Preparation method of aluminum hydroxide/expandable graphite composite material

A technology of expanded graphite and composite materials, applied in the field of materials, can solve the problems of difficult recovery of chloroform and unsaturated compounds, deterioration of mechanical properties of high polymers, hindering industrial production, etc., and achieves simple and feasible process, low cost and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

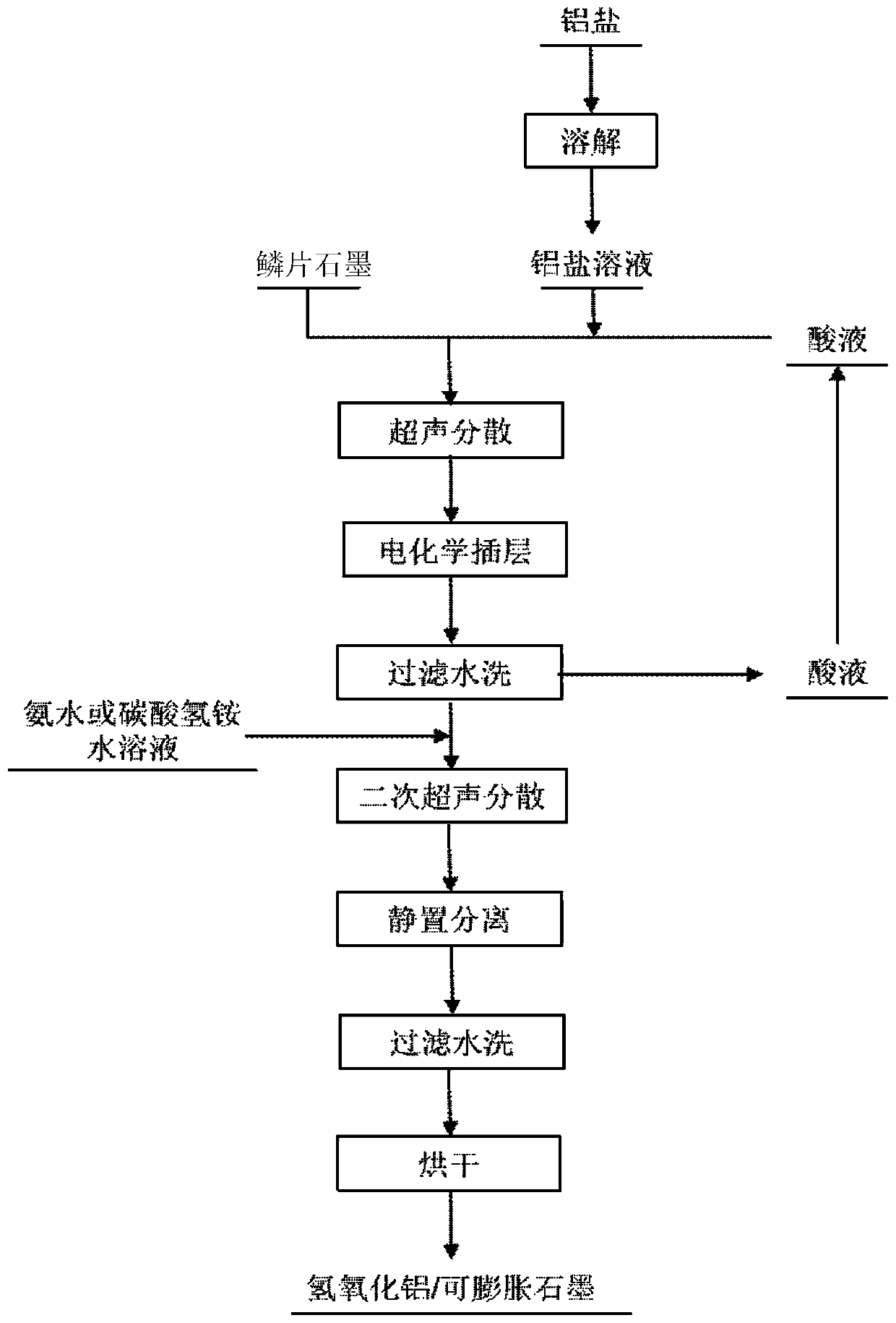

[0036] Process such as figure 1 shown;

[0037] Aluminum chloride is added with water to make a mass concentration of 10% aluminum chloride solution;

[0038] Mix perchloric acid solution and glacial acetic acid solution and then dilute with water to prepare an acid solution with a mass fraction of 80%, wherein the volume ratio of perchloric acid solution and glacial acetic acid solution is 1:1; the perchloric acid solution The mass concentration of the glacial acetic acid solution is 70%, and the mass concentration of the glacial acetic acid solution is 98%; the flake graphite, aluminum chloride solution and acid solution with a particle size of 50 to 200 meshes are mixed in a mass ratio of 1:1:10, and then ultrasonically dispersed. Time 100min, made suspension;

[0039] The suspension is introduced into the reaction tank; the reaction tank is provided with a diaphragm, and the inside of the reaction tank is divided into a cathode area and an anode area, and the cathode are...

Embodiment 2

[0045] Method is with embodiment 1, and difference is:

[0046] (1) aluminum chloride solution mass concentration 20%;

[0047] (2) The mass fraction of acid solution is 30%, and the volume ratio of perchloric acid solution and glacial acetic acid solution is 10:1; the flake graphite, aluminum chloride solution and acid solution are mixed in a mass ratio of 1:10:50, and ultrasonically dispersed 10min;

[0048] (3) Electrochemical intercalation temperature 30°C, current density 1.0A / cm 2 , replace the positive and negative poles every 20 minutes; the time is 60 minutes;

[0049] (4) Mix the solid phase with the ammoniacal liquor of pH value 8.0, and the mixing ratio is 1:2 by making the mass ratio of the solid phase and the ammoniacal liquor;

[0050] (5) The second ultrasonic dispersion treatment time is 2h, then stand still for 20min;

[0051] (6) The secondary solid phase was dried at 200°C for 60 minutes, and the expansion volume of the aluminum hydroxide / expandable gra...

Embodiment 3

[0053] Method is with embodiment 1, and difference is:

[0054] (1) aluminum chloride solution mass concentration 30%;

[0055] (2) The mass fraction of acid solution is 50%, and the volume ratio of perchloric acid solution and glacial acetic acid solution is 5:1; the flake graphite, aluminum chloride solution and acid solution are mixed in a mass ratio of 1:5:30, and ultrasonically dispersed 50min;

[0056] (3) Electrochemical intercalation temperature 5°C, current density 0.5A / cm 2 , replace the positive and negative electrodes every 40 minutes; the time is 160 minutes;

[0057] (4) The solid phase is mixed evenly with the ammoniacal liquor of pH value 8.5, and the mixing ratio is 1:5 by making the mass ratio of the solid phase and the ammoniacal liquor;

[0058] (5) The second ultrasonic dispersion treatment time is 6h, then stand still for 30min;

[0059] (6) The secondary solid phase was dried at 100°C for 100 minutes, and the expansion volume of the aluminum hydroxid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Expansion volume | aaaaa | aaaaa |

| Expansion volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com