Patents

Literature

45results about How to "The production process is economical and environmentally friendly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Monatomic iron nitrogen-doped porous carbon catalyst as well as preparation method and application thereof

ActiveCN107376970AReduce post-processing costsThe production process is economical and environmentally friendlyPhysical/chemical process catalystsOrganic chemistryHydrogen oxidation reactionBy-product

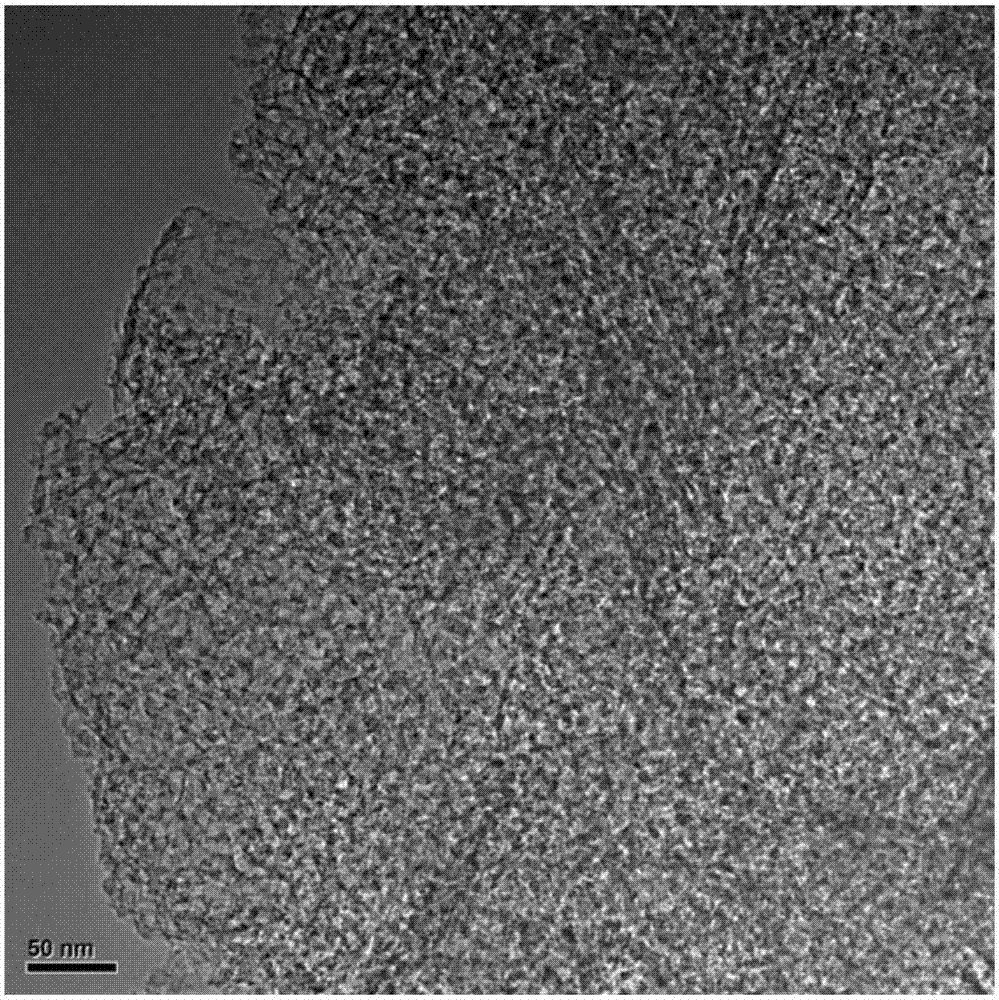

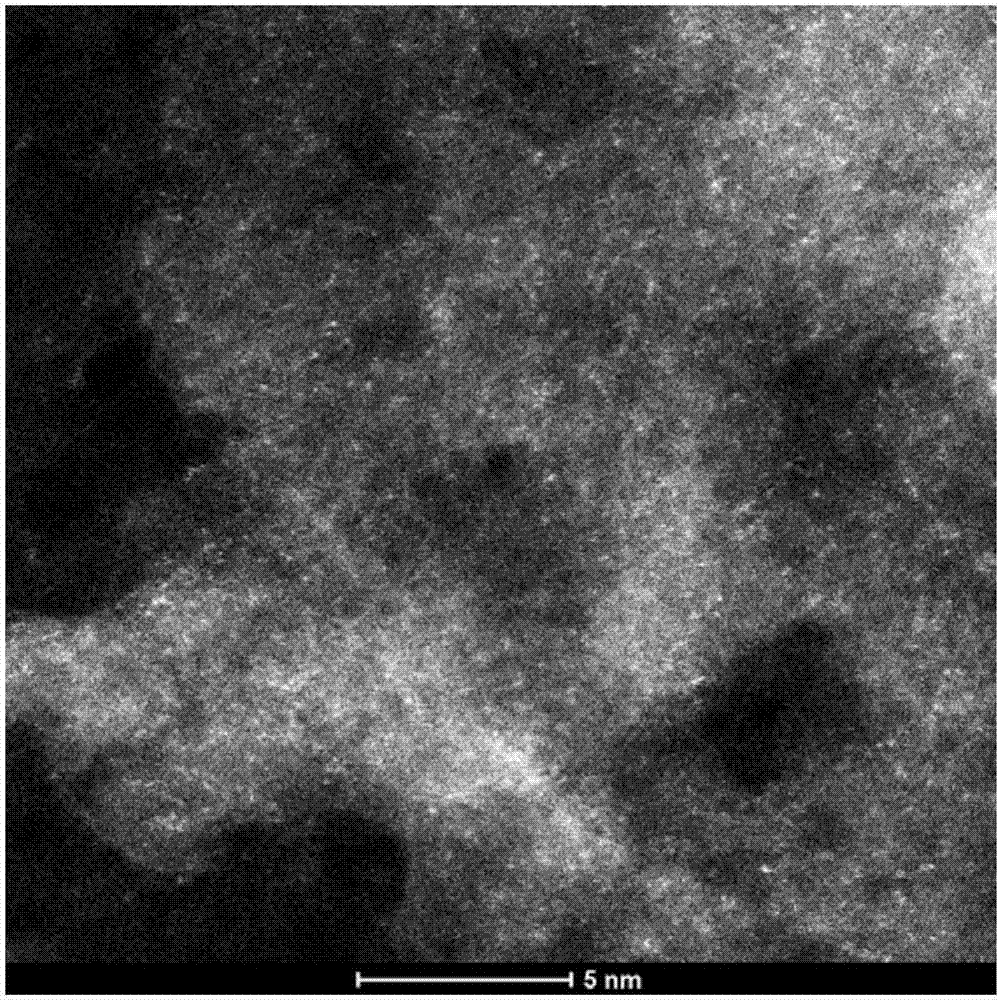

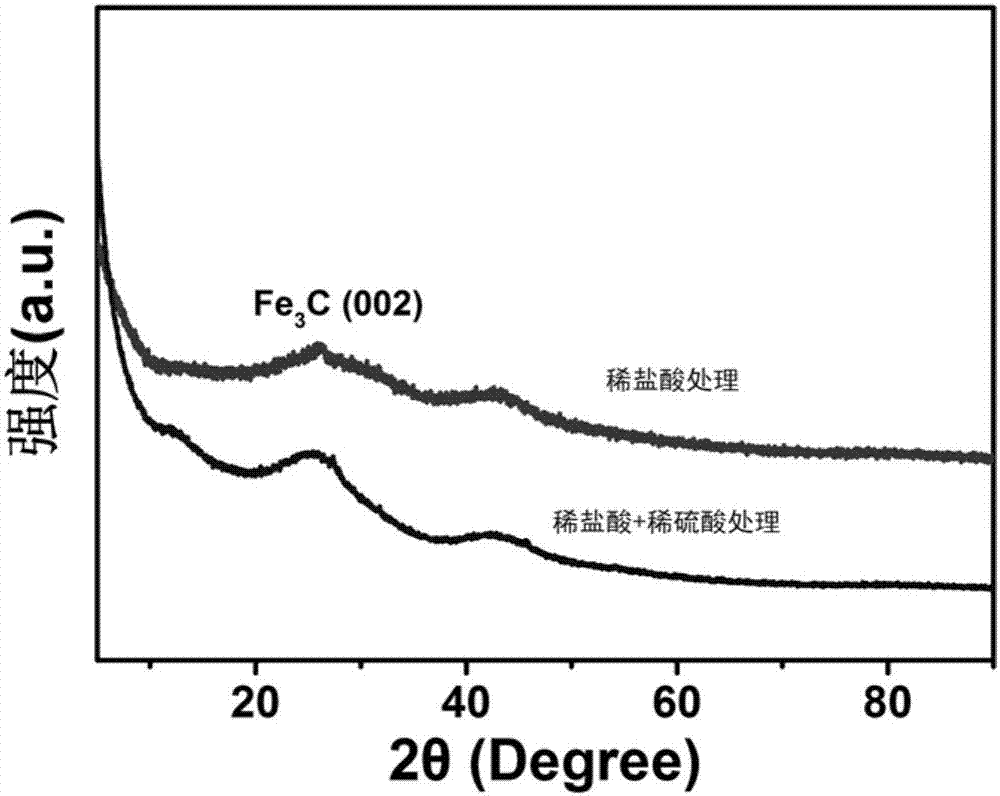

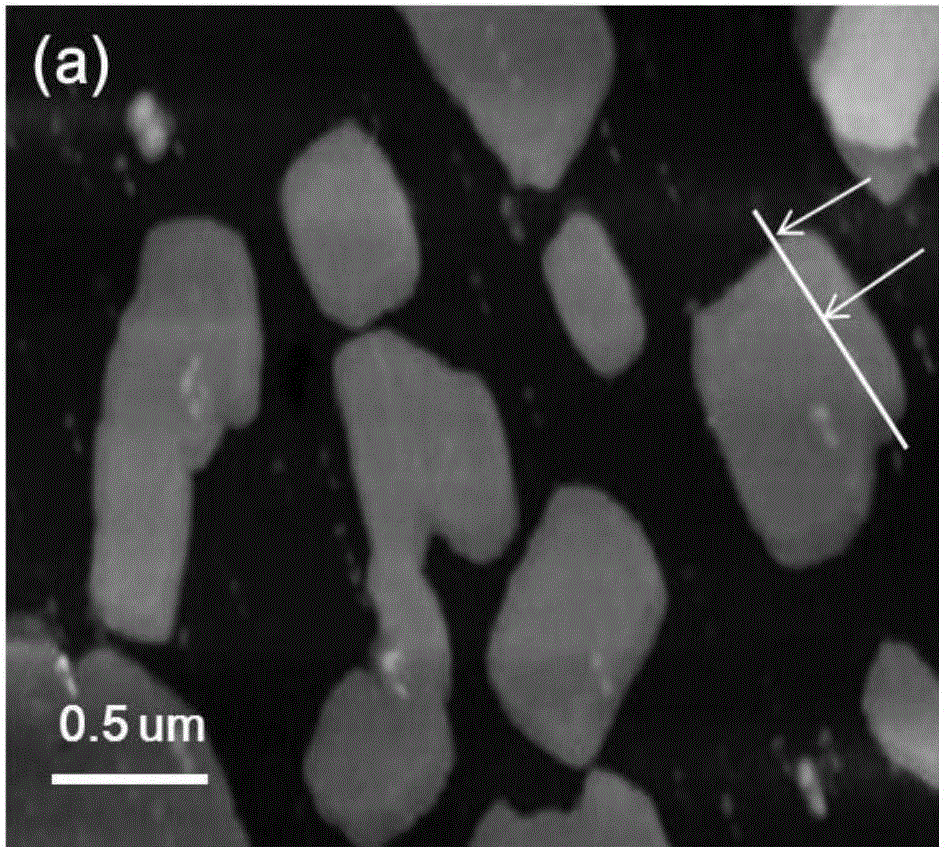

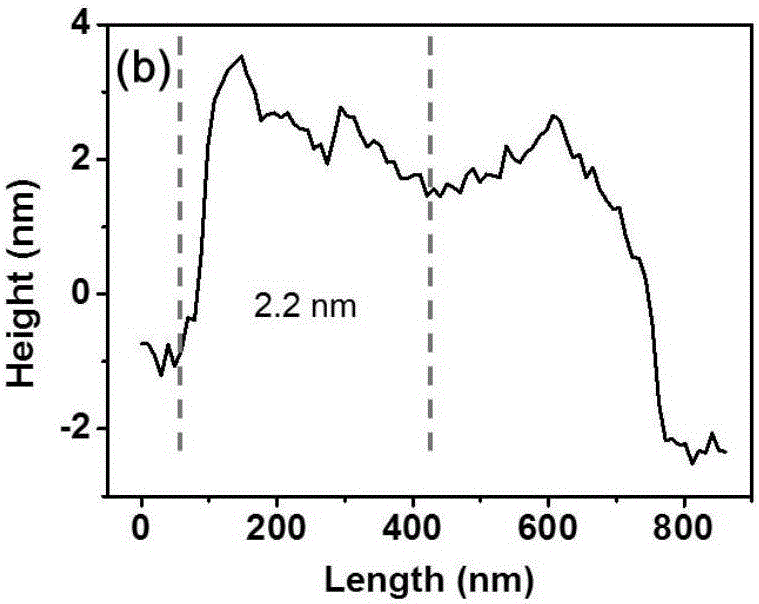

The invention provides a monatomic iron nitrogen-doped porous carbon catalyst as well as a preparation method and application thereof. In the catalyst, monatomic iron is taken as an active component, a nitrogen-doped porous carbon material is taken as a carrier, and iron is dispersed on the surface and the interior of the nitrogen-doped porous carbon material in a monatomic form, wherein every 100 wt% of the monatomic iron nitrogen-doped porous carbon catalyst contains 1.0-3.0 wt% of iron and 4.0-9.0 wt% of nitrogen. The invention also provides a method for catalyzing a nitrogen heterocyclic compound with the monatomic iron nitrogen-doped porous carbon catalyst for a dehydrogenation oxidation reaction and application of the monatomic iron nitrogen-doped porous carbon catalyst for catalyzing the nitrogen heterocyclic compound for the dehydrogenation oxidation reaction. The catalyst has an excellent catalytic effect; a product is analyzed by GC-MS (gas chromatography-mass spectrometer) after a catalytic reaction is ended; and an analysis result indicates that no by-product is produced, and the activity of the catalyst is not obviously reduced after the catalyst is used for 5 times.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

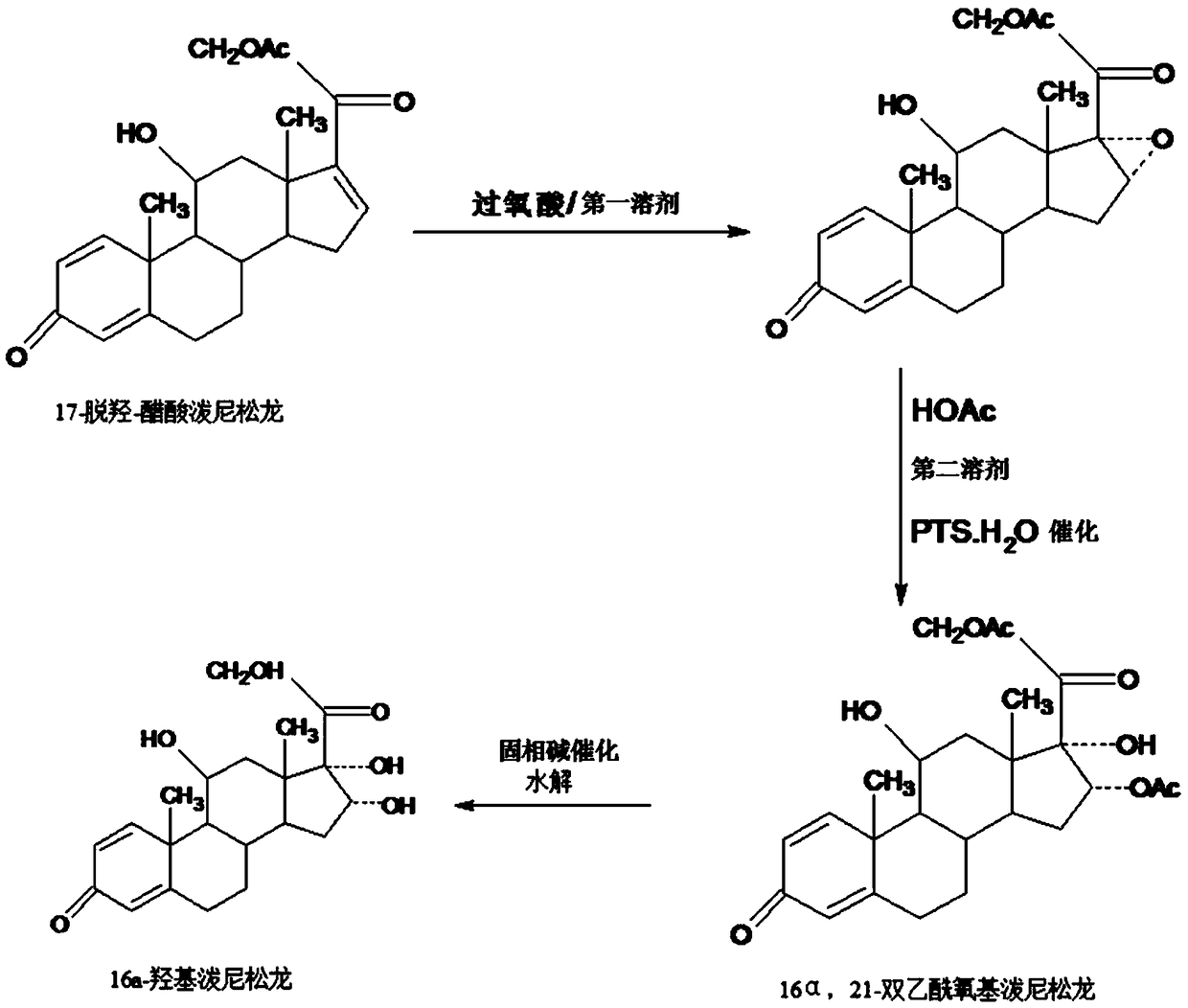

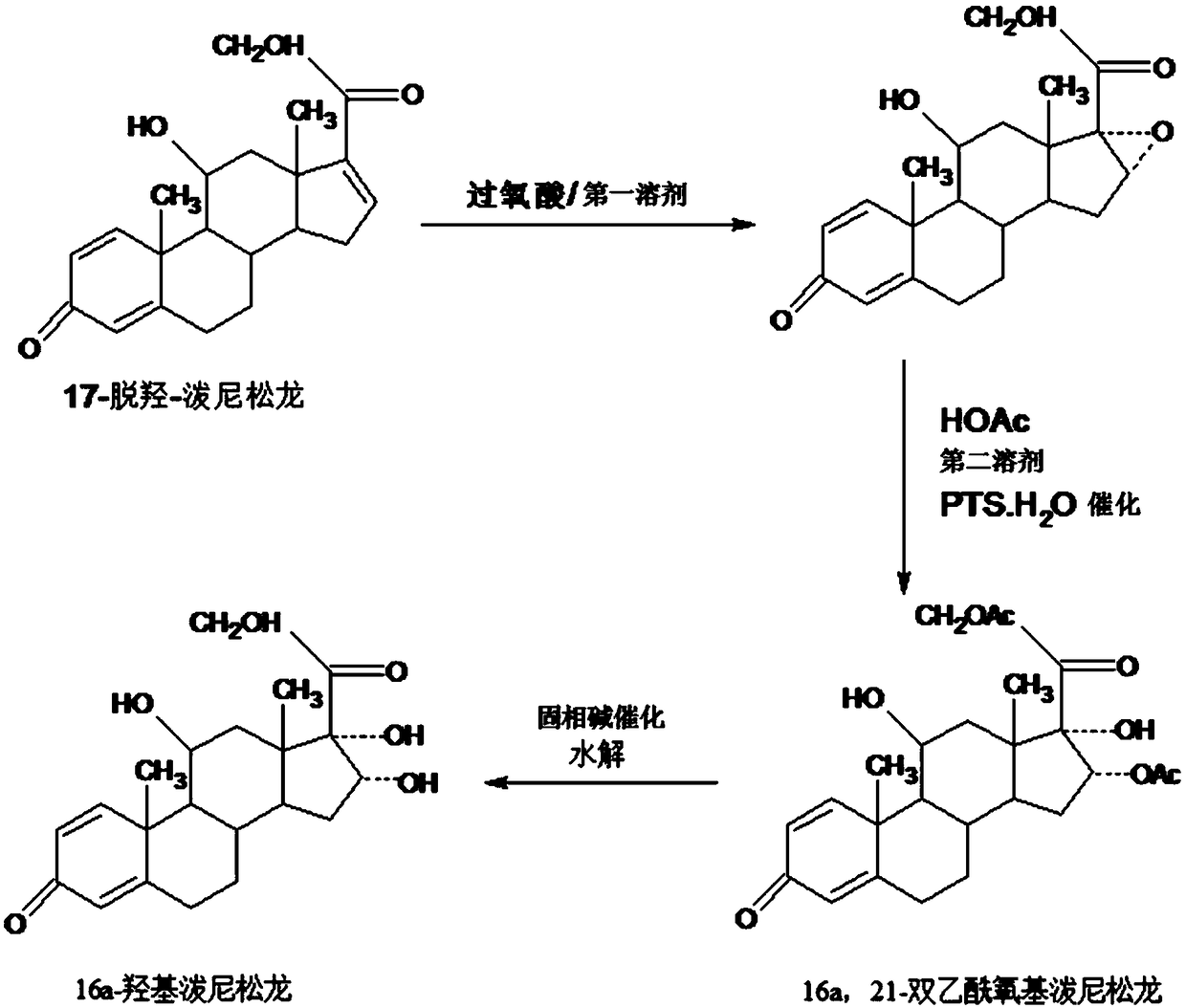

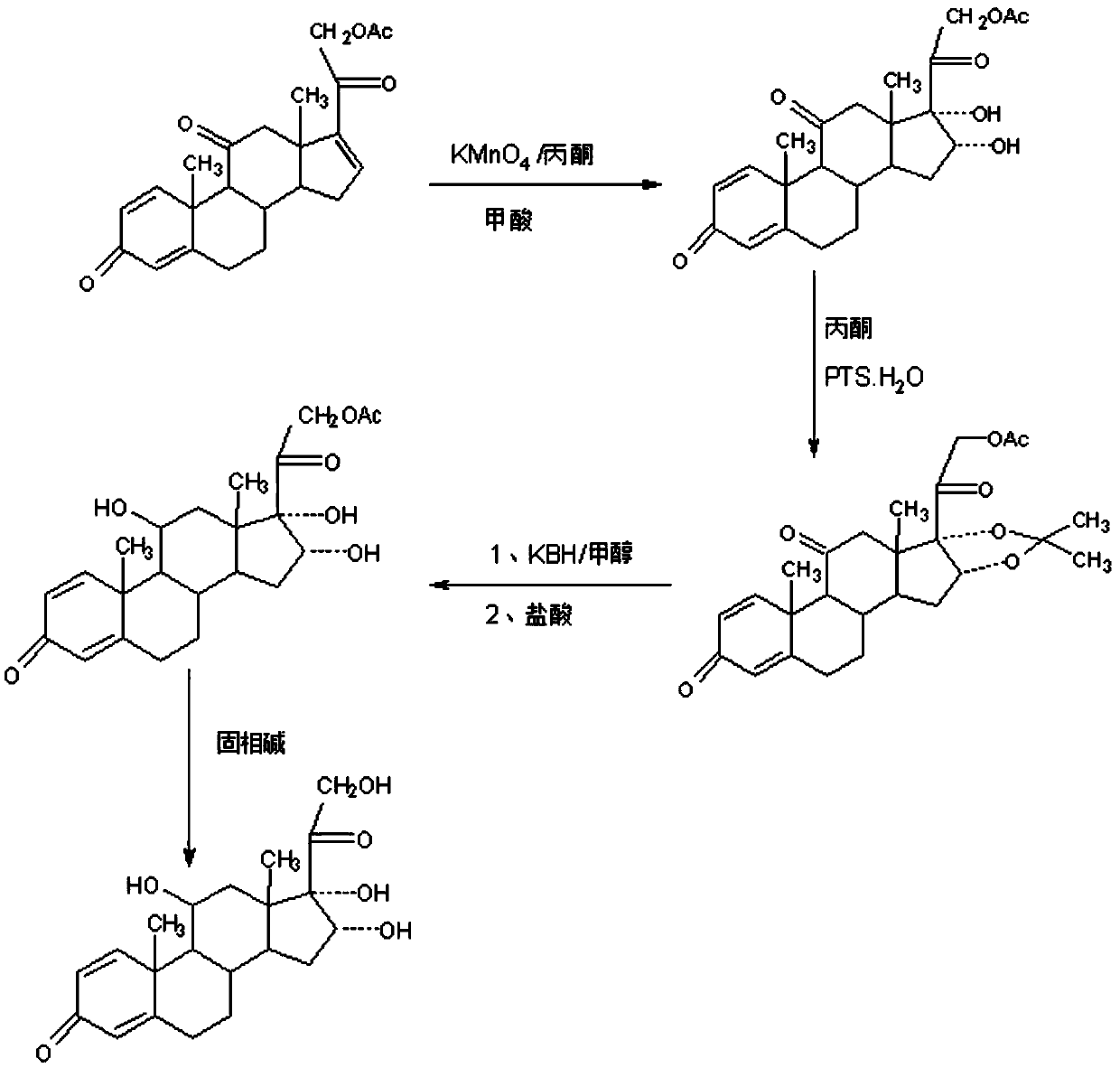

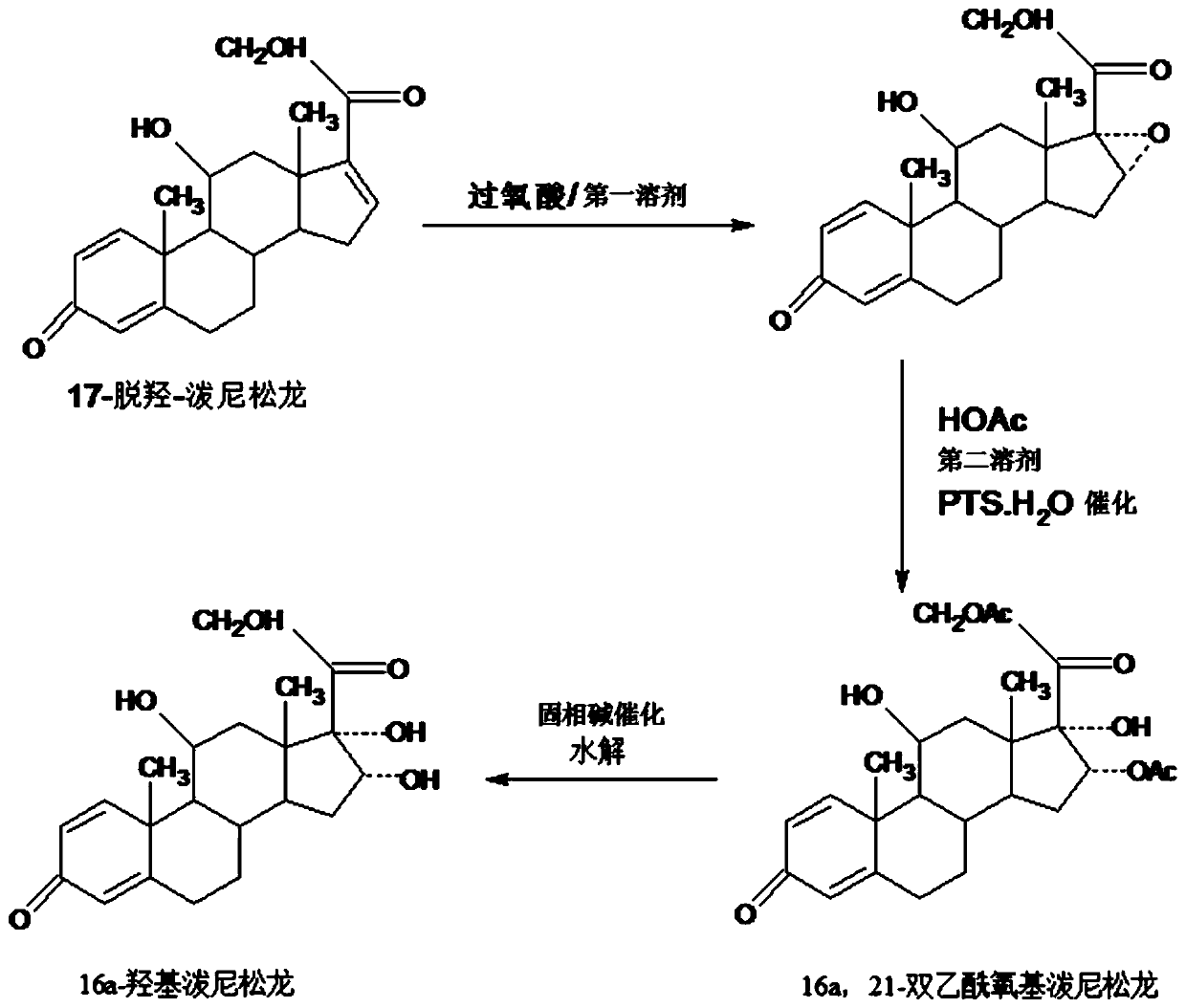

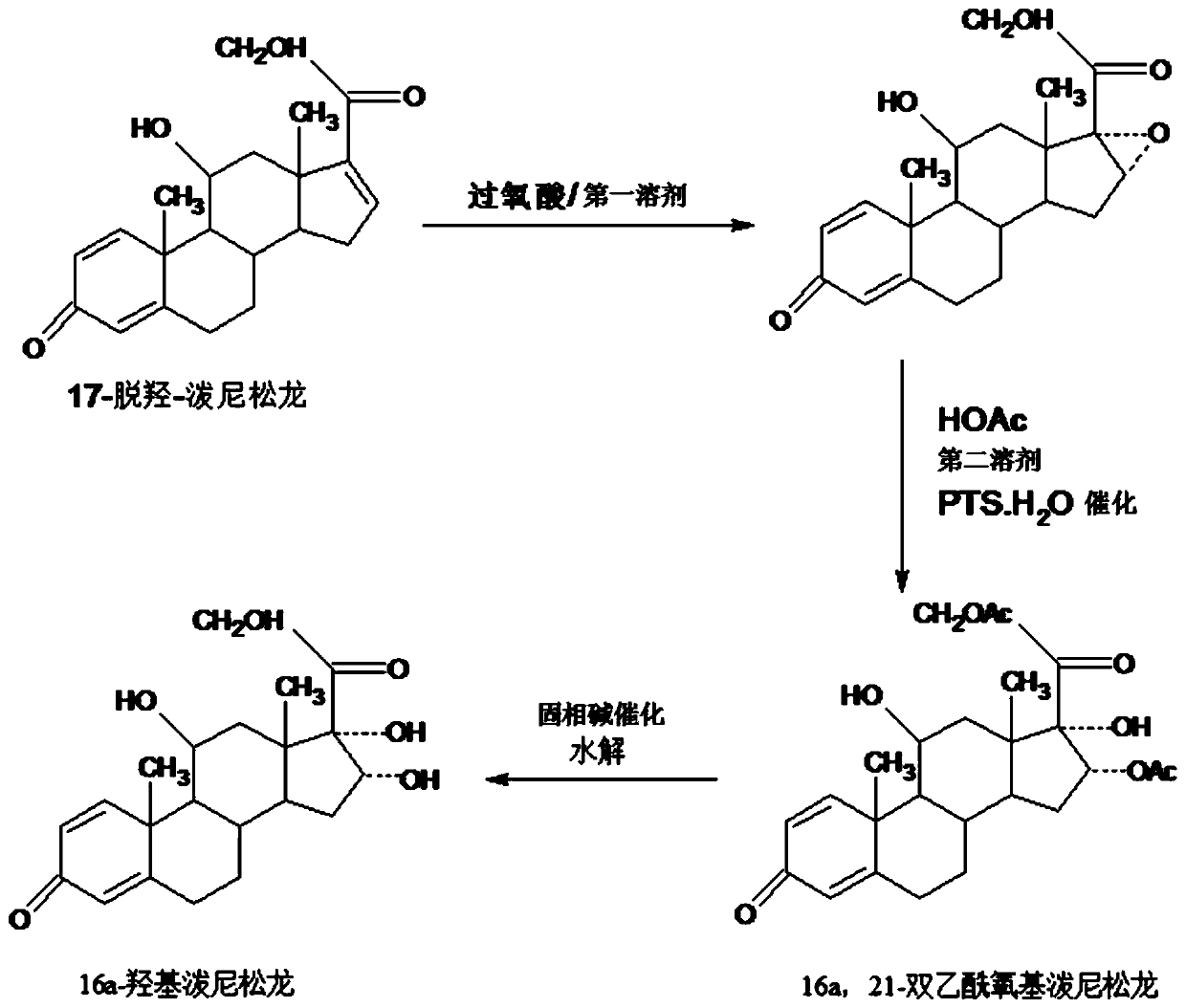

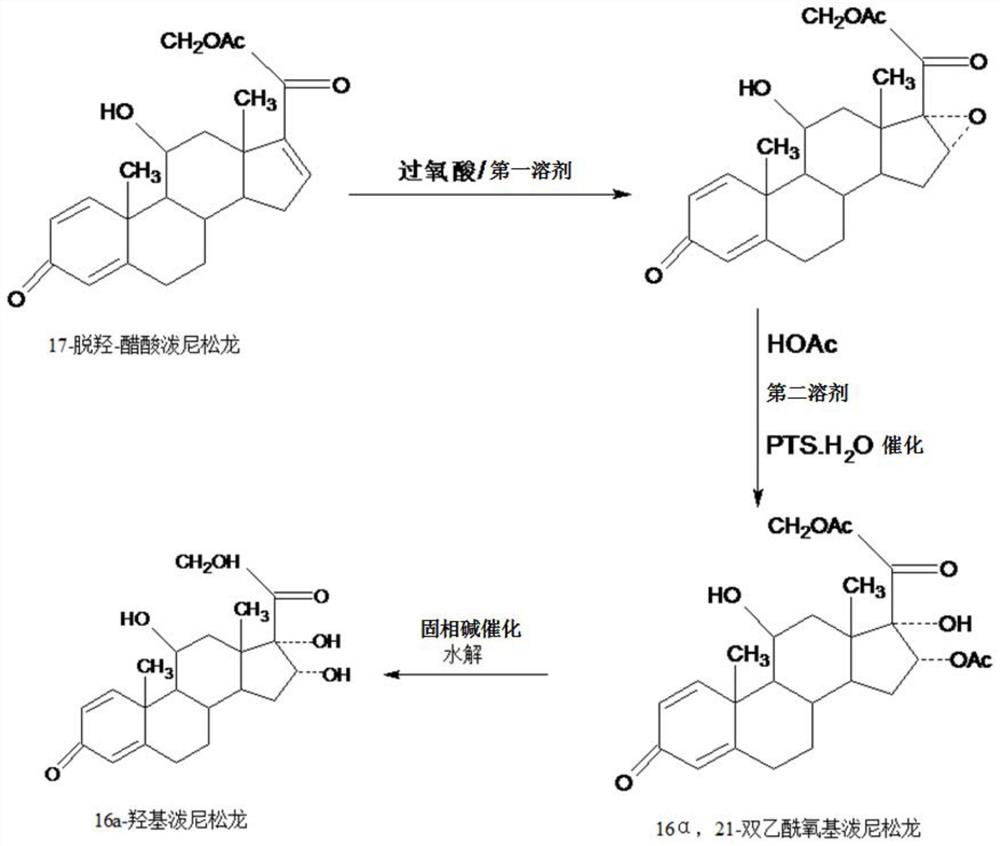

Preparation method of 16a-hydroxy prednisolone

ActiveCN107488203AInhibition of rearrangement and ring expansion side reactionsReduce generationPhysical/chemical process catalystsOrganic chemistry methodsOrganic solventAlcohol

The invention discloses a preparation method of 16a-hydroxy prednisolone. The preparation method comprises the following steps: dissolving 16a-hydroxy prednisolone acetate into an organic solvent, adding an inert solid carrier adsorbed with strong base as a hydrolysis reaction solid-phase base catalyst, and hydrolyzing 21-acetate to obtain a 16a-hydroxy prednisolone crude product; and carrying out lower alcohol recrystallization on the crude product under the condition of below C4 to obtain a 16a-hydroxy prednisolone competitive product, wherein the refined weight yield is 85% to 90%, and the preparation weight total yield is 75% to 80%. The solid carrier is selected from aluminum oxide, silica gel or calcium carbonate; the base catalyst is selected from sodium carbonate; and the organic solvent is selected from methylbenzene or chloroform. Compared with a traditional method, the method disclosed by the invention is simple and convenient in production operation, impurities generated in traditional production can be greatly reduced, and the total yield for synthesis is greatly improved; compared with the traditional method, the production cost is reduced by 10% to 15%; and a synthetic reaction solvent can be recycled, and industrial production is facilitated.

Owner:HUNAN KEREY BIOTECH

Making and sterilizing method of polypropylene plastic infusion bottle

ActiveCN102247287AImprove product qualityHigh sterility assurance valuePharmaceutical containersPackage sterilisationInternal pressureBlow molding

The invention relates to a making and sterilizing method of a polypropylene plastic infusion bottle, comprising the following steps of: (1) an injection molding and blow molding process: melting medicinal-grade polypropylene granules at high temperature, extruding to make a bottle blank, blowing into a medicine bottle by using clean high-pressure air, wherein a blow molding control mode is a five-speed five-pressure method, and stretching foreblow is carried out before blow molding shaping; (2) a cleaning, filing and sealing process: cleaning the medicine bottle in a pumping way by using clean negative ion air, then filing medicine-containing liquid, controlling the medicine-containing liquid to be filled at the constant temperature of 50-75 DEG C, filling and then sealing a cover; (3) a high-temperature sterilizing process: placing the completely-filled and cover-sealed medicine bottle into a high-pressure sterilizing tank for sterilization, wherein inner pressure is controlled between 0.20 MPa and 0.35 MPa, sterilization temperature is 117-121 DEG C, and sterilization time is 20-12 minutes.

Owner:SHIJIAZHUANG NO 4 PHARMA

Method for producing high-concentration ethanol by mixed fermentation of starch and molasses

InactiveCN102080105AIncrease profitIncrease total sugar concentrationBiofuelsFermentationHigh concentrationDistillation

The invention discloses a method for producing high-concentration ethanol by the mixed fermentation of starch and molasses which are used as raw materials. The method comprises the following steps of: adding water to the raw material of starch and stirring to constant volume, liquefying at low temperature and simultaneously fermenting and saccharifying, and then adding the raw material of molasses for mixed fermentation through the batch or continuous flow feeding supplement way. The mixing ratio of the raw materials of starch and molasses is 1:2-8:1 (W / V), the temperature of fermentation is 30-37 DEG C, the time of fermentation lasts for 40-48h, the percentage of ethanol yield is 12.43-16.67% (V / V). The invention changes the traditional single raw material fermentation way, and not only improves the total sugar concentration of the fermented mash, but also reduces the viscosity of starch raw mash and improves the liquidity, so the concentration of ethanol in the fermentation mash is increased, and the raw material utilization rate is improved, and ethanol distillation energy consumption and production cost are decreased, the amount of sewage discharge is reduced, the load of sewage treatment is lowered and the ethanol production process is more economical and environmentally friendly.

Owner:GUANGXI ACAD OF SCI

Method for preparing 16a-hydroxyl prednisolone product

InactiveCN109232696AAvoid many difficulties such as difficult purificationEasy to operateSteroidsAcetic acidOrganic solvent

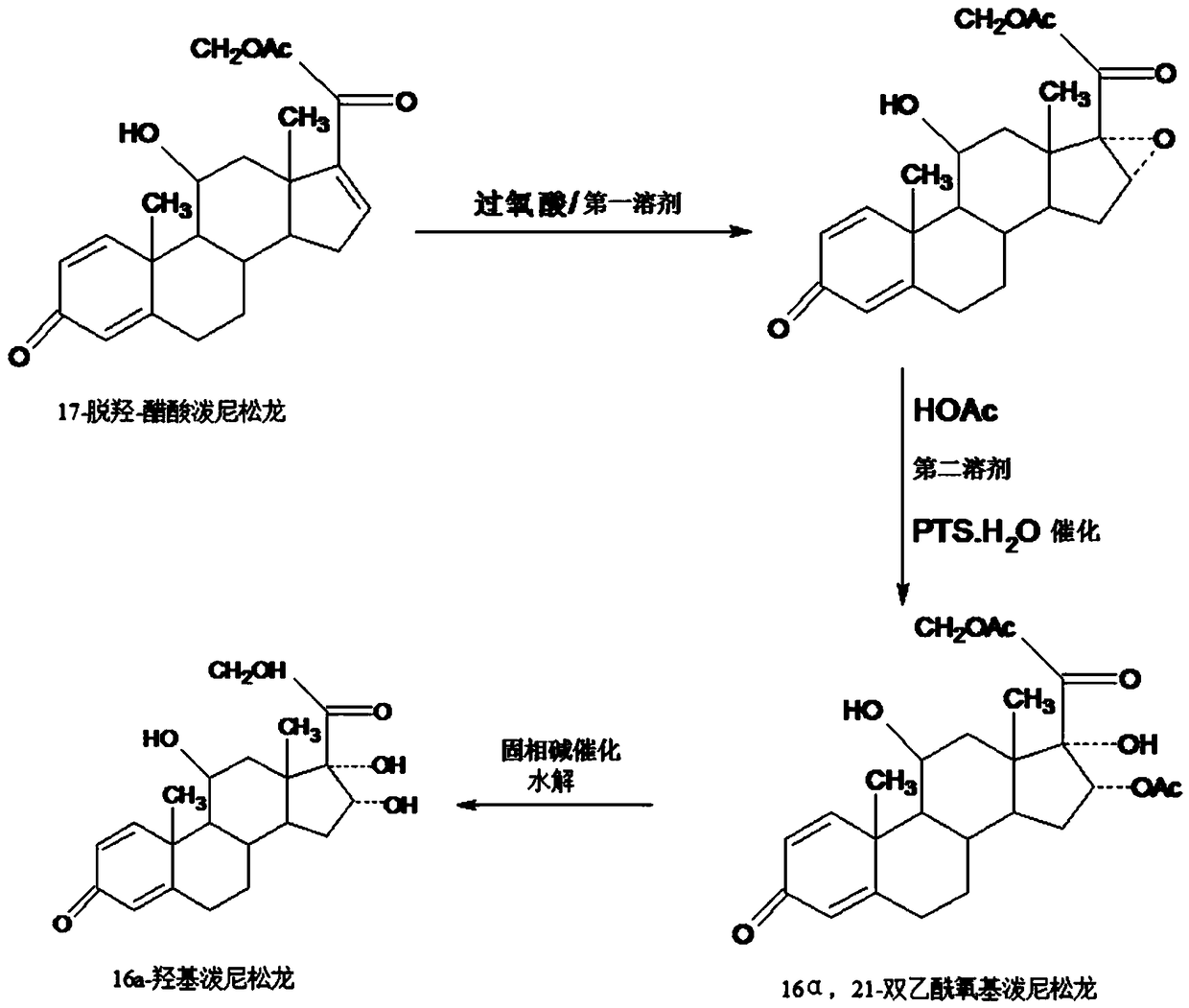

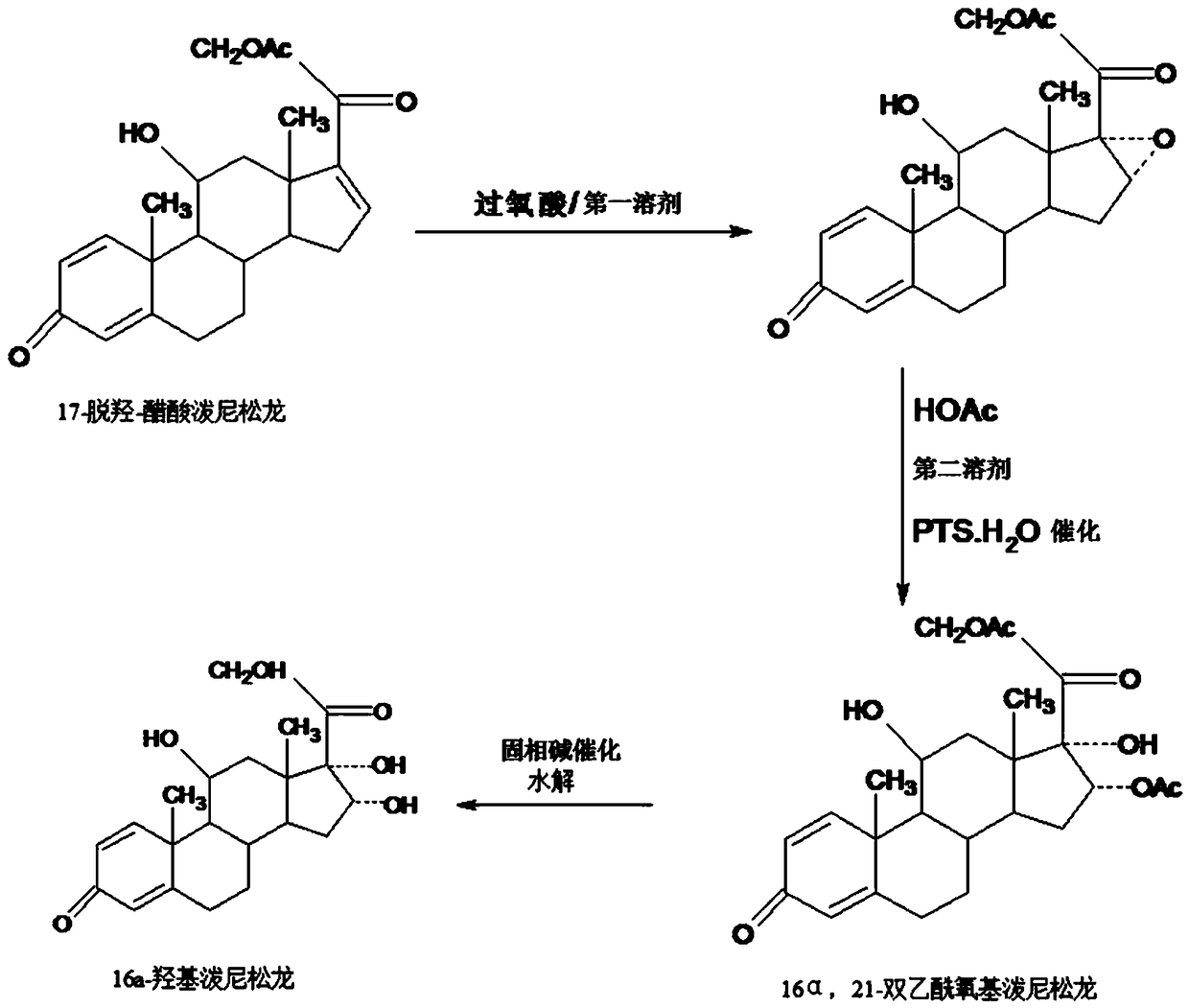

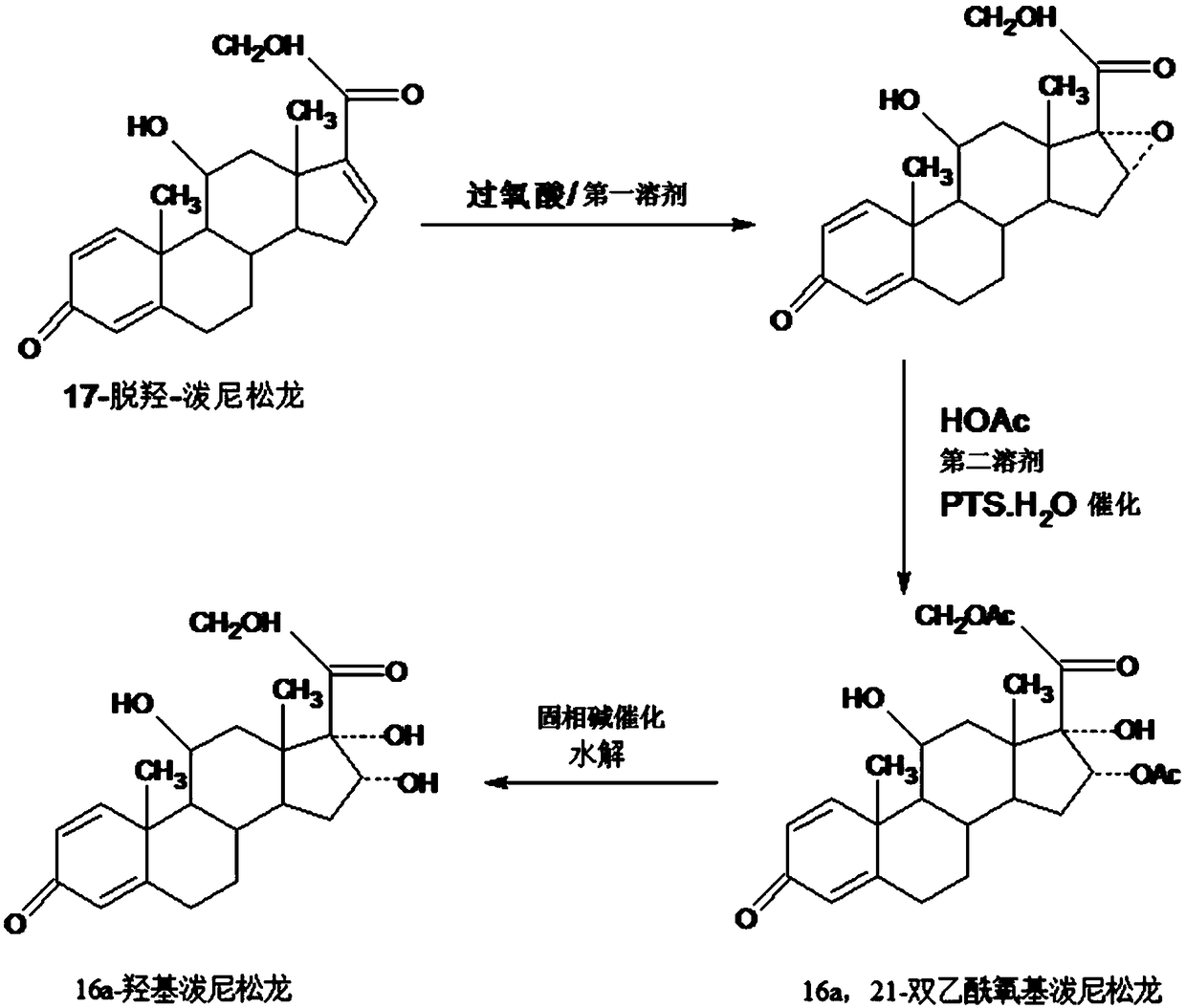

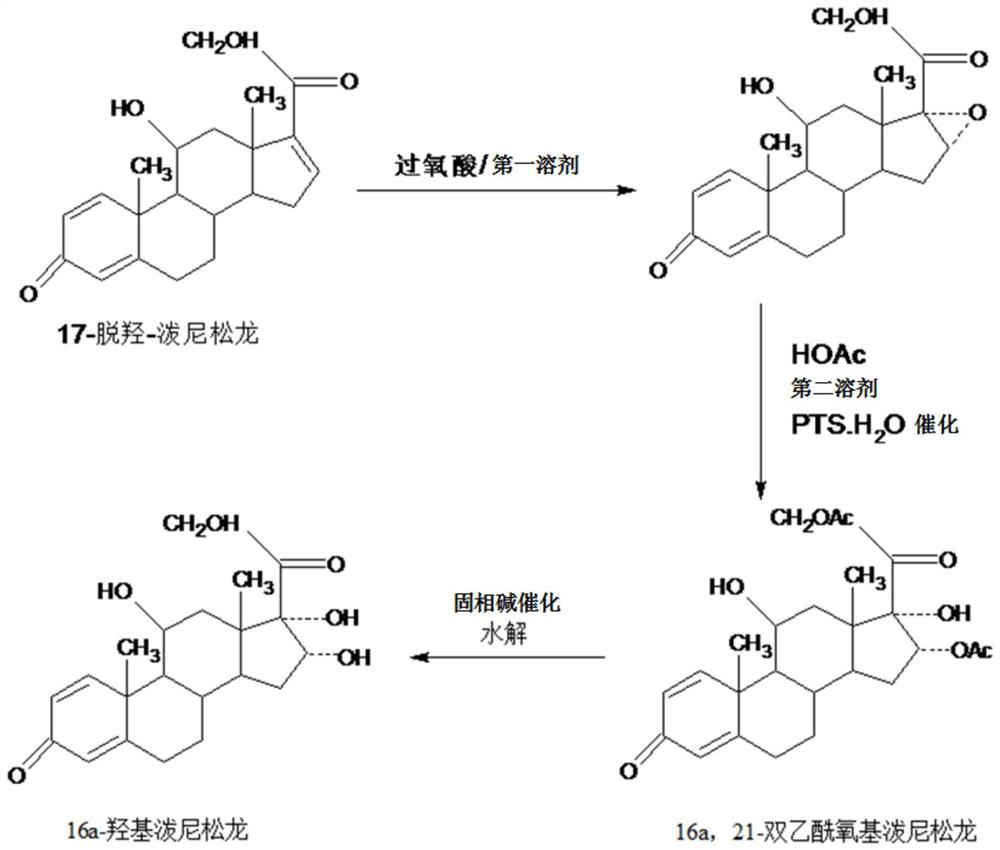

The invention provides a method for preparing a 16a-hydroxyl prednisolone product. The method comprises the steps: firstly, subjecting 17a-deshydroxy prednisolone acetate, which serves as a starting raw material, and organic peroxy acid to an epoxidation reaction at 16,17 sites in a first organic solvent, so as to prepare epoxide; subjecting the epoxide and glacial acetic acid to a ring-opening reaction under the catalysis of an acid catalyst in a second organic solvent, so as to prepare 16a,21-diacetoxyl prednisolone; then, dissolving the 16a,21-diacetoxyl prednisolone in a third organic solvent, and hydrolyzing acetate of two positions under the catalysis of a solid-phase alkali catalyst, so as to prepare 16a-hydroxyl prednisolone; finally, subjecting the crude 16a-hydroxyl prednisoloneobtained through solid-phase alkali-catalyzed hydrolysis to heated refluxing, decoloring and recrystallization by low carbon alcohols of C4 or less, thereby obtaining the 16a-hydroxyl prednisolone product. The 16a-hydroxyl prednisolone is prepared by the efficient, environment-friendly and cheap method.

Owner:HUNAN KEREY BIOTECH

Preparation method of 16alpha-hydroxy prednisolone

InactiveCN109081861AAvoid many difficulties such as difficult purificationEasy to operateSteroidsSodium carbonatePrednisolone acetate

The invention provides a preparation method of 16alpha-hydroxy prednisolone, comprising: subjecting 17alpha-deshydroxy prednisolone acetate as an initial material to 16,17-epoxidation with an organicperoxy acid in a first organic solvent to obtain an epoxide; subjecting the epoxide, in a second organic solvent, to ring-opening reaction with glacial acetic acid under the catalysis of an acid catalyst to obtain 16alpha,21-diacetoxy prednisolone; dissolving 16alpha,21-diacetoxy prednisolone in a third organic solvent, and hydrolyzing acetates in two positions under the catalysis of a solid alkaline catalyst, wherein the solid alkaline catalyst is made by adsorbing sodium carbon or sodium hydroxide to aluminum oxide, silicone or calcium carbonate as a support. The 16alpha-hydroxy prednisoloneis prepared via the method which is efficient, environmentally and fair in cost.

Owner:HUNAN KEREY BIOTECH

Method for preparing 16a-hydroxyprednisolone product

ActiveCN109232697AEasy to operateThe production process is economical and environmentally friendlySteroidsSolid phasesSolvent

The invention provides a method for preparing a 16a-hydroxyprednisolone product. The method comprises the steps that 17a-dehydroprednisolone is used as a raw material, and firstly the starting material 17a-dehydroprednisolone performs an epoxidation reaction with organic peroxide acid at 16 and 17 sites in a first organic solvent to prepare an epoxy material; then the epoxy material reacts with glacial acetic acid under catalysis of an acid catalyst in a second solvent for loop opening, and thus 16a,21-diacetoxyprednisolone is prepared; 16a,21-diacetoxyprednisolone is dissolved in a third organic solvent, under the catalytic action of a solid-phase base catalyst, acetic ester on the two sites are hydrolyzed, and thus 16a-hydroxyprednisolone is prepared; and finally the 16a-hydroxyprednisolone crude product obtained by solid-phase base-catalyzed hydrolysis is heated and refluxed, decolorized, and recrystallized through low-carbon alcohol below C4, and thus the 16a-hydroxyprednisolone product is obtained. According to the method, 16a-hydroxyprednisolone is prepared in an efficient, environment-friendly and low-cost mode.

Owner:HUNAN KEREY BIOTECH

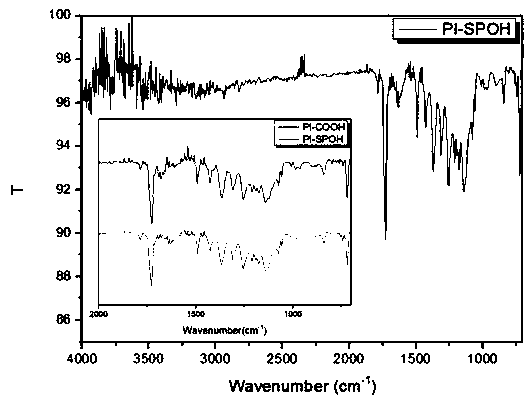

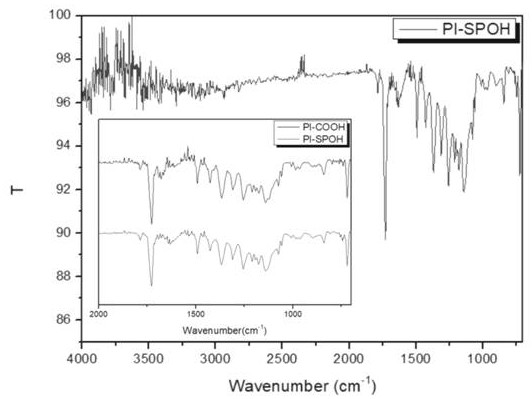

Metal patterned transparent photosensitive polyimide film, and preparation method and application thereof

ActiveCN110923677APhotosensitivitySolubleLiquid/solution decomposition chemical coatingMetal coatingPolymer science

The invention relates to a metal patterned transparent photosensitive polyimide film, and a preparation method and application thereof. The metal patterned transparent photosensitive polyimide film comprises a polyimide film and a patterned metal coating attached to the surface of the polyimide film. The polyimide resin has a structure as shown in a formula (I) or a formula (II). The metal patterned transparent photosensitive polyimide film provided by the invention has photochromic property, solubility and excellent flexibility, and can be used for preparing a circuit board of flexible electronic equipment; the adhesion between the metal coating and the polyimide surface is strong, the coating surface is smooth and fine, and the coating thickness is uniform; and the polyimide resin and the metal in the coating on the polyimide resin can be recycled after the polyimide resin is dissolved, so that zero waste and full recycling of the flexible circuit substrate and related circuit boardproducts are truly realized after the service life of an electronic circuit product is ended, and huge economic benefits and environmental protection significance are achieved.

Owner:SUN YAT SEN UNIV

Preparing method for beta-menadione

ActiveCN109265333ANo peroxidationThe production process is economical and environmentally friendlyQuinone preparation by oxidationBulk chemical productionElectrolysisOrganic solvent

The invention discloses a preparing method for beta-menadione. The preparing method includes the following steps that 1, ceric sulfate is dissolved in a sulfuric acid solution, a ceric sulfate solution is obtained, the beta-methylnaphthalene is dissolved in an organic solvent, and a beta-methylnaphthalene organic solution is obtained; 2, the ceric sulfate solution and the beta-methylnaphthalene organic solution are simultaneously added into a reaction kettle, the mixture is stirred and reacted at the constant temperature, the reaction is ended, cooling crystallization is carried out, and the finished-product beta-menadione is obtained through filtering; 3, the filtered cerous sulfate solution in a liquid phase is separated from the organic solvent, the organic solution is distilled and recycled to be reused, and the cerous sulfate solution is subjected to electrolytic oxidation through a diaphragm to be reused. Chromium oxidation is thoroughly replaced with the preparing method for thebeta-menadione, hexavalent chromium does not exist in the product, the beta-methylnaphthalene is dissolved in an organic phase and reacted, the contact area of the material is larger, the reaction rate is higher, peroxidation of the beta-menadione can be avoided, and the product purity is high.

Owner:SICHUAN YINHE CHEM

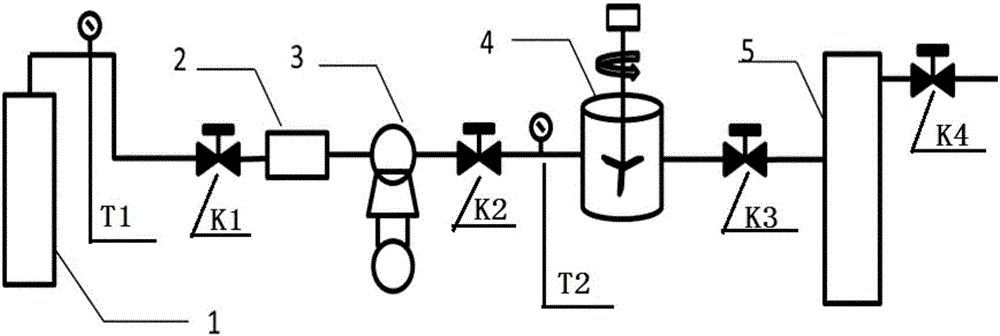

Method for polymer assisted supercritical stripping of transition metal sulfide

InactiveCN107434261AComplete crystal formLess structural defectsNanotechnologyMolybdenum sulfidesMetallic sulfidePolymer chemistry

The invention provides a method for polymer assisted supercritical stripping of transition metal sulfide. The method comprises the following steps: mixing the transition metal sulfide with polyvinylpyrrolidone according to a mass ratio (1-10):1, and placing the obtained mixture in a shearing assisted supercritical device; introducing CO2 into the shearing assisted supercritical device, and carrying out shearing assisted supercritical stripping at a temperature of 32-200 DEG C under a reaction pressure of 8-20 MPa for 10 min to 48 h; and reducing the pressure in the pressure in the shearing assisted supercritical device to half of the reaction pressure or less within 0.1 s after the supercritical stripping, releasing the pressure in the shearing assisted supercritical device to normal pressure, and collecting the above prepared few-layer transition metal sulfide.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

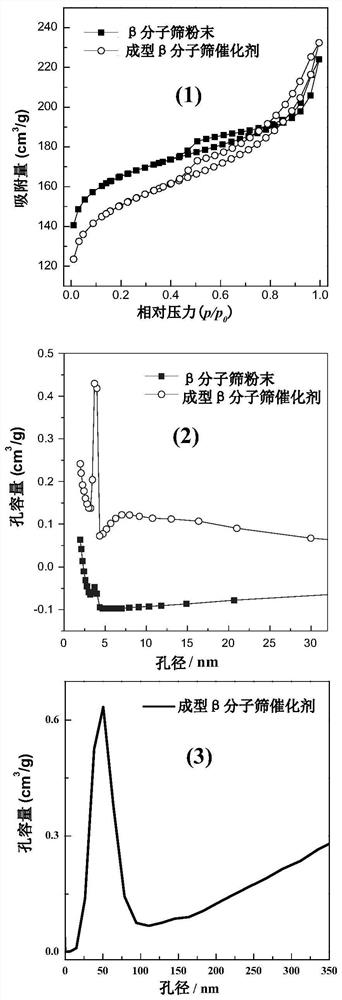

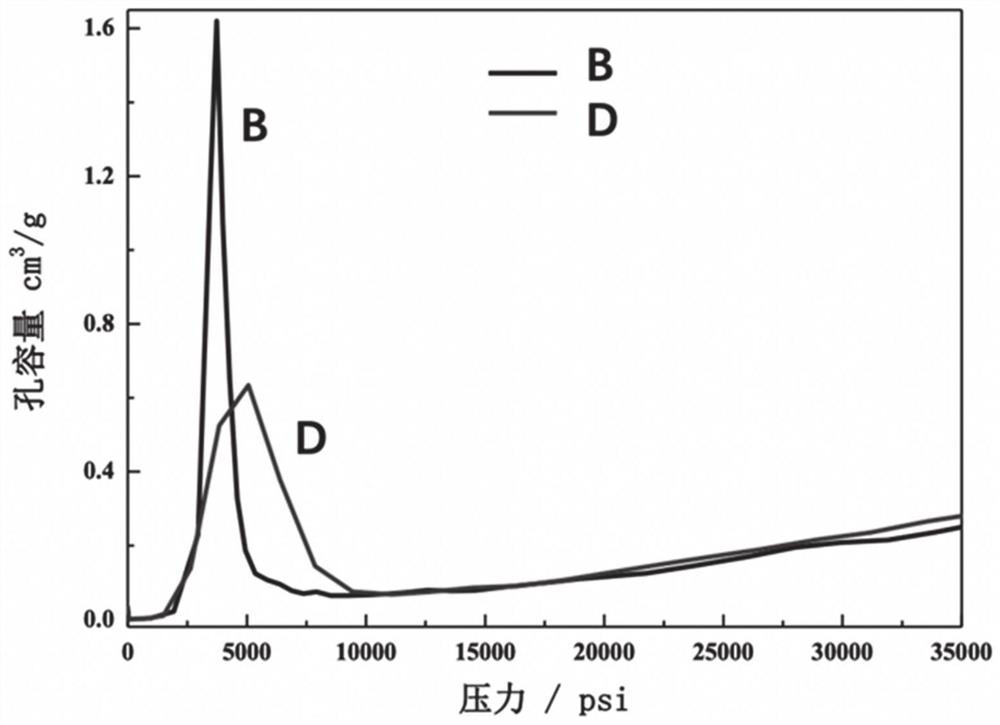

Catalyst and preparation method and application thereof

ActiveCN112007689AExtended service lifeHigh selectivityMolecular sieve catalystsOrganic compound preparationMolecular sievePtru catalyst

The invention discloses a catalyst and a preparation method and application thereof. The catalyst comprises a beta molecular sieve, the catalyst comprises a through-pore channel. The catalyst is provided with a through diffusion pore channel and can be repeatedly utilized; the pore diameter in the range can generate a shape selection effect on the reaction so that the reaction selectivity is improved. Meanwhile, the preparation method of the catalyst is simple.

Owner:DALIAN UNIV OF TECH

Preparation method of finished 16alpha,21-diacetoxy prednisolone

ActiveCN109081860AAvoid many difficulties such as difficult purificationEasy to operateSteroidsAcetic acidAlcohol

The invention provides a preparation method of finished 16alpha,21-diacetoxy prednisolone product, comprising: subjecting 17alpha-deshydroxy prednisolone acetate as an initial material to 16,17-epoxidation with an organic peroxy acid in a first organic solvent to obtain an epoxide; subjecting the epoxide, in a second organic solvent, to ring-opening reaction with glacial acetic acid under the catalysis of an acid catalyst to obtain the target product, 16alpha,21-diacetoxy prednisolone; subjecting the crude 16alpha,21-diacetoxy prednisolone to heating reflux discoloration and crystallization with a lower carbon alcohol of C4 and below so as to obtain the finished 16alpha,21-diacetoxy prednisolone. The intermediate, 16alpha,21-diacetoxy prednisolone, to 16alpha-hydroxy prednisolone is prepared herein via the method that is efficient, environmentally friendly and fair in cost.

Owner:HUNAN KEREY BIOTECH

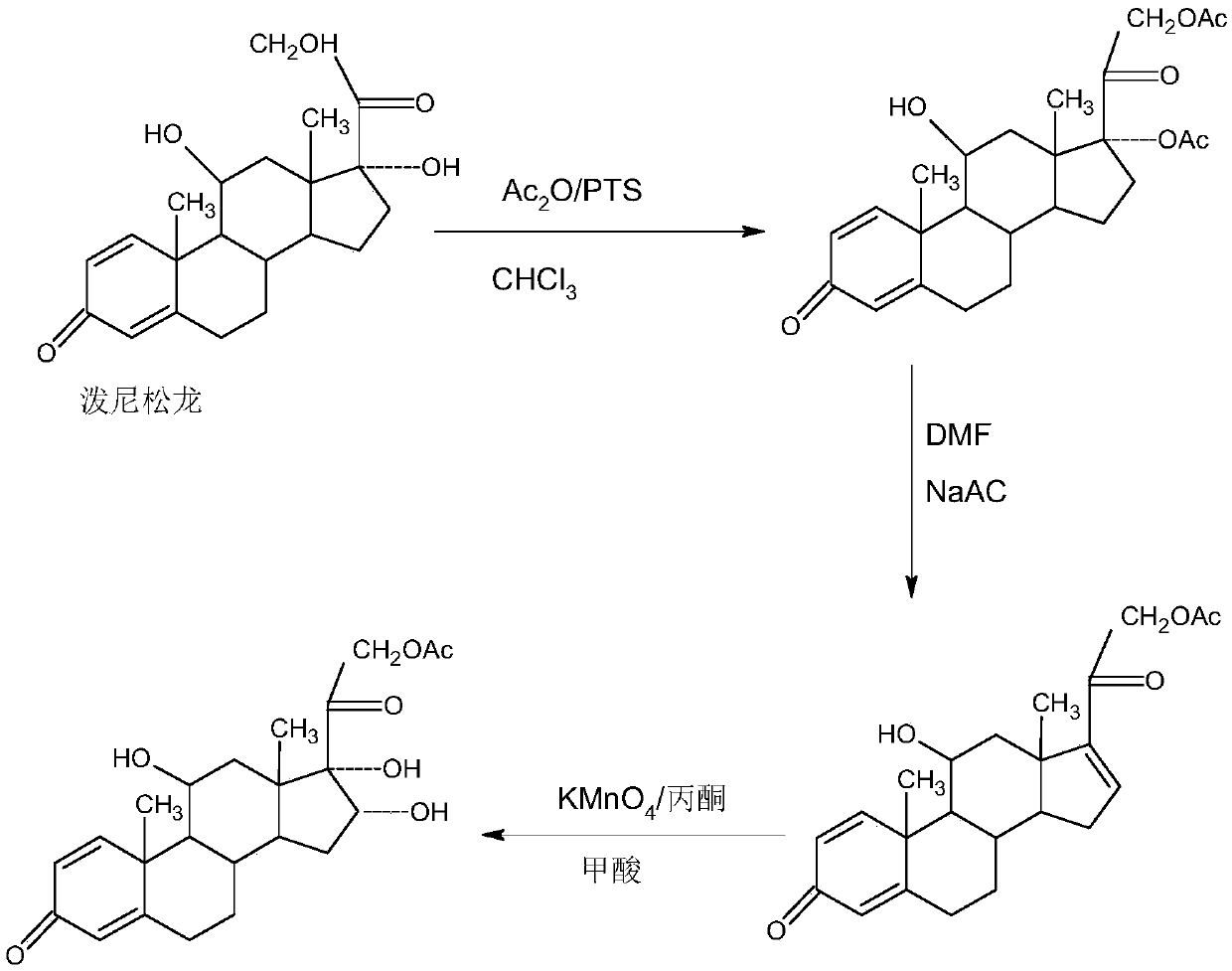

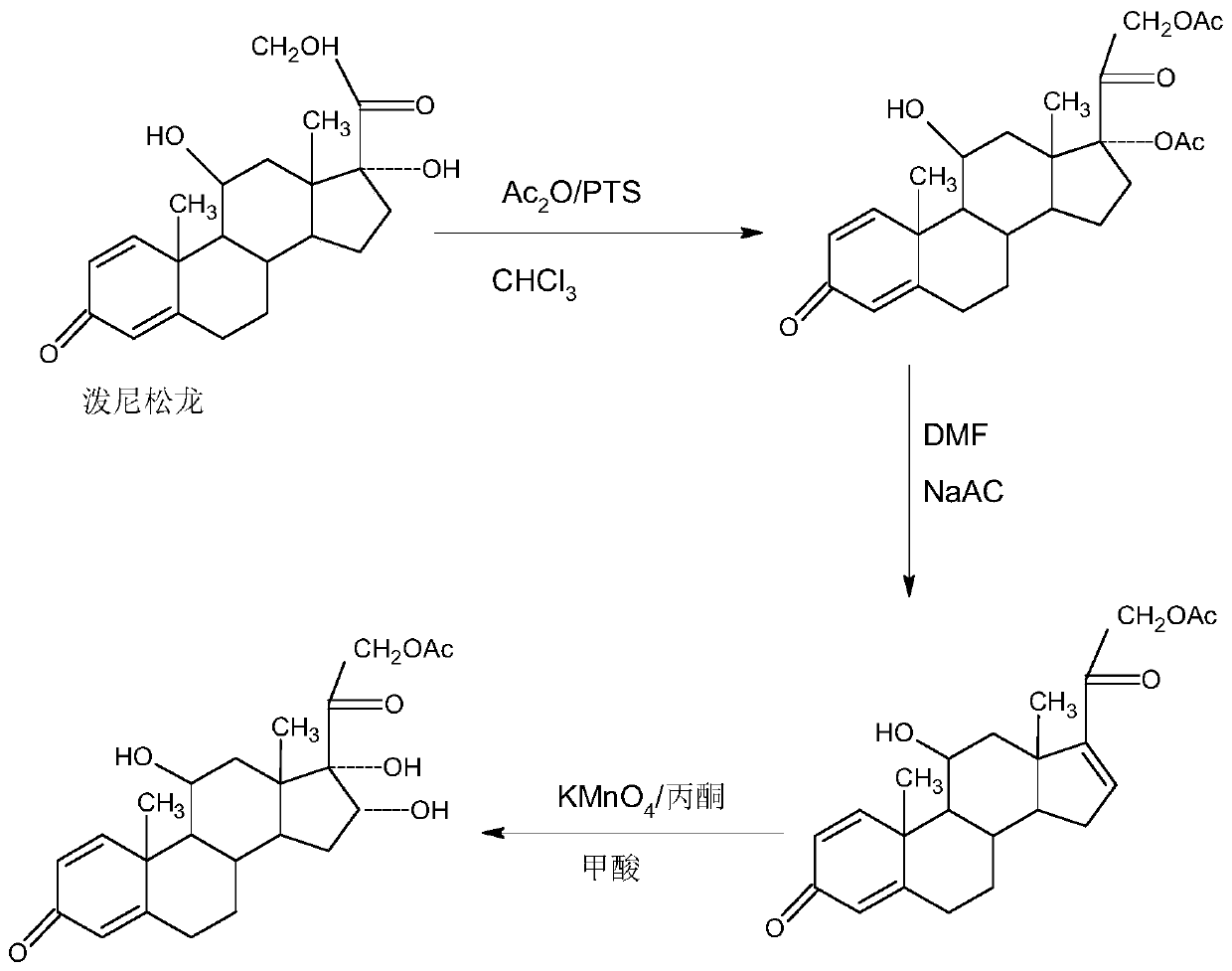

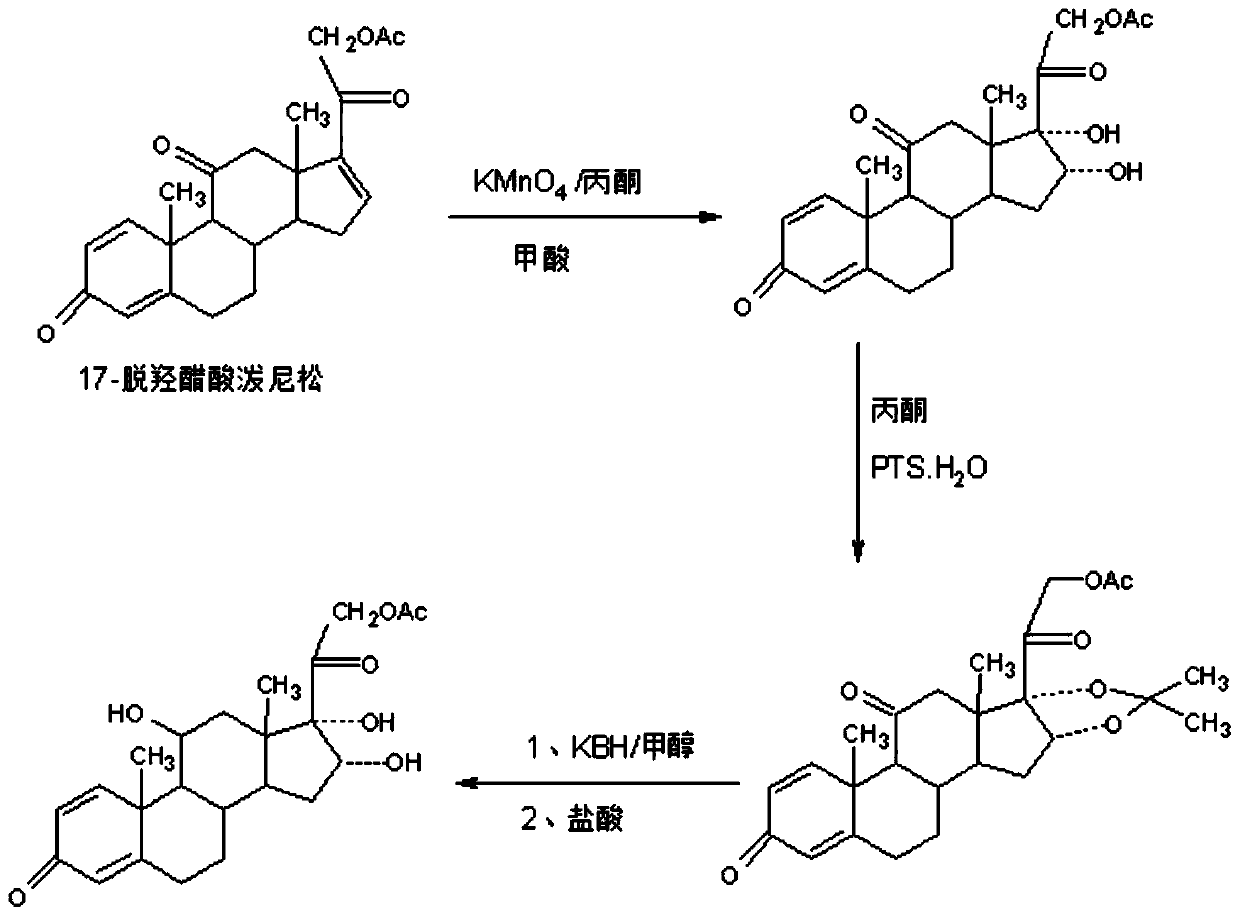

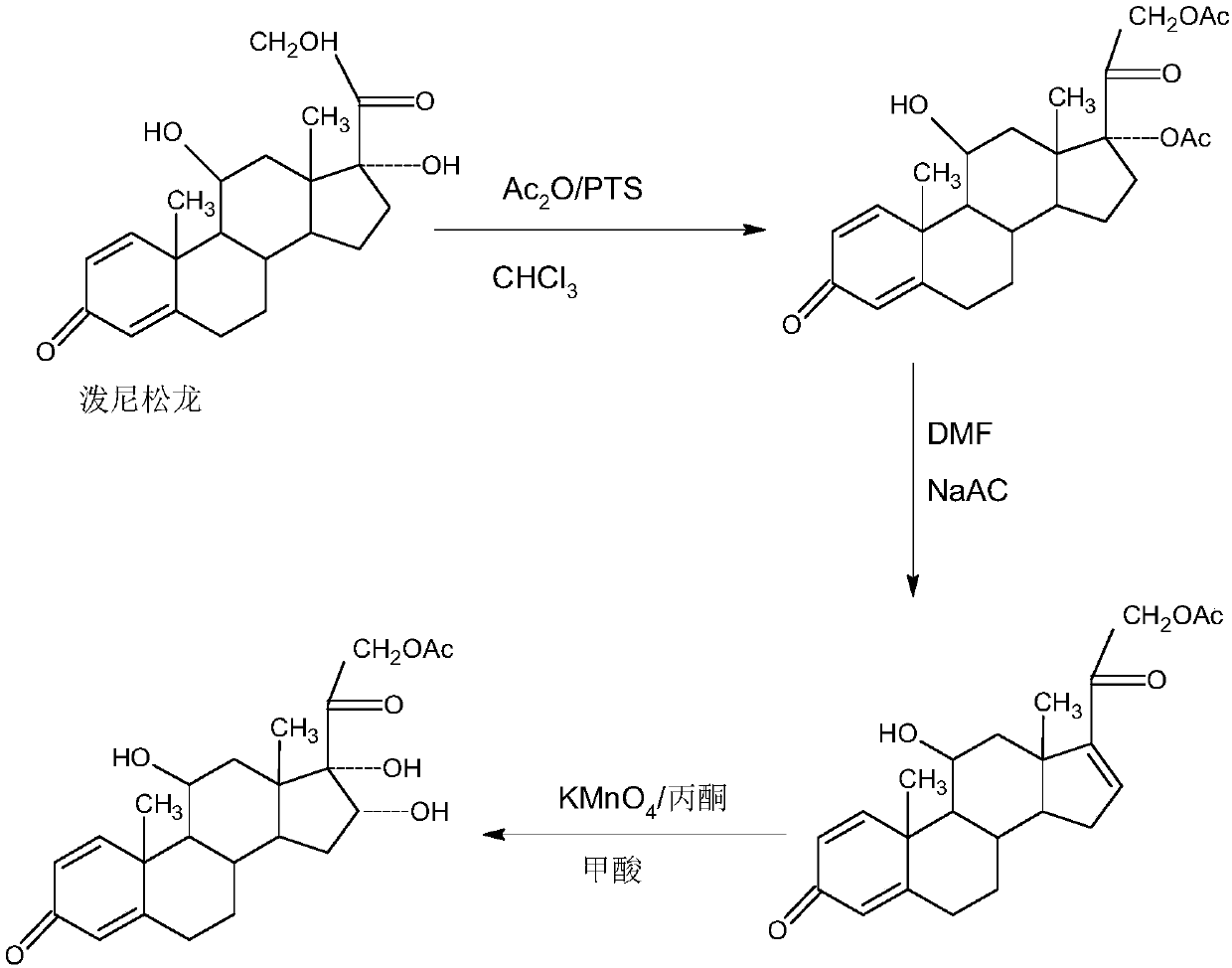

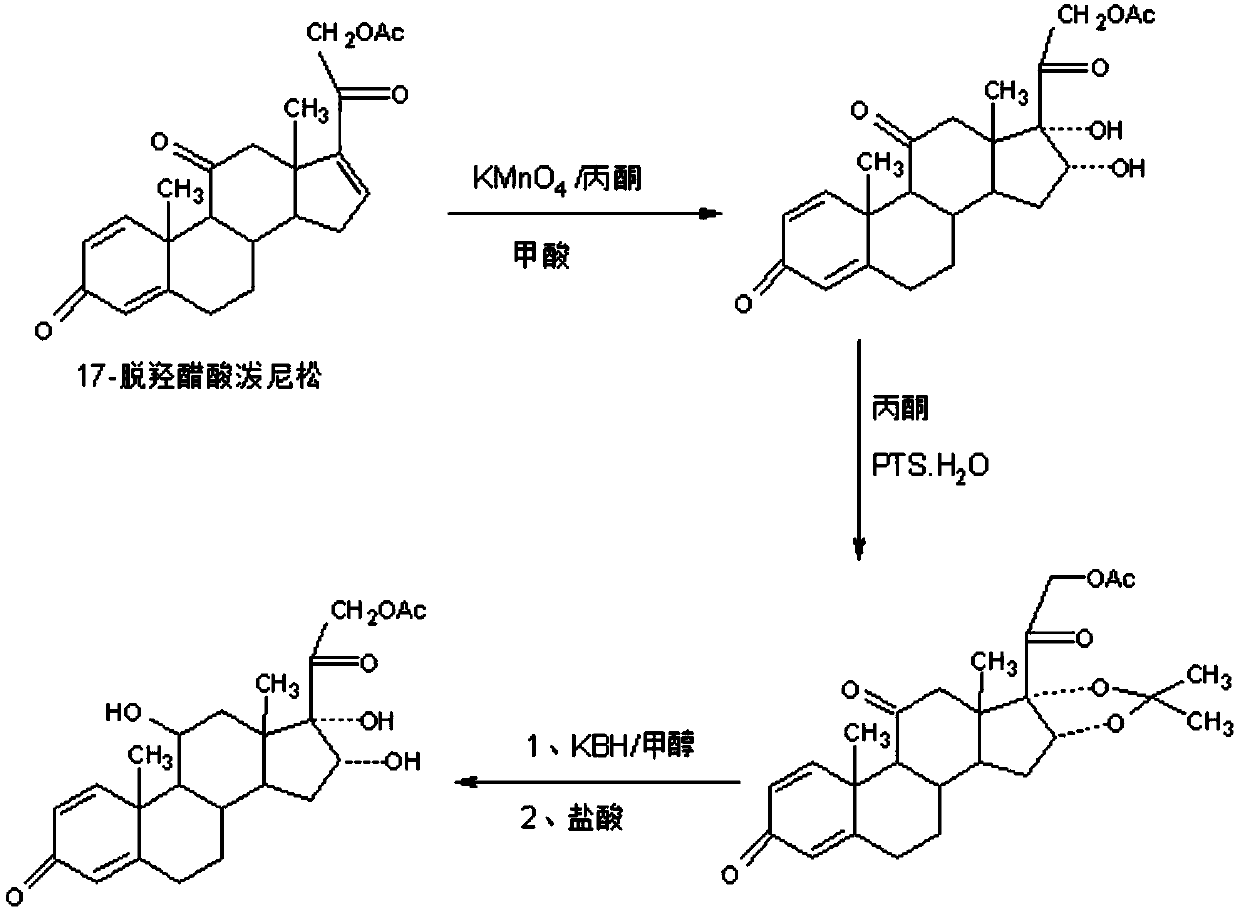

Novel preparation method of 16 alpha-hydroxyprednisolone

A novel preparation method of 16 alpha-hydroxyprednisolone comprises the following steps: dissolving 17-prednisone dehydroxyacetate as a raw material in an organic solvent, oxidizing a 16-position double bond and a 17-position double bond with potassium permanganate under acid catalysis to obtain an oxide, dissolving the obtained oxide in the organic solvent, adding acetone, and carrying out acidcatalysis reaction to obtain a protective substance; then dissolving the protective substance in an organic solvent, adding a reducing agent to reduce the 11-position ketone, and directly adding an acid aqueous solution to perform hydrolysis and deprotection after the reduction reaction to obtain the 16 alpha-hydroxyprednisolone, and dissolving 16 alpha -hydroxyacetate in an organic solvent, hydrolyzing 21-position acetic ester under the catalysis of solid-phase base to obtain 16 alpha -hydroxyprednisolone. Although two steps of the protection reaction and deprotection reaction are added, thereaction yield of each step unit is high, and the operation is simple and convenient, and the process is economical and environment-friendly, and the total synthesis yield is greatly improved; and compared with the traditional production method, the preparation cost of the method is reduced by 20-25%.

Owner:HUNAN KEREY BIOTECH

Refined natural spice liquid suitable for electronic cigarette liquid, smoke liquid and preparation method thereof

ActiveCN105029681BLarge specific surface areaGood macroporous network structureTobacco treatmentSolubilityLiquid smoke

The invention discloses natural perfume refining fluid suitable for cigarette fluid of electronic cigarettes and cigarette fluid and a preparation method thereof, and belongs to the technical field of cigarette fluid of electronic cigarettes. Separation and impurity removal are performed on natural perfume such as extract, tincture and absolute oil through a macroporous adsorption resin column chromatography technology, high-boiling-point components such as monosaccharide and disaccharide and macromolecular components such as protein, polysaccharide and pectin in the natural perfume are simultaneously and effectively removed according to the differences of polarities and molecular sizes of all the components in the mixture, the components unfavorable for the smoking mouthfeel of the electronic cigarettes are removed, and the problem that charring flavor is generated due to the fact that the substances are deposited on heating wires is solved; meanwhile, the solubleness of the natural perfume in propylene glycol and glycerinum is improved, therefore, the cigarette fluid of the electronic cigarettes becomes clear and bright, the emission performance of perfume is significantly improved, the sweet greasy feeling is reduced, and the sensory effect is significantly improved.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

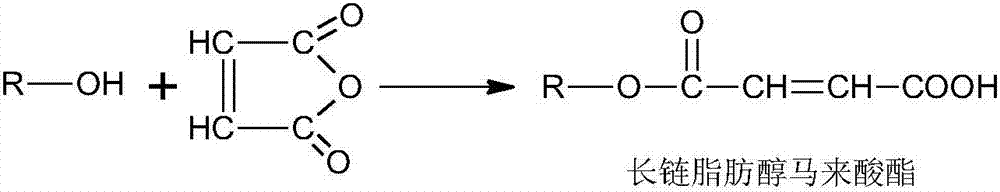

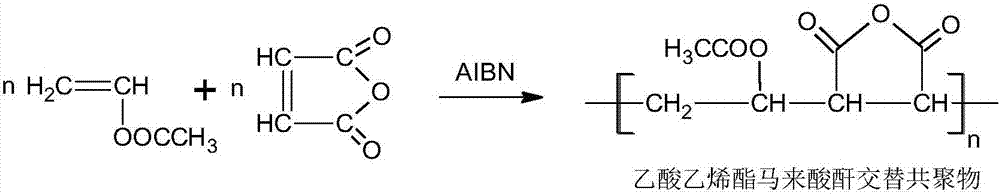

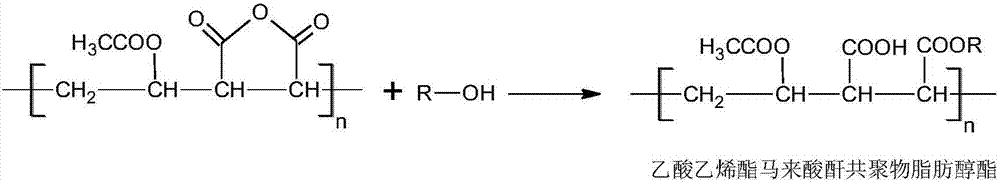

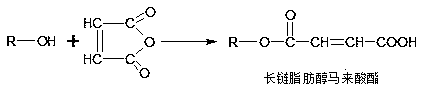

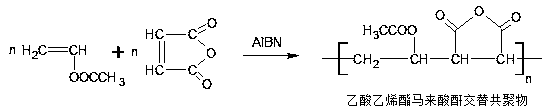

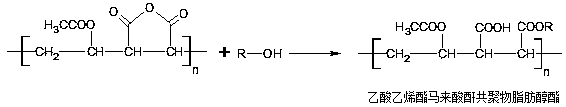

High-combination leather fatting agent and preparing method thereof

InactiveCN107988447AImprove bindingThe production process is economical and environmentally friendlyOrganic compound preparationCarboxylic acid esters preparationEnvironmental resistanceSolvent

The invention discloses a high-combination leather fatting agent and a preparing method thereof. The preparing method comprises the following steps that (1) a certain amount of long-chain fatty alcohol and maleic anhydride are added into a reactor, the temperature is raised to 80 DEG C-90 DEG C for esterification reaction, and a product A is obtained; (2) the product A is cooled to 70 DEG C-75 DEGC, a certain quantity of initiator, namely azodiisobutyronitrile is added, a certain amount of monomer acetic acid vinyl ester is dropped in for a polymerization reaction, and a product B is obtained; (3) the product B is heated to 100 DEG C-110 DEG C, a certain amount of long-chain fatty alcohol is added for an esterification reaction, and a product C is obtained; and (4) the product C is cooledto 65 DEG C-70 DEG C, a sodium hydroxide solution with the mass concentration being 30% is used for neutralizing the pH of a reactant to 7.0, then a certain quantity of sulfite aqueous solution is added, a sulfitation reaction is carried out at 80 DEG C-90 DEG C, and the high-combination leather fatting agent is obtained after cooling. The high-combination leather fatting agent and the preparingmethod have the beneficial effects that the process is simple, clean and environment-friendly, the produced product is excellent in acid-resisting stability, fat liquoring effect, filling performance,solvent extraction performance and the like, and the effluent COD content can be reduced.

Owner:WENZHOU UNIVERSITY

Method for preparing 16a, 21-diacetoxyprednisolone product

ActiveCN109180764AEasy to operateThe production process is economical and environmentally friendlySteroidsOrganic solventAlcohol

The invention provides a method for preparing a 16a, 21-diacetoxyprednisolone product. The method comprises that 17a-dehydroxyprednisolone as a raw material and an organic peroxyacid undergo an epoxidation reaction at the 16th and 17th in a first organic solvent to produce an epoxy, the epoxy and glacial acetic acid undergo a ring opening reaction in a second organic solvent in the presence of anacid catalyst to produce a desired product 16a, 21-diacetoxyprednisolone, and the crude 16a, 21-diacetoxyprednisolone is subjected to heating reflux in C1-4 lower alcohol so that the 16a, 21-diacetoxyprednisolone is decolorized and recrystallized and a 16a, 21-diacetoxyprednisolone product is obtained. The method is efficient and environmentally friendly, realizes a low cost and can prepare the 16a-hydroxyprednisolone intermediate 16a, 21-diacetoxyprednisolone.

Owner:HUNAN KEREY BIOTECH

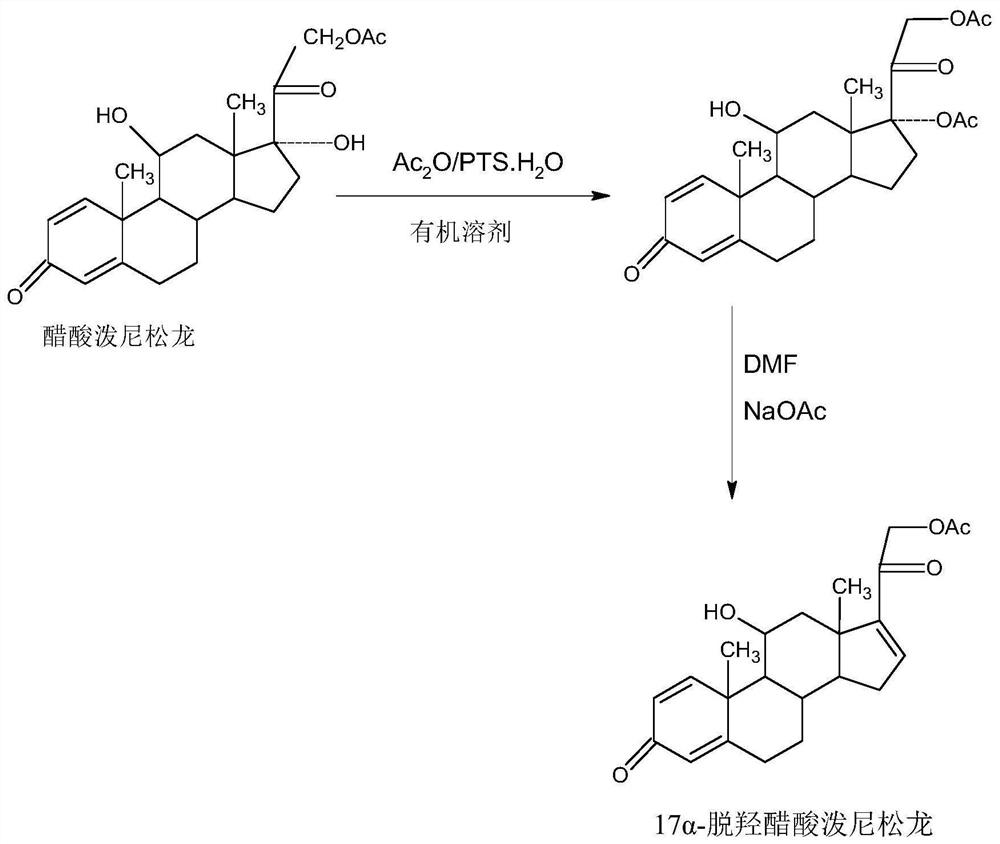

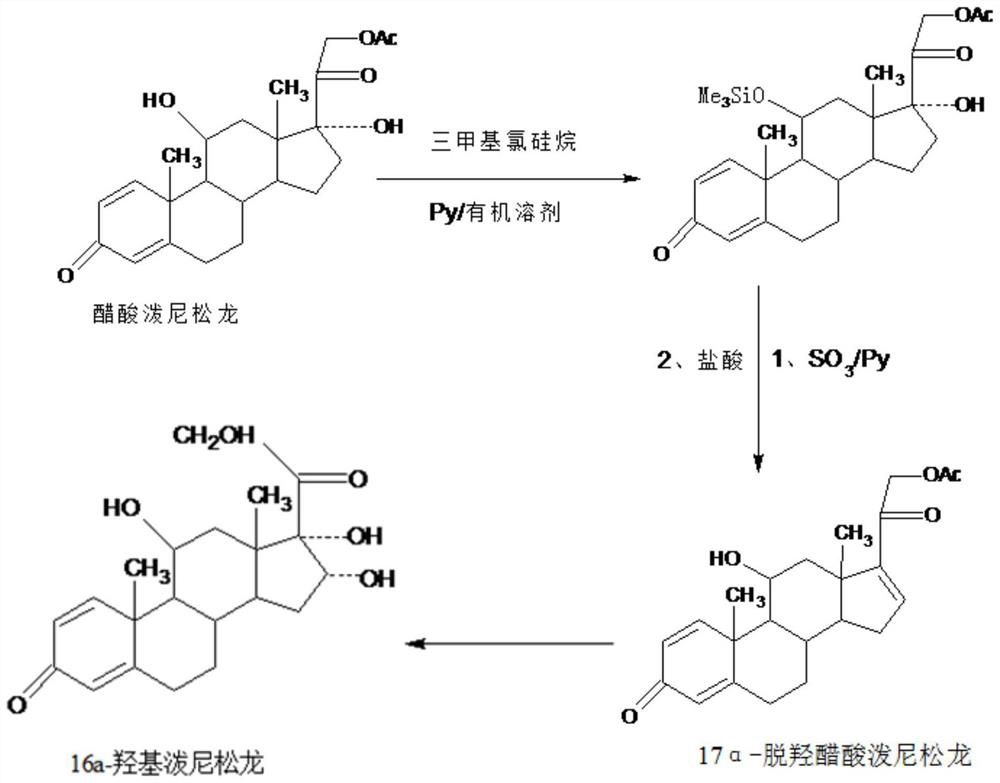

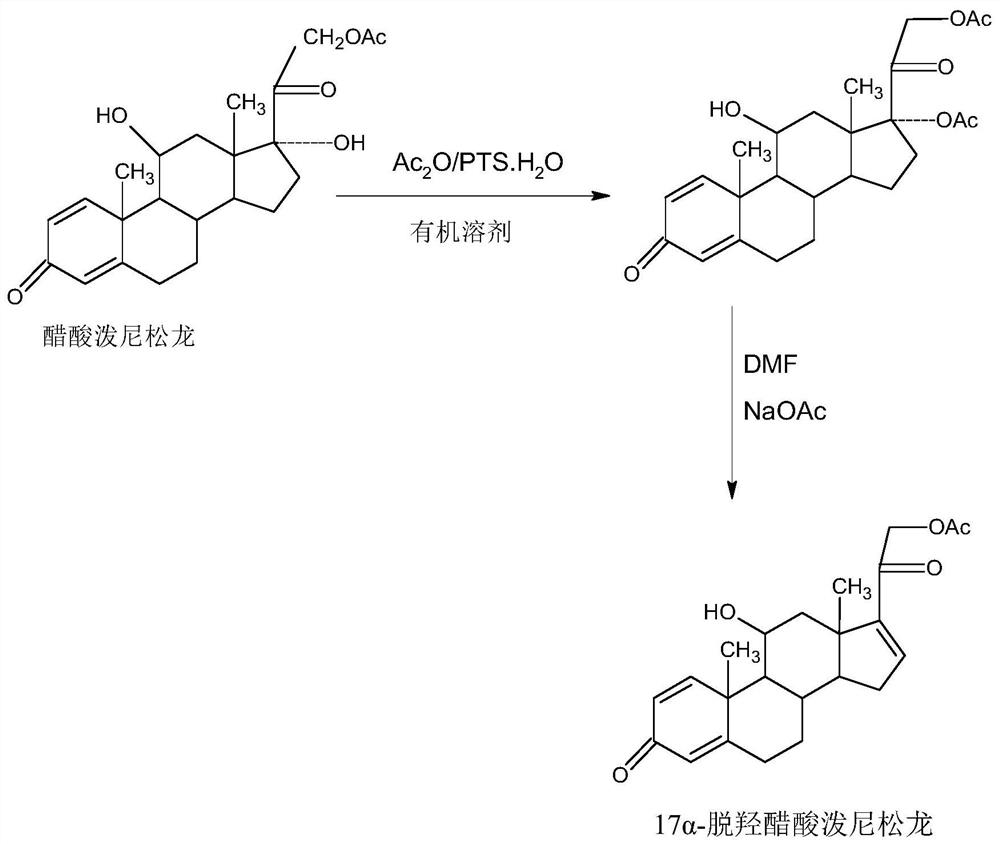

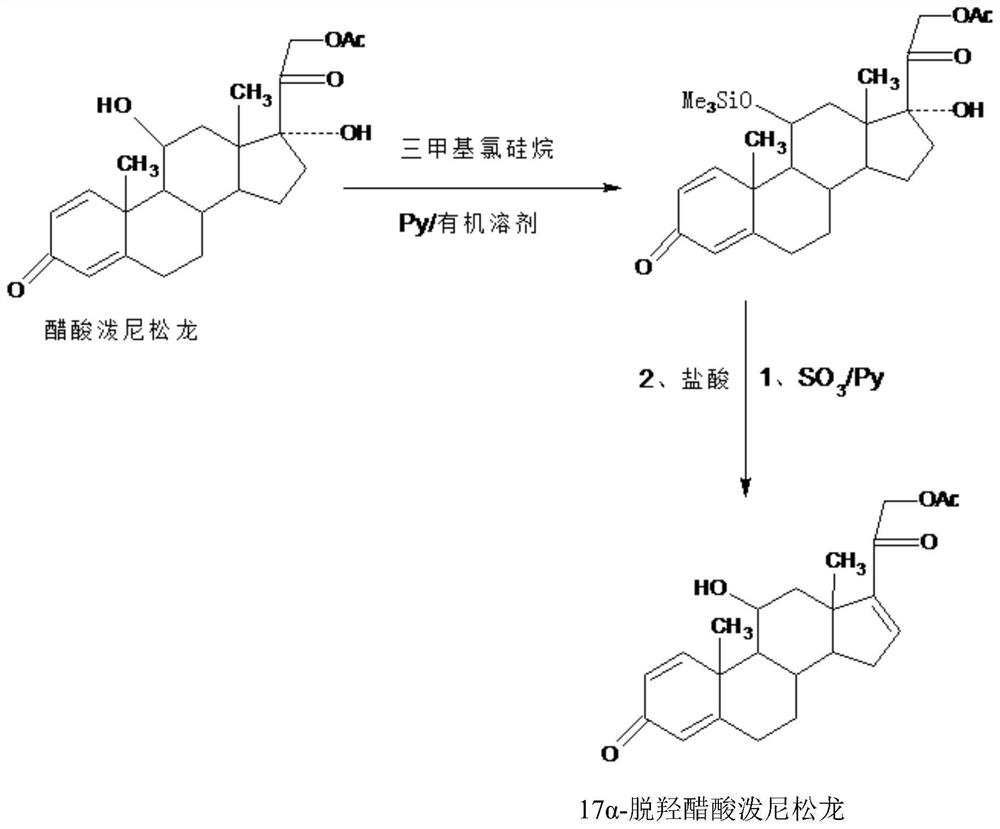

A new method for preparing 16a-hydroxyprednisolone

The invention provides a new method for preparing 16alpha-hydroxyprednisolone. The method comprises the following steps that A, a protector is prepared, wherein prednisolone acetate and trimethylchlorosilane are catalyzed by organic base to generate a 11th-site silicon etherification reaction, and then the protector is obtained; B, dehydration, hydrolysis deprotection and refining are conducted, wherein the protector and SO3 are catalyzed by organic base to generate a 17th-site dehydration reaction, after the reaction, acid is directly added to make the 11th site deprotected, and a crude 17alpha-dehydroxylated prednisolone acetate product is obtained; the crude product is refined to obtain a 17alpha-dehydroxylated prednisolone acetate product; C, the 17alpha-dehydroxylated prednisolone acetate product is used as a raw material to prepare the 16alpha-hydroxyprednisolone. The problems are solved that in a traditional production technology of the 17alpha-dehydroxylated prednisolone acetate, more side reactions and impurities are generated in the dehydration process, and the impurities are difficult to refine; the total yield of the synthesized 16alpha-hydroxyprednisolone is greatly improved, and the production cost is reduced.

Owner:HUNAN KEREY BIOTECH

A kind of preparation method of β-menaquinone

ActiveCN109265333BNo peroxidationThe production process is economical and environmentally friendlyQuinone preparation by oxidationBulk chemical productionOrganic solventFluid phase

The invention discloses a preparation method of β-menadione, comprising the following steps: step 1, dissolving ceric sulfate in a sulfuric acid solution to obtain a ceric sulfate solution, dissolving β-methylnaphthalene in an organic solvent, Obtain the β-methylnaphthalene organic solution; Step 2, add the ceric sulfate solution and the β-methylnaphthalene organic solution into the reaction kettle at the same time, keep the temperature and stir for the reaction, after the reaction, cool down and crystallize, and obtain the finished product β-methylnaphthalene through filtration Menadione; step 3, separating the cerium sulfate solution and the organic solvent in the liquid phase obtained by filtration, recycling the organic solution after distillation and recycling, and recycling the cerium sulfate solution after electrolytic oxidation of the diaphragm. The preparation method of β-menadione of the present invention completely replaces the oxidation of chromium, so that the product does not contain hexavalent chromium, and β-methylnaphthalene is dissolved in the organic phase for reaction. The material contact area is larger, and the reaction rate is faster. β ‑ Menadione will not peroxidize and the product is of high purity.

Owner:SICHUAN YINHE CHEM

A kind of method for preparing 16a-hydroxyprednisolone

ActiveCN109265507BEasy to operateThe production process is economical and environmentally friendlySteroidsPtru catalystOrganosolv

Owner:HUNAN KEREY BIOTECH

A kind of method for preparing 16a-hydroxyprednisolone product

ActiveCN109232697BEasy to operateThe production process is economical and environmentally friendlySteroidsPtru catalystOrganosolv

The invention provides a method for preparing a 16a-hydroxyprednisolone product. The method comprises the steps that 17a-dehydroprednisolone is used as a raw material, and firstly the starting material 17a-dehydroprednisolone performs an epoxidation reaction with organic peroxide acid at 16 and 17 sites in a first organic solvent to prepare an epoxy material; then the epoxy material reacts with glacial acetic acid under catalysis of an acid catalyst in a second solvent for loop opening, and thus 16a,21-diacetoxyprednisolone is prepared; 16a,21-diacetoxyprednisolone is dissolved in a third organic solvent, under the catalytic action of a solid-phase base catalyst, acetic ester on the two sites are hydrolyzed, and thus 16a-hydroxyprednisolone is prepared; and finally the 16a-hydroxyprednisolone crude product obtained by solid-phase base-catalyzed hydrolysis is heated and refluxed, decolorized, and recrystallized through low-carbon alcohol below C4, and thus the 16a-hydroxyprednisolone product is obtained. According to the method, 16a-hydroxyprednisolone is prepared in an efficient, environment-friendly and low-cost mode.

Owner:HUNAN KEREY BIOTECH

A kind of preparation method of 17a-prednisolone dehydroxyacetate product

The invention provides a preparation method of a 17a-dehydroxy prednisolone acetate product. The method includes the following steps: step A, dissolving prednisolone acetate in a first organic solvent, and subjecting the solvent and trimethylchlorosilane to 11th-position silicon etherification reaction under the catalysis of organic base to obtain a protector; step B, in a second organic solvent,subjecting the protector and SO3 to 17th-position dehydration reaction under the catalysis of the organic base, directly adding acid for treatment after the reaction to deprotect the 11th position, and obtaining a crude 17a-dehydroxy prednisolone acetate product; subjecting the crude product to decolorization and recrystallization in the presence of C4-below low carbon alcohol and activated carbonto obtain the 17a-dehydroxy prednisolone acetate product. The preparation method has the advantages that the problems such as many side reactions and impurities and difficulty in impurity refining inthe dehydration reaction in a traditional production process of 17a-dehydroxy prednisolone acetate are solved, the total synthesis yield is remarkably increased, and the production cost is reduced.

Owner:HUNAN KEREY BIOTECH

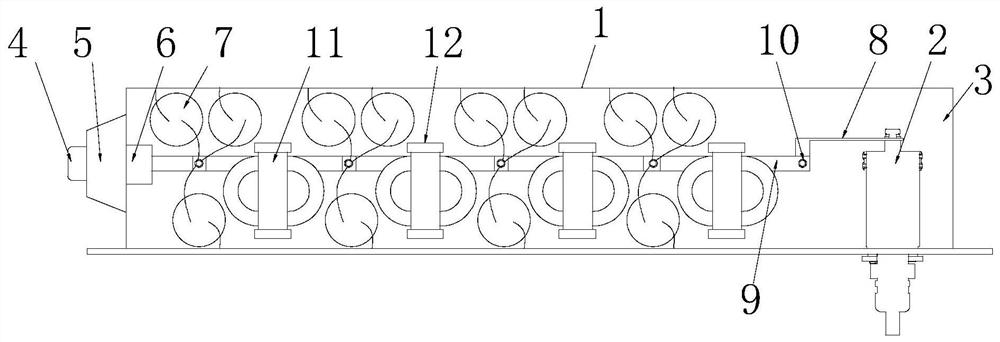

Single-phase power supply filter with novel structure

PendingCN113471975AHigh outputSolve complex structuresMultiple-port networksCasings/cabinets/drawers detailsCapacitanceCable gland

The invention relates to the technical field of single-phase power supply filters, and discloses a single-phase power supply filter with a novel structure. The single-phase power supply filter comprises a single-phase power supply filter, a feed-through filter is fixedly connected in the single-phase power supply filter, and a shell is fixedly mounted on the outer surface of the single-phase power supply filter. The interior of the feed-through filter is electrically connected with a feed-through capacitor, the inner wall of the feed-through filter is fixedly connected with a first silk screen gasket, and the outer surface of the feed-through filter is connected with a second silk screen gasket in a clamped mode. According to the single-phase power supply filter with the novel structure, a single-phase power supply signal is directly accessed from a cable gland I, and the cable gland I is used for rotationally fixing a connecting part, so that the incoming line of the single-phase power supply filter is fixed, and then the single-phase power supply signal subjected to filtering processing is transmitted to a load by a cable; and the signal processed by the single-phase power supply filter is conveniently output, so that a wire inlet cabin and a wire outlet cabin are omitted, and the effect of simplifying the product structure is achieved.

Owner:江苏沃姆克电子科技有限公司

Preparation method of 16a-hydroxy prednisolone acetate product

A preparation method of a 16a-hydroxy prednisolone acetate product includes dissolving 17-dehydroxy prednisone acetate as a raw material in an organic solvent, oxidizing 16 and 17 double bonds by potassium permanganate under acid catalysis to obtain an oxide, dissolving the obtained oxide in an organic solvent, adding acetone, and carrying out acid catalyzed reaction to obtain a protector; dissolving the protector in an organic solvent, adding a reducing agent to reduce ketone at the 11th position, directly adding an acid water solution for hydrolysis and deprotection after the reduction reaction to obtain 16a-hydroxy prednisolone acetate, and subjecting the crude product to decoloration and recrystallization by low-carbon-alcohol heating reflux to obtain the 16a-hydroxy prednisolone acetate product. Although two reaction steps, protection and deprotection, are added, the reaction yield of units in each step is high, the method is simple and convenient to operate, the process is economical and environmentally friendly, and the total synthesis yield is increased remarkably; the preparation cost of the preparation method is 20-25% lower than that of conventional production methods.

Owner:HUNAN KEREY BIOTECH

A kind of preparation 16a, the method for 21-diacetyloxy prednisolone

ActiveCN109251230BEasy to operateThe production process is economical and environmentally friendlySteroidsAcetic acidPtru catalyst

The invention provides a method for preparing 16a,21-diacetyloxy prednisolone. The method comprises the following steps: adopting 17a-deshydroxy prednisolone as a raw material, firstly, enabling the starting raw material 17a-deshydroxy prednisolone to generate epoxidation reaction with organic peroxy acid on 16 and 17 sites in a first organic solvent to prepare an epoxy product; enabling the epoxyproduct to react with glacial acetic acid under the catalysis of an acid catalyst in a second organic solvent to be subjected to ring opening, to prepare a target product, i.e., 16a,21-diacetyloxy prednisolone. According to the efficient, environment-friendly and fair-price method, the intermediate 16a,21-diacetyloxy prednisolone of 16 alpha-hydroxyprednisolone is prepared.

Owner:HUNAN KEREY BIOTECH

Preparation method of 16a-prednisolone hydroxyacetate

Disclosed is a preparation method of 16a-prednisolone hydroxyacetate. The method comprises dissolving 17-prednison dehydroxylated acetate as the raw material into organic solvent, under catalysis of acids, oxidizing 16th and 17th double bonds through potassium permanganate to obtain an oxide, and dissolving the oxide into acetone for acid-catalyzed reaction to obtain a protector; dissolving the protector into organic solvent, adding in reducing agent to reduce 11th ketone, then directly adding in acid aqueous solution for hydrolysis and deprotection to obtain the 16a-prednisolone hydroxyacetate. Although the preparation method of the 16a-prednisolone hydroxyacetate adds the two reaction steps of protection and deprotection, every unit reaction is high in yield, the third and fourth reaction steps can be completed within on pot, so that the production operation can be simple and convenient, the production processes are economical and environmentally friendly, the problems of many side reactions and impurities and difficulty impurity refining of oxidation reaction in traditional production process can be greatly solved, the total synthesizing yield can be greatly increased, and compared with traditional production methods, the preparation method of the 16a-prednisolone hydroxyacetate can reduce the production cost by 20-25%.

Owner:HUNAN KEREY BIOTECH

A kind of metal patterned transparent photosensitive polyimide film and its preparation method and application

ActiveCN110923677BSimplify the assembly line production processSimple production processLiquid/solution decomposition chemical coatingPolymer scienceFlexible circuits

The invention relates to a metal patterned transparent photosensitive polyimide film and its preparation method and application. The metal-patterned transparent photosensitive polyimide film comprises a polyimide film and a patterned metal coating attached to the surface of the polyimide film; the polyimide resin has formula (I) or formula (II) Structure shown: the metal patterned transparent photosensitive polyimide film provided by the invention has photochromism, solubility and excellent flexibility, and can be used to prepare circuit boards for flexible electronic devices; the metal coating is attached to the surface of the polyimide The surface of the coating is smooth and fine, and the thickness of the coating is uniform; after dissolving it, the polyimide resin and the metal in the coating on it can be recycled, which truly realizes the flexible circuit after the end of the service life of the electronic circuit product. Zero waste and full recycling of substrates and related circuit board products have huge economic benefits and environmental protection significance.

Owner:SUN YAT SEN UNIV

A kind of preparation method of 16a-hydroxyprednisolone

ActiveCN107488203BInhibition of rearrangement and ring expansion side reactionsReduce generationPhysical/chemical process catalystsSteroidsOrganic solventAlcohol

Owner:HUNAN KEREY BIOTECH

A kind of 16a, the preparation method of 21-diacetyloxyprednisolone product

ActiveCN109081860BAvoid many difficulties such as difficult purificationEasy to operateSteroidsAcetic acidPtru catalyst

The invention provides a preparation method of finished 16alpha,21-diacetoxy prednisolone product, comprising: subjecting 17alpha-deshydroxy prednisolone acetate as an initial material to 16,17-epoxidation with an organic peroxy acid in a first organic solvent to obtain an epoxide; subjecting the epoxide, in a second organic solvent, to ring-opening reaction with glacial acetic acid under the catalysis of an acid catalyst to obtain the target product, 16alpha,21-diacetoxy prednisolone; subjecting the crude 16alpha,21-diacetoxy prednisolone to heating reflux discoloration and crystallization with a lower carbon alcohol of C4 and below so as to obtain the finished 16alpha,21-diacetoxy prednisolone. The intermediate, 16alpha,21-diacetoxy prednisolone, to 16alpha-hydroxy prednisolone is prepared herein via the method that is efficient, environmentally friendly and fair in cost.

Owner:HUNAN KEREY BIOTECH

A kind of high combination leather fatliquoring agent and preparation method thereof

InactiveCN107988447BImprove bindingThe production process is economical and environmentally friendlyOrganic compound preparationCarboxylic acid esters preparationSulfite saltFatty alcohol

The invention discloses a high-combination leather fatliquoring agent and a preparation method thereof, comprising the following steps: (1) adding a certain amount of long-chain fatty alcohol and maleic anhydride into a reactor, raising the temperature to 80-90°C for esterification , to obtain product A; (2) cooling product A to 70-75° C., adding a certain amount of initiator azobisisobutyronitrile, and then dropwise adding a certain amount of monomer vinyl acetate to carry out polymerization reaction to obtain product B; (3 ) raising the temperature of product B to 100-110°C, adding a certain amount of long-chain fatty alcohol for esterification reaction to obtain product C; (4) cooling product C to 65-70°C, using 30% sodium hydroxide The aqueous solution neutralizes the pH of the reactant to 7.0, then adds a certain amount of sulfite aqueous solution, and carries out sulfitation reaction at 80-90°C, and after cooling down, a high-binding leather fatliquoring agent is obtained. The invention has the advantages of simple process, clean and environment-friendly, and the prepared product has excellent properties such as acid resistance stability, fatliquoring effect, filling performance and solvent extraction resistance, and can reduce the COD content of waste liquid.

Owner:WENZHOU UNIV

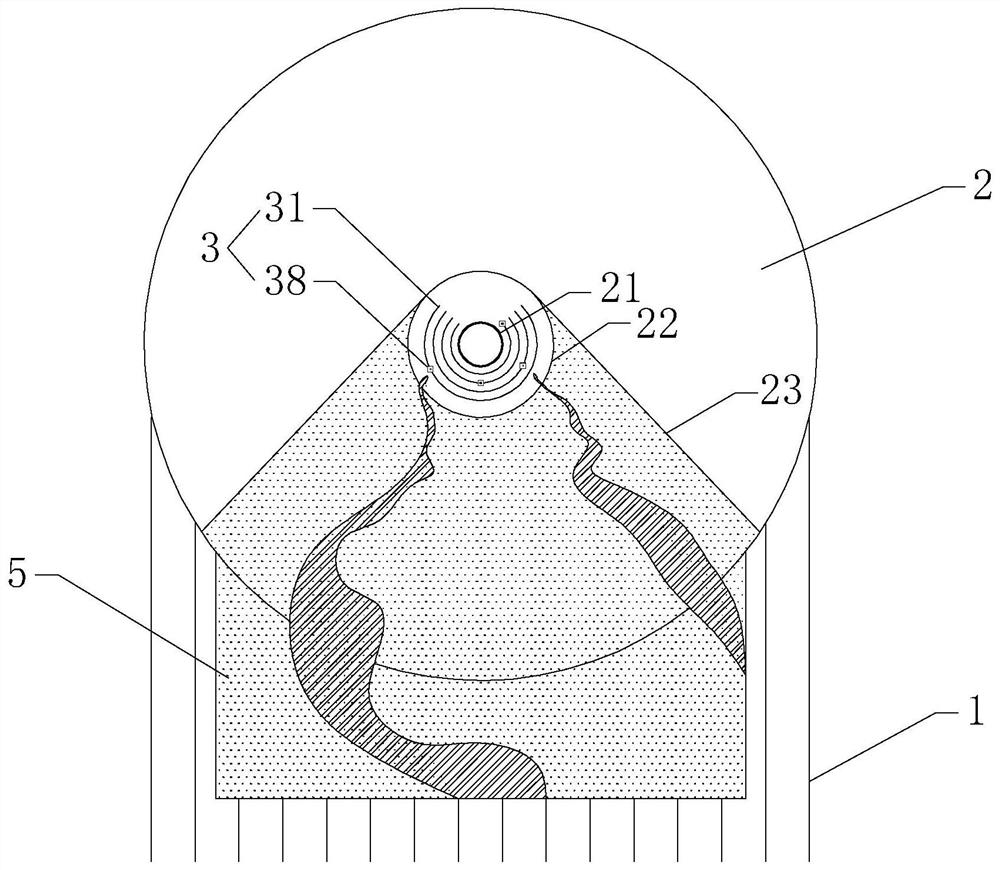

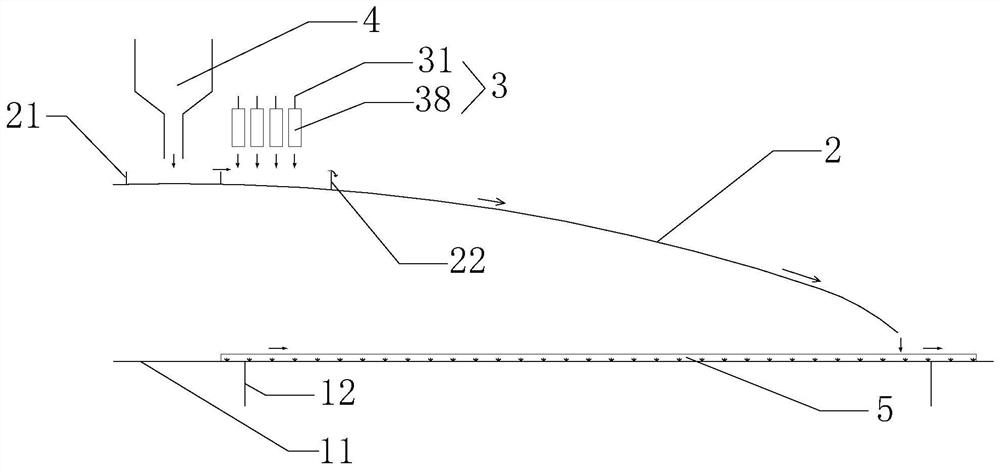

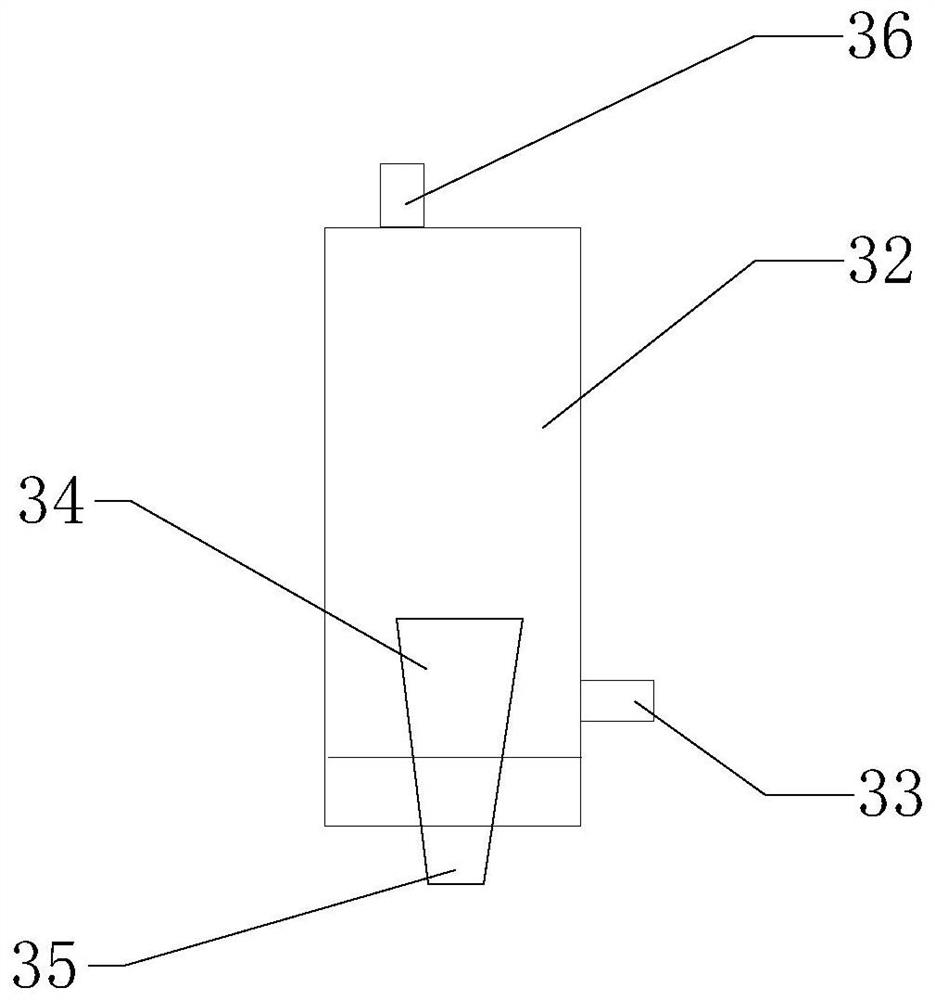

Digital guniting decorative ceramic tile and production device and production method thereof

PendingCN114454322AExpand potentialEconomic and environmental protectionCeramic shaping plantsSpecial ornamental structuresCeramic tilesGreen body

The invention relates to the field of ceramics, and discloses a digital guniting decorative ceramic tile and a production device and method thereof. The spraying clock is positioned above the ceramic green brick conveying mechanism; the basic slurry applying mechanism is positioned above the spraying clock; and the movable digital guniting mechanism is positioned above the ceramic green brick conveying mechanism and is positioned at the upstream or downstream of the spraying clock or right above the spraying clock. Decorative slurry is positioned and distributed through the movable digital slurry spraying mechanism, and is combined and matched with basic slurry which is sprayed and distributed, so that a natural and varied decorative slurry layer with various textures can be formed on the surface of a ceramic tile green body, ceramic tile surface decoration means are innovated and enriched, and the ceramic tile surface decoration effect is improved. And the ceramic tile with a new decorative effect can be obtained through subsequent processing. Compared with an existing product, the potential possibility of product pattern design is greatly expanded, the production process is economical and environmentally friendly, and the process controllability is high.

Owner:HANGZHOU NABEL CERAMIC +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com