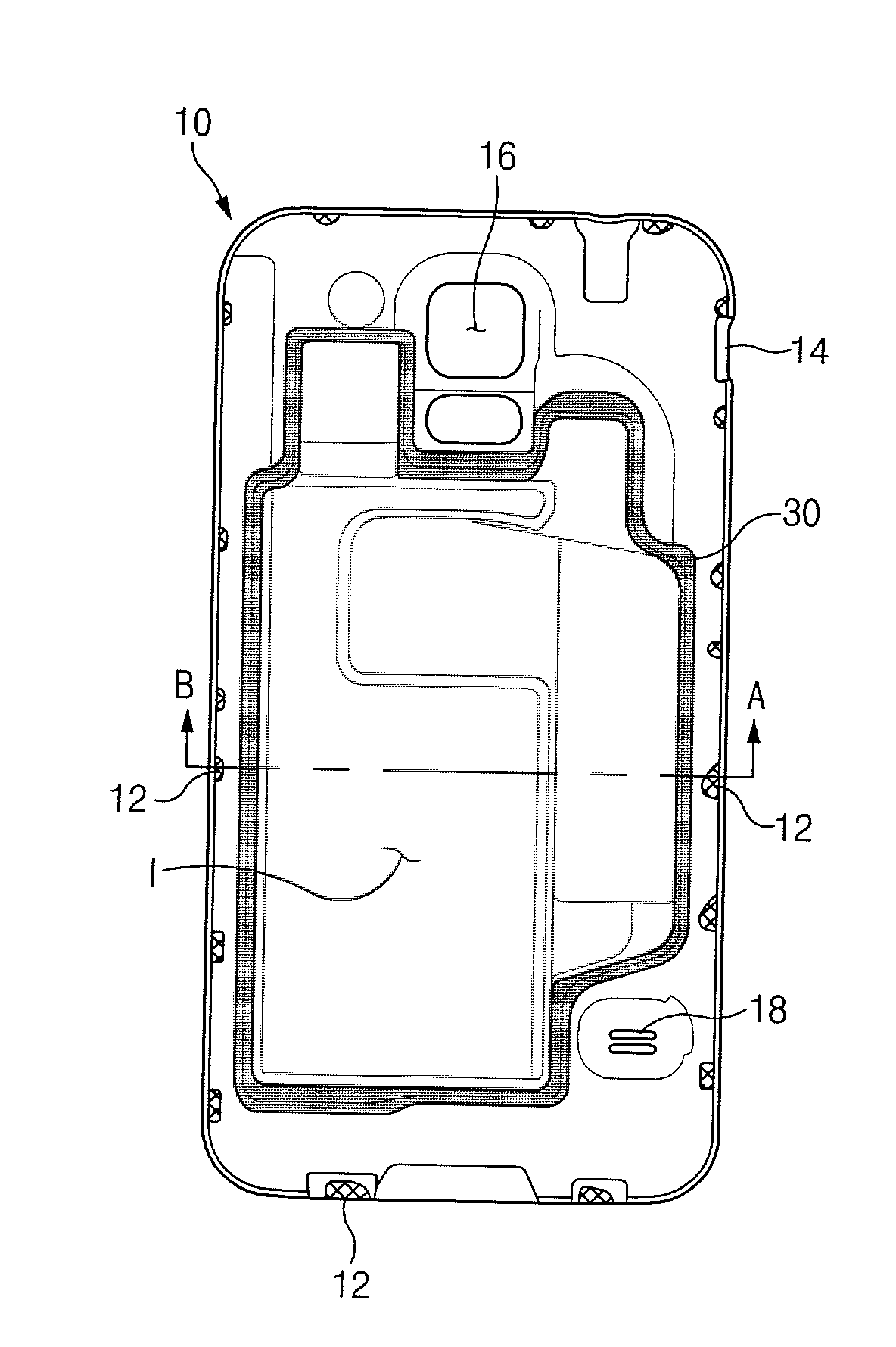

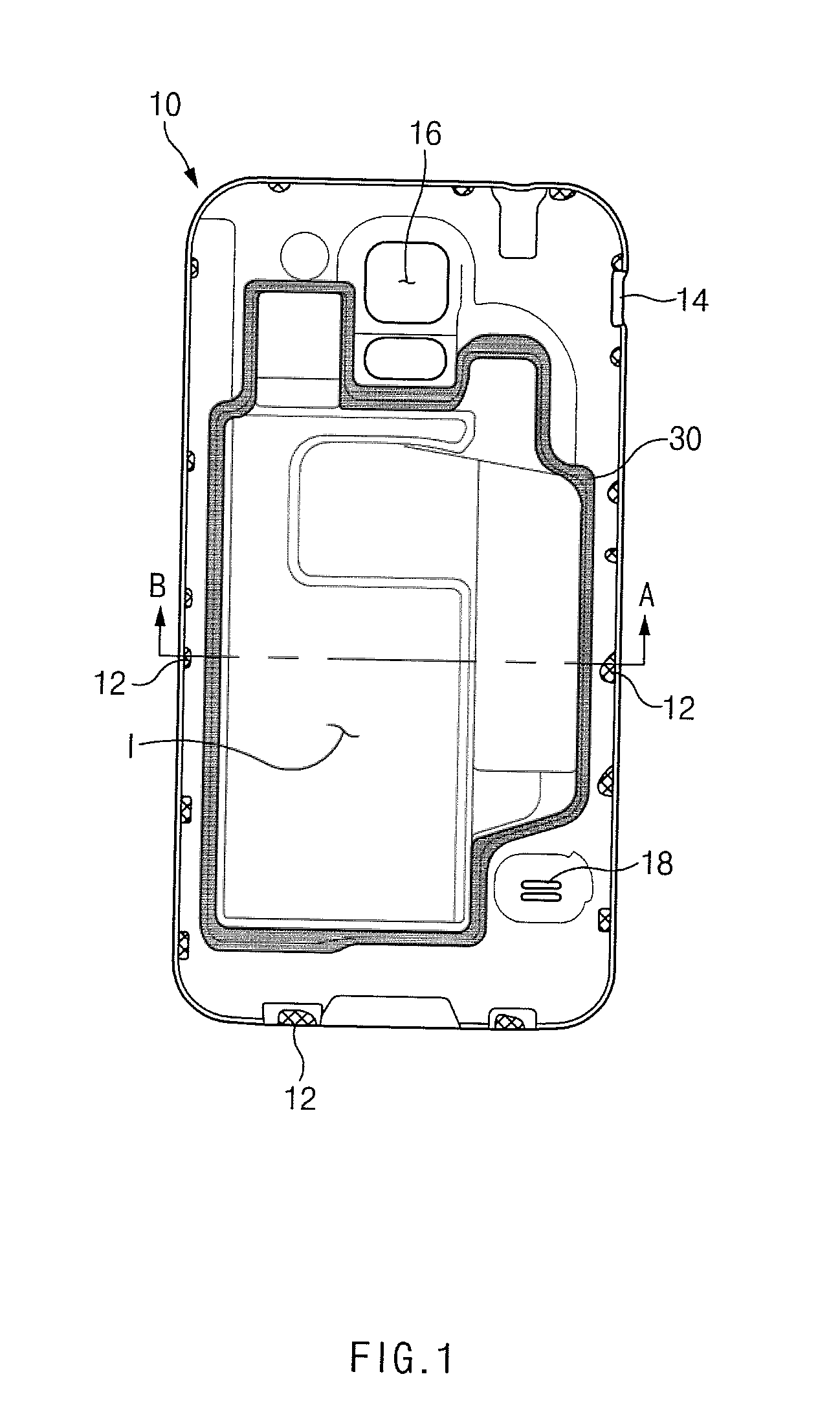

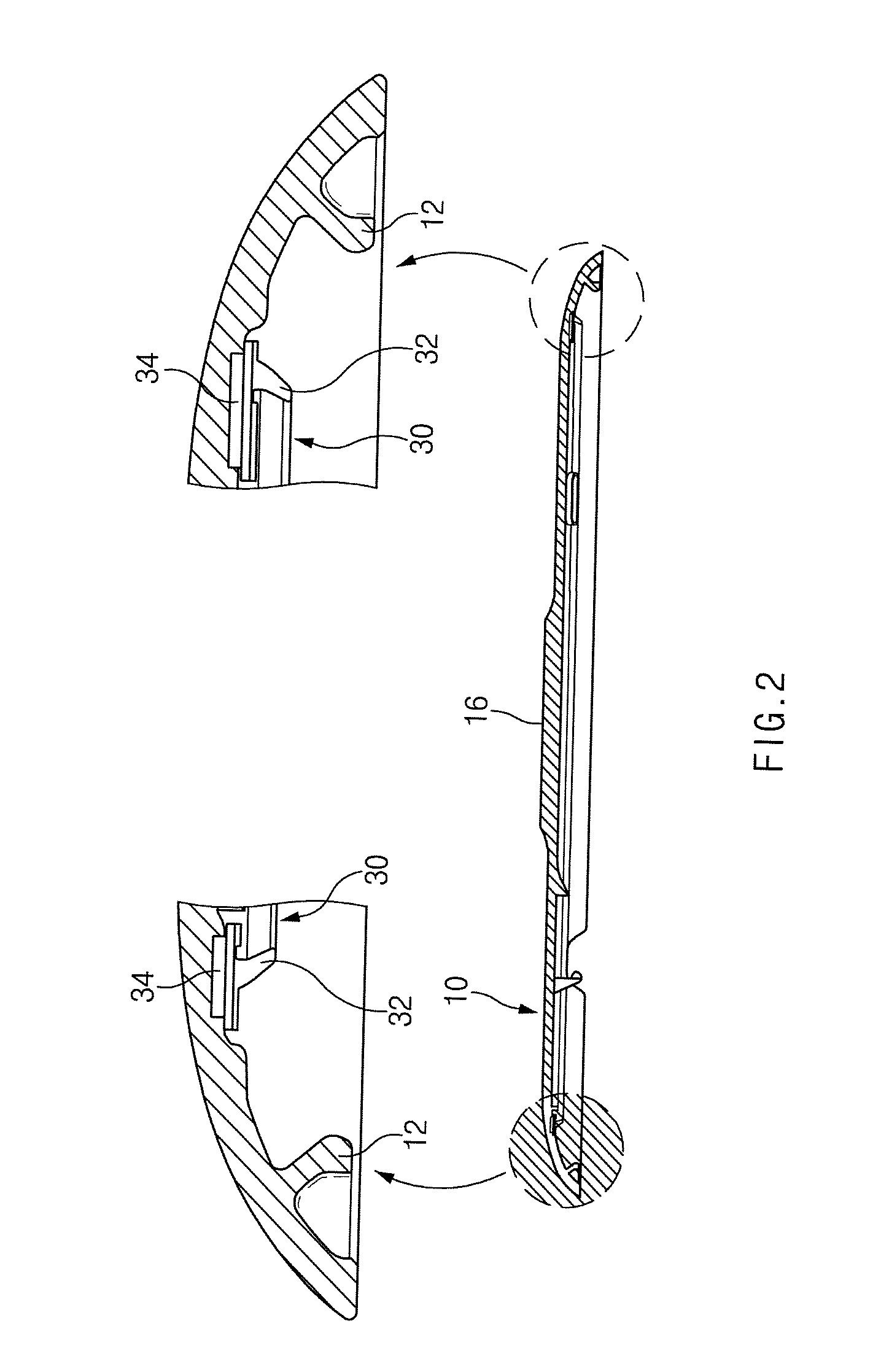

Electronic device including a function of water proof and cover thereof

ActiveUS20150282364A1Easy to looseReduce harmCasings/cabinets/drawers detailsHermetically-sealed casingsCouplingEngineering

Disclosed is an electronic device having a waterproof function. The electronic device includes a housing in which a coupling groove is formed, a cover including a hook detachably fit to the coupling groove, the cover configured to detachably couple to the housing by the hook, and a sealing band disposed on an inner side of the cover configured to contact at least a part of a surface of the housing which faces the cover when the cover is coupled to the housing, wherein the sealing band has a rib extending towards the housing, at least a part of the rib being bent in a specific direction. Other embodiments derived from the specification are possible.

Owner:SAMSUNG ELECTRONICS CO LTD

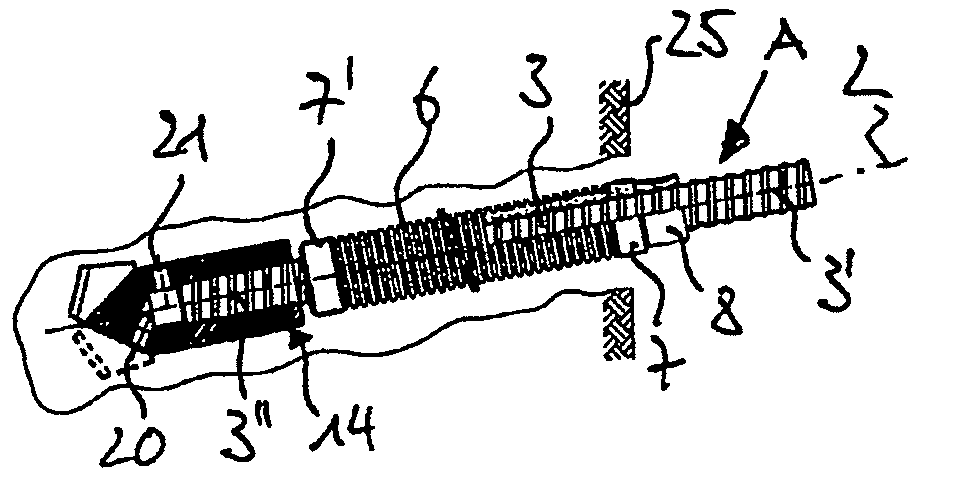

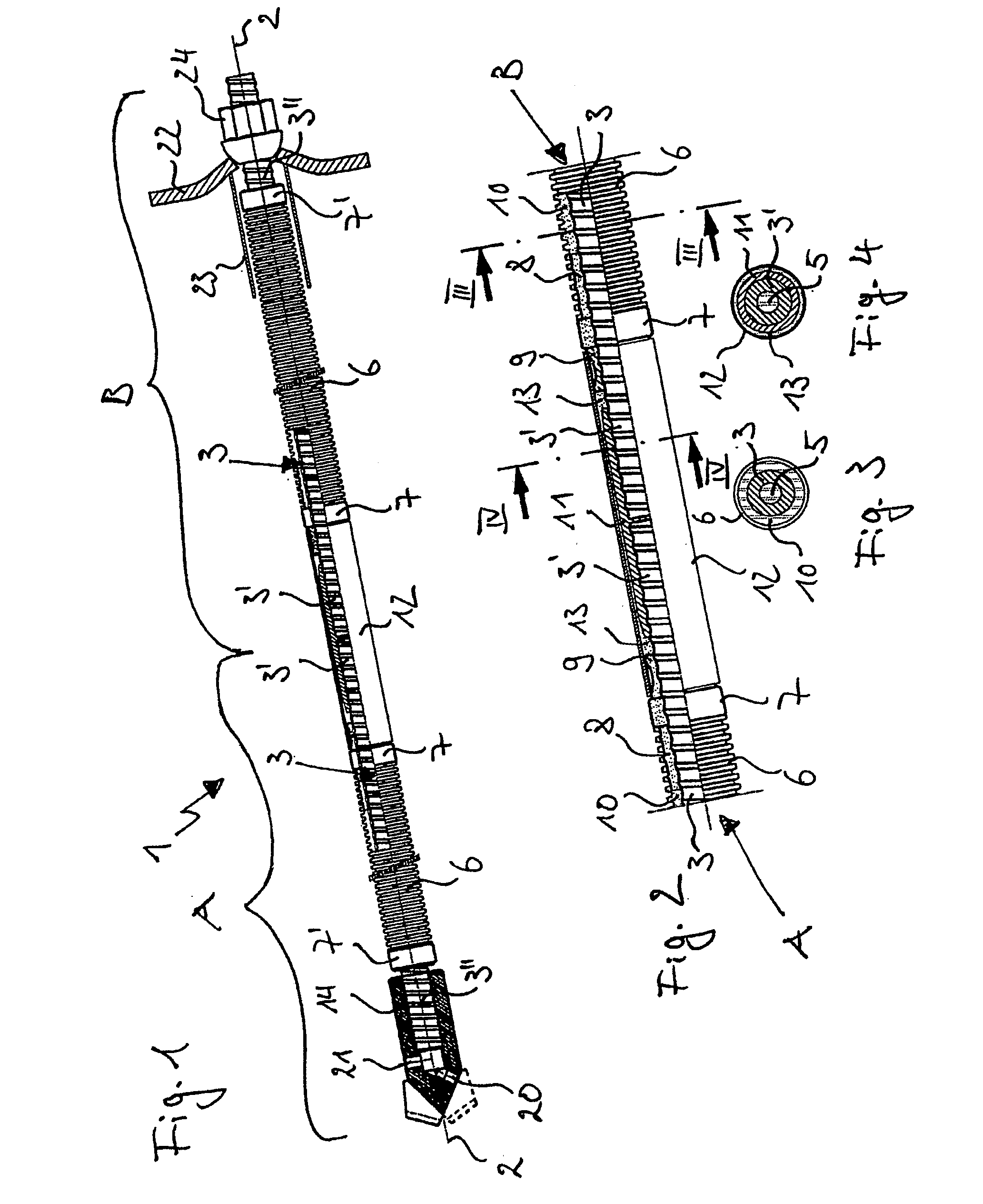

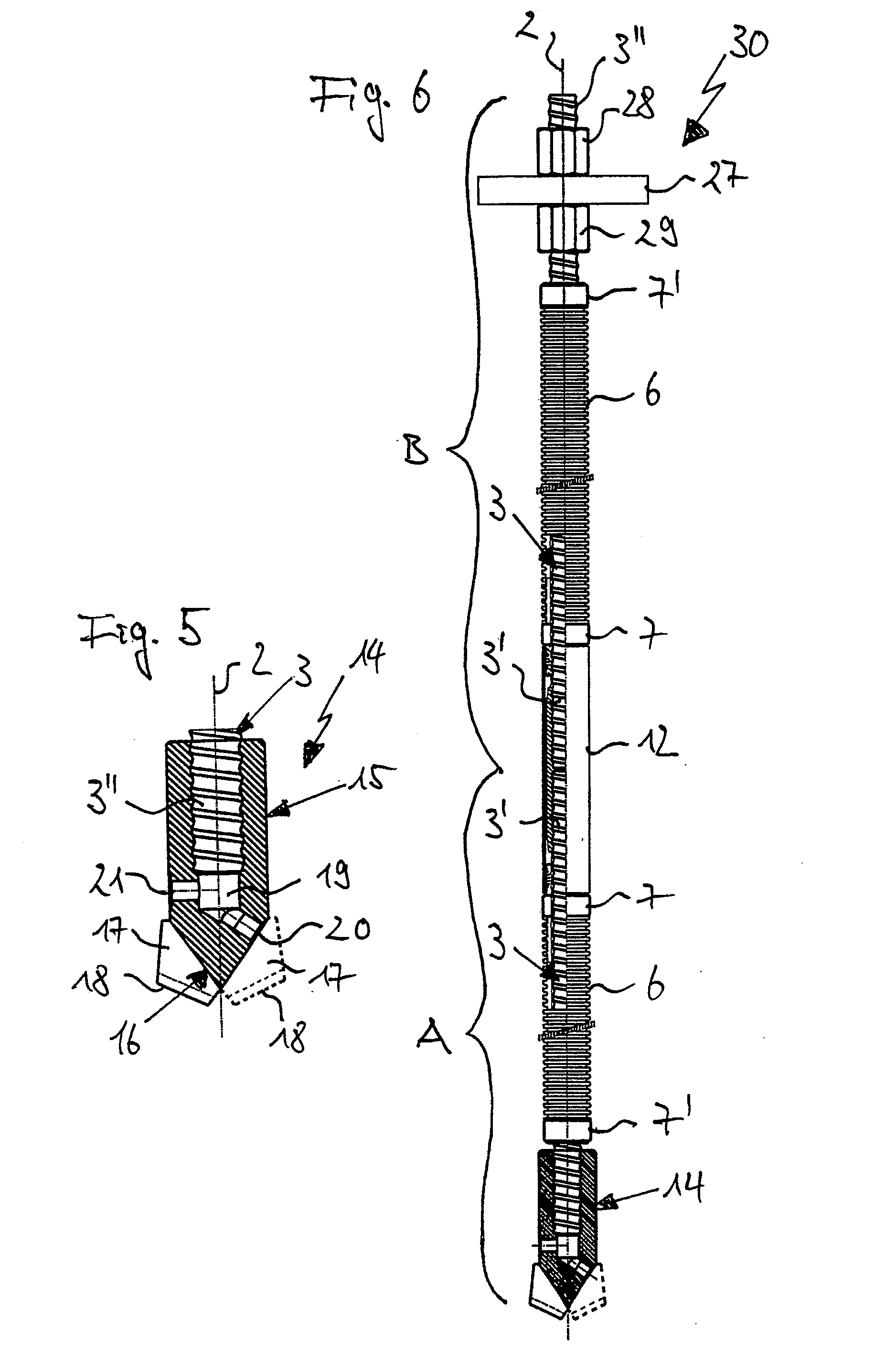

Corrosion-protected, self-drilling anchor and anchor subunit and method for the production thereof

InactiveUS20110070034A1Improve protectionAssures corrosion protectionSecuring devicesScrew-threads articlesButt jointEngineering

A corrosion-protected, self-drilling anchor and an anchor subunit and to a method for the production thereof is provided. A self-drilling anchor of the invention includes a number of anchor subunits, each with a hollow bar element, which are connected together by the formation of an axial bell butt joint to form a connected pull and pressure member. The first subunit t its end has a drill bit and the subunit is connected non-rotatably with its end to a drilling and injection device. It is provided according to the invention that each hollow bar element is surrounded by a sheathing except for its end sections and the annular gap between the sheathing and hollow bar element is grouted with a first corrosion protection compound. A coupler in the area of the bell butt joint fits tightly against the sheathings of the two hollow bar elements which are part of the bell butt joint. The hollow space between the coupler and hollow bar elements is filled with a second corrosion protection compound. A method of the invention provides for the prefabrication of a number of anchor subunits at the factory to drill these into the substrate at the site of the anchor to be produced and thereby for connecting them together with the formation of bell butt joints, whereby in the area of the bell butt joint a coupler fits tightly against the ends of two neighboring sheathings and the hollow space between the coupler and hollow bar element is filled with a second corrosion protection compound.

Owner:DYWIDAG SYST INT GMBH (DE)

String winding and unwinding apparatus

ActiveUS10264852B2Convenient tightening and looseningEasy to looseShoe lace fasteningsBucklesMechanical engineering

An apparatus enables convenient tightening and loosening of strings such as those found in shoelaces of footwear. The apparatus includes a rotating portion within a base portion. A cover portion, when operated in a first position, provides a ratchet movement that allows rotation in a tightening direction while preventing movement in a loosening direction. When the cover is moved to a second position, the ratchet mechanism disengages, and the strings can then be easily loosened.

Owner:KIM SUG WHAN +1

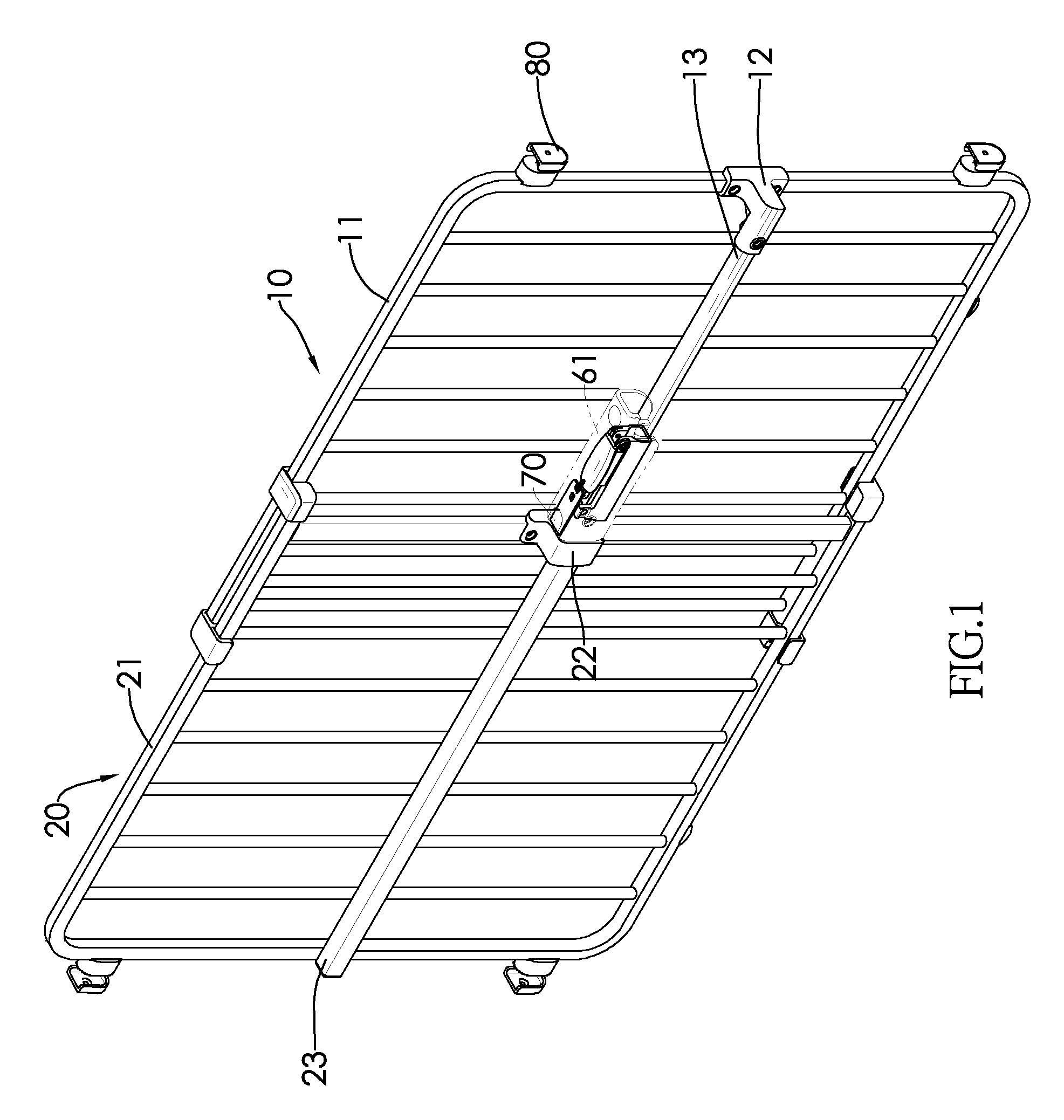

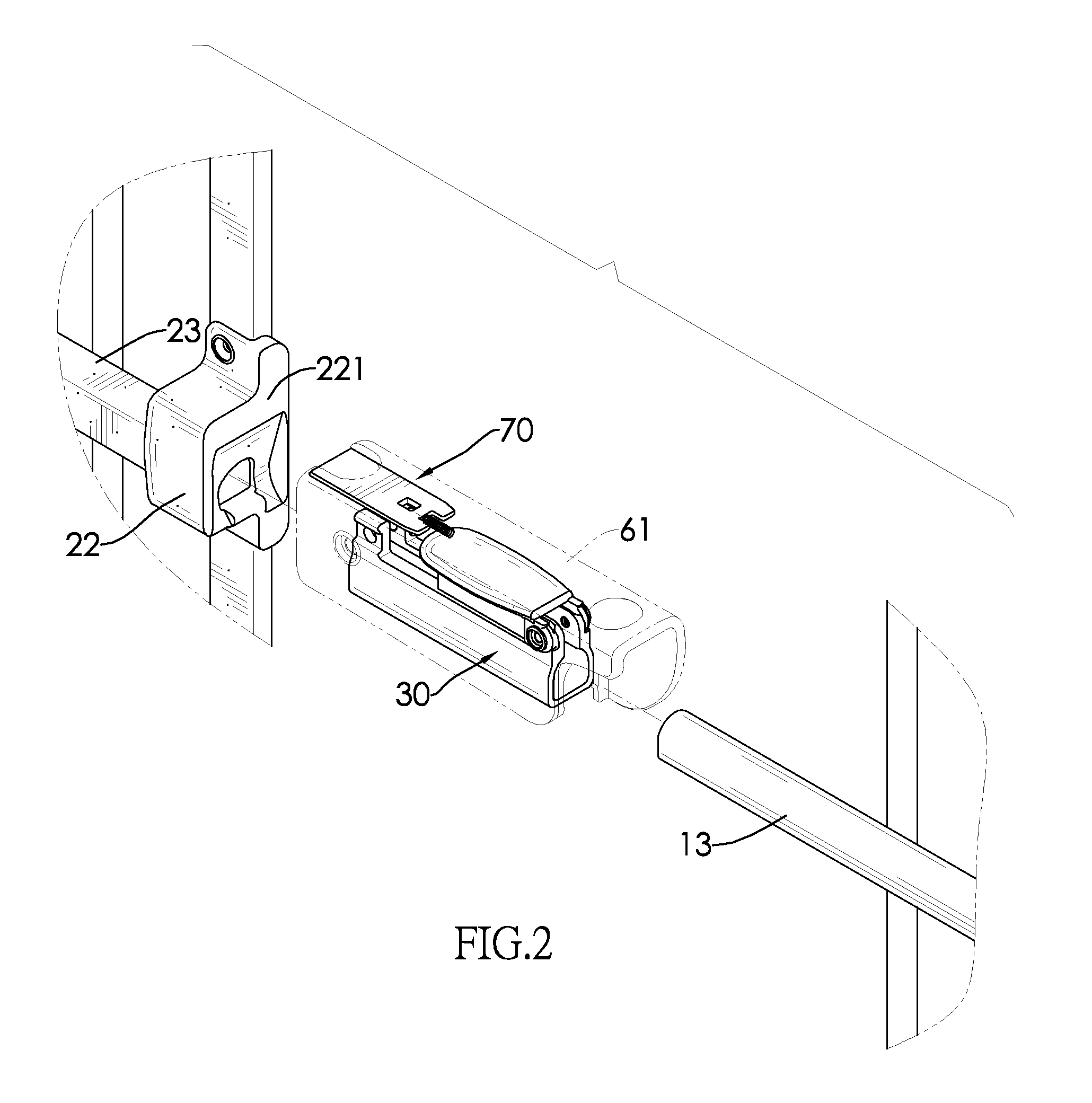

Safety gate

ActiveUS8418407B2Easy to looseEasy to installFixed grillesWing fastenersEngineeringMechanical engineering

Owner:WANG TSUNG HSIANG

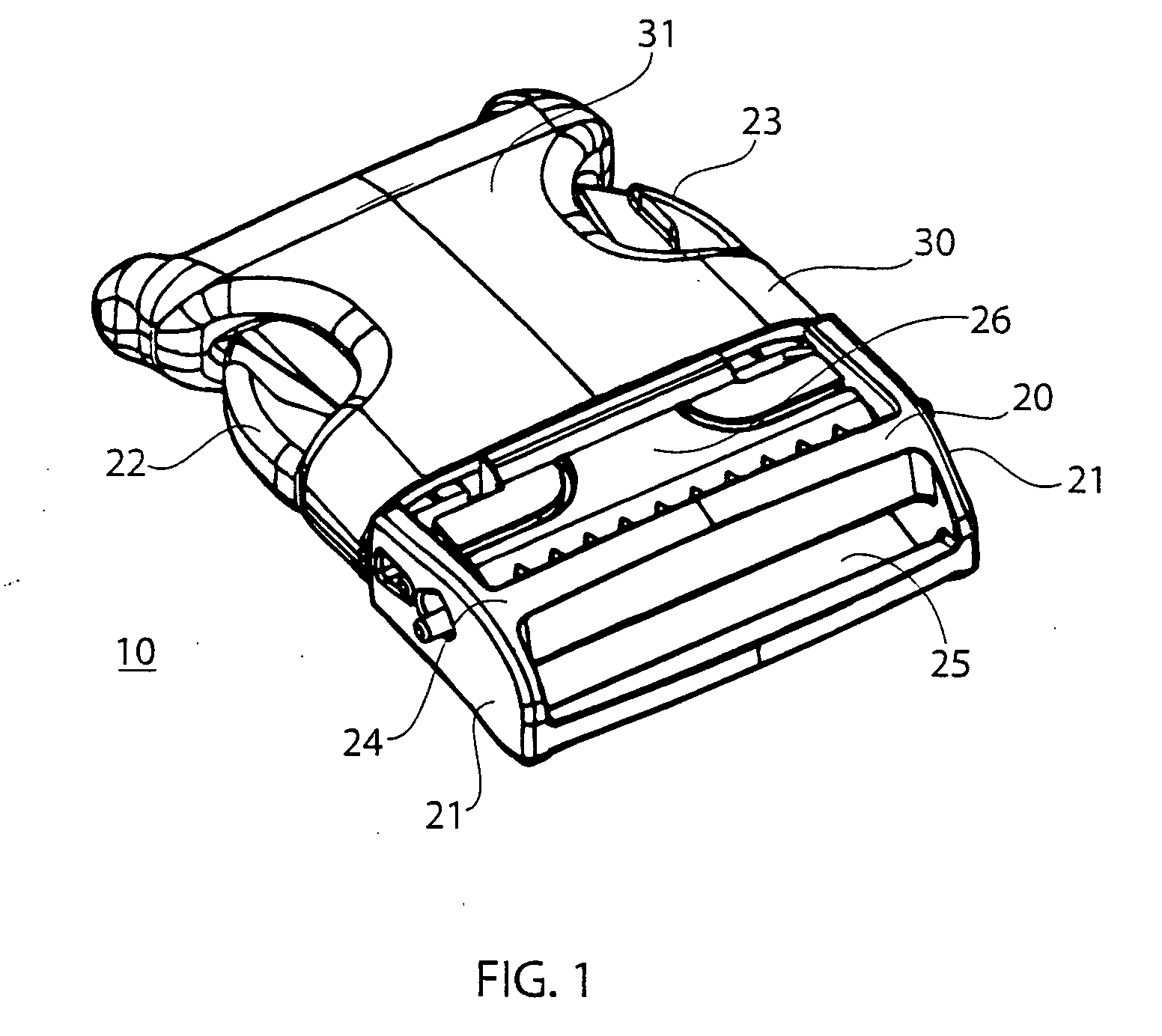

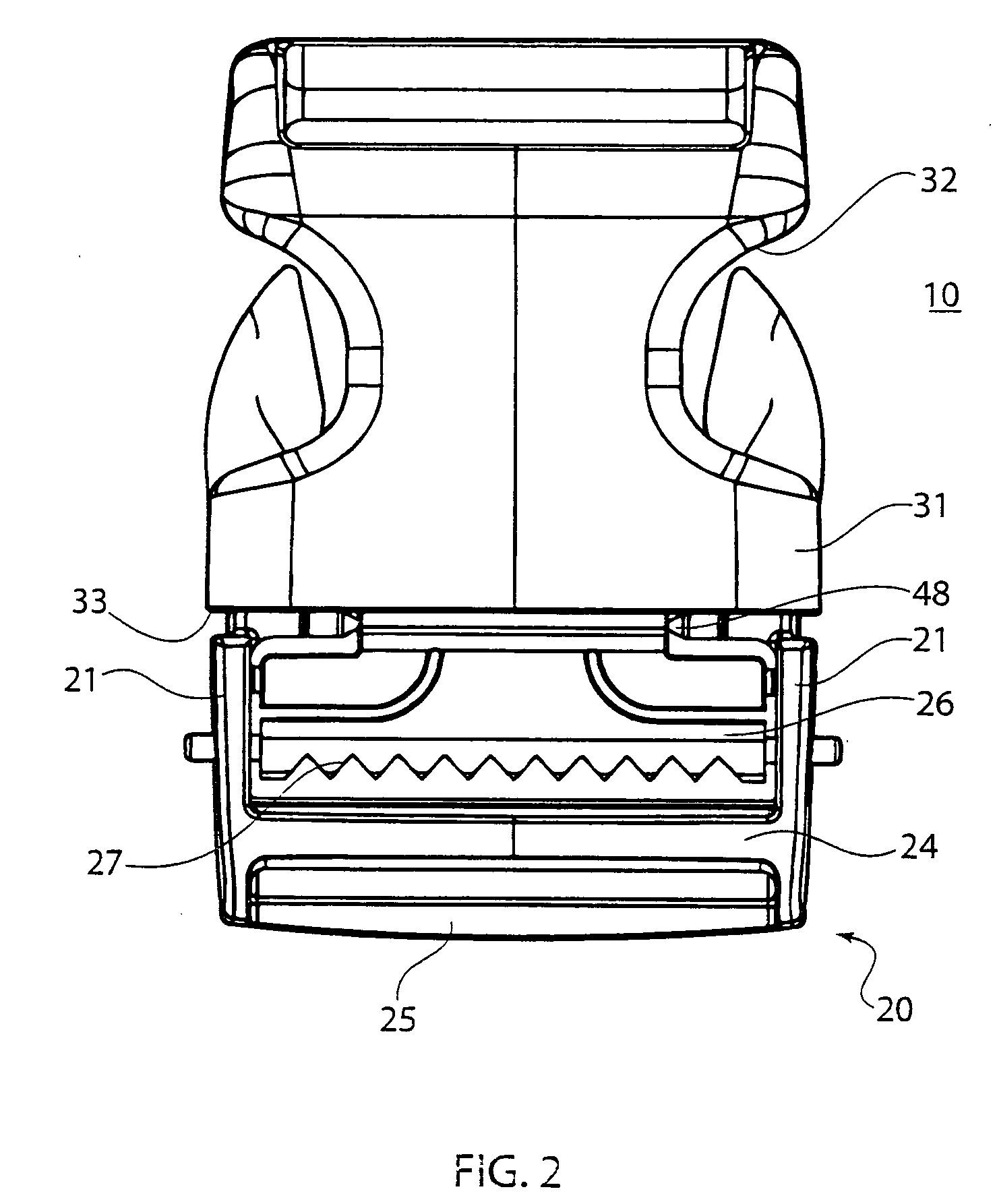

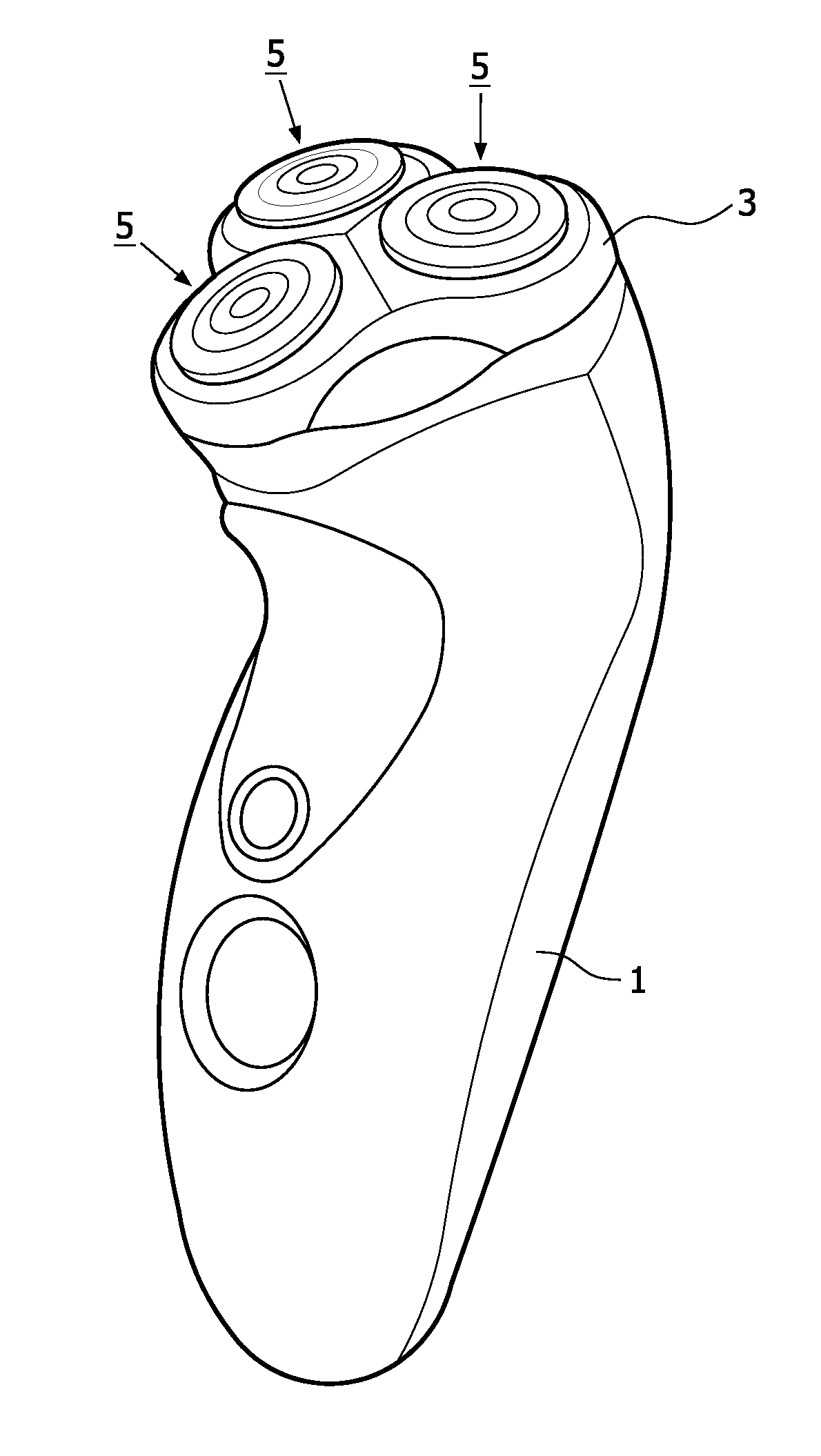

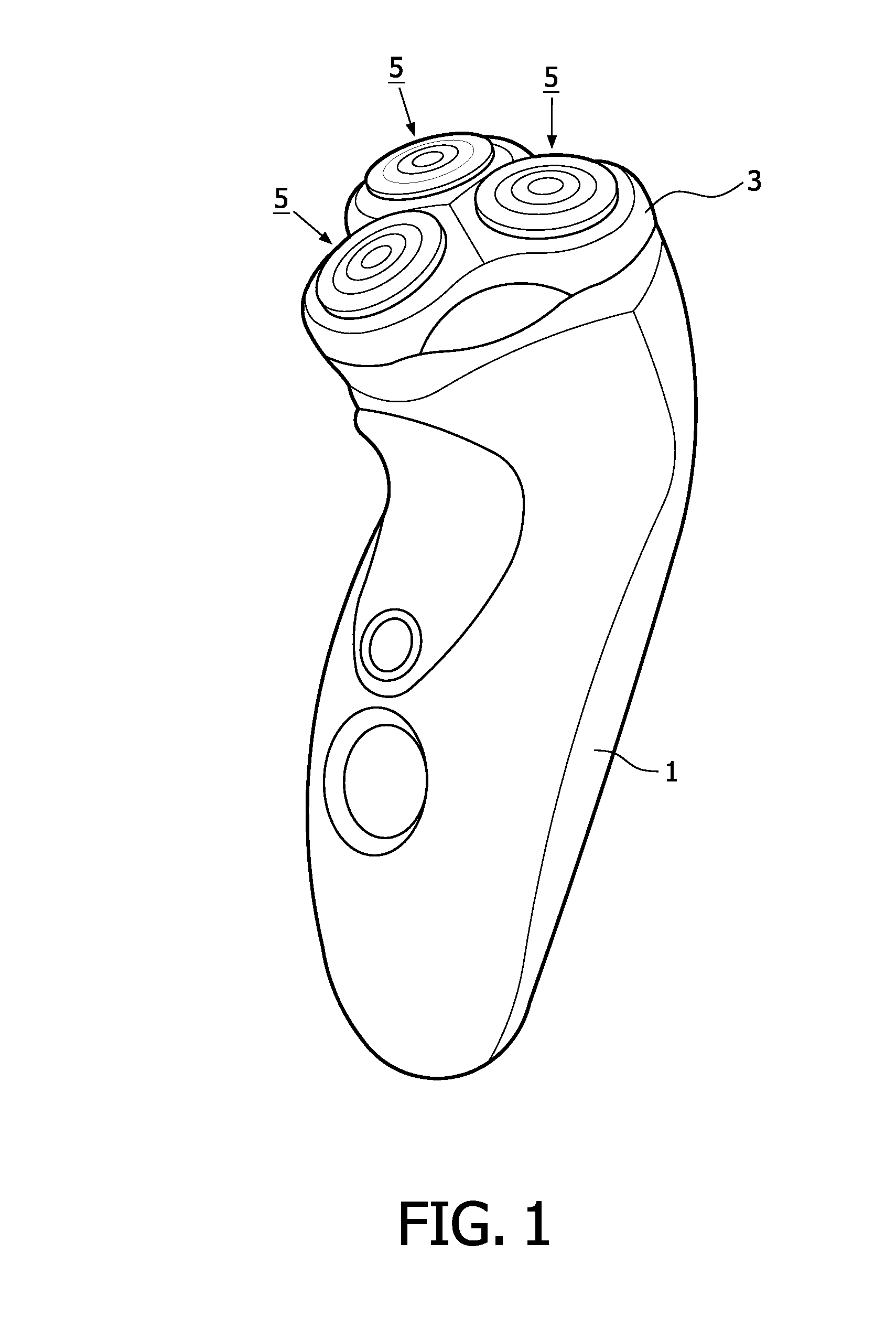

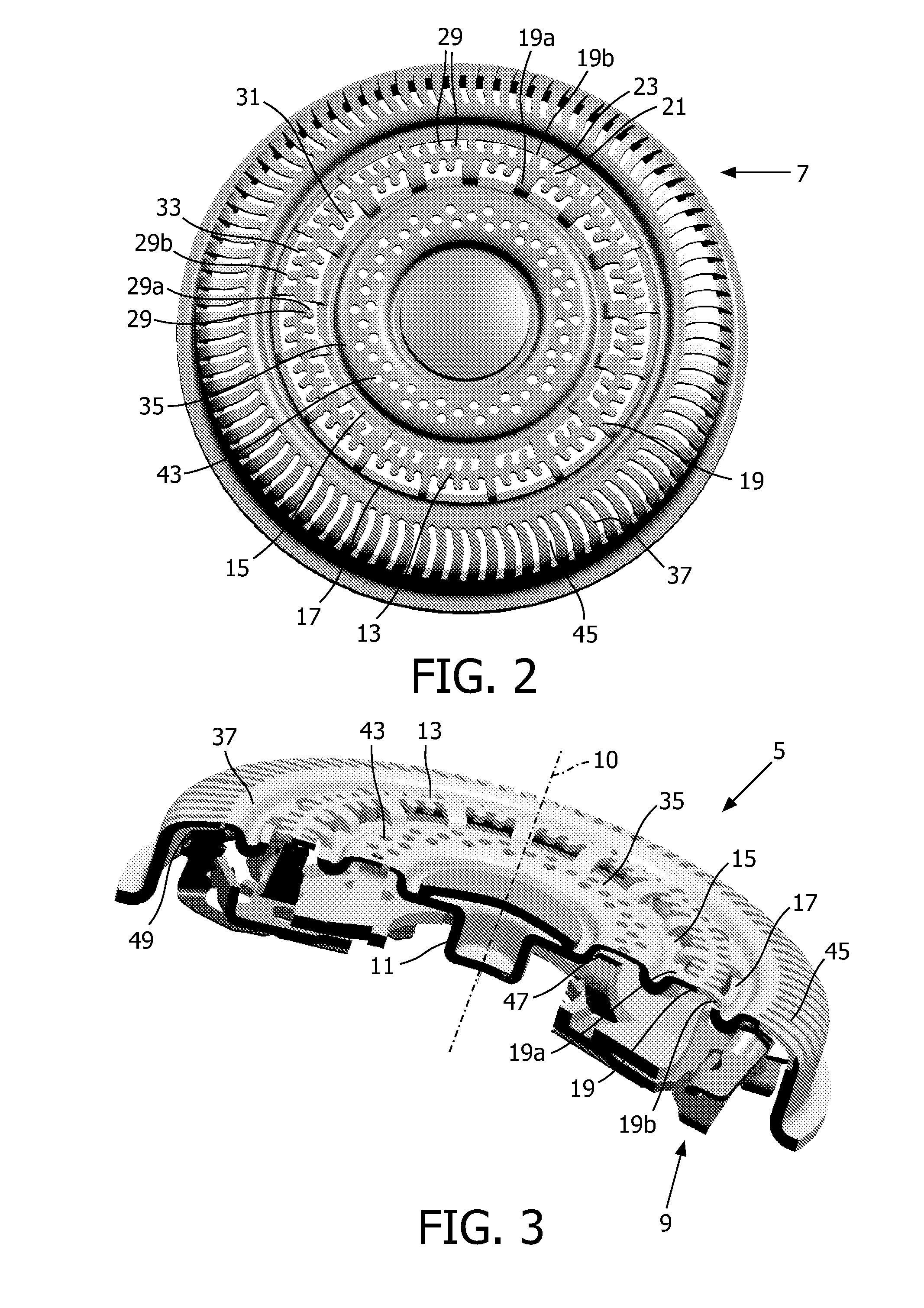

Shaving apparatus, a cutting unit and a shaving head

ActiveUS20100175258A1Better capableImprove directionMetal working apparatusEngineeringLateral border

A shaving apparatus having at least one cutting unit (5) is provided which is able to shave both short and rather long hairs. The cutting unit comprises an external cutting member (7) and an internal cutting member (9) movably arranged with respect to the external cutting member, and a driver (11) for moving the internal cutting member. The external cutting member is provided with a shaving section (13) having two mutually connected lateral borders (15, 17) between which hair entry apertures with cutting edges (23) are provided. The internal cutting member is provided with cutting elements (25) having cutting edges (27) for cooperation with the cutting edges of the external cutting member. A number of the hair entry apertures is formed by laterally open recesses (21) each extending between two substantially flat lamellae (29) of the external cutting member, which lamellae have free ends (29a, 29b) positioned between the borders of the shaving section.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

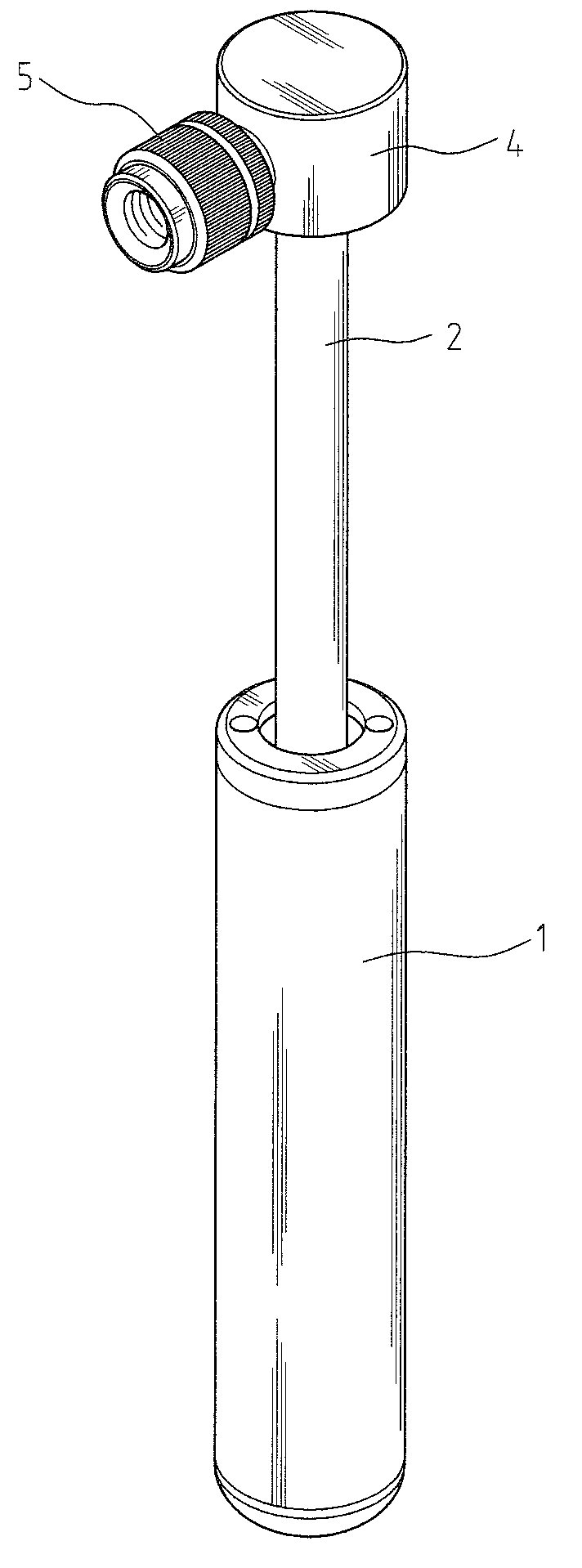

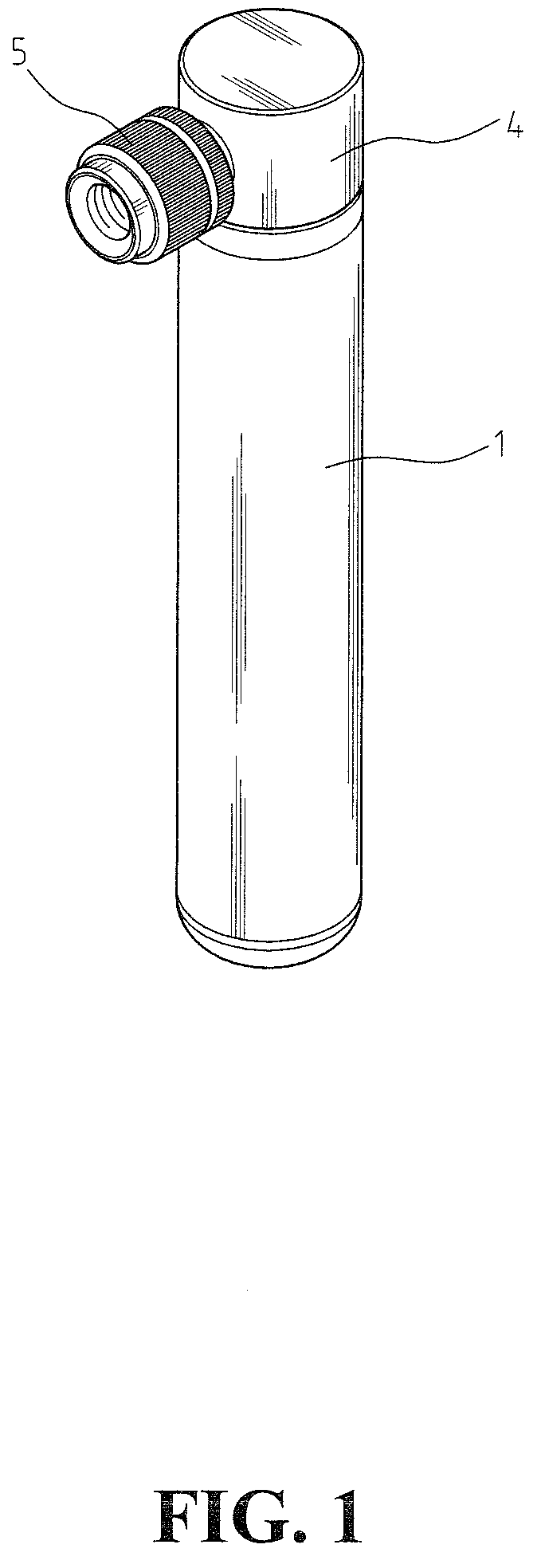

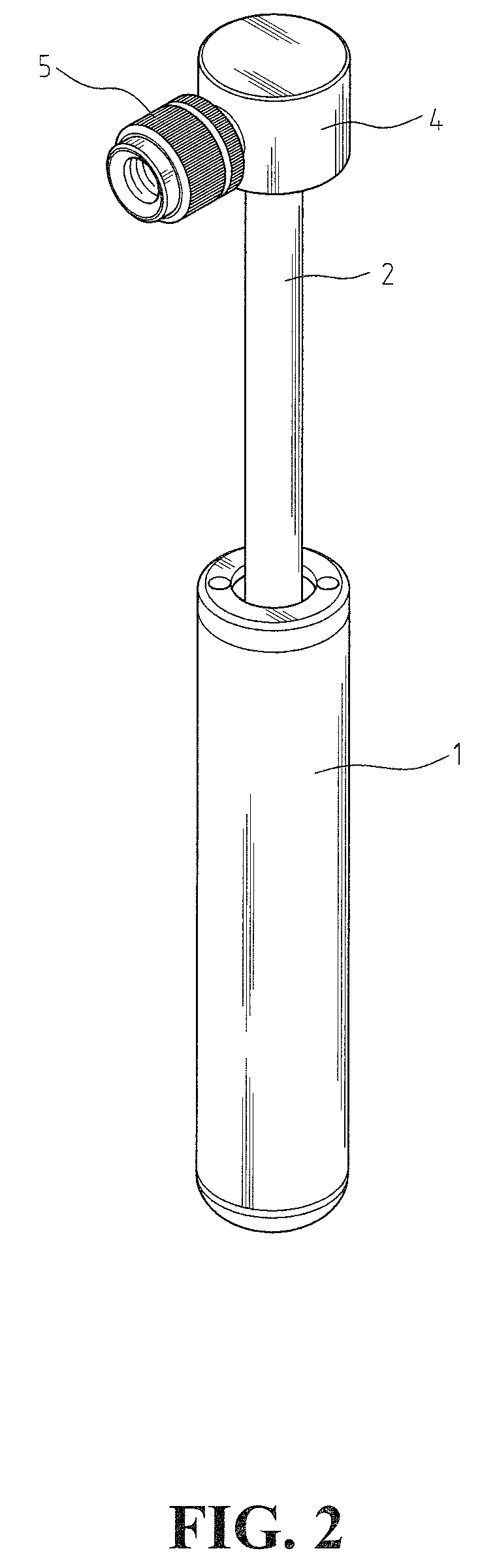

Portable air pump

InactiveUS20080247884A1Avoid collisionEasy dischargePositive displacement pump componentsPumpsAir pumpCheck valve

A portable air pump includes a tubular body, a barrel, a piston mechanism, a head, and a dispensing head. Tubular body has upper cover having air inlet holes and sealed bottom cover. Barrel has air passage running through along its axis direction. Piston, having center hole and through hole, and check valve is in between second end of the barrel and piston. As tubular body is moved in relation to barrel away from the head, air is flown into tubular body through air inlet holes and to the bottom of tubular body through the through hole. Air can be prevented from flowing out from the center hole using check valve disc. As the tubular body is moved in relation to the barrel towards the head, air on the bottom of tubular body is flown into air passage of the barrel through center hole, and out from the head and the dispensing head.

Owner:HUANG YING CHE

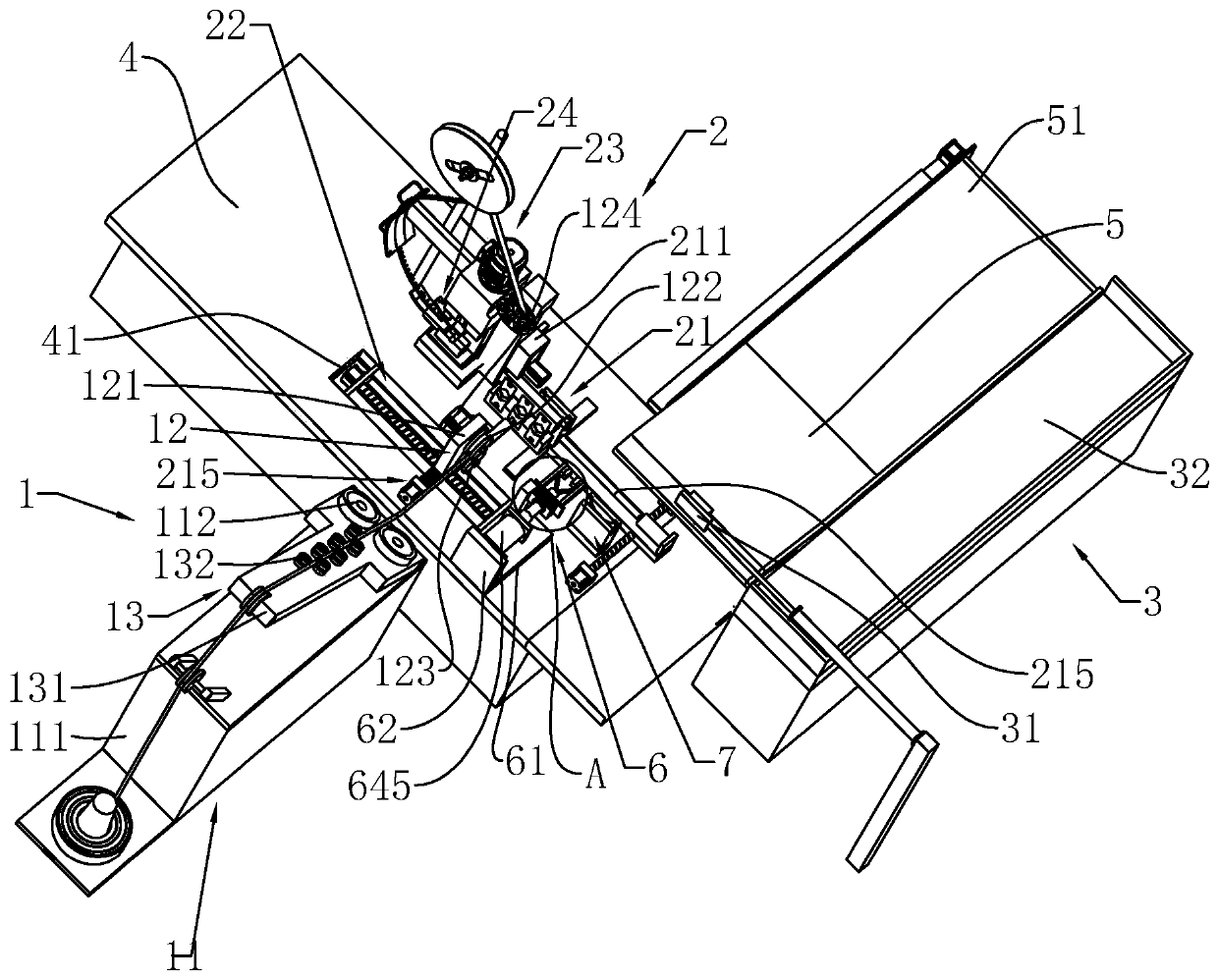

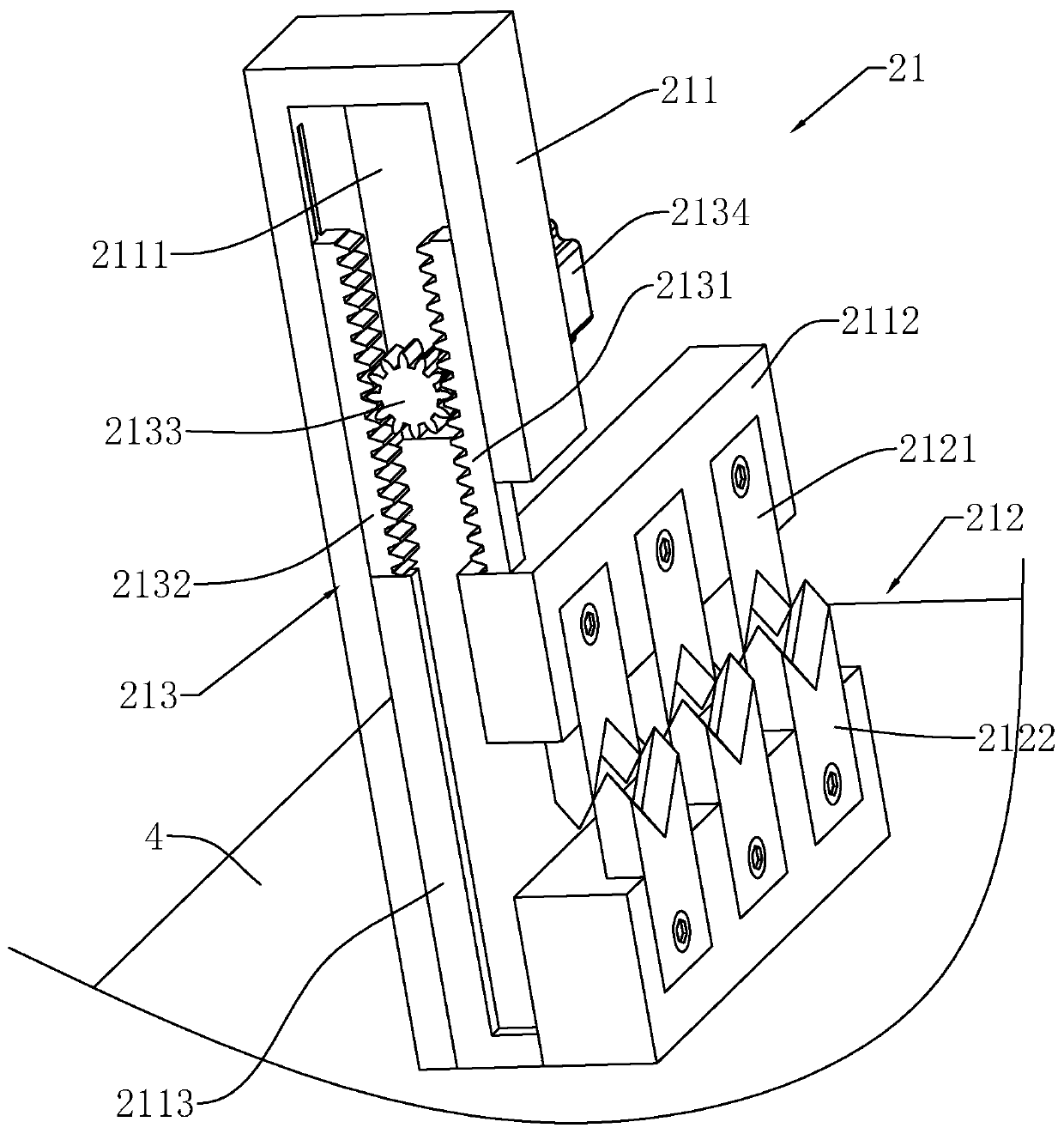

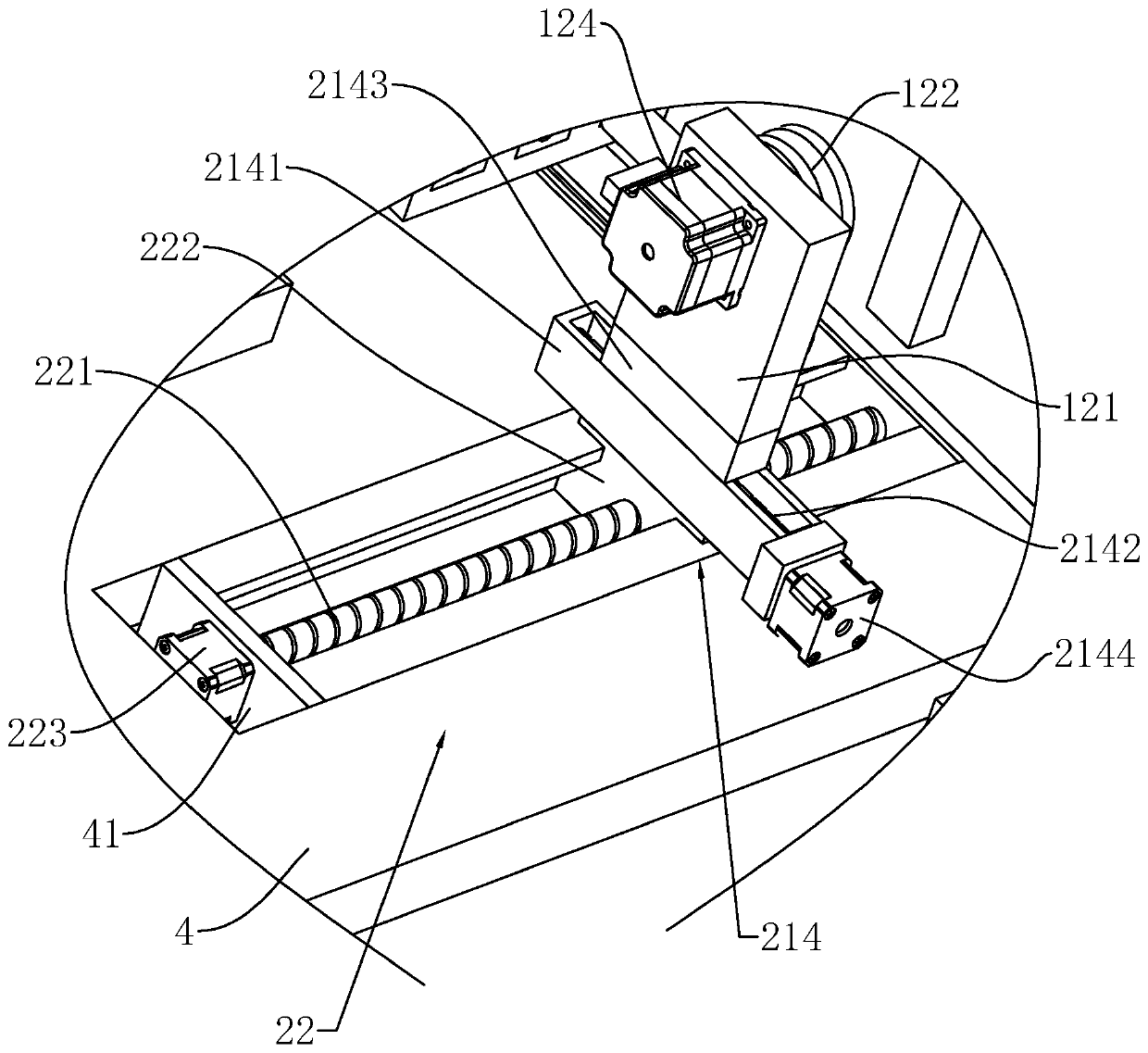

Electronic wire harness production line

ActiveCN110718829ASimple processImprove processing efficiencyConnection formation by deformationProduction lineWire cutting

The invention relates to the technical field of wire harness processing, and discloses an electronic wire harness production line, and the production line comprises a feeding device, a processing device and a collecting device which are sequentially arranged in the wire harness advancing direction; the processing device is arranged on a workbench, and the feeding device comprises a wire harness feeding unit and a wire harness conveying unit which are sequentially arranged in the feeding direction; the processing device comprises a wire cutting unit, a feeding unit, a crimping unit and a terminal chain pushing unit. The wire cutting unit comprises a knife rest arranged on the collecting table and close to one side of the movable seat; the three cutter assemblies are arranged in parallel inthe length direction of the cutter rest, a cutter driving part is arranged on the cutter rest, a pull-back part is arranged below a movable base and used for driving the movable base to move in the width direction of the workbench, and a moving part is arranged between the collecting table and the workbench and used for driving the wire harness to move. The length direction of the knife rest is parallel to that of the workbench. The production line has the following advantages and effects that the machining procedures are integrated, and the machining efficiency is high.

Owner:安徽中正电气有限公司

Large current connector

InactiveUS7214086B1Easy to looseLatched together quicklyElectrically conductive connectionsIncorrect coupling preventionEngineeringMechanical engineering

A large current connector consists of a male plug and a female socket. The male plug includes a shell, a coupling member, a first upper metal plate and a first lower metal plate. The female socket includes a sleeve, an insulation member, a second upper metal plate and a second lower metal plate. The sleeve has latch cavities on two sides corresponding to and engageable with elastic latch elements on two sides of the shell. Thus the male plug and the female socket can be coupled together rapidly. The insulation member anchors the metal plates of the male plug and the female socket to prevent loosening thereof. Deformation of the metal plates also can be prevented to avoid short circuit.

Owner:HSIEH YU CHU

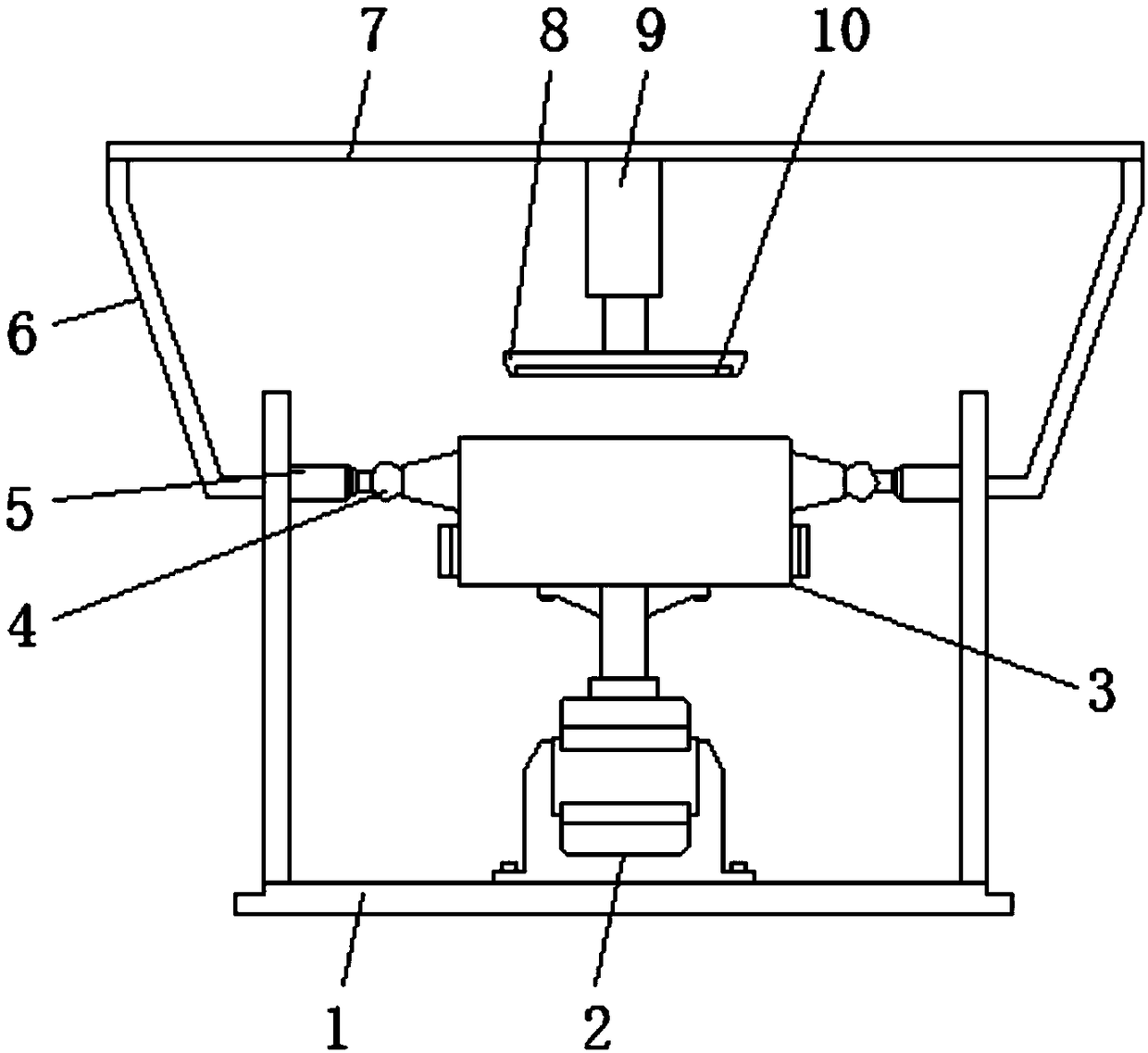

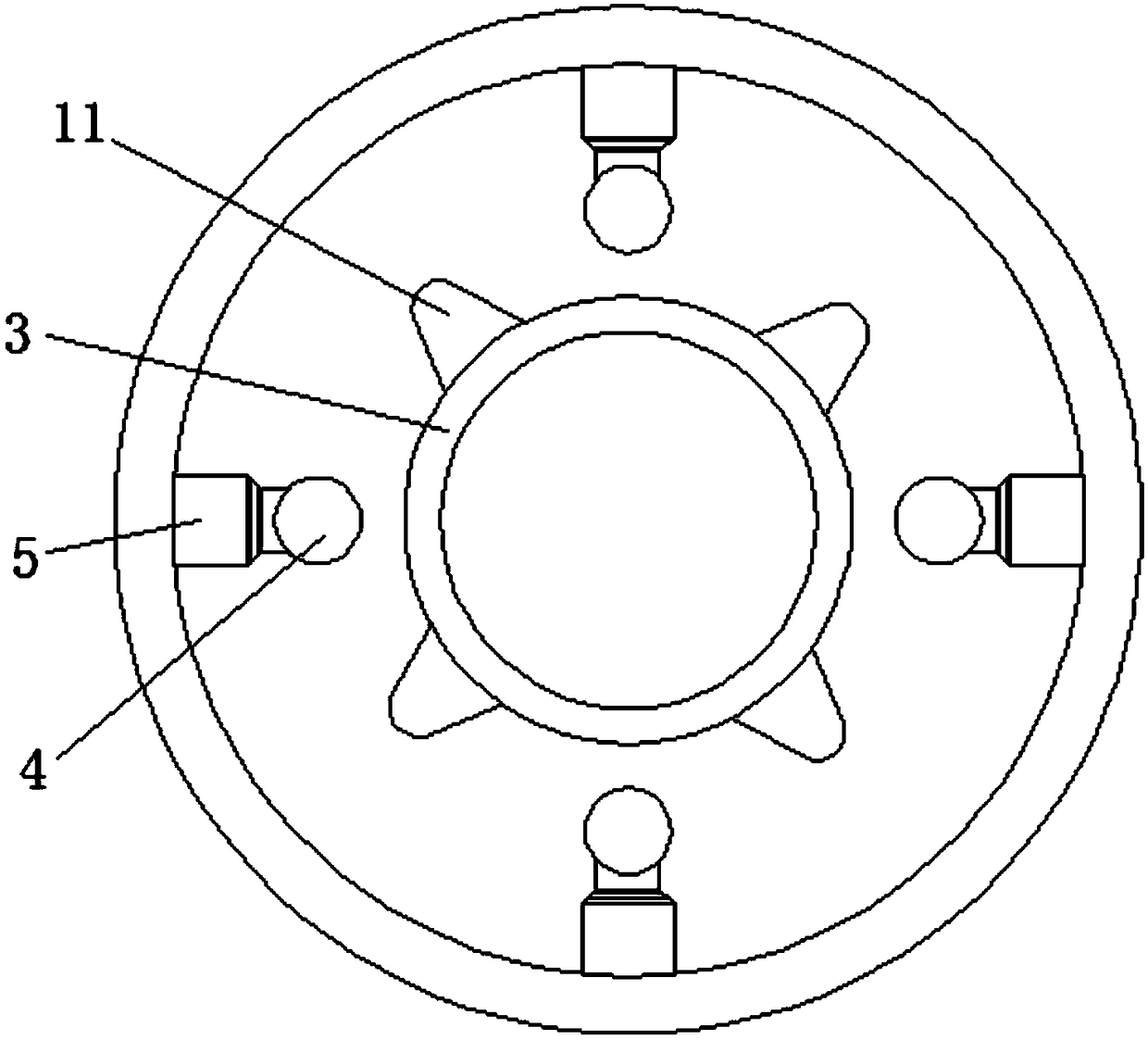

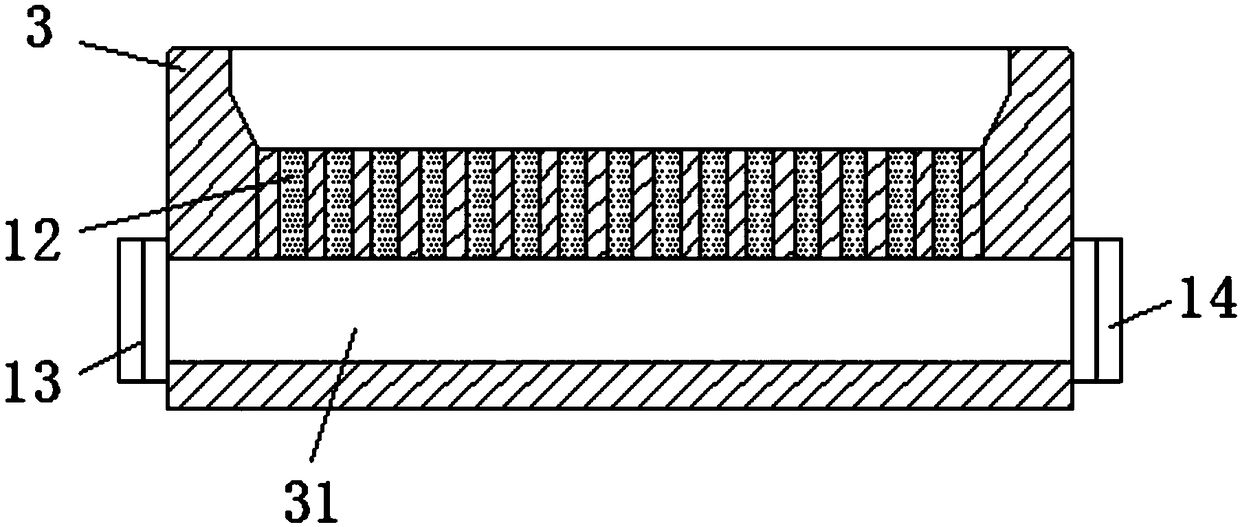

Mechanical part die with die releasing conveniently conducted

The invention discloses a mechanical part die with die releasing conveniently conducted. The mechanical part die comprises an outer cylinder body and a die body. A drive motor is fixedly connected tothe center position of the top of the inner surface wall of the bottom of the outer cylinder body, and the top of the drive motor is in drive connection with the die body through an output shaft. Multiple arc angle protruding blocks are welded to the outer side of the die body at equal angles around the circle center of the die body. According to the mechanical part die, the arc angle protruding blocks are arranged on the outer side of the die body, steel balls are arranged on the inner surface wall of the outer cylinder body, the drive motor is used for driving the die body to rotate so thatthe arc angle protruding blocks can collide with the steel balls intermittently, a knocking vibration effect is generated, and a blank part can be loosened from the die body through the knocking vibration effect. In addition, a certain centrifuging effect can be generated in the rotating process of the die body, and the blank part can be more easily loosened from the die body through the centrifugal force. Furthermore, due to the arrangement of an MYT3-23 hydraulic thruster and an electromagnetic plate, the blank part can be easily taken out, the working difficulty is lowered, and the die releasing efficiency is improved.

Owner:任大龙

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com