Patents

Literature

49 results about "Tight binding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

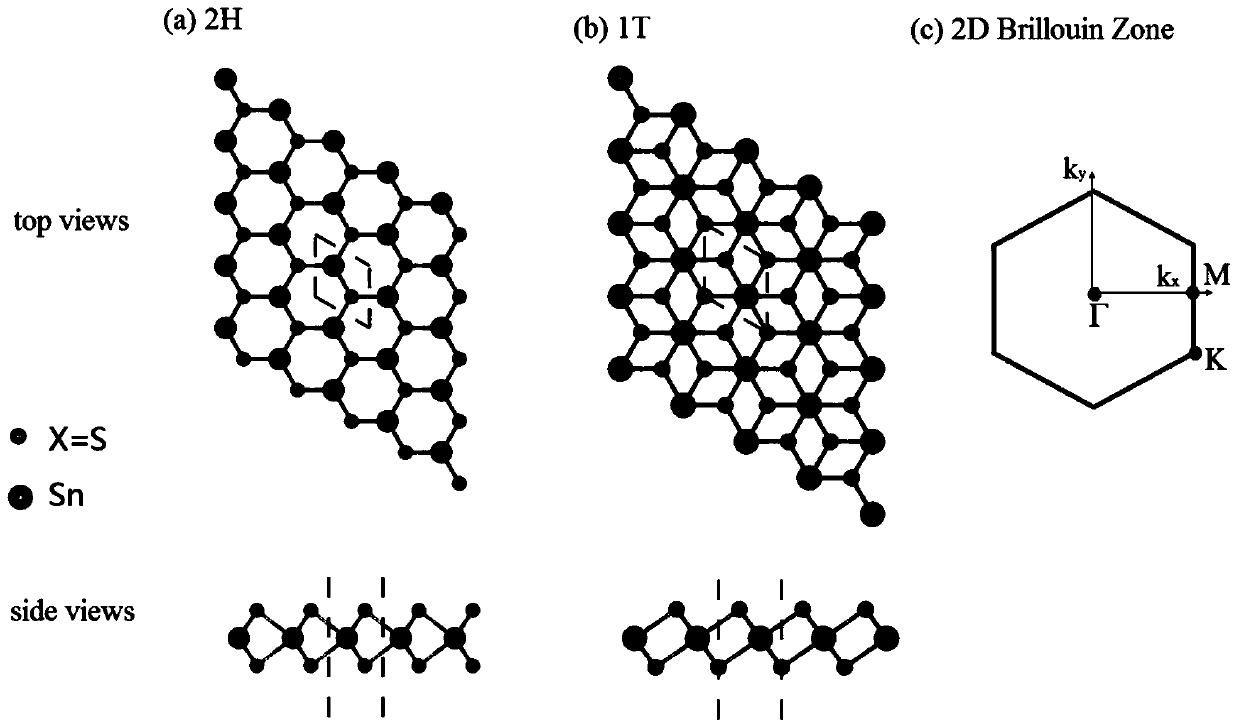

In solid-state physics, the tight-binding model (or TB model) is an approach to the calculation of electronic band structure using an approximate set of wave functions based upon superposition of wave functions for isolated atoms located at each atomic site. The method is closely related to the LCAO method (linear combination of atomic orbitals method) used in chemistry. Tight-binding models are applied to a wide variety of solids. The model gives good qualitative results in many cases and can be combined with other models that give better results where the tight-binding model fails. Though the tight-binding model is a one-electron model, the model also provides a basis for more advanced calculations like the calculation of surface states and application to various kinds of many-body problem and quasiparticle calculations.

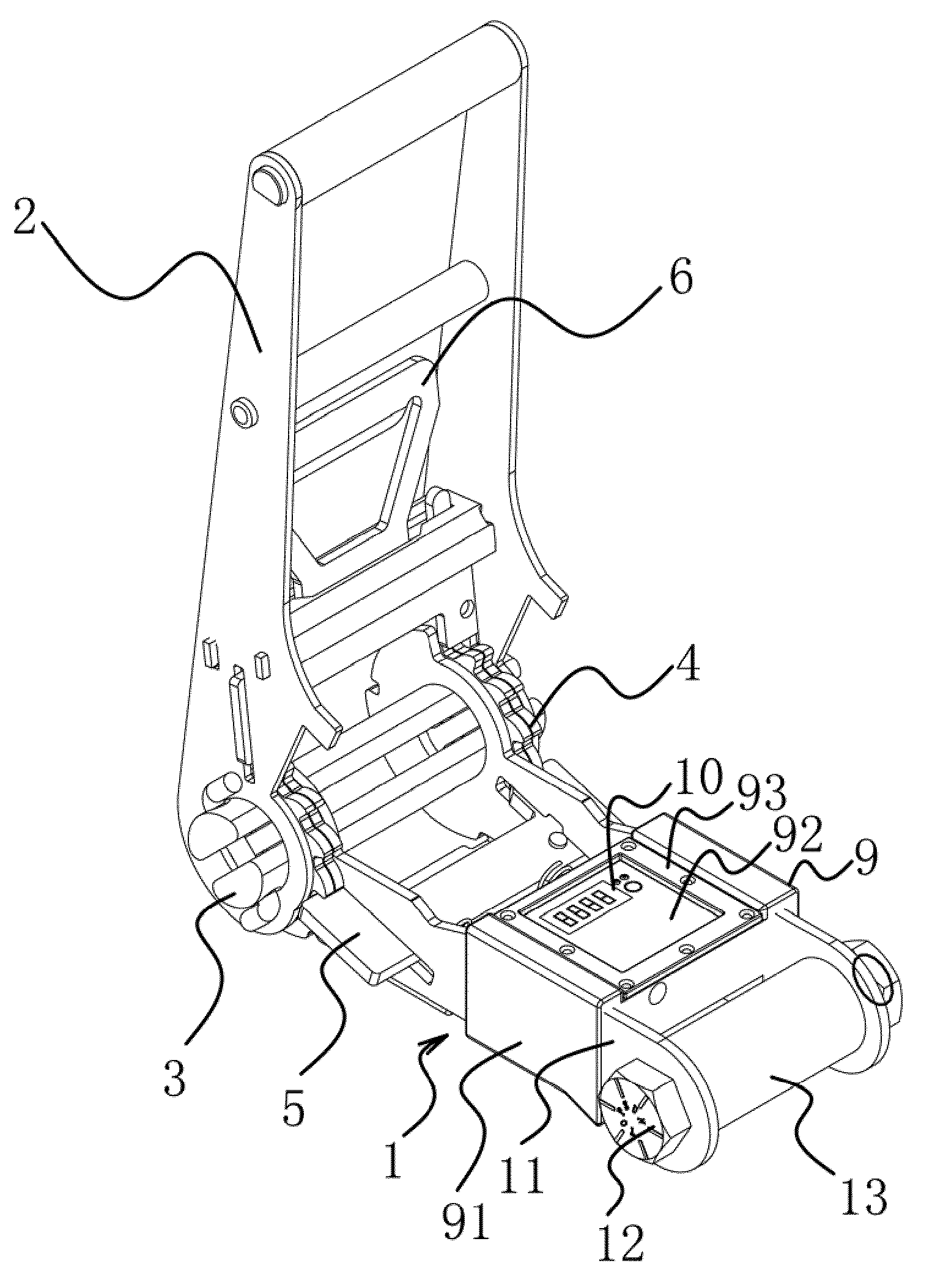

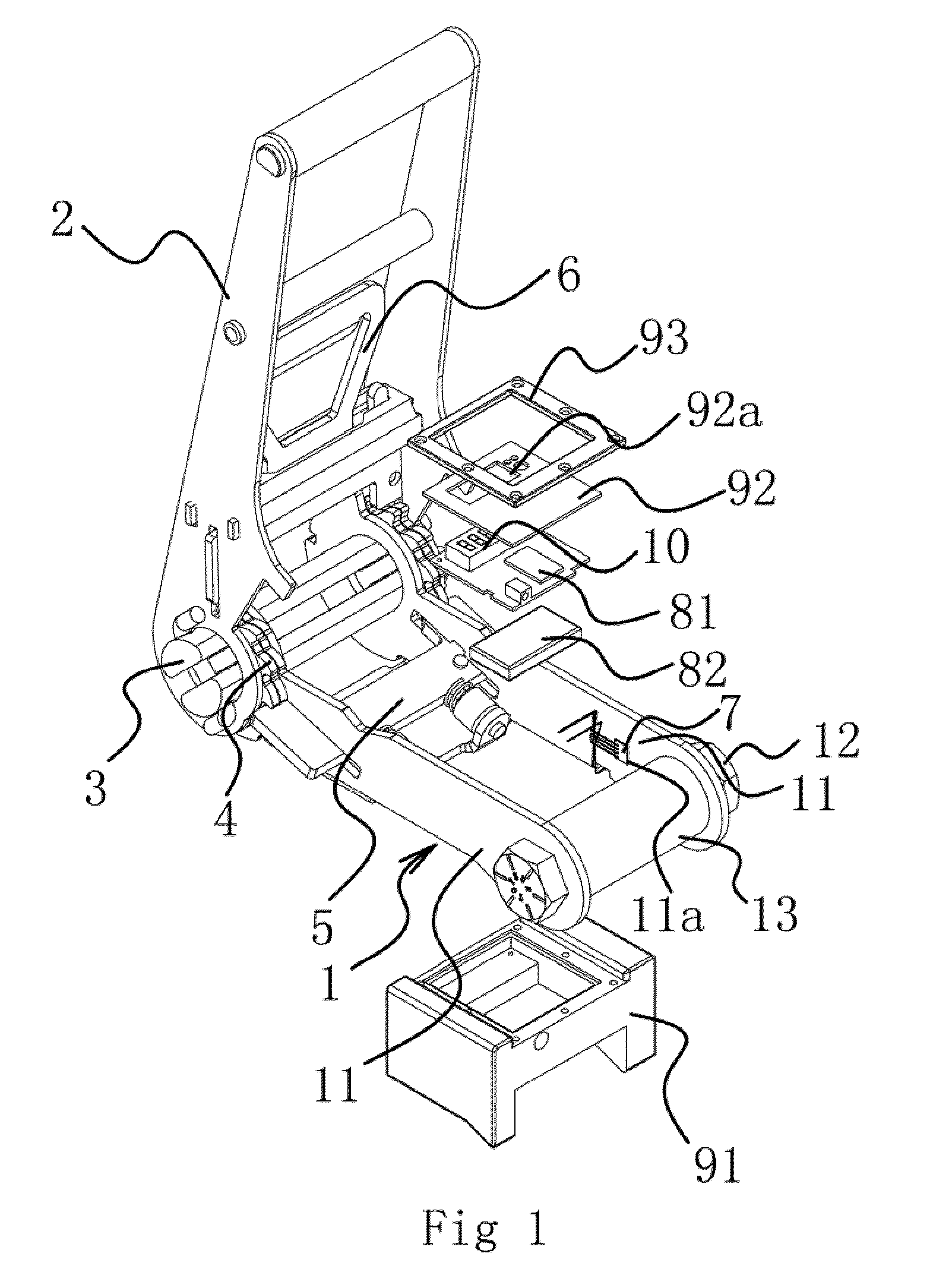

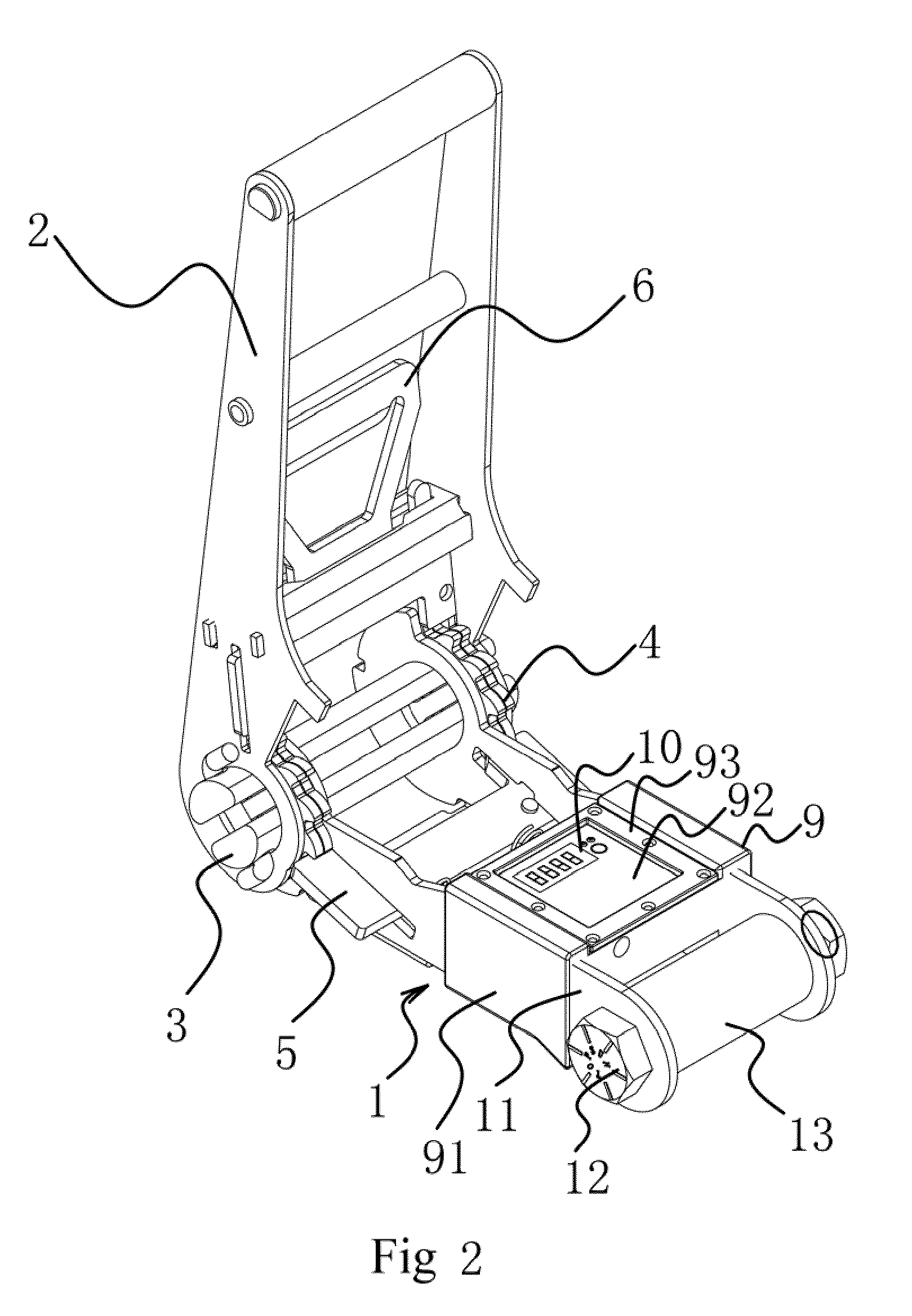

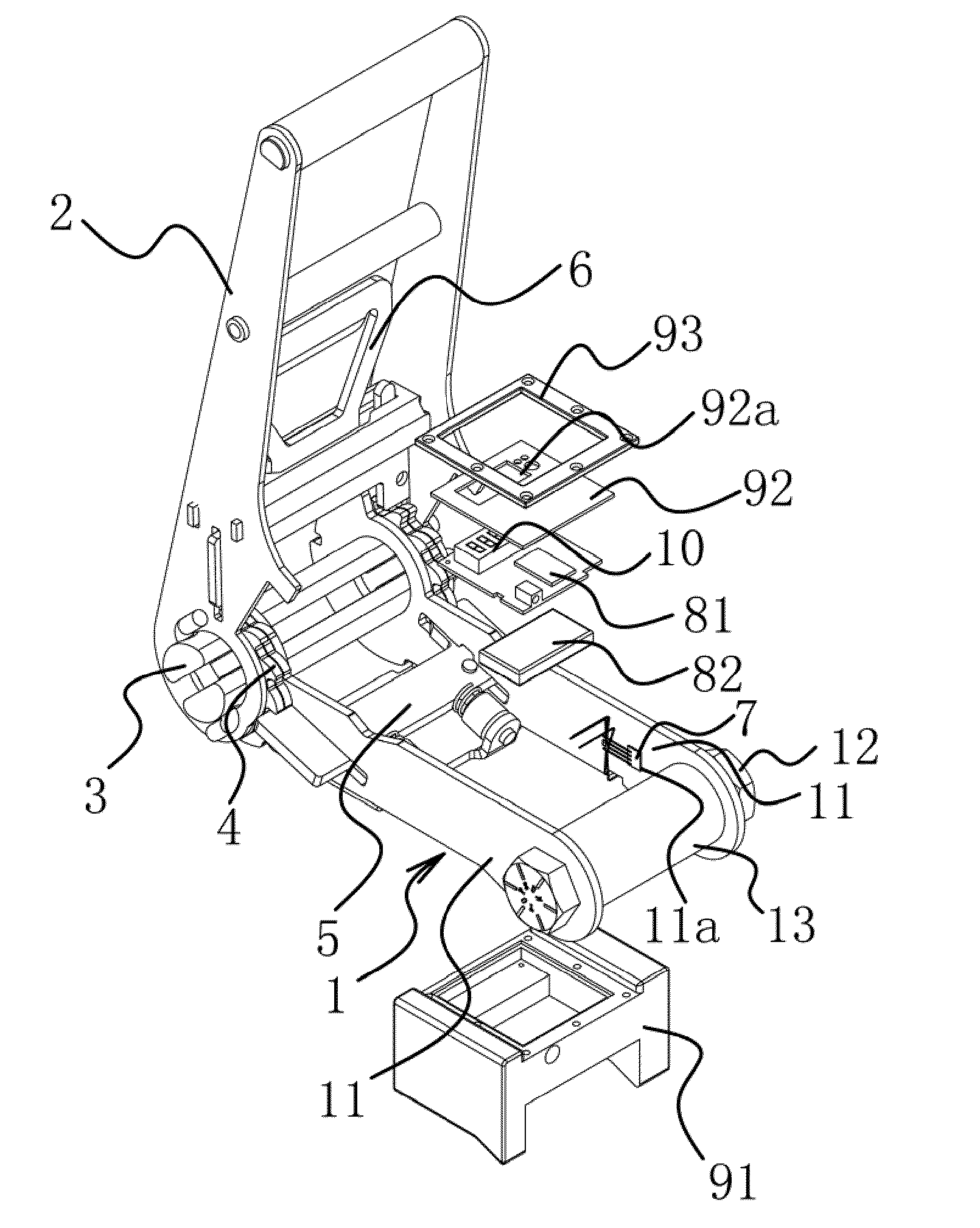

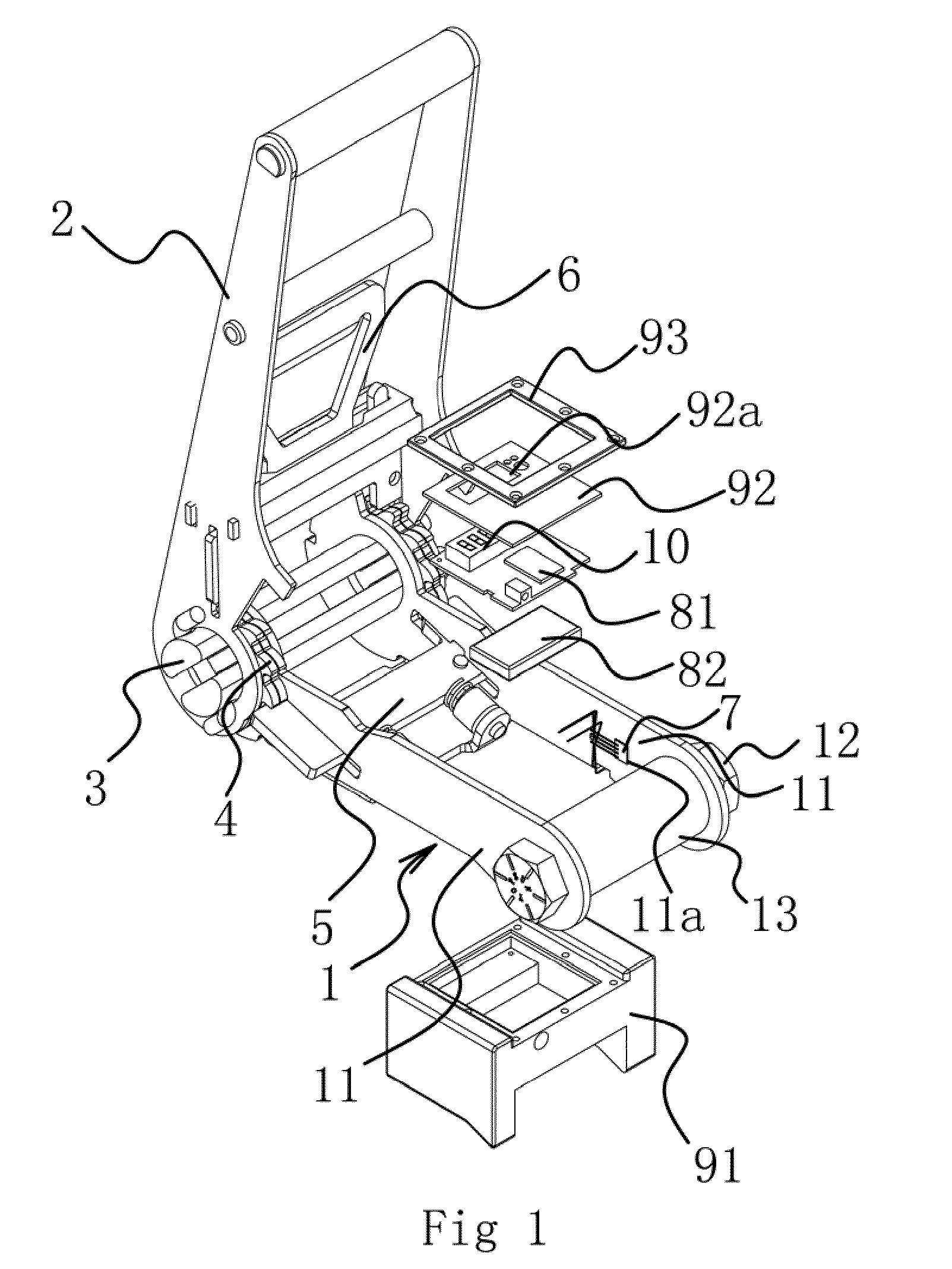

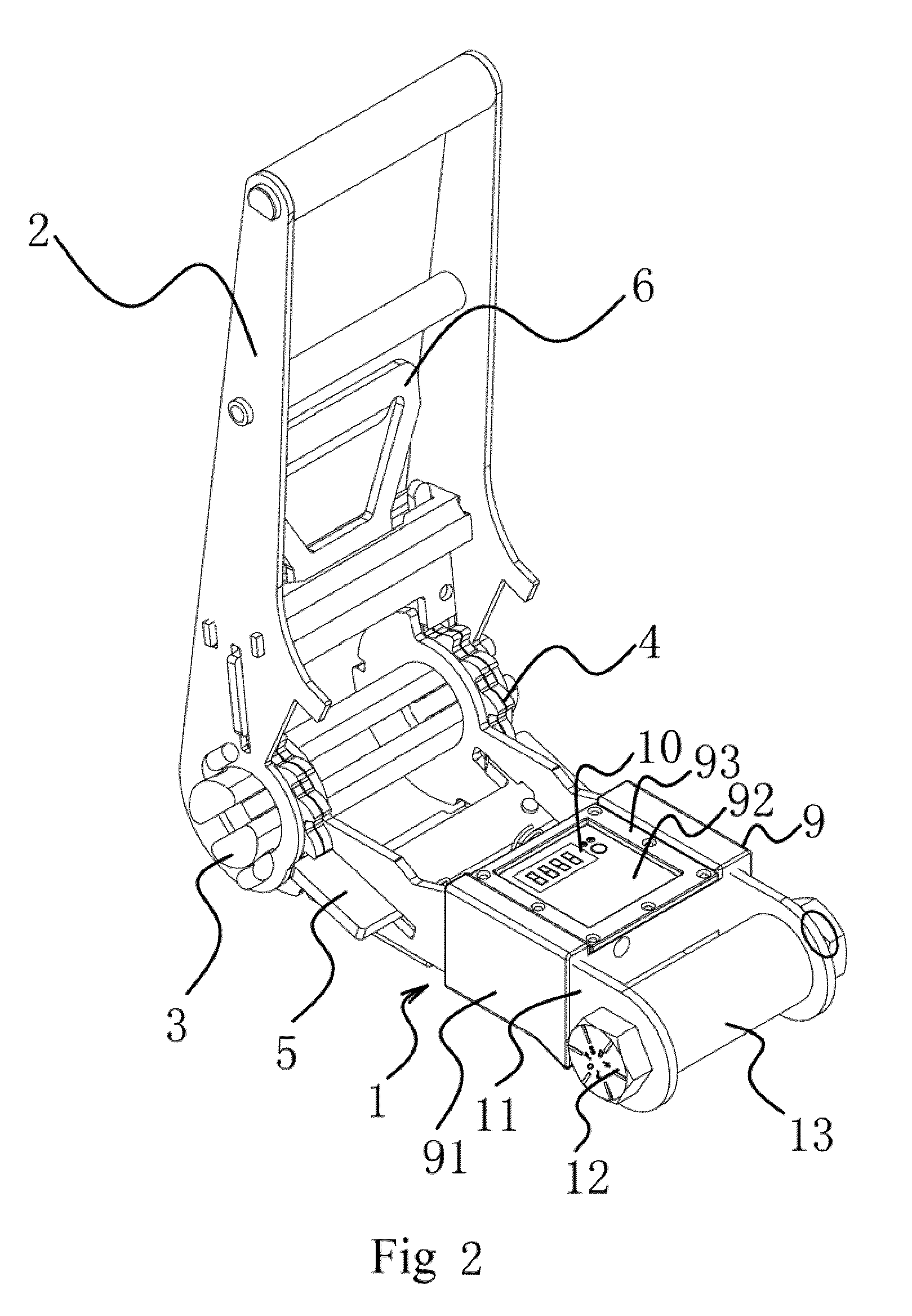

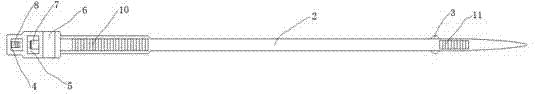

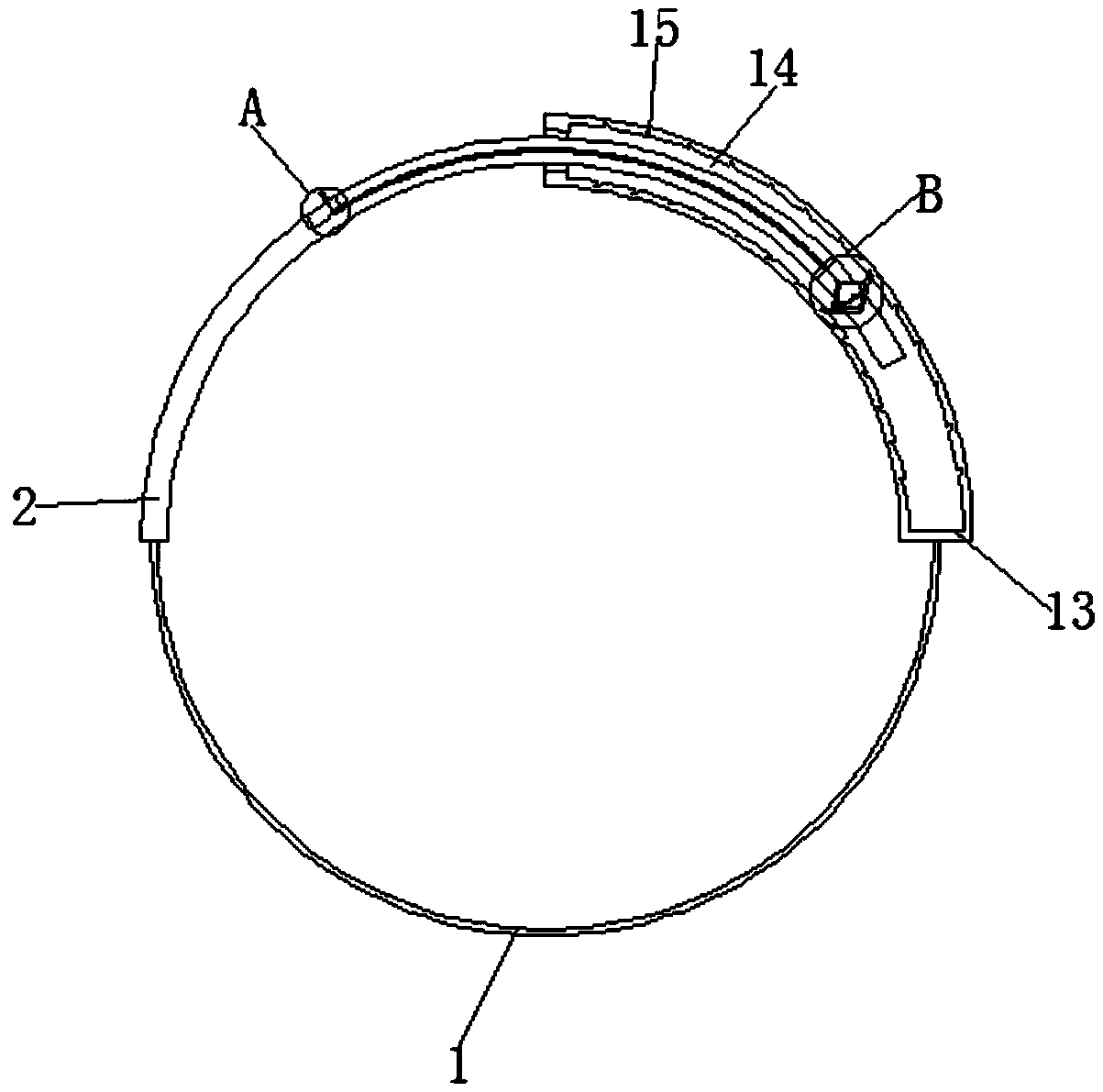

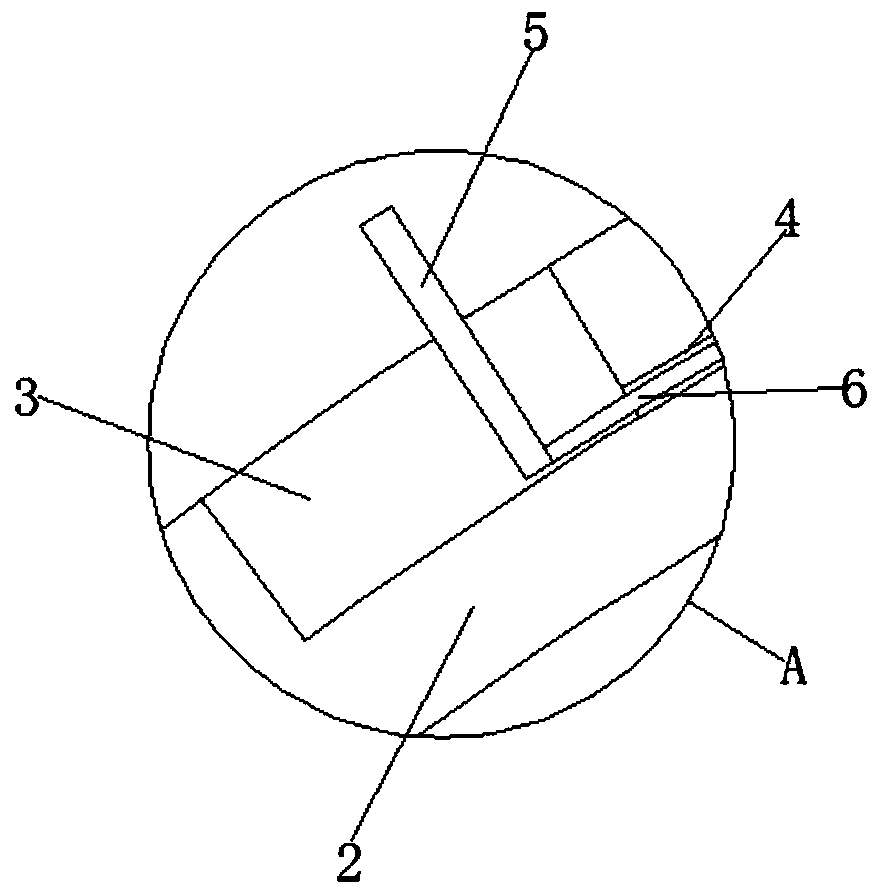

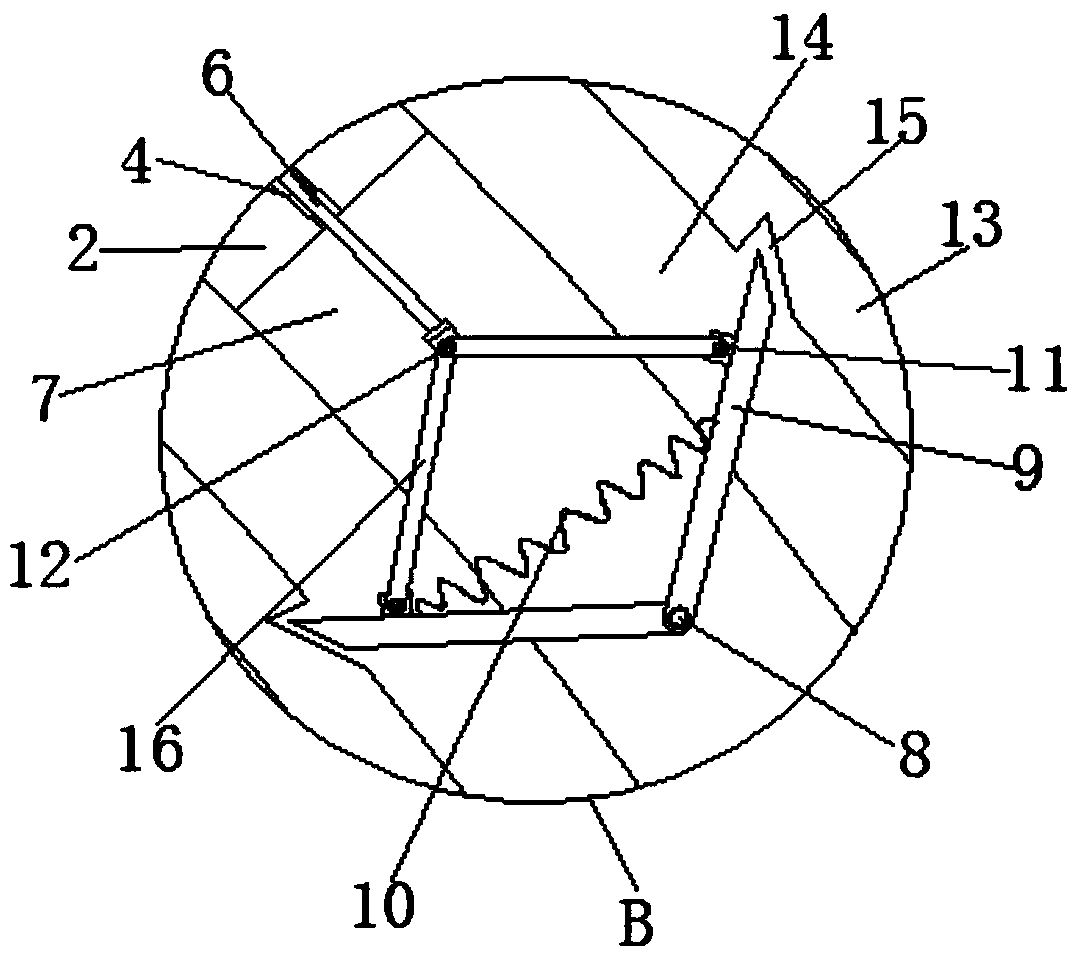

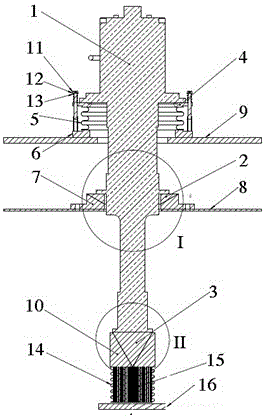

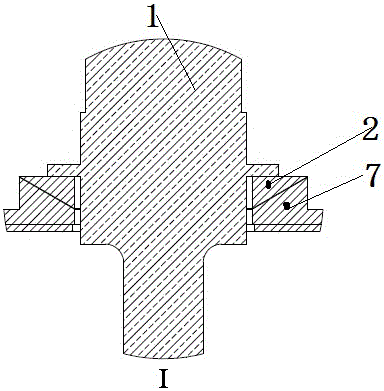

Force measuring ratchet tie down

ActiveUS20110001627A1Improve securityCompact structureSnap fastenersForce measurementSignal processing circuitsDisplay device

The present invention provides a force measuring ratchet tie down in the field of goods holding. The force measuring ratchet tie down of the invention addresses the technical problems such has insufficiently tight binding, severe difficulty in control and trouble in adjustment. The force measuring ratchet tie down includes a body assembly, a handle, a teeth stop board, a catch and a scroll. The handle is connected with the body assembly through the scroll. A binding belt having a fixable outer end is connected to the body assembly. Another binding belt having a fixable outer end is rolled on the scroll. A ratchet is fixed on the scroll. The body assembly is movably connected with a teeth stop board the end of which could be embedded among the teeth of the ratchet. The handle is movably connected with a catch the end of which could be embedded among the teeth of the ratchet. A sensor is placed at a forced part of the tie down, which is linked with a signal processing circuit and could generate a signal corresponding to the size of the tensioning force of the binding belt when the tie down is in operation. A display device is connected to the signal processing circuit. The force measuring ratchet tie down of the invention has advantages including a high safety property, a compact structure and a low manufacturing cost.

Owner:ZHEJIANG TOPSUN LOGISTIC CONTROL CO LTD

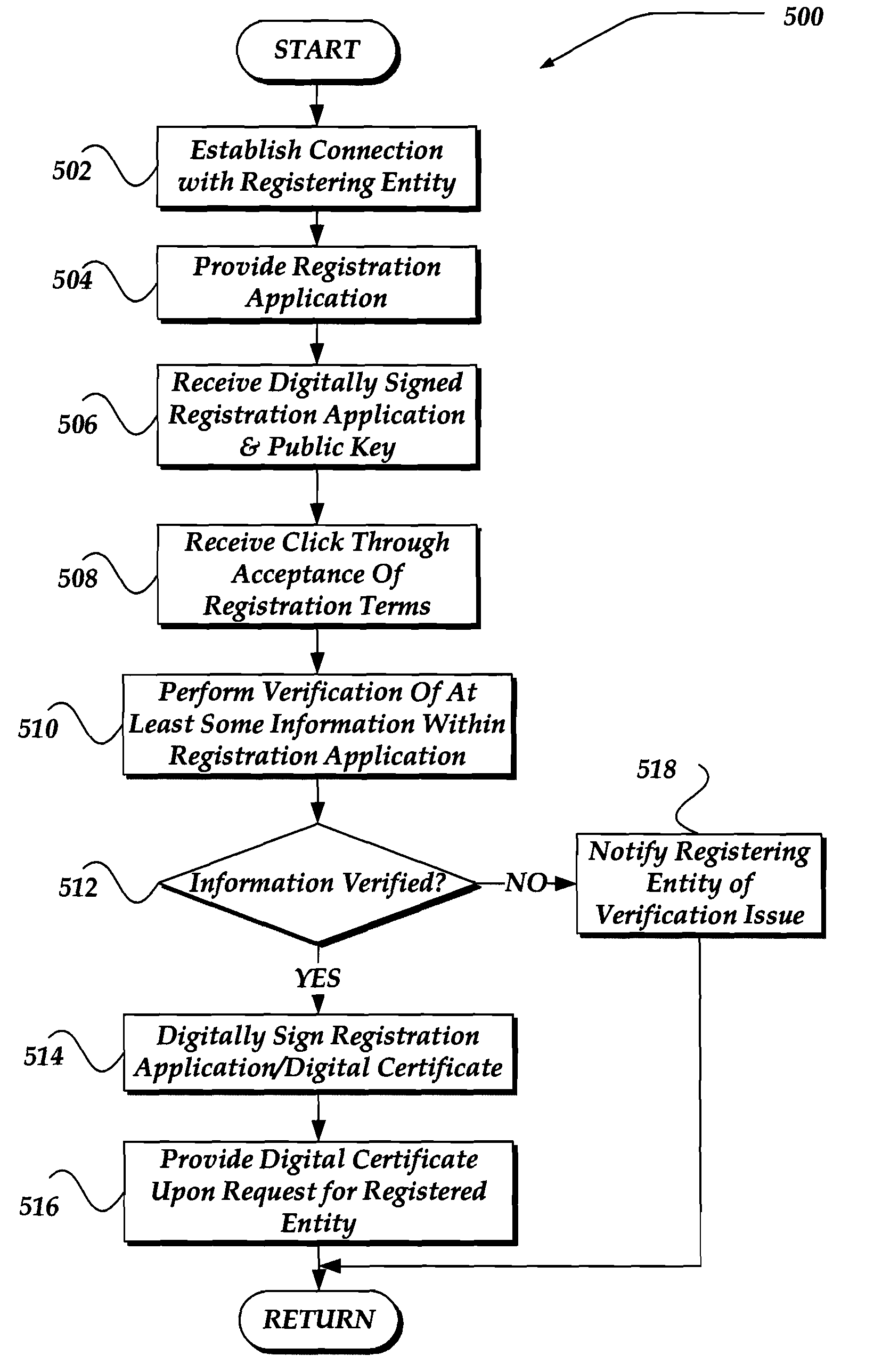

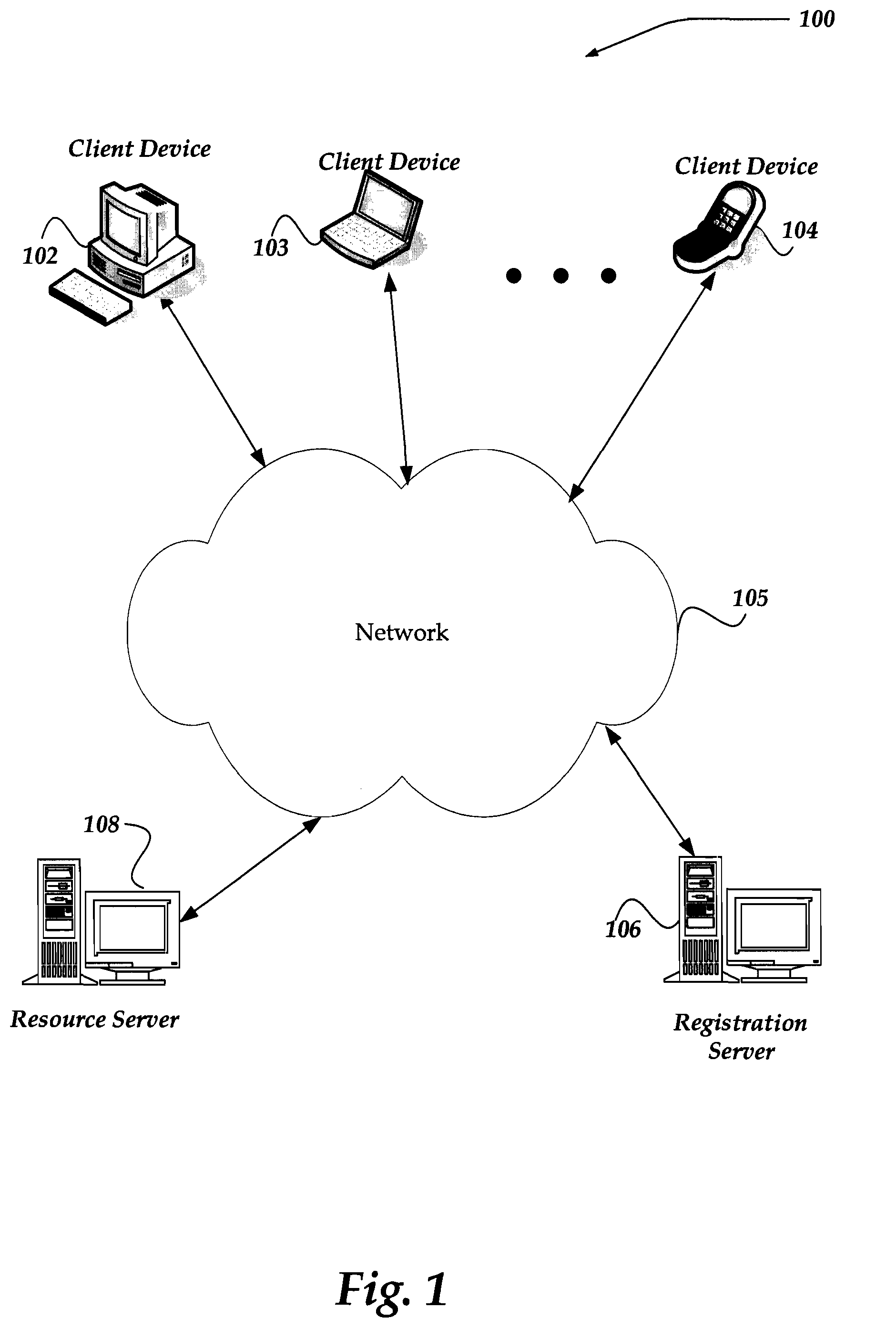

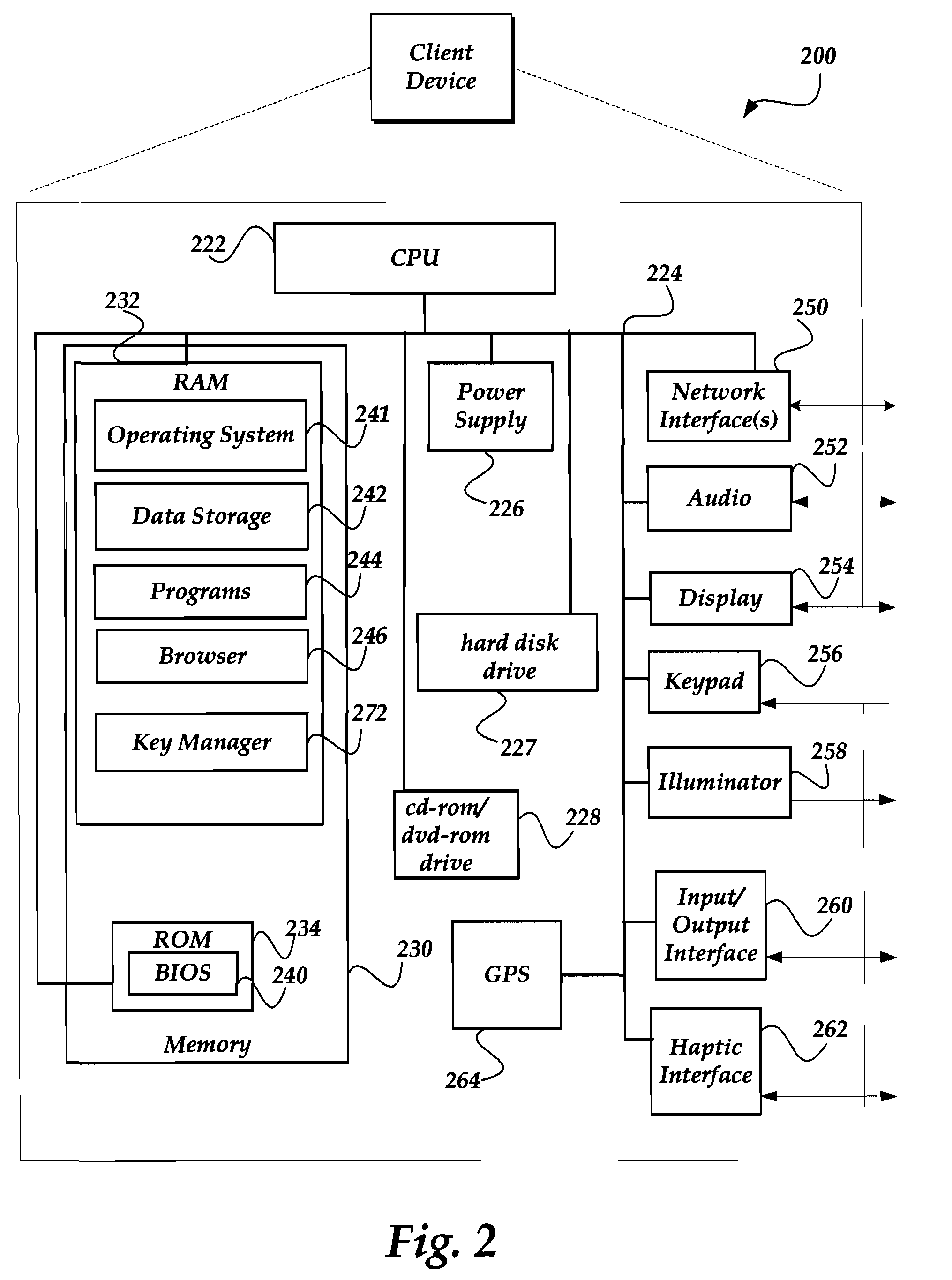

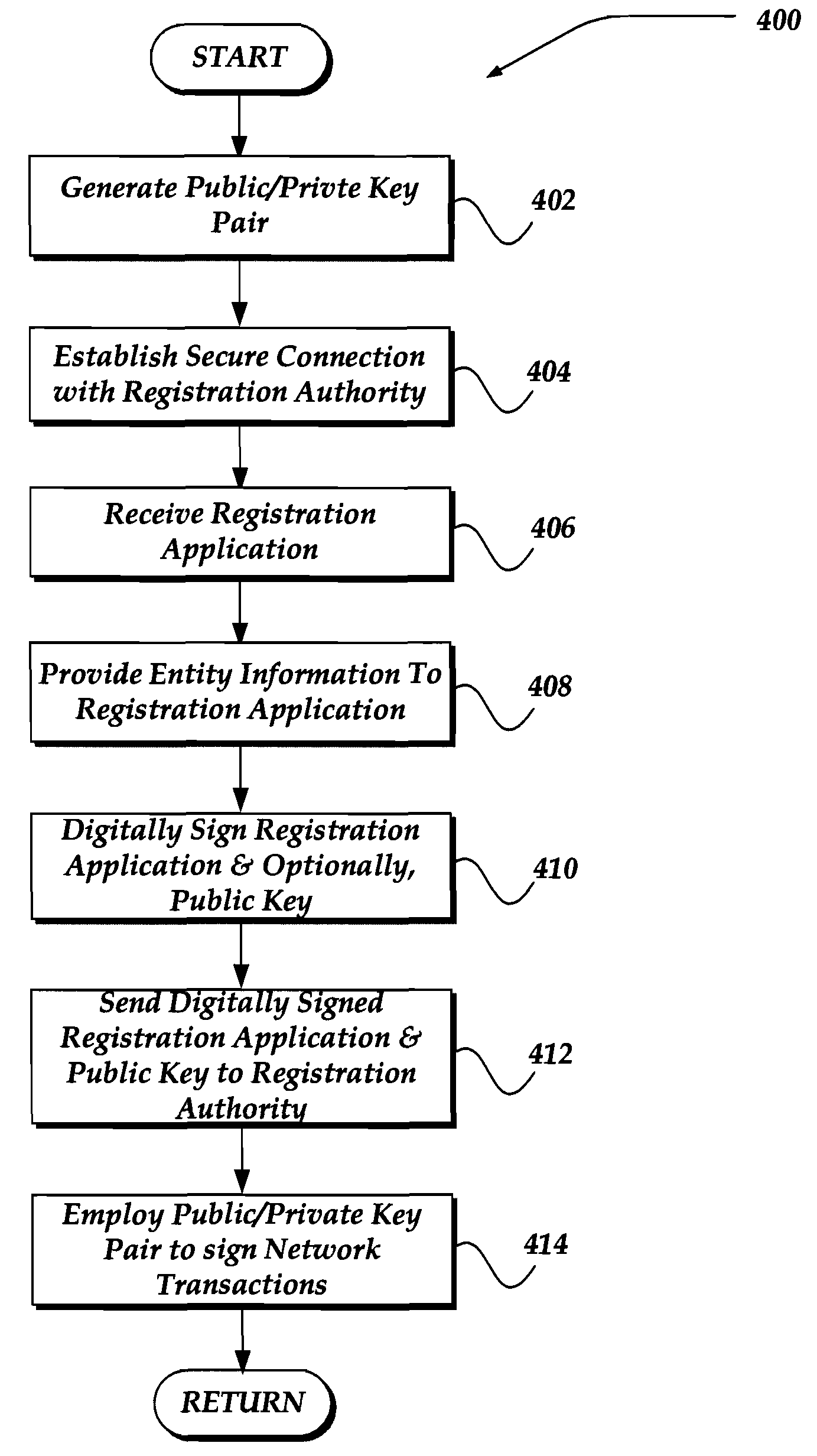

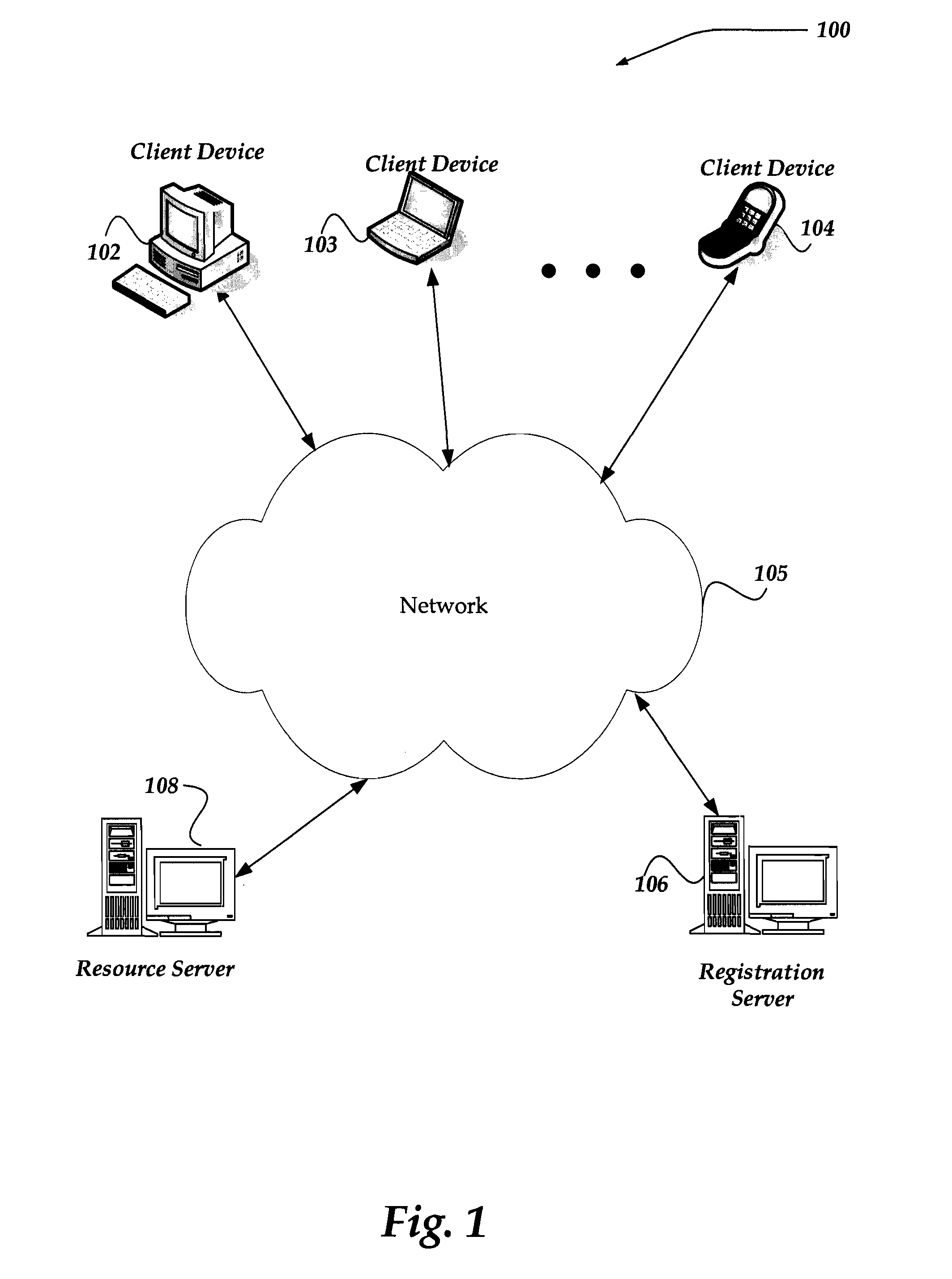

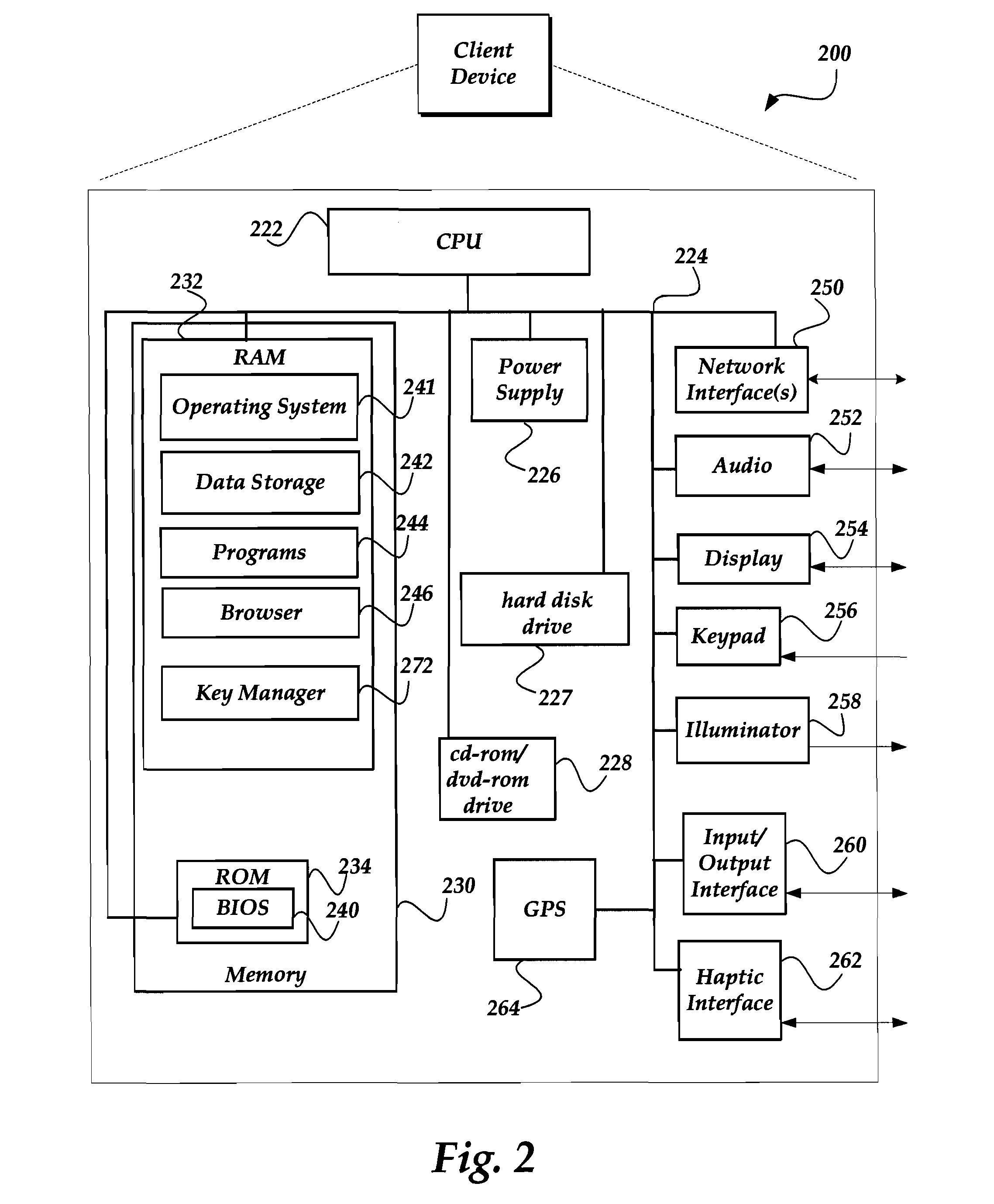

Pre-binding and tight binding of an on-line identity to a digital signature

ActiveUS8321677B2Multiple keys/algorithms usageUser identity/authority verificationRegistration authorityN application

A method, apparatus, and system are directed towards generating a public / private key pair prior to registration. The generation of the public / private key pair is performed by the entity to which the key pair is to be associated. The entity may then complete n application. The entity may then employ the generated public / private key pair to digitally sign the application. In one embodiment, the public key is provided with the application to a registration authority. Upon request, the public key and at least some of the application information may be provided to requester for use in identification, authentication, integrity, and / or non-repudiation of the registered entity. In another embodiment, the registration authority or other entity may verify the identity of the registering entity using the application. In one embodiment, the registration authority may select to digitally sign the application to indicate that the information has been verified.

Owner:GOOGLE LLC

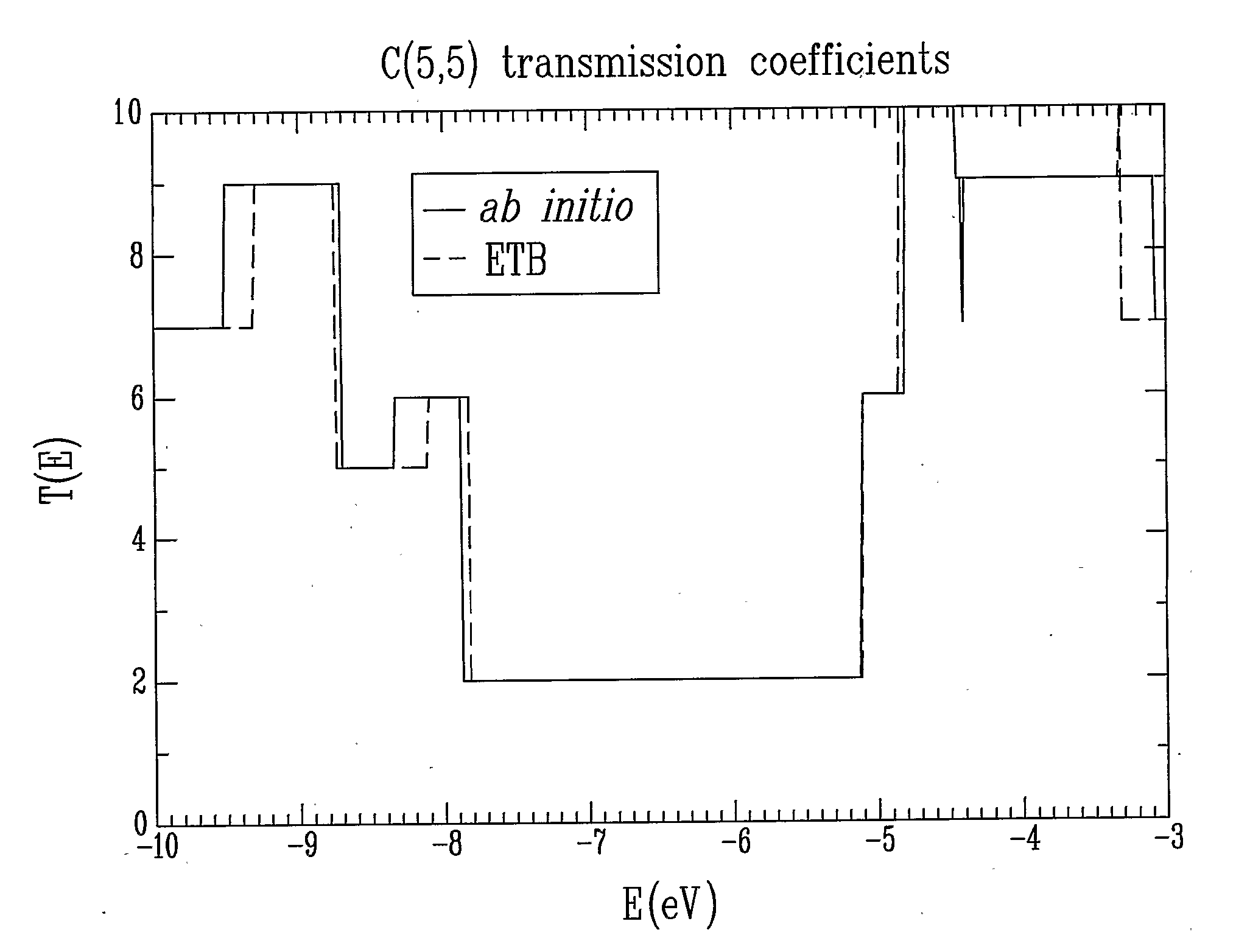

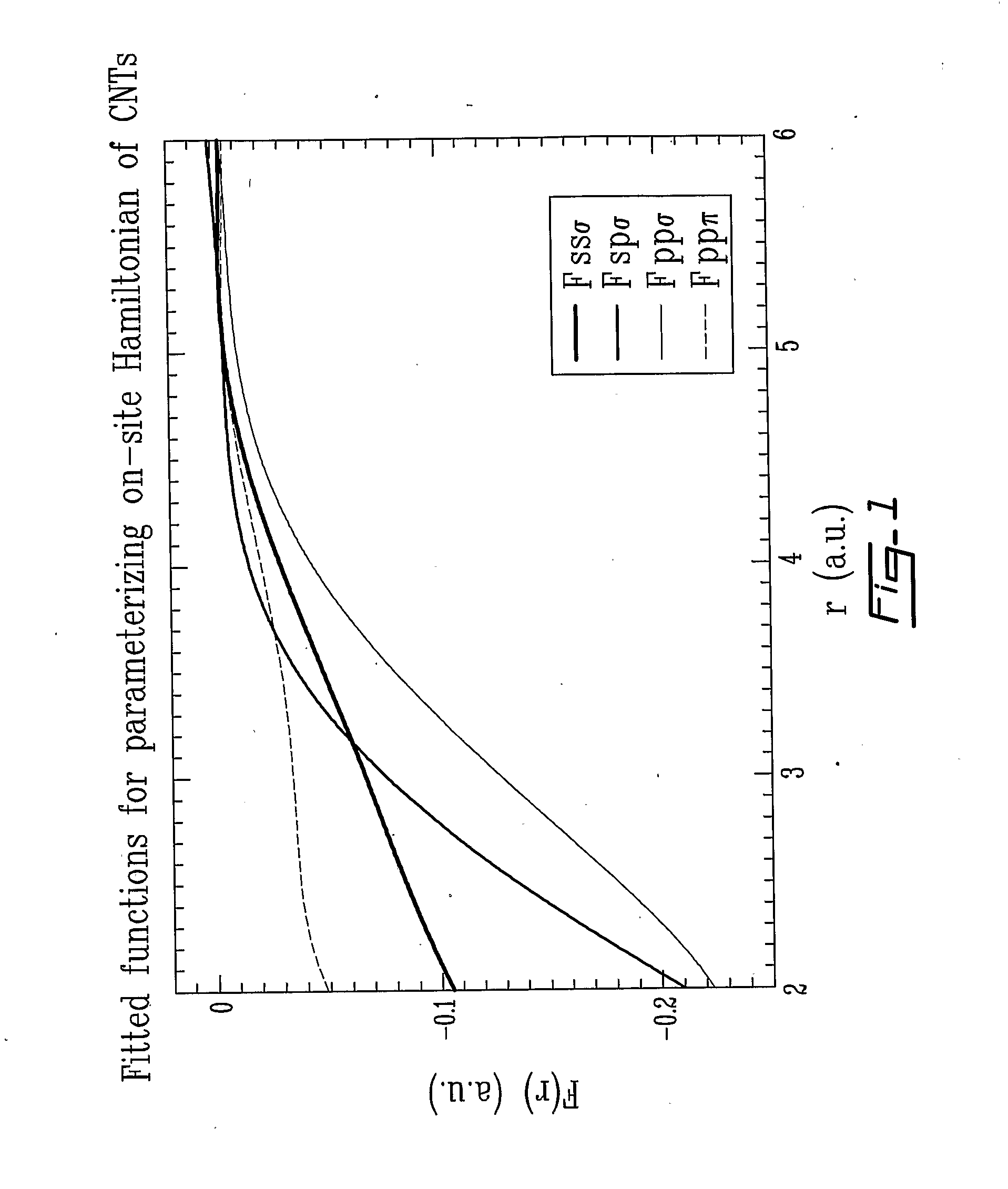

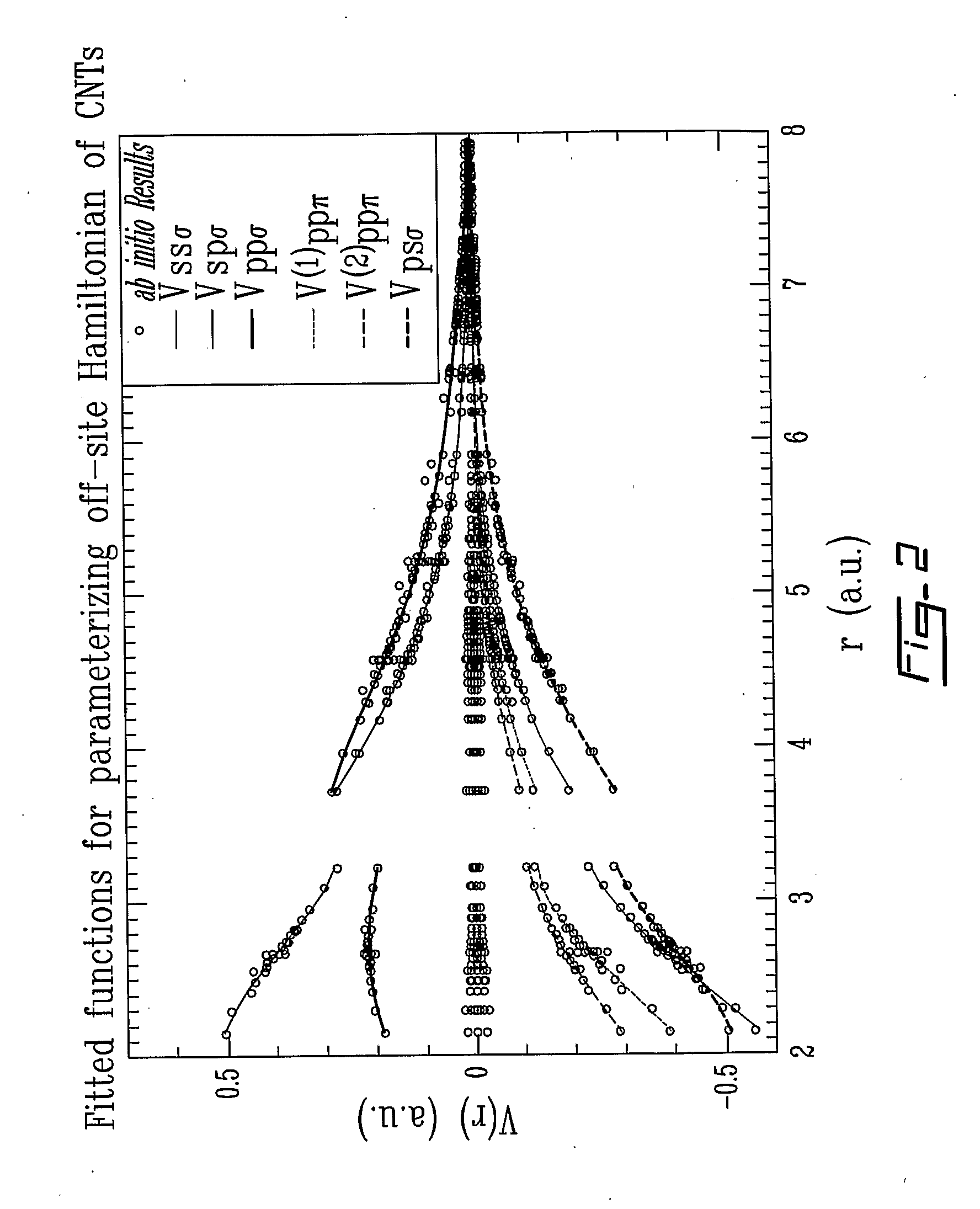

Nano molecular modeling method

A nano-technology modeling method wherein a group of atoms and an interaction thereof to an open environment are defined by Hamiltonian matrices and overlap matrices, matrix elements of the matrices being obtained by a tight-binding (TB) fitting of system parameters to a first principles atomistic model based on density functional theory (DFT) with non-equilibrium density distribution.

Owner:MCGILL UNIV

Pre-binding and tight binding of an on-line identity to a digital signature

ActiveUS20080126806A1Multiple keys/algorithms usageUser identity/authority verificationRegistration authorityDigital signature

A method, apparatus, and system are directed towards generating a public / private key pair prior to registration. The generation of the public / private key pair is performed by the entity to which the key pair is to be associated. The entity may then complete n application. The entity may then employ the generated public / private key pair to digitally sign the application. In one embodiment, the public key is provided with the application to a registration authority. Upon request, the public key and at least some of the application information may be provided to requester for use in identification, authentication, integrity, and / or non-repudiation of the registered entity. In another embodiment, the registration authority or other entity may verify the identity of the registering entity using the application. In one embodiment, the registration authority may select to digitally sign the application to indicate that the information has been verified.

Owner:GOOGLE LLC

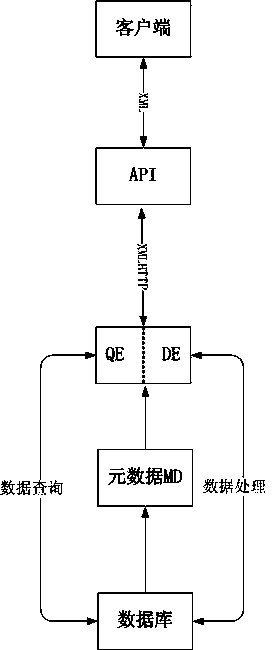

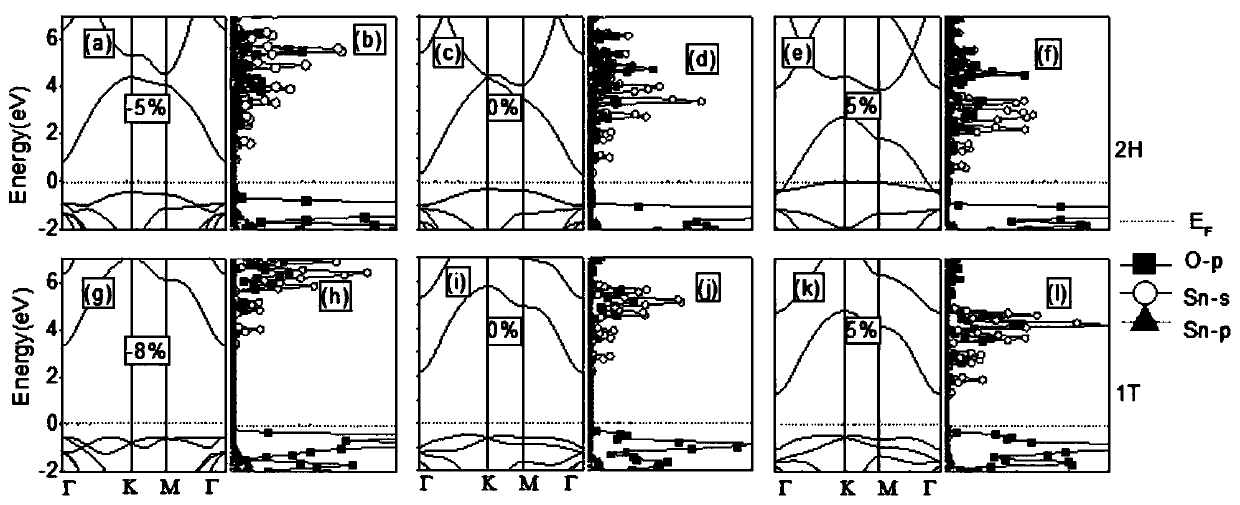

Method and system for achieving unified processing on multiple database data through middleware

ActiveCN103678575AFast transplantQuick managementDatabase management systemsSpecial data processing applicationsData displayApplication software

The invention relates to the technical field of databases, and discloses a method and system for achieving unified processing on multiple databases through middleware. The method includes the following steps: mapping each data list in the databases into an XML file; sending data requests of a user to the middleware through application software, conducting analysis after the middleware receives the data requests of the application software of a client terminal, and generating corresponding SQL statements according to contents of the data requests; displaying data through a unified client terminal access interface API, conducting data binding on HTML files on a front end page after a presentation layer receives the data, conducting data binding on nodes in the HTML files and obtained XML nodes, and accordingly conducting data display. The invention further discloses a system for achieving unified processing on the multiple databases through the middleware. The corresponding SQL statements are automatically generated according to the data requests, excessively-tight binding and excessively-tight limiting between an application layer and the databases are avoided, and rapid transplantation and rapid management on the multiple databases are accordingly achieved.

Owner:四川九洲投资控股集团有限公司

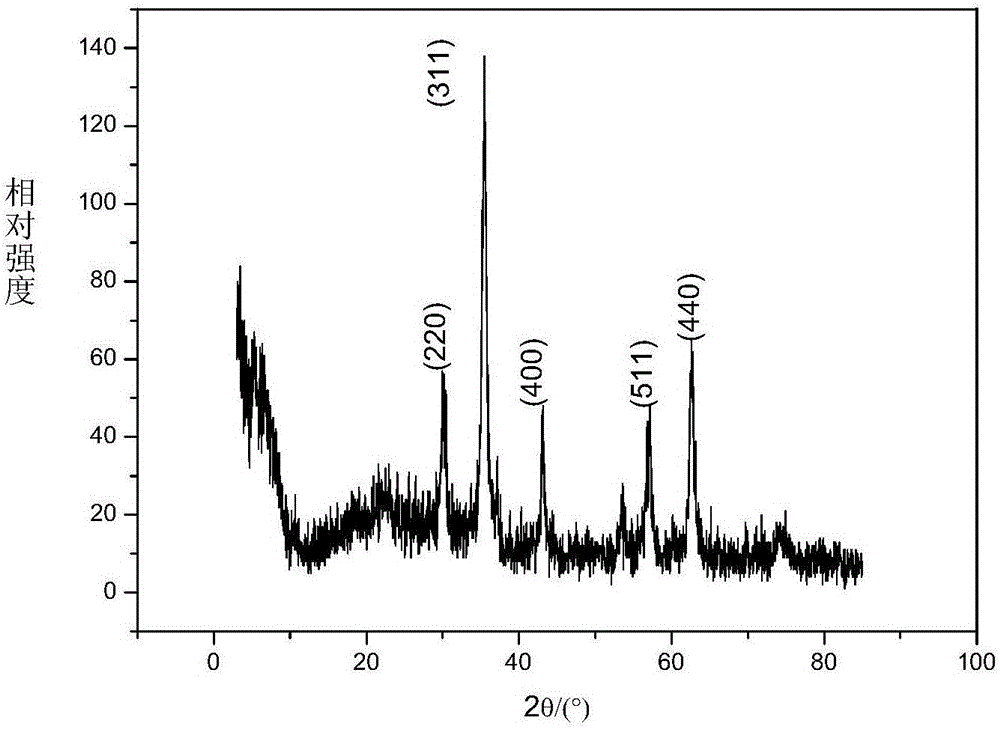

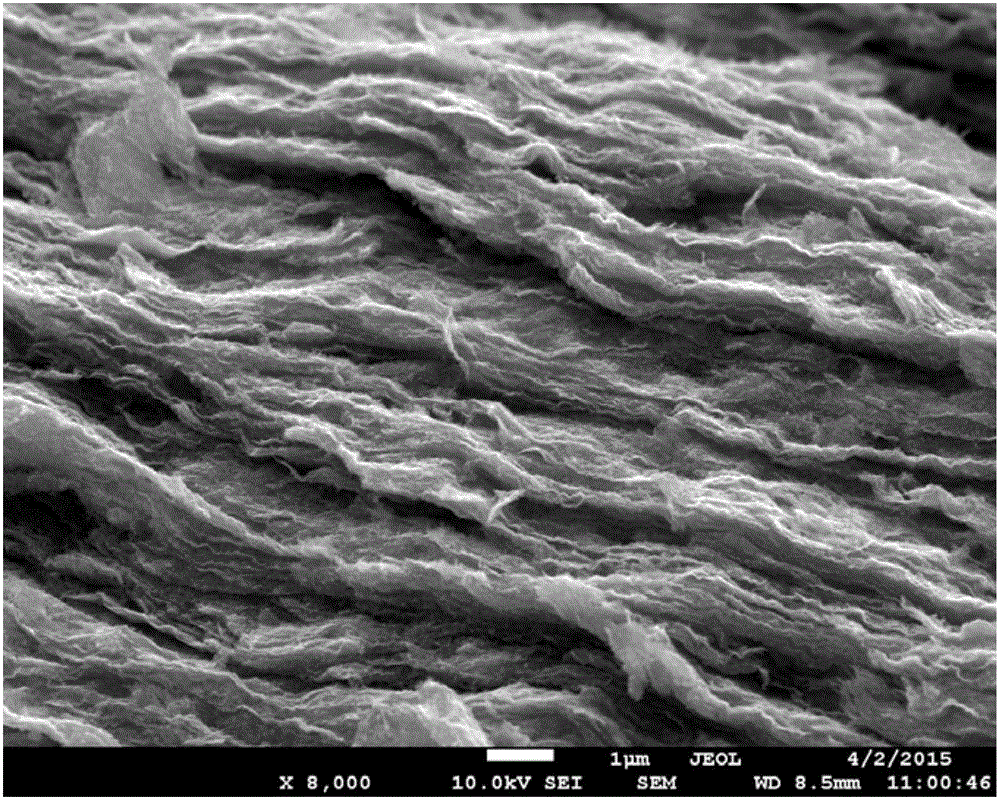

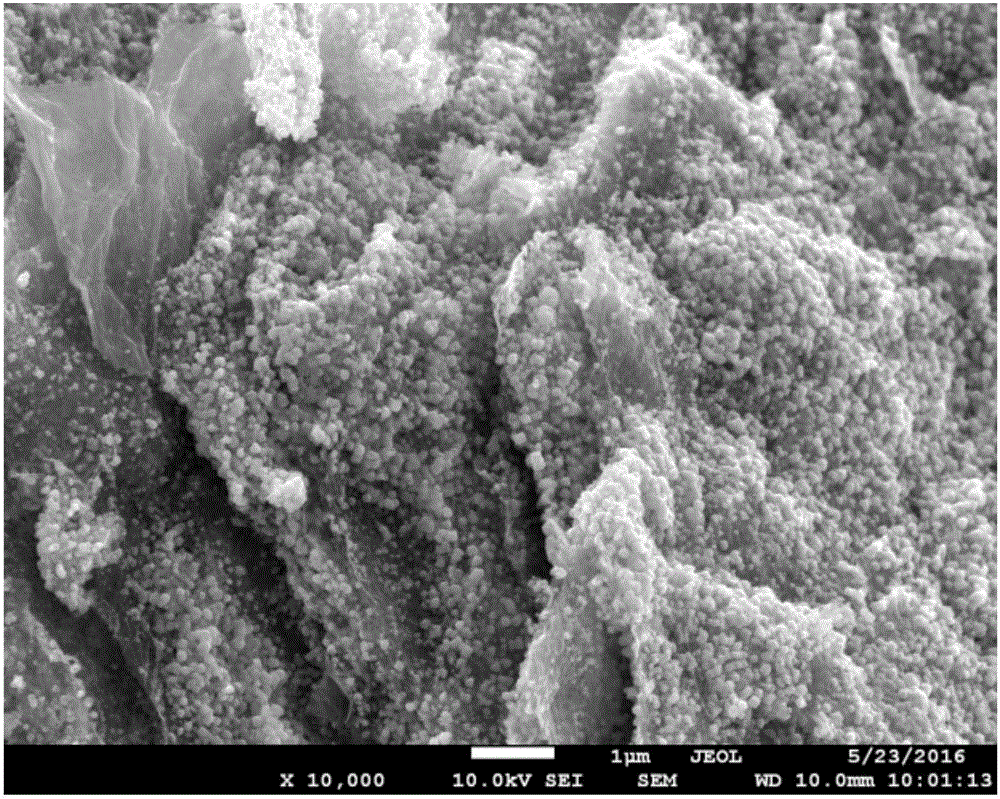

Fe3O4/graphene composite material and preparation method thereof

ActiveCN106252091AConducive to free movementGive full play to the synergistic effectHybrid capacitor electrodesCell electrodesColloidal particleNanocomposite

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

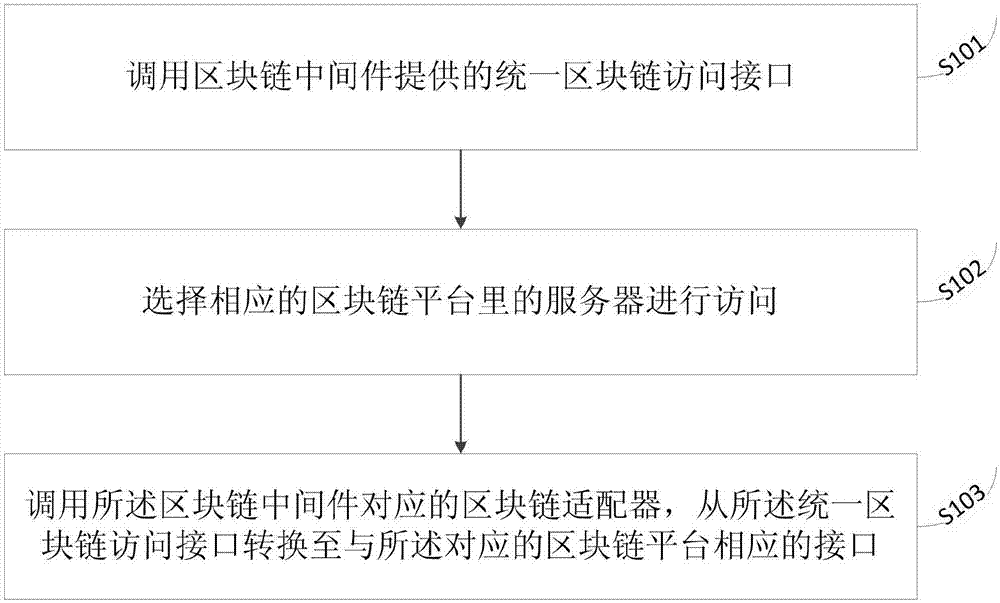

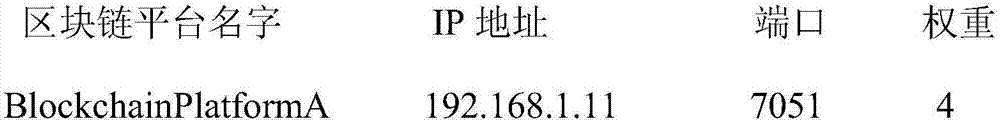

Method and device of application system for accessing heterogeneous block-chain platform

The invention discloses a method and a device of an application system for accessing a heterogeneous block-chain platform. The method comprises the steps of calling a uniform block-chain access interface provided by a block-chain middleware; selecting a server of the corresponding block-chain platform to access; and calling a block-chain adapter corresponding to the block-chain middleware, and converting the uniform block-chain access interface to an interface corresponding to the corresponding block-chain platform. By the method disclosed by the invention, the problems that too tight binding and coupling of a system application layer and the block-chain platform is not good for uniform development and displacement management in the prior art is solved.

Owner:GUANGDONG YOUMAI INFORMATION COMM TECH

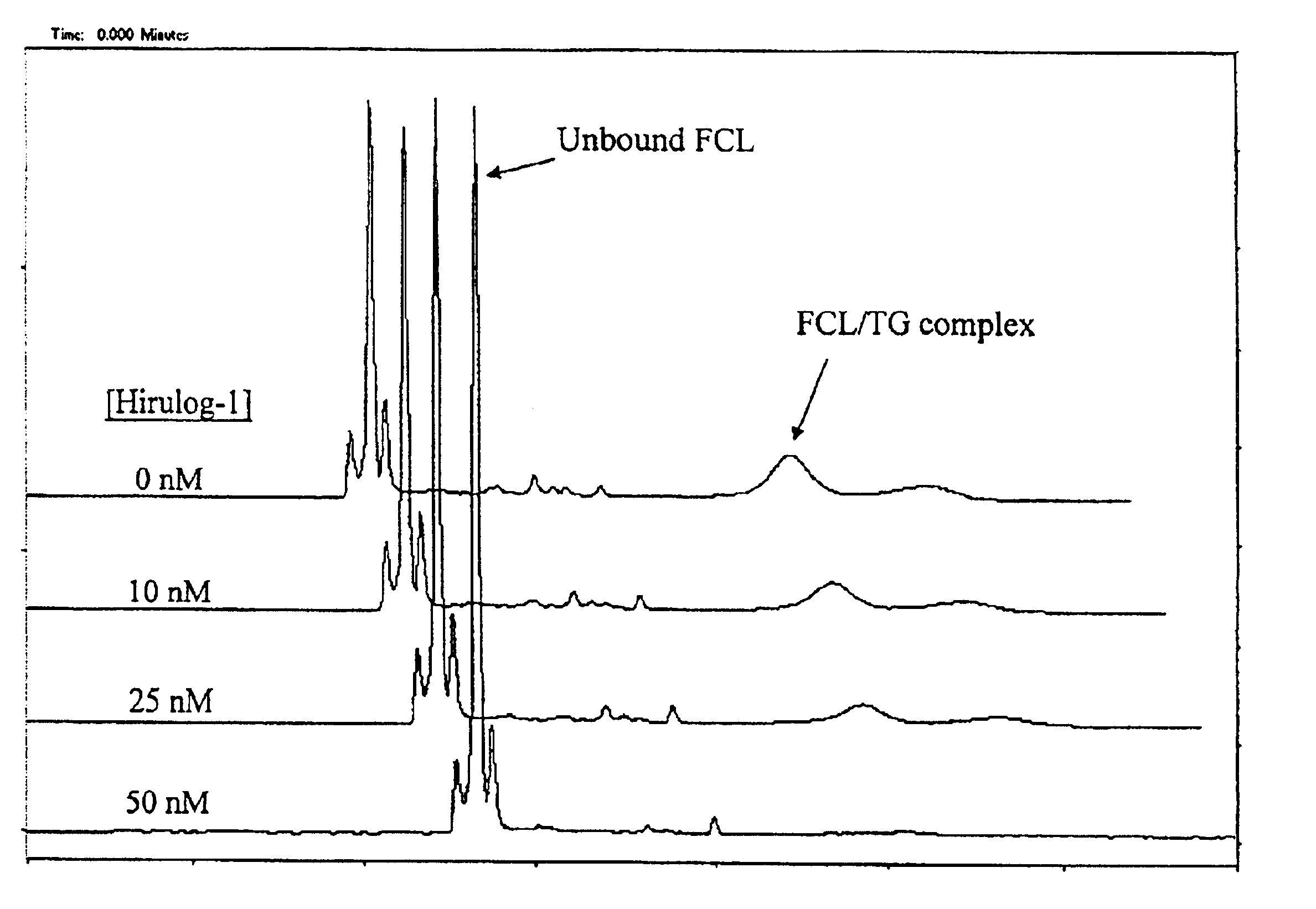

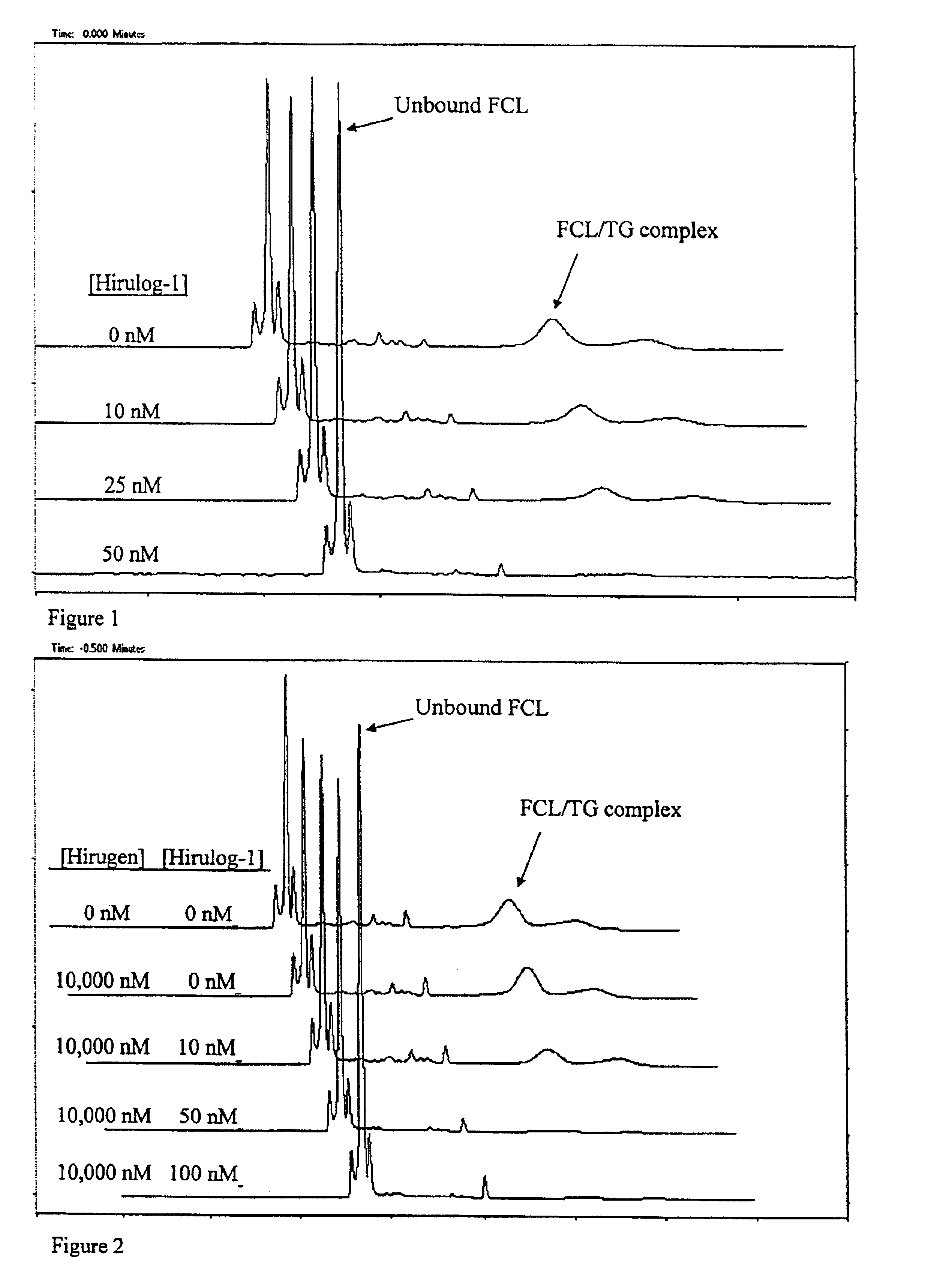

Capillary electrophoresis method for screening for affinity ligands using a detectable competitive ligand

The invention relates to a capillary electrophoresis-based method of screening complex materials for any unidentified affinity ligand that binds to a target of interest. The method subjects a plug of a mixture of the target and a complex material sample, and a separate plug of a known, tight-binding competitive ligand, to capillary electrophoresis under conditions optimized to allow mingling of the two plugs during the capillary electrophoresis run. Preferably, migration of the competitive ligand is tracked.

Owner:NORTHEASTERN UNIV

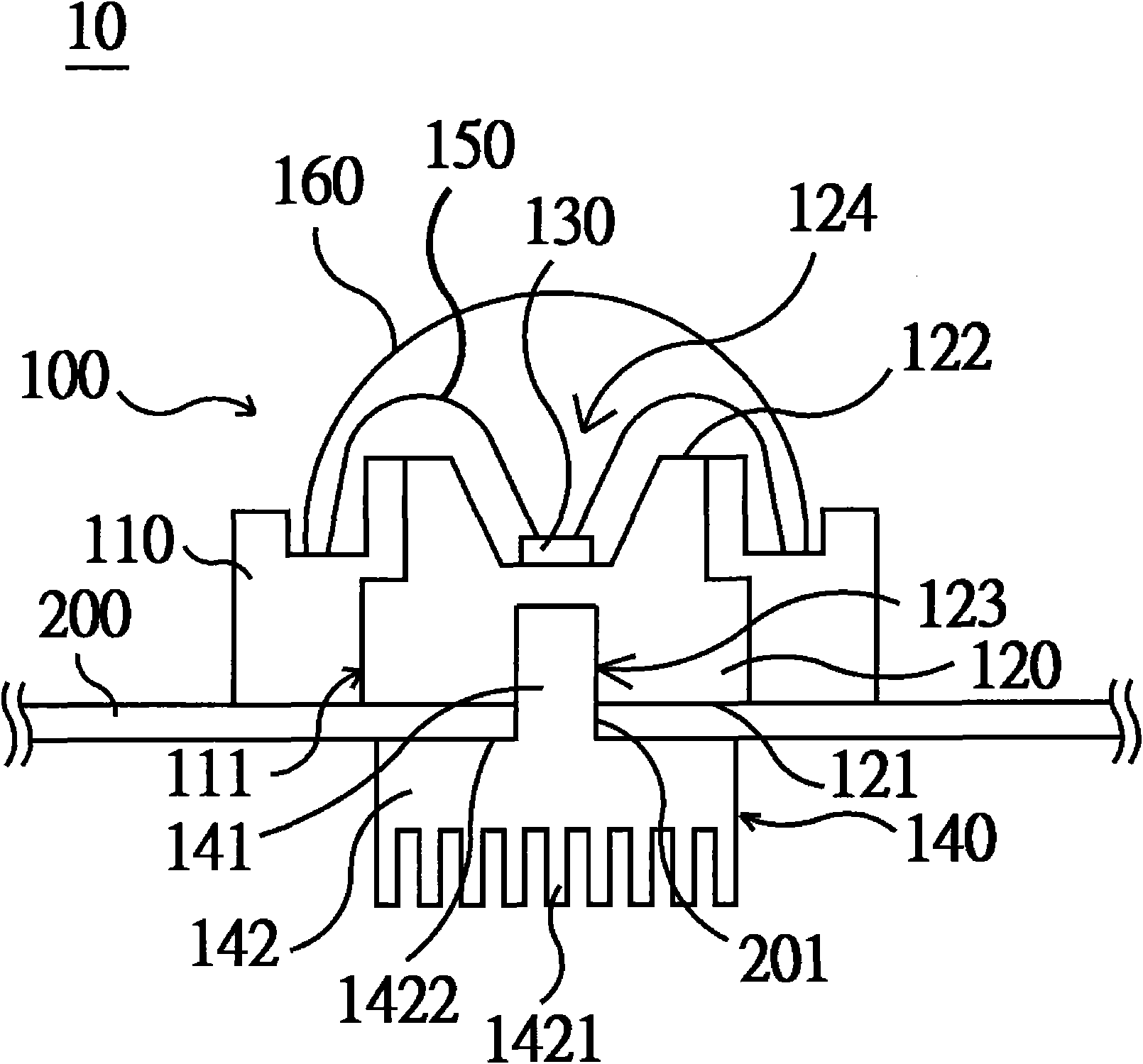

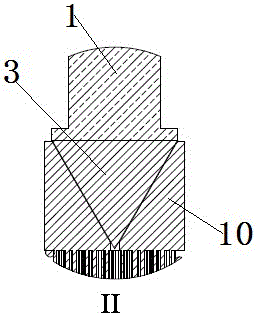

Force measuring ratchet tie down

ActiveUS8432290B2Improve securityCompact structureForce measurementFlexible elementsSignal processing circuitsDisplay device

The present invention provides a force measuring ratchet tie down in the field of goods holding. The force measuring ratchet tie down of the invention addresses the technical problems such has insufficiently tight binding, severe difficulty in control and trouble in adjustment. The force measuring ratchet tie down includes a body assembly, a handle, a teeth stop board, a catch and a scroll. The handle is connected with the body assembly through the scroll. A binding belt having a fixable outer end is connected to the body assembly. Another binding belt having a fixable outer end is rolled on the scroll. A ratchet is fixed on the scroll. The body assembly is movably connected with a teeth stop board the end of which could be embedded among the teeth of the ratchet. The handle is movably connected with a catch the end of which could be embedded among the teeth of the ratchet. A sensor is placed at a forced part of the tie down, which is linked with a signal processing circuit and could generate a signal corresponding to the size of the tensioning force of the binding belt when the tie down is in operation. A display device is connected to the signal processing circuit. The force measuring ratchet tie down of the invention has advantages including a high safety property, a compact structure and a low manufacturing cost.

Owner:ZHEJIANG TOPSUN LOGISTIC CONTROL CO LTD

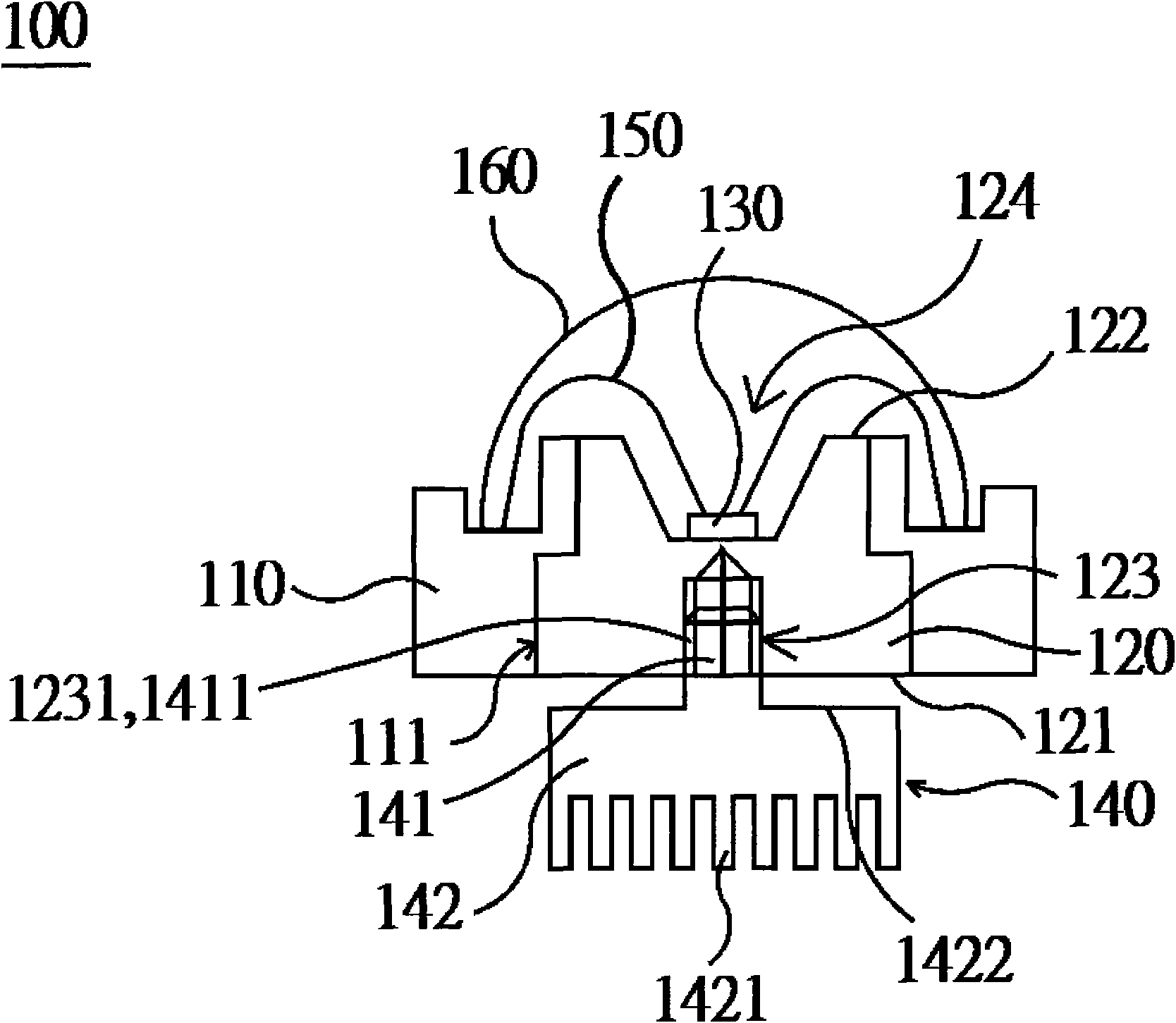

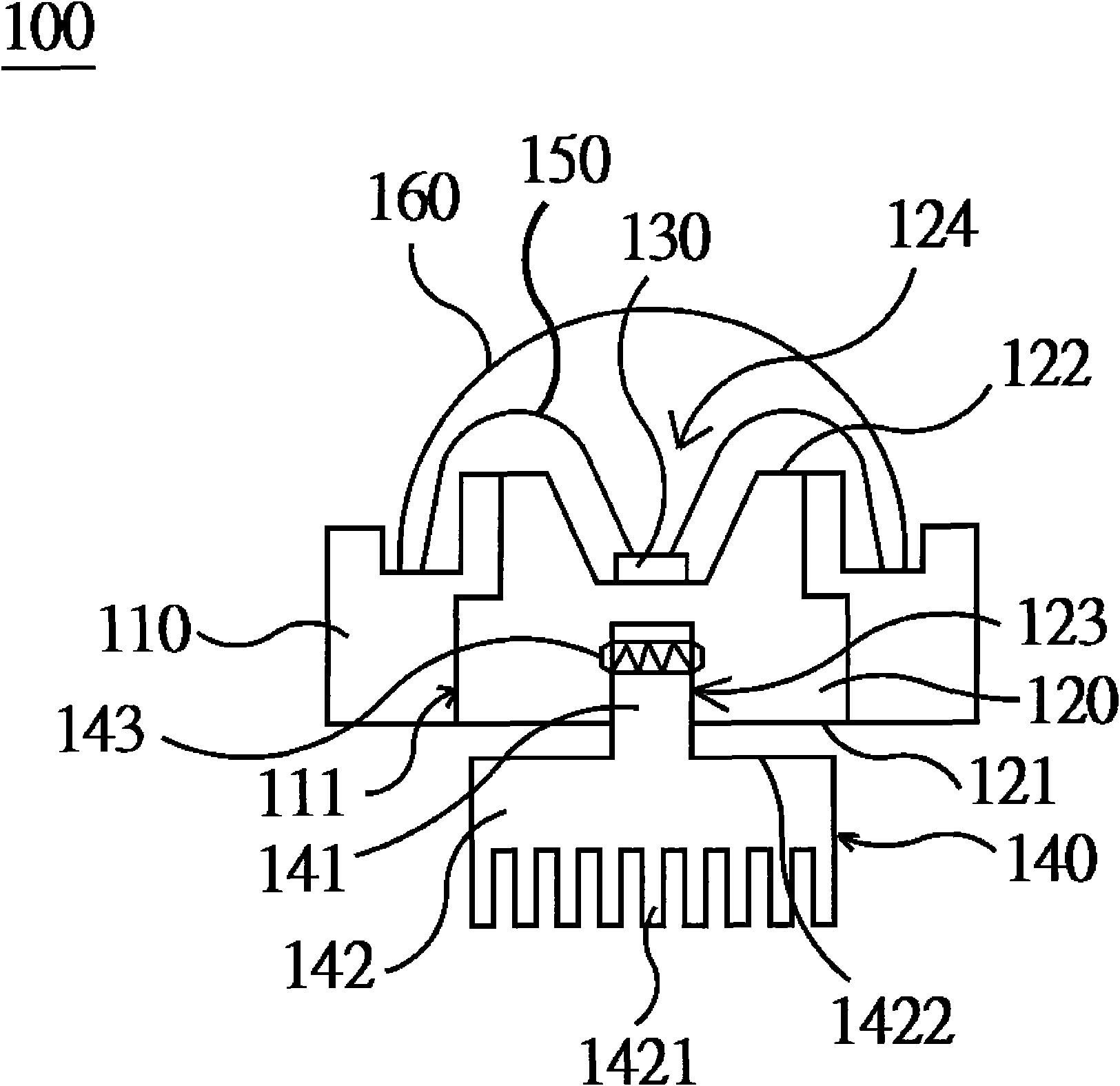

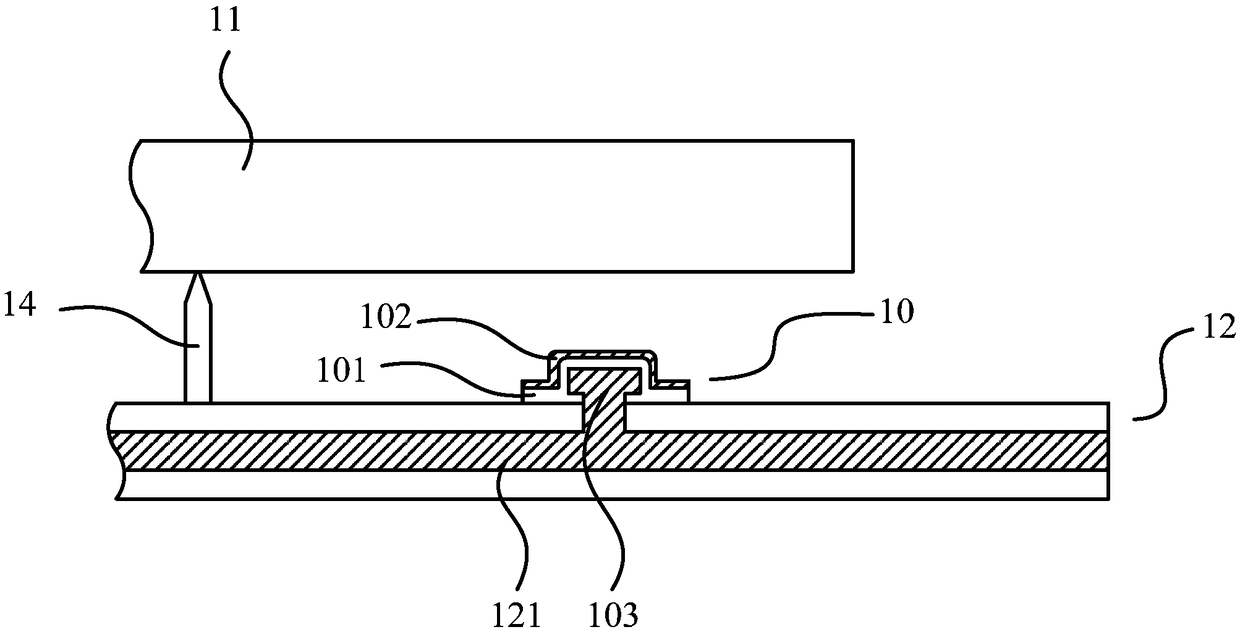

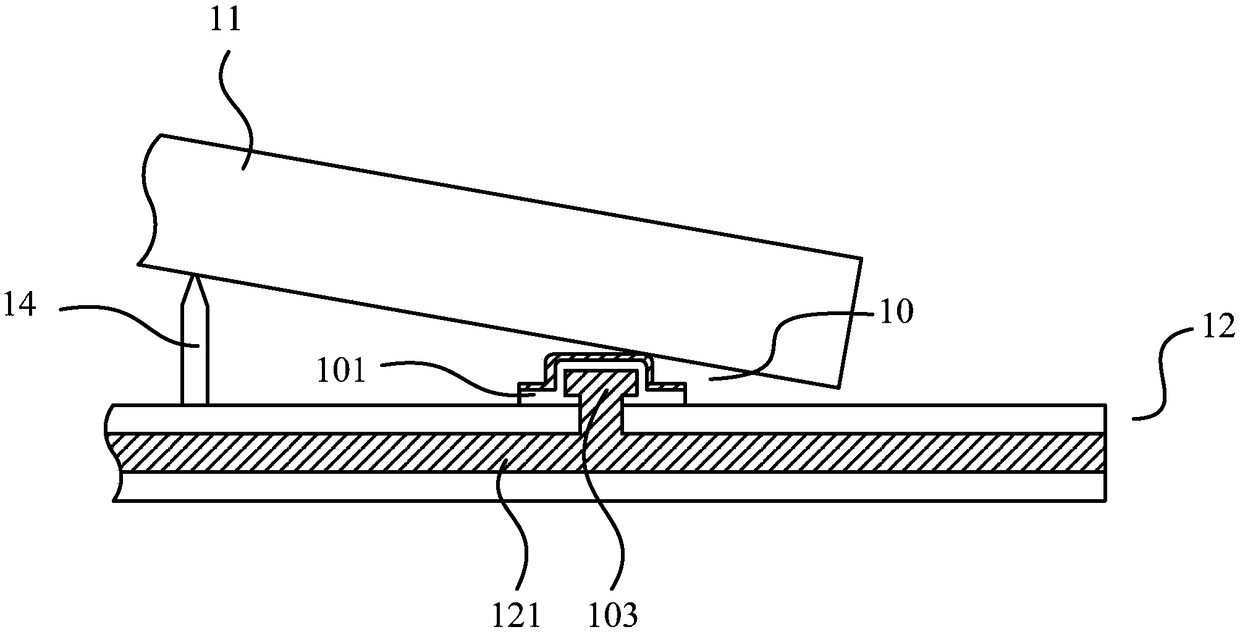

Backlight module and luminous source encapsulation structure thereof

ActiveCN101943356AEasy to assembleDecrease productivityPoint-like light sourceLighting heating/cooling arrangementsComputer moduleTight binding

The invention discloses a backlight module and a luminous source encapsulation structure thereof. The luminous source encapsulation structure comprises a heat radiating seat, at least one chip and a heat radiating and fixing piece, wherein the heat radiating seat is provided with a combining hole, the dimension of the heat radiating and fixing piece is less than that of the heat radiating seat, and the heat radiating and fixing piece comprises a combining post and a heat radiating fin with a butt surface; the combining post passes through a through hole of a fixing plate and is combined with the combining hole, the butt surface of the heat radiating fin is supported on the fixing plate, therefore, the heat radiating seat and the heat radiating and fixing piece can be stably combined on both sides of the fixing plate in order to ensure the tight binding relation with the fixing plate and increase assembling reliability, meanwhile, the heat radiating fin can be used for increasing the heat radiating effect of the heat radiating seat in extra, and therefore, the heat radiating fin can assuredly help the chip to reduce temperature in order to avoid the work efficiency reduction of the chip and is beneficial to ensuring that the chip stably operates and prolonging the service life.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Outdoor stem grafting method of rest period of fruit tree

The invention relates to an outdoor stem grafting method of the rest period of fruit tree. The method comprises the following steps: selecting time and environment, cutting stock, cutting scion, binding, wrapping the top of the scion and the like. The grafting method has the following characteristics: in the rest period and in an outdoor environment, a knife is used to cut a vertical opening on the cortex at the kerf of the stock from top to bottom, wherein the opening has the length of 2-4cm and is deep to the xylem; the scion is cut to a 3-5cm of horse ear-shaped large inclined plane, then the epidermis on the both sides of the back of the inclined plane is cut away to expose the phloem, the tip of the scion is cut to be arrowhead-shaped; the tip of the the scion is placed vertically between the phloem and xylem on the top end of the vertical opening of the stock to ensure that the inclined plane of the scion faces to the xylem; the worker holds the scion in the left hand and uses a tool in the right hand to slightly nail the tip of the scion in the stock and ensure the scion to stand in the stock, then the vertical opening of the stock is tightly pressed by the thumb of the left hand to nail the scion in the stock and ensure that 1-2mm of the upper part of the inclined plane of the scion is exposed; a plastic strip is used to perform tight binding from the kerf and joint of the stock to the lower part of the bud; and a mulch strip is used to slightly wrap the upper notch of the scion. The grafting method has high survival rate, is special for the outdoor stem grafting of the rest period of fruit tree and can prolong the grafting time.

Owner:杜安仁

Liana fixed band

InactiveCN103109717AConditions affecting growthEasy to operateCultivating equipmentsTight bindingEngineering

The invention discloses a liana fixed band which comprises a buckle body and a buckle band which is connected with one end of the buckle body and provided with a serrated surface. A narrow lock hole and a wide lock hole are formed in the buckle body, wherein the narrow lock hole and the wide lock hole penetrate in the vertical direction. An iron wire clamping groove is arranged in one side of the wide lock hole, wherein the section of the iron wire clamping groove is in a U shape. The buckle band is arranged at one side of an opening end of the iron wire clamping groove. A first lock catch is arranged at the other side of the opening end of the iron wire clamping groove and slantwise extends to the opposite side of the wide lock hole. A second lock catch is arranged in the narrow lock hole and slantwise extends upward. When the liana fixed band is in the condition of use, the iron wire clamping groove is closed by the buckle band, and the buckle band is capable of penetrating from the wide lock hole and out of the narrow lock hole. By adopting the structure, the liana fixed band has the advantages of being easy and convenient to operate, and capable of saving rime and labor to bind and avoiding happening of condition that growth of plants is influenced due to too tight binding. When the plants are out of a shelf in an area where the plants need to be overwintered and protected in winter, an unlocking spanner is opened, the buckle band is pulled out of the narrow lock hole, and then plant branches and tendrils are just divorced and fixed. The buckle band is left on iron wires of a shed frame and capable of being recycled in the next year.

Owner:镇江山水湾生态农业开发有限公司

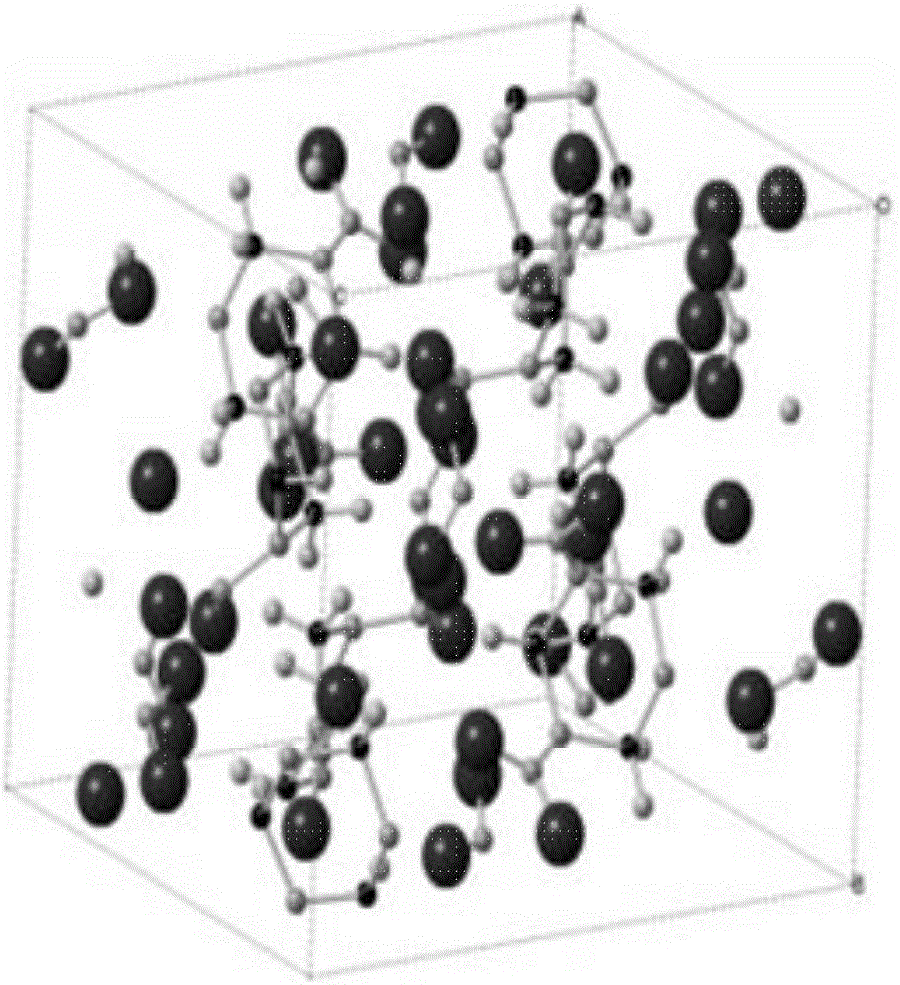

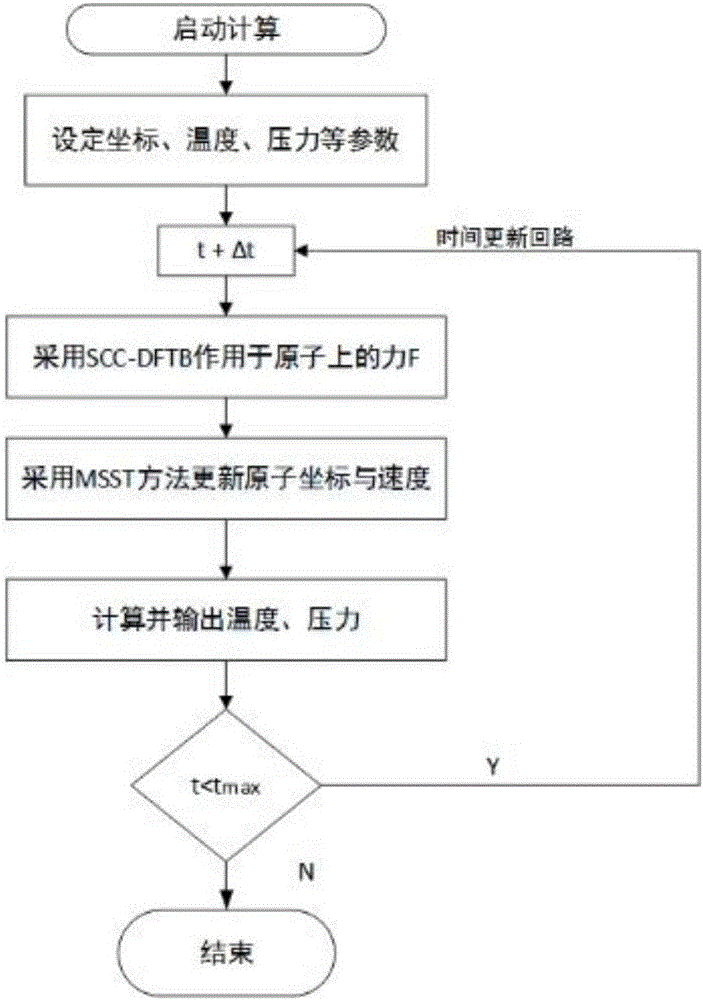

Computer simulation method for energetic material shock initiation

ActiveCN105787273ACalculation speedResolve reflectionSpecial data processing applicationsInformaticsShock waveElectric potential energy

The invention provides an efficient and relatively-high-precision quantum molecular dynamics model for initiation of an energetic material under the shock wave guide condition.The model adopts a direct dynamics simulation method, that is, a potential energy surface is not pre-constructed, energy of a system and force acting on nucleuses are calculated once being used.Acting force among atoms and electronic structure information are calculated by adopting a charge self-consistent density functional based tight-binding method (DFTB), and shock waves are described by selecting a multiscale approximation method.A stimulation result outputs the movement rule and physical state information such as the temperature, the size and the pressure of the atoms.According to the method, an early theoretical prediction and a scientific basis can be supplied to improvement of the energetic material and screen, design, optimization and the like of a novel energetic material.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

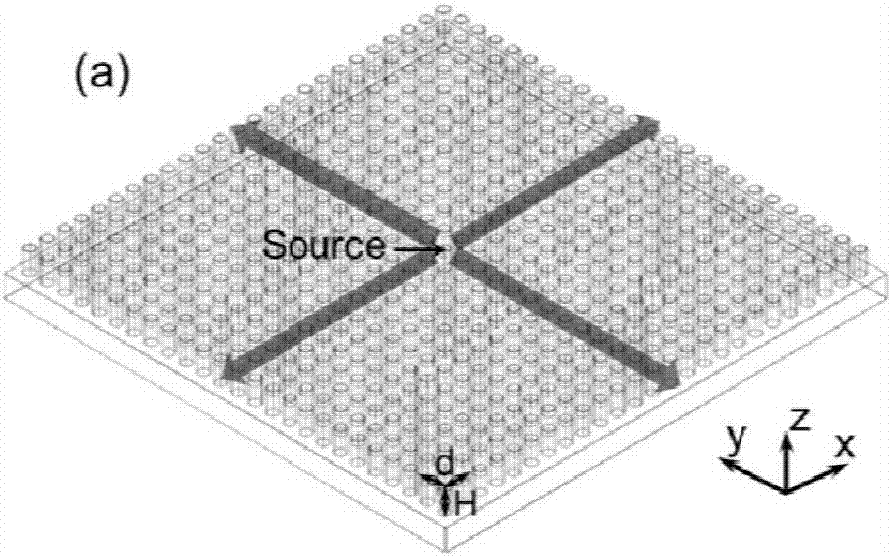

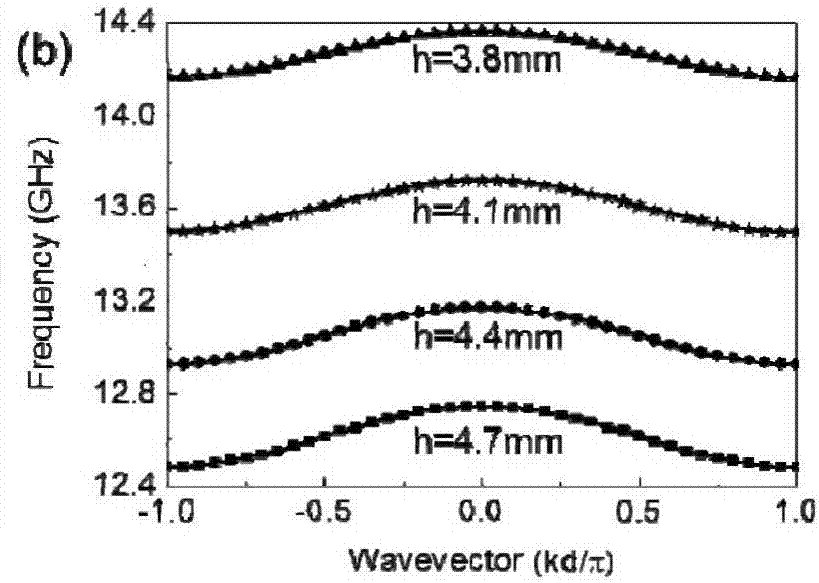

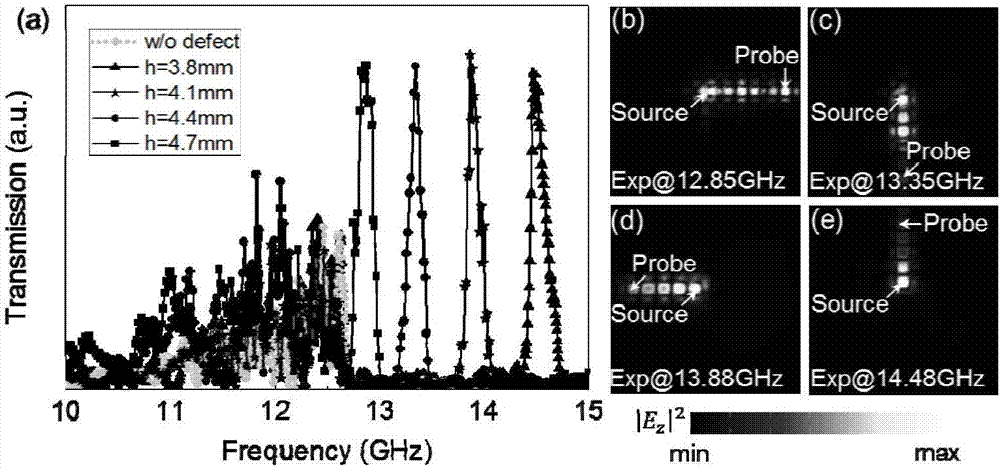

Multidirectional surface wave separator with fully-isolated bandwidth

PendingCN107069165AAchieve separationThe working frequency range can be changed arbitrarilyWaveguidesPhotonicsWaveguide

The invention discloses a multidirectional surface wave separator with a fully-isolated bandwidth. The multidirectional surface wave separator is formed by constructing multiple waveguides in different directions on a surface wave photonic crystal that is constructed by metal column array structures periodically arranged on the metal surface through a defect introducing mode, the distances between metal posts of the surface wave photonic crystal and the column are equal, and the distance is less than 1 / 2 of the working wavelength of surface waves; the waveguides are formed by reducing the height of the metal posts on the surface wave photonic crystal in the defect introducing mode, and the resonant frequency at the defect is within a forbidden band of the surrounding surface wave photonic crystals; and one end of each waveguide is connected with an excitation source. According to the multidirectional surface wave separator disclosed by the invention, the wave separation is based on a coupled resonant cavity optical waveguide that adopts a tight-binding approximation principle, rather than a dispersion relation of a traditional surface plasma waveguide, and thus the complete separation of the surface waves in different frequency ranges can be achieved; and the operating frequency range of the multidirectional surface wave separator can be randomly changed by adjusting geometrical parameters of the metal structure.

Owner:深圳凌波近场科技有限公司

Grafting method of gold pear tree

The invention discloses a grafting method of a gold pear tree. The grafting method comprises the specific steps of selecting a callery pear tree which is strong and under good field conditions as a stock and immediately grafting the gold pear tree by use of a cut-grafting method after field planting in spring, and after grafting, wrapping with a breathable film or a plastic bag and punching a plurality of pores by use of a needle; during the grafting operations, the grafted branch and the grafting cut should be smooth, the grafted branch is aligned to the grafting cut, and tight binding and high operating speed are required; after the grafted branch grows to 80mm, windproof binding is performed. The grafting method of the gold pear tree is an effective measure to keep the crisp and tender pulp and sweet flavor of the gold pear, improve the unit area efficiency of the fruit trees and inhibit aging and weakness of the tree bodies.

Owner:蔡夏莲

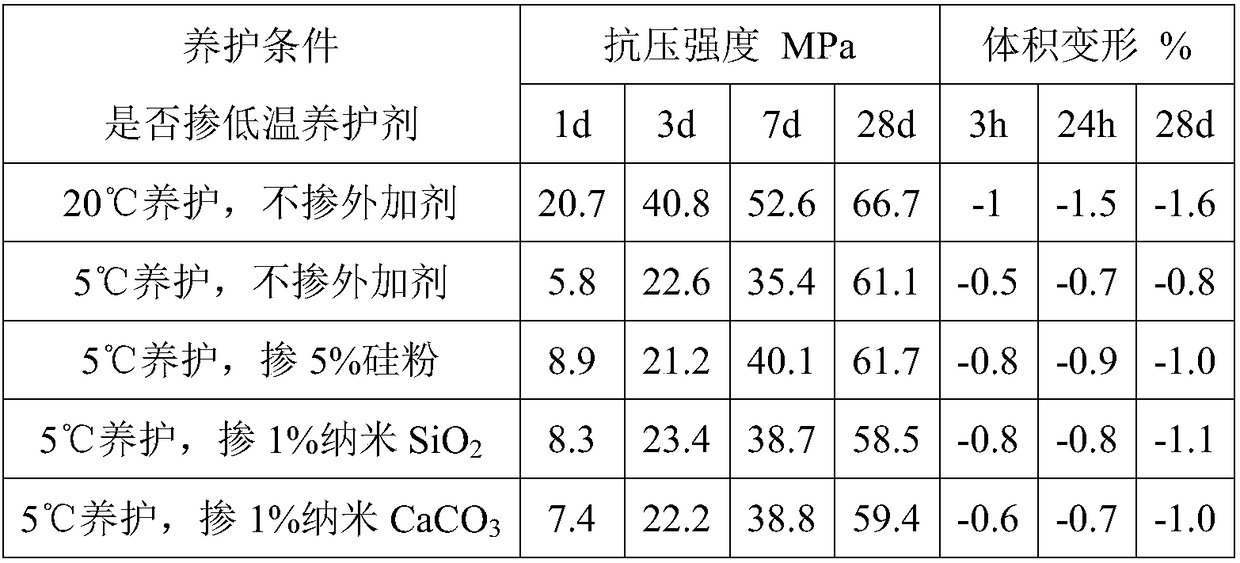

Multi-bundle tight binding device for tin plating alloy coper twisted wire production

PendingCN108899133AEasy to tightenEasy to disassembleManufacturing wire harnessesTight bindingTin plating

The invention relates to the technical field of tin plating alloy coper twisted wire production, and discloses a multi-bundle tight binding device for tin plating alloy cooper twisted wire production.The multi-bundle tight binding device comprises a tight binding belt, wherein the left end of the binding belt is fixedly connected with a first tight binding block; the upper surface of the first tight binding block is provided with a first position limiting groove penetrating through and communicated with the upper end of the first tight binding block; a second position limiting groove penetrating through and communicated with the first position limiting groove is formed inside the first tight binding block. The multi-bundle tight binding device for tin plating alloy coper twisted wire production has the advantages that the first tight binding block is inserted into a second movable groove of a second tight binding block, so that one end of the rotating block is clamped in a third position limiting groove; a reset spring is compounded, so that the first tight binding block cannot be disengaged; therefore the tight binding goal is achieved; when the dismounting is needed; the connecting block is matched by leftwards moving the movable block; the connecting block is matched with a hinging rod through a second hinging seat, so that the rotating block is outwards disengaged; at themoment, the goal of dismounting convenience can be achieved by pulling out the first tight binding block.

Owner:吴江市聚盈电子材料科技有限公司

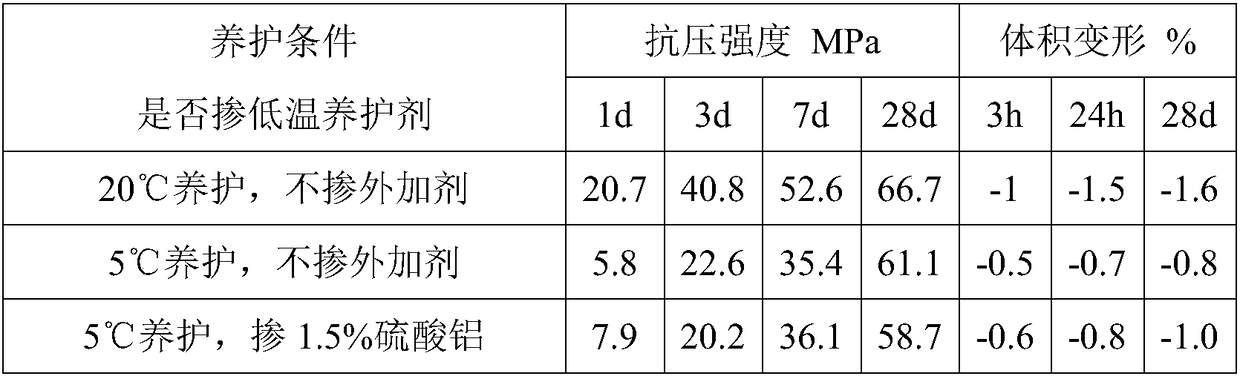

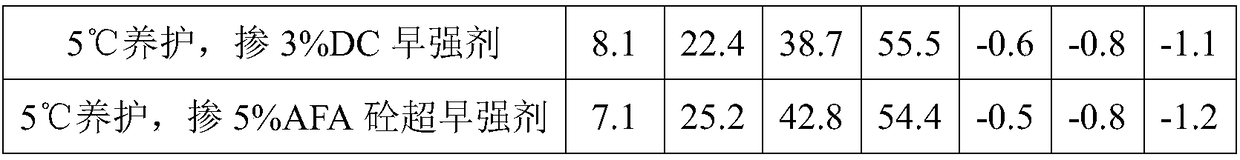

Low-temperature caring agent for deep water under-water concrete structure cement-based grouting material

The invention relates to a low-temperature caring agent for a deep water under-water concrete structure cement-based grouting material. The low-temperature caring agent is prepared from the followingingredients in percentage by mass: 15 to 50 percent of cement hydration catalysis ingredients, 45 to 80 percent of expansion ingredients and 1 to 5 percent of plasticization ingredients, wherein the cement hydration catalysis ingredients are prepared from crystal nucleus and catalysts; the crystal nucleus is formed by one kind of materials or several kinds of materials from nanometer silicon dioxide, nanometer calcium carbonate and nanometer aluminum oxide through compounding; the catalysts are prepared from two or several kinds of materials from lithium nitrate, ferric sulfate and alkaline earth metal halides. The low-temperature caring agent has the advantages that no chlorine and no alkali exist; all ingredients achieve cooperated effects; the hydration process of the cement under the low-temperature condition can be accelerated; the mixing quantity in the grouting material is 5 to 10 percent of the powder material; the intensity of the cement-based grouting material at the low-temperature environment (0 to 5 DEG C) is not lower than the intensity of the cement-based grouting material of the same mixture ratio under the 20 DEG C standard caring condition; the grouting performance of the cement-based grouting material can be improved; no shrinkage and micro expansion are realized; the tight binding with the grouting base surface can be realized.

Owner:NANJING HYDRAULIC RES INST

Cement simulated tree and terrain effect manufacturing process

InactiveCN110179191ASimple preparation processLow costArtificial flowers and garlandsTerrainWire gauze

The invention provides a cement simulated tree and a terrain effect manufacturing process. The process comprises the following steps: first, determining the position and size proportion for good foundation, during large-scale moulding, welding a skeleton by adopting galvanized channel steel, steel angles and deformed steel bars, uniformly laying steel wire gauzes on the steel skeleton, carrying out tight binding by adopting binding wires, wherein the binding knots of the binding wires face the inside of the skeleton, carrying out base-layer plastering by using 1:1 cement mortar, wherein the thickness is about 1.5cm, carrying out second-time plastering after the first-time plastering, adding iron oxide pigment or color paste into cement mortar obtained by stirring building glue, carrying out repeated processing so that the mouldling, texture, body shaping and surface carving are basically close to those of the model, wherein coloring is carried out when the moisture on the moulded faceis not completely dry, adding water into acrylic paint and cement, carrying out uniform mixing, carrying out layer-by-layer scattering-dyeing, and after coloring is completed, spraying acrylic emulsion to the colored moulded body. According to the technical scheme, the manufacturing of the cement simulated tree is carried out by adopting the ground moulding method, and the manufacturing process ofthe cement simulated tree is effectively enabled to be simple, low in cost, and energy-saving and environmentally friendly.

Owner:天地间博展科技有限公司

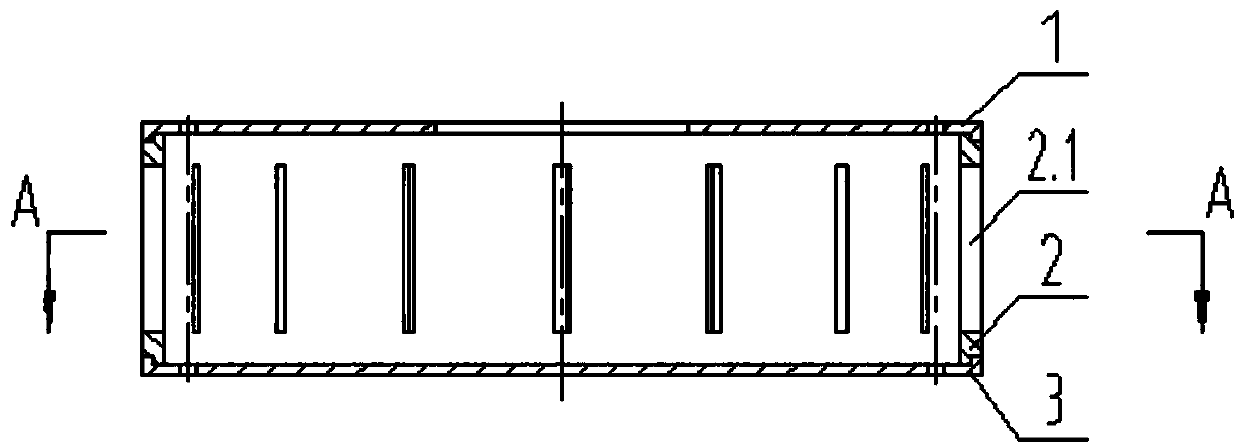

Mechanical centrifugal atomization device centrifugal pan

InactiveCN107552803AReduce or avoid deviationImprove centrifugal atomization effectTight bindingEngineering

Owner:泰州市启航石油分析仪器有限公司

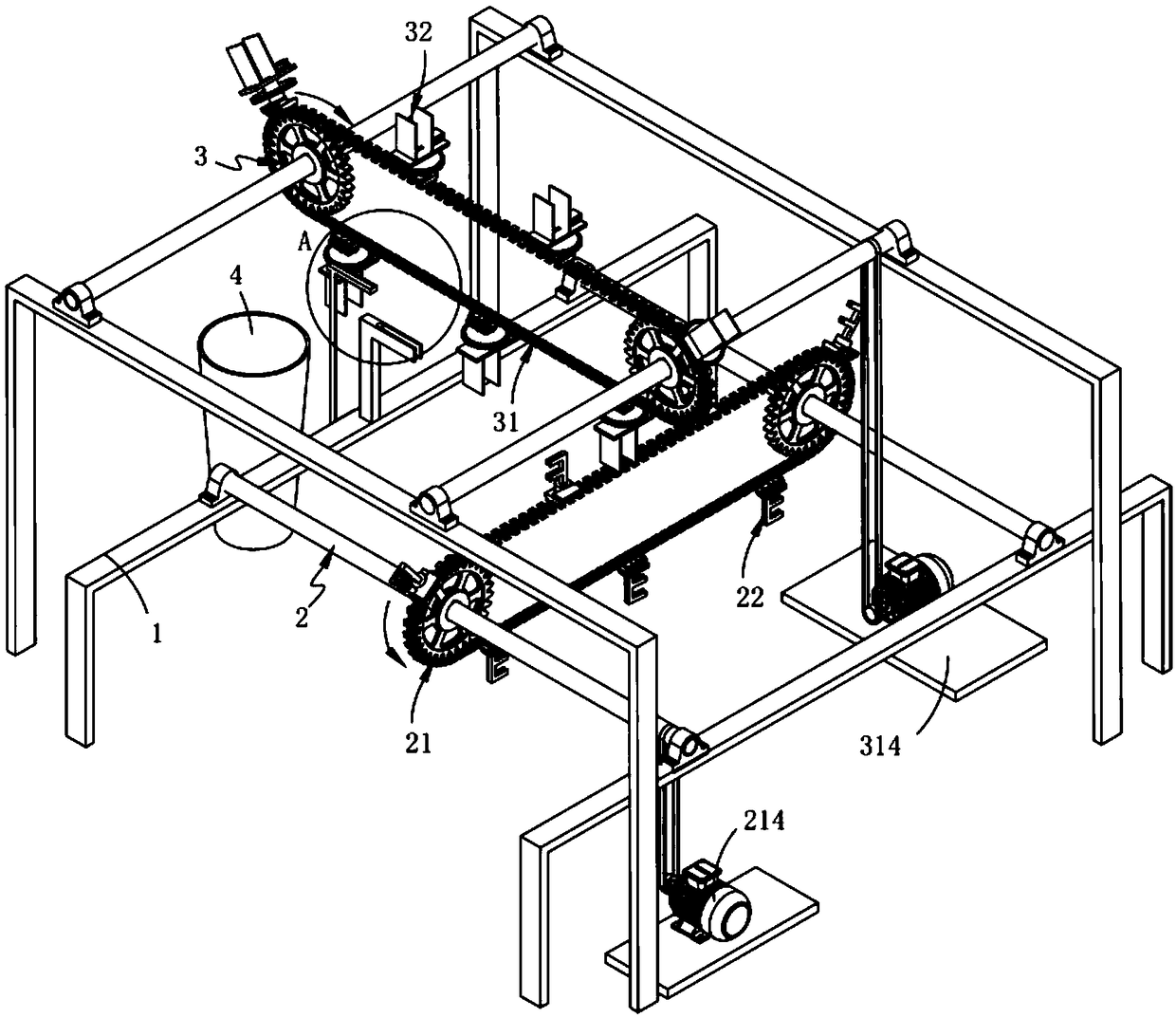

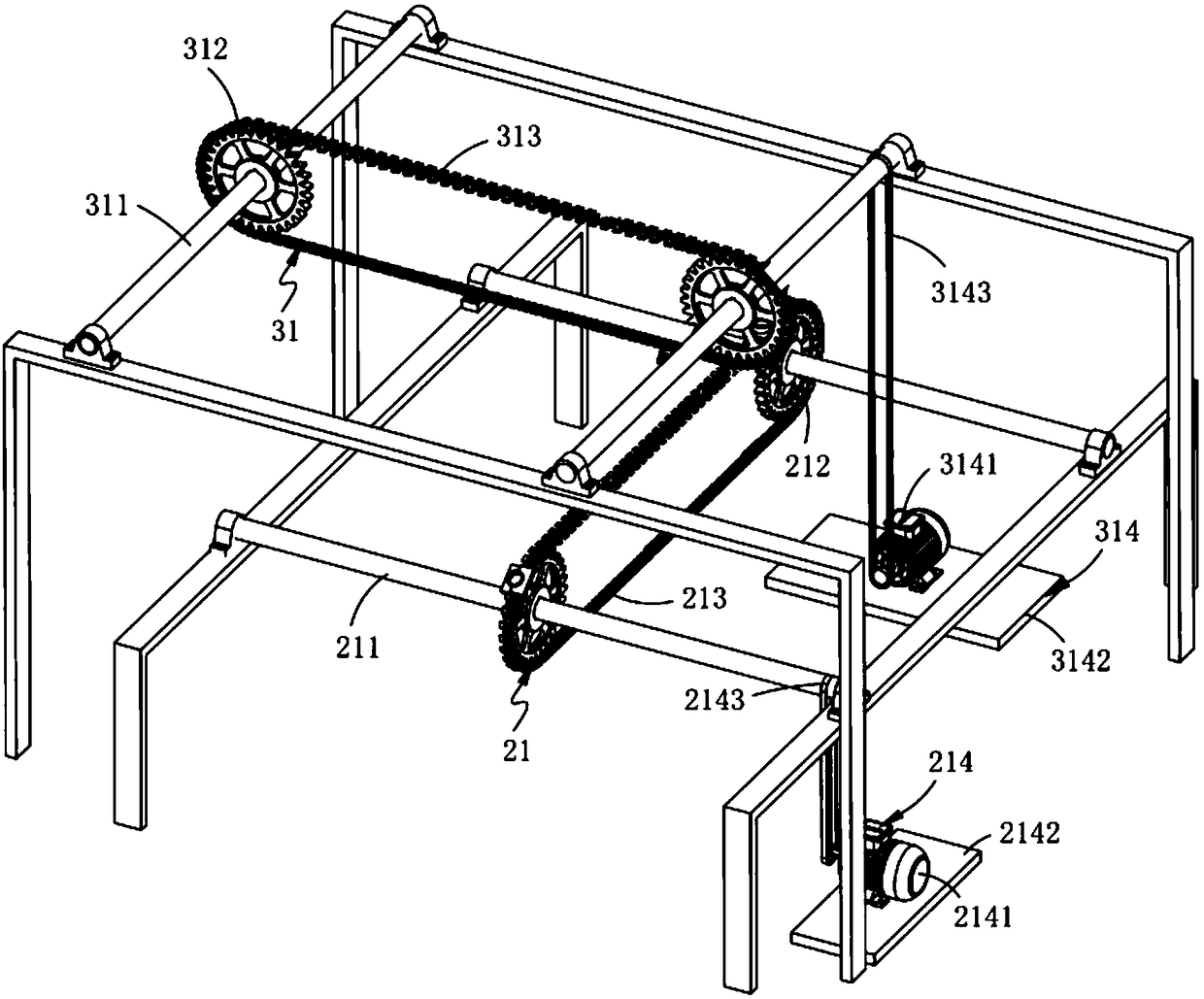

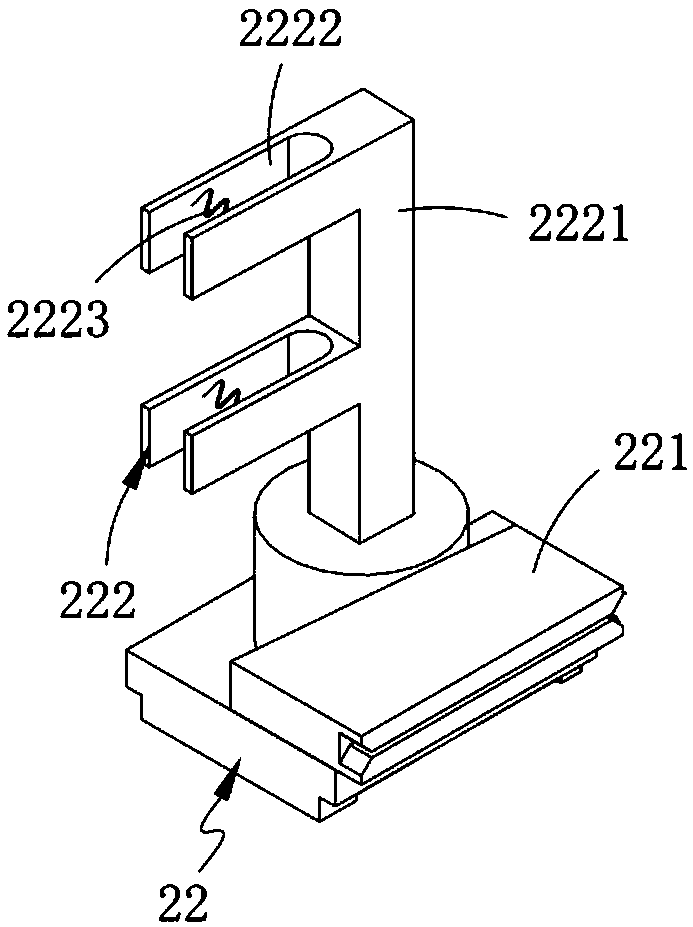

Automatic fiber arranging device

The invention relates to an automatic fiber arranging device. The device comprises a machine frame, a first transmission mechanism, a second transmission mechanism and a discharging cylinder, whereinthe first transmission mechanism is fixedly arranged on the machine frame, and the first transmission mechanism comprises a transverse driving assembly and a feeding assembly arranged on the transverse driving mechanism; the second transmission mechanism is fixedly arranged on the machine and is arranged above the first transmission mechanism, and comprises a longitudinal driving assembly which isvertically arranged with the transverse driving assembly, a clamping assembly arranged on the longitudinal driving assembly and a tightening assembly matched with the clamping assembly for transmission; and the discharging cylinder is arranged on the machine frame and is located at the tail end of the longitudinal driving assembly. According to the automatic fiber arranging device, the technicalproblems that after fibers are collected, tight binding arrangement cannot be carried out in time, and the fibers are prone to loosing in the storage process are solved; and the structure is simple, the fibers can be orderly and mechanically collected, damage to the fibers is avoided, and the working efficiency is improved.

Owner:CHANGXING HAIPU MACHINERY TECH CO LTD

Chinese holly grafting and landscaping method

The invention discloses a Chinese holly grafting and landscaping method. The method comprises the steps of taking a 6-8 cm long thorny Chinese holly stake as stock, shearing the stock at the position which is close to the ground and provided with smooth bark, cutting one side of the section of the stock by 3-5 cm, inserting three to five 0.8-1.5 thick no-thorn Chinese holly scions into the stock, aligning the forming layers of the no-thorn Chinese holly scions and the stock, conducting tight binding and earth covering for moisture maintenance, conducting sunshading and curing on the scion part, guaranteeing water and fertilizer supply of the root, and conducting pruning and shaping finally.

Owner:朱全顺

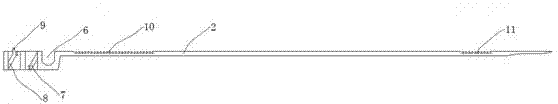

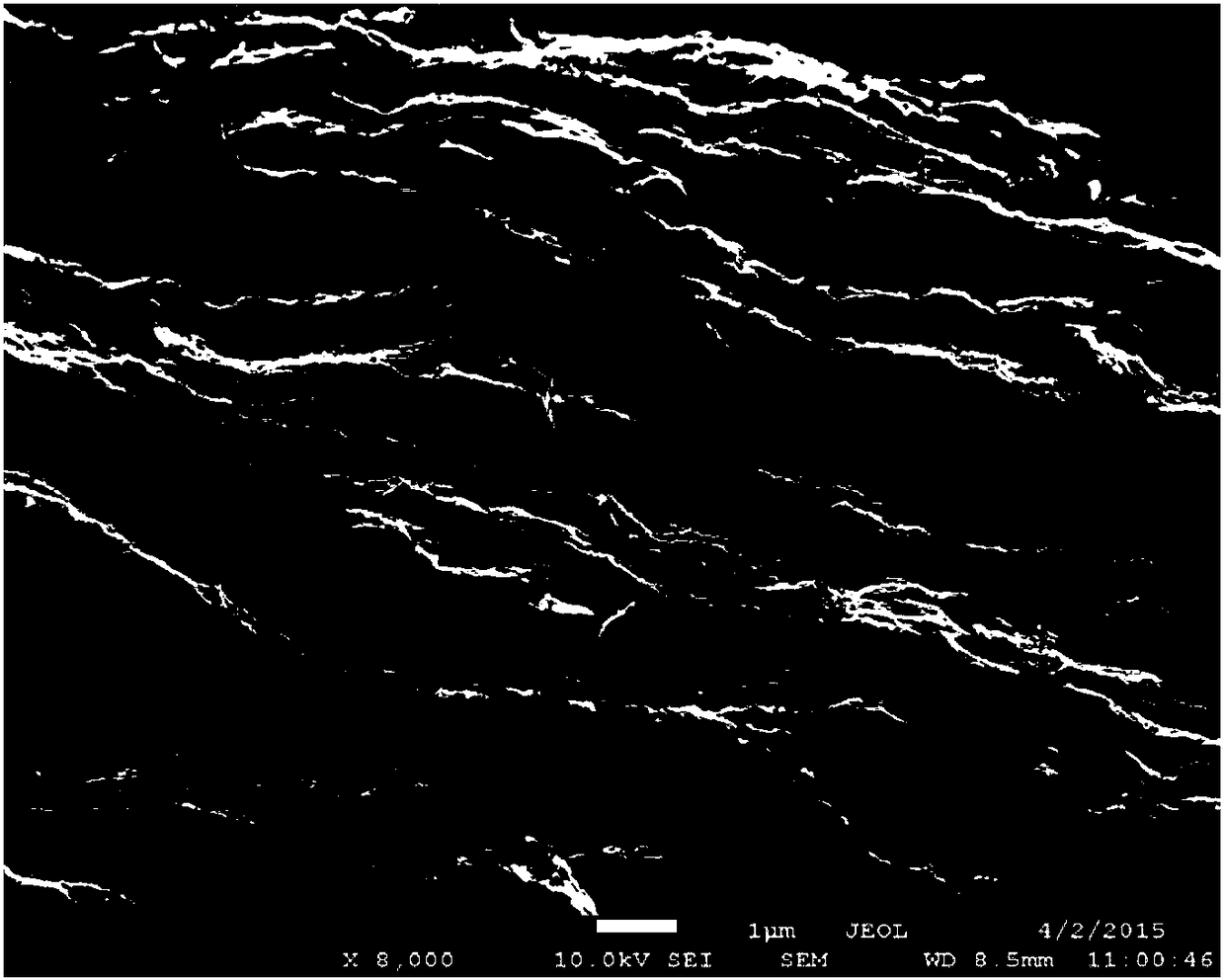

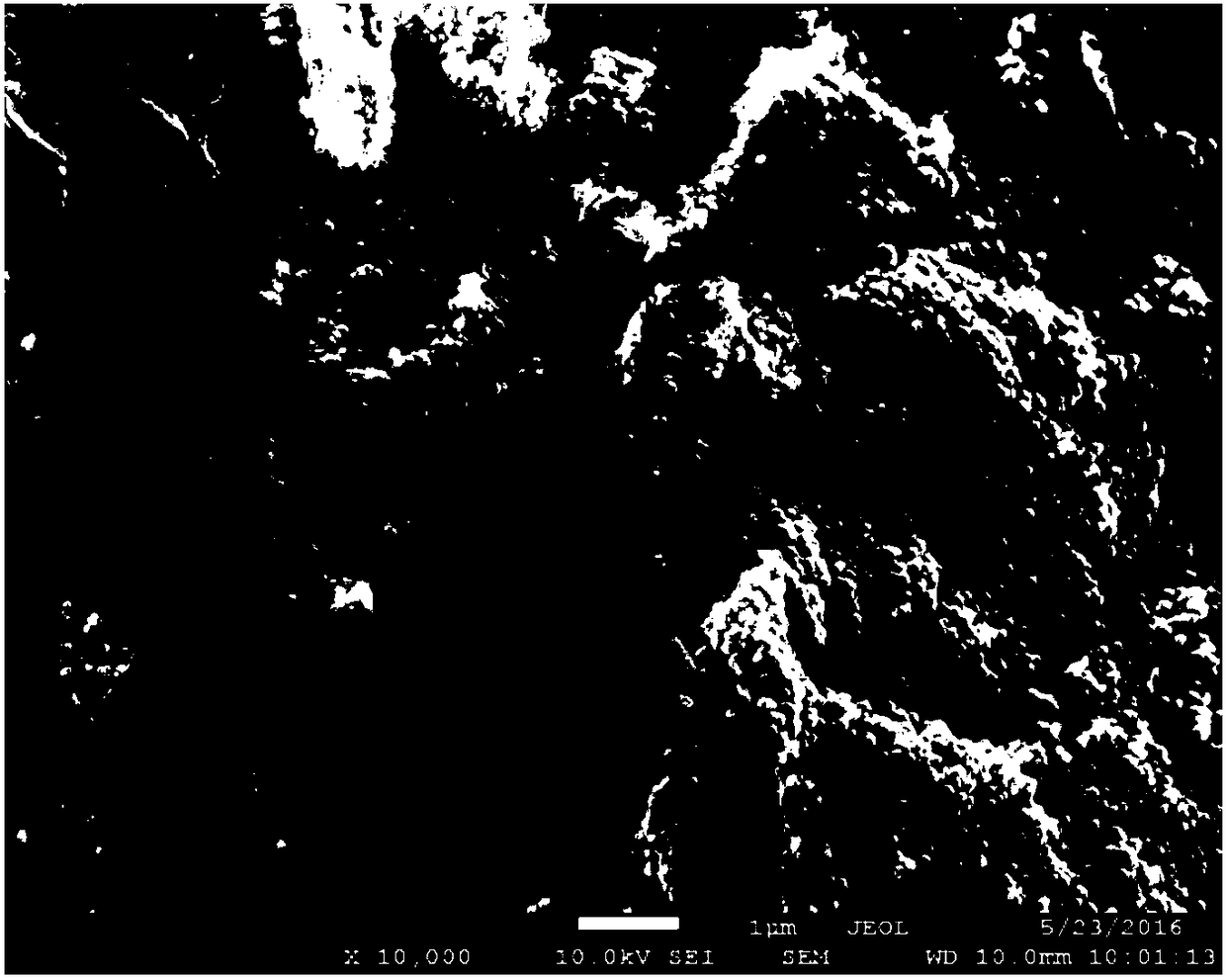

A kind of Fe3O4/graphene composite material and preparation method thereof

ActiveCN106252091BConducive to free movementGive full play to the synergistic effectHybrid capacitor electrodesCell electrodesColloidal particleNanocomposite

The invention relates to a Fe3O4 / graphene composite material and a preparation method thereof, belonging to the technical field of electrode materials for energy storage devices. The preparation method of Fe3O4 / graphene composite material of the present invention comprises the steps: graphene oxide emulsion is mixed with Fe(OH) sol uniformly, and solid-liquid separation is obtained Fe(OH)3 / graphene oxide composite material; The prepared Fe(OH)3 / graphene oxide composite material is heated at 200-500°C for 1-5h under the protection of an inert gas to obtain the obtained product. The preparation method of the present invention realizes the close combination between Fe(OH)3 colloidal particles and GO sheets through the electrostatic force between the colloidal particles, and the bonding of Fe(OH)3 nanoparticles to graphene can be realized only by simple mixing. Effective coverage. Then, by heat-treating the nanocomposite, Fe(OH)3 was transformed into Fe3O4, while the morphology of the sandwich structure was preserved.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

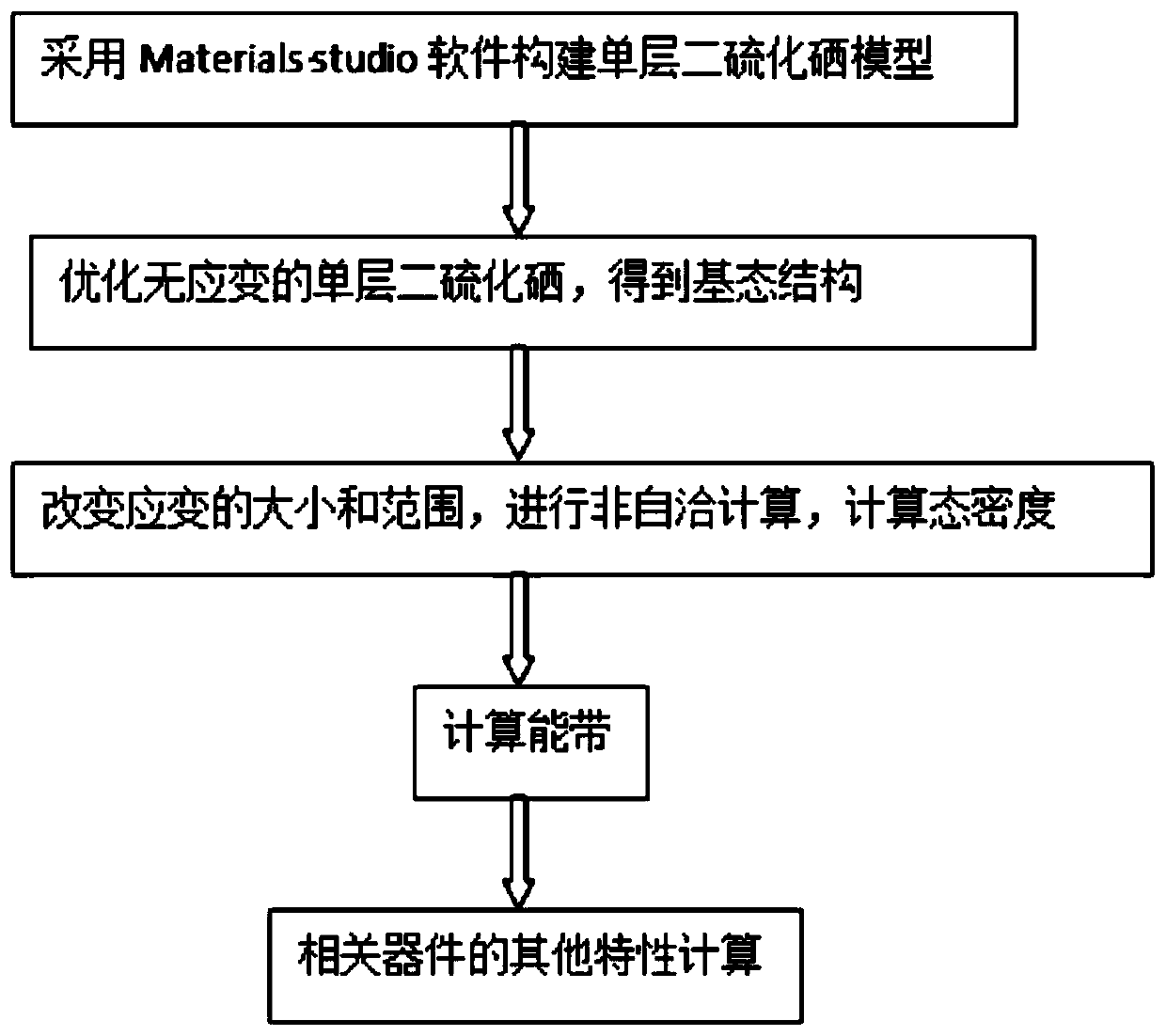

Simulation method for strain regulation and control of selenium disulfide semiconductor device

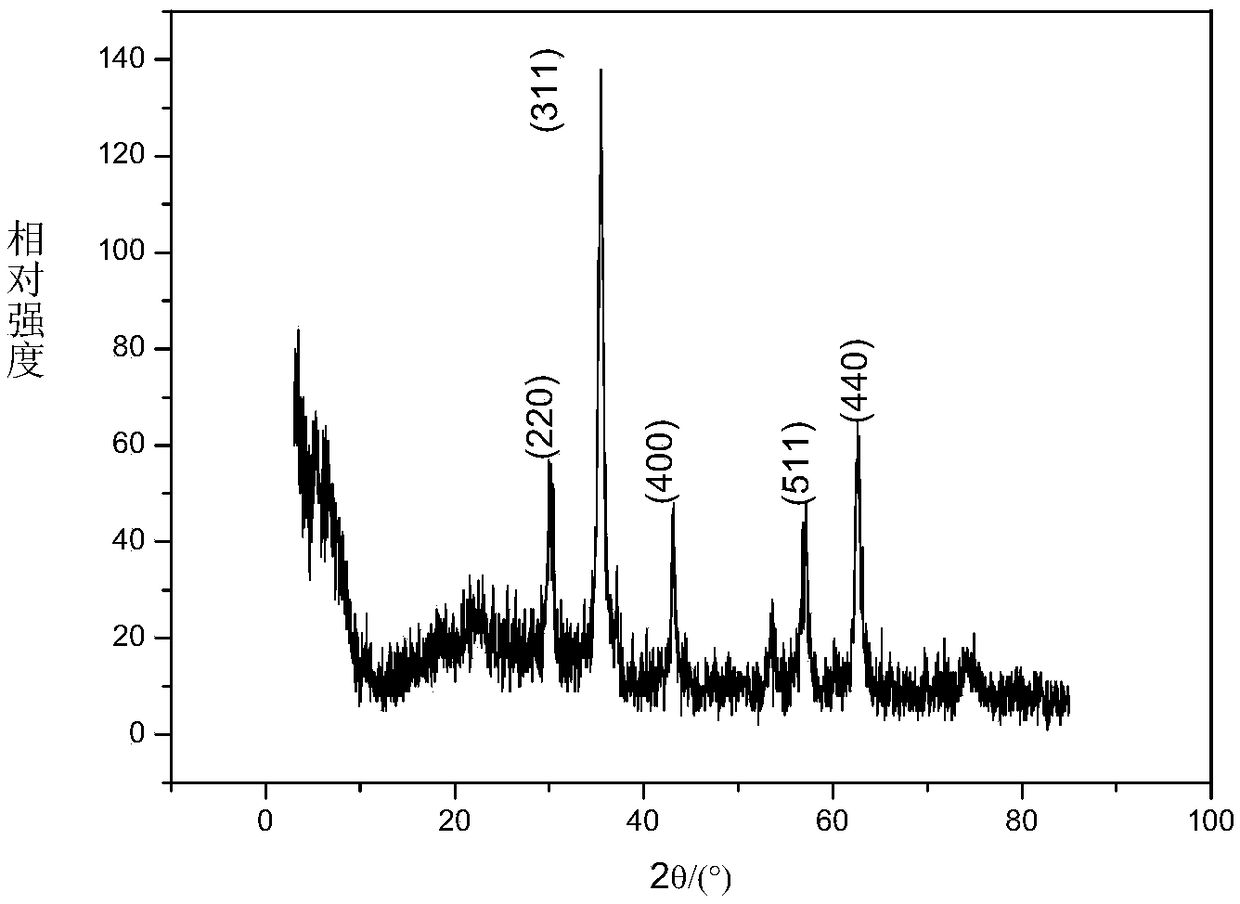

PendingCN111046625AComputer aided designSpecial data processing applicationsDevice materialDensity functional theory

The invention discloses a simulation method for strain regulation and control of a selenium disulfide semiconductor device. The method comprises the following steps: constructing a single-layer selenium disulfide model by adopting Matrials Studio software, optimizing strain-free single-layer selenium sulfide to obtain a ground state structure, changing the magnitude and range of strain, carrying out non-self-consistent calculation, calculating state density, calculating an energy band, and calculating other characteristics of related devices. According to the method, by combining the density functional theory, the plane wave and pseudopotential theory, the maximization local Wannier function and the tight binding approximation theory, guidance and theoretical basis are provided for experimental research, and blindness in the experimental process is reduced.

Owner:NANTONG UNIVERSITY

Method and system for realizing unified processing of multiple database data through middleware

ActiveCN103678575BFast transplantQuick managementDatabase management systemsSpecial data processing applicationsData displayApplication software

Owner:四川九洲投资控股集团有限公司

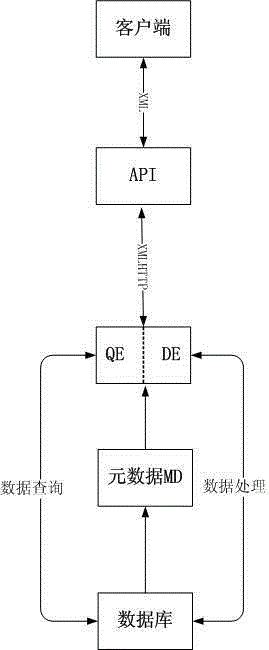

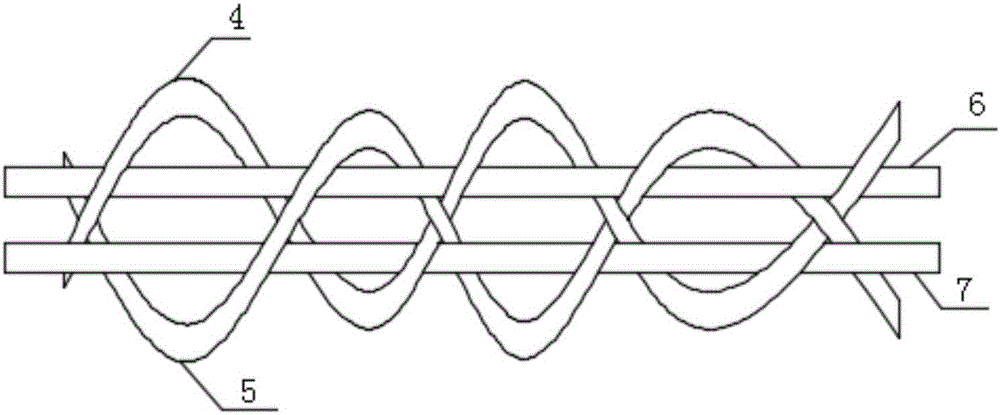

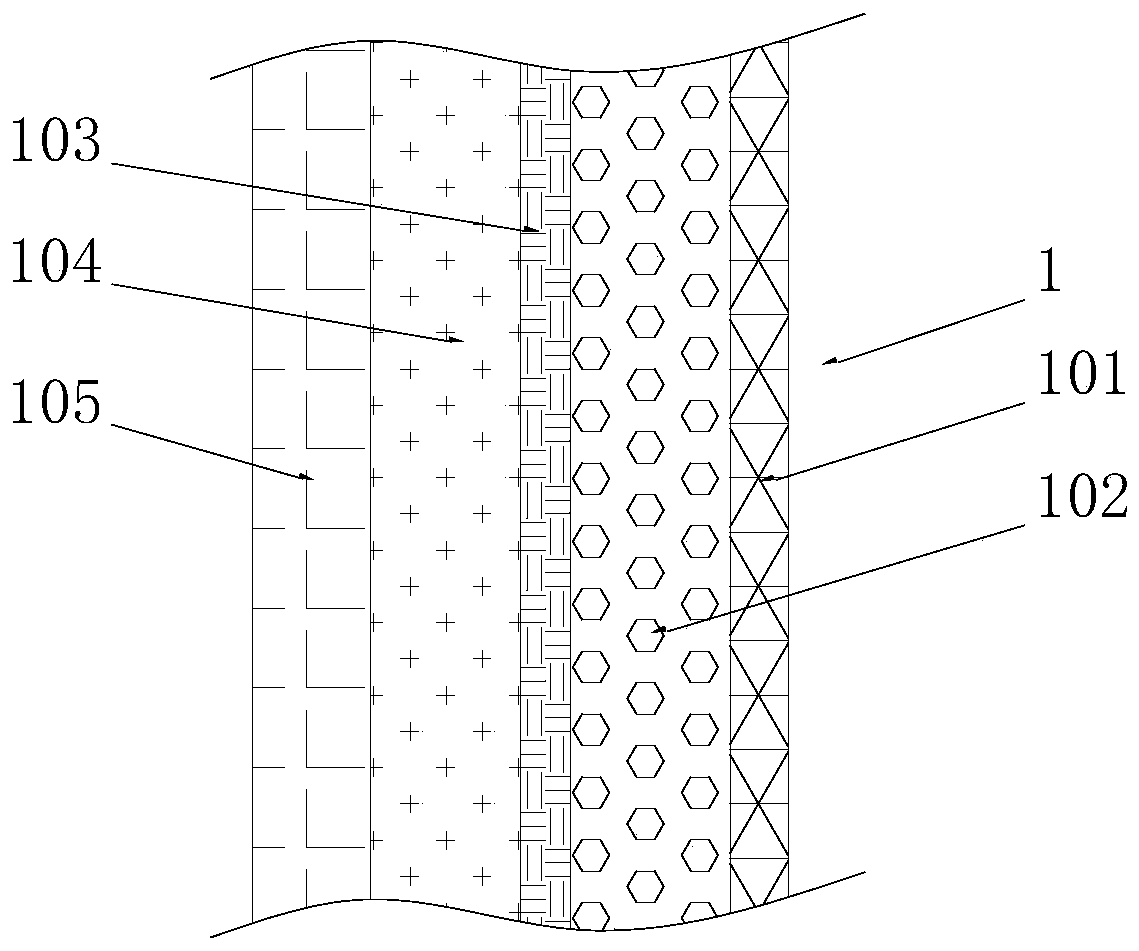

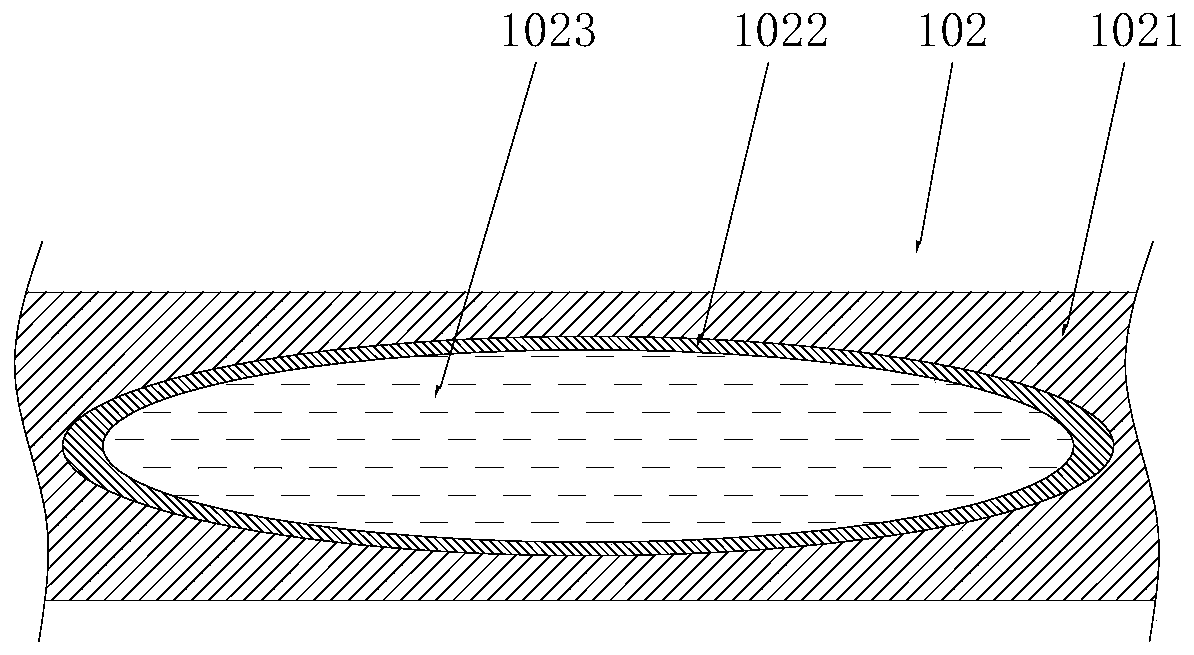

Cable solder wire for CMT welding system and CMT welding system

ActiveCN106363314AImprove welding effectReduce the number of weld layersArc welding apparatusWelding/cutting media/materialsTight bindingEngineering

The invention discloses a cable solder wire for a CMT welding system. The solder wire comprises a central solder wire. The outer side of the central solder wire is provided with a spiral solder wire which is twined tightly around the central solder wire in a spiral manner. The outer side of the spiral solder wire is provided with a protection ring. The inside of the spiral solder wire is provided evenly with 4 subordinate solder wire groups. The subordinate solder wire groups are tangentially arranged. The inside of each subordinate solder wire group is provided with a first solder wire, a second solder wire, a third solder wire and a fourth solder wire. The fusion depth in the welding operation is deep. This structure can reduce the quantity of overlapping welding seams layers and can fundamentally increase the welding efficiency, reduce the production costs with negligible splashes. The high mechanical property of the welding seam and the tight binding structure of the solder wire stabilize the solder wire feeding process, enhances the welding property of the cable solder wire and makes the CMT welding system to render a better soldering effects.

Owner:QINGDAO BRANCH CO., LTD. OF MECHANICAL SCIENCE RESEARCH INSTITUTE

Web searching engine based on block chain technology by using living biometric identity to log in

PendingCN109213914AHide social identityPrivacy protectionFinanceDigital data authenticationDigital currencyWeb search engine

The invention discloses a web searching engine based on block chain technology by using living biometric identity to log in, which comprises an identity authentication module, an area chain and an information module. The identity authentication module comprises: a front-end hardware token and a dual-camera; combined with infrared light, the user's facial and finger veins are obtained, and the unique ID of the user login system is generated. P2P digital currency rewards and punishments mechanism and information integrity are realized in the regional chain, so that the real and effective contentcan be provided to the users who need them. Information module realizes the tight binding between users and information, realizes information openness, transparency, flattening, and can return to theoriginal value and spirit of the Internet and block chain. Searching engine is no longer purely profit-driven profit-making machine. The invention adopts distributed storage and maintenance, traces the source and establishes reward and punishment mechanism, and records and binds the reward and punishment mechanism when the user inputs, modifies and uses the information, so that the reward and punishment mechanism is no longer a cost-free abuse.

Owner:蔡捷

Preparation method of fruit and vegetable fresh keeping agent

InactiveCN107712041AImprove defectsGood water vapor barrierFruits/vegetable preservation by coatingPhenolFilm material

The invention discloses a preparation method of a fruit and vegetable fresh keeping agent, and belongs to the technical field of fresh keeping. Through tight binding force of phenol substances and protein in Chinese herbal medicines, a novel film material is formed, antioxidant activity is provided, the defects of the film material are overcome, a release control carrier of a bacteriostat is prepared, and the carrier and aloe gel are combined through catalysis to form a three-dimensional net-shaped structure; and an emulsifying agent and grape seed oil are added to a fermentation mixture for performing hydrophobic character modification on the aloe gel film material, the grape seed oil is added to a protein substrate to prepare a film forming emulsion, and the emulsion film material with good vapor barrier property is constructed as the release control carrier of the bacteriostat. Besides, the emulsion film material can load a phenol substance liposoluble biological bacteria inhibitor,can achieve the effect of release slow for preservation of foods, can achieve the effect of long-acting bacteria resistance, and can prolong the shelf life. The invention solves the problems that a common fresh keeping agent at present is limited in fresh keeping effect, and has chemical components harmful to human bodies.

Owner:常州五荣化工有限公司

Stopping block for inertial sensor

PendingCN109506691AImprove stabilityNot easy to fall offMeasurement apparatus componentsInertial massTight binding

The invention provides a stopping block for an inertial sensor. The stopping block is arranged on the surface of a substrate and used for blocking inertial movement of a mass block and comprises a body, wherein the position, in contact with the inertial mass block, of the body is a round corner, and the surface of the body and the surface of the substrate are made of the same material. The surfaceof the stopping block and the surface of the substrate are made of the same material so that the firmness degree of the stopping block can be increased by utilizing the characteristic of tight binding of homogeneous materials and the stopping block is not prone to shedding from the substrate. In addition, the position, in contact with the inertial mass block, of the body is the round corner so that the effective contact area between the stopping block and the mass block can be increased, and the possibility can be reduced that the stopping block is damaged after being bumped.

Owner:QST CORP

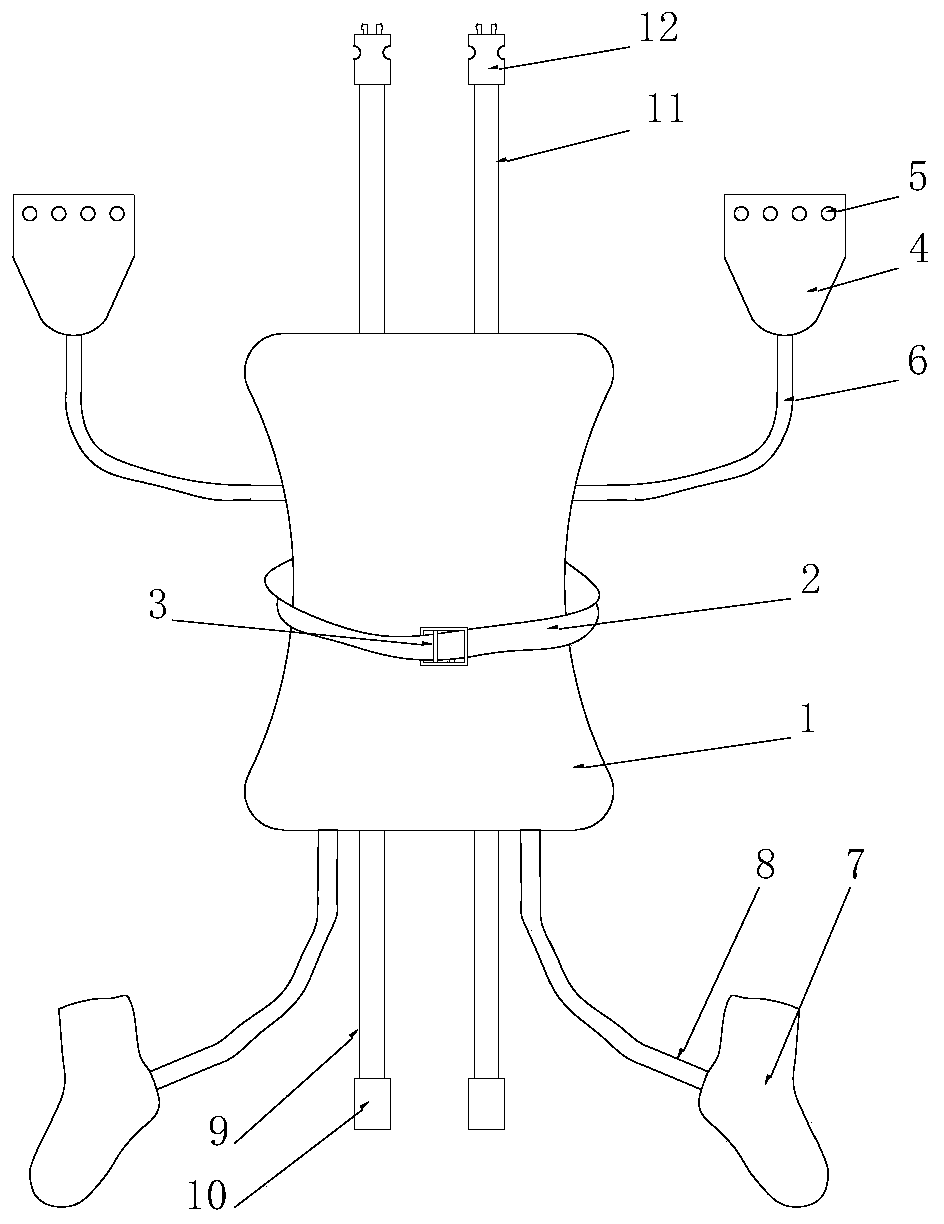

Swimming technical resistance trainer

InactiveCN110292743AProtection securityThere will be no concentrated stressMuscle exercising devicesHuman bodyTight binding

The invention discloses a swimming technical resistance trainer. The swimming technical resistance trainer includes two palm covers and two foot covers, and further includes a tight-binding garment covering a trunk of a human body, the two palm covers are fixedly connected to the left side and the right side of the tight-binding garment through upper limb resistance belts correspondingly, the twofoot covers are fixedly connected to the left side and the right side of the bottom end of the tight-binding garment through lower limb resistance belts, first binding belts are symmetrically arrangedon the left side and the right side of the bottom end of the tight-binding garment, the movable ends of the first binding belts are fixedly connected with locking sleeves, and second binding belts are arranged at the top end of the tight-binding garment in left-right symmetry. According to the swimming technical resistance trainer, training is conducted by tying the trunk of the human body with the tight-binding garment, and then putting the palm covers on hands and the foot covers on feet, since the tight-binding garment covers the trunk of the human body, when the tight-binding garment is pulled by the upper limb resistance belts and the lower limb resistance belts, force is distributed on the trunk of the human body without concentrated stress, thus the fatigue strain can be effectively prevented, and the safety of athletes can be guaranteed to the maximum limit.

Owner:HUNAN UNIV OF ARTS & SCI

A conduction cooling superconducting magnet refrigerator structure and its installation and disassembly method

ActiveCN104200950BAchieve replacementSimple structureCompression machinesInductances/transformers/magnets manufactureCold shieldConduction cooling

A conductive cooling superconducting magnet refrigerator structure and its installation and disassembly methods, including a connection flange connected with the refrigerator, the connection flange is connected with the support flange through a bellows, and the magnet outer Dewar is respectively connected with the support flange . The first-stage cold head of the refrigerator is connected with the upper assembly of the heat transfer part, the lower end of the upper part of the heat transfer part is tightly combined with the upper end of the lower part of the heat transfer part by pressure, and the lower end of the lower part of the heat transfer part is connected with the magnet cold screen flange, The secondary cold head of the refrigerator is connected to the upper part of the secondary heat transfer component, the lower part of the secondary heat transfer component is combined with the upper part supported by the secondary heat transfer component by pressure, and the upper part of the heat-conducting copper braid is connected to the support of the secondary heat transfer component. The lower part is welded together, the upper end of the supporting spring is welded together with the support of the secondary heat transfer part, the lower end of the supporting spring is fixed on the mounting plate, and the lower part of the mounting plate is connected with the winding of the magnet with a heat-conducting copper braid, which has the advantages of simple structure, easy operation and maintenance Low cost, simple installation and disassembly methods.

Owner:XIAN JUNENG SUPERCONDUCTING MAGNET TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com