Preparation method for cubic precipitated calcium carbonate

A technology of precipitating calcium carbonate and cubic shape, applied in the direction of calcium carbonate/strontium/barium, etc., can solve the problems of high pH value of products, keeping at 50-60℃, difficult to popularize and apply, etc., to achieve particle size control and pH value. Effective value control, inhibition of dissolution, simple and feasible process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

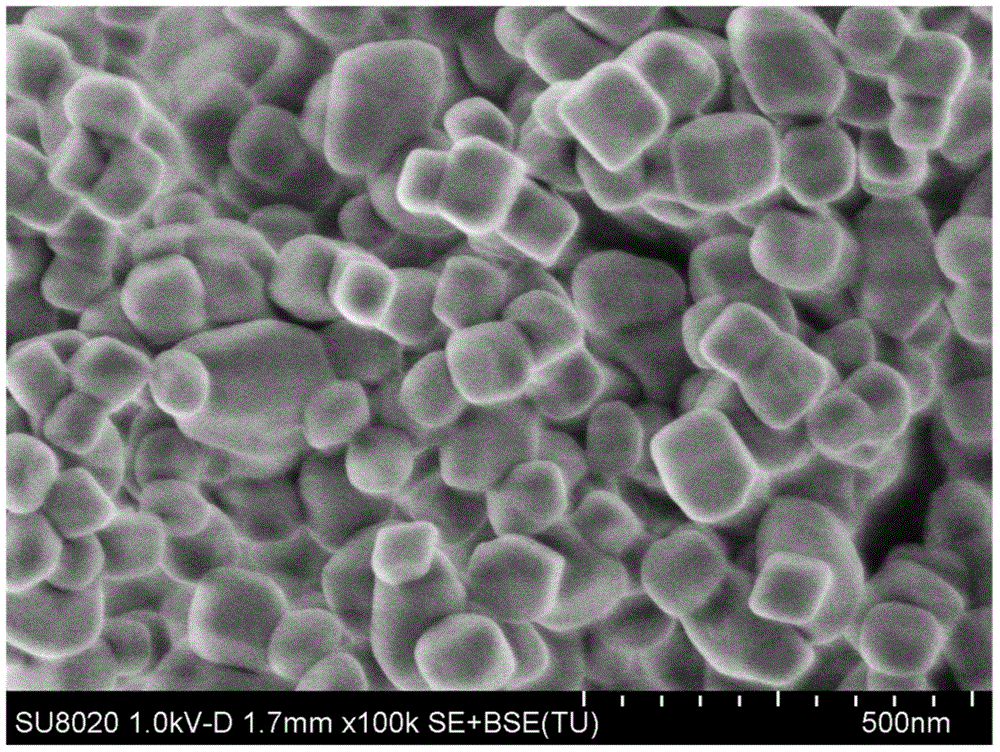

Image

Examples

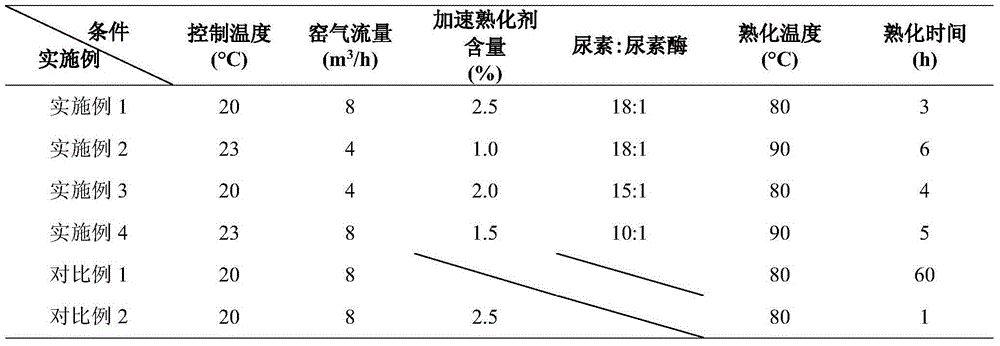

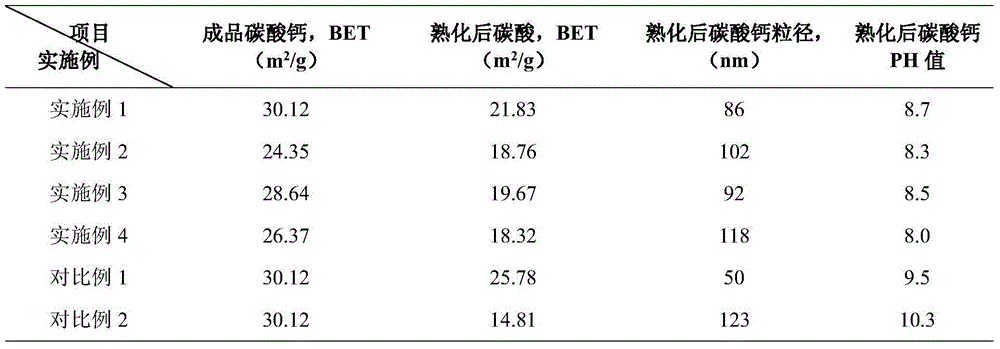

Embodiment 1

[0030] (1) Adjust the specific gravity of milk of lime refined and aged for 48 hours to 1.055, keep the temperature at 20°C, and then transfer it to a bubbling carbonation reactor with stirring.

[0031] (2) Pass the purified and cooled lime kiln gas into the carbonation reaction kettle for carbonation reaction, the kiln gas flow rate is 8m 2 / h carried out, wherein the carbon dioxide volume content was 33%, when the pH value of the reaction mixture dropped to 7.0, the carbonation reaction was stopped, and the specific surface area (BET) of the finished product calcium carbonate was 30.12m 2 / g.

[0032] (3) Add an accelerated curing agent to the calcium carbonate slurry obtained in step (2), then heat and cure it, and keep it in the temperature range of 80° C. for 3 hours.

[0033] (4) Adjust the temperature of the calcium carbonate slurry obtained in step (3) to 90° C., add a surface treatment agent, and complete the surface treatment after stirring for 60 minutes.

[0034...

Embodiment 2

[0039] (1) Adjust the specific gravity of milk of lime refined and aged for 48 hours to 1.055, keep the temperature at 23°C, and then transport it to a bubbling carbonation reactor with stirring.

[0040] (2) Pass the purified and cooled lime kiln gas into the carbonation reaction kettle for carbonation reaction, the kiln gas flow rate is 4m 2 / h carried out, wherein the carbon dioxide volume content was 33%, when the pH value of the reaction mixture dropped to 7.0, the carbonation reaction was stopped, and the specific surface area (BET) of the finished product calcium carbonate was 24.35m 2 / g.

[0041] (3) Add an accelerated curing agent to the calcium carbonate slurry obtained in step (2), then heat and cure it, and keep it in the temperature range of 90° C. for 3 hours.

[0042] (4) Adjust the temperature of the calcium carbonate slurry obtained in step (3) to 90° C., add a surface treatment agent, and complete the surface treatment after stirring for 60 minutes.

[004...

Embodiment 3

[0048] (1) Adjust the specific gravity of milk of lime refined and aged for 48 hours to 1.055, keep the temperature at 20°C, and then transfer it to a bubbling carbonation reactor with stirring.

[0049] (2) Pass the purified and cooled lime kiln gas into the carbonation reaction kettle for carbonation reaction, the kiln gas flow rate is 4m 2 / h carried out, wherein the carbon dioxide volume content was 33%, when the pH value of the reaction mixture dropped to 7.0, the carbonation reaction was stopped, and the specific surface area (BET) of the finished product calcium carbonate was 28.64m 2 / g.

[0050] (3) Add an accelerated curing agent to the calcium carbonate slurry obtained in step (2), then heat and cure it, and keep it in the temperature range of 80° C. for 4 hours.

[0051] (4) Adjust the temperature of the calcium carbonate slurry obtained in step (3) to 90° C., add a surface treatment agent, and complete the surface treatment after stirring for 60 minutes.

[0052]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com