Patents

Literature

444results about "Tar working-up by distillation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Upgrading of tar using POX/coker

ActiveUS8083931B2Reduce and eliminate needThermal non-catalytic crackingTreatment with plural serial cracking stages onlyNaphthaPartial oxidation

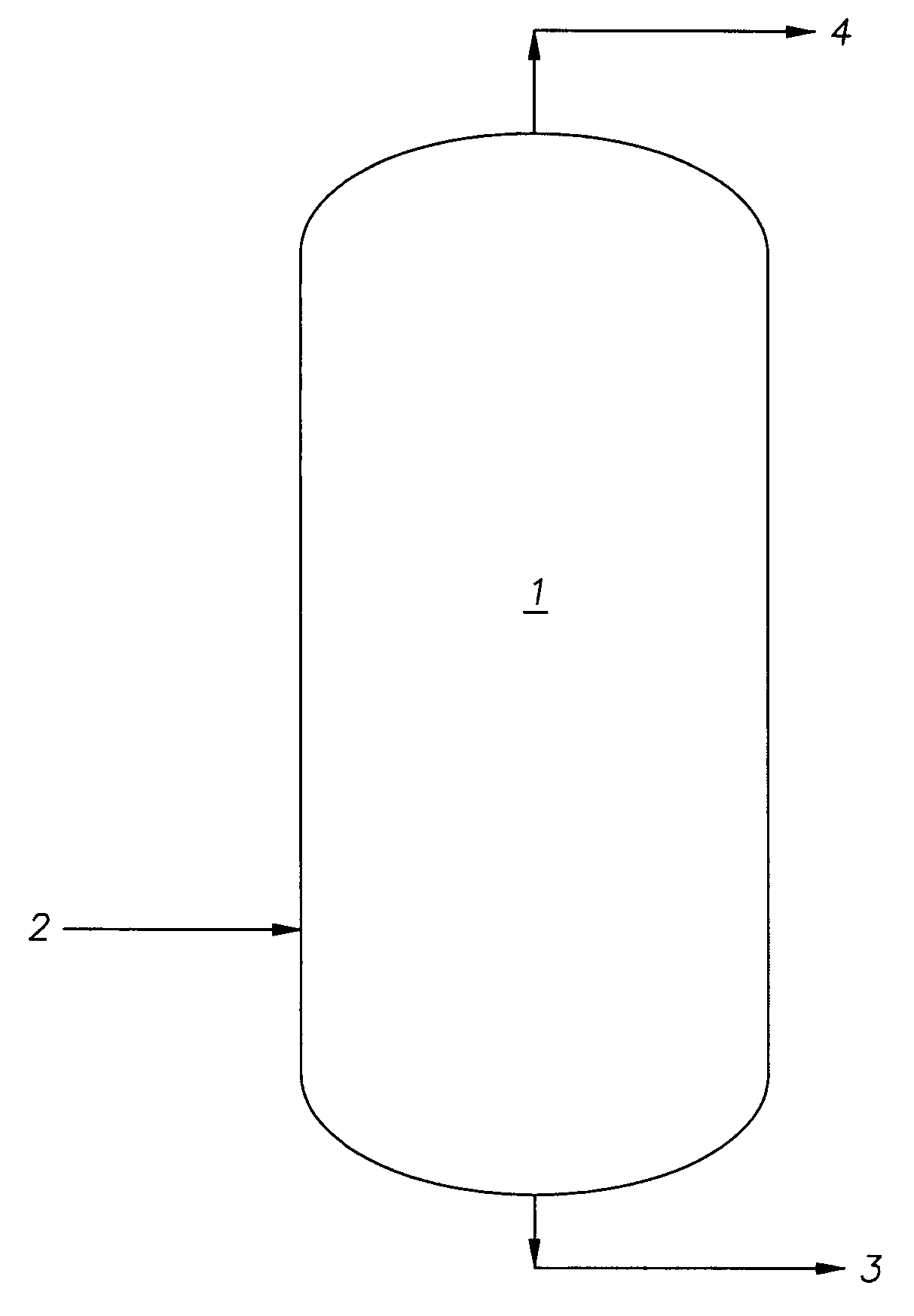

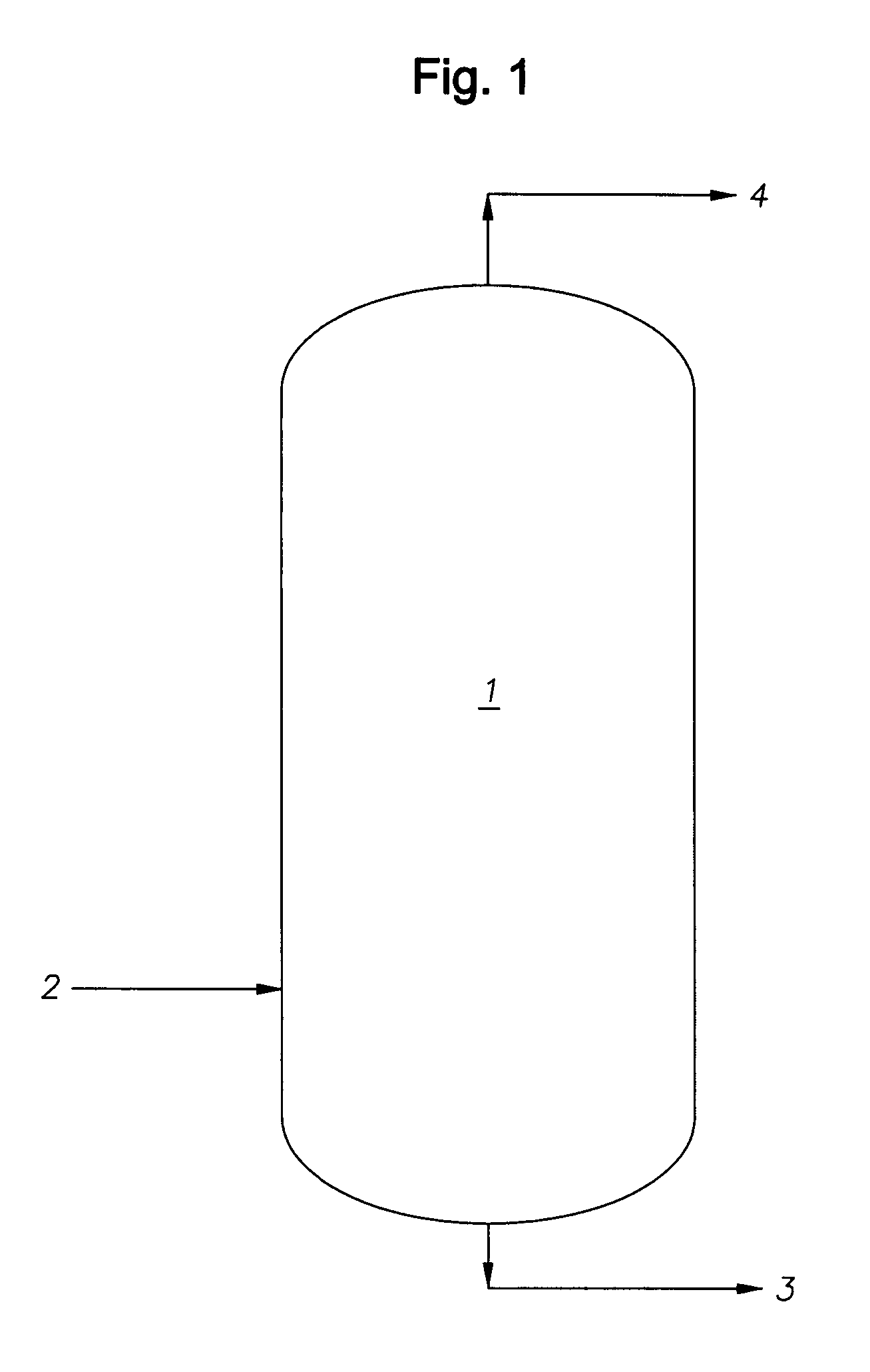

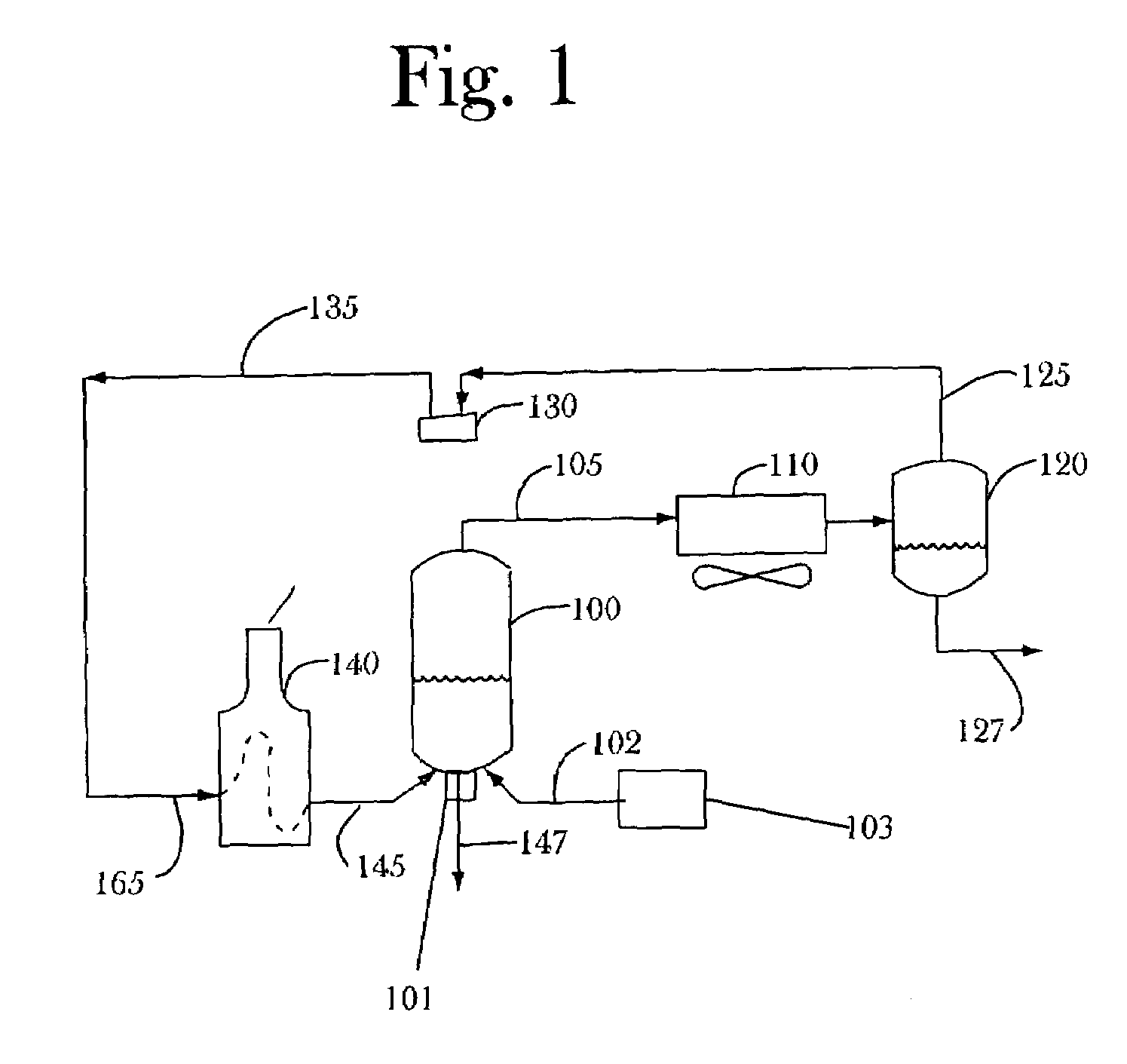

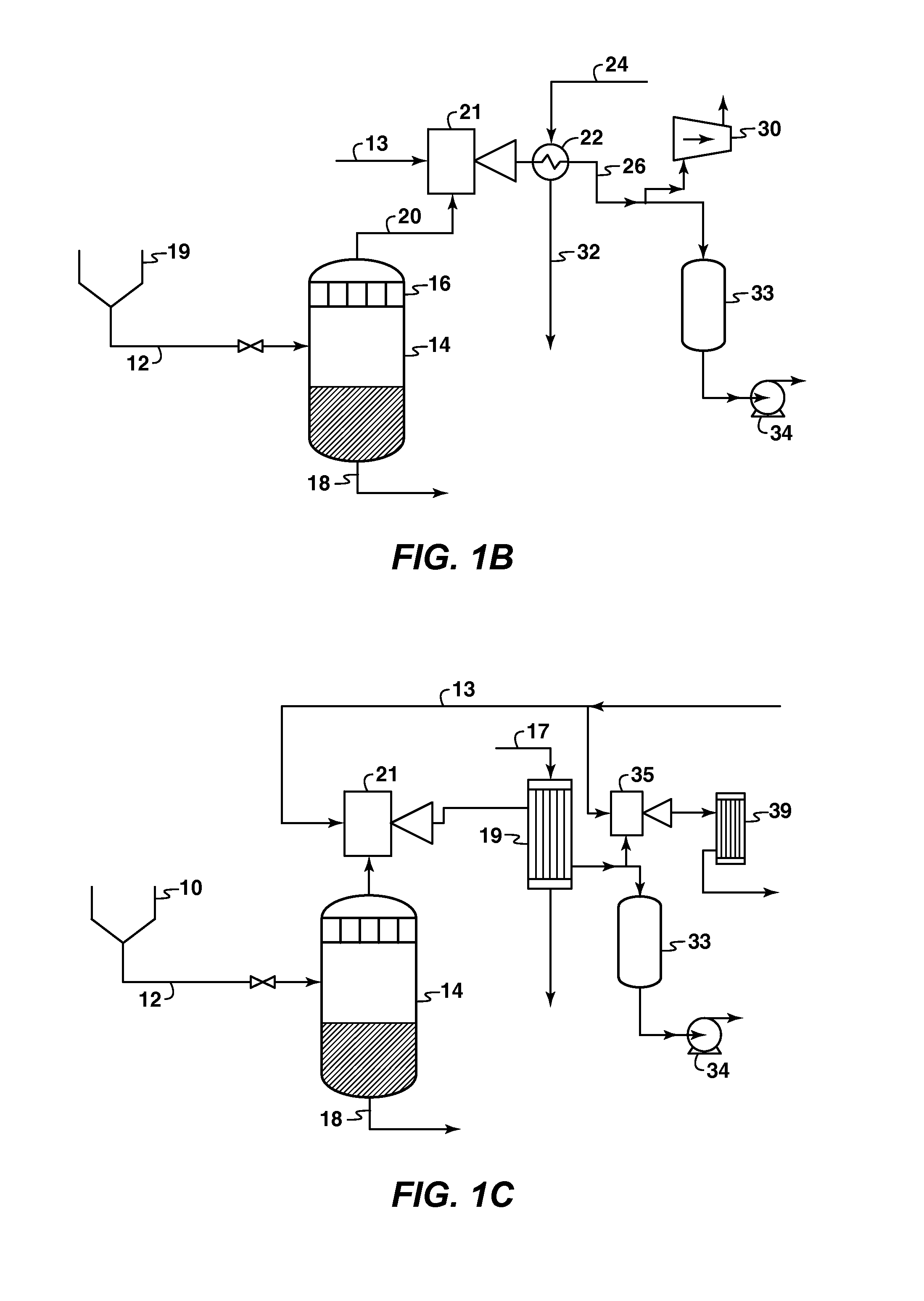

The invention is directed to a process wherein a feedstock or stream comprising steam cracker tar is passed to a vacuum pipestill. A deasphalted cut of tar is obtained as an overhead (or sidestream) and a heavy tar asphaltenic product is obtained as bottoms. In preferred embodiments, at least a portion of the bottoms product is sent to a partial oxidation unit (POX) wherein syn gas may be obtained as a product, and / or at least a portion of the bottoms product is used to produce a light product stream in a coker unit, such as coker naphtha and / or or coker gas oil. In another preferred embodiment at least a portion of the overheads product is added to refinery fuel oil pools and in yet another preferred embodiment at least a portion of the overheads product is mixed with locally combusted materials to lower soot make. Two or more of the aforementioned preferred embodiments may be combined.

Owner:EXXONMOBIL CHEM PAT INC

Systems, methods, and catalysts for producing a crude product

InactiveUS20050139522A1Working-up pitch/asphalt/bitumen by distillationCatalytic crackingHydrogenProduct system

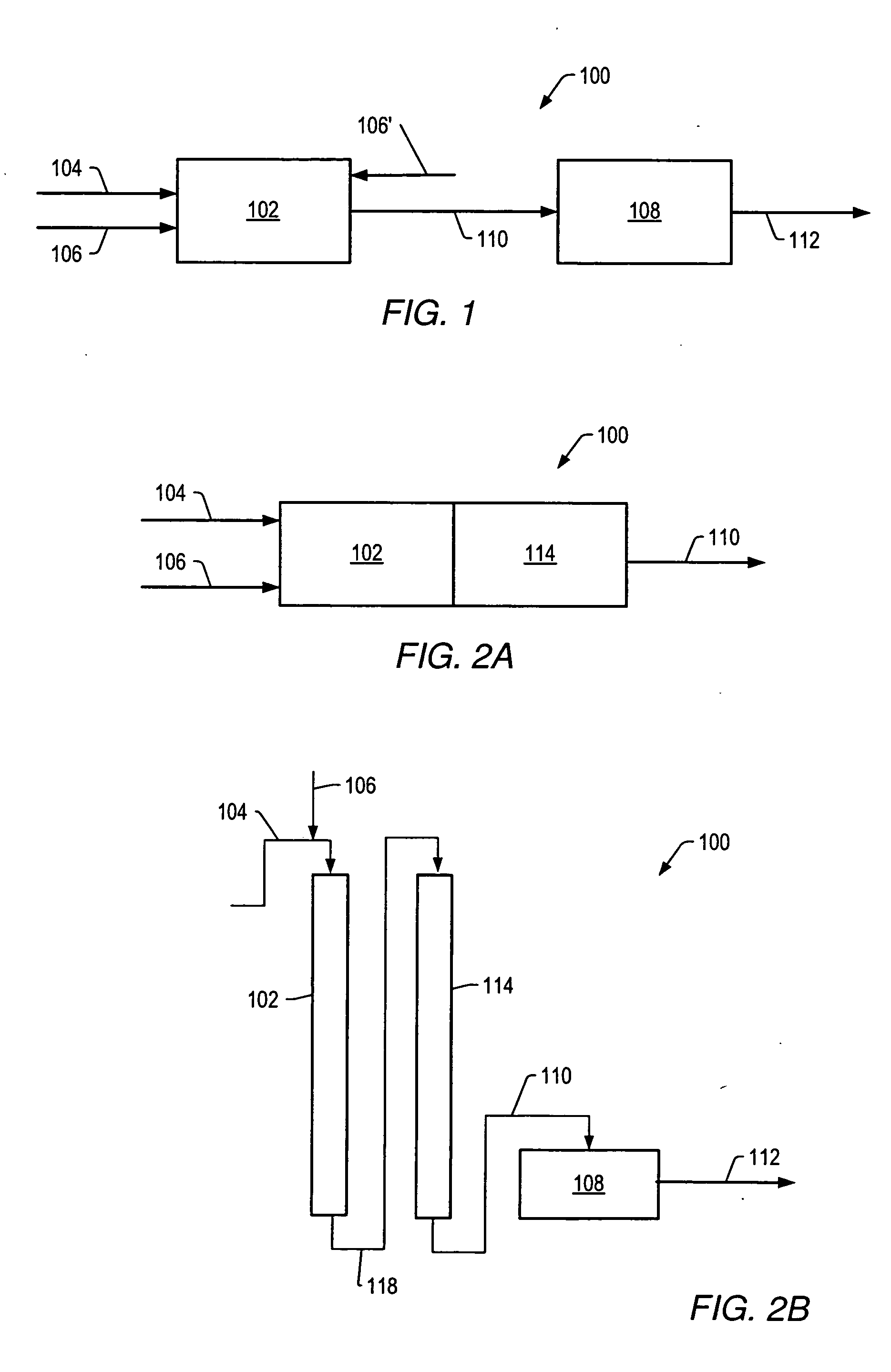

Systems and methods for contacting a crude feed with one or more catalysts produces a total product that include a crude product are described. The crude product is a liquid mixture at 25° C. and 0.101 MPa. The one or more catalysts may include one or more vanadium catalysts. Methods and compositions of the one or more vanadium catalysts are described. One or more properties of the crude product may be changed by at least 10% relative to the respective properties of the crude feed. In some embodiments, hydrogen is generated.

Owner:SHELL OIL CO

Method and apparatus for reclaiming oil from waste plastic

InactiveUS6172271B1Increase productionContinuous operationThermal non-catalytic crackingHydrocarbon distillationForeign matterBoiling point

Owner:MITSUBISHI HEAVY IND LTD

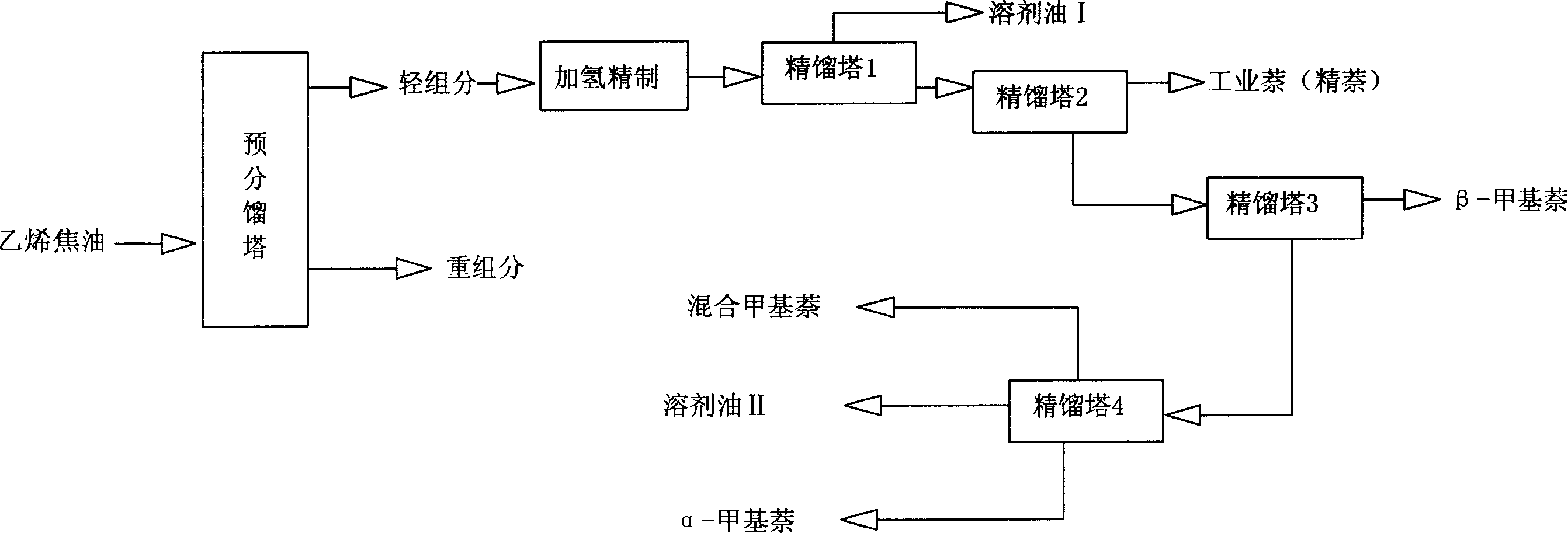

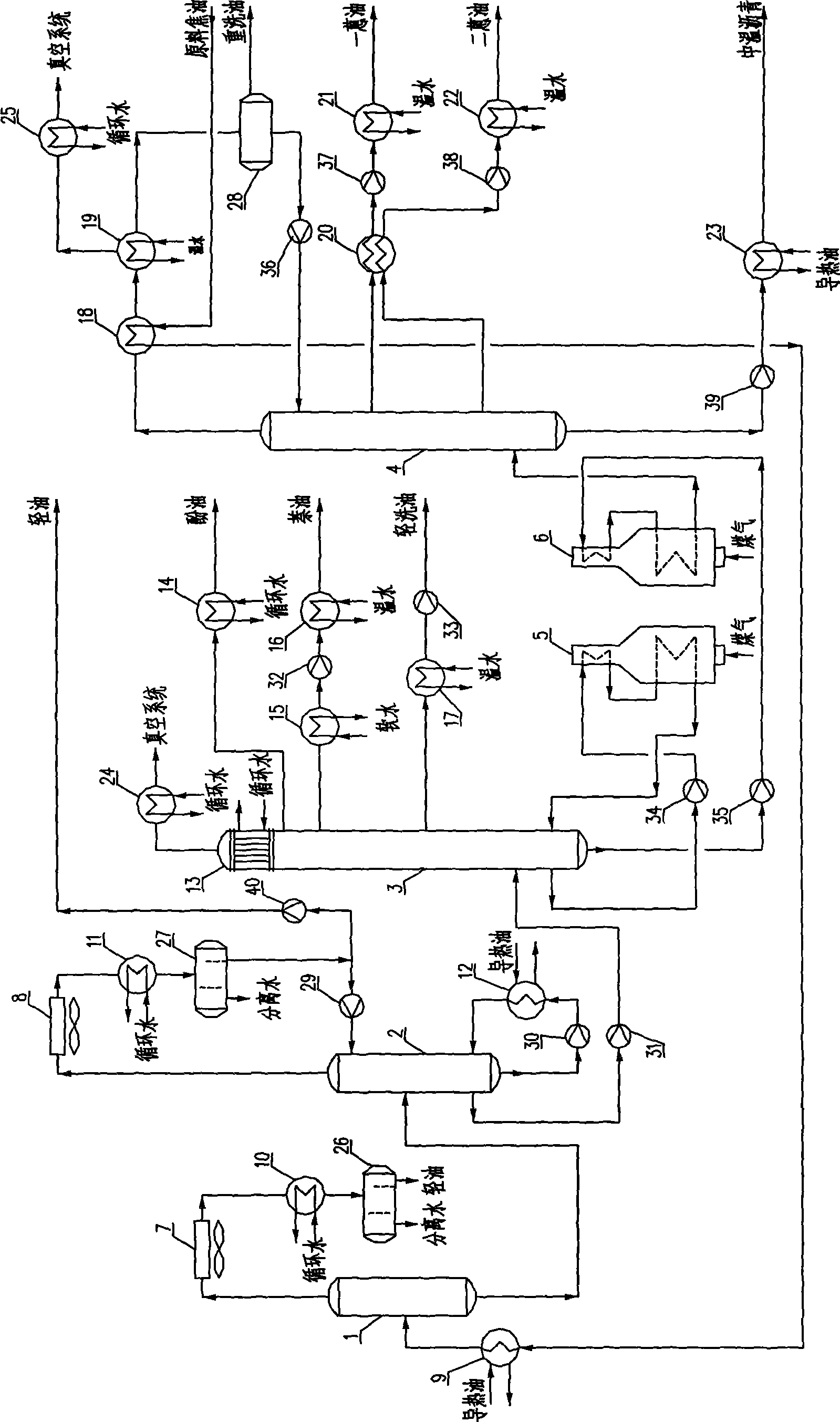

Ethylene bottom oil complex processing technology

ActiveCN1970688AHigh purityEasy to operateHydrocarbon purification/separationHydrocarbonsTarBeta-methylnaphthalene

The invention discloses an extracting method of industrial refined naphthalene, alpha-methylnaphthalene, beta-methylnaphthalene from ethylene tar, which is characterized by the following: prefractionating ethylene tar under 260-280 deg.c; hydrogenating light fractionated component under 160-300 deg.c at 3.0-4.0Mpa to remove insaturated hydrocarbons; rectifying to separate refined naphthalene with crystallizing point at 79.6 deg.c; obtaining alpha-methylnaphthalene and beta-methylnaphthalene with each purity over 95%.

Owner:浙江美阳国际工程设计有限公司

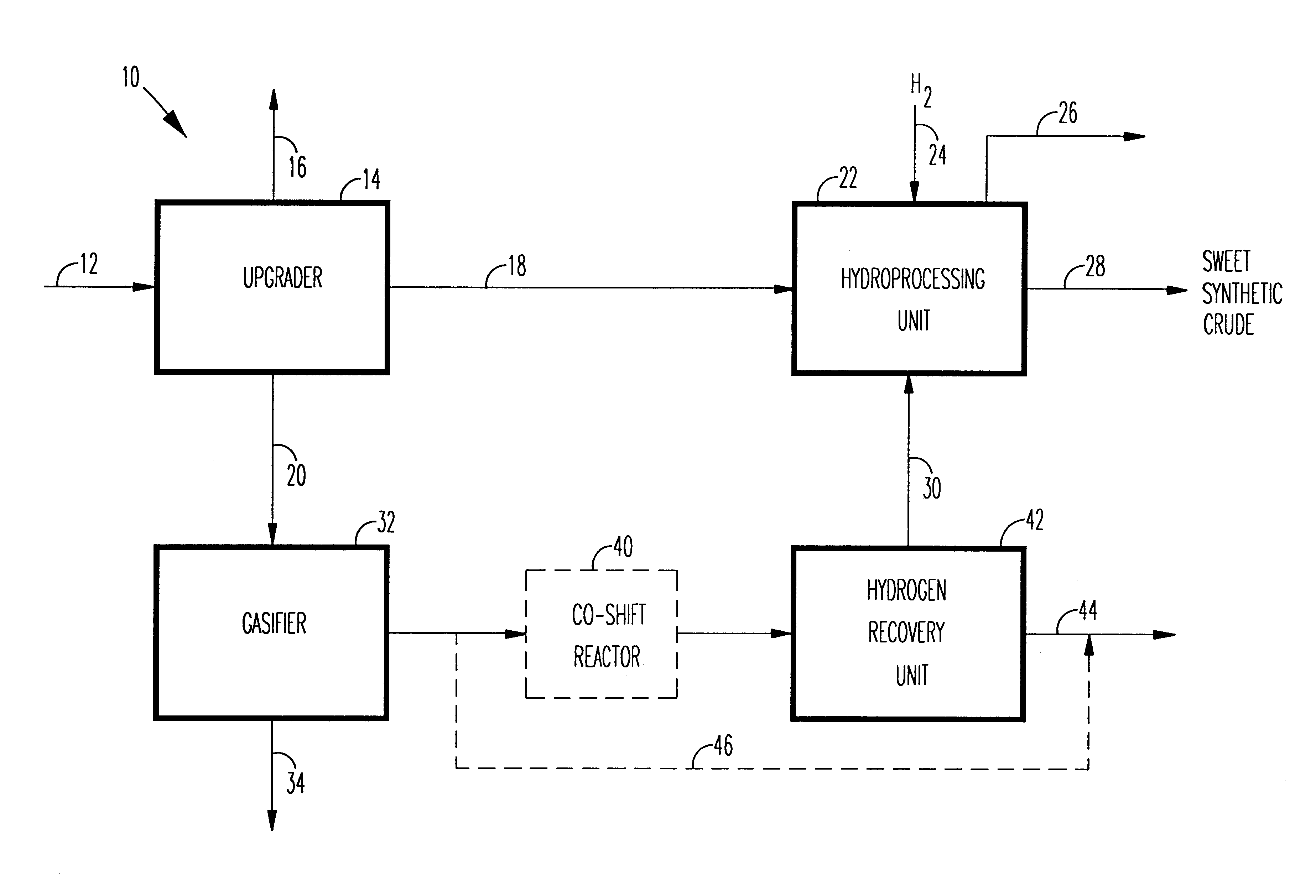

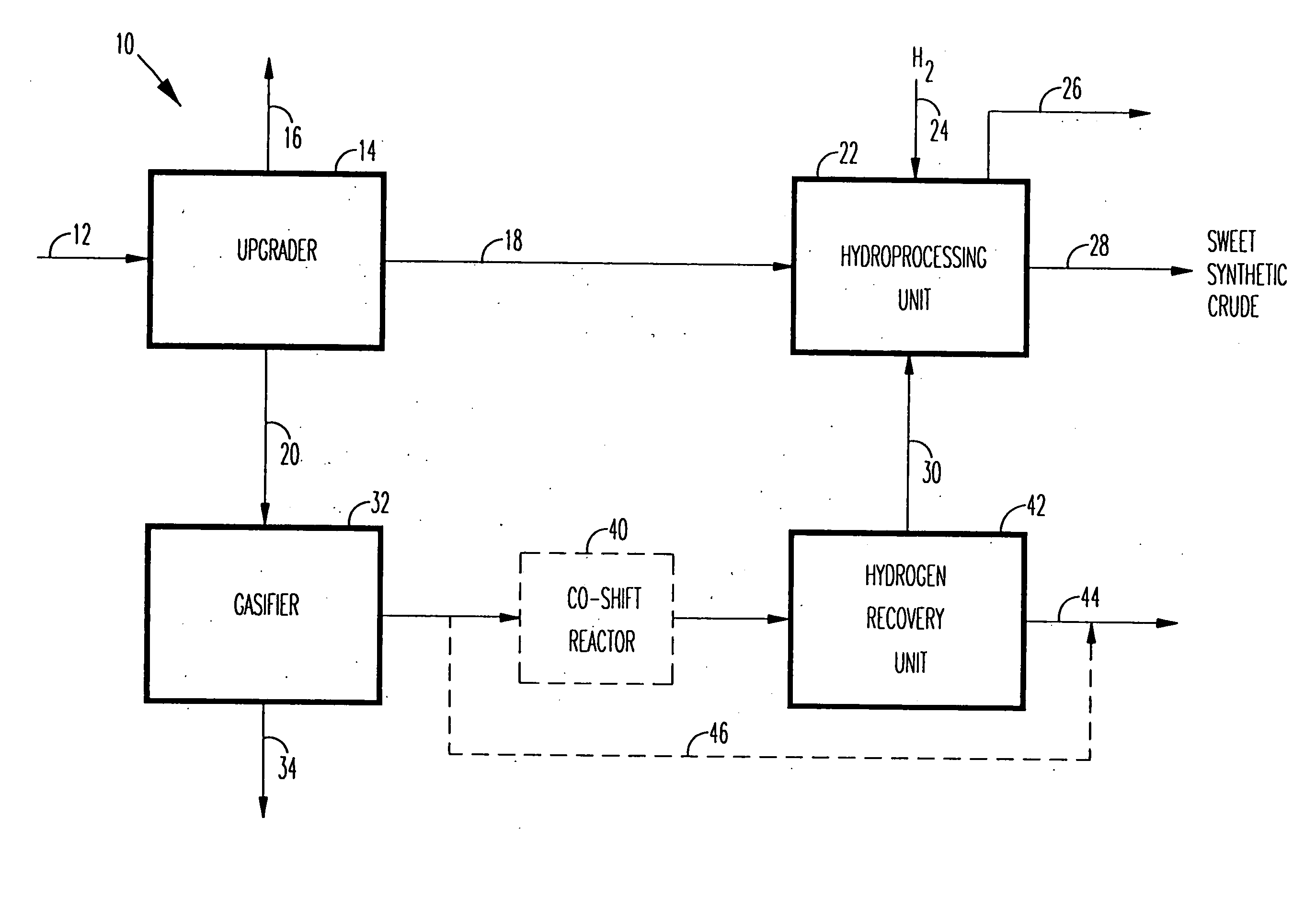

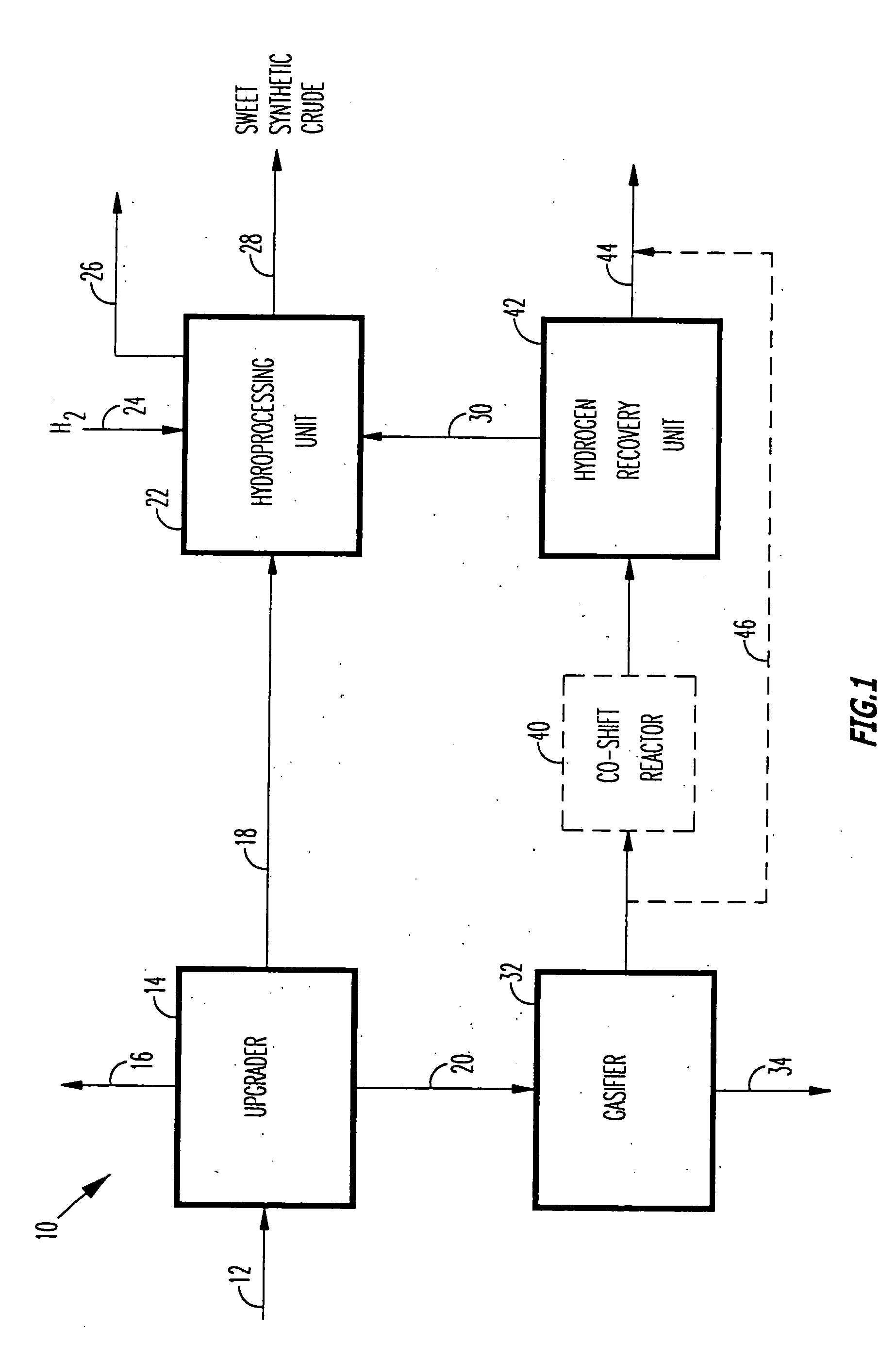

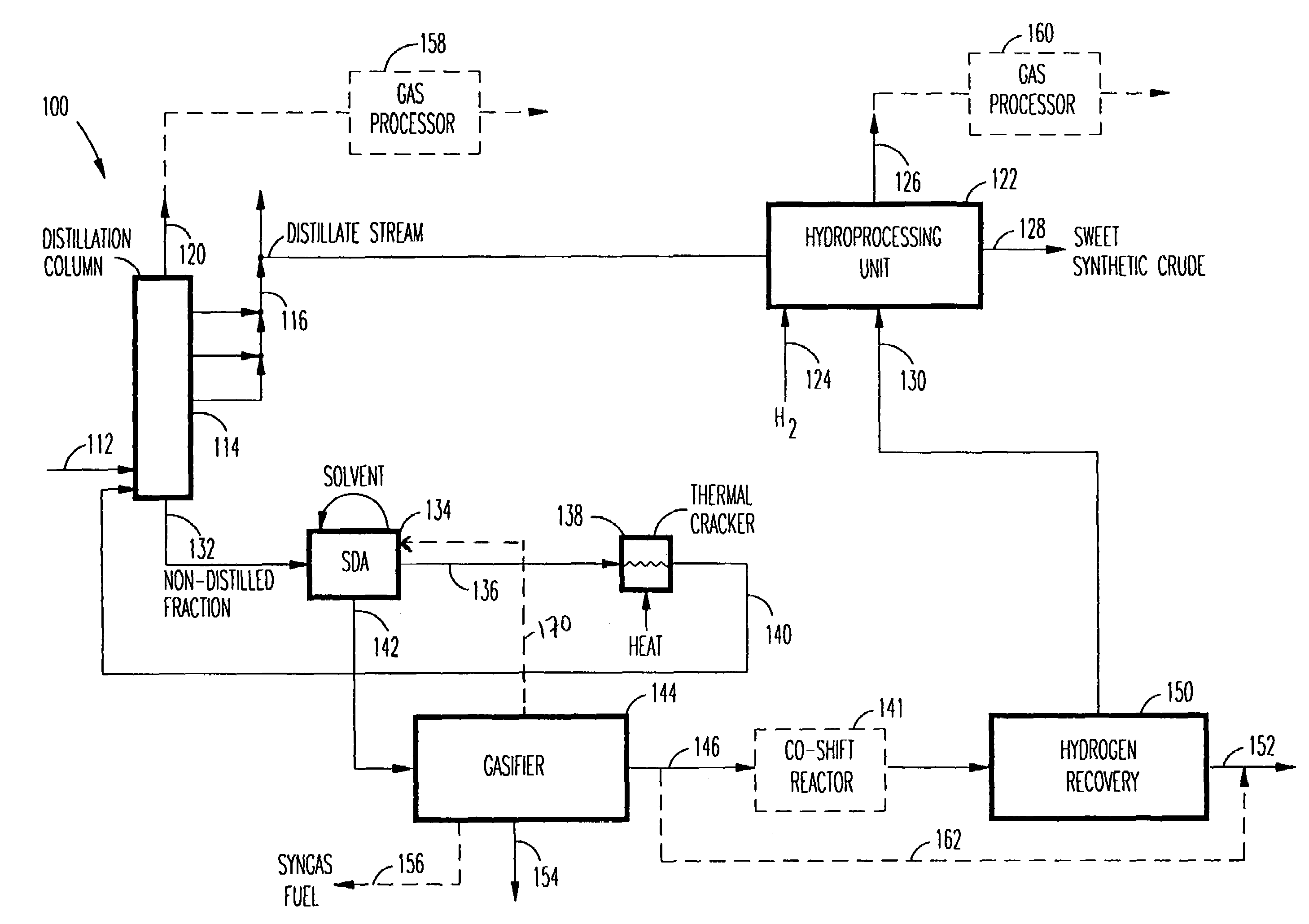

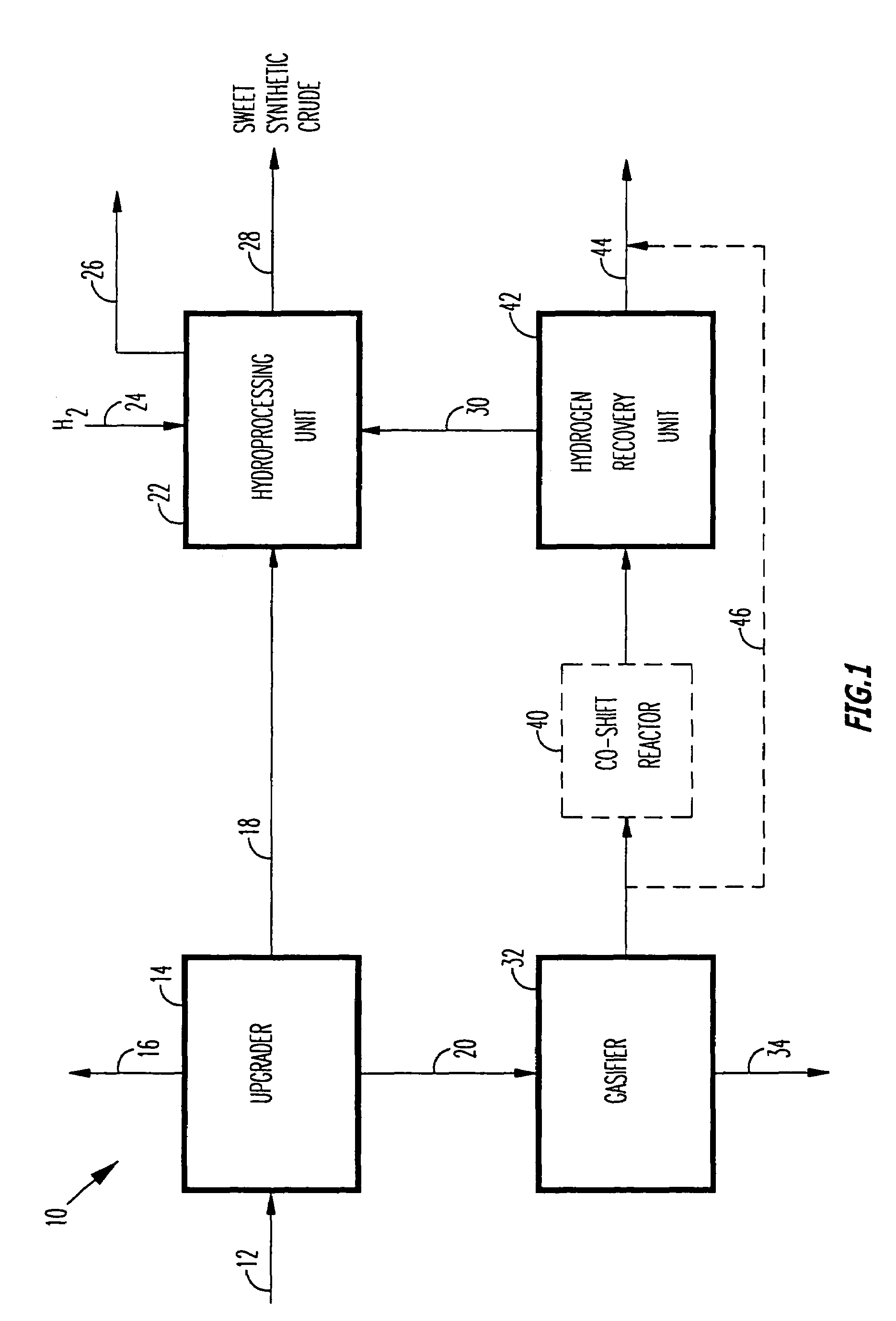

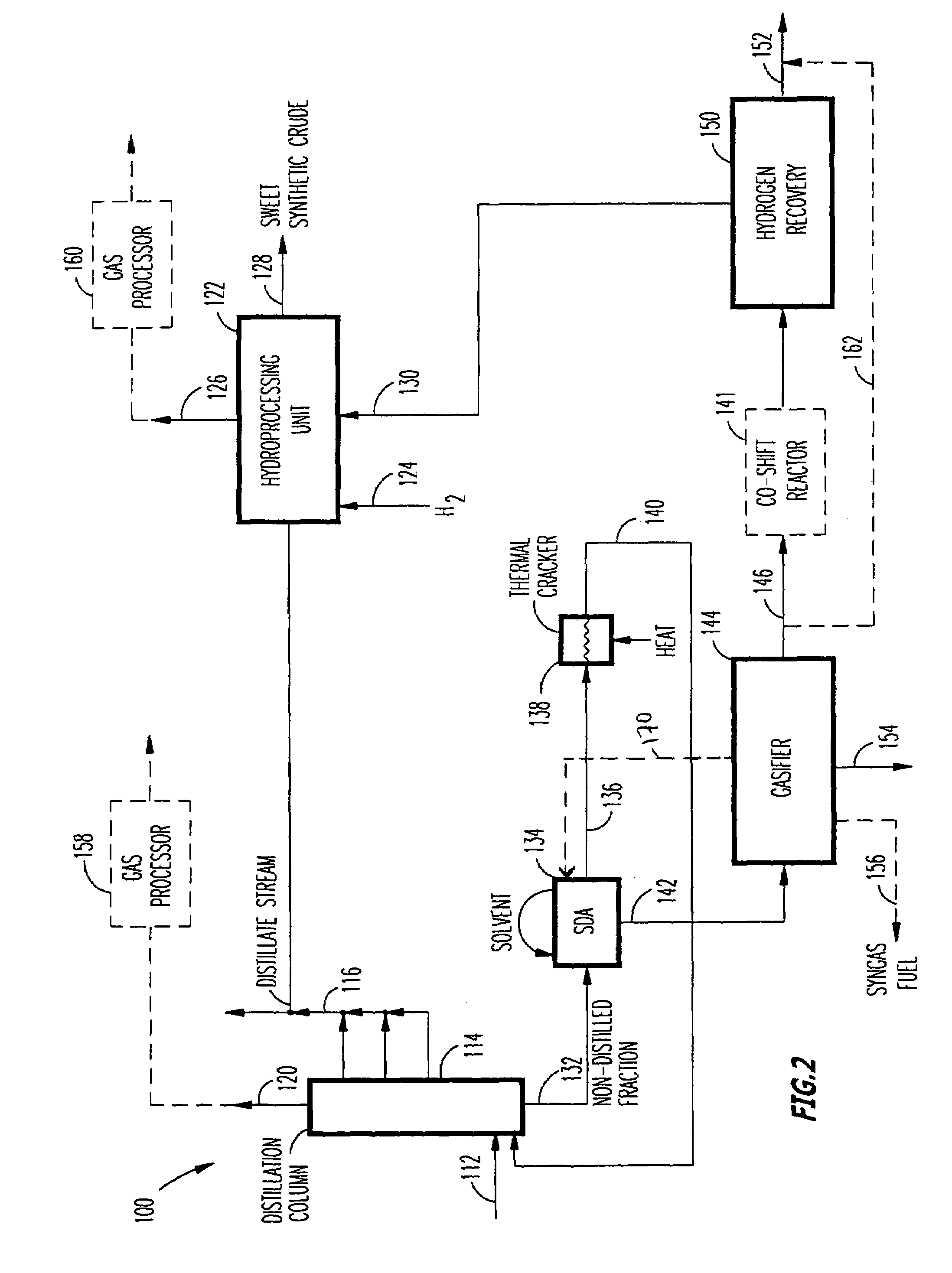

Method of and apparatus for upgrading and gasifying heavy hydrocarbon feeds

A novel apparatus for producing sweet synthetic crude from a heavy hydrocarbon feed comprising: an upgrader for receiving said heavy hydrocarbon feed and producing a distillate fraction including sour products, and high-carbon content by-products; a gasifier for receiving the high-carbon content by-products and producing synthetic fuel gas and sour by-products; a hydroprocessing unit for receiving the sour by-products and hydrogen gas, thereby producing gas and sweet crude; and a hydrogen recovery unit for receiving said synthetic fuel gas and producing further hydrogen gas and hydrogen-depleted synthetic fuel gas, said further hydrogen gas being supplied to said hydroprocessing unit.

Owner:ORMAT IND LTD

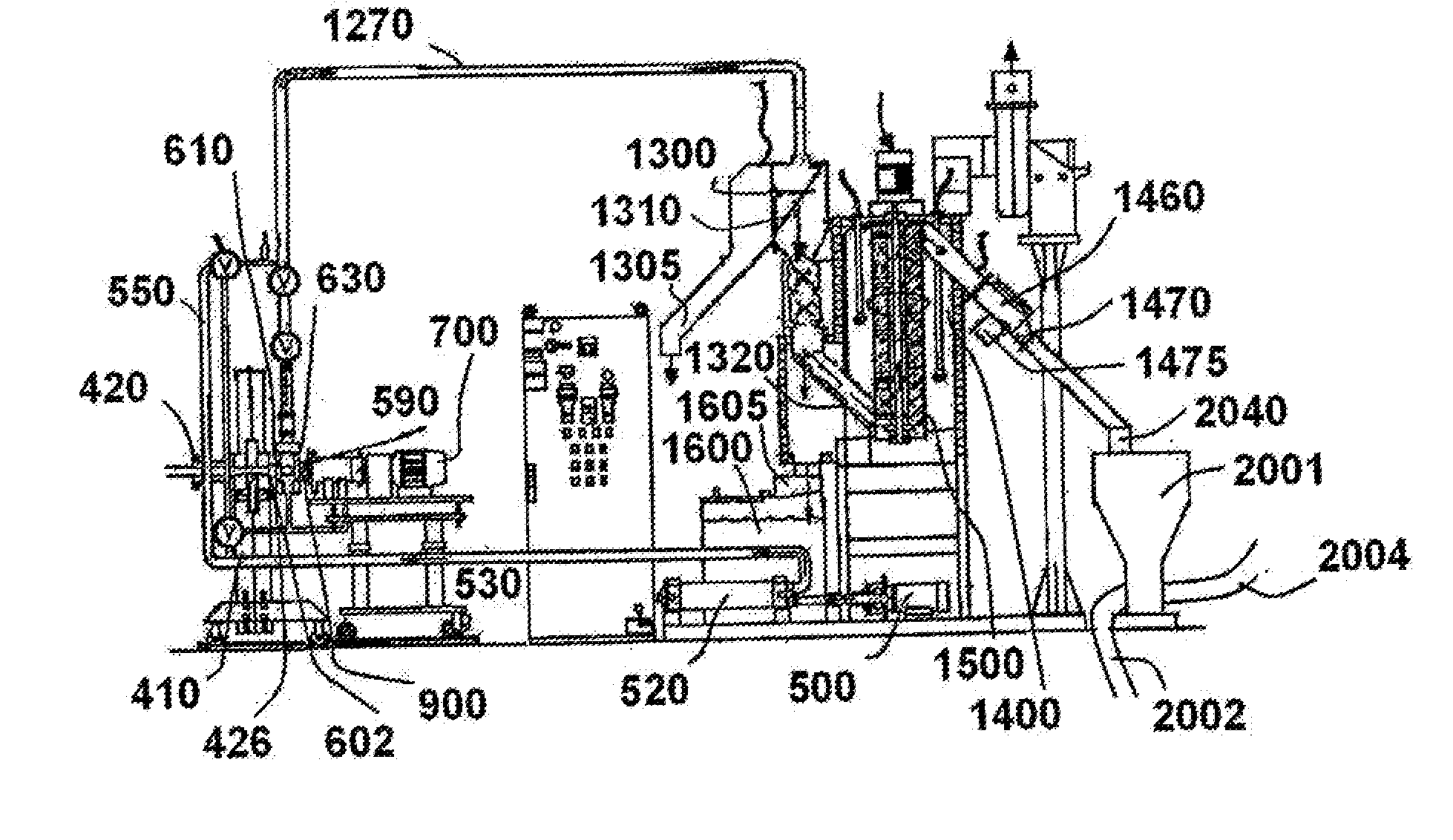

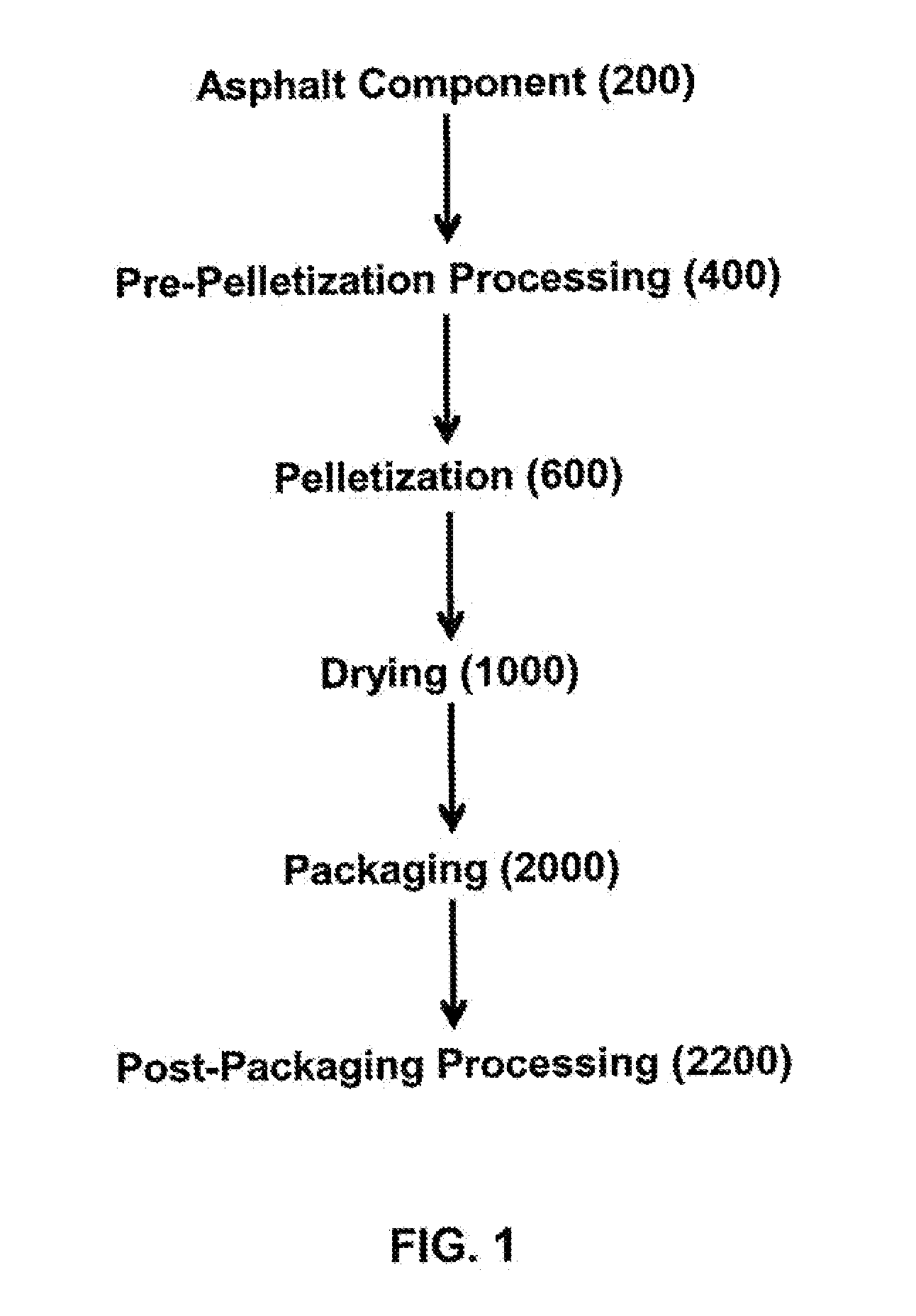

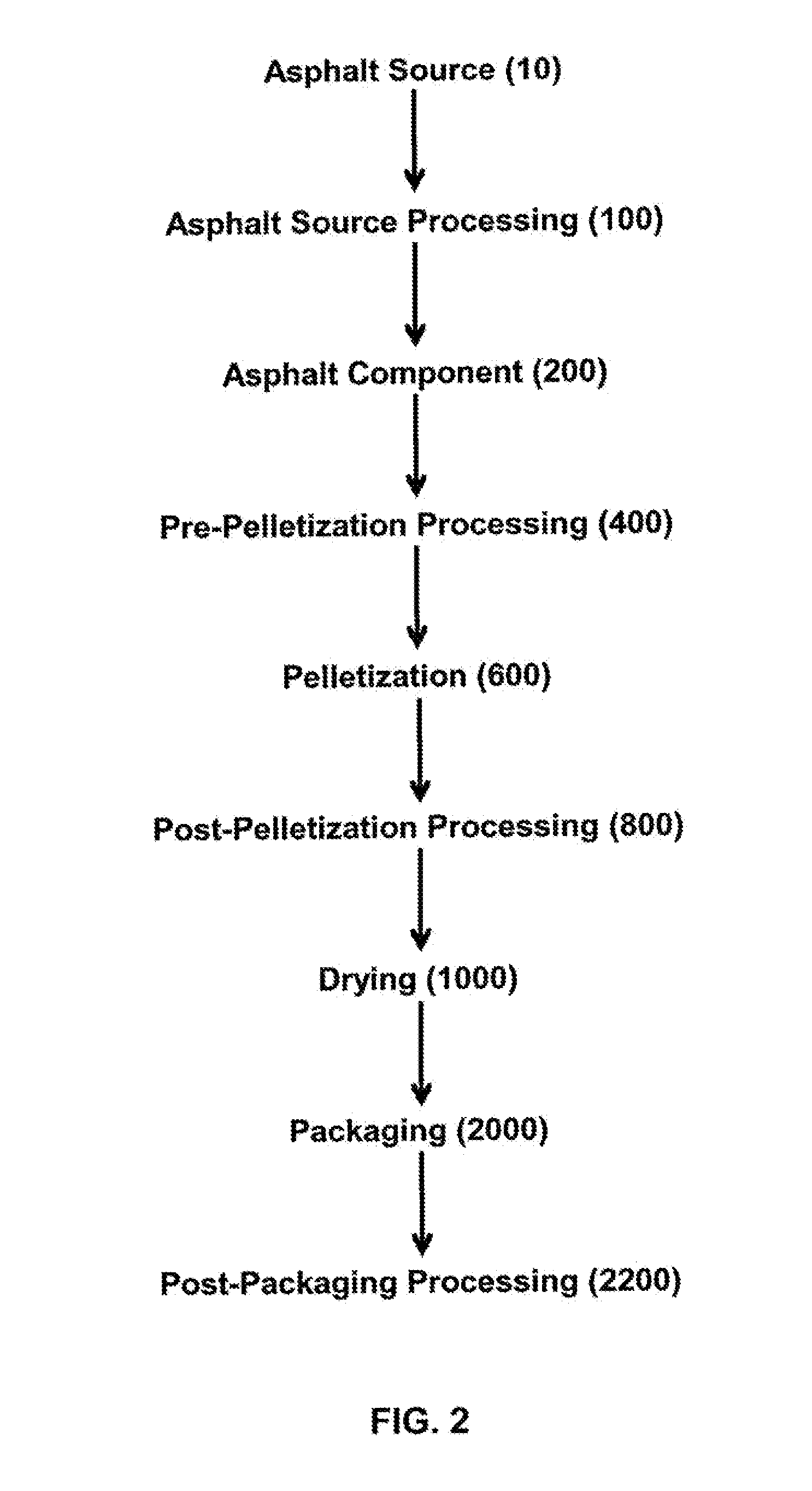

Continuous process for fractioning, combination, and recombination of asphalt components for pelletization and packaging of asphalt and asphalt-containing products

ActiveUS20130036714A1Prevent movementWorking-up pitch/asphalt/bitumen by distillationLiquid surface applicatorsEngineeringAsphalt

A continuous process for fractioning, combination, and recombination of asphalt sources into asphalt components for pelletization of asphalt and asphalt-containing products such that the pellets formed are generally uniform in dimension, freely flowing, free from agglomeration, and the pelletized asphalt is packaged, and preferably compatibly packaged, for additional processing and applications.

Owner:GALA INDUSTRIES INC

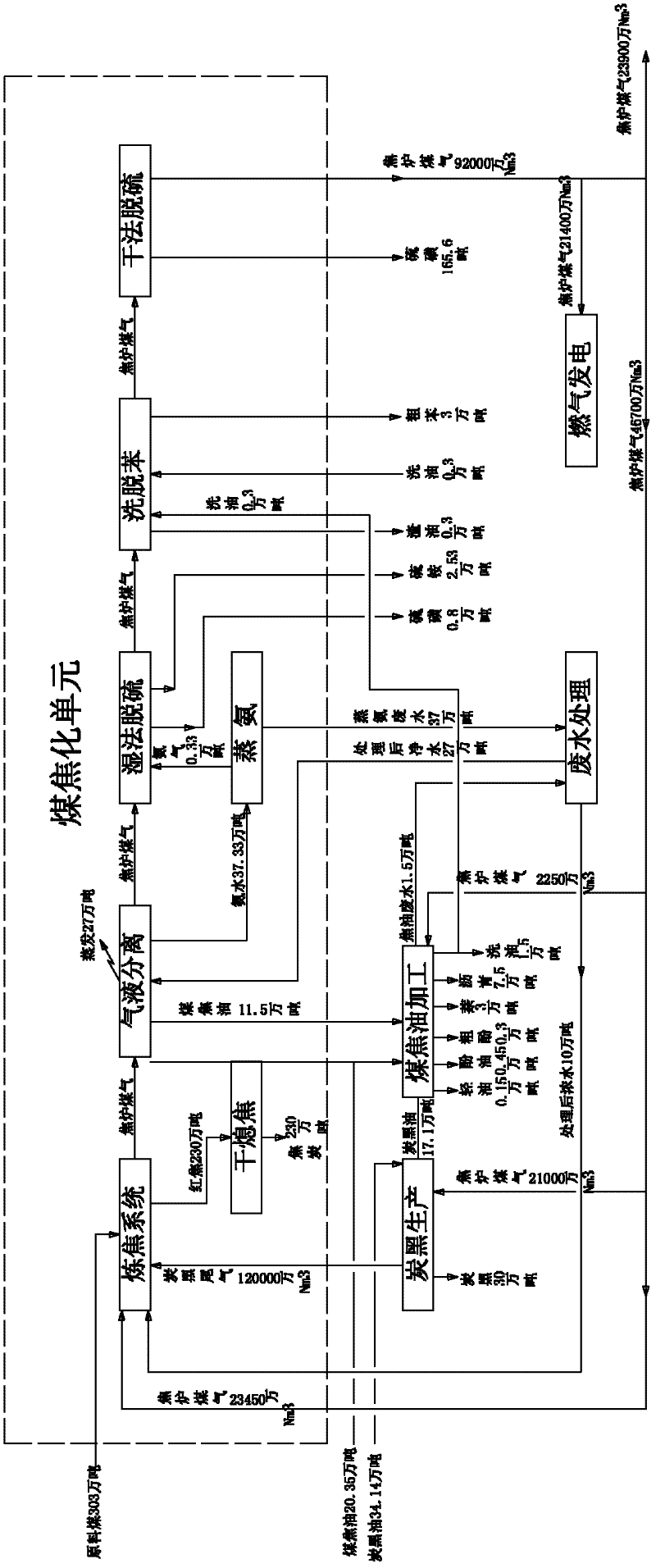

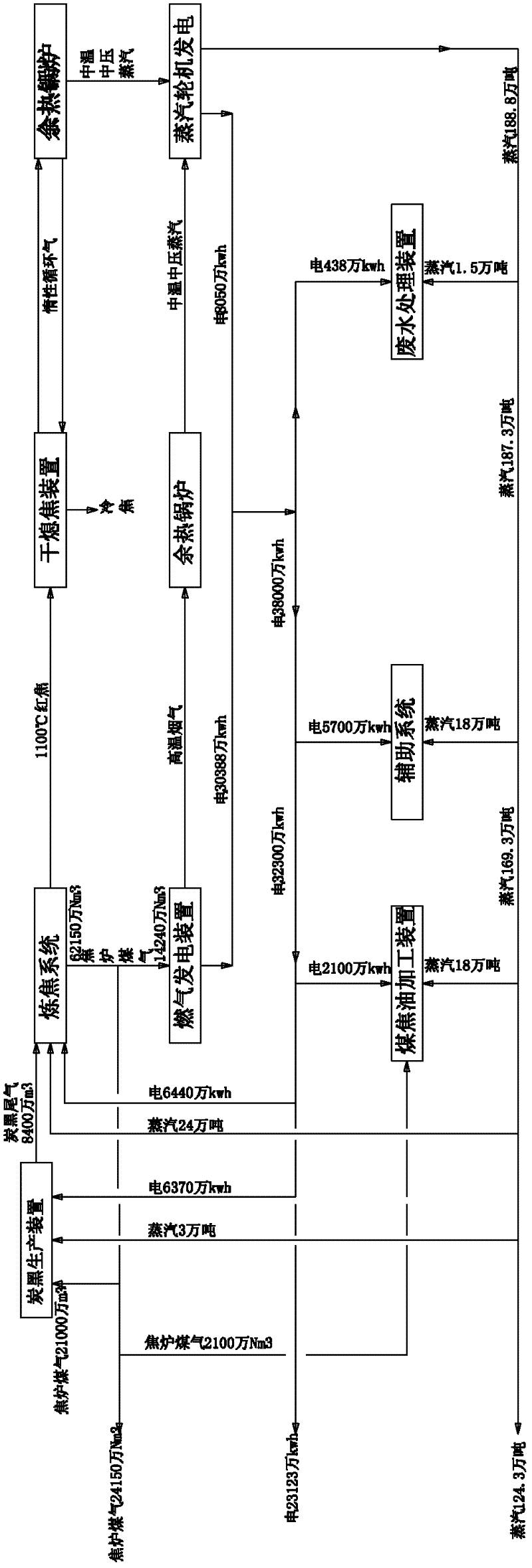

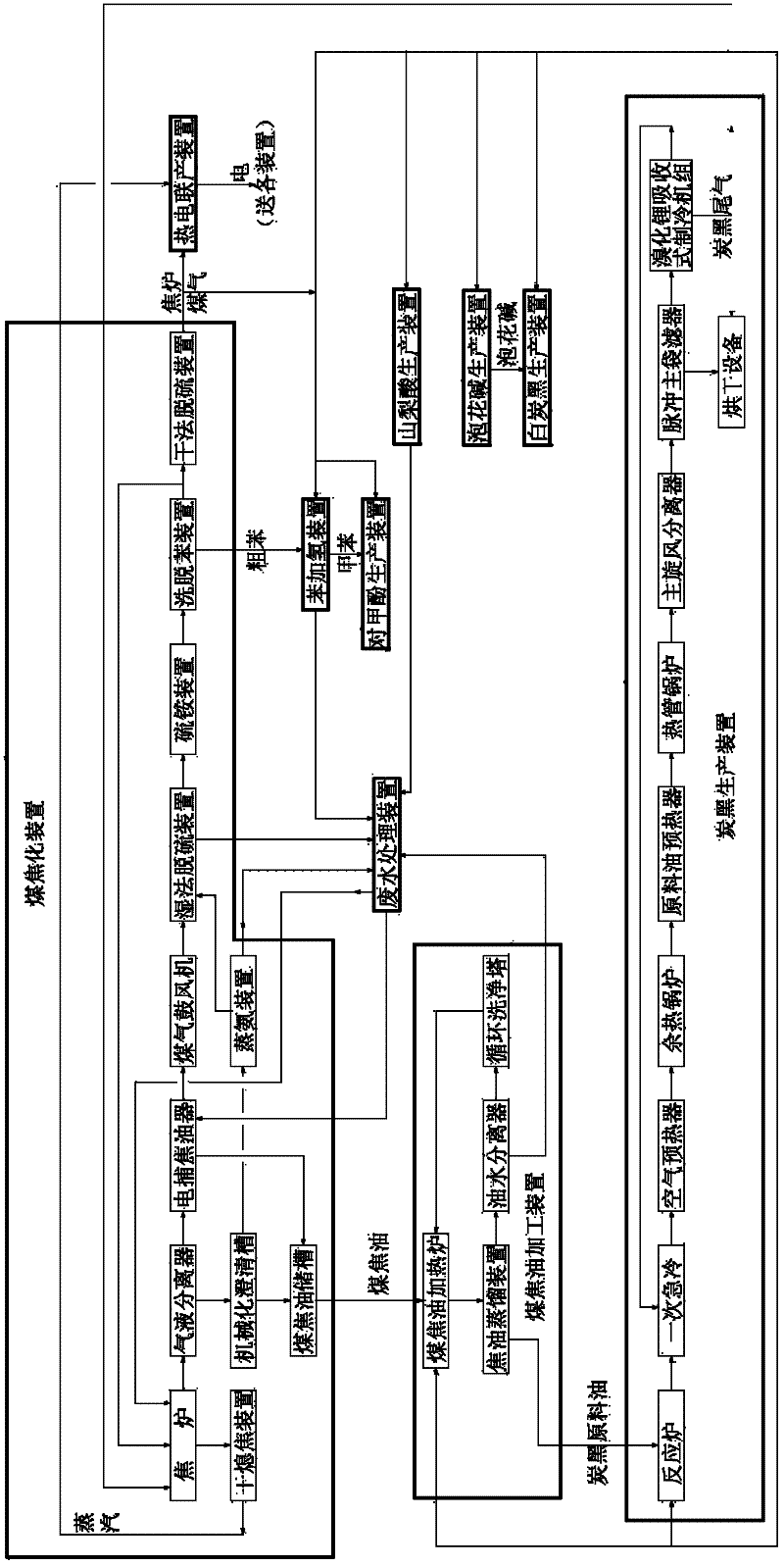

Green circular economy technology with coal coking as the main part

ActiveCN102229806AHigh aromatic contentQuality improvementPigmenting treatmentCoke quenchingCogenerationEngineering

The invention provides a green circular economy technology with coal coking as the main part. The technical scheme of the technology is as follows: a coal coking part, a coal tar processing part, a carbon black part and a part of combined power and thermoelectricity generation by coke oven gas are organically combined to form the relationship of industrial metabolism, symbiosis and coupling; suchmeasures as differentially utilizing tail gas of carbon black, recovering energy of coke drying quenching, reducing, recycling and changing the three wastes into resources, etc., enable resources to be saved, production cost to be reduced and pollution to be lessened; therefore, economic benefits of coal coking enterprises are maximized and the green circular economy technology is realized indeed. The invention also provides an apparatus for realizing the green circular economy technology with coal coking as the main part.

Owner:JINNENG SCI & TECH

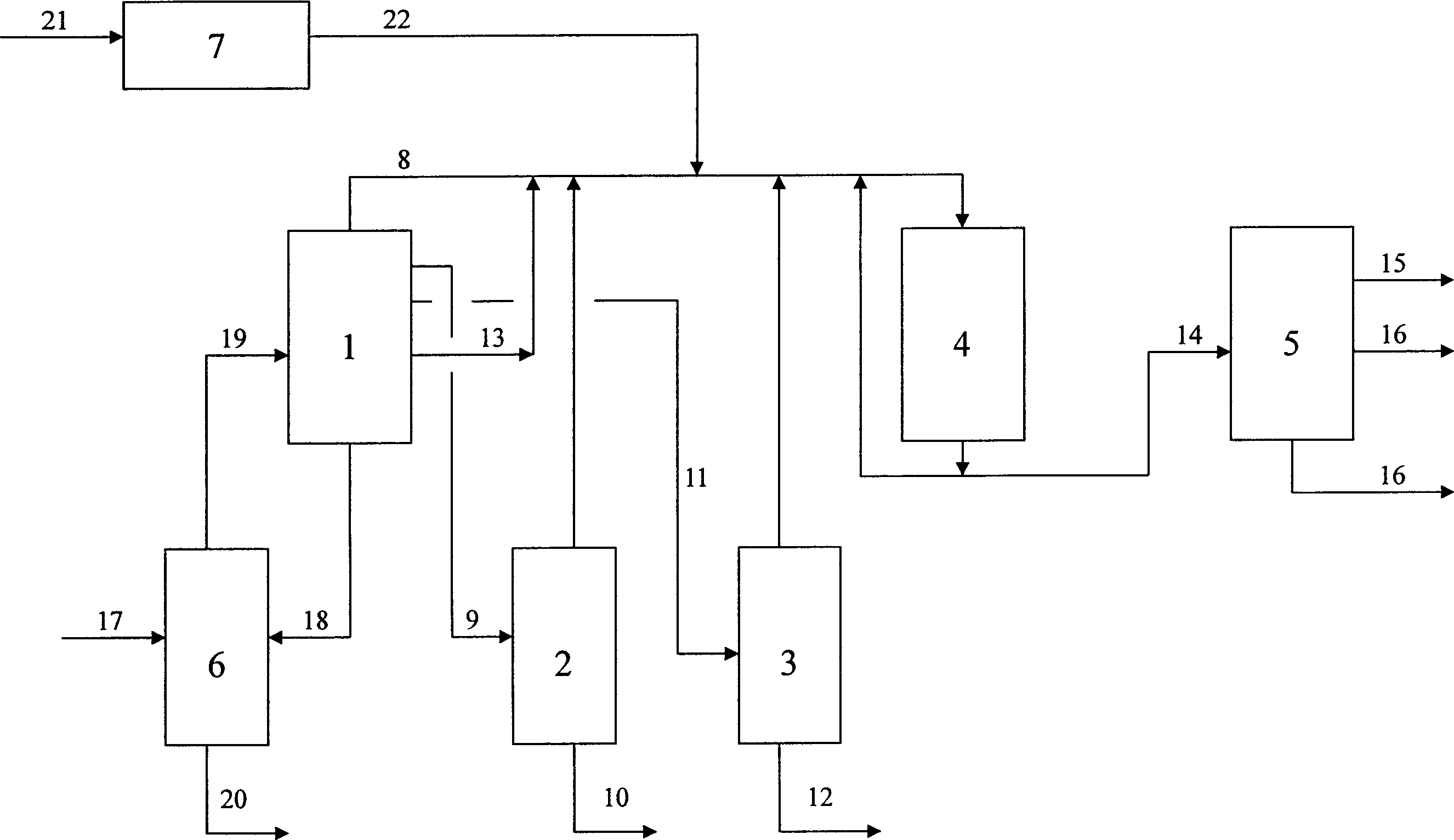

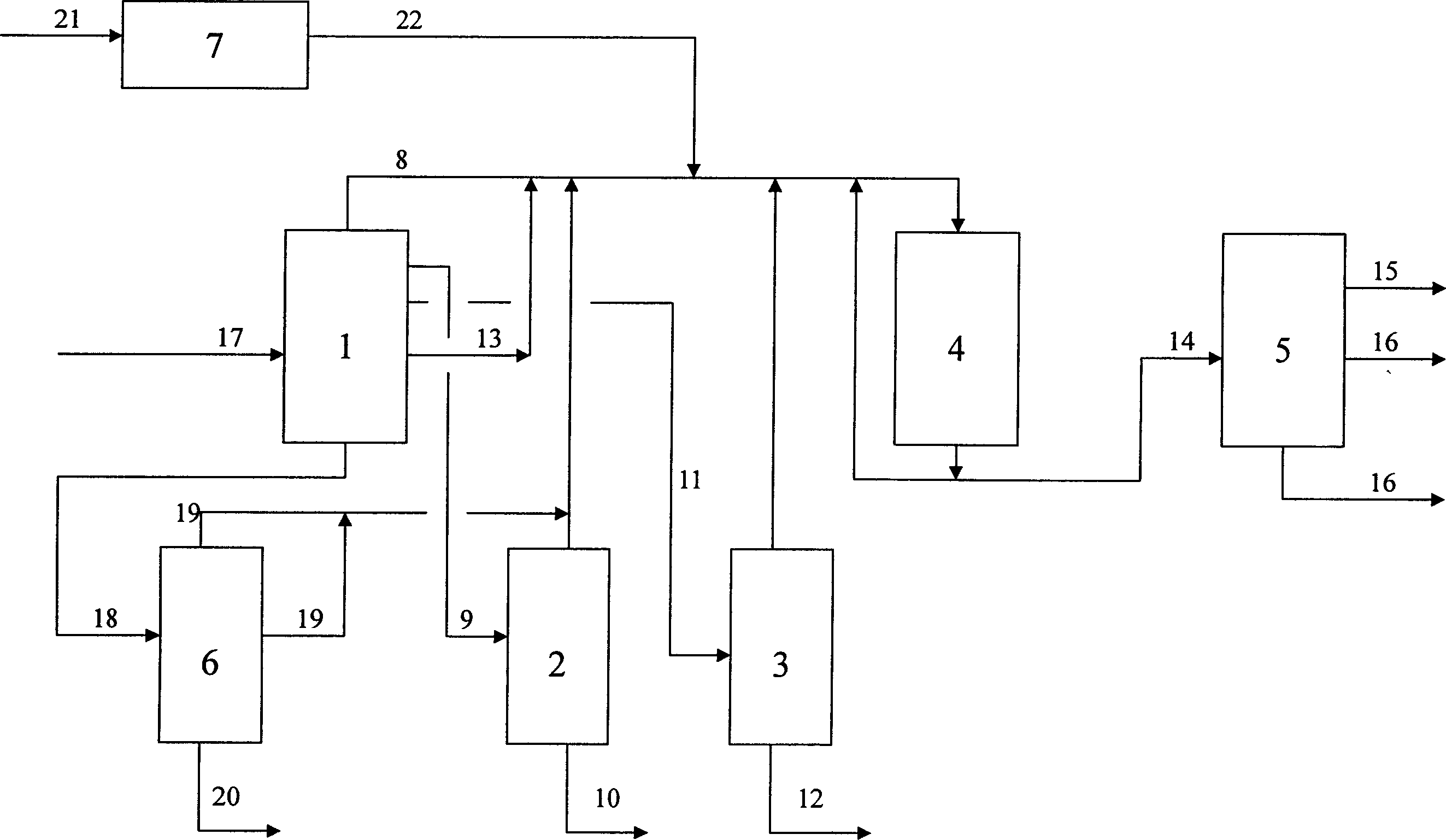

Process for producing chemical industry products and fuel oil from coal tar

InactiveCN1597866ATreatment with hydrotreatment processesTar working-up by distillationChemical industryLighter fuel

The invention is a method of producing chemical products and fuel oil by coal tar, relating to a method of producing chemical products and fuel oil by coal car, including vehicle fuel oil. And its characteristic: separating the coal tar into light and heavy fractions, where the light fraction includes light coal tar and tar pitch. The light fraction is used to produce light products by hydrofining or modifying. The processing of the tar pitch combines with coke furnace or delay coking, thus not only producing more chemical products such as phenol, naphthalene and gasoline, diesel oil / light fuel, etc, but also improving the coke quality of the coke furnace or directly producing low-ash content coke. Simultaneously, it adds an inhibitor to inhibit or slow down the coking in the furnace pipe or reactor, thus assuring long-term operation of the device.

Owner:山西东辉能源集团有限公司 +11

Preparation method of soluble mesophase pitch

InactiveCN102942945AImprove solubilityFacilitate subsequent processingWorking-up pitch/asphalt/bitumen by distillationWorking-up pitch/asphalt/bitumen by selective extractionFiberCarbon fibers

The invention belongs to the technical field of a preparation method of spinning raw materials of high-performance pitch-based carbon fibers, and particularly relates to a preparation method of soluble mesophase pitch, which mainly solves the problems of the existing mesophase pitch preparation method that the process is complicated, requirements on the equipment are high, the cost is high, the industrialization process is difficult and the like. The invention adopts the technical scheme that the preparation method of the soluble mesophase pitch comprises the following steps of (1) thermally treating raw material pitch or ethylene bottom oil with a low softening point in an inert atmosphere, then distilling the material in a short distance or flashing the material, removing light ends, and collecting heavy fraction, i.e. heavy end pitch; (2) preparing the heavy enbd pitch into mesophase pitch; and (3) cooling the mesophase pitch to 320DEG C to 400DEG C, removing internal light ends, and collecting the heavy fraction, i.e. the mesophase pitch. The preparation method has the advantages of simplicity in process, moderate in reaction condition, low equipment requirement, low cost and adaptability to industrialized production.

Owner:SICHUAN CHUANGYUE CARBON MATERIAL

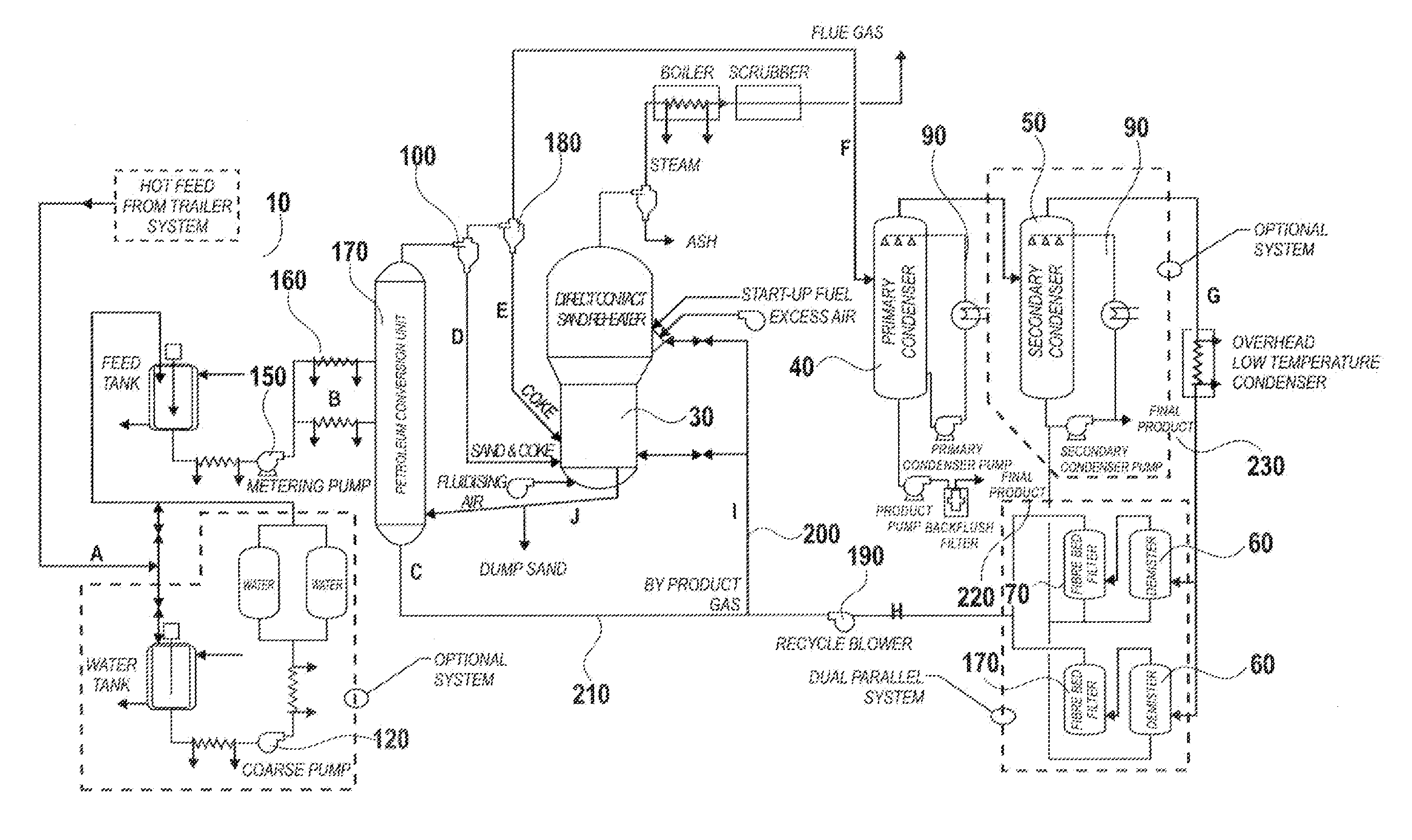

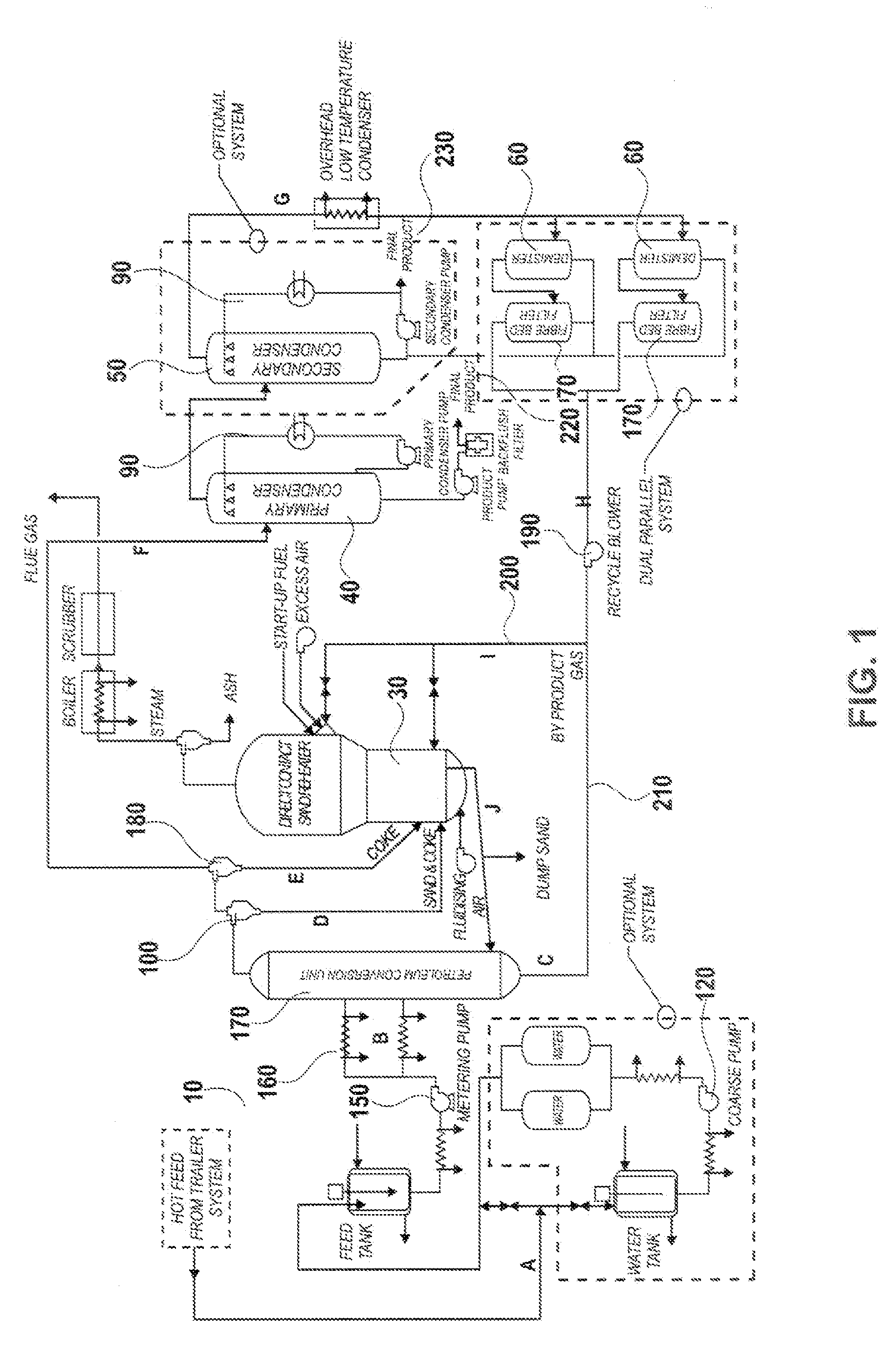

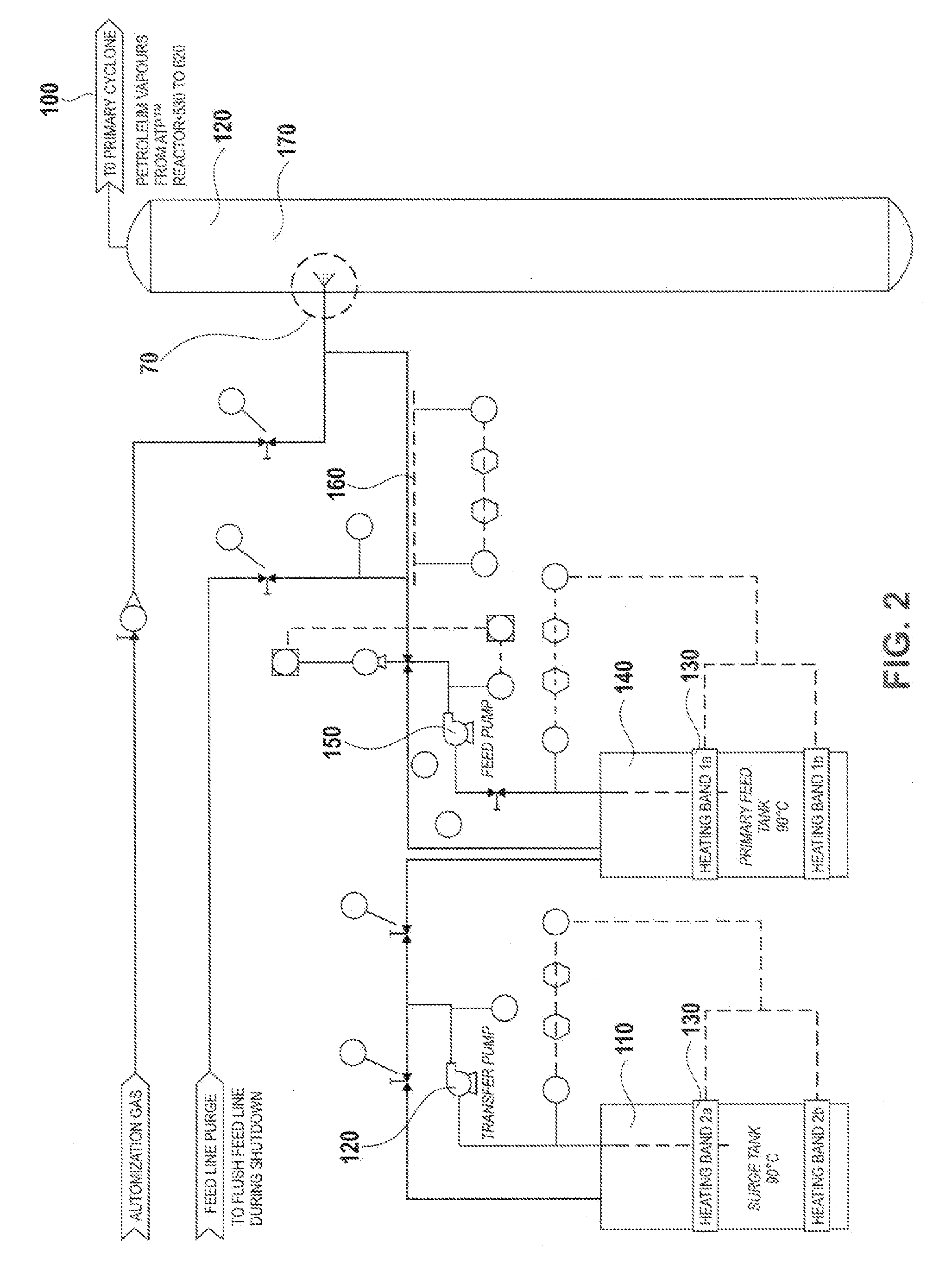

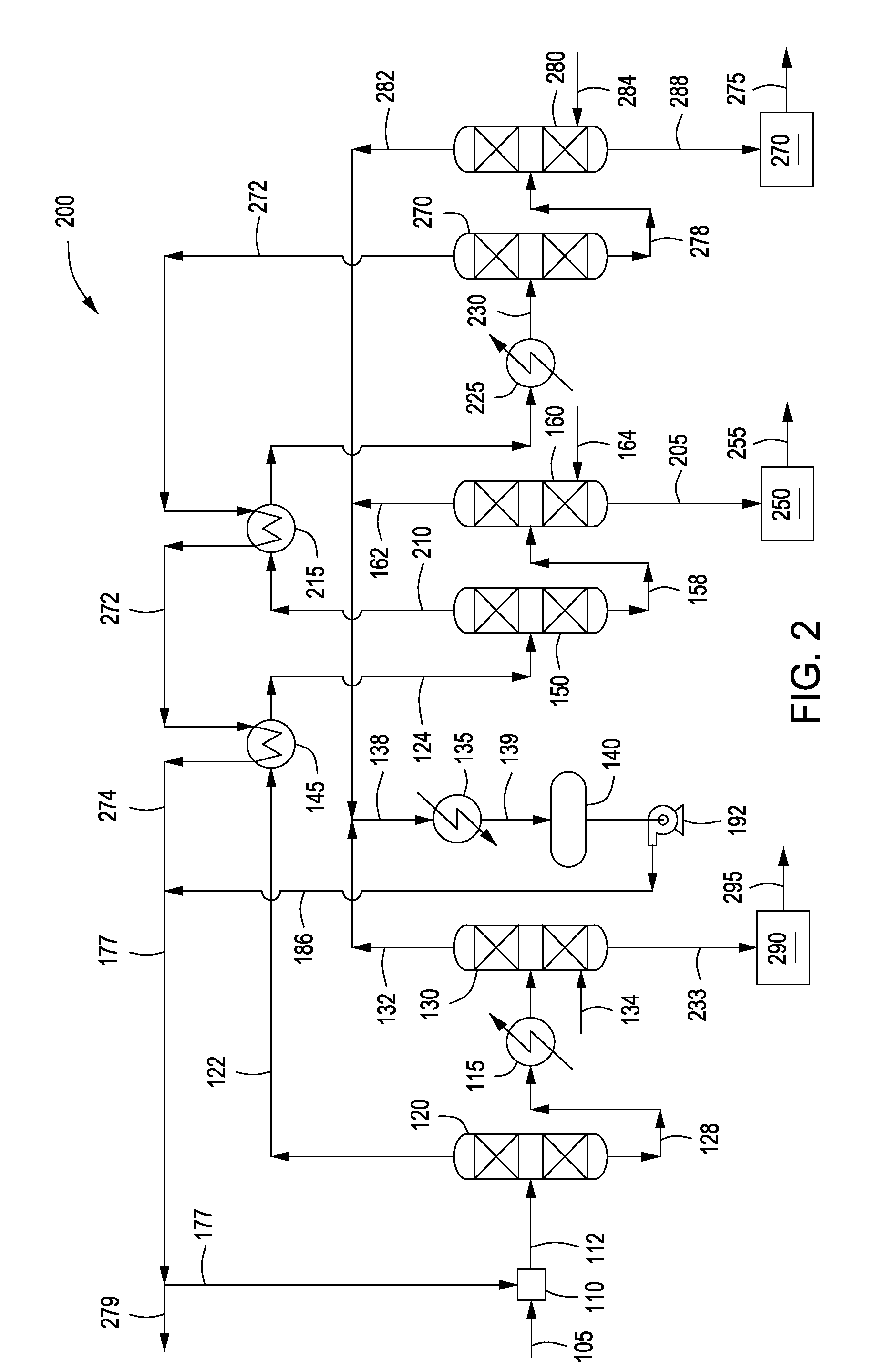

Rapid thermal processing of heavy hydrocarbon feedstocks

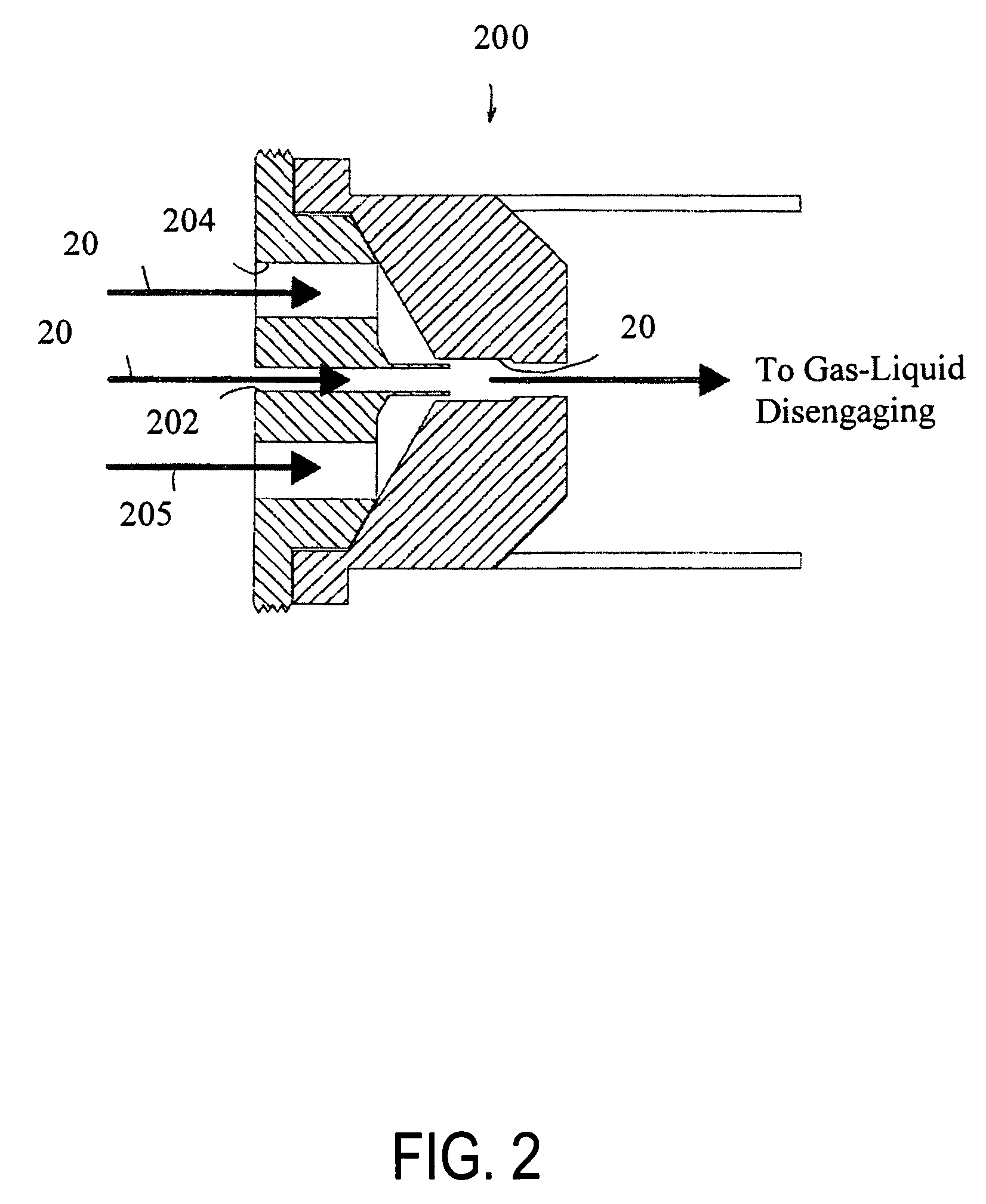

InactiveUS20120279825A1Upgrade and reduce viscosityRapid heat treatmentWorking-up pitch/asphalt/bitumen by distillationThermal non-catalytic crackingParticulatesLiquid product

The present invention is directed to the upgrading of heavy hydrocarbon feedstock that utilizes a short residence pyrolytic reactor operating under conditions that cracks and chemically upgrades the feedstock. The method for upgrading a heavy hydrocarbon feedstock comprises introducing a particulate heat carrier into an upflow reactor, introducing the heavy hydrocarbon feedstock into the upflow reactor at a location above that of the particulate heat carrier so that a loading ratio of the particulate heat carrier to feedstock is from about 15:1 to about 200:1, allowing the heavy hydrocarbon feedstock to interact with the heat carrier with a residence time of less than about 1 second, to produce a product stream, separating the product stream from the particulate heat carrier, regenerating the particulate heat carrier, and collecting a gaseous and liquid product from the product stream.

Owner:IVANHOE HTL GASOLINEEUM

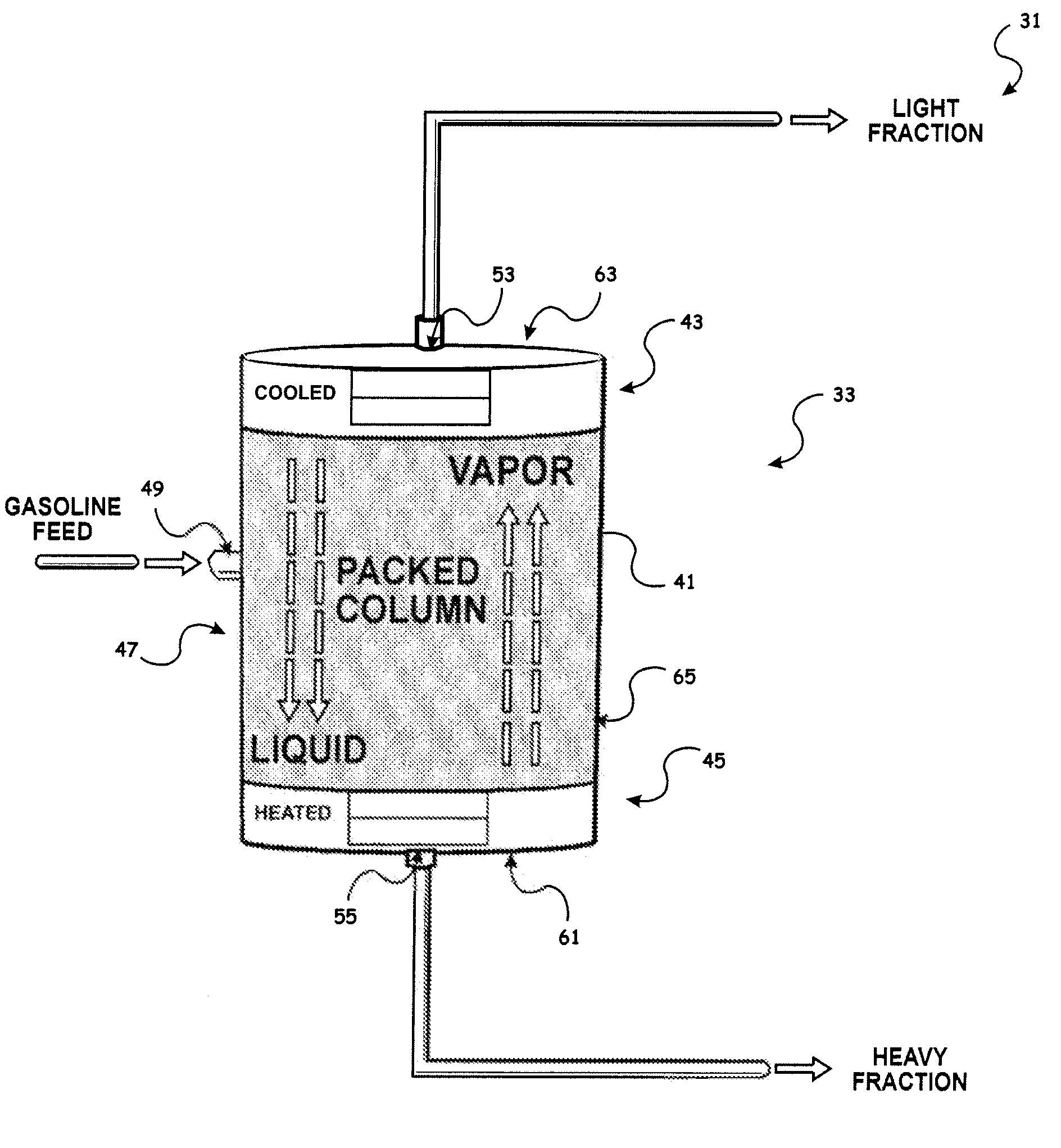

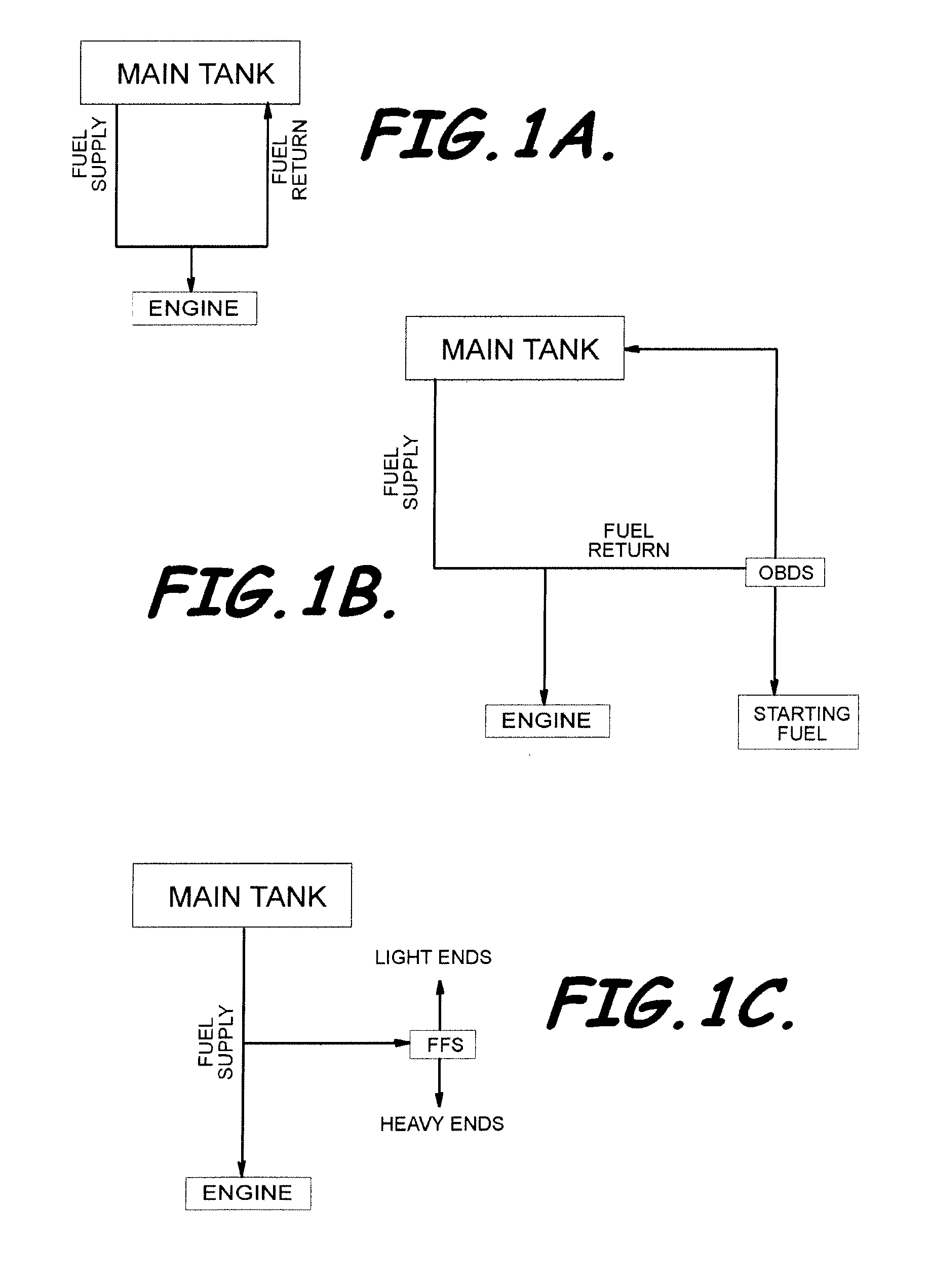

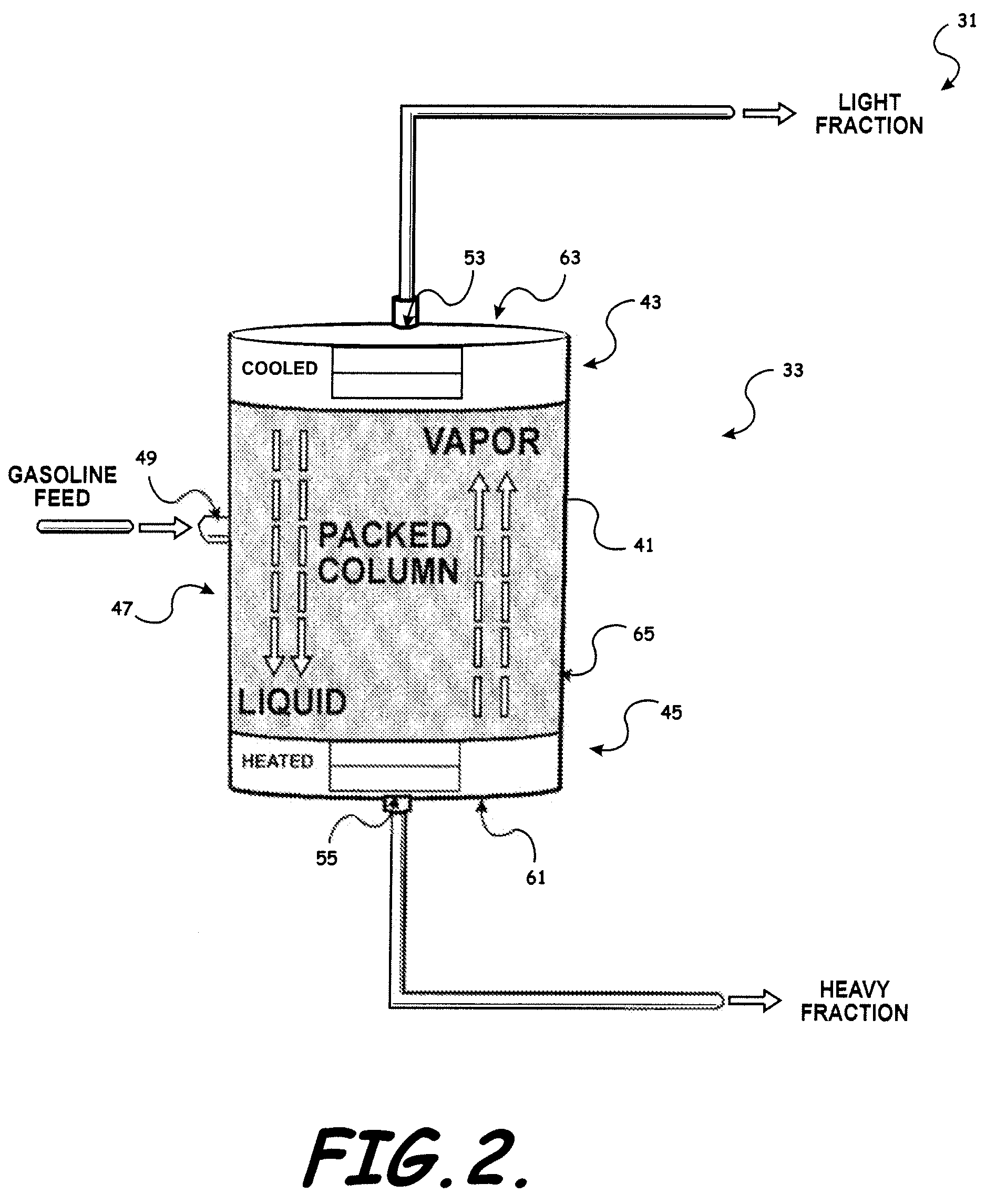

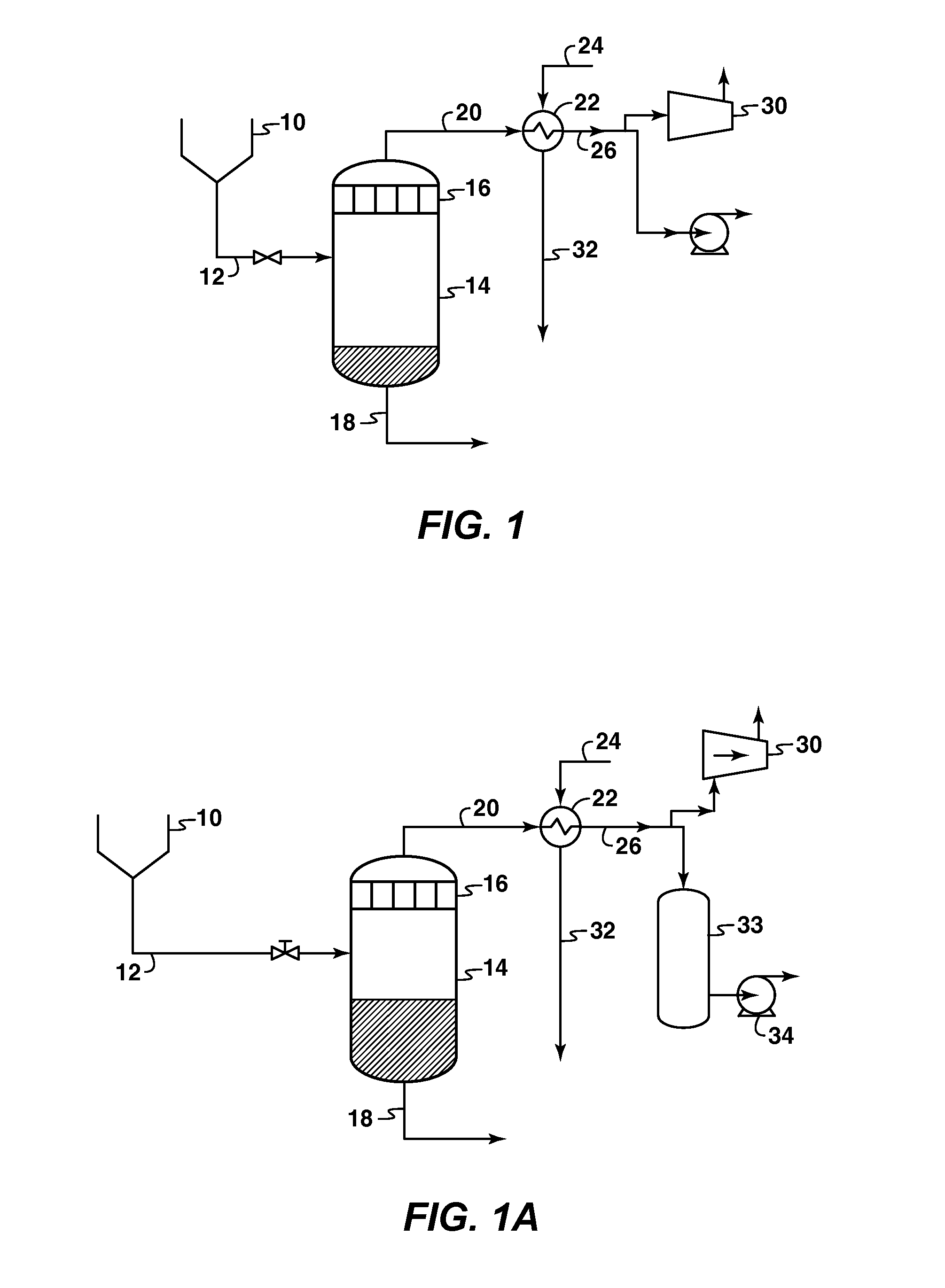

On-board fuel fractionation system and methods to generate an engine starting fuel

InactiveUS7370610B2Efficient separationAccelerate emissionsThermal non-catalytic crackingDistillation regulation/controlDistillationFractionation

A Fuel Fractionation System (FFS) and associated methods to generate and store a fuel for internal combustion engines is provided. FFS provides a distillation column assembly to distill liquid fuel to form a volatile light fraction secondary fuel. The distillation column assembly includes a vaporization module to vaporize a feed fuel in the distillation column and includes a condensation module to condense heavy fraction components of the vaporized feed fuel. FFS also provides a controller positioned to control the vaporization of feed fuel in the distillation column to thereby control the separation of the feed fuel into light fraction fuel and heavy fraction fuel components, and positioned to control the condensation of the heavy fraction components so that fuel exiting a light fraction output port in the distillation column is substantially light fraction fuel components by volume.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

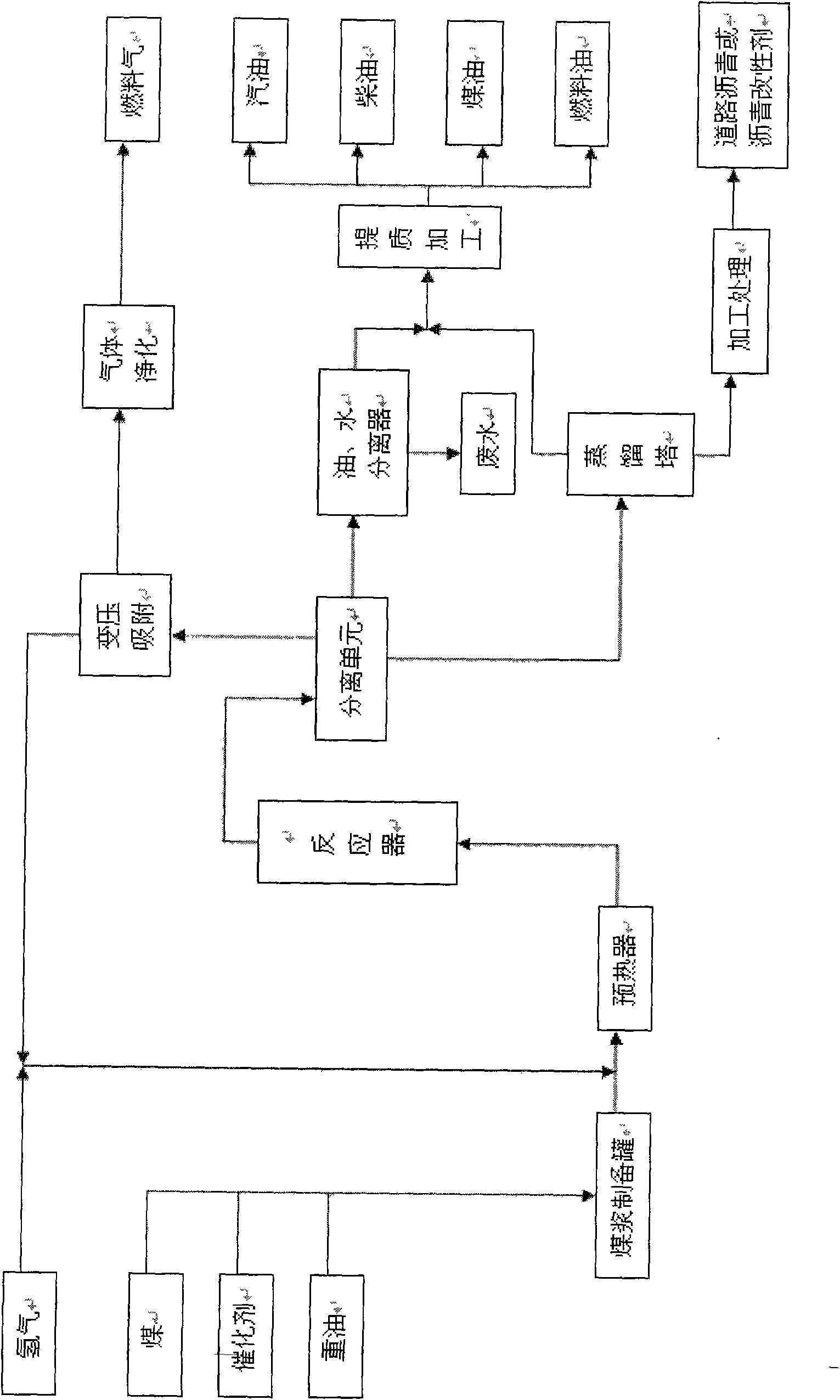

Method for simultaneously producing liquid fuel and asphalt paving materials by coprocessing coal and heavy oil

InactiveCN101649220AReduce investmentLow costHydrocarbon distillationGaseous fuelsKeroseneDistillation

The invention relates to a method for simultaneously producing liquid fuel and asphalt paving materials by coprocessing coal and heavy oil. The method comprises the following steps: mixing coal dust, catalyst and heavy oil to prepare pulp; preheating and entering a reactor to carry out reaction; separating reaction products to separate gaseous substance, light oil, water and heavy mixture; extracting hydrogen from the separated gaseous substance through pressure swing adsorption; returning the purified hydrogen to the reactor to be used circularly, and using the remaining gas as fuel after purification; carrying out oil-water separation on the separated light oil and water to obtain the light oil and the water; leading the heavy mixture into a distilling tower to obtain coarse oil and tower bottom product through distillation separation; mixing the coarse oil and the light oil to obtain liquid fuels of gasoline, kerosene, diesel fuel, fuel oil, and the like through upgrading process; and processing the tower bottom product to get the asphalt paving materials. The invention has the advantage that under the moderate process condition, the liquid fuel and asphalt paving materials canbe produced simultaneously.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Method of producing high softening point pitch

InactiveUS7220348B1Reduce partial pressureMinimizes decompositionWorking-up pitch/asphalt/bitumen by distillationCatalytic crackingSuperheated steamHydrocarbon

The present invention provides a way to increase the softening point of heavier hydrocarbons in a relatively low cost and low pressure process using superheated steam to i) increase the carbon yield of the heavier hydrocarbons, while simultaneously ii) removing volatile components with a steam stripping process.

Owner:MARATHON PETROLEUM

Two-tower type pressure reducing coke tar distillation process and apparatus therefor

ActiveCN101475819ASolve the technical problems of dealing with large-scale tarShort processTar working-up by distillationReboilerHeat conducting

The invention relates to a two-tower type process for distilling vacuum tar and a device thereof. The process comprises the following steps: removing the moisture and light oil distillate of raw tar in a pre-dehydration tower and a dehydration tower at normal pressure; performing decompressing operations in a No.1 distillation tower to obtain carbolic oil, naphthalene oil and light washing oil distillate; and performing decompressing operations in a No.2 distillation tower to obtain heavy washing oil, first anthracene oil, second anthracene oil and mid-temperature pitch. The heat for the pre-dehydration tower and the dehydration tower is supplied by heat conducting oil; the heat for the No.1 distillation tower is supplied by heating the mixed oil on the bottom of the tower circularly in a No.1 tubular heating furnace; and the heat for the No.2 distillation tower is supplied by heating the mixed oil on the bottom of the No.1 distillation tower in a No.2 tubular heating furnace and then performing flash distillation on the mixed oil on the bottom of the No.2 tower. The main devices comprise the dehydration tower, the No.1 distillation tower, the No.2 distillation tower, a dehydration tower reboiler, the No.1 tubular heating furnace, the No.2 tubular heating furnace, a heat exchanger for each distillate, a cooler, a steam generator and the like. The process has the advantages of short technological flow, less device investment, and less energy consumption, thus the process is applicable to large scale coal tar processing engineering.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

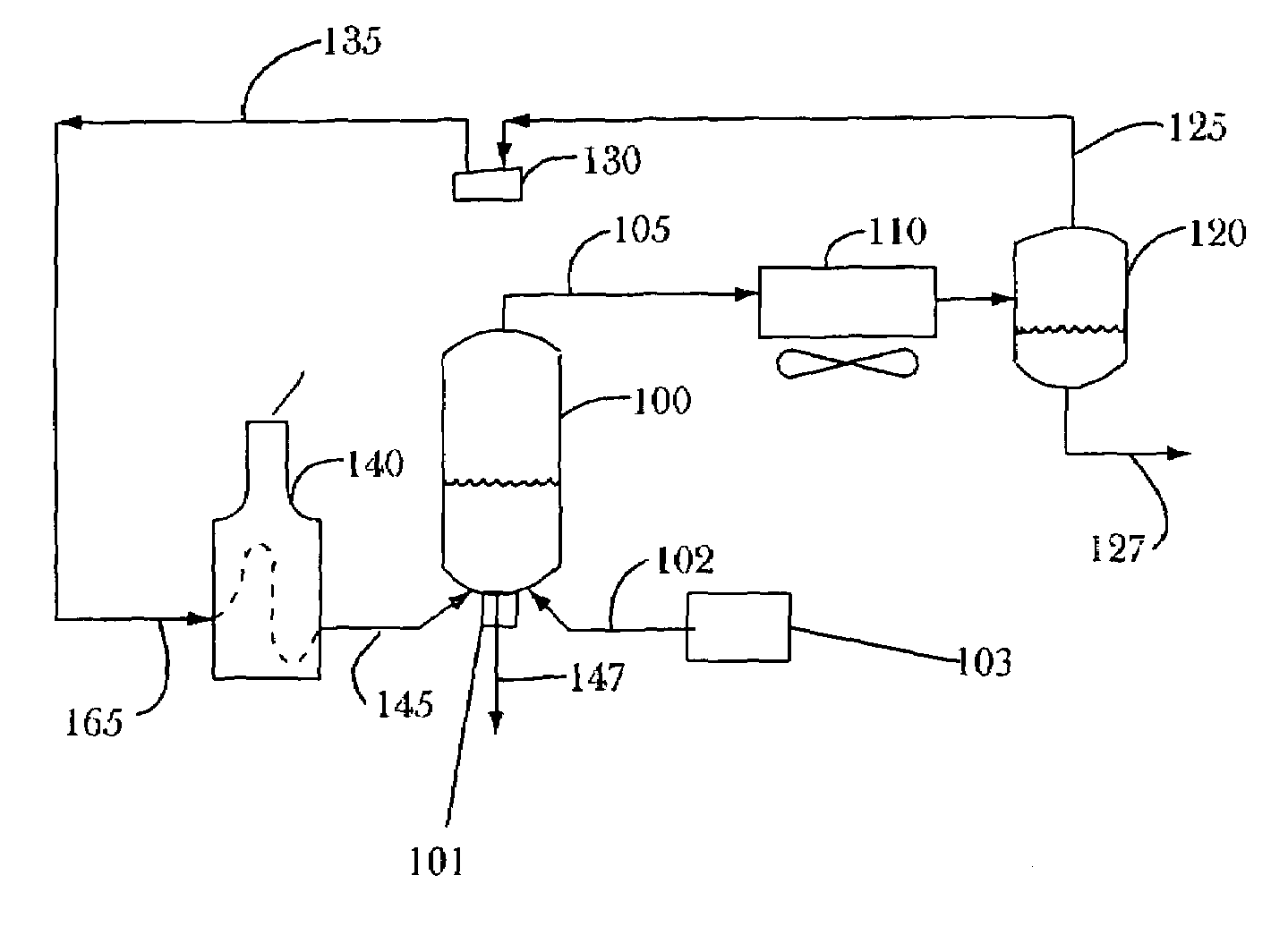

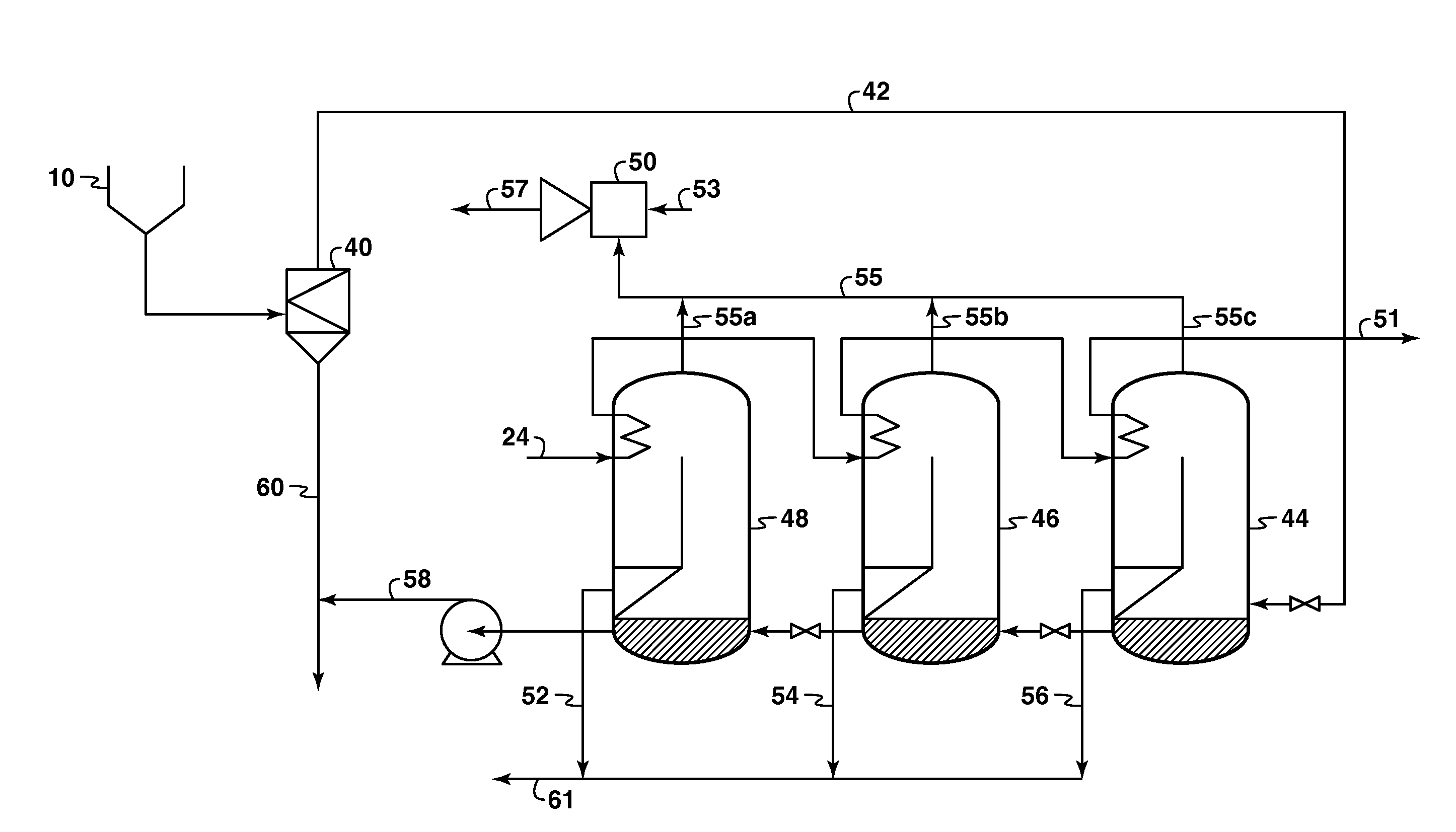

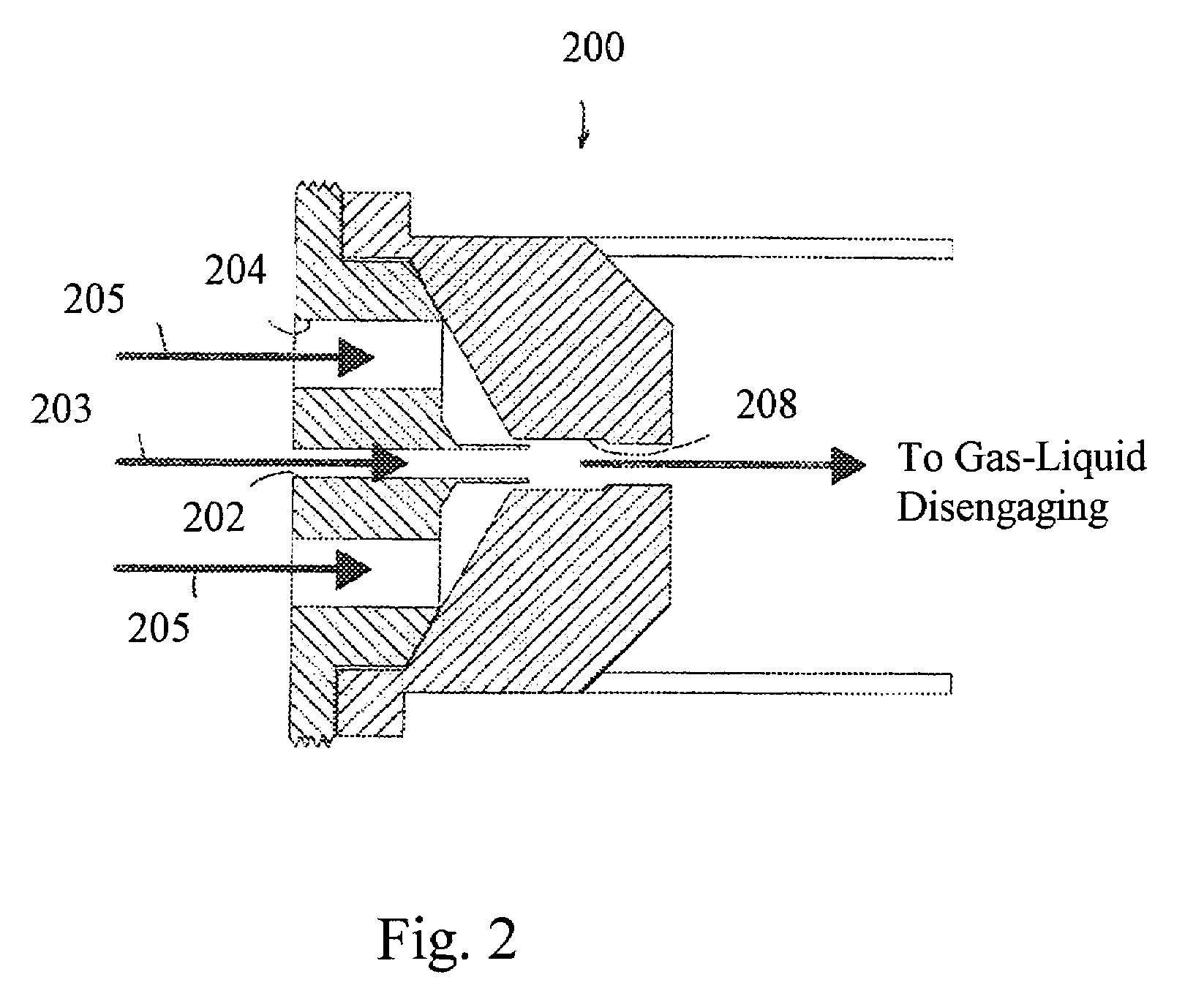

Process for Separating Pitch from Slurry Hydrocracked Vacuum Gas Oil

InactiveUS20100326887A1Easy to manageLess stickyWorking-up pitch/asphalt/bitumen by distillationHydrocarbon oil crackingParticulatesSlurry

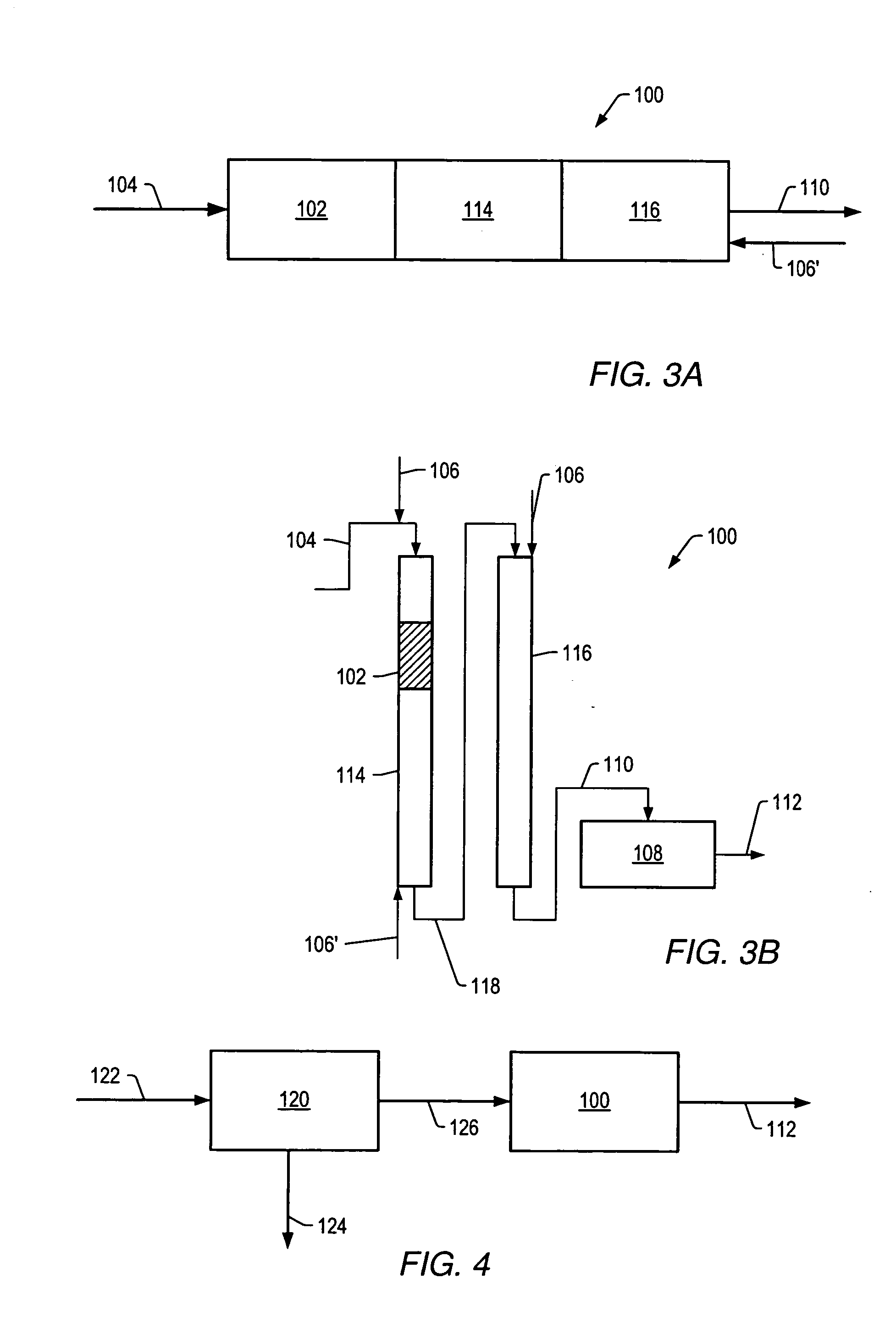

A process is disclosed for converting heavy hydrocarbon feed into lighter hydrocarbon products. The heavy hydrocarbon feed is slurried with a particulate solid material to form a heavy hydrocarbon slurry and hydrocracked in a slurry hydrocracking unit to produce vacuum gas oil (VGO) and pitch. A first vacuum column separates VGO from pitch, and a second vacuum column further separates VGO from pitch. As much as 15 wt-% of VGO can be recovered by the second vacuum column and recycled to the slurry hydrocracking unit. A pitch composition is obtained which can be made into particles and transported without sticking together.

Owner:UOP LLC

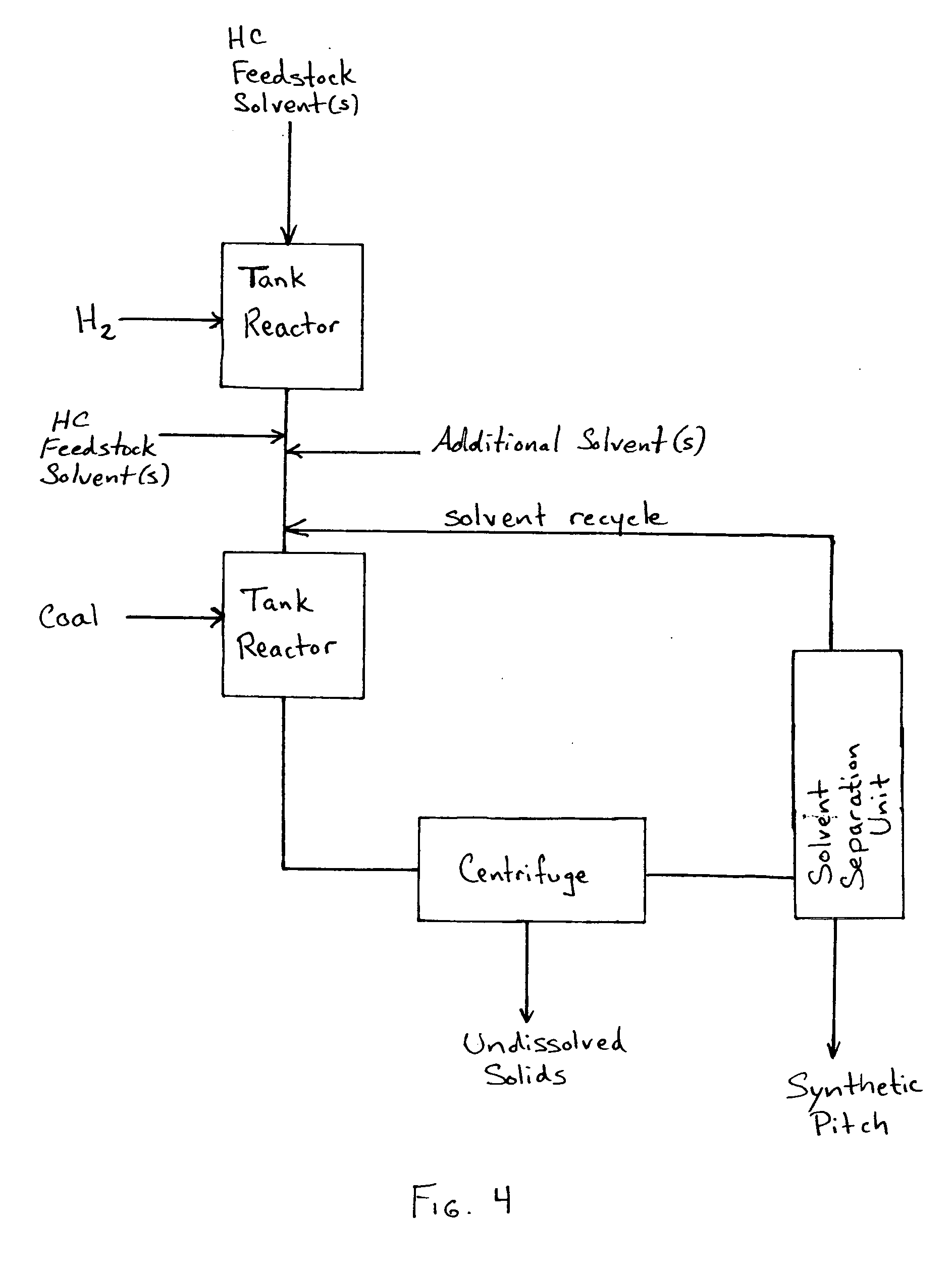

Method of producing synthetic pitch

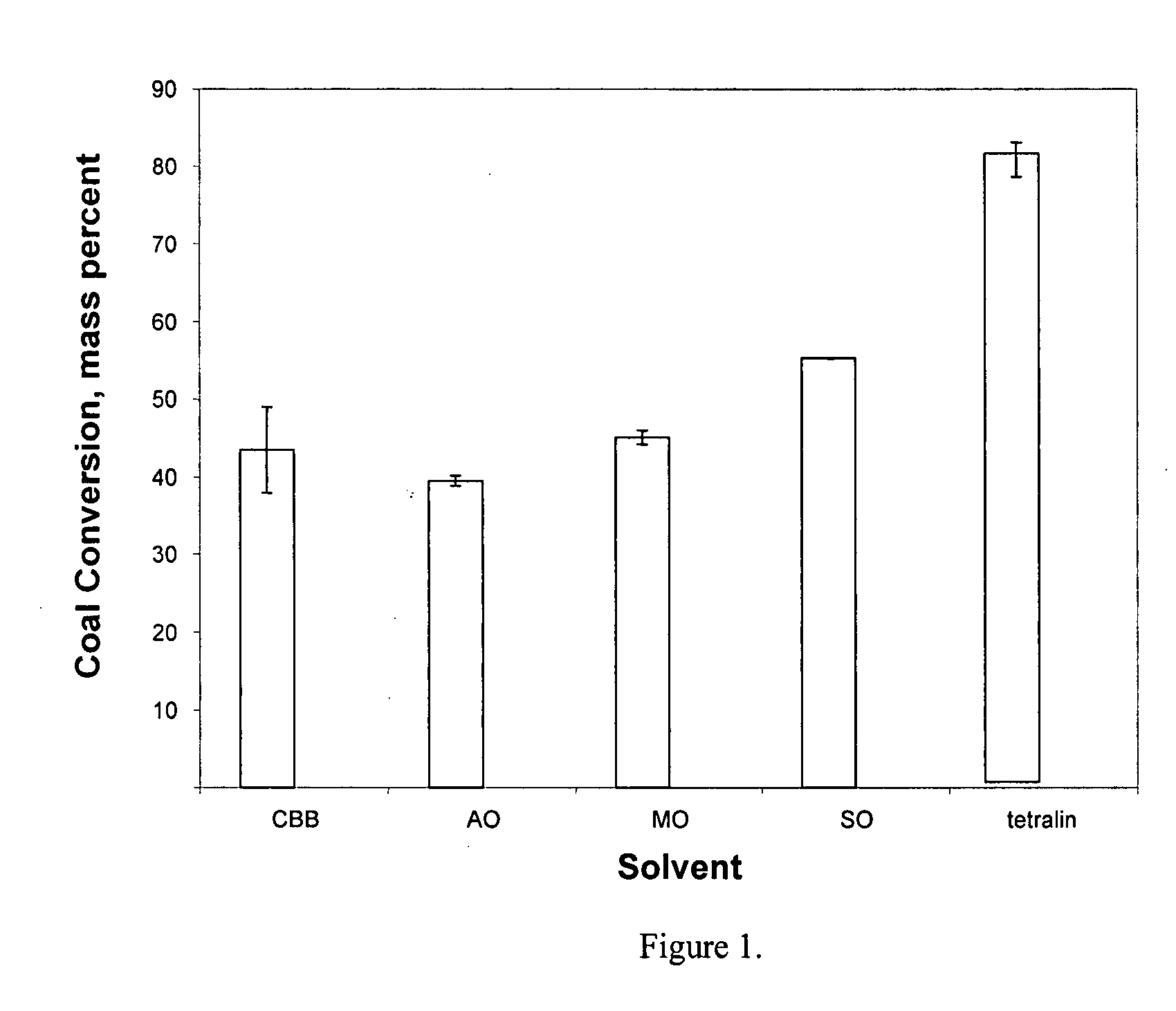

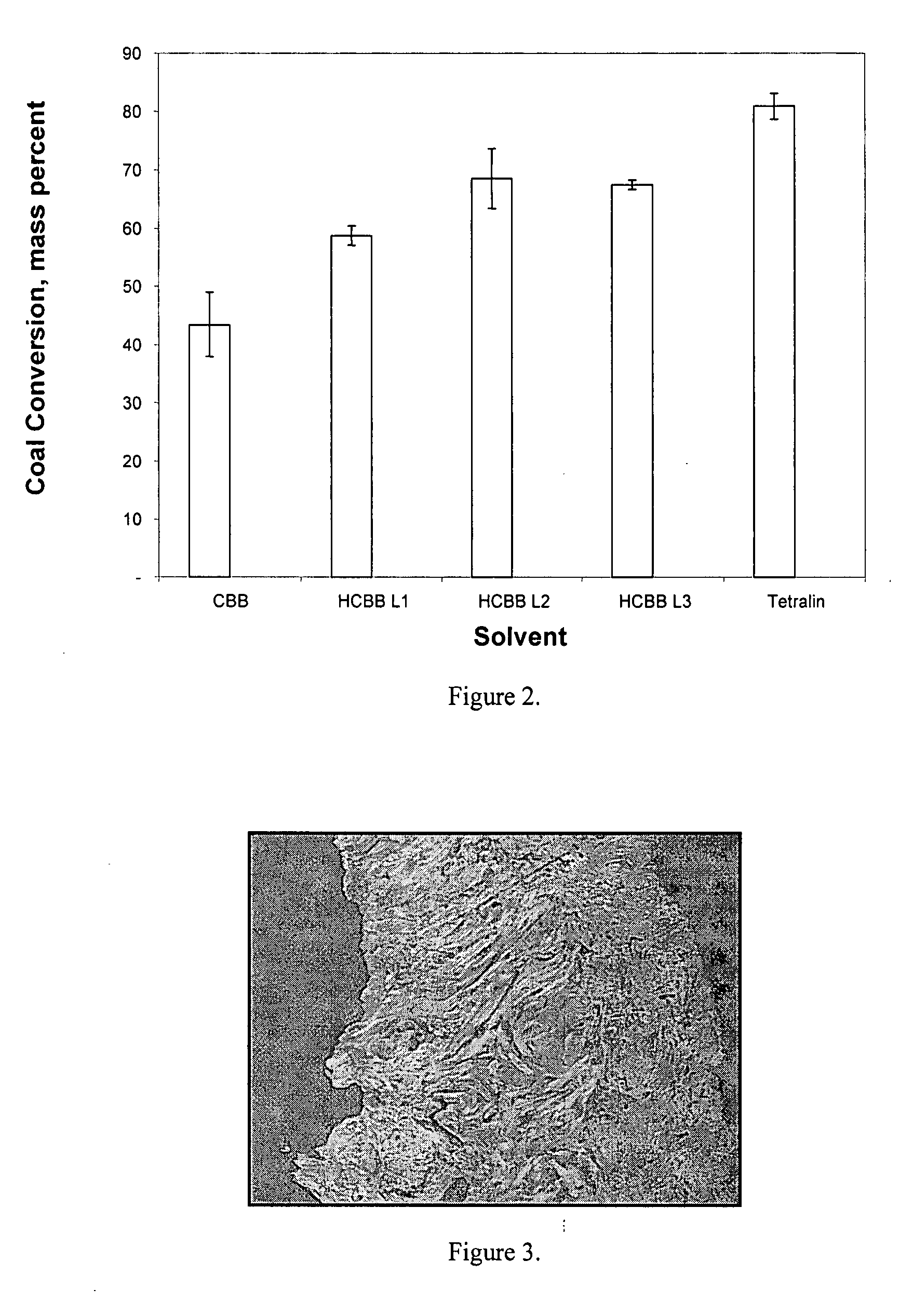

ActiveUS20080017549A1Working-up pitch/asphalt/bitumen by distillationLiquid hydrocarbon mixture productionTarSolvent

Embodiments of a method are described for modifying pitches, oils, tars, and binders by using these materials as solvents to extract organic chemicals from coal.

Owner:WEST VIRGINIA UNIVERSITY

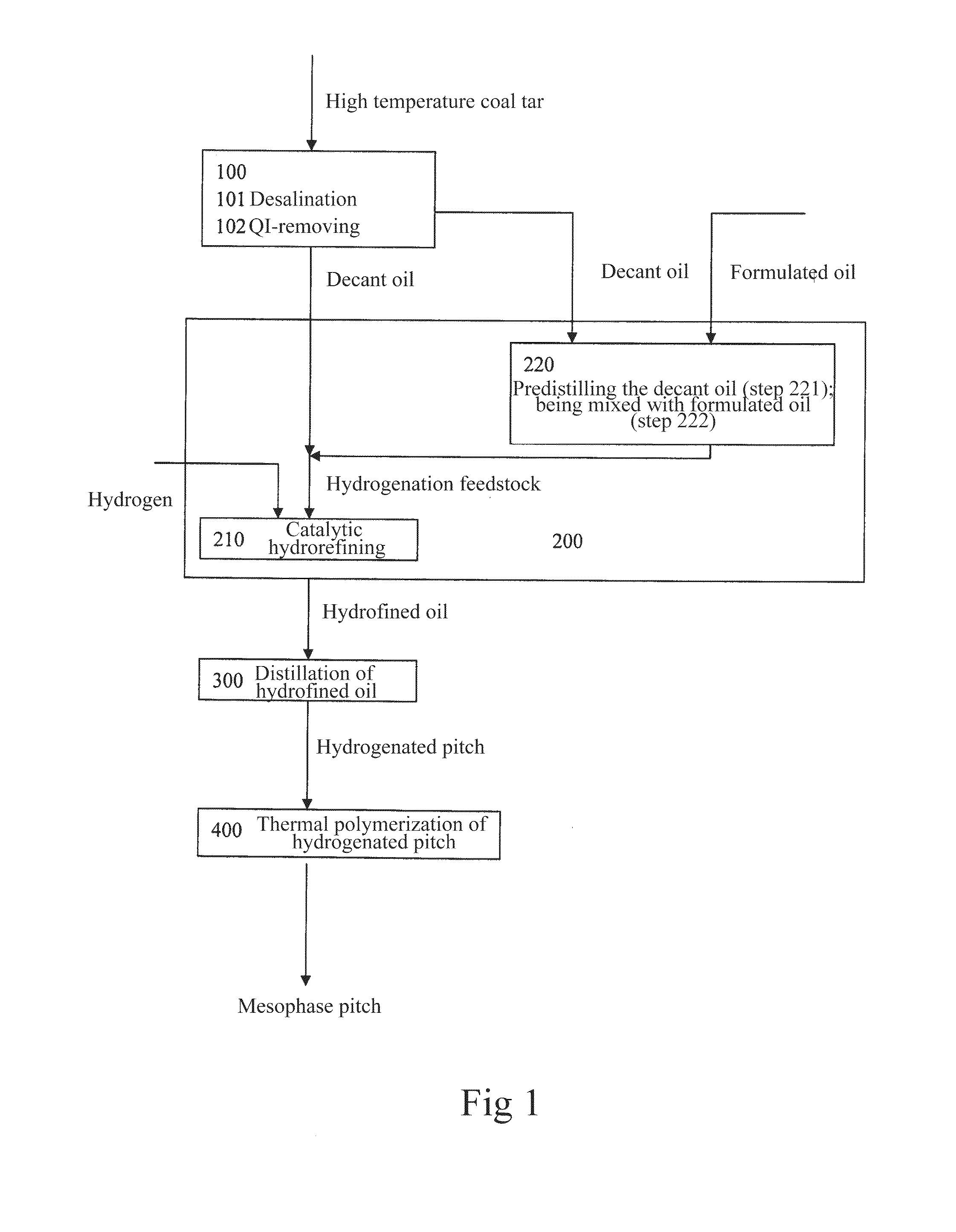

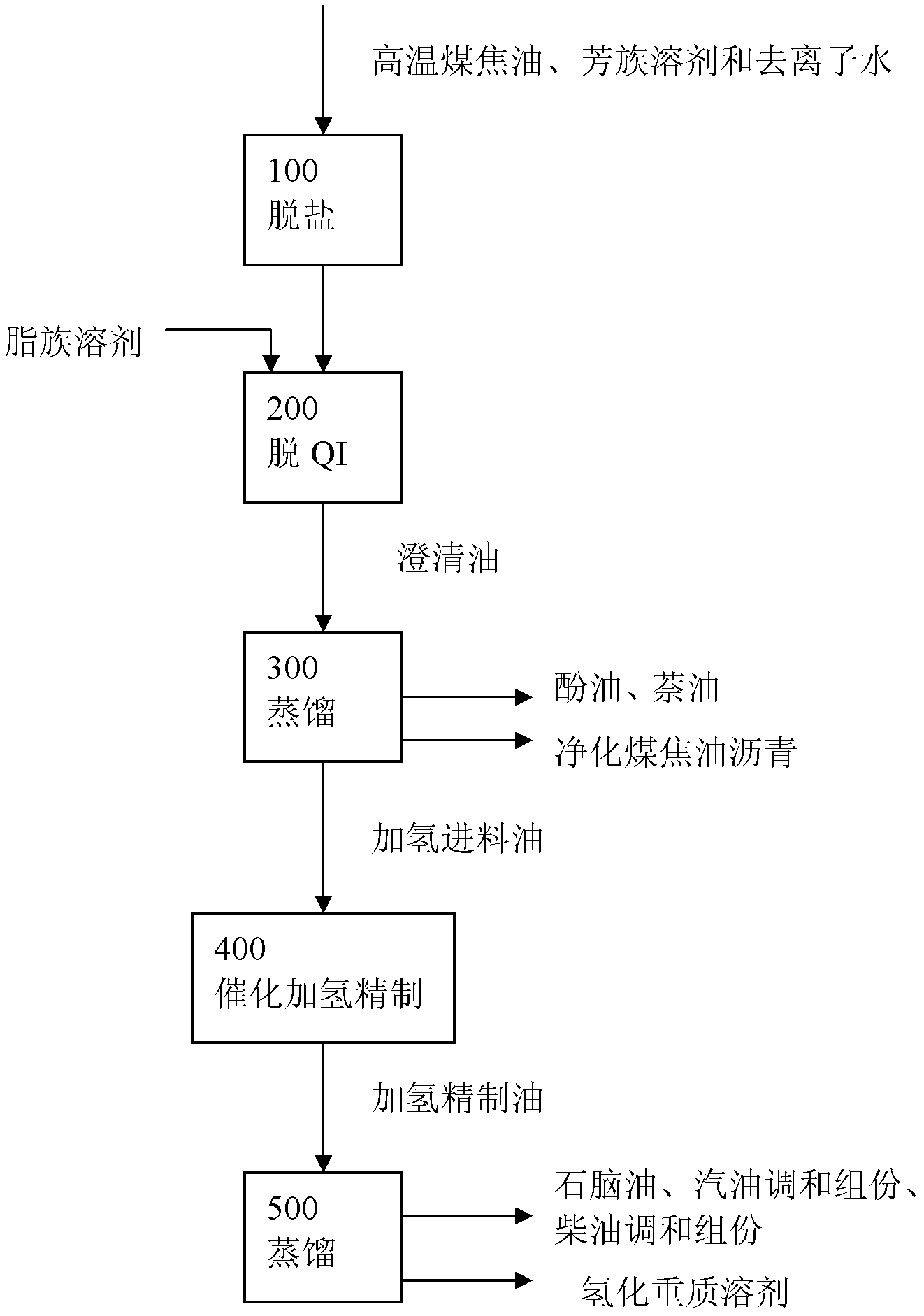

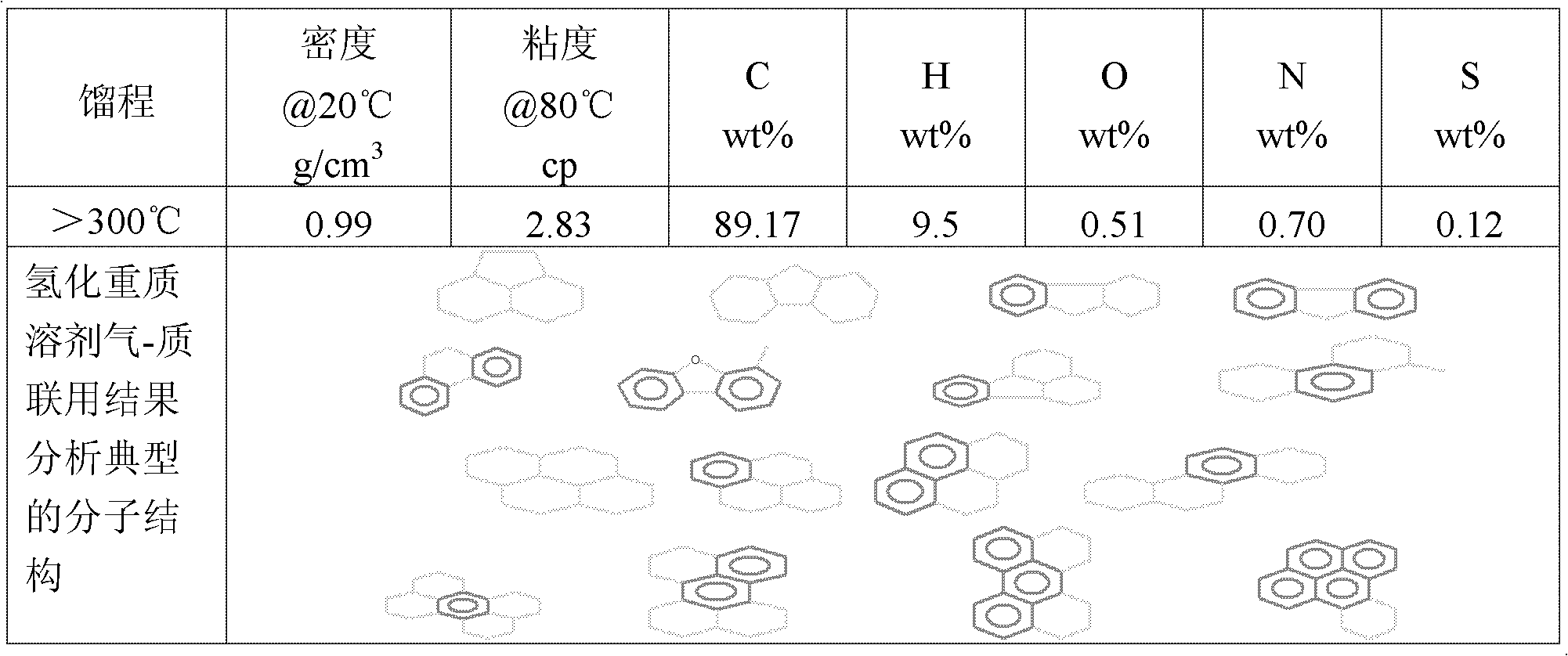

Process for Producing Mesophase Pitch by Hydrogenation of High-temperature Coal Tar

ActiveUS20150076031A1Increase H/C ratioHigh content of mesophase pitchWorking-up pitch/asphalt/bitumen by distillationLiquid hydrocarbon mixtures productionBoiling pointCoal tar

A process for producing mesophase pitch from high-temperature coal tar comprises: removing salts and quinoline insoluble fraction from a high-temperature coal tar to obtain a decant oil; using the decant oil as a hydrogenation feedstock, or pre-distilling the decant oil to obtain a residue with a boiling point higher than 230 and formulating the residue into a hydrogenation feedstock; catalytic hydrorefining the hydrogenation feedstock to obtain a hydrofined oil; distilling the hydrofined oil to obtain hydrogenated pitch; and subjecting the hydrogenated pitch to the thermal polymerization to obtain the mesophase pitch. The process has features such as an easily controllable degree of hydrogenation, complete removal of impurities, good raw material flowability, not tending to form the carbon deposition and the coking during the process, and not tending to jam the reactor. The product has a high content of mesophase pitch, a low softening point and a low impurity content.

Owner:ECO CARBON MATERIALS HLDG (SHENZHEN) CO LTD +1

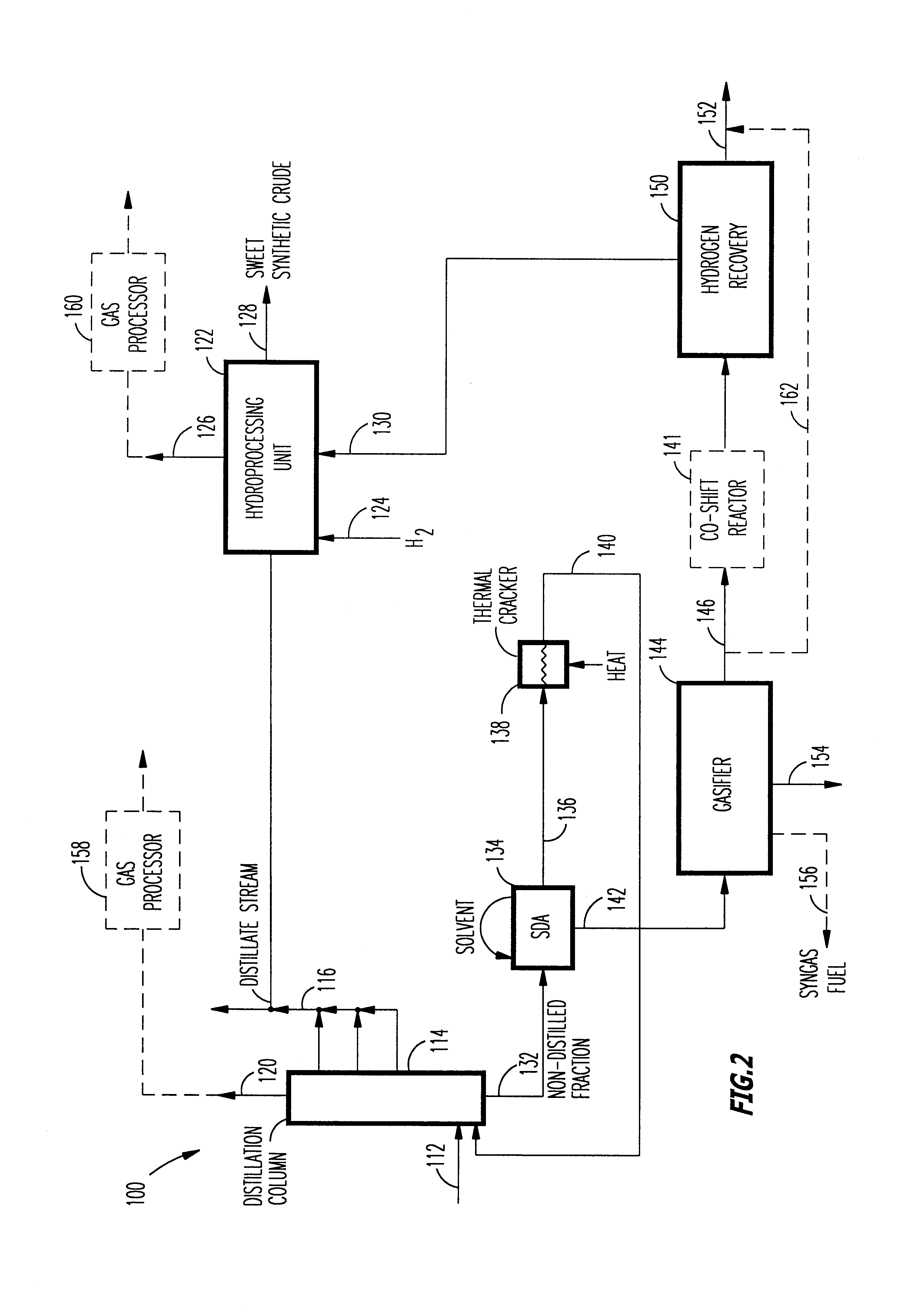

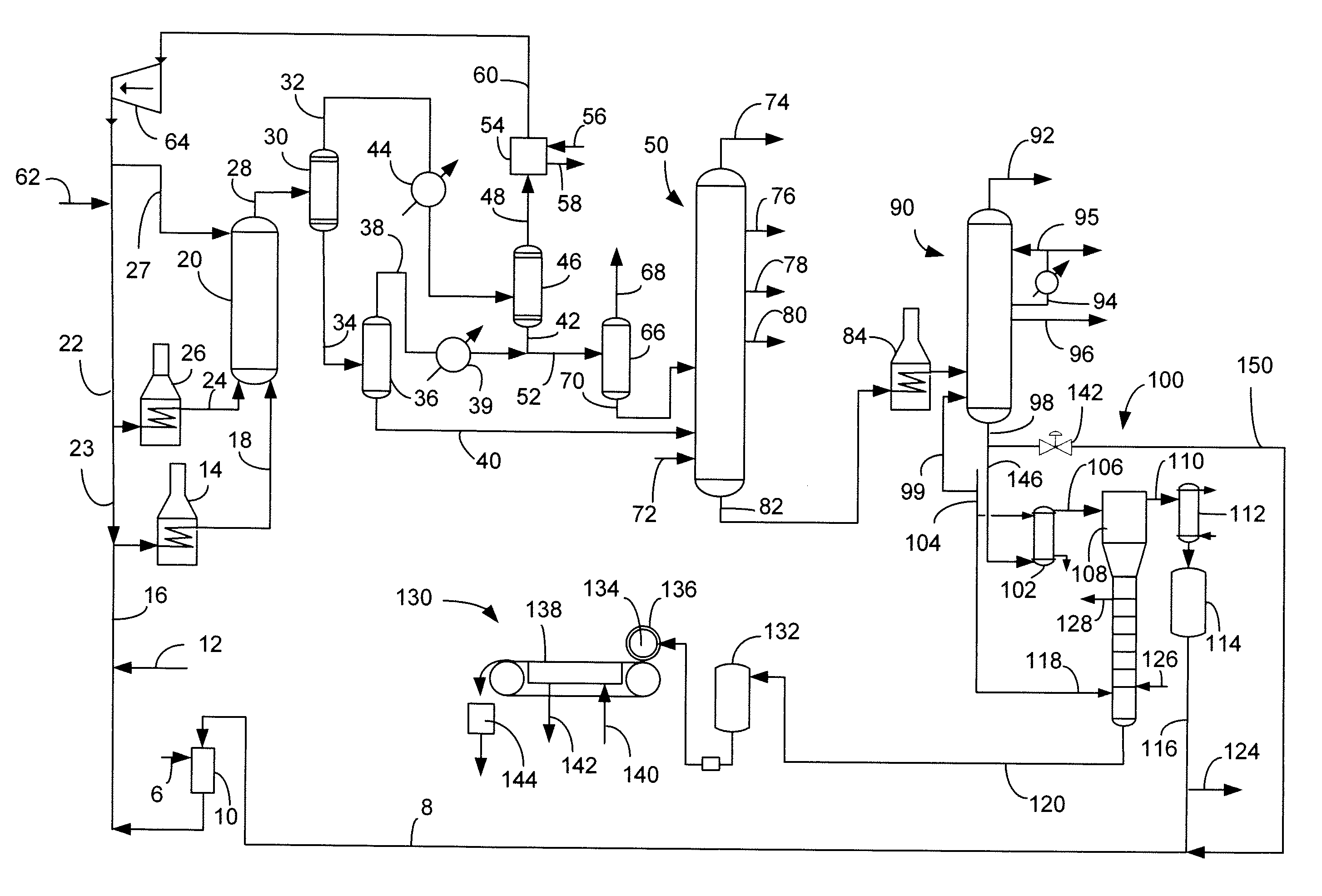

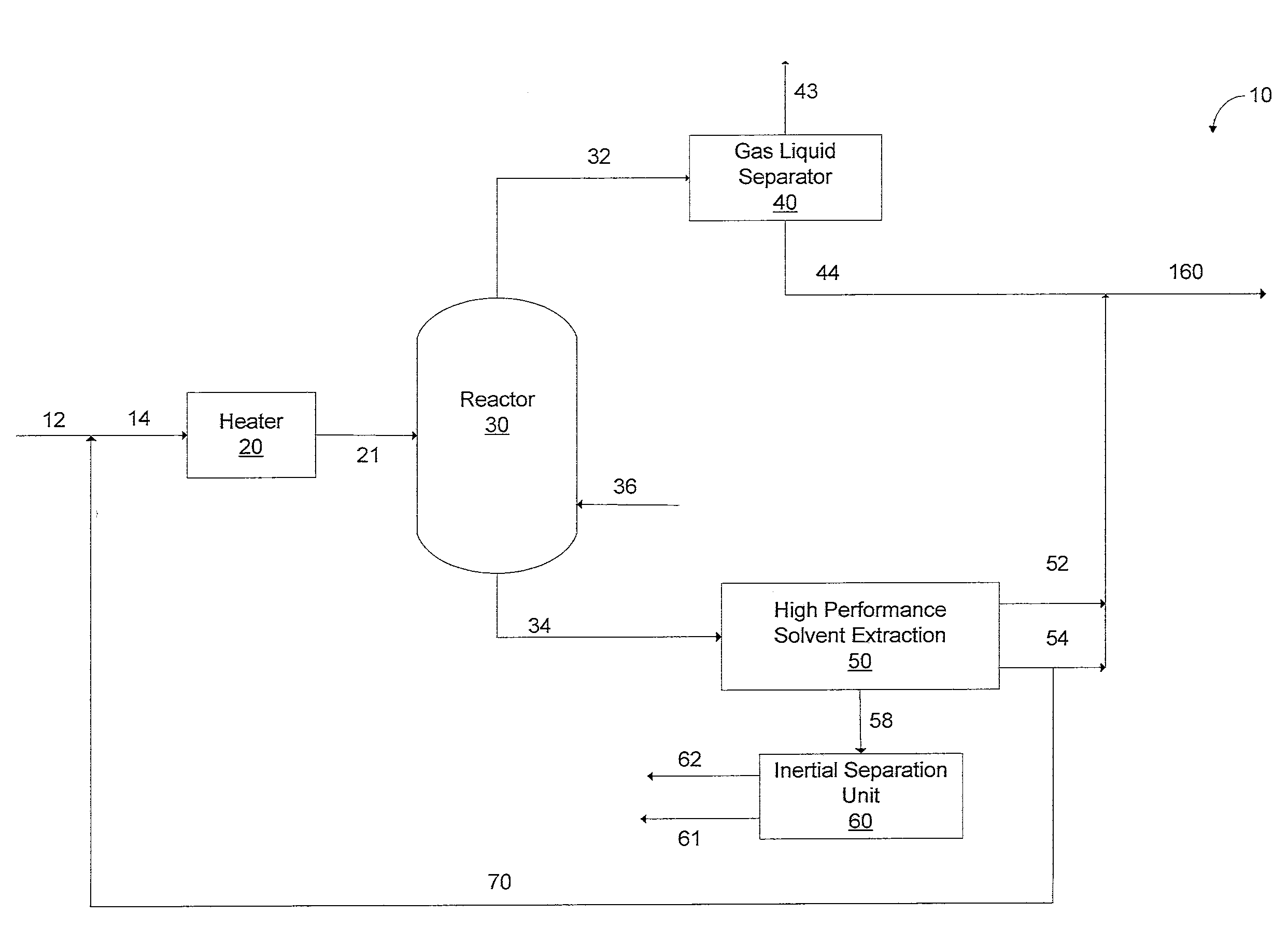

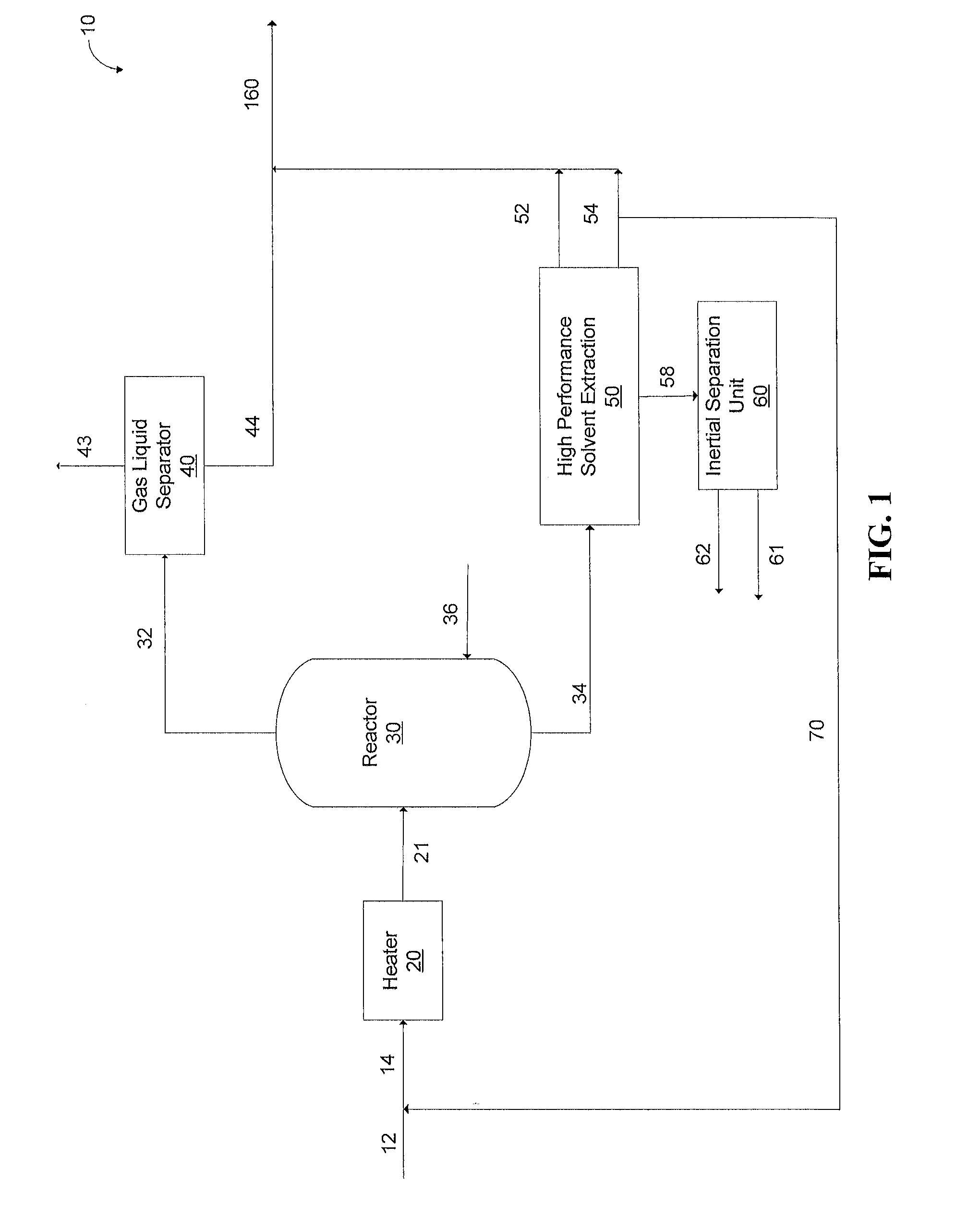

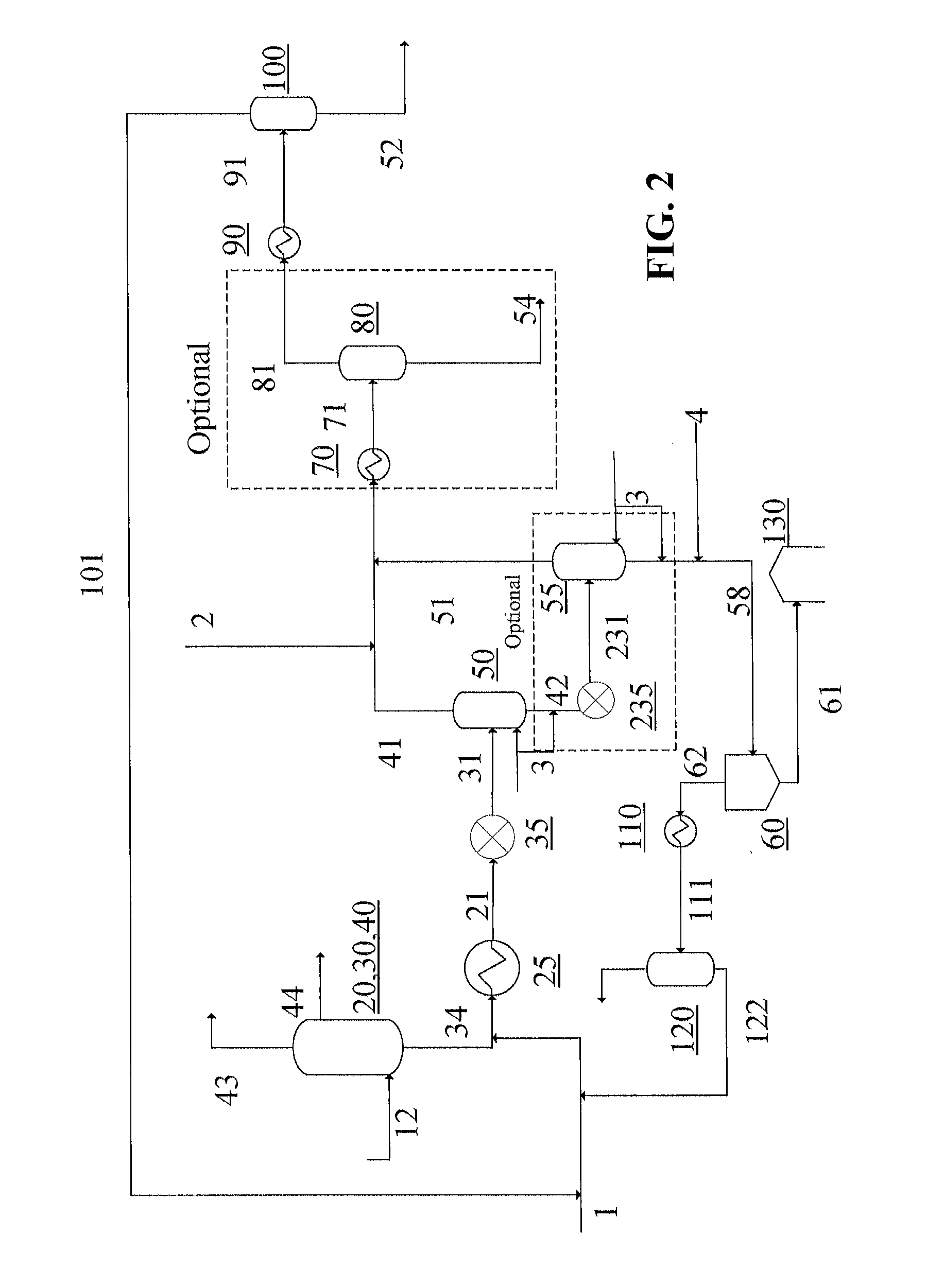

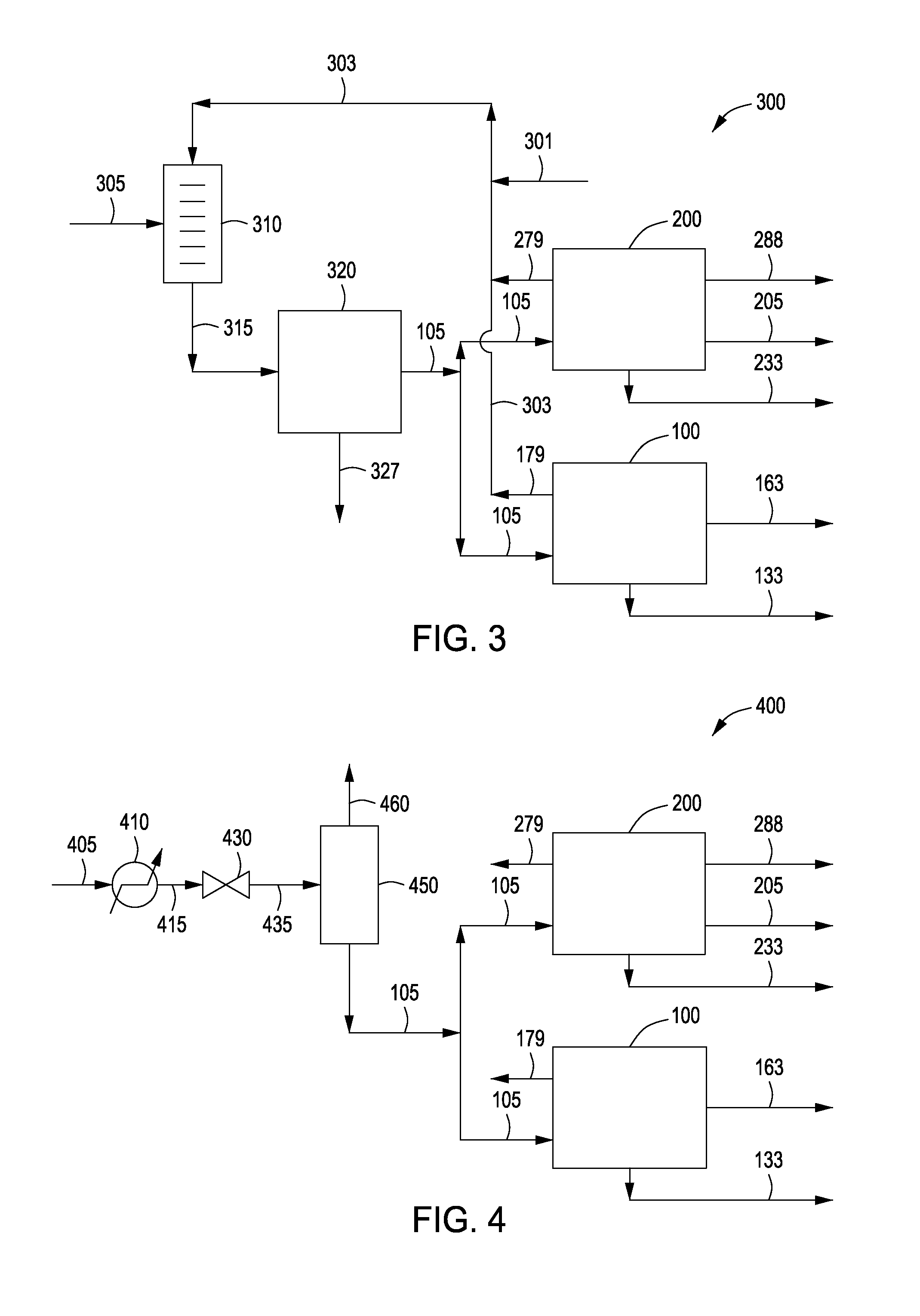

Low complexity, high yield conversion of heavy hydrocarbons

ActiveUS20130180888A1Assist in removingImproved solvent-extraction performanceWorking-up pitch/asphalt/bitumen by distillationThermal non-catalytic crackingSolventAsphaltene

A process for producing pipeline-ready or refinery-ready feedstock from heavy hydrocarbons using a high-performance solvent extraction process with high local solvent-to-process fluid ratios yet maintaining low overall solvent-to-process fluid ratios, by first performing mild thermal cracking on the heavy hydrocarbons and then separating asphaltene-rich fractions from a resulting thermally affected fluid so that the high solvent-to-oil ratio portion of the process acts only on those asphaltene-rich fractions, and producing a dry, solid asphaltene as an end-product.

Owner:SUNCOR ENERGY INC

Method Of Producing Needle Coke For Low CTE Graphite Electrodes

ActiveUS20080003167A1Improve thermal stabilityReduce CTESolid fuelsTar working-up by distillationCoal tar distillateGraphite electrode

A method of producing low CTE graphite electrodes from needle coke formed from a coal tar distillate material having a relatively high initial boiling point.

Owner:GRAFTECH INT HLDG INC

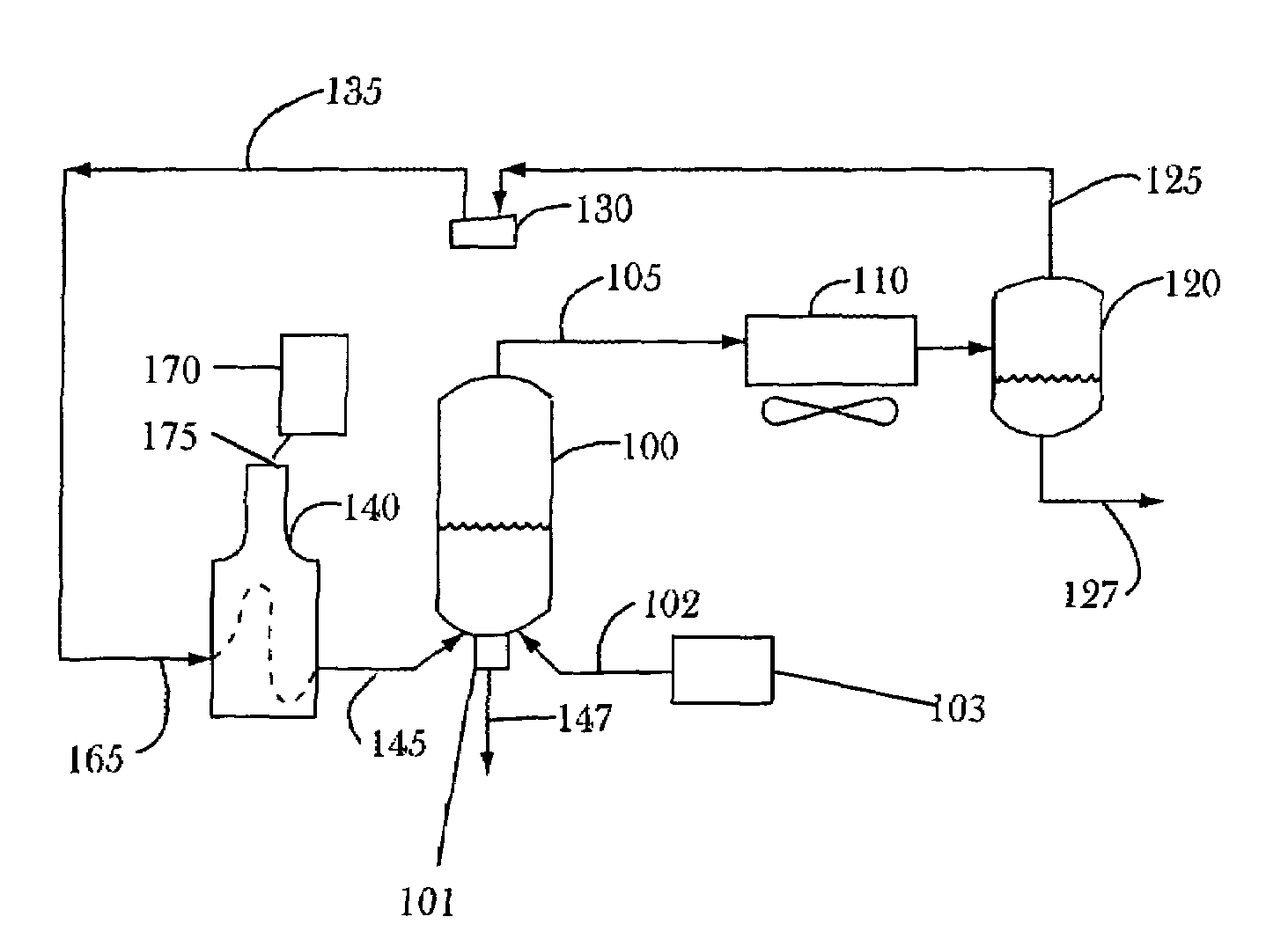

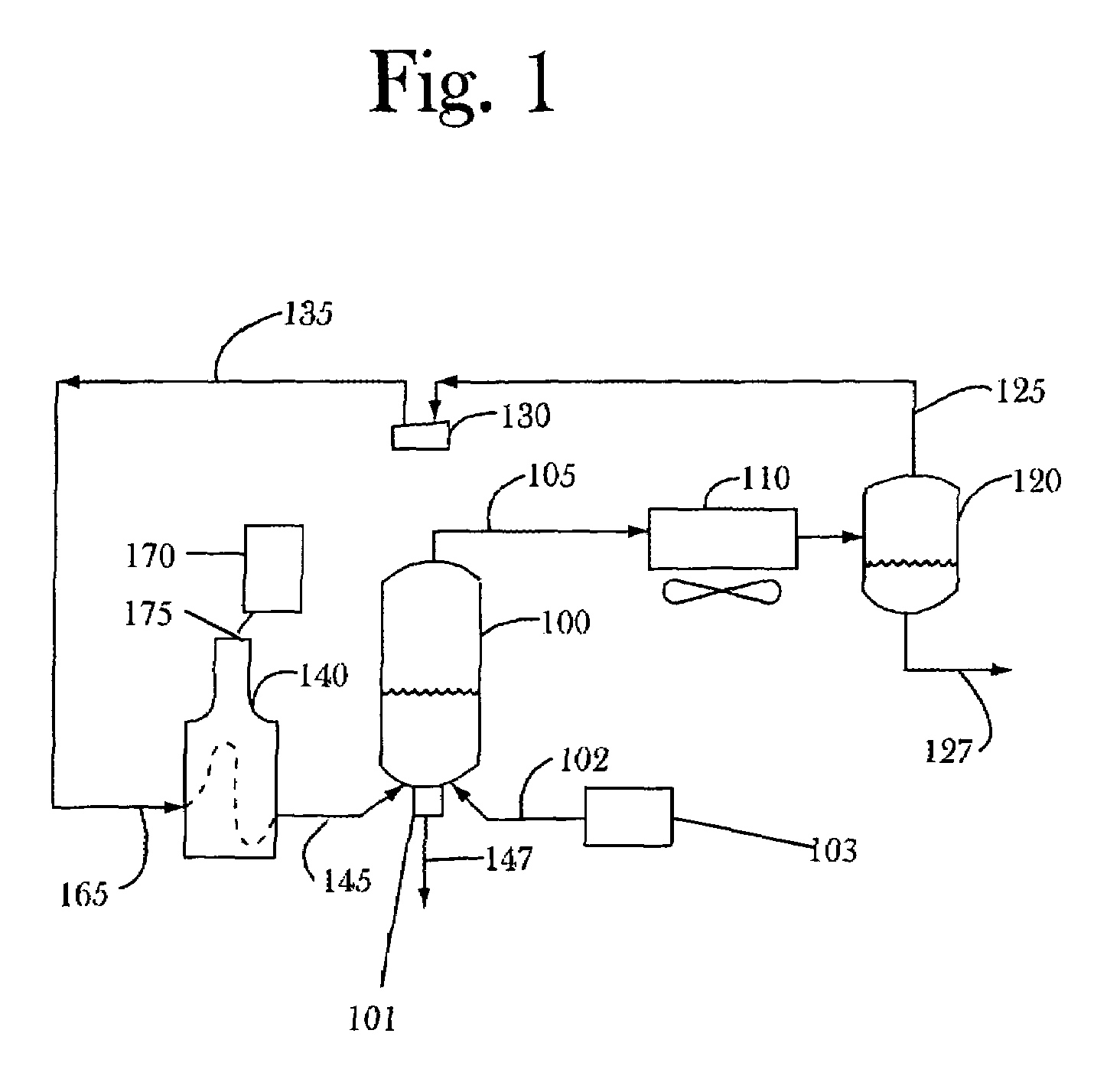

Residuum Oil Supercritical Extraction Process

InactiveUS20110094937A1Working-up pitch/asphalt/bitumen by distillationWorking-up pitch/asphalt/bitumen by chemical meansProcess systemsAsphaltene

Systems and methods for processing one or more hydrocarbons are provided. A hydrocarbon can be selectively separated to provide one or more finished products and an asphaltenic hydrocarbon using a pretreatment process. The asphaltenic hydrocarbon can be selectively separated to provide a deasphalted oil and one or more asphaltenes. At least a portion of the deasphalted oil can be converted to one or more first products using a first post-treatment process. At least a portion of the one or more asphaltenes can be converted to one or more second products using a second post-treatment process.

Owner:KELLOGG BROWN & ROOT LLC

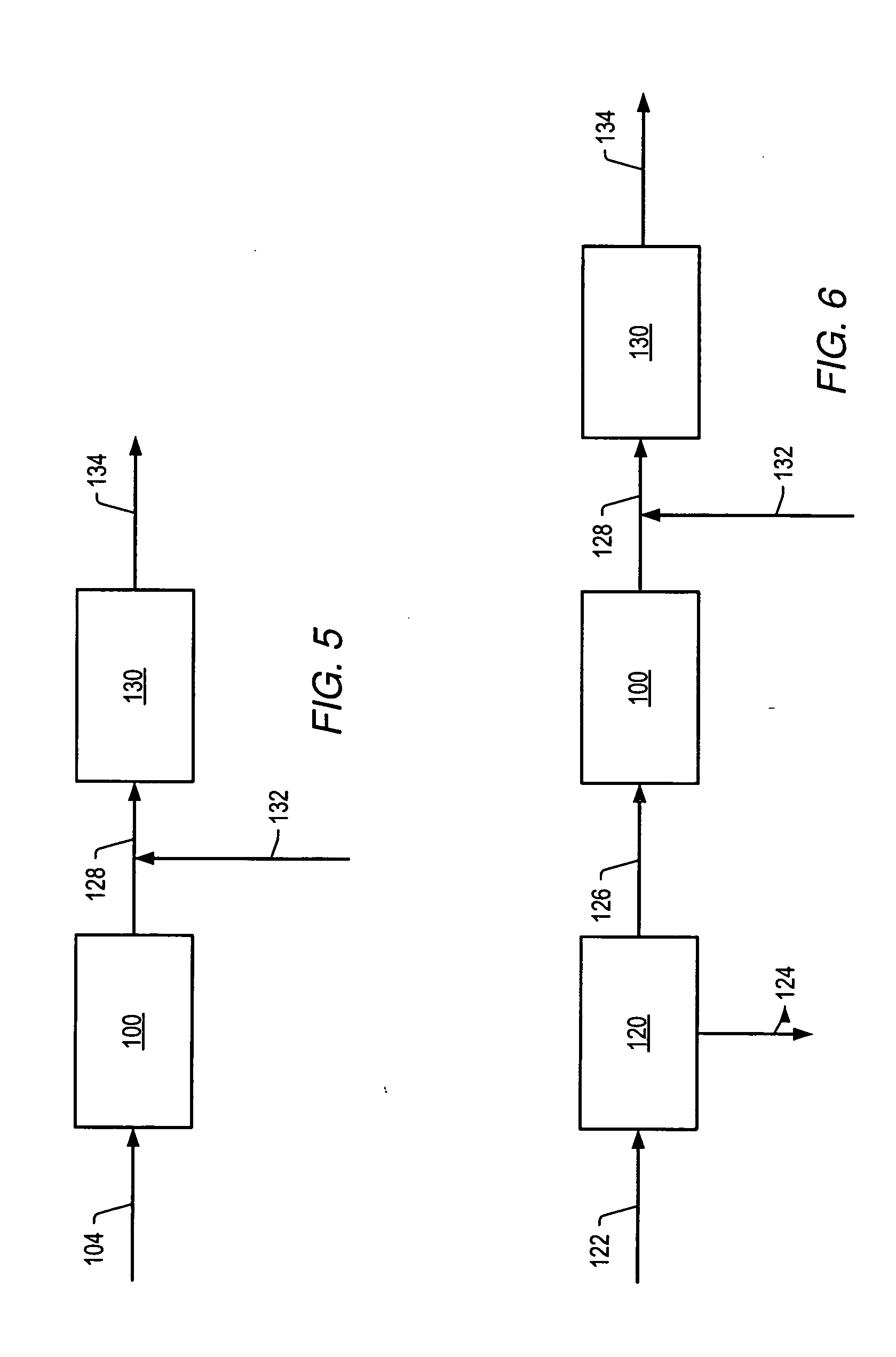

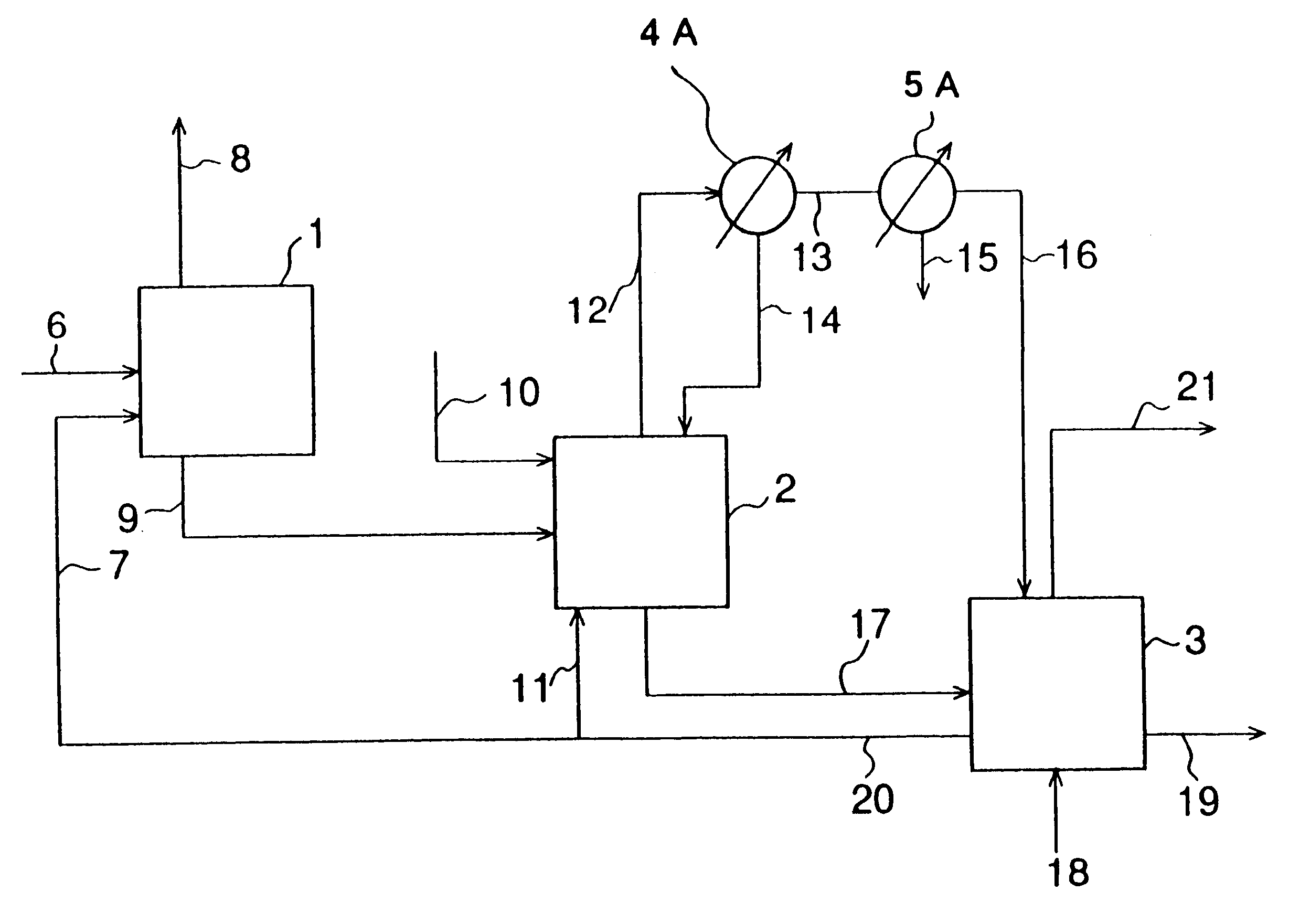

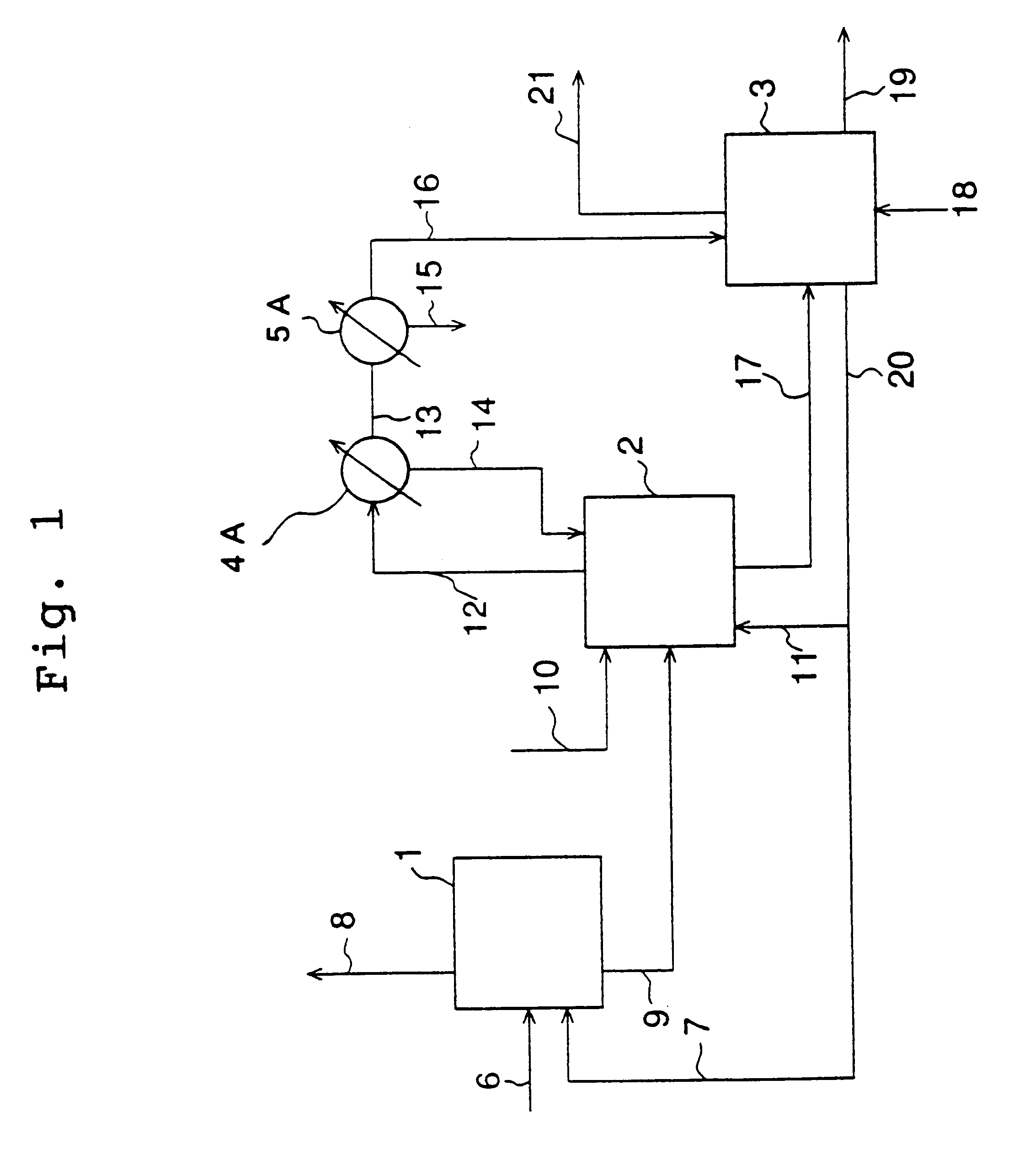

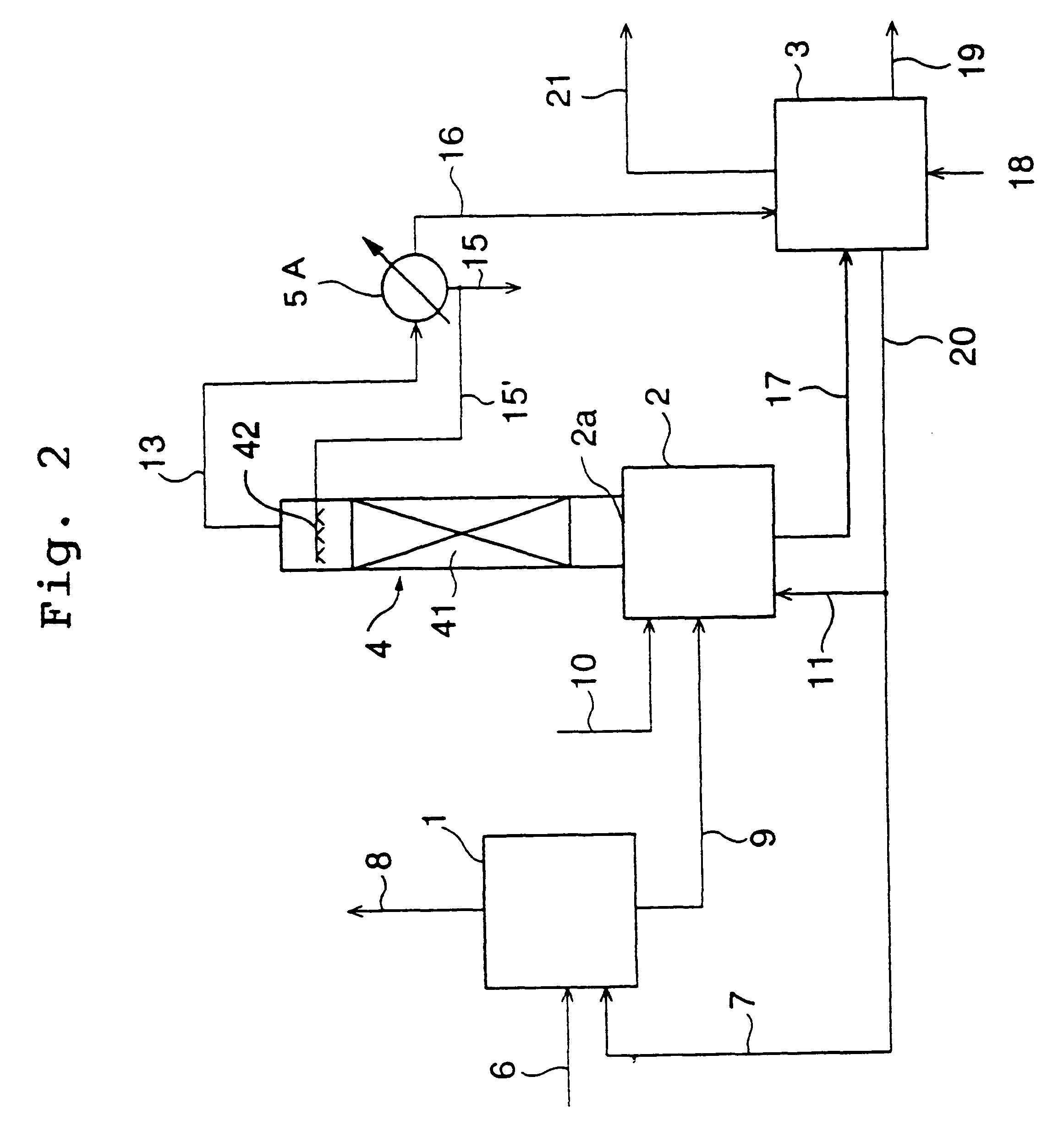

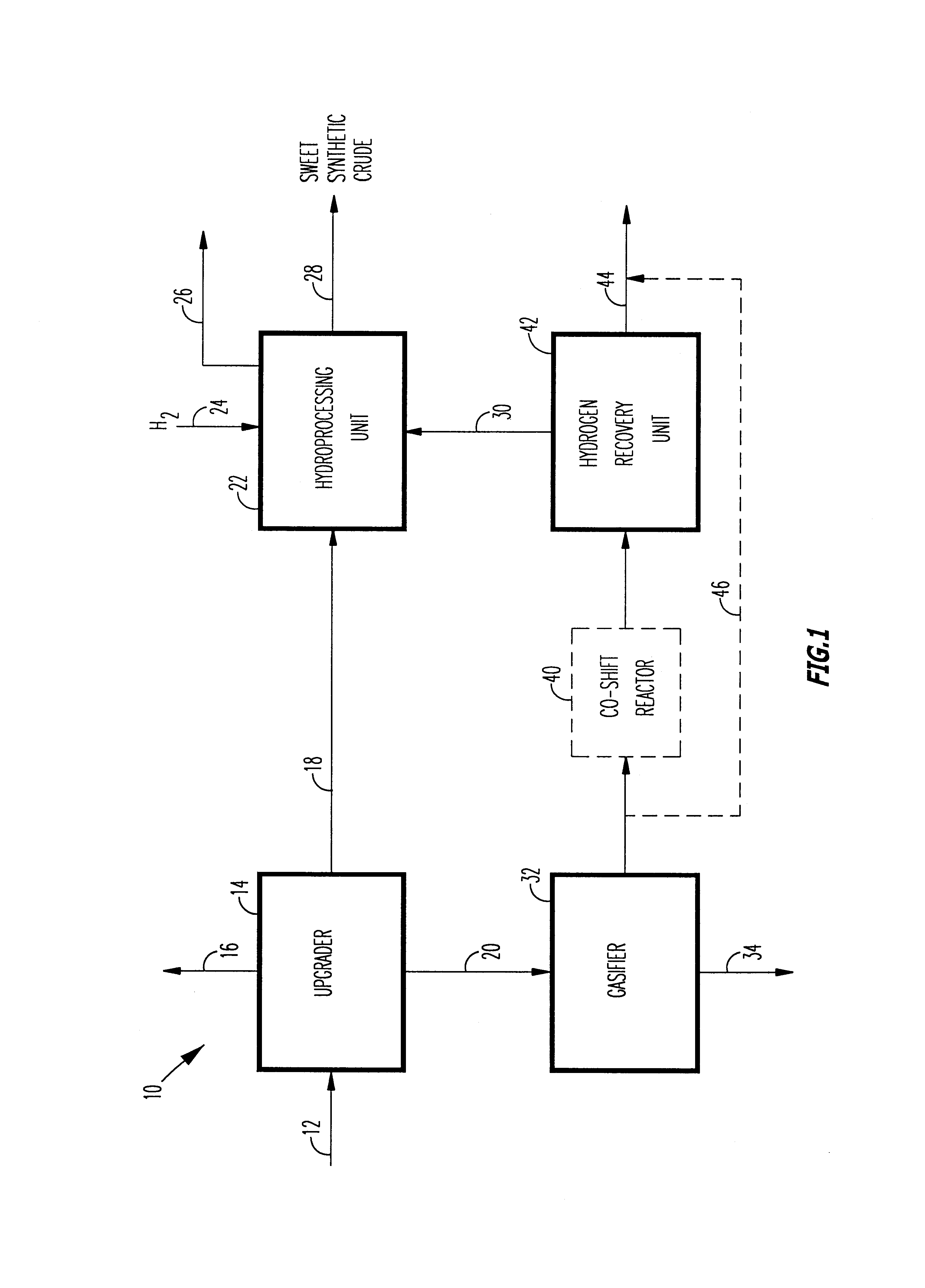

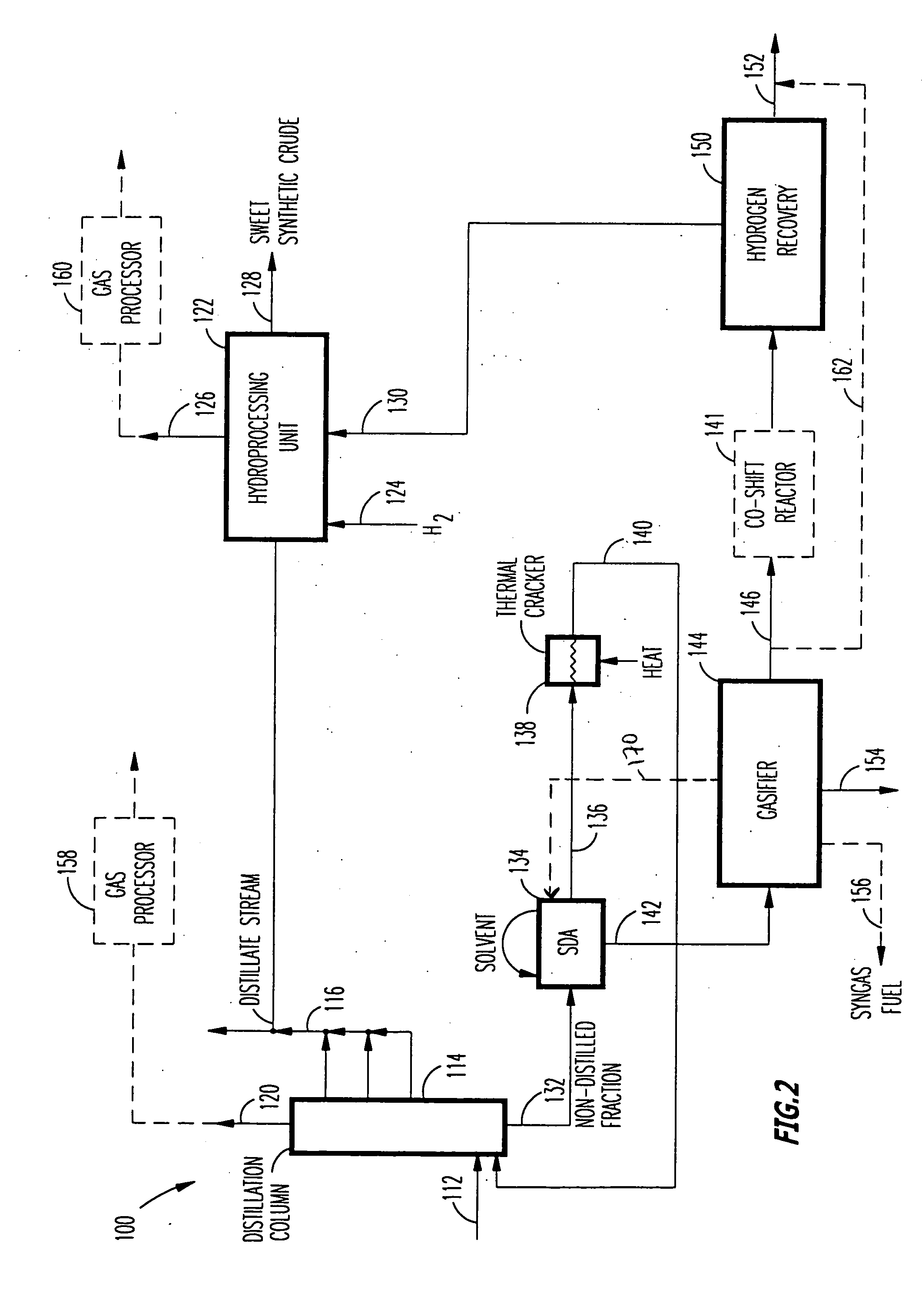

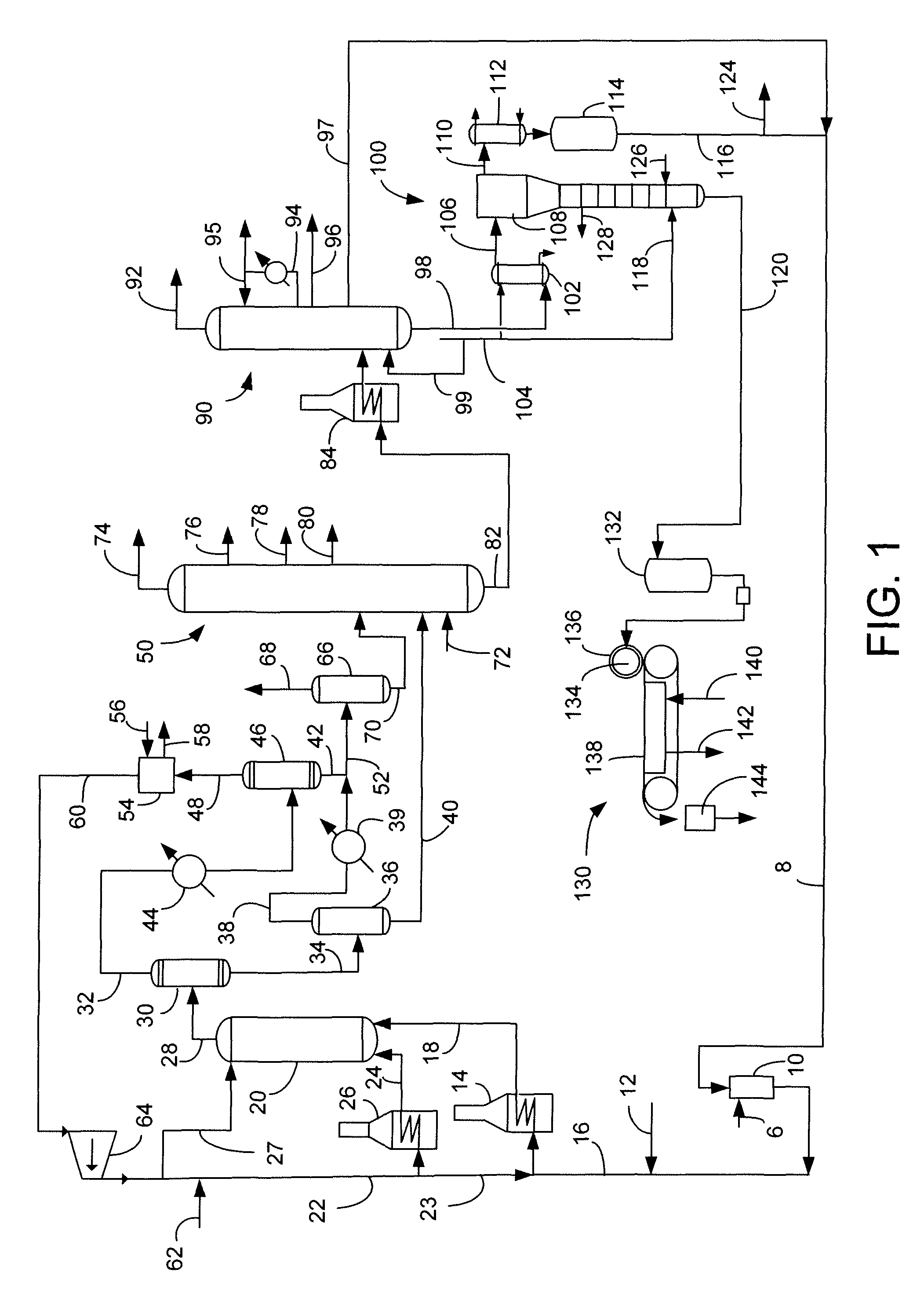

Method of and apparatus for upgrading and gasifying heavy hydrocarbon feeds

InactiveUS20040118745A1Thermal non-catalytic crackingSolvent extractionThermodynamicsProcess engineering

A novel apparatus for producing sweet synthetic crude from a heavy hydrocarbon feed includes: an upgrader for receiving the heavy hydrocarbon feed and producing a distillate fraction including sour products, and high-carbon content by-products; a gasifier for receiving the high-carbon content by-products and producing synthetic fuel gas and sour by-products; a hydroprocessing unit for receiving the sour by-products and hydrogen gas, thereby producing gas and sweet crude; and a hydrogen recovery unit for receiving the synthetic fuel gas and producing further hydrogen gas and hydrogen-depleted synthetic fuel gas, the further hydrogen gas being supplied to the hydroprocessing unit.

Owner:ORMAT IND LTD

Method of and apparatus for upgrading and gasifying heavy hydrocarbon feeds

A novel apparatus for producing sweet synthetic crude from a heavy hydrocarbon feed includes: an upgrader for receiving the heavy hydrocarbon feed and producing a distillate fraction including sour products, and high-carbon content by-products; a gasifier for receiving the high-carbon content by-products and producing synthetic fuel gas and sour by-products; a hydroprocessing unit for receiving the sour by-products and hydrogen gas, thereby producing gas and sweet crude; and a hydrogen recovery unit for receiving the synthetic fuel gas and producing further hydrogen gas and hydrogen-depleted synthetic fuel gas, the further hydrogen gas being supplied to the hydroprocessing unit.

Owner:ORMAT IND LTD

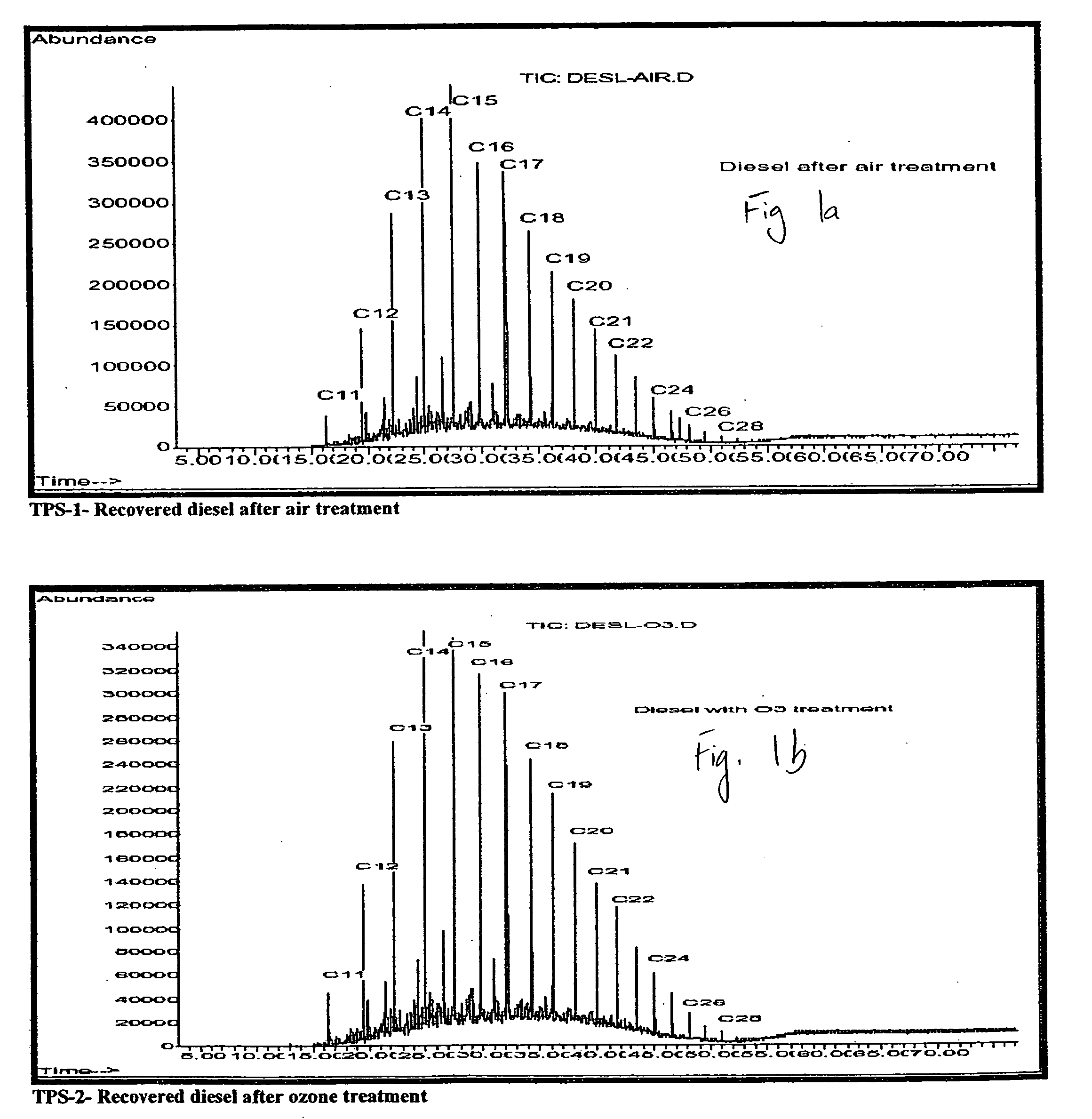

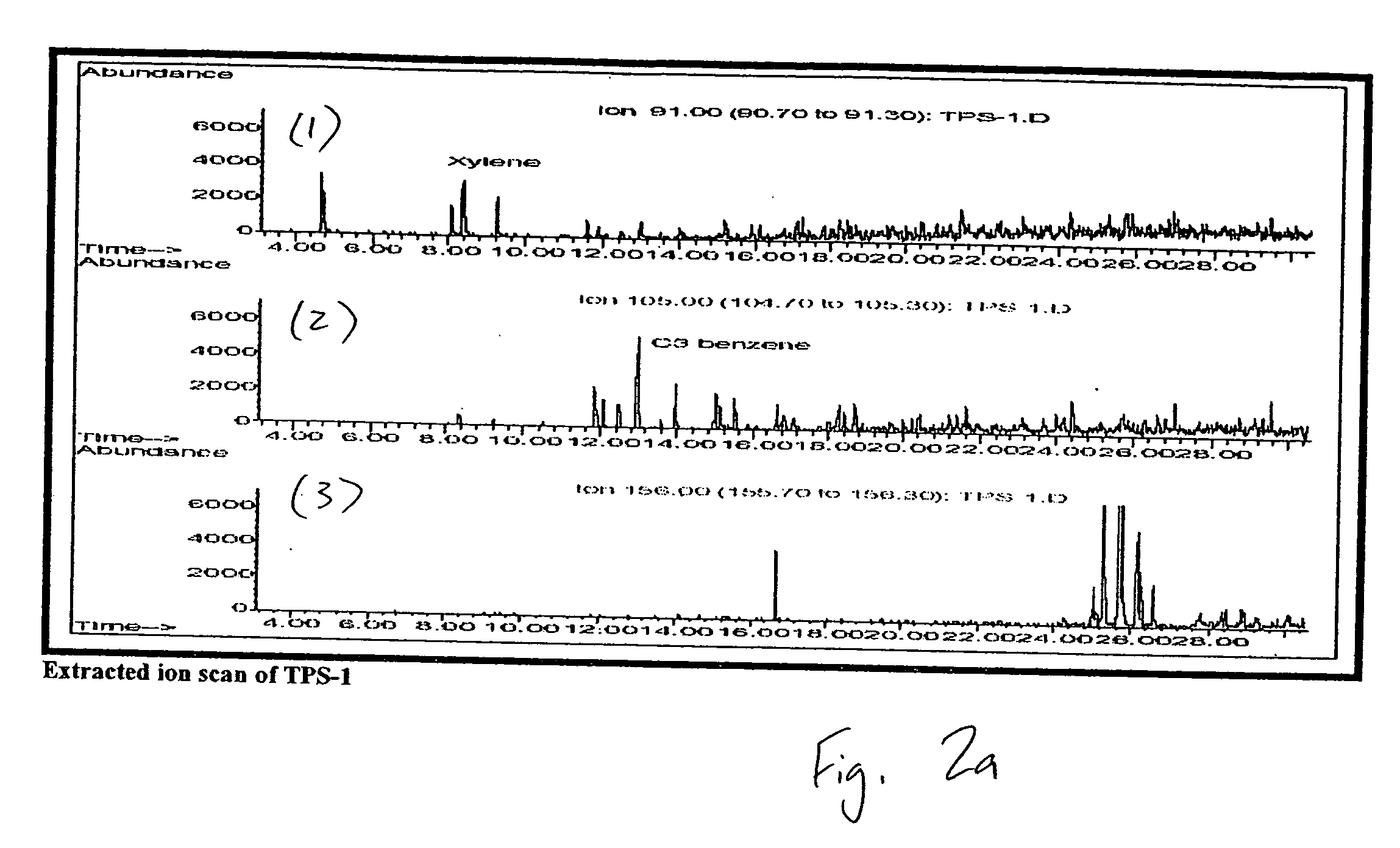

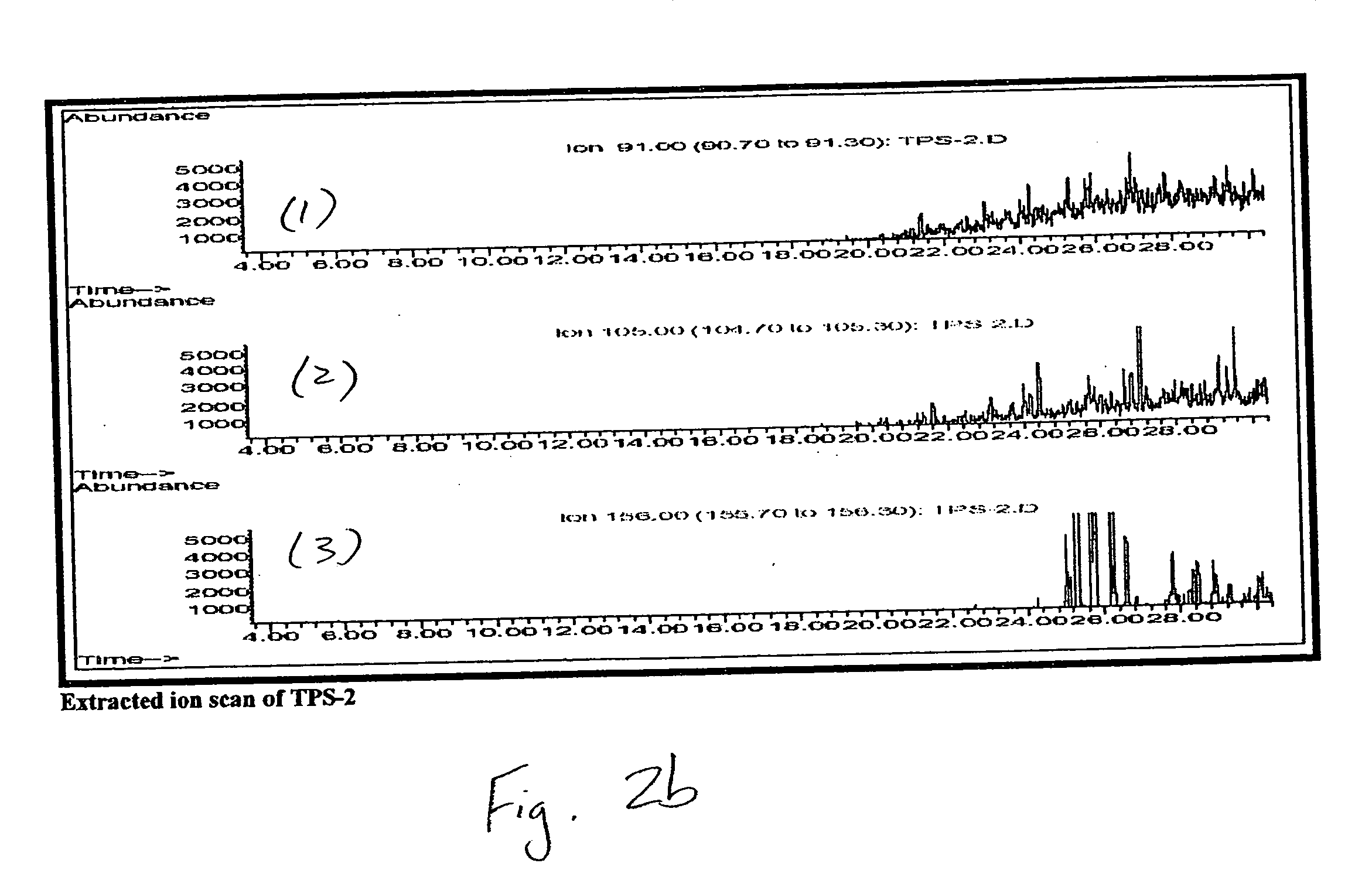

Treatment of hydrocarbon fluids with ozone

InactiveUS20050247599A1Thermal non-catalytic crackingDrying using combination processesHydrocarbonOzone

A method of treating a hydrocarbon fluid that includes contacting the hydrocarbon fluid with an effective amount of ozone. A method for separating contaminants from a contaminated material includes supplying the contaminated material to a processing chamber, moving the contaminated material through the processing chamber, heating the contaminated material by externally heating the processing chamber so as to volatilize the contaminants in the contaminated material, removing vapor resulting from the heating, wherein the vapor comprises the volatilized contaminants, collecting, condensing, and recovering the volatilized contaminants, and contacting the volatilized contaminants with an effective amount of ozone.

Owner:MI

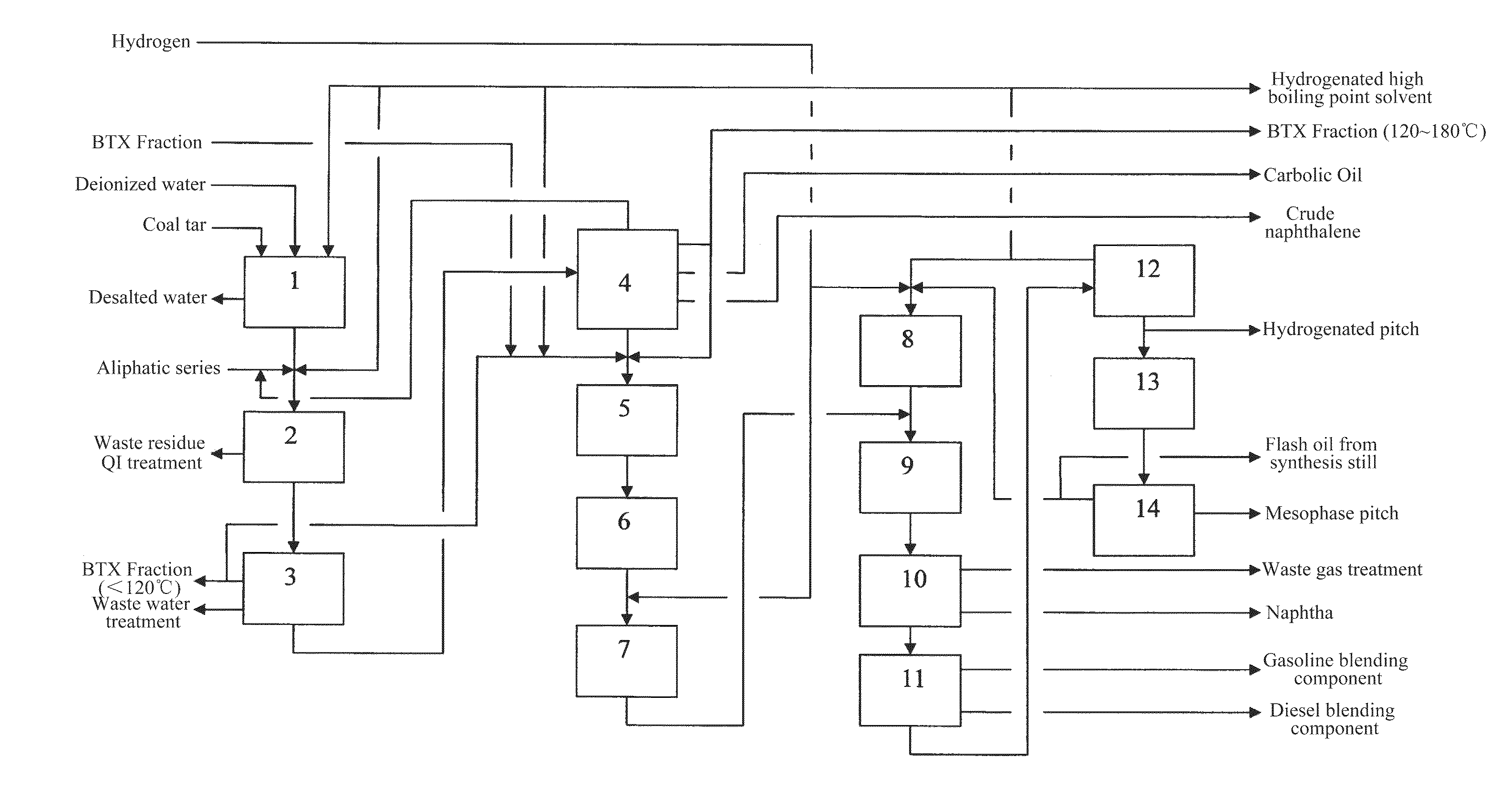

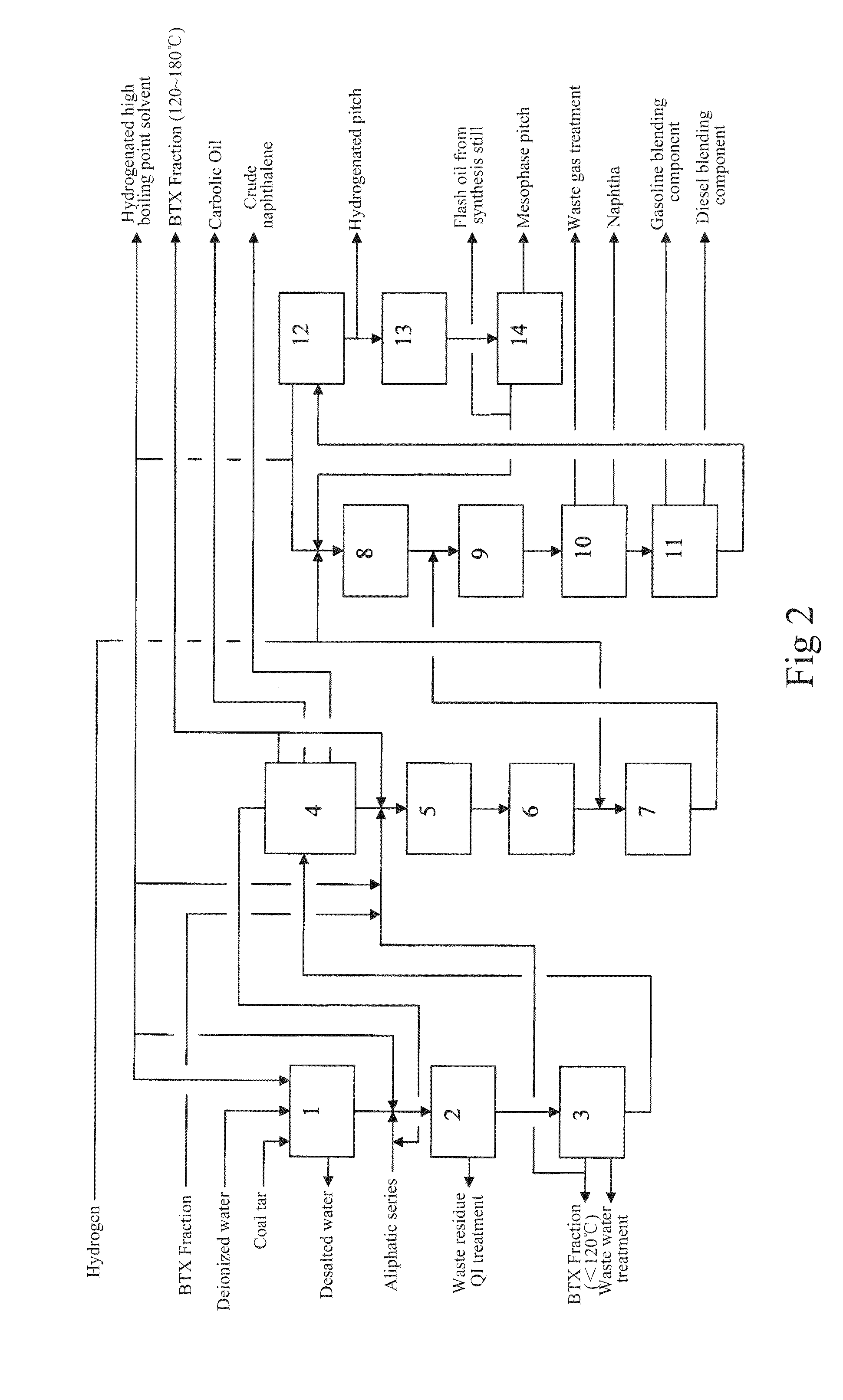

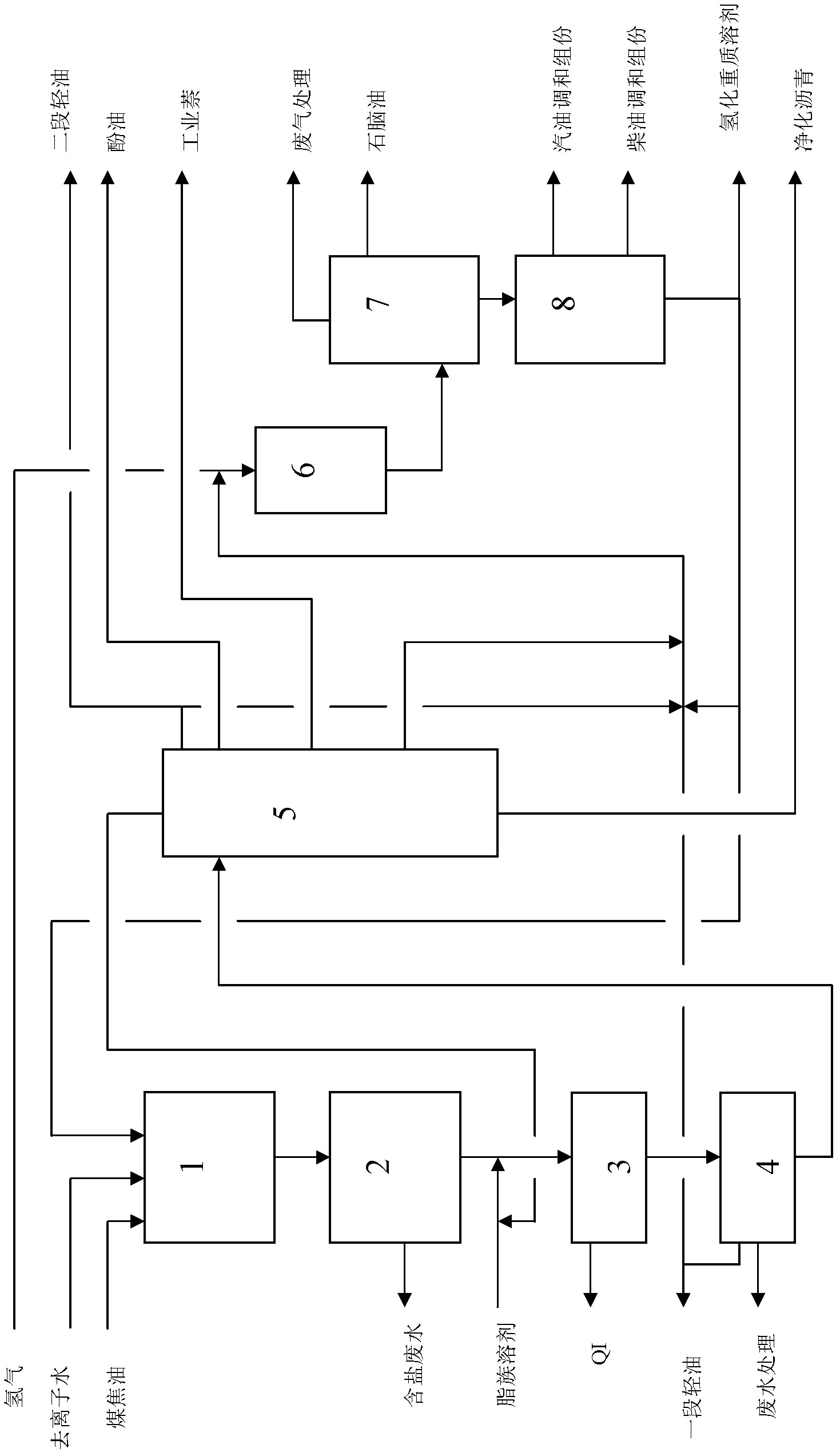

Method for production of purified coal tar pitch from high temperature coal tar

ActiveCN103205272AImprove product added valueLow quinoline insolublesTreatment with hydrotreatment processesTar working-up by distillationSolventPhenol

The invention relates to a method for production of purified coal tar pitch from high temperature coal tar. The method includes: mixing the high temperature coal tar with a hydrogenation heavy solvent and deionized water, and then removing salt to obtain salt removed high temperature coal tar; mixing the salt removed high temperature coal tar with an aliphatic solvent, and then removing quinoline insolubles to obtain clarified oil; distilling the clarified oil to obtain the aliphatic solvent, phenol oil, naphthalene oil, purified coal tar pitch and mixed oil of light oil, washing oil, anthracene oil and the hydrogenation heavy solvent, and taking the mixed oil as catalytic hydrogenation feed oil; subjecting the catalytic hydrogenation feed oil to catalytic hydrofining to obtain hydrofined oil; distilling the hydrofined oil to obtain a naphtha component, a gasoline blending component, a diesel oil blending component and the hydrogenation heavy solvent. The method greatly enhances the added value of products processed from high temperature coal tar, and the purified asphalt has low content of quinoline insolubles and metals.

Owner:易高碳材料控股(深圳)有限公司

Preparation of asphalt for producing coal-based needle coke

InactiveCN101302431AHigh yieldImprove product qualityTar working-up by distillationCoking carbonaceous materialsDistillationCoal dust

The invention discloses a method for preparing pitch used for producing coal-based needle coke. The method comprises the following steps that: coal tar and coal pitch are taken as raw materials; coal tar light compositions are taken as solvent; coal dust, metallurgical coke powder, or mixture of the metallurgical coke powder and diatomite, or mixture of the metallurgical coke powder and expanded perlite are taken as filter aid; uniform filter aid filter cakes are formed in a centrifuge by filter aid mixture at first, and then mixture of the coal pitch or the coal tar, wash oil and the filter aid is added into the centrifuge in which the uniform filter aid filter cakes are formed for centrifugal filtration; and obtained centrifugate is driven to pass through atmospheric distillation recovery solvent, so as toe obtain the refining pitch raw materials which are suitable for producing the coal-based needle coke. The yield of the pitch raw materials used for producing the coal-based needle coke prepared by the technology is improved by 10 to 15 percent compared with other methods; the manufacturing technique is simple and the preparation cost is low; and the mass production is easy to realize.

Owner:邯郸市鑫宝煤化工有限公司

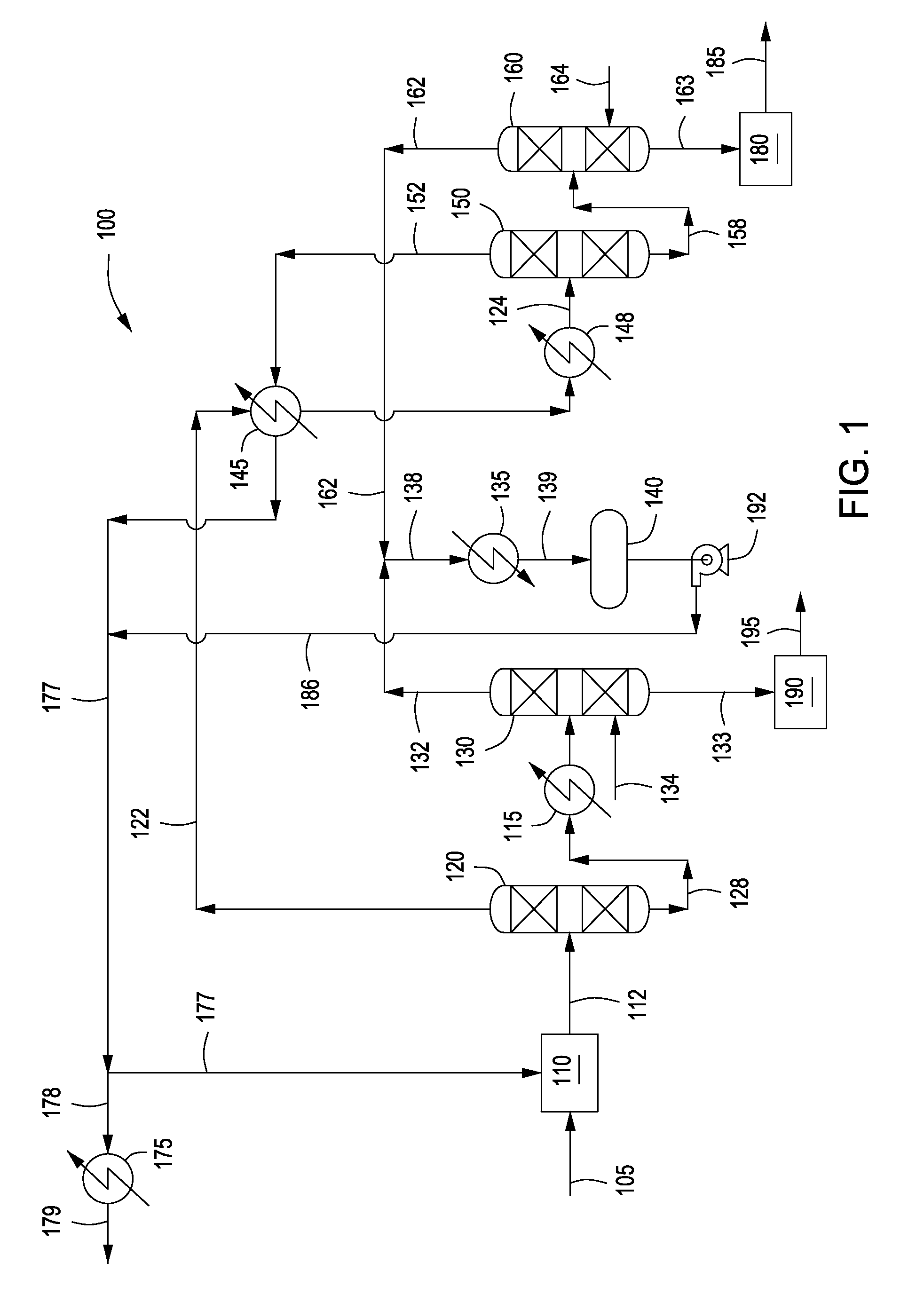

System and method of recovering heat and water and generating power from bitumen mining operations

InactiveUS20100275600A1Improve environmental performanceReducing greenhouse gas emissionThermal non-catalytic crackingAuxillariesEngineeringSlurry

A method recovering heat and water from a warm slurry, such as warm tailings from a oil sands extraction mining operation, is provided. The method comprises providing the tailings to a vacuum vessel, removing, from the vacuum vessel, warm vapor derived from the tailings, condensing the warm vapor in a condenser to produce water, and recovering the water from the condenser. Cool river or pond water can be warmed with the heat from the vapor for additional uses in the mining operation. Essentially pure water can be obtained in the process. This can also be achieved using one or flash vessels in series to condense the vapor. Power can also be generated from the vapor using a turbine.

Owner:EXXONMOBIL UPSTREAM RES CO

Continuous oxidation and distillation process of heavier hydrocarbon materials

InactiveUS7341656B1Low costLow facility requirementsWorking-up pitch/asphalt/bitumen by distillationWorking-up pitch/asphalt/bitumen by chemical meansDistillationPhysical chemistry

The present invention provides a way to process heavier hydrocarbons in a relatively low cost and low pressure process using a combination of superheated steam and at least one reaction gas to i) promote oxidation and thermal reaction of heavier hydrocarbons, while simultaneously ii) removing volatile components with a steam stripping process.

Owner:MARATHON PETROLEUM

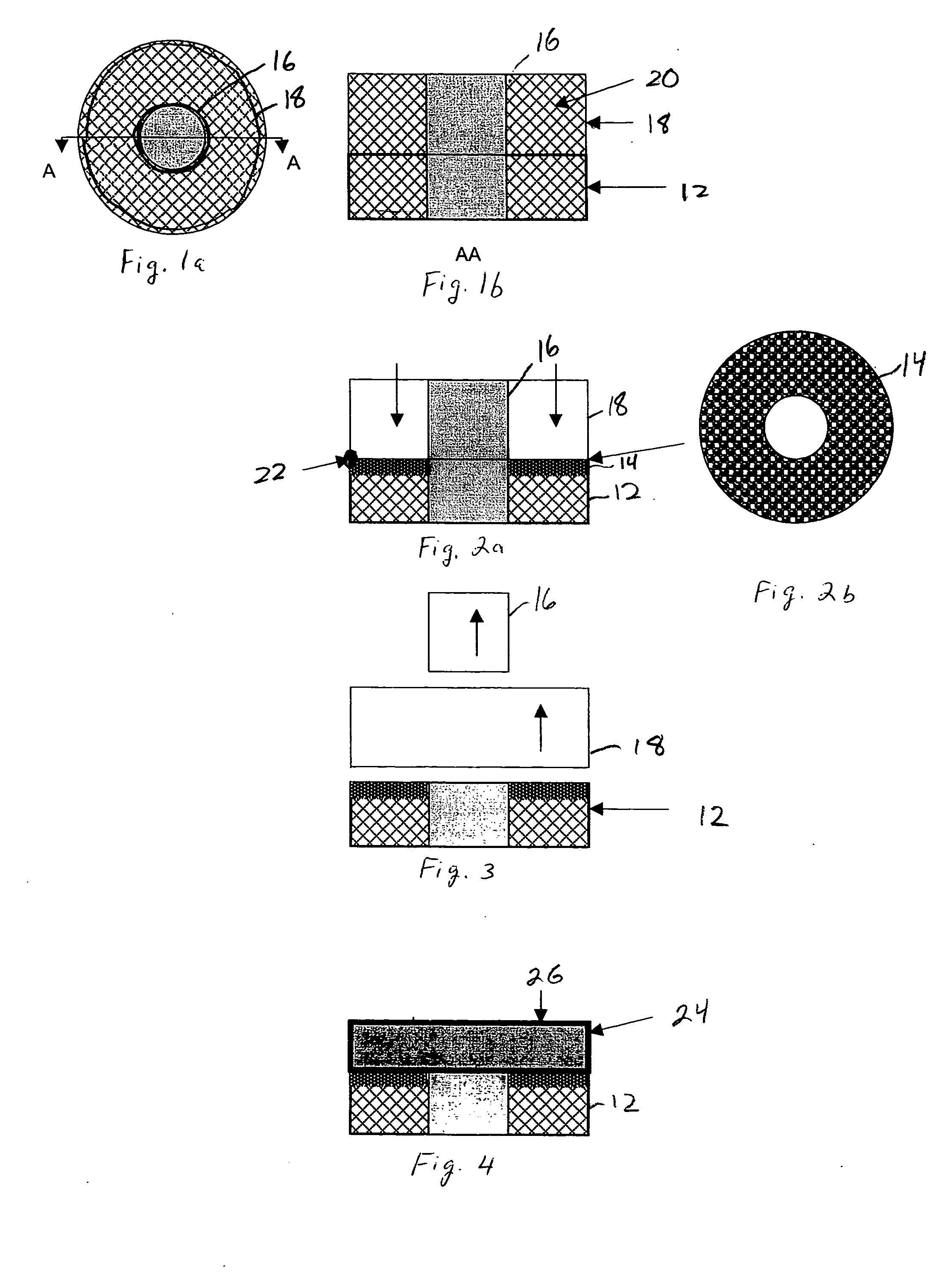

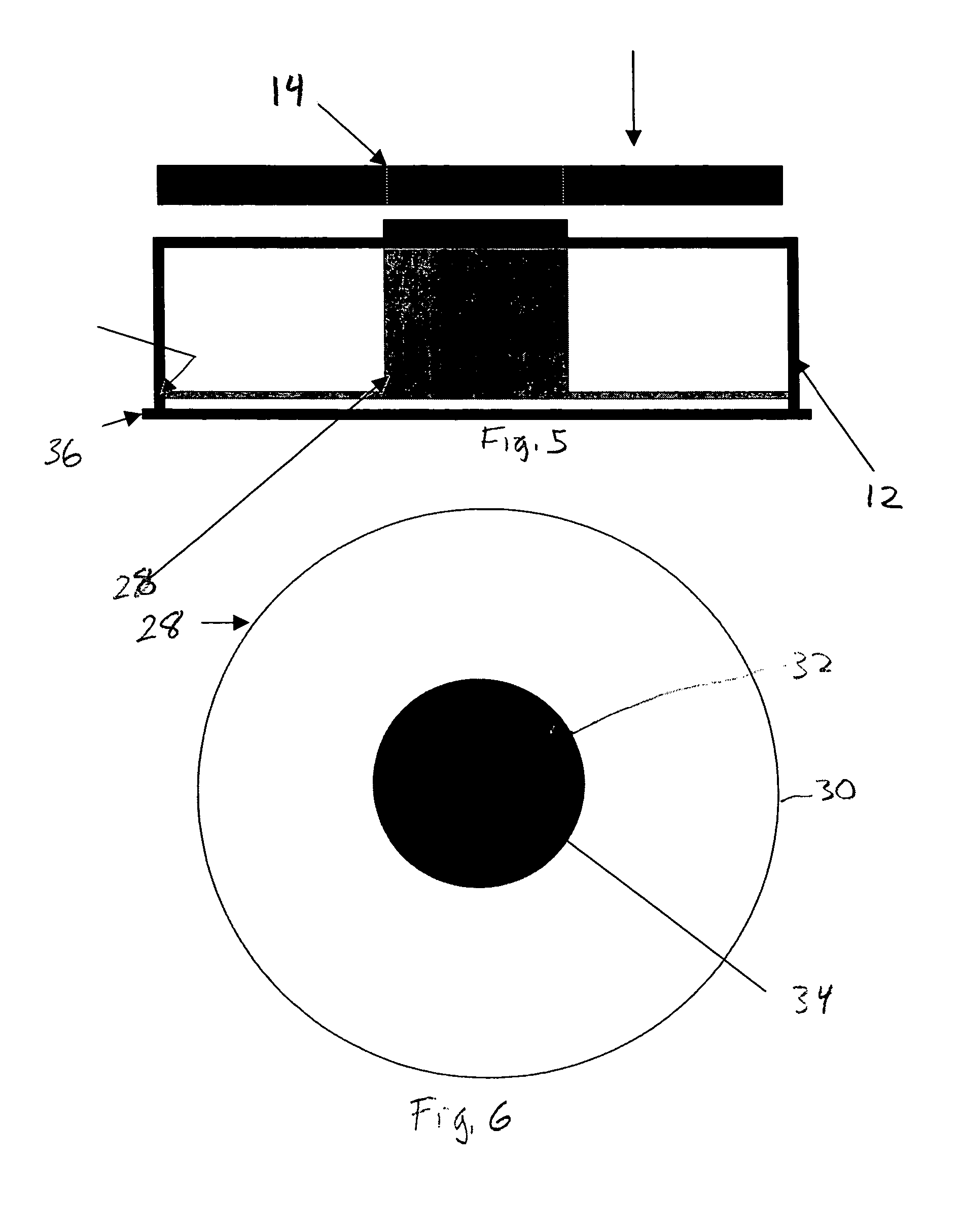

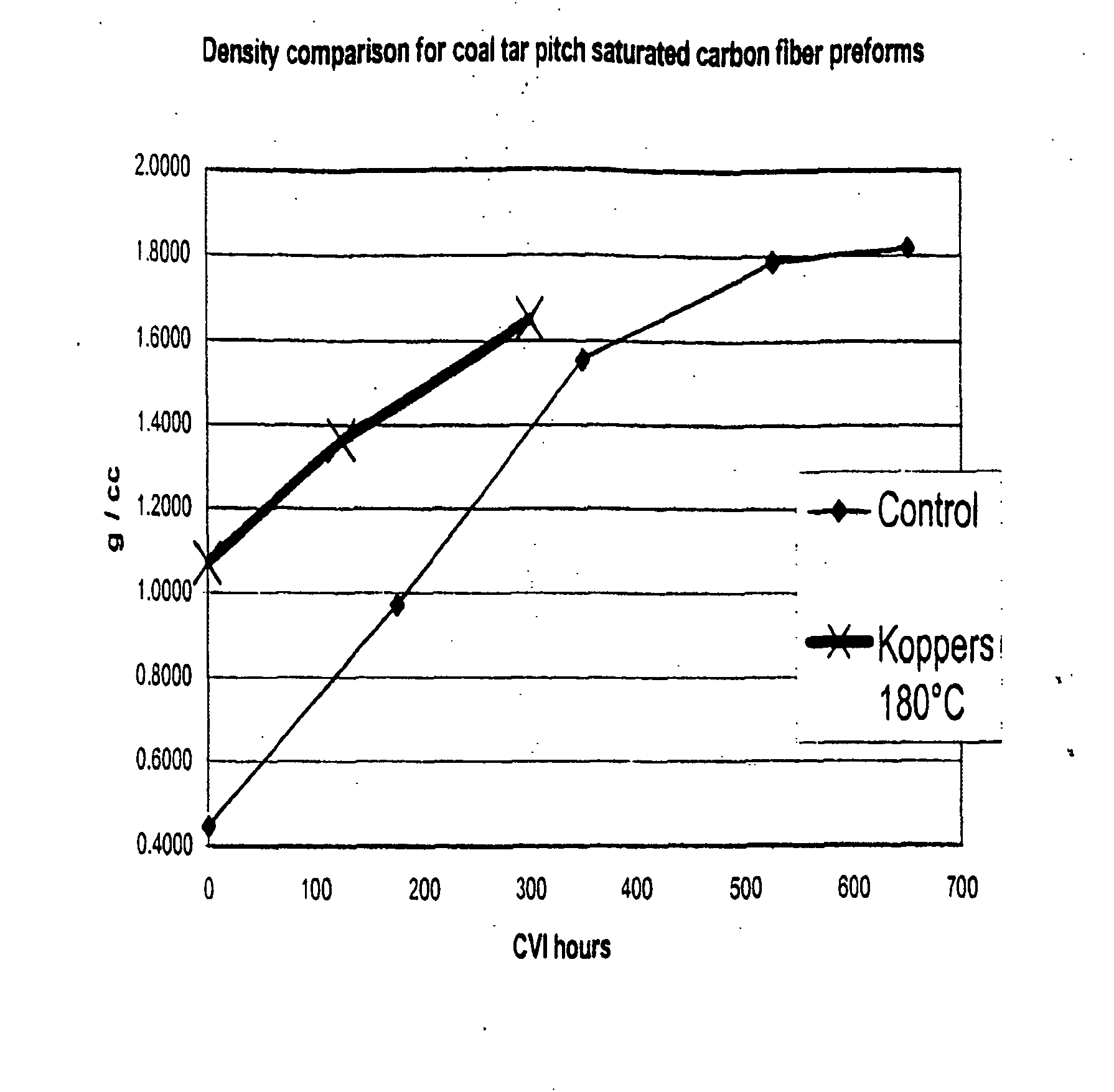

Chopped carbon fiber preform processing method using coal tar pitch binder

InactiveUS20050081752A1High densityExcellent propertyWorking-up pitch/asphalt/bitumen by distillationWorking-up pitch/asphalt/bitumen by chemical meansFiberCarbon fibers

Owner:KOPPERS DELAWARE INC

Process for separating pitch from slurry hydrocracked vacuum gas oil

InactiveUS8540870B2Easy to manageLess stickyWorking-up pitch/asphalt/bitumen by distillationWorking-up pitch/asphalt/bitumen by solidifying/disintegratingParticulatesSlurry

A process is disclosed for converting heavy hydrocarbon feed into lighter hydrocarbon products. The heavy hydrocarbon feed is slurried with a particulate solid material to form a heavy hydrocarbon slurry and hydrocracked in a slurry hydrocracking unit to produce vacuum gas oil (VGO) and pitch. A first vacuum column separates VGO from pitch, and a second vacuum column further separates VGO from pitch. As much as 15 wt-% of VGO can be recovered by the second vacuum column and recycled to the slurry hydrocracking unit. A pitch composition is obtained which can be made into particles and transported without sticking together.

Owner:UOP LLC

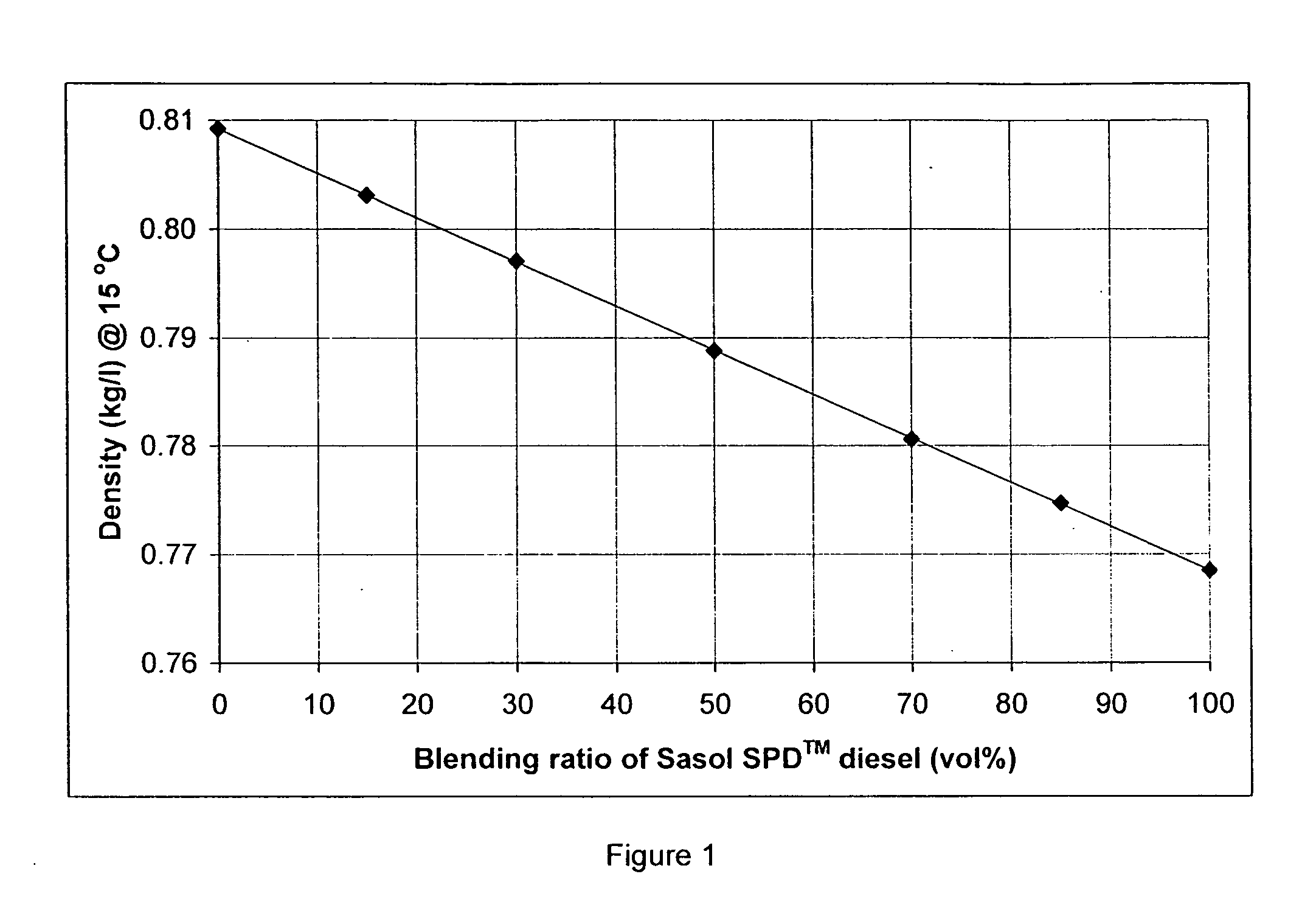

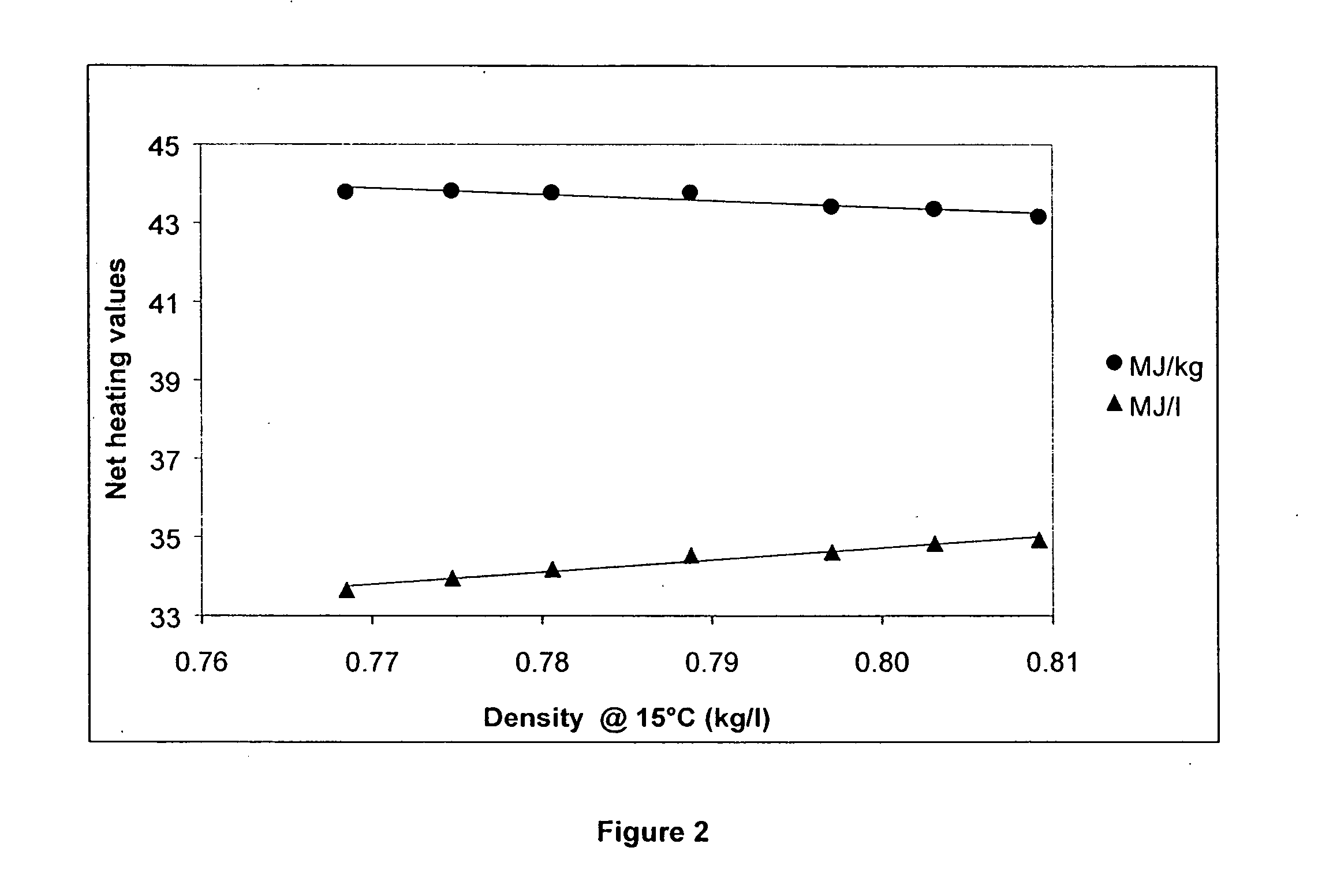

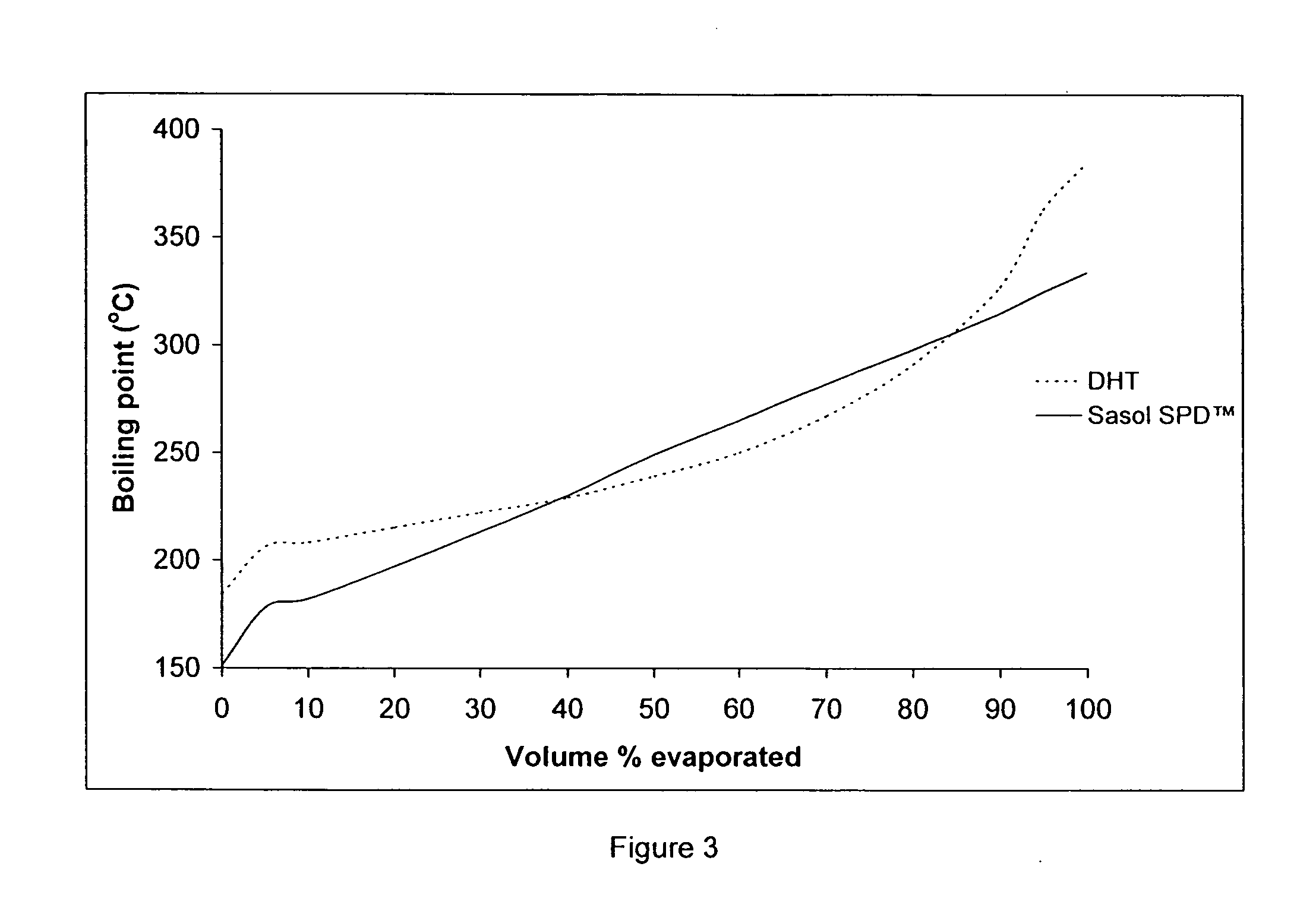

Hydrocarbon composition for use in compression-lgnition engines

The invention provides a hydrocarbon composition for use in CI engines, said composition comprising a blend of hydrocarbons derived from a LTFT and from a HTFT process, said LTFT derived hydrocarbon being blended with said HTFT derived hydrocarbon in a volumetric ratio of from 1:20 to 20:1. The invention further provides a process for the production of the hydrocarbon composition and a the fuel composition including, in addition to the hydrocarbon composition, one or more component selected from the group including a crude oil derived diesel fuel, a crude oil derived naphtha, a lubricant or light cycle oil (LCO).

Owner:SASOL TEKHNOLODZHI PROPRIEHJTEHRI LTD

Popular searches

Refining with oxygen compounds Treatment with plural serial stages only Tar working-up by chemical refining Fractional distillation Refining with metal salts Additives Angiosperms/flowering plants Hydrocarbon oils treatment Refining to eliminate hetero atoms Indirect and direct heating destructive distillation

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com