Lithium-sulfur battery cathode material and preparation method thereof

A cathode material, lithium-sulfur battery technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of difficult to control sulfur content, low sulfur utilization rate, sulfur overflow, etc., and achieve easy mass production and high sulfur content. , the effect of inhibiting dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

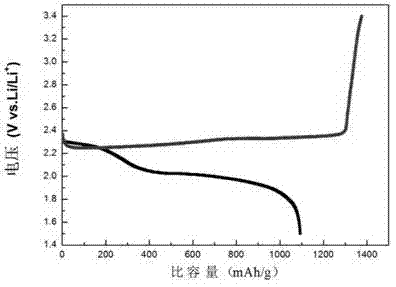

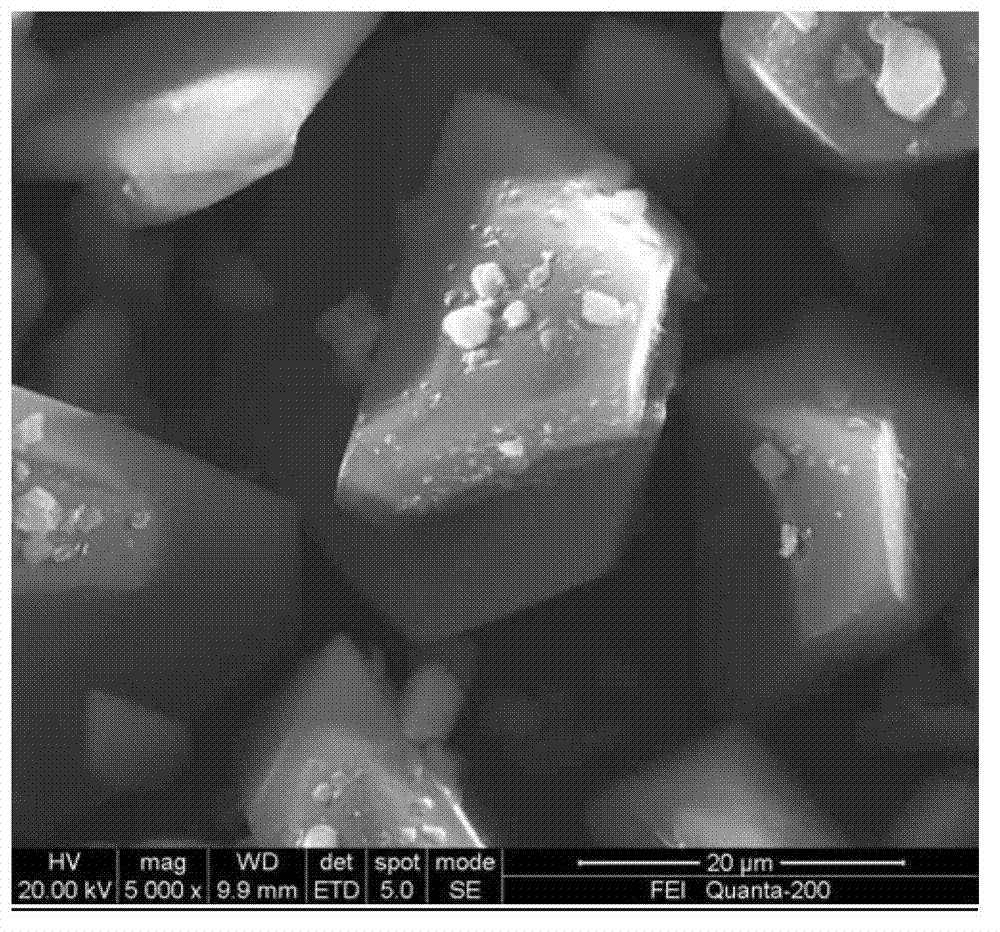

[0042] Mesoporous metal-organic framework Cr 3 F(H 2 O) 2 O(BDC) 3 ·nH 2 O as the framework material of the composite cathode material, the selected mesoporous metal-organic framework Cr 3 F(H 2 O) 2 O(BDC) 3 ·nH 2 The specific surface area of O is 3600m 2 / g, the mesopore structure of the material accounts for 30% of the entire pore structure. Completely dissolve sodium thiosulfate in deionized water to make a reactant solution with a sodium thiosulfate concentration of 0.1mol / L, take 500mL of the reactant solution and add it to a 1000mL beaker; Cr 3 F(H 2 O) 2 O(BDC) 3 ·nH 2 Adding 0.178 g of mesoporous metal-organic framework material Cr at a mass ratio of O to 9:1 3 F(H 2 O) 2 O(BDC) 3 ·nH 2 O, use a constant temperature magnetic stirrer to stir for 0.5 hours to obtain a uniformly dispersed mixed reaction stock solution; under the condition of maintaining a constant temperature of 50°C, slowly drop 0.5mol / L hydrochloric acid solution into the mixed rea...

Embodiment 2

[0046] Mesoporous metal-organic framework Cr 3 F(H 2 O) 2 O(BDC) 3 ·nH 2 O as the framework material of the composite cathode material, the selected mesoporous metal-organic framework Cr 3 F(H 2 O) 2 O(BDC) 3 ·nH 2 The specific surface area of O is 3600m 2 / g, the mesopore structure of the material accounts for 30% of the entire pore structure. Completely dissolve potassium thiosulfate in deionized water to make a reactant solution with a potassium thiosulfate concentration of 0.05mol / L, take 500mL of the reactant solution and add it to a 1000mL beaker; Cr 3 F(H 2 O) 2 O(BDC) 3 ·nH 2 Adding 0.4 g of mesoporous metal-organic framework material Cr at a mass ratio of O to 8:2 3 F(H 2 O) 2 O(BDC) 3 ·nH 2 O, use a constant temperature magnetic stirrer to stir for 1 hour to obtain a uniformly dispersed mixed reaction stock solution; under the condition of maintaining a constant temperature of 45°C, slowly drop 0.2mol / L sulfuric acid solution into the mixed react...

Embodiment 3

[0048] Mesoporous metal-organic framework Cr 3 F(H 2 O) 3 O(BTC) 2 ·nH 2 The preparation process of the composite cathode material of O, the selected mesoporous metal-organic framework Cr 3 F(H 2 O) 3 O(BTC) 2 ·nH 2 The specific surface area of O is 2700m 2 / g, the mesopore structure of the material accounts for 40% of the entire pore structure. Completely dissolve potassium thiosulfate in deionized water to make a reactant solution with a potassium thiosulfate concentration of 0.05mol / L, take 500mL of the reactant solution and add it to a 1L beaker; Cr 3 F(H 2 O) 3 O(BTC) 2 ·nH 2 Adding 0.686g of mesoporous metal-organic framework Cr at a mass ratio of O to 7:3 3 F(H 2 O) 3 O(BTC) 2 ·nH 2 O, use a constant temperature magnetic stirrer to stir for 0.5 hours to obtain a uniformly dispersed mixed reaction stock solution; under the condition of maintaining a constant temperature of 25°C, slowly drop 0.2mol / L hydrochloric acid solution into the mixed reaction s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com