Ink boxes and printing device

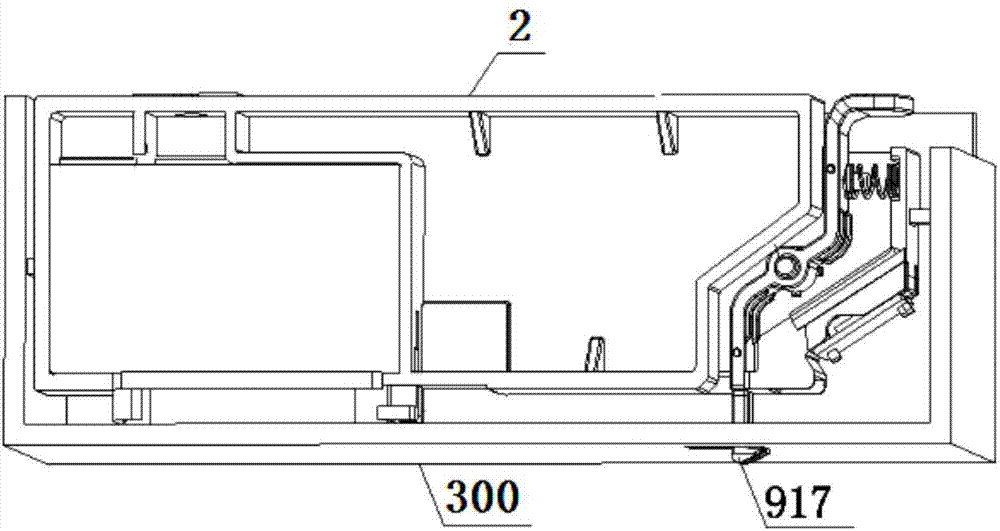

A technology of ink cartridges and mounting parts, applied in the printing field, can solve problems such as disengagement, low assembly reliability, and easy leftward deviation of the joint part 917, and achieve the effect of preventing failure of cooperation and high assembly reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079] Installation department:

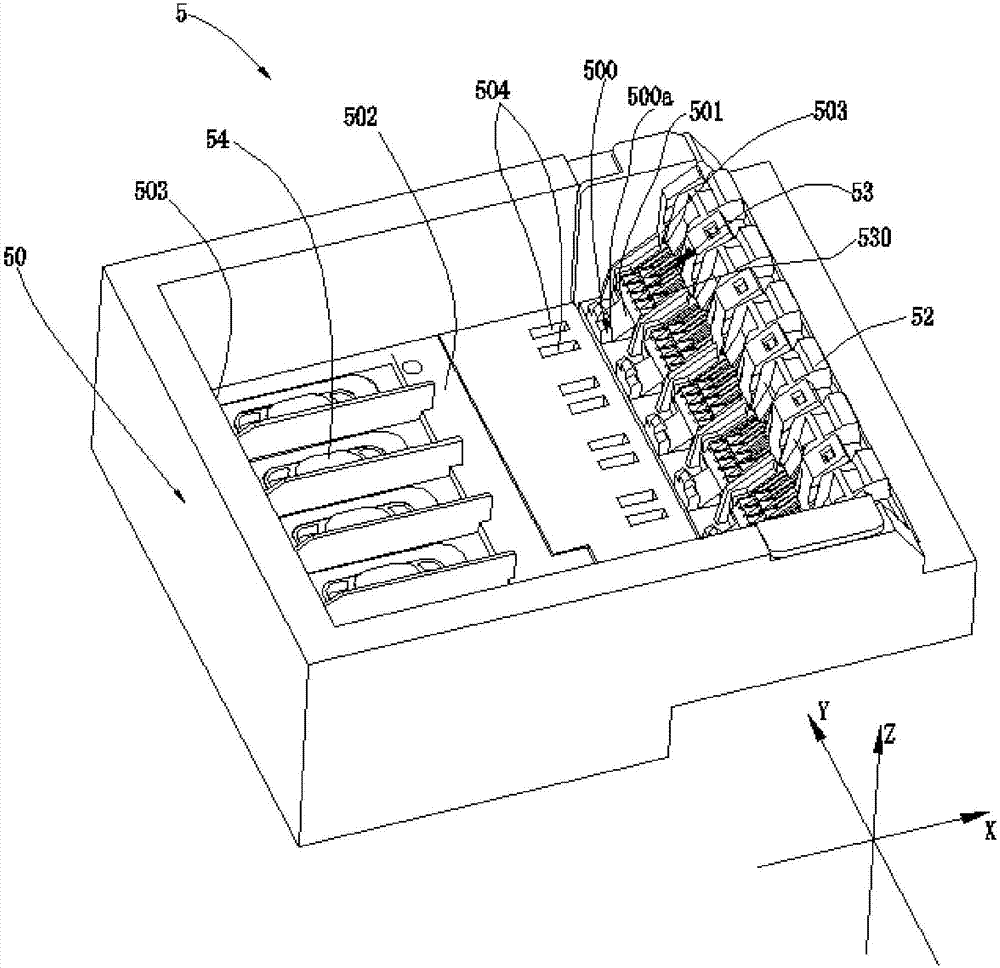

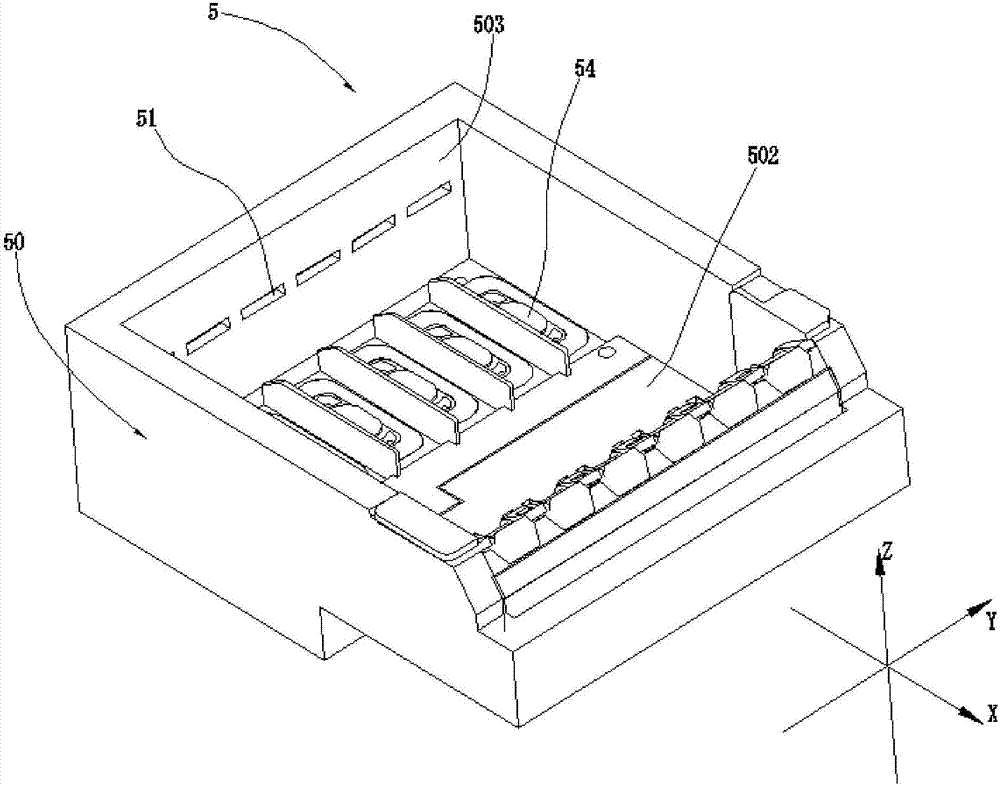

[0080] The installation part is used to install one or more ink cartridges, such as figure 2 and image 3 The shown installation part 5 can install a plurality of ink cartridges 4, and a plurality of installation positions corresponding to each ink cartridge 4 are set on the installation part 5, for example, 6 ink cartridges can be installed, and the installation part 5 has 6 installation positions. The mounting part 5 has a mounting part bracket 50 , a card slot 51 , a lever 52 , an electrical connection part 53 and an ink tube 54 . The mounting bracket 50 includes a protrusion 500 , a first hole 501 , a bottom wall 502 and two side walls 503 . Mounting part bracket 50 can also be provided with figure 2 The second hole 504 is shown, and the second hole 504 may not be provided. It can be understood that the "first holes" and "second holes" mentioned here are not limited to the number of holes, for example, there may be multiple first hol...

Embodiment 2

[0102] Compared with Embodiment 1, the difference of this embodiment lies in that the structures of the installation part 5 and the engaging mechanism are different.

[0103] Specifically, this installation portion 5 has a plurality of installation positions for installing the ink cartridge 4, such as Figure 10 As shown, the mounting part 5 has 4 mounting positions. The protrusions 500 of the 4 installation positions are integrated, and the first hole 501 is also integrated, that is, the protrusions 500 of the 4 installation positions are connected together, and there is no difference due to the installation positions of different ink cartridges 4. Split settings. The first holes 501 are also connected together and not separated.

[0104] In this embodiment, the ink supply needle 55 can also be used to replace the ink tube 54 in the first embodiment, the ink supply needle 55 can be inserted into the interior of the ink cartridge 4, and the ink can flow into the print head t...

Embodiment 3

[0113] Compared with the first embodiment, the difference of this embodiment is that both the joint part 46 and the elastic part 47 cooperate with the second hole 504 to realize the installation between the ink cartridge 4 and the installation part 5 .

[0114] Specifically, such as Figure 14 , Figure 14a As shown, the second hole 504 has a first inner wall 504a and a second inner wall 504b disposed opposite to each other. The elastic portion 47 can press fit with the second inner wall 504b. If the installation direction of the first inner wall 504a relative to the ink cartridge 4 intersects with the installation direction, the joint 46 can press fit with the first inner wall 504a; The mating surface of the portion 46 can be adjusted to be the first mating surface 56 below the second hole 504 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com