Ethylene bottom oil complex processing technology

A technology for comprehensive processing of ethylene tar, applied in the direction of tar processing through distillation, hydrocarbons, chemical instruments and methods, etc., can solve the problems of difficult control of the reaction process, low quality, complicated operation process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

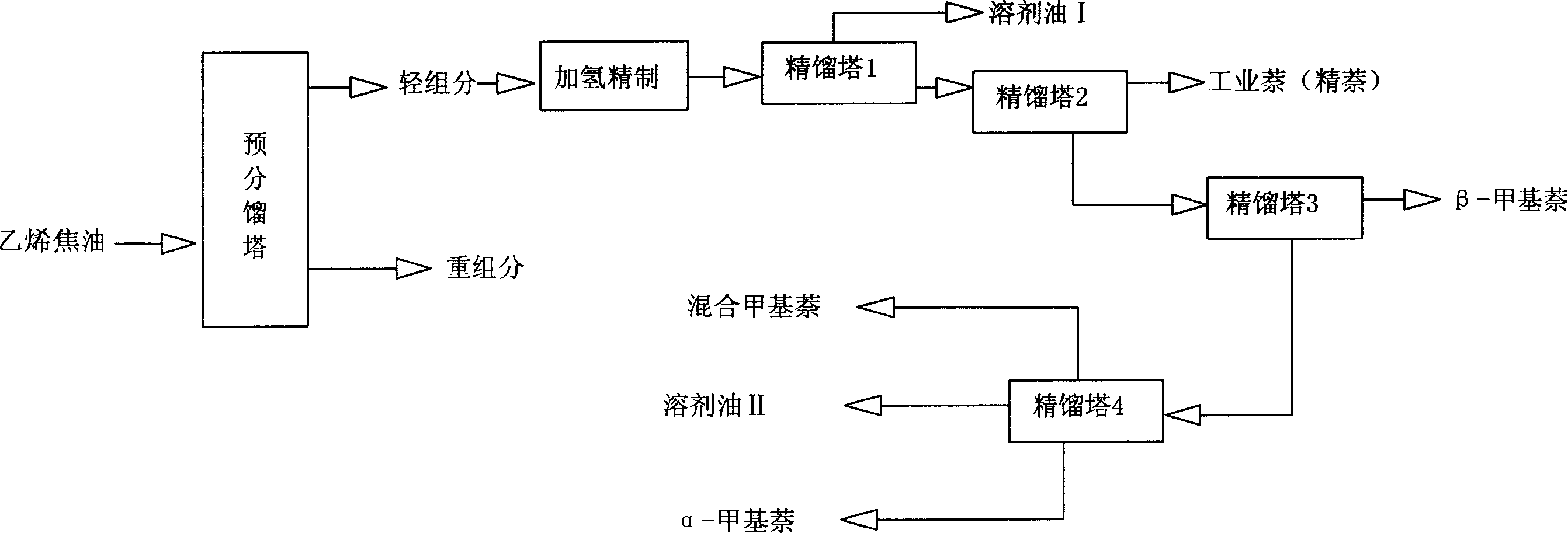

[0020] Ethylene tar first enters the pre-fractionation tower and is fractionated into light components and heavy components at 275°C. The heavy components with a boiling point greater than 275°C are used as carbon black oil or fuel oil, and those with a boiling point lower than 275°C are used as light components.

[0021] Hydrofining of light components, after hydrogenation, the bromine value of light components drops from 96.6g / 100ml to 33.9g / 100ml; the hydrogenation conditions are t=260°C, p=3.5MPa, and the catalysts used are Ni, Mo, Al 2 o 3 .

[0022] After hydrofining, it enters four series and continuous rectification towers, and solvent oil I, industrial naphthalene (refined naphthalene), β-methylnaphthalene, α-methylnaphthalene, mixed methylnaphthalene, and solvent oil II are respectively cut.

[0023] The resulting product quality is:

[0024] Refined naphthalene

Embodiment 2

[0026] Ethylene tar first enters the pre-fractionation tower and is fractionated into light components and heavy components at 270°C. The heavy components with a boiling point greater than 270°C are used as carbon black oil or fuel oil, and those with a boiling point lower than 270°C are used as light components;

[0027] Hydrofining of light components, after hydrogenation, the bromine value of light components drops from 106.3g / 100ml to 34.1g / 100ml; the hydrogenation conditions are t=260°C, p=3.5MPa, and the catalysts used are Co, Mo, Al 2 o 3 .

[0028] After hydrofining, it enters four series and continuous rectification towers, and solvent oil I, industrial naphthalene (refined naphthalene), β-methylnaphthalene, α-methylnaphthalene, mixed methylnaphthalene, and solvent oil II are respectively cut.

[0029] The resulting product quality is:

[0030] Refined naphthalene

Embodiment 3

[0032] Ethylene tar first enters the pre-fractionation tower and is fractionated into light components and heavy components at 268°C. The heavy components with a boiling point greater than 268°C are used as carbon black oil or fuel oil, and those with a boiling point lower than 268°C are used as light components.

[0033] Hydrofining of light components, after hydrogenation, the bromine value of light components drops from 95.8g / 100ml to 32.9g / 100ml; the hydrogenation conditions are t=252°C, p=3.5MPa, and the catalysts used are Ni, Mo, Al 2 o 3 .

[0034] After hydrofining, it enters four series and continuous rectification towers, and solvent oil I, industrial naphthalene (refined naphthalene), β-methylnaphthalene, α-methylnaphthalene, mixed methylnaphthalene, and solvent oil II are respectively cut.

[0035] The resulting product quality is:

[0036] Refined naphthalene

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com