Method for electrochemically assisted preparation of low-defect expanded graphite paper

An expanded graphite, low-defect technology, applied in the field of materials, can solve the problems of large-scale promotion of unfavorable preparation methods, damage to the structural integrity of graphite paper, and decreased conductivity of expanded graphite paper, so as to facilitate the transmission of ions and electrons, and reduce defects. Less, promotes the effect of uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

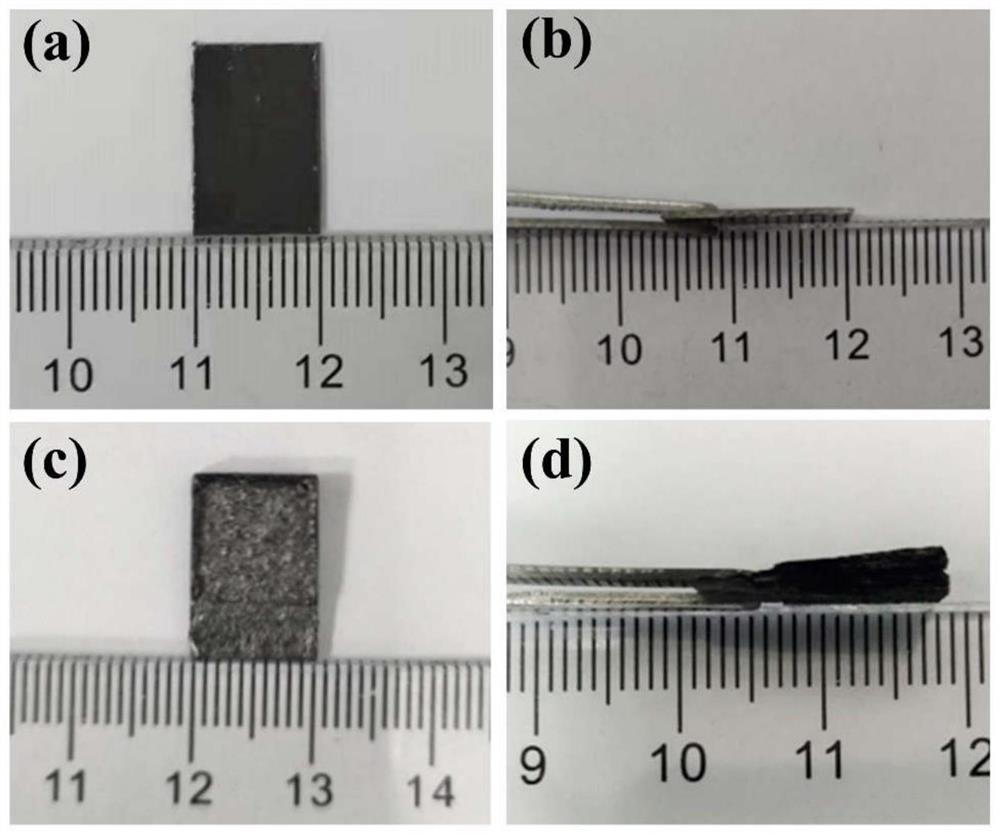

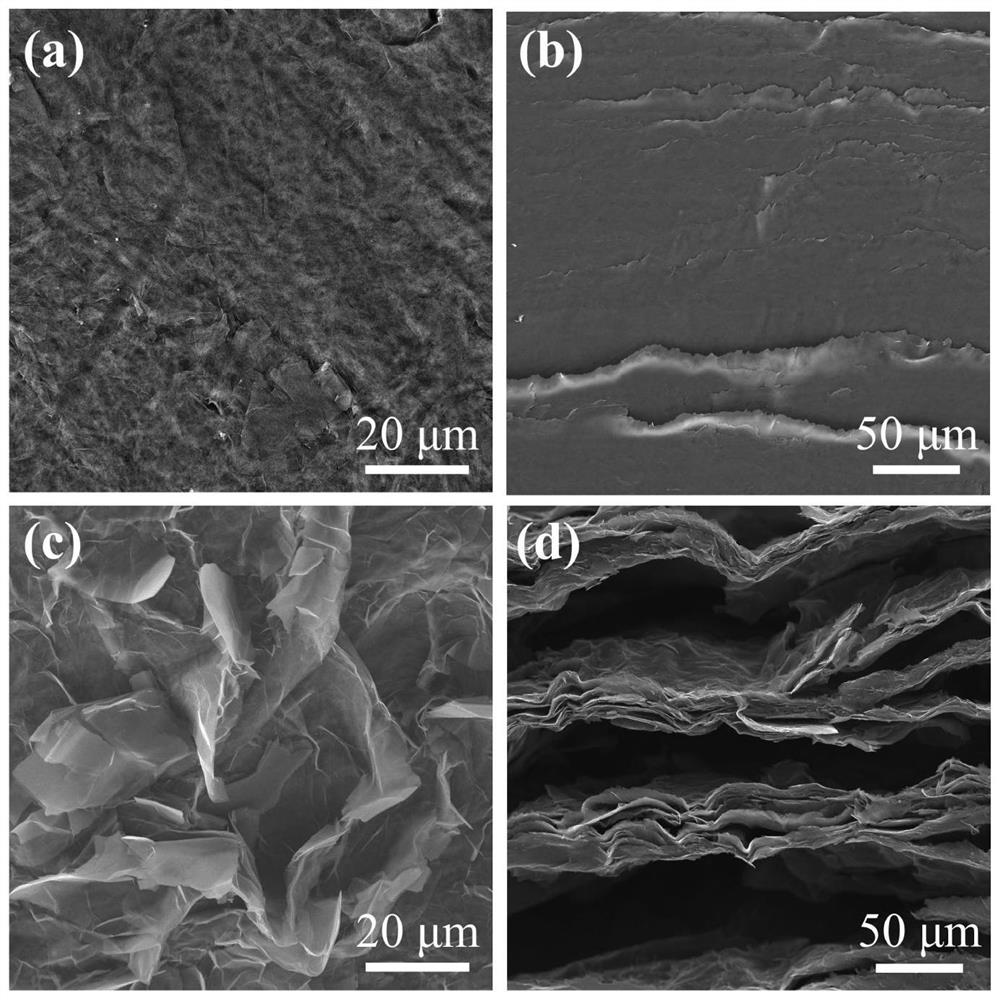

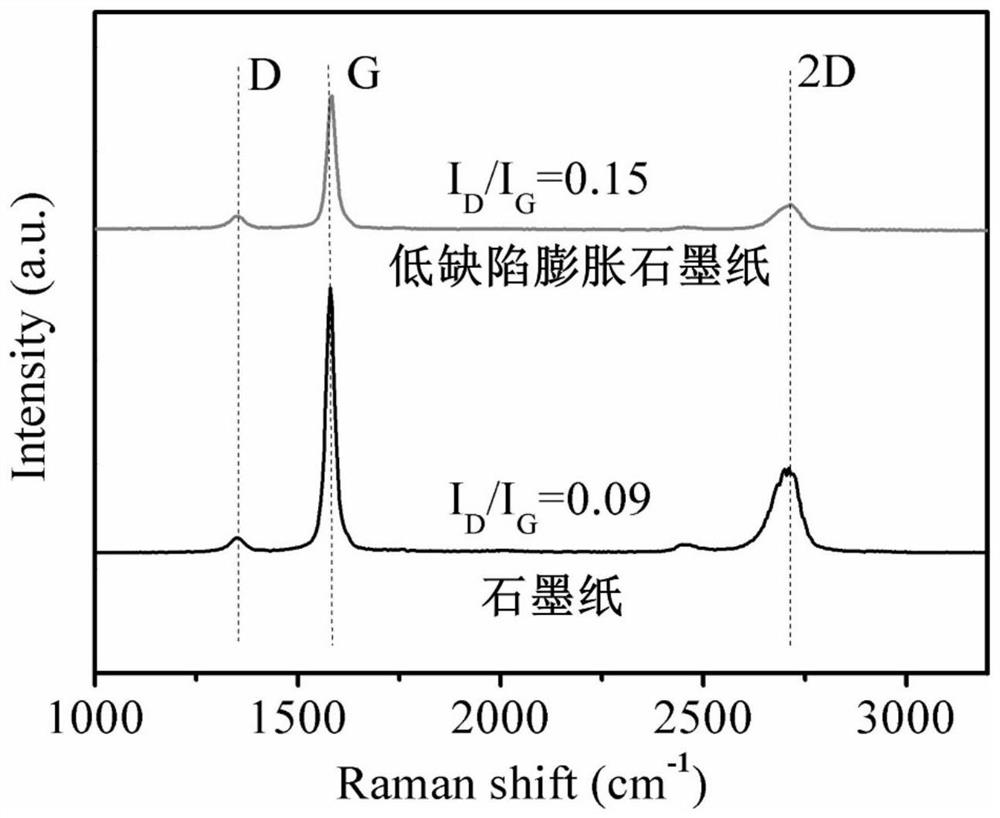

[0021] Cut graphite paper into 1cm×1.5cm, and then dry it in an oven at 80°C for 24 hours; use concentrated sulfuric acid as electrolyte, platinum wire as counter electrode, and graphite paper as working electrode (immersion surface is 1cm×1cm). Keep it under the voltage of 1.6V for 1 minute and take it out; then quickly immerse it in 50mL hydrogen peroxide solution, let it stand for 1 minute, then put it in a water bath at 50°C, let it stand for 3 hours; The graphite paper was taken out, rinsed with deionized water, and soaked in 100 mL of deionized water for 10 hours; finally, the low-defect expanded graphite paper was dried in an oven at 80°C for 10 hours to obtain a low-defect expanded graphite paper.

Embodiment 2

[0023] Cut graphite paper into 1cm×1.5cm, and then dry it in an oven at 80°C for 24 hours; use concentrated sulfuric acid as electrolyte, platinum wire as counter electrode, and graphite paper as working electrode (immersion surface is 1cm×1cm). Keep it under 1.6V voltage for 1 minute and take it out; quickly immerse it in 50mL hydrogen peroxide solution, let it stand for 1 minute, then put it in a water bath at 80°C, let it stand for 0.5 hour; after the reaction is over, expand the low defect The graphite paper was taken out, rinsed with deionized water, soaked in 100 mL of deionized water for 10 hours, and finally the low-defect expanded graphite paper was dried in an oven at 80°C for 10 hours to obtain a low-defect expanded graphite paper.

Embodiment 3

[0025] Cut graphite paper into 1cm×1.5cm, and then dry it in an oven at 80°C for 24 hours; use concentrated sulfuric acid as electrolyte, platinum wire as counter electrode, and graphite paper as working electrode (immersion surface is 1cm×1cm). Keep the voltage at 2V for 30 seconds and take it out; quickly immerse it in 50mL hydrogen peroxide solution, let it stand for 1 minute, then put it in a water bath at 65°C, let it stand for 2 hours; The paper was taken out, rinsed with deionized water, then soaked in 100 mL of deionized water for 12 hours, and finally the low-defect expanded graphite paper was dried in an oven at 80°C for 8 hours to obtain a low-defect expanded graphite paper.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com