Graphene, graphene colloidal sol, graphene powder and preparation method and preparation device

A graphene powder and graphene technology, applied in the field of graphene, can solve the problems that restrict the development of graphene application, harsh reaction conditions, environmental pollution, etc., and achieve the goal of suitable process amplification and promotion, mild process conditions, and no pollutant emissions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] A preparation method for graphene hydrosol, comprising the steps of:

[0072] (1) Electrochemical intercalation and exfoliation of graphite:

[0073] Both the reaction electrode and the counter electrode are flexible graphite paper, with a size of 4cm×6cm×0.05cm; connected to an external DC power supply of 5V, the current is 0.5A; the electrolyte is 900mL of 0.1mol / L sodium sulfate solution, and add 3. 9725g of L-glutamic acid to make the concentration 0.03mol / L; control the reaction temperature to 15°C, perform electrochemical stripping for 3 hours, and obtain graphene dispersed in the electrolyte;

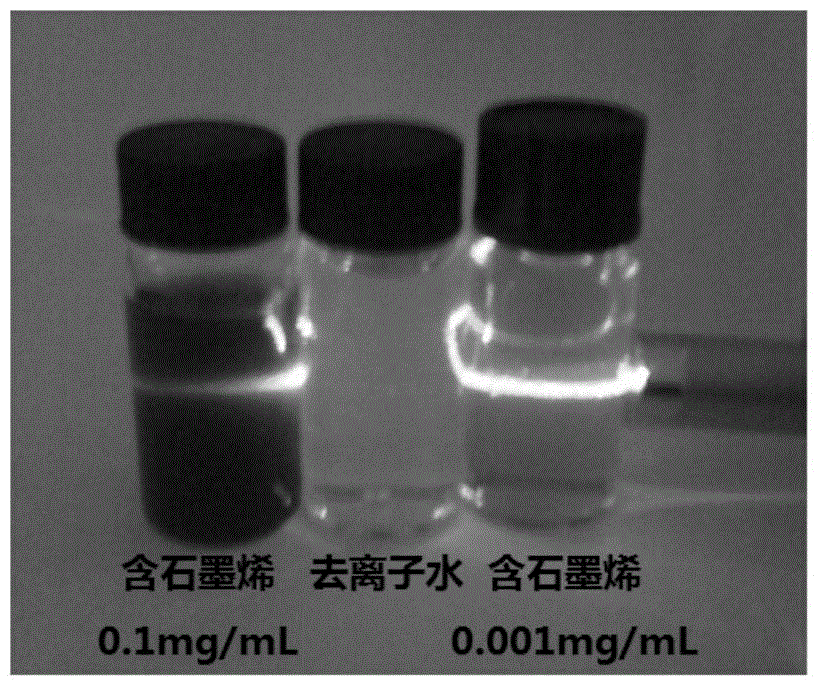

[0074] (2) Remove inorganic salts and amino acids: the graphene dispersed in the electrolyte obtained in step (1) is suction filtered, and the excess electrolyte is washed away with deionized water; then centrifuged at 2000rpm for 10min to remove unintercalated or insufficiently intercalated Graphite microflakes; finally add deionized water and ultrasonic treatment for 2 ...

Embodiment 2

[0086] A preparation method for graphene hydrosol, comprising the steps of:

[0087] (1) Electrochemical intercalation and exfoliation of graphite:

[0088] Both the reaction electrode and the counter electrode are flexible graphite paper, with a size of 4cm×6cm×0.05cm; connected to an external DC power supply of 5V, the current is 0.5A; the electrolyte is 900mL of 0.2mol / L ammonium nitrate solution, and added 7. 4334g of phenylalanine to make the concentration 0.05mol / L; control the reaction temperature to 10°C, perform electrochemistry for 3 hours, and obtain graphene dispersed in the electrolyte;

[0089] (2) Remove inorganic salts and amino acids: the graphene dispersed in the electrolyte obtained in step (1) is suction filtered, and the excess electrolyte is washed away with deionized water; then centrifuged at 2000rpm for 10min to remove unintercalated or insufficiently intercalated Graphite microflakes; finally ultrasonic treatment for 2 hours to prepare a graphene hyd...

Embodiment 3

[0094] A kind of preparation method of graphene hydrosol, the difference with embodiment 1 is:

[0095] In the electrolytic cell of electrochemical intercalation, a 50mT magnetic field is applied; wherein the graphene sol system prepared by step (2) is denoted as sol ④, and wherein the concentration of graphene is 1.5mg / mL;

[0096] The product yield of the present embodiment improves 15% compared with embodiment 1;

[0097] Performance Testing:

[0098] The graphene C / O ratio is 11.59; the mass fraction of graphene carbon is 91.6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com