Patents

Literature

1030results about How to "Strong reduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

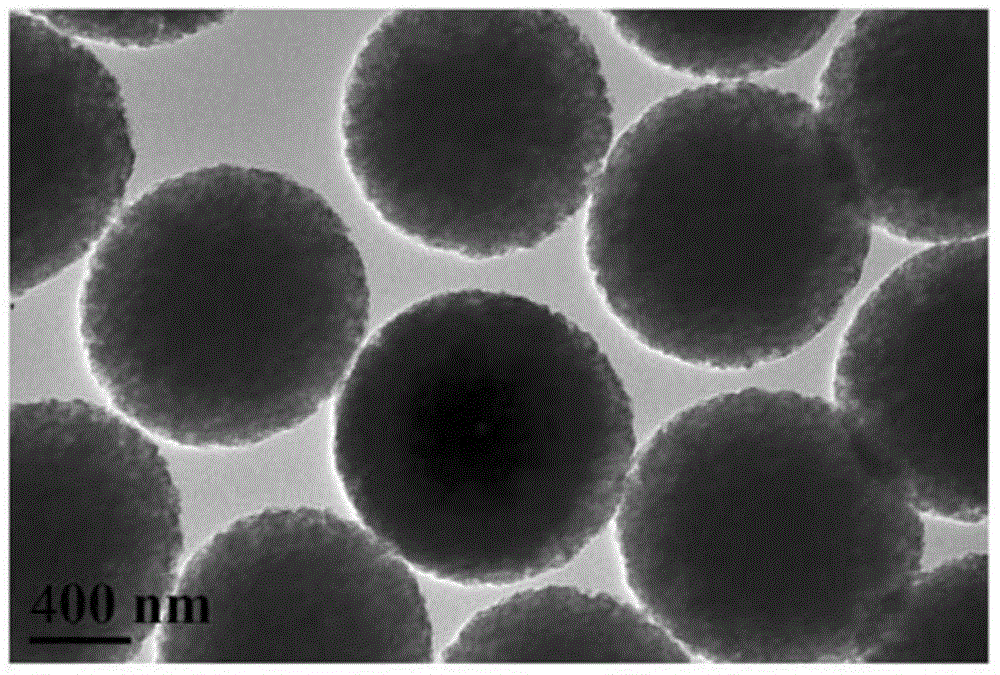

Carbon-supported core-shell type platinum cobalt-platinum catalyst for fuel cells and preparation method for carbon-supported core-shell type platinum cobalt-platinum catalyst

ActiveCN104475126AImprove utilization and stabilityLow cost of preparationCell electrodesMetal/metal-oxides/metal-hydroxide catalystsChemistryCarrying capacity

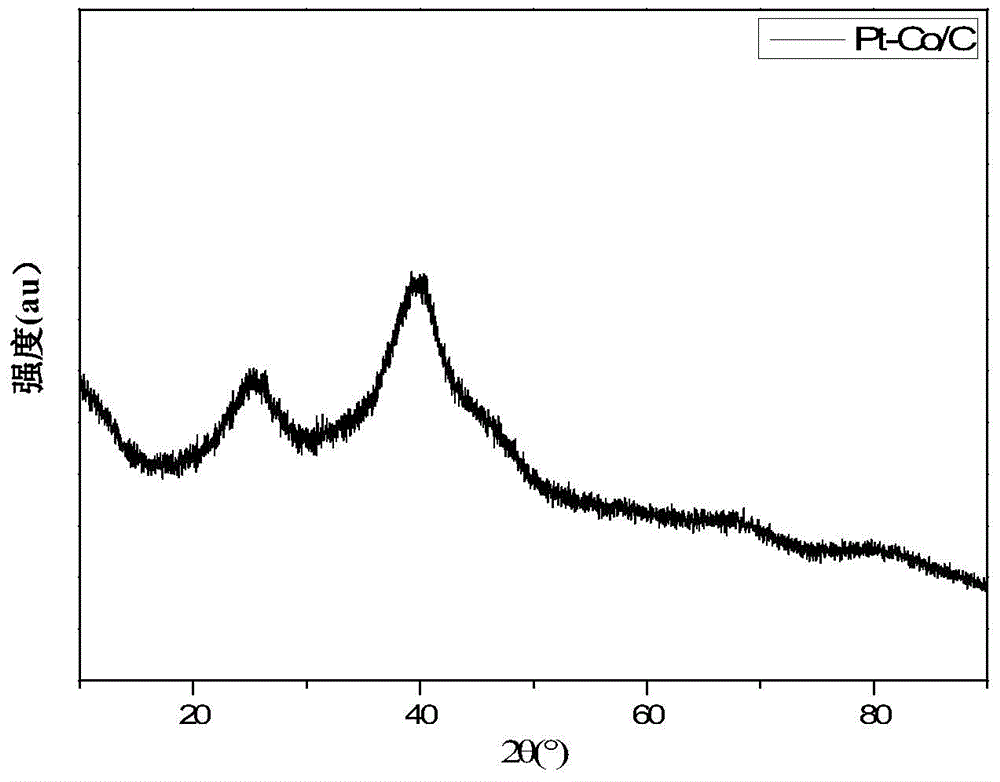

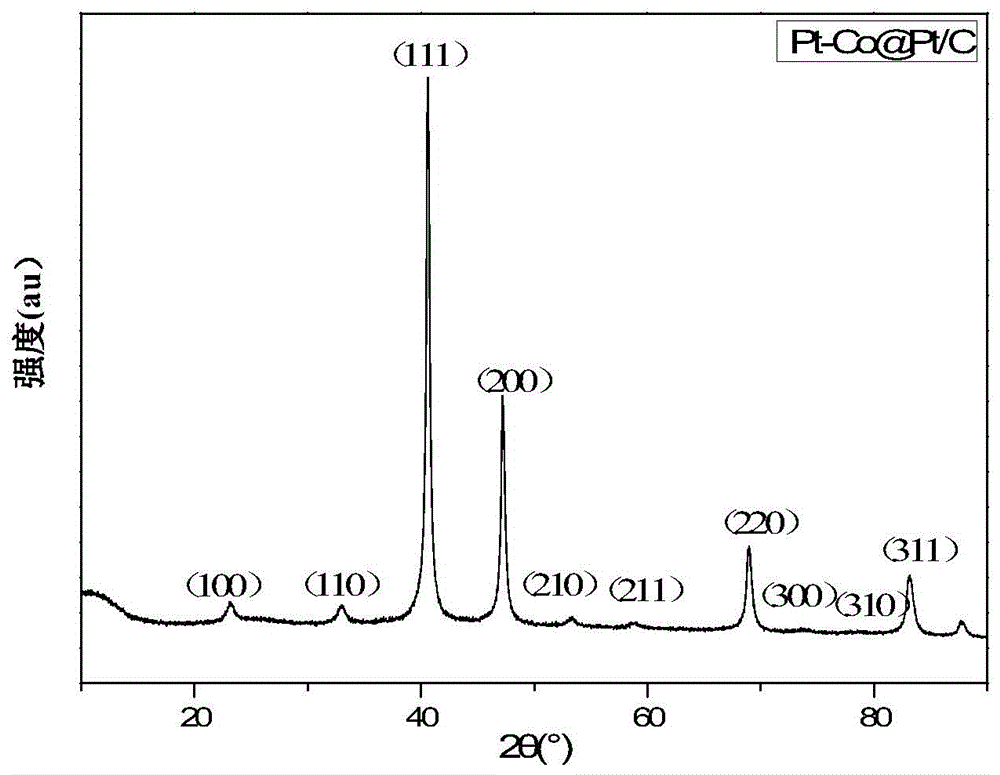

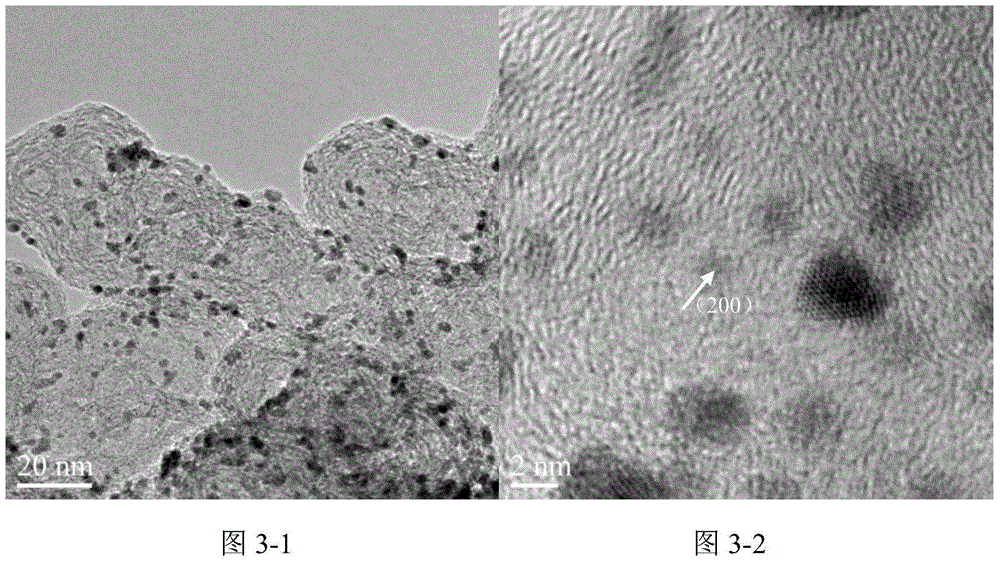

The invention relates to a carbon-supported core-shell type platinum cobalt-platinum catalyst for fuel cells and a preparation method for the carbon-supported core-shell type platinum cobalt-platinum catalyst, belonging to the field of electrochemistry. The catalyst comprises the following components in percentage by weight: 60%-90% of a carrier, 1%-20% of cobalt, and 9%-20% of platinum. According to the invention, a mixed solution of ethylene glycol and sodium borohydride acts as a reducing agent, the core-shell type platinum cobalt-platinum catalyst Pt-Co@Pt / C with an ordered structure is prepared by high-temperature annealing treatment. The catalyst with the ordered structure, which is prepared by the invention, has the advantages of low Pt carrying capacity, high catalysis activity, high stability and the like, and the development of fuel cells can be promoted further.

Owner:BEIJING UNIV OF CHEM TECH

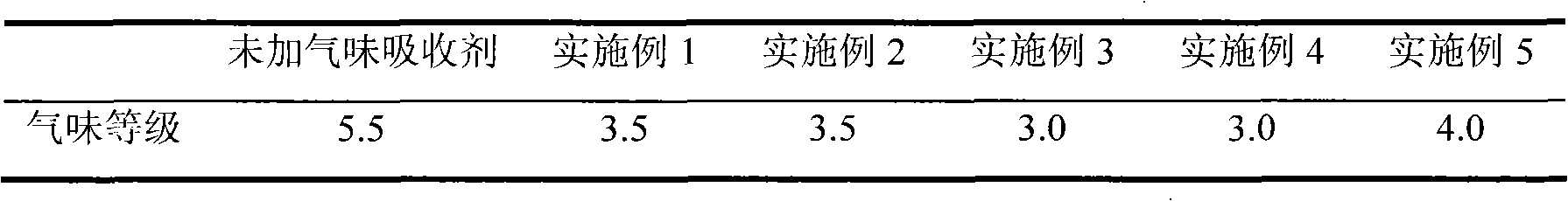

Antibacterial and low-odor decorative polypropylene material used in saloon car and preparation method thereof

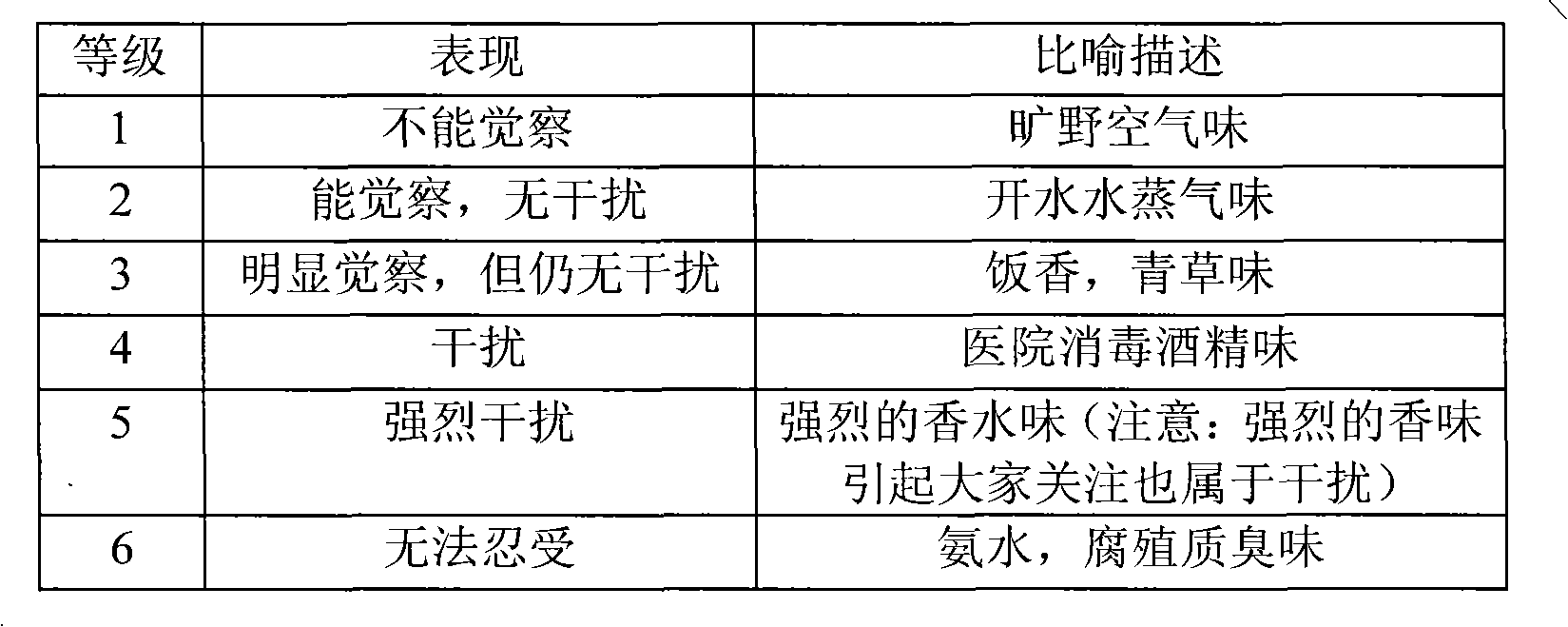

The invention discloses an antibacterial and low-odor decorative polypropylene material used in a saloon car and a preparation method thereof, wherein the material comprises the following components in percentage by weight: 60 to 80 percent of polypropylene, 1 to 20 percent of elastic body, 10 to 30 percent of talcum powder, 1 to 5 percent of photocatalytic micro-powder, 0.5 to 2.0 percent of antibacterial agent, and 0.3 to 1.0 percent of odor absorbent. The polypropylene material can keep low odor enduringly, has antibacterial and mould-proof functions, and has the advantages of strong bactericidal power, quick disinfectant effect, good durability, good stability, no secondary pollution and the like. According to the invention, odorous small molecules such as paraffin, olefins, arenes, amine, phenol, thiol, peroxide, aldehydes, ketones and the like can be effectively removed.

Owner:CHENGDU KINGFA SCI & TECH ADVANCED MATERIALS CO LTD +3

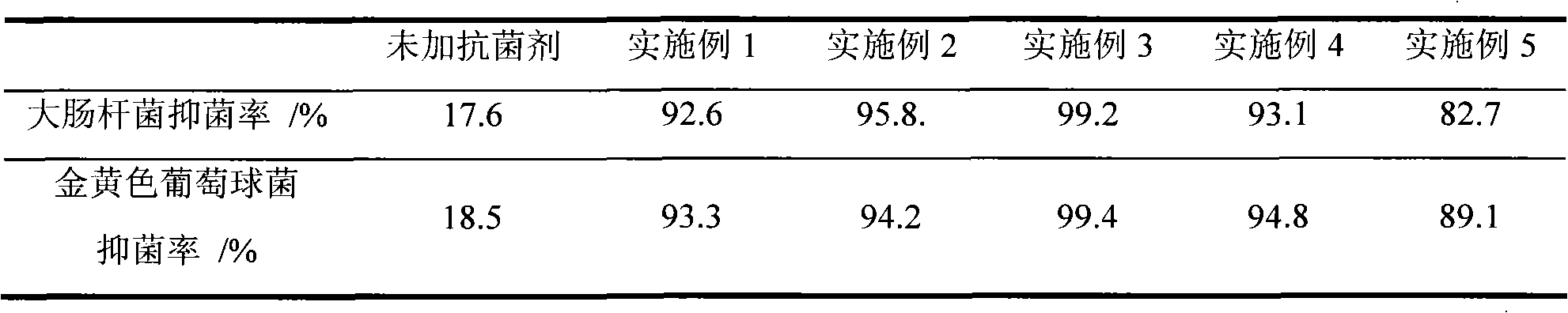

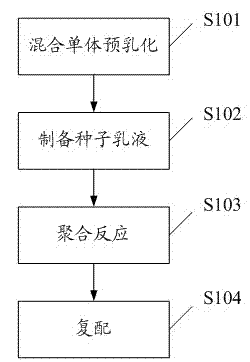

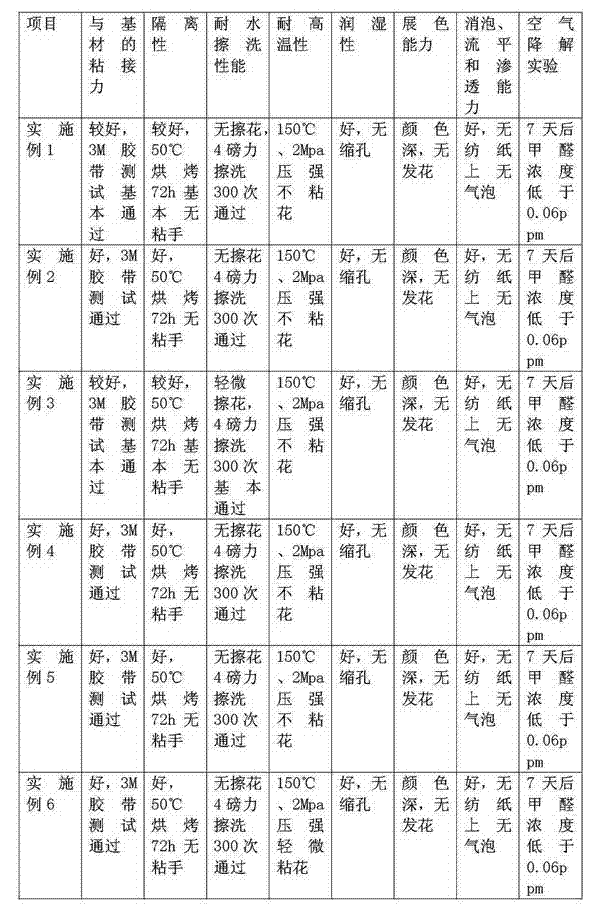

Wallpaper water-based paint, preparation method thereof and wallpaper

The invention discloses wallpaper water-based paint. The wallpaper water-based pain is water-based acrylate emulsion with solid content being 20-40% and the water-based acrylate emulsion is mainly made from a (methyl) acrylate monomer, a functional polymerizable monomer, an emulsifier, a photocatalyst, an initiator and deionized water through an emulsion polymerization method and a sol-gel method. Accordingly, the invention also discloses a method for preparing the wallpaper water-based paint and wallpaper made by adopting the wallpaper water-based paint. The wallpaper water-based paint is obviously improved in wallpaper substrate adaptability, the wallpaper water-based paint has good adhesive force, isolation, wettability and colour developing capability and is resistant to scrubbing and high temperature, defoaming is realized and the hole shrinkage phenomenon of a substrate is avoided; meanwhile, the wallpaper water-based paint also has light degradation property and can purify indoor air.

Owner:佛山市三水灏诚合成树脂有限公司

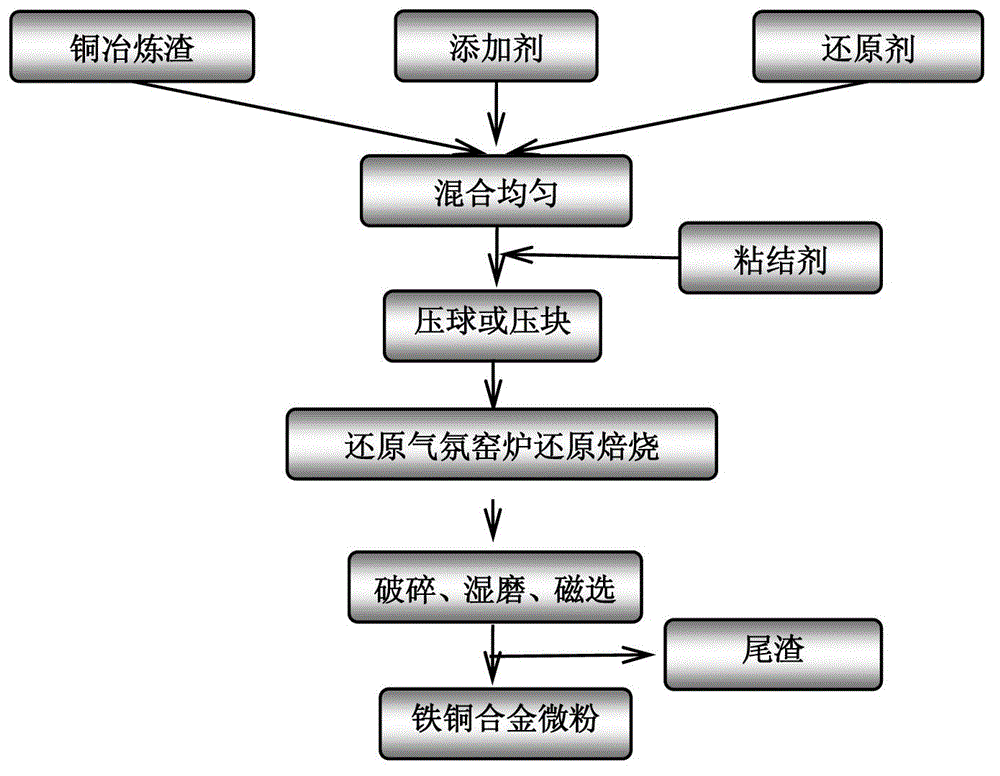

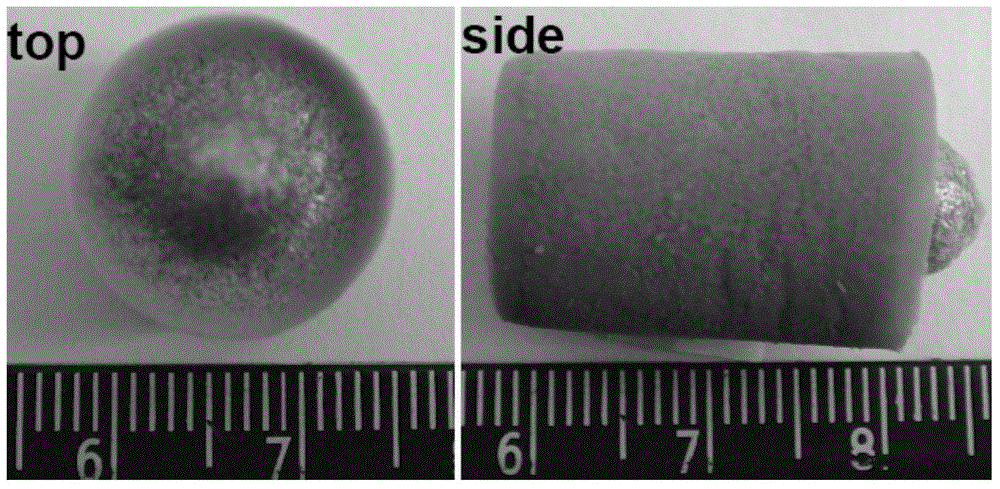

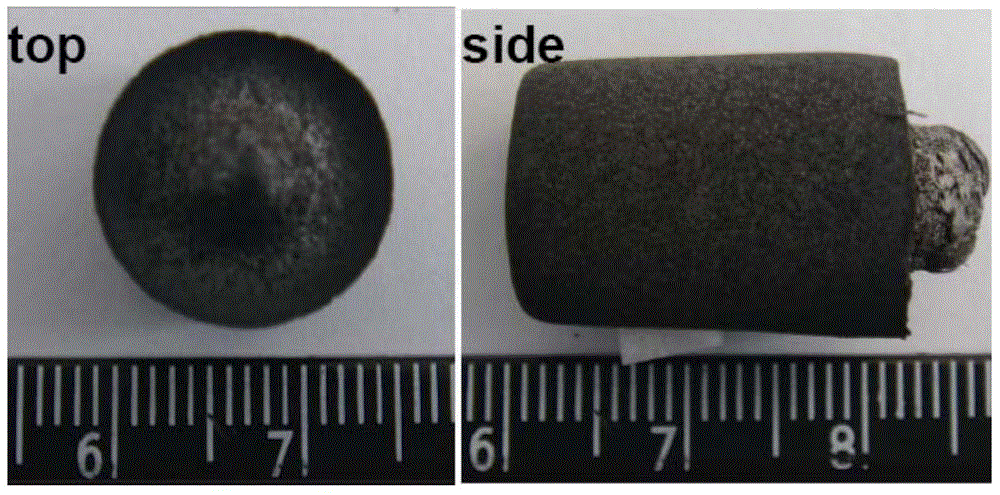

Method for rapidly reducing copper slags to produce iron-copper alloys in kiln in reducing atmosphere

ActiveCN102719676AIncrease added valueAchieve restorationProcess efficiency improvementSilicic acidReducing atmosphere

A method for rapidly reducing copper slags to produce iron-copper alloys in a kiln in a reducing atmosphere is characterized by including the steps: proportionally mixing the copper slags, reducing agents and additives, crushing or levigating the mixture to 200 meshes to obtain 20%-40% of residues on sieve; doping agglomerants and water occupying 5-20% of all materials on a dry mass basis, uniformly mixing, producing the uniformly mixed mixture to pellets with the diameters ranging from 15mm to 30mm and small cylindrical briquettes with all the heights ranging from 15mm to 30mm by a pellet press or a briquetting machine, and drying the pellets or small cylindrical briquettes; flatly laying the dried pellets or small cylindrical briquettes at the bottom of the kiln, wherein the material layer thickness ranges from 20mm to 45mm, the material layer reducing temperature ranges from 1250 DEG C to 1450 DEG C, and the reducing time is 10-40min; and subjecting the reduced pellets or the briquettes to cooling, crushing, wet grinding and wet separation so that iron-copper alloy powder with the iron recovery rate of 85%-99% is obtained. According to the method, iron in a great quantity of silicate iron in the copper slags, which cannot be separated out by the traditional technology, is extracted and turns into the iron-copper alloy micro powder with high added value so that iron and copper in the copper slags are extracted and used simultaneously, and physical and chemical heat energy in strong reducing waste gas can be completely recovered during rapid depth reduction.

Owner:TONGLING NON FERROUS METAL GROUP CORP +1

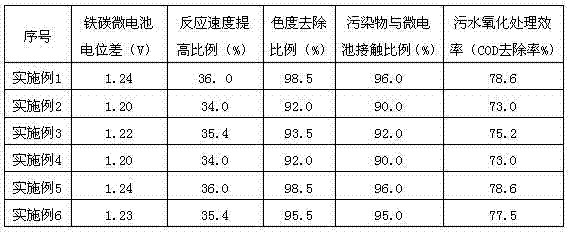

Efficient heterogeneous catalytic oxidation ferric-carbon micro-electrolysis packing and preparation method thereof

ActiveCN104761024ANo compactionHyperactive stateWater/sewage treatmentHigh current densityElectrolysis

The invention discloses efficient heterogeneous catalytic oxidation ferric-carbon micro-electrolysis packing and a preparation method thereof. The packing is prepared from the following raw materials in parts by weight: 45-65 parts of pure iron powder, 10-25 parts of cast iron powder, 2-8 parts of graphite powder, 5-15 parts of active carbon powder, 2-10 parts of copper powder, 2-10 parts of manganese powder, 2-10 parts of aluminum powder, 2-10 parts of fine wood bits, 1-6 parts of sodium silicate, 1-6 parts of sodium borate, 2-6 parts of pyrite dust and 5-15 parts of an adhesive. The efficient heterogeneous catalytic oxidation ferric-carbon micro-electrolysis packing disclosed by the invention is prepared by taking heterogeneous metal alloy with high potential difference as a catalyst and using a high-temperature micropore roasting technology and has the characteristics of heterogeneous metal and ferric-carbon integration, micropore framework type alloy structure, large specific surface area, low density, strong activity, high current density and the like; organic wastewater is treated so that COD, ammonia nitrogen and total phosphorus can be efficiently removed, the chroma can be reduced, the biodegradability can be improved, the treatment effect is extremely stable, and the phenomena of packing passivating, hardening and the like caused in the operation process can be avoided.

Owner:HUBEI QUANSHENG ENVIRONMENTAL PROTECTION SCI & TECH CO LTD

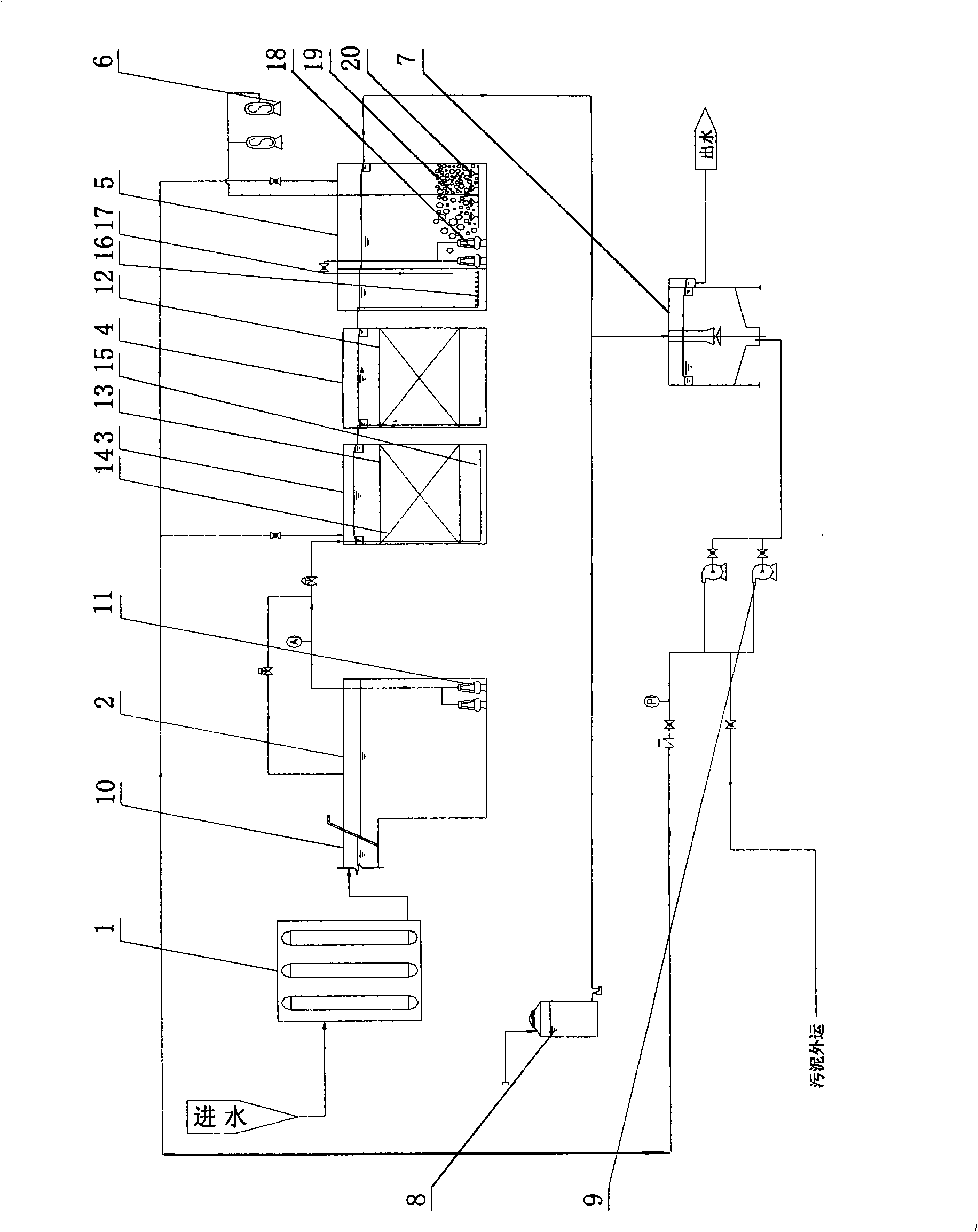

Method for processing high-toxicity high-concentration highly salt-containing organic waste water with biochemistry combination process of catalytic oxidation

InactiveCN101314510AGood effectIn line with environmental protection development ideasWater contaminantsWater/sewage treatment by electrochemical methodsComing outHigh concentration

The invention belongs to the water treatment technical field, in particular to a method for treating high-toxicity high-concentration high-salinity organic wastewater by a process of combining catalysis, oxidation and biochemistry. The method comprises the following specific steps that: wastewater enters a triple-effect distillation desalter; a pressure of the distillation desalter is controlled between 9 and 11 KG; a temperature of the distillation desalter is controlled between 85 and 95 DEG C; a water body is pretreated by a grating well and an adjusting tank and enters a micro electrolytic oxidation and oxidation tank by a lifting pump; the treated water automatically flows into a hydrolysis acidification tank, and the dwell time of water power is between 12 and 15 hours; the addition amount of combined type fillers is 50 to 70 percent of a usable capacity of the hydrolysis acidification tank; the treated water coming out from the hydrolysis acidification tank enters an oxygen compatible tank of an A / O tank; simultaneously, activated sludge is pumped into the oxygen compatible tank, and the dwell time of water power is between 5 and 8 hours; effluent water enters an aerobic tank by a circulating pipeline; the dwell time of water power in the aerobic tank is between 10 and 15 hours; the addition amount of suspended fillers is 30 to 40 percent of a volume of the aerobic tank; water treated by the A / O tank flows into a secondary sedimentation tank; the effluent water is discharged; and the residual sludge is discharged. The method applies the triple-effect distillation technology to the wastewater treatment technology and is organically combined with the subsequent catalysis oxidation technology and the biotreatment technology, thereby providing a brand-new development idea for the wastewater treatment of the type.

Owner:SHANGHAI CHEMAREA WATER TECH

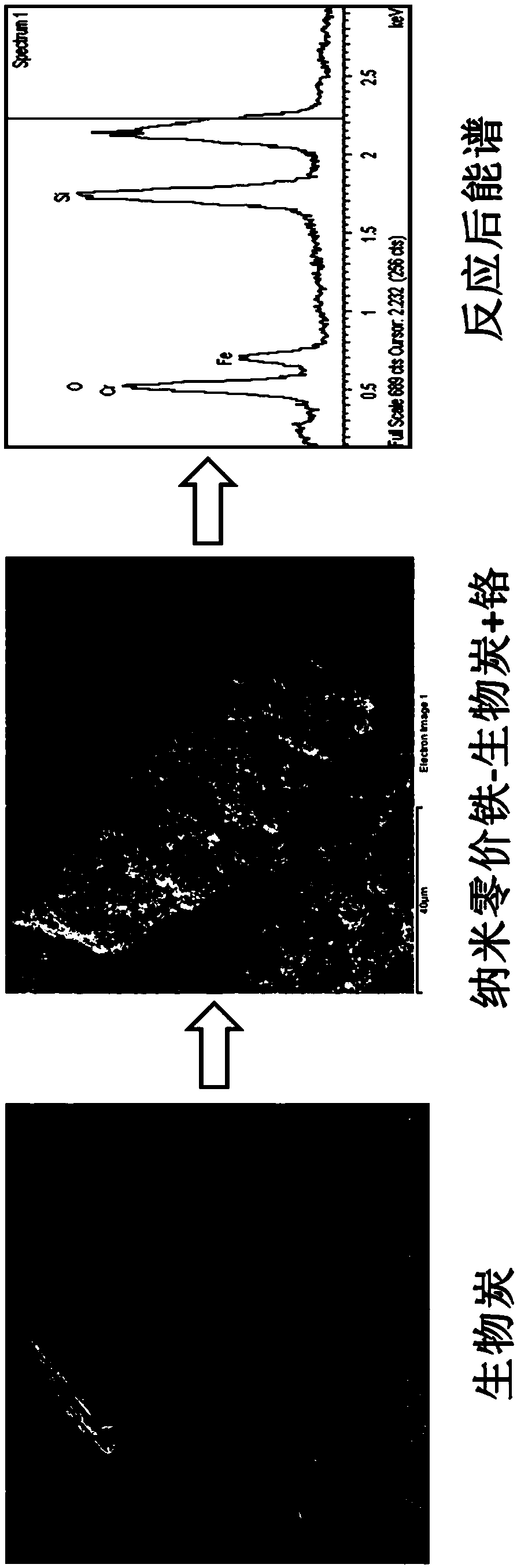

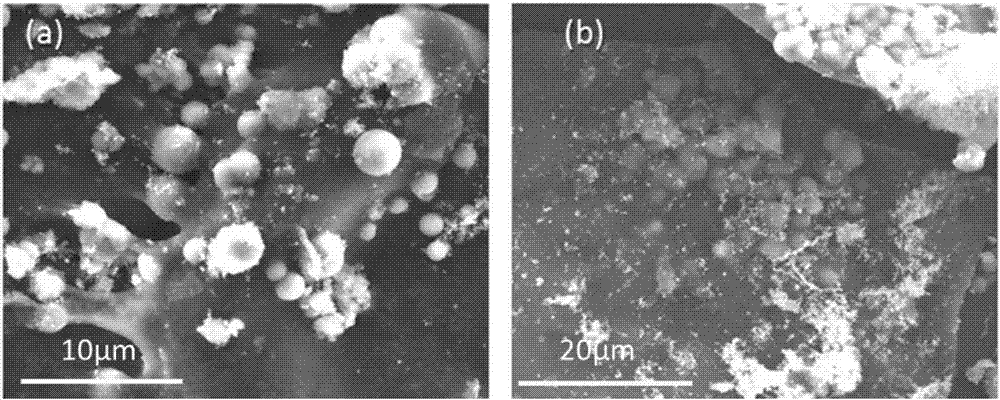

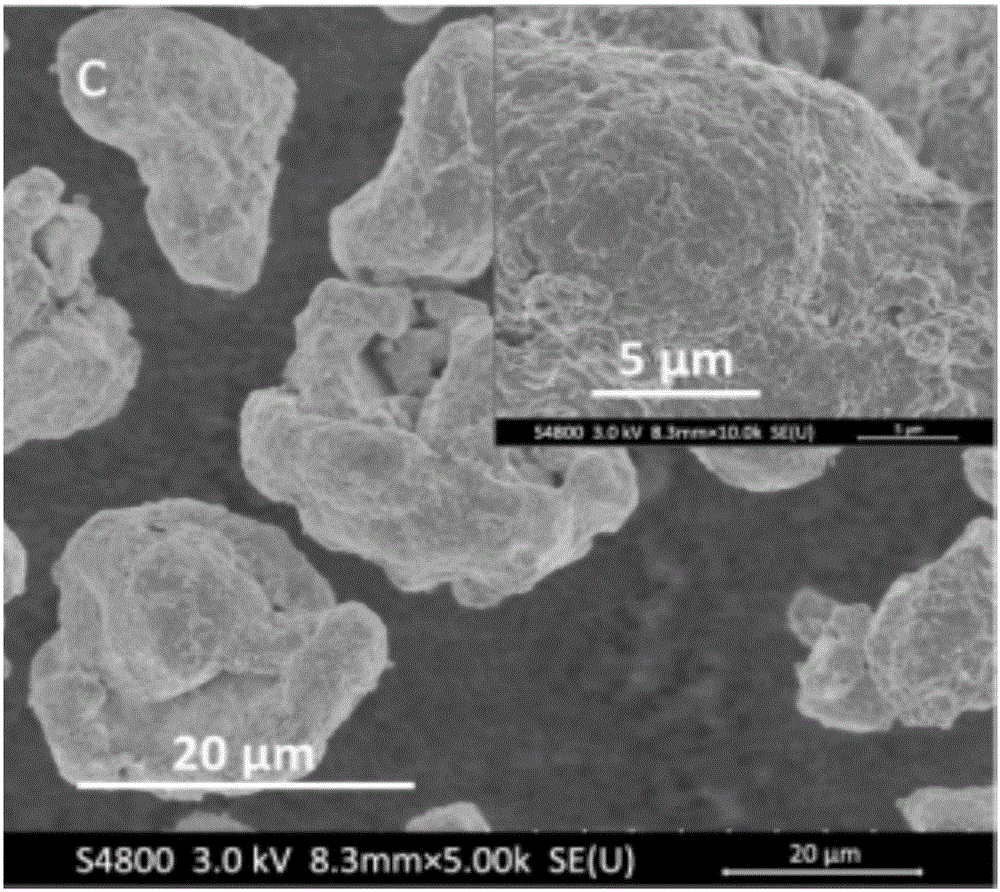

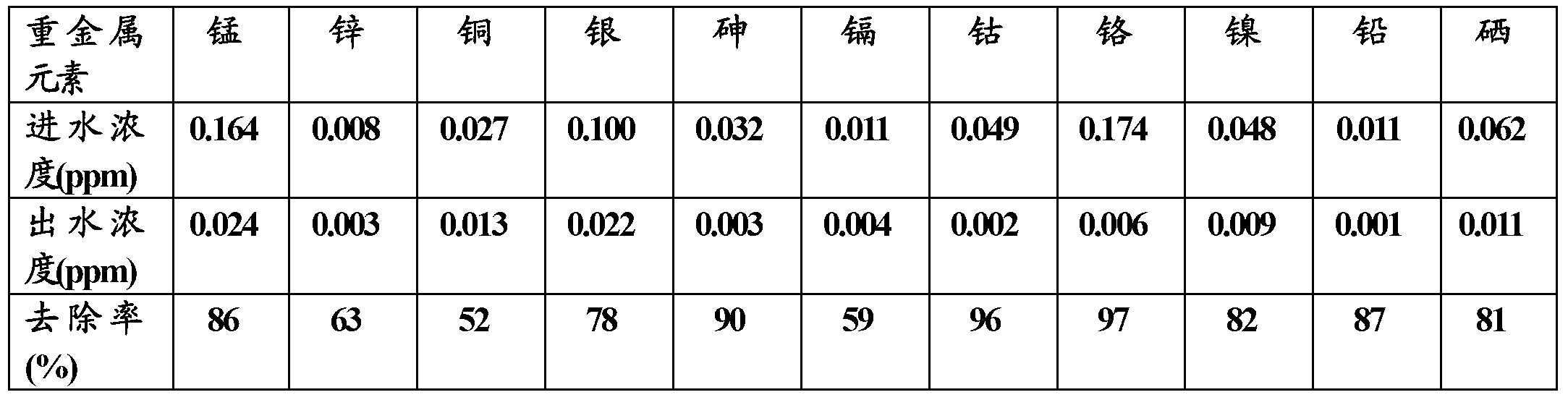

Nanometer zero-valent iron-biochar composite material, and preparation method and application thereof

ActiveCN108911005AStrong reductionStable in natureWater contaminantsWater/sewage treatment by sorptionHigh activityBiochar

The invention provides a nanometer zero-valent iron-biochar composite material, and a preparation method and application thereof. According to the invention, a carrier is a series of biochar with different cracking temperatures; the biochar is cheap and easily-available, has large specific surface area and contains a plurality of mineral components; nanometer zero-valent iron particles carried bythe carrier have strong activity; thus, the nanometer zero-valent iron particles have high activity; and the nanometer zero-valent iron-biochar composite material prepared from the carrier has high activity, and has the advantages of stable properties and low price at the same time. Screening of the series of different cracking temperatures shows that the composite material formed by the biochar generated by cracking of straw at medium and high temperatures and the nanometer zero-valent iron has strong removal effect on heavy metals. Meanwhile, the nanometer zero-valent iron-biochar compositematerial provided by the invention has excellent adsorption performance of the biochar and strong reduction capacity of the nanometer iron, and can provide theoretical basis and technical support forprevention, control and remediation of heavy metal pollution to groundwater.

Owner:INST OF SOIL SCI CHINESE ACAD OF SCI

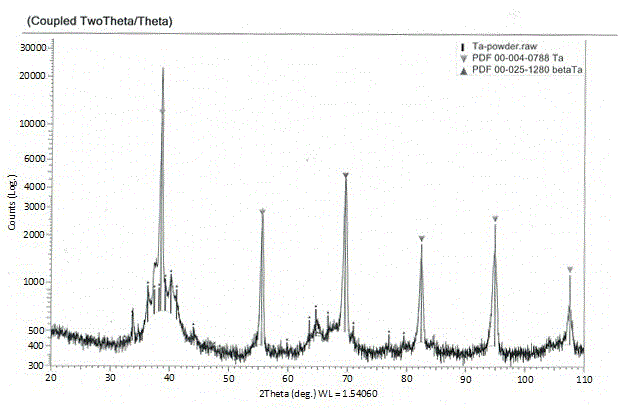

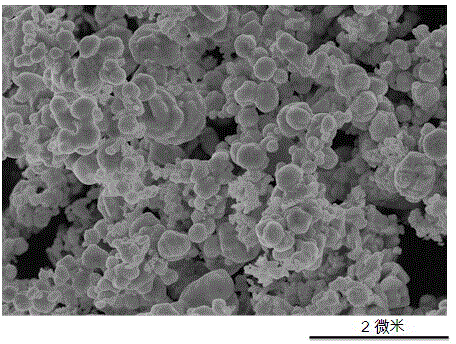

Porous nanometer zero-valent iron and porous nanometer zero-valent iron composite material

InactiveCN105081305ALarge specific surface areaNot easy to reuniteMaterial nanotechnologyNanometrePollution

The invention relates to nanometer material and in particular relates to porous nanometer zero-valent iron composite material mainly made from main active constituent component, a skeleton component and an auxiliary component. The main active constituent component is nanometer zero-valent iron; the skeleton component is made from one or more than one metal of Al, Mn, Si and Zn; and the auxiliary component is made from one or a plurality of components of the Ni, Pt, La, Cu and Pd. The invention further relates to the preparation method for the porous nanometer zero-valent iron composite material and purposes of the porous nanometer zero-valent iron composite material on fields of water pollution processing, soil pollution processing and environment repairing.

Owner:中国人民解放军军事科学院防化研究院

Preparation method of graphene aerogel and graphene-carbon nanotube aerogel

The invention relates to a preparation method of graphene aerogel and graphene-carbon nanotube aerogel. According to the method, graphene oxide or a mixture of graphene oxide and carbon nanotube is subjected to drying treatment; graphene oxide is reduced through a magnesium thermal reaction; the material is soaked in an acidic water solution; and impurities are removed, and the material is dried, such that graphene aerogel or graphene-carbon nanotube aerogel is obtained. Compared with prior arts, the method provided by the invention has the advantages of simple process, and is green and environment-friendly. Magnesium powder is adopted as a reducing agent. Compared to reducing agents such as hydrazine hydrate, sodium borohydride, formaldehyde, carbohydrate compounds, ascorbic acid and hydroiodic acid, magnesium powder has higher reducibility, such that the graphene aerogel or graphene-carbon nanotube aerogel with high carbon-oxygen ratio can be prepared. The electrical conductivity of the graphene aerogel or graphene-carbon nanotube aerogel can reach 10<4>s / cm. The graphene aerogel or graphene-carbon nanotube aerogel has large specific surface area, and is non-toxic and harmless. The graphene aerogel or graphene-carbon nanotube aerogel can be widely applied.

Owner:TONGJI UNIV

Method for eliminating dioxins in flue gas

InactiveCN101249378ASimple processNo equipment bottleneckDispersed particle separationUreaEnvironmental chemistry

The invention relates to a method used for eliminating dioxin in fume. The method has the following steps that water solution containing substance of hydrazine type is sprayed into the fume containing dioxin or potentially containing dioxin so that the fume fully touches and reacts with the water solution, and the water in the solution is completely evaporated at the temperature above 160 DEG C. In this way, dioxin in the fume is eliminated. The water solution with hydrazine type substance is fresh solution prepared based on 0.05 percent to 1 percent by weight before use, and is sprayed into the fume with the temperature ranging from 200 DEG C to 600 DEG C, or into the fume with the temperature ranging from 600 DEG C to 850 DEG C. At the temperature ranging from 600 DEG C to 850 DEG C, the water in the water solution containing hydrazine can adopt urea or ammonia. At the temperature ranging from 200 DEG C to 600 DEG C, the water to dissolve hydrazine can adopt alkaline solution or urea solution in combination with purification of other noxious gases such as SOx and NOx by using a prior or a late established purification device or system, so that NOx and acidic gases in the fume are eliminated, and toxicant content in fly ash is reduced. By adopting the method, dioxin in the fume is eliminated without production of noxious byproducts. Throughout the course, no waste water or waste solid is produced; the concentration of dioxin in fly ash is reduced; the treating process is simple, and the cost of disposal is low.

Owner:TONGJI UNIV

Colloid palladium activation solution, preparation method thereof and non-metal surface activation method

InactiveCN101928937ANon-failure decompositionBreak down evenlyLiquid/solution decomposition chemical coatingActivation methodGlyoxylic acid

The invention provides colloid palladium activation solution which comprises colloid palladium, sodium chloride, glyoxylic acid, hydrochloric acid, stannous chloride and stabilizer for stabilizing the stannous chloride, wherein the glyoxylic acid has strong reducibility and can avoid that divalent tin ions in the activation solution are oxidized, and prolong the service life of the action solution; simultaneously, the glyoxylic acid is adsorbed on the periphery of colloid palladium particles, thereby leading the dispersion of the colloid palladium to be more uniform, avoiding the gel coagulation among the colloid particles and enhancing the activity of the activation solution. The invention provides a preparation method of the colloid palladium, and the process is simple. In addition, the adoption of the colloid palladium activation solution for activating the surface of a non-metal substrate can firstly adsorb the glyoxylic acid in the activation solution on the surface of the non-metal substrate, enhance the bonding force between the colloid palladium particles and the non-metal substrate, leading a plated coating after chemical plating to have uniform thickness and flat surface, and leading the adhesion between the plated coating and the substrate to be very high.

Owner:深圳市新合富力科技有限公司

Reducing agent for dyeing reduced dyes

The invention discloses a reducing agent for dyeing reduced dyes, belonging to the technical field of printing and dyeing technologies for textiles. The reducing agent consists of the following raw materials in percentage by mass: 5-10 percent of thiourea dioxide, 5-30 percent of sodium hydrosulfite 10-40 percent of reducing sugar type substances and 20-50 percent of salt. The reducing agent disclosed by the invention can effectively replace the sodium hydrosulfite to be used for dyeing of the reducer dyes and indigo dyes, the reduced dye leuco is long in existence time and slight in environment pollution, and the price of the dye leuco is superior to that of the sodium hydrosulfite. Moreover, the thiourea dioxide contained in the reducing agent for dyeing reduced dyes disclosed by the invention can be completely biodegraded, is high in reducing capacity, can effectively reduce the dyes into leuco, does not have a pungent smell and belongs to an environment-friendly substance; the reducing sugars refers to substances existing in the nature and have a certain reducing property, and the overall reducing capacity can be maintained and last for a long time; and moreover, according to salt substances, the stability of the components of the whole reducing agent can be enhanced.

Owner:濮阳圣恺环保新材料科技股份有限公司

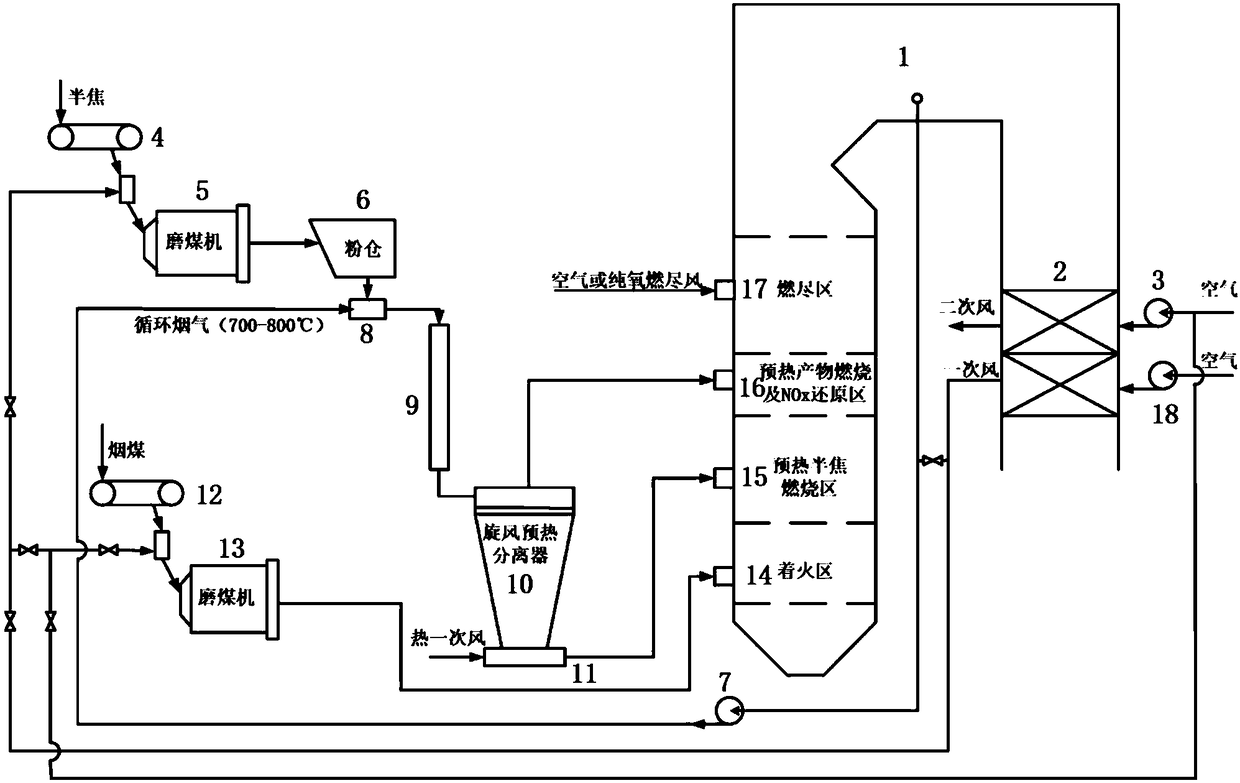

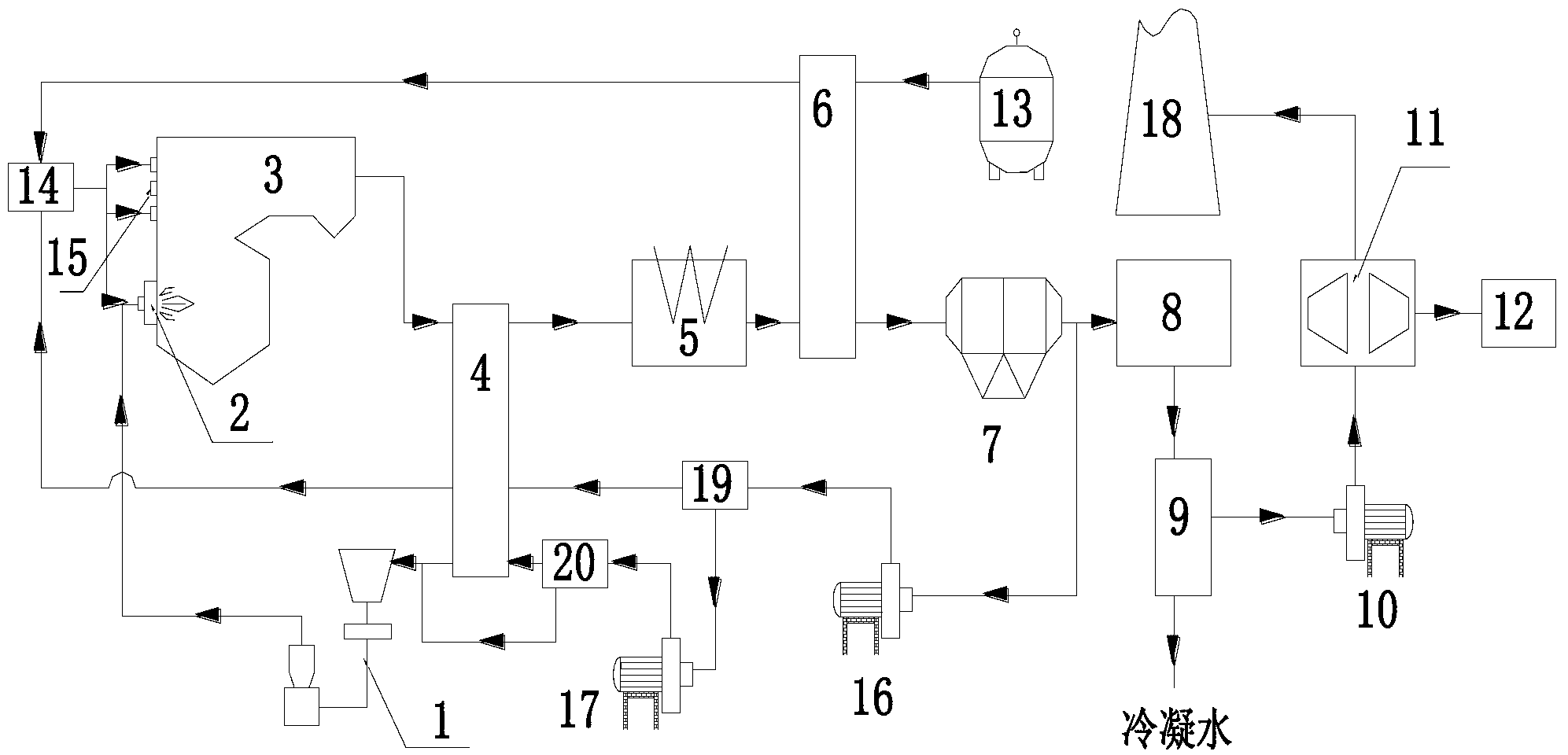

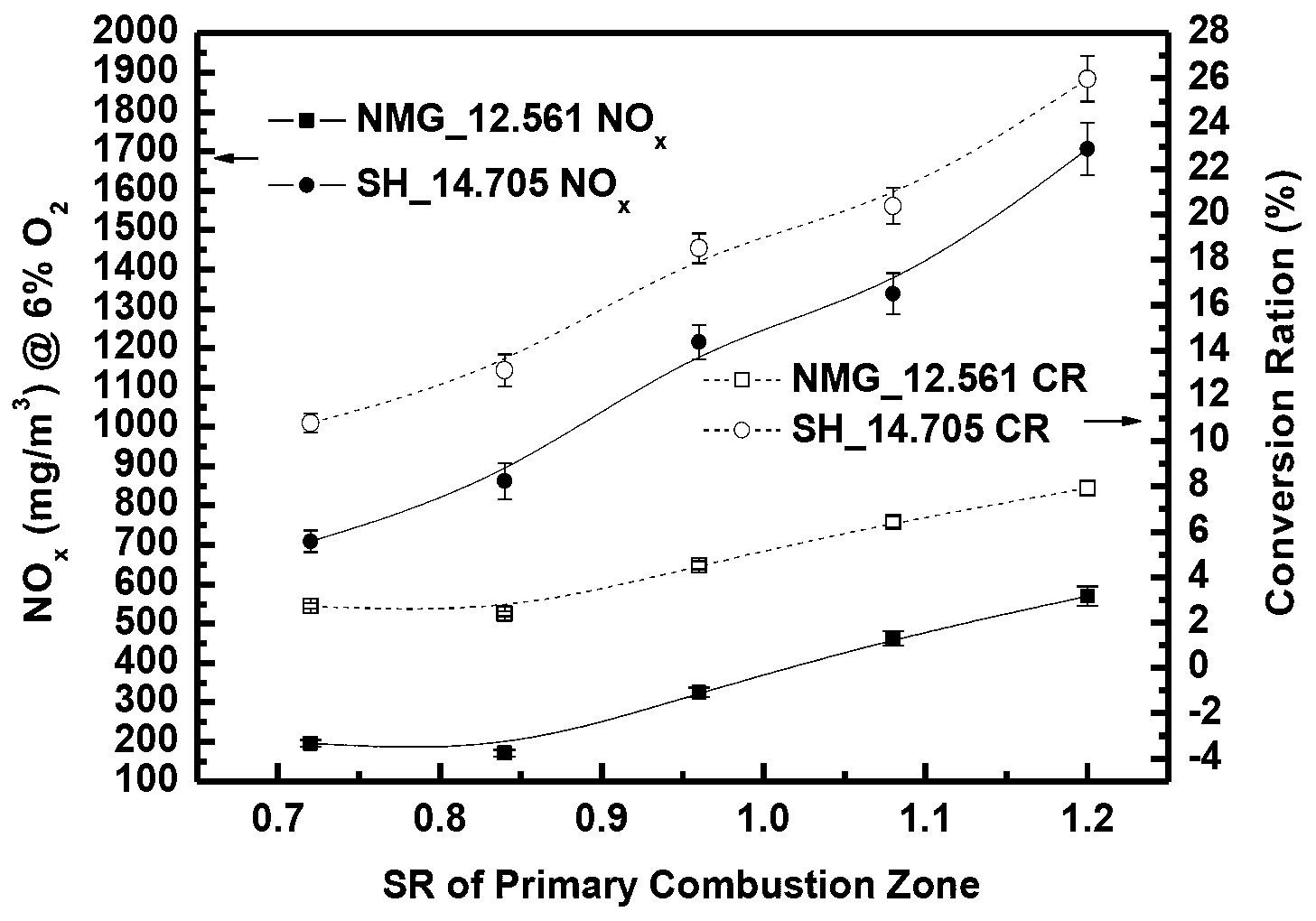

Low NOx hybrid combustion system and method for preheating semi-coke by high-temperature flue gas of power station boiler

ActiveCN108151008AIncrease temperatureFire guaranteeGas treatmentDispersed particle separationCycloneCombustion system

The invention relates to a low NOx hybrid combustion system and method for preheating semi-coke by high-temperature flue gas of a power station boiler. According to the hybrid combustion system and method, a preheating pipeline and a cyclone preheating separator are adopted, the semi-coke is directly preheated through the high-temperature flue gas, so that the temperature of the semi-coke sprayedinto a hearth is remarkably improved; meanwhile, a stable ignition region for combustion of bituminous coal is arranged at the lower part of the hearth, so that ignition and flame stabilization of combustion of ultra-low volatile semi-coke fuel are facilitated, and the large proportion (larger than or equal to 45%) blending combustion of the semi-coke fuel of the power station boiler is achieved;a preheating product with the relatively strong reducibility is produced while the semi-coke is preheated, the preheating product is directly sprayed into the middle part of the hearth through a combustor, a NOx reduction zone is formed on the upper part of a preheating semi-coke combustion zone, so that emission of NOx is greatly reduced, and low NOx combustion of ultra-low volatile carbon-basedfuel is effectively realized; and air or pure oxygen over fire air is injected into the upper part of a combustion region of the hearth so that the fuel can be completely combusted, and the carbon content of the fly ash and the NOx emission can be effectively reduced.

Owner:XI AN JIAOTONG UNIV

Alkali - free glass and liquid crystal display panel

InactiveUS20070027019A1Excellent in reducing resistanceDeterioration of propertyNon-linear opticsAlkali freeLiquid-crystal display

To provide an alkali-free glass excellent in the properties for glass substrates to be used for display, excellent in the resistance to reduction, and suitable for forming by a float process. An alkali-free glass consisting essentially of, as represented by mol %: SiO2at least 60% and less than 66%,Al2O30 to 12%,B2O35 to 10%,MgO0 to 18%,CaO0 to 18%,SrO0 to 18%,BaO0 to 6%, CaO + SrO10 to 25%, MgO + CaO + SrO + BaO15.5 to 30% and containing substantially no alkali metal oxide.

Owner:ASAHI GLASS CO LTD

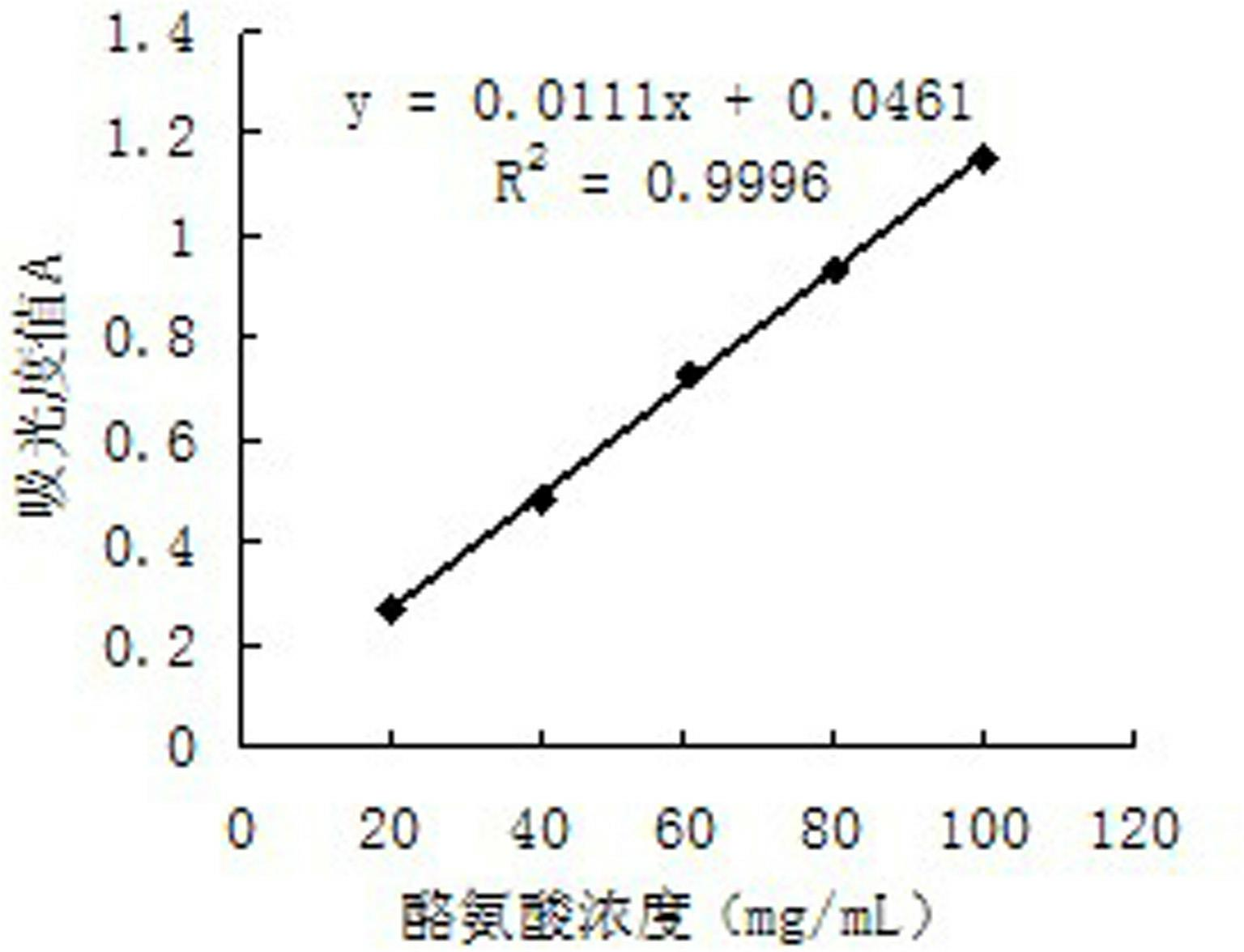

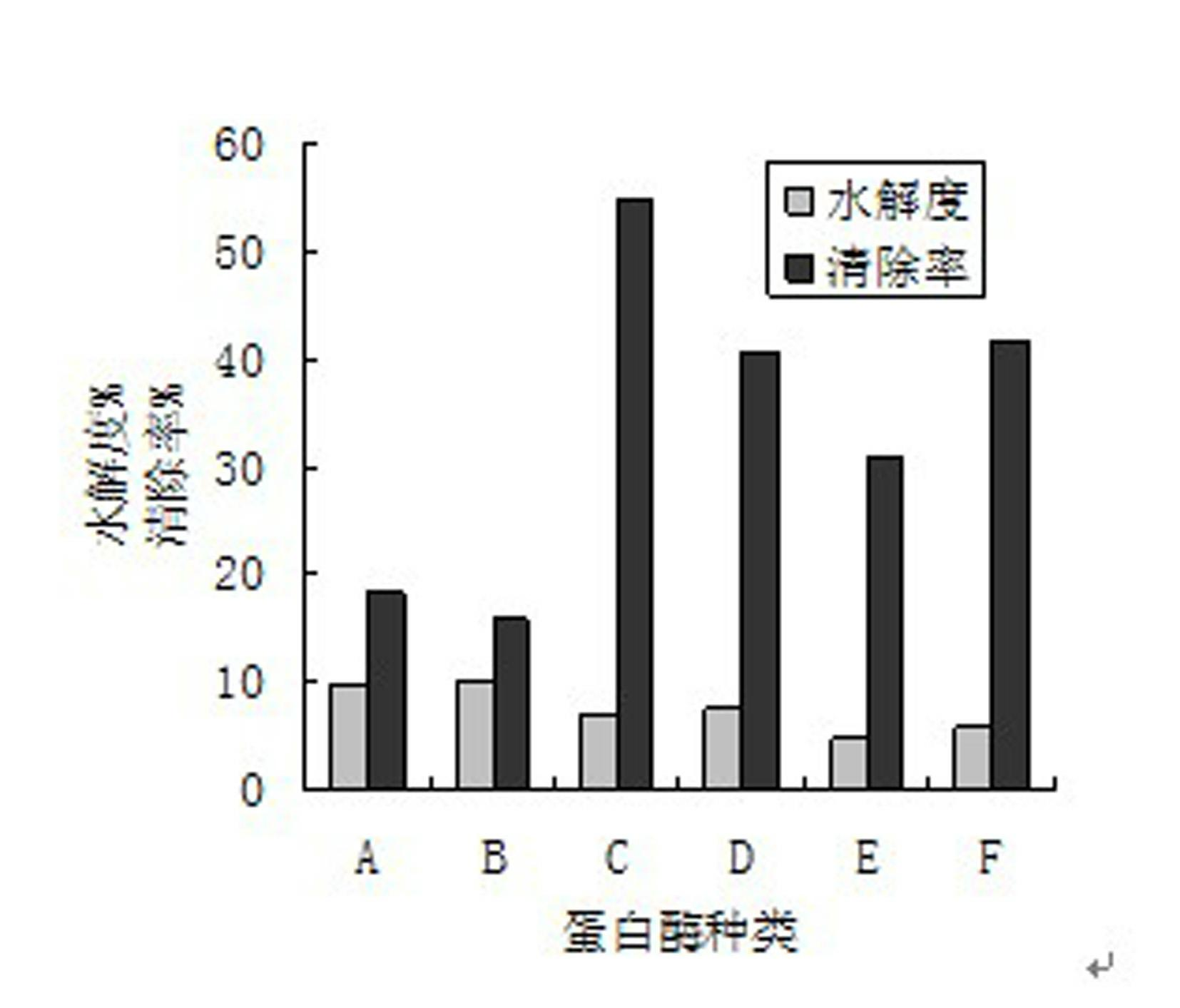

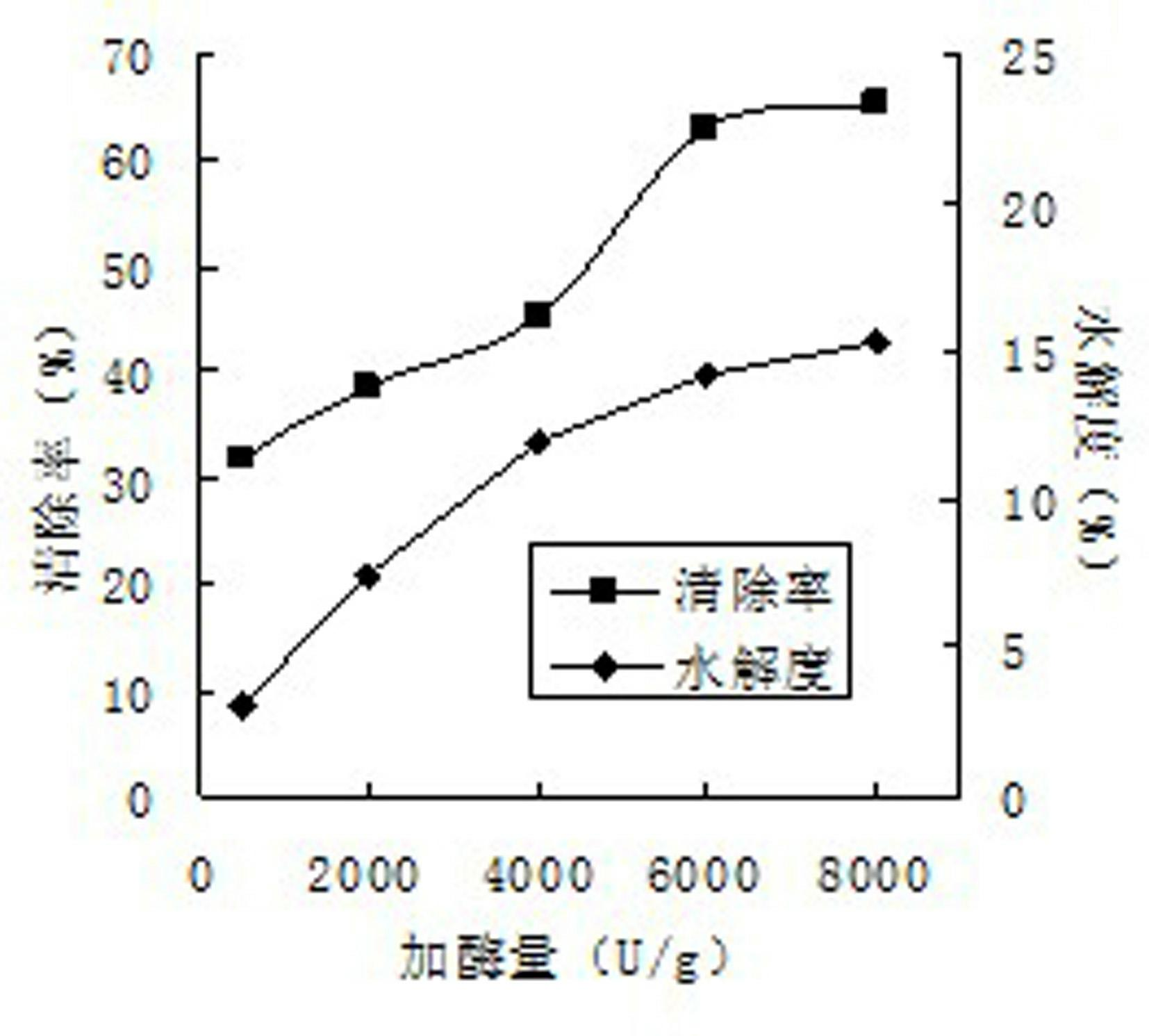

Preparation method of pumpkin seed antioxidant peptide

InactiveCN102197856AImprove cleanlinessStrong reductionProtein composition from vegetable seedsVegetable proteins working-upWater bathsProtein solution

The invention relates to a preparation method of antioxidant peptide and aims to provide a preparation method of pumpkin seed antioxidant peptide with wide sources of raw materials, low cost and high antioxidant activity. The preparation method comprises the following steps of: (1) preparing pumpkin seed isolated protein solution, namely preparing pumpkin seed isolated protein from defatted pumpkin seed powder serving as a raw material by an alkali-solution and acid-isolation method and preparing the pumpkin seed isolated protein solution by adding water; (2) performing enzymolysis, namely heating the pumpkin seed isolated protein solution in a boiling water bath to denature the protein, adjusting the pH value to be 2.5 to 3.5 after cooling, and adding protease with the dose of 5,000 to 8,000 U / g to hydrolyze in a water bath at the temperature of between 45 and 55 DEG C for 2 to 6 hours; and (3) after deactivating enzyme and performing centrifugation, allowing zymolytic solution to pass through ultrafiltration enrichment active peptide, concentrating, freezing and drying to obtain the pumpkin seed antioxidant peptide. The antioxidant peptide has remarkable reducing capacity, high free radical-removing capacity, wide application, remarkable social and economic benefits, optimal enzymolysis process conditions and wide sources of the raw material, increases utilization ratio of the raw material, and utilizes waste materials.

Owner:SHANXI UNIV

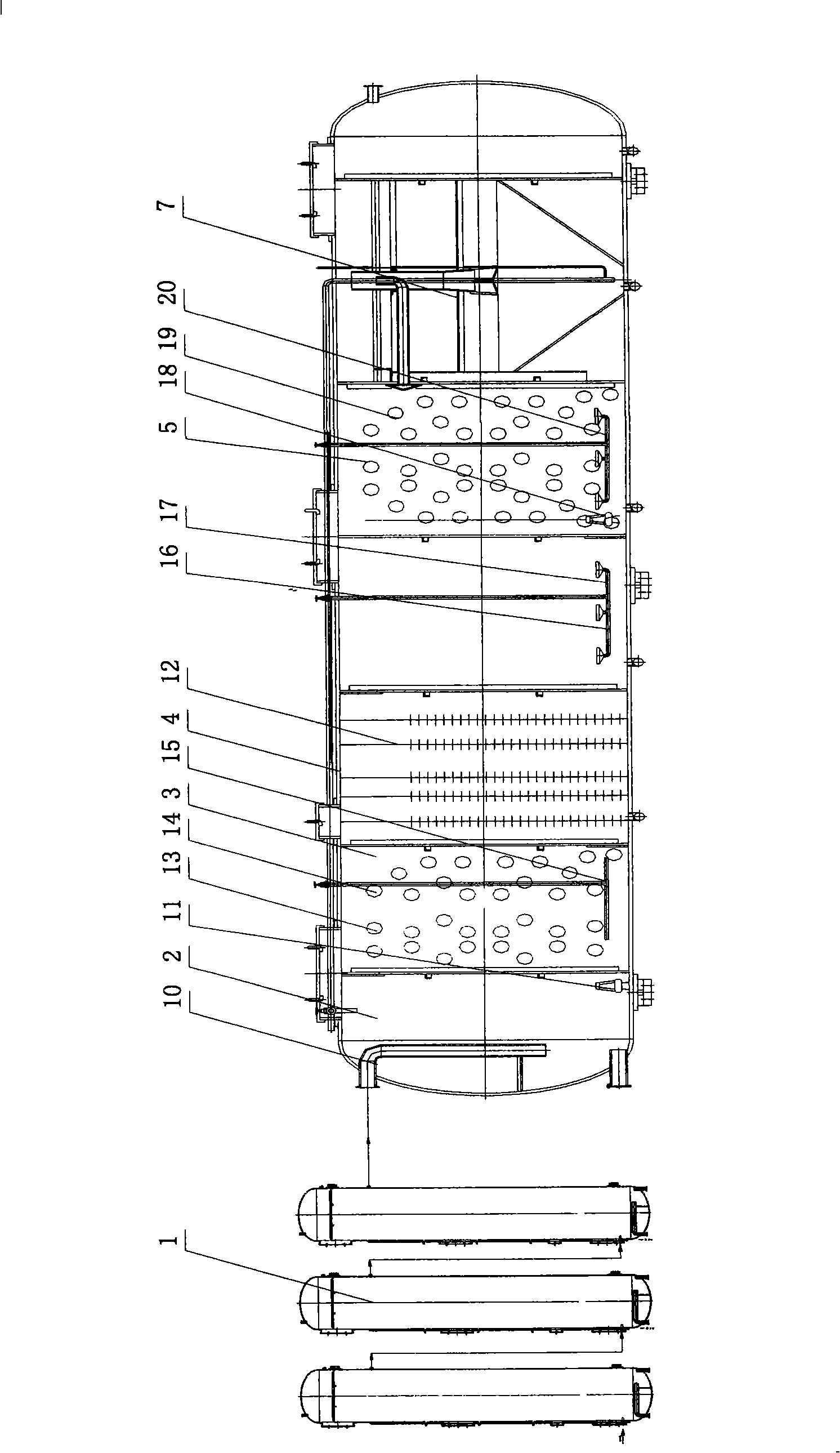

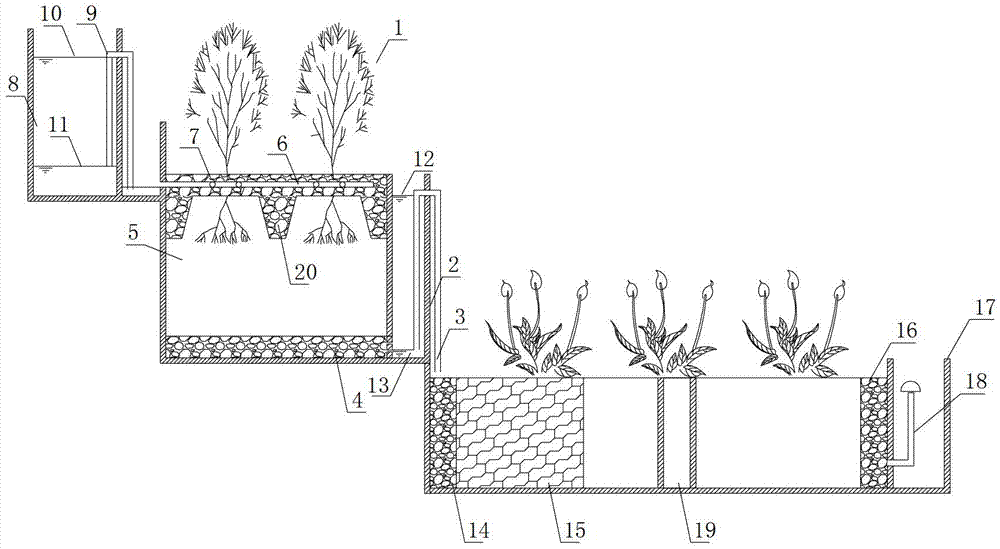

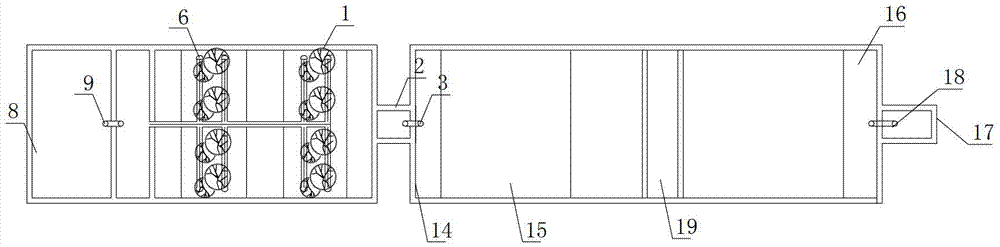

Method for enhanced nitrogen removal of tidal flow-horizontal subsurface flow hybrid constructed wetland and system thereof

InactiveCN102923860AStrong reductionAvoid secondary pollutionTreatment with aerobic and anaerobic processesSustainable biological treatmentConstructed wetlandNitration

The invention belongs to the technical field of sewage treatment and specifically relates to a method for enhanced nitrogen removal of a tidal flow-horizontal subsurface flow hybrid constructed wetland and a system thereof. The system orderly comprises a non-powered automatic water intake device (8), a tidal-flow constructed wetland bed, a non-powered automatic water drainage device (2) and a horizontal subsurface-flow constructed wetland bed. The tidal-flow constructed wetland which is high in ammonia nitrogen oxidation effect and the horizontal subsurface-flow constructed wetland which is excellent in nitrate reduction capability are rationally combined into one system by thoroughly utilizing the characteristics of the aerobic environment of the former and the anaerobic environment of the latter; therefore, conditions are created for thorough nitration / denitrification; and simultaneously, a horizontal subsurface-flow wetland slow-release carbon source enhanced region (15) and a backflow well (19) are arranged in the horizontal subsurface-flow wetland bed, so that enhanced removal of total nitrogen in the sewage can be realized and secondary pollution on the carbon source is avoided at the same time.

Owner:CHINA AGRI UNIV

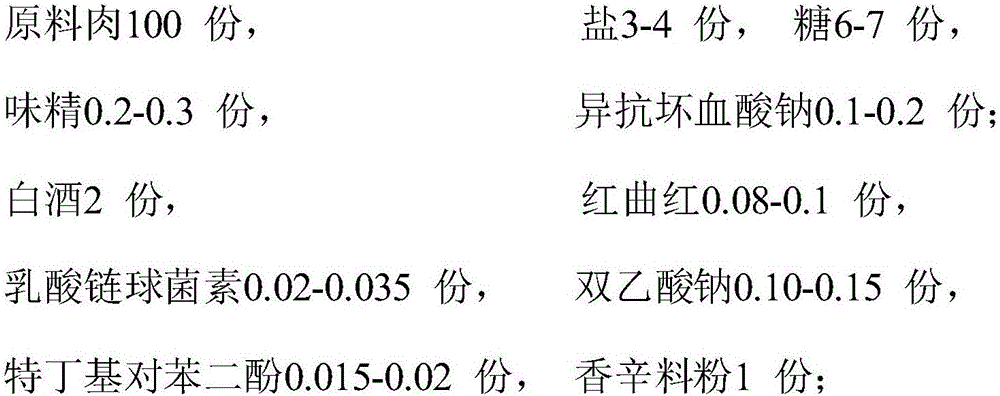

Nitrite-substituted meat processing method

InactiveCN106071907AGood effectGood muscle toneFood ingredient as antioxidantFood ingredient as taste affecting agentBetaninEthyl maltol

The invention discloses a nitrite-substituted meat processing method, and belongs to the technical field of food processing. The nitrite-substituted meat processing method comprises the following steps: selecting raw materials, carrying out pickling treatment and processing a meat product, so that the final products of the meat product are prepared; and the nitrite is substituted by a nitrite substitute during the step of carrying out pickling treatment. The nitrite substitute comprises the following components in parts by weight: 4-5 parts of monascorubin, 0.7-1.3 parts of betanin, 4-6 parts of potassium sorbate, 2-3 parts of D-sodium isoascorbate, 1.5-2.5 parts of nisin, 9-11 parts of sodium lactate, 1-2 parts of natamycin, 5-6 parts of natural vitamin E, 1-2 parts of a rosemary extract, 0.5-1.5 parts of sage essential oil, 1-2 parts of tea polyphenols, 15-16 parts of L-sodium glutamate, 0.5-1.5 parts of flavoring 5'-disodium ribonucleotide, 40-43 parts of a yeast extract, 4-5 parts of sodium tripolyphosphate and 0.5-1.5 parts of ethyl maltol. The nitrite-substituted meat processing method disclosed by the invention is simple, easy to operate and free of nitrite addition; and the prepared meat products are very good in qualities, color, luster and taste.

Owner:邯郸市锦园食品有限公司

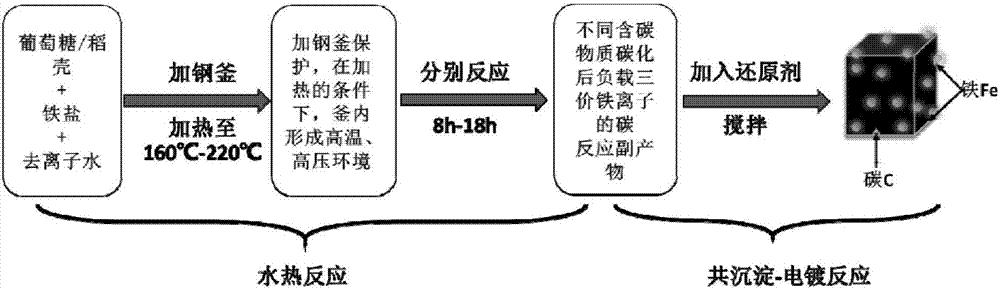

Preparation method of iron/carbon composite material

ActiveCN106881059ALow costImprove economic and technical feasibilityOther chemical processesMetal/metal-oxides/metal-hydroxide catalystsCarbon compositesIron salts

The invention relates to the technical field of materials, and specifically discloses a preparation method of an iron / carbon composite material. A hydrothermal method-coprecipitation-electroplating combination method is firstly utilized for preparing the iron / carbon composite material. A synthesis process can be divided into two steps: firstly, carbonizing organic matter raw materials in which iron salt is added by adopting a hydrothermal method; secondly, reducing a carbonized product by adopting a proper reducing agent, thus obtaining the needed iron / carbon composite material. Iron elements in the iron / carbon composite material obtained by utilizing the preparation method mainly and fixedly exist on the surface and the inner part of a porous carbon material in a form of zero-valent iron, and the carbon material is not only used as a substrate for loading the zero-valent iron, but also has a certain protection function on the zero-valent iron; the synthetic composite material has both good reducing ability of the zero-valent iron and good adsorption ability of the carbon material on organic pollutants, so that more efficient removing of the organic pollutants in water is realized.

Owner:SUZHOU INST FOR ADVANCED STUDY USTC

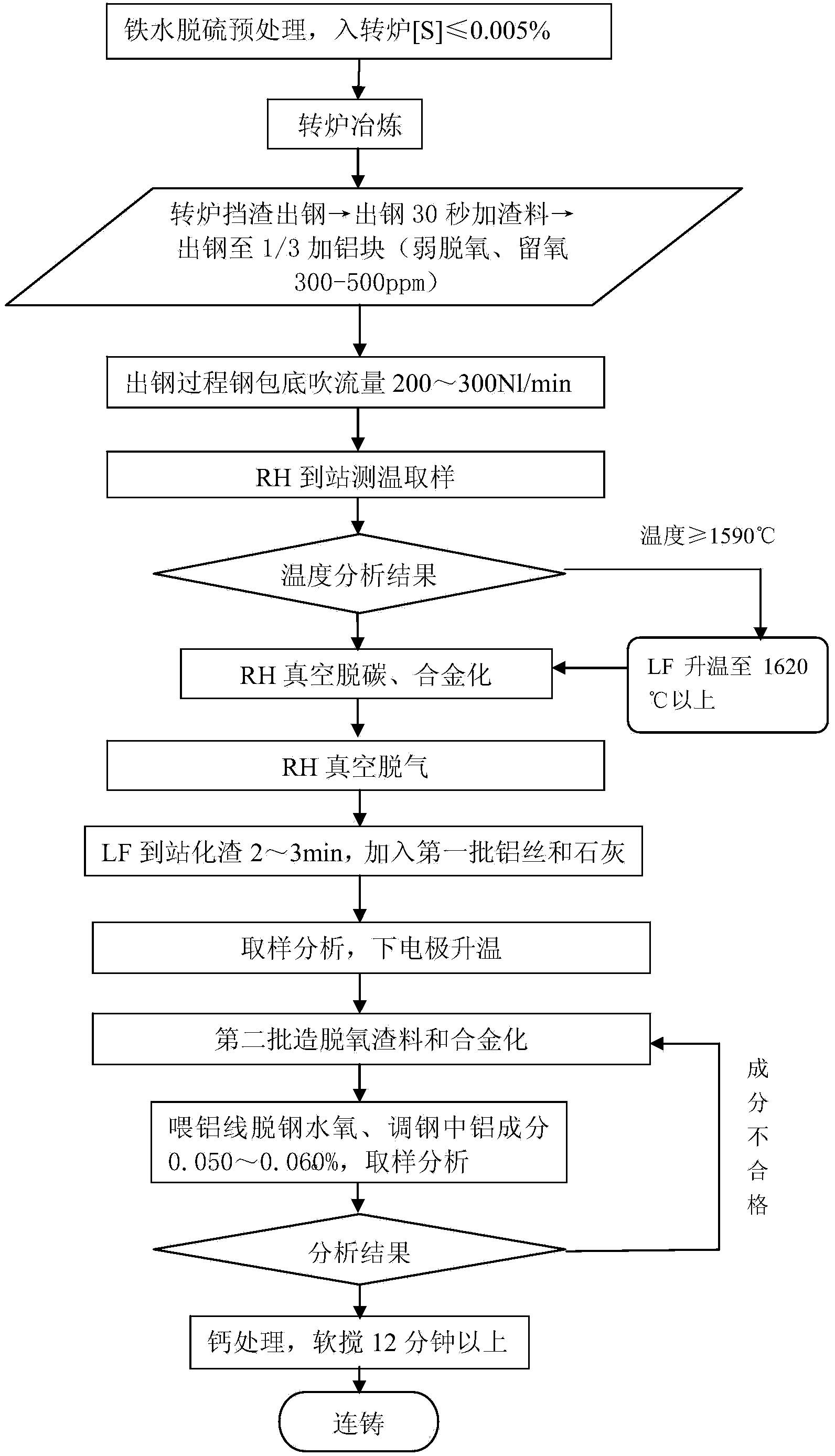

Low-carbon ultra-low sulfur steel smelting method

InactiveCN104232831AThe amount added is accurateStable flaw detection pass rateSteel manufacturing process aspectsManufacturing convertersSmelting processOxygen

The invention discloses a low-carbon ultra-low sulfur steel smelting method. The method comprises the following technological processes: pouring molten iron into a tank, pretreatment of molten iron, oxygen remaining operation of a converter, RH furnace vacuum decarburization, alloying and vacuum degassing in an RH furnace, deoxidization of aluminium yarn / aluminium wire in an LF refining furnace, slagging by using lime and CCM. Through combination of molten iron desulphurization and drossing, optimization of a converter steel tapping and oxygen remaining system and a slagging system, the vacuum decarburization, alloying and degassing control in the RH furnace, and the aluminium wire diffusing deoxidation slagging and aluminium wire sediment deoxidation in the LF furnace, deep decarburization and desulphurization are carried out. With an emphasis on combination of convertor steel tapping and oxygen remaining operations, RH deep decarburization and LF furnace deep desulphurization, technical optimization is carried out; due to reasonable ladle argon bottom blowing control in the smelting process, carbon content control and metallurgical thermodynamics and dynamics conditions of desulphurization are given a full play; the RH furnace decarburization is stable; LF furnace slagging and desulphurization and recarburization control effects are obvious; and low-carbon ultra-low sulfur steel smelting is achieved.

Owner:NANJING IRON & STEEL CO LTD

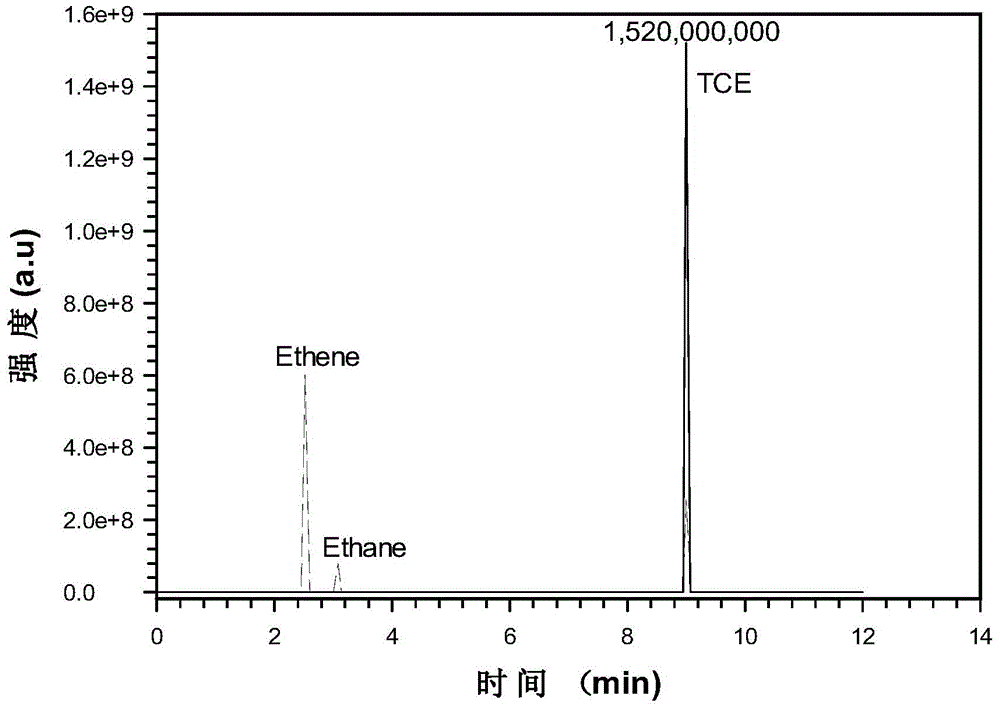

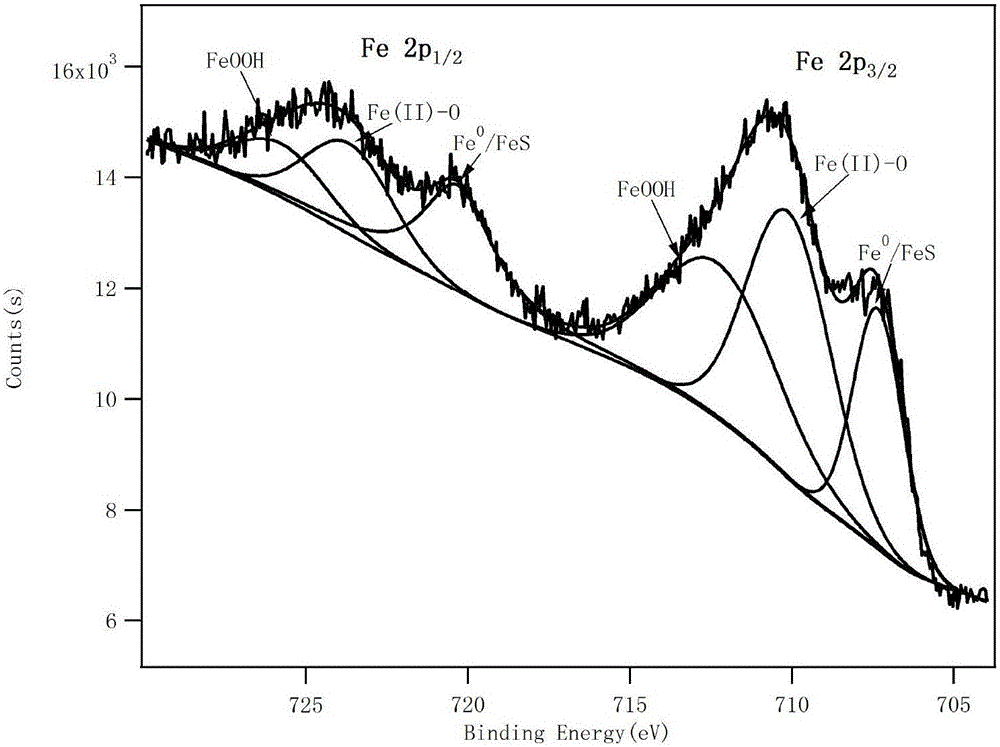

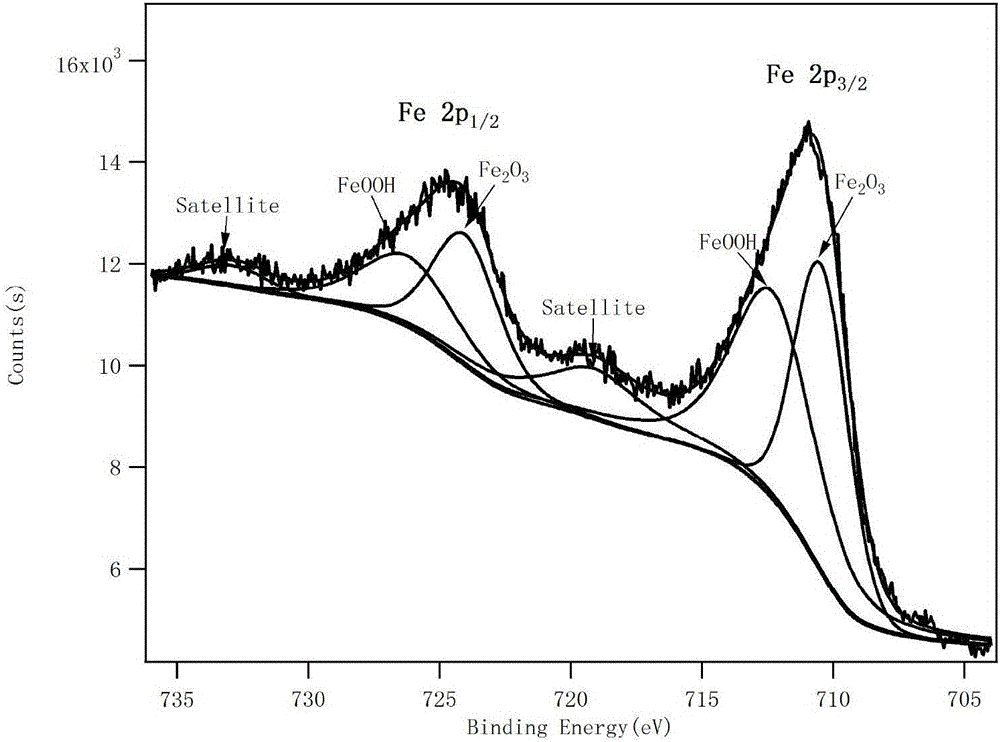

Method for removing orange yellow I in printing and dyeing wastewater by using sulfurized modified zero-valent iron material under effect of low-intensity magnetic field

InactiveCN105859015ABroaden applicationFacilitated releaseWater contaminantsMultistage water/sewage treatmentPre treatmentEnvironmental chemistry

The invention relates to a method for removing orange I in printing and dyeing wastewater by using a vulcanized modified zero-valent iron material under the action of a weak magnetic field. The vulcanized modified zero-valent iron material is a dispersed particle coated with a layer of iron sulfide on the surface of zero-valent iron. The printing and dyeing wastewater of I has a pH of 6.5-7; the sulfide-modified zero-valent iron material is added, and the reaction is stirred for 10-60 minutes under the action of a weak magnetic field. The invention improves the reactivity of the zero-valent iron and accelerates the removal rate of orange I through the method of vulcanization modification and external weak magnetic field. The removal efficiency of the method for orange I is much higher than that of zero-valent iron, and the sulfide-modified zero-valent iron material is simple to prepare, low in cost, and environmentally friendly; it has broad application prospects in organic wastewater treatment.

Owner:SHANDONG UNIV

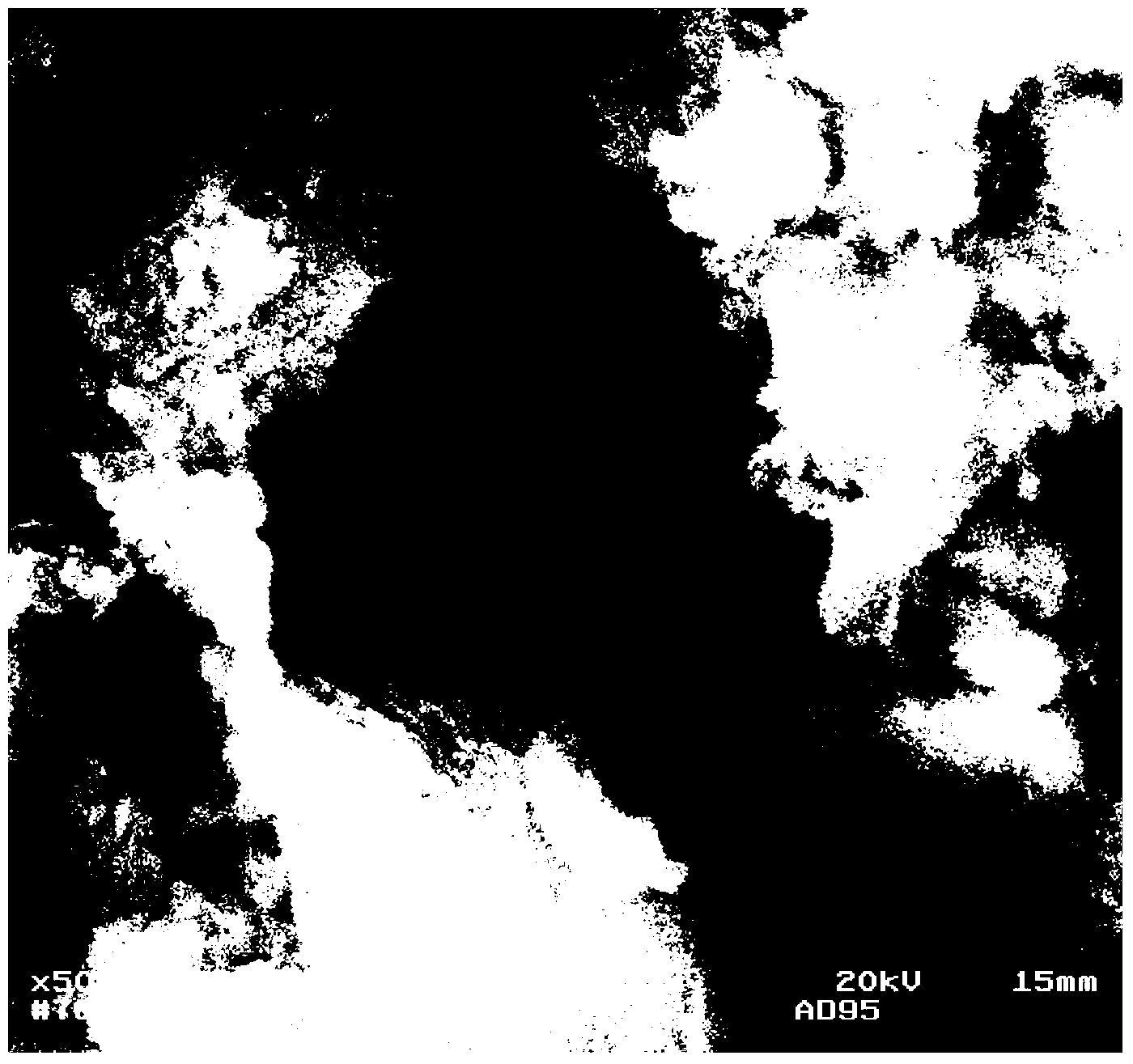

Wastewater treatment filtering material, and preparation method and use thereof

ActiveCN103316544AHigh adsorption and fixation functionStable weak alkalineOther chemical processesFiltration separationWater qualityZerovalent iron

The invention relates to a wastewater treatment filtering material, and a preparation method and a use thereof. The filtering material is formed by a porous ceramic matrix having an amount of porosity of 35-85% and nanometer zerovalent iron particles in-situ generated in the porous ceramic matrix, the micropore size of the porous ceramic matrix is 2-10mum, a fuzzy amorphous silicon-iron-carbon structure is formed in the micropore and can form an adsorbing film after absorbing water, and the material of the porous ceramic matrix is composed of 55-65 parts by weight of diatomite, 12-15 parts by weight of calcium-based bentonite, 7-12 parts by weight of carbon powder, 2-3 parts by weight of starch, and 4-6 parts by weight of kaolin. The filtering material obtained in the invention forms a nose-like porous fluffy filtering structure in the microstructure and generates the adsorbing film, so the absorbing efficiency is greatly improved, and the filtering material can be adapted to the chemical environment change of water. The shedding or heavy metal precipitation of the used filtering material does not appear, and the use safety of the filtering material is good.

Owner:SUZHOU MICRO CERAMICS HEAVY METAL FILTER TECH

Room-temperature preparation method for high-efficiency polycarboxylic acid water reducing agent

The invention relates to the technical field of building material admixtures, in particular to a room-temperature preparation method for a high-efficiency polycarboxylic acid water reducing agent. The preparation method adopts methyl allyl polyethenoxy ether and acrylic acid as reactive monomers, and adopts hydrogen peroxide as an oxide agent and sodium formaldehyde sulfoxylate as a reducing agent to build an oxidation-reduction system. The specific synthetic method comprises the following steps: adopting methyl allyl polyethenoxy ether, hydrogen peroxide and deionized water as a base solution; dropwise adding a water solution A of acrylic acid and a chain transferring agent, and a water solution B of sodium formaldehyde sulfoxylate; enabling radical polymerization reaction at room temperature. The preparation method can be carried out for synthesis at the room temperature, and is economical, environment-friendly, low in energy consumption and simple in preparation technology, and the synthesized water reducing agent is high in water-reducing rate, good in fluidity and good in slump retaining performance.

Owner:ANHUI XIN SOLID ENVIRONMENTAL CO LTD

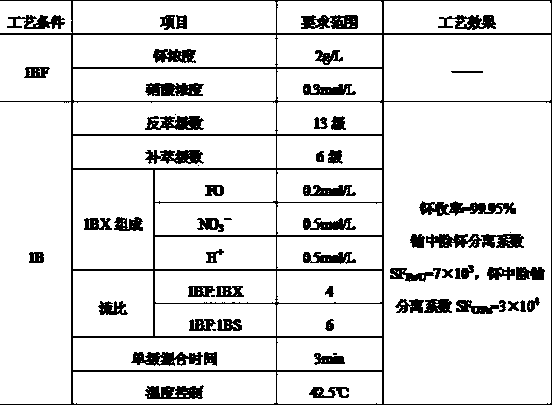

Uranium (U) and plutonium (Pu) separation technology in Purex process

ActiveCN103451455AStrong complexing abilityStrong reductionLiquid solutions solvent extractionRadioactive decontaminationPUREXSeparation technology

The invention belongs to the technical field of nuclear fuel postprocessing, and discloses a uranium (U) and plutonium (Pu) separation technology in a Purex process. According to the uranium and plutonium separation technology, Pu (IV) in 1BF material flow is reduced to Pu (III) in 1B tank by use of reducing agent 1BX and supplement extractant 1BS to enable plutonium to get into an aqueous phase and uranium to be retained in an organic phase, and uranium and plutonium separation is realized. The reducing agent 1BX which is used comprises 0.1-0.2 mol / L of formaldoxime, 0.35-0.5 mol / L of NO<3-> and 0.35-0.5 mol / L of H<+>; the flow ratio of 1BF:1BX is 1-4, and the flow ratio of 1BF:1BS is 4-6. The uranium and plutonium separation technology has the characteristics that the plutonium recovery rate is high, and the purification coefficients of removal of plutonium from uranium and removal of uranium from plutonium are large.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Superfine coal dust oxygen-enriched combustion technology and system

InactiveCN103234198AIncrease burnoutAlleviate the problem of slagging on the heating surfaceCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelTrappingFlue gas

The invention discloses a superfine coal dust oxygen-enriched combustion technology and system in the technical field of energy conservation and emission reduction. The technology comprises the following steps of: preparing superfine coal dust with an average particle size of less than 20 microns, and burning in an oxygen-enriched environment with overall concentration kept at 27-35% (v / v); extracting part of the hot flue gas in a flue at the rear part of a deduster; and circularly preparing superfine coal dust by taking the extracted flue gas and oxygen as combustion-supporting mediums again. According to the technology and system disclosed by the invention, the superfine coal dust is applied to the oxygen-enriched combustion technology, and the advantages of the two are effectively combined to realize an effect of using advantages and bypassing disadvantages; and the superfine coal dust oxygen-enriched combustion technology finishes efficient trapping of CO2 and is a new coal dust combustion technology with good combustion property and better pollutant discharge performance, and surely becomes an emerging technology for pollutant cooperative removal deserving vigorous promotion.

Owner:SHANGHAI JIAO TONG UNIV

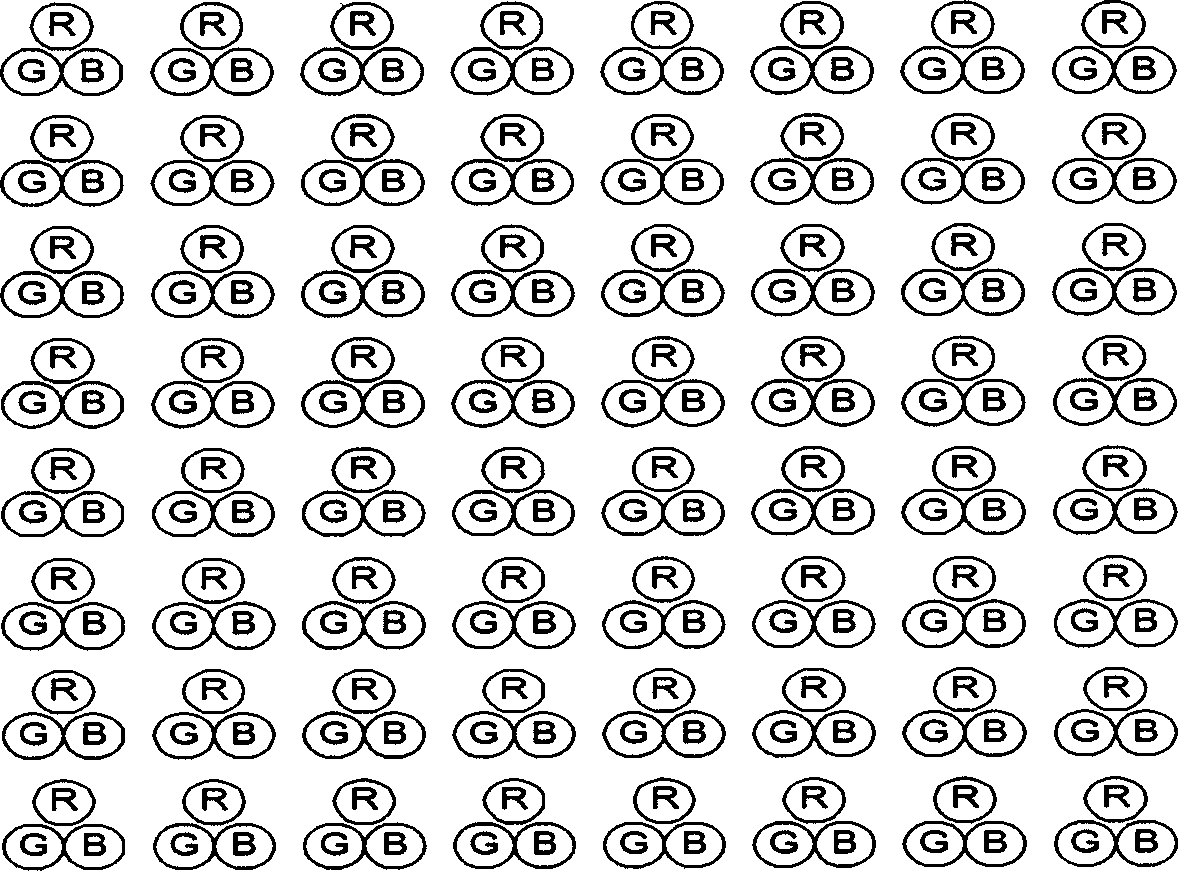

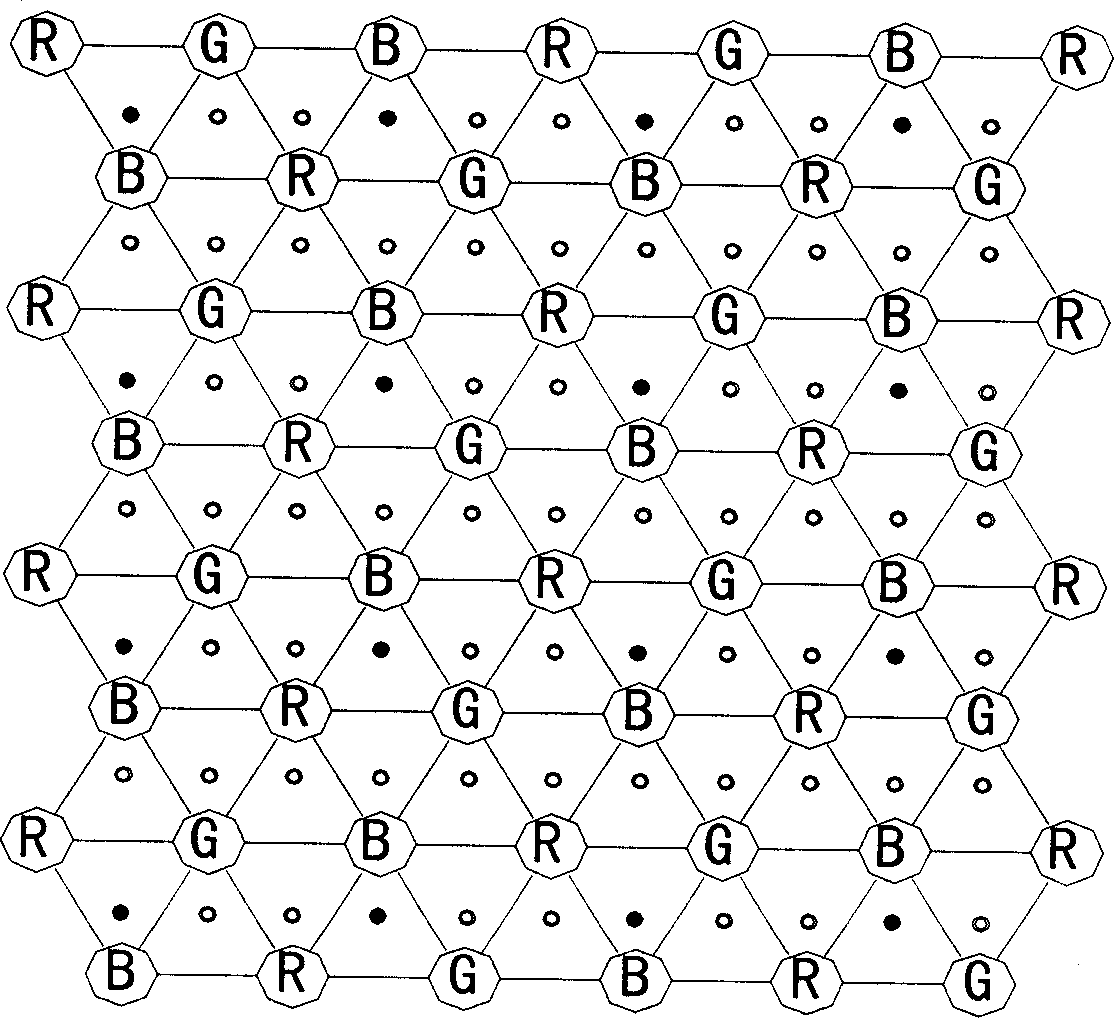

Three-light arranging method for three basic color LEDs

The invention belongs to the technology of LED display screen, and mainly relates to a three-lamp arrangement method of one type of three basic color LEDs. Its arrangement has the following characteristics: each LED is distributed uniformly and regularly, and the entire display screen is composed of RGB triangles as the basic unit arrangement. At the same time, on the display screen, three adjacent LEDs form an RGB triangle, which is the basic unit, and is evenly staggered and regularly spread out on the display screen. This arrangement solves the product cost difference caused by the quality of the LED material of the existing display screen, and at the same time better solves the problem of heat dissipation. On the premise of improving the display effect, the material cost is greatly reduced. An outdoor LED display application solution with advanced technology and worthy of promotion.

Owner:熊小梅

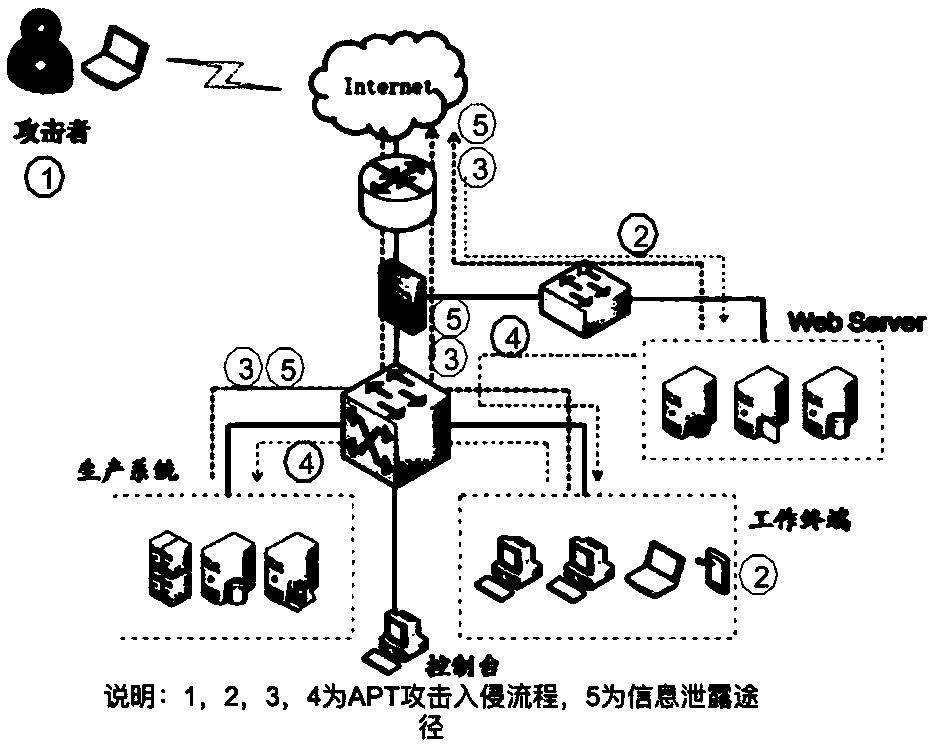

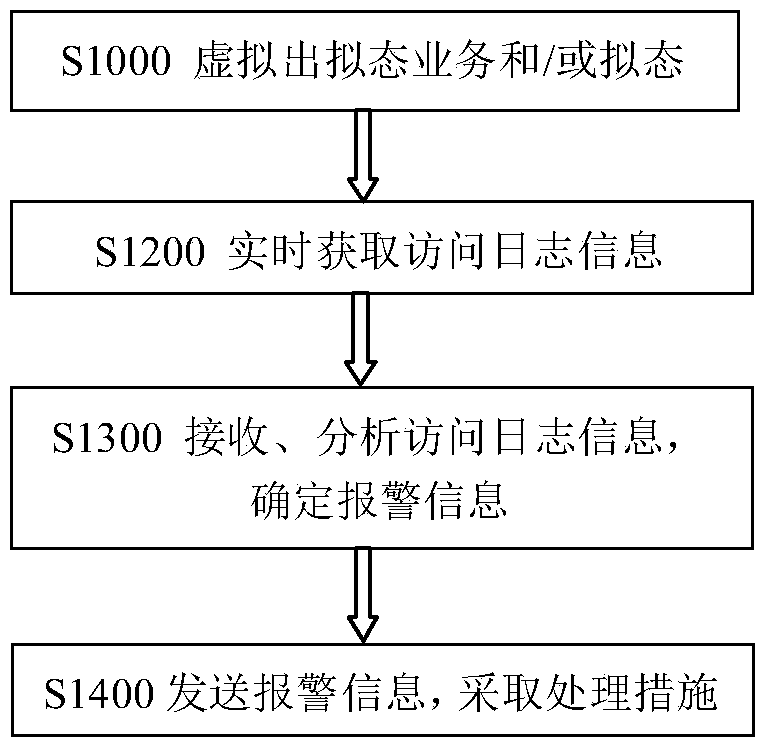

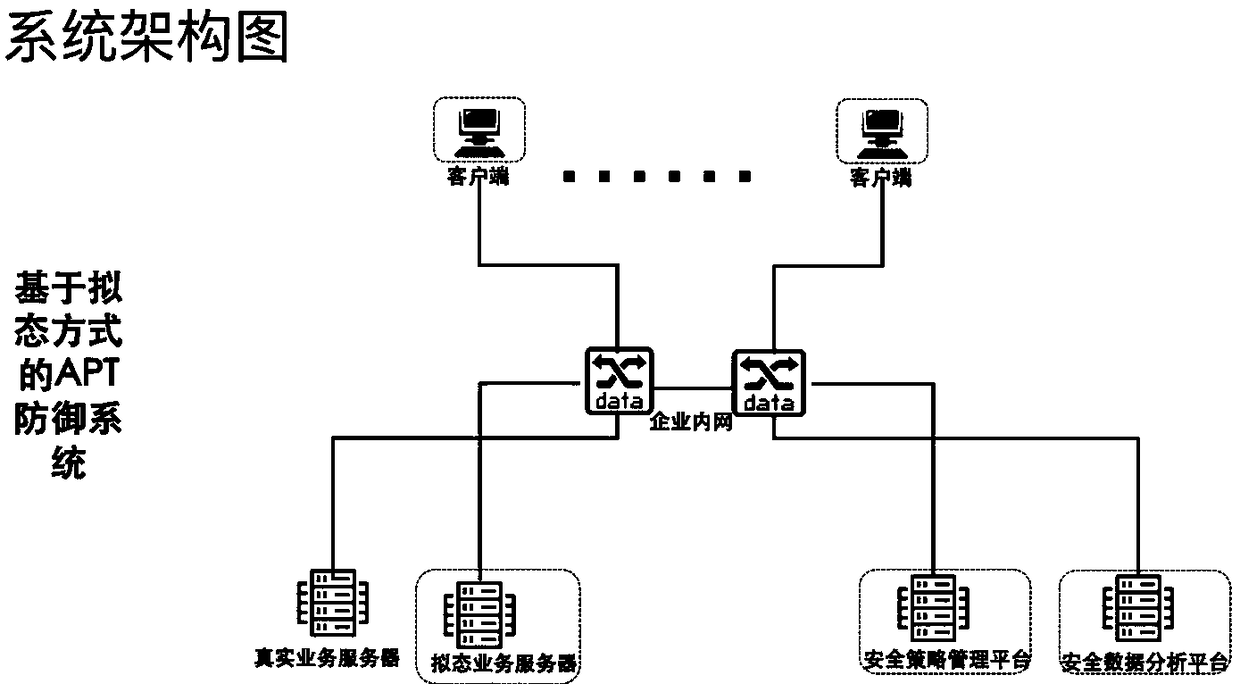

APT attack defense method and system adopting mimetic technology

InactiveCN108768989ADoes not limit the operationThe attack defense method is simpleTransmissionInjury rateComputer security

The invention discloses an APT attack defense method and system adopting the mimetic technology. The method comprises the following steps: virtualizing mimetic services of different forms of servicesand mimetic files of different types of sensitive files; and inducing the APT access attack, and once the mimetic services and / or the mimetic files are accessed, obtaining access log information in real time, analyzing the access log information, sending alarm information according to an analysis result, and adopting appropriate processing measures according to the alarm information. The defense method and system of the invention have low requirements on hardware, high defense efficiency and low accidental injury rate, and various operations of normal users, such as accessing the Internet, accessing the internal network system and the like, are normally performed without being affected.

Owner:刘勇

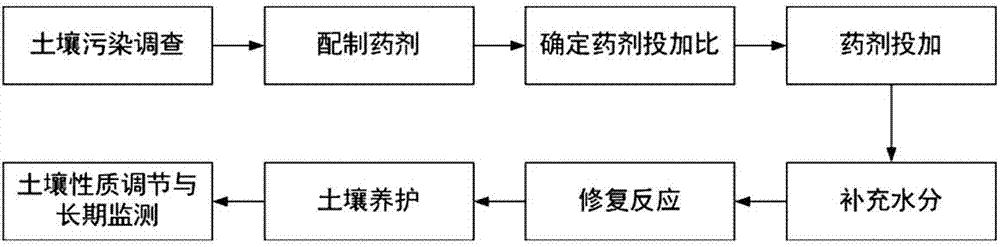

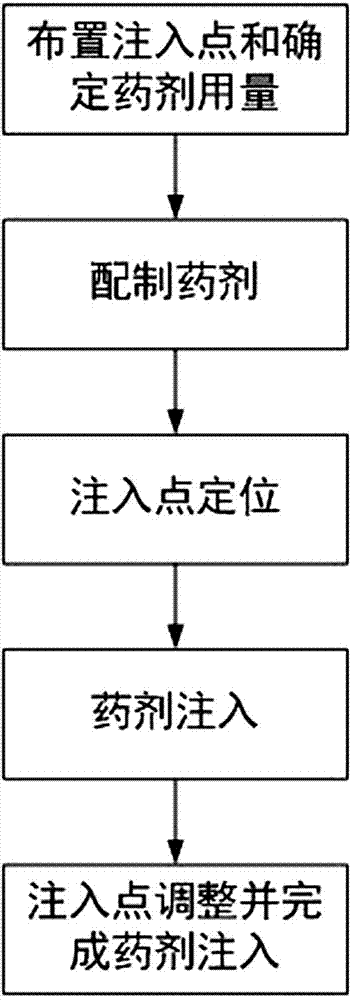

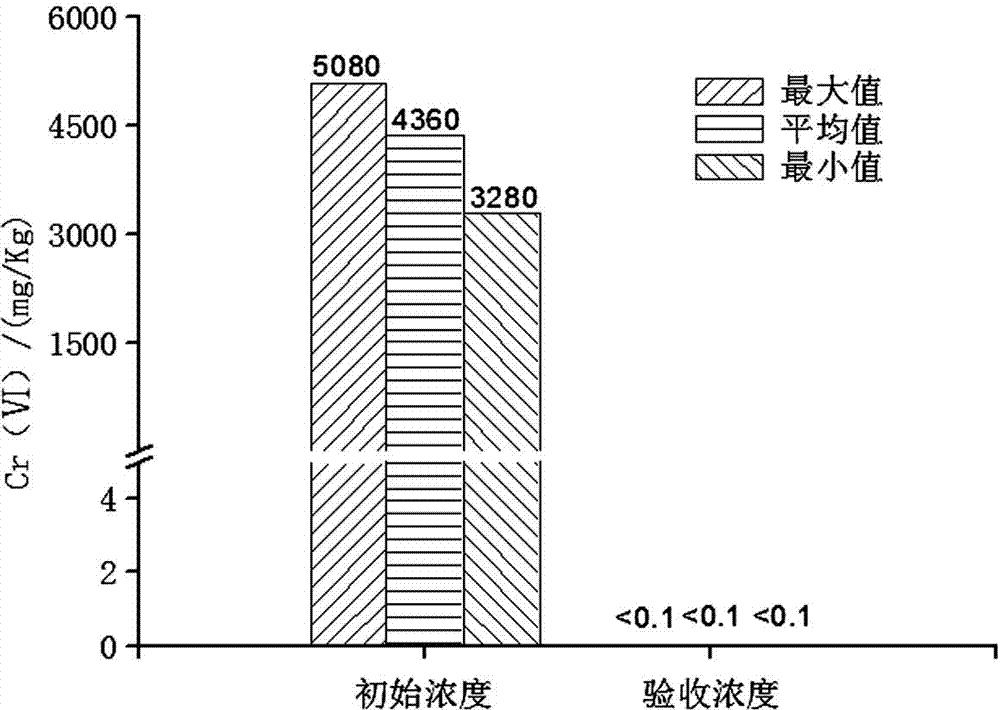

Application and remediation method of calcium polysulfide in chromium-contaminated soil or underground water remediation

ActiveCN104759458AGood repair effectThe repair effect is stableContaminated soil reclamationContaminated soilsEnvironmental chemistry

The invention discloses application and a remediation method of calcium polysulfide in chromium-contaminated soil or underground water remediation. Calcium polysulfide is adopted for chromium contamination remediation, and two remediation methods are particularly related. The method for remediating chromium-contaminated soil by calcium polysulfide comprises the following steps: investigating the chromium contamination degree of soil, preparing a calcium polysulfide water agent, determining the adding ratio of the calcium polysulfide water agent, adding the calcium polysulfide water agent, supplying water, carrying out remediation reaction, maintaining soil and adjusting the nature of the remediated soil. The method for remediating chromium-contaminated underground water by calcium polysulfide comprises the following steps: arranging injection points, determining the amount of a remediation agent, preparing the remediation agent, positioning the injection points, injecting the calcium polysulfide remediation agent, adjusting the positions and amounts of the injection points and the like. According to the invention, the operation process is simple; the agents are stable in source; the reaction speed is high; the remediation effect is good; the chromium-contaminated soil or underground water can be stable for a long time after remediation; the remediation method can be applied to large-scale implementation, is economic and reasonable, and is a relatively ideal chromium-contaminated soil or underground water remediation technique.

Owner:BCEG ENVIRONMENTAL REMEDIATION CO LTD

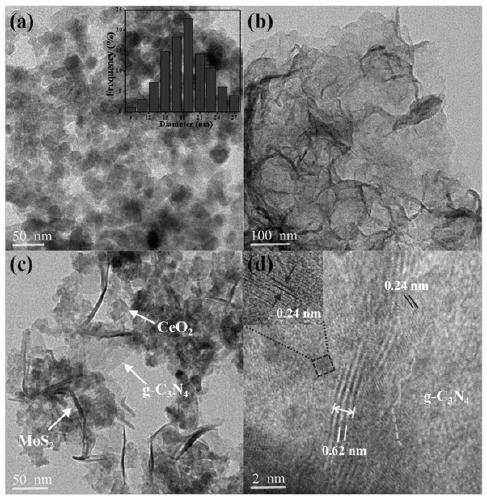

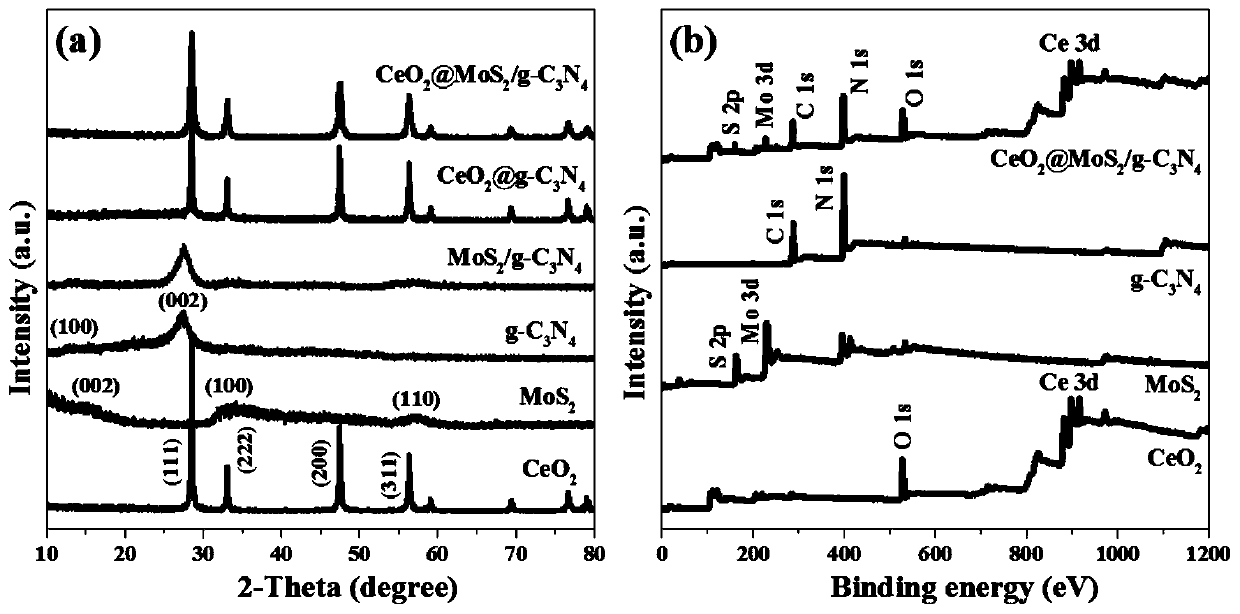

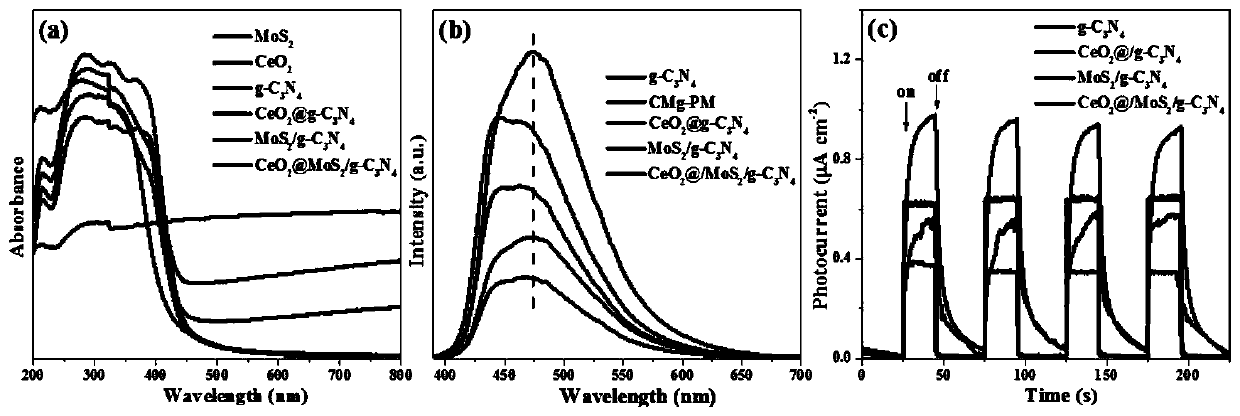

CeO2@MoS2/g-C3N4 ternary composite photocatalyst and preparation method thereof

ActiveCN110152711AImprove light responsivenessUnique two-dimensional nanostructureMaterial nanotechnologyWater/sewage treatment by irradiationNitrogen gasControllability

The invention belongs to the field of nano-material preparation, and discloses a CeO2@MoS2 / g-C3N4 composite photocatalysis material and a preparation method thereof. The preparation method comprises the following steps: (1) adding cerium oxide hexahydrate to a mixed solution of butylamine and toluene, carrying out hydrothermal treatment on the obtained mixed solution, and calcining the obtained reaction product to obtain CeO2 nanocrystals; (2) ultrasonically dispersing sodium molybdate dihydrate and g-C3N4 nanosheets in a mixed solution of L-cysteine and dimethyl sulfoxide, and carrying outhydrothermal treatment on the obtained mixed solution to obtain MoS2 / g-C3N4 nanosheets; (3) ultrasonically dispersing the CeO2 nanocrystals and MoS2 / g-C3N4 in a methanol solution, volatilizing the methanol, and collecting the obtained product to obtain a CeO2-MoS2 / g-C3N4 composite material; and (4) placing the CeO2-MoS2 / g-C3N4 composite material in a tubular furnace, and calcining in a nitrogen atmosphere to obtain the CeO2@MoS2 / g-C3N4 ternary composite photocatalyst. The preparation method of the invention is simple and has strong controllability, and the obtained composite photocatalyst hasan excellent photocatalytic degradation performance.

Owner:NANJING UNIV +1

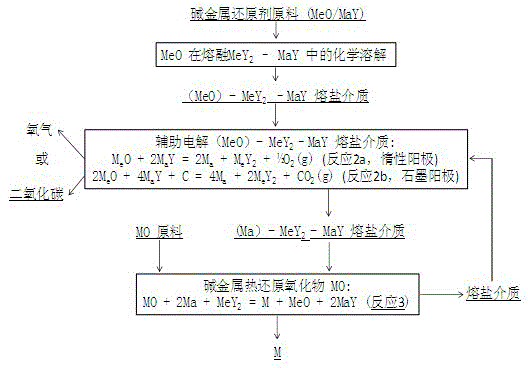

Method for preparing metal through continuous reduction in molten salt medium

InactiveCN105274576ASustainable useReduce manufacturing costMaterials preparationAlkaline earth metal

The present invention relates to a metal material preparation method, particularly to a method for preparing a metal through continuous reduction in a molten salt medium. According to the method, a molten alkali metal and alkaline earth metal mixing halide MaY-MeY2 is adopted as the flux of a molten salt medium, an alkaline earth metal oxide MeO / alkaline metal halide MaY mixture capable of being dissolving in the flux of the molten salt medium is used to replace an alkaline metal so as to be adopted as a reduction agent, the specifically-selected MeO / MaY mixture is added to the molten MaY-MeY2 flux to form a MeO-MaY-MeY2 molten salt, the molten salt medium is subjected to electrolysis to decompose the MeO dissolved in the medium so as to finally obtain the Ma-MaY-MeY2 molten salt medium, an oxide MO is added to the formed Ma-MaY-MeY2 molten salt medium under the support of the electrolysis process performing under the conditions, and the alkali metal Ma instantly performs thermal reduction on the added oxide MO so as to prepare the metal M. According to the present invention, the disadvantages of complex operation and danger of the direct alkali metal reduction agent adding in the traditional thermal reduction are overcome; the excessive use of the alkali metal reduction agent is solved, and the continuous production can be achieved; and the cost is low, and the energy consumption is low.

Owner:AUYONG ADVANCED MATERIALS TECH SHANGHAI CO LTD

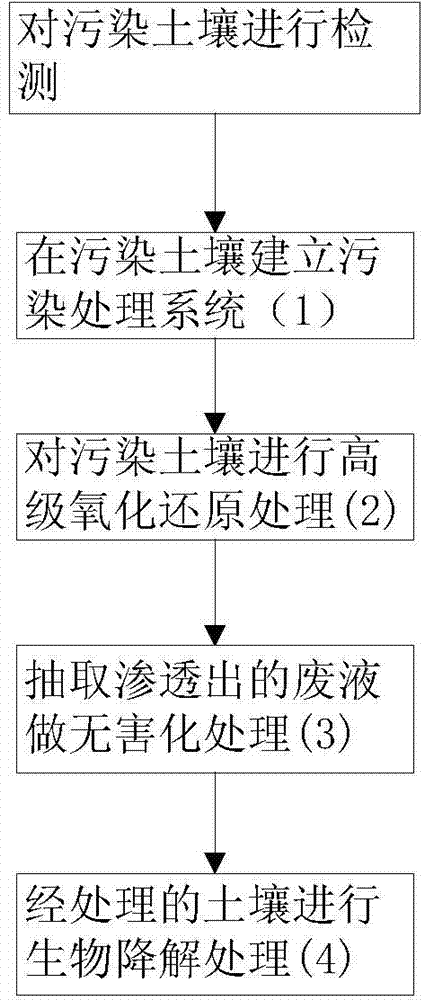

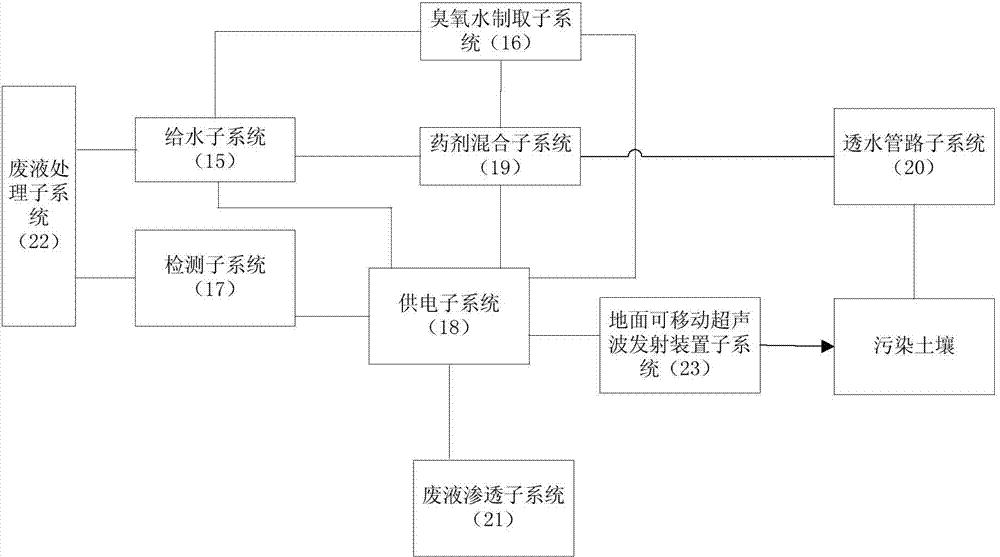

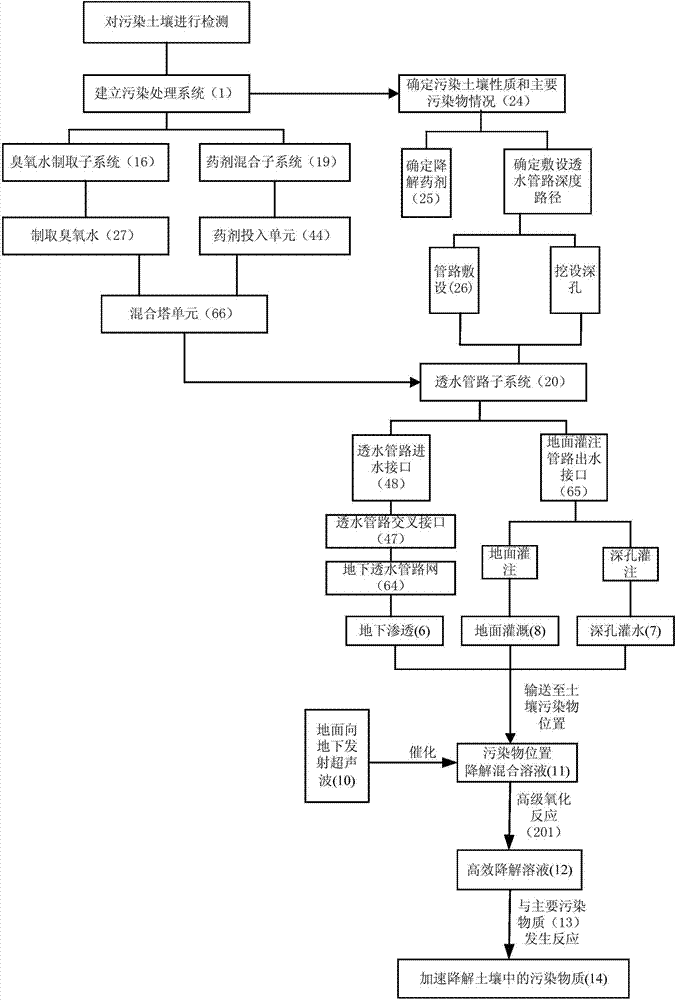

Advanced redox in-situ treatment system and method for restoring polluted soil

ActiveCN103920703AEfficient degradationPromote decompositionContaminated soil reclamationLiquid wasteTreatment system

The invention discloses an advanced redox innocent treatment system and method for waste pollutants, belonging to the technical fields of pollution treatment and restoration and environmental protection. The innocent treatment system comprises a waste degradation subsystem, a waste liquid treatment subsystem, an ozone water preparation subsystem, a degradation reagent addition subsystem, a detection control subsystem and a water level control subsystem. The method comprises the following steps: determining the type of waste pollutant, selecting the degradation reagent, pouring the waste pollutant into a treating pond, carrying out advanced redox treatment on the waste pollutant, carrying out innocent treatment on the treated waste liquid, reutilizing, and carrying out biodegradation treatment on the treated soil. The system and method have the advantages of obviously higher degradation efficiency and short time consumption, can treat organic pollutants within 2-3 days, can treat heavy metal pollutants within 3-5 days, greatly shorten the pollutant treatment time, and lower the cost by more than 70%.

Owner:QINGDAO ODO ENVIRONMENTAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com