Patents

Literature

1207 results about "Micro cavities" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for transferring a thin film comprising a step of generating inclusions

InactiveUS6756286B1Reduce surface roughnessBudget is reducedSolid-state devicesSemiconductor/solid-state device manufacturingSolid massFracture plane

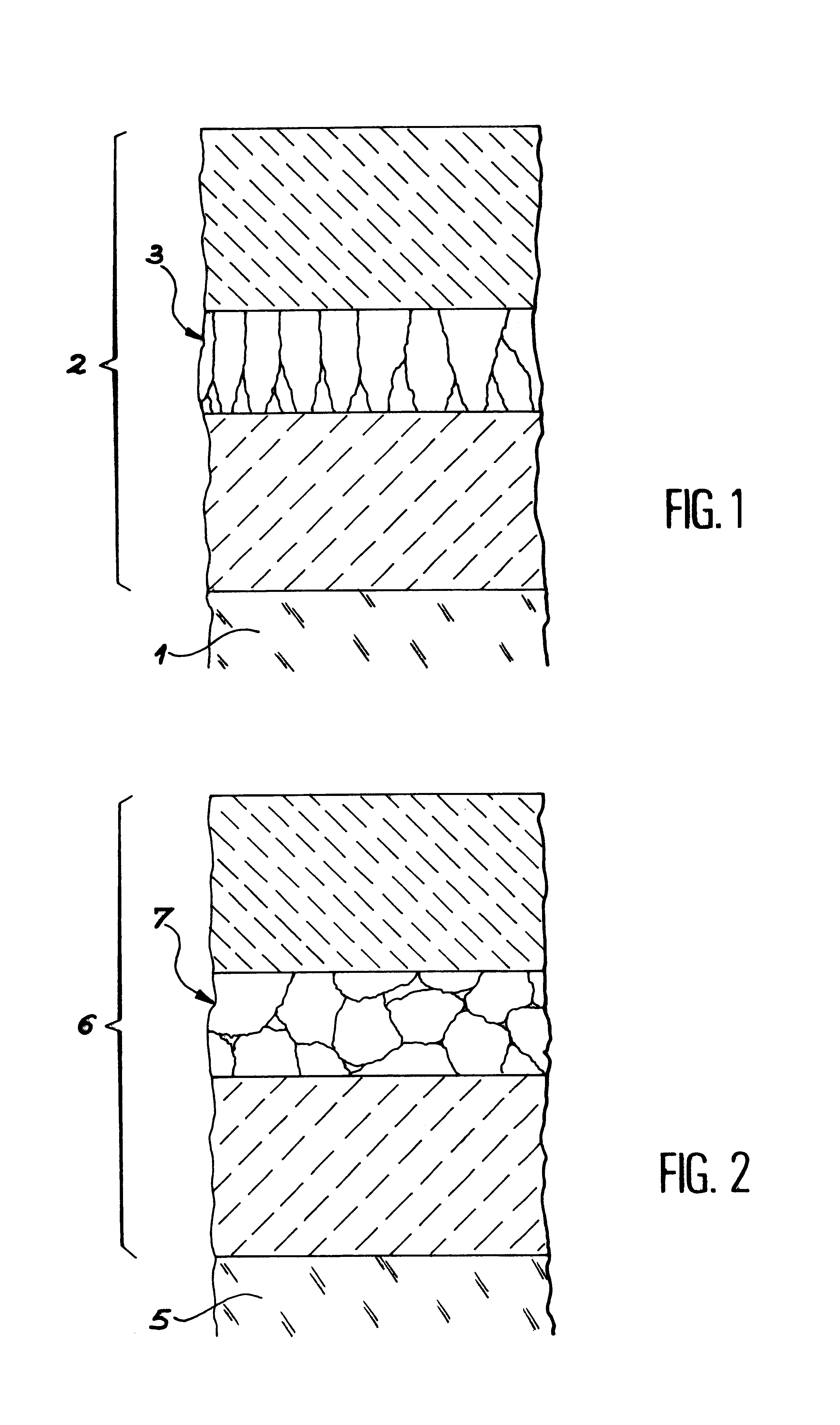

A process for transfer of at least one thin film of solid material delimited in an initial substrate. The process includes a step in which a layer of inclusions is formed in the initial substrate at a depth corresponding to the required thickness of the thin film. These inclusions are designed to form traps for gaseous compounds which subsequently are implanted. In a subsequent step gaseous compounds are implanted in a manner to convey the gaseous compounds into the layer of inclusions. The dose of implanted gaseous compounds is made sufficient to cause the formation of micro-cavities to form a fracture plane along which the thin film can be separated from the remainder of the substrate.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

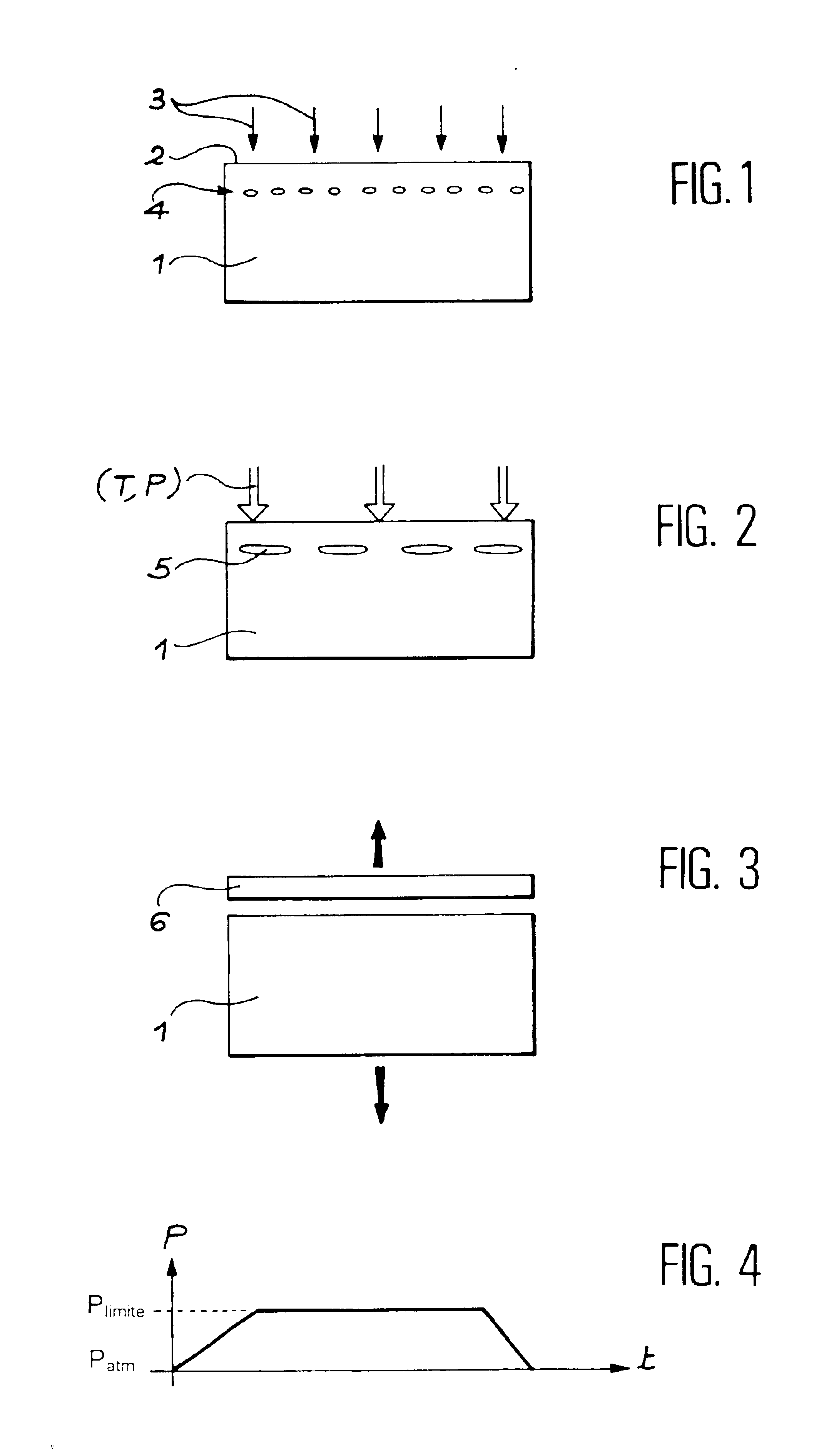

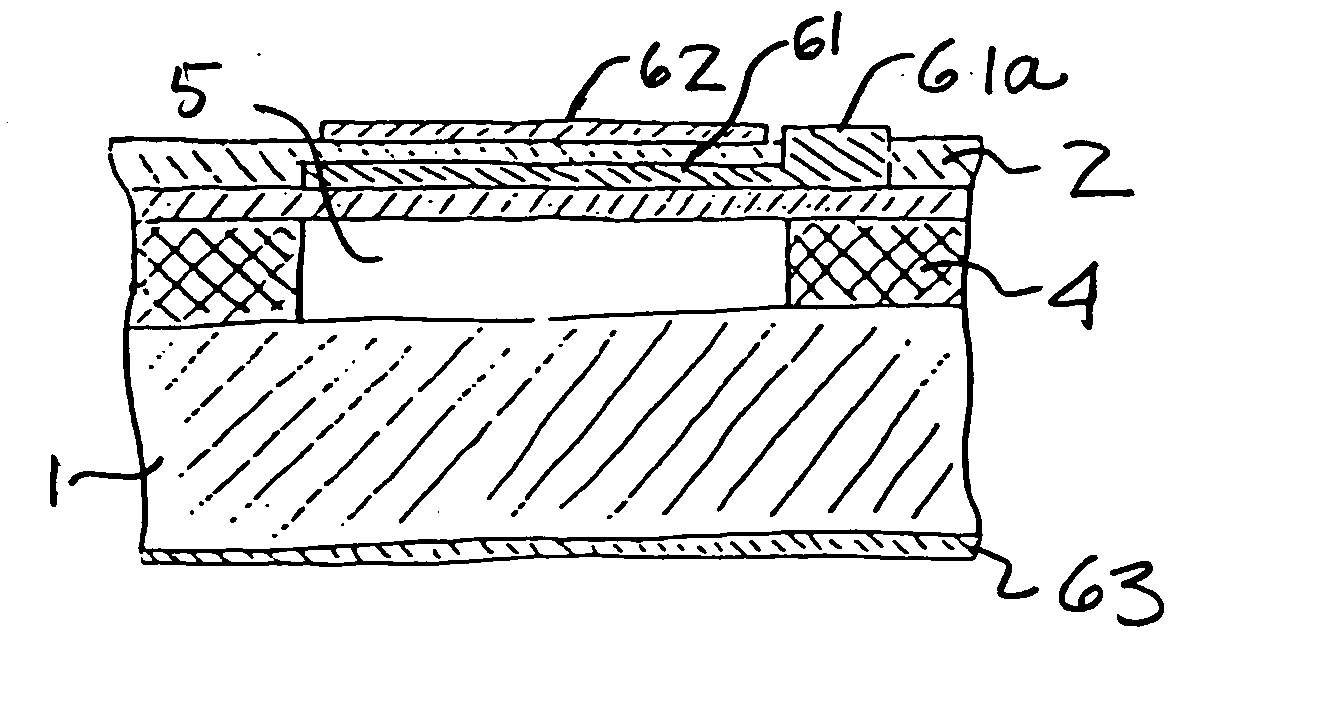

Method for making a thin film using pressurization

InactiveUS6809044B1Inhibition formationEncouraging coalescenceSemiconductor/solid-state device testing/measurementSolid-state devicesThermal energyChemistry

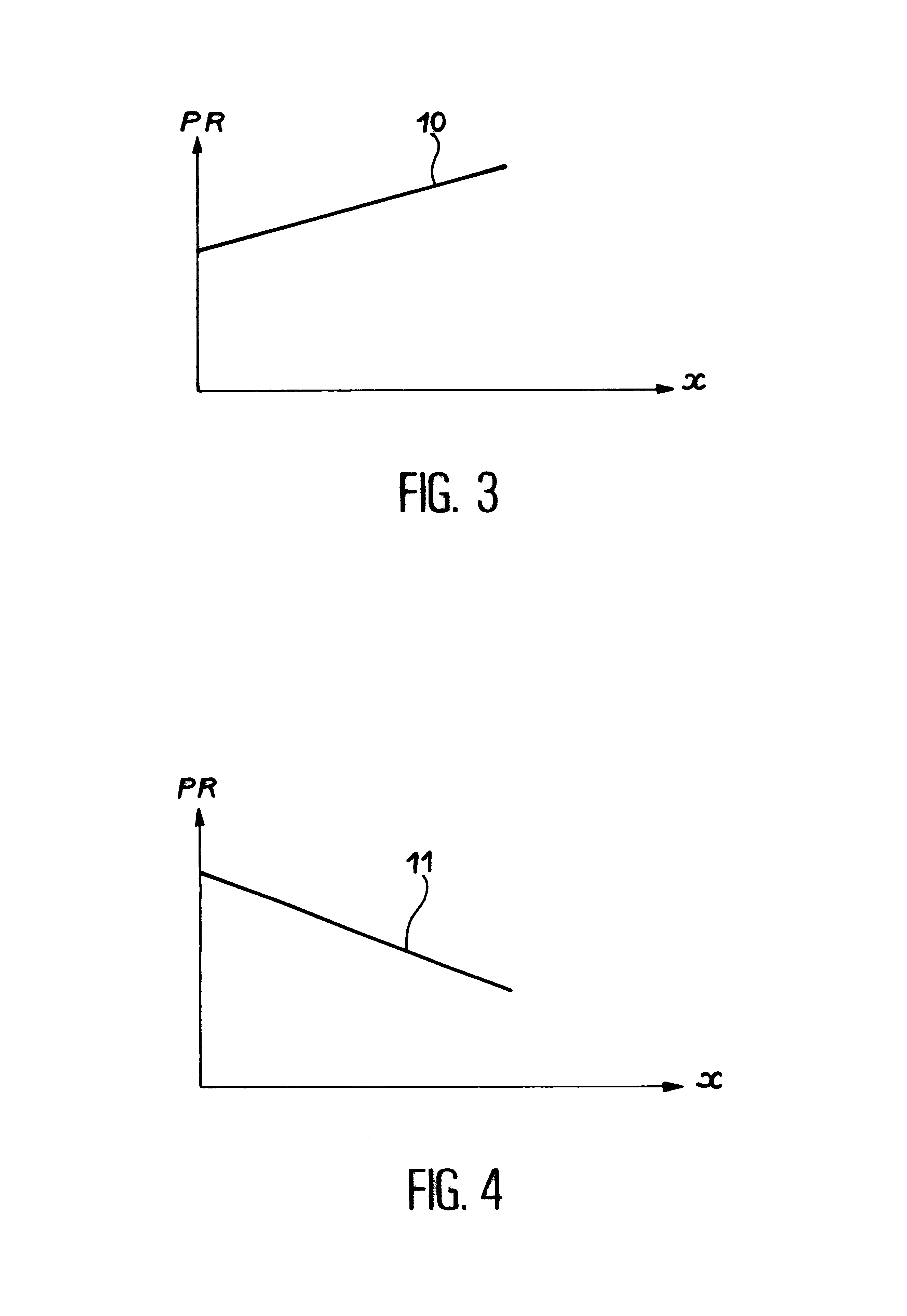

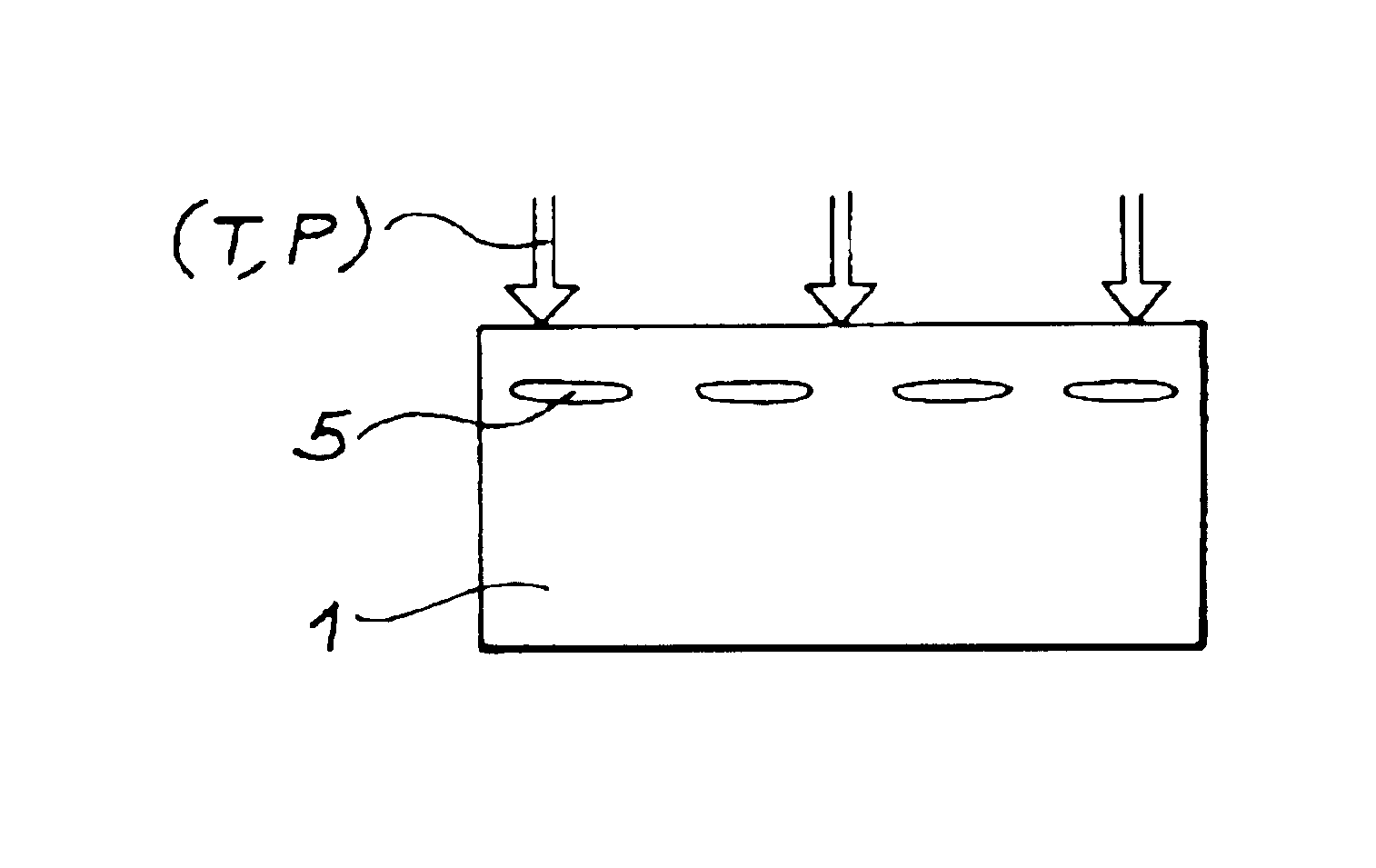

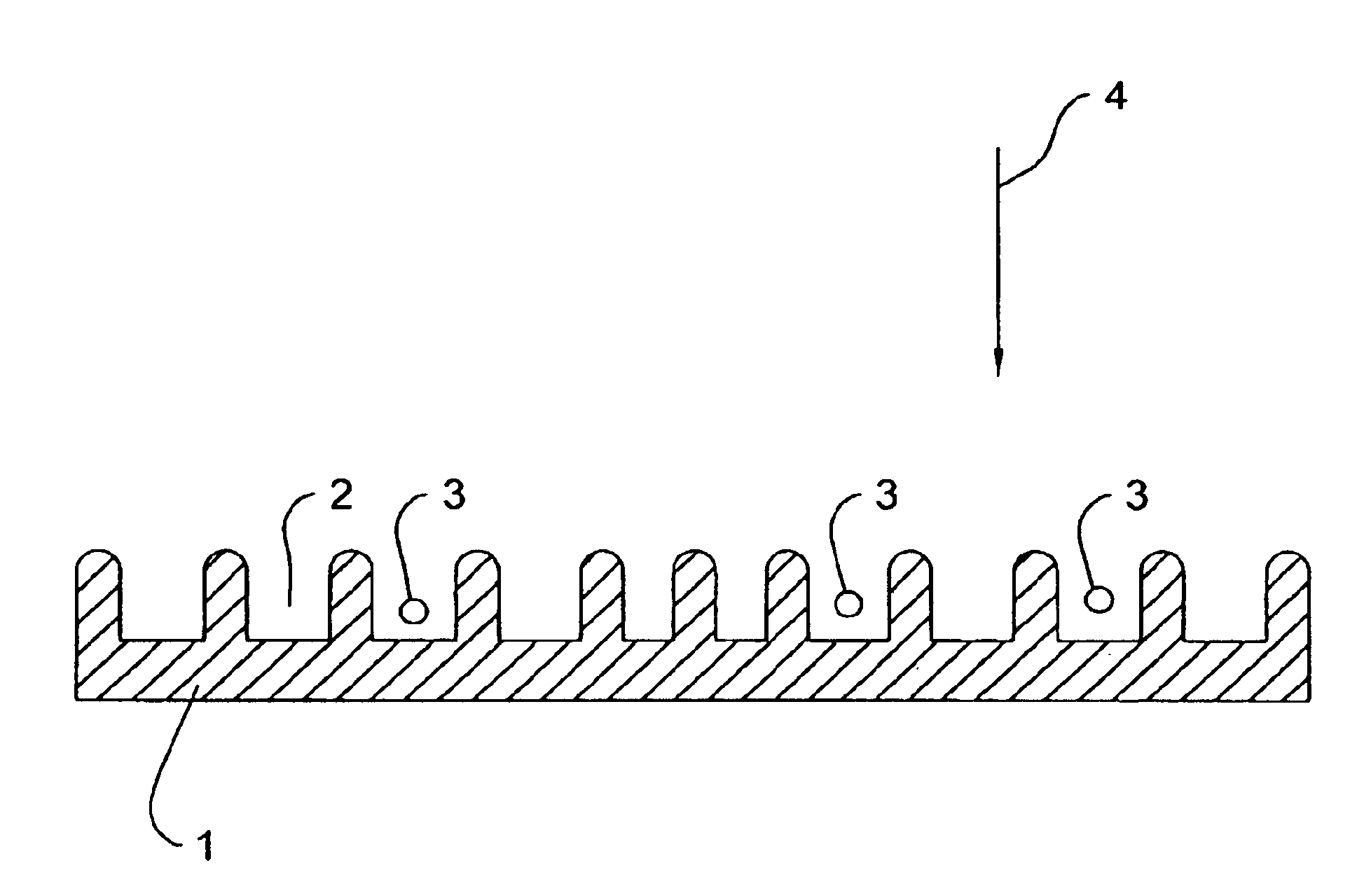

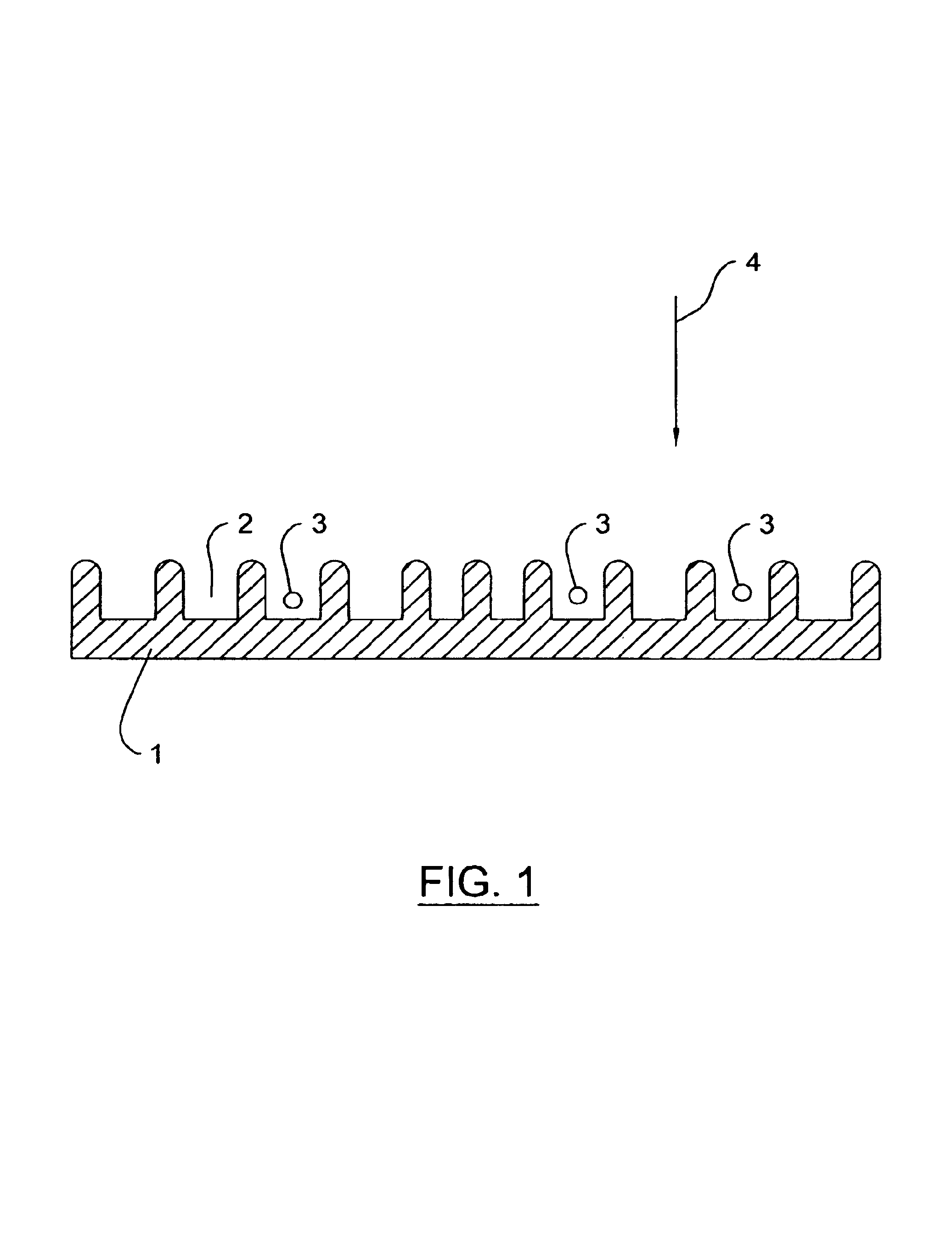

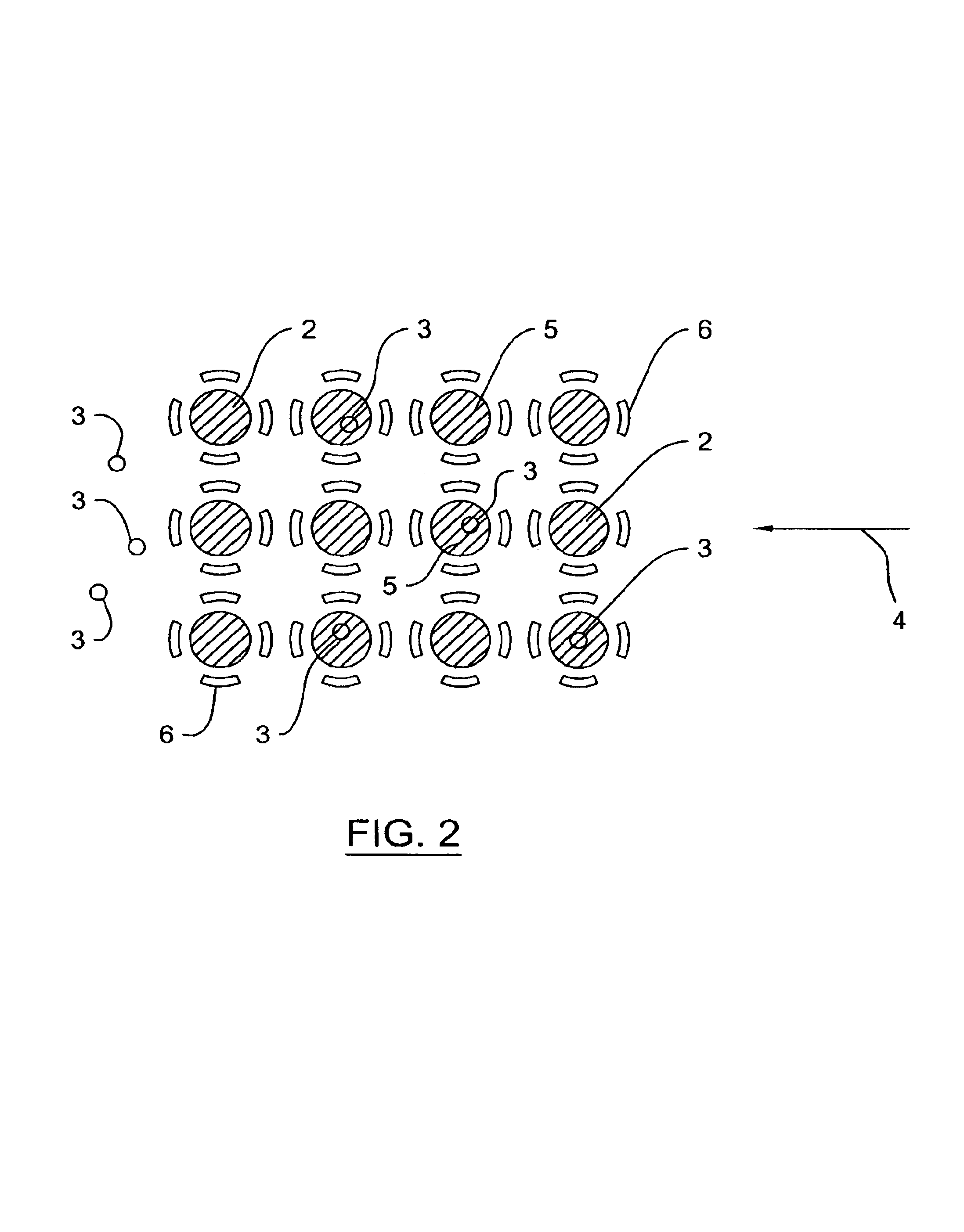

The invention relates to a process for making a thin film starting from a substrate (1) of a solid material with a plane face (2) comprising:the implantation of gaseous compounds in the substrate (1) to make a layer of micro-cavities (4) at a depth from the said plane face (2) corresponding to the thickness of the required thin film, the gaseous compounds being implanted under conditions that could weaken the substrate at the layer of micro-cavities,partial or total separation of the thin film from the rest of the substrate (1), this separation comprising a step in which thermal energy is added and pressure is applied to the said plane face (2).

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

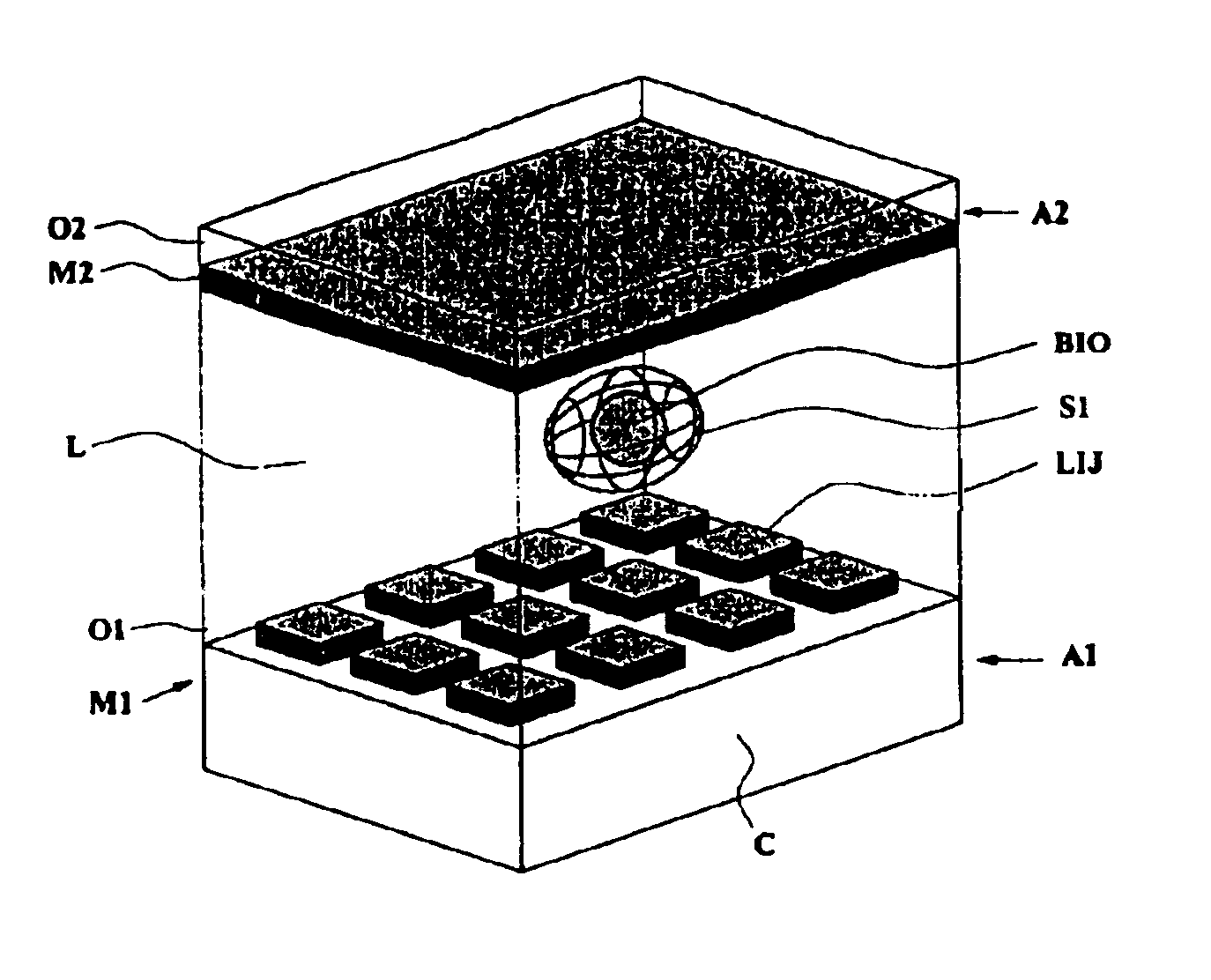

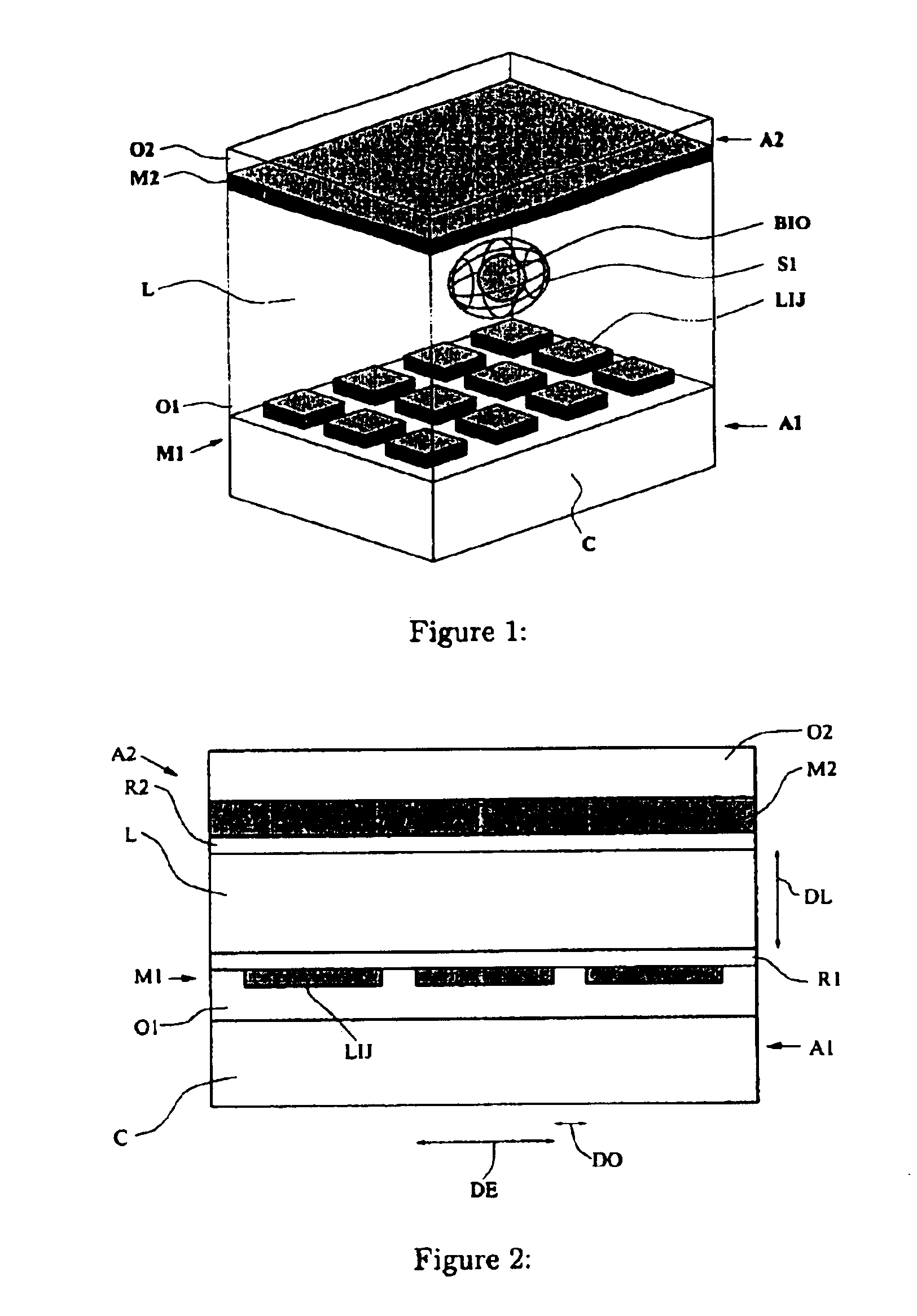

Method and apparatus for the manipulation of particles by means of dielectrophoresis

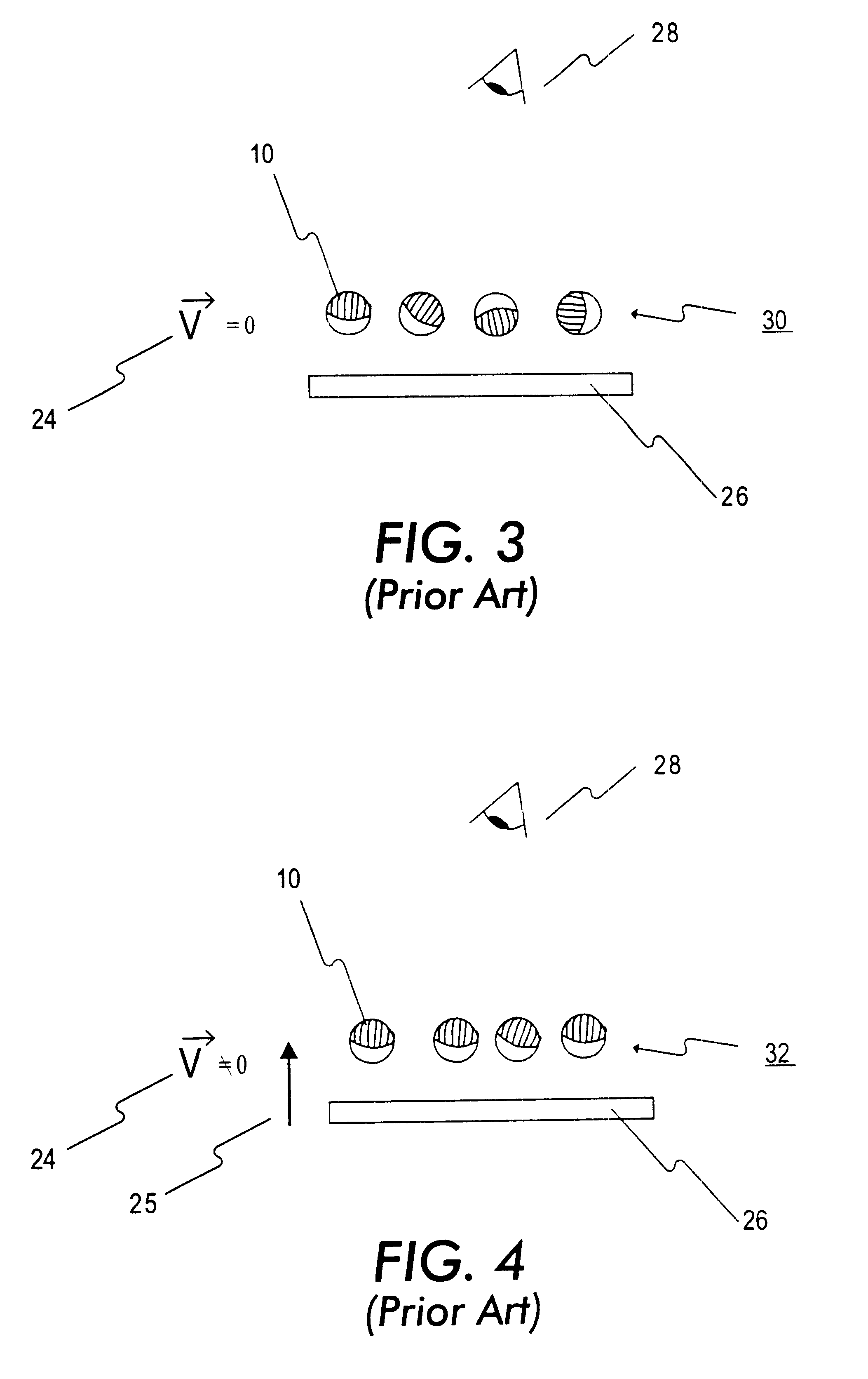

InactiveUS6942776B2Increase rangeAvoid the needElectrostatic separatorsSludge treatmentPlanar substrateEngineering

An apparatus and method for establishing closed dielectrophoretic potential cages and precise displacement thereof comprising a first array of selectively addressable electrodes, lying on a substantially planar substrate and facing toward a second array comprising one electrode. The arrays define the upper and lower bounds of a micro-chamber where particles are placed in liquid suspension. By applying in-phase and counter-phase periodic signals to electrodes, one or more independent potential cages are established which cause particles to be attracted to or repelled from cages according to signal frequency and the dielectric characteristics of the particles and suspending medium. By properly applying voltage signal patterns into arrays, cages may trap one or more particles, thus permitting them to levitate steadily and / or move. In the preferred embodiment, where one array is integrated on a semiconductor substrate, displacement of particles can be monitored by embedded sensors.

Owner:SILICON BIOSYSTEMS SPA +1

Compact sensor using microcavity structures

InactiveUS6777244B2Probing the microcavities optically is easierHigh sensitivitySemi-permeable membranesMaterial analysis by observing effect on chemical indicatorResonanceLight beam

A compact sensor for detection of chemical and / or biological compounds in low concentration. The sensor comprises electromagnetic microcavities. The agent to be detected passes the microcavities, is absorbed and / or absorbed by the microcavities, and modifies the electromagnetic field inside the microcavities. After the agent has been adsorbed and / or absorbed, a probe beam is applied to the microcavities. The change of electromagnetic field is detected by the detector, and the frequency of the probe beam at which the resonance is observed, is indicative of a particular agent being present. A method for detecting chemical and / or biological compounds using the sensor.

Owner:HRL LAB

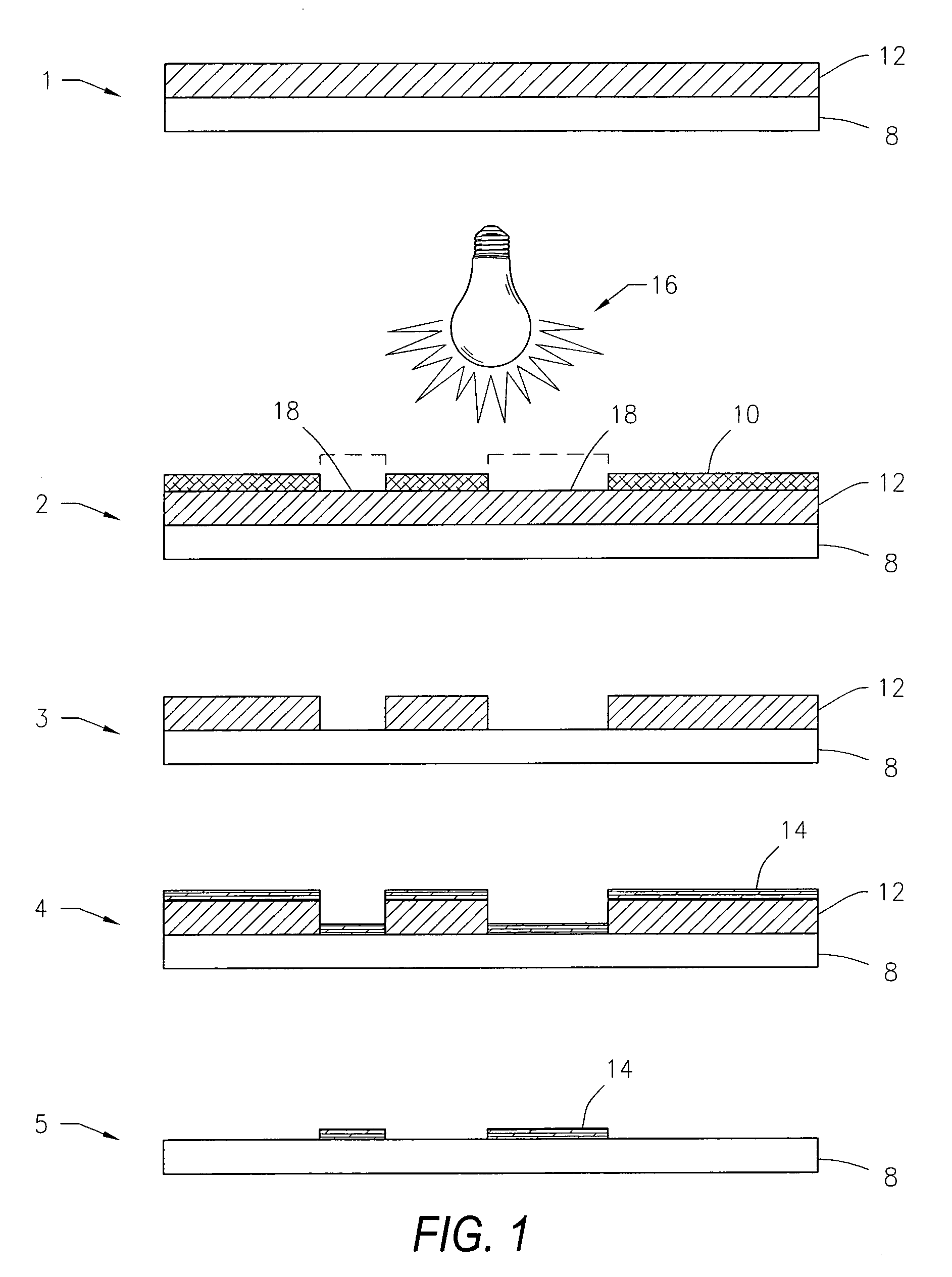

System and method of fabricating micro cavities

InactiveUS20080308920A1Decorative surface effectsSemiconductor/solid-state device detailsEpoxyMicroelectromechanical systems

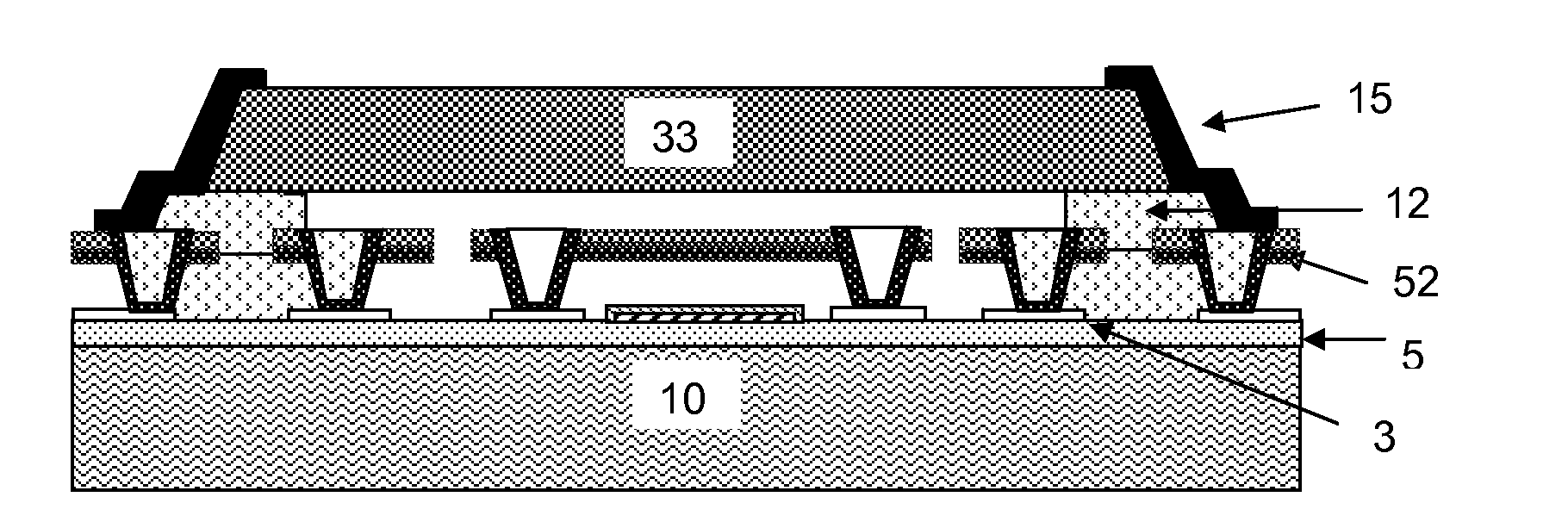

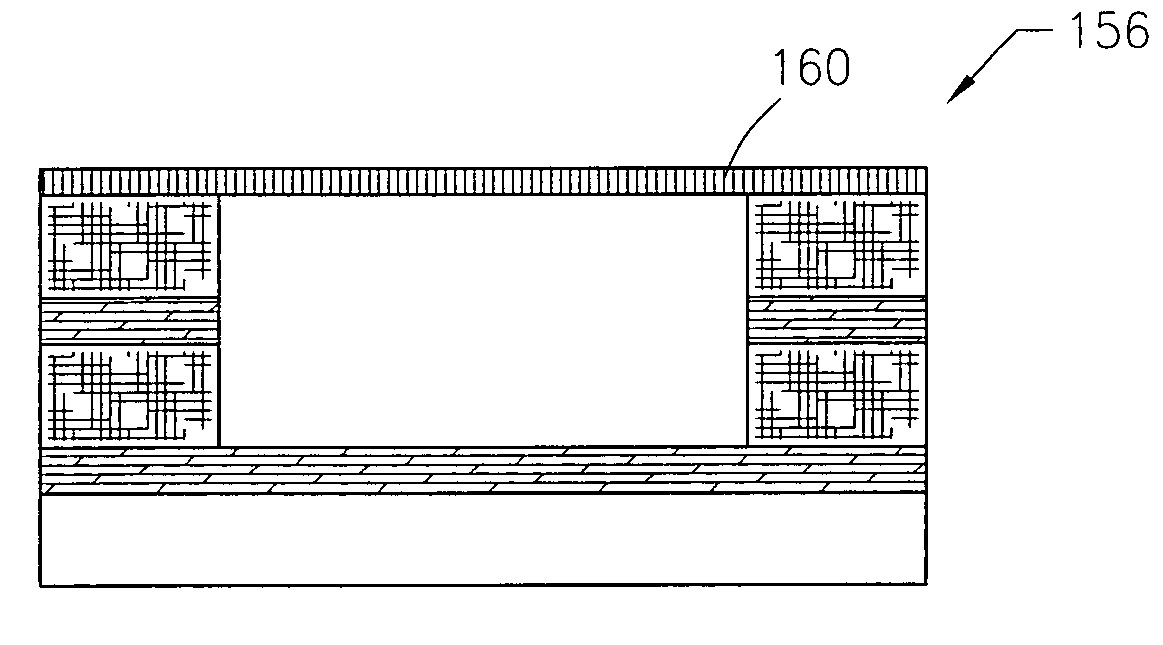

A system and method for manufacturing micro cavity packaging enclosure at the wafer level using MEMS (MicroElectroMechanical Systems) process, wherein micro cavities are formed from epoxy-bonded single-crystalline silicon wafer as its cap, epoxy and deposited metal or insulator as at least part of its sidewall, on substrate wafers.

Owner:WAN CHANG FENG

LED device having improved contrast

ActiveUS20090051283A1Discharge tube luminescnet screensLamp detailsLight-emitting diodeOptical microcavity

A light-emitting diode device, including a substrate; and a reflective electrode and a semi-transparent electrode formed over the substrate and an unpatterned white light-emitting layer formed between the reflective electrode and the semi-transparent electrode, the reflective electrode, semi-transparent electrode, and unpatterned white-light-emitting layer forming an optical microcavity, and wherein either the reflective or semi-transparent electrodes is patterned to form a plurality of independently controllable light-emitting elements with at least one light-emitting element having no color filter. Color filters are formed over a side of the semi-transparent electrodes opposite the unpatterned white light-emitting layer in correspondence with the light-emitting elements, the color filters having at least two different colors. Additionally, a reflected-light absorbing layer is located over all of the light-emitting elements.

Owner:GLOBAL OLED TECH

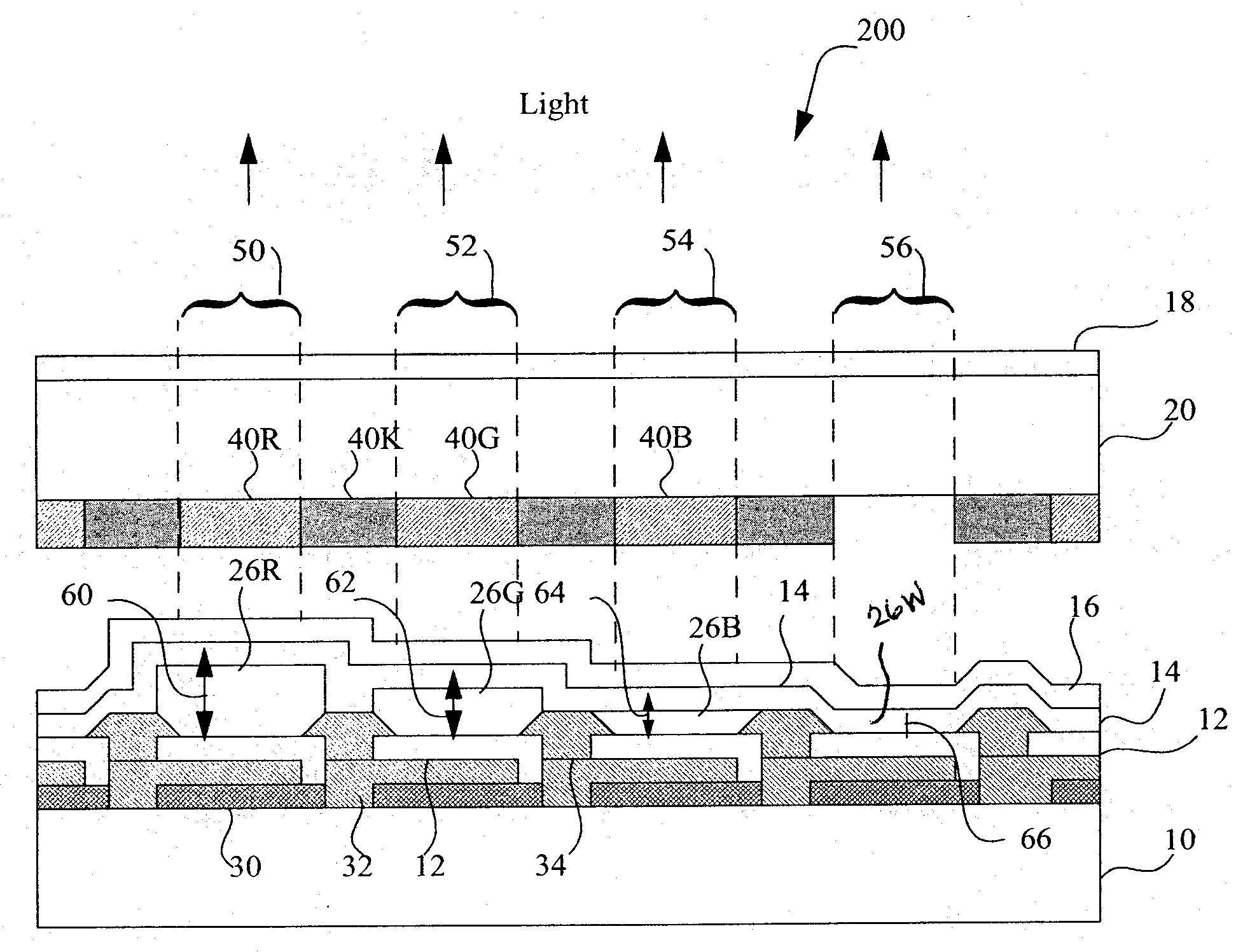

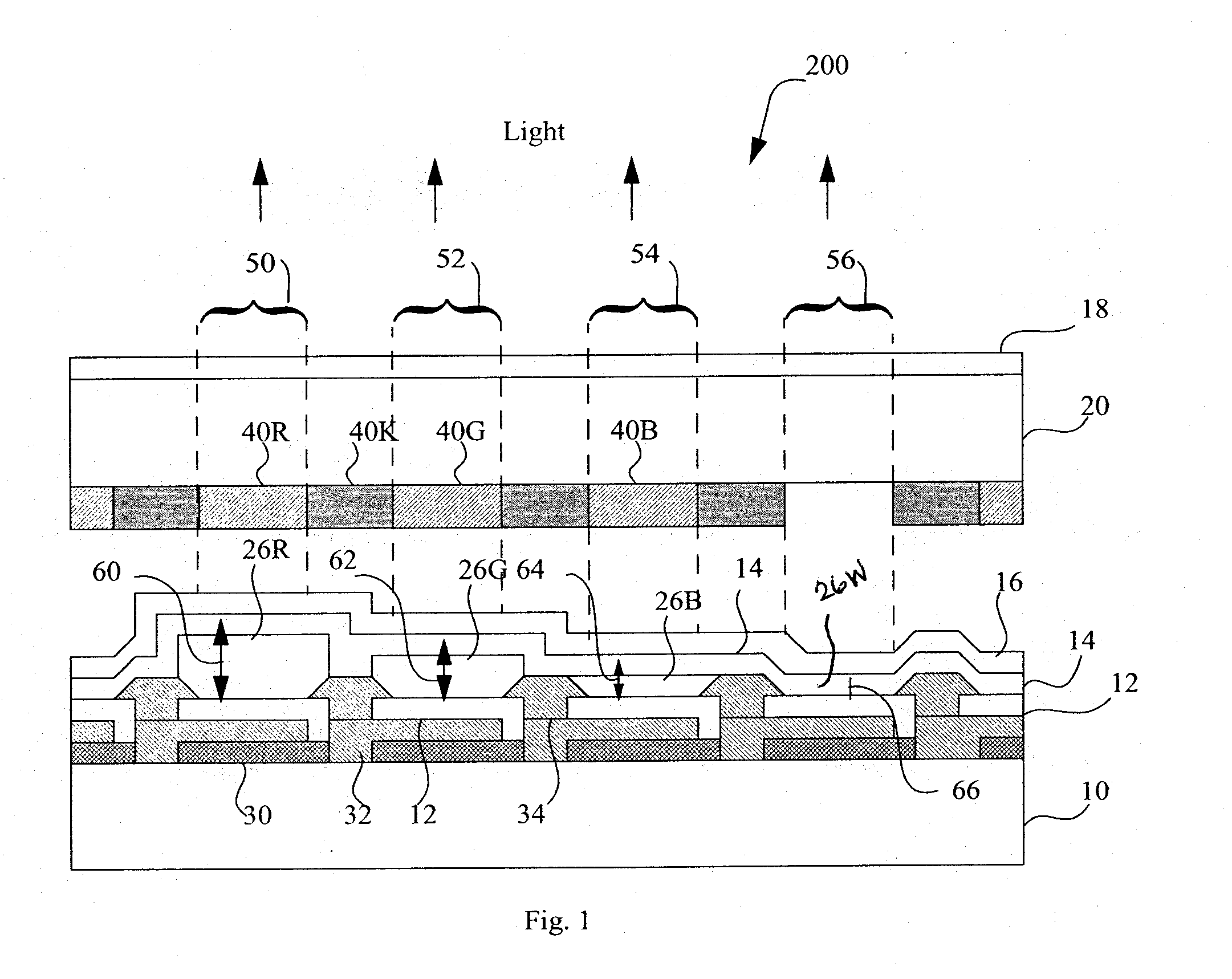

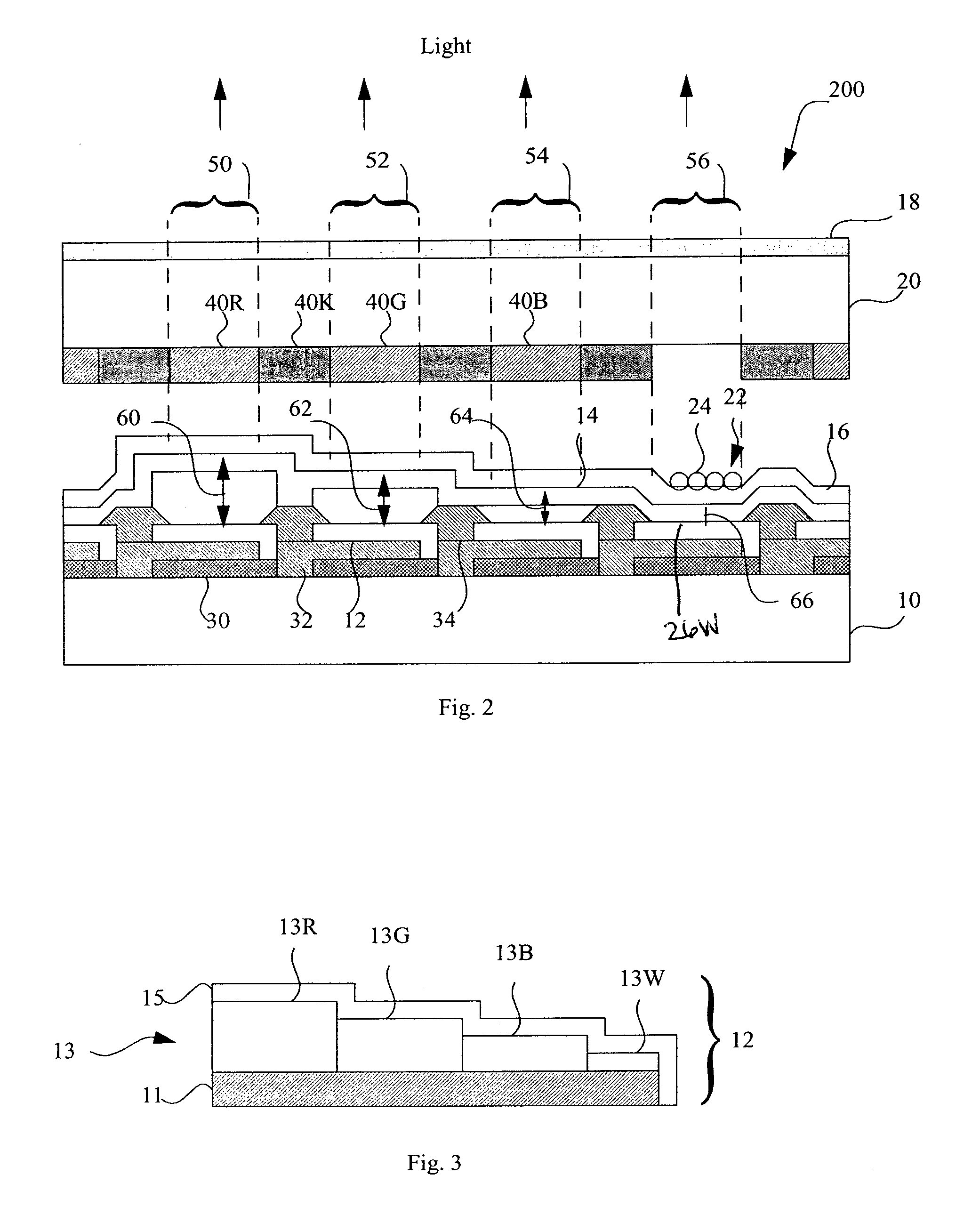

OLED device having microcavity gamut subpixels and a within gamut subpixel

ActiveUS7030553B2Improve efficiencyLow costIncadescent screens/filtersDischarge tube luminescnet screensGamutOrganic layer

An OLED device including an array of light emitting pixels, each pixel including subpixels having organic layers including at least one emissive layer that produces light and spaced electrodes, and wherein there are at least three gamut subpixels that produce colors which define a color gamut and at least one subpixel that produces light within the color gamut produced by the gamut subpixels; and wherein at least one of the gamut subpixels includes a reflector and a semitransparent reflector which function to form a microcavity.

Owner:GLOBAL OLED TECH

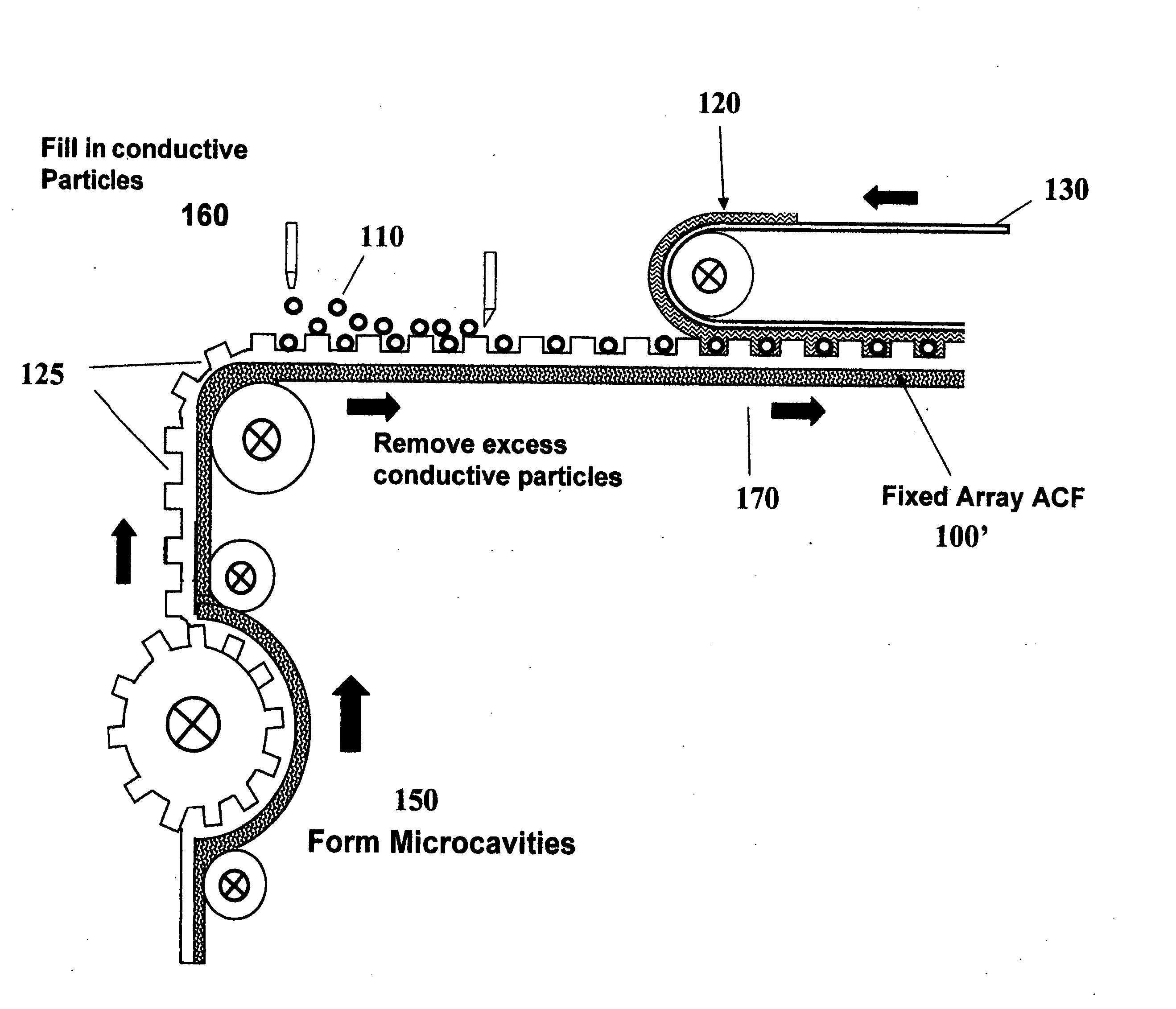

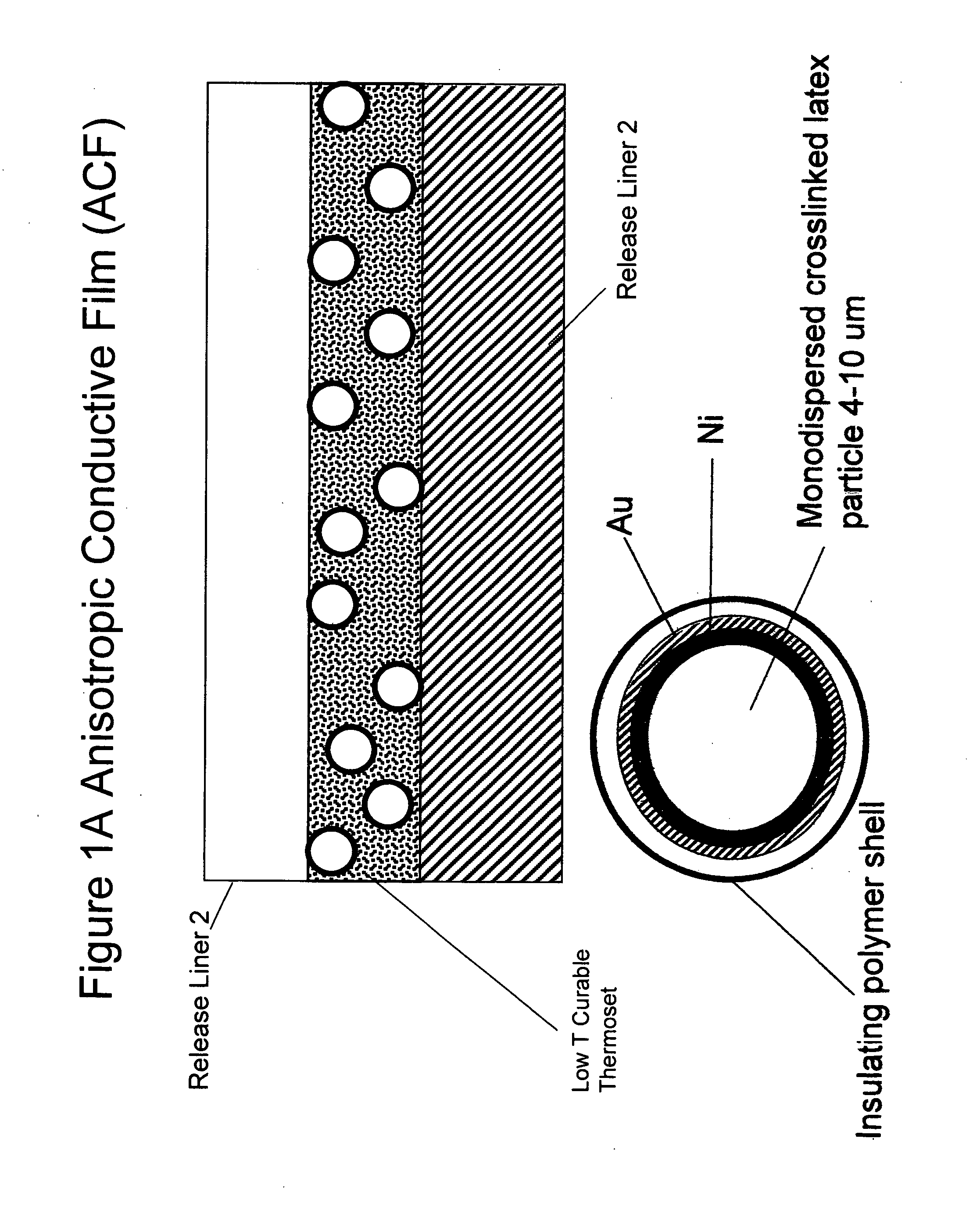

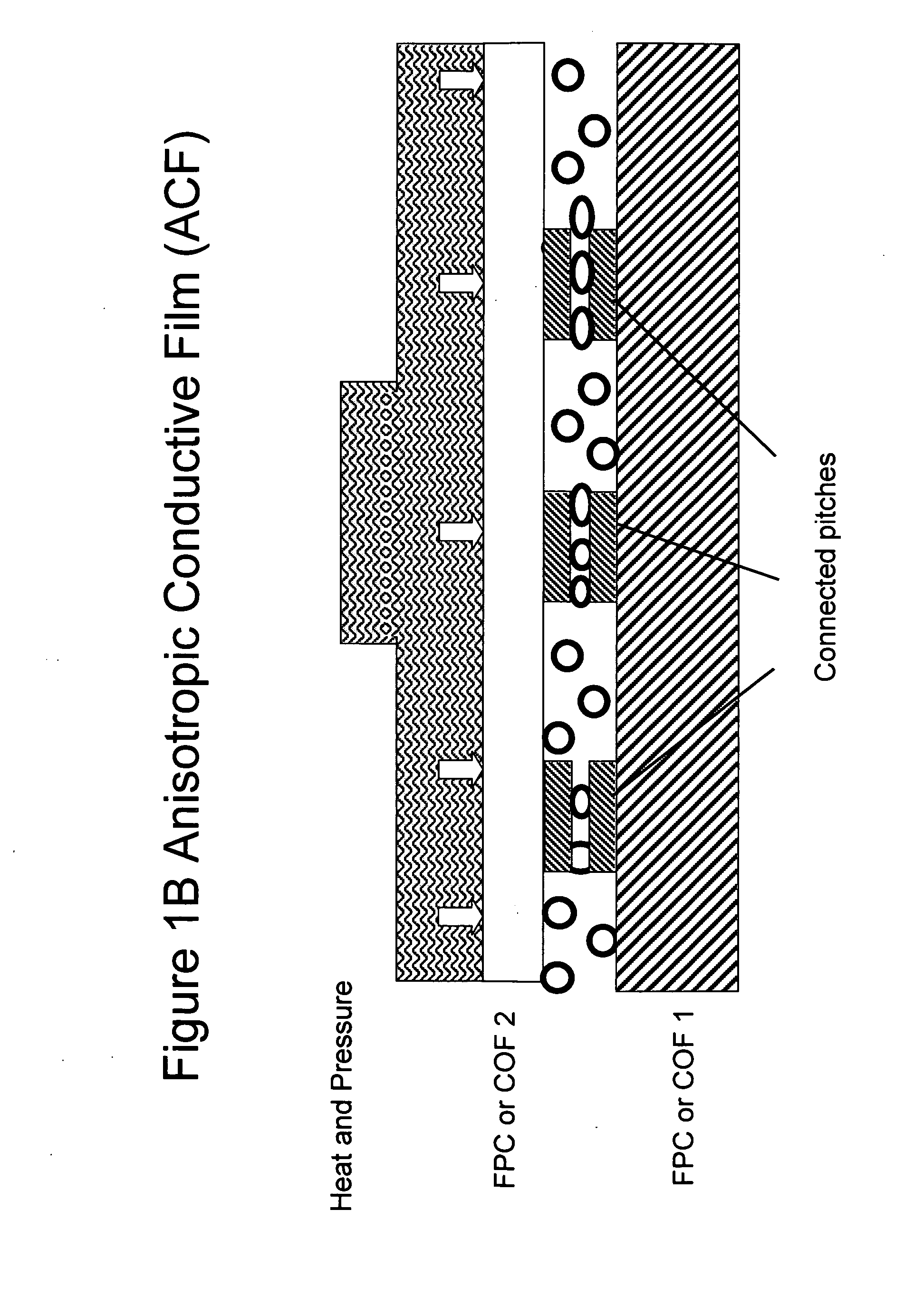

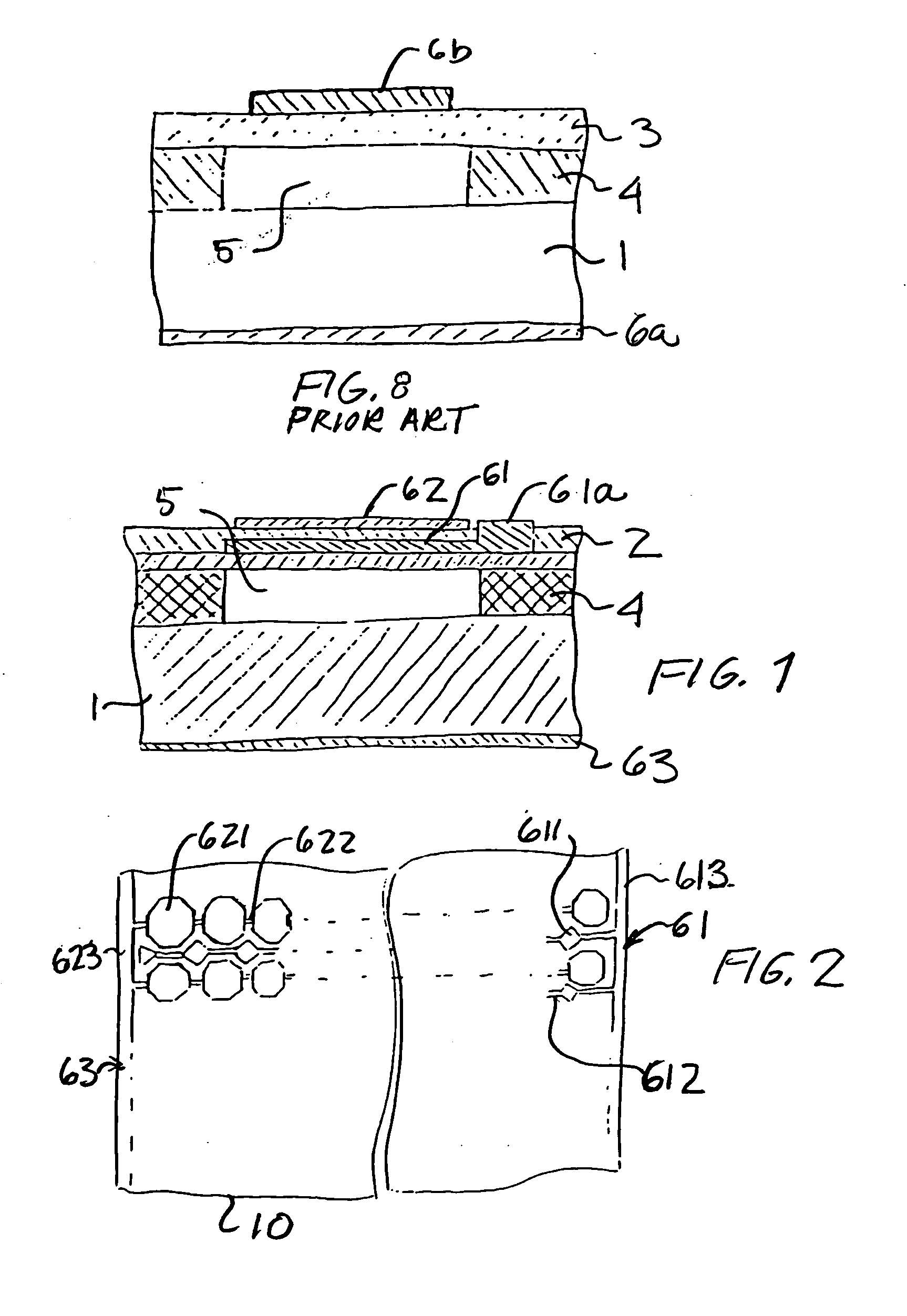

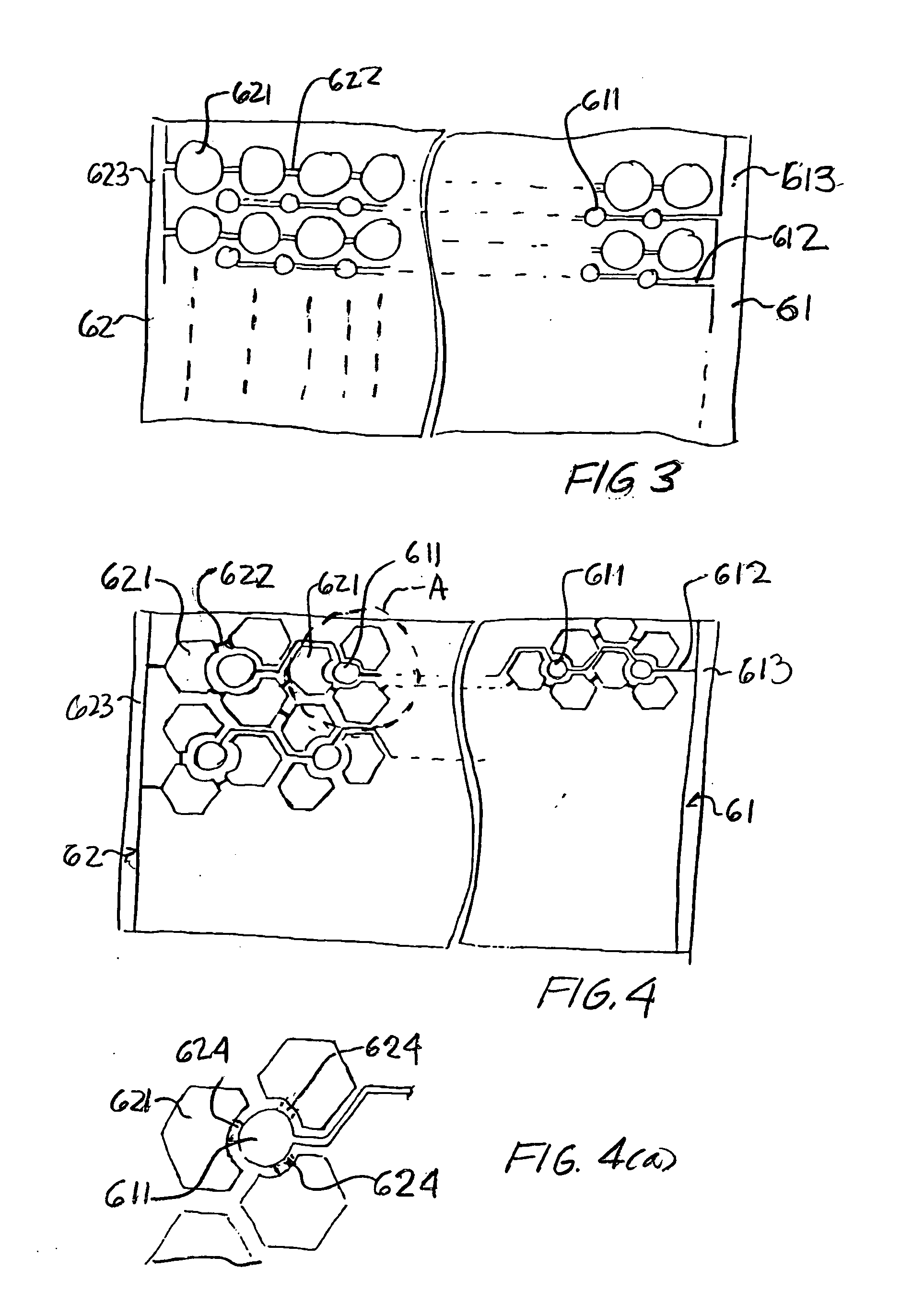

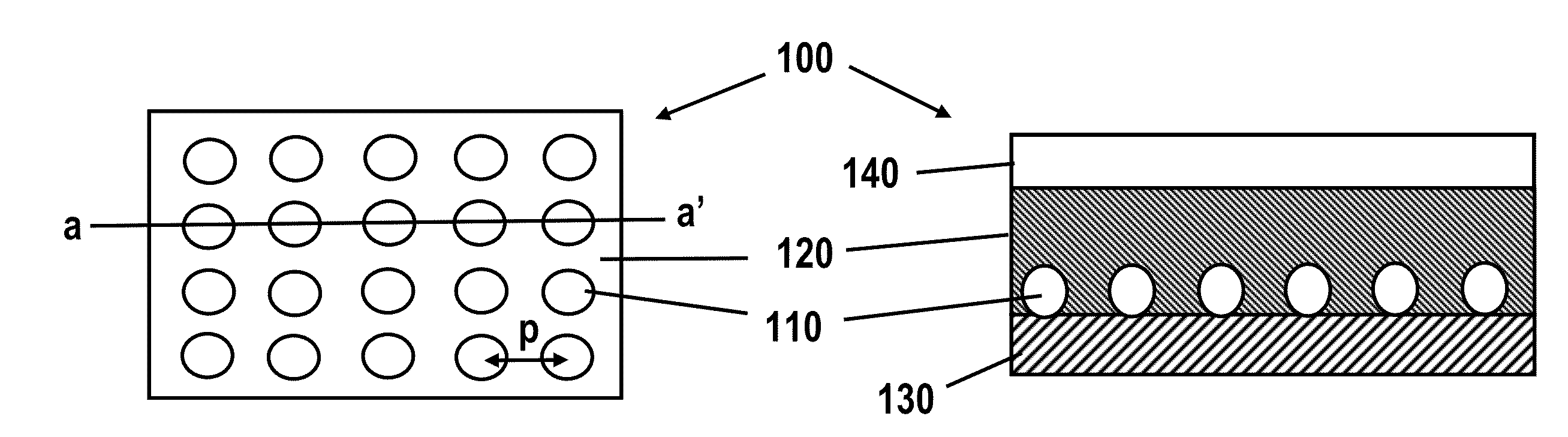

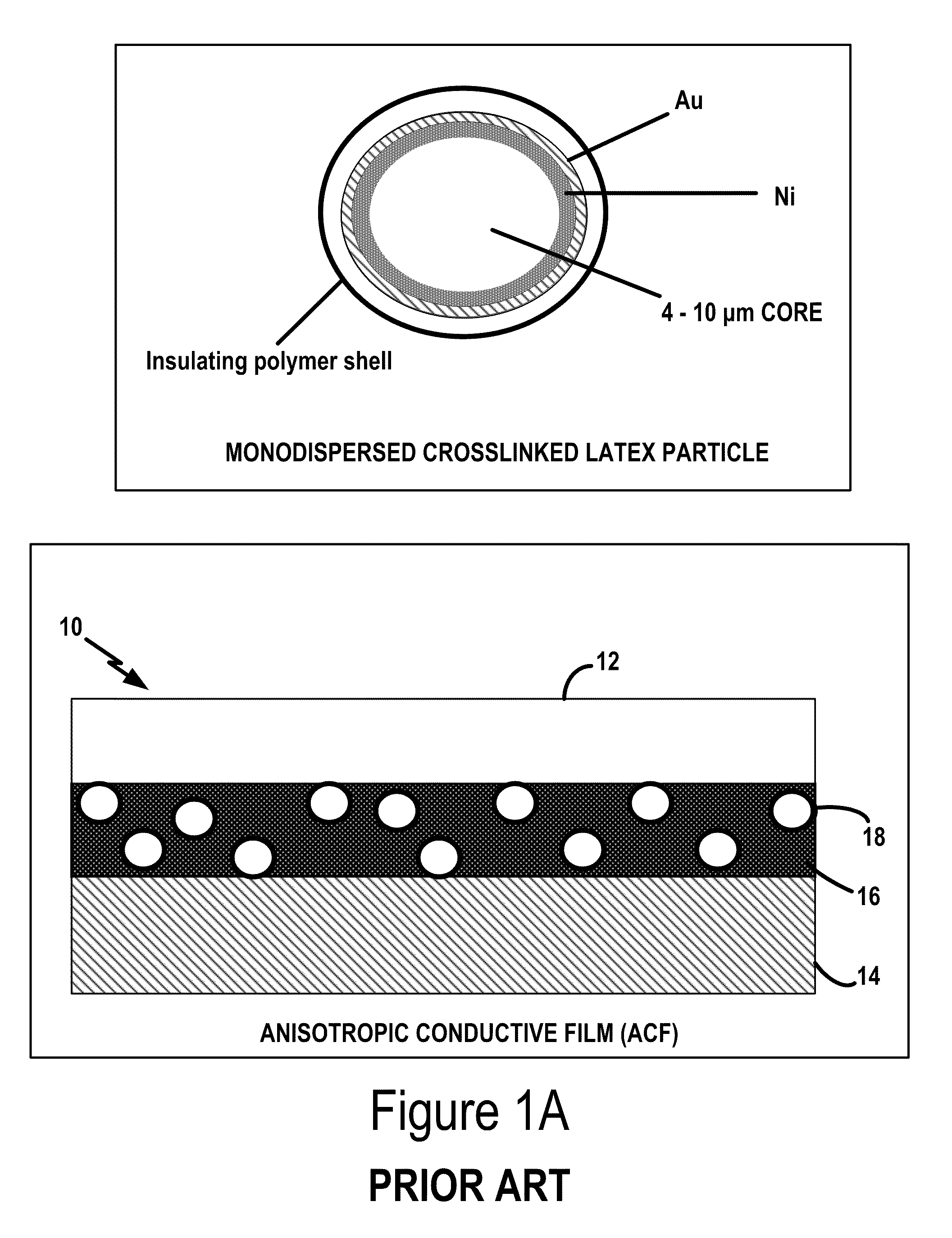

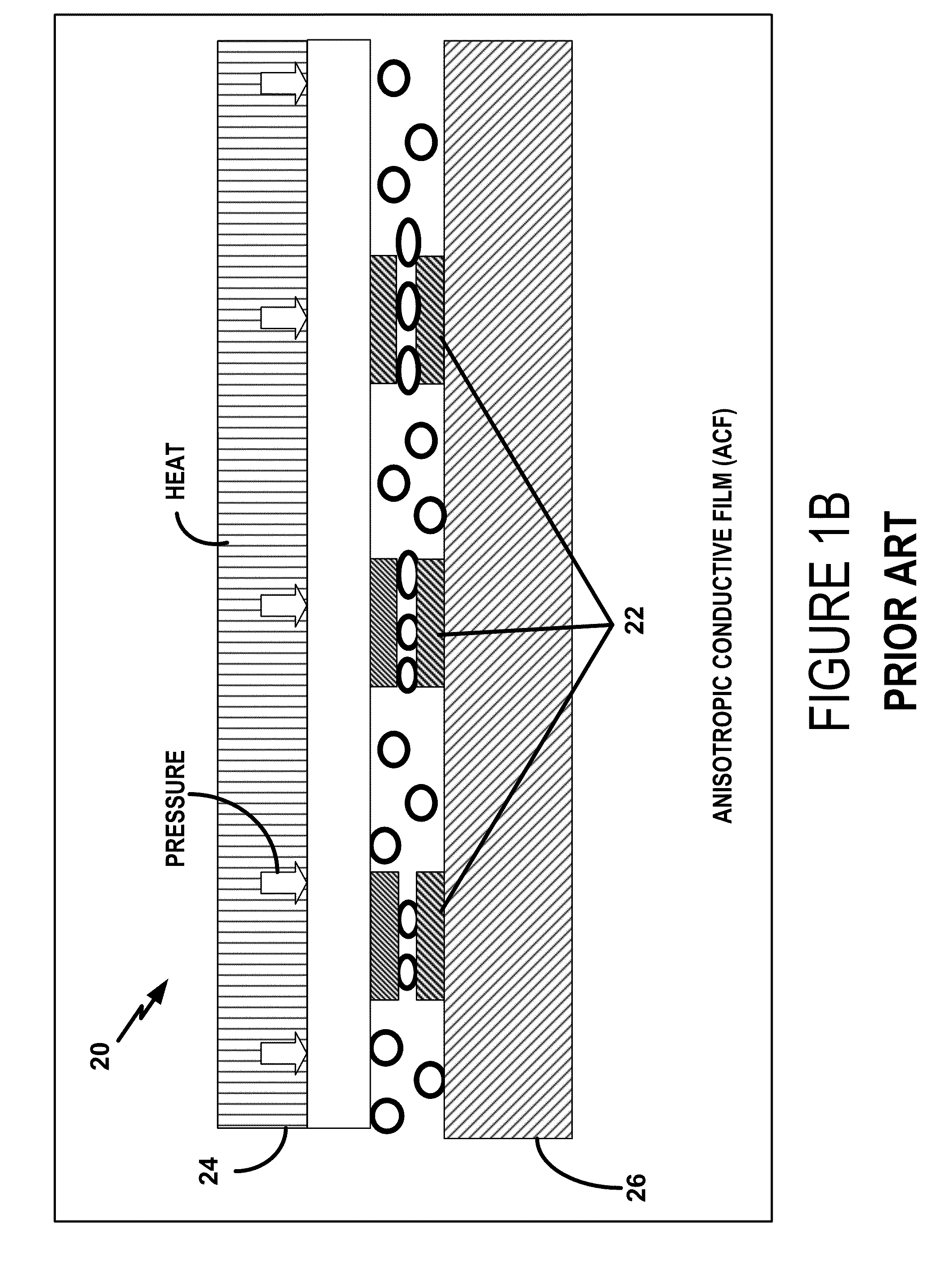

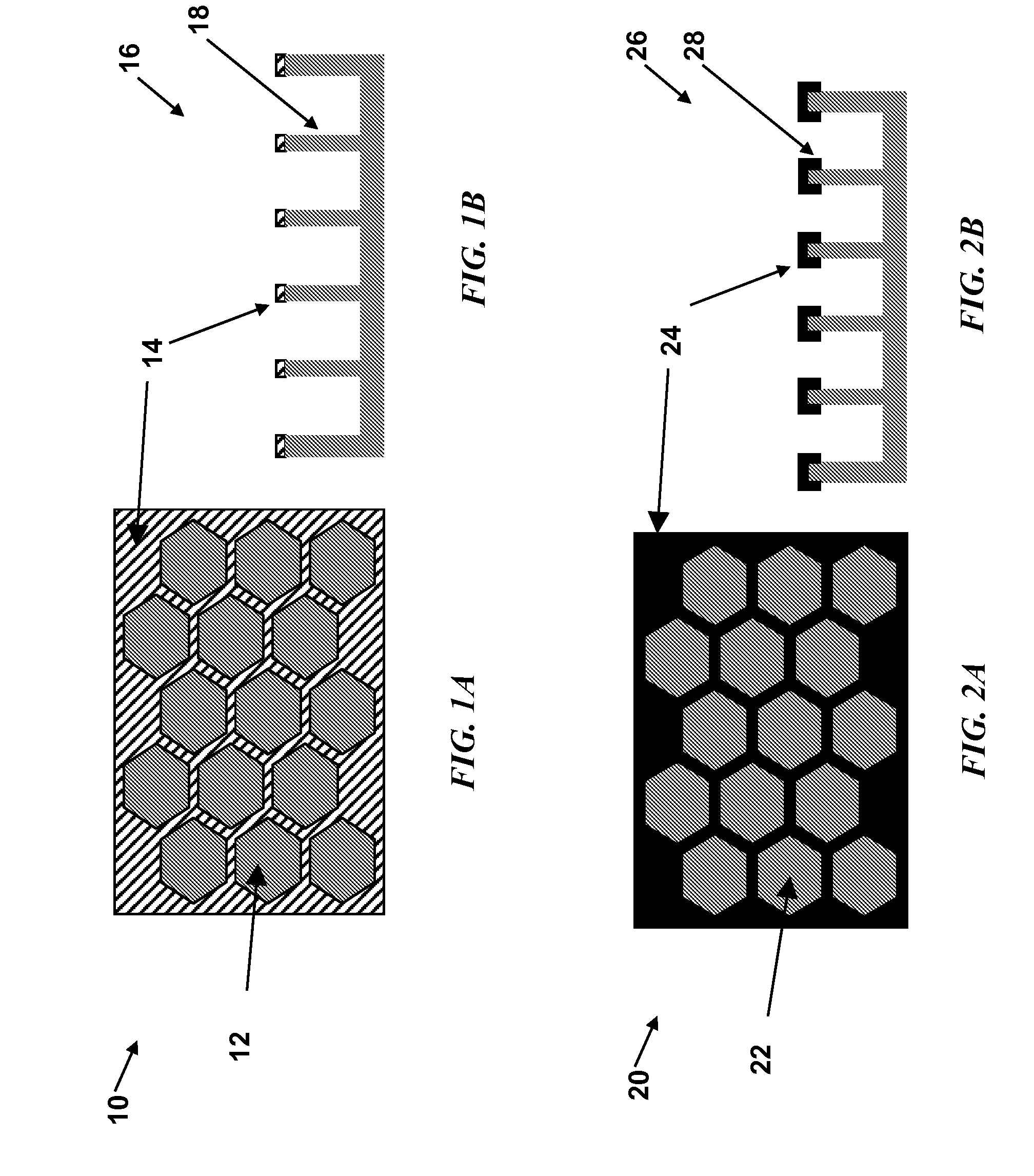

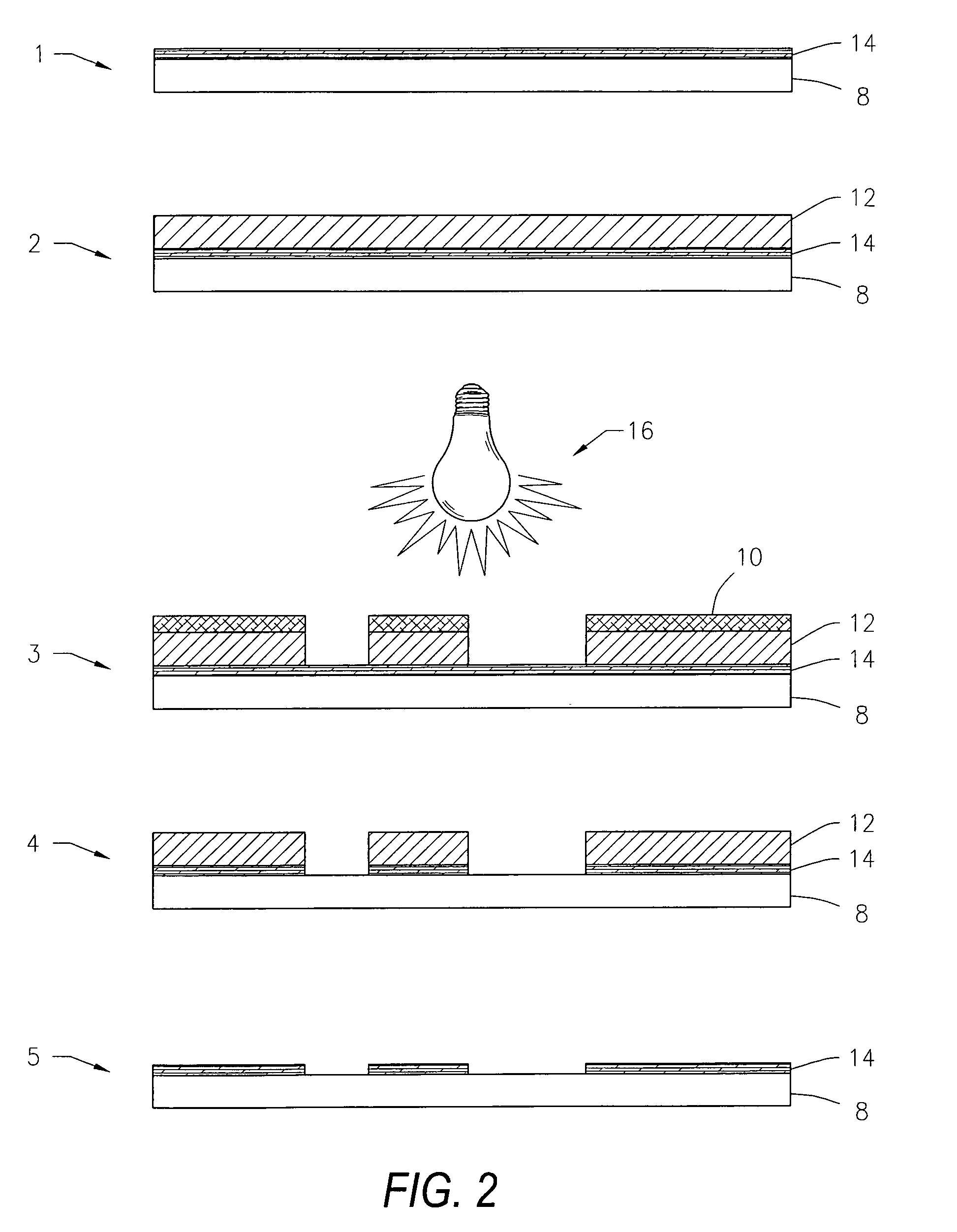

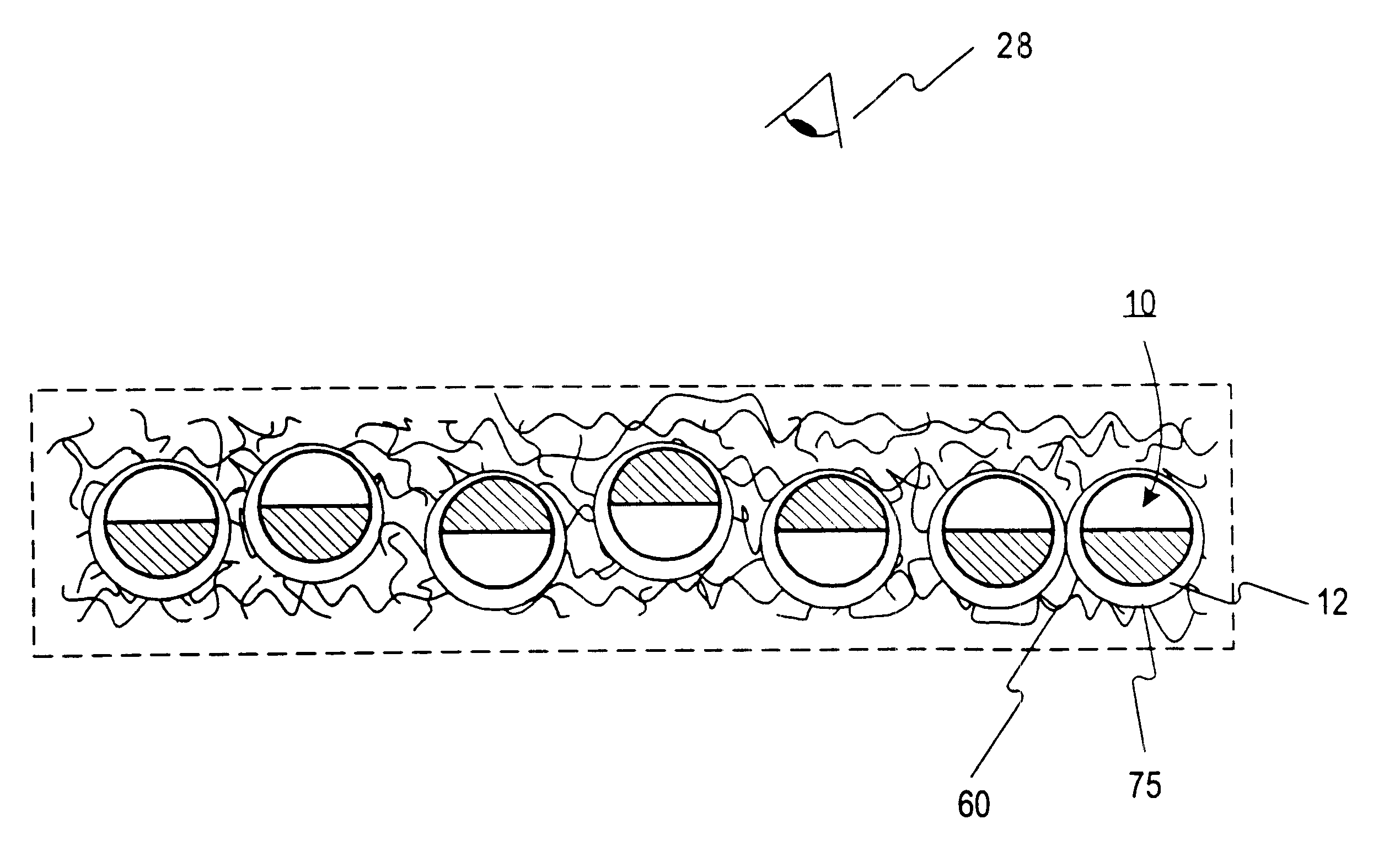

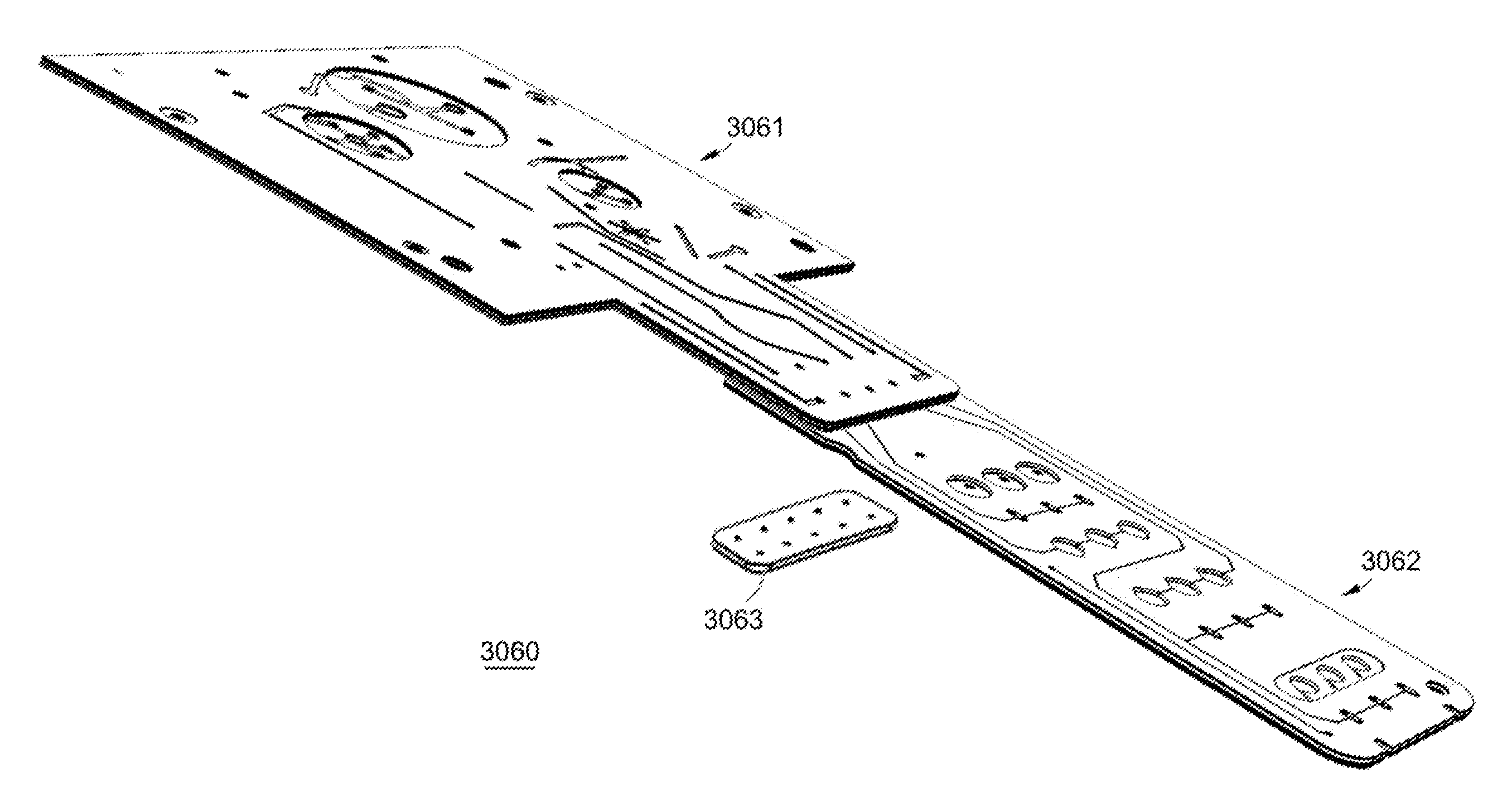

Non-random array anisotropic conductive film (ACF) and manufacturing processes

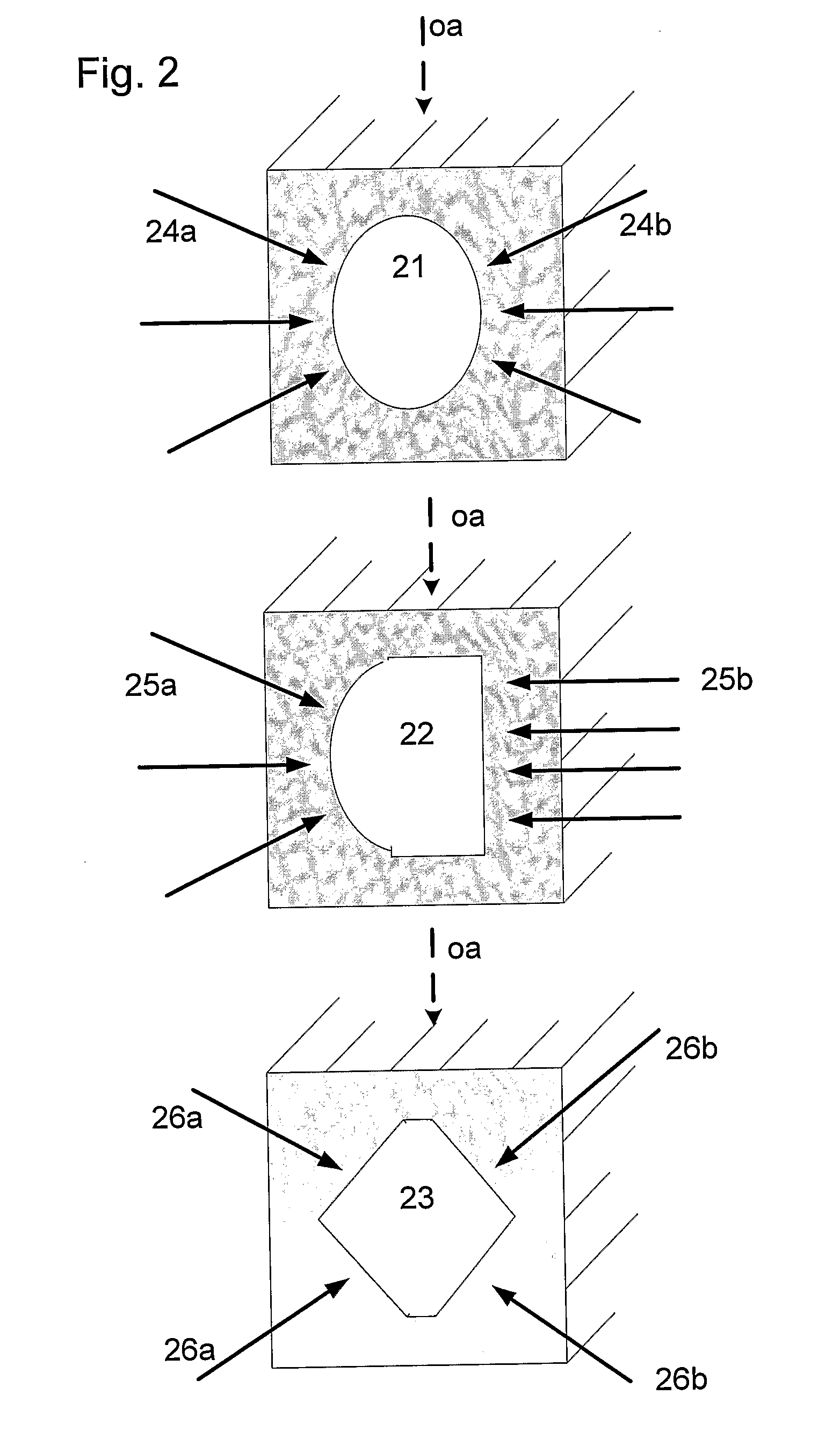

InactiveUS20060280912A1High resolutionReduce manufacturing costLayered productsCoupling device detailsAnisotropic conductive filmManufacturing technology

The present invention discloses structures and manufacturing processes of an ACF of improved resolution and reliability of electrical connection using a non-random array of microcavities of predetermined configuration, shape and dimension. The manufacturing process includes the steps of (i) fluidic filling of conductive particles onto a substrate or carrier web comprising a predetermined array of microcavities, or (ii) selective metallization of the array followed by filling the array with a filler material and a second selective metallization on the filled microcavity array. The thus prepared filled conductive microcavity array is then over-coated or laminated with an adhesive film.

Owner:TRILLION SCI INC

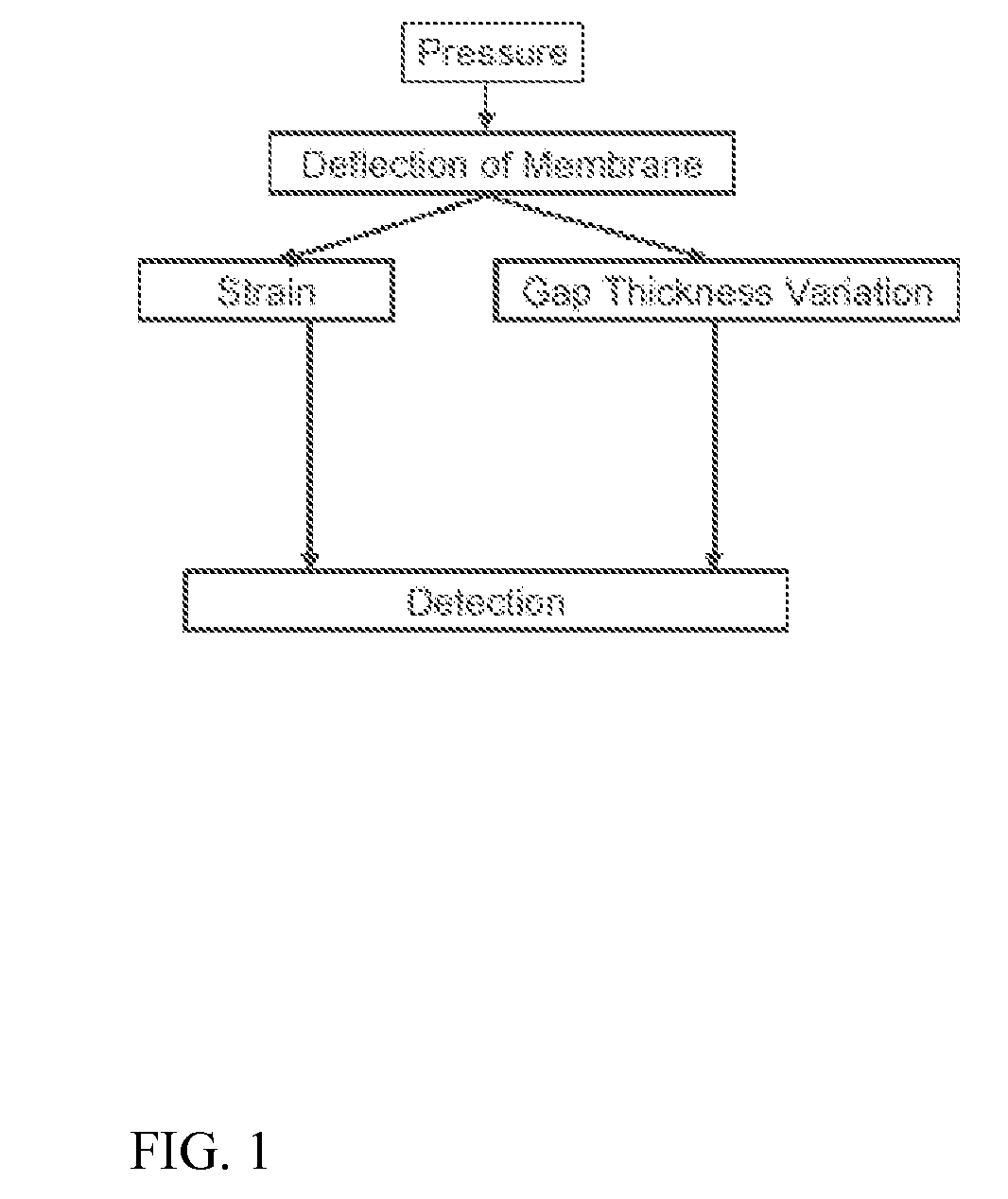

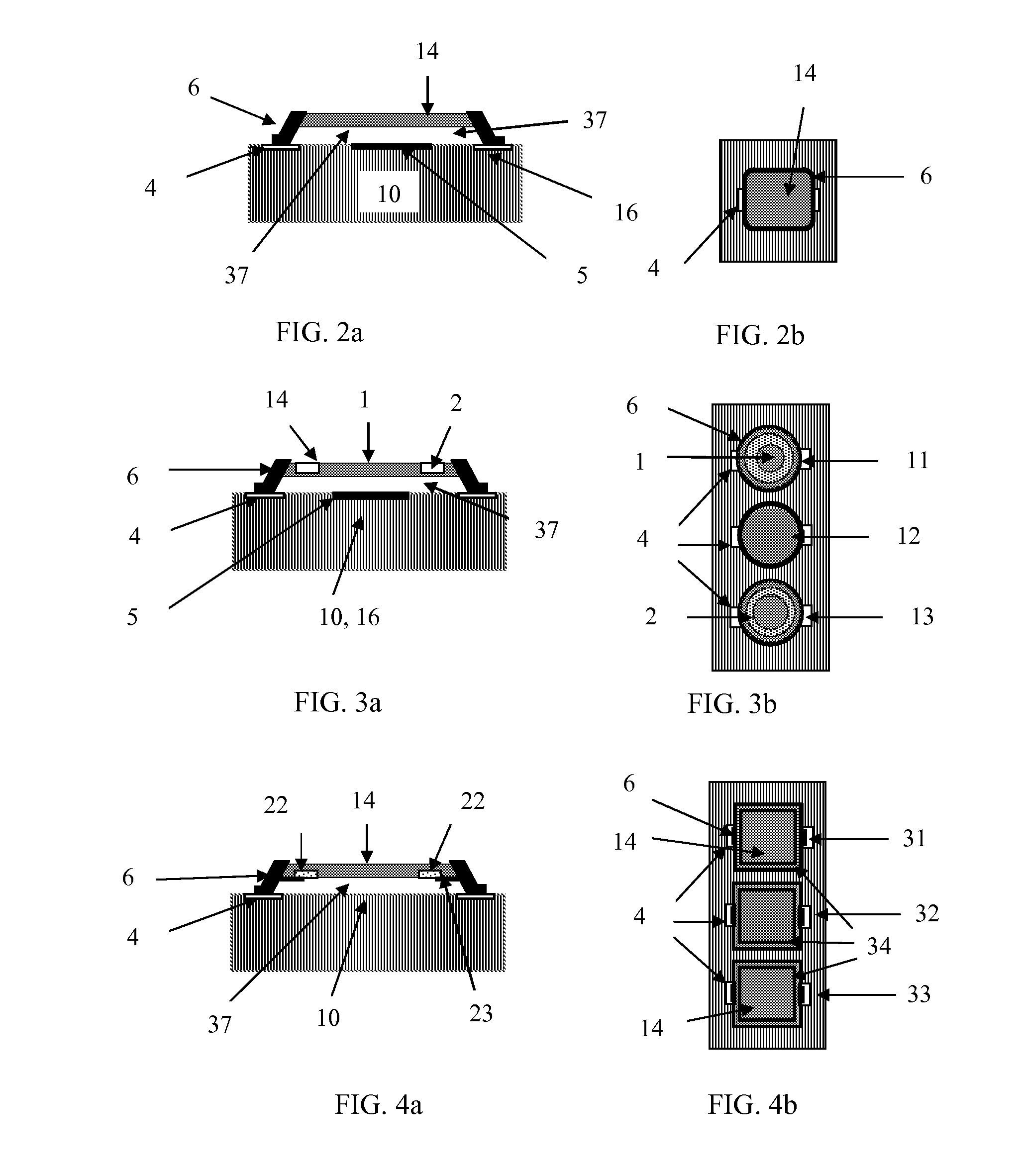

Electrostatic membranes for sensors, ultrasonic transducers incorporating such membranes, and manufacturing methods therefor

ActiveUS20060116585A1Maximize energy conversionEfficiently and effectively implementUltrasonic/sonic/infrasonic diagnosticsMechanical vibrations separationUltrasonic sensorTransducer

A micro-machined ultrasonic transducer substrate for immersion operation is formed by a particular arrangement of a plurality of micro-machined membranes that are supported on a silicon substrate. The membranes, together with the substrate, form surface microcavities that are vacuum sealed to provide electrostatic cells. The cells can operate at high frequency and can cover a broader bandwidth in comparison with conventional piezoelectric bulk transducers.

Owner:VERMON

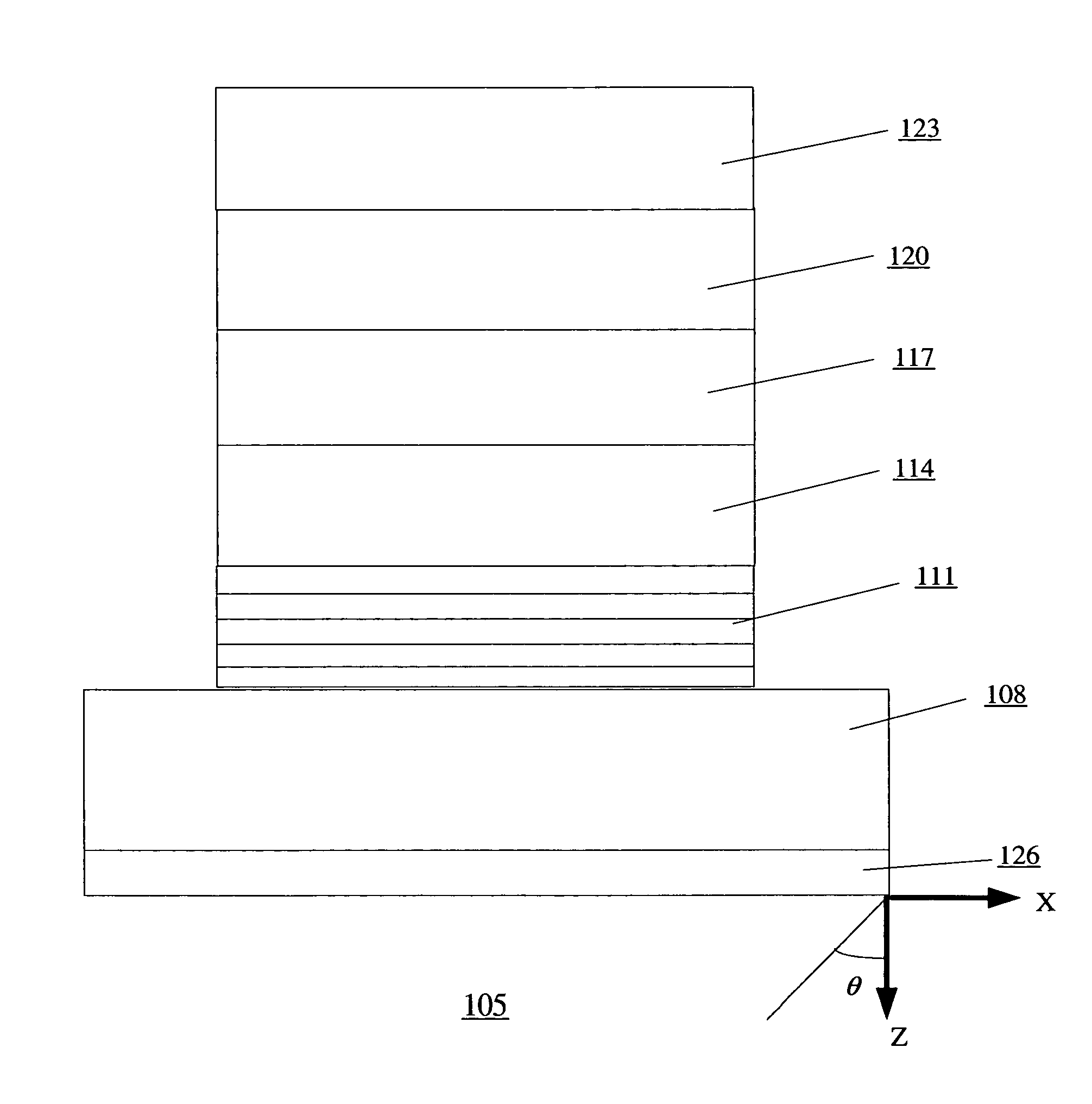

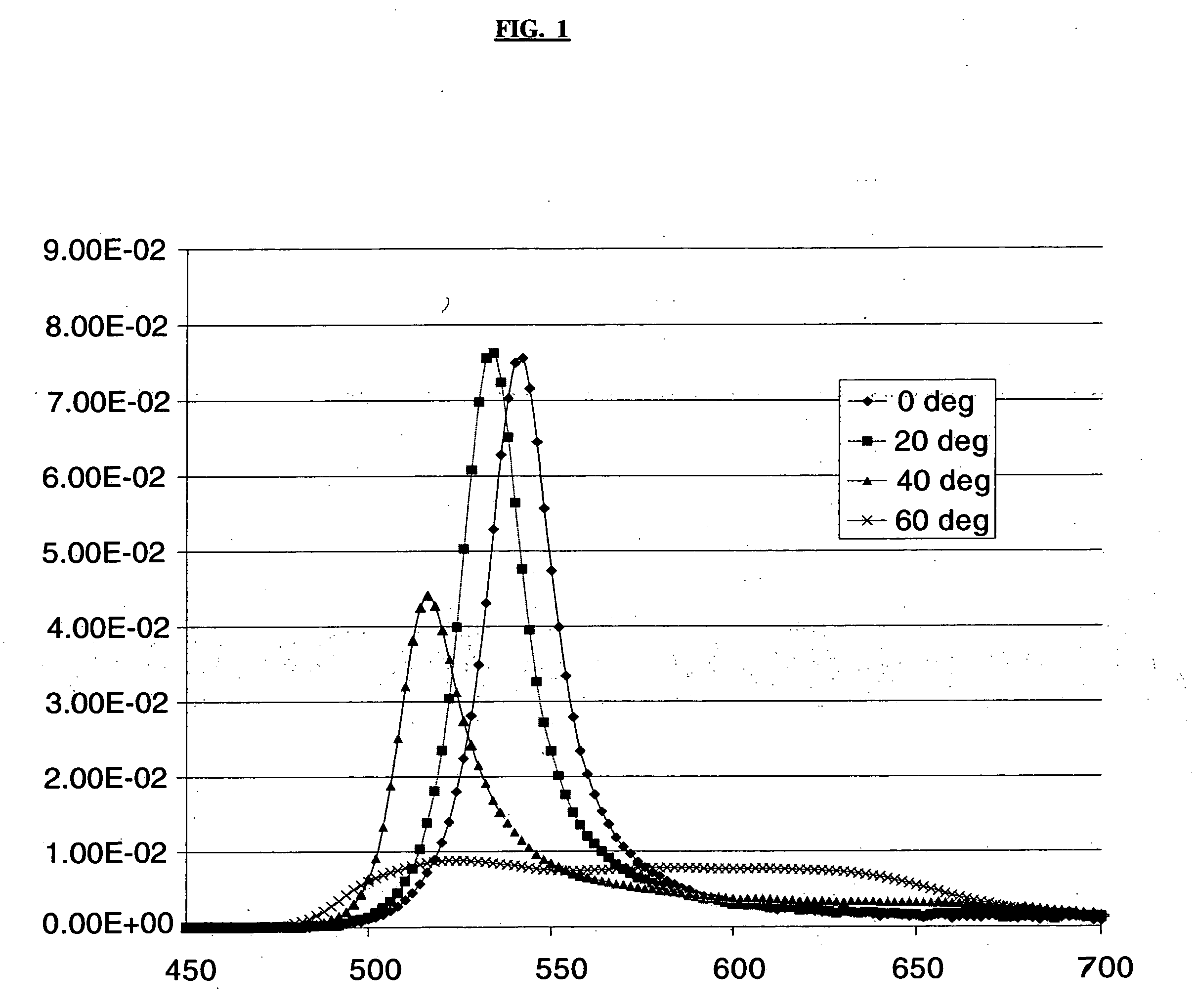

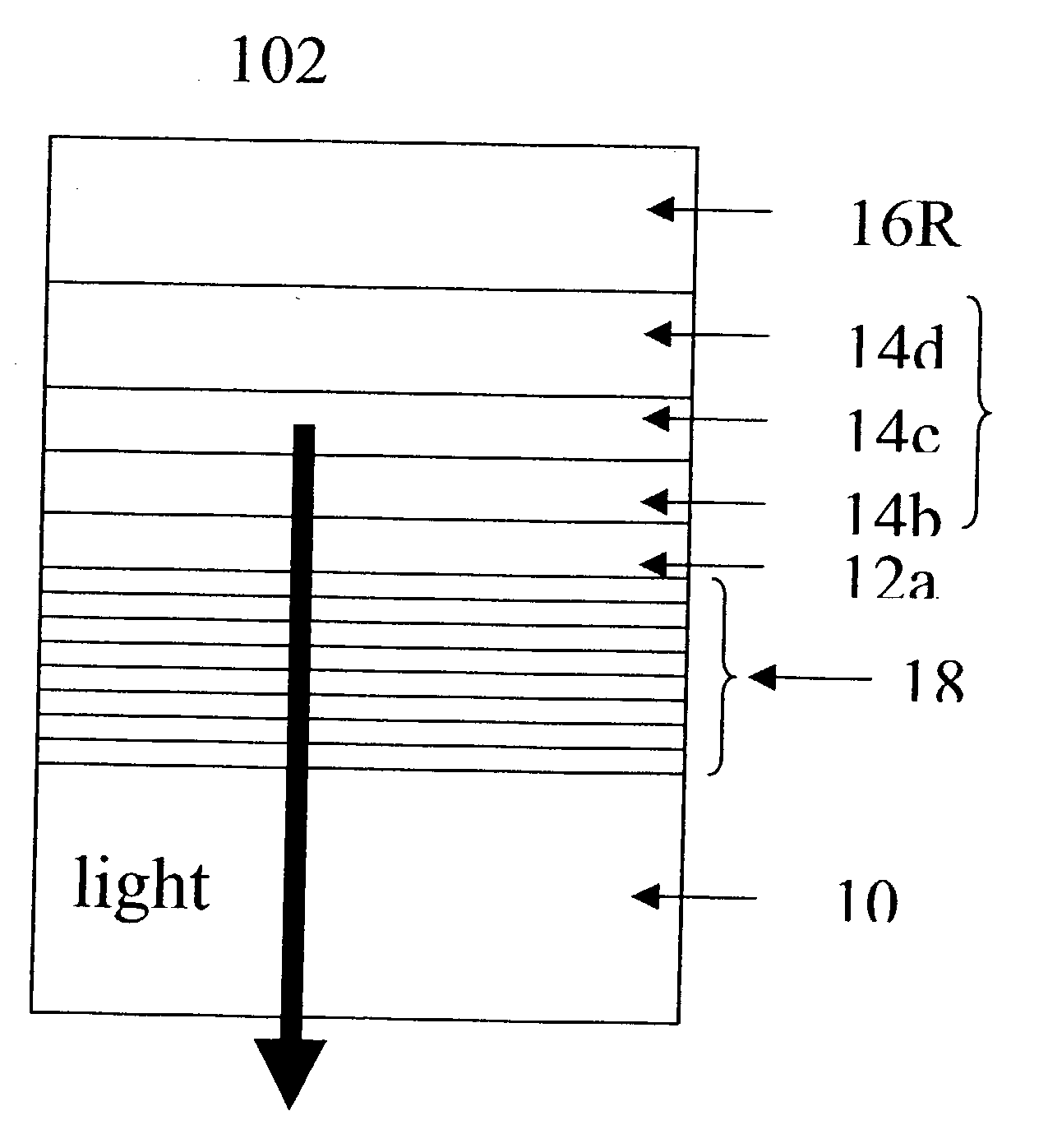

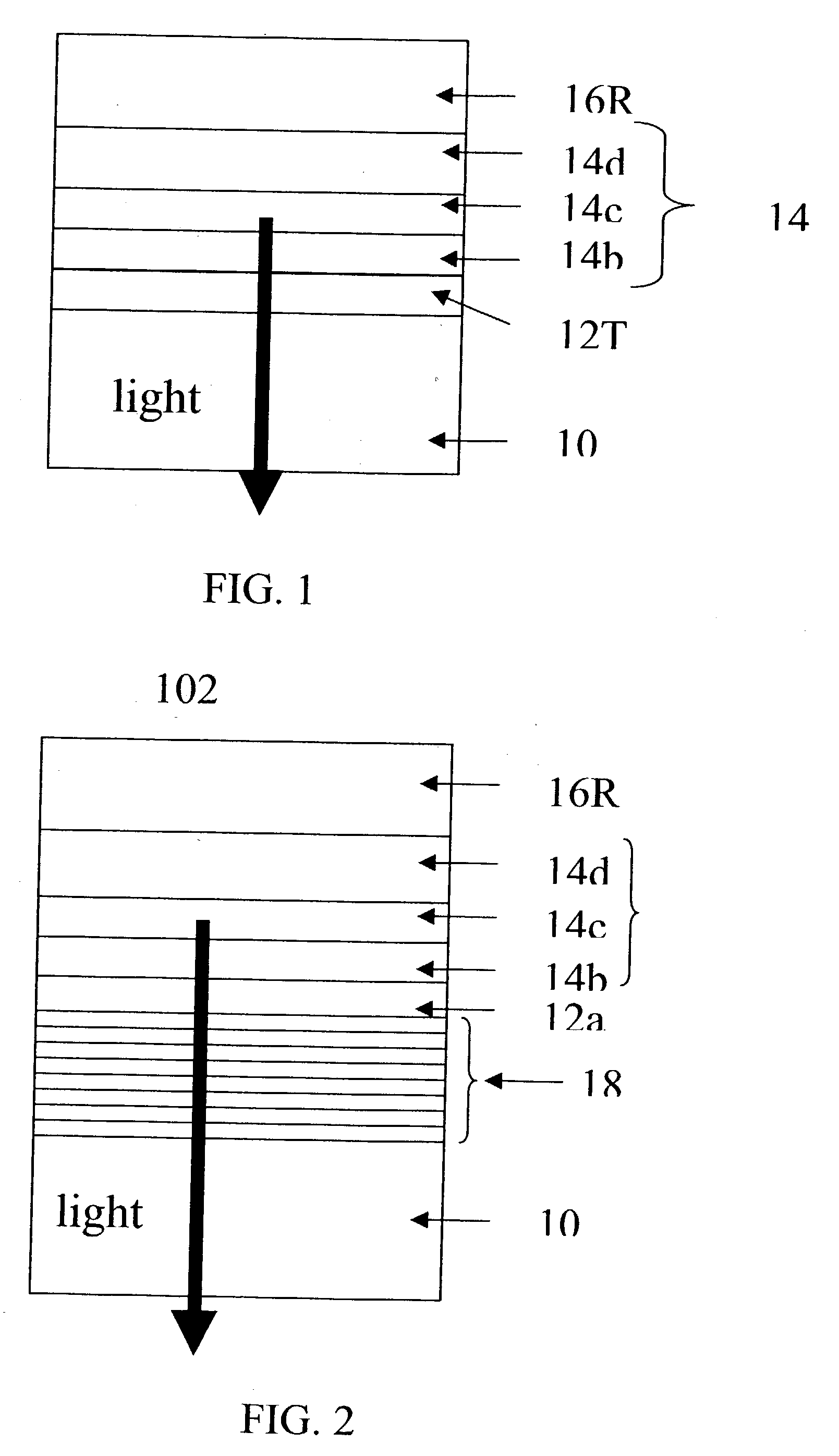

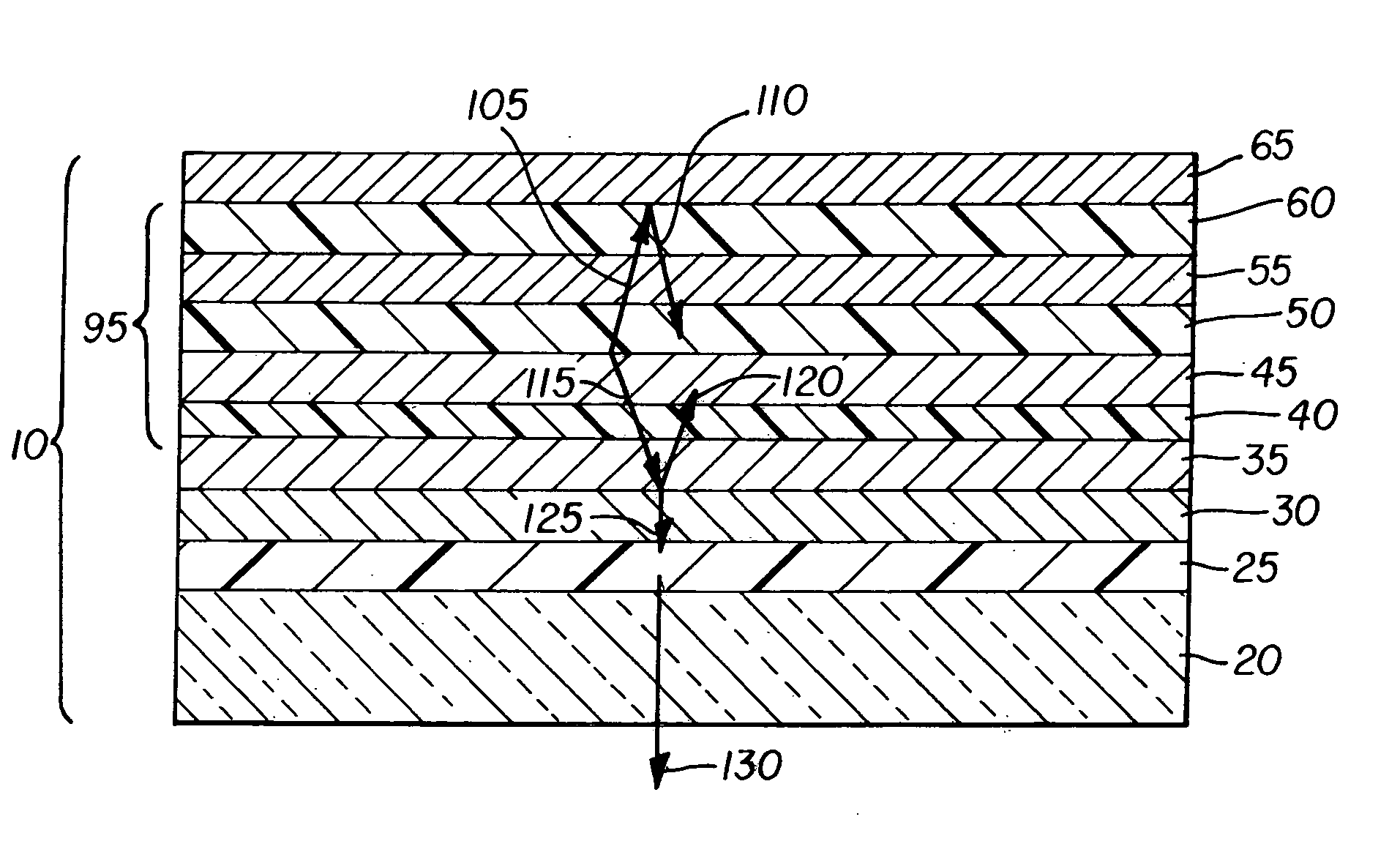

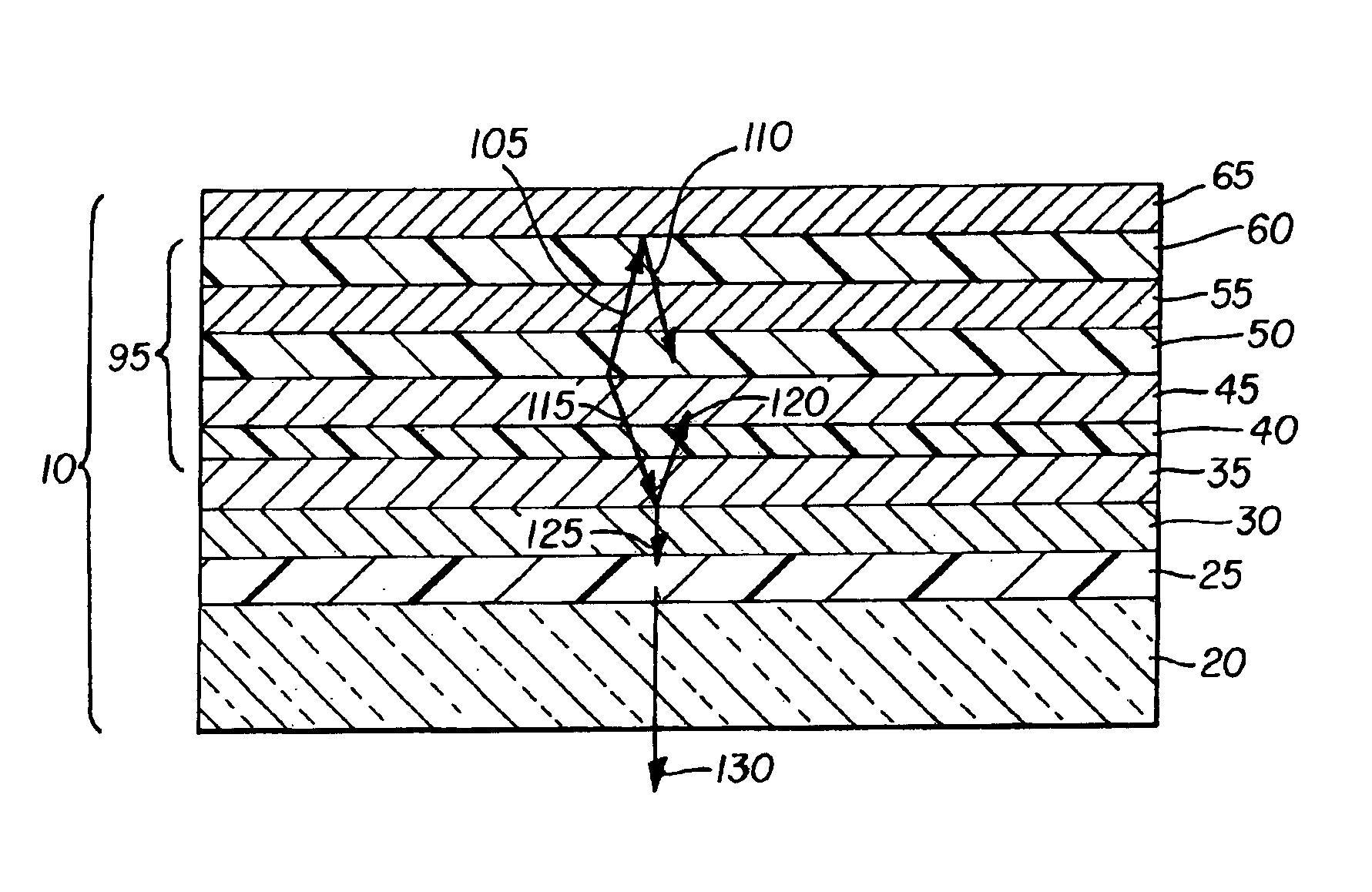

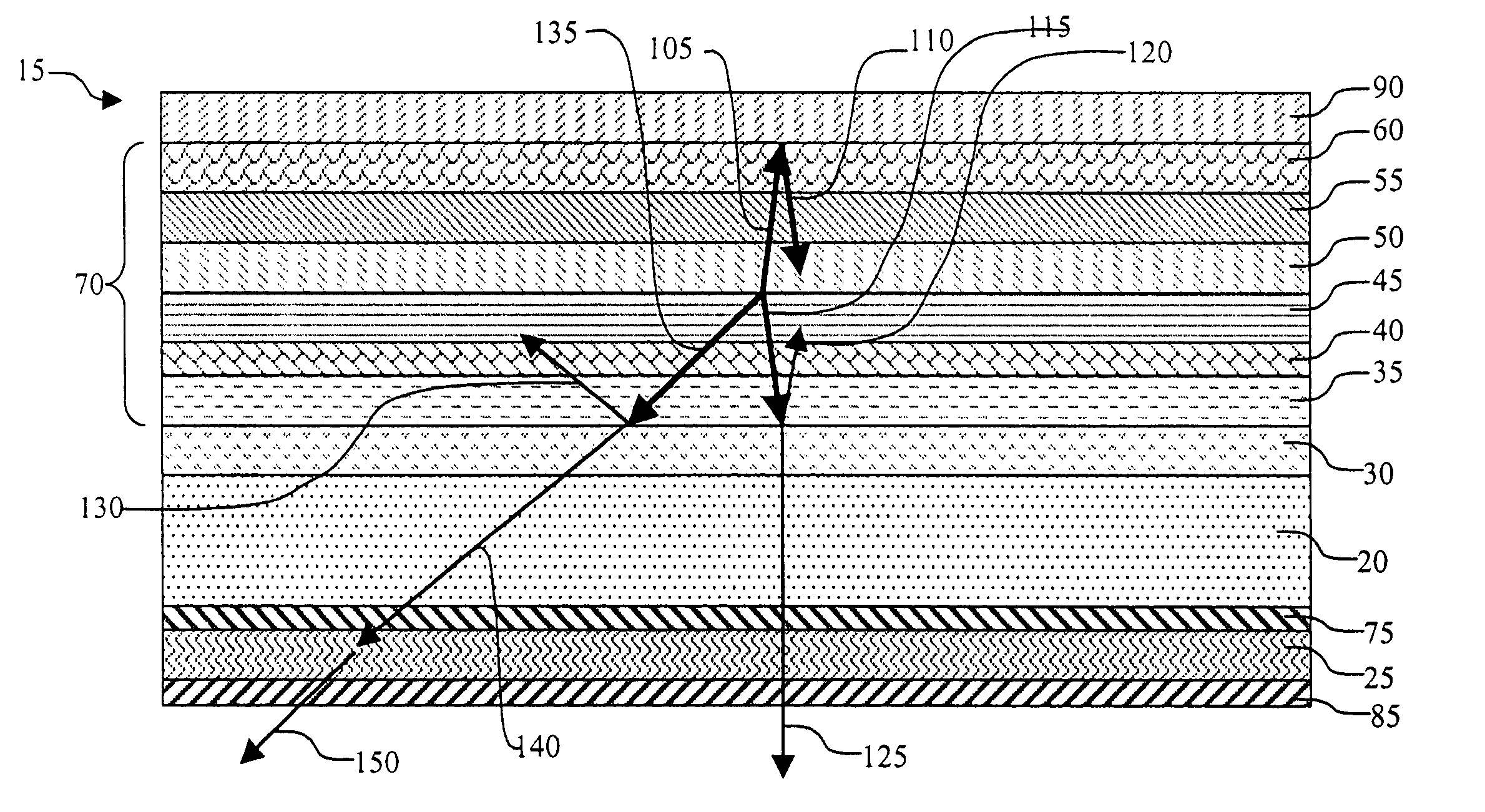

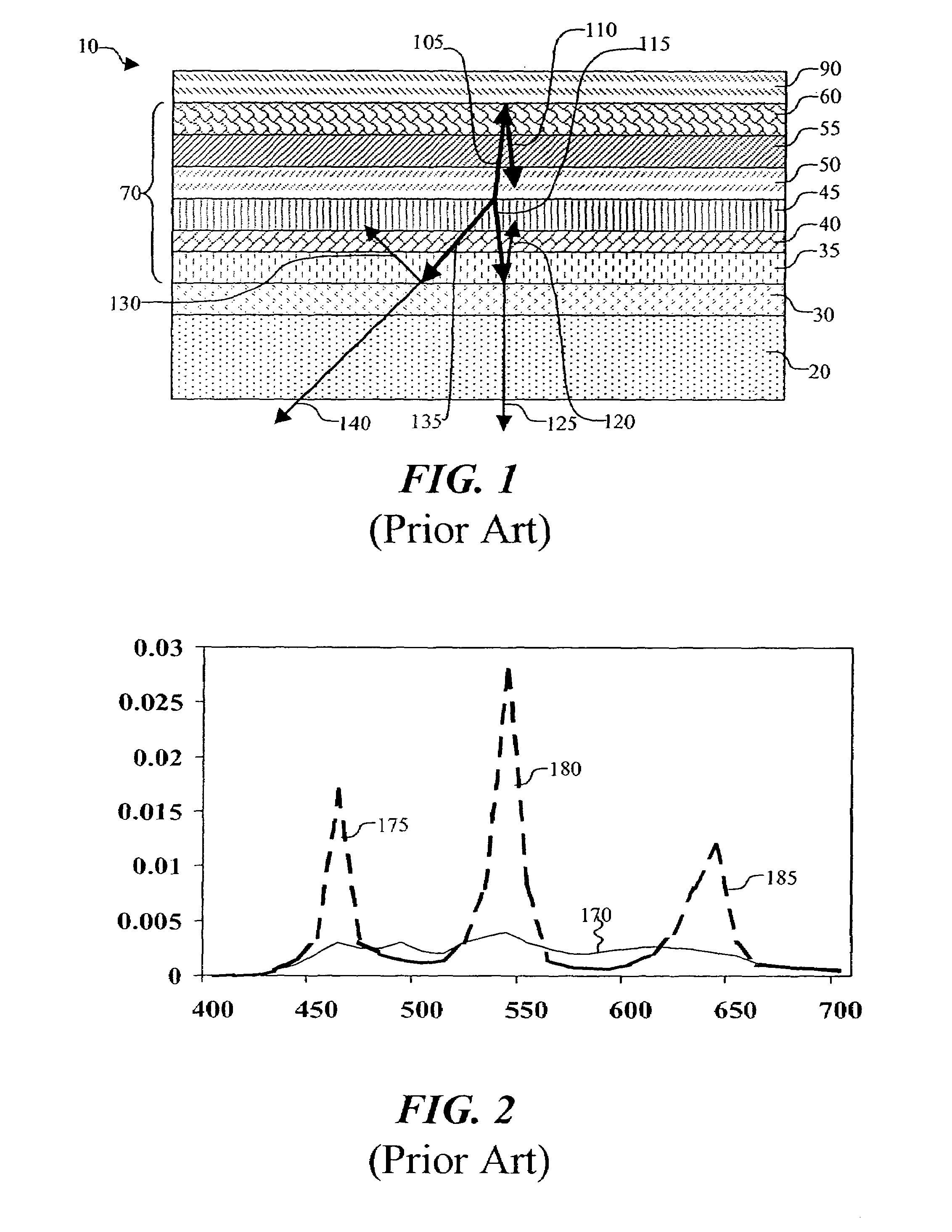

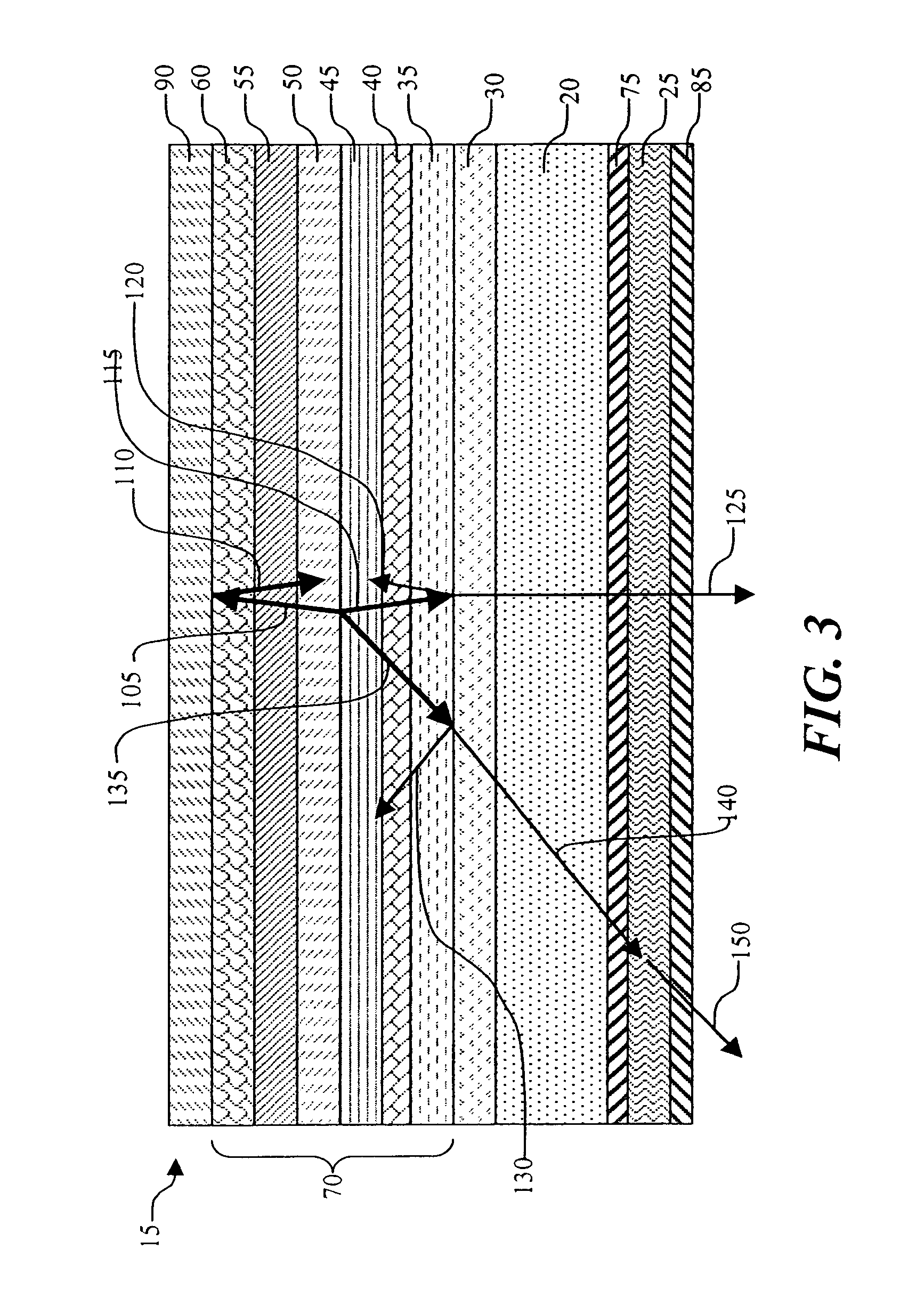

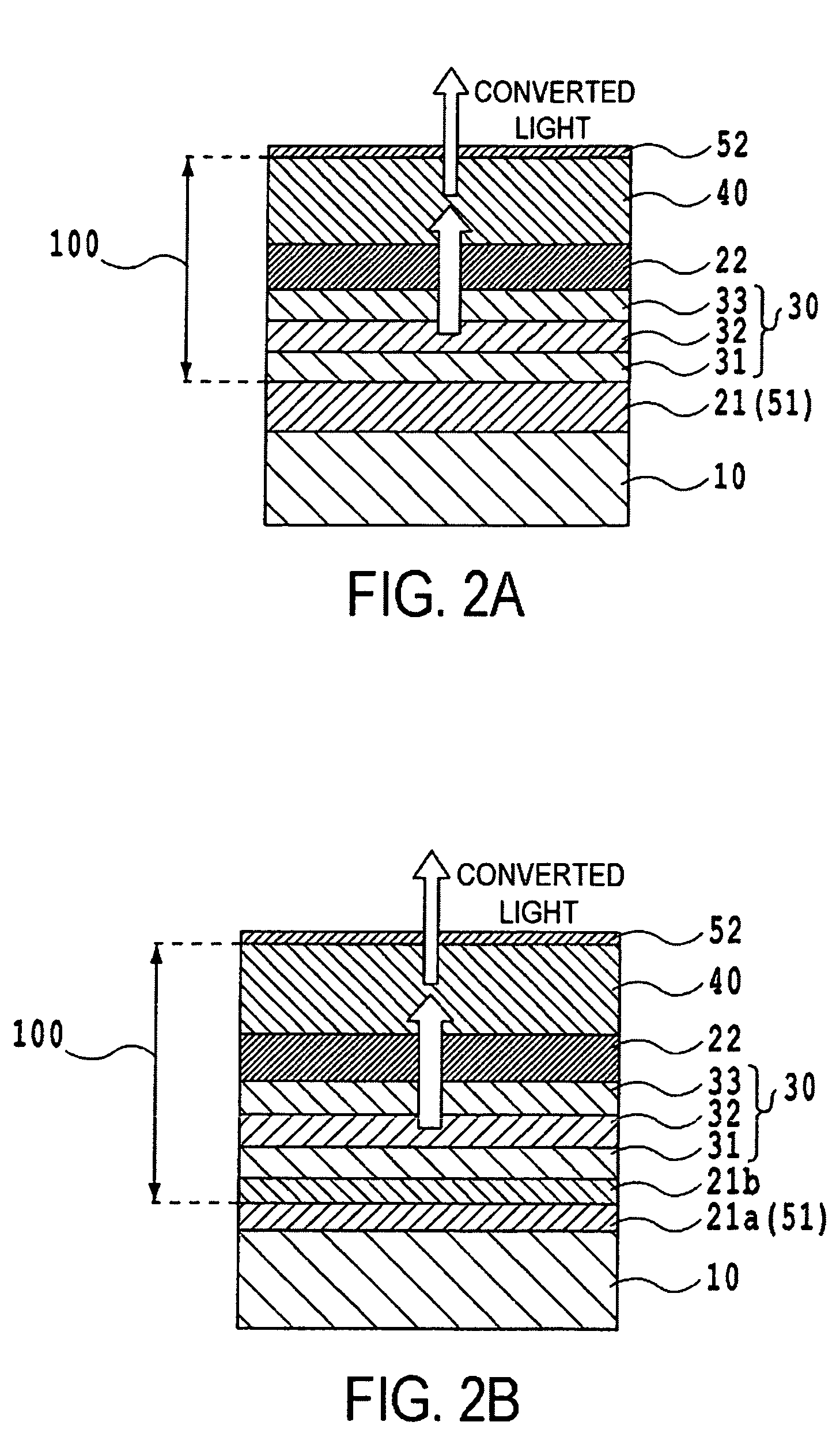

Reducing or eliminating color change for microcavity OLED devices

ActiveUS20060066228A1Reduce and eliminate color changeDischarge tube luminescnet screensElectroluminescent light sourcesDisplay deviceColor changes

In an embodiment of the invention, a microcavity OLED device that minimizes or eliminates color change at different viewing angles is fabricated. The OLED device can be, for example, an OLED display or an OLED light source used for area illumination. This OLED device includes a multi-layer mirror on a substrate, and each of the layers are comprised of a non-absorbing material. The OLED device also includes a first electrode on the multi-layered first mirror, and the first electrode is substantially transparent. An emissive layer is on the first electrode. A second electrode is on the emissive layer, and the second electrode is substantially reflective and functions as a mirror. The multi-layer mirror and the second electrode form a microcavity. On a front surface of the substrate is a light modulation thin film. The light modulation thin film can be any one of: a cut-off color filter, a band-pass color filter, a brightness enhancing film, a microstructure that attenuates an emission spectrum at an angle at which there is a perceived color change, or a microstructure that redistributes wavelengths so the outputted emission spectrums have the same perceived color.

Owner:DOLYA HOLDCO 5 LTD

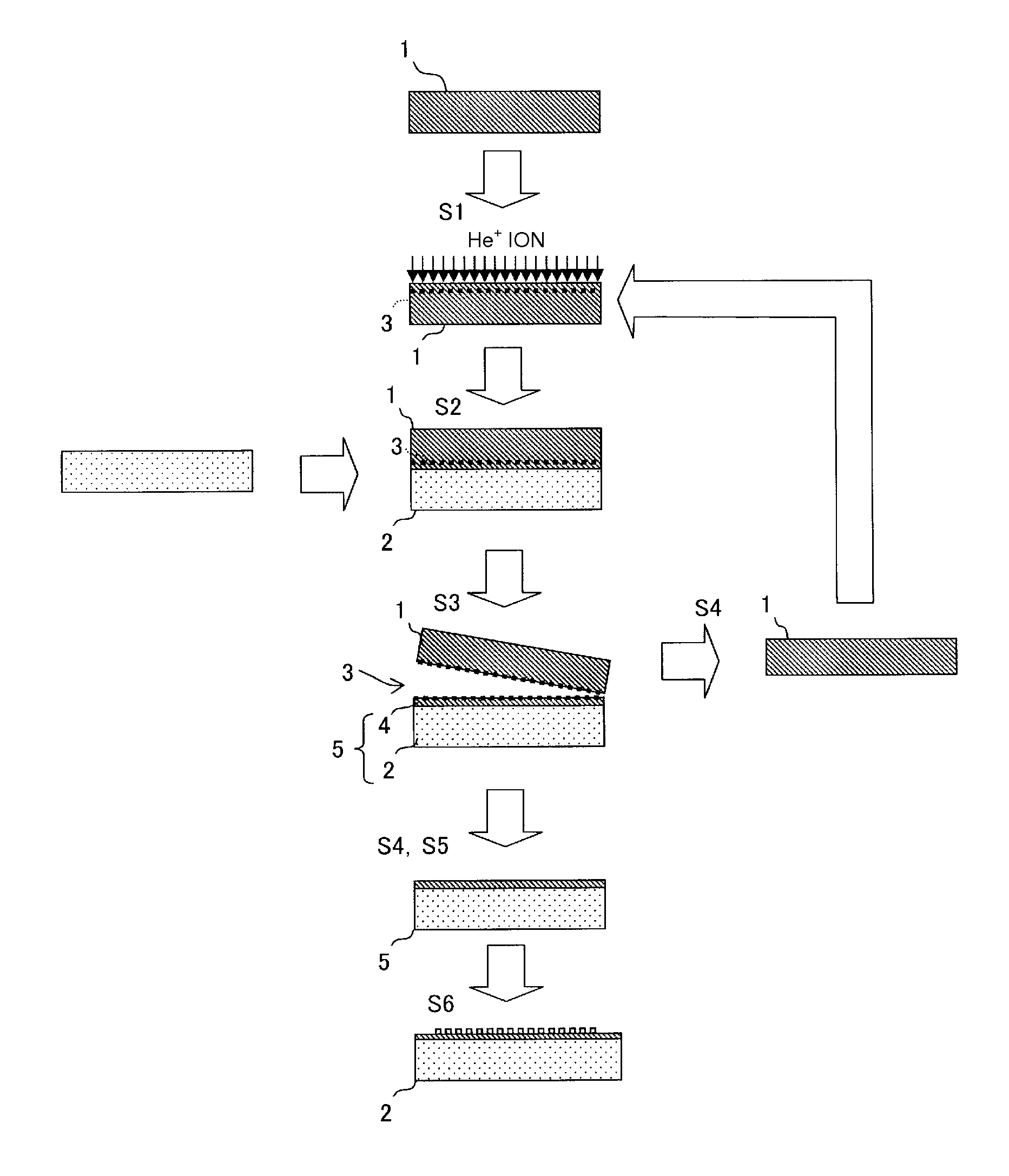

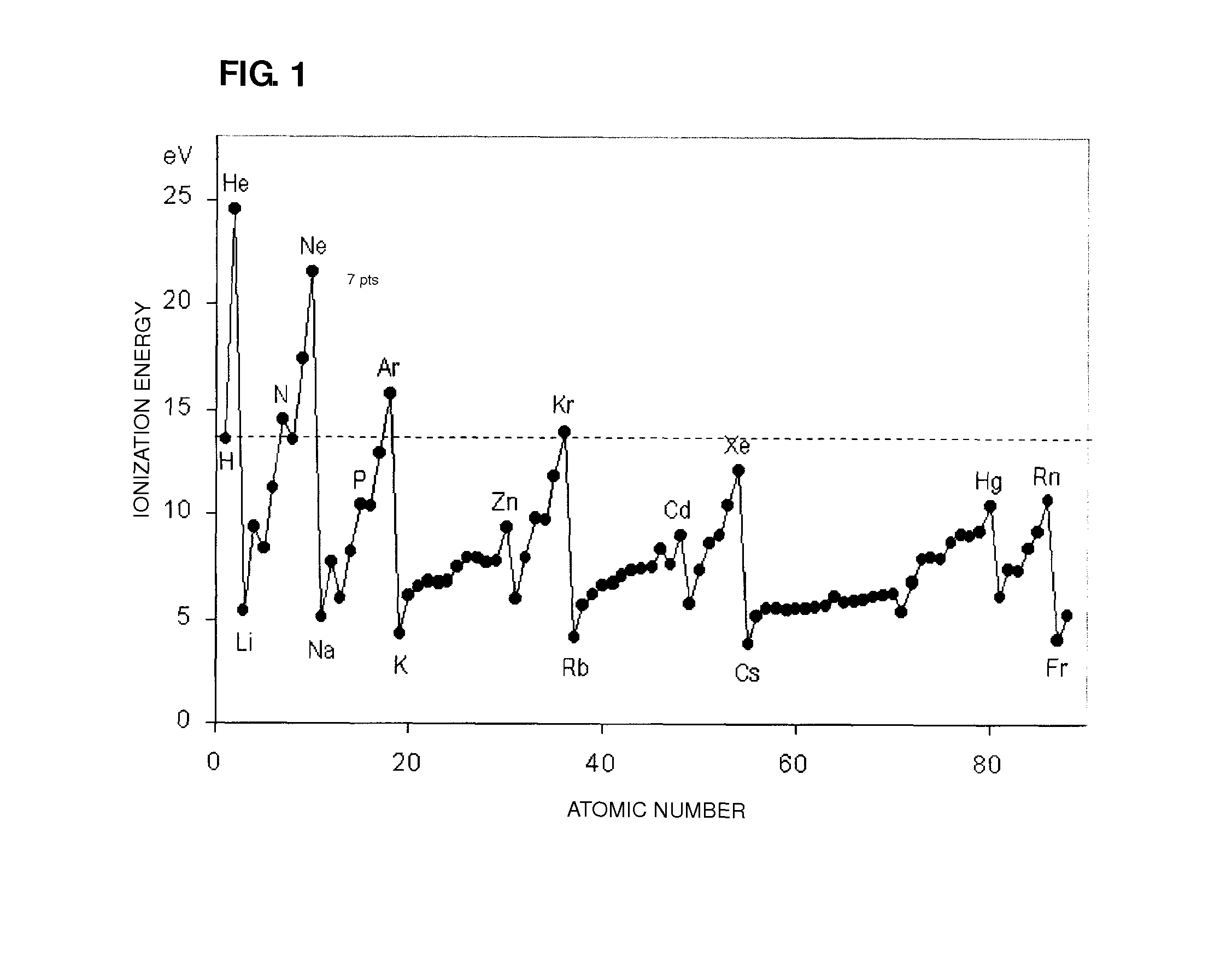

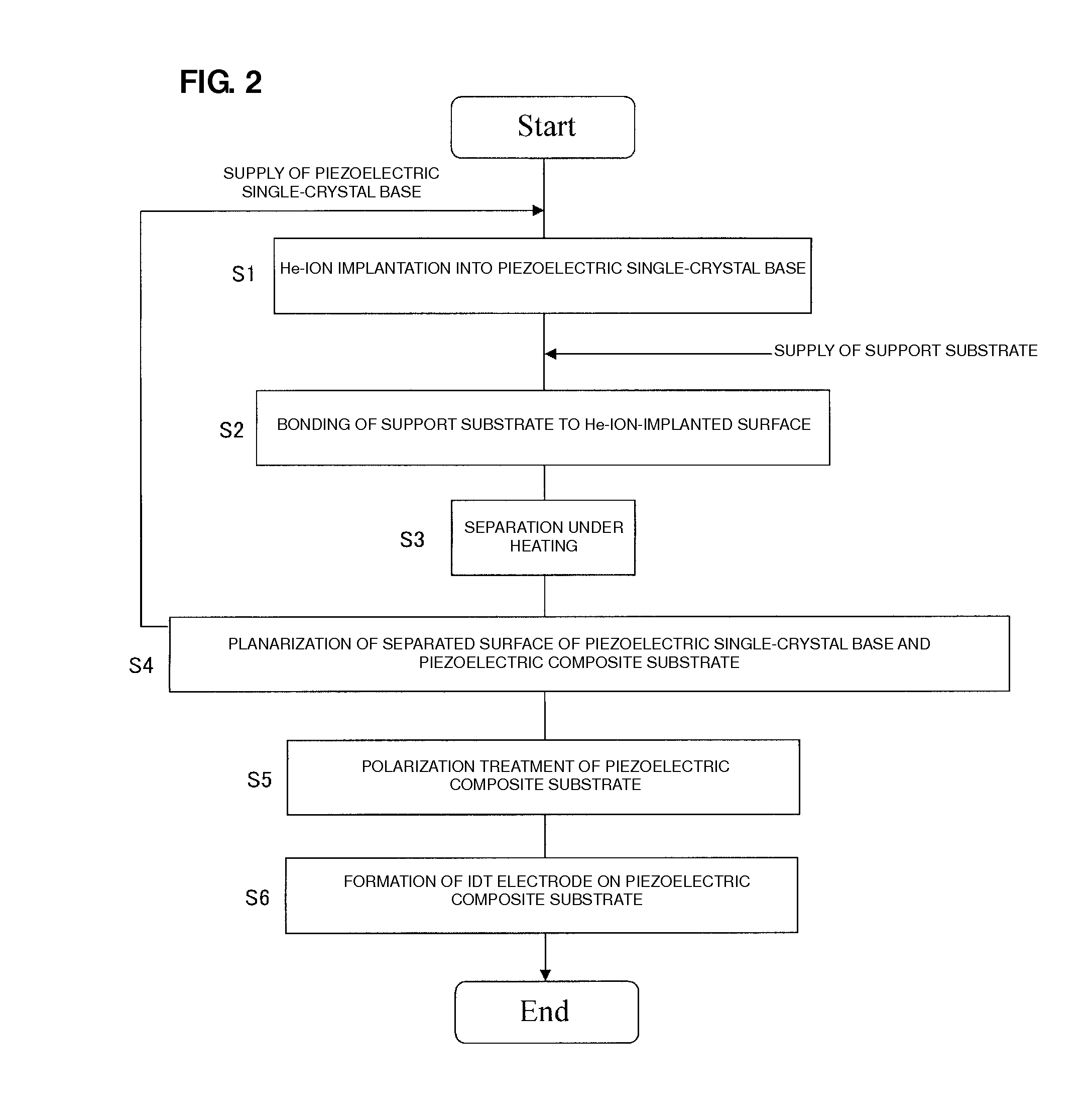

Method for producing piezoelectric composite substrate

ActiveUS8932686B2Improve utilization efficiencyUniform thicknessAfter-treatment detailsImpedence networksSingle crystalPiezoelectric composite

A method for producing a piezoelectric composite substrate having a single-crystal thin film of a piezoelectric material includes an ion-implantation step and a separation step. In the ion-implantation step, He+ ions are implanted into the single-crystal base made of the piezoelectric material to form localized microcavities in a separation layer located inside the single-crystal base and apart from a surface of the single-crystal base. In the separation step, the microcavities formed in the ion-implantation step are subjected to thermal stress to divide the separation layer of the piezoelectric single-crystal base, thereby detaching the single-crystal thin film.

Owner:MURATA MFG CO LTD

Non-random array anisotropic conductive film (ACF) and manufacturing processes

ActiveUS20100101700A1High resolutionReduce manufacturing costSemiconductor/solid-state device detailsSolid-state devicesAnisotropic conductive filmRandom array

Structures and manufacturing processes of an ACF array using a non-random array of microcavities of predetermined configuration, shape and dimension. The manufacturing process includes fluidic filling of conductive particles onto a substrate or carrier web comprising a predetermined array of microcavities, or selective metallization of the array followed by filling the array with a filler material and a second selective metallization on the filled microcavity array. The thus prepared filled conductive microcavity array is then over-coated or laminated with an adhesive film. Cavities in the array, and particles filling the cavities, can have a unimodal, bimodal, or multimodal distribution.

Owner:POLAROID IP BV

Microcavity OLED devices

InactiveUS20040140757A1Discharge tube luminescnet screensElectroluminescent light sourcesMetallic electrodeMaterials science

A microcavity OLED device including a substrate; a metallic bottom-electrode layer disposed over one surface of the substrate; an organic EL element disposed over the metallic bottom-electrode layer; and a metallic top-electrode layer disposed over the organic EL element, one of the metallic electrode layers is semitransparent and the other one is essentially opaque and reflective; and one of the metallic electrode layers is semitransparent and the other one is essentially opaque and reflective; and wherein the materials for the opaque and reflective metallic electrode layer are selected from Ag, Au, Al, or alloys thereof, the materials for the semitransparent metallic electrode layer are selected from Ag, Au, or alloys thereof, and the thickness of the semitransparent metallic electrode layer and the location of the light emitting layer are selected to enhance the emission output of the microcavity OLED device above that of a similar device without the microcavity.

Owner:EASTMAN KODAK CO

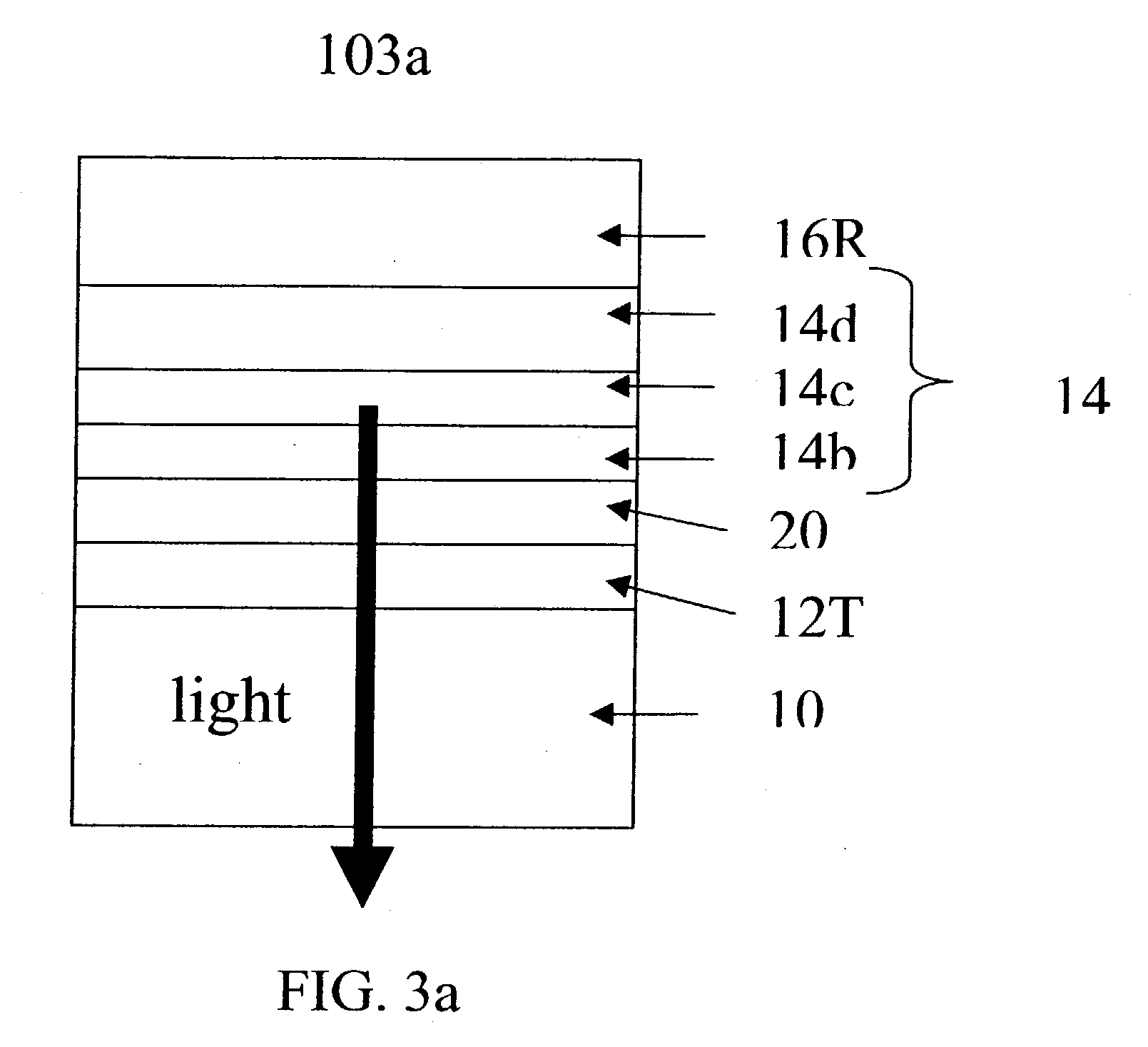

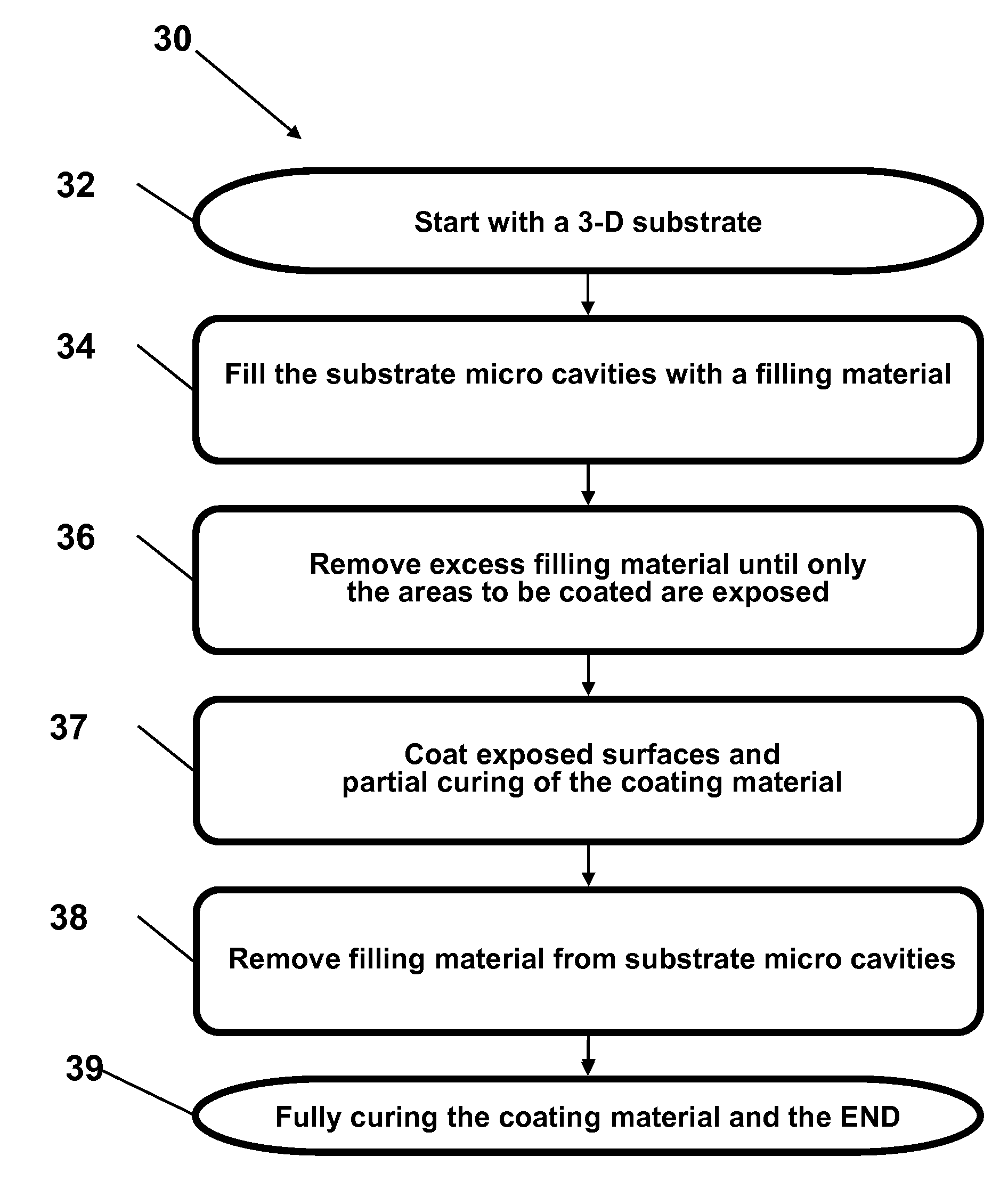

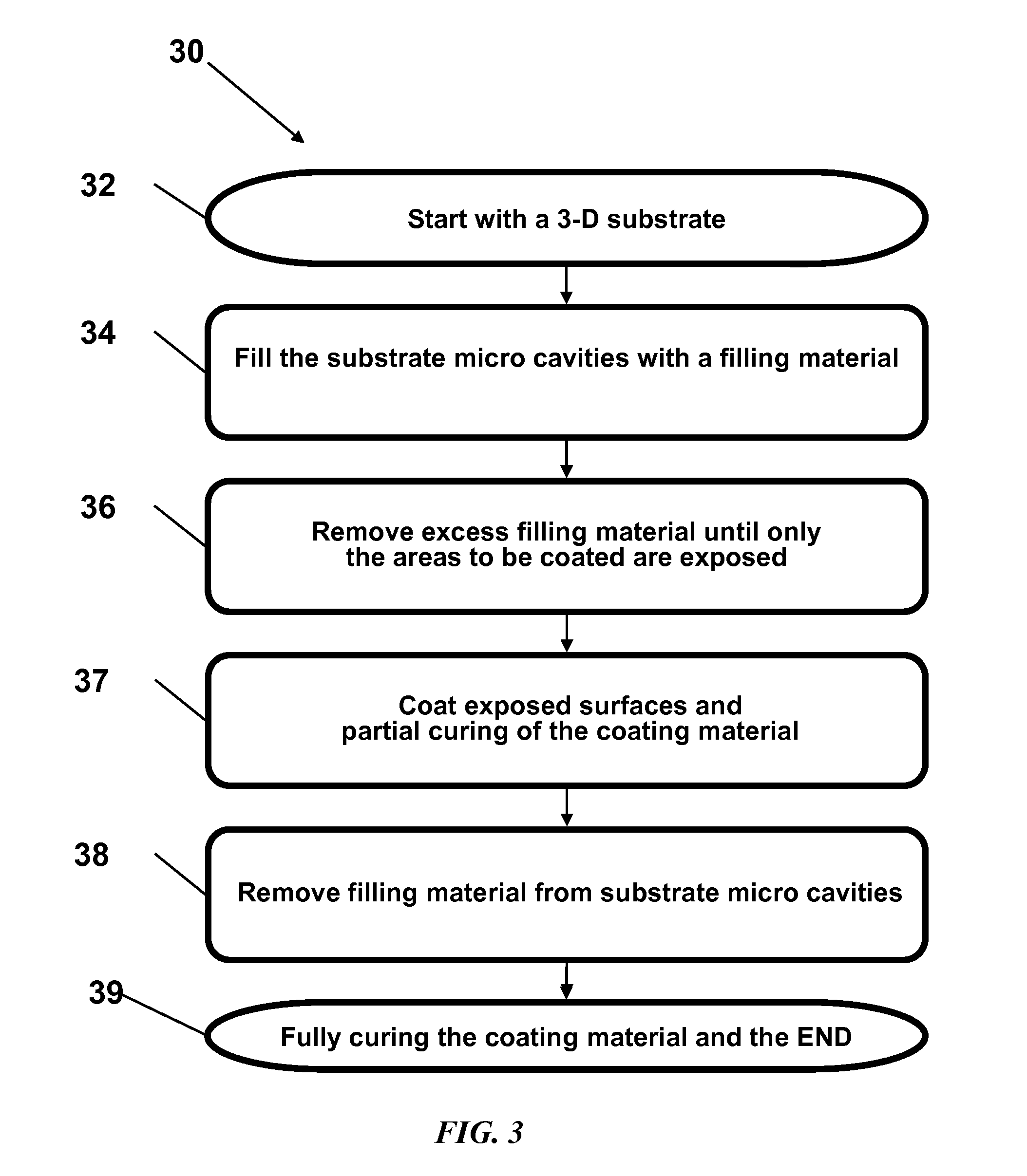

Methods for liquid transfer coating of three-dimensional substrates

InactiveUS20090042320A1Reduce surface tension3D rigid printed circuitsSemiconductor/solid-state device testing/measurementFilling materialsEngineering

Methods here disclosed provide for selectively coating the top surfaces or ridges of a 3-D substrate while avoiding liquid coating material wicking into micro cavities on 3-D substrates. The substrate includes holes formed in a three-dimensional substrate by forming a sacrificial layer on a template. The template includes a template substrate with posts and trenches between the posts. The steps include subsequently depositing a semiconductor layer and selectively etching the sacrificial layer. Then, the steps include releasing the semiconductor layer from the template and coating the 3-D substrate using a liquid transfer coating step for applying a liquid coating material to a surface of the 3-D substrate. The method may further include coating the 3-D substrate by selectively coating the top ridges or surfaces of the substrate. Additional features may include filling the micro cavities of the substrate with a filling material, removing the filling material to expose only the substrate surfaces to be coated, coating the substrate with a layer of liquid coating material, and removing said filling material from the micro cavities of the substrate.

Owner:BEAMREACH SOLAR INC

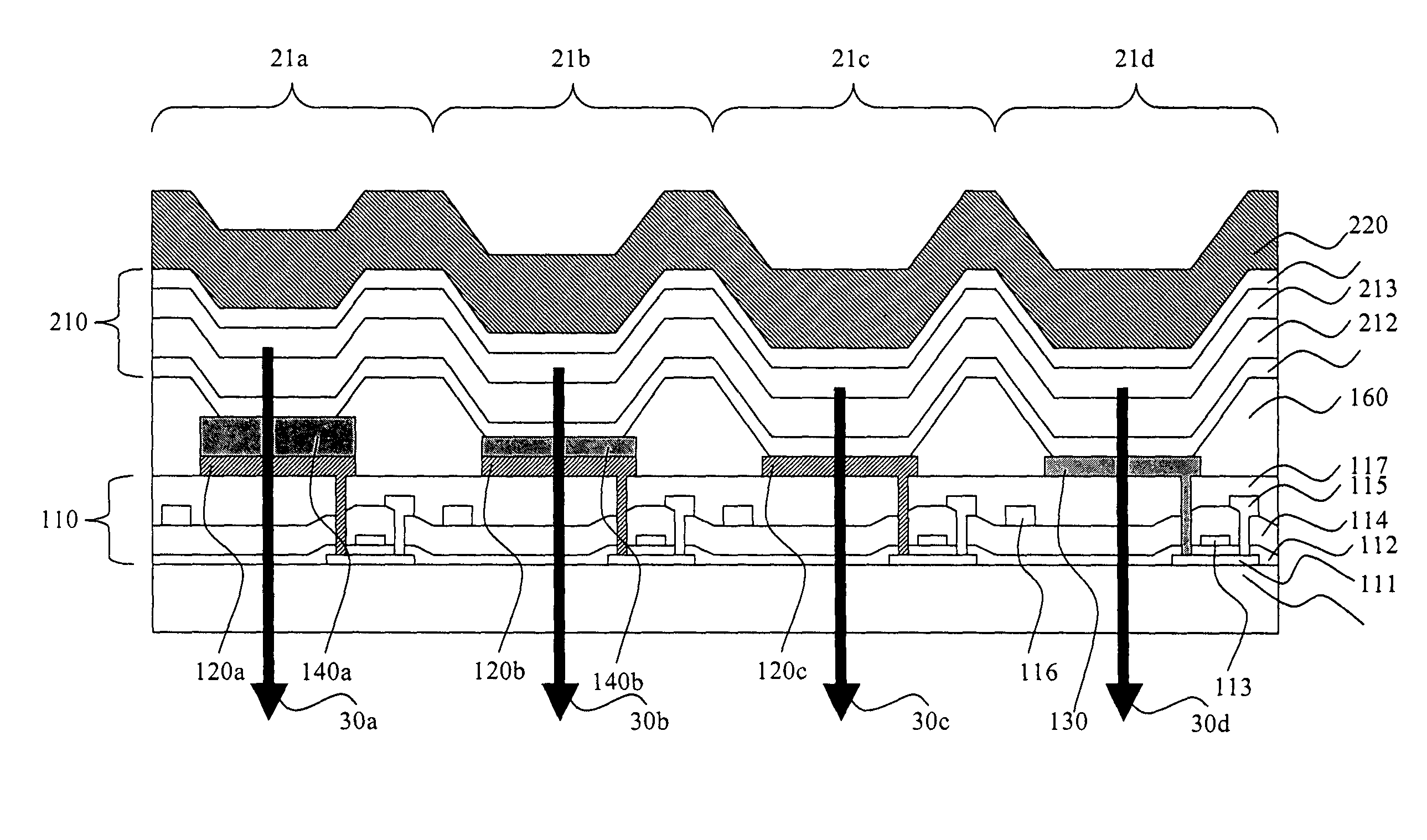

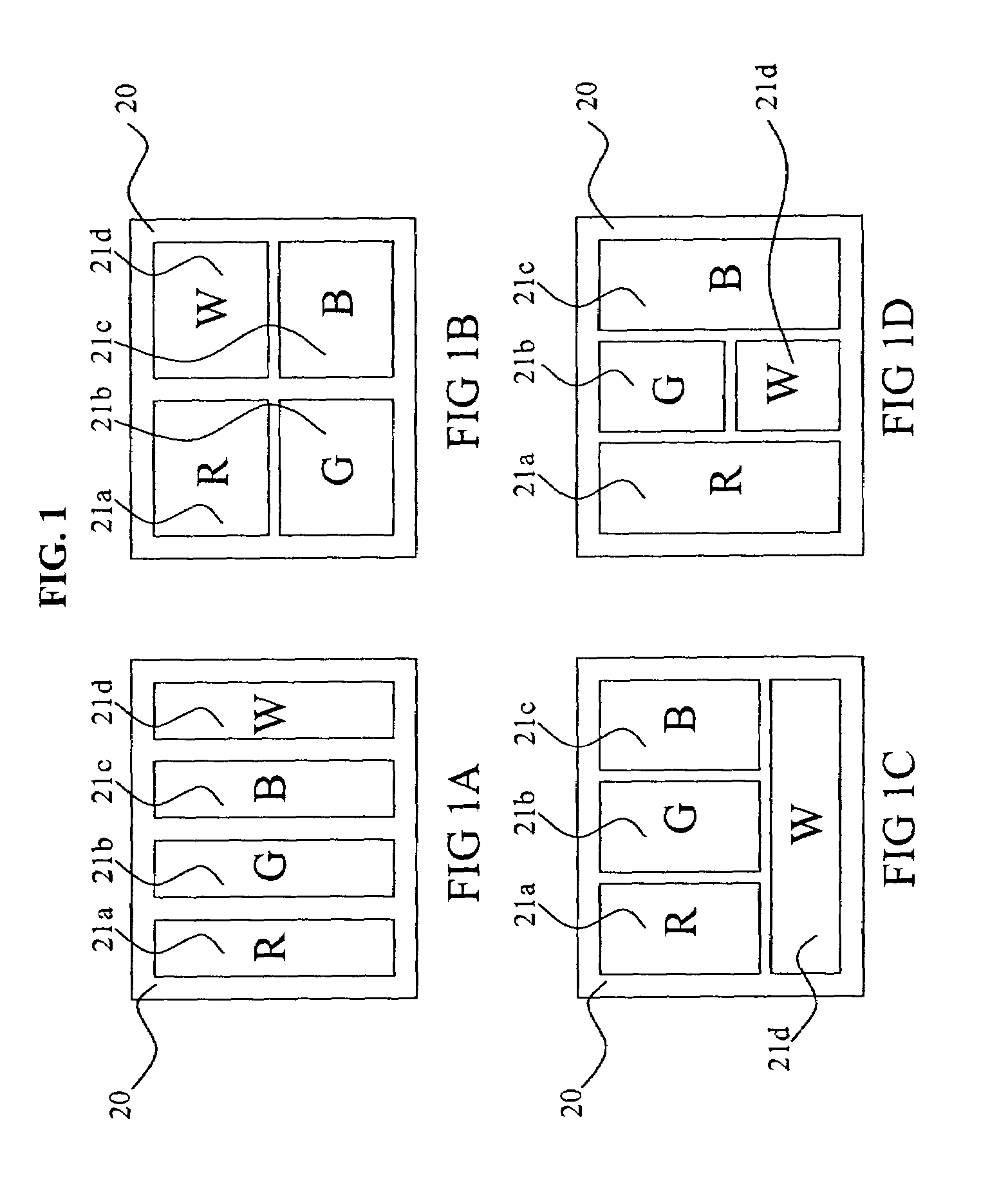

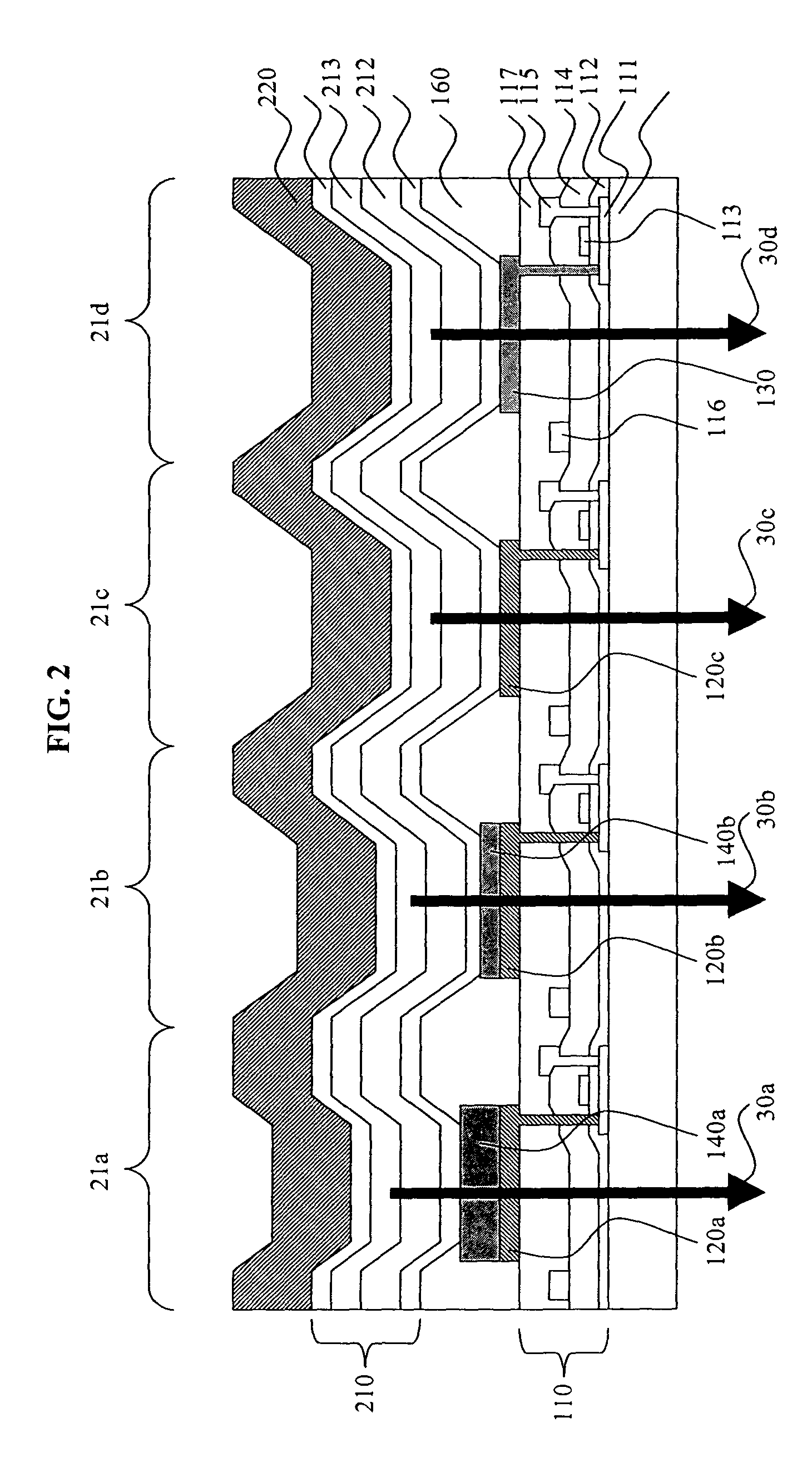

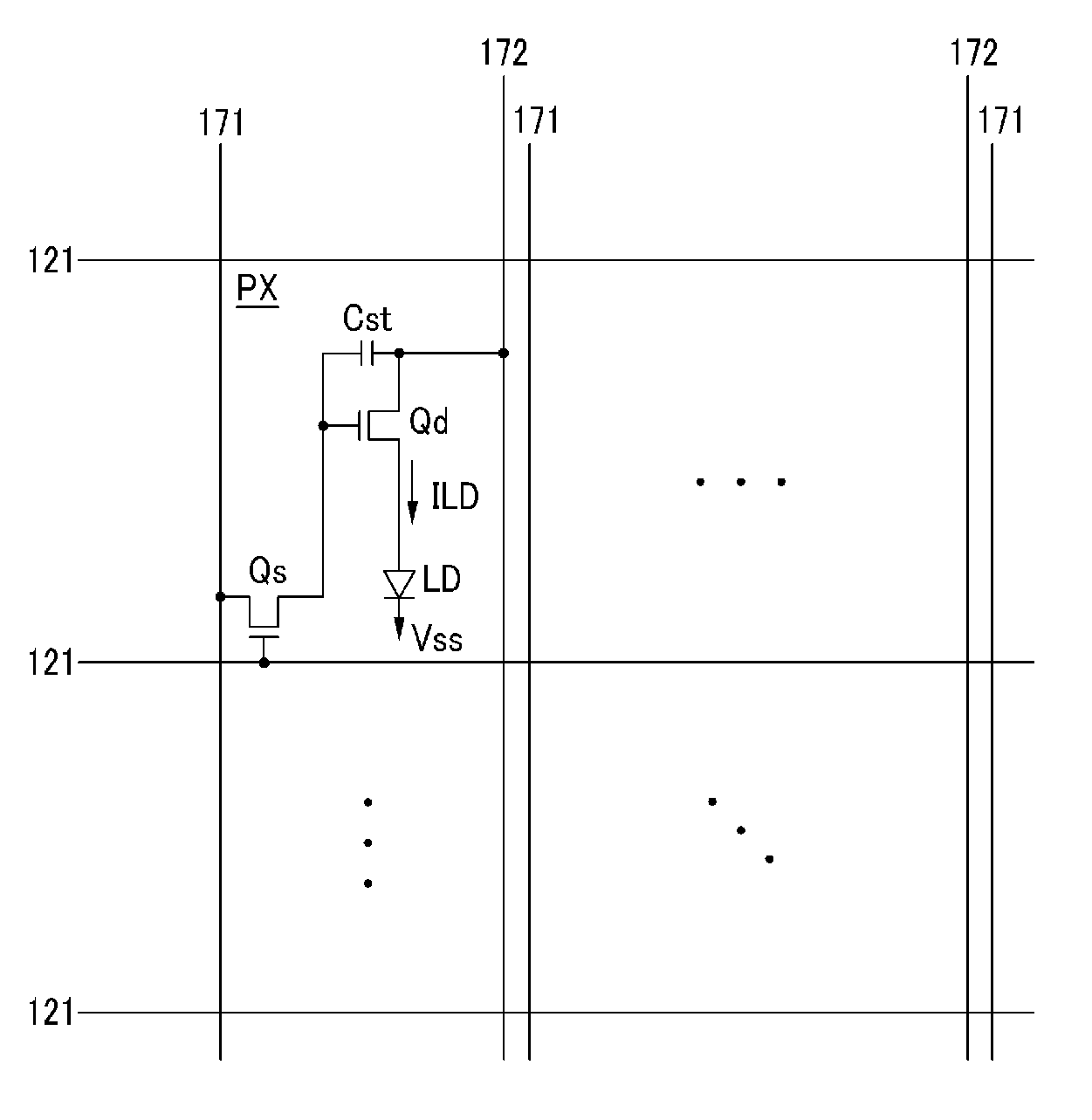

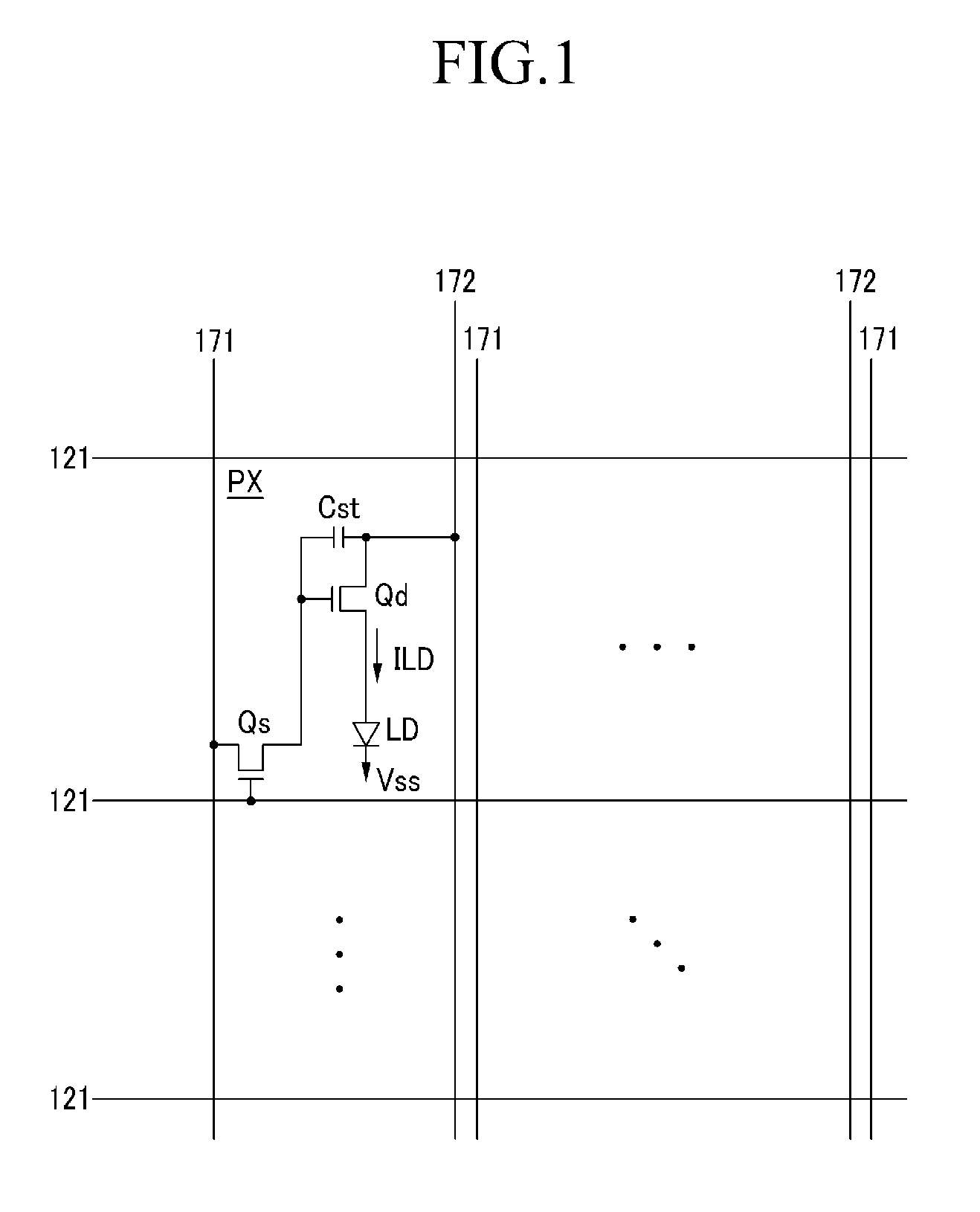

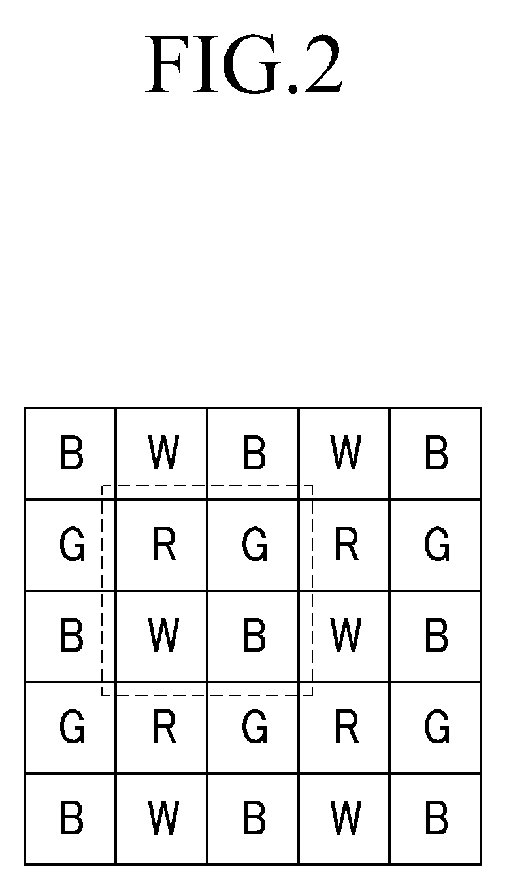

Organic light emitting diode display and method for manufacturing the same

ActiveUS20090115706A1Improve color reproducibilityImprove luminanceStatic indicating devicesElectroluminescent light sourcesPath lengthOrganic light emitting device

An organic light emitting device including a first pixel, a second pixel and a third pixel displaying different colors from each other according to the present invention, the organic light emitting device includes a reflecting electrode and a translucent member forming a micro-cavity along with the reflecting electrode, wherein a optical path length is an interval between the reflecting electrode and the translucent member, and wherein the light path lengths of at least two pixels among the first pixel, the second pixel and the third pixel are the same.

Owner:SAMSUNG DISPLAY CO LTD

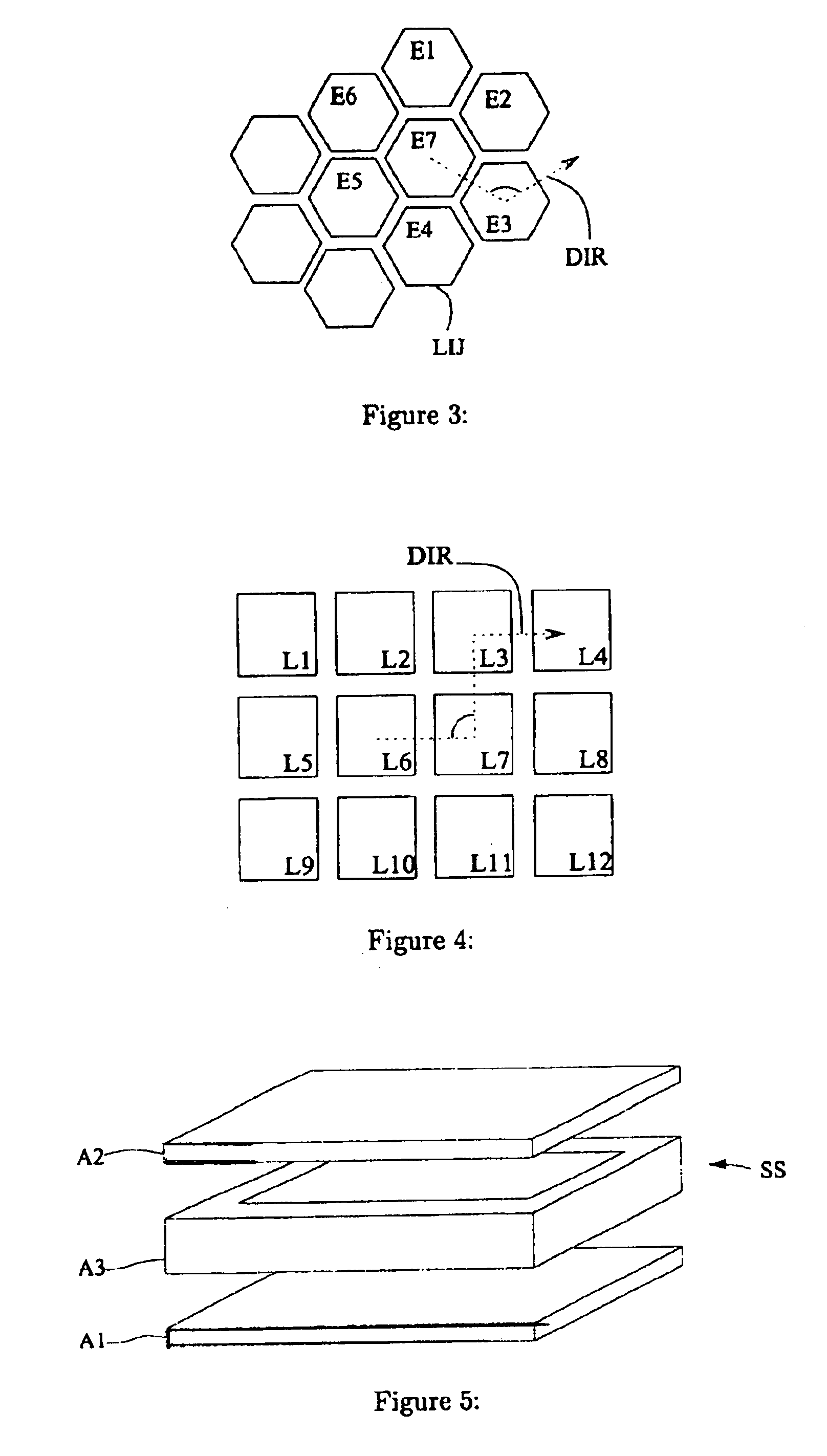

Method for producing a thin membrane and resulting structure with membrane

InactiveUS6465327B1Easy to separateSeparation can be delayedSolid-state devicesSemiconductor/solid-state device manufacturingThin membraneThin layer

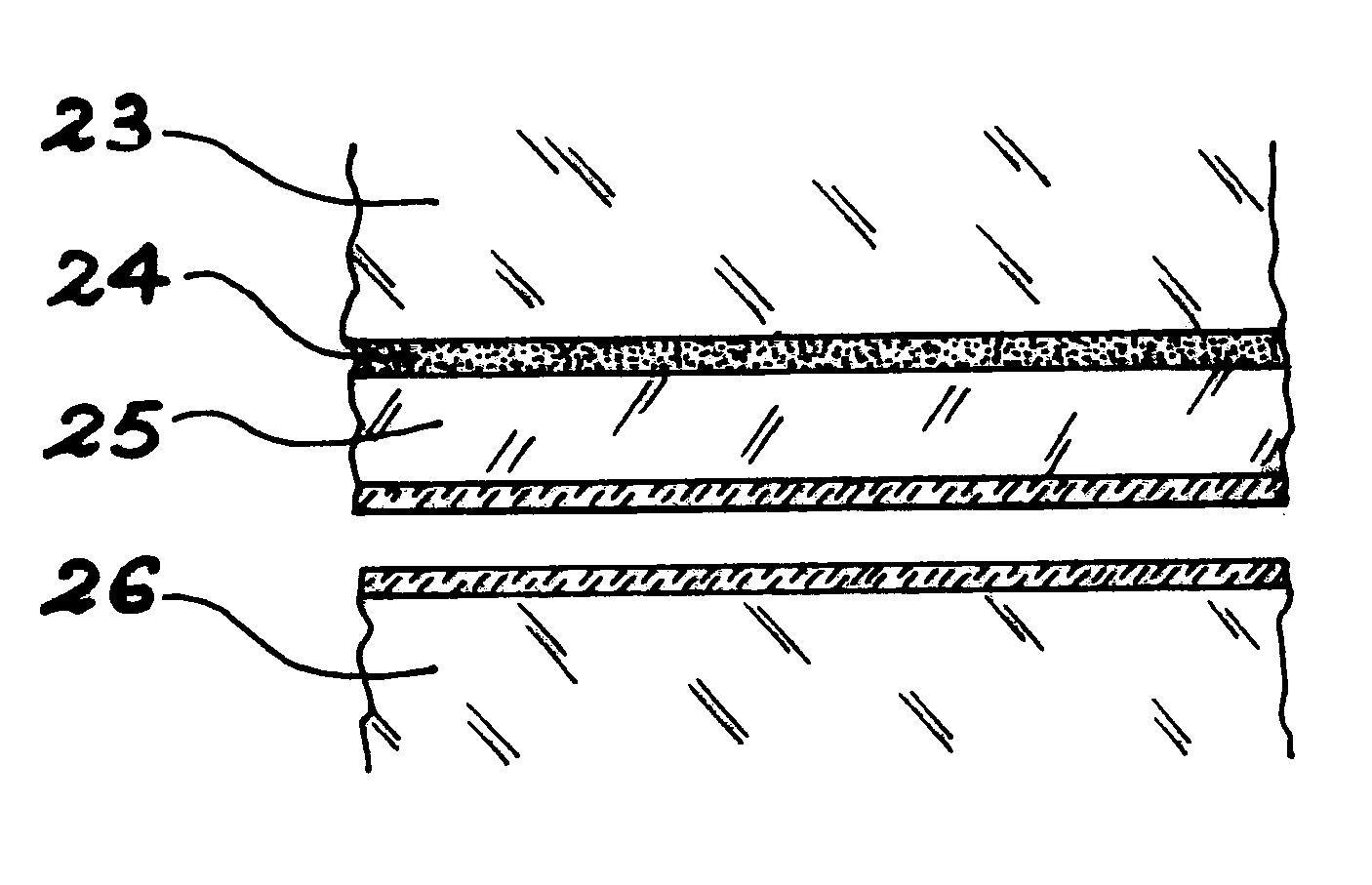

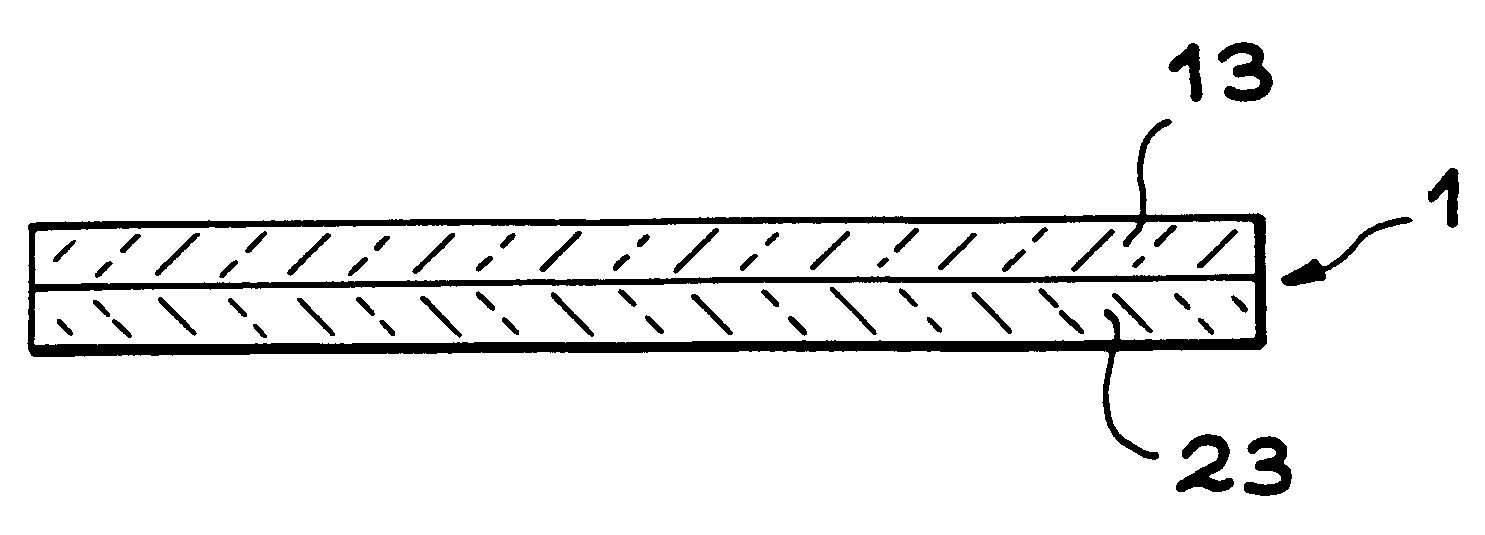

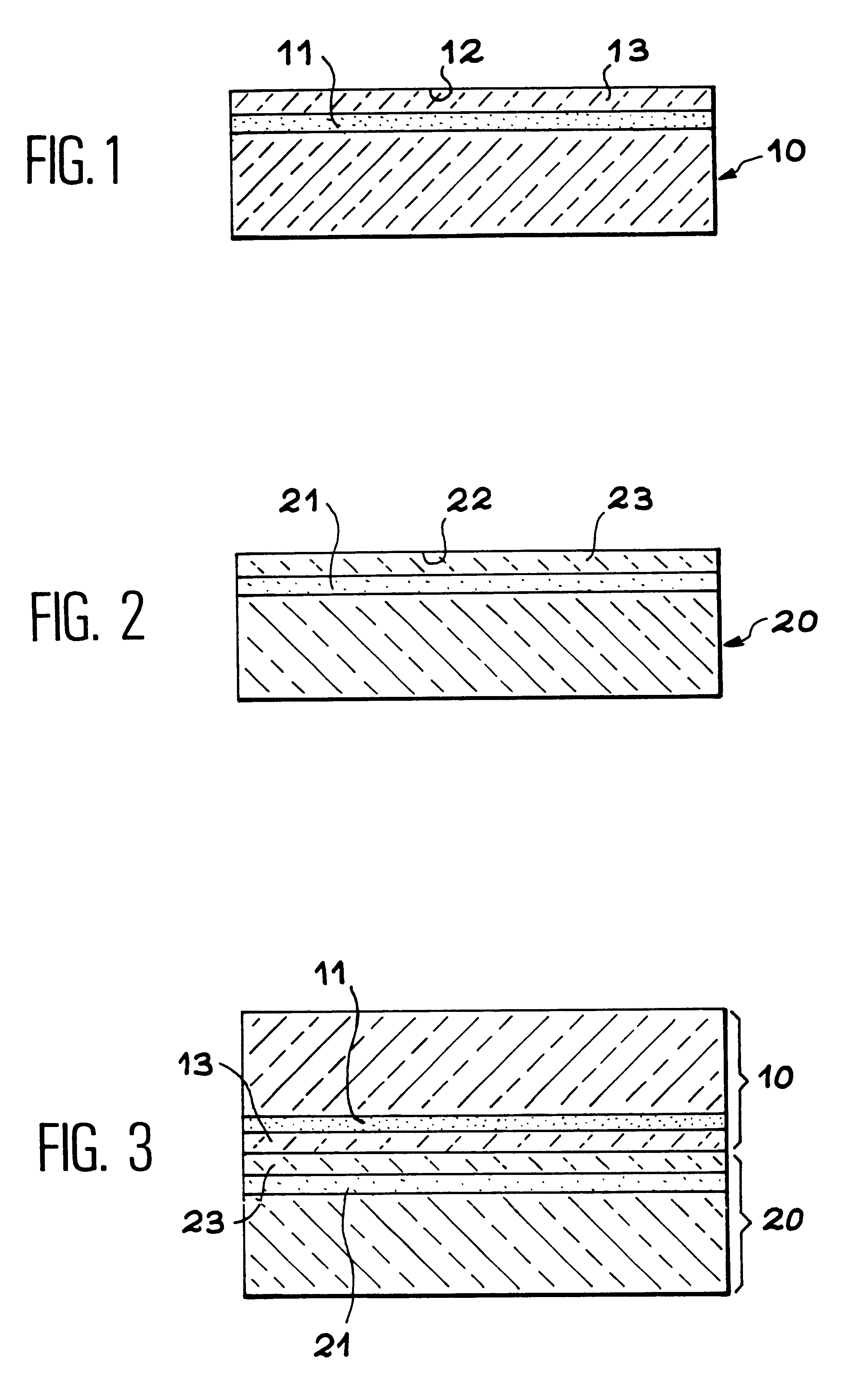

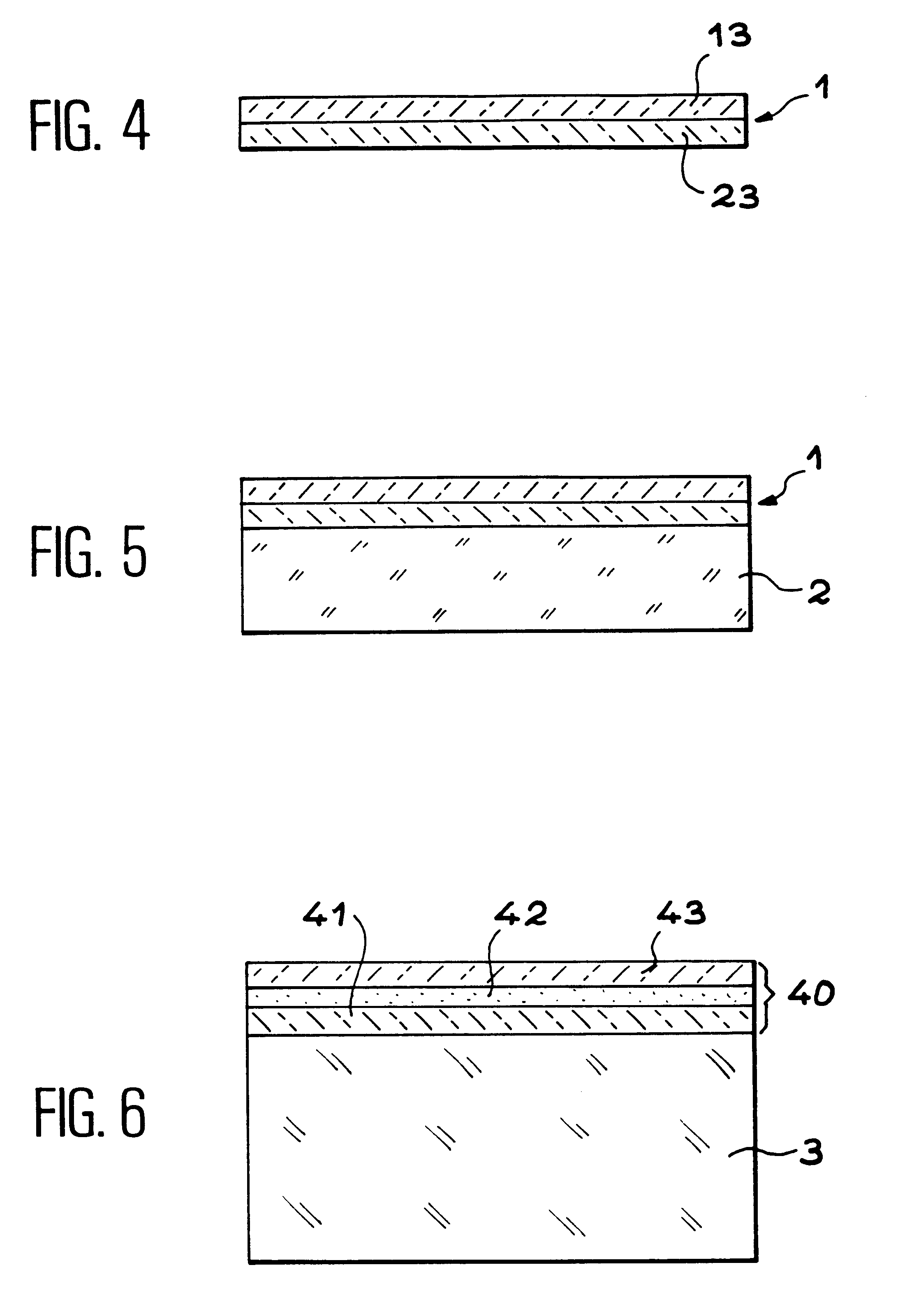

The invention relates to a method for producing a thin membrane, comprising the following steps:implanting gas species, through one surface of a first substrate (10) and through one surface of a second substrate (20), which in said substrates are able to create microcavities (11, 21) delimiting, for each substrate, a thin layer (13, 23) lying between these microcavities and the implanted surface, the microcavities being able, after their implantation, to cause detachment of the thin layer from its substrate;assembly of the first substrate (10) onto the second substrate (20) such that their implanted surfaces face one another;detaching each thin layer (13, 23) from its substrate (10, 20), the thin layers remaining assembled together to form said thin membrane.The invention also concerns a thin membrane structure obtained with this method.

Owner:S O I TEC SILICON ON INSULATOR THECHNOLOGIES

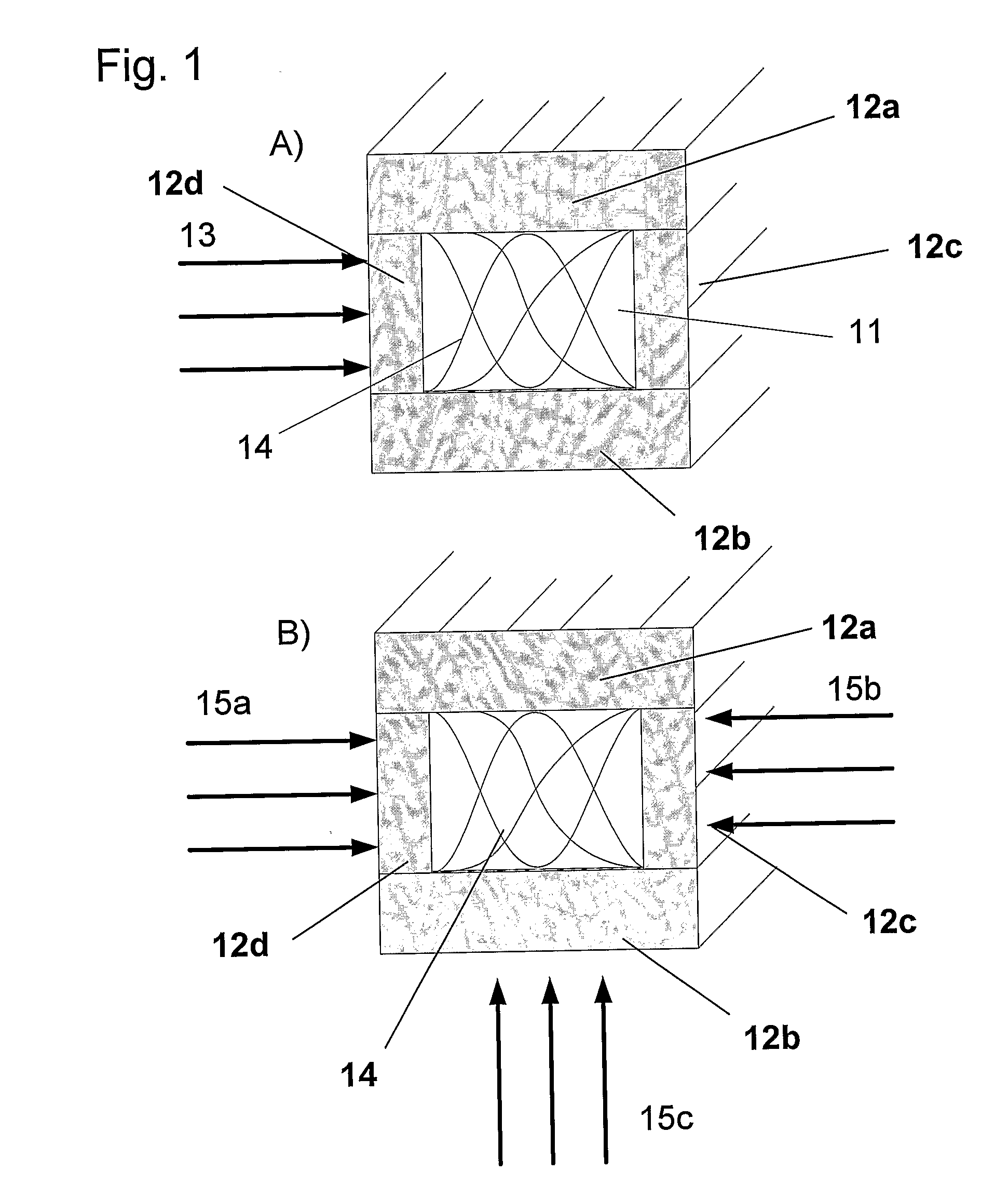

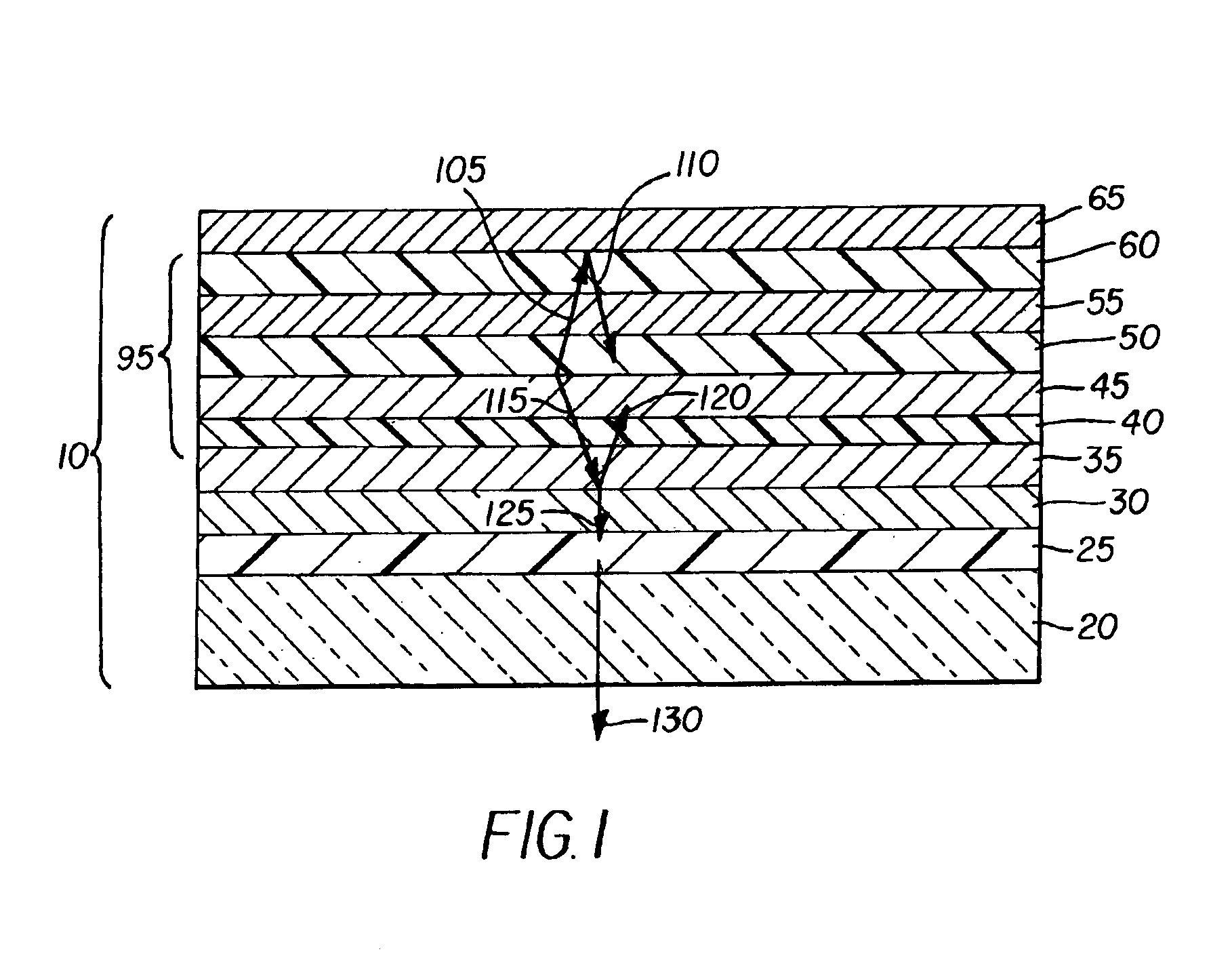

Multilayer microcavity devices and methods

InactiveUS7144486B1Rapid Detection AnalysisImmobilised enzymesBioreactor/fermenter combinationsConductive materialsPolyimide membrane

Microcavities and micropores that are microscopic (<1 mm) in width and depth and contain any number of individually-addressable electrodes, separated by insulators, along the walls of each cavity. The conducting materials, and the insulator materials can be deposited alternately onto a starting substrate, which is typically an oxidized silicon wafer or polyimide film, but may be any substrate that shows good adhesion to the materials layered on it. The cavities are etched through these layers, perpendicular to the plane of the substrate, exposing the layers at their edges. Pores may be carved entirely through the device.

Owner:SMITHKLINE BECKMAN CORP +1

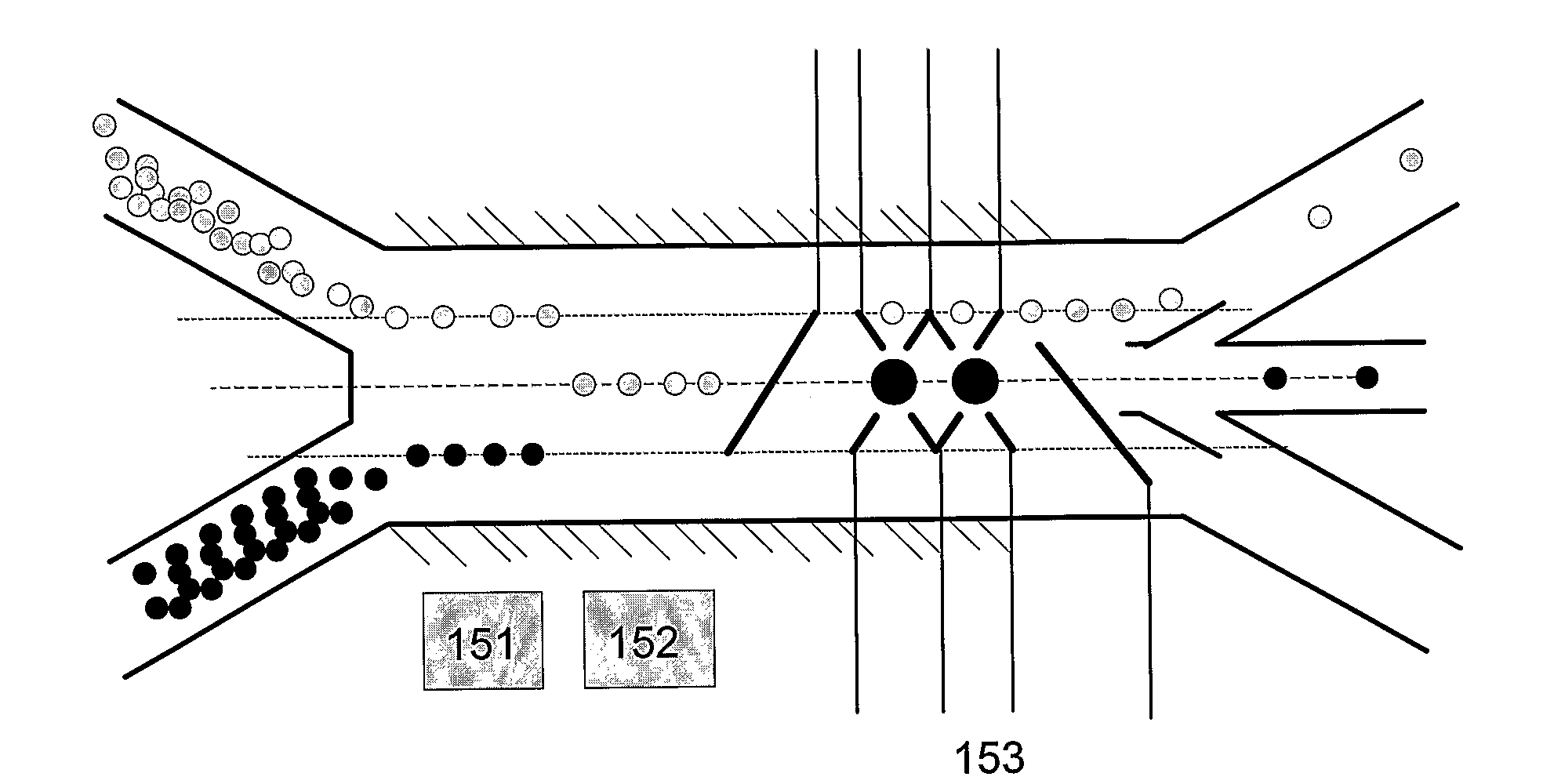

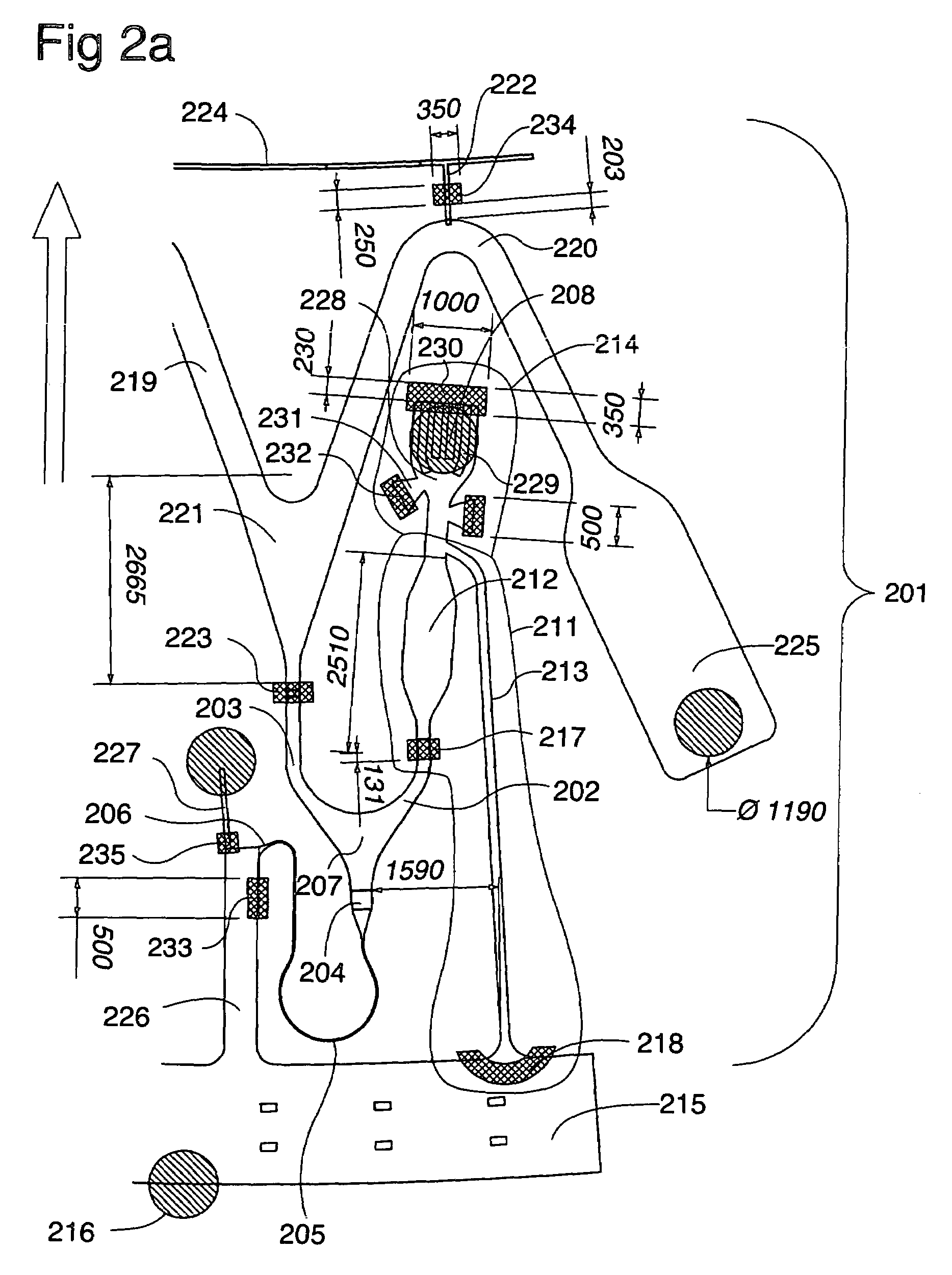

Method and Device for Acoustic Manipulation of Particles, Cells and Viruses

InactiveUS20090226994A1Efficient couplingEasy to controlBioreactor/fermenter combinationsBiological substance pretreatmentsSuspended particlesPresent method

The present invention relates to a method and device for non-intrusively manipulating suspended particles and / or cells and / or viruses, which are supplied to a micro-chamber or to a micro-channel (46) of a substrate, said micro-chamber or micro-channel (46) having at least a bottom wall as well as lateral walls. At least one acoustic wave (41) is applied via at least one acoustic transducer (42, 44) from outside of said substrate to an inner volume of said micro-chamber or micro-channel (46), a frequency of said acoustic wave (41) being selected to generate a standing and / or stationary acoustic wave in said volume. In the present method and device the acoustic wave (41) is applied laterally to said volume. The present device and method allow an efficient coupling of energy into the channels as well as an improved control of standing and / or stationary acoustic wave fields along the channels. Furthermore the device and method allow for transmission optical microscopy to observe the manipulated particles in the channels during manipulation.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

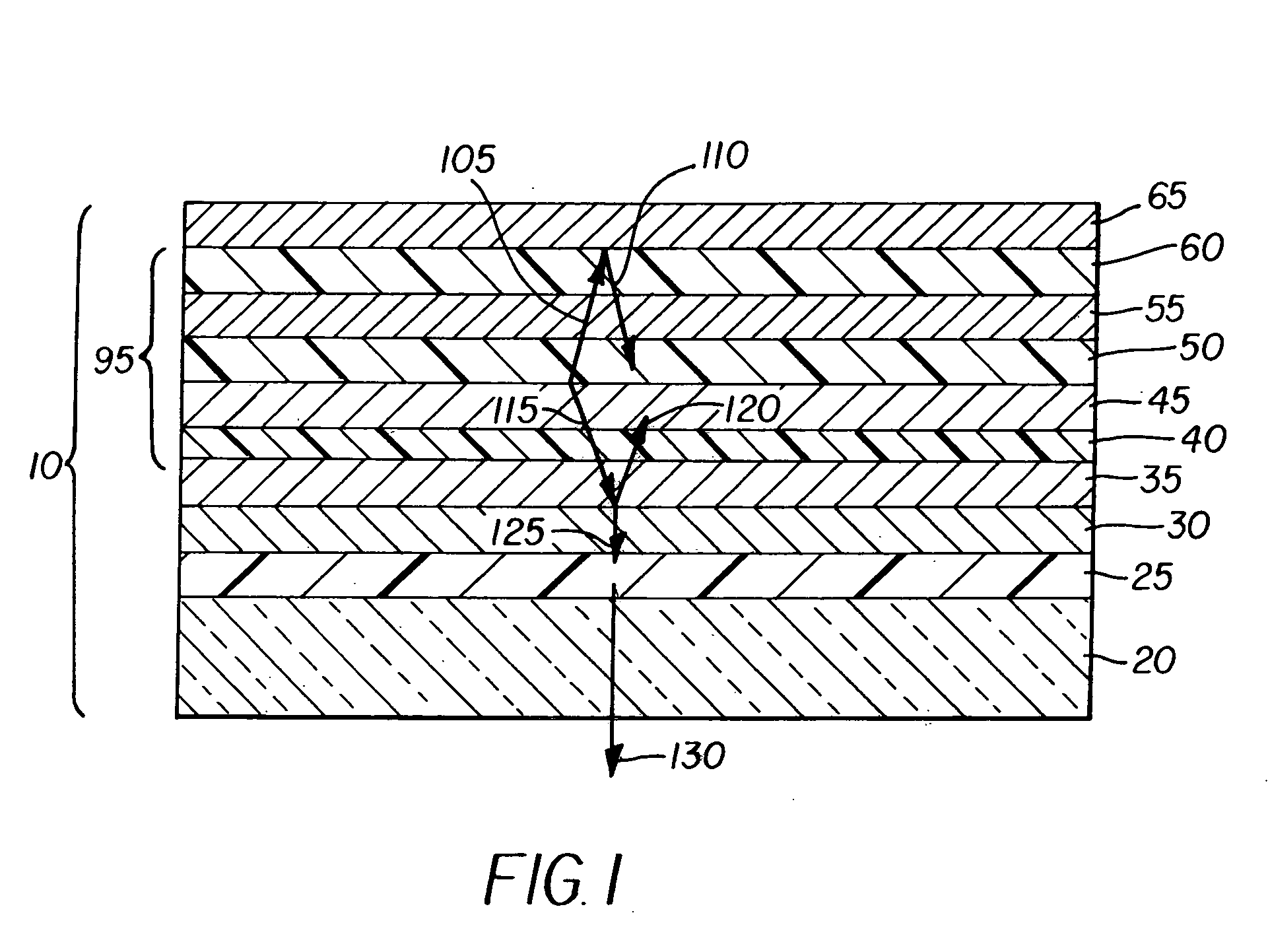

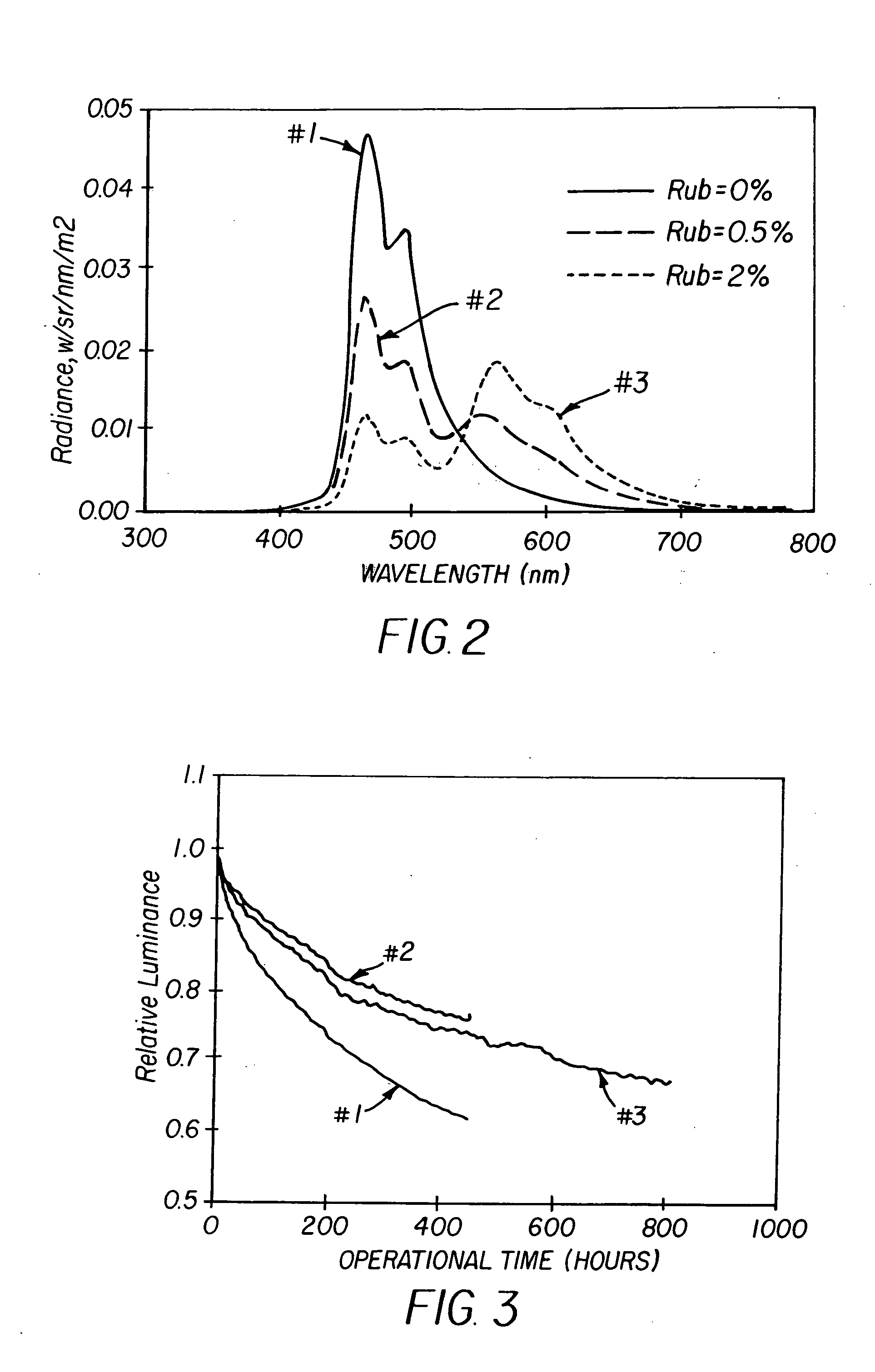

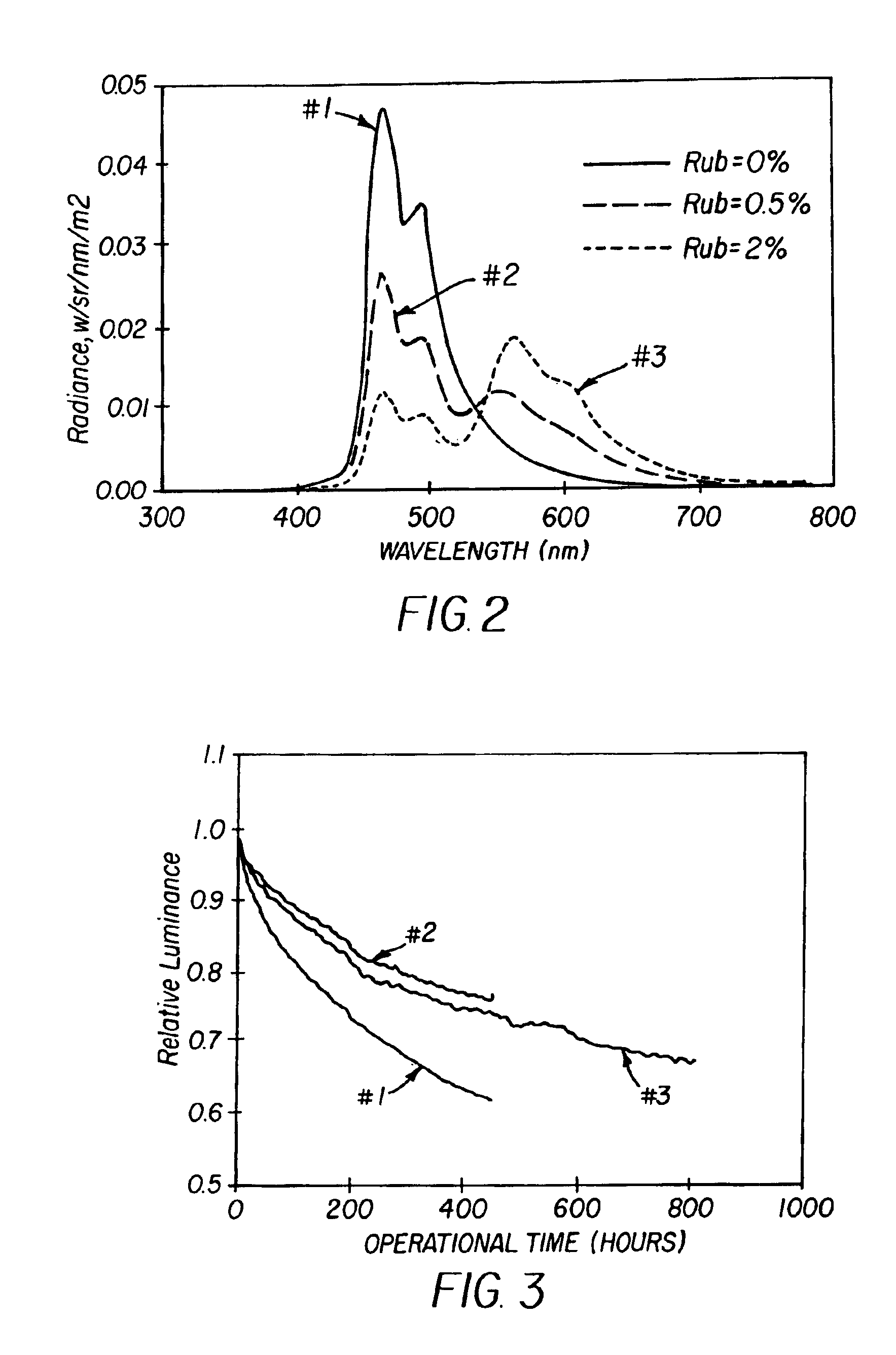

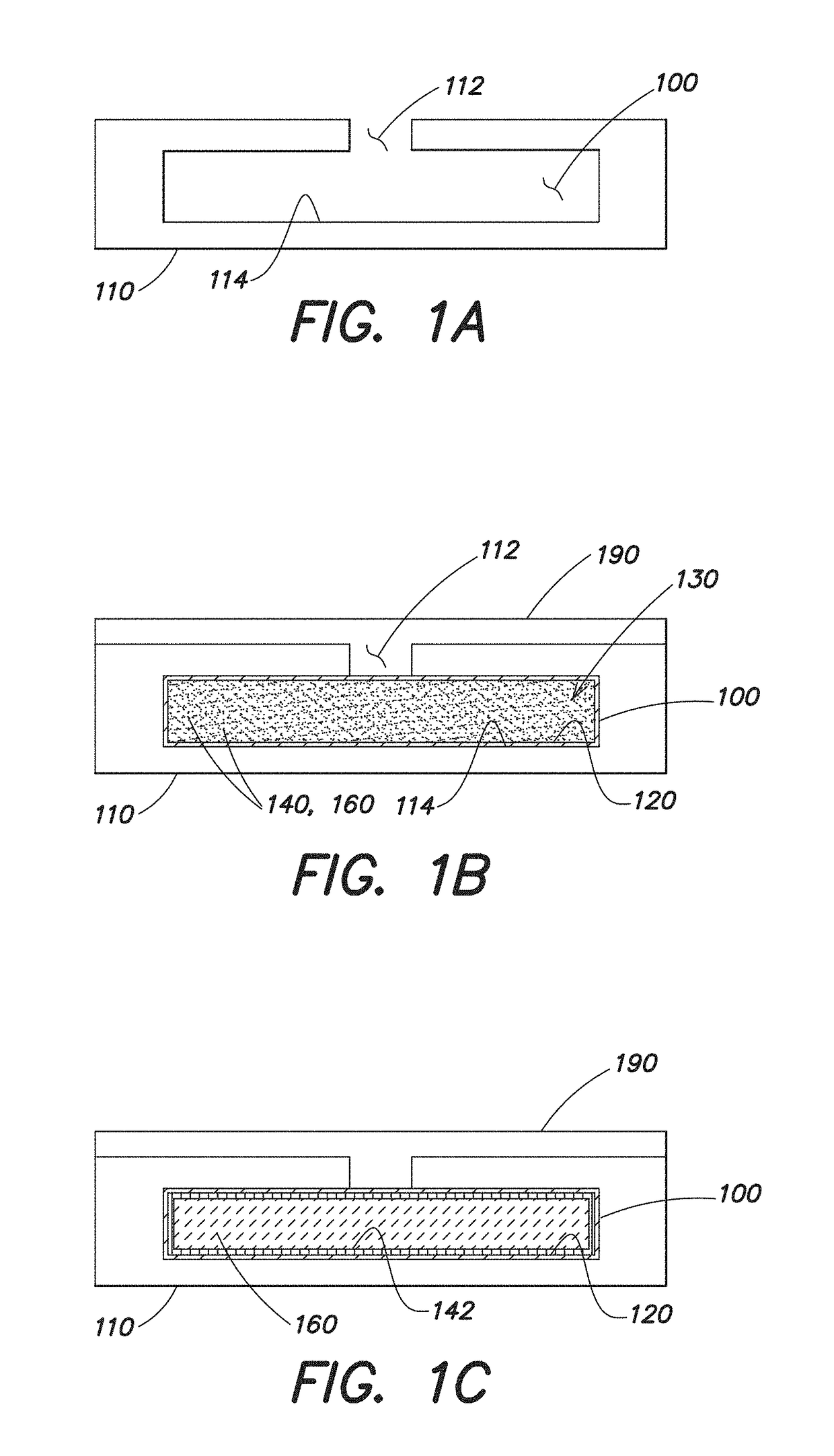

Stabilized OLED device

ActiveUS20050058852A1Improve stabilityImprove performanceIncadescent screens/filtersDischarge tube luminescnet screensDopantDevice form

A stabilized OLED device for emitting light of a specific color includes a metallic anode and a metallic cathode spaced from the metallic anode. The device also includes a light-emitting layer including a host and a dopant, the dopant selected to produce light having a spectrum including light of the specific color, and a stabilizer provided in one of the device layers which improves the useful lifetime of the OLED device, wherein the stabilizer has an emission spectrum different from that of the light-emitting layer. One of the electrode layers is semitransparent and the other one is substantially opaque and reflective such that the stabilized OLED device forms a microcavity that emits a narrow band light with the specific color.

Owner:GLOBAL OLED TECH

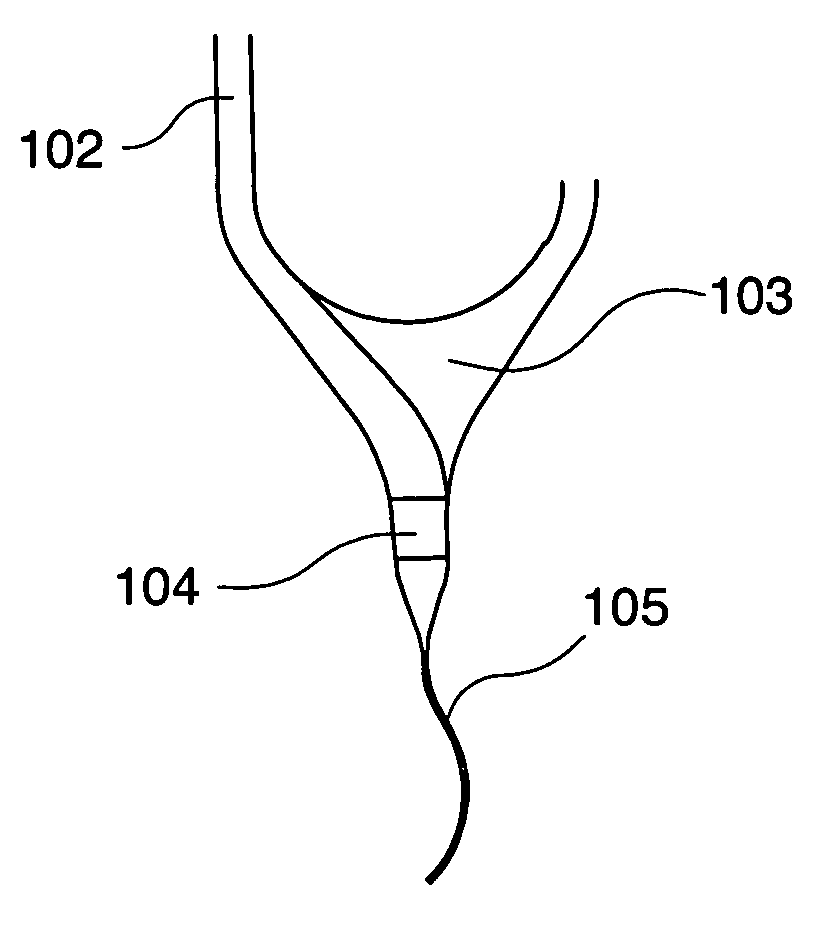

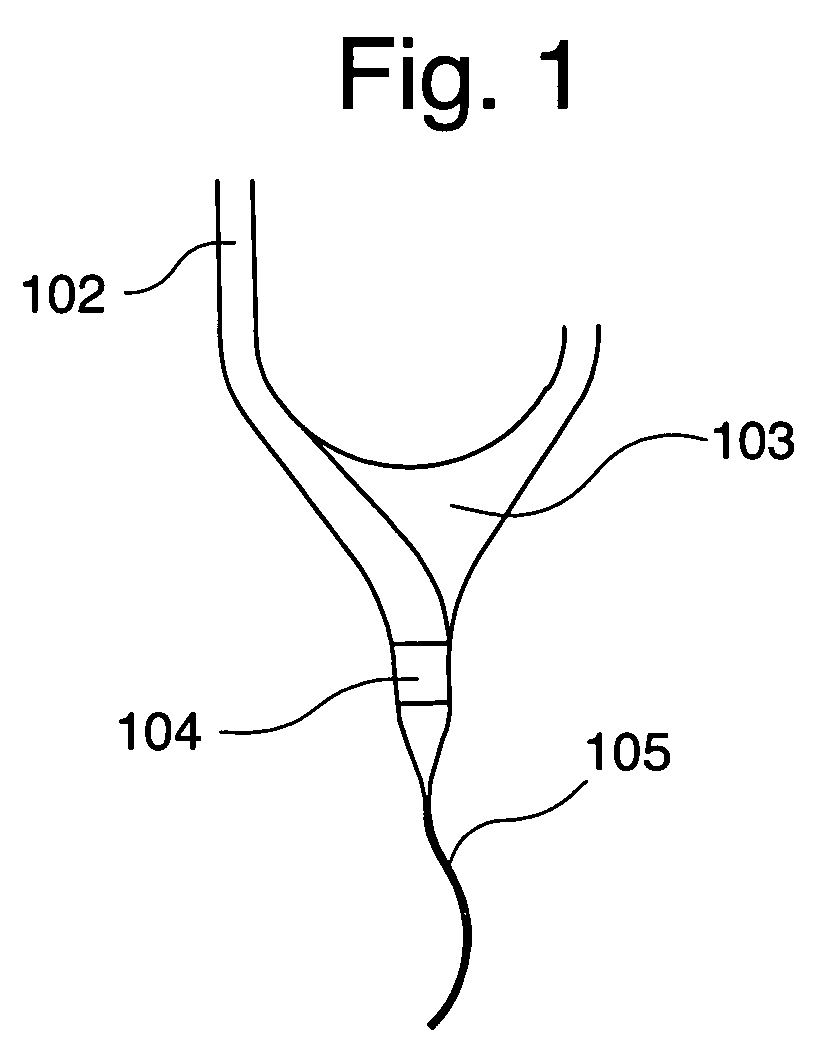

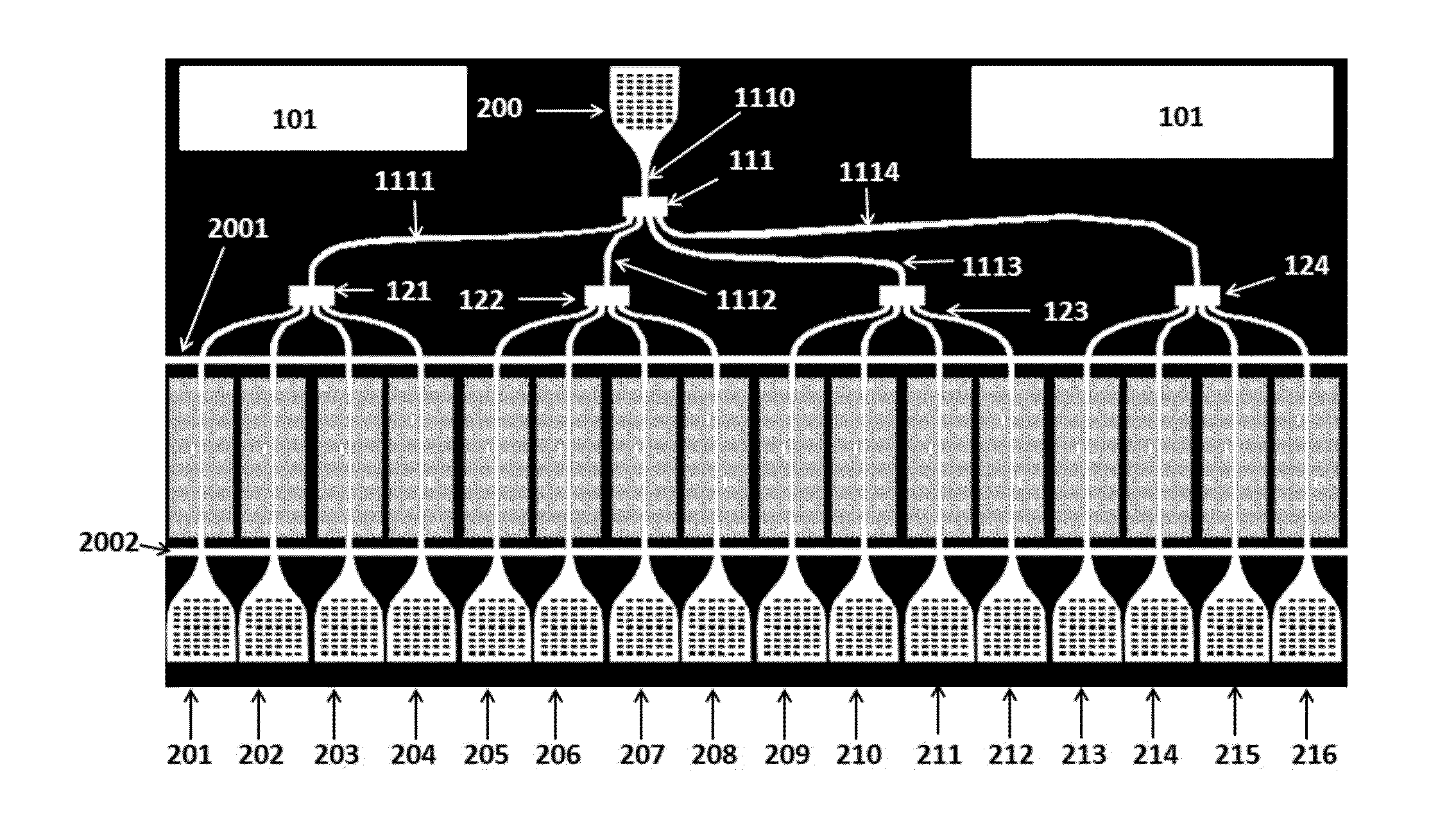

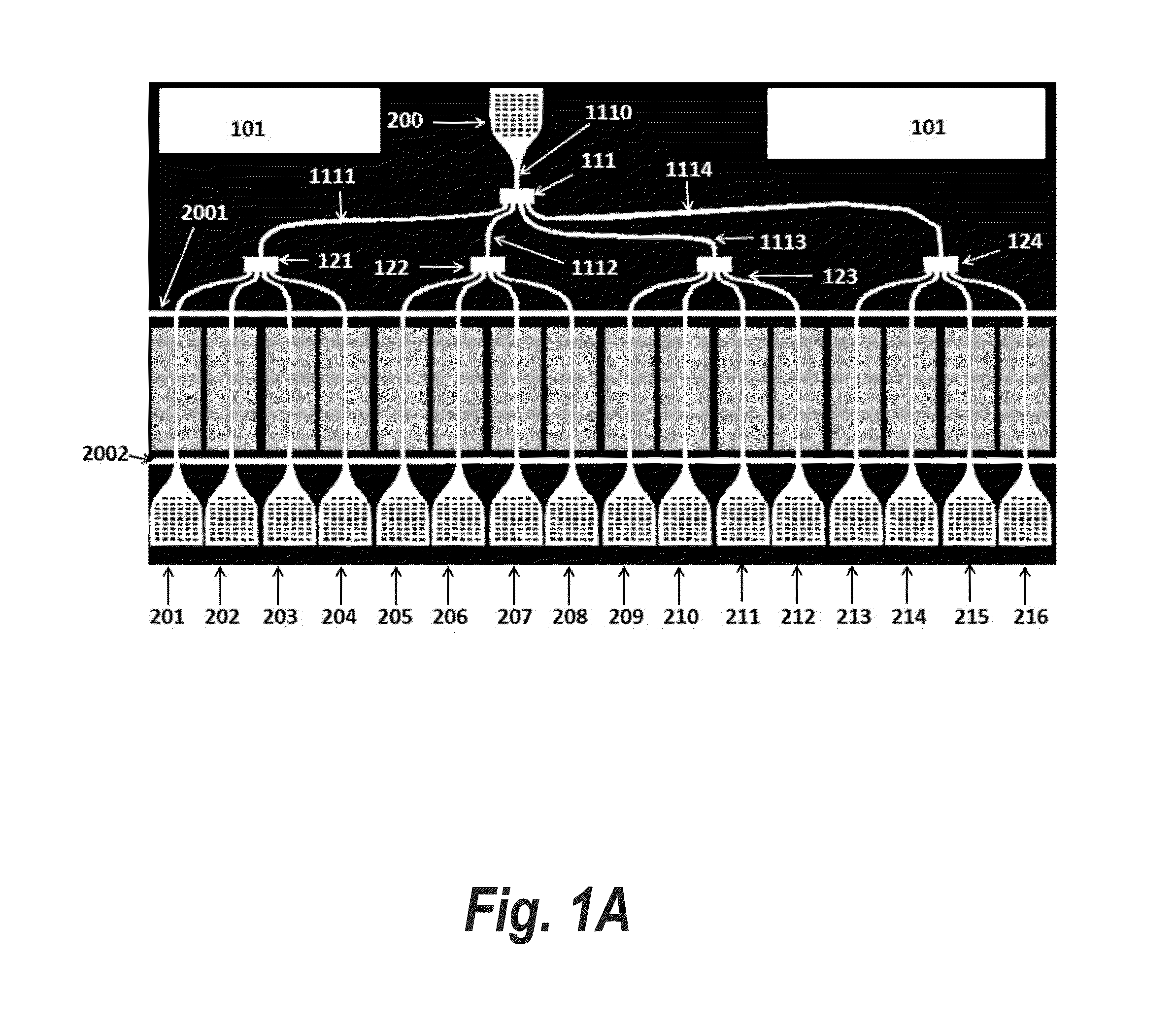

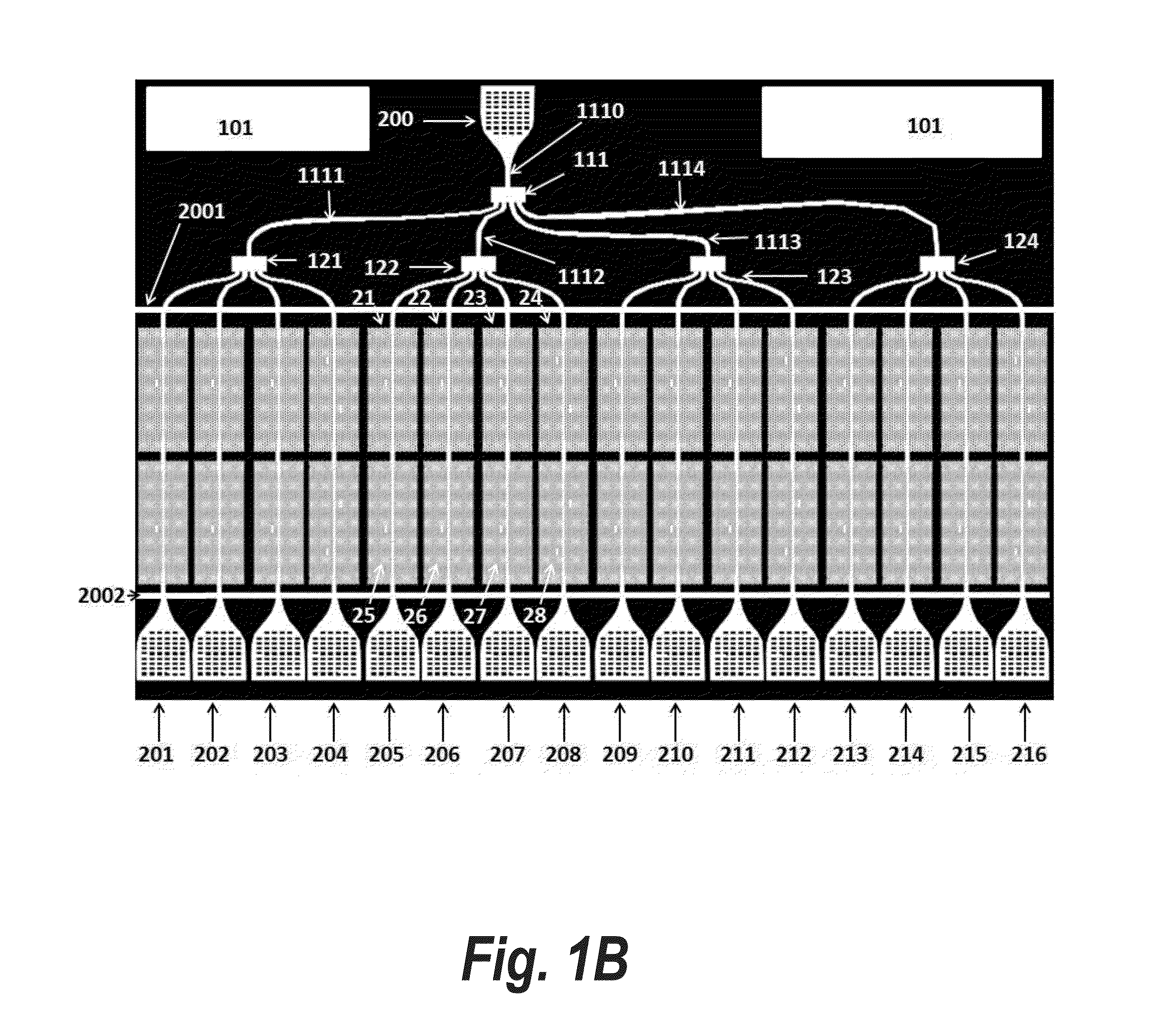

Functional unit enabling controlled flow in a microfluidic device

A microfluidic device which comprises two or more microchannel structures (set 1), each of which comprises a structural unit which comprises (i) one or more inlet microconduits, and (ii) an outlet microconduit downstream said one or more inlet microconduits, and (iii) a flow path for a liquid passing through either of said inlet microconduits and said outlet microconduit. The device is characterized in that each outlet microconduit in said two or more microchannel structures is a restriction microconduit. There may also be a microcavity between the inlet microconduit(s) and the restriction microconduit in each microchannel structure. Typically common flow control is used for driving a liquid flow within the device. The innovative design is useful for creating flow with low inter-channel variation with respect to the microchannel structures of the device.

Owner:GYROS

Stabilized OLED device

InactiveUS6905788B2Improved stability and performanceImprove efficiency and stabilityIncadescent screens/filtersDischarge tube luminescnet screensDopantDevice form

A stabilized OLED device for emitting light of a specific color includes a metallic anode and a metallic cathode spaced from the metallic anode. The device also includes a light-emitting layer including a host and a dopant, the dopant selected to produce light having a spectrum including light of the specific color, and a stabilizer provided in one of the device layers which improves the useful lifetime of the OLED device, wherein the stabilizer has an emission spectrum different from that of the light-emitting layer. One of the electrode layers is semitransparent and the other one is substantially opaque and reflective such that the stabilized OLED device forms a microcavity that emits a narrow band light with the specific color.

Owner:GLOBAL OLED TECH

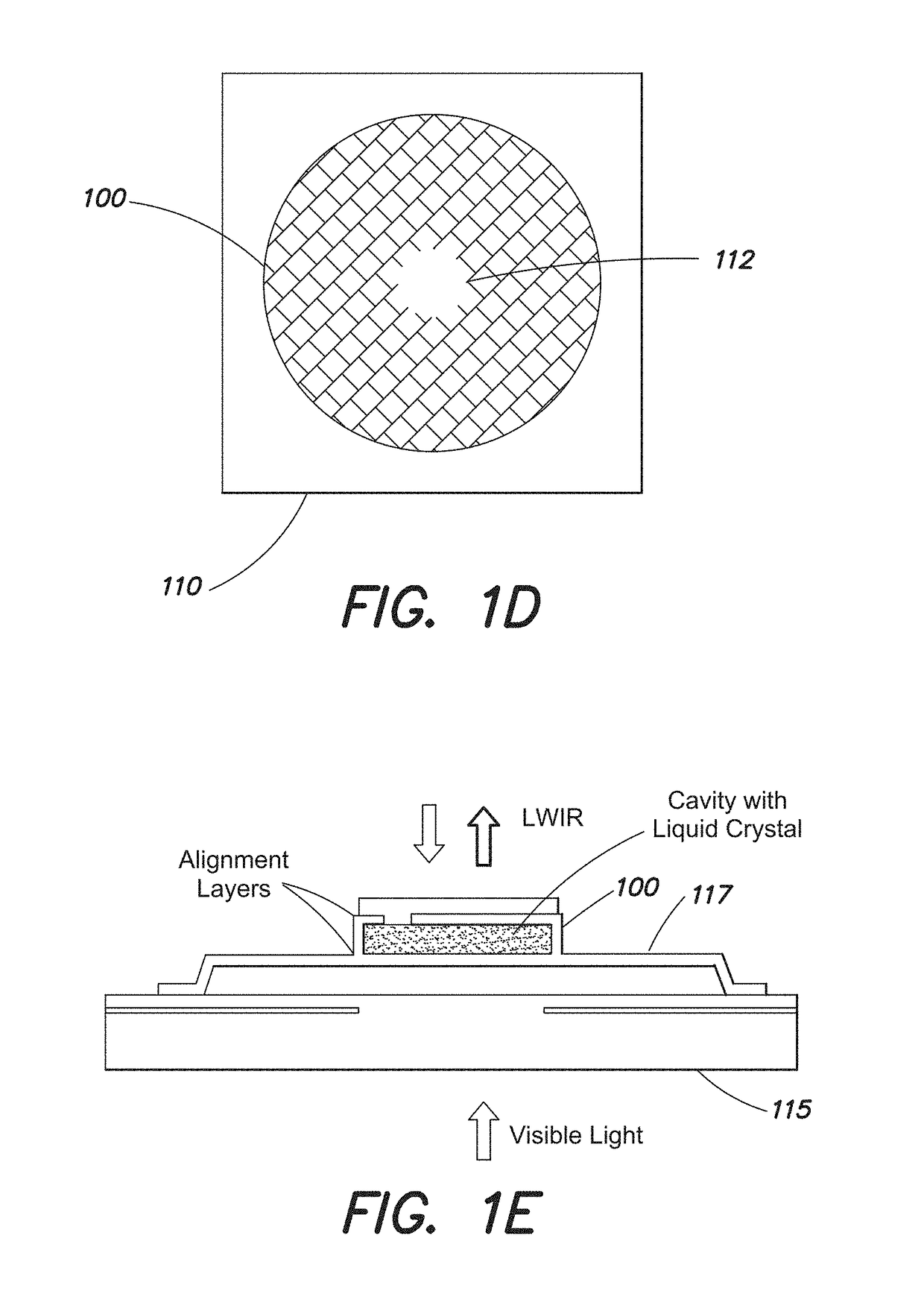

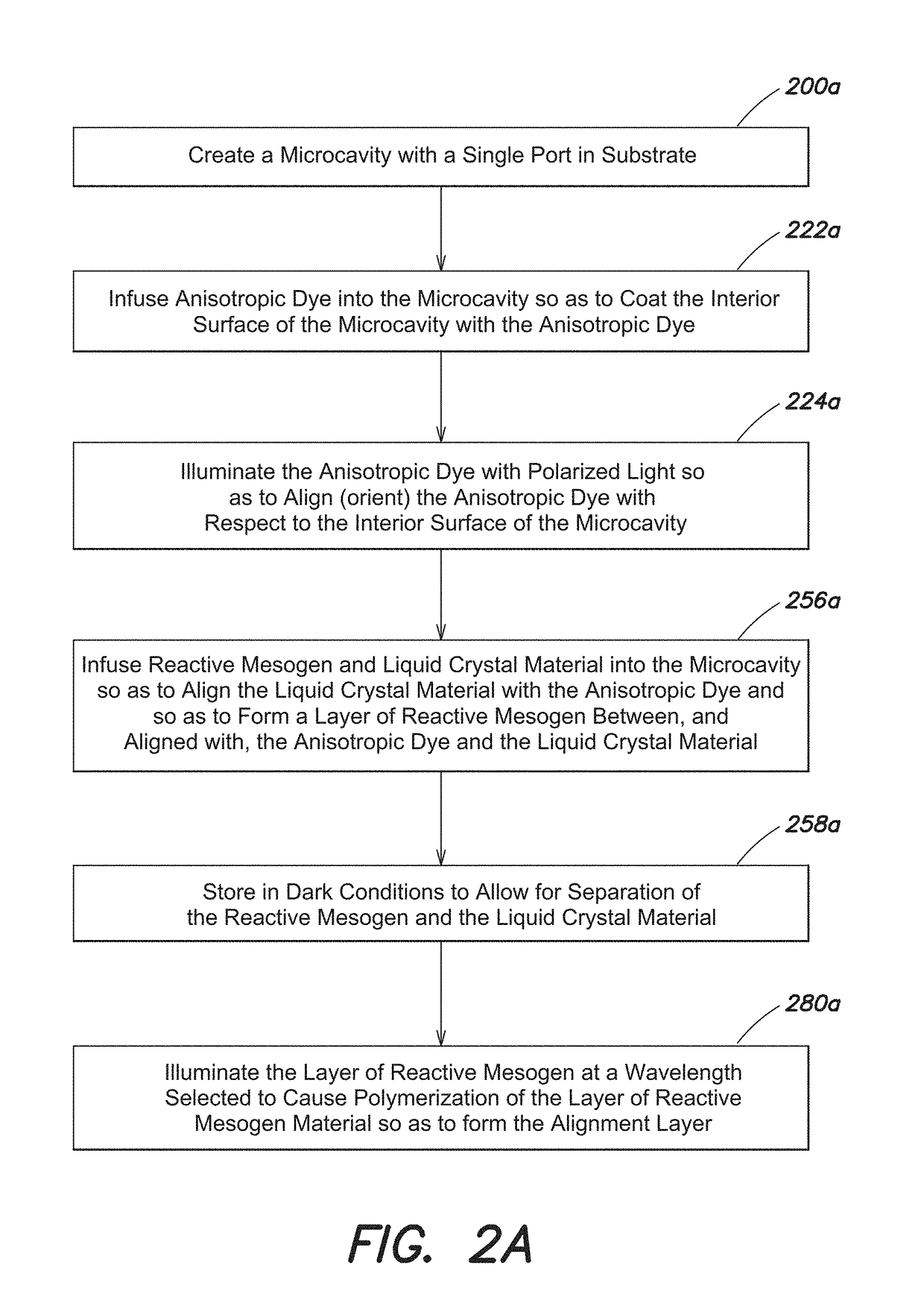

Methods and Apparatus for Liquid Crystal Photoalignment

ActiveUS20180364526A1Effective and stableLiquid crystal compositionsNon-linear opticsDye injectionPhotonics

Liquid crystal photonic devices and microcavities filled with liquid crystal materials are becoming increasingly popular. These devices often present a challenge when it comes to creating a robust alignment layer in pre-assembled cells. Previous research on photo-definable alignment layers has shown that they have limited stability, particularly against subsequent light exposure. A method of infusing a dye into a microcavity to produce an effective photo-definable alignment layer is described, along with a method of utilizing a pre-polymer infused into the microcavity mixed with the liquid crystal to provide photostability. In this method, the polymer layer, formed under optical irradiation of liquid crystal cells, is effectively localized to a thin region near the substrate surface and thus provides a significant improvement in the photostability of the liquid crystal alignment. This versatile alignment layer method, which can be used in microcavities to displays, offers significant promise for new photonics applications.

Owner:KENT STATE UNIV +1

OLED with color change media

ActiveUS7057339B2Reduce color distortionEfficient OLEDIncadescent screens/filtersDischarge tube luminescnet screensLength waveColor changes

A tuned OLED device includes a microcavity structure including a light-emitting layer for producing light, a semitransparent reflector, and a reflector layer disposed on opposite sides of the light-emitting layer, the microcavity structure enhancing on-axis light produced from the light-emitting layer in at least one particular wavelength to produce a desired on-axis viewed color while not substantially enhancing on-axis other wavelengths of such light; and a layer including a color change medium which is responsive to wavelengths of light shorter than the particular wavelength by absorbing such shorter wavelengths of light and emitting light corresponding in color to the particular wavelength, thereby improving the color of the light produced by the OLED device when viewed in an off-axis direction.

Owner:GLOBAL OLED TECH

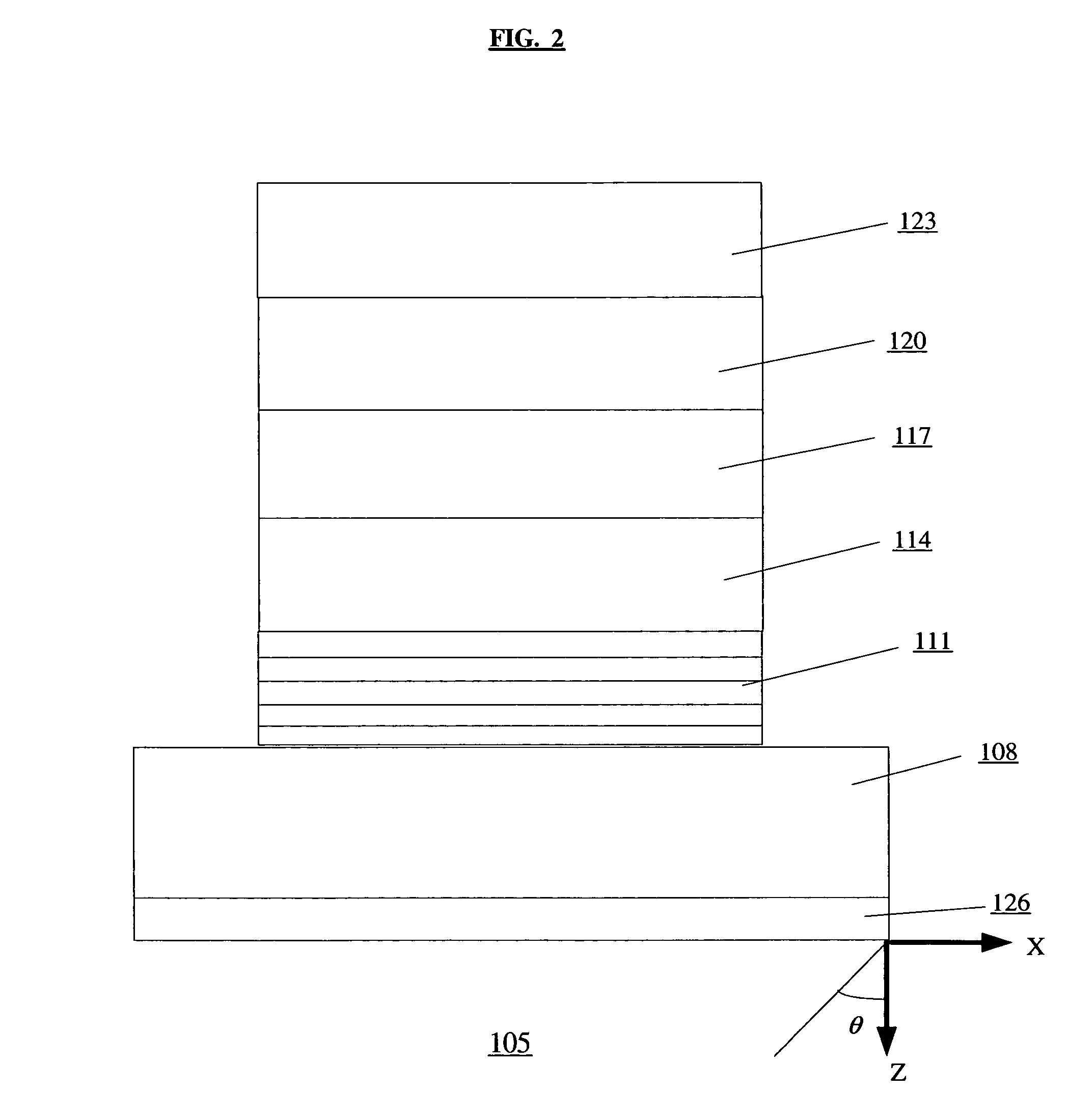

Packaged Chip For Multiplexing Photonic Crystal Microcavity Coupled Waveguide And Photonic Crystal Slot Waveguide Devices For Chip-Integrated Label-Free Detection And Absorption Spectroscopy With High Throughput, Sensitivity, Specificity, And Wide Dynamic Range

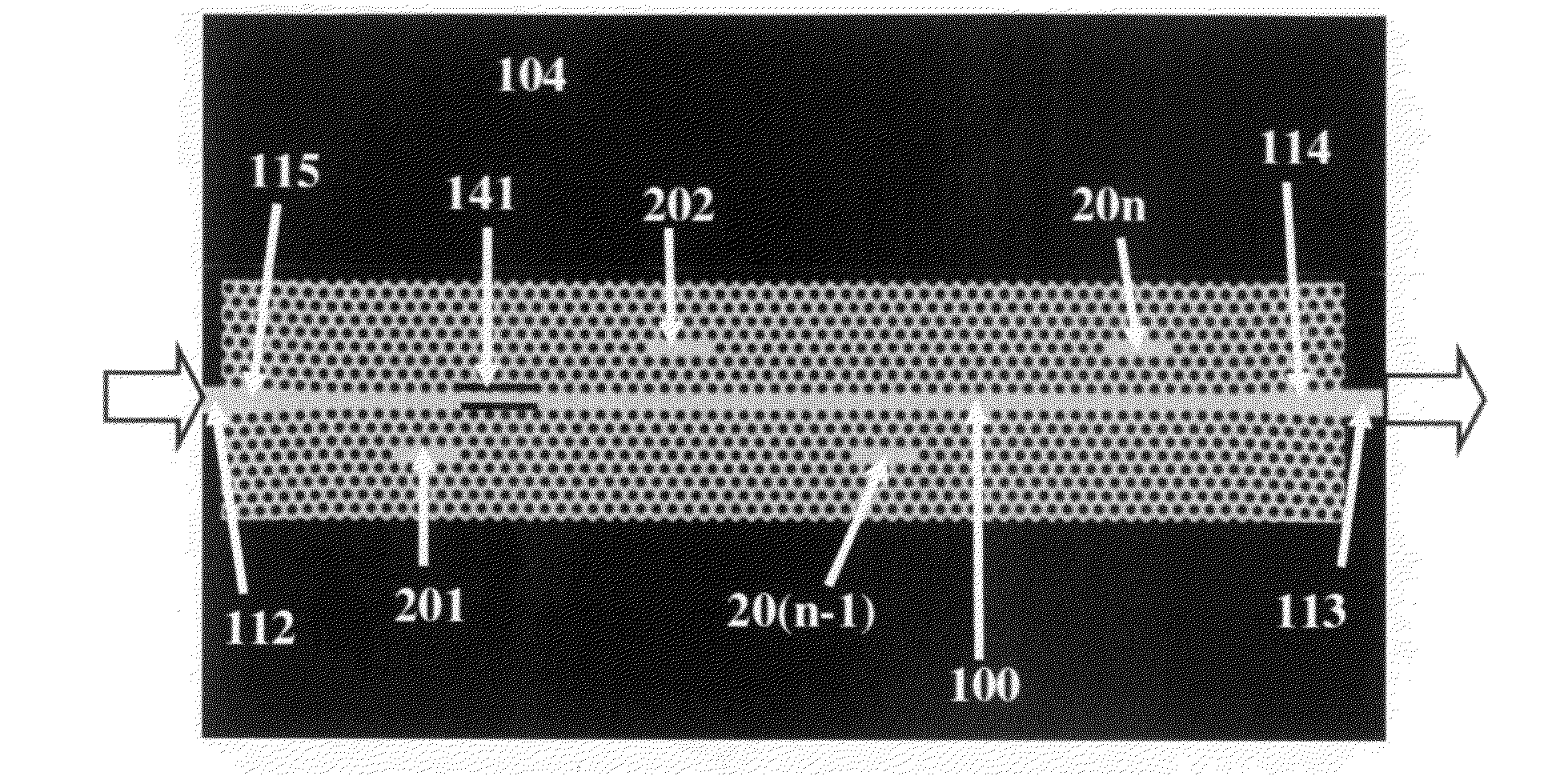

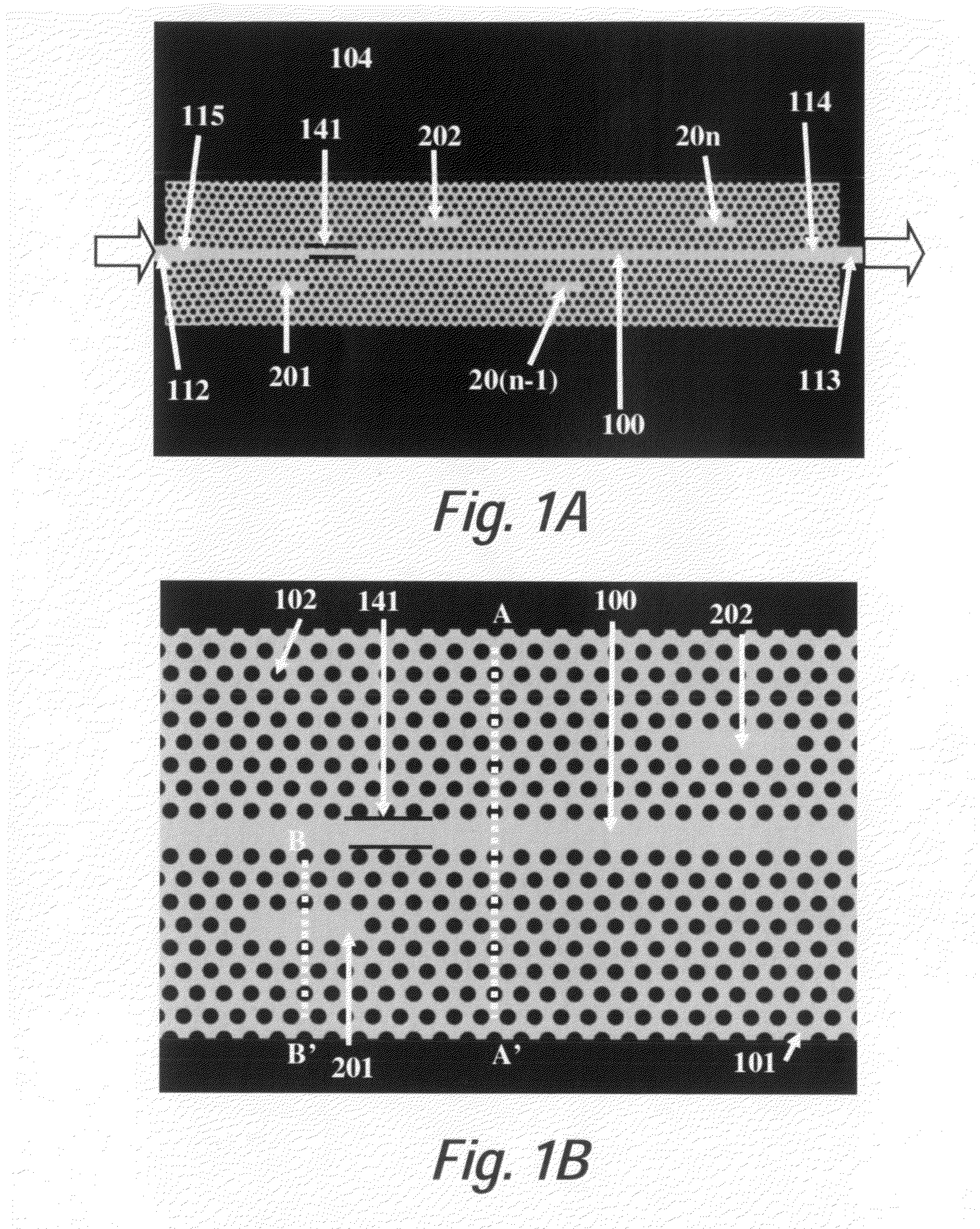

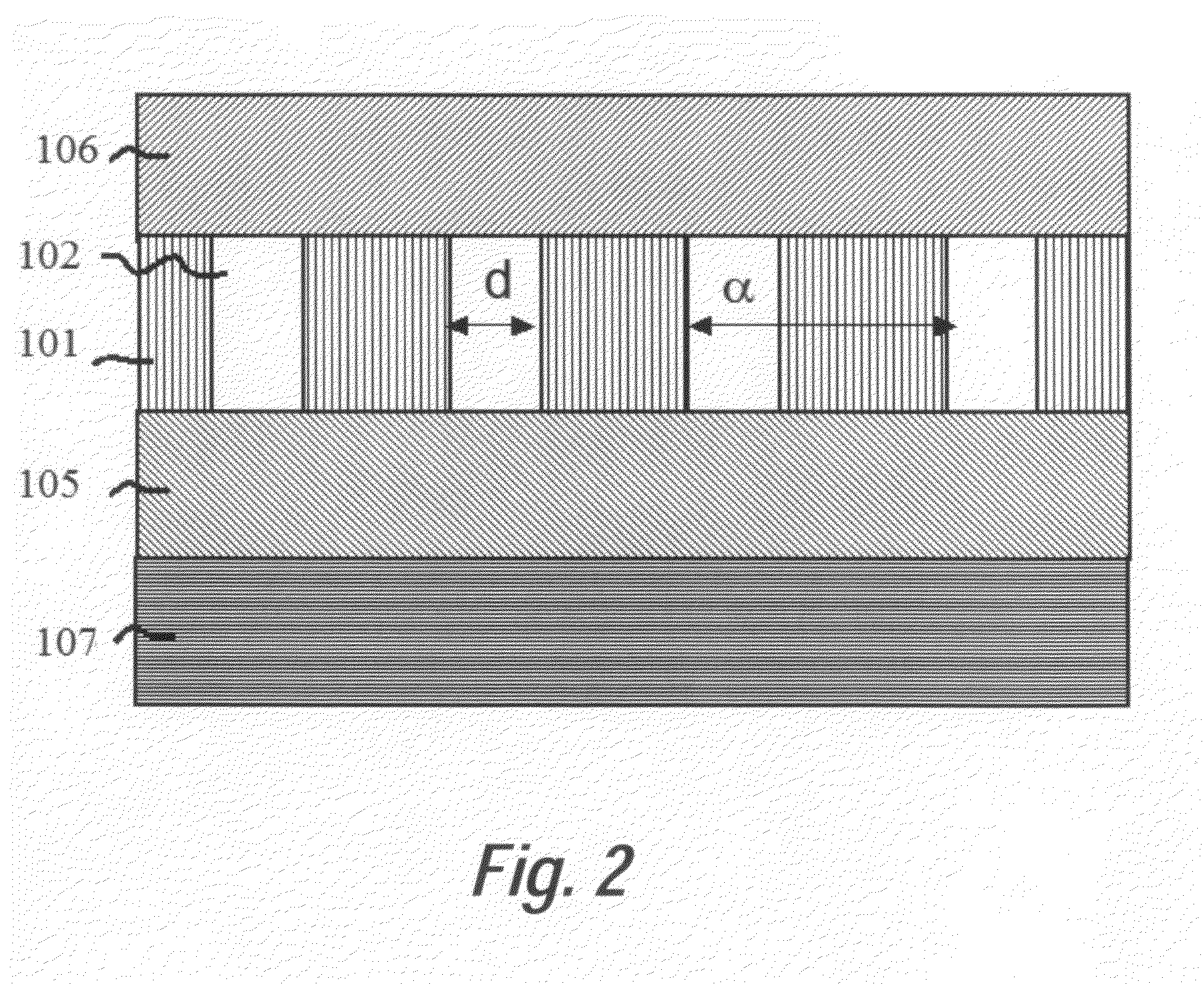

ActiveUS20140140655A1Specificity of bindingHigh sensitivityMaterial analysis by optical meansNanoopticsMicrofluidic channelWaveguide

Systems and methods for chip-integrated label-free detection and absorption spectroscopy with high throughput, sensitivity, and specificity are disclosed. The invention comprises packaged chips for multiplexing photonic crystal microcavity waveguide and photonic crystal slot waveguide devices. The packaged chips comprise crossing waveguides to prevent leakage of fluids from the microfluidic channels from the trenches or voids around the light guiding waveguides. Other embodiments are described and claimed.

Owner:OMEGA OPTICS

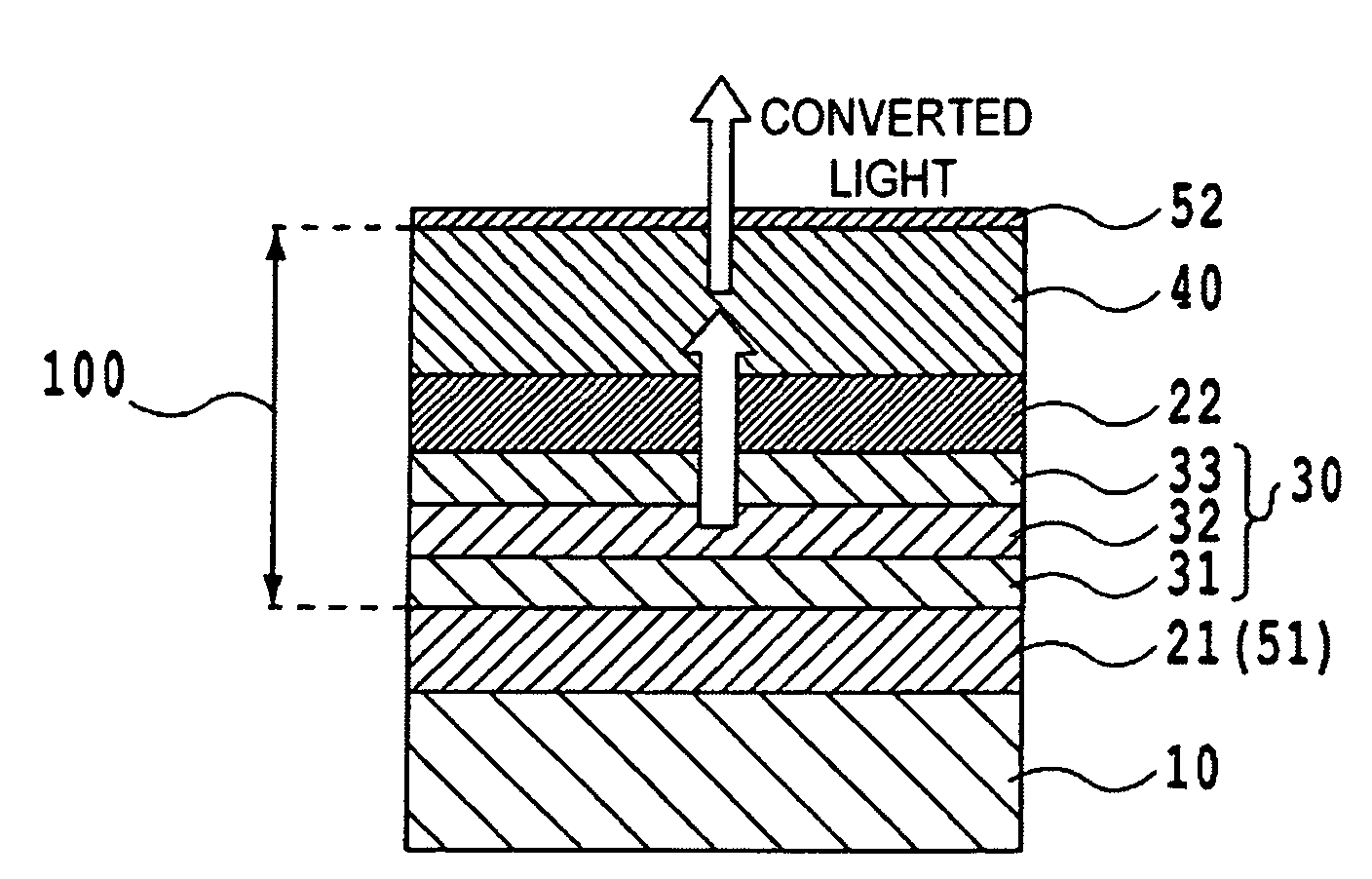

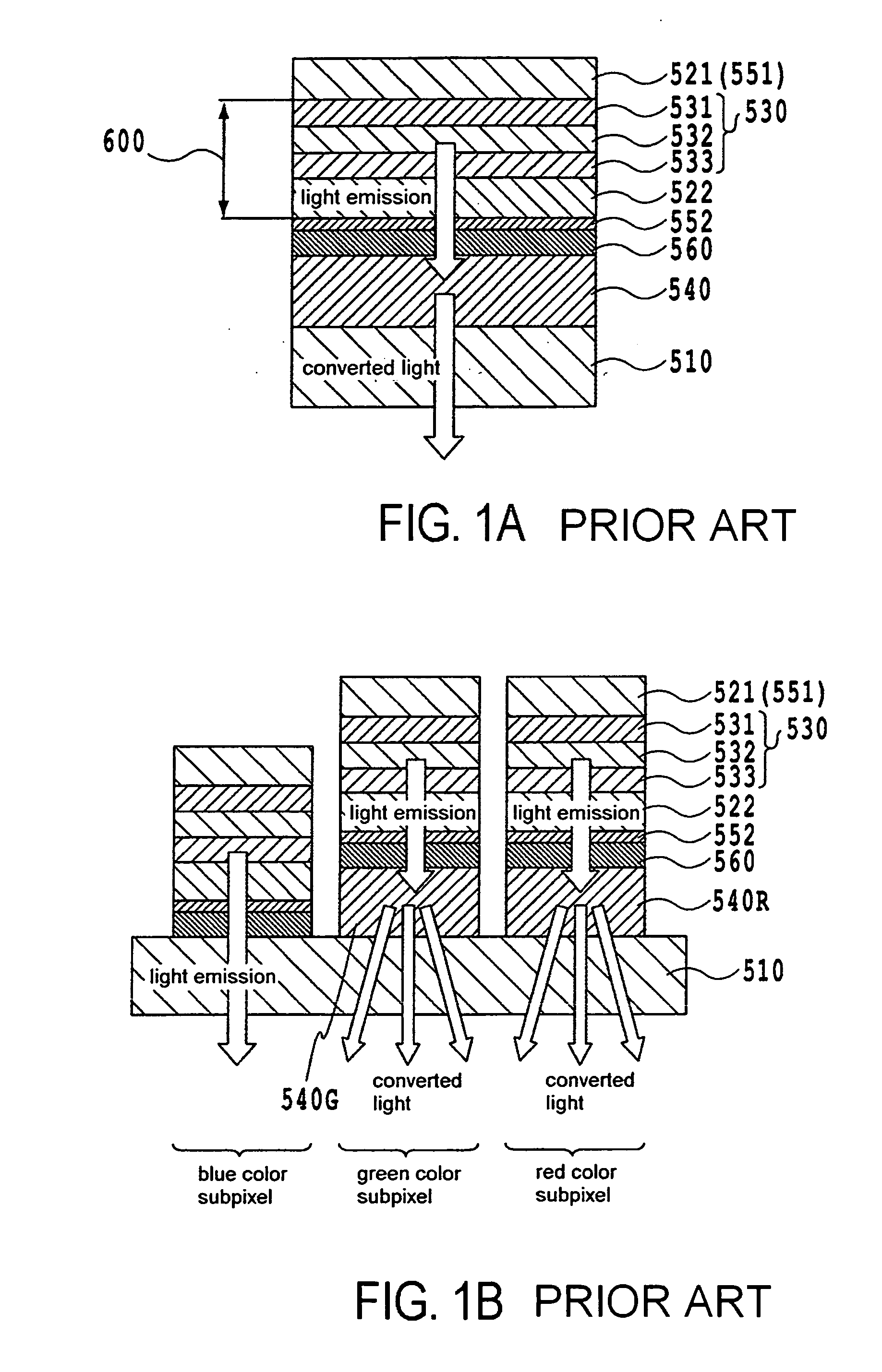

Resonant cavity color conversion el device and organic el display device using the same

ActiveUS20090212696A1Good colorSimple manufacturing methodDischarge tube luminescnet screensSemiconductor/solid-state device testing/measurementResonant cavityColor transformation

A resonant cavity color conversion EL element in which intensity of converted light from a color conversion layer is increased and an organic EL display device in which viewing angle dependence of the color tone is small and the manufacturing process is simple. The EL element includes at least a pair of electrodes; a functional layer includes a light-emitting layer and is sandwiched by the pair of electrodes; a color conversion layer that absorbs light emitted from the light-emitting layer and emits light with a different wavelength; and a pair of light reflective layers. Notably, the pair of light reflective layers are composed of a non-transparent reflective layer and a semi-transparent reflective layer that have a distance therebetween that is set at an optical distance to construct a microcavity that increases intensity of light with a specific wavelength emitted from the color conversion layer.

Owner:GLOBAL OLED TECH

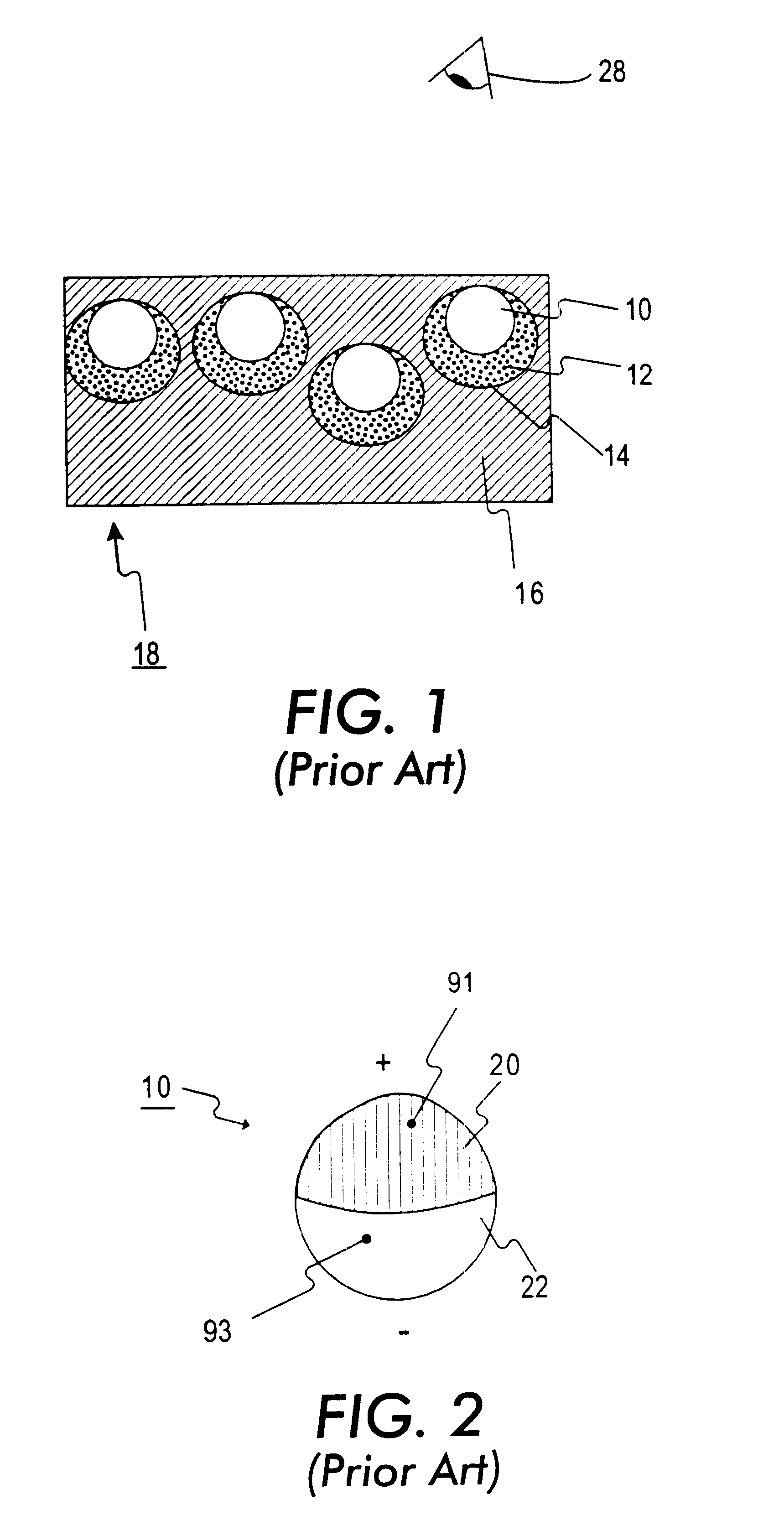

Rotating element sheet material with generalized containment structure

The present invention relates to rotating element sheet material with a generalized containment structure and methods of fabricating such rotating element sheet material, where the rotating element sheet material comprises a fibrous matrix, a plurality of rotatable elements, and an enabling fluid, and where the plurality of rotatable elements are disposed within the fibrous matrix and are in contact with the enabling fluid. In addition, rotating element sheet material with a generalized containment structure, and methods of fabricating such rotating element sheet material, includes rotating element sheet material which comprises a fibrous matrix and a plurality of micro-capsules, and where the micro-capsules define a hollow space therein, and the hollow space contains a subset of a plurality of rotatable elements and an enabling fluid, and where the plurality of micro-cavities are disposed within the fibrous matrix.

Owner:E INK CORPORATION

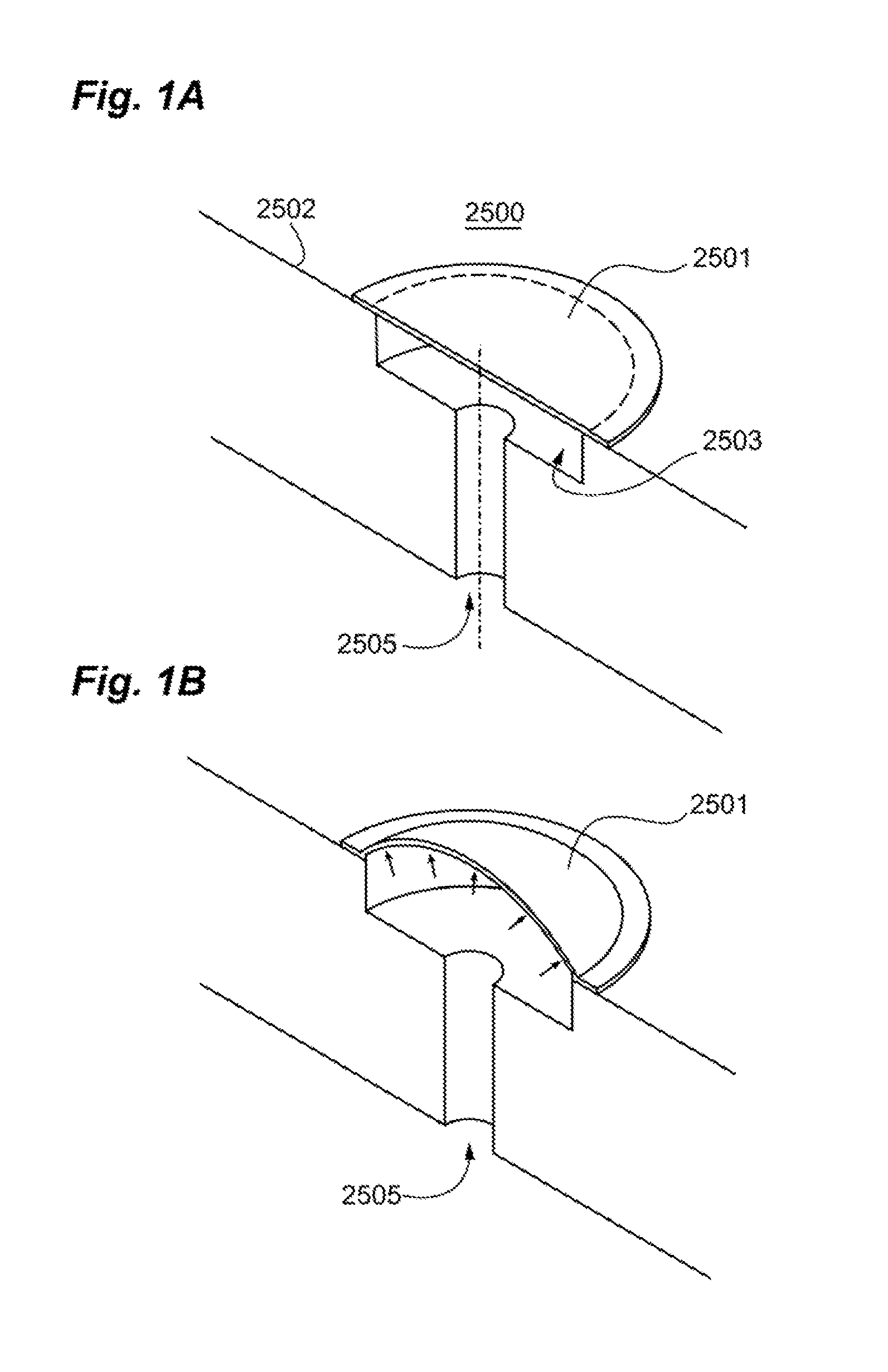

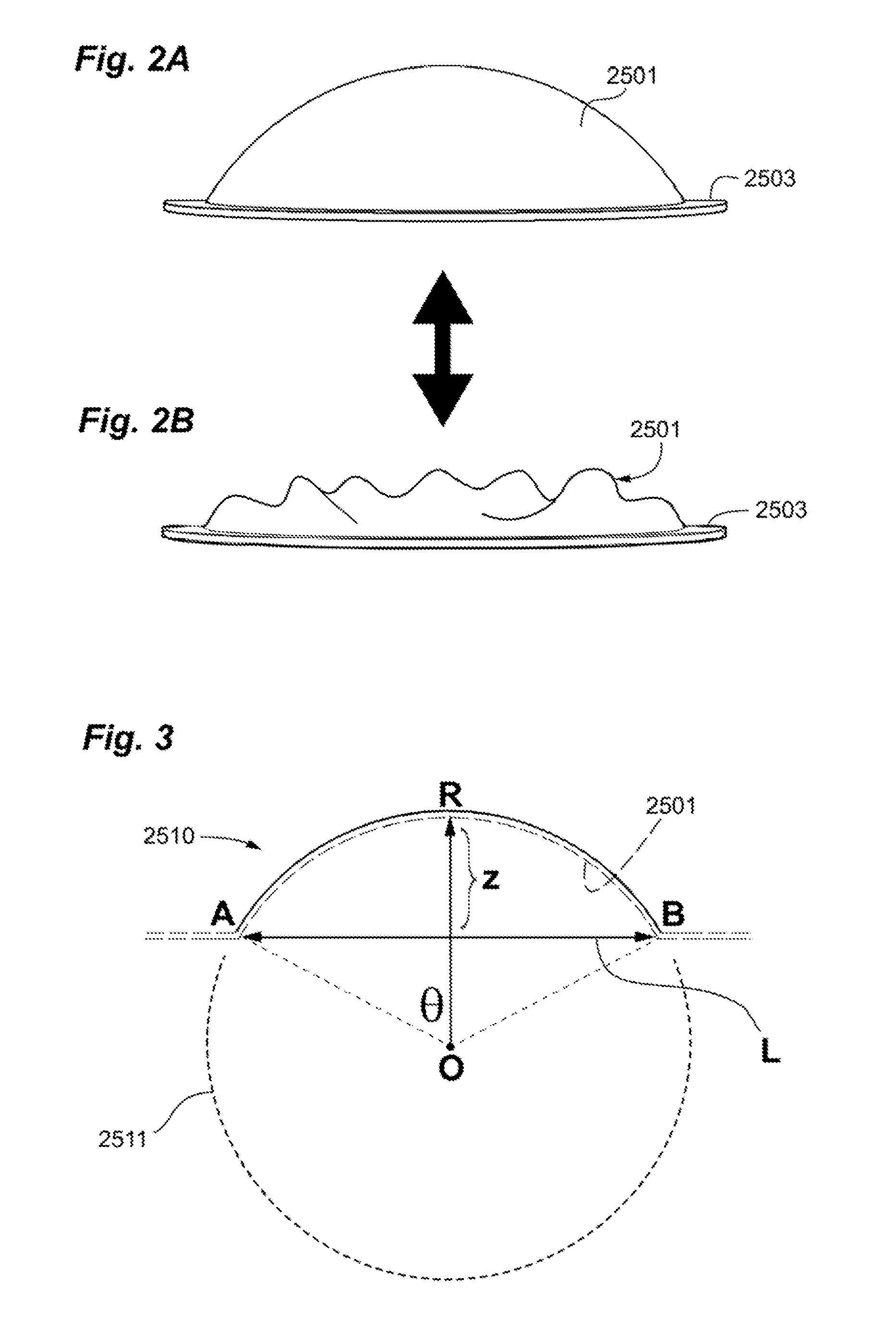

Low elasticity films for microfluidic use

ActiveUS20150321193A1Improve efficiencyIncrease speedValve arrangementsFlexible member pumpsMicro assayThin membrane

Microfluidic circuit elements, such as a microvalve, micropump or microvent, formed of a microcavity divided by a diaphragm web into a first subcavity bounded by a first internal wall and a second subcavity bounded by a second internal wall, where the diaphragm web is characterized as a thin film having a first state contacting the first internal wall and a second state contacting the second internal wall and exhibiting essentially no elasticity in moving between the first state and the second state, the thin film web having been stretched beyond its yield point before or during use are provided. The disclosed elements enable faster and more efficient cycling of the diaphragm in the microcavity and increases the diaphragm surface area. In a preferred embodiment, the microfluidic circuit element is pneumatically driven and controls the motion of fluids in a microassay device.

Owner:PERKINELMER HEALTH SCIENCES INC

Photonic crystal microarray device for label-free multiple analyte sensing, biosensing and diagnostic assay chips

ActiveUS20110028346A1Increase measurement throughputHigh sensitivityLibrary screeningMaterial analysis by optical meansMultiple speciesThroughput

Methods and systems for label-free multiple analyte sensing, biosensing and diagnostic assay chips consisting of an array of photonic crystal microcavities along a single photonic crystal waveguide are disclosed. The invention comprises an on-chip integrated microarray device that enables detection and identification of multiple species to be performed simultaneously using optical techniques leading to a high throughput device for chemical sensing, biosensing and medical diagnostics. Other embodiments are described and claimed.

Owner:OMEGA OPTICS

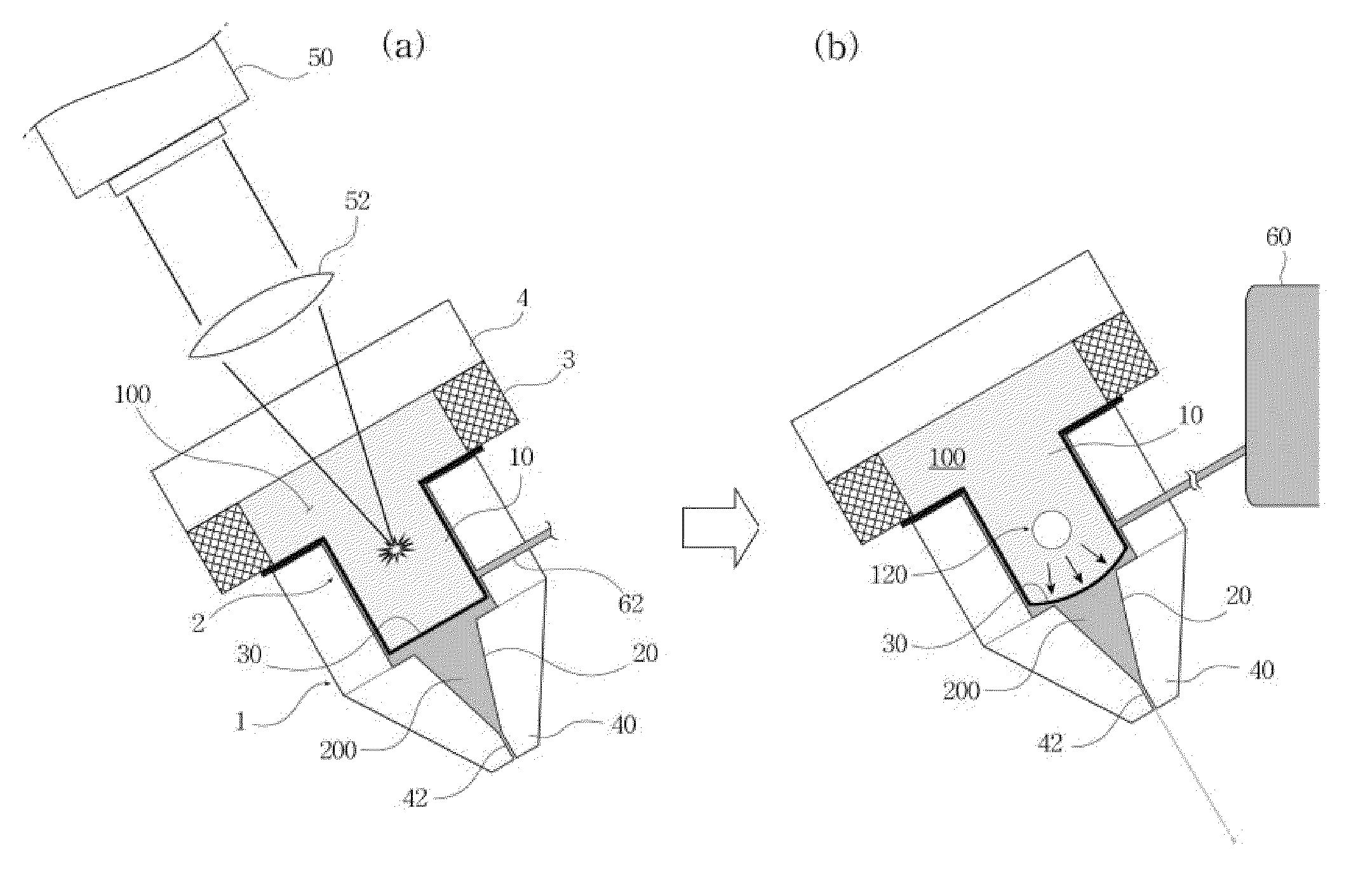

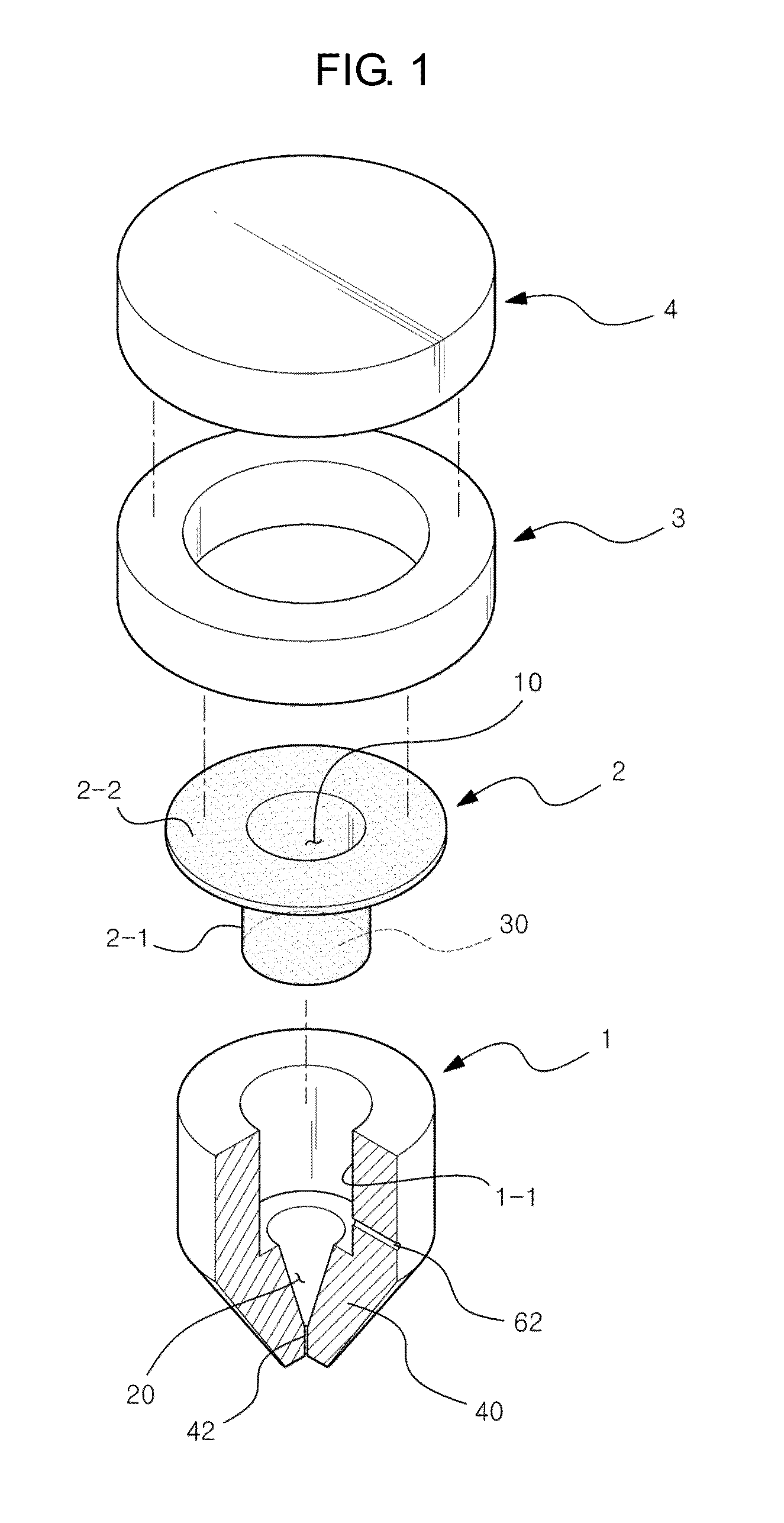

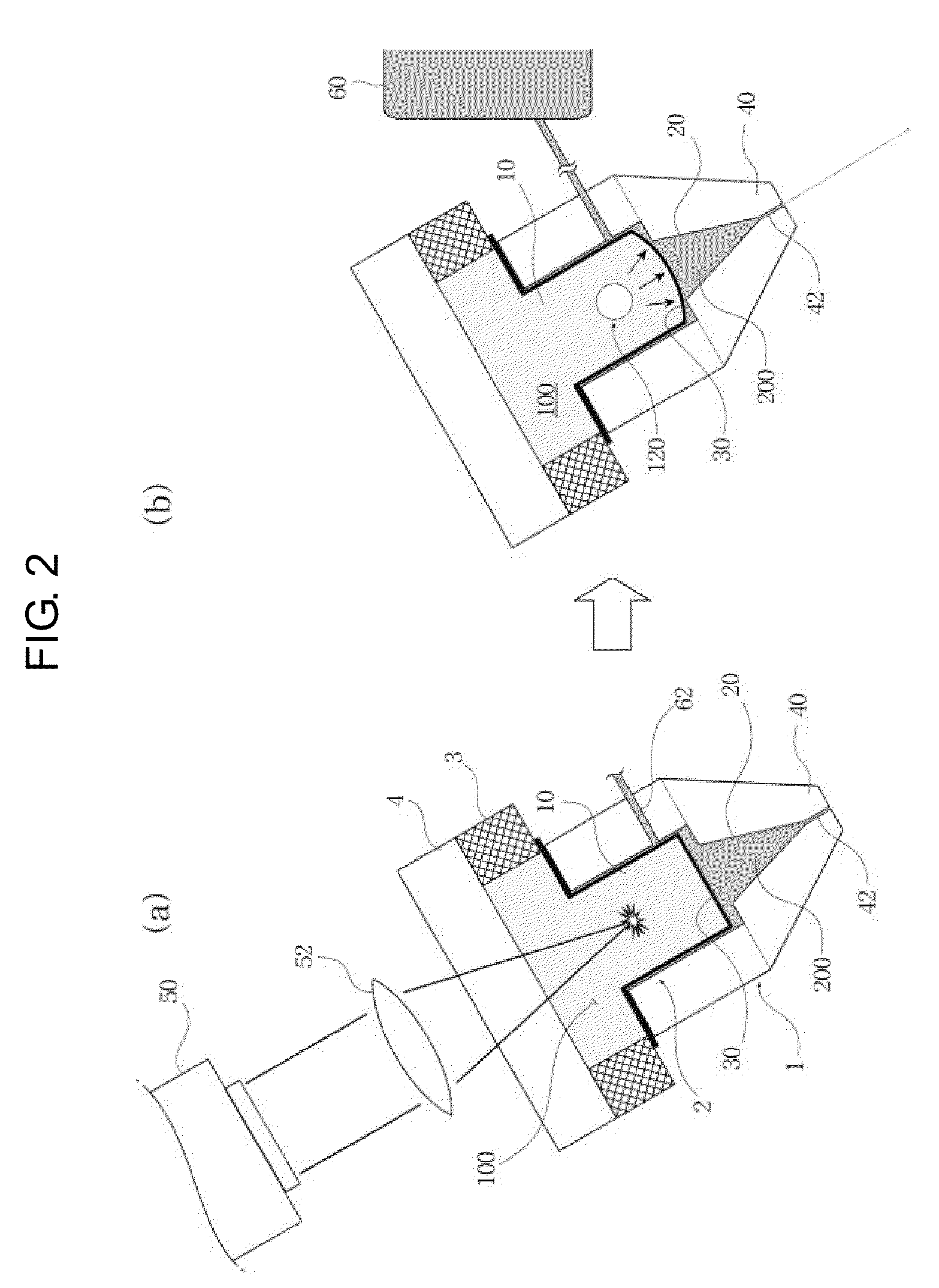

Microjet drug delivery system

ActiveUS20110230826A1Relieve painReusable and very advantageous in a hygienic aspectJet injection syringesMedical devicesNeedle freeDrugs solution

The present invention relates to a novel type of a needle-free drug delivery system in which strong energy such as a laser beam is focused inside liquid contained in a sealed pressure chamber to cause bubble growth and the volume expansion in the sealed pressure chamber due to the bubble growth so as to elongate an elastic membrane, so that an instantaneous pressure is applied to a drug solution contained in a drug microchamber adjacent to the elastic membrane to allow the drug solution to be injected in the form of a liquid microjet, thereby enabling the drug solution to rapidly and accurately penetrate into the bodily tissues of the patient.

Owner:BAZ BIOMEDIC CO LTD

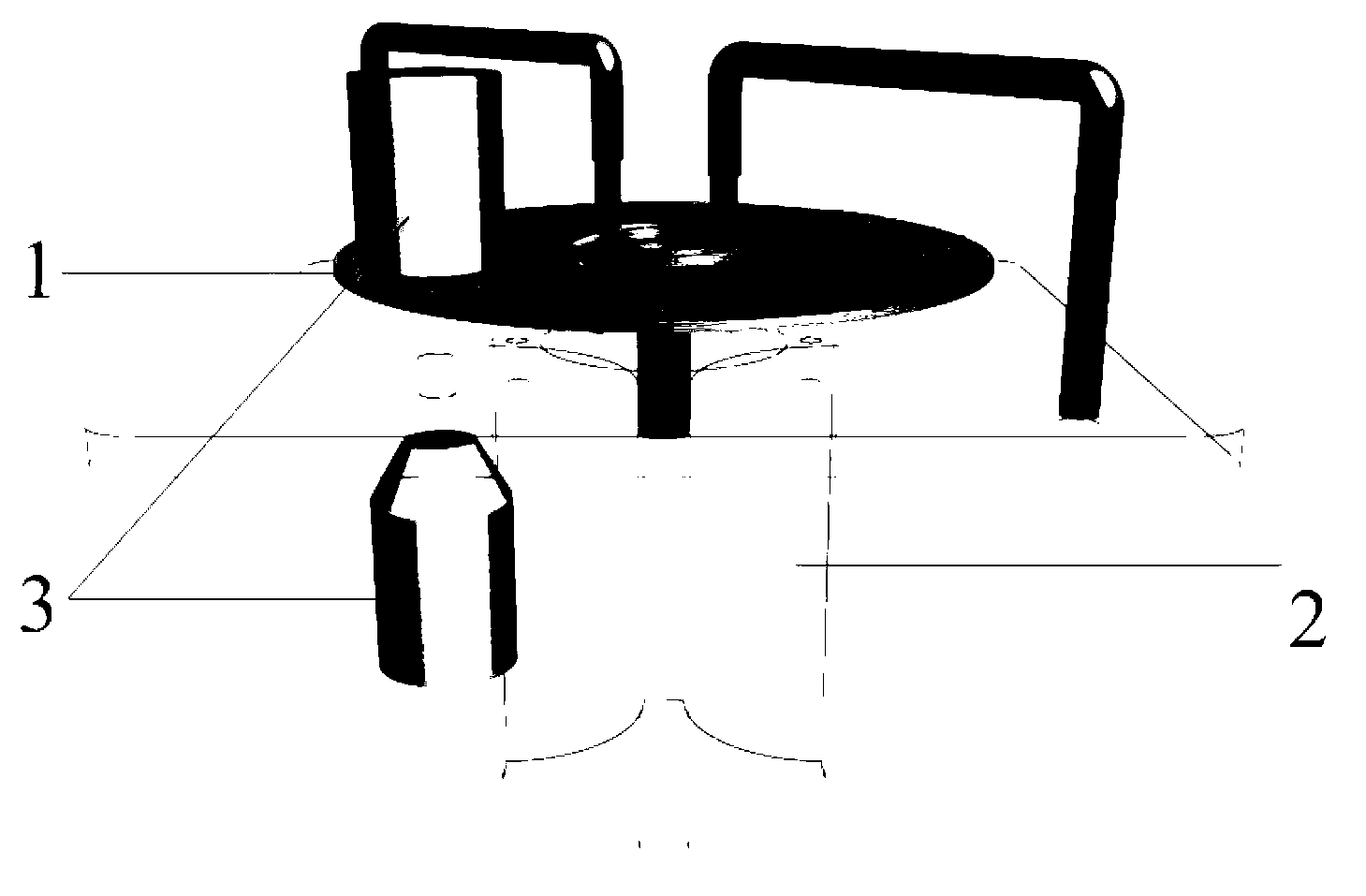

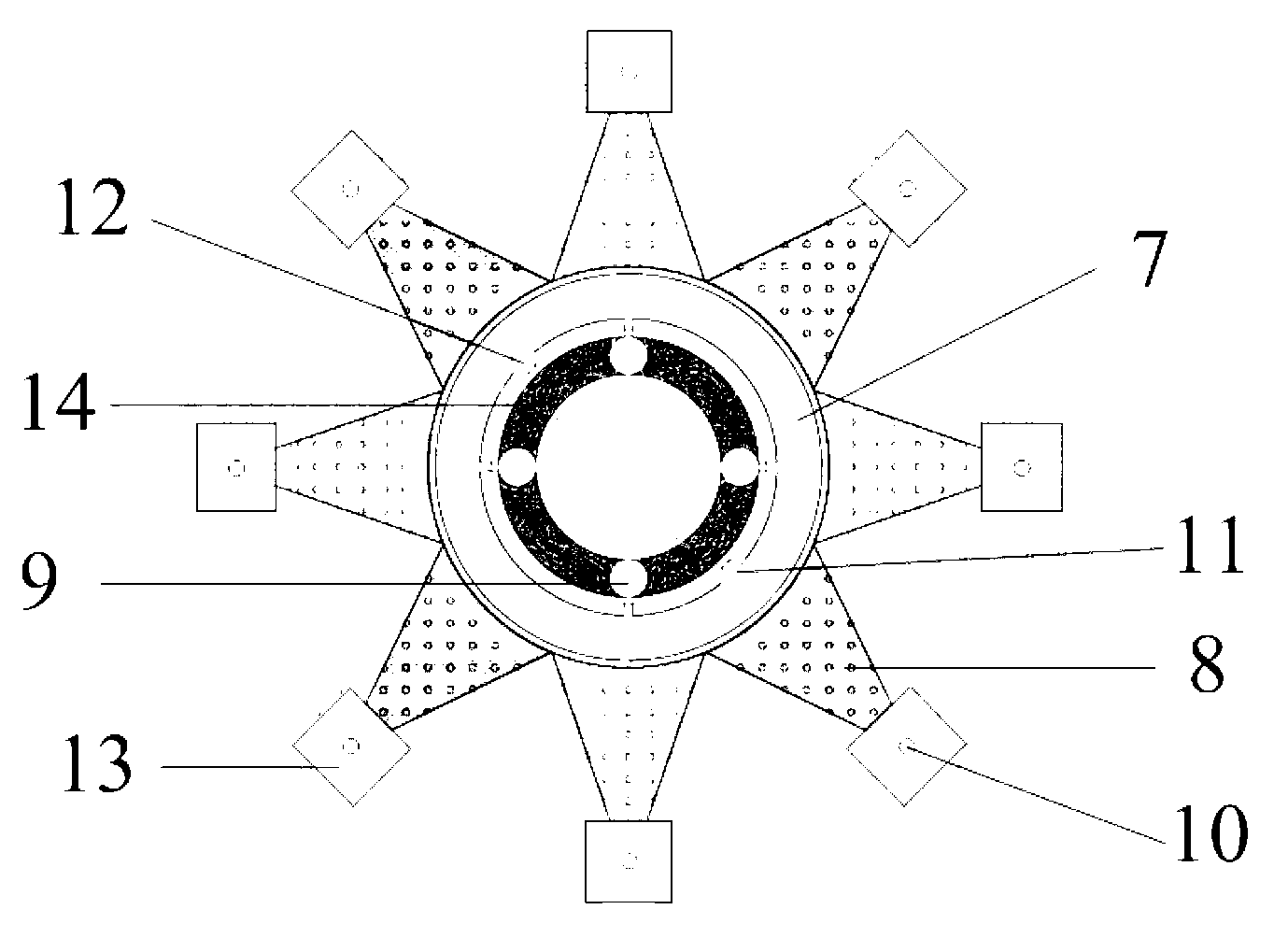

Separate detection system and method of rare cells based on centrifugal micro-fluidic technology

ActiveCN103018224ARealize in-situ automatic detectionAvoid lostPreparing sample for investigationBiological testingLiquid wasteLow speed

The invention discloses a separate detection system and method of rare cells based on a centrifugal micro-fluidic technology. The system comprises a micro-fluidic chip similar to an optical disk, a centrifugal drive module and an optical detection module, wherein the micro-fluidic chip comprises a plurality of groups of micro-channels and micro-cavities arranged in a radiation manner; and the entire chip structure is composed of an elastic micro-column guide rail layer, a deformable film layer, a pipeline / cavity layer, a filtering membrane layer and a liquid waste collecting layer. The method comprises the steps of: firstly, leading a sample solution and immune modified microspheres into a liquid storage cavity through an injection port of the micro-fluidic chip in use, putting the sample solution and the immune modified microspheres on a centrifugal platform of the centrifugal drive module, assembling an elastic micro-column, and rotating at a low speed, so as to achieve fully mixing and reacting of the sample solution and immune modified microsphere liquid in the liquid storage cavity, separating by a high-speed rotary chip, and then dropwise adding a specifically recognized fluorescently-labeled antibody solution in each separate cell collection area, carrying out incubate reaction, adding a buffer solution and centrifuging, and finally identifying and analyzing through the optical detection module.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com