CeO2@MoS2/g-C3N4 ternary composite photocatalyst and preparation method thereof

A ternary composite, photocatalyst technology, used in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., to achieve the effects of increasing conduction rate, prolonging life, and reducing adsorption energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

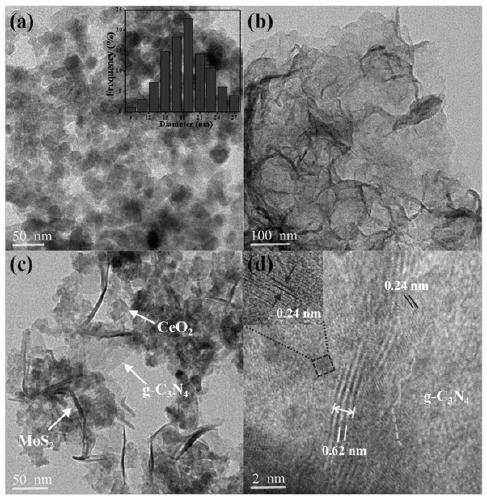

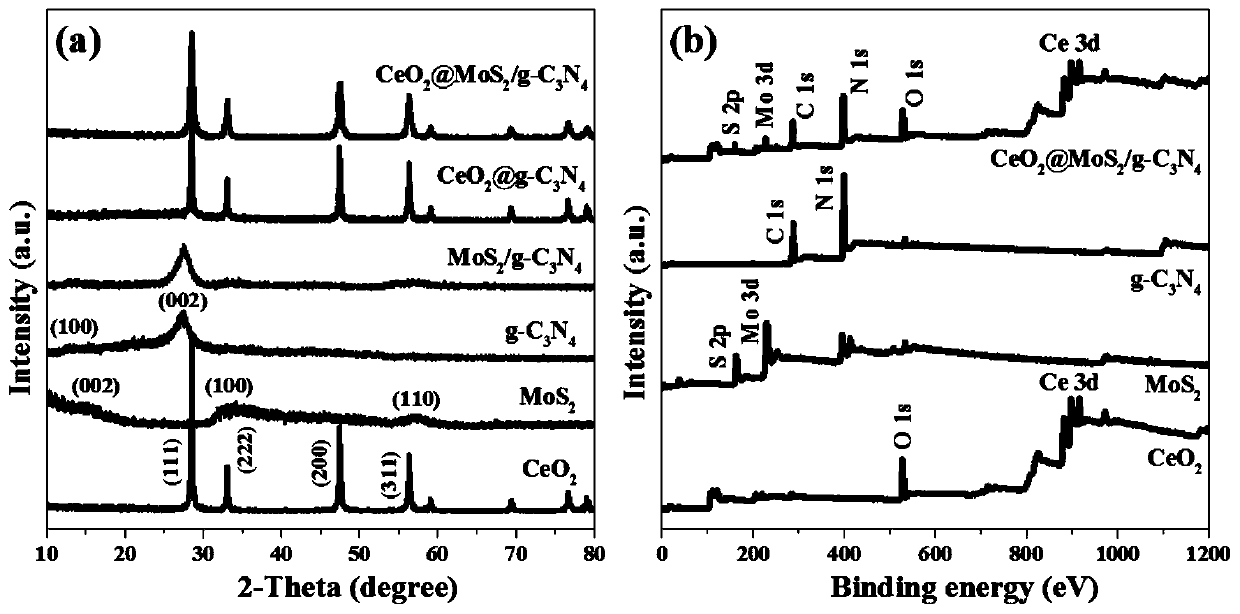

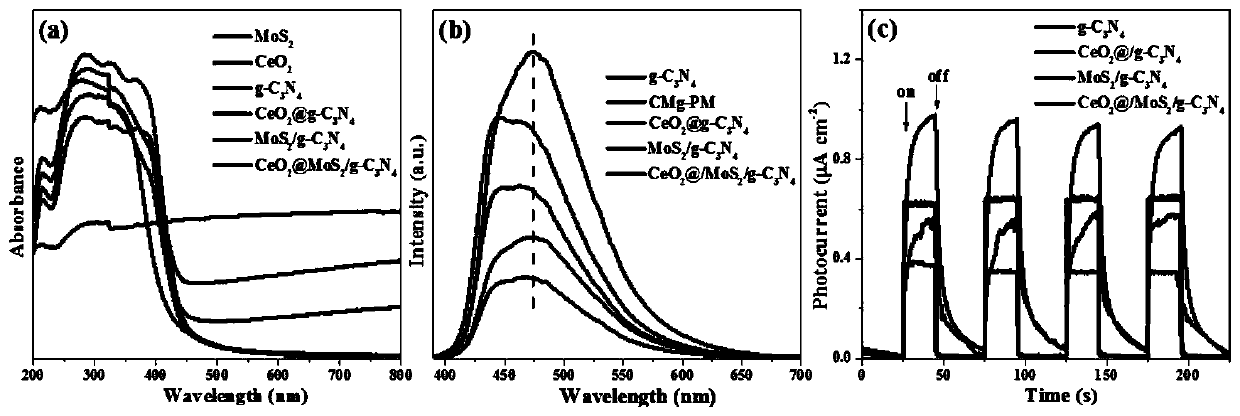

[0038] (1) Take 5g of urea in a muffle furnace, uniformly heat up to 550°C at a heating rate of 2°C / min, calcinate at a constant temperature for 6 hours, and after natural cooling, grind the obtained solid into fine powder to obtain g-C 3 N 4 Nanosheets. like figure 1 , 2 , 3, 4, 5, pure g-C 3 N 4 The morphology of the compound is a two-dimensional sheet structure without obvious stacking phenomenon, and the characteristic peaks attributed to C and N elements can be clearly observed in the X-ray diffraction pattern and X-ray photoelectron spectrum, which shows that this method is suitable for synthesis g-C 3 N 4 Nanosheets are of extremely high purity.

[0039] In (2), 0.2g of cerium oxide hexahydrate can be dissolved in a mixed solution of 0.05ml of butylamine, 10ml of toluene and 20ml of distilled water, stirred evenly until completely dissolved, then the resulting mixed solution is transferred to a hydrothermal reaction kettle, and the reaction kettle is sealed Afte...

Embodiment 2

[0044] (1) Take 5g of urea and place it in a muffle furnace, uniformly heat up to 550°C at a heating rate of 2°C / min, calcinate at a constant temperature for 6 hours, and after natural cooling, grind the obtained solid into fine powder to obtain g-C 3 N 4 Nanosheets.

[0045] (2) Get 0.4g cerium oxide hexahydrate and dissolve in the mixed solution of 0.15ml butylamine, 20ml toluene and 30ml distilled water, stir until completely dissolved, then transfer the gained mixed solution to the hydrothermal reaction kettle, after sealing the reaction kettle, Placed in a 170°C oven for hydrothermal treatment for 24 hours. After the reaction, the obtained product was repeatedly washed with ethanol and deionized water, filtered and dried at 60°C, and then the dried reaction product was calcined at 170°C for 24 hours to obtain CeO 2 Nanocrystalline.

[0046] (3) Take 0.30g sodium molybdate dihydrate, 0.10g g-C 3 N 4 The nanosheets were ultrasonically dispersed in a mixed solution of 0...

Embodiment 3

[0051] (1) Take 5g of urea and place it in a muffle furnace, uniformly heat up to 600°C at a heating rate of 5°C / min, calcinate at a constant temperature for 4 hours, and after natural cooling, grind the obtained solid into fine powder to obtain g-C 3 N 4 Nanosheets.

[0052] (2) Get 0.6g of cerium oxide hexahydrate and dissolve it in a mixed solution of 0.25ml of butylamine, 30ml of toluene and 25ml of distilled water, stir until completely dissolved, transfer the resulting mixed solution to a hydrothermal reaction kettle, and seal the reaction kettle, Placed in a 180°C oven for hydrothermal treatment for 24 hours. After the reaction, the obtained product was repeatedly washed with ethanol and deionized water, filtered and dried at 60°C, and then the dried reaction product was calcined at 180°C for 24 hours to obtain CeO 2 Nanocrystalline.

[0053] (3) Take 0.40g sodium molybdate dihydrate, 0.15g g-C 3 N 4 The nanosheets were ultrasonically dispersed in a mixed solution ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| band gap | aaaaa | aaaaa |

| quantum efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com