Patents

Literature

469 results about "Turpentine Oil" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The oily fluid obtained by the distillation of various pine resins. Turpentine is used as a solvent, industrial ingredient, and medicinal ingredient.

Externally applied antibacterial and antiphlogistic medicament and preparation method thereof

InactiveCN102114216AHas inhibitory effectImprove antibacterial propertiesAntibacterial agentsInorganic boron active ingredientsSide effectPeppermints

The invention discloses an externally applied antibacterial and antiphlogistic medicament and a preparation method thereof, and relates to an antiphlogistic medicament and the preparation method thereof. The antiphlogistic medicament is processed and prepared by the following raw materials: peppermint, fineleaf schizonepeta herb, divaricate saposhnikovia root, rhubarb, amur corktree bark, common andrographis herb, fructus forsythiae, baical skullcap root, Philippine violet herb, radix salviae miltiorrhizae, lightyellow sophora root, dahurian angelica root, tree peony bark, aloe, membranous milkvetch root, indigowoad leaf, sweet wormwood herb, Chinese gentian, sinkiang arnebia root, liquoric root, Chinese gall, golden thread, cassia seed, indigowoad root, honeysuckle flower, chrysanthemum, hawthorn fruit, sessile stemona root, argy wormwood leaf, common cnidium fruit, borneol powder, borax powder, honey, propanetriol, propanediol, Tween-60, OP10, castor oil and turpentine oil. The product has good antibacterial and antiphlogistic effects, bacteria can not generate an antibody and can not generate the resistance to the medicament, the bacteria can be prevented from being mutated to superbacteria, and the antiphlogistic medicament has no toxicity or side effects and is safe to use.

Owner:郑延明

Process for preparing levogyrate alpha-terpineol

InactiveCN1482113AIncrease temperatureReduce dosagePreparation by hydroxy group additionAlcoholTurpentine Oil

The present invention provides one-step levo-alpha-terpineol synthesizing process, in which turpentine oil with alpha-pinene as main component is used as the material, low-carbon alcohol or ketone assolvent and modified strong acid styrene cationic exchange resin as catalyst and the catalytic hydration is completed in a fixed bed reactor. It has catalyst / alpha-pinene weight ratio of 1 to 1-10, alpha-pinene / water molar ratio of 1 to 1.1-2, water / solvent molar ratio of 1 to 0.1-0.9, reaction temperature of 70-100 deg.c, reaction period of 5-13 hr, alpha-pinene converting rate over 95 % and levo-alpha-terpineol yield over 65 %.

Owner:GUANGXI RES INST OF CHEM IND CO LTD

Analgesic and refreshing herbal composition and a process for preparing the same

The invention provides an analgesic and refreshing herbal composition useful as dentrifrices, said composition comprising 50-60% Wt. of betle extract (from Piper betle leaves); 40-50% Wt. of one or more group I essential oil selected from Levender officinal, Dementholised oil (ex-Mentha arvensis), Fennel oil and Ocimum gratissimum; 3.5-6% Wt. of one or more group II essential oils and their isolates selected from Ocimum Sanctum, Pulegone (ex Mentha pulegonium), Carvone (ex. Dill seed) and Menthol (ex. Mentha arvensis); 1-5% Wt. of one or more group III essential oils selected from Camphor, turpentine oil, Cedarwood oil and Safrole oil, along with 0.5-2% Wt. of Thymol and 0.25-1% Wt. of preservative / antioxidant, and a process for preparing the composition.

Owner:COUNCIL OF SCI & IND RES

Adhesive removing agent as well as preparation and using methods thereof

InactiveCN105199877AEasy to useEfficient removalOrganic non-surface-active detergent compositionsCleaning using liquidsKeroseneHexamethylenetetramine

The invention discloses an adhesive removing agent as well as preparation and using methods thereof. The adhesive removing agent comprises turpentine oil, rosin water, 120# gasoline, kerosene, benzene, methylbenzene, dimethylbenzene, acetone, urotropine, oxalic acid, ethyl acetate, butyl acetate and ethyl alcohol. The turpentine oil, the rosin water, the 120# gasoline and the kerosene are evenly mixed firstly, the benzene, the methylbenzene and the dimethylbenzene are sequentially added, the mixture is evenly mixed, the urotropine is added after complete dissolution, then the oxalic acid, the ethyl acetate and the butyl acetate are added sequentially, the acetone and the ethyl alcohol are added finally, and the mixture is evenly mixed. A plastic layer on the surface of an object is removed by hand, the adhesive removing agent is sprayed on the surface of the adhesive object and soaks the object, the adhesive is wiped with rag, and the object is washed with clear water. The adhesive removing agent can effectively remove the adhesive object and thoroughly remove adhesive objects such as signboards, adhesive tapes and the like, the using method is simple, heating is not required, and the adhesive removing agent can be used through brushing or spraying at the normal temperature and is short in washing time, good in removal effect, environment-friendly and efficient.

Owner:朱建权

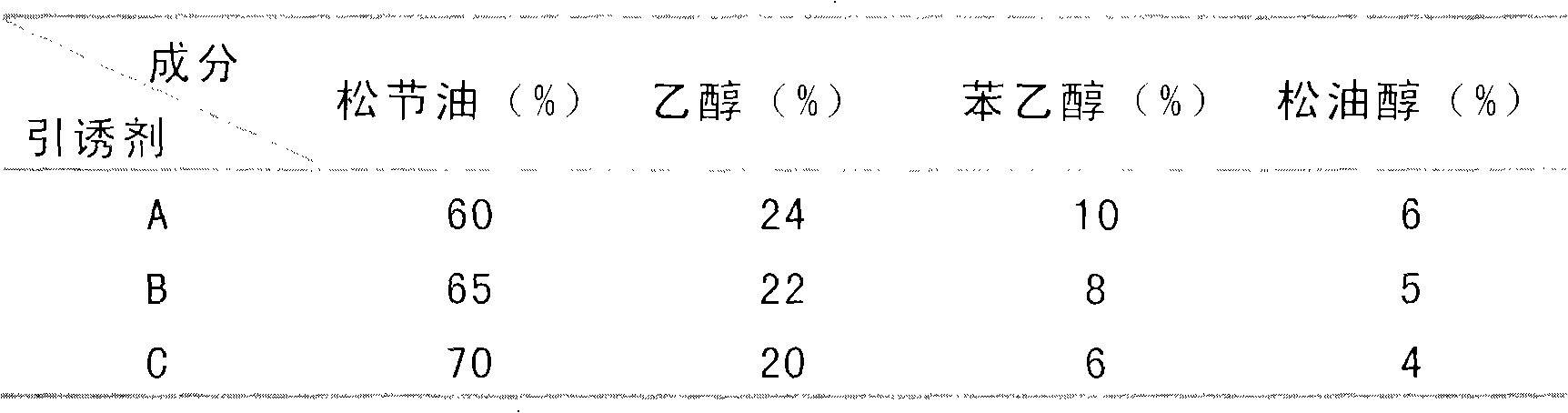

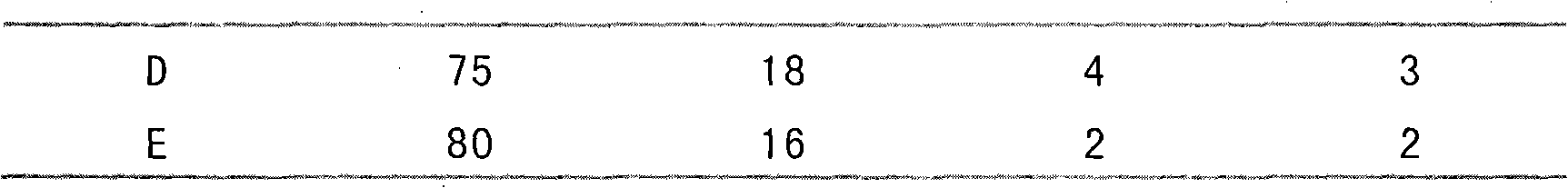

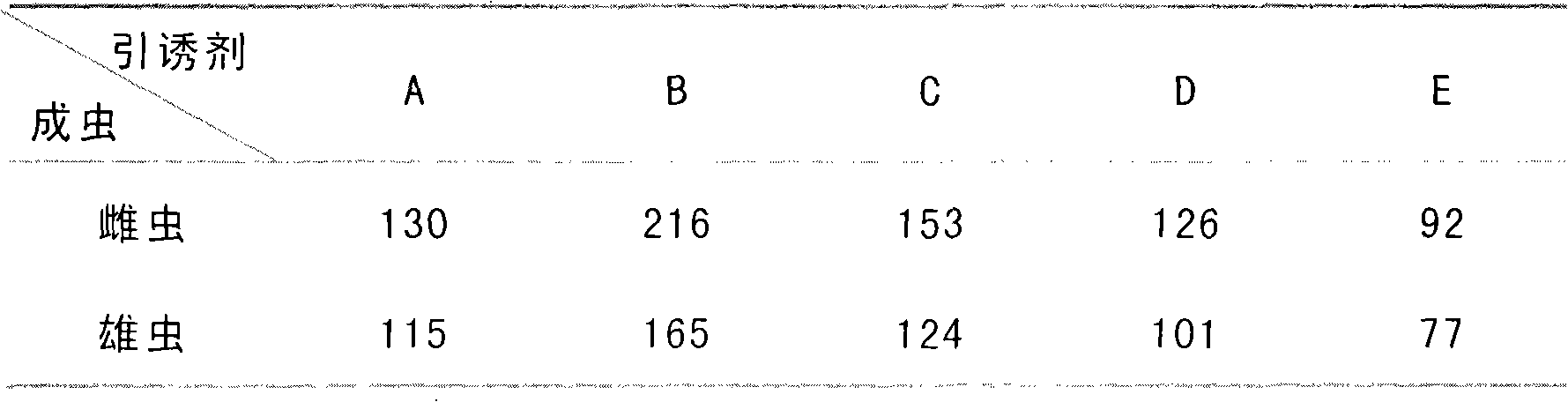

Monochamus alternatus imago attractant

InactiveCN101564051AGood trapping effectStrong ability to seduceBiocidePest attractantsForest industryAdditive ingredient

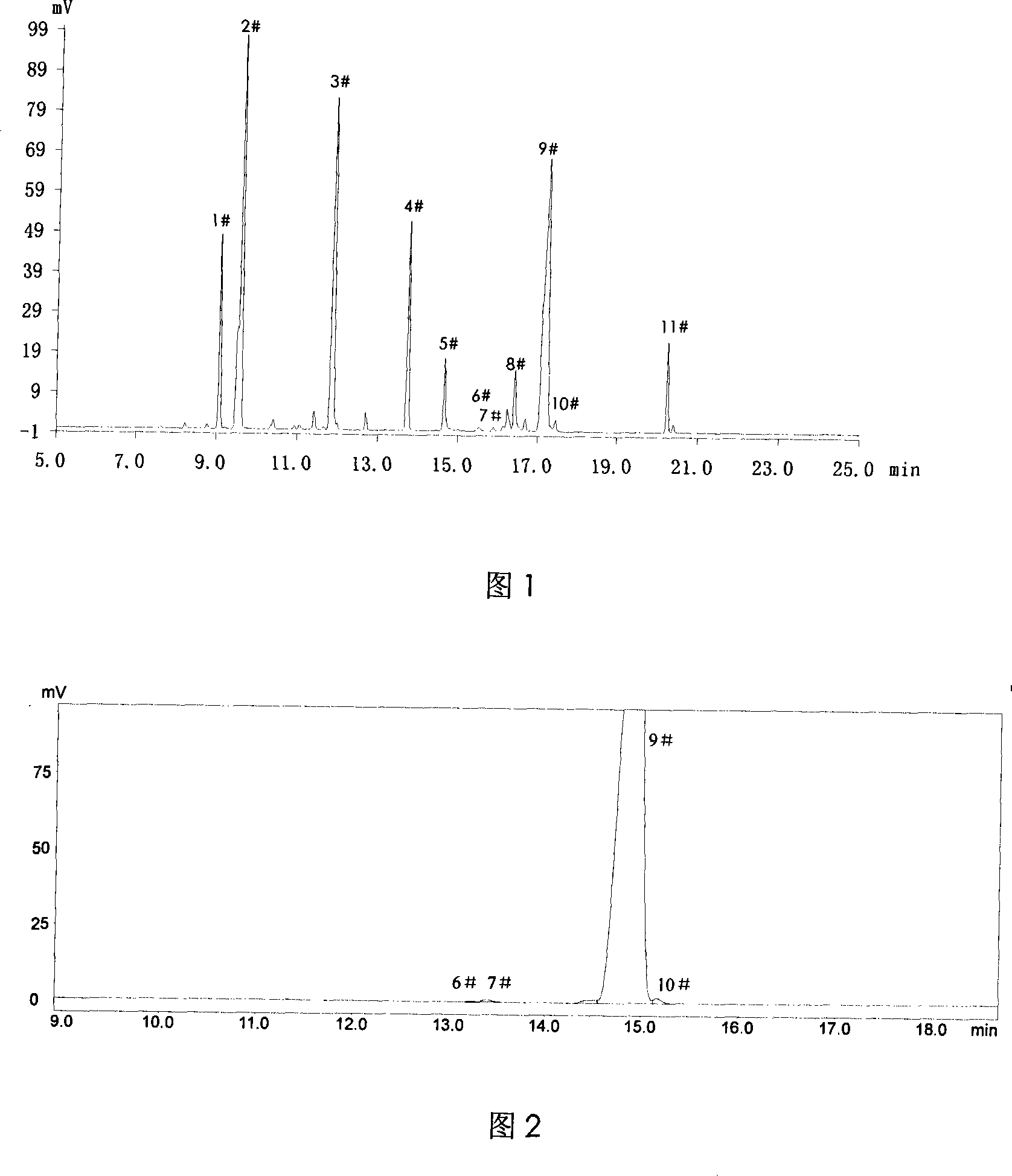

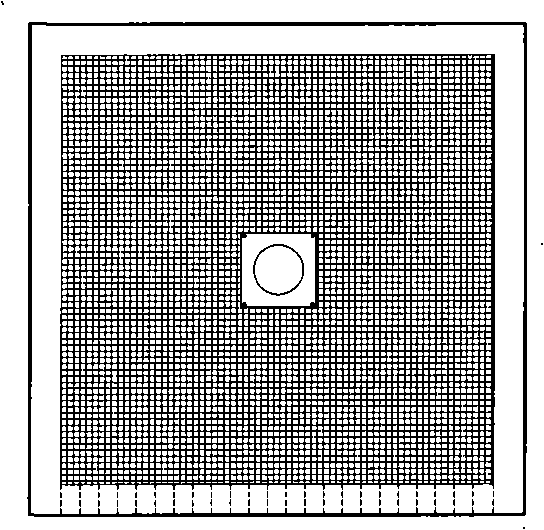

The invention relates to a monochamus alternatus imago attractant which belongs to the technical field of pest control. The monochamus alternatus imago attractant contains the following components according to volume percent: 60-80 percent of turpentine oil, 16-24 percent of ethanol, 2-10 percent of phenethyl alcohol and 2-6 percent of terpilenol. The monochamus alternatus imago attractant contains the following ingredients according to volume percent: 24.64-32.86 percent of Alpha-pinene, 22.91-30.55 percent of Beta-pinene, 6.51-8.68 percent of 3-carene, 2.97-3.96 percent of Beta-phellandrene, 0.74-0.99 percent of terpinolene, 0.62-0.83 percent of laurene, 1.60-2.13 percent of others, 16-24 percent of ethanol, 2-10 percent of phenethyl alcohol and 2-6 percent of terpilenol. The monochamus alternatus imago attractant has remarkable attracting effect to both monochamus alternatus female worms and male worms, and stronger attracting effect to the male worms; and also has certain attracting effect to other coleopteran forestry pests. The invention has the advantages of high efficiency, environmental protection, simple and convenient preparation, low cost and good durability, can be used for prediction and control in monochamus alternatus forest with the control effect up to 53.59-67.30 percent and can effectively control the population density in the monochamus alternatus forest and restrains the spread and the extension of pine wood nematode disease.

Owner:YUNNAN AGRICULTURAL UNIVERSITY

Wood wax oil and preparation technology thereof

The invention discloses wood wax oil for maintenance and decoration of buildings, furniture and the like and preparation technology thereof. The wood wax oil contains wood oil, linseed oil, catalpa oil, perilla oil, pine oil, castor oil, rosin modified resin, bee wax or wood wax and turpentine oil, wherein the content of each component is 5 to 10 percent; and each component is a pure natural extract. The preparation technology for the wood wax oil comprises the following steps: polymerizing the wood oil, the linseed oil, the catalpa oil, the perilla oil, the pine oil, the castor oil, the rosin modified resin and the bee wax or the wood wax at a high temperature of between 290 and 300 DEG; adding the turpentine oil into the polymerized product to dilute; filtering the mixture; and adding a drier into the filtered product to adjust. The wood wax oil has the advantages of natural health, good durability and permeability, and recoverability.

Owner:董学明

In situ extraction of hydrocarbons from hydrocarbon-containing materials

Owner:GREEN SOURCE HLDG LLC

Method for catalyzing hydrogenation of alpha-pinene to prepare cis-pinane

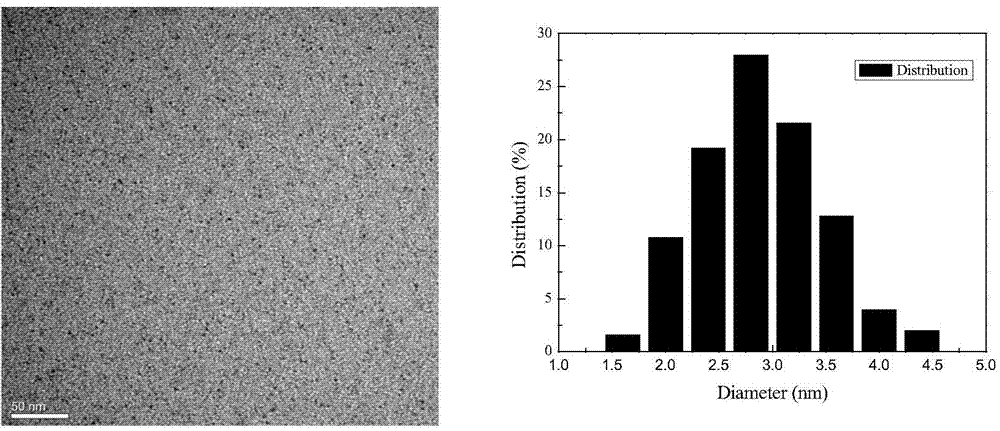

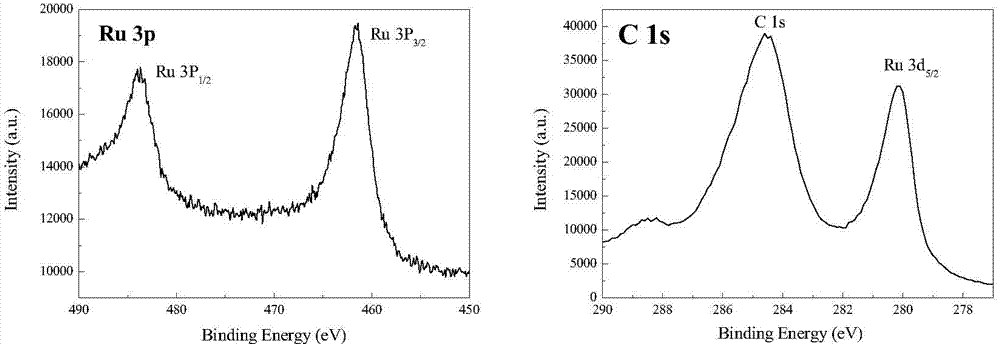

ActiveCN104844408AHigh catalytic activityHigh selectivityOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbon by hydrogenationPolymer sciencePtru catalyst

The invention relates to a method for catalyzing hydrogenation of alpha-pinene to prepare cis-pinane to efficiently prepare cis-pinane by virtue of a metal nanoparticle hydrosol with stable polymers and belongs to the field of preparation and application of catalysts. A catalyst adopted in the invention is a ruthenium nanoparticle hydrosol which is prepared by virtue of hydrogenation reduction in a water medium by taking P123 (a polyoxyethylene-polypropylene oxide-polyoxyethylene triblock copolymer) as a stabilizer. The ruthenium nanoparticle hydrosol with stable polymers can be used for catalyzing hydrogenation of alpha-pinene so as to prepare cis-pinane with high activity, high selectivity and high stability under a mild condition. According to the preparation method provided by the invention, the metal nanoparticle hydrosol with stable polymers is used for the catalytic hydrogenating process of alpha-pinene for the first time. Preparation of the catalyst and catalytic hydrogenation are mild in reaction condition, environmentally friendly and free of any organic solvents. The catalyst has a remarkable recycling performance, thereby providing an efficient method for high added value utilization of oil of turpentine.

Owner:QINGDAO UNIV OF SCI & TECH

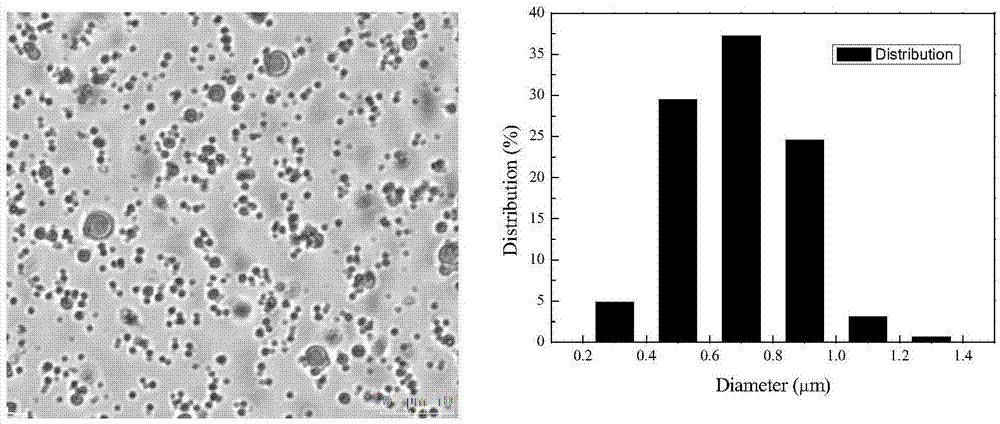

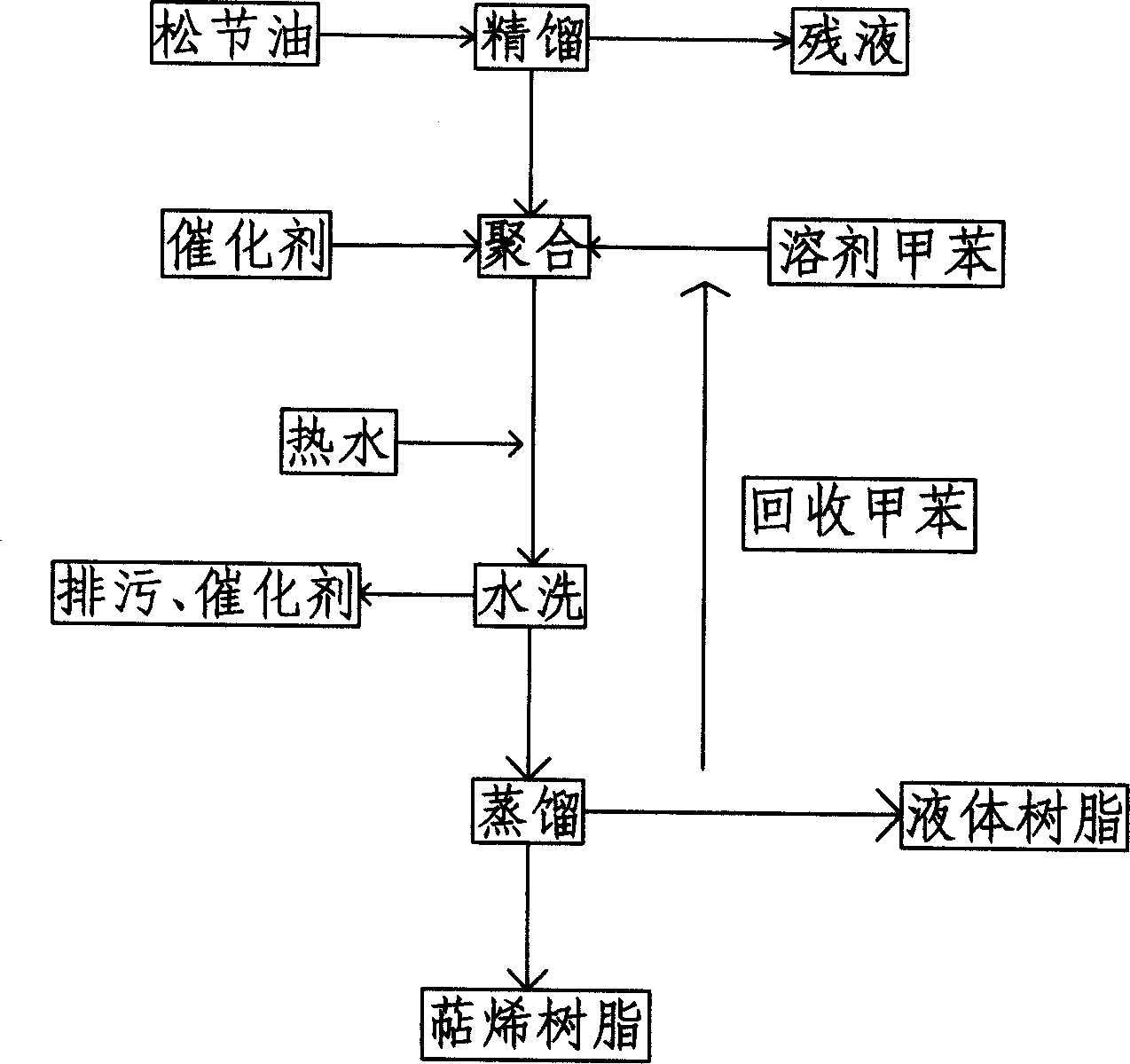

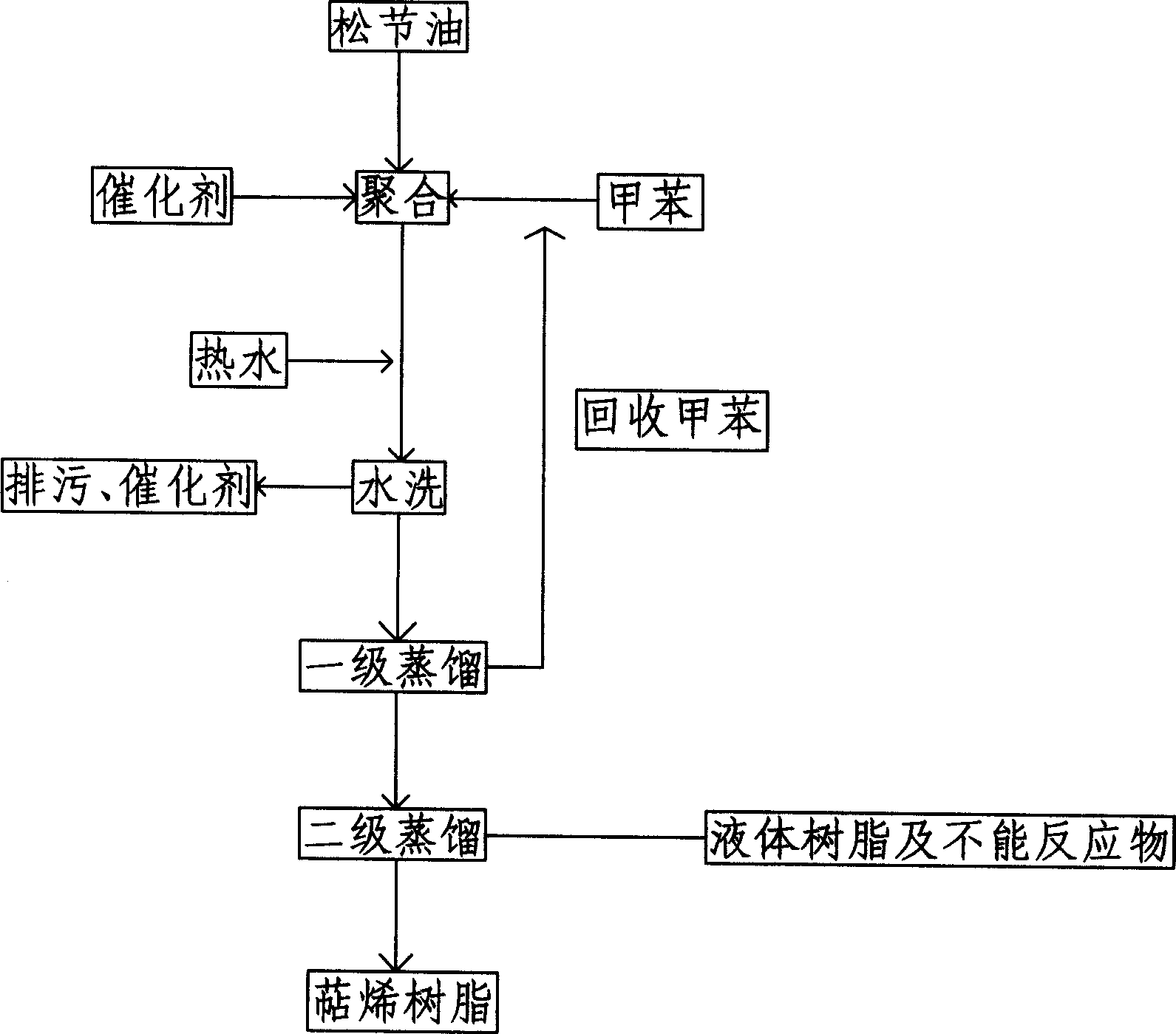

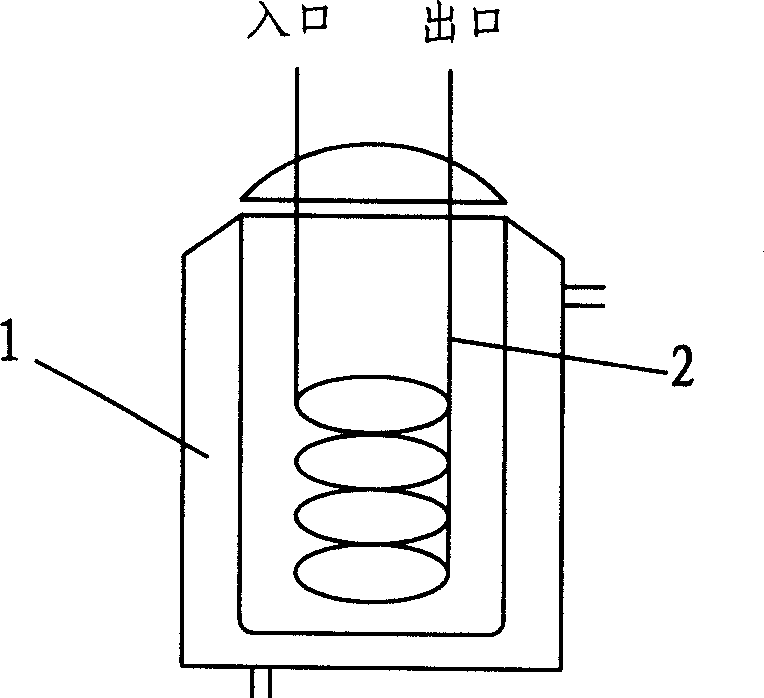

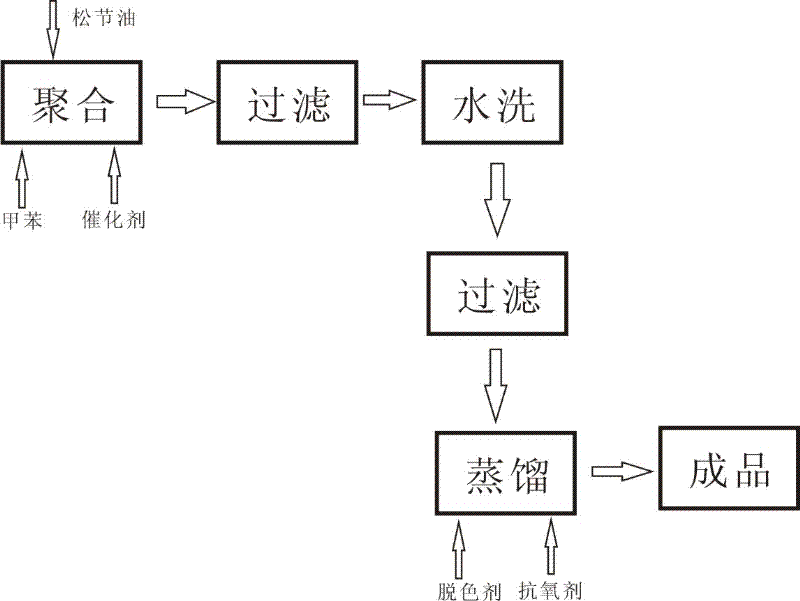

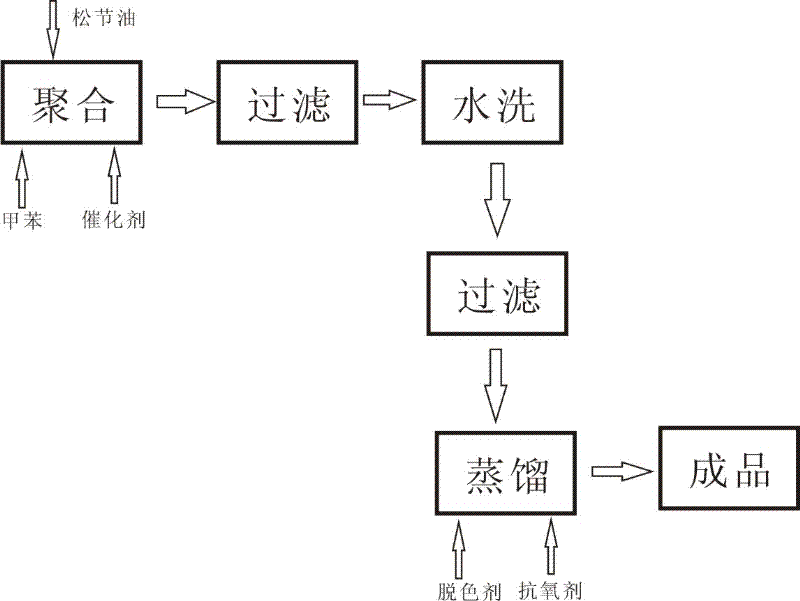

Production method of terpene resin

InactiveCN1631916AMild and even reactionThe reaction temperature fluctuation range is smallAluminium chlorideDistillation

A method for producing terpine resin has the steps follows: turpentine oil, toluene, catalyst aluminium chloride have polymerization in the wash the mixed outcome with hot water for draining the catalyst and waste out, then distil the outcome, recycle toluene and clear the liquid resin and the material which did not join the reaction in the course of distillation, then the toluene is made. The reactor includes enamel glass and inside cooling device which is steelless pipe groups filled with saturated salt solution of indoor temperature in the polymerization. The invention has friendly reaction, small fluctuating range of temperature, stable operation, productiving being raised by 20%, fewer equipments, low cost fir energy and production good economic benefit.

Owner:蓝运泉

Method of manufacturing high purity alpha-terpineol

ActiveCN101108788ALow costSimple operating conditionsPreparation by hydroxy group additionHydration reactionPhosphoric acid

The invention discloses a preparation method of the Alpha hyphen Terpinene with high purity, which comprises the following steps: first, synthesizing Alpha hyphen Terpinene: the turpentine oil or one of the Alpha hyphen pinene or Beta hyphen pinene of industrial grade is mixed with the organic solvent and the water and one or two or the mixture of the sulphuric acid, the phosphoric acid, the p-toluene sulfonic acid and the chloroactic acid or the macropore cation exchange resin are used ascatalysts to directly react with water to generate Alpha hyphen Terpinene reaction product; the generation of the Gamma hyphen Terpinene are reduced by the method of controlling the mixture ratio and the reaction temperature of the Terpinene, the organic solvent and the water to form the transparent homogeneous solution system; second, separating the Alpha hyphen Terpinene with high purity. The invention forms the transparent homogeneous solution system through the turpentine oil or one of the Alpha hyphen pinene or Beta hyphen pinene of industrial grade and the organic solvent and water, therefore effectively inhibiting the generation of the main impurity- Gamma hyphen Terpinene.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY +1

PET (polyethylene glycol terephthalate) color masterbatch

The invention belongs to the technical field of high polymer materials, and particularly provides PET (polyethylene glycol terephthalate) color masterbatch. The PET color masterbatch is prepared from components in parts by weight as follows: 30-60 parts of PET vectors, 3-12 parts of turpentine oil, 5-15 parts of an anti-blocking agent, 10-20 parts of a slipping agent, 10-20 parts of an antistatic agent, 10-25 parts of pigments, 2-5 parts of a nucleating agent, 5-10 parts of liquid soap, 6-12 parts of an antioxidant, 15-25 parts of a flame retardant, 10-15 parts of a moisture-proof additive, 5-15 parts of polydimethylsiloxane, 2-10 parts of an antibacterial agent, 5-8 parts of low-molecular-weight polyethylene wax and 5-10 parts of a flatting agent. The preparation process is simple, the cost is lower, and the prepared color masterbatch has good coloring effect and less environmental pollution.

Owner:天津毅兴彩科技有限公司

Method for reclaiming rosin and terebinth using resin plant residue waste liquor

InactiveCN101302402AReduce dosageLow costFatty/oily/floating substances removal devicesNatural resin processTurpentine OilRosin

The invention discloses a method for recovering rosin and turpentine oil through utilizing residual waste liquor. The technique of the method is the stream method. The working procedures of the method are dissolution, standing, clarification, pressure filtration of residues, distillation, and package of finished products; and a frame type filter is adopted during the working procedure of pressure filtration of the residues. The method has the advantages that: the residual waste liquor in the rosin factory is used as raw material and recovery processing is performed with the rosin processing method, thereby the yield of active ingredients reaches over 96 percent. The method can rapidly separate impurities and recover the rosin and the turpentine oil. The pressure filtration method can be used for sewage treatment of the rosin factory; and all the process water is recycled so as to realize zero draining of sewage.

Owner:古远亮

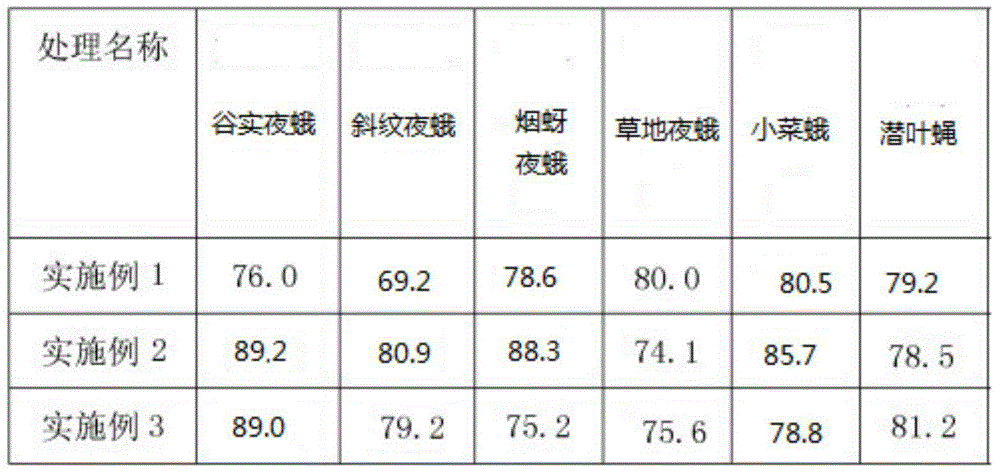

Biological pesticide

ActiveCN104082352AReduce pollutionNon-toxic and harmlessBiocideAnimal repellantsEcological environmentPesticide residue

The invention relates to a biological pesticide. The biological pesticide is characterized by being prepared from the raw materials in percentage by weight: 10-60wt% of cinnamyl aldehyde and toosendan fruit extracts, 8-10wt% of surfactant, 0.01-0.5wt% of chitosan, 10-50wt% of synergist and the balance of 95% ethanol, turpentine oil, lavender essential oil, ageratum oil and purple perilla leaf oil. According to the biological pesticide disclosed by the invention, the cinnamyl aldehyde and toosendan fruit extracts are taken as main active ingredients, so that the biological pesticide has non-toxic and harmless properties and has good volatility, and the disadvantages of pesticide residue increase and ecological environment destruction can be overcome; although the cost of the biological pesticide is slightly higher than that of chemical pesticides currently, the social benefit is better, the environmental pollution is less, and thus, the biological pesticide has a lot of advantages in the long run.

Owner:PINGLE AGRI CHEM PLANT GUANGXI PROV

Botanical biopesticide

InactiveCN104082357ANo pollution in the processImprove efficacyBiocidePlant growth regulatorsAdditive ingredientBULK ACTIVE INGREDIENT

The invention relates to a botanical biopesticide. The botanical biopesticide is an aqueous emulsion composed of the extracts of plant active ingredients and auxiliaries, wherein the plant active ingredients include the extracts of sophora alopecuroide, cynanchum komarovii and thymus serpyllum, and the water extracts of onion, garlic and rheum; the auxiliaries include white sugar, turpentine oil and an emulsifying agent. Prepared from the reproducible edible plants used as the raw materials, the botanical biopesticide is pollution-free, has no pollution on the environment, complies with the pollution-free green ecological agricultural input norms and also has no withdrawal time. The botanical biopesticide is prepared compatibly from the Chinese herbal medicines, namely sophora alopecuroide, cynanchum komarovii and thymus serpyllum, added with the garlic as the major ingredient, onion as the auxiliary ingredient and rheum as the initiator; in the formula, the onion, similar to the garlic, contains a plurality of biological sulfides, and the sulfides are combined with the sulfides in the garlic to generate new allicin under the action of the alliinase. As the rheum and table vinegar are added, the efficacy and stability of the botanical biopesticide are further improved and the botanical biopesticide can be preserved for a long time without losing efficacy; the quality of crops can be improved.

Owner:何芳

Electrode silver slurry for crystalline silicon solar cell

InactiveCN105655005AIncrease contact areaImprove conductivityNon-conductive material with dispersed conductive materialPhotovoltaic energy generationCarbon nanotubeSlurry

The invention belongs to a photocell electrode material, and discloses electrode silver slurry for a crystalline silicon solar cell. The electrode silver slurry is prepared from, by weight, 40-60 parts of silver powder, 5-10 parts of antimony powder, 10-20 parts of manganese copper alloy powder, 1-5 parts of lithium iron phosphate and carbon nanotube composite materials, 1-8 parts of glass powder, 0.5-2 parts of silane coupling agent, 8-10 parts of propylene glycol mono-n-butyl ether, 1-5 parts of turpentine oil, 1-3 parts of lecithin, 0.1-0.5 part of ethyl cellulose and 0.25-1 part of fumed silica. The invention further discloses a preparation method of the electrode silver slurry. The obtained electrode silver slurry is free of lead and completely meets the environment protection requirement; when the electrode silver slurry is applied to production of the solar cell, the adhesion of the electrode silver slurry on the surface of the solar cell is high, and the photoelectric conversion efficiency of the solar cell is high; meanwhile, the technology is simple, the cost is low, and therefore the electrode silver slurry has a wide application prospect.

Owner:GUANGXI JIKUAN SOLAR ENERGY EQUIP

Pollution-free pine timber modifying method and composition

A pine timber modification method is to eliminate its turpentine oil, fix its rosin and inject water-soluble resin capable of being cured. After deoiling and rosin fixing at 80-105 deg.C and under normal pressure for 3-10 hr, the pine timber is vacuum pumped for 0.5-1 hr, made to suck water-soluble fireproof polymer resin under 0.09-0.095 MPa vacuum and soaked for 1-5 hr under normal pressure. The deoiling and rosin fixing composition contains water-soluble nitogen-contained organic compound, magnesium, salt, boric acid, emulsifier, penetrant, and has pH value of 7.5-8.0. The pint timber thus processed has no rosin overflow and deformation, high strength and durability, and certain fireproof performance.

Owner:陈万利 +2

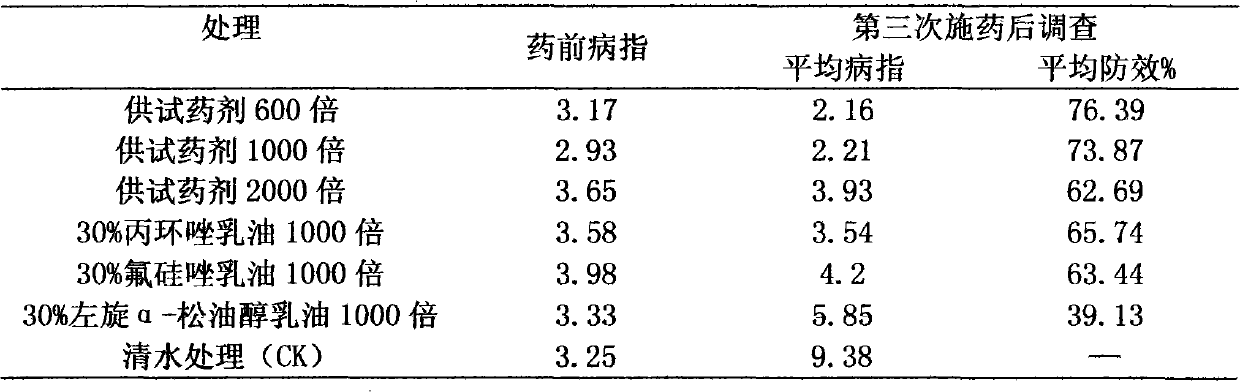

Bactericide composition containing propiconazole, flusilazole and levo-alpha-terpineol and production method thereof

The invention discloses a bactericide composition containing propiconazole, flusilazole and levo-alpha-terpineol and a production method thereof, and the bactericide composition comprises the following active ingredients by weight percent: 1%-50% of propiconazole, 1%-50% of flusilazole, 1%-50% of levo-alpha-terpineol and the balance of auxiliaries. The formulation can be missible oil, microemulsion and emulsion in water. The bactericidal spectrum is expanded after complex of the composition, the bactericide composition further has obvious synergy, the usage amount and the using times of the bactericide can be significantly reduced, the cost is reduced, and the emergence of drug resistance to diseases can be also delayed. The bactericide composition can be used for control of banana leaf spot disease, banana scab, venturia pirina, peanut leaf spot disease, apple anthracnose and grape anthracnose. Simultaneously, the levo-terpineol has low toxicity and is easy for degradation as a monoterpene alcohol synthesized by a plant renewable resource-turpentine, thereby being in line with requirements on green and environmental protection. The micro-emulsion and the aqueous emulsion in the invention, wherein, the water part can replace an organic solvent,, thereby reducing the environmental pollution.

Owner:GUANGXI RES INST OF CHEM IND CO LTD

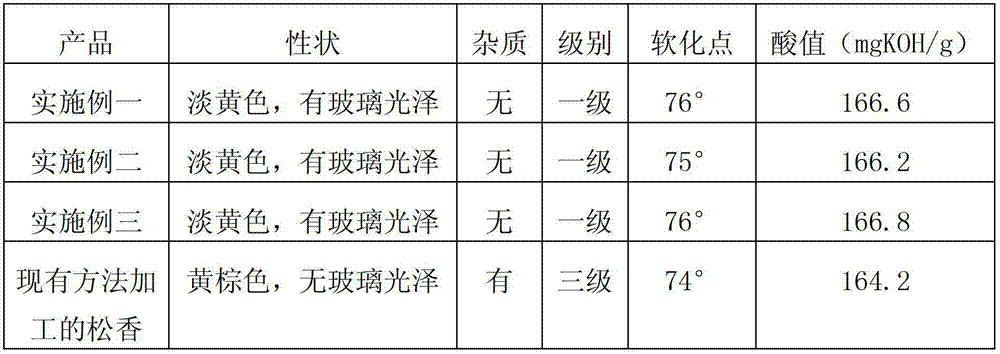

Processing method of pine resin

InactiveCN103087635AQuality improvementImprove solubilityTurpentine spiritsNatural resin purificationOxalatePine resin

The invention relates to a processing method of pine resin and belongs to the field of rosin production. The processing method of pine resin comprises the following steps of: a, dissolving, namely dissolving the pine resin by adopting a dissolving solution, wherein the dissolving solution comprises the following components in percentage by weight: 55-82% of turpentine oil, 17.5-44.5% of water and 0.1-0.5% of oxalic acid; b, clarifying and colating, namely placing the dissolved pine resin liquid in a transition pot to be clarified and then colating to obtain colature; c, acid washing, namely adding the oxalic acid for washing; d, washing, namely adding hot water for washing; e, clarifying and carrying out refined filtration, namely placing the pine resin liquid into the transition pot to be clarified and then carrying out refined filtration; and f, heating and distilling, namely placing the pine resin liquid in a rectifying tower to be subjected to the heating and distilling, so that rosin and turpentine oil finished products are respectively obtained. The processing method of rosin provided by the invention has the beneficial effect that the qualities of the rosin and turpentine oil obtained by processing pine resin are excellent, so that demand of downstream industries is met.

Owner:云南茶花林化有限公司

Medicine for swelling and relieving pain and its preparation method and application

InactiveCN101143166AHas anti-inflammatory and analgesic effectsHydroxy compound active ingredientsAntipyreticExternal applicationGinseng

The invention relates to a drug combination for detumescence and acesodyne and in particular to a drug combination for detumescence and acesodyne, which is made from the raw material of Chinese herbal medicines of plants, and the preparation method and the application of the drug combination. The drug combination for detumescence and acesodyne of the invention consists of ten Chinese herbal medicines of a peony bark, a pricklyash root, a safflower, a root of pseudo-ginseng, a Szechwan aconite, a terebinth, a borneol, a camphor, cinnamon oil and menthol. The invention has the efficacies of activating blood circulation, dispersing blood stasis, extending tract, activating collateral flow, detumescence and acesodyne; the external application can directly remedying partial ill parts; the drug efficacy penetrates quickly, and the stasis, the turgescence and the ache are eliminated fast; the drug combination is a good external anodyne salve for remedying the trauma of muscle, tendon, and parenchyma and the turgescence and the ache which are caused by the bone arthropathy and belong to blood stasis, retardarce and inside invading by cold-dampness.

Owner:广东中大南海海洋生物技术工程中心有限公司

Ground source heat pump well drilling wear-resistance bit and manufacturing method thereof

InactiveCN101598005AAvoid crackingNot easy to crack, not easy to fall offDrill bitsMetallic material coating processesSlurryMaterials science

The invention discloses a ground source heat pump well drilling wear-resistance bit and a manufacturing method thereof. The manufacturing method is characterized by comprising the following steps: uniformly mixing tungsten carbide powder and nickel base alloy powder according to a weight ratio of 3:10-60, adding rosin-containing turpentine oil serving as a bonding agent into the mixture in an amount of 3 to 10 percent of the weight of the powder to make slurry through stirring, and coating the slurry on a damageable working face of a steel blank of the bit to form a 1.3 to 6.5 millimeter coating; and drying the bit in an oven at a temperature of between 80 and 160 DEG C for 1 to 3 hours, heating the bit at a vacuum of 10 to 30 Pa to 1,080 to 1,180 DEG C for vacuum melting, keeping the temperature for 30 to 55 minutes, furnace cooling the bit to 260 DEG C, and tapping air cooling the bit to obtain ground source heat pump well drilling wear-resistance bit of which the working face of the steel blank is melt with 1 to 5 millimeter nickel-base carbon tungsten alloy. The bit has the advantages of a damageable working face hardness of HRC58-71, excellent plasticity, low manufacturing cost, service life which is 3 to 5 times that of the prior roller bit and easy damaged working face repair.

Owner:祖国全

Cold-resistant rubber seal ring

The invention discloses a cold-resistant rubber seal ring. The cold-resistant rubber seal ring is prepared from the following raw materials in parts by weight: 30-50 parts of ethylene propylene diene monomer, 50-80 parts of butadiene rubber, 2-3.5 parts of zinc stearate, 3-5 parts of diphenyl silandiol, 1-3 parts of dioctyl phthalate, 2.6-3.5 parts of microcrystalline wax, 6-8 parts of high wear-resistant carbon black, 10-15 parts of magnesium oxide, 12-15 parts of modified silica powder, 4-6 parts of rutile type titanium dioxide, 3-6 parts of alum powder, 5-8 parts of nanometer calcium carbonate, 5-8 parts of naphthenic rubber oil, 1-2 parts of sodium pyrophosphate, 2-3 parts of antiager, 3-5 parts of accelerant PZ, 0.15-0.3 part of sodium lignin sulfonate, 5-7 parts of solid coumarone, 1.2-1.4 parts of turpentine oil, 20-30 parts of cold-resistant agent and 2-2.5 parts of sulfur. The cold-resistant rubber seal ring disclosed by the invention has very good cold resistance and does not crack at a low temperature; in subzero 30 DEG C environments, the cold-resistant rubber seal ring does not become brittle, and the good performances of the cold-resistant rubber seal ring are maintained.

Owner:安徽金科橡塑制品有限公司

High-temperature-resistant plastic woven bag and preparation method thereof

InactiveCN107057193AAvoid contactReduce surface temperatureDomestic articlesLinear low-density polyethyleneStearic acid

The invention relates to a high-temperature-resistant plastic woven bag and a preparation method thereof. The high-temperature-resistant plastic woven bag is prepared from raw materials in parts by weight as follows: 100 parts of polypropylene granules, 185-195 parts of nano calcium carbonate powder, 4.3-4.7 parts of paraffin, 3-4 parts of stearic acid, 5.2-5.8 parts of a coupling agent, 0.4-0.5 parts of an antioxidant, 7-8 parts of polyoxymethylene, 20-30 parts of nano aluminum hydroxide, 0.5-1 part of graphene, 26-28 parts of linear low density polyethylene, 0.25 parts of polyethylene wax, 3.8-4.0 parts of an ethylene-methyl acrylate copolymer 1125AC, 1.8-2.0 parts of tributyl citrate and 0.3-0.5 parts of turpentine oil. The high-temperature-resistant plastic woven bag has excellent performance of common woven bags in the market, and heat resistant strength of the woven bag is further greatly improved.

Owner:LIAONING TENGHUA PLASTIC

Modified vegetable oil aerial pesticide auxiliary agent, and preparation method and application thereof

InactiveCN108935459ALow costEase of mass productionBiocideAnimal repellantsVegetable oilTurpentine Oil

The invention relates to a modified vegetable oil aerial pesticide auxiliary agent, and a preparation method and application thereof, and belongs to the technical field of plant protection. The raw materials of the auxiliary agent include, by weight, 42-56 parts of modified turpentine oil, 14-20 parts of a surfactant, 10-20 parts of a wetting spreader and 10-20 parts of an anti-drifting agent. Theauxiliary agent is low in cost, and can effectively improve liquid medicine performance and droplet performance and enhance control effects. The preparation method includes dissolving the wetting spreader and the anti-drifting agent into the modified turpentine oil, and then mixing with the surfactant. The preparation method is simple and easy to operate, so that large-scale production of the auxiliary agent can be realized. The auxiliary agent can be used to mix with liquid medicine to control crop diseases through an unmanned aerial vehicle, so that liquid medicine droplet performance can be effectively improved, and aerial pesticide control effects in fields can be increased.

Owner:ENVIRONMENT & PLANT PROTECTION INST CHINESE ACADEMY OF TROPICAL AGRI SCI

Natural plant type paint and its preparation method

The present invention relates to a natural plant type coating and its preparation method. Said coating is formed from high-molecular film-forming material, pigment, adjuvant and solvent. It is characterized by that the oil material adopted in the high-molecular film-forming material contains 30-40 portions of linseed oil, 35-45 portions of limonene, 5-15 portions of polybasic alcohol, the polybasic acid contains 8-15 portions of phthalic anhydride and 2-5 portions of trimellitic anhydride, the adjuvant is 0.02-0.1 portion of catalyst lithium hydroxide, the dryer is 1-3 portions of composite rare earth, and the solvent contains 5-10 portions of pine cone oil and 5-10 portions of terpineol, the above-mentioned raw materials are mixed to obtain the invented film-forming material. Besides, it adopts deionized water, adds 18-35 portions of pigment titanium dioxide, adds drying, dispersing, anti-freezing, defoaming, anti-corrosion and film-forming adjuvants, and adds medicinal talcum powder and natural calcium carbonate and stirs them to obtain slurry material for stand-by, then said invention utilizes 10-20 portions of film-forming material to make emulsification, adds deionized water and the above-mentioned slurry material, and adds thickening agent, mixes them so s to obtain the invented coating.

Owner:TIANJIN LIUHONG TECH DEV

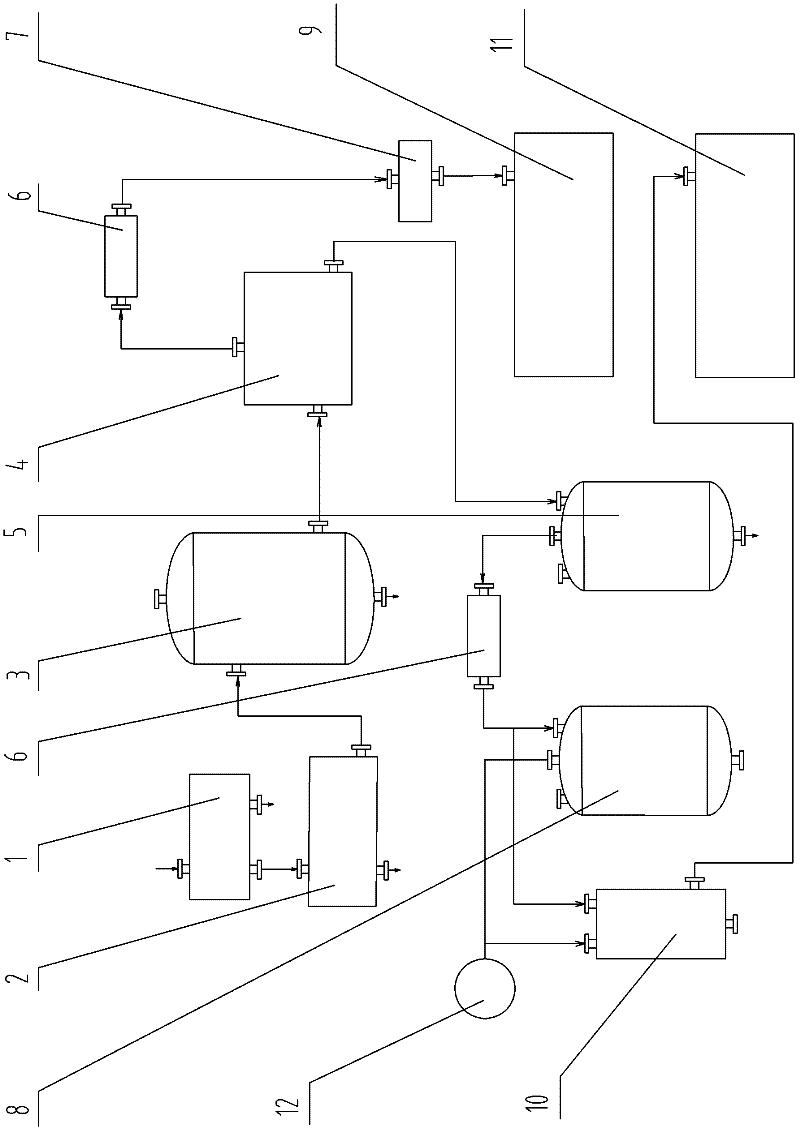

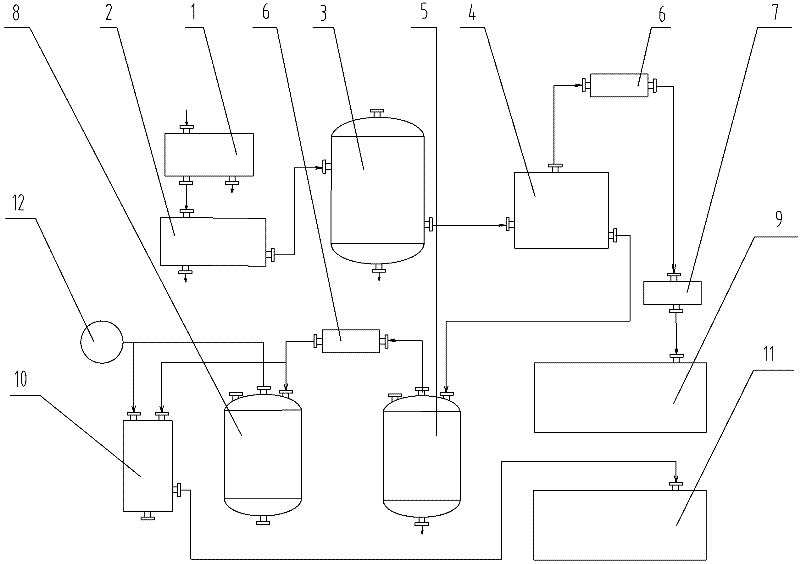

Ultralight-colored polyterprene resin production process

The invention discloses an ultralight-colored polyterprene resin production process. The ultralight-colored polyterprene resin production process includes polymerizing, washing and distilling, and turpentine oil and catalyst of alchlor are polymerized in a reactor during the polymerizing procedure. The ultralight-colored polyterprene resin production process is characterized in that 0.2% by weight of hindered phenol oxidation inhibitor and 0.1 % by weight of decolorizer are added into a polymerized mixed product which is washed during the distilling procedure. Since the core technology at international advanced level is combined with the antioxidant decolorizer and the hindered phenol oxidation inhibitor, the product can be decolored effectively, and mother liquid in color luster ranging from 7# to 8# can be decolored into the product in color luster of 1#. Besides, the filtering procedures are added before and after the washing procedure respectively, so that aluminum dross and impurities can be separated more thoroughly, separation rate can be up to 98% or above. Further, ions, low-boiling-point components and by-products can be separated completely by the aid of precise distilling equipment integrating with the optimum process, odor of products is lightened, and pollution to the environment is reduced.

Owner:GUANGDONG HUALIN CHEM

High-efficiency energy-saving low-cost high-quality rosin production process and production line equipment

ActiveCN102643611AShorten production timeIncrease productivityTurpentine spiritsNatural resin purificationProduction lineDistillation

The invention discloses a high-efficiency energy-saving low-cost high-quality rosin production process, which comprises the steps of: firstly carrying out turpentine impurity removal and liquification working procedure: firstly adding a little dissolving oil (5-10%) to turpentine, carrying out pressure filtration with a spiral filter press to remove main mechanical impurities in turpentine, heating refined turpentine at 50-70 DEG C, carrying out pressure filtration with a chamber filter press to further separate the mechanical impurities of turpentine, and inputting the purified turpentine liquid to a turpentine liquid storage tank; and then carrying out turpentine liquid distillation working procedure: inputting the purified turpentine liquid to a distillation tank, separating out rosin and turpentine oil, inputting the turpentine liquid with turpentine oil separated into a reaction kettle, carrying out reduced-pressure distillation to distill heavy turpentine oil, then keeping on heating to gasify the rosin liquid, condensing the rosin vapor into rosin liquid, and inputting to a rosin finished product storage tank. The production line equipment comprises the filter press, the turpentine liquid storage tank, the distillation tank, the reaction kettle, the rosin finished product storage tank, a heavy oil storage tank, a turpentine oil storage tank and a heavy turpentine oil storage tank.

Owner:桂林兴松林化有限责任公司

Waterproof oil paint

InactiveCN106147333AImprove migration efficiencyGood weather resistanceWax coatingsAntifouling/underwater paintsPolyesterPolystyrene

The invention discloses a waterproof oil paint. The waterproof oil pain is prepared from the following raw materials in parts by weight: polyester urethane resin 30-44 parts, core-shell acrylic elastic emulsion 33-43 parts, AS resin 3-8 parts, paraffin 15-22 parts, a natural chitosan-inorganic metal ion coordination compound 0.3-0.6 part, a heat-resistant agent 3-6 parts, a chemicals-resistant modifying agent 0.8-2.2 parts, heat-conduction packing 10-25 parts, infrared reflection titanium dioxide 1.25-2.75 parts, a light stabilizer 0.6-1 part, polymerization flax seed oil 2.3-4.7 parts, siritch 31-39 parts, turpentine oil 1.4-3.6 parts, polystyrene glycol 4-8 parts, and color paste 7-13 parts. The weight-average molecular weight of the AS resin is 3-10 W, and the AN content is 20-35%. The waterproof oil paint is good in effect, high in adhesion and good in weather fastness and corrosion resistance, has certain antibacterial property and is not easy to crack.

Owner:XINXIANG UNIV

Environment-friendly liquid fuel with high heating value and preparation method

InactiveCN101531927AReduce consumption costReduce consumptionLiquid carbonaceous fuelsParaffin waxLiquid fuel

The invention relates to an environment-friendly liquid fuel with high heating value, comprising the ingredients with the following weight ratio contents: 70-75 of methanol, 10-15% of water, 13-16 turpentine oil and 1-4 of additive. The additive is prepared by hydrogen peroxide with weight percent concentration of 30%, cyclohexane, ferrocene, liquid paraffin and ethanol. The preparation method comprises the following steps: firstly preparing the additive, then adding the methanol, water and turpentine oil into an agitated tank, finally adding the prepared additive in proportion to obtain the product after agitating. The invention has the advantages of low fuel cost, simple and convenient production technique, high heat value of combustion, easy procurement of raw materials, no pollution and saved energy, produces no harmful gases in the process of combustion, thus being convenient, practical, safe and environment-friendly.

Owner:SHAOGUAN FUDE ENVIRONMENTALLY FRIENDLY FUELS

Wound disinfecting spraying film agent and preparation method thereof

ActiveCN106361816AEasy to useSimple preparation processAntibacterial agentsHydroxy compound active ingredientsPeppermintsGlycerol

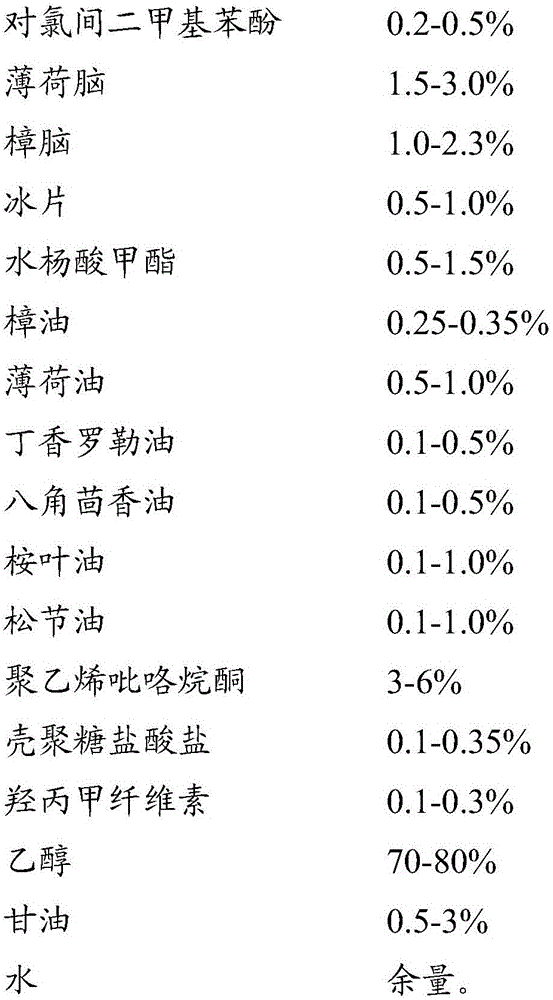

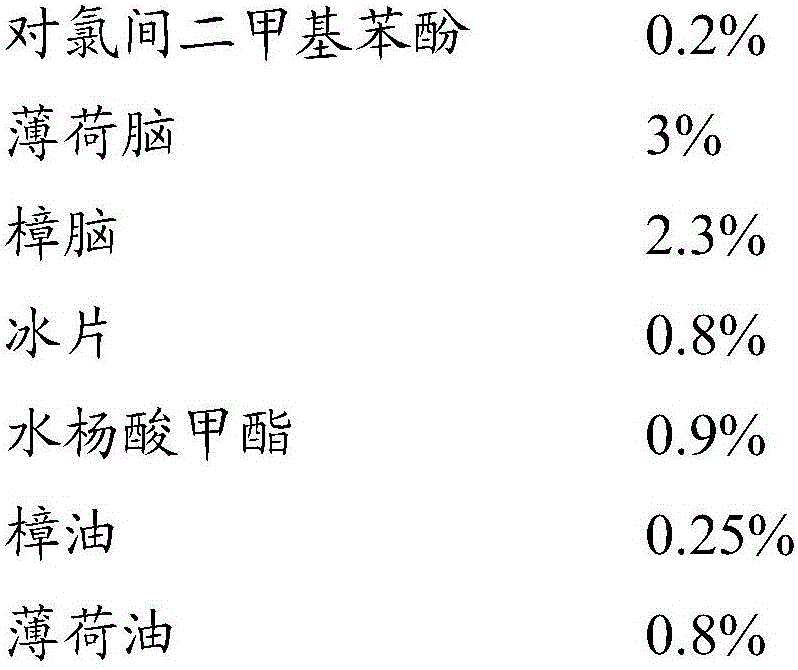

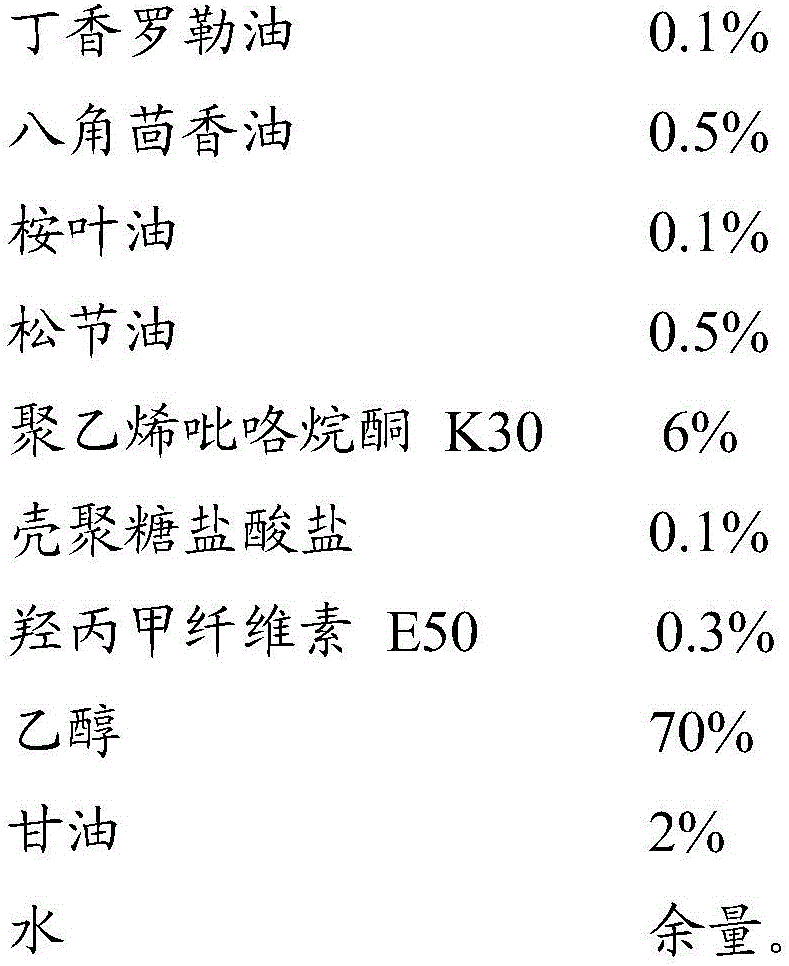

The invention discloses a wound disinfecting spraying film agent and a preparation method thereof. The wound disinfecting spraying film agent consists of the following components in percentage by mass: 0.2-0.5% of p-chloro-m-xylenol, 1.5-3.0% of menthol, 1.0-2.3% of camphor, 0.5-1.0% of borneol, 0.5-1.5% of methyl salicylate, 0.25-0.35% of camphor oil, 0.5-1.0% of peppermint oil, 0.1-0.5% of ocimi gratissimi oil, 0.1-0.5% of star anise oil, 0.1-1.0% of eucalyptus oil, 0.1-1.0% of turpentine oil, 3-6% of polyvinylpyrrolidone, 0.1-0.35% of chitosan hydrochloride, 0.1-0.3% of hydroxypropyl methylcellulose, 70-80% of ethanol, 0.5-3% of glycerol and the balance of water. The wound disinfecting spraying film agent provided by the invention has broad-spectrum bactericidal, rapid bactericidal and long-acting antibacterial functions and the like, and the wound disinfecting spraying film agent is rapid to stop bleeding and promote healing; a film can be formed on skin within several minutes so as to isolate bacteria and prevent re-infection of a wound; and in addition, the wound disinfecting spraying film agent is low in irritation of the human skin and is safe and convenient to use.

Owner:GUANGDONG LUOFUSHAN SINOPHARM

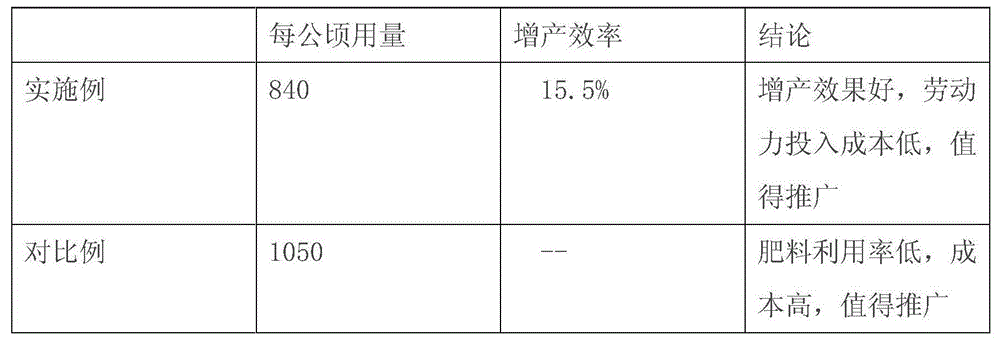

Special slow-release fertilizer taking attapulgite as matrix for paddy rice and preparation method of special slow-release fertilizer

InactiveCN104311233AIncrease productionIncrease profitAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersPolyvinyl alcoholBamboo charcoal

The invention provides a special slow-release fertilizer taking attapulgite as a matrix for paddy rice. The special slow-release fertilizer comprises the following raw material components in parts by weight: 60-80 parts of attapulgite, 10-20 parts of bamboo charcoal powder, 10-15 parts of melamine, 4-6 parts of polyvinyl alcohol, 10-12 parts of urea, 50-60 parts of diammonium phosphate, 80-90 parts of potassium sulfate, 6-8 parts of sodium lignin sulfonate, 1-2 parts of turpentine oil, 3-4 parts of a herbicide, 2-4 parts of disodium cocoyl monoethanolamide sulfosuccinate, 3-4 parts of super absorbent resin and 10-15 parts of fertilizer additives. The fertilizer provided by the invention can slowly release nutrients by fertilizing once, improves the utilization rate of the fertilizer and reduces the loss of fertilizer efficiency; and by adding the super absorbent resin, the effects of fighting against drought and retaining water are realized, the yield of the paddy rice is improved, and the cost is saved.

Owner:ANHUI HEQUAN SEED IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com