Patents

Literature

50 results about "Beta-methylnaphthalene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

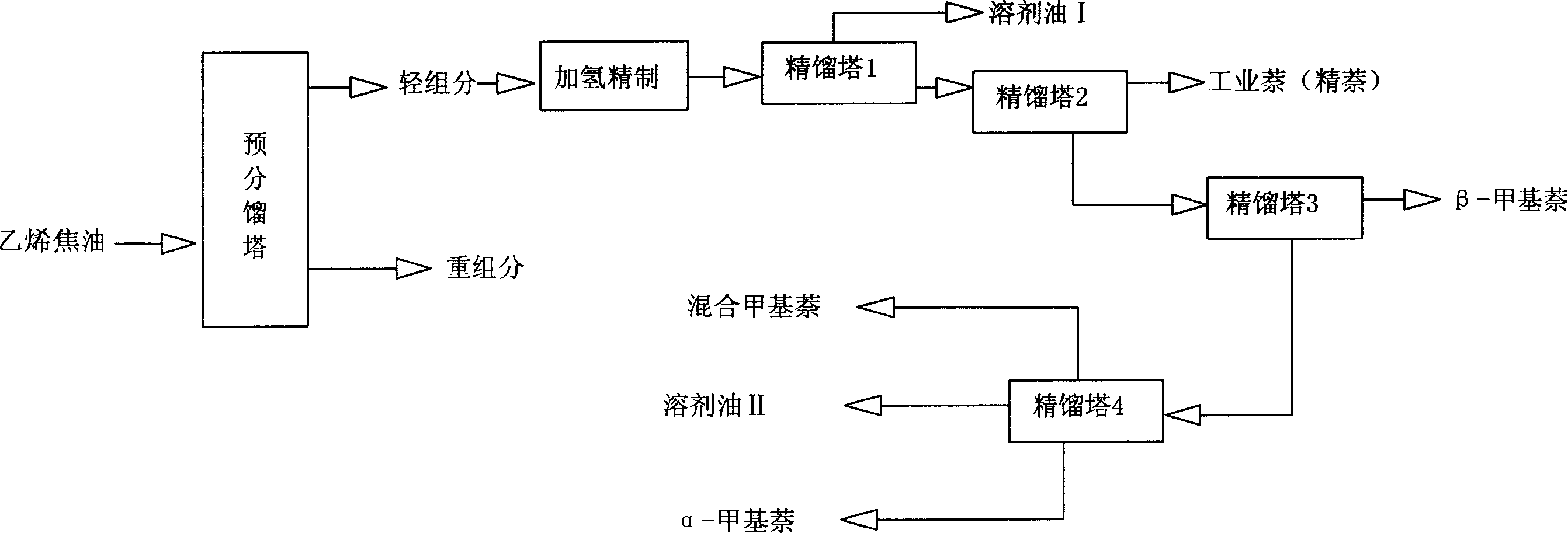

Ethylene bottom oil complex processing technology

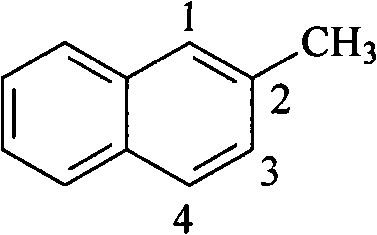

ActiveCN1970688AHigh purityEasy to operateHydrocarbon purification/separationHydrocarbonsTarBeta-methylnaphthalene

The invention discloses an extracting method of industrial refined naphthalene, alpha-methylnaphthalene, beta-methylnaphthalene from ethylene tar, which is characterized by the following: prefractionating ethylene tar under 260-280 deg.c; hydrogenating light fractionated component under 160-300 deg.c at 3.0-4.0Mpa to remove insaturated hydrocarbons; rectifying to separate refined naphthalene with crystallizing point at 79.6 deg.c; obtaining alpha-methylnaphthalene and beta-methylnaphthalene with each purity over 95%.

Owner:浙江美阳国际工程设计有限公司

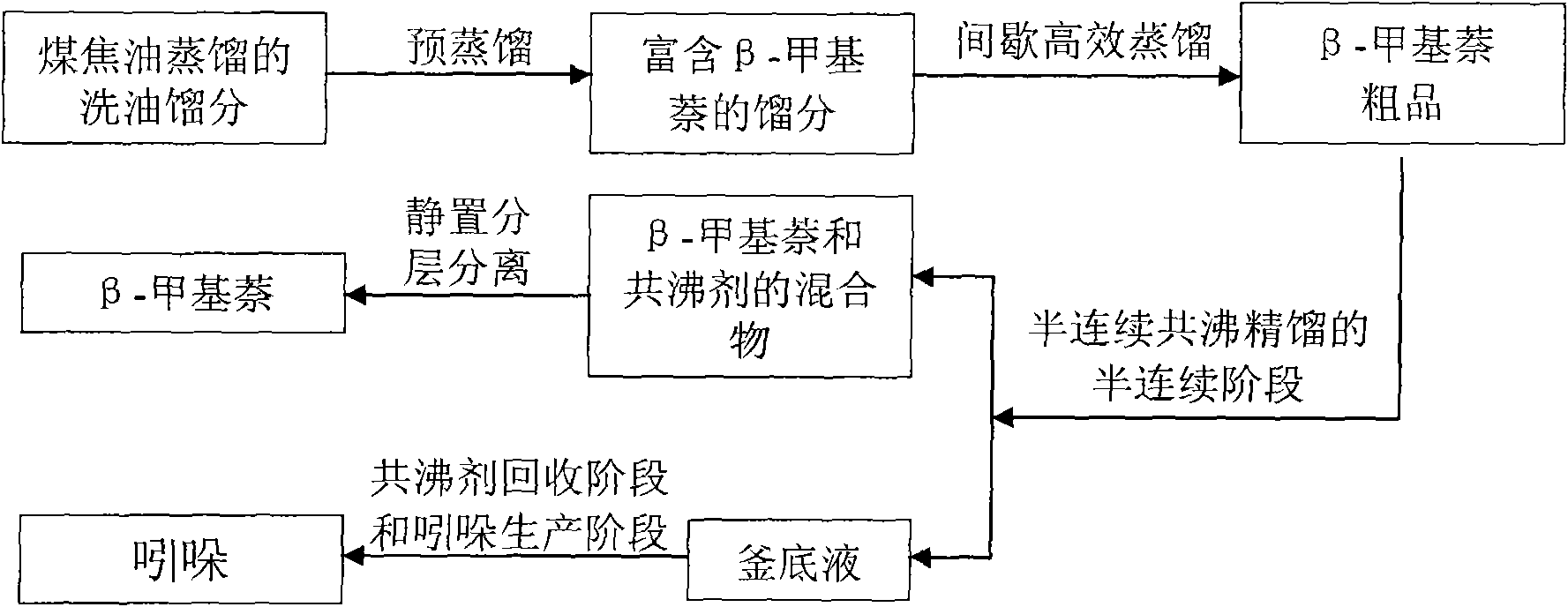

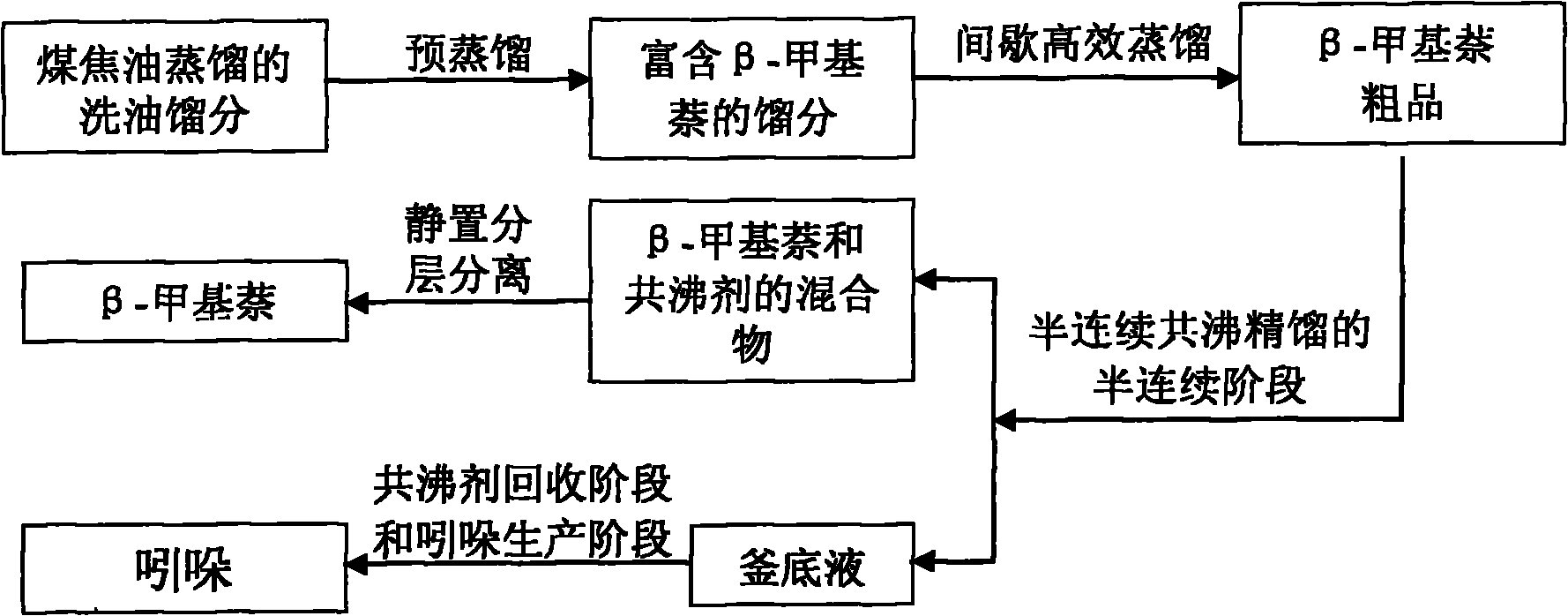

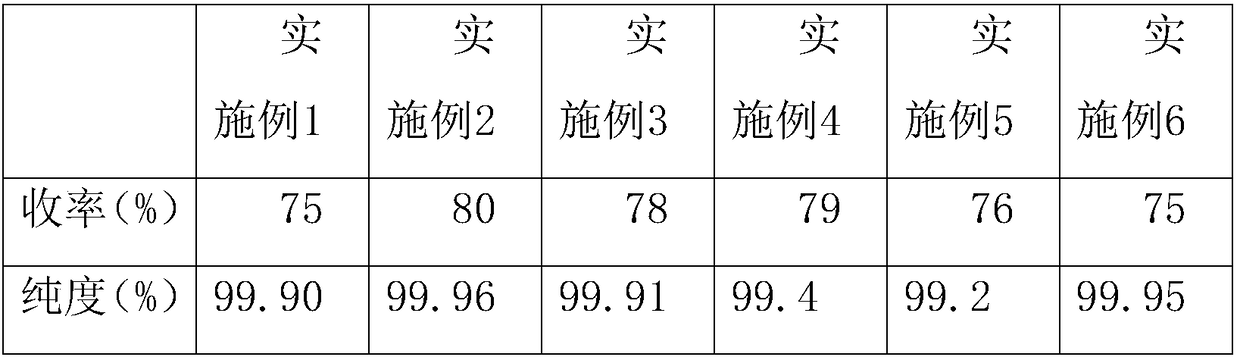

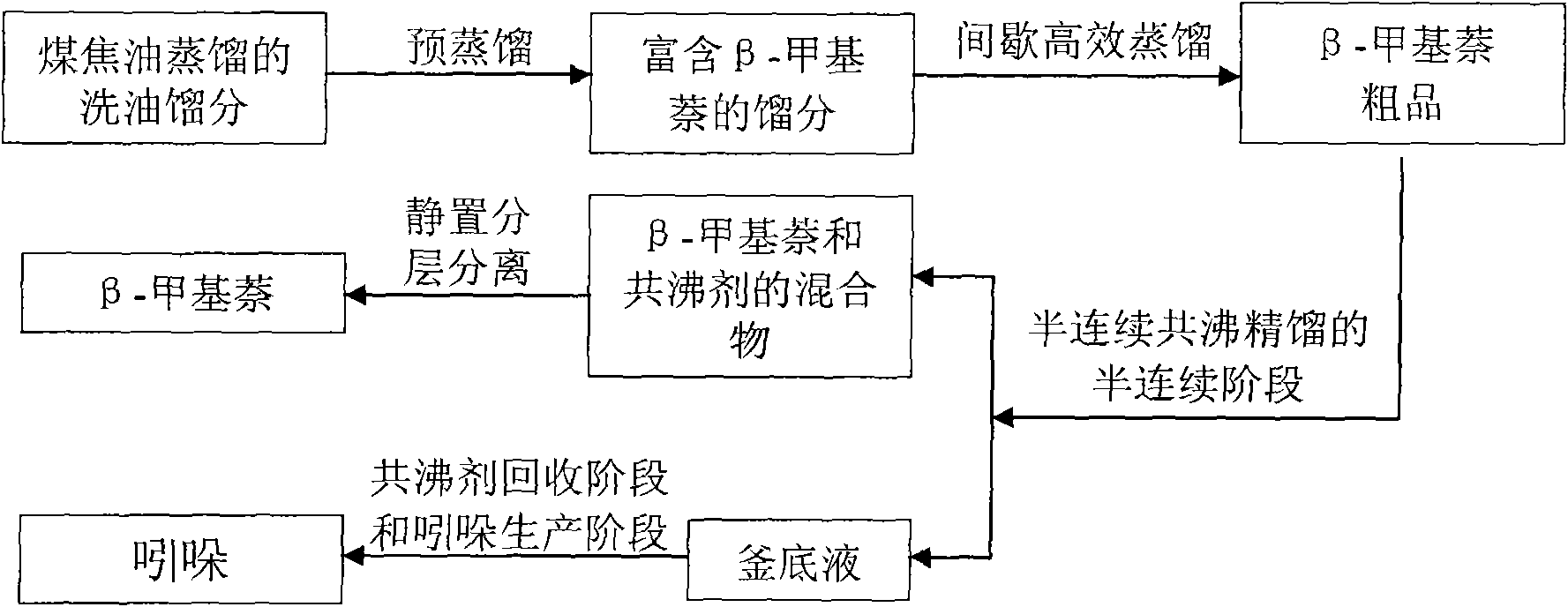

Method for simultaneously extracting high-purity beta-methylnaphthalene and indole from coal tar

ActiveCN101774879AAdaptableAbandon pollutionDistillation purification/separationBeta-methylnaphthaleneTower

The invention relates to a method for extracting high-purity beta-methylnaphthalene and indole, in particular to a method for simultaneously extracting high-purity beta-methylnaphthalene and indole from coal tar, which belongs to the field of coal fine chemistry industry. The method is realized by the following steps of: rectifying washing oil distillate distilled from coal tar in a vacuum distillation tower under vacuum, and acquiring a distillate product rich in beta-methylnaphthalene from the side of the tower; introducing the distillate product of beta-methylnaphthalene into a highly-effective intermittent rectification tower, cutting front distillates, and remixing the front distillates, the crude product of beta-methylnaphthalene, back distillates and tower bottom liquid; and then, conducting semicontinuous azeotropic distillation to the crude product of beta-methylnaphthalene, acquiring a mixture of beta-methylnaphthalene and entrainer, and settling, laying and separating the mixture to obtain beta-methylnaphthalene; after each cycle of processing technologies, continuing to distill to obtain indole. The invention solves the problems of single product, serious pollution, serious equipment corrosion and the like existing in the traditional process for refining beta-methylnaphthalene.

Owner:BAOWU CHARCOAL MATERIAL TECH CO LTD

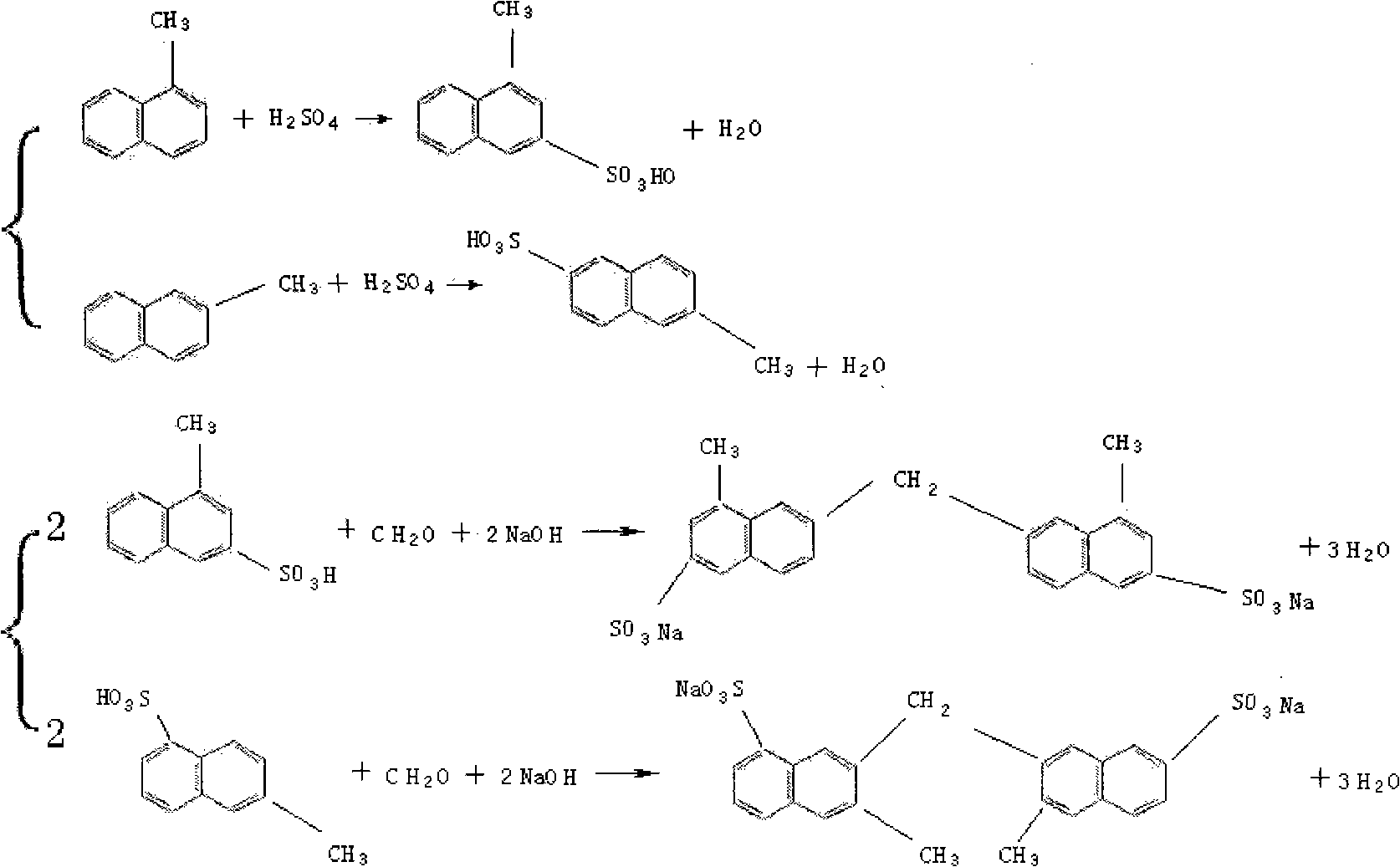

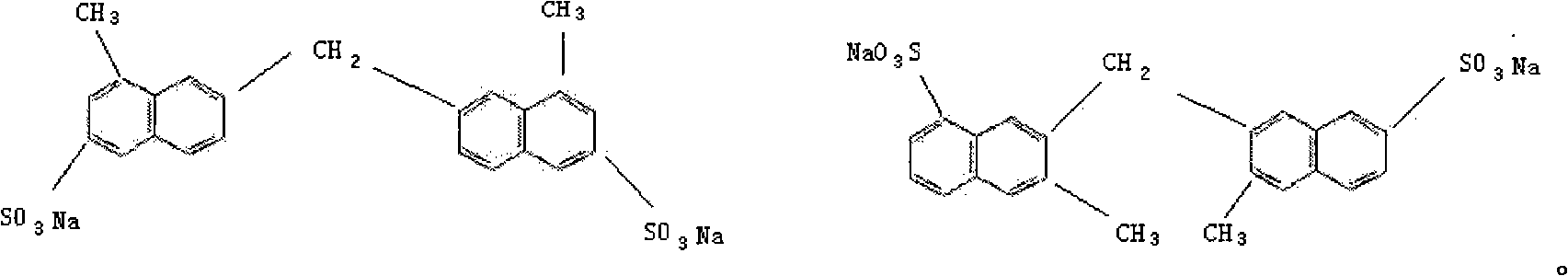

Non-quinoline dispersant MF and production process

The invention discloses a non-quinoline dispersant MF and a production process, wherein the non-quinoline dispersant MF comprises the following main components in percentage by weight: 35 percent of alpha-methylnaphthalene naphthalene sulfonate-formaldehyde condensates and 65 percent of beta-methylnaphthalene naphthalene sulfonate-formaldehyde condensates. The production process of the non-quinoline dispersant MF comprises the steps of: adding hexadecyl-carbon methylnaphthalene into a reactor, heating the reactor to be a temperature of 50 to 60 DEG C, adding inorganic acid, stirring for one hour, separating and heating the refined hexadecyl-carbon methylnaphthalene to be at the temperature of 110 DEG C, dripping sulfuric acid and rising the temperature to be 130 to 140 DEG C, and conducting sulfonation at normal pressure and heat preservation for four hours; cooling to be a temperature of 110 DEG C and then conducting hydrolyzation; dripping formaldehyde after the refined hexadecyl-carbon methylnaphthalene is cooled to be a temperature of 80 DEG C, rising the refined hexadecyl-carbon methylnaphthalene to be a temperature of 105 to 115 DEG C, and conducting condensation at normal pressure and heat preservation for three hours; and adding liquid caustic soda for neutralization, adding lime for adjusting the pH value to range from 7 to 8, conducting filter pressing, and drying, thus being packaged into finished products. The product is used for dyeing, and the clothes manufactured by the dyed cloths have no damage to a human body.

Owner:江阴市盛通化工有限公司

Method for refining beta-methylnaphthalene by melting crystallization

ActiveCN101177377AHigh purityHigh yieldCrystallisation purification/separationOperational costsBeta-methylnaphthalene

The invention relates to a method of refining Beta-methylnaphthalene by fusing crystallization, comprising the following procedures: firstly, the temperature of the crystallizer condensate is reduced to 0 to 10 DEG C, and the fusing Beta-methylnaphthalene with high purity is led into the crystallizer for about 1 to 2 minutes, then the Beta-methylnaphthalene is let out; the temperature of the crystallizer is increased to 15 to 25 DEG C, and the feed liquid at 25 to 40 DEG C is transferred into the crystallizer and the crystal layer is let to grow for 0.5 to 2.5 hours, and then the crystal layer is made to regenerate for 1.5 to 6 hours with the cooling speed of 2 to 4 DEG C per hour; the crystallizer is kept for 15 to 25 minutes with the temperature and then is warmed up with the heating rate of 2 to 5 DEG C per hour to fuse the crystal layer. When the crystallizer is warmed up to above 40 DEG C, the whole crystal layer is melted and then the Beta-methylnaphthalene with high purity can be collected. The invention has the advantages of simple technology and equipment, low operational cost, no pollution, high purity and high yield of the obtained Beta-methylnaphthalene, completely closed device, and greatly improved operation conditions of the workers.

Owner:天津天达联合工程技术有限公司

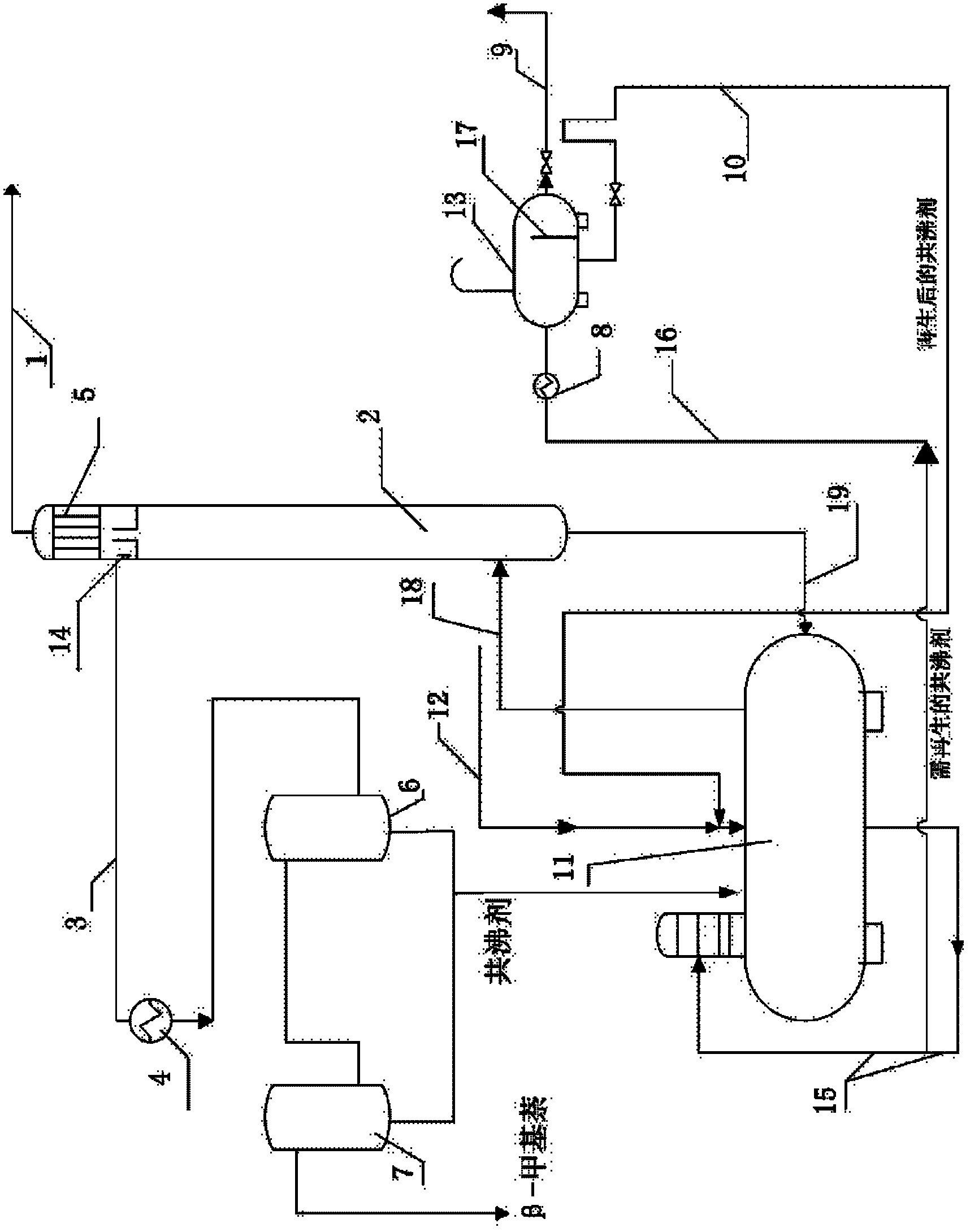

Process of producing beta-methylnaphthalene

InactiveCN1974502ALow indole contentLow indoleDistillation purification/separationTheoretical plateBeta-methylnaphthalene

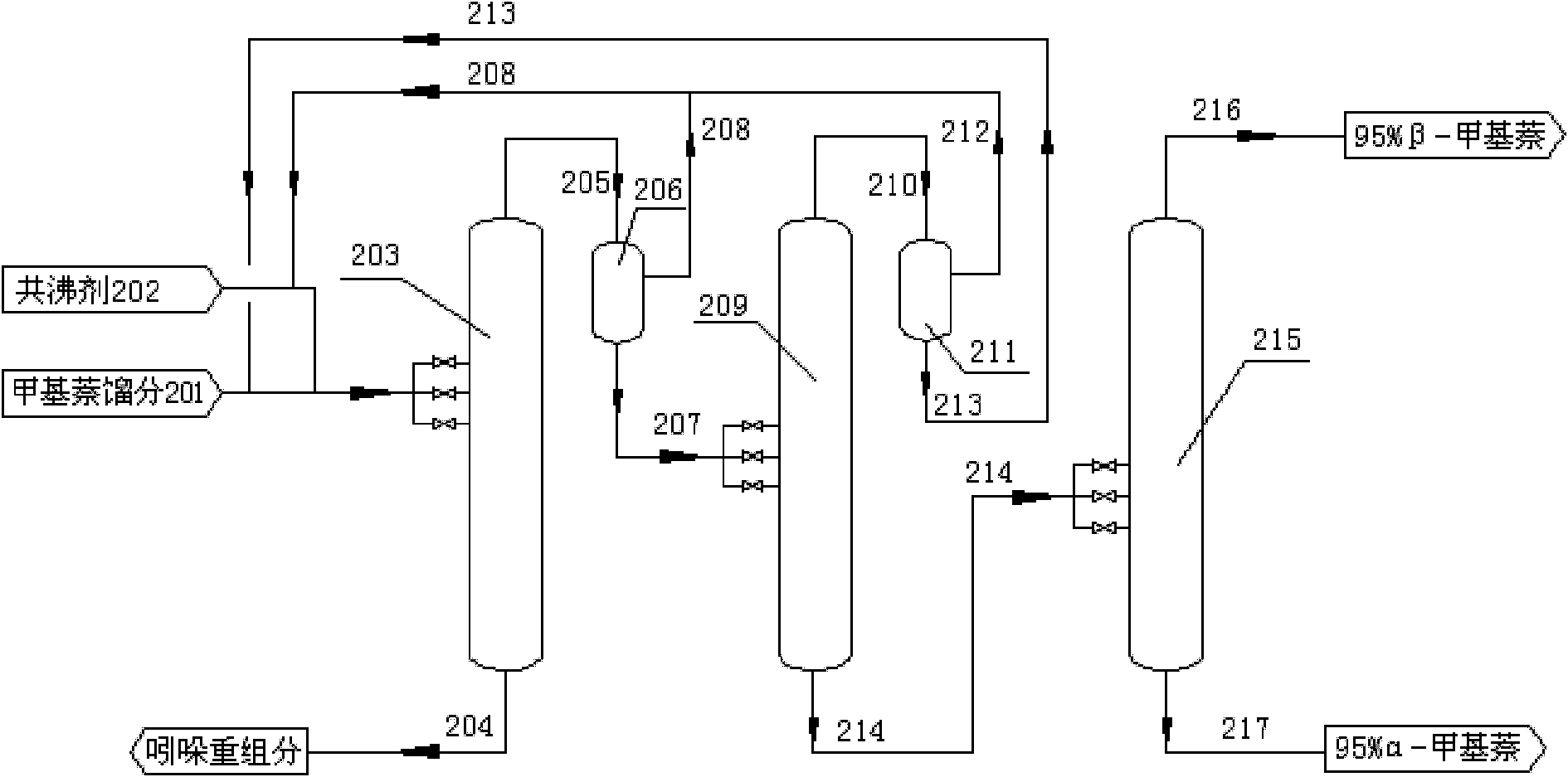

The present invention relates to coal chemical technology, and is especially process of producing beta-methylnaphthalene. The materials including industrial methylnaphthalene and azeotropic agent in the volume ratio of 1 to 0.4-0.6 are rectified through heating in an intermittent rectifying still, and the product is recovered in a rectifying tower with theoretical plate number of 50-80 to obtain fraction successively. The beta-methylnaphthalene fraction and the alpha-methylnaphthalene fraction are separated in separator to eliminate azeotropic agent and rectified to obtain beta-methylnaphthalene product and alpha-methylnaphthalene product with content over 95 %. The present invention has one increased oil-oil separator and the product has indole content lower than 0.5 %.

Owner:ANGANG STEEL CO LTD

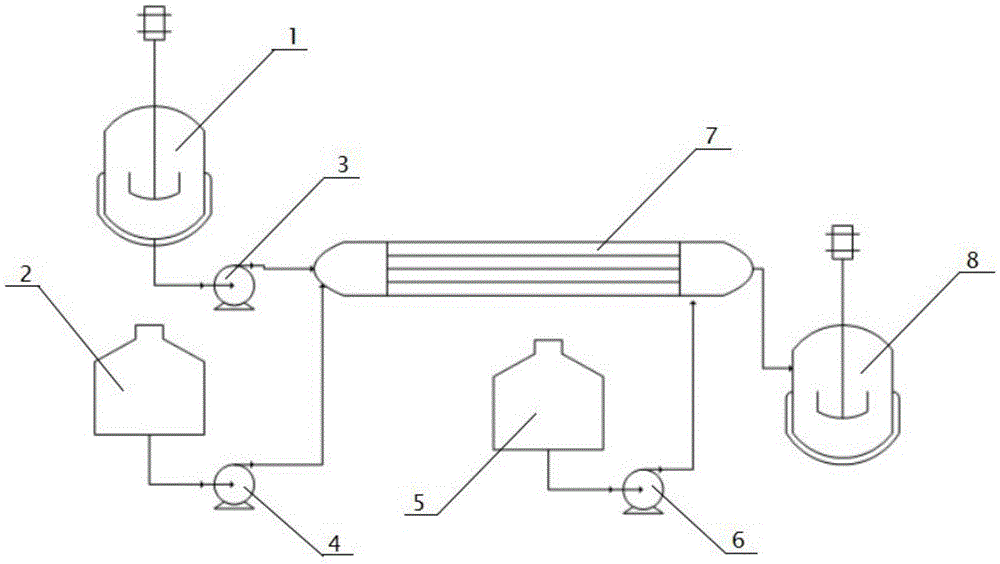

Tubular continuous method for preparing beta-menadione

ActiveCN105481673AImprove production continuityHigh yieldQuinone preparation by oxidationAutomatic controlRetention time

The invention discloses a tubular continuous method for preparing beta-menadione, which comprises the following steps: preparing a beta-methylnaphthalene emulsion, heating the beta-methylnaphthalene emulsion, metering the beta-methylnaphthalene emulsion and an oxidation solution respectively by a measuring pump, adding into a tubular reactor provided with an ultrasonic generator, and carrying out ultrasonic reaction, wherein the retention time of the reactants in the tubular reactor is 1-300 minutes; supplementing dilute sulfuric acid to the outlet of the tubular reactor, adding into a curing tank, and curing for 1-10 hours while keeping the temperature; after finishing curing, filtering, washing, carrying out centrifugal dehydration and drying to obtain the beta-menadione finished product. By using the tubular reactor to produce the beta-menadione, the method has the advantages of high production continuity and short period; and the product has the advantages of high yield, low impurity content and stable quality. The reaction process is easy to control, simple to operate and high in automatic control degree; the material performs forced flow in the tubular reactor to substitute mechanical stirring, thereby implementing industrialized continuous production; and thus, the method has the characteristics of low input cost and short reconstruction period, and can perform large-scale industrial production.

Owner:SICHUAN YINHE CHEM

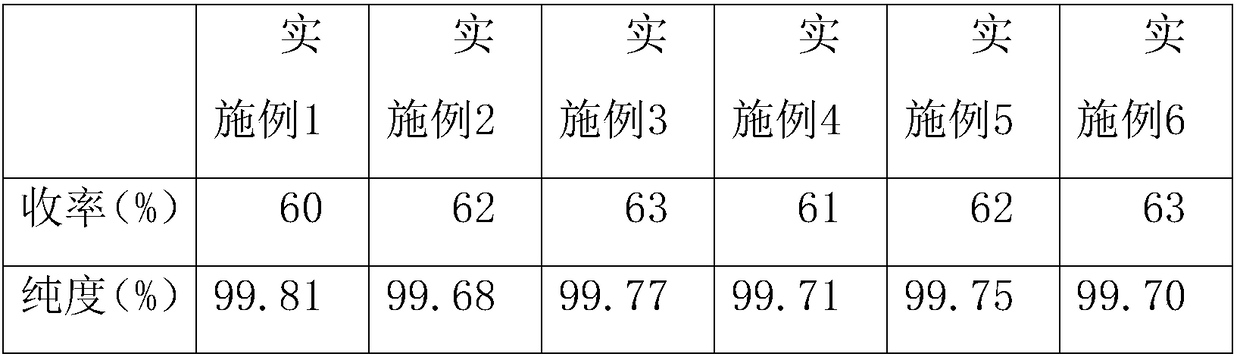

Indole producing process

The present invention relates to coal chemical technology, and is indole producing process. The residual oil from beta-methylnaphthalene and containing indole in about 30 % is used as material for producing indole through azeotropic rectification and washing crystallization. The production process includes azeotropic rectification to obtain indole fraction, water washing to eliminate azeotrope agent, re-crystallization in solvent and centrifuging to obtain indole product with content over 99 %.

Owner:ANGANG STEEL CO LTD

Indole separation and purification

InactiveCN1746159AIncrease the recrystallization refining processHigh purityOrganic chemistryBeta-methylnaphthaleneMedicinal chemistry

A separation and purification of indole is carried out by rectifying industrial methylnaphthalene or washing oil dequinazine at 6-30Kpa and 25-45 block column plate, extracting beta-methylnaphthalene, taking residue as indole cuts containing indole 10-20% and methylnaphthalene 70-80%, extracting and separating for indole cuts containing indole 10-20% from extractant, obtaining first indole extract, taking the indole extract as raw material, rectification purifying at 6-30Kpa, 25-45 block column plate and reflux ratio=4-20, and obtaining indole product with purity>99.0%. It costs low and has high recovery rate.

Owner:BAOWU CHARCOAL MATERIAL TECH CO LTD

Method for preparing mixed methylnaphthalene by using C+10 heavy aromatic hydrocarbon as raw material

ActiveCN101250078AConvenient sourceReduce process stepsDistillation purification/separationBeta-methylnaphthaleneSolvent

A method for preparing mixed methylnaphthalene from C10 heavy Aromatic Hydrocarbon material belongs to the preparation technical field of alpha and beta-methylnaphthalene, which comprises leading C10 heavy Aromatic Hydrocarbon material from the inlet of a first distillation column into the first distillation column at normal temperature to be distilled, controlling the top temperature, pressure, reflux ratio and bottom heating temperature of the first distillation column, exchanging the heat and condensing the light fraction at the top of the first distillation column, feeding the condensate into a first column top reflux tank, leading out the top distillate of the first distillation column as solvent, leading out liquid naphthalene at the side pipeline of the first distillation column, leading the heavy fraction at the bottom of the first distillation column into a second distillation column to be distilled further, controlling the top temperature, pressure and reflux ratio and bottom heating temperature of the second distillation column, exchanging the heat and condensing the light fraction of the second distillation column, feeding the condensate into a seond column top reflux tank to obtain the final product of mixed methylnaphthalene, and leading out the heavy fraction at the bottom of the second distillation column from the bottom of the second distillation column. The invention has simple process, simple operation, low cost and non generation of three wastes in whole preparation.

Owner:常熟华虞环境科技有限公司

Cotton topping agent and preparation method thereof

InactiveCN110199997AEffectively control prosperityControl prosperityPlant growth regulatorsBiocidePaichongdingSulfonate

The present invention provides a cotton topping agent, which comprises, by weight, 0.8-2 parts of paichongding, 0.8-2 parts of hydroxypropylmethylcellulose, 3-6 parts of beta-methylnaphthalene, 5-10 parts of fosamine-ammonium, 10-15 parts of isonicotinic acid, 10-15 parts of iodophenoxyacetic acid, 15-20 parts of p-chlorotoluene, and 15-20 parts of sodium disec-octyl maleate sulfonate. According to the present invention, the cotton topping agent is organically dissolved, such that the cotton top can be killed, the cotton length can be effectively controlled, the ideal plant type can be shaped,the flower and the bud can be retained, the photosynthesis of cotton can be enhanced, the cotton boll can be increased, the diseases can be prevented and controlled, the boll opening early maturity can be achieved in advance by more than seven days, the micronaire value of cotton is not affected, and the purposes of high yield and stable production are achieved.

Owner:高俊毅

Method for preparing beta-methyl naphthoquinone through catalytic oxidation of beta-methylnaphthalene by MCM-41 molecular sieve with iron-containing framework

InactiveCN102249886AImprove conversion rateShort reaction timeQuinone preparation by oxidationCatalytic oxidationNaphthoquinone

The invention relates to a method for preparing beta-methyl naphthoquinone through catalytic oxidation of beta-methylnaphthalene by an MCM-41 molecular sieve with an iron-containing framework. Specifically, an MCM-41 molecular sieve with an iron-containing framework is employed as a catalyst to oxidize beta-methylnaphthalene for preparing beta-methyl naphthoquinone, with a beta-methylnaphthalene conversion rate of 65% and a beta-methyl naphthoquinone selectivity of 37%. The method of the invention can substantially improve the conversion rate in beta-methyl naphthoquinone production through beta-methylnaphthalene oxidation, and greatly shorten the reaction time. Wherein, the catalyst is repeatedly usable.

Owner:NANJING UNIV +1

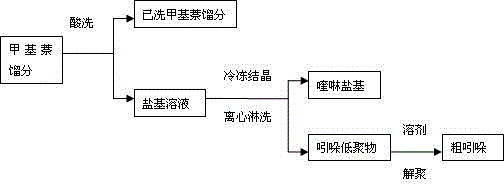

Method for extracting indole from methyl naphthalene fraction

The invention relates to a method for extracting indole from a methyl naphthalene fraction. The method comprises the following steps: with the methyl naphthalene fraction in coal tar washing oil as a raw material, adding 50%-60% sulfuric acid solution, heating, reacting, and standing and layering, so as to obtain a quinolinium-based solution dissolved with an indole oligomer; freezing, crystallizing, and centrifugally separating to obtain an indole oligomer salt of earthy yellow particles; washing with diluted alkali; and adding a solvent, heating and depolymerizing to obtain crude indole of which the content is greater than 90% and the yield is 90%. The method aims at extraction of the indole from the methyl naphthalene fraction; meanwhile, production of quinoline and beta-methylnaphthalene are taken into account; and the method has the advantages of being short in flow, simple to operate, good in product quality, high in yield and small in environmental burden.

Owner:LIAONING INST OF SCI & TECH

Separation purification process for 2-methylnaphthalene

InactiveCN101293808AMeet production needsReduce energy consumptionCrystallisation purification/separationBeta-methylnaphthaleneEnergy consumption

The invention relates to a method for separating and purifying 2-methylnaphthalene (Beta-methylnaphthalene). The method comprises the main steps: 70 wt% of 2-methylnaphthalene fraction is used as original material, and is subjected to fused crystallization at 34 DEG C to -15 DEG C for at least four times to obtain a target product. The method has the advantages of easily-accessible material, simple operation, low energy consumption, environment friendliness, etc.

Owner:EAST CHINA UNIV OF SCI & TECH +1

Method for preparing 2-methyl-1,4-naphthoquinone through microwave radiation

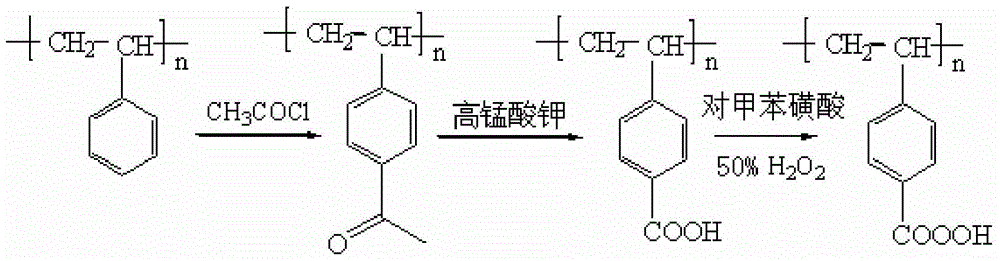

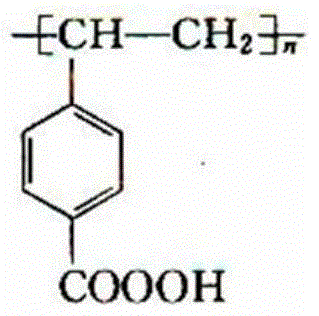

InactiveCN105669413AHigh activityHeating evenlyQuinone preparation by oxidationPolystyrenePeroxy acid

The invention relates to a method for preparing 2-methyl-1,4-naphthoquinone through microwave radiation. The 2-methyl-1,4-naphthoquinone is prepared from beta-methylnaphthalene in a solvent acetate acid gracial under the action of microwave radiation with a polystyrene type polymeric peroxy acid as an oxidant, and the yield reaches 65.0% or above. Microwave radiation heating is adopted, so the reaction time is obviously shortened, and the product yield is improved; and the polymeric peroxy acid oxidant is adopted, so the method has the advantages of high product yield, convenient post-treatment , avoiding of heavy metal pollution of chromium salt oxidants, environmental protection, and important application values.

Owner:LIAOCHENG UNIV

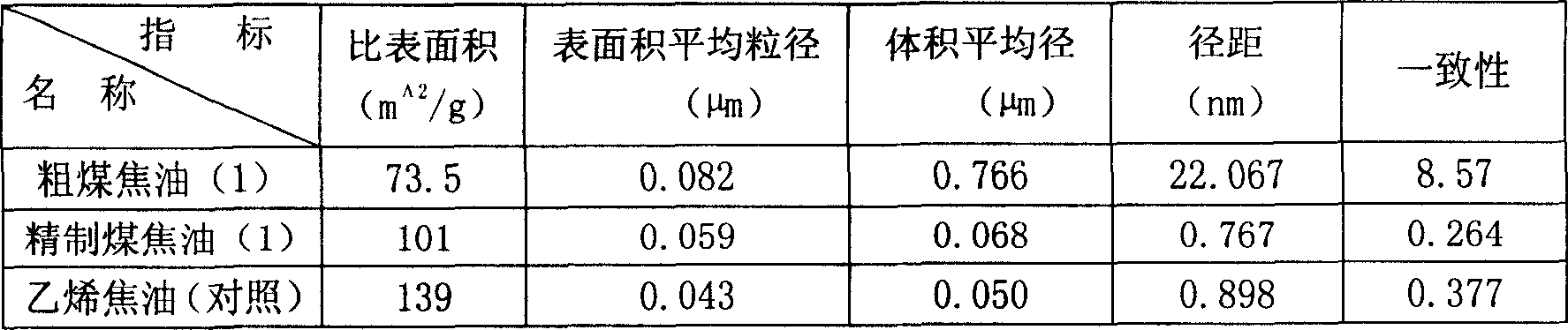

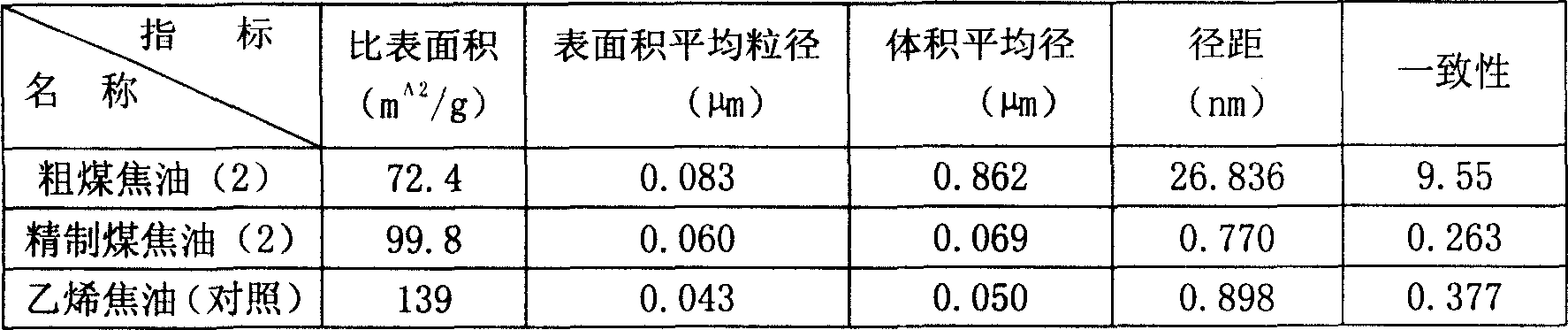

Process for purifying feedstocks of carbon black

The invention discloses a process for purifying feedstocks of carbon black which mainly comprises, charging forward dissolvent comprising benzene, toluene and alpha-methylnaphthalene or beta-methylnaphthalene into crude coal tar, wherein the weight ratio of the crude coal tar and the forward dissolvent is 1:0.1-3, after 0.5-1 hour, charging backward dissolvent comprising aminoethyl alcohol, propanone, alcohol isopropylicum and phenylethene into the miscible liquid of the crude coal tar and the forward dissolvent, wherein the weight ratio of the crude coal tar and the backward dissolvent is 1:0.05-0.5, at the temperature of 10-60 deg. C, pressure 0.1-0.1Mpa, sustaining 0.5-2 hours, carrying out solid-liquid separation to obtain the refined coal tar.

Owner:EAST CHINA UNIV OF SCI & TECH +1

Purifying process of beta-methylnaphthalene

InactiveCN101898932ABest wayReduce dosageHydrocarbon purification/separationHydrocarbonsWastewaterBeta-methylnaphthalene

The invention relates to a purifying process, in particular to the purifying process of beta-methylnaphthalene, which adopts the way of adding alkali for regulation, thereby changing the viscosity of indole, leading the indole to be capable of being reacted with acid solution for removing an indole impurity in a finished product of the beta-methylnaphthalene, further improving the product purity of the beta-methylnaphthalene and leading the beta-methylnaphthalene to be in line with the requirements in industrial production; simultaneously, the adoption of the process can greatly reduce the amount of waste water in acid oil in the finally obtained wastes, thereby not only achieving the requirements on environmental protection, but also saving the wastewater treatment cost of enterprises and reducing the production cost.

Owner:莱芜雅鲁生化有限公司

Method for preparing 2-methyl-6-tert-butylnaphthalene from 2-methylnaphthalene through alkylation

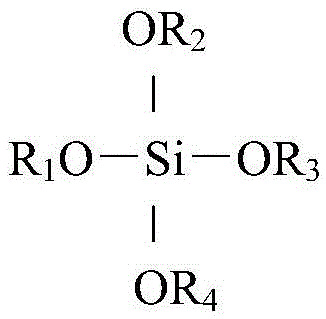

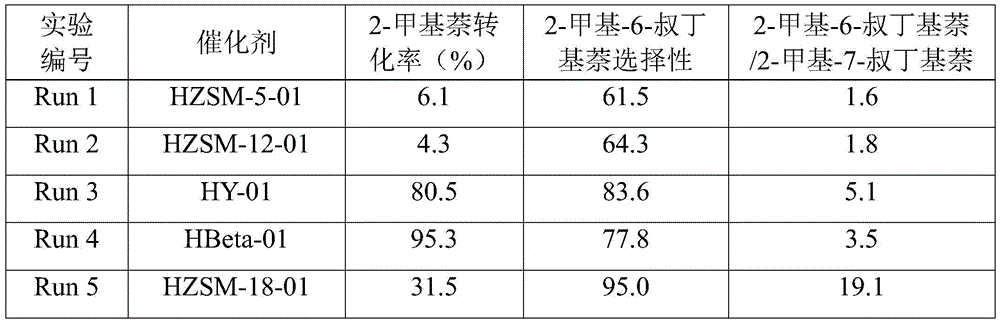

ActiveCN105601459AEasy to purifyReduce lossesHydrocarbon by hydrocarbon and non-hydrocarbon condensationMolecular sieveAlkyl transfer

The invention provides a method for preparing 2-methyl-6-tert-butylnaphthalene from 2-methylnaphthalene through alkylation, belonging to the field of chemistry and chemical engineering. The method uses 2-methylnaphthalene (beta-methylnaphthalene) as a raw material and highly selectively prepares 2-methyl-6-tert-butylnaphthalene by subjecting 2-methylnaphthalene (beta-methylnaphthalene) and tert-butyl alcohol or isobutene to alkylation. A siloxane-based compound modified molecular sieve catalyst is used for catalyzing a reaction of 2-methylnaphthalene with tert-butyl alcohol or isobutene to prepare 2-methyl-6-tert-butylnaphthalene, and the selectivity of 2-methyl-6-tert-butylnaphthalene in products and a ratio of 2-methyl-6-tert-butylnaphthalene to 2-methyl-7-tert-butylnaphthalene can be effectively increased. The method is simple to operate and low in cost and has potential application value.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Preparation method of beta-methylnaphthalene

InactiveCN101250083AReduce pollutionEasy to prepareDistillation purification/separationCrystallisation purification/separationBeta-methylnaphthaleneChemistry

The invention relates to a preparation method of beta-methylnaphthalene, which uses oil level mixed methylnaphthalene containing 50-70% of beta-methylnaphthalene as raw material, depressurizes and distills to obtain beta-methylnaphthalene product containing at least 80% of beta-methylnaphthalene, freezing and centrigually treating the beta-methylnaphthalene to obtain the beta-methylnaphthalene product. The preparation method can obtain the beta-methylnaphthalene whose purity is higher than 97%, with simple operation, low production cost and little environment pollution.

Owner:苏州市锋齐高新技术有限公司

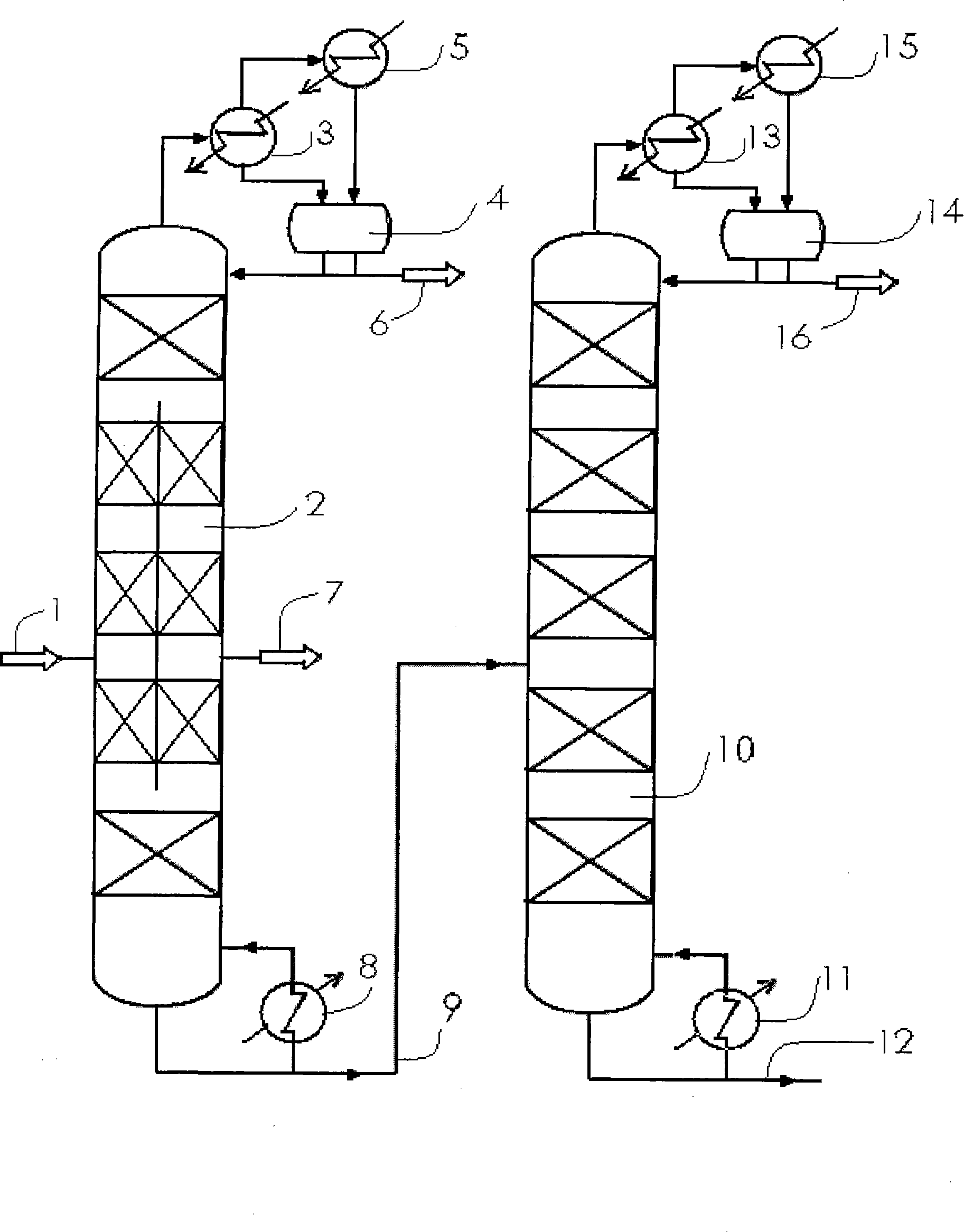

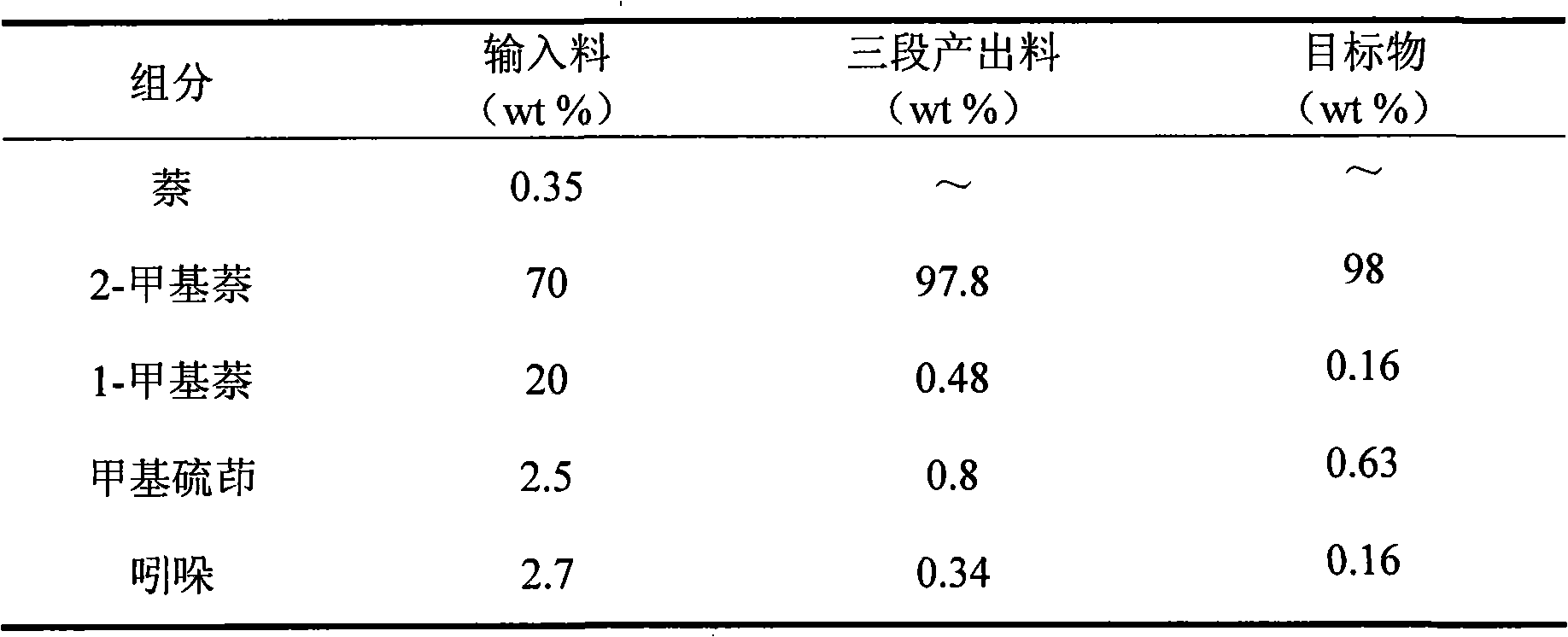

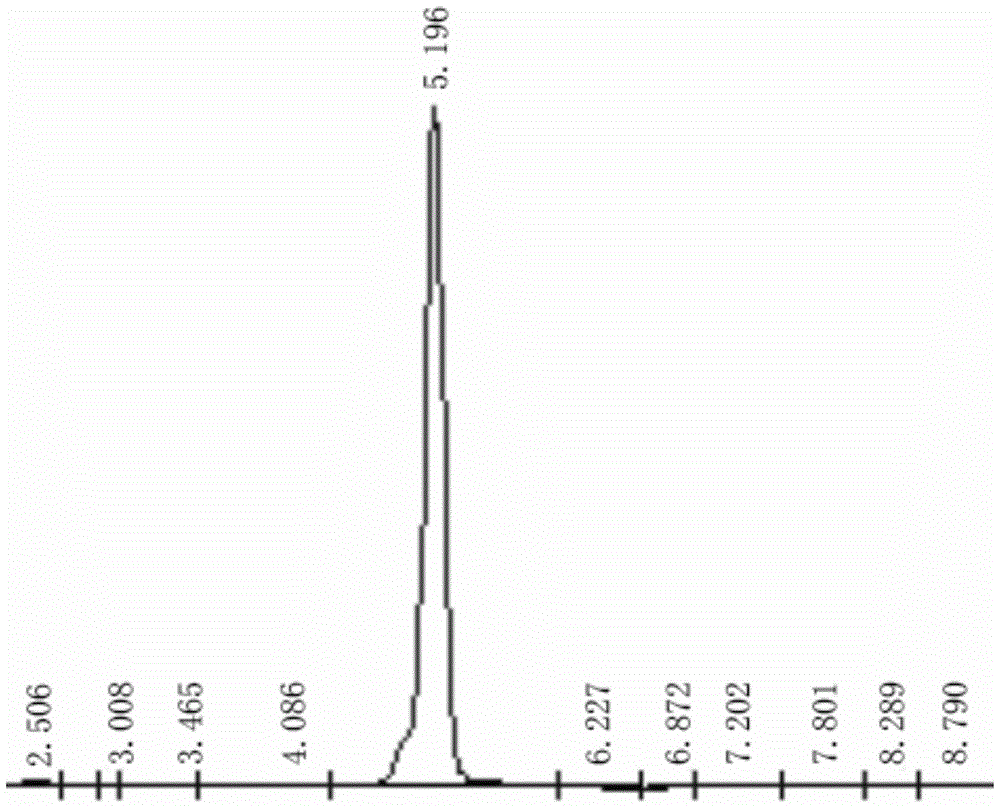

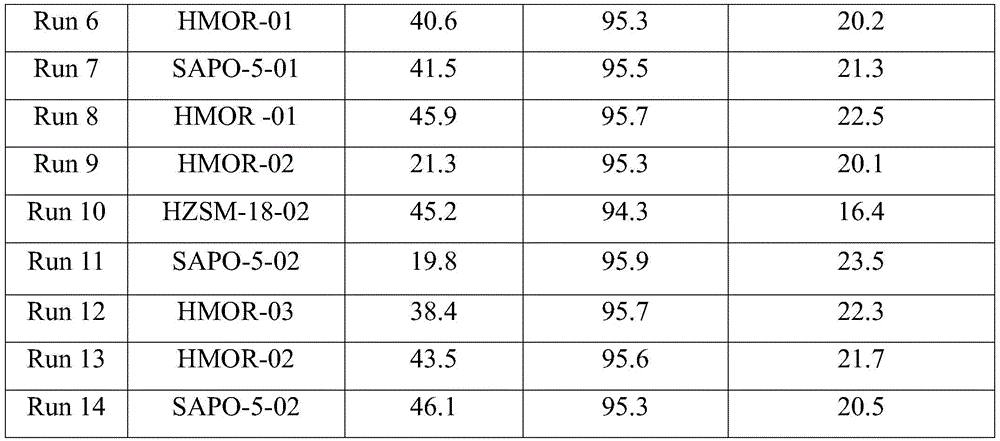

Method for producing beta-methylnaphthalene by using coal tar washing oil for continuously distilling

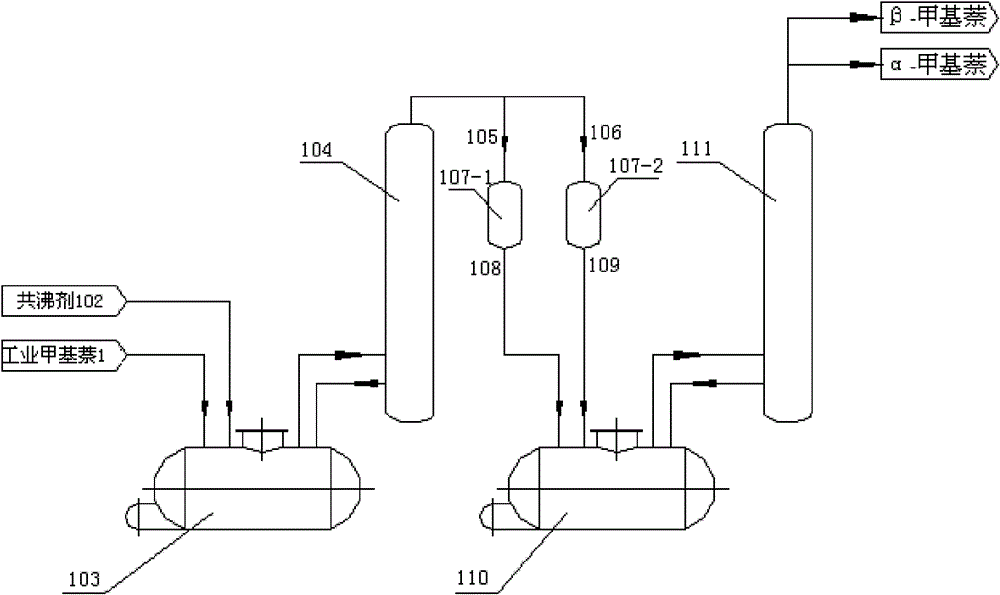

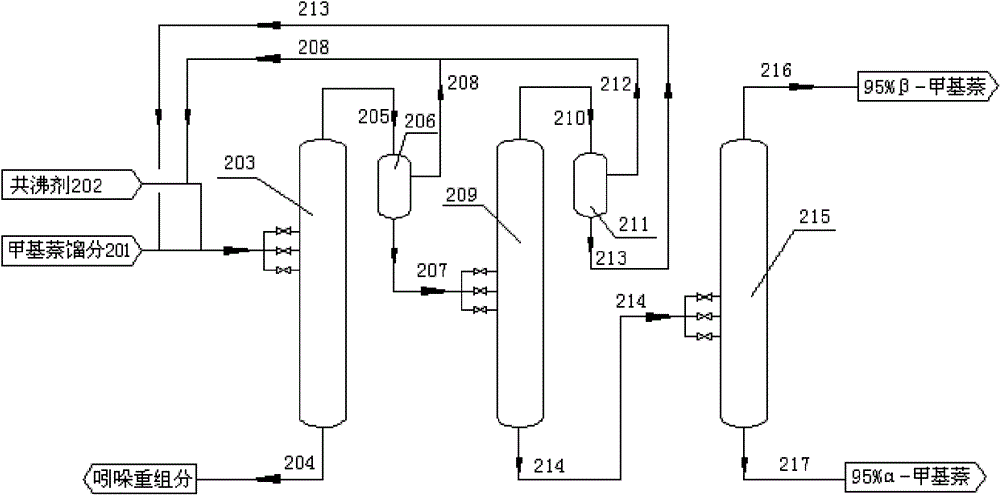

ActiveCN103212214AHigh yieldIncrease the level of automationDistillation purification/separationFractional distillationEngineeringTower

The invention relates to a method for producing beta-methylnaphthalene by using coal tar washing oil for continuously distilling, the method employs three towers continuous distillation, an industrial beta-methylnaphthalene product containing greater than or equal to 95% of beta-methylnaphthalene and less than or equal to 0.2% of indole can be cut at tower top or side line after the rectification treatment is carried out at a rectifying tower finally, an alpha-methylnaphthalene ingredient or industrial alpha-methylnaphthalene can be cut at the bottom of the tower; and an azeotropic solvent and methylnaphthalene can be reused after being separated. The yield of beta-methylnaphthalene is greater than or equal to 90%, the alpha-methylnaphthalene with yield greater than or equal to 90% can be collected; an azeotropic distillation tower and an intermediate rectifying tower can employ a mode of a single tower or multiple towers connected in series. Compared with the prior art, the method for producing beta-methylnaphthalene by using coal tar washing oil for continuously distilling has the advantages of simple production technology, high yield of industrial beta-methylnaphthalene, low power consumption, high labor productivity and good environmental protection effect. The continuous rectification technology has high automation level, and is easy to being controlled and adjusted, and is more suitable for processing the large-scale coal tar washing oil.

Owner:鞍钢集团工程技术有限公司

A kind of method of producing β-methylnaphthalene by continuous distillation of coal tar washing oil

ActiveCN103212214BHigh yieldIncrease the level of automationDistillation purification/separationFractional distillationEngineeringOil production

The invention relates to a method for producing beta-methylnaphthalene by using coal tar washing oil for continuously distilling, the method employs three towers continuous distillation, an industrial beta-methylnaphthalene product containing greater than or equal to 95% of beta-methylnaphthalene and less than or equal to 0.2% of indole can be cut at tower top or side line after the rectification treatment is carried out at a rectifying tower finally, an alpha-methylnaphthalene ingredient or industrial alpha-methylnaphthalene can be cut at the bottom of the tower; and an azeotropic solvent and methylnaphthalene can be reused after being separated. The yield of beta-methylnaphthalene is greater than or equal to 90%, the alpha-methylnaphthalene with yield greater than or equal to 90% can be collected; an azeotropic distillation tower and an intermediate rectifying tower can employ a mode of a single tower or multiple towers connected in series. Compared with the prior art, the method for producing beta-methylnaphthalene by using coal tar washing oil for continuously distilling has the advantages of simple production technology, high yield of industrial beta-methylnaphthalene, low power consumption, high labor productivity and good environmental protection effect. The continuous rectification technology has high automation level, and is easy to being controlled and adjusted, and is more suitable for processing the large-scale coal tar washing oil.

Owner:鞍钢集团工程技术有限公司

Method for alkyl transfer of beta-methylnaphthalene to prepare 2,6-dimethylnaphthalene

InactiveCN1762932AInhibit carbon depositionExtend your lifeHydrocarbonsBulk chemical productionAlkyl transferReaction temperature

The present invention relates to preparation of 2, 6-dimethyl naphthalene, and is especially beta-methyl naphthalene transalkylating process of preparing 2, 6-dimethyl naphthalene. The beta-methyl naphthalene transalkylating process of preparing 2, 6-dimethyl naphthalene includes compounding mixture with beta-methyl naphthalene, transalkylating agent and solvent in the molar ratio of 1 to 1-2 to 0.5-8; and transalkylating reaction in catalyst bed layer at reaction temperature 350-550 deg.c, supercritical reaction pressure 3.1-12.0 MPa and space velocity 0.1-3 / hr to synthesize 2, 6-dimethyl naphthalene. The preparation process of the present invention has short production period, long catalyst service life and low production cost.

Owner:HEILONGJIANG UNIV

Preparing method for beta-menadione

ActiveCN109265333ANo peroxidationThe production process is economical and environmentally friendlyQuinone preparation by oxidationBulk chemical productionElectrolysisOrganic solvent

The invention discloses a preparing method for beta-menadione. The preparing method includes the following steps that 1, ceric sulfate is dissolved in a sulfuric acid solution, a ceric sulfate solution is obtained, the beta-methylnaphthalene is dissolved in an organic solvent, and a beta-methylnaphthalene organic solution is obtained; 2, the ceric sulfate solution and the beta-methylnaphthalene organic solution are simultaneously added into a reaction kettle, the mixture is stirred and reacted at the constant temperature, the reaction is ended, cooling crystallization is carried out, and the finished-product beta-menadione is obtained through filtering; 3, the filtered cerous sulfate solution in a liquid phase is separated from the organic solvent, the organic solution is distilled and recycled to be reused, and the cerous sulfate solution is subjected to electrolytic oxidation through a diaphragm to be reused. Chromium oxidation is thoroughly replaced with the preparing method for thebeta-menadione, hexavalent chromium does not exist in the product, the beta-methylnaphthalene is dissolved in an organic phase and reacted, the contact area of the material is larger, the reaction rate is higher, peroxidation of the beta-menadione can be avoided, and the product purity is high.

Owner:SICHUAN YINHE CHEM

Method and device for removing indole from beta-methylnaphthalene

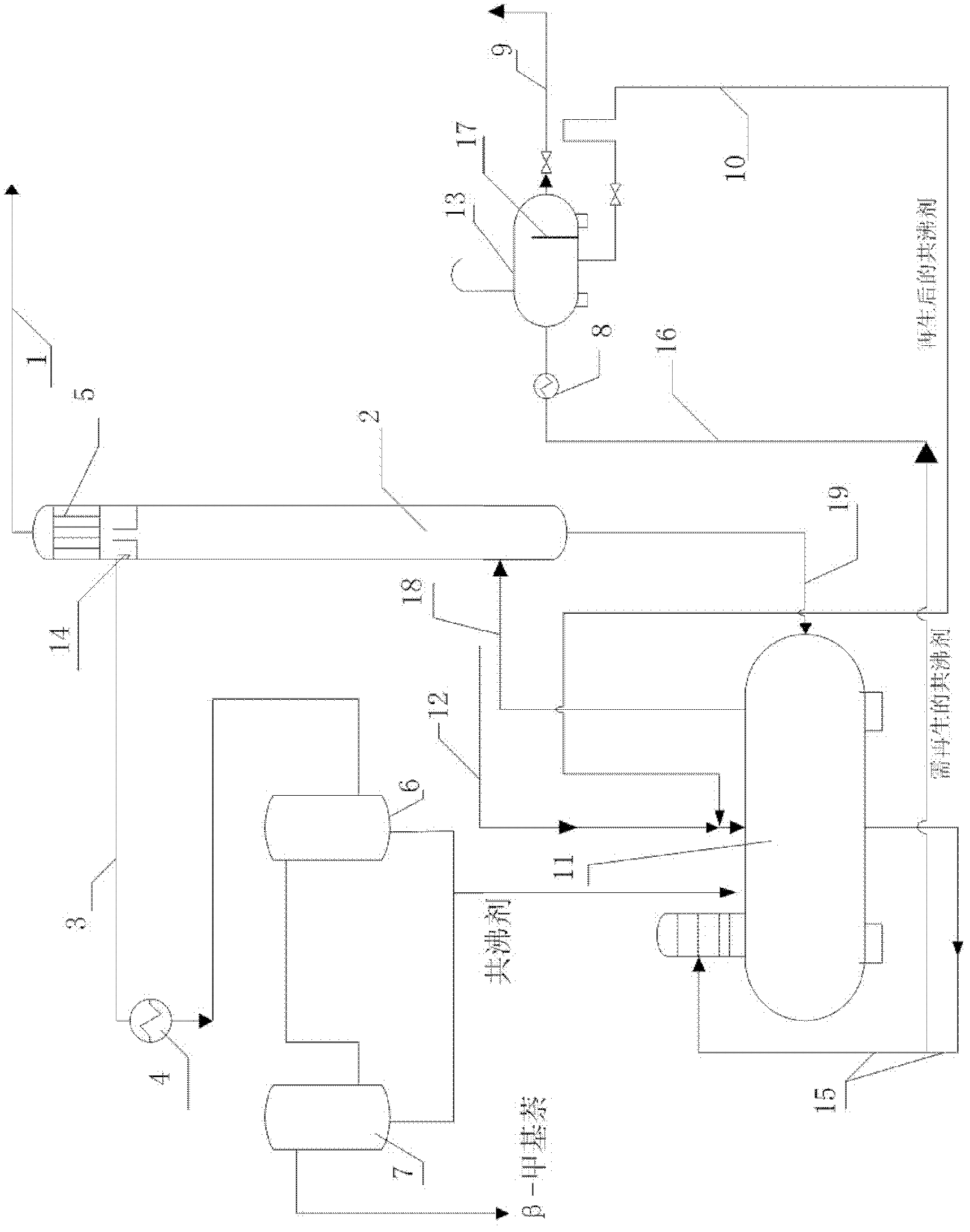

ActiveCN102935292BImprove difficult situationsMeet export demandDistillation purification/separationDistillation separationChemical industryReflux

Relating to the field of chemical industry, the invention discloses a method and a device for removing indole from beta-methylnaphthalene. Structurally, the device comprises a distillation kettle and azeotropic distillation tower. An overflow recovery baffle is disposed at a tower top recovery outlet of the azeotropic distillation tower. A tower top recovery pipeline is connected to a cooler, a separation tank A and a separation tank B in order. The method includes: adding a mixture of the raw material beta-methylnaphthalene and an azeotropic agent into the distillation kettle, controlling the temperature of the kettle bottom at 145-147DEG C; maintaining the azeotropic distillation tower at a pressure of -70-90kpa and the tower top at a temperature of 140-142DEG C; carrying out intermittent azeotropic distillation separation, subjecting the evaporated liquid to cooling by the tower top cooler and internal reflux; and subjecting the azeotropic distillation tower top recovered liquid to cooling by the cooler, then leaving the liquid to flow into the separation tank A and the separation tank B in order, performing standing layering, and recovering the product. By means of the method and the device, after distillation separation, the content of the raw material beta-methylnaphthalene can be increased to over 98%, and the indole content decreased to an undetectable degree. The device and the method provided in the invention are simple and are easy to operate.

Owner:BAOWU CHARCOAL MATERIAL TECH CO LTD

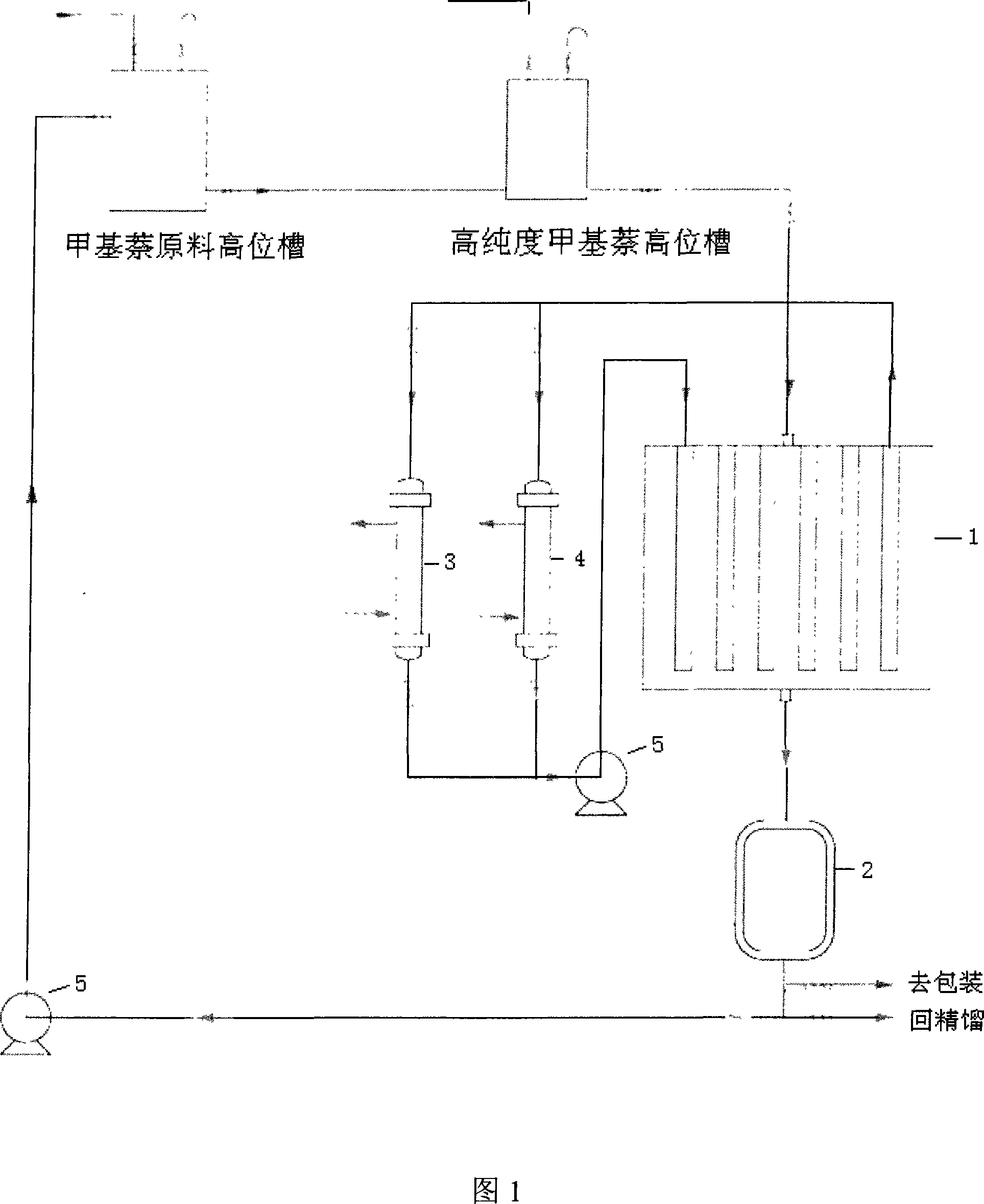

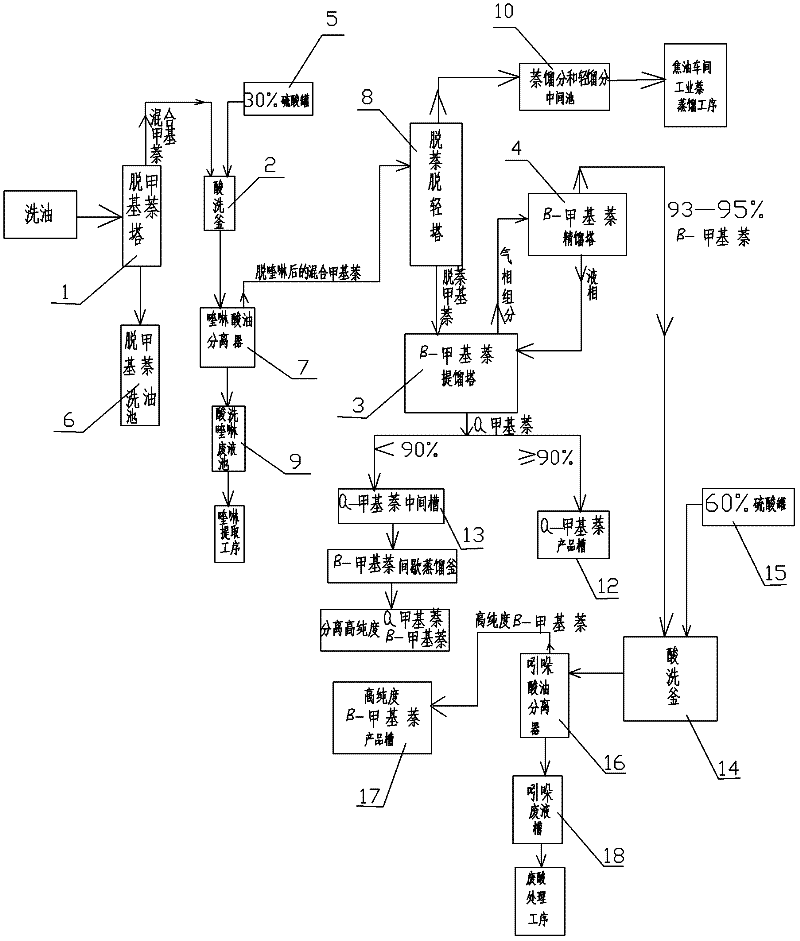

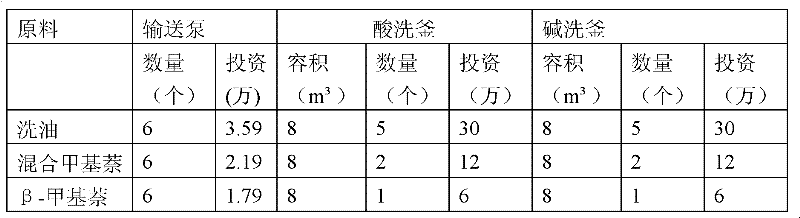

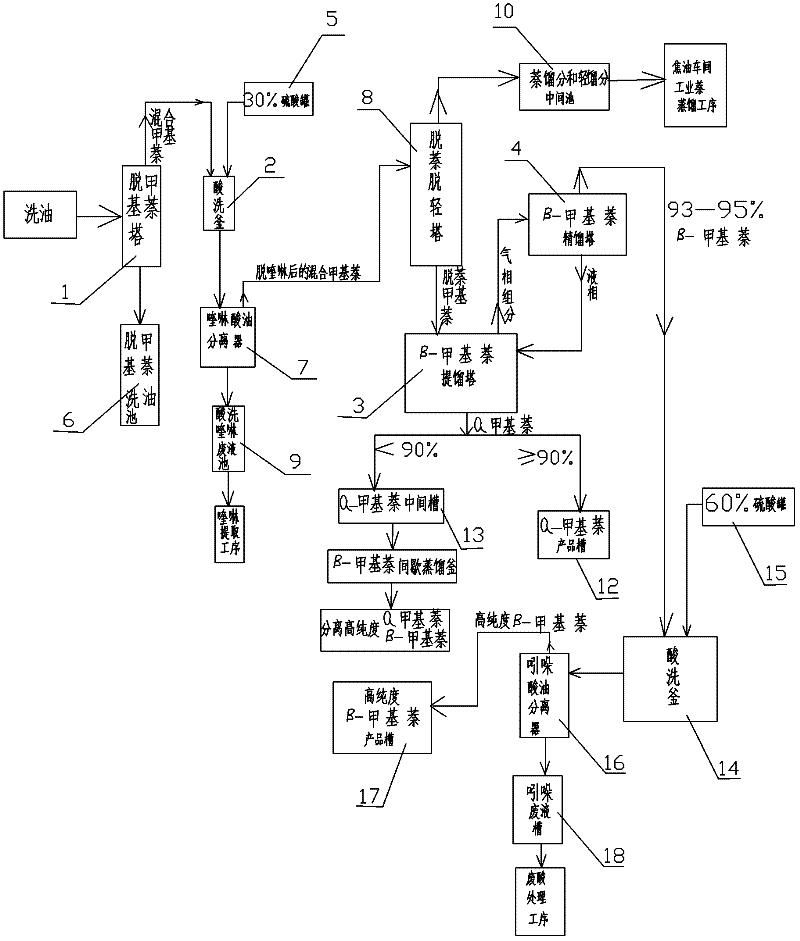

Method and special equipment for production of high-purity beta-methylnaphthalene by wash oil

InactiveCN102381928AHigh purityOmit the step of removing naphthalene firstDistillation purification/separationHydrocarbonsQuinolineAcid washing

The invention discloses a method and special equipment for production of high-purity beta-methylnaphthalene by wash oil. The method is characterized by including steps of firstly, preparing mixed methylnaphthalene by wash oil for one step, secondly, removing quinoline from the methylnaphthalene by means of acid washing, thirdly, removing naphthalene and light component from the mixed methylnaphthalene, fourthly, gathering and distilling, and fifthly, preparing high-purity beta-methylnaphthalene. The special equipment comprises methyl-removing inner tower, an acid washing kettle, a naphthalene-removing and light component removing tower, a separator, a distilling tower and a rectifying tower. Due to the step of preparing mixed methylnaphthalene by wash oil for one step, the step of preliminary naphthalene removing is omitted, a naphthalene removing tower and equipment matched with the same are omitted, and investment on equipment is partially saved. Since the procedures of acid washing of quinoline and indole are completed later, acid washing amount is reduced, wastewater generated in acid washing is reduced, and sewage discharging volume and cost for wastewater treatment are reduced. Besides, produced beta-methylnaphthalene is high in purity.

Owner:SHANDONG GUDE CHEM

Method and device for removing indole from beta-methylnaphthalene

ActiveCN102935292ASimple processEasy to operateDistillation purification/separationDistillation separationChemical industryTower

Relating to the field of chemical industry, the invention discloses a method and a device for removing indole from beta-methylnaphthalene. Structurally, the device comprises a distillation kettle and azeotropic distillation tower. An overflow recovery baffle is disposed at a tower top recovery outlet of the azeotropic distillation tower. A tower top recovery pipeline is connected to a cooler, a separation tank A and a separation tank B in order. The method includes: adding a mixture of the raw material beta-methylnaphthalene and an azeotropic agent into the distillation kettle, controlling the temperature of the kettle bottom at 145-147DEG C; maintaining the azeotropic distillation tower at a pressure of -70-90kpa and the tower top at a temperature of 140-142DEG C; carrying out intermittent azeotropic distillation separation, subjecting the evaporated liquid to cooling by the tower top cooler and internal reflux; and subjecting the azeotropic distillation tower top recovered liquid to cooling by the cooler, then leaving the liquid to flow into the separation tank A and the separation tank B in order, performing standing layering, and recovering the product. By means of the method and the device, after distillation separation, the content of the raw material beta-methylnaphthalene can be increased to over 98%, and the indole content decreased to an undetectable degree. The device and the method provided in the invention are simple and are easy to operate.

Owner:BAOWU CHARCOAL MATERIAL TECH CO LTD

Supercritical technology-ultrasonic wave-based method for separating and refining beta-methylnaphthalene

ActiveCN108586184AHigh purityMild oxidation methodDistillation purification/separationHydrocarbonsLiquid productUltrasound - action

The invention provides a supercritical technology-ultrasonic wave-based method for separating and refining beta-methylnaphthalene. The method comprises the following steps of: treating a methylnaphthalene fraction firstly by using an aqueous solution of ammonium bisulfate, adding ethanolamine, conducting even mixing by using a pre-mixer, transferring the mixture to a supercritical reactor, raisingthe temperature to 180 DEG C at a rate of 20-25 DEG C / min, performing cool stirring by introducing condensed water, then decreasing the temperature to 166-168 DEG C at a rate of 5-10 DEG C / min, performing a constant temperature reaction for 1-6 h, stopping heating, and performing separation and collection on gas-liquid products to obtain a nitrogen-removed methylnaphthalene composition; preheating the composition to 65-75 DEG C, adding an acetic anhydride catalyst and hydrogen peroxide slowly and dropwise, performing high-speed stirring for 60-90 min under the action of ultrasonic waves at 70-80 DEG C, performing extraction and rectification to obtain a sulfur-removed methylnaphthalene composition, adding ethylene glycol into the sulfur-removed methylnaphthalene combination, heating the mixture to 190-195 DEG C under the action of ultrasonic waves, collecting gas, condensing the collected gas to obtain a high-purity alpha+beta methylnaphthalene composition, then placing the high-purity alpha+beta methylnaphthalene composition in a freezing microtome, performing freezing crystallizing at -25-(-15) DEG C, performing separation, and performing redissolving to prepare the beta-methylnaphthalene at 36-38 DEG C.

Owner:PENG CHEN NEW MATERIALS TECH CO LTD

Method for simultaneously extracting high-purity beta-methylnaphthalene and indole from coal tar

ActiveCN101774879BAdaptableAbandon pollutionDistillation purification/separationTowerBeta-methylnaphthalene

The invention relates to a method for extracting high-purity beta-methylnaphthalene and indole, in particular to a method for simultaneously extracting high-purity beta-methylnaphthalene and indole from coal tar, which belongs to the field of coal fine chemistry industry. The method is realized by the following steps of: rectifying washing oil distillate distilled from coal tar in a vacuum distillation tower under vacuum, and acquiring a distillate product rich in beta-methylnaphthalene from the side of the tower; introducing the distillate product of beta-methylnaphthalene into a highly-effective intermittent rectification tower, cutting front distillates, and remixing the front distillates, the crude product of beta-methylnaphthalene, back distillates and tower bottom liquid; and then, conducting semicontinuous azeotropic distillation to the crude product of beta-methylnaphthalene, acquiring a mixture of beta-methylnaphthalene and entrainer, and settling, laying and separating the mixture to obtain beta-methylnaphthalene; after each cycle of processing technologies, continuing to distill to obtain indole. The invention solves the problems of single product, serious pollution, serious equipment corrosion and the like existing in the traditional process for refining beta-methylnaphthalene.

Owner:BAOWU CHARCOAL MATERIAL TECH CO LTD

Method for continuously extracting beta-methylnaphthalene crude product from methylnaphthalene enrichment liquor

ActiveCN108440233AWell distributed holesUniform pore sizeDistillation purification/separationVapor condensationCarbon fibersOil phase

The invention provides a method for continuously extracting a beta-methylnaphthalene crude product from a methylnaphthalene enrichment liquor. The method comprises steps as follows: methylnaphthalenefractions are treated with an ammonium bisulfate water liquor and a heptane and ethanol amine mixed liquor sequentially, separation is performed, an upper-layer oil phase is taken, and alkyl methylnaphthalene subjected to secondary purification is obtained; an entrainer is added to alkyl methylnaphthalene subjected to secondary purification, indirect reduced pressure distillation operation is performed, the reduced pressure distillation is performed under the vacuum degree of minus 0.09 MPa and at the tower top temperature of 80 DEG C and the tower bottom temperature of 150 DEG C, a gas phasepasses through a porous alumina membrane / carbon fiber filler cold trap at the tower top, and the beta-methylnaphthalene crude product is obtained; the beta-methylnaphthalene crude product is put in afreezing microtome and frozen and crystalized at the temperature of subzero 25 DEG C to subzero 15 DEG C, separation is performed, then, redisliquor is performed at the temperature of 36-40 DEG C, andbeta-methylnaphthalene is obtained, wherein the porous alumina membrane / carbon fiber filler cold trap comprises alternate porous alumina layers and carbon fiber layers.

Owner:PENG CHEN NEW MATERIALS TECH CO LTD

Method for preparing 2,6-dimethylnaphthalene through dismutation of beta methylnaphthalene under catalysis of ion liquid

InactiveCN1660726AMild reaction conditionsEasy to operateHydrocarbonsBulk chemical productionBeta-methylnaphthaleneSolvent

An ionic liquid catalyzing process for preparing 2,6-dimethyl naphthalene by dismutating beta-methyl naphthalene includes proportionally mixing beta-methyl naphthalene with solvent, adding ionic liquid catalyst, and dismutation reaction at 120-160 deg.C for 2-4 hr under protection of inertial gas. Its advantages are high selectivity and no environmental pollution.

Owner:HEILONGJIANG INST OF PETROCHEM

Supercritical technology-based method for separating and purifying high-purity alpha-methylnaphthalene

ActiveCN108586183AHigh purityReduce usageDistillation purification/separationHydrocarbonsLiquid productAcetic anhydride

The invention provides a supercritical technology-based method for separating and purifying high-purity alpha-methylnaphthalene. The method comprises the steps of: adding ethanolamine into a methylnaphthalene fraction, conducting even mixing by using a pre-mixer, transferring the mixture to a supercritical reactor, raising the temperature to 180 DEG C, performing cool stirring by introducing condensed water, then decreasing the temperature to 166-168 DEG C, performing a constant temperature reaction, stopping heating, and performing separation and collection on gas-liquid products to obtain anitrogen-removed methylnaphthalene composition; preheating the nitrogen-removed methylnaphthalene composition, adding an acetic anhydride catalyst and hydrogen peroxide slowly and dropwise, performinghigh-speed stirring under the action of heating and ultrasonic waves, performing extraction and rectification to obtain a sulfur-removed methylnaphthalene composition, adding ethylene glycol into thesulfur-removed methylnaphthalene combination, performing azeotropy, collecting gas, condensing the collected gas to obtain a high-purity alpha+beta methylnaphthalene composition, then adding 2-amino-3-methylpyridine to the high-purity alpha+beta methylnaphthalene composition, and performing azeotropy and separation to obtain the high-purity alpha-methylnaphthalene with a purity up to 99.8%.

Owner:PENG CHEN NEW MATERIALS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com