Patents

Literature

172 results about "1,3,3,3-Tetrafluoropropene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

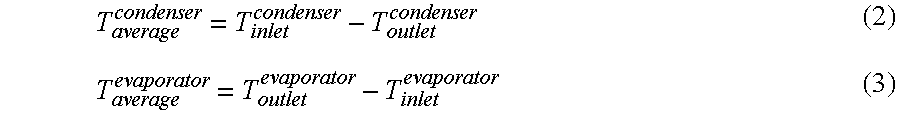

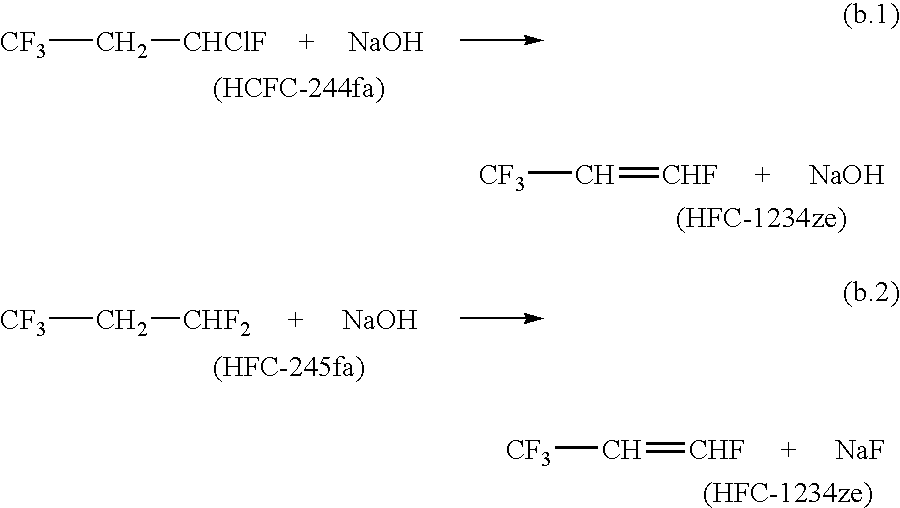

1,3,3,3-Tetrafluoropropene (HFO-1234ze(E)) is a hydrofluoroolefin. It was developed as a "fourth generation" refrigerant to replace fluids as R-134a and as a blowing agent for foam and aerosol applications. The use of R-134a is being phased out because of its high global-warming potential. HFO-1234ze(E) has zero ozone-depletion potential (ODP=0), a very low global-warming potential (GWP < 1 ), even lower than CO₂, and it is classified by ANSI/ASHRAE as class A2L refrigerant (lower flammability and lower toxicity).

Pentafluoropropene-based compositions

ActiveUS6858571B2Reduce flammabilityMaximize effectivenessBiocideOrganic chemistry1,1-Difluoroethane1,3,3,3-Tetrafluoropropene

Provided are azeotrope-like compositions comprising pentafluoropropene (HFO-1225) and a fluid selected from the group consisting of 3,3,3-trifluoropropene (“HFO-1243zf”), 1,1-difluoroethane (“HFC-152a”), trans-1,3,3,3-tetrafluoropropene (“HFO-1234ze”), and combinations of two or more thereof. Also provided are uses thereof including as refrigerants, blowing agents, sprayable compositions, flame suppressant, and the like.

Owner:HONEYWELL INT INC

PROCESS FOR THE PRODUCTION OF HFO TRANS-1234ze FROM HFC-245fa

ActiveUS20080051611A1Preparation by hydrogen halide split-offPreparation by halogen halide additionHydrogen fluoride1,3,3,3-Tetrafluoropropene

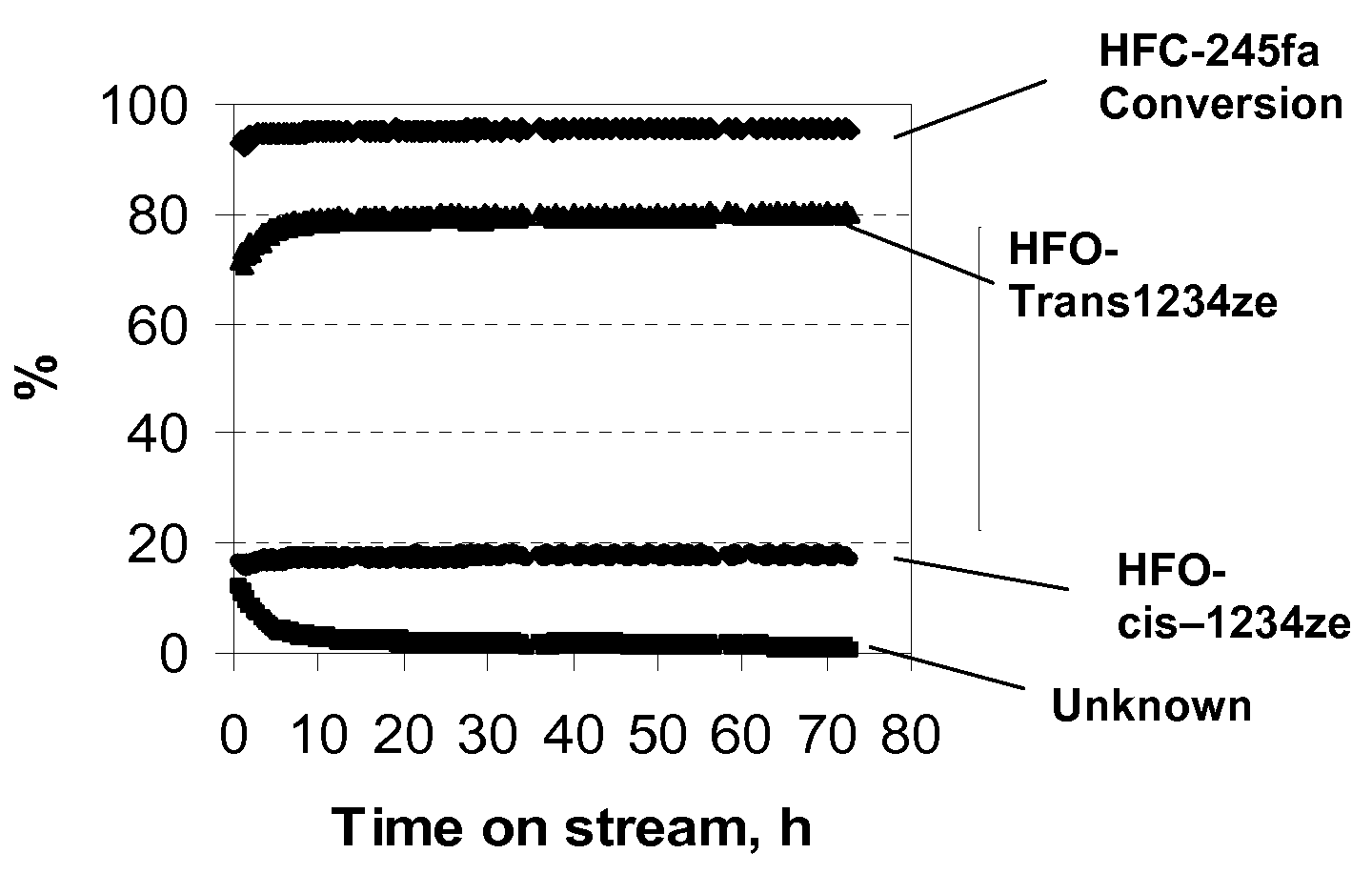

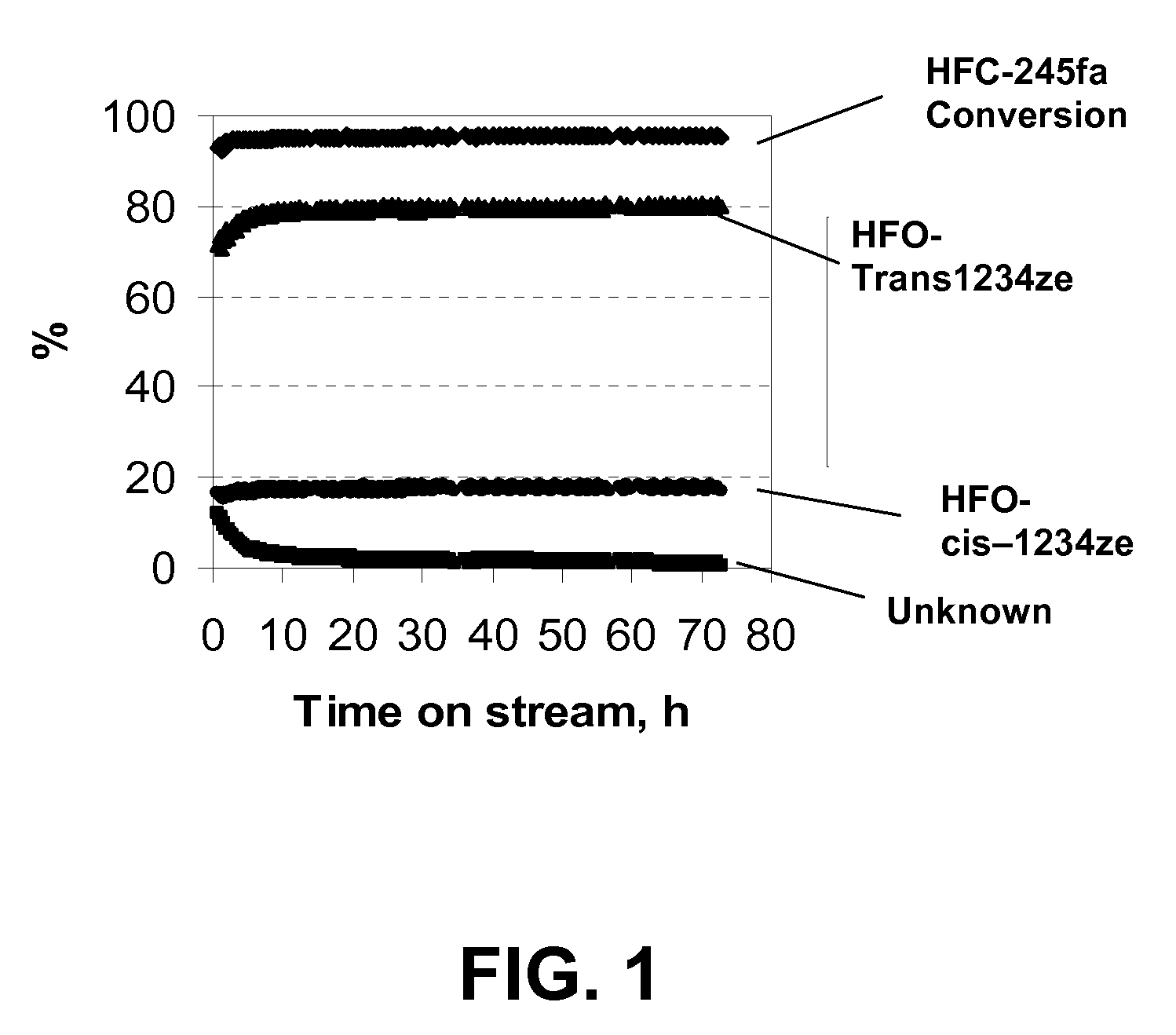

This invention relates a process for the manufacture of the HFO trans-1,3,3,3-tetrafluoropropene (HFO trans-1234ze). More particularly, the invention pertains to a process for the manufacture of the HFO trans-1234ze by first dehydrofluorinating 1,1,1,3,3-pentafluoropropane to thereby produce a mixture of cis-1,3,3,3-tetrafluoropropene, trans-1,3,3,3-tetrafluoropropene and hydrogen fluoride. Then optionally recovering hydrogen fluoride and then recovering trans-1,3,3,3-tetrafluoropropene.

Owner:HONEYWELL INT INC

Catalytic isomerization processes of 1,3,3,3-tetrafluoropropene for making 2,3,3,3-tetrafluoropropene

InactiveUS20080058562A1Increase volumePreparation by halogen halide additionIsomerization1,3,3,3-Tetrafluoropropene

The present invention relates to a process of catalyzed isomerization of HFC-1234ze to make HFC-1234yf. The process comprises contacting HFC-1234ze with a suitable catalyst in a reactor to obtain a product mixture comprising HFC-1234yf.

Owner:THE CHEMOURS CO FC LLC

Process for the manufacture of 1,3,3,3-tetrafluoropropene

ActiveUS7829748B1Physical/chemical process catalystsPreparation by hydrogen halide split-offAlkaline earth metalOxidation state

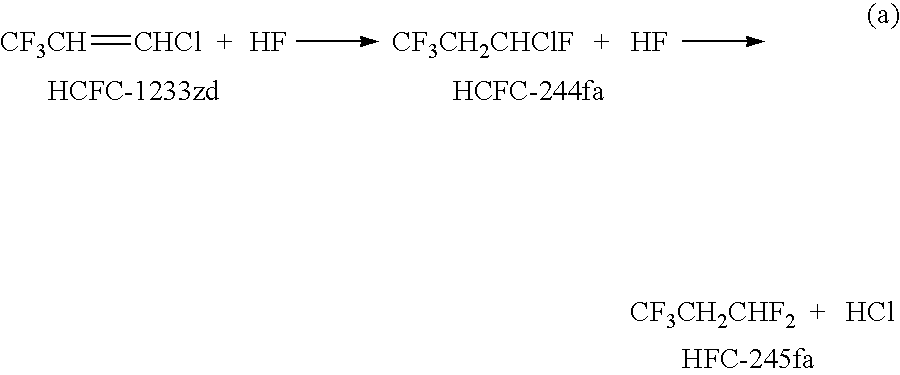

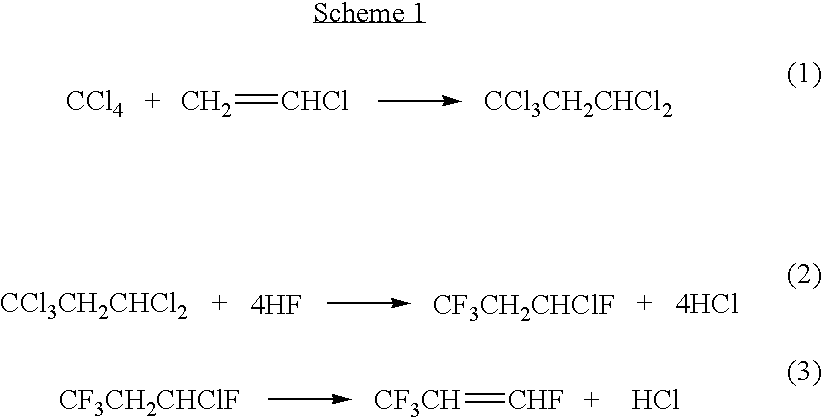

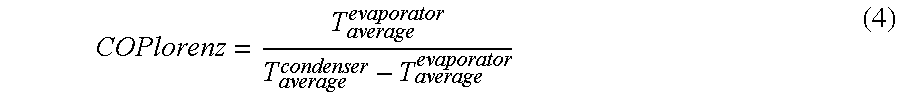

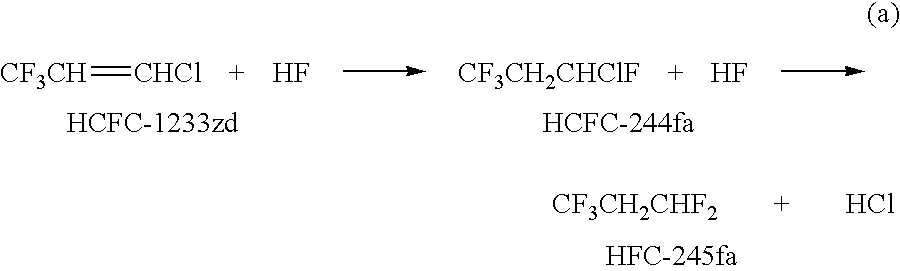

The invention provides an economic process for the manufacture of 1,3,3,3-tetrafluoropropene (HFO-1234ze) by a two stage process. A vapor phase hydrofluorination of 1-chloro-3,3,3-trifluoropropene (HCFC-1233zd) into 1-chloro-1,3,3,3-tetrafluoropropane (HCFC-244fa) and / or 1,1,1,3,3-pentafluoropropane (HFC-245fa) is conducted, followed by the thermal dehydrochlorination of HCFC-244fa and dehydro fluorination of HFC-245fa into HFO-1234ze in the presence of a catalyst which comprises one or more of alkali metal halides, alkaline earth metal halides, halogenated metal oxides, zero oxidation state metals, zinc halides, palladium halides, and activated carbon.

Owner:HONEYWELL INT INC

Processes for synthesis of 1,3,3,3-tetrafluoropropene

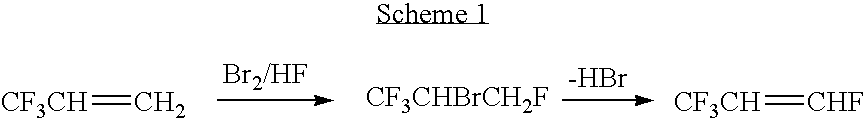

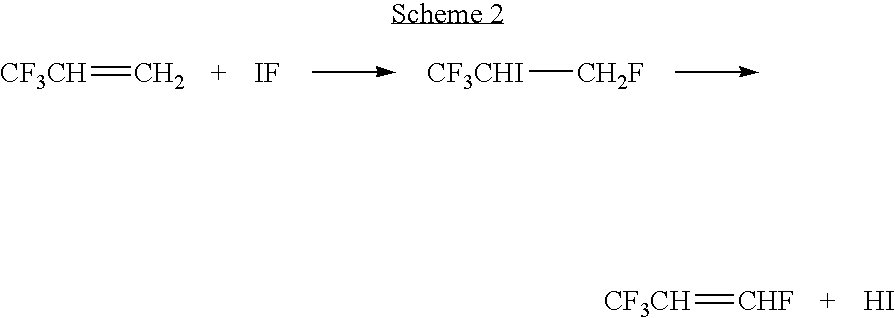

InactiveUS7345209B2Preparation by dehalogenationPreparation by hydrogen halide split-off1,3,3,3-TetrafluoropropeneBromine

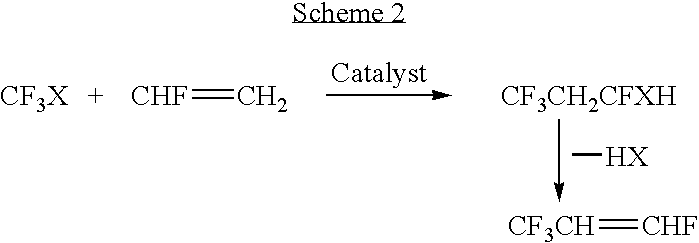

Disclosed is a process for the synthesis of 1,3,3,3-tetrafluoropropene that comprises, in one preferred embodiment, providing a compound of the formula CF3CH2CHFX, wherein X is a selected from the group consisting of chlorine, bromine and iodine, and exposing said compound to reaction conditions effective to convert said compound to 1,3,3,3-tetrafluoropropene. Other processes for forming 1,3,3,3-tetrafluoropropene are also disclosed.

Owner:HONEYWELL INT INC

Azeotrope compositions comprising E-1,3,3,3-tetrafluoropropene and hydrogen fluoride and uses thereof

ActiveUS20070100173A1Preparation by hydrogen halide split-offHydrogen fluorideHydrogen fluoride1,3,3,3-Tetrafluoropropene

Disclosed herein are azeotrope and near-azeotrope compositions comprising E-1,3,3,3-tetrafluoropropene and hydrogen fluoride. These azeotrope and near-azeotrope compositions are useful in processes to produce E-1,3,3,3-tetrafluoropropene and in processes to purify E-1,3,3,3-tetrafluoropropene from mixtures of E-1,3,3,3-tetrafluoropropene with 1,1,1,3,3-pentafluoropropane and / or with hydrogen fluoride.

Owner:THE CHEMOURS CO FC LLC

Processes for synthesis of 1,3,3,3-tetrafluoropropene

InactiveUS20050245773A1Overcome deficienciesPreparation by hydrogen halide split-offPreparation by halogen halide addition1,3,3,3-TetrafluoropropeneBromine

Disclosed is a process for the synthesis of 1,3,3,3-tetrafluoropropene that comprises, in one preferred embodiment, providing a compound of the formula CF3CH2CHFX, wherein X is a selected from the group consisting of chlorine, bromine and iodine, and exposing said compound to reaction conditions effective to convert said compound to 1,3,3,3-tetrafluoropropene. Other processes for forming 1,3,3,3-tetrafluoropropene are also disclosed.

Owner:HONEYWELL INT INC

Integrated HFC trans-1234ze manufacture process

ActiveUS7485760B2Preparation by hydrogen halide split-offPreparation by halogen replacementHydrogen fluoride1,3,3,3-Tetrafluoropropene

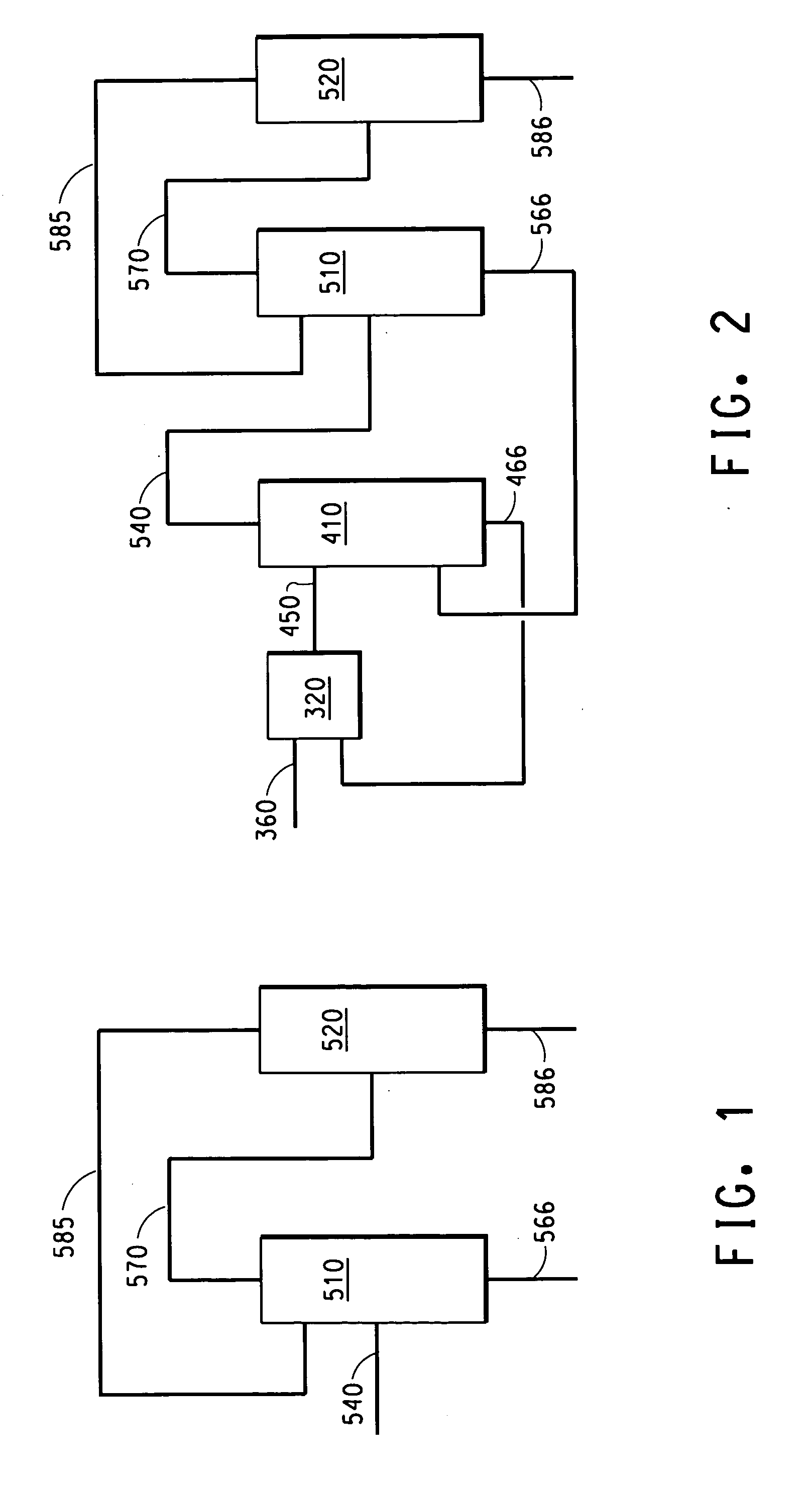

An integrated process for the manufacture of HFO trans-1,3,3,3-tetrafluoropropene (HFO trans-1234ze) by first catalytically dehydrofluorinating 1,1,1,3,3-pentafluoropropane to thereby produce a mixture of cis-1,3,3,3-tetrafluoropropene, trans-1,3,3,3-tetrafluoropropene and hydrogen fluoride. Then optionally recovering hydrogen fluoride, catalytically isomerizing cis-1234ze into trans-1234ze, and recovering trans-1,3,3,3-tetrafluoropropene.

Owner:HONEYWELL INT INC

Compostion based on 2,3,3,3-tetrafluoropropene

The subject of the present application is a composition comprising a lubricant based on polyol esters (POEs) or PVE and a refrigerant F comprising from 1 to 99% by weight of 2,3,3,3-tetrafluoropropene (HFO-1234A and from 1 to 99% by weight of trans-1,3,3,3-tetrafluoropropene (trans-HFO-1234ze). The subject of the present application is also the use of said composition in refrigeration, air conditioning and heat pumps.

Owner:ARKEMA FRANCE SA

Integrated HFC trans-1234ZE manufacture process

ActiveUS20080051610A1Preparation by hydrogen halide split-offPreparation by halogen replacementHydrogen fluoride1,3,3,3-Tetrafluoropropene

An integrated process for the manufacture of HFO trans-1,3,3,3-tetrafluoropropene (HFO trans-1234ze) by first catalytically dehydrofluorinating 1,1,1,3,3-pentafluoropropane to thereby produce a mixture of cis-1,3,3,3-tetrafluoropropene, trans-1,3,3,3-tetrafluoropropene and hydrogen fluoride. Then optionally recovering hydrogen fluoride, catalytically isomerizing cis-1234ze into trans-1234ze, and recovering trans-1,3,3,3-tetrafluoropropene.

Owner:HONEYWELL INT INC

Compositions of tetrafluoropene and polyol ester lubricants

InactiveUS20130099154A1Heat-exchange elementsLubricant composition1,3,3,3-TetrafluoropropeneEngineering

The present invention relates to heat transfer fluid combinations for use in refrigeration, heat transfer, heat pump, and air conditioning applications. More particularly, the present invention relates to heat transfer fluid combinations of 1,3,3,3-tetrafluoropropene and polyol ester (POE) oils which are useful in refrigeration, heat transfer, heat pump, and air conditioning systems.

Owner:ARKEMA INC

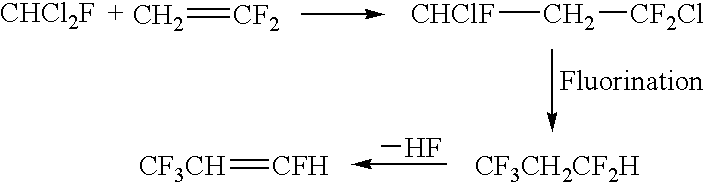

Process for Producing 1,3,3,3-Tetrafluoropropene

InactiveUS20110172472A1High selectivityHigh yieldChlorine/hydrogen-chloride purificationPreparation by hydrogen halide split-offHydrogen fluoride1,3,3,3-Tetrafluoropropene

According to the first characteristic of the present invention, there is provided a production process for 1,3,3,3-tetrafluoropropene including: the first step of reacting 1,1,1,3,3-pentachloropropane with hydrogen fluoride thereby obtaining 1-chloro-3,3,3-trifluoropropene; and the second step of reacting 1-chloro-3,3,3-trifluoropropene obtained in the first step with hydrogen fluoride in a gaseous phase in the presence of a fluorination catalyst. According to the second characteristic of the present invention, there is provided a dehydration process including bringing 1,3,3,3-tetrafluoropropene containing at least water into contact with zeolite.

Owner:CENT GLASS CO LTD

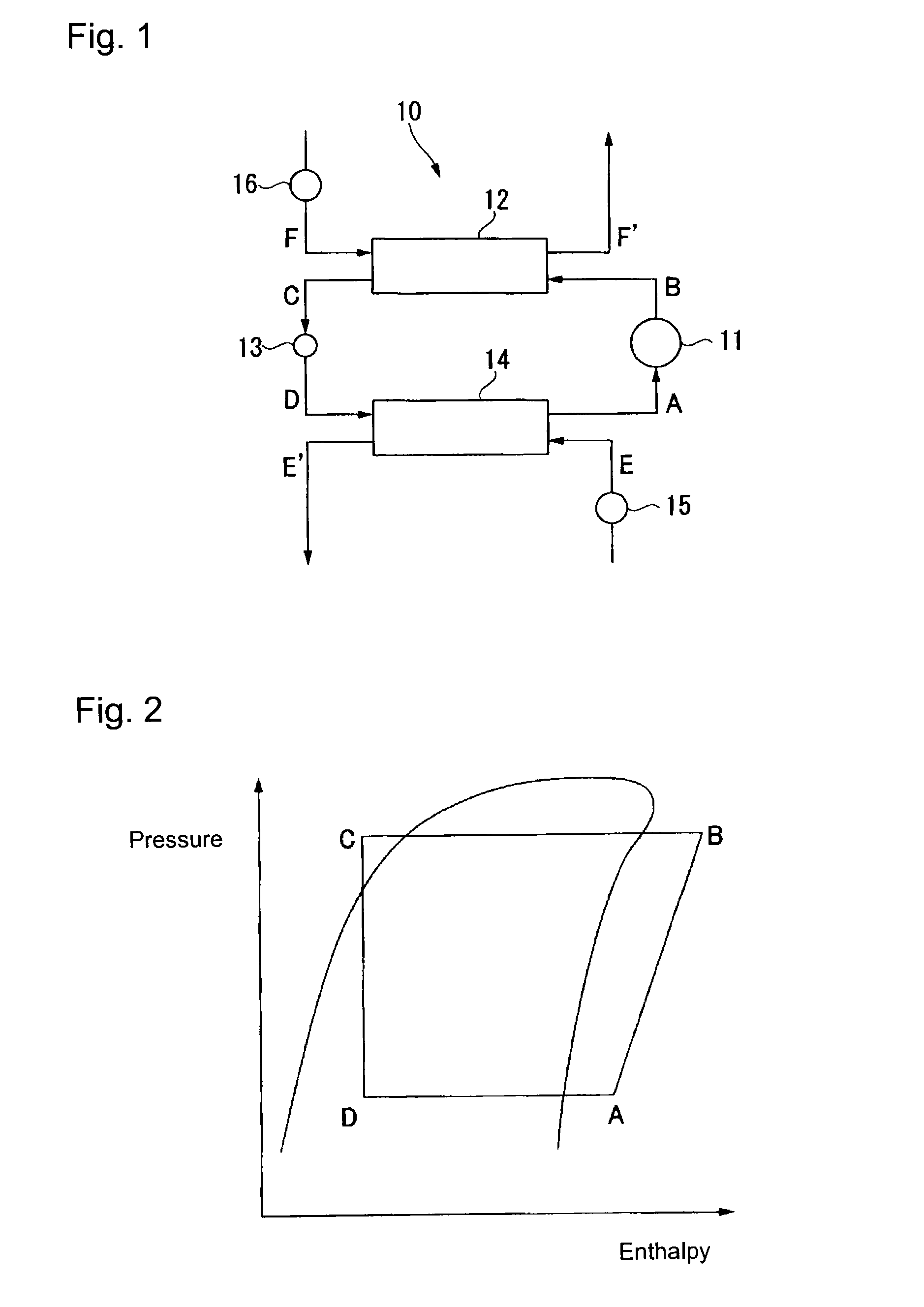

Heat-transfer fluids and use thereof in countercurrent heat exchangers

ActiveUS20130055739A1Good energy performance levelReduce environmental impactHeat-exchange elementsRefrigeration components1,1-Difluoroethane1,3,3,3-Tetrafluoropropene

The invention relates to a ternary composition comprising difluoromethane, 1,3,3,3-tetrafluoropropene and a hydrocarbon-derived compound containing at least two fluorine atoms and having a boiling point of between −30 and −20° C., which is selected from 1,1-difluoroethane, 1,1,1,2-tetrafluoroethane and 2,3,3,3-tetrafluoropropene. This composition is particularly suitable for use as a heat-transfer fluid in the presence of countercurrent heat exchangers.

Owner:ARKEMA FRANCE SA

Heat-transfer fluids and use thereof in countercurrent heat exchangers

InactiveUS20130055733A1Reduced GWPImprove performanceCompression machines with non-reversible cycleCompression machines with cascade operationBoiling point1,3,3,3-Tetrafluoropropene

The invention relates to a ternary composition comprising difluoromethane, 3,3,3-trifluoropropene and a hydrocarbon-derived compound containing at least two fluorine atoms and having a boiling point of between −30 and −18° C., which is selected from 1,1-difluoroethane, 2,3,3,3-tetrafluoropropene and 1,3,3,3-tetrafluoropropene. This composition is particularly suitable for use as a heat-transfer fund in the presence of countercurrent heat exchangers.

Owner:ARKEMA FRANCE SA

Process for the manufacture of 1,3,3,3-tetrafluoropropene

ActiveUS7592494B2Physical/chemical process catalystsPreparation by hydrogen halide split-off1,3,3,3-TetrafluoropropenePentafluoropropane

The invention provides an economic process for the manufacture of 1,3,3,3-tetrafluoropropene (HFC-1234ze) by a two stage process. A hydrofluorination of 1-chloro-3,3,3-trifluoropropene (HCFC-1233zd) into 1-chloro-1,3,3,3-tetrafluoropropane (HCFC-244fa) and 1,1,1,3,3-pentafluoropropane (HFC-245fa) is conducted, followed by the dehydrochlorination of HCFC-244fa and dehydrofluorination of HFC-245fa into HFC-1234ze.

Owner:HONEYWELL INT INC

Azeotrope-like compositions comprising 1-chloro-3,3,3-trifluoropropene

ActiveUS20120128964A1Cosmetic preparationsOrganic active ingredientsZeotropic mixture1,3,3,3-Tetrafluoropropene

An azeotrope-like mixture consisting essentially of a binary azeotrope-like mixture consisting essentially of trans-1-chloro-3,3,3-trifluoropropene (trans-HFO-1233zd) and a second component selected from the group consisting of 2,3,3,3-tetrafluoropropene (HFO-1234yf) and trans-1,3,3,3-tetrafluoropropene (trans-HFO-1234ze), and combinations of these and various uses thereof.

Owner:HONEYWELL INT INC

Catalytic isomerization processes of 1,3,3,3-tetrafluoropropene for making 2,3,3,3-tetrafluoropropene

InactiveUS7420094B2Increase volumePreparation by halogen halide additionPreparation by hydroxy group additionIsomerization1,3,3,3-Tetrafluoropropene

Owner:THE CHEMOURS CO FC LLC

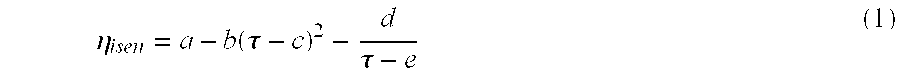

Heat-transfer fluid for a centrifugal compressor

ActiveUS20130061613A1Reduce wearReduce speedCompressorCompression machines with non-reversible cycle1,1-Difluoroethane1,3,3,3-Tetrafluoropropene

The invention relates to a process for cooling or heating a fluid or a body by means of a vapour compression circuit comprising a centrifugal compressor and containing a heat-transfer fluid, the heat-transfer fluid comprising at least two compounds selected from 2,3,3,3-tetrafluoropropene, 1,3,3,3-tetrafluoropropene, 1,1,1,2-tetrafluoropropene, 1,1-difluoroethane and 3,3,3-trifluoropropene, in which: the ratio of the Mach number of the centrifugal compressor to the Mach number which the centrifugal compressor has under the same operating conditions if the heat-transfer fluid is replaced with 1,1,1,2-tetrafluoroethane in the vapour compression circuit is greater than or equal to 0.97 and less than or equal to 1.03; the compression ratio of the centrifugal compressor is less than or equal to the compression ratio which the centrifugal compressor has under the same operating conditions if the heat-transfer fluid is replaced with 1,1,12-tetrafluorethane in the vapour compression circuit. The invention also relates to equipment suitable for implementing this cooling or heating process, and also to a process for converting existing equipment.

Owner:ARKEMA FRANCE SA

Integrated Process to Co-Produce Trans-1-Chloro-3,3,3-Trifluoropropene and Trans-1,3,3,3-Tetrafluoropropene

ActiveUS20110245549A1Low costPreparation by dehalogenationPreparation by hydrogen halide split-offDistillation1,3,3,3-Tetrafluoropropene

The disclosed integrated manufacturing process includes a combined liquid phase reaction and purification operation which directly produces trans-1-chloro-3,3,3-trifluoropropene and 3-chloro-1,1,1,3-tetrafluoropropane which is a precursor to the manufacture of trans-1,3,3,3-tetrafluoropropene. The mixture of co-products is easily separated by conventional distillation and 3-chloro-1,1,1,3-tetrafluoropropane is then dehydrochlorinated to produce trans-1,3,3,3-tetrafluoropropene by contacting in the liquid phase with a caustic solution or in the vapor phase using a dehydrochlorination catalyst.

Owner:HONEYWELL INT INC

Processes for synthesis of 1,3,3,3-tetrafluoropropene

ActiveUS7371904B2Thermal non-catalytic crackingPreparation by halogen replacementBromine1,3,3,3-Tetrafluoropropene

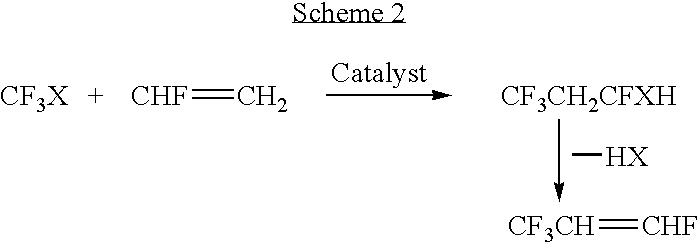

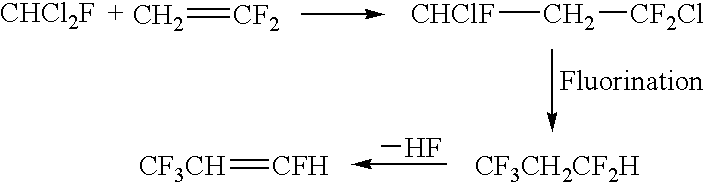

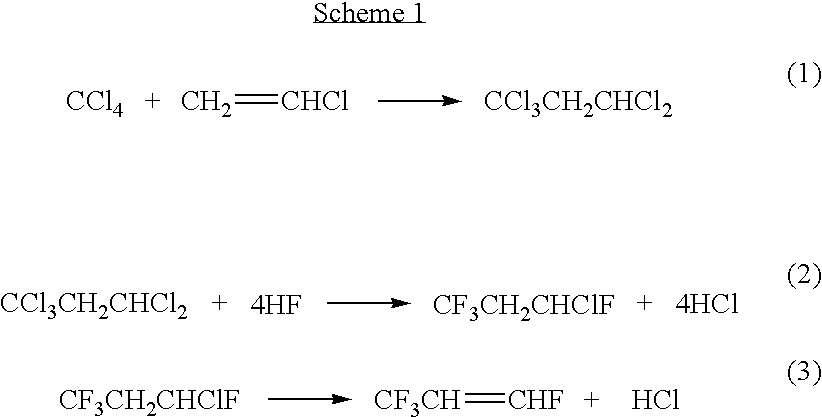

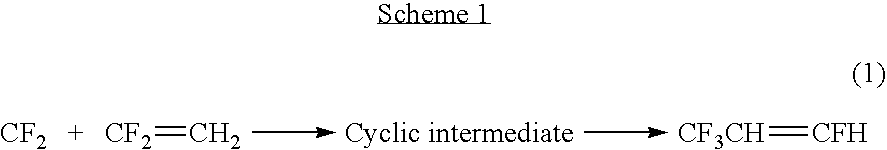

Disclosed is a process for the synthesis of 1,3,3,3-tetrafluoropropene which comprises, in one embodiment, reacting a compound of CF3X1 with a compound of CX2H═CHX3, wherein X1, X2, and X3 are each independently selected from the group consisting of fluorine, chlorine, bromine and iodine, to produce a reaction product comprising a compound of CF3CH═CHX3, wherein X3 is as described above; and when X3 is not fluorine, fluorinating the compound to produce 1,3,3,3-tetrafluoropropene. The process in another embodiment comprises preparing tetrafluoropropene comprising thermally cracking one or more compounds capable of producing a reaction mixture which preferably comprises diflurocarbene radicals and vinylidene fluoride, and converting said reaction mixture into—tetrafluoropropene (1,3,3,3-tetrafluoropropene).

Owner:HONEYWELL INT INC

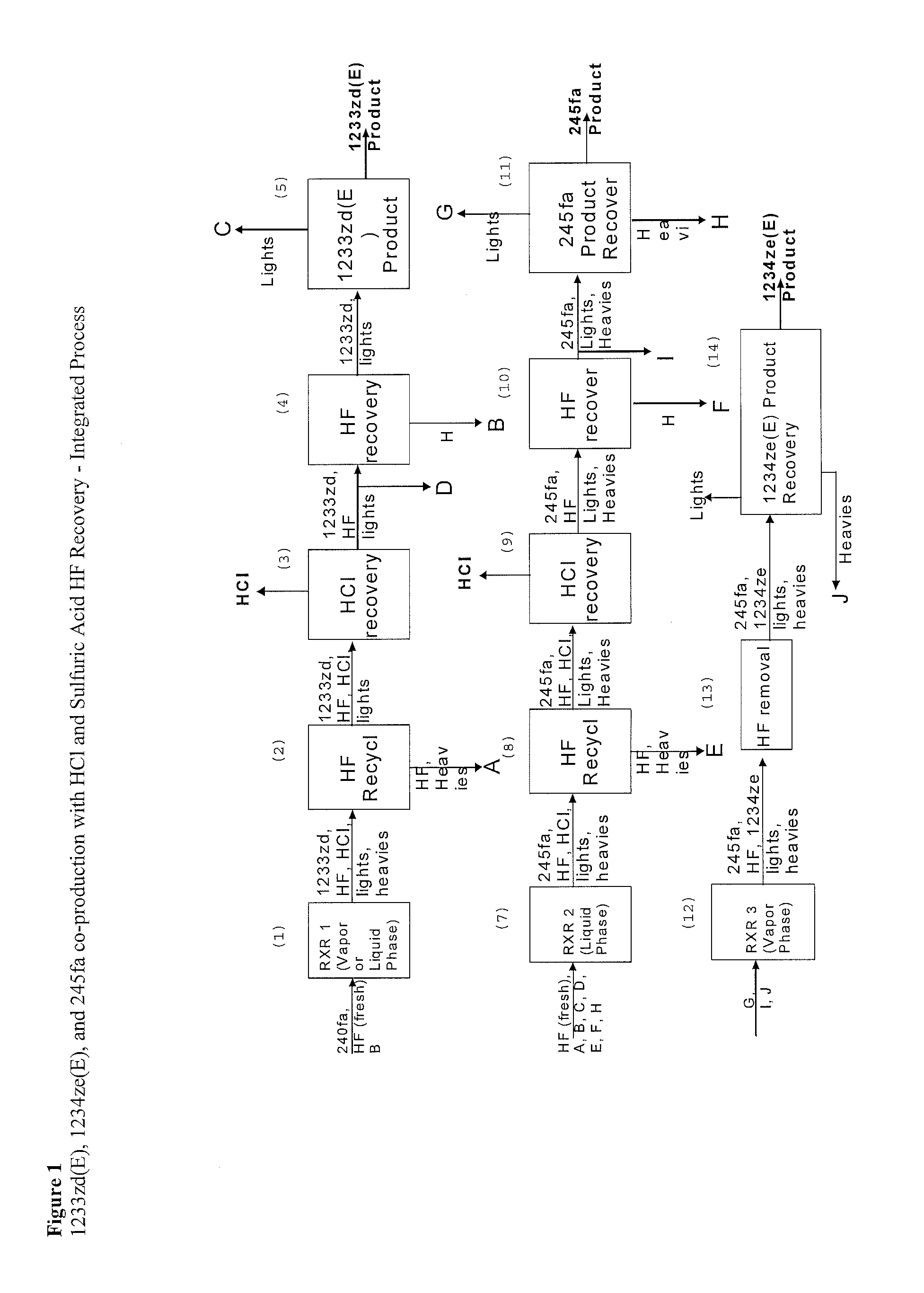

Integrated Process to Coproduce Trans-1-Chloro-3,3,3-Trifluoropropene, Trans-1,3,3,3-Tetrafluoropropene, and 1,1,1,3,3-Pentafluoropropane

ActiveUS20120059200A1High selectivityImprove production yieldPreparation by dehalogenationHydrocarbon from carbon oxidesGas phase1,3,3,3-Tetrafluoropropene

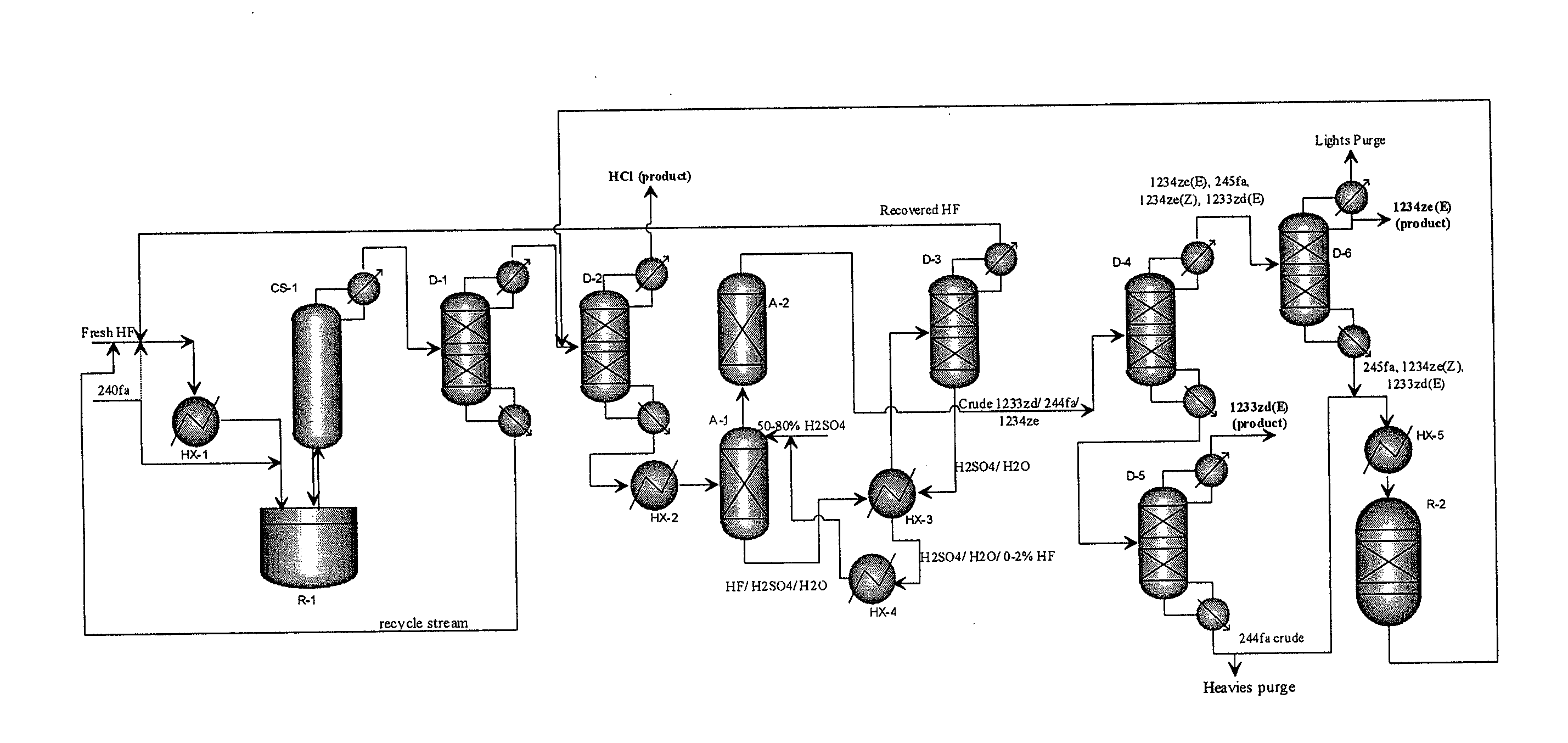

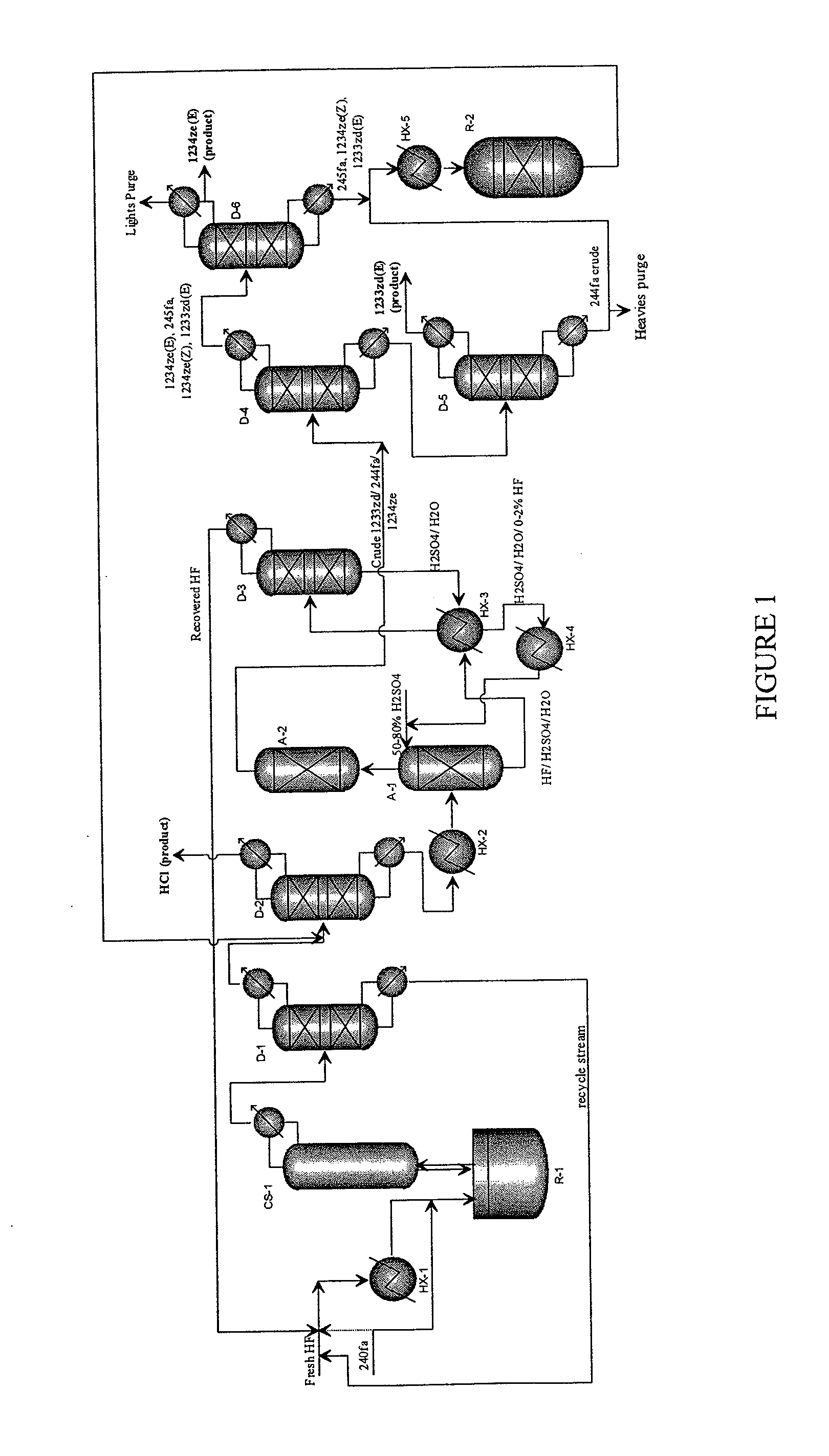

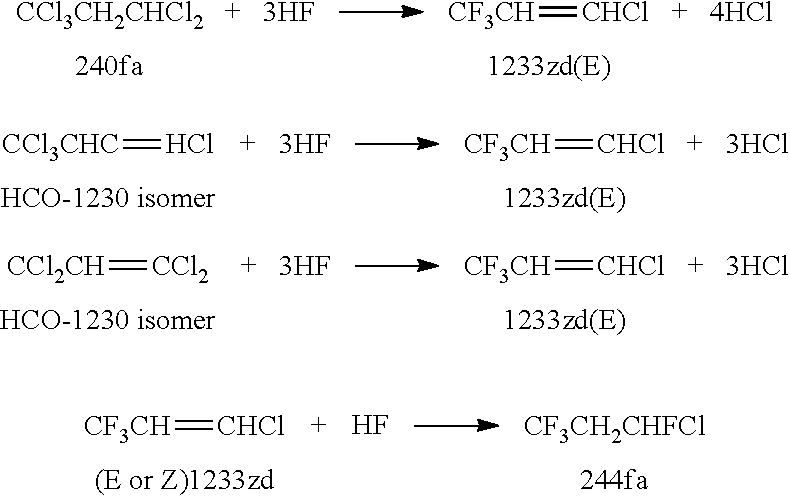

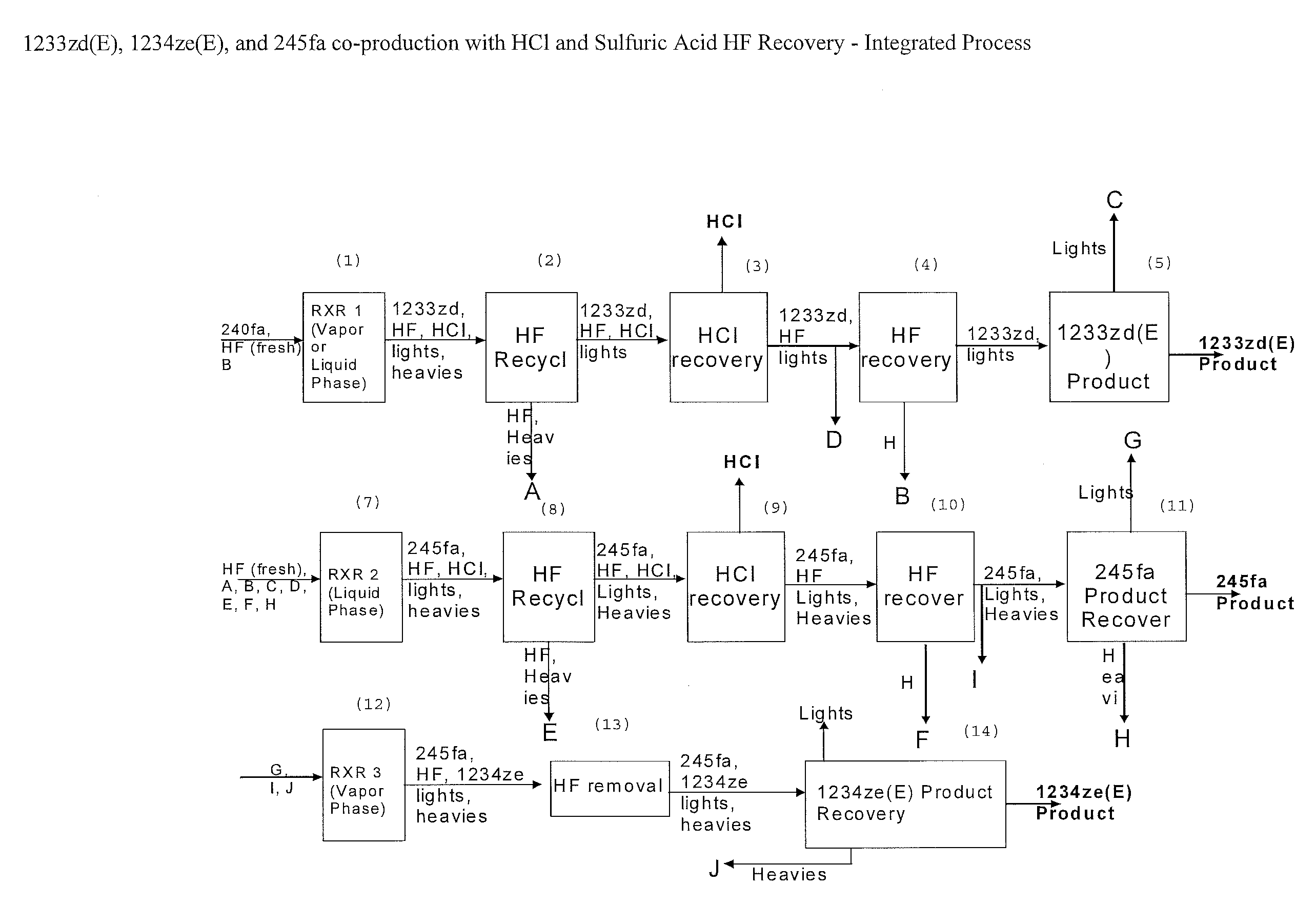

Disclosed is an integrated manufacturing process to co-produce (E)1-chloro-3,3,3-trifluoropropene, (E)1,3,3,3-tetrafluoropropene, and 1,1,1,3,3-pentafluoro-propane starting from a single chlorinated hydrocarbon feed stock, 240fa. The process includes a combined liquid or vapor phase reaction / purification operation which directly produces (E)1-chloro-3,3,3-trifluoropropene (1233zd(E)) from 240fa. In the second liquid phase fluorination reactor 1233zd(E) is contacted with HF in the presence of catalyst to produce 1,1,1,3,3-pentafluoropropane (245fa) with high conversion and selectivity. A third reactor is used for dehydrofluorination of 245fa to produce (E)1,3,3,3-tetrafluoropropene (1234ze(E)) by contacting in the liquid phase with a caustic solution or in the vapor phase using a dehydrofluorination catalyst. This operation may be followed by one or more purification processes to recover the 1234ze(E) product.

Owner:HONEYWELL INT INC

Azeotrope or Azeotrope-Like Composition Comprising 1,1,2,2-tetrafluoro-1-methoxyethane

InactiveUS20100004155A1Improve featuresLow toxicityNon-ionic surface-active compoundsOther chemical processes1,3,3,3-TetrafluoropropeneMethoxyethane

There is provided an azeotrope or azeotrope-like composition containing (A) 1,1,2,2-tetrafluoro-1-methoxyethane and (B) a compound formed of at least one selected from the group consisting of (Z)-1-chloro-3,3,3-trifluoropropene, 2-bromo-3,3,3-trifluoropropene, and (E)-2-bromo-1,3,3,3-tetrafluoropropene.

Owner:CENT GLASS CO LTD

Hfo-1234ze mixed isomers with hfc-245fa as a blowing agent, aerosol, and solvent

A composition which is a blowing agent which comprises from about 75% to about 90% by weight trans-1,3,3,3-tetrafluoropropene, from about 1% to about 15% by weight cis-1,3,3,3-tetrafluoropropene, and from about 1% about 15% by weight 1,1,3,3,3-pentafluoropropane.

Owner:HONEYWELL INT INC

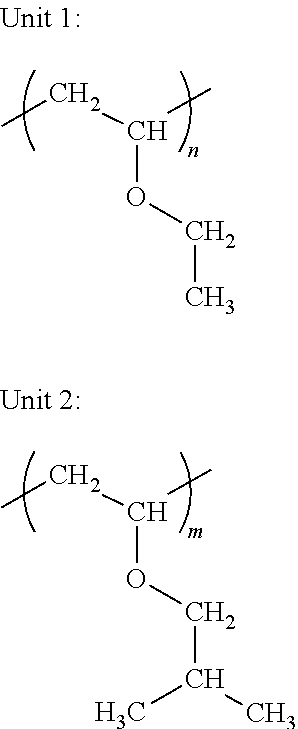

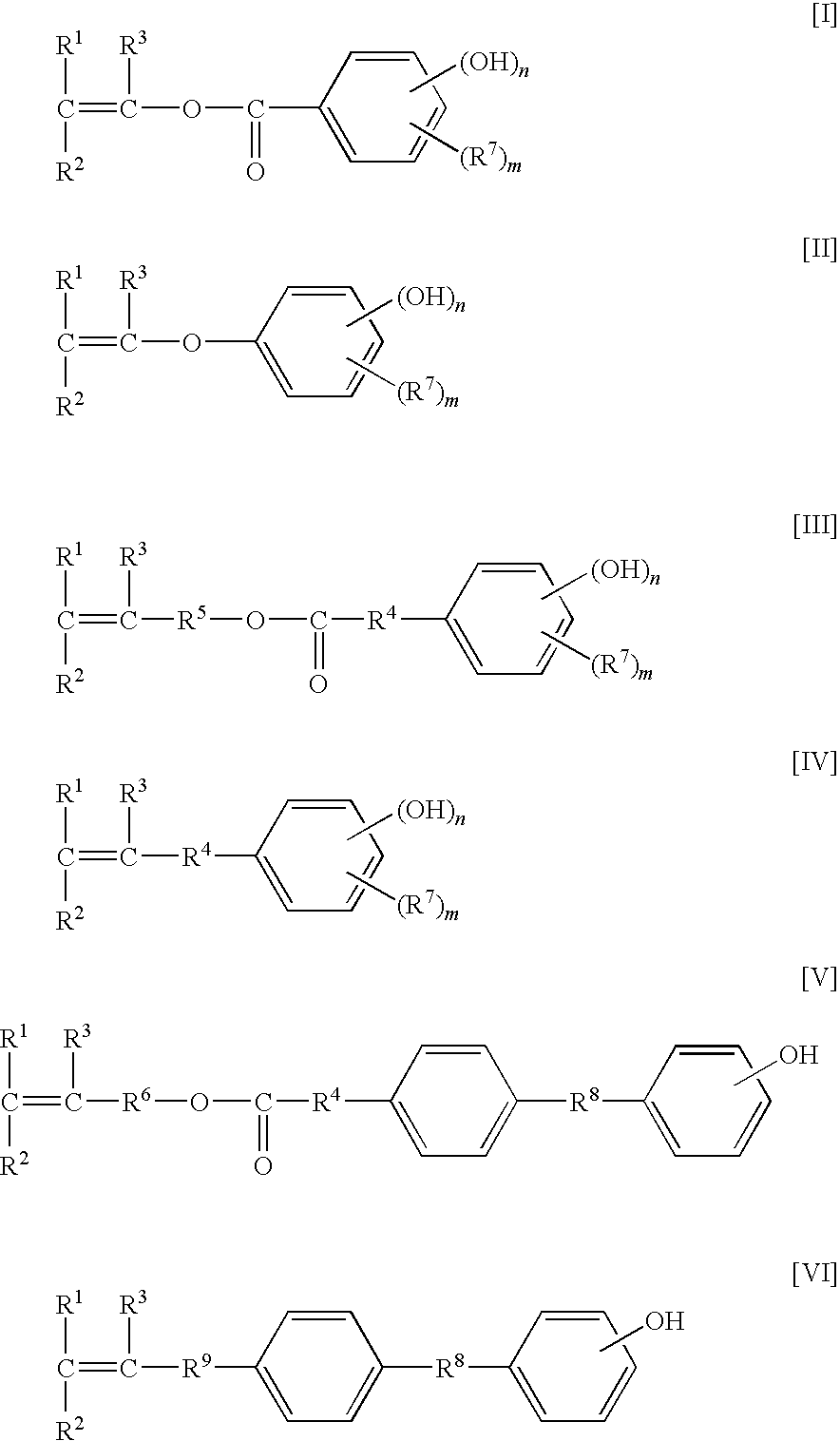

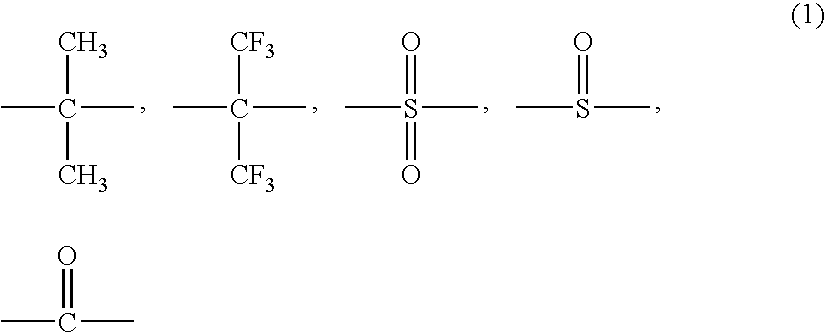

Novel fluorinated polymer

InactiveUS20090186986A1Excellent cross-linking reactivityMaintain good propertiesPolymer scienceHexafluoropropylene

The present invention provides a fluorinated polymer excellent in the crosslinking reactivity, crosslinked rubber physical properties and chemical resistance, and its crosslinked rubber.A fluorinated polymer comprising repeating units (a) based on at least one monomer selected from the group consisting of ethylenic unsaturated compounds each having a hydroxyphenyl group, repeating units (b) based on at least one fluoromonomer selected from the group consisting of tetrafluoroethylene, hexafluoropropylene, vinylidene fluoride, 3,3,3-trifluoropropene, 1,3,3,3-tetrafluoropropene, 1,1,2-trifluoroethylene, vinyl fluoride, 1,2-difluoroethylene and CF2═CF—O—Rf (wherein Rf is a C1-8 saturated perfluoroalkyl group or a perfluoro(alkoxyalkyl) group) and, if necessary, repeating units (c) based on at least one hydrocarbon monomer selected from the group consisting of ethylene, propylene and CH2═CH—O—R1.

Owner:ASAHI GLASS CO LTD

Working medium for heat pump, and heat pump system

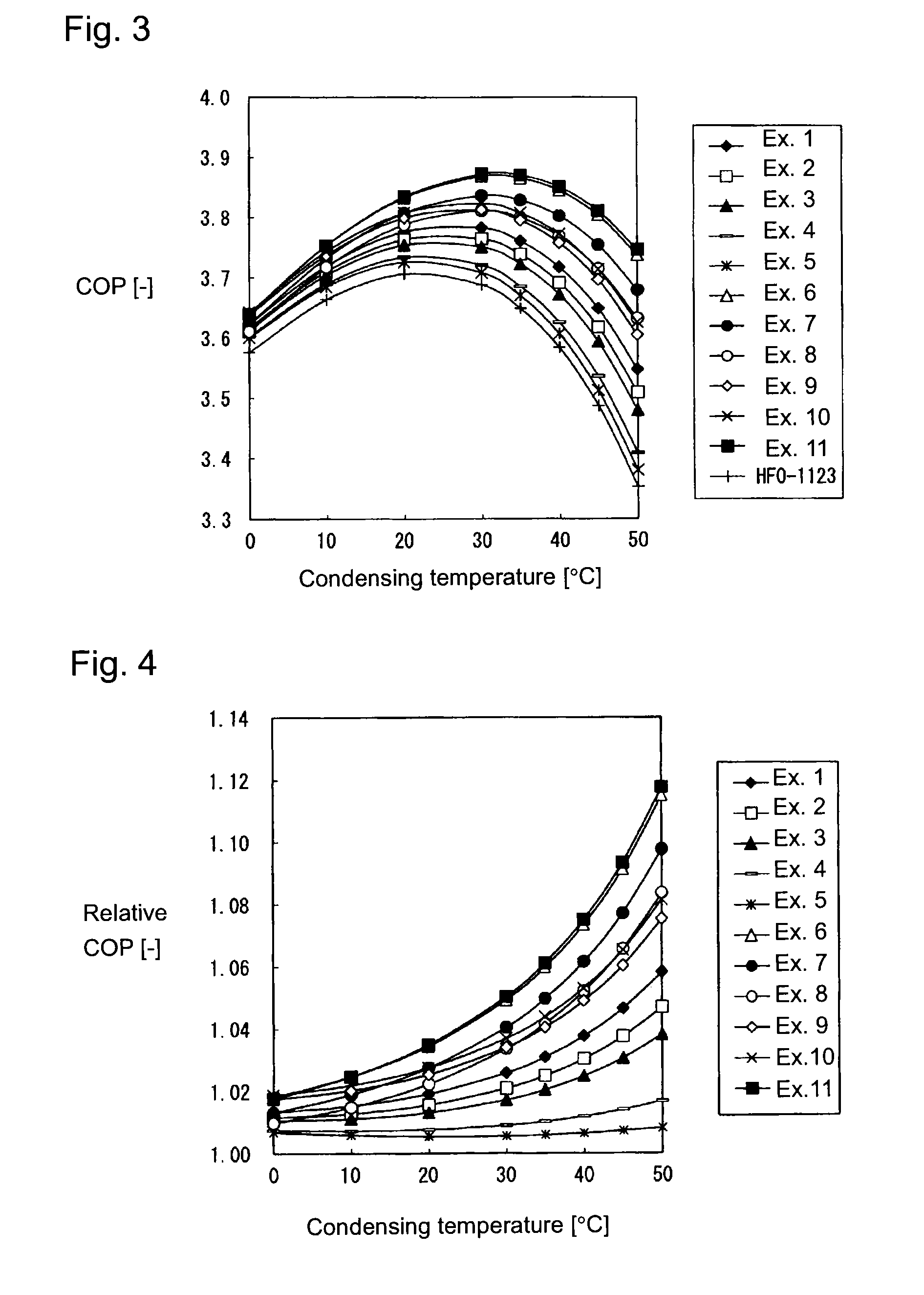

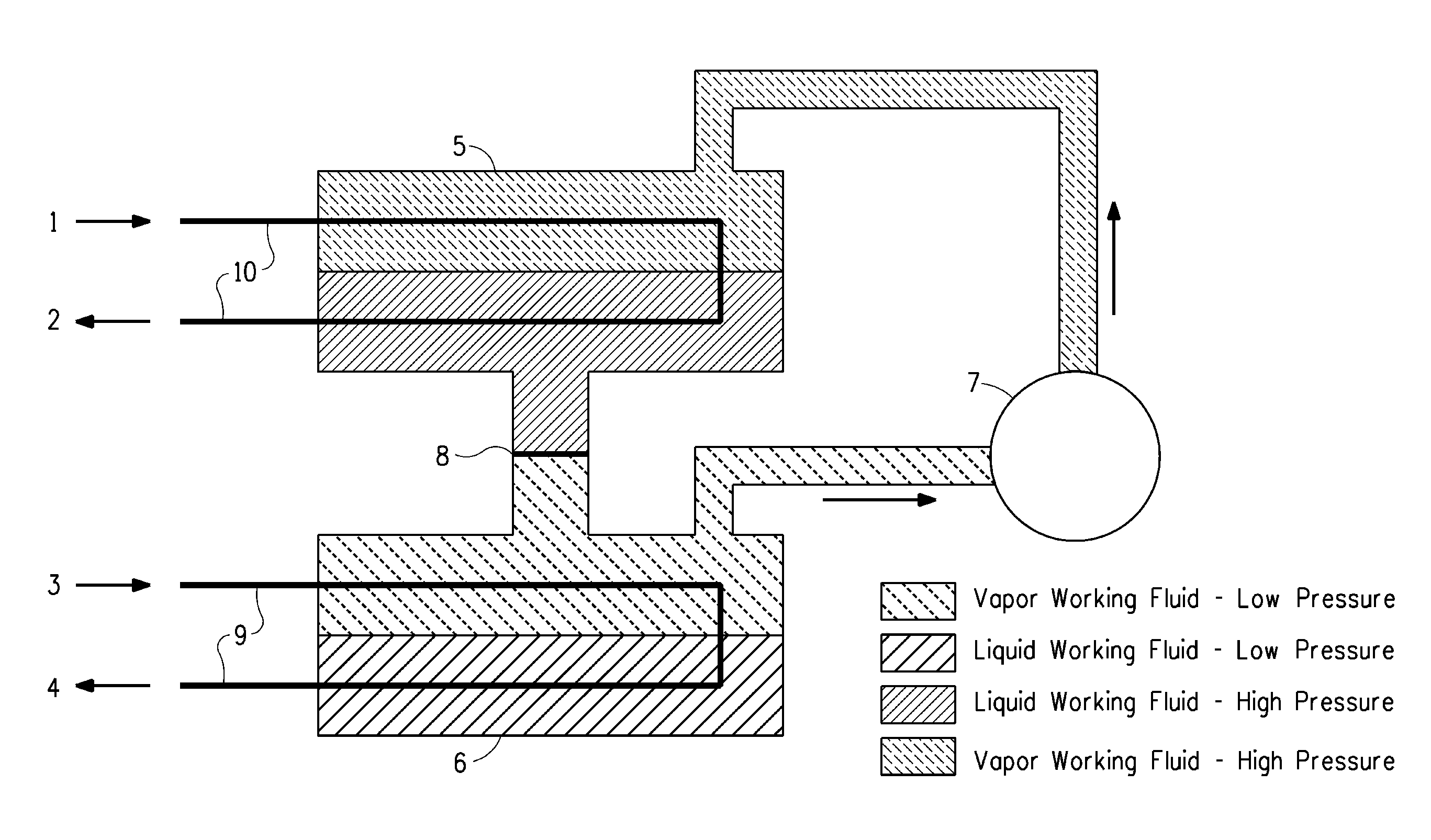

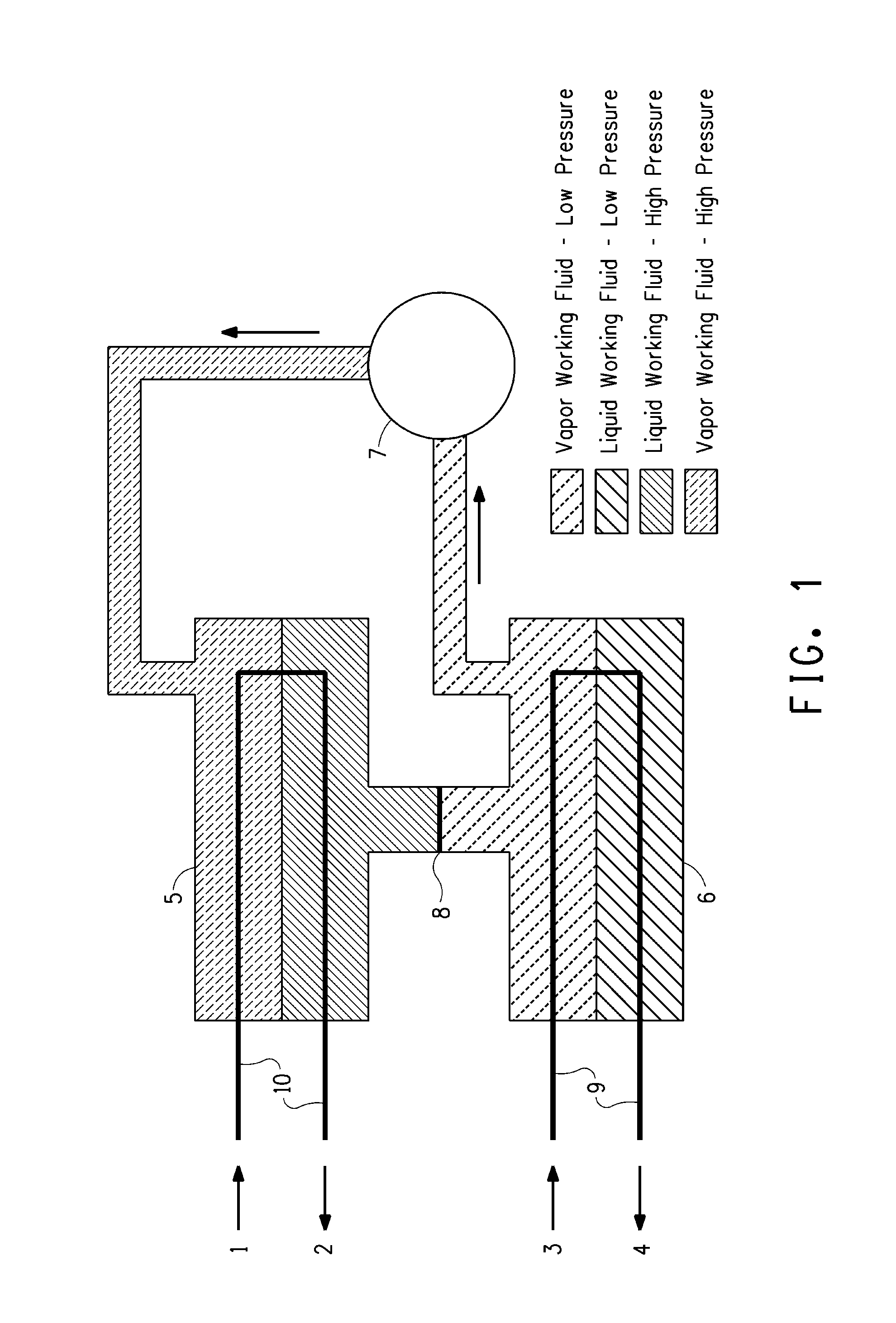

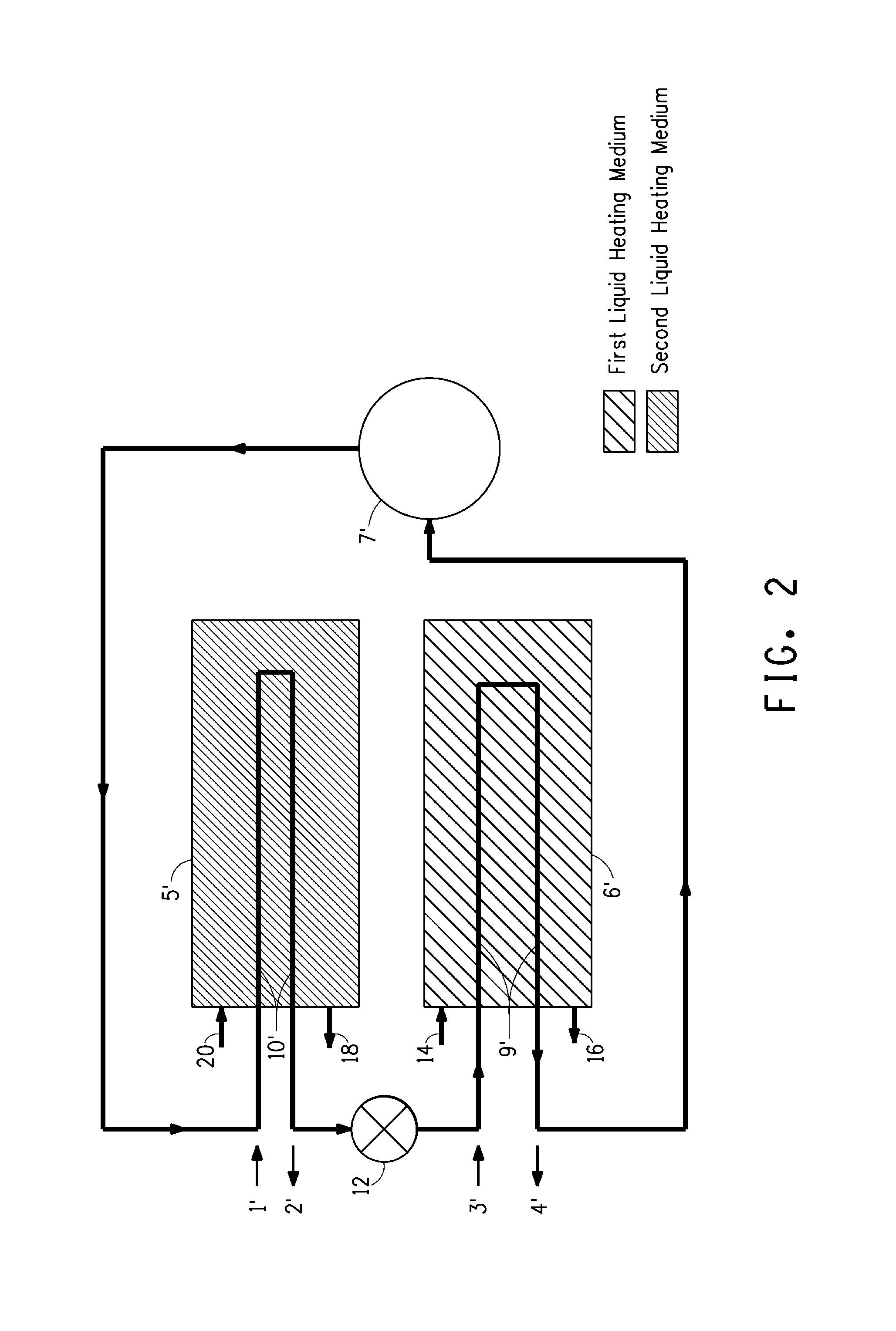

ActiveUS20150337191A1Less influenceImprove flame retardant performanceHeat-exchange elementsCompression machines with reversible cycle1,3,3,3-TetrafluoropropeneWorking temperature

To provide a working medium for a heat pump which has less influence over global warming, which has favorable flame retardancy as compared with a working medium consisting solely of 1,1,2-trifluoroethylene, and with which a heat pump system stably exhibiting heat pump performance even at a higher working temperature can be obtained.A working medium for a heat pump, which comprises 1,1,2-trifluoroethylene, at least one member selected from the group consisting of 1,1,1,2-tetrafluoroethane and pentafluoroethane, and at least one member selected from the group consisting of 2,3,3,3-tetrafluoropropene, 1,3,3,3-tetrafluoropropene and 3,3,3-trifluoropropene.

Owner:ASAHI GLASS CO LTD

1,3,3,3-tetrafluoropropene process azeotropes with hf

The present invention pertains to azeotropic and azeotrope-like compositions of the following three blends:1. Trans-1,3,3,3-tetrafluoropropene (HFO-1234ze(E)), cis-1,3,3,3-tetrafluoropropene (HFO-1234ze(Z)) and hydrogen fluoride (HF);2. HFO-1234ze(E), 1,1,1,3,3-pentafluoropropane (HFC-245fa) and HF; and3. HFO-1234ze(Z), HFC-245fa and HF.These azeotropic and azeotrope-like compositions are useful as intermediates in the production of HFO-1234ze(E).

Owner:HONEYWELL INT INC

INTEGRATED PROCESS TO CO-PRODUCE 1,1,1,3,3-PENTAFLUOROPROPANE, TRANS-1-CHLORO-3,3,3-TRIFLUOROPROPENE and TRANS-1,3,3,3-TETRAFLUOROPROPENE

InactiveUS20120271070A1Easy to adjustPreparation by hydrogen halide split-offOrganic chemistry methods1,3,3,3-TetrafluoropropenePentafluoropropane

Disclosed is a fully integrated process for making 1,1,1,3,3-pentafluoropropane (HFC-245fa), trans-1-chloro-3,3,3-trifluoropropene (HCFO-1233zd(E)), and trans-1,3,3,3-tetrafluoropropene (HFO-1234ze(E)). The chemistry involves (a) the reaction of 1,1,1,3,3-pentachloropropane (HCC-240fa), or a derivative thereof selected from 1,1,3,3-tetrachloropropene and 1,3,3,3-tetrachloropropene, with anhydrous HF in excess in the presence of a catalyst in a liquid-phase reactor in such a way as to co-produce HCFO-1233zd, HFO-1234ze, HCFC-244fa (3-chloro-1,1,1,3-tetrafluoropropane), and HFC-245fa in a first reactor; (b) the reaction of HCFO-1233zd and HFO-1234ze with HCl in excess in the presence of a catalyst in a second reactor to convert these two olefins into HCFC-243fa and HCFC-244fa, respectively; (c) the reaction of HCFC-243fa and HCFC-244fa over a dehydrochlorination catalyst or in a caustic solution in a third reactor to form HCFO-1233zd and HFO-1234ze; and (d) the reaction of HCFO-1233zd(Z) and HFO-1234ze(Z) in the presence of a catalyst in a fourth reactor to form trans-1233zd and trans-1234ze, respectively.

Owner:HONEYWELL INT INC

Compositions comprising difluoromethane, pentafluoroethane, tetrafluoropropene, and tetrafluoroethane and uses thereof

Disclosed herein is a composition comprising (a) from 1 to 29 weight percent difluoromethane; (b) from 1 to 19 weight percent pentafluoroethane; (c) from 9 to 42 weight percent 1,1,2,2-tetrafluoroethane, 1,1,1,2-tetrafluoroethane, or a mixture thereof; and (d) from 34 to 68 weight percent 2,3,3,3-tetrafluoropropene, E-1,3,3,3-tetrafluoropropene or mixture thereof; wherein when the composition contains 2,3,3,3-tetrafluoropropene, the composition also contains at least some 1,1,2,2-tetrafluoroethane; wherein the ratio of component (a) to component (b) is at most 1.5:1; and wherein the ratio of component (c) to component (d) is at least 0.04:1. The compositions are useful in methods for producing cooling and heating, methods for producing air conditioning, methods for replacing HCFC-22, R-410A, R-407C, HFC-134a, CFC-12, HCFC-22 and HCFC-124 and in heat transfer systems including heat pumps and air conditioners.

Owner:THE CHEMOURS CO FC LLC

Processes for synthesis of 1,3,3,3-tetrafluoropropene

ActiveUS20060030744A1Preparation by hydrogen halide split-offPreparation by halogen halide additionHydrogenBromine

Disclosed in one embodiment is a process for the synthesis of 1,3,3,3-tetrafluoropropene that comprises (a) reacting a compound of formula (I) X1X2 with a compound of formula (II) CF3CH═CH2 to produce a reaction product comprising a compound of formula (III) CF3CHX1CH2X2, wherein X1 and X2 are each independently selected from the group consisting of hydrogen, chlorine, bromine and iodine, provided that X1 and X2 are not both hydrogen; (b) when X2 in formula (III) is not fluorine, fluorinating the compound of formula (III) to produce a reaction product comprising a compound of formula (III) wherein X1 is as described above and X2 is fluorine; and (c) exposing said compound of formula (III) to reaction conditions effective to convert said compound to 1,3,3,3-tetrafluoropropene. In another embodiment, the process comprises (a) reacting chlorine with a compound of formula (I) CH3CH═CH2 to produce a reaction product comprising a compound of formula (II) CCl3CHC1CH2C1; (b) fluorinating the compound of formula (II) to produce a reaction product comprising a compound of formula (III) CF3CHC1CH2F; and (c) exposing said compound of said formula (III) to reaction conditions effective to convert said compound to 1,3,3,3-tetrafluoropropene.

Owner:HONEYWELL INT INC

Processes for geometric isomerization of halogenated olefins

Disclosed are processes for the conversion of isomerizable halogenated C2-C6 olefins from one geometric form to a more preferred geometric form. Preferred process aspects involve converting C2-C6 olefin in a cis-form to a trans-form under conditions effective to convert at least about 50 percent, and even more preferably at least about 70 percent, of the cis-form compound to the trans-form compound. In preferred embodiments the C2-C6 olefin comprises tetrafluoropropene, with cis-1,3,3,3 tetrafluoropropene (cis-HFO-1234ze) being converted, preferably at high conversion rates and high selectivity, to trans-1,3,3,3 tetrafluoropropene (trans-HFO-1234ze). In preferred embodiments the conditions effective to achieve the desired high levels of conversion and selectivity include exposing the feed to a metal based catalyst selected from the group consisting of halogentated metal oxides, Lewis acid metal halides, zero-valent metals, and combinations of these, preferably under reaction conditions, including reaction temperature and residence time, effective to convert at least about 5% of the cis-form of the compound to other compounds and to further achieve a selectivity to the trans-form of the compound of at least about 70%.

Owner:HONEYWELL INT INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com