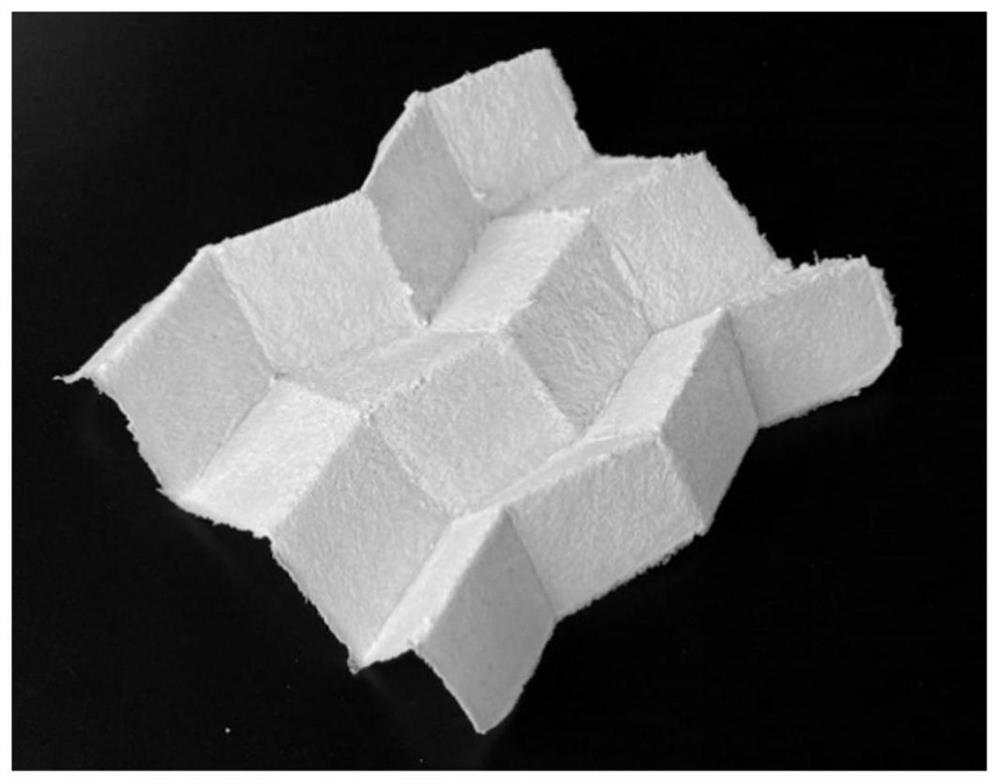

A universal method for the preparation of functional nanomaterials/cellulose composite aerogels using the principle of origami

A composite aerogel and nanomaterial technology, which is applied in the field of functional nanocomposite material preparation, can solve the problems of complicated preparation methods, stacking of functional materials, etc., achieves good repeatability, strong universality, and solves stacking problems. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

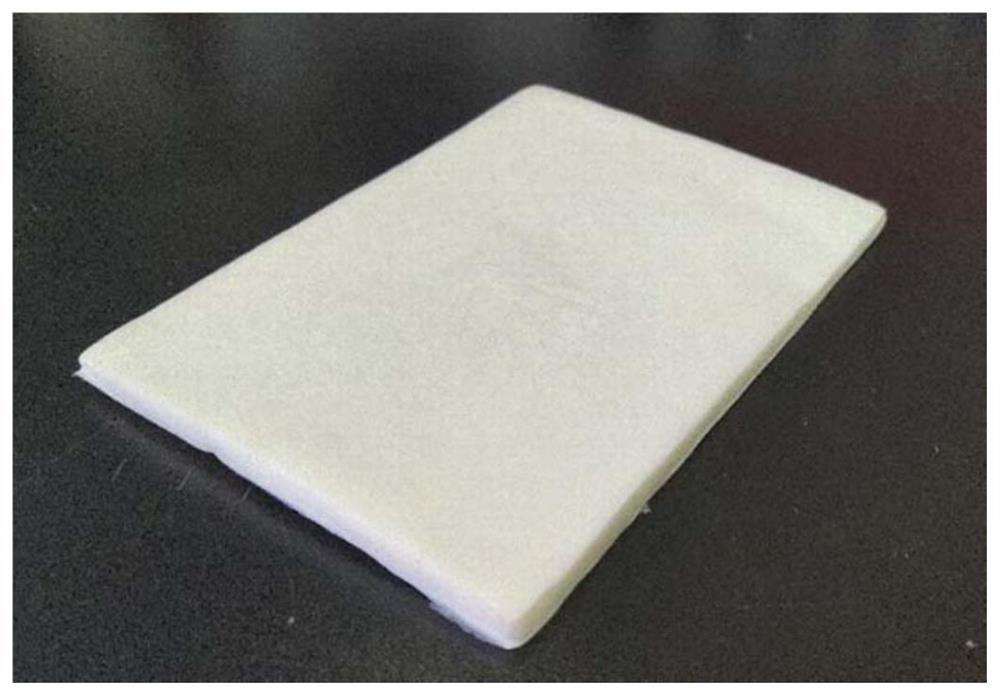

[0054] A universal method for preparing functional nanomaterial / cellulose composite aerogel using Miura origami principle, the method comprises the following steps:

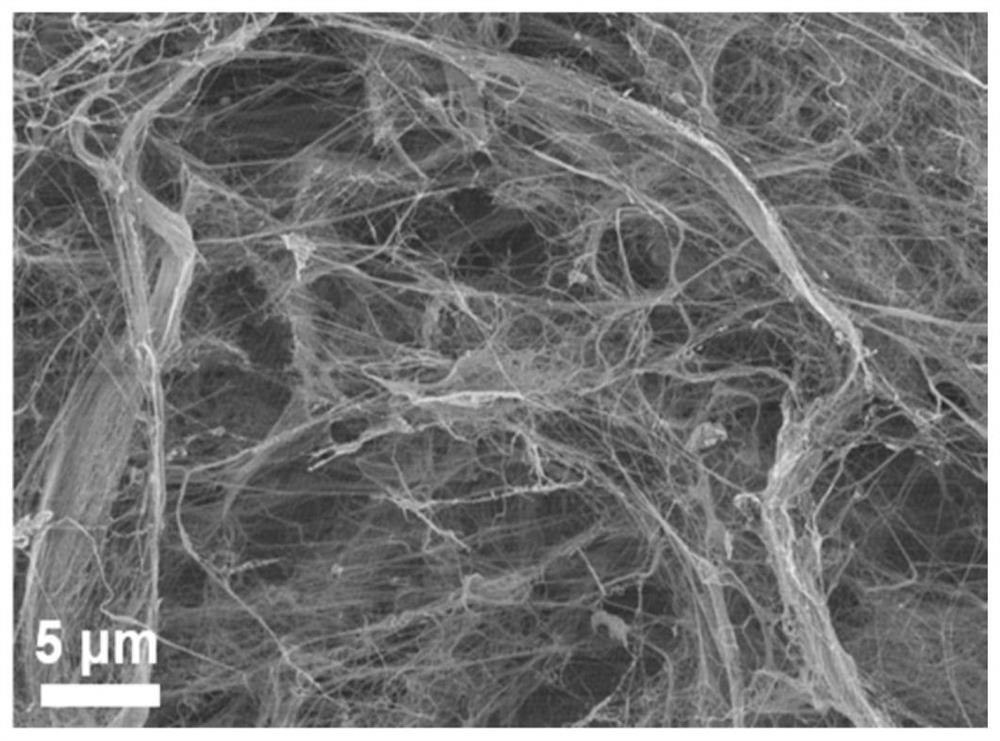

[0055] (1) Weigh a certain mass of functional nanomaterials and dissolve them in ultrapure water, in which the functional nanomaterials TiO 1.47 The mass of / C is 10mg, the volume of ultrapure water is 10mL, and the resistivity is 18.20MΩ·cm -1 , shake and shake well, then add bacterial cellulose solution with a mass concentration of 0.5% and a volume of 5 mL into the system, seal with the parafilm, and stir at room temperature for 1 h, the rotation speed is 300 rpm, and then stand for 8 h, and the obtained uniform mixing The solution undergoes a gel reaction;

[0056] (2) adding a certain volume of tert-butanol solution to the solution after the above-mentioned gel reaction, wherein the volume ratio of the tert-butanol solution and the above-mentioned overall solution is 1:20, stirring at room temperature for 5...

Embodiment 2

[0073] A universal method for preparing functional nanomaterial / cellulose composite aerogel using Miura origami principle, the method comprises the following steps:

[0074] (1) Weigh a certain mass of functional nanomaterials and dissolve them in ultrapure water, in which the functional nanomaterials TiO 1.47 The mass of / C is 10mg, the volume of ultrapure water is 50mL, and the resistivity is 18.20MΩ·cm -1 , shake and shake well, then add bacterial cellulose solution with a mass concentration of 0.5% and a volume of 5 mL into the system, seal with the parafilm, and stir at room temperature for 1 h, the rotation speed is 300 rpm, and then stand for 8 h, and the obtained uniform mixing The solution undergoes a gel reaction;

[0075] (2) adding a certain volume of tert-butanol solution to the solution after the above-mentioned gel reaction, wherein the volume ratio of the tert-butanol solution and the above-mentioned overall solution is 1:20, stirring at room temperature for 5...

Embodiment 3

[0078] A universal method for preparing functional nanomaterial / cellulose composite aerogel using Miura origami principle, the method comprises the following steps:

[0079] (1) Weigh a certain mass of functional nanomaterials and dissolve them in ultrapure water, in which the functional nanomaterials TiO 1.47 The mass of / C is 100mg, the volume of ultrapure water is 10mL, and the resistivity is 18.20MΩ·cm -1 , shake and shake well, then add bacterial cellulose solution with a mass concentration of 0.5% and a volume of 5 mL into the system, seal with the parafilm, and stir at room temperature for 1 h, the rotation speed is 300 rpm, and then stand for 8 h, and the obtained uniform mixing The solution undergoes a gel reaction;

[0080] (2) adding a certain volume of tert-butanol solution to the solution after the above-mentioned gel reaction, wherein the volume ratio of the tert-butanol solution and the above-mentioned overall solution is 1:20, stirring at room temperature for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com