Energy-saving cloth dyeing machine

A technology for dyeing machines and fabrics, applied in the direction of processing textile material equipment configuration, spraying/jetting textile material processing, etc., can solve the problems of large amount of water resources, high processing cost, uneven color, etc., to eliminate uneven dyeing and simple operation. , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to further understand the present invention, preferred embodiments of the present invention are described below in conjunction with examples, but it should be understood that these descriptions are only to further illustrate the features and advantages of the present invention, rather than limit the claims of the present invention.

[0023] The solutions in the embodiments of the present invention are clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

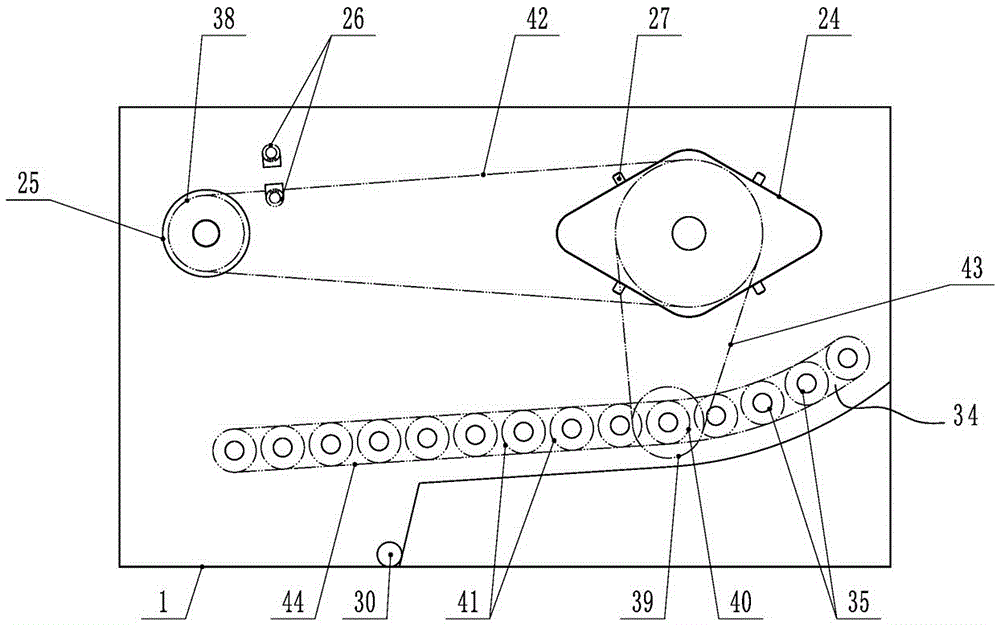

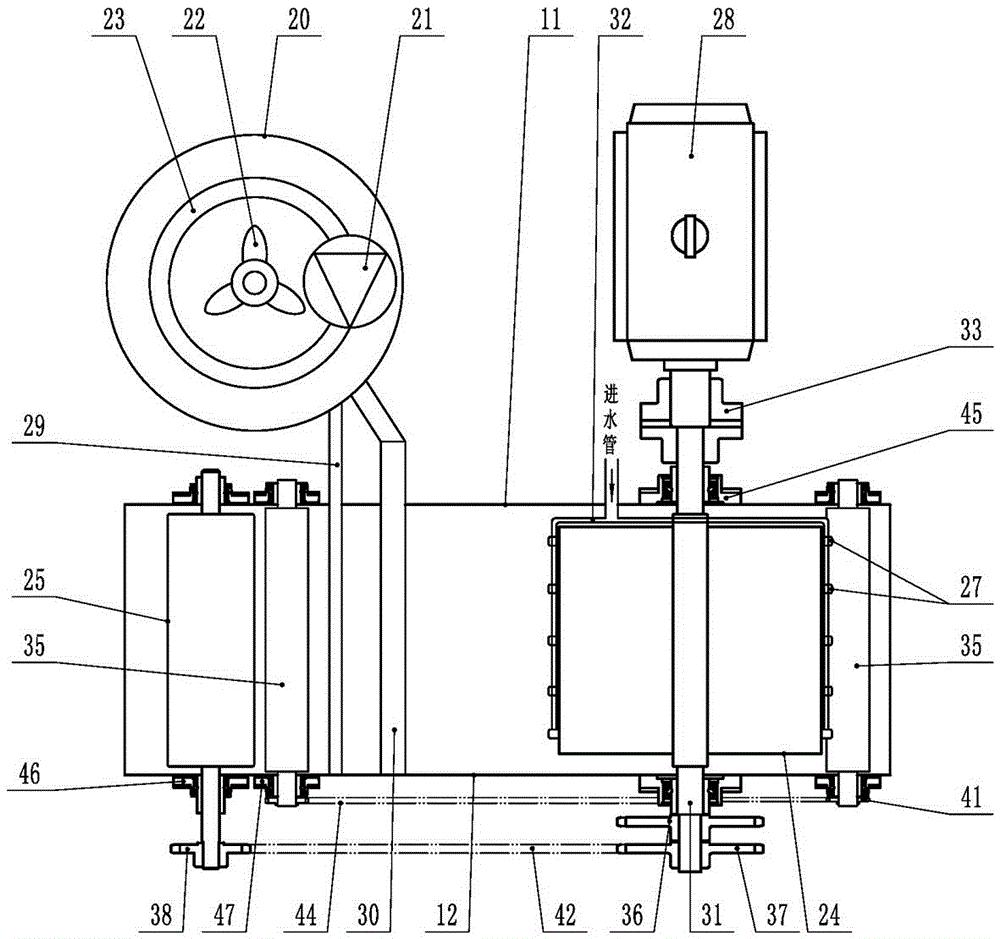

[0024] An energy-saving fabric dyeing machine according to an embodiment of the present invention includes a box body 1, a water tank 20, a transmission device 28, a conveying material row pipe 34, and a dye injection probe. The box body 1 includes an upper frame 11 and a lower frame 12; A driving shaft 31, a cloth lifting roller 24, and a guide roller 25 are arranged in the body 1, and a high-pressure pump 21, a turbine agitator 22, and a steam el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com