Method for polymer assisted supercritical stripping of transition metal sulfide

A polymer-assisted, transition metal technology, used in chemical instruments and methods, molybdenum sulfide, tungsten compounds, etc., can solve the problems of long production cycle, surface and end defects, high production cost, and achieve economical and environmental protection in the production process. Less, complete crystal form effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

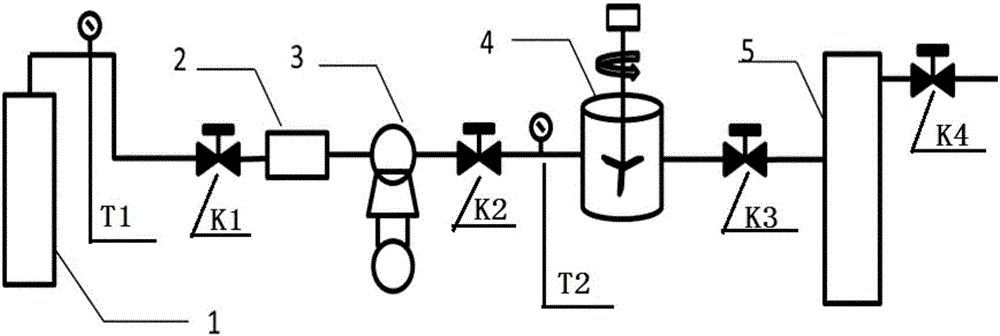

[0038] This embodiment provides a method for polyvinylpyrrolidone shear-assisted supercritical stripping of molybdenum disulfide, which adopts a device such as figure 1 As shown, the device comprises a gas cylinder 1, a refrigerator 2, a high-pressure pump 3, a shear-assisted supercritical device 4, a buffer tank 5 and a mechanical pump ( figure 1 not identified in);

[0039] Gas cylinder 1 communicates with refrigerator 2, refrigerator 2 communicates with high-pressure pump 3, high-pressure pump 3 communicates with shearing auxiliary supercritical device 4, shearing auxiliary supercritical device 4 communicates with buffer tank 5, buffer tank 5 communicates with mechanical pump connected, the shear assisted supercritical device 4 is internally provided with a reactor and a heating device, and the volume of the buffer tank 5 is 10 times the volume of the reactor, and the reactor is provided with a stirring shaft and a temperature detector, and the bottom of the stirring shaft ...

Embodiment 2

[0044] This embodiment provides a method for polyvinylpyrrolidone shear-assisted supercritical exfoliation of tungsten disulfide, which uses the device in Example 1 to perform polyvinylpyrrolidone shear-assisted supercritical exfoliation of tungsten disulfide, which specifically includes the following steps:

[0045] Mix 5 grams of multi-layer tungsten disulfide raw materials with a thickness of more than 20 layers and 1 gram of polyvinylpyrrolidone according to the mass ratio and place them in the reaction kettle of the shear-assisted supercritical device 4. The tungsten disulfide raw materials and polyvinylpyrrolidone The dosage accounts for 1 / 4 of the reactor volume, then close the reactor, open the first valve K1 and the second valve K2, the CO in cylinder 1 2 Freezing by refrigerator 2 to form liquid CO 2 , and pass in the reactor of shearing auxiliary supercritical device 4 by high pressure pump 3, until the indication of pressure gauge T2 shows that the pressure in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com