Patents

Literature

38 results about "Dye injection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dye Injection: Dye can be used to mark and visualize particular regions of flow or individual fluid streamlines. To mark streamlines adjacent to a test body, dye is injected from small ports on the surface of the object.

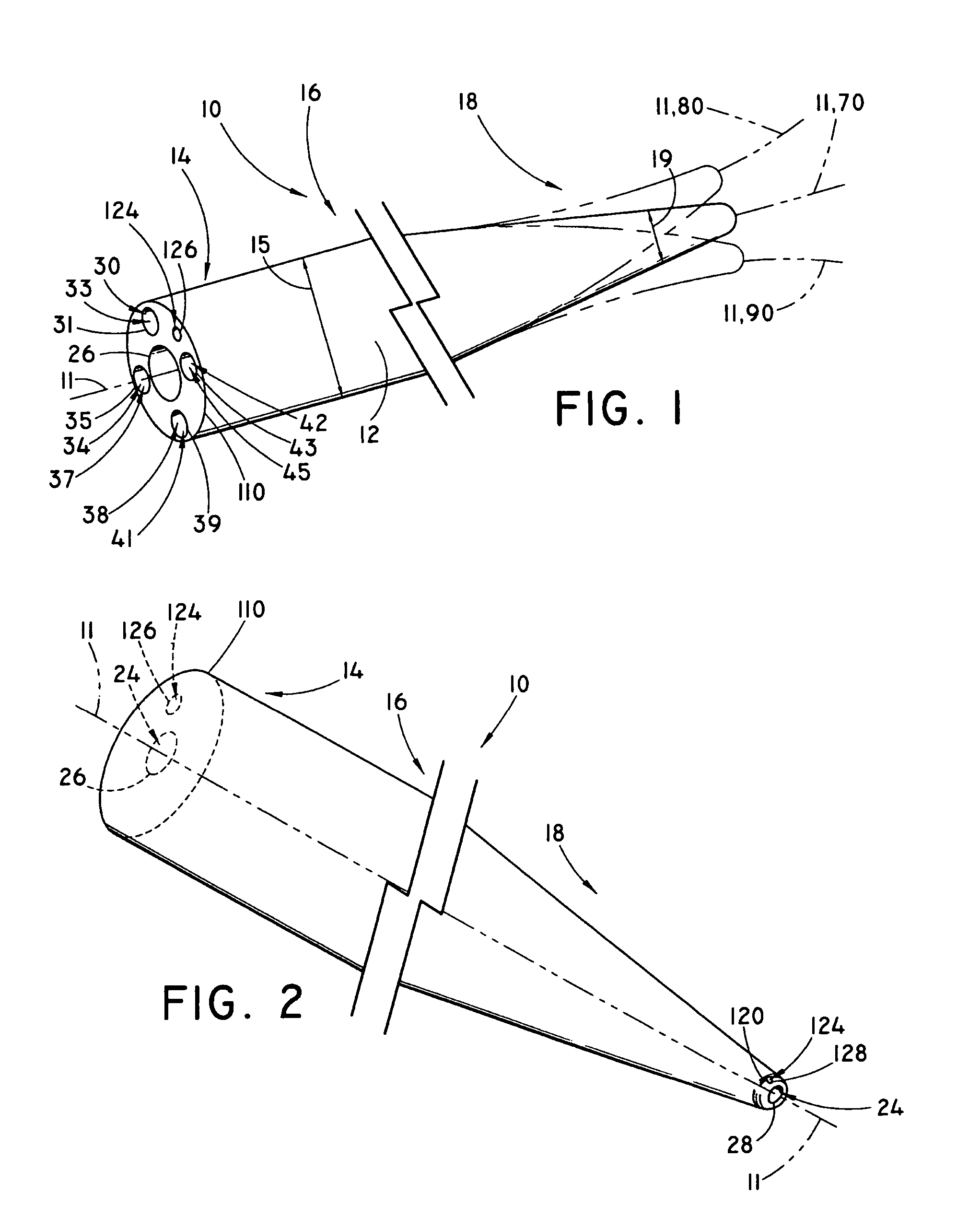

Steerable catheter devices and methods of articulating catheter devices

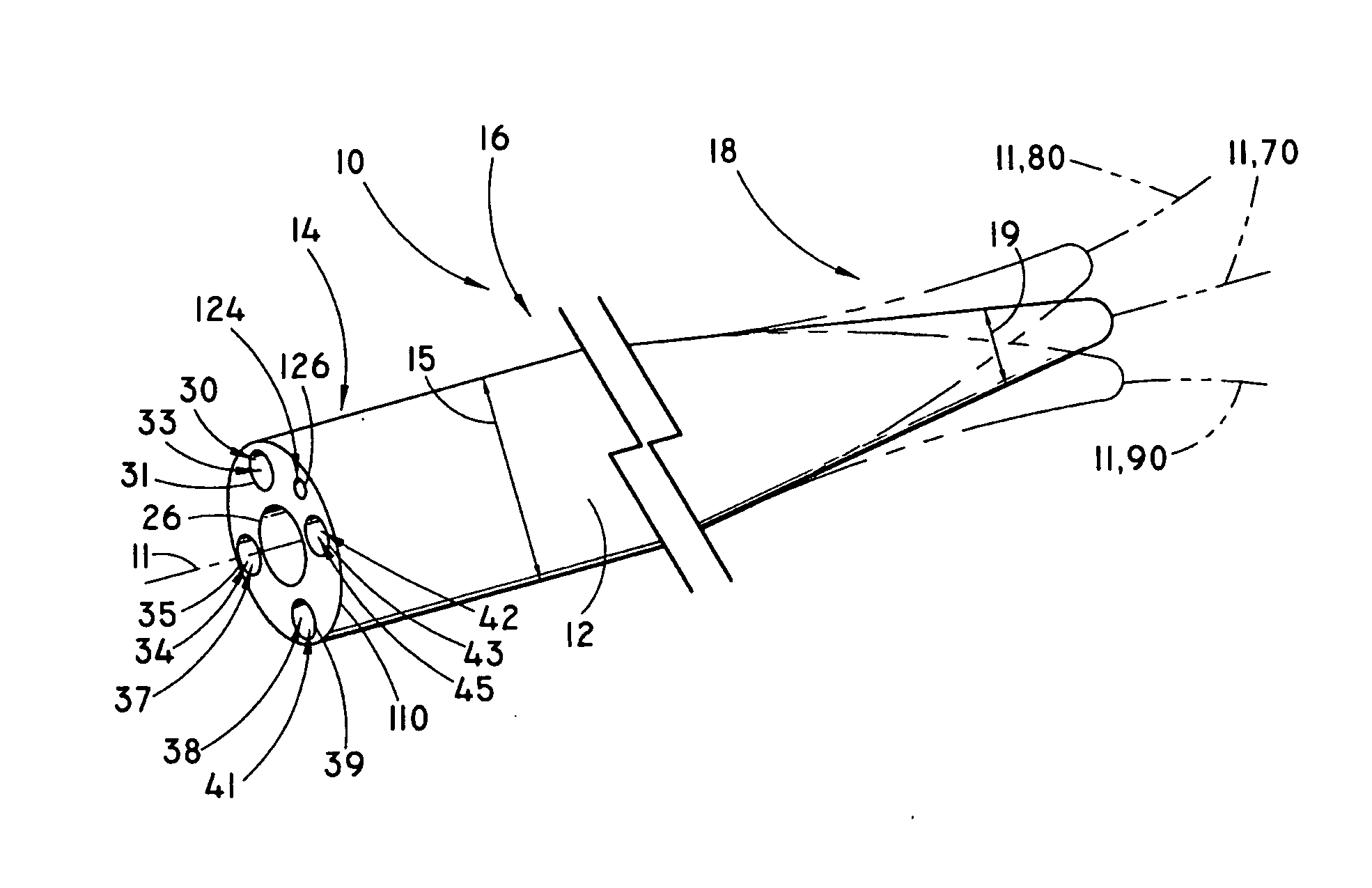

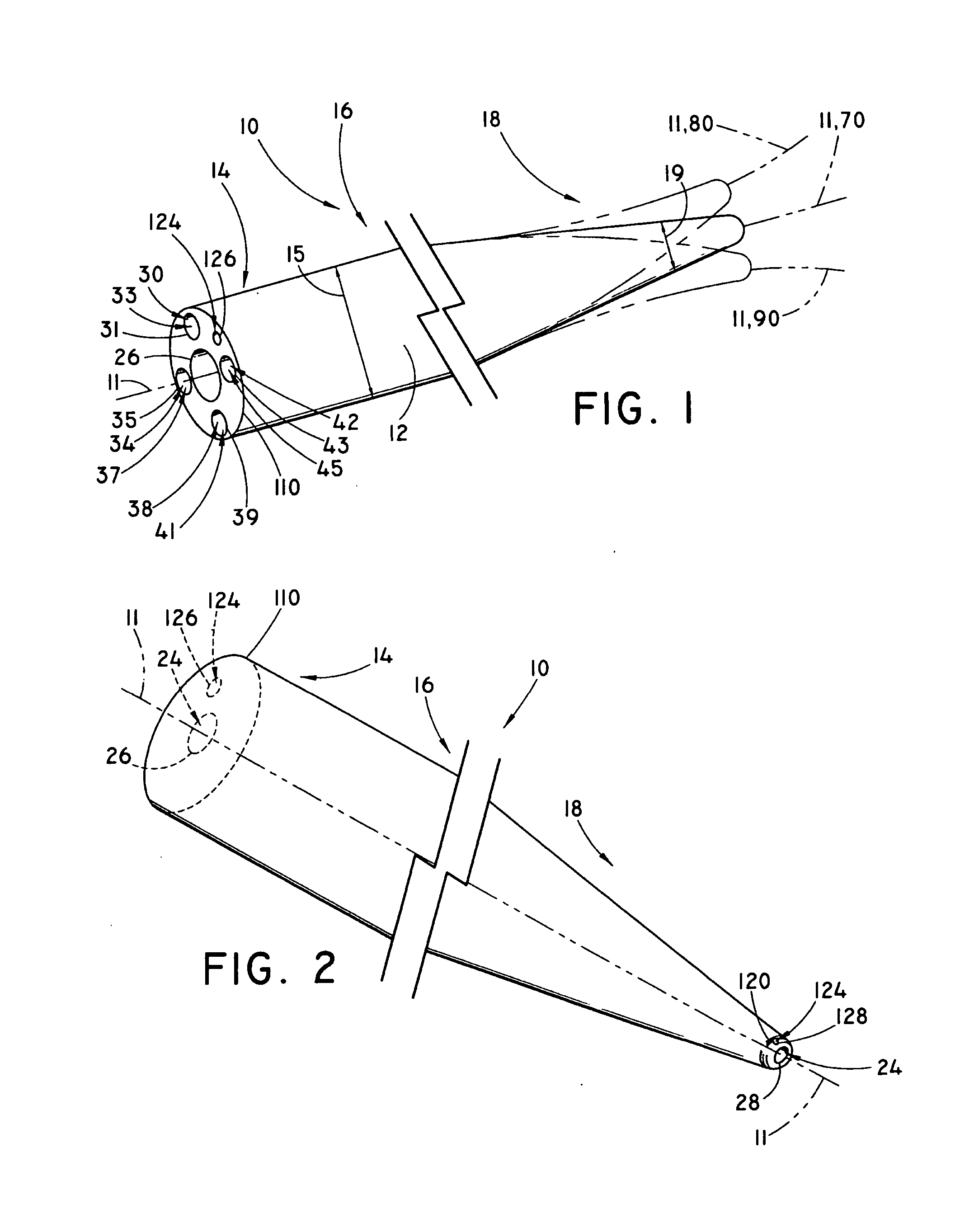

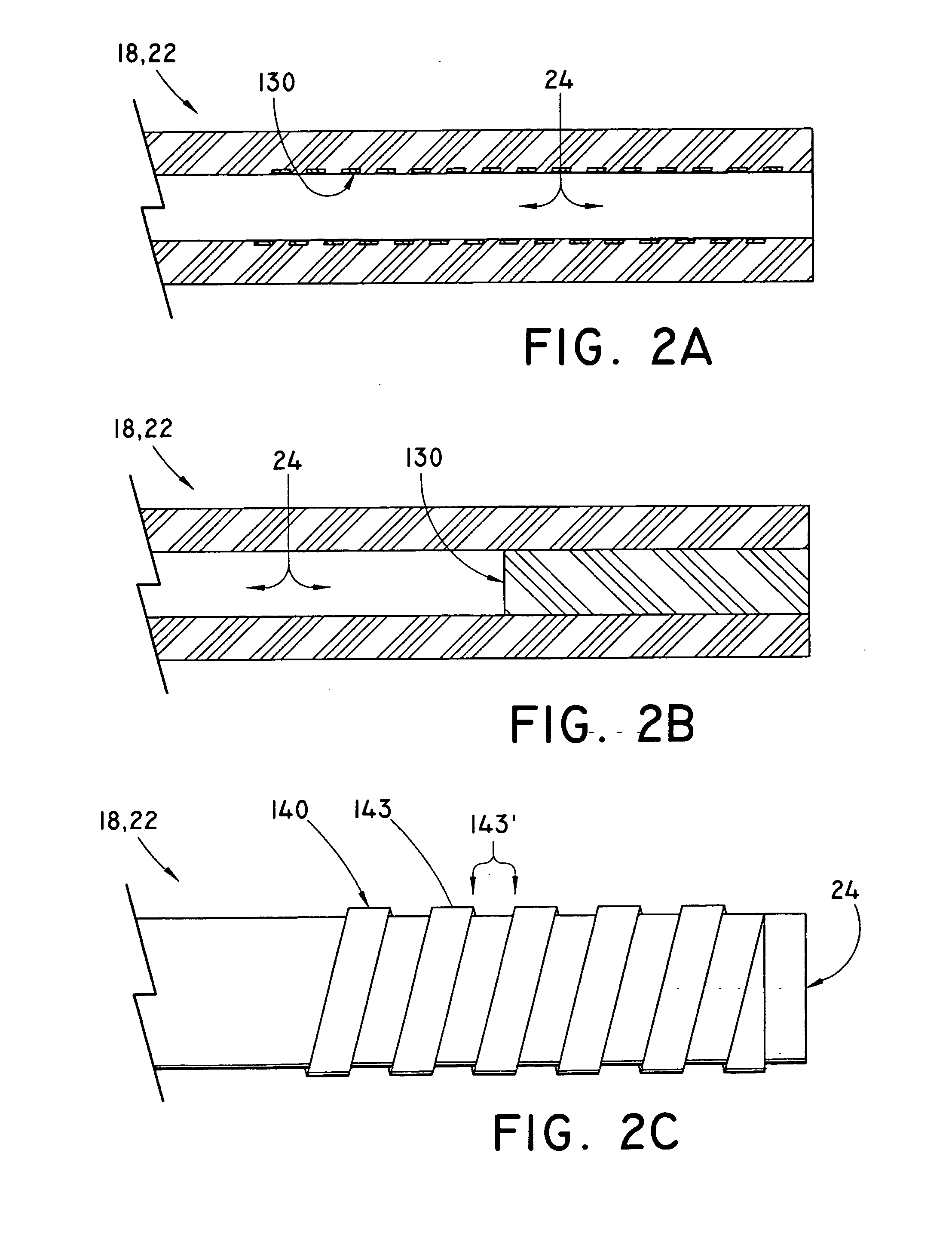

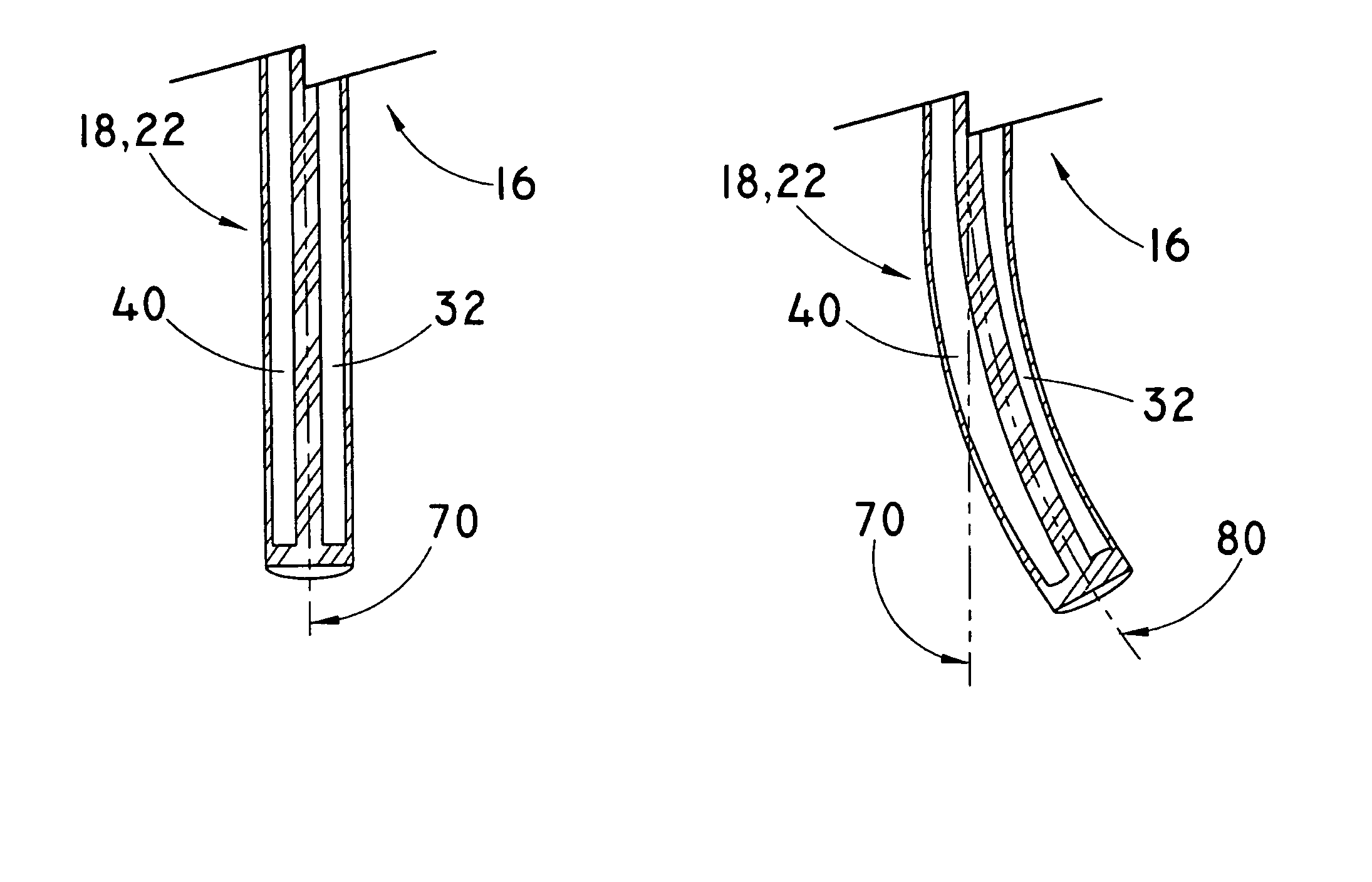

Steerable catheter devices are provided having a proximal first end portion, an elongate intermediate portion, and a distal flexible second end portion defining a longitudinal axis, and at least one channel having a proximal opening and terminating at an occluded distal end radially offset relative to the central longitudinal axis and positioned within the catheter flexible second end portion substantially straight in a relaxed position and bent when the occluded distal end is under a change in internal fluid pressure. Optionally, the catheter further has a dye injection lumen and a tool receiving passageway extending from the first end portion to the second end portion. The occluded distal end is axially elastically distensible under an internal fluid pressure to deflect (thereby to steer) the catheter second end portion through the tortuous path of a vessel passageway when used percutaneously or working channel of an endoscope or endoscope accessory device.

Owner:COOK MEDICAL TECH LLC

Steerable catheter devices and methods of articulating catheter devices

Steerable catheter devices are provided having a proximal first end portion, an elongate intermediate portion, and a distal flexible second end portion defining a longitudinal axis, and at least one channel having a proximal opening and terminating at an occluded distal end radially offset relative to the central longitudinal axis and positioned within the catheter flexible second end portion substantially straight in a relaxed position and bent when the occluded distal end is under a change in internal fluid pressure. Optionally, the catheter further has a dye injection lumen and a tool receiving passageway extending from the first end portion to the second end portion. The occluded distal end is axially elastically distensible under an internal fluid pressure to deflect (thereby to steer) the catheter second end portion through the tortuous path of a vessel passageway when used percutaneously or working channel of an endoscope or endoscope accessory device.

Owner:COOK MEDICAL TECH LLC

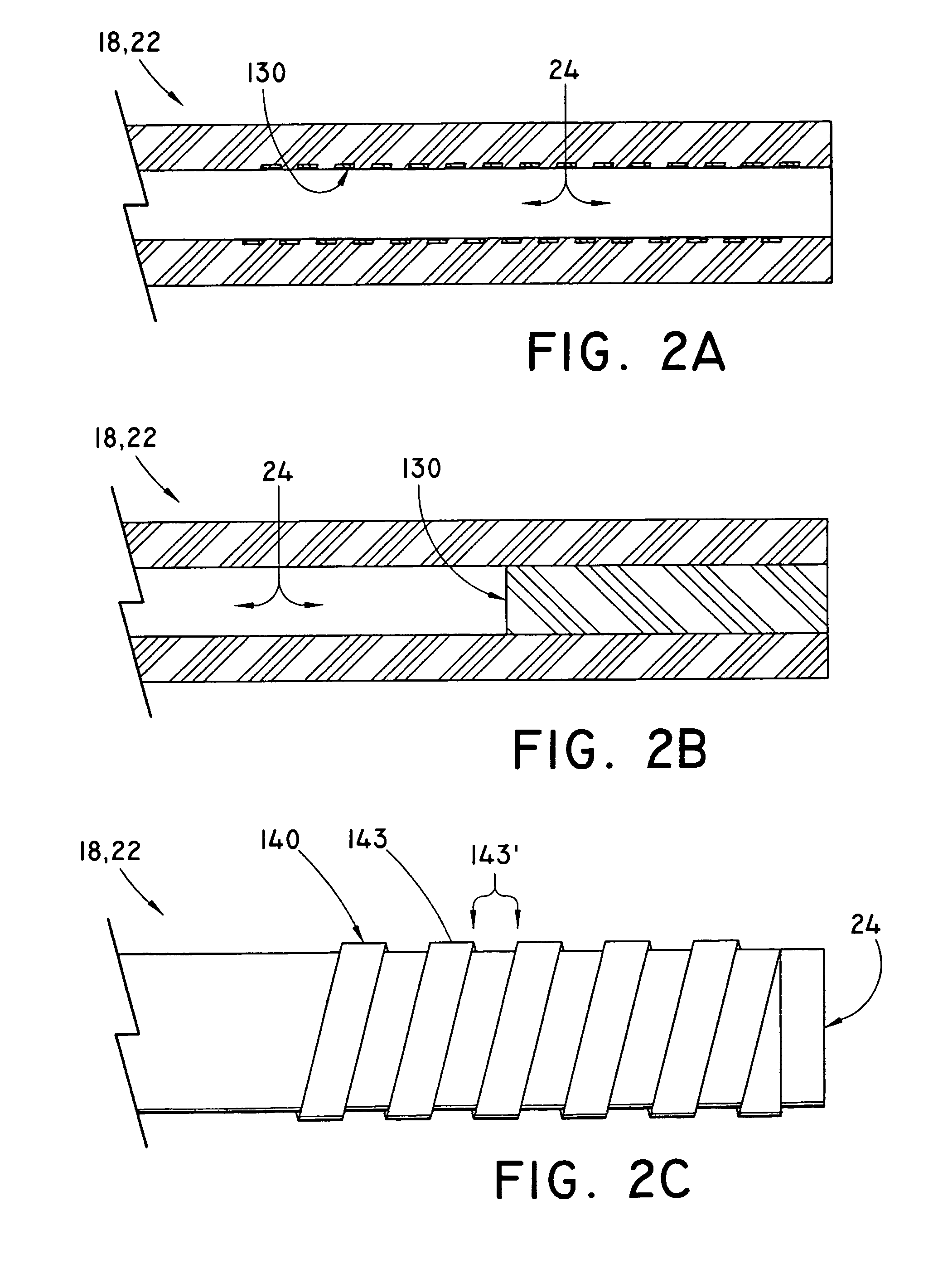

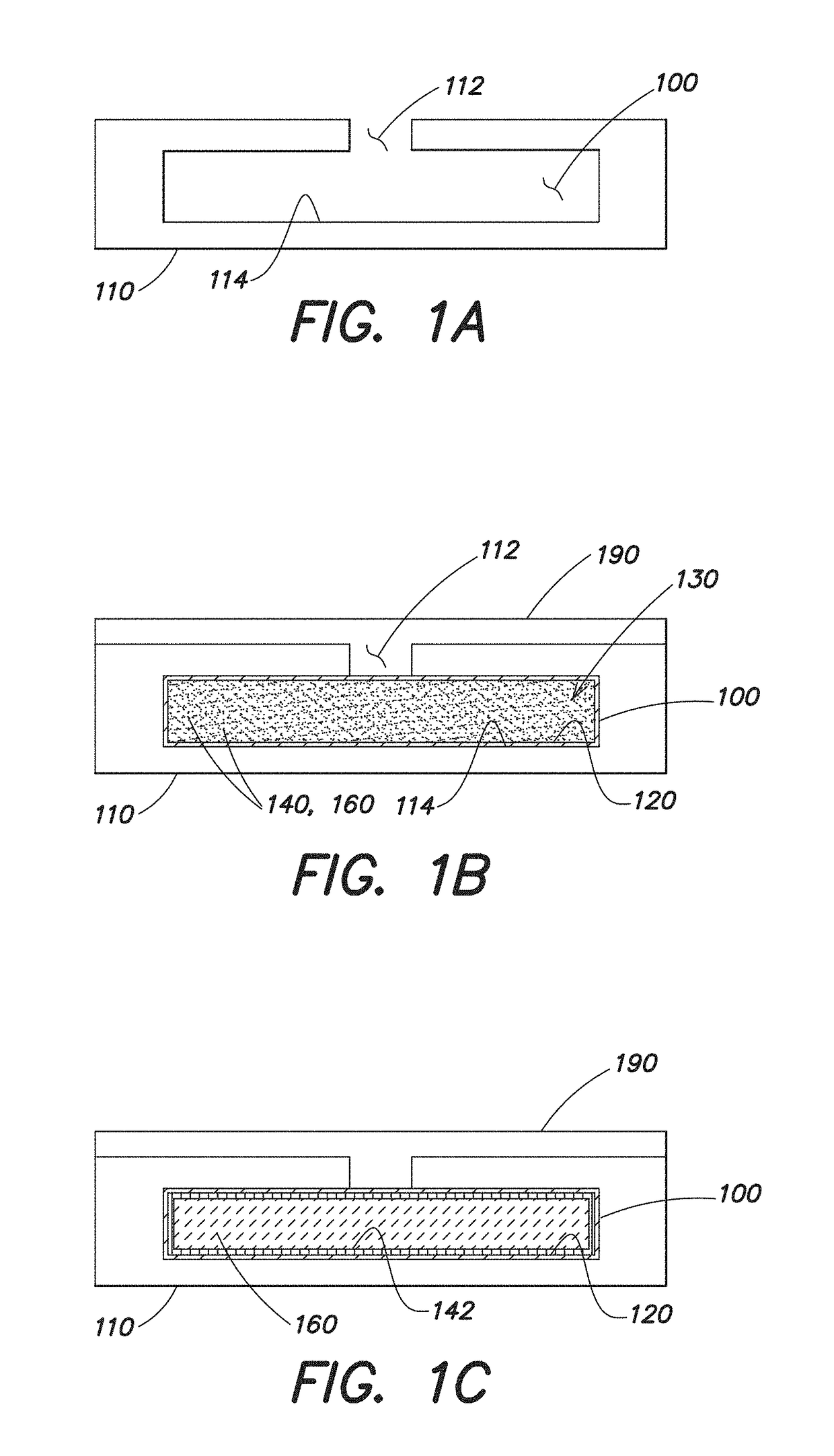

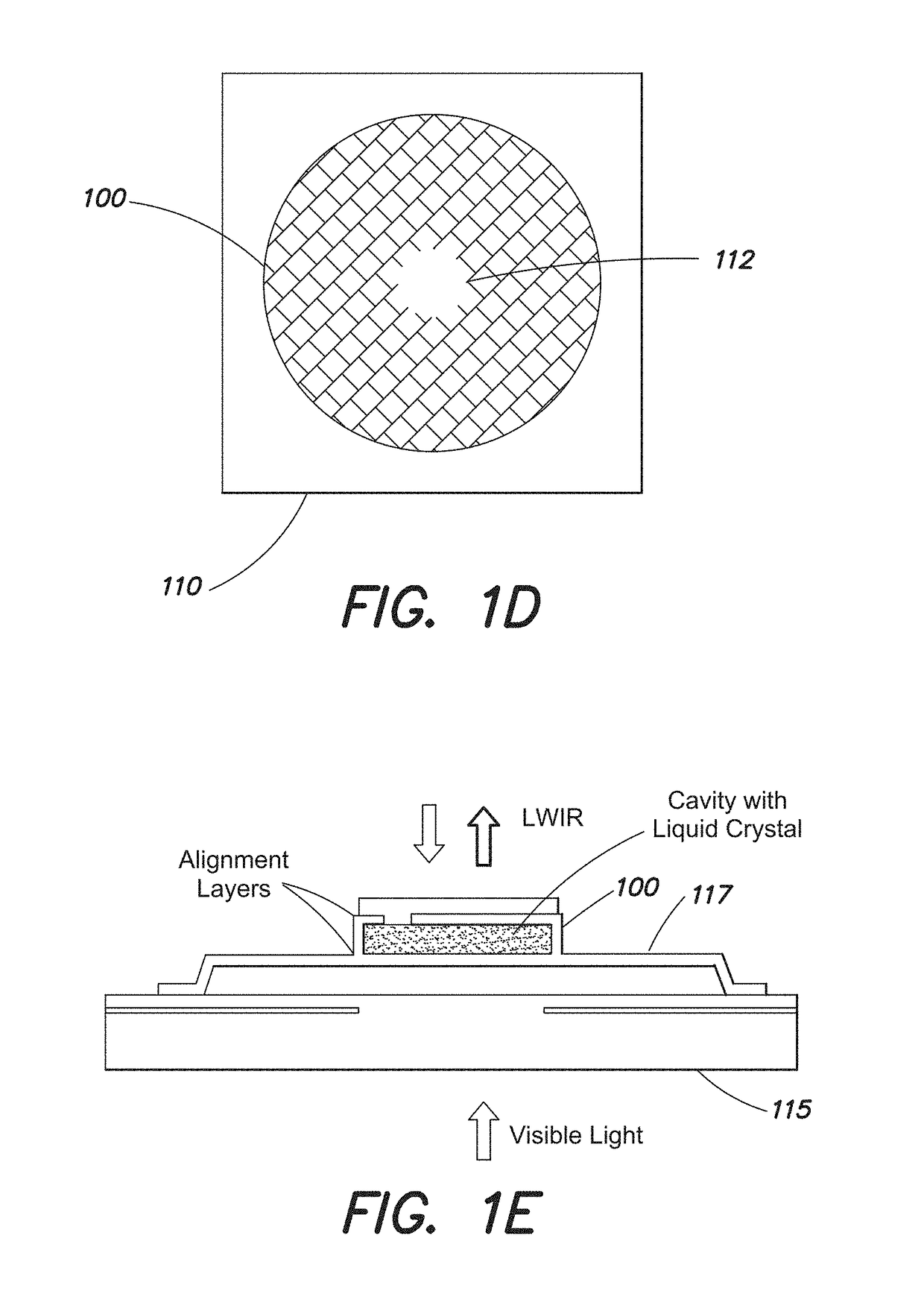

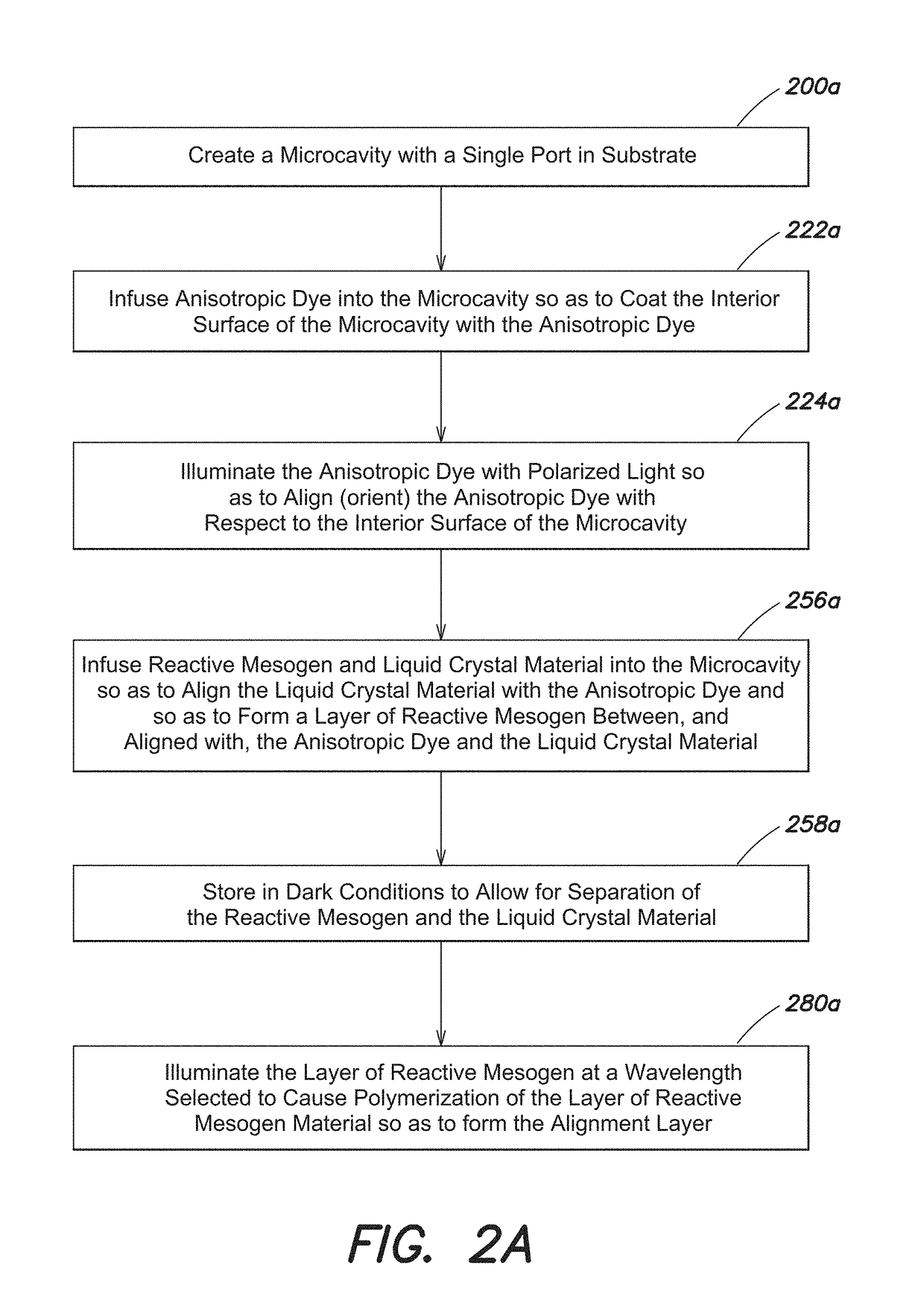

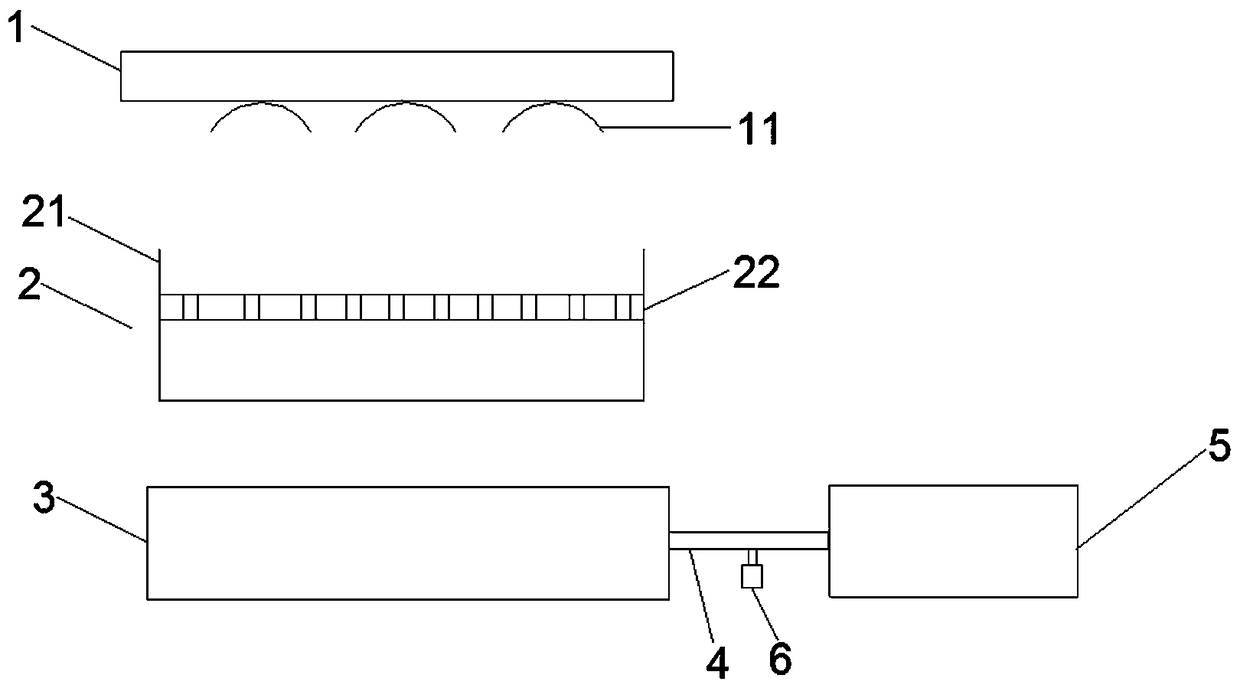

Methods and Apparatus for Liquid Crystal Photoalignment

ActiveUS20180364526A1Effective and stableLiquid crystal compositionsNon-linear opticsDye injectionPhotonics

Liquid crystal photonic devices and microcavities filled with liquid crystal materials are becoming increasingly popular. These devices often present a challenge when it comes to creating a robust alignment layer in pre-assembled cells. Previous research on photo-definable alignment layers has shown that they have limited stability, particularly against subsequent light exposure. A method of infusing a dye into a microcavity to produce an effective photo-definable alignment layer is described, along with a method of utilizing a pre-polymer infused into the microcavity mixed with the liquid crystal to provide photostability. In this method, the polymer layer, formed under optical irradiation of liquid crystal cells, is effectively localized to a thin region near the substrate surface and thus provides a significant improvement in the photostability of the liquid crystal alignment. This versatile alignment layer method, which can be used in microcavities to displays, offers significant promise for new photonics applications.

Owner:KENT STATE UNIV +1

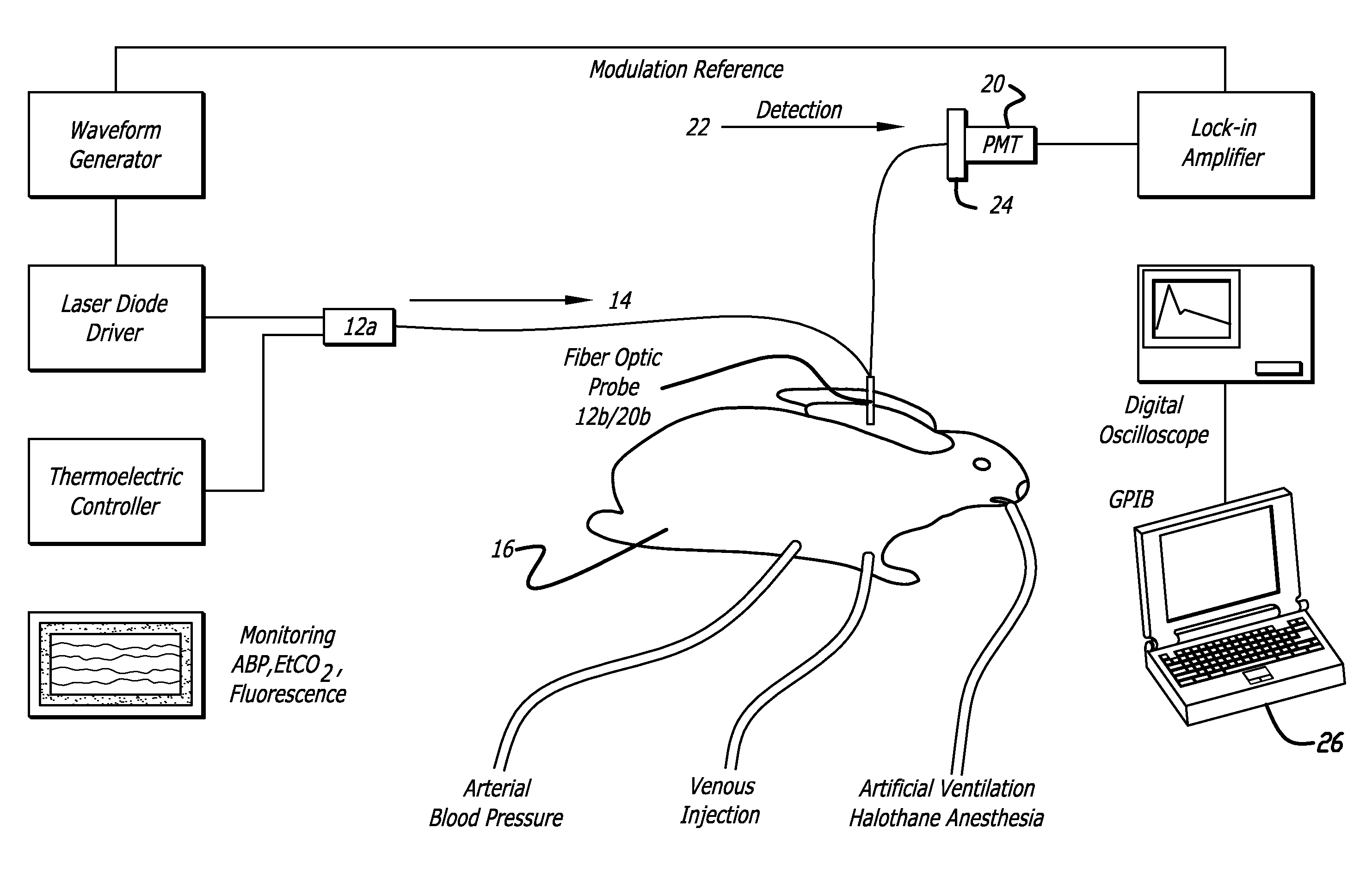

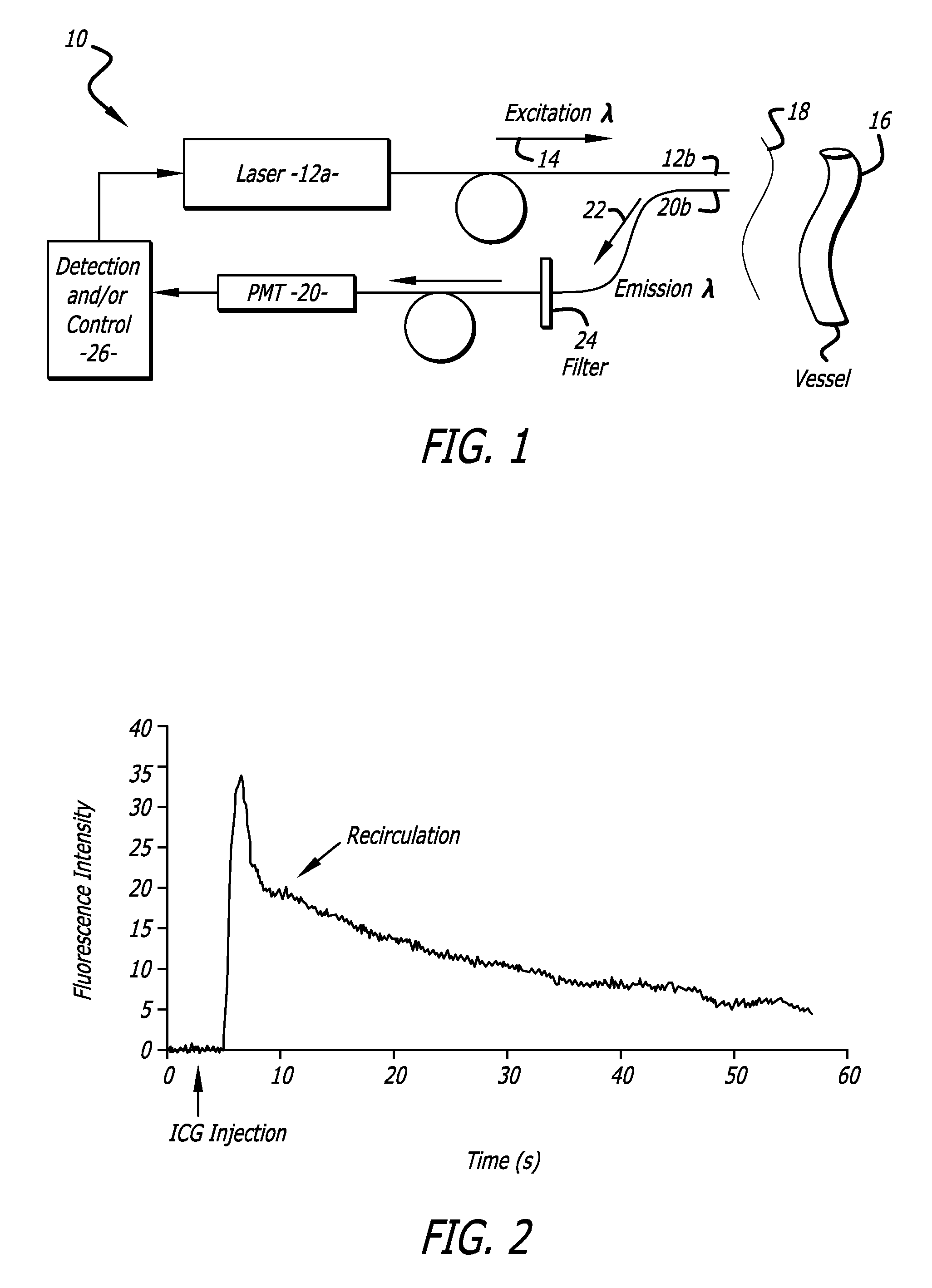

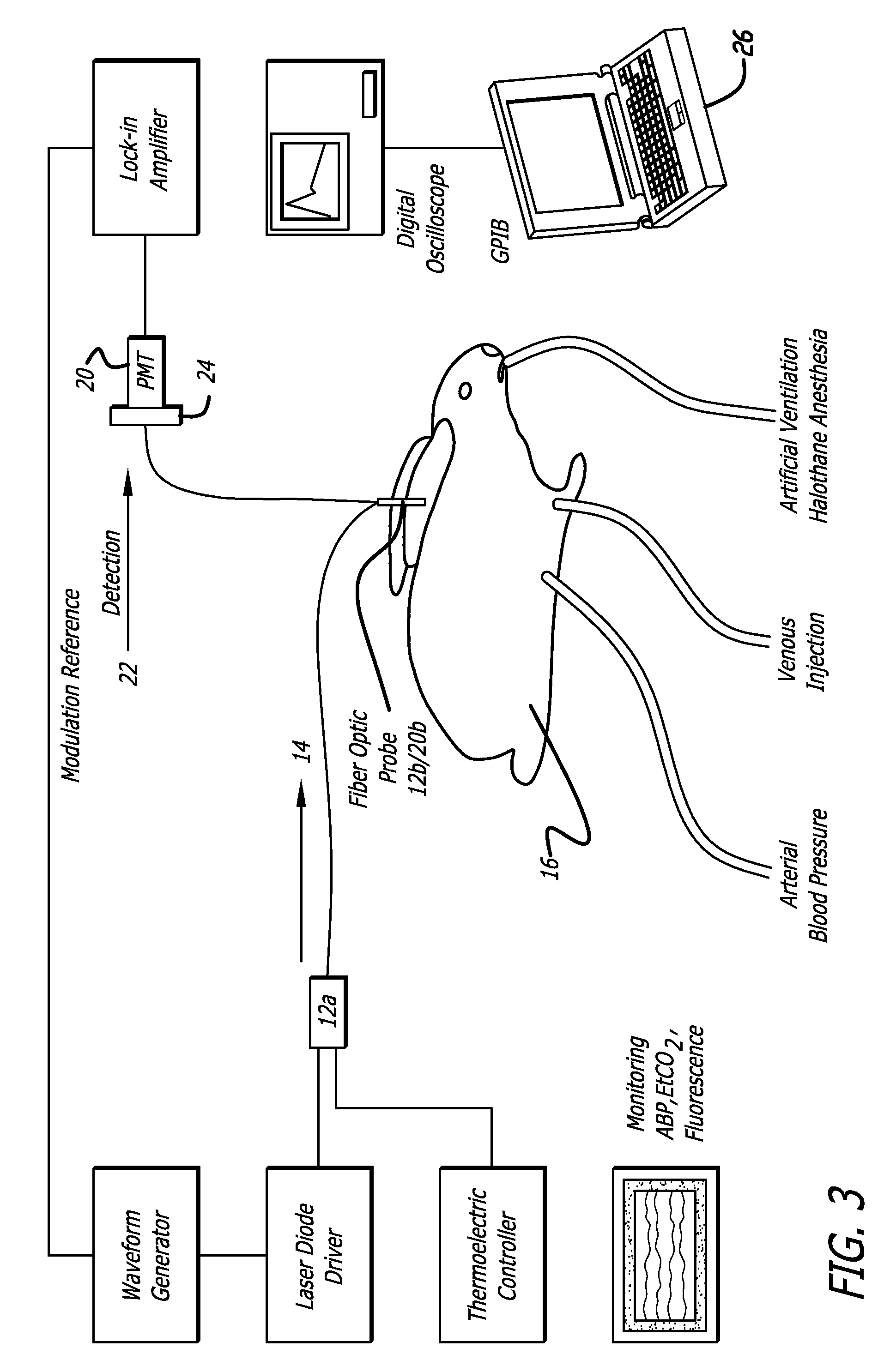

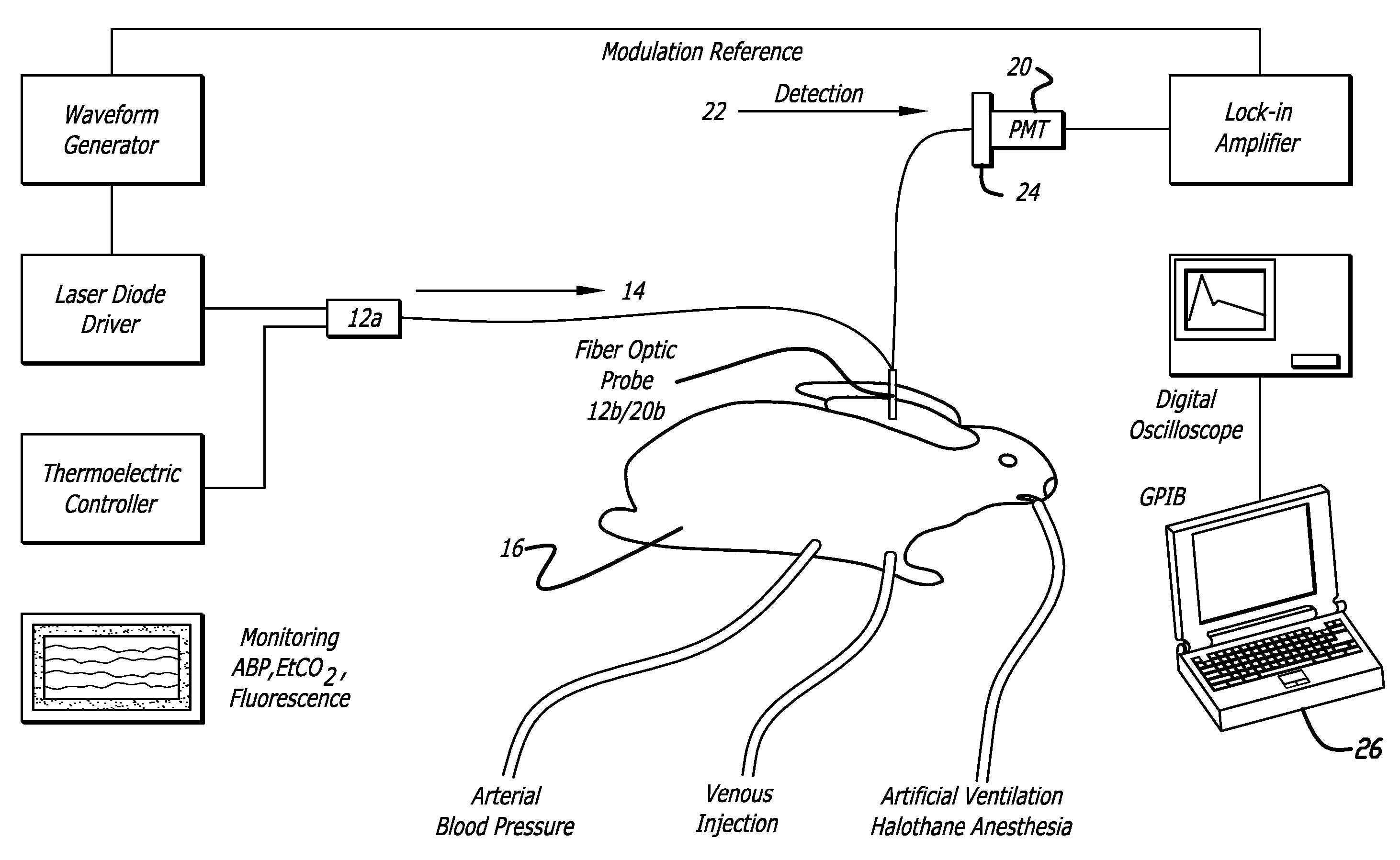

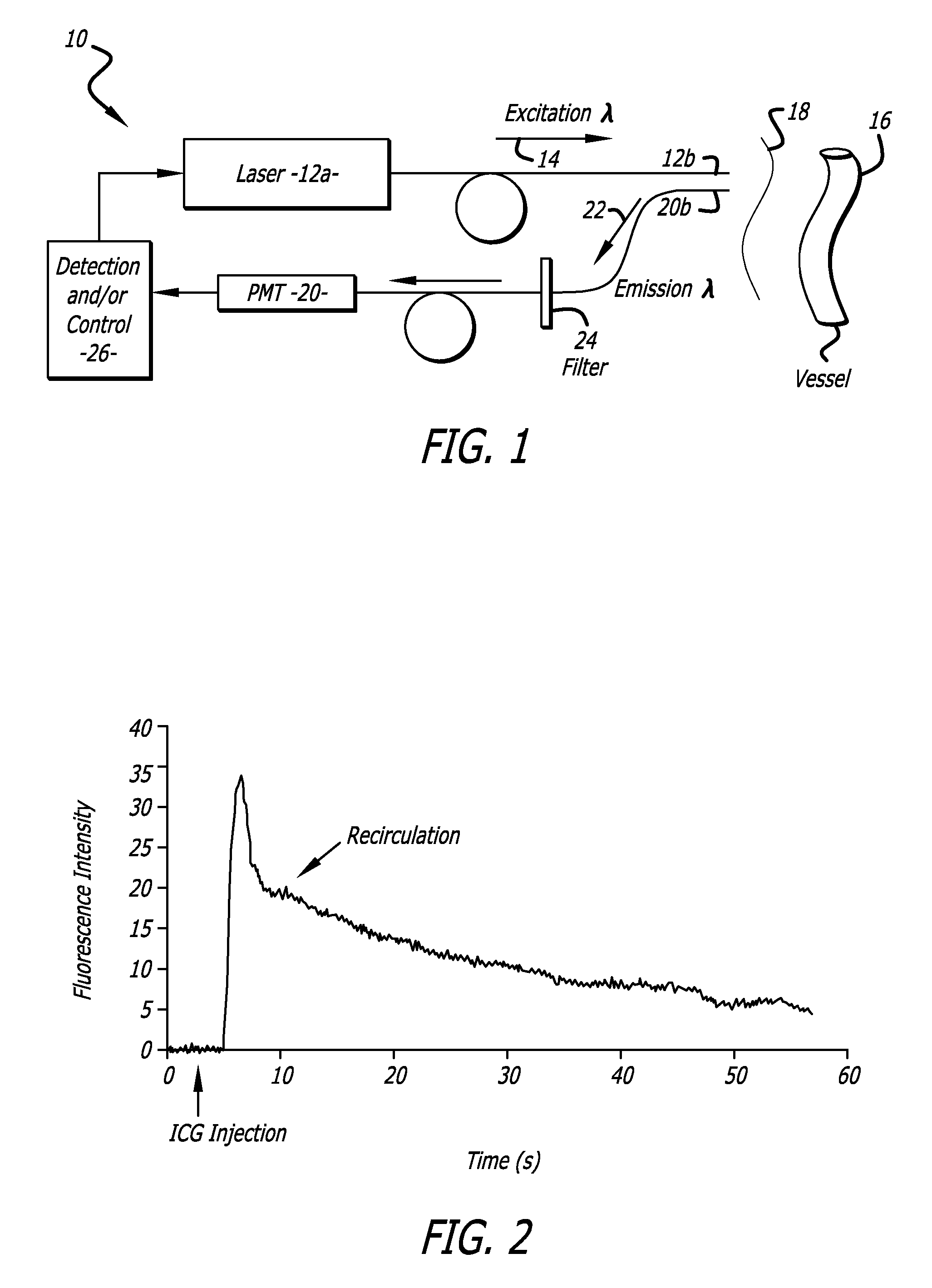

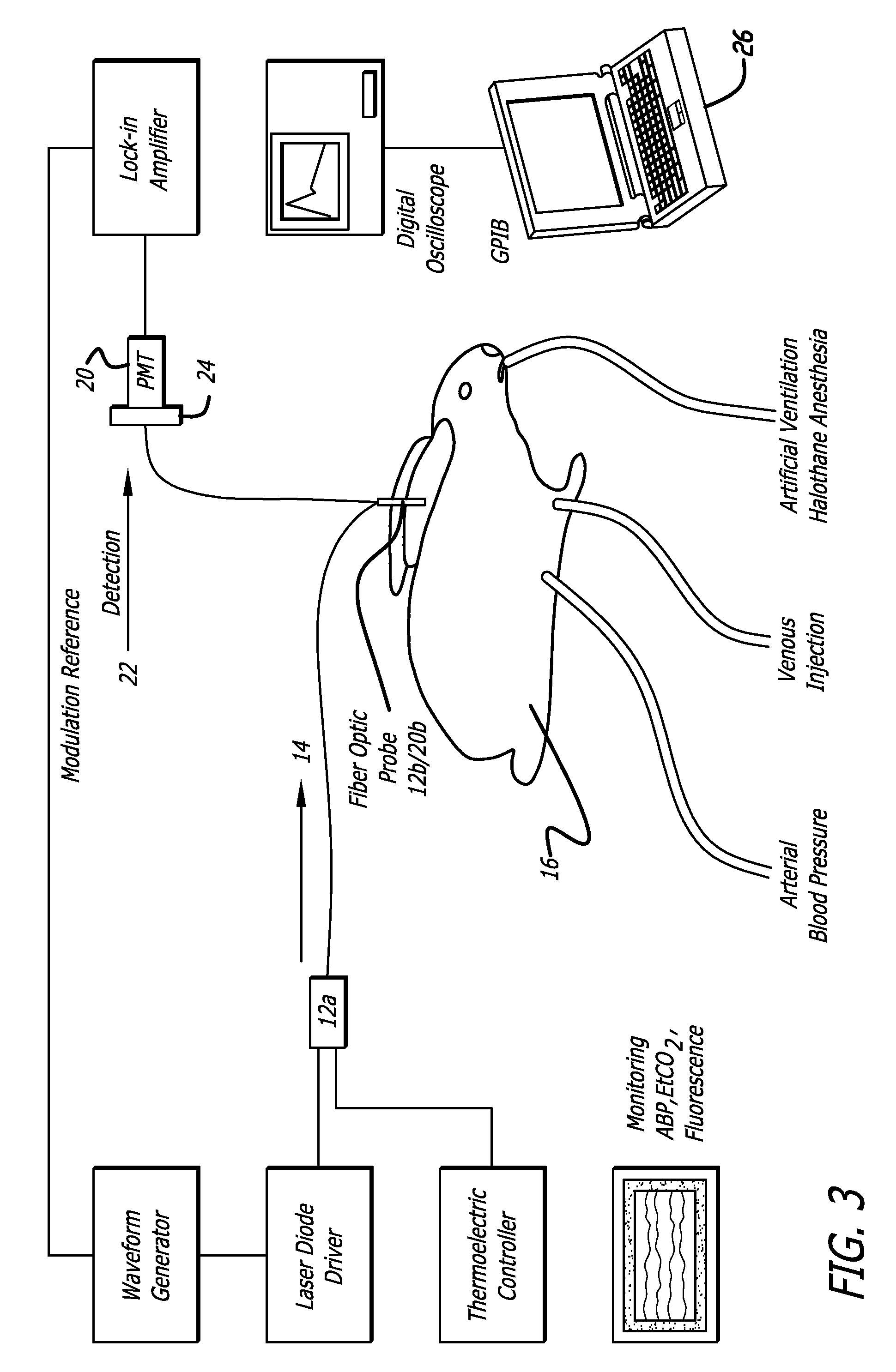

Method for dye injection for the transcutaneous measurement of cardiac output

InactiveUS7474906B2Reduce complicationsReduction procedureDiagnostics using lightMaterial analysis by optical meansIndicator dilutionDye injection

A system for evaluating the cardiovascular system parameters using indicator dilution and non-invasive or minimally invasive detection and calibration methods are disclosed. Intravascular indicators are stimulated, and emissions patterns detected for computation of cardiac output, cardiac index, blood volume and other indicators of cardiovascular health.

Owner:ALFRED E MANN INST FOR BIOMEDICAL ENG AT THE UNIV OF SOUTHERN CALIFORNIA

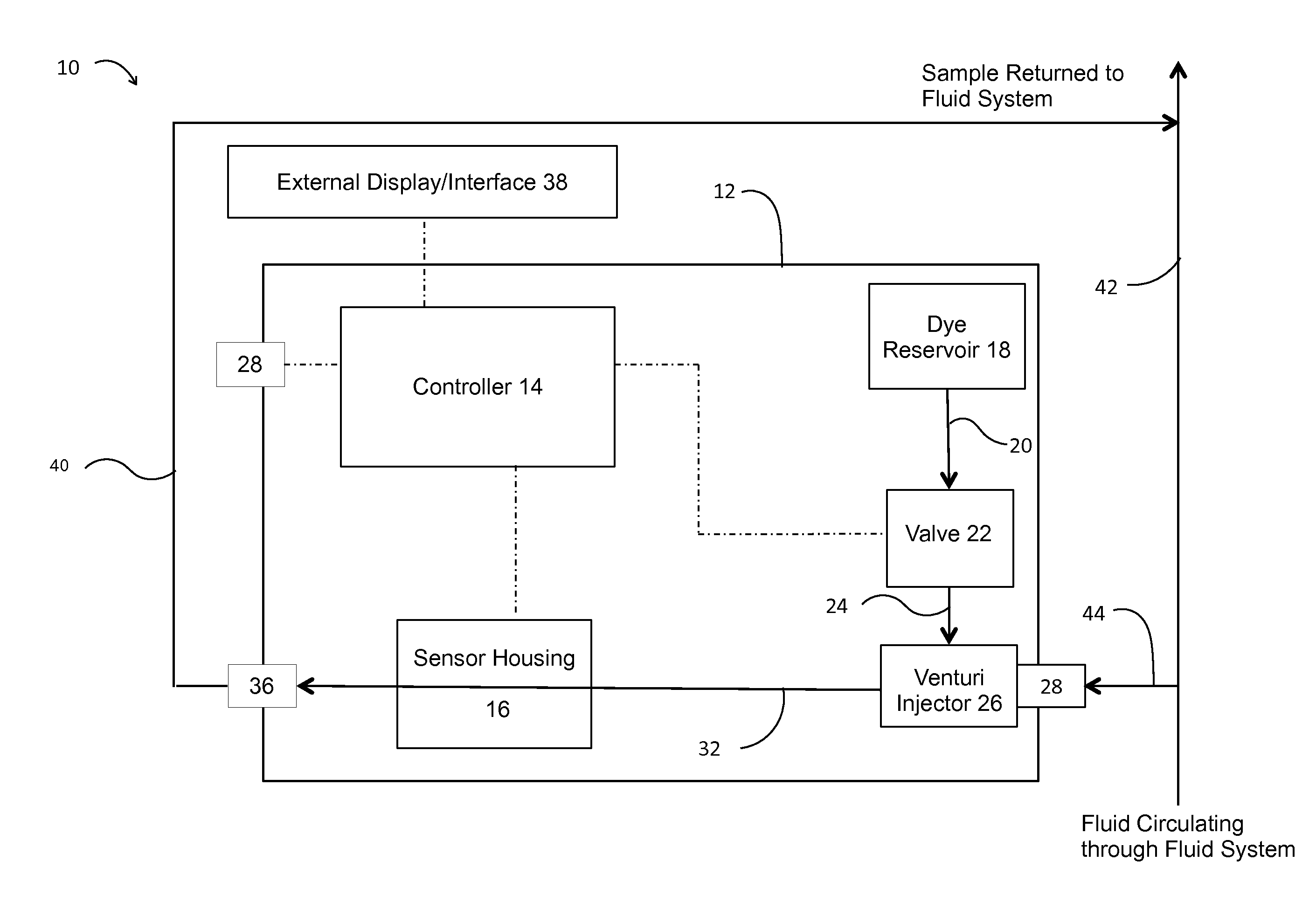

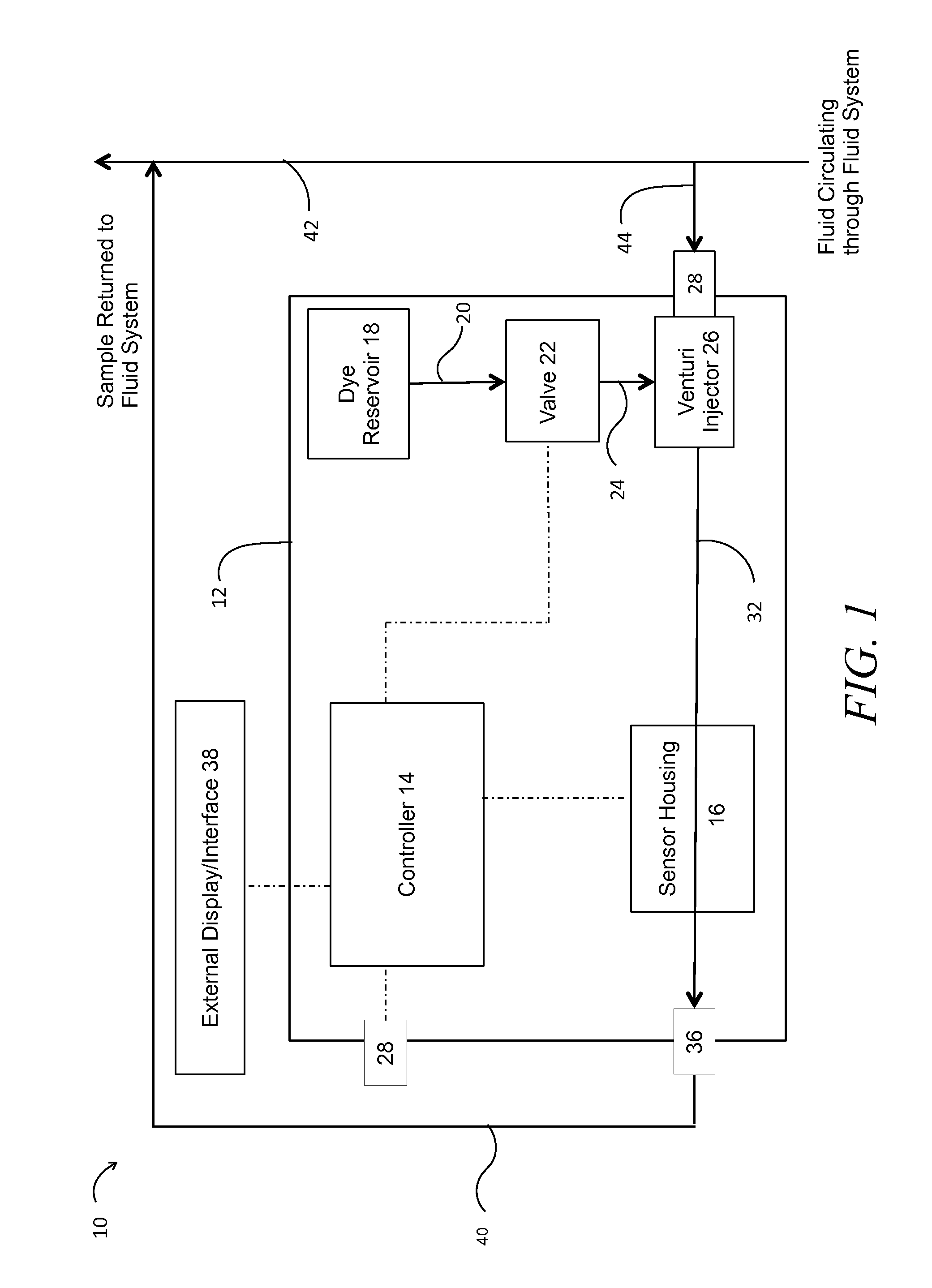

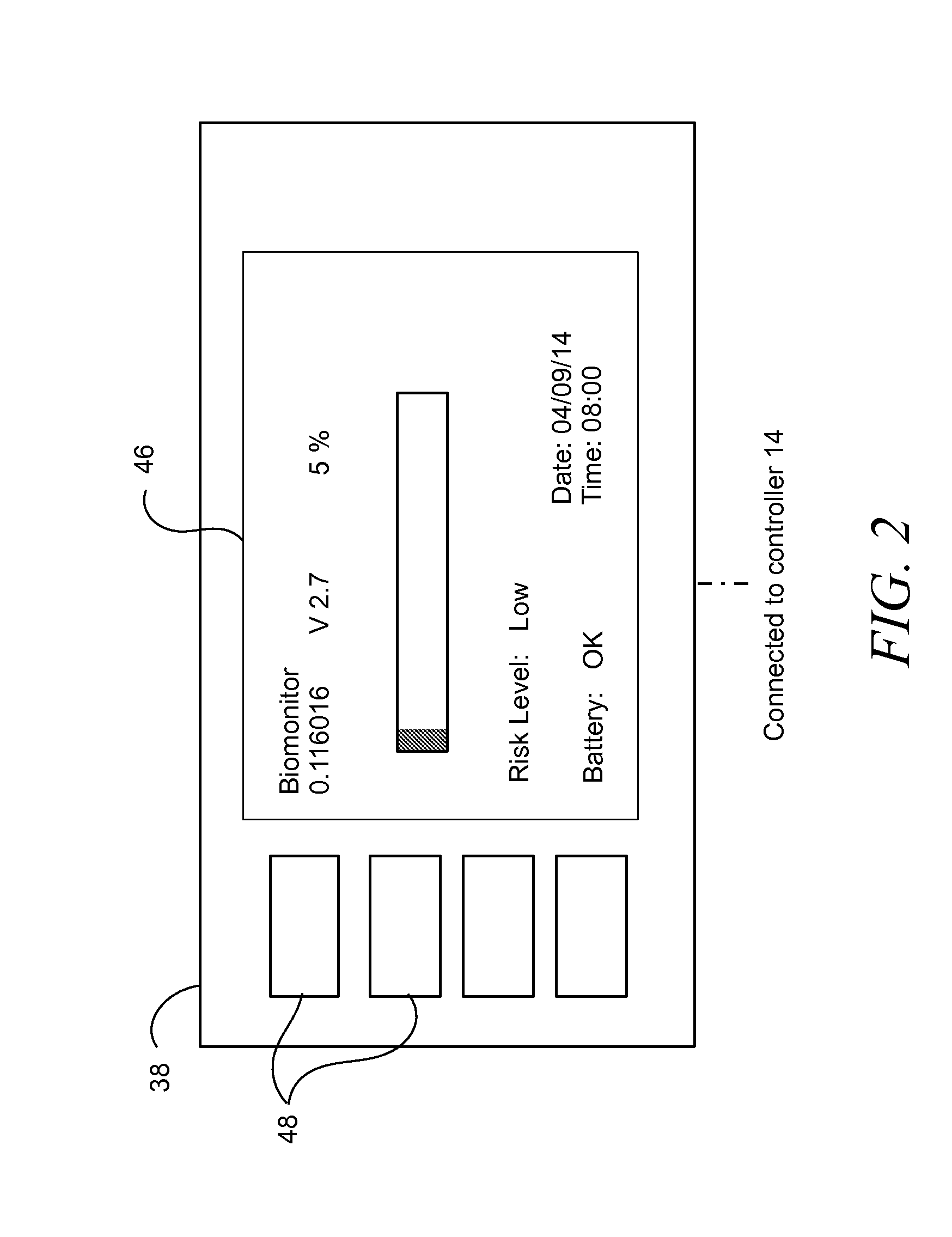

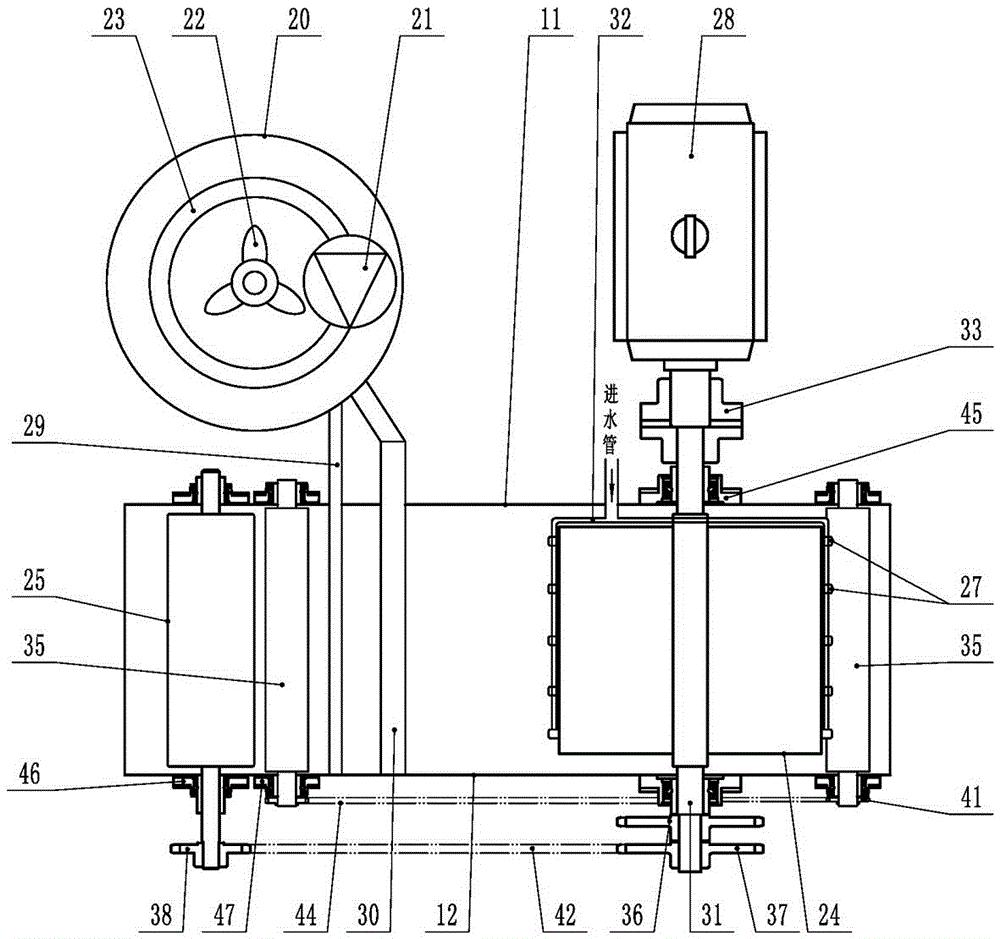

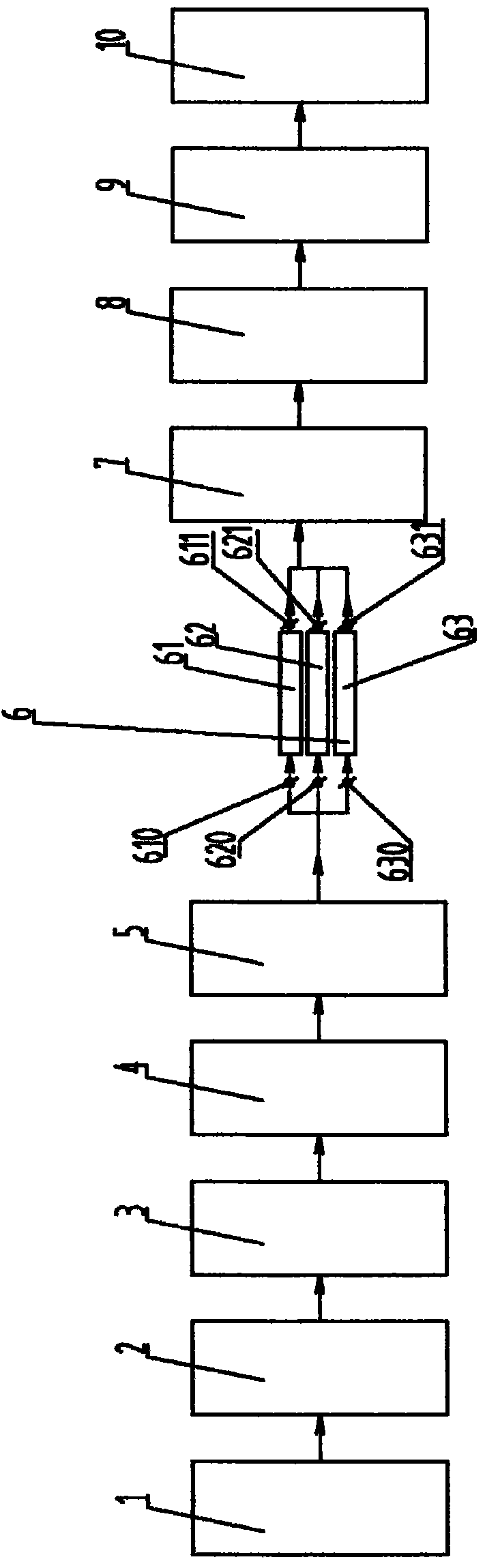

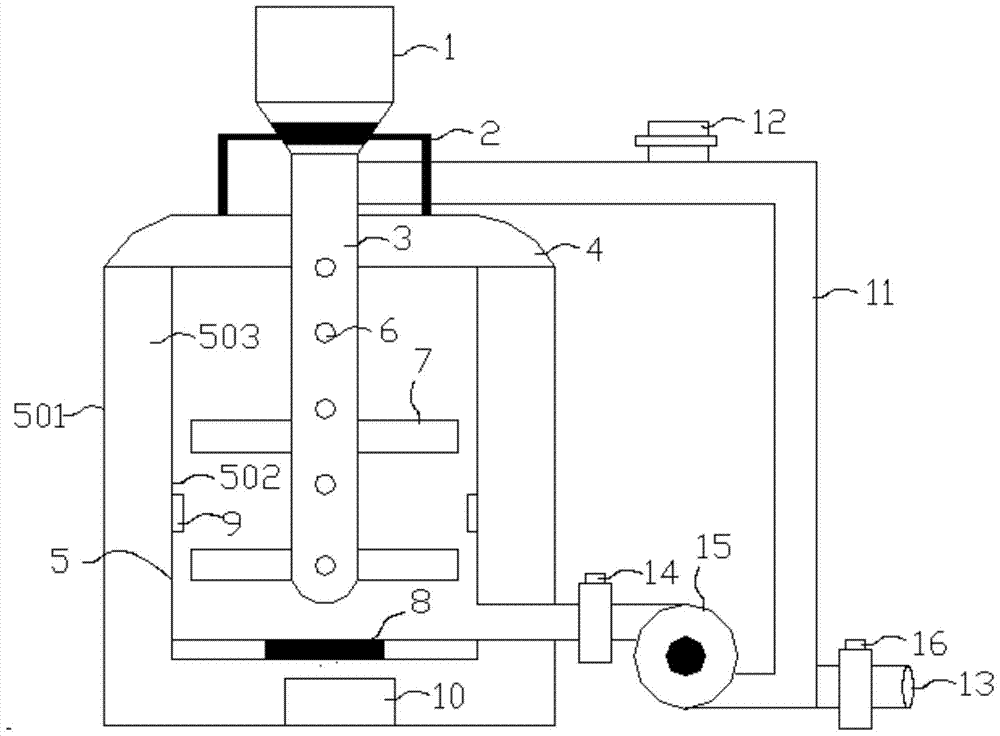

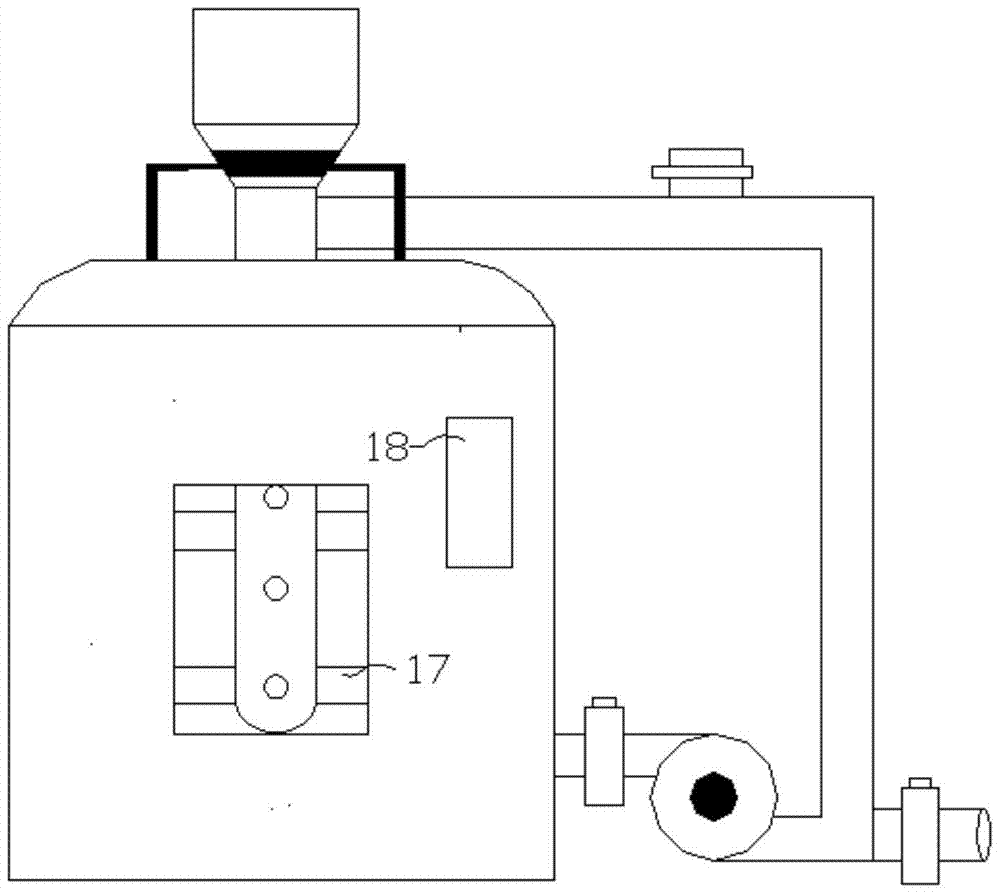

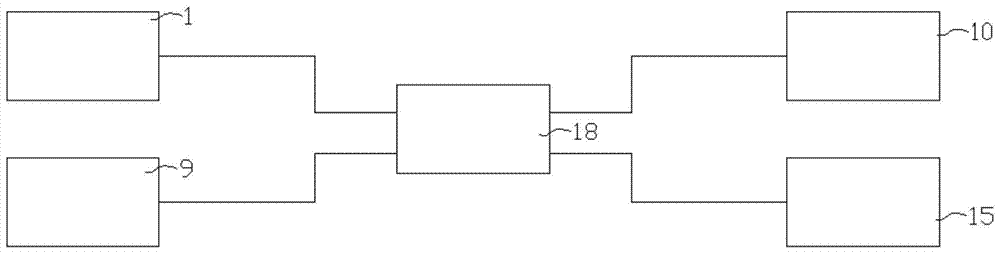

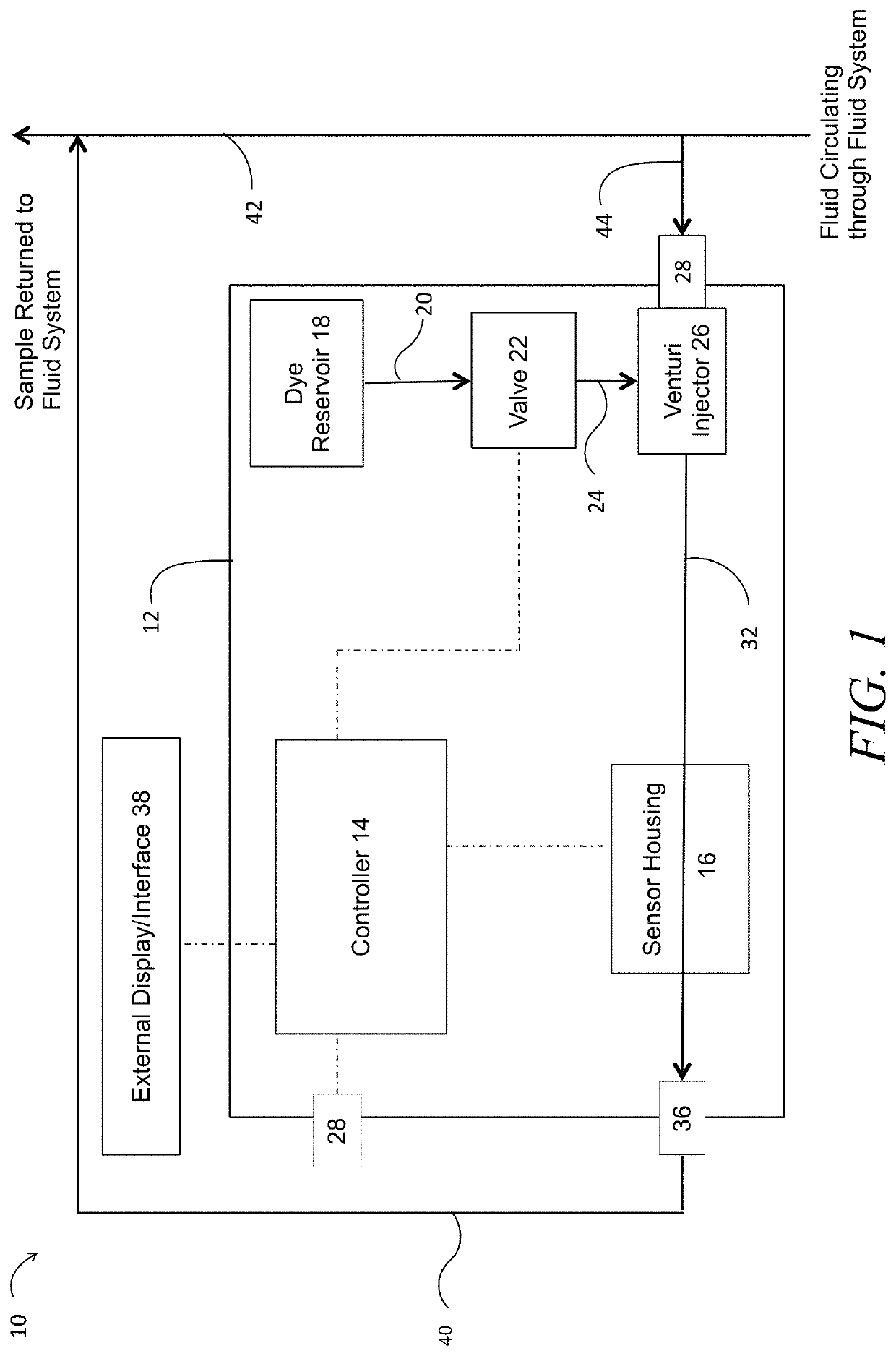

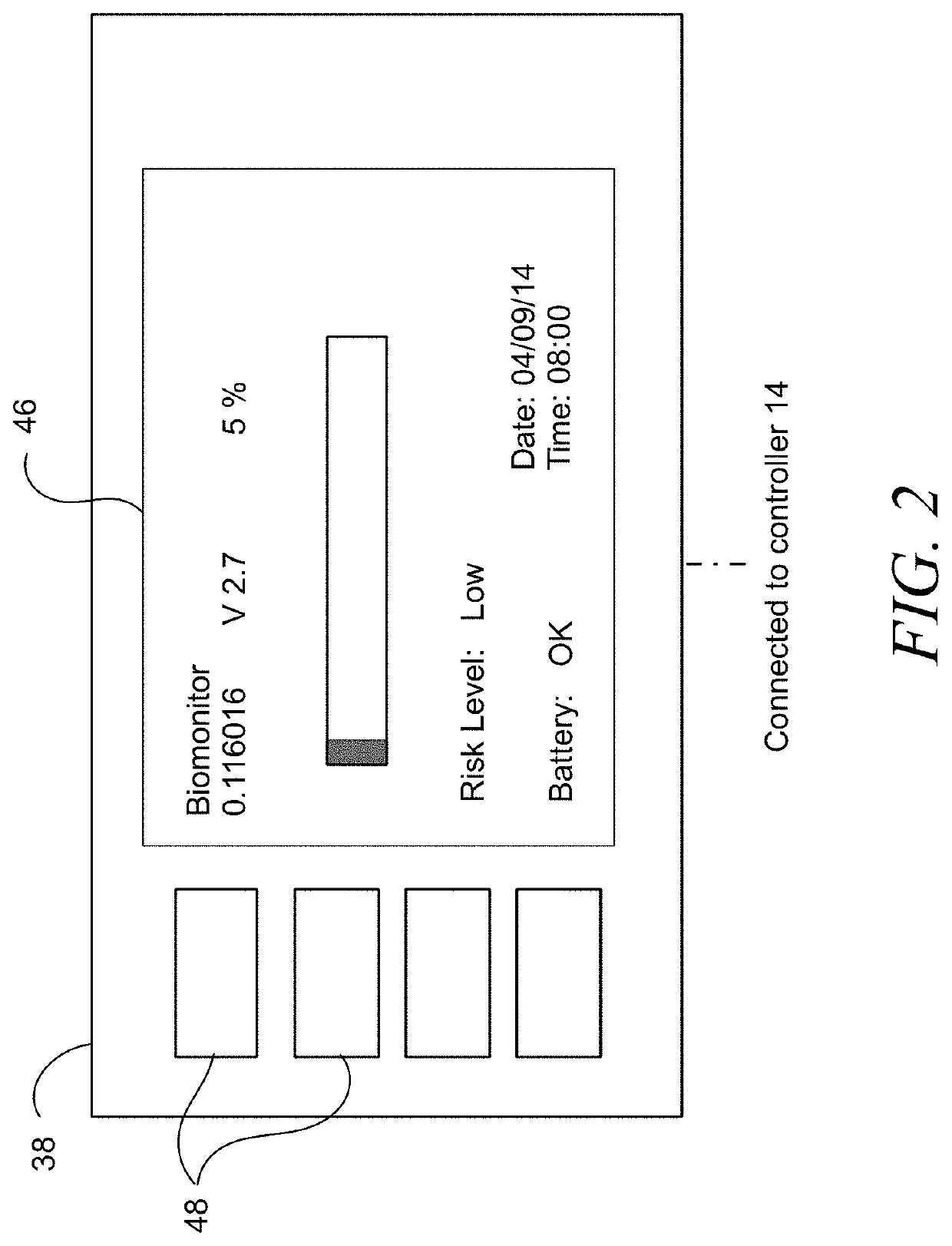

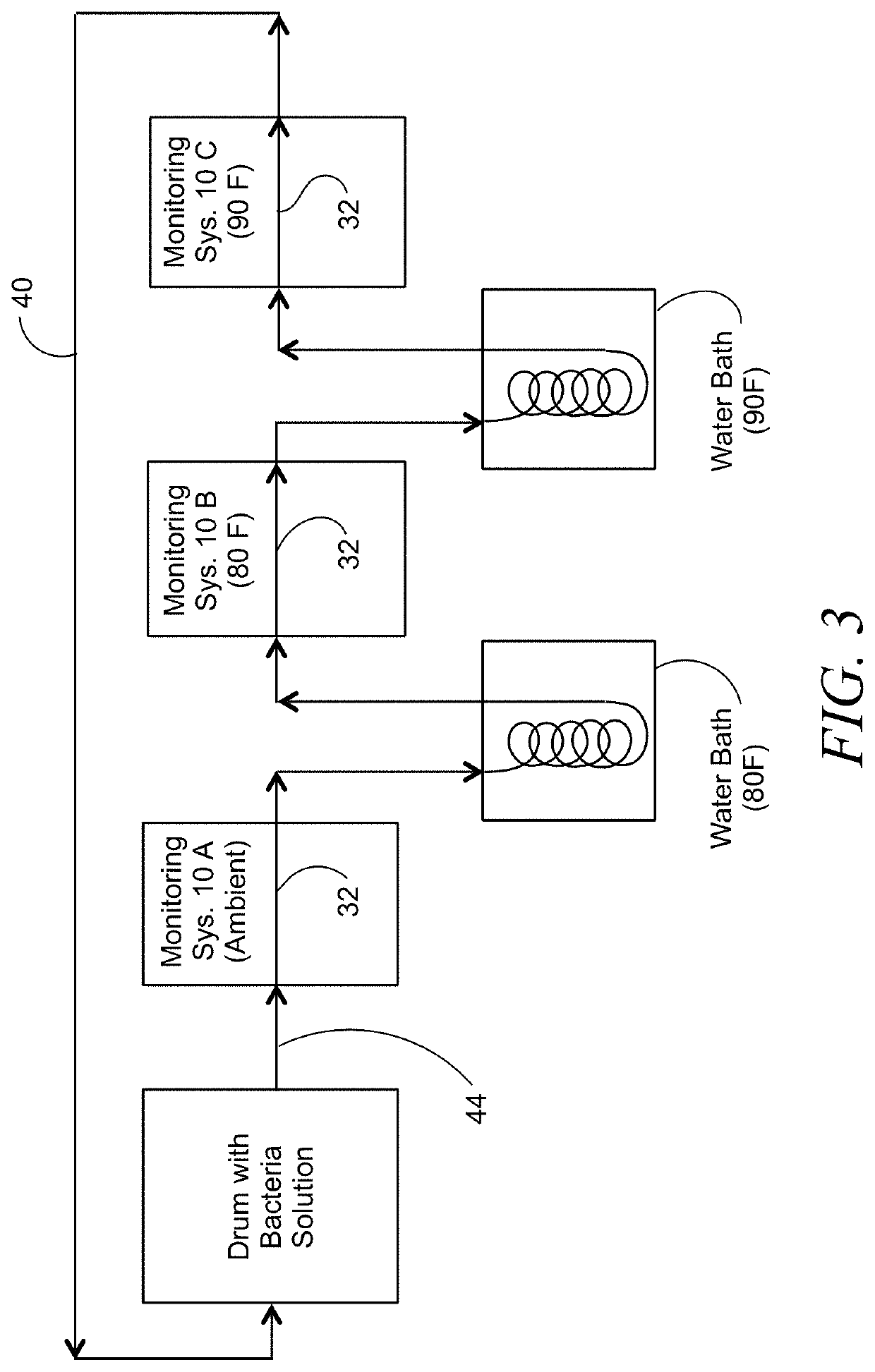

System and Method for Detecting Biofilm Growth in Water Systems

InactiveUS20150291993A1Save amountEasy to installBioreactor/fermenter combinationsBiological substance pretreatmentsBiofilm growthDye injection

A system and method for monitoring or detecting a level of biofilm growth in a fluid system and controlling operating parameters of the fluid system based a measured level of growth. The monitoring system and method comprises a dye injection system for periodically injecting dye into a portion of fluid from the fluid system, passing the portion of fluid though a narrow lumen tube to achieve laminar flow and using a light source and optical sensor to detect a transmission or emission indicating a level of biofilm growth in the tube corresponding to a level of growth on components in the fluid system. Information based upon the measurements or calculations made by the monitoring system may be used to manually or automatically alter various operating parameters to control the fluid system and aid in maintaining stable operation of the fluid system within preferred specifications.

Owner:NCH CORP

Method for Dye Injection for the Transcutaneous Measurement of Cardiac Output

InactiveUS20080004511A1Improve accuracyReduce complicationsDiagnostics using lightMaterial analysis by optical meansIndicator dilutionDye injection

A system for evaluating the cardiovascular system parameters using indicator dilution and non-invasive or minimally invasive detection and calibration methods are disclosed. Intravascular indicators are stimulated, and emissions patterns detected for computation of cardiac output, cardiac index, blood volume and other indicators of cardiovascular health.

Owner:ALFRED E MANN INST FOR BIOMEDICAL ENG AT THE UNIV OF SOUTHERN CALIFORNIA

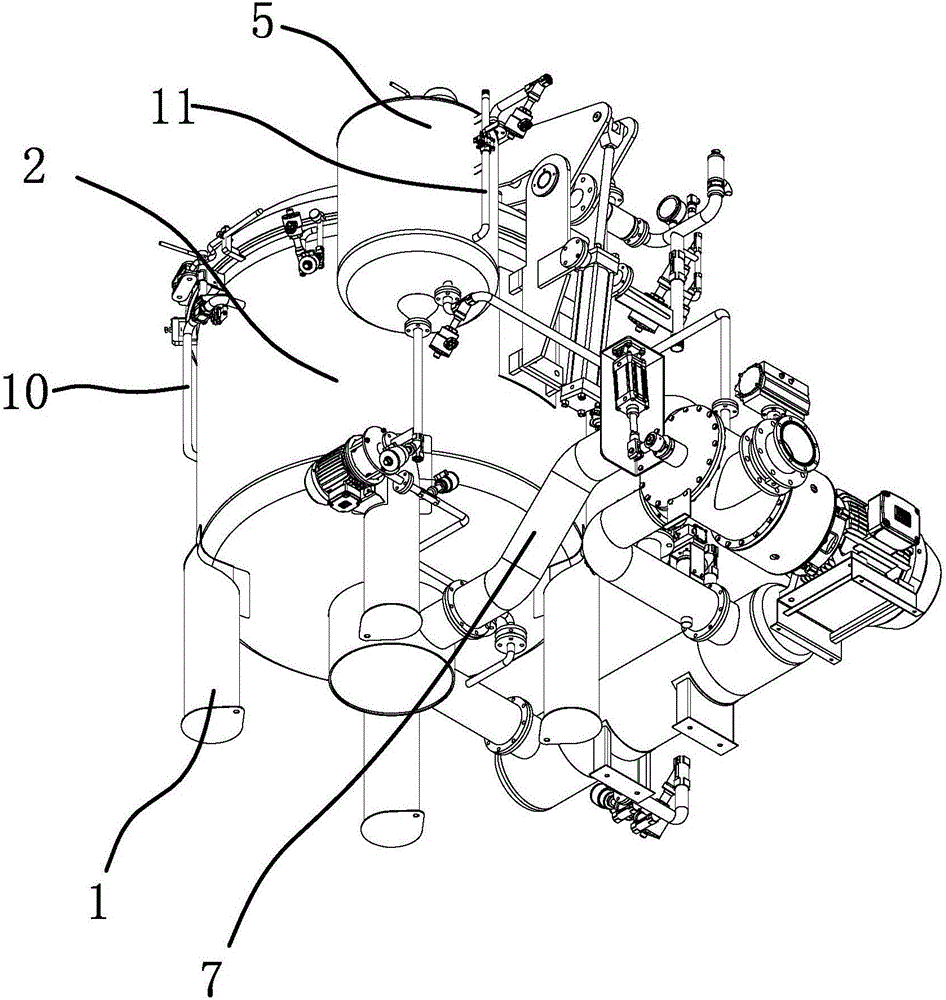

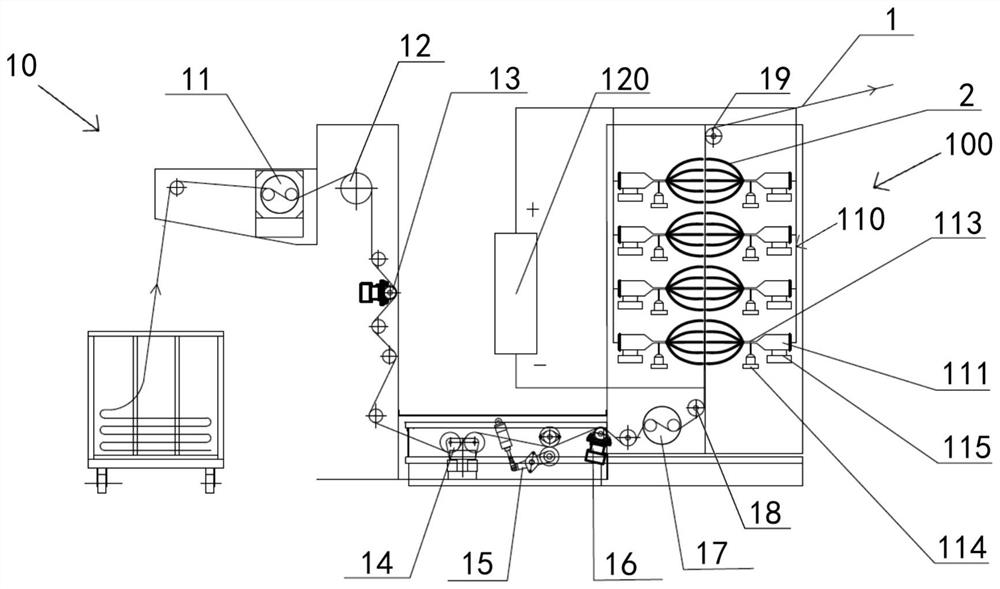

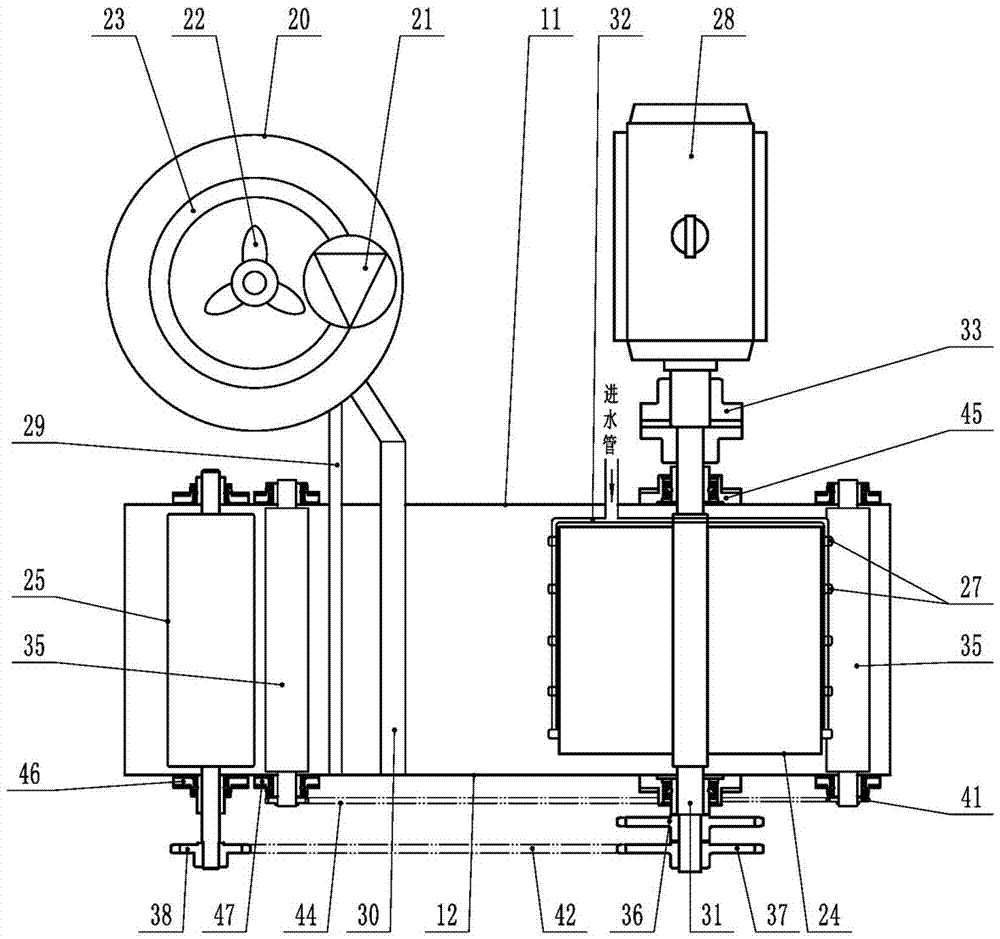

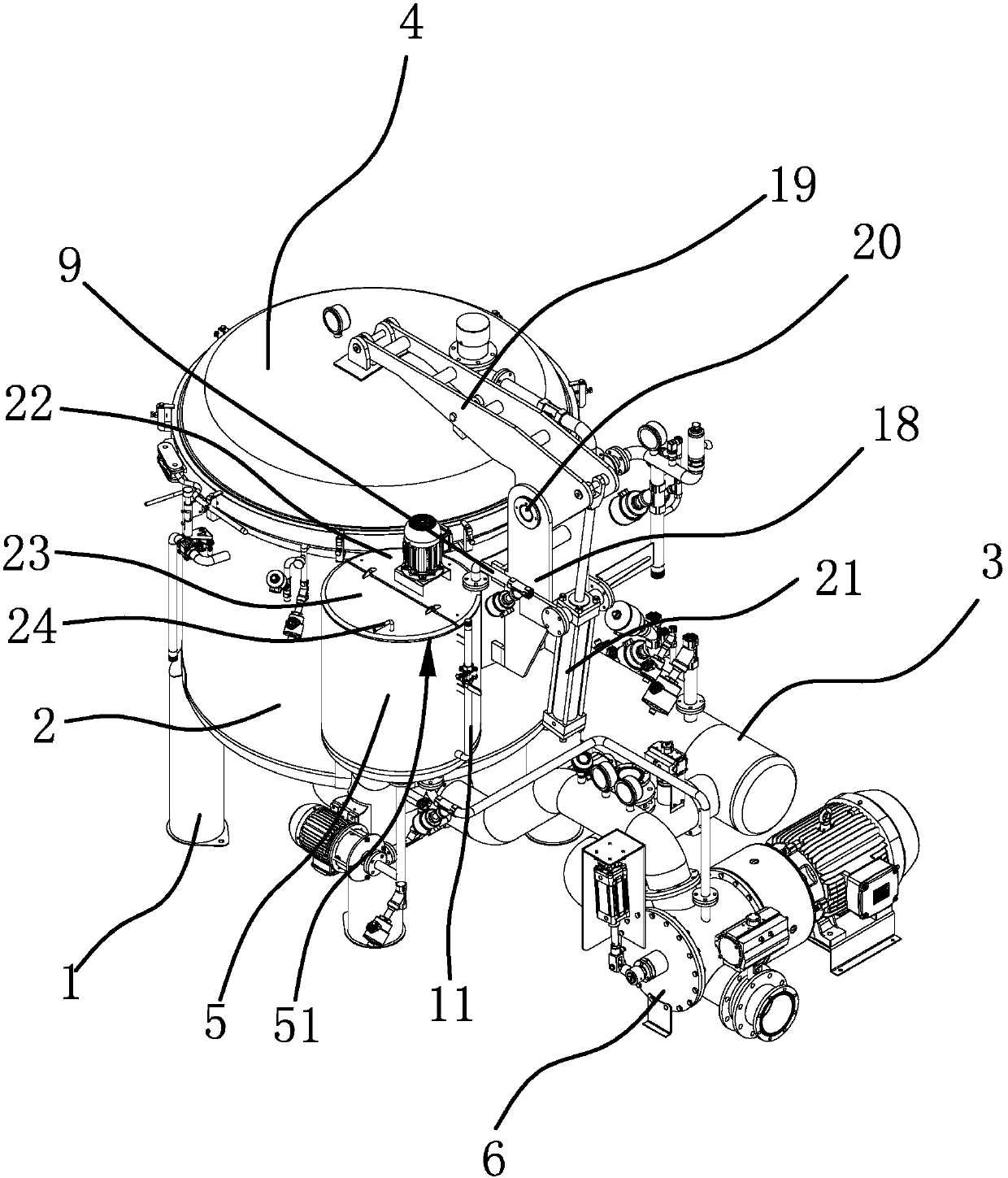

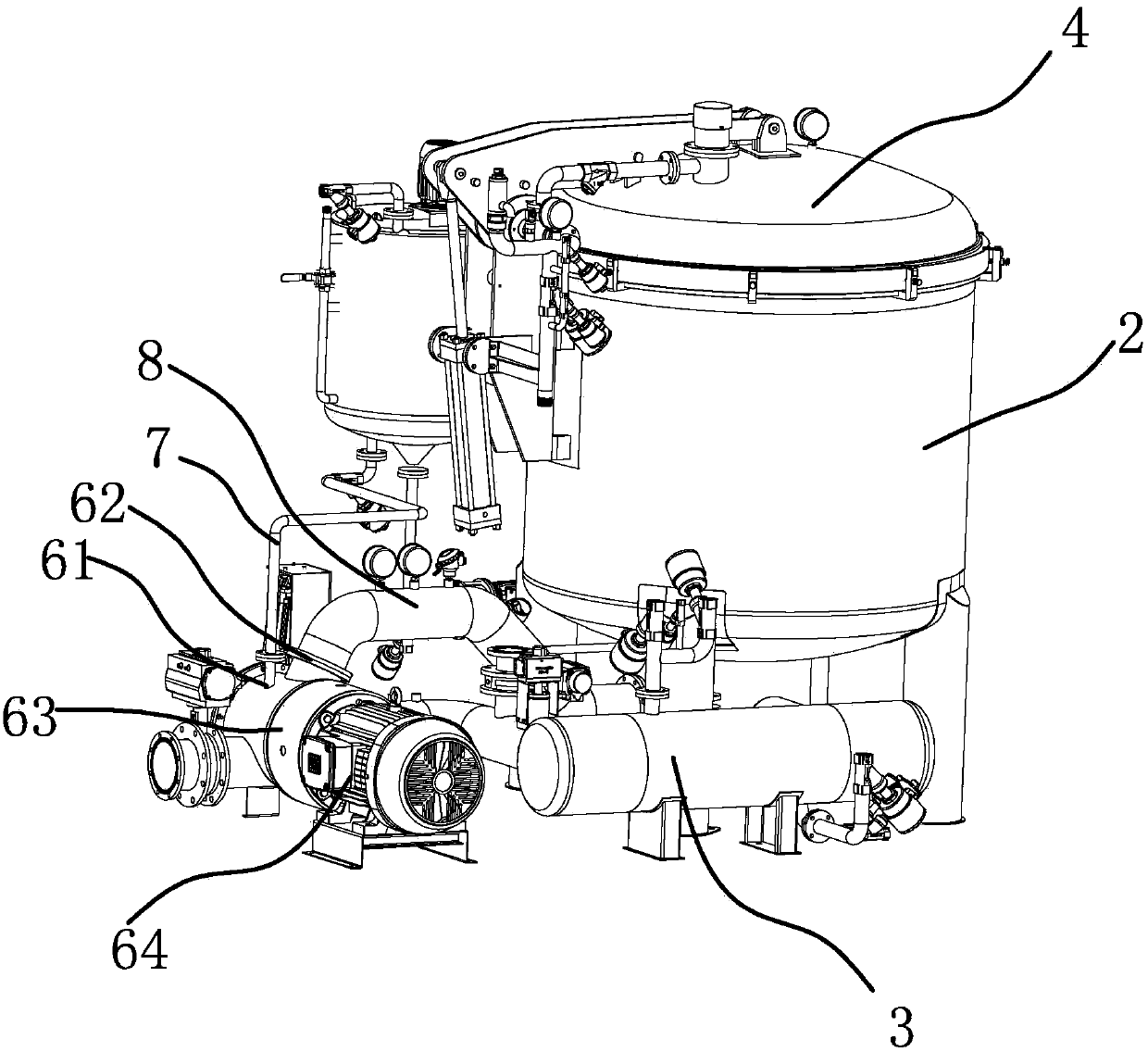

Supercritical carbon dioxide fluid dyeing device with two dye vats

InactiveCN104342869ARealize diverse productionSatisfy small batches and multiple varietiesTextile treatment containersTextile treatment machine arrangementsDye injectionInlet valve

A supercritical carbon dioxide fluid dyeing device with two dye vats comprises a liquid carbon dioxide storage tank, a carbon dioxide injection high-pressure pump, a heater, a dye mixing tank, a mixed dye injection high-pressure pump, a dye vat set, a pressure reduction cooler, a separation kettle, a condenser and a precise filter. The supercritical carbon dioxide fluid dyeing device is characterized in that the liquid carbon dioxide storage tank is sequentially connected with the carbon dioxide injection high-pressure pump, the heater, the dye mixing tank, the mixed dye injection high-pressure pump, the dye vat set, the pressure reduction cooler, the separation kettle, the condenser and the precise filter. The dye vat set includes the two dye vats. Each dye vat is connected with a dye vat inlet valve and a dye vat outlet valve. The inlet valve of each dye vat is connected with the mixed dye injection high-pressure pump. The outlet valve of each dye vat is connected with the pressure reduction cooler. The supercritical carbon dioxide fluid dyeing device has the advantages that generation of dyeing waste water and other wastes is avoided, environment-friendly and clean production can be achieved, and the device is low in cost and evident in economical and environmental benefits.

Owner:WUXI CITY HUAYANG DYEING & FINISHING MACHINERY

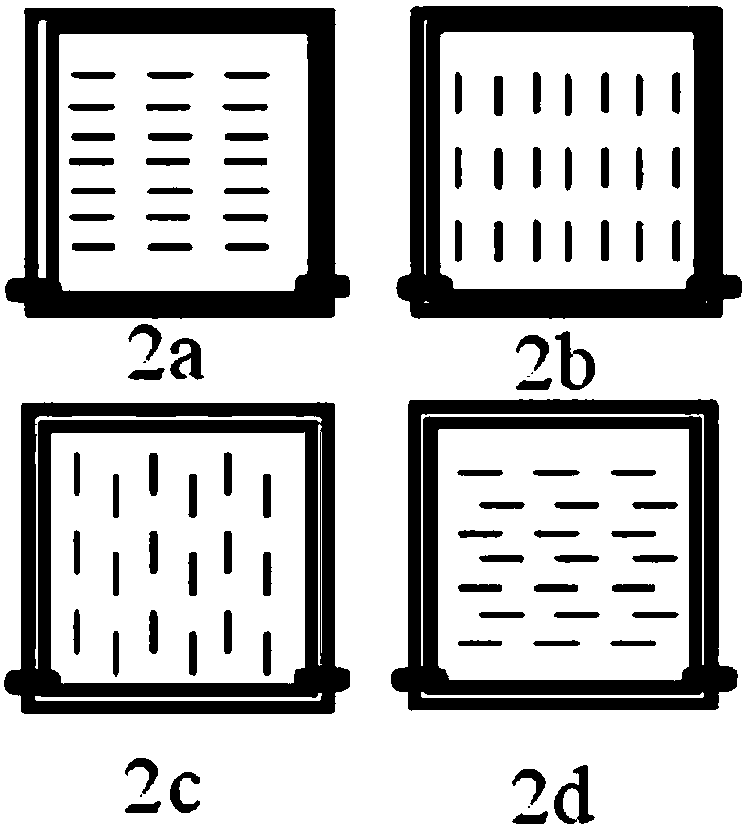

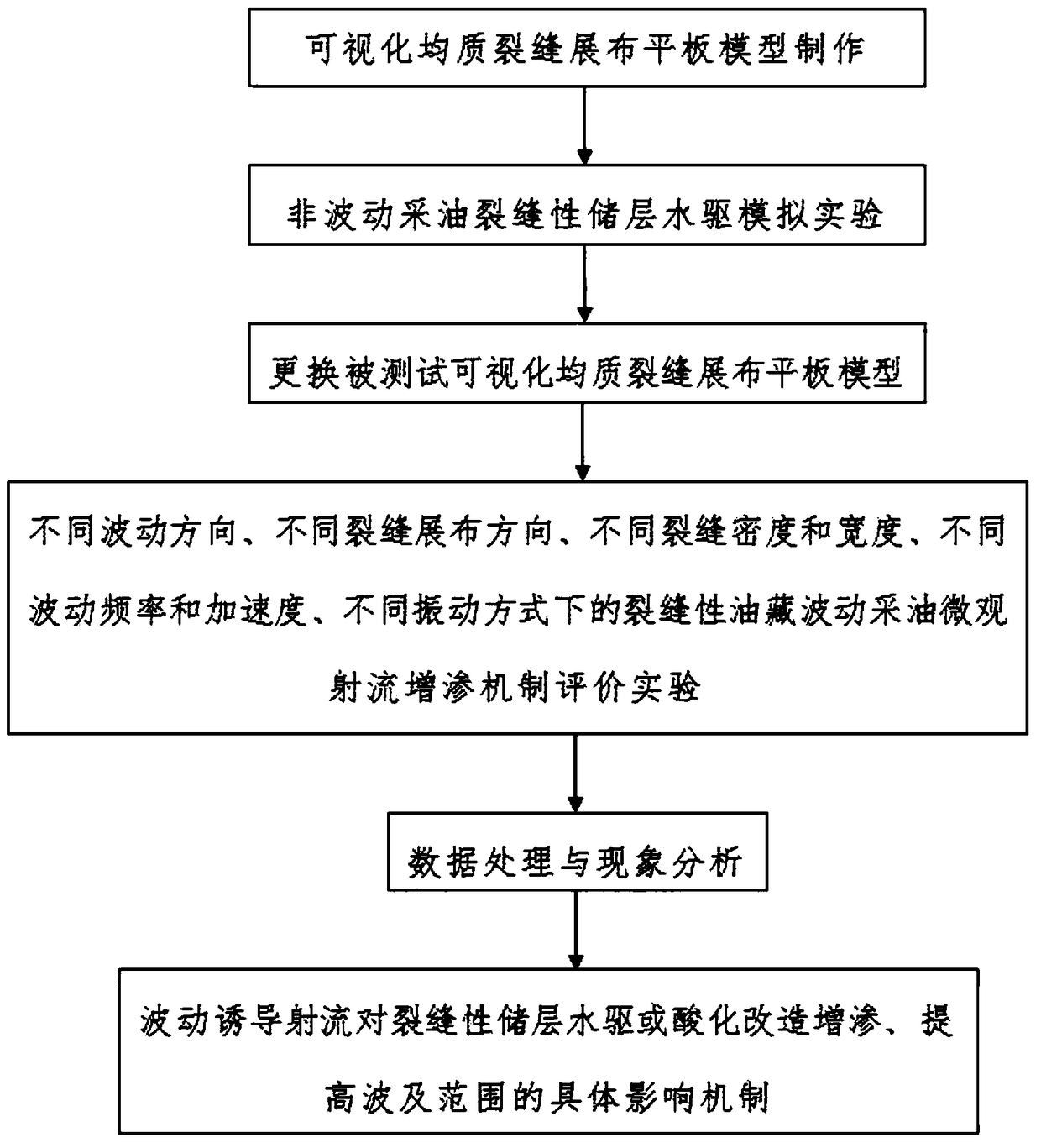

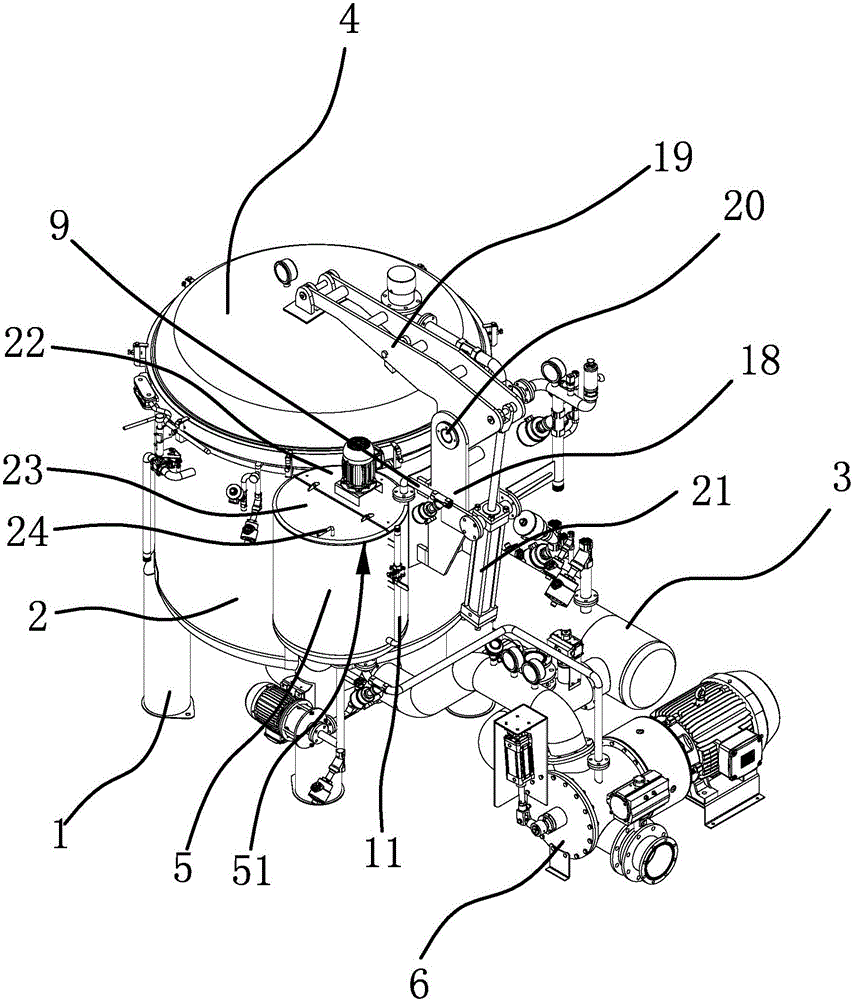

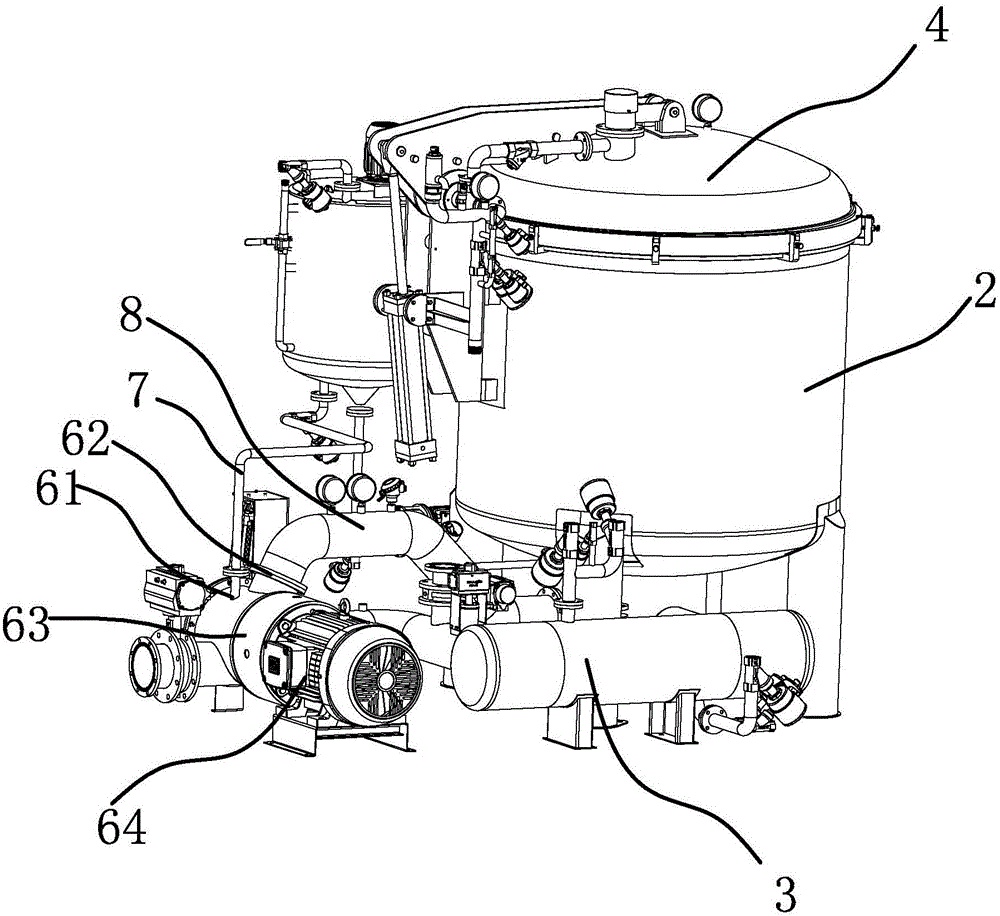

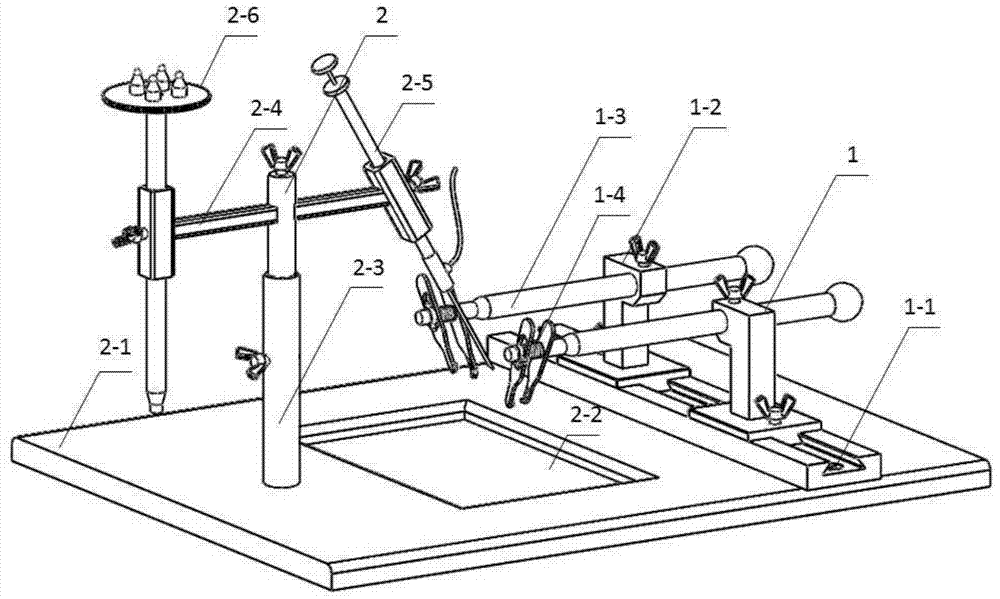

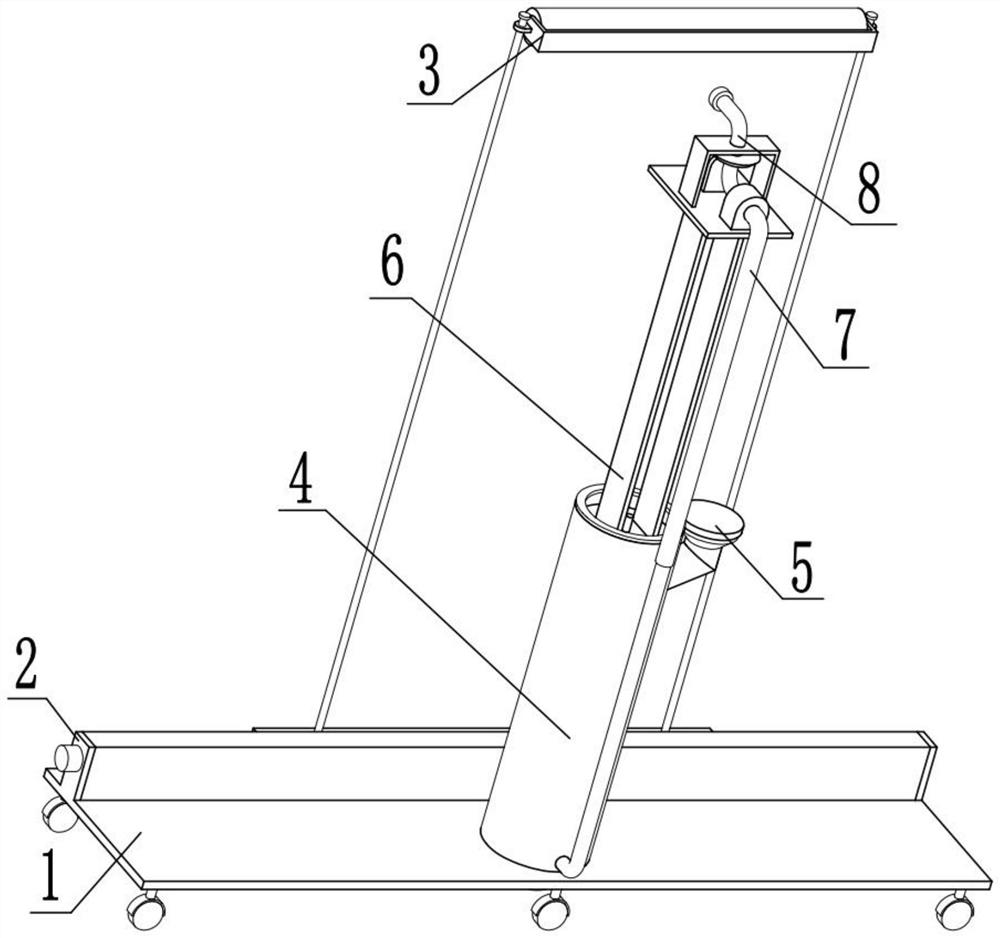

Experimental device and method for evaluating micro jet-flow permeation-increasing mechanism of fluctuation oil production of fractured reservoir

ActiveCN108266166ASimple structureEasy installation and layoutFluid removalVibration devicesWork performanceJet flow

The invention relates to an experimental device and method for evaluating a micro jet-flow permeation-increasing mechanism of fluctuation oil production of a fractured reservoir. The experimental device comprises a resonant wave test bed, a visual homogeneous crack distribution flat plate model, an annular pressure supplying part, a displacement pump, a formation water delivering middle container,an oil delivering middle container, a dyeing injection agent delivering middle container, a liquid container and a phenomenon observation part; the visual homogeneous crack distribution flat plate model is mounted on the resonant wave test bed and comprises an inlet, an outlet and an annular pressure opening; the output end of the annular pressure supplying part is connected with the annular pressure opening; input openings of the formation water delivering middle container, the oil delivering middle container and the dyeing injection agent delivering middle container are connected with an output opening of the displacement pump; output openings of the formation water delivering middle container, the oil delivering middle container and the dyeing injection agent delivering middle container are connected with the input end of the visual homogeneous crack distribution flat plate model; the liquid container is connected with the outlet; and the phenomenon observation part is mounted on the position corresponding to the visual homogeneous crack distribution flat plate model. The experimental device and method has the characteristics that the structure is simple, mounting and arrangement are convenient, the working performance is reliable, visualization is achieved, and the simulating effect is good; and the specific mechanism of the wave-induced micro jet-flow permeation-increasing effect of the fractured reservoir and expanding of the spread range can be effectively explained.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Yarn dyeing method

ActiveCN105821613AImprove efficiencyLower liquor ratioTextile treatment containersTextile treatment machine arrangementsRing dyeingDye injection

The invention provides a yarn dyeing method, and belongs to the technical field of textile related equipment. The technical problems that for an existing dyeing method, the dyeing efficiency is low, and dyeing is inconvenient are solved. The yarn dyeing method comprises the steps of 1, yarn preparation and inspection, wherein the yarn quality is inspected before yarn dyeing is conducted, and it is required that the appearance of yarns is clean and free of stain, the yarns are neutral, the stacking time must not be over 8 h, and the yarns are covered with wet cloth; 2, feeding, wherein yarns are put into a dye vat and arranged on a yarn dyeing rod; 3, dye preparation, wherein anthraquinone vat dye is prepared in a dye barrel, 5 g-6 g of caustic soda and 5-6 g of rongalite are added according to each part by mass of raw material with an anthraquinone type structure, water is injected to obtain a solution, and 0.2 g / L-0.5 g / L of bone glue retarding agent is added; 4, dye injection and dyeing, wherein the prepared dye is injected into the dye vat; 5, yarn taking-out. The yarn dyeing method has the advantages of being high in dyeing efficiency and uniform in dyeing, and the yarns subjected to dyeing is fluffy and full in hand feeling.

Owner:ZHEJIANG DUOYUAN TEXTILE TECH CO LTD

Switchable cloth dyeing and printing equipment

InactiveCN106968065AFlexible switchingAct as a fixed limitTextile treatment machine arrangementsTextile treatment by spraying/projectingInternal pressureWrinkle skin

The invention relates to a switchable cloth printing and dyeing equipment, which includes a dyeing box part, the dyeing box part includes a switching mechanism and a spraying mechanism; the switching mechanism includes a spraying support unit, a switching unit and a walking support unit; the spraying mechanism includes a spraying mechanism device and a pressure regulating device arranged on the spraying device; the spraying part, the spraying part is arranged below the spraying support unit, the spraying part includes a spraying station, and a support is arranged below the spraying station , the front end of the support is provided with a wrinkle removal unit, and the rear end of the support is provided with an absorption unit; the adjustment part, the adjustment part is arranged above the spraying mechanism, and the adjustment part includes a lifting mechanism that moves up and down under the action of gravity of the cloth, and the lifting mechanism Cooperate with the spraying mechanism on the spraying station to drive the pressure regulating device on the spraying mechanism to adjust the pressure inside the spraying device; it overcomes the problem that the equipment does not have the flexibility to switch different color dyeing boxes and does not have the ability to self-adjust the amount of dye injection question.

Owner:CHANGXING JIAPU YIHANG TEXTILE FACTORY

Energy-saving cloth dyeing machine

ActiveCN105648678AEliminate the dipping processResolve stackTextile treatment machine arrangementsTextile treatment by spraying/projectingDye injectionEngineering

The invention discloses an energy-saving cloth dyeing machine which comprises a box, a water bucket and a transmission device. A drive rotating shaft, a cloth lifting roll, a guide roll, a cloth conveying calandria and dye injection probes are arranged in the box; the cloth lifting roll is provided with water spray probes connected with a water inlet pipe; the dye injection probes are close to the guide roll and connect a dye discharge pipe to the water bucket; the cloth conveying calandria is formed by combining a plurality of drums. According to the energy-saving cloth dyeing machine, the structure is simple, use is convenient; the two faces of cloth are simultaneously spray-dyed by the dye spray probes, a dye tank is not arranged, and dip dyeing does not needed to be performed; the two faces of the dyed cloth are rinsed by the water spray probes, water is saved, and sewage is not generated; the cloth smoothly and slowly moves in the dyeing machine through the cloth lifting roll, the guide roll and the cloth conveying calandria, the cloth can be prevented from being stacked, and uniform dyeing can be achieved.

Owner:吴江市奕萱纺织有限公司

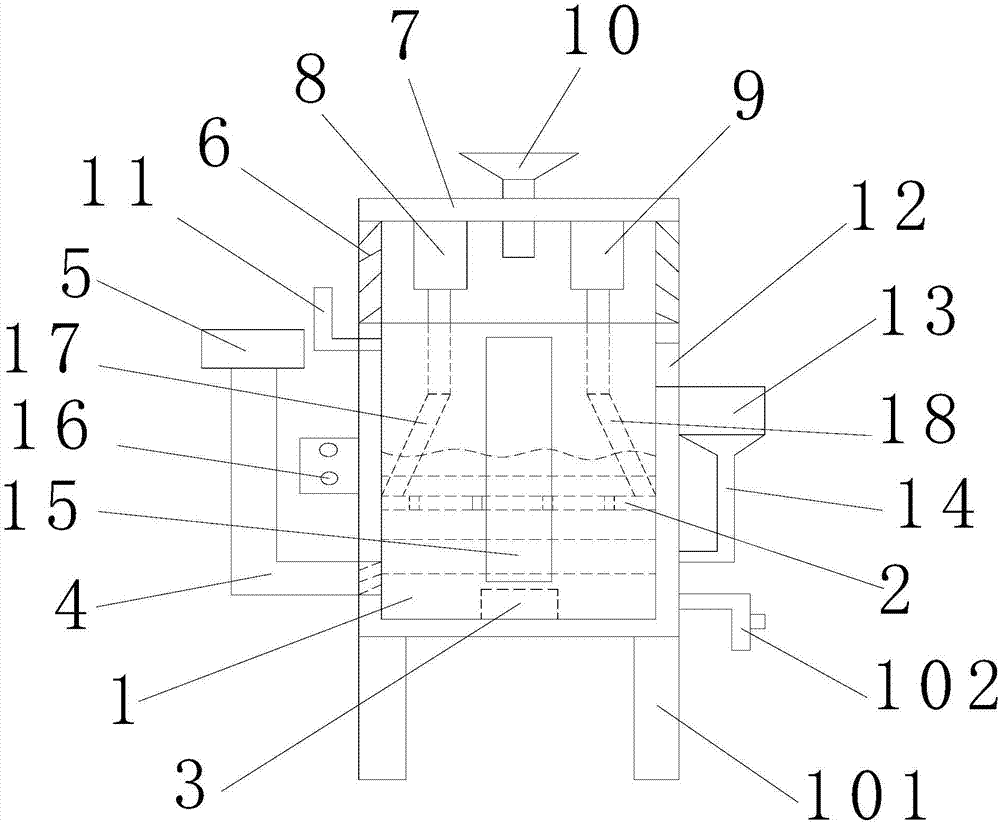

Multifunctional electric spraying dying roll-over frame clothes dyeing machine

InactiveCN104178959AImprove dyeing pass rateLiquid/gas/vapor article treatmentTextile treatment by spraying/projectingDye injectionEngineering

The invention discloses a multifunctional electric spraying dying roll-over frame clothes dyeing machine. The clothes dyeing machine comprises a dyeing vessel, a fixed base frame, a clothes roll-over frame and a dye injection pump, wherein the fixed base frame is installed and fixed in the dyeing cylinder, a roll-over shaft rod is arranged at the upper end of the fixed base frame, a rotary motor is arranged at one end of the roll-over shaft rod, the output end of the rotary motor is coaxially connected with the roll-over shaft rod, one end of the clothes roll-over frame is fixedly connected with the roll-over shaft rod, a frame rod at the other end of the clothes roll-over frame and a frame rod at the upper end of the fixed base frame are respectively provided with clothes clips, a telescopic lifting rod device is further arranged in each of the frame rods on the two sides of the clothes roll-over frame, and the dye injection pump is arranged on the inner side wall of the upper end of the dyeing vessel. Due to the mode, clothes can be soaked in the dyeing vessel through rolling over of the clothes roll-over frame, meanwhile, color supplementing can be performed on the dyed clothes through the dye injection pump, dyeing dead angles are avoided, and the dyeing qualification rate is increased.

Owner:无锡市万邦机械制造厂

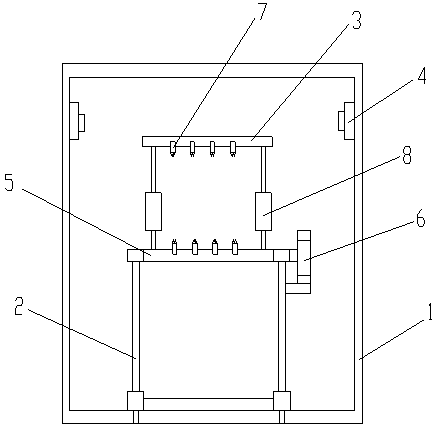

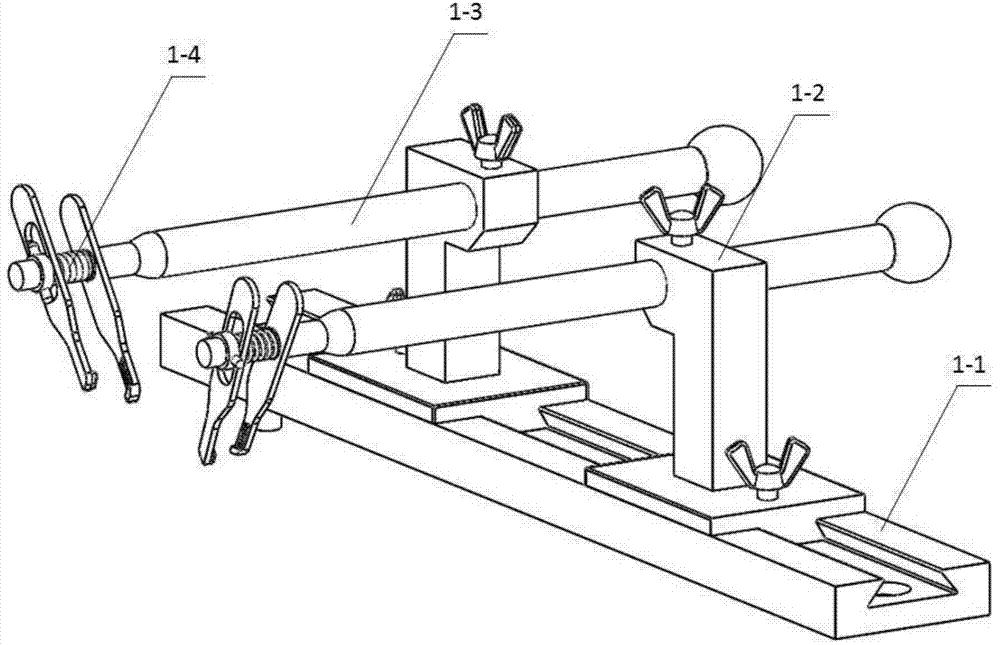

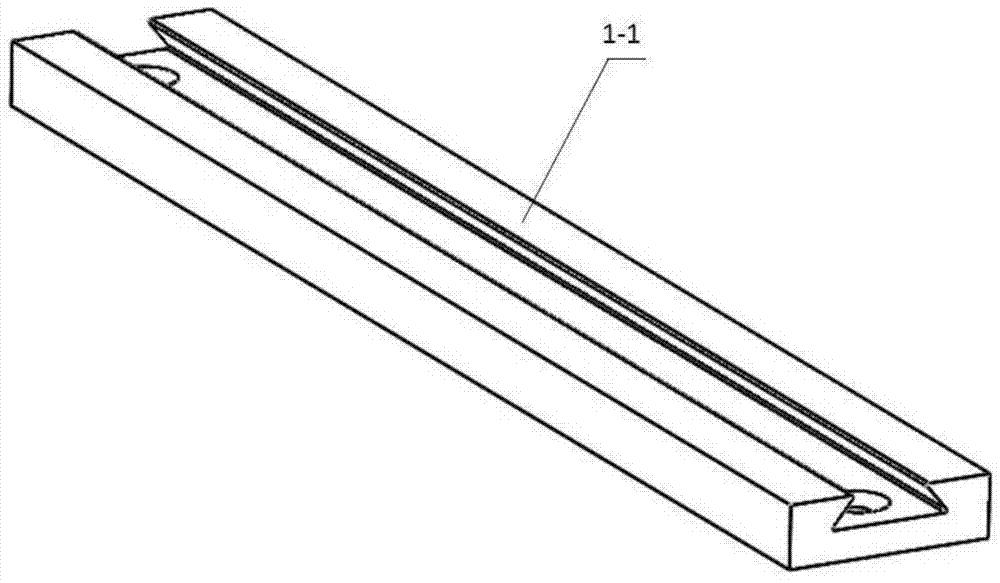

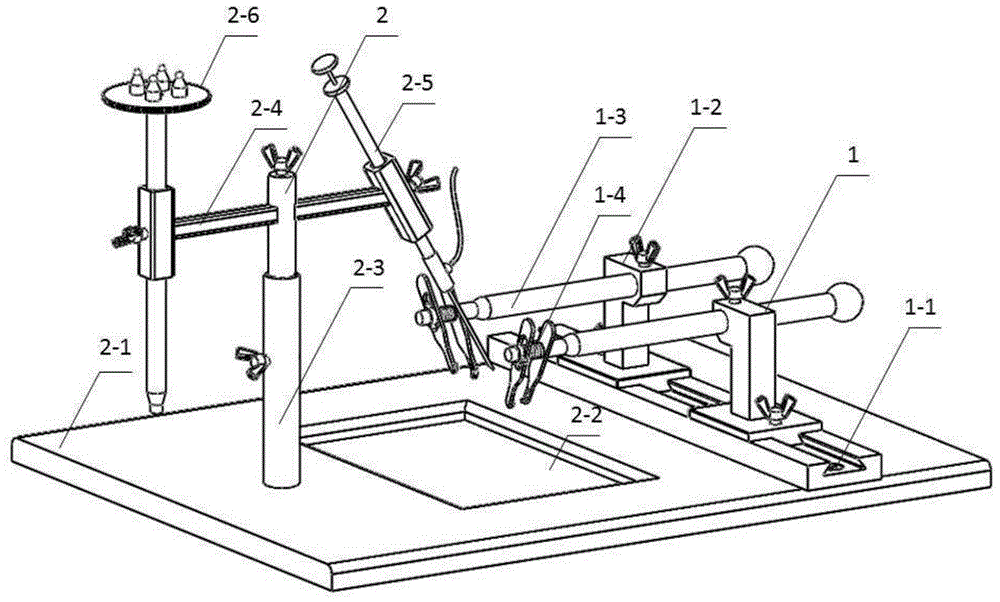

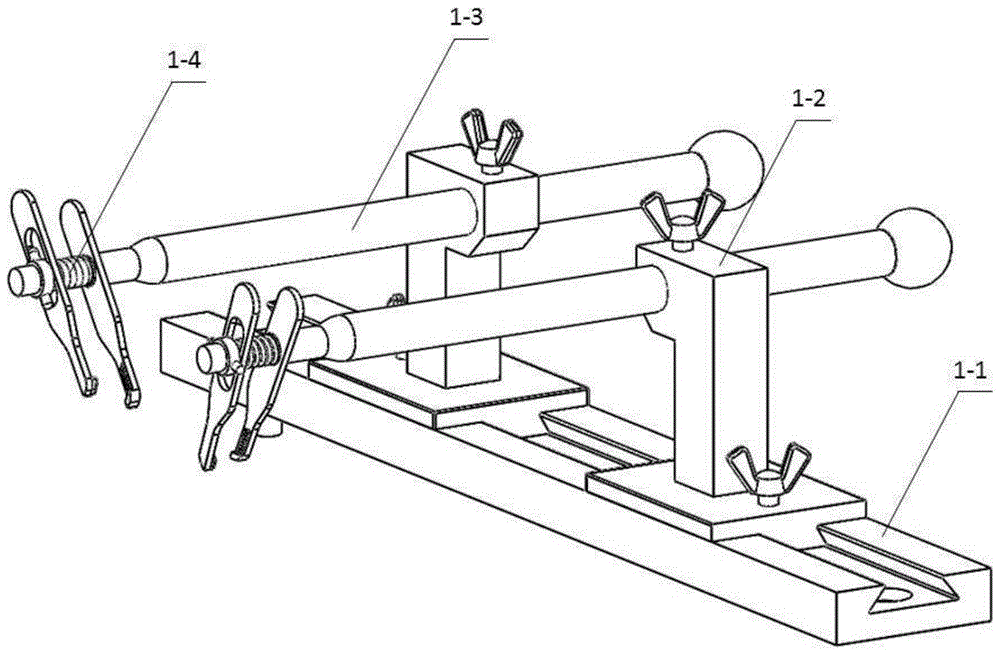

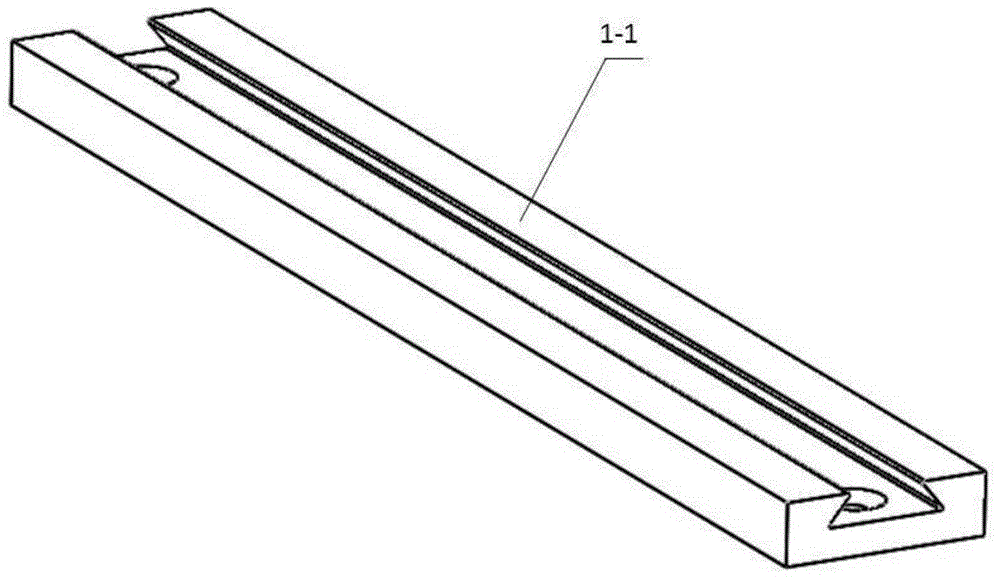

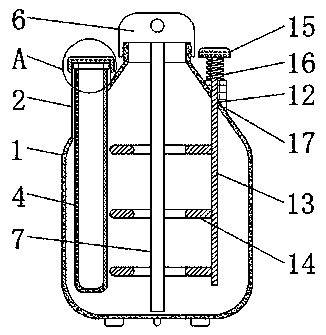

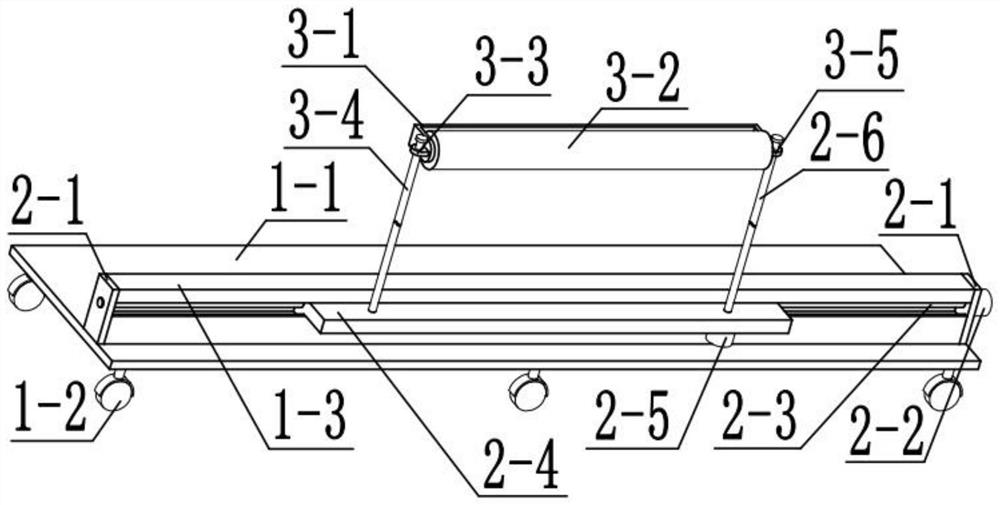

Animal dorsal root ganglion-spinal cord fixed imaging and compression injury combining device

InactiveCN104771145AAchieve stable positioningOvercome Imaging DeficienciesMusculoskeletal system evaluationDiagnostics using lightDye injectionMicroscope

The invention relates to an animal dorsal root ganglion-spinal cord fixed imaging and compression injury combining device, which comprises a dorsal root ganglion-spinal cord fixed imaging device and a microscopic fluorescent dye injection and spinal cord compression injury integrating device, wherein the animal dorsal root ganglion-spinal cord fixed imaging device (1) comprises a horizontal slide block guide rail (1-1), a fixing component (1-2), a slide rod (1-3) and a spine fixing clamp (1-4), and the microscopic fluorescent dye injection and spinal cord compression injury integrating device (2) comprises a vertical-rotating regulating side rod (2-3), a horizontal regulating component (2-4), a microscopic injection component (2-5) and a spinal cord compression component (2-6). The combining device has the advantages that multiple functions are integrated, the operation is simple and convenient, the switching can be realized at any time, different-degree spinal cord injury animal models can be conveniently manufactured, and after the fluorescent dye microscopic injection, a two-photon microscope is used for dynamically observing the pathological and physiological change process of the dorsal root ganglion-spinal cord injury in real time.

Owner:GENERAL HOSPITAL OF PLA

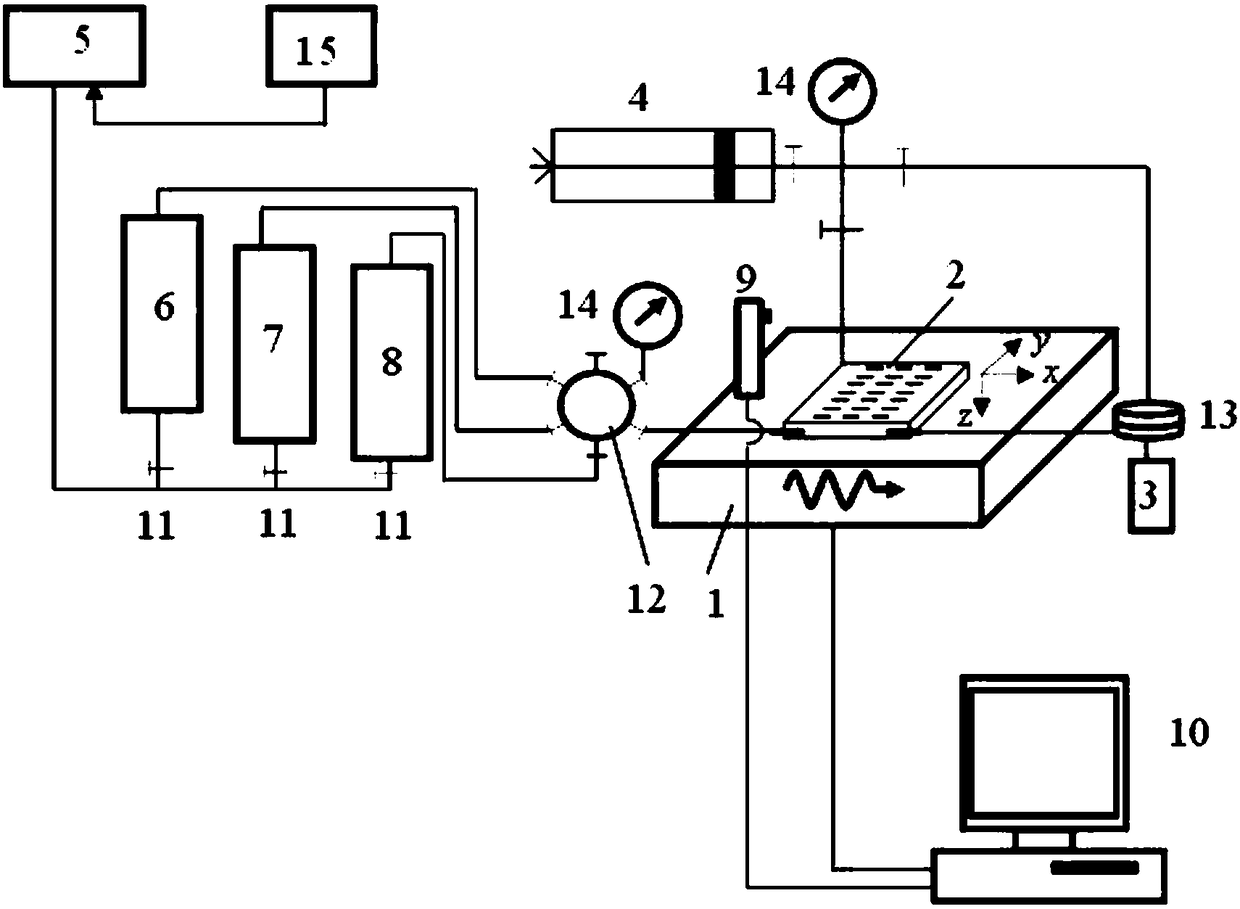

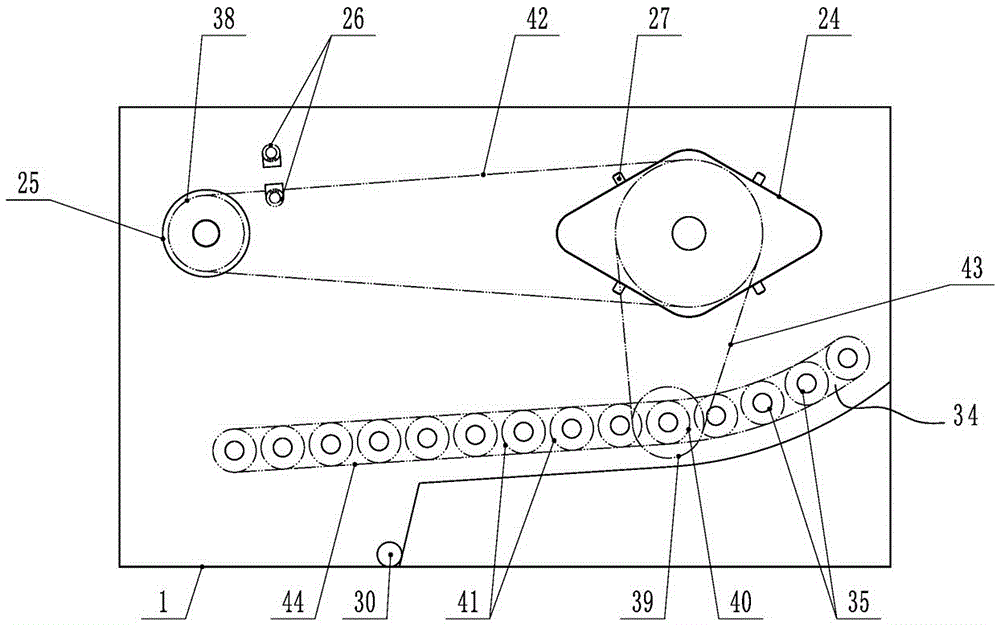

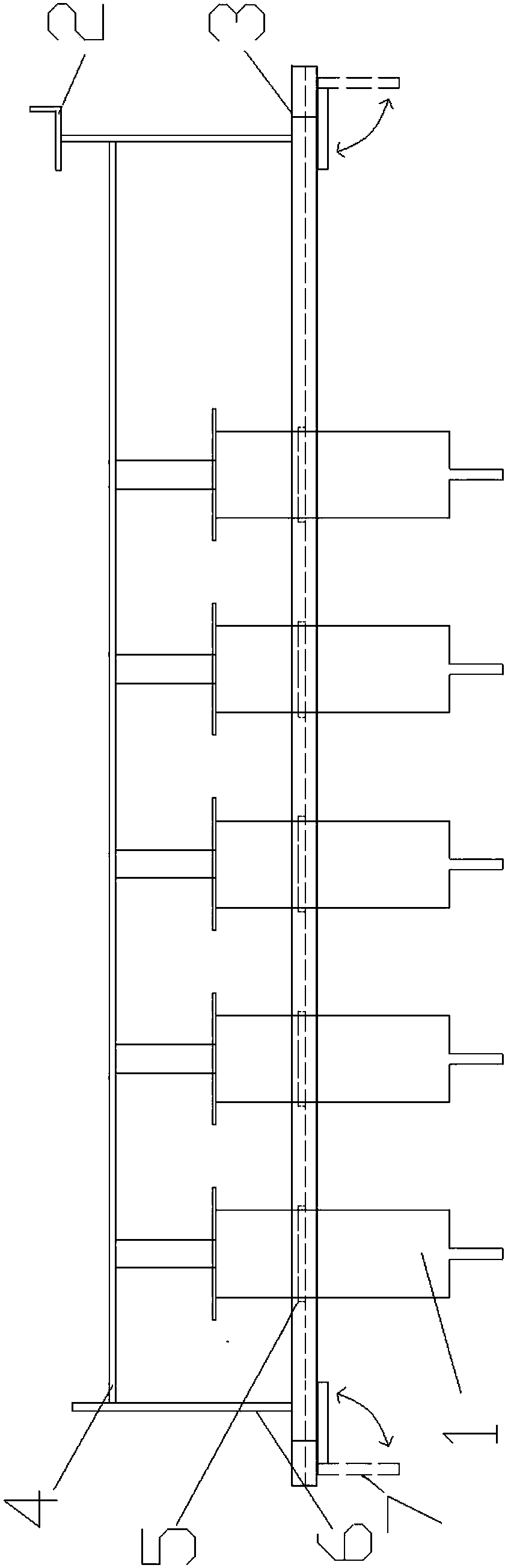

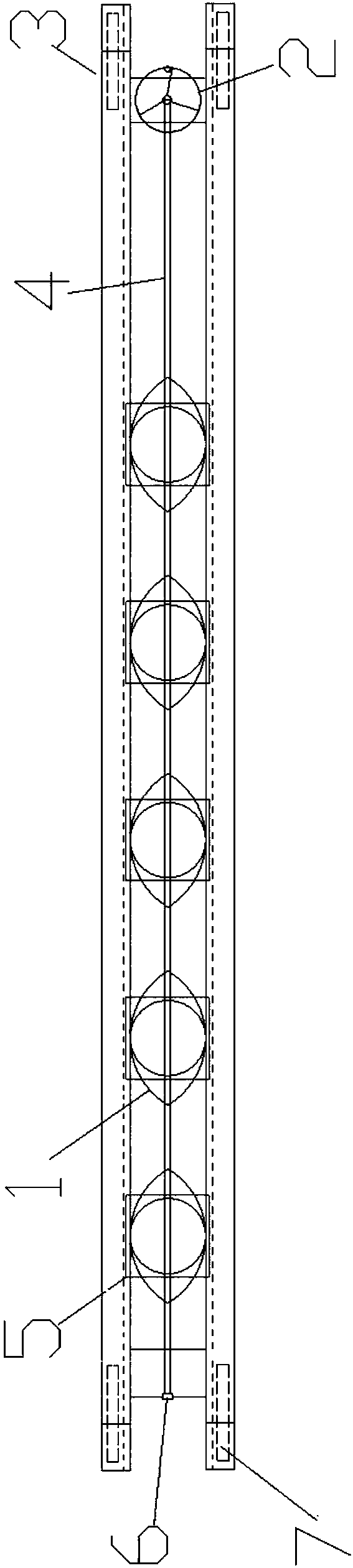

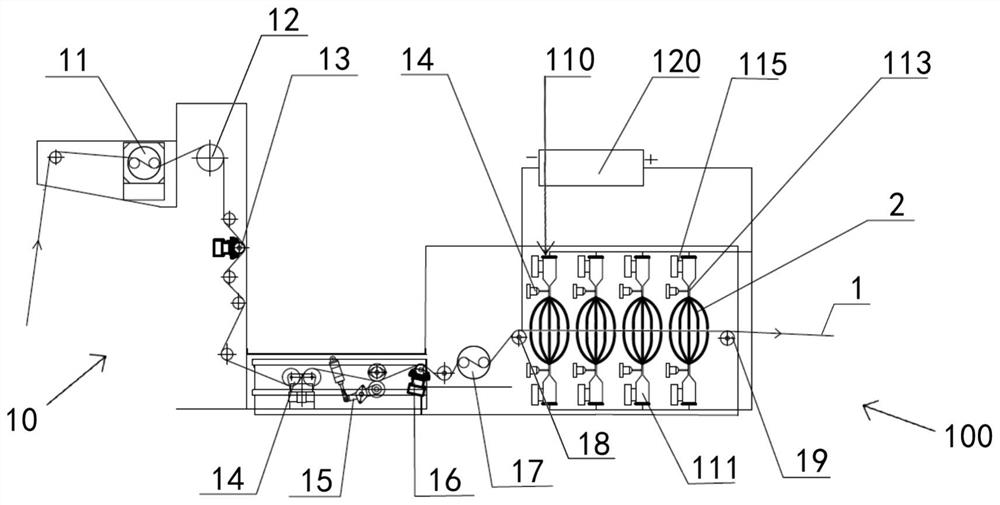

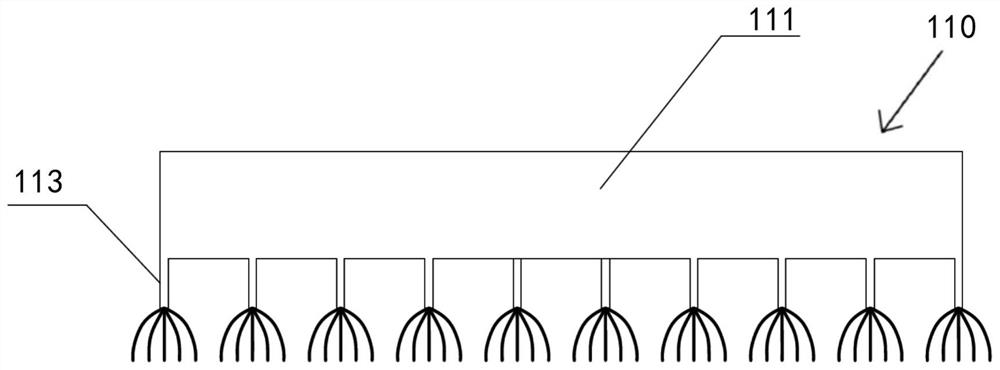

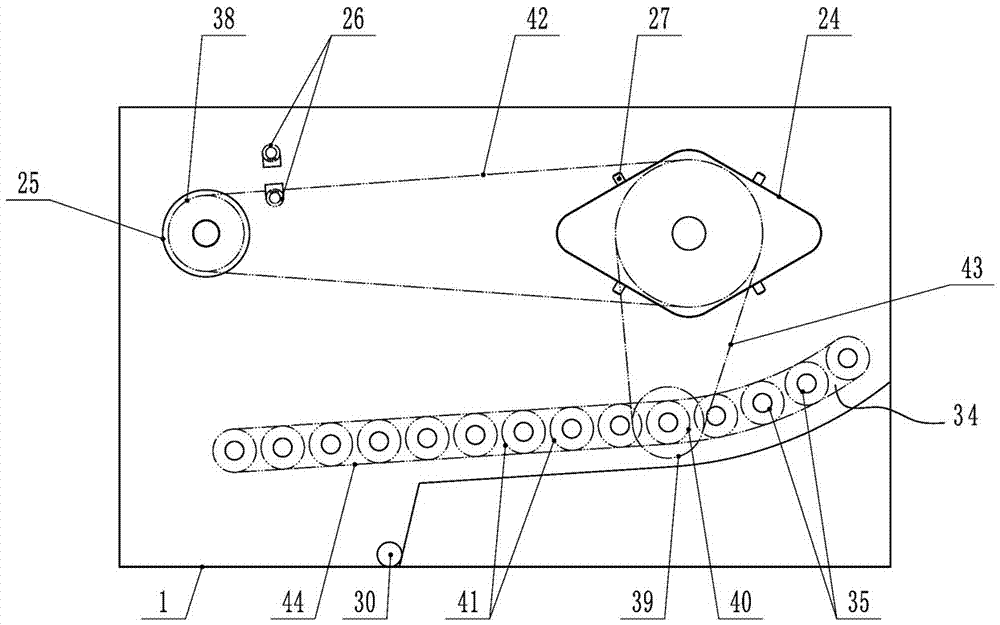

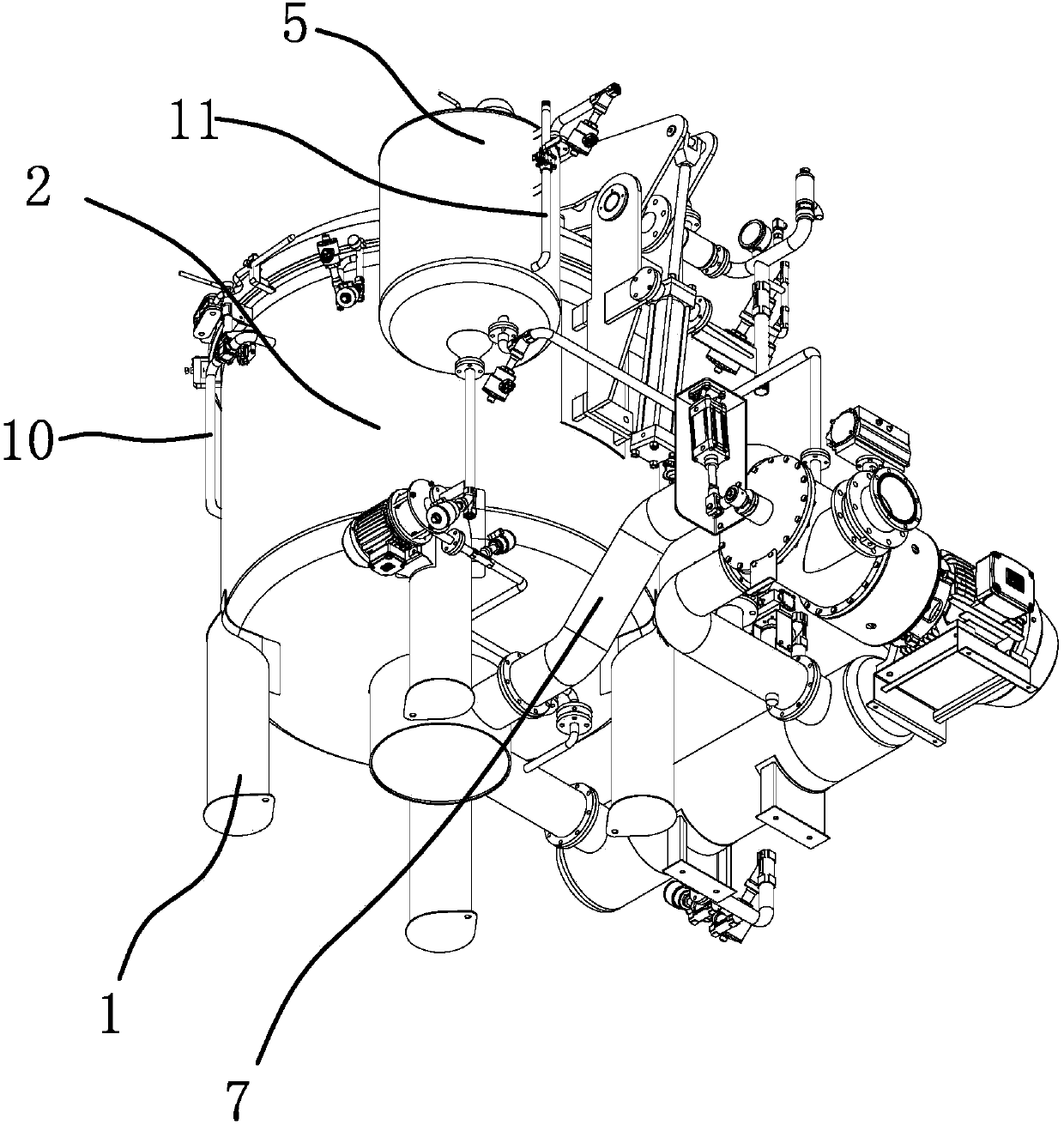

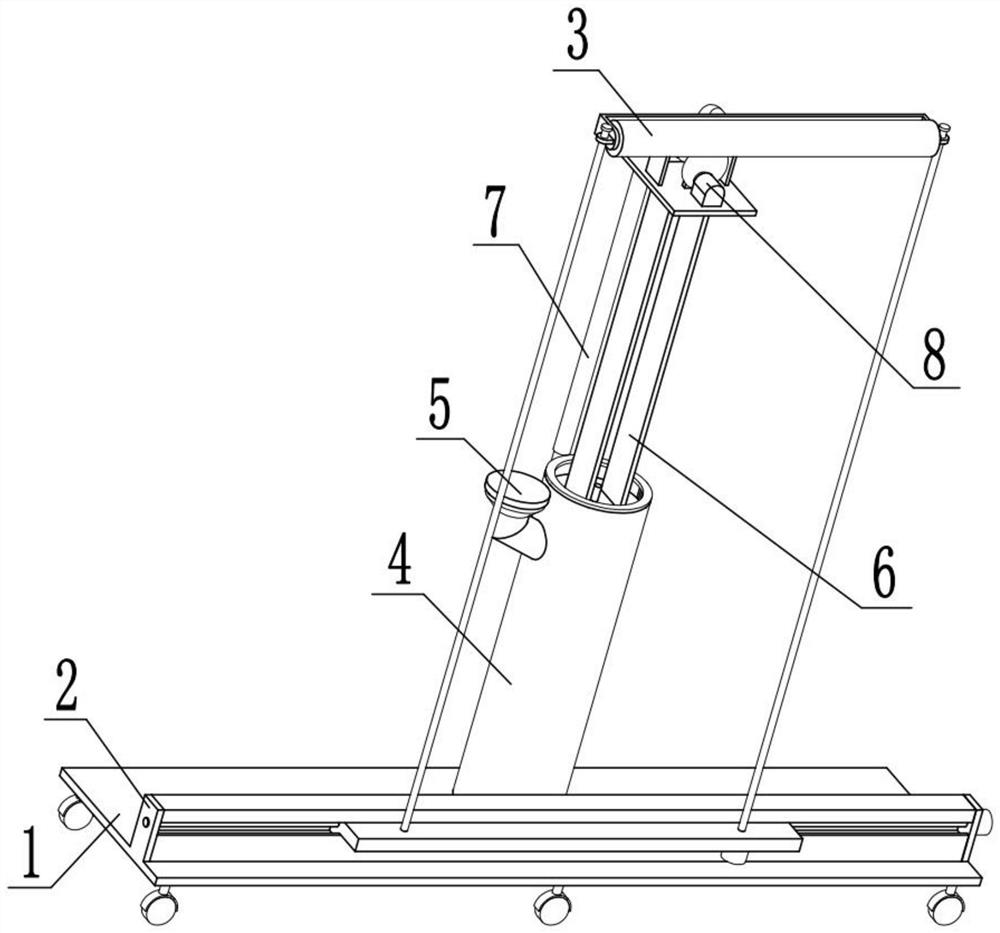

Dye filling apparatus for hydraulics flow visualization test and test method

ActiveCN108398232AImprove injection efficiencyEasy to adjustHydrodynamic testingDye injectionWater flow

The invention discloses a dye filling apparatus for a hydraulics flow visualization test. The apparatus comprises a plurality of needle cylinder syringes, an elevating rotary wheel, a telescoping framed bent, a pressing rod, a mobile slide block, upper support racks and lower support racks, wherein the mobile slide block is horizontally connected on needle cylinders of the needle cylinder syringesin a clamped manner, two ends of the mobile slide block are positioned in a groove, the upper support racks are respectively arranged on connection blocks on two ends of the telescoping framed bent,the elevating rotary wheel is arranged on the upper support rack on one end, two ends of the pressing rod which is fixedly connected to piston handles of the needle cylinder syringes are respectivelyand movably connected to the upper support racks on the two ends, the elevating rotary wheel is connected with the pressing rod in a transmitting manner, and the invention also discloses a hydraulicsflow visualization test based on the filling apparatus. The beneficial effects of the dye filling apparatus and the test method are that dye liquor of a plurality of point locations can be injected atthe same time, the apparatus and the method are suitable for water flow visualization tests of test riverways of different specifications, and dye injection efficiency can be improved.

Owner:SICHUAN UNIV

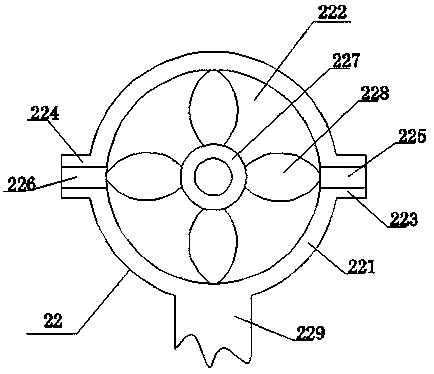

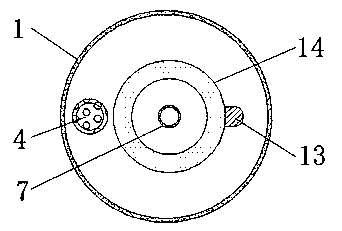

Clothes dyeing machine with air blowing rotary clothes rack

InactiveCN104178951ARotational dyeing balanceNo spray dead angleTextile treatment by spraying/projectingTextile treatment carriersDye injectionElectric machinery

The invention discloses a clothes dyeing machine with an air blowing rotary clothes rack. The clothes dyeing machine with the air blowing rotary clothes rack comprises a base, a dyeing vessel, an annular dyeing frame, a blowing plant and a dye injection pump, wherein the dyeing vessel is arranged on the base, the annular dyeing frame is installed in the dyeing vessel, a dyeing frame rotary shaft is arranged in the middle of the annular dyeing frame, evenly-distributed air blowing vent holes are formed in the side wall of the dyeing frame rotary shaft, a rotary motor is arranged at the bottom of the dyeing vessel, one end of the dyeing frame rotary shaft is coaxially connected with the rotary motor, the other end of the dyeing frame rotary shaft is connected with the blowing plant, the upper end and the lower end of the annular dyeing frame are respectively provided with a rotary disk frame, clothes fixing clips are arranged on the rotary disk frames, and the dye injection pump is arranged on the inner side wall of the dyeing vessel. Due to the mode, air can be blown to the annular dyeing frame through the blowing plant, clothes can be unfolded better through air blow, the clothes can be rotationally dyed more evenly, dyeing is through, and no injection dead angles exist.

Owner:无锡市万邦机械制造厂

Button dyeing machine

InactiveCN107138341AImprove dyeing effectEasy to drainLiquid surface applicatorsCoatingsDye injectionPulp and paper industry

The invention discloses a button dyeing machine. The button dyeing machine comprises a dye vat, a containing sieve, an electric heater, an air inlet pipe, an air pump, mounting racks, a top plate, a first air cylinder, a second air cylinder, a discharging hopper, a dye injection pipe, a discharge opening, a draining box, a guide pipe, an observation window, a first connecting rod and a second connecting rod. The horizontally-arranged containing sieve is arranged on the inner side of the dye vat in a sliding manner. The electric heater is arranged at the bottom of the inner side of the dye vat. The lower side of the dye vat communicates with the air inlet pipe. The air pump is arranged at the outer end of the air inlet pipe. The two symmetrically-arranged mounting racks are fixedly arranged on the two sides of the upper portion of the dye vat. The horizontally-arranged top plate is fixedly connected between the upper ends of the two mounting racks. The first air cylinder and the second air cylinder arranged side by side left and right are fixedly arranged at the bottom of the top plate. Compared with the prior art, buttons can be dyed fast and efficiently; the button dyeing efficiency and effect are improved; the labor intensity of workers is reduced; and great convenience is brought to button production.

Owner:嘉兴瑜浩服饰辅料有限公司

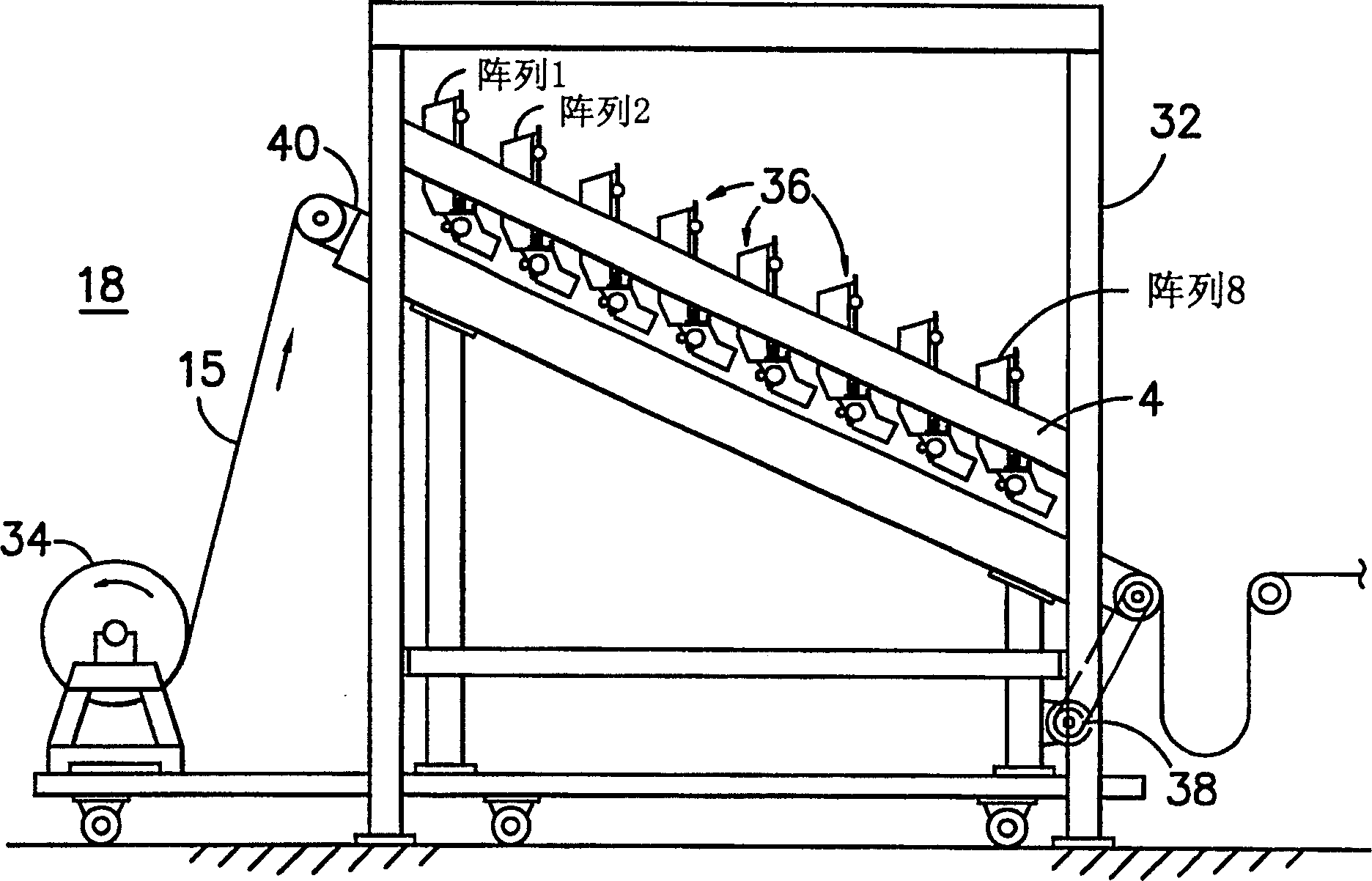

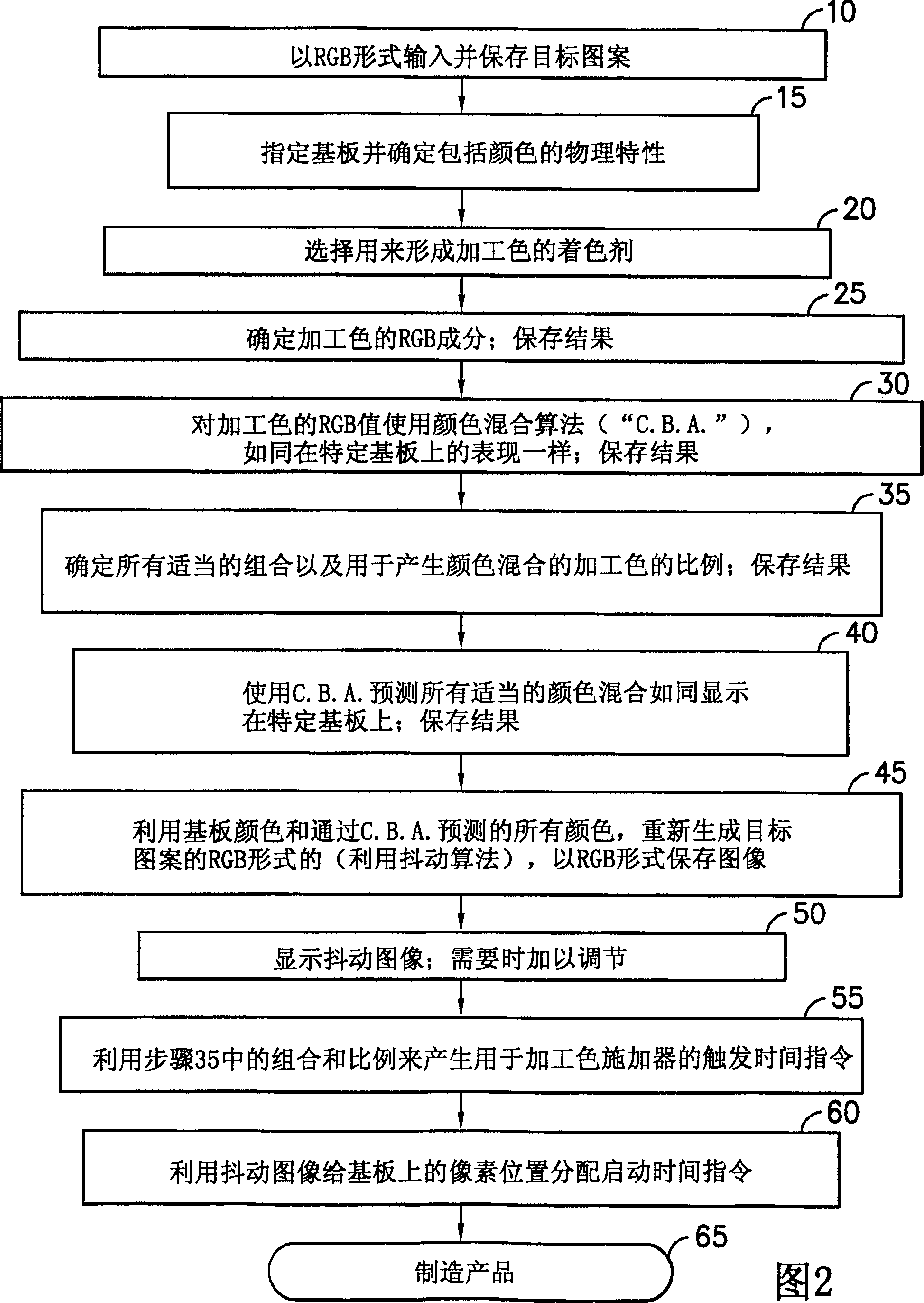

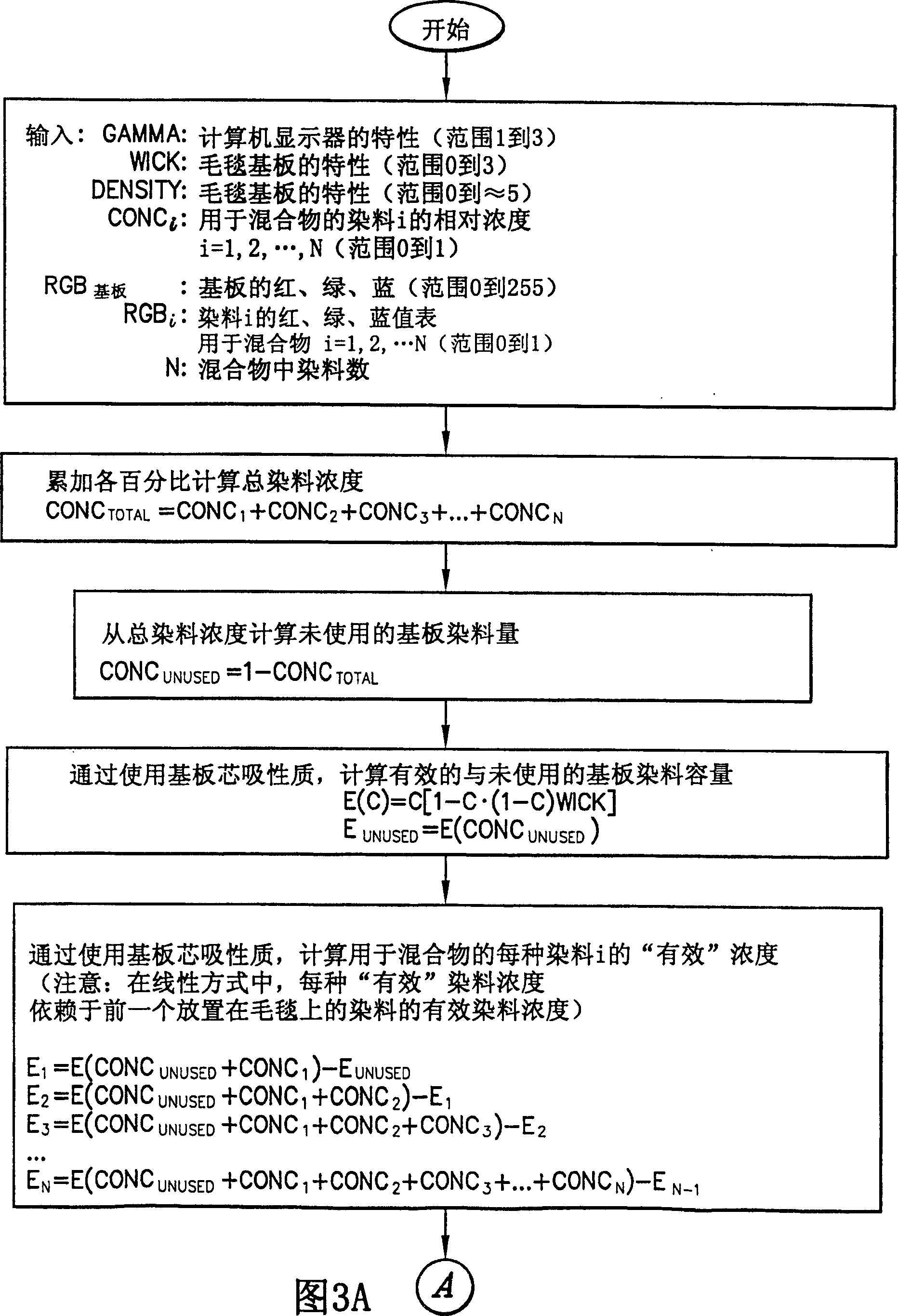

Reproduction of colored images on absorbent substrates using color blending techniques

InactiveCN1545678ADyeing processTextile treatment by spraying/projectingComputer Aided DesignDye injection

A process by which dithering techniques may be used to reproduce a desired multi-colored dyed pattern on a substrate using precisely delivered quantities of liquid colorants that are available in only a relatively few colors. In one embodiment, the process is one in which a designer, working with a conventional computer-aided design system, can be provided with an image that accurately predicts the appearance of individual colorants, or a specific combination of colorants that are physically blended on the substrate within specified pixels, as those colorants would appear on the substrate selected by the designer. In other embodiments incorporating the process disclosed herein, specific actuation instructions for a specific dye injection machine capable of patterning a moving textile substrate may be generated.

Owner:MILLIKEN & CO

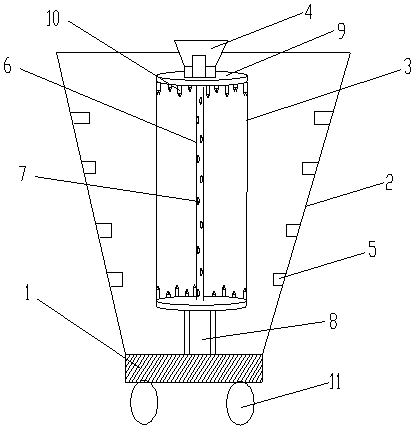

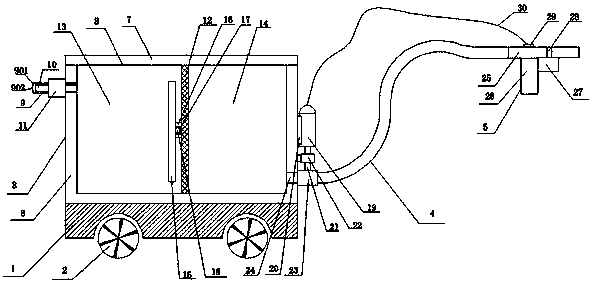

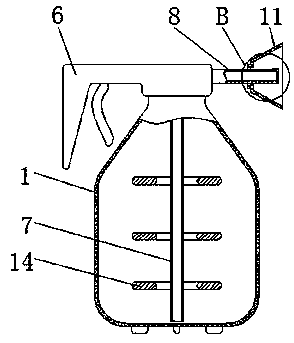

Improved trolley with high-capacity dye mixing paint spraying function

InactiveCN109127201AWith balancePreventing accelerated curing problemsLiquid spraying apparatusDye injectionEngineering

The invention discloses an improved trolley with a high-capacity dye mixing paint spraying function. The trolley comprises a bottom plate, a dye mixing device and a spray gun device, wherein a plurality of dye injection pipes which are connected with a dye stirring box are arranged on one end face of the dye stirring box, a motor is arranged outside the end face of one end, close to a dye finishedproduct area, of the dye stirring box, a boosting device is arranged at the part in the middle part of a multi-purpose rod of the motor, a dye extraction device is connected with one end, penetratingthrough the boosting device, of the multi-purpose rod, and the other end of a hose is provided with the spray gun device. According to the trolley, the dye stirring box is provided with the pluralityof dye injection pipes, the feeding speed of each kind of dye can be controlled through a flow control valve, and the requirement for the proportion of different dyes during blending color can be met; and an internal electric stirring mechanism can automatically stir the dye, the working of the motor on the outer side of the stirring box drives the dye extraction device to extract the mixed dye,then the dye is sprayed out through a spray gun, so that the paint spraying speed of the spray gun can be conveniently controlled, and the paint spraying can be more uniform.

Owner:陈月玲

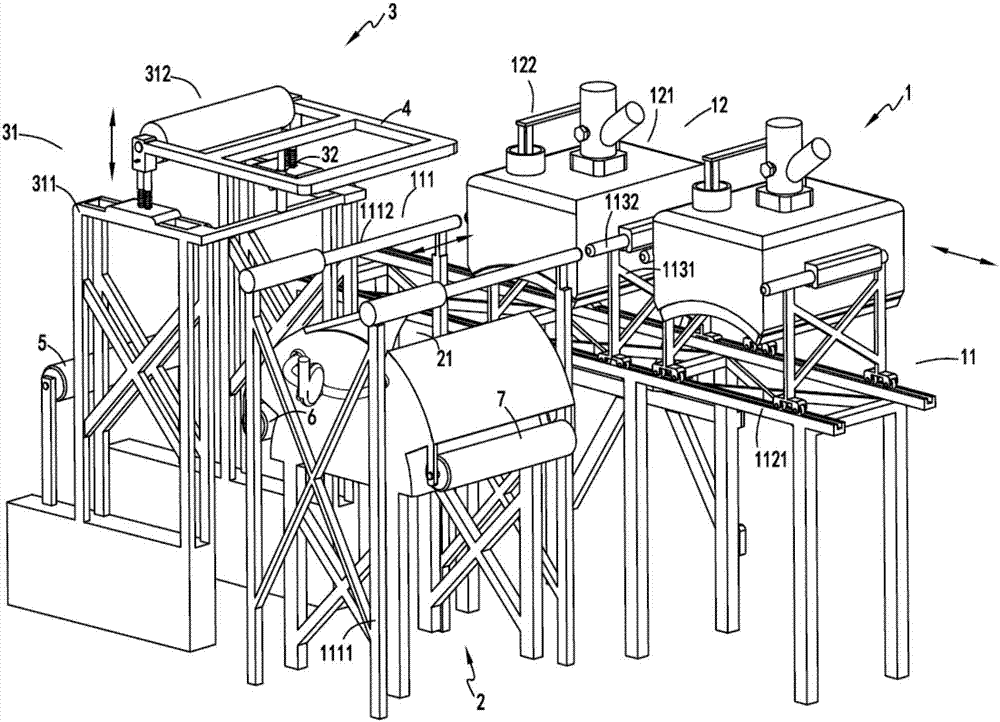

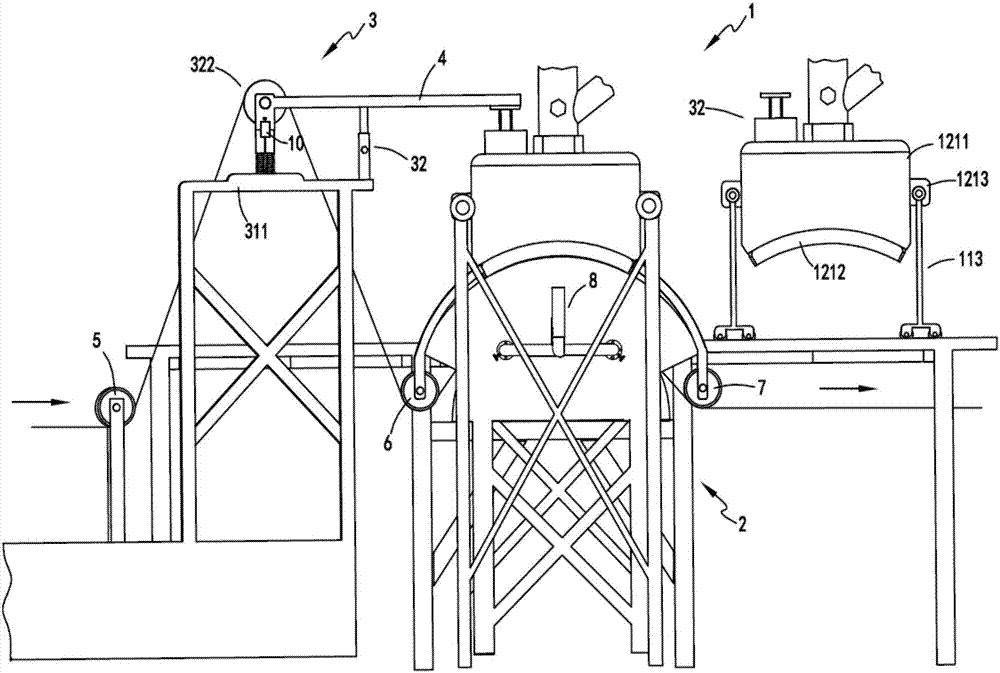

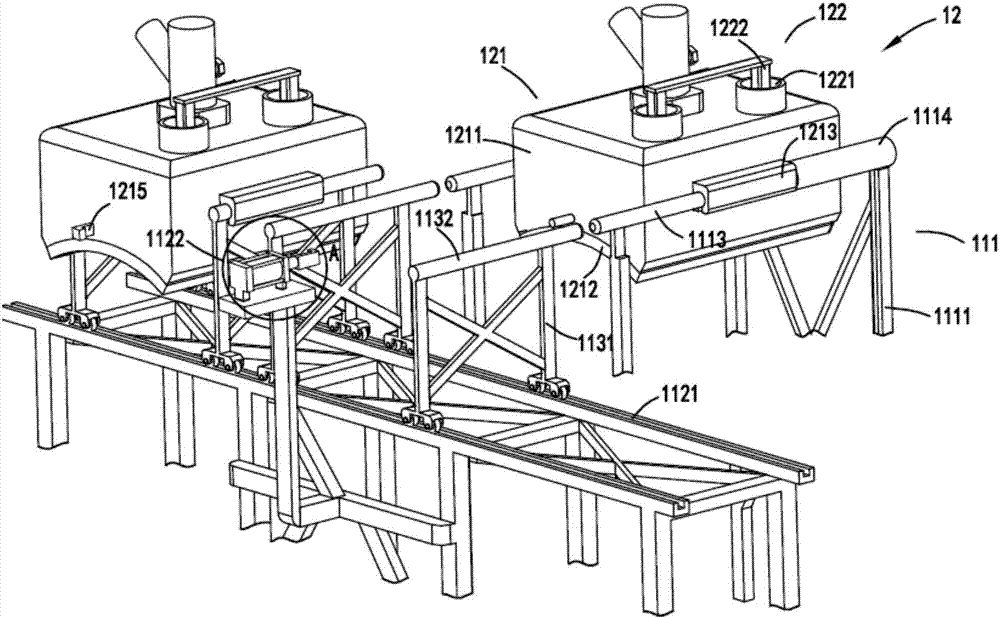

Field jet fabric dyeing method and field jet fabric dyeing system

PendingCN113584752AA system for dyeingMethod implementationDyeing processTextile treatment by spraying/projectingPolymer scienceDye injection

Owner:NEWTECH TEXTILE TECH DEV SHANGHAI

An animal dorsal root ganglion-spinal cord fixed imaging and compression injury combination device

InactiveCN104771145BAchieve stable positioningOvercome Imaging DeficienciesMusculoskeletal system evaluationDiagnostics using lightCompression injuryDye injection

The invention relates to an animal dorsal root ganglion-spinal cord fixed imaging and compression injury combining device, which comprises a dorsal root ganglion-spinal cord fixed imaging device and a microscopic fluorescent dye injection and spinal cord compression injury integrating device, wherein the animal dorsal root ganglion-spinal cord fixed imaging device (1) comprises a horizontal slide block guide rail (1-1), a fixing component (1-2), a slide rod (1-3) and a spine fixing clamp (1-4), and the microscopic fluorescent dye injection and spinal cord compression injury integrating device (2) comprises a vertical-rotating regulating side rod (2-3), a horizontal regulating component (2-4), a microscopic injection component (2-5) and a spinal cord compression component (2-6). The combining device has the advantages that multiple functions are integrated, the operation is simple and convenient, the switching can be realized at any time, different-degree spinal cord injury animal models can be conveniently manufactured, and after the fluorescent dye microscopic injection, a two-photon microscope is used for dynamically observing the pathological and physiological change process of the dorsal root ganglion-spinal cord injury in real time.

Owner:GENERAL HOSPITAL OF PLA

Supercritical carbon dioxide fluid dyeing device with condenser

InactiveCN104342867AWith energy saving and emission reductionWide variety of adaptabilitySolvent treatment with solvent recoveryTextile treatment machine arrangementsDye injectionWastewater

A supercritical carbon dioxide fluid dyeing device with a condenser comprises a liquid carbon dioxide storage tank, a carbon dioxide injection high-pressure pump, a heater, a dye mixing tank, a mixed dye injection high-pressure pump, a dye vat, a pressure reduction cooler, a separation kettle and a condenser. The supercritical carbon dioxide fluid dyeing device is characterized in that the liquid carbon dioxide storage tank is sequentially connected with the carbon dioxide injection high-pressure pump, the heater, the dye mixing tank, the mixed dye injection high-pressure pump, the dye vat, the pressure reduction cooler, the separation kettle and the condenser. The supercritical carbon dioxide fluid dyeing device has the advantages that generation of dyeing waste water and other wastes is avoided, environment-friendly and clean production can be achieved, and the device is low in cost and evident in economical and environmental benefits.

Owner:WUXI CITY HUAYANG DYEING & FINISHING MACHINERY

An energy-saving fabric dyeing machine

ActiveCN105648678BEliminate the dipping processResolve stackTextile treatment machine arrangementsTextile treatment by spraying/projectingDye injectionEngineering

Owner:吴江市奕萱纺织有限公司

Supercritical carbon dioxide fluid dyeing device with three dye vats

InactiveCN104342872ARealize diverse productionSatisfy small batches and multiple varietiesSolvent treatment with solvent recoveryTextile treatment machine arrangementsDye injectionInlet valve

A supercritical carbon dioxide fluid dyeing device with three dye vats comprises a liquid carbon dioxide storage tank, a carbon dioxide injection high-pressure pump, a heater, a dye mixing tank, a mixed dye injection high-pressure pump, a dye vat set, a pressure reduction cooler, a separation kettle, a condenser and a precise filter. The supercritical carbon dioxide fluid dyeing device is characterized in that the liquid carbon dioxide storage tank is sequentially connected with the carbon dioxide injection high-pressure pump, the heater, the dye mixing tank, the mixed dye injection high-pressure pump, the dye vat set, the pressure reduction cooler, the separation kettle, the condenser and the precise filter. The dye vat set includes the three dye vats. Each dye vat is connected with a dye vat inlet valve and a dye vat outlet valve. The inlet valve of each dye vat is connected with the mixed dye injection high-pressure pump. The outlet valve of each dye vat is connected with the pressure reduction cooler. The supercritical carbon dioxide fluid dyeing device has the advantages that generation of dyeing waste water and other wastes is avoided, environment-friendly and clean production can be achieved, and the device is low in cost and evident in economical and environmental benefits.

Owner:WUXI CITY HUAYANG DYEING & FINISHING MACHINERY

Spraying device for kapok dyes

InactiveCN109225710ASolve the problem of being vulnerable to collision damage,Solve operational problemsSingle-unit apparatusDye injectionStorage tank

The invention discloses a spraying device for kapok dyes. The spraying device comprises a storage tank and a spraying gun. An injection opening is embedded in the left side wall of the storage tank. Afilter screen penetrating through the injection opening is installed at the lower end of a bearing block. The spraying gun is fixed to the top end of the storage tank through threaded connection. Anoutput pipe is arranged on the rear side of the spraying gun. A shielding cover is installed on the outer side of a connecting block. A spraying nozzle is detachably installed at the tail end of the output pipe. A limiting hole is formed in the right side of the storage tank. A stirring plate is fixedly installed on the left side of a limiting rod. The lower surface of a pressing block is fixedlyconnected with the upper end of a spring sleeving the outside the limiting rod. The spraying device solves the problems that a spraying gun of an existing spraying device for kapok dyes is prone to collision damage and complicated in operation in the dye injection process, the dyes in the storage tank precipitate and the spraying effect can be poor.

Owner:JIANGSU DELIHENG COTTON

A low-cost energy-saving dyeing vat

ActiveCN105063921BReduce churnEmission reductionTextile treatment containersTextile treatment machine arrangementsInsulation layerDye injection

The invention provides a low-cost energy-saving dyeing vat, the side of the stirring motor is provided with a motor support frame and the bottom end of the stirring motor is connected to a stirring shaft, the motor support frame is installed on the top of the cylinder head, and the stirring shaft passes through the vat The cover is arranged inside the dyeing vat body, the stirring shaft is provided with a dye solution injection hole and a stirring blade, the inside of the dyeing vat body is provided with a heating device and a temperature sensor, and the dyeing vat body includes a dye vat body shell and a dye vat body liner. An insulation layer is arranged between the inner wall of the vat body shell and the outer wall of the inner tank of the dye vat body, a storage battery is arranged inside the insulation layer, one end of the circulation pipe passes through the insulation layer and communicates with the interior of the dye vat body, and the other end of the circulation pipe communicates with the cavity of the stirring shaft , the circulation pipe is provided with a feed pipe interface, a discharge pipe, a dye flow control valve and a dye pump, and the discharge pipe is provided with a dye removal valve. The cost is saved, the use is convenient, and the dyeing quality of the product is guaranteed.

Owner:WUJIANG HUAYUN TEXTILE

Printing and dyeing equipment capable of conducting dye recycling

InactiveCN108589099ADye evenly and completelyPrinting and dyeing fullyTextile treatment machine arrangementsTextile treatment by spraying/projectingDye injectionEngineering

The invention discloses printing and dyeing equipment capable of conducting dye recycling. The equipment comprises a dye injection plate, a printing and dyeing operation desk, a dye recycling tank, adye recycling pipeline and a dye storage tank which are arranged in parallel from top to bottom in sequence; the dye recycling pipeline is connected with the dye storage tank, the printing and dyeingoperation desk comprises a rectangular groove, a printing and dyeing plate with multiple through holes is arranged on the upper portion of a rectangular groove body, the dye injection plate is provided with multiple dye injection orifices, a feeding device is arranged on the upstream of the printing and dyeing operation desk, and a discharging device is arranged on the downstream of the printing and dyeing operation desk. The printing and dyeing equipment is provided with the printing and dyeing plate with the multiple through holes, a to-be-dyed cloth is placed on the printing and dyeing plate, it can be ensured that cloth dyeing is uniform and complete, and residual dye falls back into the dye recycling groove through the through holes formed in the printing and dyeing plate and is recycled into the dye storage tank. The printing and dyeing equipment capable of conducting dye recycling can have the advantages of achieving full printing and dyeing and saving the dye.

Owner:TAICANG HONGYING PRINTING

A kind of yarn dyeing method

ActiveCN105821613BImprove efficiencyLower liquor ratioTextile treatment containersTextile treatment machine arrangementsRing dyeingDye injection

The invention provides a yarn dyeing method, and belongs to the technical field of textile related equipment. The technical problems that for an existing dyeing method, the dyeing efficiency is low, and dyeing is inconvenient are solved. The yarn dyeing method comprises the steps of 1, yarn preparation and inspection, wherein the yarn quality is inspected before yarn dyeing is conducted, and it is required that the appearance of yarns is clean and free of stain, the yarns are neutral, the stacking time must not be over 8 h, and the yarns are covered with wet cloth; 2, feeding, wherein yarns are put into a dye vat and arranged on a yarn dyeing rod; 3, dye preparation, wherein anthraquinone vat dye is prepared in a dye barrel, 5 g-6 g of caustic soda and 5-6 g of rongalite are added according to each part by mass of raw material with an anthraquinone type structure, water is injected to obtain a solution, and 0.2 g / L-0.5 g / L of bone glue retarding agent is added; 4, dye injection and dyeing, wherein the prepared dye is injected into the dye vat; 5, yarn taking-out. The yarn dyeing method has the advantages of being high in dyeing efficiency and uniform in dyeing, and the yarns subjected to dyeing is fluffy and full in hand feeling.

Owner:ZHEJIANG DUOYUAN TEXTILE TECH CO LTD

System and Method for Detecting Biofilm Growth in Water Systems

ActiveUS20200224240A1Save amountEasy to installWeather/light/corrosion resistanceMicrobiological testing/measurementBiofilm growthDye injection

A system and method for monitoring or detecting a level of biofilm growth in a fluid system and controlling operating parameters of the fluid system based a measured level of growth. The monitoring system and method comprises a dye injection system for periodically injecting dye into a portion of fluid from the fluid system, passing the portion of fluid though a narrow lumen tube to achieve laminar flow and using a light source and optical sensor to detect a transmission or emission indicating a level of biofilm growth in the tube corresponding to a level of growth on components in the fluid system. Information based upon the measurements or calculations made by the monitoring system may be used to manually or automatically alter various operating parameters to control the fluid system and aid in maintaining stable operation of the fluid system within preferred specifications.

Owner:NCH CORP

Device and method for spraying wall paint with gradient colors

InactiveCN113027084AGood effectRealize automatic dye refillBuilding constructionsLiquid spraying apparatusDye injectionEngineering

The invention relates to the technical field of spraying, and particularly relates to a device and a method for spraying wall paint with gradient colors. The method for spraying the wall paint with the gradient colors through the device comprises the following steps that 1, a lifting sliding cavity is opened, gradient dye is added into a dye barrel, a sealing cover cavity is installed, and pressure relief in the dye barrel is prevented; 2, the position of an injection pipe is adjusted, a motor IV is started to drive a bevel gear II to swing through an eccentric wheel, an extraction pump is started, and the dye in a communicating curved pipe is extracted out and transmitted into a discharge pipe and finally sprayed to a wall through a spray head; 3, in the swing injection process, the dye in the dye barrel can be squeezed into the communicating curved pipe, and dye supply is achieved; and 4, after dye injection is completed, a motor II is started to drive a contact rolling brush to move downwards, and thus wall painting is completed; and a motor I is started to adjust the position of the contact rolling brush, and thus painting of the gradient dye on the whole wall is completed.

Owner:周辉

Patterning system using a limited number of process colors

A process by which dithering techniques and in situ blending techniques may be used to reproduce a desired multi-colored dyed pattern on a substrate using precisely delivered quantities of liquid colorants that are available in only a relatively few colors. Specific preferred process colors, as well as procedures for expanding the range of reproduced colors using such process colors, are presented Optionally, specific actuation instructions for a specific dye injection machine capable of patterning a moving textile substrate may be generated.

Owner:MILLIKEN & CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com