Universal electrochemical modification preparation method for effectively enhancing electricity storage performance of various transition metal oxides

A transition metal and oxide technology, applied in the field of universal electrochemical modification preparation, can solve the problems of inability to realize electrochemical activation, increase material production cost, low power density, etc., and achieve enhanced rate performance and cycle stability, The effect of improving and enhancing energy storage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

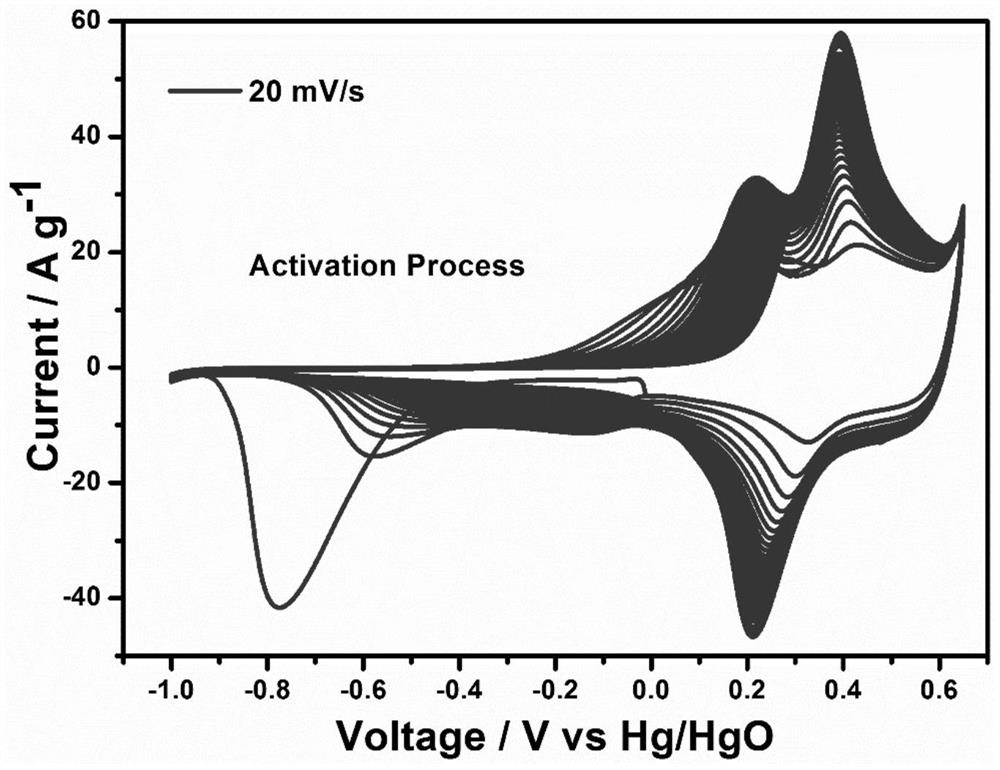

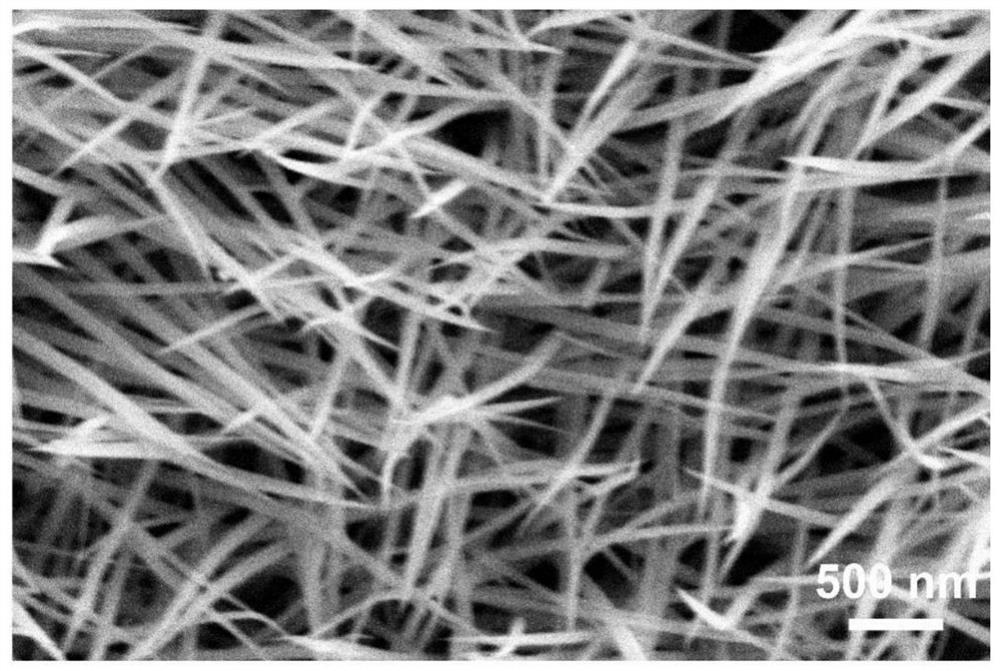

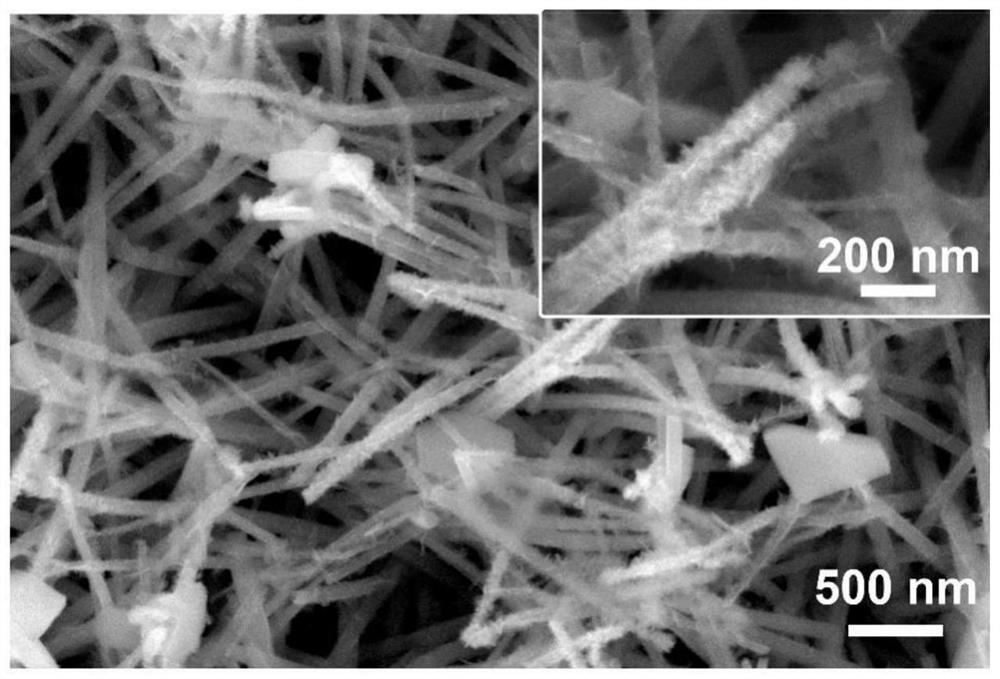

[0031] Embodiment 1: A method for preparing electrochemically activated nickel cobalt oxide (NiCoO) nanowire arrays, comprising the following steps: preparing nickel cobalt oxide nanowire arrays (NiCoO NWAs) through a simple hydrothermal reaction and air annealing process. First, 10 mM nickel nitrate hexahydrate (Ni(NO 3 ) 2 ·6H 2 O,AR), 20mM cobalt nitrate hexahydrate (Co(NO 3 ) 2 ·6H 2 O,AR) and 20mM urea (CO(NH 2 ) 2 , AR) dissolved in 15mL ultrapure water (18.2MΩ.cm) to form a homogeneous solution. The solution was then transferred to a 20 mL Teflon-lined steel autoclave, and then immersed in a piece of nickel foam (1 × 4 cm 2 ), nickel foam was pre-cleaned with 0.1M hydrochloric acid, acetone, ethanol and deionized water. After being maintained in an oven at 120° C. for 10 hours, the autoclave was taken out to cool naturally. Remove the final product, sonicate for 2 minutes in deionized water, and rinse with copious amounts of deionized water to remove loose part...

Embodiment 2

[0032] Embodiment 2: a kind of method that is used to prepare electrochemically activated NiCoO nanosheet array comprises the following steps: 1) first prepare nickel-cobalt double metal hydroxide, under magnetic stirring, the 2-methylimidazole (MIM of 40mM ) methanol solution was added to another solution containing 10mM Ni(NO 3 ) 2 ·6H 2 O and 10mM Co(NO 3 ) 2 ·6H 2 O in methanol solution. On this basis, the reaction solution was put into a tetrafluoroethylene-lined stainless steel reaction kettle, and a piece of pre-cleaned carbon fiber cloth growth substrate (CFC, 1 × 4 cm 2 ), the solvothermal reaction was carried out at 140°C for 14h, and the sample was rinsed with methanol after the reaction, and dried in an air oven at 70°C. 2) Then prepare nickel-cobalt oxide, put the dried sample into a tube furnace, and anneal at 350°C for 30min in air, with a programmed temperature rise rate of 5°Cmin -1 , to obtain NiCoO nanosheet arrays. 3) Finally, the electrochemical ac...

Embodiment 3

[0033] Embodiment 3: a kind of method for preparing electrochemically activated zinc cobaltate (ZnCoO) nanowire array comprises the following steps: 1) using 25mM zinc nitrate hexahydrate (Zn(NO 3 ) 2 ·6H 2 O,AR) and 25mM cobalt nitrate hexahydrate (Co(NO 3 ) 2 ·6H 2 O, AR) as the metal cation precursor, using 15 mM NH 4 F and 25mM CO(NH 2 ) 2 As the alkali source, pour the solution containing the alkali source into the solution containing metal ions, and stir evenly for 10 minutes. The reaction solution was then transferred to a 20 mL Teflon-lined steel autoclave while immersed in a nickel foam substrate (1 × 4 cm 2 ), nickel foam was pre-cleaned with 0.1M hydrochloric acid, acetone, ethanol and deionized water. After being maintained in an oven at 120° C. for 10 hours, the autoclave was taken out to cool naturally. 2) Take out the nickel foam, rinse it three times with ultrapure water, put it into a vacuum drying oven, and dry it at 70°C for 8 hours. Finally, the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com