Patents

Literature

61results about How to "Shape and size controllable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

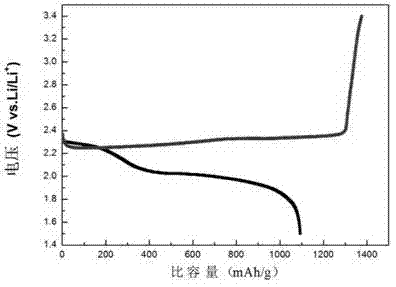

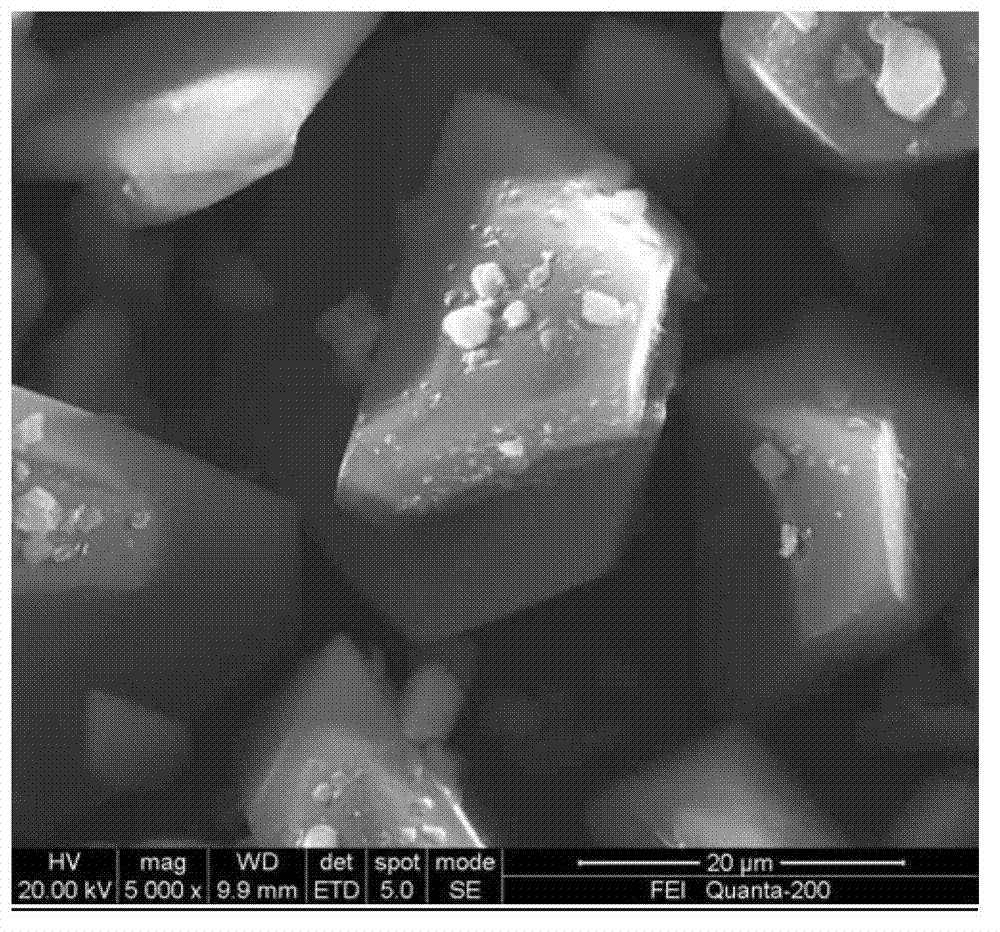

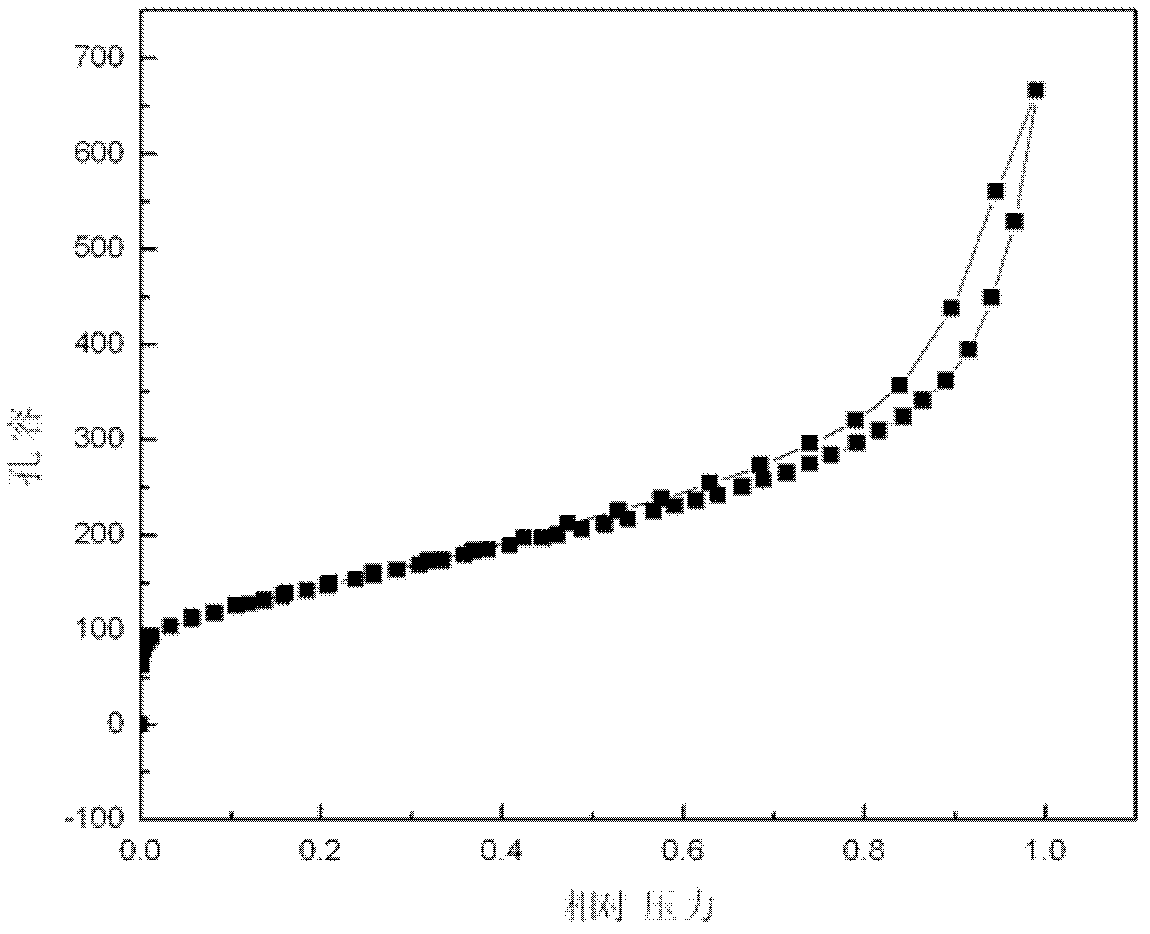

Lithium-sulfur battery cathode material and preparation method thereof

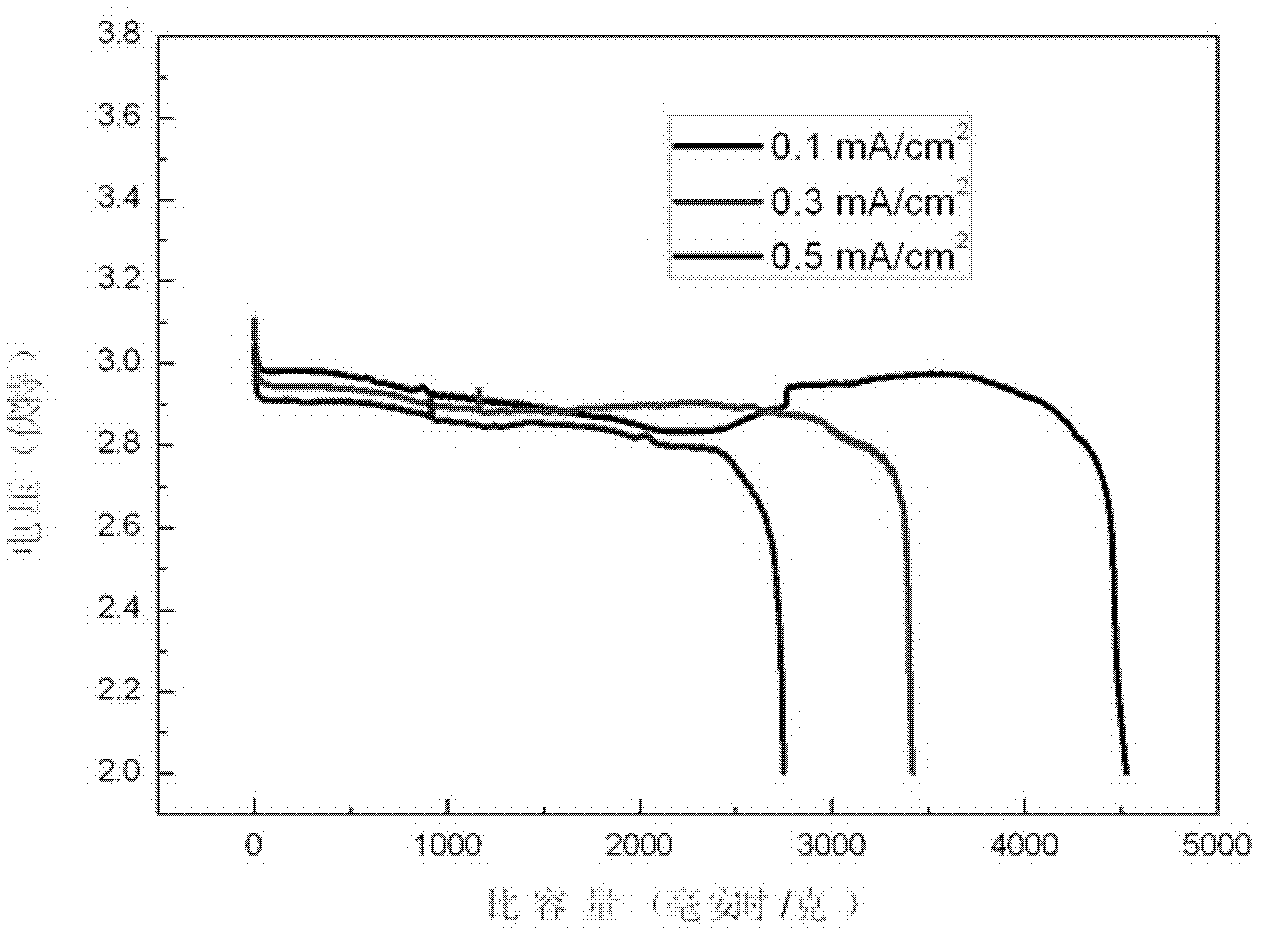

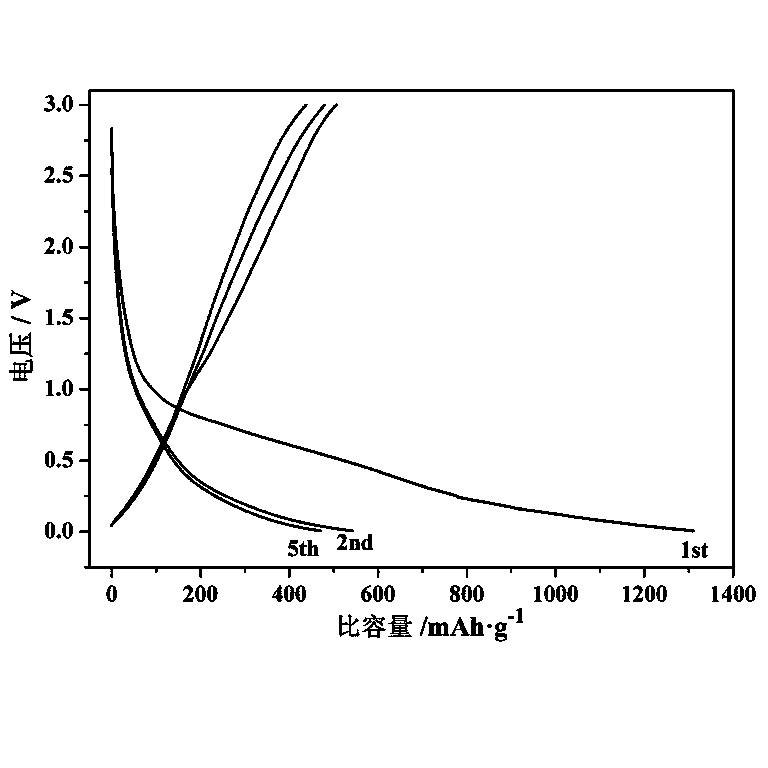

ActiveCN102780001AInhibition of dissolutionImprove cycle performanceCell electrodesMetal-organic frameworkDissolution

The invention discloses a lithium-sulfur battery cathode material and a preparation method thereof. The cathode material is formed by in-situ compositing of a mesoporous metal-organic framework and elemental sulfur. The mesoporous metal-organic frame is of a laminated pore structure consisting of a macro pore, a meso pore and a micro pore, wherein the pores are communicated with one another. The structure can adsorb more elemental sulfur and can simultaneously inhibit the dissolution of sulfur elementary substance and multi-sulfur compounds in electrolyte, so that the cycle performance of a lithium-sulfur battery is improved and high utilization rate of an active substance of the cathode material is kept. A sulfur and metal-organic framework material composite cathode material is prepared by a two-step process of low-temperature liquid phase composition and sulfur extraction, a composite material precursor with homogeneously dispersed high load sulfur content can be obtained through in-situ compositing at a low temperature with a liquid-phase preparation method, redundant sulfur on the surface of the precursor and in pore passages is extracted by an organic solvent, the aperture of the composite material can be further effectively adjusted and controlled, selective distribution of sulfur is realized, and the composite material with excellent electrochemical performance is obtained. By adopting the preparation method, the distribution of the sulfur in the composite material can be effectively improved, and the electrochemical performance of the composite material is optimized. Meanwhile, the preparation method is simple and is easy to perform industrially, and mass production is facilitated.

Owner:CENT SOUTH UNIV +1

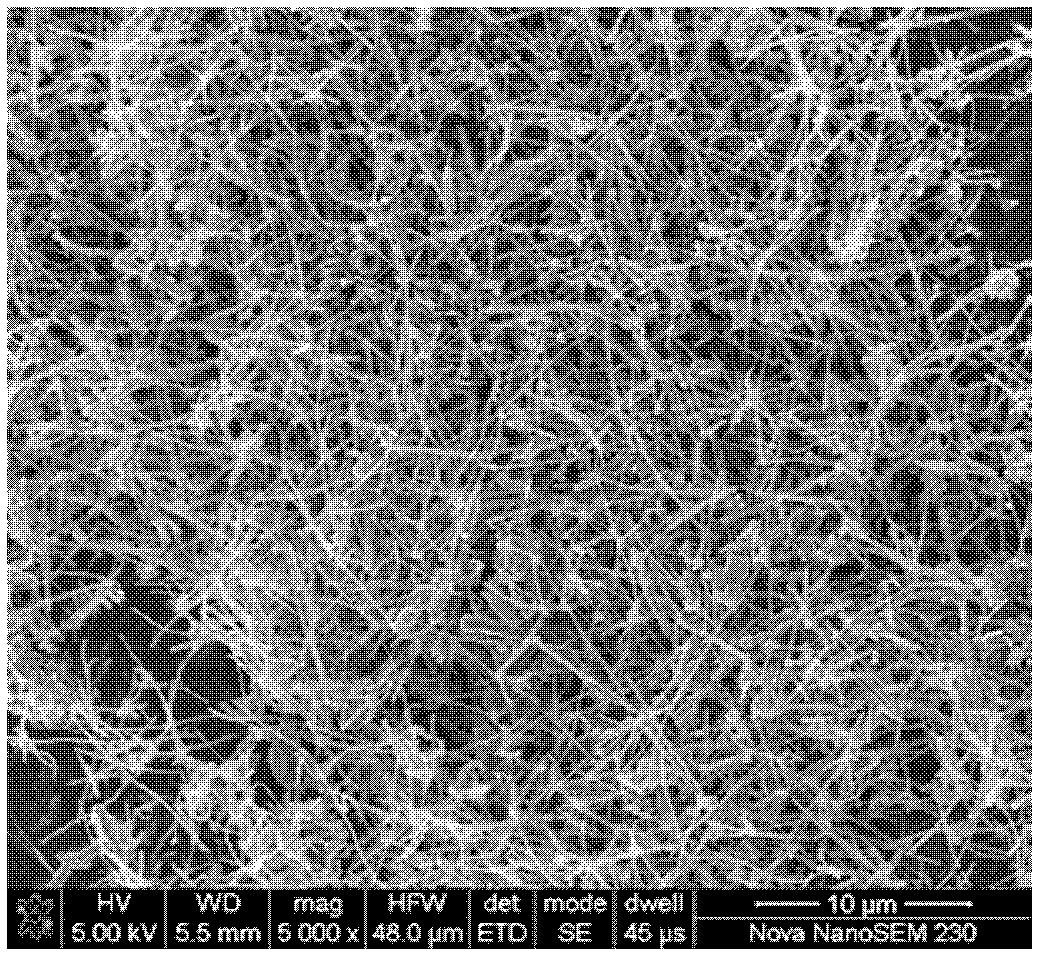

Micro-nano-structure anode material for Li-air battery and preparation method of micro-nano-structure anode material

The invention relates to a micro-nano-structure anode material for a Li-air battery and a preparation method of the micro-nano-structure anode material. The preparation method comprises the following steps of: preparation of hollow composite precursor fibers through electrostatic spinning by blending a metal nitride catalyst precursor with a high-carbon polymer in an organic solvent, preprocessing of the precursor fiber material, nitridation of complex fibers, and pore-forming and pore-expansion through activation. The preparation method is simple in technique and convenient to operate and is easy to realize the uniform distribution of nanoscale catalyst particles in hollow carbon fibers. A prepared anode material tube is hollow internally, a plurality of holes are formed on the wall of the tube, and metal nitride catalysts are uniformly distributed in the three-dimensional holes of the wall of the tube, so that high specific surface area provides a sufficient place for the reaction of the battery, and the hollow pore passage in the tube can ensure an oxygen diffusion channel to be smooth and has good ion transport capacity and electrical conductivity. According to the invention, the charge-discharge capacity of the Li-air battery can be improved effectively, the power multiplying performance and the power density of the Li-air battery can be improved, the internal resistance of the battery can be reduced, and the charge-discharge polarization can be lessened through the uniform distribution of the nanoscale metal nitride, therefore, the micro-nano-structure anode material has good industrialization prospect.

Owner:CENT SOUTH UNIV

Method for preparing fluorine contained polyacrylate/dual-sized nano SiO2 composite emulsion

InactiveCN102911308AImprove water resistanceGood solvent resistanceFibre treatmentAcrylic resinNano sio2

Disclosed is a method for preparing a fluorine contained polyacrylate / dual-sized nano SiO2 composite emulsion. The method includes preparing and modifying small particle size SiO2, preparing and modifying large particle size SiO2, preparing and modifying dual-sized nano SiO2, and finally preparing the fluorine contained polyacrylate / dual-sized nano SiO2 composite emulsion. The dual-sized nano SiO2 is used for constructing surface roughness, and organic fluorine and long chain organic silicon are used for reducing surface free energy, so that fabrics are provided with super-hydrophobic performances, and simultaneously, defects that acrylic resins are poor in water-proof and solvent resistant performances are overcome.

Owner:SHAANXI UNIV OF SCI & TECH

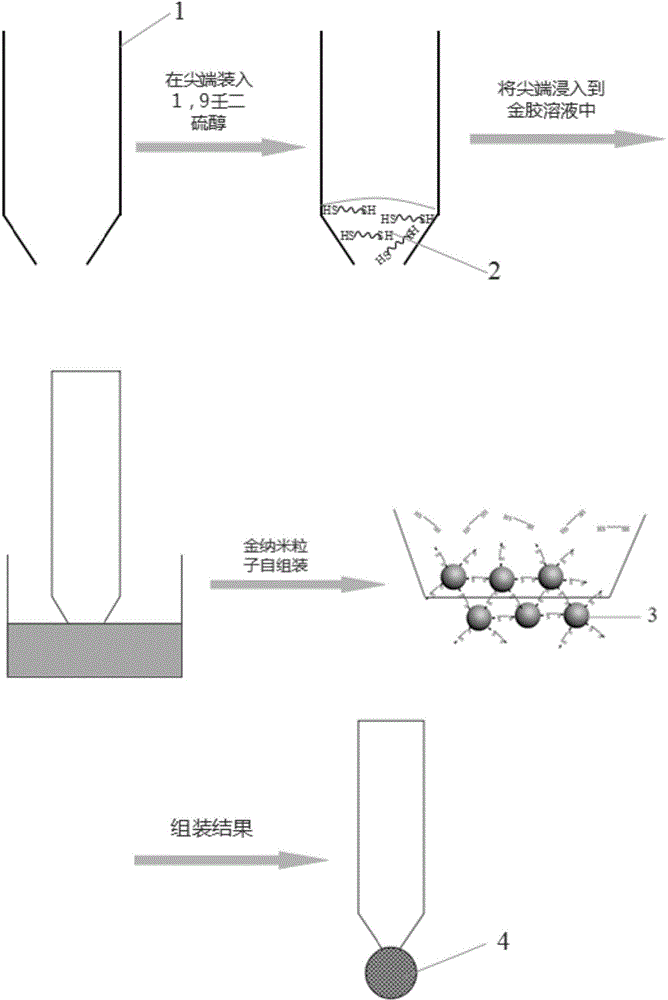

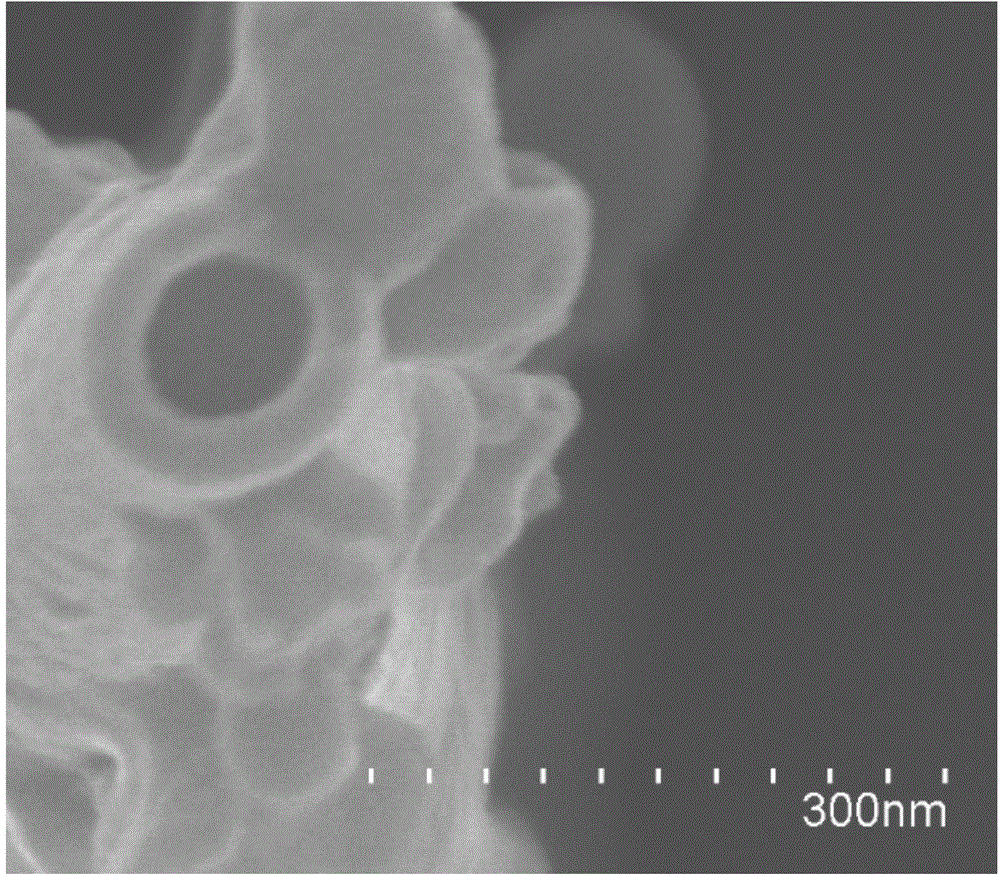

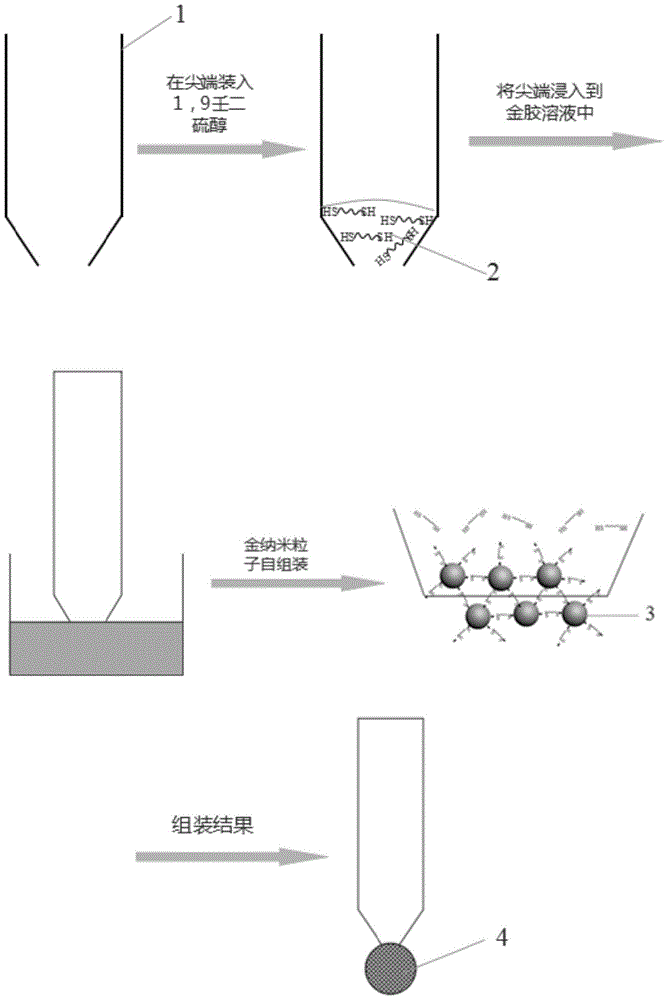

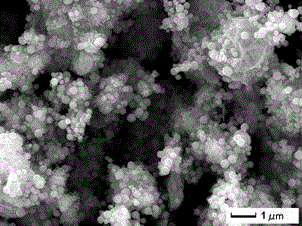

Method for preparing nano-porous structure based on nano-particle self-assembly and application thereof

ActiveCN104101630AMature processing technologyGood repeatabilityRaman scatteringNanosensorsNanoparticleCapillary Tubing

The invention relates to a method for preparing a nano-porous structure based on nano-particle self-assembly. Particularly, a capillary tube serves as a support body, and relying on the support body, nano-particles are self-assembled at the pointed end of the capillary tube through a cross-linking agent to form the nano-porous structure. The method for preparing the nano-porous structure is simple and low in cost, has the advantages that the nano aperture is adjustable in size, is convenient to move and position, and has an extensive application range.

Owner:NANJING UNIV

Preparation method of porous graphene and applications of finished product thereof

InactiveCN103490050AEvenly distributedLarge specific surface areaCell electrodesSecondary cellsPorous grapheneTubing types

The invention relates to a preparation method of porous graphene and applications of finished product thereof. The preparation method comprises following steps: (1) ultrasonically dispersing graphene oxide in deionized water; (2) dissolving a certain amount of water-soluble transition metal salts in deionized water, dropwise adding the solution into the graphene oxide solution, and stirring at the same time; (3) subjecting the mixed solution to treatments of centrifugation and washing to extract products, drying the products for 1 to 20 hours; (4) putting the obtained materials into a tube-type furnace, heating, burning the materials at a constant temperature of 500 to 1050 DEG C for 1 to 20 hours, while controlling the flow speed of inert gas in the range of 10 to 300 mL / min, cooling, and collecting the solid products; (5) processing the solid products with dilute hydrochloric acid to remove the transition metal oxides in the solid products so as to obtain the porous graphene material. The porous graphene material prepared by the method has the advantages of few layers and controllable hole size, and solves the problems of non-conductivity of electrons in the vertical direction to the horizontal surface of the graphite material multi-layer graphene and obstructed route of Li. Furthermore, the construction of nano micro-hole structure is beneficial for storage, diffusion, and transportation of charges.

Owner:上海一广新能源科技有限公司

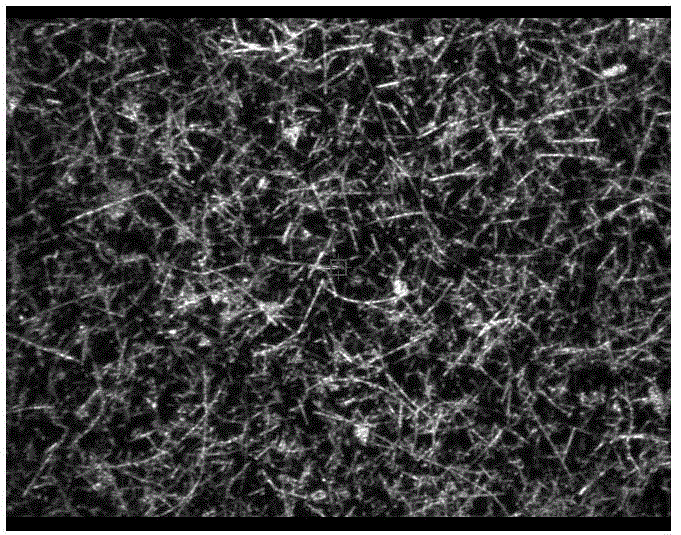

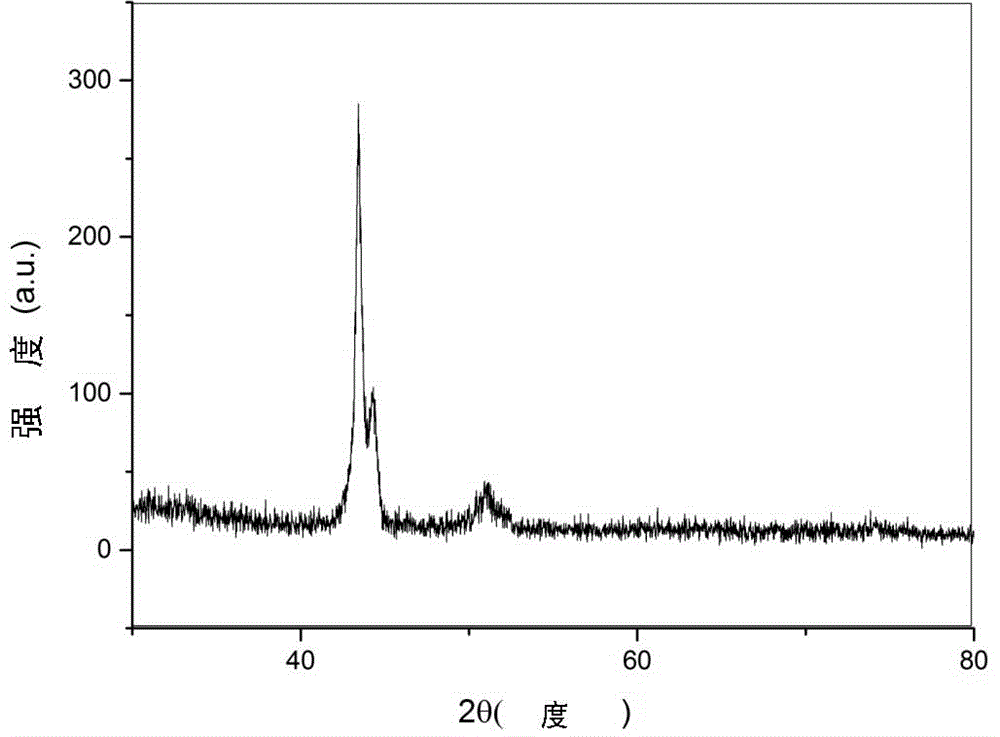

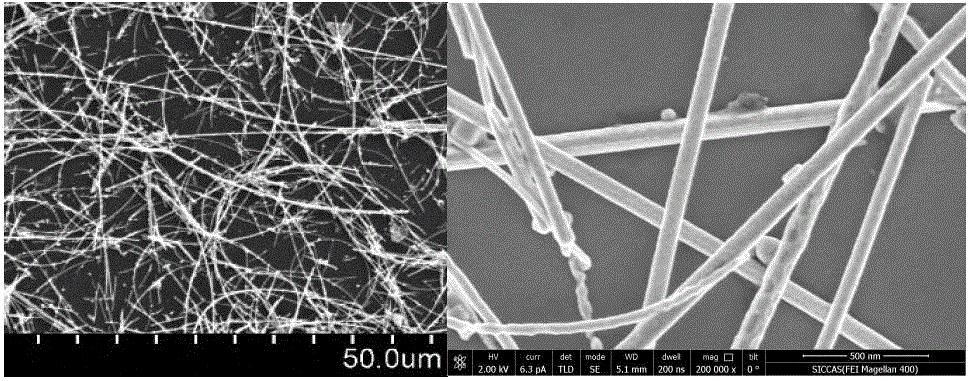

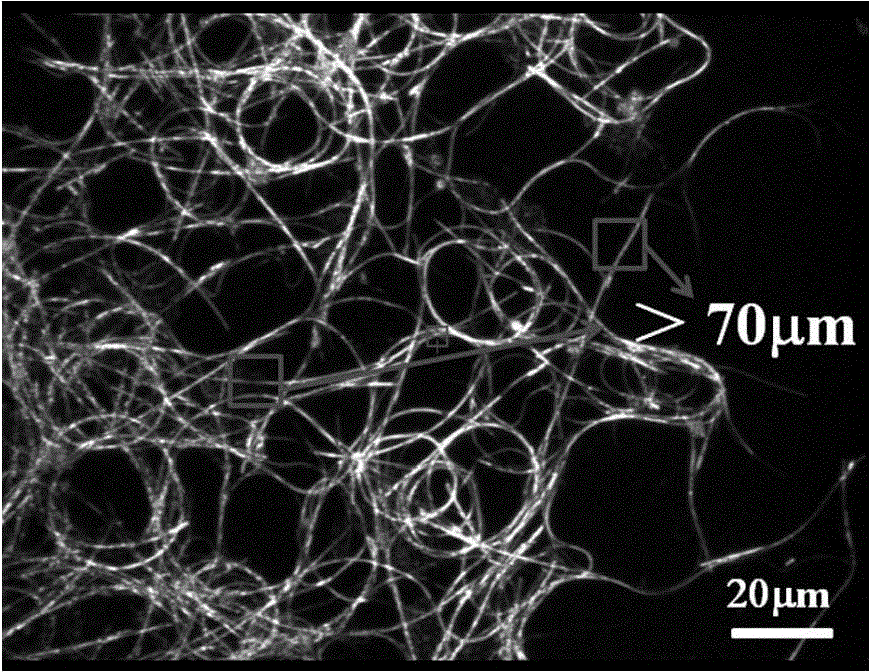

Copper-silver double-metal nanowire and preparation method thereof

The invention relates to a copper-silver double-metal nanowire and a preparation method thereof. The preparation method comprises the following steps: 1) dissolving a cationic surfactant into an organic reductant to form an organic reducing system, wherein the organic reductant comprises long-chain alkyl amine; 2) adding copper salt dissolvable in the organic reducing system and metal nanoparticles as a catalyst into the organic reducing system prepared in the step 1), and reacting at a first specified temperature; 3) adding silver salt dissolvable in the organic reducing system into the organic reducing system after reaction in the step 2), reacting at a second specified temperature, filtering, cleaning and drying to obtain the copper-silver double-metal nanowire.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

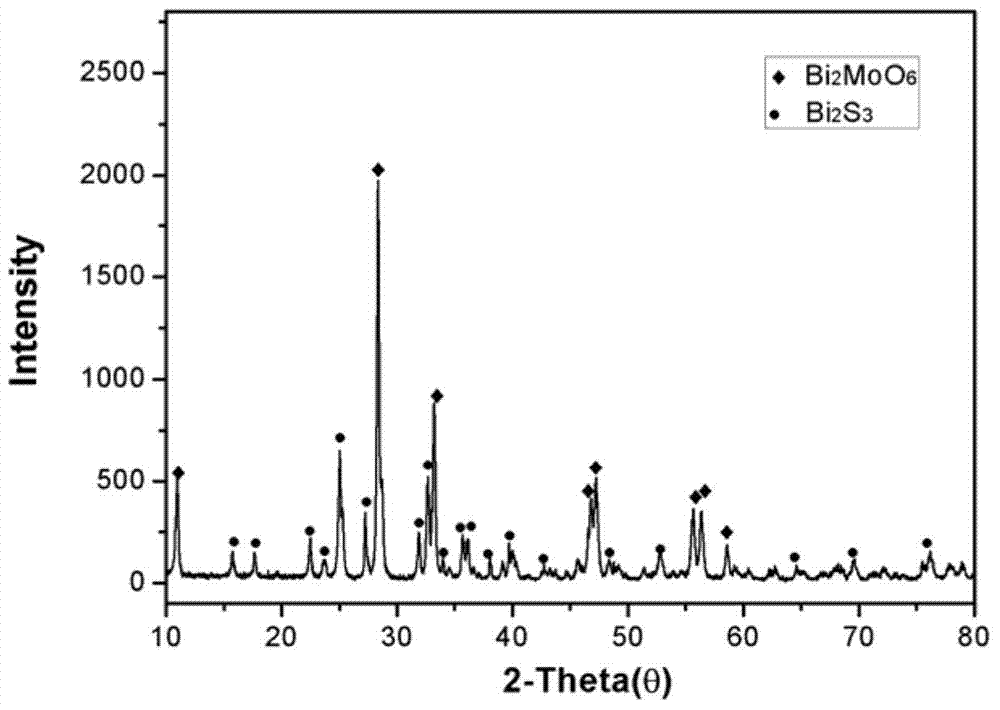

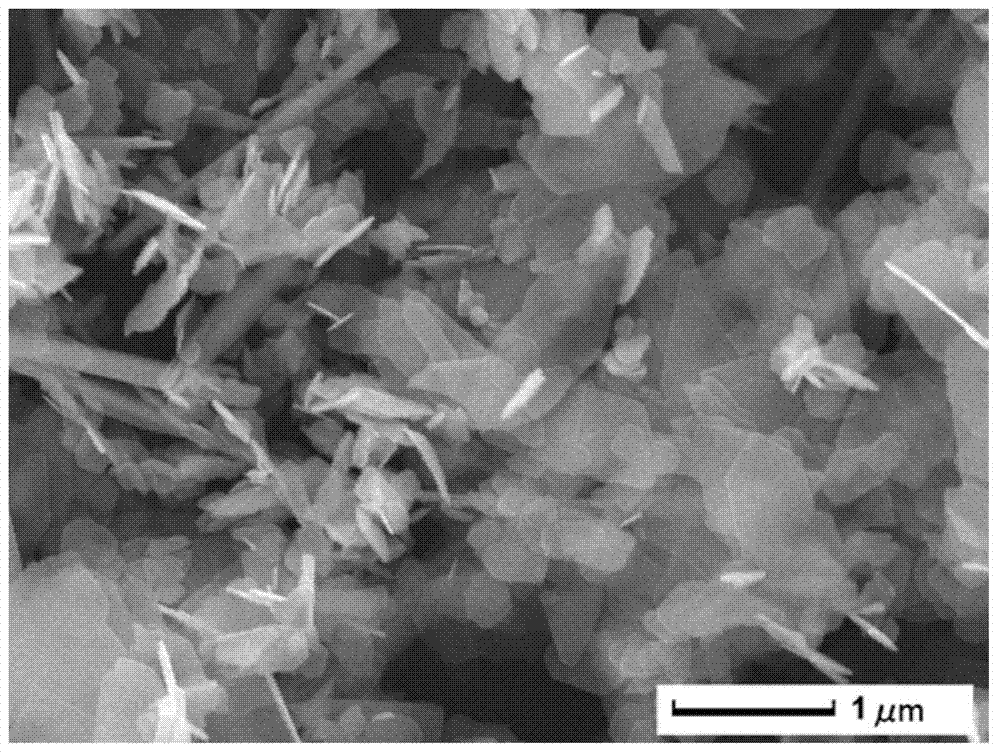

Preparation method of bismuth sulfide/bismuth molybdenum oxide heterojunction photocatalytic composite material

ActiveCN103611551ASimple processHigh crystallinityPhysical/chemical process catalystsHeterojunctionBismuth sulfide

The invention relates to a preparation method of a bismuth sulfide / bismuth molybdenum oxide heterojunction photocatalytic composite material. The preparation method is characterized by comprising the steps of dispersing BiOBr micro-sphere particles in de-ionized water in a proportion of 7.7g / L, and uniformly stirring; adding a molybdenum source: sodium molybdate, sodium chloride, sodium thiocyanate and a surfactant to a solution (1) and stirring for 30-60min; regulating pH value of the solution to be acid through hydrochloric acid; pouring the mixed solution into a stainless steel reaction kettle, and reacting for 24-48 hours at 150-200 DEG C; after reaction, naturally cooling, centrifuging and washing a reaction product for times through de-ionized water and ethanol, and drying the product to obtain the Bi2S3 / Bi2MoO6 heterojunction composite material. The preparation method is simple and convenient to operate and is low in reaction temperature, and the prepared composite material is excellent in photocatalytic performance.

Owner:ZHENJIANG COLLEGE

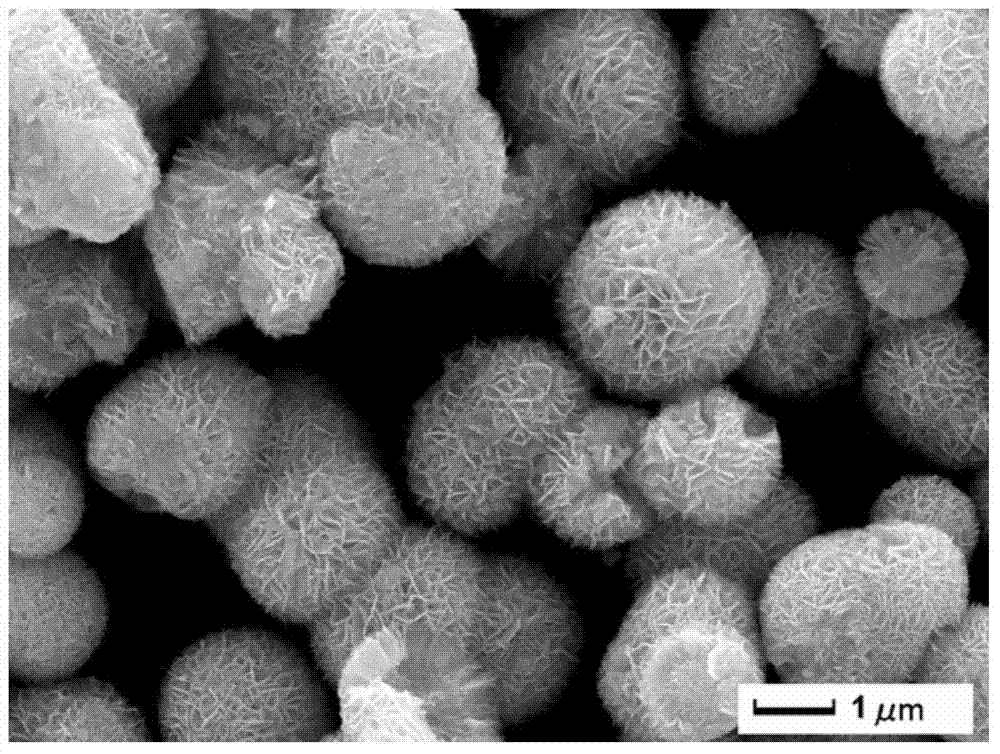

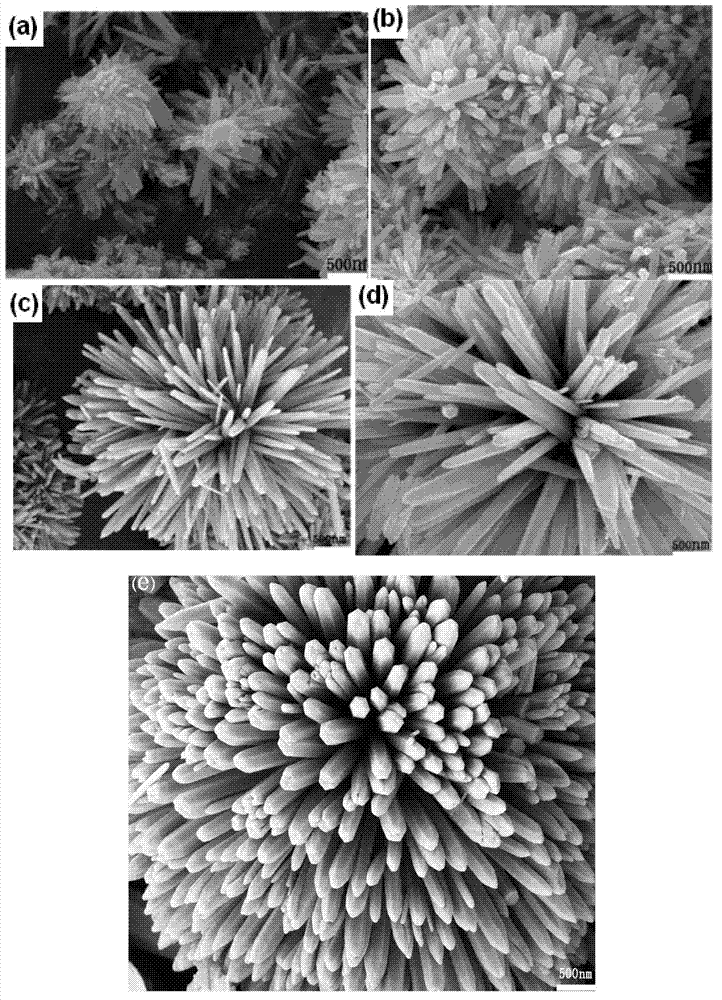

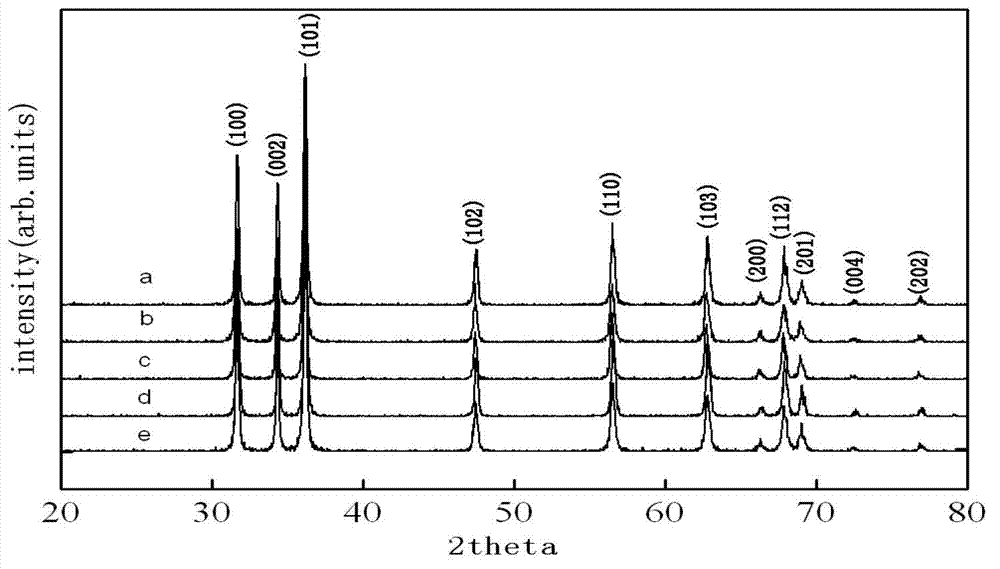

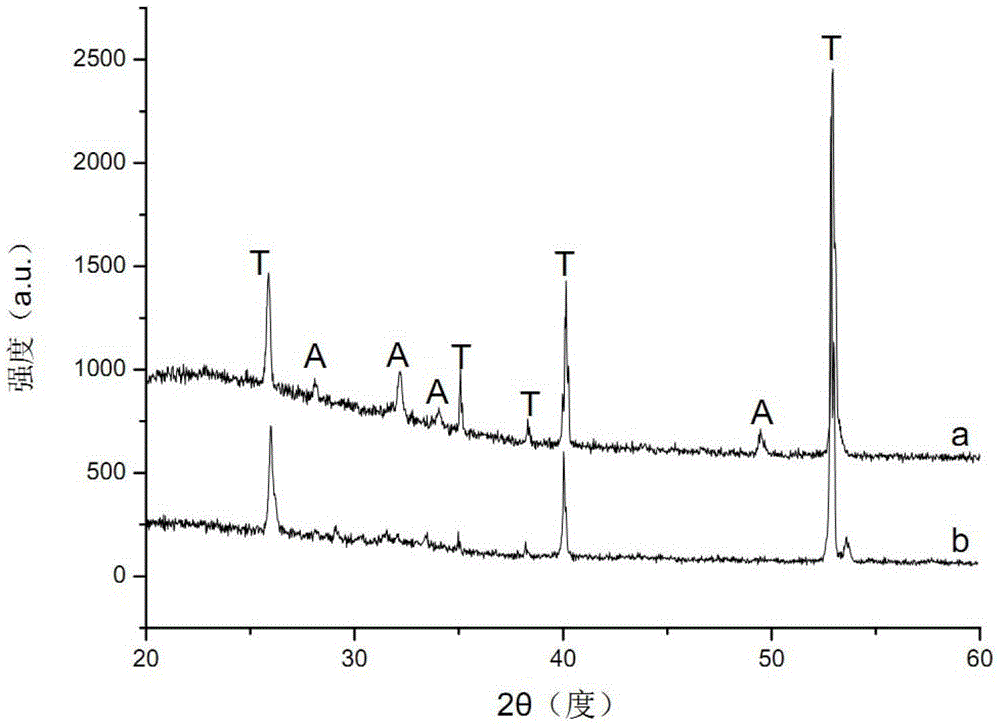

Hierarchical titanium dioxide microspheres based on surface oriented growth nano-rods and preparation method thereof

InactiveCN104843786AUnique three-dimensional hierarchical structureLarge specific surface areaPhysical/chemical process catalystsNanotechnologyMicrosphereCarbonization

The invention relates to hierarchical titanium dioxide microspheres based on surface oriented growth nano-rods and a preparation method thereof. The hierarchical titanium dioxide microspheres are three-dimensional microspheres formed by a cluster of one-dimensional nano-rods which own a common core and grow uniformly and outwards in a radiation manner along the core. The preparation method comprises the following main steps of: adding a titanium precursor in a polycondensation reaction process of resorcinol-formaldehyde, then preparing organic gel in a sol-gel process, and finally carrying out high-temperature carbonization to obtain the titanium dioxide nano-rod microspheres with hierarchical structures. The hierarchical titanium dioxide microspheres based on the surface oriented growth nano-rods, prepared by the method, have a good adsorption performance and a good pollutant photocatalytic degradation performance; and after being used, the hierarchical titanium dioxide microspheres based on the surface oriented growth nano-rods are separated from water simply and conveniently, thus easily realizing the recycling and reusing of photocatalytic materials. In addition, the preparation method is simple in technology, the mass production is easily realized by adopting the preparation method, the appearance and size of the products are controllable, and the products are high in crystalline of degree and conform to practical production application requirements.

Owner:SHANDONG UNIV

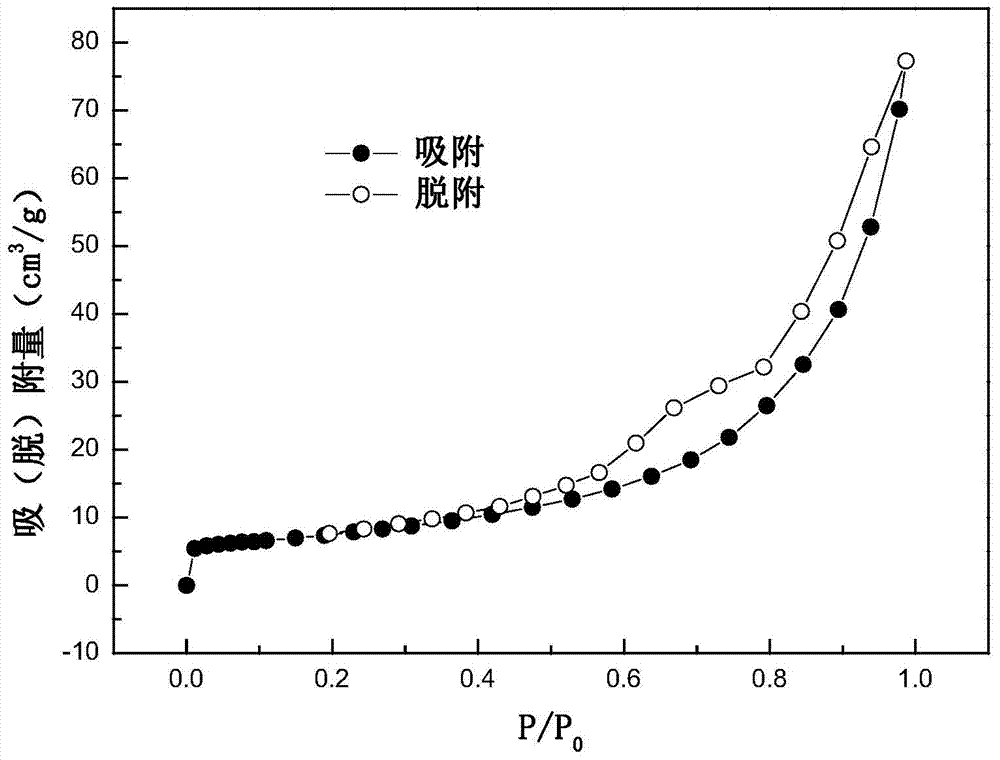

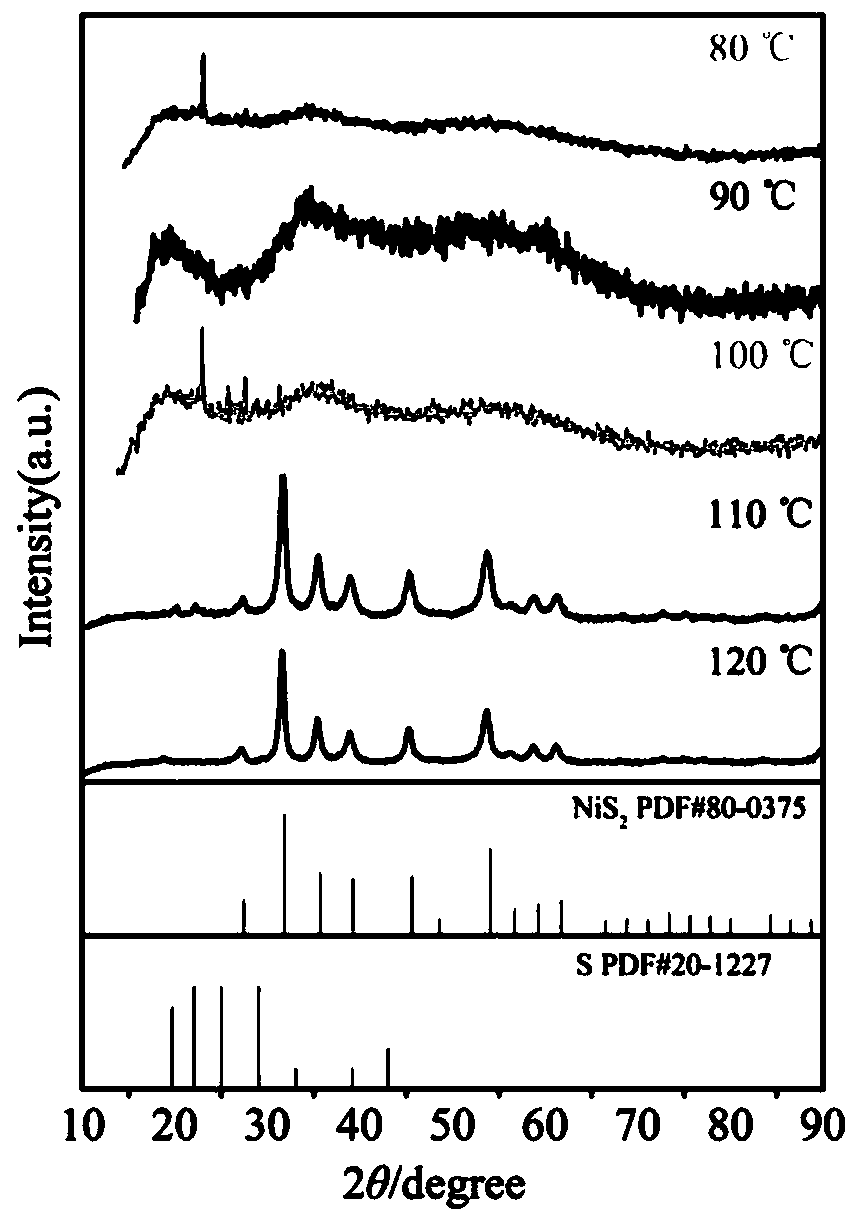

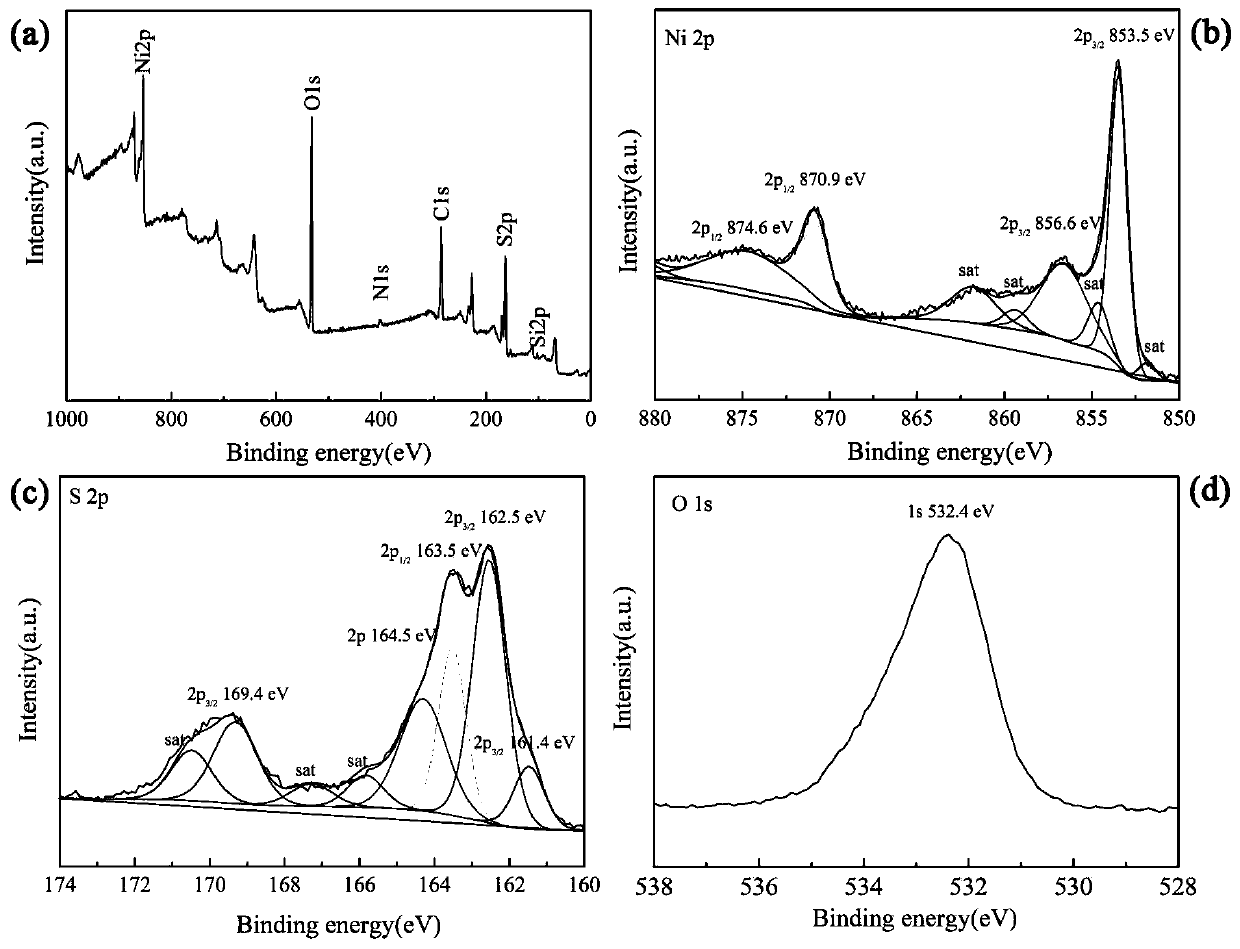

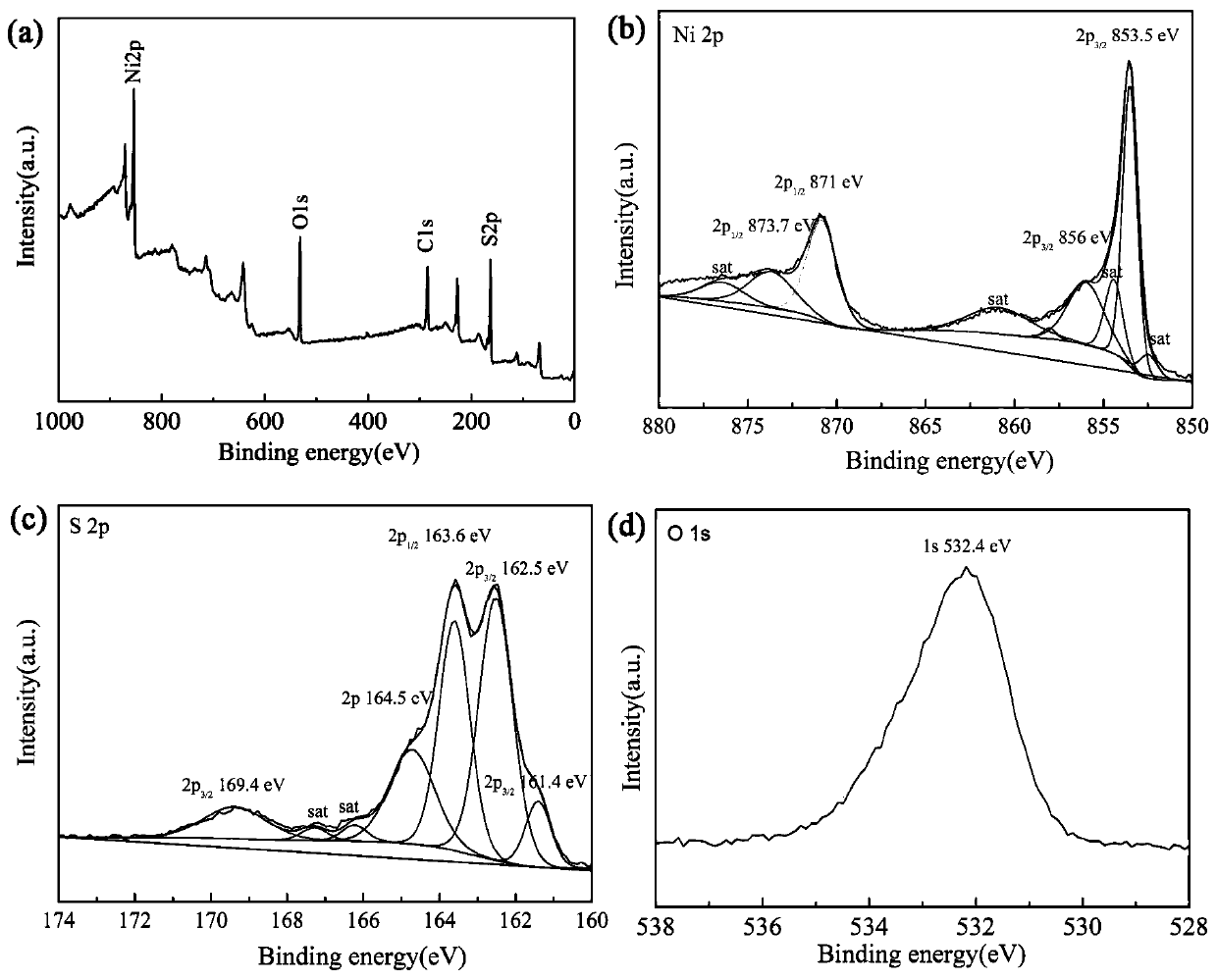

Nano nickel-sulfur compound based on eutectic solvent one-step synthesis method

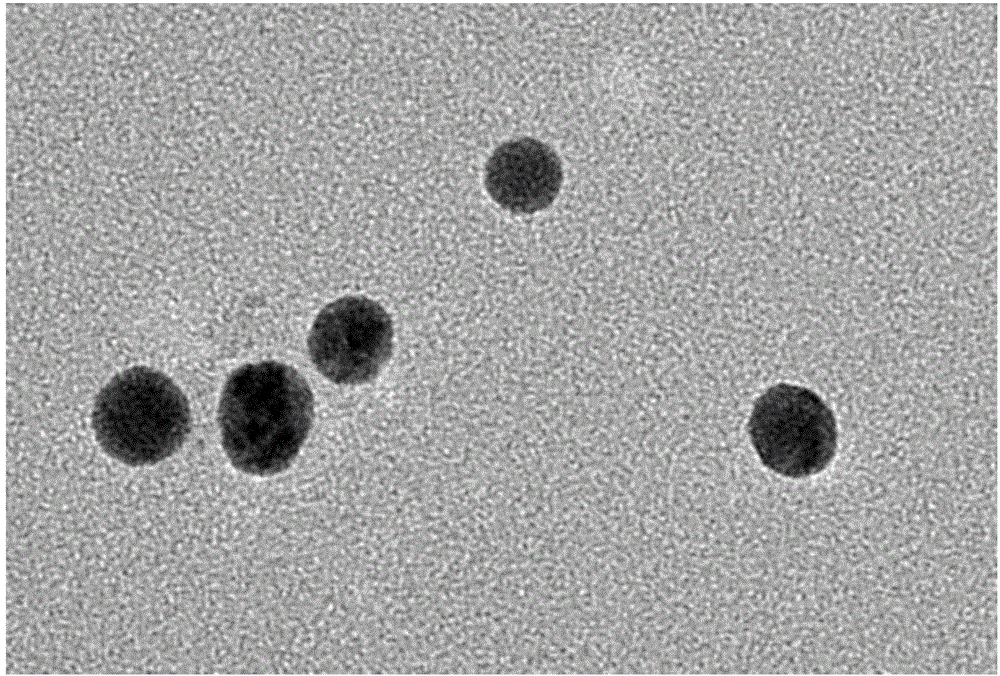

ActiveCN110182860ASmall particle sizeUniform sizeNanotechnologyNickel sulfidesSynthesis methodsSulfur

The invention provides a method for preparing a nano nickel-sulfur compound based on a eutectic solvent one-step synthesis method. The method includes the steps of preparing a eutectic solvent; controlling the addition amount of a nickel source, a sulfur source and a reactant; adding the nickel source, the sulfur source and the reactant to the eutectic solvent to completely dissolve, thereby obtaining a eutectic solvent-nickel-sulfur system, wherein in the eutectic solvent-nickel-sulfur system, the nickel ion concentration is not less than 0.01 mol / L, the sulfur source concentration is not less than 0.01 mol / L, and the reactant concentration is not less than 0.01 mol / L. The eutectic solvent-nickel-sulfur system is heated and stirred, and after the reaction is completed, the product is taken out, washed, and dried to obtain a nano nickel-sulfur compound. The preparation method of the invention has the advantages of low equipment requirement, low temperature requirement, short process flow, controllable shape and size, and the like, the eutectic solvent used is environmentally friendly, simple in synthesis and low in price, and the method is an efficient and environment-friendly synthesis method.

Owner:KUNMING UNIV OF SCI & TECH

Super-long copper-nickel alloy nanowire and manufacturing method thereof

The invention relates to a super-long copper-nickel alloy nanowire and a manufacturing method thereof. The method comprises: a) dissolving a cationic-type surfactant in an organic reducing agent; b) adding copper salt used as a copper source in the organic reducing agent obtained in the step a), and adding precious metal nano-particles which is used as a catalyst, reacting at the temperature of first specified temperature; c) adding nickel salt used as a nickel source in the reducing agent after reaction in the step b), reacting at the temperature of second temperature, cleaning and drying obtained products, and the product is the copper-nickel alloy nanowire.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Nano-hydroxyapatite/silk fibroin composite membrane material and preparation method thereof

ActiveCN103656756AEvenly dispersedShape and size controllableProsthesisNano hydroxyapatiteMechanical property

The invention discloses a nano-hydroxyapatite / silk fibroin composite membrane material and a preparation method thereof. The preparation method comprises the following steps: (a) preparing a silk fibroin membrane; and (b) preparing the nano-hydroxyapatite / silk fibroin composite membrane material, wherein the size of the nano-hydroxyapatite in the composite membrane material is 10-500nm. The invention develops a novel preparation method of the nano-hydroxyapatite / silk fibroin composite membrane material in simple preparation process, so that the problem that the mechanical properties of the nano-hydroxyapatite / silk fibroin composite membrane material are poor is solved. The composite membrane material prepared can be biodegradable and is harmless to a human body, so that the composite membrane material is an ideal biomedical material.

Owner:苏州盛泽科技创业园发展有限公司

Super-long silver nanowire and preparation method thereof

The invention relates to a super-long silver nanowire and a preparation method thereof. The preparation method comprises the following steps: 1) dissolving a cationic surfactant in an organic reducing agent so as to form an organic reduction system, wherein the cationic surfactant and silver salt which can be dissolved in an organic reduction system perform complexation, and the organic reducing agent comprises long-chain alkylamine; 2) adding the silver salt which can be dissolved in the organic reduction system in the prepared organic reduction system, performing a reaction under 120-180 DEG C, filtering reacted substances, and washing the filtered substances.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

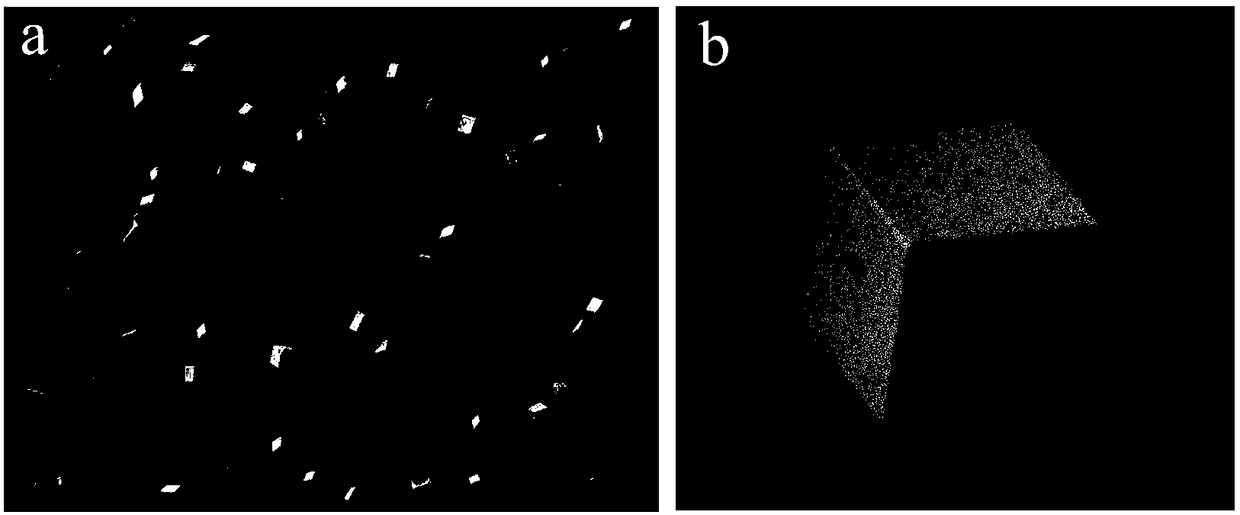

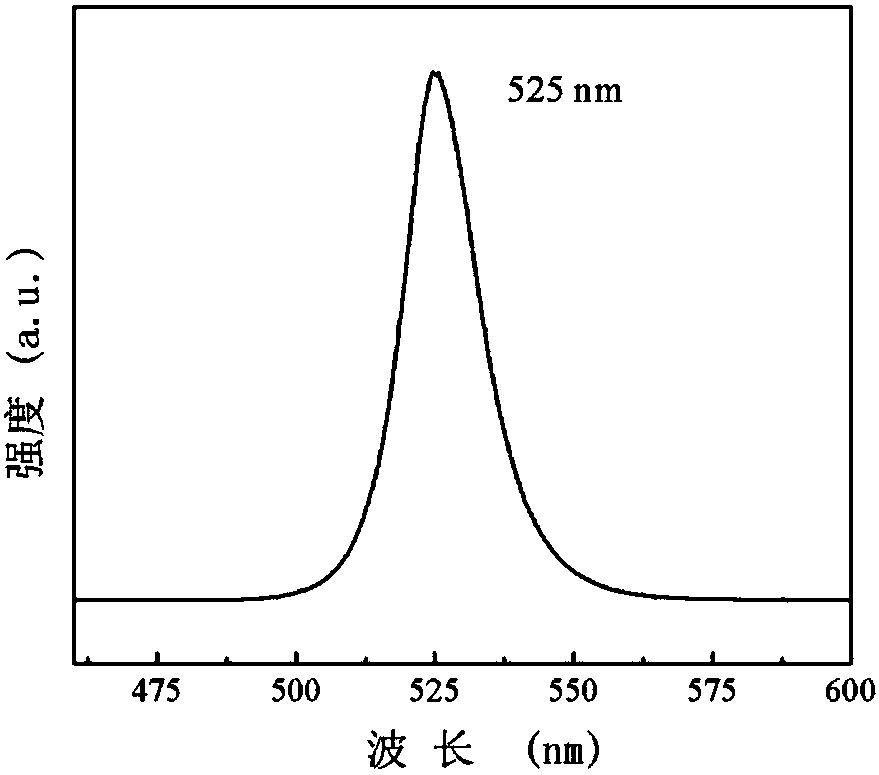

Preparation method of CsPbBr3 perovskite three-dimensional cube microcavity sample

ActiveCN108275716AEasy to operateHigh repeatabilityLaser active region structureLuminescent compositionsTube furnaceNitrogen

The invention discloses a preparation method of a CsPbBr3 perovskite three-dimensional cube microcavity sample. The preparation method comprises weighing CsBr and PbBr2 powders, putting the CsBr and PbBr2 powders in a flat quartz boat, putting the flat quartz boat into a quartz tube of a tube furnace, putting a sedimentary sheet in the quartz tube of the tube furnace and in an air outlet of the quartz tube; raising the temperature of the furnace under the protection of nitrogen to 600 DEG C, and reacting, wherein a yellow sediment on the sedimentary sheet is the CsPbBr3 perovskite three-dimensional cube microcavity sample. The surface of a prepared CsPbBr3 three-dimensional cube perovskite microcavity is smooth, the size of the three-dimensional cube microcavity is 1-15 mum, the size and the height are adjustable, and the preparation method has the excellent characteristics of convenient operation, high repeatability, high crystalline quality, controllable morphological size and height, etc.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Preparation method of zinc oxide nanorod with strong blue-violet light after being excited

ActiveCN103043706AHigh strengthGood monochromaticityZinc oxides/hydroxidesNanotechnologyActive agentKetone

The invention discloses a preparation method of a zinc oxide nanorod with strong blue-violet light after being excited. According to the preparation method, a reaction system is composed of soluble zinc salt, alkali, amine, non-aqueous solvent alcohol or ketone, a dispersing agent and a surfactant at the same time; the zinc oxide nanorod is prepared by using a solvent thermal method, so that the nanorod is rich in clearance zinc among crystal lattices and has the advantages of short time consumption, good effect and controllability in nanorod morphology. The nanorod prepared by using the method has a strong blue-violet light emission characteristic, has excellent photocatalysis property as the nanorod is likely to generate photoproduction electron / cavity after being excited under a certain condition, and has tremendous application values.

Owner:SOUTH CHINA NORMAL UNIVERSITY

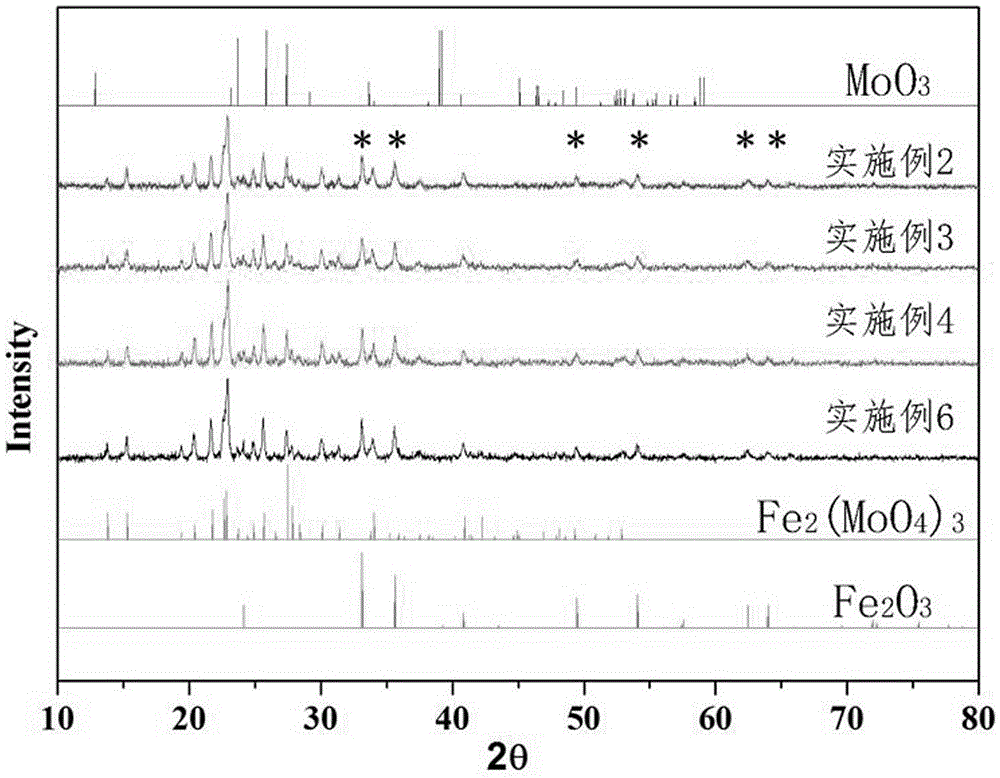

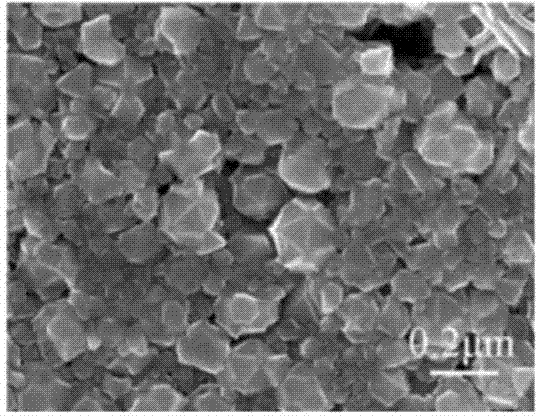

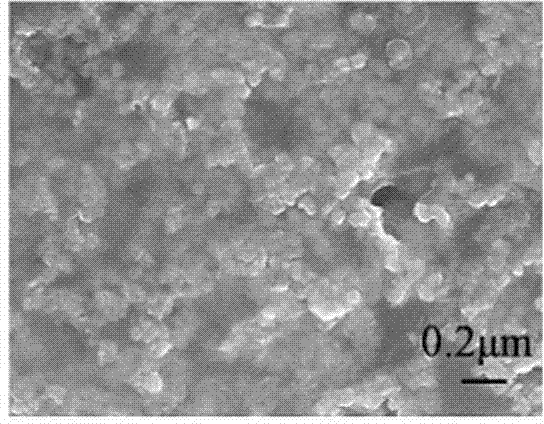

Catalyst used for methanol ammoxidation and preparation and forming method thereof

InactiveCN106669705AEasy to manufactureSimple compositionMetal/metal-oxides/metal-hydroxide catalystsHydrogen cyanide preparation/purification/separationChemical compositionAmmonia

The invention provides a preparation and forming method of a catalyst used for preparation of hydrogen cyanide through methanol ammoxidation. An existing catalyst used for preparation of hydrogen cyanide through methanol ammoxidation is mostly complex in composition, a preparation process is more difficult to control, and the applicabilityin an industrial fixed bed reactor is poor. The catalyst provided by the invention mainly comprises Fe-Mo metal oxide, wherein the atomic ratio of Fe to Mo is 0.5-5, and main ingredients of the catalyst are Fe2(MoO4)3 and Fe2O3, wherein Fe2(MoO4)3 has an ammoxidation catalysis effect, and Fe2O3 has a co-catalysis effect. The formed catalyst is controllable in particle size, has better activity and stability, and can be used for fixed bed reactors in various scales.

Owner:HUAYANG NEW MATERIAL TECH GRP CO LTD

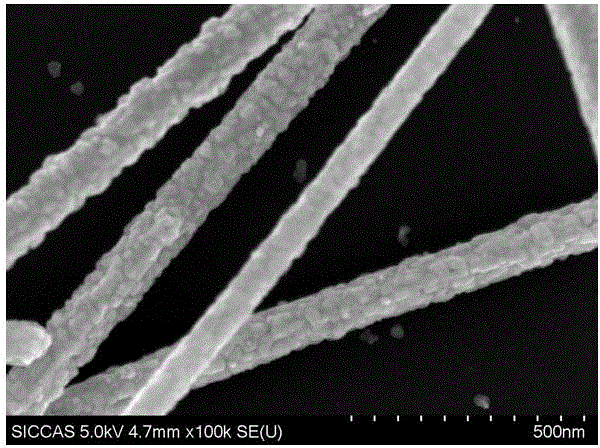

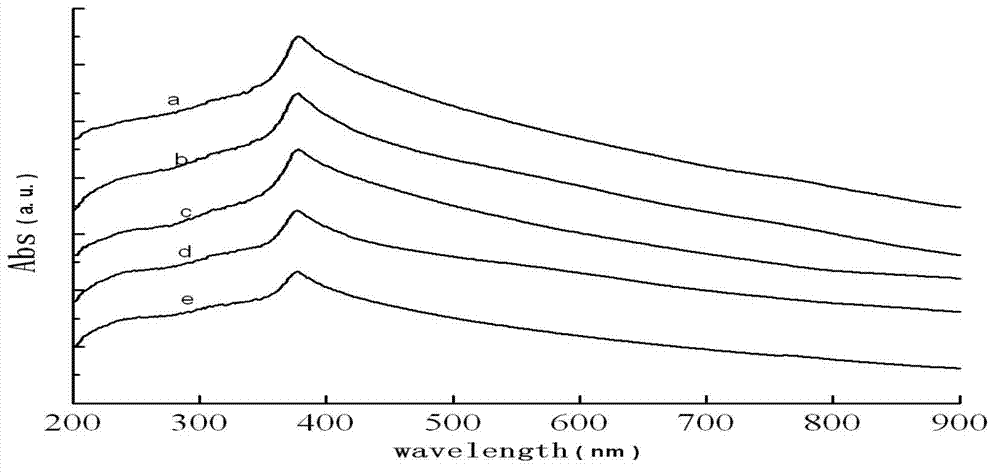

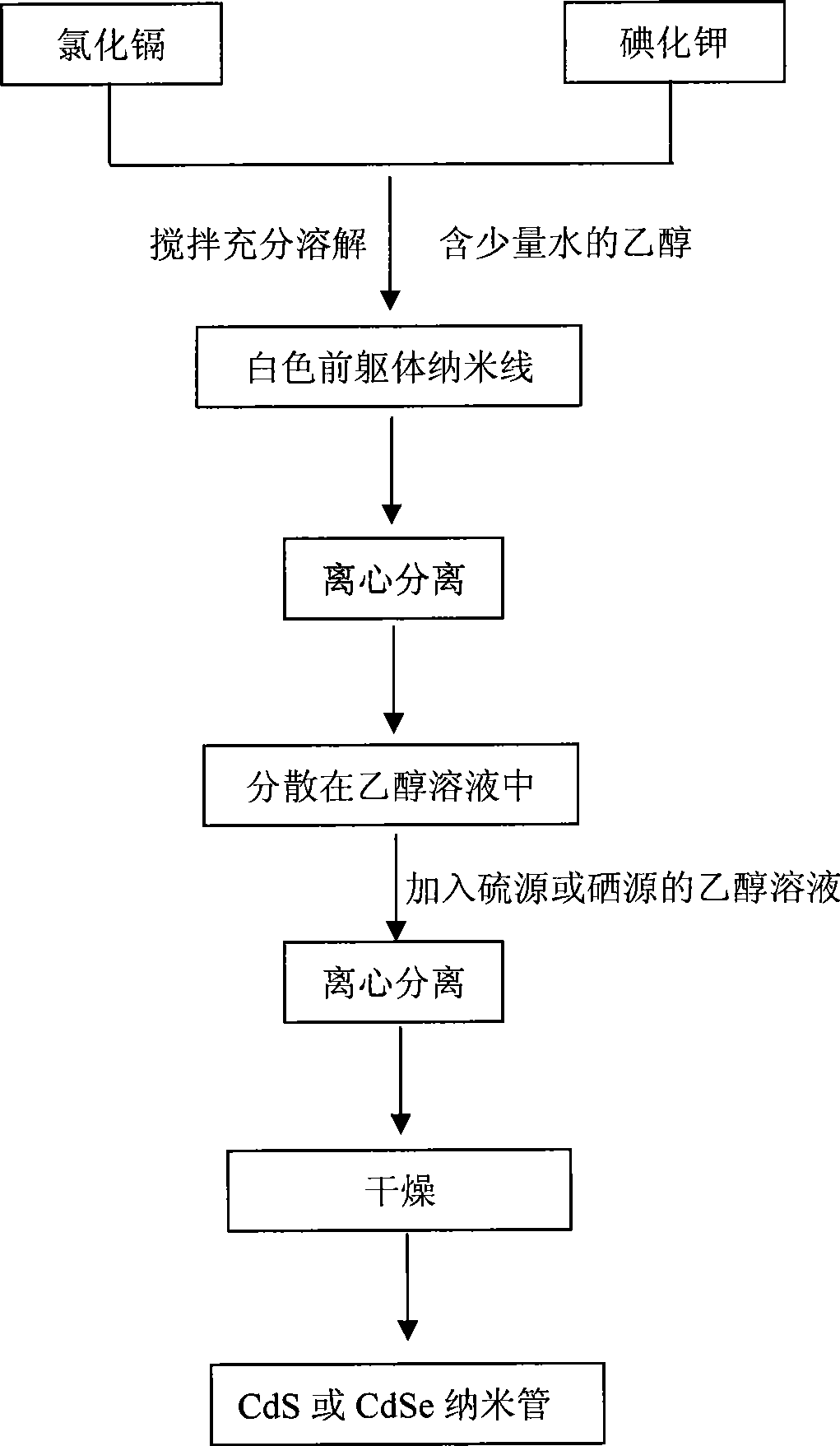

Method for preparing CdS or CdSe nano-tube with KCdCl3 nanowire as template

InactiveCN101475148ASimple processSave raw materialsCadmium sulfidesBinary selenium/tellurium compoundsSolubilityNanowire

The invention relates to a method for preparing a CdS or CdSe nanotube by using a KCdCl3 nano wire as a template, and belongs to the field of nano material preparation. The method comprises the following steps: using ethanol and little water as a reaction solvent, using water-soluble cadmium chloride and potassium iodide as raw materials, and preparing a precursor of the KCdCl3 nano wire with water-solubility and reactivity at room temperature; collecting the precursor nano wire, dispersing the precursor nano wire into the ethanol, and adding a sulfur source or a selenium source into the ethanol so that the sulfur source or the selenium source has anion replacement reaction on the surface of the nano wire to generate CdS or CdSe nano crystals to be assembled on the surface of the precursor nano wire to form a tube wall, while the precursor nano wire has formation reaction in the nanotube and simultaneously is continuously consumed so as to form the polycrystalline nanotube assembled by the CdS or CdSe nano crystals. The method has the characteristics of simple process, cheap raw materials, room temperature preparation, low cost, controllable shape and dimension, and the like.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

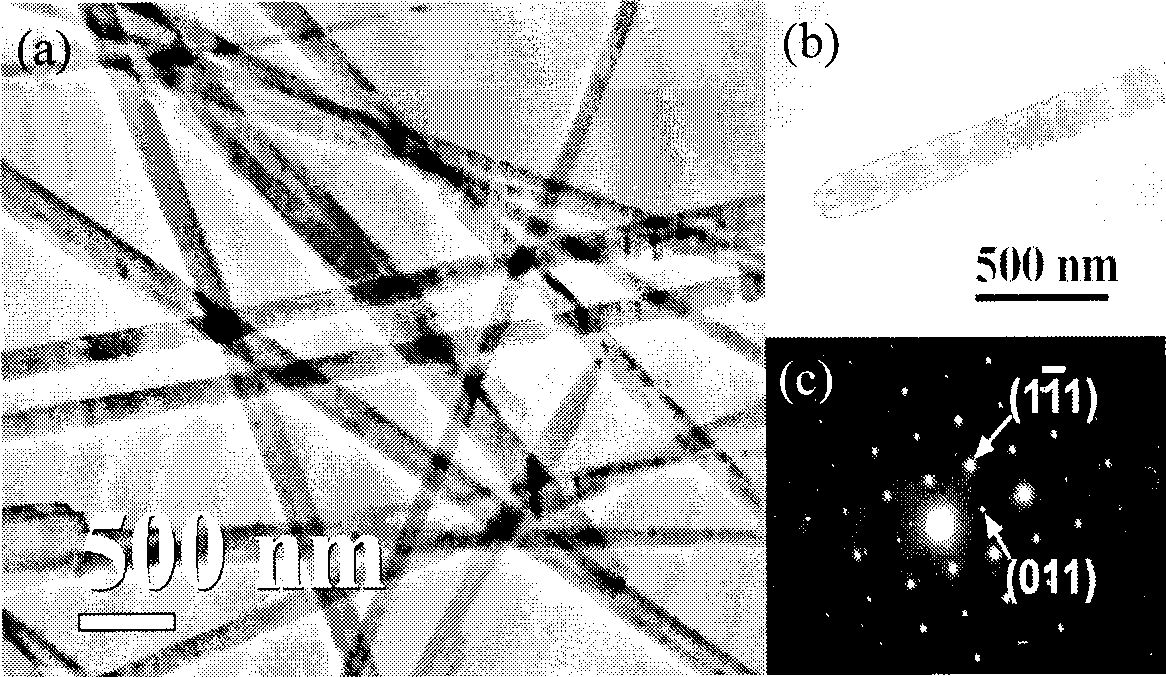

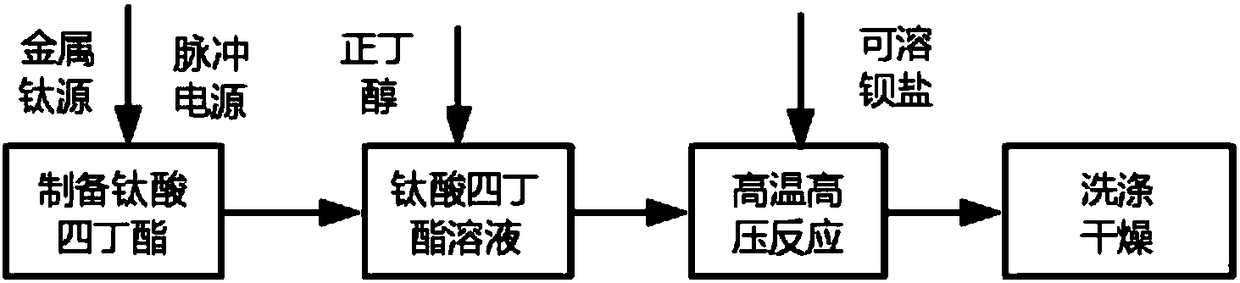

Preparation method of barium titanate nanometer powder

ActiveCN108455662AShape and size controllableMild responseAlkaline earth titanatesElectrolysis componentsTitanium chlorideElectrolysis

The invention provides a preparation method of barium titanate nanometer powder. According to the preparation method, metallic titanium is used as an anode, and under the action of a pulse power source, dissolving is performed to prepare butyl titanate; under high temperature and high pressure, vapour is inflated into the butyl titanate solution and barium salt for slow control of the hydrolyzingrate, so that the barium titanate powder is prepared. According to the method, a metallic titanium electrolysis method is adopted, preferably, a titanium plate and titanium sponge are adopted, titanium tetrachloride which can be acutely hydrolyzed is not used as a titanium source, the reaction process is mild, reaction products are controllable in shape and size, a reaction by-product namely butanol is used as an electrolytic metallic titanium reactant, and the effects of being recycle, environmentally friendly and economic can be achieved.

Owner:安徽通湾科技有限公司

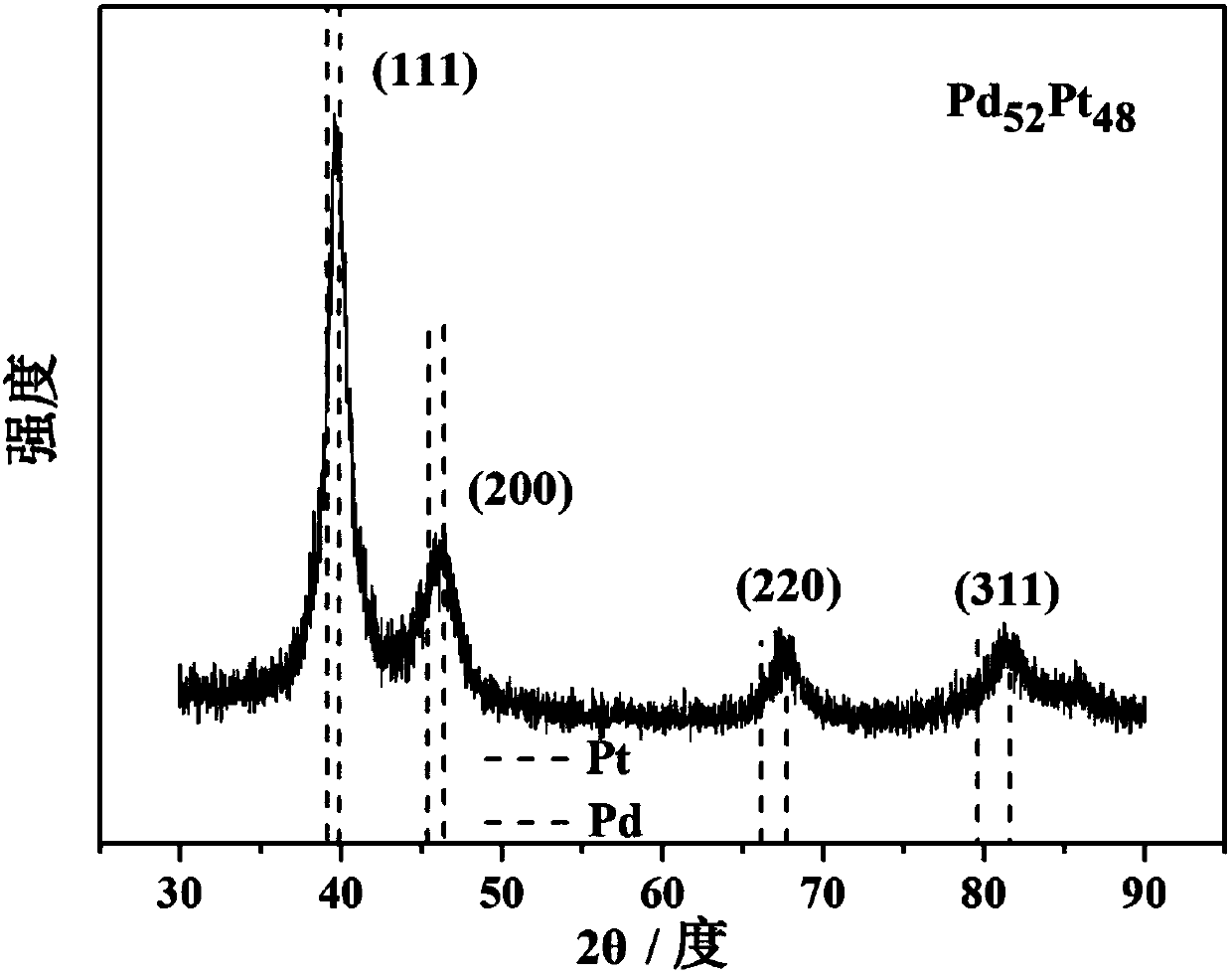

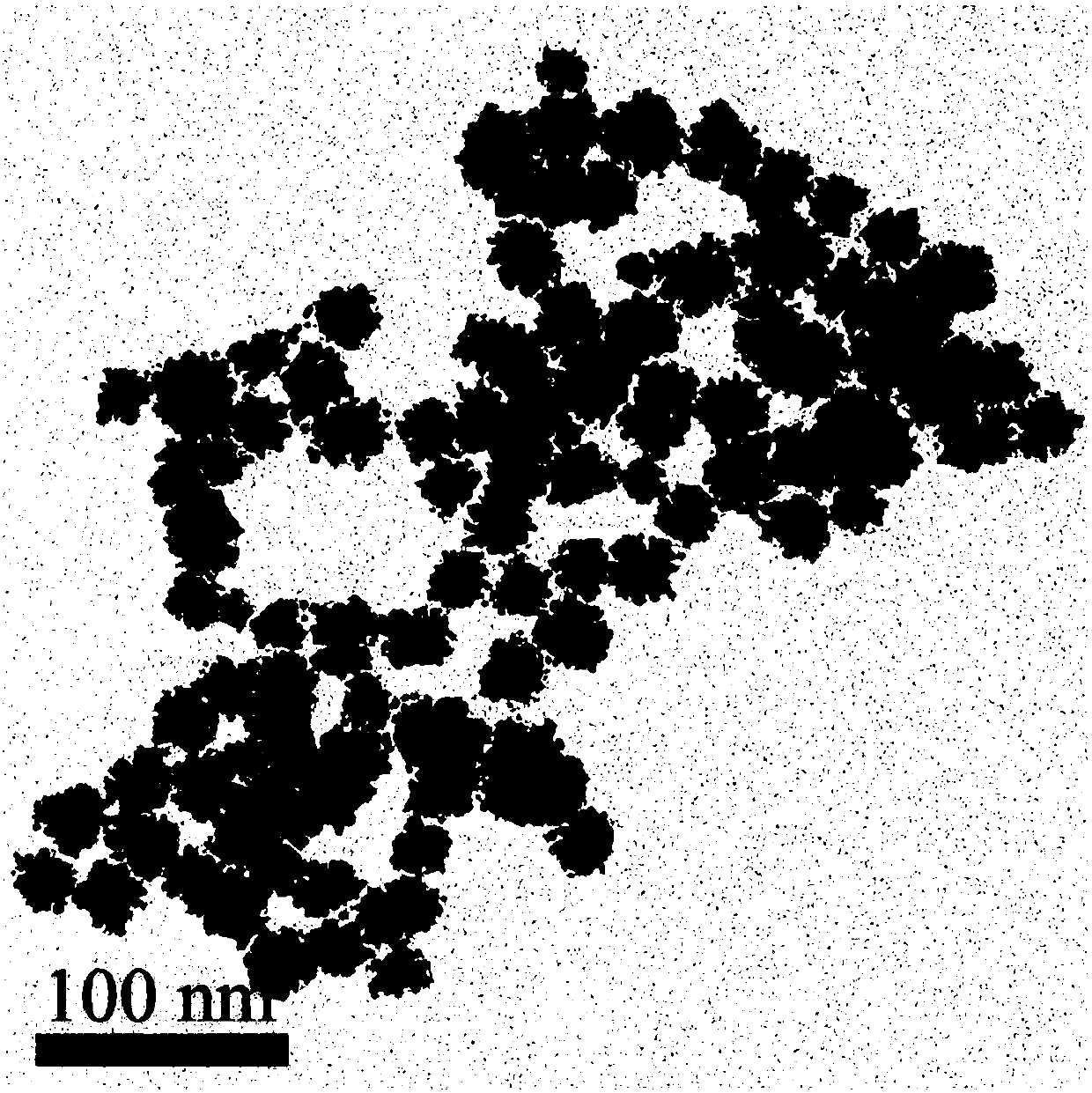

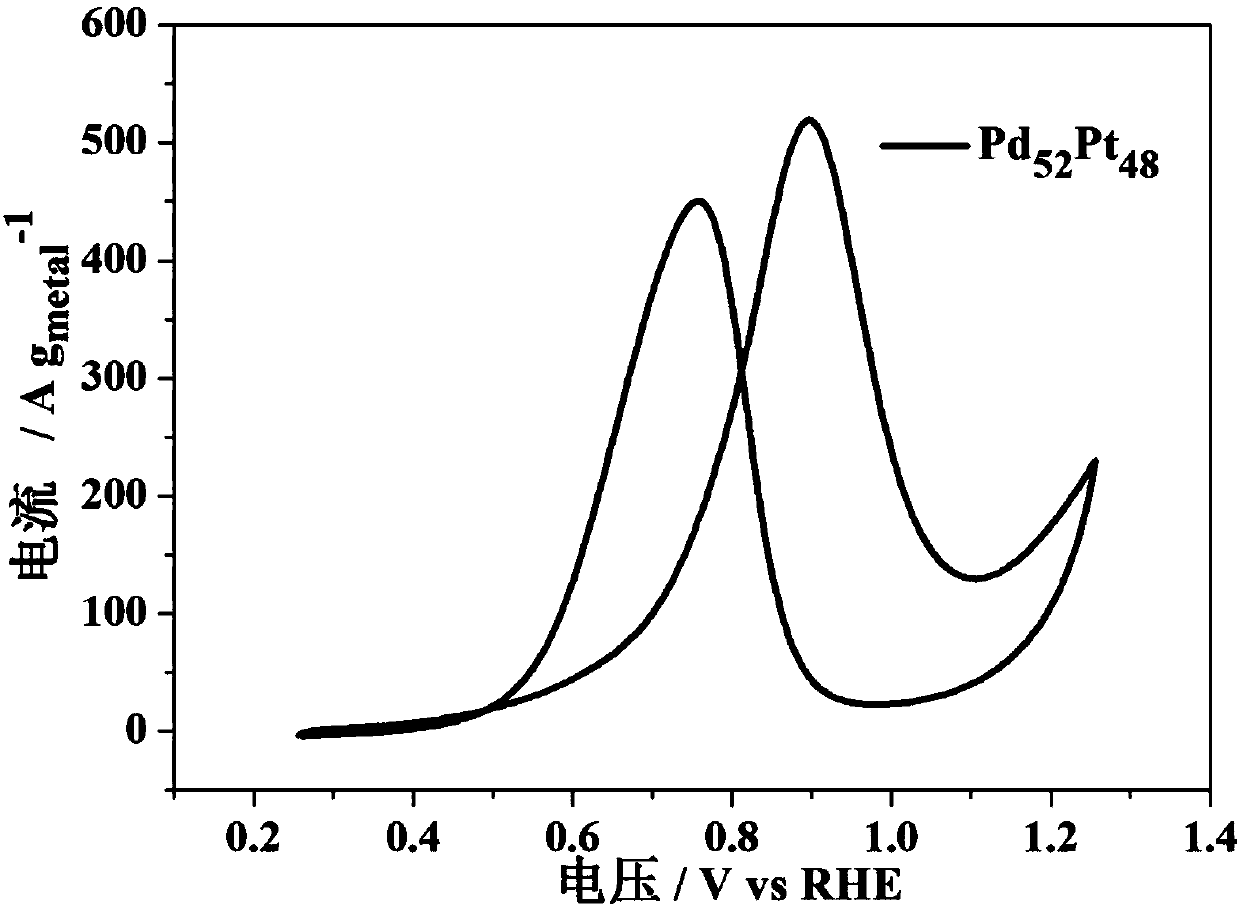

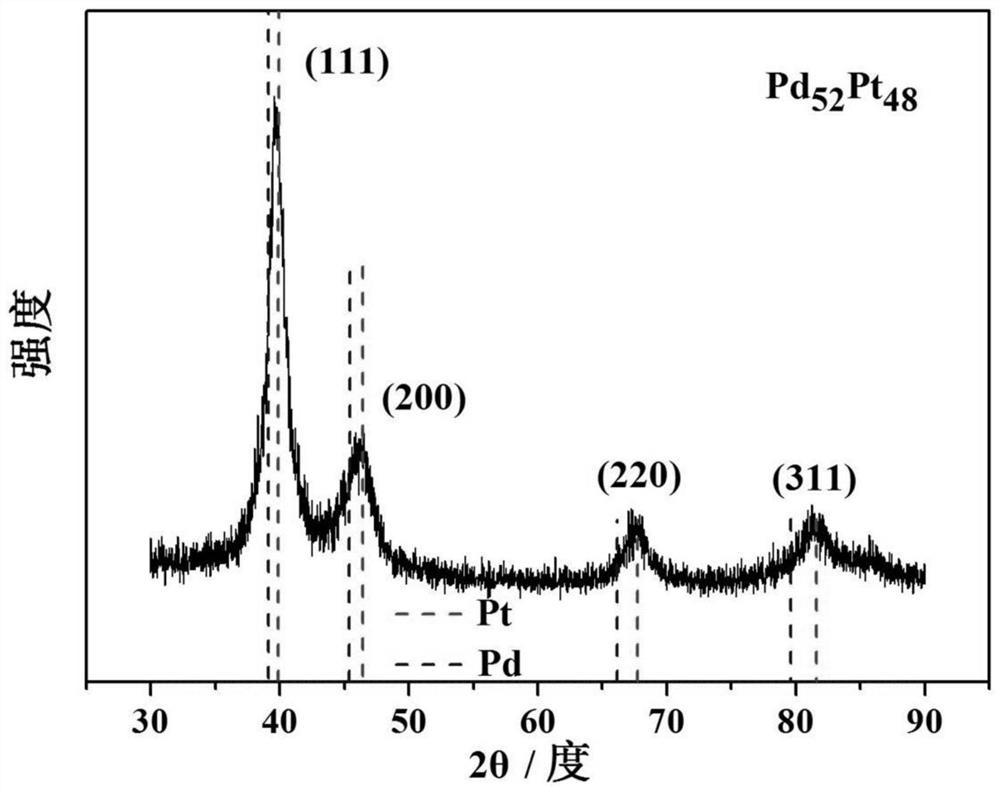

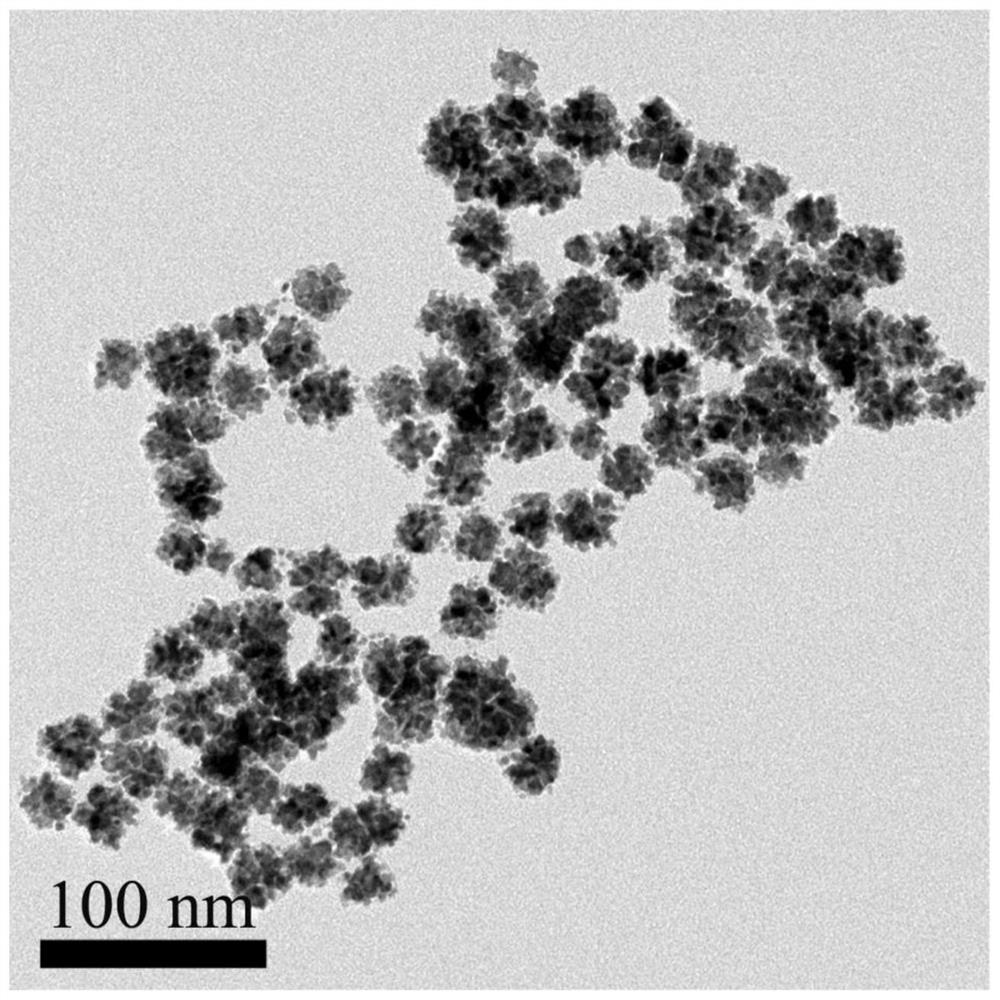

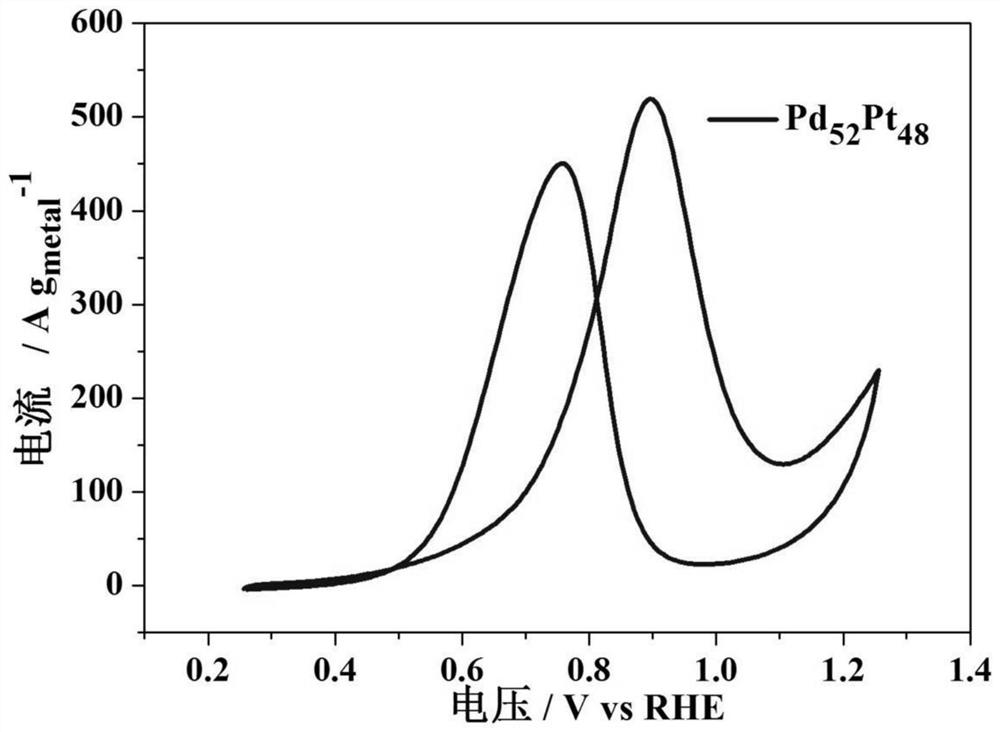

Dendritic PdPt nanoparticle for electrocatalytic methanol oxidization and preparation method of dendritic PdPt nanoparticle

ActiveCN109599570ALow costHigh catalytic activityMaterial nanotechnologyCell electrodesIonPlatanic acid

The invention provides dendritic PdPt nanoparticle for electrocatalytic methanol oxidization and a preparation method of the dendritic PdPt nanoparticle. The preparation method comprises the steps offirstly, mixing a palladium salt and hydrochloric acid with certain concentration according to a certain proportion to obtain a palladium precursor solution; secondly, weighing a certain amount of tannic acid, dropwise adding the palladium precursor solution, a chloroplatinic acid solution and deionized water according to a sequence; and finally, continuously stirring the mixture for certain timeunder a room temperature, transferring to a stainless steel high-pressure reaction kettle, and centrifugally cleaning the product after hydrothermal reaction to obtain the dendritic PdPt nanoparticle.The preparation method has the advantages of high repeatability, constituent controllability, safety and environmental friendliness and is simple and convenient, and the prepared dendritic PdPt nanoparticle has excellent electrocatalytic methanol oxidization performance.

Owner:TIANJIN UNIV

Method for preparing silicon carbide nanoparticles by use of agricultural waste biomass

InactiveCN104310402AReduce manufacturing costSimple processMaterial nanotechnologySolid waste disposalHexamethylenetetramineArgon atmosphere

The invention discloses a method for preparing silicon carbide nanoparticles by use of agricultural waste biomass. The method comprises the following steps: dissolving 1.5g of cobalt nitrate in 100ml of absolute ethyl alcohol and adding 50ml of tetraethylortho silicate after the cobalt nitrate is completely dissolved; under powerful stirring, adding 8ml of oxalic acid liquid; thoroughly stirring for 24 hours and then adding 36g of corn bract powder, mixing evenly, and then adding 8ml of hexamethylenetetramine; drying the obtained solidified sol in a drying oven at 100 DEG C; putting the dry xerogel into a high-temperature tubular furnace, and under the protection of an argon atmosphere, increasing the temperature from a room temperature to 1000 DEG C at the temperature rise rate of 10 DEG C per minute firstly, and then increasing the temperature to 1300 DEG C by 2 DEG C per minute and keeping the temperature constant for 7 hours; and after the temperature is reduced to the room temperature by cooling, taking out the sample, calcining the sample in air at 700 DEG C for 3 hours, cleaning the product by use of hydrochloric acid and hydrofluoric acid, and finally, washing, filtering and drying to obtain the final product, namely the silicon carbide nanoparticles. The method for preparing the silicon carbide nanoparticles by use of the agricultural waste biomass is capable of realizing large-scale preparation of evenly distributed small-size silicon carbide nanoparticles by use of a simple process.

Owner:WEINAN NORMAL UNIV

Preparation method of pattern and size controllable CuInSe2 nanoparticles

ActiveCN103030118AShape and size controllableHigh selectivityMaterial nanotechnologySelenium/tellurium compundsSolventSelenium

The invention discloses a preparation method of pattern and size controllable CuInSe2 nanoparticles, and relates to CuInSe2 nanoparticles. The method comprises the following steps that indium trichloride and cuprous chloride are dissolved in an oleylamine solvent, heated, stirred and prepared to form an oleylamine solution of indium trichloride and cuprous chloride; elemental selenium powder is added to the oleylamine solution, stirred and heated, and dissolved; the solution obtained in Step (1) is injected into a solution obtained in Step (2), heated to 190-290 DEG C and reacted for 10-240min; after the reaction is accomplished, a product is cleaned, centrifuged and collected; and the CuInSe2 nanoparticles are obtained. The method can selectively synthesize the CuInSe2 nanoparticles with different sizes and patterns through one step, is low in cost and environment-friendly, and facilitates large-scale production; the sizes and the patterns of the product are controllable; and the repeatability is good.

Owner:ZHONGBEI UNIV

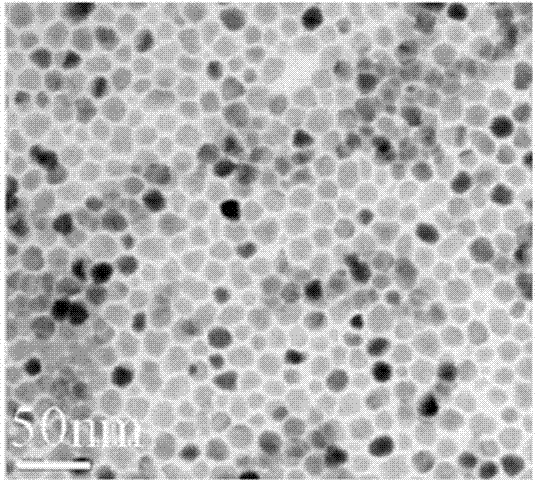

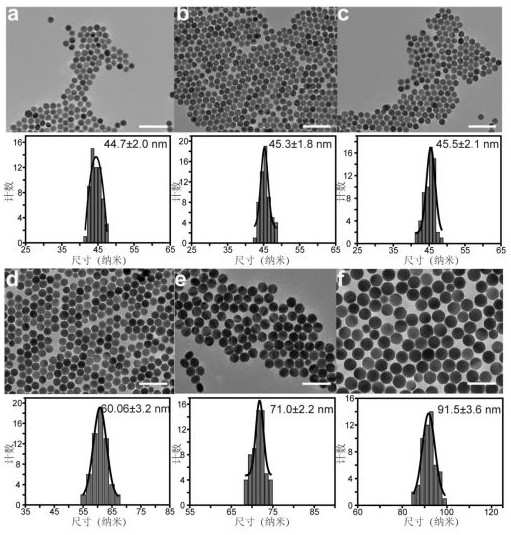

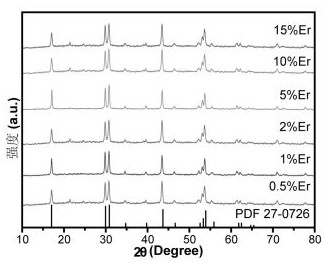

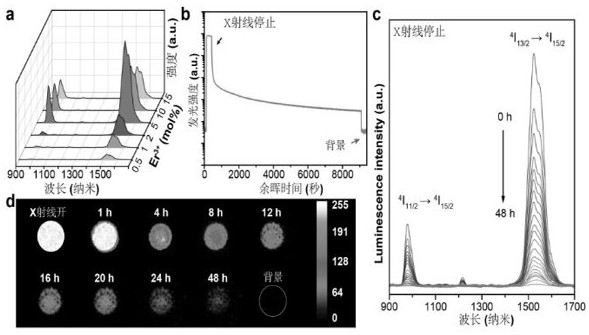

Near-infrared two-zone light-emitting long afterglow nanoprobe based on X-ray excitation, preparation method and application of nanoprobe in living body imaging analysis

ActiveCN112480925AShape and size controllableReduce background noiseMaterial analysis using wave/particle radiationLuminescent compositionsLanthanideTissue penetration

The invention relates to the field of near-infrared two-zone living body imaging in biomedical detection, in particular to a near-infrared two-zone light-emitting long afterglow nanoprobe based on X-ray excitation, a preparation method and application of the nanoprobe in living body imaging analysis. The method comprises the following steps of firstly, synthesizing a lanthanide long afterglow fluorescent probe NaLu0.8F4:Gd0.2-x / LnX@NaReF4 based on near-infrared two-zone light emitting excited by X rays, then exciting the nanoparticles to emit near-infrared two-zone fluorescence by using X-rays, and obtaining 900-1600 nm emission-adjustable near-infrared two-zone fluorescence and long afterglow light emitting by changing the types and contents of rare earth ion doping elements and adjustingthe coating type of a shell layer. The lanthanide series long afterglow nanoparticles can be used as a biocompatible probe with higher tissue penetration depth for imaging analysis of living tissuesof mice, and the analysis technology has the advantages of high sensitivity, high resolution and high signal-to-noise ratio.

Owner:FUZHOU UNIVERSITY

Iron-manganese-sulfur ternary micron material as well as preparation method and application thereof

InactiveCN112142112AAvoid gatheringShape and size controllableOther chemical processesWater contaminantsCation-exchange capacityManganese

The invention relates to an iron-manganese-sulfur ternary micron material as well as a preparation method and application thereof. The iron-manganese-sulfur ternary micron material consists of the following components in percentage by weight: 20-60 percent of iron source, 10-50 percent of manganese source, 5-35 percent of sulfur, 1-5 percent of dispersing agent and 0.5-3 percent of thickening agent. According to the preparation method, the defect that agglomeration is likely to happen in the traditional Fe-Mn and Fe-S nano composite material preparation process is overcome, and more importantly, the problem that the heavy metal adsorption amount is low due to agglomeration of the Fe-Mn and Fe-S nano composite material is solved. The S element is introduced into the Fe-Mn-containing composite material, so that the chemical state of Fe can be effectively changed, and meanwhile, the cation exchange capacity of the Fe-Mn-S composition is stronger due to a synergistic effect. The prepared iron-manganese-sulfur ternary micron material is stable in performance, capable of being stored for a long time and convenient to use. The iron-manganese-sulfur ternary micron material is widely applied to heavy metal treatment.

Owner:HUBEI FORBON TECH

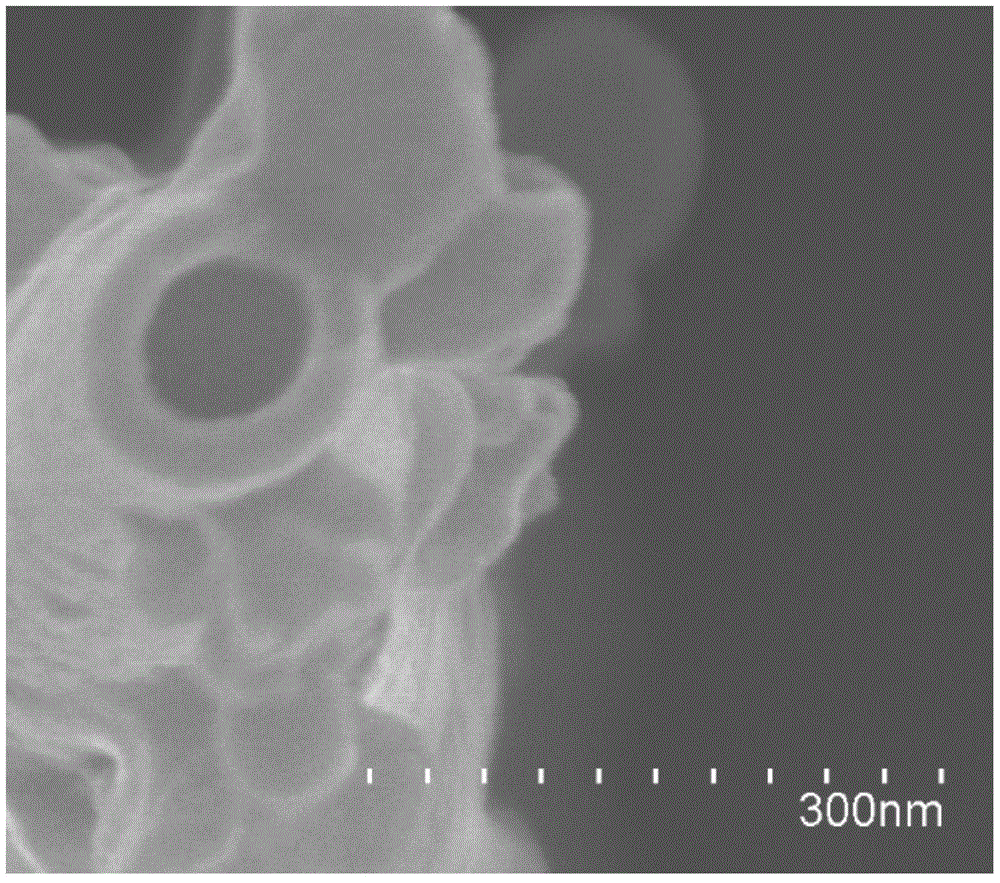

A method for preparing nanoporous structures based on nanoparticle self-assembly and its application

ActiveCN104101630BMature processing technologyGood repeatabilityRaman scatteringNanosensorsCapillary TubingCross linker

The invention relates to a method for preparing a nano-porous structure based on nano-particle self-assembly. Particularly, a capillary tube serves as a support body, and relying on the support body, nano-particles are self-assembled at the pointed end of the capillary tube through a cross-linking agent to form the nano-porous structure. The method for preparing the nano-porous structure is simple and low in cost, has the advantages that the nano aperture is adjustable in size, is convenient to move and position, and has an extensive application range.

Owner:NANJING UNIV

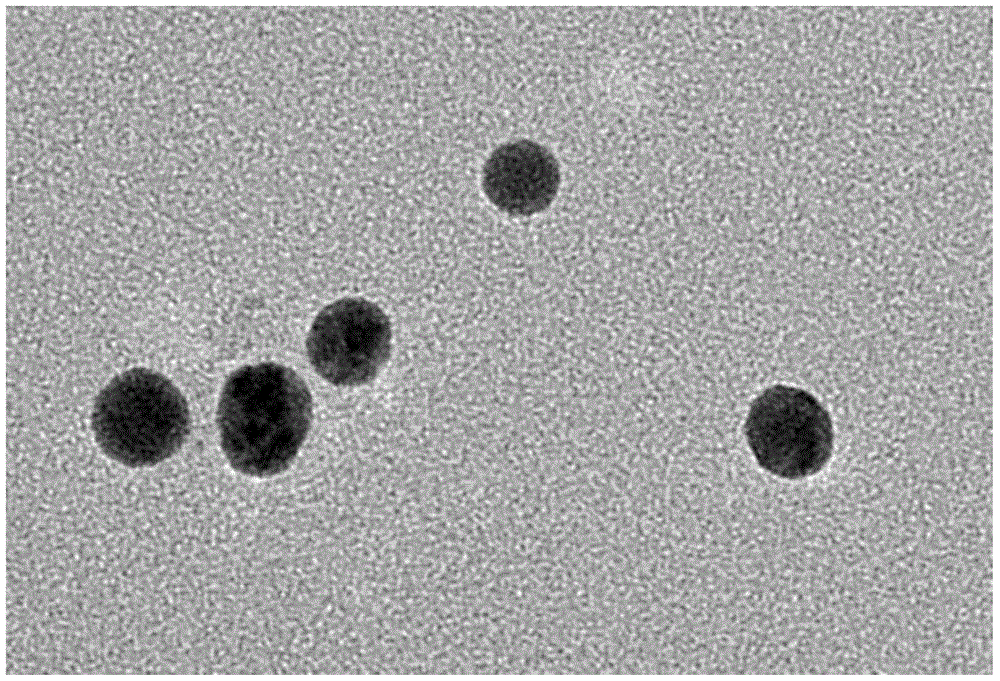

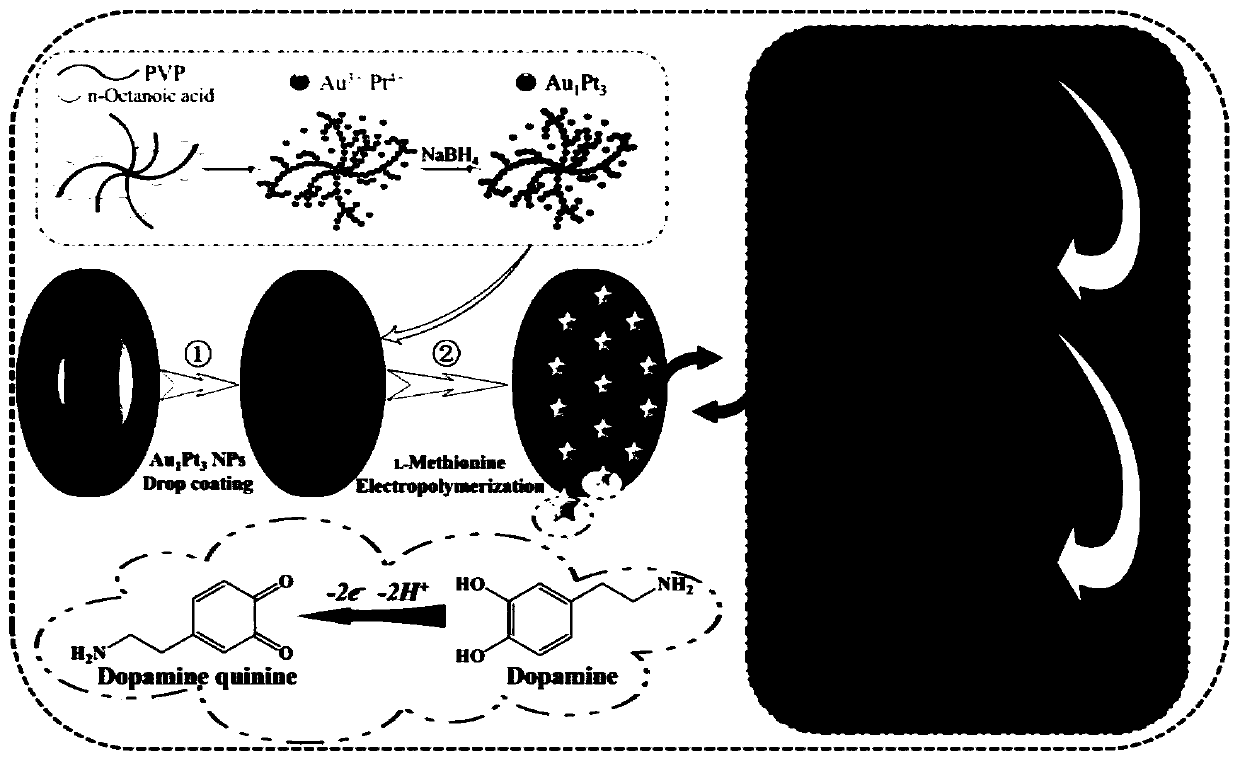

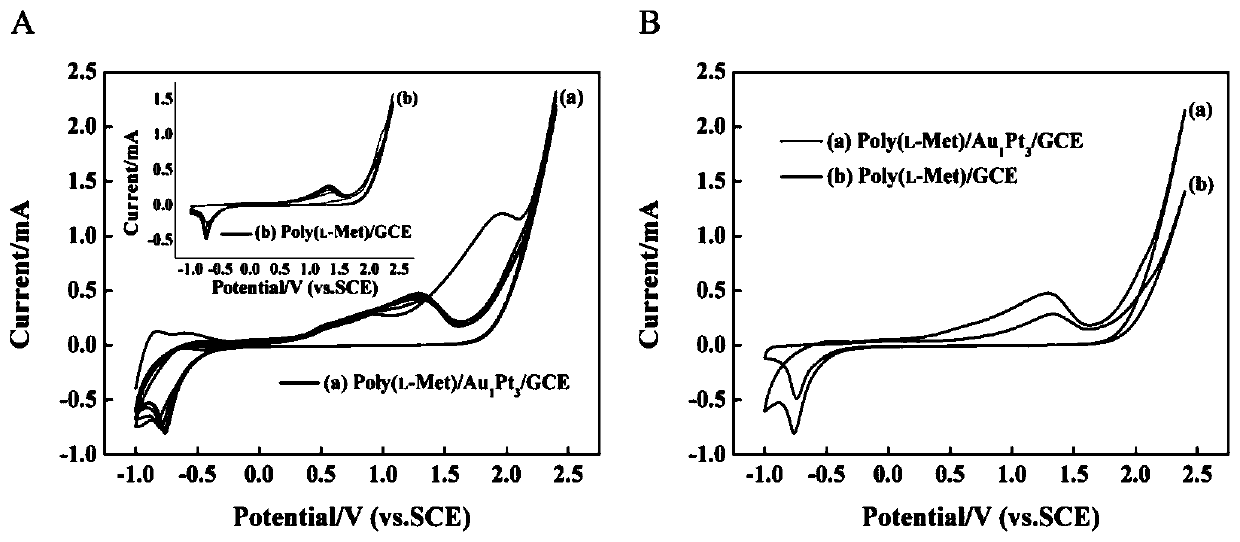

Preparation method of Au1Pt3 alloy colloidal solution and electrochemical sensor for detecting dopamine

ActiveCN110632159ALarge electrochemically active areaIncrease roughnessMaterial electrochemical variablesSolventMaterials science

The invention discloses a preparation method of an Au1Pt3 alloy colloidal solution. According to the preparation method, polyvinylpyrrolidone is dissolved in an N, N-dimethylacetamide solvent; stirring is performed until the PVP is completely dissolved, n-caprylic acid is added, an obtained mixture is subjected to ultrasonic treatment; a chloroauric acid / chloroplatinic acid mixed solution is gradually dropwise added into the solution; ultrasonic treatment is carried out; a sodium borohydride solution is added; a reaction is carried out, and a Au1Pt3 alloy colloidal solution is obtained; the alloy colloidal solution is used for preparing Au1Pt3 / GCE at first, methionine is electrochemically polymerized on the surface of the Au1Pt3 / GCE, so that a poly (L-Met) / Au1Pt3 / GCE sensor can be prepared; and the poly (L-Met) / Au1Pt3 / GCE sensor is applied to the qualitative and quantitative electrochemical detection of dopamine. The Au1Pt3 alloy prepared by the method is simple in preparation process;and the Au1Pt3 alloy nanoparticles modifying the surface of a glassy carbon electrode not only improve the electrochemical activity area of the electrode, but also provide a rough surface which facilitates electro-polymerization for L-Met.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

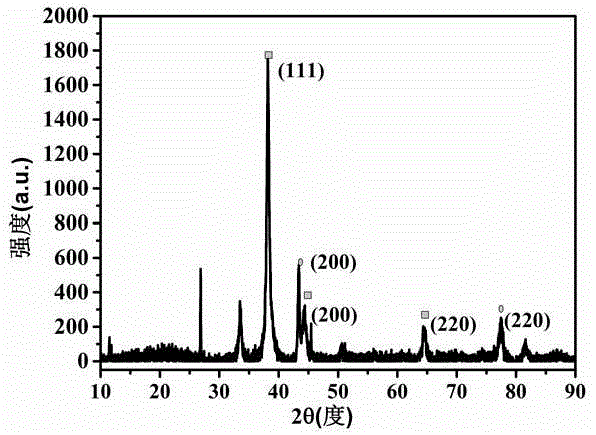

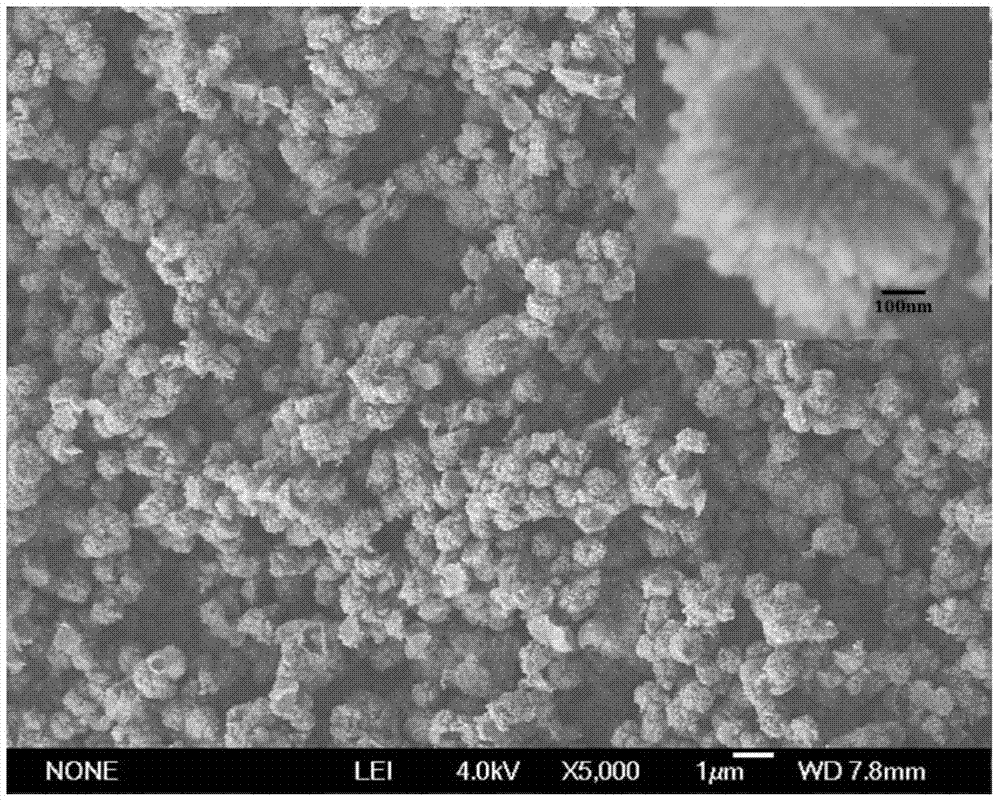

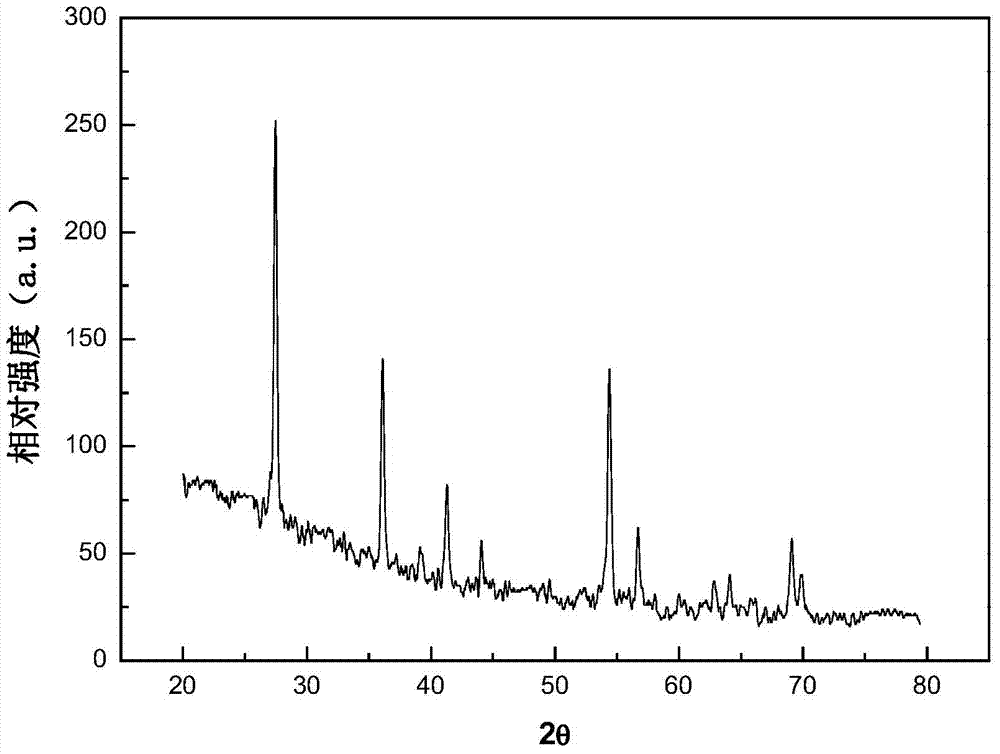

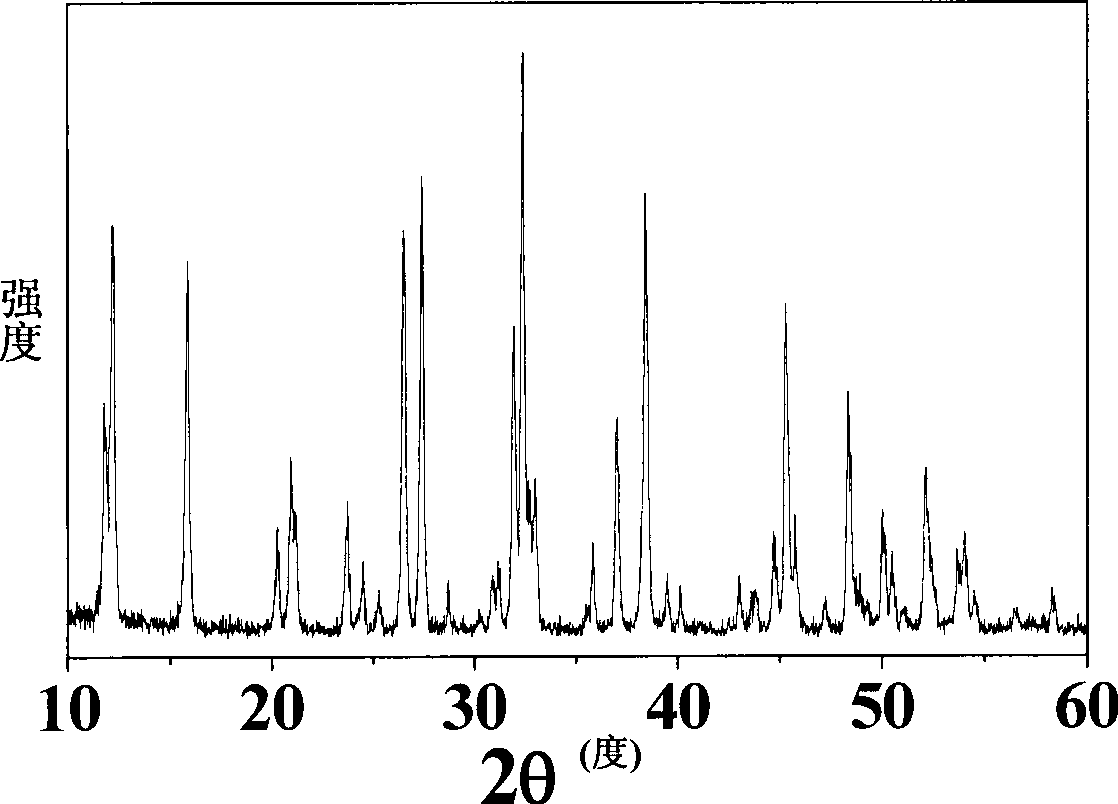

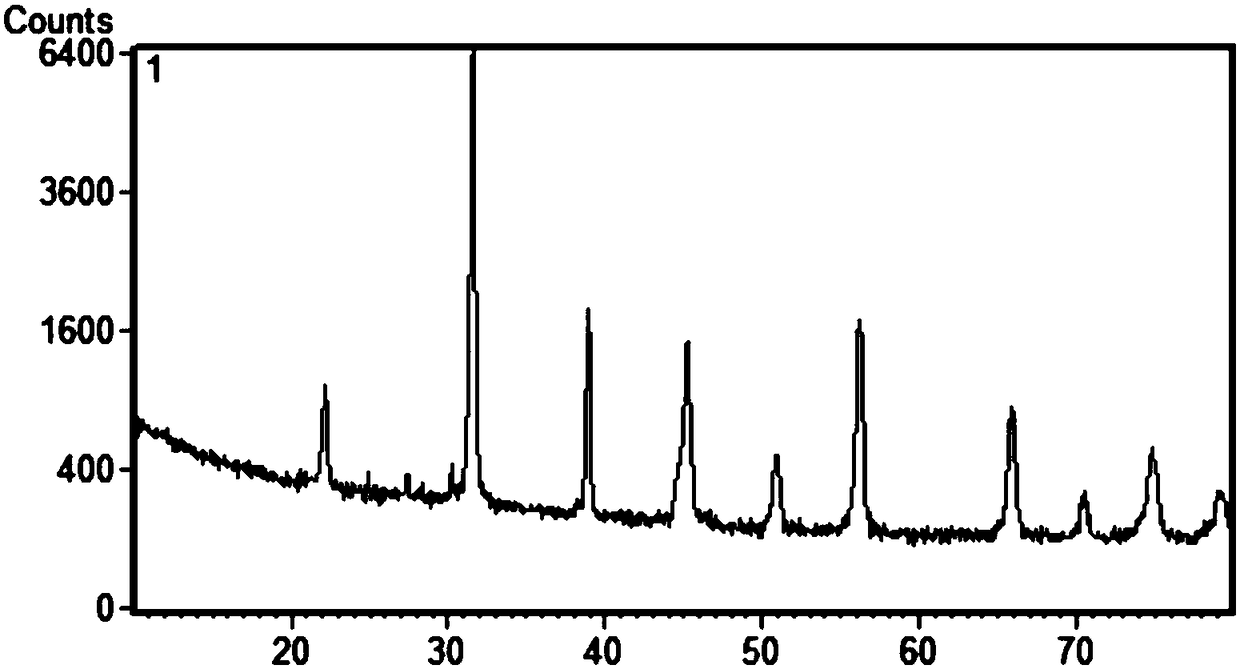

Preparation method for synthesizing MoS2/Fe3O4 nano composite material

InactiveCN103028352BSimple processHigh crystallinityInorganic material magnetismMicroballoon preparationSodium molybdateSodium thiocyanate

Owner:JIANGSU UNIV

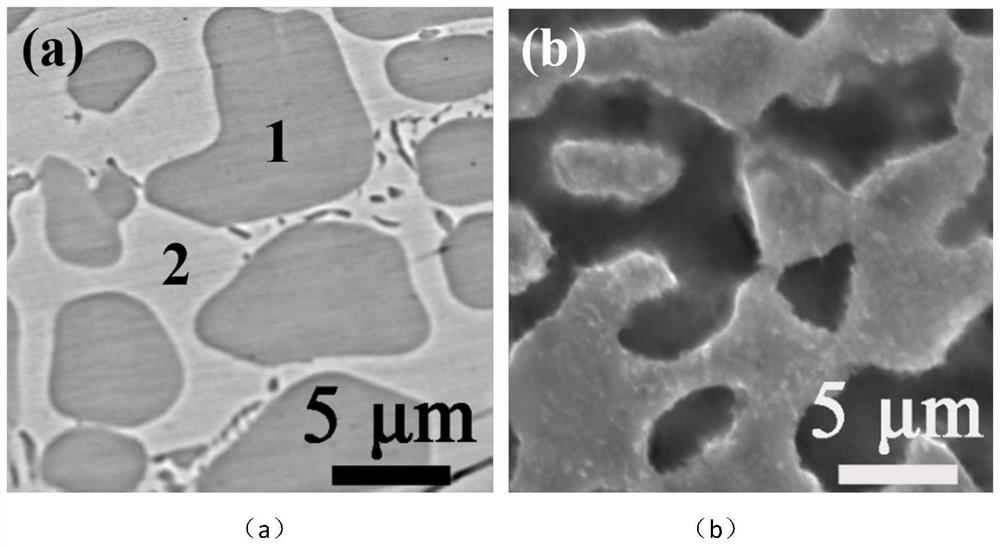

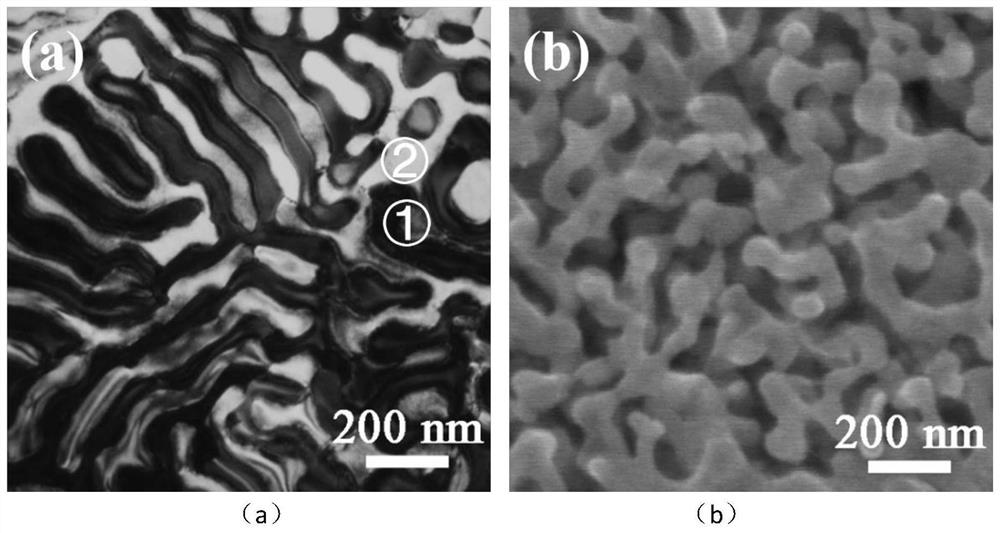

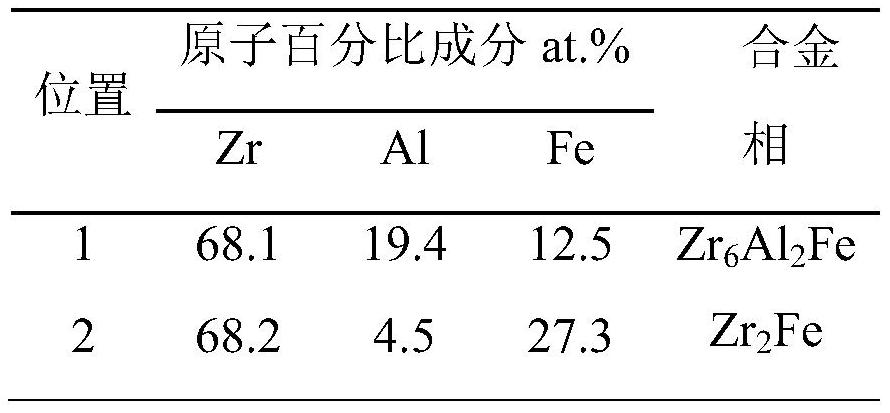

Zr-based micro/nano porous alloy and preparation method thereof

The invention discloses a Zr-based micro / nano porous alloy and a preparation method thereof, and belongs to the technical field of new materials. The chemical composition of the porous alloy is Zr2TM or ZrTM, TM = Fe1-x-yCoxNiy, x is more than or equal to 0 and less than or equal to 1, and y is more than or equal to 0 and less than or equal to 1. In the preparation process, firstly, components are selected in a Zr100-p-qAlpTMq (p is more than or equal to 15 and less than or equal to 25, and q is more than or equal to 15 and less than or equal to 25) region to prepare a precursor alloy; secondly, the electrochemical performance of the precursor alloy is measured through an electrochemical workstation, and the voltage parameter range of the Zr-based porous material prepared through subsequent electrochemistry is determined; and finally, electrochemical treatment is carried out by taking the precursor alloy as a working electrode, so that selective corrosion of an alloy phase of the precursor alloy is smoothly carried out, a Zr2TM phase or a ZrTM phase is left, and the Zr-based porous material with high structural integrity and uniform communication of pores is obtained. The technical bottleneck of preparing the porous material by a dealloying method is broken through, and the Zr-based porous material is successfully obtained; The prepared Zr-based micro-nano porous material is high in structural integrity and controllable in shape and size; and the preparation process flow is simple, efficient and good in reproducibility, and industrial production is easy to realize.

Owner:DALIAN UNIV OF TECH

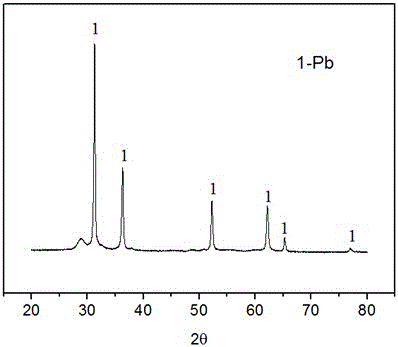

Method for preparing high-dispersity spherical nano lead powder through lead-bearing soldering tin in electronic waste

ActiveCN106563815AHigh purityShape and size controllableMaterial nanotechnologyTransportation and packagingDispersityForced convection

The invention discloses a method for preparing high-dispersity spherical nano lead powder through lead-bearing soldering tin in electronic waste. Waste soldering tin obtained and separated out on a waste printed circuit board is put into a vacuum furnace, a vacuum evaporation and forced convection inert gas condensation method is adopted, and the high-dispersity spherical nano lead powder is prepared by controlling the factors such as the heating temperature, the nitrogen pressure intensity, the condensation temperature and the powder collecting distance; and meanwhile, tin which is not evaporated is concentrated through the method, environmental heavy metal pollution is reduced, and the nano product with high additional value is prepared. The obtained product has wide application prospects in the field of lubricant additives, superconducting material studying, radiation protection, composite additives, electrode preparing and the like.

Owner:EAST CHINA NORMAL UNIV

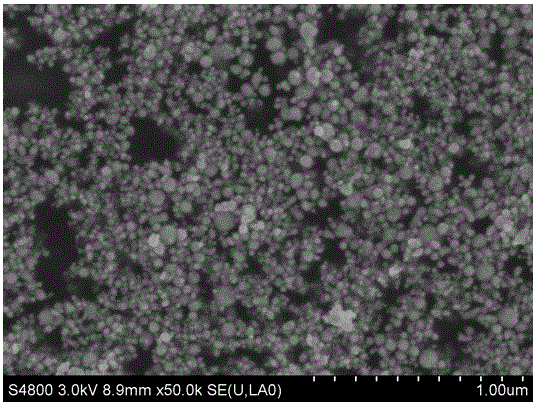

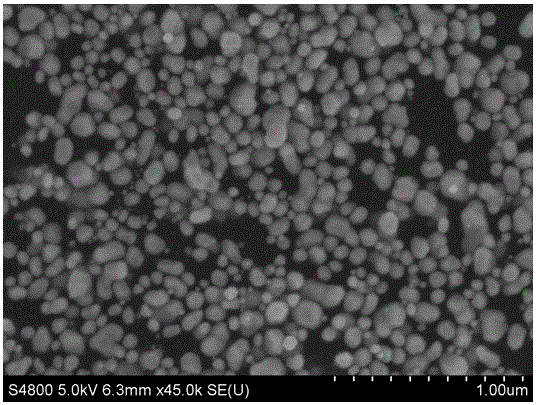

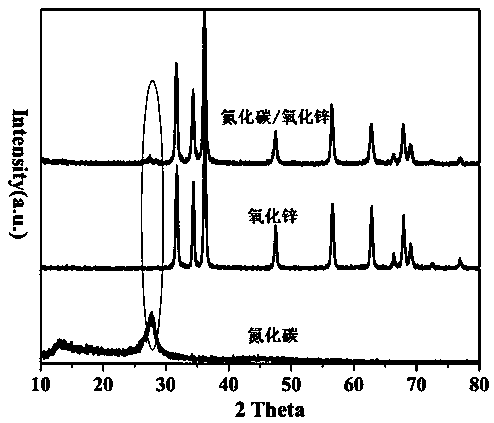

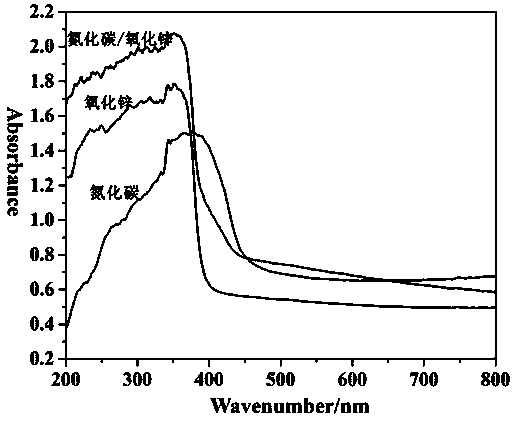

Preparation method of carbon nitride/nanometer zinc oxide ultraviolet shielding agent close to skin color

InactiveCN110240191AEasy to makeEasy to operateCosmetic preparationsMaterial nanotechnologyThioureaUltraviolet

The invention discloses a preparation method of a carbon nitride / nanometer zinc oxide ultraviolet shielding agent close to the skin color. The preparation method is characterized by comprising the following steps: (1) dissolving melamine and thiourea into deionized water according to a certain proportion, carrying out uniform stirring, transferring the solution into a reaction kettle to carry out a reaction at 180 DEG C for 12 h, carrying out cooling to the room temperature, then, carrying out filtration, and calcining the obtained filter cake at 520 DEG C for 3 h to obtain carbon nitride; and (2) sufficiently and uniformly grinding carbon nitride and a certain quantity of zinc chloride in an agate mortar, placing the ground powder into a crucible, and carrying out calcination at a certain temperature for 2 h to obtain the carbon nitride / nanometer zinc oxide ultraviolet shielding agent close to the skin color. The carbon nitride / nanometer zinc oxide ultraviolet shielding agent prepared by adopting the method has the advantages that the preparation process is simple, rapid and easy to operate and a product is high in yield, simple in aftertreatment, controllable in shape, size and composition, nontoxic, antibacterial and closer to the skin color, and particularly, the carbon nitride / nanometer zinc oxide ultraviolet shielding agent has a relatively good application prospect in the field of cosmetics.

Owner:SHANGQIU NORMAL UNIVERSITY

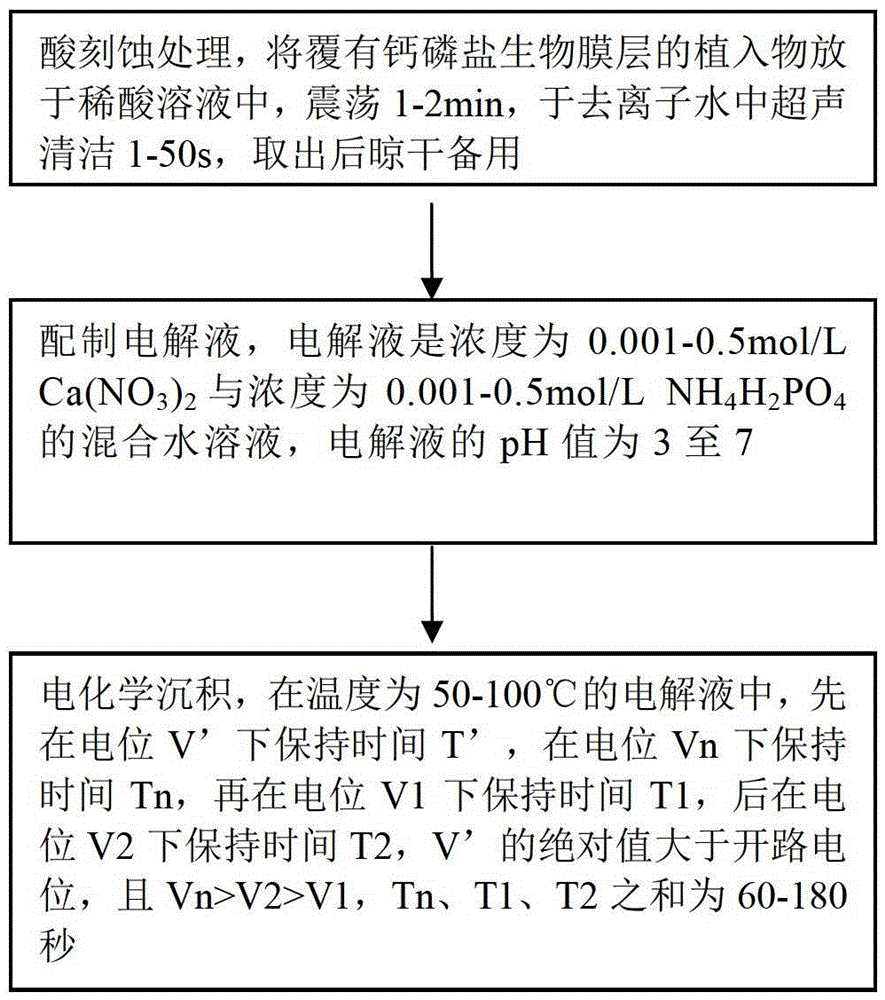

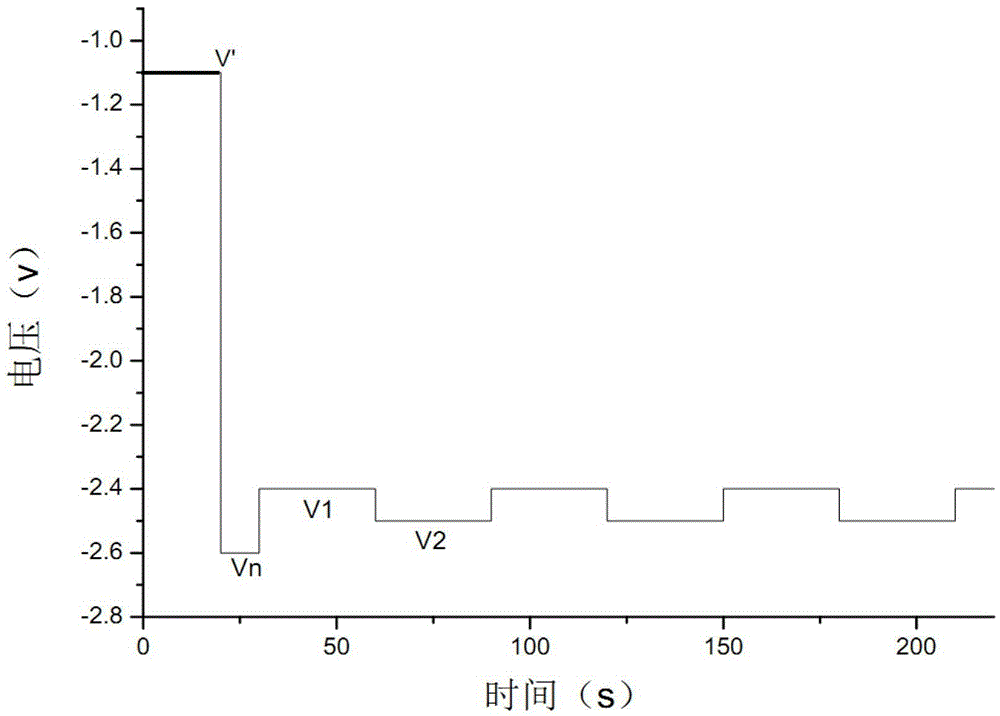

Calcium phosphate biofilm layer and its pulse electrochemical modification method

ActiveCN103866368BHigh bonding strengthReduce energy consumptionElectrolytic inorganic material coatingAcid etchingPhosphate

The invention provides a calcium and phosphate salt biofilm layer and an electrochemistry modification method thereof. The electrochemistry modification method comprises: carrying out an acid etching treatment, wherein an implant covered with a plasma-coated calcium and phosphate salt biofilm layer is placed into a dilute acid solution, shocking is performed for 1-2 min, ultrasonic cleaning is performed for 1-50 seconds in deionized water, and the obtained implant is taken out and is subjected to air-drying so as to be spare; preparing an electrolyte, wherein the electrolyte is a mixed aqueous solution comprising Ca(NO3)2 with a concentration of 0.001-0.5 mol / L and NH4H2PO4 with a concentration of 0.001-0.5 mol / L, the pH value of the electrolyte is 3-7, and deposition is performed in the electrolyte with a temperature of 50-100 DEG C; and carrying out electrochemical deposition, wherein the time T' is maintained under an electric potential V', the time Tn is maintained under an electric potential Vn, the time T1 is maintained under an electric potential V1, the time T2 is maintained under an electric potential V2, the absolute value of the V' is greater than the open circuit potential, Vn is more than V2, V2 is more than V1, and the sum of the Tn, the T1 and the T2 is 60-180 seconds. The calcium and phosphate salt biofilm layer modified through the method has high bonding strength with the substrate, and has high biological activity.

Owner:BEIJING NATON TECH GRP CO LTD

Dendritic PDPT nanoparticles for electrocatalytic oxidation of methanol and preparation method thereof

ActiveCN109599570BImprove performanceEasy to useMaterial nanotechnologyCell electrodesNanoparticlePhysical chemistry

The present invention provides dendritic PdPt nanoparticles for electrocatalytic oxidation of methanol and a preparation method thereof. The palladium salt is mixed with a certain concentration of hydrochloric acid in a certain proportion to obtain a palladium precursor solution; secondly, a certain amount of tannin is weighed, Add palladium precursor solution, chloroplatinic acid solution and deionized water dropwise in sequence. Then the mixture is continuously stirred at room temperature for a certain period of time, and then transferred to a stainless steel high-pressure reactor, and the product after the hydrothermal reaction is cleaned by centrifugation to obtain dendritic PdPt nanoparticles. The invention has the advantages of simple and convenient operation, high repeatability, controllable composition, safety and environmental protection, and the prepared dendrite nanoparticles have excellent electrocatalytic methanol oxidation performance.

Owner:TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com