Mechanical part die with die releasing conveniently conducted

A technology of mechanical parts and molds, which is applied in the field of mechanical molds, can solve problems such as single structure, low work efficiency, and low production efficiency, and achieve the effects of improving work efficiency, improving demoulding efficiency, and reducing work difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

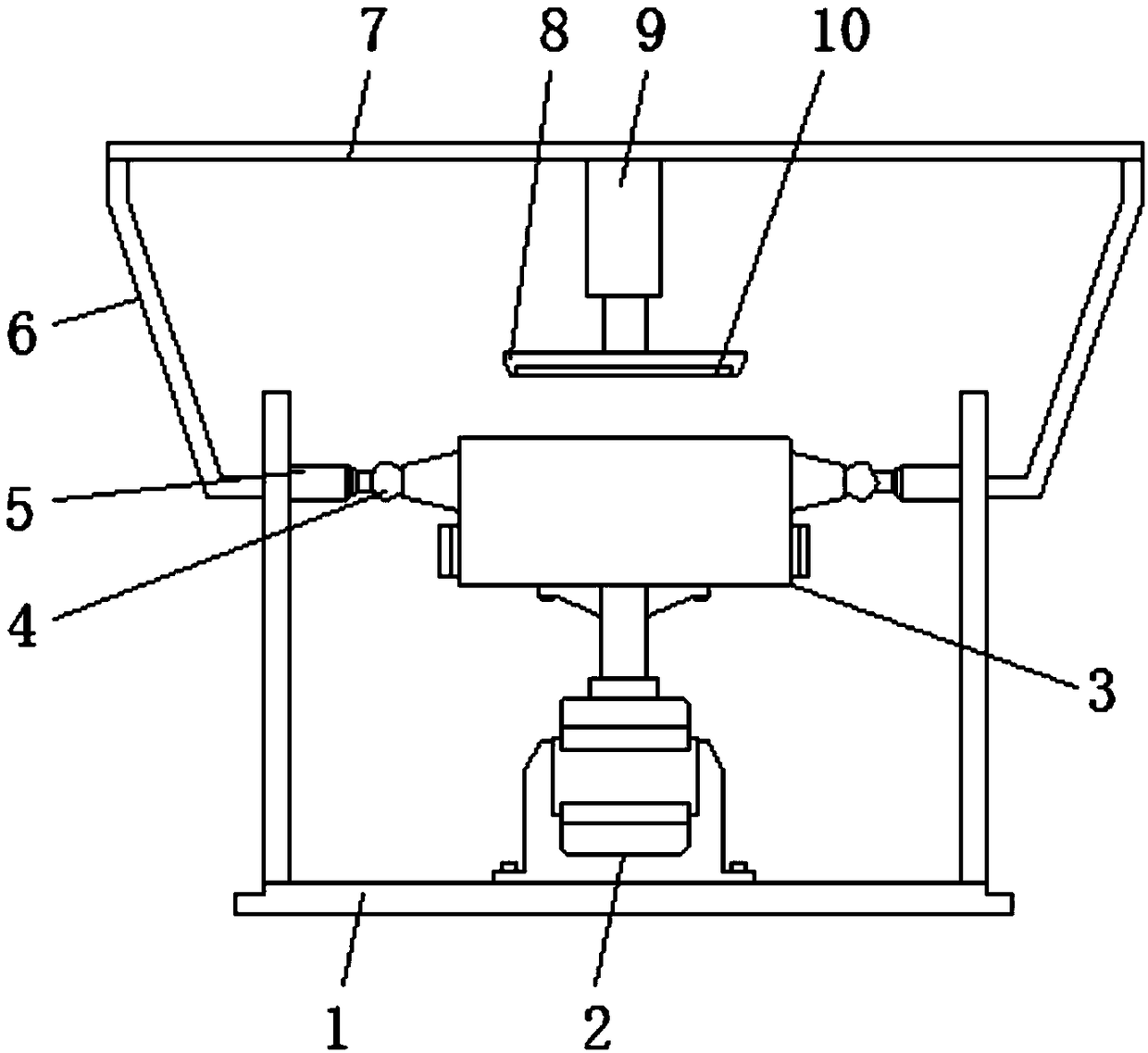

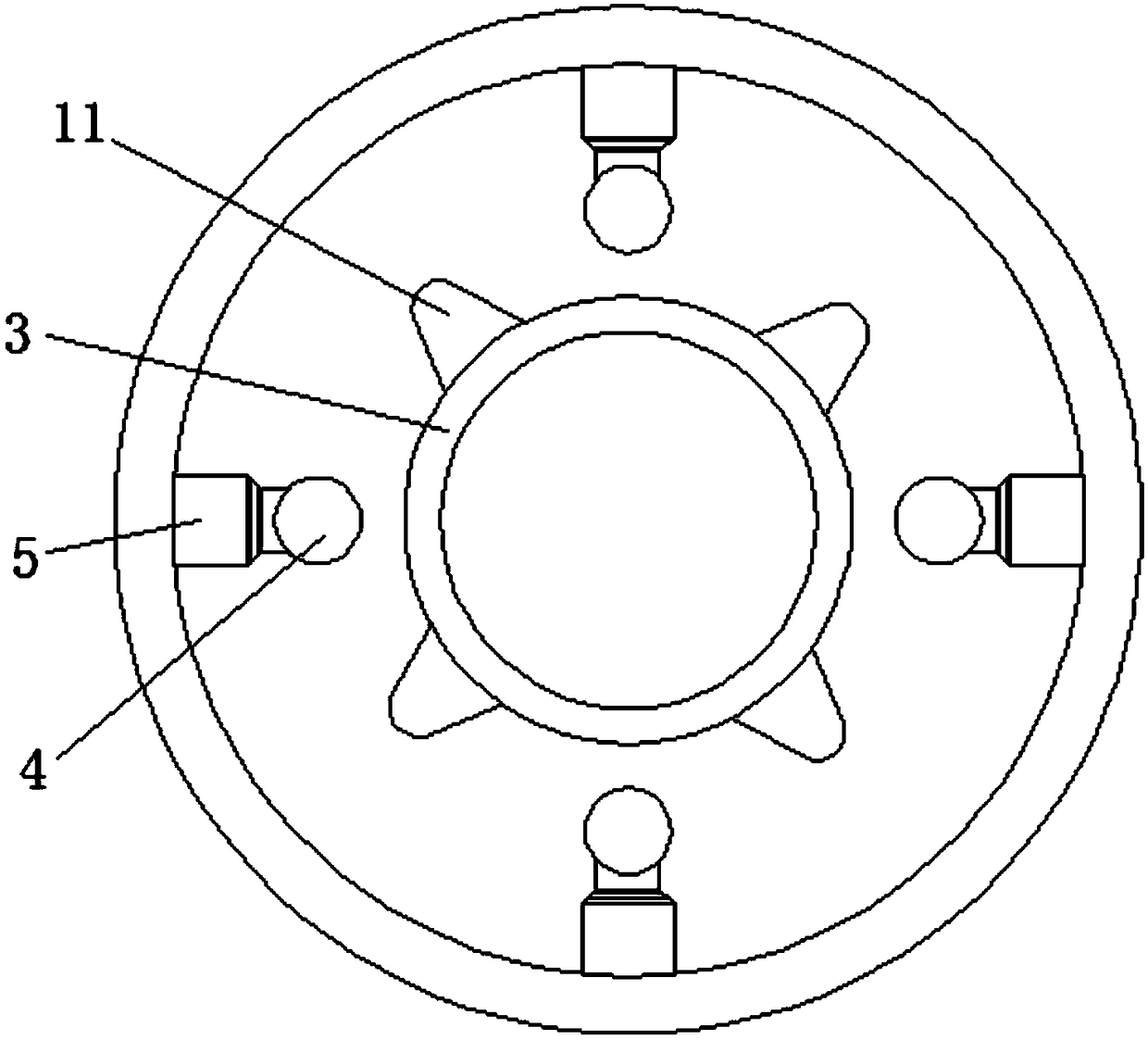

[0025] Embodiment one, with reference to Figure 1-2 , a mold for mechanical parts that is easy to demould, including an outer cylinder body 1 and a mold body 3, a drive motor 2 is fixedly connected to the top center of the inner surface wall at the bottom of the outer cylinder body 1, and the top of the drive motor 2 passes through the output shaft The transmission is connected with a mold body 3, and the outer side of the mold body 3 is welded with a plurality of arc angle bumps 11 equiangularly around its center, and the outer sides of the plurality of arc angle bumps 11 are welded equiangularly on the inner surface wall of the outer cylinder body 1 There are a plurality of telescopic rods 5, steel balls 4 are welded to the ends of the plurality of telescopic rods 5 near the mold body 3, and the plurality of telescopic rods 5 and the plurality of arc angle bumps 11 are located on the same horizontal straight line, driven by The motor 2 drives the mold body 3 to rotate, so t...

Embodiment 2

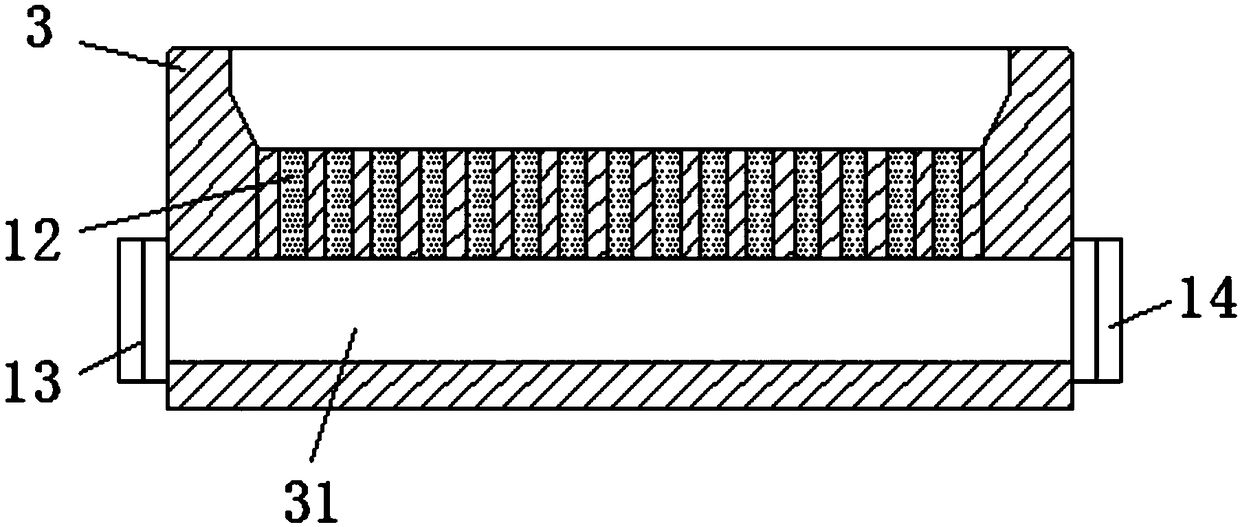

[0026] Embodiment two, refer to Figure 4 , a plurality of telescopic rods 5 are combined by return spring 51, sleeve 52, 5 slider 53 and pole 54, the inside of sleeve 5 is slidingly sleeved with slider 53, and one side of slider 53 passes through the return spring 51 is elastically connected to the inner surface wall of one side of the sleeve 52, and a strut 54 is welded on the other side. When the arc angle protrusion 11 contacts the steel ball 4, the strut 54 pushes the slider 53 to slide in the sleeve 5, The return spring 51 is compressed under force, thereby avoiding the deviation of the steel ball 4 under force and ensuring its position stability.

Embodiment 3

[0027] Embodiment three, refer to figure 1 , the top of the outer wall on both sides of the outer cylinder body 1 is welded to the top plate 7 through the symmetrically arranged fixing frame arms 6, and the center of the bottom of the top plate 7 is connected to the fixed plate 8 through the MYT3-23 hydraulic pusher 9, and the bottom of the fixed plate 8 The electromagnetic plate 10 is fixedly connected. When the blank and the inner wall of the mold body 3 become loose, the electromagnetic plate 10 is controlled to descend by the MYT3-23 hydraulic pusher 9 and contacts the upper surface of the blank. After the electromagnetic plate 10 is energized, a strong magnetic field is generated. Thereby, the blank can be absorbed and recovered by the MYT3-23 hydraulic pusher 9, and the blank can be easily taken out.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com