Automatic closed forging forming die

A technology of forming die and automatic blocking, which is used in manufacturing tools, forging/pressing/hammer devices, forging/pressing/hammering machines, etc., which can solve the problem of low unlocking flexibility of jaws, small size range of forgings, and locking accuracy. problems such as decline, to ensure the quality of forging, the forging process is easy to operate, and the effect of avoiding changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

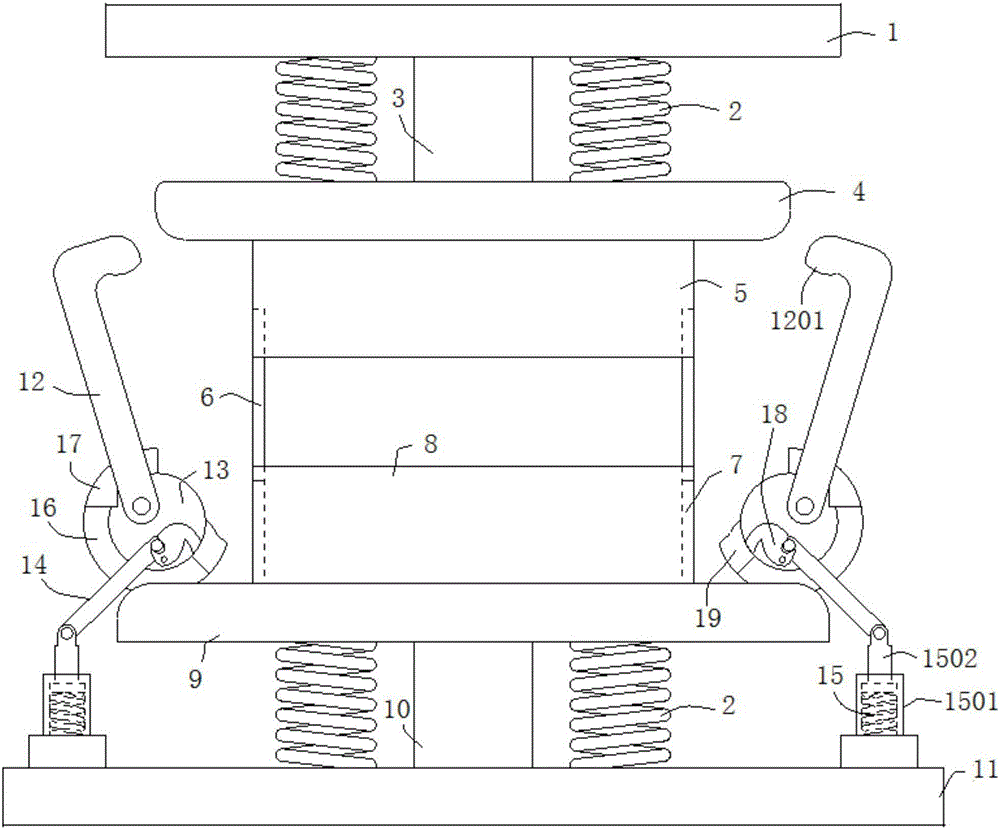

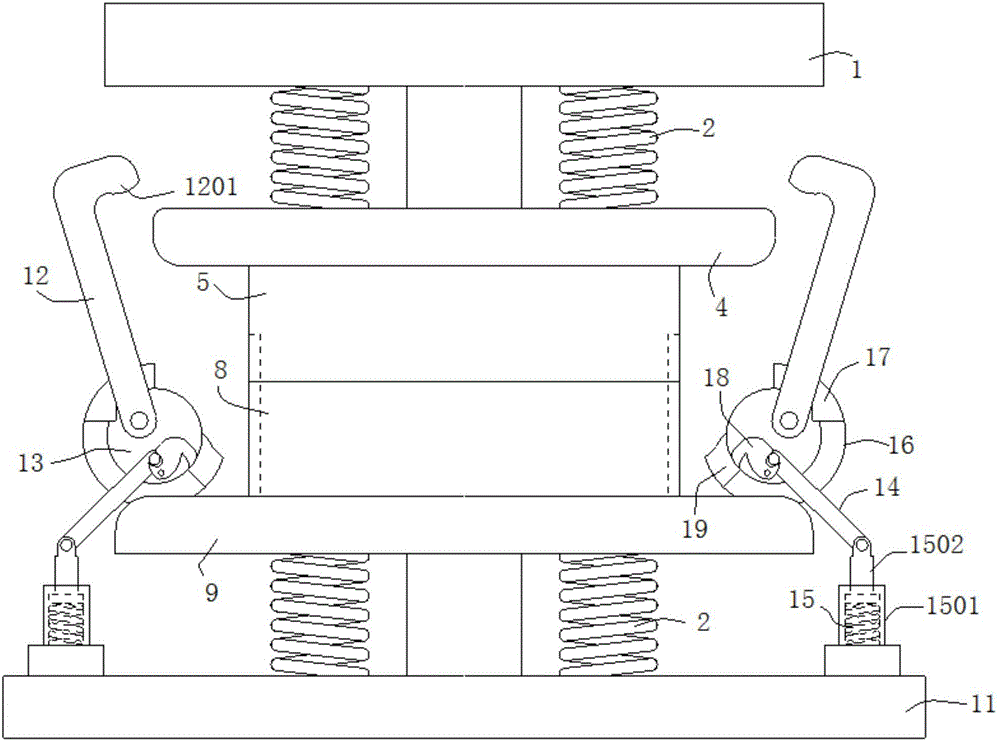

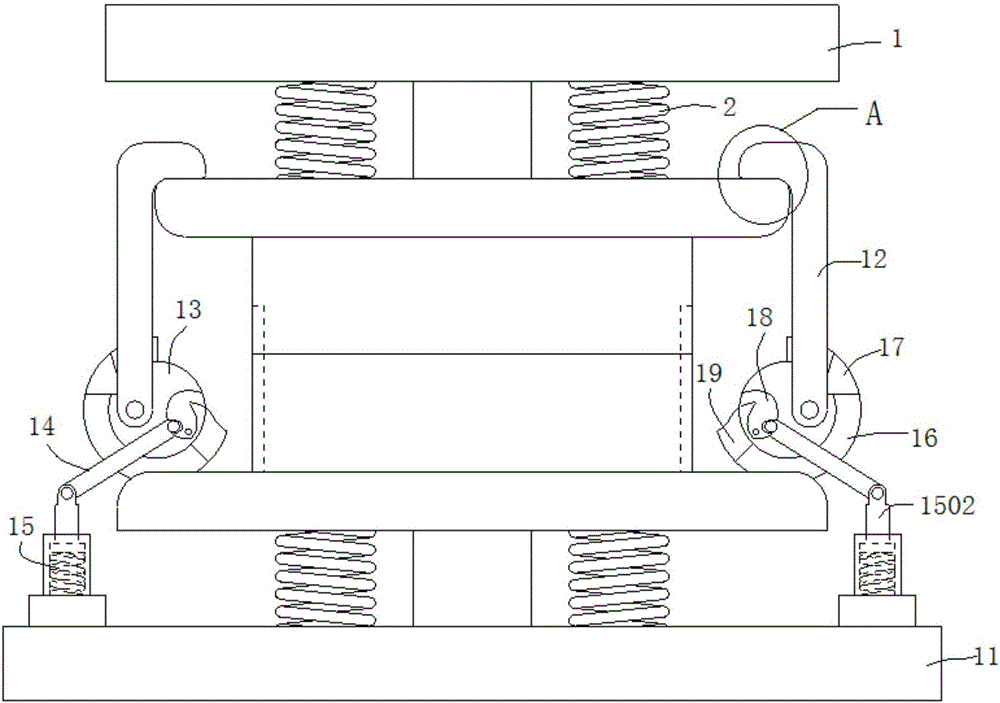

[0049] A kind of automatic occlusion forging forming die of this embodiment comprises rigid mold base, floating die and automatic clamping device, such as figure 1 As shown, the rigid die base includes an upper die base 1, an upper punch 3, a lower die base 11 and a lower punch 10, the upper punch 3 is fixedly installed on the upper die base 1, and the lower punch 10 is fixedly installed on the lower die base 11. The floating die includes an upper die holder 4, an upper die holder 5, a lower die holder 8 and a lower die holder 9, wherein the upper die holder 4 is floatingly connected with the upper die holder 1 through a mold spring 2, and the lower die holder The base 9 is floatingly connected with the lower mold base 11 through the mold spring 2. The mold spring 2 can be a metal coil spring, a nitrogen gas spring or a polyurethane spring. Specifically, in this embodiment, the mold spring 2 is a metal coil spring. The upper die 5 and the lower die 8 are correspondingly fixed ...

Embodiment 2

[0054] A self-closing forging forming die of this embodiment is basically the same as that of Embodiment 1. Further, the power mechanism in this embodiment includes a rotating disk 13, a driving connecting rod 14 and an elastic element 15, such as figure 1 As shown, the lower die base 9 is provided with a fixed seat 16, and the rotating disk 13 is movably arranged inside the fixed seat 16. Specifically, the fixed seat 16 is a ring concentric with the rotating disk 13, and the rotating disk 13 is embedded in the Inside the ring and capable of rotating around the center of the circle, the two axial ends of the fixed seat 16 are provided with limiting pieces, which extend toward the direction close to the rotating disk 13, and the limiting pieces surround the rotating disk 13 in the circumferential direction. Distributed at intervals, the limit piece clamps the rotating disc 13 in the fixed seat 16, and acts as an axial limit for the rotating disc 13, preventing the rotating disc ...

Embodiment 3

[0067] A self-blocking forging forming die of this embodiment is basically the same as that of Embodiment 2. Furthermore, in this embodiment, the locking hook 18 is connected with the rotating disk 13 through the third connecting shaft 1801, as Figure 9 , Figure 10 As shown, the locking hook 18 can rotate around the third connecting shaft 1801 , and the third connecting shaft 1801 is located at the center of the arc-shaped side wall of the above-mentioned arc-shaped sliding slot 1301 . When the second connecting shaft 1401 at one end of the driving link 14 slides along the arc-shaped chute 1301, the locking hook 18 is driven to rotate around the third connecting shaft 1801, so as to realize the cooperative locking or disengagement of the locking hook 18 and the locking block 19 , and connecting the lock hook 18 with the rotating disk 13 helps to improve the structural strength and structural stability of the lock hook 18, ensures the stability of its operation process, and m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com