Sulfur-carbon composite material with nitrogen-doped porous carbon nanofiber net-shaped structure, as well as preparation method and application of composite material

A technology of sulfur-carbon composite material and network structure, applied in structural parts, electrical components, battery electrodes, etc., can solve the problems of positive electrode material influence, low sulfur conductivity, battery capacity attenuation, etc. Simple, evenly distributed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

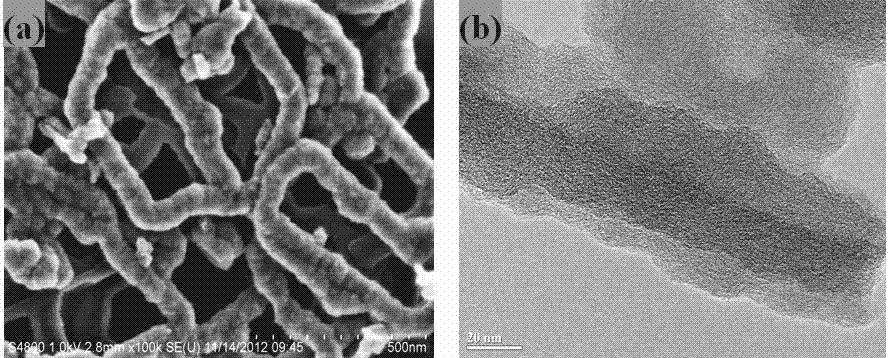

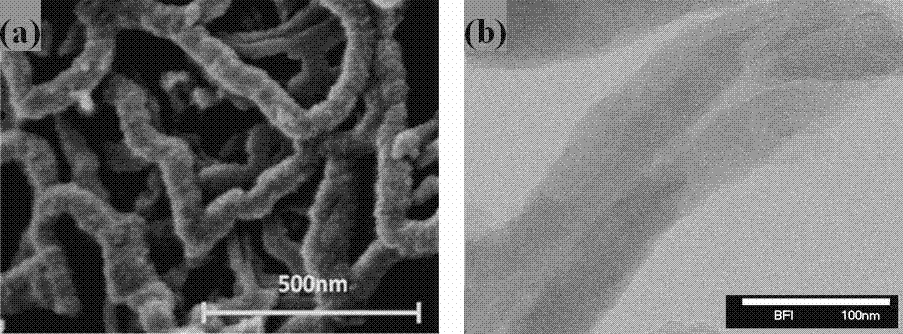

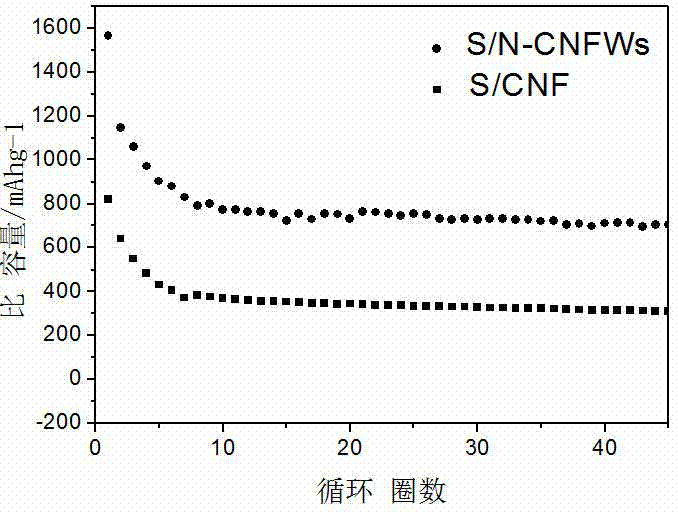

Image

Examples

Embodiment 1

[0017] 1. The synthesis steps of polypyrrole template are as follows: completely dissolve 0.02-0.03 mol CTAB in 120-180 ml HCl solution (1-1.5 mol / L), stir magnetically for 5-10 min, then add 0.06-0.09 mol Ammonium sulfate, continue to stir for 0.5-1 h (keep the temperature of the reaction system below 5 ℃), add 8.3-12.2 ml of pyrrole monomer, continue to react in an ice-water bath for 20-24 h, and then filter the resulting solution And wash with 1-1.5 mol / L HCl solution and deionized water until it is colorless and neutral, collect the solid product and dry it in a vacuum oven at 70-80 °C for 10-12 h to obtain it.

[0018] 2. The synthesis steps of nitrogen-doped porous carbon nanofiber (N-CNFWs) network structure precursor are as follows: the polypyrrole template obtained in step a is raised to 650-700 at 2-4 ℃ / min in nitrogen atmosphere ℃ and kept for 1-2 h, then the obtained nitrogen-doped carbon nanofibers and potassium hydroxide were uniformly dispersed in 30-40 ml aqueo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com