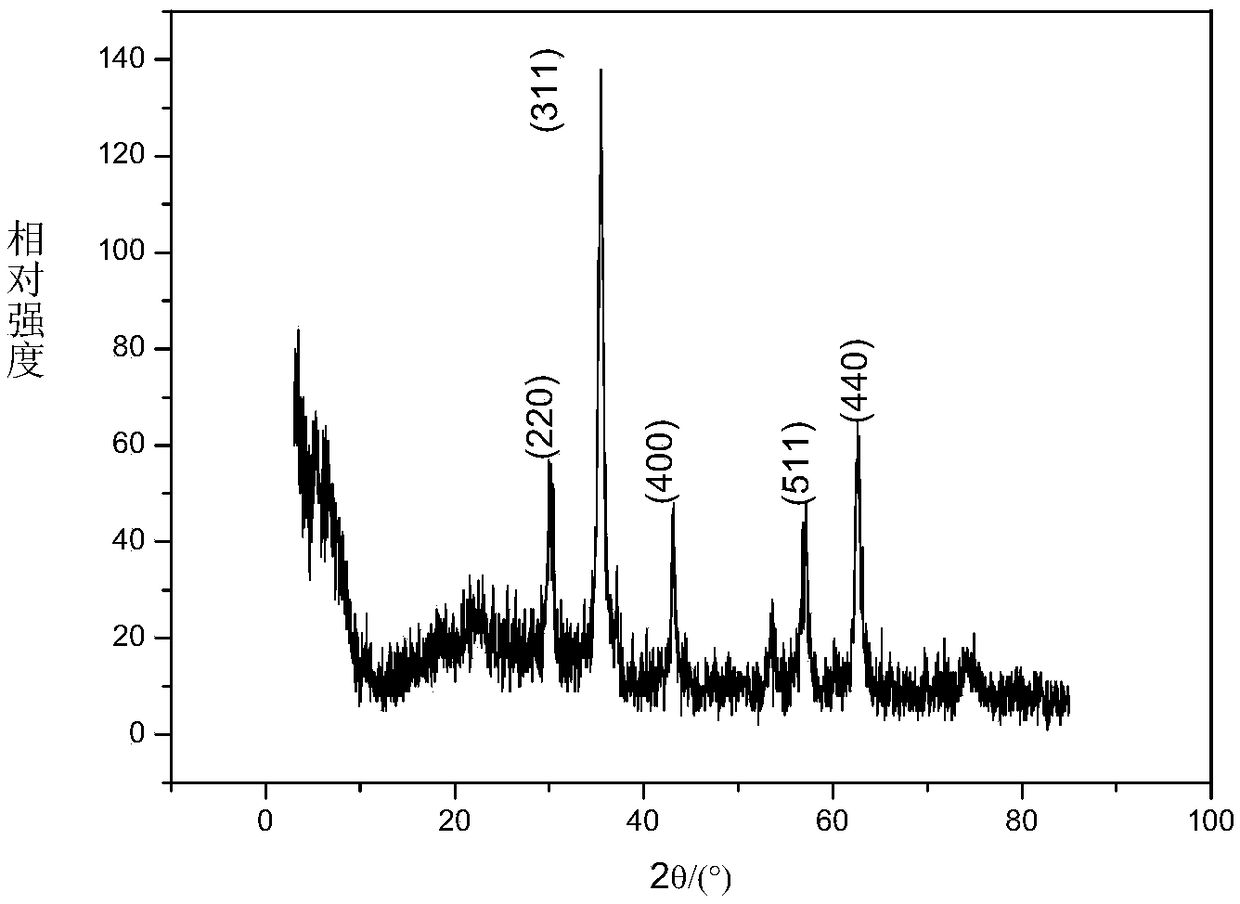

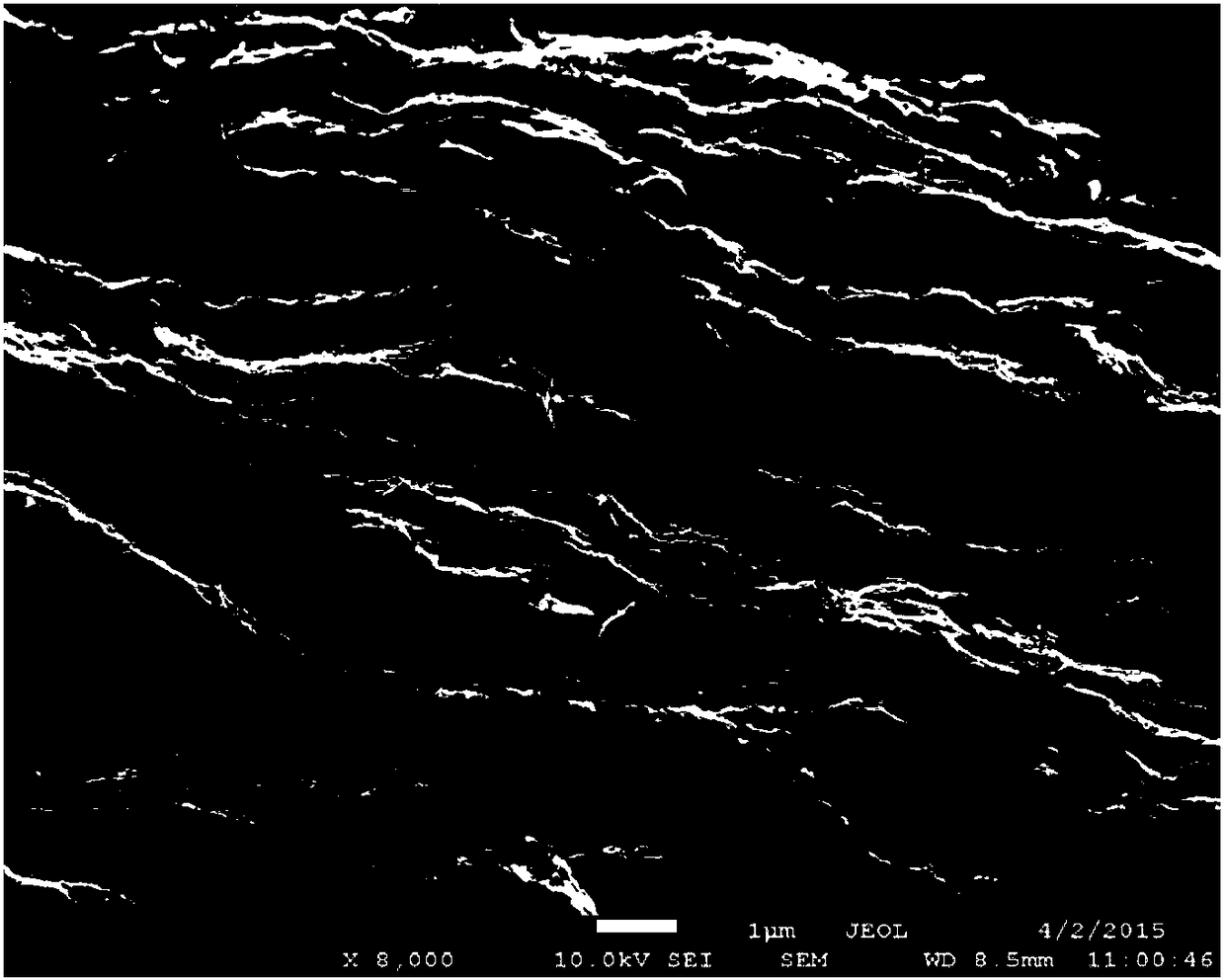

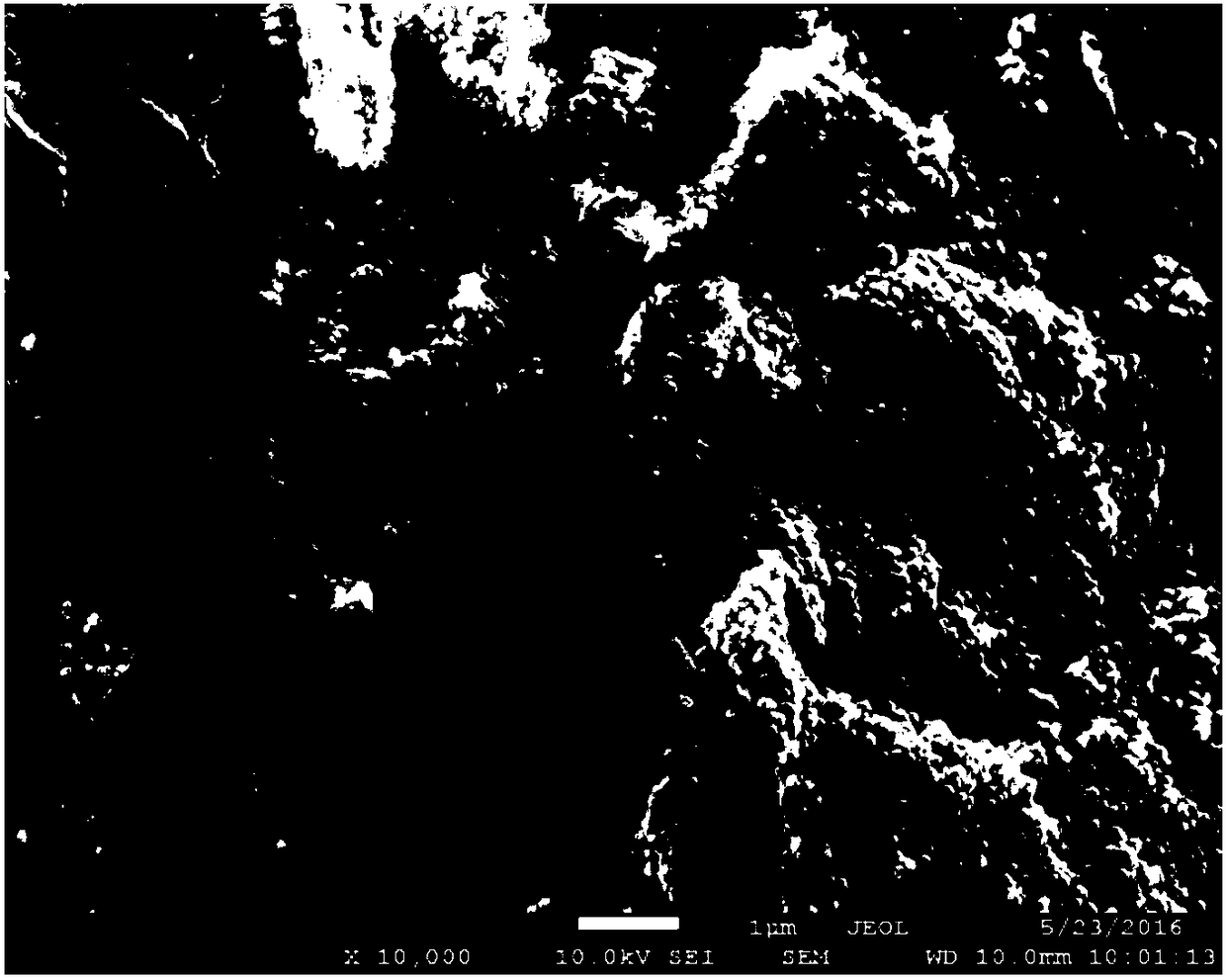

A kind of Fe3O4/graphene composite material and preparation method thereof

A composite material, graphene technology, applied in the manufacture of hybrid/electric double-layer capacitors, hybrid capacitor electrodes, electrical components, etc., can solve problems such as high requirements for synthesis equipment, increase production costs, and difficulty in industrialization, and achieve high power The effect of density, high energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Fe in this example 3 o 4 / The preparation method of graphene composite material, comprises the steps:

[0046] 1) Prepare an aqueous ferric chloride solution with a concentration of 0.01mol / L, prepare an aqueous urea solution with a concentration of 0.02mol / L, add 20mL of urea aqueous solution to 100mL of ferric chloride solution dropwise, and perform magnetic force during the dropping process Stir, let stand at room temperature for 1 h after the dropwise addition, and then react for 5 h under the condition of heating in a water bath at 80 ° C to obtain bright reddish-brown Fe(OH) 3 Sol, wherein the surface of ferric hydroxide colloidal particles is positively charged;

[0047] Weigh 2g of graphite powder and 2g of sodium nitrate, and add 100mL of concentrated sulfuric acid with a concentration of 98%, and stir for 15min in an ice bath at 0°C to make them evenly mixed, then add 12g of potassium permanganate, Leave to cool in an ice bath for 30 minutes, then stir and ...

Embodiment 2

[0050] Fe in this example 3 o 4 / The preparation method of graphene composite material, comprises the steps:

[0051] 1) Prepare an aqueous ferric chloride solution with a concentration of 0.2mol / L, prepare an aqueous urea solution with a concentration of 0.5mol / L, add 10mL of urea aqueous solution to 100mL of ferric chloride solution dropwise, and perform magnetic force during the dropping process Stir, let stand at room temperature for 5h after the dropwise addition, and then react for 10h under the condition of heating in a water bath at 70°C to obtain bright reddish-brown Fe(OH) 3 Sol, wherein the surface of ferric hydroxide colloidal particles is positively charged;

[0052] Weigh 2g of graphite powder and 2g of sodium nitrate, and add 100mL of concentrated sulfuric acid with a concentration of 98%, and stir for 15min in an ice bath at 0°C to make them evenly mixed, then add 12g of potassium permanganate, Leave to cool in an ice bath for 30 minutes, then stir and react...

Embodiment 3

[0055] Fe in this example 3 o 4 / The preparation method of graphene composite material, comprises the steps:

[0056] 1) Prepare an aqueous ferric chloride solution with a concentration of 0.5mol / L, prepare an aqueous urea solution with a concentration of 1mol / L, add 12.5mL of urea aqueous solution to 100mL of ferric chloride solution dropwise, and perform magnetic force during the dropping process Stir, let stand at room temperature for 10h after the dropwise addition, and then react for 0.5h under the condition of heating in a water bath at 90°C to obtain bright reddish-brown Fe(OH) 3 Sol, wherein the surface of ferric hydroxide colloidal particles is positively charged;

[0057] Weigh 2g of graphite powder and 2g of sodium nitrate, and add 100mL of concentrated sulfuric acid with a concentration of 98%, and stir for 15min in an ice bath at 0°C to make them evenly mixed, then add 12g of potassium permanganate, Leave to cool in an ice bath for 30 minutes, then stir and rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com