Preparation method of pattern and size controllable CuInSe2 nanoparticles

A nanoparticle and morphology technology, applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., to achieve the effects of controllable product size and shape, simple preparation process, and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A CuInSe 2 The shape and size controllable preparation method of nanoparticles includes the following steps:

[0024] (1) Add 1.5 mmol of indium trichloride and 1.5 mmol of cuprous chloride to 5 mL of oleylamine, heat and stir to dissolve indium trichloride and cuprous chloride, and prepare indium trichloride and cuprous chloride. Cuprous oleylamine solution;

[0025] (2) Add 3 mmol of elemental selenium powder to 30 mL of oleylamine, stir and heat up to dissolve the elemental selenium powder;

[0026] (3) injecting the solution obtained in step (1) into the solution obtained in step (2);

[0027] (4) After the solution obtained in step (3) is heated to 260 °C, the reaction is performed for 60 min;

[0028] (5) After the reaction is completed, the product is washed and collected by centrifugation to obtain CuInSe 2 Nanoparticles;

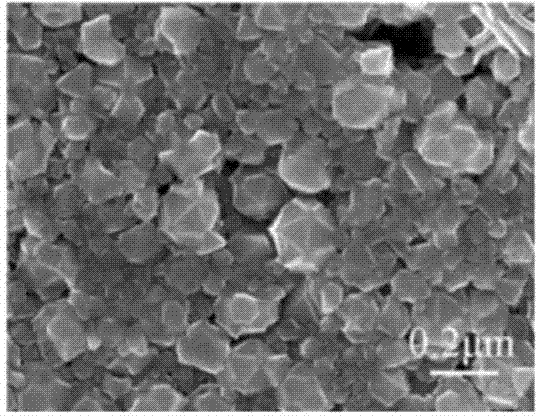

[0029] (6) The morphology of the sample was characterized, and the scanning electron microscope observation showed that the obtained pr...

Embodiment 2

[0031] A CuInSe 2 The shape and size controllable preparation method of nanoparticles includes the following steps:

[0032] (1) Add 0.5 mmol of indium trichloride and 0.5 mmol of cuprous chloride to 5 mL of oleylamine, heat and stir to dissolve indium trichloride and cuprous chloride, and prepare indium trichloride and cuprous chloride. Cuprous oleylamine solution;

[0033] (2) Add 1 mmol elemental selenium powder to 30 mL of oleylamine, stir and heat up to dissolve the elemental selenium powder;

[0034] (3) injecting the solution obtained in step (1) into the solution obtained in step (2);

[0035] (4) After the solution obtained in step (3) was heated to 245°C, the reaction was carried out for 180 min;

[0036] (5) After the reaction is completed, the product is washed and collected by centrifugation to obtain CuInSe 2 Nanoparticles;

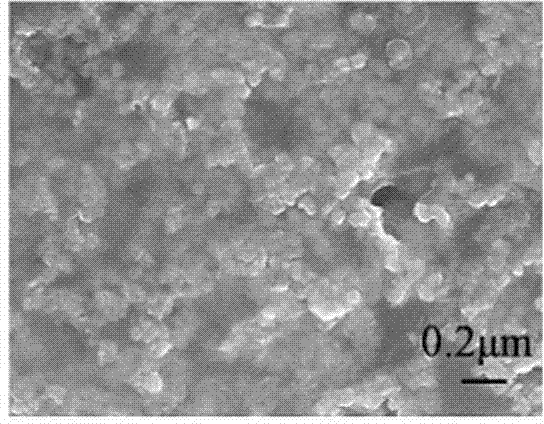

[0037] (6) The morphology of the sample was characterized, and the scanning electron microscope observation showed that the obtained p...

Embodiment 3

[0039] A CuInSe 2 The shape and size controllable preparation method of nanoparticles includes the following steps:

[0040] (1) Add 0.25 mmol of indium trichloride and 0.25 mmol of cuprous chloride to 5 mL of oleylamine, heat and stir to dissolve indium trichloride and cuprous chloride, and prepare indium trichloride and cuprous chloride. Cuprous oleylamine solution;

[0041] (2) Add 0.5 mmol elemental selenium powder to 30 mL of oleylamine, stir and heat up to above 200°C to dissolve the elemental selenium powder;

[0042] (3) injecting the solution obtained in step (1) into the solution obtained in step (2), and cooling to 70°C;

[0043] (4) After the solution obtained in step (3) was rapidly heated to 230°C, the reaction was carried out for 60 min;

[0044] (5) After the reaction is completed, the product is washed and collected by centrifugation to obtain CuInSe 2 Nanoparticles;

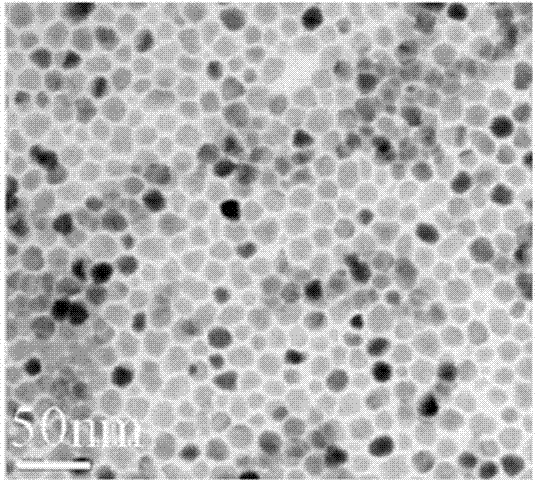

[0045] (6) The morphology and phase state of the sample were characterized, and the tra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com