Patents

Literature

635results about "Preparation by hydroxy group addition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

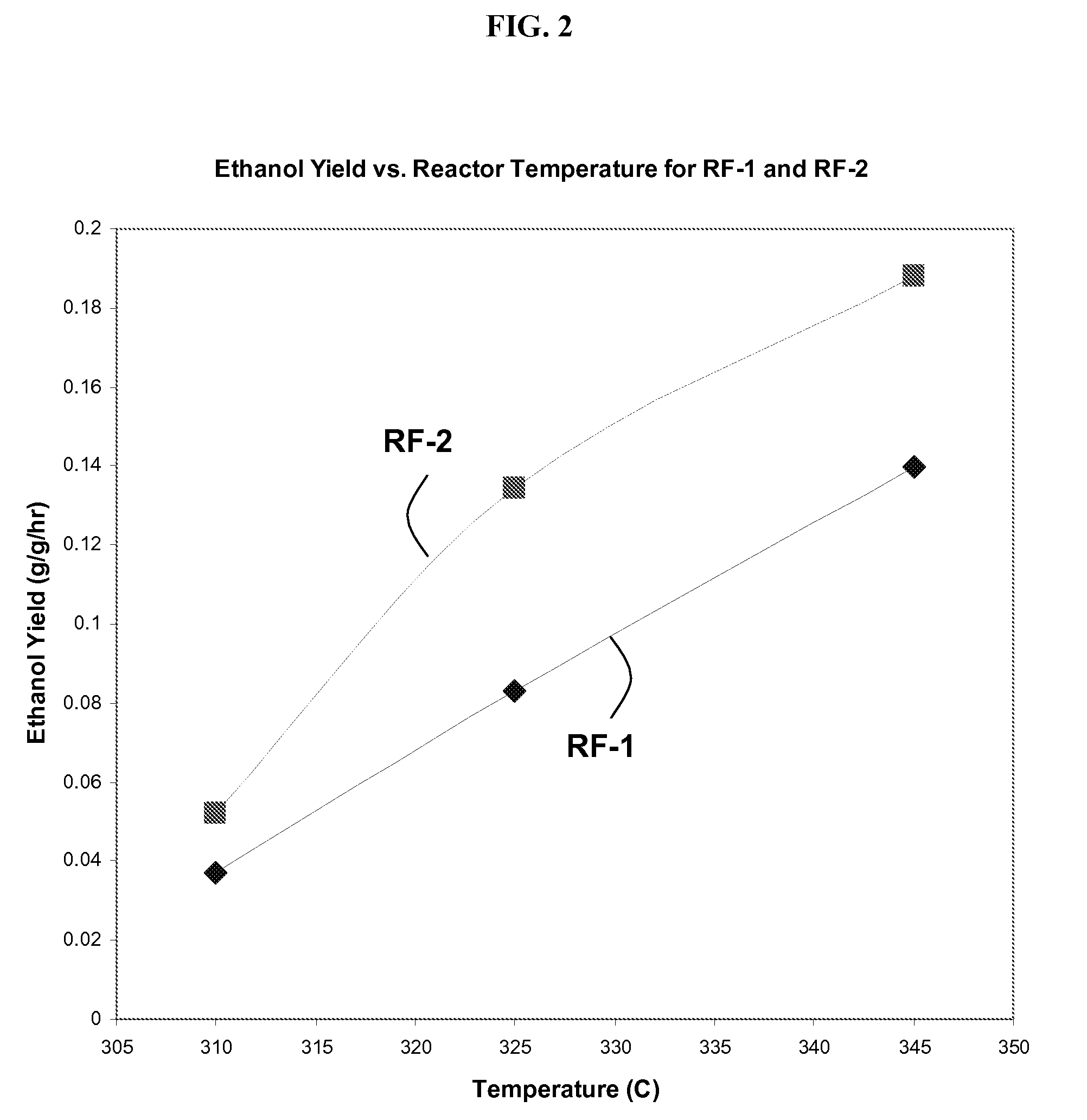

Cobalt-molybdenum sulfide catalyst materials and methods for ethanol production from syngas

The present invention provides methods and compositions for the chemical conversion of syngas to alcohols. The invention includes catalyst compositions, methods of making the catalyst compositions, and methods of using the catalyst compositions. Certain embodiments teach compositions for catalyzing the conversion of syngas into products comprising at least one C1-C4 alcohol, such as ethanol. These compositions generally include cobalt, molybdenum, and sulfur. Preferred catalyst compositions for converting syngas into alcohols include cobalt associated with sulfide in certain preferred stoichiometries as described and taught herein.

Owner:ALBEMARLE CORP

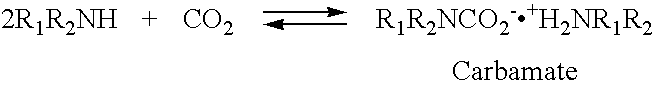

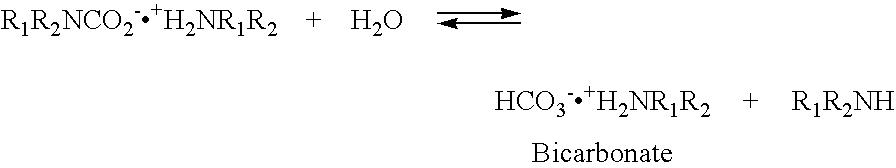

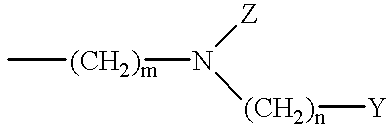

Nano-structure supported solid regenerative polyamine and polyamine polyol absorbents for the separation of carbon dioxide from gas mixtures including the air

ActiveUS20080293976A1Increased CO absorption capacityIncreased COMaterial nanotechnologyElectrolysis componentsPolyolSorbent

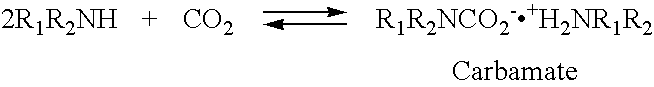

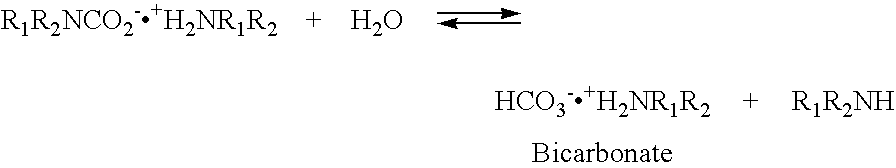

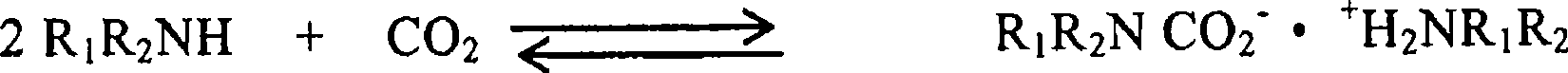

The invention relates to regenerative, supported amine sorbents that includes an amine or an amine / polyol composition deposited on a nano-structured support such as nanosilica. The sorbent provides structural integrity, as well as high selectivity and increased capacity for efficiently capturing carbon dioxide from gas mixtures, including the air. The sorbent is regenerative, and can be used through multiple operations of absorption-desorption cycles.

Owner:UNIV OF SOUTHERN CALIFORNIA

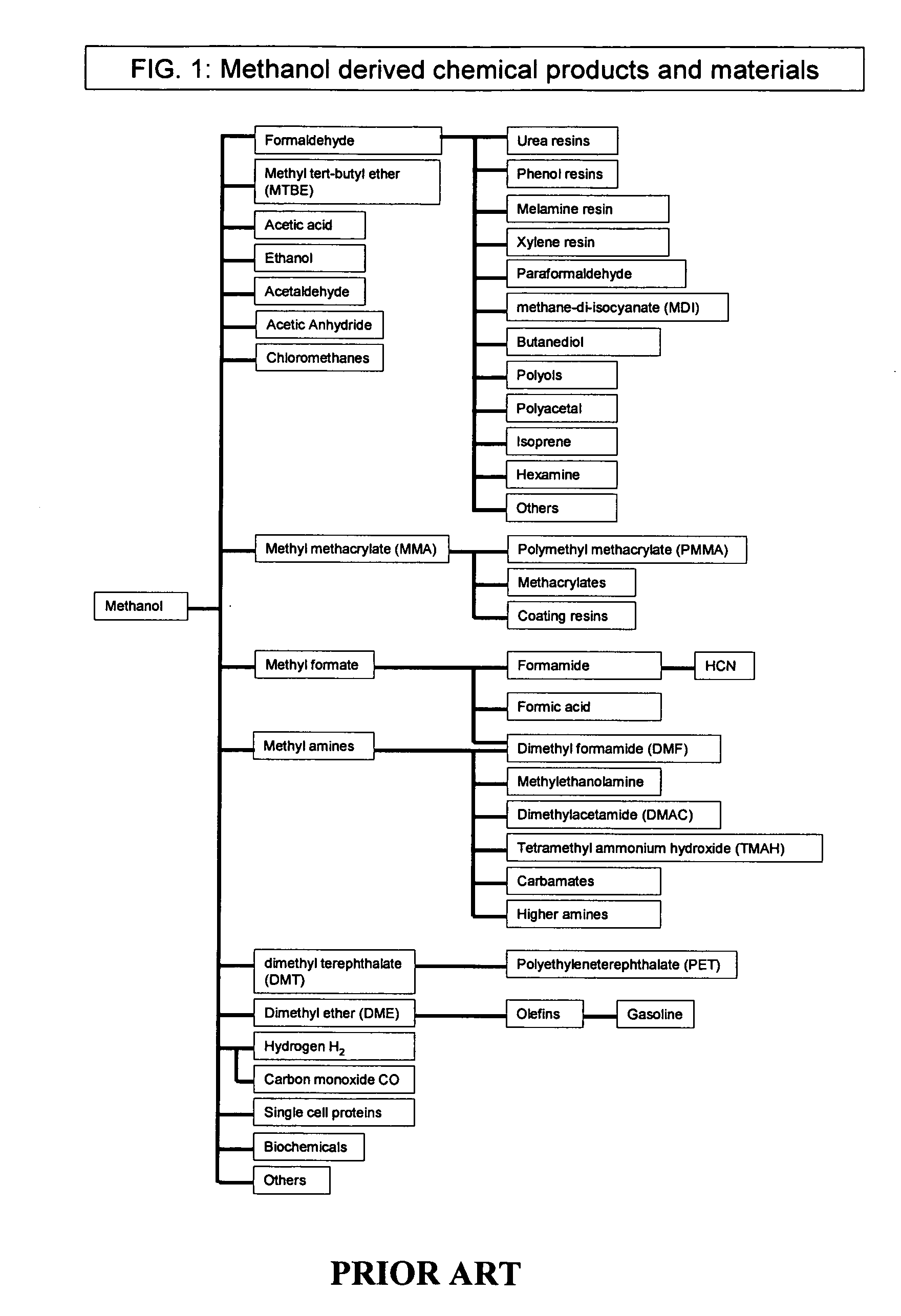

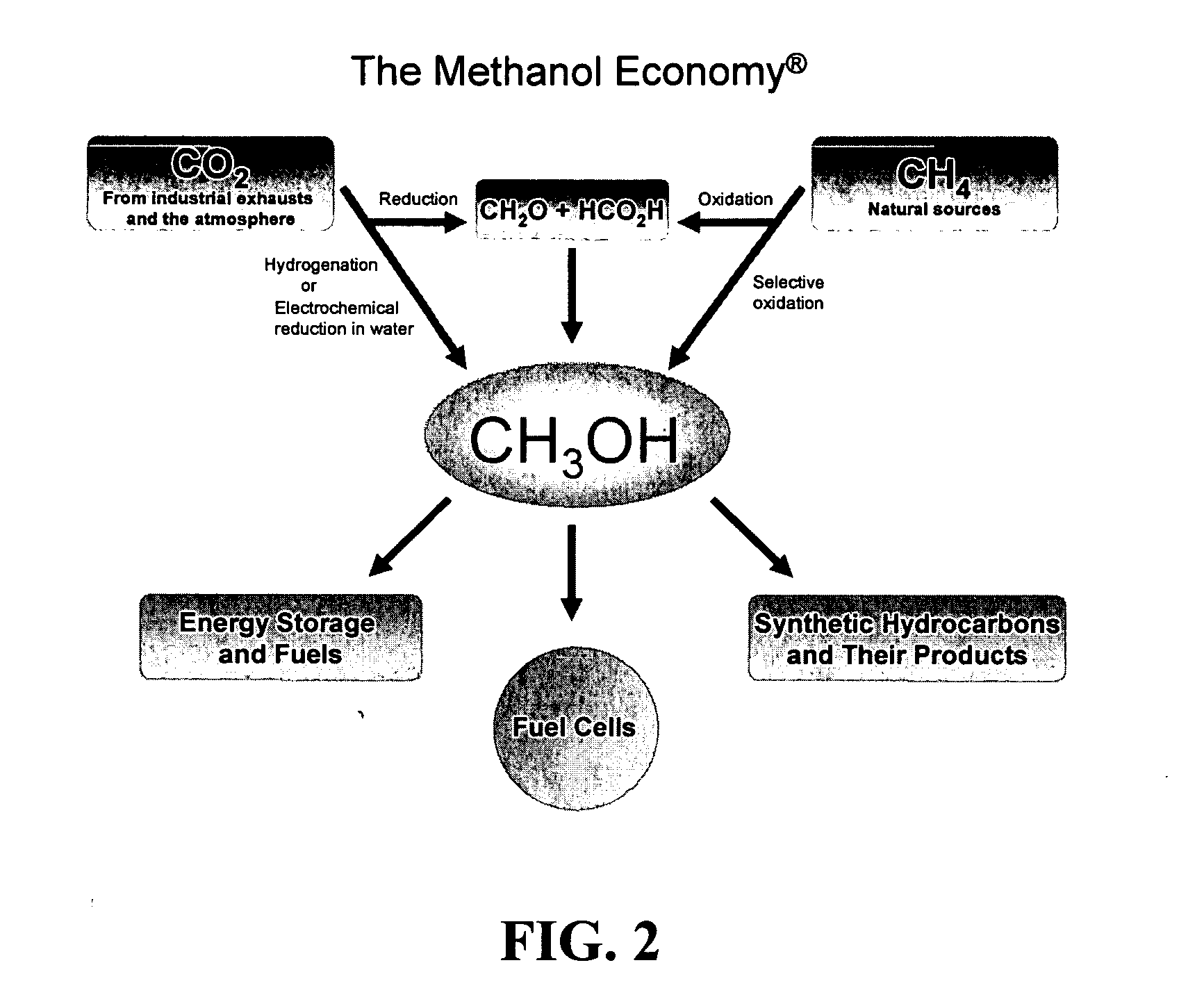

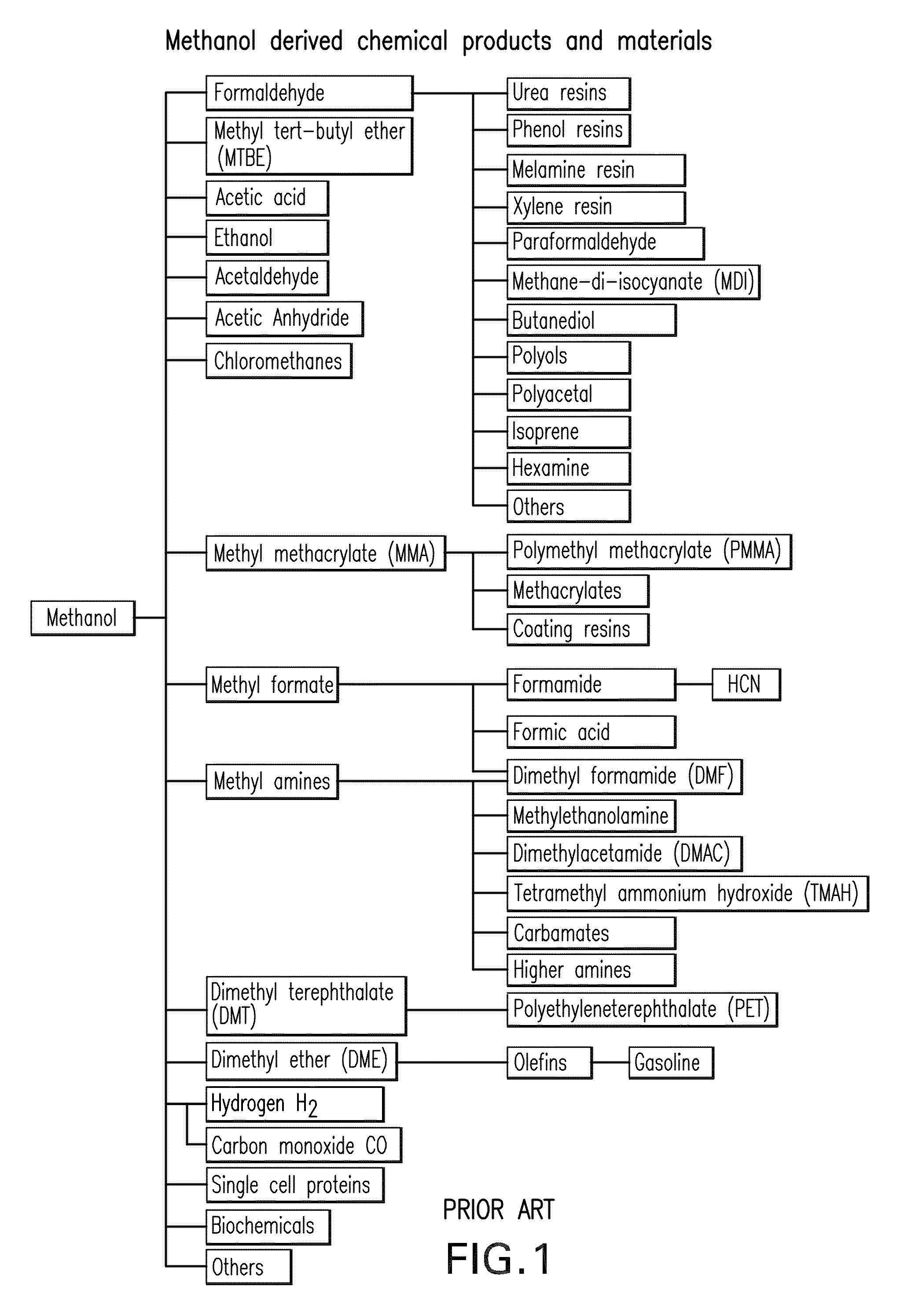

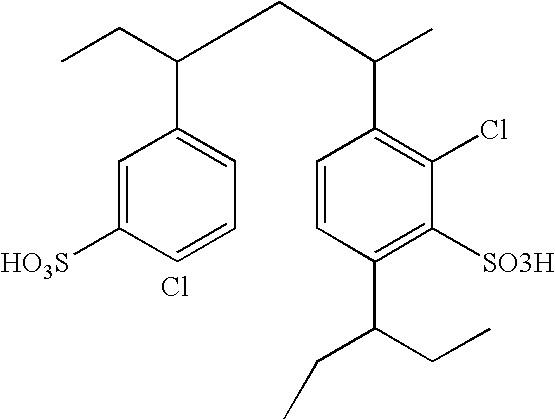

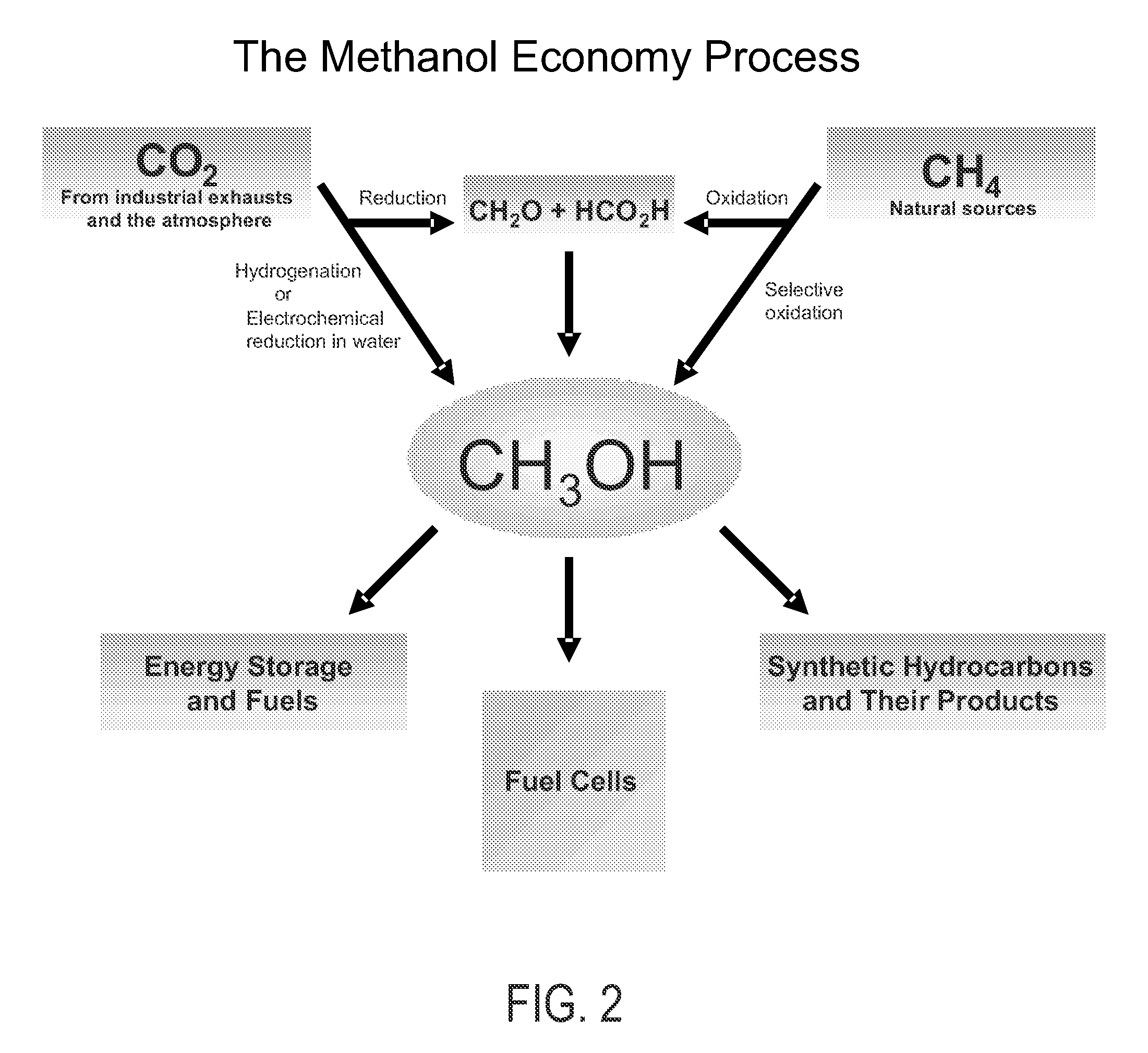

Efficient and selective chemical recycling of carbon dioxide to methanol, dimethyl ether and derived products

ActiveUS20070254969A1Avoid emissionsElectrolysis componentsOxygen compounds purification/separationElectrochemistryDimethyl ether

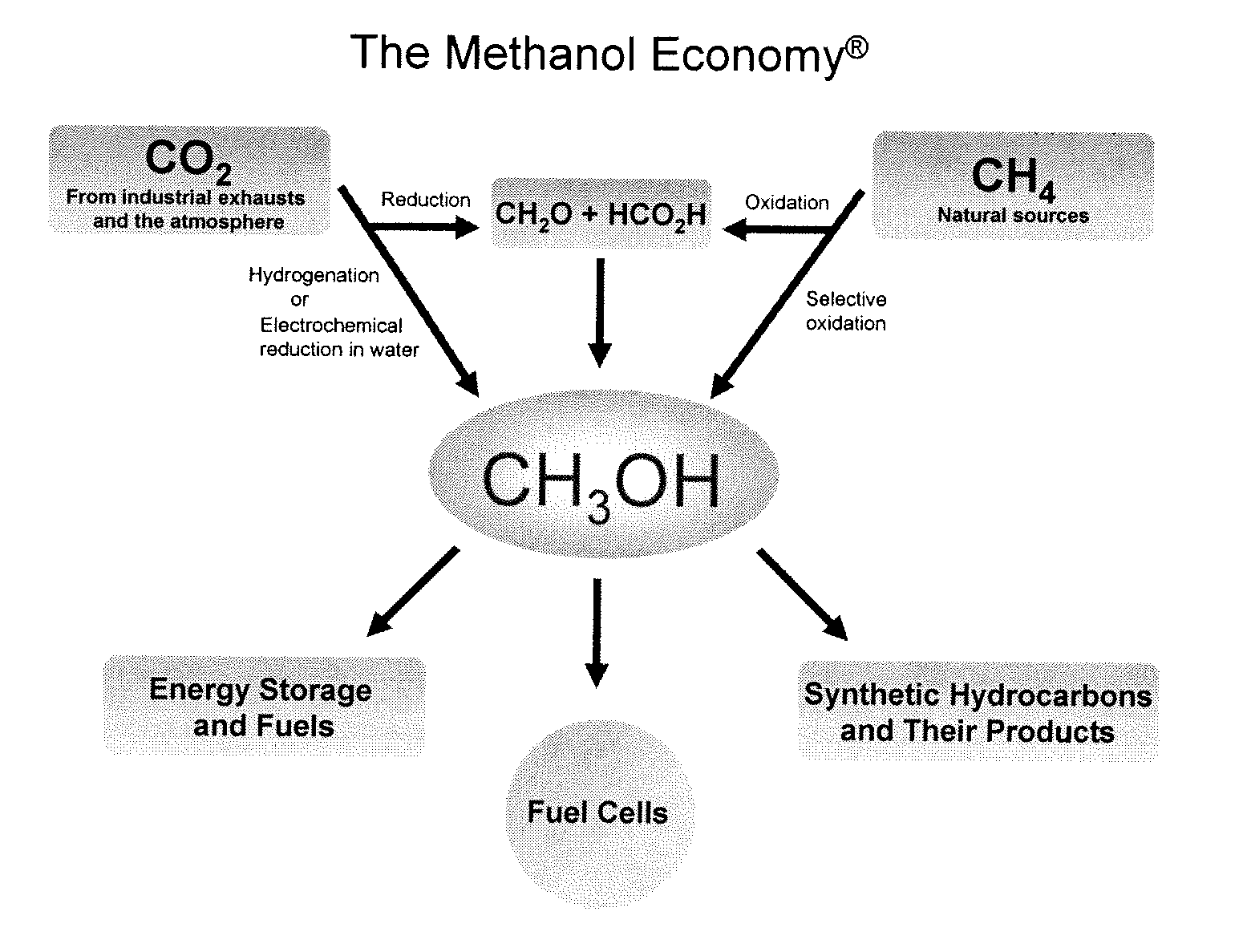

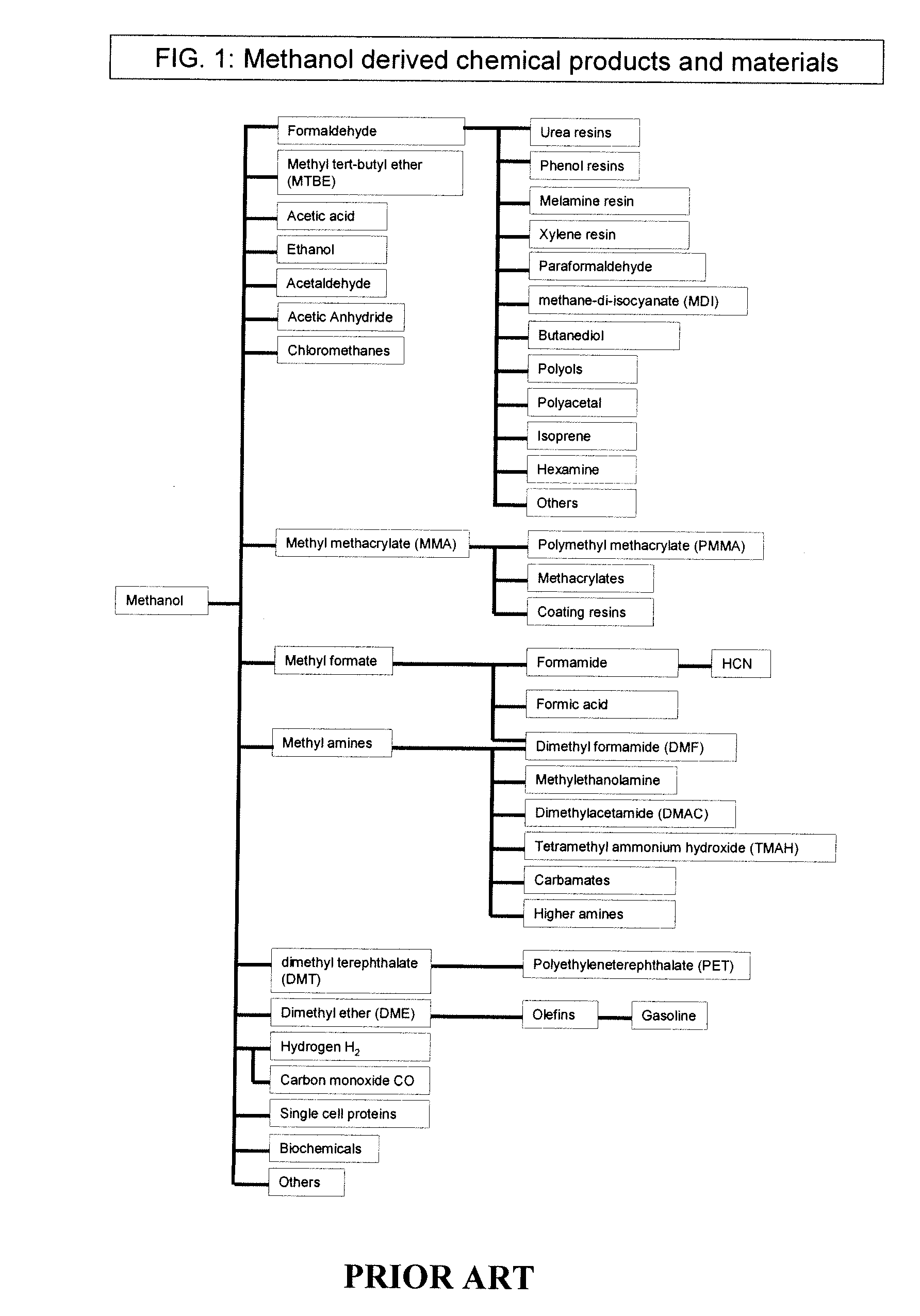

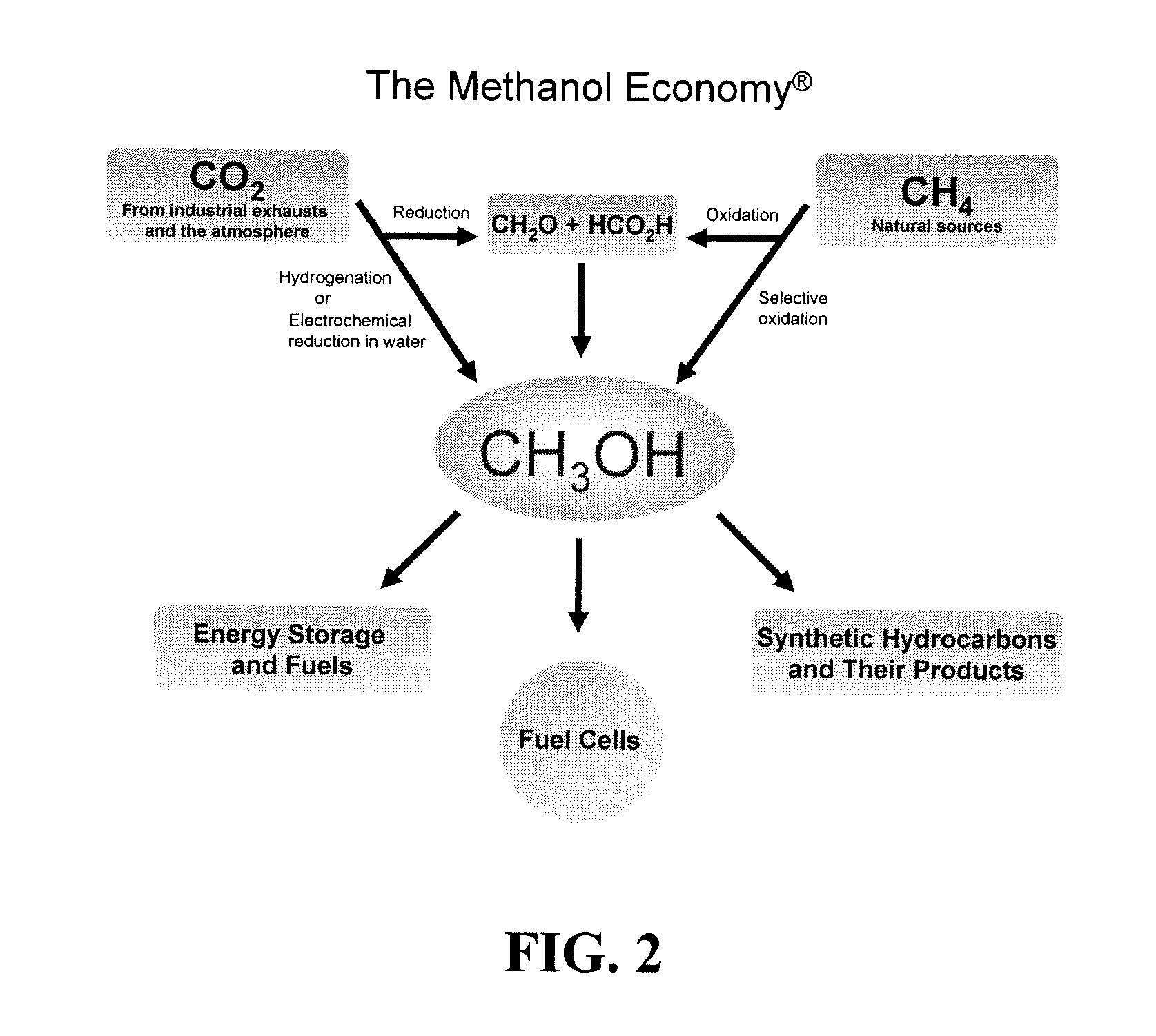

An efficient and environmentally beneficial method of recycling and producing methanol from varied sources of carbon dioxide including flue gases of fossil fuel burning powerplants, industrial exhaust gases or the atmosphere itself. Converting carbon dioxide by chemical or electrochemical reduction secondary treatment to produce essentially methanol, dimethyl ether and derived products.

Owner:UNIV OF SOUTHERN CALIFORNIA

Efficient and selective conversion of carbon dioxide to methanol, dimethyl ether and derived products

ActiveUS20060235091A1Minimize or eliminate the disadvantages or dangers inherentElectrolysis componentsCarbon compoundsHydrogenFlue gas

An environmentally beneficial method of producing methanol from varied sources of carbon dioxide including flue gases of fossil fuel burning powerplants, industrial exhaust gases or the atmosphere itself. Converting carbon dioxide by electrochemical reduction produces formic acid acid and some formaldehyde and methanol mixtures. The formic acid can be used as source of carbon as well as hydrogen to produce methanol, dimethyl ether and other products.

Owner:UNIV OF SOUTHERN CALIFORNIA

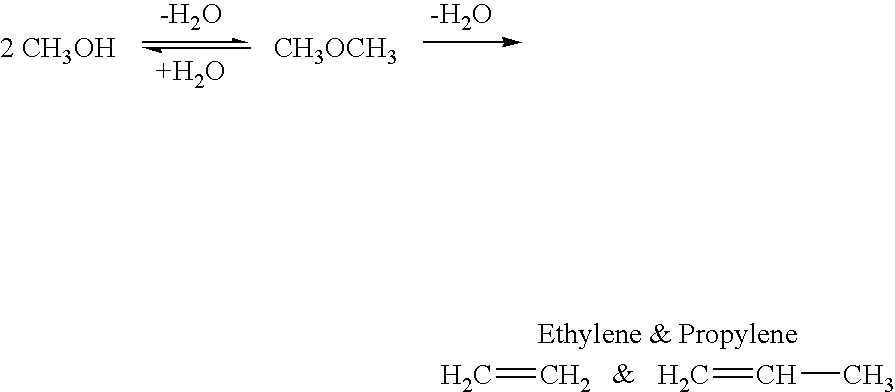

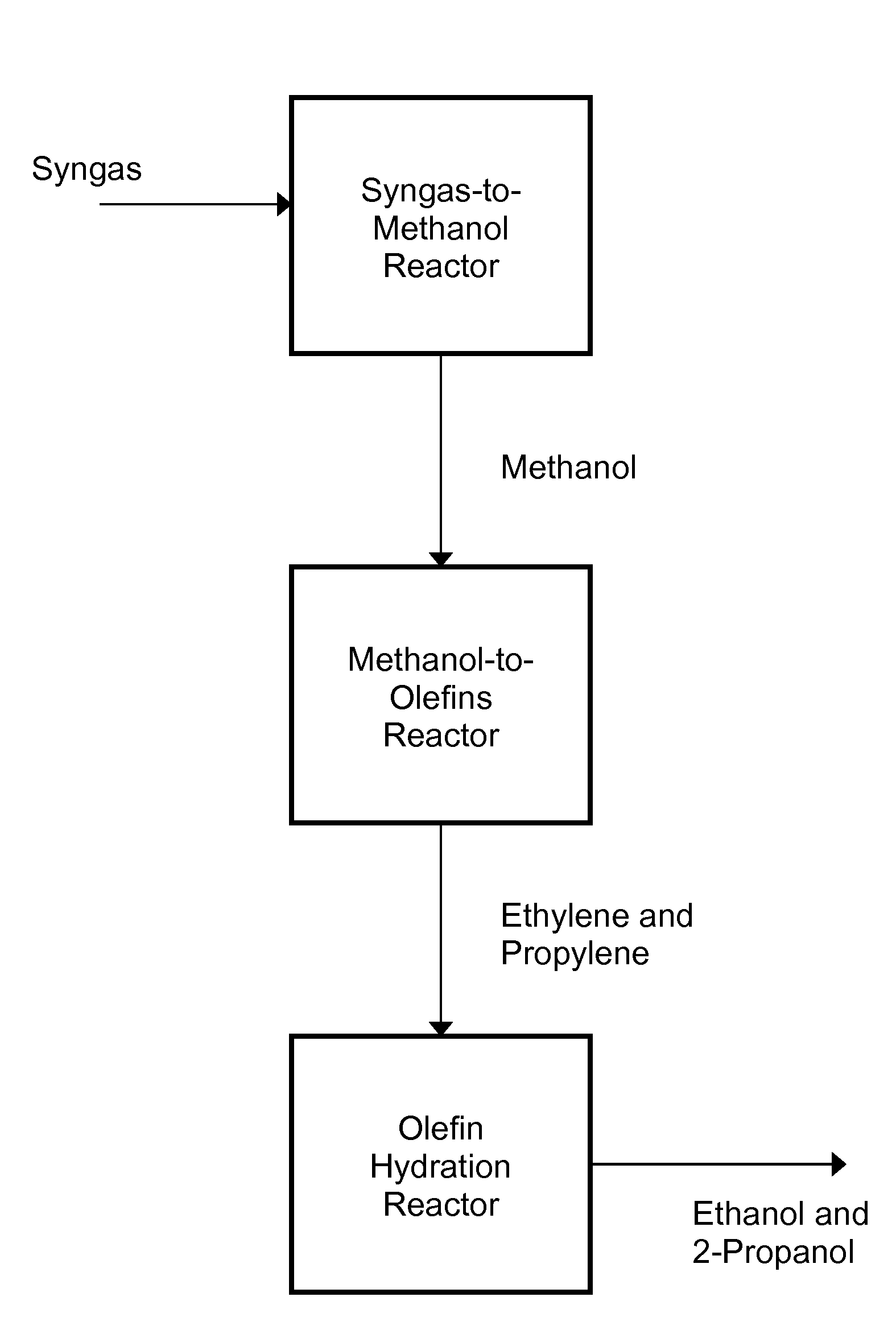

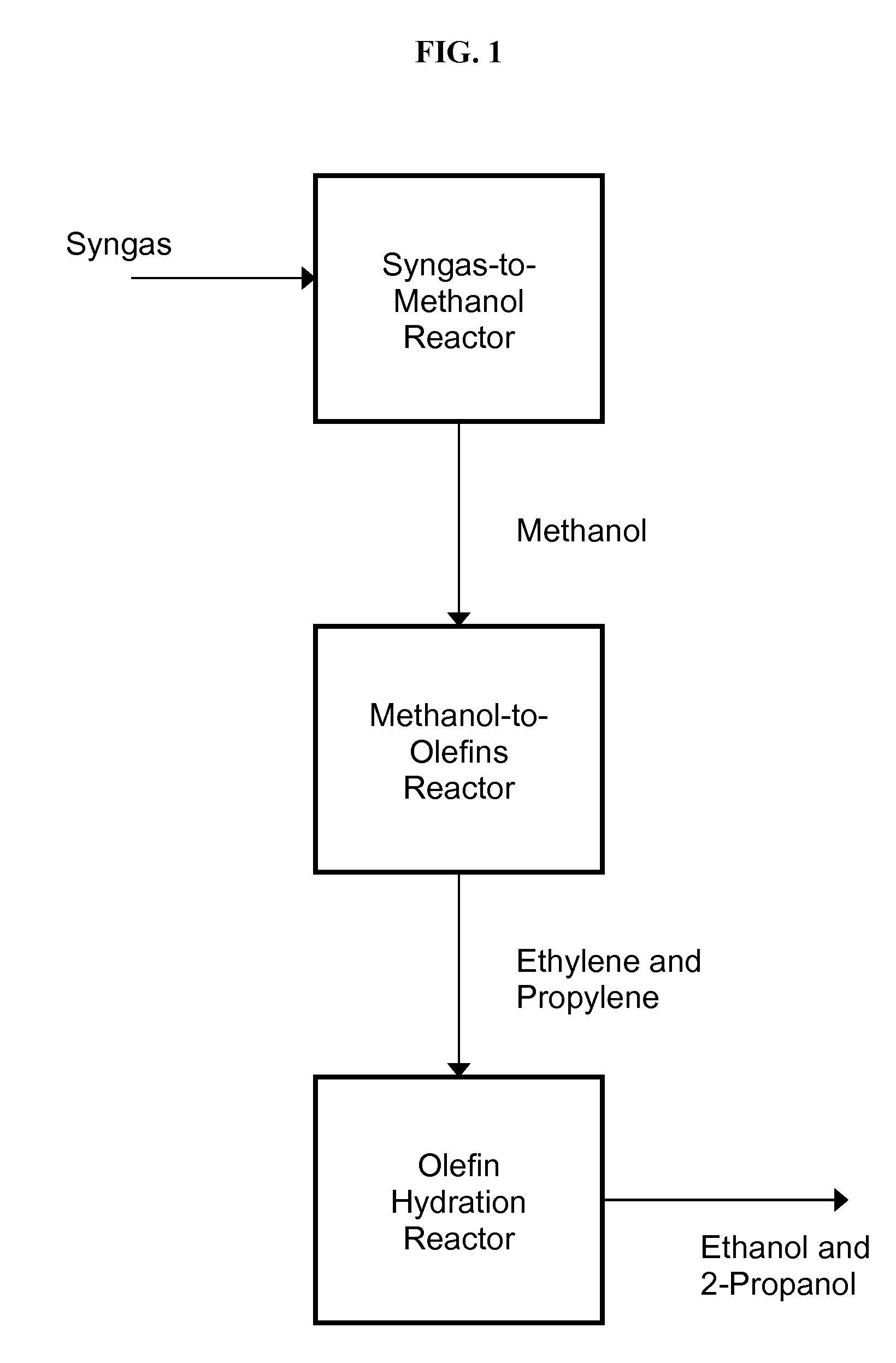

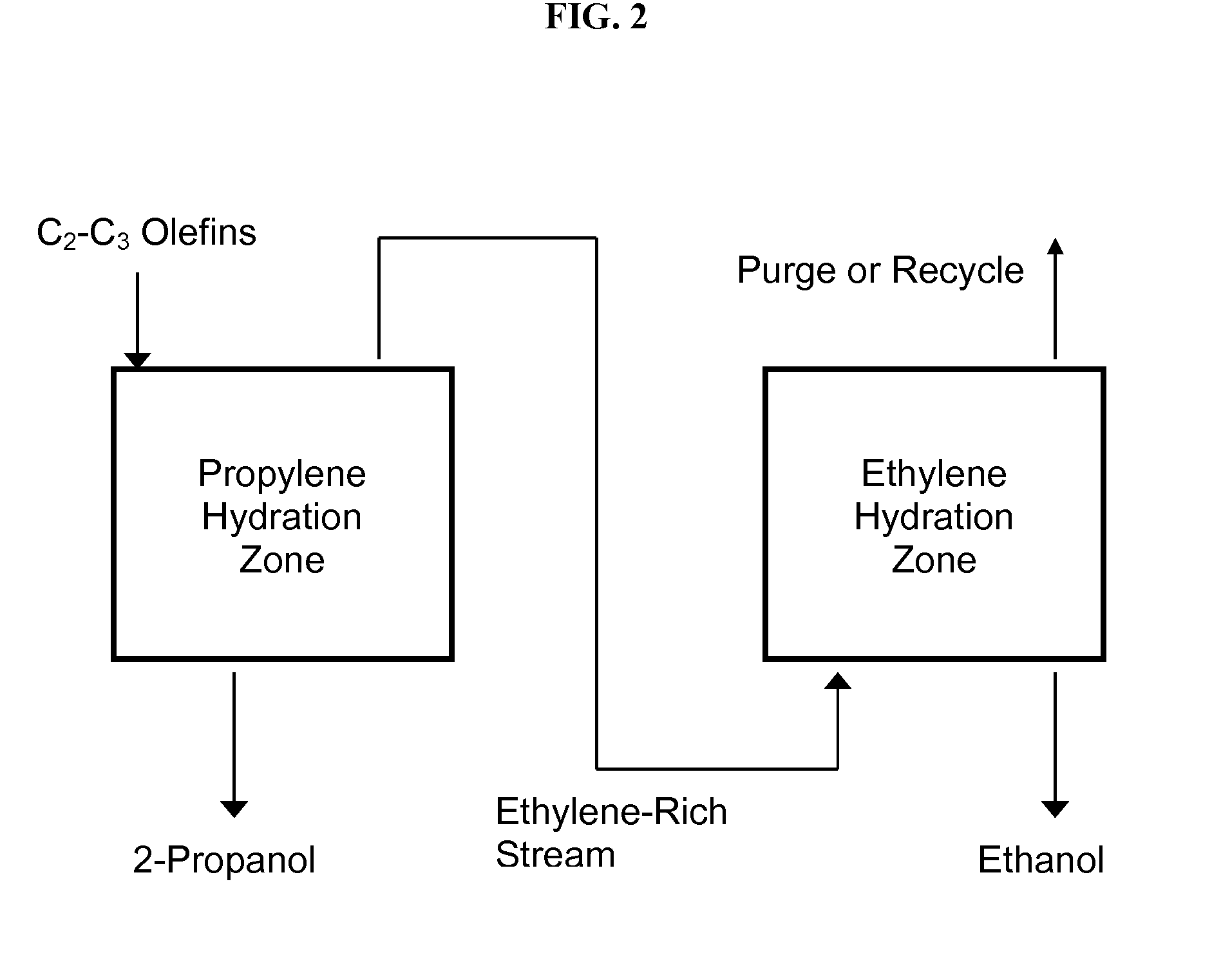

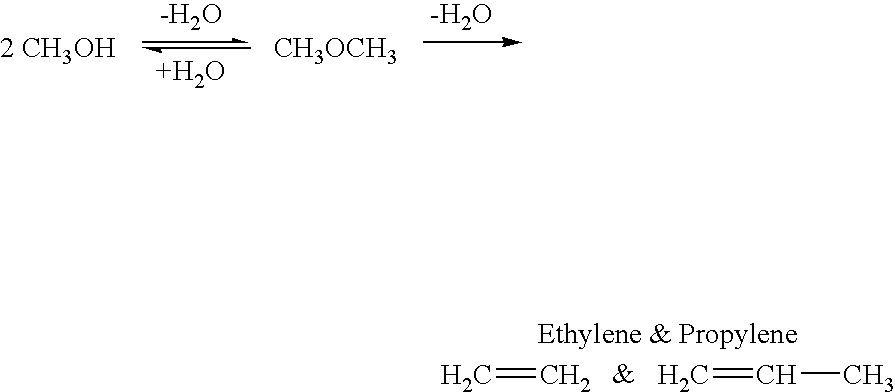

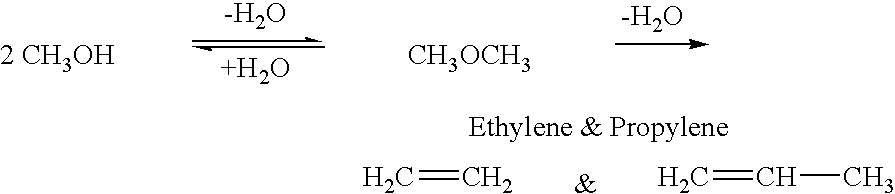

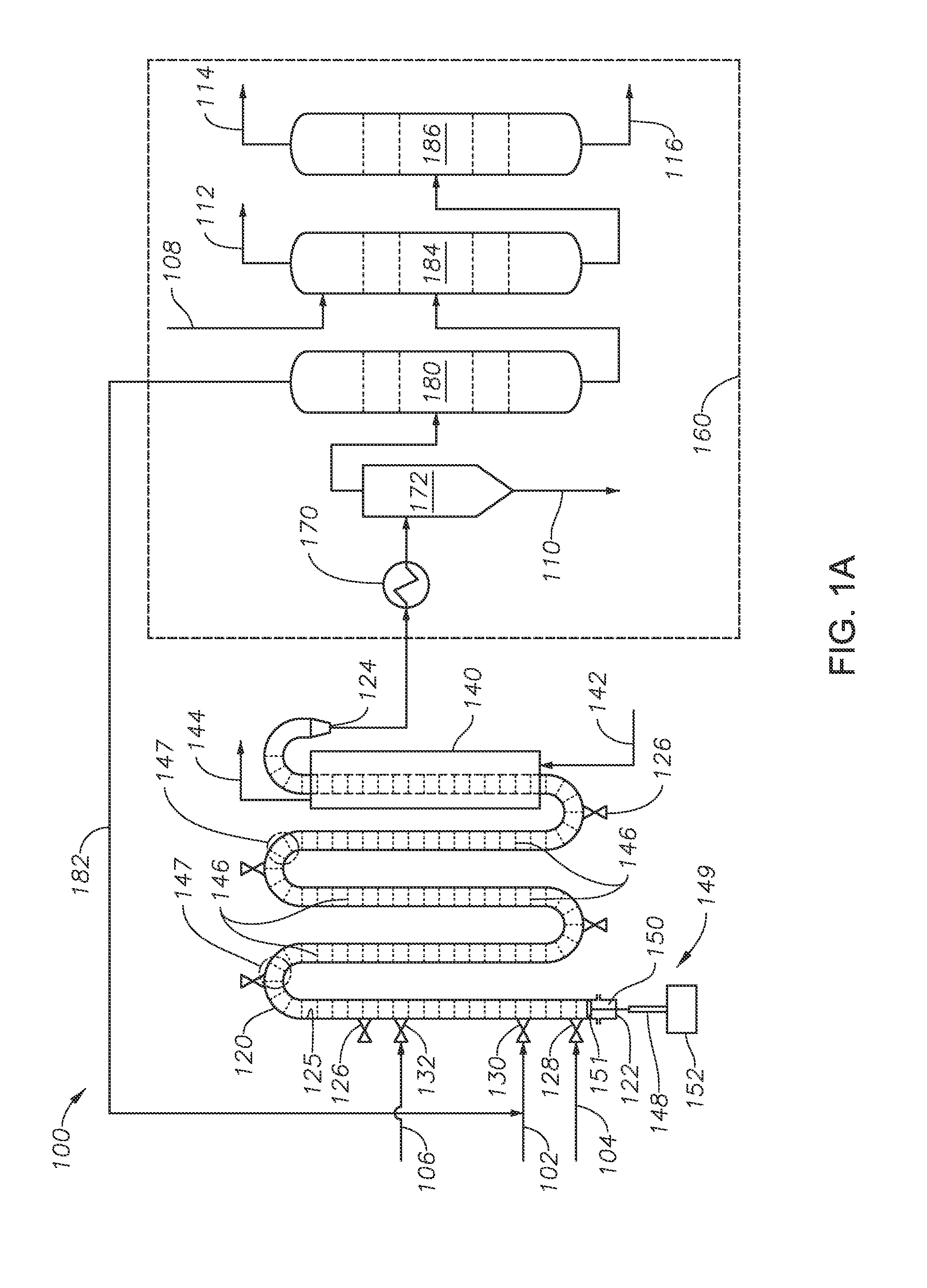

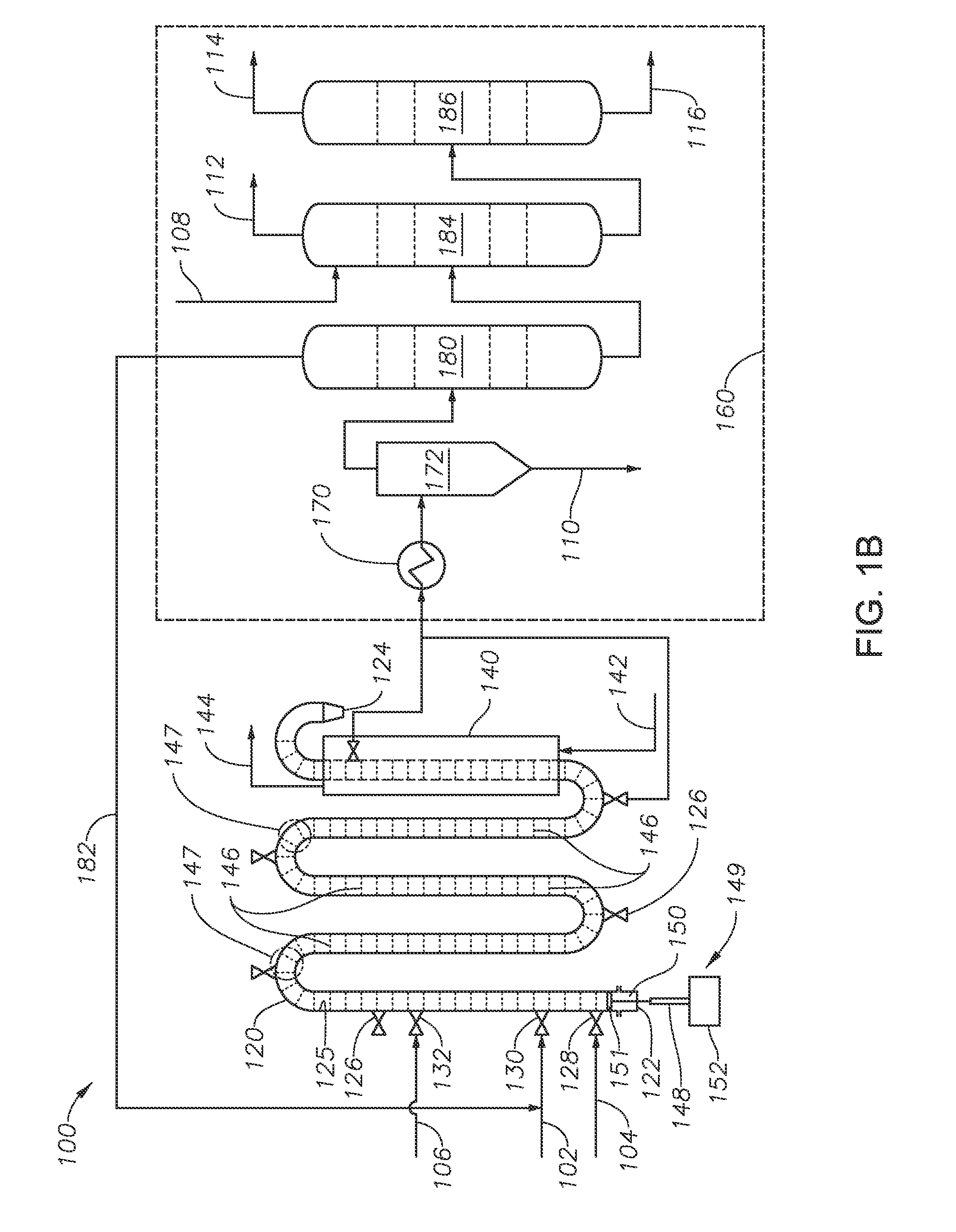

Methods and apparatus for synthesis of alcohols from syngas

This invention provides a method for producing ethanol and 2-propanol from syngas, the method comprising: (a) converting syngas into methanol using a methanol-synthesis catalyst; (b) converting methanol into ethylene and propylene using a methanol-to-olefins catalyst; and (c) hydrating ethylene into ethanol and propylene into 2-propanol. As taught herein, the combined yield of the ethanol and the 2-propanol from biomass can be at least 100 gallons per dry ton biomass. In certain embodiments, the yield of ethanol is at least 100 gallons per dry ton biomass. In some embodiments, the yield of 2-propanol is at least 50 gallons per dry ton biomass.

Owner:ALBEMARLE CORP +1

Nano-structure supported solid regenerative polyamine and polyamine polyol absorbents for the separation of carbon dioxide from gas mixtures including the air

The invention relates to regenerative, supported amine sorbents that includes an amine or an amine / polyol composition deposited on a nano-structured support such as nanosilica. The sorbent provides structural integrity, as well as high selectivity and increased capacity for efficiently capturing carbon dioxide from gas mixtures, including the air. The sorbent is regenerative, and can be used through multiple operations of absorption-desorption cycles.

Owner:UNIV OF SOUTHERN CALIFORNIA

Nano-structure supported solid regenerative polyamine and polyamine polyol absorbents for the separation of carbon dioxide from gas mixtures including the air

Owner:UNIV OF SOUTHERN CALIFORNIA

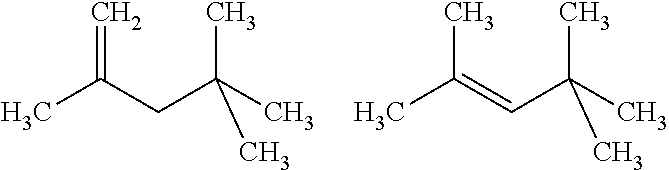

Method for contemporaneously dimerizing and hydrating a feed having butene

ActiveUS20130104449A1Increased research octane numberImprove responseLiquid hydrocarbon mixtures productionCatalystsButeneOligomer

Methods for producing alcohols and oligomers contemporaneously from a hydrocarbon feed containing mixed butenes using an acid based catalyst are provided. Additionally, methods for producing fuel compositions having alcohols and oligomers prepared from mixed olefins are also provided as embodiments of the present invention. In certain embodiments, the catalyst can include a dual phase catalyst system that includes a water soluble acid catalyst and a solid acid catalyst.

Owner:SAUDI ARABIAN OIL CO

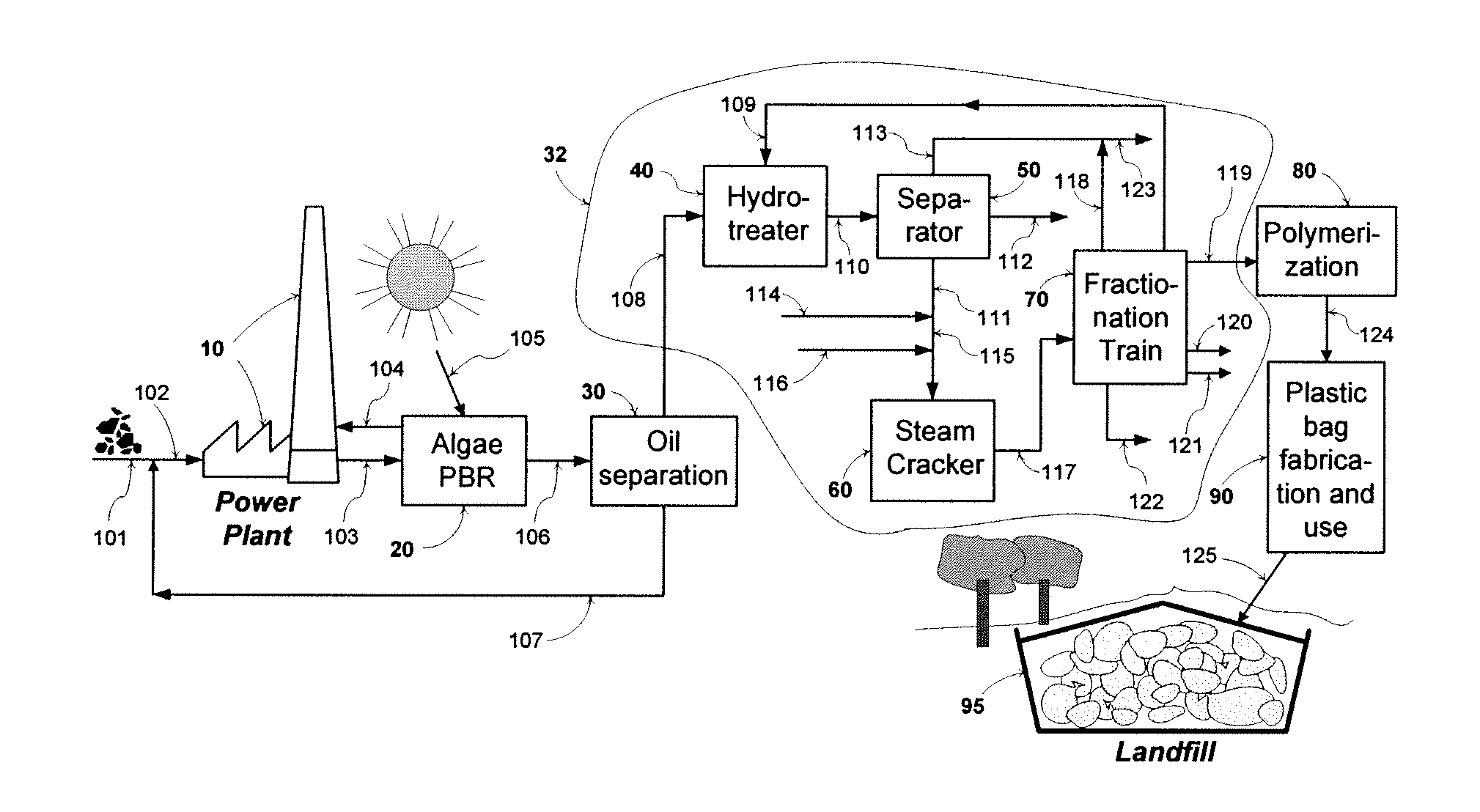

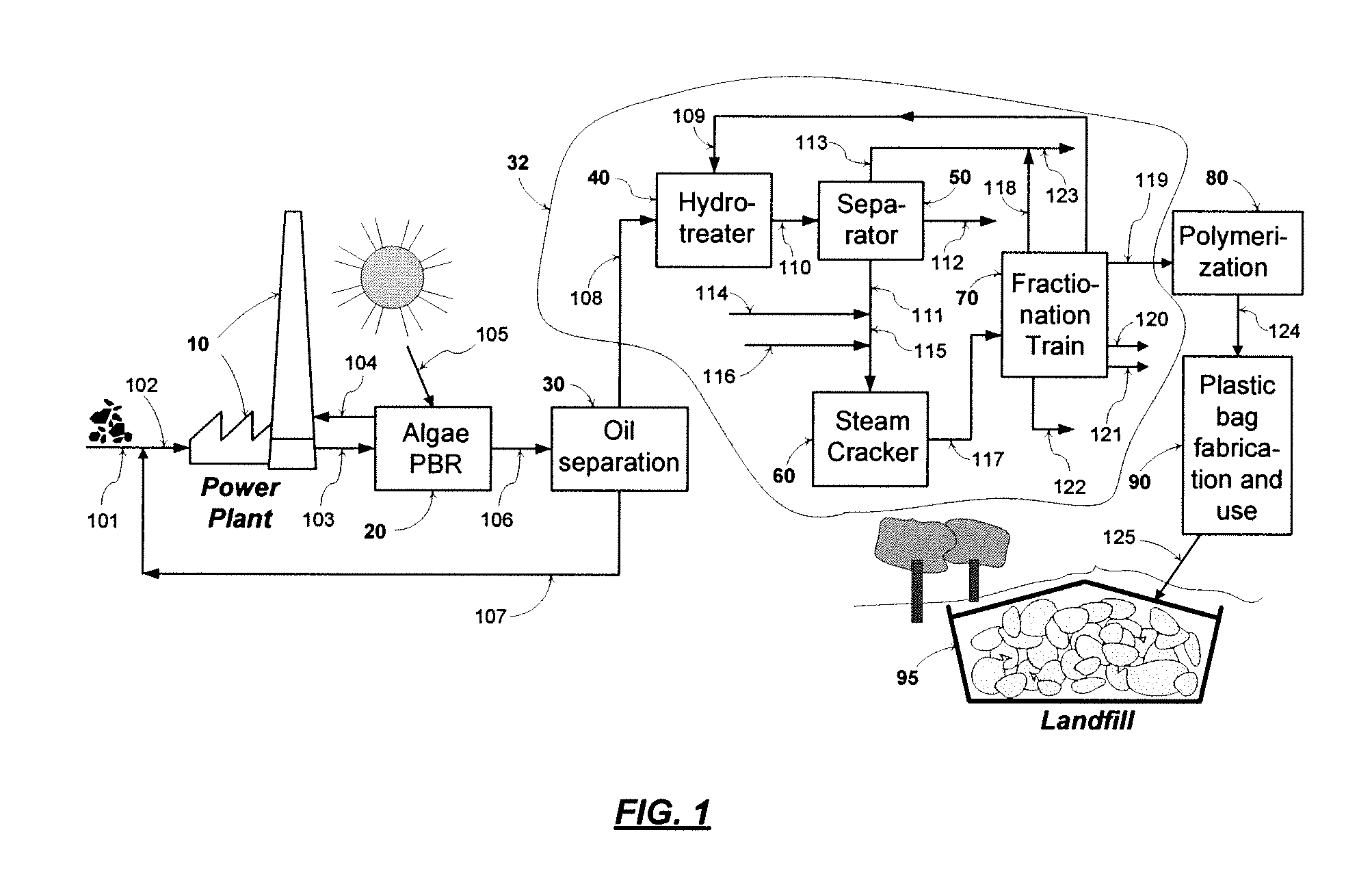

Profitable method for carbon capture and storage

The present invention generally relates to a method for sequestering carbon dioxide. Biomass is converted into paraffinic hydrocarbons. The paraffinic hydrocarbons are steam cracked into olefins. The olefins are polymerized into non-biodegradable polyolefins.

Owner:REG SYNTHETIC FUELS LLC

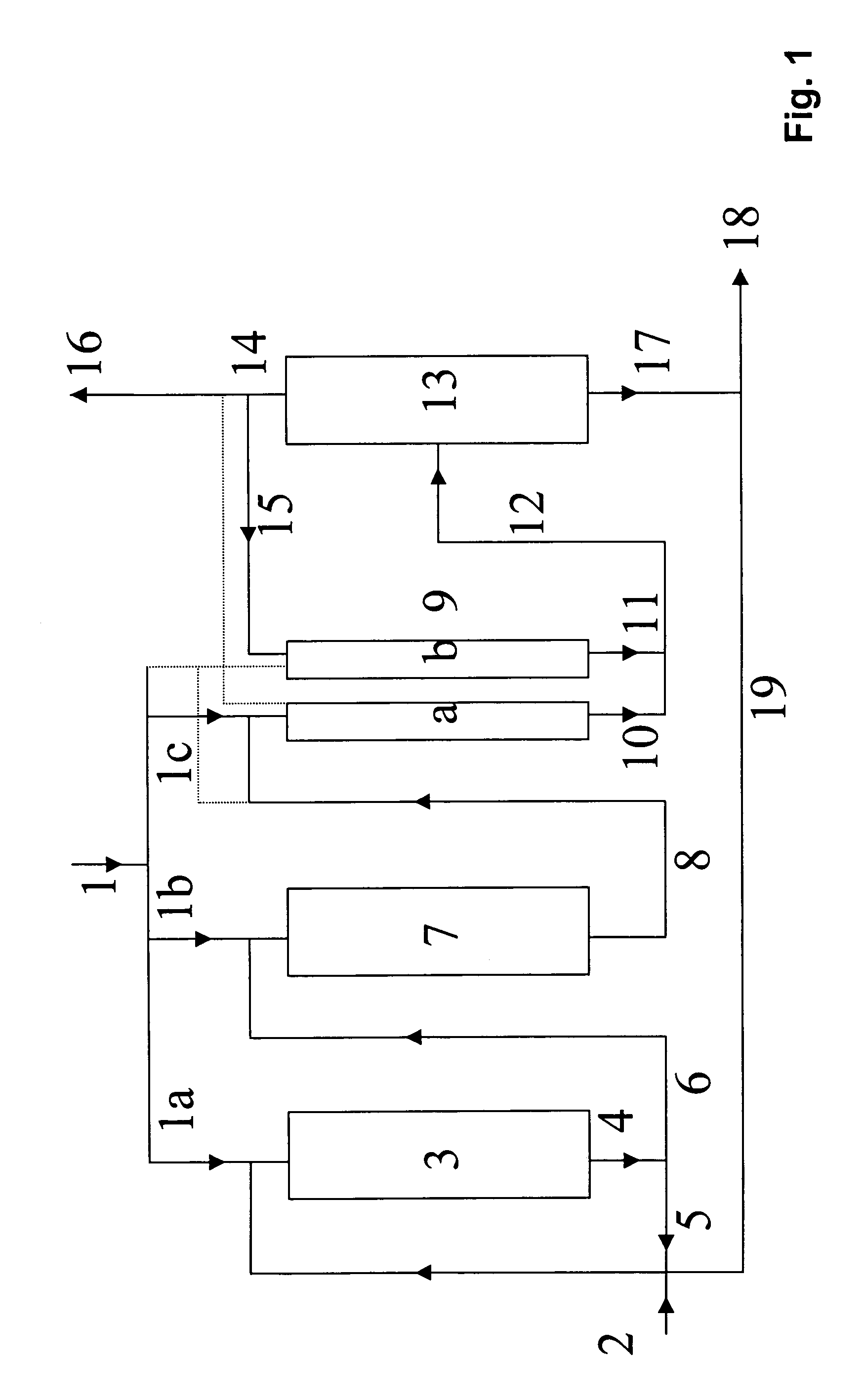

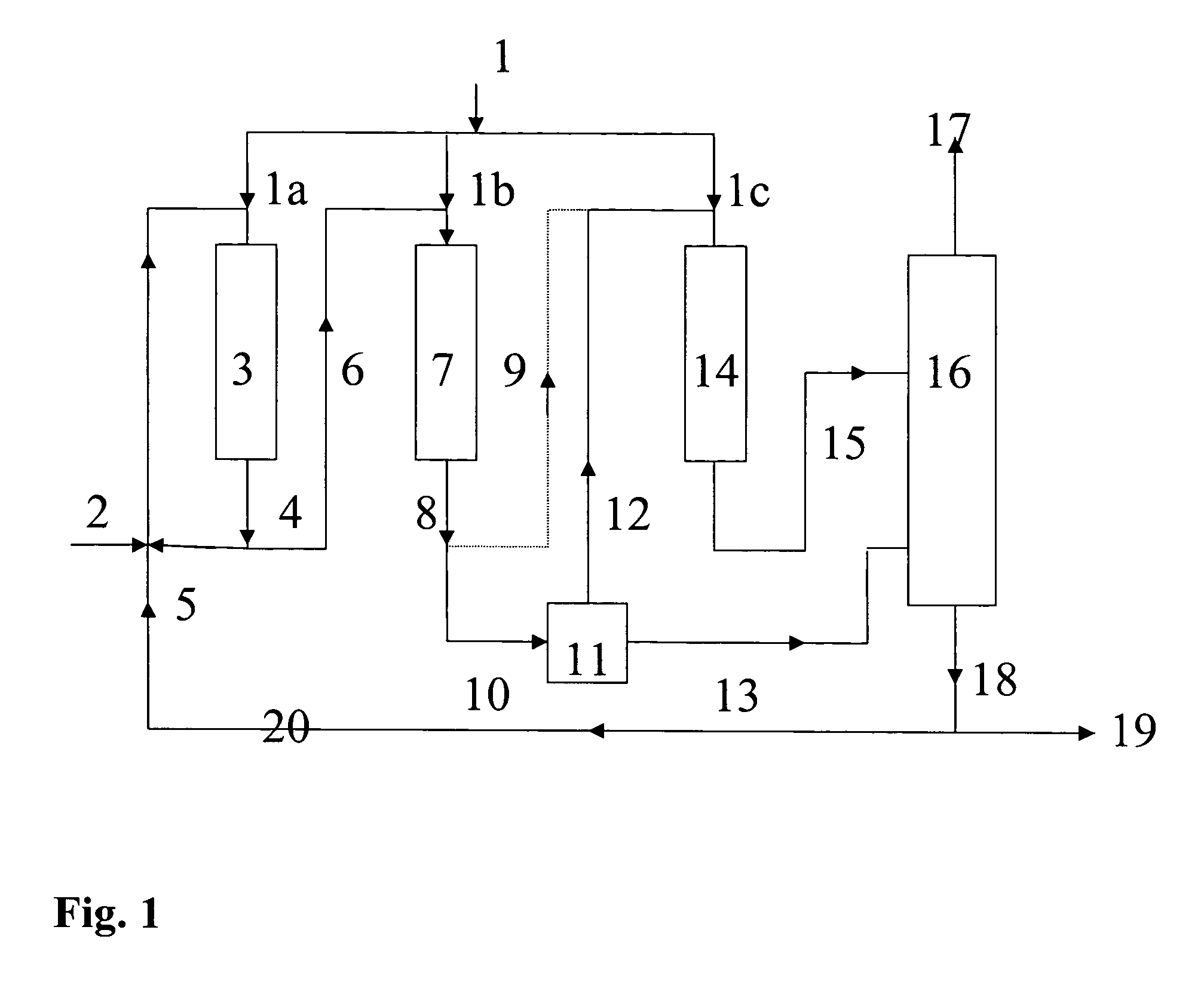

Process for preparing tert-butanol from isobutene-containing hydrocarbon mixtures

InactiveUS7002050B2Increase productionOrganic compound preparationOxygen compounds preparation by reductionHydrocarbon mixturesSolid acid

The present invention relates to a process for preparing tert-butanol (TBA) by reacting an isobutene-containing hydrocarbon mixture with water over a solid acid catalyst in a reactor cascade, wherein at least one reactor is supplied alternately with two different isobutene-containing hydrocarbon mixtures, of which one has both a higher tert-butanol content and a higher water content than the other mixture.

Owner:EVONIK DEGUSSA GMBH

Efficient and selective conversion of carbon dioxide to methanol, dimethyl ether and derived products

ActiveUS7605293B2Minimize or eliminate the disadvantages or dangers inherentElectrolysis componentsCarbon compoundsHydrogenFlue gas

An environmentally beneficial method of producing methanol from varied sources of carbon dioxide including flue gases of fossil fuel burning powerplants, industrial exhaust gases or the atmosphere itself. Converting carbon dioxide by electrochemical reduction produces formic acid acid and some formaldehyde and methanol mixtures. The formic acid can be used as source of carbon as well as hydrogen to produce methanol, dimethyl ether and other products.

Owner:UNIV OF SOUTHERN CALIFORNIA

Extraction solvents derived from oil for alcohol removal in extractive fermentation

ActiveUS20110312044A1Reduce the amount requiredReduce decreaseFatty oils/acids recovery from wasteOxygen-containing compound preparationSolventFatty alcohol

In an alcohol fermentation process, oil derived from biomass is chemically converted into an extractant available for in situ removal of a product alcohol such as butanol from a fermentation broth. The glycerides in the oil can be chemically converted into a reaction product, such as fatty acids, fatty alcohols, fatty amides, fatty acid methyl esters, fatty acid glycol esters, and hydroxylated triglycerides, and mixtures thereof, which forms a fermentation product extractant having a partition coefficient for a product alcohol greater than a partition coefficient of the oil of the biomass for the product alcohol. Oil derived from a feedstock of an alcohol fermentation process can be chemically converting into the fermentation product extractant. The oil can be separated from the feedstock prior to the feedstock being fed to a fermentation vessel, and the separated oil can be chemically converted to a fermentation product extractant, which can then contacted with a fermentation product comprising a product alcohol, whereby the product alcohol is separated from the fermentation product.

Owner:GEVO INC

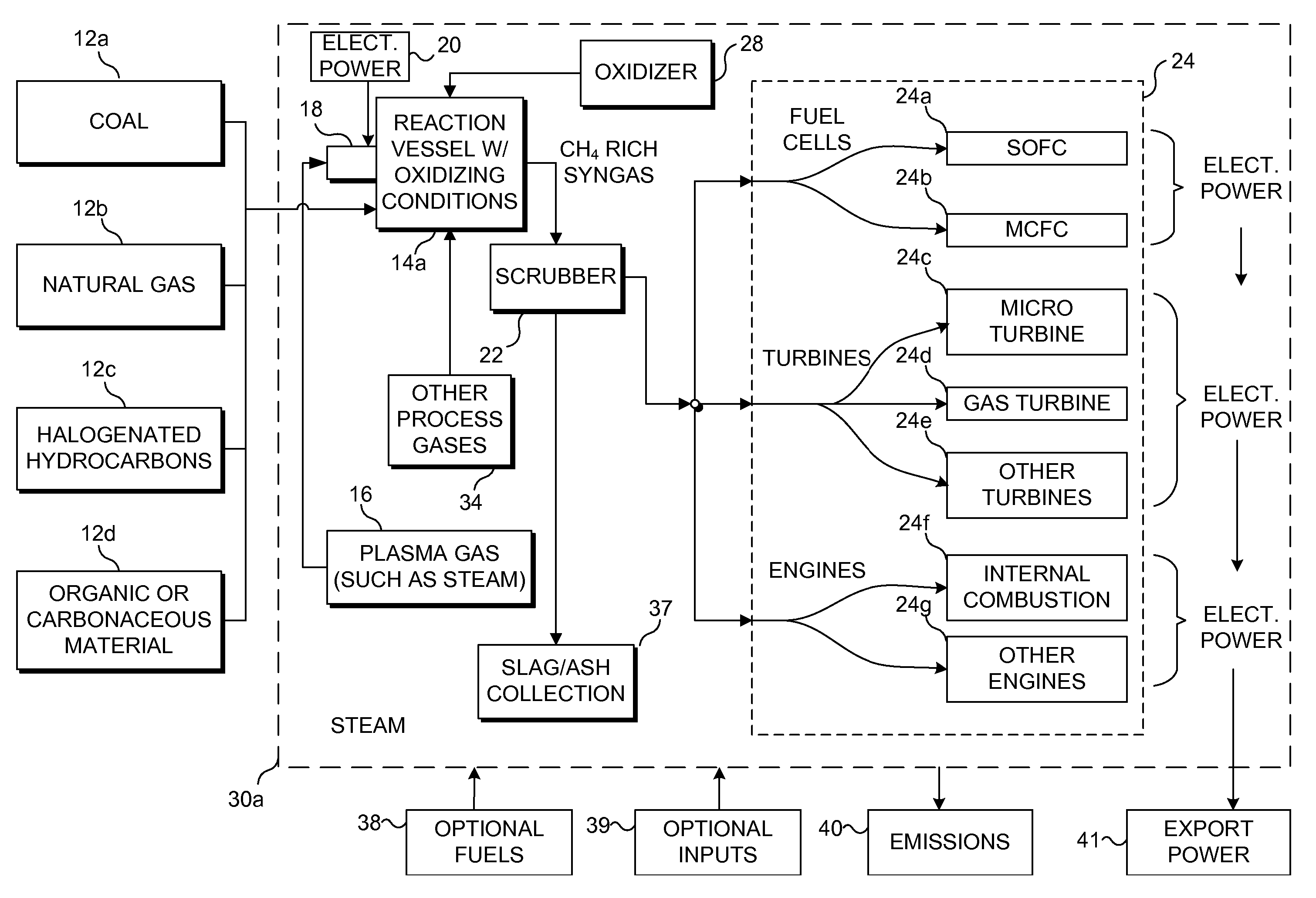

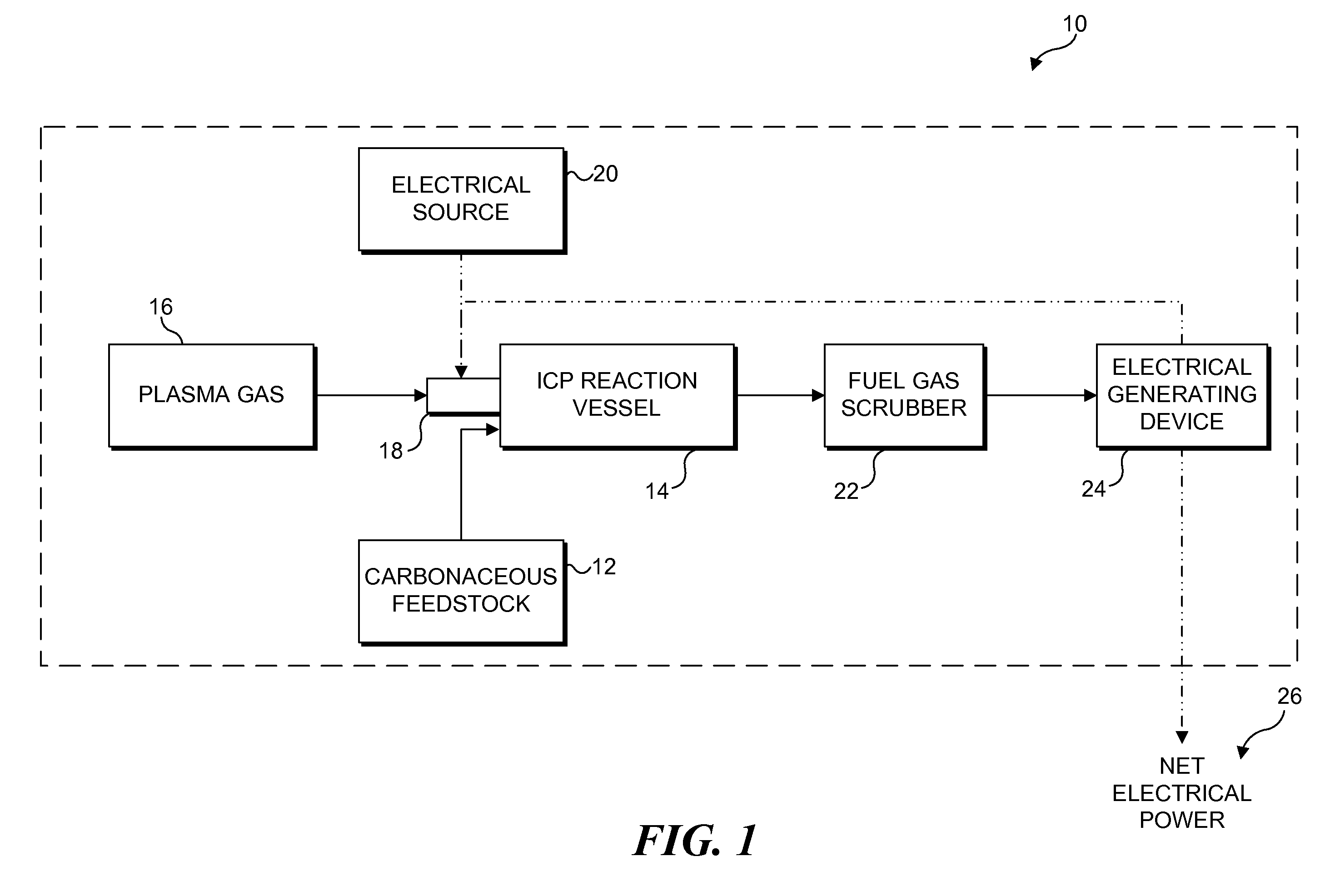

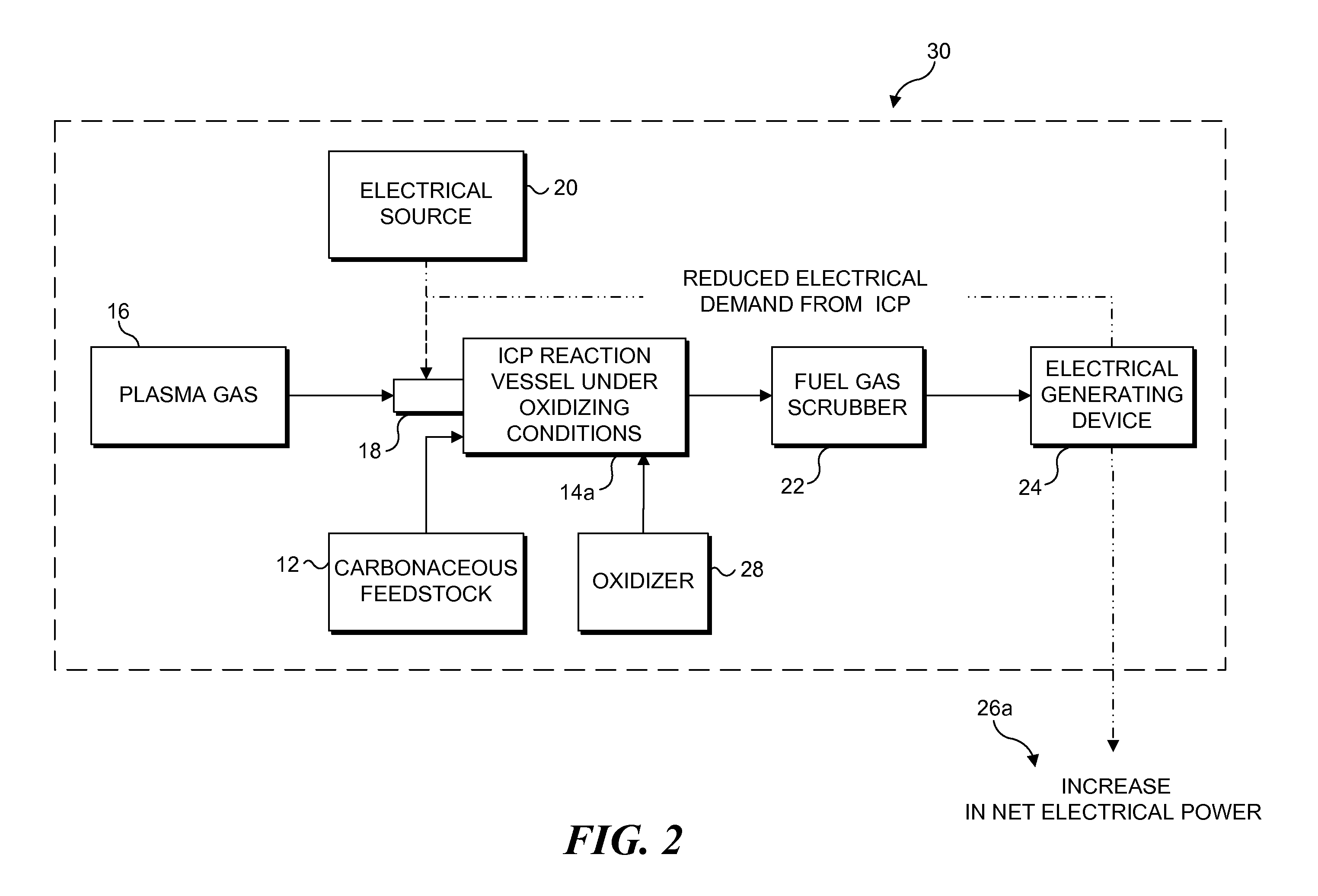

Inductively coupled plasma/partial oxidation reformation of carbonaceous compounds to produce fuel for energy production

InactiveUS20080041829A1Increase the amount of carbonMore electricityElectricity cogenerationFuel cell auxillariesThermal energyPartial oxidation

Owner:SEQUOYAH FINANCE ONE

Crystalline MWW-type titanosilicate catalyst for producing oxidized compound, production process for the catalyst, and process for producing oxidized compound by using the catalyst

InactiveUS20040092757A1Material nanotechnologyPreparation by oxidation reactionsDouble bondOxidizing agent

A crystalline titanosilicate catalyst which is usable as a catalyst in the oxidation reaction of a compound having a carbon-carbon double bond and at least one other functional group, a process for producing the catalyst, and a process for producing an oxidized compound by an oxidation reaction using the catalyst. It has been found that a crystalline titanosilicate having a structural code of MWW effectively functions as a catalyst in an oxidation reaction of a compound having a carbon-carbon double bond and at least one other functional group wherein the carbon-carbon double bond of the compound is oxidized by using a peroxide as an oxidizing agent, thereby to highly selectively provide an intended oxidized compound.

Owner:SHOWA DENKO KK

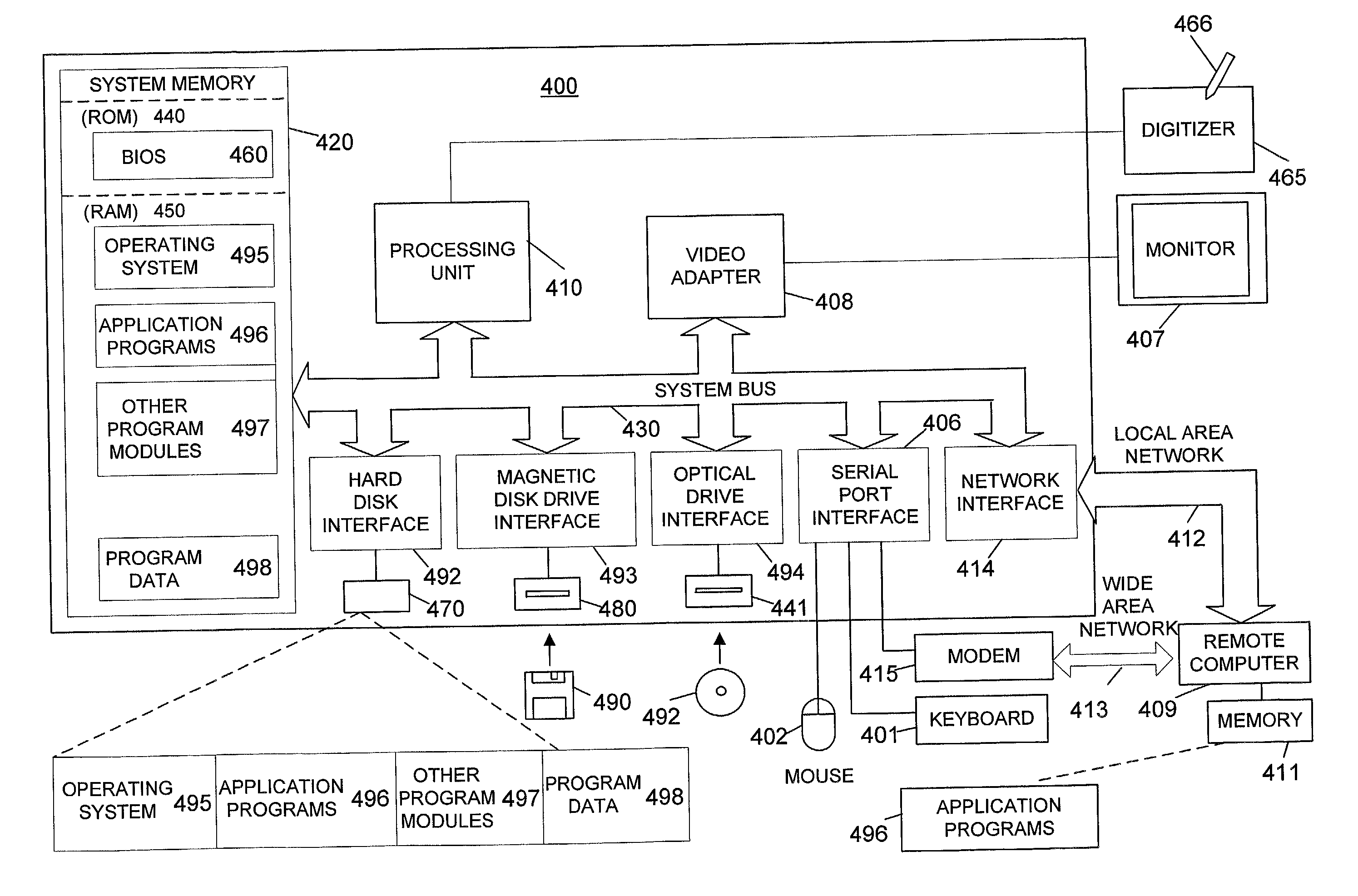

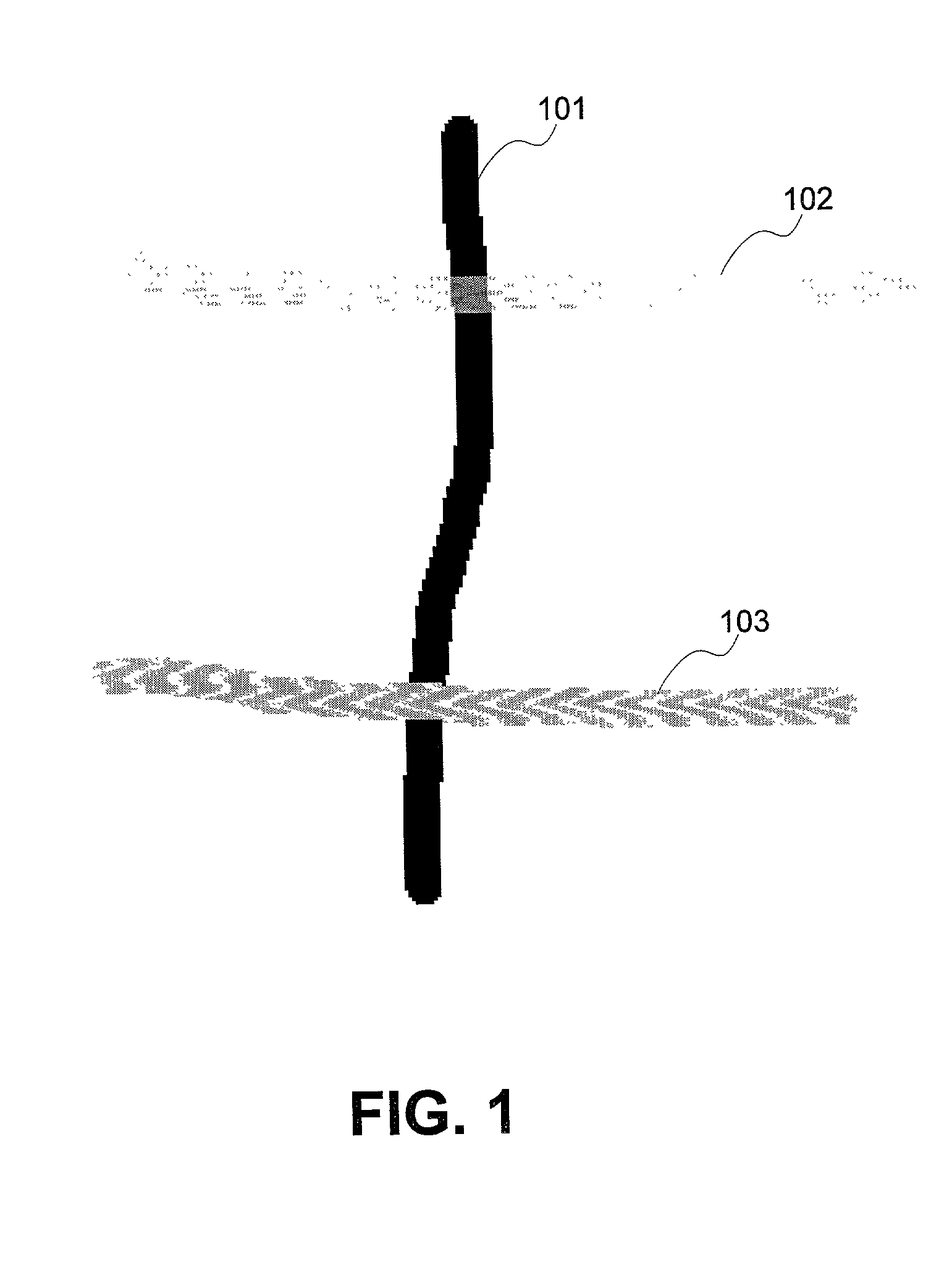

Dynamic rendering of ink strokes with transparency

Apparatus and methods for dynamically rendering transparent ink strokes, in some situations such that the rendered ink stroke has transparency similar to physical ink while it is being drawn. For example, the ink stroke may be dynamically rendered as a stroke having uniform transparency while it is being drawn. Only the new ink segment that has most recently been added to the stroke may be drawn, and areas of the new ink segment that overlap older segments of the ink stroke may be frozen, or excluded from being re-painted.

Owner:MICROSOFT TECH LICENSING LLC

Catalytic isomerization processes of 1,3,3,3-tetrafluoropropene for making 2,3,3,3-tetrafluoropropene

InactiveUS7420094B2Increase volumePreparation by halogen halide additionPreparation by hydroxy group additionIsomerization1,3,3,3-Tetrafluoropropene

Owner:THE CHEMOURS CO FC LLC

Process for the production of olefins and use thereof

The present invention relates to the process of production of olefins by means of the dehydration of light alcohols using ionic liquids as an acidic medium. Furthermore, the present invention relates to the use of such olefins, for example, for the production of polymers and ethylene glycol.

Owner:UNIVERSIDADE FEDERAL DO RIO GRANDE DO SUL +1

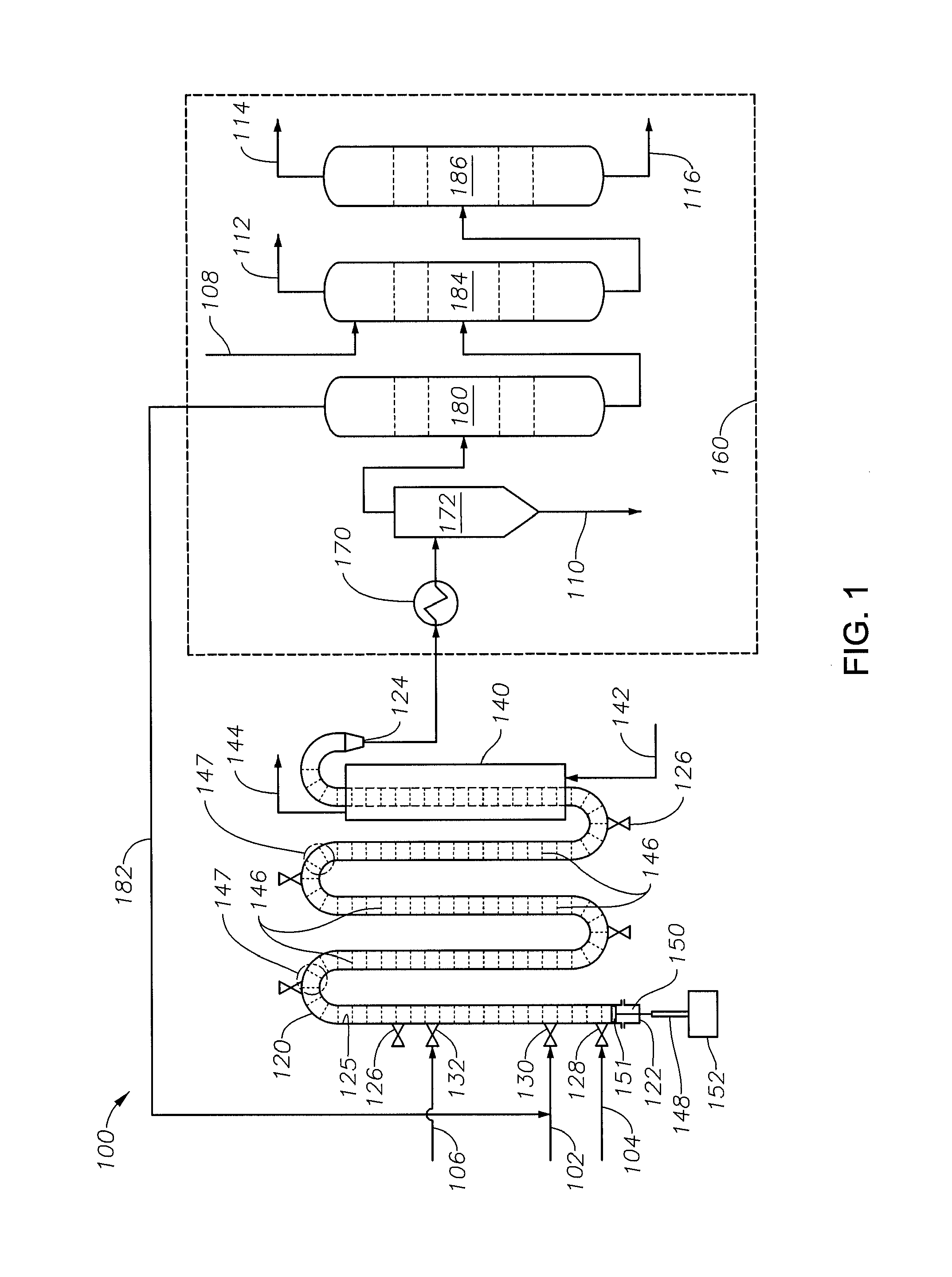

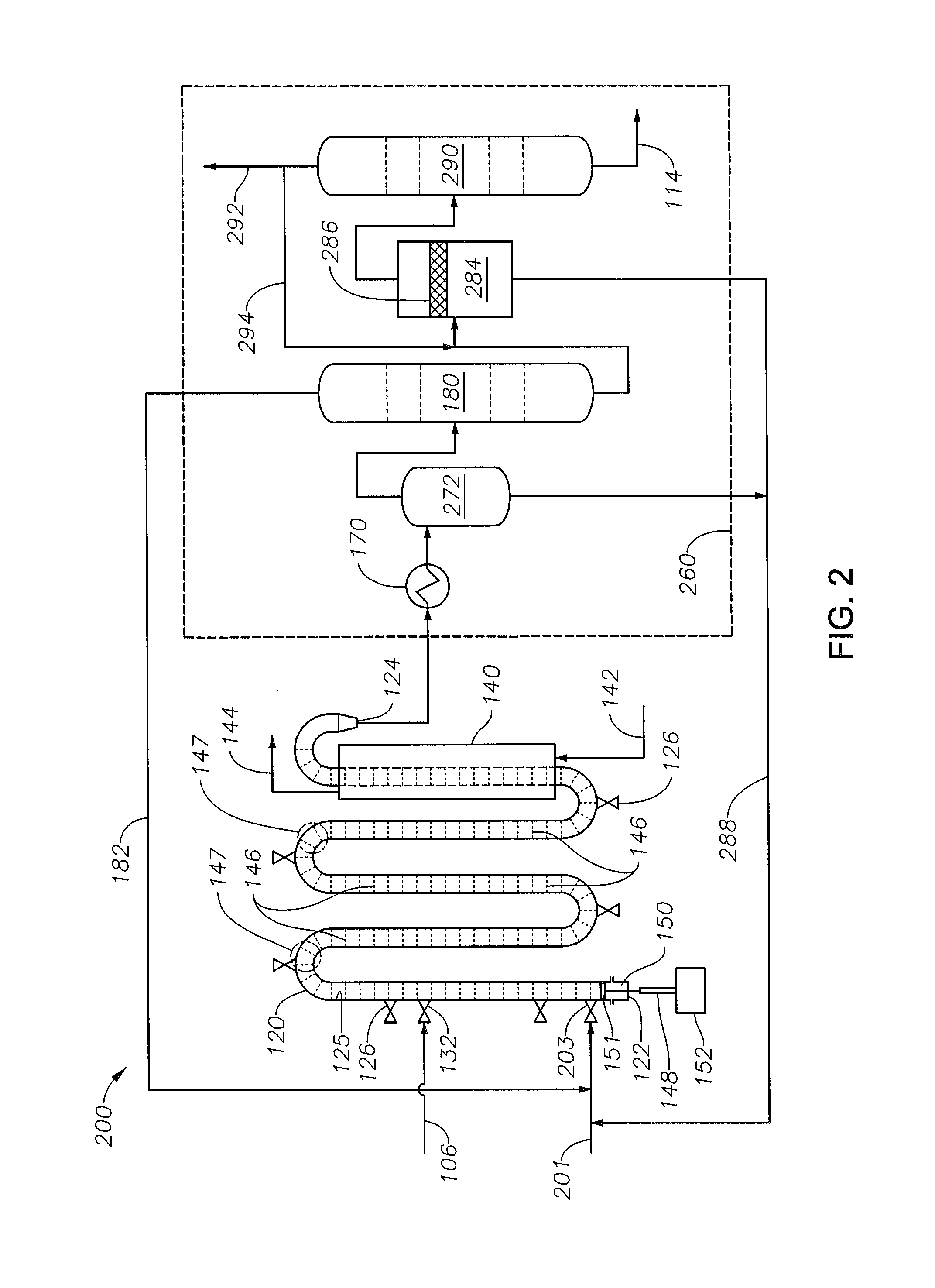

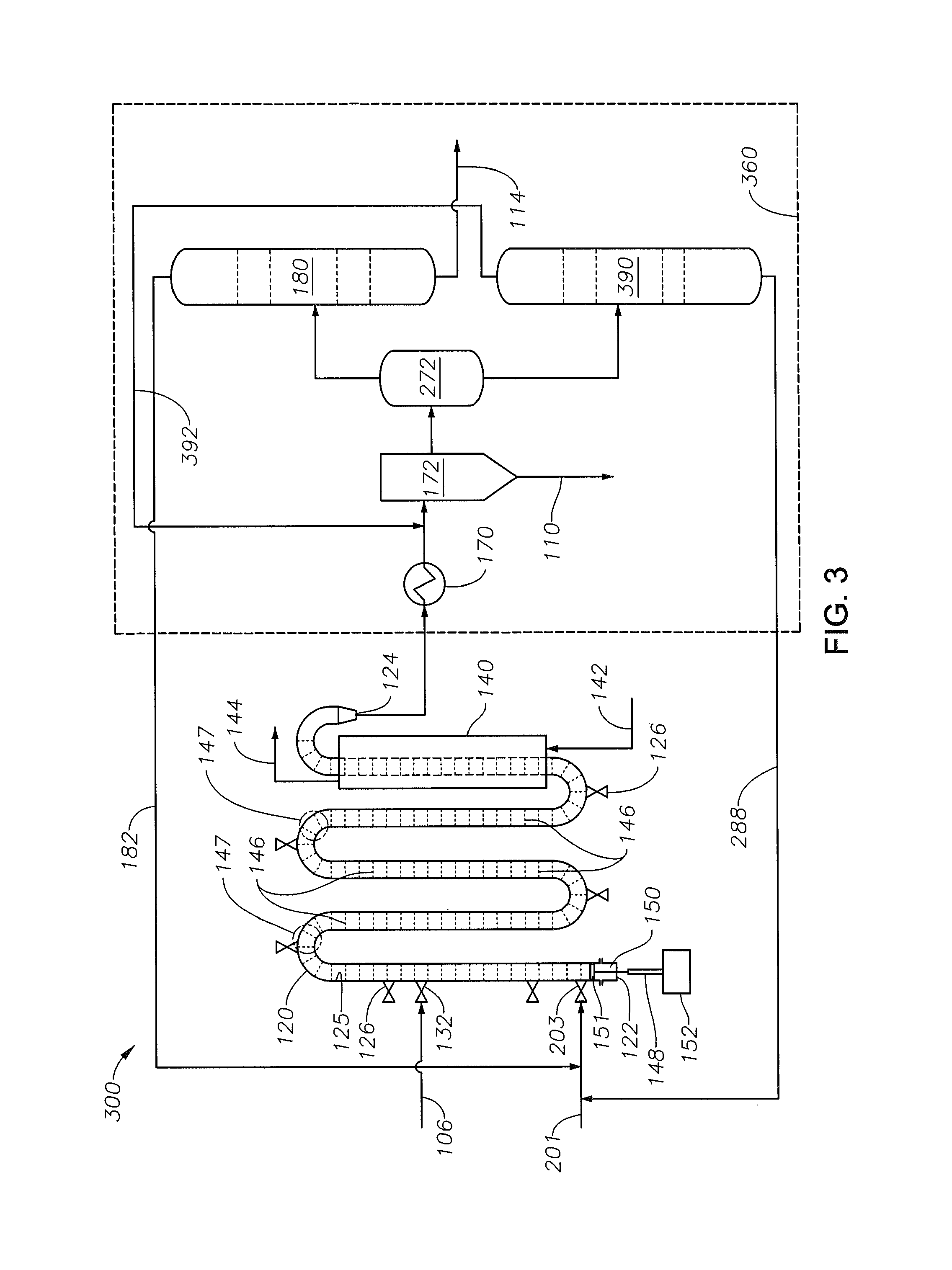

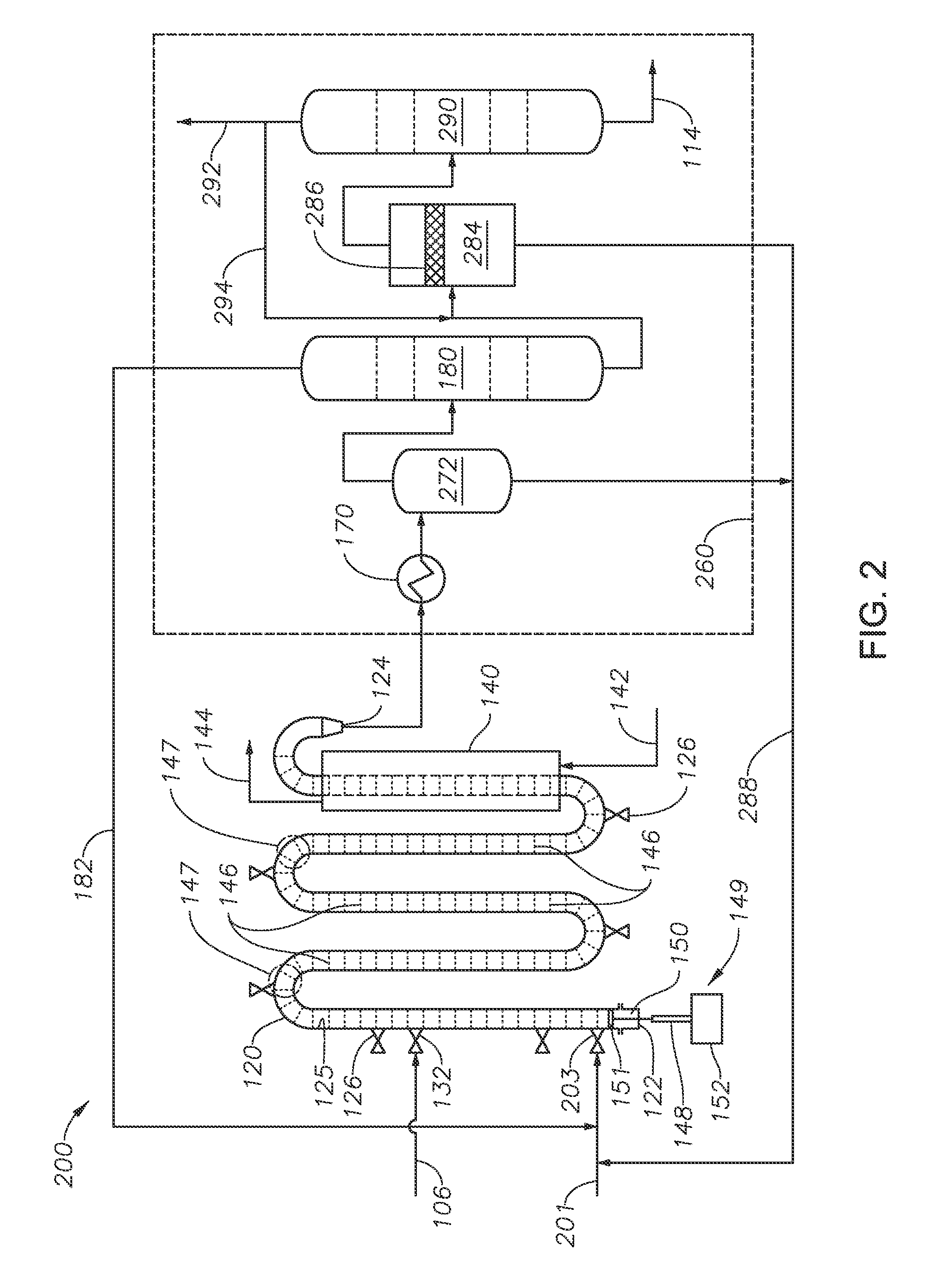

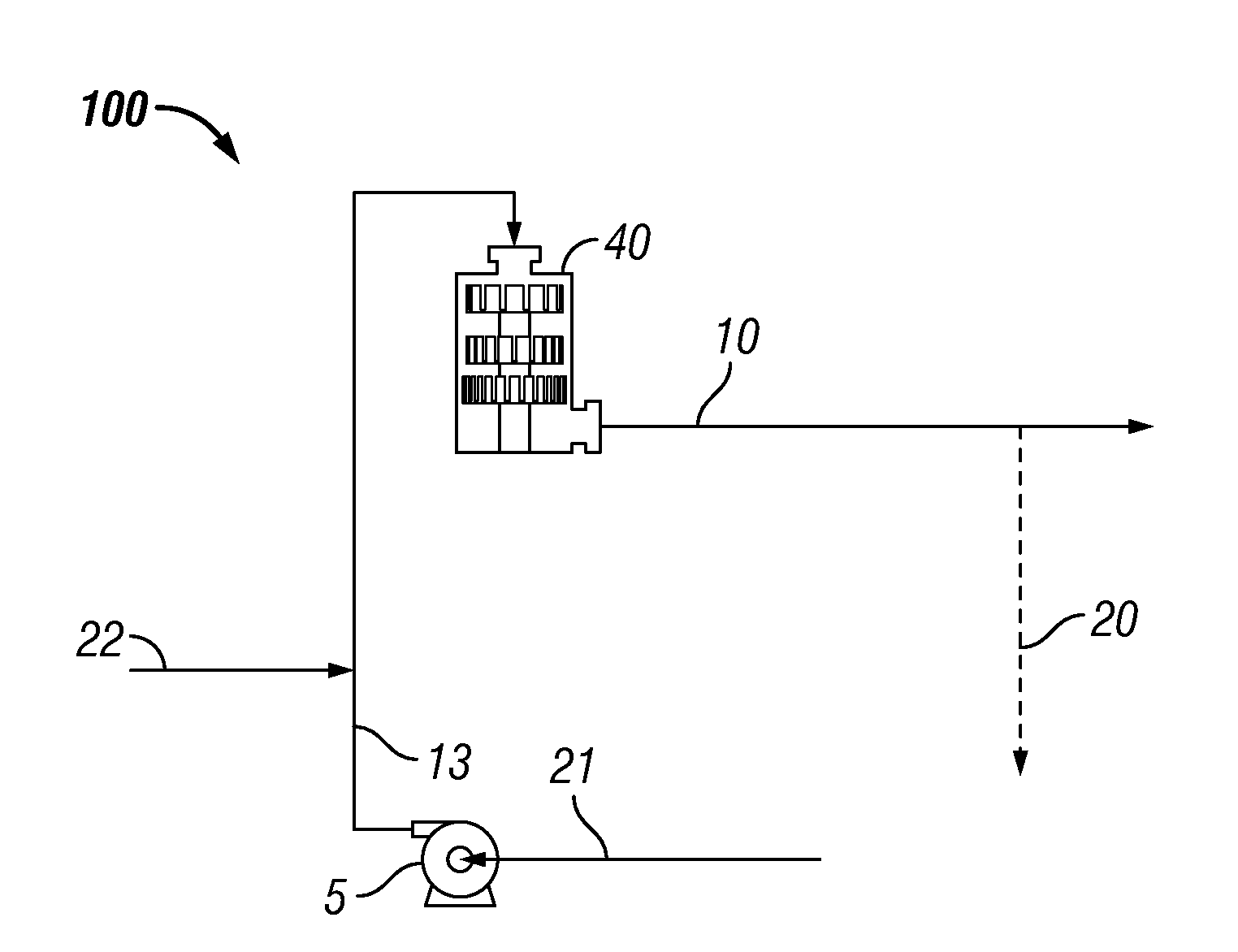

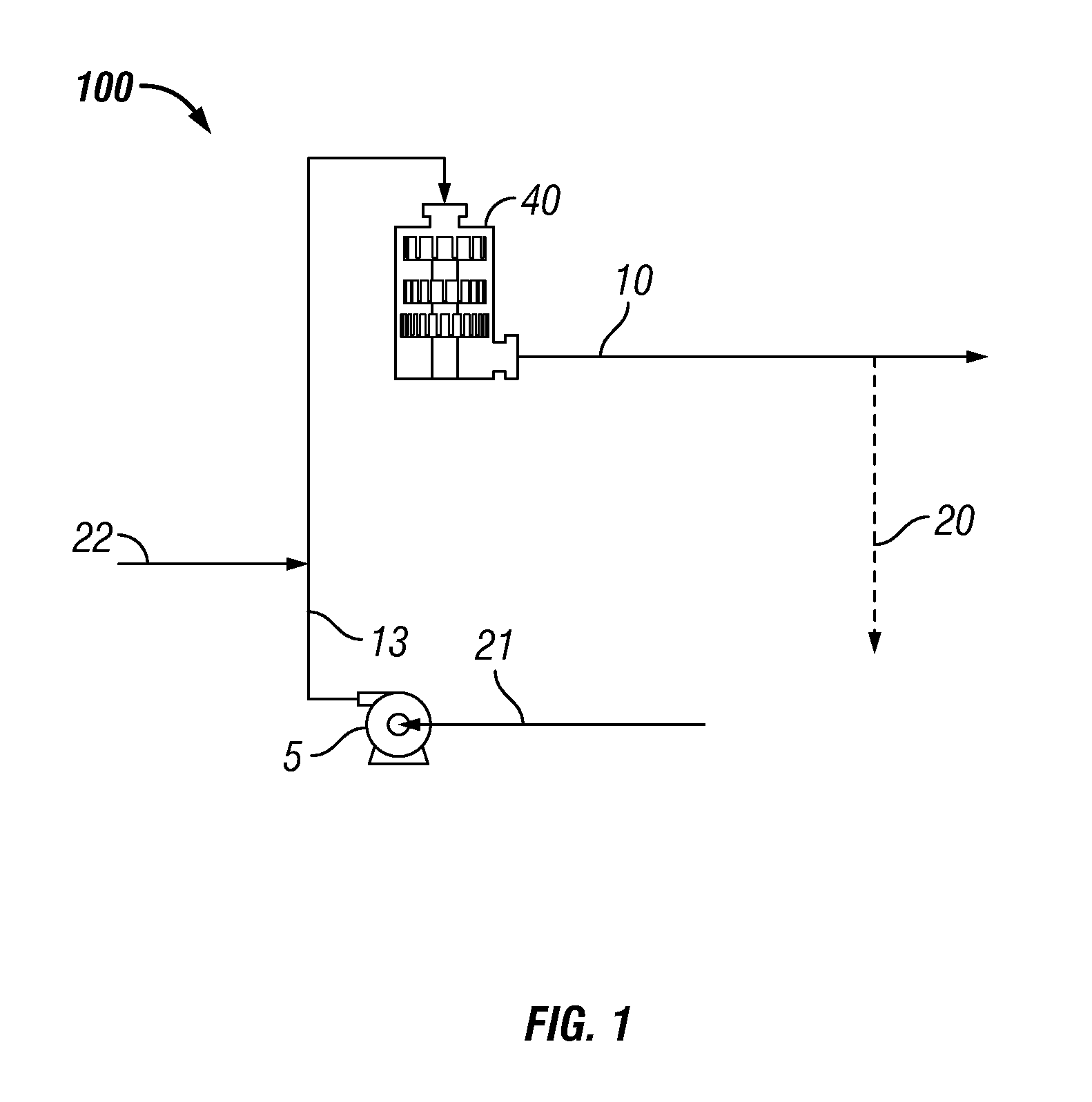

Olefin hydration process using oscillatory baffled reactor

ActiveUS9187388B2Well mixedIncrease surface area exposureChemical/physical/physico-chemical reactor detailsChemical/physical/physico-chemical stationary reactorsButeneInstability

A butanol production system and method of producing refined mixed butanols from water and mixed butenes. The system includes an internal baffle single pass reactor, a separation system and an exterior motion driver. The reactor has baffled cells. The separations system is operable to separately selectively separate water and mixed butenes from the crude product such that a refined mixed butanols is produced. The exterior motion driver is operable to induce unsteadiness in the fluid flow of the process fluid through the reactor. A method for producing refined mixed butanols includes introducing mixed butenes, water and a butene hydration catalyst into the reactor, operating the butanol production system such that the external motion driver induces unsteadiness in the process fluid flow and the reaction of mixed butenes and water occurs in the presence of the butene hydration catalyst such that mixed butanols form.

Owner:SAUDI ARABIAN OIL CO

Process for preparing levogyrate alpha-terpineol

InactiveCN1482113AIncrease temperatureReduce dosagePreparation by hydroxy group additionAlcoholTurpentine Oil

The present invention provides one-step levo-alpha-terpineol synthesizing process, in which turpentine oil with alpha-pinene as main component is used as the material, low-carbon alcohol or ketone assolvent and modified strong acid styrene cationic exchange resin as catalyst and the catalytic hydration is completed in a fixed bed reactor. It has catalyst / alpha-pinene weight ratio of 1 to 1-10, alpha-pinene / water molar ratio of 1 to 1.1-2, water / solvent molar ratio of 1 to 0.1-0.9, reaction temperature of 70-100 deg.c, reaction period of 5-13 hr, alpha-pinene converting rate over 95 % and levo-alpha-terpineol yield over 65 %.

Owner:GUANGXI RES INST OF CHEM IND CO LTD

Dual phase catalysts system for mixed olefin hydrations

Processes for producing mixed alcohols from mixed olefins and the catalyst systems for making such alcohols are provided. Additionally, processes for producing fuel compositions having mixed alcohols prepared from mixed olefins are also provided as embodiments of the present invention. The catalyst systems include a dual phase catalyst system that includes a water soluble acid catalyst and a solid acid catalyst.

Owner:SAUDI ARABIAN OIL CO

Process for the preparation of 3-hydroxypropanal

InactiveUS6284930B1Increase pressureDrop-off in conversion in the reactor is reduced significantlyOrganic compound preparationOrganic chemistry methodsAcroleinCarboxylic acid

3-Hydroxypropanal is prepared by reacting acrolein with water under pressure and in the presence of an ion exchange resin while adding a carboxylic acid to the reaction mixture.

Owner:EI DU PONT DE NEMOURS & CO

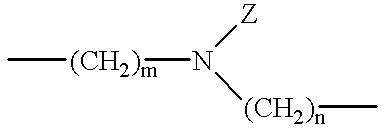

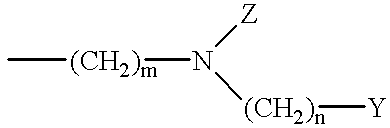

Methods, systems and catalysts for the hydration of olefins

InactiveUS20040236158A1Low compressibilityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsButenePolymer science

The present invention provides a system, method and catalyst for olefin hydration. The method includes hydrating the olefin using a base treated, sulfonated, halogenated and acid regenerated thermally stable catalyst. In several variants, the olefin hydration comprises butene hydration, propene hydration, hydration of cyclohexene, propylene hydration, pentene hydration, hexene hydration, and heptene hydration. The present invention also provides a method of making a catalyst for olefin hydration, and provides alcohols manufactured by the catalyst(s), systems and methods described herein.

Owner:COLLIN JENNIFER REICHI +1

Hydrated Niobium Oxide Nanoparticle Containing Catalysts for Olefin Hydration

An olefin hydration catalyst and method for producing same is provided. The olefin hydration catalyst can be prepared by contacting a niobium containing compound with a strong Bronsted acid, such as sulfuric or phosphoric acid, to produce niobium oxo sulfate or niobium oxo phosphate nanoparticles. The nanoparticles can be separated, dried and utilized in a reactor for the hydration of olefins to their corresponding alcohols.

Owner:SAUDI ARABIAN OIL CO

Efficient and selective chemical recycling of carbon dioxide to methanol, dimethyl ether and derived products

ActiveUS7608743B2Avoid emissionsElectrolysis componentsOxygen compounds purification/separationFlue gasExhaust fumes

An efficient and environmentally beneficial method of recycling and producing methanol from varied sources of carbon dioxide including flue gases of fossil fuel burning powerplants, industrial exhaust gases or the atmosphere itself. Converting carbon dioxide by chemical or electrochemical reduction secondary treatment to produce essentially methanol, dimethyl ether and derived products.

Owner:UNIV OF SOUTHERN CALIFORNIA

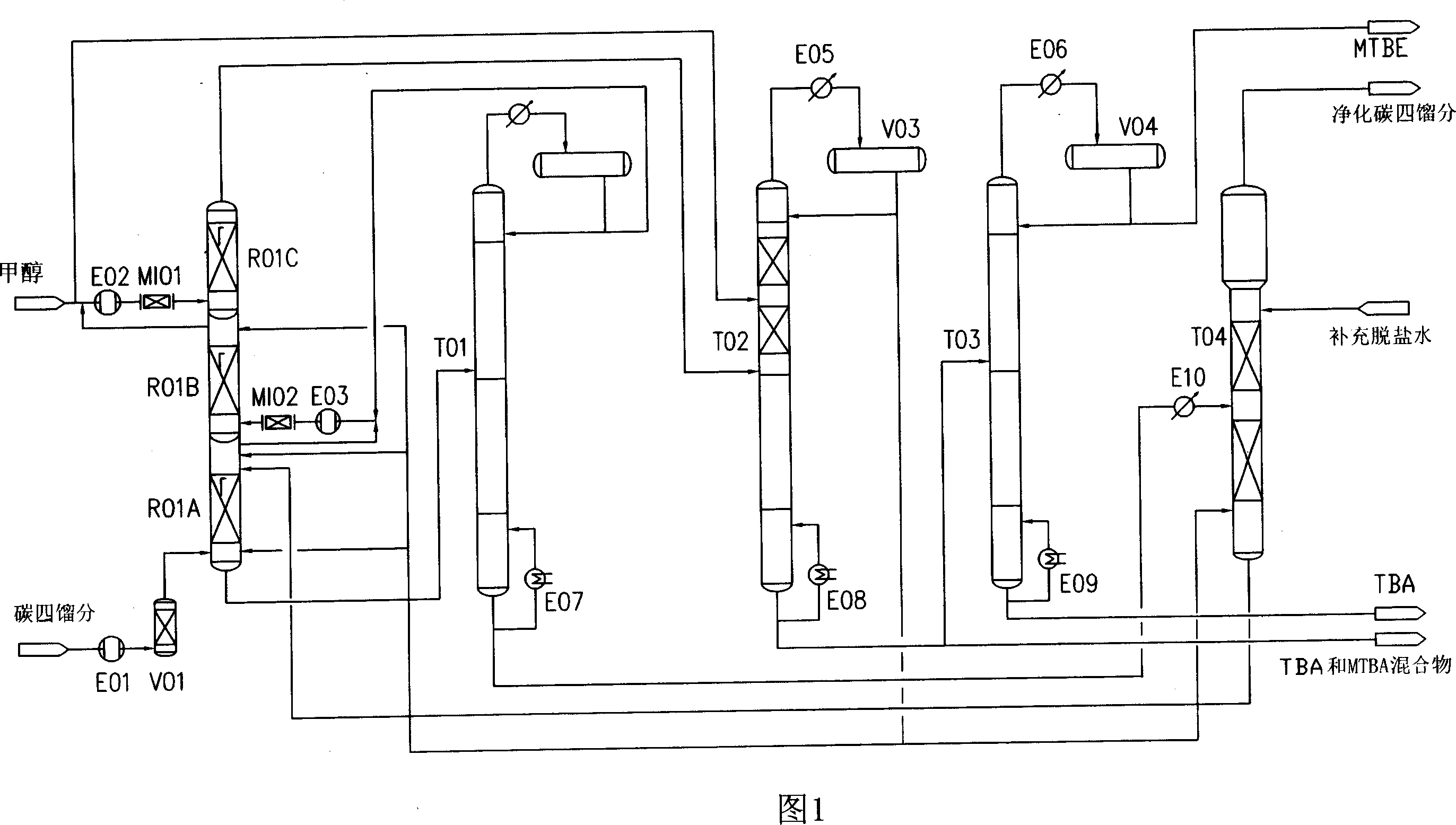

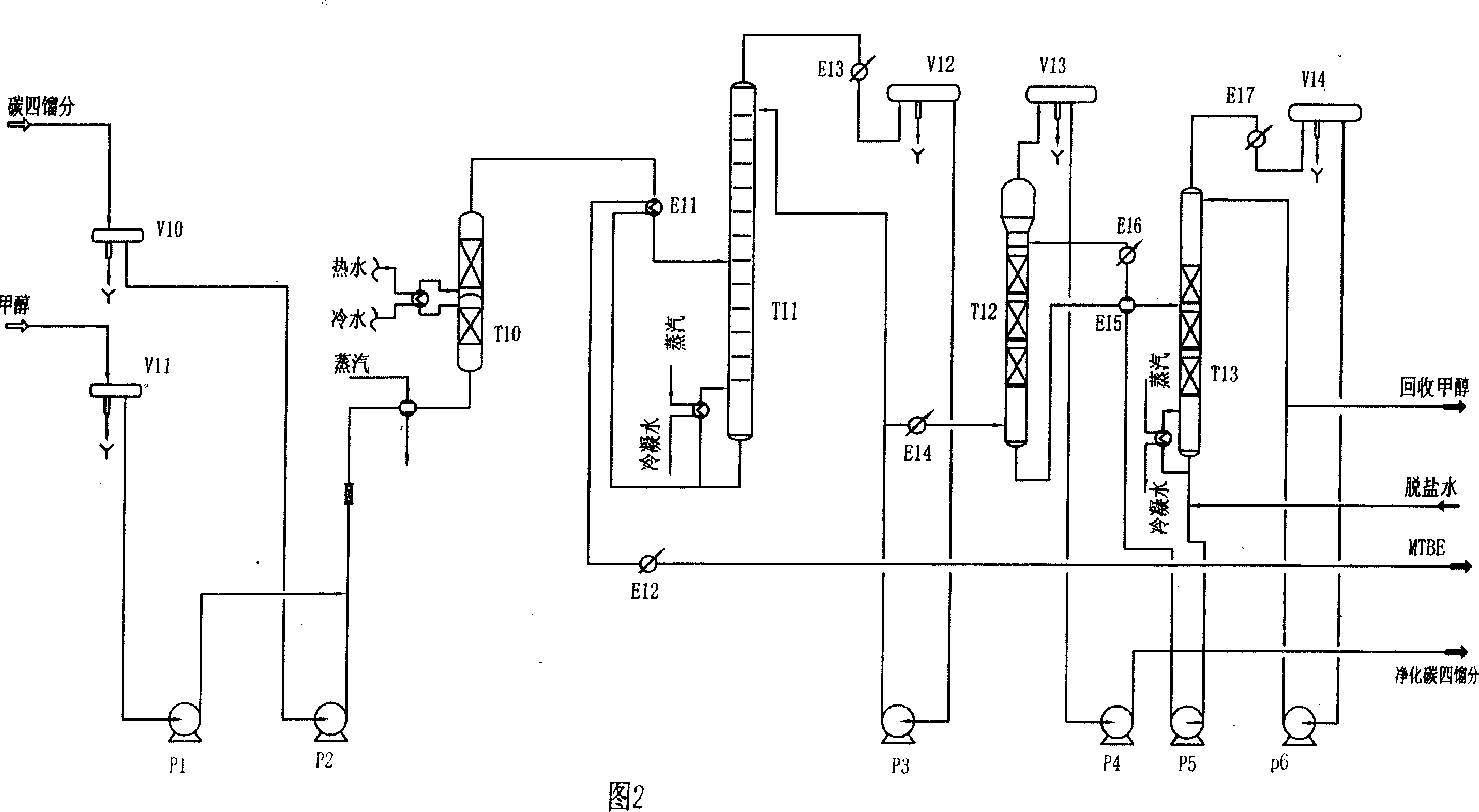

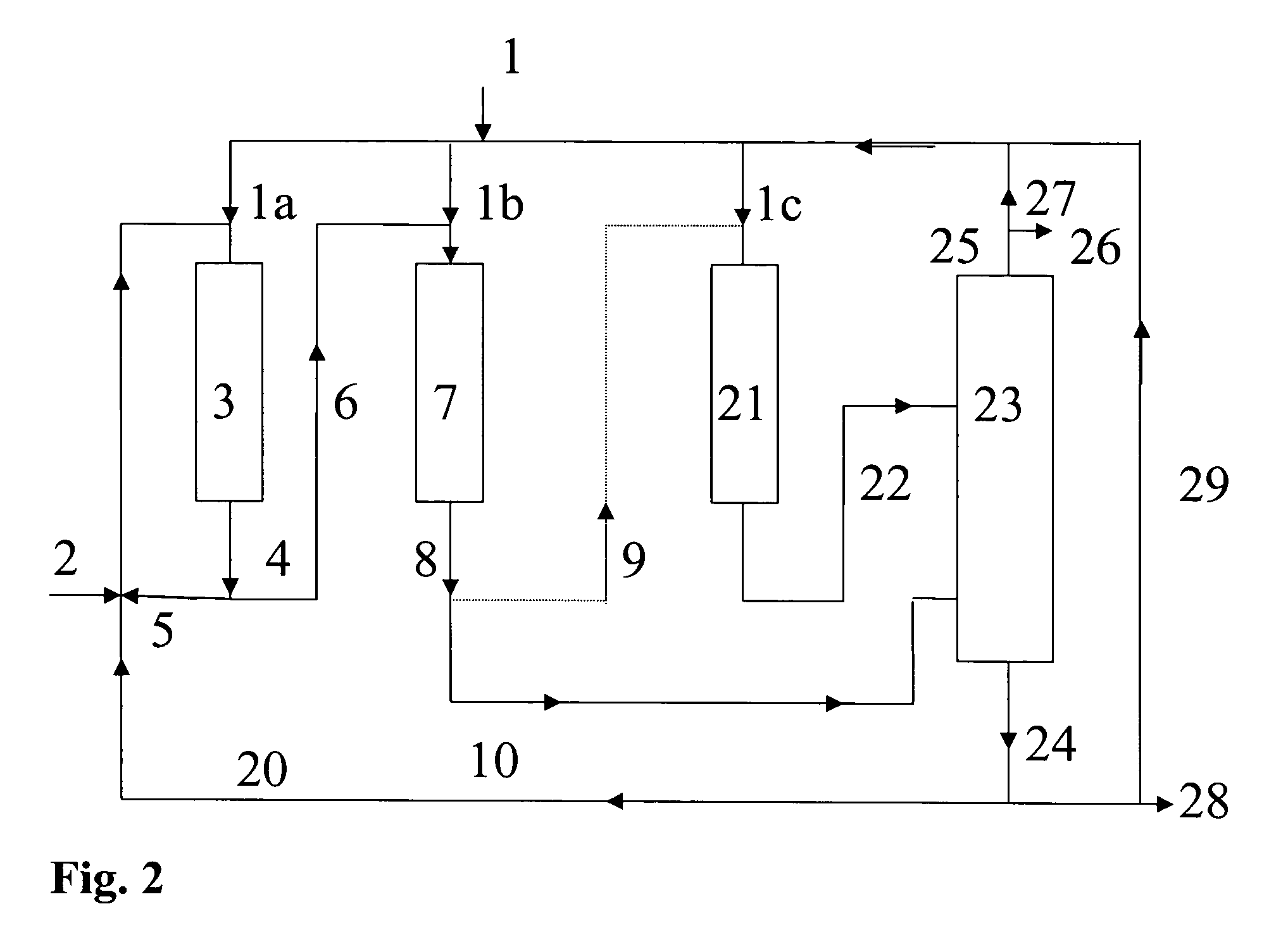

Phrcess of coproducing methyl tert-butyl ether and tert-butyl alcohol

InactiveCN101020622ASave energyLess investmentPreparation by hydroxy group additionEther preparation by compound additionMethanol waterMethyl t-butyl ether

The present invention relates to process of co-producing methyl tert-butyl ether and tert-butyl alcohol with isobutene and methanol in C4 fraction. The present invention features that two kinds of product are produced in an identical equipment with reduced investment, and that separation is completed through several reactions, resulting in simplified equipment and facilitated separation.

Owner:西安道特石化工程有限公司

Olefin Hydration Process Using Oscillatory Baffled Reactor

ActiveUS20160115107A1Organic compound preparationChemical/physical/physico-chemical reactor detailsLinear motionEngineering

A butanol production system and method for producing refined mixed butanols includes an internal baffle single pass reactor having an internal fluid conduit defined by an internal wall. The internal fluid conduit contains a process fluid comprising water, mixed butenes and mixed butanols, to form a crude product. Internal flow baffles are located along a length of the internal fluid conduit. Baffled cells are defined at an outer diameter by the internal wall and at ends by the internal flow baffles. A separation system separates water and mixed butenes from the crude product to produce refined mixed butanols. An oscillator assembly is coupled to the internal baffle single pass reactor and has a reciprocating oscillator head selectively movable in a back and forth linear motion, and in communication with the process fluid such that the process fluid undergoes a general sinusoidal movement along the internal baffle single pass reactor.

Owner:SAUDI ARABIAN OIL CO

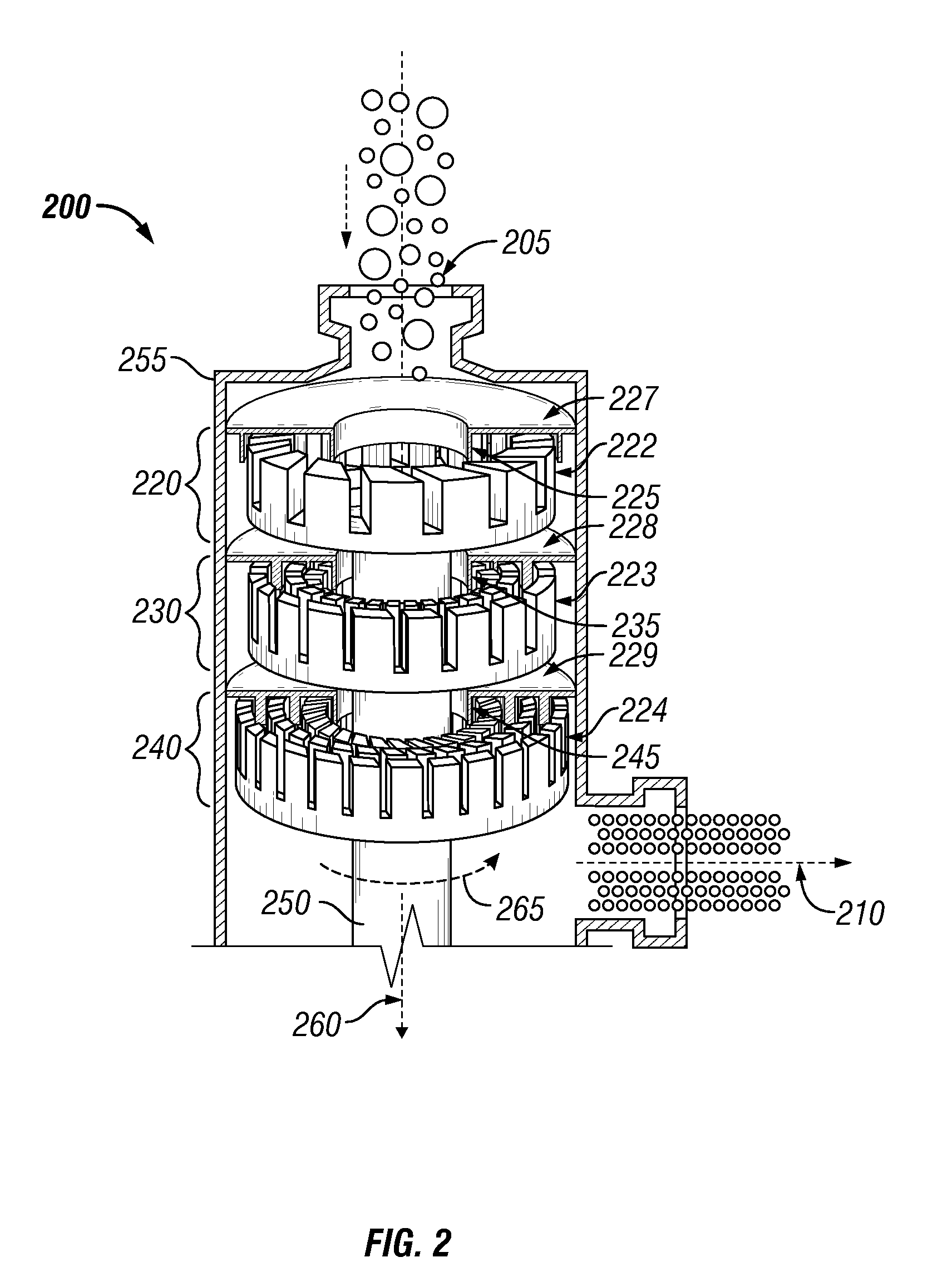

High shear rotary fixed bed reactor

InactiveUS20100004419A1Low costReduce usageTransportation and packagingRotary stirring mixersFixed bedHomogeneous catalysis

A reactor comprising at least one contact surface made from, coated with, or impregnated by a catalyst, wherein the contact surface comprises a sintered metal or a ceramic, and wherein the reactor is configured to subject a reactant stream to shear. A system for carrying out a heterogeneously catalyzed reaction, the system comprising a reactor as described above and a pump configured for delivering reactants to the at least one reactor. A method for carrying out a heterogeneously-catalyzed reaction by introducing reactants into a reactor comprising at least one contact surface made from, coated with, or impregnated by a catalyst under conditions which promote production of a desired product, wherein the contact surface comprises a sintered metal or a ceramic, and forming a dispersion of reactants within the reactor, wherein the dispersion comprises droplets or gas bubbles of reactant with an average diameter of less than about 5 μm.

Owner:HRD CORP

Obtaining tert-butanol

InactiveUS7026519B2Speed up the conversion processImprove viabilityOrganic compound preparationOrganic chemistry methodsHydrocarbon mixturesChemistry

The invention relates to a process for preparing tert-butanol (TBA) by reacting isobutene-containing hydrocarbon mixtures with water over acidic solid catalysts in a plurality of reactors, wherein the conversion is increased upstream of the last reactor by removing a portion of the TBA present in the reaction mixture.

Owner:EVONIK DEGUSSA GMBH

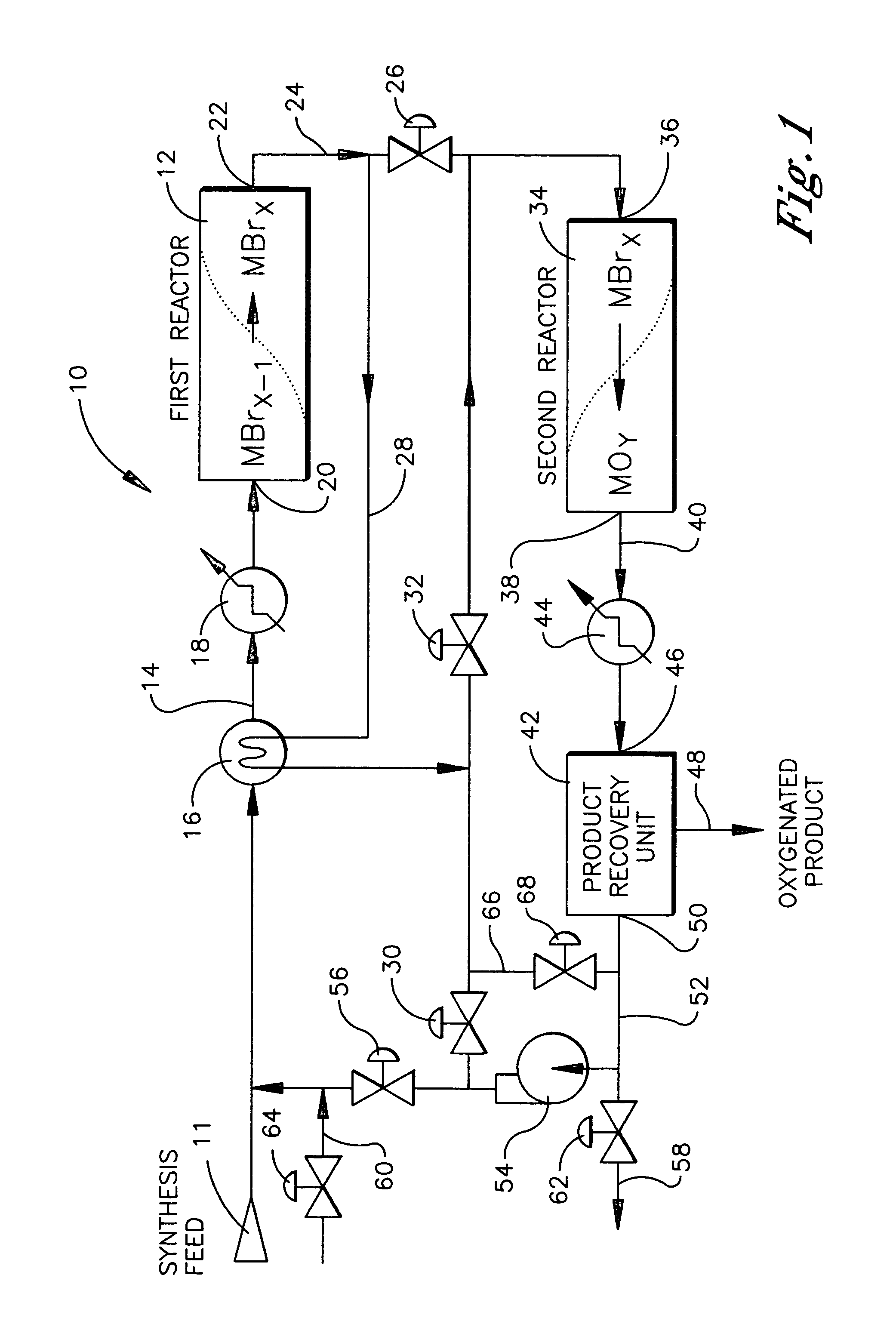

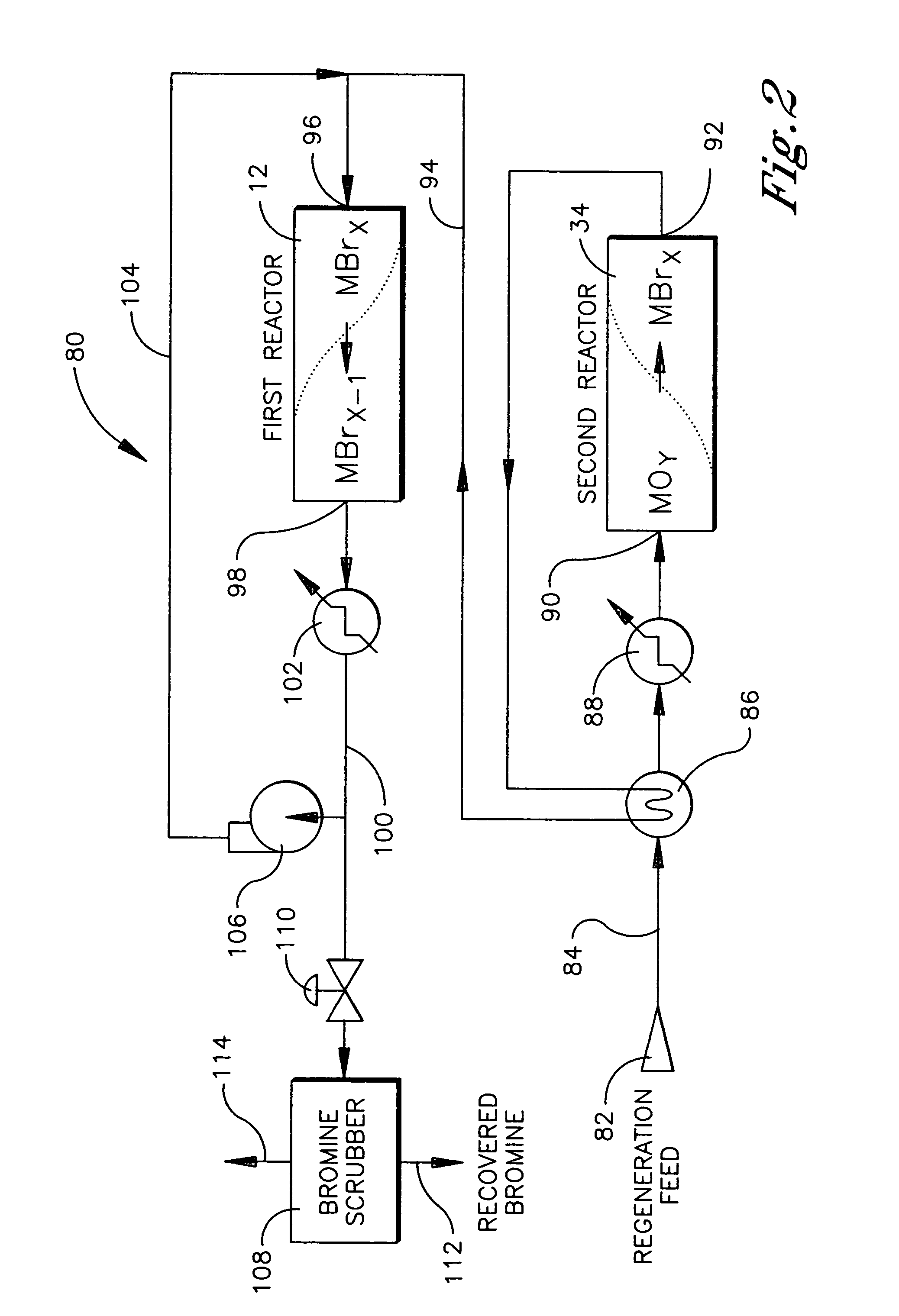

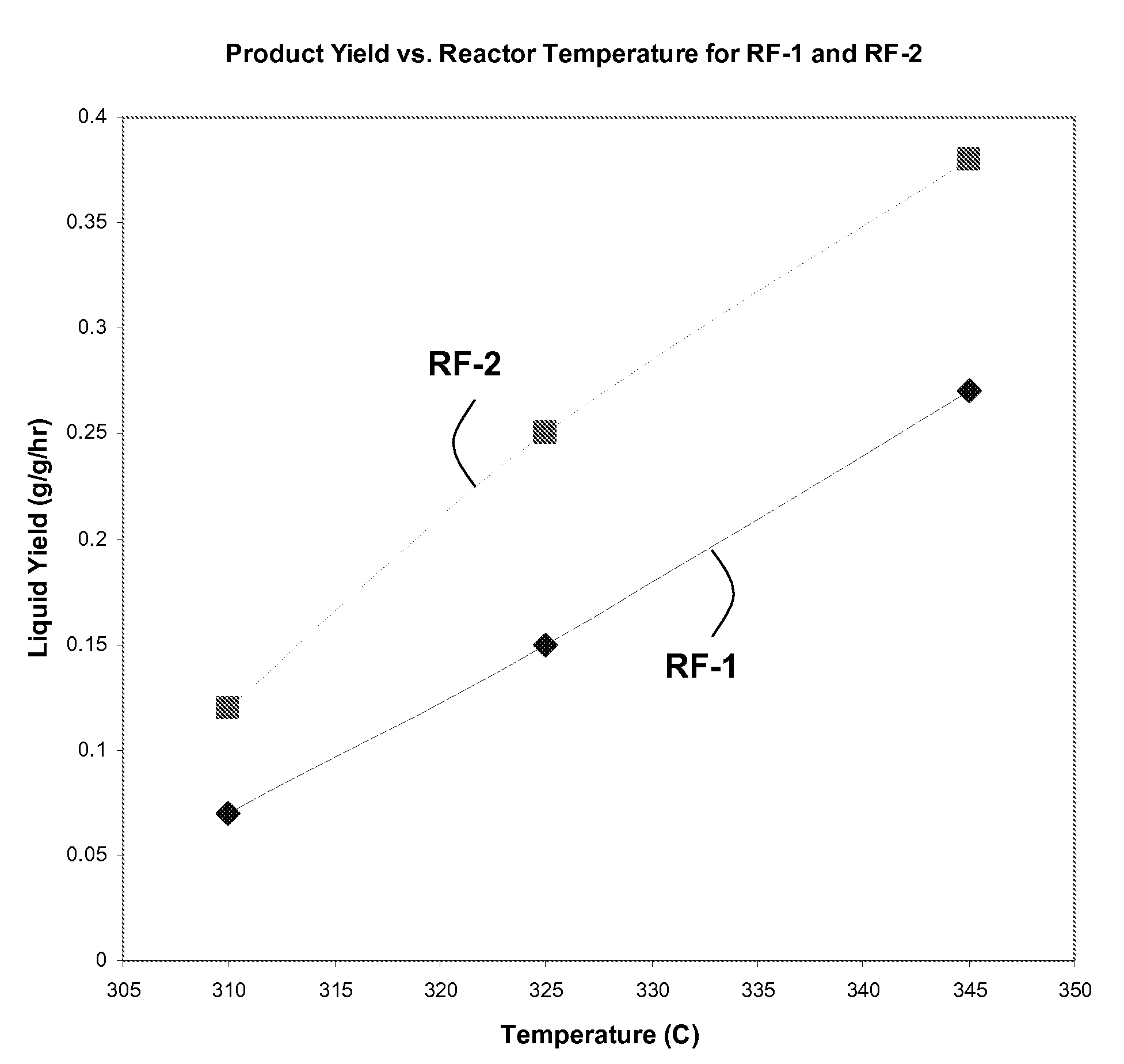

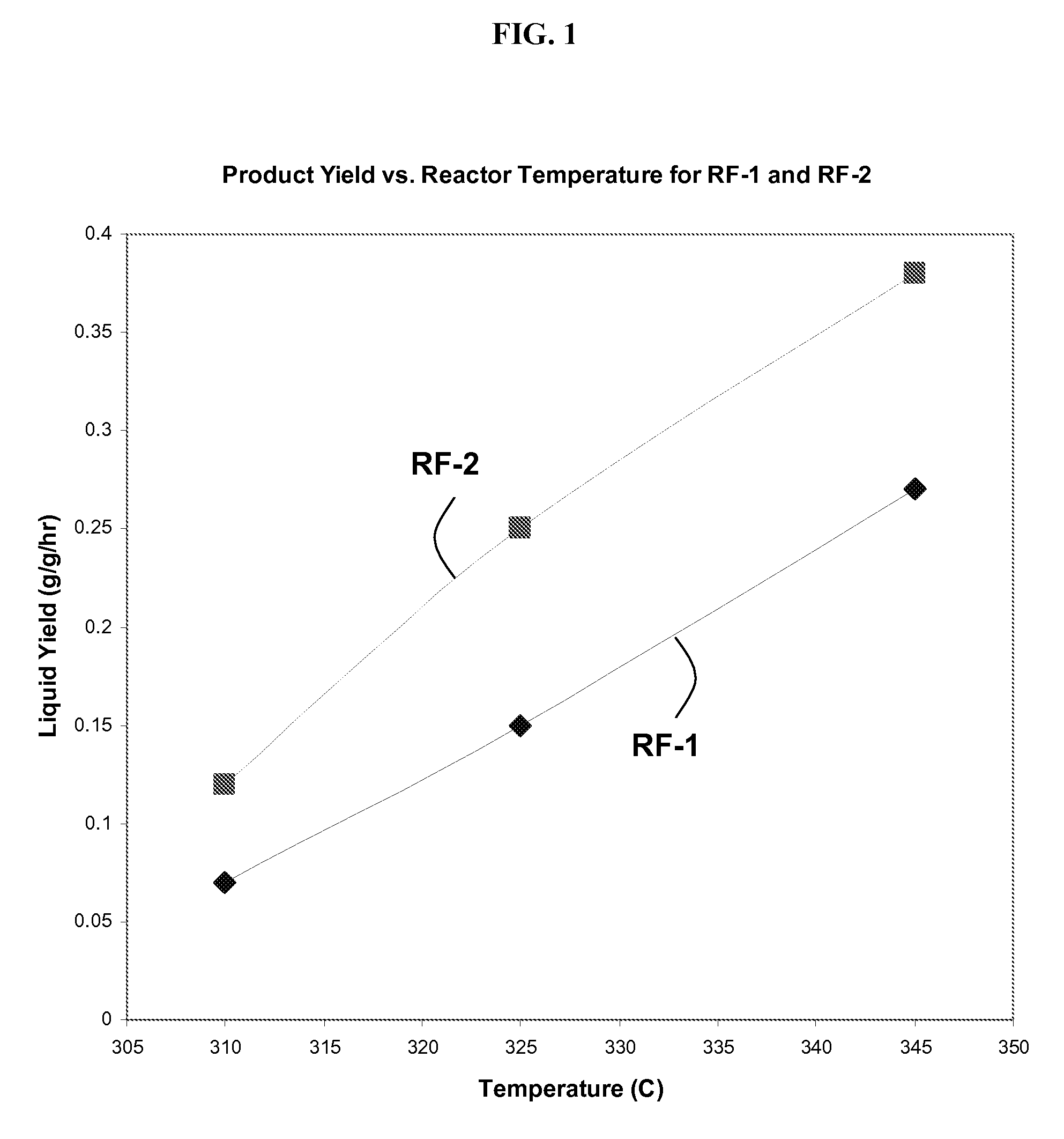

Conversion of alkanes to oxygenates

Owner:MARATHON OIL CO

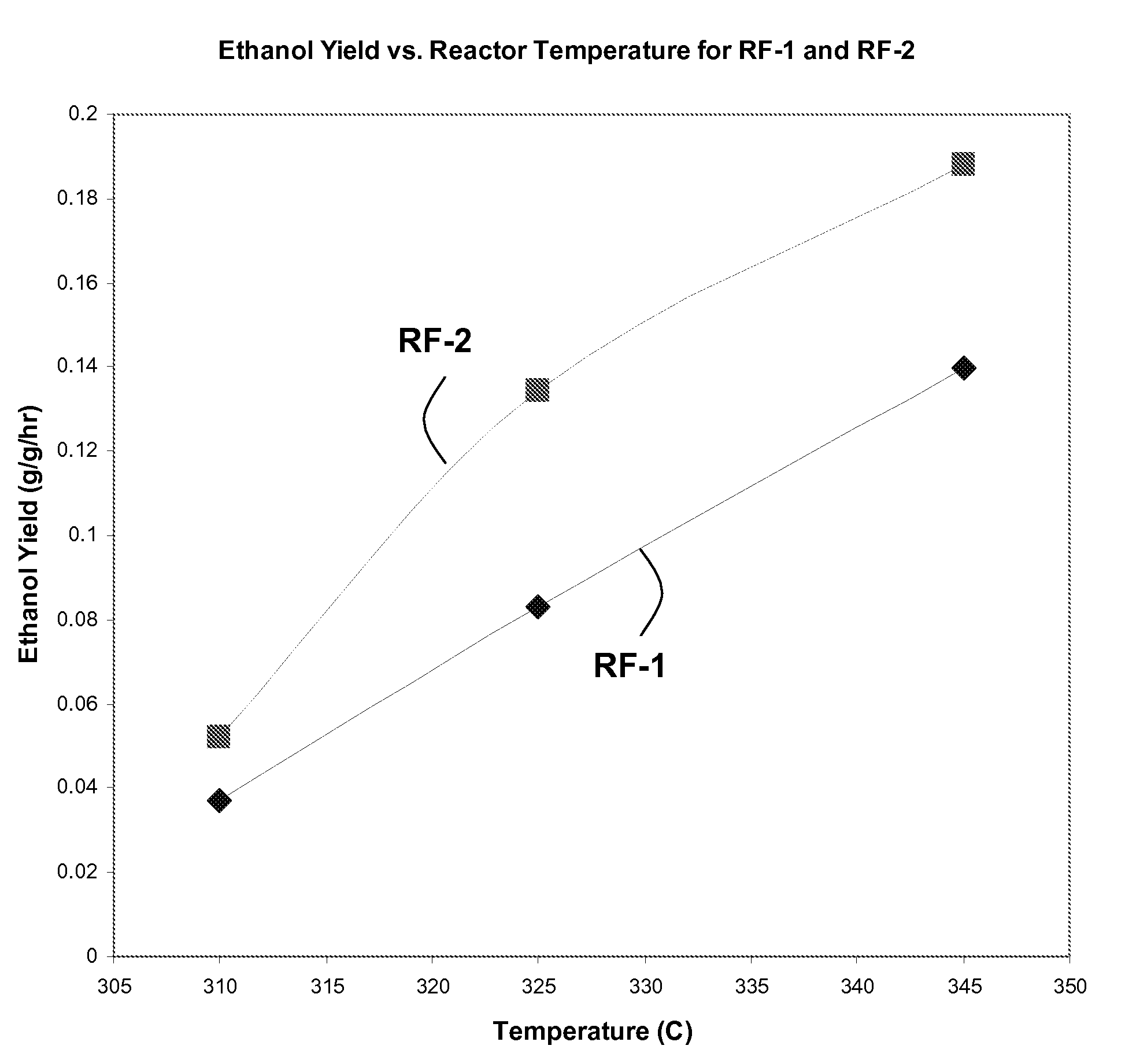

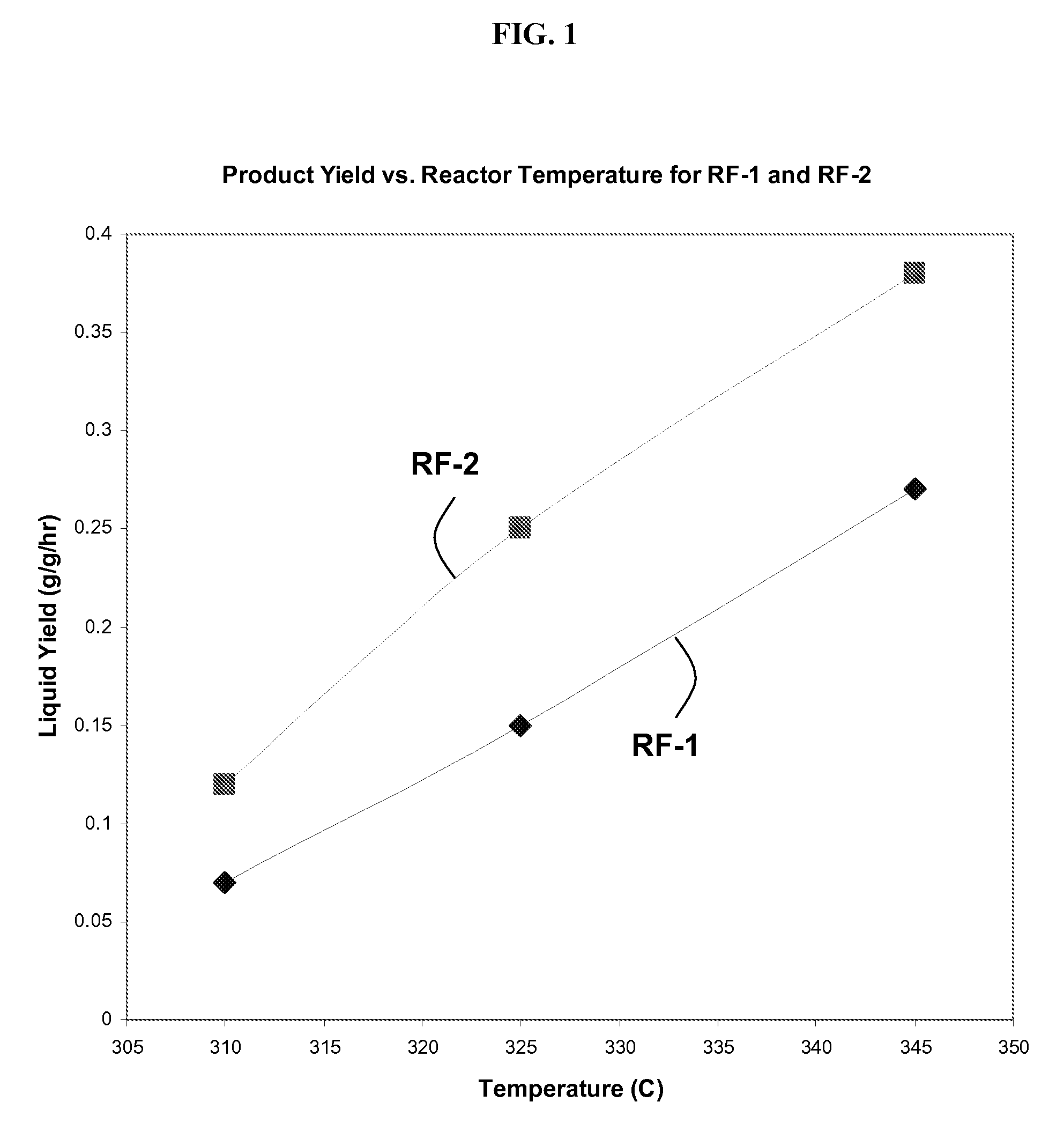

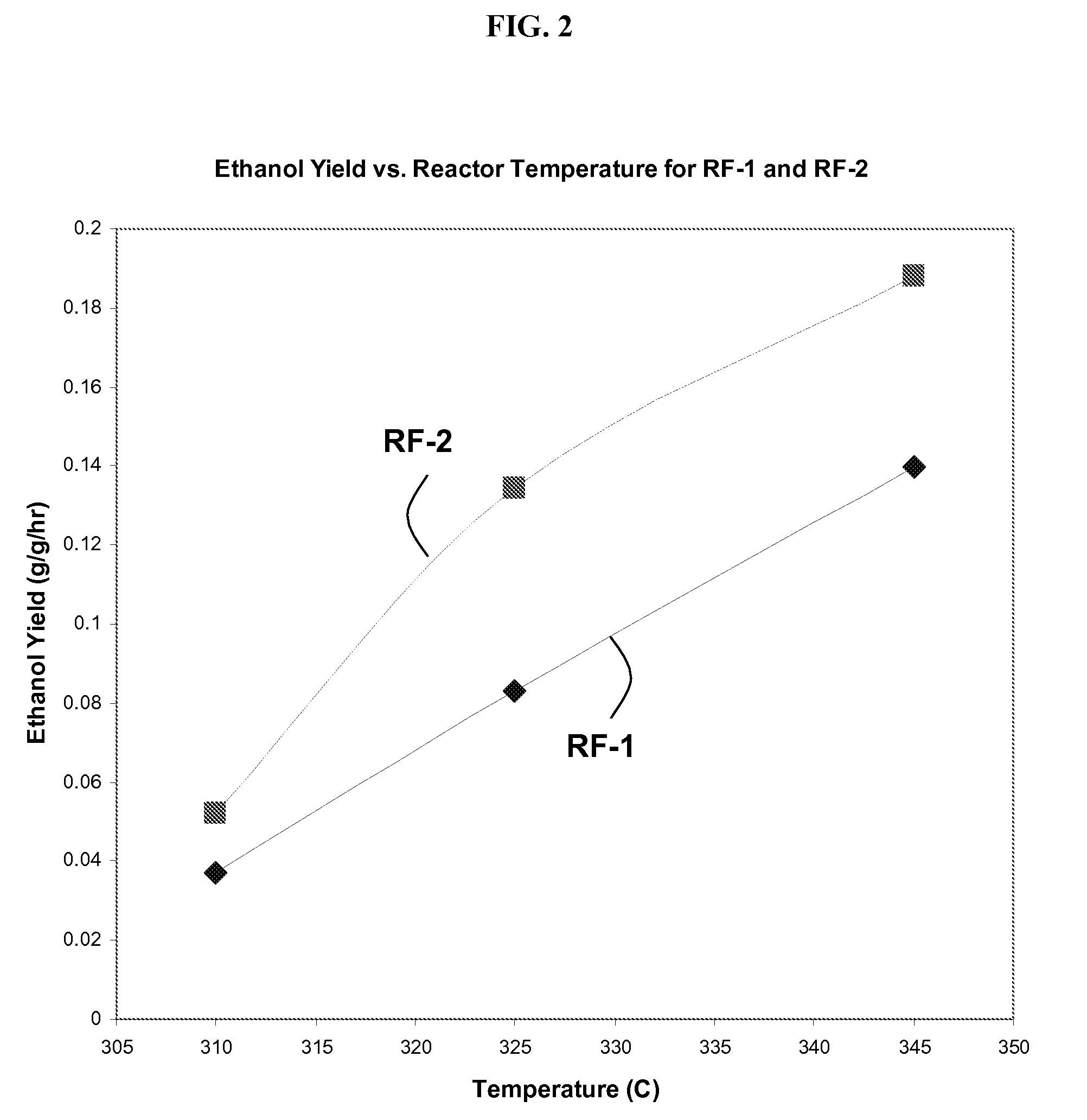

Cobalt-molybdenum sulfide catalyst materials and methods for ethanol production from syngas

The present invention provides methods and compositions for the chemical conversion of syngas to alcohols. The invention includes catalyst compositions, methods of making the catalyst compositions, and methods of using the catalyst compositions. Certain embodiments teach compositions for catalyzing the conversion of syngas into products comprising at least one C1-C4 alcohol, such as ethanol. These compositions generally include cobalt, molybdenum, and sulfur. Preferred catalyst compositions for converting syngas into alcohols include cobalt associated with sulfide in certain preferred stoichiometries as described and taught herein.

Owner:ALBEMARLE CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com