Zr-based micro/nano porous alloy and preparation method thereof

A nanoporous and alloy technology, applied in the field of new materials, achieves the effect of simple preparation process, high structural integrity, and controllable shape and size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

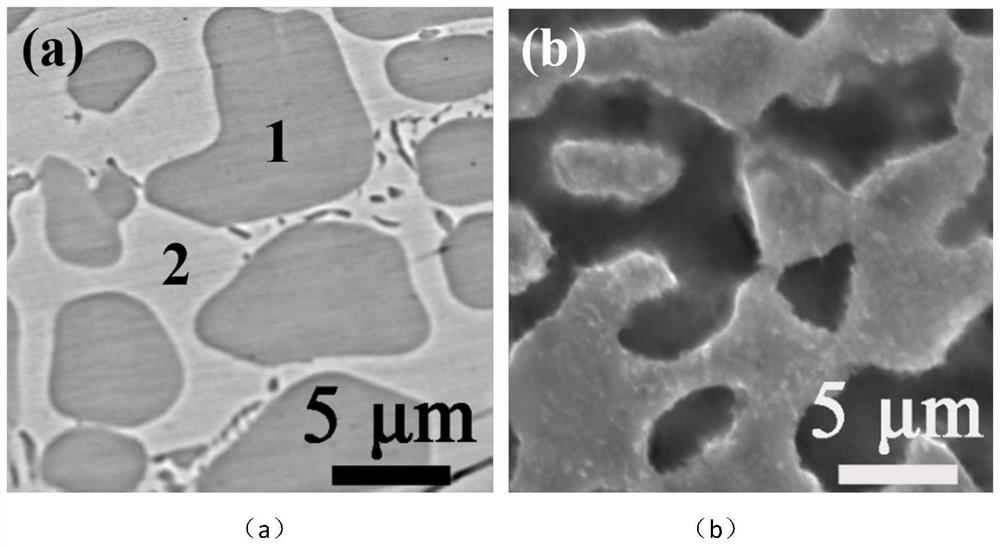

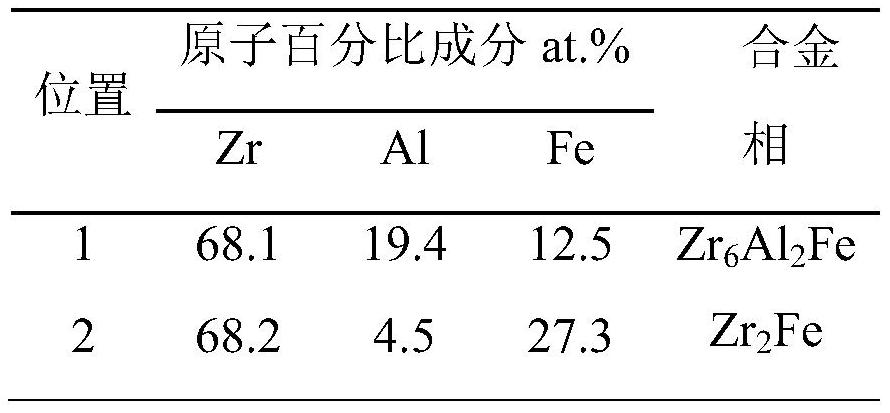

[0021] Example 1 Zr 2 Fe Microporous Alloy

[0022] Step 1: Zr 70 al 15 Fe 15 Preparation of precursor alloys

[0023] Select Zr 70 al 15 Fe 15 As the precursor alloy composition, industrially pure Zr (>99%), Al (>99.9%) and Fe (>99%) metals are used as raw materials, and the composition of Zr by atomic percentage 70 al 15 Fe 15 Conversion, weighing, and alloy preparation; mix the raw materials and place them in a water-cooled copper crucible in a non-consumable arc melting furnace, and then evacuate to 1×10 -2 Pa, filled with 0.05MPa industrial pure Ar atmosphere for smelting, the arc melting working current is 250A; the alloy ingot is turned upside down and smelted repeatedly 4 times to obtain an alloy ingot with uniform composition. Then, using the suction casting method, under the condition of cooling rate of 300K / s, the precursor alloy is prepared, and the backscattered electron image of its structure is shown in the attached figure 1 As shown in (a), it shows ...

Embodiment 2

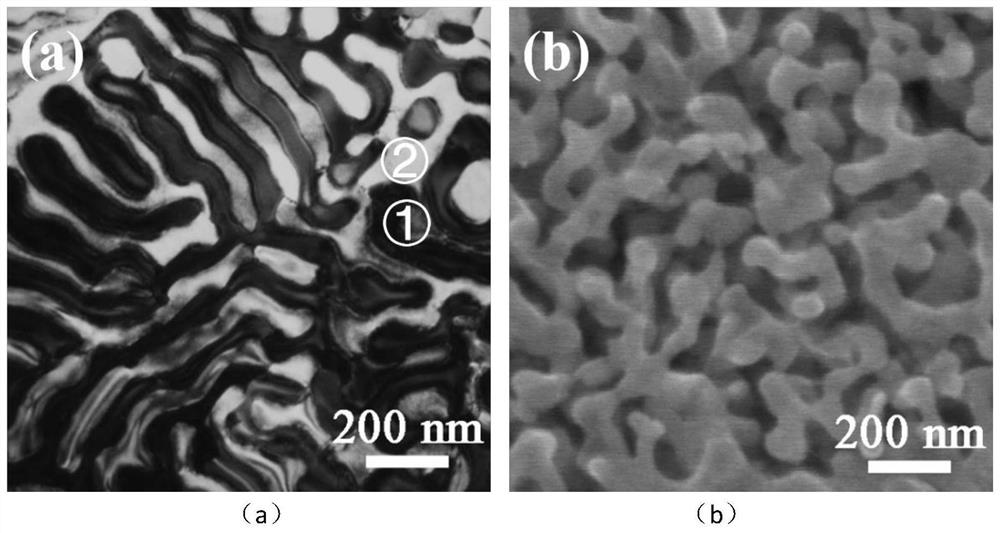

[0029] Example 2 ZrCo nanoporous alloy

[0030] Step 1: Zr 60 al 15 co 25 Preparation of (TM=Co) precursor alloy

[0031] Select Zr 60 al 15 co 25 As a precursor alloy composition, industrially pure Zr (>99%), Al (>99.9%) and Co (>99%) metals are used as raw materials, and the composition of Zr by atomic percentage 60 al 15 co 25 Conversion, weighing, and alloy preparation; mix the raw materials and place them in a water-cooled copper crucible in a non-consumable arc melting furnace, and then evacuate to 1×10 -2 Pa, filled with 0.05MPa industrial pure Ar atmosphere for smelting, the arc melting working current is 250A; the alloy ingot is turned upside down and smelted repeatedly 4 times to obtain an alloy ingot with uniform composition. Then, using the suction casting method, the precursor alloy is prepared at a cooling rate of about 800K / s, and the backscattered electron image of its structure is shown in the attached figure 2 As shown in (a), it shows a typical na...

Embodiment 3

[0038] Example 3 Zr 2 Ni microporous alloy

[0039] Step 1: Zr 55 al 25 Ni 20 Preparation of (TM=Ni) precursor alloy

[0040] Select Zr 55 al 25 Ni 20 As the precursor alloy composition, industrially pure Zr (>99%), Al (>99.9%) and Ni (>99%) metals are used as raw materials, and the composition of Zr by atomic percentage 55 al 25 Ni 20 Conversion, weighing, and alloy preparation; mix the raw materials and place them in a water-cooled copper crucible in a non-consumable arc melting furnace, and then evacuate to 1×10 -2 Pa, filled with 0.05MPa industrial pure Ar atmosphere for smelting, the arc melting working current is 250A; the alloy ingot is turned upside down and smelted repeatedly 4 times to obtain an alloy ingot with uniform composition. Then, using the suction casting method, the precursor alloy was prepared at a cooling rate of 400K / s. The backscattered electron image of the structure showed a typical nanoscale amplitude modulation structure, and its constitue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com