Patents

Literature

668 results about "Tert-Butanol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tert-Butyl alcohol (TBA), also called tert-butanol or t-butanol, is the simplest tertiary alcohol, with a formula of (CH 3) 3 COH (sometimes represented as t-BuOH).It is one of the four isomers of butanol. tert-Butyl alcohol is a colorless solid, which melts near room temperature and has a camphor-like odor.It is miscible with water, ethanol and diethyl ether

Method for preparing N-long chain acyl neutral amino acid

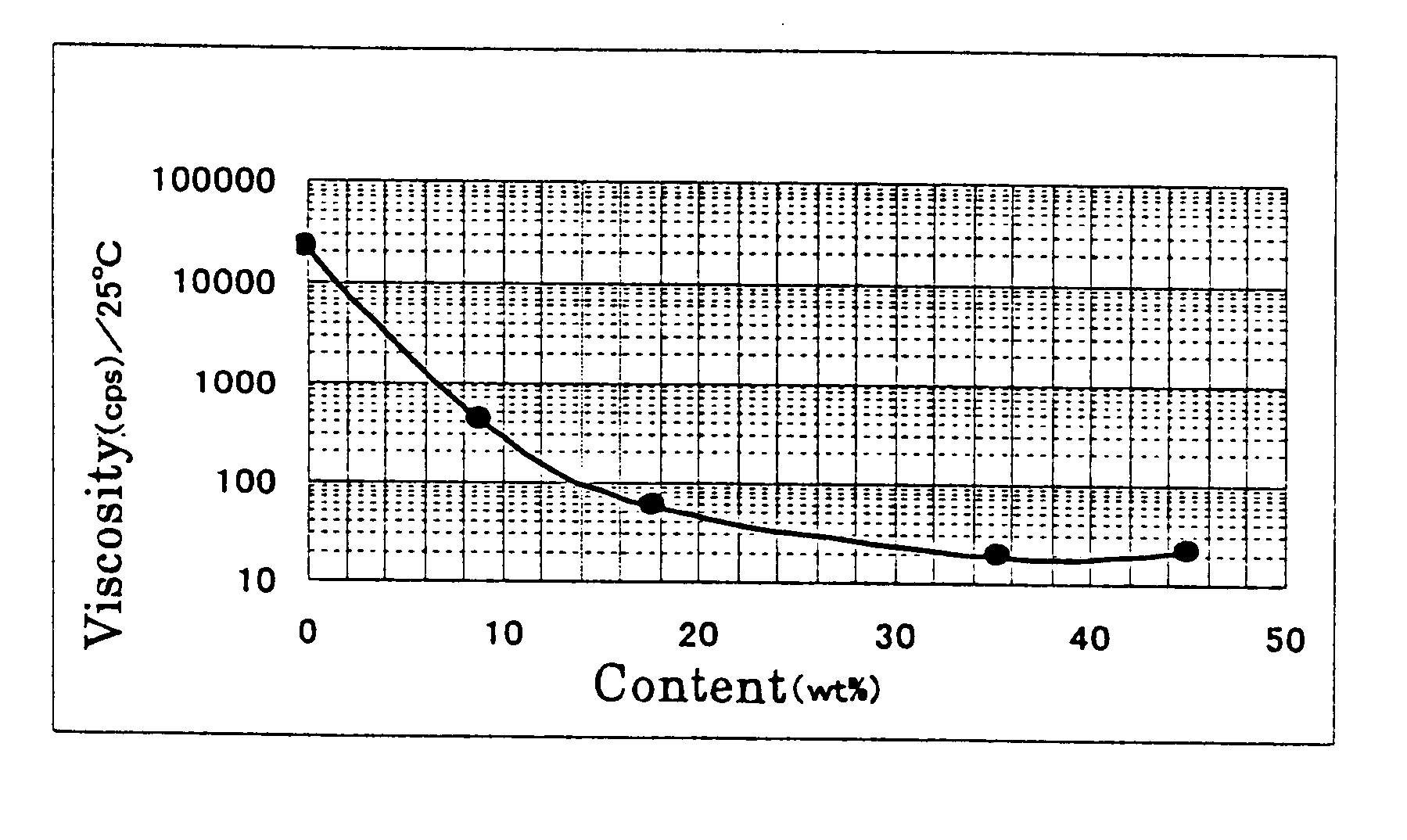

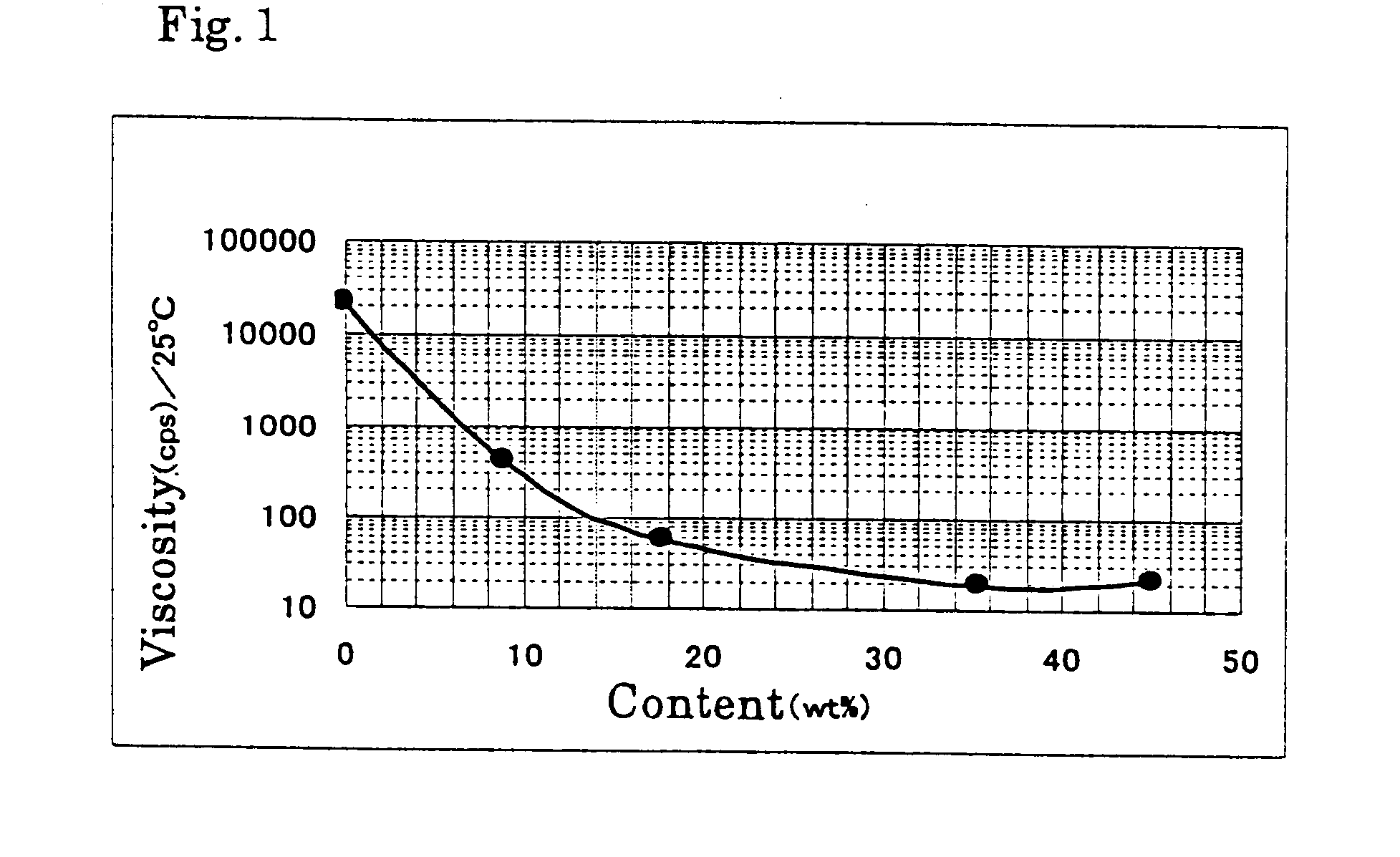

InactiveUS6703517B2Efficient conductionLow viscosityCosmetic preparationsHair cosmeticsNeutral Amino AcidsAlanine

A method for preparing a highly purified N-long chain acyl neutral amino acid for use of a detergent and the like in a simple and convenient manner and in a high yield by reacting a neutral amino acid such as glycine, gamma-aminobutyric acid, and alanine, with a saturated or unsaturated fatty acid halide having 8 to 22 carbon atoms, wherein the reaction is performed in a mixture of water and one or more kinds of hydrophilic organic solvents selected from the group consisting of acetone, acetonitrile, a secondary alcohol having 3 or 4 carbon atoms, and a tertiary alcohol having 4 carbon atoms such as isopropanol, sec-butanol, and tert-butanol in the presence of a base.

Owner:AJINOMOTO CO INC

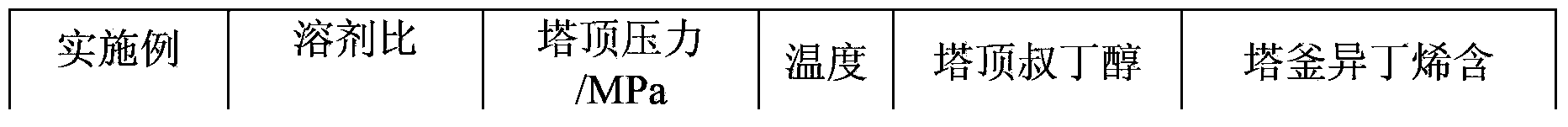

Process for preparing tert-butanol from isobutene-containing hydrocarbon mixtures

InactiveUS7002050B2Increase productionOrganic compound preparationOxygen compounds preparation by reductionHydrocarbon mixturesSolid acid

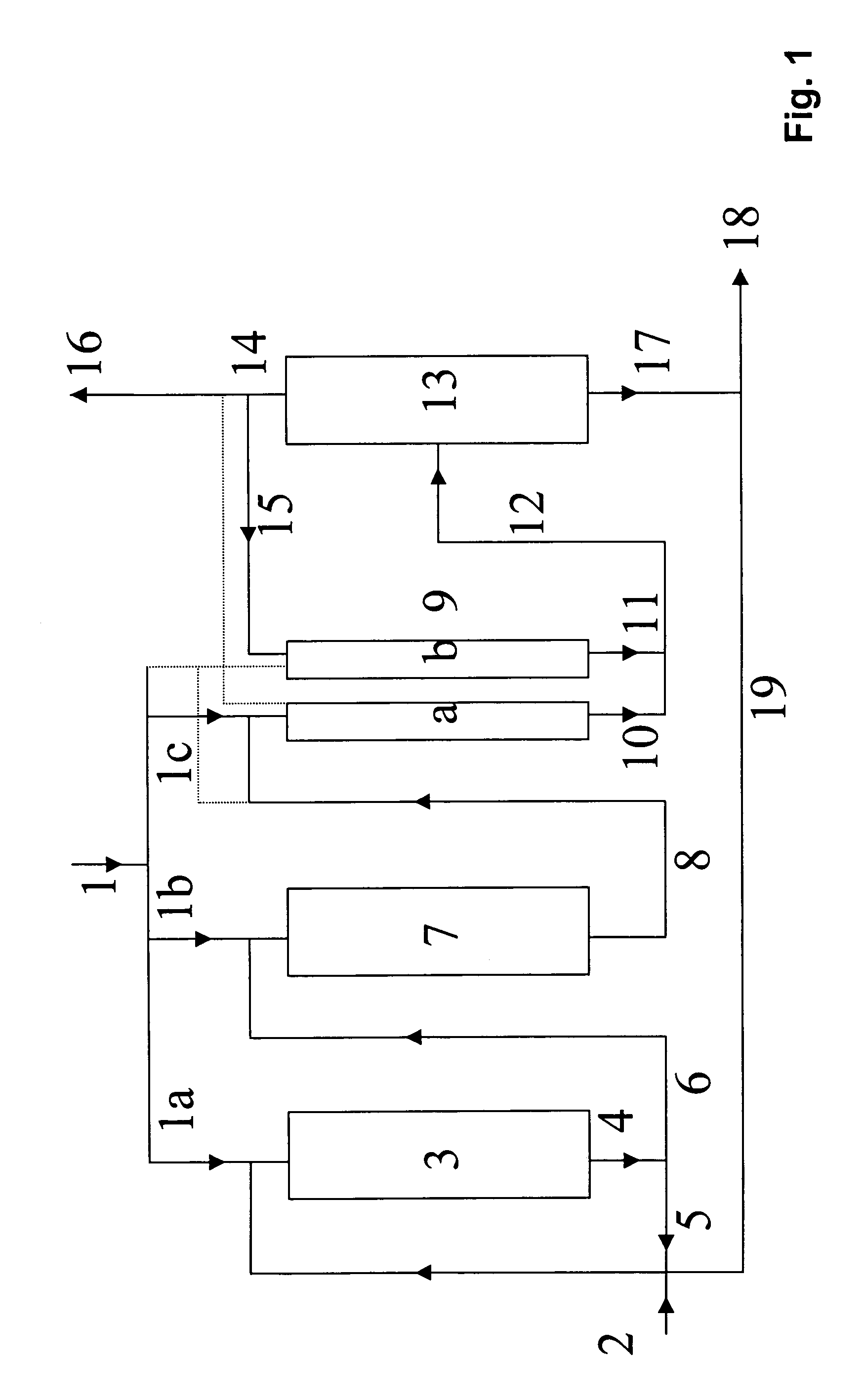

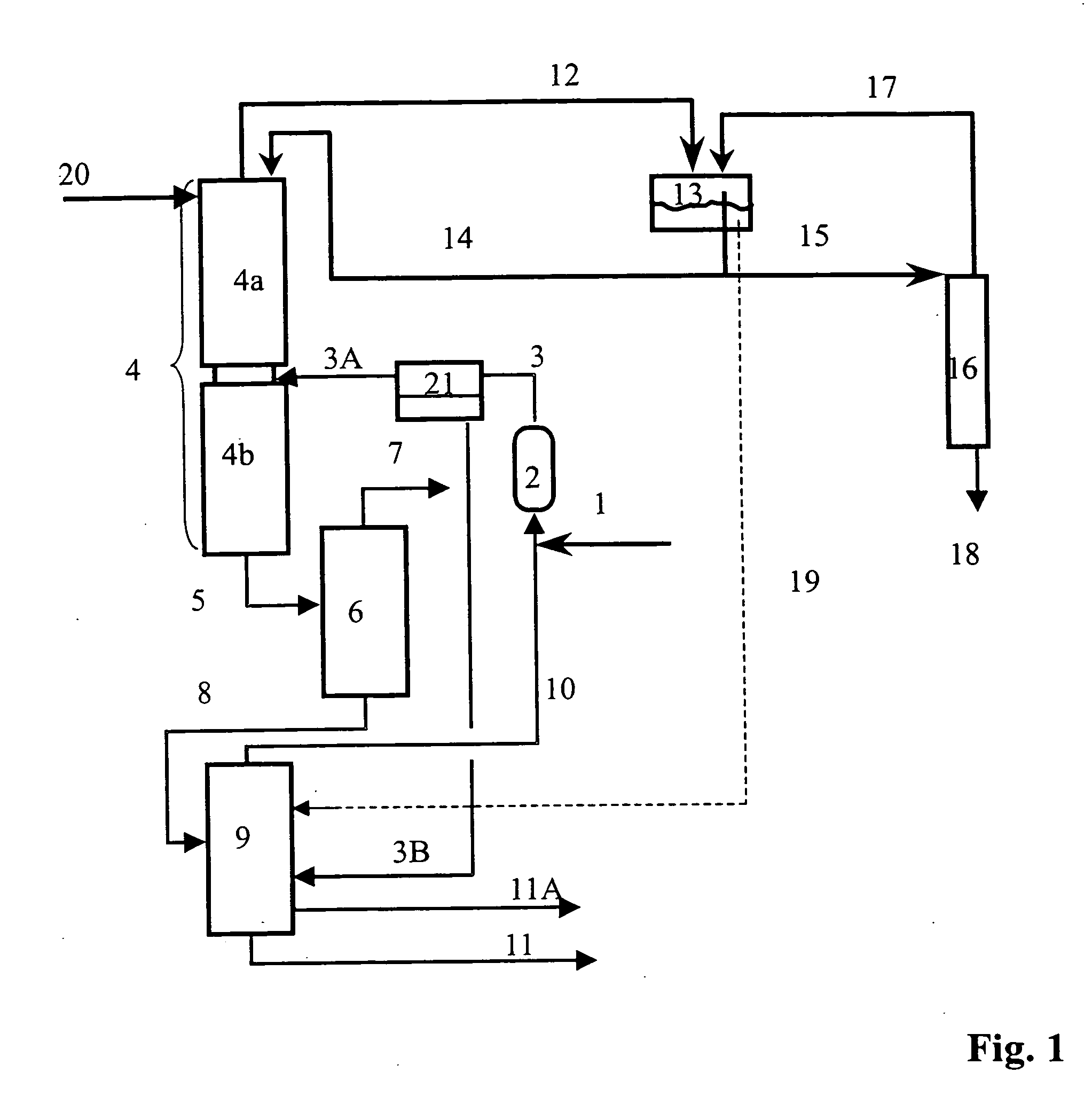

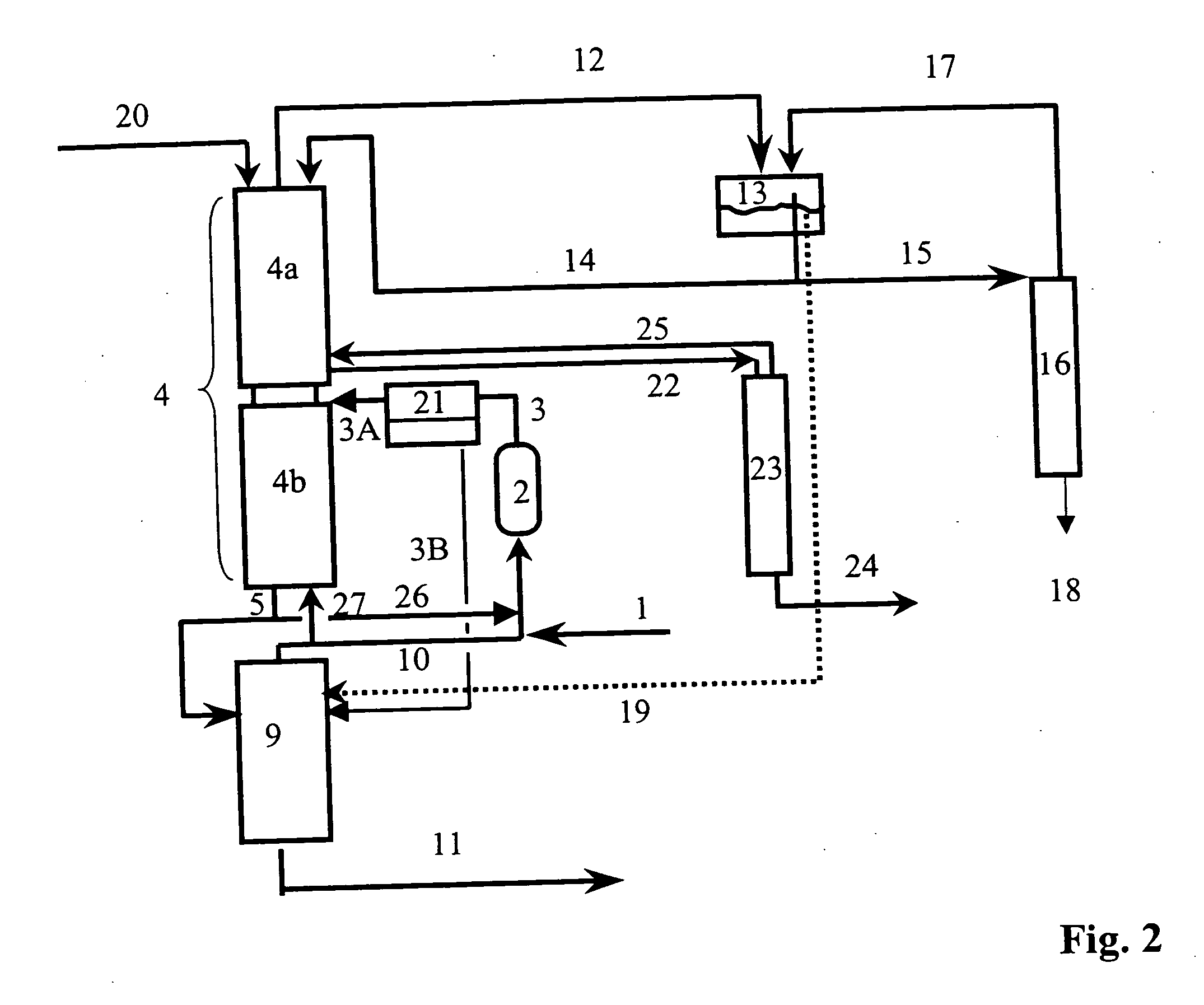

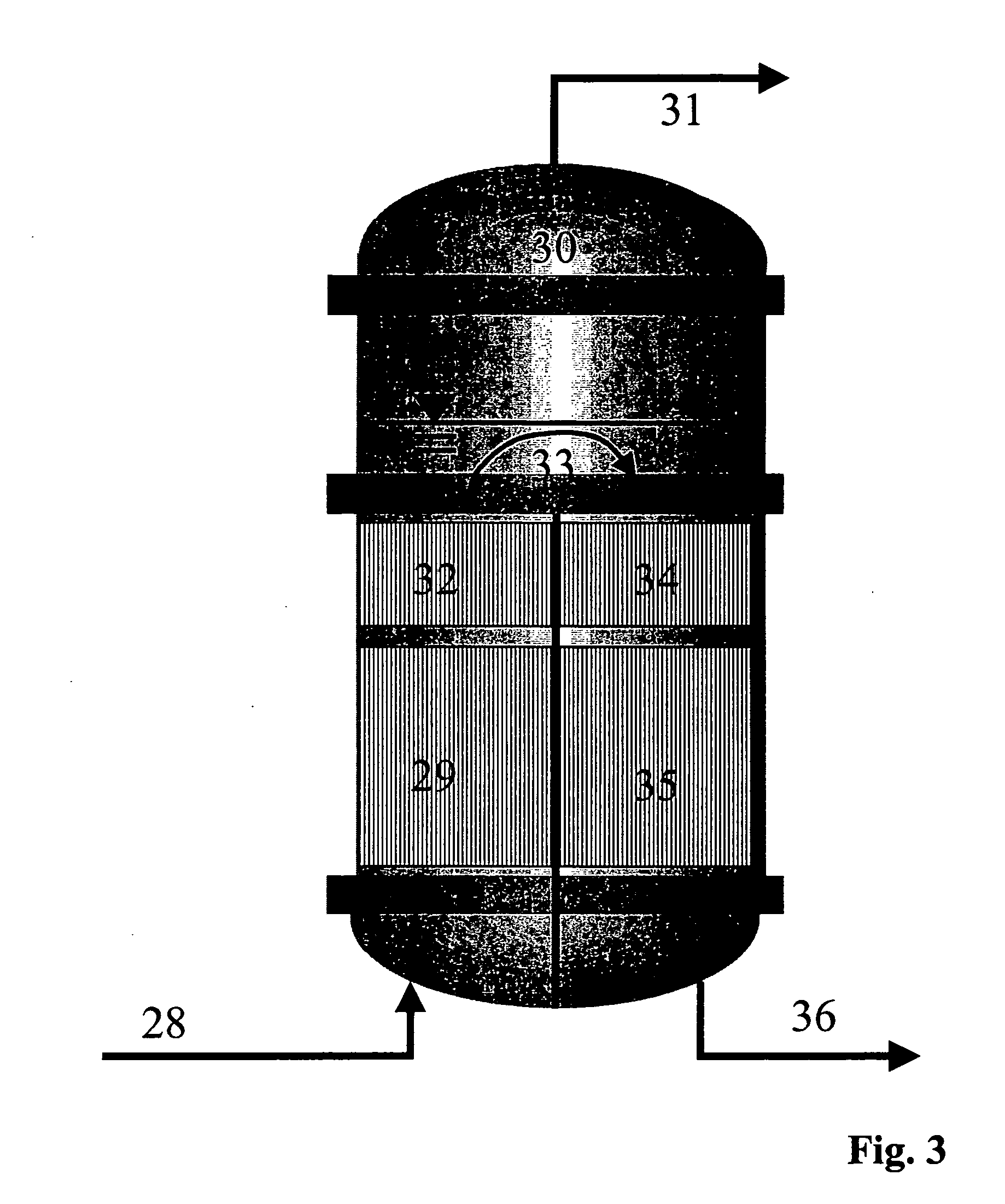

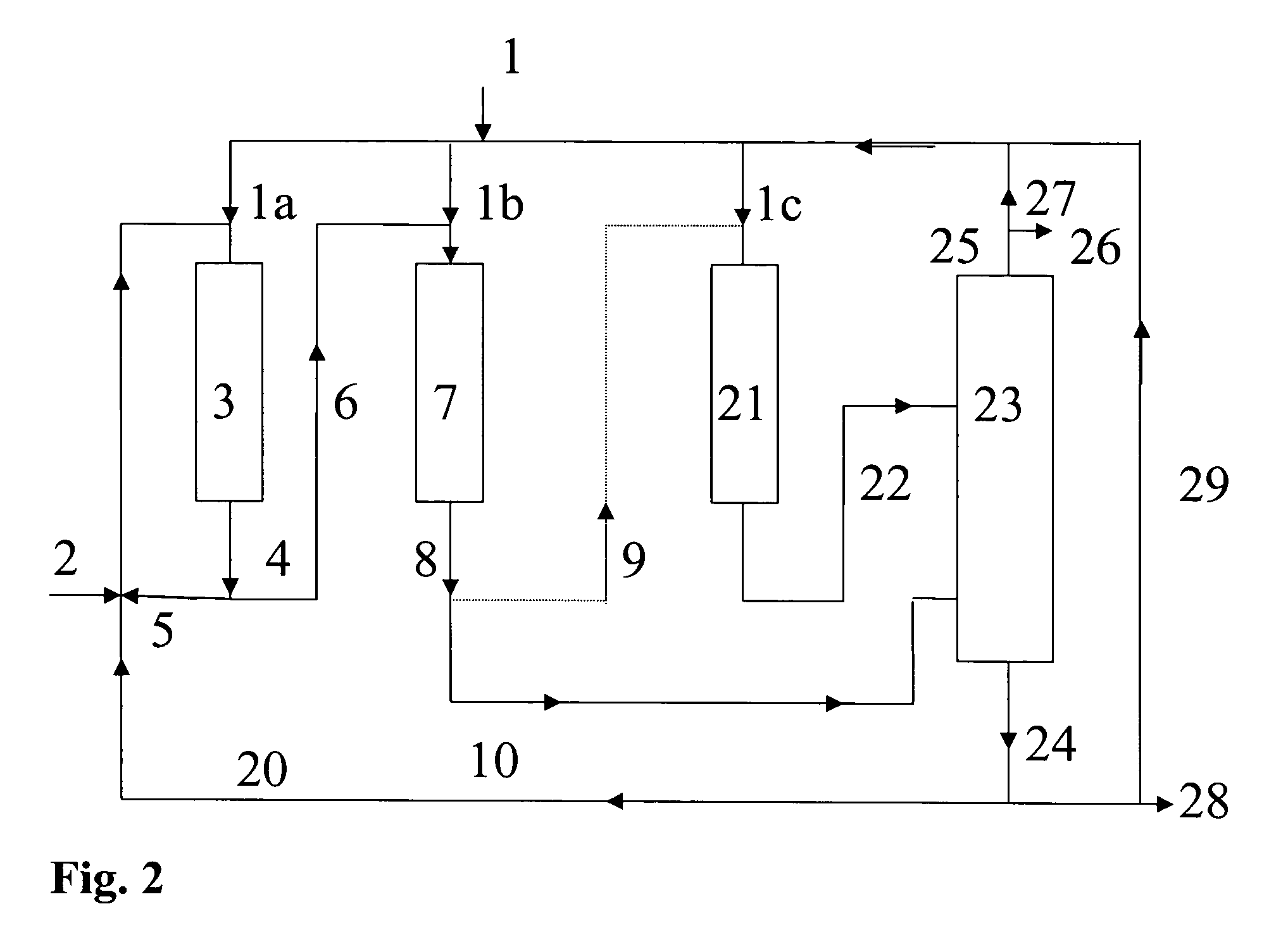

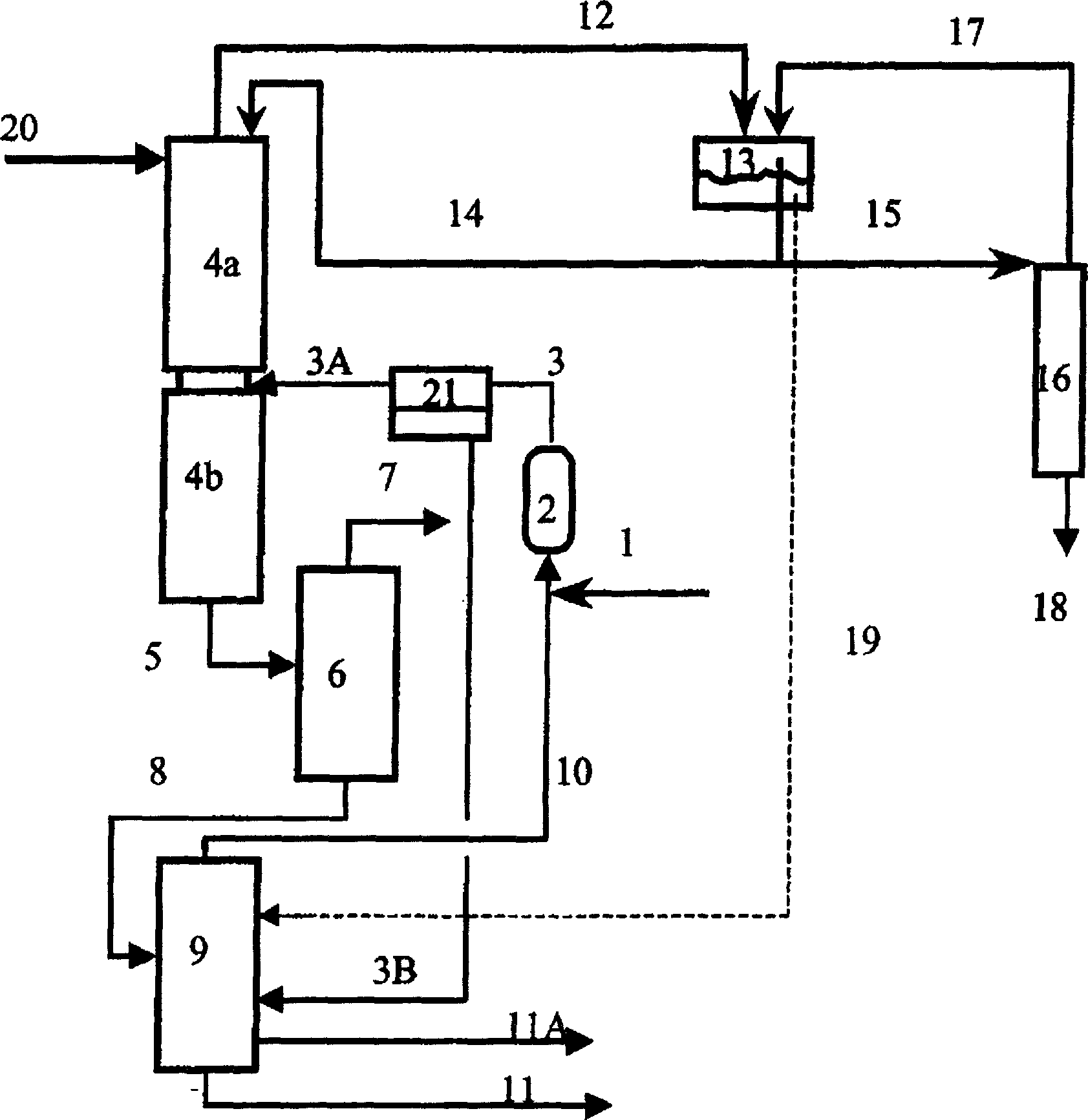

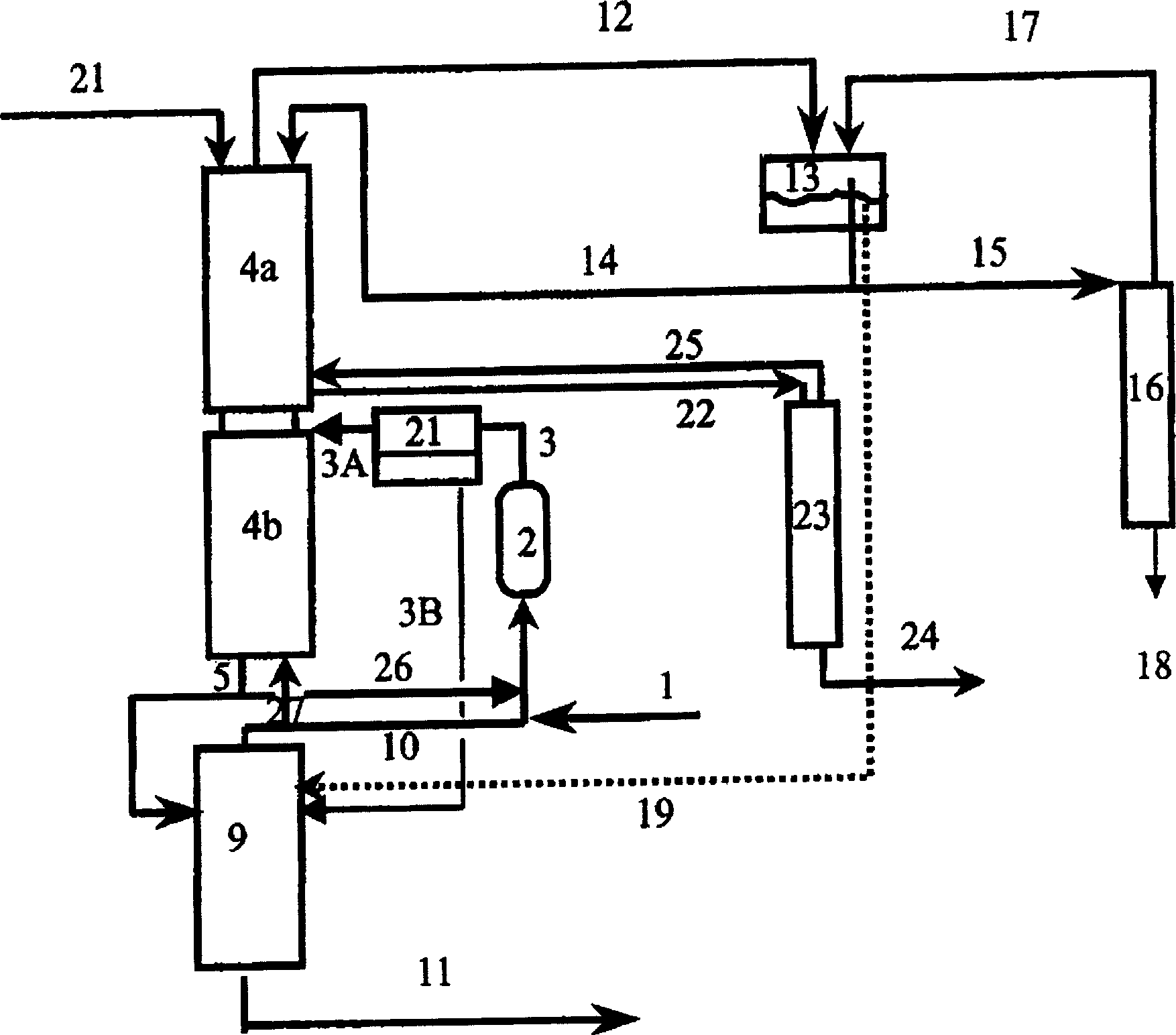

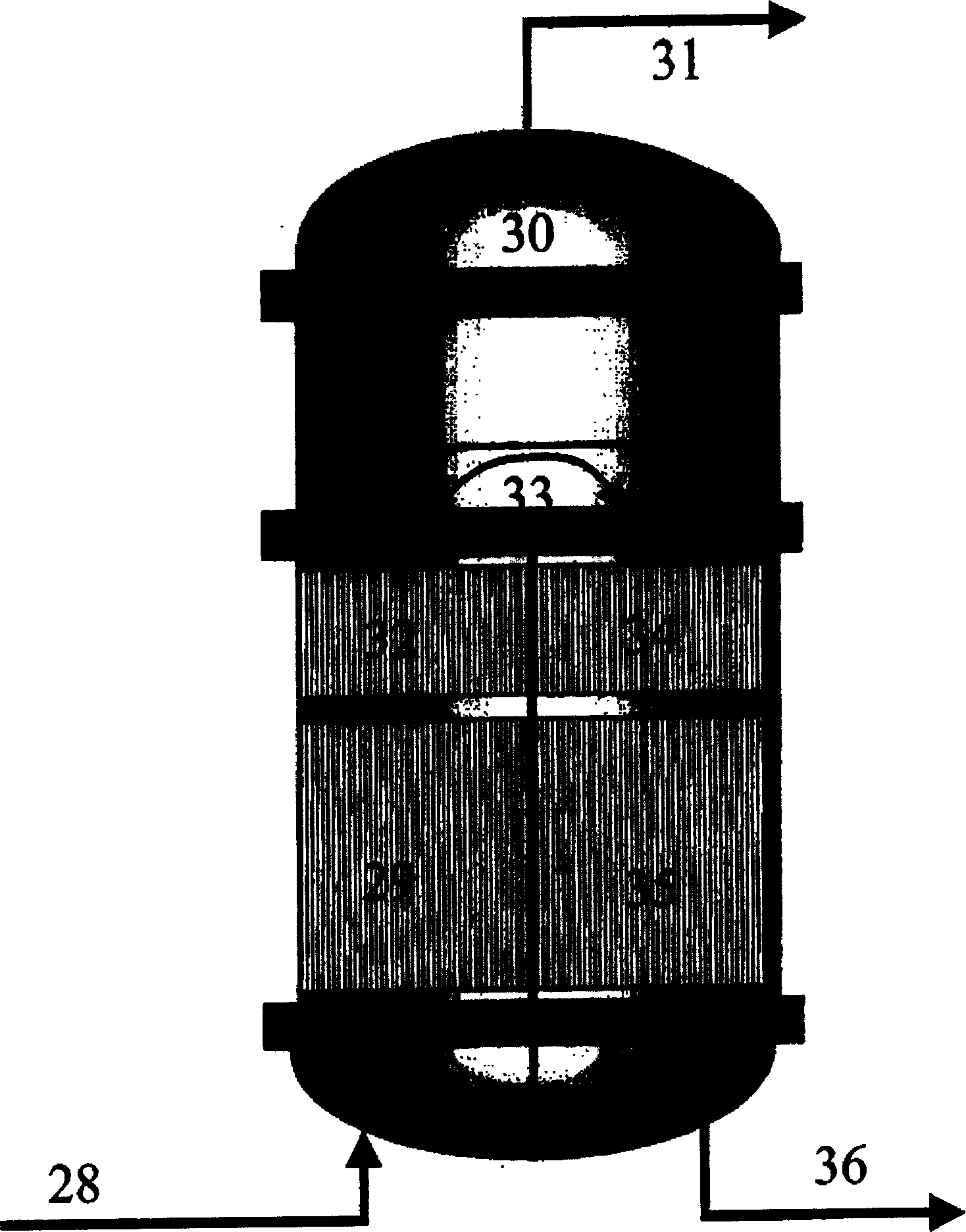

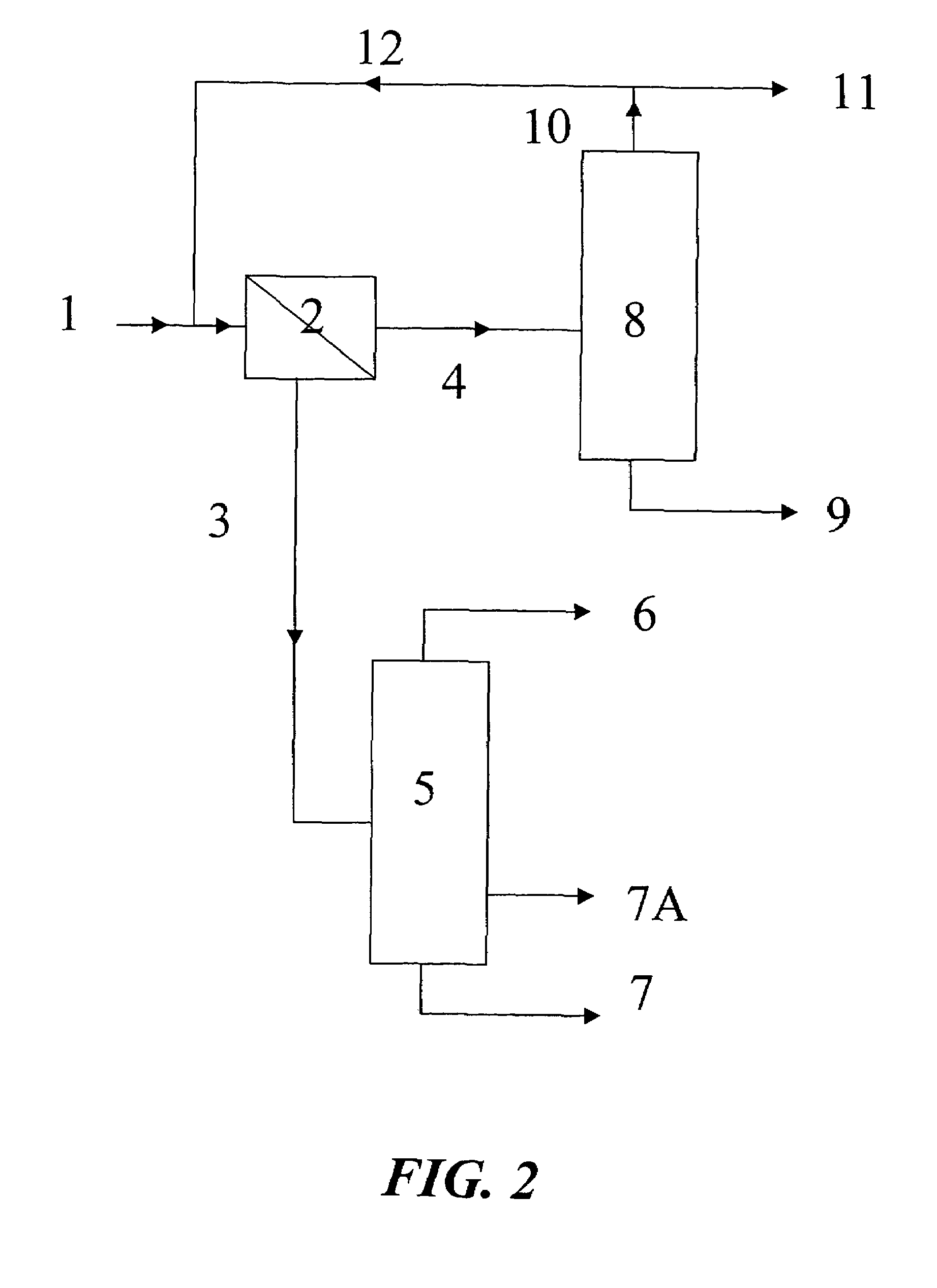

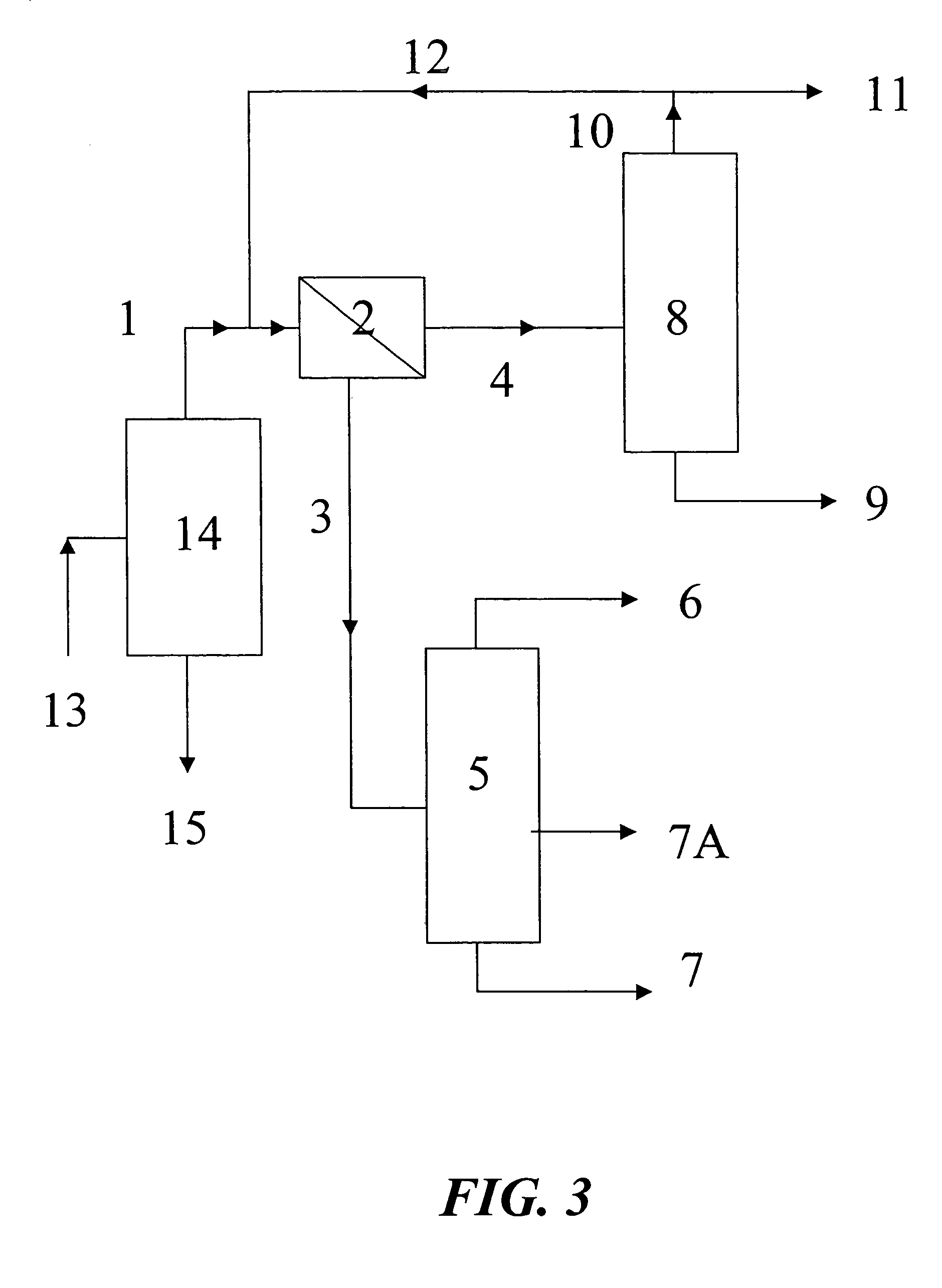

The present invention relates to a process for preparing tert-butanol (TBA) by reacting an isobutene-containing hydrocarbon mixture with water over a solid acid catalyst in a reactor cascade, wherein at least one reactor is supplied alternately with two different isobutene-containing hydrocarbon mixtures, of which one has both a higher tert-butanol content and a higher water content than the other mixture.

Owner:EVONIK DEGUSSA GMBH

Process for preparing isobutene from tert-butanol

InactiveUS20050014985A1Low mass flowHigh selectivityExhaust apparatusOrganic chemistry methodsFixed bedTemperature difference

Isobutene is prepared by dissociating tert-butanol into isobutene and water over an acid ion-exchange resin arranged as a fixed bed in at least one reactor at a temperature of from 80 to 150° C. and at a pressure of from 5 to 25 bar to obtain a reaction mixture, separating the reaction mixture into isobutene, a by-product, water and at least one mixture of undissociated tert-butanol and water. The reactor is operated pseudo-isothermally, with a temperature difference between inflowing and outflowing streams of less than 15 K.

Owner:EVONIK DEGUSSA GMBH

Obtaining tert-butanol

InactiveUS7026519B2Speed up the conversion processImprove viabilityOrganic compound preparationOrganic chemistry methodsHydrocarbon mixturesChemistry

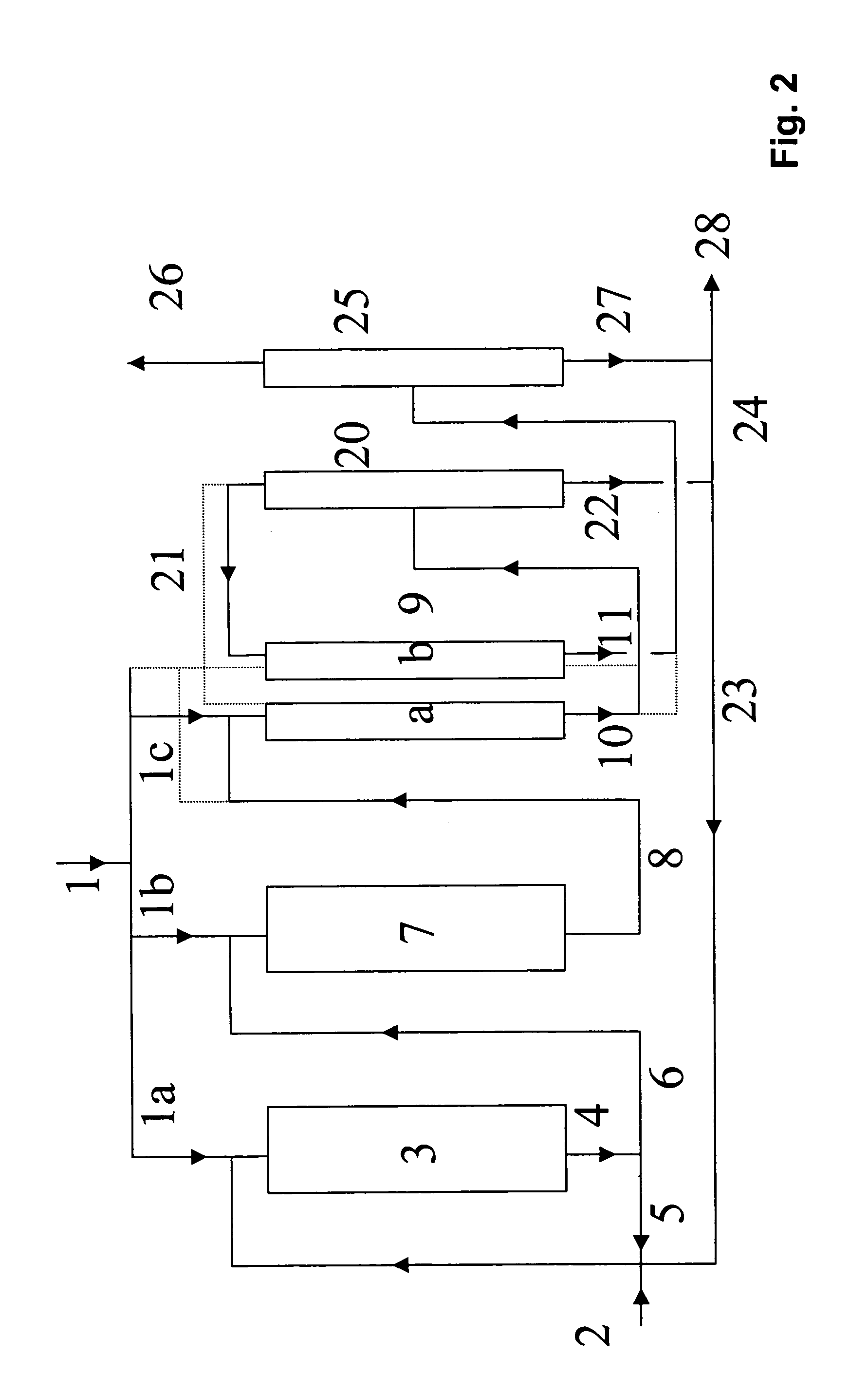

The invention relates to a process for preparing tert-butanol (TBA) by reacting isobutene-containing hydrocarbon mixtures with water over acidic solid catalysts in a plurality of reactors, wherein the conversion is increased upstream of the last reactor by removing a portion of the TBA present in the reaction mixture.

Owner:EVONIK DEGUSSA GMBH

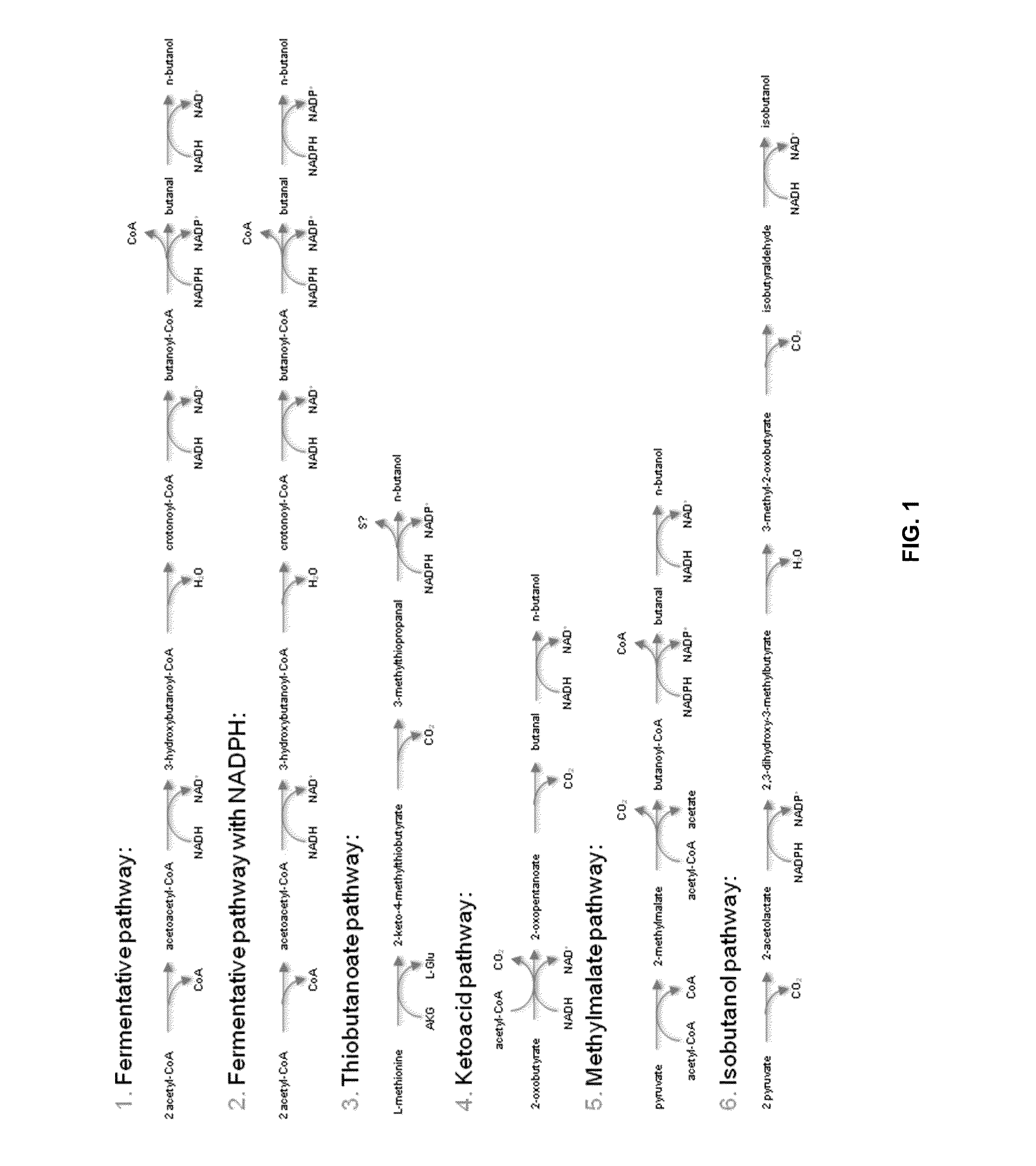

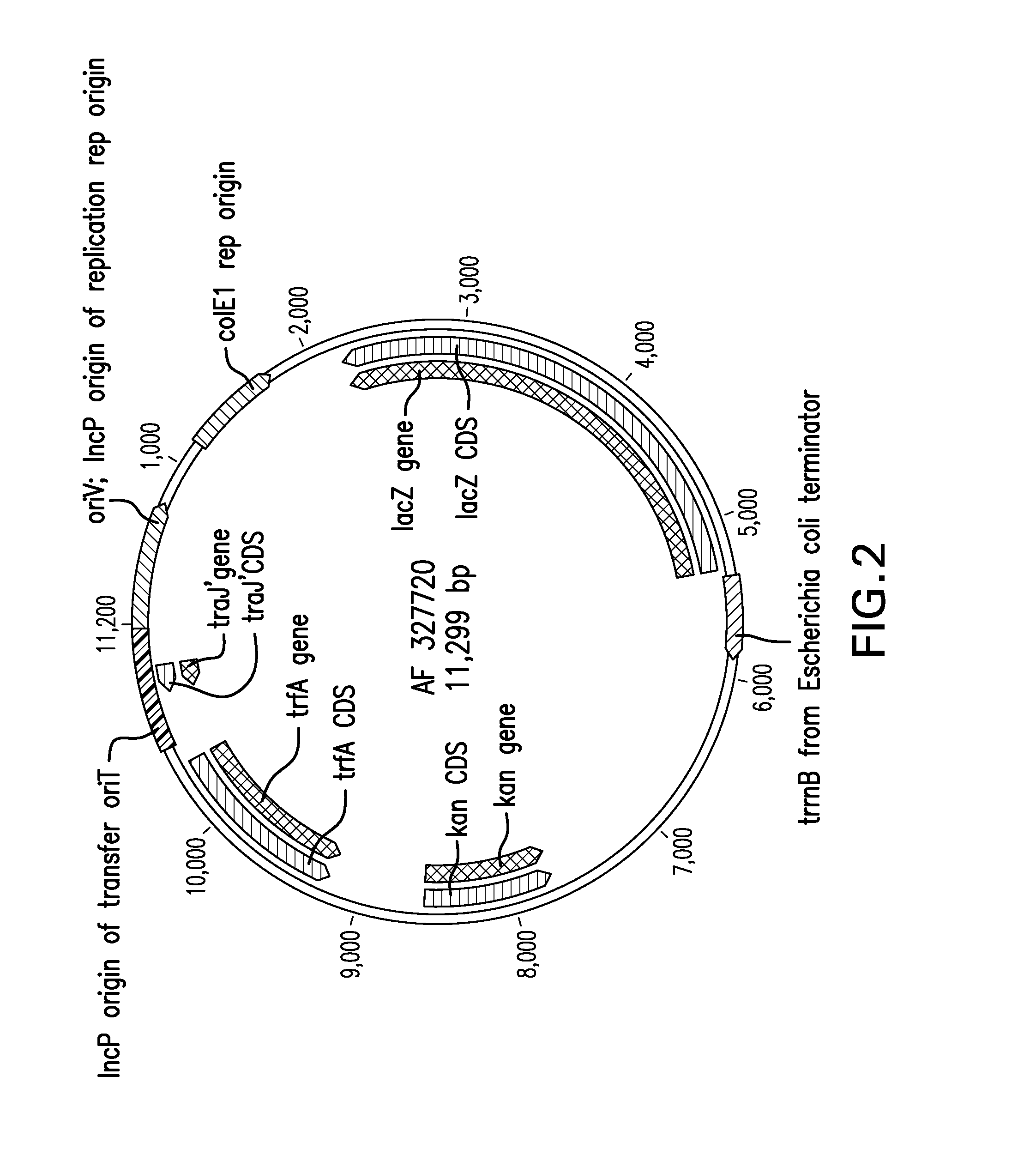

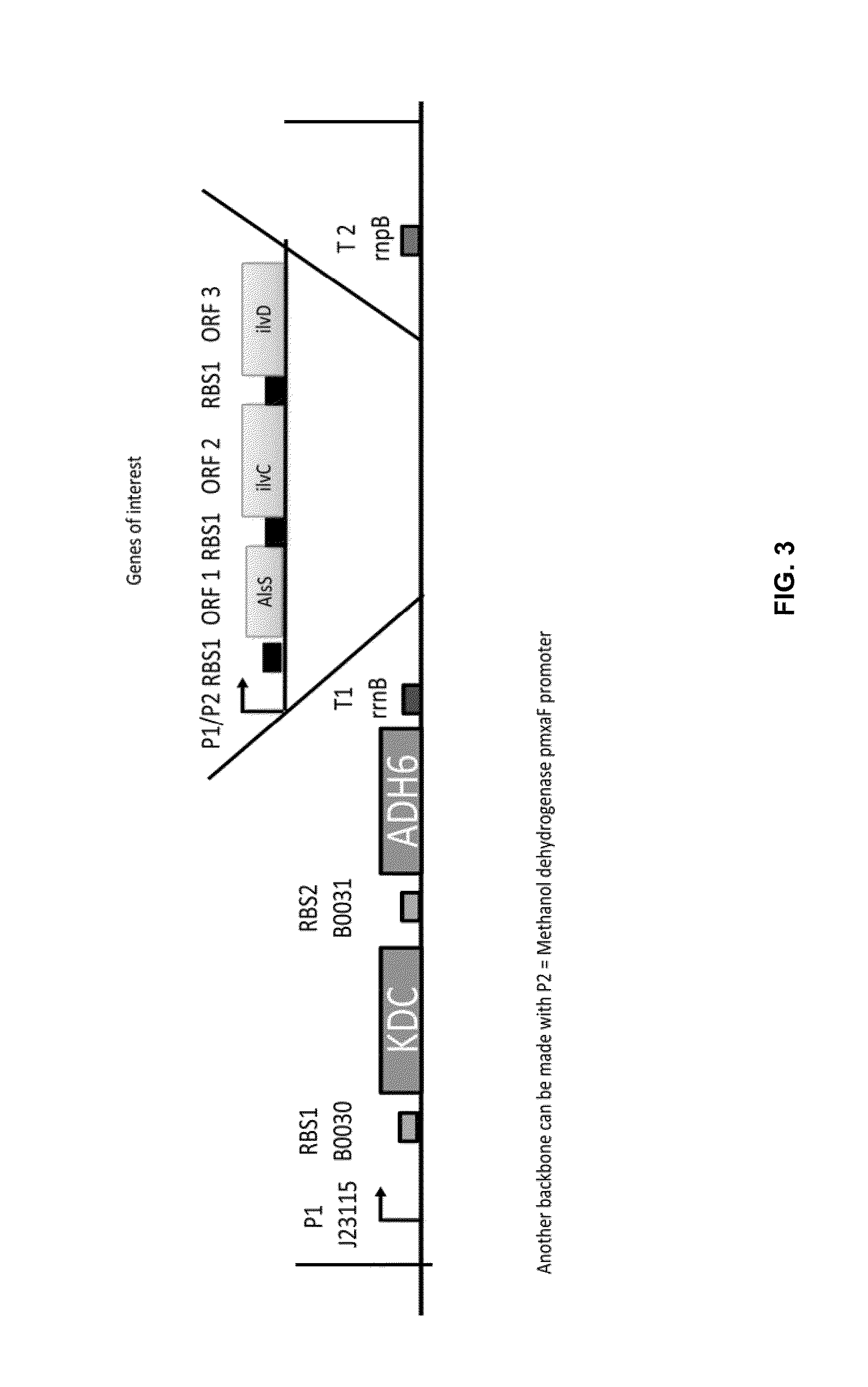

Biological Conversion of Multi-Carbon Compounds from Methane

Multi-carbon compounds such as ethanol, n-butanol, sec-butanol, isobutanol, tert-butanol, fatty (or aliphatic long chain) alcohols, fatty acid methyl esters, 2,3-butanediol and the like, are important industrial commodity chemicals with a variety of applications. The present invention provides metabolically engineered host microorganisms which metabolize methane (CH4) as their sole carbon source to produce multi-carbon compounds for use in fuels (e.g., bio-fuel, bio-diesel) and bio-based chemicals. Furthermore, use of the metabolically engineered host microorganisms of the invention (which utilize methane as the sole carbon source) mitigate current industry practices and methods of producing multi-carbon compounds from petroleum or petroleum-derived feedstocks, and ameliorate much of the ongoing depletion of arable food source “farmland” currently being diverted to grow bio-fuel feedstocks, and as such, improve the environmental footprint of future bio-fuel, bio-diesel and bio-based chemical compositions.

Owner:PRECIGEN INC

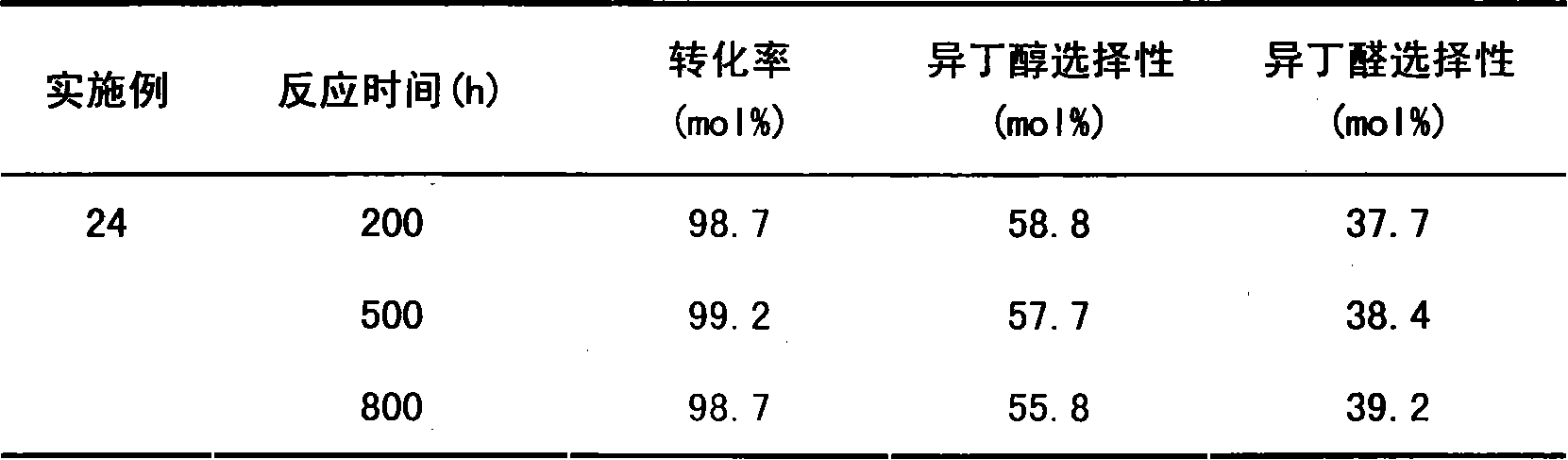

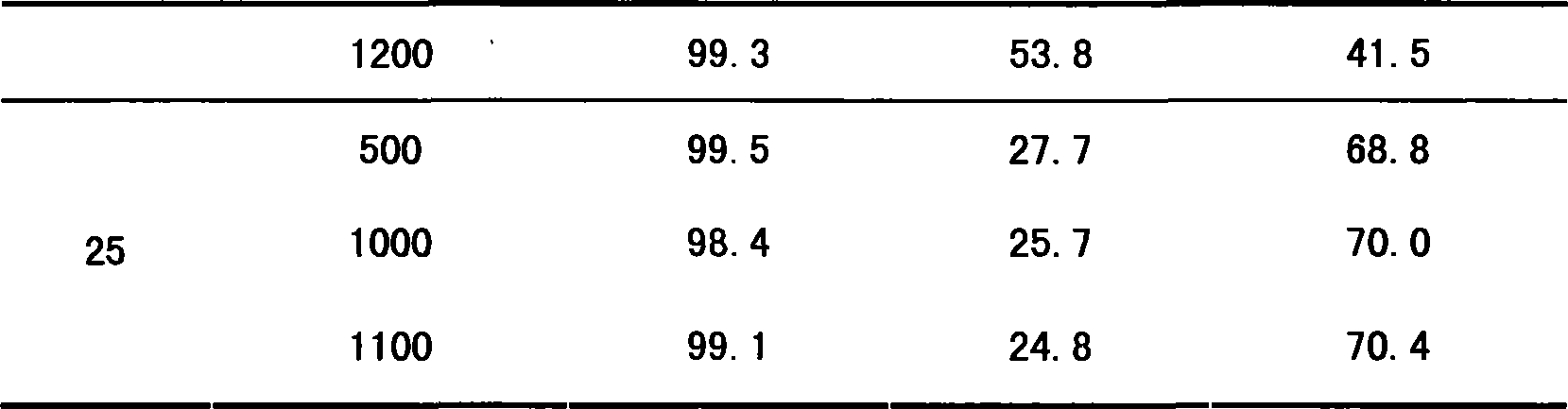

Method for preparing iso-butyraldehyde and isobutyl alcohol by methylacrolein hydrogenation

ActiveCN101239892ALow costHigh selectivityMolecular sieve catalystsOrganic compound preparationIsobutanolMetal catalyst

The invention relates to a method for hydrogenation preparing isobutyraldehyde and isobutyl acohol from methacrolein. The method comprises using a supported metal catalyst, and hydrogenating methacrolein obtained by oxidating isobutene under gentle conditions. The invention provides a novel synthesis process for hydrogenation preparing isobutyraldehyde and isobutyl acohol from methacrolein which is obtained by air-oxidating low-utilization C4 material isobutene or tert-butanol. The methacrolein conversion rate is larger than 98%, the total selectivity of isobutyraldehyde and isobutyl acohol is larger than 95%, the performance of the catalyst is stable even the reaction lasts more than 1000 hours. The invention has the advantages of high activity and high selectivity of catalyst, good stability of catalyst, cheap material isobutene, low productin cost of isobutene, environment-protecting process, and suitability of industrialisation production. The process is flexible, can change the proportion of isobutyraldehyde and isobutyl acohol through adjusting the reaction process condition, thereby cogenerating isobutyraldehyde and isobutyl acohol, or only generating isobutyl acohol by cycling and hydrogenating isobutyraldehyde.

Owner:SHANGHAI HUAYI NEW MATERIAL

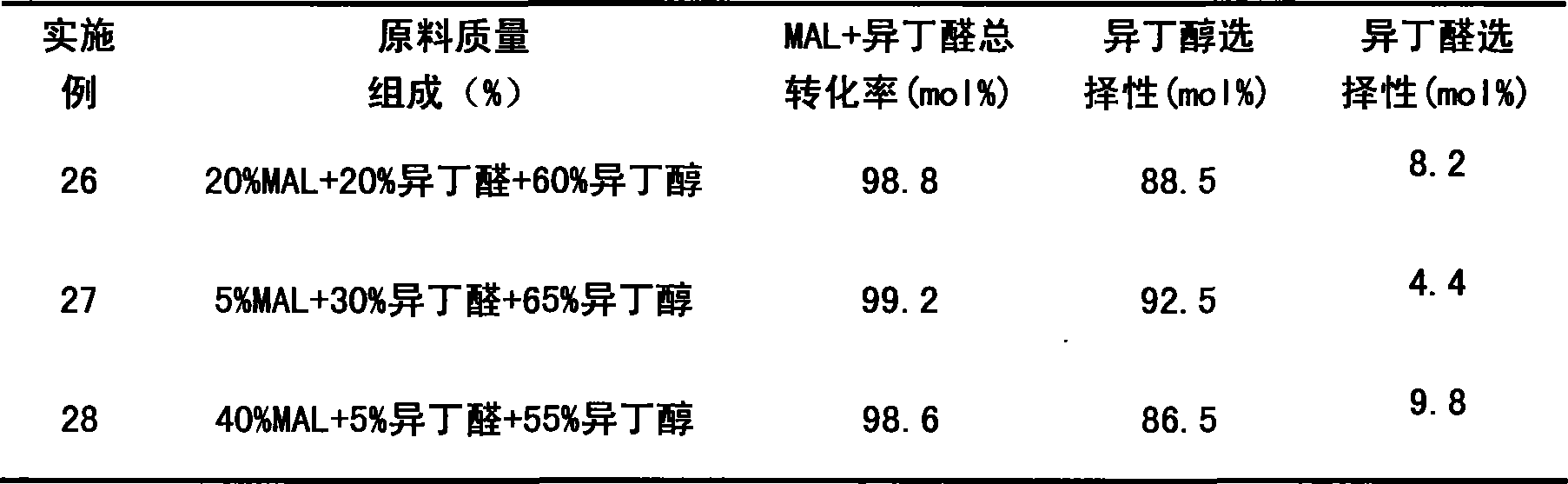

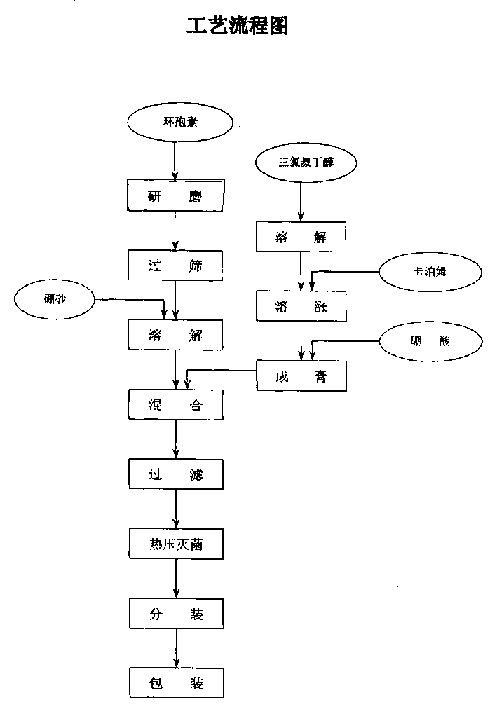

Eye cyclosporin gel

InactiveCN1456350ANot easy to diluteGood water solubilitySenses disorderPharmaceutical delivery mechanismCyclosporinsWhole body

A cyclosporin eye gel for treating the rejection reaction of corneal transplantation, keratoconjunctival xerosis, catarrhal conjunctivitis, and chemical burn of eye is prepared from cyclosporin, boric acid, borax, trichloro-tert-butanol, etc. Its advantages are long stay time in eye and high curative effect.

Owner:刘继东

Blocking remover for reservoir of oil well

The invention discloses a blocking remover for a reservoir of an oil well. The blocking remover is applied to the technical field of oil extraction in an oil field, comprises an agent A and an agent B, and is characterized in that the weight percentage of the agent A is 25-35%; the weight percentage of the agent B is 65-75%; the agent A comprises the following components by weight: 45-50% of petroleum mixed xylene, 1-2% of nonyl phenol polyoxyethylene (4) ether, and the balance of 0# diesel oil; the agent B comprises the following components by weight: 6-10% of glacial acetic acid or sulfamic acid, 2-2.5% of ammonium bifluoride, 2% of ammonium chloride, 1-2% of citric acid, 1.5-2% of corrosion inhibitor 7801, 3-5% of tertiary butanol, 0.5-1% of octyl phenol polyoxyethylene (10) ether and the balance of water. The blocking remover has the following effects that: the agent A and the agent B are respectively prepared so as to be beneficial to storing the blocking remover for a long time, the agent A of the blocking remover has strong dissolving capacity on crude oil heavy components, such as wax colloid asphalt, and the washing oil efficiency on oil sand is more than 90%. The dissolving rate of the agent B of the blocking remover on carbonate is more than 80%, and the corrosion speed on N80 steel is low and is smaller than 2 g / m<2>.h.

Owner:PETROCHINA CO LTD

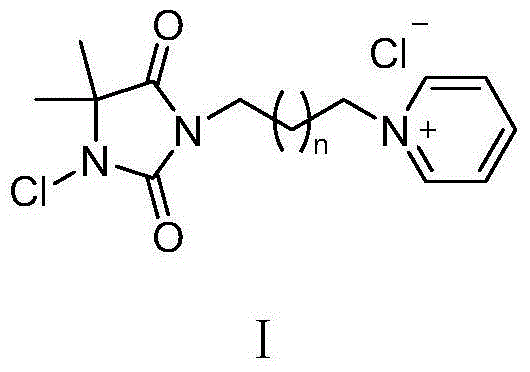

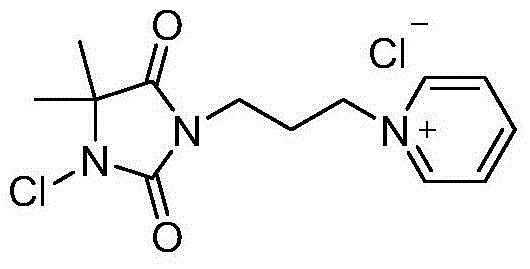

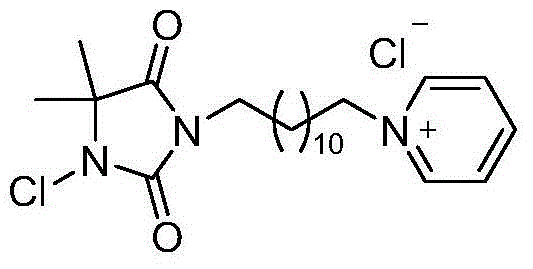

Pyridine quaternary ammonium salt type halamine antibacterial agent and preparation method thereof

InactiveCN104926787AImprove hydrophilicityHigh antibacterial activityAntibacterial agentsBiocidePyridineIon-exchange resin

The invention discloses a pyridine quaternary ammonium salt type halamine antibacterial agent with a structure represented by a general formula I, wherein n is an integer of 1-10. The preparation method comprises the following steps: a, 5,5-dimethyl hydantoin is placed in an acetone solution doped with anhydrous potassium carbonate; refluxing is carried out for 30min, and dibromoalkane is added; refluxing is continued for 4h, such that a bromo-alkyl hydantoin compound is obtained; b, the obtained bromo-alkyl hydantoin compound is dissolved in acetonitrile; excessive pyridine is added; heating and refluxing are carried out overnight; concentration is carried out, such that a pyridine bromide quaternary ammonium salt type halamine precursor is obtained; the precursor is delivered through chlorine-type anion exchange resin, such that a pyridine chloride quaternary ammonium salt type halamine precursor is obtained; and c, the obtained pyridine chloride quaternary ammonium salt type halamine precursor is dissolved in a mixed solution composed of deionized water and tert-butanol; tert-butyl hypochlorite is added, and stirring is carried out for 2-4h while protected from light, such that the pyridine quaternary ammonium salt type halamine is obtained. The method has the advantages of easy-to-obtain raw materials, and relatively simple synthesis method. The method has a prospect of industrialized application.

Owner:DALIAN UNIV OF TECH

Catalysts for production of unsaturated aldehyde and unsaturated carboxylic acid and a process for producing unsaturated aldehyde and unsaturated carboxylic acid using the catalysts

InactiveUS6583316B1High yieldGuaranteed uptimeOrganic compound preparationOrganic chemistry methodsGas phaseCerium

Improved catalysts for use in vapor phase oxidation of at least one compound selected from the group consisting of propylene, isobutylene, t-butanol and methyl-t-butyl ether with molecular oxygen or a molecular oxygen-containing gas to produce the corresponding unsaturated aldehyde and unsaturated carboxylic acid are provided. The improved catalysts are compositions comprising (A) a complex oxide containing as essential components molybdenum, bismuth and iron, which is known per se as a catalyst for said reaction and (B) a complex oxide containing cerium and zirconium as the essential components. When the improved catalysts are used, the production operation of unsaturated aldehyde and unsaturated carboxylic acid can be continued stably for over prolonged period.

Owner:NIPPON SHOKUBAI CO LTD

Oxaliplatinum liposome glucose preparation and its preparation method and application

ActiveCN101103972AImprove the quality of lifeReduce inhibitionPowder deliveryPharmaceutical non-active ingredientsCholesterolLiposome

The invention discloses an oxaliplatin liposome glucose preparation and the preparation method and application, relating to an oxaliplatin liposome glucose solution preparation used for tumor resistance and the preparation method and application. An oxaliplatin liposome glucose preparation is formed by liposome which prepared by oxaliplatin, hydrogenated phosphorus, cholesterol and DSPE-PEG2000, and is dissolved in glucose solution; wherein the weight ratio of the hydrogenated phosophorus and the oxaliplatin is 1:1-50; the weight ratio of the hydrogenated phosophorus, cholesterol and the DSPE-PEG2000. The preparation method is that the hydrogenated phosophorus, cholesterol and the DSPE-PEG2000 are weighed according to proportioning by weight in a description and then fixed together; tertiary butyl alcohol is added into the fixture for the fixture to be stirred and dissolved, then the fixture is precooled; the oxaliplatin saturated water solution with 4-10 percent of glucose after cooling and drying is stirred, dissolved and emulsified by an emulsion balancing machine and then prepared into liposome solution by a homogenizer and a nanometer extruder, separated and refined through a filter column to prepare the oxaliplatin liposome glucose solution.

Owner:JIANGSU AOSAIKANG PHARMA CO LTD

Co-solvent composition for compounding methanol gasoline

InactiveCN1740283APromote mutual solubilityHigh calorific valueLiquid carbonaceous fuelsAntioxidantMethyl carbonate

The co-solvent composition for compounding methanol gasoline consists of methyl tert-amyl ether 0-61 weight portions, dimethyl carbonate 0-52 weight portions, methyl tert-butyl ether 0-47 weight portions, allcyl polyoxyethylene ether 0.1-10 weight portions, isopropyl ether 0-10 weight portions, ethyl ether 0-30 wt%, tert-butanol 0-45 weight portions, iso-butanol 0-25 weight portions, isopropanol 0-15 weight portions, antioxidant í‹501íŒ 0-8 weight portions, xylene 0-20 weight portions, urotropin 0-7 weight portions, butanone 0-36 weight portions and acetone 0-20 weight portions. It is added while compounding methanol gasoline to raise the intersolubility between methanol and gasoline and raise the relevant physical and chemical performances of methanol gasoline.

Owner:翟雁萍

Process for preparing isobutene from tertiary butanol

InactiveCN1609082AReduce energy consumptionSmall sizeOrganic-compounds/hydrides/coordination-complexes catalystsOrganic chemistry methodsAlcoholIon exchange

The present invention relates to a method for preparing isobutene, wherein in at least one reactor with temperature from 80 to 150 DEG C and pressure from 5 to 25 B, to crack tert-butyl alcohol into isobutene and water in strong acid ion exchange resin setting on a fixing bed of the reactor, and then to separate the reaction mixture. According to the present invention, the method is actualized with fault constant temperature in the reactor, thus to reduce needed cycle fluid and equipment cost.

Owner:EVONIK DEGUSSA GMBH

Process for separating 2-butanol from tert-butanol/water mixtures

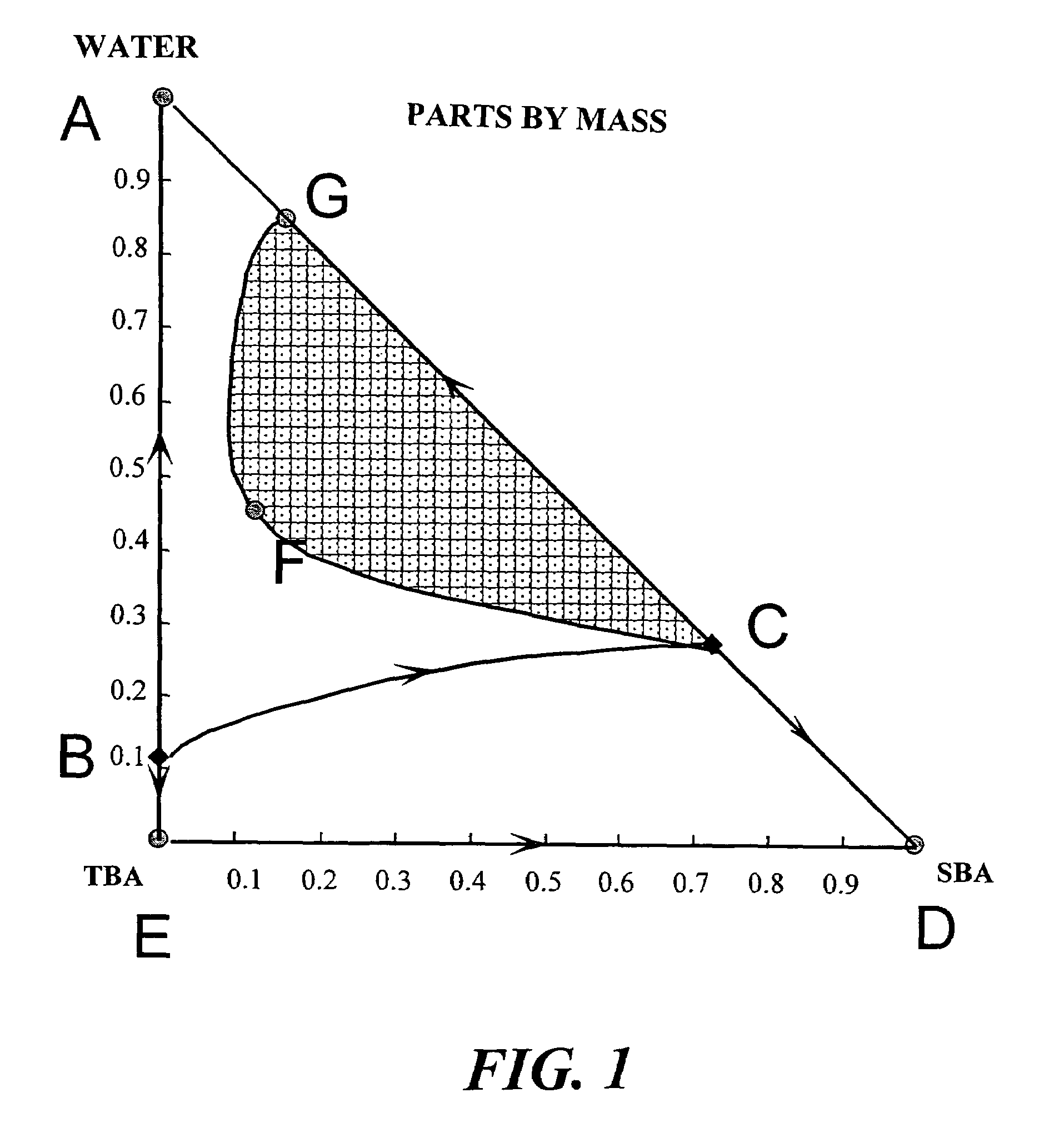

The present invention relates to a process for separating 2-butanol from tert-butanol / water mixtures using a membrane to reduce a water concentration to less than the limit concentration of the distillation boundary line connecting the two azeotropes TBA / water and SBA / water and is subsequently worked up by distillation.

Owner:EVONIK DEGUSSA GMBH

Preparing method for tert-butyl group hydroquinol

InactiveCN1583698AReduce usageReduce pollutionOrganic chemistryOrganic compound preparationAlkyl transferOrganic solvent

A process for preparing tert-butyl hydroquinone (TBHQ) includes such steps as dewatering alkylation reaction between hydroqainone and tert-butanol under catalysis of acid to obtain TBHQ, and purifying by reducing agent and acid.

Owner:GUANGZHOU YOUBAO IND

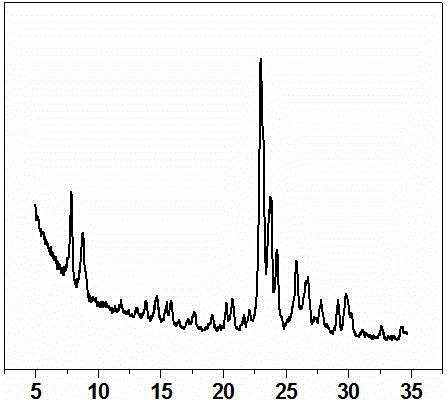

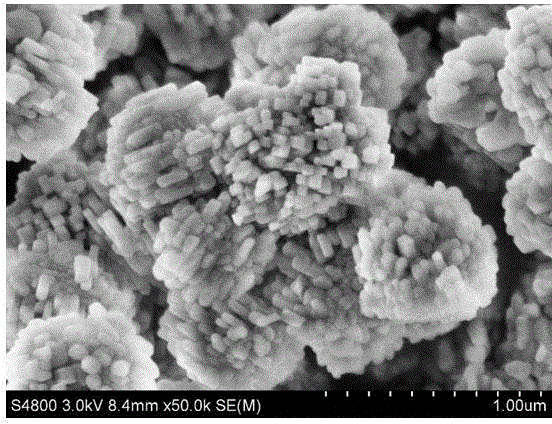

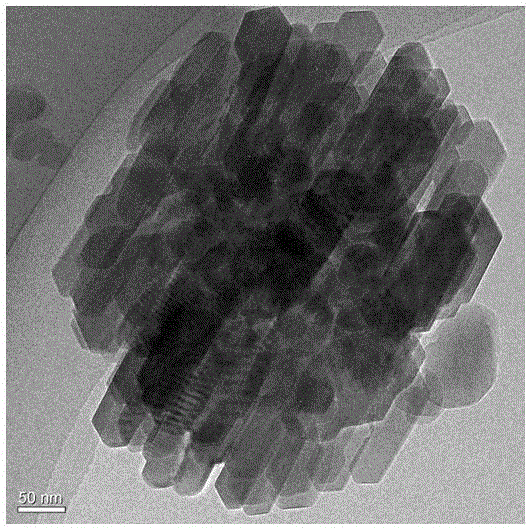

Preparation and application of porous ZSM-5 zeolite molecular sieve aggregate

InactiveCN104649295AIt has the prospect of industrialization promotion and applicationProcess to reduce secondary roastingOrganic chemistryMolecular sieve catalystsPtru catalystPhenol

The invention discloses a preparation and an application of a porous ZSM-5 zeolite molecular sieve aggregate. The preparation is characterized in that by adopting silicon-aluminum sol-gel, which is synthesized by an inorganic aluminum source and an organic silicon source, and added with seed crystal prepared by tetra propyl ammonium, as a guiding agent, the porous ZSM-5 zeolite molecular sieve aggregate with an open pore duct is synthesized through one-step process. The aggregate is taken as a catalyst for hydroxylation reaction of cyclohexane, tertiary butanol and phenol. Compared with the prior art, the aggregate structure, which is formed by stacking nano particles with particle size of 20-150 nm, has a specific surface area up to 600 m<2> / g, total pore volume up to 0.8cm<3> / g, and high conversation rate and selectivity, keeps the activities of monodisperse nano particles, effectively solves the problem that the nano particle catalyst is difficult to separate and short in service life in phenol hydroxylation reaction, and has a certain industrial popularization and application prospect and a remarkable economic value.

Owner:EAST CHINA NORMAL UNIVERSITY

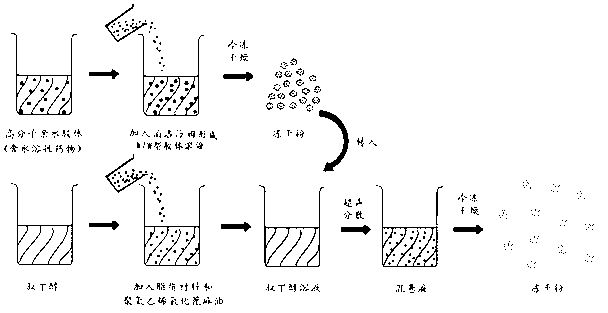

New method for preparing liposome

InactiveCN1444927ALong term storageSuitable for mass productionLiposomal deliveryLipid formationFreeze-drying

A process for preparing the liposome of medicine includes such steps as dissolving the lipid in tert-butanol, dissolving the medicine in water, proportional mixing, freeze drying, and hydrating. Its advantages are simple process and high stability.

Owner:SHENYANG PHARMA UNIVERSITY

Azeotrope-like compositions of tetrafluoropropene and alcohols

ActiveUS8114828B2Cosmetic preparationsDomestic cooling apparatusIsobutanol1,3,3,3-Tetrafluoropropene

A composition including an effective amount of trans-1,3,3,3-tetrafluoropropene component combined with an effective amount of an alcohol selected from the group of methanol, ethanol, propanol, isopropanol, tert-butanol, isobutanol, 2-ethyl hexanol and any combination thereof, where the composition has azeotropic properties.

Owner:HONEYWELL INC

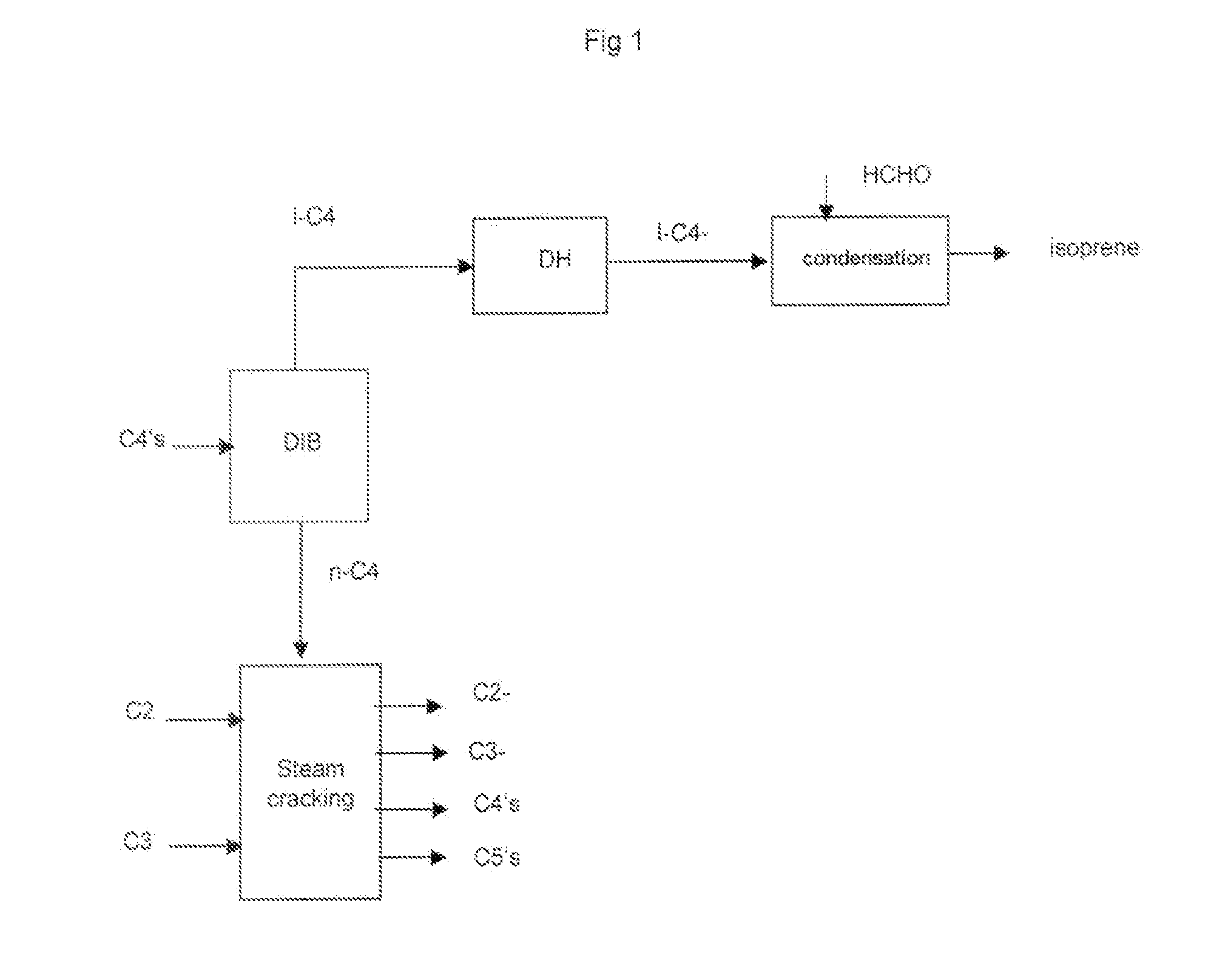

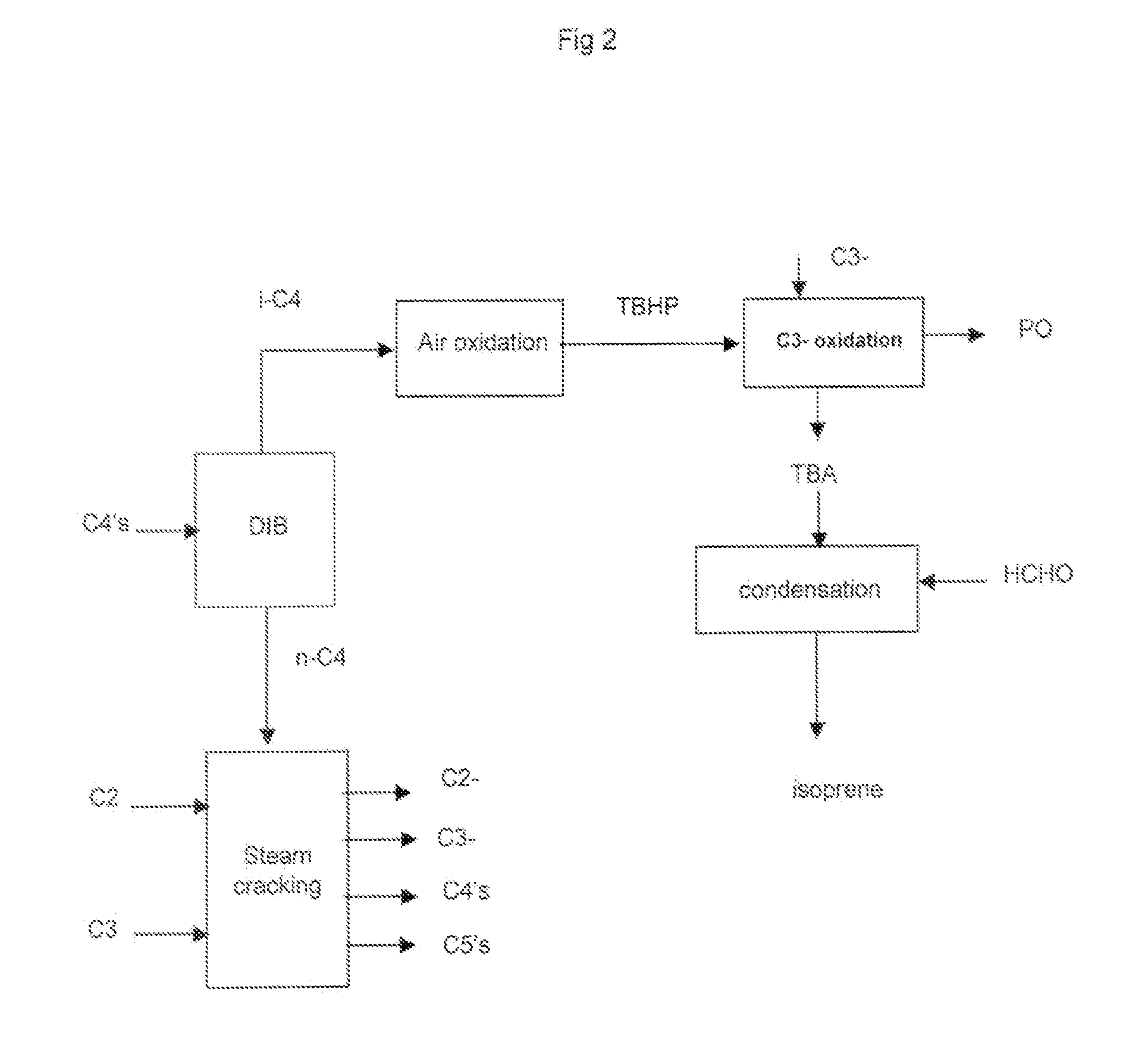

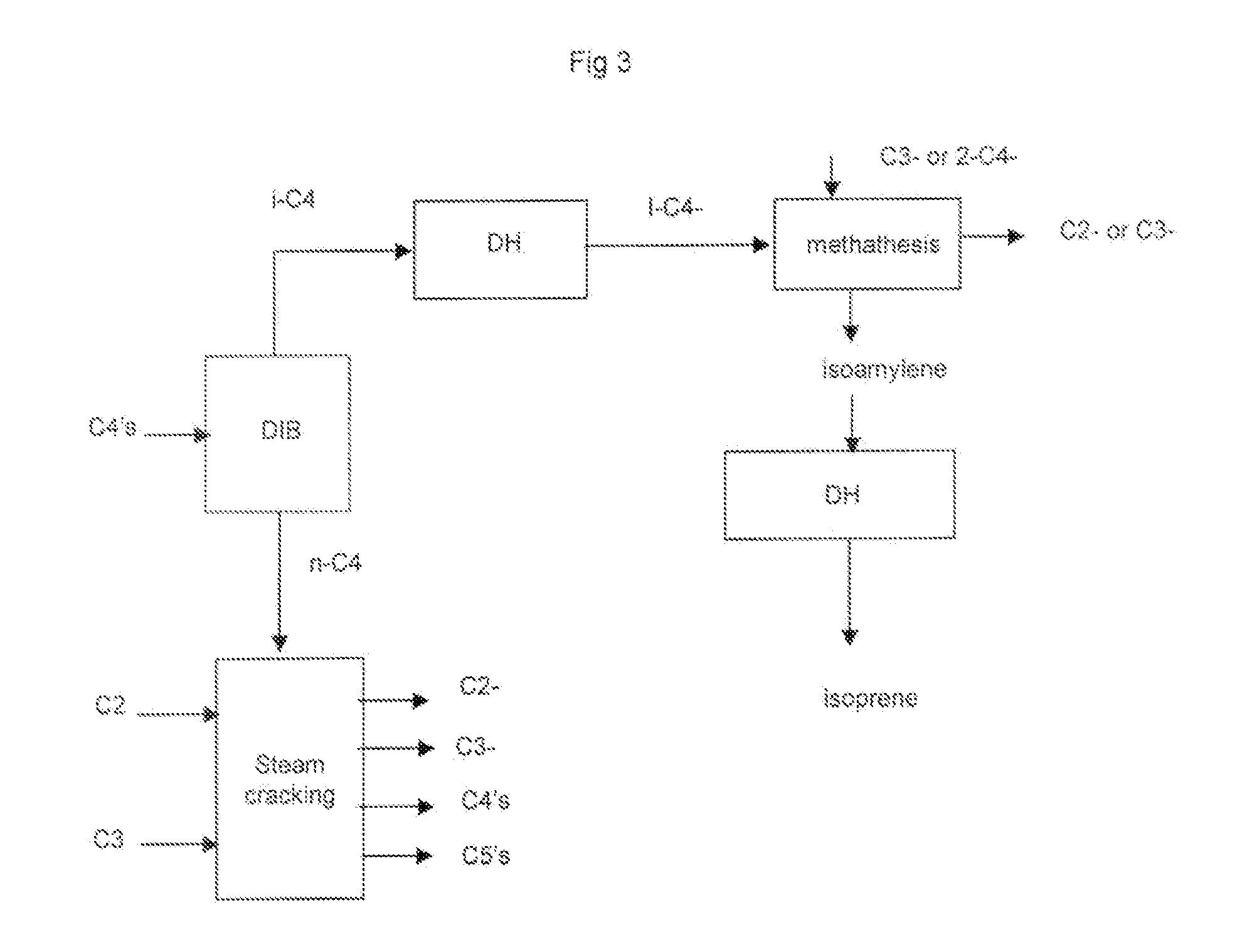

Production of Light Olefins and Isoprene from Butane

InactiveUS20110040133A1Increase valueImprove cokingOrganic compound preparationDistillation purification/separationButeneDehydrogenation

Process for the selective production of ethylene, propylene and isoprene from light hydrocarbons comprising: a) fractionating a butane fraction in a de-isobutanizer to obtain an enriched iso-butane fraction and an enriched normal-butane fraction, b) cracking said normal-butane fraction and optionally an ethane fraction, optionally a propane fraction, in a non-catalytic cracking zone to produce an olefin rich stream, c) treating said olefin rich stream in a separating section to recover: an ethylene stream, a propylene stream, d) transforming the recovered iso-butane of step a) into iso-butene or t-butyl hydroperoxide or partly into iso-butene and partly into t-butyl hydroperoxide, e) optionally reacting iso-butene of step d), if any, with formaldehyde to make isoprene, f) optionally reacting t-butyl hydroperoxide of step d), if any, with an olefin to give an epoxide and t-butanol and further separating t-butanol, or optionally having t-butyl hydroperoxide of step d), if any, decomposed to t-butanol and reacted with formaldehyde to give isoprene, or reacting a part of the t-butyl hydroperoxide of step d) with an olefin and having the remaining part decomposed to t-butanol and reacted with formaldehyde to give isoprene, g) dehydrating the t-butanol recovered at step f), if any, into iso-butene and reacting said iso-butane with formaldehyde to make isoprene, or reacting directly the t-butanol recovered at step f), if any, with formaldehyde to make isoprene, or dehydrating the t-butanol recovered at step f), if any, into iso-butene, hydrogenating said iso-butene to iso-butane and oxidizing said iso-butane into t-butyl hydroperoxide, and recycling said t-butyl hydroperoxide, or dehydrating the t-butanol recovered at step f), if any, into iso-butene, then disproportionating said iso-butene and propylene recovered at step c) (or 2-butene recovered at step c)), separating an isoamylene stream and converting the isoamylene into isoprene by dehydrogenation, or making any combination of above routes of said step g), h) optionally disproportionating iso-butene of step d), if any, and propylene recovered at step c) (or 2-butene recovered at step c)), separating an isoamylene stream and converting the isoamylene into isoprene by dehydrogenation, at least one of steps e), f) and h) is not optional.

Owner:TOTAL RES & TECH FELUY

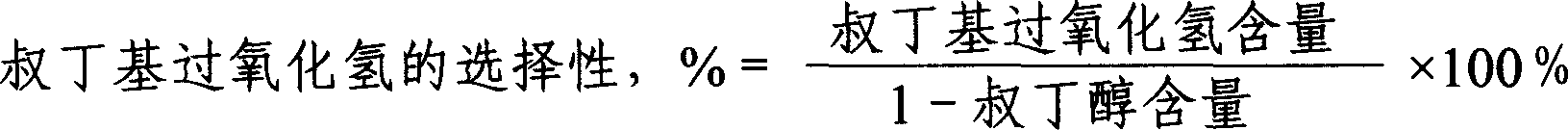

Process for preparing tert-butyl hydroperoxide

ActiveCN1699339AIncrease profitHigh activityOrganic compound preparationPeroxy compound preparationCatalytic oxidationTitanium

The invention provides a process for preparing tert-butyl hydroperoxide, which comprises contacting tert-butanol and hydrogen dioxide by the mol ratio of 0.5-10 for 0.5-10hours at 40-100 deg. C at the presence of titanium-silicon molecular screen, the content of titanium-silicon molecular screen is 0.005-0.1g molecular screen in each one ml of reaction liquid.

Owner:CHINA PETROLEUM & CHEM CORP +1

Modification method of cellulose ether product

The invention discloses the modifying method for cellulose ether product, comprising: mixing the reaction raw material with solvent and getting the product, then washing, drying and breaking the product, the solvent used in the reacting and washing course is water, alcohol isopropylicum and butyl alcohol; or water, alcohol isopropylicum and isobutyl alcohol; or water, alcohol isopropylicum and tert-butanol. The invention is characterized by the little pollution to environment, high reaction efficiency, easy to remove solvent and high efficiency for product washing, which effectively improves the quality of cellulose ether product such as hydroxypropyl cellulose (HPC), hydroxypropylmethylcellulose (HPMC),glycol cellulose (HEC), cellulose ethyl ether (EC) and cationic cellulose.

Owner:SOUTH CHINA UNIV OF TECH

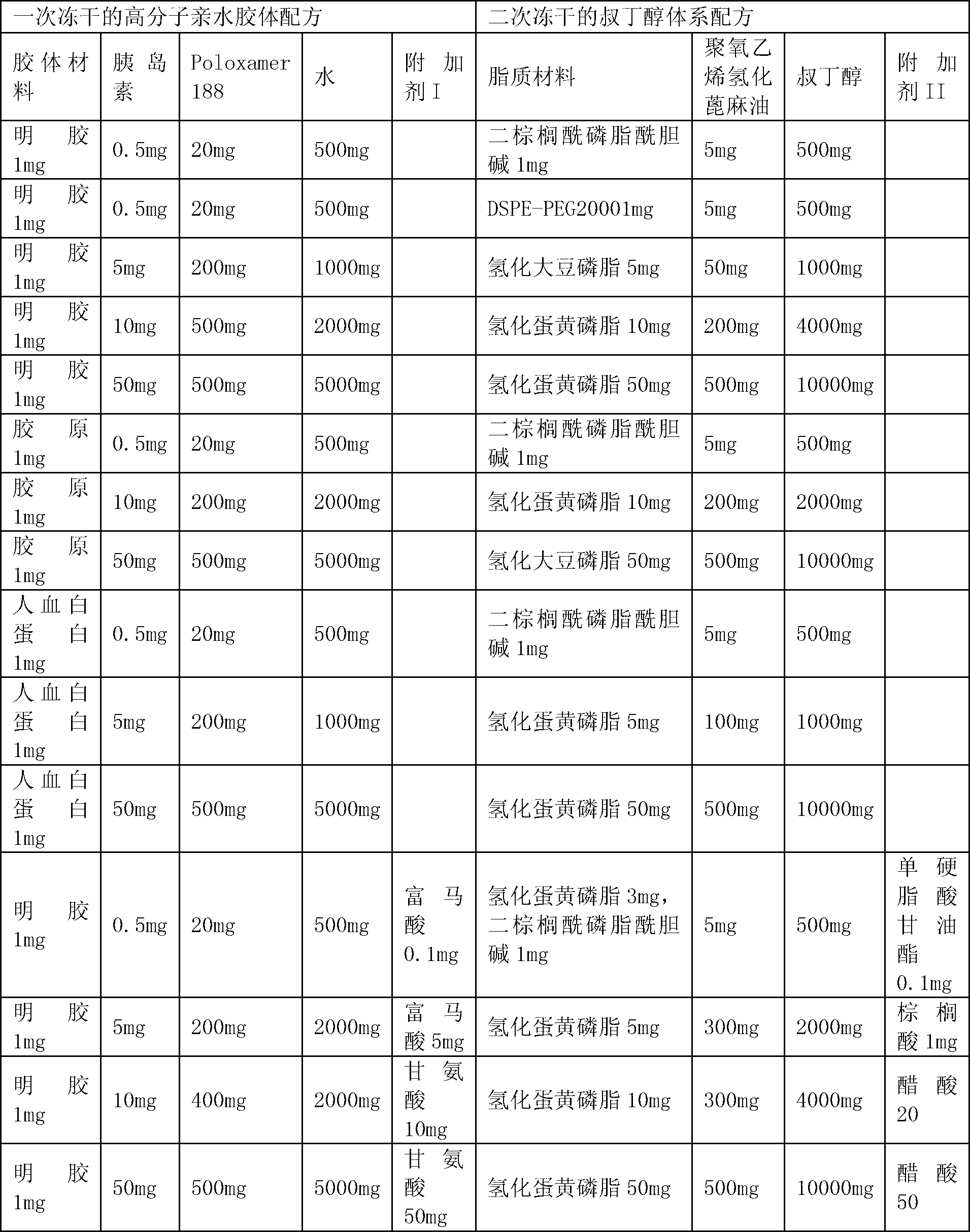

Preparation method of liposome entrapping water-soluble medicines

InactiveCN102935068AGood dispersionGuaranteed stabilityPharmaceutical product form changeMacromolecular non-active ingredientsWater soluble drugEntrapment

The invention relates to a preparation method of a liposome entrapping water-soluble medicines. According to the invention, a water-soluble medicine is dissolved in amino-acid-structure-containing high-molecular hydrophilic colloids such as gelatin, collagen or albumin; poloxamer is added and the mixture is well mixed, such that a W / W type colloidal solution is formed; the solution is lyophilized; the formed lyophilized powder is transferred into a tert-butanol solution containing a liposome material, and the mixture is well dispersed; and the mixture is subjected to lyophilization, such that high-entrapment-efficiency liposome entrapping the water-soluble medicine is formed. According to the liposome preparation method, W / W type colloid is combined with a two-step lyophilization preparation technology, such that problems such as low water-soluble medicine load, low entrapment efficiency and poor stability of existing preparation methods of liposome entrapping water-soluble medicines are solved. The method provided by the invention is used for preparing liposome used for entrapping water-soluble medicines, and is especially suitable for preparing liposome used for entrapping poor-thermal-stability or macromolecular medicines. The method can also be used for covering medicine bitterness or odor, and for separating medicines from other components.

Owner:ZHEJIANG HISUN PHARMA CO LTD +1

Method for preparing isobutylene from tert-butanol

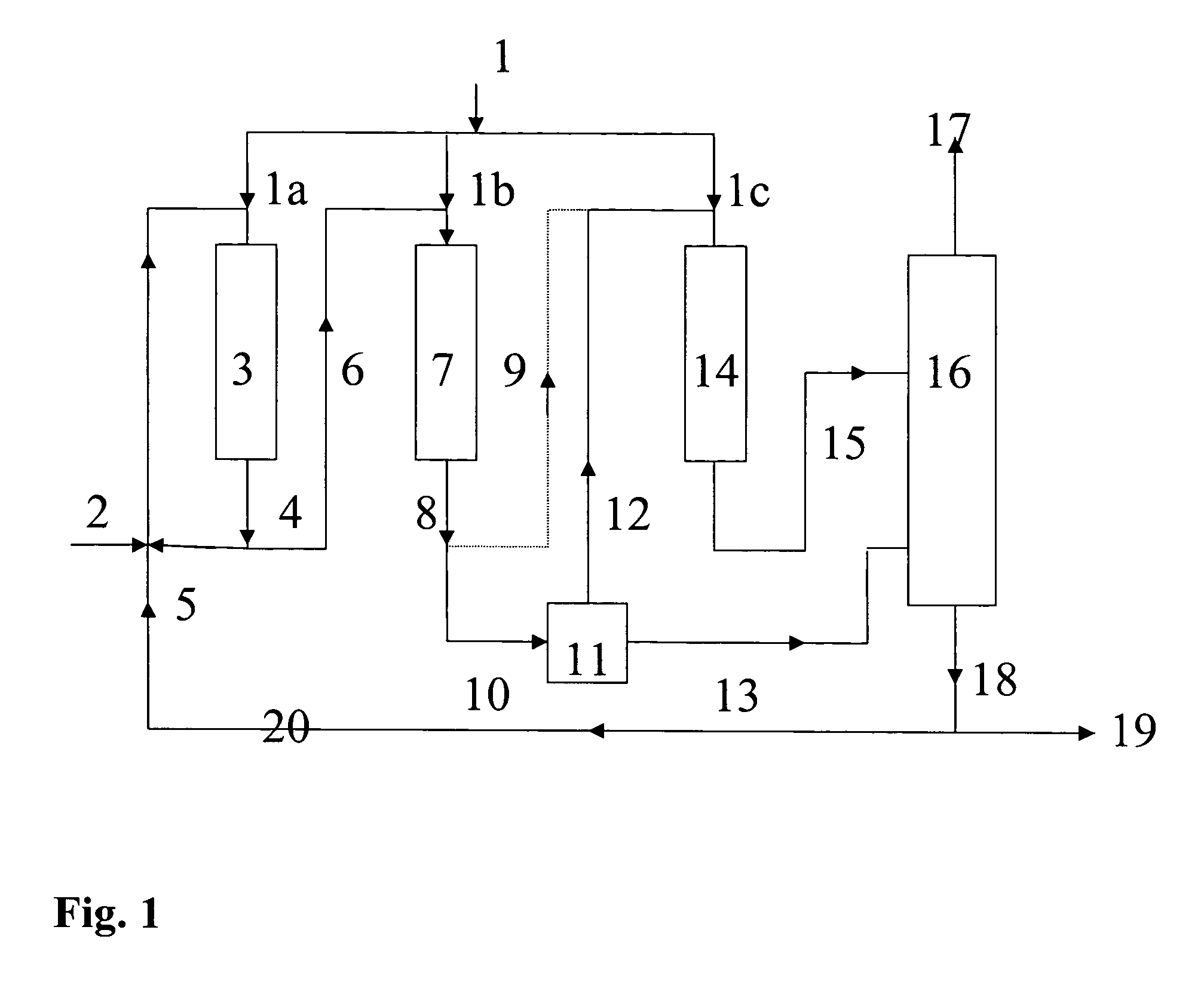

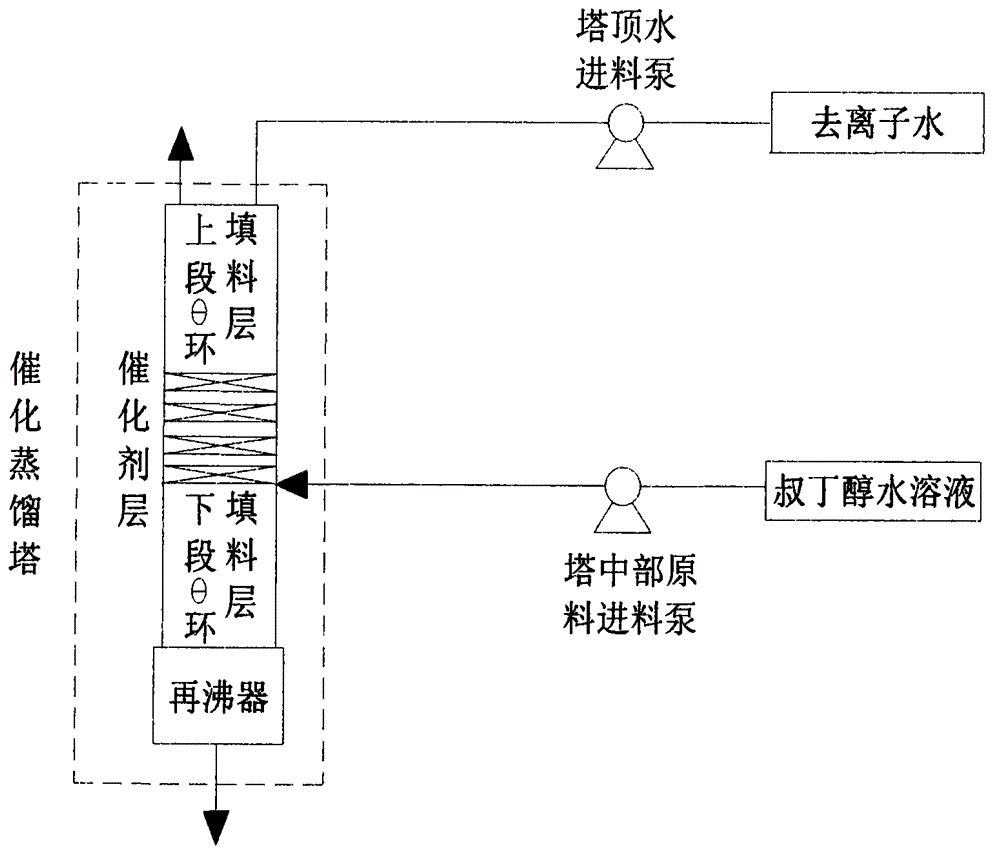

ActiveCN104478644AImprove production efficiencyLow costChemical industryHydrocarbon from oxygen organic compoundsReboilerCatalytic distillation

The invention relates to a method for preparing high-purity isobutylene from a low-concentration tert-butanol aqueous solution. The method comprises the following steps: (1) firstly respectively filling catalyst sections arranged in the middle of a catalytic distillation tower with theta-ring packing; and sectioning the catalyst and filling each catalyst section with the catalyst; (2) introducing the tert-butanol aqueous solution and deionized water into the catalytic distillation tower; carrying out heating distillation on the tert-butanol aqueous solution by virtue of a tower bottom reboiler to form a tert-butanol-water azeotrope, dehydrating tert-butanol in the tert-butanol-water azeotrope by virtue of a catalyst layer to generate isobutylene, enabling unreacted tert-butanol to be absorbed by virtue of deionized water to reach the catalyst layer and further dehydrating to generate isobutylene; and (3) producing high-purity isobutene at the top and ionized water at the tower bottom. The method has the advantages of simplicity in operation flow, low cost and high conversion rate and selectivity and the produced isobutylene is high in purity and the preparation efficiency is high.

Owner:BEIJING ENZE FULAI TECH +1

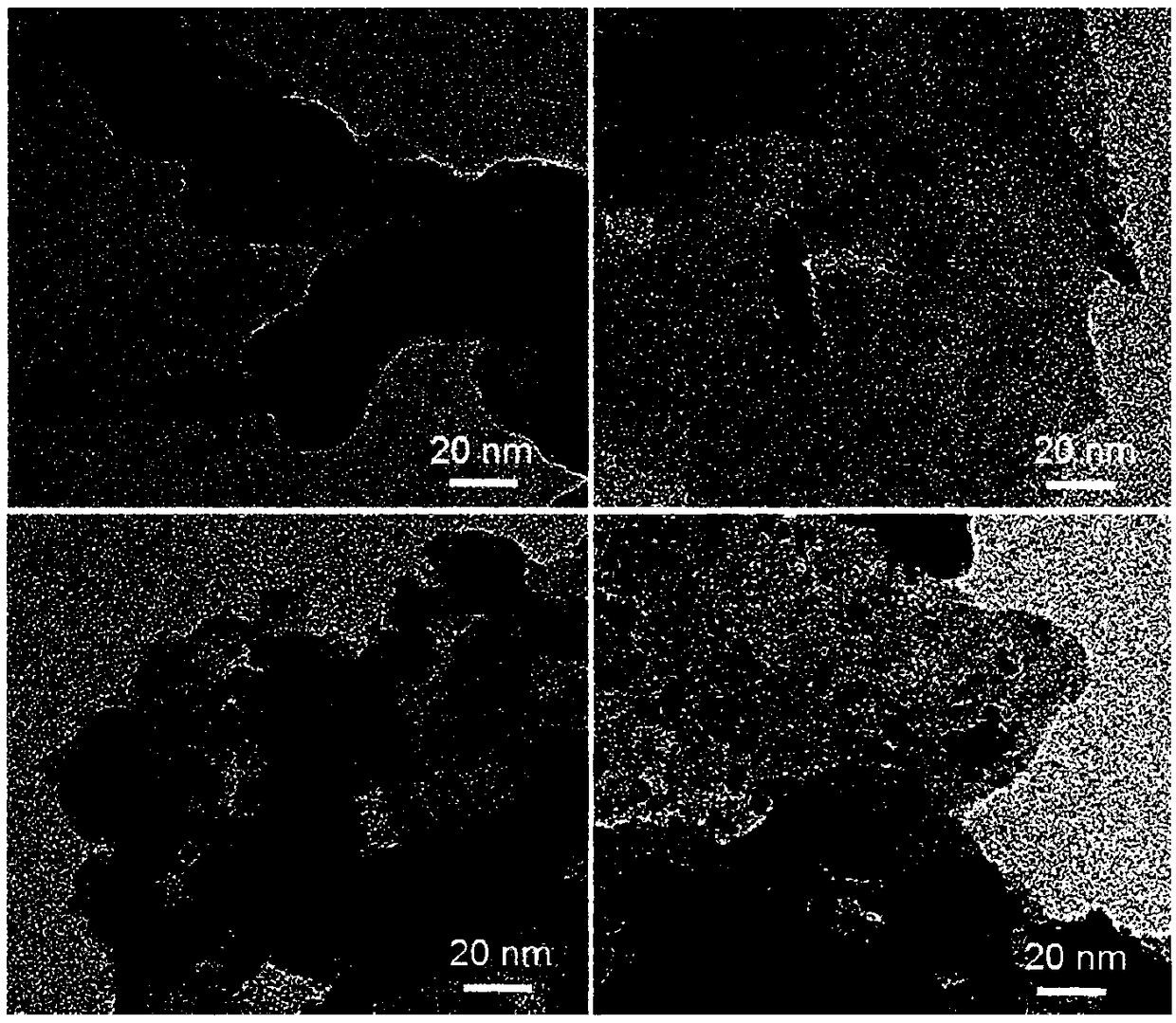

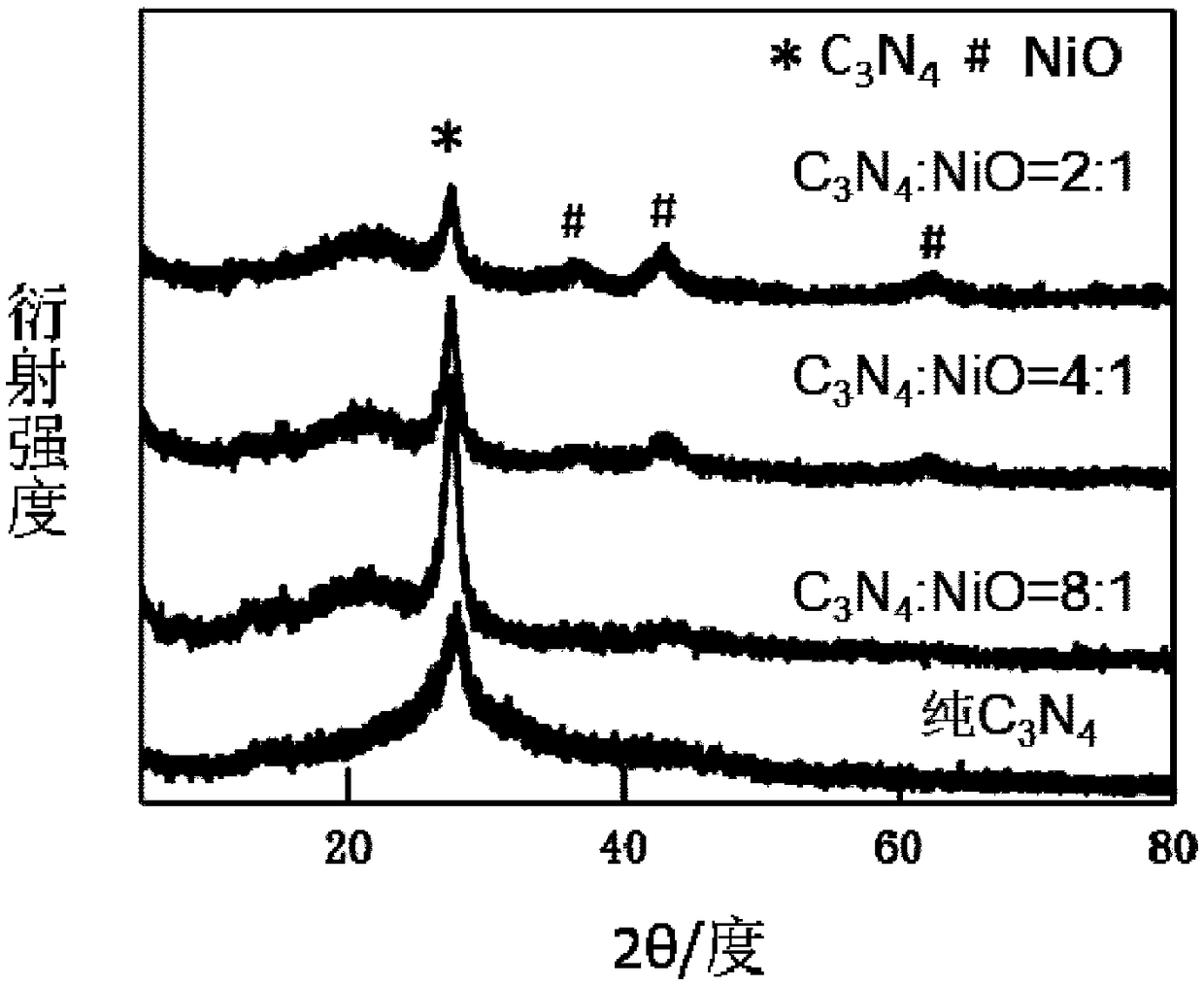

Preparation method of nickel oxide-carbon nitride composite photocatalyst

InactiveCN108816262APromote formationImprove utilizationPhysical/chemical process catalystsNanoparticleCarbon nitride

The invention discloses a preparation method of a nickel oxide-carbon nitride composite photocatalyst. The preparation method comprises the steps: firstly, calcining urea under a certain condition toobtain carbon nitride powder; then, carrying out ultrasonic dispersion at a certain temperature, dispersing the carbon nitride powder into tert-butanol with a certain volume, then, adding a certain amount of nickel acetylacetonate into a mixed solution, and carrying out ultrasonic dispersion and continuous magnetic stirring to obtain a precursor solution; and finally, carrying out a solvothermal reaction on the precursor solution to obtain carbon nitride nanopowder of which the surface is modified with nickel oxide nanoparticles. The preparation method has the advantages that: (1) compared with other methods, the method is simple in process, free of complex equipment and harsh environments and low in cost; (2) the loading amount of the nickel oxide nanoparticles on the surface of carbon nitride can be conveniently controlled by using the method; and (3) the nickel oxide-carbon nitride composite photocatalyst prepared by using the method has excellent photocatalytic hydrogen production,and the hydrogen production amount of the catalyst is obviously increased after the nickel oxide nanoparticles are loaded.

Owner:XI AN JIAOTONG UNIV

Process for enzymatic synthesis of ethyl lactate in solvent phase

The invention discloses a ethyl lactate synthesis enzyme catalysis method in solvent phase and belongs to ethyl lactate preparation technology using lactic acid and ethanol, characterizing in the following steps: using chloroform, tert-butanol or tetrahydrofuran as sovent, or adding in the said solvent of lactic acid and ethanol in ratio of (1:5)-(1:10) and lipase according to 10-30 g enzyme catalysis per mol lactic acid, mixing sufficiently, constant temperature water bath in 60-70 DEG C while lactic acid concentration is 0.3-0.6mol / L, concussion table revolution being controlled 200-250revolution / min, reacting 24-48 hours, obtaining crude products containing ethyl lactate. Advantage of the invention compared with existing ethyl lactate preparation method lies in: temperate reaction condition, low energy consumption, easy operation of separating catalyst and products, apparatus not easy corroding, no pollution, high product quality and yield.

Owner:HEBEI UNIV OF TECH

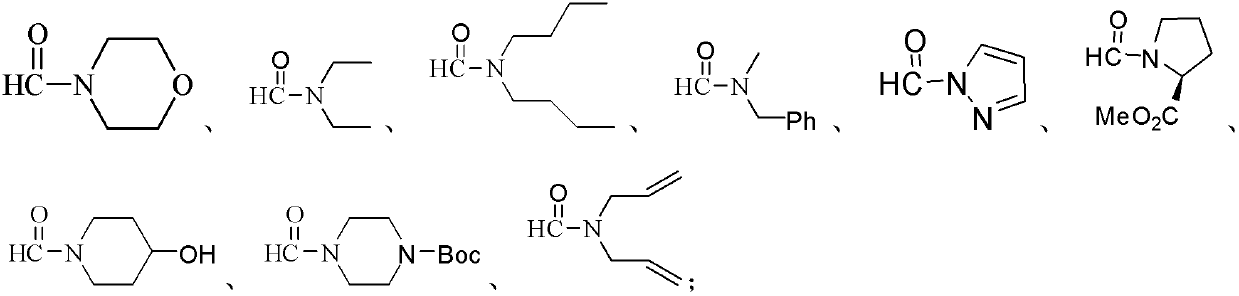

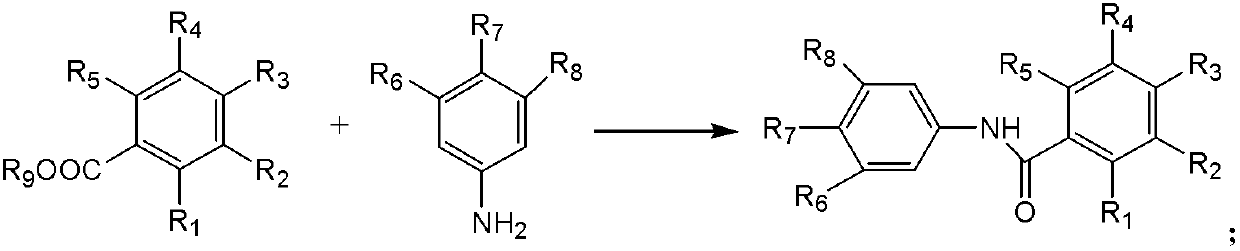

Preparation method of amide

ActiveCN102584509AReact SafeMild reaction conditionsCarboxylic acid nitrile preparationOrganic compound preparationTetramethylammonium iodideSodium iodide

The invention discloses a preparation method of amide. With an aldehyde derivative and a formamide derivative as a reaction substrate, iodide as catalyst and tert-butanol hydrogen peroxide as an oxidizing agent, the amide is prepared through decarbonylation double free radical cross-coupling reaction, wherein the chemical structural formula of the aldehyde derivative is shown in the description, R1 is selected from a naphthyl, a heterlcyclic ring, an alkylene or a mono-substituted aryl; and the iodide is one selected from sodium iodide, potassium iodide, cuprous iodide, lithium iodate, an iodine elementary substance, tetrabutyl ammonium iodide, tetraheptylammonium iodide, tetramethylammonium iodide and benzyltrimethylammonium iodide. According to the invention, because the amide is prepared by using the iodide as the catalyst and using the double free radical cross-coupling method, the use of the traditional metal catalyst with expensive price and larger toxicity as well as a complicated experiment method is avoided so that the reaction is simpler, more convenient, easier, safer, greener and more economic; moreover, the preparation method of the amide disclosed by the invention has the advantages of quite moderate reaction condition, simpler post-treatment and potential industrial application value.

Owner:铜陵市官作文化有限公司

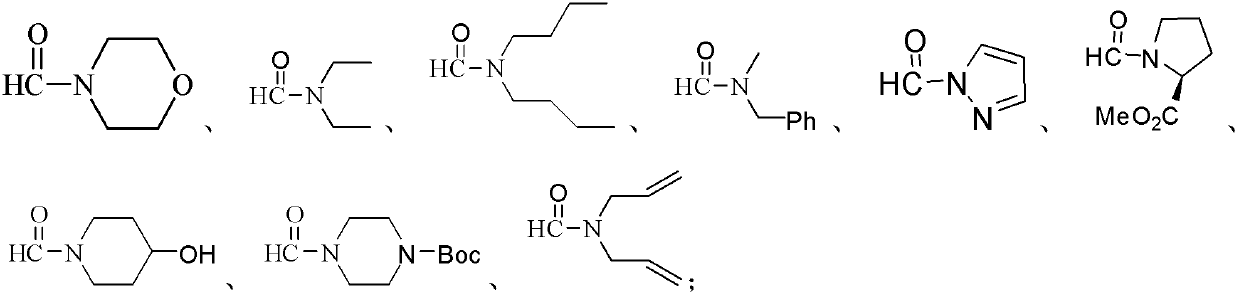

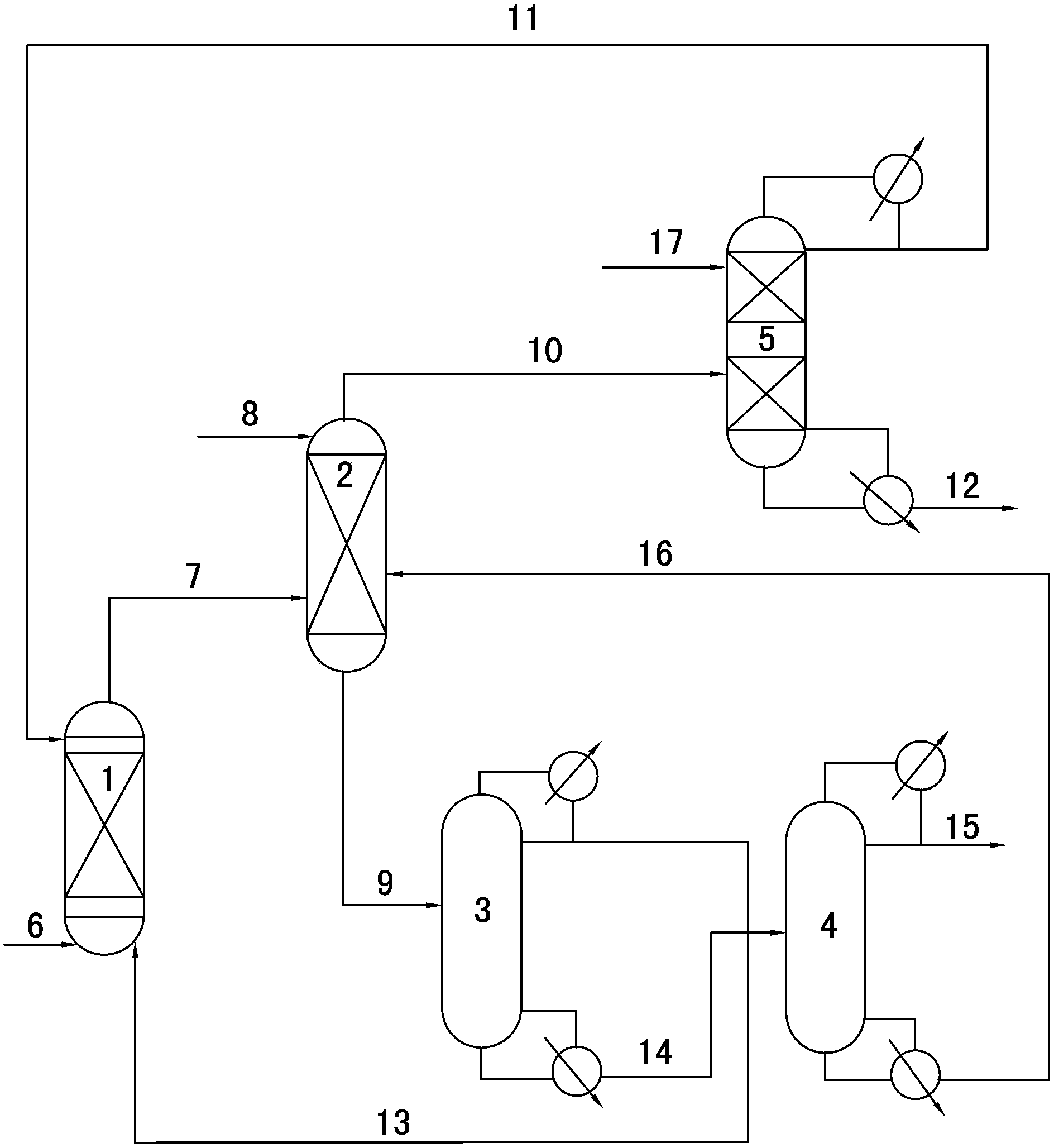

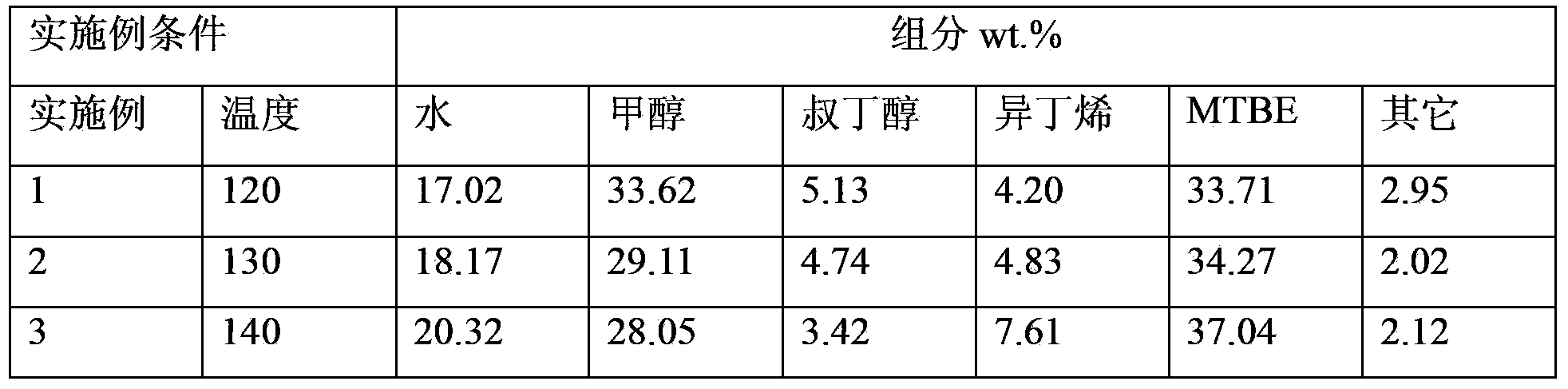

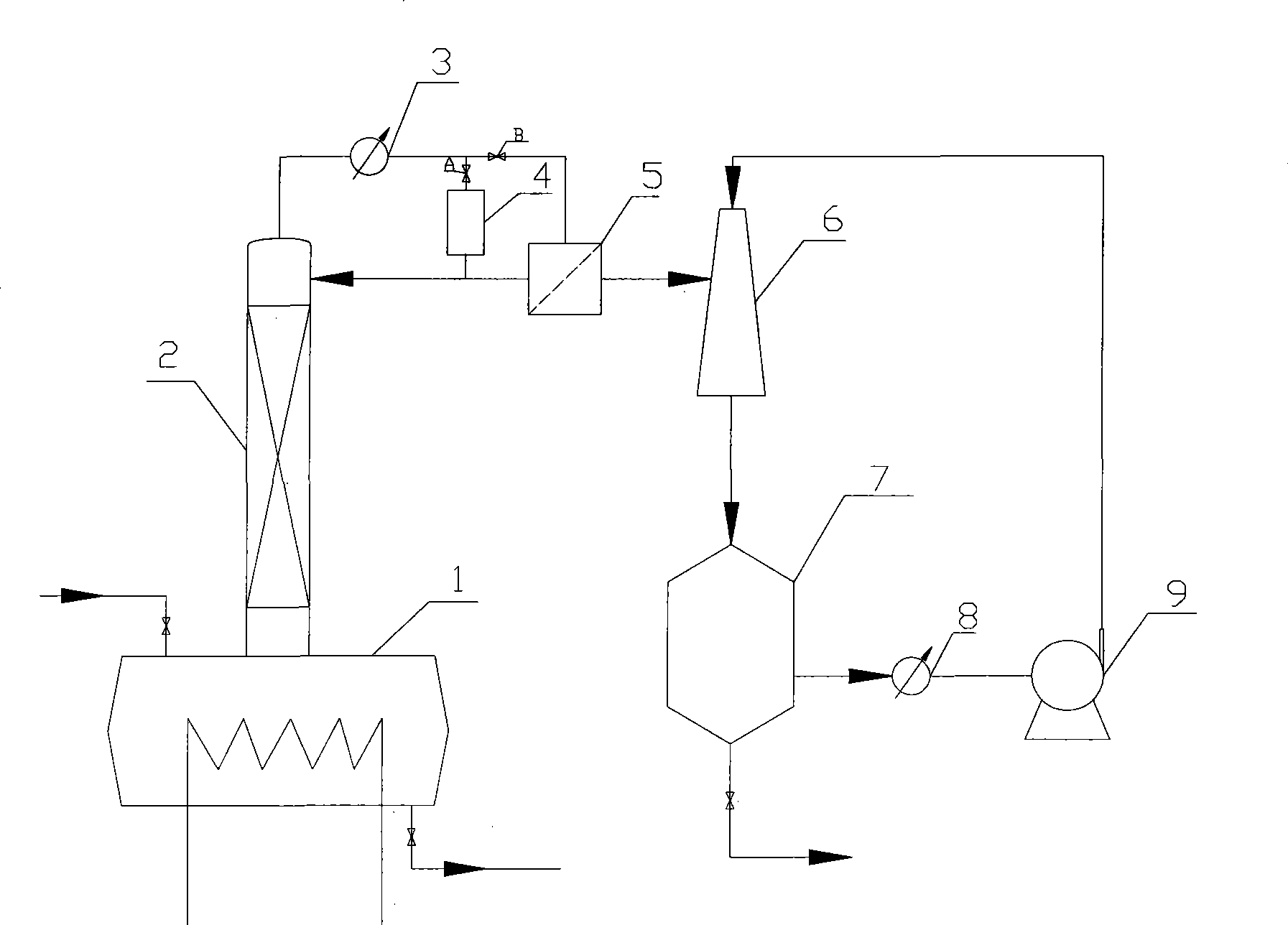

Preparation method and device of methyl tertiary-butyl ether (MTBE)

ActiveCN104250205AImprove conversion rateHigh yieldEther separation/purificationChemical industryWater flowCatalytic distillation

The invention relates to an ether production technology and especially relates to a method and production device for preparing methyl tertiary-butyl ether (MTBE) by a reaction of tertiary butanol and methanol. The method comprises that tertiary butanol and methanol are mixed and undergo a reaction to produce mixed gas, the mixed gas is fed into an extraction tower and is extracted, isobutene and MTBE are distilled off from the tower top, tertiary butanol, methanol, a trace amount of MTBE, water and an extractant flow out of the tower bottom, methanol is supplied for a tower top component of the extraction tower, the mixture is fed into a catalytic distillation tower, a methanol- and isobutene-containing tower top product of the catalytic distillation tower is fed back to a reactor and then undergoes a reaction, the MTBE is discharged from the bottom of the catalytic distillation tower, the materials discharged from the bottom of the catalytic distillation tower enters into a first extractant recovery tower, tertiary butanol, methanol and a trace amount of MTBE are distilled off from the top of the first extractant recovery tower, then are fed back to the reactor and then undergo a reaction, and the extractant and water flow out of the tower bottom, then enter into a second extractant recovery tower and then is recovered for recycle by reduced pressure distillation. The method and device solve the problem of azeotropy of tertiary butanol and water and improve a tertiary butanol one-step conversion rate to 87-94%.

Owner:CHINA PETROLEUM & CHEM CORP

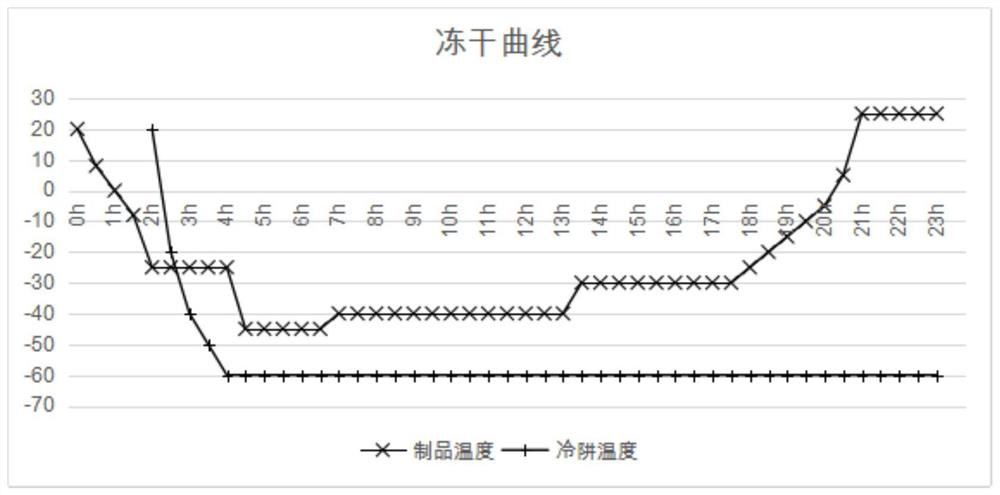

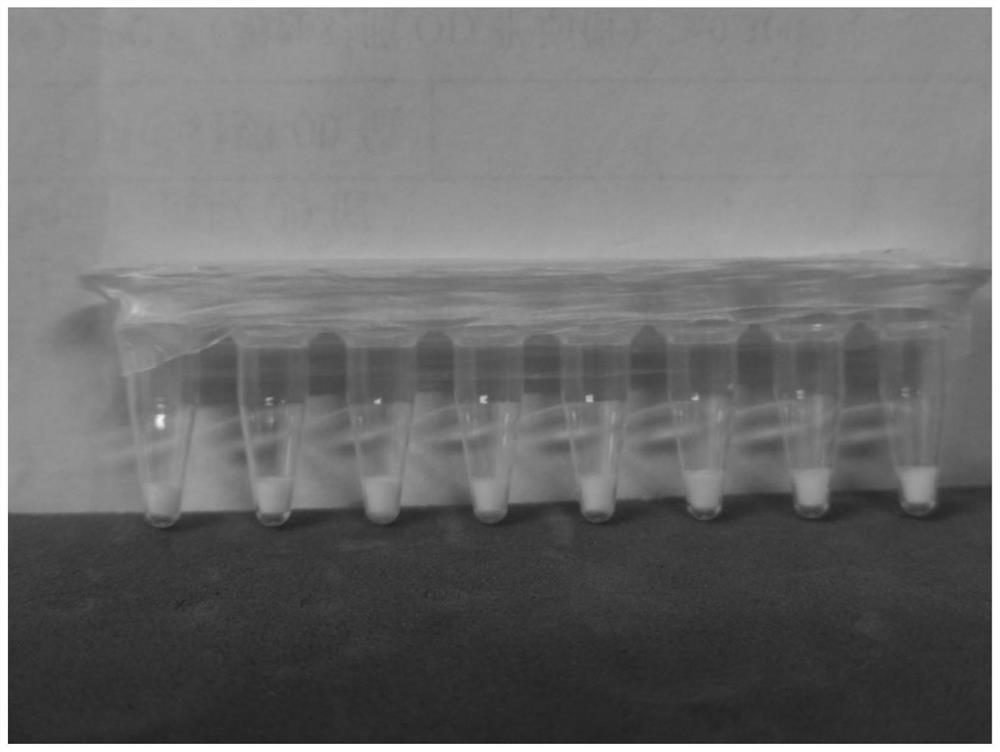

Freeze-drying protective agent, PCR amplification reagent, freeze-drying method and application thereof

ActiveCN112048545AEasy to transportEasy to operateMicrobiological testing/measurementSucroseGlycerol

The invention is applicable to the field of biotechnology diagnosis and detection, and provides a freeze-drying protective agent, a PCR amplification reagent, a freeze-drying method and application thereof. The PCR amplification reagent comprises an amplification reaction system and the freeze-drying protective agent, wherein the freeze-drying protective agent comprises the following components: glycerol, trehalose, sucrose, Tween-80, dextran-40, glycine, histidine, sodium glutamate, a bacteriostatic agent and tert-butyl alcohol. The freeze-drying protective agent provided by the invention canbe prepared together with components required for fluorescent PCR, and can also be matched with any primers and probes required for PCR detection, and freeze-drying is carried out to prepare the PCRamplification reagent; and the PCR amplification reagent can be transported and stored at normal temperature, and only ddH2O is needed to be dissolved and then sample nucleic acid is added when the PCR amplification reagent is used, so that the PCR amplification reagent has the advantage of convenient operation.

Owner:SHANGHAI CHUANG HONG BIOTECH +1

Apparatus and method for separating tert-butanol and water using batch fractionating and pervaporation

InactiveCN101372442AHigh purityHigh yieldDispersed particle separationHydroxy compound separation/purificationWater useHigh concentration

The invention relates to a device and a method for separating tert-butyl alcohol from water by combining batch rectification and pervaporation. The device mainly comprises a rectification tower body, a rectification tower kettle, a condenser, a membrane separator, a water jet pump, a condensate storage tank and a circulating pump. The tert-butyl alcohol aqueous solution is added to the batch rectification tower kettle, and firstly total-reflux operation is carried out in the batch rectification tower by switching a valve positioned at the condensate outlet at the tower top; after the mixture in the tower becomes stable, azeotrope of the tert-butyl alcohol and the water enters the membrane separator by the condenser for further dehydration and separation; osmotic lateral pressure is kept at 1000Pa by the jetting of the water jet pump, thus the tert-butyl alcohol and the water in the tert-butyl alcohol aqueous solution are separated by the membrane separator; the high-concentration tert-butyl product can be obtained from the rectification tower kettle, and the water is vaporized at the downstream of the membrane separator by an osmotic membrane; after vaporization and condensation, the high-concentration tert-butyl product is put in the condensate storage tank, and then cooled by the condenser and sent to the water jet pump by the circulating pump for circulation. The method has the advantages of simple operations and high tert-butyl alcohol yield without adding other solvents.

Owner:TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com