High-efficiency energy-saving low-cost high-quality rosin production process and production line equipment

A high-efficiency, energy-saving, production process technology, applied in the field of rosin production, can solve the problems of difficult to guarantee the quality of rosin, repeated use of energy, large energy consumption, etc., and achieve the effects of saving production time, reducing investment costs, and shortening distillation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

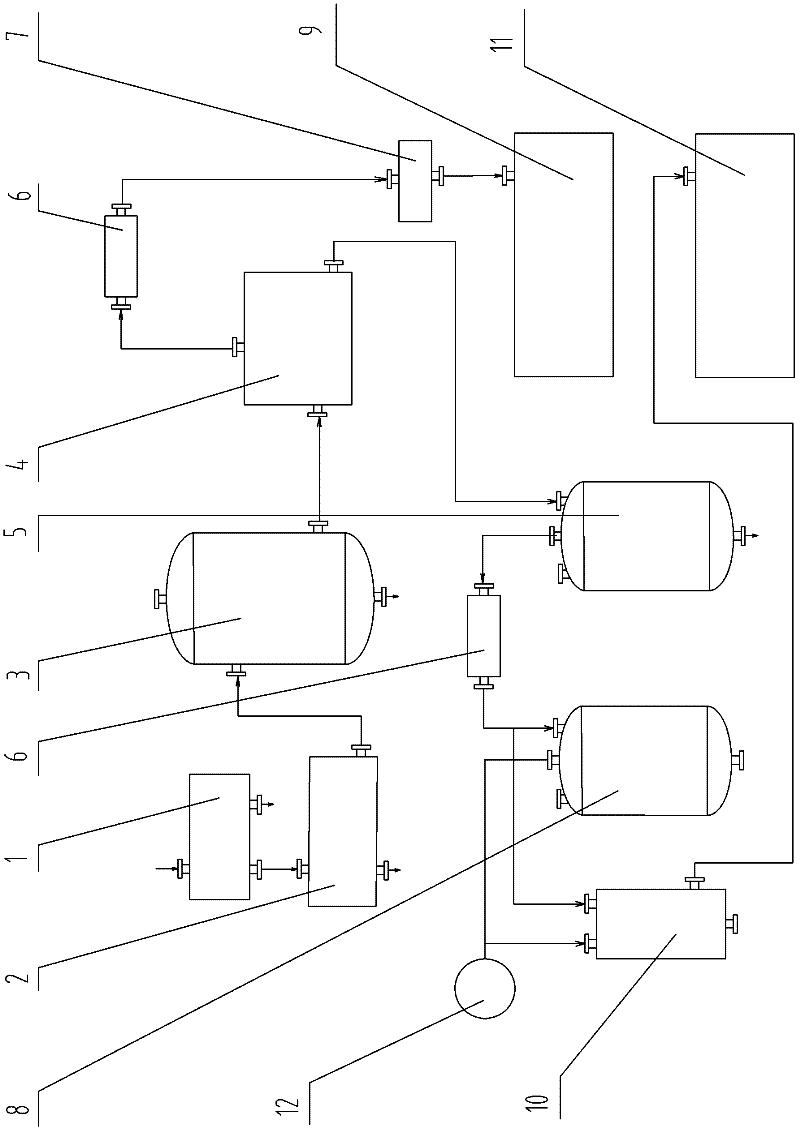

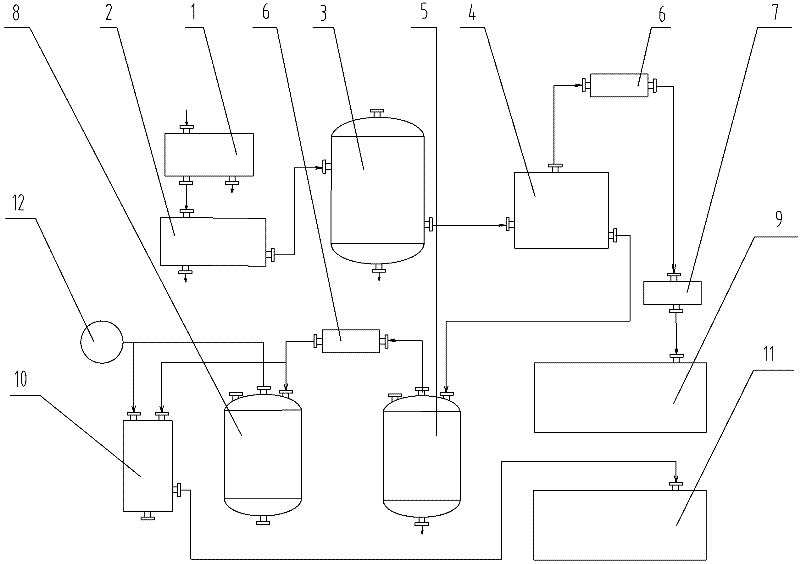

[0031] The technical scheme of the present invention will be further described below in conjunction with accompanying drawing:

[0032] The high-efficiency, energy-saving, low-cost and high-quality rosin production process of the present invention is divided into two major processes of rosin removal and liquefaction and fat liquid distillation. The process is as follows: figure 1 shown.

[0033] 1. Pine resin impurity removal and liquefaction process:

[0034] 1. After adding a small amount of dissolved oil (5% to 10%) to the rosin, use a screw press 1 to filter the rosin once, and the waste residue is discharged from the screw press 1.

[0035] 2. After heating (50° C. to 70° C.) the thinned rosin, press filter again with the box filter press 2 to obtain a net fat-making liquid, and discharge the waste residue from the box filter press 2 .

[0036] 3. Transfer (pump) the net fat making liquid into the fat liquid storage tank 3, and the residual moisture in the clean fat mak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com