Method for catalyzing hydrogenation of alpha-pinene to prepare cis-pinane

A hydrogen preparation and cis technology, applied in the field of catalyst preparation and application, can solve the problems of harsh reaction conditions, low cis pinane selectivity, easy coking of the catalyst, etc., and achieves mild reaction conditions, stable catalytic performance, high cis The effect of formula pinane product selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] [Example 1] Preparation of P123 polymer-stabilized ruthenium nanoparticles hydrosol catalyst

[0023] Add 30mg of P123 and 2mL of water into a stainless steel reaction kettle, and stir evenly at room temperature. Then add 0.01mmol of RuCl 3 ·3H 2 O, after fully stirring, first use 1MPa of H 2 The air in the kettle was replaced 4 times, and then filled with 0.5MPa H 2 , react at 60°C for 1 h, and obtain P123 stable ruthenium nanoparticle aqueous sol catalyst.

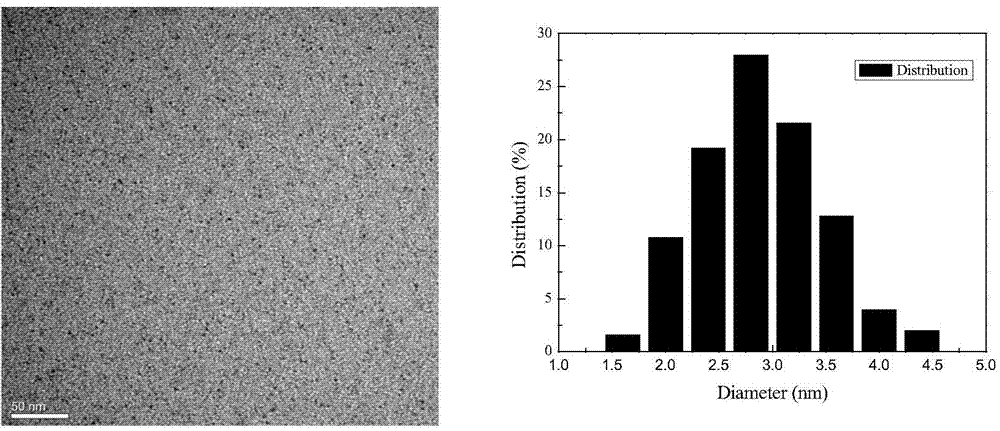

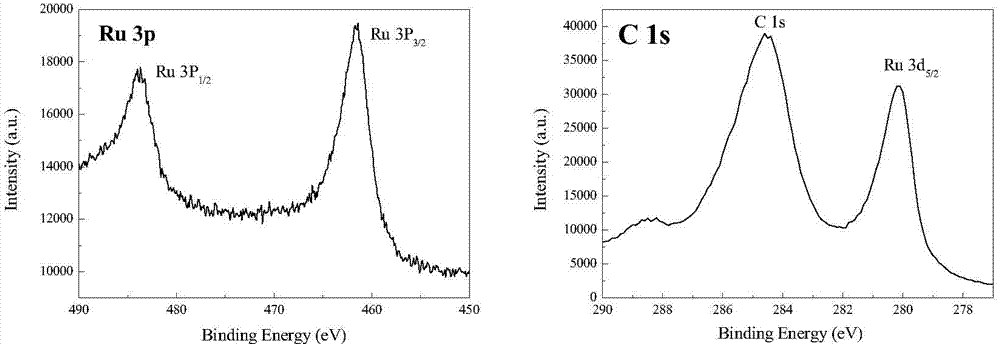

[0024] attached figure 1 It is shown that the prepared ruthenium nanoparticles have a particle size of about 2.8nm and good dispersion. attached figure 2 The data show that most of the prepared ruthenium nanoparticles (≈91.5%) are zero-valent metal ruthenium, which is due to exposure to air during the sample preparation process before detection, and a very small part (≈8.5%) is oxidized into ruthenium oxide.

Embodiment 2

[0025] [Example 2] 2mmol α-pinene is added in the stainless steel reaction kettle that the 0.010mmol ruthenium nanoparticle hydrosol catalyst that the P123 polymer that embodiment 1 makes is stable is housed (the mol ratio of α-pinene and ruthenium nanoparticle 200), mix evenly, replace the air in the kettle with 1MPa hydrogen for 4 times, and fill with 0.7MPa H 2 , The reaction was stirred at 40°C for 2h. After the reaction, the upper product phase was collected and quantitatively analyzed by gas chromatography. The conversion rate of α-pinene was 99.9%, and the selectivity was 98.9%.

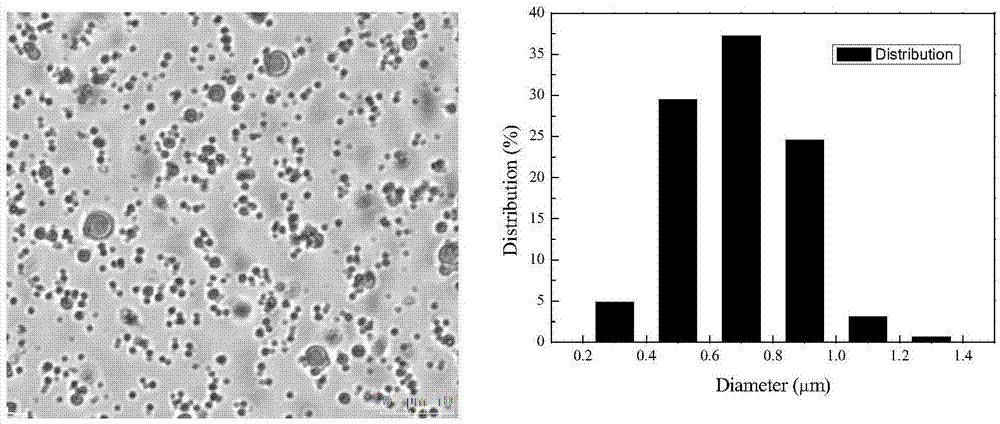

[0026] attached image 3 The laser confocal microscopy (CLSM) irradiation characterization results show that in the reaction process of Example 2, the hydrogenation reaction of α-pinene is carried out in the micellar microreactor formed by P123 polymer hydrosol, and its micellar microreaction The device size is around 700nm.

Embodiment 3-26

[0027] [Example 3-26] Experimental conditions and reaction steps are the same as in Example 2. After the reaction is over, the product phase is removed, and 2 mmol α-pinene is added to the water sol catalyst phase at the bottom, and the experimental steps of Example 2 are repeated. The experiment was repeated 24 times. After the catalyst was recycled for 14 times, the conversion rate of α-pinene was still 98.1%; after 24 times of repeated use, the conversion rate of α-pinene was 95.6%, and the selectivity of cis-pinane was 98.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com