Patents

Literature

64 results about "Electrochemical intercalation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

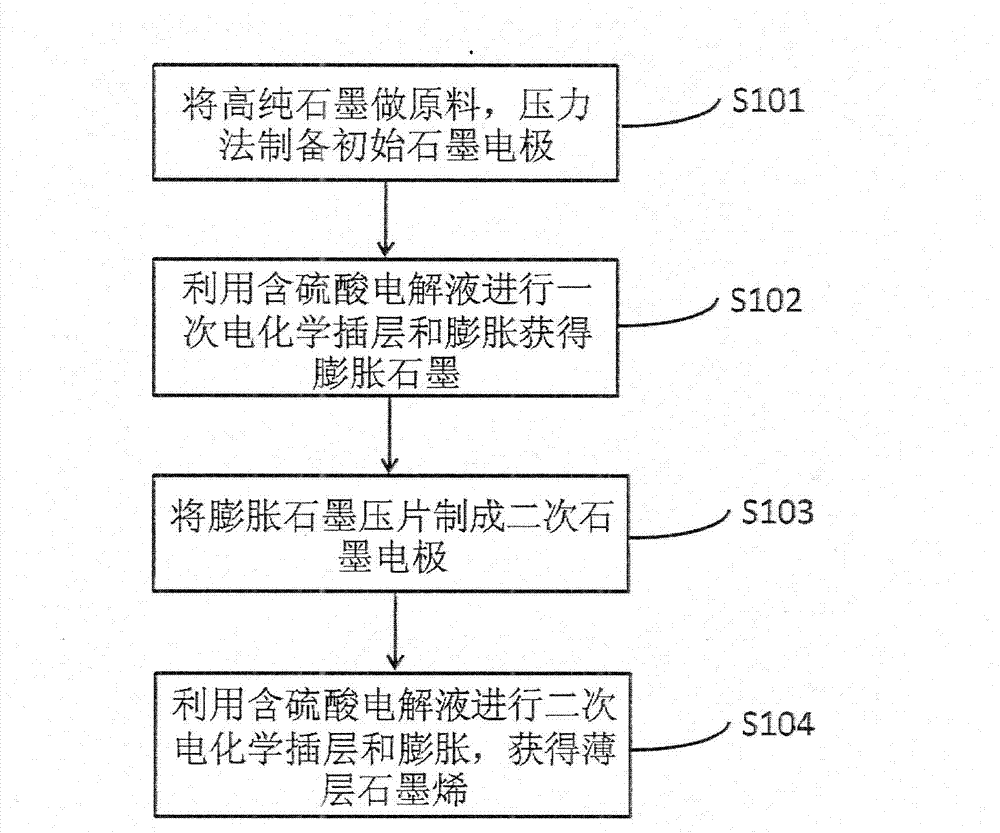

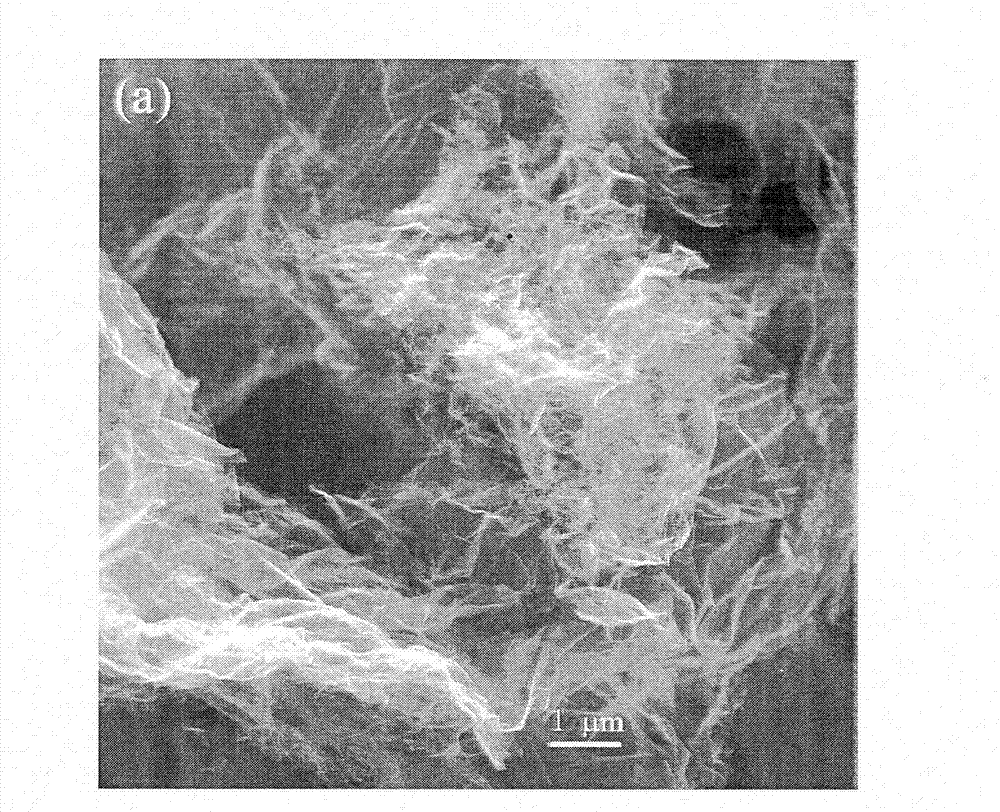

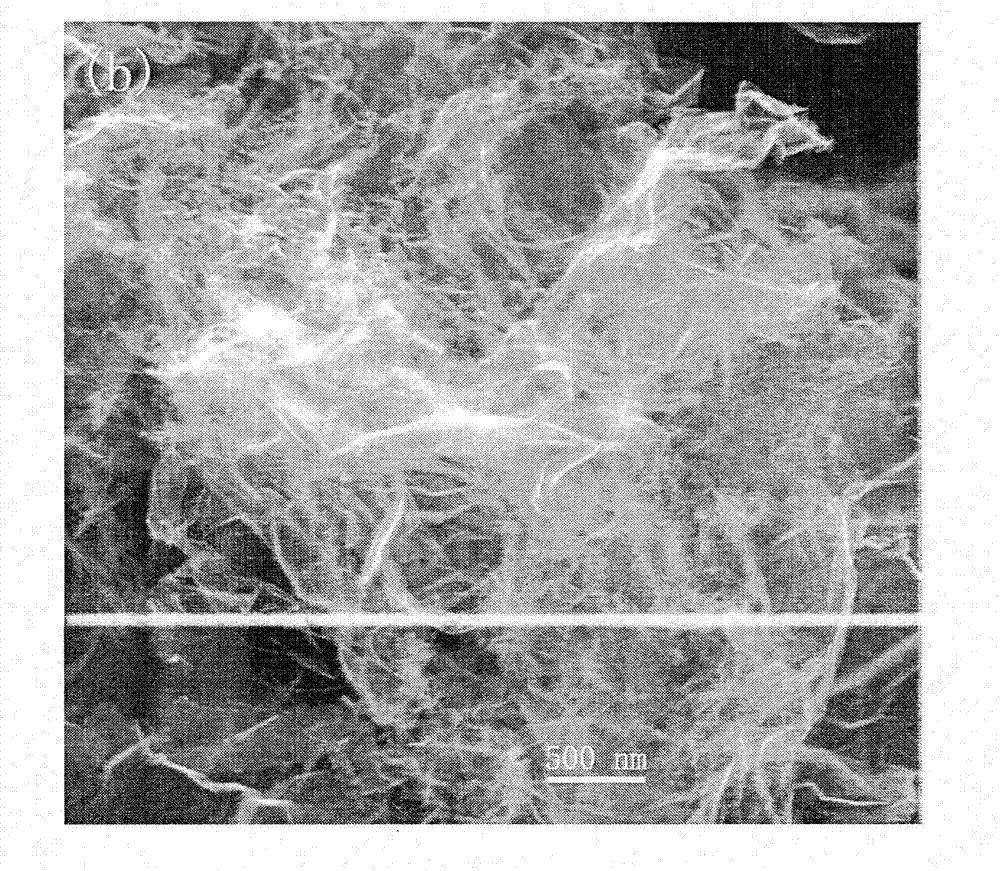

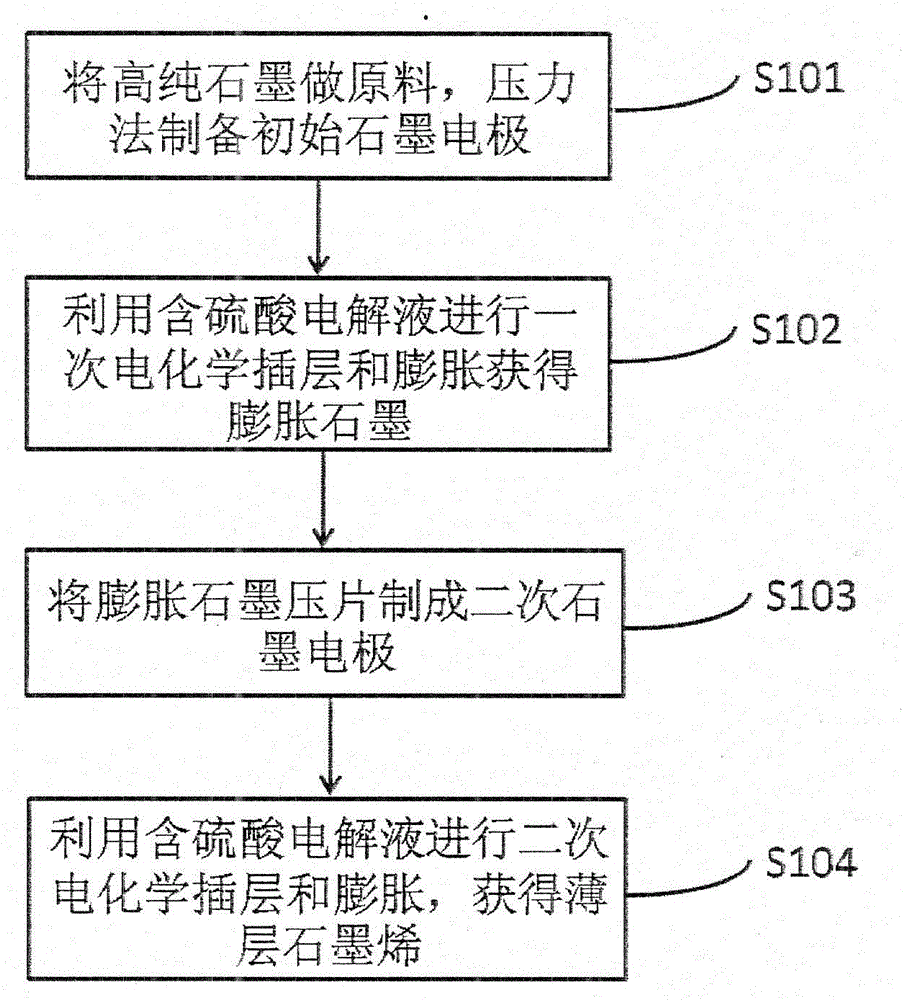

Method for electrochemically preparing graphene

The invention discloses a method for electrochemically preparing graphene, which preferably comprises the steps of pressing a high-purity graphite raw material to form a graphite electrode, carrying out anodization through the graphite electrode by using sulfuric acid aqueous solution or acetic acid and the like mixed acid solution as an electrolyte to prepare a graphite intercalation product, and obtaining expanded graphite by high temperature or microwave and other methods; and then pressing the expanded graphite to prepare a reaction electrode, and carrying out secondary electrochemical intercalation and expansion to finally obtain laminar graphene. According to the invention, in the preparing process, potassium permanganate and other strong oxidizers are not used, and the damage of the strong oxidizers to the structure and performance of graphene are avoided; alkali metal, fuming sulfuric acid oxydol and other inflammable and explosive dangerous substances are not used, and toxic or harmful substances are not introduced, so that the production is safe and environment friendly; and at the same time, the method is simple in process flow, easy to operate, low in cost, high in yield, mild in reaction conditions and low in energy consumption, and is suitable for industrialized large-scale production.

Owner:苏州格瑞丰纳米科技有限公司

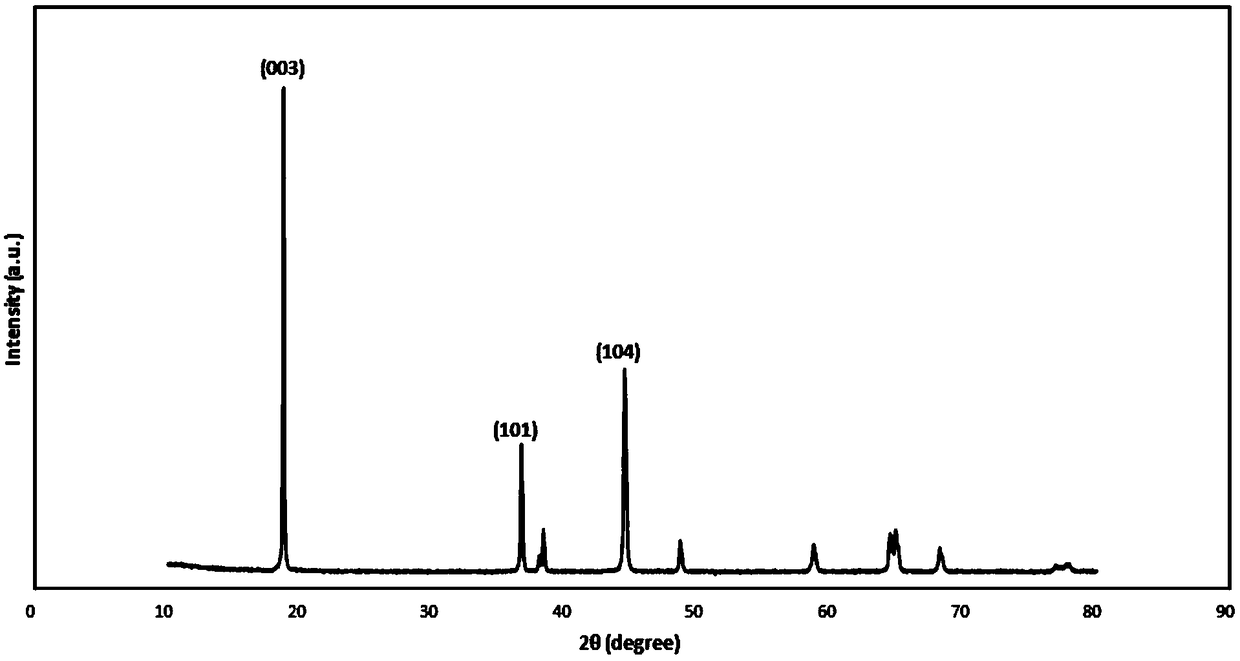

A high-nickel cathode material, a preparation method thereof, and a lithium ion battery

InactiveCN109244436AIncrease the proportion of layered structuresAccelerated electrochemical intercalation-extraction rateSecondary cellsPositive electrodesPhysical chemistrySodium-ion battery

The invention provides a high-nickel cathode material. The high nickel cathode material Co / Mn >= 2 provided by the invention increases the proportion of the layered structure in the material and accelerates the electrochemical intercalation-stripping rate of lithium ions in the cathode material. The discharge capacity and cycle characteristics can be effectively improved. In addition, the residualLi on the surface of the material is removed by detergent, thus effectively reducing the residual alkali content and pH value of the finished product; At the same time, the doping element can effectively stabilize the internal lattice structure of the material, improve the electrochemical stability and safety of the cathode material. The coating can not only increase the discharge capacity of thematerial by accelerating the Li + desembedding speed, but also alleviate the damage of the electrolyte to the surface structure of the material, and improve the discharge capacity and cycle life of the material.

Owner:NINGBO RONBAY LITHIUM BATTERY MATERIAL CO LTD

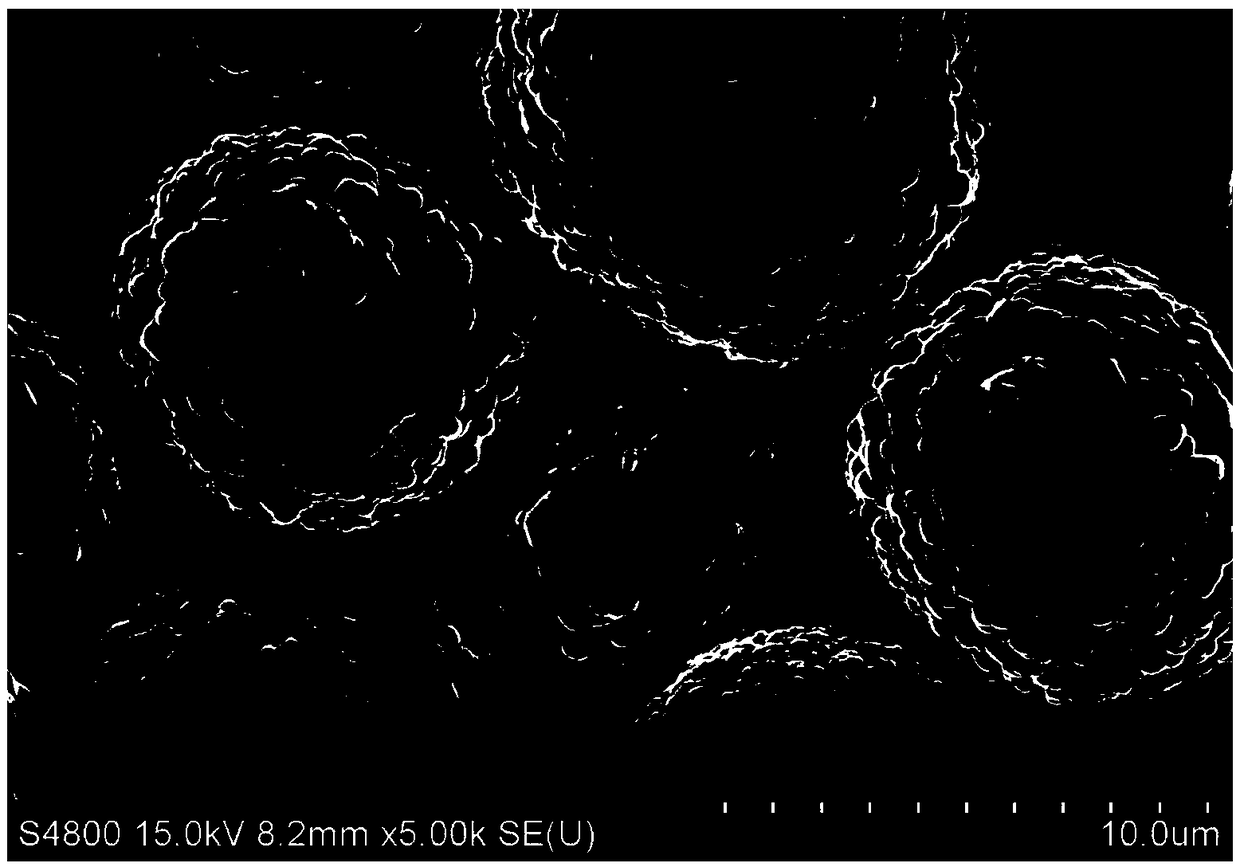

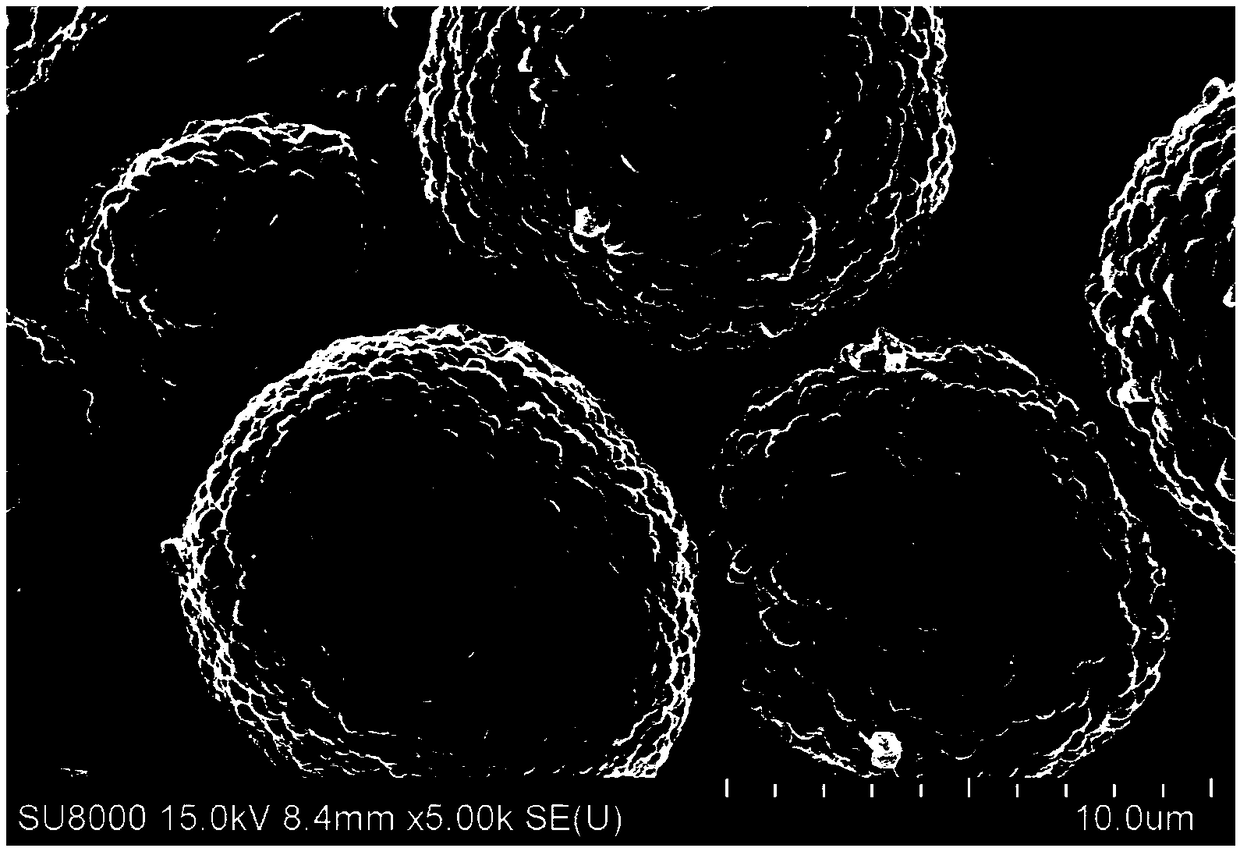

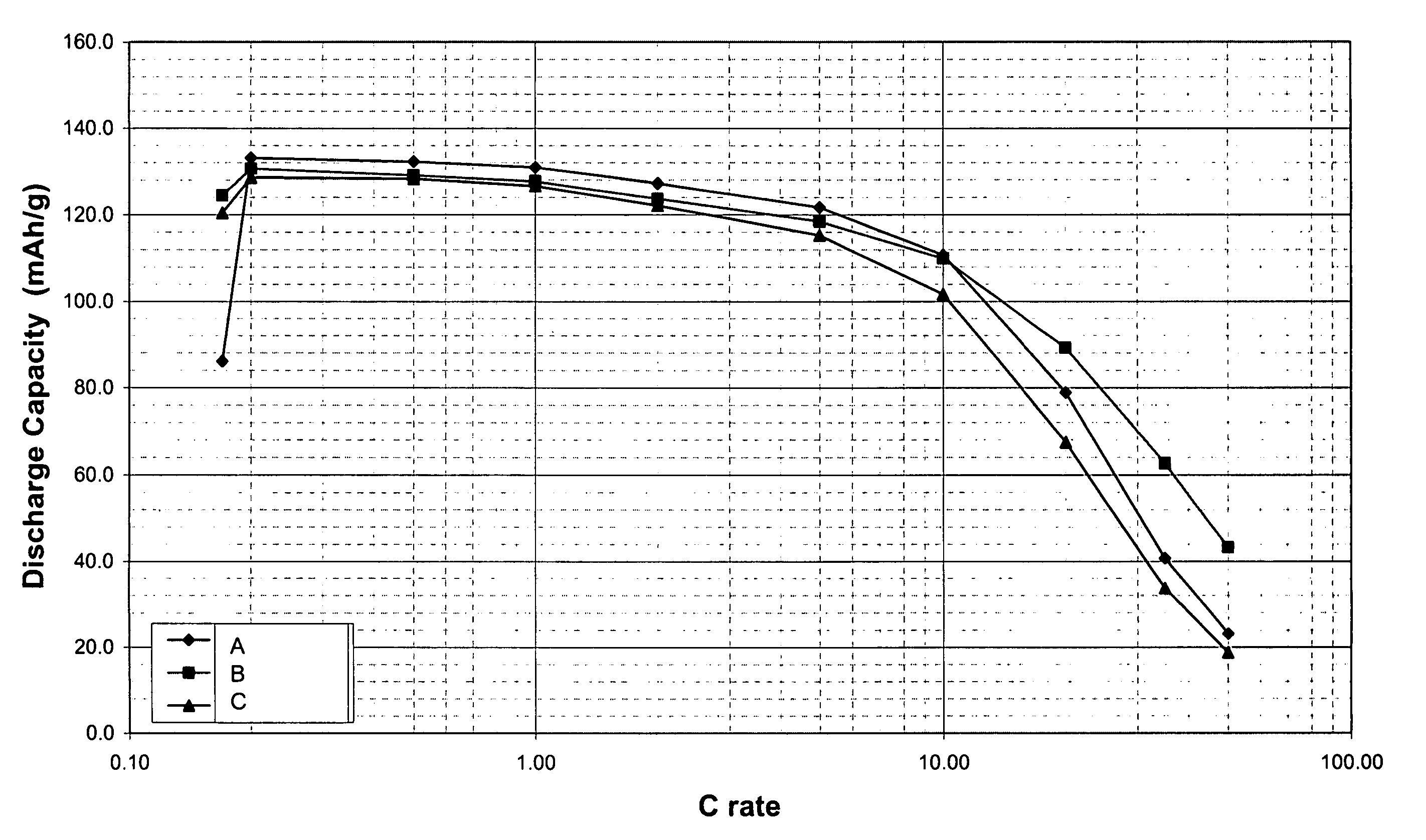

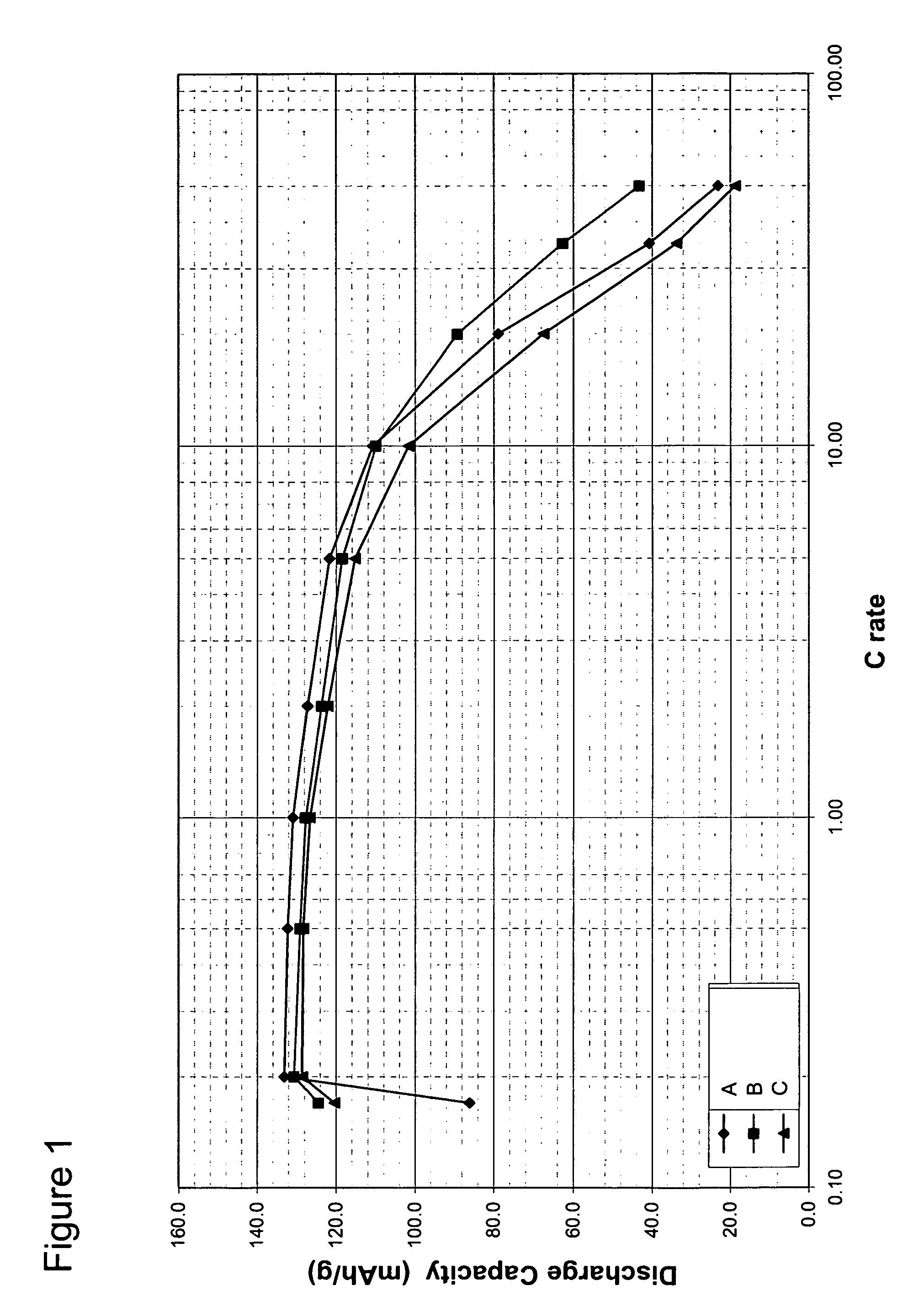

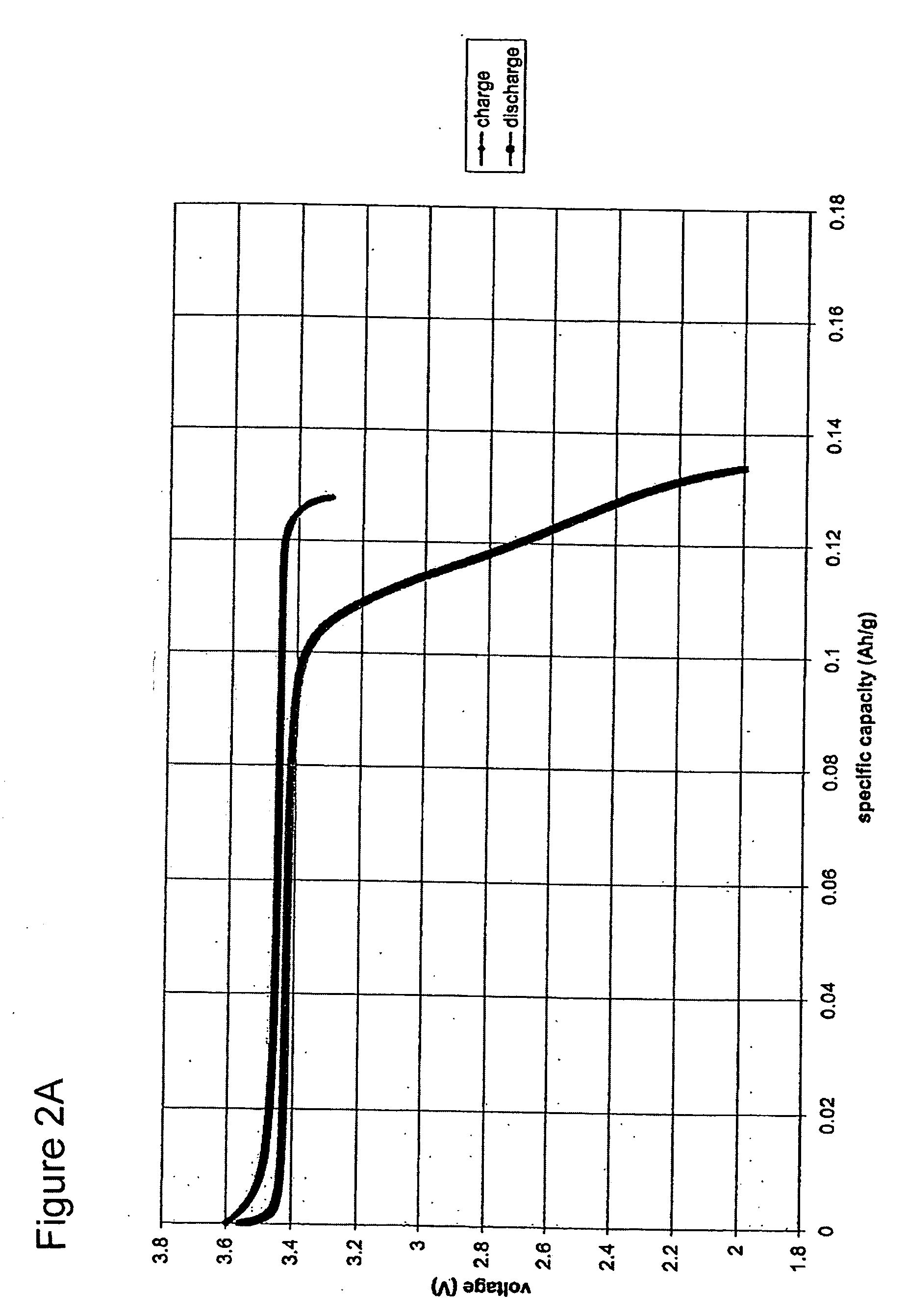

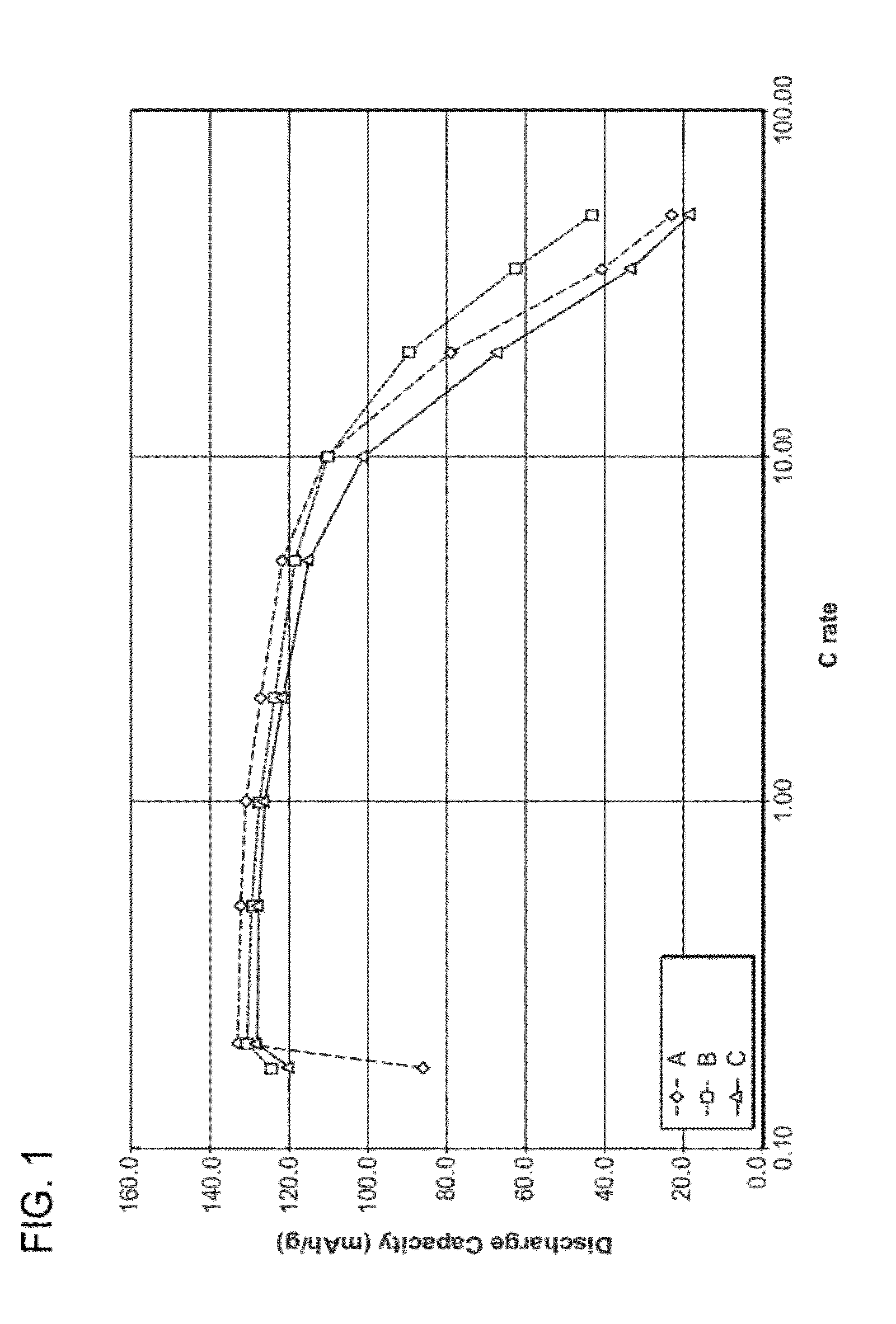

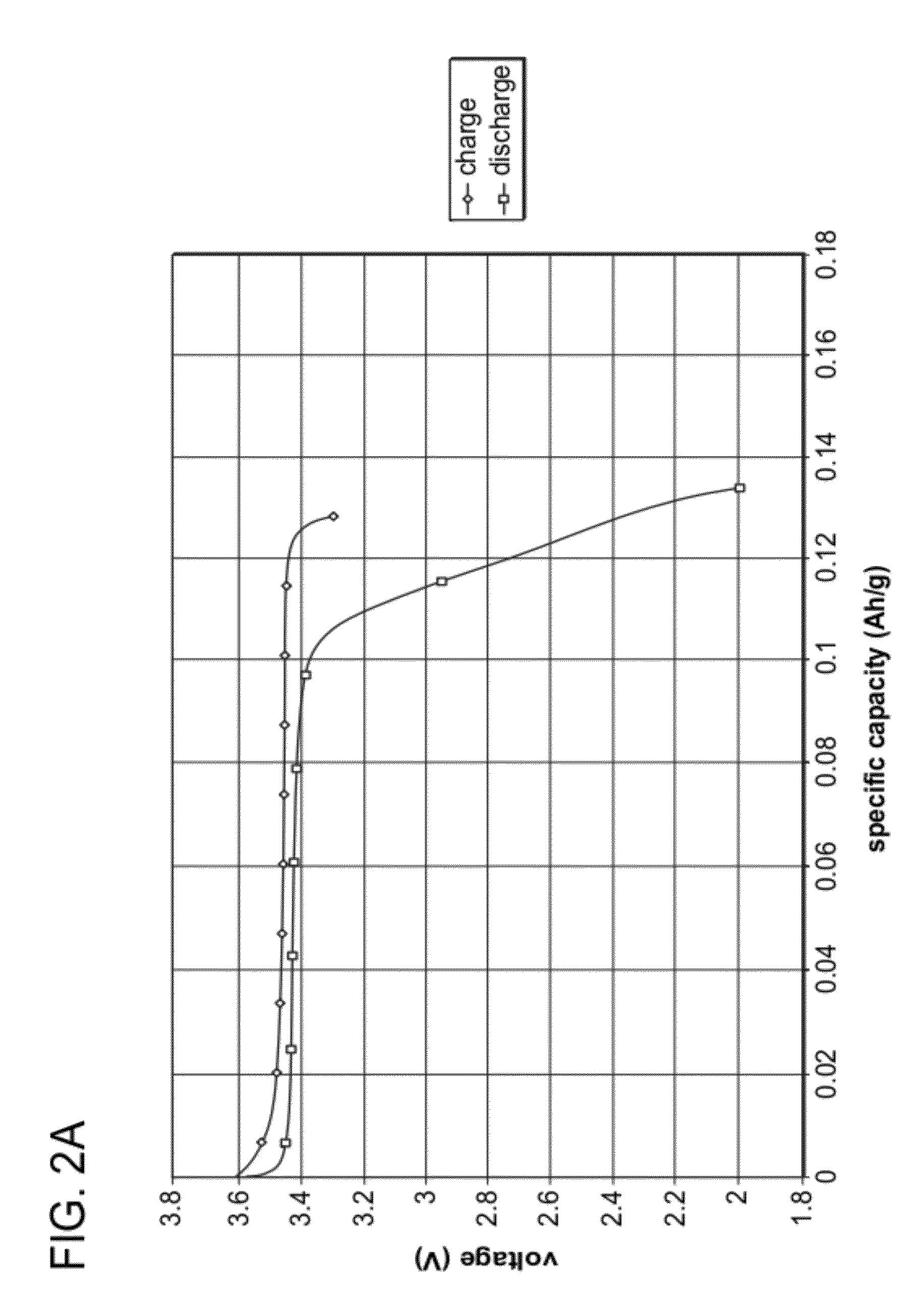

Amorphous and partially amorphous nanoscale ion storage materials

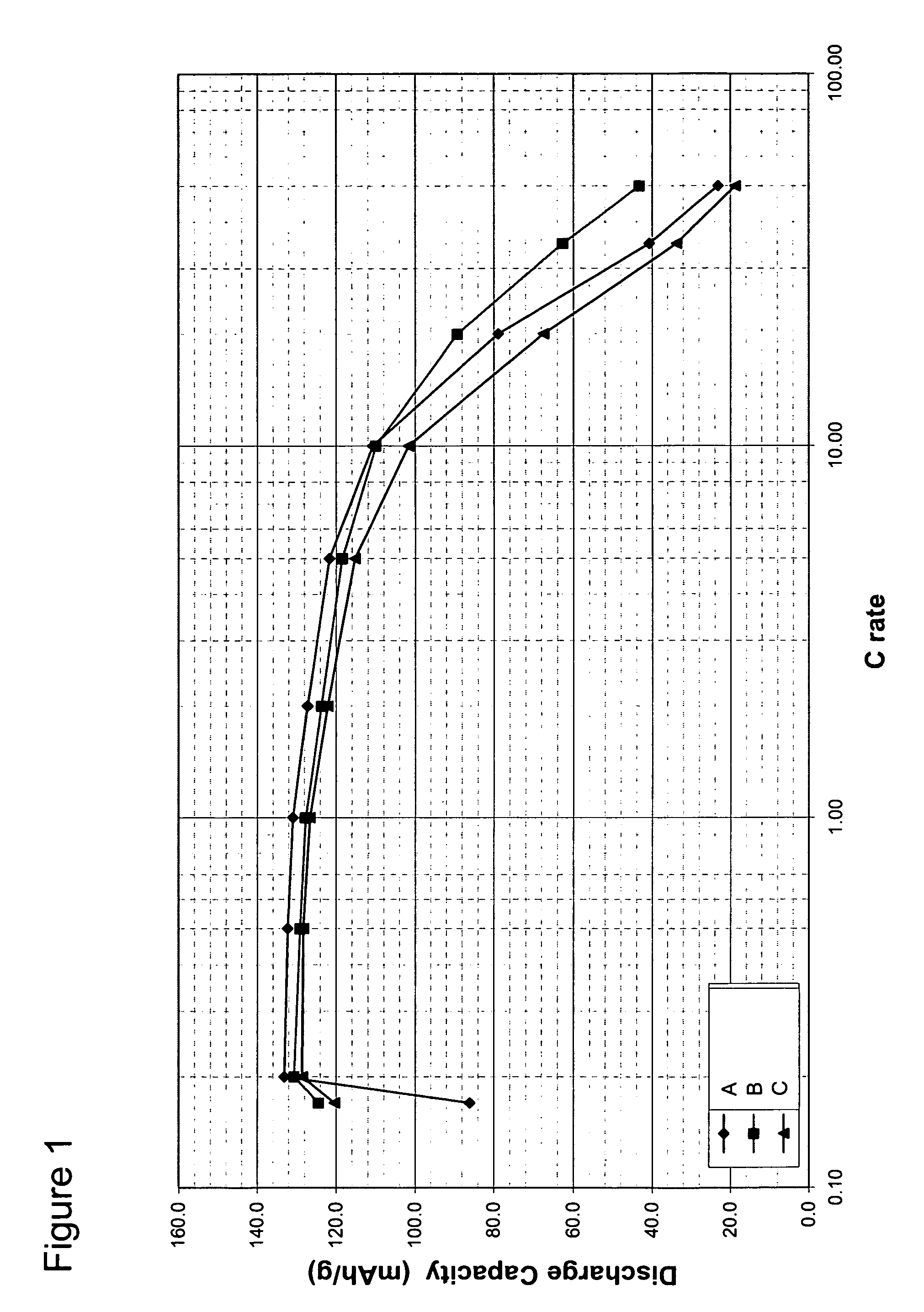

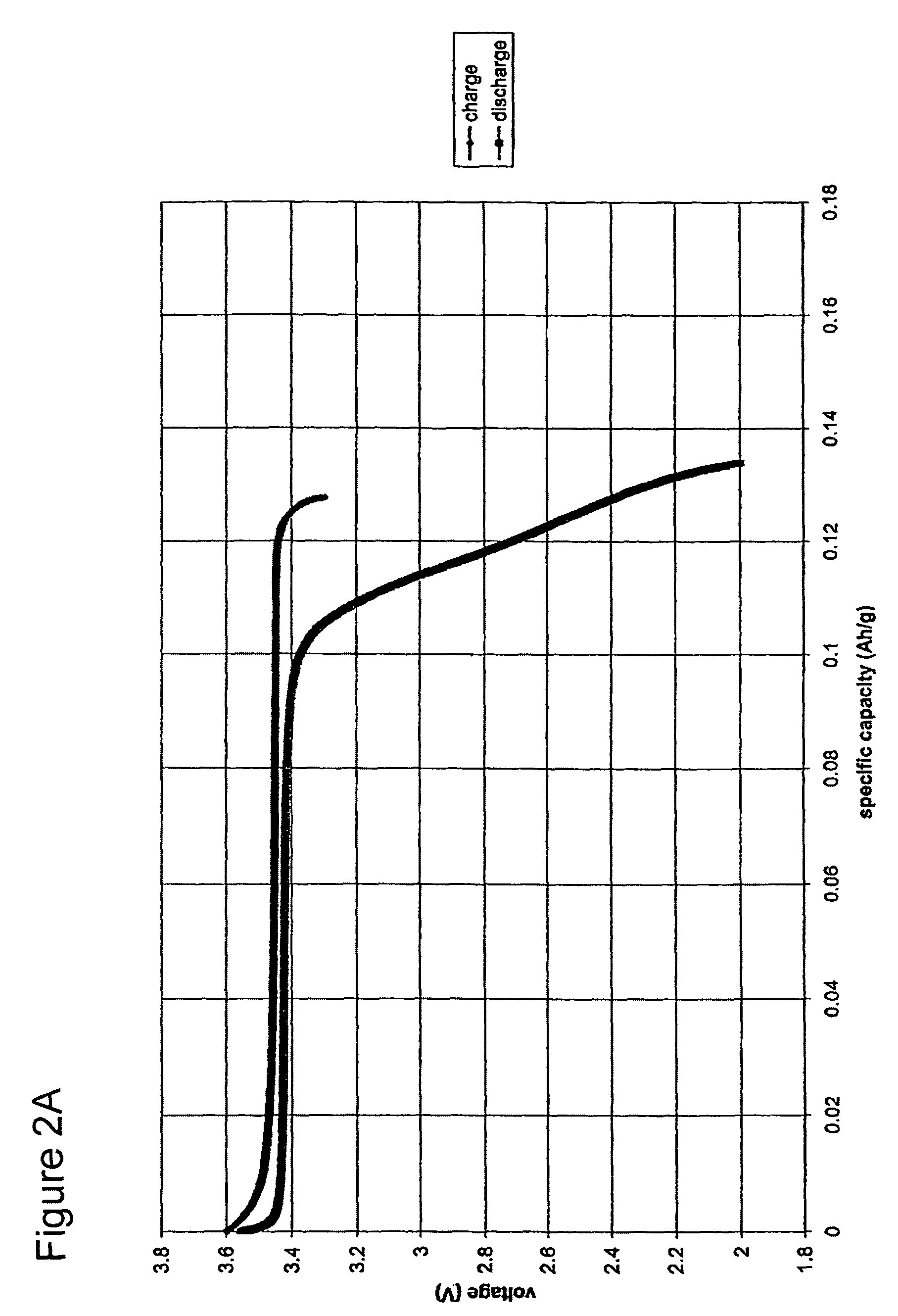

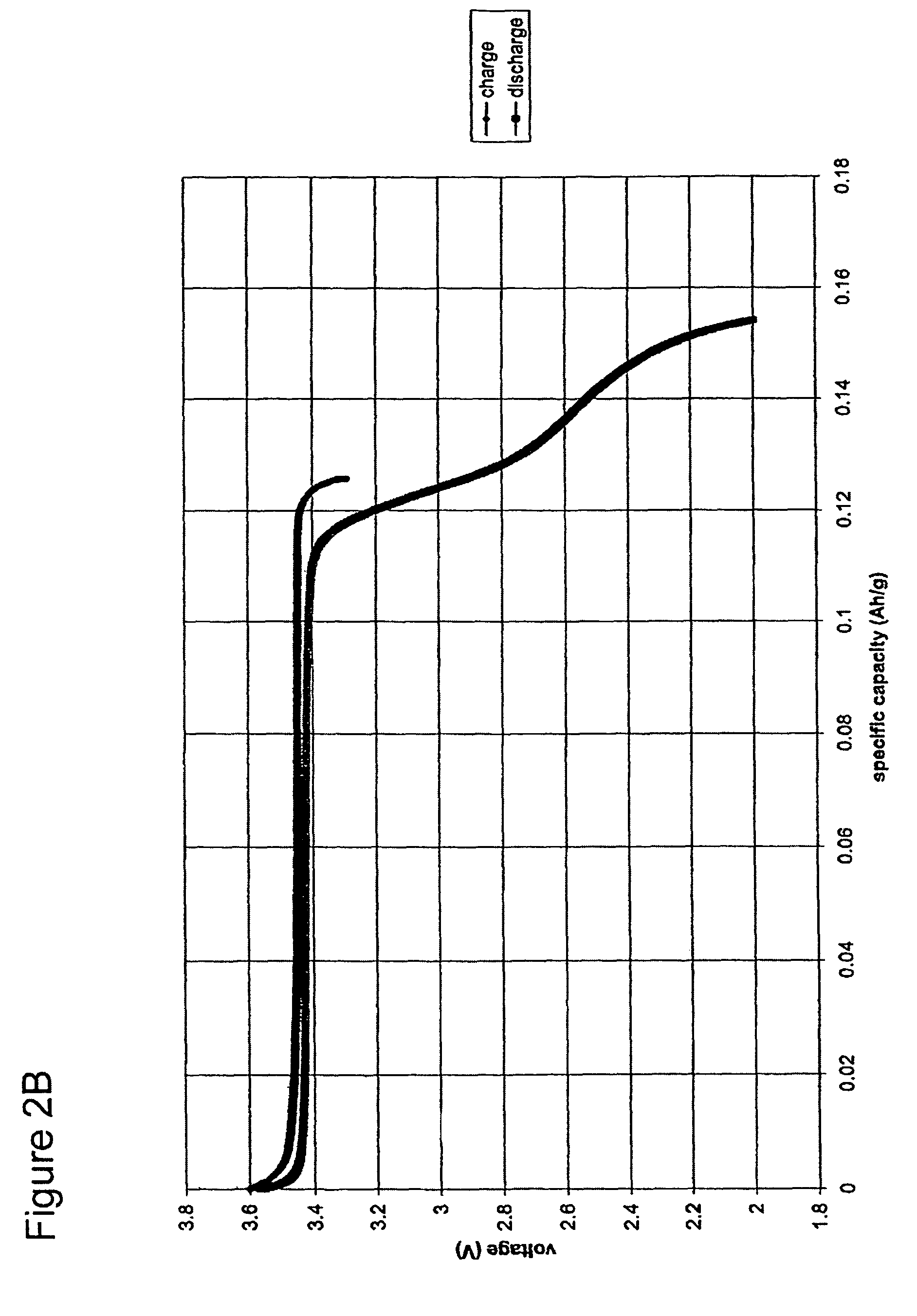

ActiveUS20070292747A1Increase amorphous contentPhosphatesPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesPhosphateHigh energy

Amorphous or partially amorphous nanoscale ion storage materials are provided. For example, lithium transition metal phosphate storage compounds are nanoscale and amorphous or partially amorphous in an as-prepared state, or become amorphous or partially amorphous upon electrochemical intercalation or de-intercalation by lithium. These nanoscale ion storage materials are useful for producing devices such as high energy and high power storage batteries.

Owner:LITHIUM WERKS TECH BV

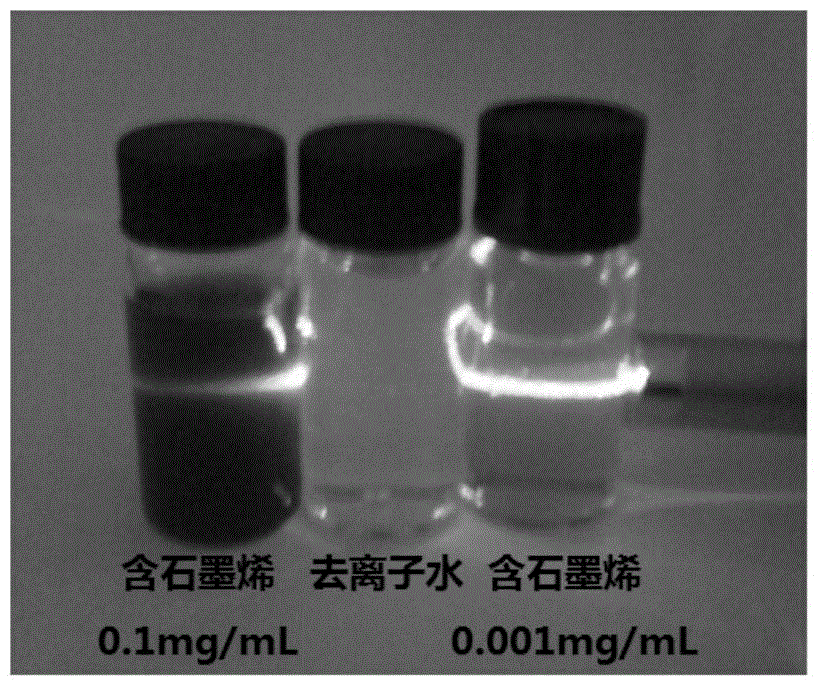

Graphene, graphene colloidal sol, graphene powder and preparation method and preparation device

The invention provides graphene, graphene hydrosol, and graphene powder obtained by drying the graphene hydrosol, wherein the edge of the graphene comprises active groups, and the active groups comprise amino groups. The preparation method of the graphene hydrosol comprises the following steps: (1), performing electrochemical intercalation and exfoliation on graphene to obtain graphene dispersed in electrolyte; the electrolyte after electrochemical intercalation and exfoliation contains both inorganic salt and amino acid; after intercalation, removing free inorganic salt and amino acid compounds from the solution to obtain the graphene hydrosol. According to the graphene, graphene colloidal sol, graphene powder and the preparation method and the preparation device, provided by the invention, the graphene hydrosol is provided, the use of a great deal of an organic solvent in the graphene hydrosol based on the organic solvent is reduced, the stability is good, the preparation method is simple, the operation is easy, the equipment and material requirements are low, the environmental friendliness is achieved, and the industrialization is facilitated.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

Expandable polystyrene beads prepared from expandable few-layer graphene and preparing method of expandable polystyrene beads

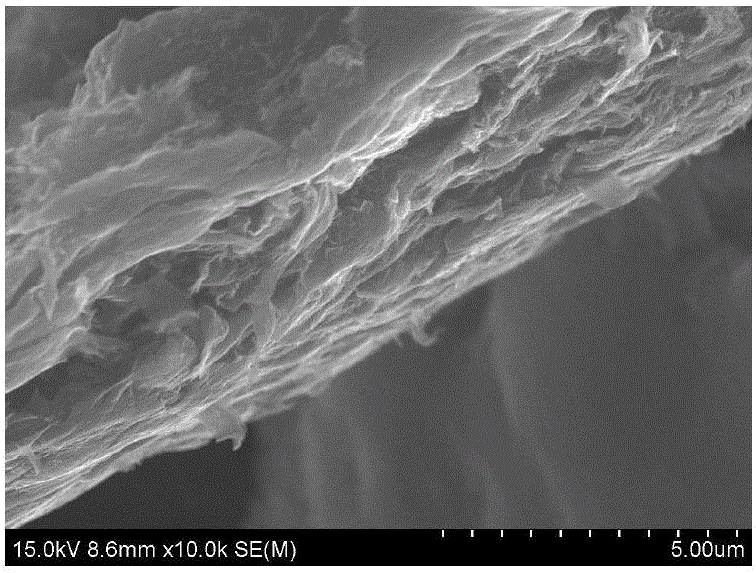

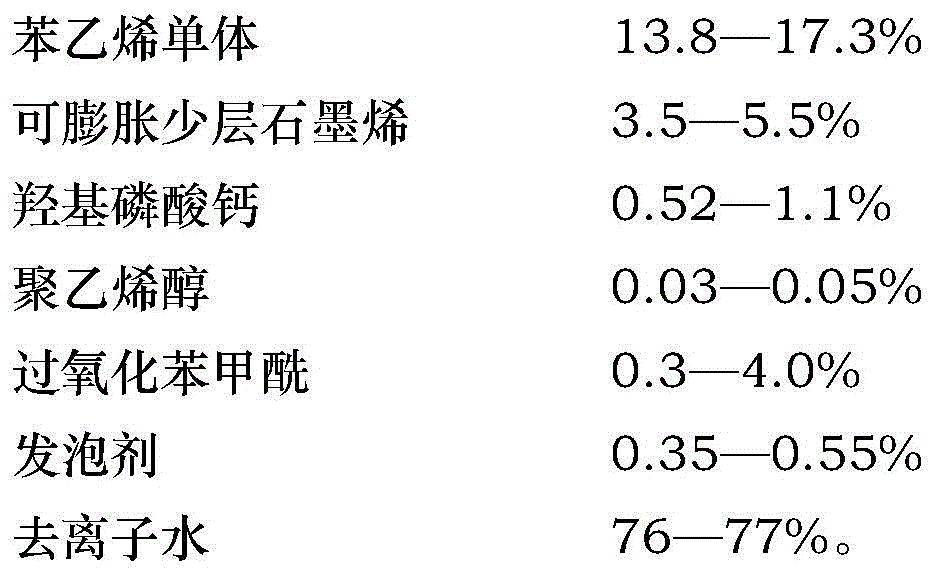

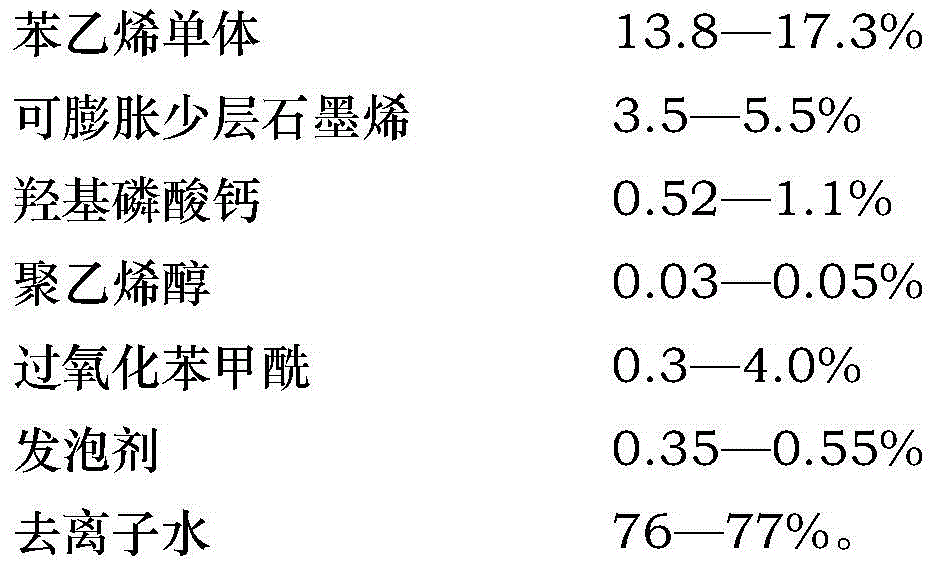

The invention relates to expandable polystyrene beads prepared from expandable few-layer graphene and a preparing method of the expandable polystyrene beads.Electrochemical intercalation is carried out on natural flake graphite with concentrated sulfuric acid, and a graphite interlayer compound with the interlayer space enlarged is obtained; few-layer graphene is obtained through ultrasonic concussion layer removing, the few-layer graphene is subjected to secondary intercalation with a chemical method, water washing and drying, and the expandable few-layer graphene is obtained; then, the expandable few-layer graphene and polystyrene monomers are subjected to suspension polymerization, and the expandable polystyrene beads prepared from the expandable few-layer graphene is obtained.According to the expandable polystyrene beads prepared from the expandable few-layer graphene and the preparing method of the expandable polystyrene beads, the expandable few-layer graphene is introduced into expandable polystyrene, and expandable graphene can be highly and uniformly dispersed in the expandable polystyrene beads, so that high infrared reflectivity in a cavity of expandable polystyrene is ensured, the heat insulation performance is good, and the expandable few-layer graphene can show the flame-retardant effects of smothering flames and insulating heat radiation.The flame retardant grade of a foam plate prepared from the expandable polystyrene beads reaches the B1 grade, and the heat conductivity value ranges from 0.028 W / (m.K) to 0.032 W / (m.K).

Owner:JILIN YUNTING ENERGY SAVING TECH CO LTD

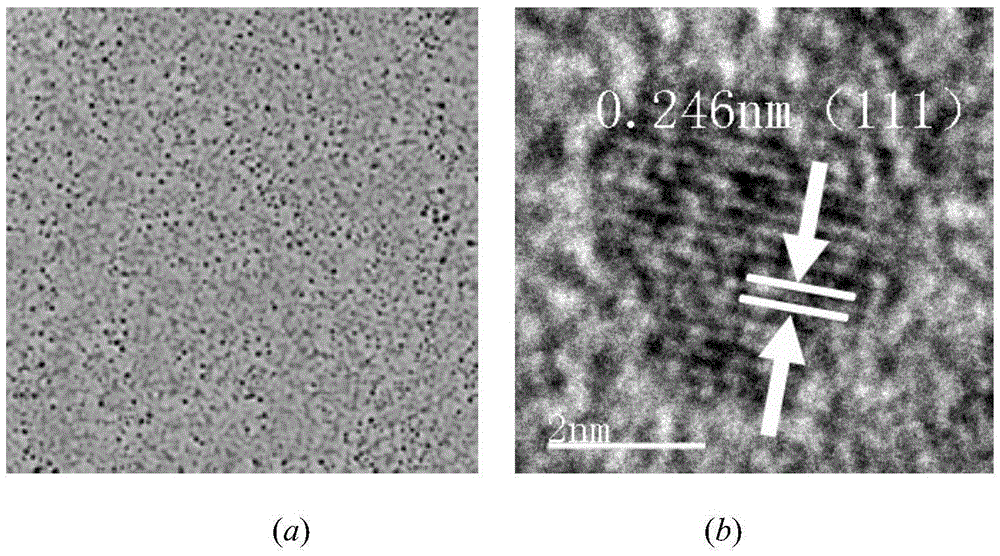

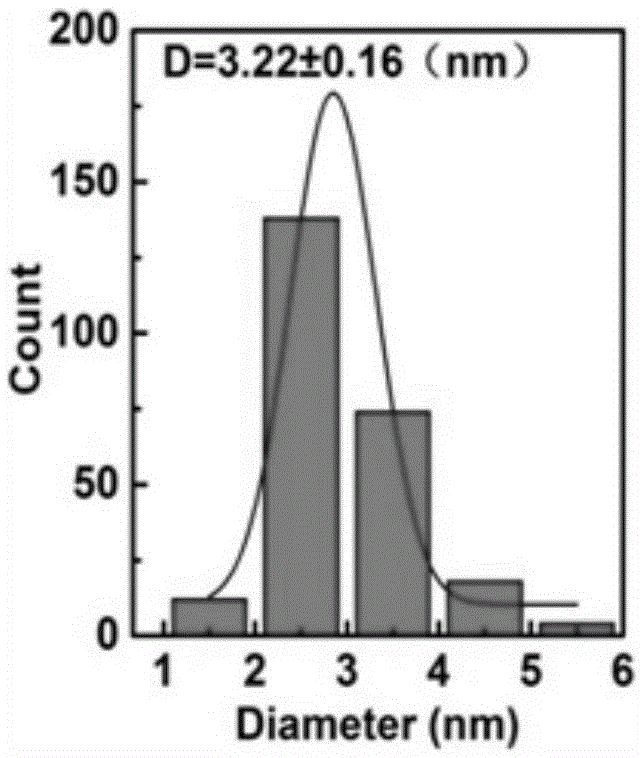

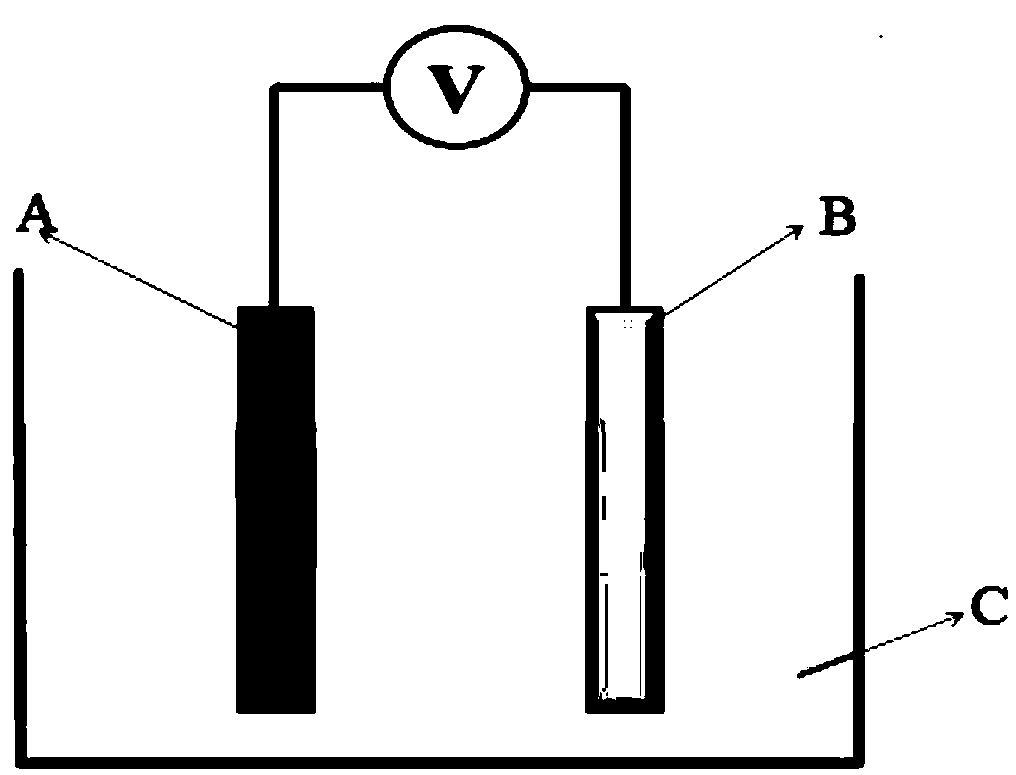

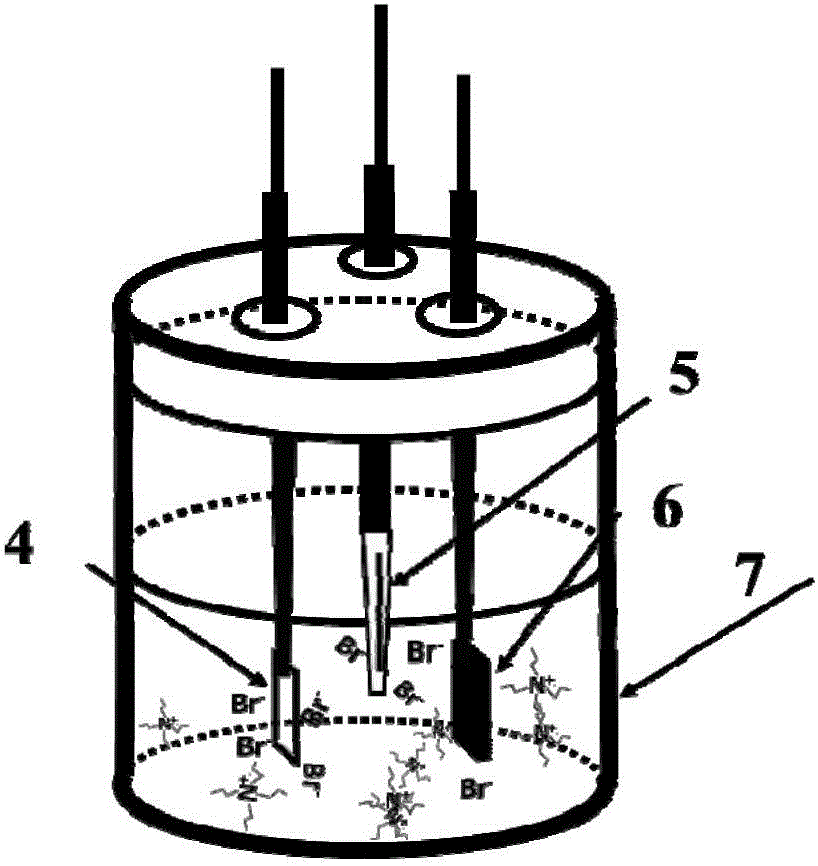

Electrochemical preparation method of black phosphorus quantum dots

The invention discloses an electrochemical preparation method of black phosphorus quantum dots. An electrochemical intercalation method is adopted for dissolving black phosphorus crystals in an organic solvent so as to obtain the black phosphorus quantum dots. According to the specific implementation method, firstly, the black phosphorus crystals are fixed to a metal bar through conducting resin to serve as a working electrode, a platinum electrode serves as a counter electrode, and the working electrode and the counter electrode are placed in the organic solvent containing electrolytes; and then, the working electrode is connected to a positive electrode of a direct-current power source, the counter electrode is connected to a negative electrode of the direct-current power source, the voltage within the set range is applied, ion electrolytes are migrated to the black phosphorus crystals, and an electrochemical intercalation reaction is made, so that the black phosphorus quantum dots fall off to the organic solvent from the black phosphorus crystals, and black phosphorus quantum dot dispersion liquid is obtained. The preparation method of the black phosphorus quantum dots has the beneficial effects of being low in cost, capable of carrying out large-scale preparing, high in efficiency and short in production period.

Owner:SOUTHEAST UNIV

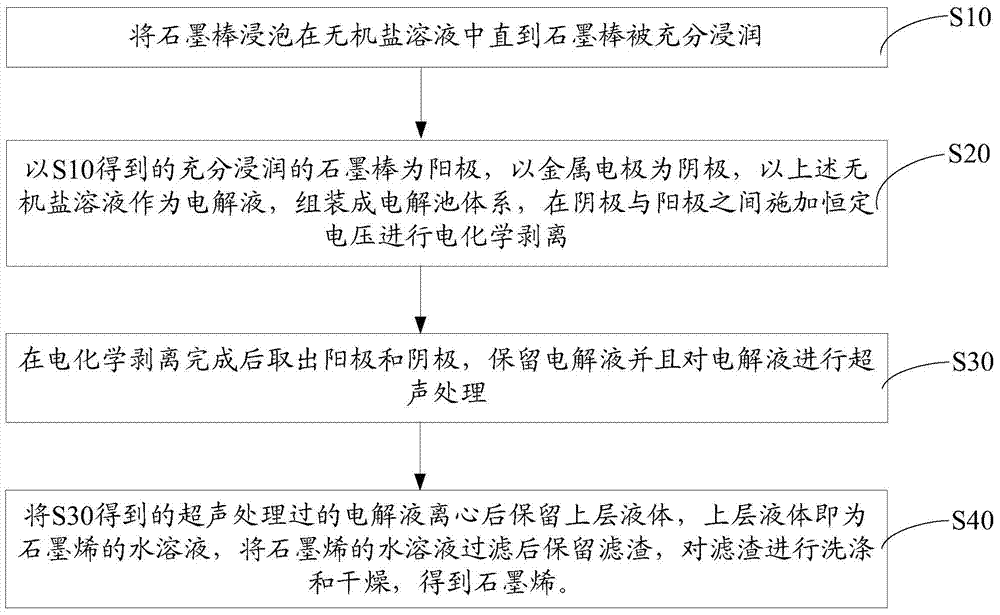

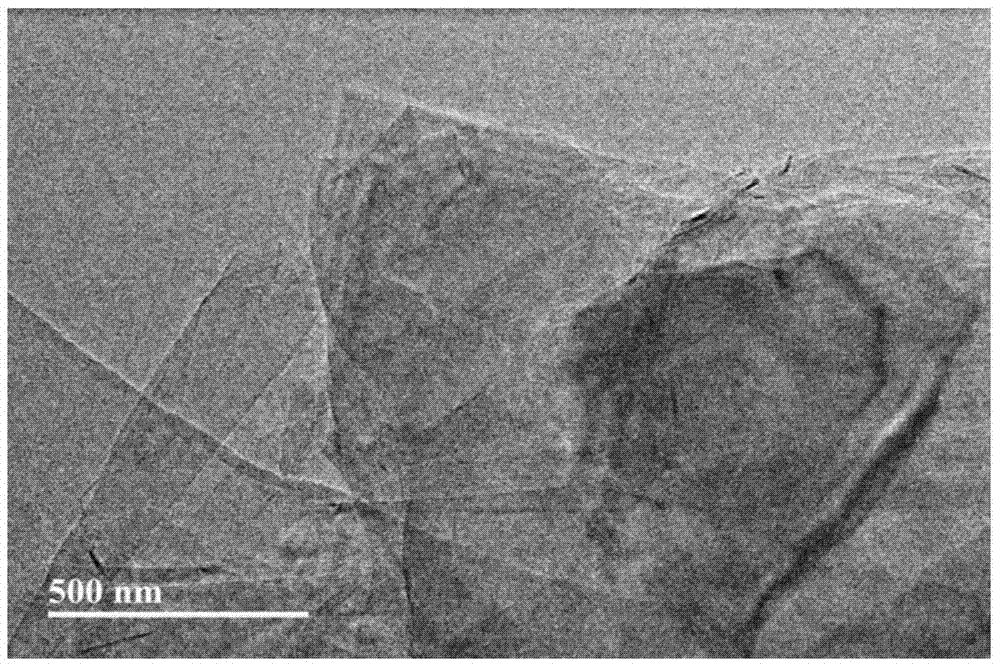

Method for preparing graphene

The invention discloses a method for preparing graphene. The method comprises the following steps that a graghite rod is soaked in inorganic salt solution until the graghite rod is soaked fully; the fully-soaked graghite rid serves as a positive pole, a metal electrode serves as a negative pole, the inorganic salt solution serves as electrolyte solution, a electrolytic cell is assembled, and a constant voltage is imposed between the negative pole and the positive pole to conduct electrochemical stripping; the positive pole and the negative pole are taken out after electrochemical stripping is finished, the electrolyte solution is retained, and ultrasonic treatment is conducted on the electrolyte solution; supernatant liquid is retained after the electrolyte solution after being conducted the ultrasonic treatment is centrifuged, the supernatant liquid is aquoeous solution of graphene, residue is retained after the supernatant liquid of the graphene is filtered, washing and drying are conducted on the residue, and the graphene is obtained. According to the method for preparing the graphene, the thin-layer graphene is produced through electrochemical intercalation and expansive action, and the produced graphene lamella is comparatively thin.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

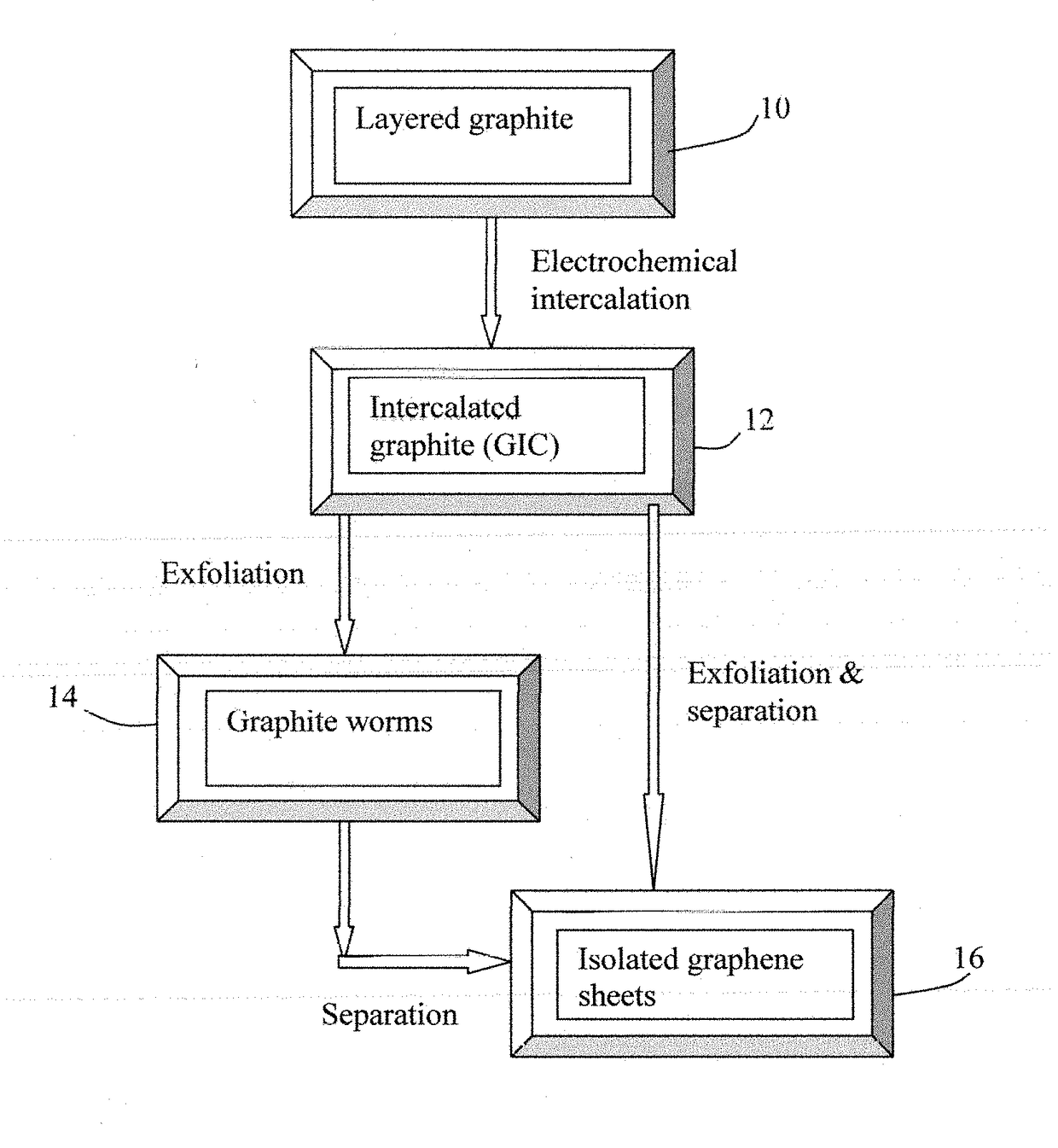

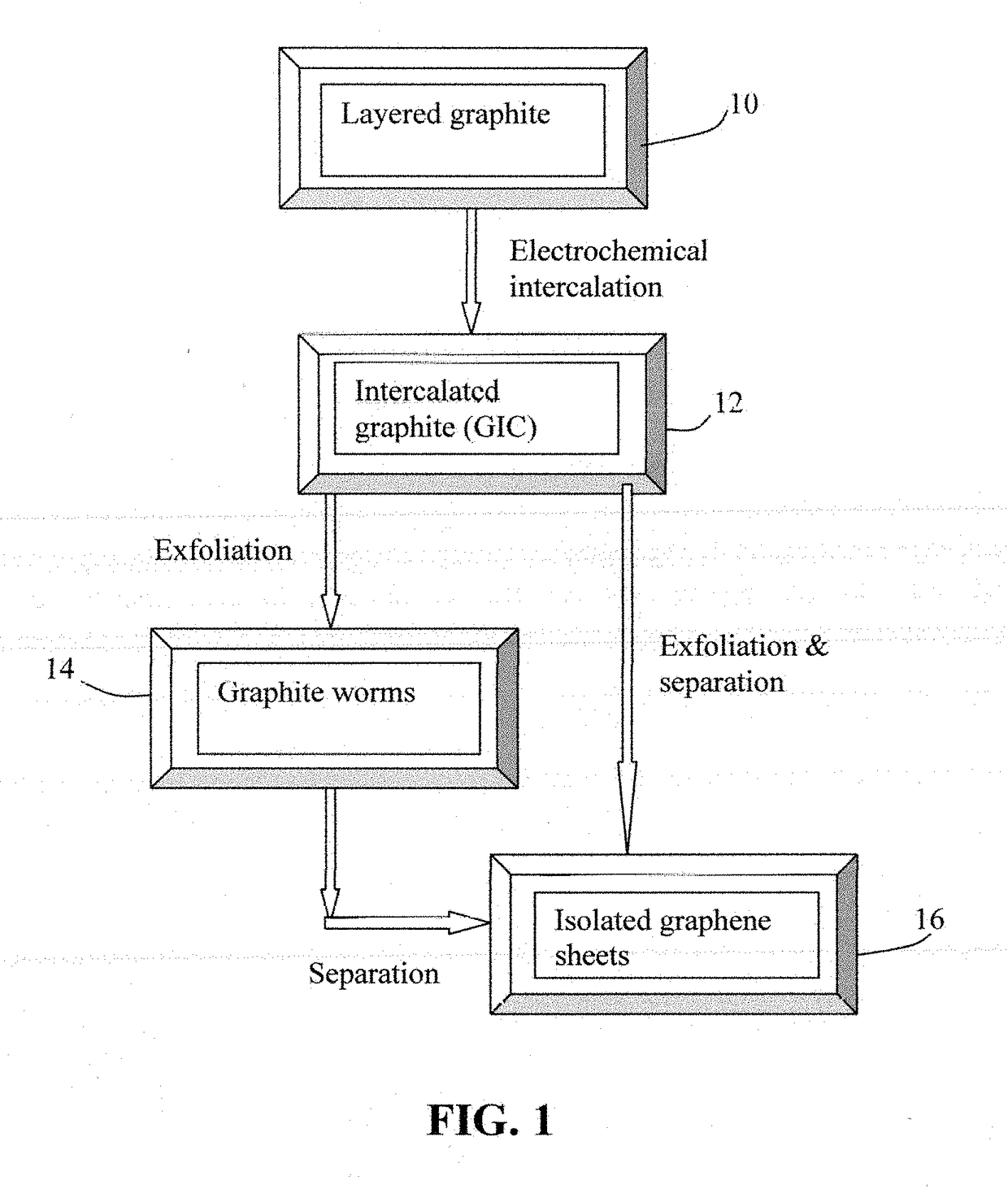

Electrochemical Method Of Producing Single-Layer Or Few-Layer Graphene Sheets

A method of producing isolated graphene sheets from a layered graphite, comprising: (a) forming an alkali metal ion-intercalated graphite compound by an electrochemical intercalation which uses a liquid solution of an alkali metal salt dissolved in an organic solvent as both an electrolyte and an intercalate source, layered graphite material as an anode material, and a metal or graphite as a cathode material, and wherein a current is imposed upon a cathode and an anode at a current density for a duration of time sufficient for effecting the electrochemical intercalation of alkali metal ions into interlayer spacing; and (b) exfoliating and separating hexagonal carbon atomic interlayers (graphene planes) from the alkali metal ion-intercalated graphite compound using ultrasonication, thermal shock exposure, exposure to water solution, mechanical shearing treatment, or a combination thereof to produce isolated graphene sheets.

Owner:GLOBAL GRAPHENE GRP INC

Lithium intercalation manganese dioxide-titanium nitride nanotube composite material and preparing method and application thereof

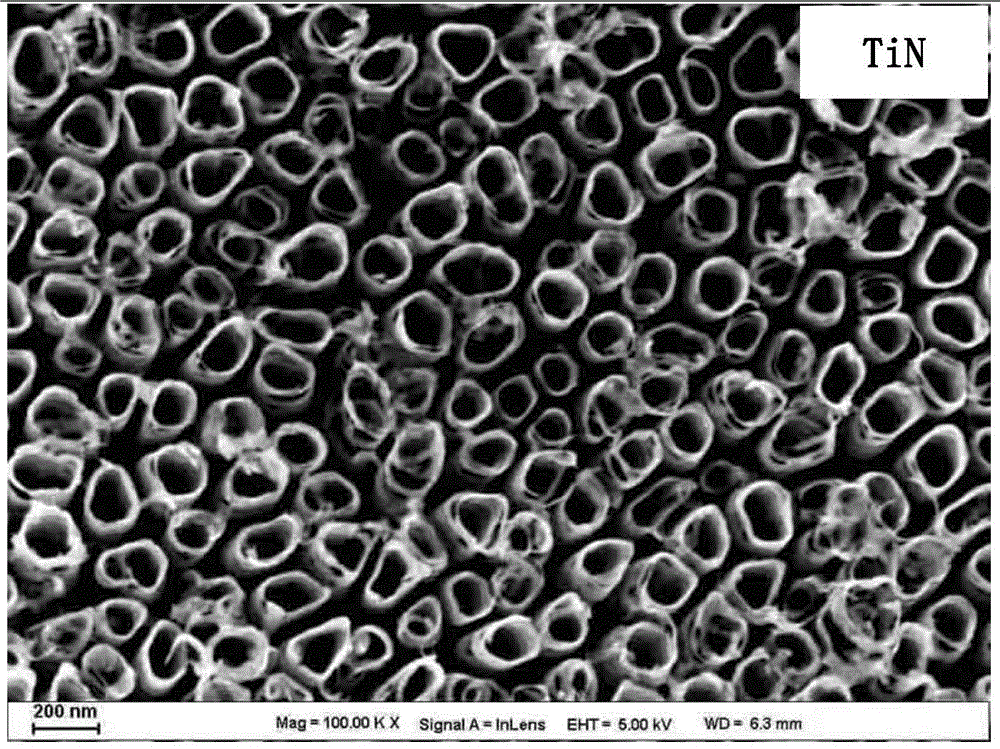

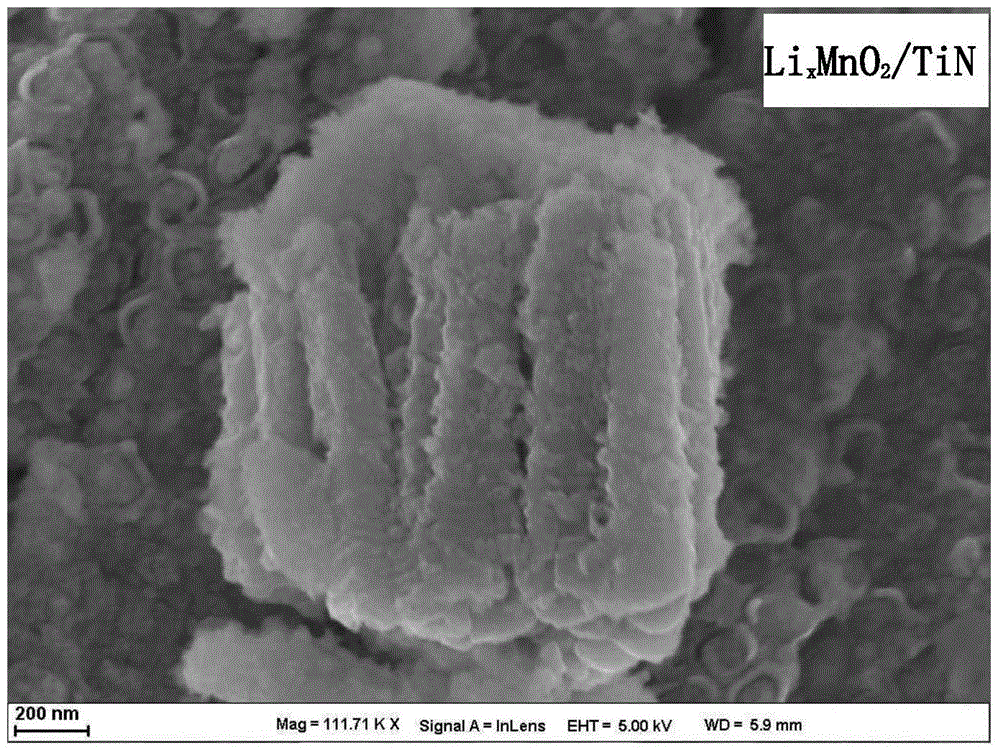

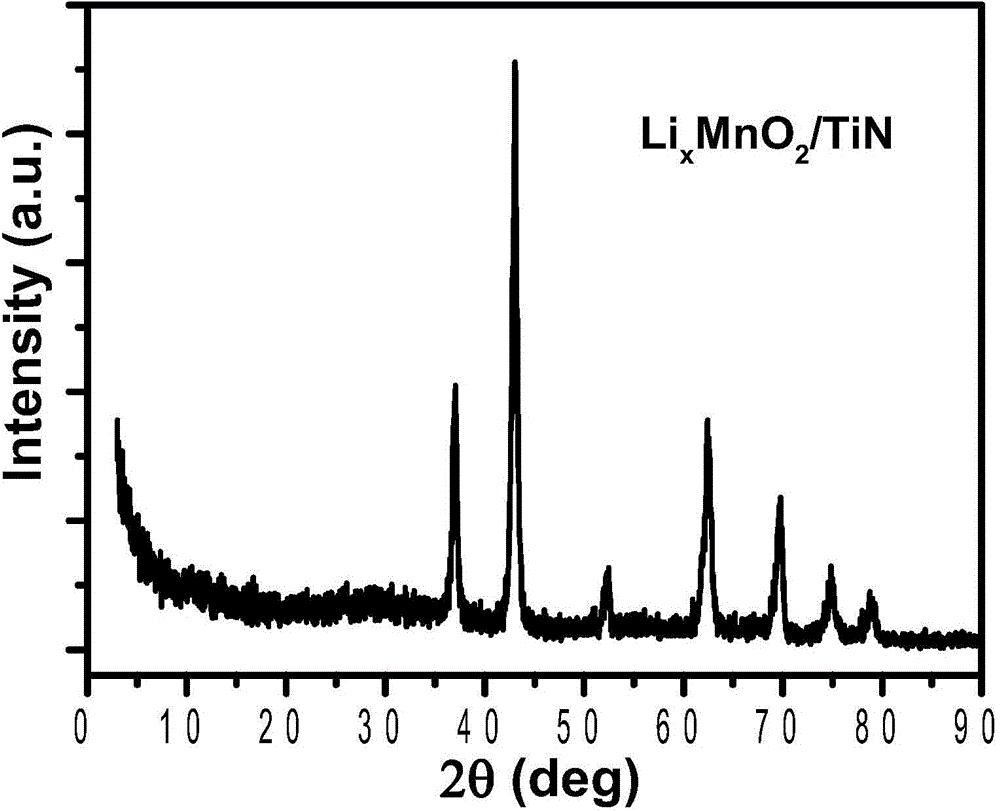

ActiveCN103985563AImprove conductivityImprove power storage capacityHybrid capacitor electrodesDouble layer capacitorsSynthesis methodsTitanium nitride

The invention provides a lithium intercalation manganese dioxide-titanium nitride nanotube composite material which comprises titanium nitride nanotubes and lithium intercalation manganese dioxide deposited inside the titanium nitride nanotubes and gaps between the titanium nitride nanotubes. A coaxial heterogeneous nanotube array structure is formed by the titanium nitride nanotubes and the lithium intercalation manganese dioxide deposited inside the titanium nitride nanotubes and the gaps between the titanium nitride nanotubes. The invention further provides a preparing method of the composite material and application of the composite material to lithium ion supercapacitor preparation. The lithium intercalation manganese dioxide-titanium nitride nanotube composite material is high in electric conductivity, electricity storage performance and large-current charging and discharging performance and capable of being prepared through a simple and feasible electrochemistry intercalation-deposition reaction synthesis method.

Owner:SOUTHEAST UNIV

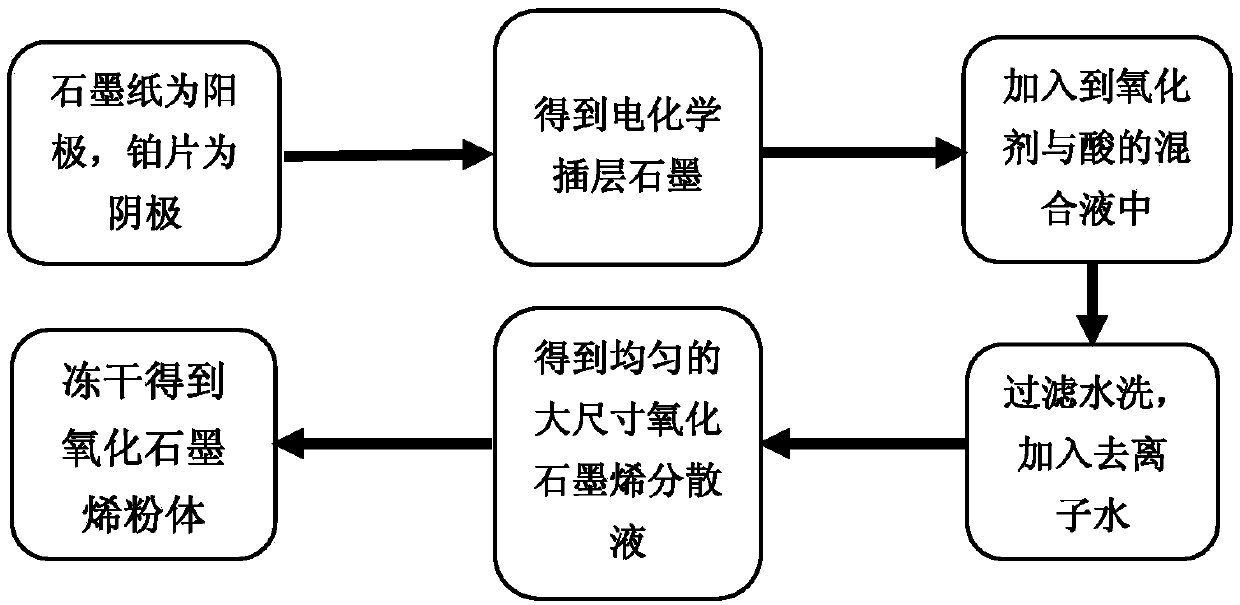

Preparation method of large-dimension graphene oxide and large-dimension graphene oxide obtained by method

The invention relates to a preparation method of large-dimension graphene oxide. The method comprises the following steps of using graphite paper as an anode; using a platinum sheet as a cathode; performing electrochemical pretreatment in electrolyte; performing intercalation on an anode material; peeling graphite; adding the materials into a mixed solution of an oxidizing agent and acid for oxidization reaction; peeling the graphene oxide under the oscillator oscillation or magnetic power stirring conditions, so that the multilayer graphene oxides are peeled into single-layer and few-layer graphene oxides and are dispersed into deionized water to form large-dimension graphene oxide dispersion liquid; performing centrifugal separation to obtain graphene oxide slurry; performing freeze drying treatment to obtain large-dimension graphene oxide powder. The invention also provides the large-dimension graphene oxide obtained by the preparation method. The electrochemical intercalation graphene is used as raw materials to perform oxidization reaction to realize the fast oxidization on the graphene; through natural settling cleaning and mild mechanical peeling, the fast peeling on the large-dimension graphene oxide is realized; the characteristics of high efficiency, high yield and low cost are achieved.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI +1

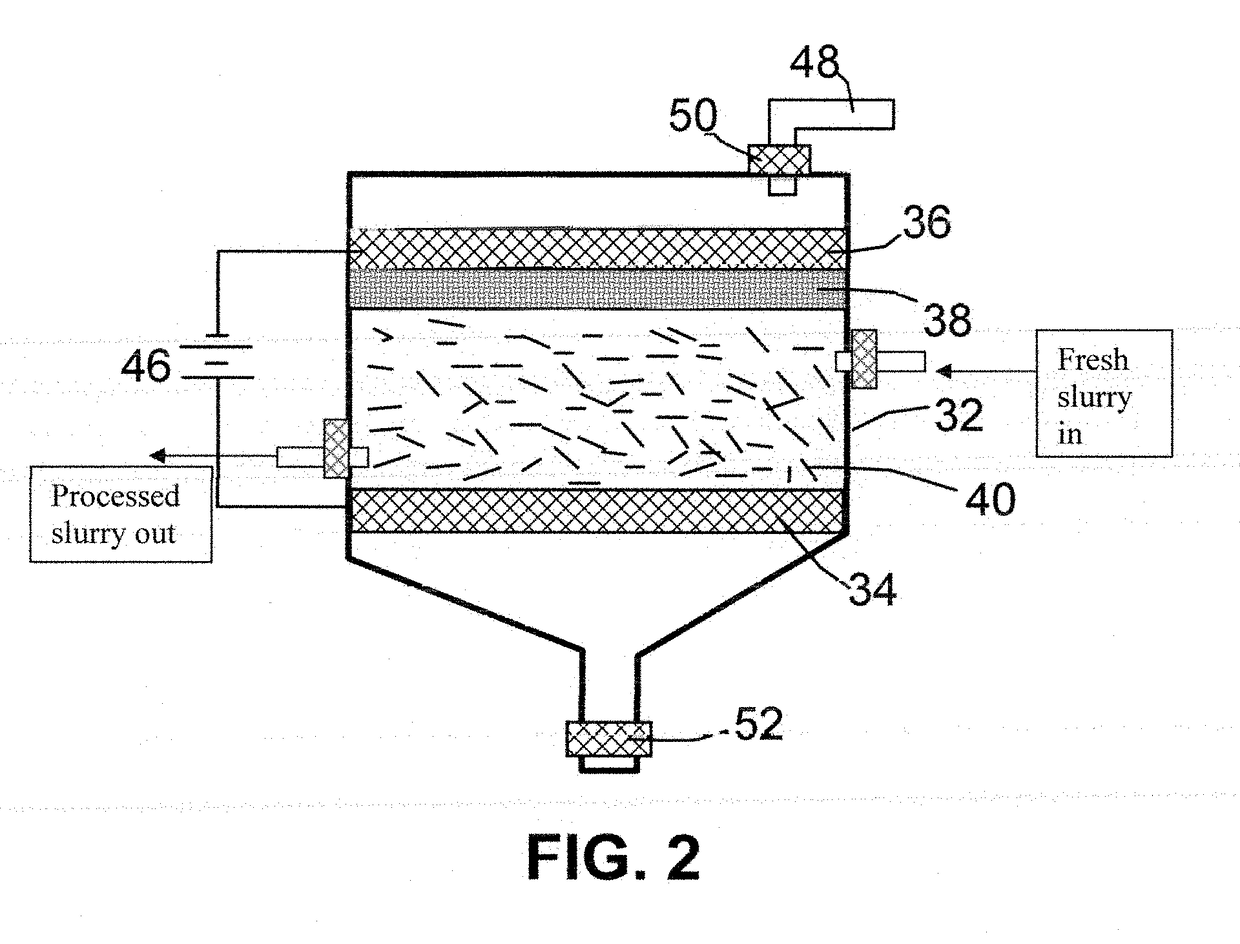

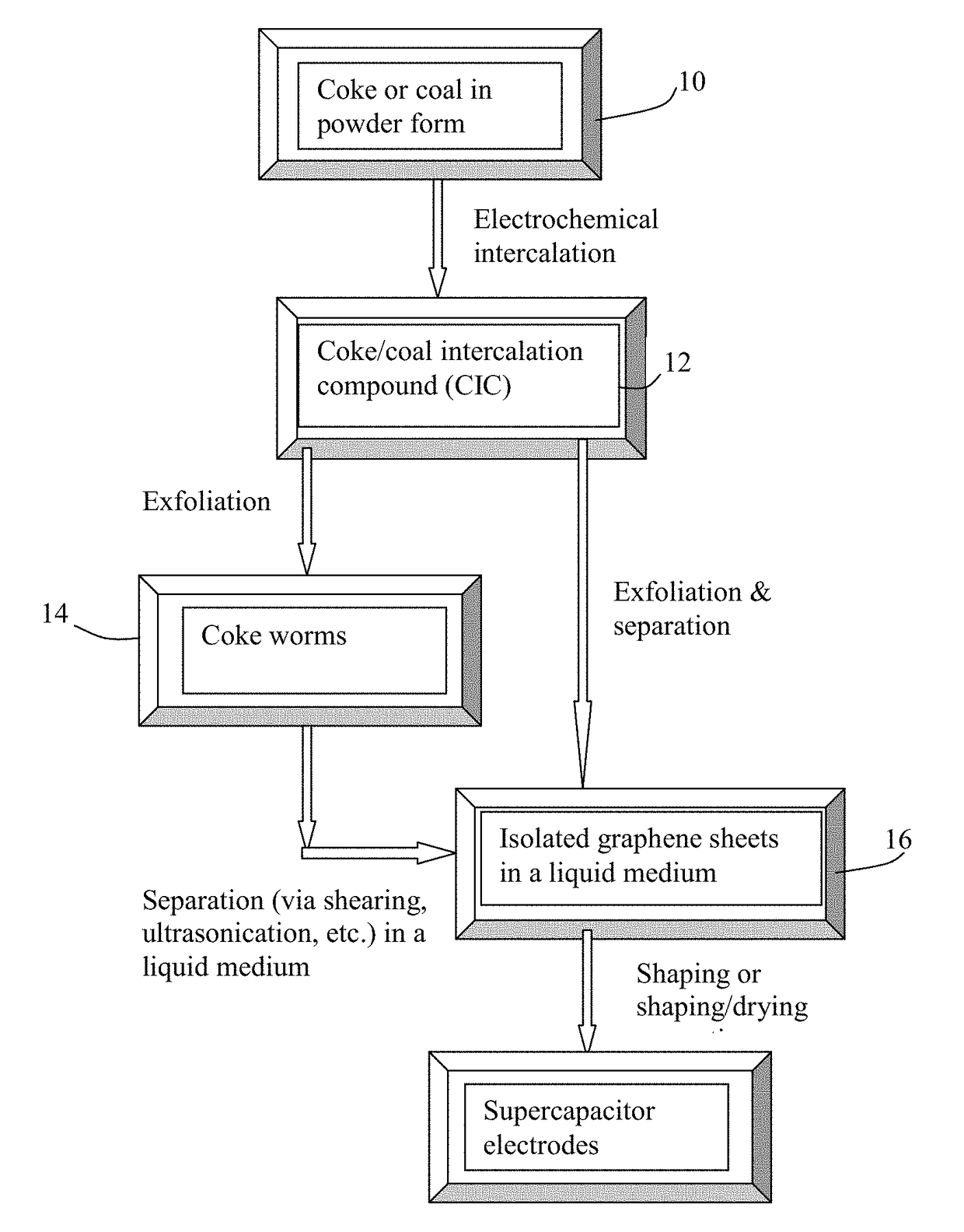

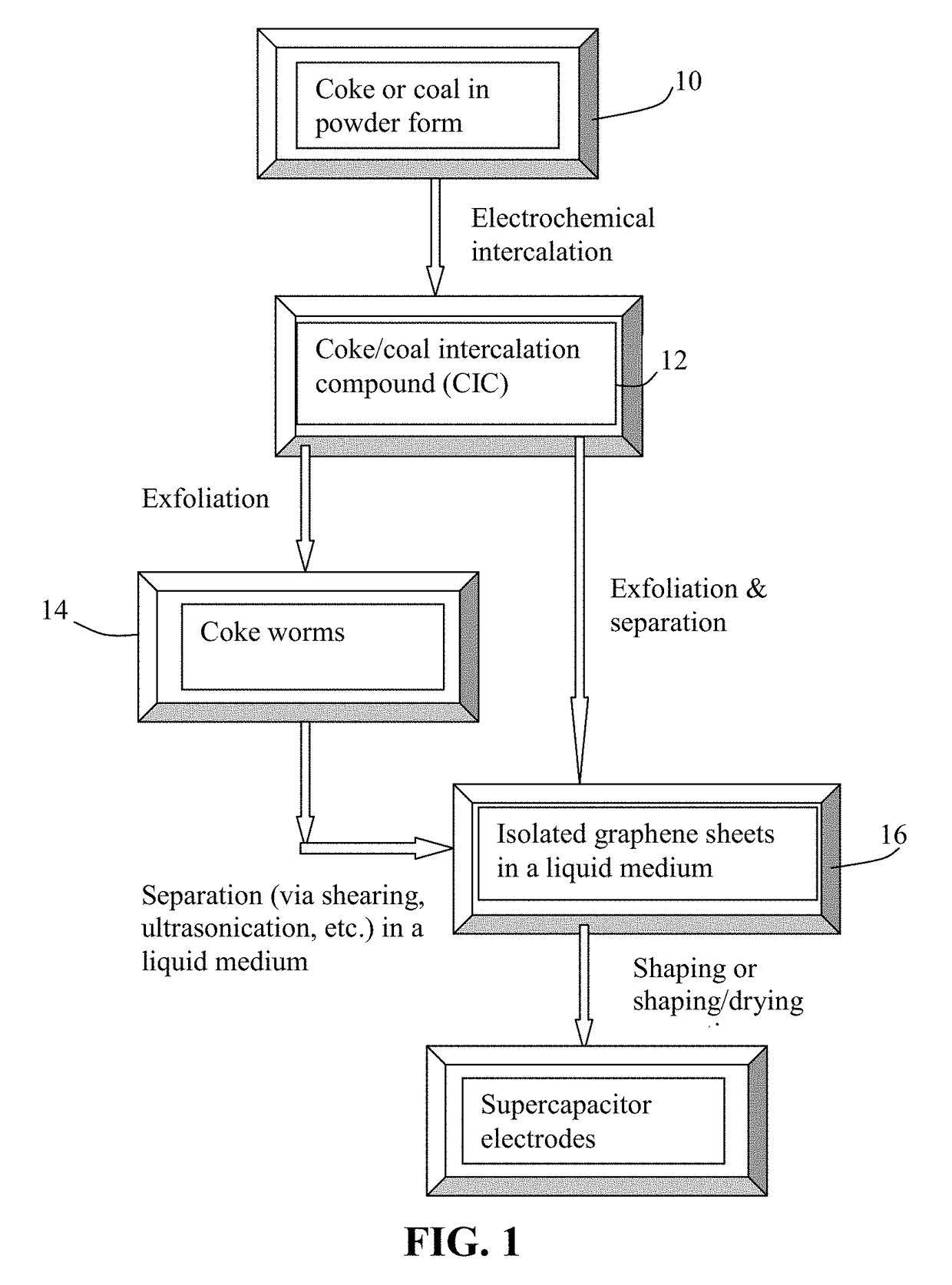

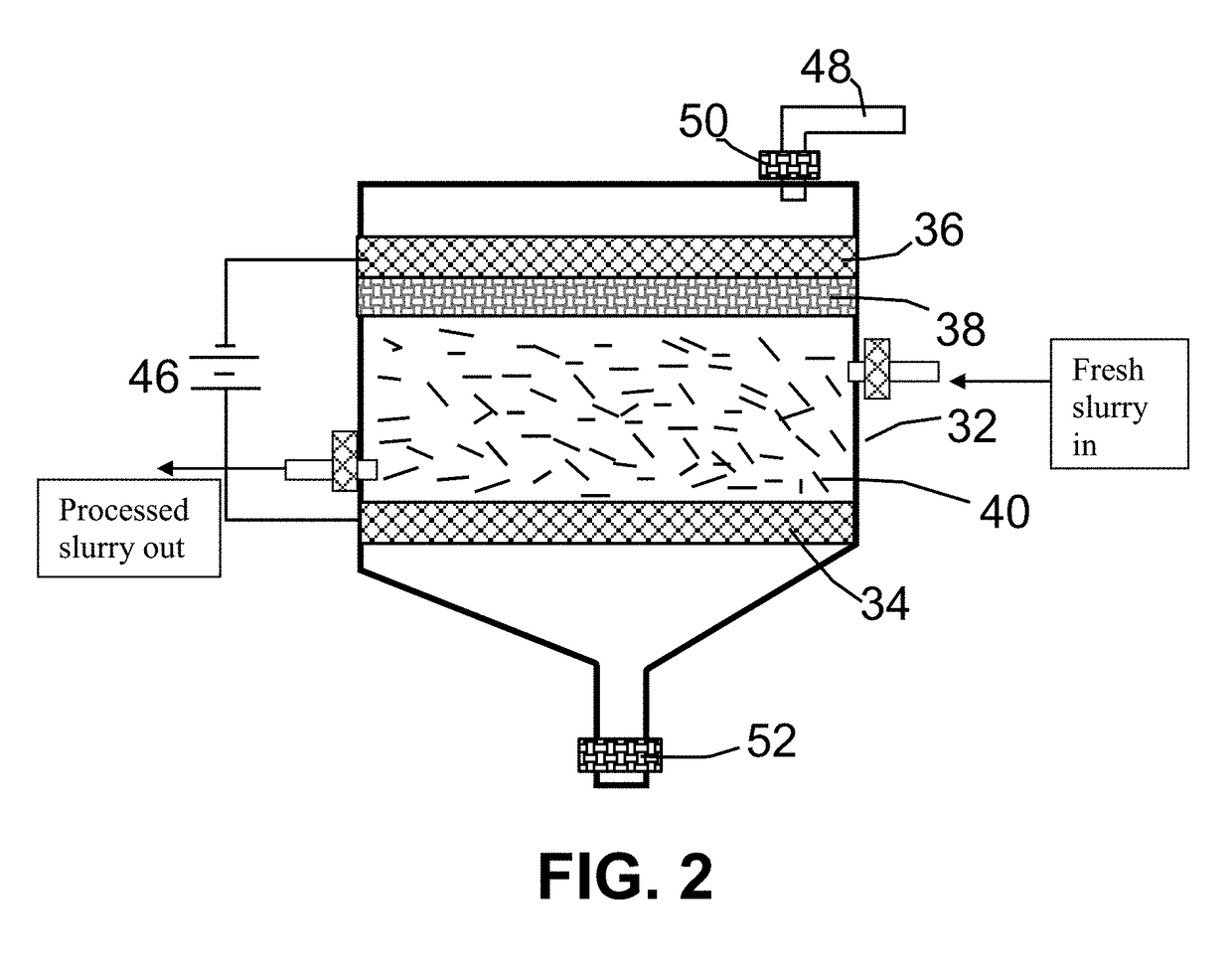

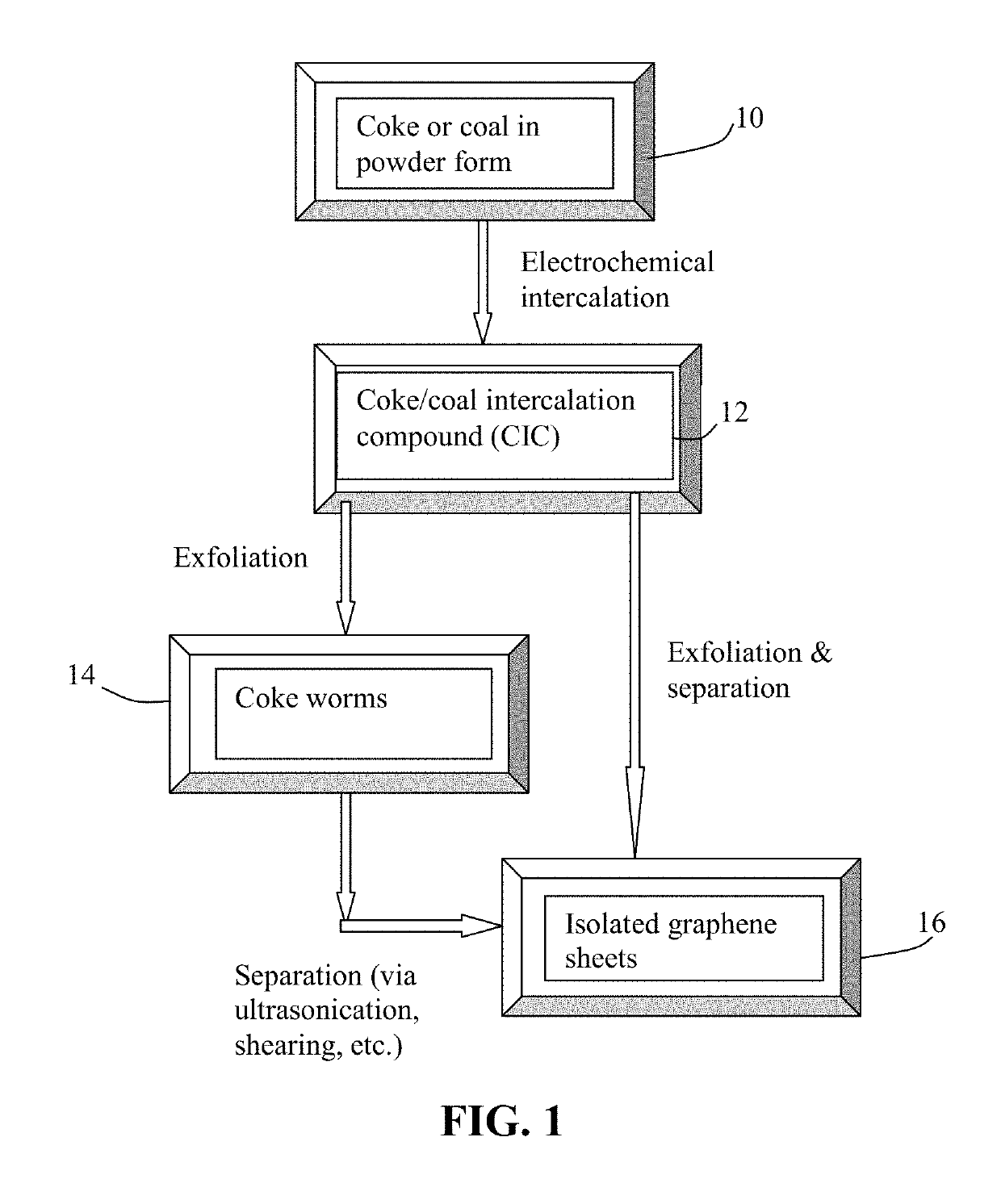

Electrochemical Method of Producing Graphene-Based Supercapacitor Electrode from Coke or Coal

PendingUS20180019072A1Reduce thin electrolyte layer thicknessImprove directionLiquid surface applicatorsElectrolysis componentsSupercapacitorCvd graphene

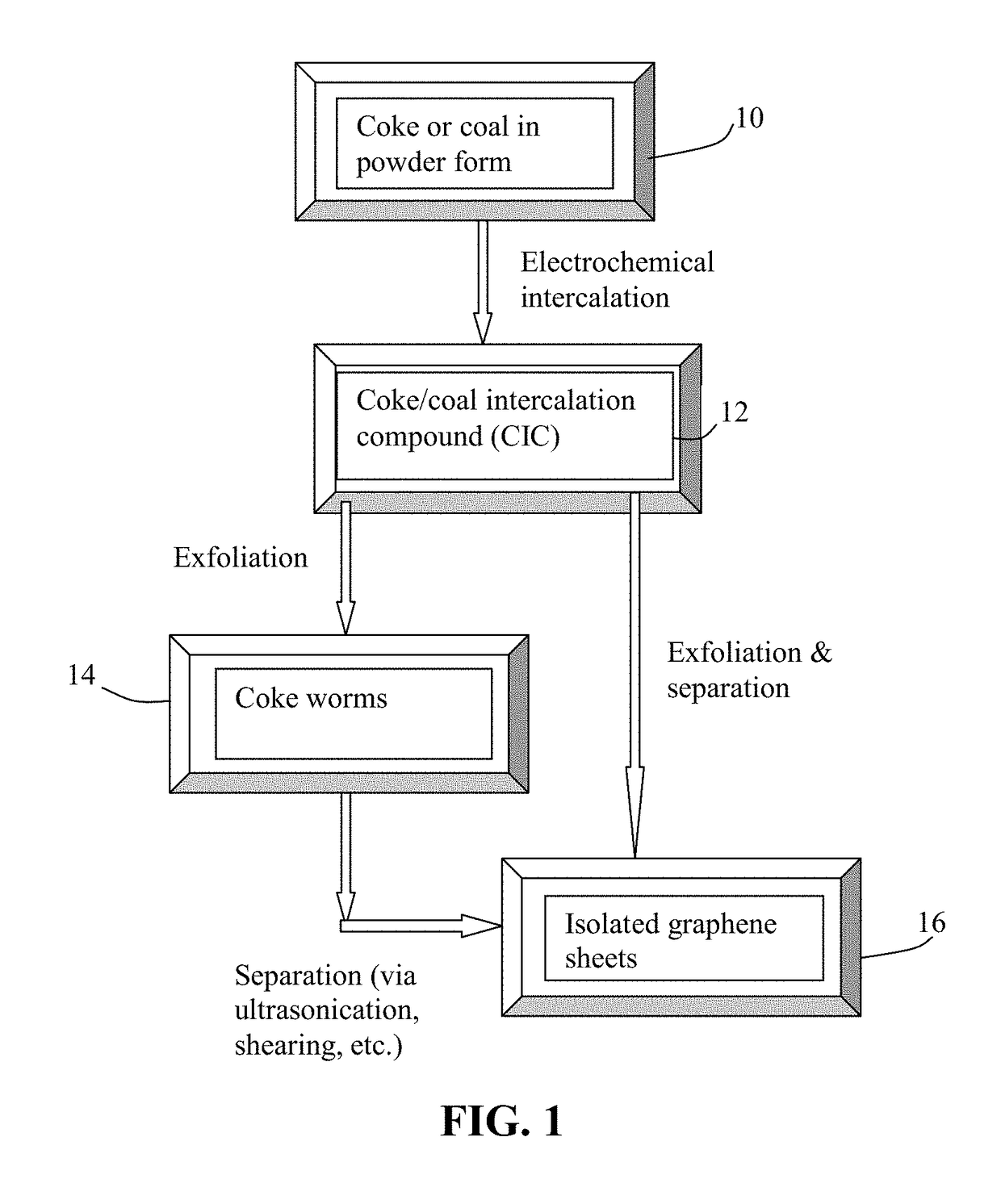

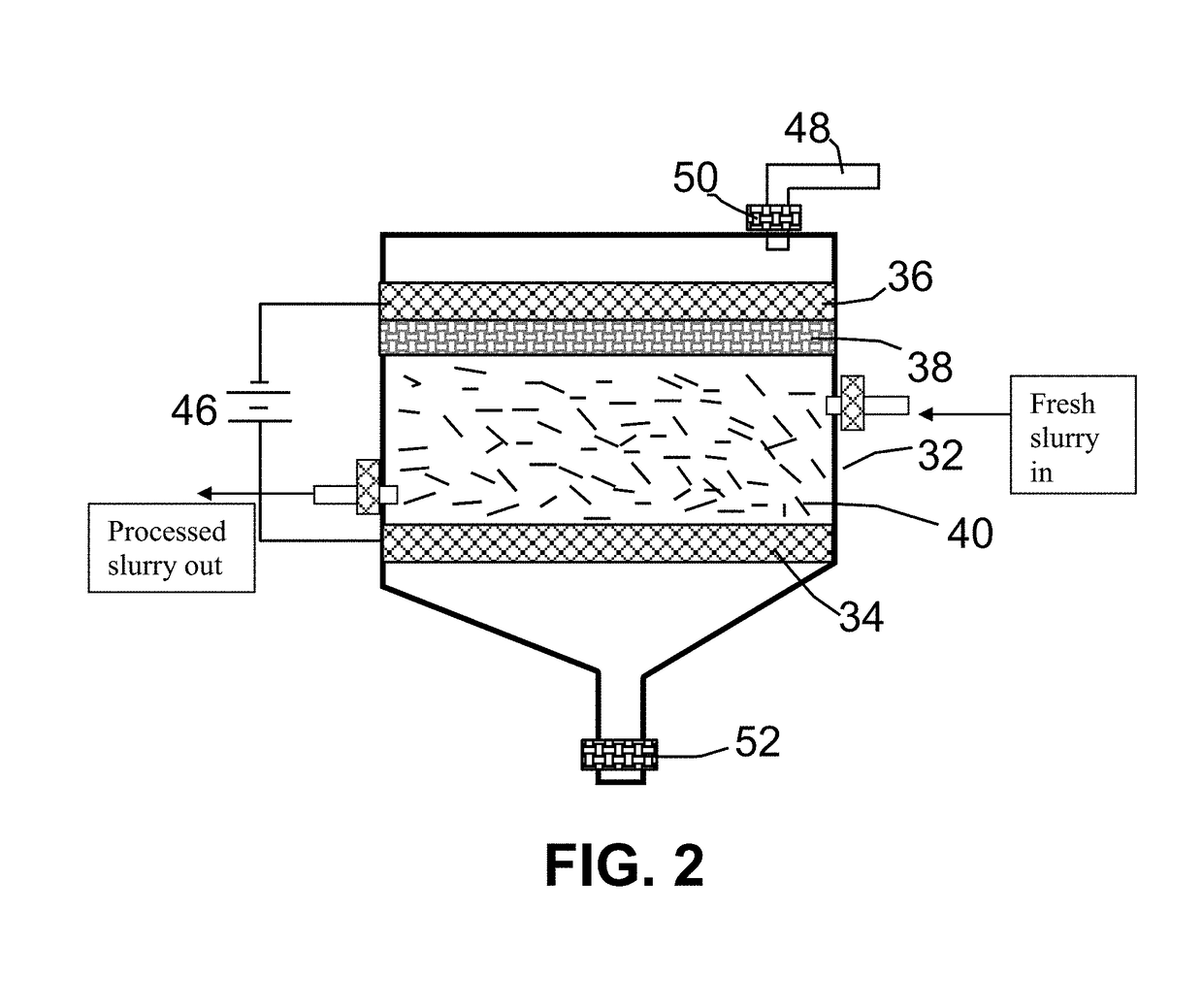

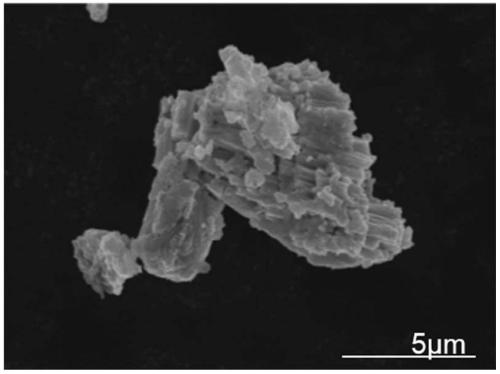

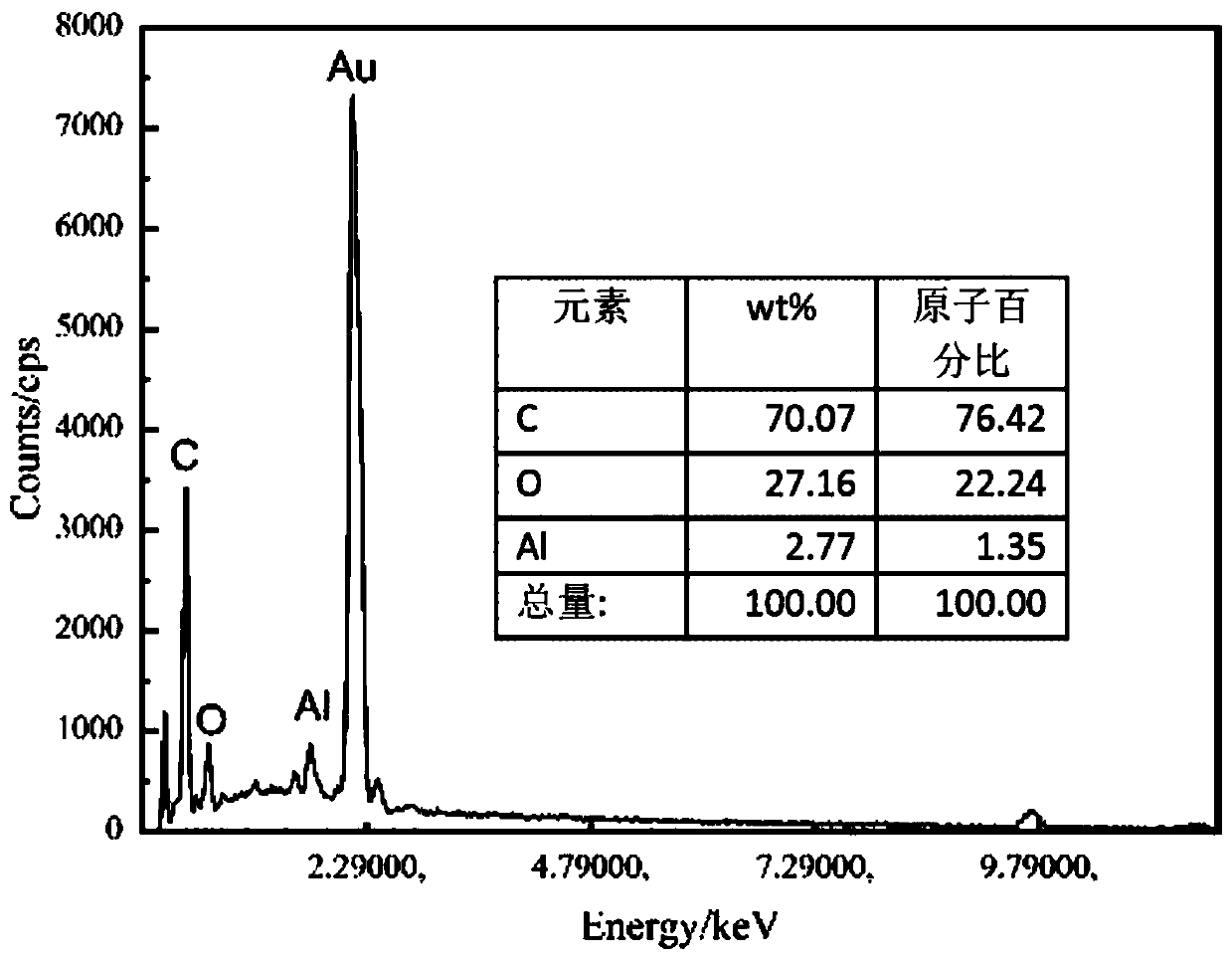

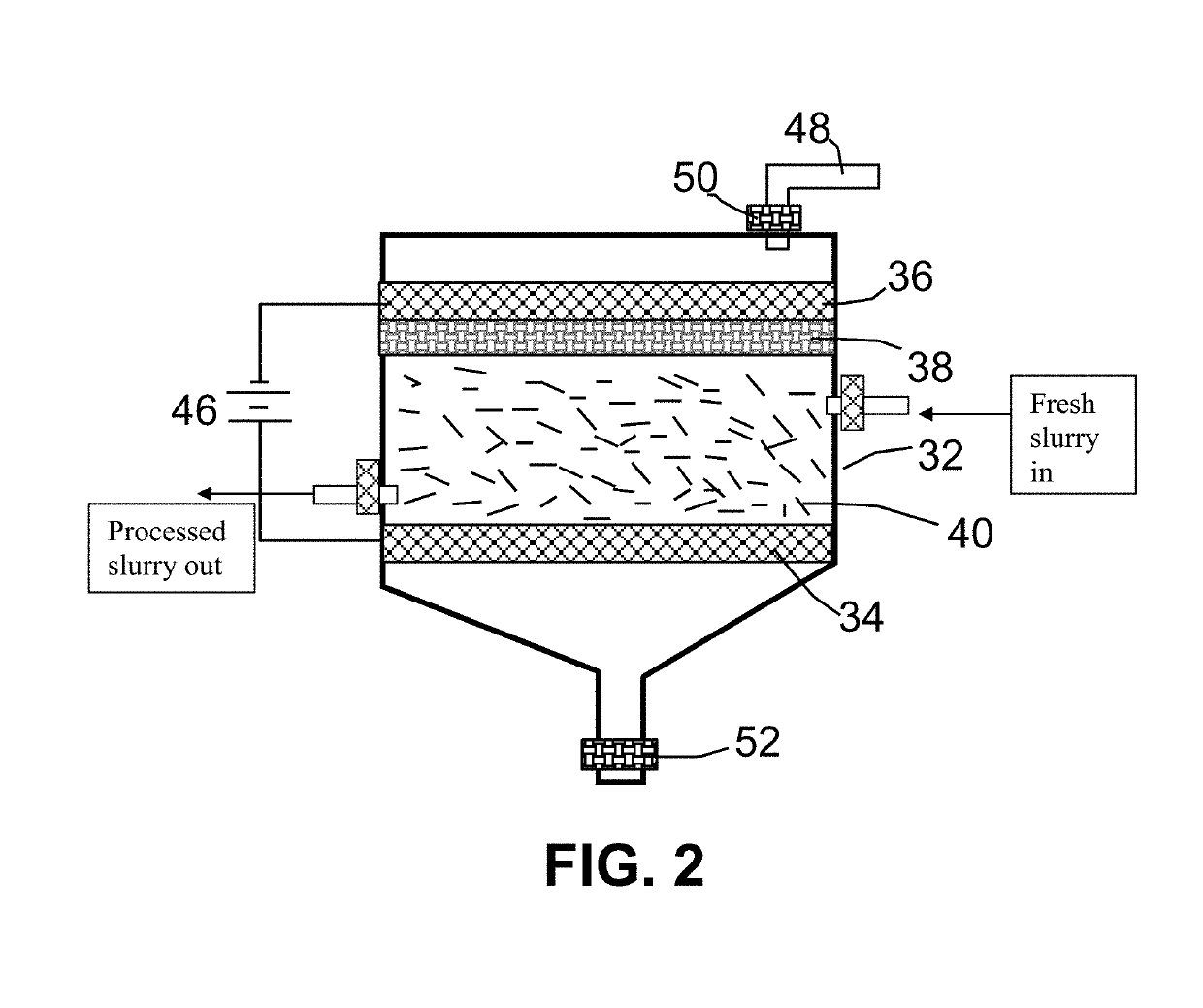

A method of producing graphene sheets from coke or coal powder, comprising: (a) forming an intercalated coke or coal compound by electrochemical intercalation conducted in an intercalation reactor, which contains (i) a liquid solution electrolyte comprising an intercalating agent; (ii) a working electrode that contains the powder in ionic contact with the liquid electrolyte, wherein the coke or coal powder is selected from petroleum coke, coal-derived coke, meso-phase coke, synthetic coke, leonardite, lignite coal, or natural coal mineral powder; and (iii) a counter electrode in ionic contact with the electrolyte, and wherein a current is imposed upon the working electrode and the counter electrode for effecting electrochemical intercalation of the intercalating agent into the powder; and (b) exfoliating and separating graphene planes from the intercalated coke or coal compound using an ultrasonication, thermal shock exposure, mechanical shearing treatment, or a combination thereof to produce isolated graphene sheets.

Owner:NANOTEK INSTR GRP LLC

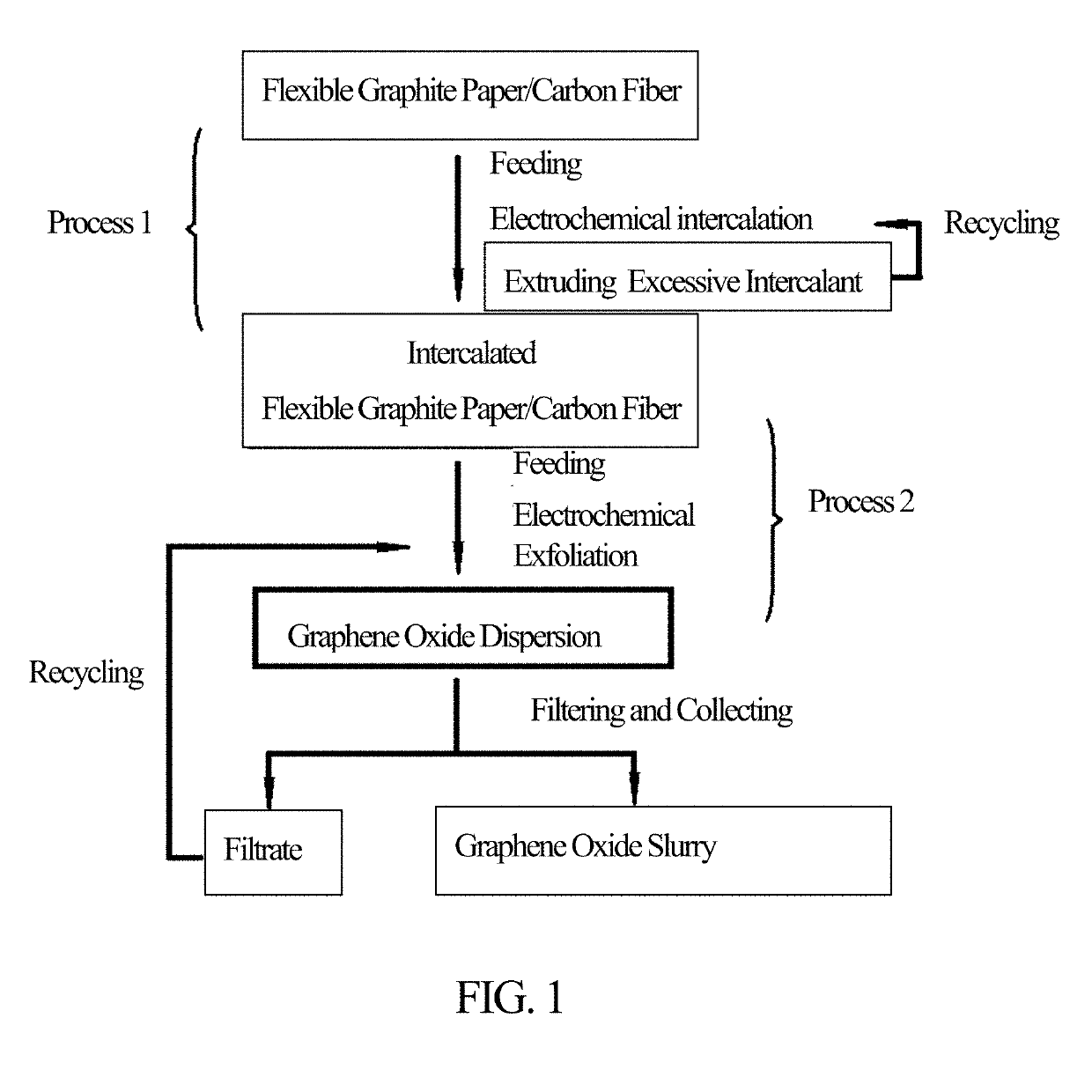

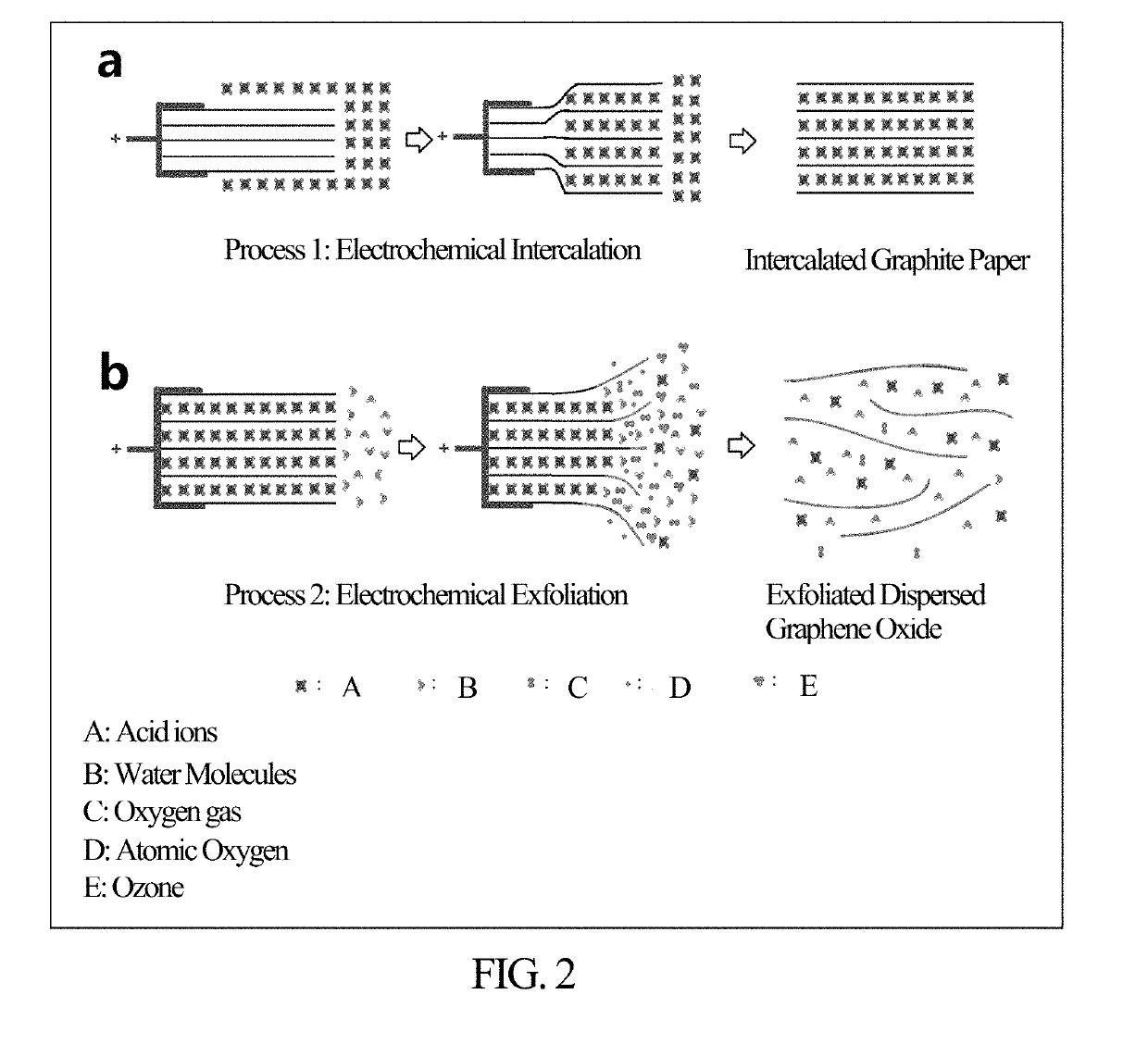

Method for Continuously Preparing Graphene Oxide Nanoplatelet

ActiveUS20190112195A1Reduce environmental pollutionLow pollutant emissionCellsMaterial nanotechnologyElectrolysisMetal impurities

Provided is a method for continuously preparing graphene oxide nanoplatelets by electrochemical treatment, comprising using a continuous graphite product, successively processing two step treatments, i.e. an electrochemical intercalation and an electrolytic oxidation stripping. The electrochemical intercalation is carried out in a concentrated acid, using a graphite material as an anode and energizing under a soaking condition such that acid radical ions enter into graphite interlamination under the drive of an electric field, to form an intercalated graphite continuous material with first-order or low-order intercalation. The electrolytic stripping is using the intercalated continuous graphite material as an anode, energizing in an aqueous electrolyte solution, and performing oxidation stripping. The method has the following advantages: a product does not contain a metal impurity, the oxidation degree of graphene is controllable, the process is continuable and automatable, and the method is safe and has low emissions, etc.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

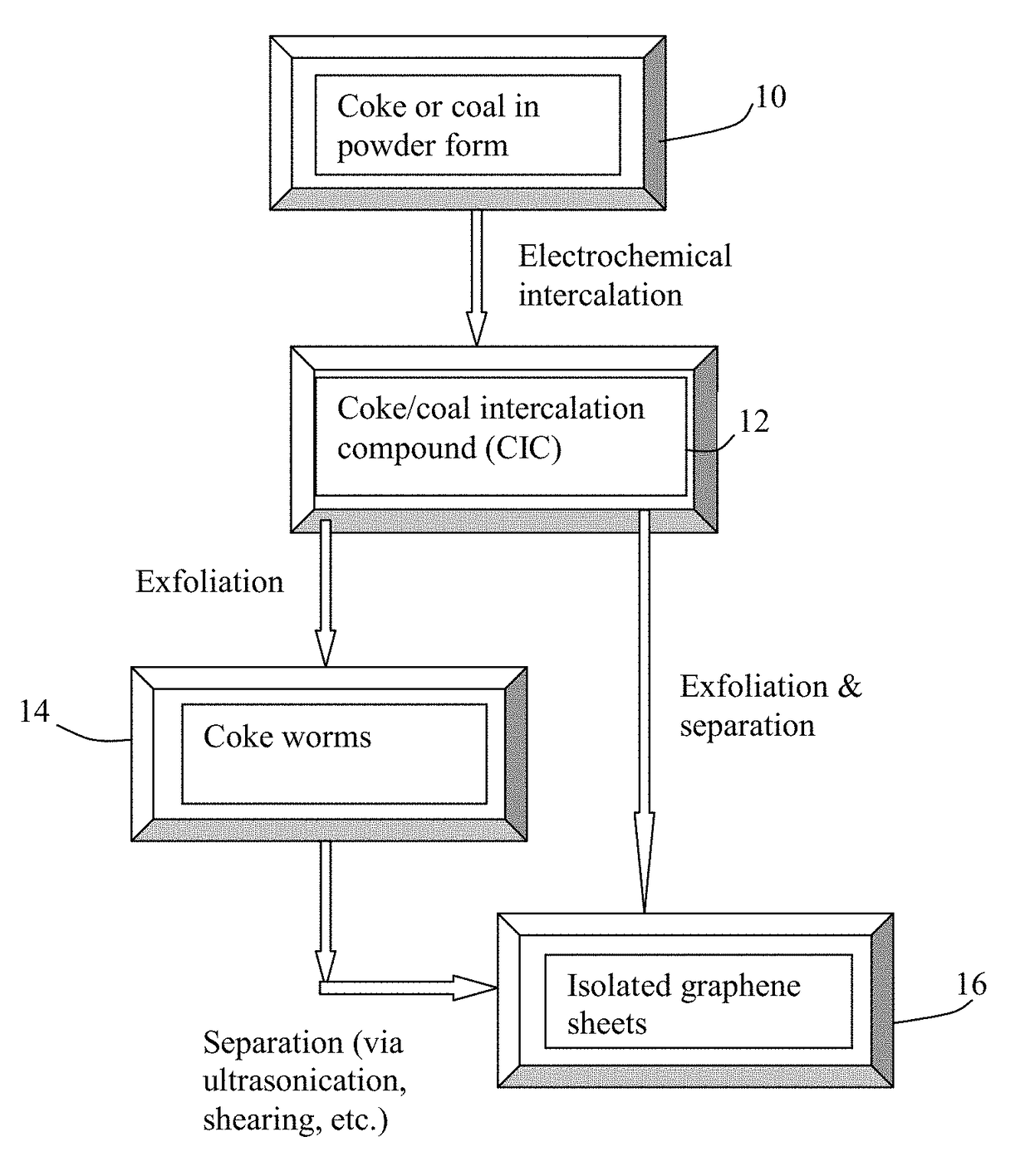

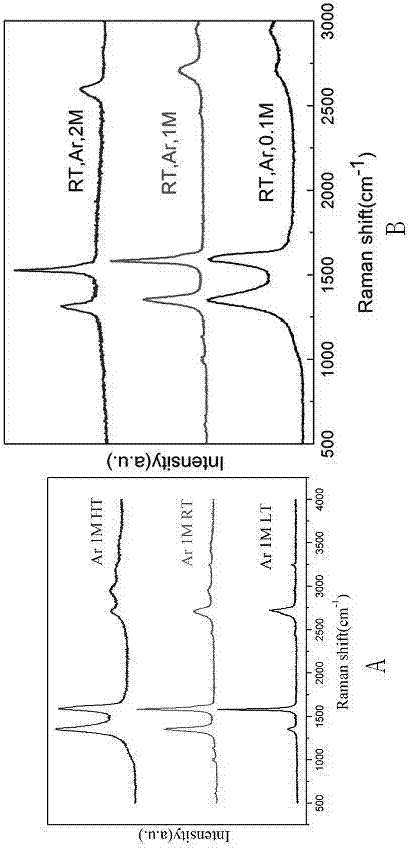

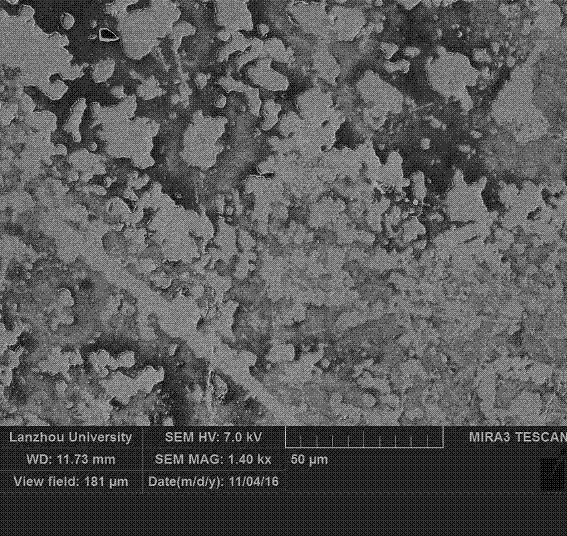

Electrochemical Production of Graphene Sheets from Coke or Coal

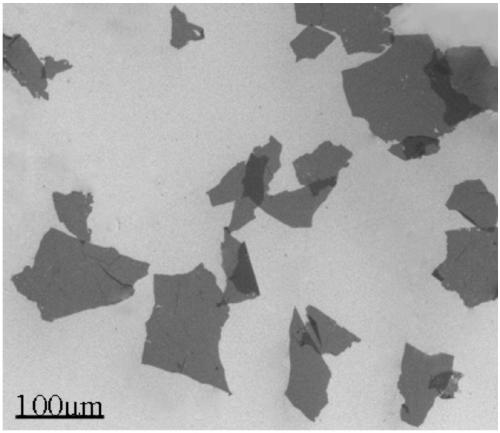

ActiveUS20170370009A1Promoting exfoliationPromoting intercalationCellsGrapheneGraphenePetroleum coke

A method of producing graphene sheets from coke or coal powder, comprising: (a) forming an intercalated coke or coal compound by electrochemical intercalation conducted in an intercalation reactor, which contains (i) a liquid solution electrolyte comprising an intercalating agent; (ii) a working electrode that contains the powder in ionic contact with the liquid electrolyte, wherein the coke or coal powder is selected from petroleum coke, coal-derived coke, meso-phase coke, synthetic coke, leonardite, lignite coal, or natural coal mineral powder; and (iii) a counter electrode in ionic contact with the electrolyte, and wherein a current is imposed upon the working electrode and the counter electrode for effecting electrochemical intercalation of the intercalating agent into the powder; and (b) exfoliating and separating graphene planes from the intercalated coke or coal compound using an ultrasonication, thermal shock exposure, mechanical shearing treatment, or a combination thereof to produce isolated graphene sheets.

Owner:GLOBAL GRAPHENE GRP INC

Method for producing graphene in green and large-scale manner

InactiveCN107572511AThe separation method is simpleAchieve recyclingGrapheneFiltrationGraphene flake

The invention relates to a method for producing graphene in a green and large-scale manner. The method comprises the following steps of: (1) preparing 0.1-10M of electrolytic solution; (2) adding an anode material into an electrolytic tank containing the electrolytic solution, fixing by using foam paper, and fixing a cathode material at the middle of the foam paper; (3) inserting a thin pipe connected with insert gas into the electrolytic solution, and fixing on the foam paper; (4) adding cooling equipment at the periphery of the electrolytic solution to maintain the temperature of the electrolytic solution to 5-15 DEG C; (5) respectively connecting a positive electrode and a negative electrode of a direct-current power supply to the anode material and the cathode material in the electrolytic tank; (6) introducing the inert gas for protection at the anode material, turning on the power supply, simultaneously adjusting the voltage of the power supply to 8-20V, and starting electrochemical intercalation and peeling; (7) carrying out suction filtration and washing on intercalation graphene flakes after electrochemical intercalation, peeling and dropping, and after electrolyte ions arewashed off, carrying out ultrasonic treatment and centrifugation in a solvent to obtain graphene dispersing solution; and (8) carrying out vacuum filtration on the graphene dispersing solution, freezing and drying to obtain the graphene. The method is extremely low in cost and simple and environmental-friendly in process.

Owner:LANZHOU UNIVERSITY

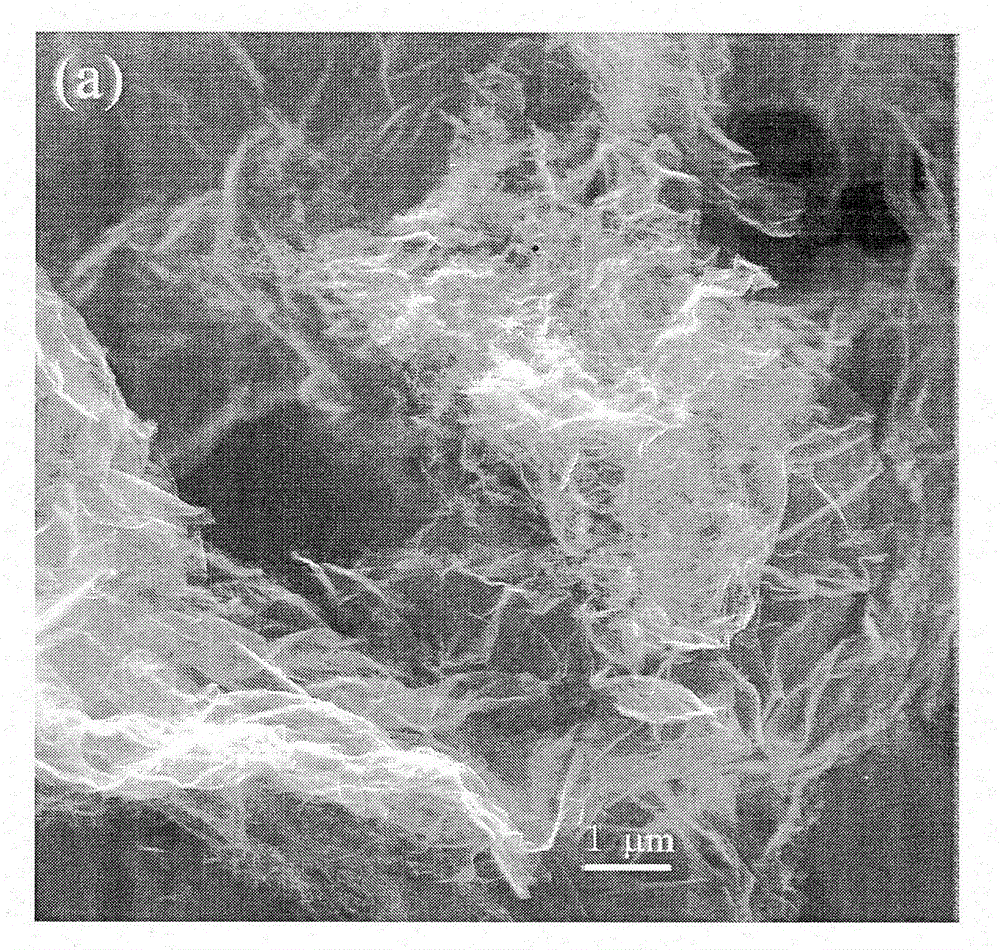

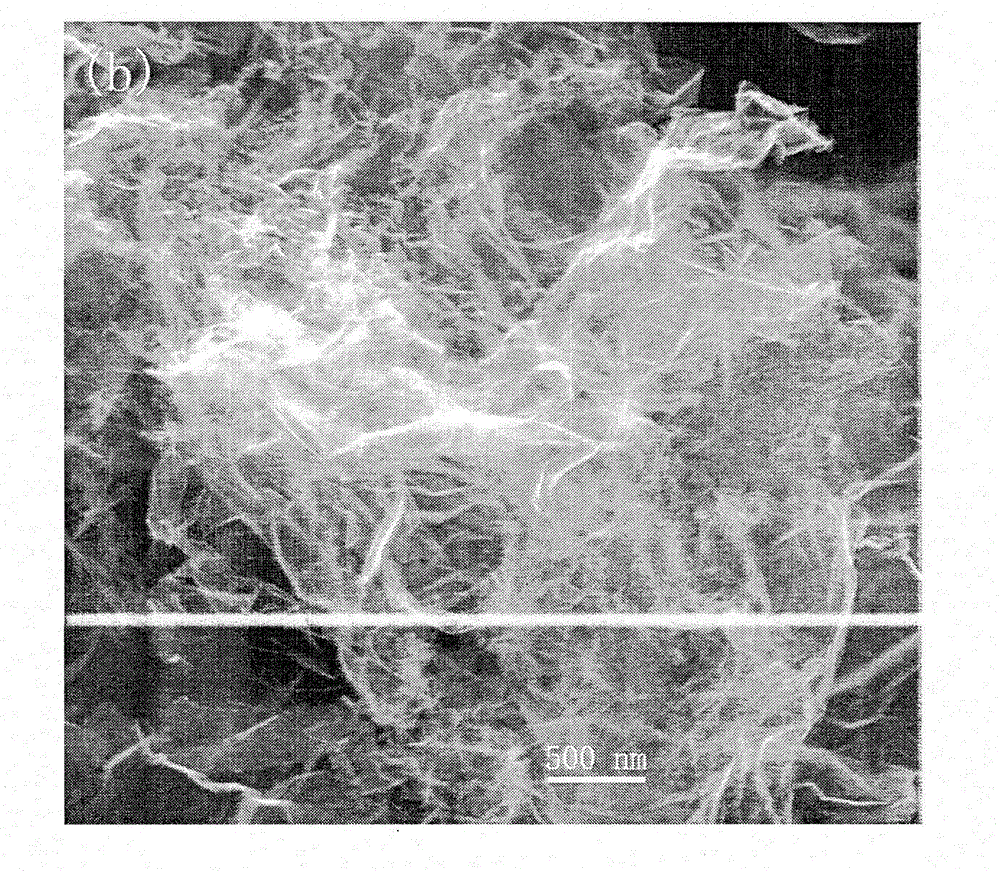

Graphene and preparation method thereof

ActiveCN103964418ALarge specific surface areaImprove energy storage performanceCarbon nanotubesPlatinumGraphite

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

Method for preparing anode material of lithium-ion battery

InactiveCN101521278AEnhanced electrochemical intercalation/extraction capabilitiesHigh discharge specific capacityElectrode manufacturing processesVacuum evaporation coatingSurface layerLithium-ion battery

The invention discloses a method for preparing anode composite material of a lithium-ion battery, comprising the following steps of preparing delta-MnO2 by adopting a high-temperature decomposition method; preparing composite material delta-MnO2-X by adopting an ion injection method, wherein X is a transition metal element, and injecting transition metal ions into the prepared delta-MnO2 which takes flake-shaped as matrix; preparing the composite material into an anode sheet of the battery; scraping off the delta-MnO2-X formed on the surface layer for being used as anode active material and proportionally mixed with other substances; and preparing the anode sheet of the lithium-ion battery after the steps of film coating, drying, tabletting, parching, weighing and the like. As the ion injection technology is adopted, a certain number of transition metal ions are injected into the surface layer of the laminated MnO2, so as to modify the laminated MnO2, strengthen the electrochemical intercalation / deintercalation capability of the lithium ions to the material, and increase the discharge specific capacity of the laminated MnO2. The prepared lithium-ion battery has the advantages of low cost, good performance and environmental protection.

Owner:黄河宁 +2

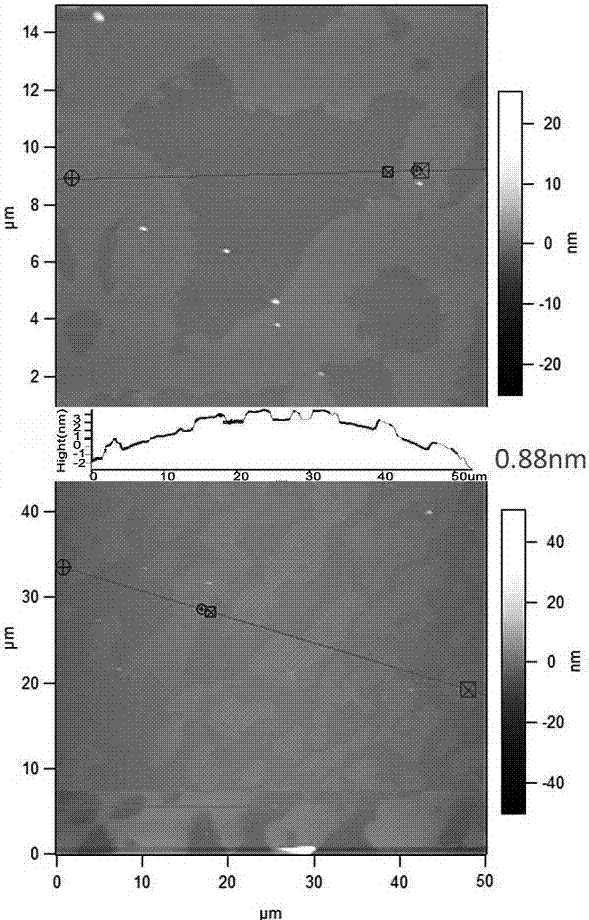

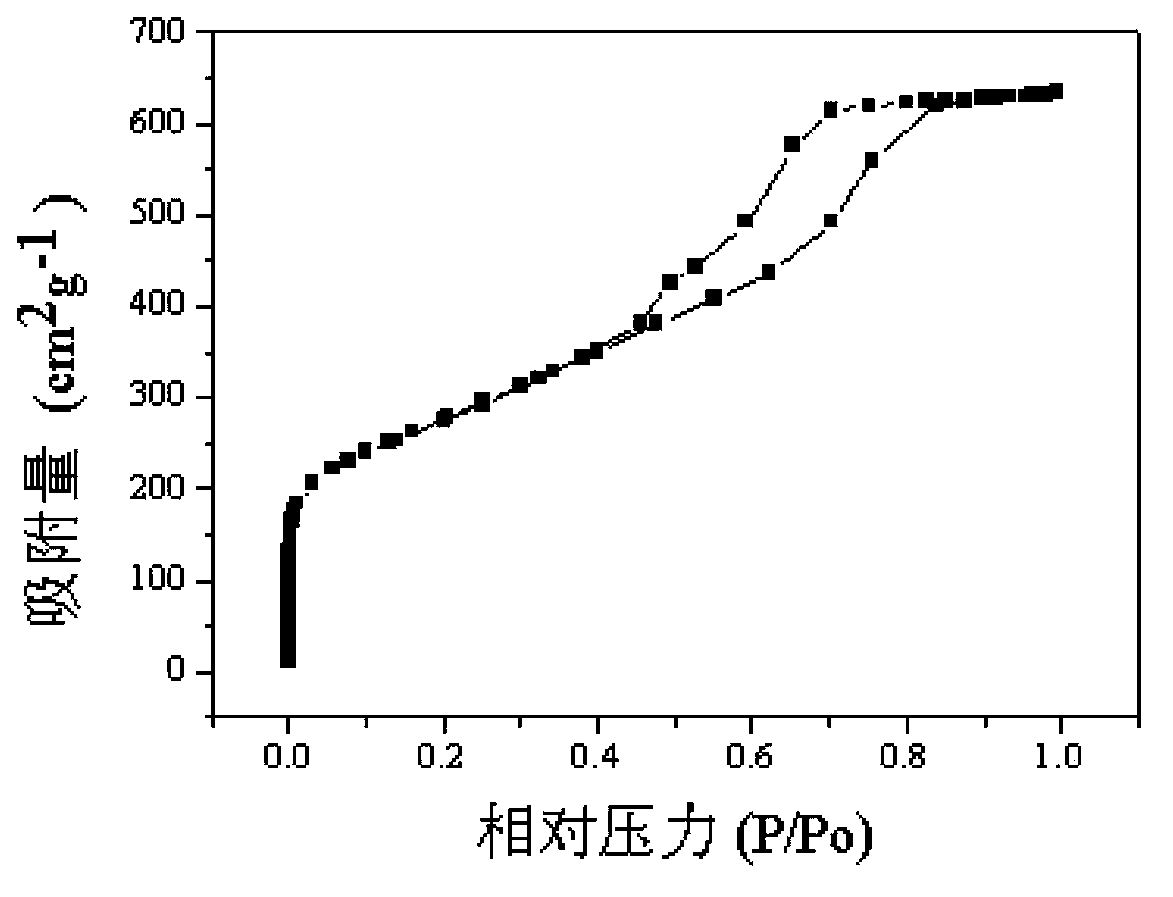

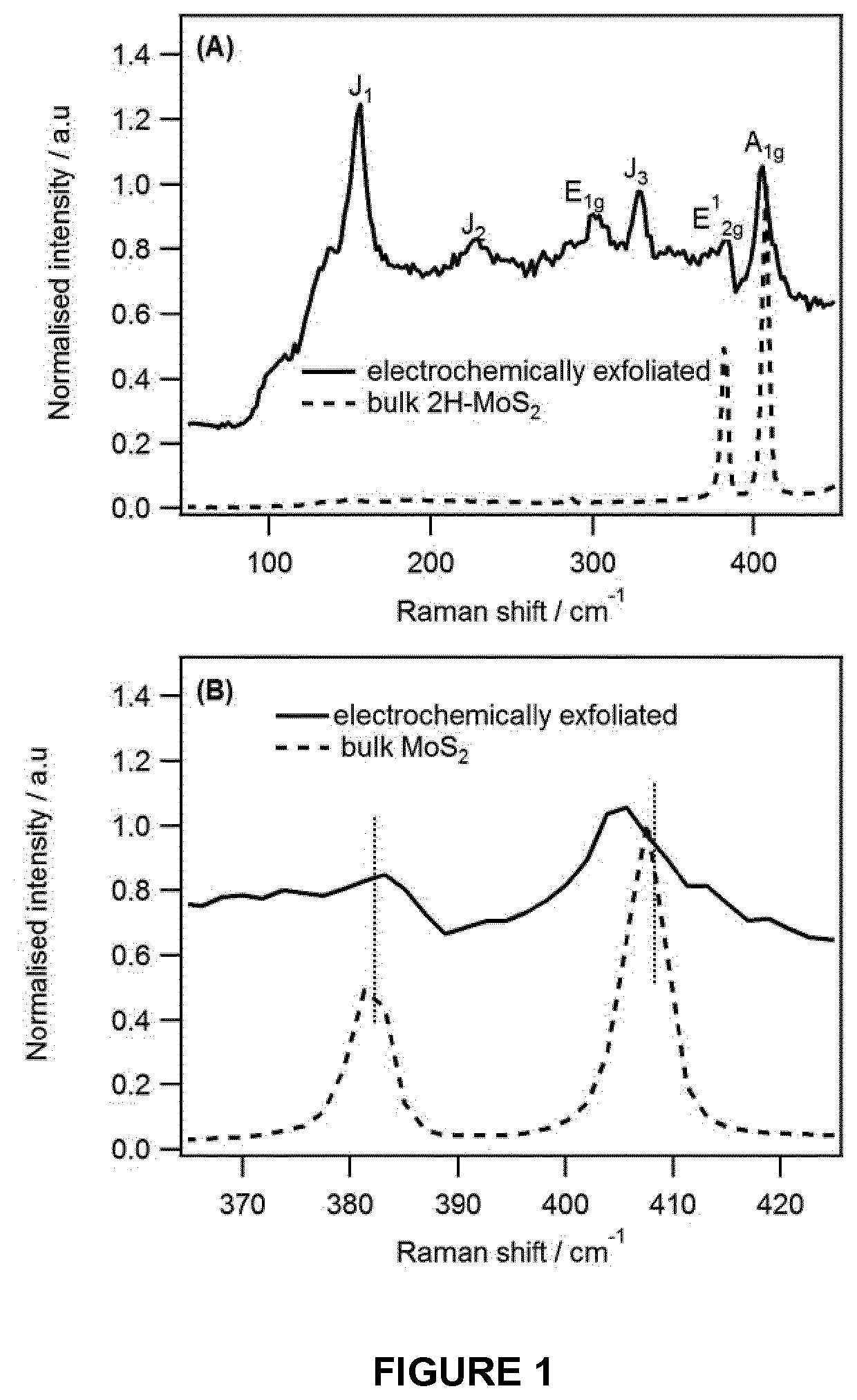

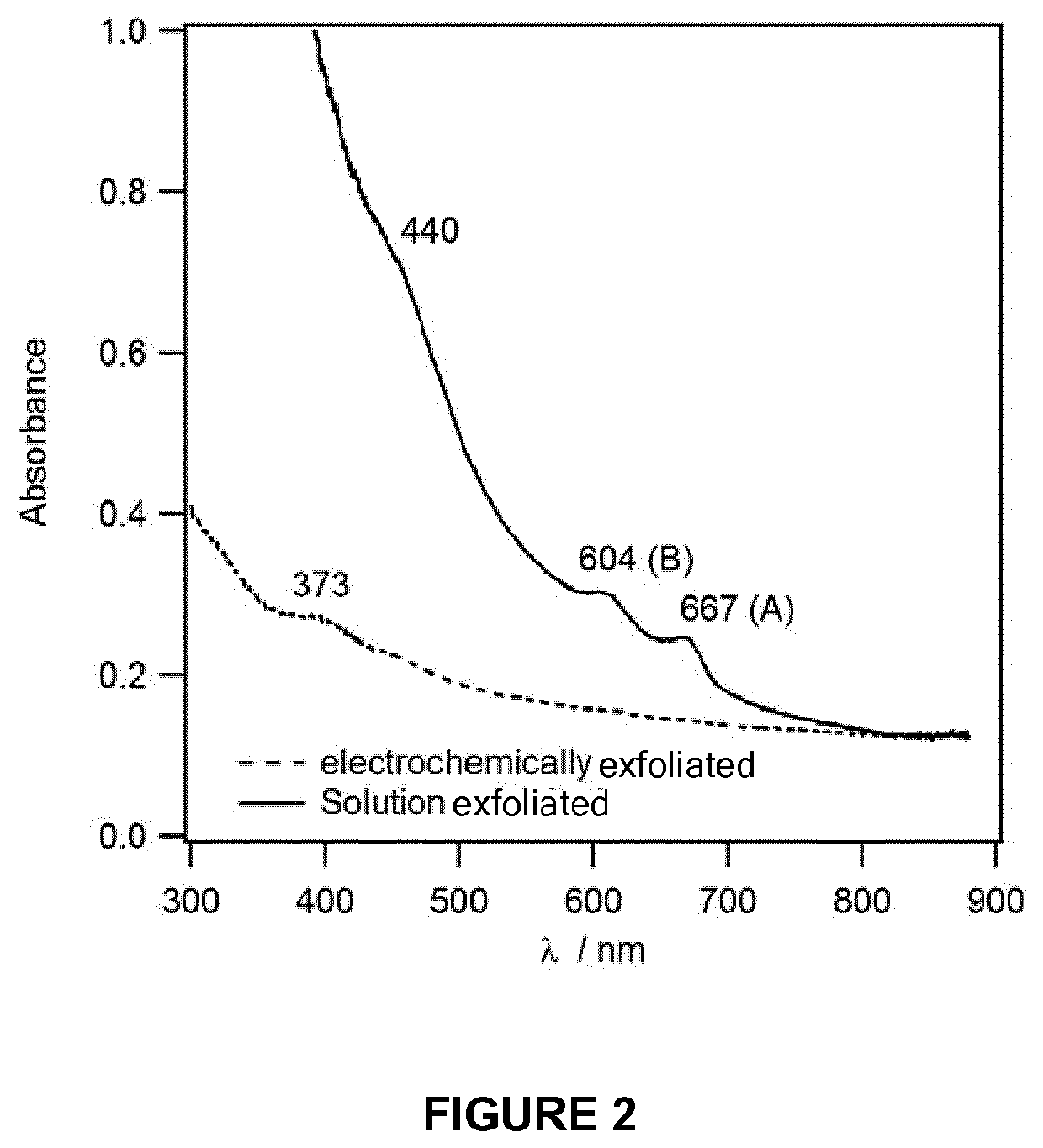

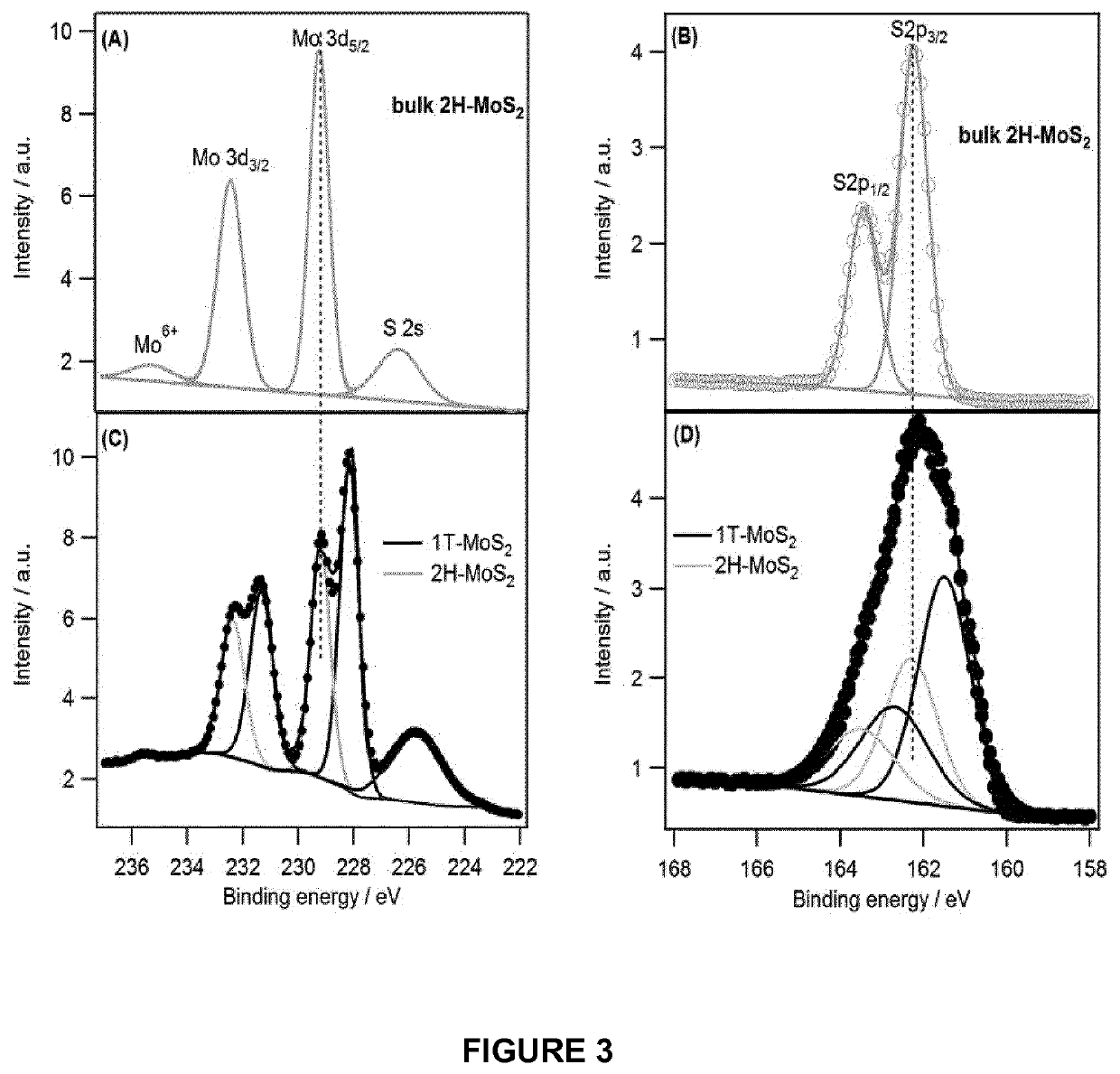

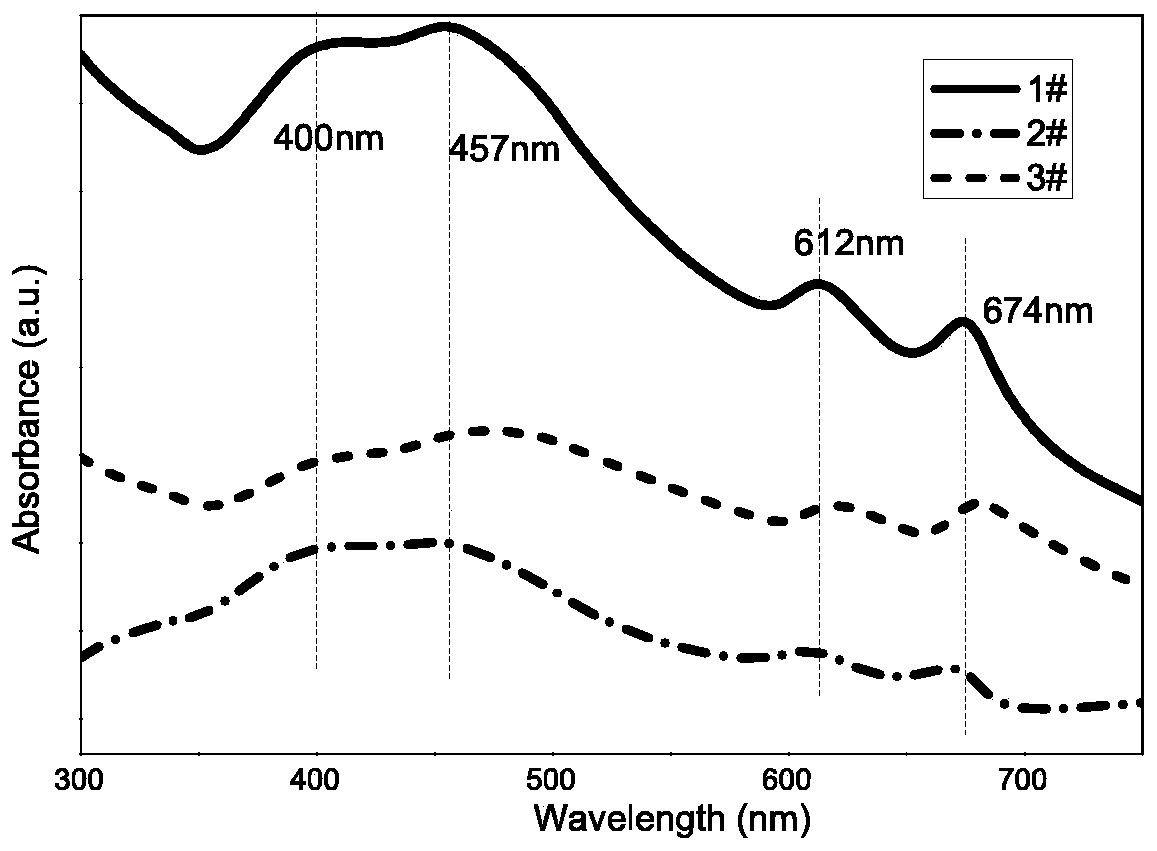

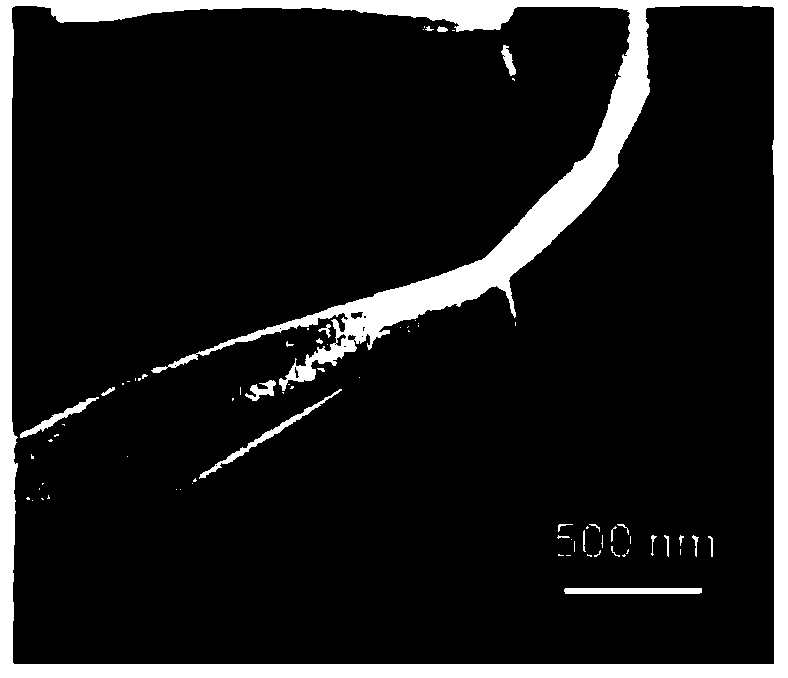

1t-phase transition metal dichalcogenide nanosheets

ActiveUS20190352190A1Reducing or preventing solvent co-intercalationPreventing exfoliationElectrolysis componentsHybrid capacitor electrodesComposite electrodeGraphene

A method for the production of 1T-transition metal dichalcogenide few-layer nanosheets and / or monolayer nanosheets comprising electrochemical intercalation of lithium ions into a negative electrode comprising a bulk 2H-transition metal dichalcogenide to provide an intercalated electrode, and an exfoliation step comprising contacting the intercalated electrode with a protic solvent to produce 1T-transition metal dichalcogenide few-layer nano sheets and / or monolayer nanosheets. An electrochemical capacitor comprising a composite electrode comprising 1T-MoS2 nanosheets and graphene, and a method of producing a composite electrode for use in an electrochemical capacitor.

Owner:UNIV OF MANCHESTER

Preparation method for transition metal chalcogenide layered compound nanosheet material

ActiveCN110776012AResidue reductionHigh yieldMaterial nanotechnologyMolybdenum sulfidesElectrochemical responseChemical reaction

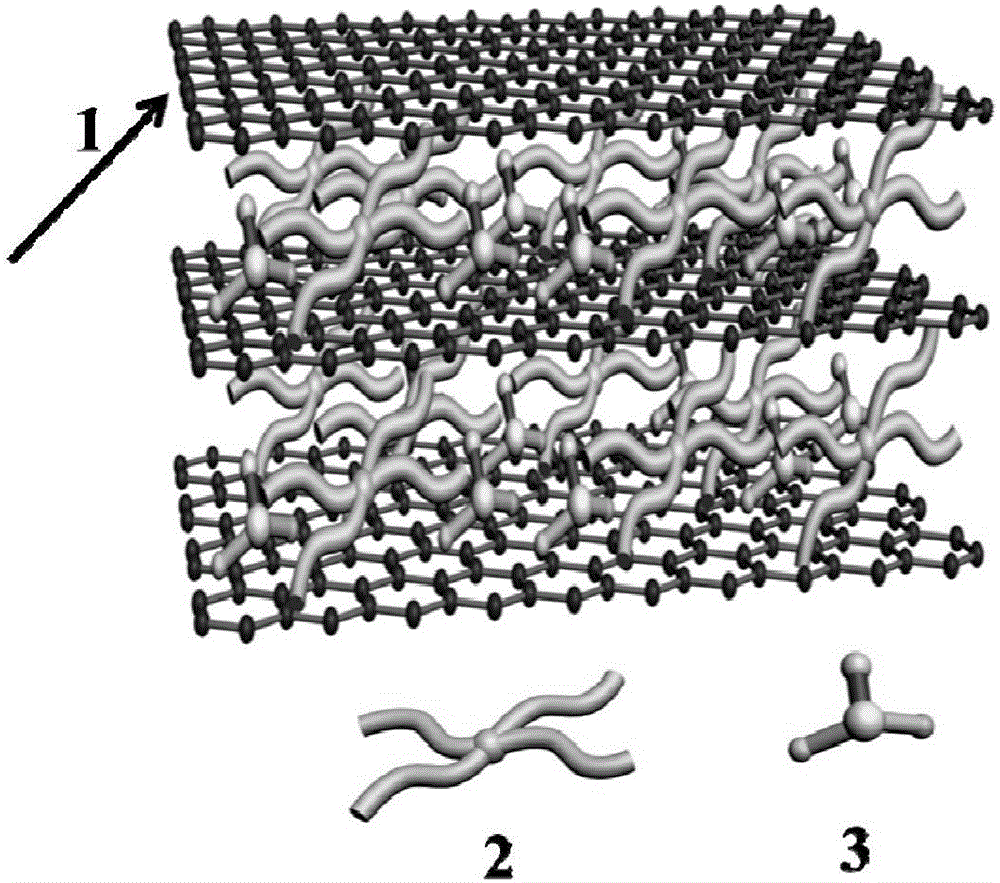

The invention discloses a preparation method for a transition metal chalcogenide layered compound nanosheet material. According to the method, an electrochemical intercalation method is combined witha mechanical physical peeling method, two electroconductive materials are used to prepare an electrochemical reaction electrode in an interlayer manner, a material flow system is introduced, electrochemical intercalation is performed in a water system and physical stripping is performed in a water-organic solvent mixed solvent system having a suitable surface tension to prepare the few-layer transition metal chalcogenide layered nanomaterial, the reaction can be performed at normal temperature and pressure, and the obtained product has a high yield, a small amount of residual intercalating agent, a small amount of residual un-stripped raw materials, high product purity, and preparation efficiency superior to that of a traditional electrochemical method and an organic solvent liquid phase stripping method.

Owner:XIAMEN HONGLU TUNGSTEN MOLYBDENUM IND CO LTD

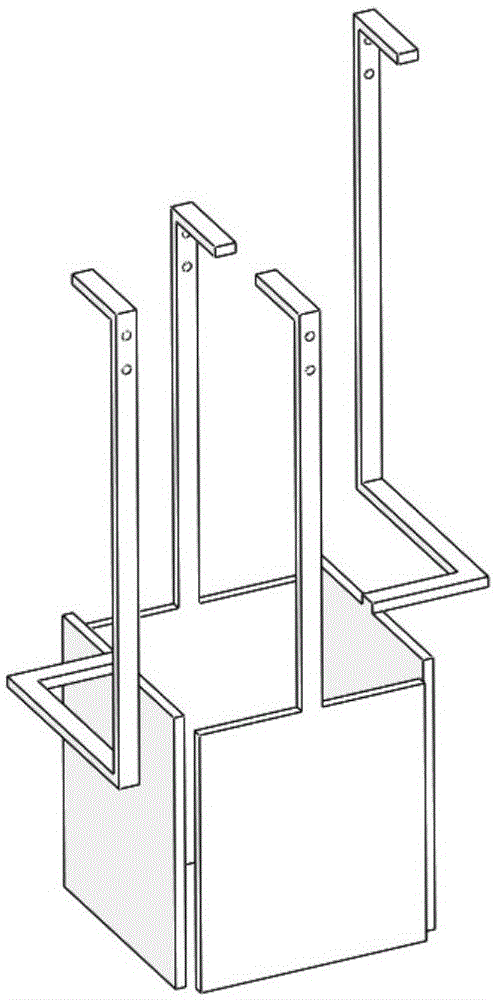

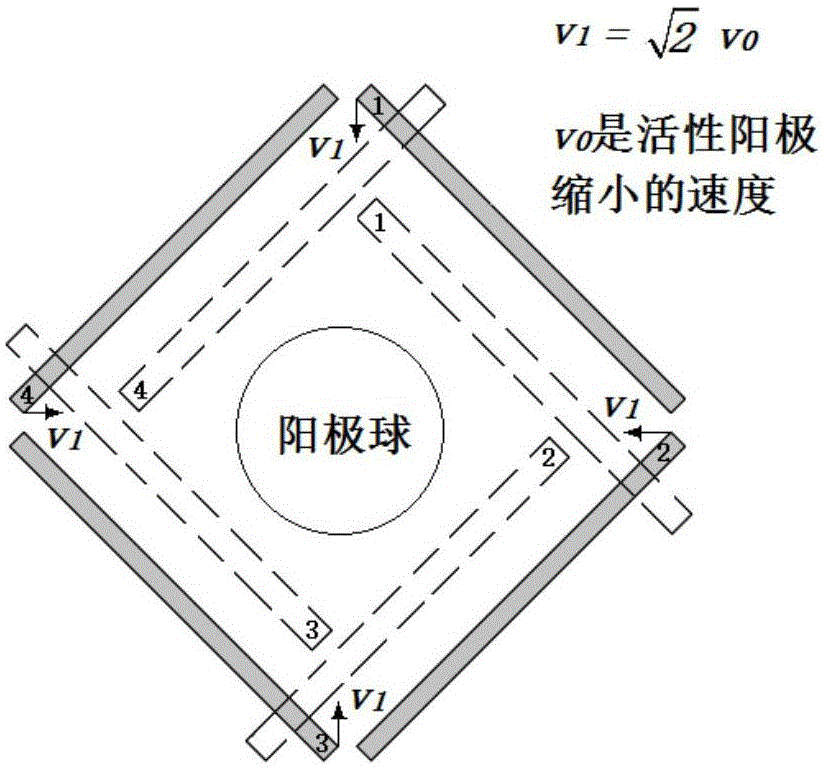

Following cathode device with distance between following cathode device and active anode kept unchanged and application of following cathode device

ActiveCN105040037ANo loss of effective areaLower resistanceElectrodesElectrical resistance and conductanceDiagonal

The invention belongs to the technical field of electrochemical electrolysis, and particularly relates to a following cathode device with the distance between the following cathode device and an active anode kept unchanged and application of the following cathode device. The cathode device comprises four special-shaped flat plates. The special-shaped flat plates are arranged according to the four edges of the external square of the active anode. When the active anode is shrunk, the special-shaped flat plates move along the diagonal lines of the square towards center of the square. The moving speeds of the four special-shaped flat plates are the same and are square root of 2 times of the shrinkage speed of the active anode. The following cathode device can be used as a cathode when high-temperature reactor fuel element matrix graphite is disassembled through an electrochemical intercalation method. The following cathode device is simple in structure, the effective area of a cathode pole plate is large, the distance between the cathode and the anode is kept unchanged in the whole electrolysis process, and resistance in the electrolysis process is effectively reduced.

Owner:TSINGHUA UNIV

Amorphous and partially amorphous nanoscale ion storage materials

ActiveUS8158090B2PhosphatesPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesHigh energyPhosphate

Amorphous or partially amorphous nanoscale ion storage materials are provided. For example, lithium transition metal phosphate storage compounds are nanoscale and amorphous or partially amorphous in an as-prepared state, or become amorphous or partially amorphous upon electrochemical intercalation or de-intercalation by lithium. These nanoscale ion storage materials are useful for producing devices such as high energy and high power storage batteries.

Owner:LITHIUM WERKS TECH BV

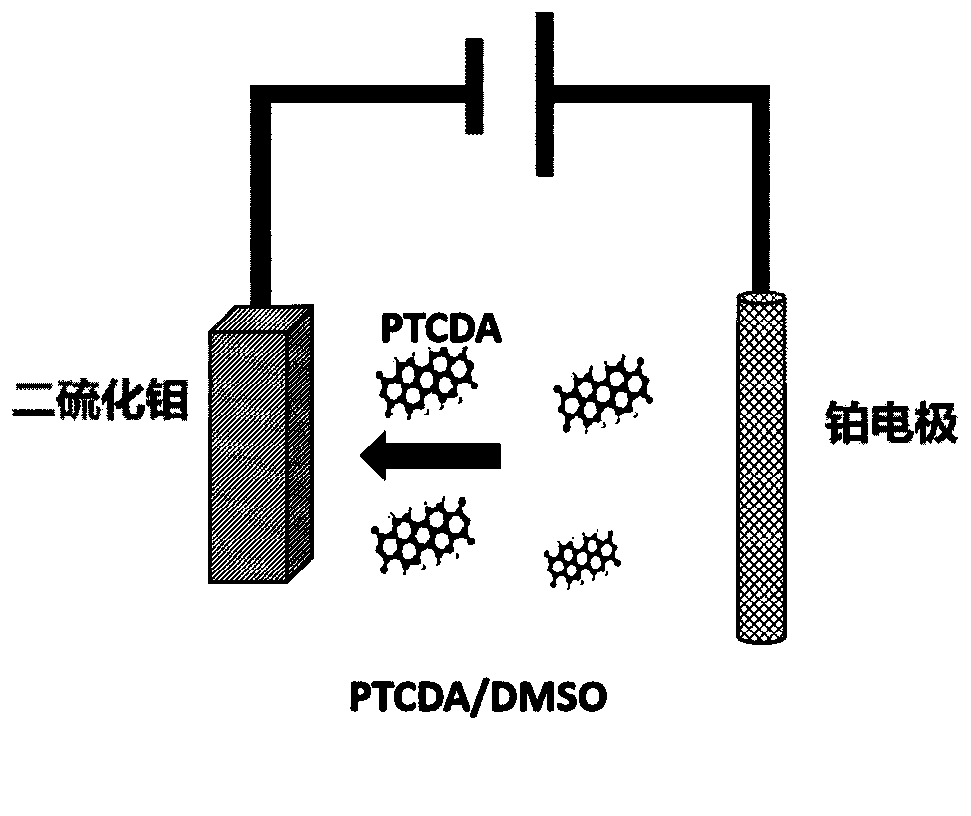

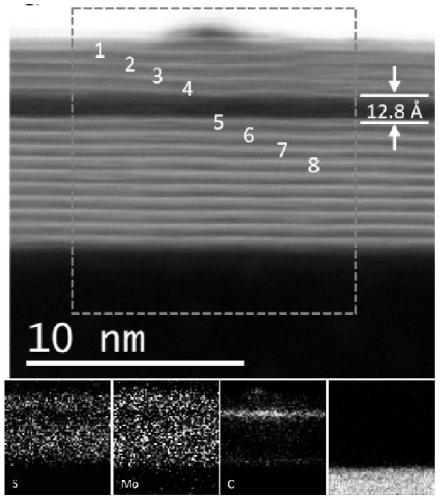

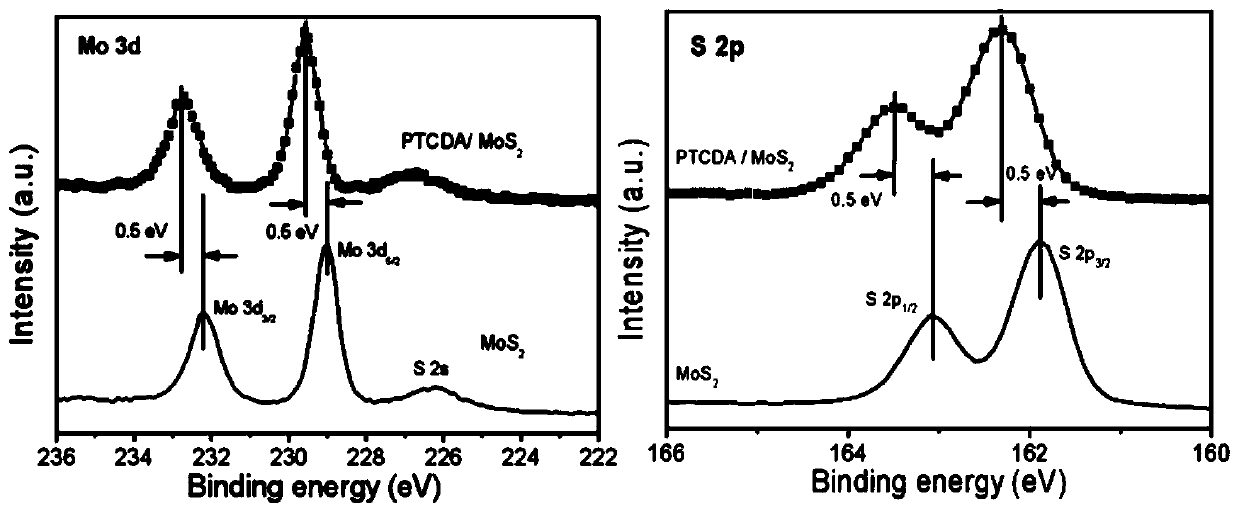

Preparation method and application of organic-inorganic heterojunction

ActiveCN111430540AHigh electron mobilityWon't hurtSolid-state devicesSemiconductor/solid-state device manufacturingHeterojunctionOrganic layer

The invention discloses a preparation method and application of an organic-inorganic heterojunction. The preparation method is characterized by adopting an electrochemical intercalation method, takinga two-dimensional organic molecule solution as an electrolyte and a two-dimensional inorganic crystal as a working electrode, constructing an electrochemical system, embedding the two-dimensional organic molecules with optical or electrical properties into the two-dimensional inorganic crystal under the current action, and obtaining an inorganic-organic-inorganic sandwich heterostructure. According to the method, the preparation of the organic-inorganic heterojunction is achieved, the prepared organic-inorganic heterojunction is of the inorganic-organic-inorganic sandwich structure, an inorganic protective layer is further arranged outside the organic layer and is not directly exposed outside, and when the organic-inorganic heterojunction is used for preparing the electronic devices, thesmall organic molecules cannot be damaged. The prepared organic-inorganic heterojunction can be used as a channel material of the electronic device, so that the contact barrier with an electrode can be effectively reduced or eliminated, and the device can have higher electron mobility.

Owner:NANJING UNIV

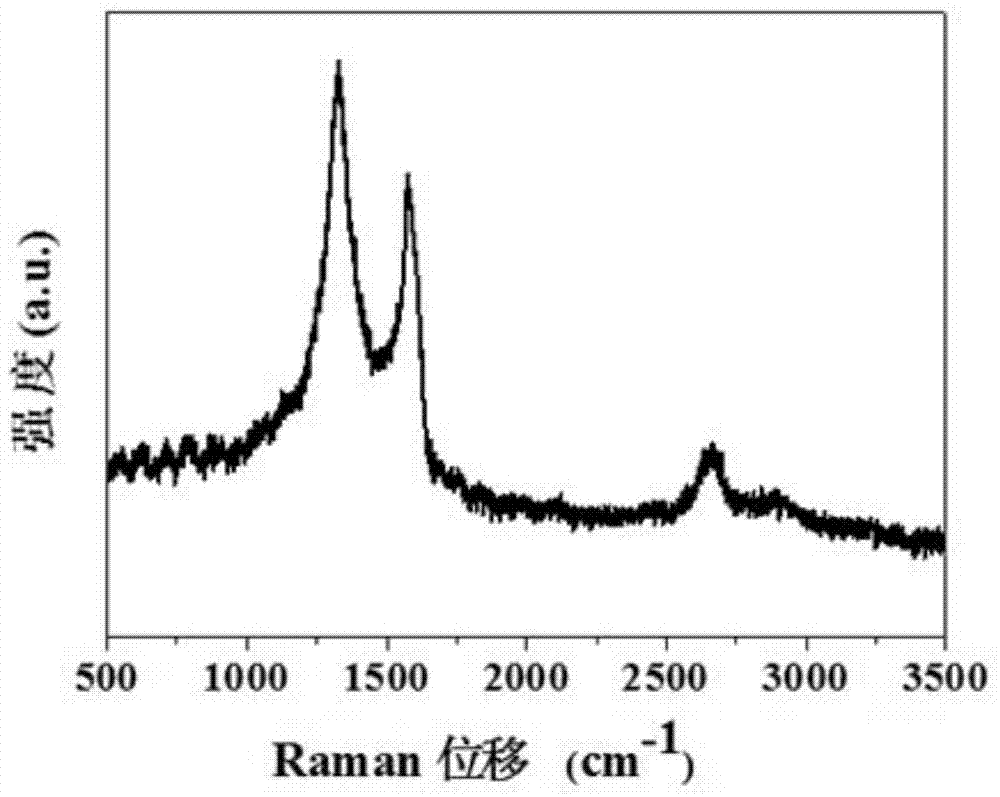

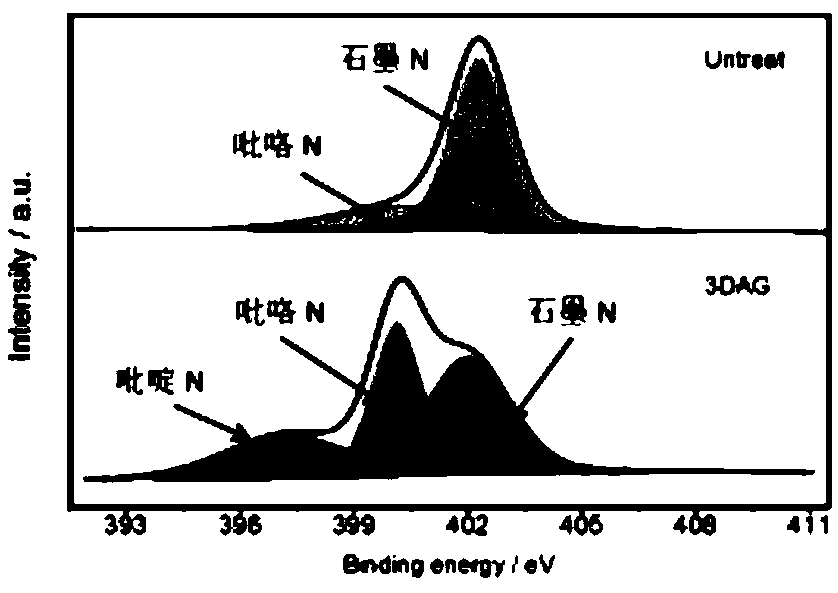

N-doped graphene and preparation method thereof

The invention relates to the field of nanomaterials, in particular to N-doped graphene and a preparation method thereof. The preparation method of N-doped graphene comprises following steps: step 1, graphite is subjected to electrochemical intercalation, and expanded graphite is obtained; step 2, expanded graphite and an N source are mixed and heated to 100-800 DEG C, a mixture is annealed, and N-doped graphene is obtained. The invention further provides N-doped graphene prepared with the method. According to N-doped graphene and the preparation method thereof, the technical problems of lowerpurity and poorer performance of a graphene material prepared with an existing graphene preparation method which is higher in cost and complicated in preparation process are solved.

Owner:GUANGDONG POWER GRID CO LTD +1

Method for electrochemically preparing graphene

The invention discloses a method for electrochemically preparing graphene, which preferably comprises the steps of pressing a high-purity graphite raw material to form a graphite electrode, carrying out anodization through the graphite electrode by using sulfuric acid aqueous solution or acetic acid and the like mixed acid solution as an electrolyte to prepare a graphite intercalation product, and obtaining expanded graphite by high temperature or microwave and other methods; and then pressing the expanded graphite to prepare a reaction electrode, and carrying out secondary electrochemical intercalation and expansion to finally obtain laminar graphene. According to the invention, in the preparing process, potassium permanganate and other strong oxidizers are not used, and the damage of the strong oxidizers to the structure and performance of graphene are avoided; alkali metal, fuming sulfuric acid oxydol and other inflammable and explosive dangerous substances are not used, and toxic or harmful substances are not introduced, so that the production is safe and environment friendly; and at the same time, the method is simple in process flow, easy to operate, low in cost, high in yield, mild in reaction conditions and low in energy consumption, and is suitable for industrialized large-scale production.

Owner:苏州格瑞丰纳米科技有限公司

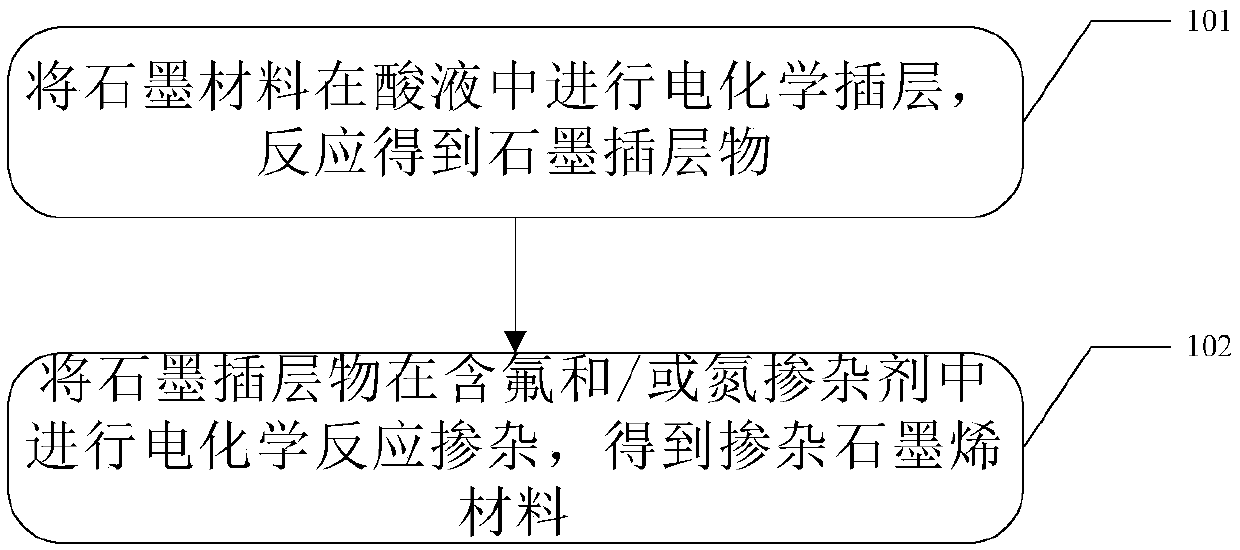

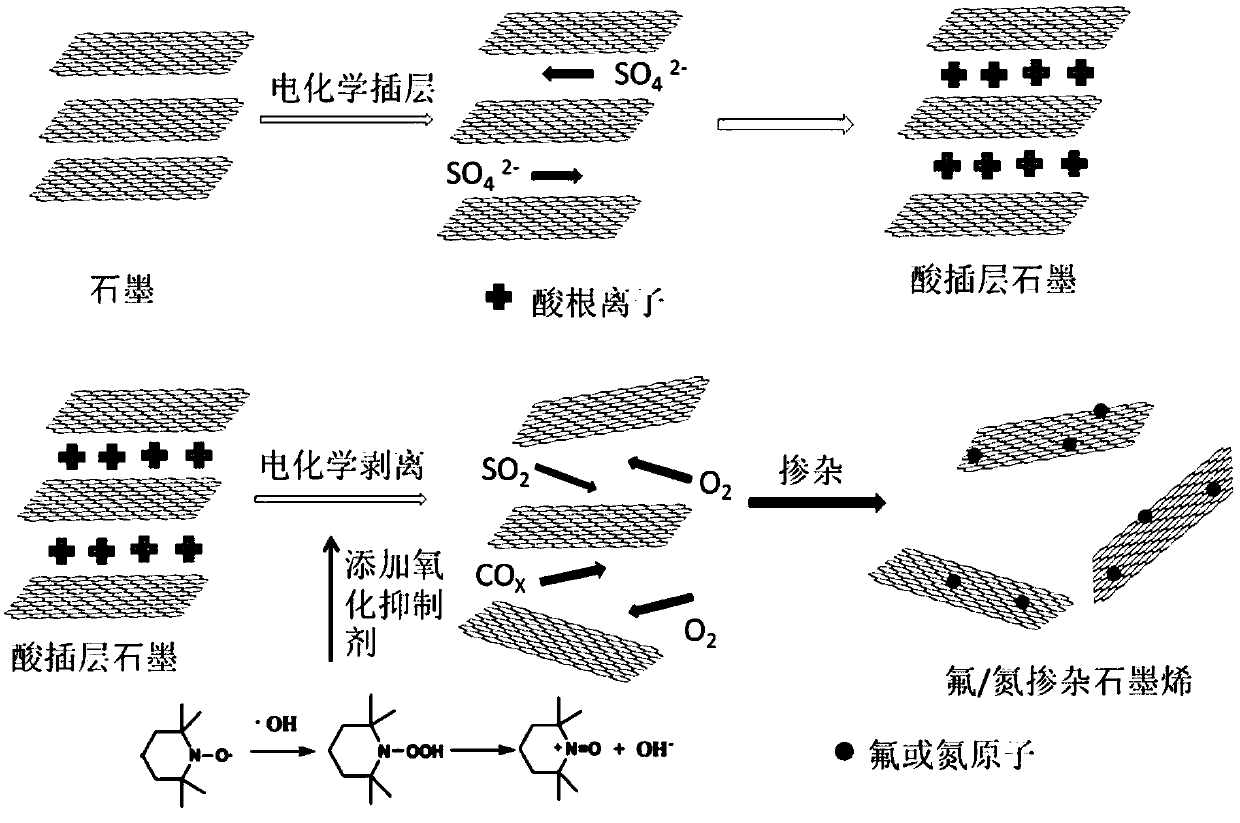

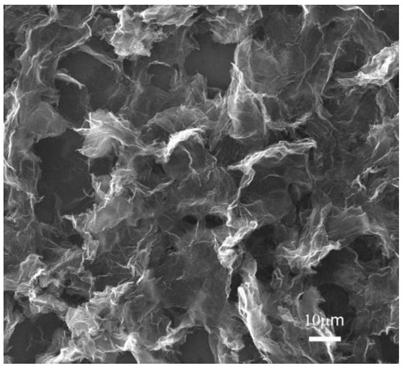

Doped graphene material and preparation method and application thereof

InactiveCN109607521AReduce oxygen contentHigh yieldPhysical/chemical process catalystsGrapheneElectrochemical responseDoped graphene

The invention discloses a doped graphene material and a preparation method and application thereof. The preparation method comprises the steps that a graphite material is subjected to electrochemicalintercalation in an acid liquor, and a reaction is carried out to obtain a graphite intercalation material; the graphite intercalation material is subjected to electrochemical reaction doping in a fluorine-containing and / or nitrogen-containing dopant, and the doped graphene material is obtained. The doped graphene material and the preparation method and application thereof have the advantages thatnitrogen-doped and fluorine-doped graphene has thin graphene sheet layers, low oxygen content, high yield and the like; the preparation conditions are controllable, the cost is low, and the preparation method is suitable for mass production; the prepared doped graphene has wide application prospects in energy storage devices, sensors, biomedicine, industrial catalysis and other fields.

Owner:NINGBO GRAPHENE INNOVATION CENT CO LTD

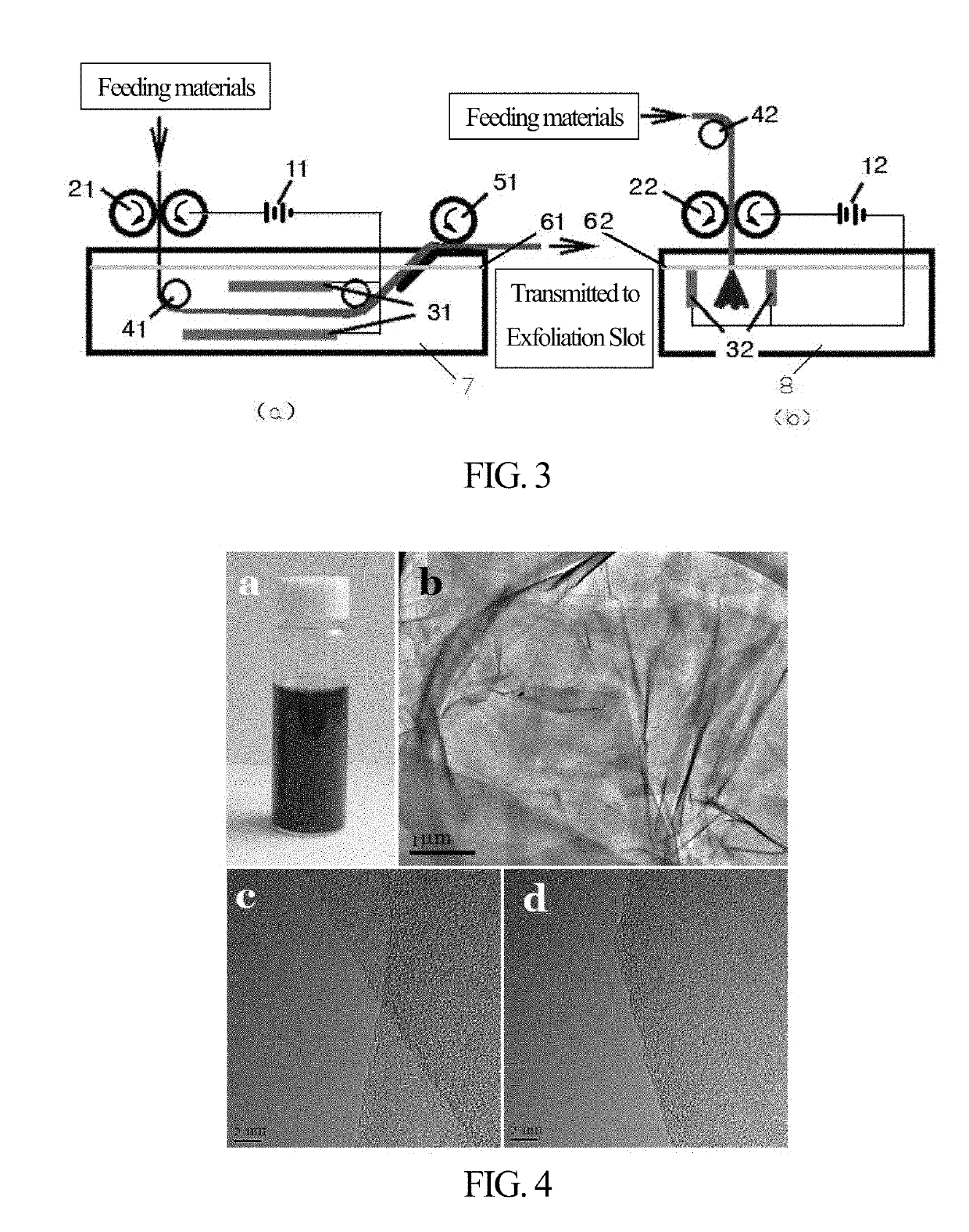

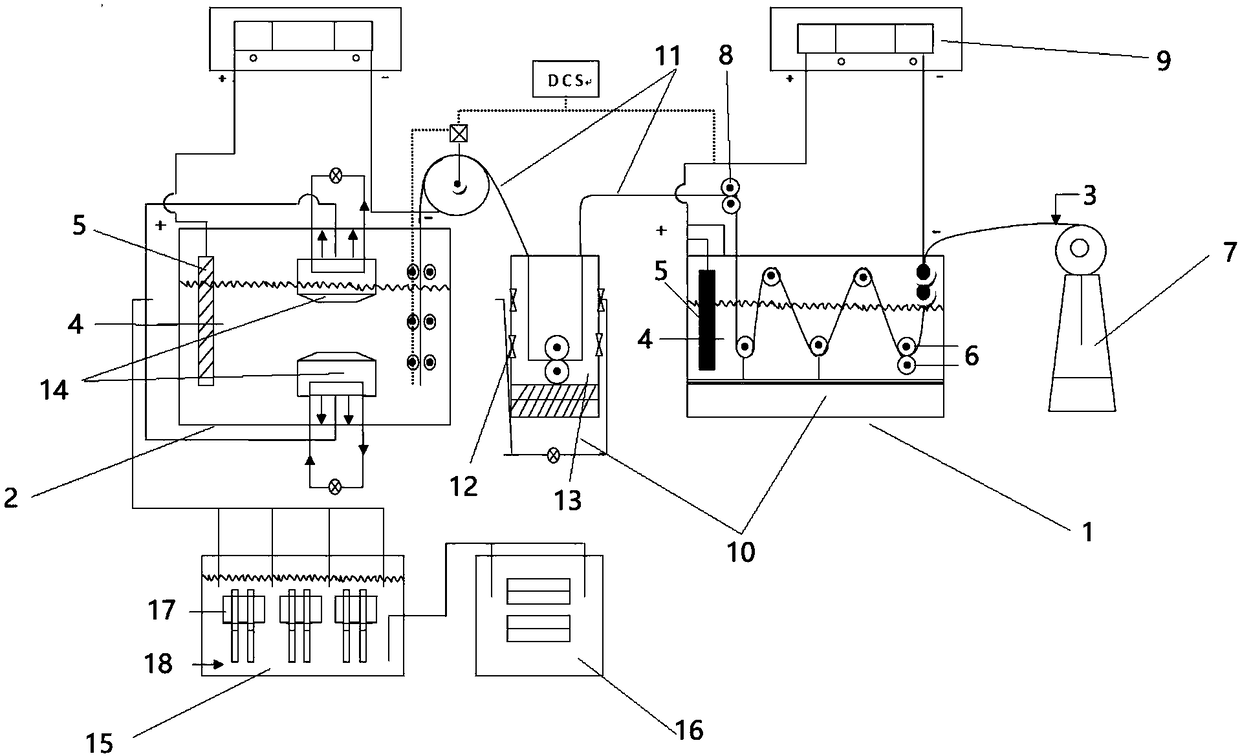

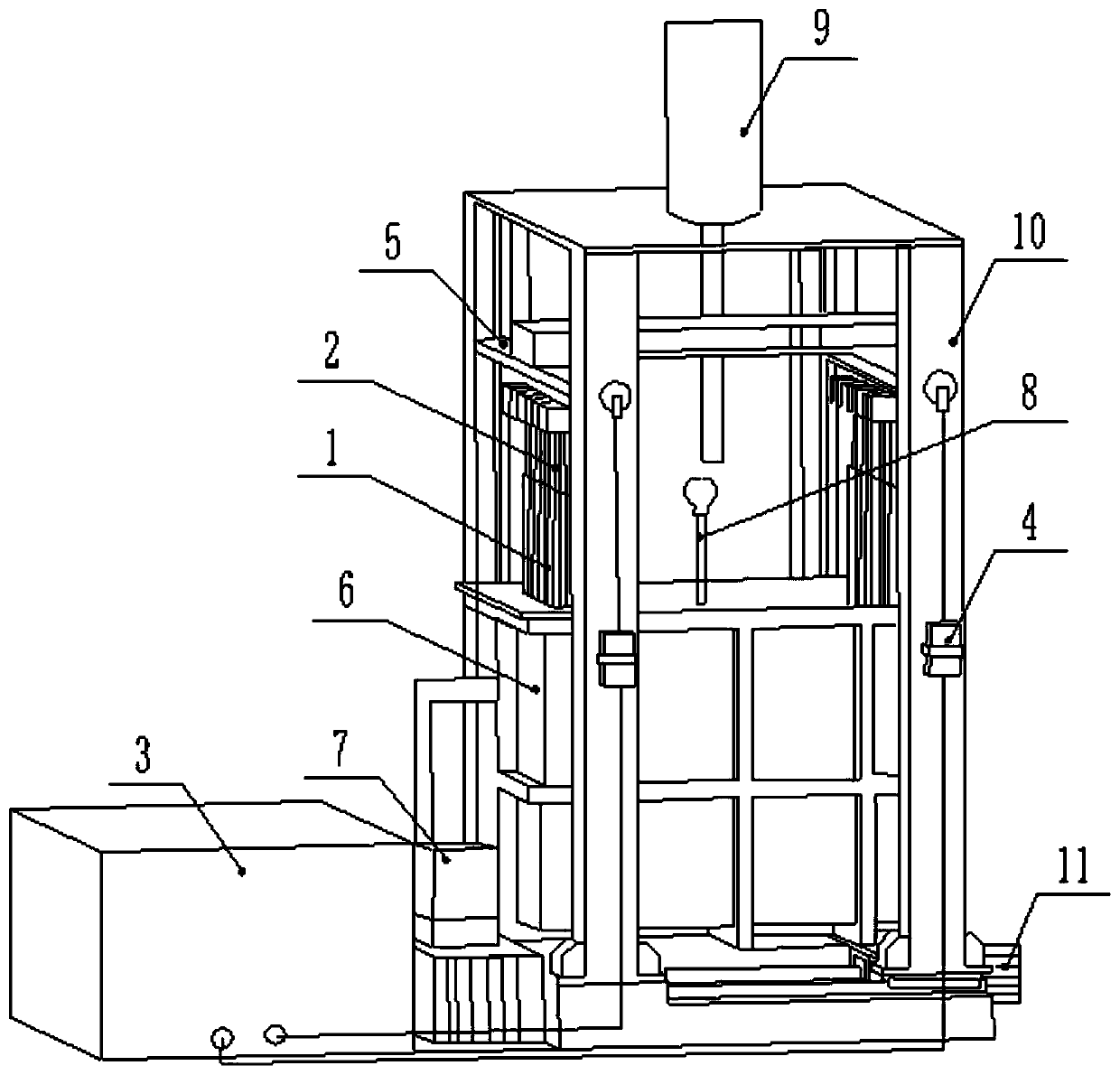

Device and method for one-step mass production of graphene by electrochemical process

PendingCN108117067APromote safe productionControllable and continuous productionGrapheneEnvironmental resistanceInorganic salts

The invention discloses a device and a method for one-step mass production of graphene by an electrochemical process. The device comprises an electrochemical intercalation slot and an electrochemicalstripping slot in sequence, wherein the electrochemical intercalation slot and the electrochemical stripping slot are filled with inorganic salt electrolyte; the positive electrodes of the electrochemical intercalation slot and the electrochemical stripping slot are metal bars; the negative electrode of the electrochemical intercalation slot is flexible graphene paper; the intercalated flexible graphene paper in the electrochemical intercalation slot is taken as the negative electrode of the electrochemical stripping slot; the electrochemical intercalation slot and the electrochemical stripping slot are connected with direct-current power supply equipment of 1.5V to 3V and direct-current power equipment of 8V to 11V respectively. Intercalation is performed in the electrochemical intercalation slot for a certain time to obtain strippable flexible graphene, then the strippable flexible graphene is introduced into the electrochemical stripping slot, and the intercalated flexible grapheneis stripped immediately at the moment when the intercalated flexible graphene enters the electrolyte, so that the flexible graphene is stripped into fewer-layer graphene. The graphene is produced in an electrochemical way, so that the device and the method have the advantages of great reduction in the environment pollution load, short time, low energy consumption, time saving and safety; an environment-friendly, safe and efficient process method and device for mass production of the graphene are realized.

Owner:北京新希望科技发展有限公司

Amorphous and partially amorphous nanoscale ion storage materials

Amorphous or partially amorphous nanoscale ion storage materials are provided. For example, lithium transition metal phosphate storage compounds are nanoscale and amorphous or partially amorphous in an as-prepared state, or become amorphous or partially amorphous upon electrochemical intercalation or de-intercalation by lithium. These nanoscale ion storage materials are useful for producing devices such as high energy and high power storage batteries.

Owner:LITHIUM WERKS TECH BV

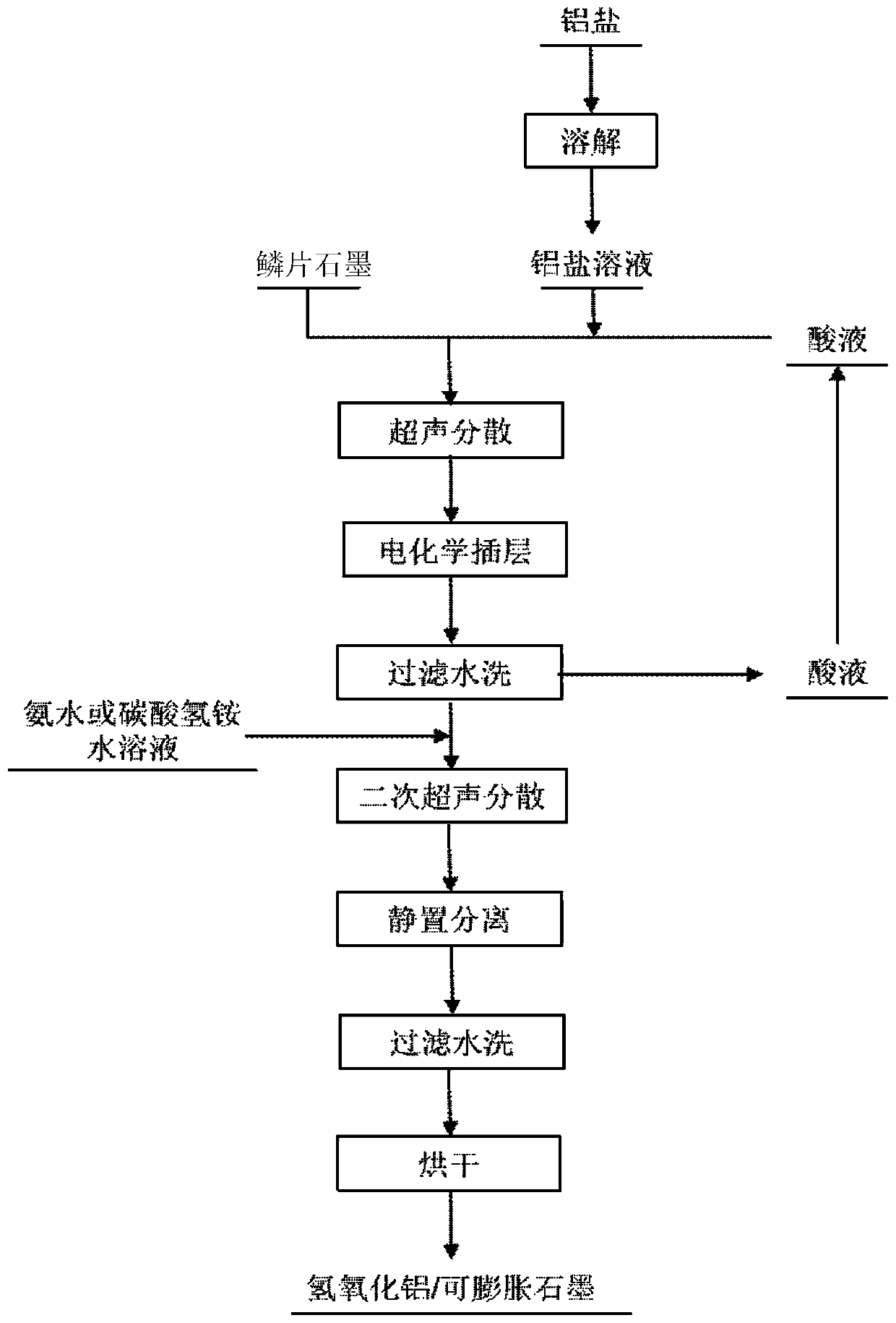

Preparation method of aluminum hydroxide/expandable graphite composite material

ActiveCN109972155AGood physical and chemical propertiesMaximize expansion volumeCellsGraphiteMaterials scienceFlake graphite

A preparation method of an aluminum hydroxide / expandable graphite composite material comprises following steps: (1) adding water into aluminum salts to prepare an aluminum salt solution; (2) mixing aperchloric acid solution and a glacial acetic acid solution, adding water, and mixing the mixed solution with flake graphite and the aluminum salt solution to prepare a turbid liquid; (3) introducingthe turbid liquid into a reactor, and carrying out electrochemical intercalation through a periodical direction changing method; (4) filtering the materials, and washing the materials by water to obtain a solid phase; (5) evenly mixing the solid phase with ammonia water or a water solution of ammonium bicarbonate; (6) carrying out a secondary ultrasonic dispersing treatment, carrying out separation to remove the upper-layer supernate, filtering, and performing water washing; and (7) performing drying to obtain the aluminum hydroxide / expandable graphite composite material. The raw materials aresimple, easily available and cheap; through an electrochemical intercalation method, the using amount of an oxidizing agent is reduced; the acid solution can be recovered and repeatedly used, the environmental pollution is small, the cost is low, and the technical process is simple and feasible.

Owner:NORTHEASTERN UNIV

Expandable graphite preparation device and electrochemical intercalation method thereof

The invention discloses an expandable graphite preparation device and an electrochemical intercalation method thereof, and belongs to the field of crystalline flake graphite electrochemical intercalation. The device comprises a wrapping pocket, an electrode, a direct current voltage-stabilizing and current-stabilizing power supply, a quick plug connector, a cross beam, an electrolytic cell, a circulating cooling device, a thermocouple, a first servo motor, a support frame and a second servo motor. The method comprises the steps of preparation of a chemical electrolyte, bag filling of natural crystalline flake graphite, electrode assembly and electrochemical intercalation preparation, electrochemical intercalation treatment, and treatment of an intercalation compound. According to the method, natural crystalline flake graphite can be efficiently intercalated to prepare expandable graphite, the prepared expandable graphite does not generate smoke and irritant gas in the microwave expansion and high-temperature expansion processes, and the expansion ratio can reach 200-300 mg / L. The problems of production safety and environmental pollution related to expandable graphite preparation can be solved from the source, large-scale preparation and engineering application of expandable graphite can be actively promoted, and the market application prospect is wide.

Owner:鹰领航空高端装备技术秦皇岛有限公司

Electrochemical production of graphene sheets from coke or coal

A method of producing graphene sheets from coke or coal powder, comprising: (a) forming an intercalated coke or coal compound by electrochemical intercalation conducted in an intercalation reactor, which contains (i) a liquid solution electrolyte comprising an intercalating agent; (ii) a working electrode that contains the powder in ionic contact with the liquid electrolyte, wherein the coke or coal powder is selected from petroleum coke, coal-derived coke, meso-phase coke, synthetic coke, leonardite, lignite coal, or natural coal mineral powder; and (iii) a counter electrode in ionic contact with the electrolyte, and wherein a current is imposed upon the working electrode and the counter electrode for effecting electrochemical intercalation of the intercalating agent into the powder; and (b) exfoliating and separating graphene planes from the intercalated coke or coal compound using an ultrasonication, thermal shock exposure, mechanical shearing treatment, or a combination thereof to produce isolated graphene sheets.

Owner:GLOBAL GRAPHENE GRP INC

Solid-liquid composite based on electrochemical intercalated graphite and preparation method and application thereof

ActiveCN106367159AReduce the impactImprove the lubrication effectGraphiteBase-materialsSynthesis methodsCarbon chain

The invention provides a solid-liquid composite based on electrochemical intercalated graphite and a preparation method and application thereof and belongs to the technical field of lubricating materials and preparation thereof. According to the composite, a graphite material serves as a body, preparation is carried out through an electrochemical three-electrode system, alkylammonium salt cations containing different carbon chain lengths and molecules of a dimethyl sulfoxide solvent are inserted between layers of the graphite material, and all the layers are periodically stacked together. The simple electrochemical synthesis method is adopted, and the method is simple in process, high in efficiency and low in influence on environments; the prepared electrochemical intercalated graphite serves as a lubricating material, and has high lubricating performance.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com