Variable-diameter mold for making hollow wheaten food

A technology of hollow noodles and molds, which is applied in the fields of dough molding machinery or equipment, food science, dough extruders, etc. It can solve the problems of thick dough, deformation of pasta and cavity, and cavity can not be too large, etc., to achieve increased The effect of filling content and quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

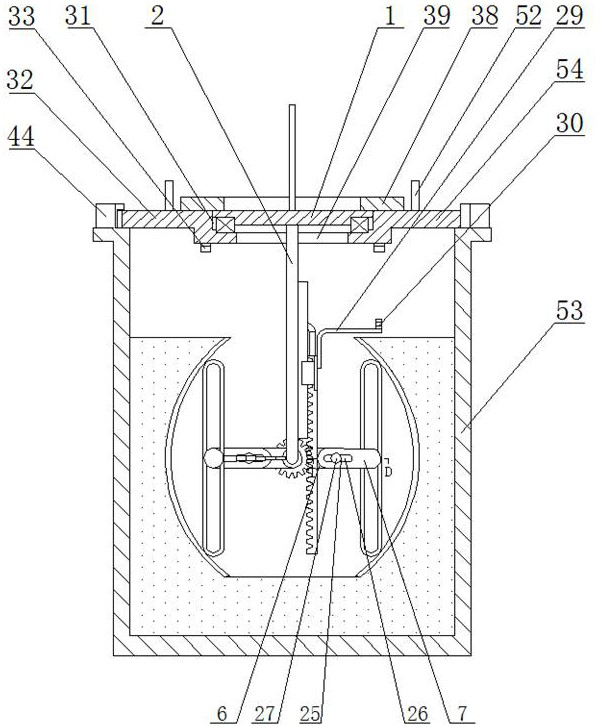

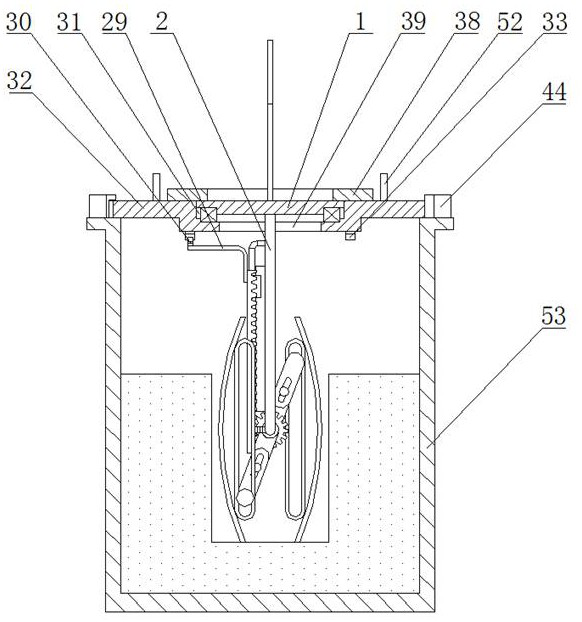

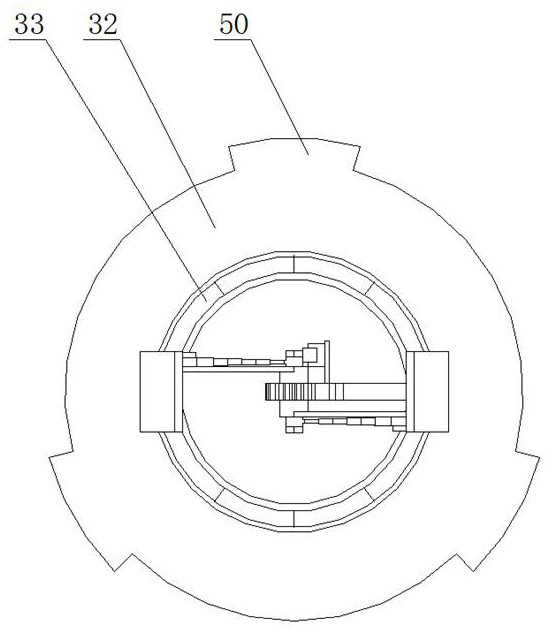

[0060] The embodiment provides a variable diameter mold for making hollow pasta and its use method, such as figure 1 , figure 2 As shown, it includes: a mold 53 with an opening above the mold 53 and a certain volume inside to hold the dough. The upper end surface of the mold 53 is equipped with a cavity expansion assembly 54, the cavity expansion assembly 54 includes an upper cover plate 32, the upper cover plate 32 is placed on the upper end surface of the mold 53, and the upper cover plate 32 is circular , the center of the upper cover plate 32 is provided with a mounting groove 31, the mounting groove 31 is a circular groove, and the center of the lower bottom surface of the mounting groove 31 is provided with a through hole A39. A mounting plate 1 is installed in the mounting groove 31 , the mounting plate 1 is connected with the upper cover plate 32 through a bearing, and the mounting plate 1 can rotate in the mounting groove 31 . A fixed cover 38 is connected with bol...

Embodiment 2

[0073] This embodiment provides a variable-diameter mold for making hollow pasta and its use method, which includes all the technical features in Embodiment 1, and also includes: the surface of the expanding cavity template 12 that is in contact with the dough is provided with several Rib groove 23, such as Figure 13 As shown, the rib grooves 23 are arranged along the vertical direction, each of the rib grooves 23 has the same width, and the distance between two adjacent rib grooves 23 is equal. When the cavity expansion template 12 squeezes the dough during the cavity expansion process, the surface of the cavity of the dough will form a structure of reinforcing ribs to enhance the strength of the inner wall of the dough cavity and prevent the deformation of the dough cavity after the cavity expansion template is retracted.

Embodiment 3

[0075] This embodiment provides a device for making a pasta hollow cavity and a method of use thereof, such as Figure 14 As shown, it includes all the technical features in the second embodiment, and also includes: a protective cover 43 is respectively installed between the front and rear edges of the two expansion templates 12, and one end of the protective cover 43 is fixedly connected with a bolt On the edge of the cavity expansion template 12 on the left side, the other end is fixedly connected to the edge of the cavity expansion template 12 on the left side with bolts. The protective cover 43 is an organ cover, and its surface is repeatedly folded along the front and rear directions to form several Z-shaped creases, so that the protective cover 43 can be elongated or shortened. When the expansion template 12 moved, the protective cover 43 could be elongated with the opening of the two expansion templates 12, and retracted with the closing of the two expansion templates 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com