Patents

Literature

139results about How to "Improve power storage capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

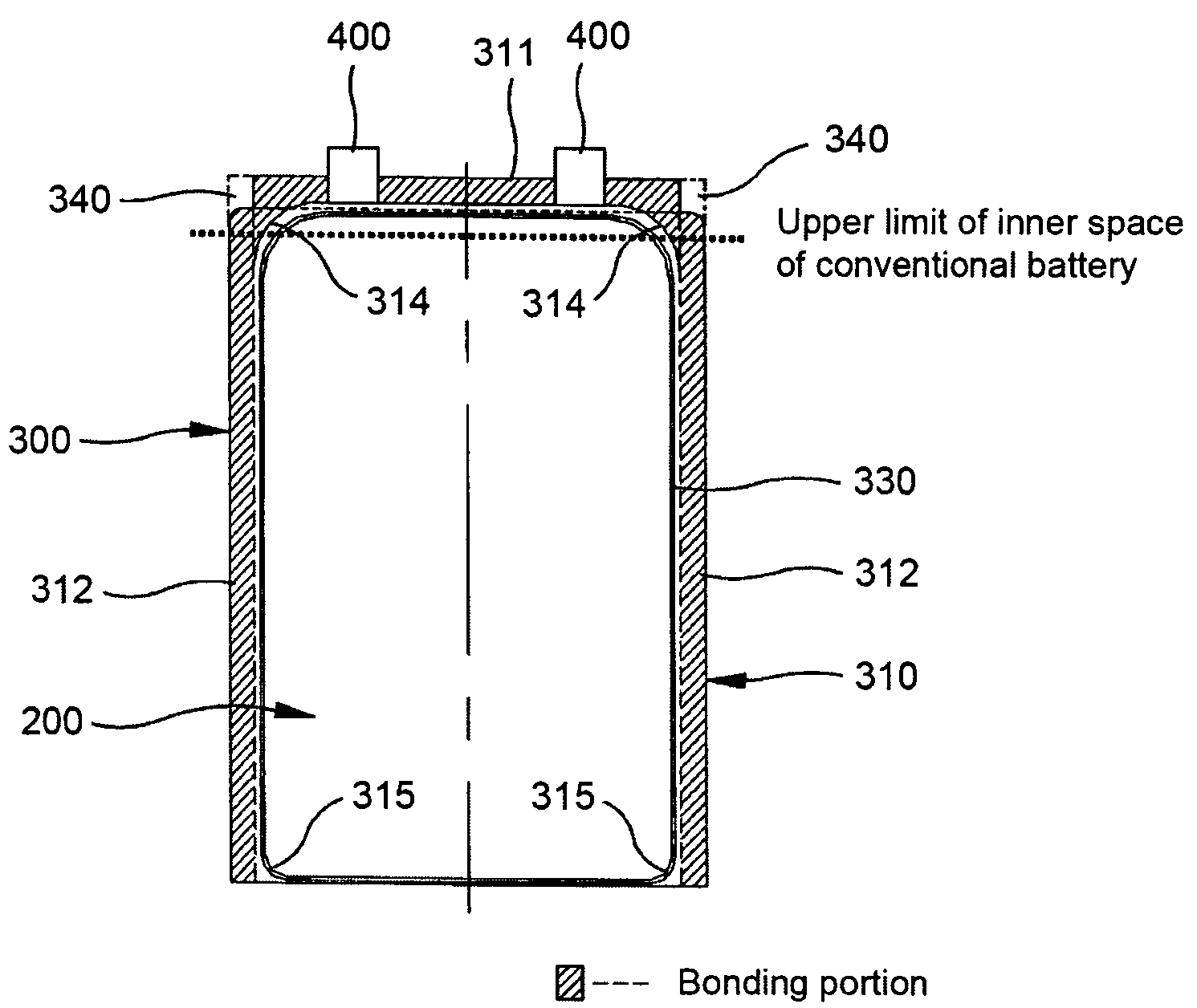

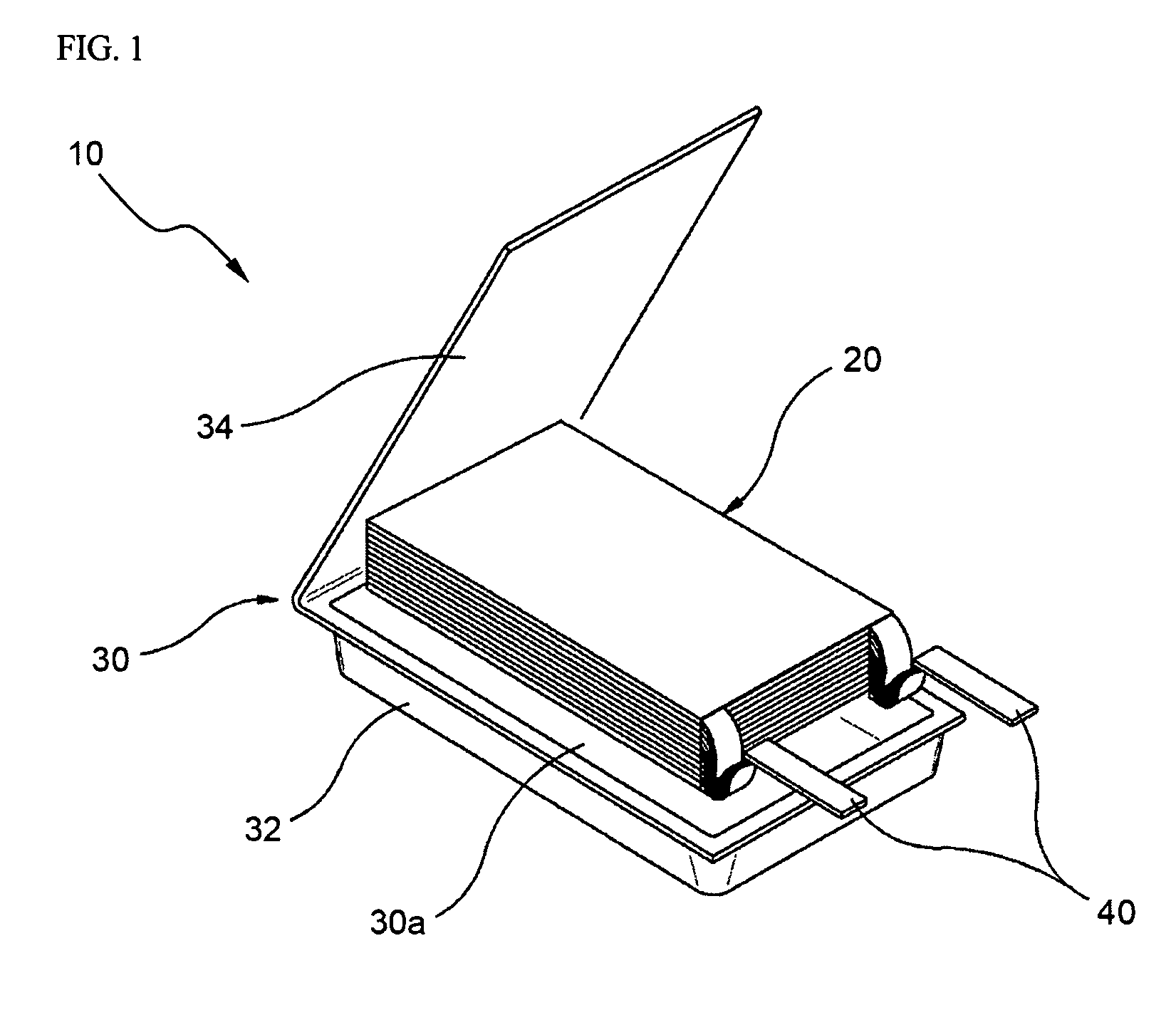

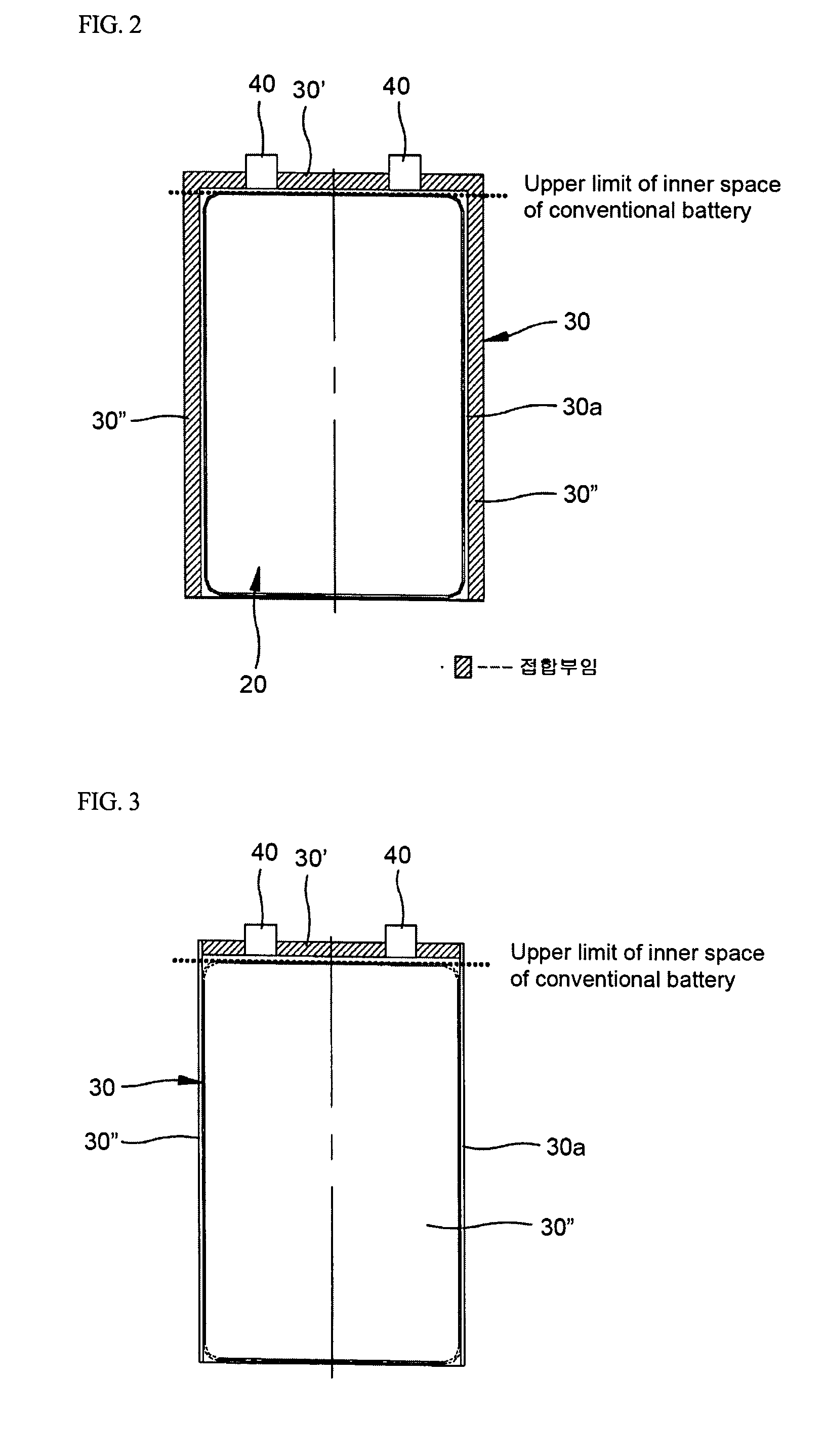

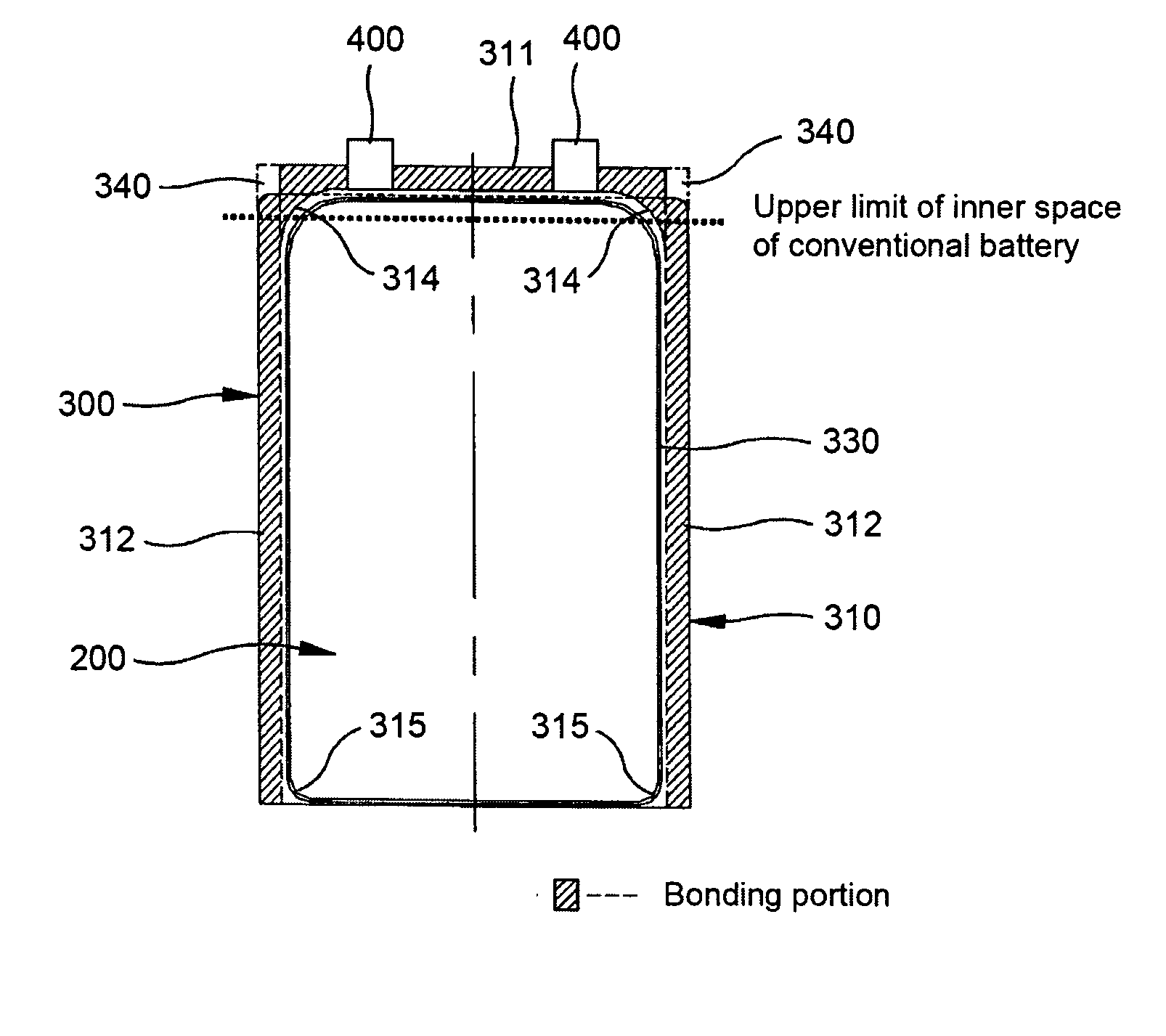

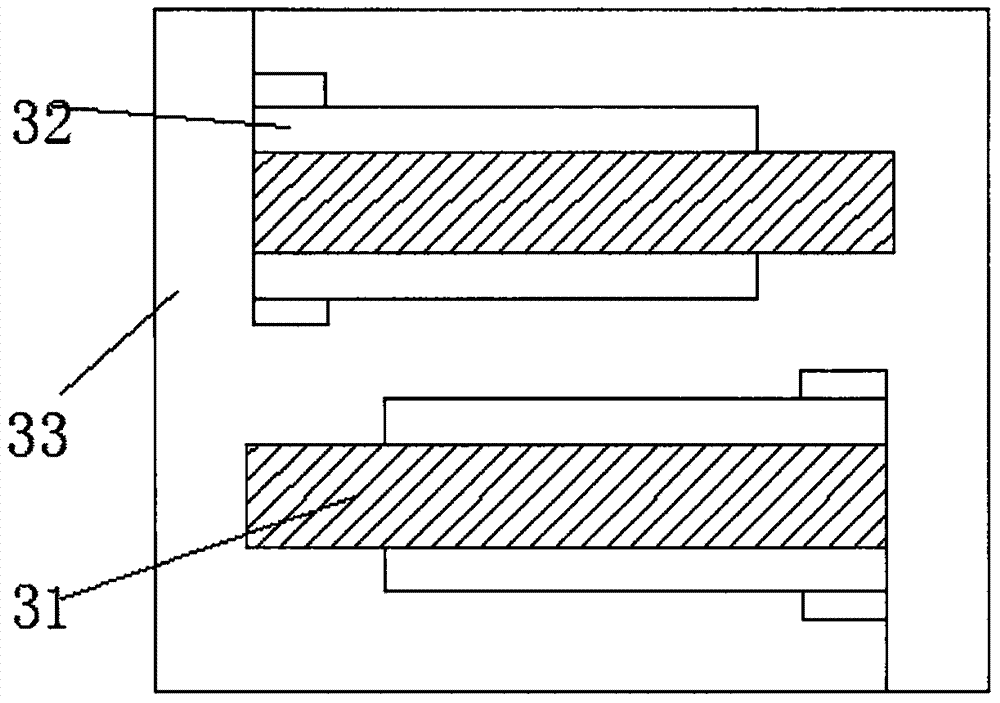

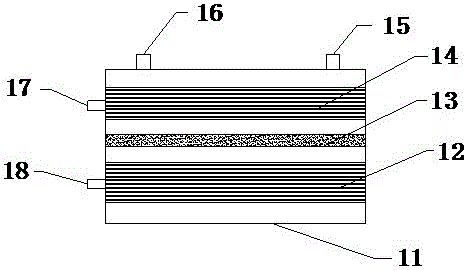

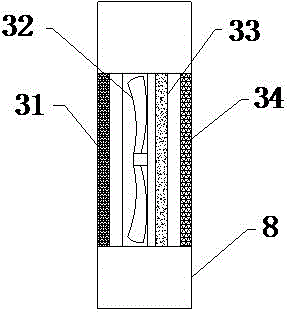

Battery having specific package structure

ActiveUS7595132B2Improve power storage capacityEasy to foldFinal product manufactureSmall-sized cells cases/jacketsEngineeringElectrolyte

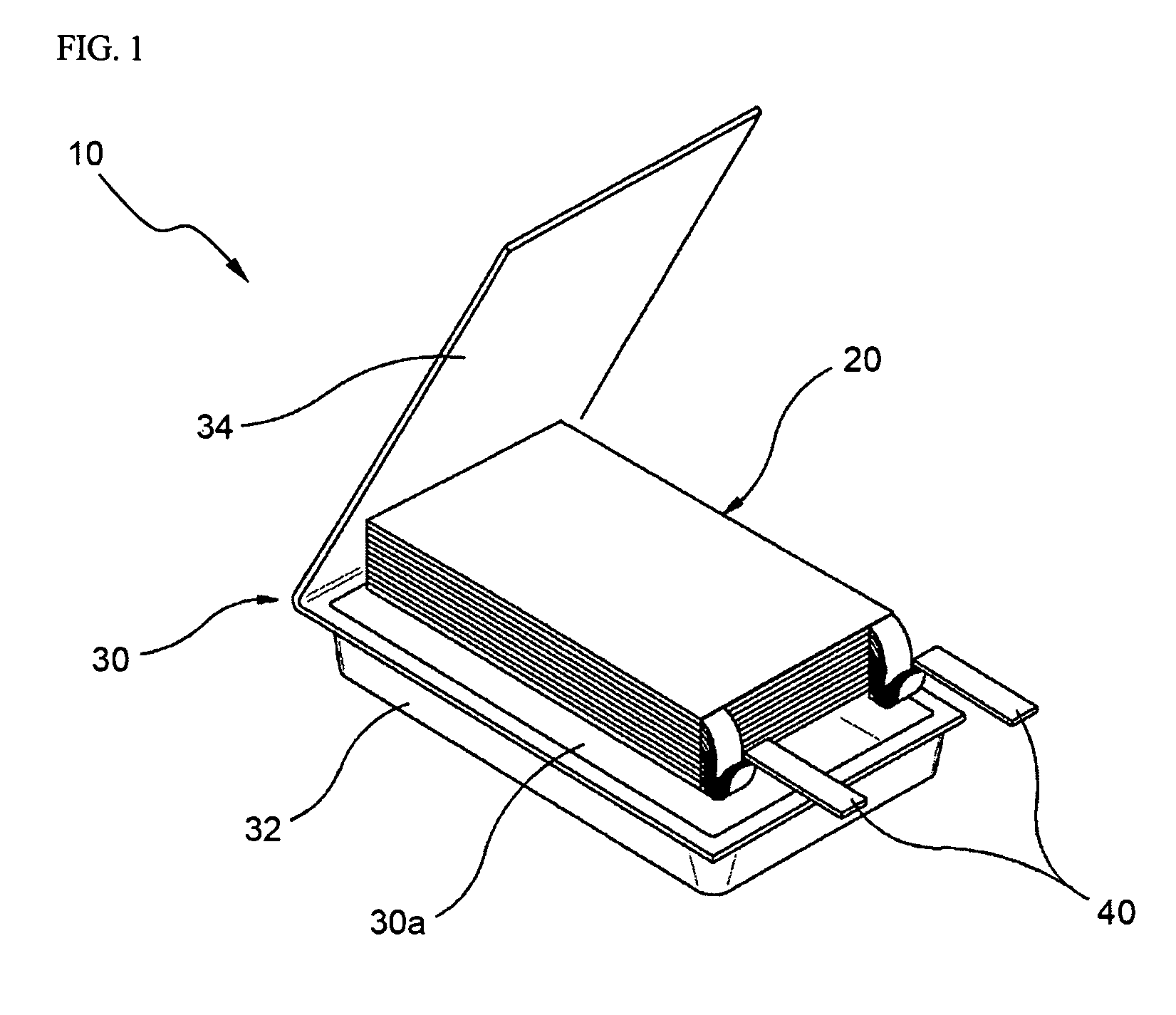

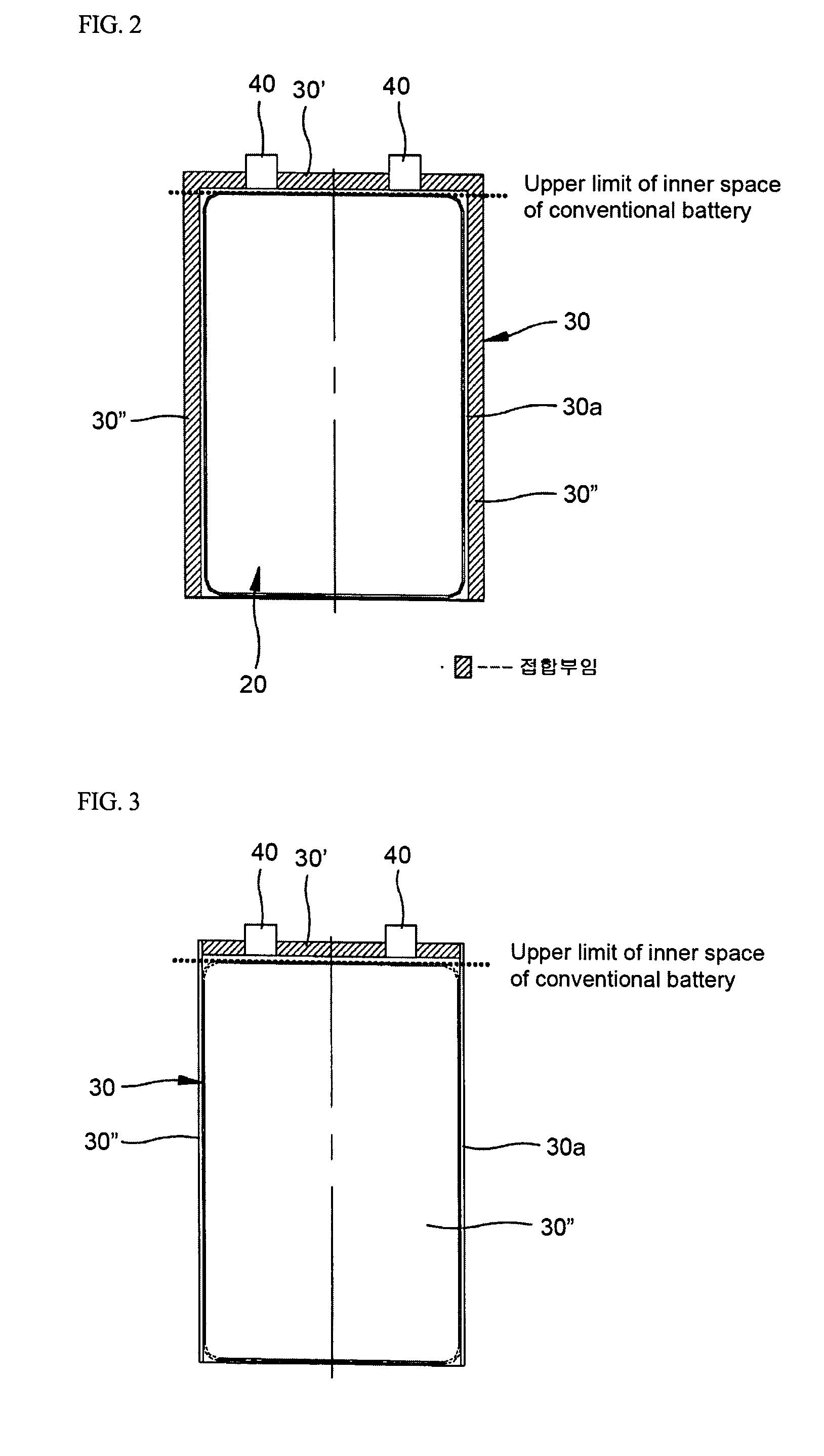

The present invention provides a battery having a structure for increasing the power storage capacity and output thereof In accordance with the present invention, in a battery comprising an electrode assembly including anode plates, cathode plates and separators; and a battery case, both side bonding portions of which are folded toward adjacent sides thereof, for accommodating the electrode assembly and a designated amount of electrolyte, and sealing the electrode assembly such that two electrode terminals connected to corresponding electrode taps of the anode and cathode plates of the electrode assembly are exposed to the outside, an upper bonding portion of the battery case is folded toward the upper end of the battery case, and / or common portions of the upper bonding portion and both side portions of the battery case are cut off, and / or inner corners corresponding to the upper bonding portion have larger radiuses of curvature, and / or receipt portions for receiving the electrode assembly are respectively formed in upper and lower bodies of the battery case. The battery having the above structure has high power storage capacity and output at the same size of the battery package, and high sealing capacity and safety.

Owner:LG ENERGY SOLUTION LTD

Battery having specific package structure

ActiveUS20050191549A1Improve power storage capacityHigh outputFinal product manufactureSmall-sized cells cases/jacketsPower storageElectrolyte

The present invention provides a battery having a structure for increasing the power storage capacity and output thereof In accordance with the present invention, in a battery comprising an electrode assembly including anode plates, cathode plates and separators; and a battery case, both side bonding portions of which are folded toward adjacent sides thereof, for accommodating the electrode assembly and a designated amount of electrolyte, and sealing the electrode assembly such that two electrode terminals connected to corresponding electrode taps of the anode and cathode plates of the electrode assembly are exposed to the outside, an upper bonding portion of the battery case is folded toward the upper end of the battery case, and / or common portions of the upper bonding portion and both side portions of the battery case are cut off, and / or inner corners corresponding to the upper bonding portion have larger radiuses of curvature, and / or receipt portions for receiving the electrode assembly are respectively formed in upper and lower bodies of the battery case. The battery having the above structure has high power storage capacity and output at the same size of the battery package, and high sealing capacity and safety.

Owner:LG ENERGY SOLUTION LTD

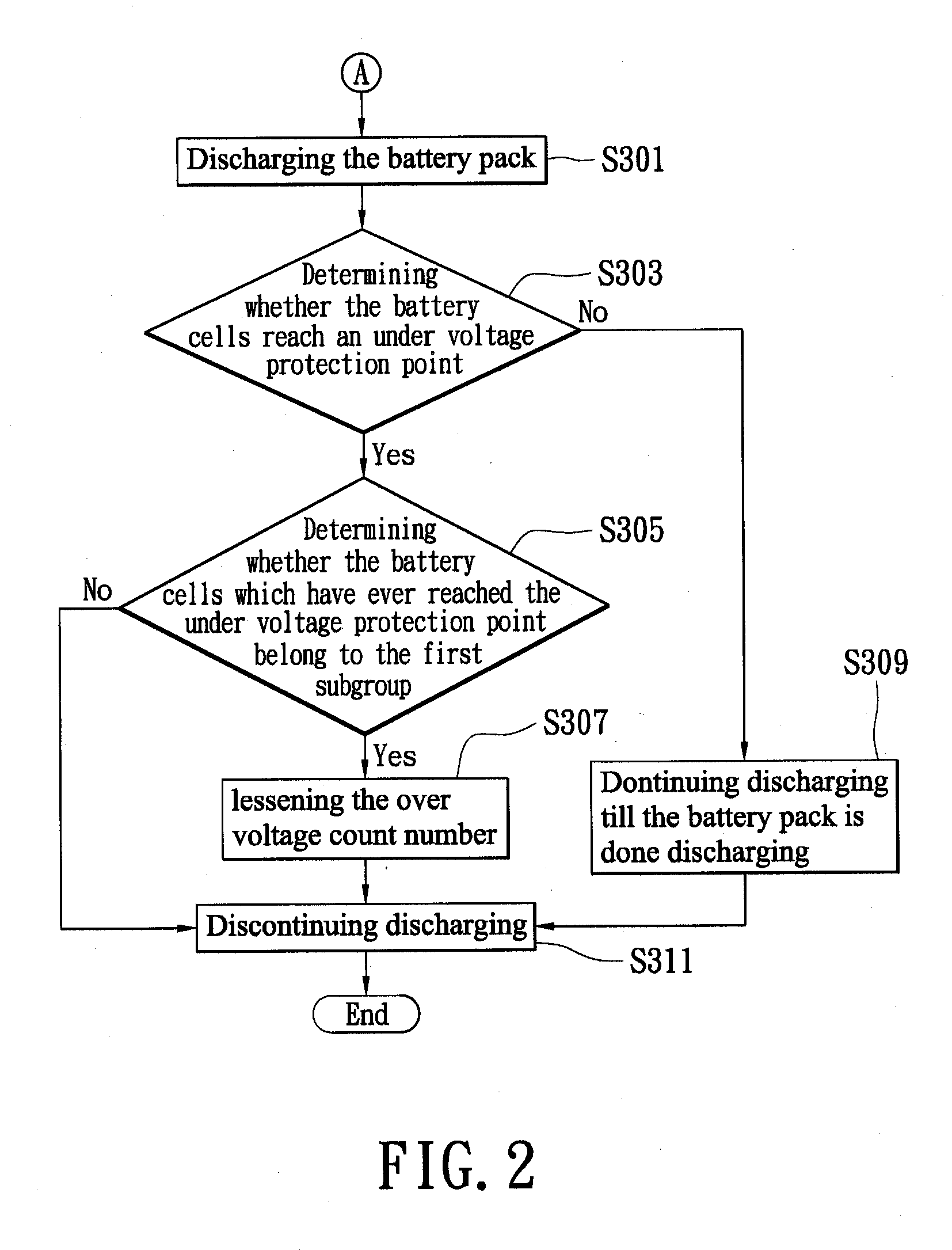

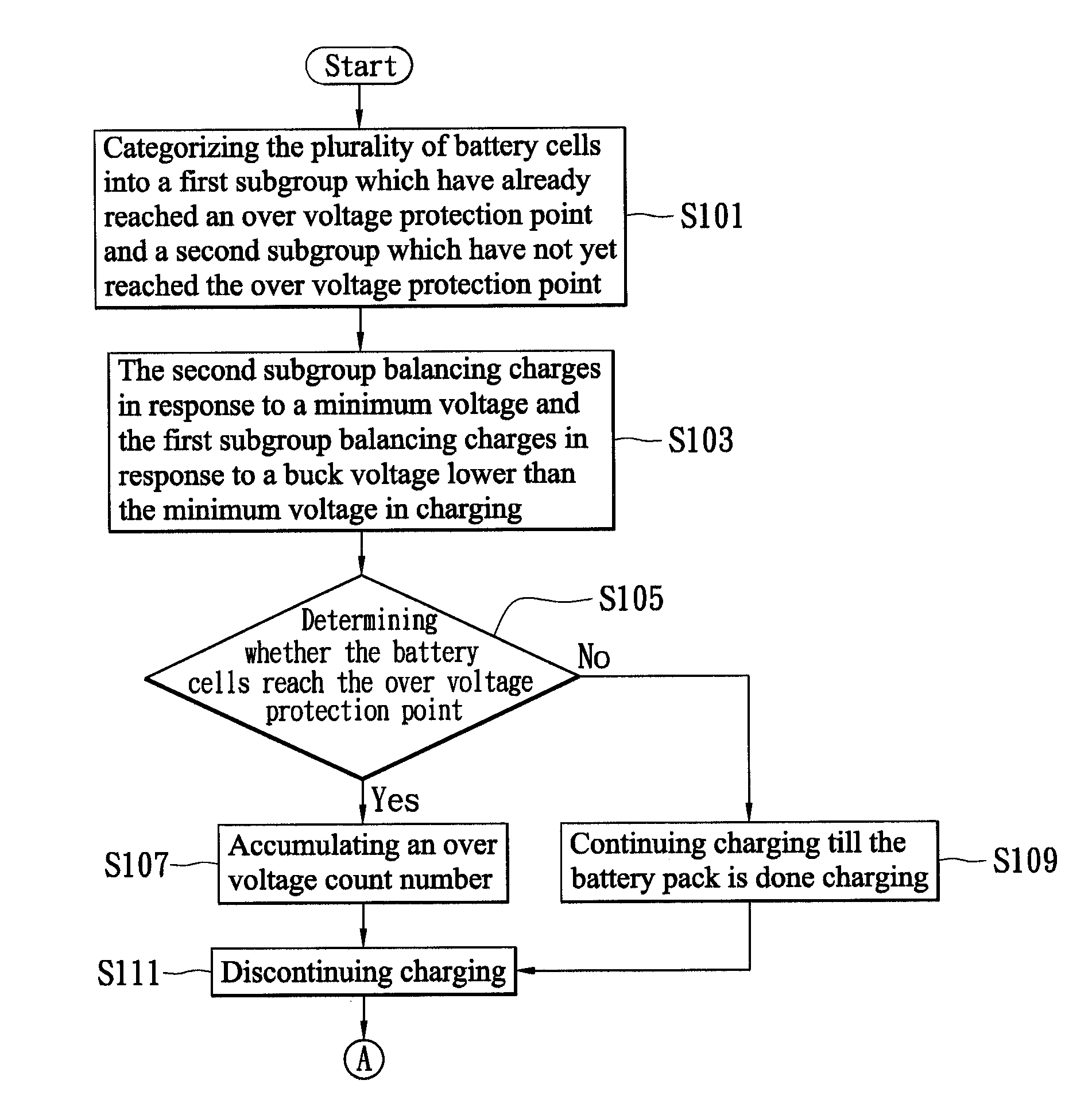

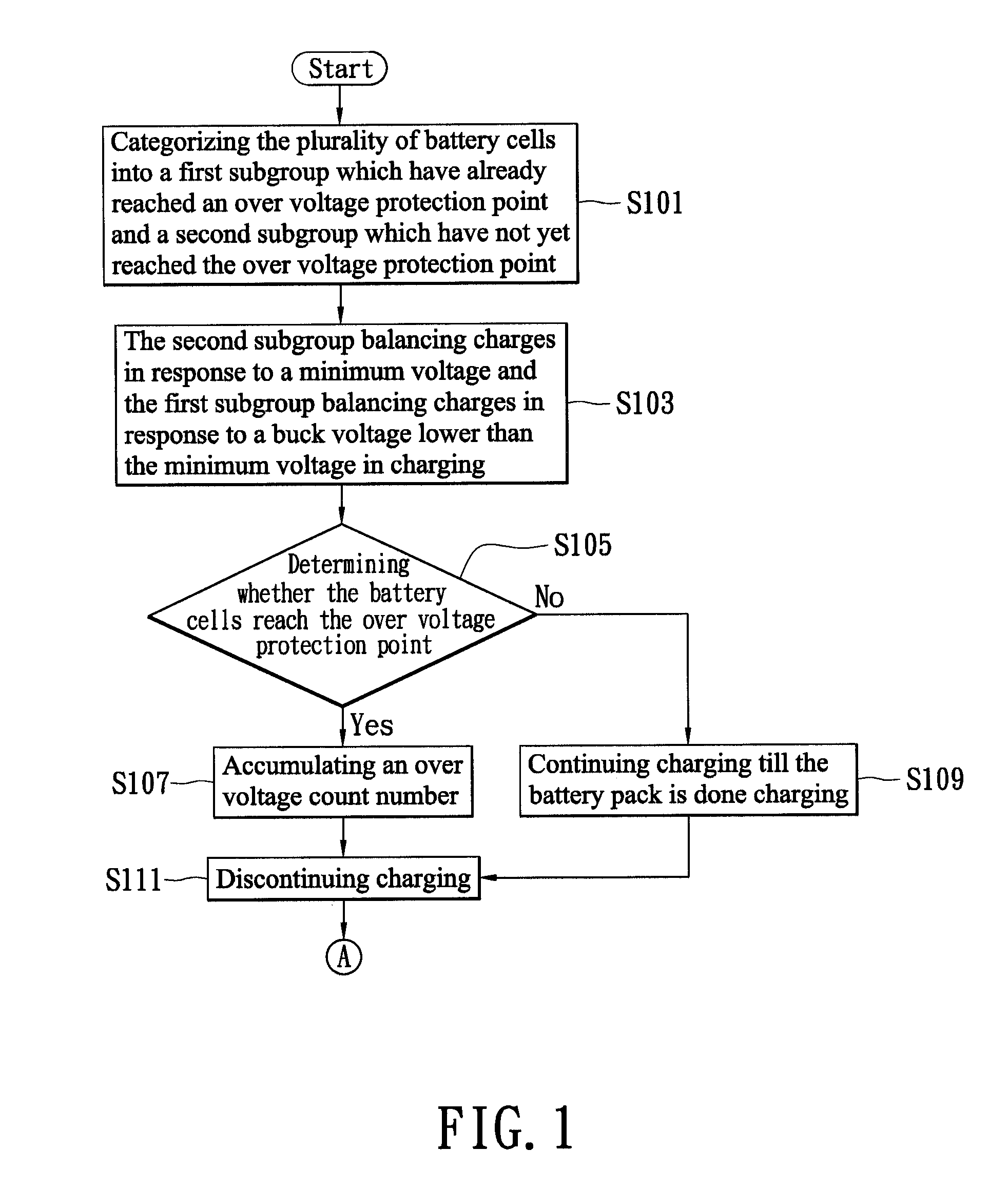

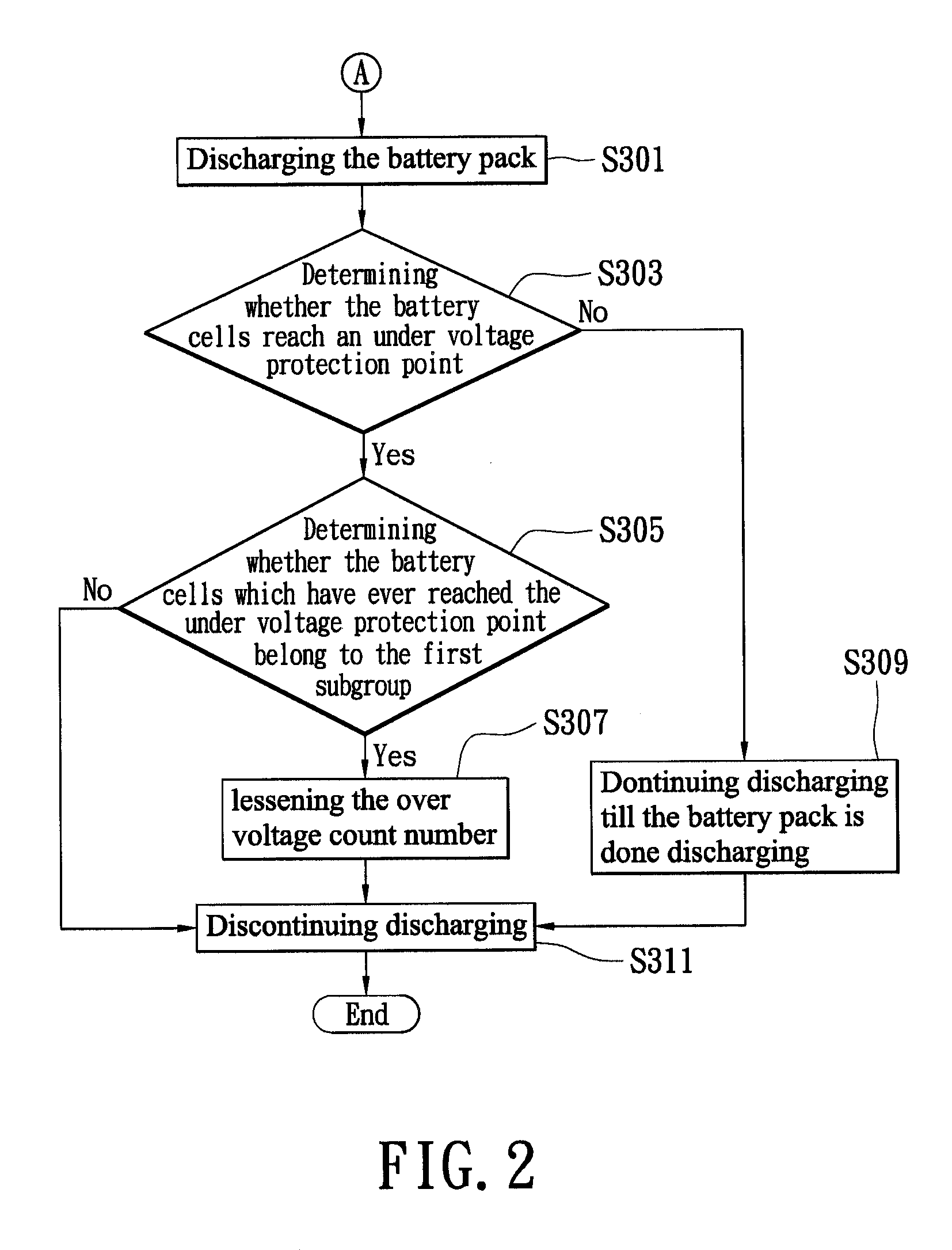

Battery balancing method

InactiveUS20110156649A1Improve power storage capacityExtended service lifeCharge equalisation circuitSafety/protection battery circuitsCounting NumberElectrical battery

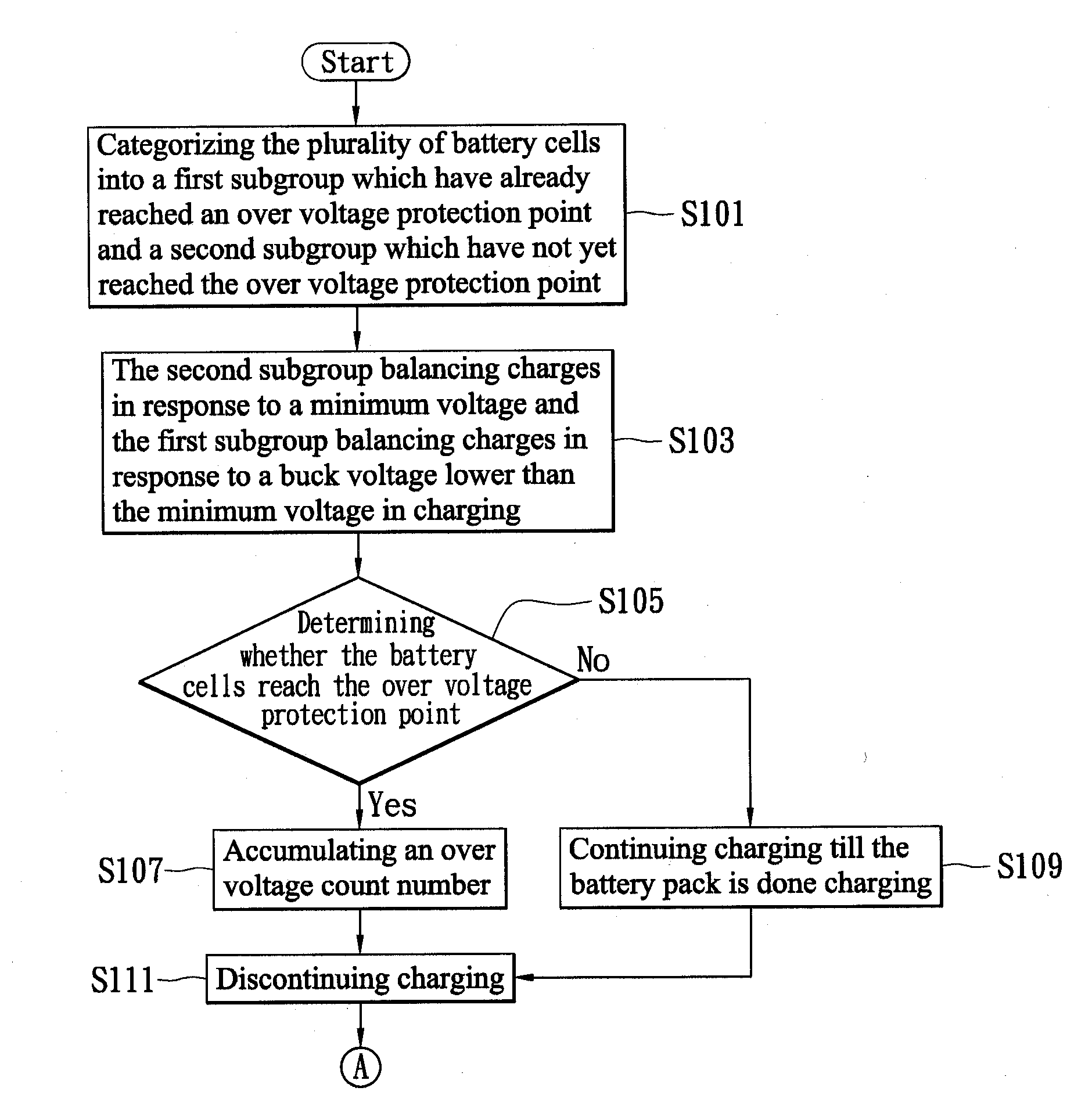

A battery balancing method for a battery pack is disclosed, wherein the battery pack includes a plurality of rechargeable battery cells. The method categorizes the plurality of battery cells into a first subgroup and a second subgroup. Each battery cell in the first subgroup has an over voltage count number that records the times of the battery cells reaching an over voltage protection point. A minimum voltage of the battery cells in the second subgroup is detected. Then the voltage of each battery cell in the first subgroup is decreased to a buck voltage lower than the minimum voltage of the second subgroup. While any one cell in the first group reaches the over voltage protection point again during the charging procedure, the over voltage count numbers for the particular battery cells already reached the over voltage protection point are accumulated and then the charging procedure is terminated.

Owner:LITE ON ELECTRONICS (GUANGZHOU) LTD +1

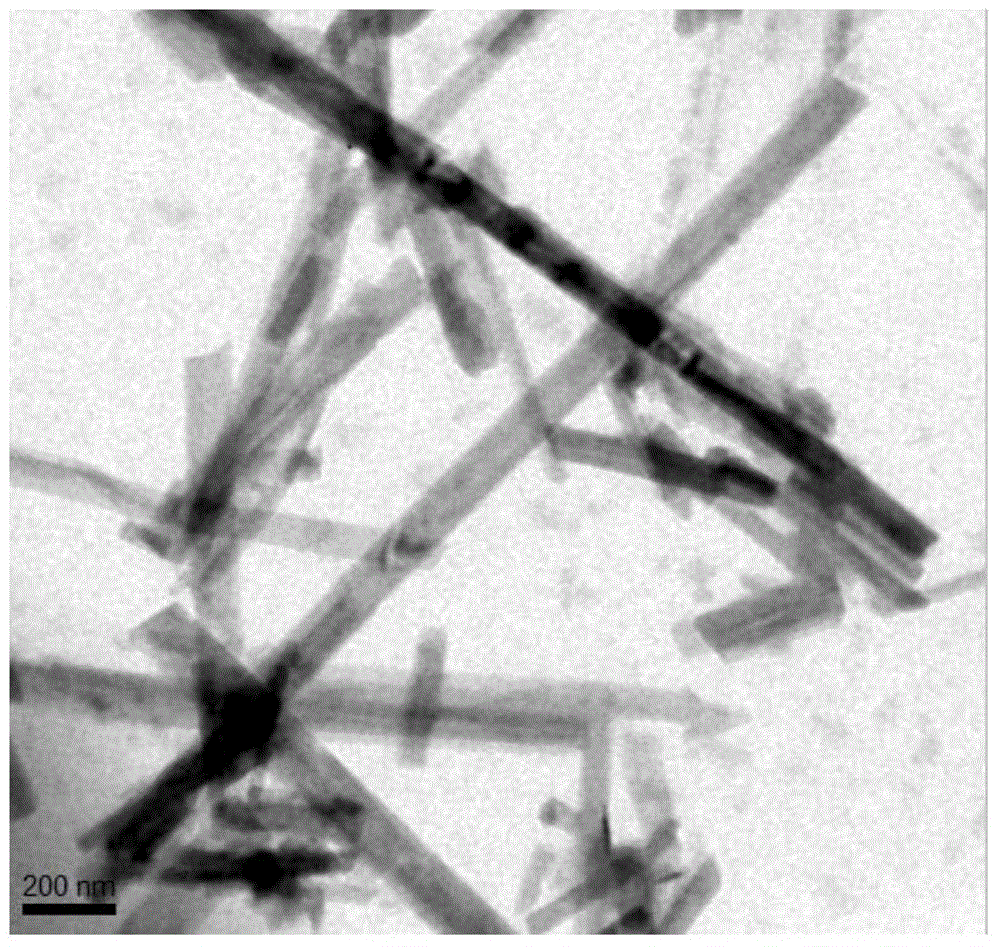

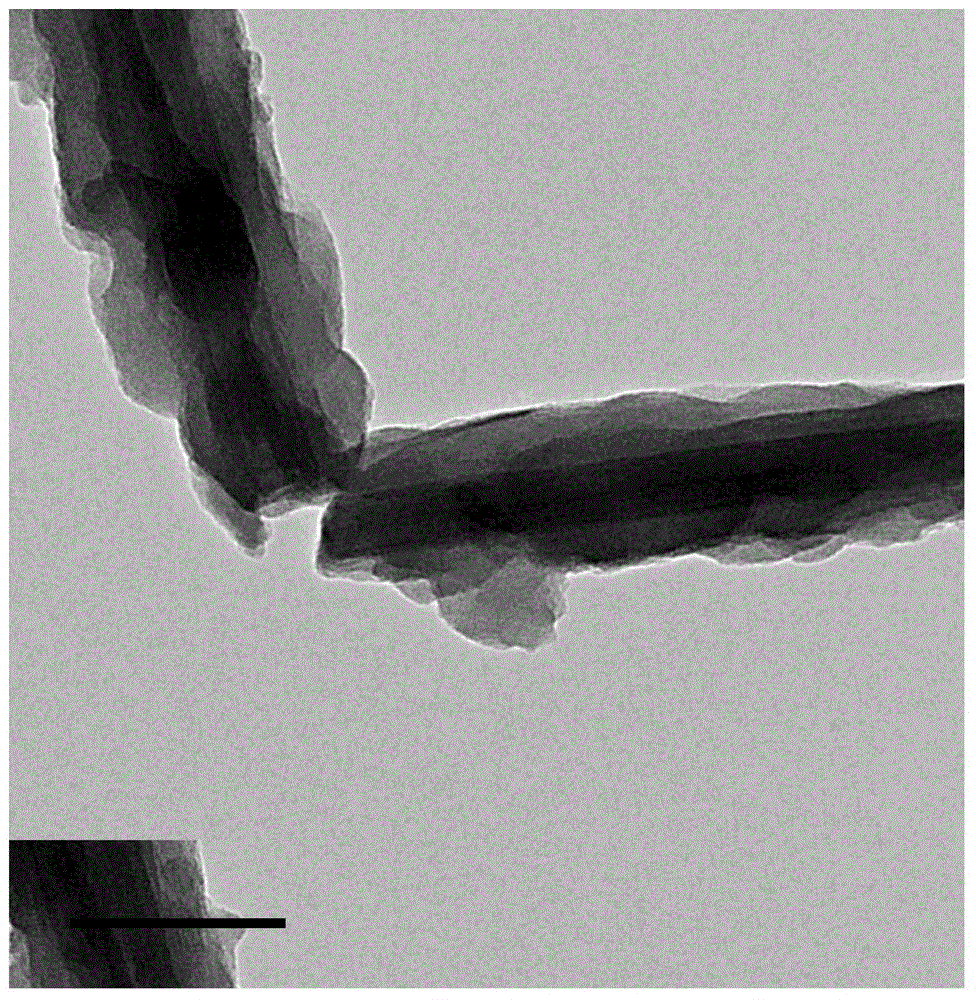

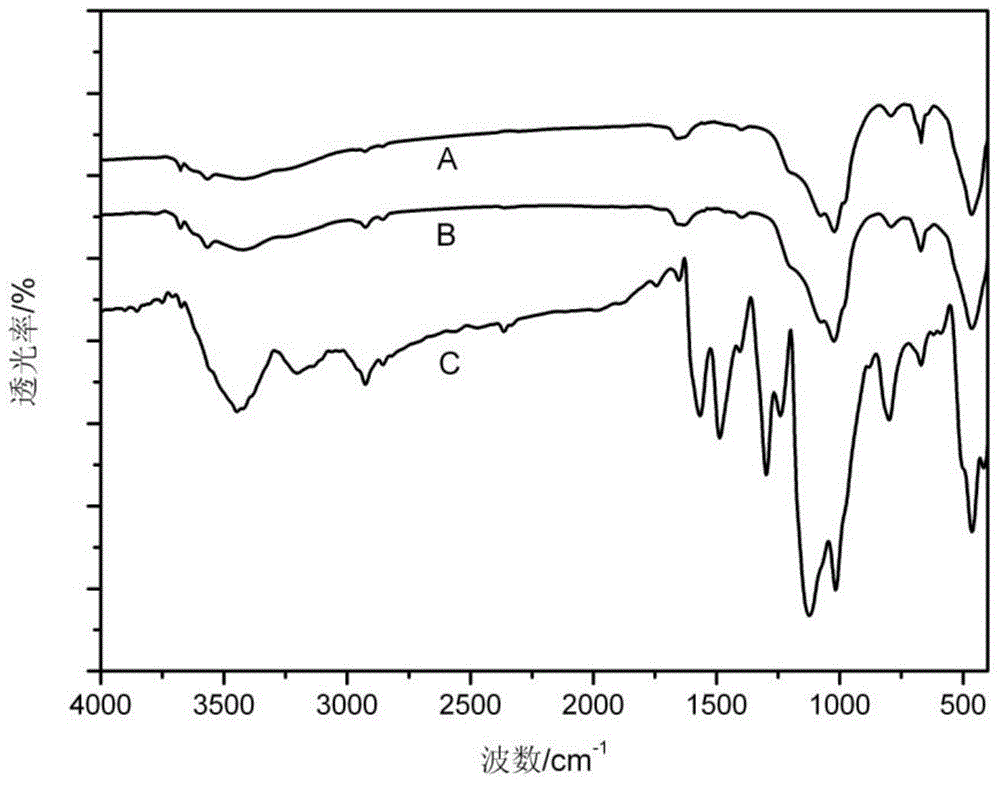

Preparation method of sepiolite/polyaniline nanocomposite material

The invention discloses a preparation method of a sepiolite / polyaniline nanocomposite material. The preparation method is characterized by comprising the following steps: mixing sepiolite with water, standing, filtering an upper-layer sepiolite suspension liquid, washing with water, and drying to obtain washed sepiolite; mixing the washed sepiolite with hydrochloric acid, stirring in a water bath, filtering, washing solids with water, and drying to obtain acid activated sepiolite; mixing the acid activated sepiolite with an organic solvent, adding amino-carrying silane coupling agent, mixing, stirring in the water bath, filtering, washing, and drying to obtain organized modified sepiolite; mixing the organized modified sepiolite with water into a dispersion liquid; adding a dopant and phenylamine while stirring, cooling, adding an oxidant for stirring, reacting and then washing and drying materials, to obtain a product sepiolite / polyaniline nanocomposite material. The prepared composite material has high electric conductivity and high specific capacitance, and is applicable to the fields of a supercapacitor electrode material, a secondary material, an electromagnetic shielding material and the like.

Owner:SOUTHWEAT UNIV OF SCI & TECH +1

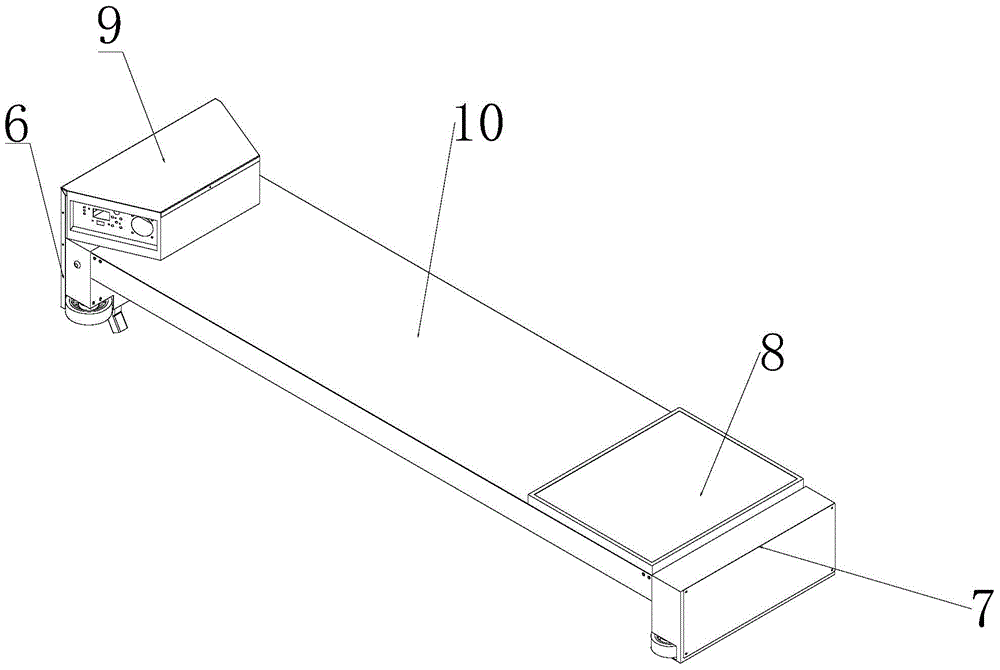

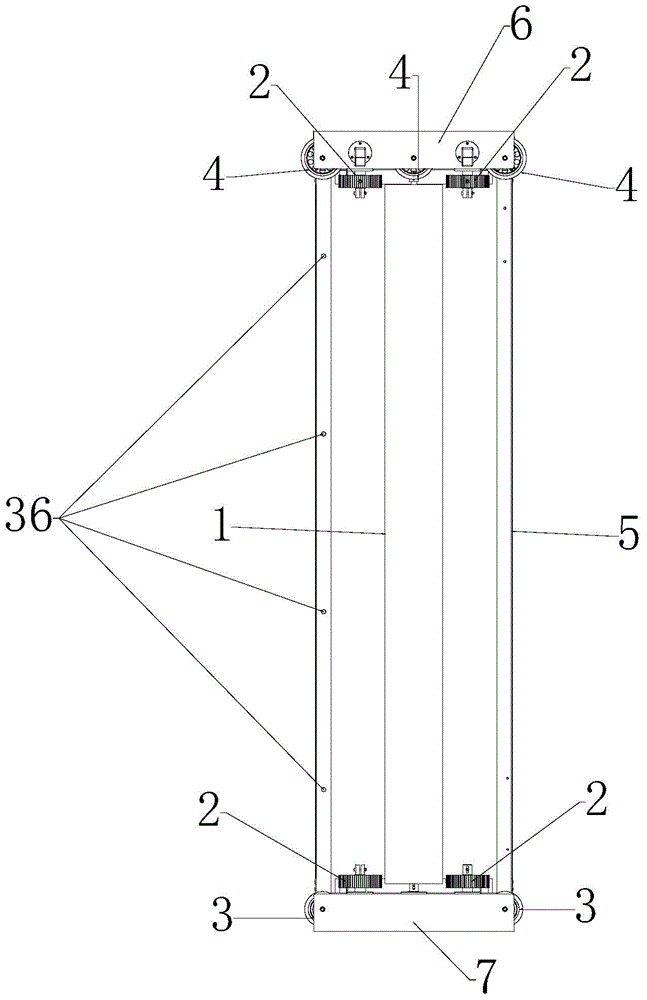

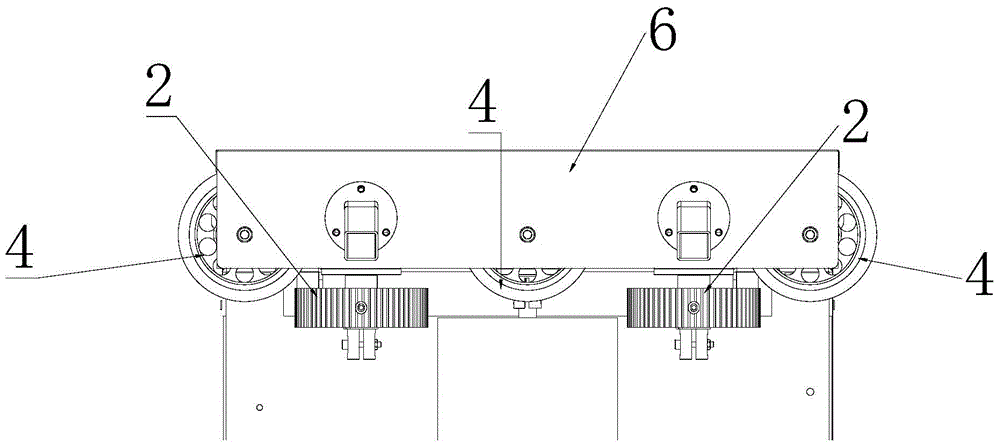

Detection system and detection method for detecting faults of photovoltaic module

InactiveCN104980107AImprove power generation efficiencyExtended service lifePhotovoltaic monitoringPhotovoltaic energy generationElectricityCommunication unit

The invention discloses a detection system and a detection method for detecting the faults of a photovoltaic module. The system is arranged on an automatic cleaning device of the photovoltaic module. The automatic cleaning device is used for cleaning a to-be-cleaned photovoltaic panel while moving along the photovoltaic panel. The detection system comprises a first temperature detection unit, an intelligent control unit and a wireless communication unit. The first temperature detection unit is used for detecting the temperature of the photovoltaic panel during the cleaning process of the photovoltaic panel by the automatic cleaning device. The intelligent control unit is connected with the first temperature detection unit and is used for receiving and processing the detected temperature of the first temperature detection unit. The wireless communication unit is connected with the intelligent control unit and is used for sending the processed temperature of the intelligent control unit to a master control chamber. According to the invention, the photovoltaic panel is cleaned, while the temperature of the photovoltaic panel is detected at the same time. Meanwhile, the detected temperature is transmitted to the master control chamber. Therefore, once a photovoltaic panel generates electricity abnormally, the photovoltaic panel can be replaced just in time. As a result, the power generation efficiency of the photovoltaic module is greatly improved, and the service life of the photovoltaic module is greatly prolonged.

Owner:KASHGAR SOL BRIGHT PHOTOVOLTAIC TECH CO LTD

Lead-acid storage battery and preparation method thereof

InactiveCN104466266AImprove stabilityStrong low temperature starting abilityFinal product manufactureElectrode carriers/collectorsCharge dischargeEngineering

The invention provides a lead-acid storage battery. The lead-acid storage battery comprises a housing, a positive electrode plate, a negative electrode plate, a separating plate and electrolyte, wherein the positive electrode plate, the negative electrode plate and the separating plate are arranged in the housing; the electrolyte is injected into the housing; the positive electrode plate comprises a positive electrode plate grid, and positive electrode lead acid layers which cover two surfaces of the positive electrode plate grid; the positive electrode plate grid is prepared from the following components in percentage by weight: 0.05 to 0.2% of calcium, 0.6 to 1.0% of tin, 0.01 to 0.05% of aluminum, and the balance of lead; the negative electrode plate comprises a negative electrode plate grid, and negative electrode lead acid layers which cover two surfaces of the negative electrode plate grid; the negative electrode plate grid is prepared from the following components in percentage by weight: 0.05 to 0.2% of calcium, 0.1 to 0.5% of tin, 0.01 to 0.05% of aluminum, and the balance of lead. The lead-acid storage battery has the advantages of being high in large-current discharging stability, high in low-temperature starting capacity, outstanding in corrosion resistance, long in circular charging-discharging life, and remarkable in comprehensive performances.

Owner:萍乡市天东电器科技有限公司

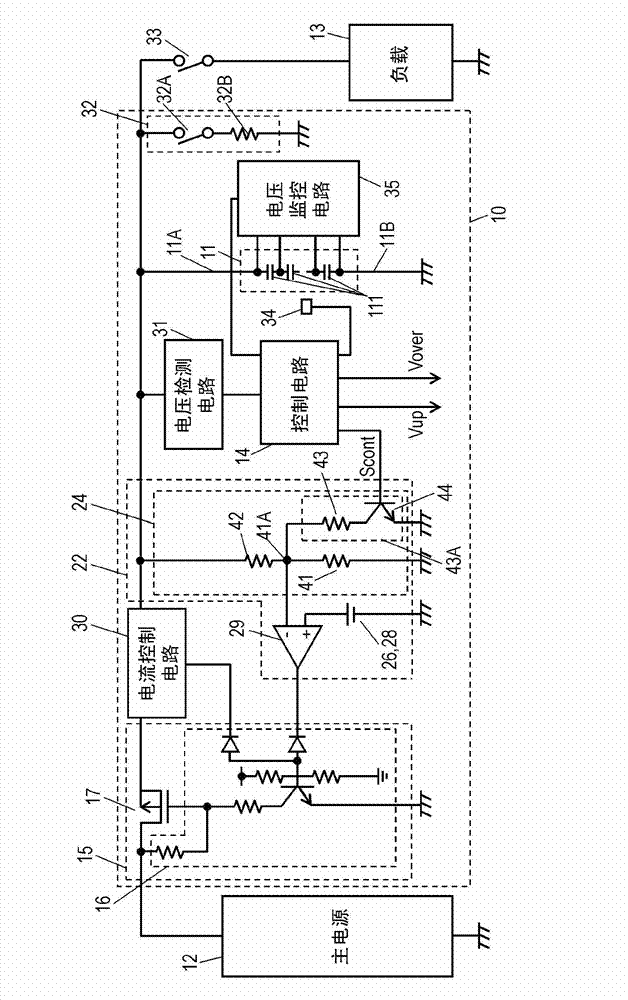

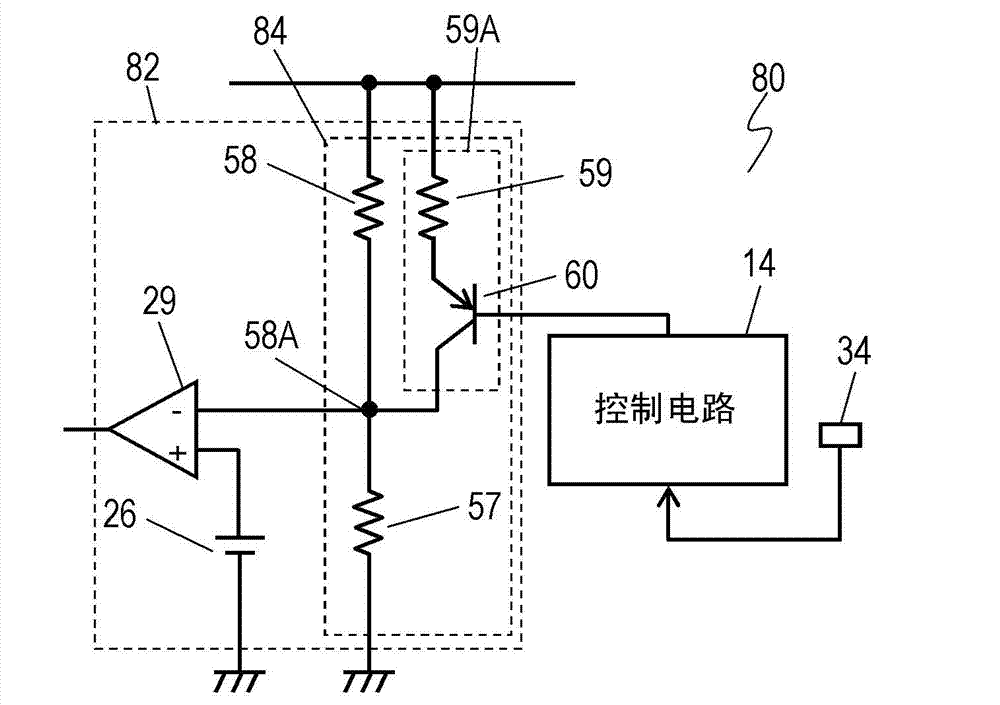

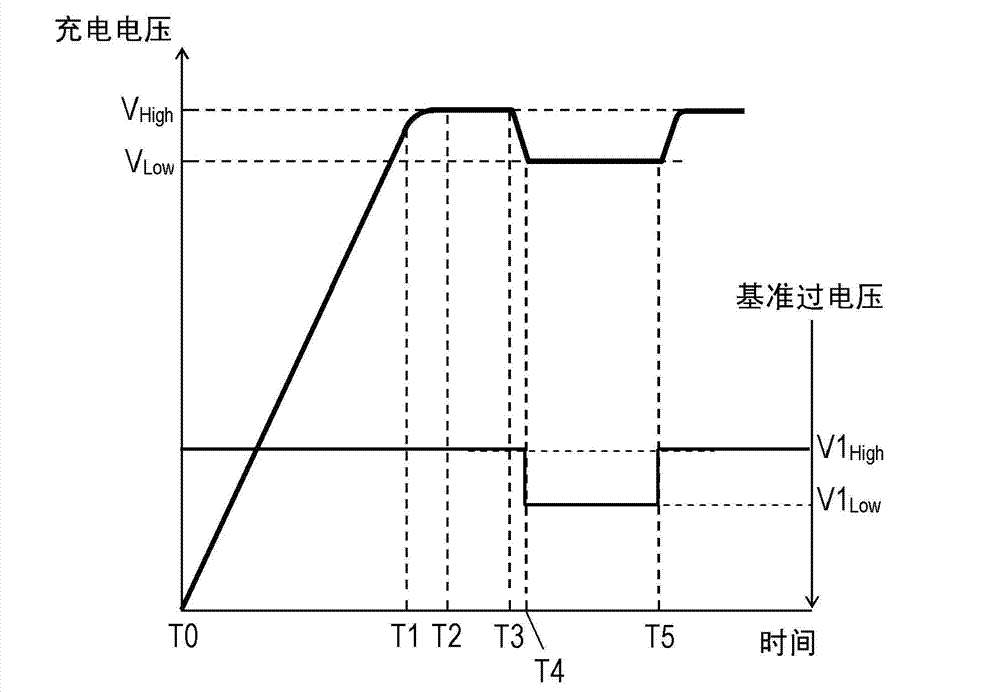

Capacitor device

ActiveCN103166454AImprove power storage capacityInhibit deteriorationApparatus without intermediate ac conversionVehicular energy storageDividing circuitsComparators circuits

A capacitor device includes a capacitor unit, a voltage-dividing circuit for outputting a divided voltage obtained by dividing a voltage of the capacitor unit, and a comparator circuit. The comparator circuit causes the charge circuit to operate such that the voltage of the capacitor unit reaches a full-charge voltage. The voltage-dividing circuit includes a semiconductor switching element, and outputs a divided voltage. A control circuit is operable to determine the full-charge voltage to be a high-temperature full-charge voltage by turning off the first semiconductor switching element when a temperature at the capacitor unit exceeds a reference temperature. The control circuit is operable to determine the full-charge voltage to be a low-temperature full-charge voltage that is higher than the high-temperature full-charge voltage by turning on the first semiconductor switching element when the detected temperature is not higher than the reference temperature.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

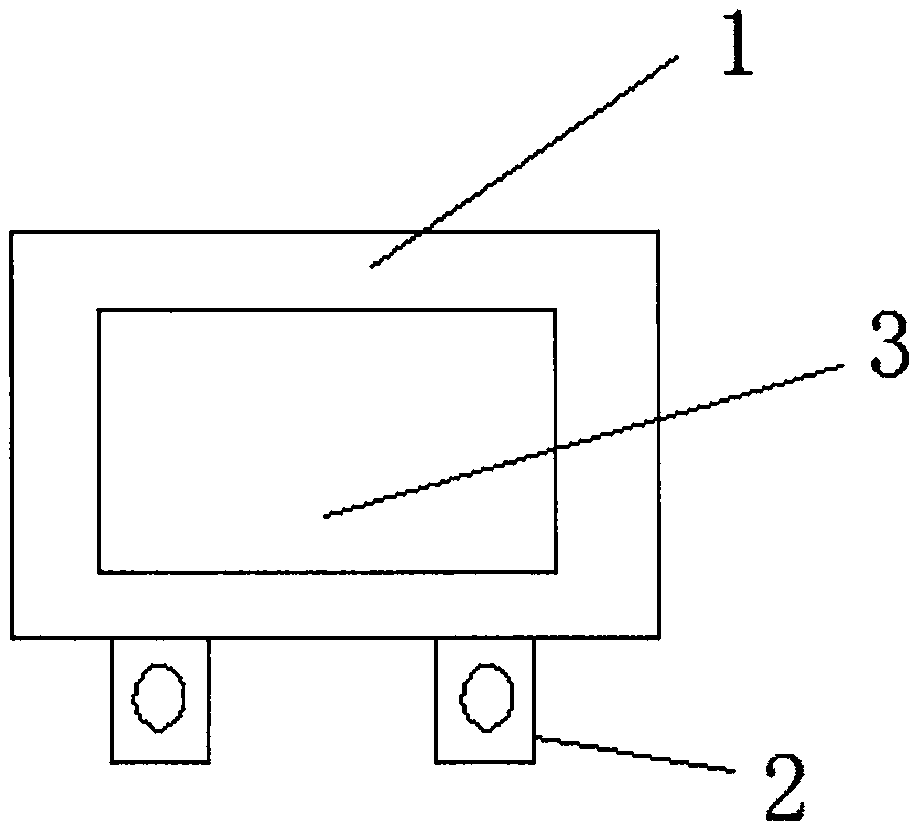

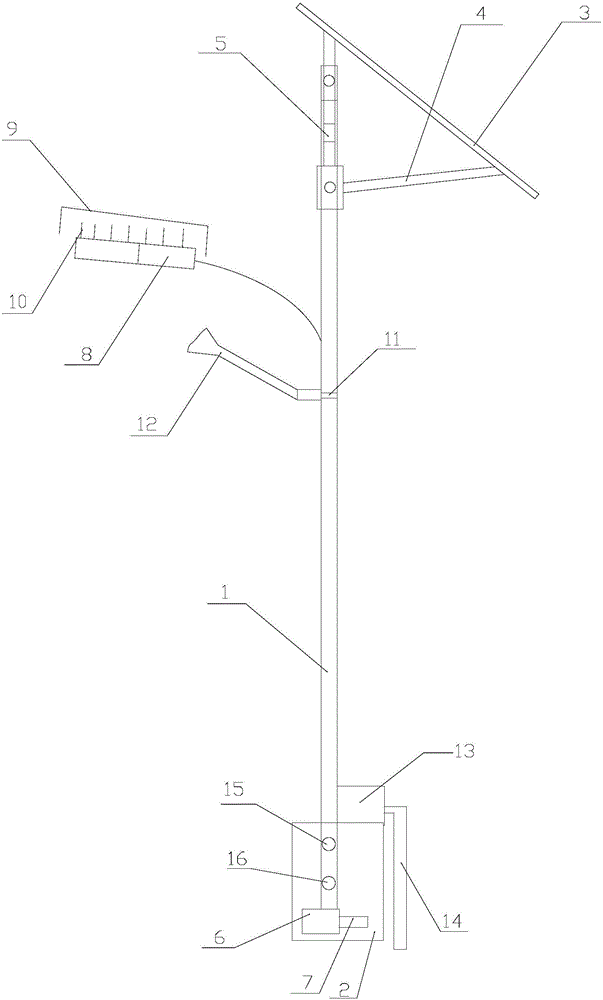

Solar energy mobile new energy vehicle charging pile

InactiveCN109177787ASolve immovableEasy to chargePhotovoltaic supportsSolar heating energyNew energyElectric vehicle

The invention discloses a solar energy mobile new energy vehicle charging pile. The solar energy mobile new energy vehicle charging pile includes a housing, wherein the bottom of the left side of thehousing is movably connected with a cable; the top end of the cable is movably connected with a charging gun; a display screen is arranged on the top of the front side of the housing; a support columnis fixedly connected to the center of the top of the housing; the top of the support column is movably connected with a solar panel through a movable shaft; the bottom of the housing is fixedly connected with a box body; two sides of the bottom of the internal cavity of the box body are provided with through grooves; and both sides of the internal cavity of the box body are vertically fixedly connected with sliding rods. The solar energy mobile new energy vehicle charging pile can move the charging pile through the cooperation of the box body, the sliding rod, the servo motor, the spiral column, the bearing seat, the spiral sleeve, the fixing plate, the sliding sleeve, the pulley and the through grooves, and can solve the problem that the traditional solar charging pile is not movable, thus facilitating the charging operation of the electric vehicle by the user, avoiding wasting long time of the user, and being valuable for popularizing and using.

Owner:陈肖兰

Positive plate used for lead-acid storage battery and preparation method of positive plate

InactiveCN104485445AImprove stabilityStrong low temperature starting abilityElectrode carriers/collectorsLead-acid accumulator electrodesPower flowAlloy

The inventionprovides a positive plate used for a lead-acid storage battery. The positive plate comprises an alloy plate grid and lead-acid layers coating two surfaces of the alloy plate grid, wherein the alloy plate grid is prepared from the following components in percentage by weight: 0.05-0.2% of calcium, 0.6-1.0% of tin, 0.01-0.05% of aluminum and the balance of lead;each lead-acid layer is mainly prepared from the following components in parts by weight: 950-1050 parts of lead powder, 100-110 parts of water and 90-100 parts of sulfuric acid in the specification of 1.4g / cm3. The lead-acid storage battery with the positive platehas the advantages of good heavy-current discharge stability, highlow-temperature start capacity, excellentanti-corrosion performance, longcirculating charge and discharge life and excellent comprehensive performance.

Owner:萍乡市天东电器科技有限公司

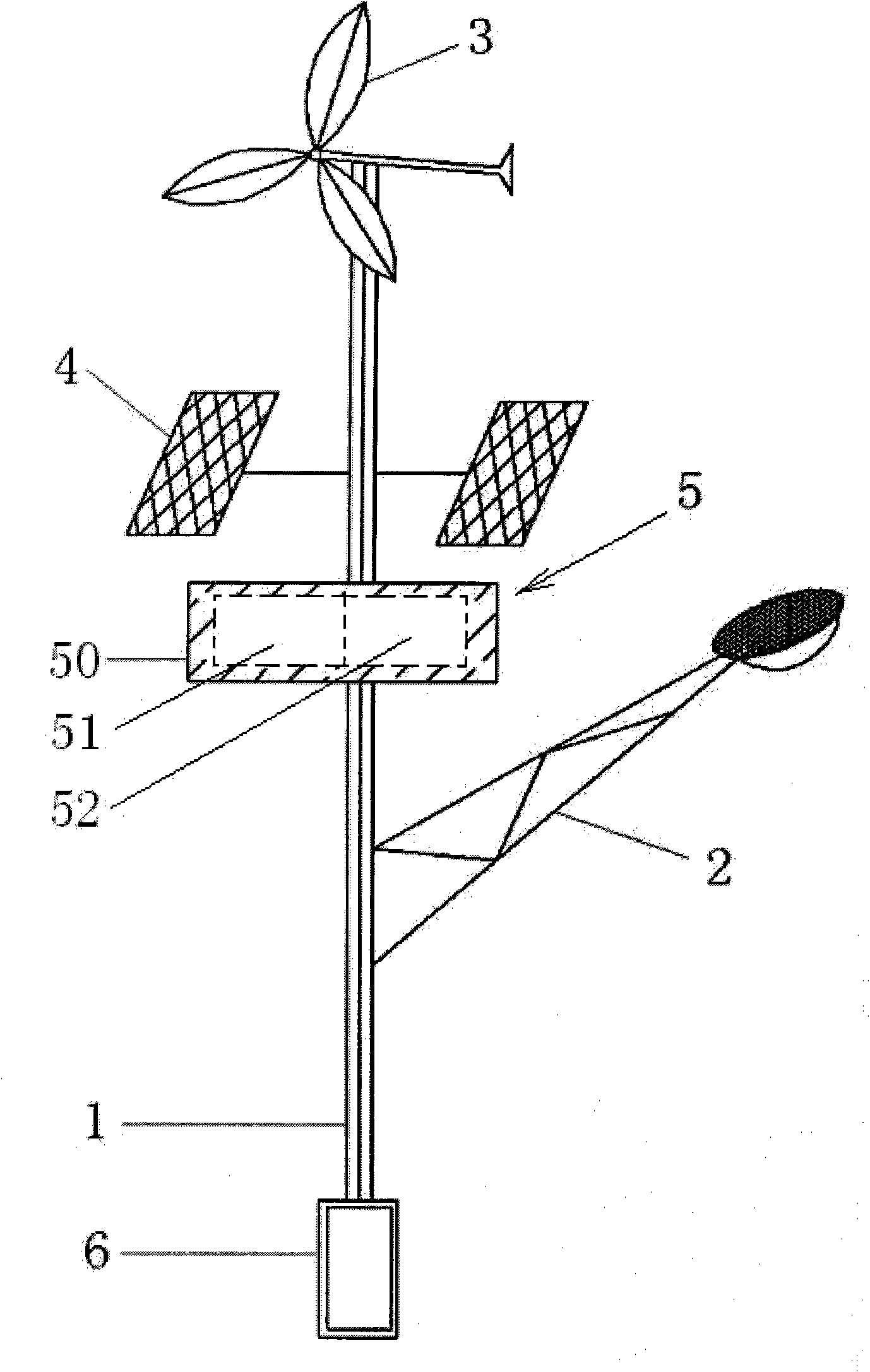

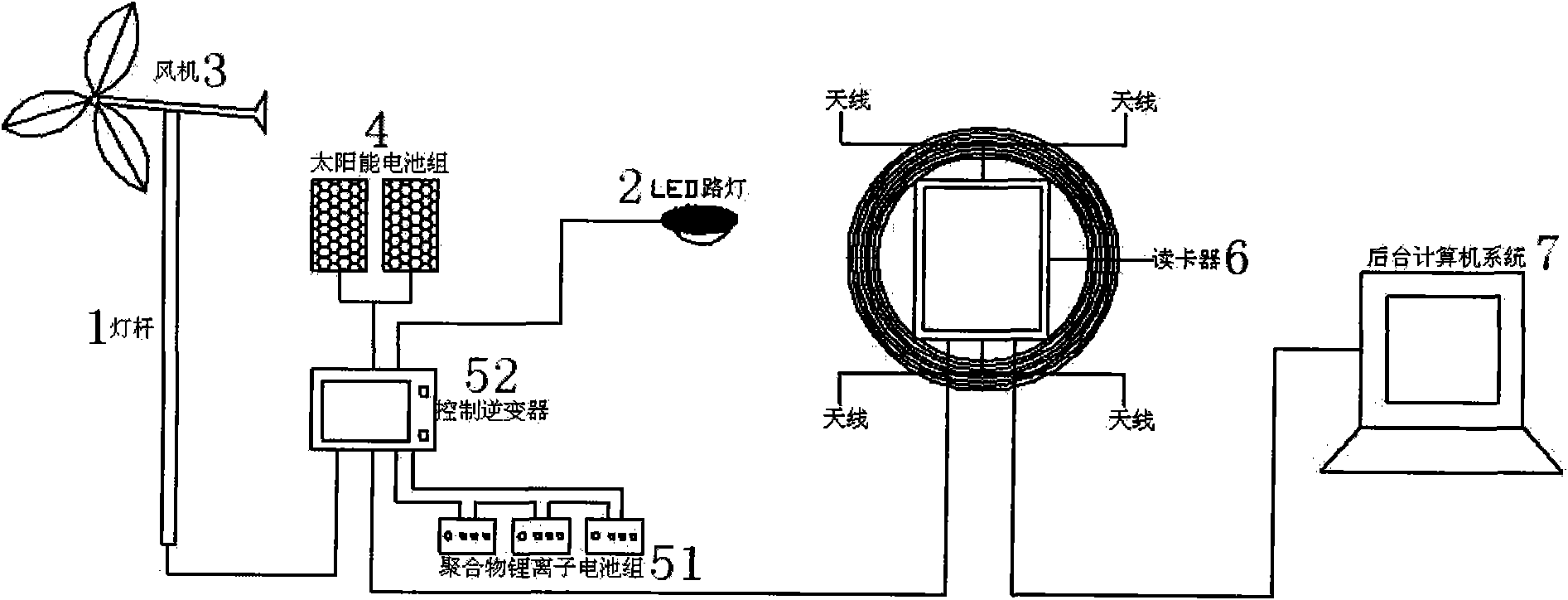

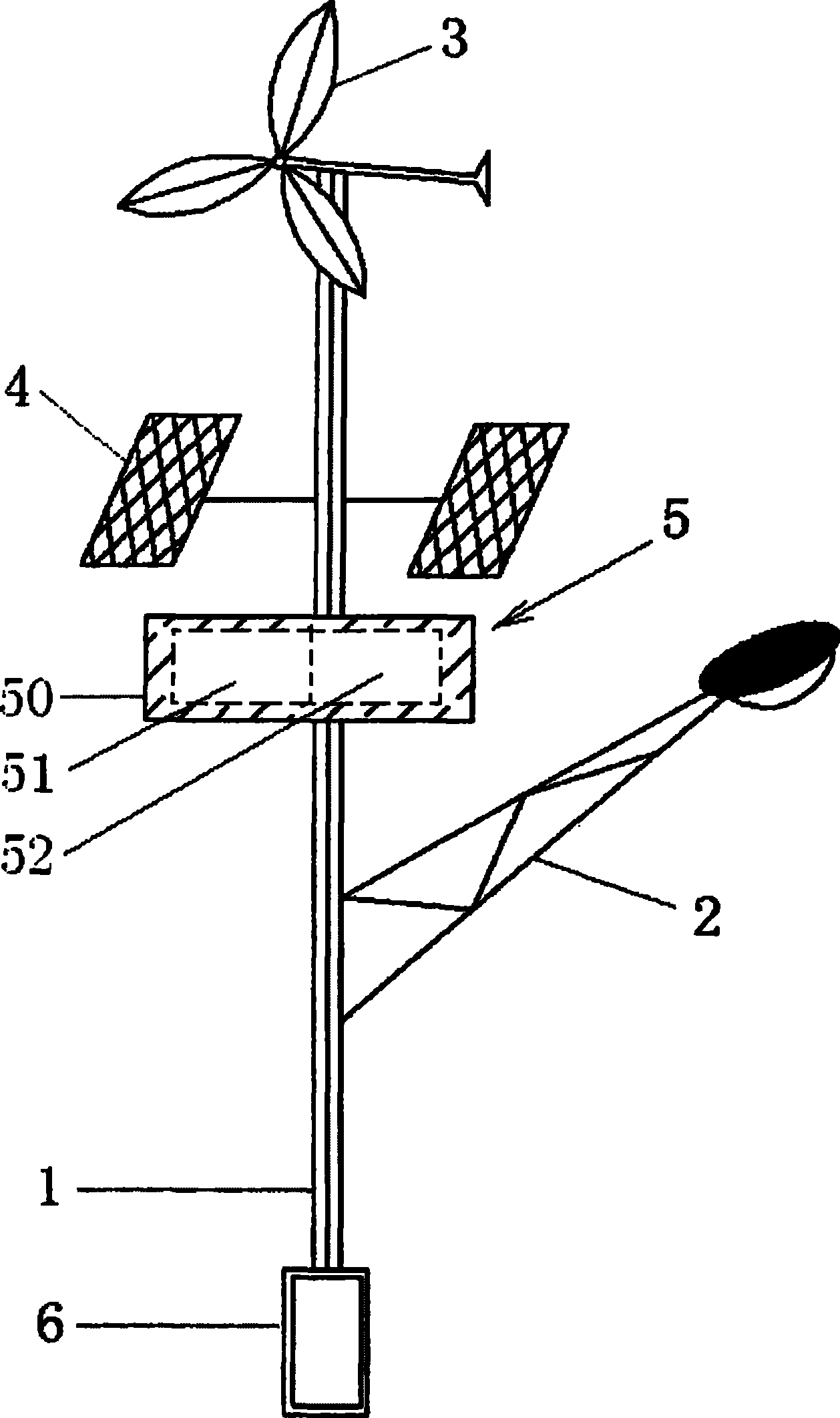

Intelligent streetlamp system capable of accumulating a great quantity of electricity

InactiveCN101994977AExtend your lifeSimple structureBatteries circuit arrangementsPoint-like light sourceLithiumElectricity

The invention relates to an intelligent streetlamp system capable of accumulating a great quantity of electricity, which comprises a lamp post, a lighting device, a wind driven generator, a solar battery pack, a battery chamber and an RFID (Radio Frequency Identification Device) card reader, wherein the battery chamber comprises a chamber body, a storage battery and a controller, the chamber body is arranged between the solar battery pack and the lighting device, the storage battery and the controller are arranged in the chamber body, and the RFID card reader is arranged at the lower part of the lamp post; the wind driven generator and the solar battery pack are connected with the storage battery through the controller; and the controller and the lighting device are connected with the RFID card reader. The invention achieves the purposes of environment protection and stable lighting by adopting a dye sensitization solar battery technology and a lithium ion polymer battery, greatly prolongs the service life of the battery because the lithium ion polymer battery can be charged and discharged for thousands of times, has excellent safety property and greatly enhanced storage capacity, and can realize long-term stable streetlamp lighting and RFID card reading function under the control of the controller.

Owner:SHANGHAI TAILOR STEEL STRUCTURE ENG

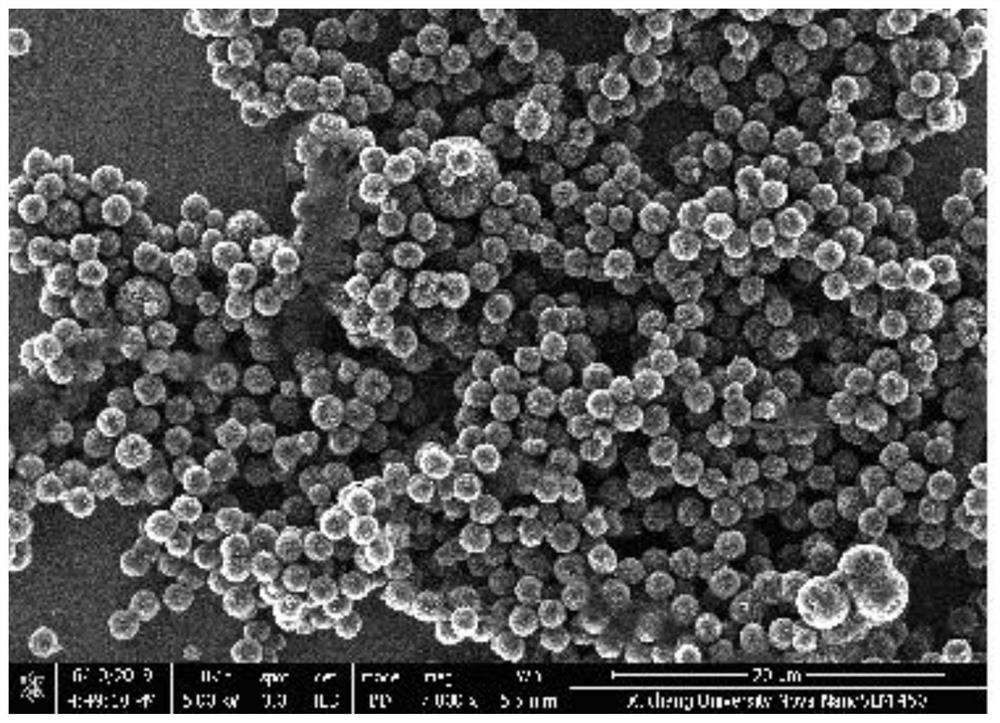

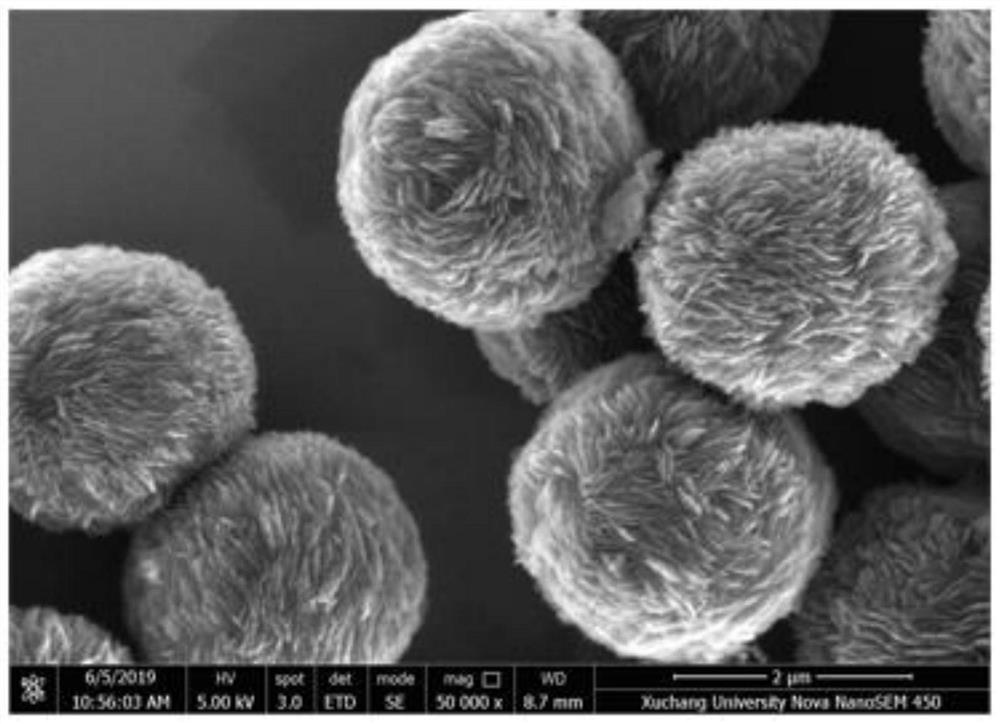

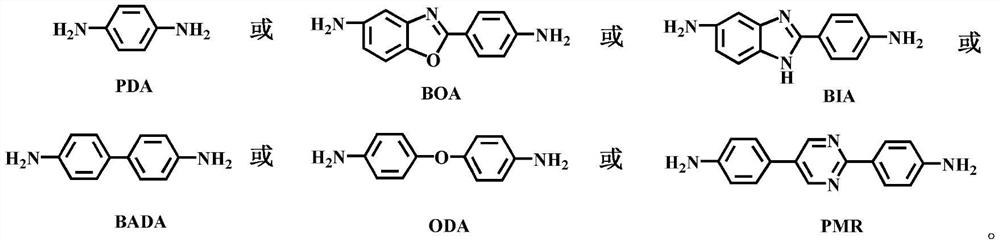

Electrode material based on polyimide mesocarbon microbead structure and preparation method thereof

ActiveCN111943165AUniform sizeIncrease spacingNegative electrodesSecondary cellsMicrospherePolyamide

The invention discloses an electrode material based on a polyimide mesocarbon microbead structure and a preparation method of the electrode material. The preparation method comprises the following steps: (1) preparation of a polyamide acid solution; (2) self-assembly reaction of polyimide (PI). (3) carbonization reaction of polyimide. (4) preparation of a template skeleton agent. (5) preparation of an electrode material. With the polyimide as a matrix, the porous, nitrogen-rich and uniform-size mesophase carbon microspheres are prepared through a thermal polycondensation hydrothermal reactionand control of sintering process parameters; the graphite interlayer spacing is increased by means of the unique curved surface effect of the mesophase carbon microspheres, and more structural defectsare provided through induction of the homogeneous nitrogen doping effect, so that lithium ion transmission is facilitated; in addition, during interlayer lithium intercalation, lithium storage micropore sites are increased, so that the electricity storage performance of the electrode material is improved.

Owner:许绝电工股份有限公司

Thin film capacitor

ActiveCN106971847AImprove density and conductivityImprovement of permittivity and power storage performanceThin/thick film capacitorStacked capacitorsThin membraneInorganic nanoparticles

The invention discloses a thin film capacitor. A capacitor core comprises a composite film, a double-side metalized ZnAl film, and a metal spraying layer. The composite film and the double-side metalized ZnAl film are arranged in a staggered manner. The double-side metalized ZnAl film is evaporated on two side surfaces of the composite film. Moreover, the outer end of the capacitor core is provided with the metal spraying layer. The composite layer is made of the following raw materials: polyethylene glycol terephthalate, 2-chloro-3-nitrotoluene, silicon-contained polycarbonate resin, conductive black, barium titanate, chemical resistant modifier, acetone, heat resistant agent, flame retardant synergist, cerous nitrate, chloro-series fire retardant, antioxygen, 3-cyano-5-fluborophenylboronic acid, nanocrystal cellulose, silver oxide, lactate cobalt, ammonium tetrathiomolybdate, sodium borohydride and inorganic nanoparticles. Through employing the self-made composite thin film, the capacitor is small in size, is light in weight, and is good in self-healing performance. The capacitor employs the technology of ZnAl edge thickening evaporation, is excellent in electrical performance, and is high in reliability.

Owner:PUTIAN UNIV

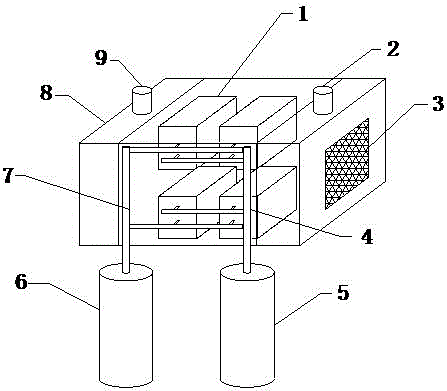

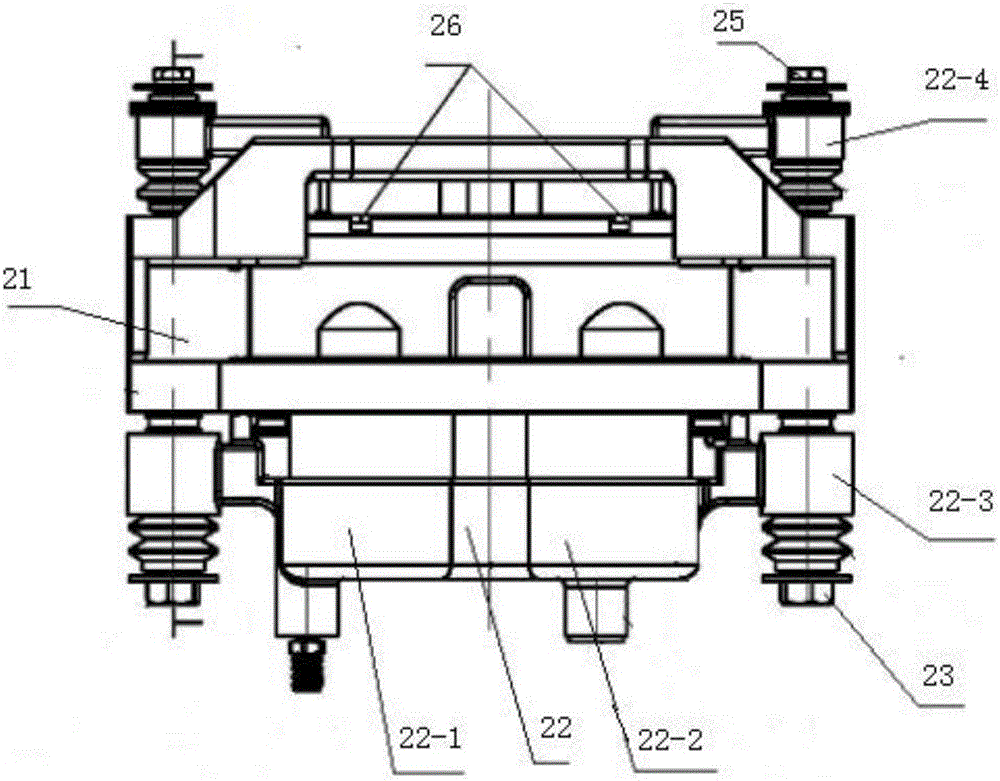

Ship all-vanadium redox flow battery galvanic pile module

InactiveCN106252683AExtended sailing distanceImprove power storage capacityFuel cell heat exchangeFuel cells groupingOxidation-Reduction AgentActivated carbon filtration

The present invention provides a ship all-vanadium redox flow battery galvanic pile module, comprising a box body, a housing, a negative plate, a diaphragm, a positive plate, a negative column, a positive column, a first liquid injecting hole, a second liquid injecting hole, an air inlet, a cooling fan, a alkaline adsorption board, and an active carbon filter screen. The diaphragm is installed in a middle position inside the housing, the positive plate and the negative plate are symmetrically assembled upper and lower sides of the diaphragm, the positive column and the negative column are symmetrically installed on left and right sides of an upper end face of the housing, the first liquid injecting hole is installed on a left end face of the housing, the second liquid injecting hole is assembled at a bottom position of the first liquid injecting hole, the air inlet is disposed inside a right end face of the box body, the cooling fan is installed inside the right end face of the box body behind the air inlet, the alkaline adsorption board is assembled behind the cooling fan, and the active carbon filter screen is installed outside the right end face of the box body. The ship all-vanadium redox flow battery galvanic pile module is novel in structure, reasonable in technique, strong in power storage capability, high in running stability, and safe and reliable.

Owner:安徽浙科智创系统服务有限公司

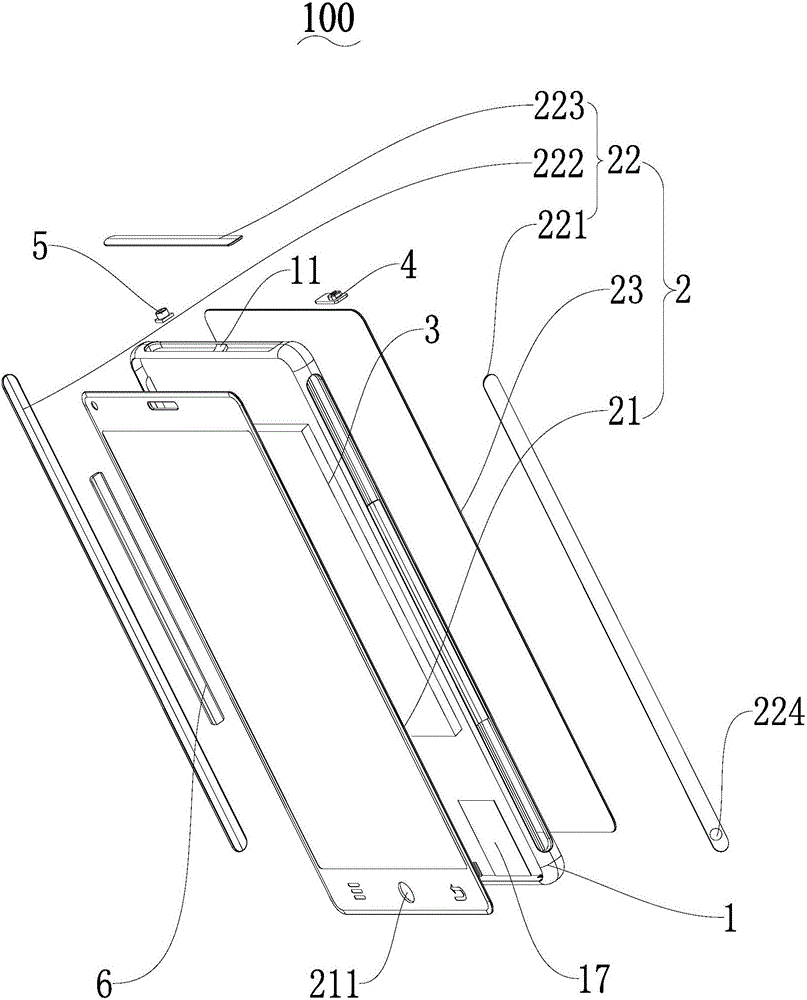

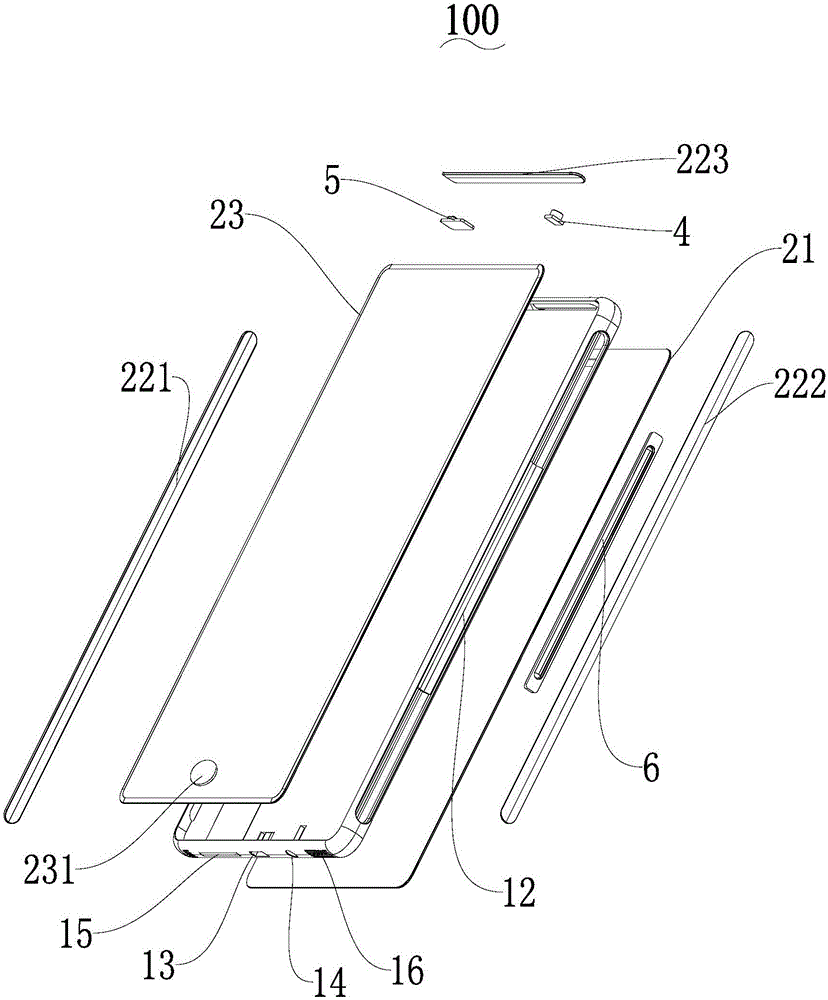

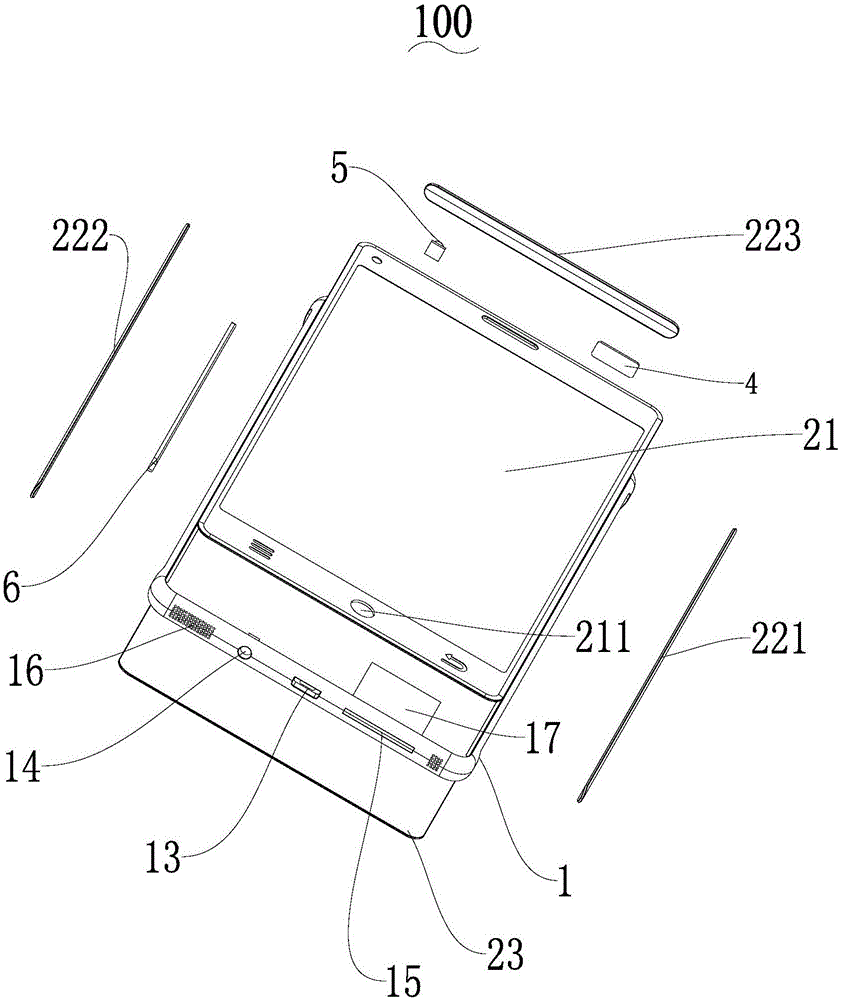

Smart multi-surface touch phone

InactiveCN106453711AImprove experienceExquisite structureTelephone set constructionsEngineeringHome screen

Disclosed in the invention is a smart multi-surface touch phone comprising a touch screen arranged on a phone case and a control circuit board arranged inside the phone case. The touch screen includes a main screen coating the front side of the phone and a side screen coating at least one side of the phone, wherein a 90-degree included angle is formed between the main screen and the side screen. The main screen and the side screen are connected with the control circuit board electrically. According to the provided phone, because of the touch screen arranged at the side of the phone, a display function at the side with the 90-degree included angle between the side and the main screen is realized and the structure is beautified; and the operation becomes convenient and the user experience is improved.

Owner:广东凯驰科技有限公司

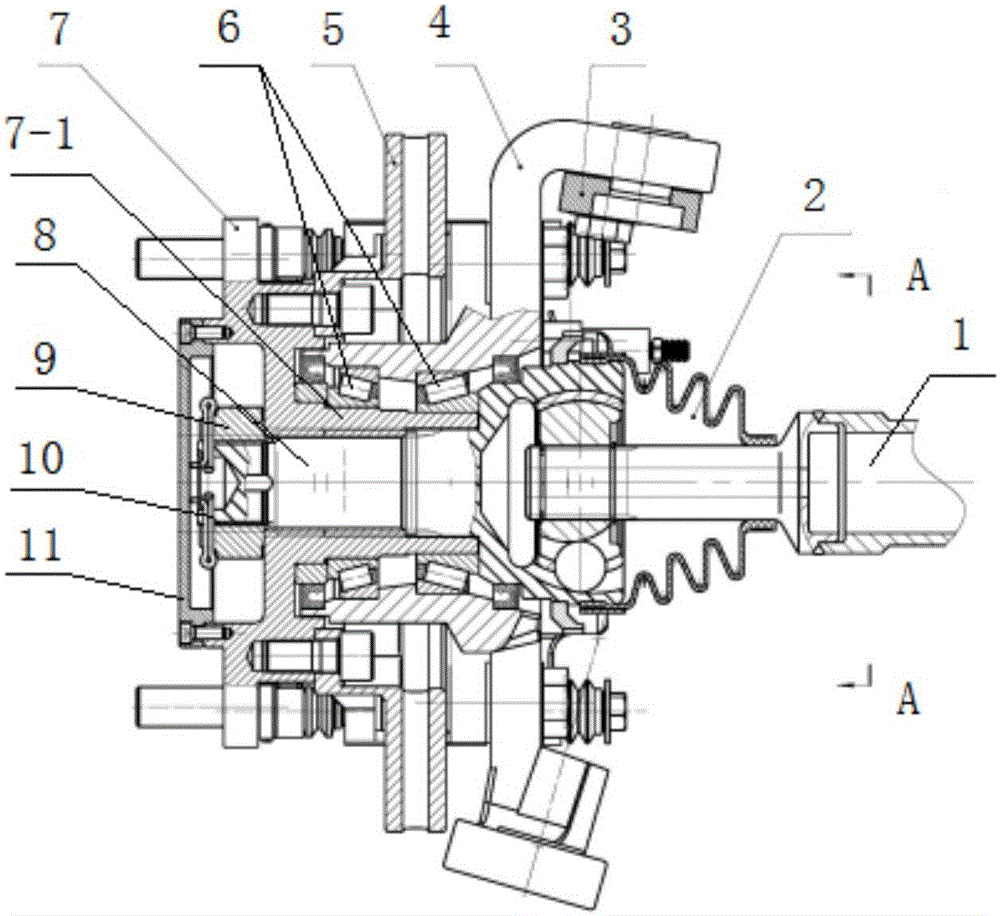

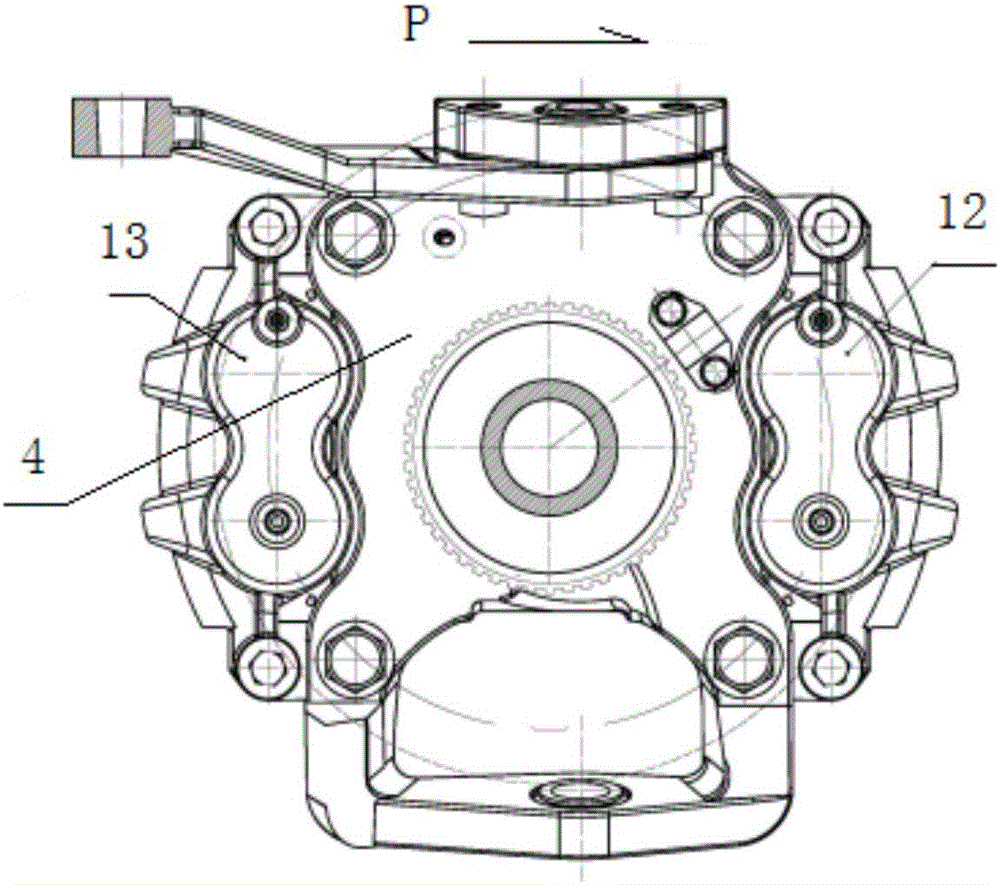

Independently suspended front drive front axle assembly

InactiveCN106364260AReduce weightImprove ride comfortHubsSteering linkagesDrive shaftRadial position

The invention discloses an independently suspended front drive front axle assembly. The front end of each transmission semi-axle is provided with a front drive shaft assembly. A sleeve type steering knuckle is installed at the front end of each front drive shaft assembly in the radial direction, and a transmission spline shaft is arranged at the front end of each front drive shaft assembly in the axial direction. Each transmission spline shaft is engaged with a spline sleeve on the inner side of a left front wheel hub and a spline sleeve on the inner side of a right front wheel hub. The front end of each transmission spline shaft is provided with a screw rod which is matched with a locking nut fastened to one end of the corresponding spline sleeve. Each spline sleeve is sleeved with a bearing pedestal, and each bearing pedestal is arranged at the front end of the corresponding steering knuckle. Conical roller bearings are arranged between the bearing pedestals and the spline sleeves in pairs. A brake disc is fixed to the inner side of the front wheel hub. Brake assemblies in friction joint with the brake disc are symmetrically arranged on the brake disc front and back in the transverse direction. The brake assemblies are fixed to the two sides of a flange plate. Brakes are hydraulic drive brakes. As for a front drive mechanism, an original transmission shaft structure for connecting an engine with a rear wheel is omitted, the height of a chassis of a large / medium-sized passenger vehicle can be reduced properly, meanwhile, the weight of the passenger vehicle is reduced, and running stability is improved advantageously.

Owner:通天汽车桥(天津)有限公司

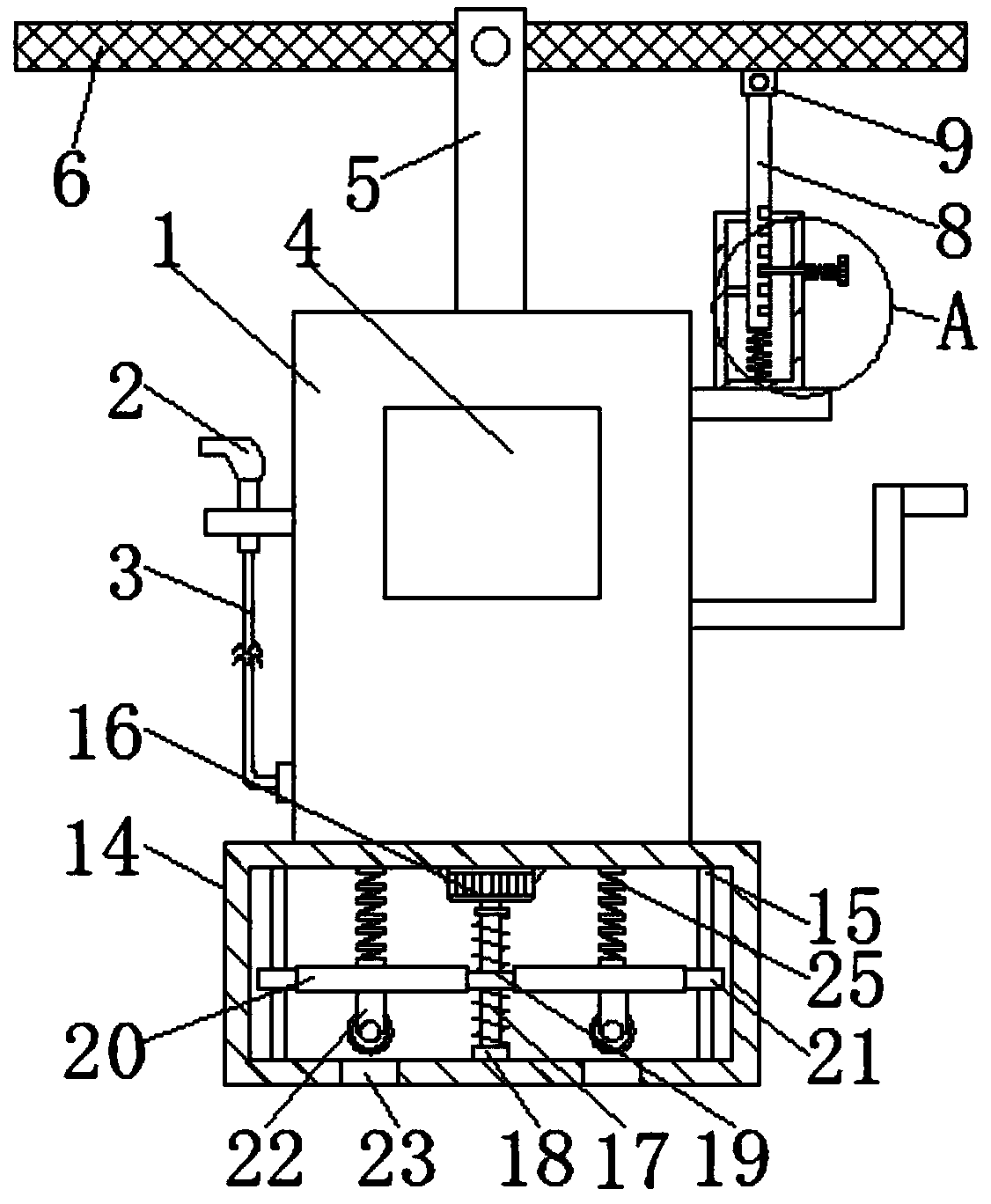

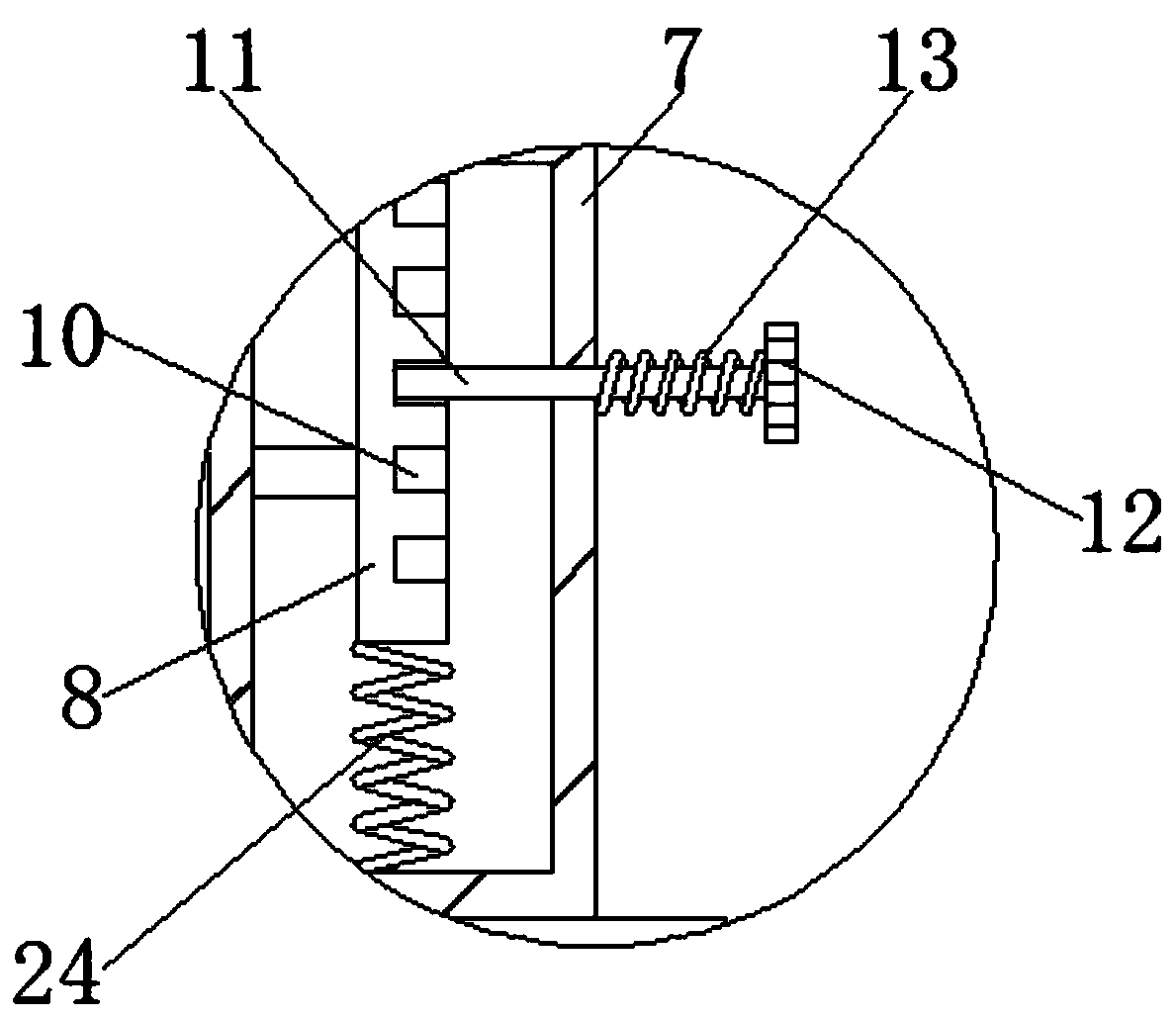

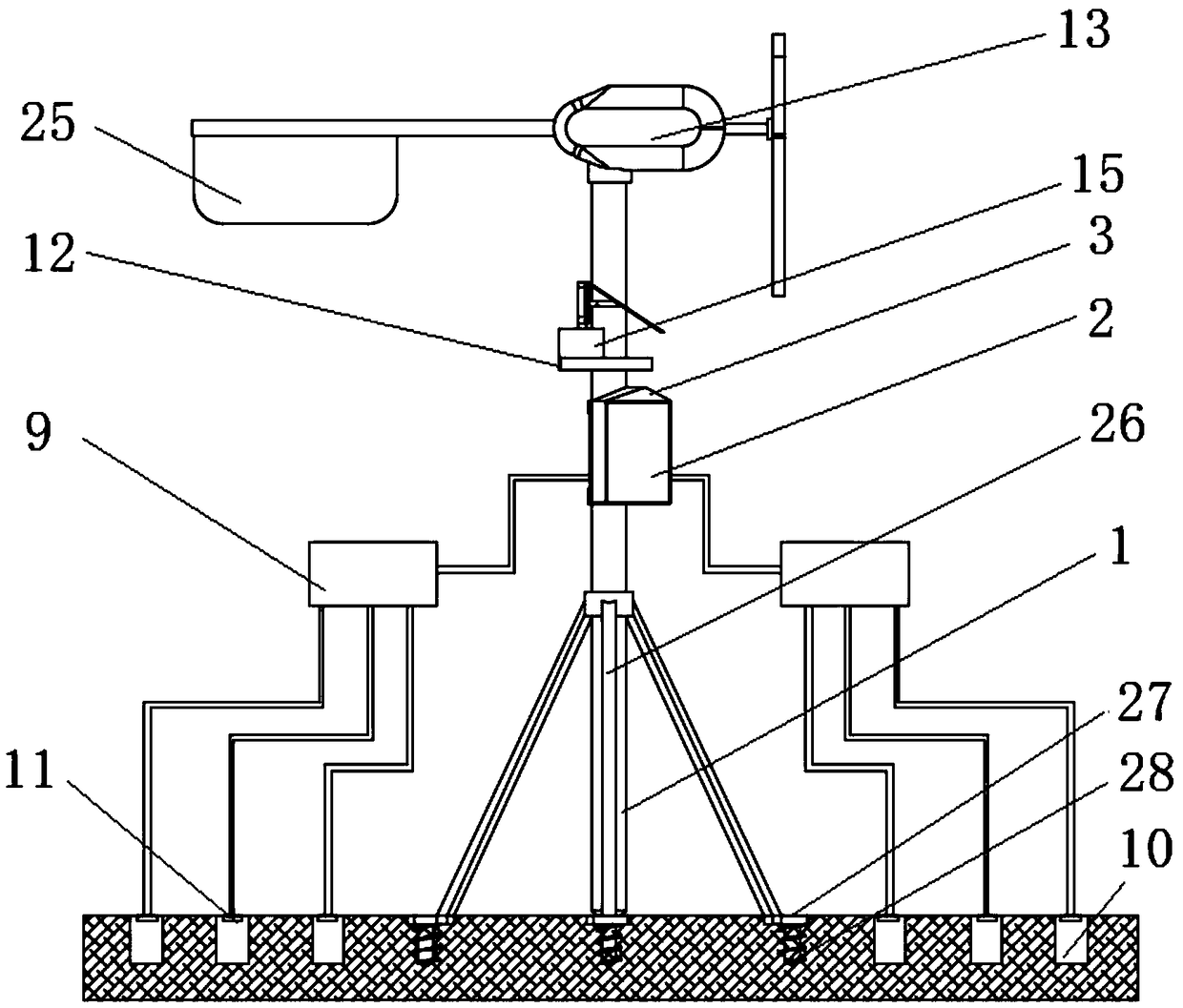

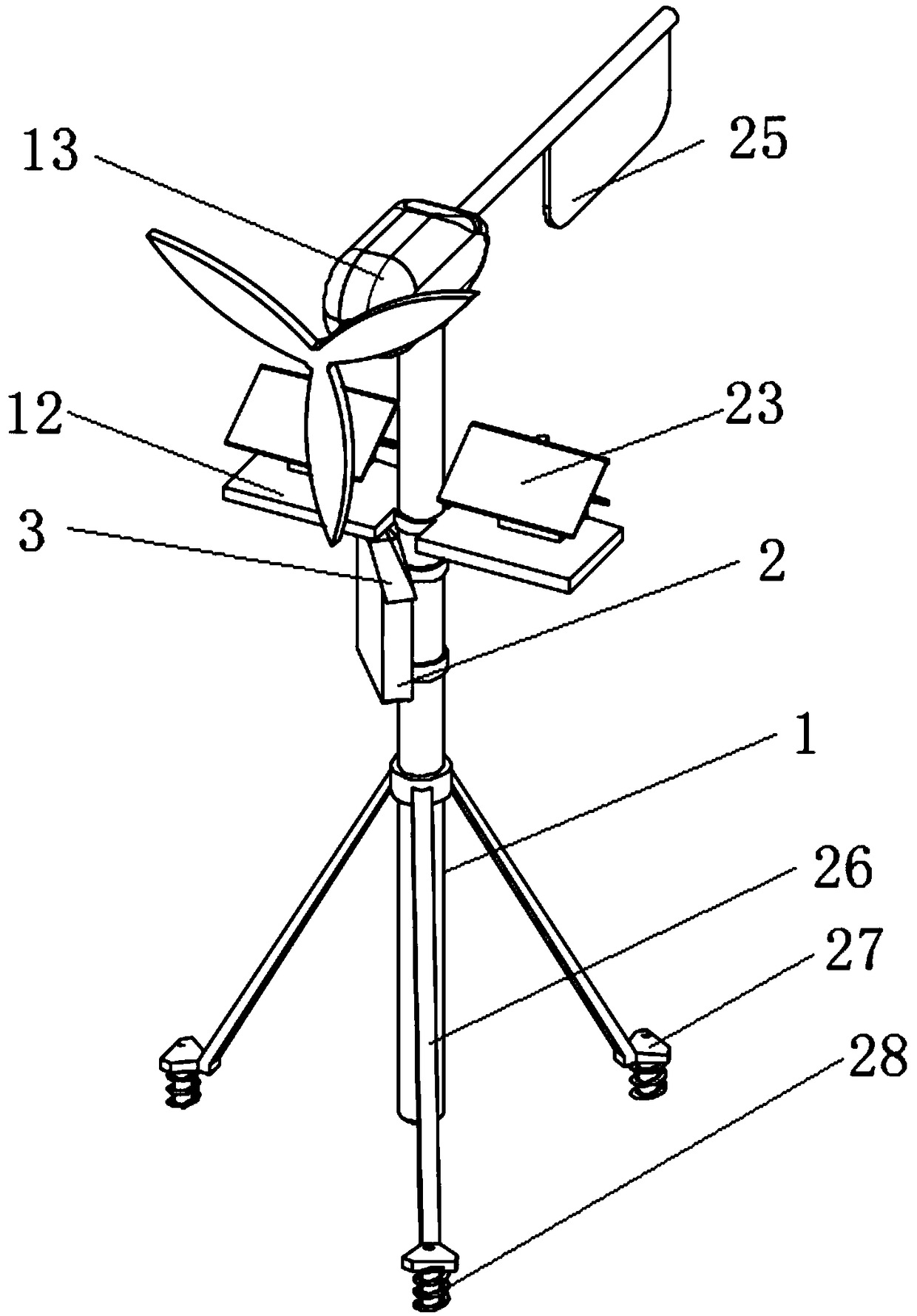

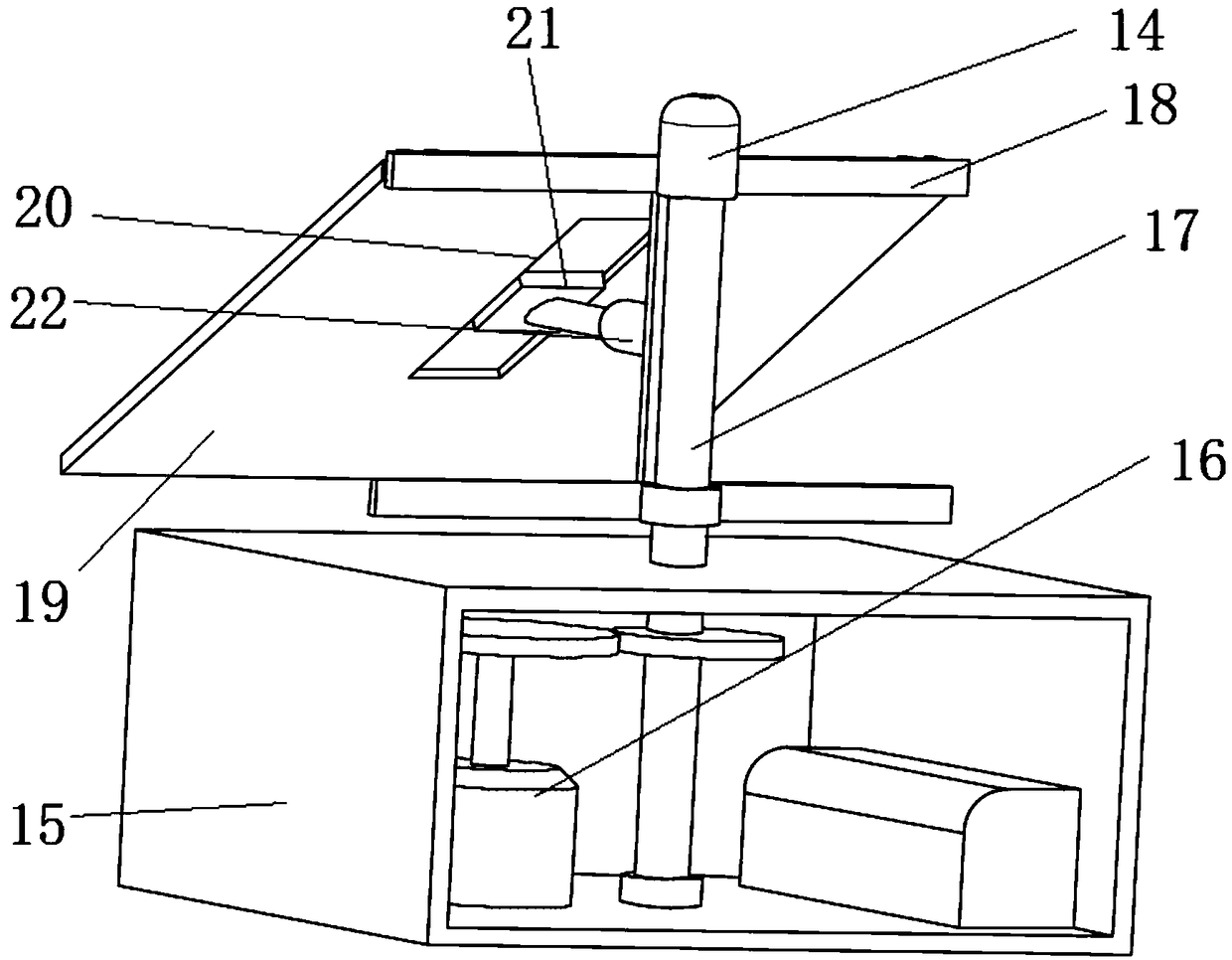

Multifunctional road lamp

InactiveCN106287540AImprove power storage capacitySimple structureMechanical apparatusLighting support devicesRoad surfaceEngineering

The invention belongs to the technical field of illumination and particularly relates to a multifunctional road lamp. A spraying pipe capable of spraying water is connected to a road lamp post, is communicated with a water pump and can clean the lamp in a timed mode, and the phenomenon that the lamp is covered by dust due to long-term usage and usage is affected is avoided. The spraying pipe is further connected with a rotating motor, direction change can be performed when the lamp is not needed to be cleaned, the spraying pipe sprays water to the air in dry weather so as to achieve the effects of wetting the air and preventing dust raising. The spraying pipe can be also used for watering a green belt, can achieve the local cooling purpose through spraying when the air temperature is high, facilitates air cooling around the road lamp, meanwhile can decrease the dust above the road surface, can be used for performing spraying towards the road surface to moistening the road surface.

Owner:江苏天虹照明集团有限公司

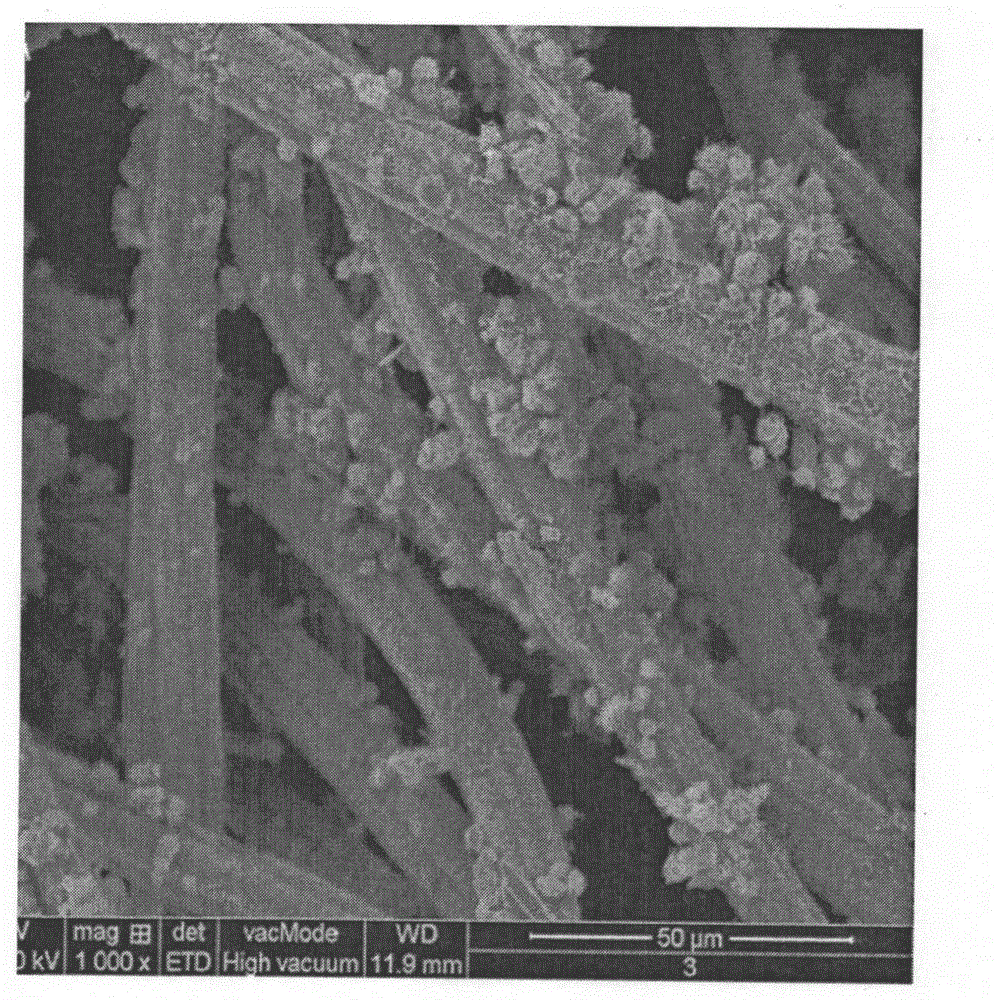

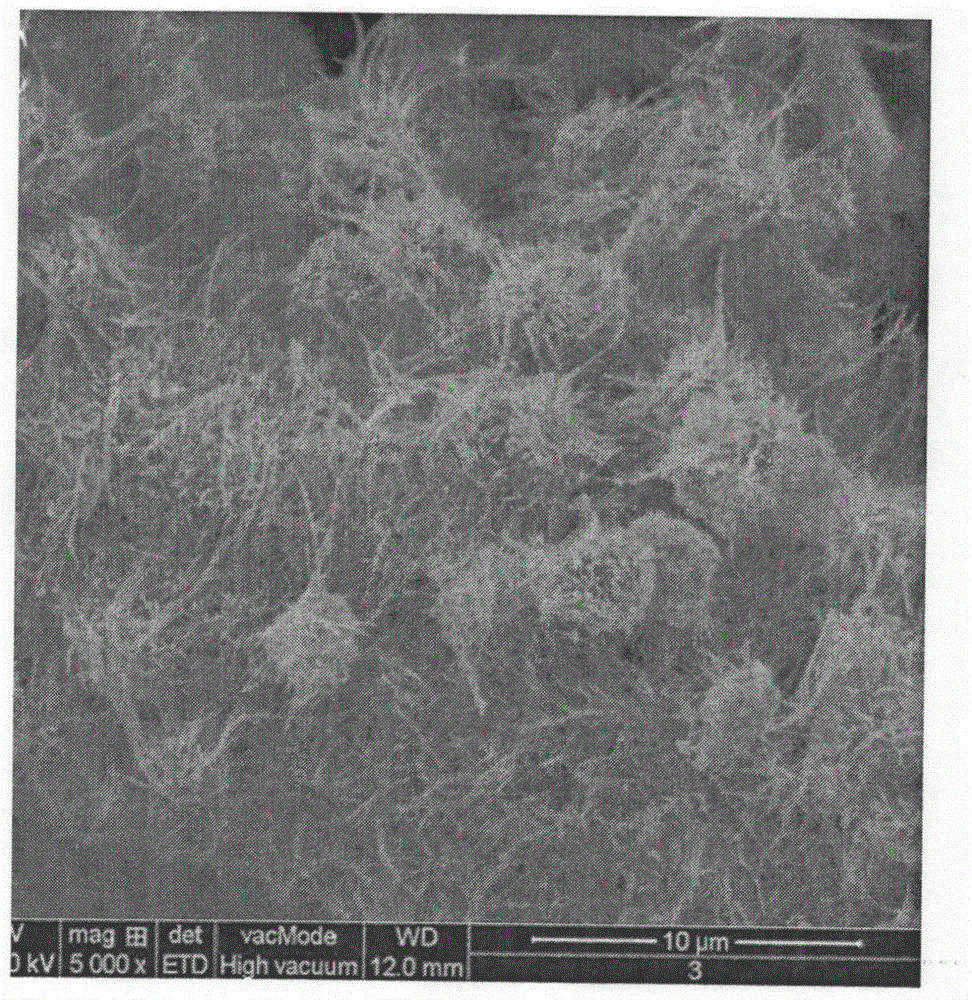

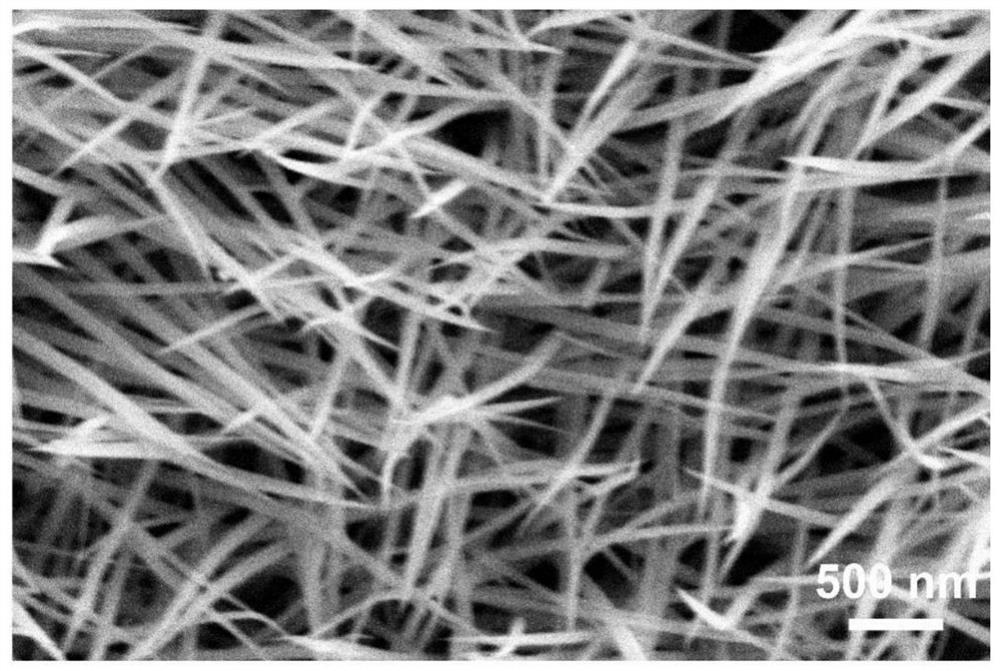

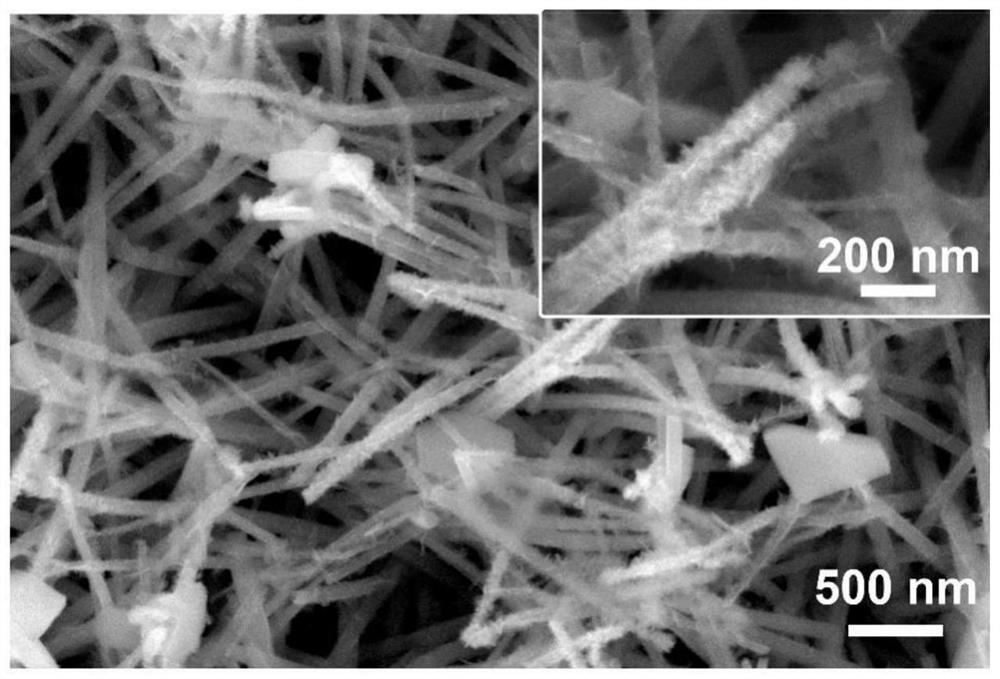

Metallic oxide nanowire coil/active carbon fiber composite electrode material and preparation thereof

InactiveCN104576079AFluffy network structureLarge specific surface areaHybrid capacitor electrodesDouble layer capacitorsFiberNanowire

The invention provides a metallic oxide nanowire coil / active carbon fiber composite electrode material and a preparation method thereof. The metallic oxide nanowire coil / active carbon fiber composite electrode material comprises active carbon fiber, cobalt oxide and nickel oxide, wherein the cobalt oxide and nickel oxide grow on the surface of the active carbon fiber in a covering manner in the form of nanowire or nanowire coil. The electrode material disclosed by the invention adopts a fluffy network structure, has large specific area and is in full contact with electrolyte; electrolyte ions have a short moving path, so that high convenience and rapidity are realized. Metallic oxides have larger surfaces and more active sites to participate in electrode reaction, so that the electric charge storage capacity and the power performance of the electrode are improved; in addition, the active carbon fiber can store electric charges, can also serve as a matrix to be easily processed into the electrode and is not dense. The composite electrode expresses the advantages of two types of electrode materials and overcomes the defects of a single electrode material.

Owner:DONGHUA UNIV +1

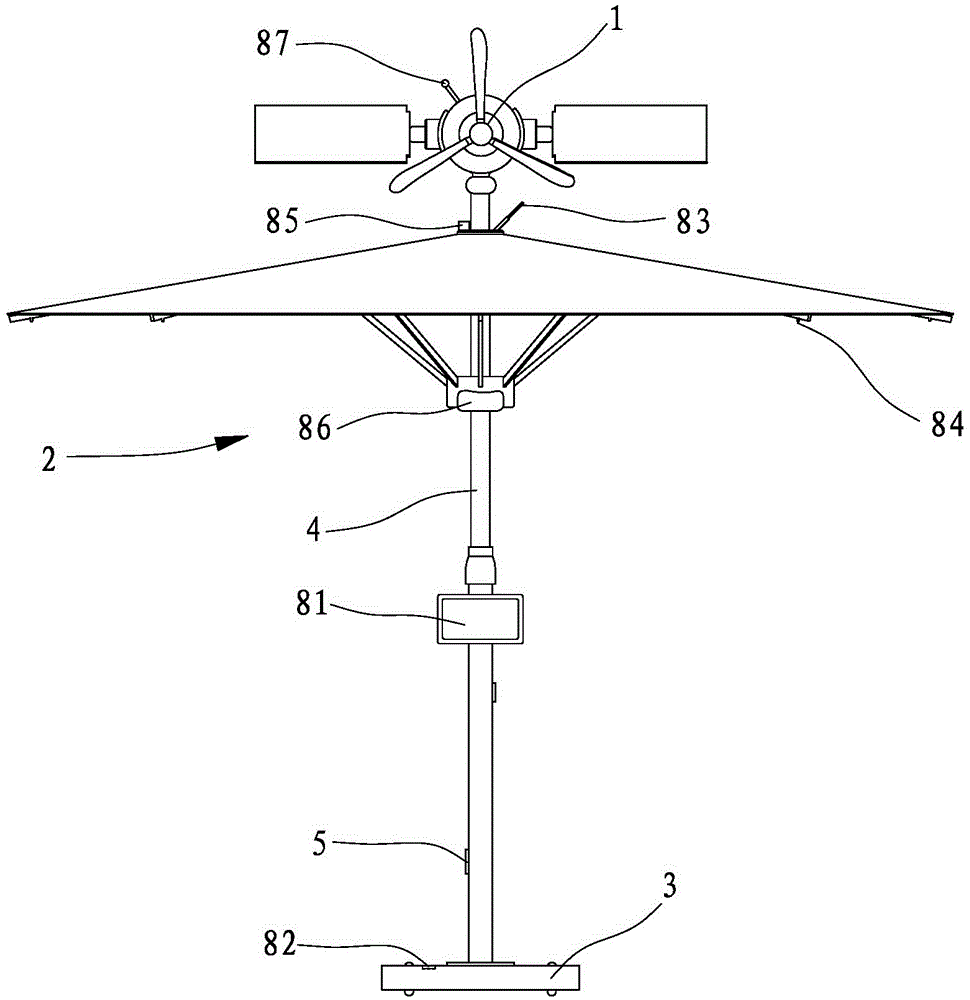

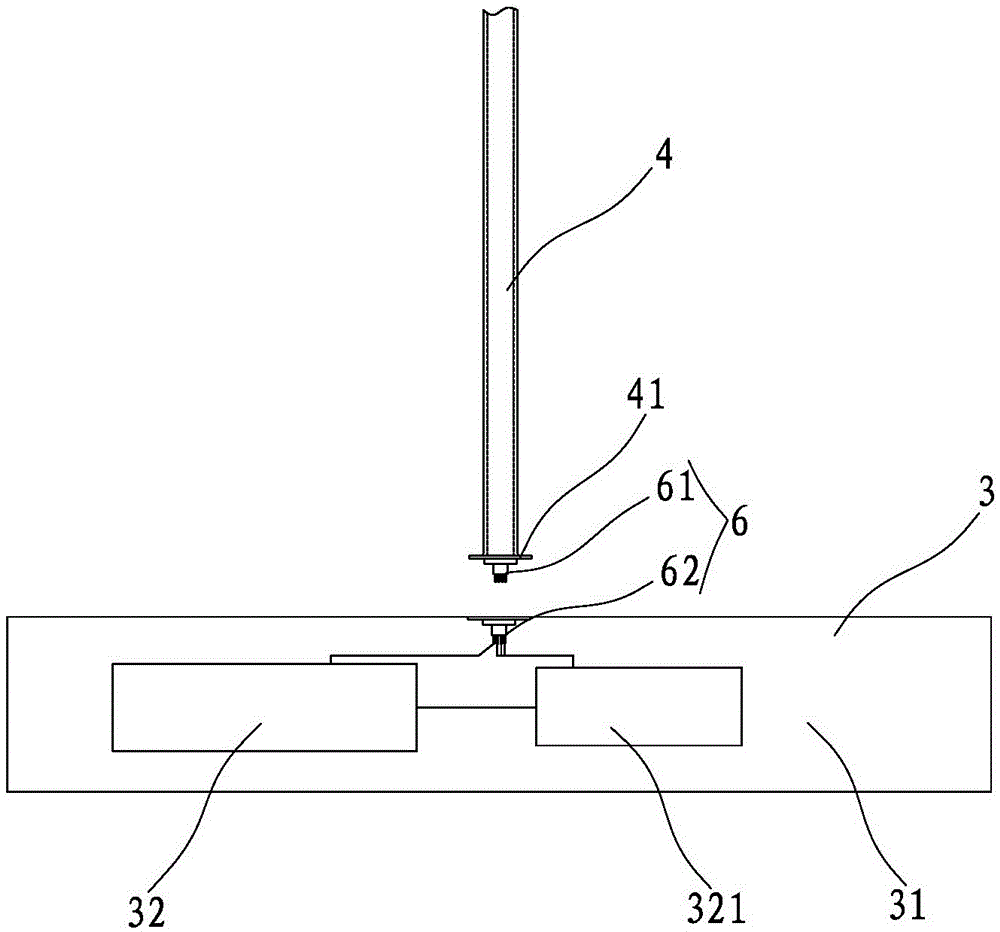

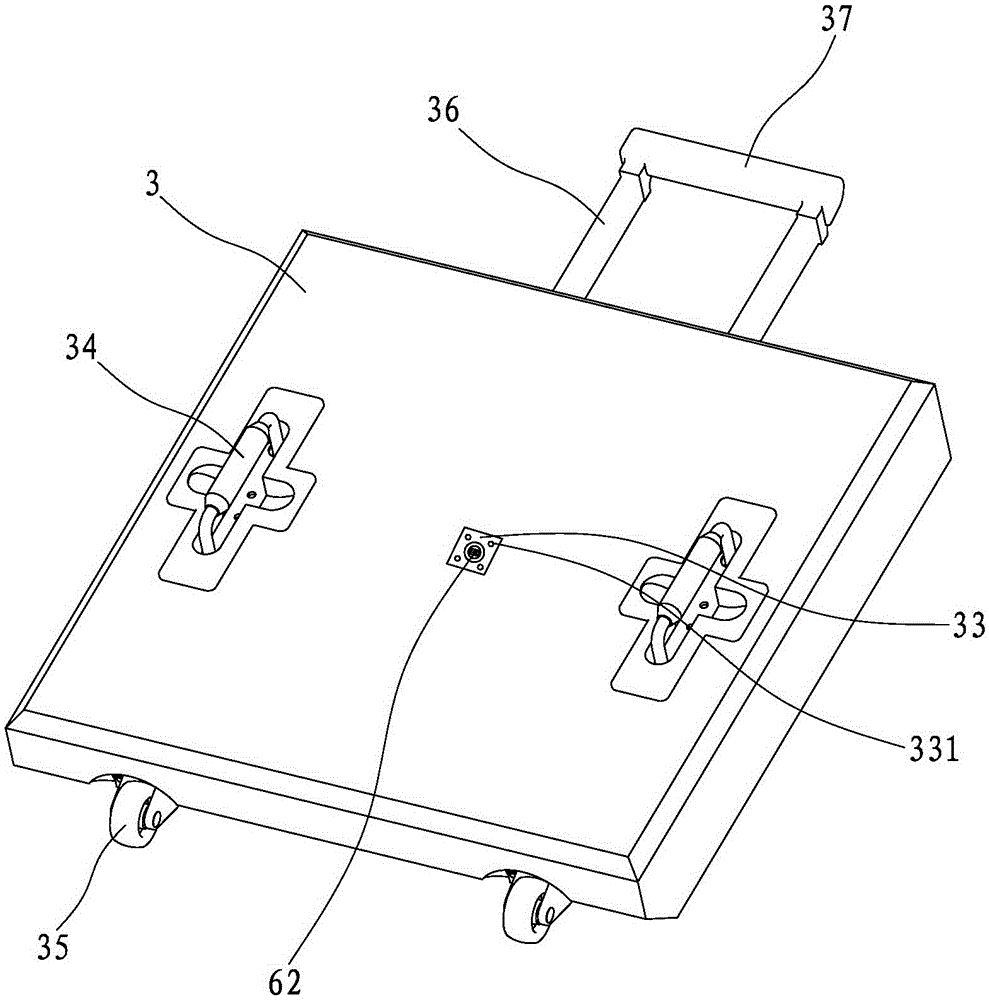

Multifunctional outdoor sun umbrella capable of providing wireless information interaction

The invention discloses a multifunctional outdoor sun umbrella capable of providing wireless information interaction. The multifunctional outdoor sun umbrella comprises a power generation device, an umbrella part and a base. The power generation device is mounted over the umbrella part. The base is detachably mounted at the lower end of an umbrella rod of the umbrella part. A containing cavity is formed in the base, and a storage battery is mounted in the containing cavity. An electric wire is mounted inside the umbrella rod, and the umbrella rod is connected with the power generation device and the storage battery through the electric wire. The umbrella rod and the base are in electric wire connection through an electric wire fast butt joint with a male terminal and a female terminal. The umbrella part or the base is provided with a wireless communication device which is electrically connected with the storage battery. According to the multifunctional outdoor sun umbrella, the design that the base and the storage battery are integrated is adopted, and thus electric power storage cruising ability is greatly improved; the wireless communication device capable of working continuously is mounted, and thus information can be acquired and transmitted more conveniently and rapidly; besides, the outdoor sun umbrella is detachably mounted, and therefore transportation is quite convenient.

Owner:HUACHUANG FUJIAN DECORATE THINGS CO LTD

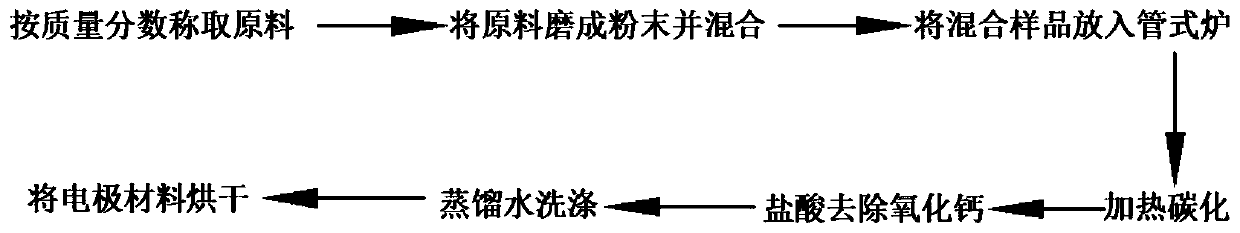

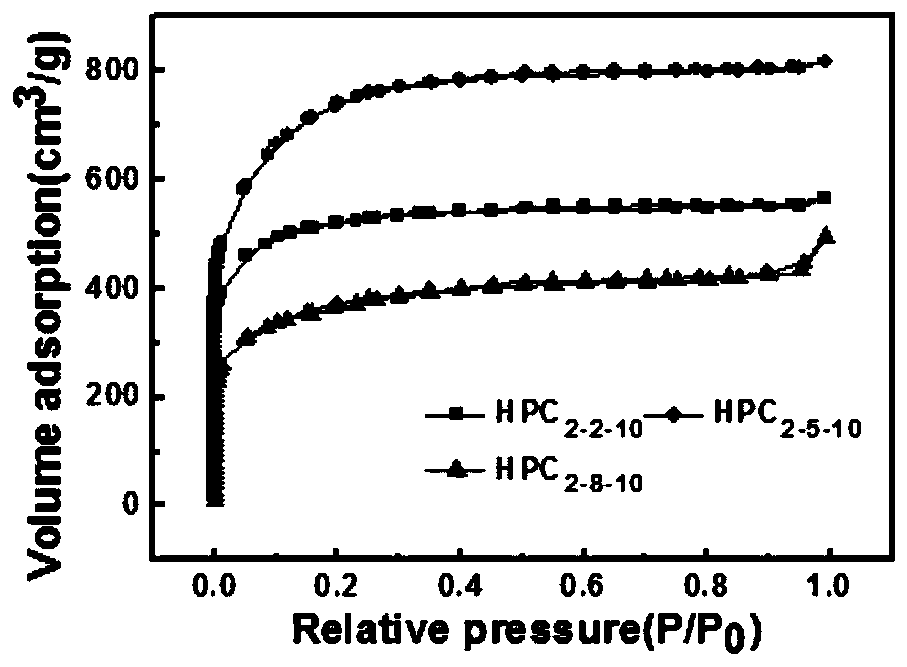

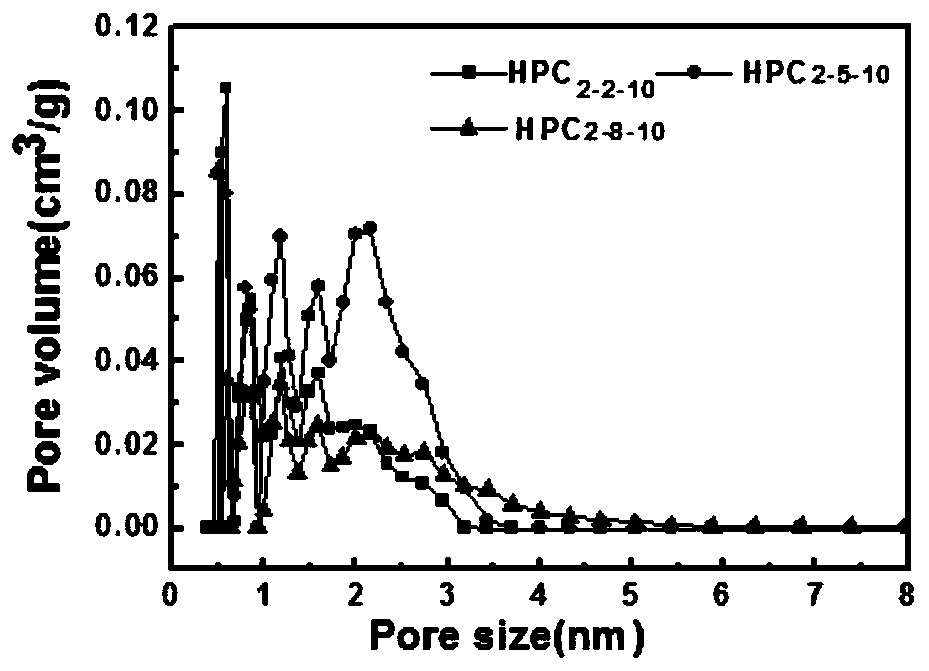

Electrode material, preparation method and application thereof

ActiveCN110459409AHigher than capacitanceImprove electrochemical performanceHybrid capacitor electrodesHybrid/EDL manufactureCapacitancePotassium hydroxide

The invention provides an electrode material as well as a preparation method and the application thereof. The electrode material takes coal pitch as a carbon source, takes nano calcium oxide as a template agent and takes potassium hydroxide as an activating agent. The preparation method comprises the following steps: S1, weighing the raw materials in parts by mass; S2, grinding the raw materials into powder and mixing; S3, putting the mixed sample into a tubular furnace, and introducing inert gas; S4, heating and carbonizing; S5, performing acid pickling to remove nano calcium oxide; s6, washing with distilled water; S7, drying the electrode material. The electrode material prepared by the method has the characteristics of large specific surface area, proper pore size distribution range and high oxygen element content, so that the electrode material is high in specific surface area utilization rate, high in specific capacitance, high in energy density and good in cycle performance. Thematerial can be used as an electrode material for a supercapacitor.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY +1

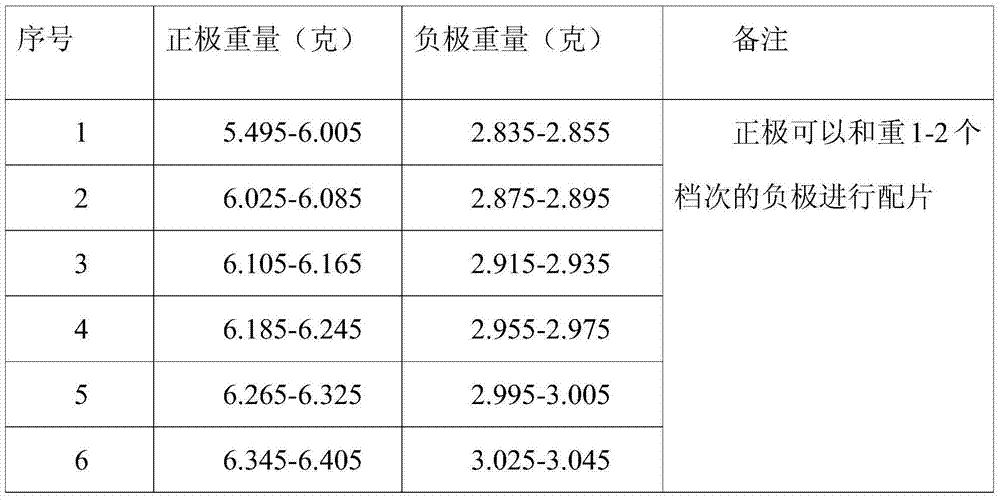

Preparation technology applied to produce soft-shell lithium battery

InactiveCN104505536APrevent leakageAvoid safety accidentsCell electrodesFinal product manufactureAssembly lineSlurry

The invention discloses a preparation technology applied to produce a soft-shell lithium battery. The preparation method comprises: 1) preparing cathode and anode formula materials; 2) performing material mixing and slurry dragging for cathode and anode, concretely, a) performing cathode material mixing and slurry dragging, and b) performing anode material mixing and slurry dragging, further concretely, in the a), performing pretreatment on cathode ingredients, performing ball milling on the cathode ingredients, preparing a slurry from the cathode ingredients, and performing slurry dragging operation on the cathode ingredients, and in the b), performing pretreatment on anode ingredients, performing ball milling on anode ingredients, preparing a slurry from anode ingredients, and performing slurry dragging operation on anode ingredients; preparing the battery, concretely, preparing a cathode sheet from the cathode ingredients subjected to slurry dragging, preparing an anode sheet from the anode ingredients, overlaying the cathode sheet and the anode sheet according to the internal structure of the lithium battery, and then performing packaging by utilizing an aluminium-plastic membrane or an aluminium-plastic composite membrane as a shell, and then winding an electric-leakage protective layer around the polar ends and the shell of the lithium battery. The lithium battery manufactured by employing the new technological process is capable of effectively avoiding electric leakage phenomenon caused by heating, thereby avoiding similar accidents during usage, and the whole technological process is scientific, reasonable and high in handleability, and can be easily implanted into industrial assembly line operation.

Owner:GUANGAN DINGHENG NEW ENERGY LITHIUM BATTERY MFG

Soil moisture monitoring device and method

InactiveCN109490506AEffective against rain and moistureEliminate the effect of errorEarth material testingUsing optical meansMultiple pointEngineering

The invention discloses a soil moisture monitoring device and method and relates to the technical field of monitoring devices. The soil moisture monitoring device comprises a fixing pole; a master control box is fixedly connected to the circumference of the fixing pole; a rainproof cover is fixedly connected to one surface of the master control box; a heating plate is fixedly connected to one surface of the rainproof cover; a temperature and humidity sensor, an information acquisition unit and a wireless transmitter are fixedly connected to the inner surface of the master control box respectively; an input end of the information acquisition unit is connected with a plurality of junction boxes fixedly through conductor wires; input ends of the junction boxes are fixedly connected with a plurality of tubular moisture detectors through conductor wires respectively. With the arrangement design of the junction boxes and the tubular moisture detectors, and designs of the the wireless transmitter and moisture monitoring probes, the device can realize multiple-point sampling, error influence caused by single-point sampling can be eliminated, monitoring results can be more representative and accurate; with designs of the rainproof cover, water guide slots and the electric heating plate, the electric appliance box of the device can be protected against rain and damp effectively.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

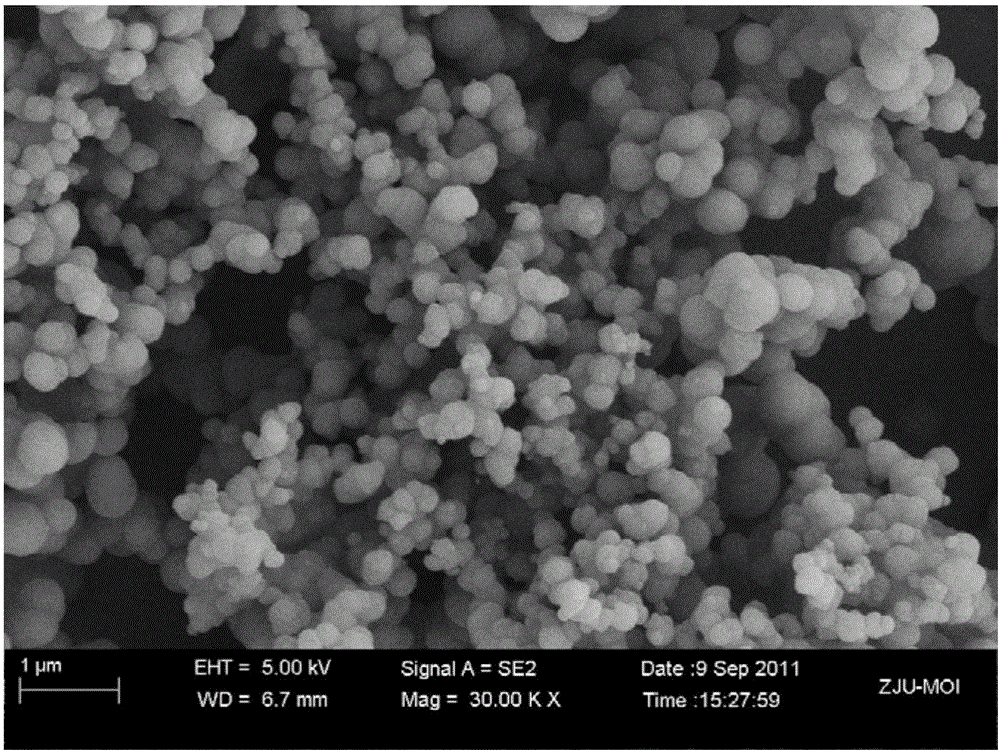

Doped graphene-modified lithium titanate composite anode material and preparation method thereof

ActiveCN105680007AImprove conductivityImprove power storage capacityCell electrodesSecondary cellsPower batteryDoped graphene

The invention provides a doped graphene-modified lithium titanate composite anode material and a preparation method thereof. Doped graphene is coated with or doped into a lithium titanate material, wherein the coating amount or the doping amount of the doped graphene is 10%-20%. By the technical scheme of the invention, the electrical conductivity of the lithium titanate material is improved with a graphene doping body; the capacity development and the high-rate charge-discharge property are improved; the development requirements of a high-energy and high-power power battery are met; and the preparation technology and production equipment are convenient to operate and are suitable for industrial large-scale production.

Owner:李震祺 +1

Binder-free porous silicon/carbon composite electrode and application thereof

The invention discloses a binder-free porous silicon / carbon composite electrode and an application thereof. The composite electrode is prepared by the following steps of (1) mixing absolute ethyl alcohol, nitrate or perchlorate water solution and silicate alkyl ester, then adjusting pH to 2.0-6.0, and stirring to obtain a precursor solution; (2) performing surface oxide removing and oil removing on a copper foil substrate or a nickel foil substrate; (3) taking the processed copper coil substrate or the nickel foil substrate as working electrodes, and putting the working electrodes in an electrode groove loaded with the precursor solution, and taking a platinum sheet or graphite as a counter electrode to carry out electro-deposition to obtain a micro-nano silicon oxide coating on the surface of the copper coil substrate or the nickel foil substrate; (4) carrying out magnesiothermic reduction on the copper coil substrate or the nickel foil substrate coated with the micro-nano silicon oxide coating to obtain a copper foil or a nickel foil with a porous silicon-based material on the surface; and (5) carrying out chemical vapor deposition on the copper foil or the nickel foil with the porous silicon-based material on the surface to obtain the binder-free porous silicon / carbon composite electrode. The porous silicon / carbon composite electrode can be applied to the negative electrode of a lithium ion battery.

Owner:ZHEJIANG UNIV OF TECH

Battery balancing method

InactiveUS8310203B2Improve power storage capacityExtended service lifeCharge equalisation circuitSafety/protection battery circuitsCounting NumberElectrical battery

A battery balancing method for a battery pack is disclosed, wherein the battery pack includes a plurality of rechargeable battery cells. The method categorizes the plurality of battery cells into a first subgroup and a second subgroup. Each battery cell in the first subgroup has an over voltage count number that records the times of the battery cells reaching an over voltage protection point. A minimum voltage of the battery cells in the second subgroup is detected. Then the voltage of each battery cell in the first subgroup is decreased to a buck voltage lower than the minimum voltage of the second subgroup. While any one cell in the first group reaches the over voltage protection point again during the charging procedure, the over voltage count numbers for the particular battery cells already reached the over voltage protection point are accumulated and then the charging procedure is terminated.

Owner:LITE ON ELECTRONICS (GUANGZHOU) LTD +1

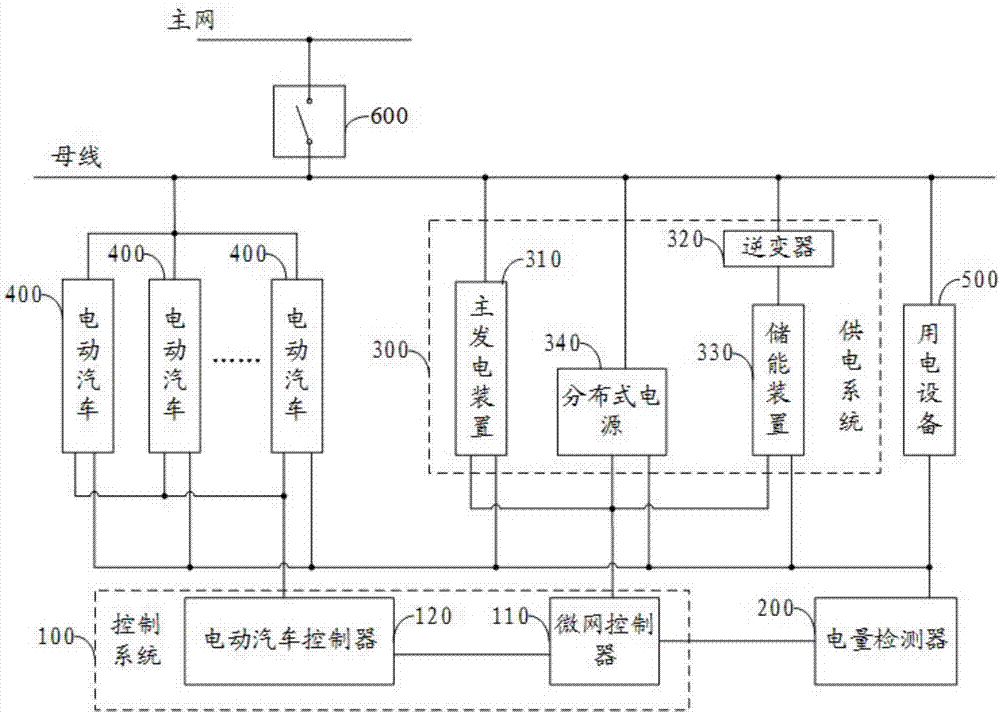

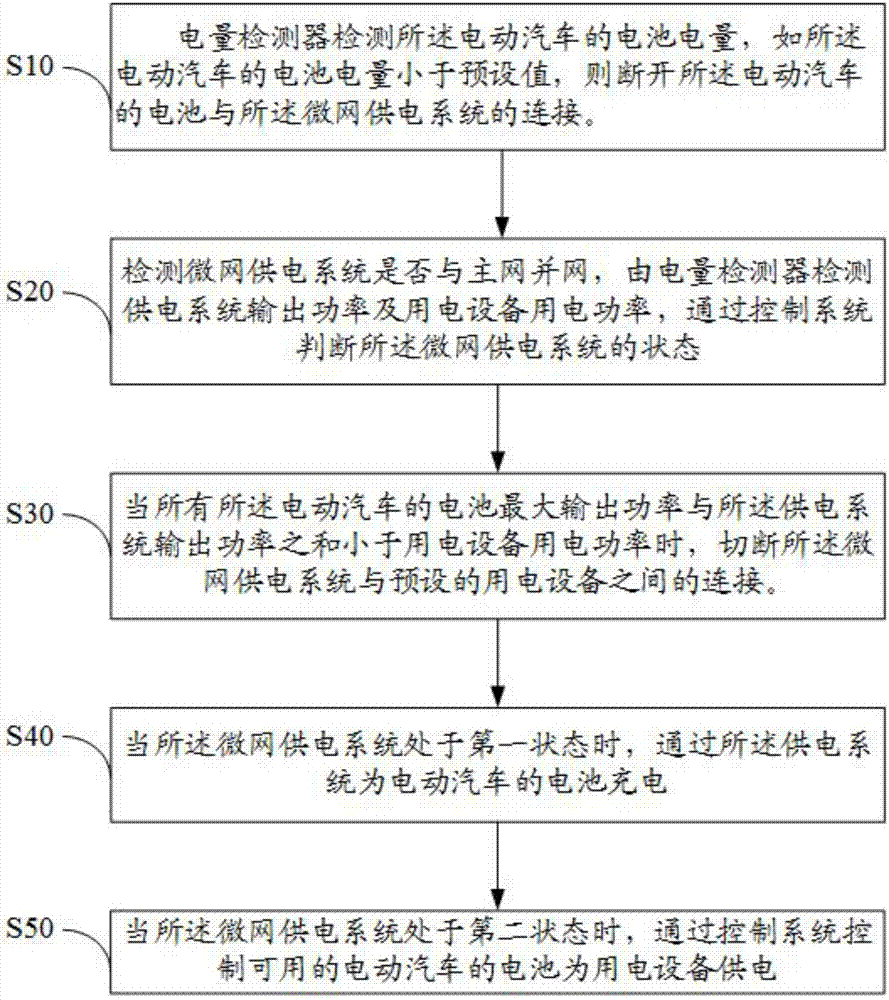

Microgrid power supply system and microgrid power supply method

InactiveCN107046282AImprove power storage capacityCharging stationsAc network load balancingElectrical batteryElectric energy

The invention discloses a microgrid power supply system and a microgrid power supply method. The microgrid power supply system comprises a control system, an electrical quantity detector, a power supply system and at least one electric vehicle, wherein the electrical quantity detector is used for detecting electrical quantity of a battery of the electric vehicle, electricity utilization power of electricity utilization equipment and an output power of the power supply system and sending power information, the control system is used for receiving the power information and controlling charging or discharging of the electric vehicle and the power supply system, and the electric vehicle is used for supplying power to the electricity utilization equipment when the output power of the power supply system is smaller than the electricity utilization power of the electricity utilization equipment, and receiving electric energy of the power supply system to charge the battery when the output power of the power supply system is larger than the electricity utilization power of the electricity utilization equipment. By the technical scheme, the battery of the electric vehicle is effectively utilized, so that a microgrid is more flexible and variable in power supply.

Owner:POTEVIO NEW ENERGY SHENZHEN

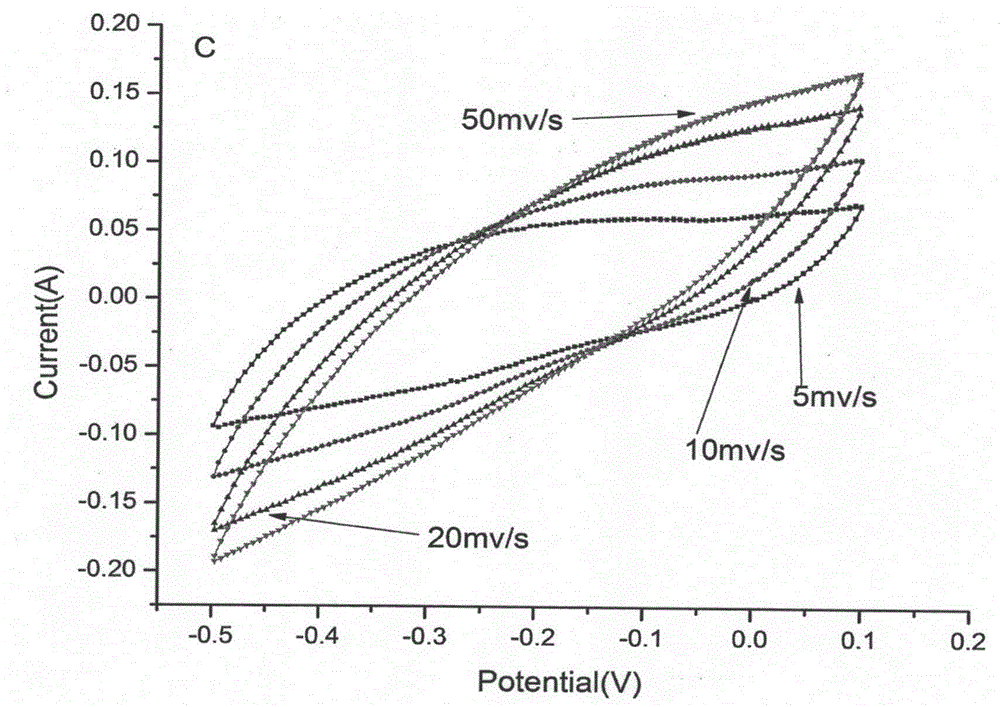

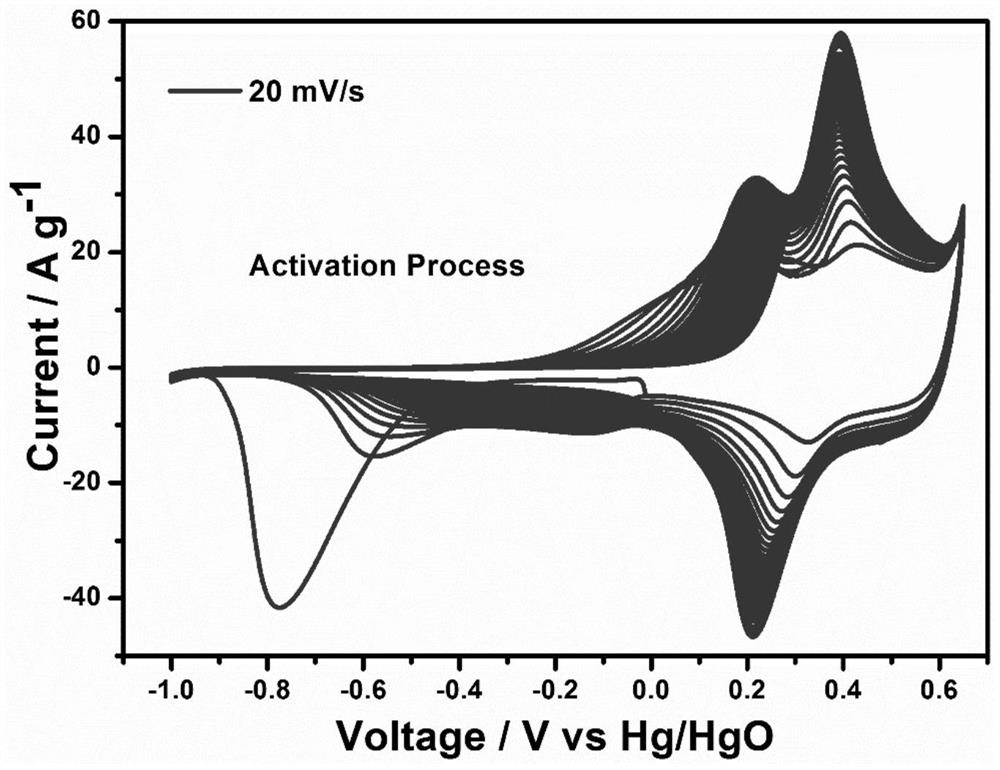

Universal electrochemical modification preparation method for effectively enhancing electricity storage performance of various transition metal oxides

InactiveCN112467077AImprove power storage capacityImprove general performanceAlkaline accumulatorsHybrid capacitor electrodesElectrolytic agentElectrical battery

The invention relates to a universal electrochemical modification preparation method for effectively enhancing the electricity storage performance of various transition metal oxides, and belongs to the technical field of production of super capacitors and alkaline secondary battery electrodes. The method is characterized in that cyclic voltammetry curve scanning under a wide voltage window is carried out on transition metal oxide electrode materials (including cobalt oxide, nickel cobaltate, manganese cobaltate, zinc cobaltate, cobalt-nickel-zinc oxide and the like) in the alkaline electrolyteby utilizing an electrochemical workstation, so that the electrochemical activity of the electrode materials is greatly improved, and then a high-performance super capacitor and an alkaline water system secondary battery are prepared. According to the invention, a simple electrochemical activation method is adopted, the equipment is simple, the operation is simple, the reaction is rapid, the costis low, the method can be simultaneously used for modifying various materials, the energy storage performance can be improved by more than 5 times, and the universality is strong.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

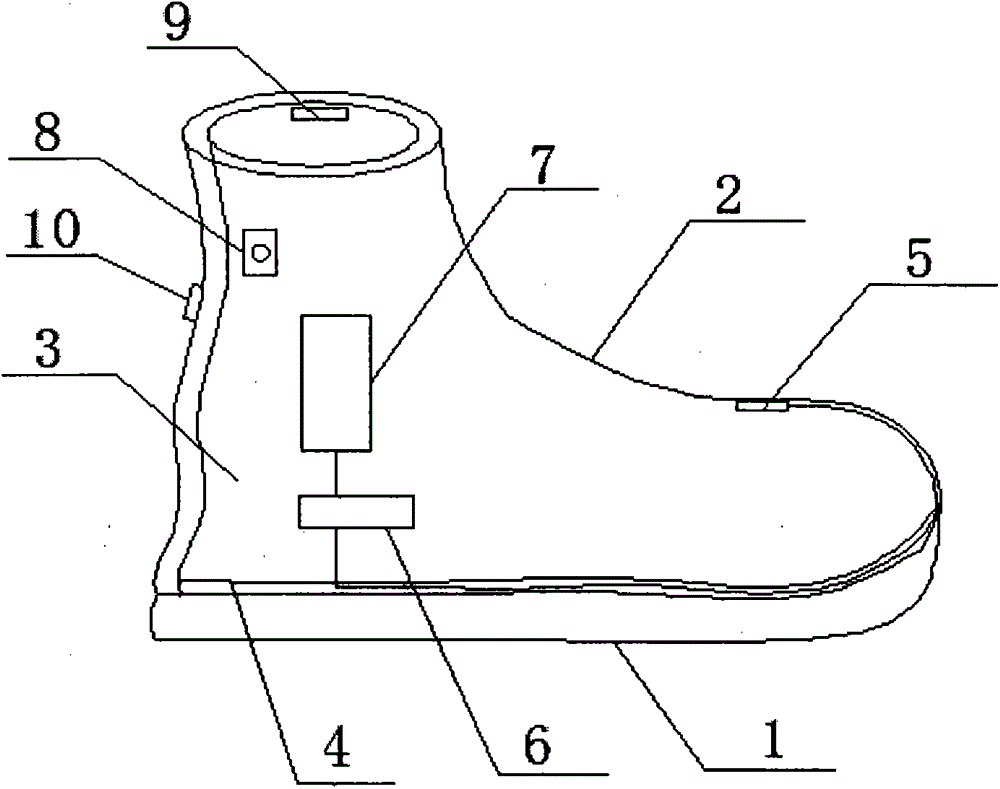

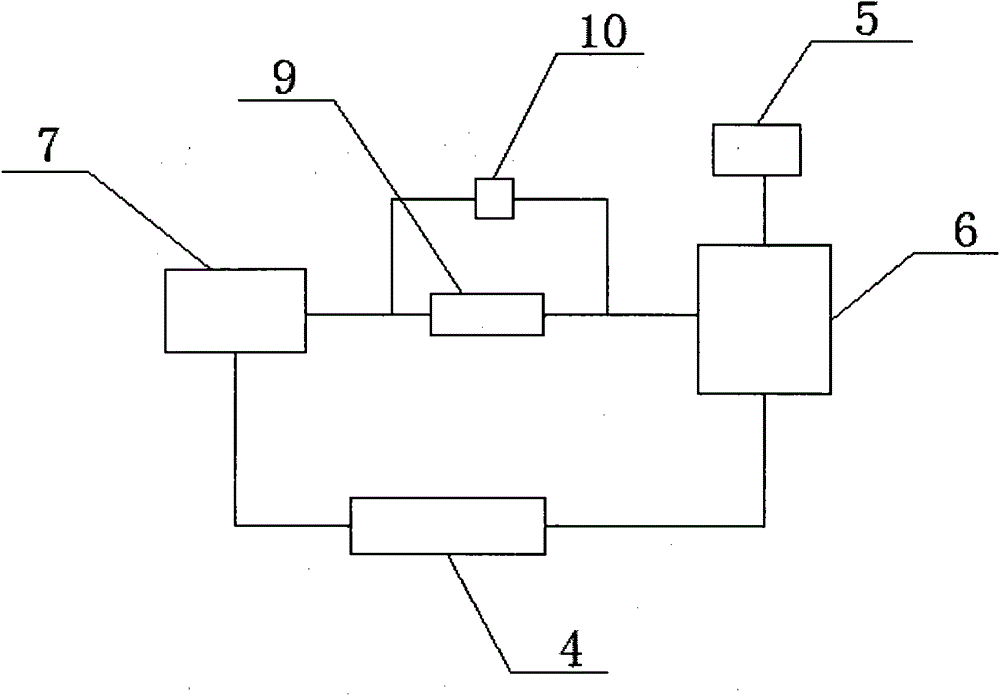

Heating and warming snow jogging shoe

The invention discloses a heating and warming snow jogging shoe which comprises a shoe sole, a shoe vamp and a shoe upper. An electric heating shoe pad is arranged on the upper surface of the shoe sole, a temperature sensor is arranged on the lower surface of the shoe vamp, an infrared inductive switch is arranged on the inner wall of the shoe upper, and a control circuit and a power module are arranged in the shoe upper. The infrared inductive switch, the electric heating shoe pad and the temperature sensor are connected with the control circuit. The power module supplies power. Due to the fact that the electric heating shoe pad made of PET heating materials is adopted on the heating and warming snow jogging shoe, the heating speed is high, and the temperature is controlled to range from 37 DEG C to 42 DEG C to make the foot feel comfortable; the power module is arranged in the shoe upper to be away from lower temperature, a rechargeable lithium battery is always kept in the working states of high electric power storage capability and long service life by means of shoe upper heat preservation and human body temperature; the infrared inductive switch and the control circuit are combined to start and stop heating of the electric heating shoe pad in time, and power is saved. The heating and warming snow jogging shoe is suitable for being worn by an outdoor sporter for a long time.

Owner:王桂彬

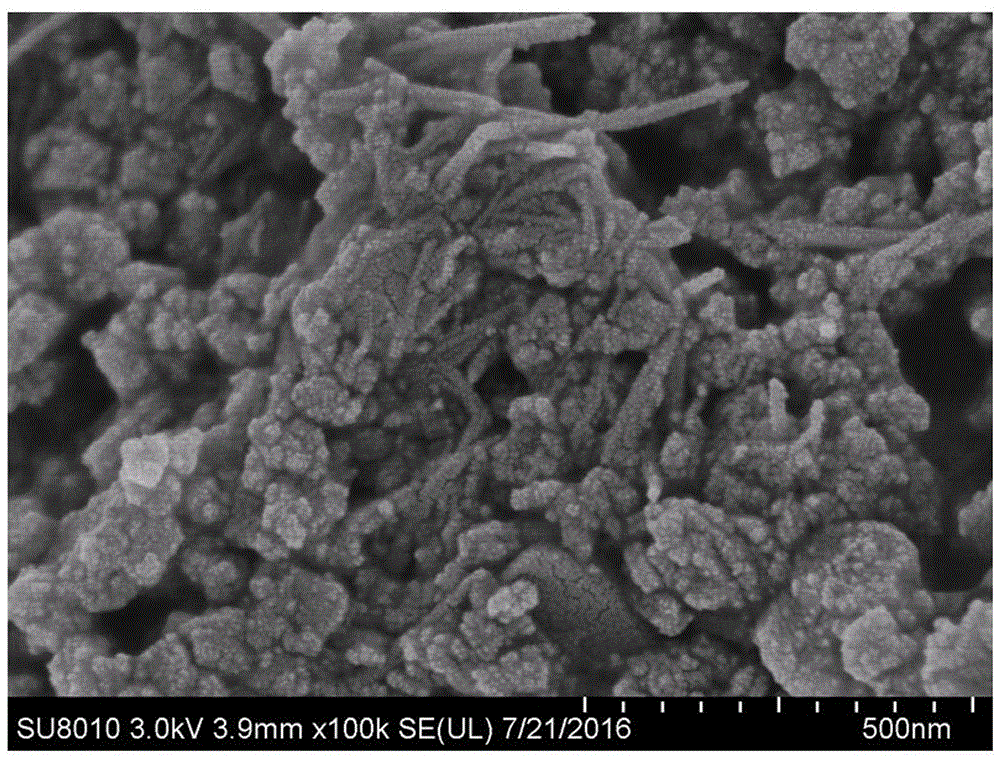

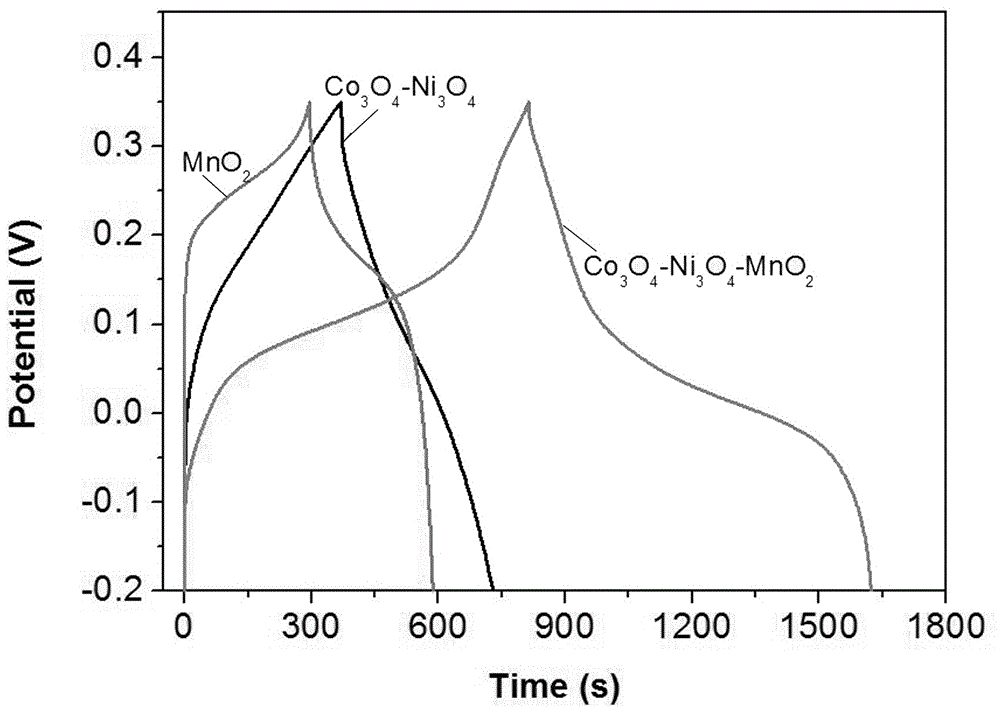

Preparation method for three-element oxide composite material and application

ActiveCN106531466AStrong reductionStrong oxidation abilityHybrid capacitor electrodesHybrid/EDL manufactureIn situ chemical reductionOxide composite

The invention discloses a preparation method for a three-element oxide composite material and an application in the field of super capacitors. According to the method, an in-situ chemical reduction method is employed to prepare a Co-Ni-B alloy material in solution, then the alloy and potassium permanganate realize oxidation reduction reaction to acquire a Co3O4-Ni3O4-MnO2 ternary oxide. Through the method, strong reductibility of the Co-Ni-B alloy and strong oxidizability of the potassium permanganate are utilized to realize oxidation reduction reaction of the two, the Co-Ni-B is oxidized to be Co3O4-Ni3O4, the potassium permanganate is reduced to be MnO2, the method is simple, an application scope is wide, and manufacturing cost is low; the three oxides are composed together, under the synergistic effect among the materials, excellent electricity storage property is realized, the three-element oxide composite material can be applied to the super capacitors, excellent electrical performance is realized, moreover, the method is applicable to mass-scale production, and the application effect is good.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Supercapacitor electrolyte

InactiveCN107680827AModerate viscosityStable in natureHybrid capacitor electrolytesCapacitanceGlycidyl methacrylate

The invention mainly relates to the technical field of electrolyte, and discloses a supercapacitor electrolyte which is manufactured by the raw materials of the following parts by weight: 51-53 partsof 1,4-butyrolactone, 37-39 parts of propylene carbonate, 32-34 parts of 2-methyl-2-propanol, 28-30 parts of glycidyl methacrylate, 24-26 parts of acrylic acid-2-hydroxyethyl ester, 13-15 parts of sec-butyl acetate, 11-13 parts of acrylic acid-2-ethyl hexyl acrylate, 1.6-1.8 parts of ditrifluoromethane lithium sulfimide, 1.1-1.3 parts of lithium hexafluorophosphate and 0.3-0.5 part of benzyl triethylammonium chloride. The supercapacitor electrolyte is safe and environment-friendly, and the situation of volatilization of toxic substances caused by overcharging of the capacitor does not occur inuse so that the environment and the human health can be protected; the electrolyte is appropriate in viscosity, convenient to use and stable in the property, and the specific capacitance is enhancedfor 10.8%, the electric storage capacity is enhanced for 13.5%, the sales volume is enhanced for 11.4% and the economic income is enhanced for 13.7%.

Owner:五河县绍峰电器有限公司

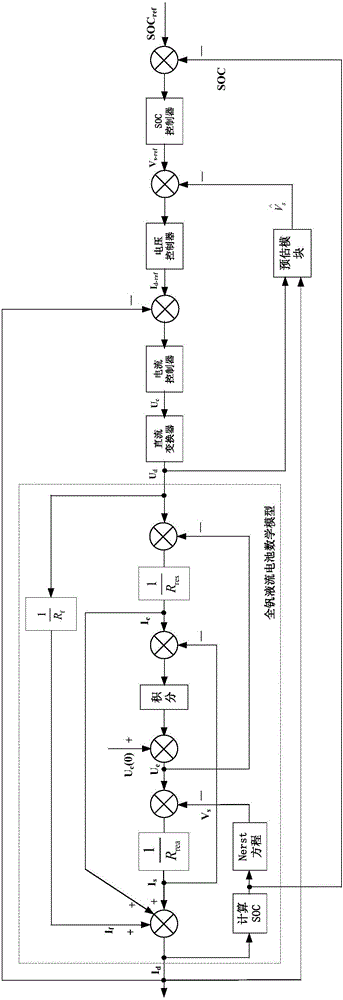

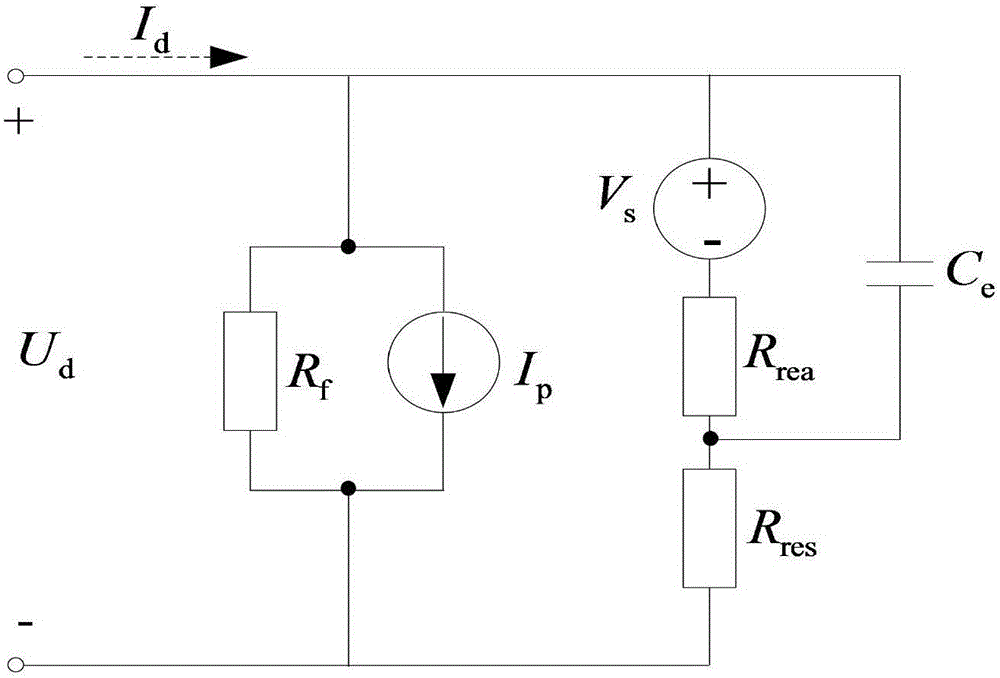

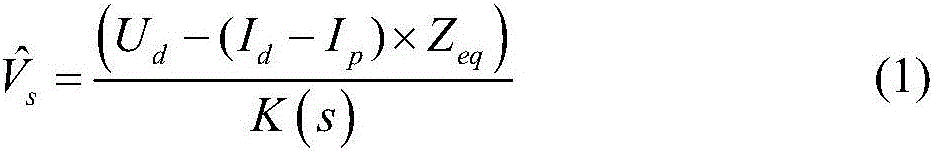

All-vanadium redox flow battery charging and discharging control system based on three-closed loop structure and control strategy thereof

ActiveCN105790361AEnsure safetySolve the problem of inaccurate state of charge estimationElectric powerBattery overcharge protectionControl systemClosed loop

The present invention discloses an all-vanadium redox flow battery charging and discharging control system based on a three-closed loop structure and a control strategy thereof. The all-vanadium redox flow battery charging and discharging control system comprises a SOC controller, a voltage controller, a current controller, an all-vanadium redox flow battery, a pre-estimation module and a direct current convertor. The control strategy employs three closed loop structure, the real charge state of the all-vanadium redox flow battery is fed back to the input end of the SOC controller, and a first closed loop structure is formed; the stack voltage estimation value of the all-vanadium redox flow battery is fed back to the input end of the voltage controller, and a second closed loop structure is formed; the real charging and discharging current of the all-vanadium redox flow battery is fed back to the input end of the current controller, and a third closed loop structure is formed. The all-vanadium redox flow battery charging and discharging control system based on a three-closed loop structure and the control strategy thereof are able to realize the estimation of the stack voltage of the all-vanadium redox flow battery, realize the charging and discharging control of the all-vanadium redox flow battery so as to improve the power storage capability of the all-vanadium redox flow battery and enhance the charging speed of the batter in the safe condition.

Owner:HEFEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com