Supercritical technology-ultrasonic wave-based method for separating and refining beta-methylnaphthalene

A refining method and technology of methylnaphthalene fractions, applied in the field of separation and purification of β-methylnaphthalene, can solve the problems of harsh process conditions of β-methylnaphthalene and low product yield, and achieve mild oxidation method and high desulfurization efficiency , the effect of less acid consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

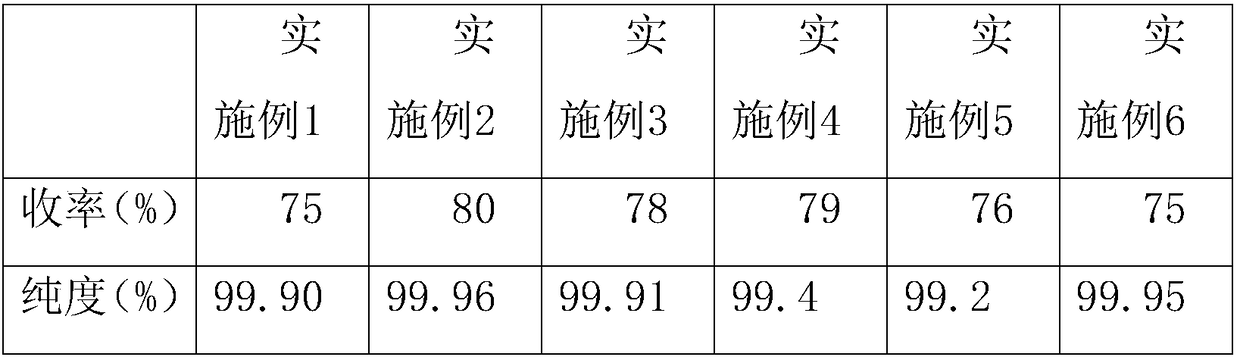

Examples

Embodiment 1

[0024] (1) Methylnaphthalene containing sulfides such as methylnaphthalene, quinoline, indole, biphenyl, methylbenzothiophene, thianaphne, and methylthiane, and the total methylnaphthalene composition is not less than 60% After the fraction was first treated with 10% ammonium bisulfate aqueous solution, according to the volume ratio of ethanolamine and total methylnaphthalene as 3:5, after adding ethanolamine and mixing uniformly through a premixer, it was transferred to and placed in a supercritical reactor. Raise the temperature to 120°C at a rate of ℃ / min, turn on the condensed water and cool and stir at a rate of 150r / min for 0.5h, raise the temperature to 180°C at a rate of 20°C / min, turn on the condensed water and cool and stir at a rate of 150r / min for 2h, and then Cool down to 166°C at a rate of 5°C / min, stop heating after 1 hour of constant temperature reaction, and separate and collect gas-liquid products to obtain a nitrogen-removing methylnaphthalene composition.

...

Embodiment 2

[0028] (1) Methylnaphthalene containing sulfides such as methylnaphthalene, quinoline, indole, biphenyl, methylbenzothiophene, thianaphne, and methylthiane, and the total methylnaphthalene composition is not less than 60% After the cut was first treated with 20% ammonium bisulfate aqueous solution, according to the volume ratio of ethanolamine and total methylnaphthalene as 3:10, add ethanolamine after the premixer mixes uniformly, transfer to be placed in the supercritical reactor, with 16 The temperature is raised to 130°C at a rate of ℃ / min, the condensed water is cooled and stirred at a rate of 150r / min for 1h, the temperature is raised to 180°C at a rate of 25°C / min, the condensed water is cooled and stirred at a rate of 150r / min for 4h, and then The temperature was lowered to 168°C at a rate of 10°C / min, the heating was stopped after 6 hours of constant temperature reaction, and the gas-liquid products were separated and collected to obtain a nitrogen-removing methylnapht...

Embodiment 3

[0032] (1) Methylnaphthalene containing sulfides such as methylnaphthalene, quinoline, indole, biphenyl, methylbenzothiophene, thianaphne, and methylthiane, and the total methylnaphthalene composition is not less than 60% After the cut was first treated with 15% ammonium bisulfate aqueous solution, according to the volume ratio of ethanolamine and total methylnaphthalene as 3:7, add ethanolamine after the premixer mixes uniformly, transfer to be placed in the supercritical reactor, with 15 Raise the temperature to 125°C at the rate of ℃ / min, cool and stir at the rate of 150r / min for 0.8h when the condensed water is turned on, raise the temperature to 180°C at the rate of 23°C / min, cool and stir at the rate of 150r / min for 3h when the condensed water is turned on, and then The temperature was lowered to 167°C at a rate of 7°C / min, the heating was stopped after 3 hours of constant temperature reaction, and the gas-liquid products were separated and collected to obtain a nitrogen-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com