Ground source heat pump well drilling wear-resistance bit and manufacturing method thereof

A ground source heat pump and drill bit technology, which is used in drill bits, drilling equipment, earth-moving drilling, etc., can solve the problems of high damage frequency, difficult to repair, and hard objects are fragile, and achieve long service life, not easy to fall off, and not easy to crack. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

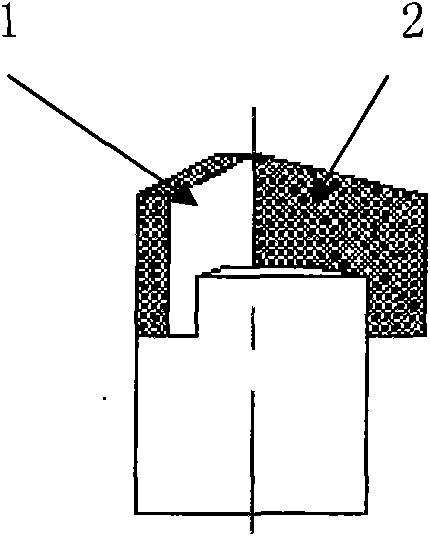

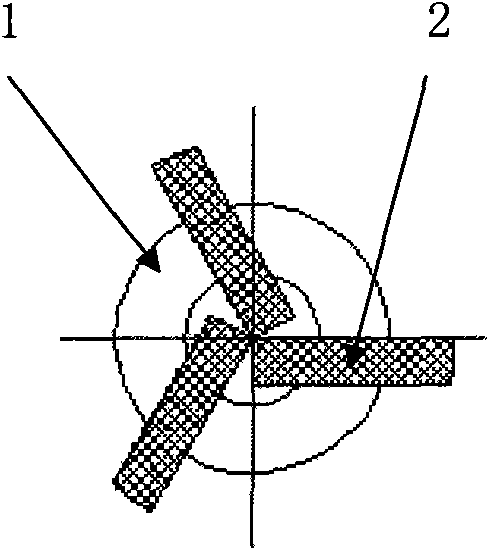

Image

Examples

Embodiment 1

[0013] The specific implementation steps of the present invention for preparing the ground source heat pump drilling wear-resistant drill bit are as follows:

[0014] A. Clean, degrease and decontaminate the surface of the steel rough drill bit to be processed;

[0015] B. Preparation of slurry and coating: Take 200g of tungsten carbide powder and nickel-based alloy powder according to the weight ratio of 3:10-60 and mix them evenly, add 6-20g of turpentine containing 1-10g of rosin as a binder , after stirring evenly, a slurry is formed, and the slurry is coated on the clean surface to be processed on the pretreated steel blank of the drill bit, and the thickness of the coating layer is adjusted to 1.3-6.5mm; The drill bits coated with slurry are placed in an oven, baked at 80-160°C for 1-3 hours, and can be precisely shaped according to specific needs after being out of the oven;

[0016] C. Carry out vacuum sintering on the above-mentioned drill bit after drying and shapin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com