Patents

Literature

43results about How to "Increase clamping pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

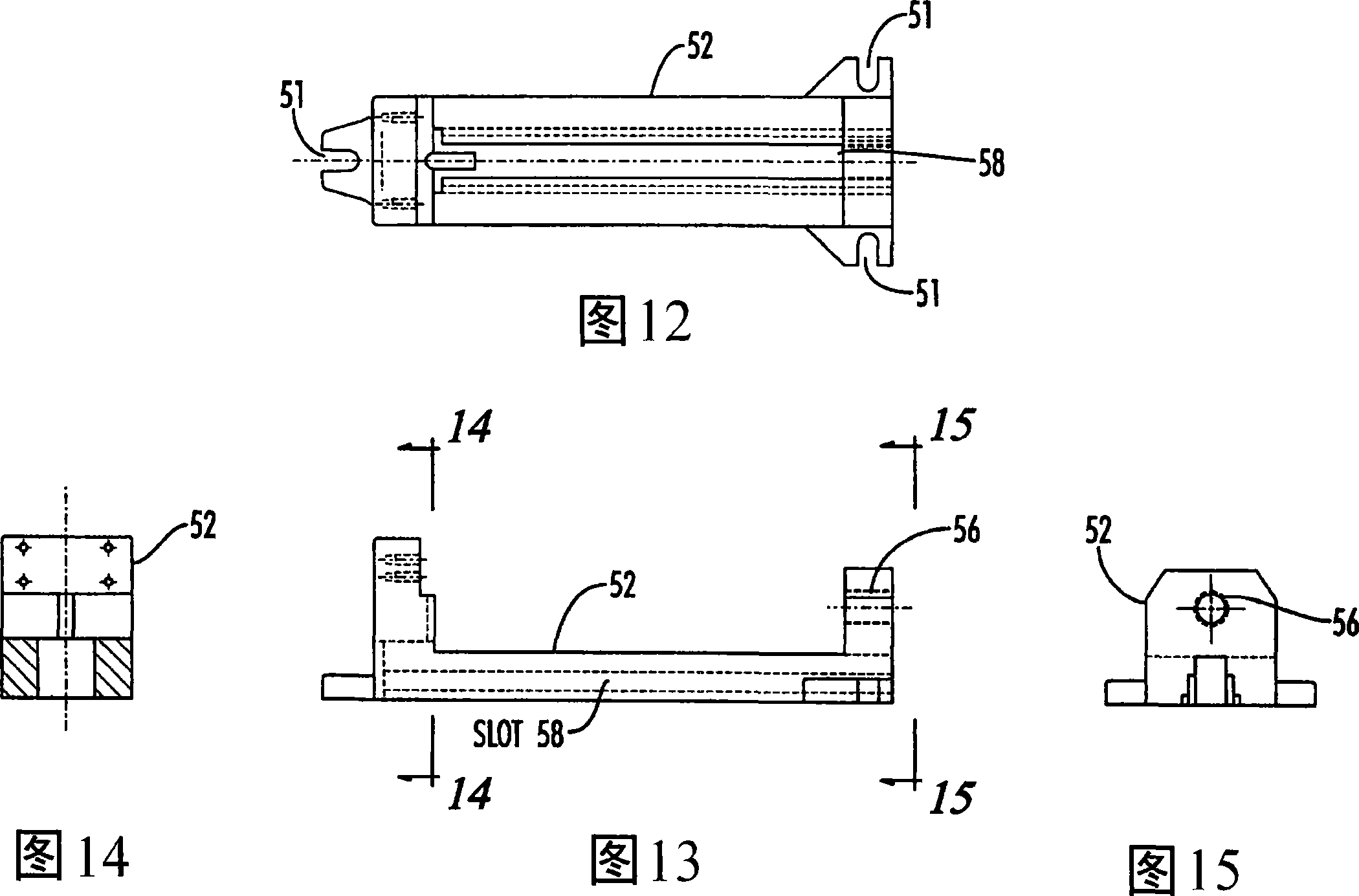

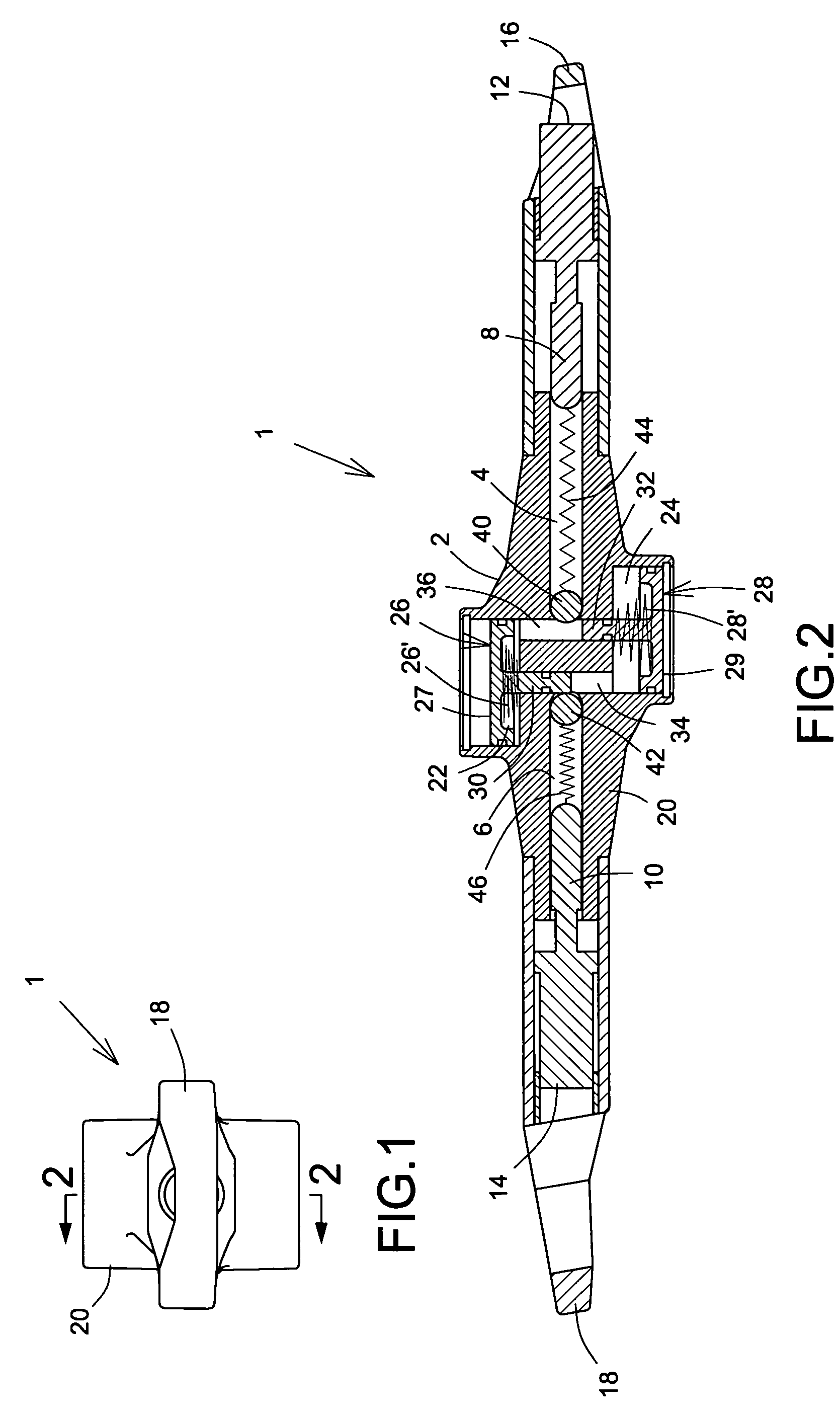

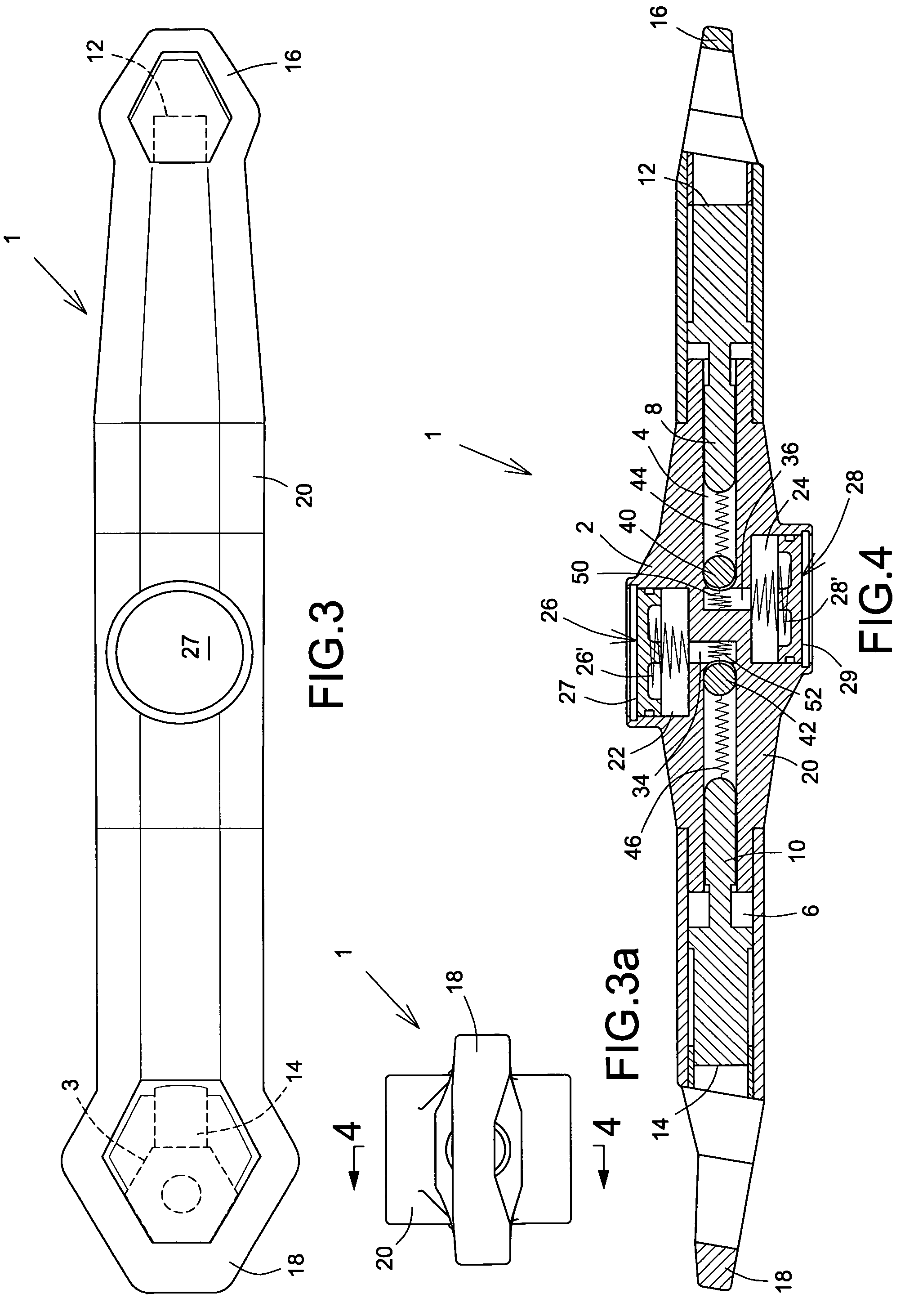

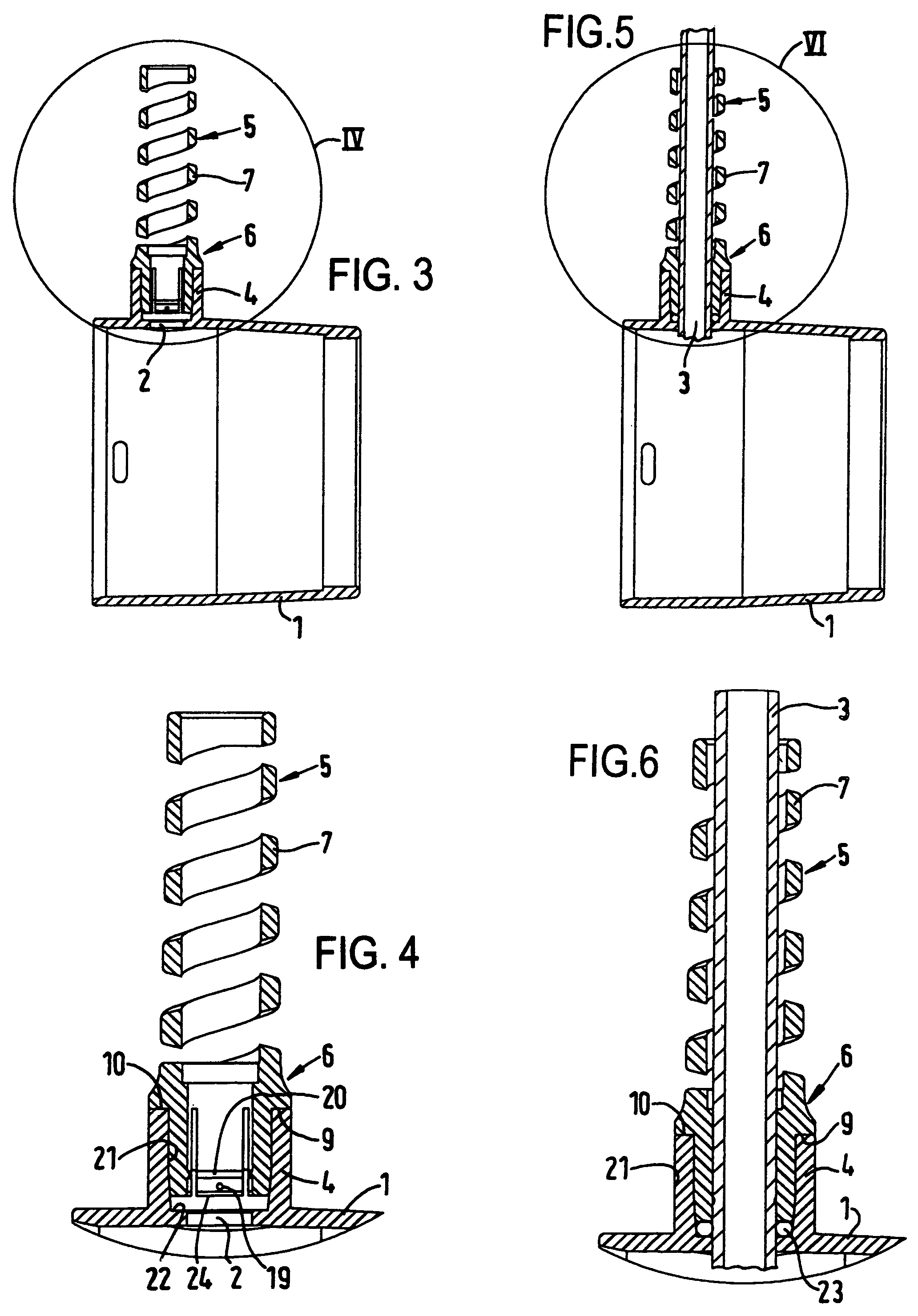

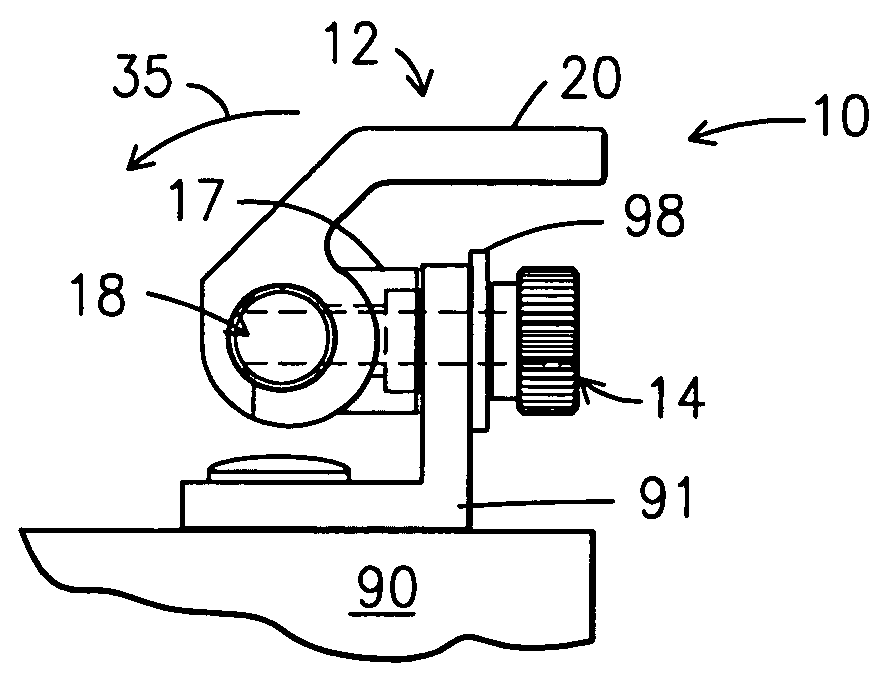

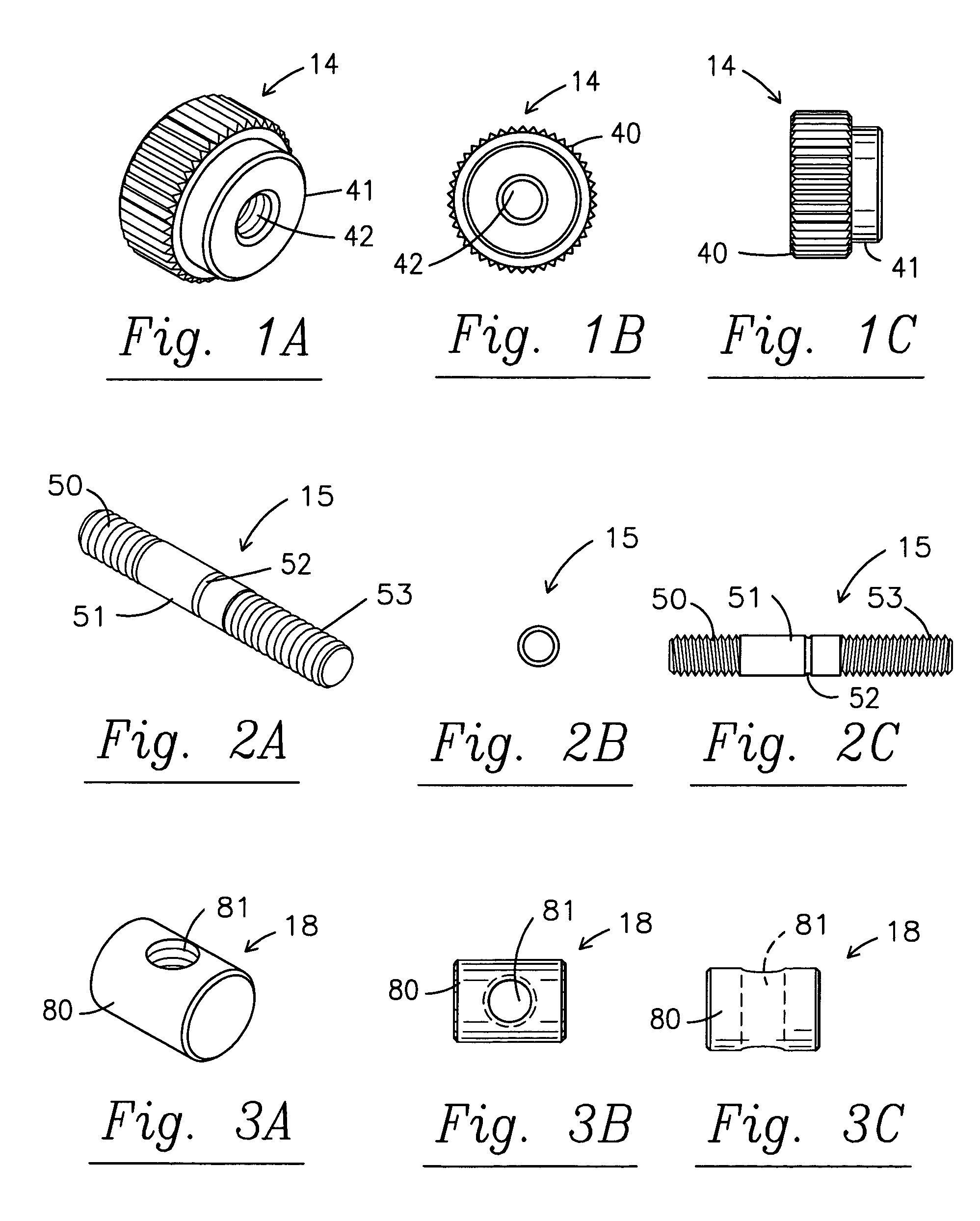

Rotatable connector for a battery cable clamp

InactiveUS6971925B1Increase pressureIncrease clamping pressureElectric connection basesClamped/spring connectionsEngineeringElectrical and Electronics engineering

An improved rotatable battery cable clamp connector is designed for use with applying pressure to legs of the clamp intermediate the cable section and post section of the clamp. Self-lubricating and non-corrosive materials are also used to advantage in the manufacture of the connector.

Owner:FENELON MARGARET FENE +1

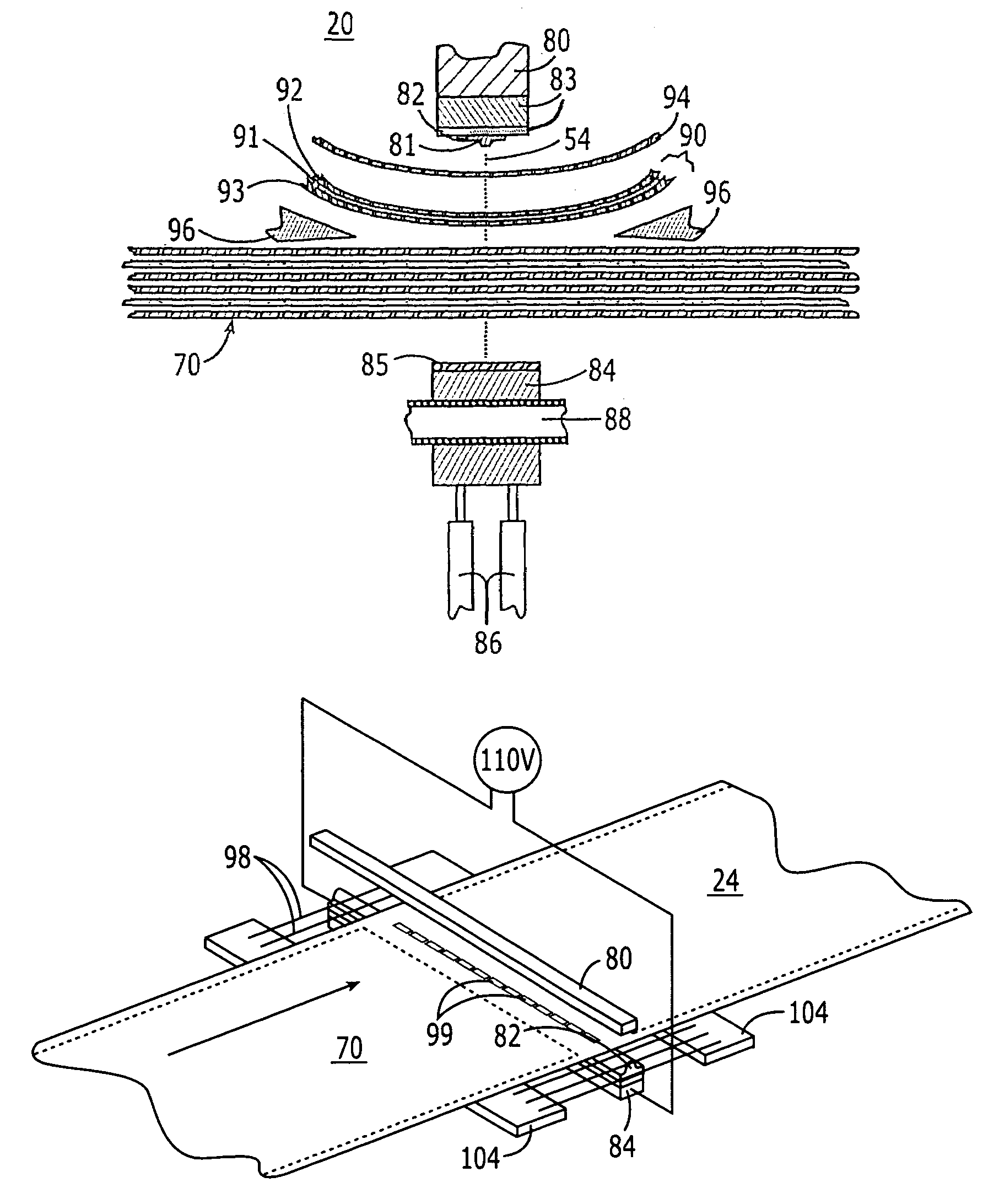

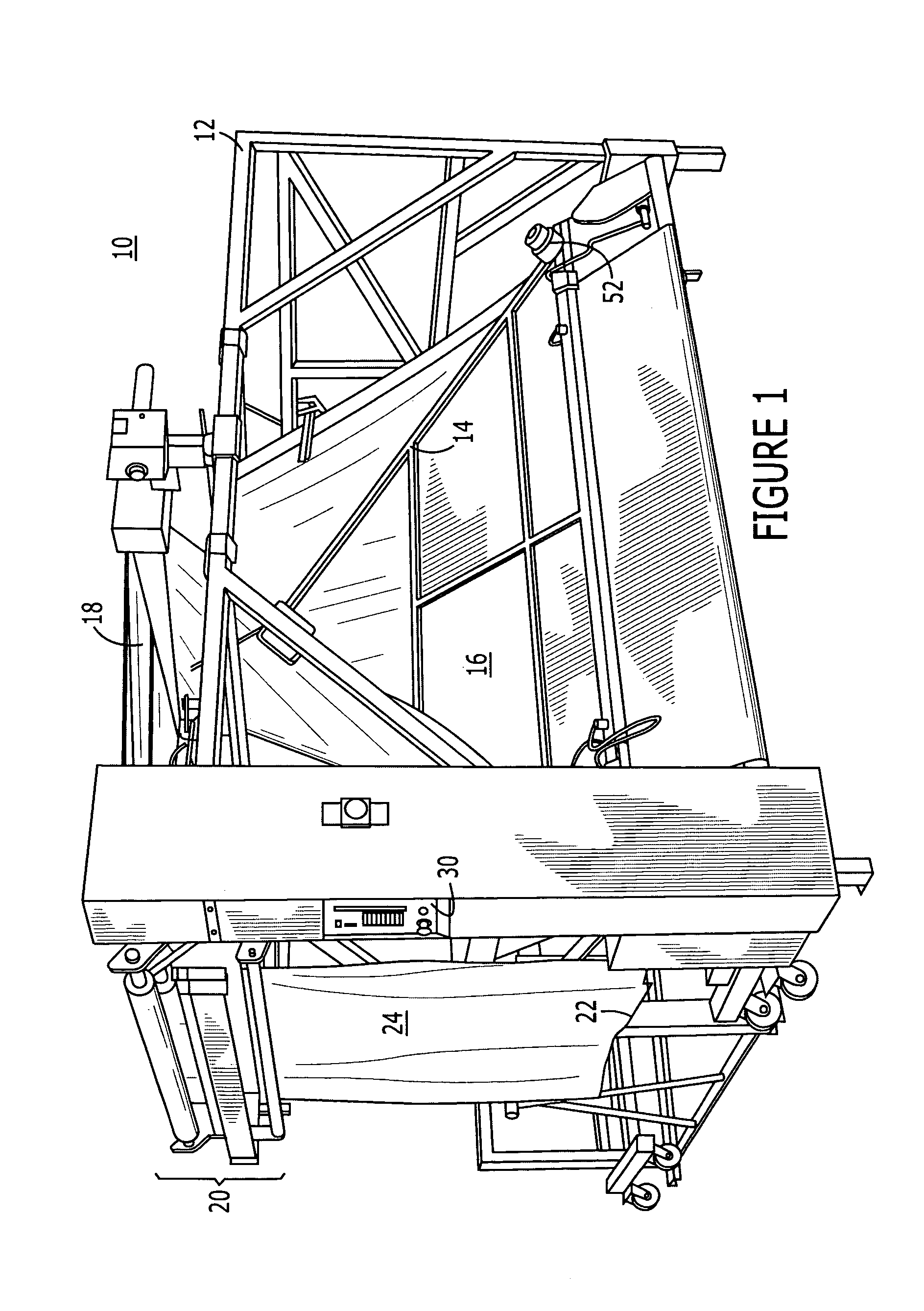

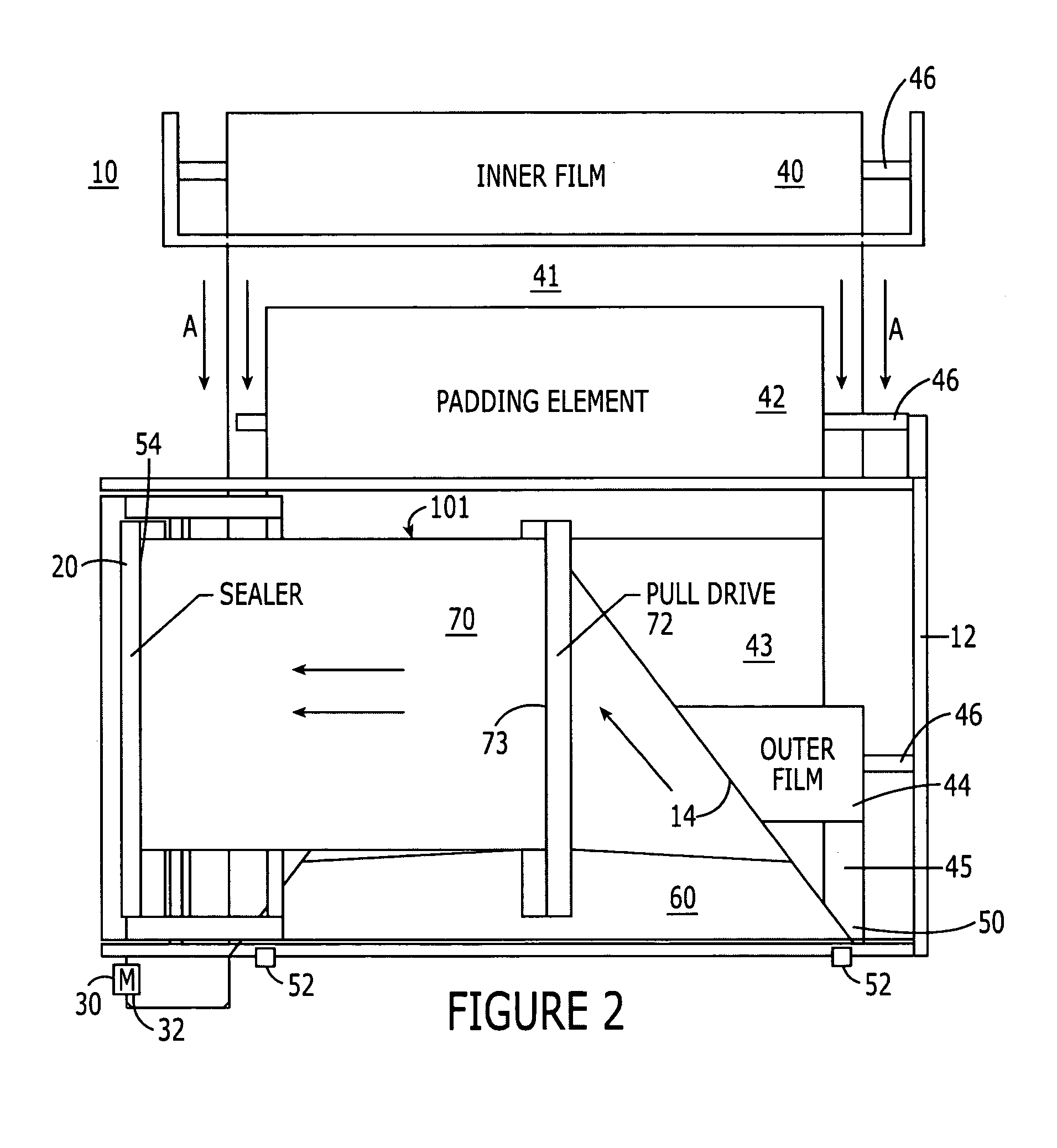

Queue-based bag forming system and method

InactiveUS7115086B1Easy to captureEasy heat transferEnvelopes/bags making machineryMechanical working/deformationEngineeringElectrical and Electronics engineering

A method of forming a series of bags for bulky articles from rolled thermoplastic film and padding element includes arranging a linear, longitudinally traveling queue of layers of film and padding element according to a set of desired bag dimensions and characteristics and controlling the advancement of the queue to make padding element and seal cuts to form the bags. The invention also includes a system for fabricating bags substantially in the manner identified in the method of the present invention, as well as a method of forming seal cuts in which an envelope is first clamped, then sealed and cut by heat and pressure, then allowed to cool before being released.

Owner:AUTOMATED SOLUTIONS

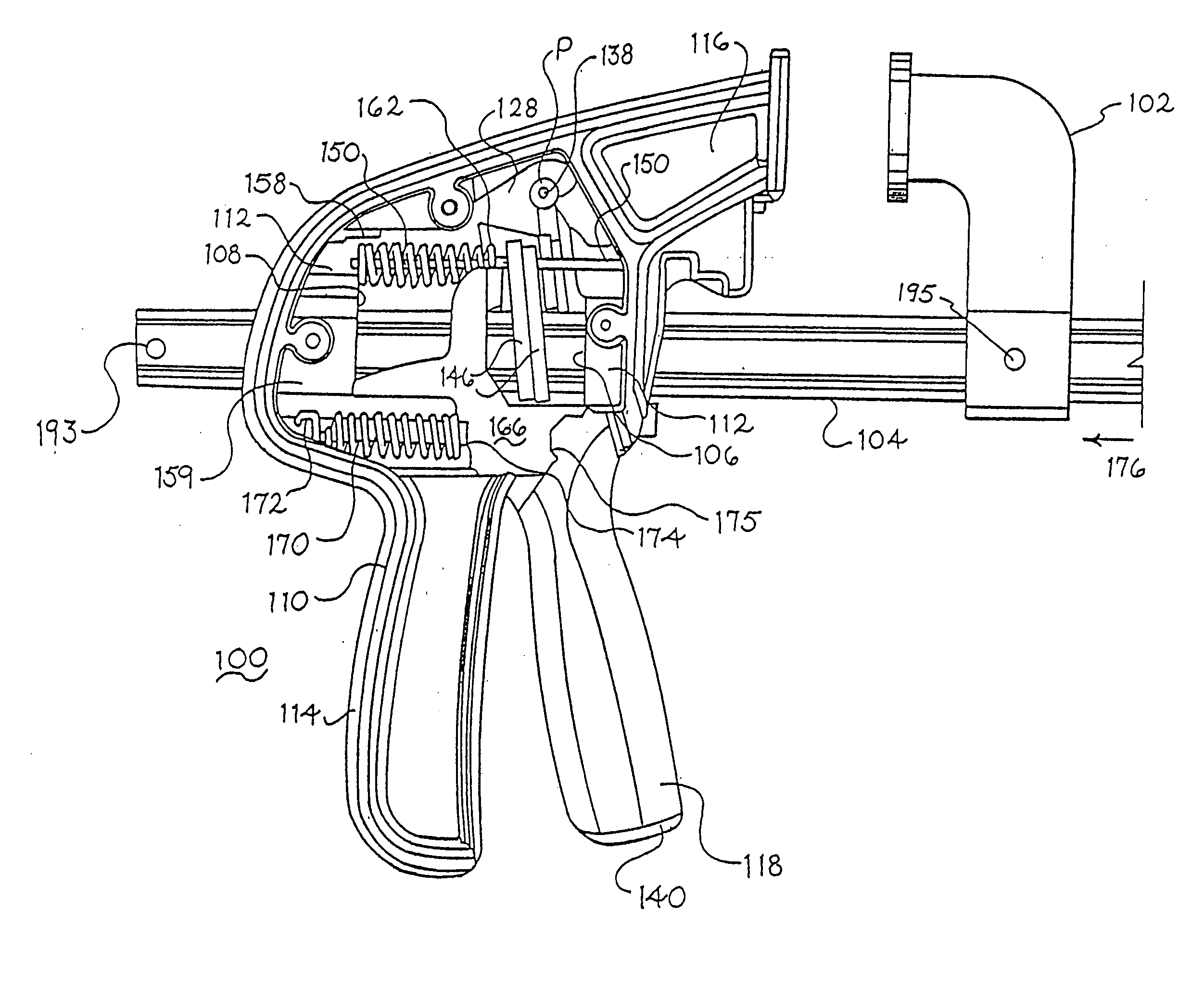

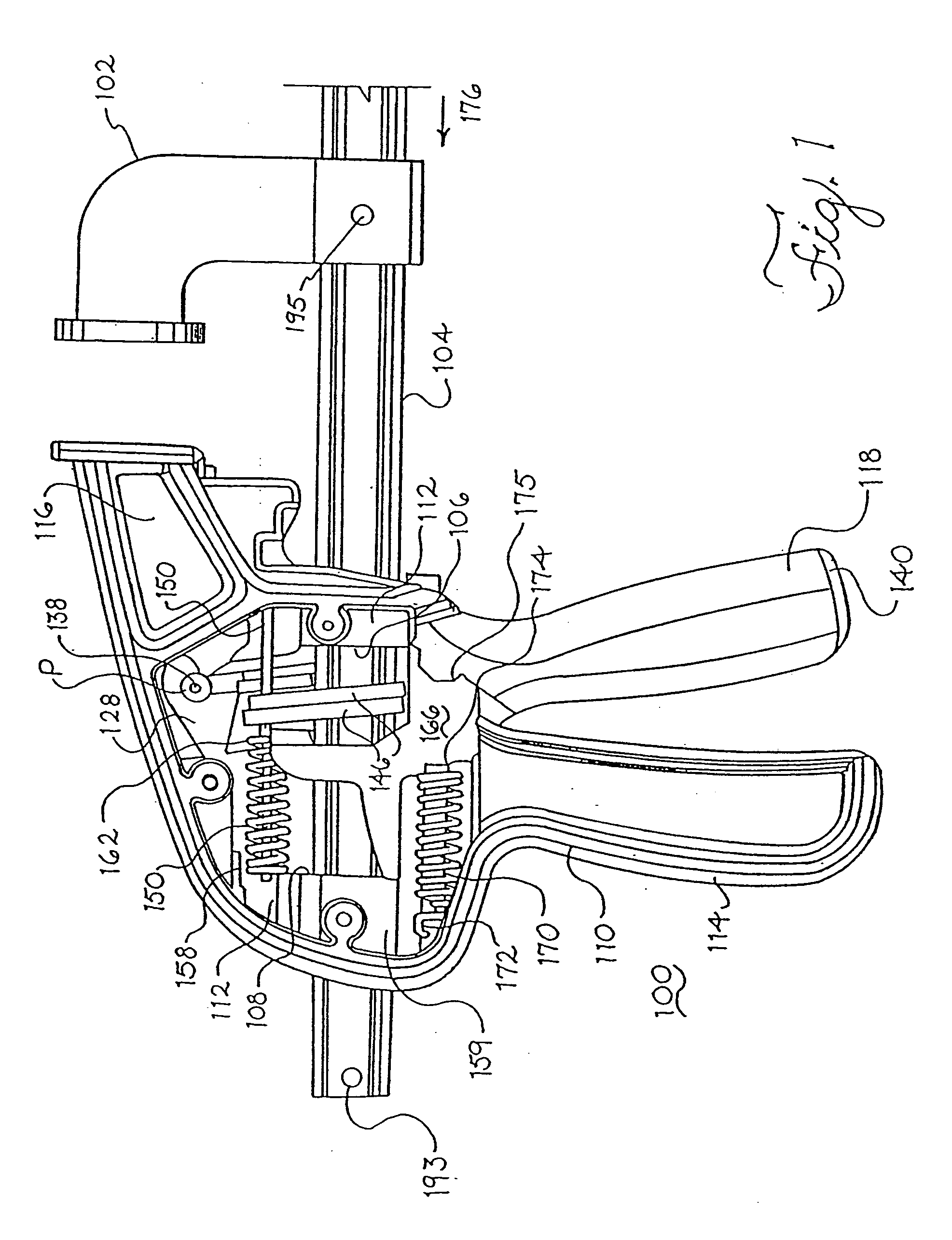

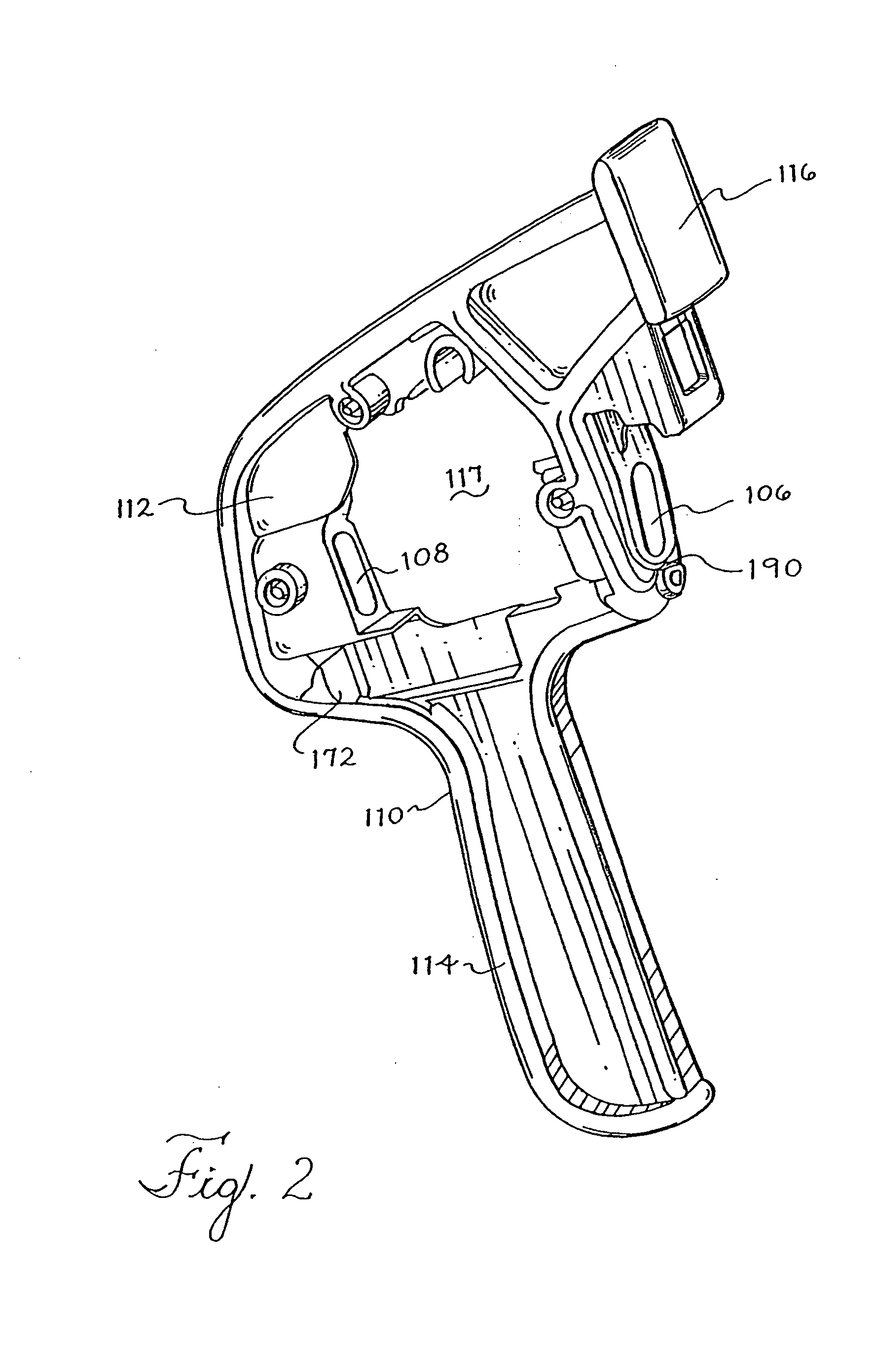

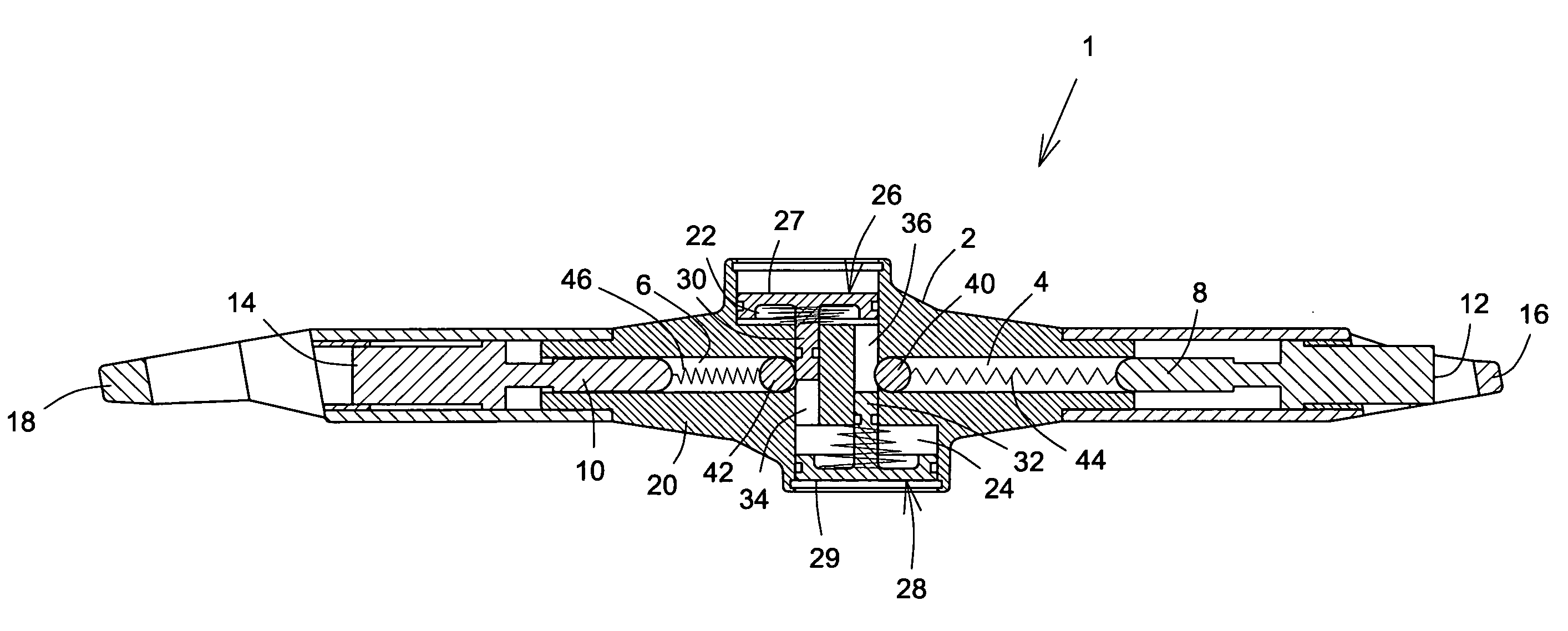

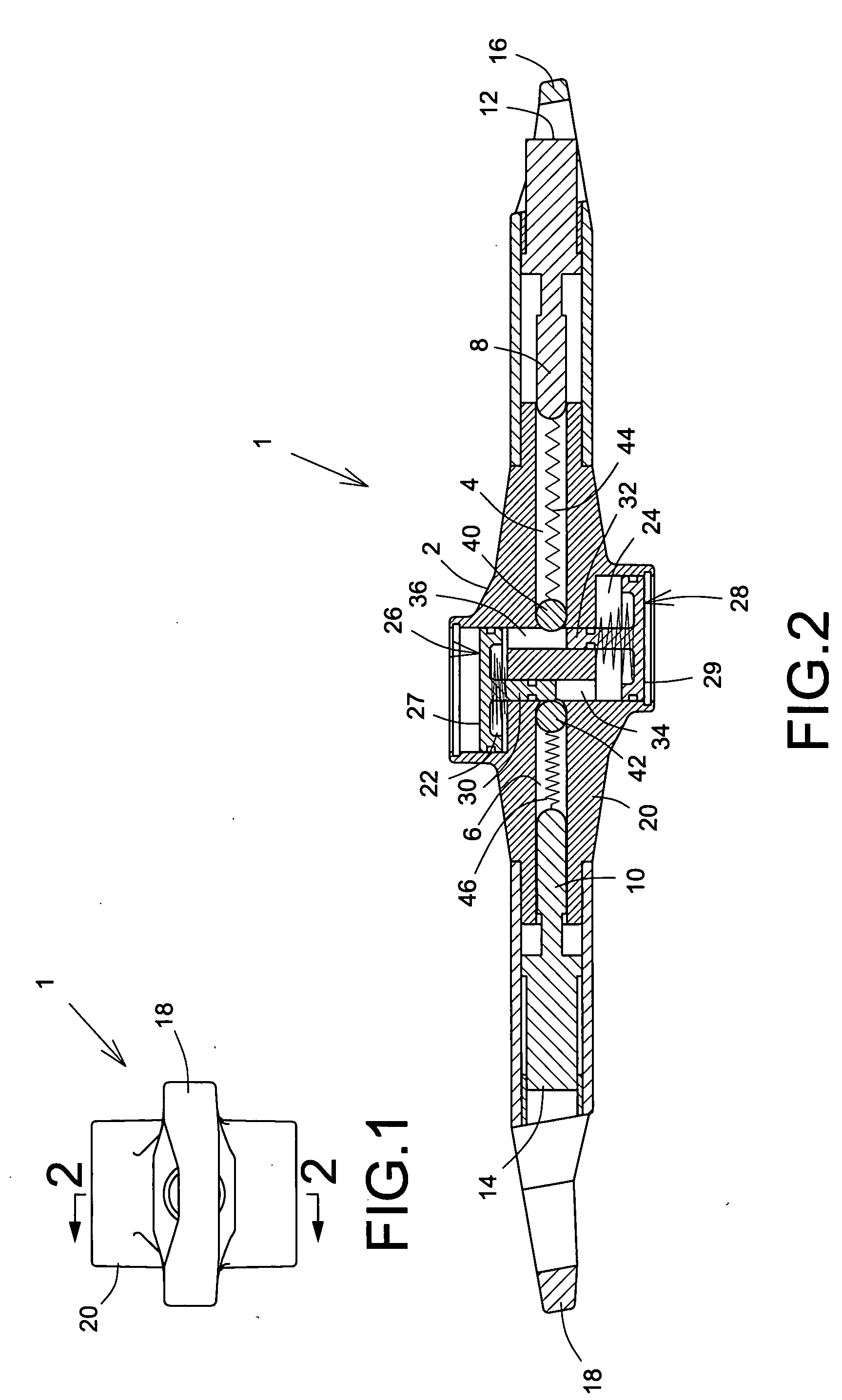

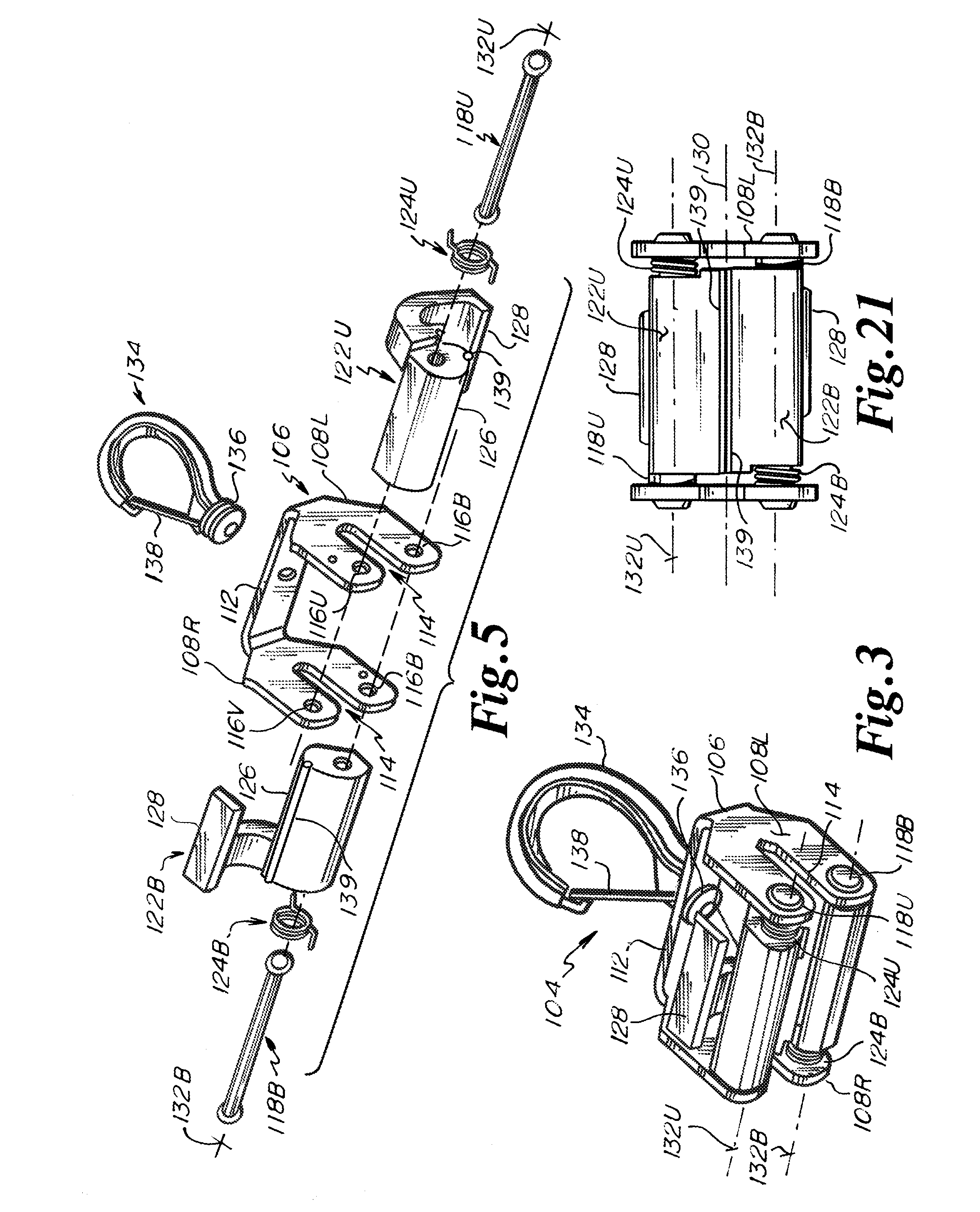

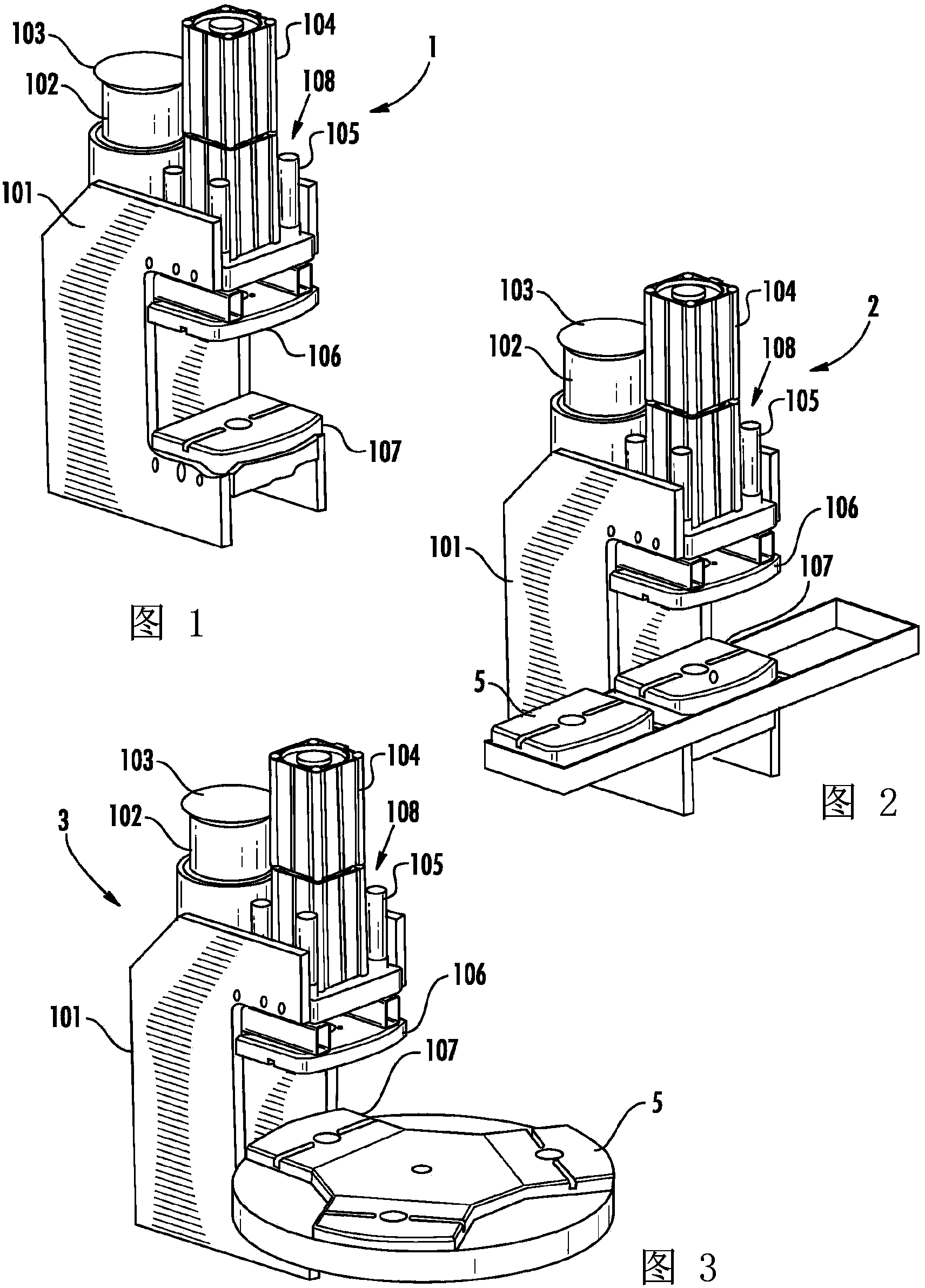

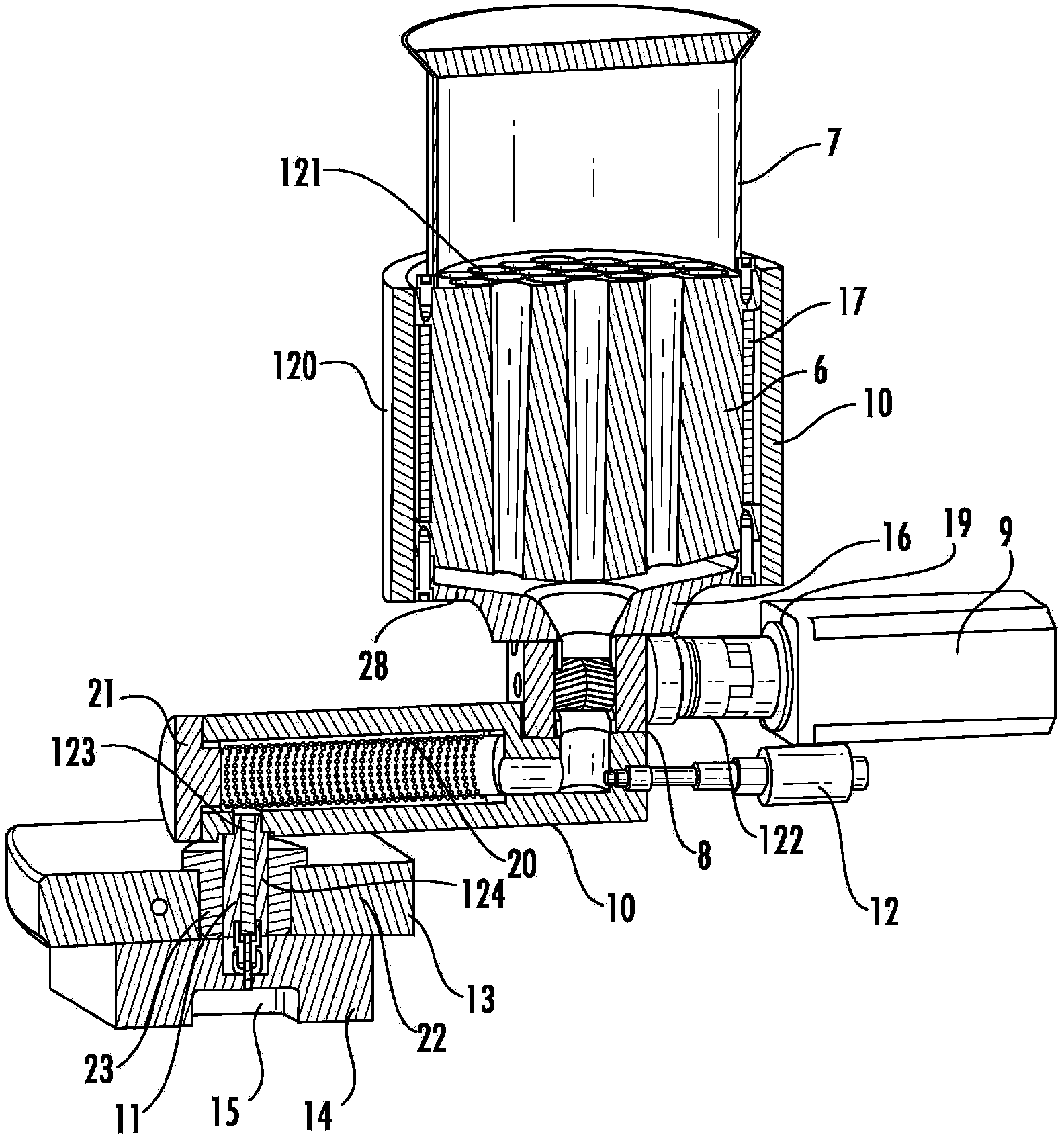

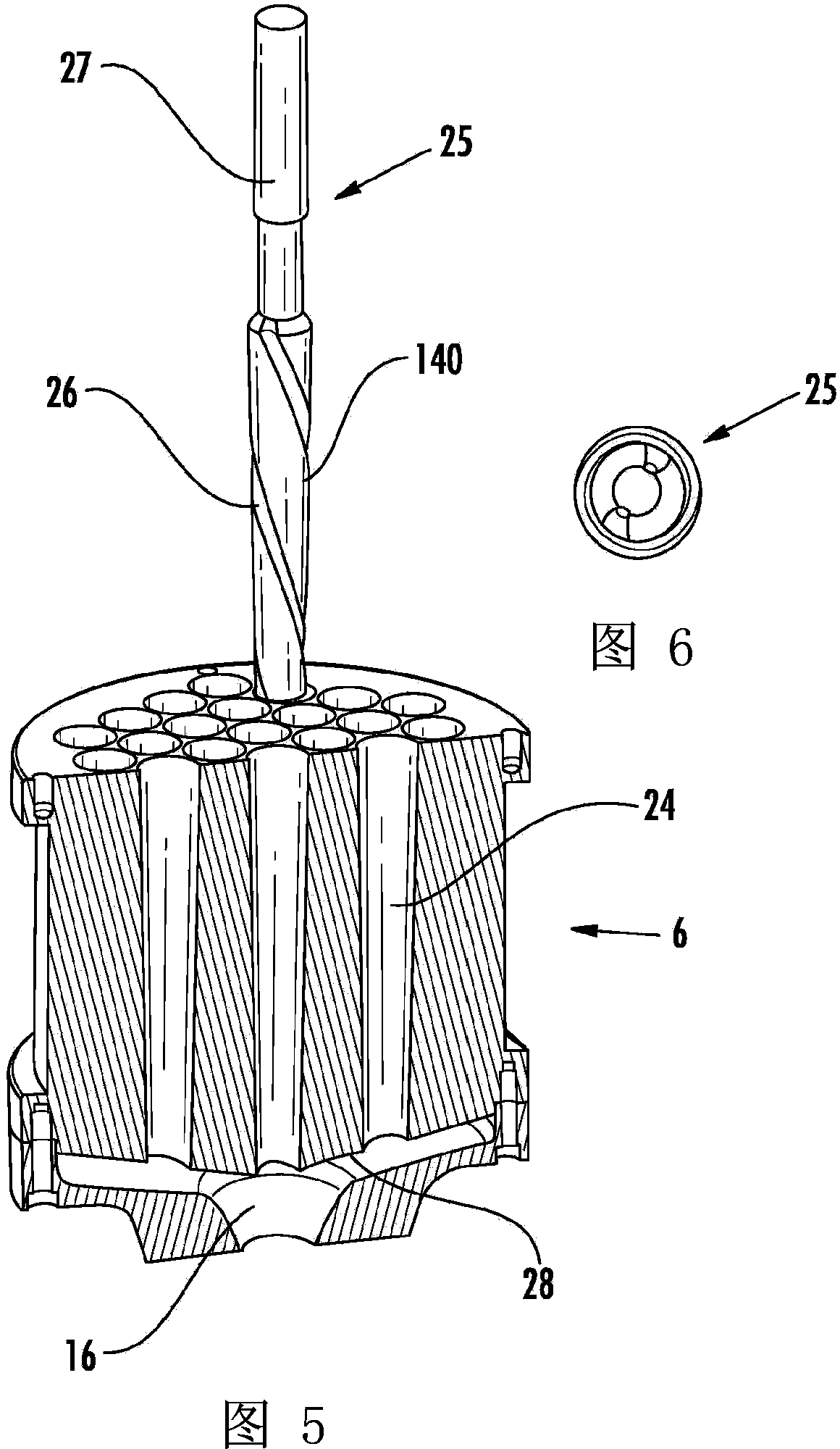

Increased and variable force and multi-speed clamps

A method of operating a clamp (100) that includes a first clamping jaw (102), a support element (104) to which the first clamping jaw is attached and a trigger handle (118) pivotably mounted to a clamp body (112). The method includes actuating the trigger handle causing the first clamping jaw to experience incremental motion and varying the incremental motion as a function of a load encountered by the support element by varying an effective lever arm of the trigger handle by moving a fulcrum point into contact or out of contact with the trigger handle based on the load.

Owner:BLACK & DECKER INC

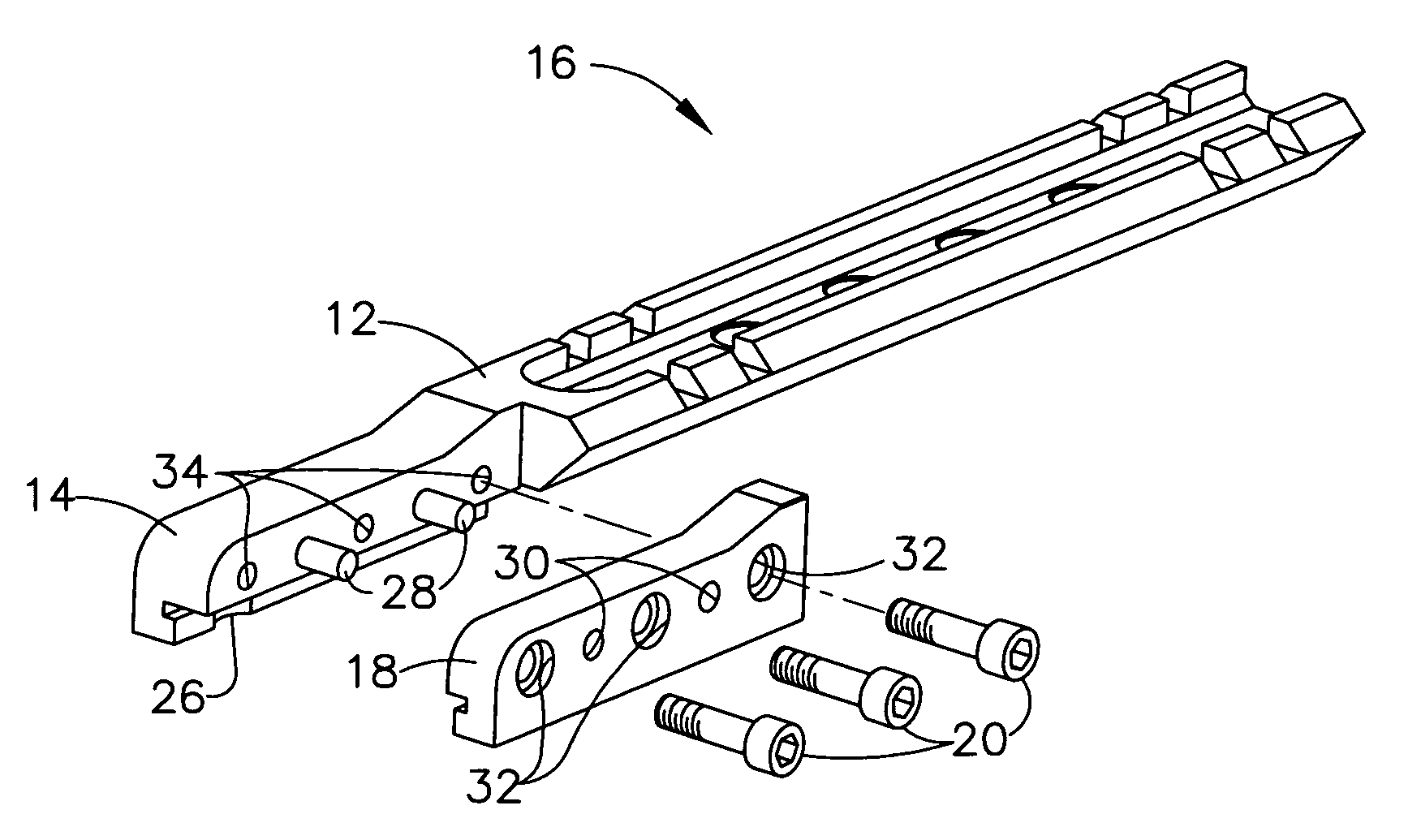

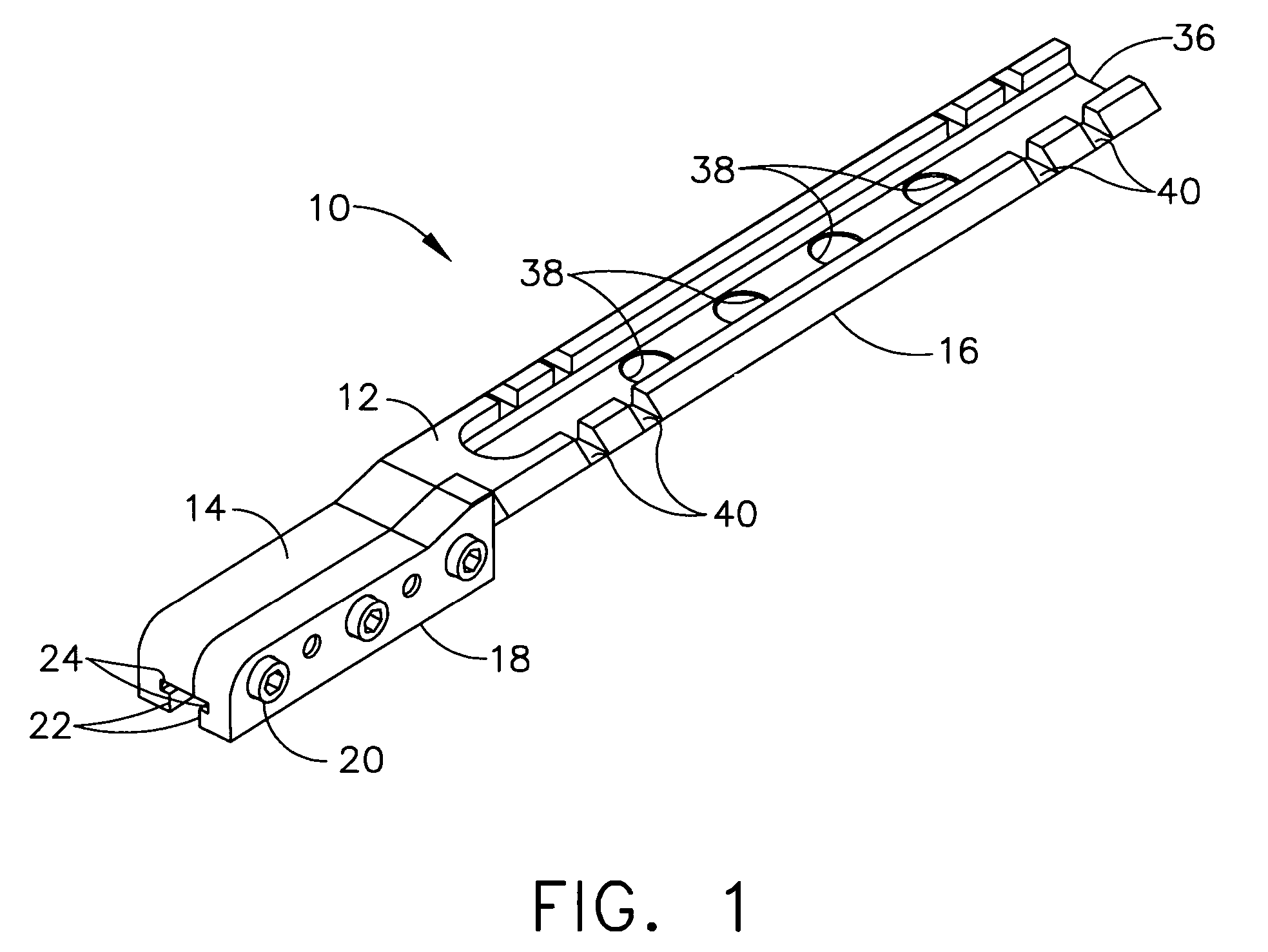

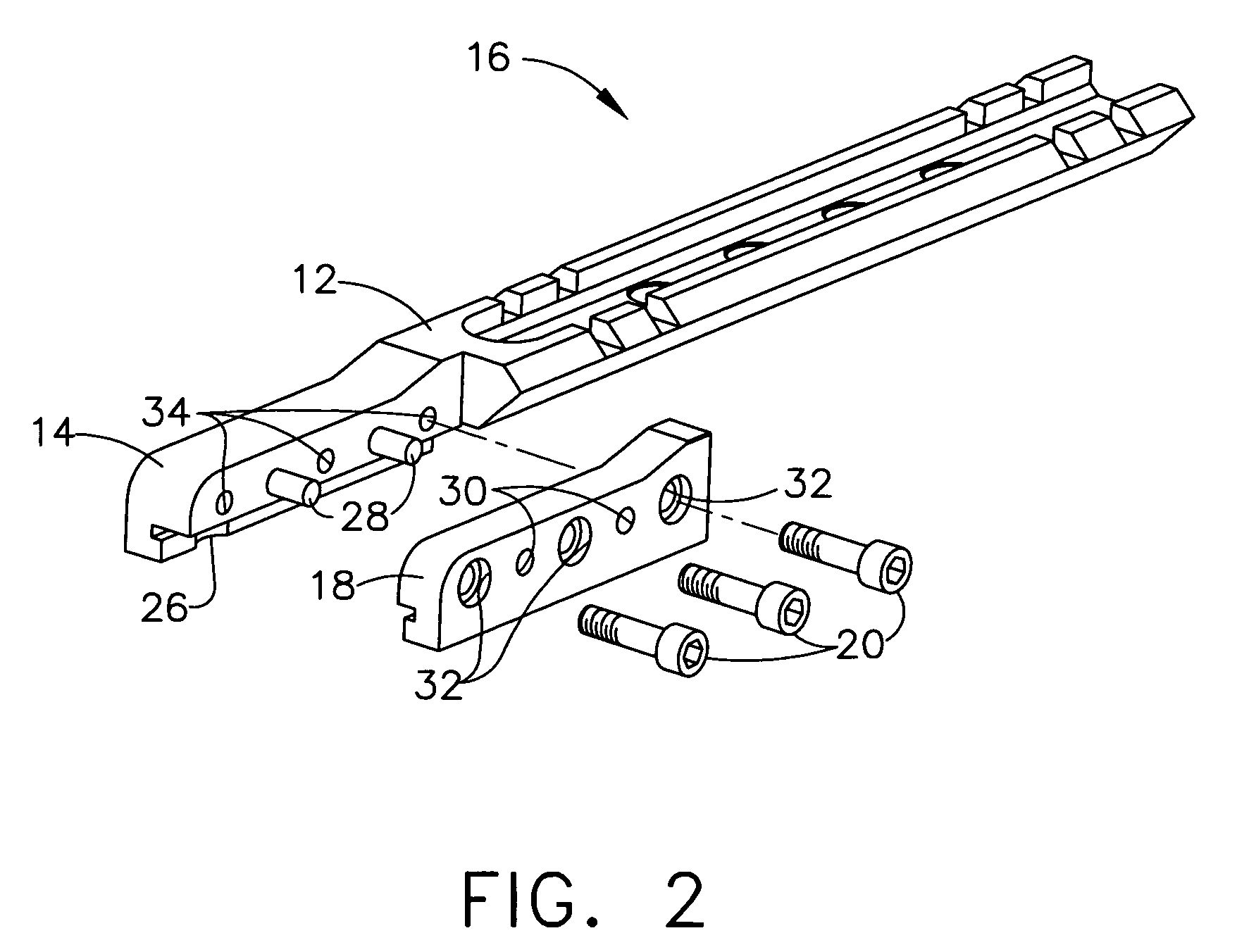

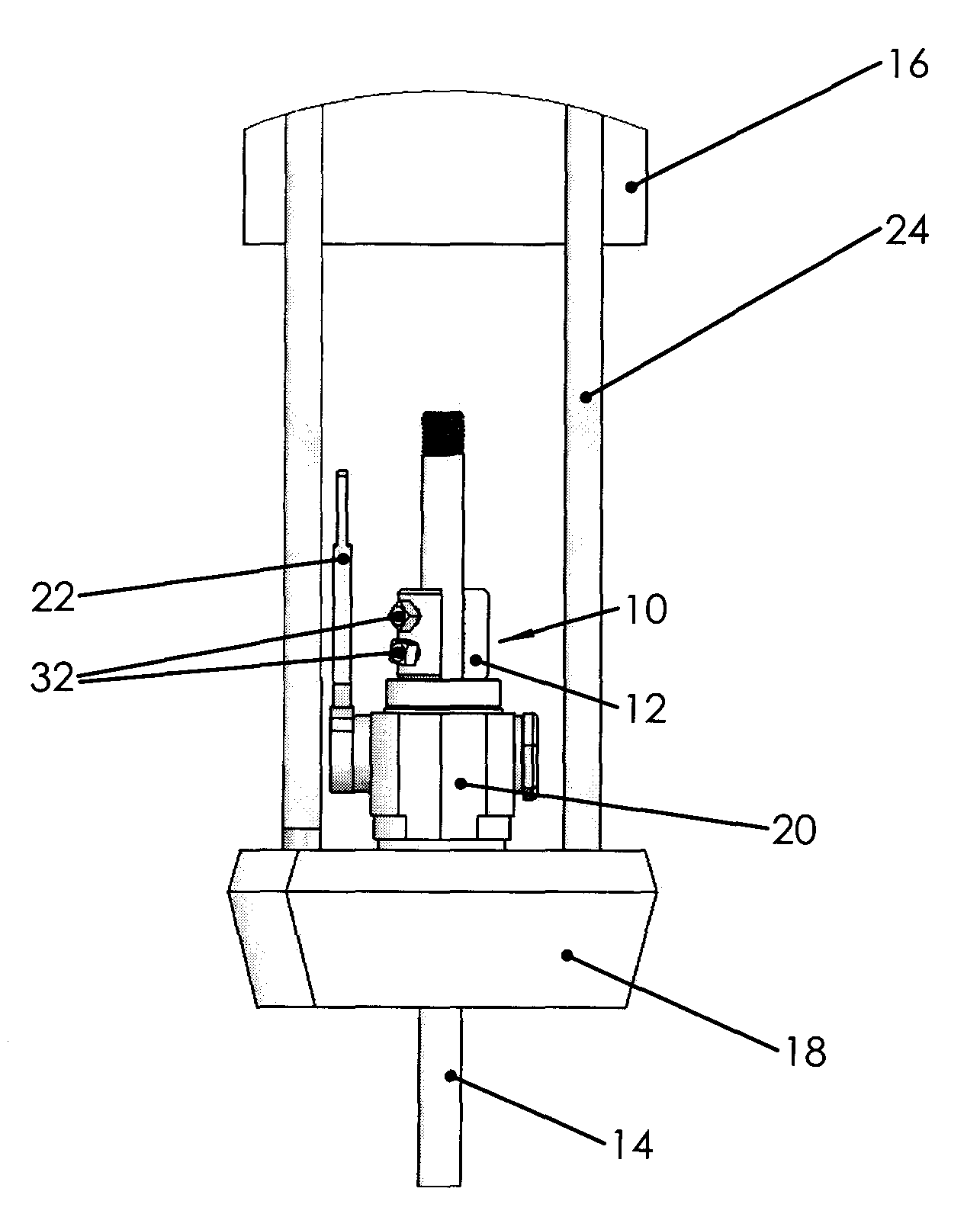

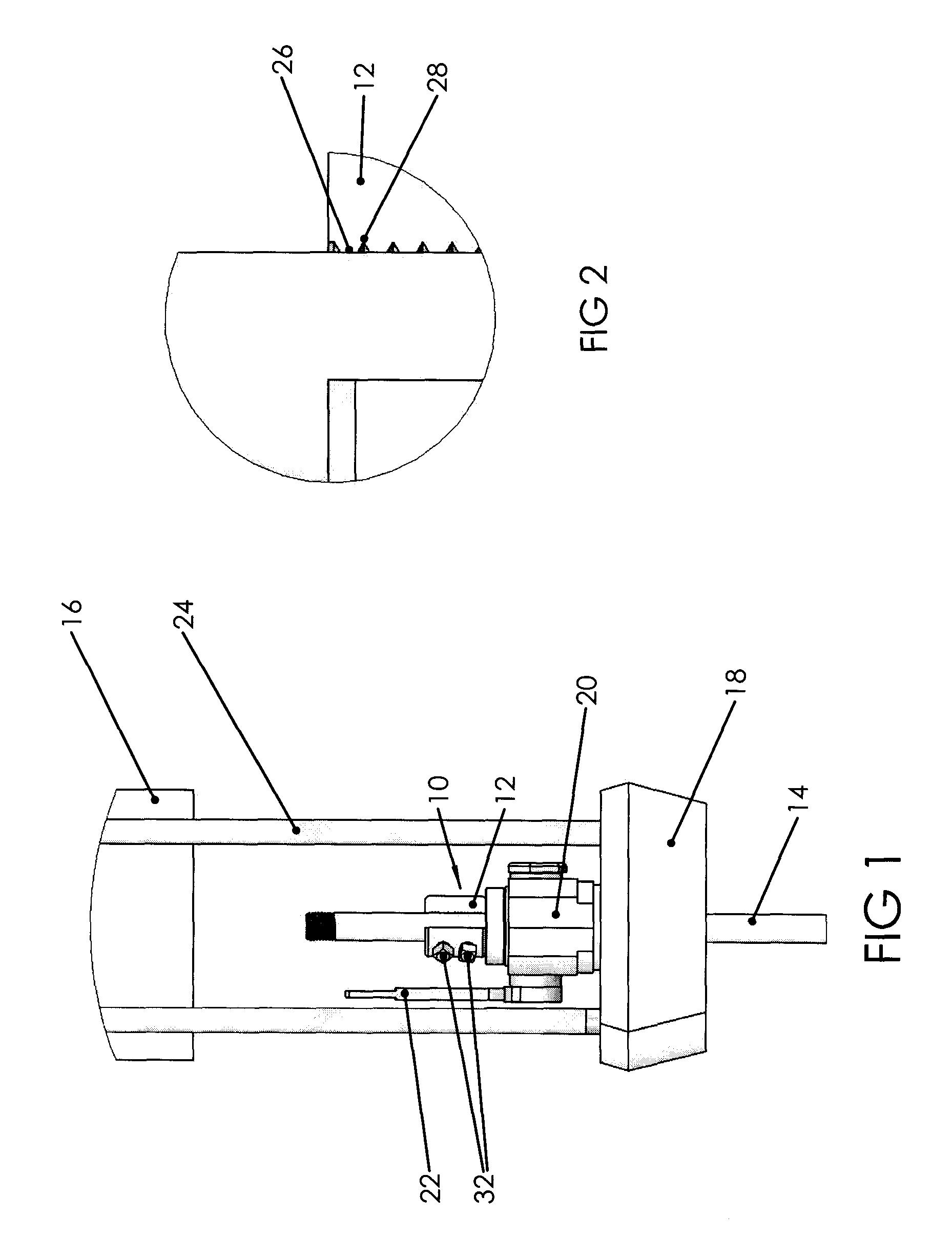

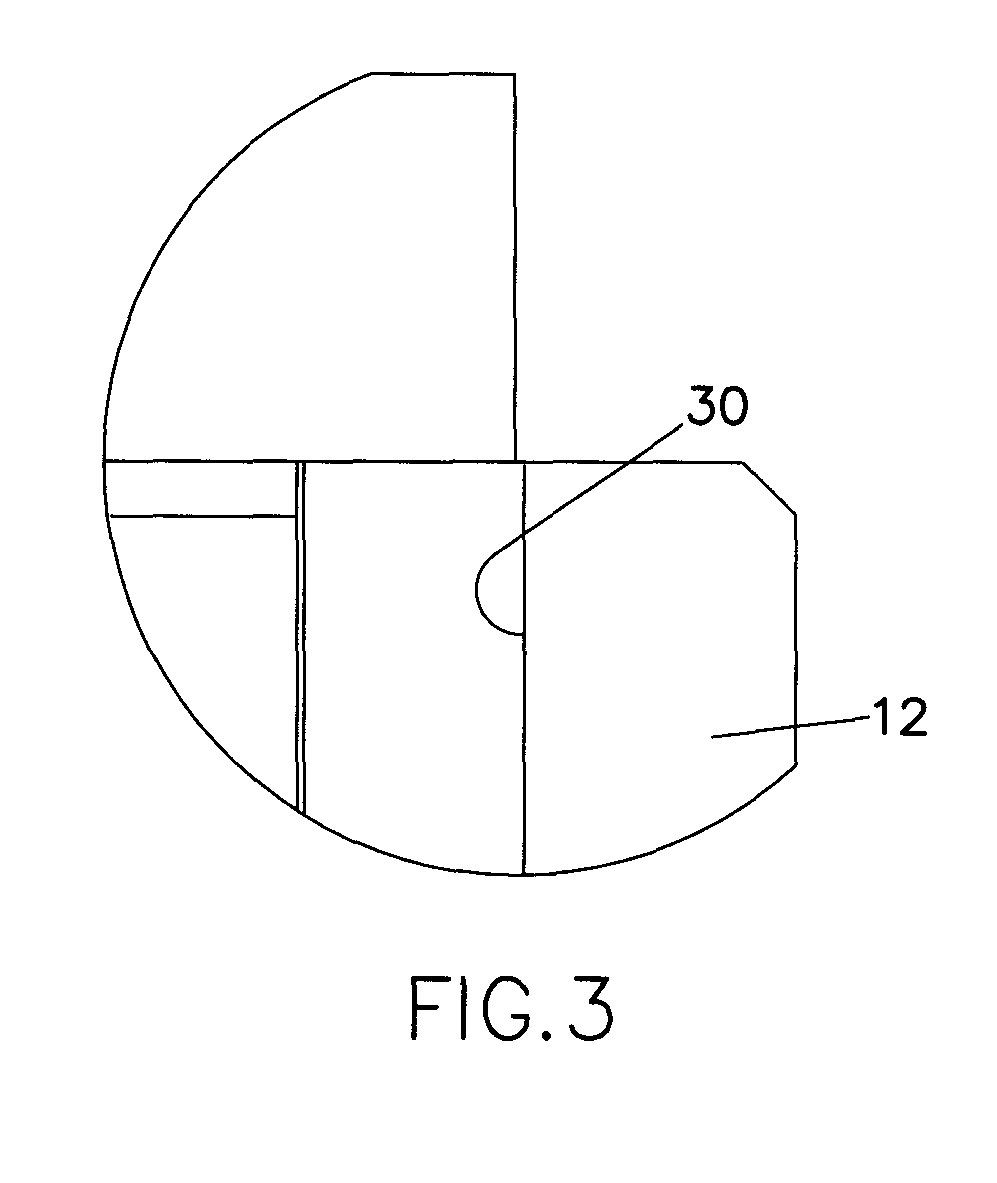

Telescope sight mount for a firearm

InactiveUS7240451B2Large clamping pressureIncrease clamping pressureSighting devicesEngineeringCantilever

The present invention is a telescopic sight mount for attachment to a firearm having a longitudinal vent rib on its barrel. The mount is readily attachable and detachable and includes a cantilevered main body having a front portion and a back portion, a clamp portion, and at least three clamping screws. The screws adjoin the front portion of the main body with the clamp portion and draw the front and clamp portions horizontally towards one another and into rigid clamping engagement with the vent rib. The back portion of the main body is able to receive and mount a telescopic sight. The mount can be rigidly mounted onto the firearm with stability sufficient to remain in place permanently despite recoil, and can also be easily detached from the firearm if desired.

Owner:NTR GROUP VENTURES

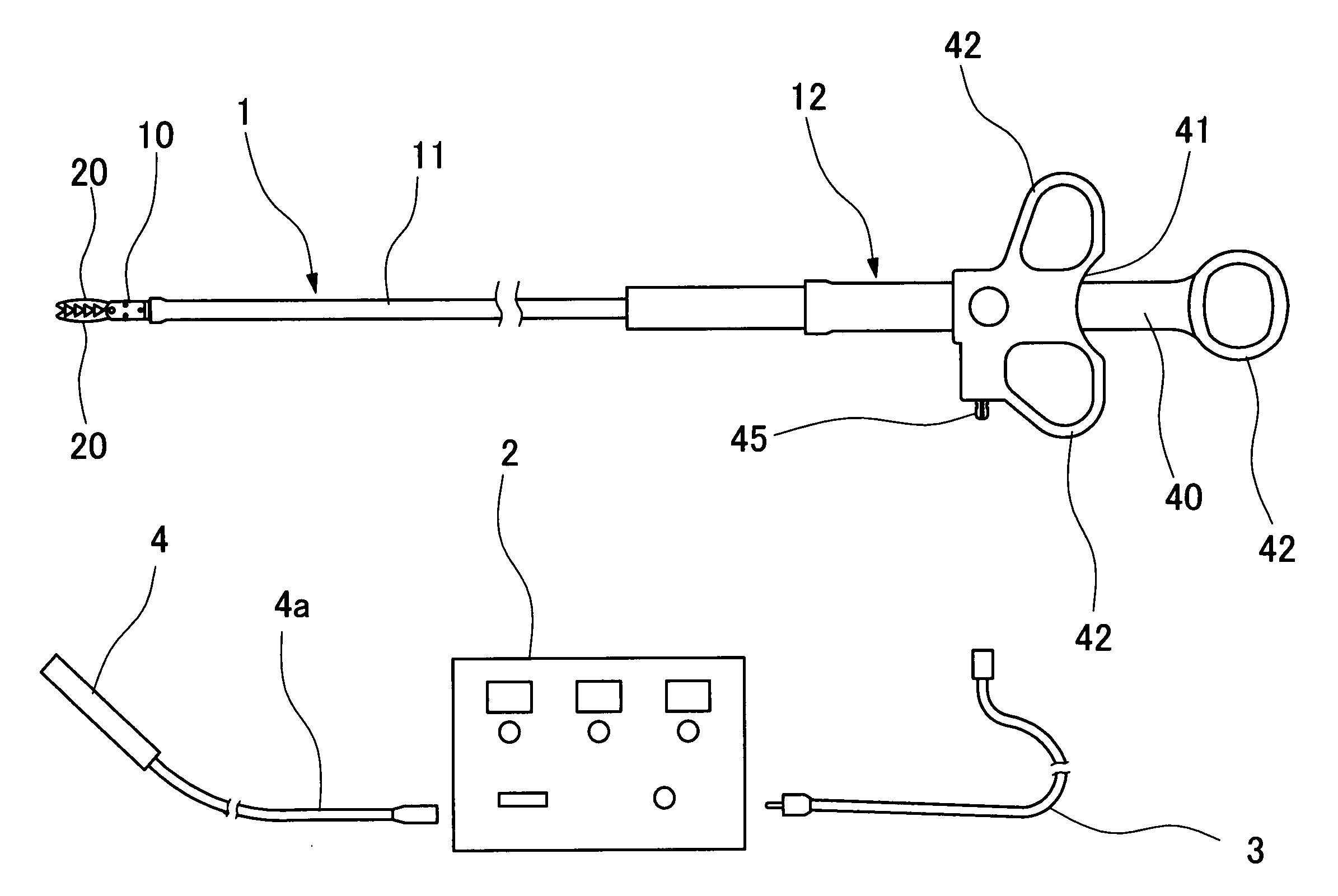

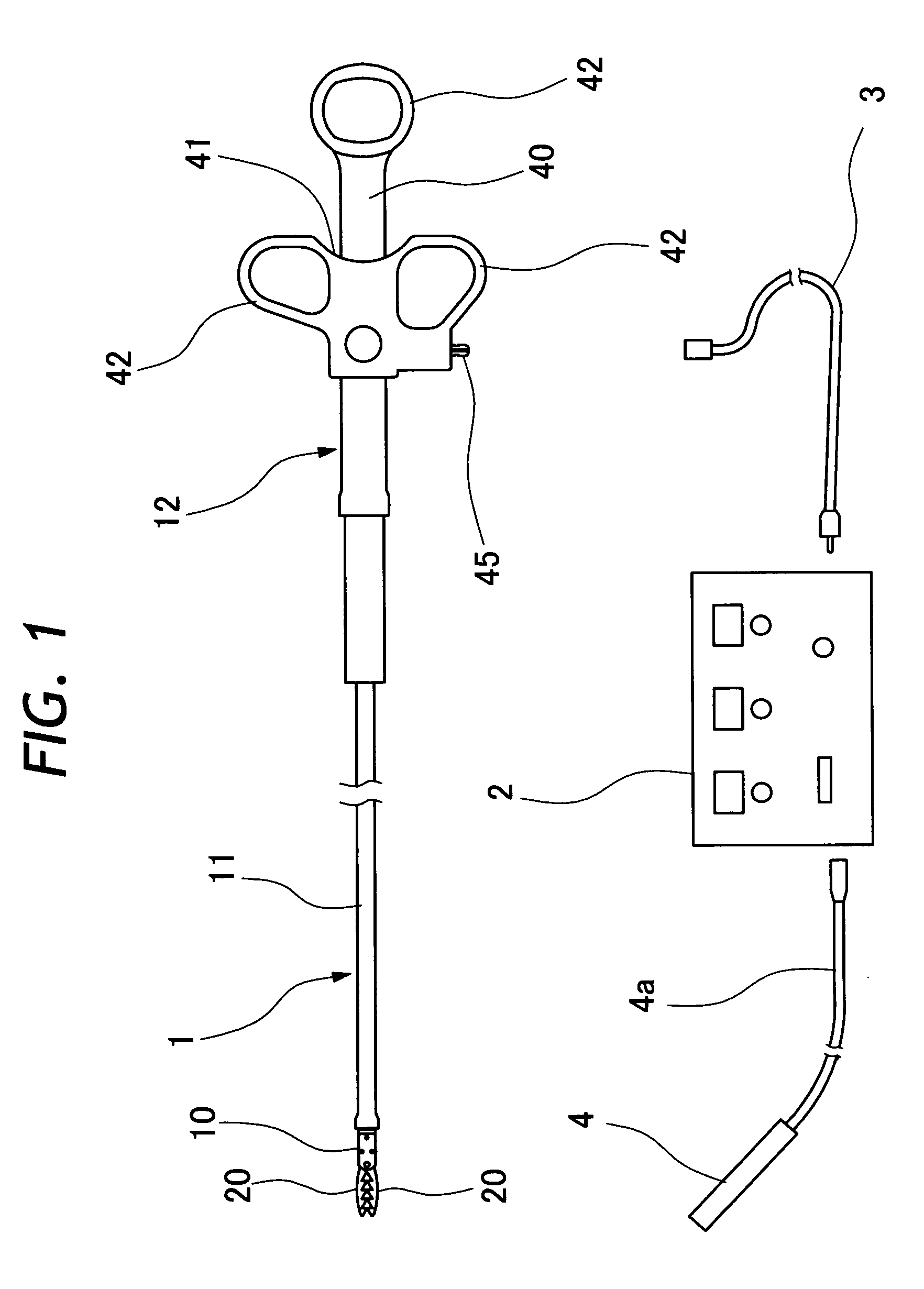

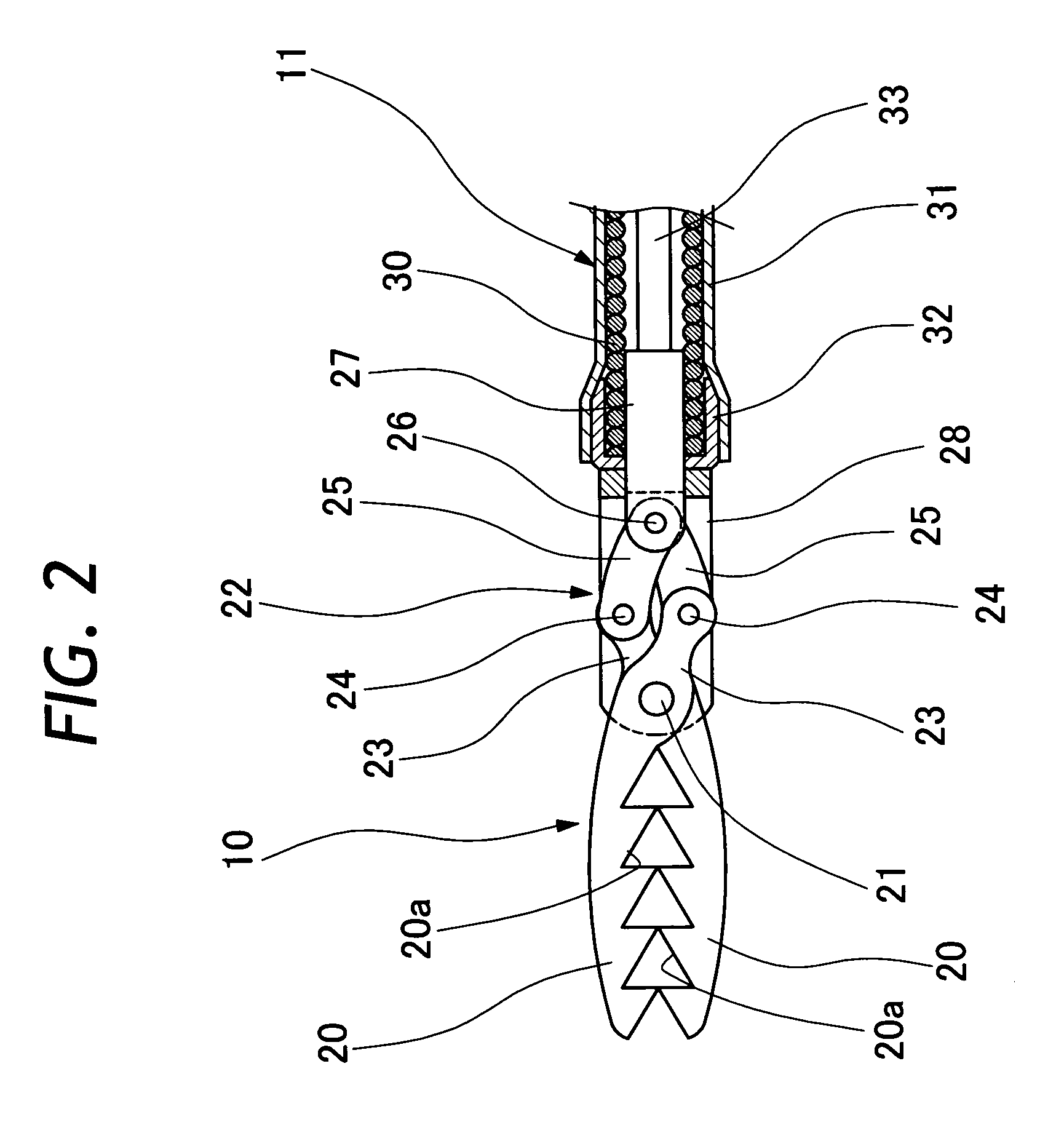

High frequency surgical instrument

InactiveUS20080294159A1Increase clamping pressureReduce widthSurgical instruments for heatingSurgical forcepsHigh frequency powerForceps

A high frequency surgical instrument having a forceps assembly at a fore distal end of an elongated insertion member, the forceps assembly being constituted by a pair of opening and closing grasper members which are shaped with a series of saw teeth on an inner meeting side in such a way that saw tooth portions on the two grasper members are at least partly brought into abutting engagement with each other when the grasper member are closed. For manipulating opening and closing actions of the grasper members, a manipulative transmission means is threaded through the insertion member, connecting the paired grasper members of the forceps to a manipulation handle which is attached to a proximal end of the insertion member. Each one of the grasper members is formed of a conducting material and arranged to have a width narrower than outside diameter of the insertion member on the saw-toothed inner side. The grasper members are electrically connectible to a high frequency power source, and are entirely covered with an insulating coat except saw tooth portions.

Owner:FUJIFILM CORP +1

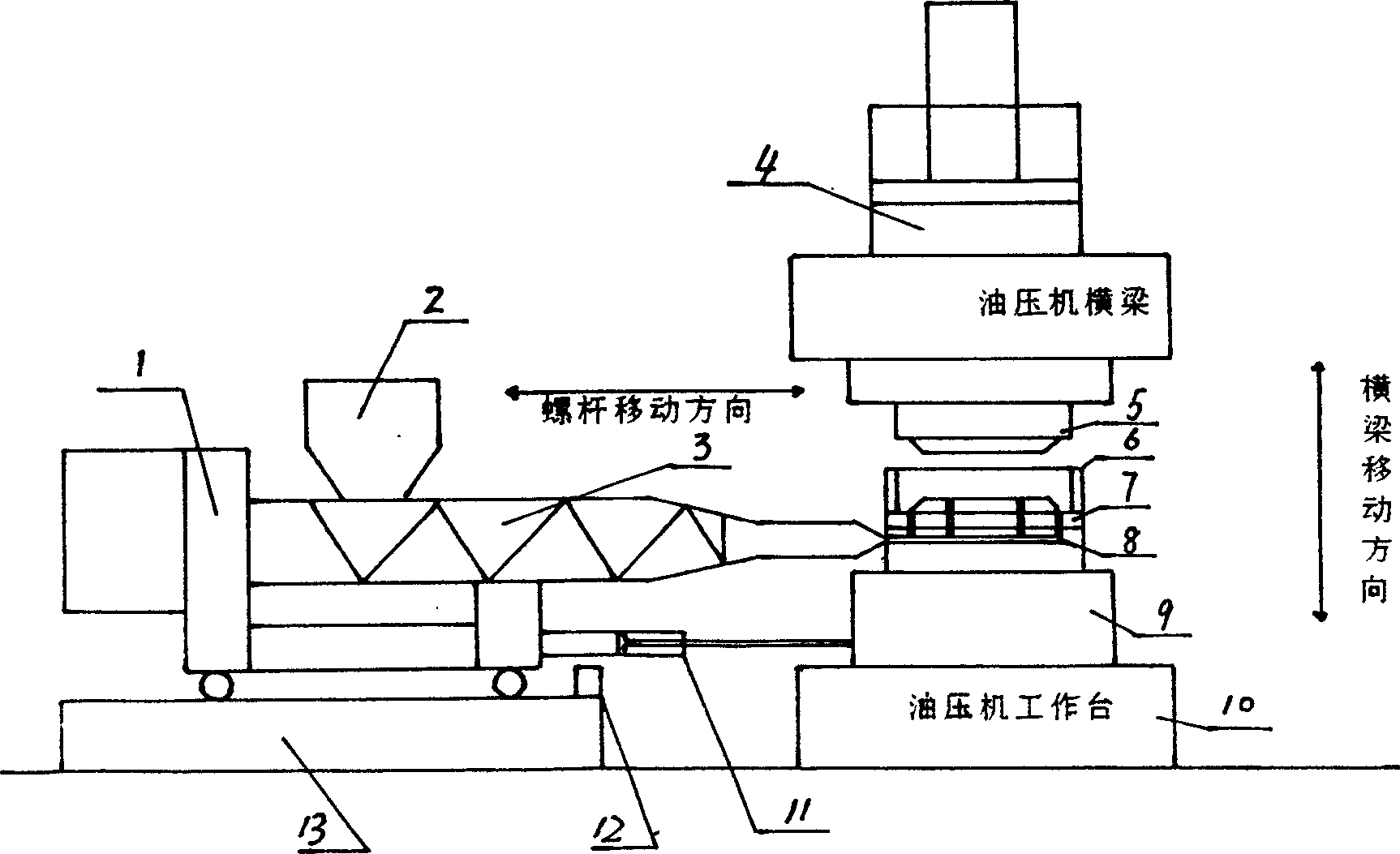

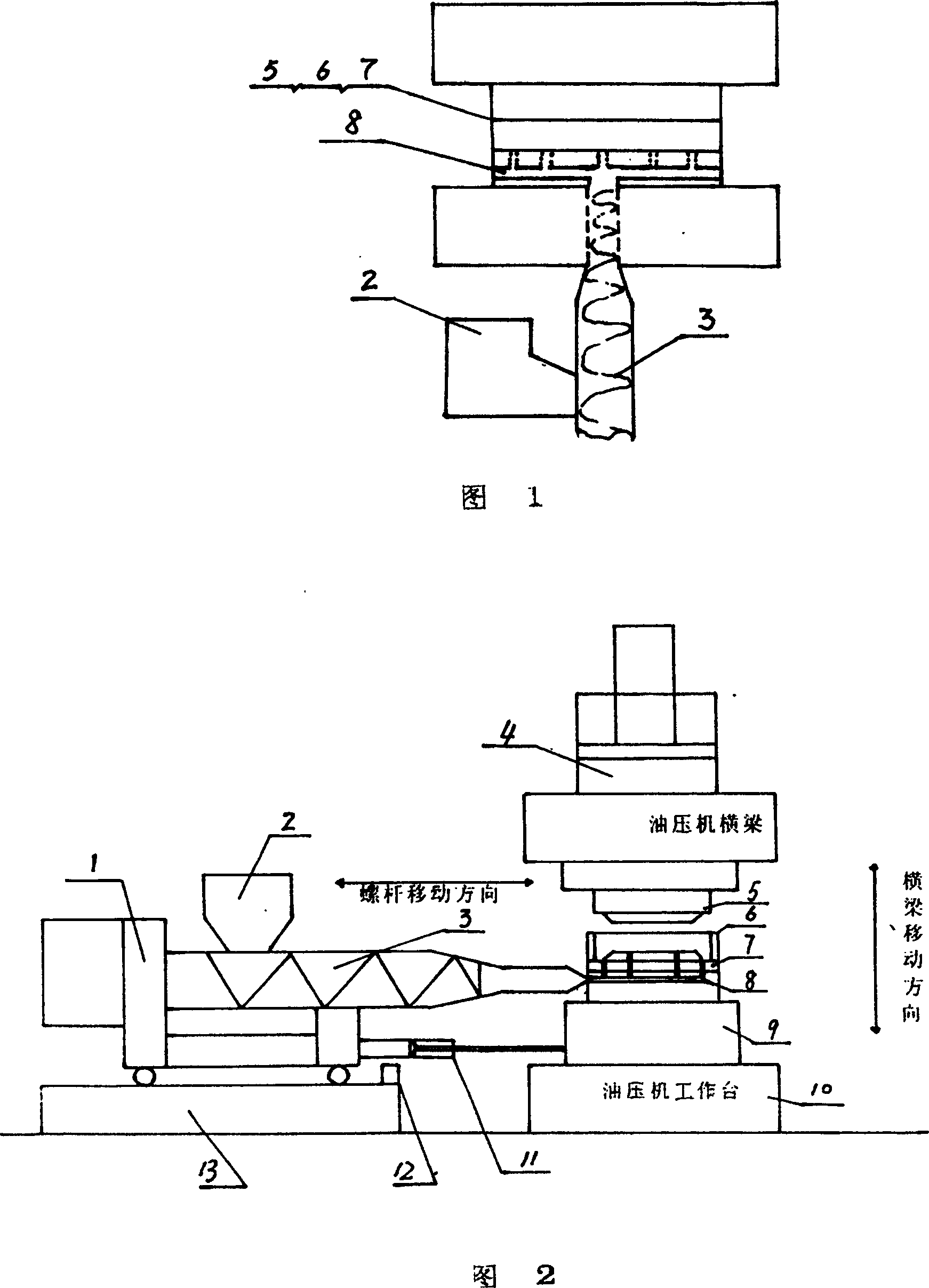

Plastic filtering board or board forming process

A process for preparing the plastic filter plate or plastic plate features that its mould is controlled by hydraulic press, its heat channel is positioned at the bottom of lower mould and communicated with said lower mould, and the plasticized plastics is injected in said mould via heat channel.

Owner:ZHEJIANG LONGYUAN ENVIRONMENTAL TECH CO LTD

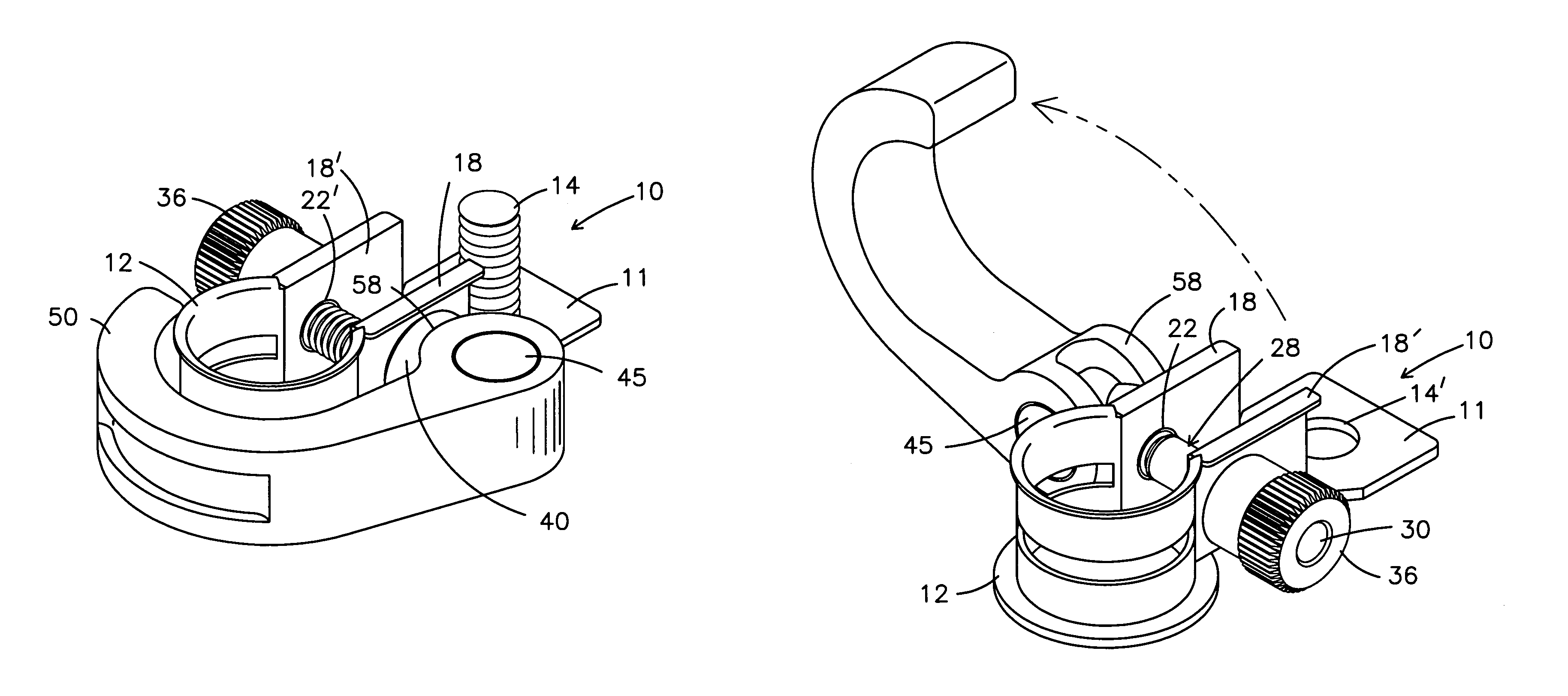

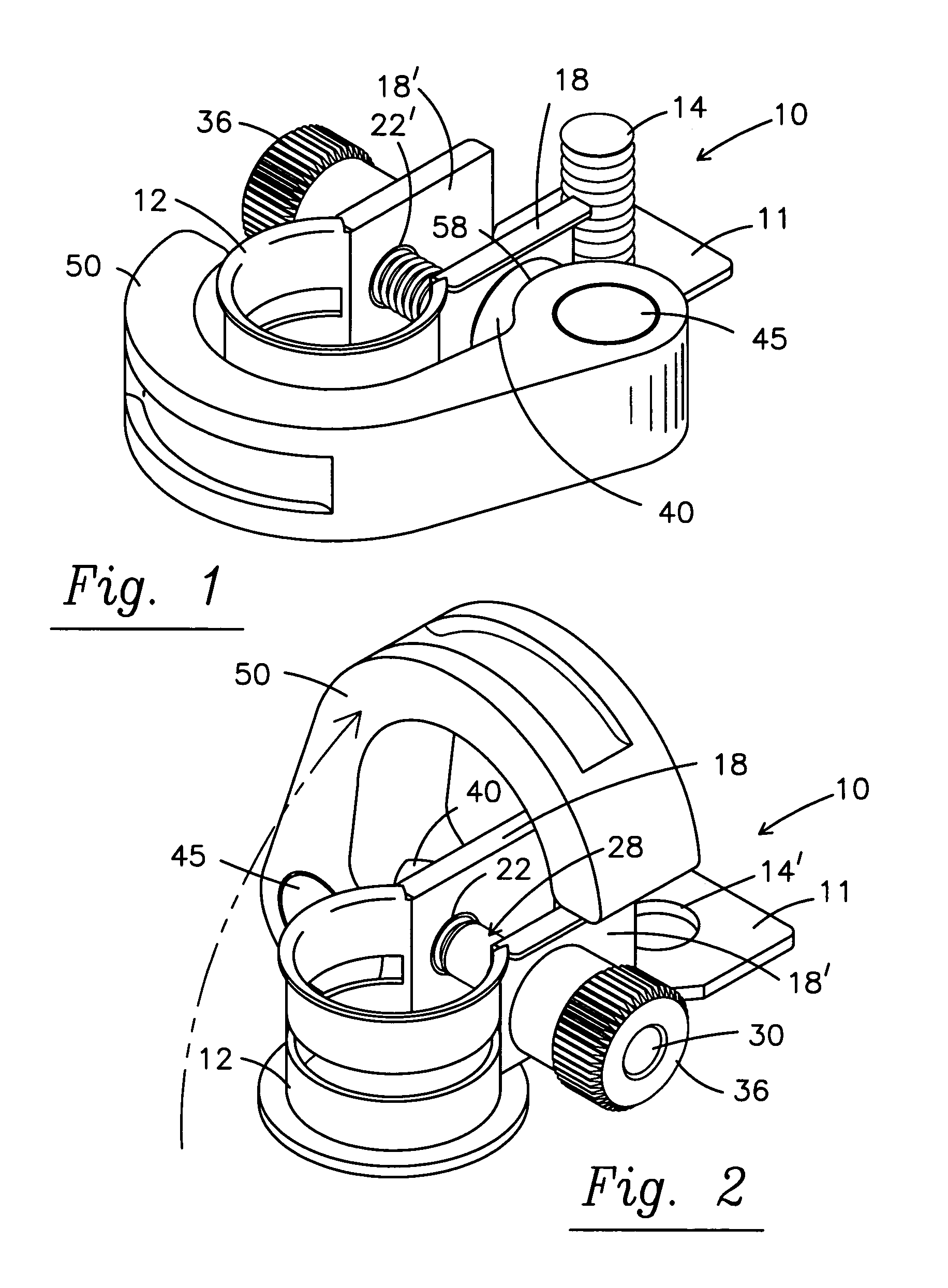

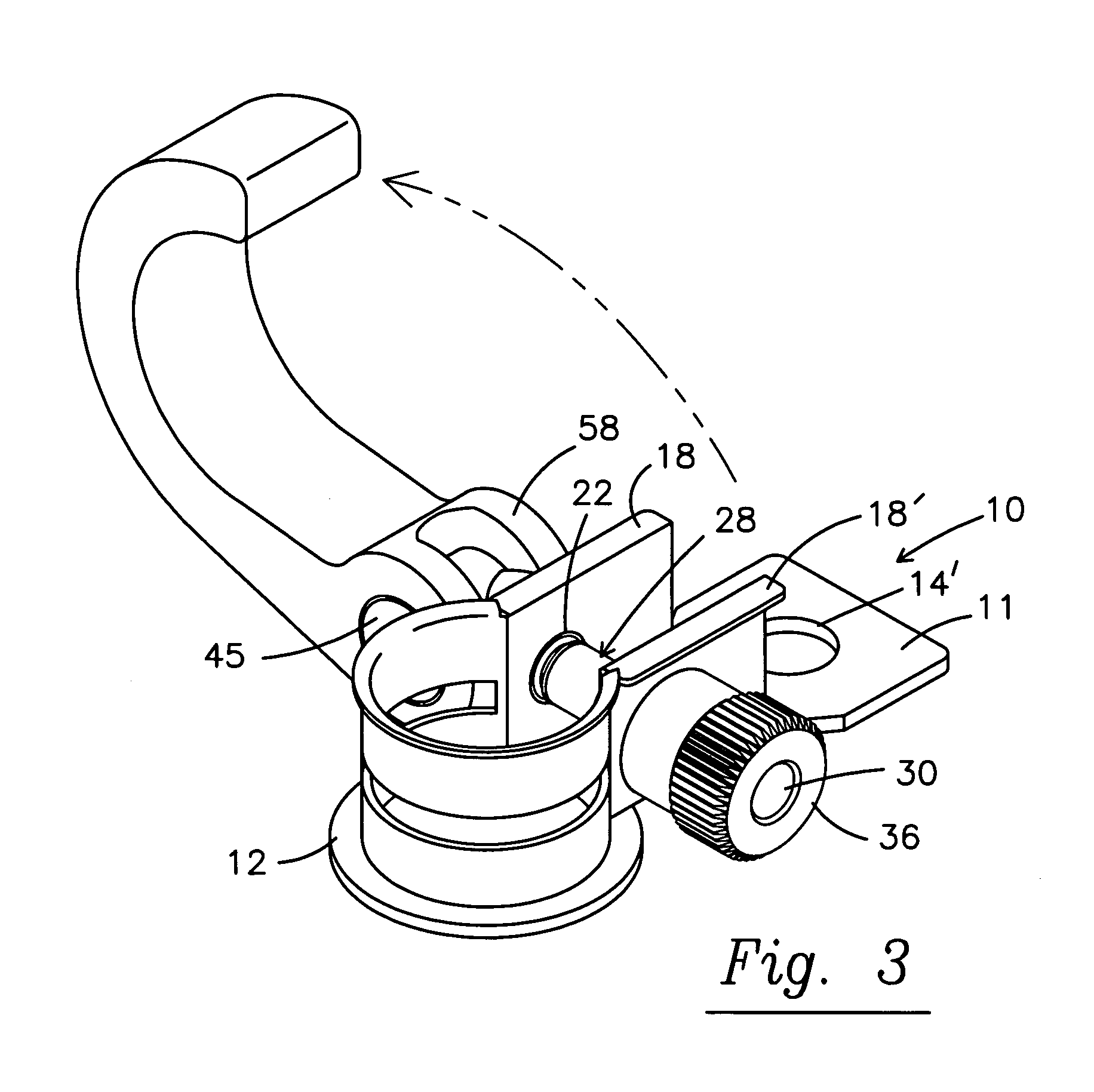

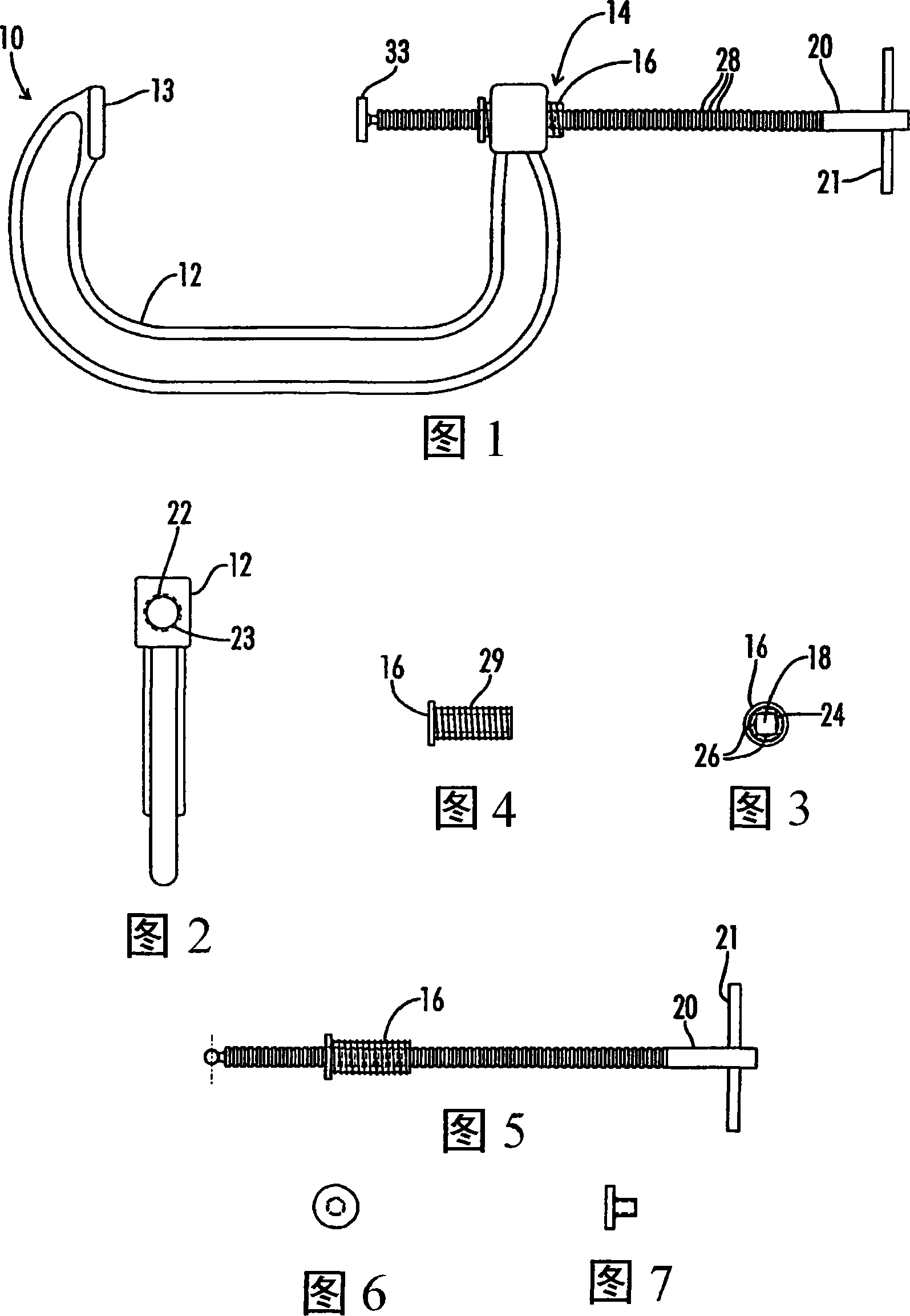

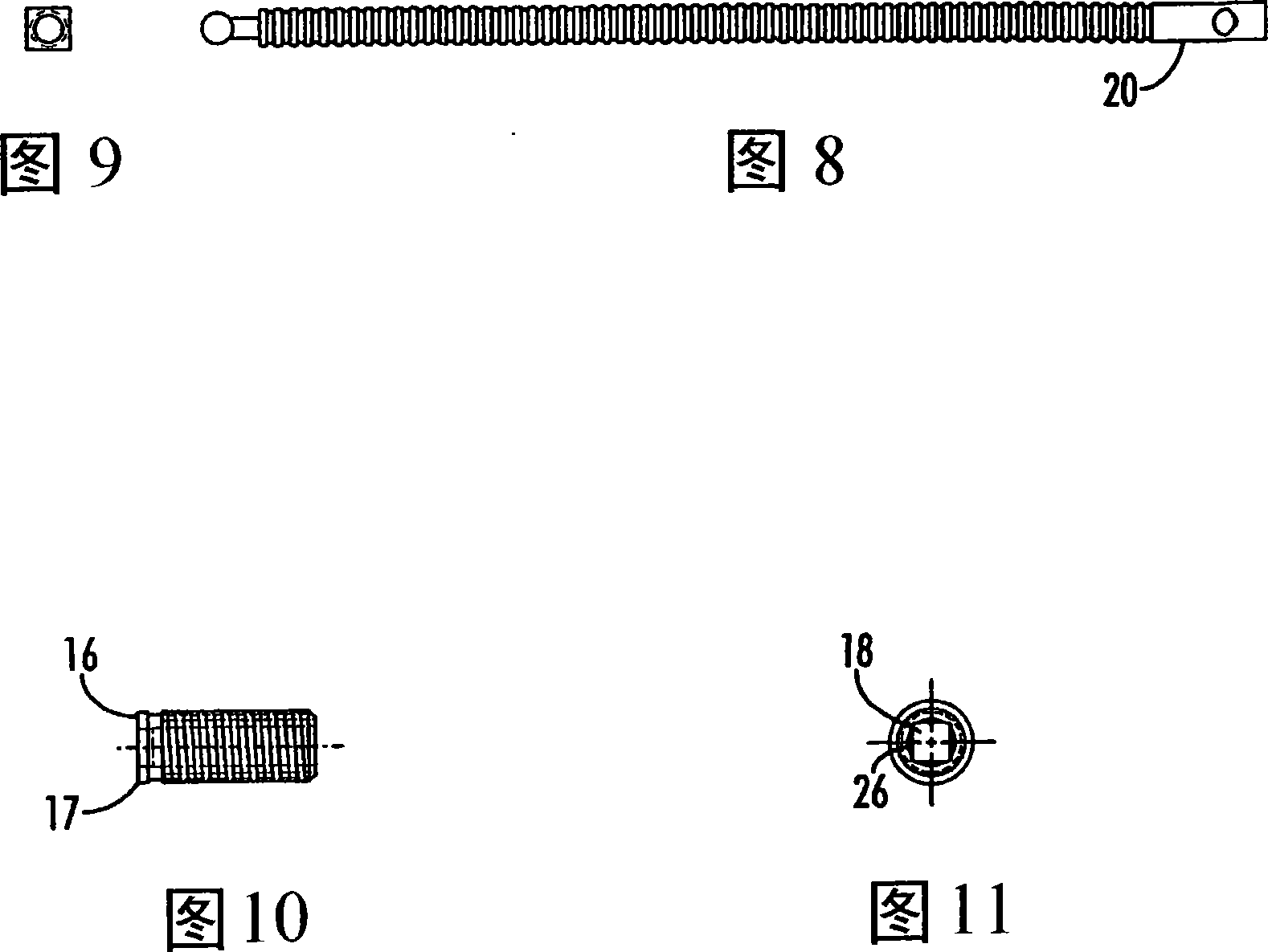

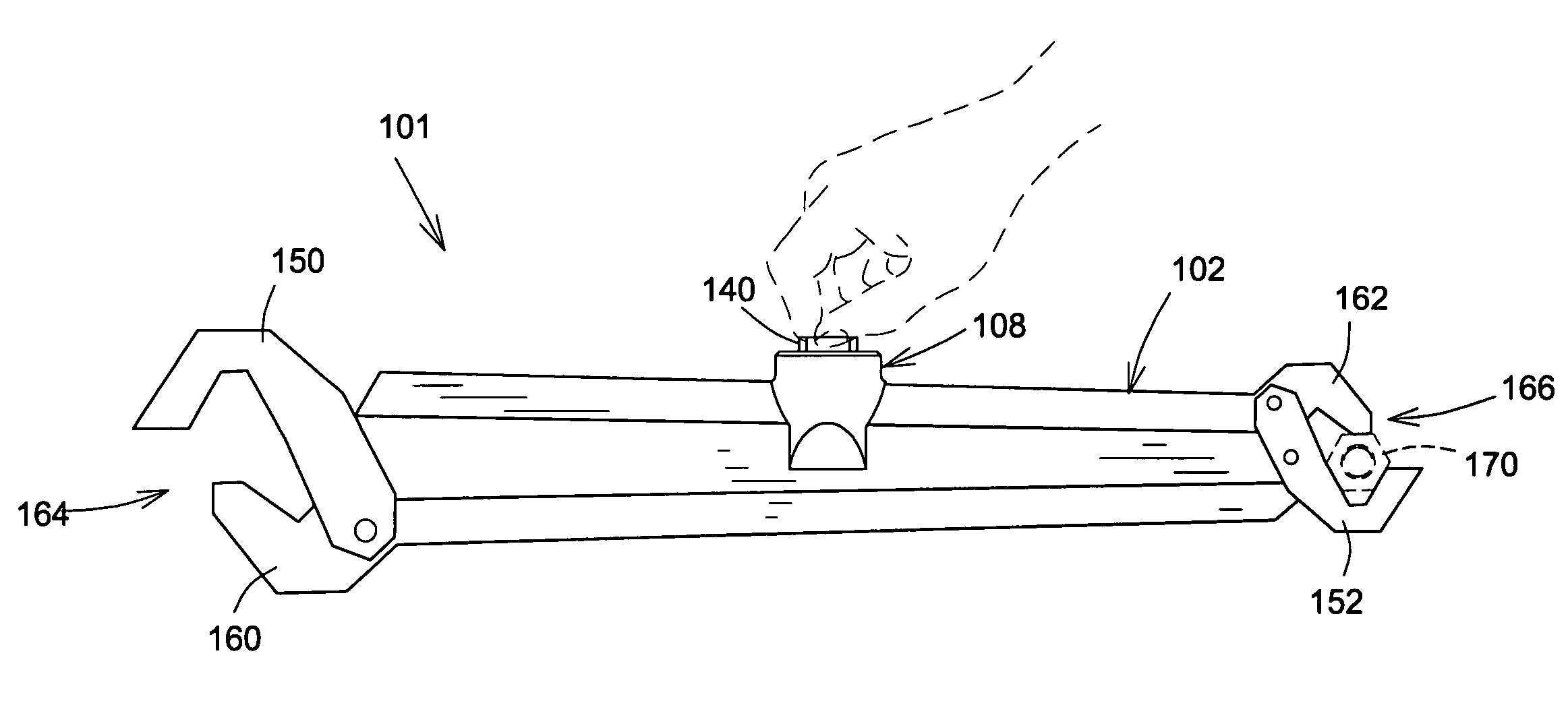

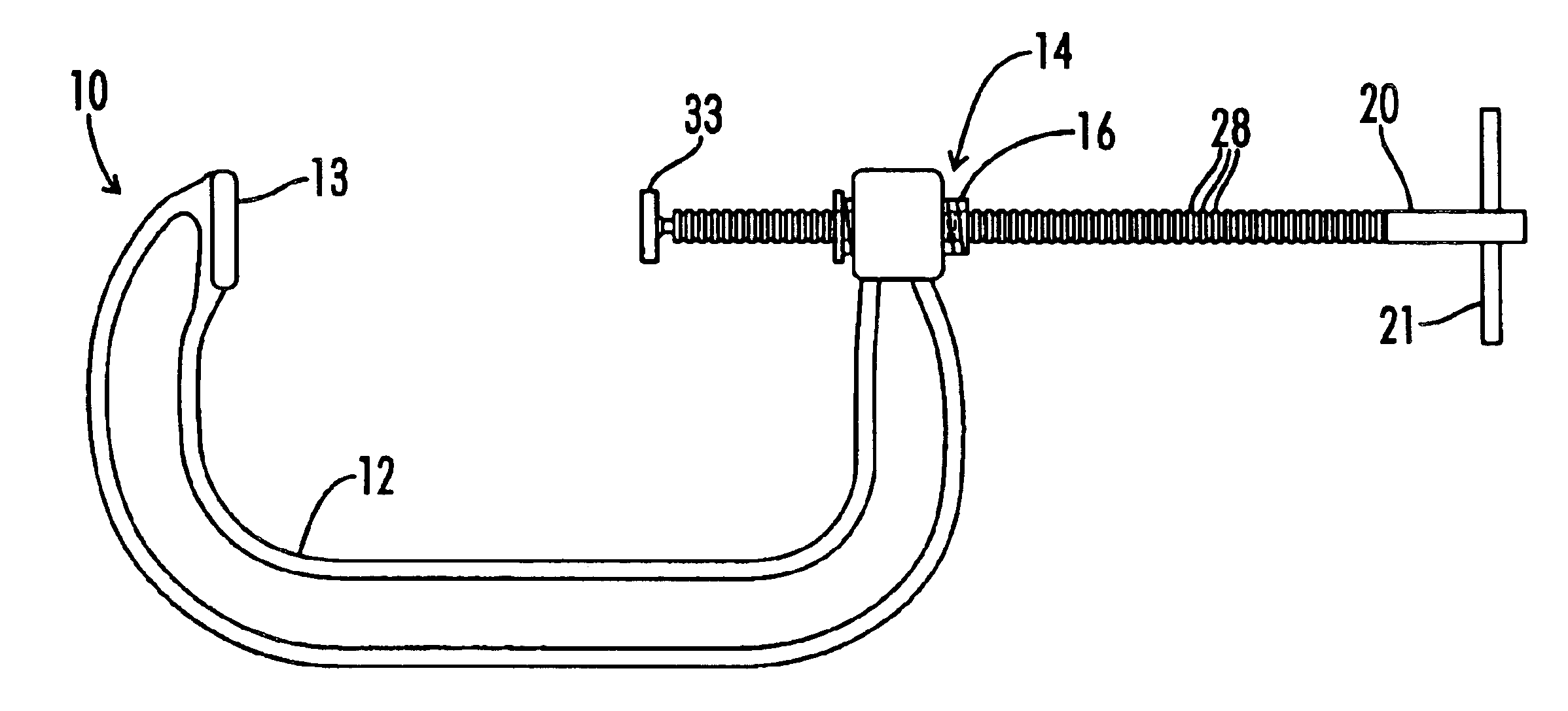

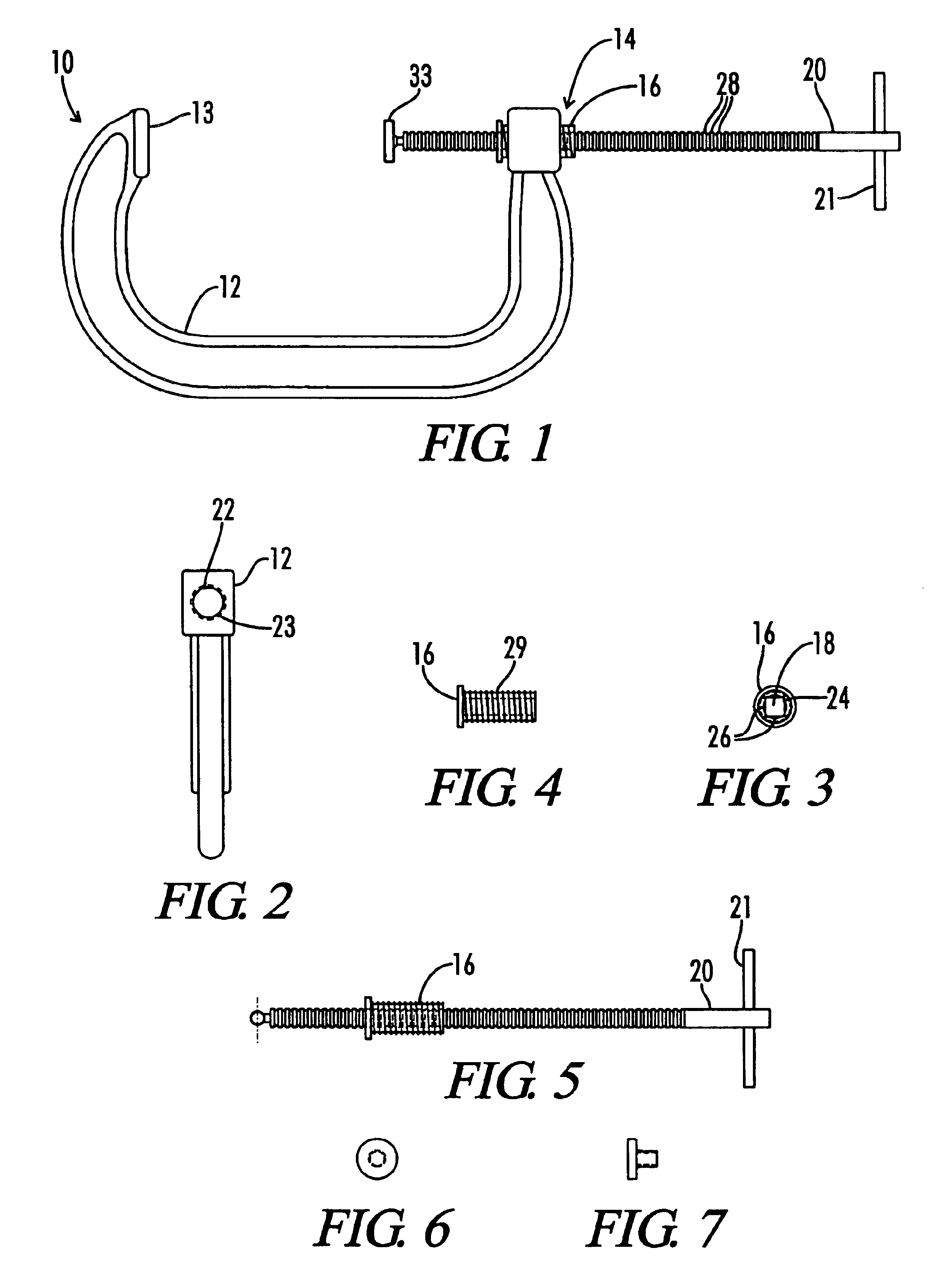

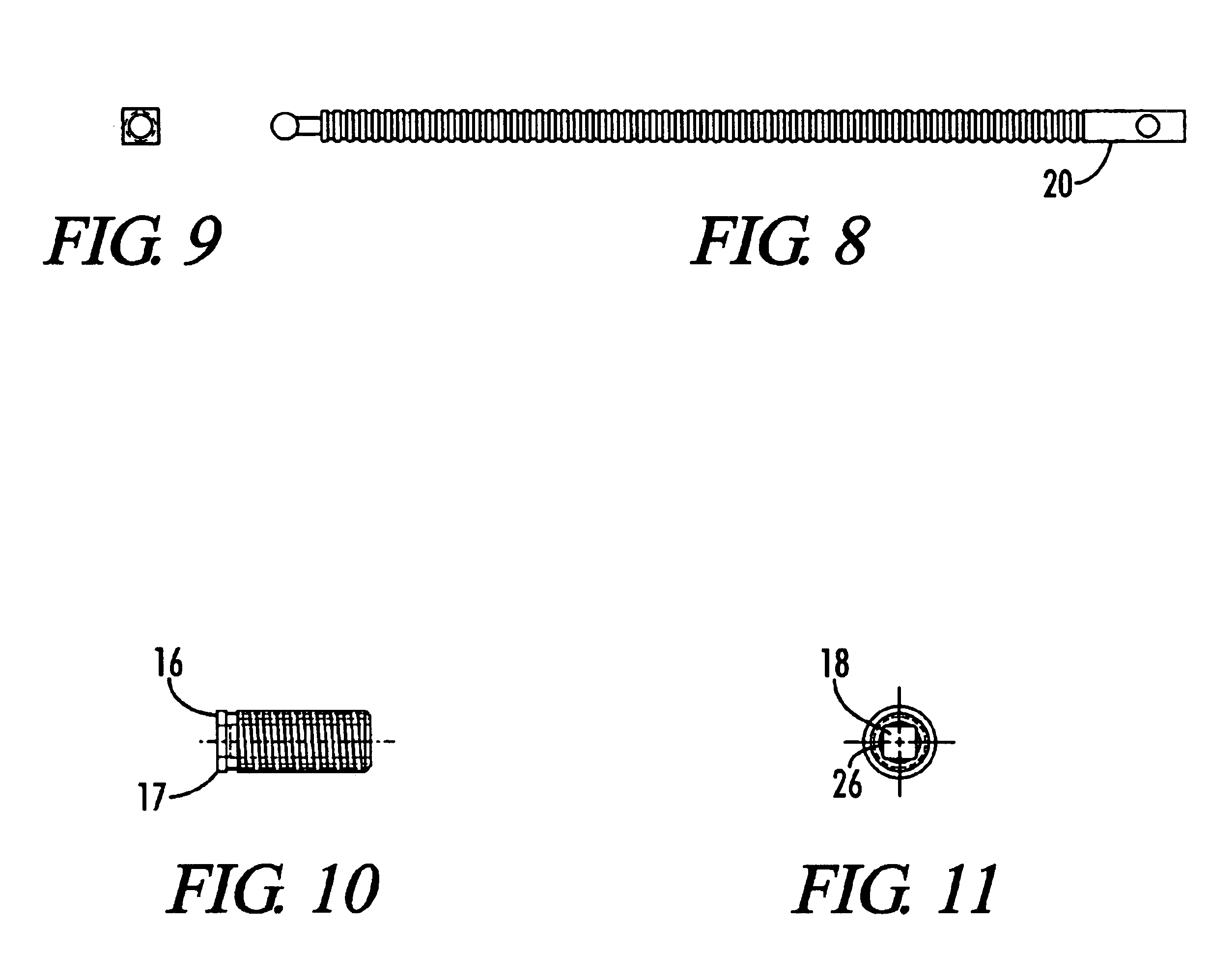

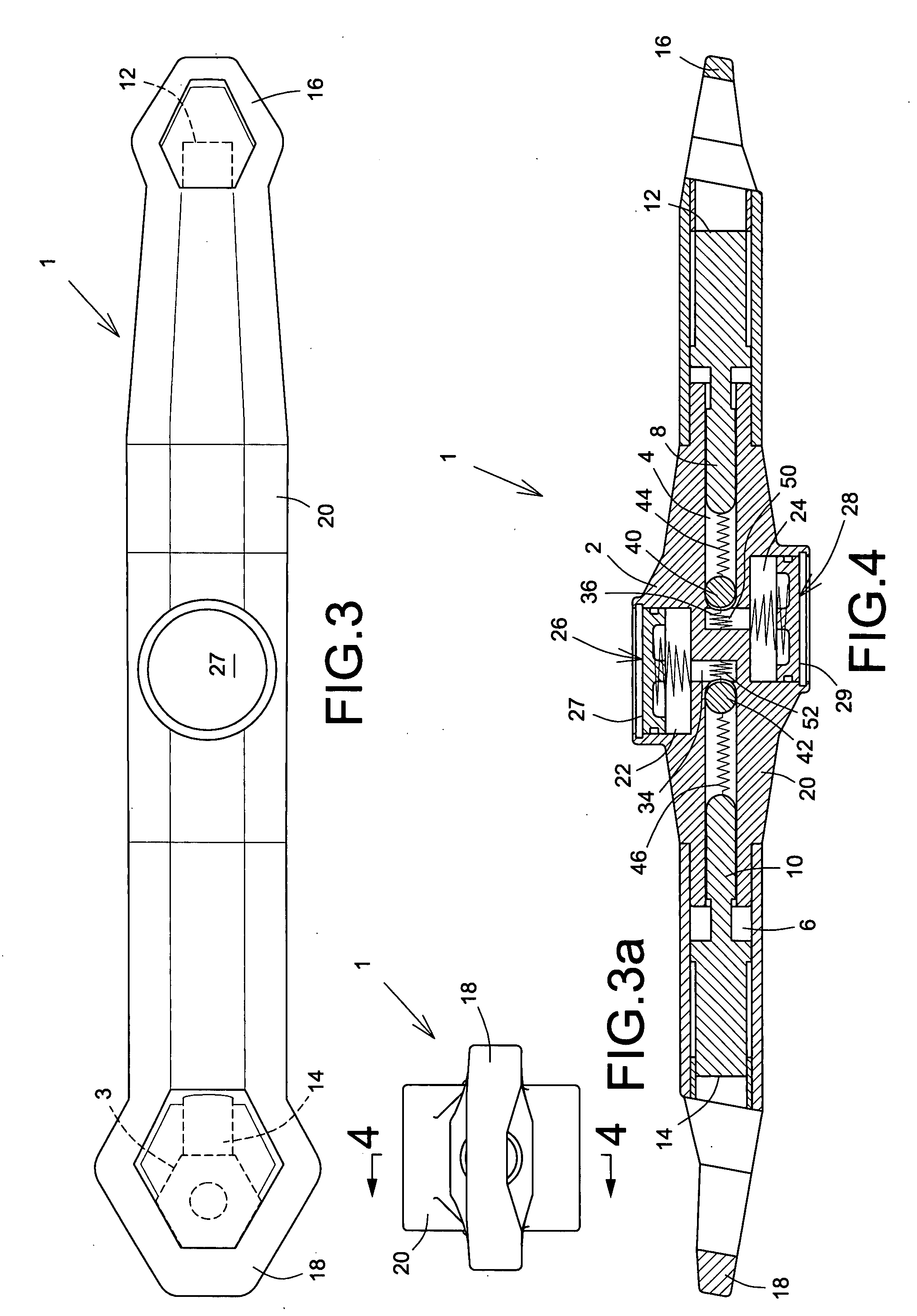

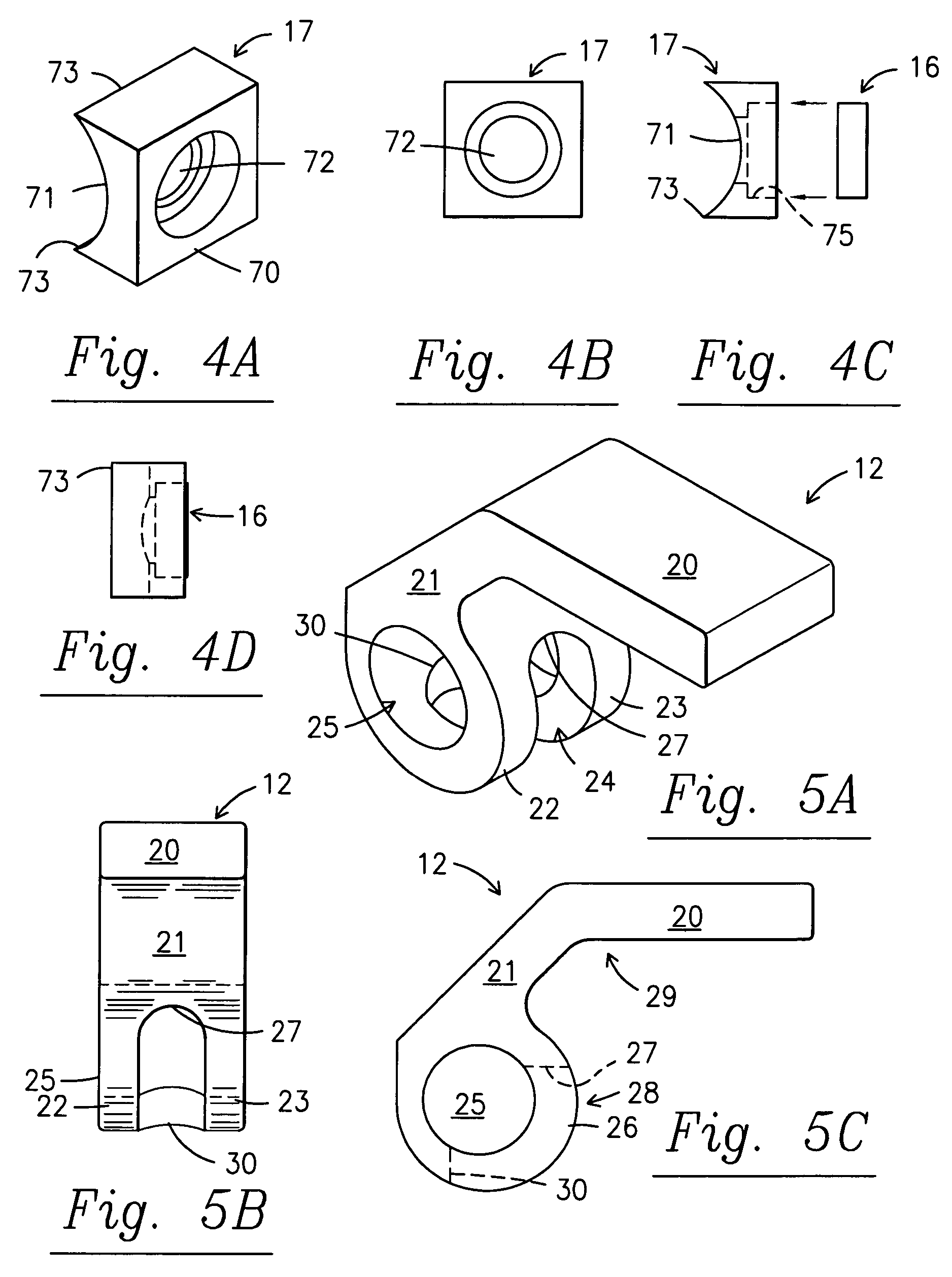

Quick action clamp and vise

A tension rod positioning apparatus and method including a shaped threaded rod (20) inserted into a shaped threaded hole (22, 56) on an engagement collar (16). When the shaped rod (20) and shaped hole (22, 56) are aligned, the rod (20) may be freely positioned within the collar (16). When the shaped rod (20) is inserted into the collar (16) and turned, the rod (20) engages and turns the engagement collar (16). The engagement collar (16) includes an external thread (29) sized to fit an internal thread (23) on a clamp base (52). The rod (20) may be inserted and then turned to both engage the engagement collar (16) and increase the clamping pressure. The shaped rod (20) may be turned in the opposite direction to loosen the clamping pressure and disengage the engagement collar (16). Once the rod (20) and collar (16) have been disengaged by aligning the shaped rod (20) and shaped hole (22, 56), the rod (20) may be freely moved within the engagement collar (16) to reposition the clamp (10) for the next operation.

Owner:THE CLAMP

Adjusting device for a hand-held tool

A hand tool device incorporates a fluid operated mechanism actuable by a plunger pressurizing a reservoir to force fluid past a resiliently biased valve to a fluid filled cylinder accommodating a piston carrying a contact member for clamping a work piece in the manner of an adjustable wrench or pliers. Continued operation of the plunger increases the pressure applied to the work piece.

Owner:FRANCIS INT

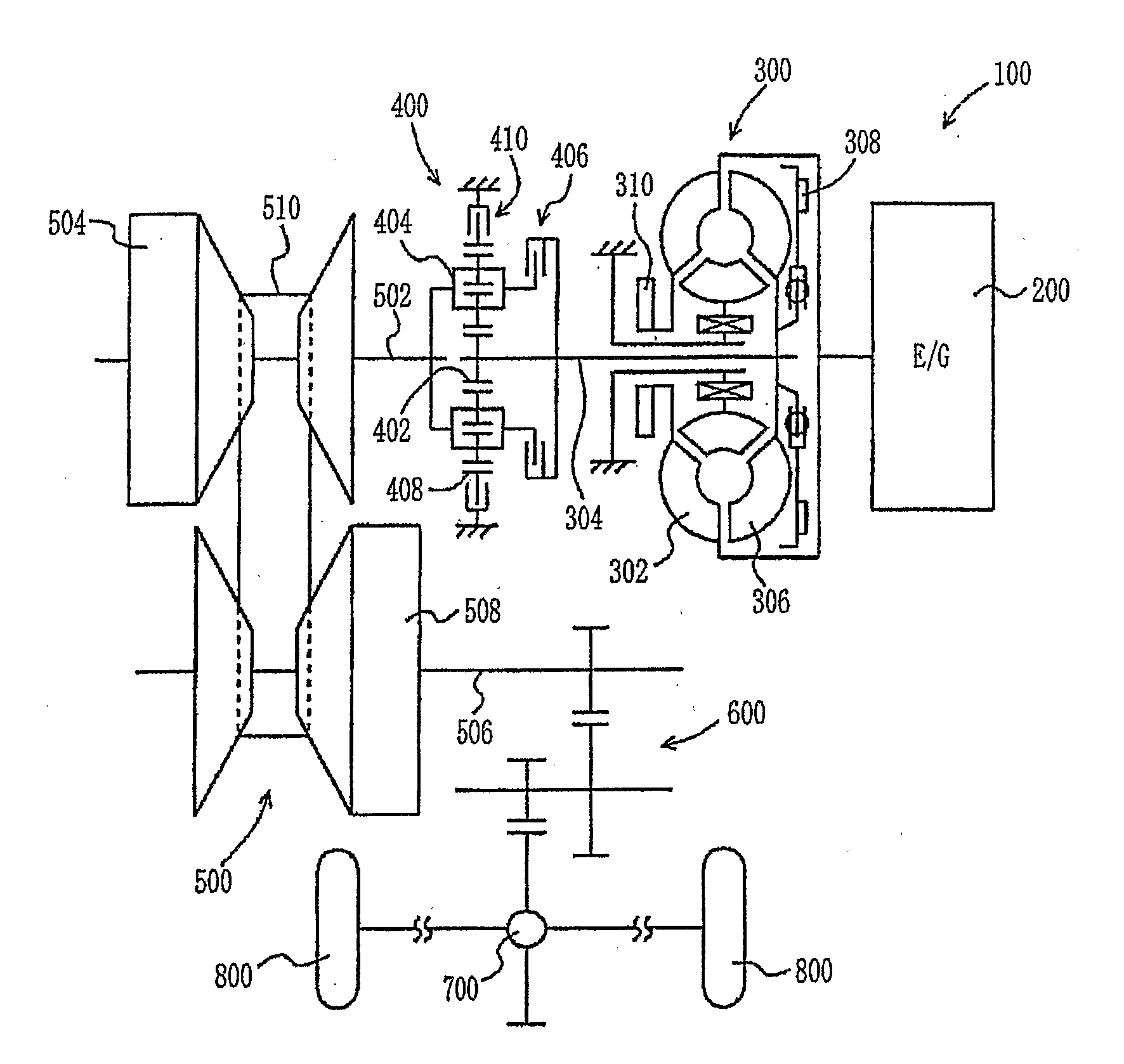

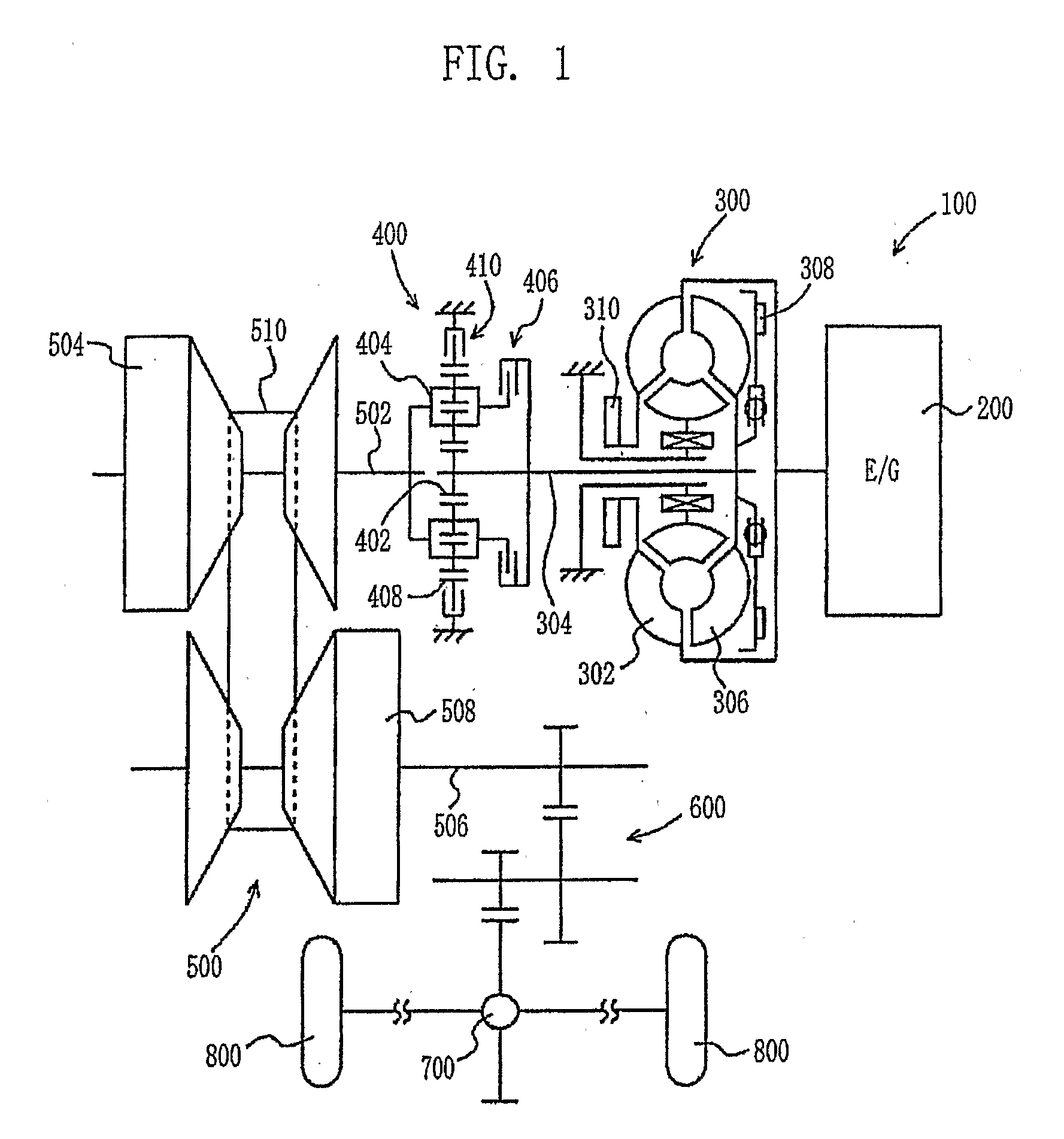

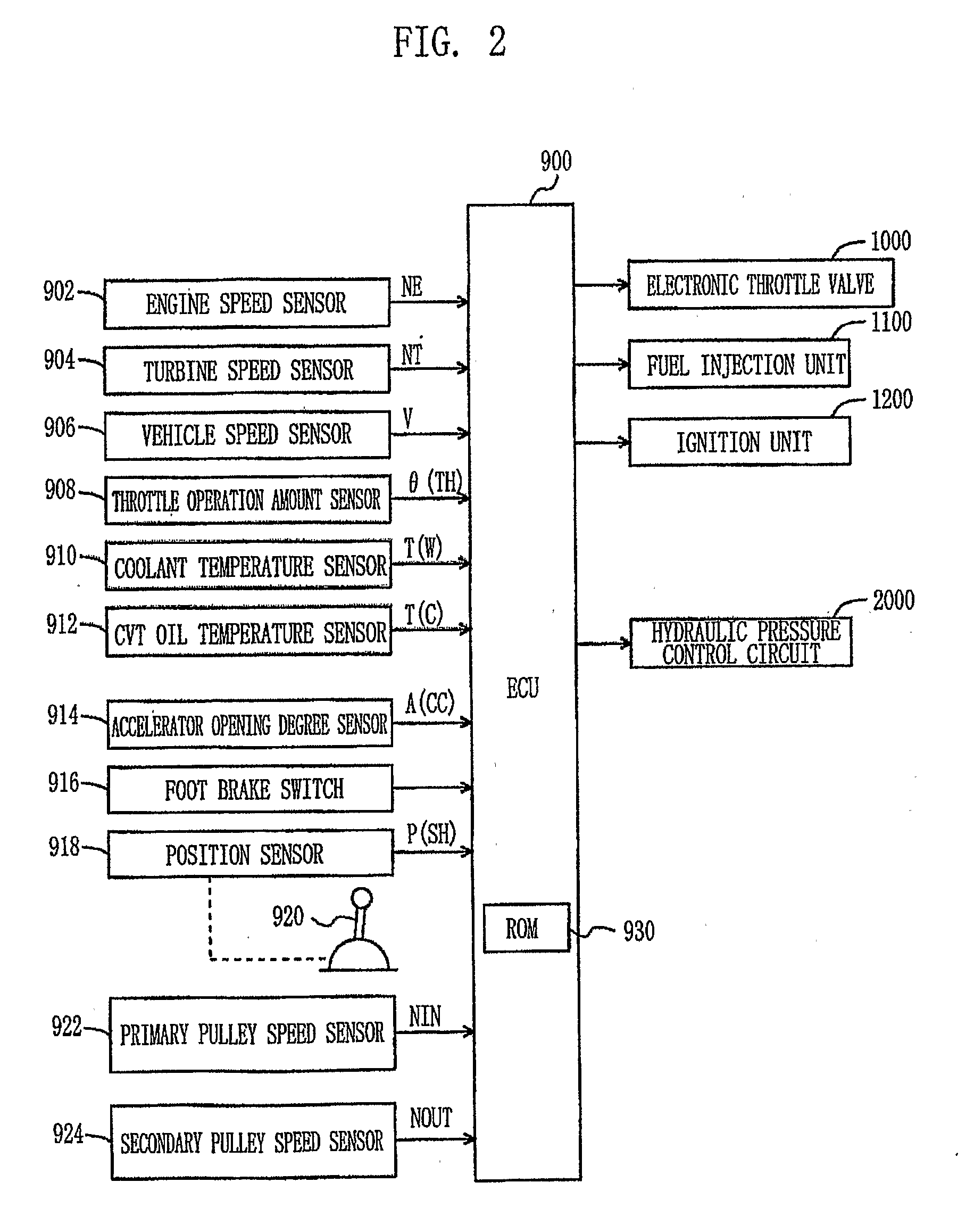

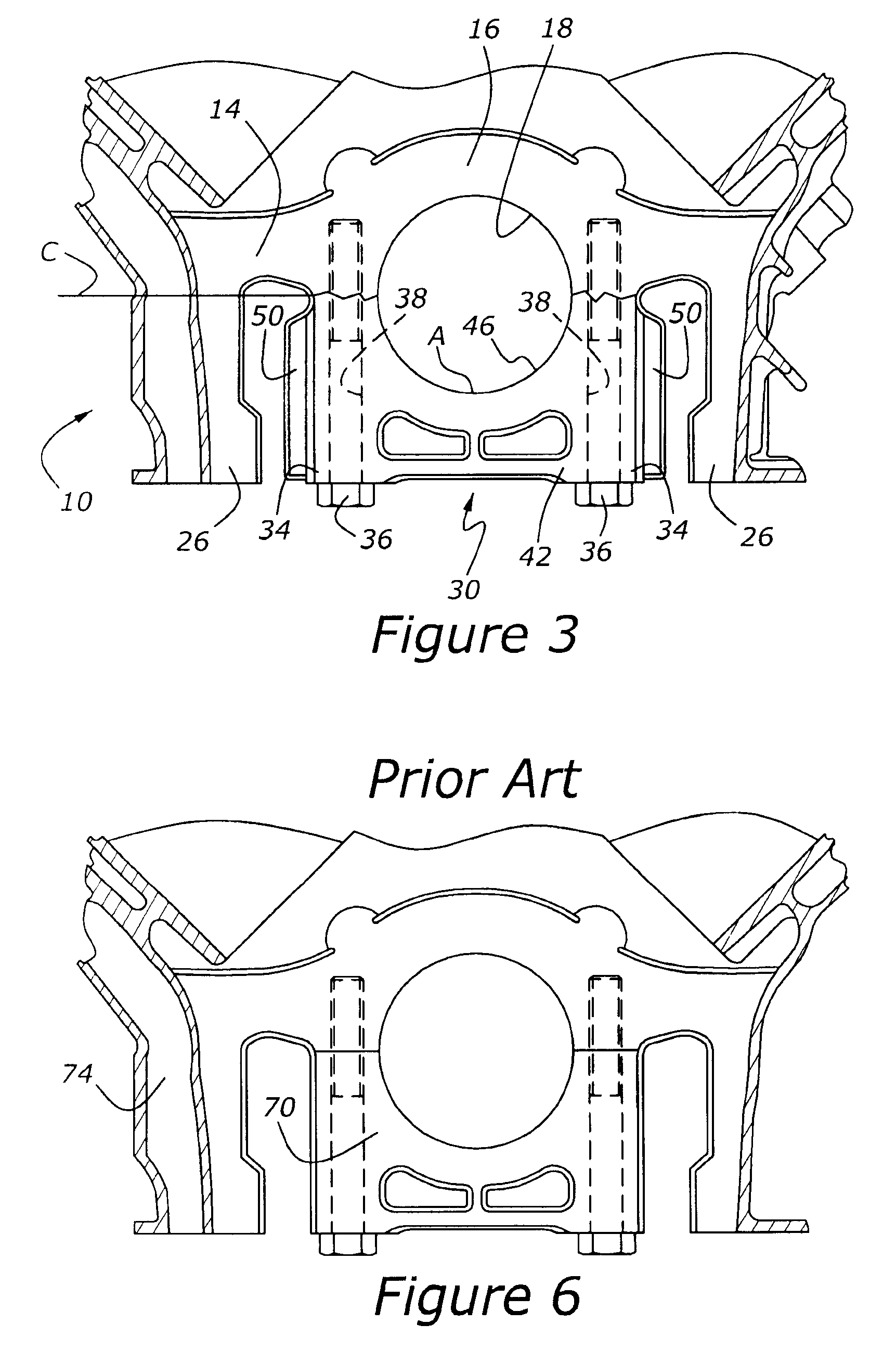

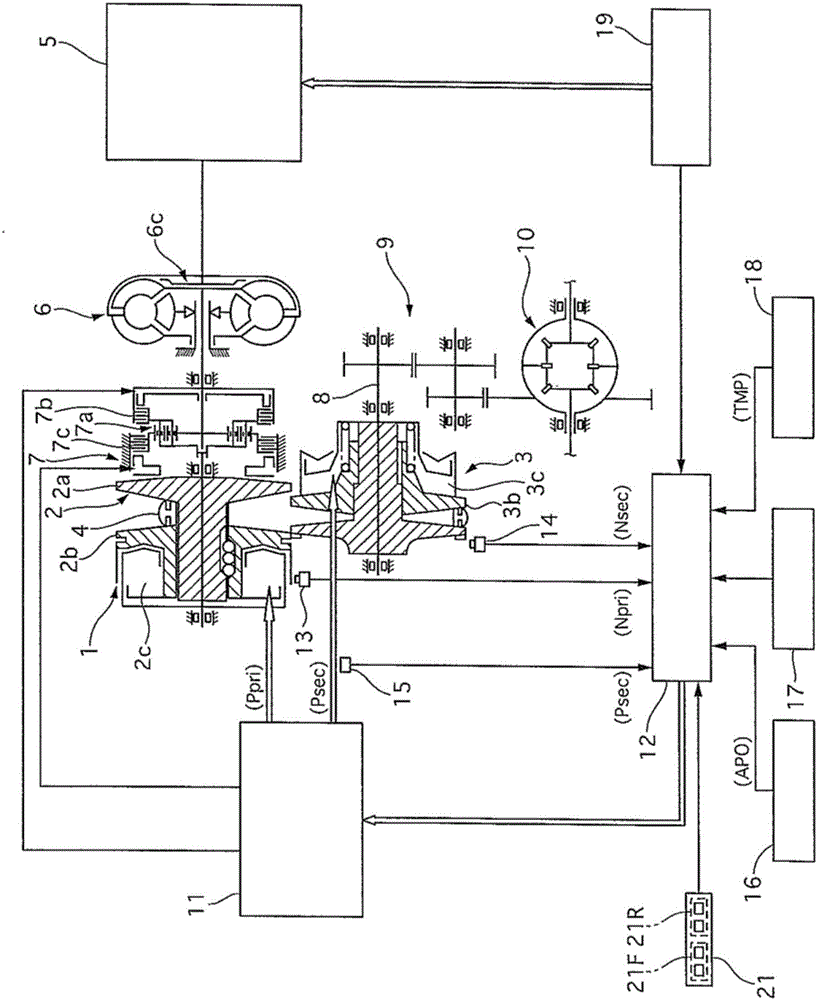

Apparatus and method for controlling continuously variable transmission and program for performing the control method

ActiveUS20090176618A1Increase in clamping pressure of prohibitedIncrease clamping pressureDigital data processing detailsGearingExecution controlVariator

An apparatus and method for controlling a CVT (continuously variable transmission), and a program for executing the control method that reduces a transmission shock during a braking operation. When a foot brake switch is turned on and a vehicle speed is less than or equal to a threshold speed, the ECU increases a clamping pressure applied to a transmission belt to a pressure level higher than a normal pressure. When the vehicle speed falls to or below the threshold speed when the foot brake switch is turned on, the ECU prohibits an increase in the clamping pressure applied to the transmission belt.

Owner:TOYOTA JIDOSHA KK

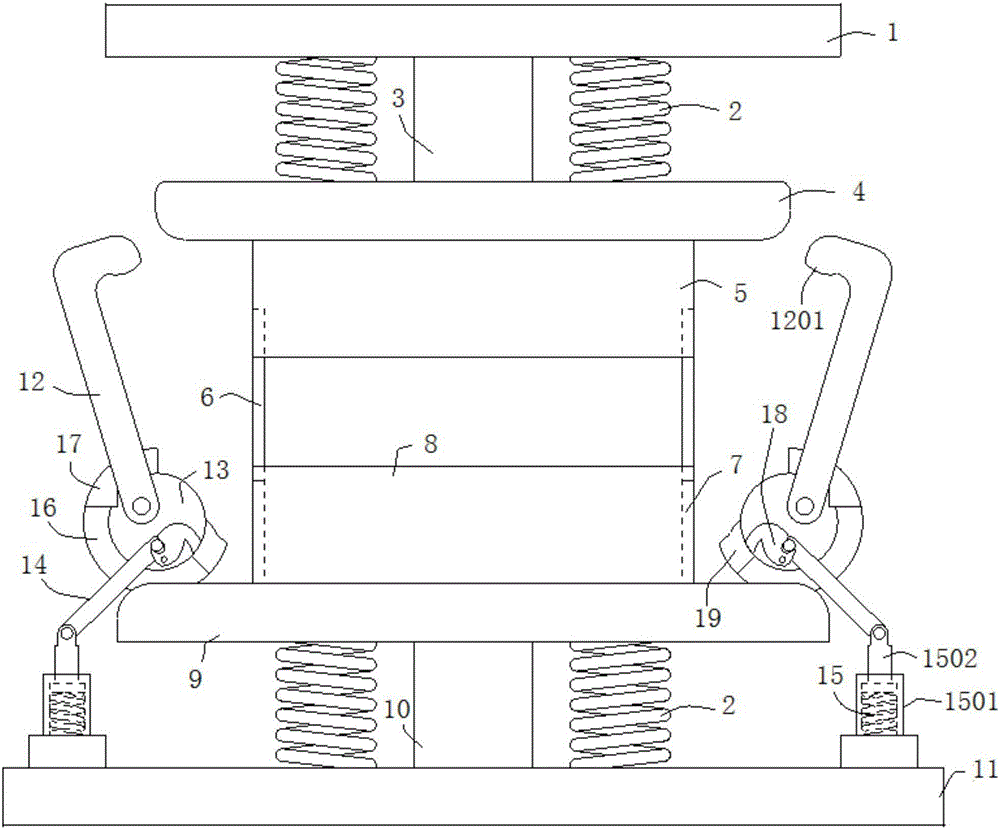

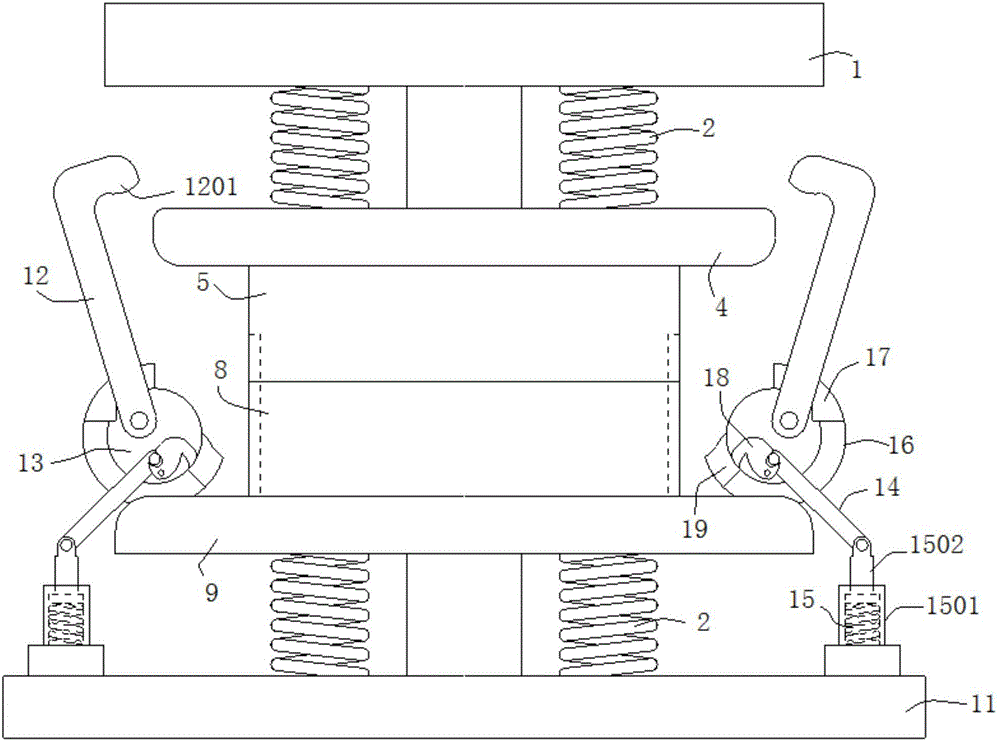

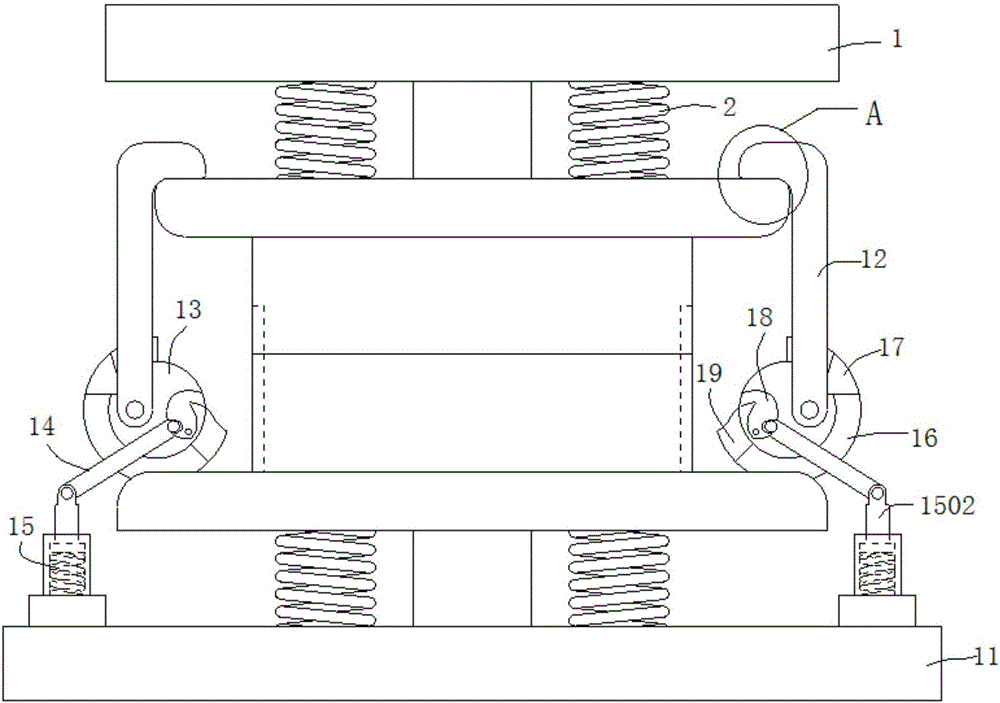

Automatic closed forging forming die

ActiveCN106623722APrevent savingImprove processing pass rateForging/hammering/pressing machinesAutomatic controlEngineering

The invention discloses an automatic closed forging forming die, and belongs to the technical field of metal press machining. The die comprises a rigid die base, a floating female die, and automatic die locking devices symmetrically arranged on the two sides of a lower female die base. The two sides of the upper end face of an upper female die base are symmetrically provided with clamping grooves. Each automatic die locking device comprises a swinging lock rod and a power mechanism driving the swinging lock rod to swing. Lock heads clamped to the clamping grooves in a matched mode are arranged on the tops of the swinging lock rods. During combination of an upper female die and a lower female die, the power mechanisms drive the swinging lock rods to swing in the direction close to the upper female die till the lock heads make contact with the clamping grooves to be clamped; During opening of the upper female die and the lower female die, the power mechanisms drive the swinging lock rods to swing in the direction away from the upper female die till the lock heads get away from the clamping grooves to be reset. The die clamping pressure can be increased, and automatic control over locking and unlocking of the upper and lower female dies of a die locking device is achieved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Oil well polish rod clamp for use with a rotator on a beam pumping unit

InactiveUS20090065190A1Increases longitudinalIncreases axial gripping capacityDrilling rodsFluid removalEngineeringMechanical engineering

Owner:ROBBINS & MYERS ENERGY SYST

Quick position clamp and vise

A tension rod positioning apparatus and method for C-type clamps and Vises including a shaped threaded rod inserted into a shaped threaded hole on an engagement collar. When the shaped rod and shaped hole are aligned, the rod may be freely positioned within the collar. When the shaped rod is inserted into the collar and turned, the rod engages and turns the engagement collar. The engagement collar includes an external thread sized to fit an internal thread on a clamp base. In this manner, the rod may be inserted and then turned in one direction to both engage the engagement collar and increase the clamping pressure. After clamping, the shaped rod may be turned in the opposite direction to loosen the clamping pressure and disengage the engagement collar. Once the rod and collar have been disengaged by aligning the shaped rod and shaped hole of the engagement collar, the length of the rod may be freely moved within the engagement collar to reposition the clamp for the next operation.

Owner:THE CLAMP

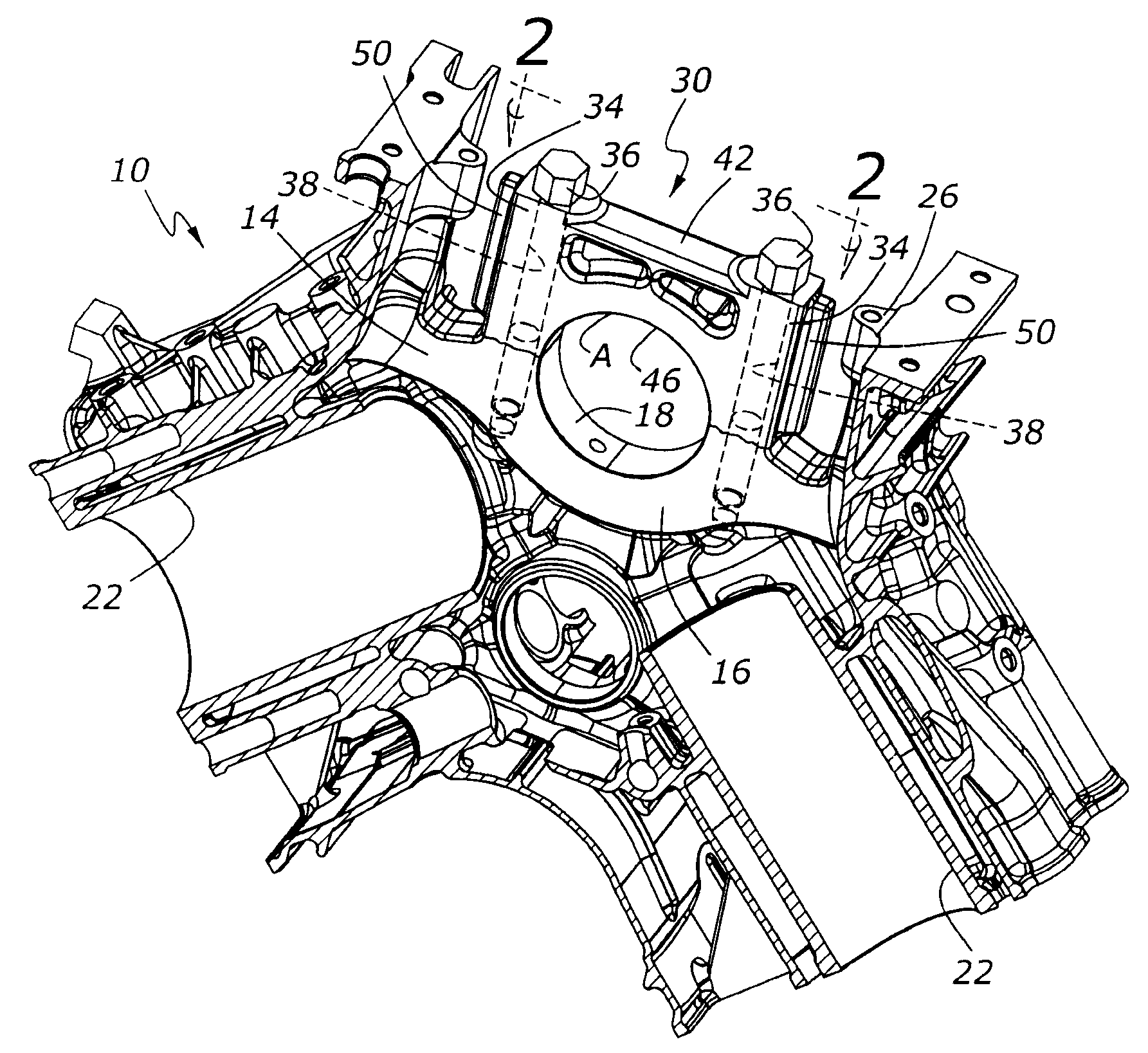

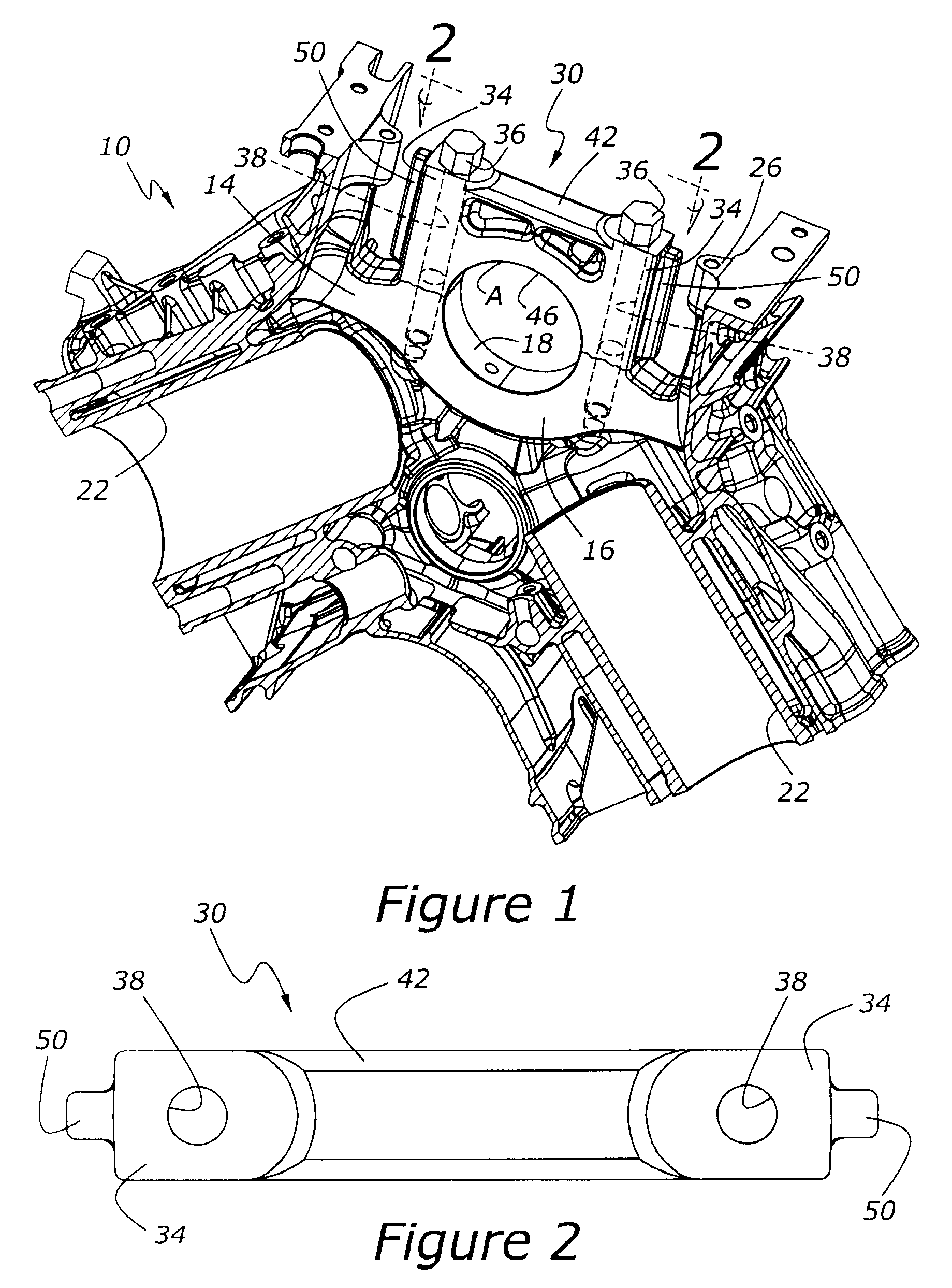

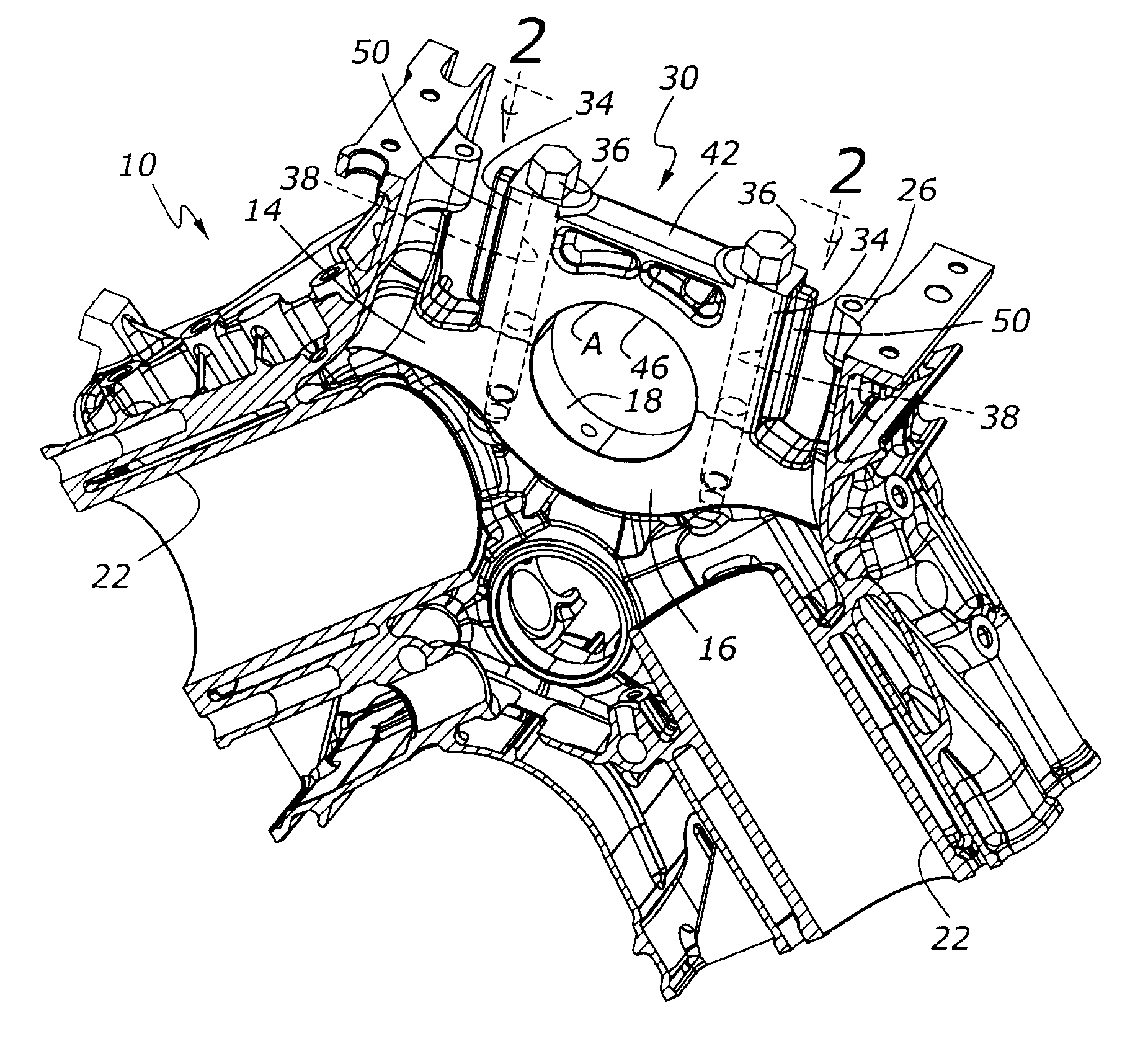

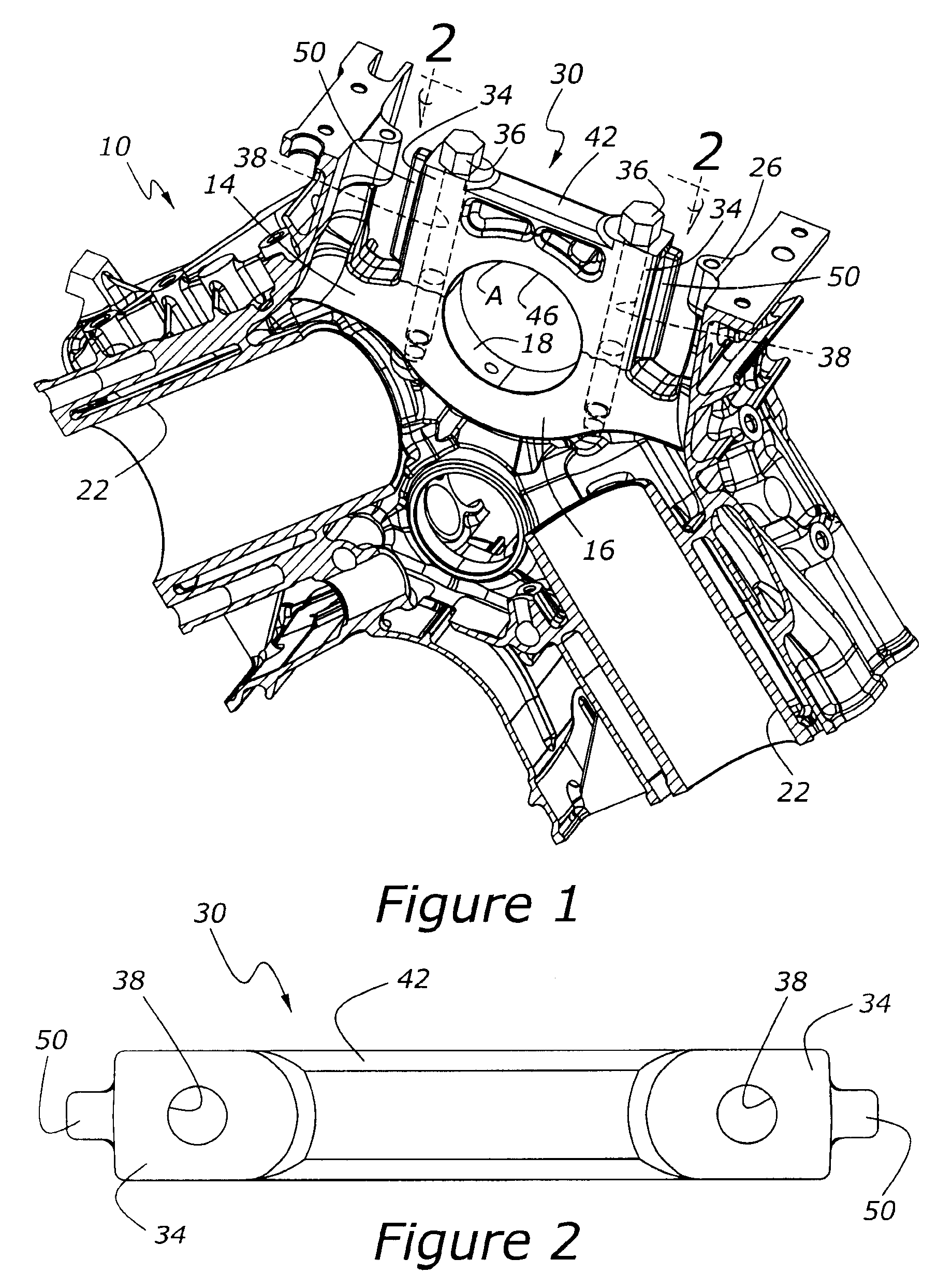

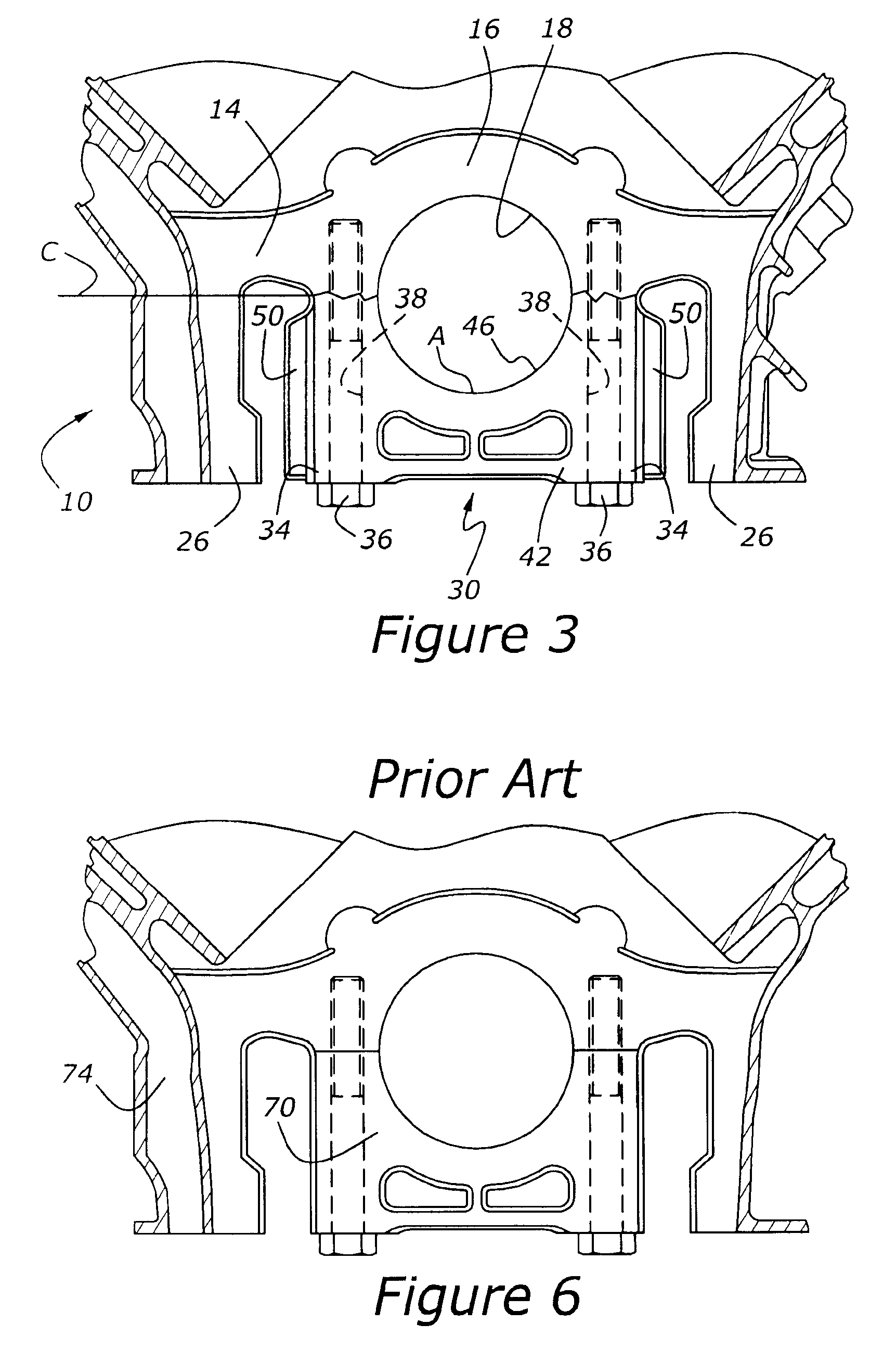

Automotive engine bearing

A bearing for an automotive engine includes a base having a first bearing segment formed therein, and a bearing cap removably mounted to the base, with the bearing cap including fastener towers in contact with the base. A second bearing segment extends between the fastener towers. A number of non-contact stiffening ribs extend parallel to the fastener towers. The stiffening ribs are attached to outboard portions of the fastener towers. The stiffening ribs cause the bearing cap to avoid excessive flexing and distortion, while at the same time avoiding fretting corrosion which would occur were the clamp loads of the cap to the base be reduced by materially increasing the size of the fastener towers.

Owner:FORD GLOBAL TECH LLC

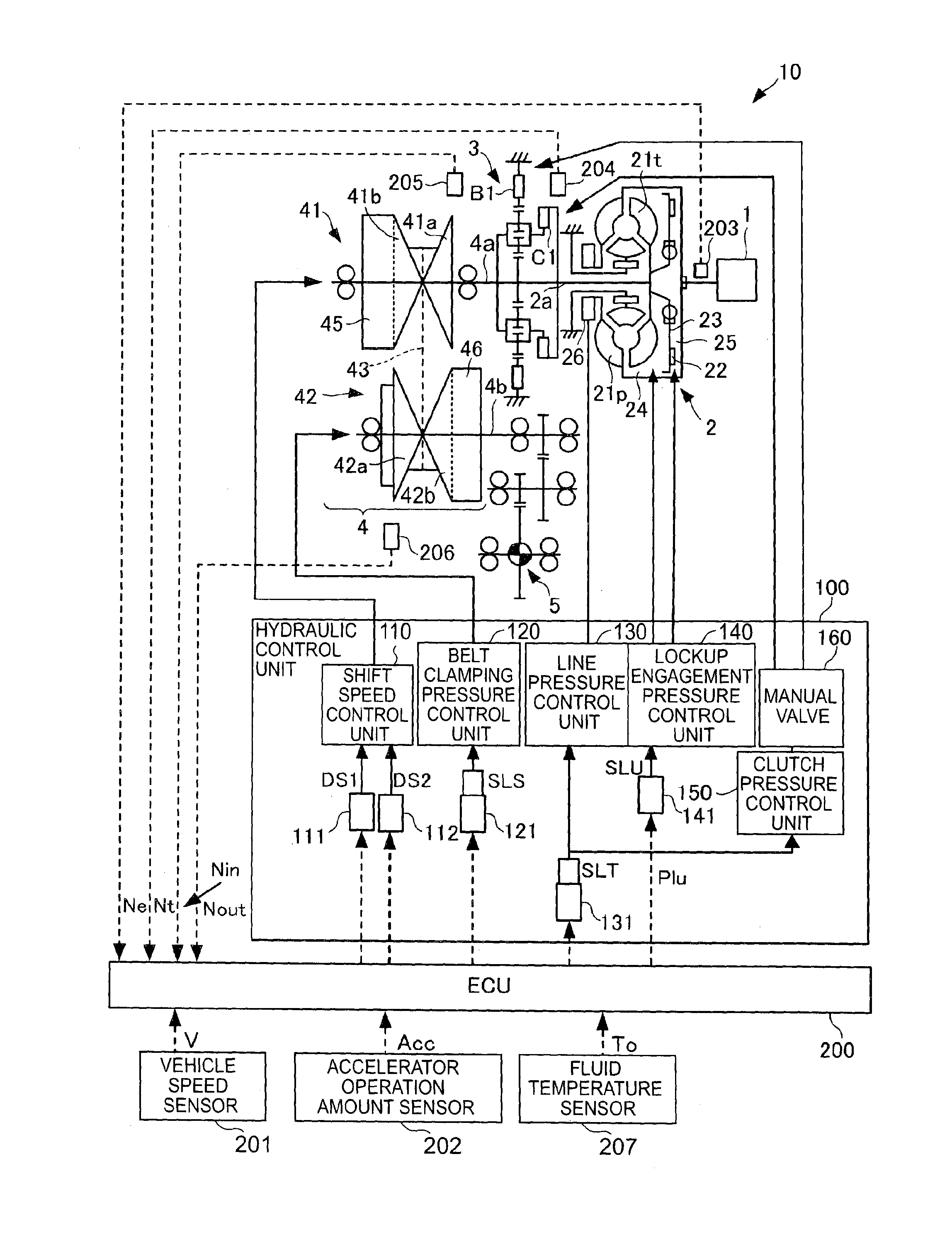

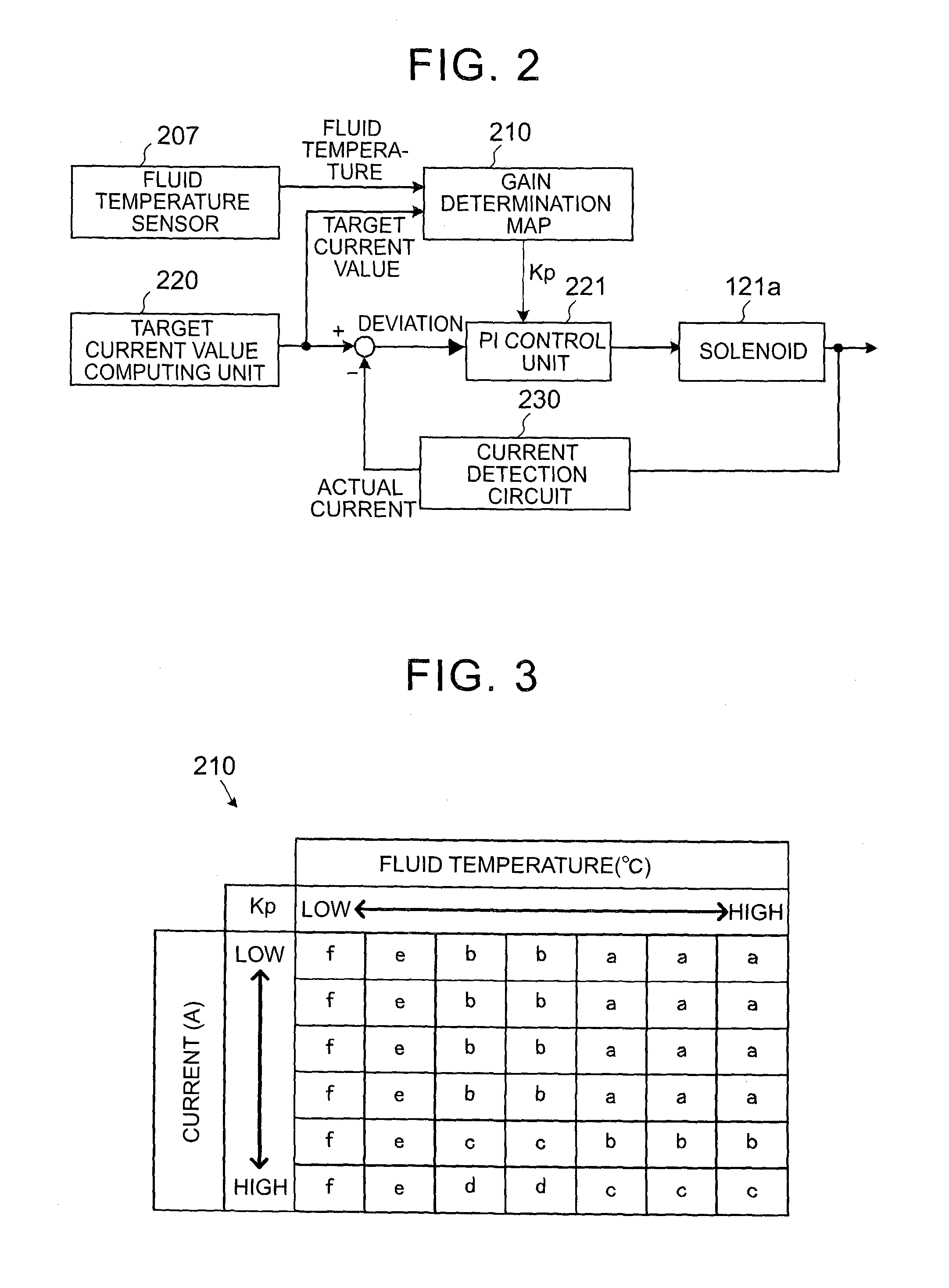

Control device for automatic transmission

ActiveUS20150148158A1Current be suppressIncrease clamping pressureServomotor componentsServomotorsEngineeringActuator

A control device for an automatic transmission including a hydraulic actuator that is actuated on the basis of a hydraulic pressure supplied and a linear solenoid valve that controls the hydraulic pressure supplied to the hydraulic actuator on the basis of a driving current of a solenoid includes an ECU that executes current feedback control over a current value of the driving current that is flowed to the solenoid using at least a proportional term and an integral term on the basis of a deviation (ΔI) between a target current value (Itgt) and actual current value (Ir) of the solenoid such that the hydraulic pressure supplied to the hydraulic actuator becomes a target hydraulic pressure. The ECU increases a proportional gain (Kp) in the current feedback control as a fluid temperature (To) detected by a fluid temperature sensor increases.

Owner:TOYOTA JIDOSHA KK

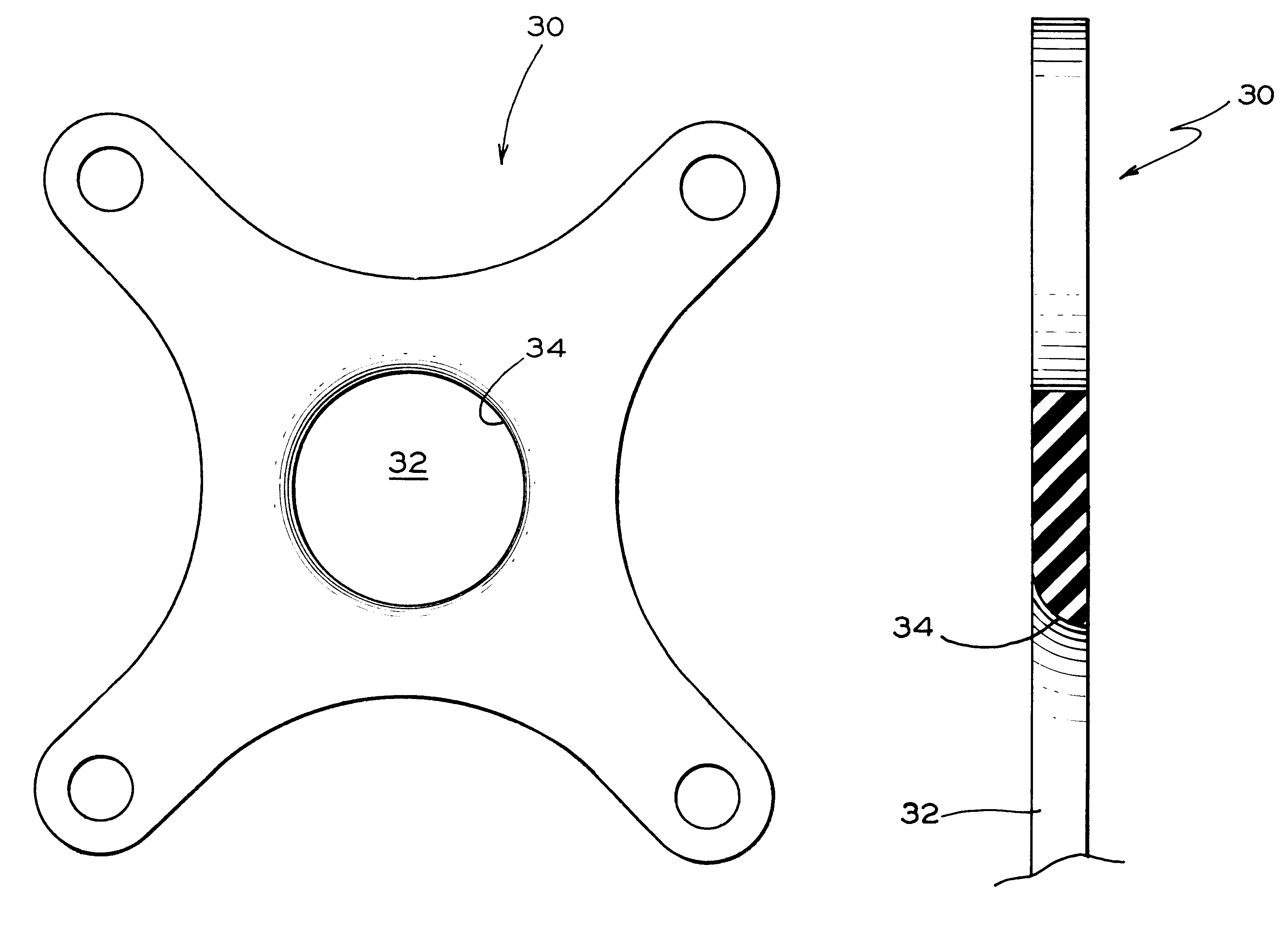

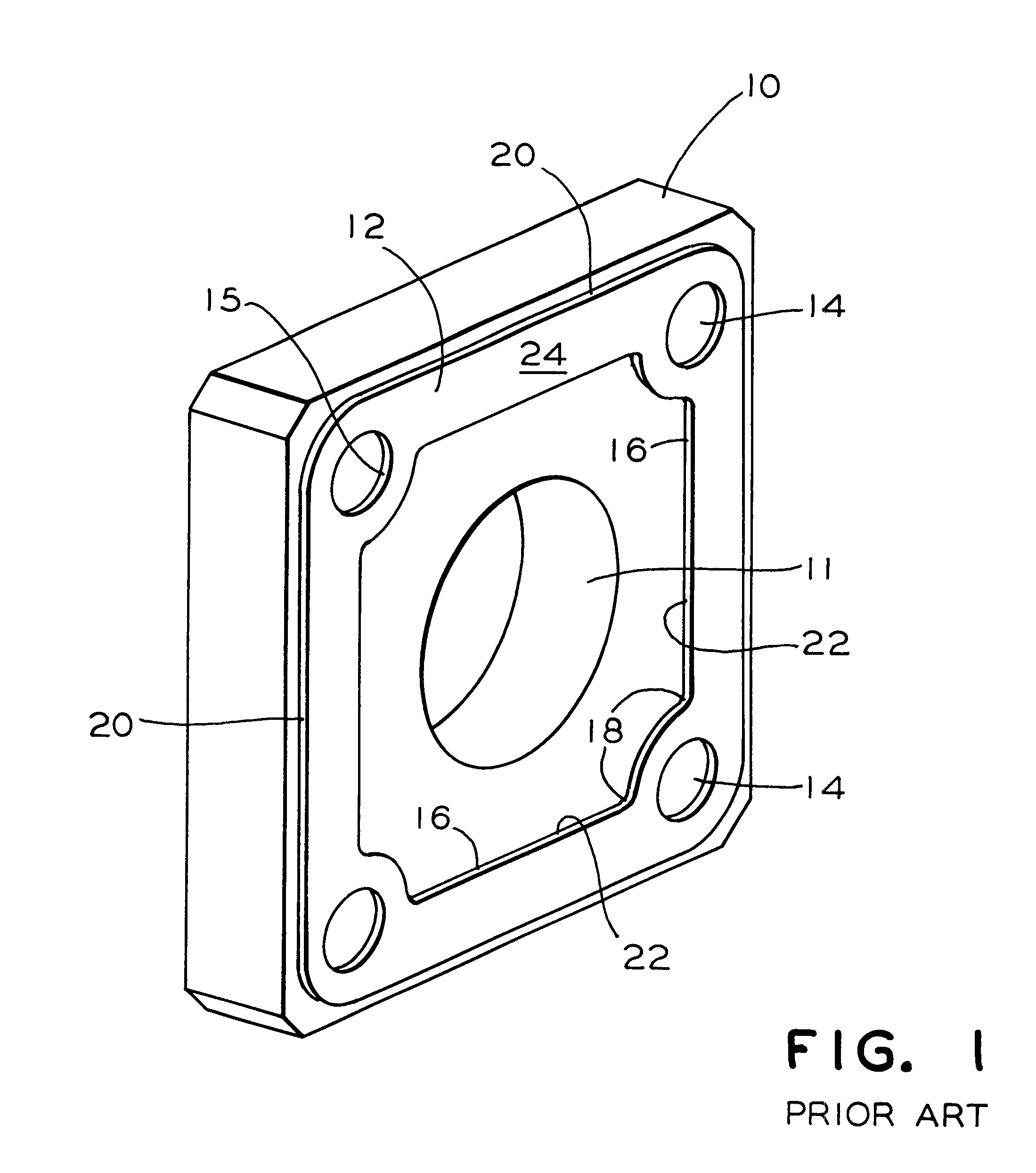

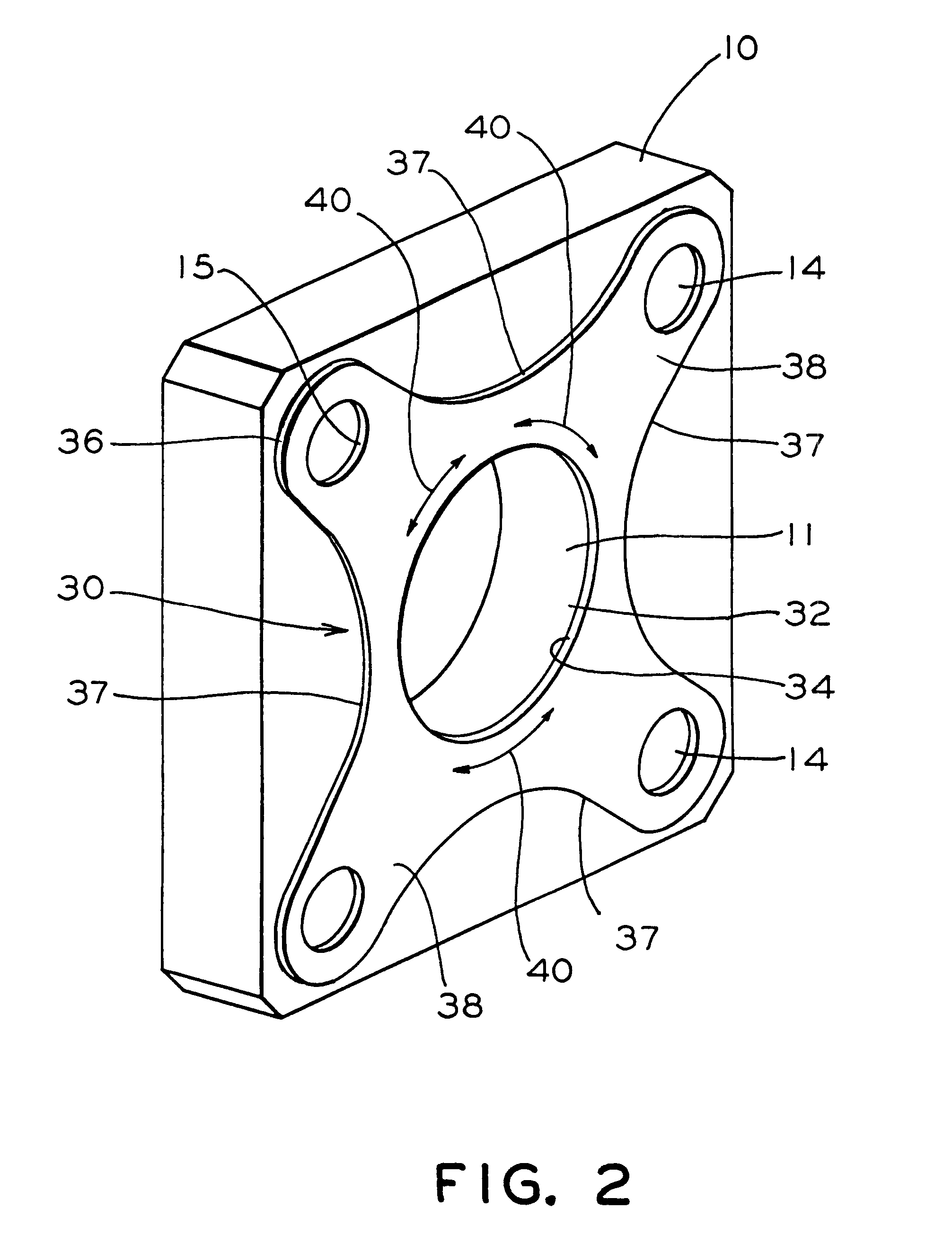

Gasket for pressurized fluid system

InactiveUS6481722B1High clamping pressureStress minimizationEngine sealsFlanged jointsBiomedical engineeringFluid system

Gasket for sealing between flanges in a pressurized fluid system. A central opening is disposed within an inner periphery of the gasket, the inner periphery being curved toward the central opening. Fluid pressure on the inner periphery is reacted by hoop tension in the gasket. The outer periphery of the gasket has concave segments between fastener holes so the area of the gasket is substantially less than the area of the flanges. In this manner, the clamping pressure exerted by the flanges on the gasket is increased.

Owner:WESTINGHOUSE AIR BRAKE CO

Adjusting device for a hand-held tool

InactiveUS20080289457A1Eliminate needIncrease clamping pressureRotary clutchesTelemotorsHand heldEngineering

A hand tool device incorporates a fluid operated mechanism actuable by a plunger pressurizing a reservoir to force fluid past a valve to a fluid filled cylinder accommodating a piston carrying a contact member for clamping a work piece in the manner of a wrench. Continued operation of the plunger increases the pressure applied to the work piece.

Owner:ANDERSON DWAIN

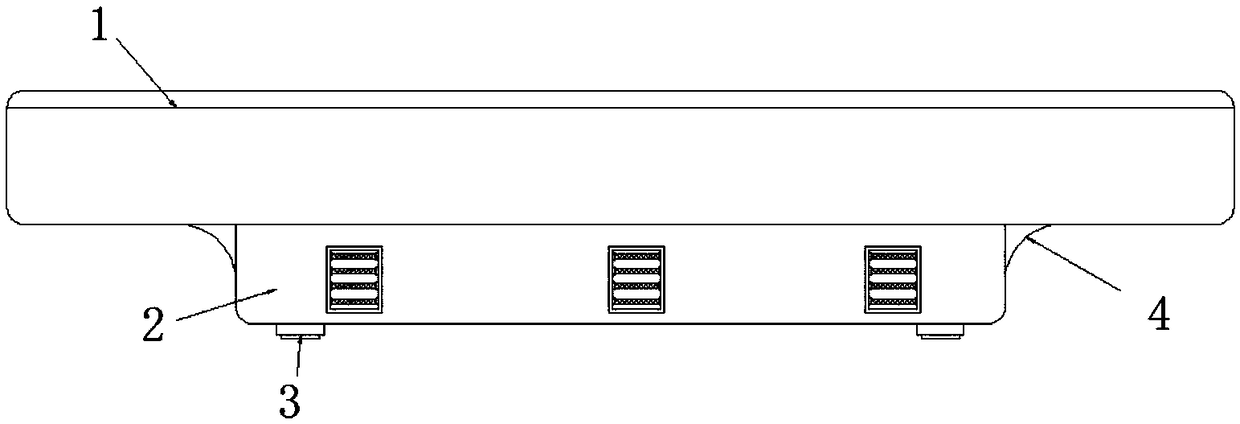

Drawing workbench for industrial design

InactiveCN109480480AIncrease contact areaIncrease air temperatureFurniture partsDrawing desksEngineeringIndustrial design

The invention discloses a drawing workbench for industrial design. The drawing workbench comprises a base. The top outer wall of the base is provided with embedding grooves formed equidistantly and annularly, a drawing board is placed in each embedding groove, and the bottom inner wall of each embedding groove is provided with a receiving groove. A connecting block is welded on the inner wall on one side of each receiving groove, a fixed shaft is welded on the outer wall on one side of the connecting block, the outer wall on one side of the fixed shaft is in sleeve connection with a rotating block, a telescopic rod is fixed on the outer wall on one side of the rotating block through bolts, a rotating shaft is connected with the top end of a telescopic rod extension rod, the outer wall on one side of the rotating shaft is in sleeve connection with a shaft sleeve, a connecting lug is welded on the outer wall on one side of the shaft sleeve, the outer wall on one side of the connecting lug is fixed with the corresponding drawing board through bolts, and a curved baffle is welded to the edge on one side of the top outer wall of the corresponding drawing board. The drawing workbench cannot only achieve heat preservation and heating work for a user, but also improve the use comfort when the temperature is low, and the drawing angle can be flexibly adjusted.

Owner:湖南全望信息科技有限公司

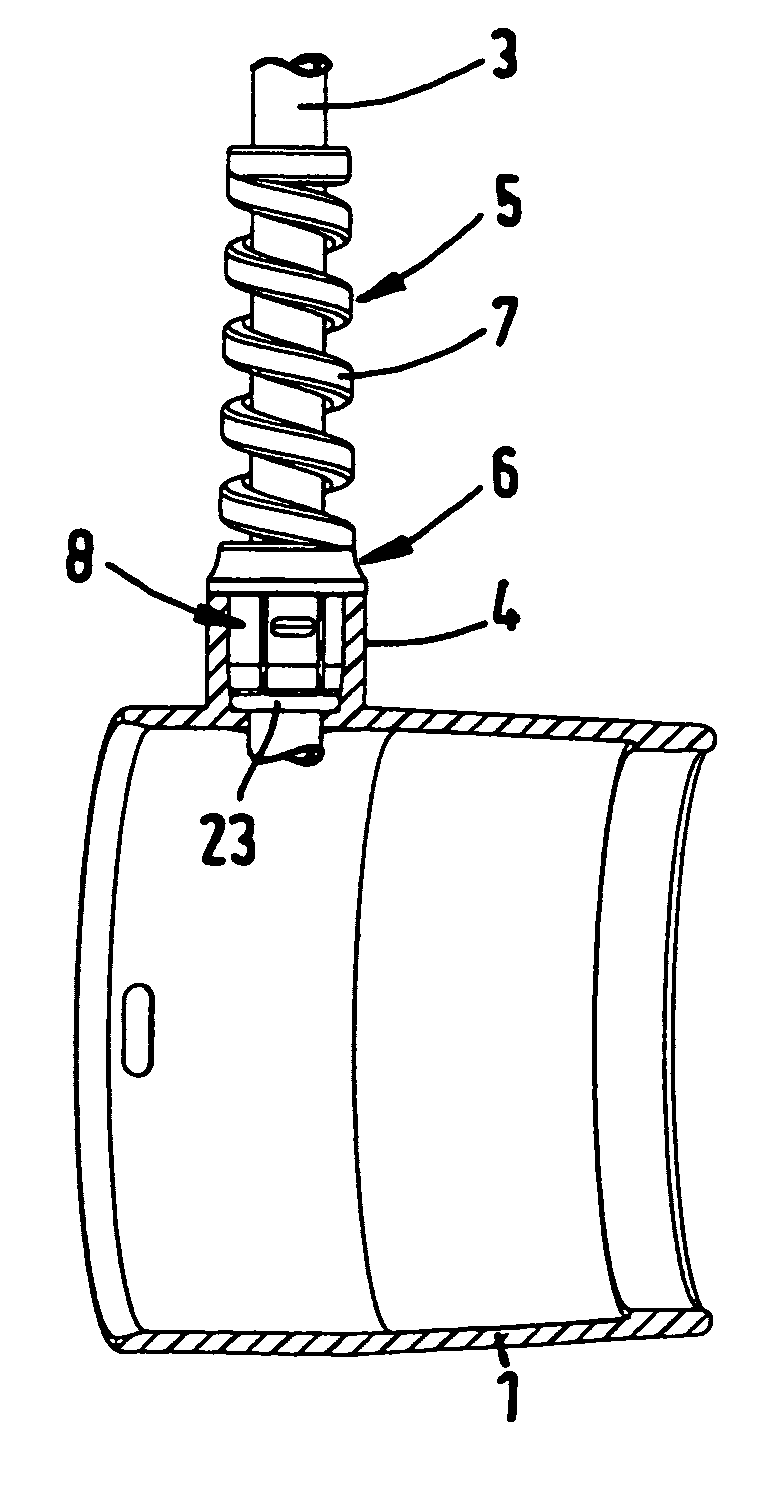

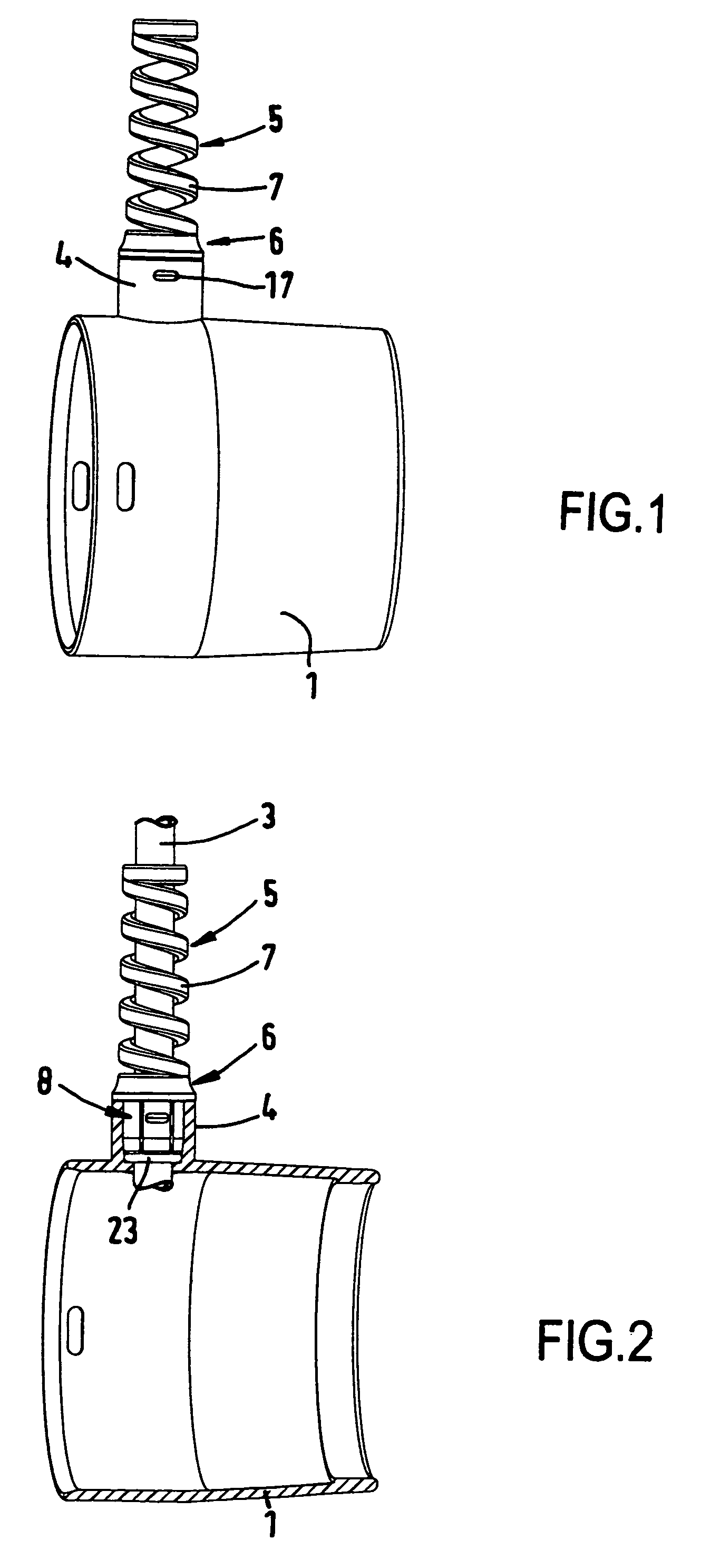

Kink protector for a line

InactiveUS7837157B2Avoid breakingConstrictions of preventedPipe supportsSuction cleanersMechanical engineeringHelix

A kink protector for a line which is led outwardly through a wall opening in a connecting sleeve of a hose or a pipe. The kink protector has a mounting cap which encloses the line, and a support helix which is integral with the cap and surrounds the line and which is resilient in bending. An outlet stub is provided at the connecting sleeve and is connected with the wall opening and into which the mounting cap can be pushed with at least axial fixing of the line in mechanically positive and detenting manner for the line.

Owner:TRUPLAST KUNST STOFFTECHNIK GMBH

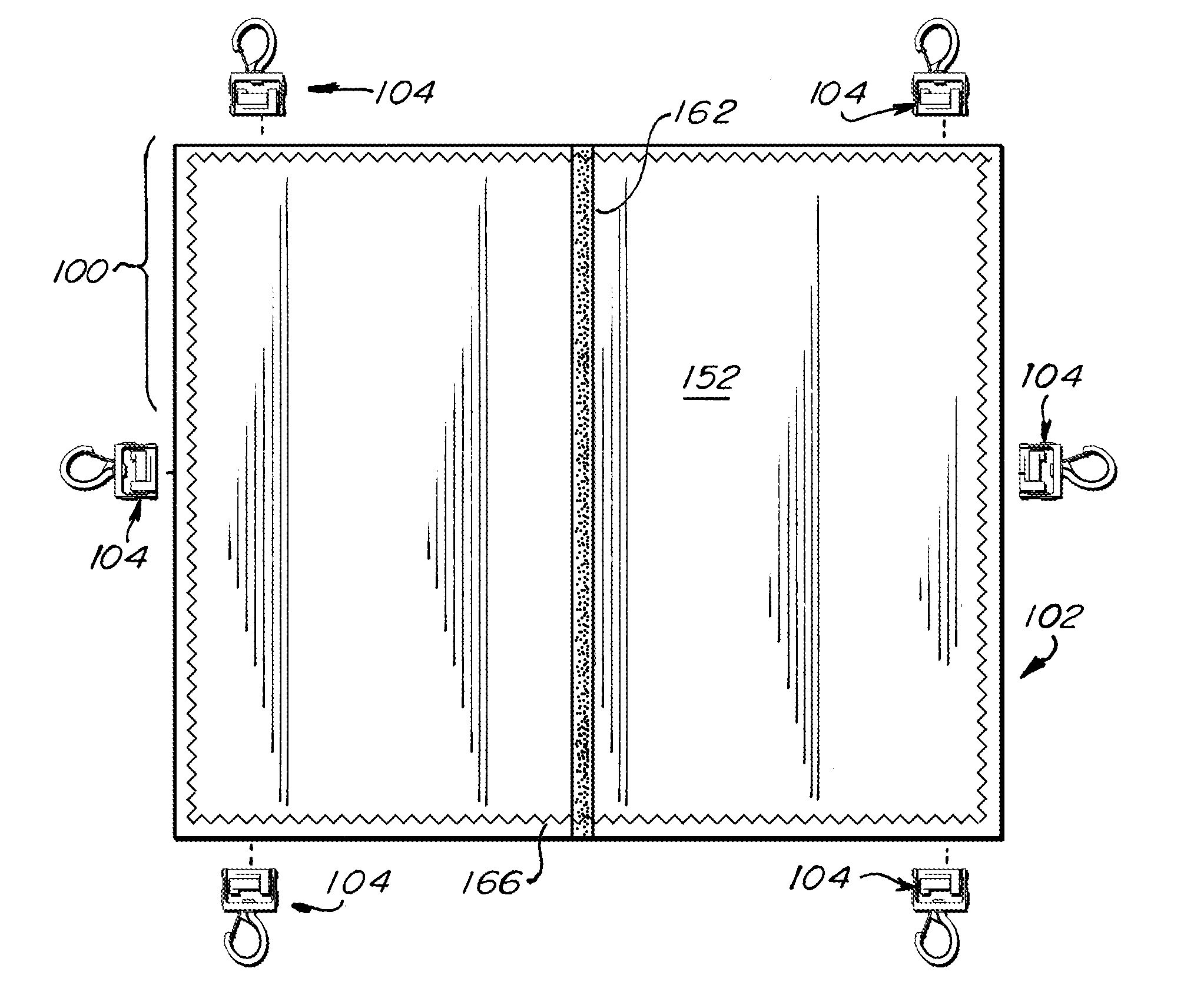

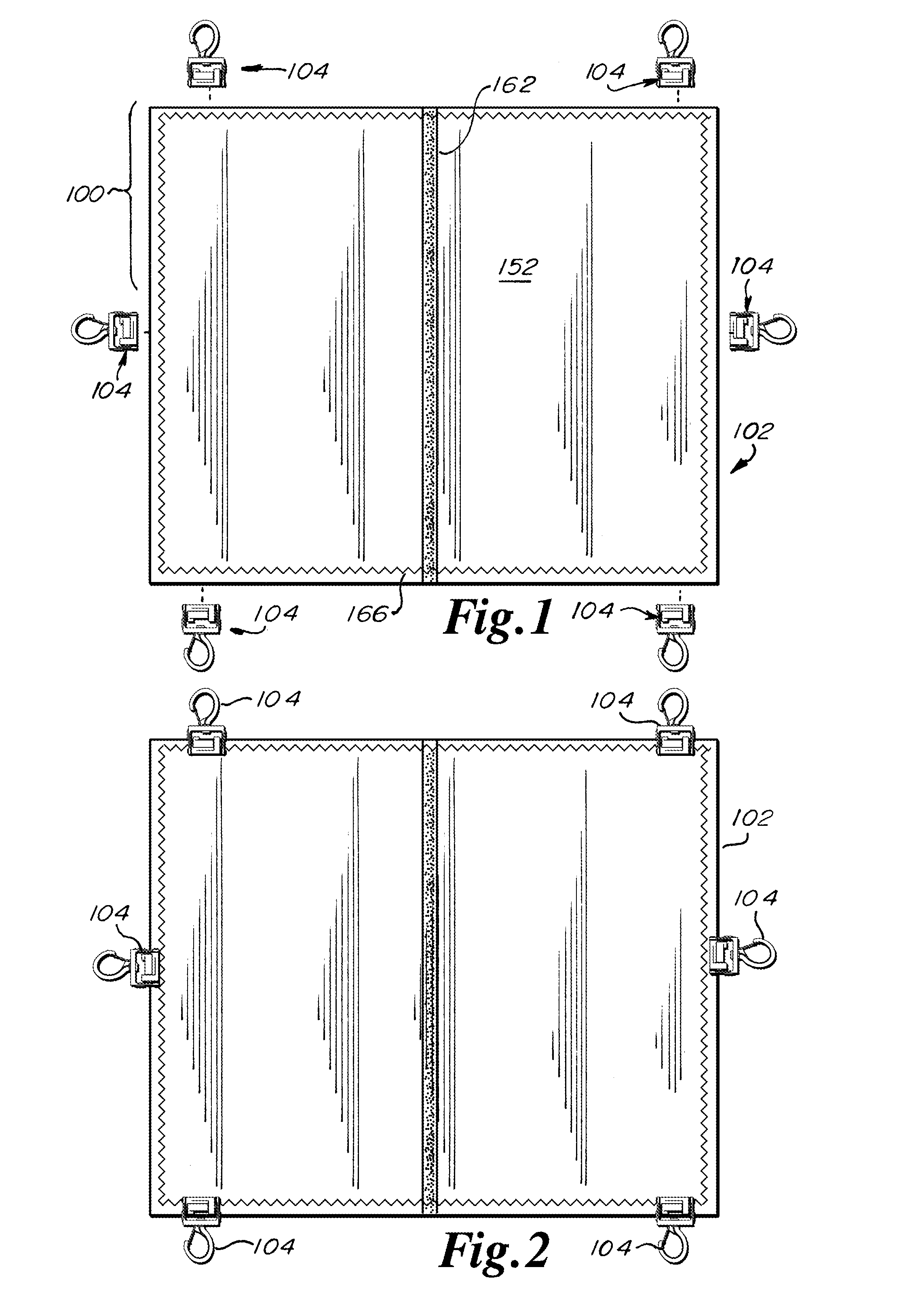

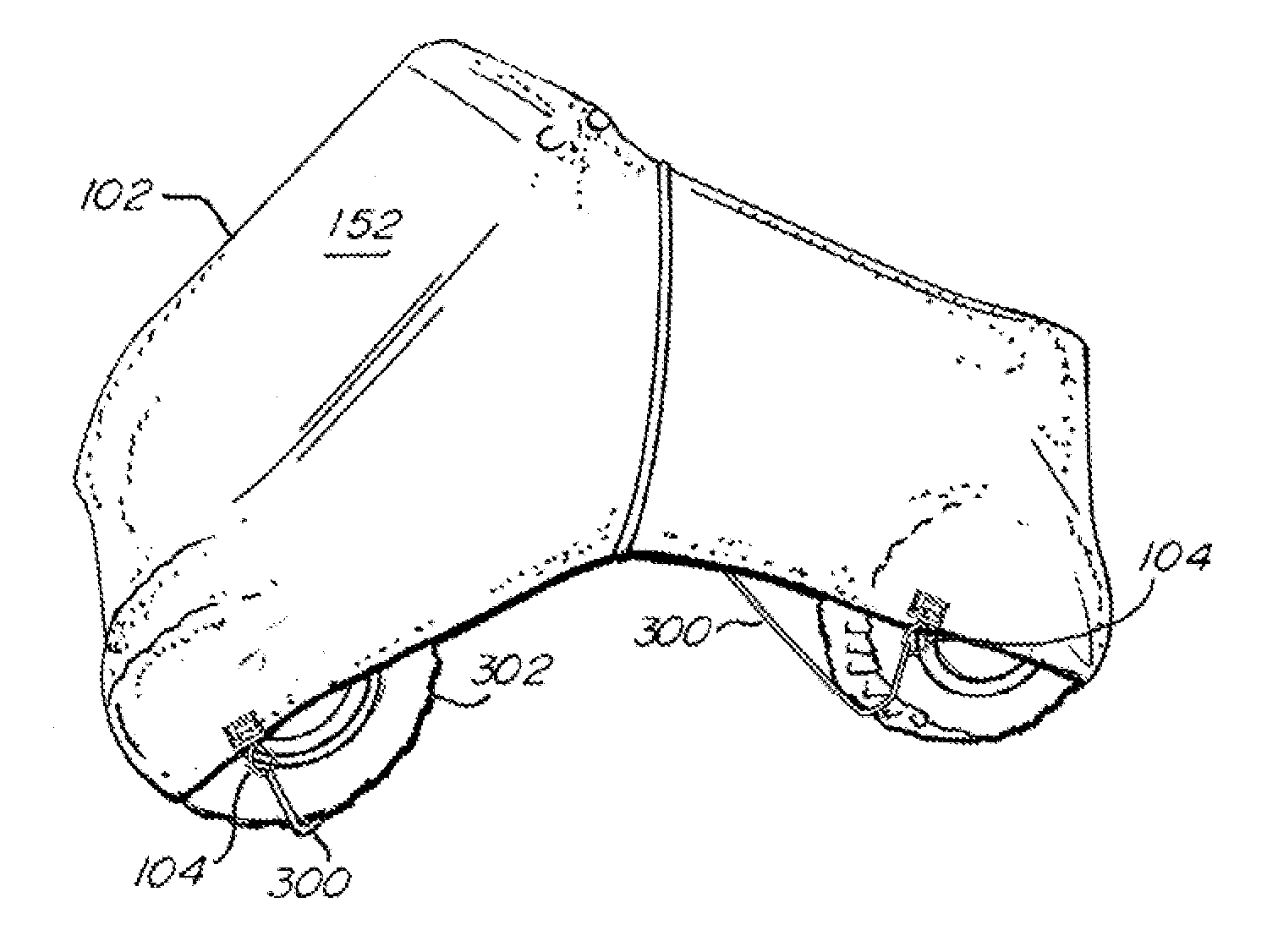

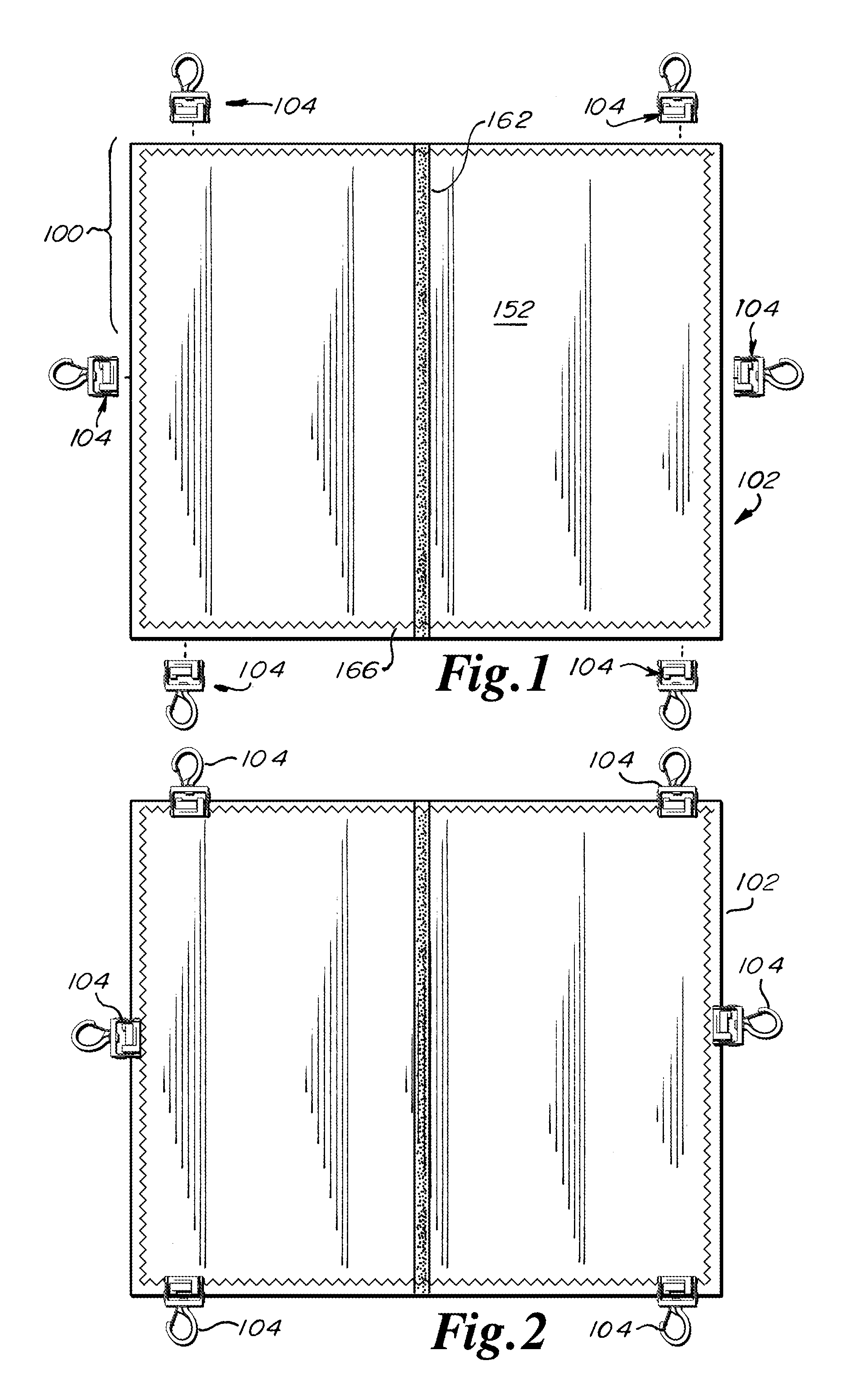

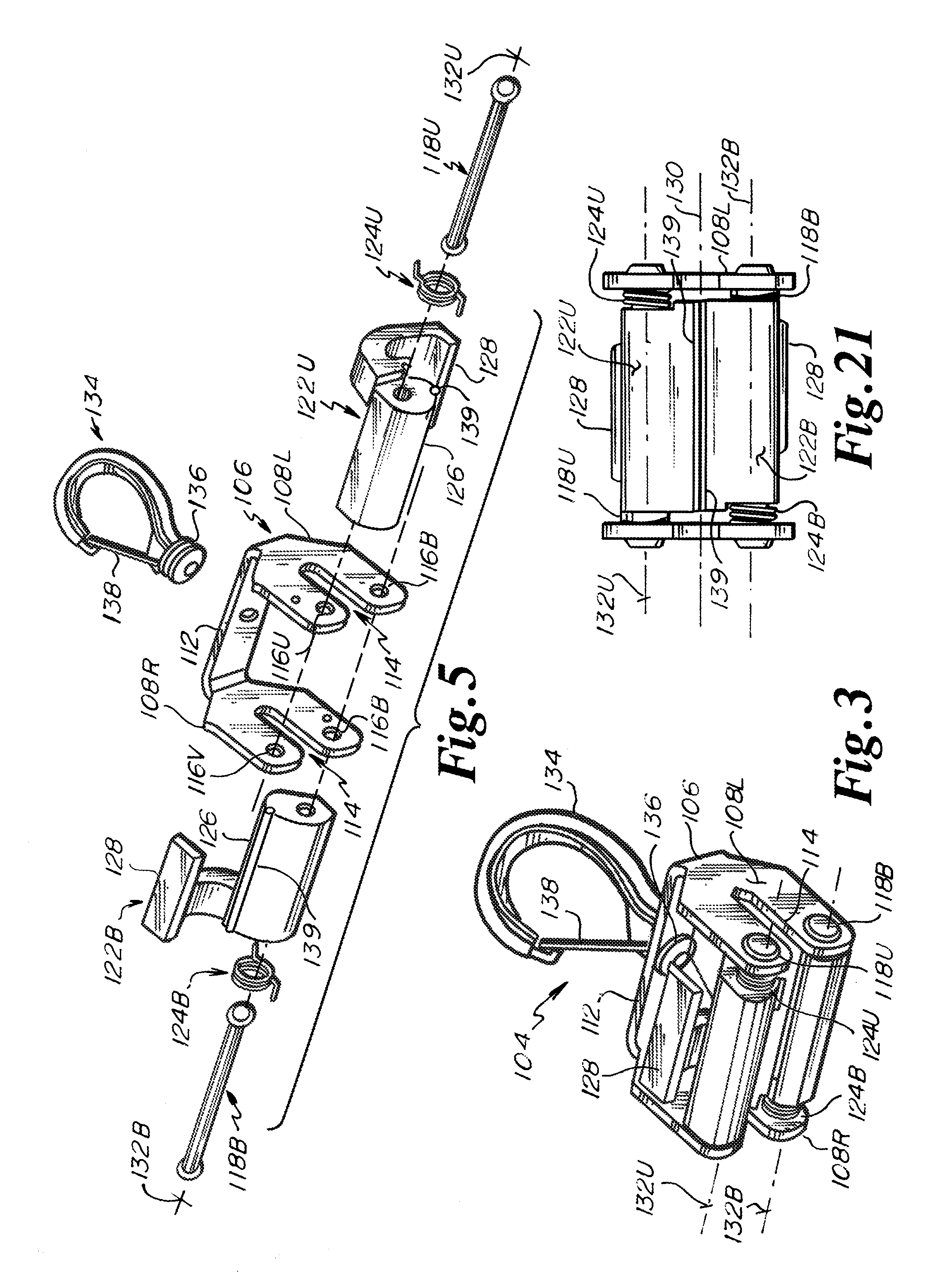

Universal covering system

InactiveUS8991448B2Reduce tensionIncrease clamping pressureSnap fastenersWrappersCovering systemBiomedical engineering

A covering system includes a tarp made of an elastic membrane and a plurality of tarp fastening hooks. The fastening hooks allow the elastic membrane to be stretched over valuables and affixed to environmental anchors so that creases and puddle-enabling pockets in the membrane are eliminated. The fastening hooks clamp onto the elastic membrane and hook onto the environmental anchors to cause tension in the membrane. The clamping forces of the tarp fasteners are inherently increased in proportion to the tension in the clamped membrane.

Owner:WHITE MATTHEW

Molding apparatus

A method and apparatus for low pressure molding are disclosed. The molding apparatus comprises a frame, a mold assembly and a transmission assembly. The mold assembly may comprise a first mold and a second mold, the second mold being coupled to the frame. The transmission assembly may be coupled to the frame and to the first mold. A motor may be coupled to the transmission assembly for moving the first mold relative to the second mold. A pneumatic actuator may also be coupled to the transmission assembly for increasing clamping pressure between the first mold and the second mold.

Owner:THE CAVIST CORP

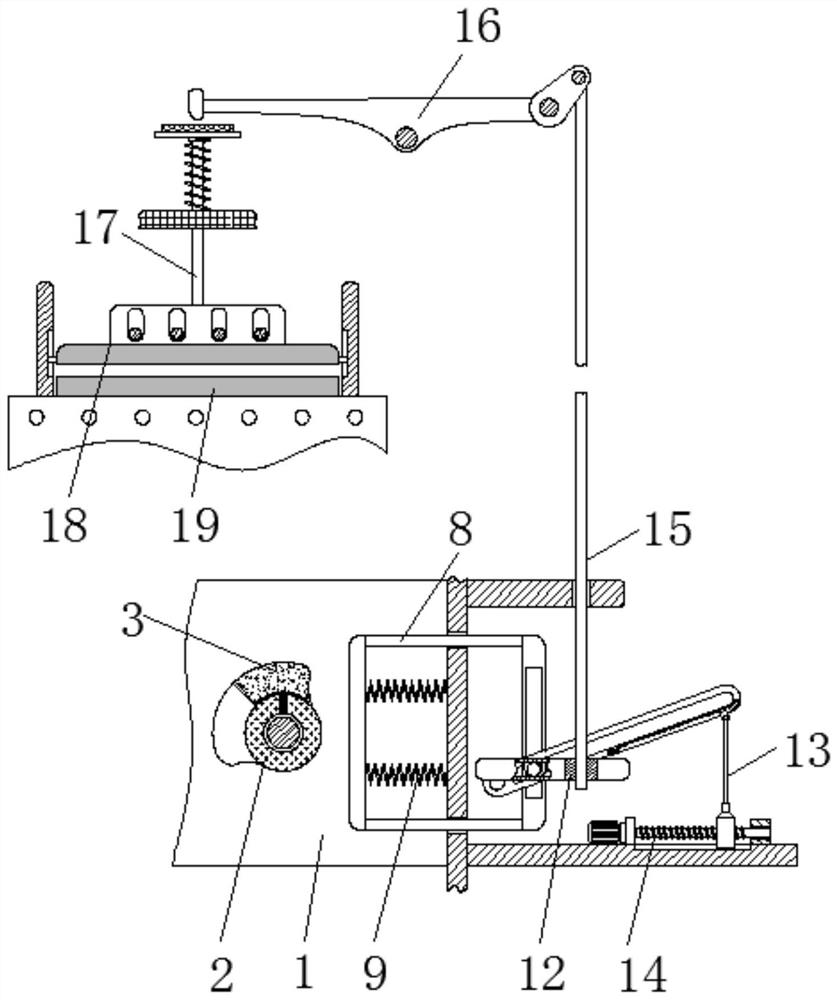

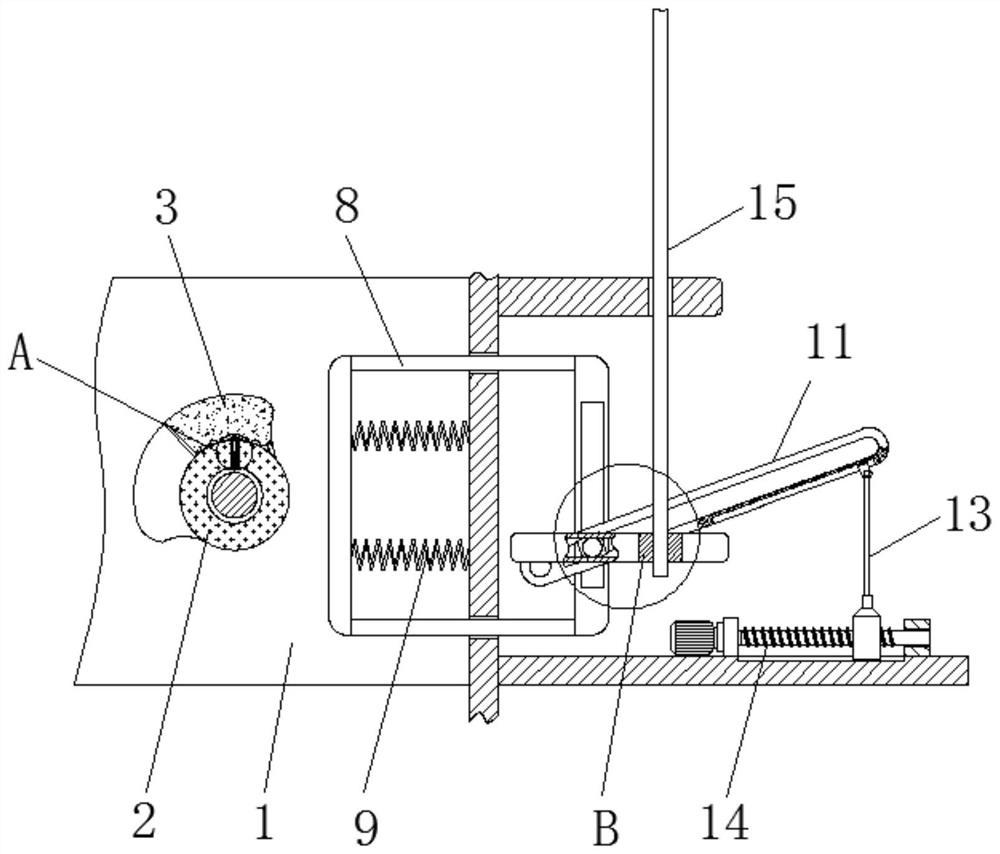

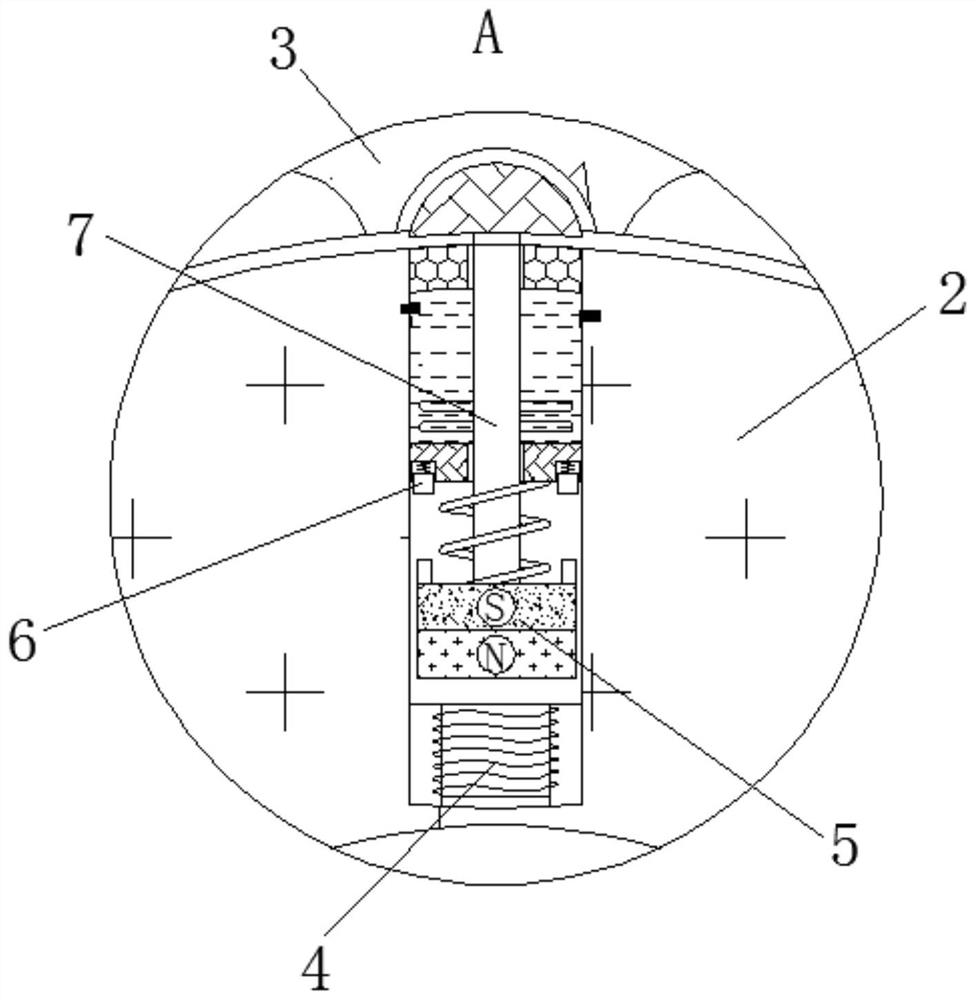

Pressure-adjustable yarn gripper for air-jet loom based on intelligent manufacturing principle

The invention relates to the technical field of textile equipment, and discloses a pressure-adjustable yarn gripper for an air-jet loom based on the intelligent manufacturing principle. The pressure-adjustable yarn gripper comprises a machine frame, a cam is movably connected into the machine frame, a movable protruding block is movably connected to the exterior of the cam, an electromagnet is fixedly connected into the cam, a permanent magnet block is movably connected to the exterior of the electromagnet, and an electric contact block is movably connected to the exterior of the permanent magnet block. Through cooperative use of a pressure rod, a limiting sliding block, a sliding rod, a lifting rod, an adjusting rod and a threaded rod, the effect of increasing the yarn clamping pressure in the yarn clamping process is achieved, so that the yarn gripper meets the requirement for fabrics with small warp and weft density or small warp and weft cross weaving friction force, the use rangeof the yarn gripper is effectively widened, and the use effect of the yarn gripper is effectively improved; and loosening of the finished fabrics due to insufficient weft tension caused by insufficient clamping force is effectively avoided, so that the quality of the woven finished fabrics is effectively guaranteed, the textile effect is effectively improved, untwisting or retracting of yarns is effectively prevented, and the production efficiency is guaranteed.

Owner:嘉兴市恒丰纺织股份有限公司

Automotive engine bearing

Owner:FORD GLOBAL TECH LLC

Universal covering system

InactiveUS20140083579A1Reduce tensionIncrease clamping pressureSnap fastenersFlexible coversCovering systemBiomedical engineering

A covering system includes a tarp made of an elastic membrane and a plurality of tarp fastening hooks. The fastening hooks allow the elastic membrane to be stretched over valuables and affixed to environmental anchors so that creases and puddle-enabling pockets in the membrane are eliminated. The fastening hooks clamp onto the elastic membrane and hook onto the environmental anchors to cause tension in the membrane. The clamping forces of the tarp fasteners are inherently increased in proportion to the tension in the clamped membrane.

Owner:WHITE MATTHEW

Plastic filtering board or board forming process

ActiveCN100360296CIncrease clamping pressureRealize automated productionDomestic articlesHot runnerFilter press

A process for preparing the plastic filter plate or plastic plate features that its mould is controlled by hydraulic press, its heat channel is positioned at the bottom of lower mould and communicated with said lower mould, and the plasticized plastics is injected in said mould via heat channel.

Owner:ZHEJIANG LONGYUAN ENVIRONMENTAL TECH CO LTD

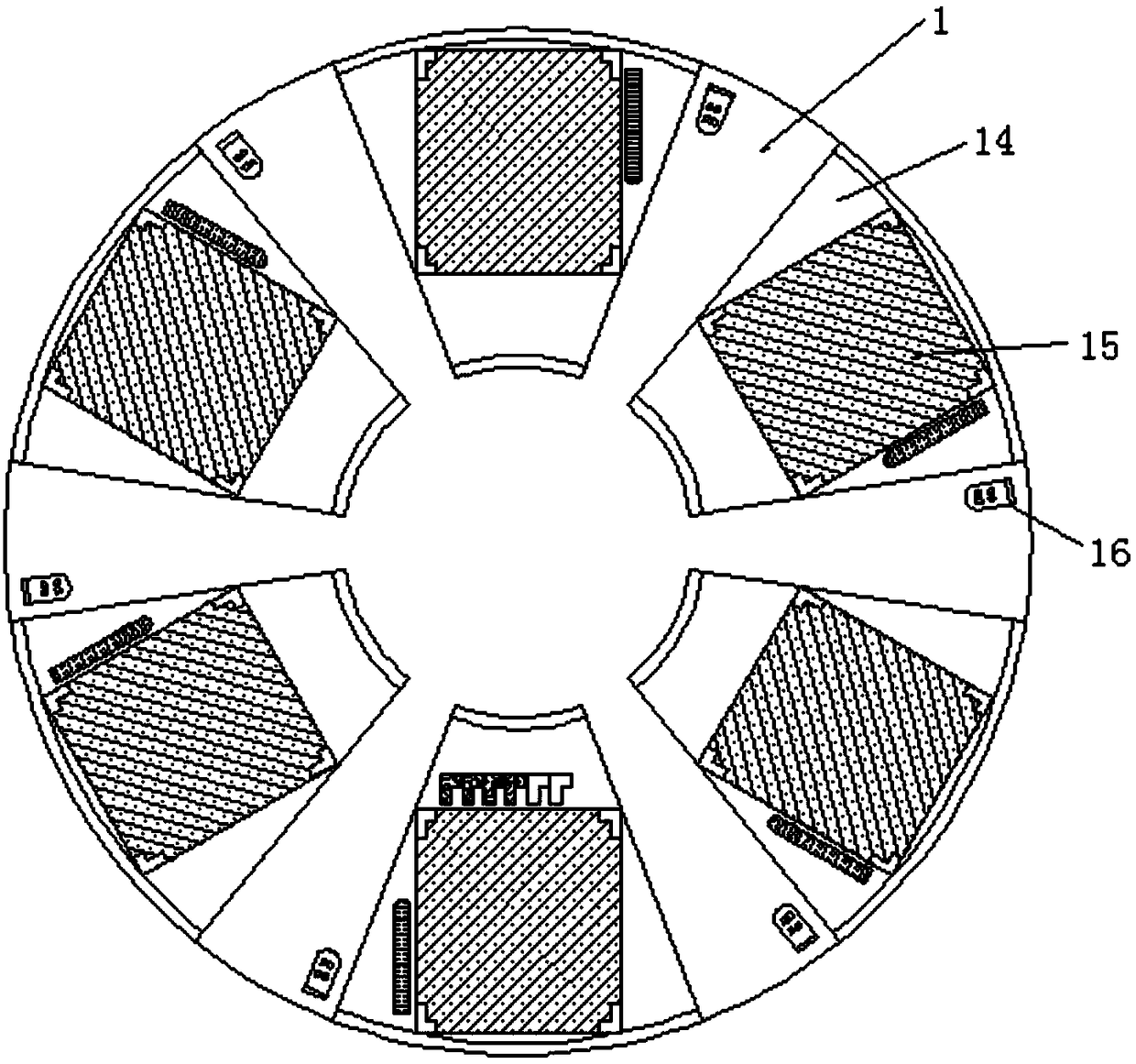

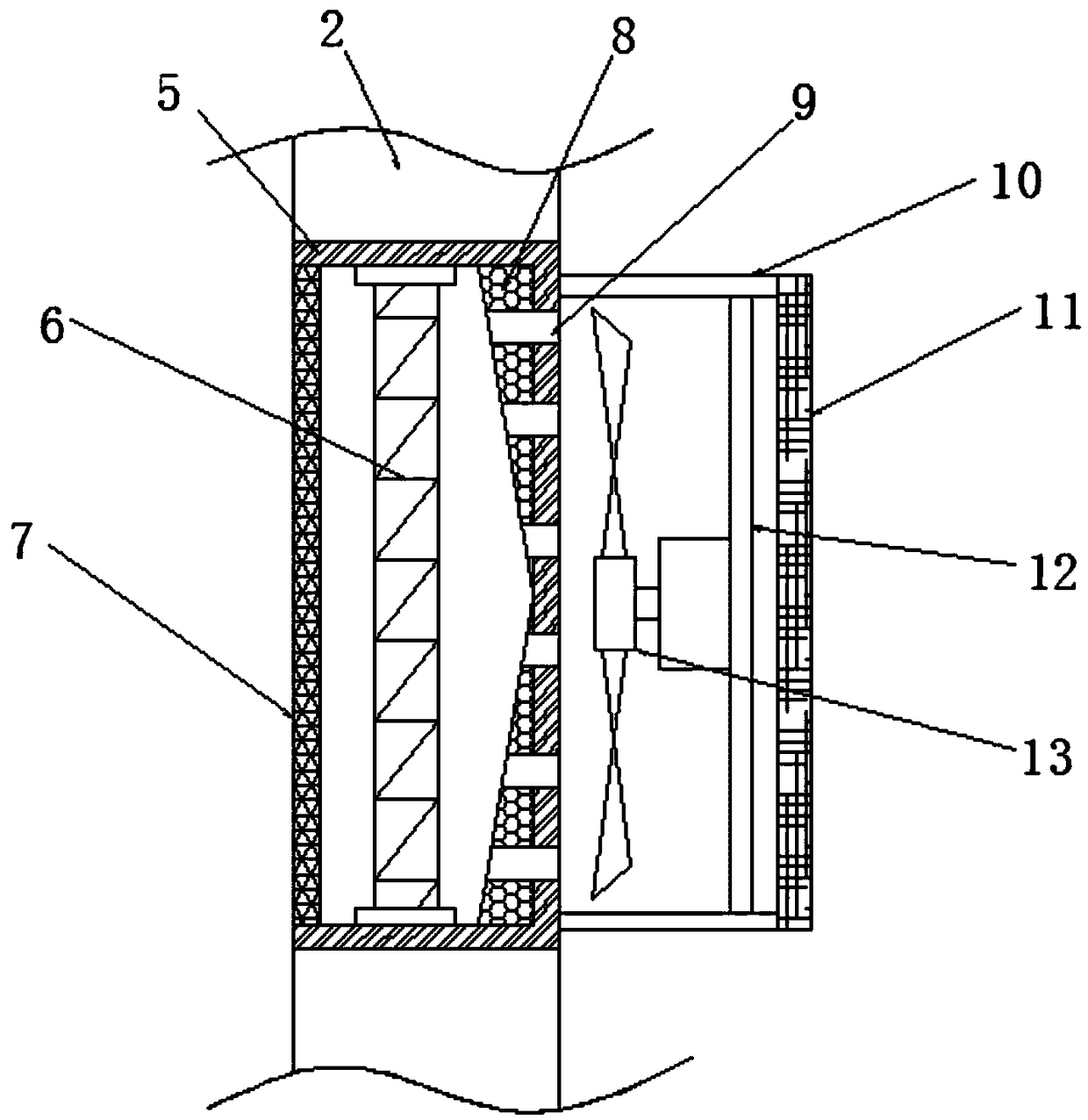

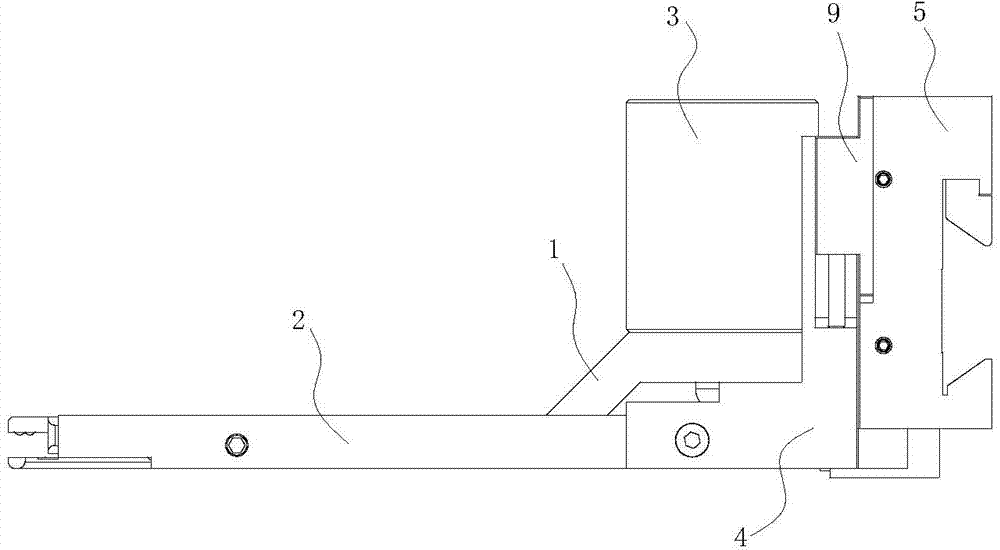

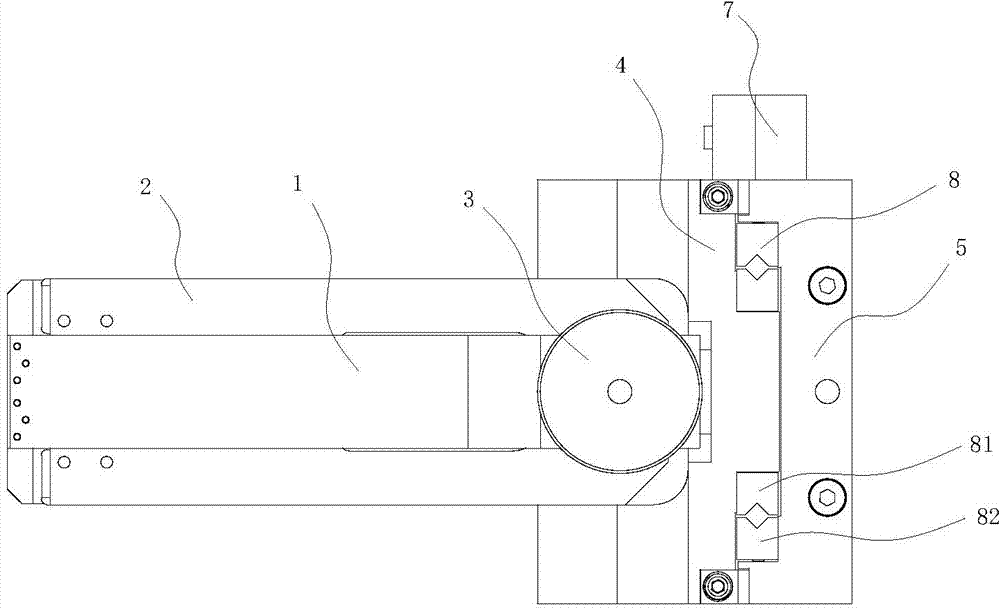

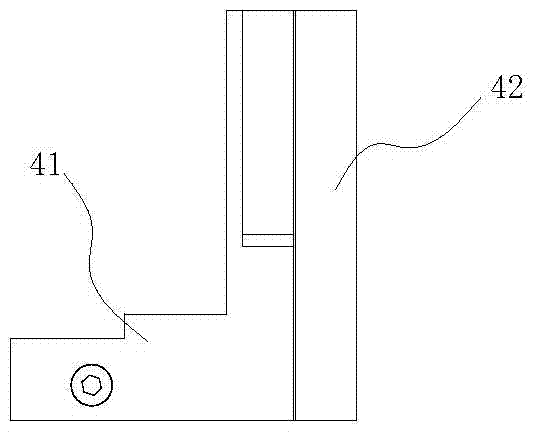

Split type board floating clamp on numerical control press

ActiveCN103878263AImprove reliabilityExtended service lifeMetal-working feeding devicesPositioning devicesEngineeringMachine tool

The invention provides a split type board floating clamp on a numerical control press. The split type board floating clamp on the numerical control press is simple in structure, convenient to assemble, high in clamping reliability and capable of guaranteeing the position accuracy of a board. The split type board floating clamp on the numerical control press comprises an upper clamp body, a lower clamp body and an air cylinder. The upper clamp body is hinged to the lower clamp body. The split type board floating clamp further comprises a base, a dovetail base, an air cylinder cushion column, a laser locating device, a pair of intersecting roller guides and a pair of elastic guide mechanisms. The air cylinder cushion column is connected between the tail end of the upper clamp body and the tail end of the lower clamp body and used for being communicated with an air channel of the air cylinder. A first guide portion of the base and a second guide portion of the dovetail base maintain guiding operation in the perpendicular direction through the intersecting roller guides and are movably connected in the perpendicular direction through the elastic guide mechanisms. The laser locating device is fixedly connected to one side of the lower portion of the second guide portion of the dovetail base. According to the split type board floating clamp on the numerical control press, the board machining reliability is improved and the service life of a machine tool is prolonged.

Owner:YANGZHOU HENGDE IND TECH CO LTD

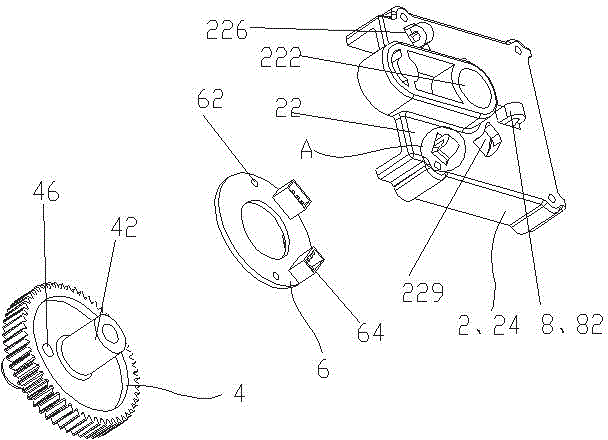

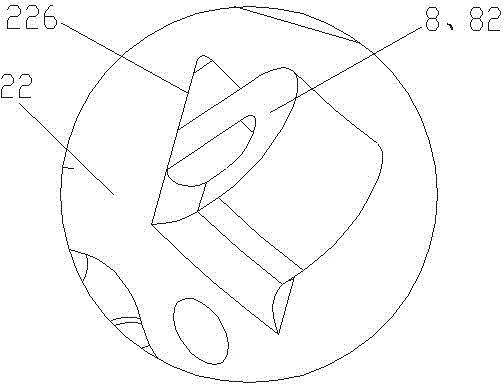

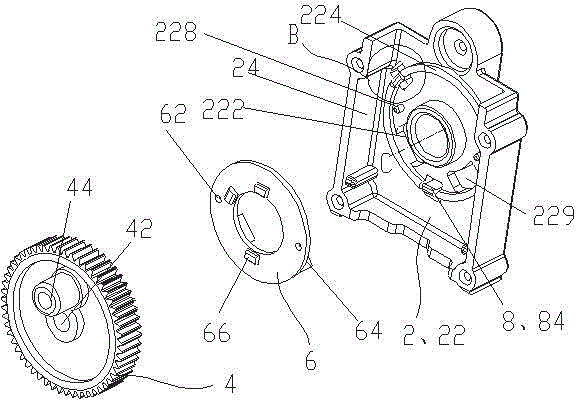

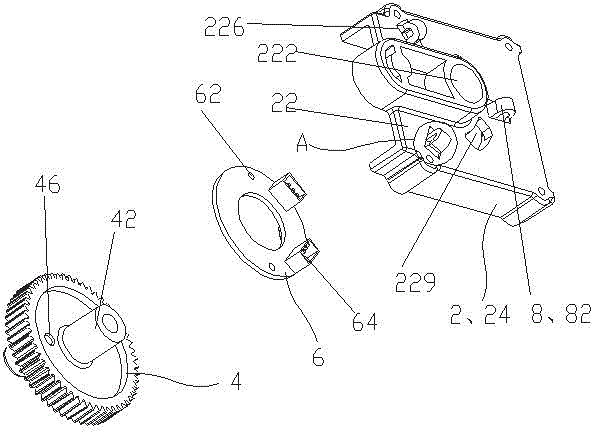

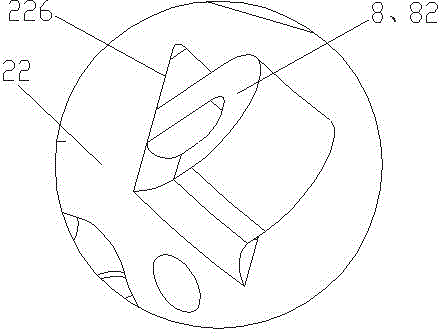

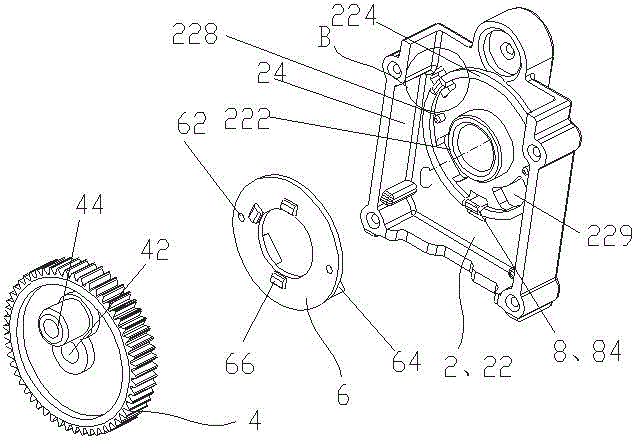

Gear component

InactiveCN103982622AAchieve regulationSimple structureOperating means/releasing devices for valvesPortable liftingHall elementGear wheel

The invention relates to a gear component, comprising a gear seat and a gear ratably arranged on the gear seat; an annular circuit board which is fixed on the gear seat and is used for sensing the rotation angle of the gear is also arranged between the gear and the gear seat; a magnet is arranged on the gear; hall elements for sensing the magnet are arranged on the annular circuit board. According to the gear component, disclosed by the invention, the position of the magnet is sensed by the hall elements by means of the specially-designed annular circuit board structure, as so to determine the rotation angle of the gear, the structure is simple, and the sensing is accurate and effective. Particularly, multiple hall elements distributed in the circumferential distribution can be arranged on the annular circuit board, the multiple different rotation angles and positions of the gear can be sensed, and different requirements are met. For instance, when the gear is connected with a valve rod of a valve and controls the valve rod to perform reciprocating motion, the position change of the gear can control the displacement of the valve rod, and the regulation of the valve is realized.

Owner:江苏宇海环保设备有限公司

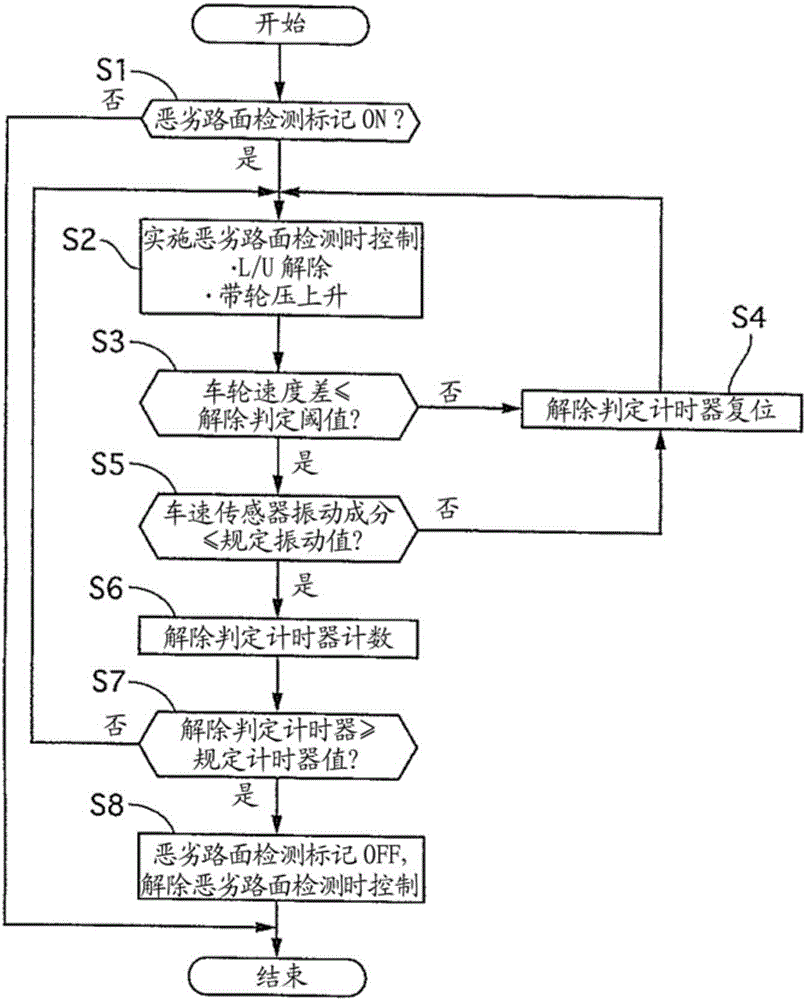

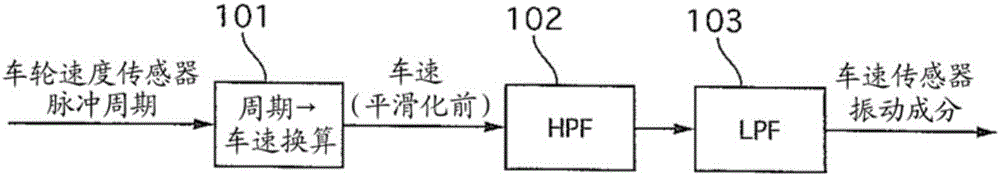

Controller for continuously variable transmission

ActiveCN106574714APrevent slippingIncrease clamping pressureGearing controlDrive wheelWheel speed sensor

A controller for a continuously variable transmission (1) is provided with: a wheel speed sensor (21F) for detecting the rotational speed of a driving wheel; a wheel speed sensor (21R) for detecting the rotational speed of a driven wheel; and a transmission controller (12). When the wheel speed difference between the driving wheel and the driven wheel is equal to or greater than a start determination threshold value, the transmission controller (12) determines the road surface being travelled to be a bad road (S1) and then increases the clamping force of the continuously variable transmission (1) (S2). When a vehicle speed vibration is detected on the basis of a detection value acquired by the wheel speed sensor (21R), and it is found that the wheel speed difference is equal to or less than a release determination threshold value (S3) and the detected vibration is equal to or less than a predetermined vibration value (S5), the transmission controller (12) reduces the raised clamping force (S8).

Owner:JATCO LTD +1

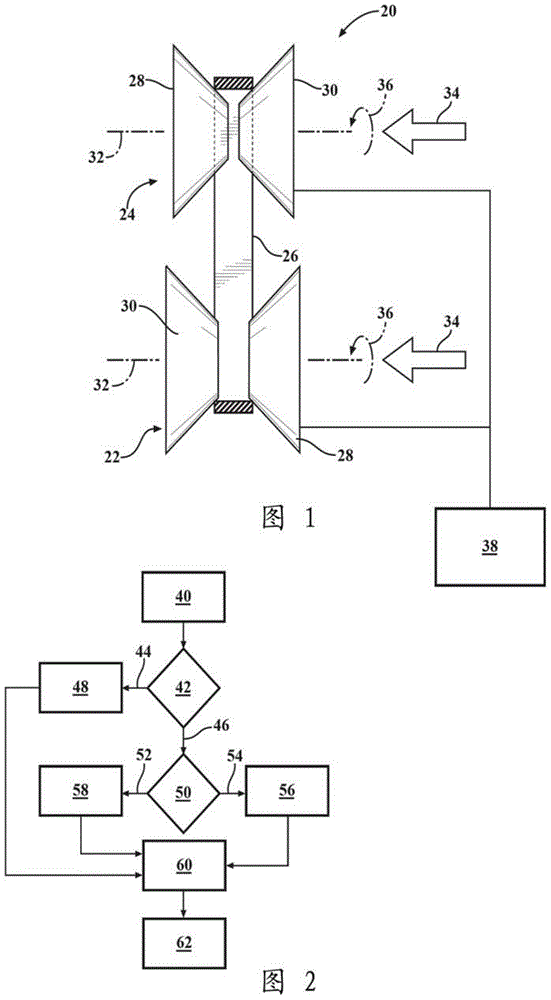

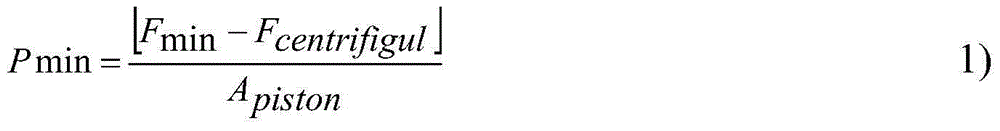

Method of controlling a variator

InactiveCN105134941AMinimize Energy EfficiencySlide to minimizeGearingGearing controlControl theoryVariator

A method of controlling a variator that requires clamping pressure between a first component and a second component to transfer torque therebetween, such as a continuously variable transmission, includes calculating a theoretical clamping pressure, and multiplying the theoretical clamping pressure by a multiplier to define a commanded clamping pressure. The multiplier includes a value that is variable between a minimum multiplier value and a maximum multiplier value. The value of the multiplier is based on current operating conditions of the variator. The commanded clamping pressure is applied to the first component and the second component to generate friction and transfer torque between the first component and the second component.

Owner:GM GLOBAL TECH OPERATIONS LLC

Gear component

InactiveCN103982623AImprove sensing accuracyPrevent circumferential rotationOperating means/releasing devices for valvesPortable liftingGear wheelEngineering

The invention relates to a gear component which comprises a gear base and a gear rotatably arranged on the gear base, wherein an annular inductor used for inducing the rotation angle of the gear is arranged between the gear and the gear base; the inner side of the gear base is provided with multiple clamping pieces peripherally arranged; the annular inductor is in clamping joint with the clamping piece so as to be matched and fixed on the gear base; the annular inductor is provided with a plurality of axial spacing holes; the gear base is provided with spacing columns which pass through the corresponding spacing holes. According to the gear component, the gear base is provided with the clamping pieces so as to fix the annular inductor, so that the gear component is convenient in assembly and disassembly, and free from worrying about loss of parts and loose connection; the arranged spacing columns are matched with the spacing holes of the annular inductor, so that the inductor is well prevented from rotating peripherally, and the gear inducting precision of the inductor is improved.

Owner:江苏宇海环保设备有限公司

Lawn and garden battery clamp

InactiveUS7189123B2Easy to looseEasy to disassembleSemiconductor/solid-state device manufacturingElectric connection structural associationsEngineeringCam

An improved battery cable clamp provides for toolless attachment of battery cable connectors to lawn and garden-type battery terminal posts utilizing a bossed handle, cam seat and thumbnut, preferably made of non-corrosive materials.

Owner:SPC INT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com