Photocatalytic device taking porous ceramic as carrier as well as preparation method and application thereof

A technology of porous ceramics and photocatalysis, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of difficult separation and recycling of powdered photocatalysts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

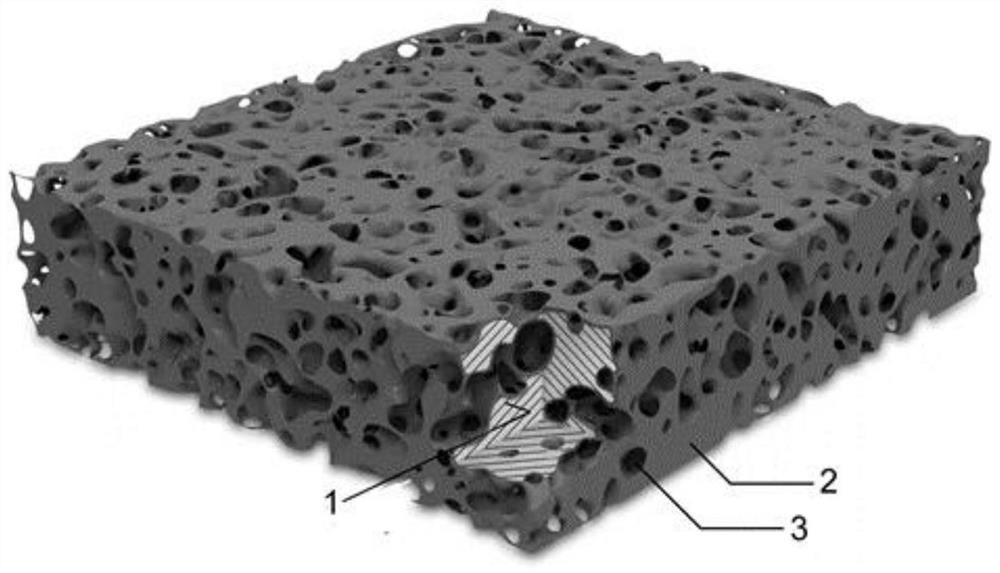

Image

Examples

preparation example Construction

[0023] In the present invention, the preparation method of the porous ceramic carrier preferably includes the following steps:

[0024] Mix silica gel and water for hydrothermal reaction to obtain porous ceramic carrier;

[0025] In the present invention, the hardness of the silicone gel is preferably 80-140 g, the viscosity range is preferably 0.01-1.50 mJ, and the wire drawing length is preferably 0.58-5.21 mm. In the present invention, the mass ratio of the silica gel to water is preferably (85-95):(5-15), more preferably 90:10. The present invention has no special requirements on the mixing method, and a mixing method well known to those skilled in the art can be used.

[0026] In the present invention, the pressure of the hydrothermal reaction is 20-1050MPa, preferably 100-500MPa; the temperature of the hydrothermal reaction is 200-500°C, preferably 350-400°C; the time of the hydrothermal reaction 10 to 240 min, more preferably 60 to 120 min. In the present invention, ...

Embodiment 1

[0053] In the reaction kettle, the porous ceramic carrier was grown by hydrothermal-hot static pressing method: the silica gel and water were mixed at a mass ratio of 9:1, the pressure of the autoclave was set to 110MPa, and the hydrothermal reaction was carried out at 360°C for 110min; After the hydrothermal reaction ends, a porous ceramic carrier is obtained; the surface and interior of the obtained porous ceramic carrier have microcavity holes, and the bulk density is 0.9g / cm 3 The pore volume is 1.2cm / g; the pore diameter range of the microcavity is 200-500nm; the thickness of the porous ceramic carrier is 200μm.

[0054] Mix glacial acetic acid, distilled water, and absolute ethanol at a volume ratio of 3:1:3, and stir evenly to form the first solution; mix butyl titanate, glacial acetic acid, and absolute ethanol at a volume ratio of 5:1:6 to form the second solution. Second solution; slowly add the first solution to the second solution under the condition of stirring in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com